Patents

Literature

10543results about How to "Feel good" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

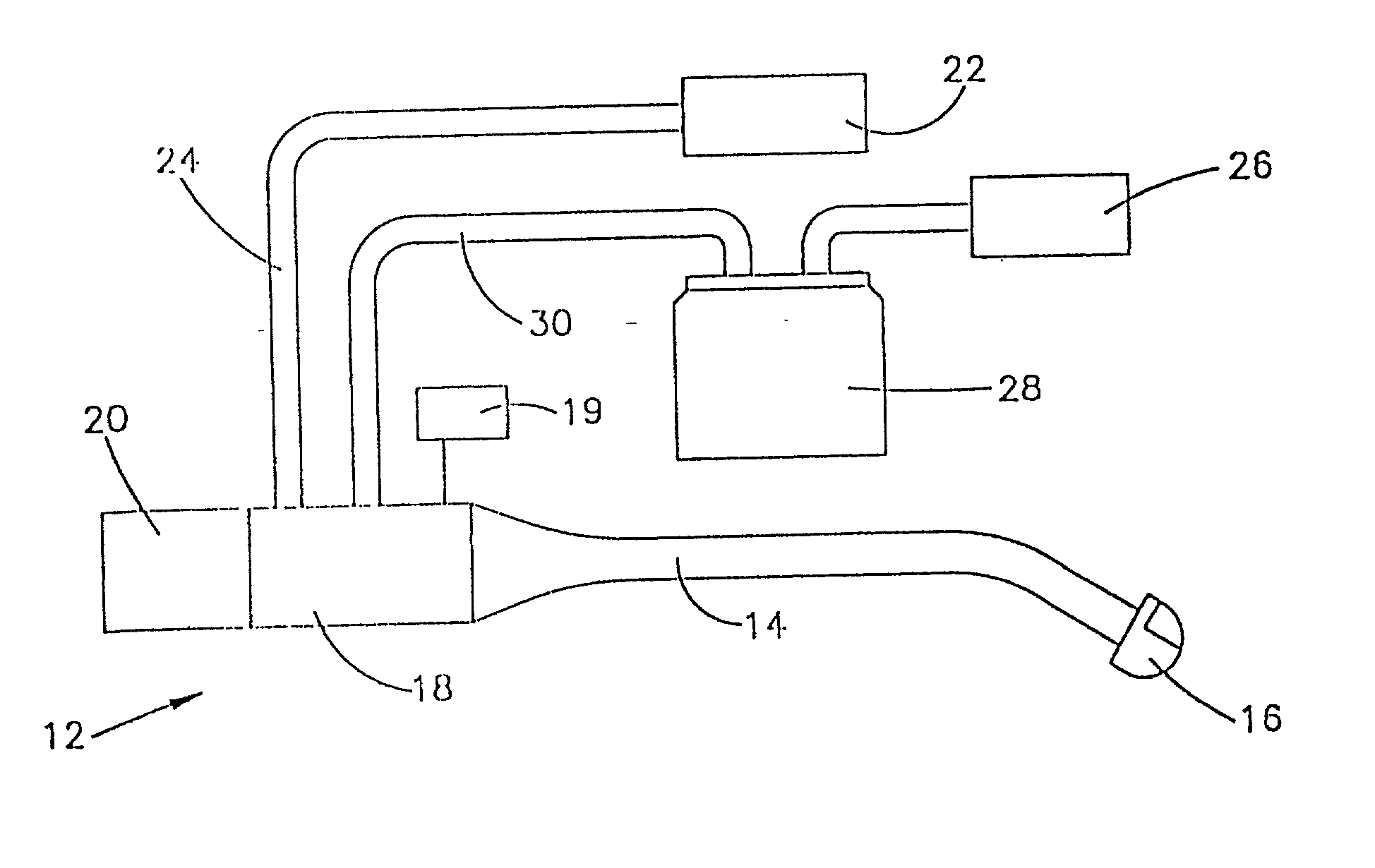

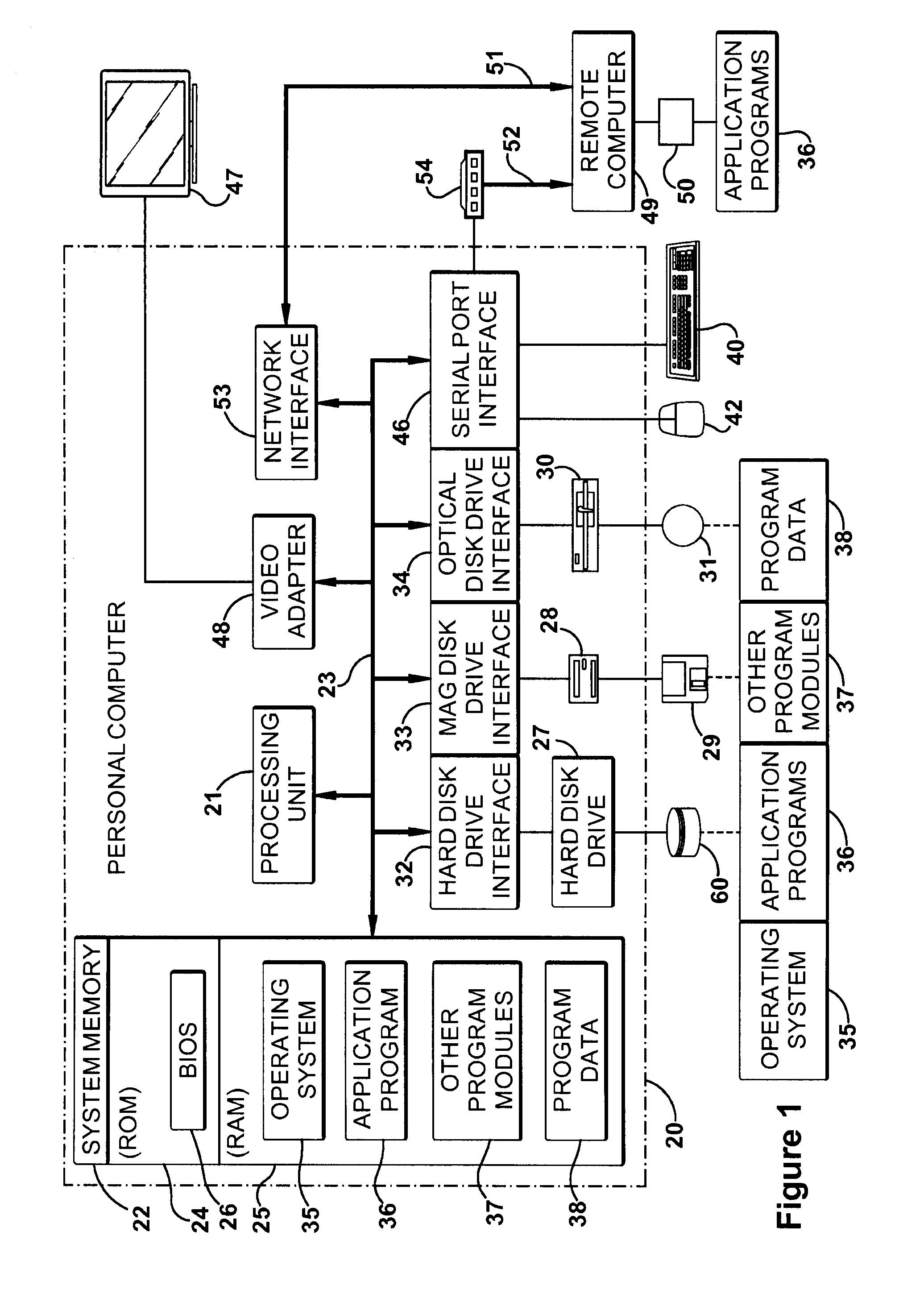

