Environmental-protective cleaning agent sued for lossless disassembly of equipment part

A component and environmentally friendly technology, applied in the direction of detergent compounding agent, detergent composition, surface active detergent composition, etc., can solve the problems of lost remanufacturing, scrapped parts, and difficulty in dismantling equipment parts, etc. Achieve the effects of preventing rust, removing oil and rust, improving dismantling efficiency and remanufacturing utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

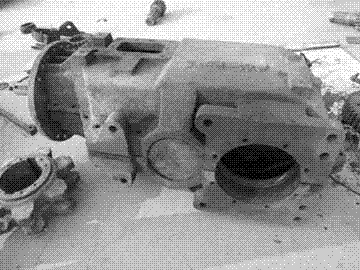

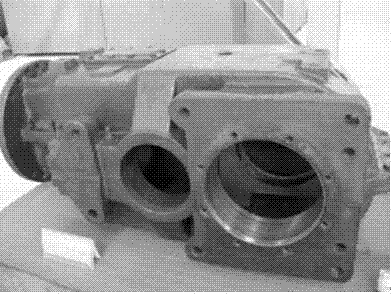

Image

Examples

Embodiment 1

[0017] Example 1 Preparation of an environmentally friendly cleaning agent for non-destructive disassembly of equipment parts

[0018] The formula is: oxalic acid, 4%; dodecyltrimethylammonium bromide, 1.5%; hexamethylenetetramine, 0.08g / L; hydroxymethylcellulose, 0.15%; the balance is water.

[0019] The preparation method is as follows: take all the raw materials except water, dissolve them separately, and mix them evenly to obtain the product.

[0020] The method of use is: apply the cleaning agent to the connecting parts of the parts for 1 to 2 hours.

[0021] This example uses the effective compounding of environmentally friendly raw materials to obtain an environmentally friendly and efficient cleaning agent with weak acidity, complexation, high permeability and surface transformation. After use, it can quickly penetrate into the contact parts of parts and remove the contact surface. At the same time, an insoluble oxalate film is formed on the fresh interface, which pla...

Embodiment 2

[0023] Example 2 Preparation of an environmentally friendly cleaning agent for non-destructive disassembly of equipment parts

[0024] The formula is: oxalic acid, 2%; OP-10, 2%; hexamethylenetetramine, 0.05g / L; hydroxymethylcellulose, 0.2%; the balance is water.

[0025] The preparation method is the same as in Example 1.

Embodiment 3

[0026] Example 3 Preparation of an environmentally friendly cleaning agent for non-destructive disassembly of equipment parts

[0027] The formula is: oxalic acid, 5%; polyethylene glycol, 1%; allylthiourea, 0.1g / L; hydroxymethylcellulose, 0.1%; the balance is water.

[0028] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com