Patents

Literature

419 results about "Packaging industry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The packaging industry is a business sector involved with the design and production of packaging products. Packaging includes everything from shelf displays to crates used during shipment to protect goods while they are on the move.

Bamboo shoot clothing packaging box and production process thereof

The invention relates to a packaging box, in particular to a bamboo shoot clothing packaging box which is formed by adopting bamboo shoot clothing (commonly called bamboo shoot shells, bamboo shells and indocalamus shells) made of moso bamboos (phyllostachys pubescens), phyllostachys parvifolia, dendrocalamus latiflorus, phyllostachys praecox, fargesia utilis, overlord bamboos and the like as raw materials (give priority to the moso bamboos) and processing through the processes of raw material purchasing and storage, rinsing, harmless treatment (insect control, mildew prevention, fiber softening, color development and mercerization), washing, drying, flattening, cutting, gluing (glue spraying or blanching and gluing), collage (blanching and collage), polishing, laser printing, inspecting, warehousing and the like. The bamboo shoot clothing packaging box has the main characteristics of moisture absorption and mildew prevention, insect control and corrosion resistance, stain repellence and scale prevention, is an ideal preferred package of tea leaves, tobaccos, food, instruments, jewelry and other products and has very extensive purpose; meanwhile, the bamboo shoot clothing packaging box is fashionable and attractive in appearance, realizes low carbon and environmental protection, is durable and fully embodies the change of wastes into valuables; moreover, a new high-quality laying and decoration material and a processing technology can be provided for the packaging industry in China.

Owner:CHIBI JIAXIANG BAMBOO SHOOT DEV

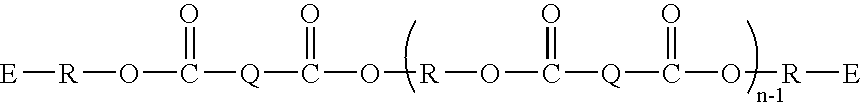

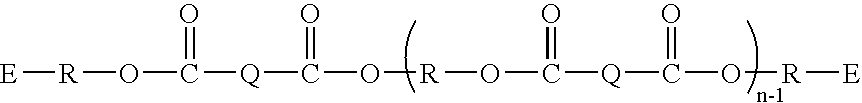

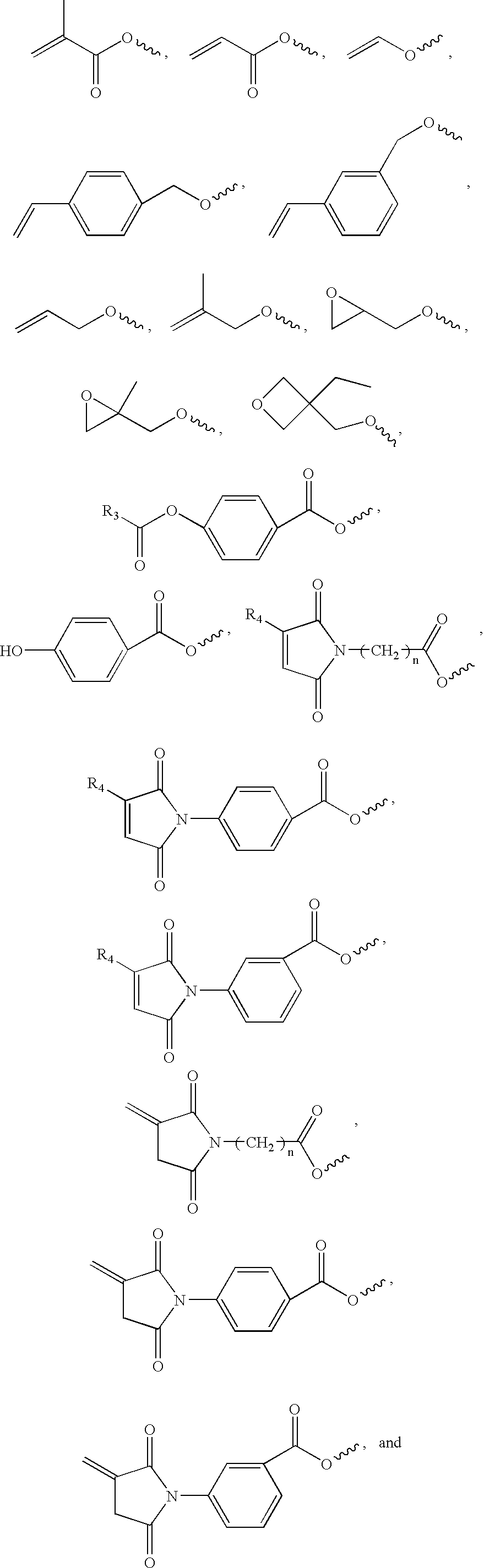

Underfill compositions and methods for use thereof

ActiveUS20060069232A1Other chemical processesSemiconductor/solid-state device detailsPolyesterPackaging industry

The invention is based on the discovery that certain polyester-linked compounds are useful as components in underfill compositions for the microelectonic packaging industry.

Owner:DESIGNER MOLECULES

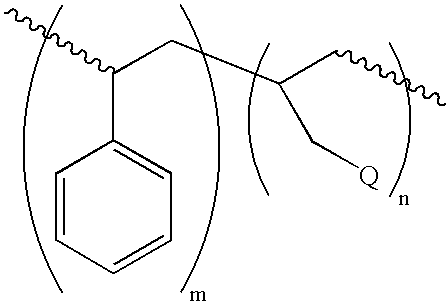

Derivatives of poly(styrene-co-allyl alcohol) and methods for use thereof

ActiveUS20080017308A1Low in ionic impurityEasy to convertAdhesive processes with surface pretreatmentSolid-state devicesCombinatorial chemistryMonomer

The invention provides derivatives of poly(styrene-co-allylalcohol). These materials are useful as thermosetting monomers that can be incorporated into adhesive compositions. In some embodiments, the adhesive compositions are useful in the microelectronic packaging industry.

Owner:DESIGNER MOLECULES

Method and system for reducing lead-time in the packaging industry

InactiveUS7225040B2Reduce packaging lead-timesData augmentationTechnology managementVisual presentationComputerized systemLead time

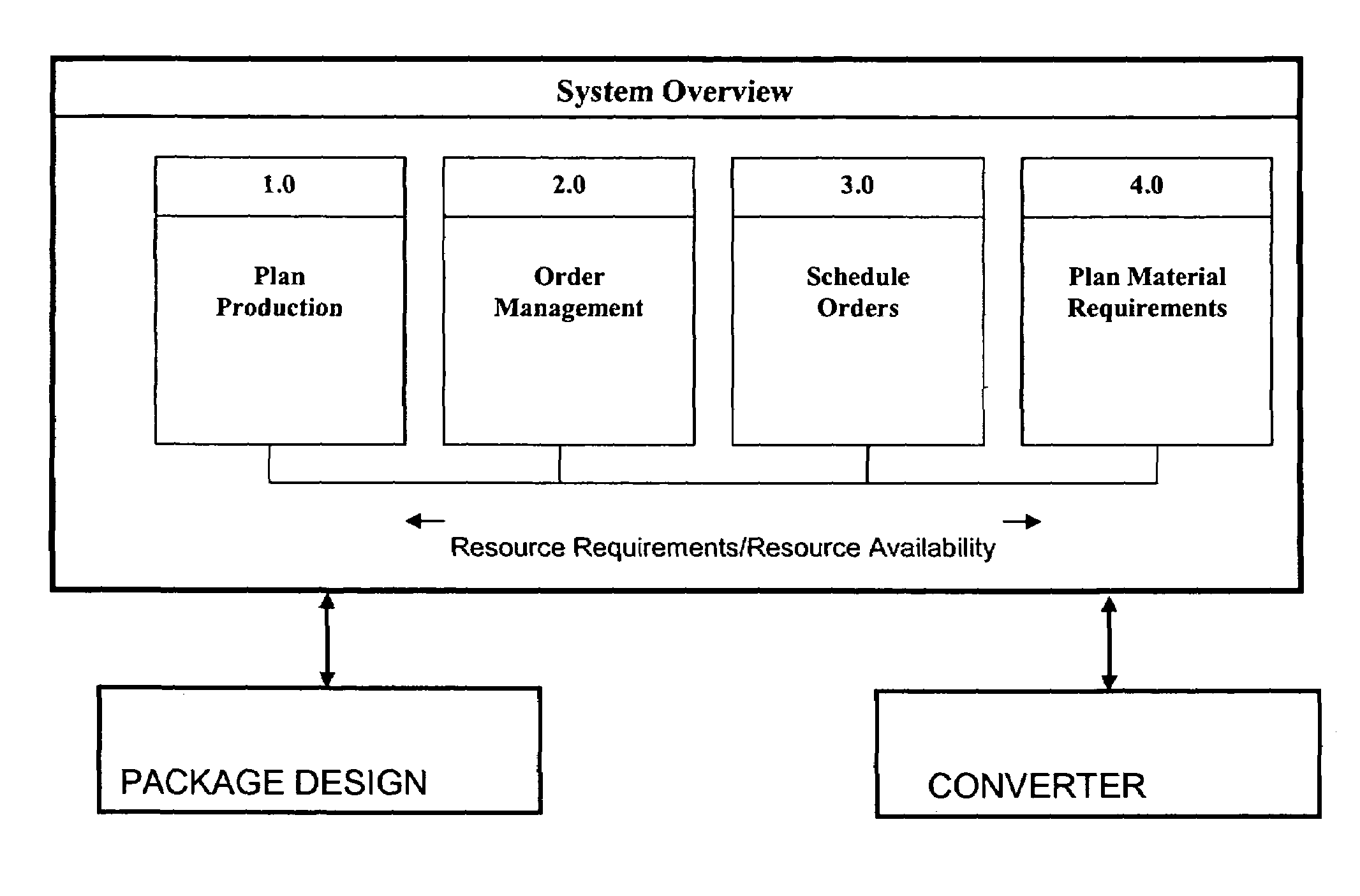

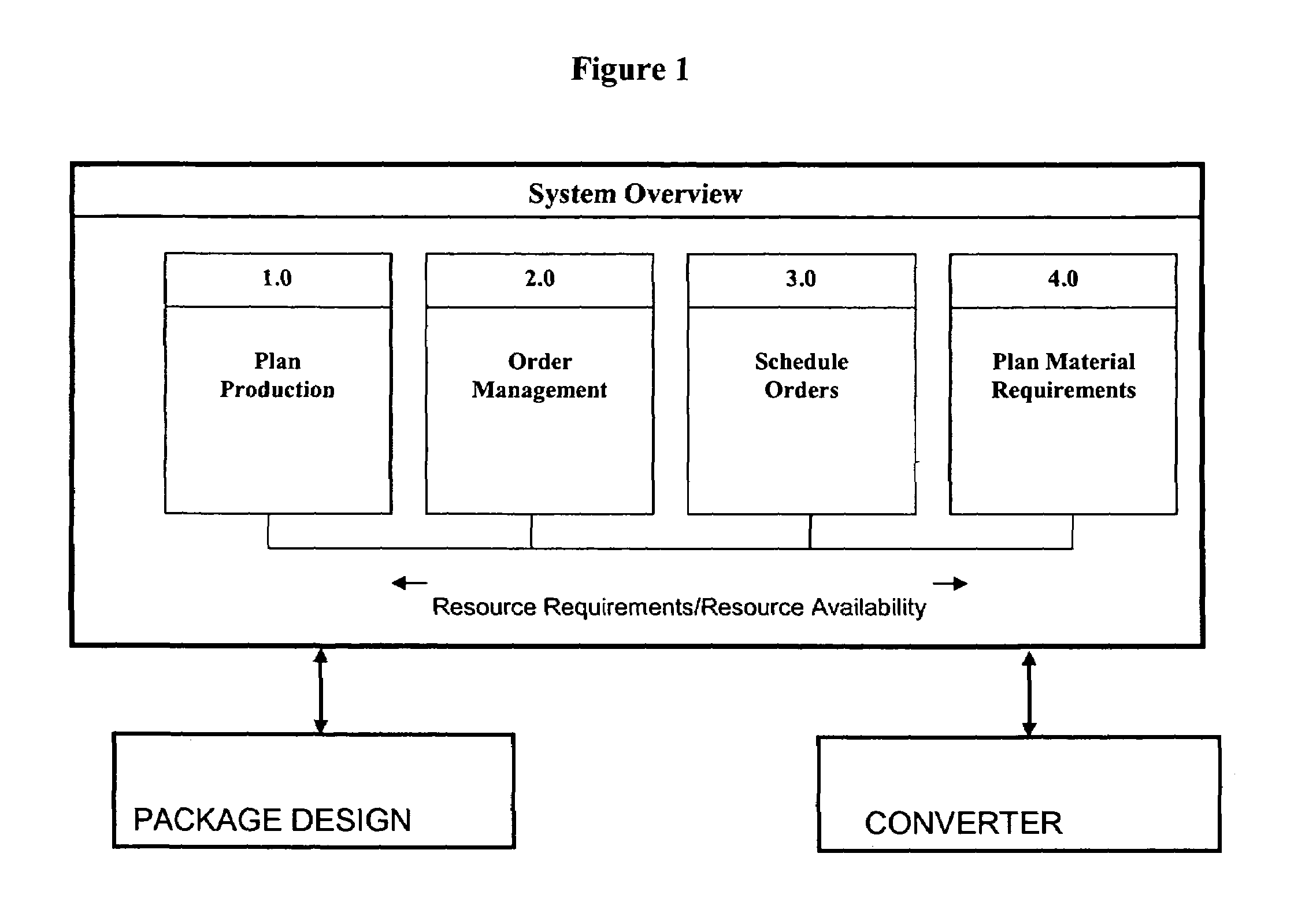

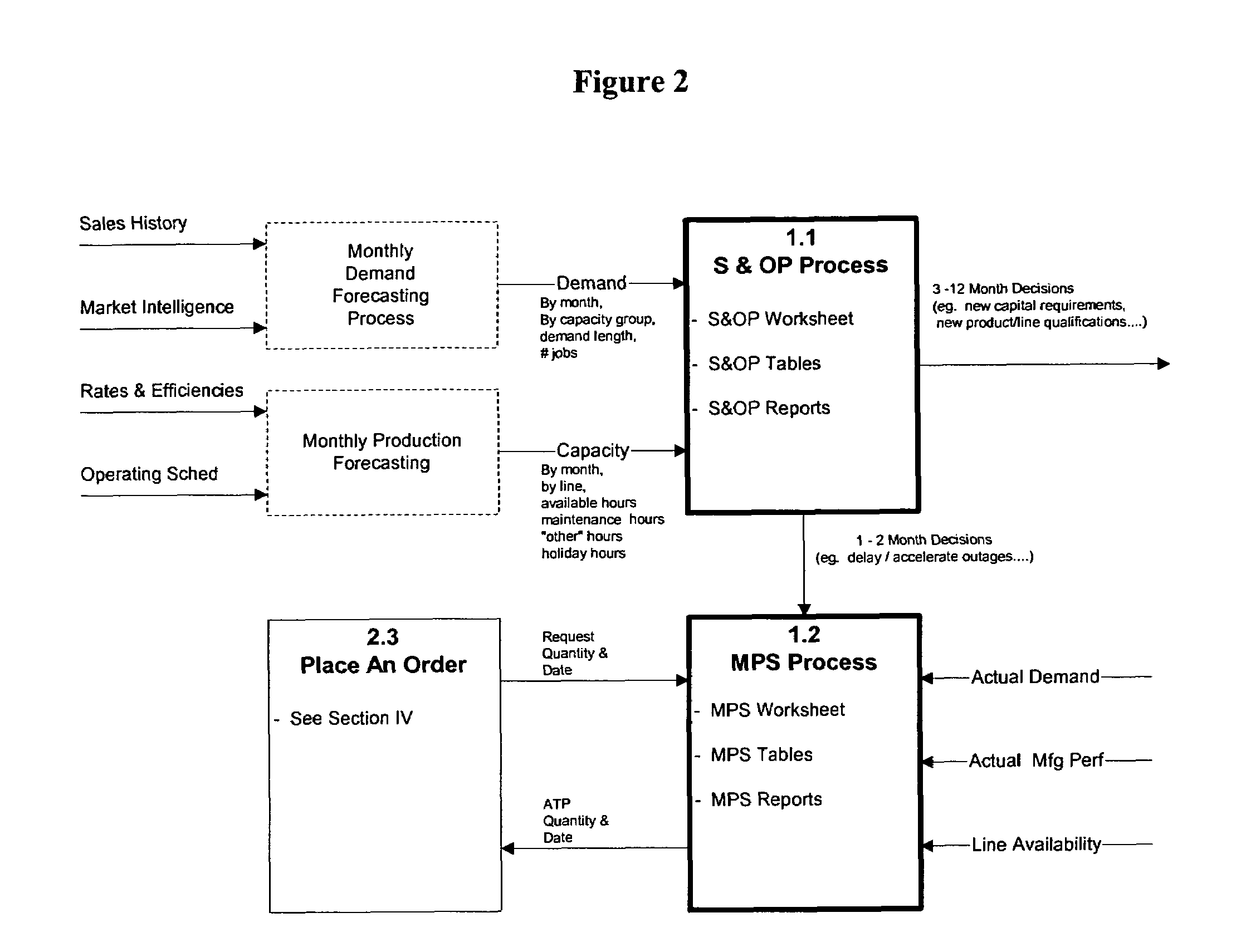

A system for integrating a packaging supply chain from a point that a digital contract proof is available through delivery of finished packaging materials to an end user, wherein said system comprises a computer system accessible for interactive communications with users, said computer system comprising a first memory area for storing functionality and data for end user members of the supply chain; a second memory area for storing functionality and data for converter members of the supply chain; and a third memory area for storing functionality and data for other members of the supply chain.