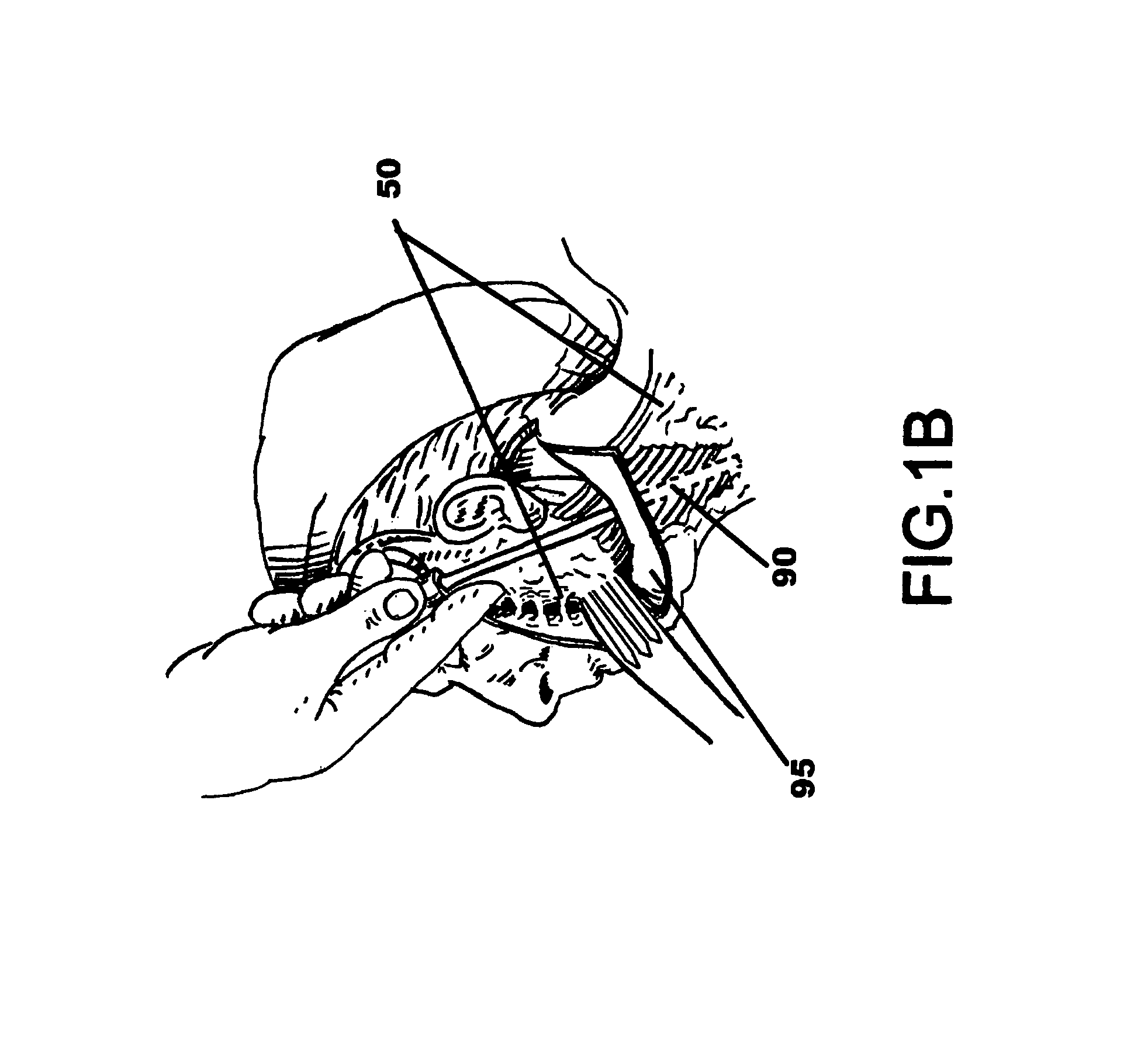

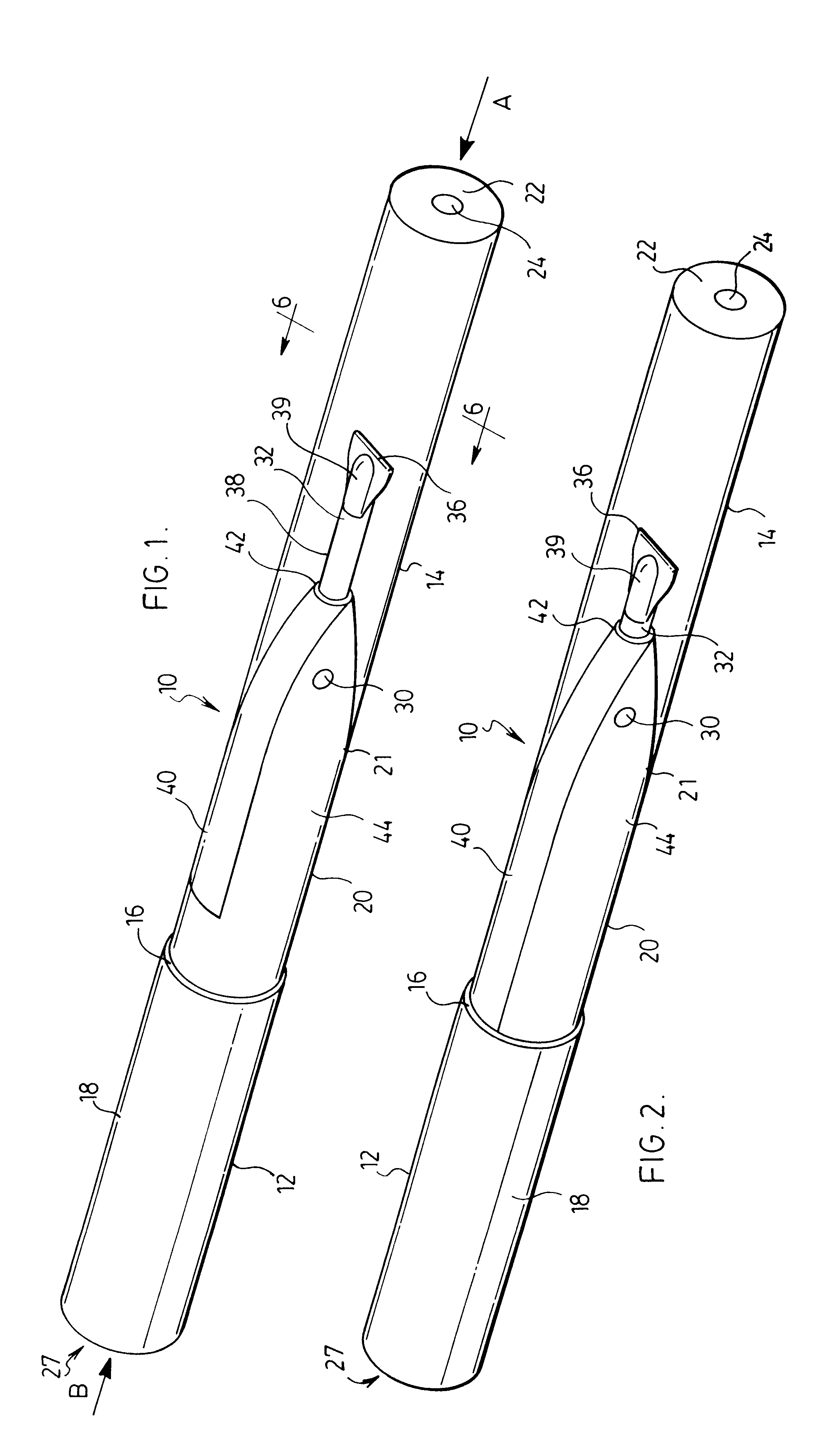

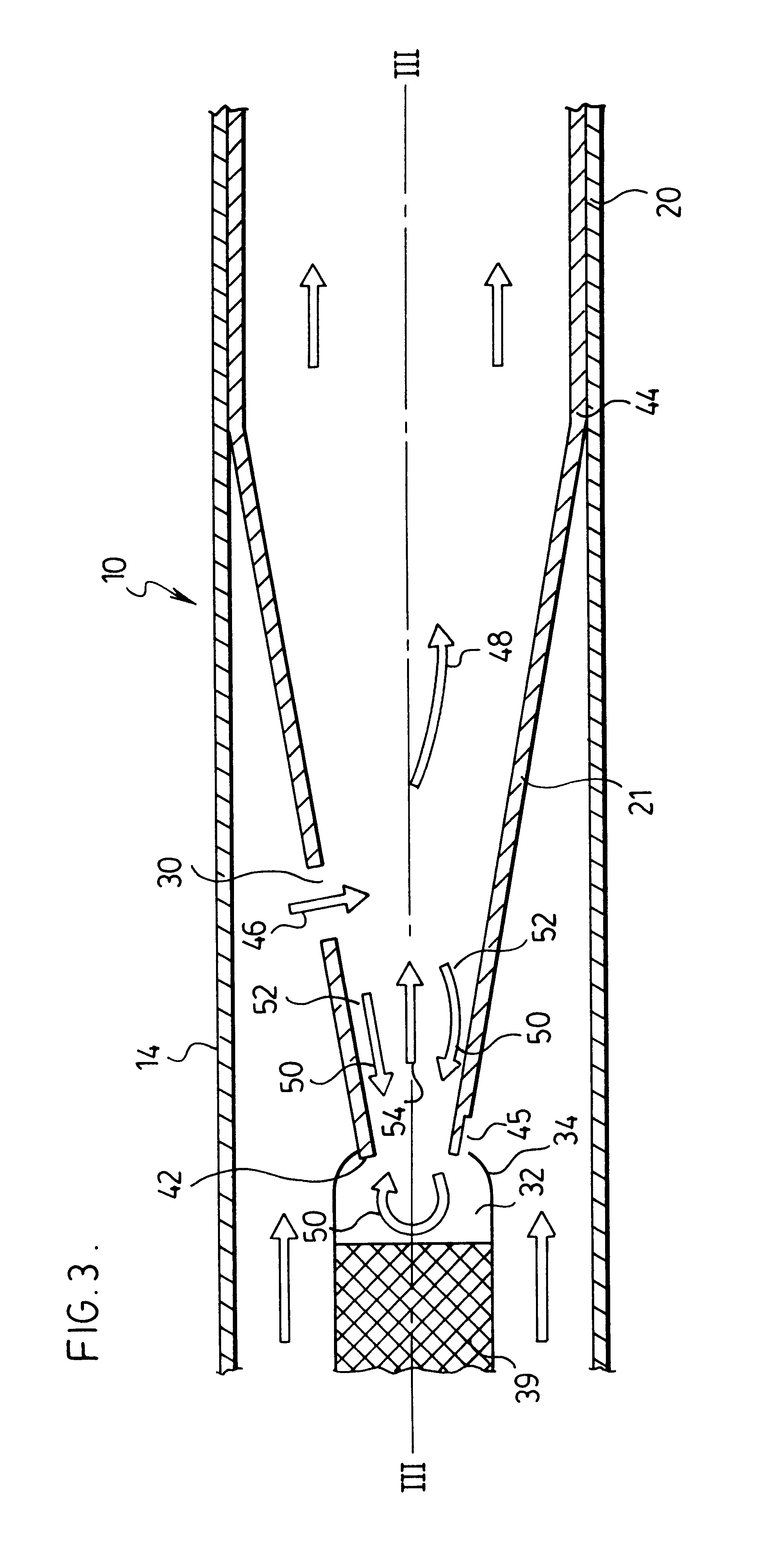

