Foam system suitable for profile control and oil displacement of oil field and oil displacement method

A foam system and oil displacement technology, applied in chemical instruments and methods, production fluids, earthwork drilling, etc., can solve the problem of low oil displacement efficiency, reduce ineffective water circulation, improve oil displacement efficiency, and achieve good biodegradation. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment one, the interface of foam system and foam performance

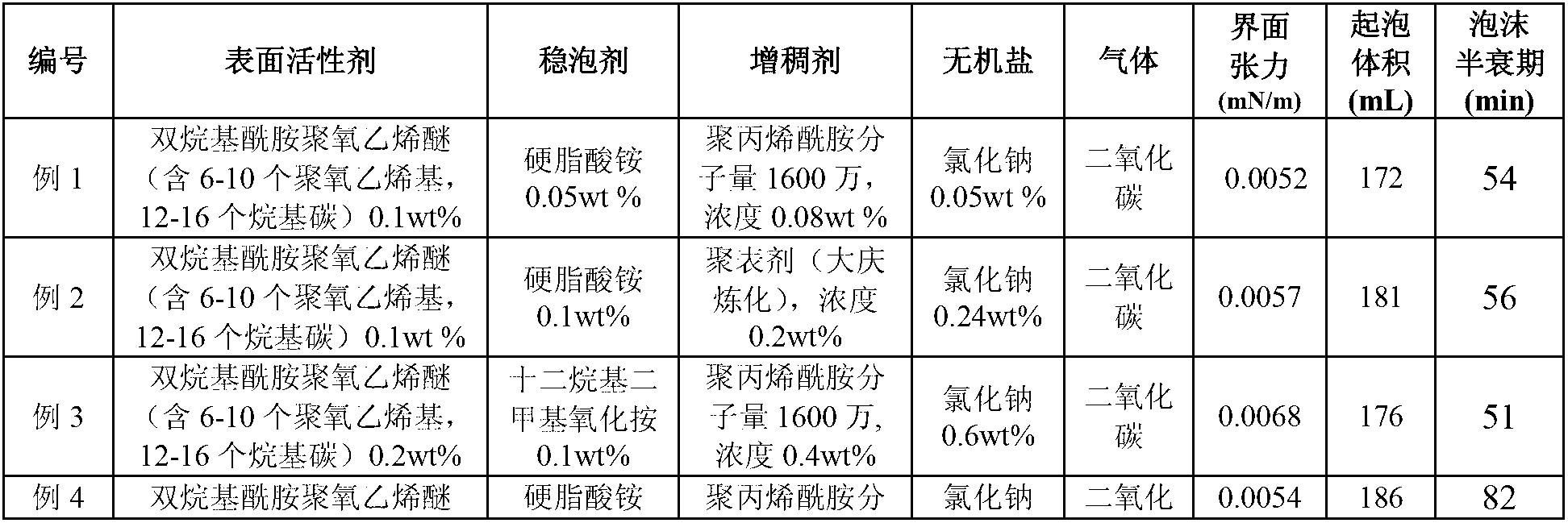

[0047] Table 1 provides specific examples 1-18 of foam systems suitable for oilfield profile control and oil displacement. The preparation method of the foam system is: dissolve the thickener in water at 45°C. Stir with a blender for 2 hours to completely dissolve and obtain a thickener solution. Add the inorganic salt to the thickener solution and stir it with a mixer for 0.5 hour to dissolve it completely. Then add the foam stabilizer and stir with a mixer for 0.5 hour to completely dissolve it. Finally, add the surfactant and dilute it with water to the target concentration, and stir slowly with a mixer for 0.5 hour to make it dissolve completely. Interfacial tension, foam volume and foam half-life were determined.

[0048] The US TX500C spinning drop interfacial tensiometer was used to measure the oil-water interfacial tension at 45°C and 4000 rpm. The oil used in the experiment was Daqing crude...

Embodiment 2

[0053] Example 2. Foam profile control and oil displacement effect

[0054] This embodiment provides a foam profile control flooding method, including water flooding and polymer flooding followed by a foam profile control flooding method.

[0055] (1) Foam profile control flooding experiment after water flooding:

[0056] (1) The man-made three-layer heterogeneous positive-rhythm core is selected, the size is 4.5cm×4.5cm×30cm, and the coefficient of variation of permeability is 0.72.

[0057] (2) Vacuumize the core to -1MPa at 45°C for two hours, inject water into the saturated oil field, and measure the pore volume of the core. Saturated Daqing Oilfield simulated oil (viscosity 9.5cp), determined oil saturation, and then aged for more than 12 hours.

[0058] (3) Water drive oil to 98% water cut, and determine water drive recovery.

[0059] (4) Foam profile control, foam injection method selection ①0.3PV foam system + 0.2PV polymer; ②0.05PV polymer + 0.3PV foam system + 0.1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com