Owner:EXXONMOBIL CORP (US)

High solid content vinyl acetate-ethylene copolymer emulsion and method for synthesizing the same

ActiveCN101200518AReduce consumptionIncrease the conversion rate of the polymerization reactionMonocarboxylic acid ester polymer adhesivesSodium bicarbonatePhenol

The present invention relates to high solid content vinyl acetate-ethylene copolymer latex for binder and the synthetic method, including 55 to 75 portion of vinyl acetate, 24 to 45 portion of ethylene, 3 to 5 portion of N-methylol acrylamide, 2 to 4 portion of PVA1788 and PVA0588, 0.4 to 1.0 portion of the compound of nonionic emulsifying agent nonyl phenol polyoxyethylene alkyl ether and anion emulsifying agent alkyl sulphate with 2:1 mixture ratio, 0.2 to 1.0 portion of 35 percents oxydol with 1:1 mixture ratio, 0.05 to 0.4 portion of formol zinc sulphate, 0.1 to 0.5 portion of ferrous sulphate, 0.5 to 1.0 portion of regular dodeca-carbon thiol-alcohol, 0.05 to 0.35 portion of potassium phosphate, 0.1 to 0.5 portion of sodium bicarbonate and 45 to 55 portion of de-ionized water. With the adoption of latex polymerization, low-residual monomer VAE latex with solid content more than 65 percents is synthesized, which is used as binder to be applied in timber processing industry and packaging industry.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

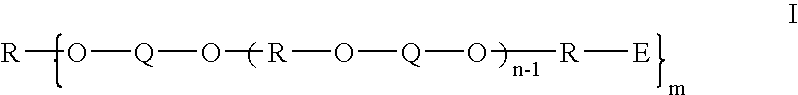

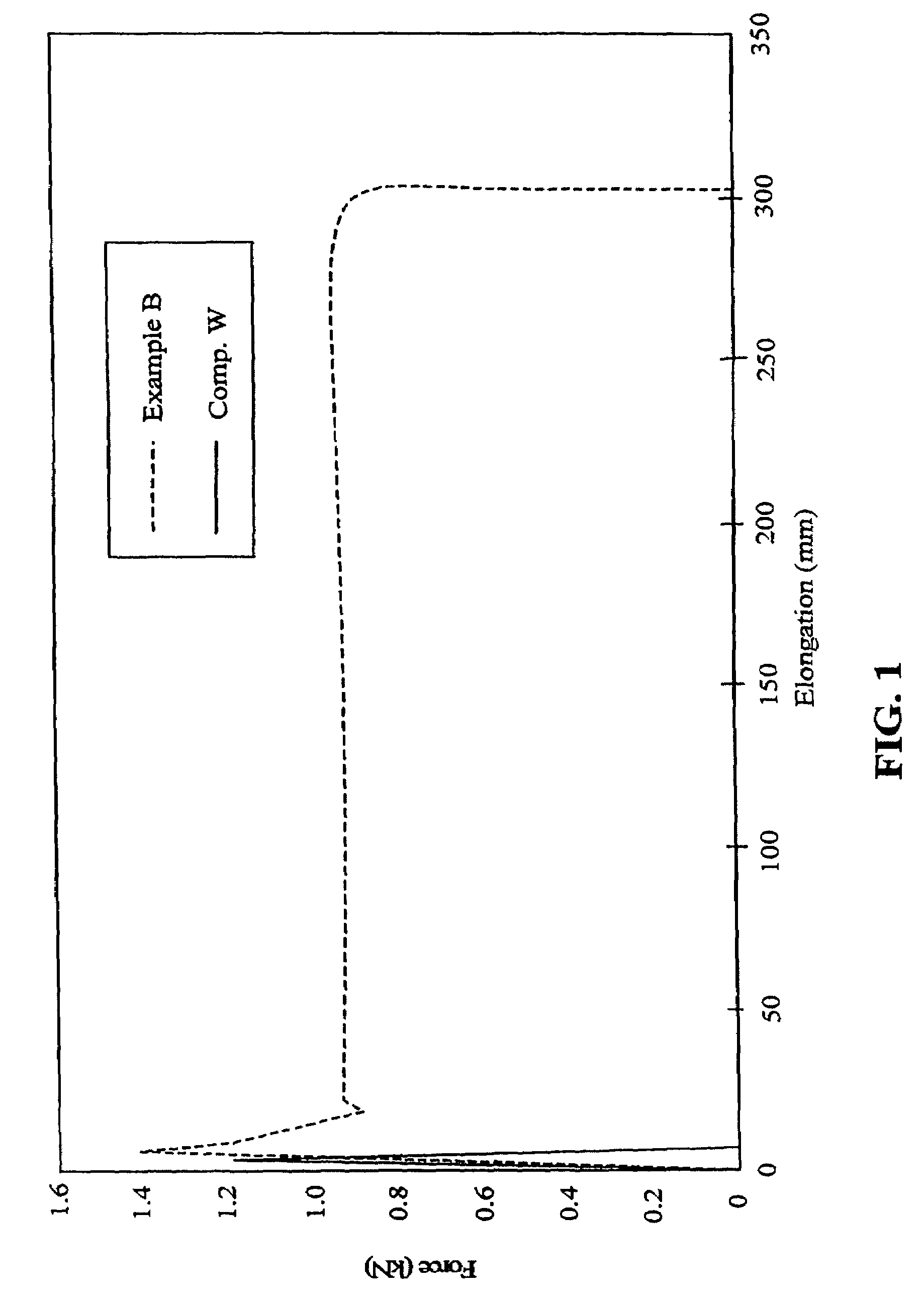

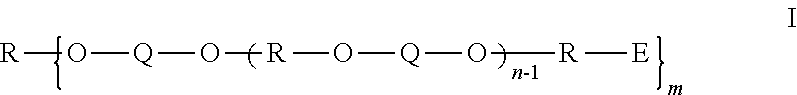

Thermosetting polyether oligomers, compostions and methods for use thereof

InactiveUS20090061244A1Low viscosityImprove conductivityOrganic chemistryOrganic compound preparationOligomerAdhesive

The invention is based on the discovery that certain polyether oligomers bearing curable moieties are useful as adhesives for the microelectonic packaging industry. Specifically, certain thermoset adhesive compositions containing polyether oligomers of the invention have good adhesion with lower viscosity, lower resistivity, higher conductivity and higher thixotropy when compared to acrylate- and maleimide-based thermoset adhesives.

Owner:DESIGNER MOLECULES

Polymeric nanocomposites comprising epoxy-functionalized graft polymer

InactiveUS7220484B2Increase heightEnhanced interactionMaterial nanotechnologySynthetic resin layered productsEpoxyPolyolefin

Disclosed is a nanocomposite comprising a nano-reinforcing material (e.g., layered clay), a polymer matrix (e.g., a polyolefin), and, an epoxy-functionalized graft polymer compatible with the polymer matrix (e.g., epoxy-grafted polyolefin). Such nanocomposites are useful in the fabrication of a variety of materials including parts for the transportation and packaging industries, electronics, business equipment, building and construction materials.

