Bag-feeding pillow type packaging machine

A pillow packaging machine and bag feeding technology, which is applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of low degree of automation, low production efficiency, and inability to adapt to the development needs of the packaging industry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

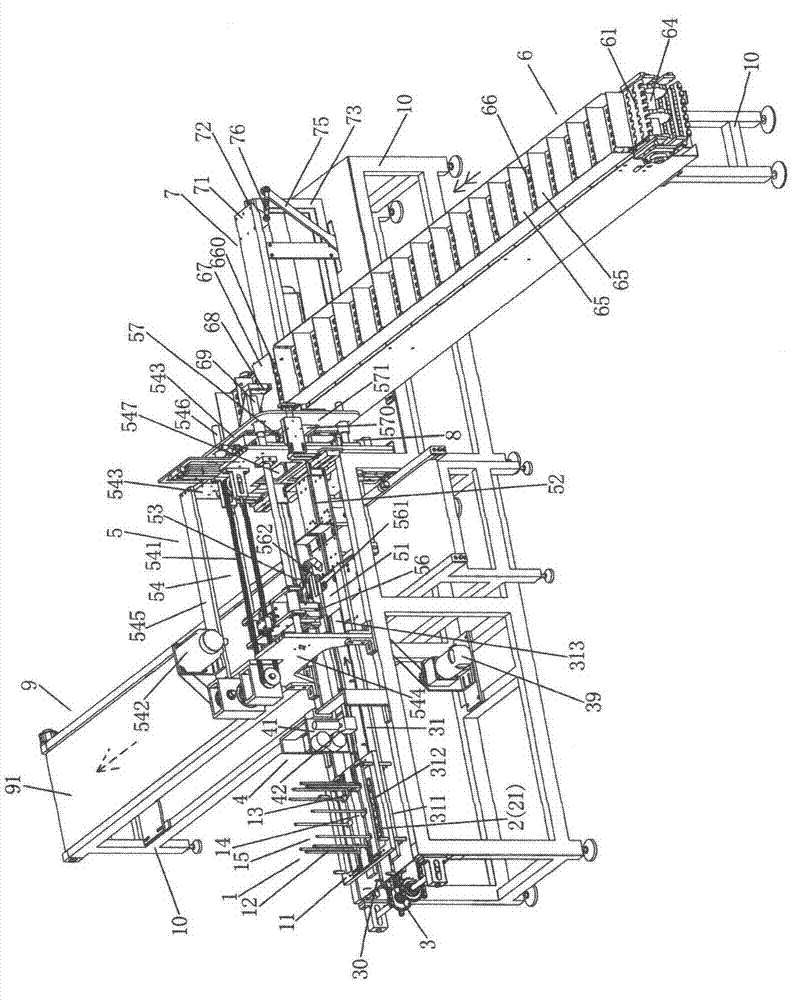

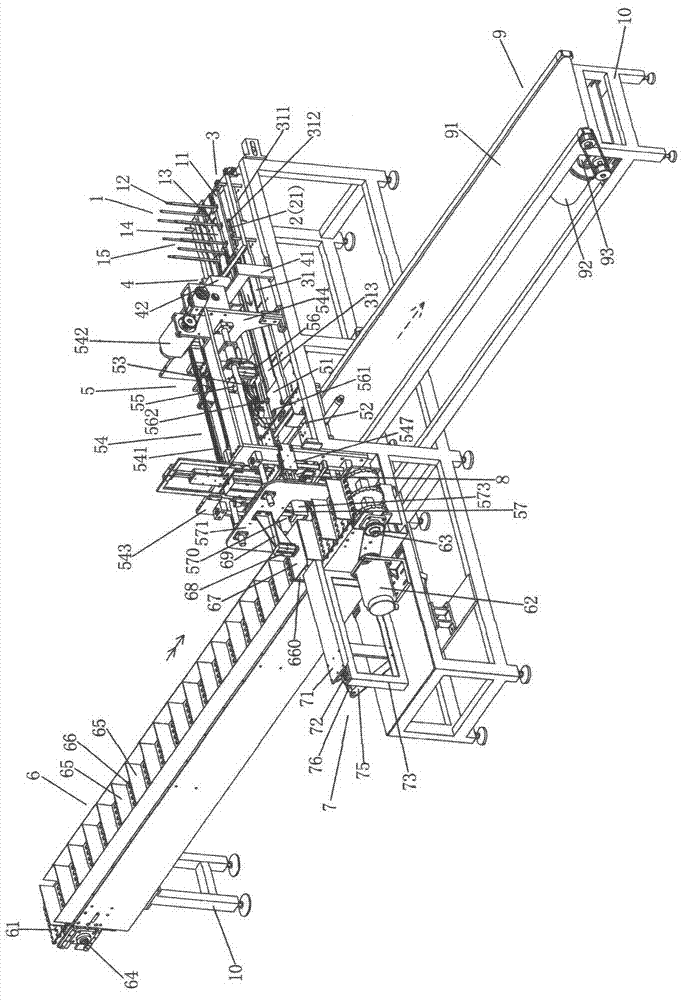

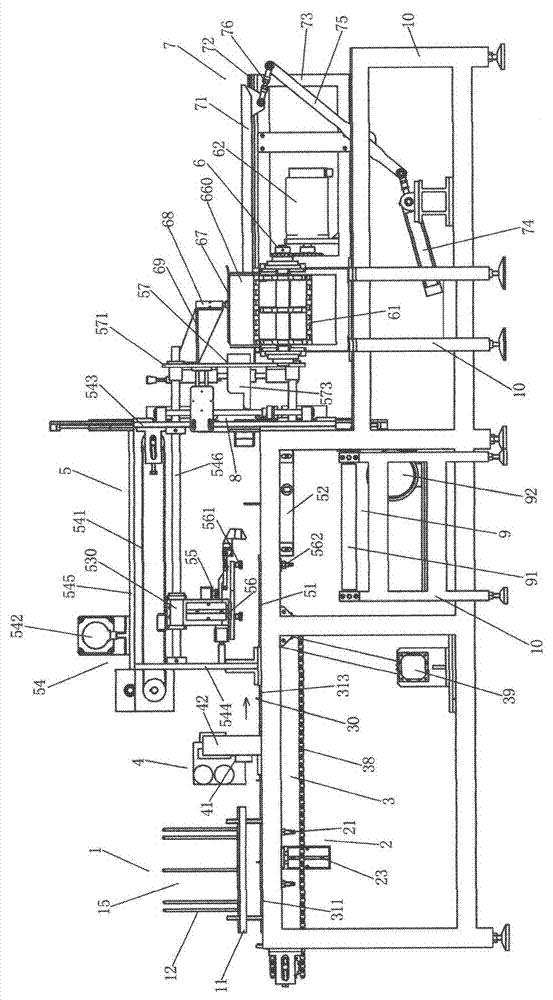

[0075] Such as Figure 1 to Figure 3 As shown, the bag-giving pillow type packaging machine in this preferred embodiment includes a frame 10 and a bag-putting device 1, a bag-taking device 2, a horizontal bag-feeding device 3, a coding device 4, Horizontal bag opening device 5, feeding device 6, horizontal feeding device 7, sealing device 8, finished product output device 9;

[0076] Such as Figure 1 to Figure 3 As shown, the above-mentioned bag releasing device 1 includes a mounting seat 11, a limit rod 12 and a bag holder block 13; the above-mentioned mounting seat 11 is fixed on the frame 10; the center of the above-mentioned mounting seat 11 is provided with a bag outlet 14, and the above-mentioned outlet The bag mouth 14 is positioned above the bag inlet portion of the horizontal bag feeding device 3, and the size of the bag outlet 14 matches the size of the packaging bag; the above-mentioned stop bar 12 is vertically installed on the mounting seat 11, and the stop bar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com