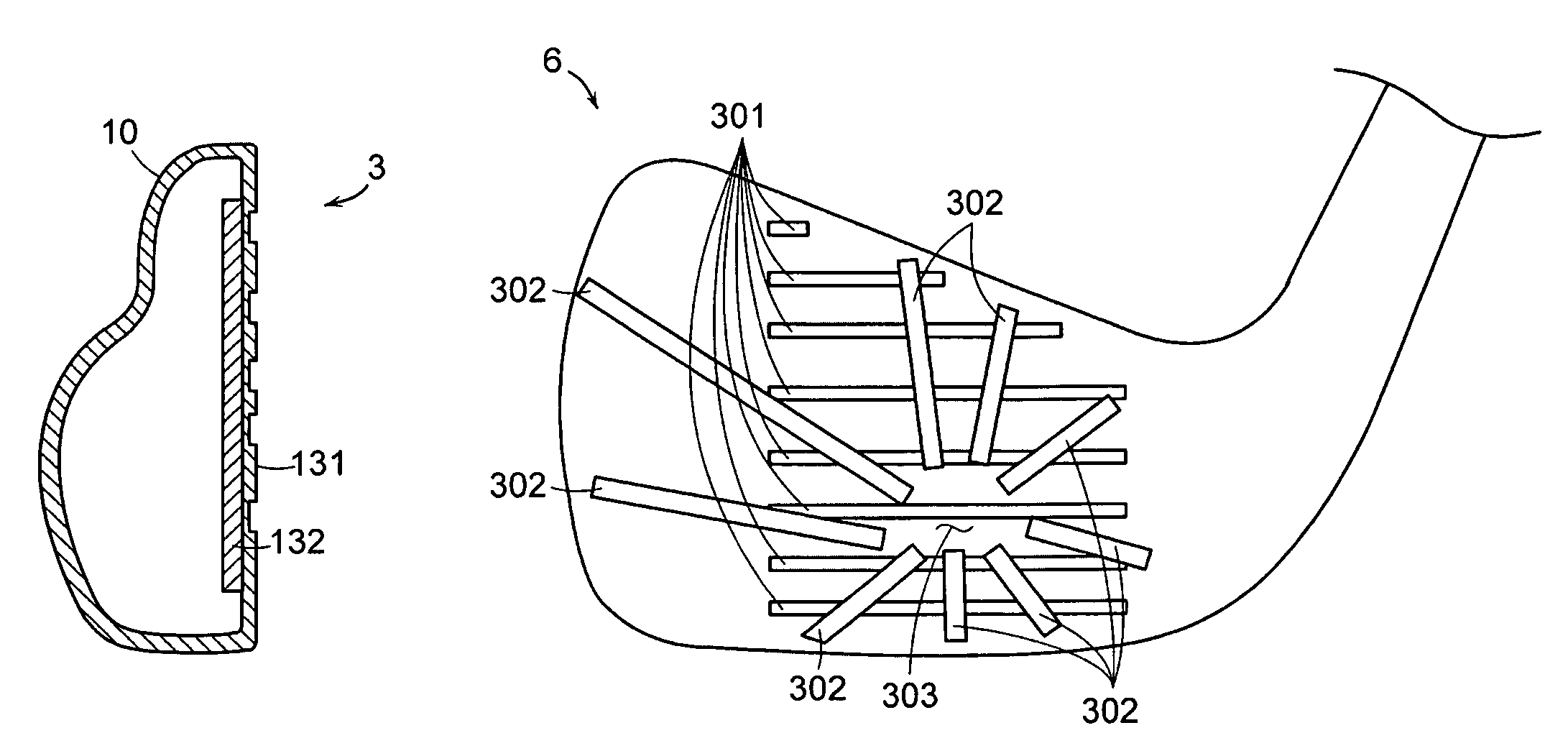

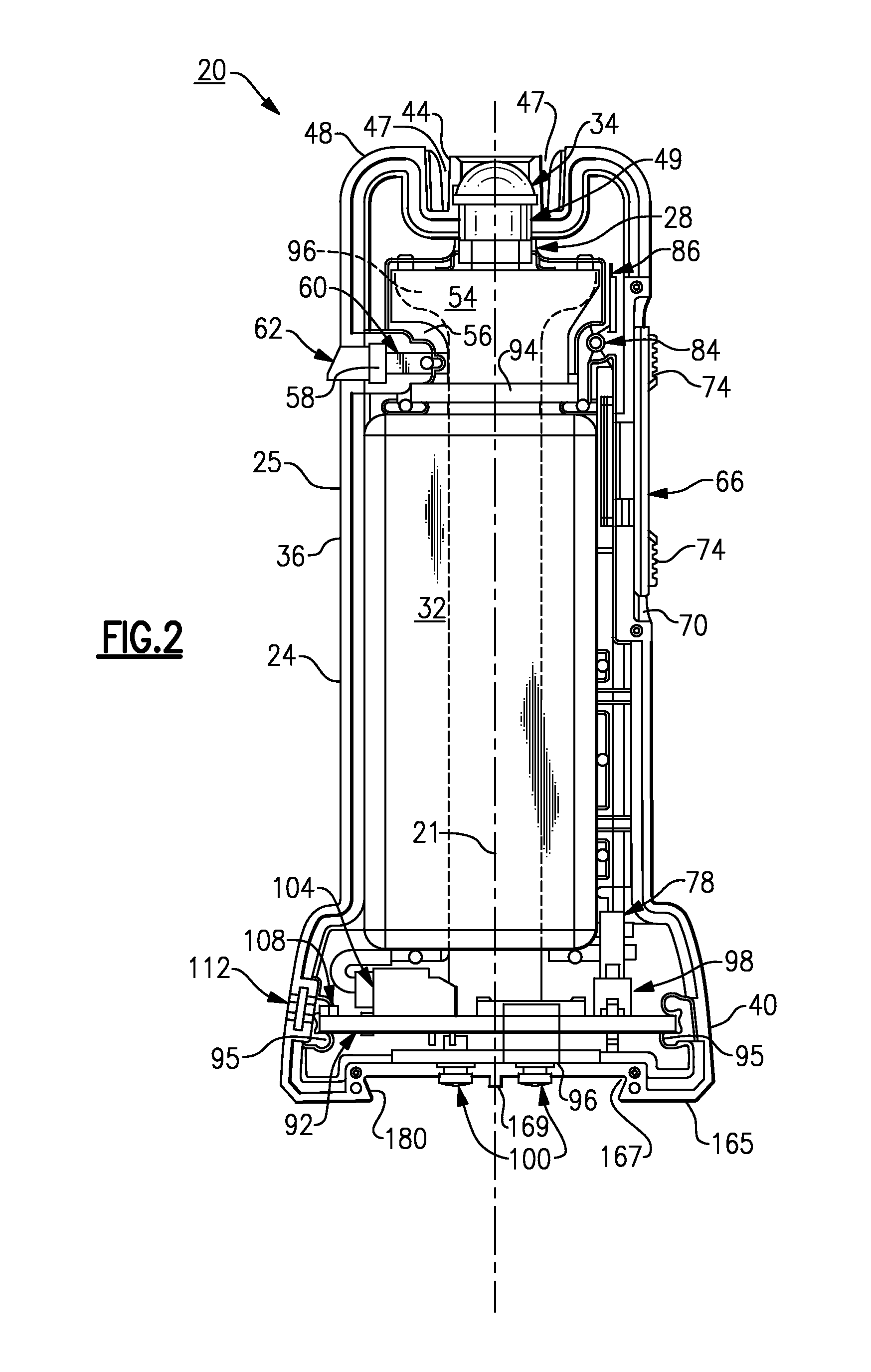

