Patents

Literature

1793 results about "Injection pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

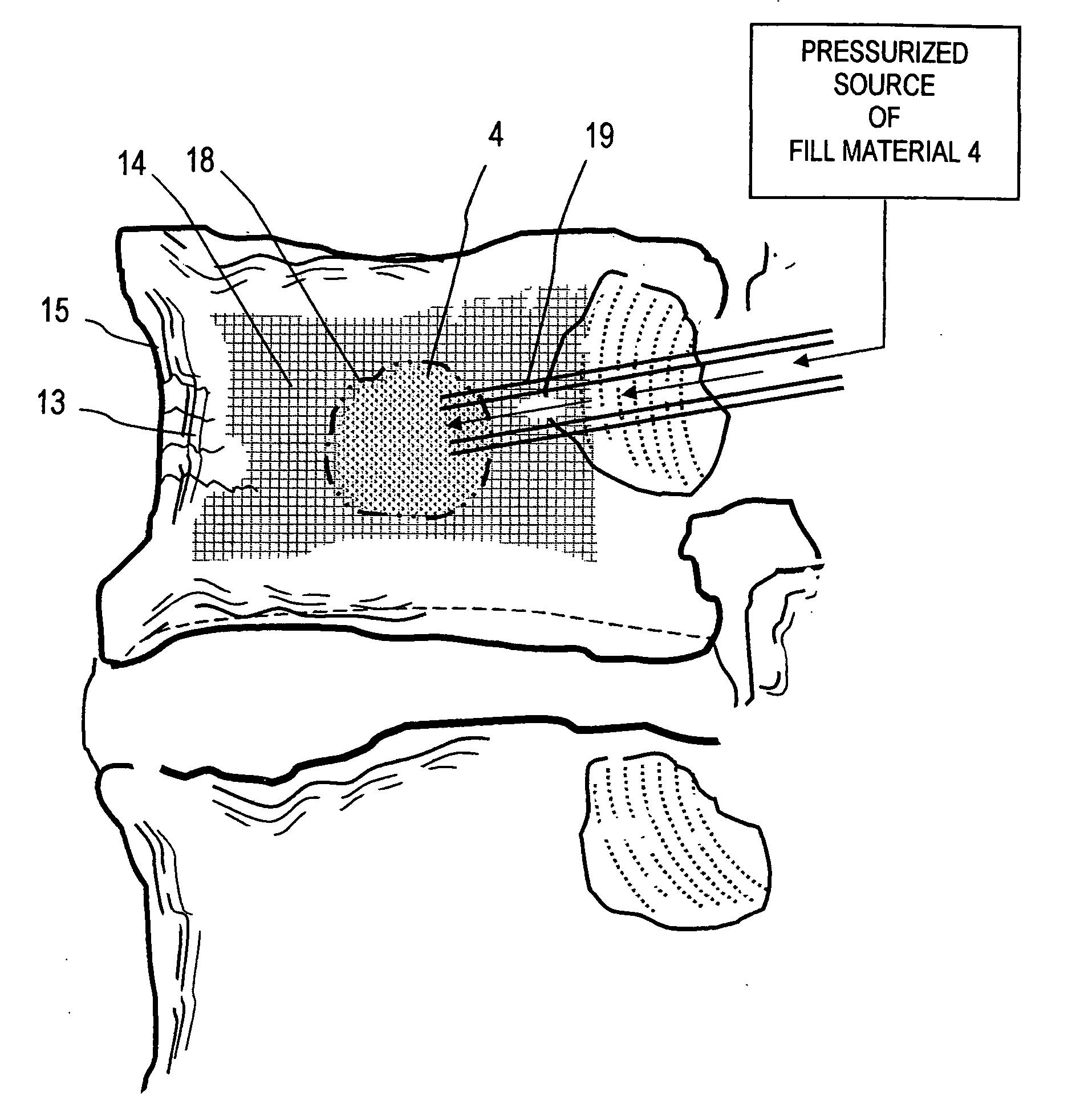

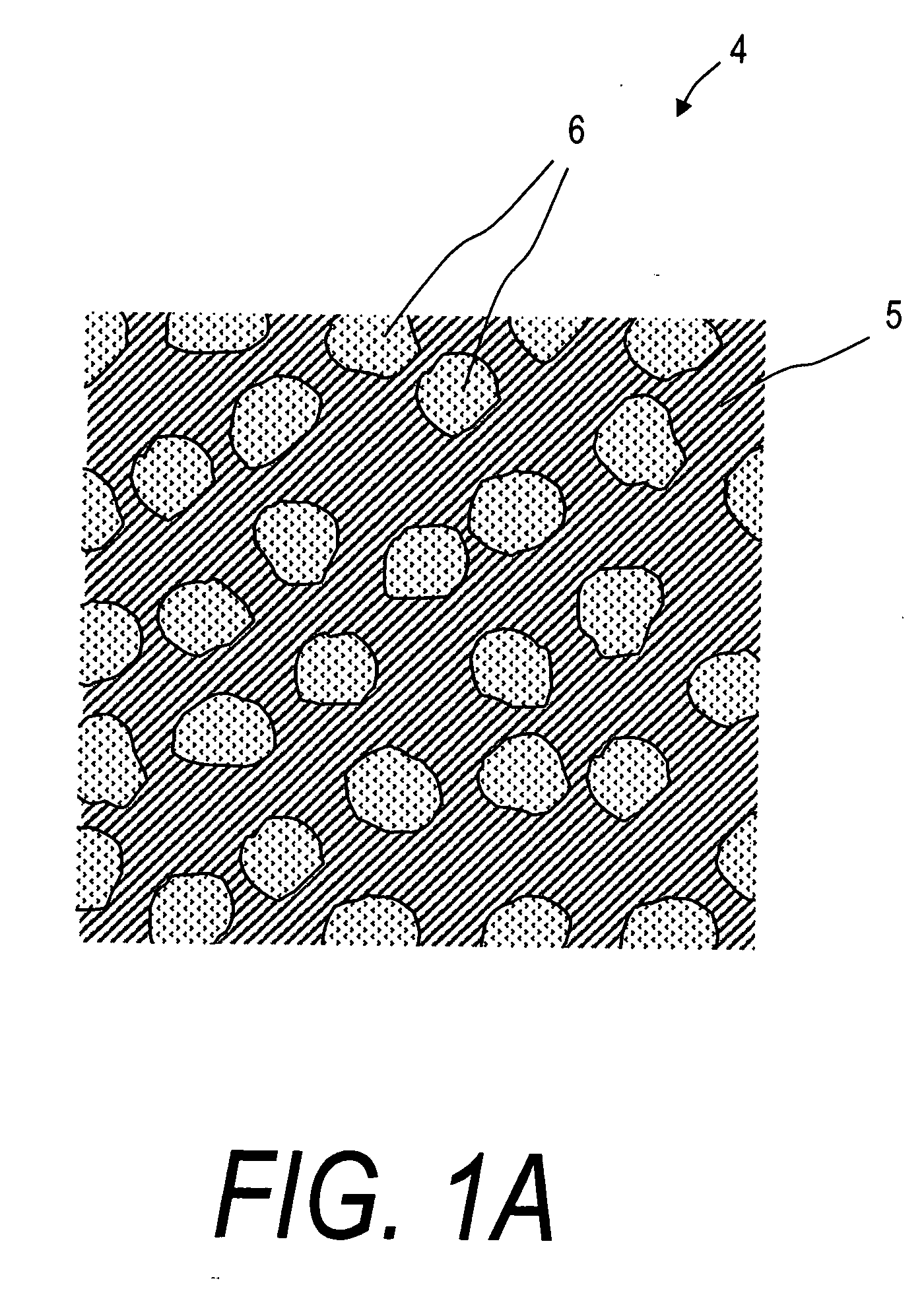

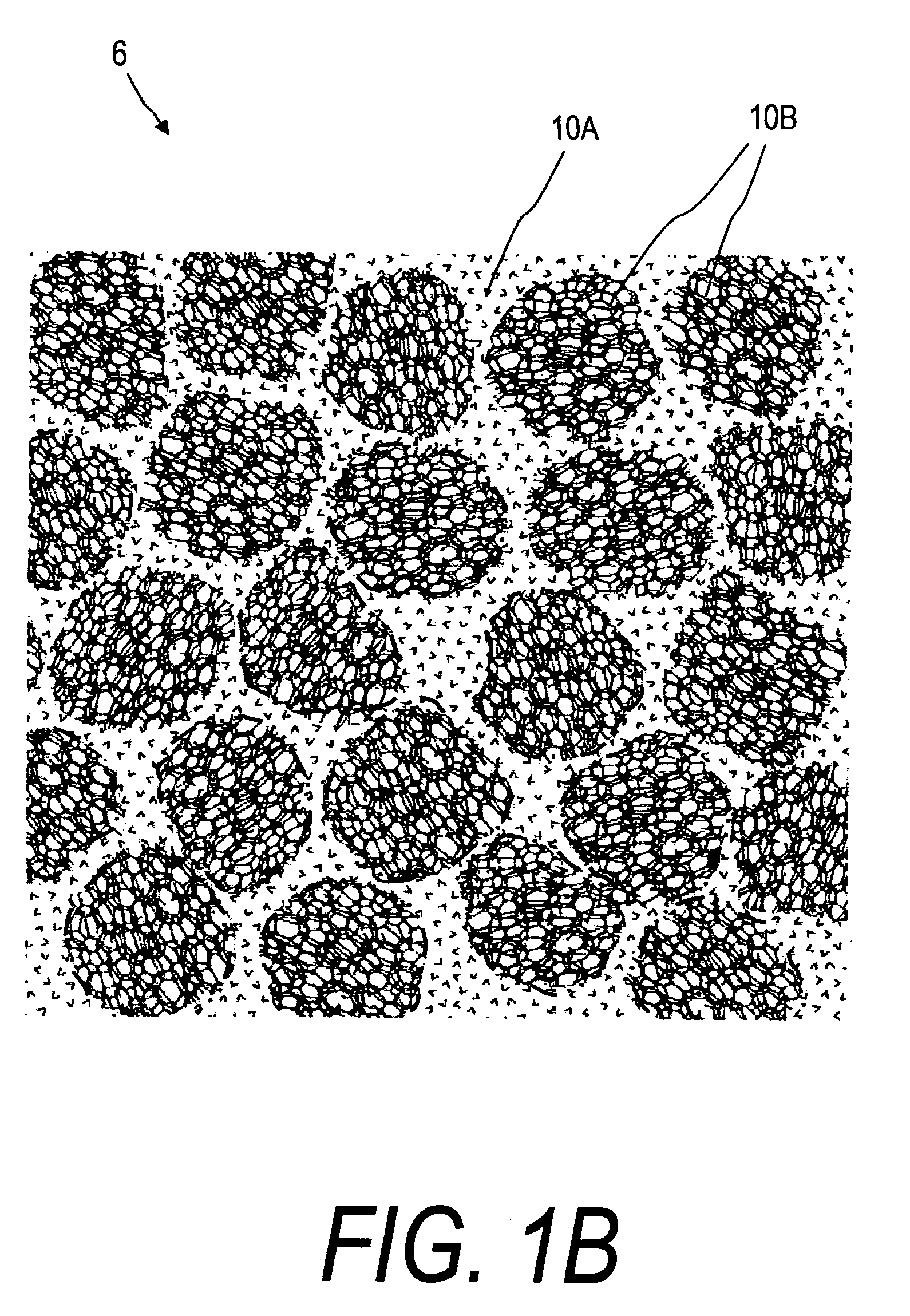

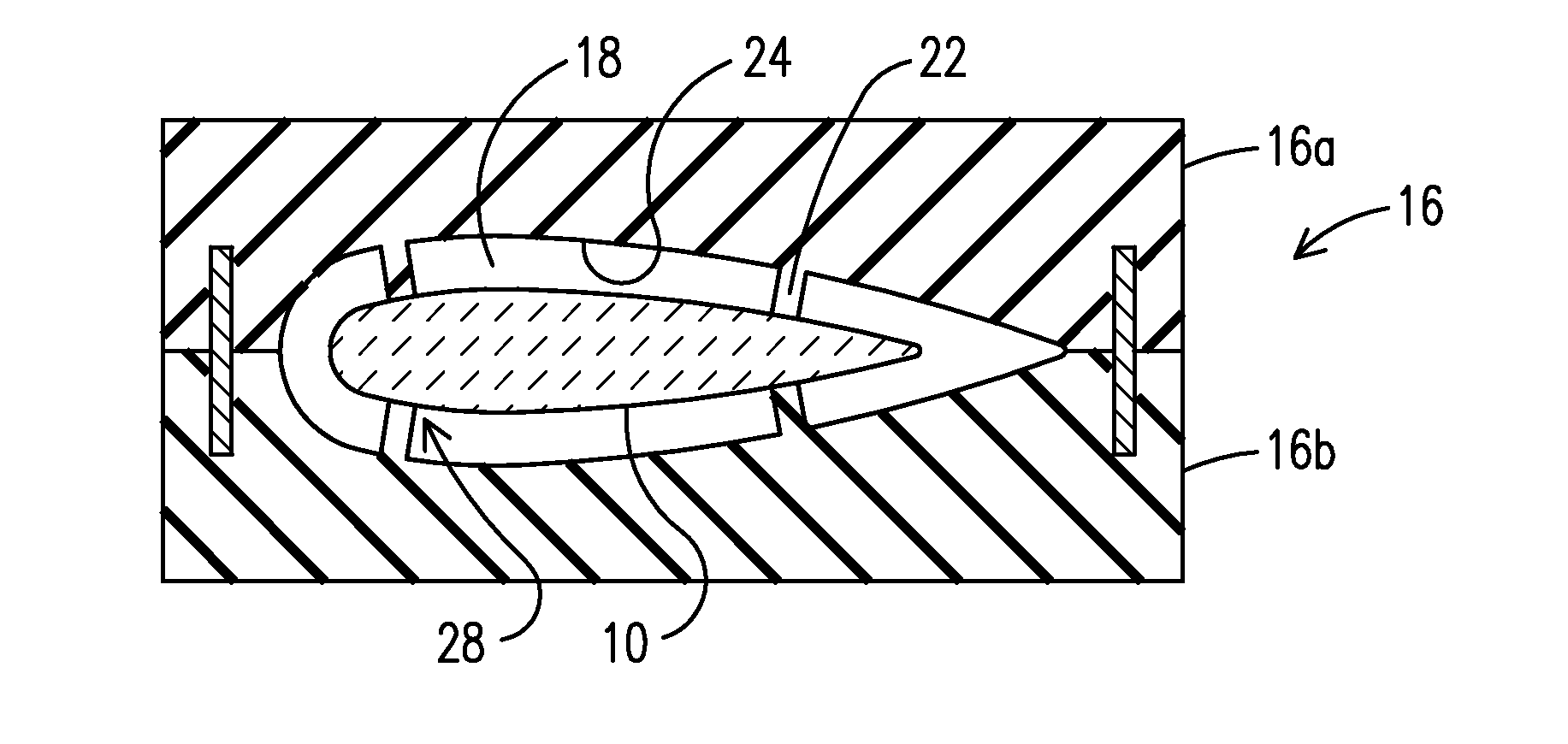

Composites and methods for treating bone

A system and method for treating bone abnormalities including vertebral compression fractures and the like. In one vertebroplasty method, a fill material is injected under high pressures into cancellous bone wherein the fill material includes a flowable bone cement component and an elastomeric polymer component that is carried therein. The elastomer component can further carry microscale or mesoscale reticulated elements. Under suitable injection pressures, the elastomeric component ultimately migrates within the flowable material to alter the apparent viscosity across the plume of fill material to accomplish multiple functions. For example, the differential in apparent viscosity across the fill material creates a broad load-distributing layer within cancellous bone for applying retraction forces to cortical bone endplates. The differential in apparent viscosity also transitions into a flow impermeable layer at the interface of cancellous bone and the flowable material to prevent extravasion of the flowable bone cement component.