Owner:NAT RES COUNCIL OF CANADA

Low shrinkage polyester thermosetting resins

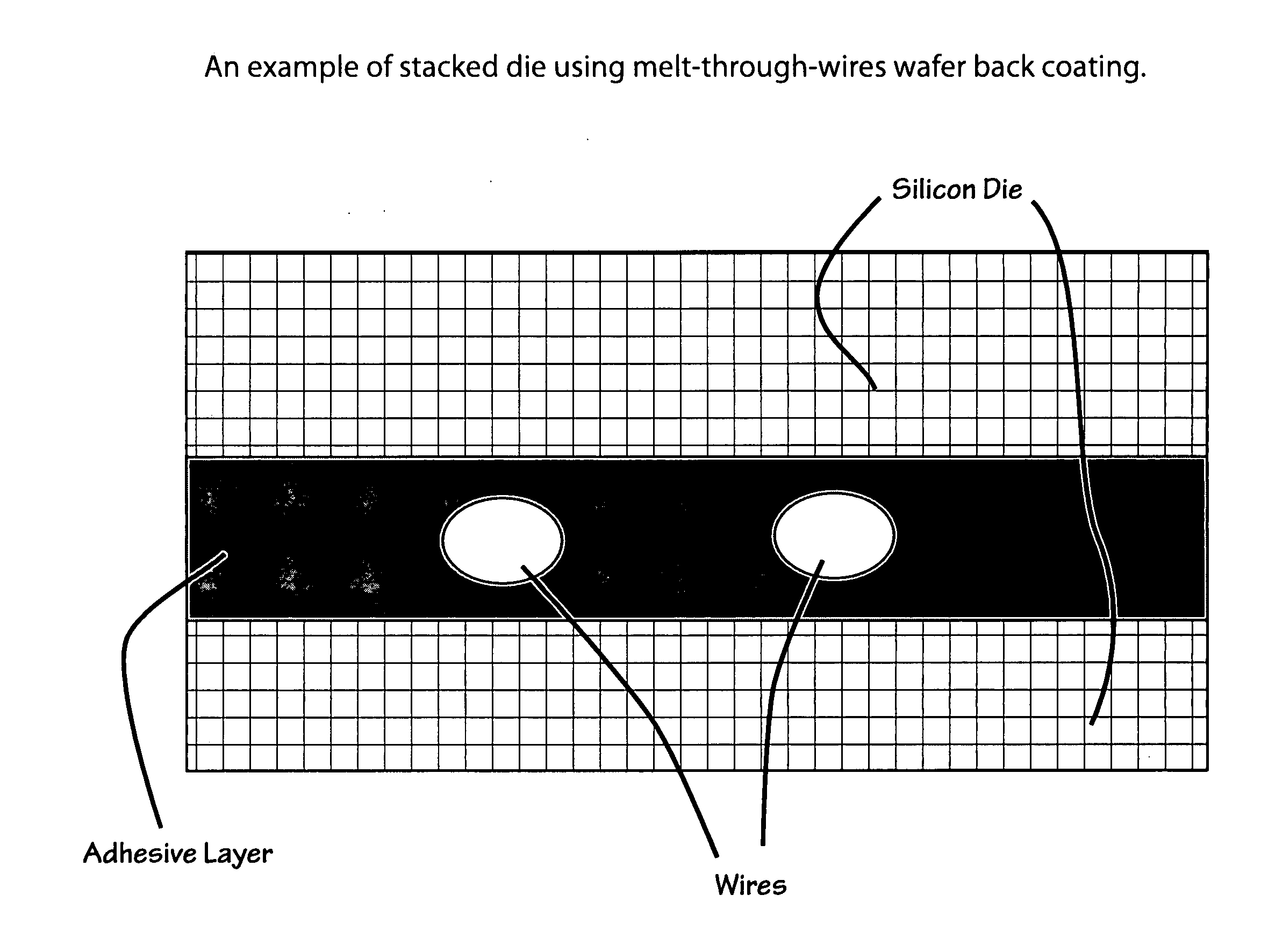

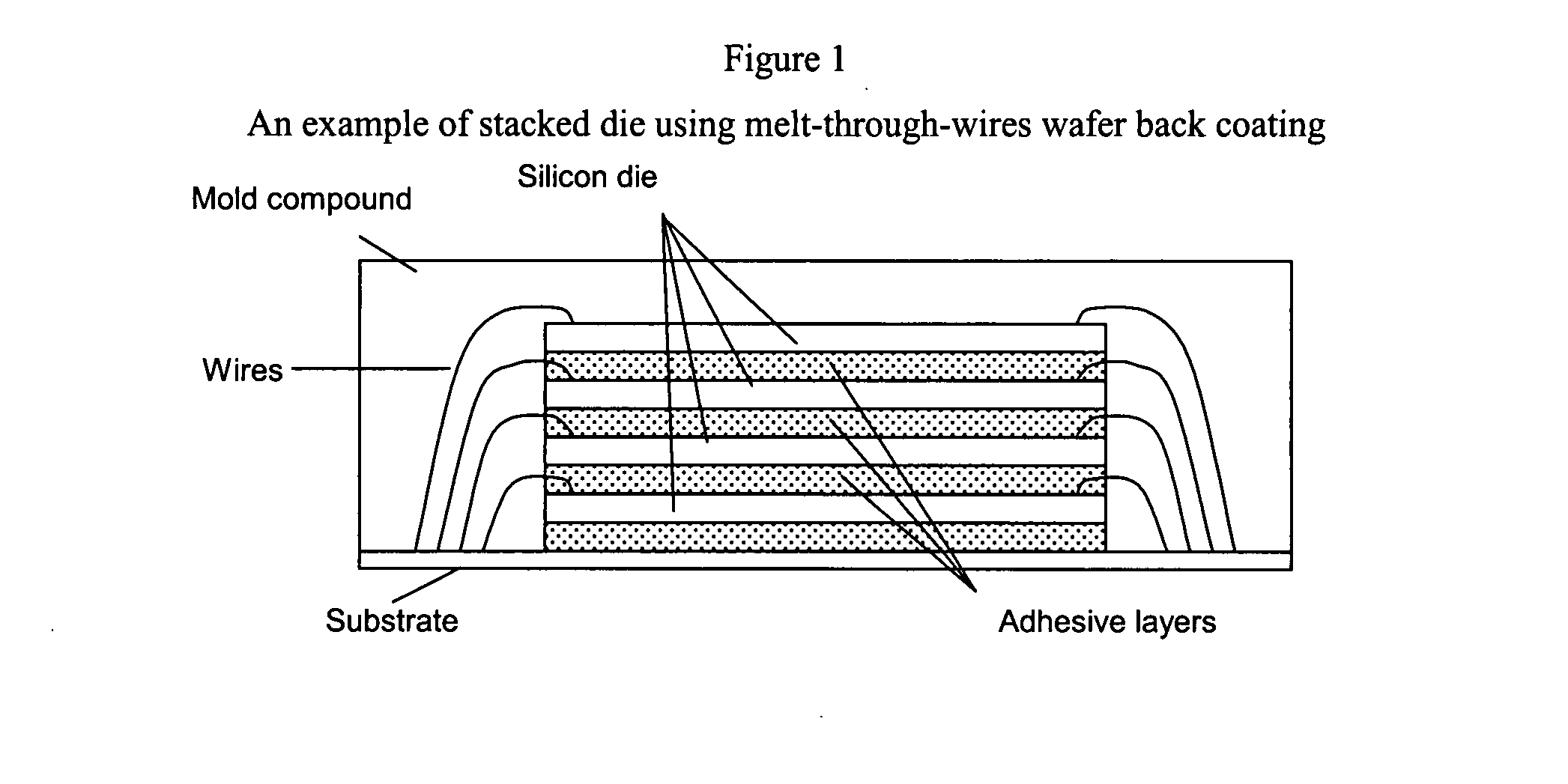

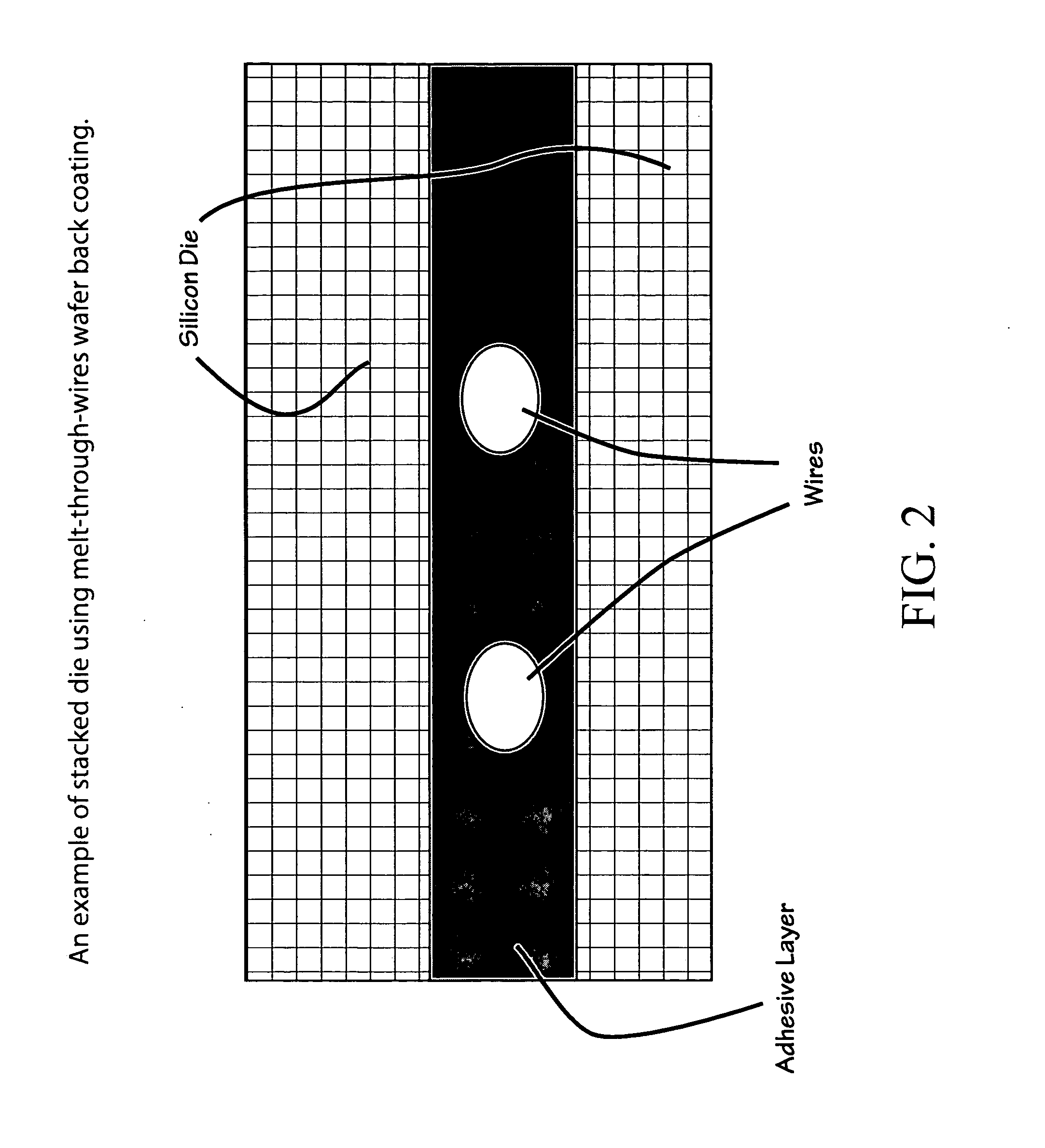

The invention is based on the discovery that a certain polyester compounds are useful as b-stageable adhesives for the microelectonic packaging industry. The polyester compounds described herein contain ring-opening or ring-forming polymerizable moieties and therefore exhibit little to no shrinkage upon cure. In addition, there are provided well-defined b-stageable adhesives useful in stacked die assemblies. In particular, there are provided assemblies wherein the b-stageable adhesive encapsulates a portion of the wiring members contained within the bondline gap between the stacked die.

Owner:DESIGNER MOLECULES

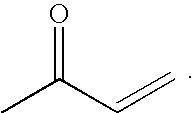

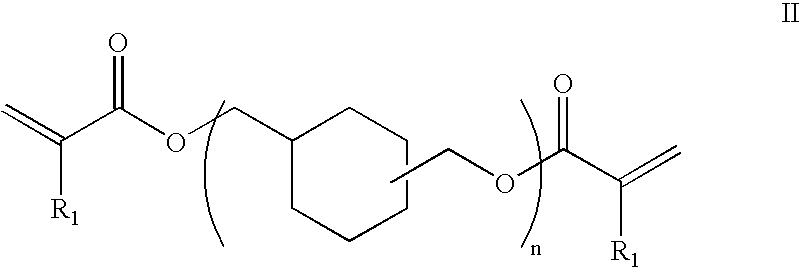

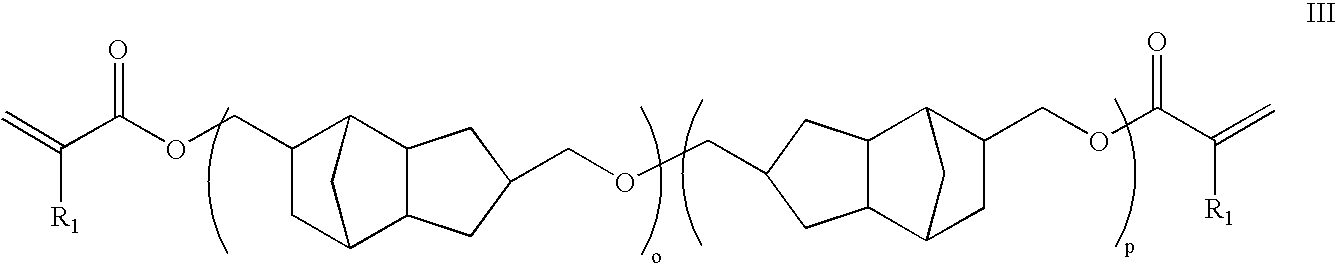

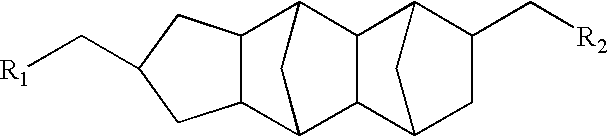

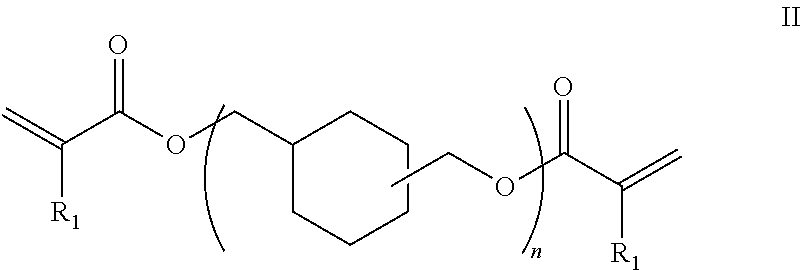

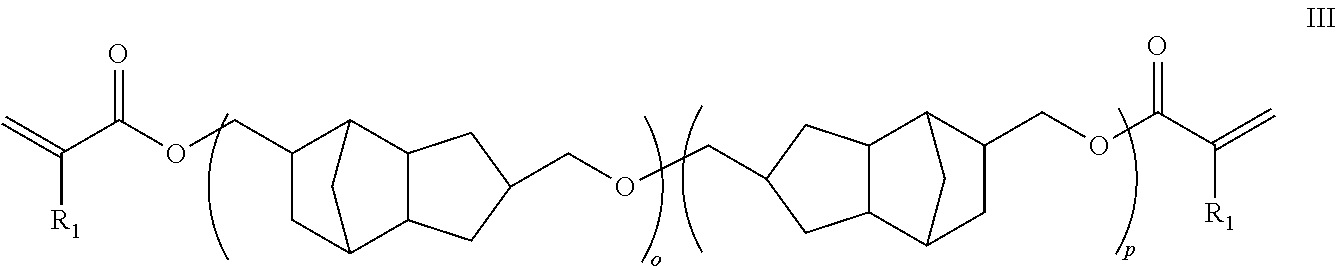

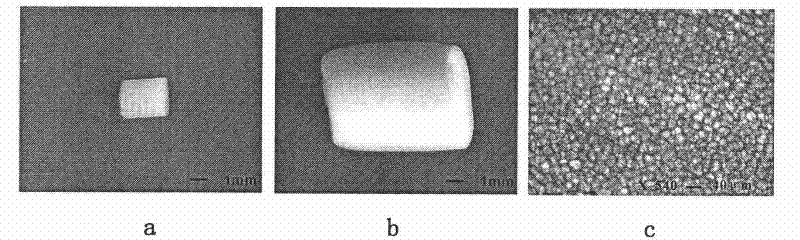

Monomers derived from pentacyclopentadecane dimethanol

ActiveUS20080257493A1Reduce cure-induced shrinkageStressAdhesive processesOrganic compound preparationAdhesiveSemiconductor package

The invention is based on the discovery that certain well-defined compounds derived from pentacyclopentadecane dimethanol are useful components in adhesive formulations. In particular, the invention compounds described herein provide high Tg values and low shrinkage. Compounds of the invention are useful as adhesives for use in the semiconductor packaging industry.

Owner:DESIGNER MOLECULES

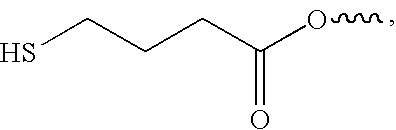

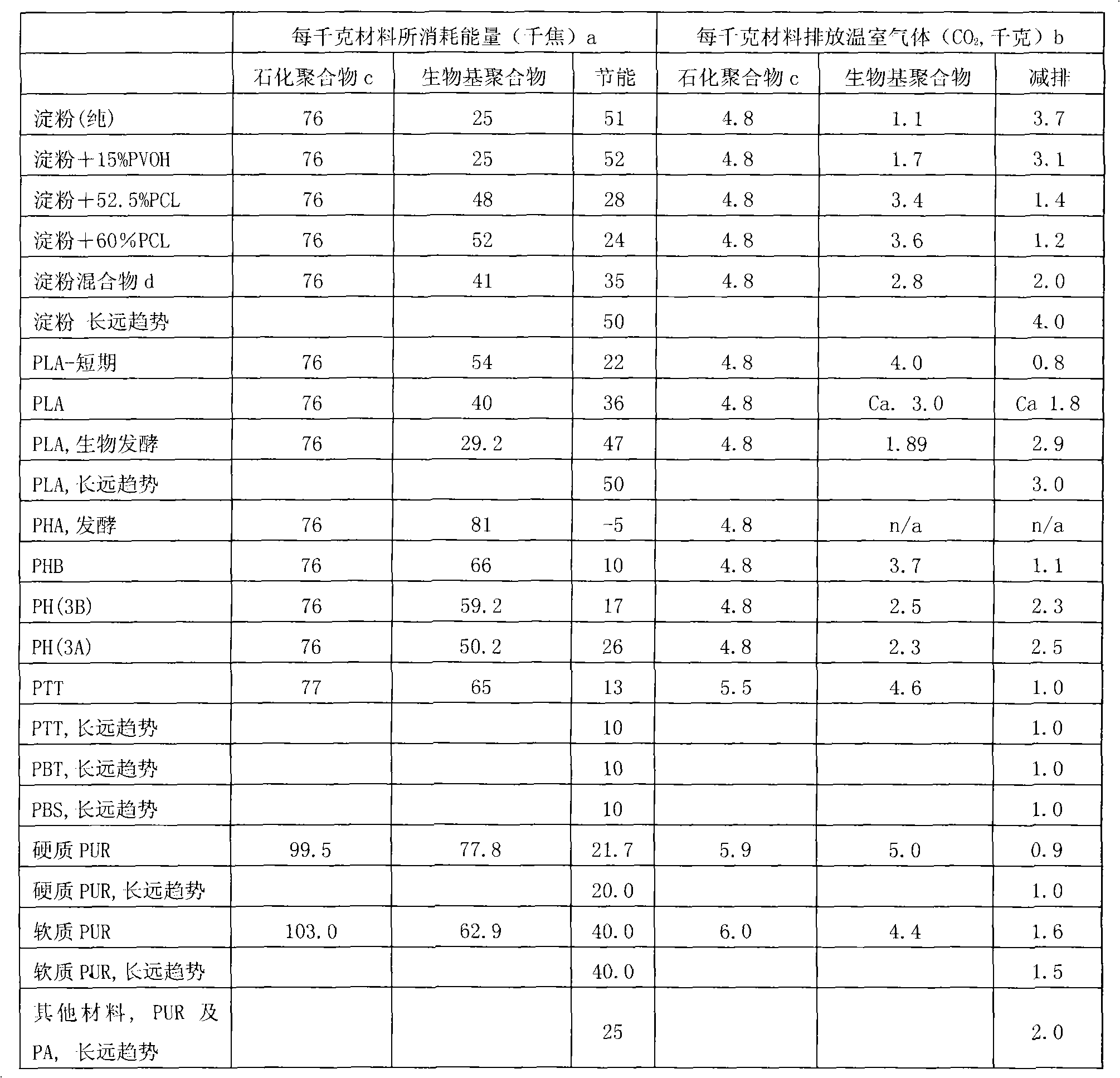

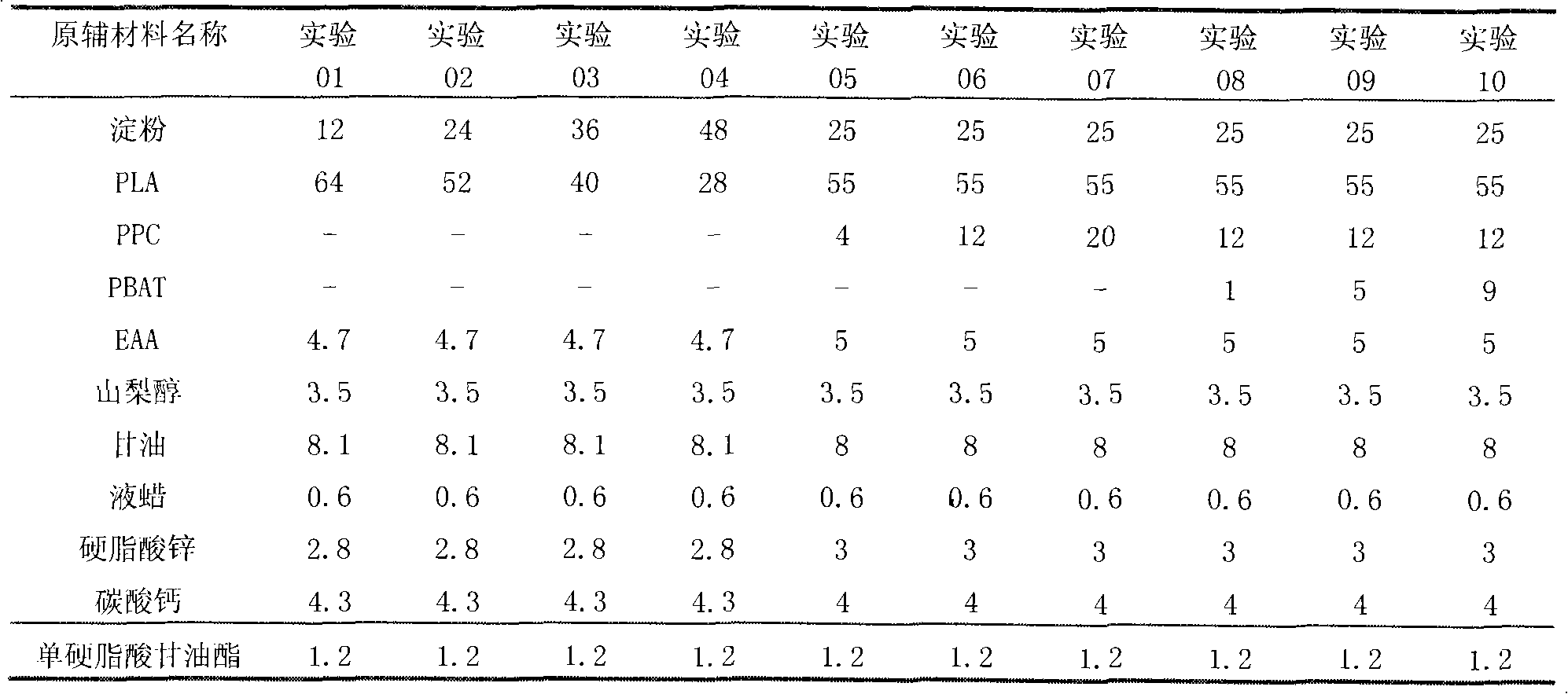

Full-degradable thermoplastic composite material and sheet thereof

The invention discloses a full-degradable thermoplastic composite material which is prepared from polylactic acid and starch which serve as base materials, PBAT and PCC, a sheet which is prepared from the material and is applicable to hot pressing and forming, and a preparation method thereof. The main components of the full-degradable thermoplastic composite material and the sheet of the invention are polylactic acid, starch and the like with biological sources, and the material and the sheet thereof can be degraded into water and carbon dioxide under the condition of compost, thereby saving a large amount of energy and reducing the environment pollution. The full-degradable thermoplastic composite material and the sheet thereof of the invention are mainly used for manufacturing sheets which are processed through plastic suction in the packaging industry, can be applied in the processing of disposable cups, disks, bowls, plates, boxes and the like through a plastics suction method, are widely applied to the packaging of food, vegetables, fruits, drinks, dairy food and industrial parts, and have stronger popularization significance.