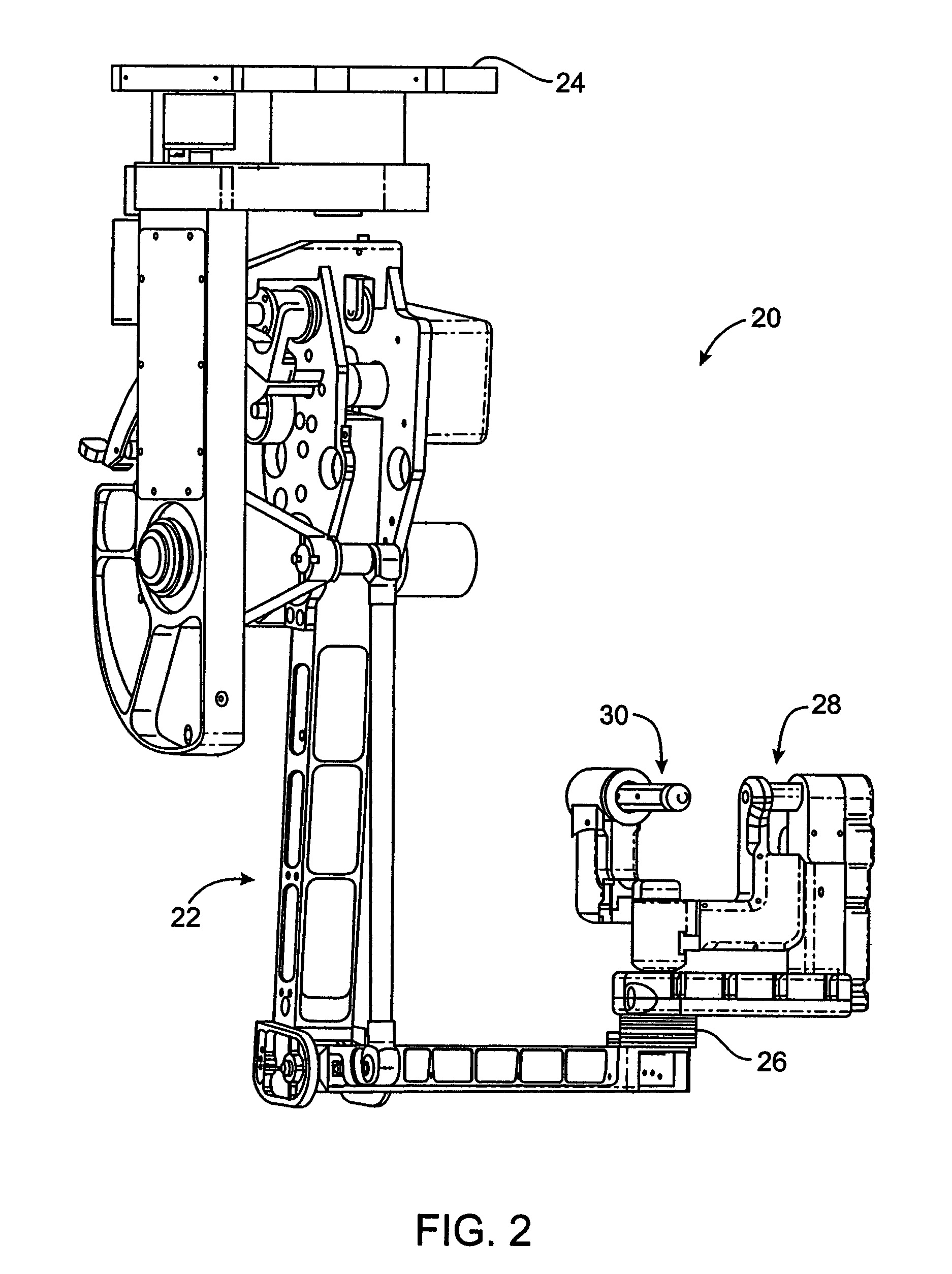

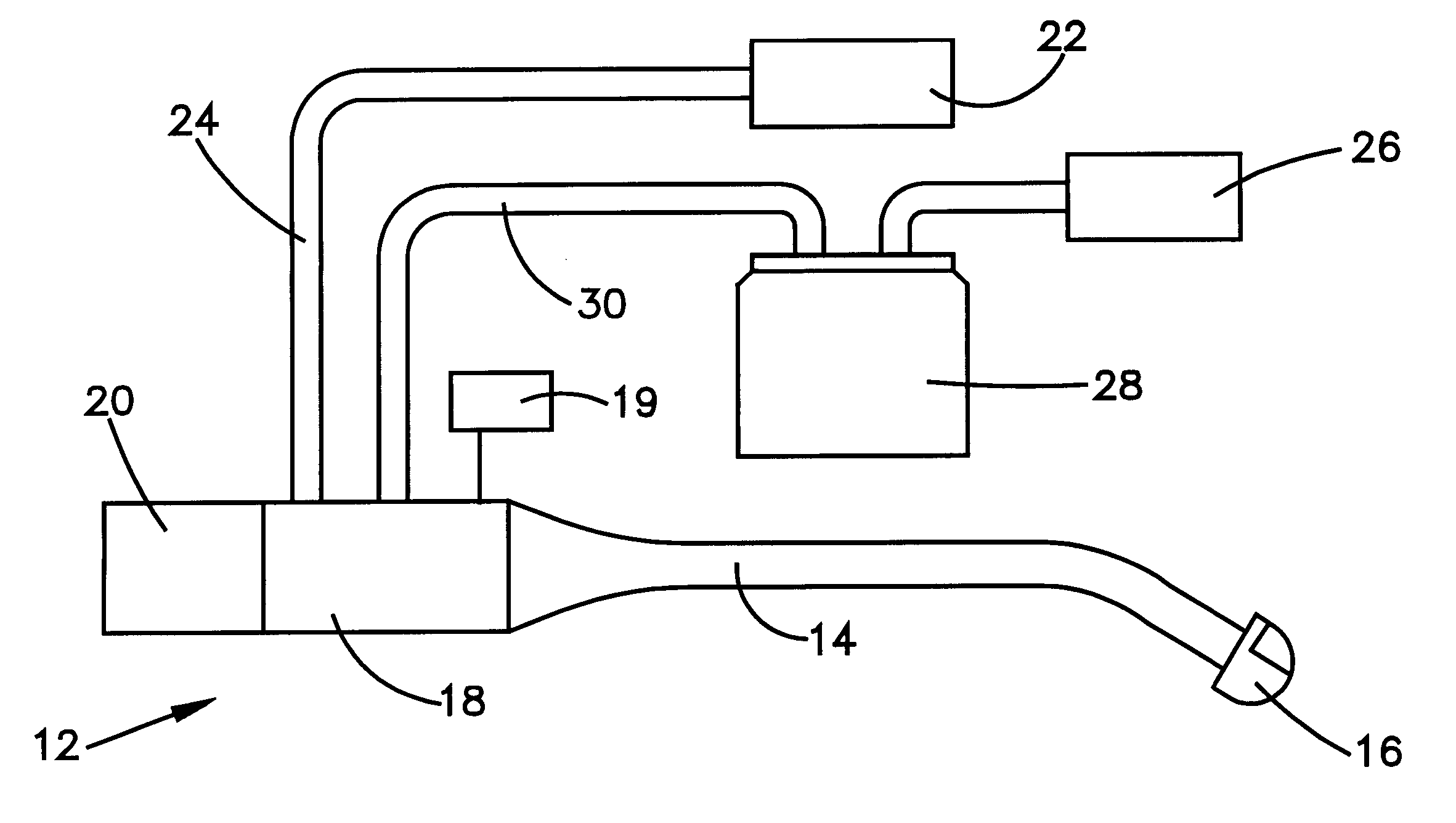

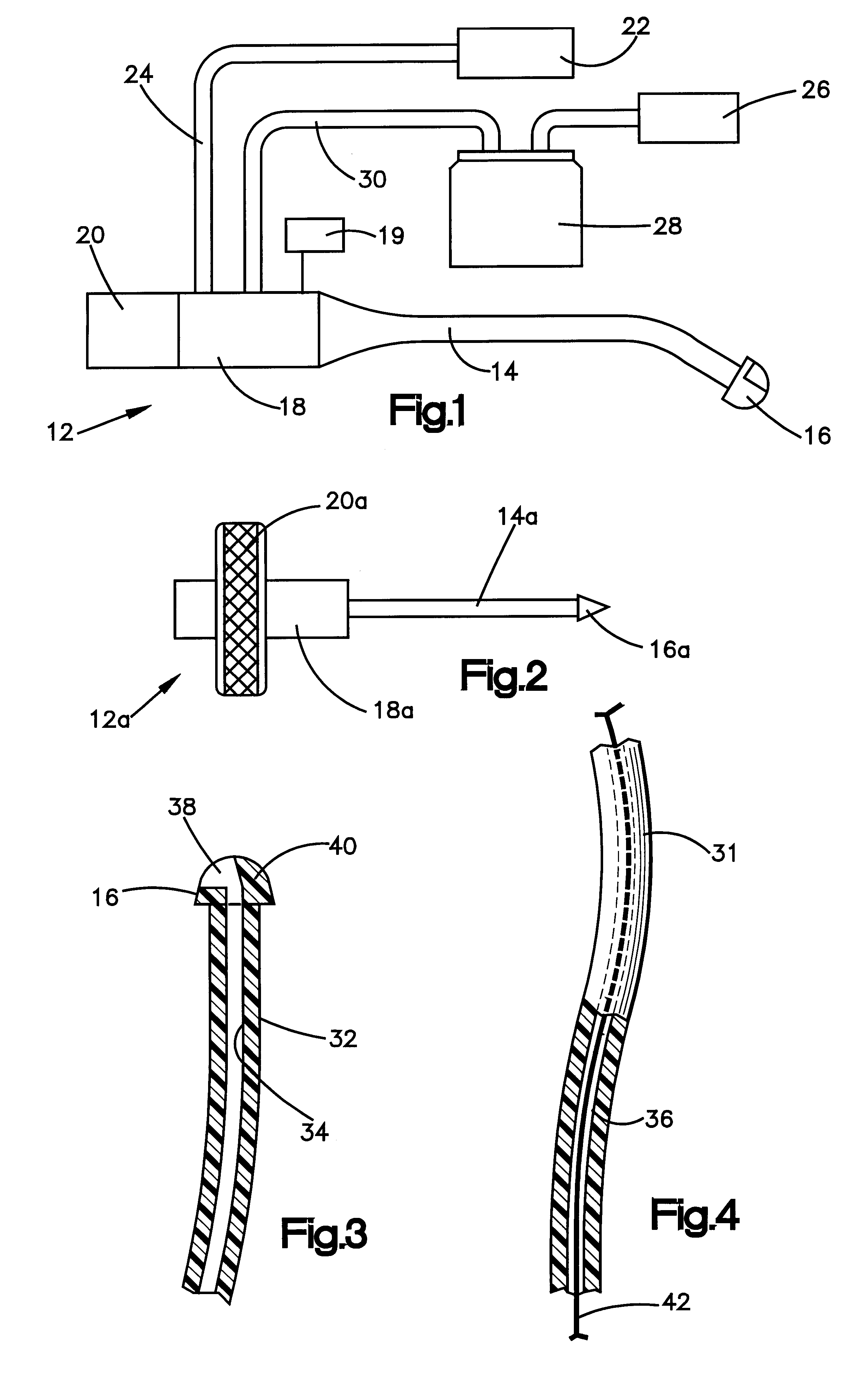