Owner:DFINE INC

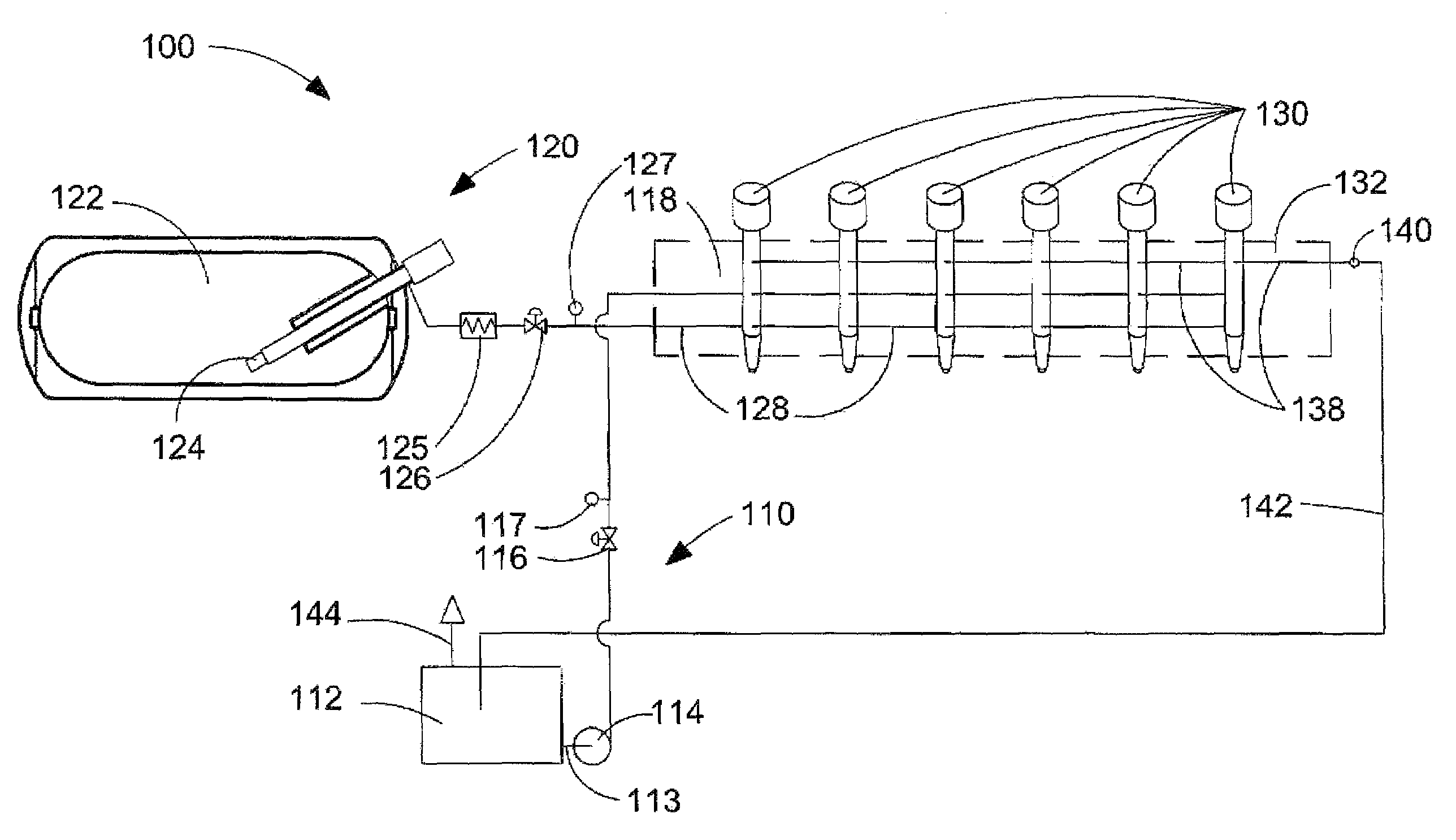

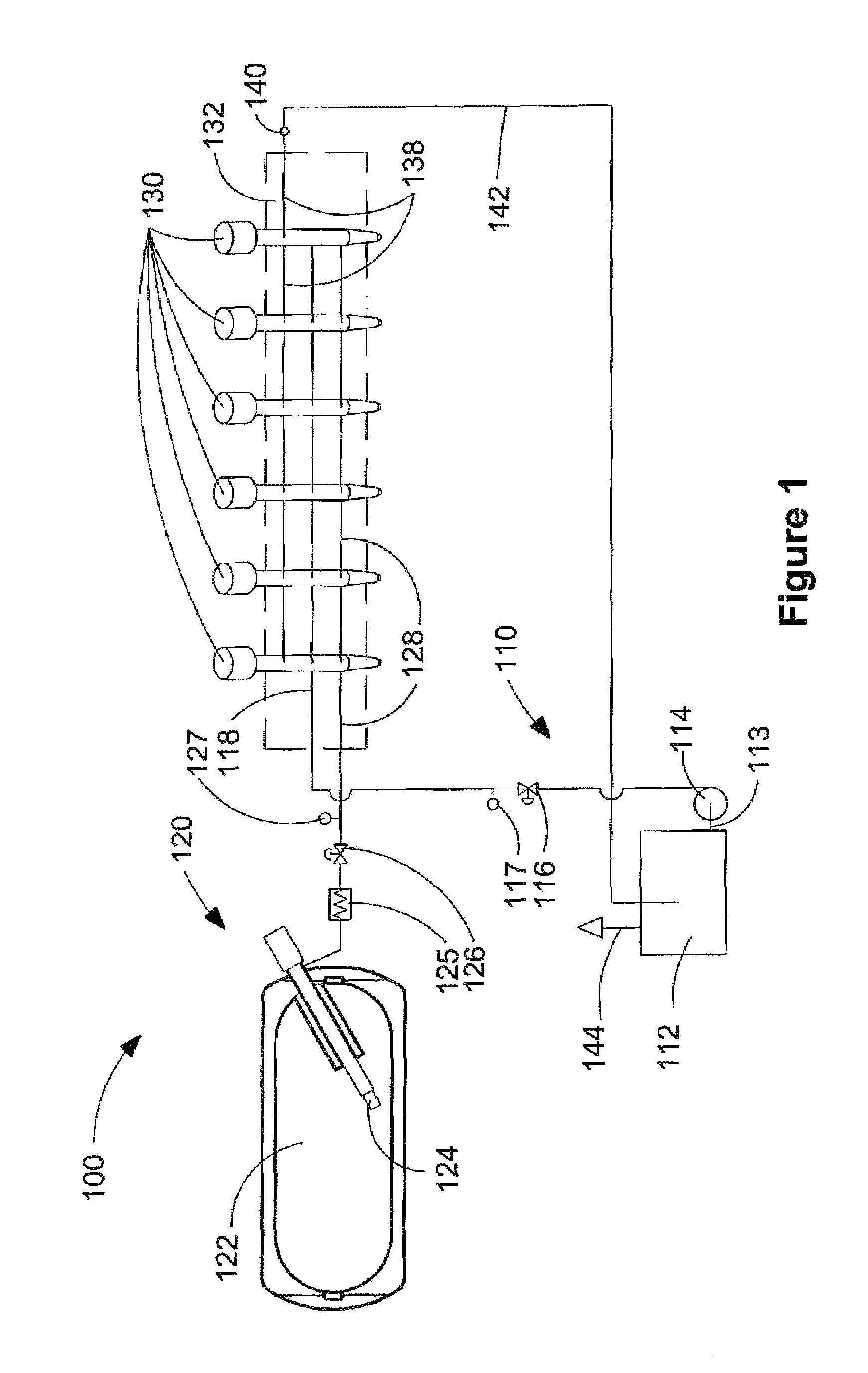

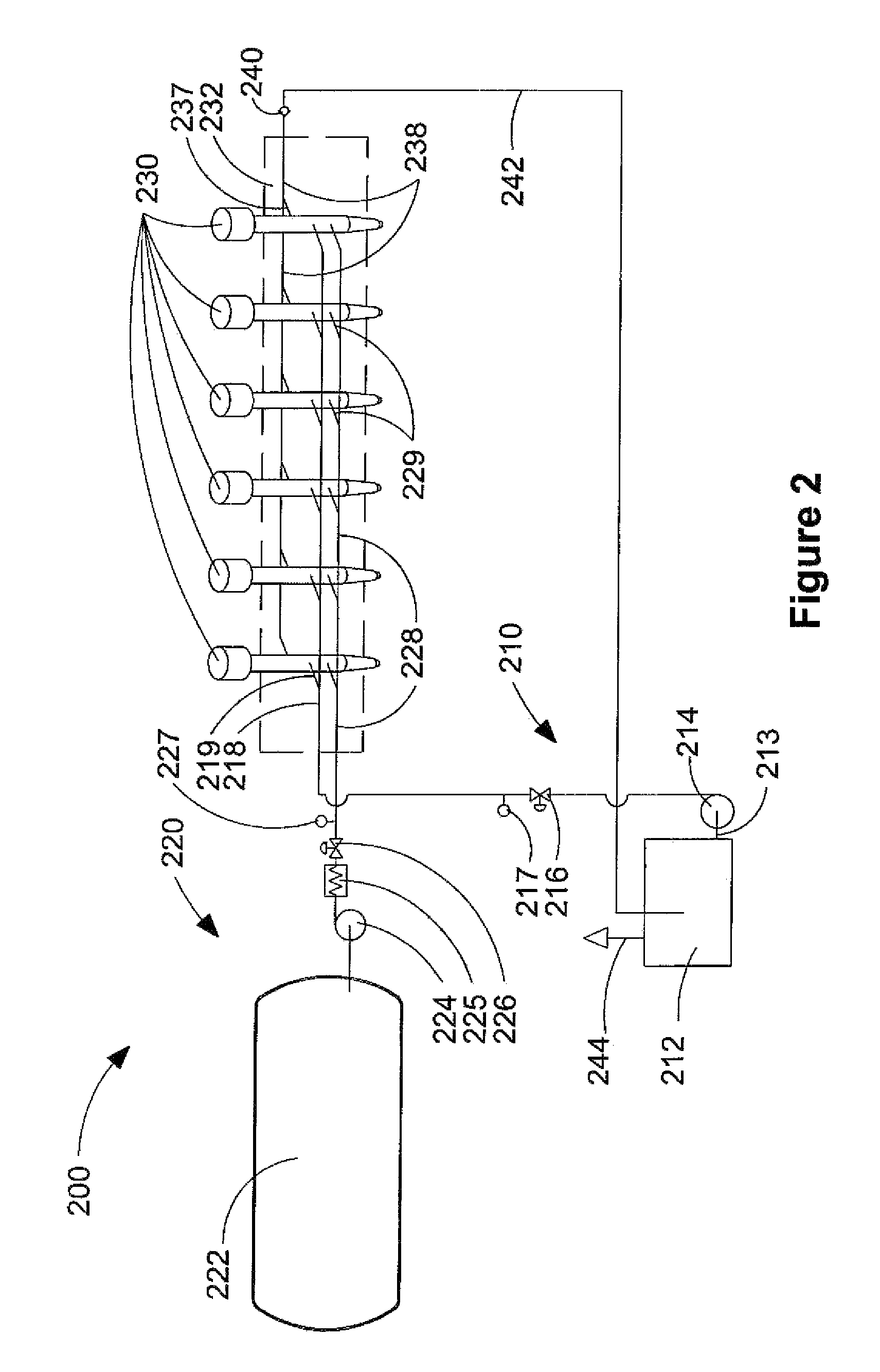

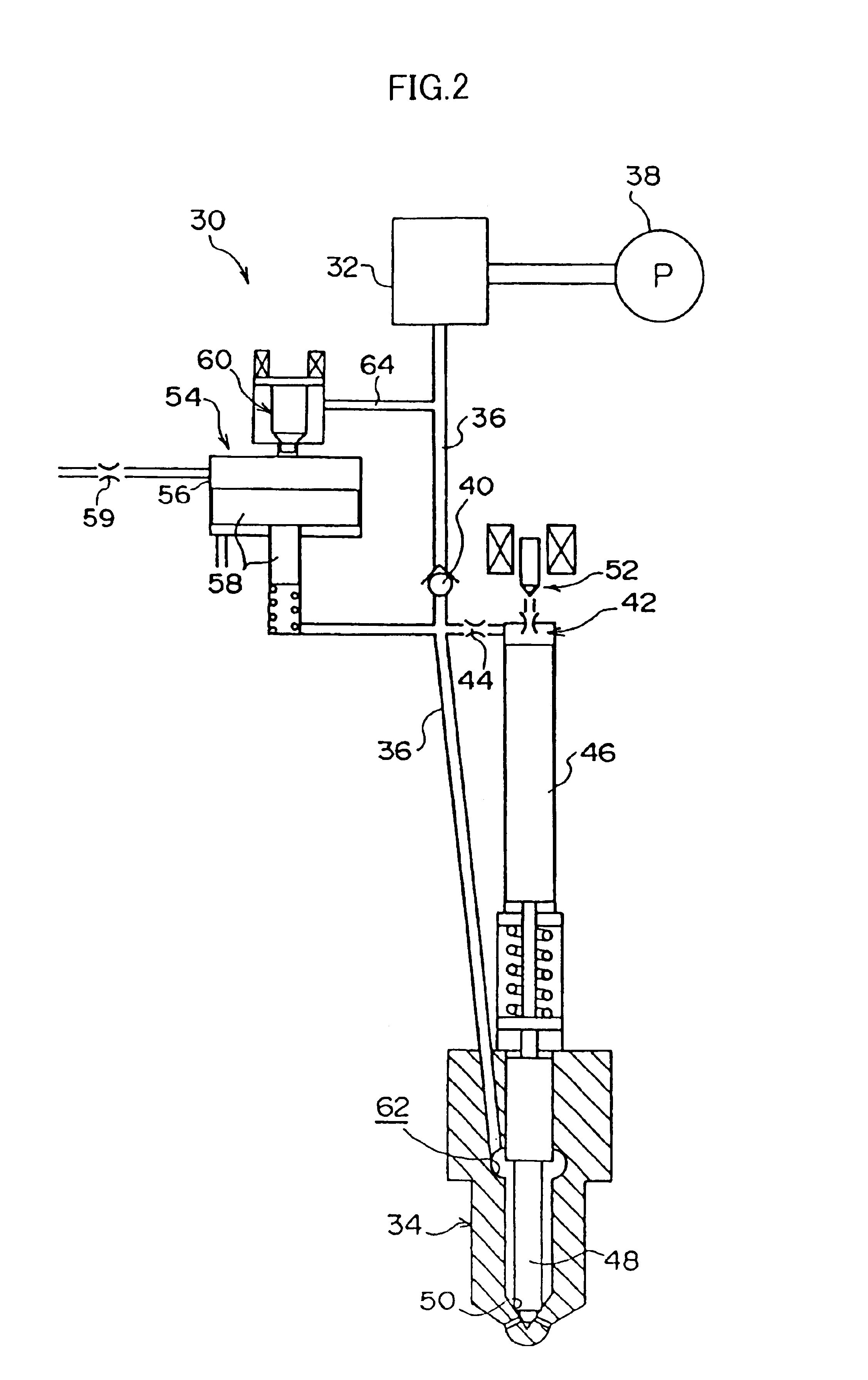

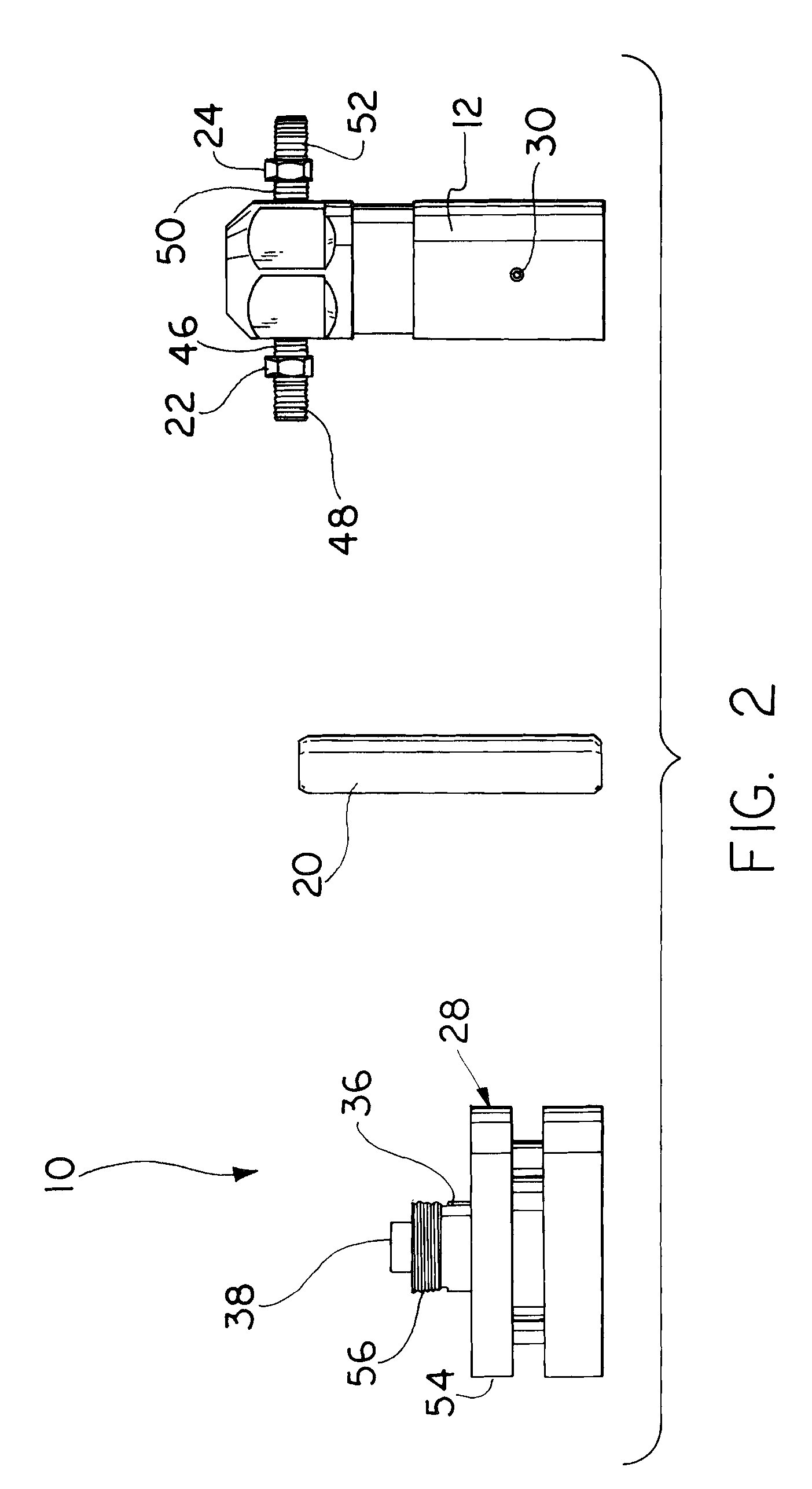

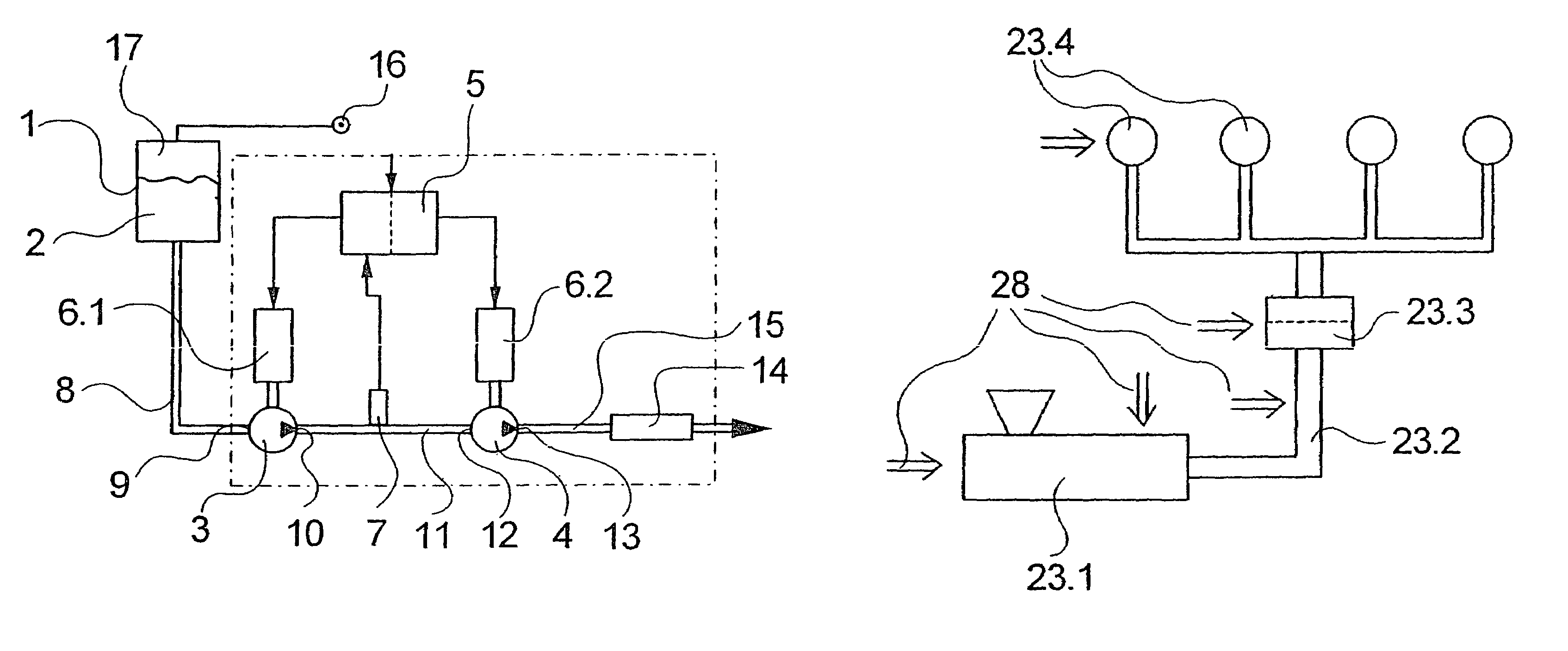

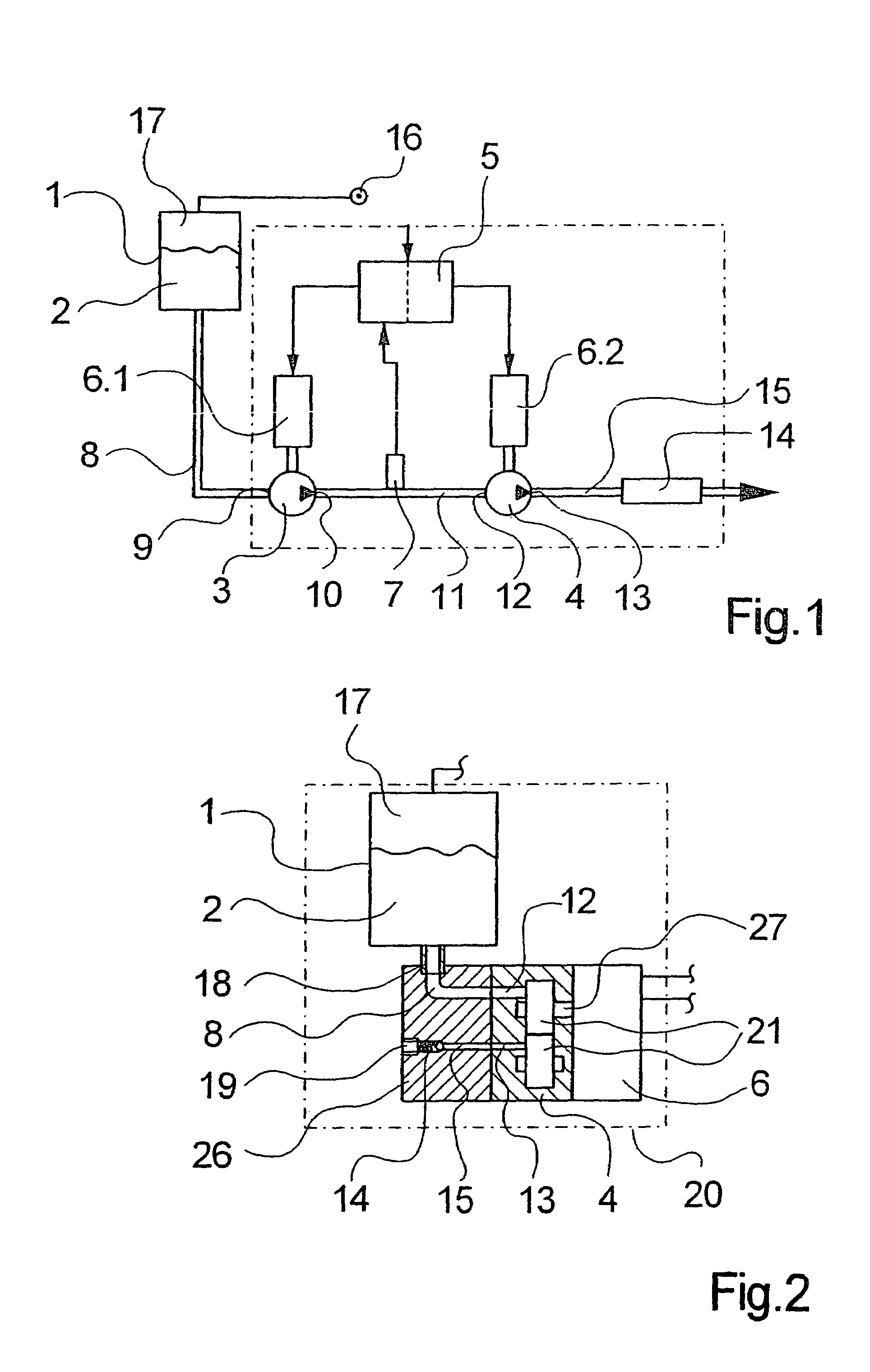

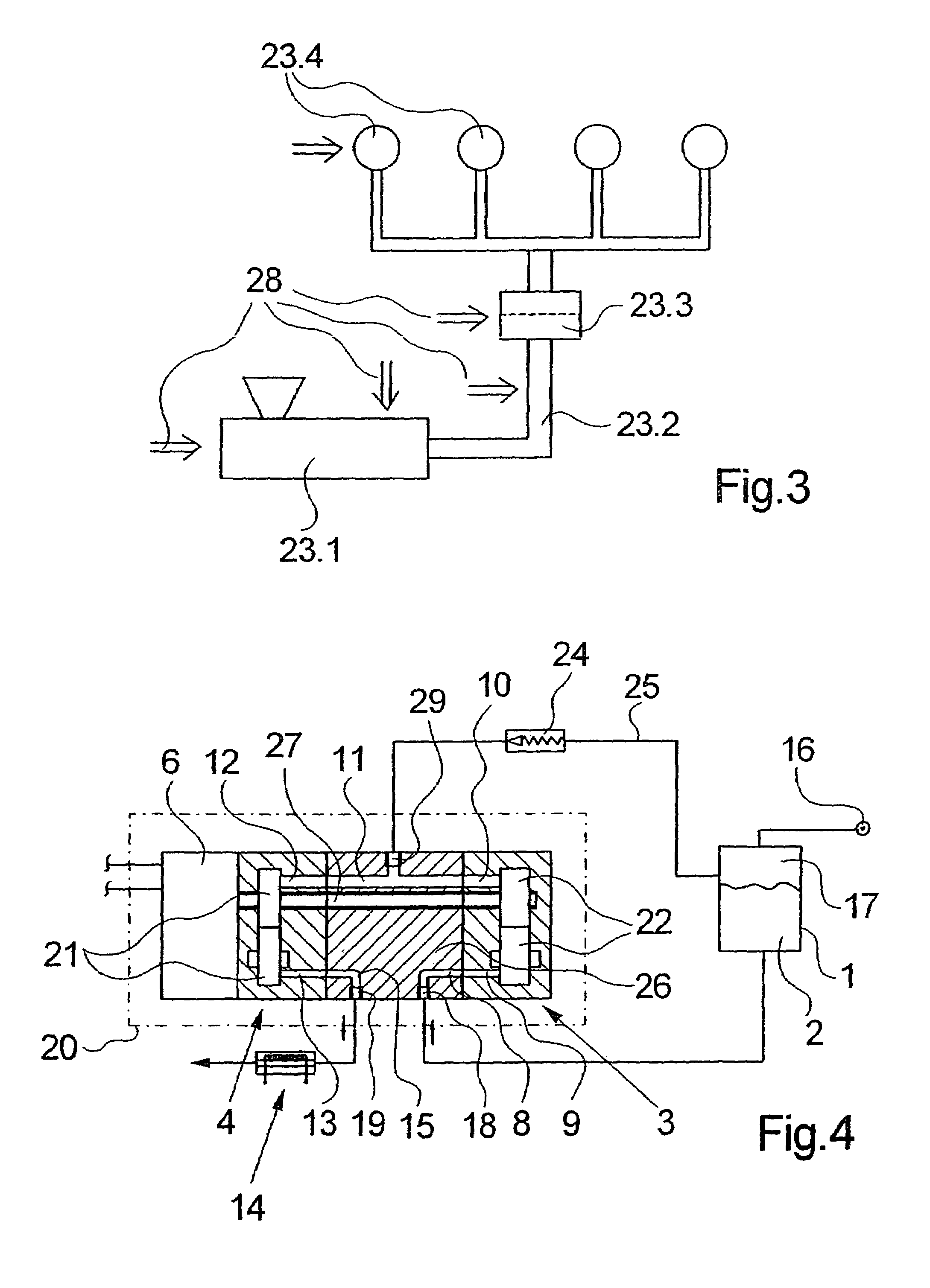

Method and apparatus for delivering two fuels to a direct injection internal combustion engine

ActiveUS7373931B2Increase energy densityReadily availableInternal combustion piston enginesFuel supply apparatusInjection pressureCombustion chamber

An apparatus for delivering two fuels to a direct injection internal combustion engine comprises a liquid-fuel supply rail, a gaseous-fuel supply rail, a drain system with a shared drain rail for collecting both liquid fuel and gaseous fuel, and a venting device for venting gaseous fuel collected by the drain rail. The method comprises separately delivering a liquid fuel at injection pressure to an injection valve through a liquid-fuel rail, and actuating the liquid-fuel injection valve to introduce liquid fuel directly into the combustion chamber. The method further comprises delivering a gaseous fuel at injection pressure to an injection valve through a gaseous-fuel rail and actuating the gaseous-fuel injection valve to introduce gaseous fuel directly into the combustion chamber. The method further comprises collecting in a drain rail liquid fuel and gaseous fuel from the liquid-fuel injection valve and the gaseous-fuel injection valve, directing liquid fuel to a storage vessel, and directing gaseous fuel to a vent pipe.

Owner:WESTPORT FUEL SYST CANADA INC

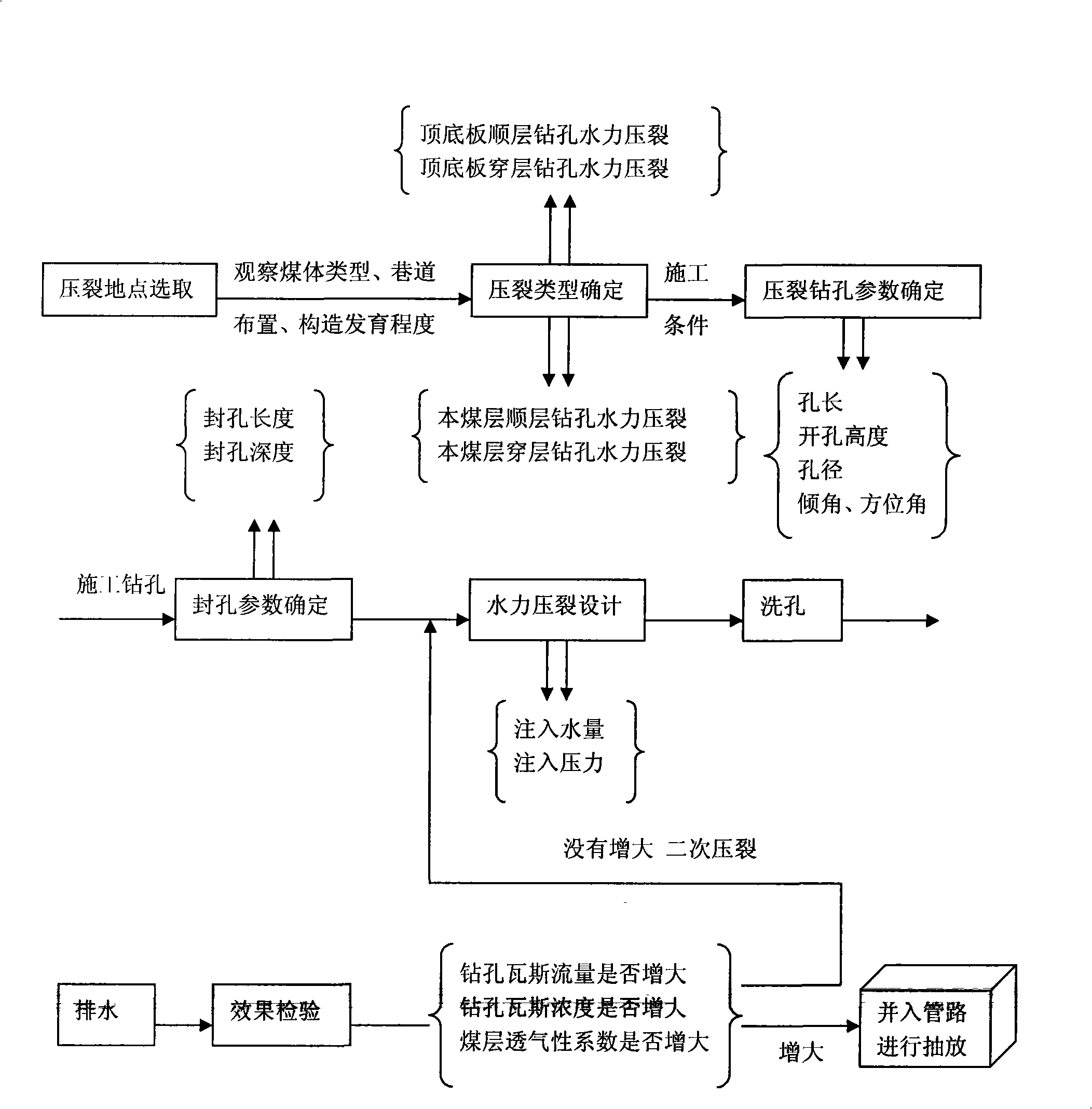

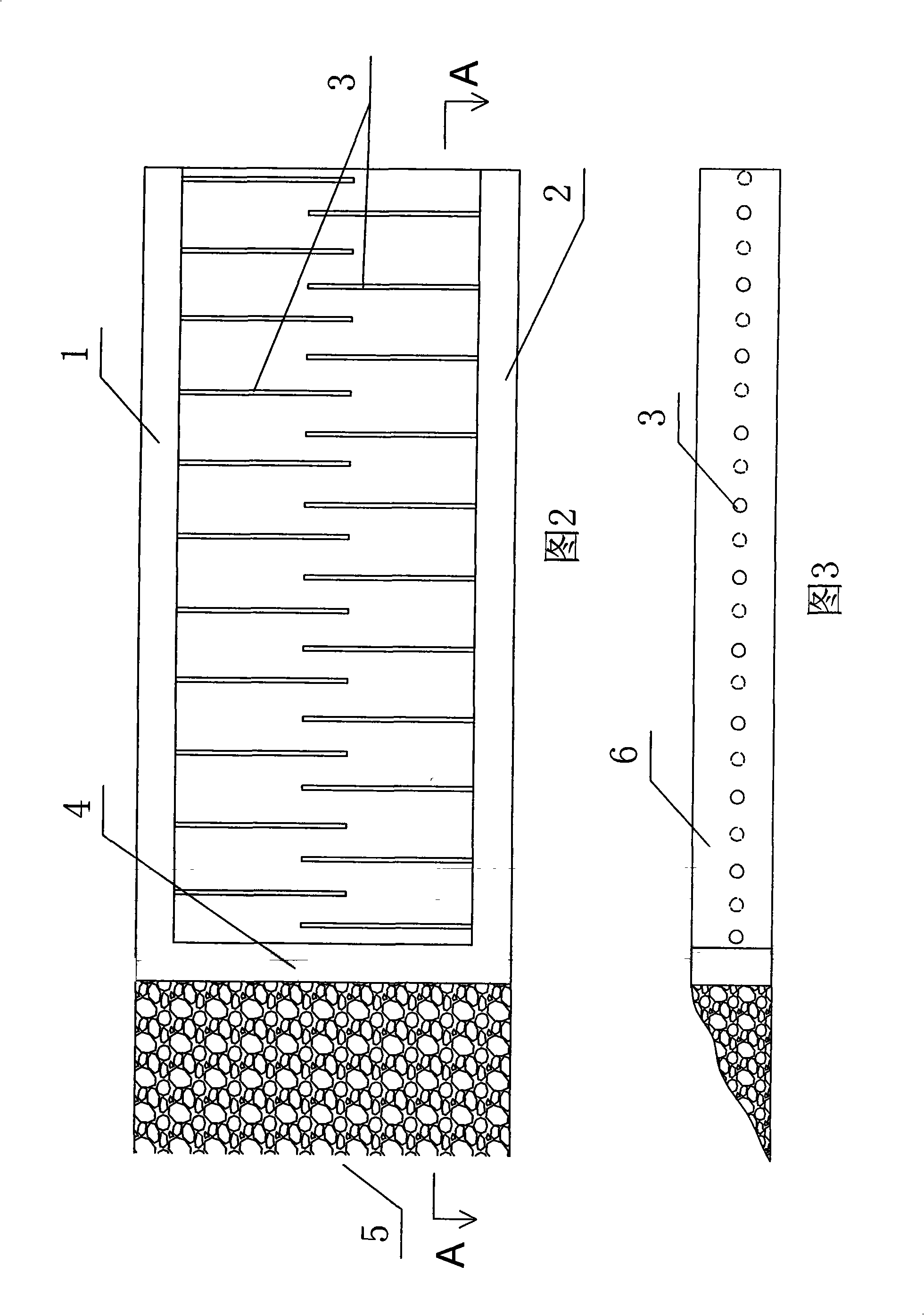

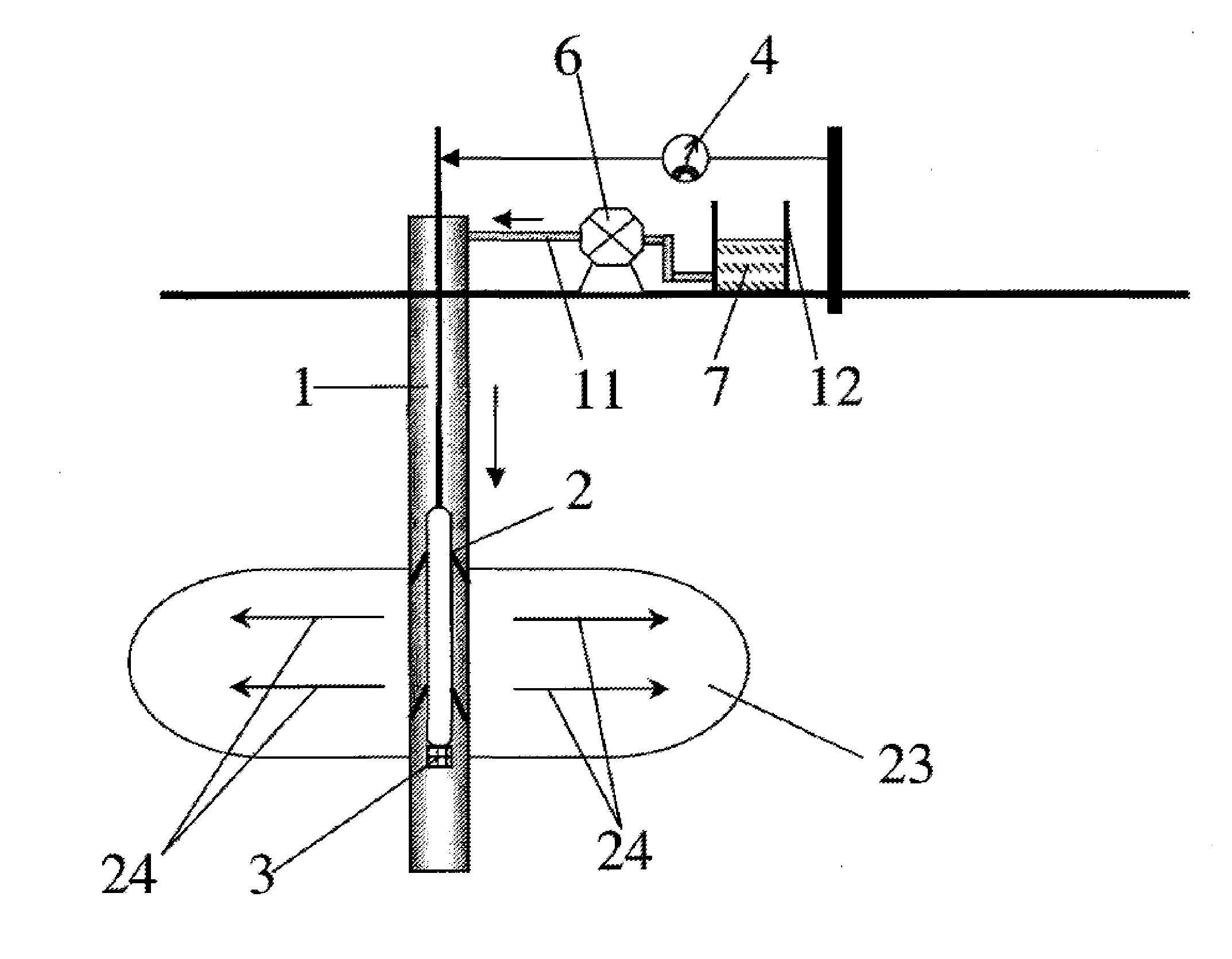

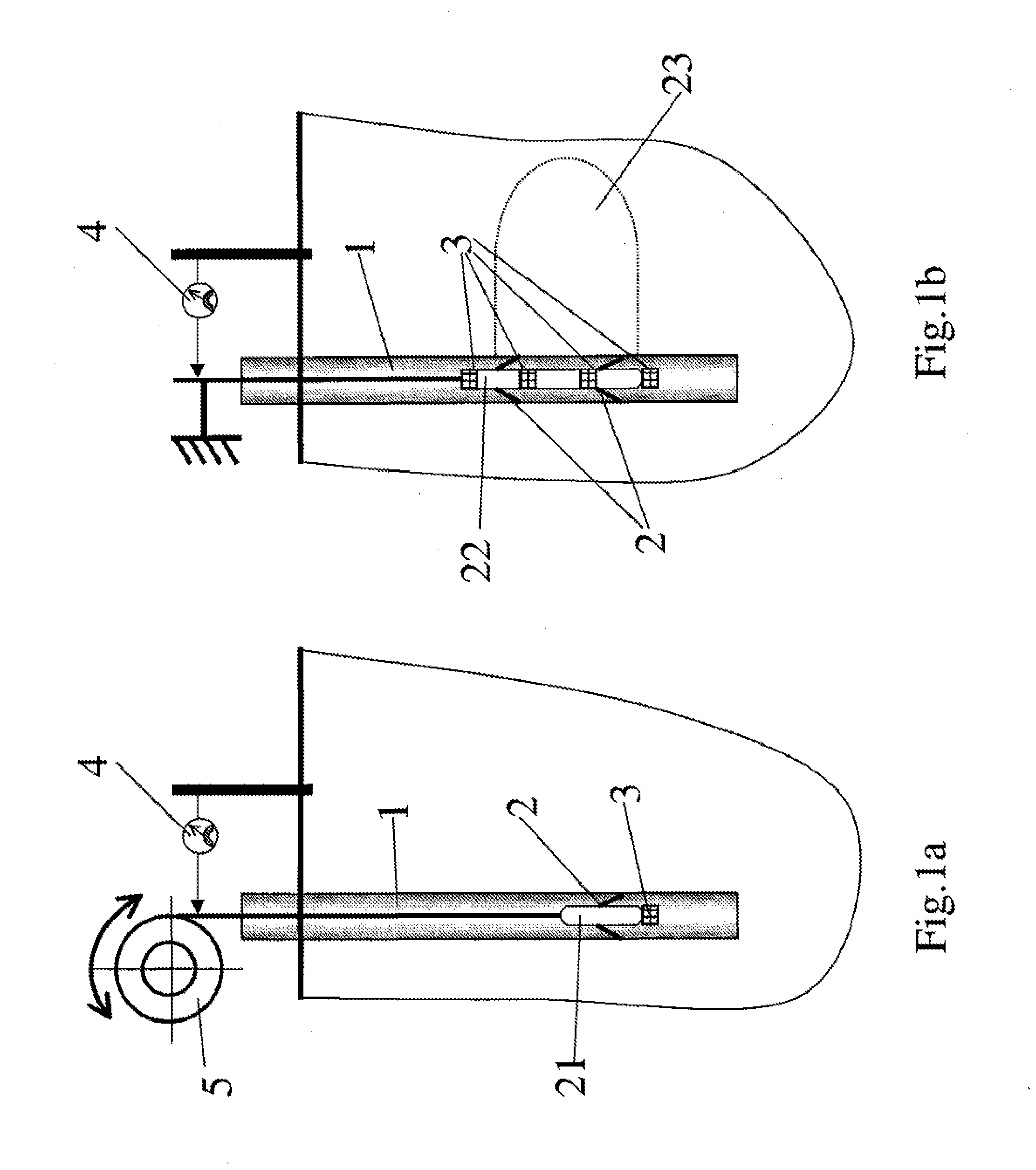

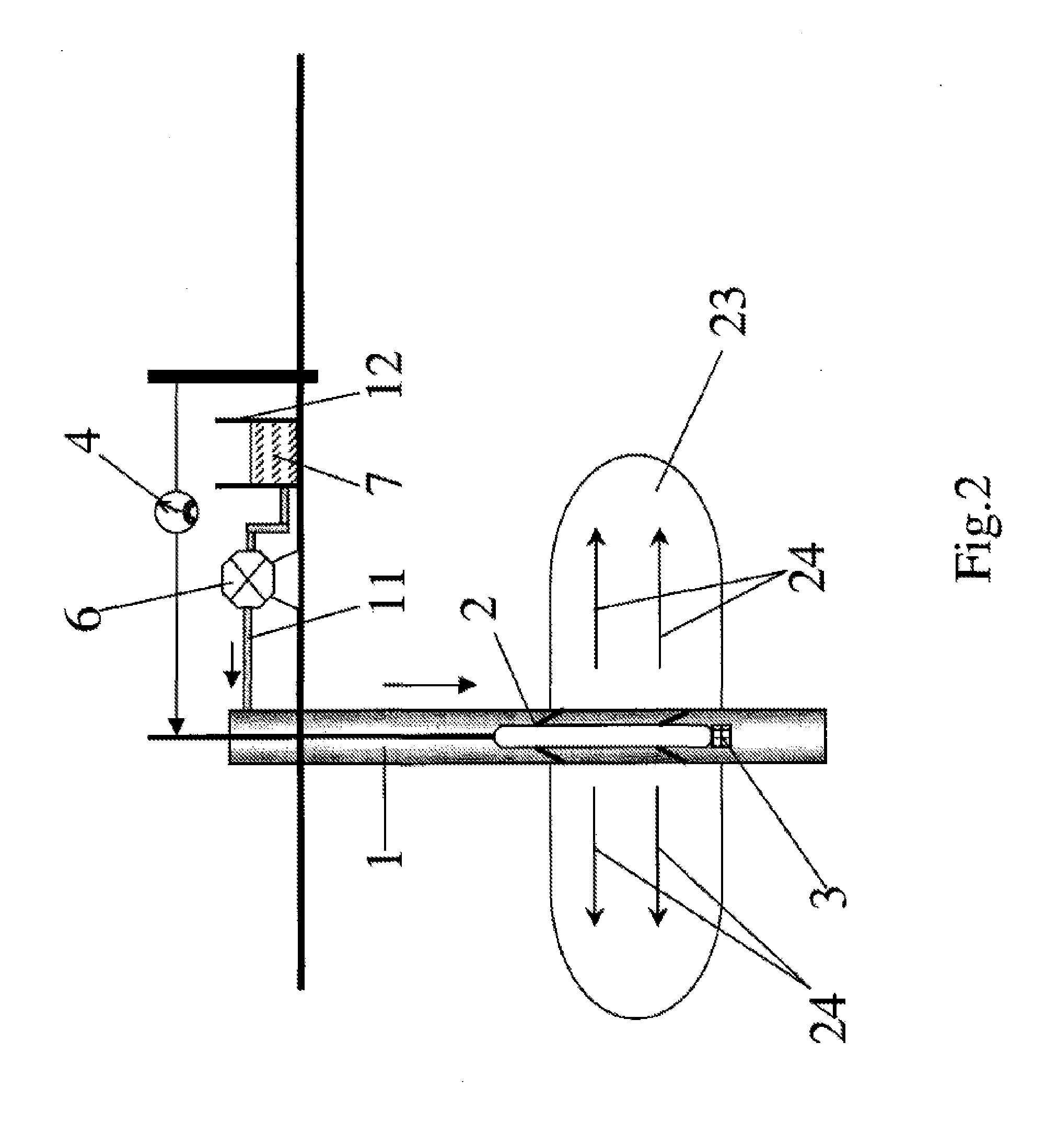

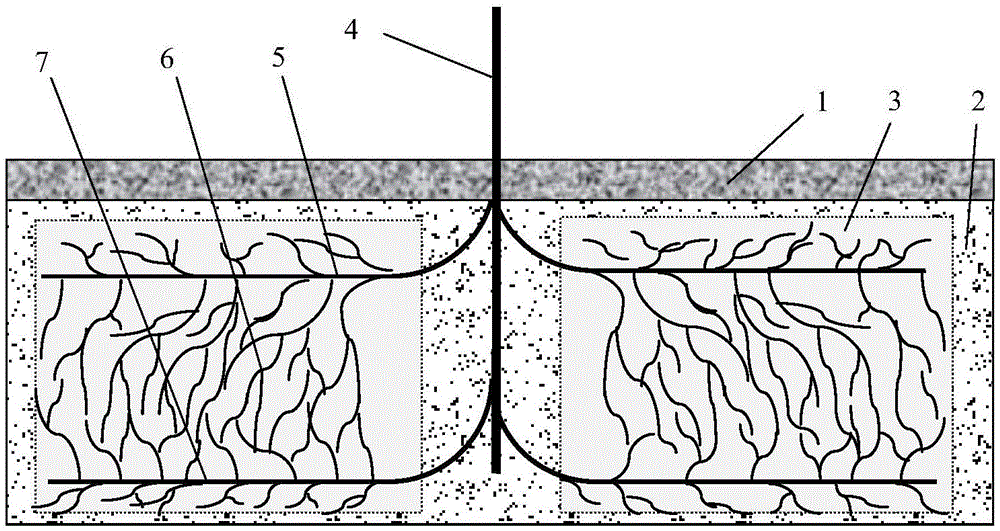

Coal mine down-hole drilling hydraulic fracturing anti-reflection mash gas extraction technique

ActiveCN101403314ALess gushEliminate disastersFluid removalGas removalDischarge efficiencyInjection pressure

The invention relates to a hydraulic fracturing anti-reflection technology for pumping and exploring gas by drilling a hole in a coal mine well, comprising the following steps sequentially: (1) selecting a fracturing location; (2) determining the pressure type according to observed coal type, laneway arrangement and construction development degree, and ways of top soleplate bedding plane borehole hydraulic fracturing, top soleplate translamellar borehole hydraulic fracturing, the coal bed bedding plane borehole hydraulic fracturing or the coal bed translamellar borehole hydraulic fracturing can be adopted; (3) determining borehole parameters for constructing drilling, wherein, the borehole parameters include borehole length, borehole height, aperture, obliquity angle and azimuth angle; (4) designing the hydraulic fracturing, including injected water volume and injection pressure; (5) borehole washing; (6) draining; (7) examining the fracturing effect, if the fracturing effect is in accordance with the requirement, the following step is carried out, if not, turning to step (4); and (8) entering a pipeline for pumping and discharging. The technology enhances the air permeability of the coal bed, reduces the gas emission rate of an excavation working face, and obviously promotes the pumping and exploring capability and the pumping and exploring effect of the single borehole. The pumping and discharging efficiency is improved, the pumping and discharging time is shortened and the damage of the gas is maximally eliminated.