Owner:任伟

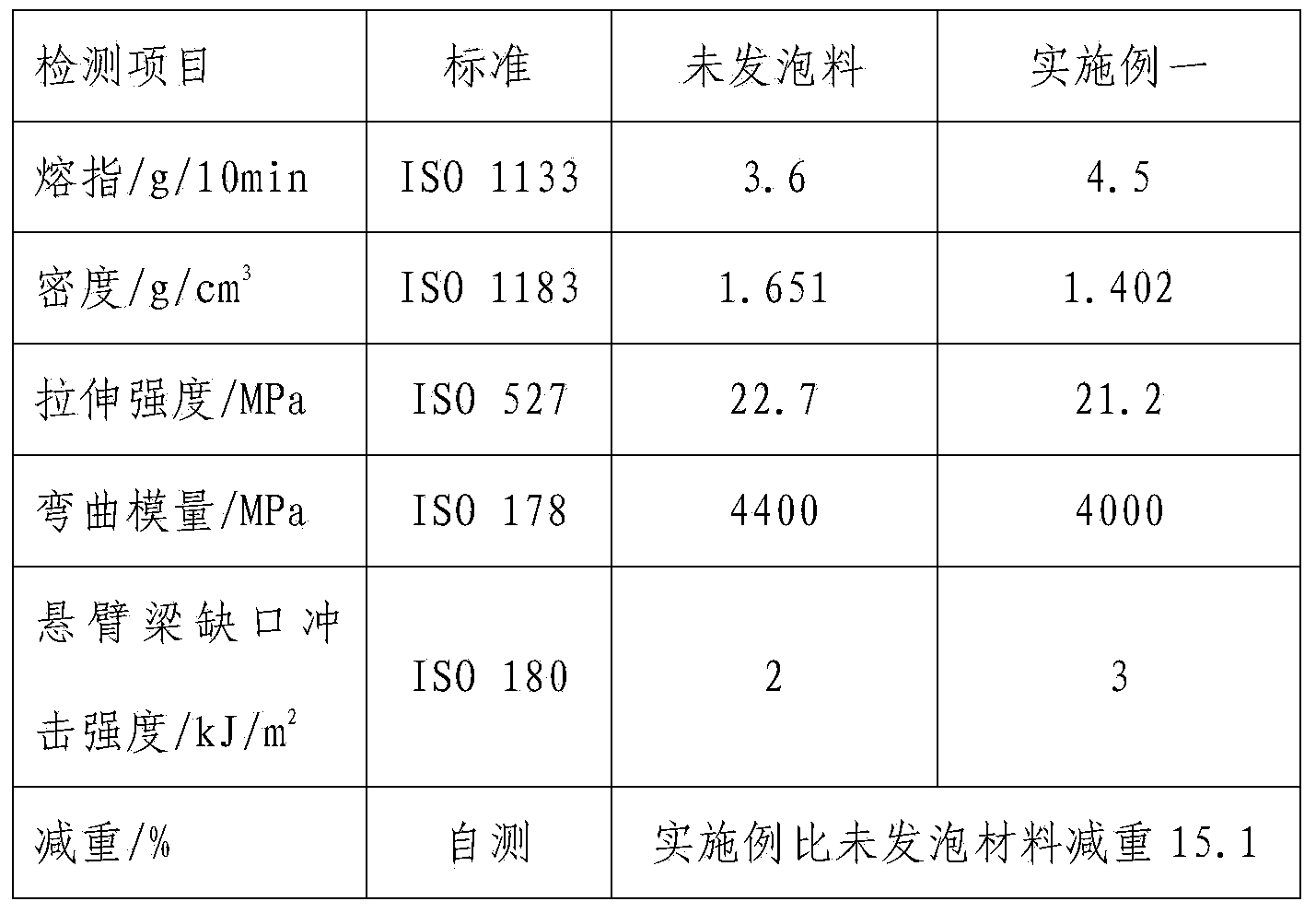

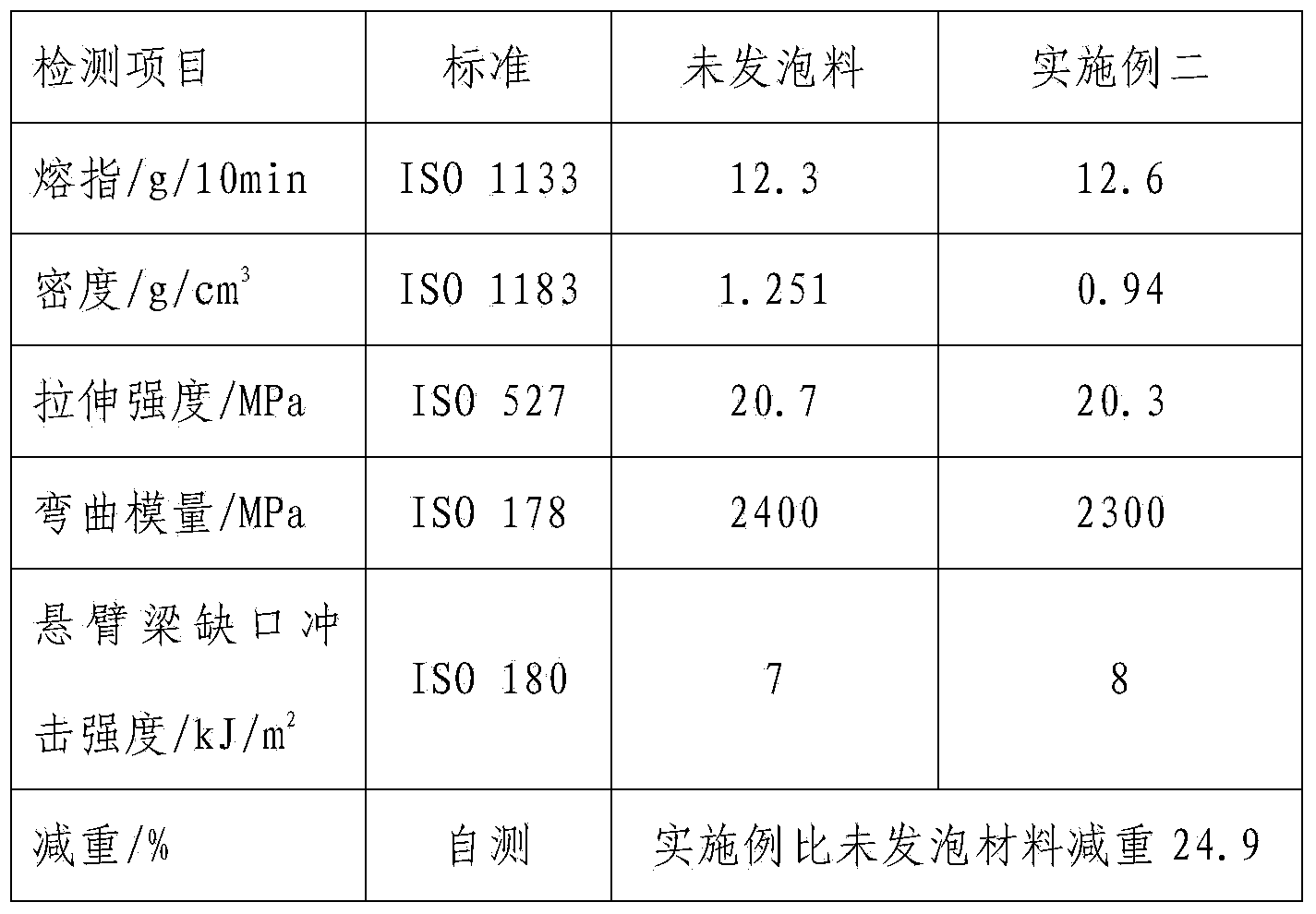

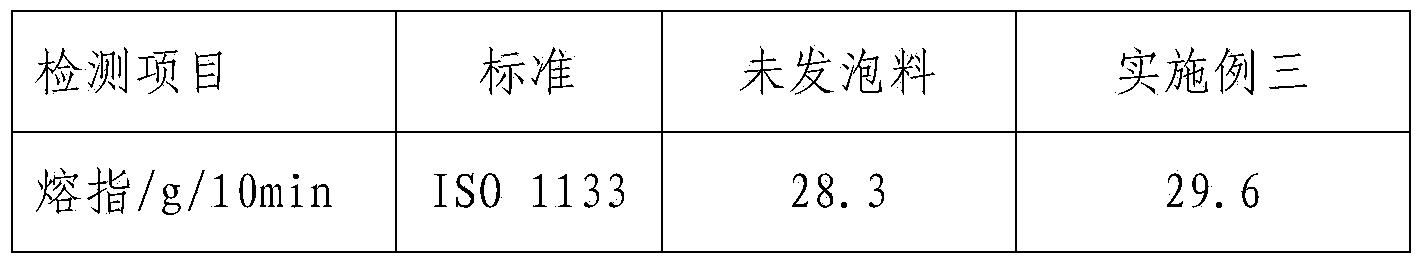

Highly filled micro foamed polypropylene composite material and preparation method thereof

The invention relates to a polypropylene composite material and a preparation method thereof, in particular to a highly filled micro foamed polypropylene composite material and a preparation method thereof, and belongs to the technical field of high polymer materials. The highly filled micro foamed polypropylene composite material comprises, by weight, 20-50 parts of polypropylene, 40-70 parts of inorganic powder, 0.5-10 parts of blowing master batch, 1-10 parts of toughening agents and 0.2-2 parts of antioxidants. The highly filled micro foamed polypropylene composite material has the advantages that on the premise that material performance is not lost, the weight of the material is obviously reduced, the impact property is improved, production cost is greatly lowered, and the highly filled micro foamed polypropylene composite material which is excellent in performance and friendly to environment is obtained. The highly filled micro foamed polypropylene composite material can be applied to inner and outer accessories of automobiles even a part of structure components, and light weight of automotive materials is achieved. The highly filled micro foamed polypropylene composite material can also be used for other fields such as building, electronics and packaging industries.

Owner:NANJING JULONG SCI&TECH CO LTD

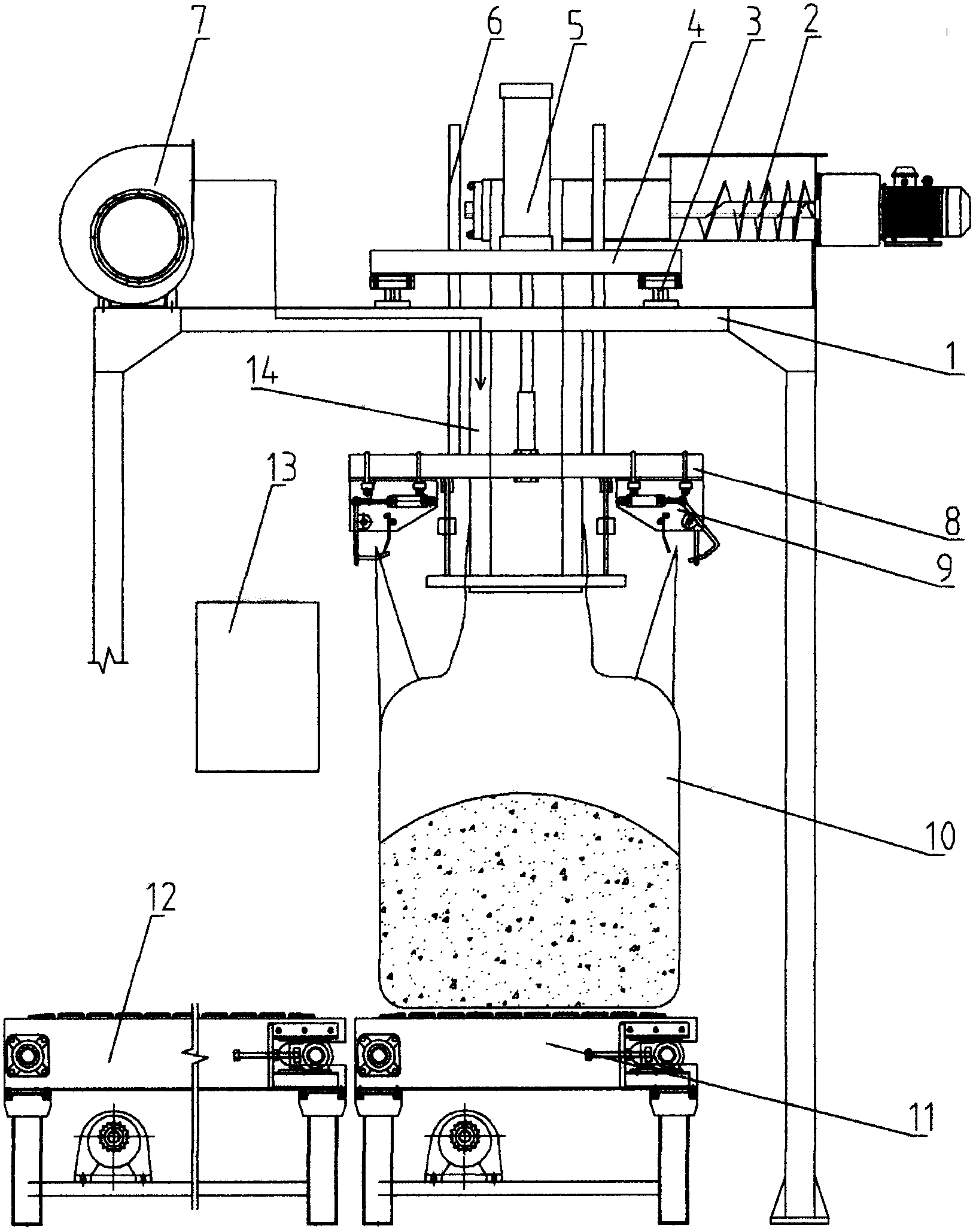

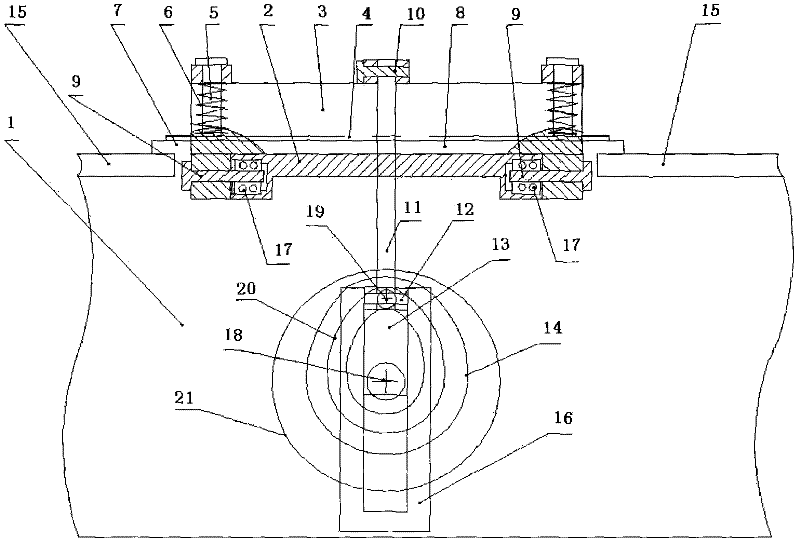

Powder material ton bag quantitative packing scale and packing method

InactiveCN102700735AIncrease productionRealize automatic liftingSolid materialControl systemEngineering

The invention provides a powder material ton bag quantitative packing scale and a packing and weighing method. The powder material ton bag quantitative packing scale comprises a platform, a frequency-variable spiral mechanism, a weighing module, a weighing frame, an air cylinder, a fan, a lifting bag clamping mechanism, an automatic bag releasing mechanism, a chain plate conveying machine, a weighing control system and an air passage, wherein the frequency-variable spiral mechanism controls the feeding speed, the weighing module is connected with the platform and the weighing frame, the weighing frame is used for transmitting the weighing weight, and the air cylinder is arranged on the weighing frame and drives the lifting bag clamping mechanism. The powder material ton bag quantitative packing scale has the advantages that in the packing and weighing processes, the labor is saved, the automation degree is high, the automatic bag expansion can be realized, the automatic lifting, the automatic filling and the weighing control of the lifting bag clamping mechanism can be realized, the powder material ton bag quantitative packing scale can be widely applied to packing industries of different powder materials, the automation degree is high, the operation is simple, convenient and fast, the production capability is high, and the work intensity and the operation cost are low.

