Highly filled micro foamed polypropylene composite material and preparation method thereof

A composite material, polypropylene technology, applied in the field of polymer materials, can solve the problem of inability to take into account the lightweight of materials, and achieve the effects of environmental protection, simple operation, and reduced production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

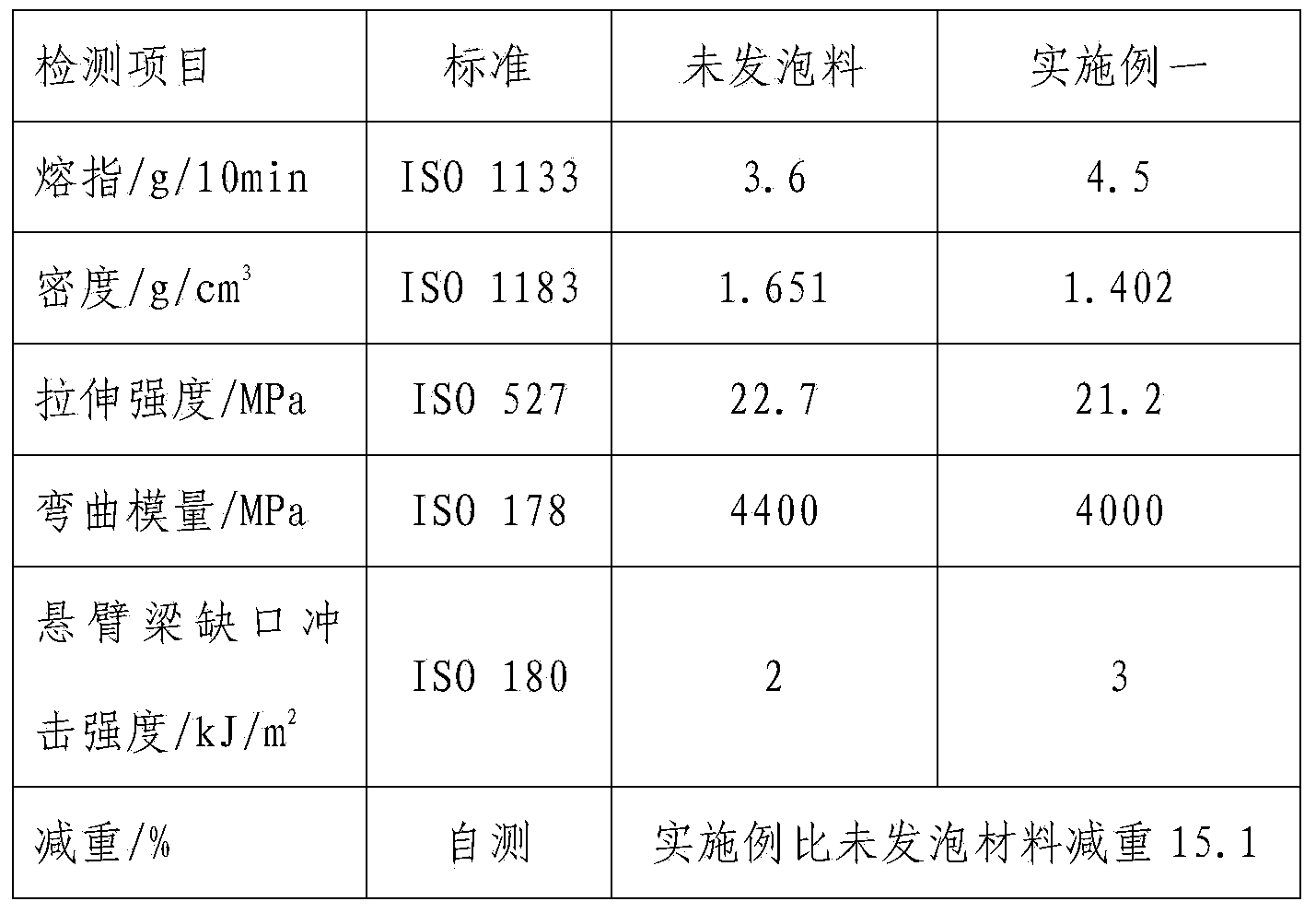

[0012] The melt index is 2g / 10min, and the IZOD impact strength is 50kJ / m 2 A mixture of 20 parts of polypropylene, 70 parts of talcum powder, 4.5 parts of ethylene-octene copolymer, 0.3 parts of antioxidant 168, and 0.2 parts of antioxidant 1010 was put into a high-speed mixer and mixed for 6 minutes. Then, the above group The mixture was extruded in a twin-screw extruder and pelletized. The barrel temperature of the twin-screw extruder is set at 170-270°C, and the screw speed is 50r / min; finally, 5 parts of foaming masterbatch and 95 parts of the above extruded pellets are evenly mixed, put into the single-screw extruder, and extruded Obtain highly filled micro-foamed polypropylene composites. The screw temperature is set at 160-240° C., and the screw speed is 50 r / min. The performance comparison of the obtained composite materials is shown in the table below:

[0013] Table 1 Performance comparison of highly filled micro-foamed materials and unfoamed materials

[0014] ...