Owner:HENAN POLYTECHNIC UNIV

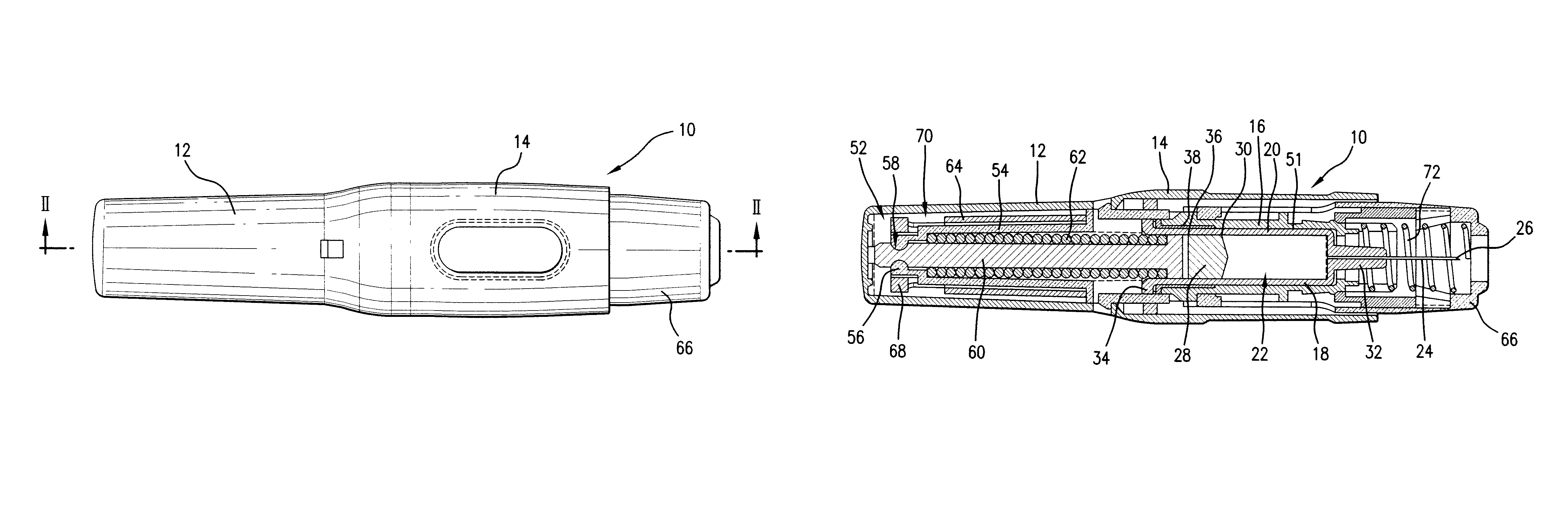

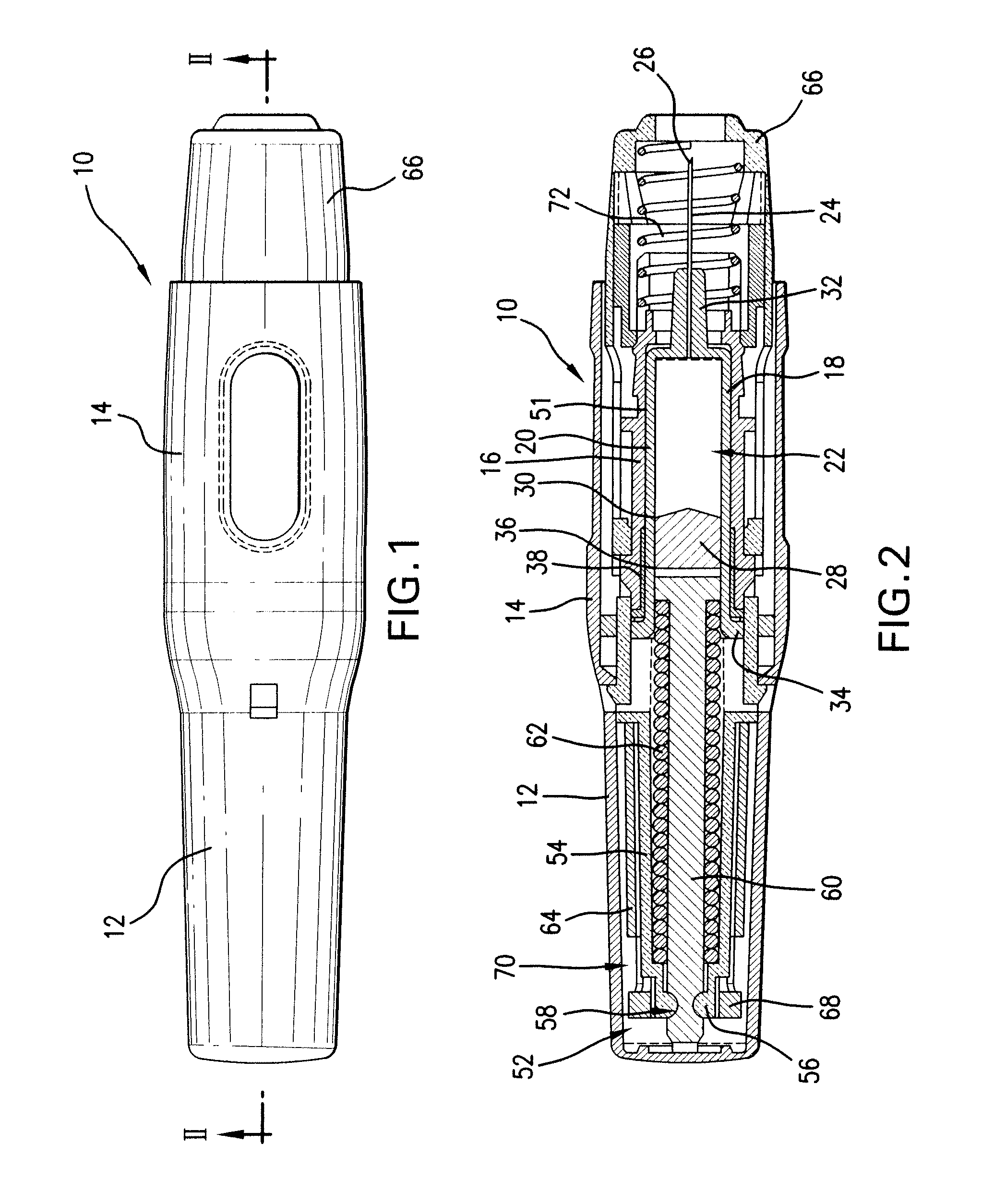

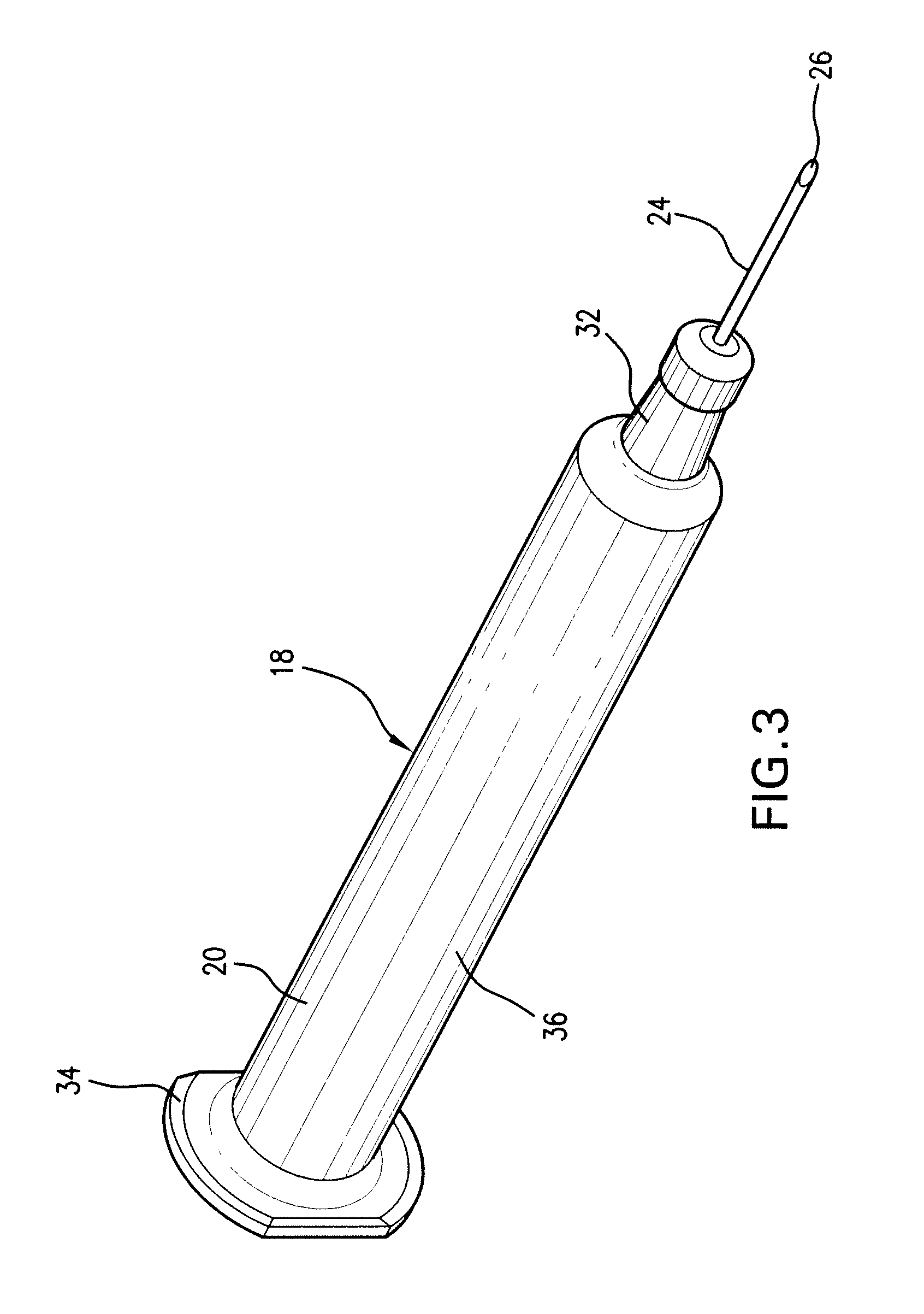

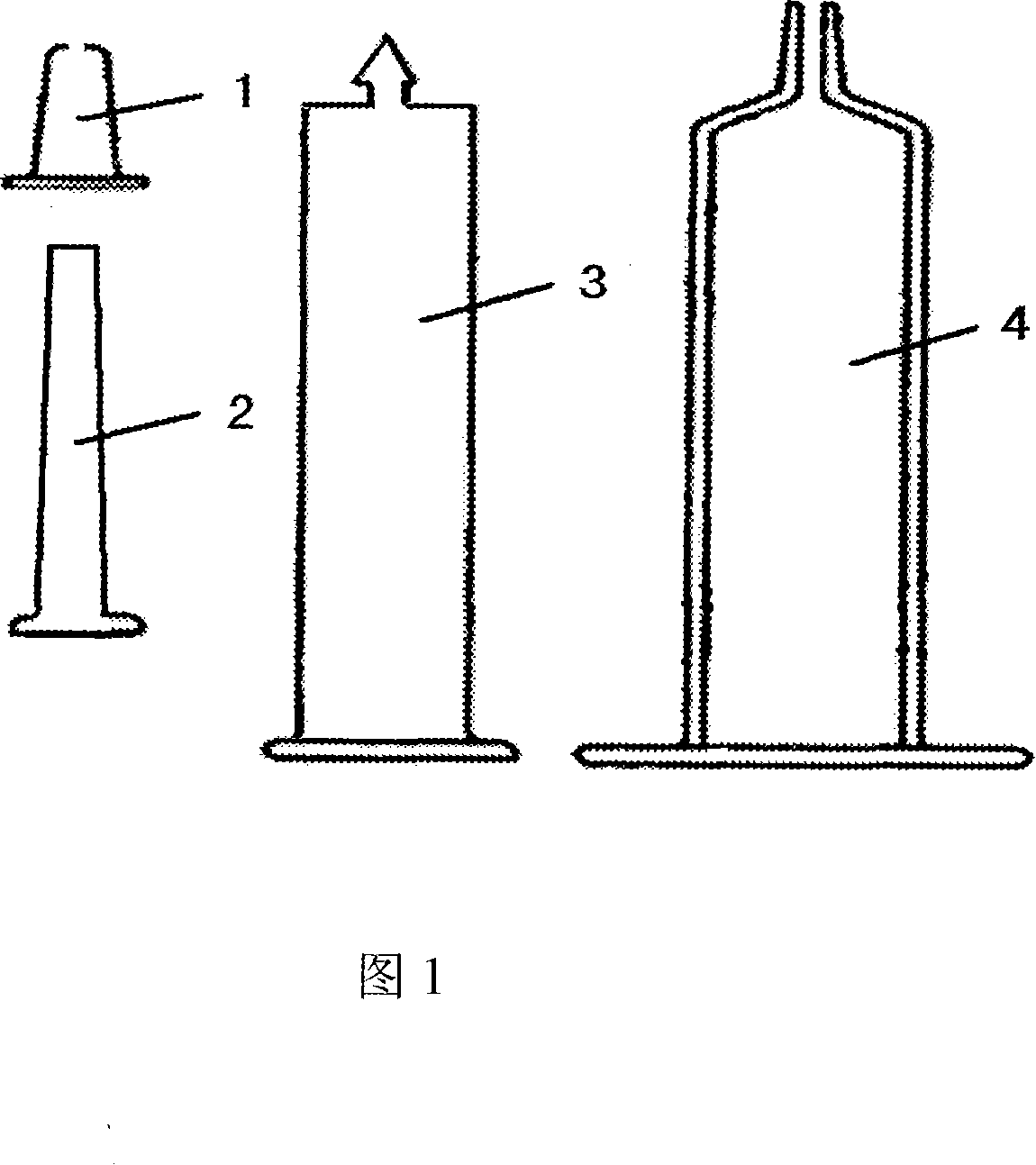

Prefilled syringe jet injector

ActiveUS8021335B2Prevent backflowImprove distributionAmpoule syringesJet injection syringesInjection pressureInjection site

A jet injector that includes a prefilled syringe. The syringe includes a fluid chamber that contains a medicament. The syringe also has an injection-assisting needle, and a plunger is movable within the fluid chamber. A housing is configured for allowing insertion of the needle to a penetration depth. An energy source is configured for biasing the plunger to produce an injecting pressure in the medicament in the fluid chamber of between about 80 and 1000 p.s.i. to jet inject the medicament from the fluid chamber through the needle to an injection site.

Owner:ANTARES PHARMA INC

Method and an apparatus for evaluating a geometry of a hydraulic fracture in a rock formation

InactiveUS20070256830A1Minimize any discrepancyError minimizationElectric/magnetic detection for well-loggingSurveyInjection pressureCoupling

Owner:SCHLUMBERGER TECH CORP

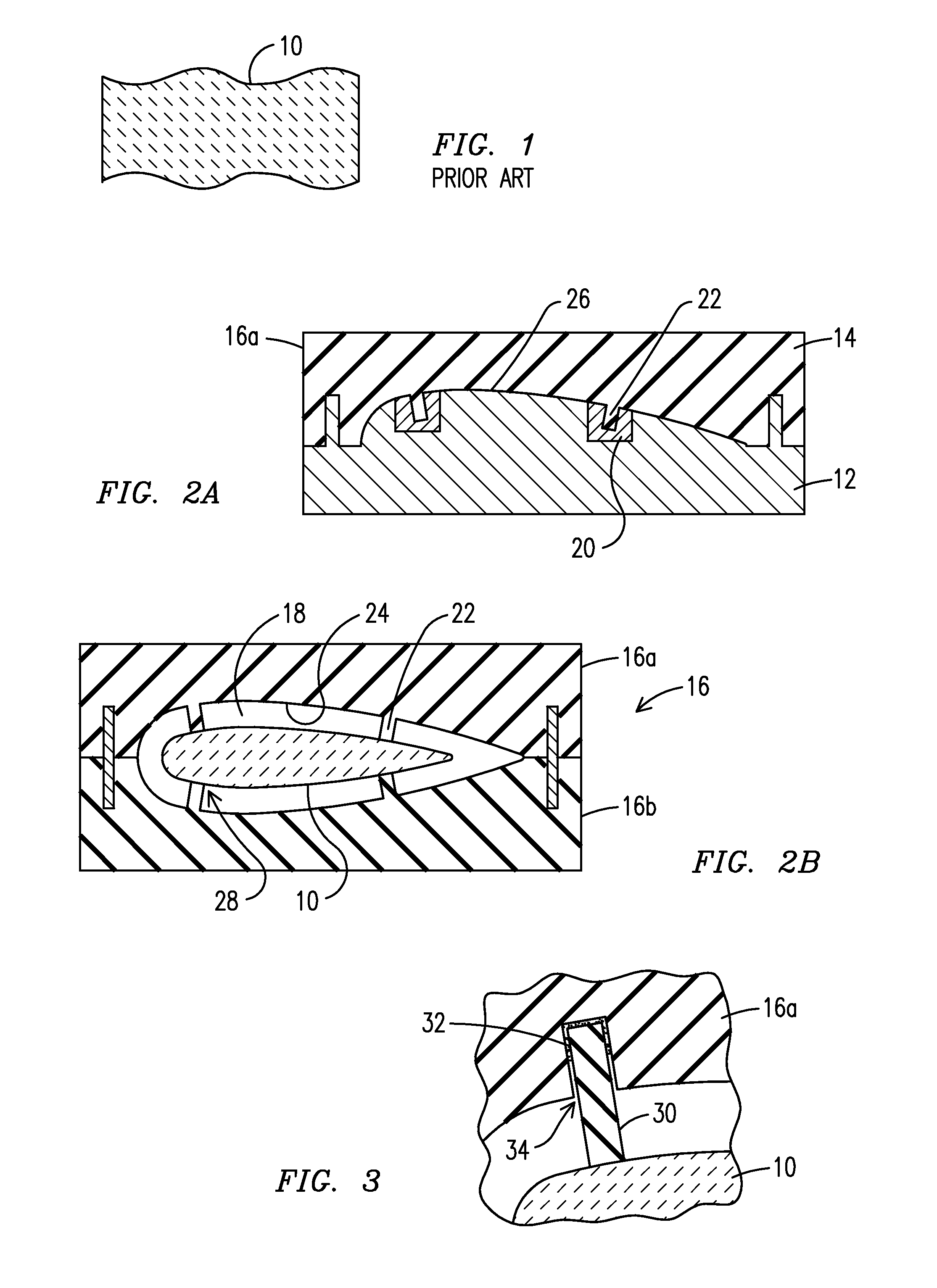

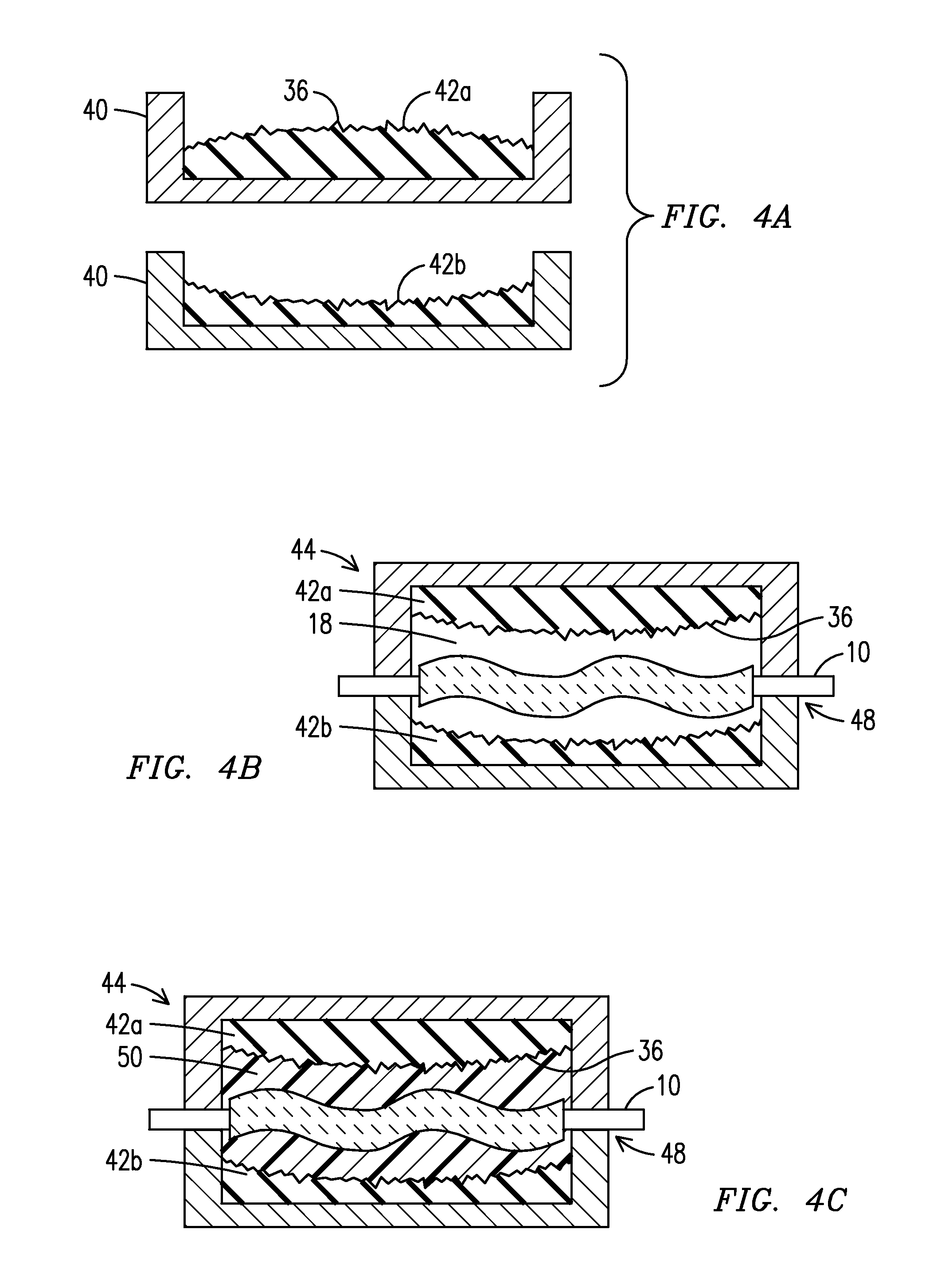

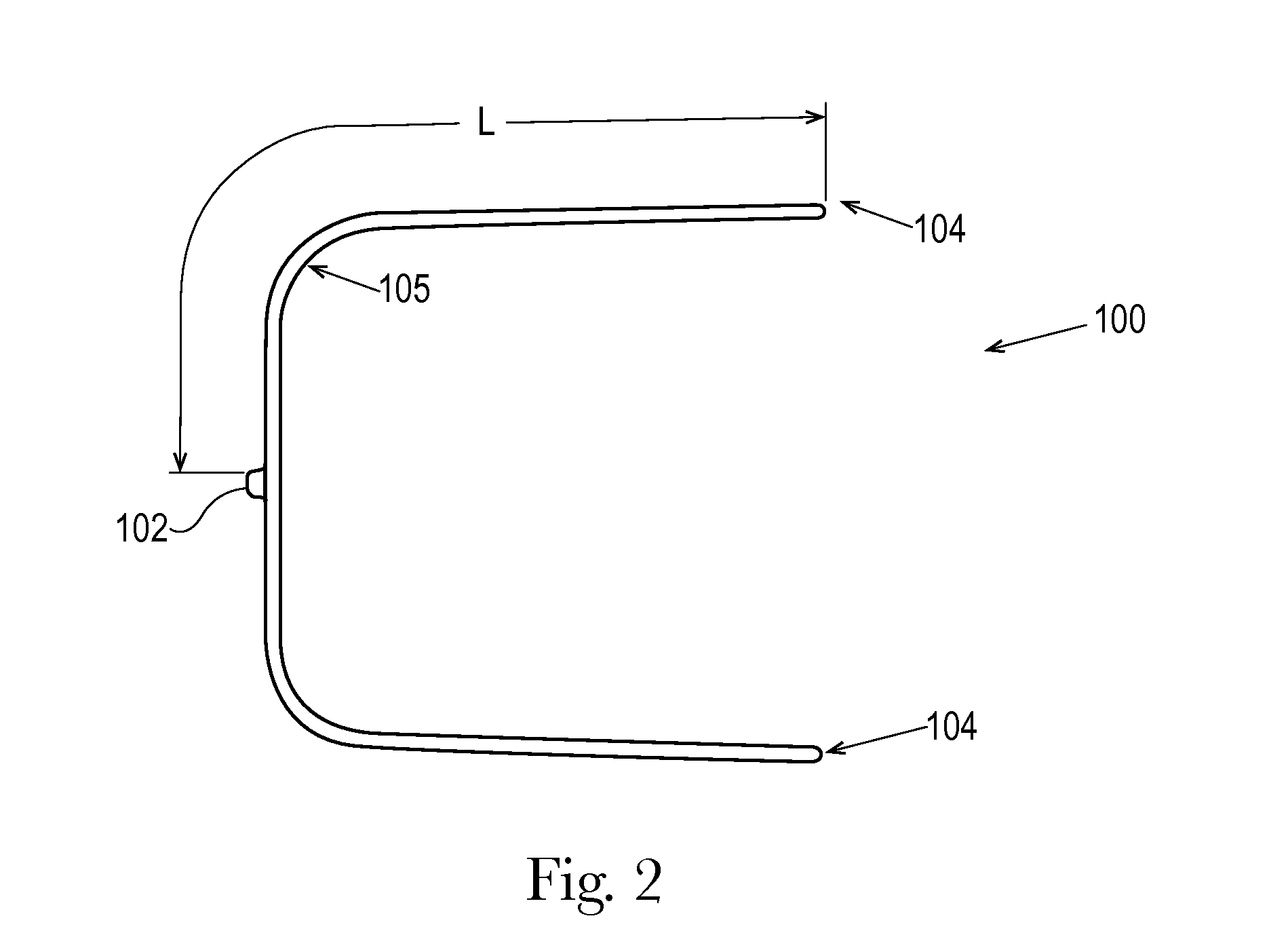

Investment casting utilizing flexible wax pattern tool for supporting a ceramic core along its length during wax injection

InactiveUS20130333855A1Reducing incidence of damage and movementIncrease pressureFoundry mouldsFoundry coresInjection pressureInvestment casting

An investment casting process wherein the wax pattern tool (42) is flexible to provide compliant support for an enclosed ceramic core (10) and to facilitate removal of the tool from the cast wax pattern (52) even when the cast shape would otherwise require multiple pull planes. Positioning pins (106) may extend from the flexible tool to make compliant contact against the core during the wax injection step. The pins may cooperate with a pedestal (128) formed on the core to support the core along multiple axes during wax injection, thereby allowing a higher wax injection pressure without damage to the core.

Owner:MIKRO SYSYTEMS INC +1

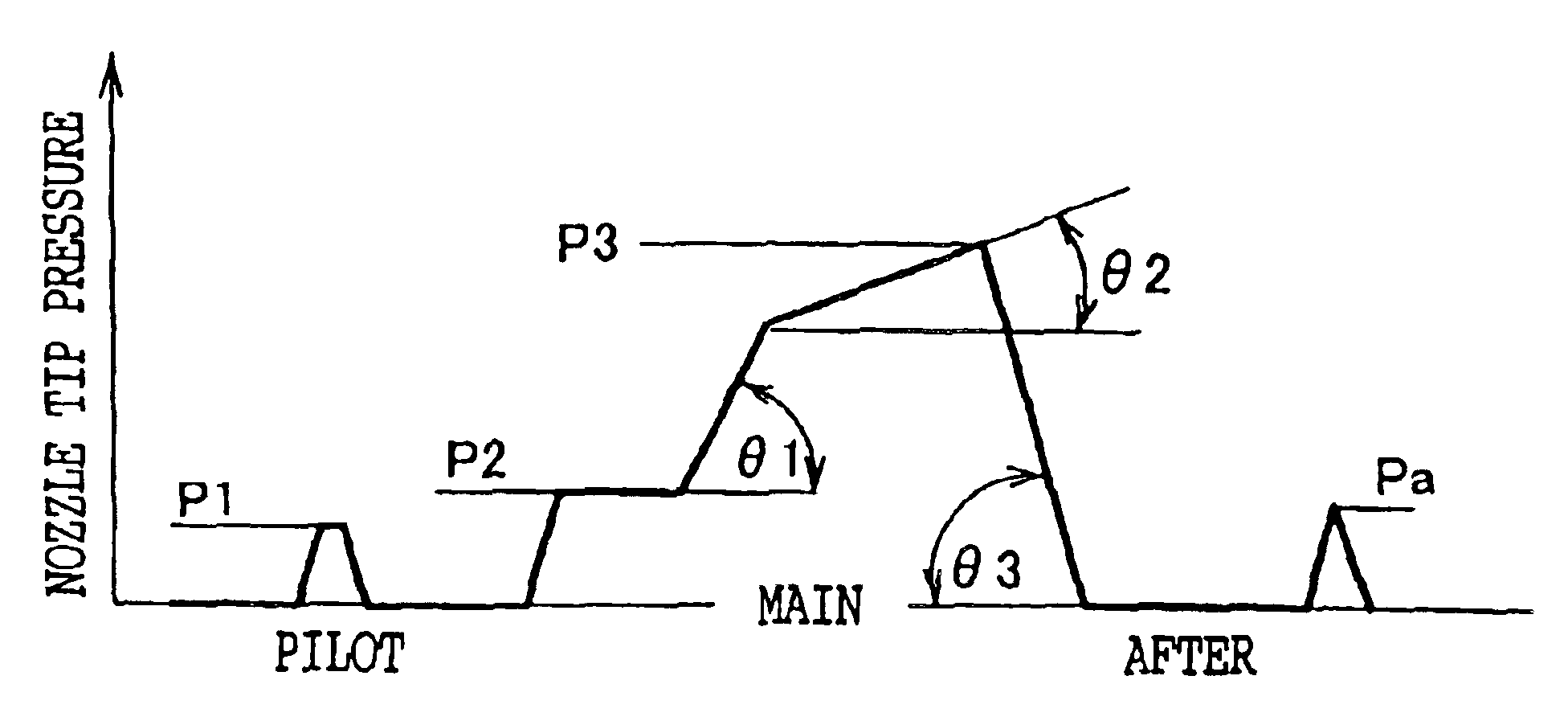

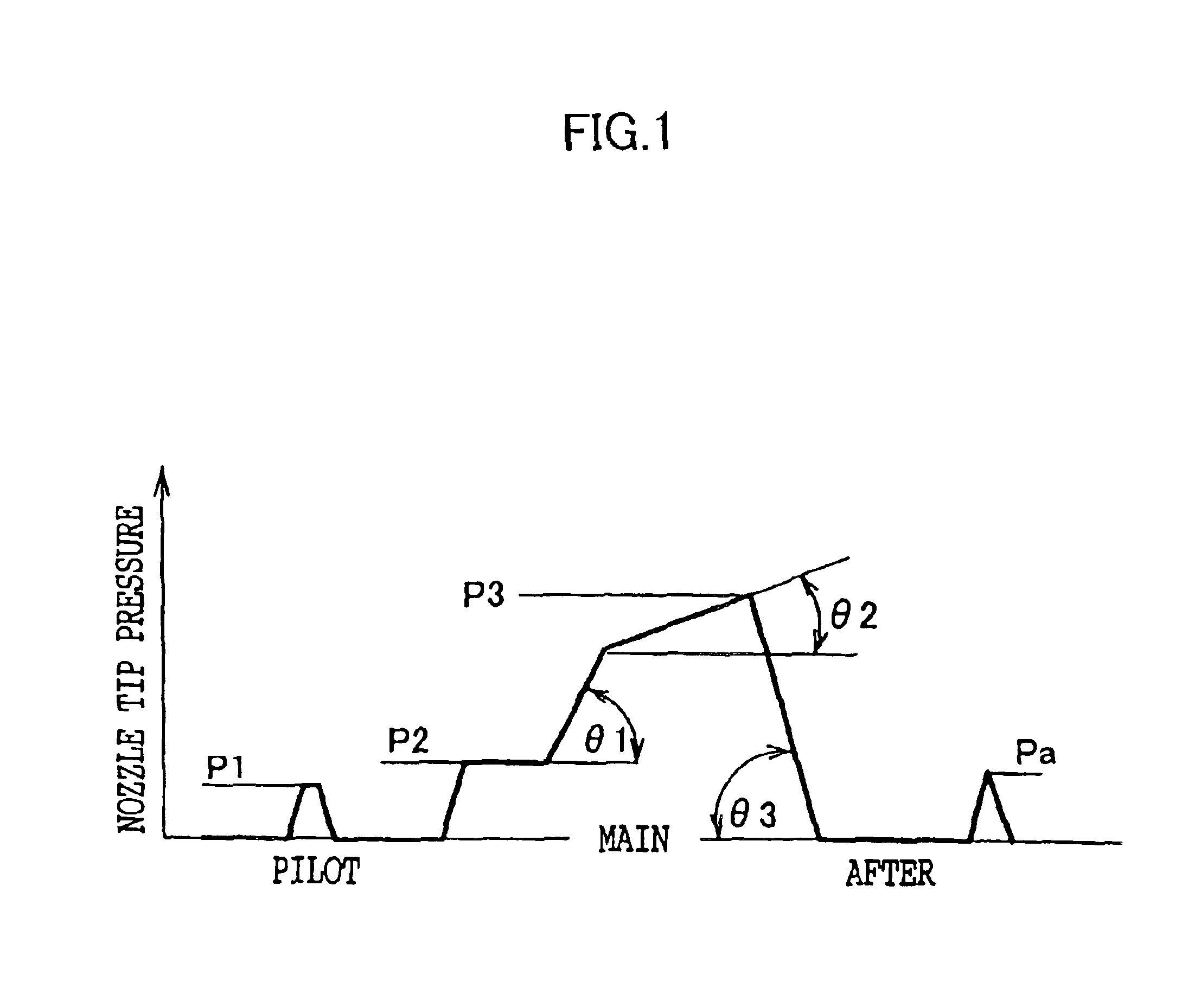

Fuel injection method in fuel injector

InactiveUS6904893B2Increase freedomRealize the structureElectrical controlInternal combustion piston enginesPhase differenceEngineering

In fuel injector including an accumulator and an intensifier, fuel is injected such that an injection control valve and a piston control valve are individually controlled, an operational phase difference therebetween is regulated, and at least one of a maximum injection pressure, a rate of increase of an injection pressure at the start of an increase of pressure, a rate of decrease of the injection pressure at the completion of injection, a pilot injection pressure, and an after injection pressure of fuel injected from a fuel injection nozzle is arbitrarily changed. Namely, a pressure during a movement from a base common rail pressure of the accumulator to a static maximum pressure statically determined by an operation of the intensifier is positively used as a control factor of injection, whereby a fuel injection pattern can be implemented with an extremely high degree of freedom.

Owner:TOYOTA JIDOSHA KK

A w/o/w active heavy oil plugging agent for oil wells and its preparation method

InactiveCN102277143AEffective blockingSolve water problemsFluid removalDrilling compositionInjection pressureSURFACTANT BLEND

The invention discloses a W / O / W type active viscous oil blocking agent. The blocking agent comprises internal phase water, viscous oil and external phase water. A nonionic surfactant is adopted between the internal phase water and the viscous oil. An ionic surfactant is adopted between the viscous oil and the external phase water. According to the invention, a W / O / W composite structure is adopted, W / O with a relatively large viscosity is coated by the external phase water layer, such that defects in prior arts of high viscosity, high construction pressure and poor selectivity upon an oil-water layer during an active viscous oil blocking agent injection process are overcome. With the blocking agent provided by the invention, the ground fluidity is good, and the injection pressure is low. When the blocking agent enters the stratum, the emulsion is demulsified, and W / O emulsion with a high viscosity is released, such that oil well water exits can be effectively blocked, and defects of existing active viscous oil blocking agents are overcome. The technical scheme provided by the invention is especially suitable for technical features of offshore oilfields.