Owner:WUXI DADONG MACHINERY MFG

Preparation of water resistant polyvinyl alcohol biodegradable film through melt extrusion method

InactiveCN102241862AImprove water resistanceImprove mechanical propertiesBlow moldingPolymer science

The invention relates to a formula and a process for preparing water resistant polyvinyl alcohol biodegradable film through a melt extrusion and blow molding processing method. The process is characterized by: uniformly mixing polyvinyl alcohol and various assistants through a specific mixing method; carrying out extruding and granulating through a twin-screw extruder; carrying out melt extrusion through a single screw extruder to prepare the water resistant polyvinyl alcohol biodegradable film. The preparation process for the water resistant polyvinyl alcohol biodegradable film has the following advantages that: the melt extrusion and blow molding processing method is adopted; compared to the traditional tape casting method, the process provided by the present invention has high continuous degree, short production period, stable process, and the prepared water resistant polyvinyl alcohol biodegradable film has adjustable thickness and folding diameter; the water resistance and processability of the polyvinyl alcohol film are improved through adding a crosslinking agent, a processing modifier and the like, such that each performance of the prepared film provided by the present invention are excellent, and the prepared water resistant polyvinyl alcohol biodegradable film can be widely applicable for packaging industries such as food, daily chemical products, pharmaceutical electronic components and the like.

Owner:BEIJING UNIV OF CHEM TECH

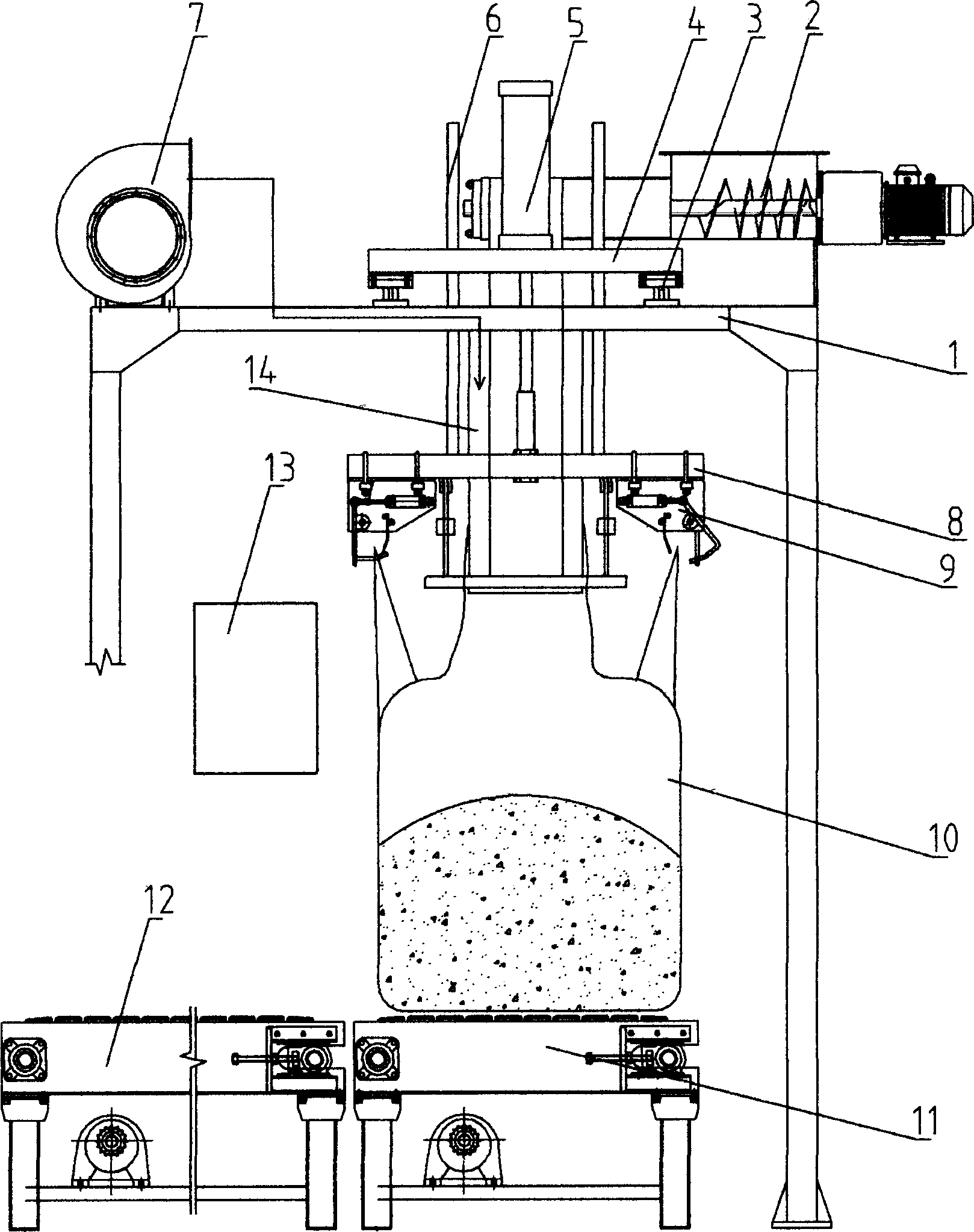

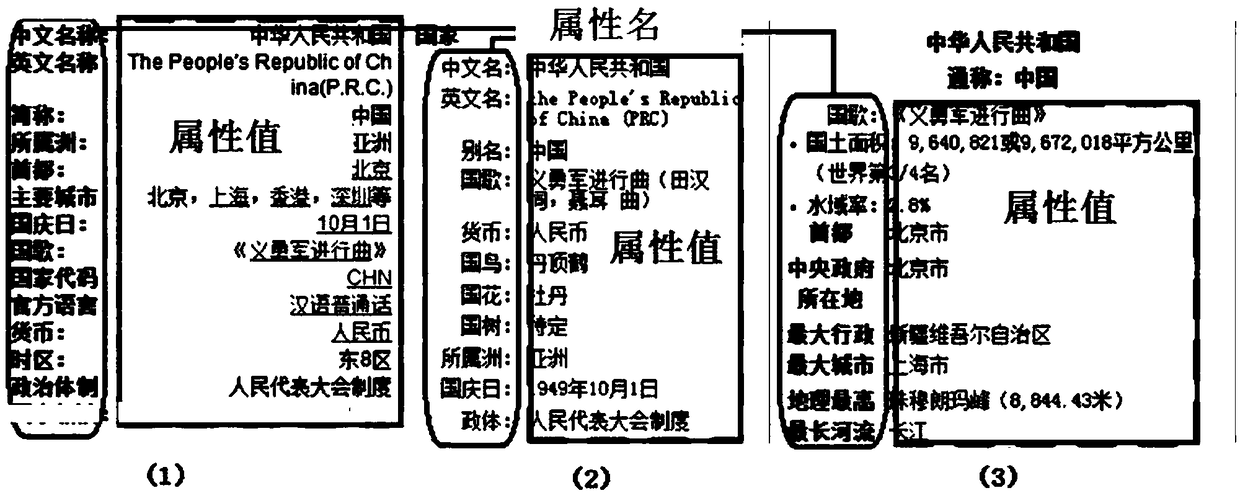

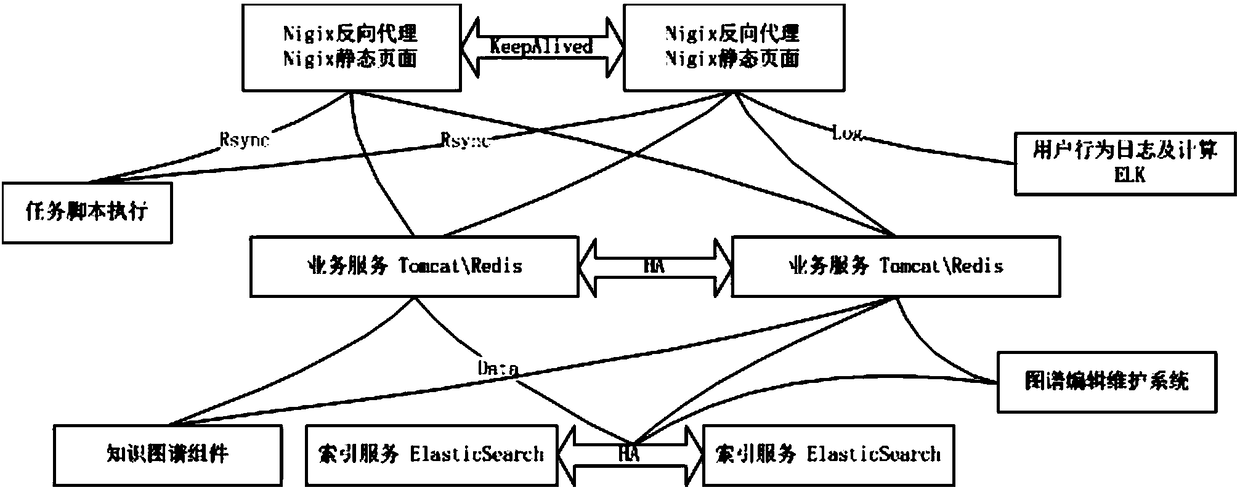

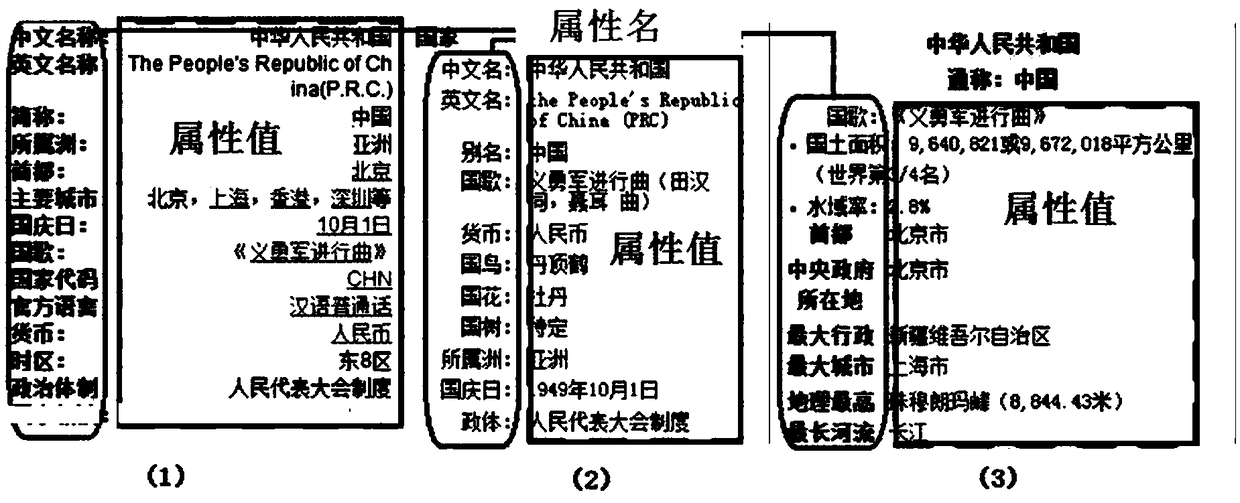

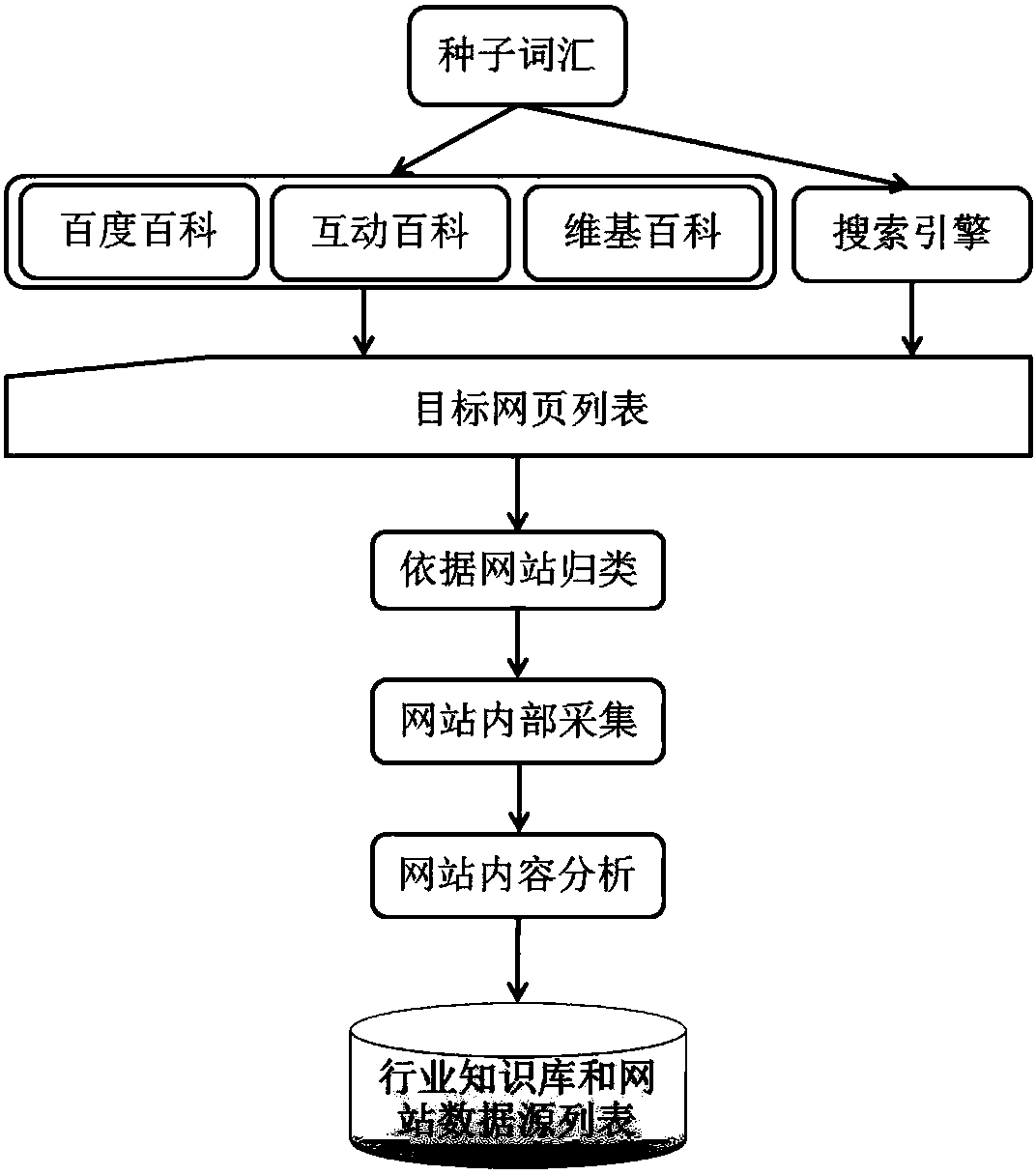

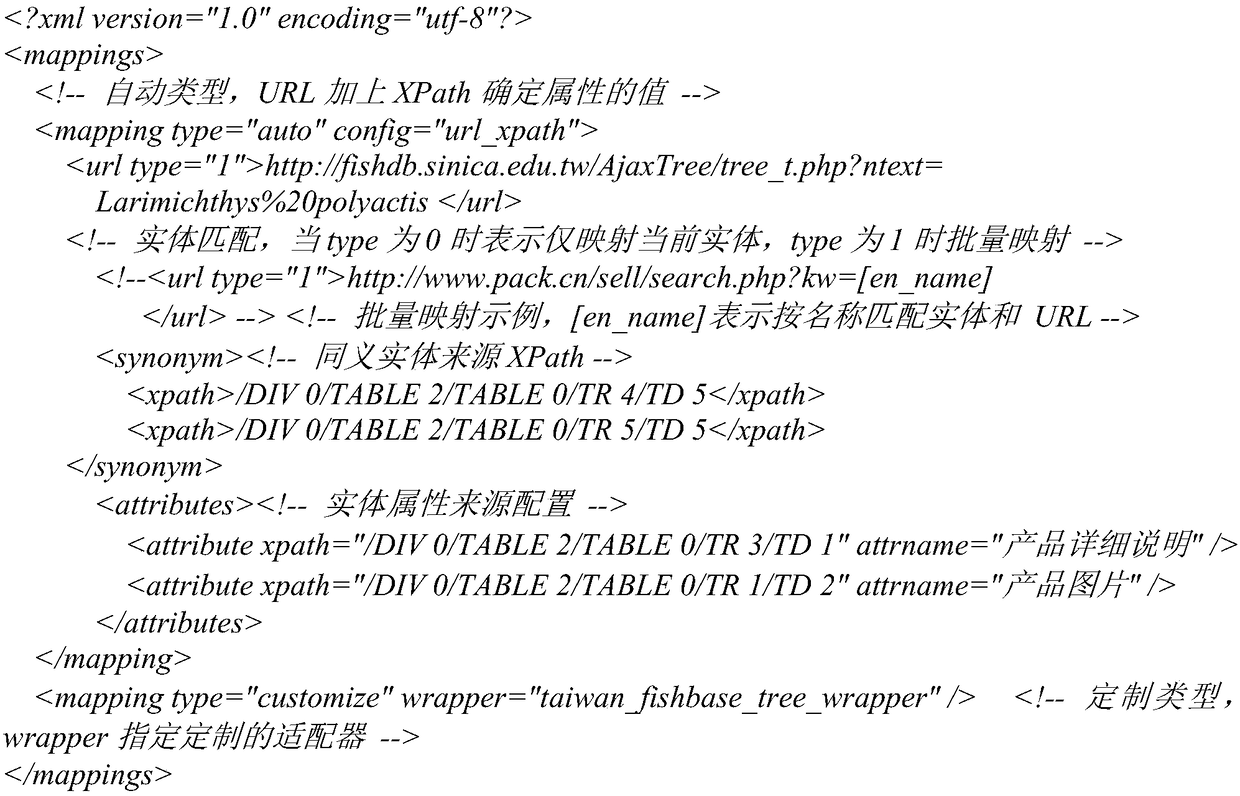

Knowledge graph-based packaging industry data search method and device

InactiveCN108446367AFree and flexible expansionGood retrieval efficiencySpecial data processing applicationsKnowledge graphVertical field

The invention provides a knowledge graph-based packaging industry data search method and device. A packaging industry vertical field search engine can realize optimal retrieval efficiency and effect of the packaging industry field; a natural language query can be deeply understood; a user query intention is analyzed at a semantic level; massive structured knowledge bases can be utilized; an accurate answer is provided for a user query; and in addition, a synonym lexicon can be freely and flexibly expanded.

