A kind of synthetic fatliquoring agent and preparation method thereof

A fatliquor and fat technology, applied in the field of synthetic fatliquor and its preparation, can solve the problems of adverse effects on the appearance of synthetic fatliquor products, difficulty in obtaining appearance fluidity, peculiar smell of leather, etc., and achieve good appearance fluidity. , The effect of emulsion stability and strong foam feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

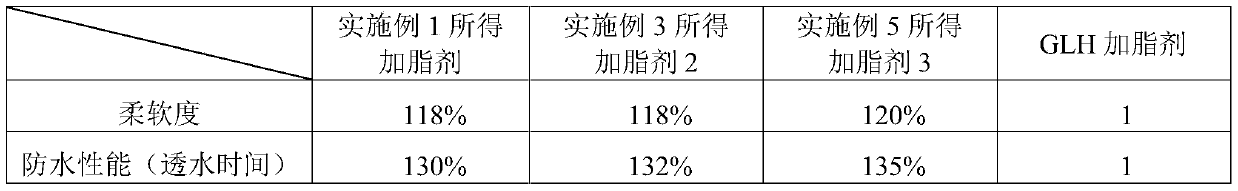

Embodiment 1

[0039] First, 100g of vaseline and 98g of maleic anhydride are added in proportion to the reactor, protected by nitrogen gas, and the dibenzoyl peroxide initiator whose total consumption accounts for 5g of long-carbon paraffins is added in equal amounts in 6 times, with an interval of 20 minutes each time. , Reaction at 80°C for 2h. Then add 58g of C12-C14 mixed alcohol (hydroxyl value 290) and keep warm at 100°C for 1 hour; add 270g Pingpingjia O-3 (hydroxyl number 145) and continue the heat preservation reaction for 1 hour. Then add a saturated solution containing 126g of sodium sulfite and react at 85°C for 3h. Finally, the pH was adjusted to 6.5 with 25% liquid caustic soda, and the solid content was adjusted to 50% to obtain Synthetic Fatliquoring Agent 1.

Embodiment 2

[0041] First, 100g of vaseline and 98g of maleic anhydride are added in proportion to the reactor, protected by nitrogen gas, and the dibenzoyl peroxide initiator whose total consumption accounts for 4g of long-carbon paraffins is added in equal amounts in 6 times, with an interval of 20 minutes each time. , Reaction at 80°C for 2h. Then add 96.5g of C12-C14 mixed alcohol (hydroxyl value 290) and keep warm at 100°C for 1 hour; add 193.4g Pingpingjia O-3 (hydroxyl number 145) and continue to keep warm for 1 hour. Then add a saturated solution containing 110 g of sodium sulfite and react at 85° C. for 3 h. Finally, adjust the pH to 6.5 with 25% liquid caustic soda, and adjust the solid content to 50% to obtain the synthetic fatliquoring agent 2.

Embodiment 3

[0043] First 100g of solid paraffin and 98g of maleic anhydride are added in the reactor in proportion, and nitrogen protection is added, and the azobisisobutyronitrile initiator that the total consumption accounts for 5g of the long-carbon chain alkane consumption is added in equal amounts in 6 times, and each interval is 20 Minutes, react at 80°C for 2h. Then add 78.3g of C16-C18 mixed alcohol (hydroxyl value 215) and keep warm at 100°C for 1 hour; add 270g Pingpingjia O-3 (hydroxyl number 145) and continue to keep warm for 1 hour. Then add a saturated solution containing 115g of sodium sulfite and react at 85°C for 3h. Finally, the pH was adjusted to 7.0 with 25% liquid caustic soda, and the solid content was adjusted to 50% to obtain synthetic fatliquoring agent 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com