Owner:CHINA NAT OFFSHORE OIL CORP +1

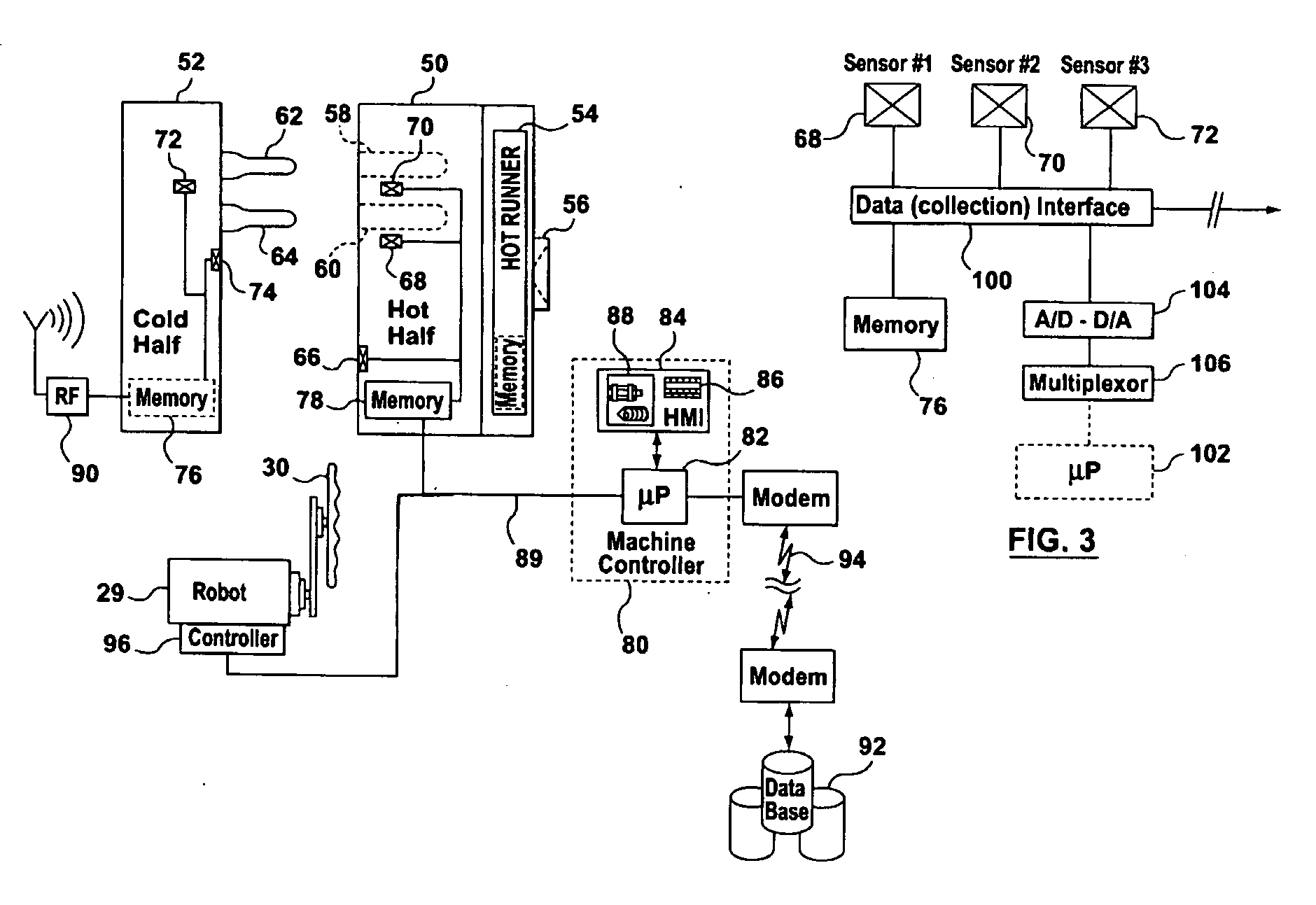

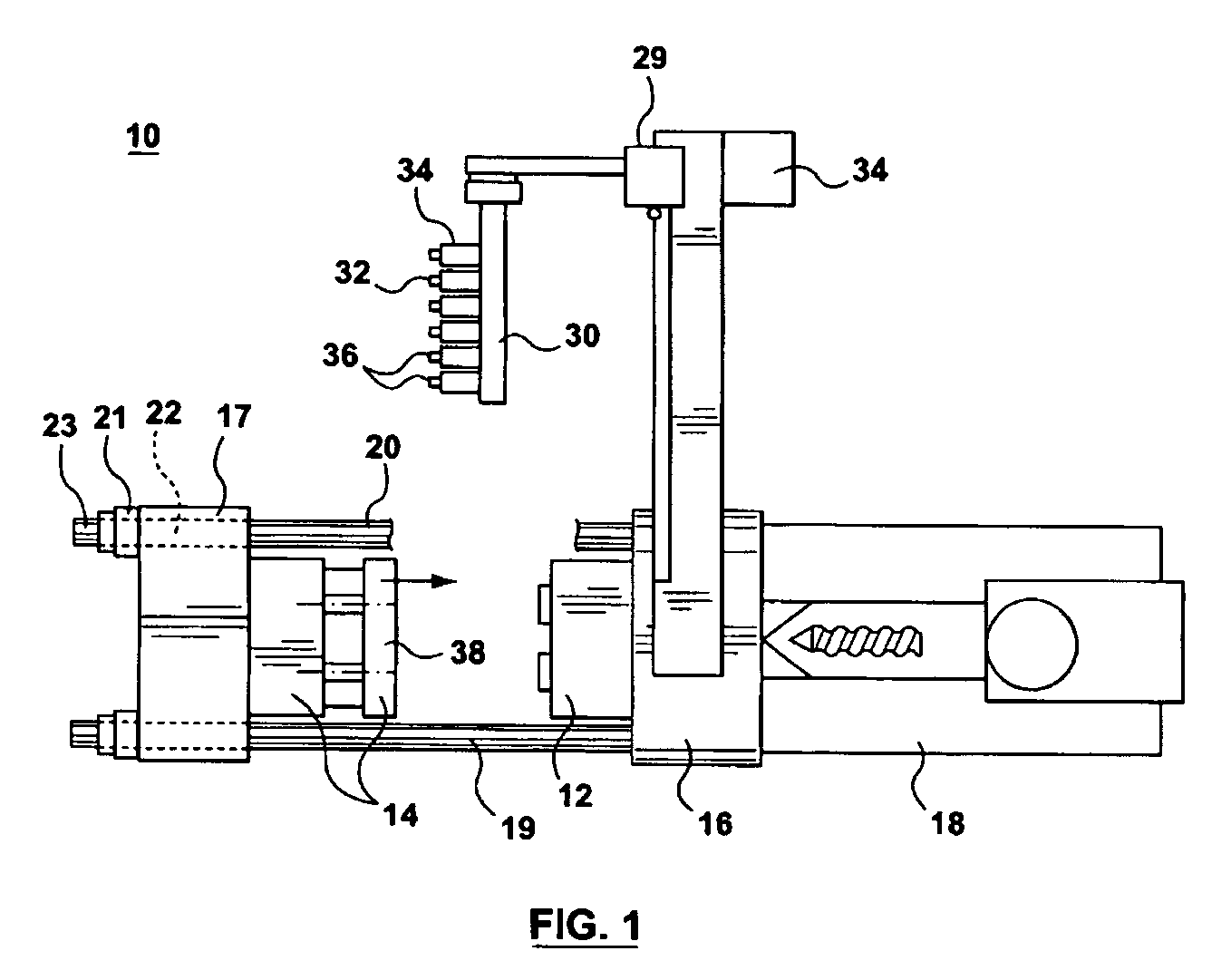

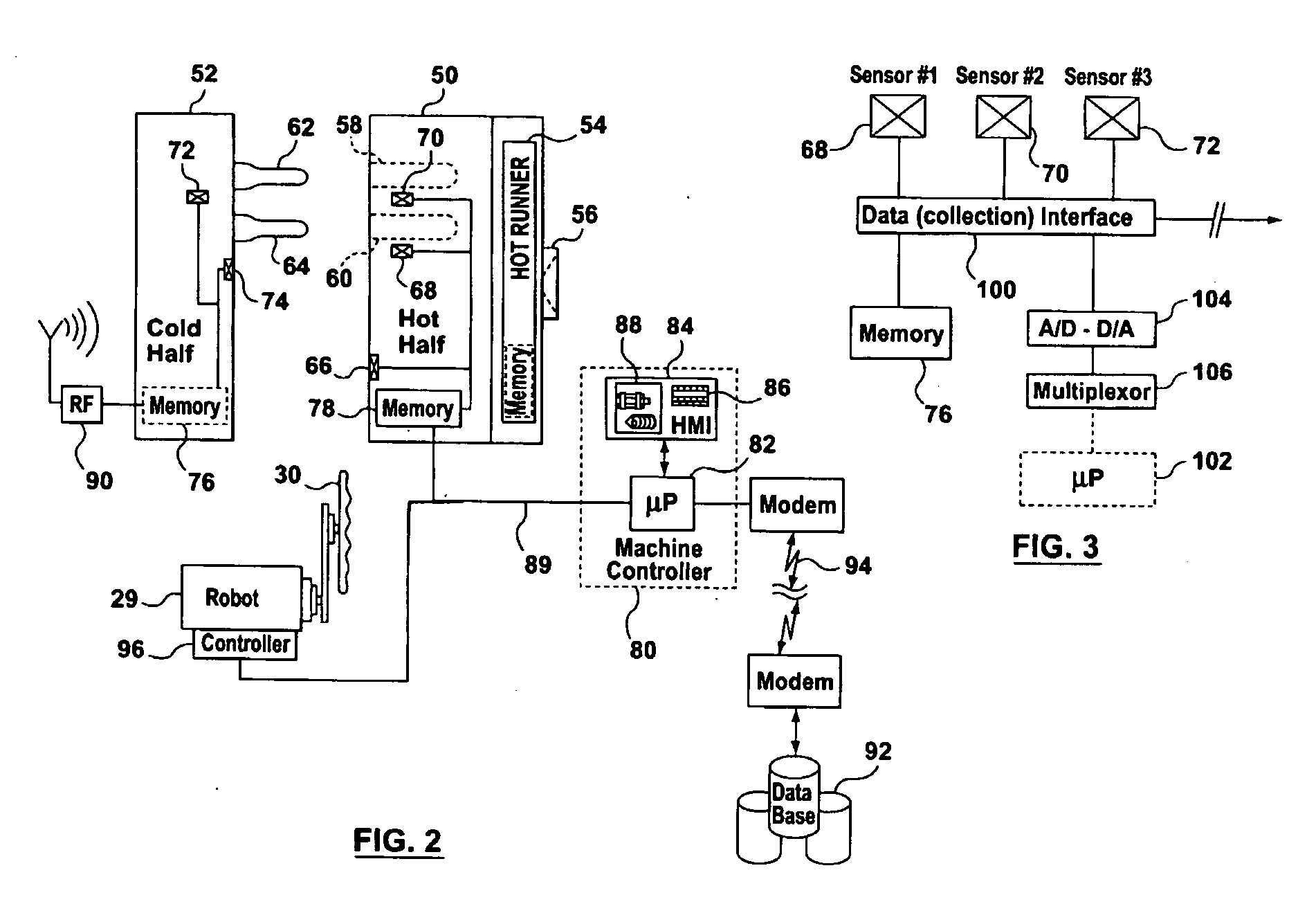

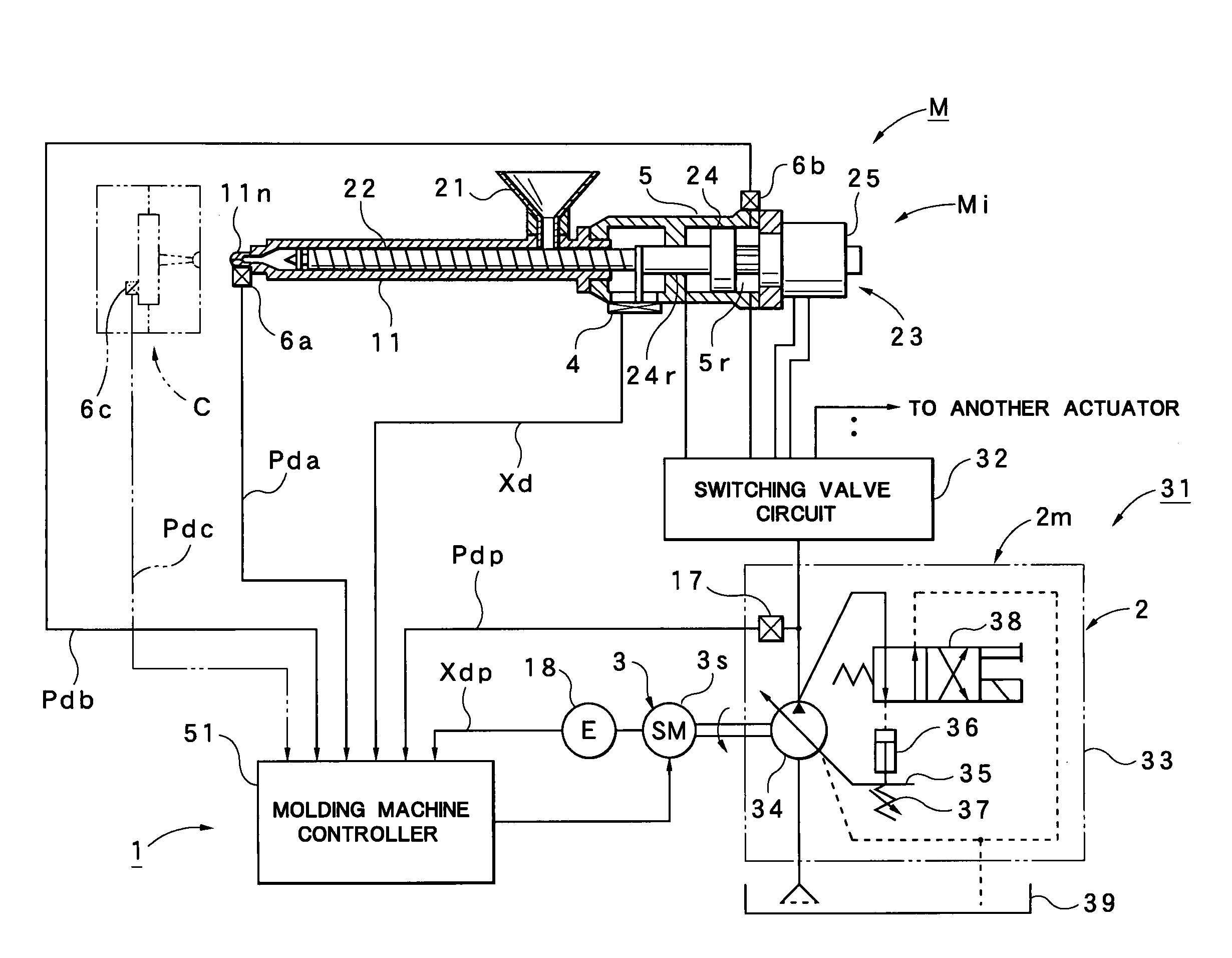

Intelligent molding environment and method of controlling applied clamp tonnage

InactiveUS20060082010A1Easy to operate and controlReduced component wearAuxillary shaping apparatusInjection pressureClosed loop

Rather than developing full closure tonnage for a substantial portion of the duration of an injection cycle, closed loop control of the clamp pressure (such as through control of hydraulic pistons) permits clamp pressure to balance exactly, but preferably slightly exceed, the instantaneous injection pressure. A first approach mimics the injection pressure profile with time, whereby applied tonnage is varied with time according to sensed pressure measurements. A second approach looks to pre-stored or historically accumulated injection pressure information and, instead of varying the tonnage, applies a constant tonnage reflecting the maximum recorded or most likely injection pressure to be experienced in the mold (as recorded stored in a look-up table associated with the particular mold configuration). A machine controller (80, 82) causes the application of applied tonnage through the platen (16, 17) and tie-bars (19, 20) of an injection molding machine (10). Pressure sensors (66-74) located either on a mold surface (50), relative to stack components (58-64) and / or relative to a force closure path of permit a microprocessor (82) to control applied clamp closure tonnage. In this way, the system consumes less power and component wear is reduced.

Owner:HUSKY INJECTION MOLDING SYST LTD

Degradation type disposable syringe and method of producing the same

ActiveCN101152588AThe preparation process is detailed and reasonableFast degradationInfusion syringesInfusion needlesPolyolefinInjection moulding

The invention relates to a degradation disposable syringe and a method of preparing the syringe. The syringe includes an outer cover, a core pin, a needle seat and a needle cap, which can be degraded in the natural environment. The basic material for degradation is prepared with degradable polymer main material, plasticizer, stabilizer, stabilizing additive and filling compound, etc. The detailed injection molding process for all parts of the syringe is: the injection temperature for a feeding opening is 20 to 60 DEG C; the injection temperature for a compression section is 100 to 200 DEG C; the injection temperature for a measurement section is 130 to 240 DEG C; the injection temperature for a spray nozzle is 130 to 220 DEG C; the mold temperature is 20 to 50 DEG C; the injection pressure is 40 to 200MPa; the injection time is 8 to 90 seconds; the pressure holding time is 0 to 5 seconds; the screw speed is 20 to 180 r / m; all performances of the degradation syringe totally meet the national standard (GB15810-2001). After being abandoned, the syringe does not pollute the environment, prevents illegal recycling, and can totally replace the disposable polyolefin syringes.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

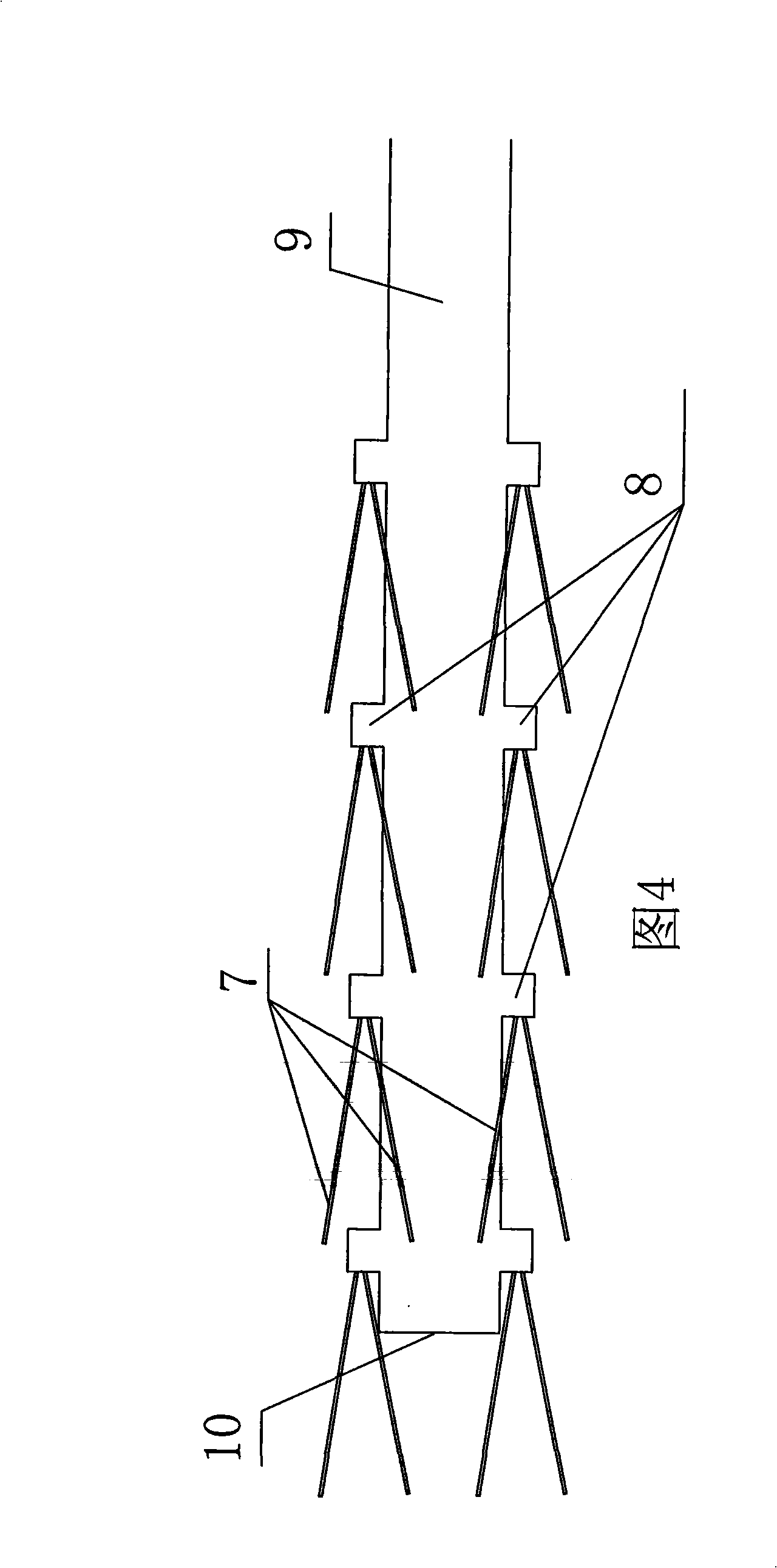

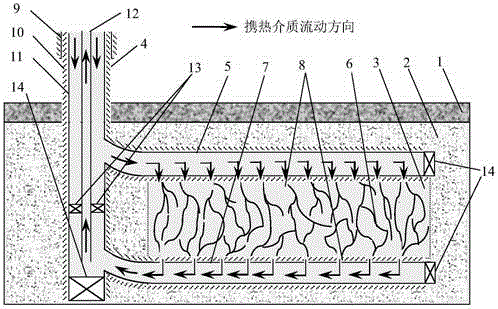

Method for self-circulation exploitation of geothermal energy of hot dry rock with multilateral well and volume fracturing technologies

InactiveCN105840146AAvoid the problem of not being able to connect efficientlyIncrease temperatureOther heat production devicesGeothermal energy generationInjection pressureDual action

The invention relates to the field of geothermal exploitation and provides a method for self-circulation exploitation of geothermal energy of hot dry rock with multilateral well and volume fracturing technologies. According to the method, firstly, multilateral well holes are drilled in different depths of a reservoir of the hot dry rock, the reservoir between upper and lower multilateral well holes is fractured with the volume fracturing technology, a high-permeability hot dry rock reservoir is constructed, and finally, thermal-carrying media are injected and exploited for geothermal exploitation. Annularly-injected low-temperature thermal-carrying media flow to the fractured reservoir of the hot dry rock along the multilateral well holes in the upper part of the reservoir, flow to the multilateral well holes in the lower part under the double actions of injection pressure and potential-energy difference and finally flow back to the ground along an oil pipe. According to the method, the multilateral well and fracturing technologies are sufficiently utilized, the reservoirs of the hot dry rock are effectively communicated, the problem about crack communication during conventional double-well fracturing for injection and exploitation is solved, the potential-energy difference in different depths can be further effectively utilized, and the flowing capability of the thermal-carrying media is greatly improved. With the use of the thermal insulation oil pipe, the thermal loss in the exploitation process of the thermal-carrying media is further reduced, and the exploitation efficiency of geothermal energy is improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

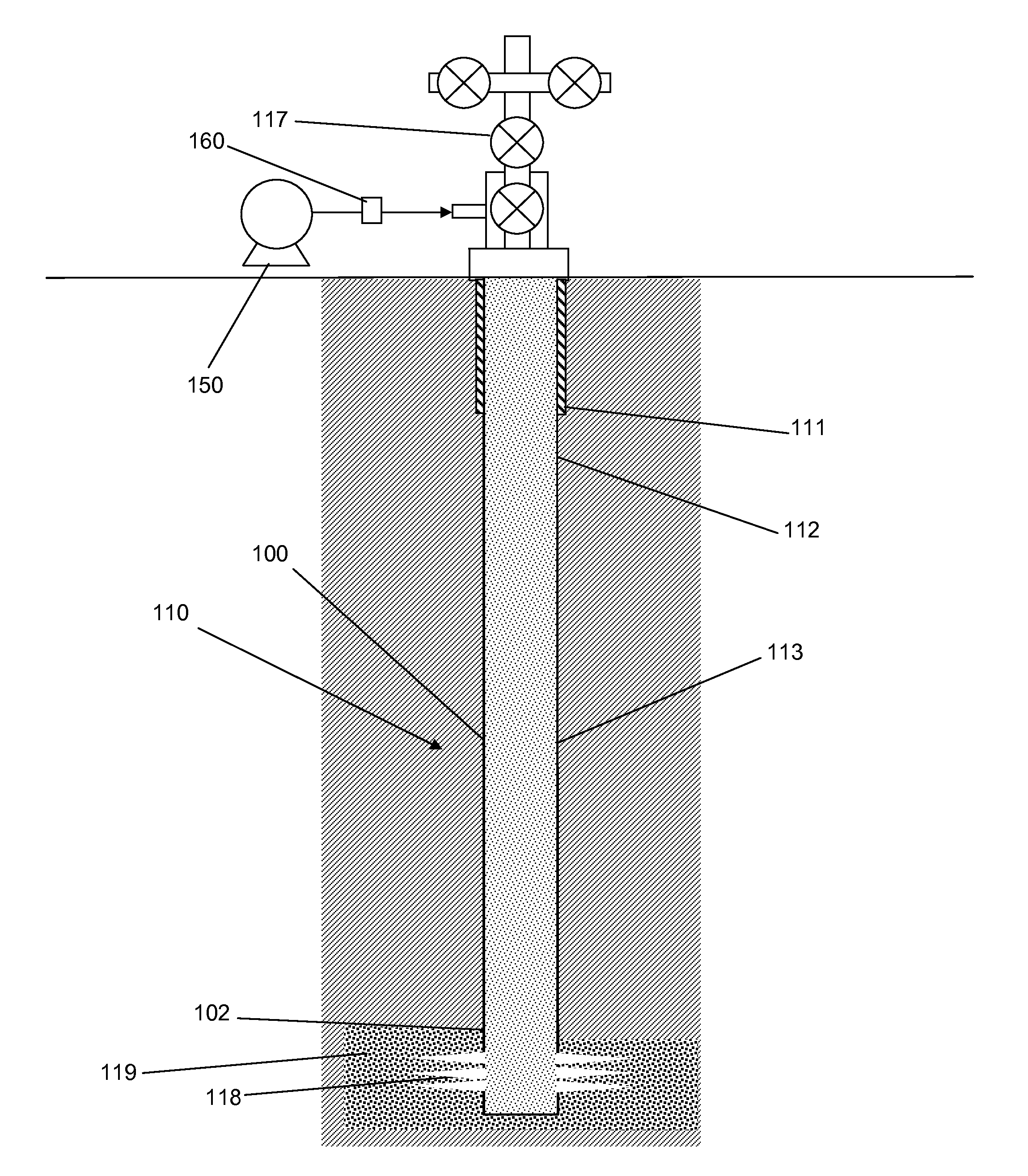

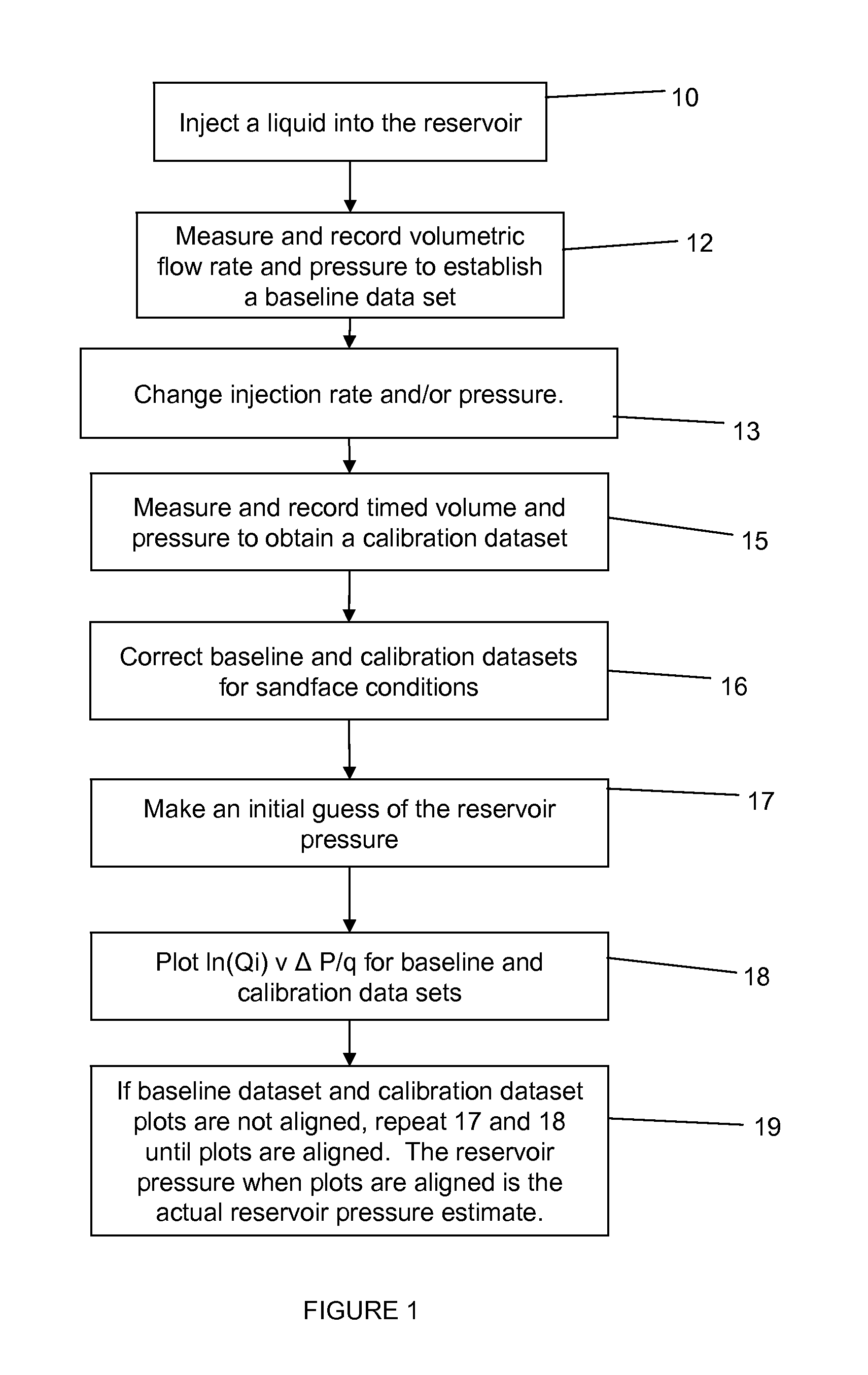

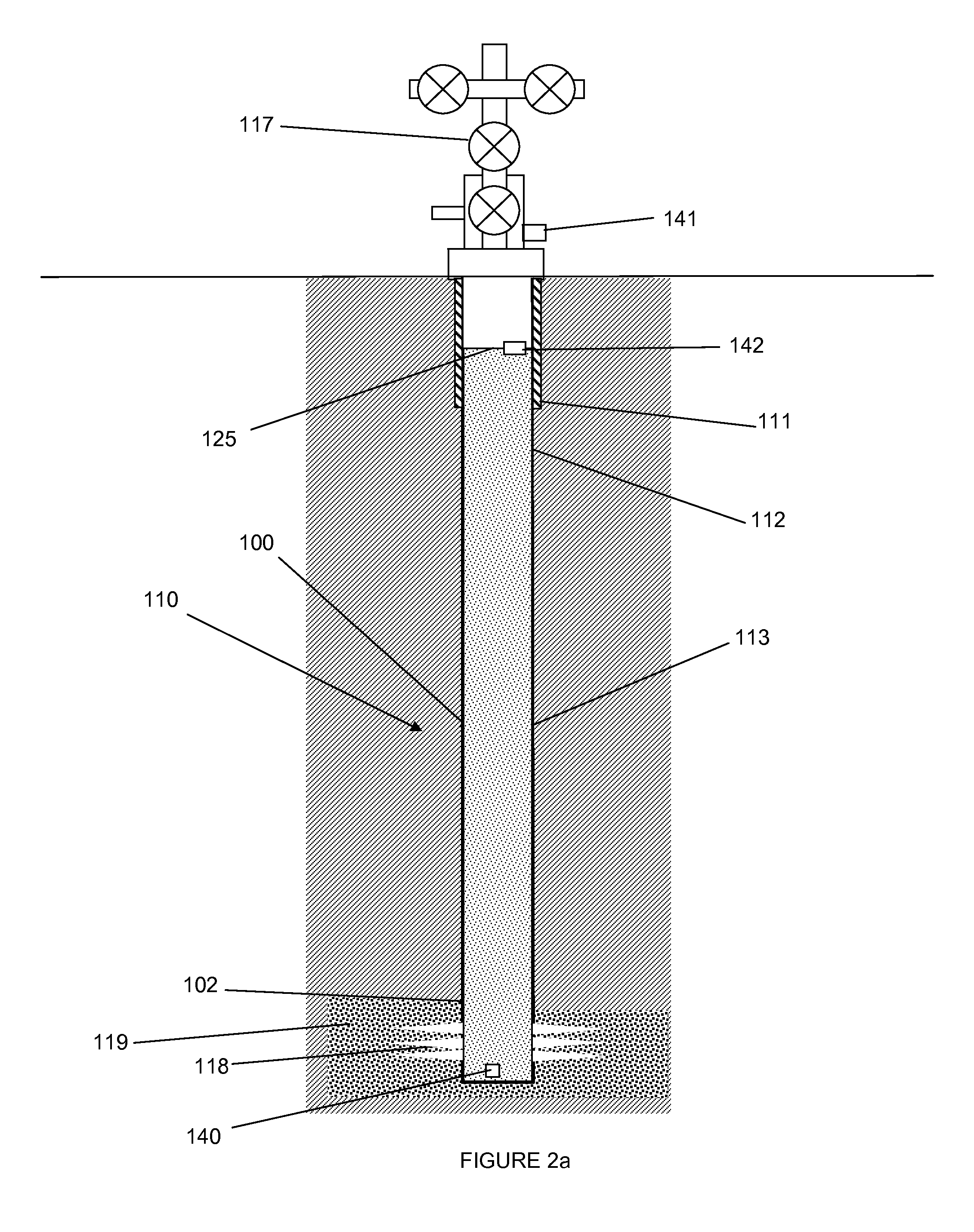

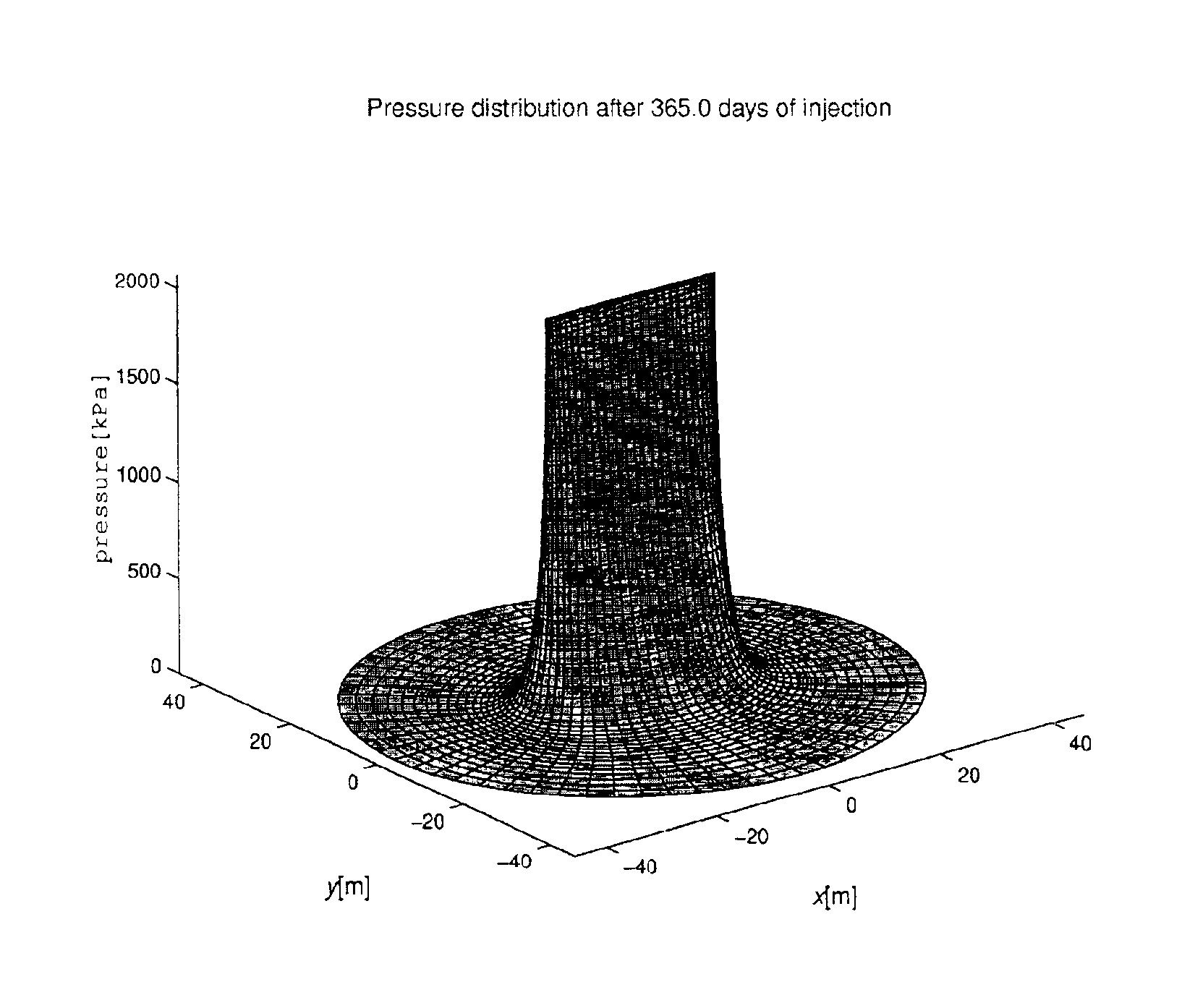

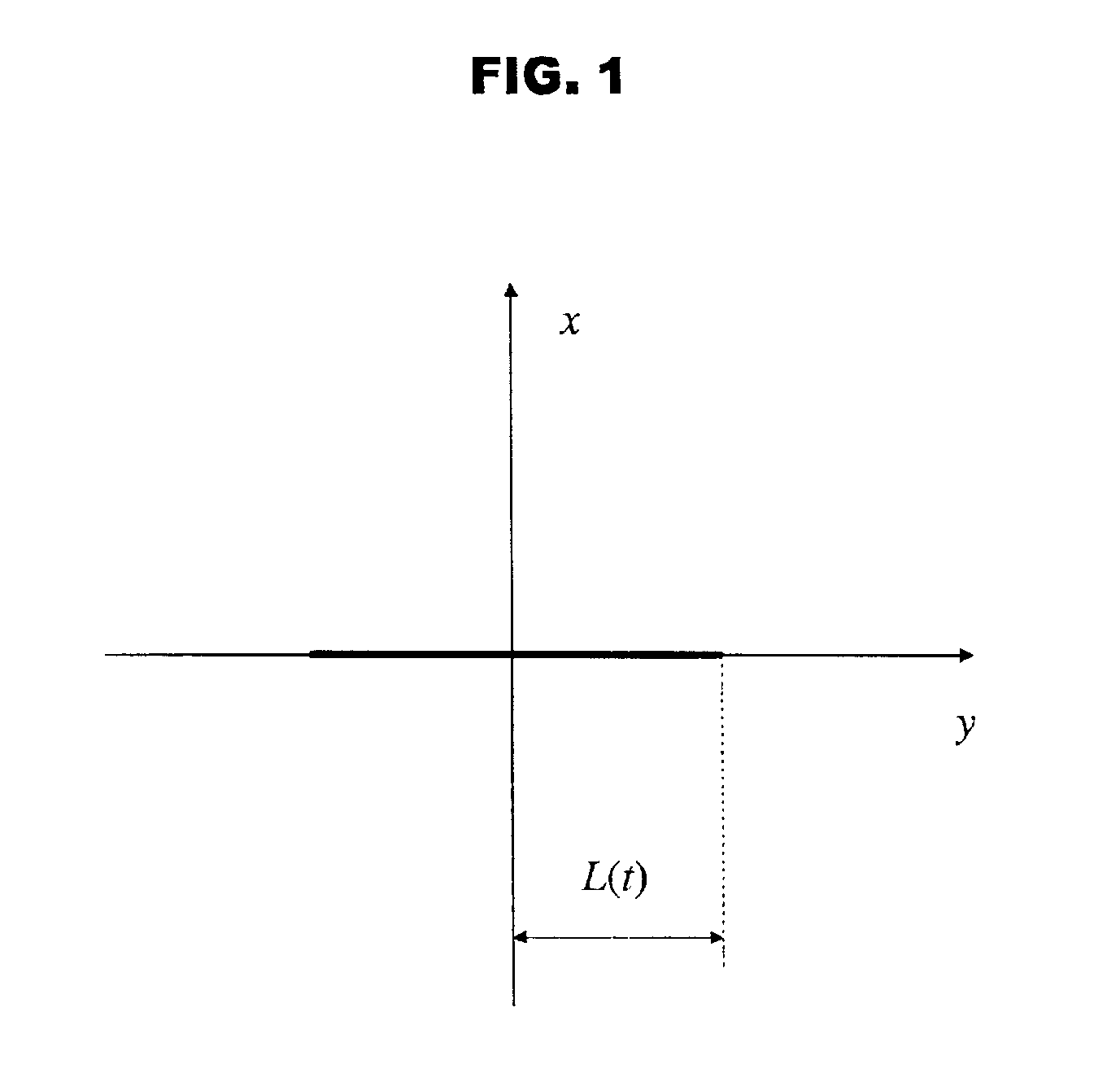

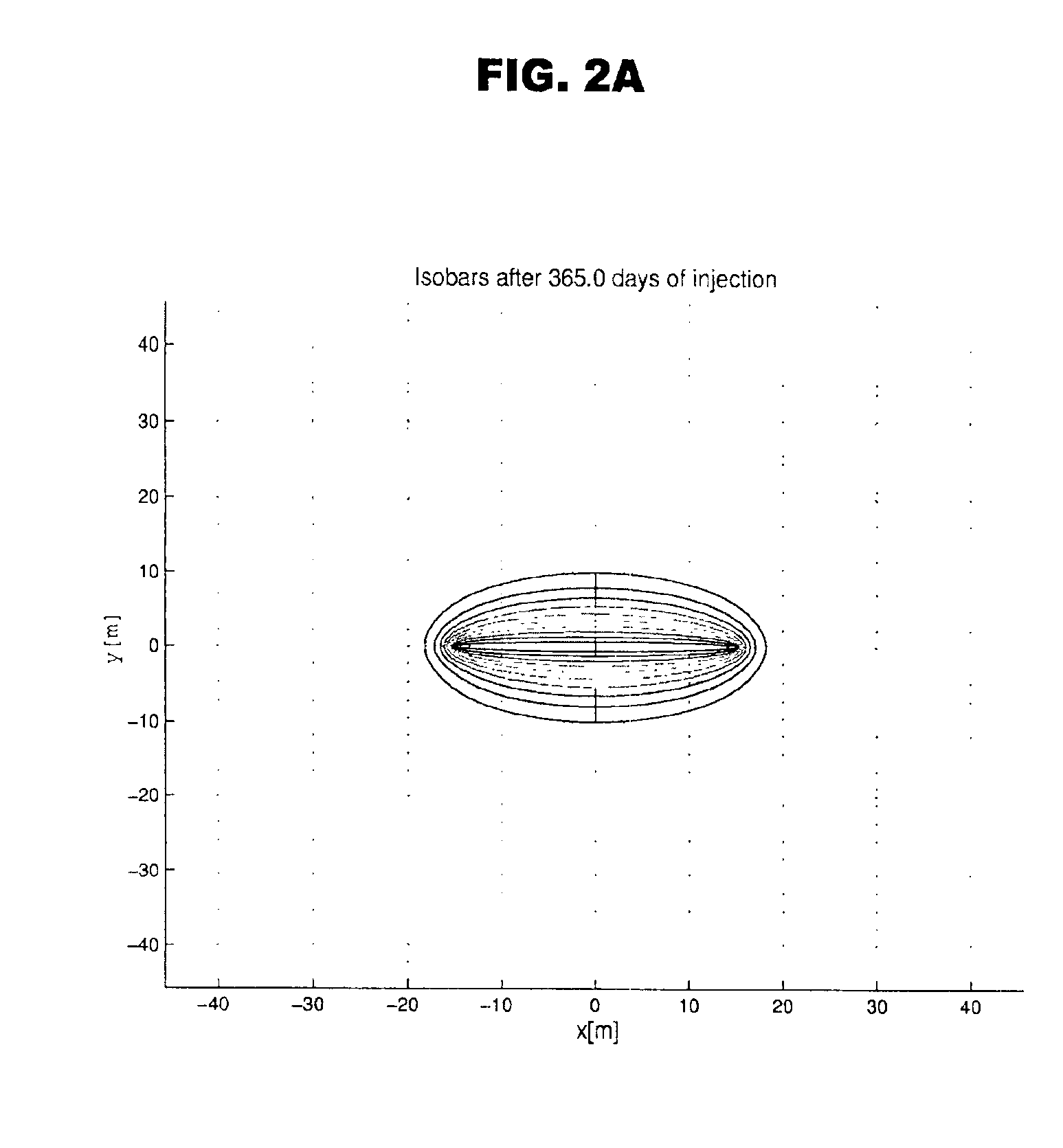

Method of determining reservoir pressure

ActiveUS20120158310A1Reduce penetrationElectric/magnetic detection for well-loggingSurveyBaseline dataInjection pressure