Owner:HUNAN UNIV OF TECH +1

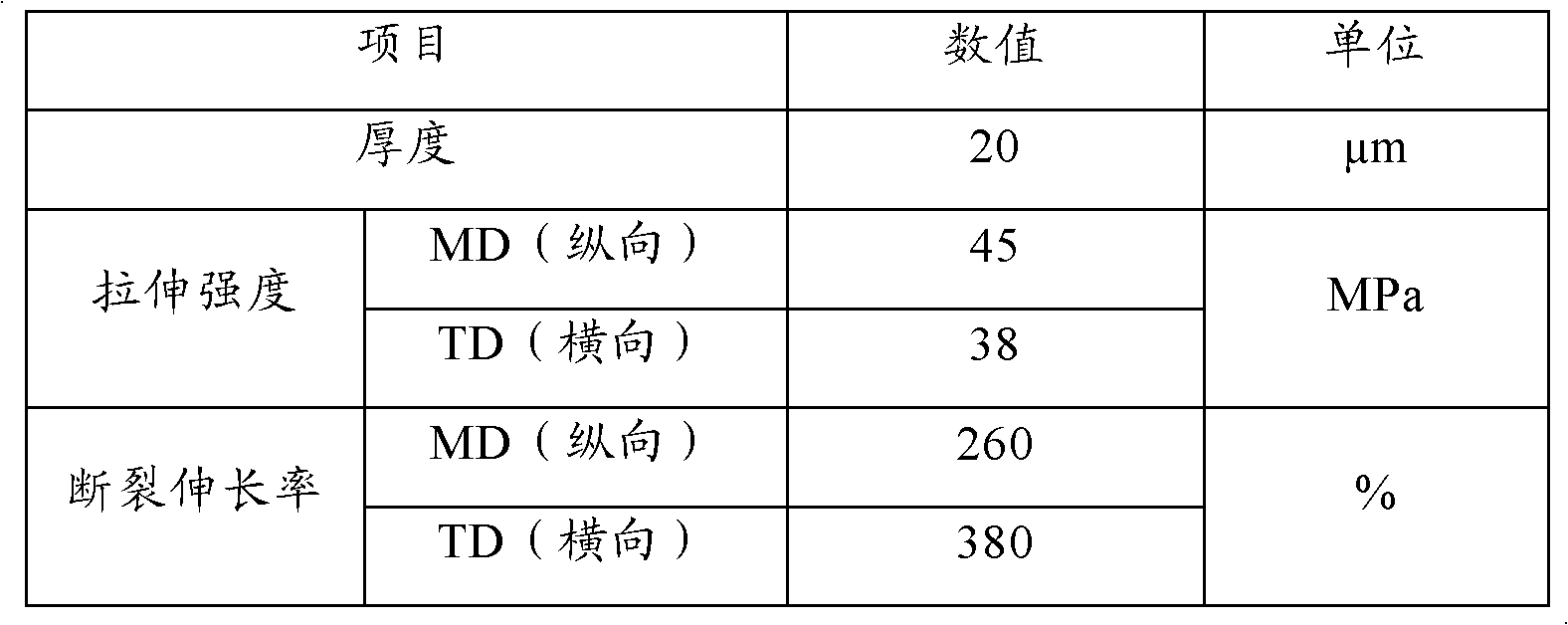

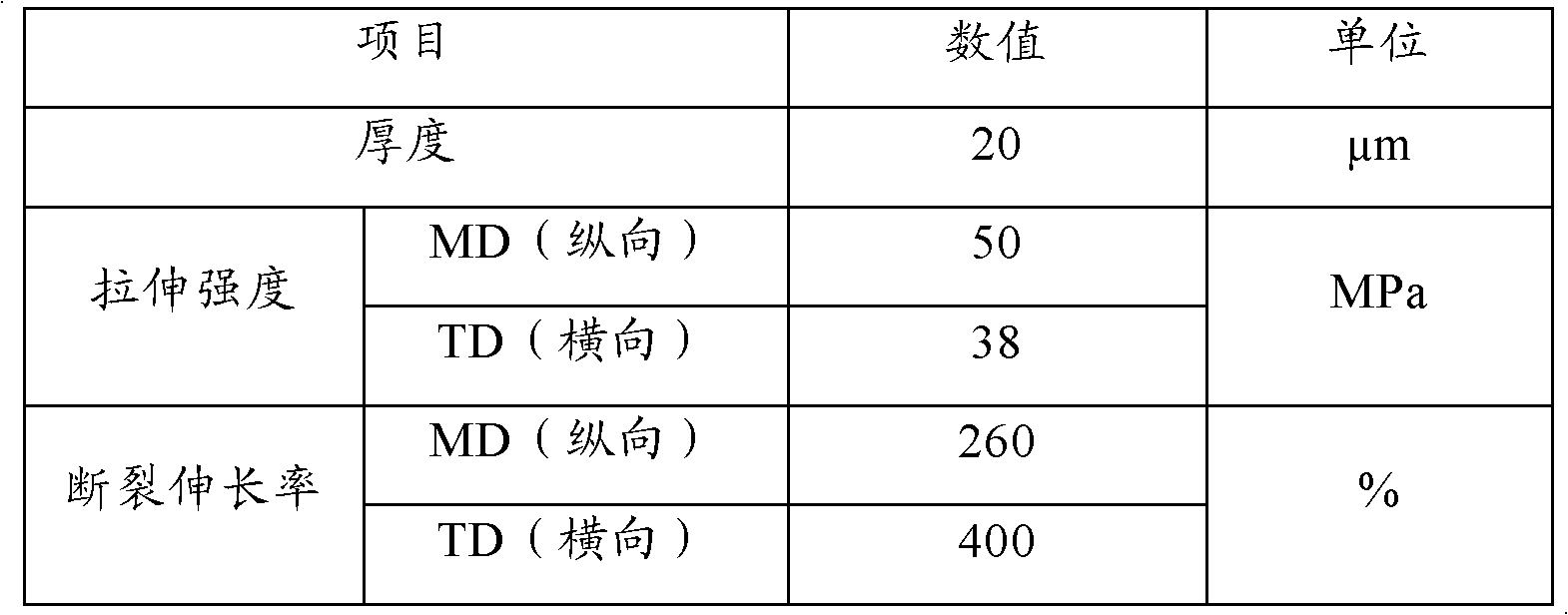

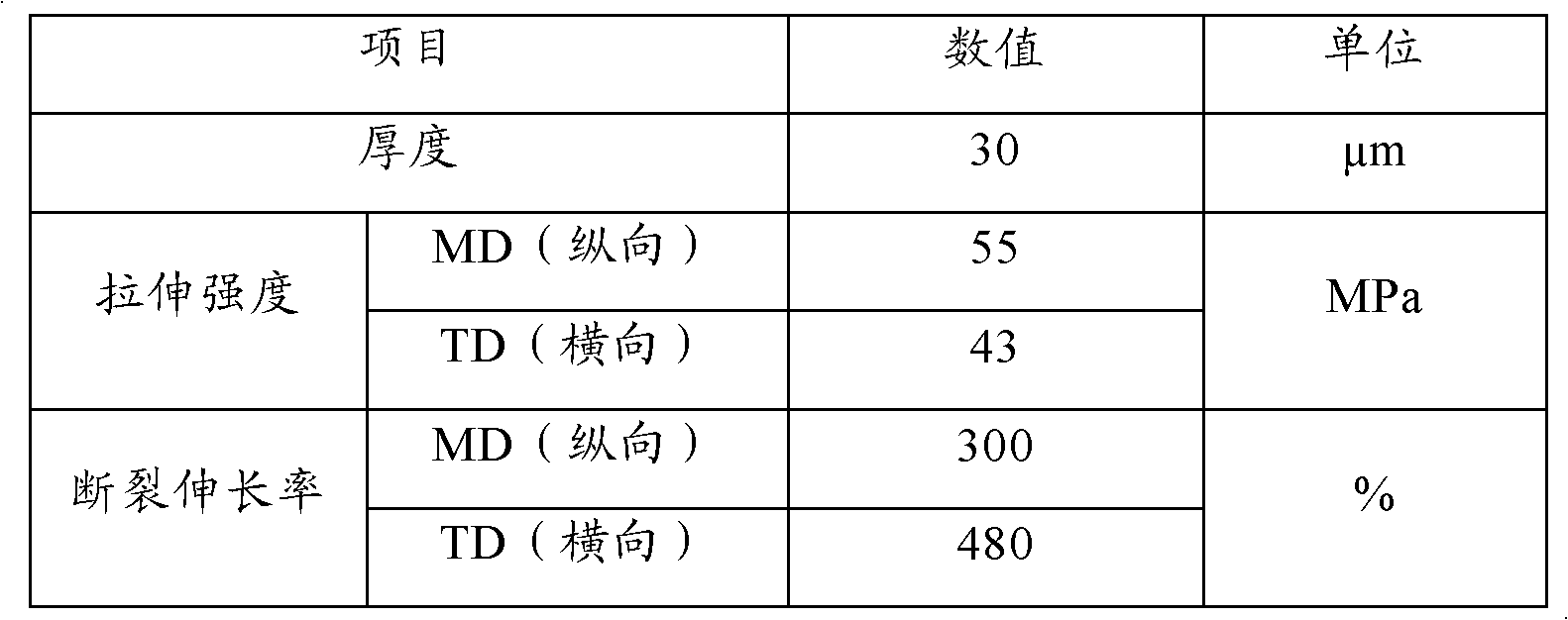

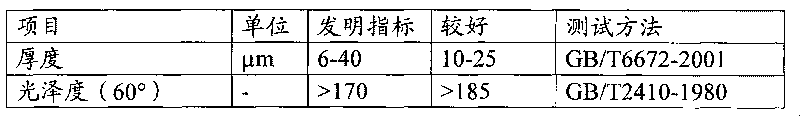

Polyester film, and a preparation method and applications thereof

InactiveCN102432984AThe preparation method is simple and scientificStable Intrinsic ViscosityPolyesterPunching

The invention discloses a polyester film, and a preparation method and applications thereof. The polyester film is prepared by adopting processes of casting and setting and comprises the following components according to the weight ratio: 300-1200ppm of antiblocking inorganic additive and the balance polyethylene glycol terephthalate or modified resin with the intrinsic viscosity being more than 0.78dL / g. In the invention, the defects in the prior art are overcome, and the advantages of low degree of orientation, high elongation at break (up to 480%), good toughness for long time, large molecular weight and narrow distribution are realized. The polyester film has the characteristics of good adhesiveness on metal, low lining temperature, good deep-punching processing resistance, excellent printing effect, low small-molecular mobility and the like and has wide use prospect in the industries such as metal package and flexible package.

Owner:ORG TECH CO LTD

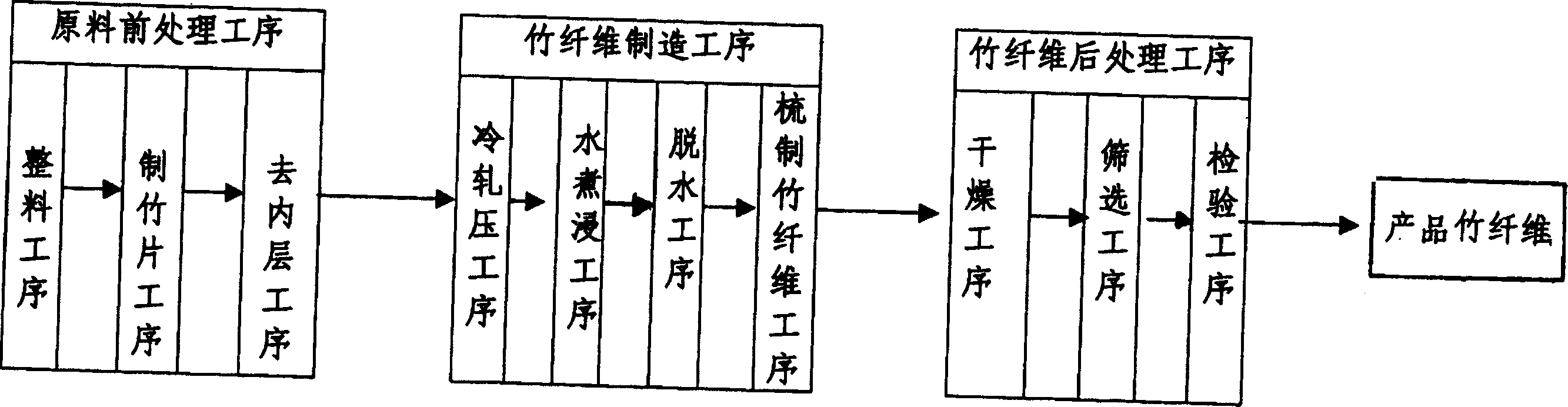

Bamboo fibres and preparing process thereof

InactiveCN1185086CNo pollution in the processSimple processWood working apparatusFiberMaterials science

A bamboo fibre with 0.04-0.5 mm of diameter and more than 10 mm of length is prepared from bamboo through pre-treating of raw material, preparing fibres (including cold rolling, boiling in water, immersing in water, dewatering and carding), and post-treating. Its advantages are simple technology, low cost and no environmental pollution. Said bamboo fibres can be used to make bamboo fibreboard and sections.