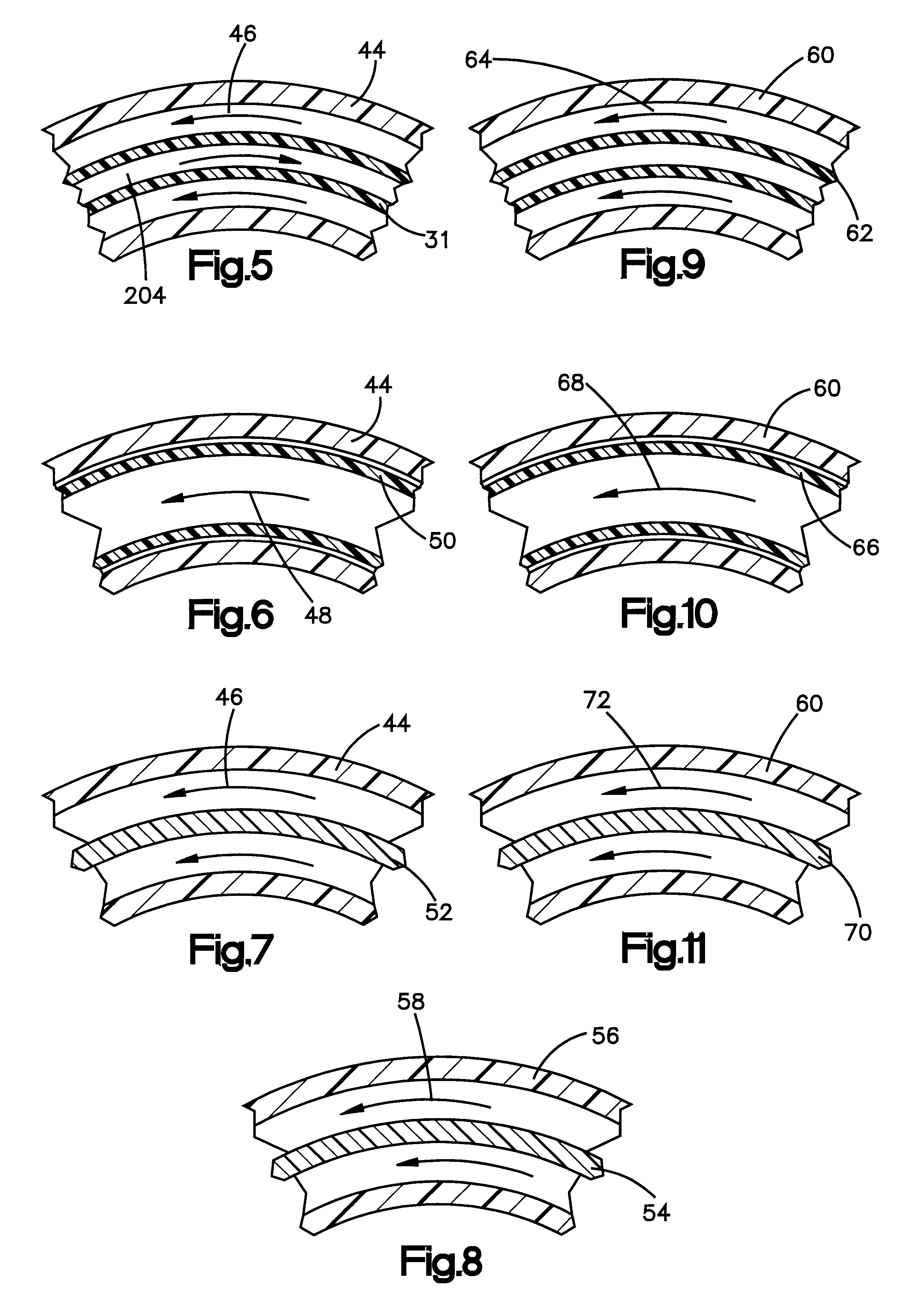

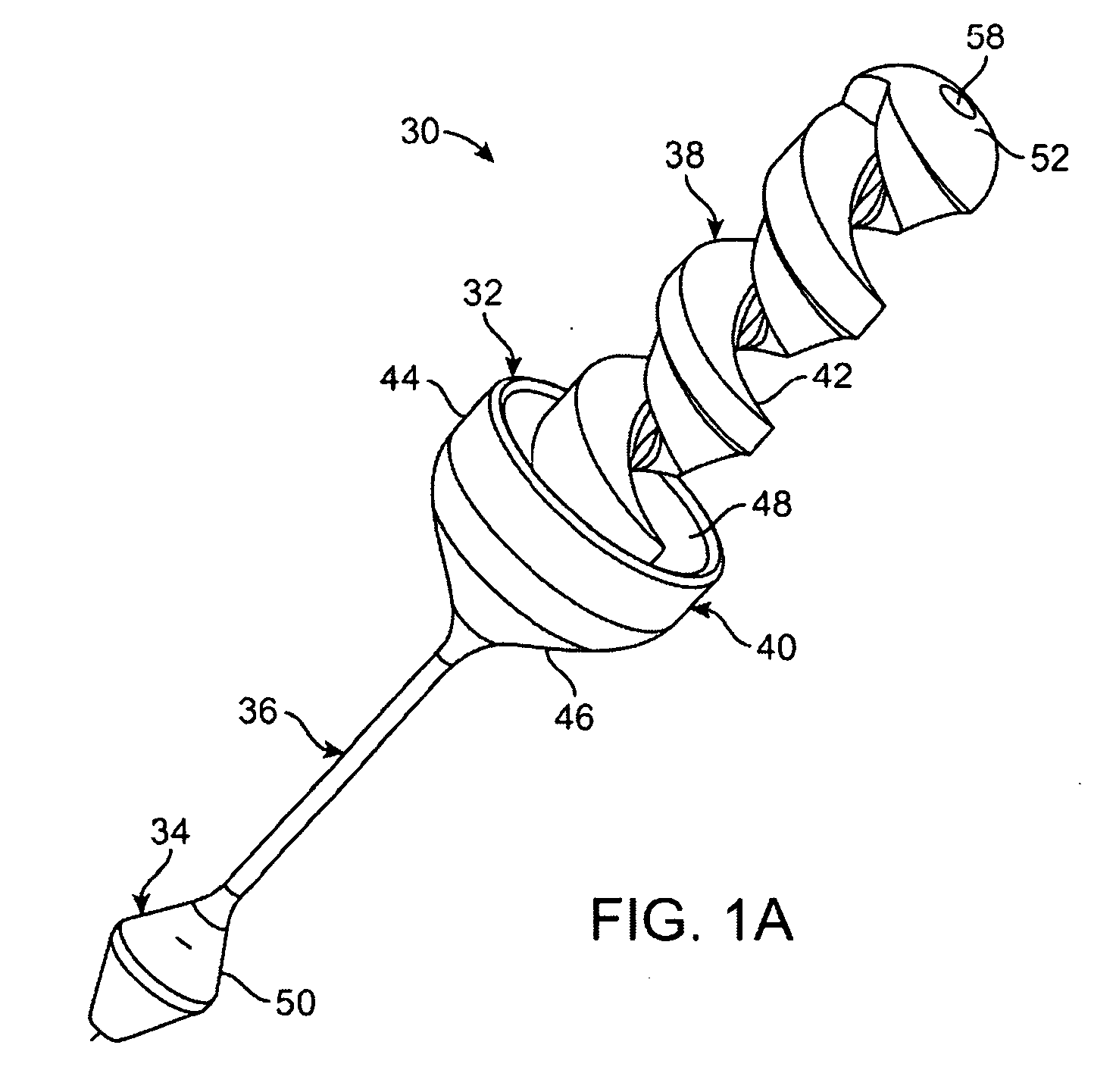