A new approach is disclosed for measuring the pressure of tight gas reservoirs, using information obtain from continuous injection prior to hydraulic fracture stimulation. The technique can be obtained utilizing either bottom-hole or surface pressure gauges and properly instrumented surface injection pumps. The analysis is completed by plotting injection and rate data in a specialized form from terms arranged in Darcy's radial flow equation to obtain a curve or trend. The key component to proper application of this technique is to obtain both baseline and one or more calibration data sets. These calibration data sets are obtained by either increasing or decreasing the injection pressure and / or rate from the baseline data. Initial reservoir pressure is assumed, but the calibration data indicates if the guess was too high or low. Accurate estimates of reservoir pressure may be obtained in a few iterations.

Owner:BP CORP NORTH AMERICA INC

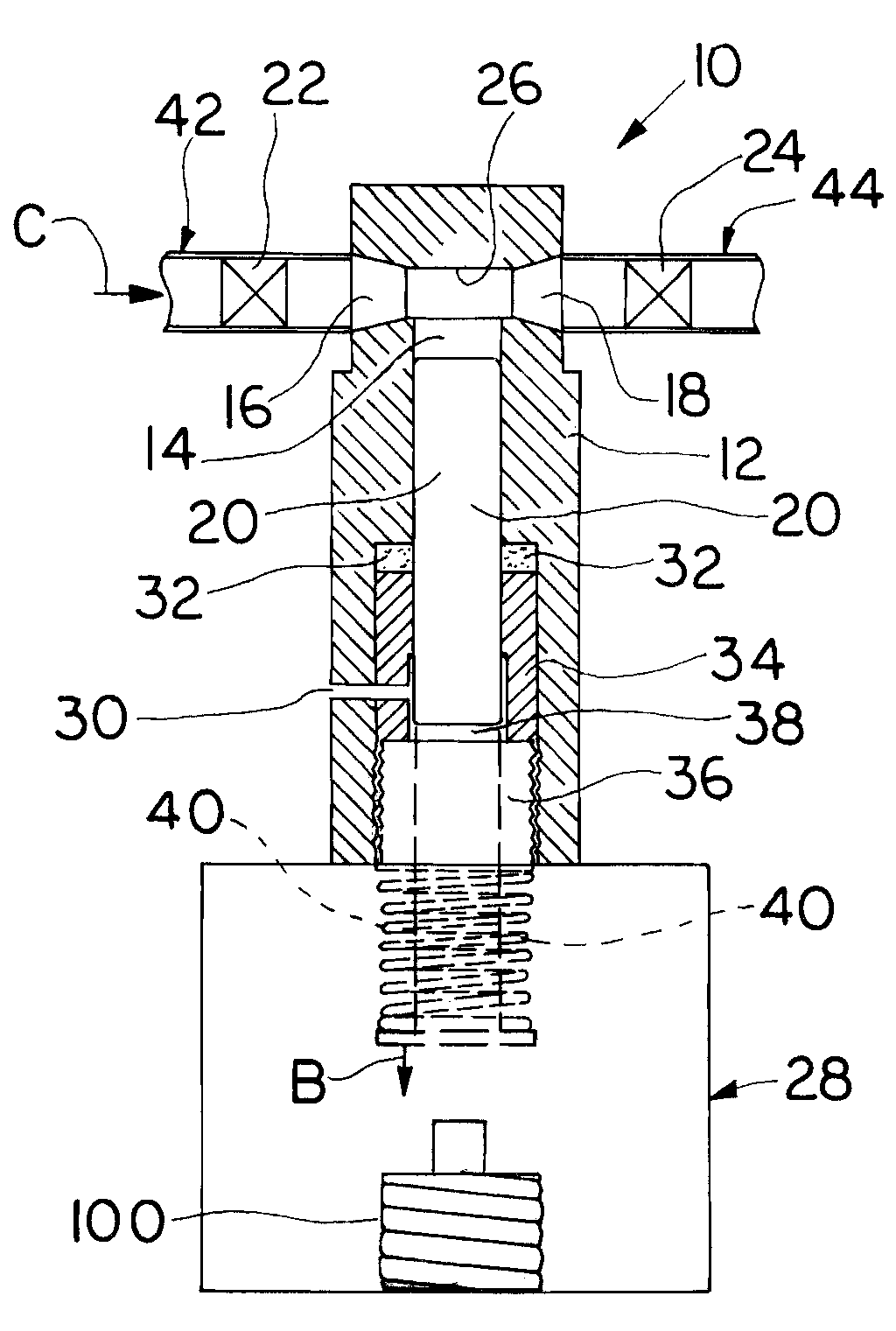

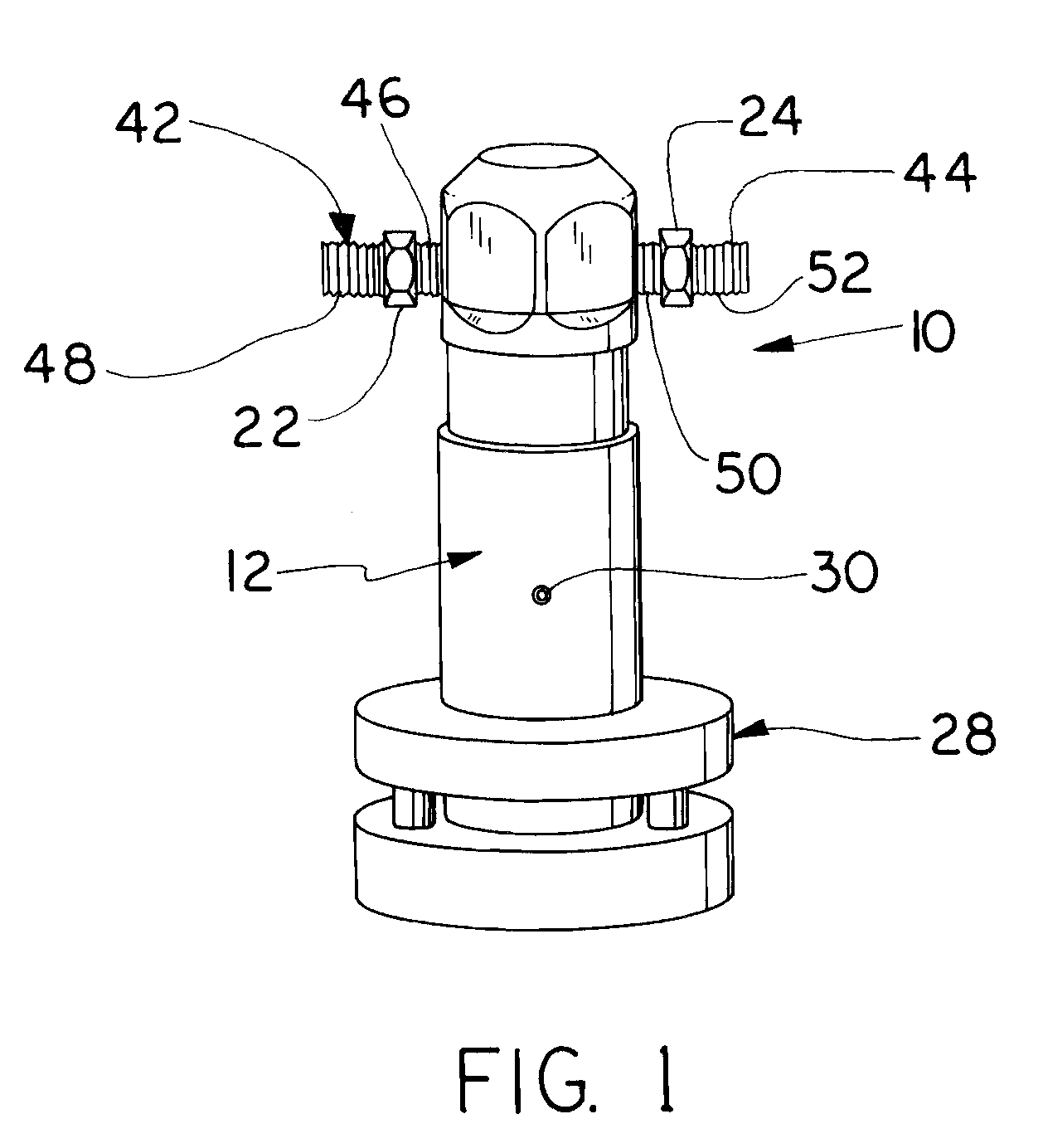

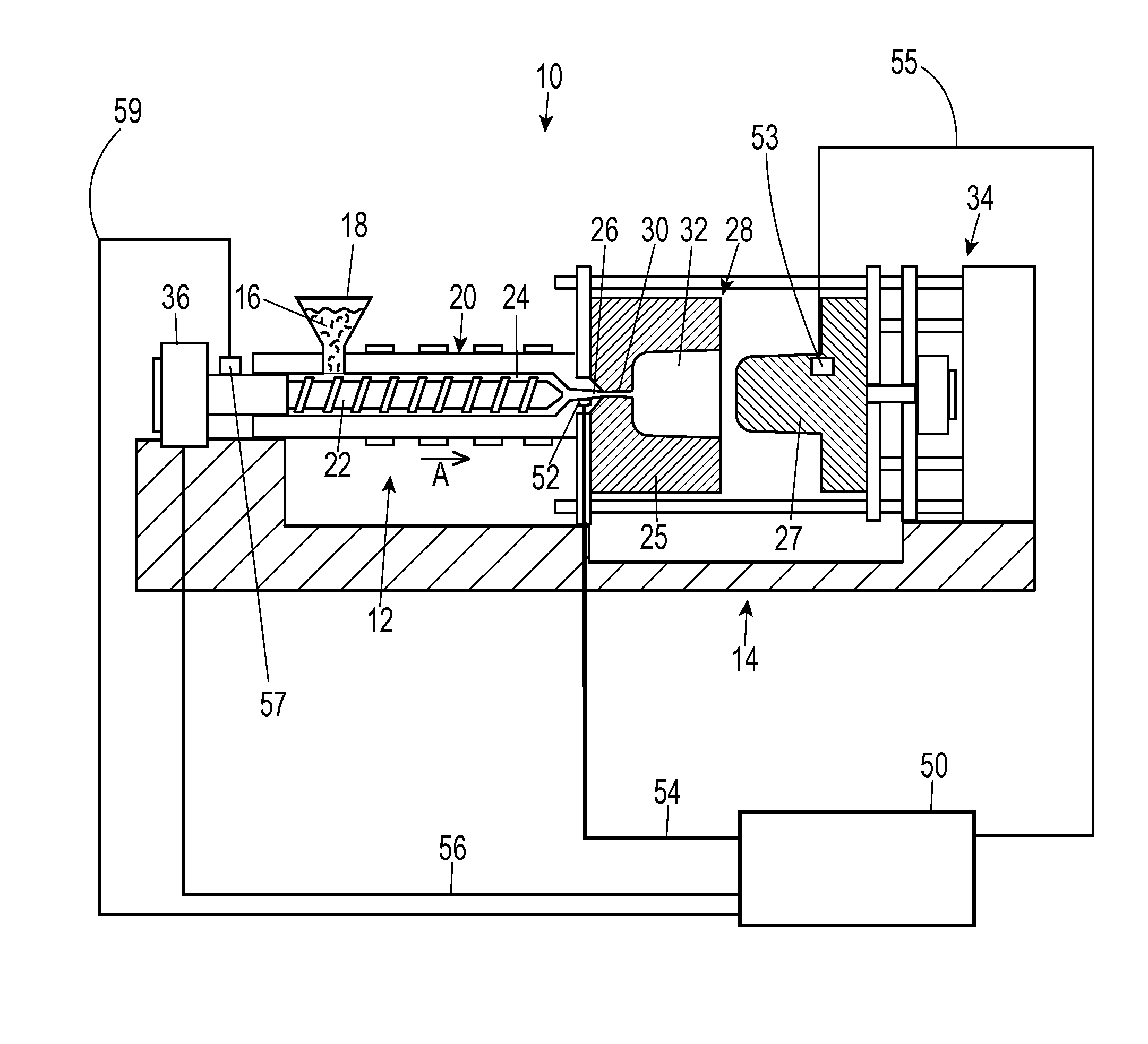

Liquid color injection pressure booster pump and pumping methods

InactiveUS7980834B2Low costNo expensive partPositive displacement pump componentsPiston pumpsInjection pressureEngineering

A pump for boosting pressure of liquid color for injection into plastic resin in molding or extrusion apparatus includes a housing having a first bore extending in a first direction and second and third bores extending through the housing and communicating with the first bore proximate a first end of the first bore with the first end of the first bore being blind. The pump further includes an inlet check valve connectable to the second bore for permitting liquid flow through the second bore into the first bore. Further included is an outlet check valve connective to the third bore for permitting liquid flow out of the first bore through the third bore. A member is reciprocally axially movable within the first bore. A solenoid applies air pulses to the end of the first member facing oppositely from the blind end of the first bore.

Owner:MAGUIRE STEPHEN B

Waterflood control system for maximizing total oil recovery

InactiveUS6904366B2Electric/magnetic detection for well-loggingSurveyInjection volumeInjection pressure

A control system and method for determining optimal fluid injection pressure is based upon a model of a growing hydrofracture due to waterflood injection pressure. This model is used to develop a control system optimizing the injection pressure by using a prescribed injection goal coupled with the historical times, pressures, and volume of injected fluid at a single well. In this control method, the historical data is used to derive two major flow components: the transitional component, where cumulative injection volume is scaled as the square root of time, and a steady-state breakthrough component, which scales linearly with respect to time. These components provide diagnostic information and allow for the prevention of rapid fracture growth and associated massive water break through that is an important part of a successful waterflood, thereby extending the life of both injection and associated production wells in waterflood secondary oil recovery operations.

Owner:RGT UNIV OF CALIFORNIA

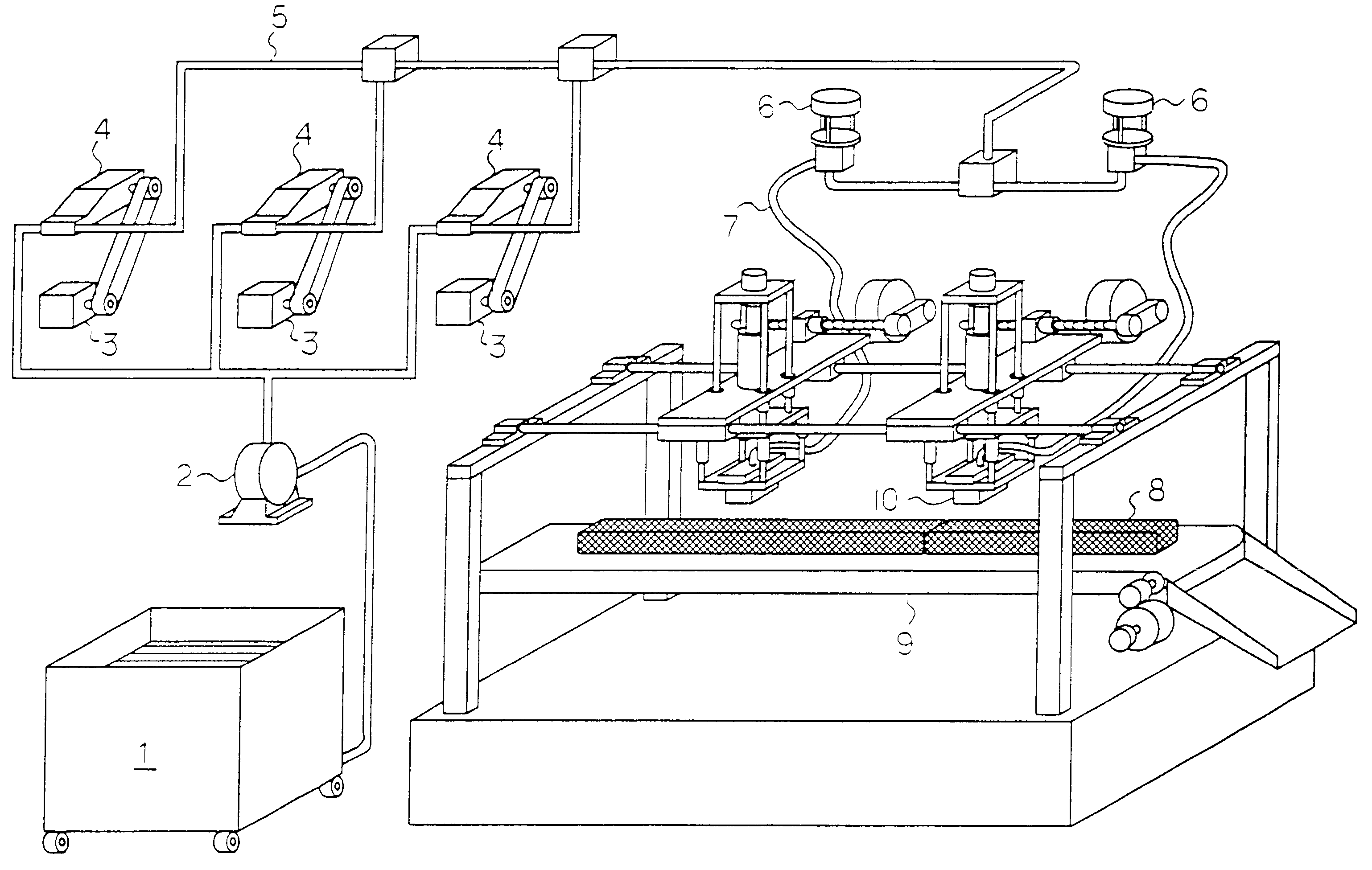

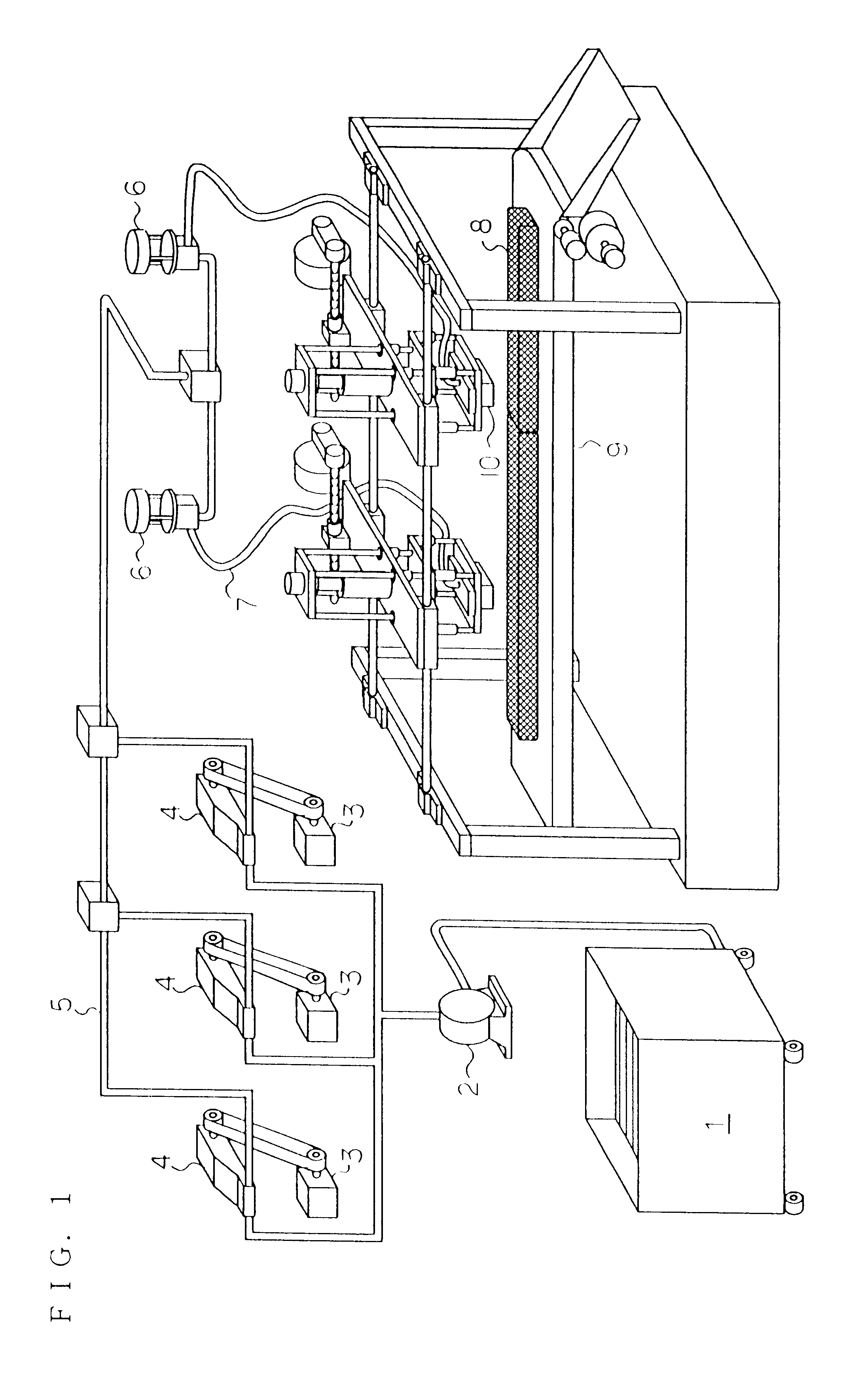

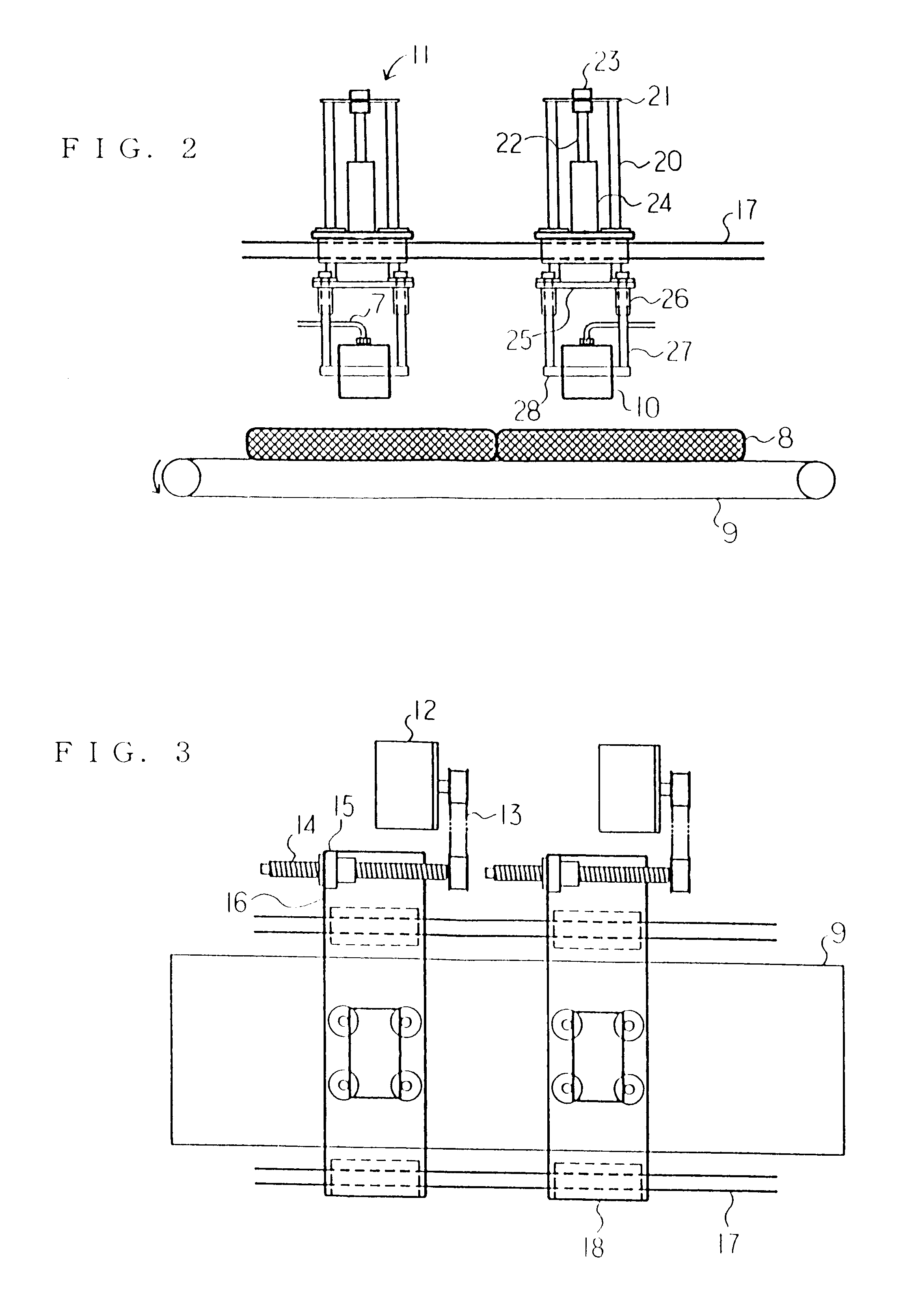

Continuous high-speed pickle injector

InactiveUS6386099B1Improve productivityIncrease speedGrain huskingGrain polishingSaline waterInjection pressure

A continuous high-speed pickle injector is provided with improved productivity that can inject a liquid substance such as brine for curing, seasoning or the like into a block of meat such as pork, beef, livestock meat and the like continuously, and disperse the liquid substance uniformly. A pickle injector which can inject a liquid substance such as brine for curing and the like into a block of meat being conveyed continuously while gradually raising the injection pressure from 0 or a low pressure includes two or more injecting sections being able to repeat an injecting operation, that is, from the start to the completion of the injection of a liquid substance. The two or more injecting sections inject a liquid substance while moving at a speed synchronized with the conveying speed of a block of meat continuously being conveyed during the operation of injection. The timing of the injecting operation for each injecting section is controlled.

Owner:PRIMA MEAT PACKERS LTD

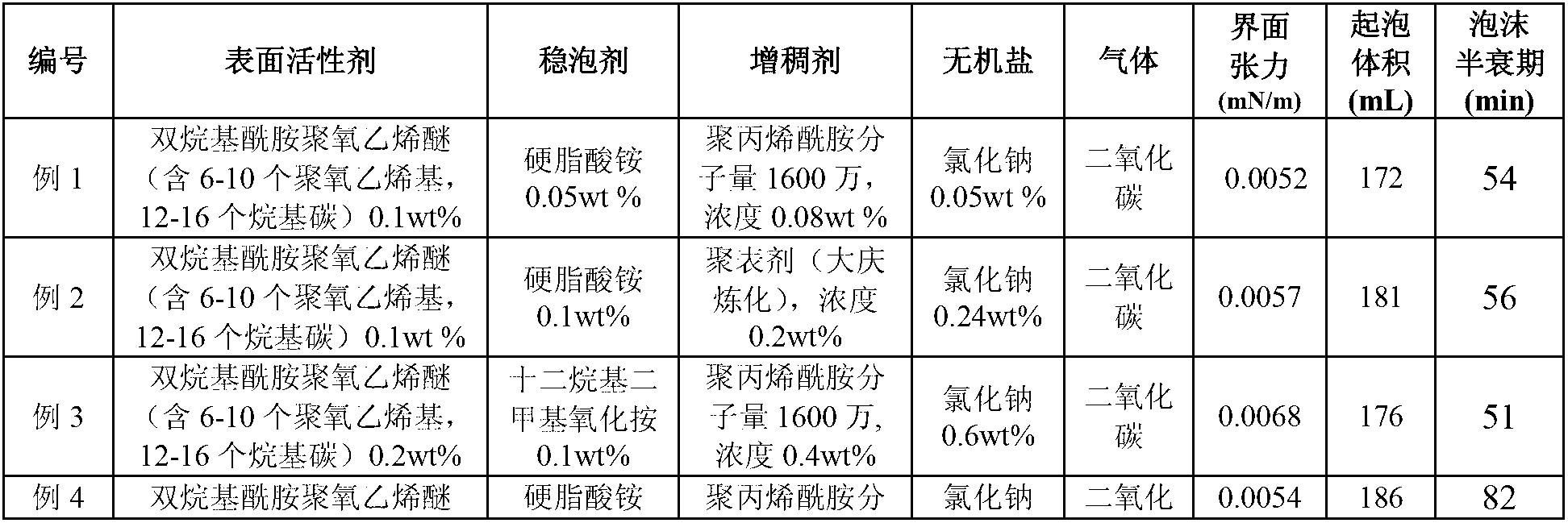

Foam system suitable for profile control and oil displacement of oil field and oil displacement method

ActiveCN102703052ASuper foamStrong foamFluid removalDrilling compositionInorganic saltsInjection pressure

The invention relates to a foam system suitable for profile control and oil displacement of an oil field and an oil displacement method, in particular to a foam system formula used for profile control and oil displacement of the oil field after polymer flooding and a foam profile control oil displacement method. The foam system formula comprises in percentages by weight: 0.1-0.5 wt% of surfactant, 0.05-0.4 wt% of foam stabilizer, 0.08-0.4% of thickening agent, 0.05-1.2 wt% of inorganic salt and the balance of water. In the foam profile control oil displacement method, a ratio of gas to liquid of the foam system is as follows: the volume ratio of gas to liquid is 0.4: 1-1: 1 under an injection pressure. The foam system, provided by the invention, has super strong foam performance and ultra-low interface tension. The foam profile control effect is remarkable after polymer flooding, the yield is improved for more than 20%, and the economic benefit is remarkable.