Embodiment 2

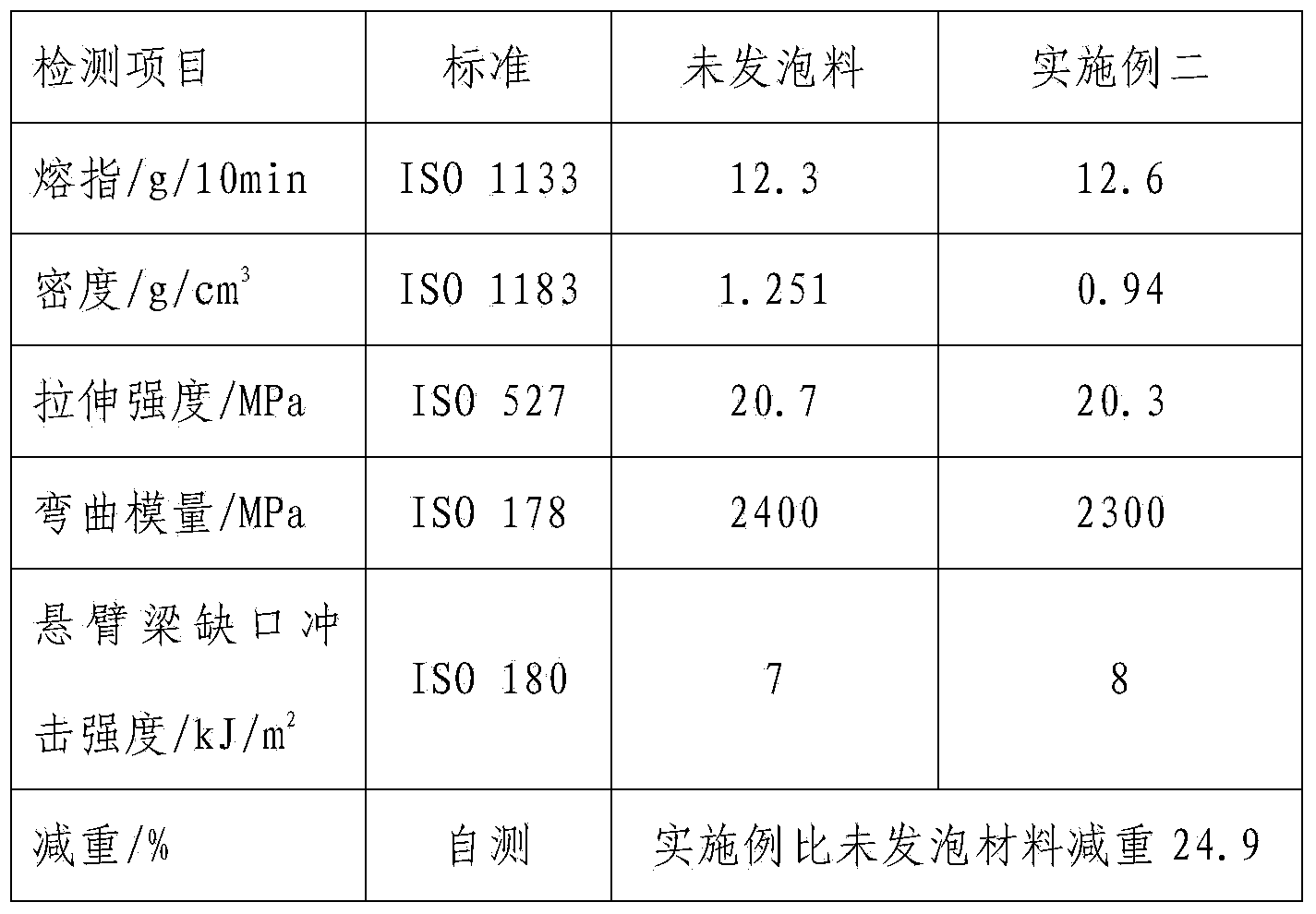

[0016] The melt index is 15g / 10min, and the IZOD impact strength is 48kJ / m 2 A mixture of 50 parts of polypropylene, 40 parts of talcum powder, 1 part of EPDM, 1.2 parts of antioxidant 168, and 0.8 parts of antioxidant 1010 was put into a high-speed mixer and mixed for 3 minutes. Then, the above components The mixture is extruded and pelletized in a twin-screw extruder. The barrel temperature of the twin-screw extruder is set at 170-270°C, and the screw speed is 50r / min; finally, 7 parts of foaming masterbatch and 93 parts of the above-mentioned extruded pellets are evenly mixed, and added to the injection molding machine, and injection molding is obtained. Bubble high filled polypropylene composite. The barrel temperature of the injection molding machine is set at 180-240°C, the injection pressure is 60MPa, the injection speed is 80mm / s, and the cooling time is 10s. The performance comparison of the obtained composite materials is shown in the table below:

[0017] Table 2...

Embodiment 3

