Hot disassembly equipment for electronic circuit board component

An electronic circuit board and circuit board technology, which is applied in welding equipment, metal processing equipment, auxiliary devices, etc., can solve problems such as poor practicability, low efficiency, and low degree of automation, and achieve labor cost reduction, safe operation, and dismantling The effect of high solution efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

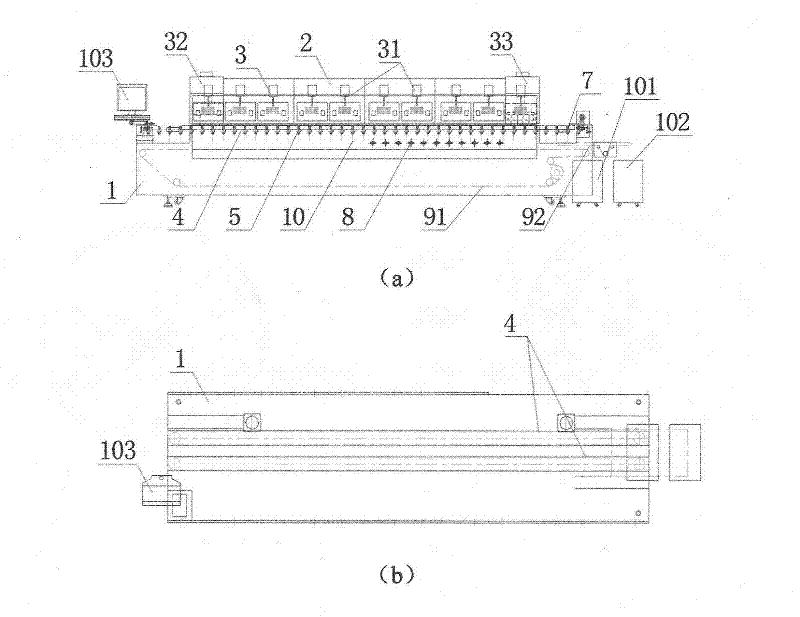

[0026] figure 1 It is a structural schematic diagram of a preferred embodiment of the present invention. Wherein (a) is a front view, and (b) is a downward top view after opening the thermostat 2 . As shown in the figure, the present invention relates to a thermal disassembly equipment for electronic circuit board components, which includes an organic platform 1, a large incubator 2 in the middle part above the incubator, and a heating device 3 on the top (top) of the incubator. Be eight heating units 31 in the present embodiment, and the both sides of heating unit are exhaust outlets 32,33, are used to get rid of exhaust gas, and eight heating units are divided into two groups, and the left side is close to one group of incubator inlet (four one) for preheating, and another group (four) near the outlet of the incubator for insulation. When the circuit board passes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com