Owner:PETROCHINA CO LTD +1

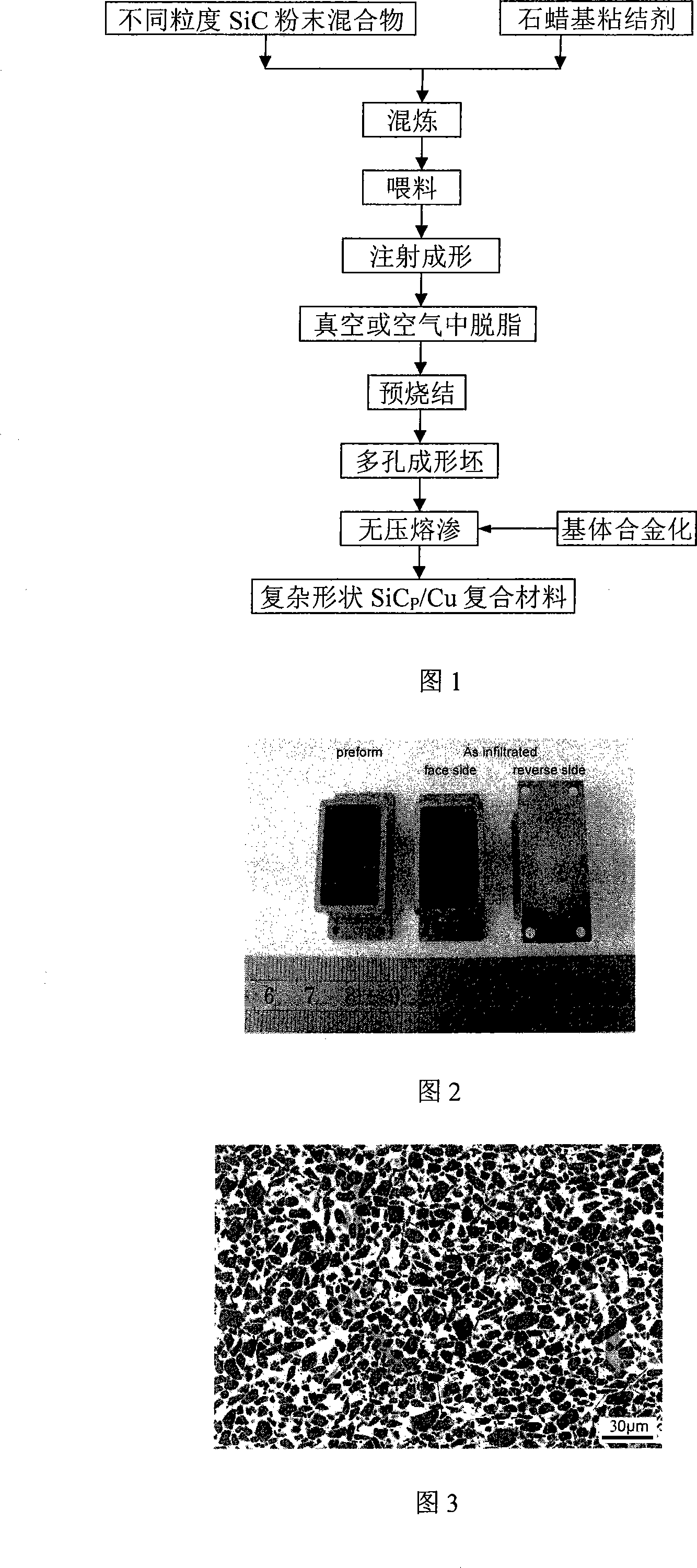

Method for preparing high volume-fraction carborundum granule-reinforced copper-based composite material

ActiveCN101157993AHigh densityThermophysical property adjustmentVolumetric Mass DensityParticle-size distribution

The invention relates to a method to prepare high volume fraction silicon carbide particle to enhance copper matrix composite, belonging to the field of metal matrix composites. The technique is that: proper blended particle size distributed SiC powder is mixed with polymer component paraffin base binder in a volume proportion of 57-68% load in sudarpress, fine blended feedstock is obtained; injection mold in powder injection molding machine in the injection temperature of 150-175 DEG C and the injection pressure of 75-125MPa to obtain a required billet, the billet is degreased in a solution-doff + thermal-doff process, and is first sintered in 600-1120 DEG C to obtain pre-molded billet of porous SiC. Infiltrate copper alloy to the porous SiC pre-molded billet in the temperature of 1400-1450 DEG C in vacuum via non-pressure infiltration. So the high volume fraction SiCp / Cu composite is obtained. The invention can prepare intricate shaped thin wall SiCp / Cu composite parts, enhance the content of phase as high as 57-67% volume fraction, the density of the composite is high, the microstructure is evenly distributed, and the invention has the advantages of high utilization rate of material, high productivity, and low production cost.

Owner:UNIV OF SCI & TECH BEIJING

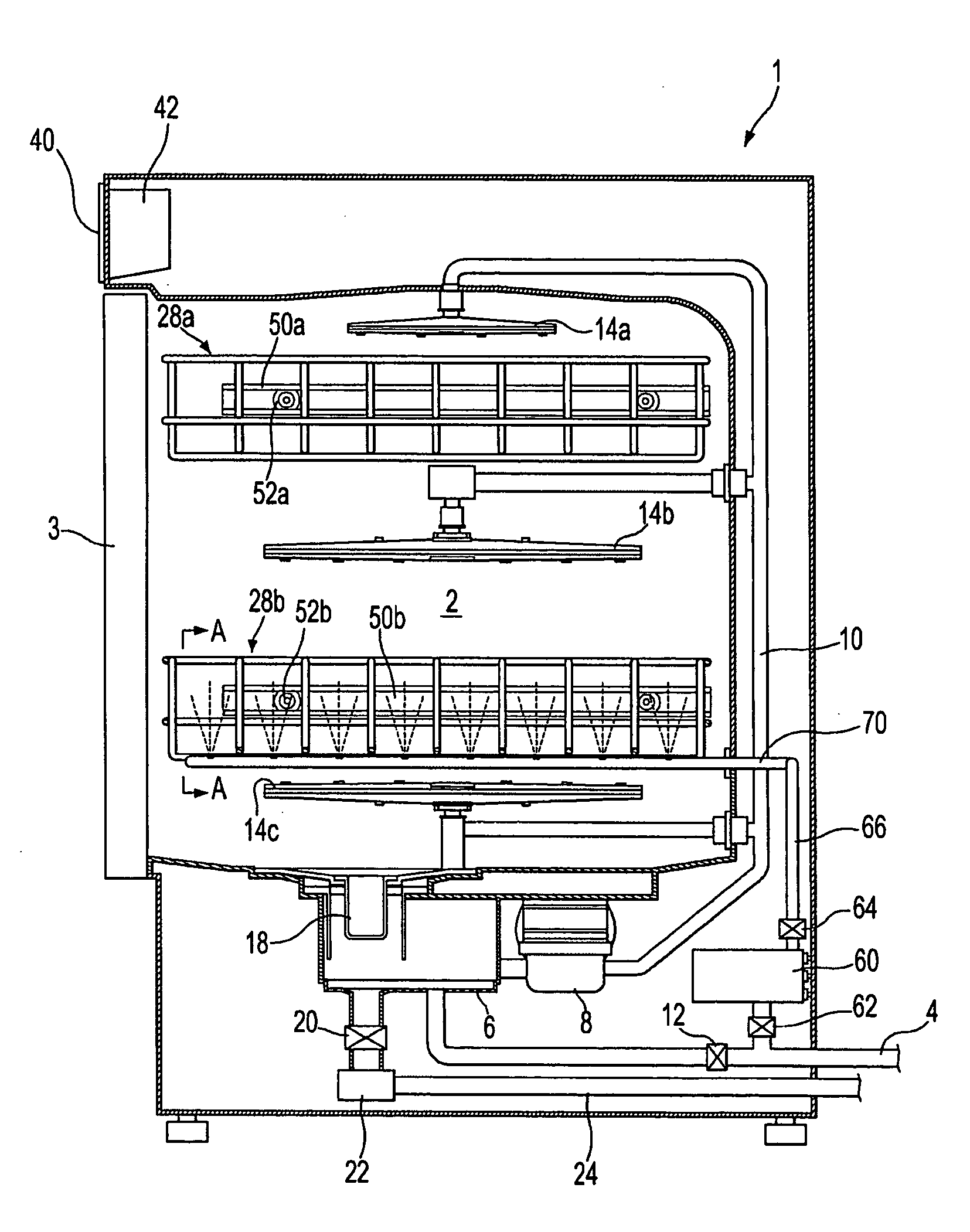

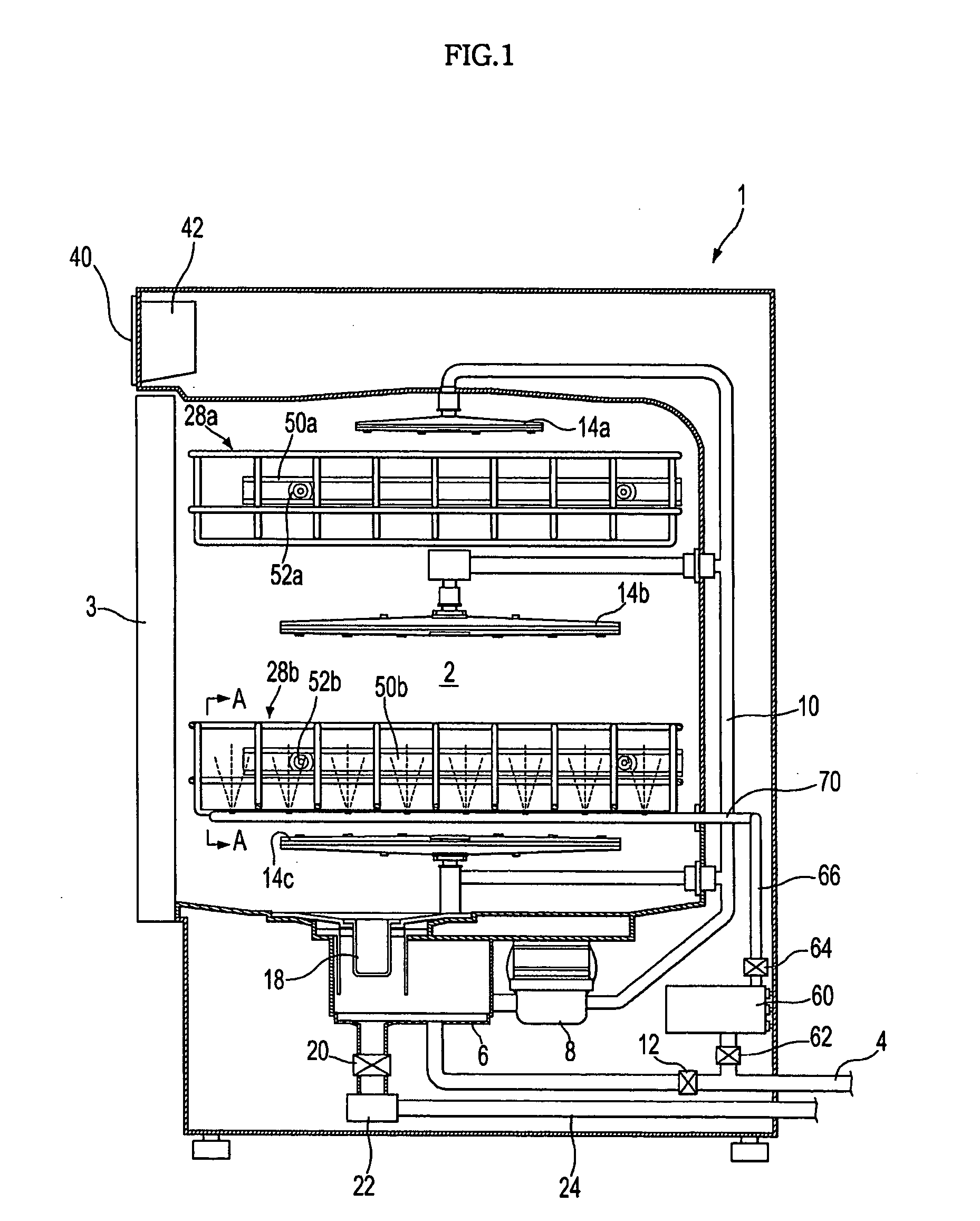

Dishwasher having steam washing function and dishwashing method

InactiveUS20070235063A1Prevent leakageImprove performanceTableware washing/rinsing machine detailsWashing processesInjection pressureWash water

A steam / water mixed dishwasher using steam and water together, and, more particularly, a dishwasher and dishwashing method of achieving improvement in washing performance and efficiency via direct steam injection to dishes. The dishwasher includes a body containing a dishwashing tub, at least one dish basket disposed in the dishwashing tub and adapted to receive dishes therein, a steam generator to generate steam by heating wash water, and steam injection nozzles to inject the steam generated from the steam generator. The steam injection nozzles are disposed at the same height as a lower surface of the dish basket. The dishwashing method includes injecting steam from a number of the plurality of steam injection nozzles by opening a number of the plurality of control valves, to thereby maintain an injection pressure of the steam generated from the steam generator.

Owner:SAMSUNG ELECTRONICS CO LTD

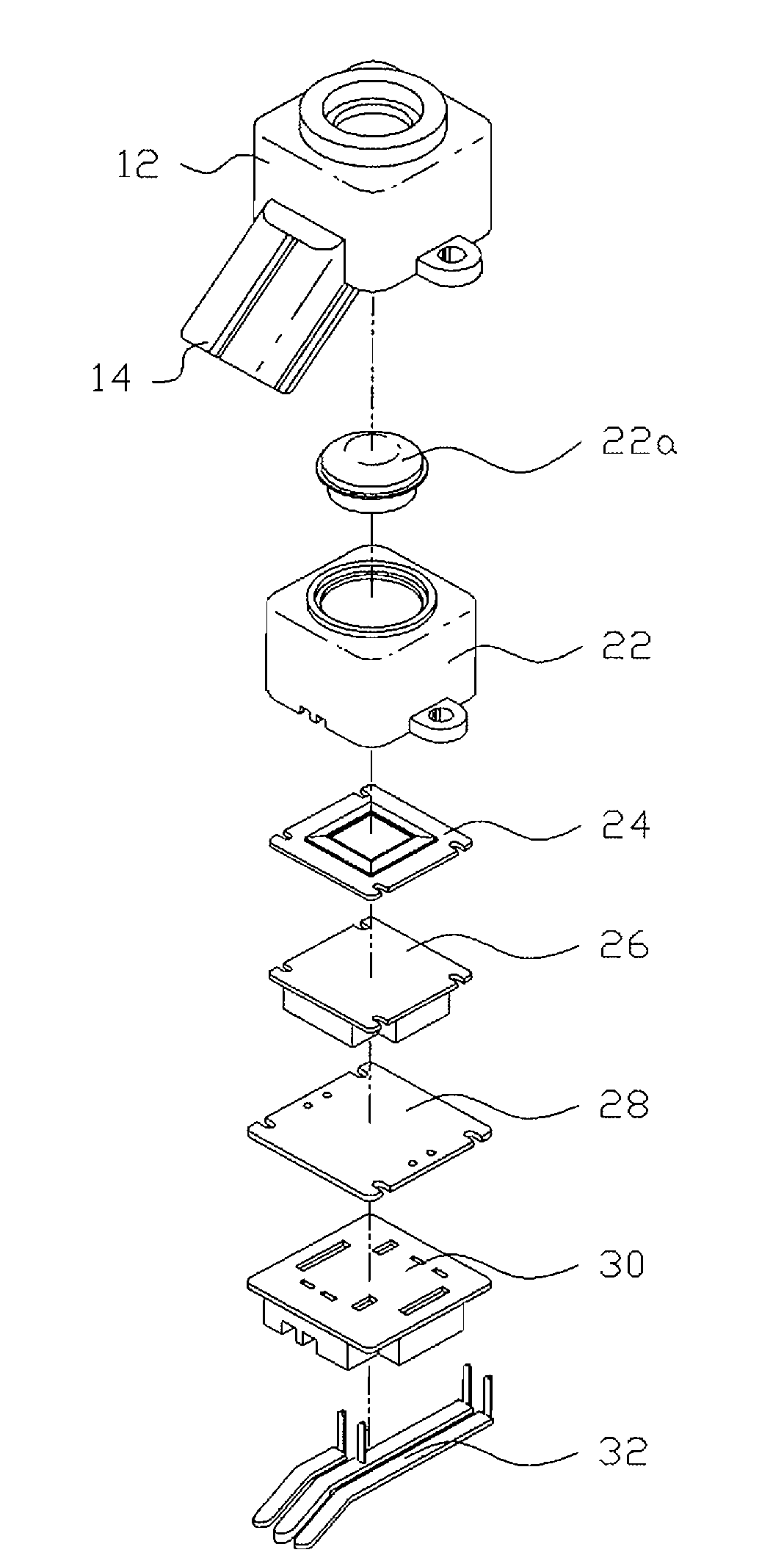

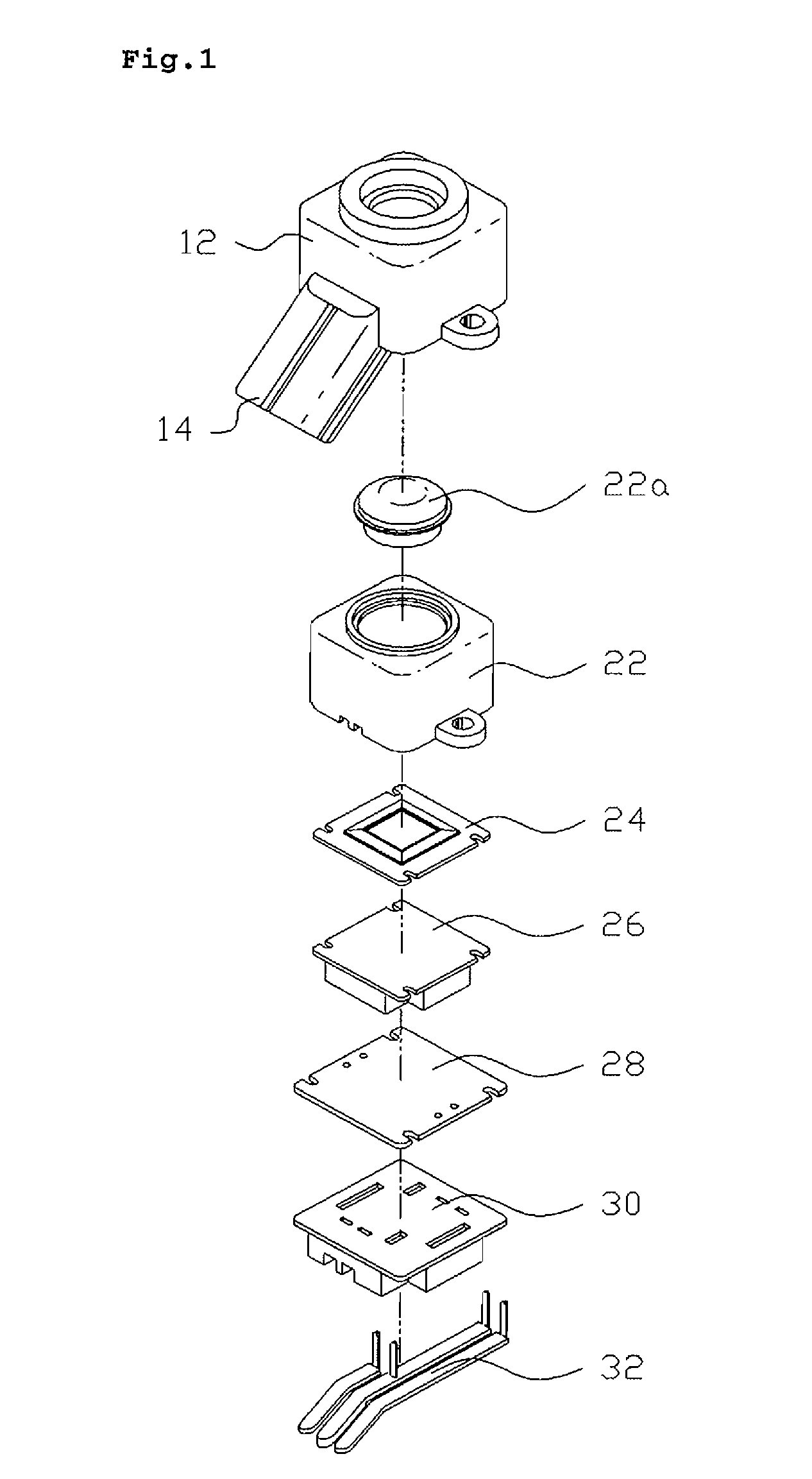

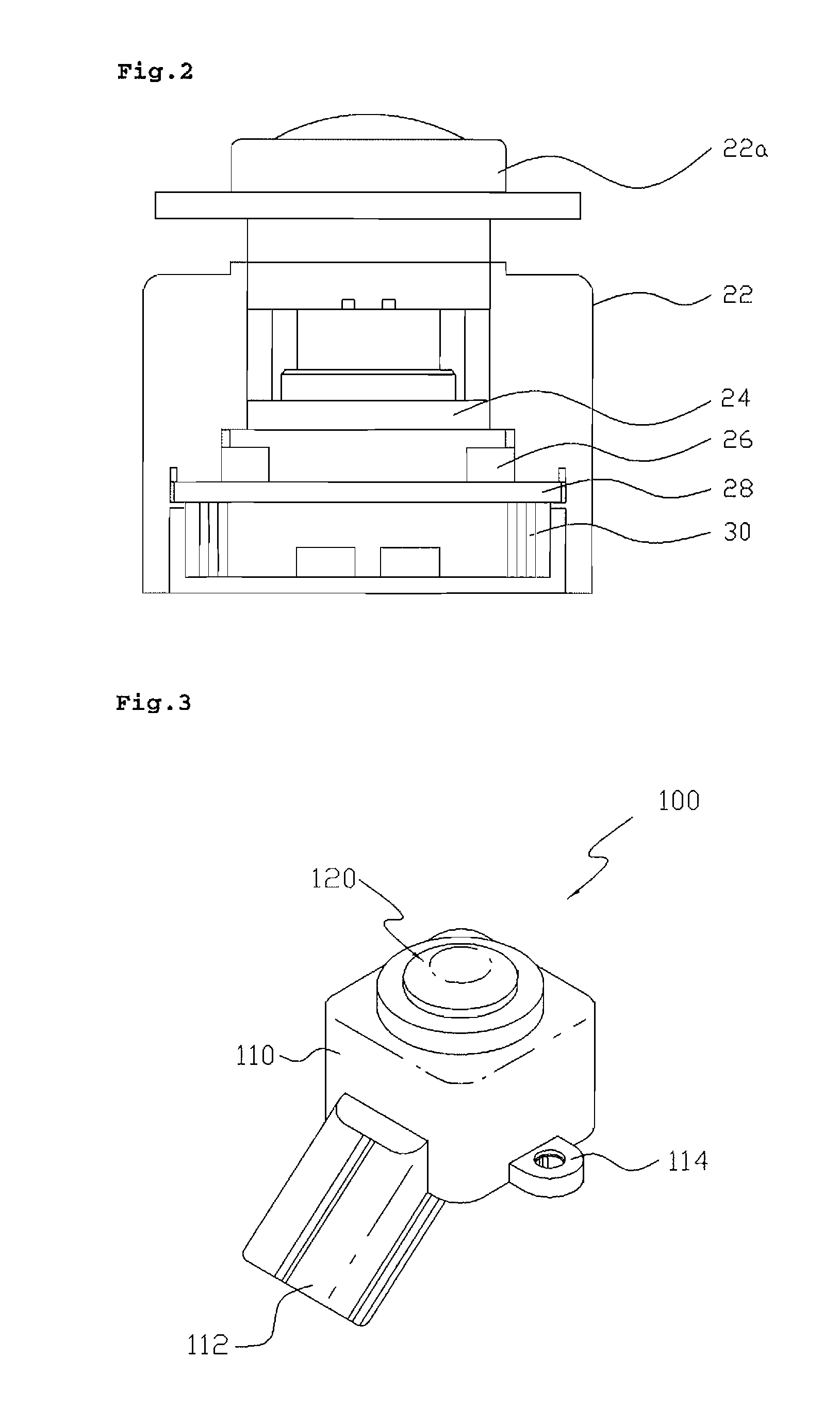

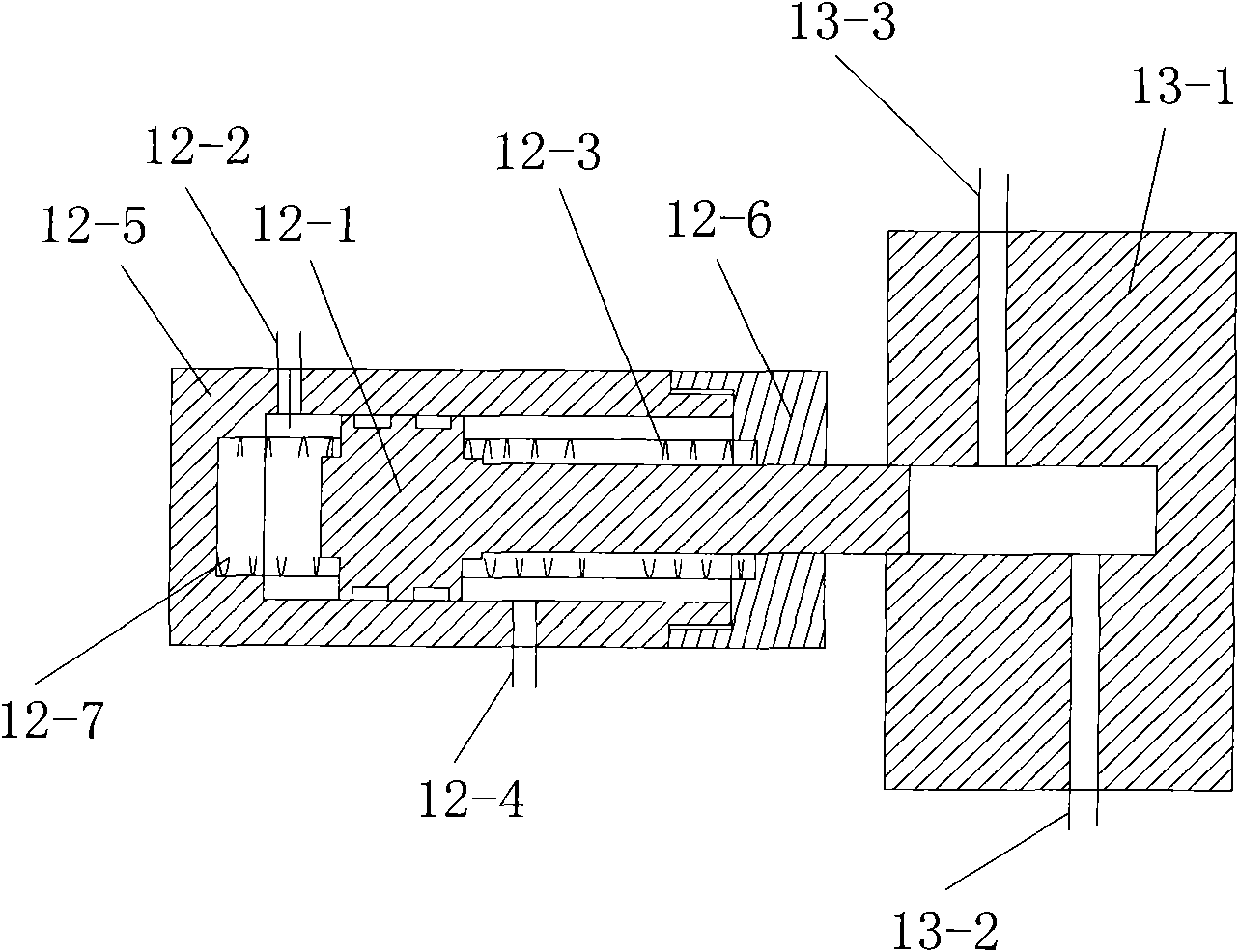

Camera Integrated with Connector for Vehicle and Method of Manufacturing Thereof

InactiveUS20130321696A1Television system detailsMetal rolling stand detailsInjection pressureCamera module

The present invention relates to a camera integrated with a connector for a vehicle and a method of manufacturing thereof, and the camera integrated with a connector for a vehicle includes: a housing; and a camera module accommodated inside the housing, in which a connector unit is formed in one piece at a certain position on one side of the housing, and a protection cover for protecting the camera module from being damaged by injection pressure and injection temperature generated when the housing is molded by injection is combined outside the camera module. The method of manufacturing camera integrated with a connector for a vehicle includes: a camera module assembly step, a camera module inserting step, an injection molding step and an extraction step.

Owner:A&P CREBIZ

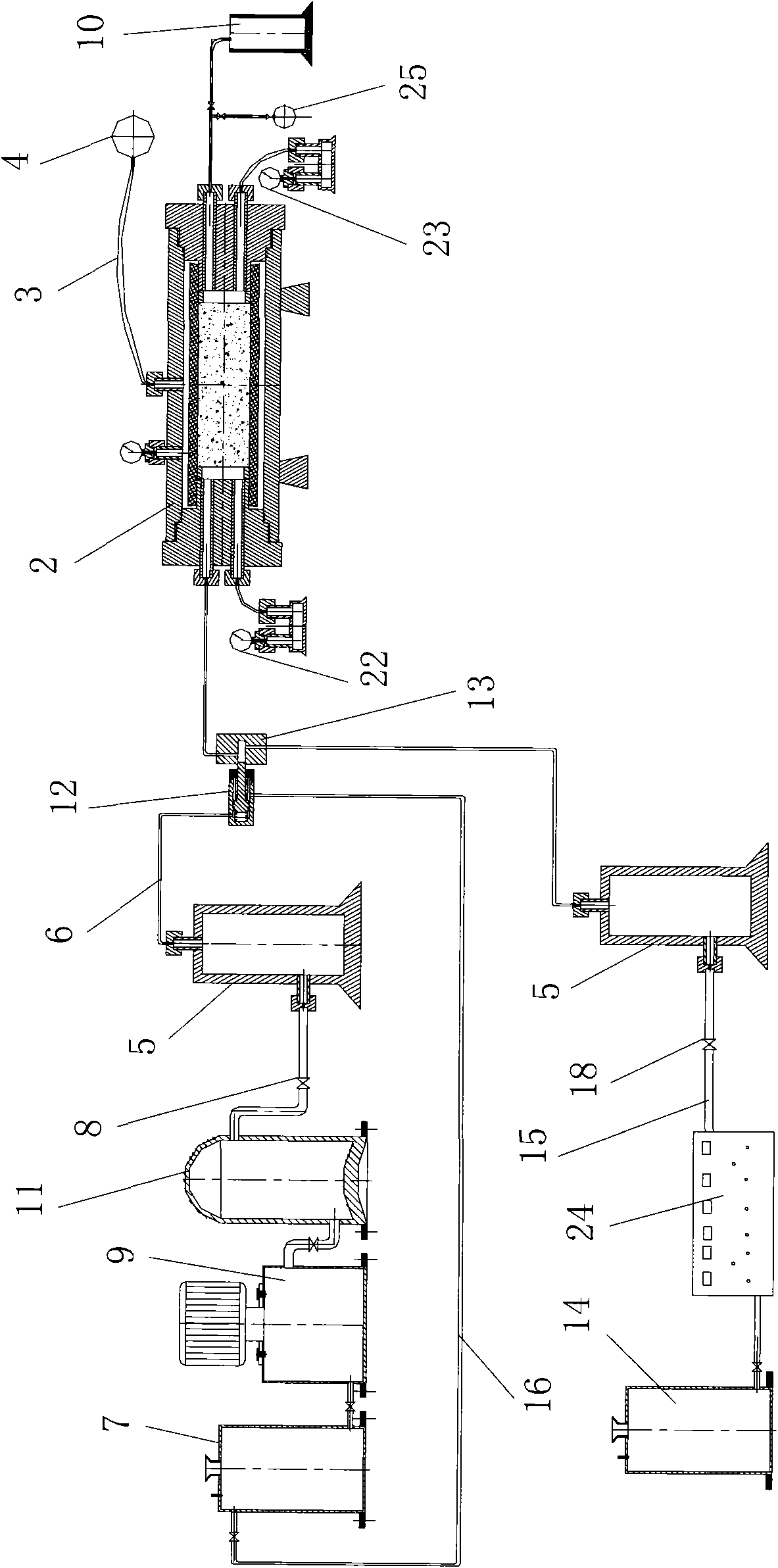

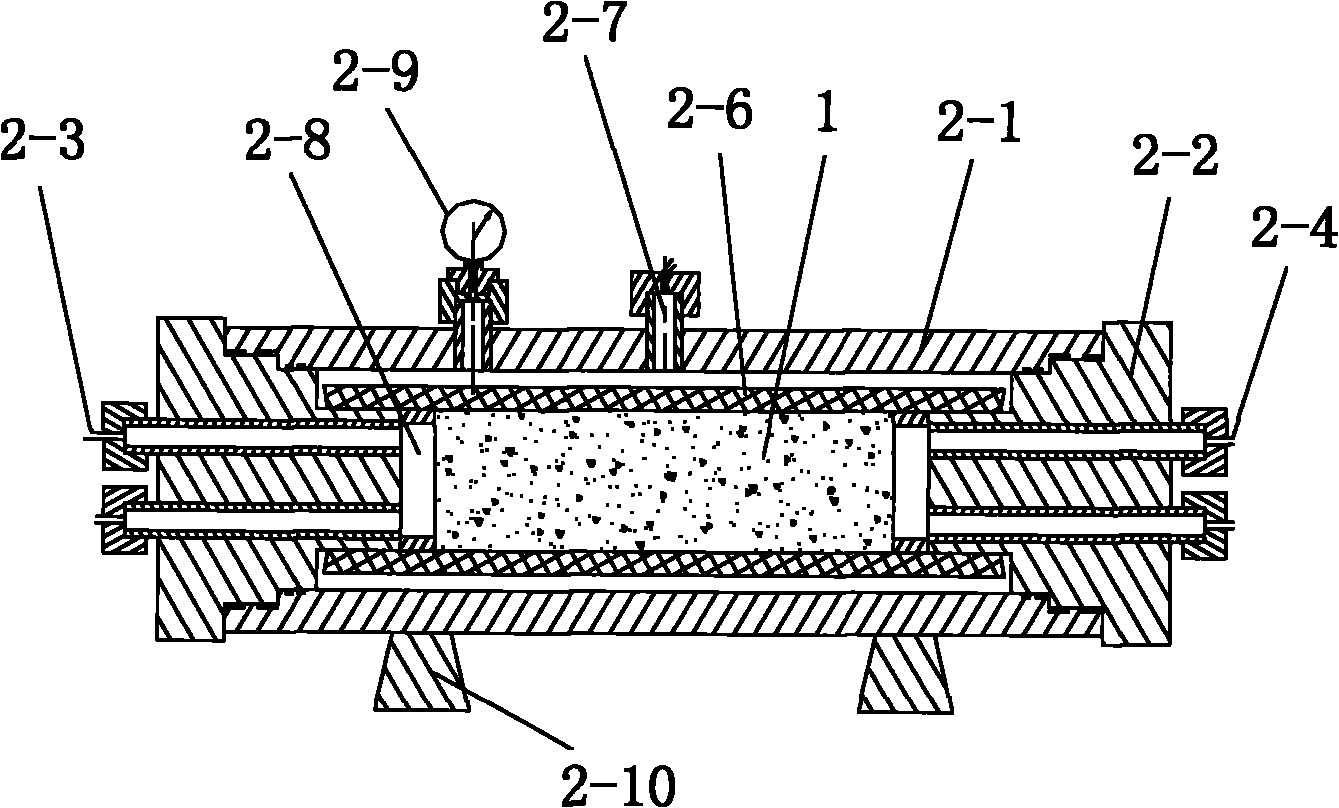

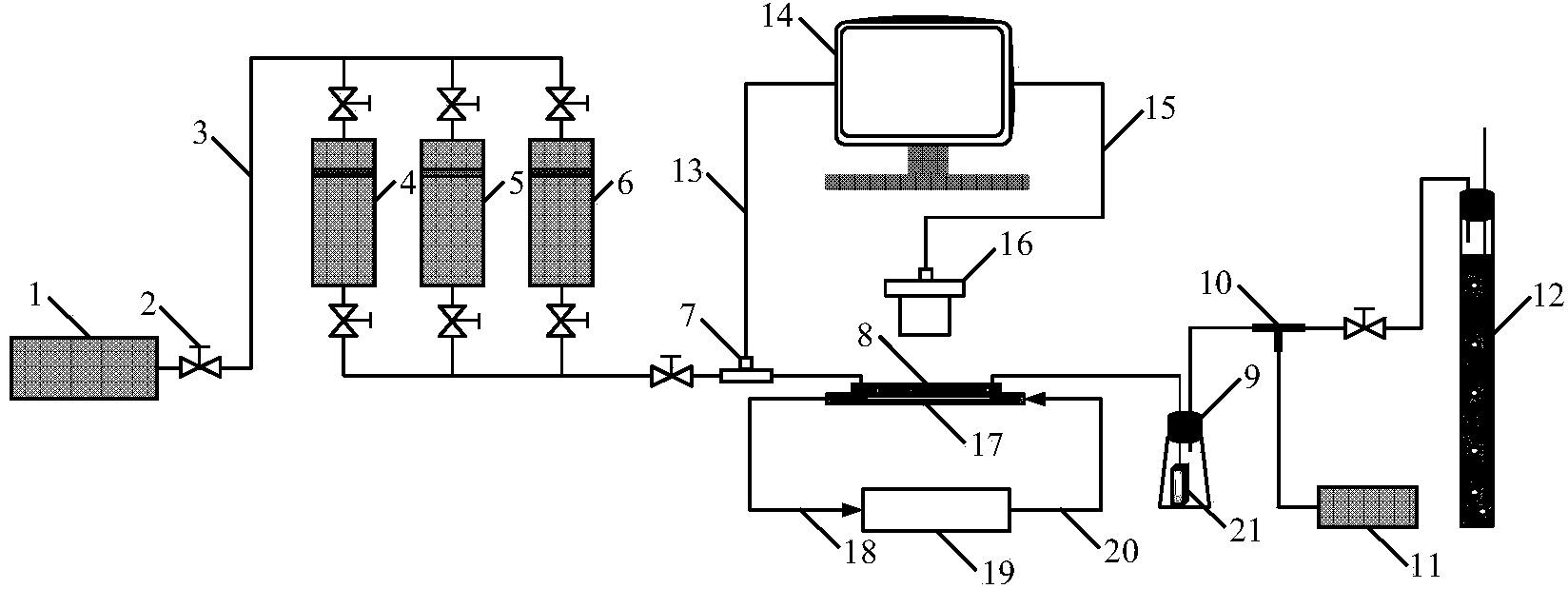

Hydraulic pulse-assisted reservoir chemical remedial treatment experiment device and method