Owner:曹玉海

Ternary built poly lactic acid type composite material and its use

InactiveCN1749316AGood physical and chemical propertiesImprove heat resistanceHeat resistanceUltimate tensile strength

The ternary built polylactic acid type composite material consists of PLA 45.0-80.0 wt%, PPC 4.0-40.0 wt%, PHB 4.0-40.0 wt% and various assistants. The ternary built polylactic acid type composite material is used as mother material for preparing thermoplastic material with improved forming machining property and heat resistant, raised tearing strength and high product size stability. It may be blow molded to produce various film products with excellent physical and chemical performance and controllable biodegradation speed for wide application in packing and agriculture.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

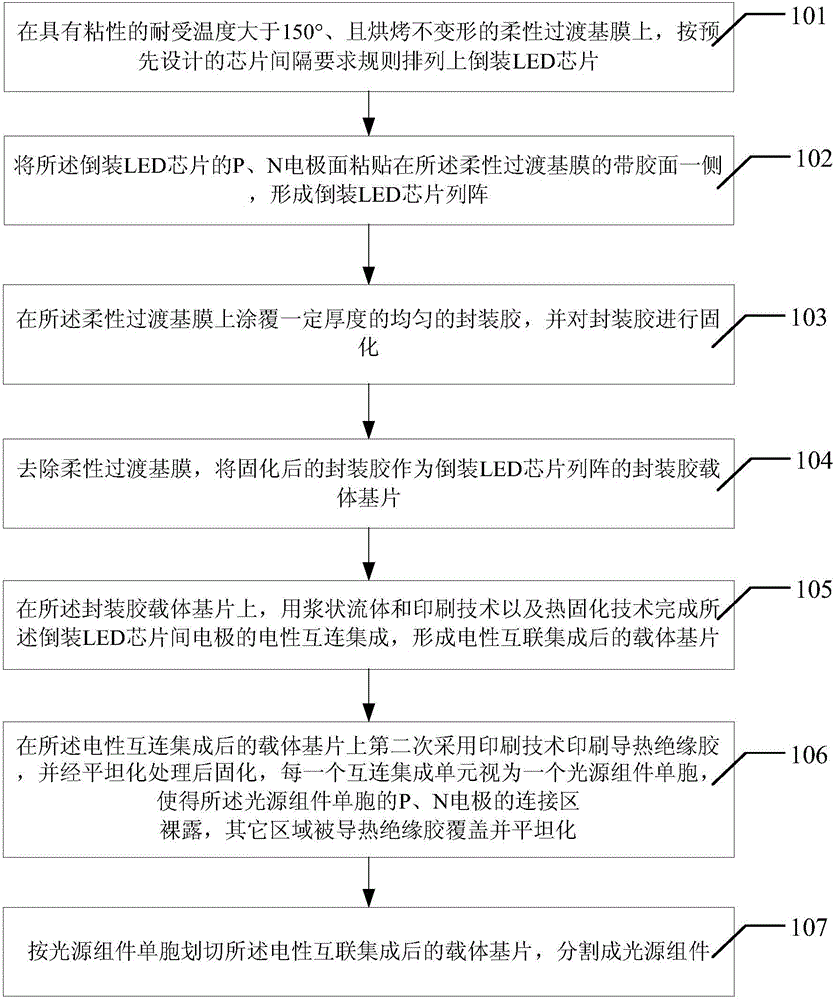

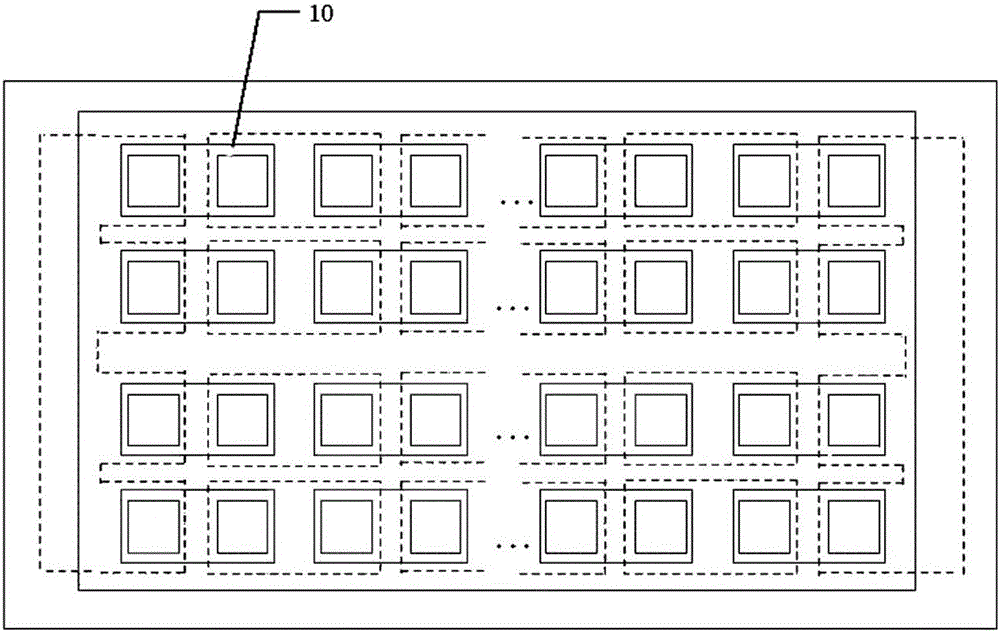

Optical source assembly structure of flip LED chip integrated package and manufacturing method thereof

ActiveCN105895785AImprove qualityHigh optical densitySolid-state devicesSemiconductor devicesElectricitySurface mounting

The invention discloses an optical source assembly structure of flip LED chip integrated package and a manufacturing method thereof. The method comprises the steps of arranging flip LED chips on a flexible transition base film to form a chip array; coating the base film uniformly with packaging glue to a certain thickness, and curing the packaging glue; removing the flexible transition base film, and using the cured packaging glue as a carrier substrate of the chip array; completing the electrical interconnect integration of electrodes among the chips on the packaging glue carrier substrate; printing and curing thermally conductive and insulation glue on the carrier substrate after electrical interconnect integration, to form various optical source assembly unit cells; and obtaining a separated optical source assembly in accordance with the various optical source assembly unit cells. The optical source assembly is bonded and assembled with a thermally conductive substrate to achieve electrical connection with an external circuit to be combined into an optical source. The method is free from the form of isolated chip interconnect integrated package on a COB board in the current packaging industry, eliminates the process steps of surface mounting and crystal curing and the like on the COB board, and simplifies the manufacturing process.

Owner:湖南省日晶照明科技有限责任公司

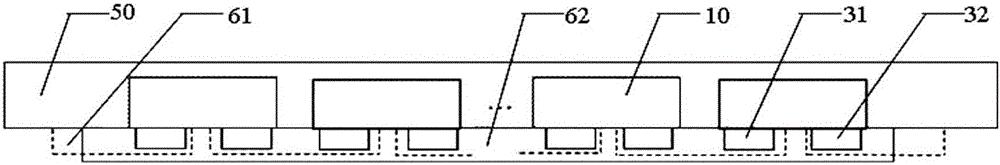

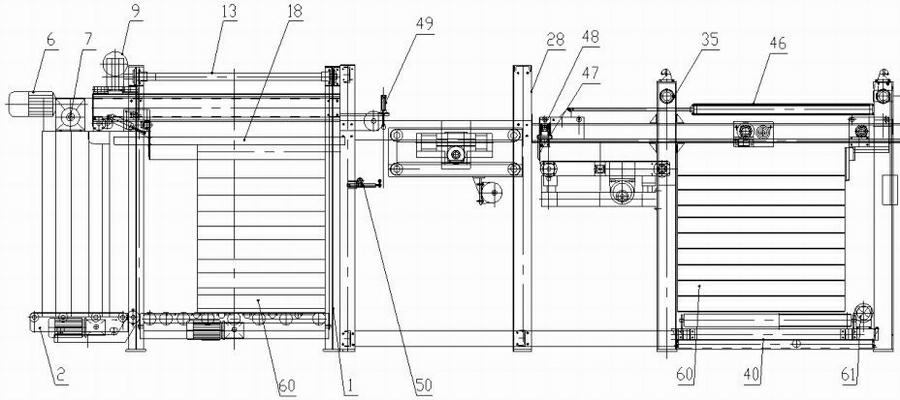

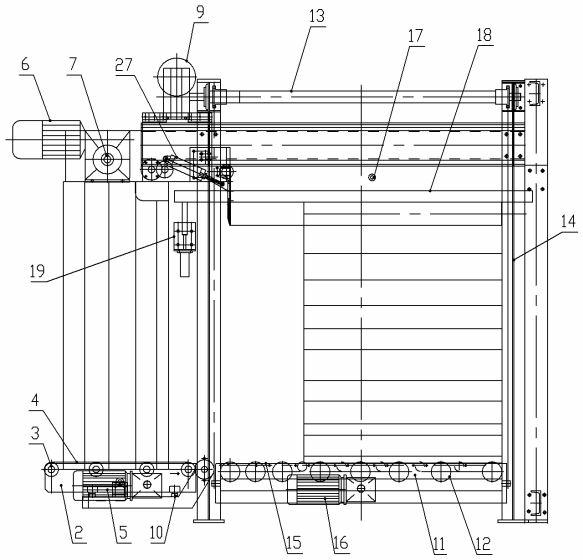

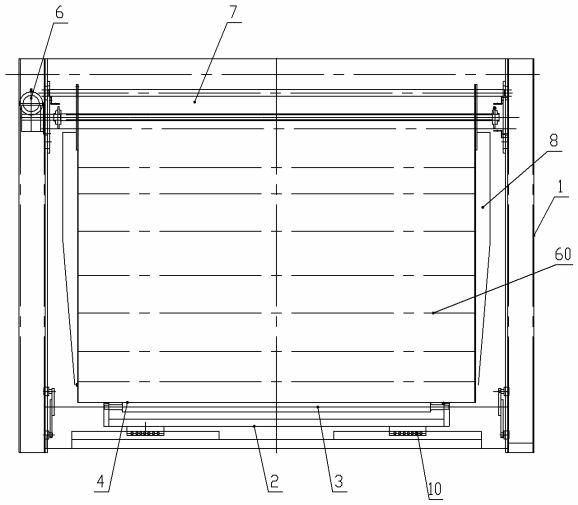

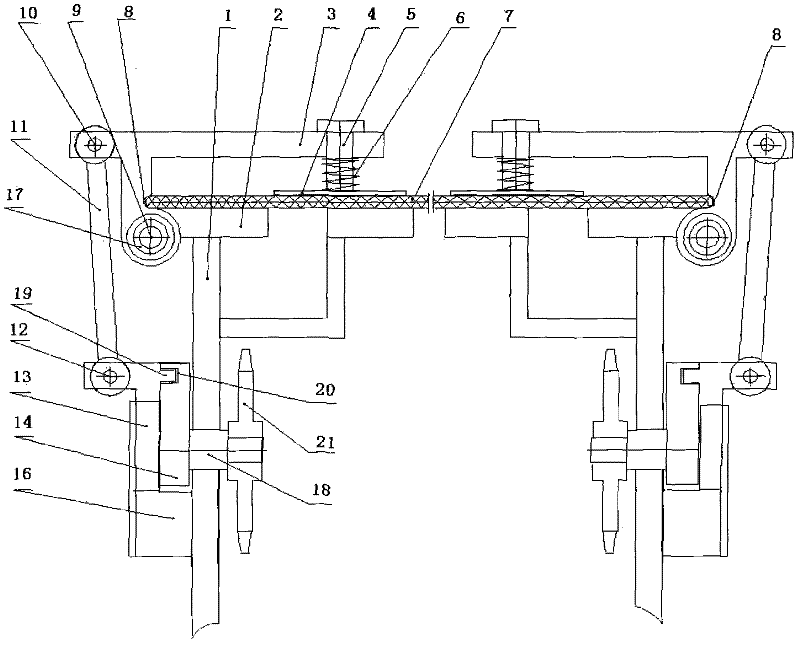

Full-automatic counting board-turning stack aligner

InactiveCN102583072AResolve dependenciesSolve efficiency problemsPaper article packagingOverturning articlesProduction lineCardboard

The invention discloses a full-automatic counting board-turning stack aligner, which comprises an arrangement counting conveying system, a board turning system and a rear conveying accumulation arrangement system. An output end of the arrangement counting conveying system is connected with an input end of the board turning system, an output end of the board turning system is connected with an input end of the rear conveying accumulation arrangement system, and a packing device is arranged between the output end of the arrangement counting conveying system and the input end of the board turning system. The full-automatic counting board-turning stack aligner is certainly well received by enterprises in the packaging industry for improving automation level, precision, intelligence and the like, and also solves the problems that online manual paper board counting, board turning, packing and stack alignment of a corrugated paper board production line greatly rely on manual operation for a long period, and production efficiency is restricted. According to huge market demands, successful development of efficient energy-saving equipment such as the full-automatic counting board-turning packing stack aligner and the like can become the development trend of the efficient equipment in nationwide and global packaging industries.

Owner:河南远航包装机械有限公司

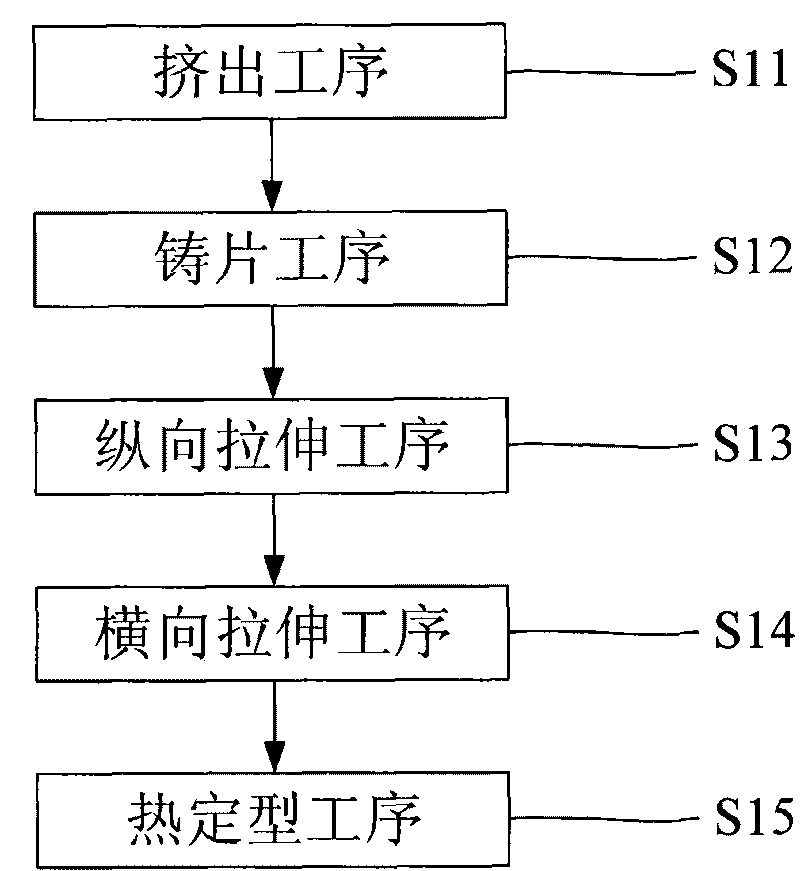

Low-haze multi-layer co-extrusion two-way stretching polyamide film and preparation method

InactiveCN101722700AReduce gapGood optical performanceSynthetic resin layered productsSurface layerPolyamide

The invention provides a low-haze multi-layer co-extrusion two-way stretching polyamide film and a preparation method. The two-way stretching polyamide film comprises at least three co-extrusion structures, namely a surface layer A, a surface layer C and a middle layer B, wherein the surface layer A and the surface layer C contain antiblocking agents. The invention also discloses a preparation method of the two-way stretching polyamide film, comprising the following steps of: preparing polyamide raw materials, extruding, casting pieces, thermoforming, slacking, drawing, winding, and the like. The two-way stretching polyamide film has the advantages of low haze, high gloss and high transparency and can be widely applied to the field of the packaging industry.

Owner:SHANGHAI ZIDONG CHEM MATERIALS

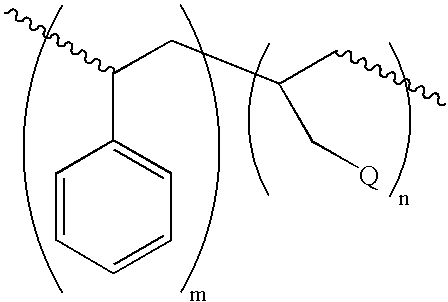

Thermosetting polyether oligomers, compositions and methods for use thereof

InactiveUS7928153B2Low viscosityImprove conductivityOrganic chemistryOrganic compound preparationAdhesiveHigh conductivity

Owner:DESIGNER MOLECULES

Biodegradable poly (butylene adipate terephthalate) micro-pore foaming particle with high foamability and preparation method thereof

The invention discloses a biodegradable poly (butylene adipate terephthalate) (PBAT) micro-pore foaming particle with high foamability and a preparation method thereof. The preparation method comprises the following steps: placing a chain extension PBAT particle with a melting point of Tm DEG C into a high-pressure mould of a mould-pressing physical gas foaming device; filling 8-20MPa CO2; keeping pressure for 5-20 minutes at a constant temperature within a range of Tm minus 30 DEG C to Tm plus 5 DEG C; releasing pressure at a speed of 5-30MPa / s; and sampling and cooling within 30 seconds, thereby acquiring the micro-pore foaming particle with high foamability. Compared with the raw material, the acquired micro-pore foaming particle with high foamability has the advantages that the volumeis increased by 10-30 times, the diameter of foaming pore is less than 100 microns, the foaming pore distribution is uniform, and the cortex structure does not exist. The preparation method provided by the invention has the advantages that the process flow is simple, the production period is short, the cost is low, the product property is excellent, and the preparation method is beneficial to industrial production, thereby being beneficial to the developing application of the biodegradable material in disposable catering and packaging industries.