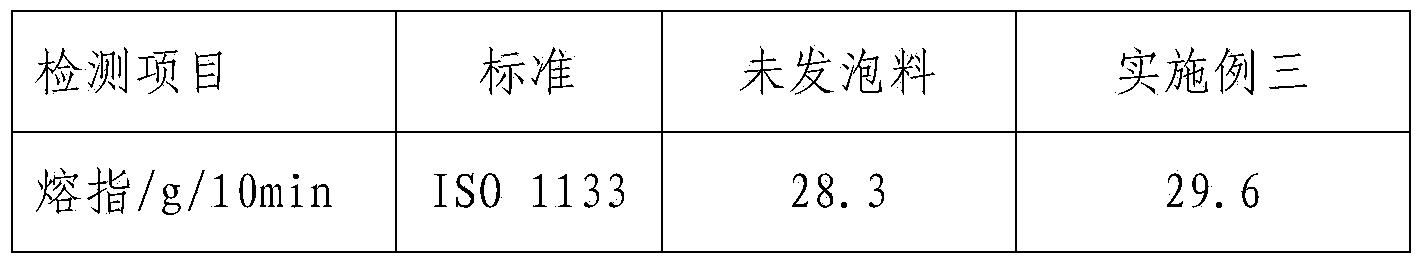

[0020] The melt index is 5g / 10min, and the IZOD impact strength is 56kJ / m 2 A mixture of 35 parts of polypropylene, 50 parts of talcum powder, 4 parts of ethylene-butylene copolymer, 0.6 part of antioxidant 168, and 0.4 part of antioxidant 1010 was put into a high-speed mixer and mixed for 5 minutes. Then, the above group The mixture was extruded in a twin-screw extruder and pelletized. The barrel temperature of the twin-screw extruder is set at 170-270°C, and the screw speed is 50r / min; finally, mix 10 parts of foaming masterbatch with 90 parts of the above-mentioned extruded pellets, add them to the injection molding machine, and inject them to obtain micro-foam Bubble high filled polypropylene composite. The barrel temperature of the injection molding machine is set at 180-240°C, the injection pressure is 40MPa, the injection speed is 40mm / s, and the cooling time is 30s. The performance comparison of the obtained composite materials is shown in the table below:

[0021] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com