ActiveCN101985875AEfficient chemical plugging removal experimentRapid chemical plugging removal experimentFluid removalPermeability/surface area analysisInjection pressureInitial permeability

The invention discloses a hydraulic pulse-assisted reservoir chemical remedial treatment experiment device and a hydraulic pulse-assisted reservoir chemical remedial treatment experiment method. The experiment device comprises a core holder, an annular pressure supply device, a chemical reagent storage tank, a water storage tank, an oil storage tank and a liquid container, wherein the chemical reagent storage tank, the water storage tank and the oil storage tank are connected with a liquid inlet of the core holder through delivery pipes; the liquid container is connected with a liquid outlet of the core holder; and a hydraulic pulse generating device is arranged on each delivery pipe. The experiment method comprises the following steps of: 1, preprocessing a tested core; 2, measuring the initial permeability of the core by water drive; 3, polluting the core; 4, measuring the permeability of the core by water drive after pollution; 5, performing a hydraulic pulse-assisting chemical reagent remedial treatment experiment; 6, measuring the permeability of the core by water drive after remedial treatment; 7, performing the hydraulic pulse-assisted chemical reagent remedial treatment experiment under the conditions of different frequencies and different amplitudes; and 8, arranging data. The device is rational in design, convenient to arrange, complete in function, simple to operateand good in using effect and can realize pulse fluctuation of the chemical remedial treatment under the action of an injection pressure.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

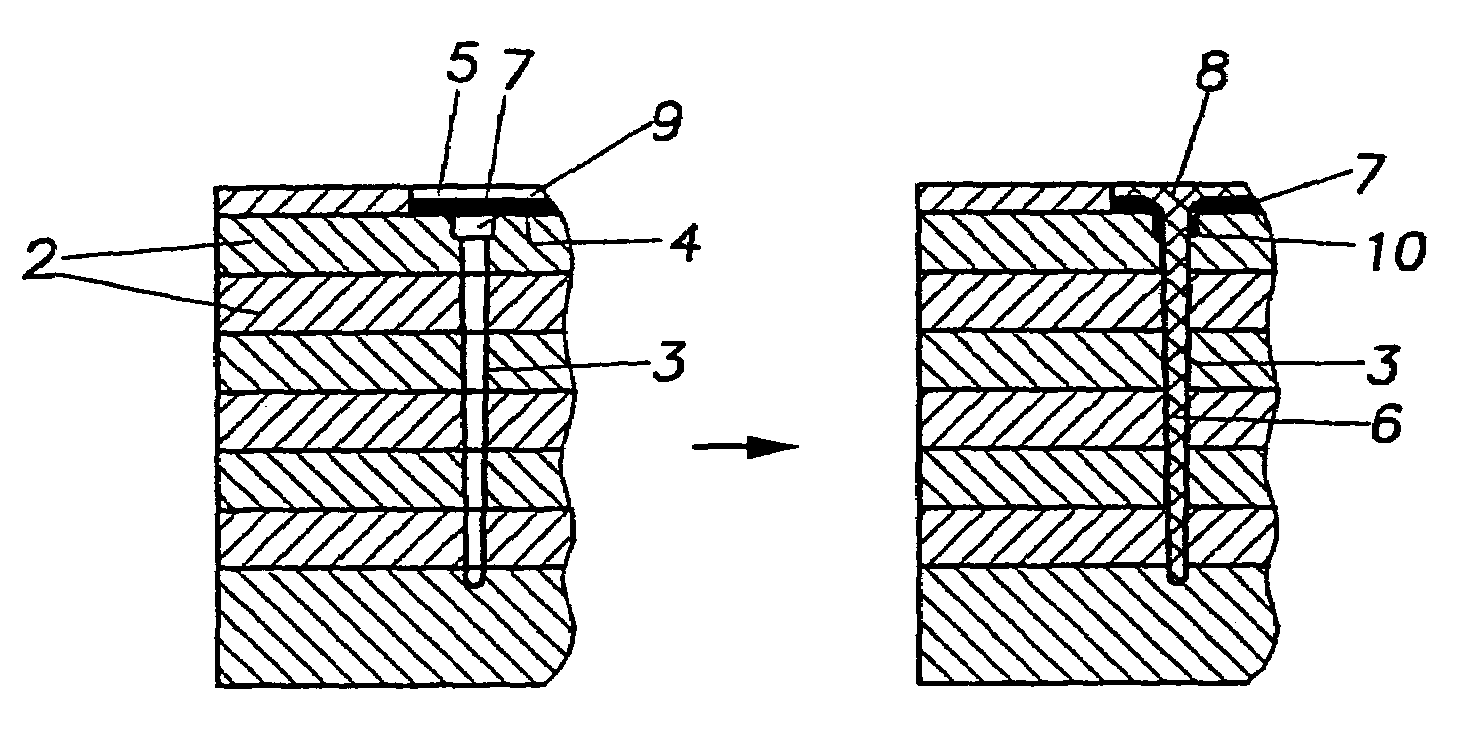

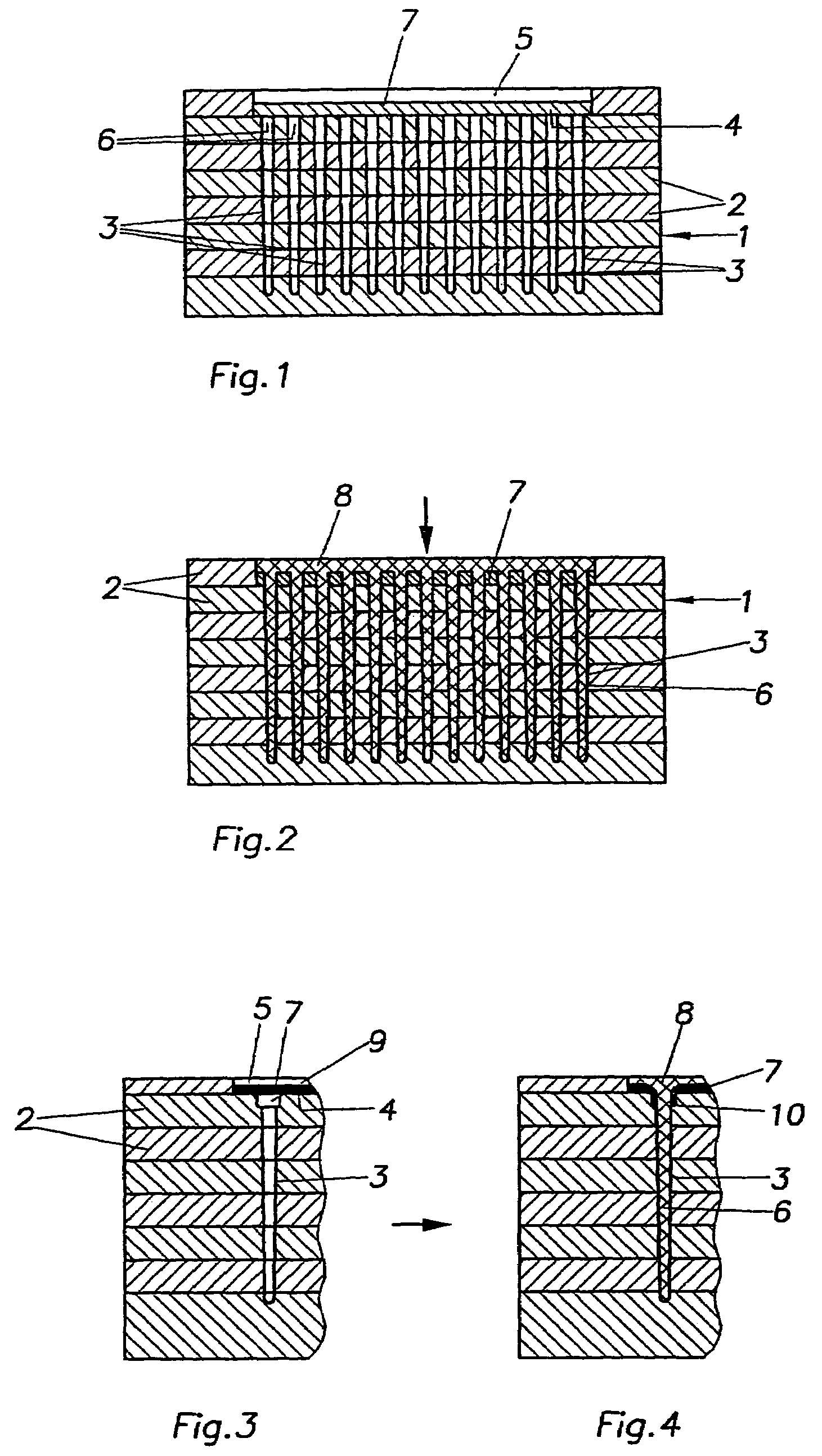

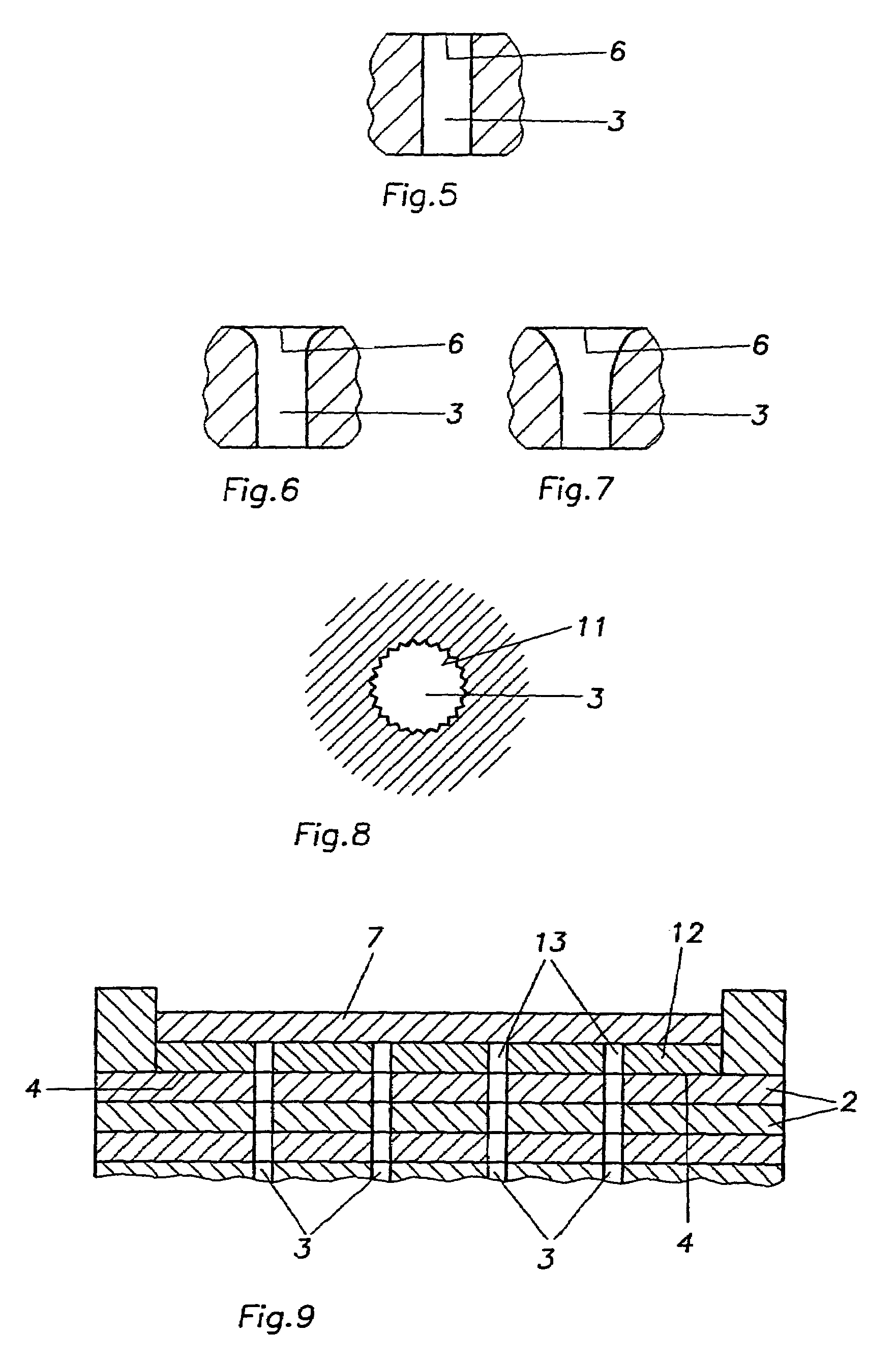

Method for the production of a bristle structure on a carrier

A method for the production of bristles structures on an arbitrary kind of carrier using a mold tool is described having channels extending from channel walls for shaping bristles, wherein a mold mass for forming the bristles is introduced under pressure into the channels, preferentially using the injection molding technique. Towards this end, the carrier is disposed directly or indirectly onto the mold walls of the channels in such a fashion that the free cross-section of the channels is completely covered and the mold mass is subsequently introduced onto the carrier with a sufficient mold pressure (injection pressure) that the carrier is broken-through in the vicinity of the free cross-section of the channels thereby displacing the carrier material, with the carrier mass subsequently filling the channels.

Owner:GEKA

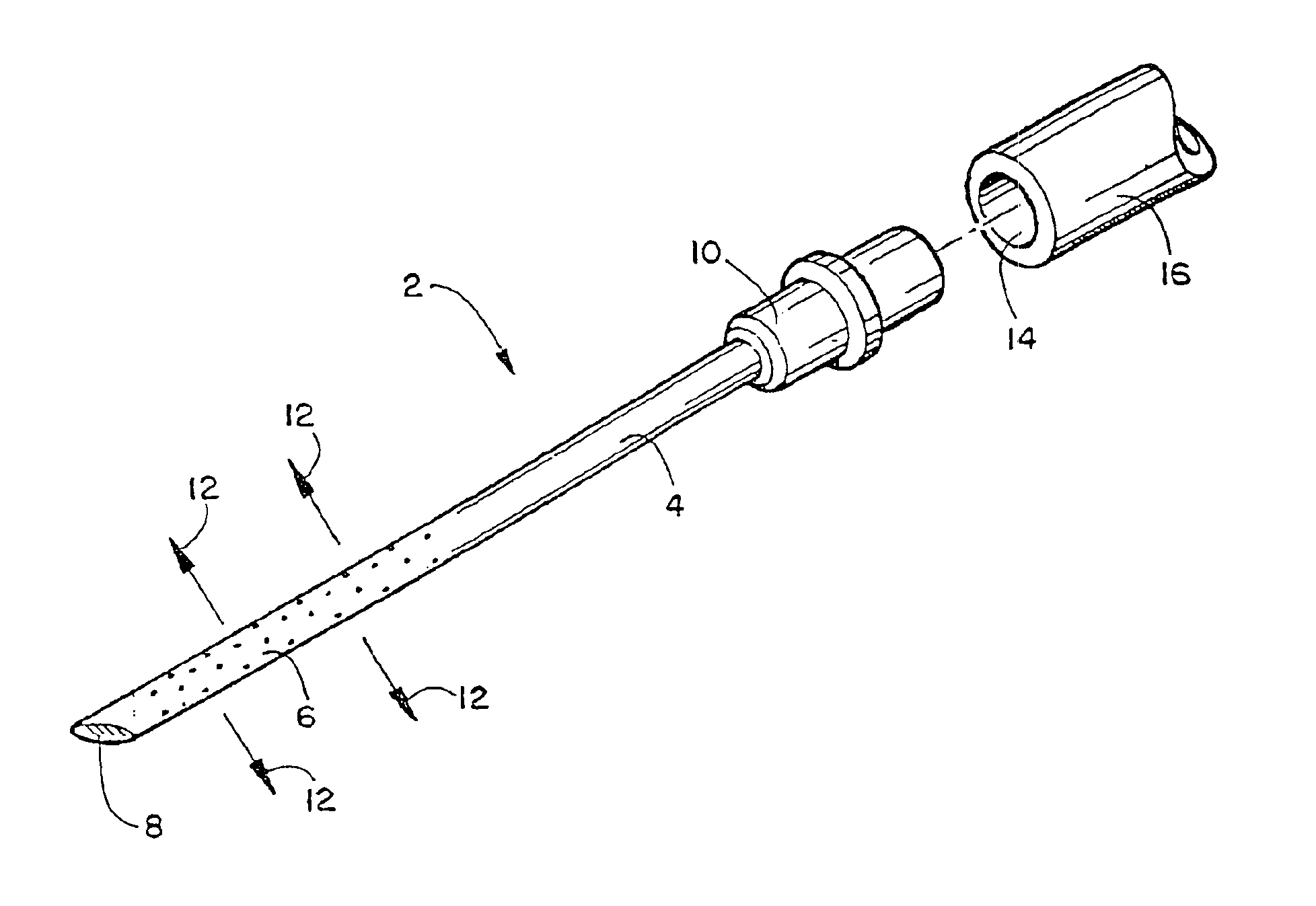

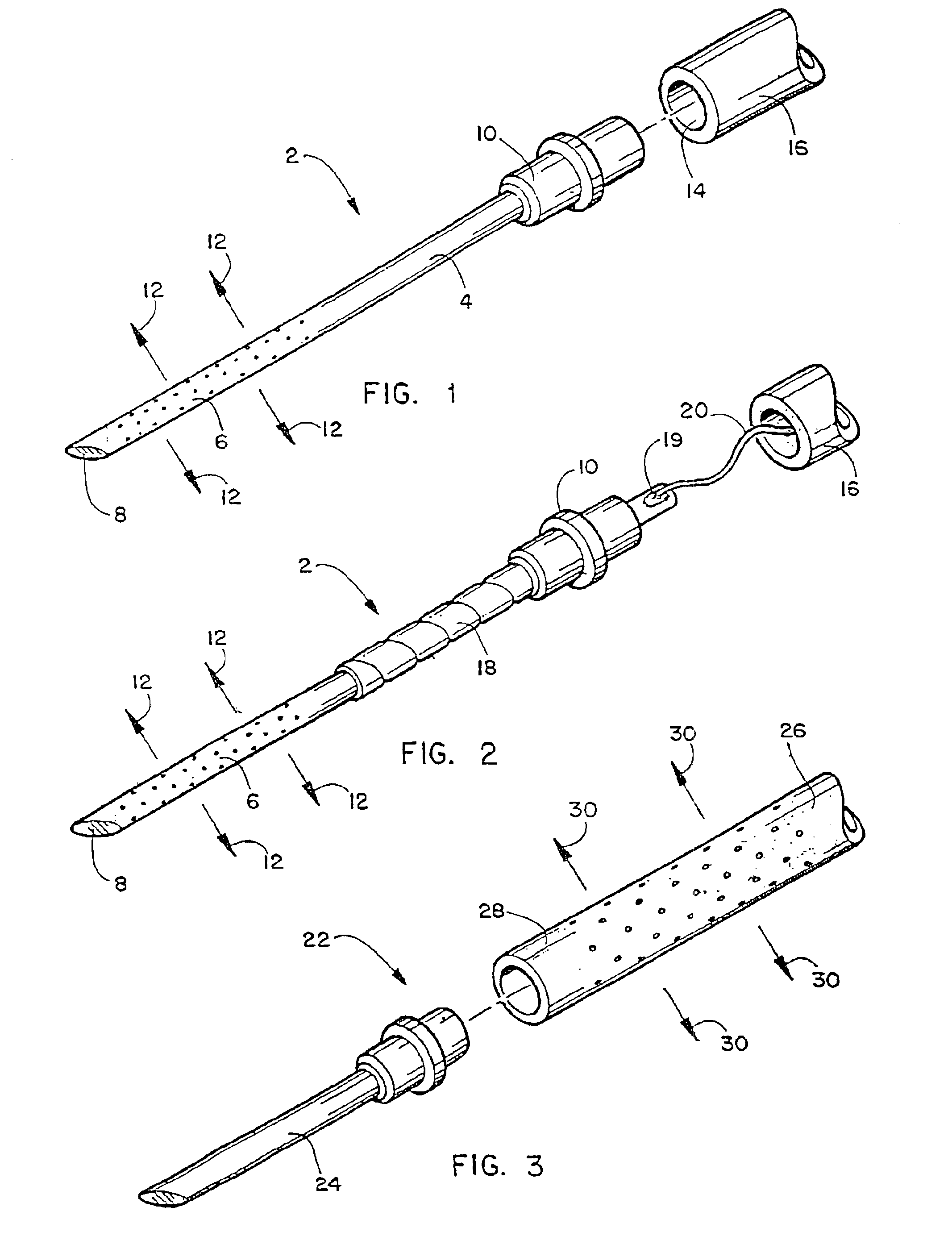

Apparatus with weeping tip and method of use

InactiveUS6949087B2Organic active ingredientsGenetic material ingredientsInjection pressureInjection site

The invention provides surgical needles with a porous distal portion from which a liquid injectate will weep or ooze multidirectionally under injection pressure while the porous distal portion of the needle is inserted into a body surface. The porous distal portion of the needle can be fabricated from a porous carbon, metal, ceramic or polymer and preferably has a decreasing gradient of impedance to fluid flowing to the point of the needle to compensate for the falling off of injection pressure as fluid moves towards the point, thereby ensuring uniform weeping of the injectate along the injection course. The needle is adapted for attachment to a catheter or syringe. In another embodiment, a surgical assemblage is provided wherein a porous distal portion having similar fluid flow characteristics is located along the distal end of a catheter, and a needle point is attached to the distal end of the catheter (e.g., a steerable catheter) for piercing tissue. A guidance catheter can be used to direct the invention devices to a remote internal injection site. The invention devices and methods can be used to inject fluids (including those containing nucleic acids for gene therapy) into interior body walls or tissue, such as a beating heart, without substantial loss of fluid and without substantial damage to tissue caused by injectate.

Owner:TRICARDIA

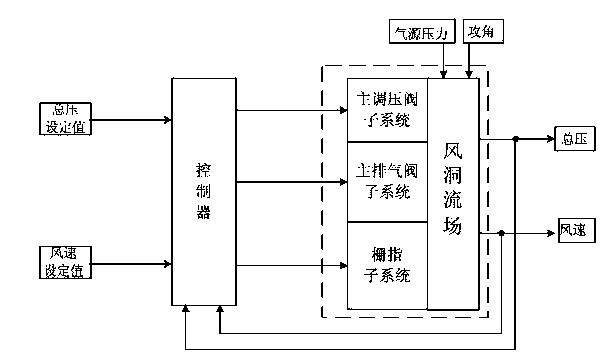

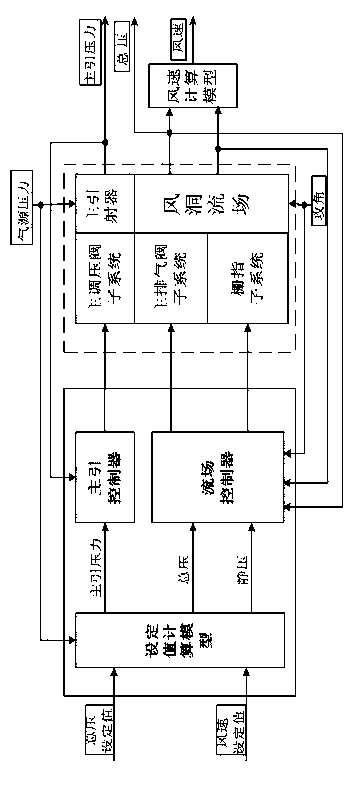

High-precision temporary punching type injecting transonic speed wind tunnel flow field control structure

ActiveCN104932565AReduce the impactSolve time-varying problemsFluid pressure control using electric meansEngineeringInjection pressure

The invention relates to a high-precision temporary punching type injecting transonic speed wind tunnel flow field control structure and a method. According to the control structure, a wind tunnel flow field is decomposed into a main injection pressure control portion and a total pressure-static pressure control portion, and the control structure is mainly composed of such three modules as a set value calculation model, a main injection controller and a flow field controller. In the main injection pressure control portion, a main pressure regulating valve is adopted to control the main injection pressure. In the total pressure-static pressure control portion, the total pressure and the static pressure are controlled through a main air release valve and a gate finger. The set value calculation model is formed by a one-dimensional variable cross-section tube unsteady Euler equation set, and a main injection pressure set value and a static pressure set value of a wind tunnel model are solved through computational fluid dynamics software. The main injection controller is formed by using a segmented incremental PID control algorithm, and main injection pressure at an outlet of a main ejector is regulated. The flow field controller is formed by taking a model attitude feed-forward dynamic matrix control method as a core, the total pressure of a stable section and the static pressure of a test section are regulated. The control method is good in real-time performance and high in control precision, and variations of the Mach number in a test stage are controlled to a range of 0,001.

Owner:INST OF HIGH SPEED AERODYNAMICS OF CHINA AERODYNAMICS RES & DEV CENT

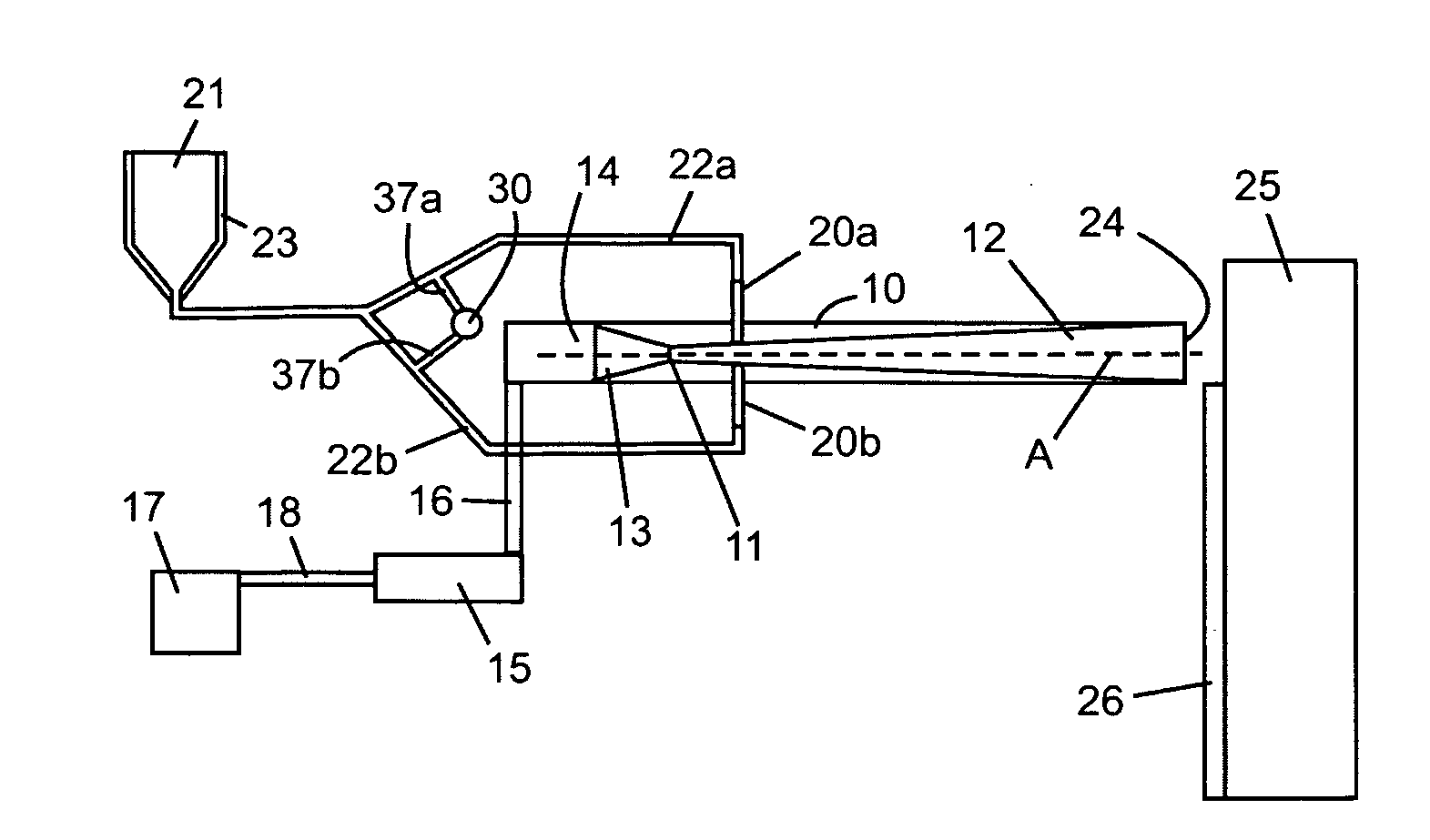

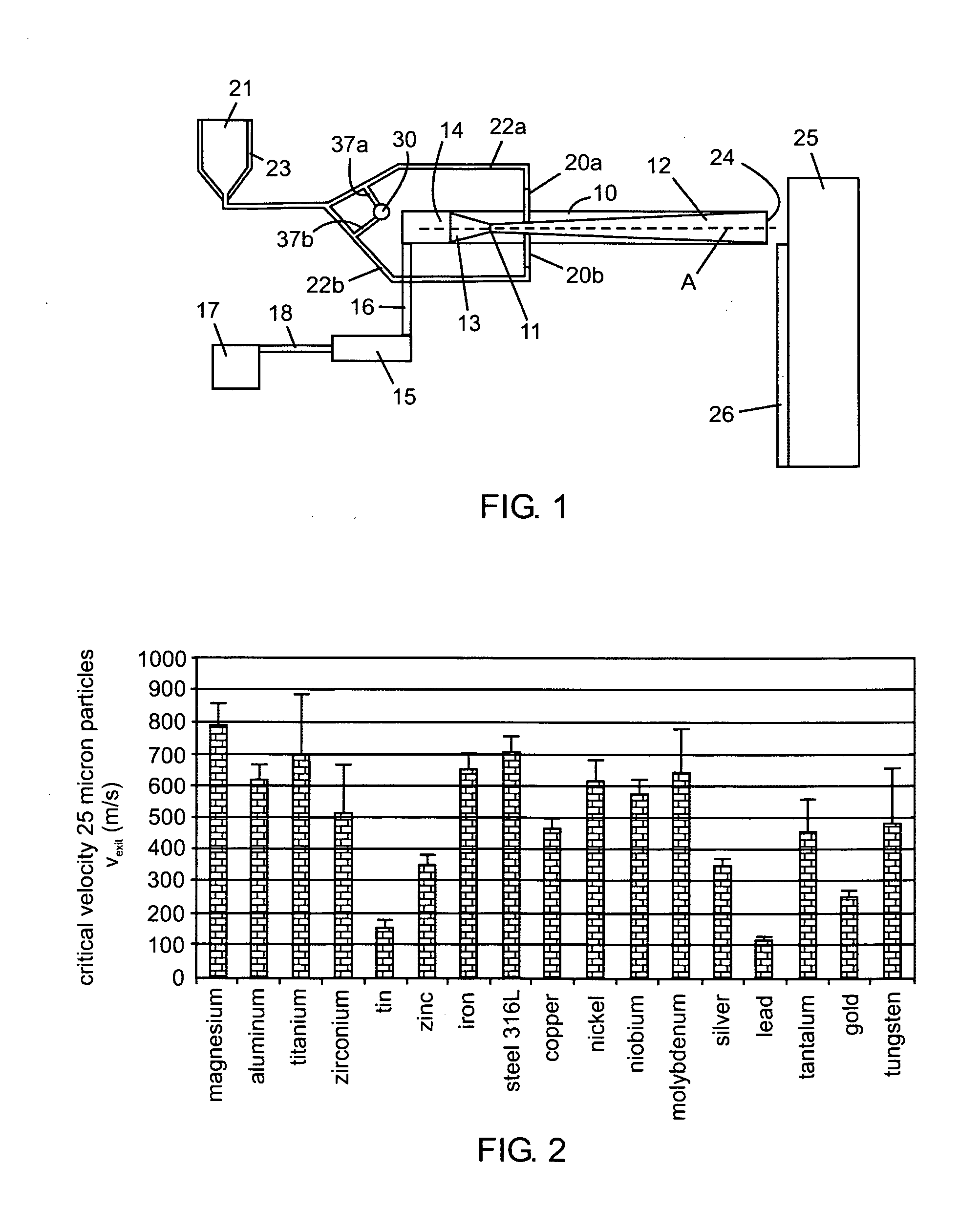

Cold gas dynamic spray apparatus, system and method

ActiveUS20100151124A1Large operating rangeEasy to clogLiquid surface applicatorsMolten spray coatingInjection pressureSpray nozzle

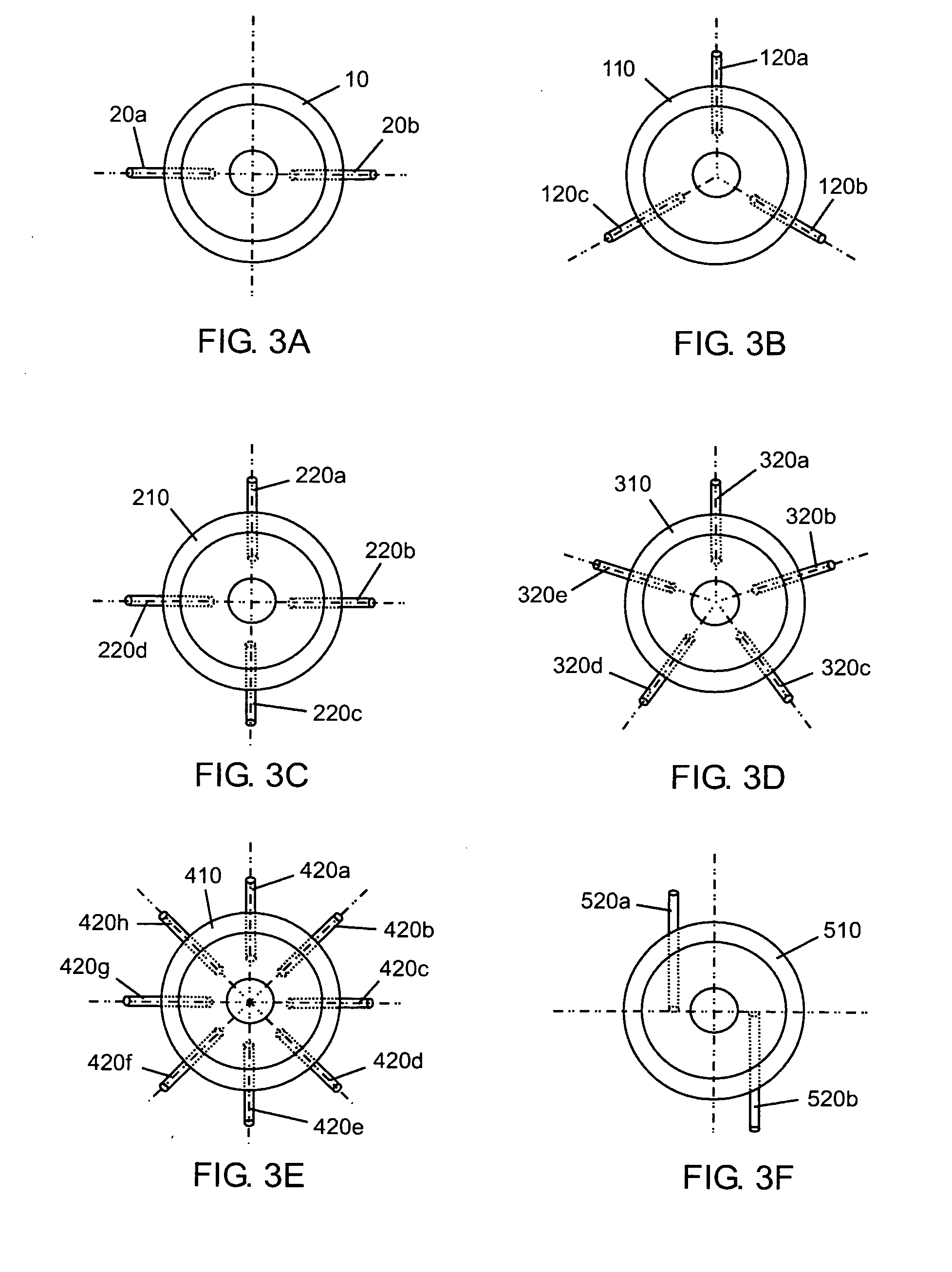

A system for cold gas dynamic spraying of particulate material has a de Laval nozzle and two or more radial particle inlets located between the throat and the outlet of the nozzle, the two or more particle inlets arranged symmetrically around a linear flow path of the nozzle. Blocking of the inlets is reduced by controlling pressure of particle carrier gas to provide a stable particulate material injection pressure before and during introduction of working gas into the nozzle, and / or by clearing the particle inlets of residual particles after a spraying process. Such a system and associated method combines benefits of both downstream and upstream cold gas spray systems. Further, a nozzle for spraying particulate material having a cross-sectional shape that is narrower in a middle section compared to edge sections provides coatings with superior cross-sectional profiles.