Owner:浙江博发新材料股份有限公司

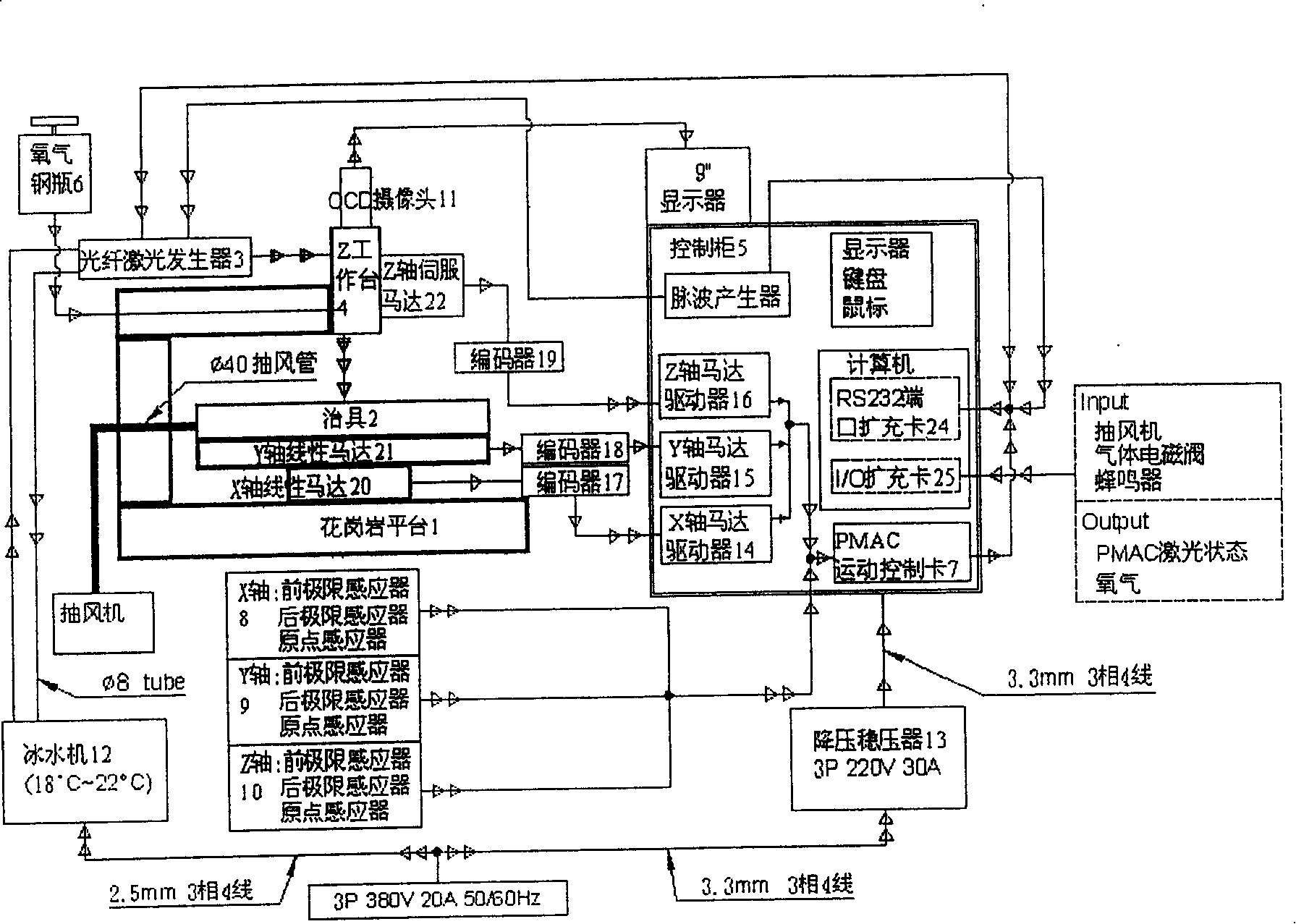

Laser cutting device

InactiveCN101190476AEasy CalibrationImprove cutting accuracyLaser detailsLarge fixed membersMetallic materialsHigh pressure oxygen

The invention discloses a laser cutting device, comprising a laser cutting head system, an X-Y workbench and a granite workbench of counterweight and a workpiece clamping mechanism. The laser cutting head system comprises a laser generator, a Z workbench and a control cabinet. The invention is characterized in that the X-Y workbench adopts a sliding block to carry out limitless circular restricted linear motion on a linear sliding track through steel balls between the sliding block and the linear sliding track; the laser generator is an optical fiber generator; the laser cutting head system also comprises a high-pressure oxygen nozzle at the circumference of the laser beam; when cutting, the oxygen flow basically coaxial with the laser beam is spouted out from the cutting head. The invention has the advantages of high cutting precision, high processing efficiency, low manufacture cost, low application cost, simple optical path correction, conveniently implementing miniaturization, being suitable for the cutting process of most of metal and non-metal material, also having the functions of sign marking, carving, punching, etc., and being widely applicable to industries of mechanism, steel, automobile, shipping, petrochemicals, cases and cabinets, and packages.

Owner:SHENZHEN MUSEN TECH

Packaging industry big data knowledge graph construction method and device

InactiveCN108446368AFreely extend data schemaWeb data retrievalSpecial data processing applicationsGraph spectraUnstructured data

The invention provides a packaging industry big data knowledge graph construction method and device. While a packaging knowledge graph is constructed, non-structured data can be structured, so that afoundation is laid for further semantic analysis calculation. In addition, data of the packaging industry is modeled by utilizing the knowledge graph, and a data mode can be freely expanded.

Owner:HUNAN UNIV OF TECH +1

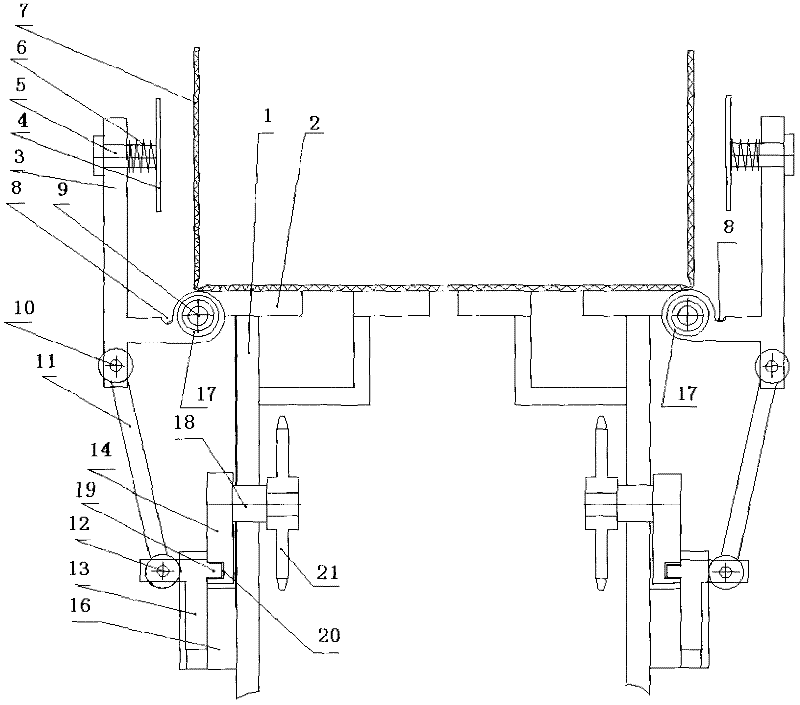

Directional automatic folding device for corrugated carton gluing machines

InactiveCN102343688AGeometrically accuratePrecise positioning of geometric dimensionsContainer making machineryCardboardEngineering

The invention discloses a directional automatic folding device for corrugated carton gluing machines. The device comprises a paper pressing assembly and a moving connection assembly, wherein the paper pressing assembly comprises a folding substrate, a folding support arm, a sliding shaft and a paper pressing plate which are sequentially connected; the moving connection assembly comprises a connecting bar, a slide block and an eccentric cam which are sequentially connected; and the folding substrate is arranged at the upper end of an external side guide seat of a corrugated carton gluing machine, and the eccentric cam is arranged on the outside of the external side guide seat of the corrugated carton gluing machine. The directional automatic folding device disclosed by the invention replaces the traditional belt continuous rolling and folding, the stressed area of a folded carton is large and equalized in exerted force; the folded carton moves along a preset direction, thus being precisely positioned, and no scissors gap and 'fishtail' phenomenon is generated; and a corrugated carton can have a precise geometric size, thereby meeting the need for large-scale and automatic production of the packaging industry.

Owner:施从高

Quaternary built completely biological degradation polylactic acid type composite material and use

The quaternary built completely biodegradable polylactic acid type composite material consists of PLA 45.0-80.0 wt%, PPC 3.0-38.0 wt%, PCL 3.0-38.0 wt%, PHB 3.0-38.0 wt% and various assistants. The quaternary built completely biodegradable polylactic acid type composite material is one kind of thermoplastic material, and has improved forming machining property, raised tearing strength and high product size stability. It may be blow molded to produce various film products with excellent physical and chemical performance and controllable biodegradation speed for wide application in packing and agriculture.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

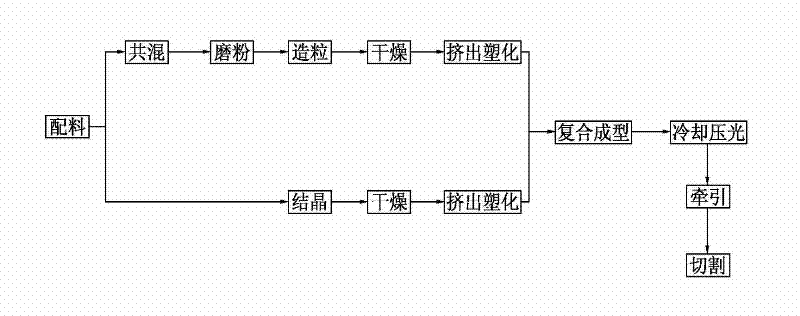

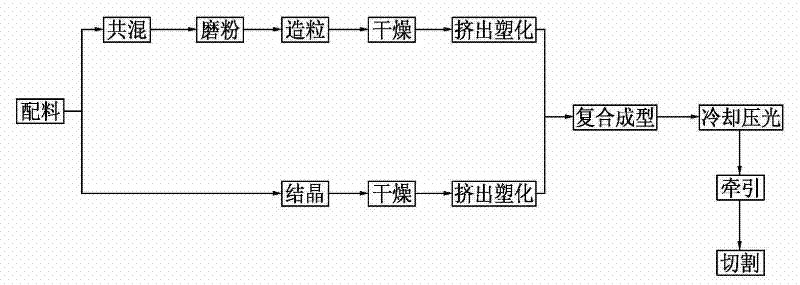

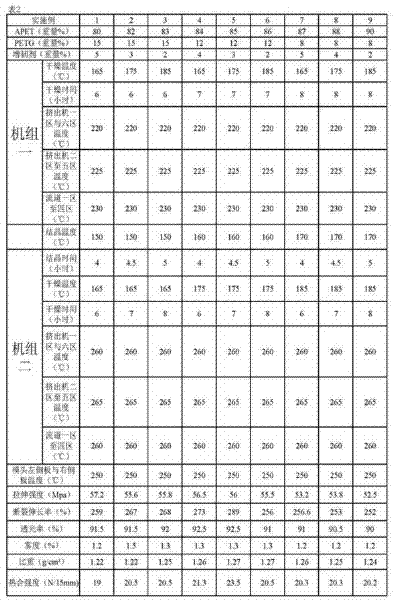

APET/PETG composite material and its production technology

The invention discloses an APET / PETG composite material and its production technology, which belongs to the filed of composite material production technology. The composite material is produced by processes of stirring, milling, granulating, crystallizing, drying, extruding, cooling and glazing, drawing and cutting a combination of 80 to 90% of APET slice, 8 to 15% of PETG slice and 2 to 5% of flexibilizer, flexibilizer is added in the production process for increasing polymer molecular weight generated in the processes of extruding and plasticizing, unidirectional tension becomes bidirectional tension in the production process, the reaction of the tension direction stretches in net shape, therefore the impacting and stretching performance of the material can be enhanced; after decreasingof the thickness of a produced composite material PETG slice layer, the heat combination performance and the processing effect at a low temperature can be still reached to that of material while the thickness of the PETG slice layer is 20%, which enables the dosage of PETG slice and the cost to be greatly reduced. The material provided by the invention can be used in the foodstuff, medical and packaging industries.

Owner:YANGZHOU SANXING PLASTIC

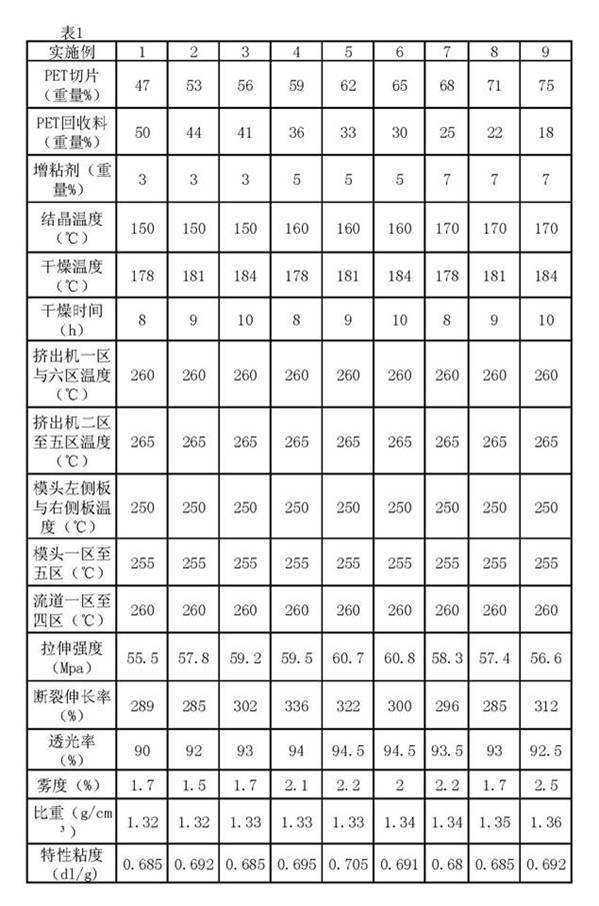

Toughening process for high-tensile-strength recycled polyester sheet

ActiveCN102120868AImprove impact performanceImprove tensile propertiesPolyesterUltimate tensile strength

The invention discloses a toughening process for a high-tensile-strength recycled polyester sheet in the production field of the polyester sheet. The recycled polyester sheet is manufactured from 47-75wt% of PET (polyester) slices, 18-50wt% of PET recycled materials and 3-7wt% of tackifier through the steps of mixing, crystallizing and drying, extruding and plasticizing, calendaring and shaping, cooling and polishing and cutting. By adding the tackifier to the raw materials for production, the polymer molecular weight generated in the extruding and plasticizing process is increased under certain reaction conditions, the production process is changed into bidirectional stretching from unidirectional stretching, and the force reaction is in mesh stretching, thereby reinforcing the impact and tensile property of the sheet. The obtained sheet can be applied to the food, medical and packaging industries.

Owner:YANGZHOU SANXING PLASTIC

Application of waterborne back-coating emulsion (humectant) in packaging industry

InactiveCN104594124AChange flatnessControl balanceDefoamers additionPaper coatingEmulsionAcrylic resin

The invention provides an application of a waterborne back-coating emulsion (humectant), and in particular discloses an application of the waterborne back-coating emulsion (humectant) in the packaging industry. The waterborne back-coating emulsion (humectant) is coated on the back surface of a piece of paper before an article is packaged by the paper, namely the waterborne back-coating emulsion (humectant) is pre-coated on the back surface of the paper by virtue of a coating machine before the article is packaged by the paper, wherein the waterborne back-coating emulsion (humectant) accounts for 0.8-2.4% of the weight of the paper, is obtained by the steps of adding an appropriate amount of an auxiliary agent into an acrylic resin solution, mixing, stirring for dispersion and filtering, is simple and convenient to prepare and is obvious in effect. By applying the waterborne back-coating emulsion (humectant) to the packaging industry, particularly, the aluminized paper processing industry, the flatness of the paper cannot be reduced due to changes of air humidity in the long-term storage process of the paper, so that the paper is ensured to be beautiful, the operation is relatively simple and smooth in the use processes including printing and the like, and special requirements on equipment are avoided.

Owner:江苏琛亚印材科技有限公司

Method for the production of a bioactive cellulose fiber with a high degree of whiteness

InactiveUS20100124861A1Control releaseCheap productionBiocideMaterial nanotechnologyWound dressingCellulose fiber

The invention relates to a method for the production of cellulose shaped bodies according to the dry-wet extrusion method (Lyocell method) with high degree of whiteness and bioactive action for use in the textile sector and paper production. In the context of the invention, the term “bioactive” refers to antimicrobial efficacy, based on the antibacterial action of the element silver, which is used as nanoscale reagent for increasing the efficacy thereof. The chemically inert and, at the same time, bactericidal effect is used in the production of sports and leisure clothing with a high degree of whiteness and papers with a long shelf life. Use is possible in the medical sector, for example, for wound dressings, textiles for hospitals, and in the filter and packaging industry.

Owner:THURINGISCHES INSTITUT FUR TEXTIL & KUNST FORSCHUNG

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com