Owner:NAT RES COUNCIL OF CANADA

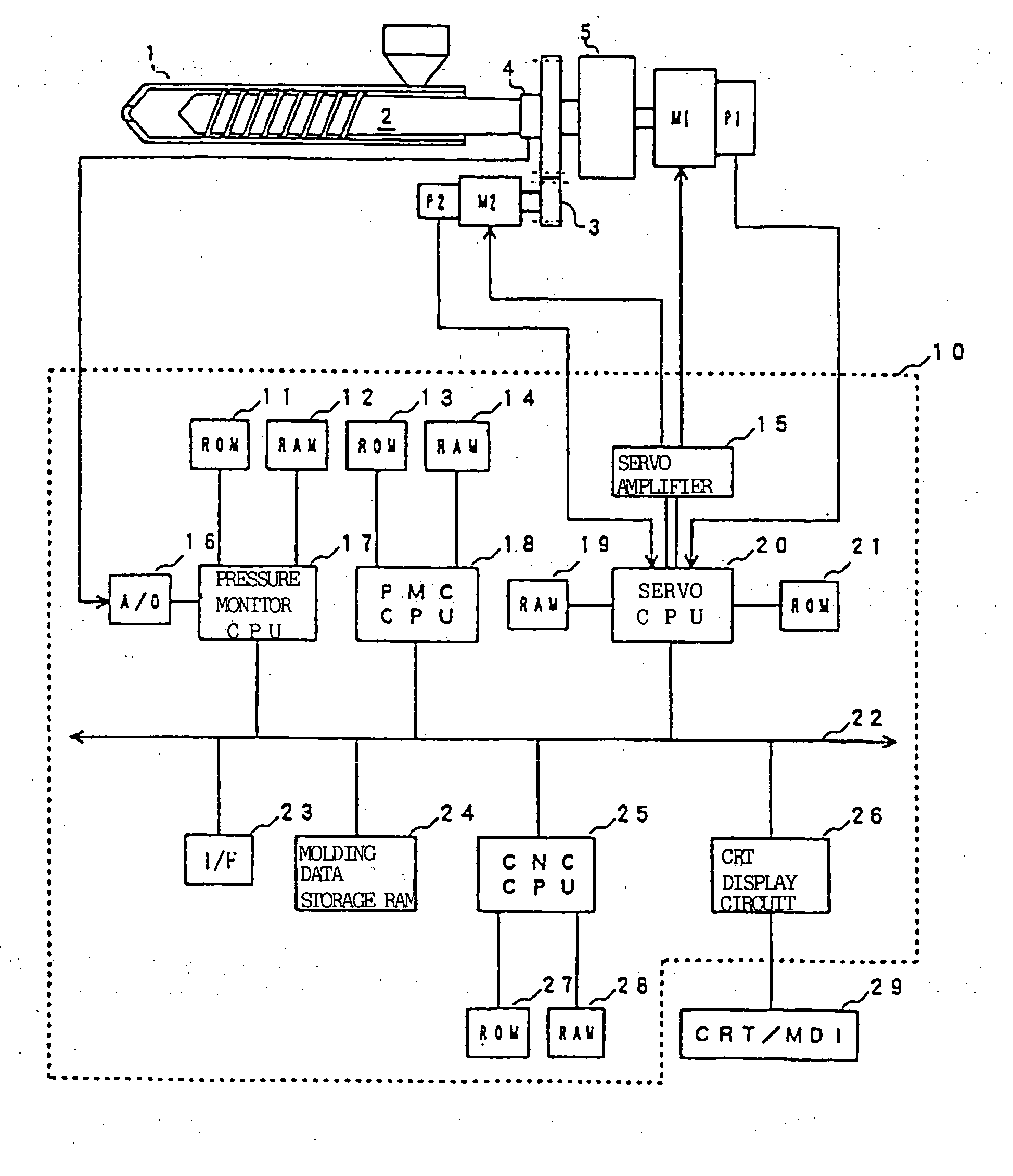

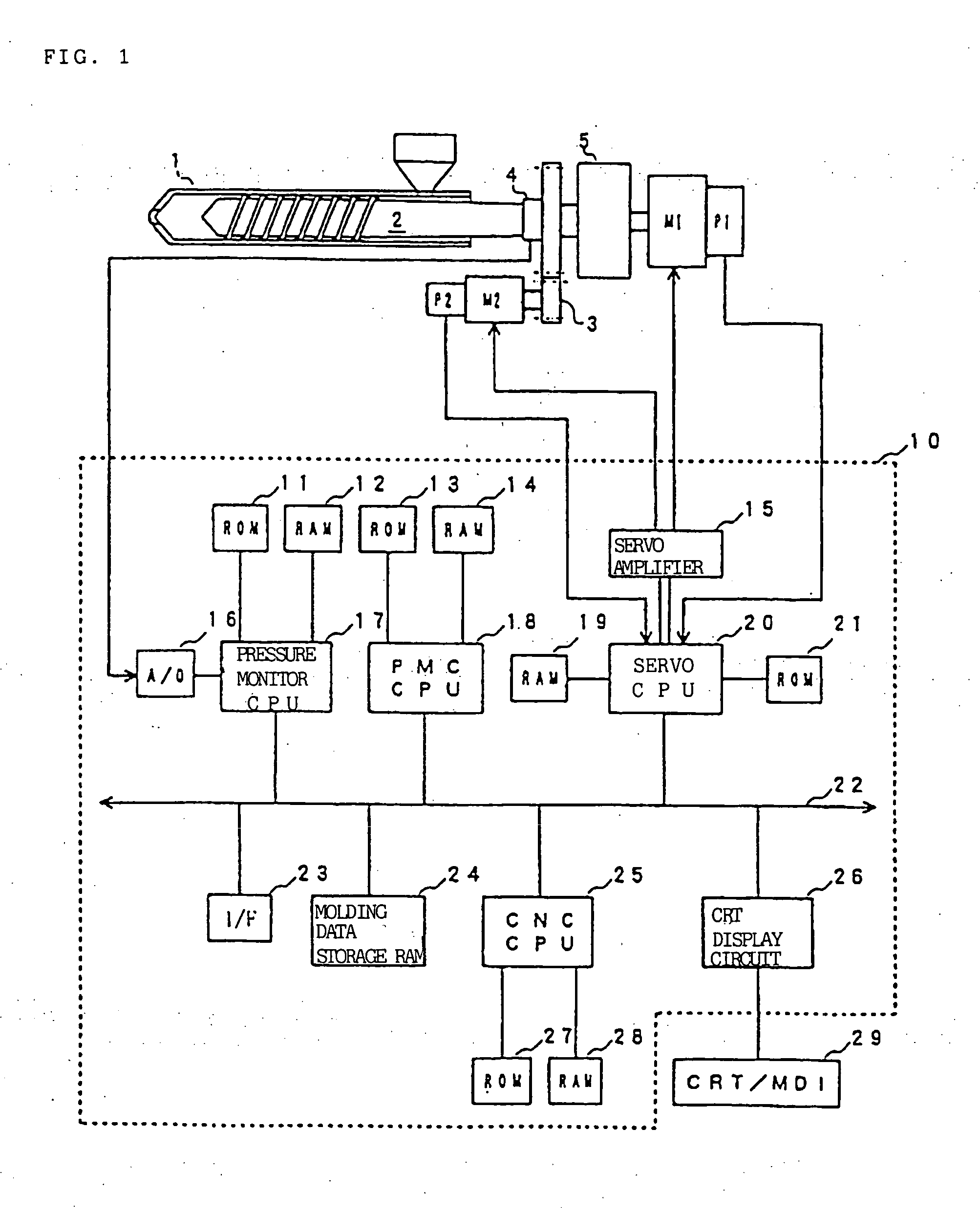

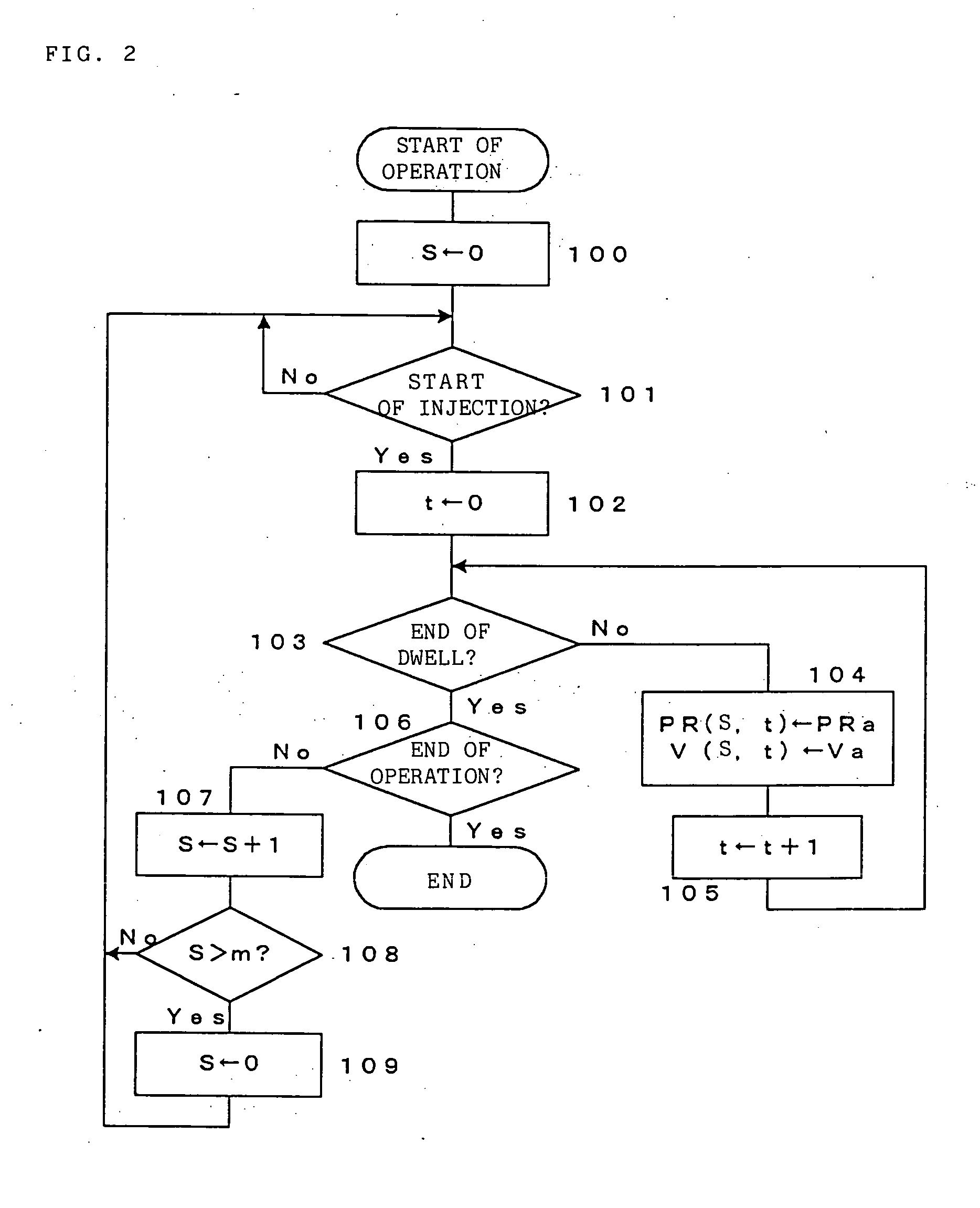

Monitor for injection molding machine

ActiveUS20040139810A1Auxillary shaping apparatusSimultaneous indication of multiple variablesInjection pressureEngineering

Variables such as injection pressure and injection velocity are detected at a predetermined sampling cycle for each molding cycle and the variables for a plurality of past molding cycles starting from the latest molding cycle are stored. Change patterns of the stored variables of the respective molding cycles are displayed in the form of graphs in which the first axis represents time (the number of times of sampling), the second axis represents the variable values, and the third axis represents the molding cycle.

Owner:FANUC LTD

Injection Molding Machines and Methods for Accounting for Changes in Material Properties During Injection Molding Runs

ActiveUS20150115491A1Reduce hardnessEfficient and cost-effectiveAuxillary shaping apparatusInjection pressureControl signal

A method and a machine account for changes in material properties of molten plastic material during an injection run. A change in a control signal is calculated by a controller during the injection molding run. If the change in the control signal indicates a change in material flowability, the controller alters a target injection pressure to ensure that molten plastic material completely fills and packs a mold cavity to prevent part flaws such as short shots or flashing.

Owner:IMFLUX INC

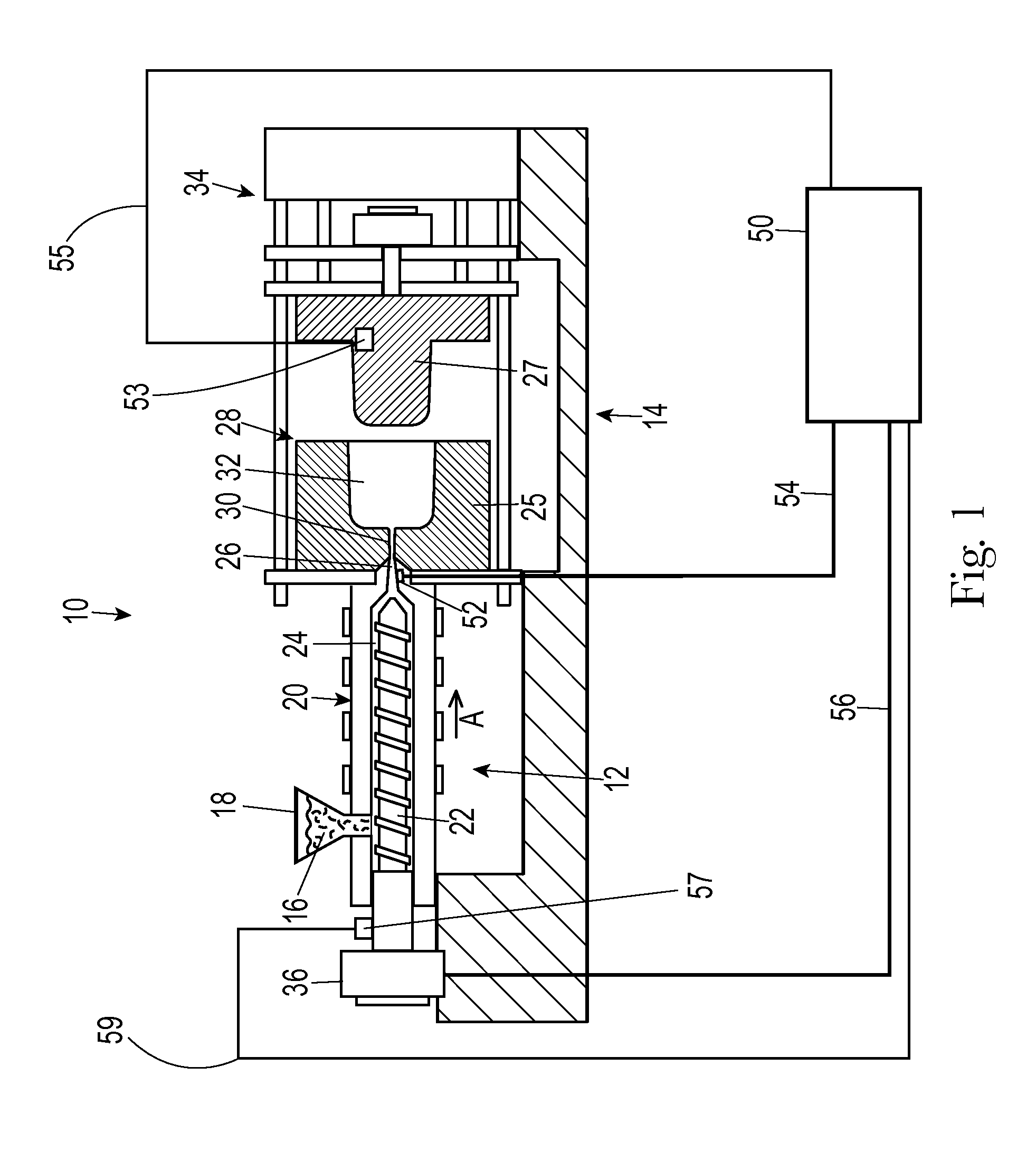

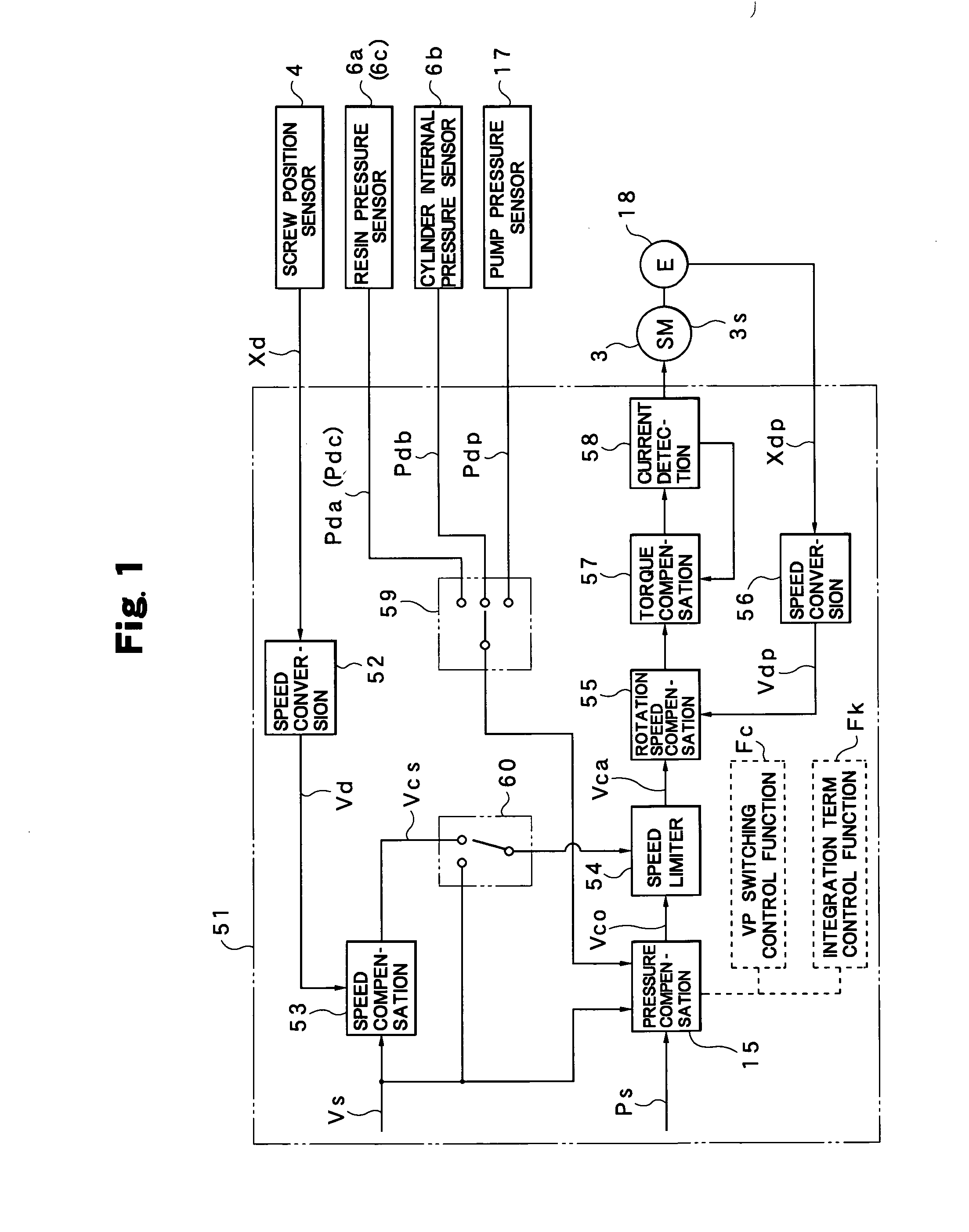

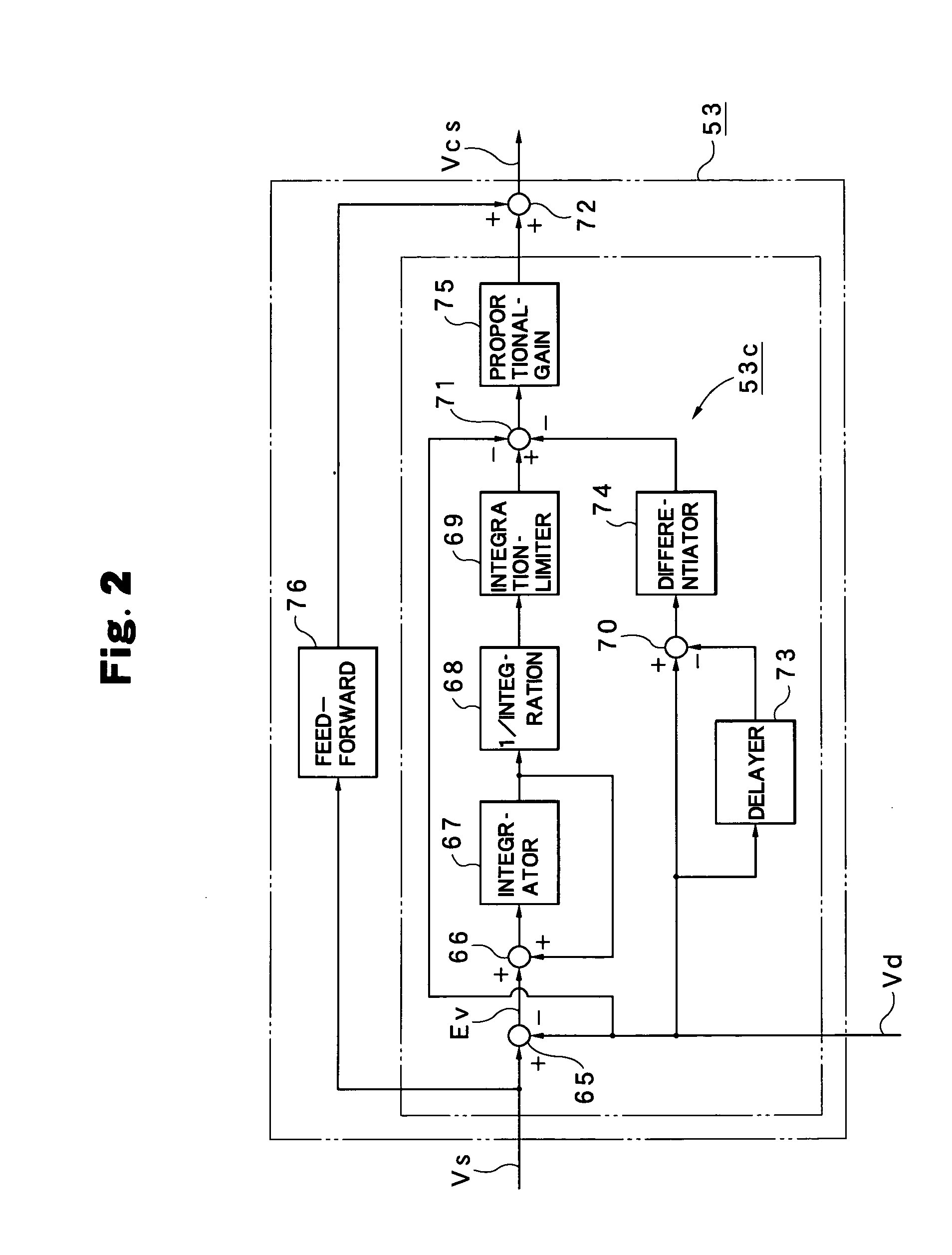

Controller of injection molding machine

ActiveUS20090087510A1Significant changeSolve unqualifiedAuxillary shaping apparatusInjection pressureScrew position

The present invention comprises a speed feedback control system for carrying out speed feedback control on the basis of a speed detected value Vd obtained by converting a position detected value Xd obtained from a screw position sensor 4, a pressure feedback control system for carrying out a pressure feedback control on the basis of a pressure detected value Pdb obtained from an injection pressure sensor 6b, and a VP switching control function portion Fc for carrying out switching from a speed control region to a pressure control region Zp when a pressure deviation Ep between a preset pressure set value Ps and the pressure detected value Pdb becomes a preset switching determination value Eps or less and carrying out the switching to the pressure control region Zp after control of a speed command value in the speed control region Zv by a predetermined control pattern Dp at this switching.

Owner:NISSEI PLASTIC IND CO LTD

Apparatus and method for injecting a liquid dye into a polymer melt

InactiveUS7278776B2Easy to addImprove accuracyPump componentsSpinning head liquid feederInjection pressureFuel tank

An apparatus and a method for injecting a liquid dye into a polymer melt, which includes a metering pump with a metering inlet and a metering outlet. The metering inlet connects to a dye tank and the metering outlet connects to a polymer melt carrying component. To add the liquid dye to the polymer melt in the melt carrying component in a quantity that is as uniform and accurate as possible, the invention provides for connecting the metering inlet of the metering pump to a feed outlet of a feed pump, which connects with its feed inlet to the tank. With that, it is possible to generate a feed pressure at the metering inlet of the metering pump, which can be adapted to an injection pressure at the metering outlet of the metering pump.

Owner:SAURER GMBH & CO KG

Pore-level simulation experimental apparatus for migration of pore-throat scale elastic microspheres in porous medium

ActiveCN103674806AReal-timeRealize acquisitionPermeability/surface area analysisPorous mediumMicrosphere

The invention relates to a pore-level simulation experimental apparatus for migration of pore-throat scale elastic microspheres in a porous medium, belonging to the field of pore-level flow simulation technology. Aiming at the pore throat characteristics of the real oil reservoir rocks and the dimension characteristics of the pore-throat scale elastic microspheres, the invention designs a microcosmic visual transparent quartz sand model suitable for the pore-throat scale elastic microspheres and constructs an image real-time acquisition and data analysis system to realize real-time observation, acquisition and quantitative analysis of the migration process of the pore-throat scale elastic microspheres, a distribution image and a remaining oil distribution image, real-time measurement of migration of the pore-throat scale elastic microspheres and injection pressure during oil displacement and measurement and analysis of output concentration, water content and oil production of the pore-throat scale elastic microspheres; the designed microcosmic visual transparent quartz sand model can reflect the pore throat characteristics of the real oil reservoir rocks, and as the model is made of transparent quartz sands through filling, the model is convenient to clean and can be repeatedly filled.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

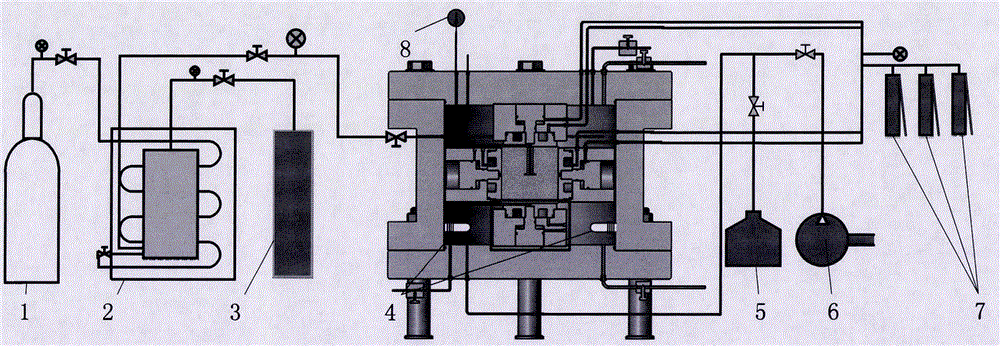

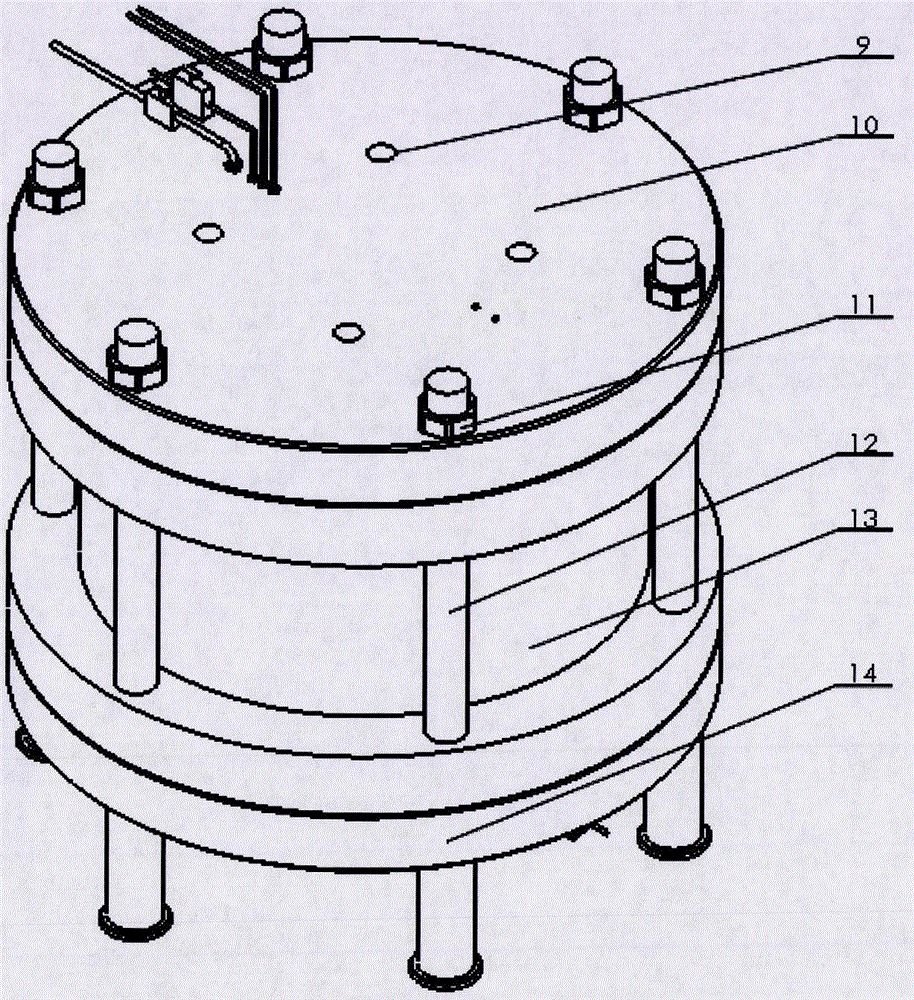

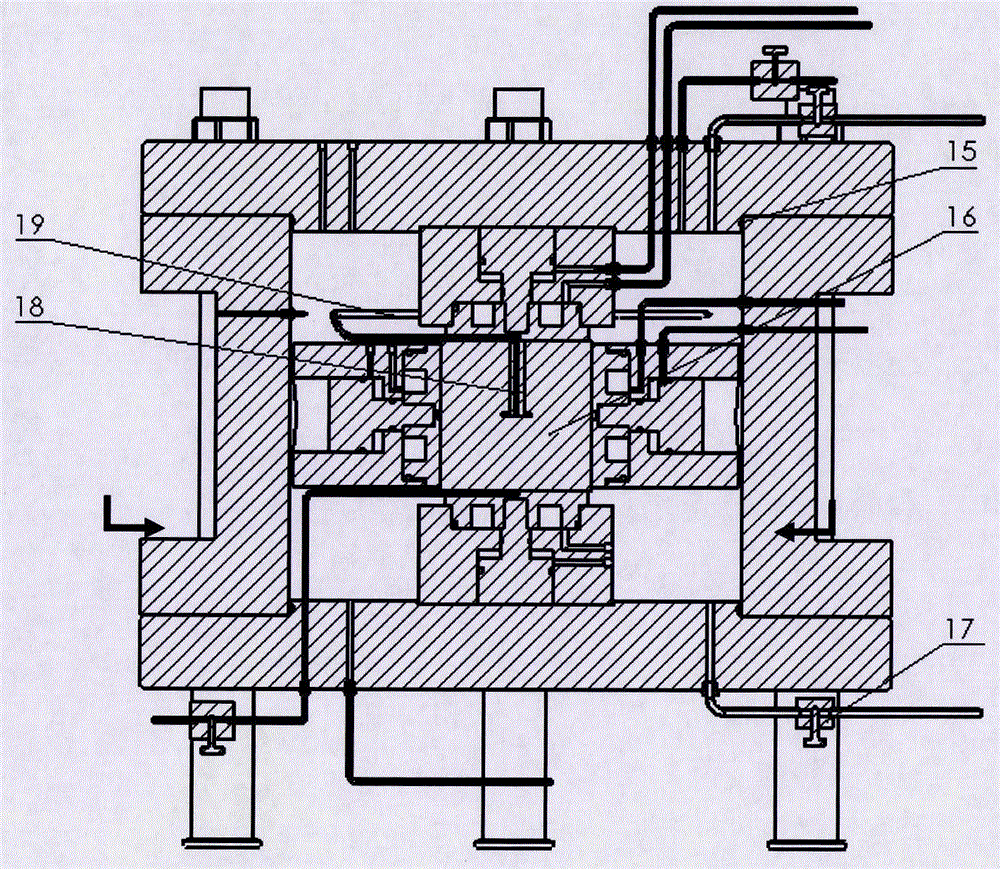

Supercritical carbon dioxide fracturing simulation experiment device

ActiveCN106404549AFully infiltratedSimulate the realMaterial strength using tensile/compressive forcesInjection pressureFracturing fluid

The invention discloses a supercritical carbon dioxide fracturing simulation experiment device. The device is characterized in that a pressure chamber, a vacuum saturation system and a carbon dioxide phase state transformation system are included; the pressure chamber comprises a closed cavity, flat jacks and heating rods, wherein the closed cavity is composed of an upper cover plate, a confining pressure barrel and a pressure chamber base which are sealed through a seal ring, the four flat jacks are evenly distributed on the side wall of the confining pressure barrel, the upper cover plate and the pressure chamber base are each fixedly provided with one flat jack, and the heating rods are fixed to the pressure chamber base; the vacuum saturation system comprises a vacuum pump and a saturation hydraulic station; the carbon dioxide phase state transformation system comprises a carbon dioxide gas source, a cooling device and an injection pump, and carbon dioxide is liquefied by lowering the temperature and then transformed to be in a supercritical state through pressurizing and temperature increasing. According to the supercritical carbon dioxide fracturing simulation experiment device, a supercritical carbon dioxide fracturing simulation experiment is conducted on rock and an artificial test piece under the saturated pore pressure condition, the parameters such as the injection pressure, the temperature and the output volume of fracturing fluid in the fracturing process are monitored in real time, a fracture extension rule is acquired, and the device is an experimental platform for researching the supercritical carbon dioxide fracturing mechanism.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com