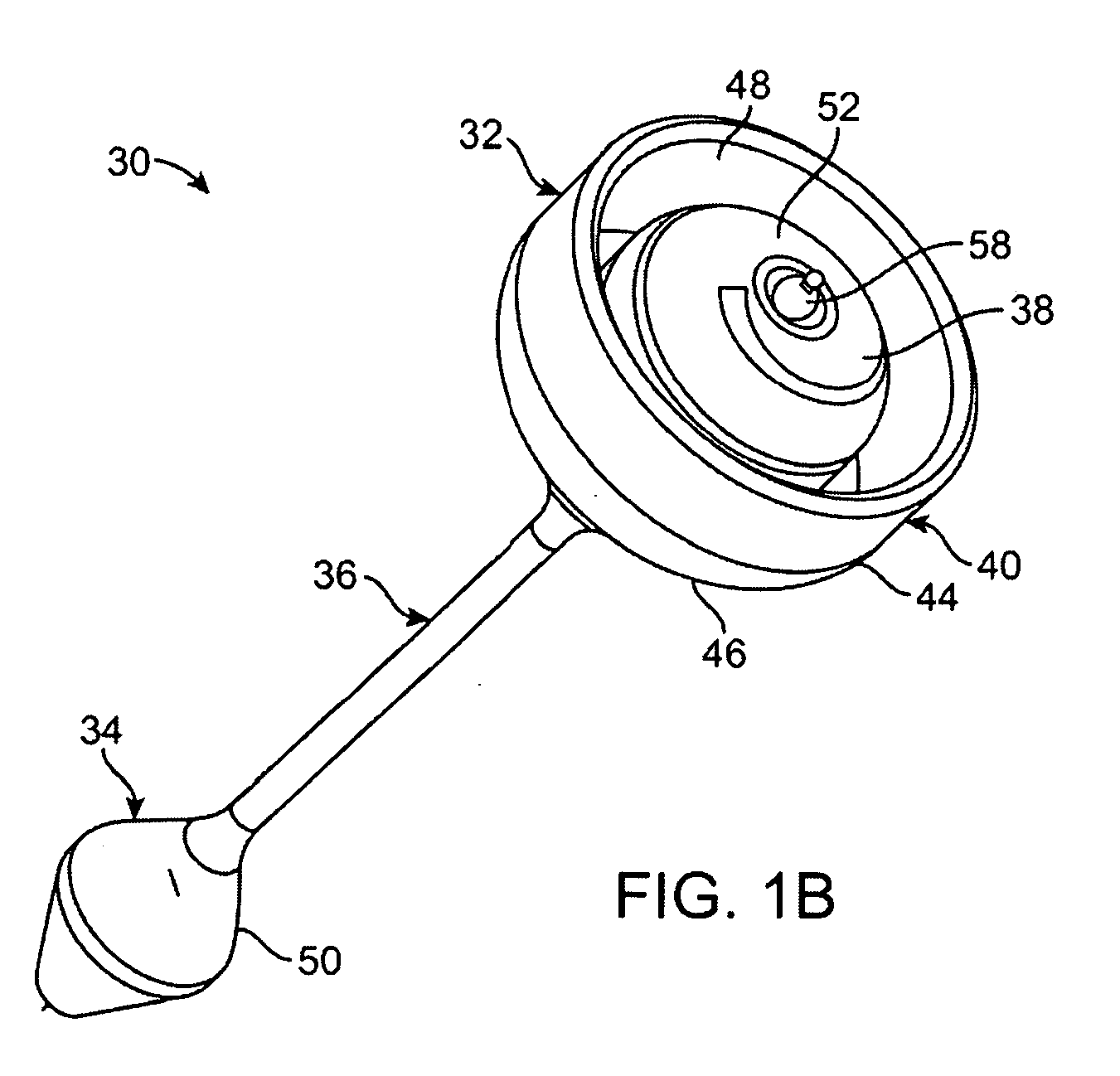

Apparatus and method for tissue removal

InactiveUS20020029055A1Less energyReduce frictionSurgical needlesVaccination/ovulation diagnosticsWood splinterMotion transfer

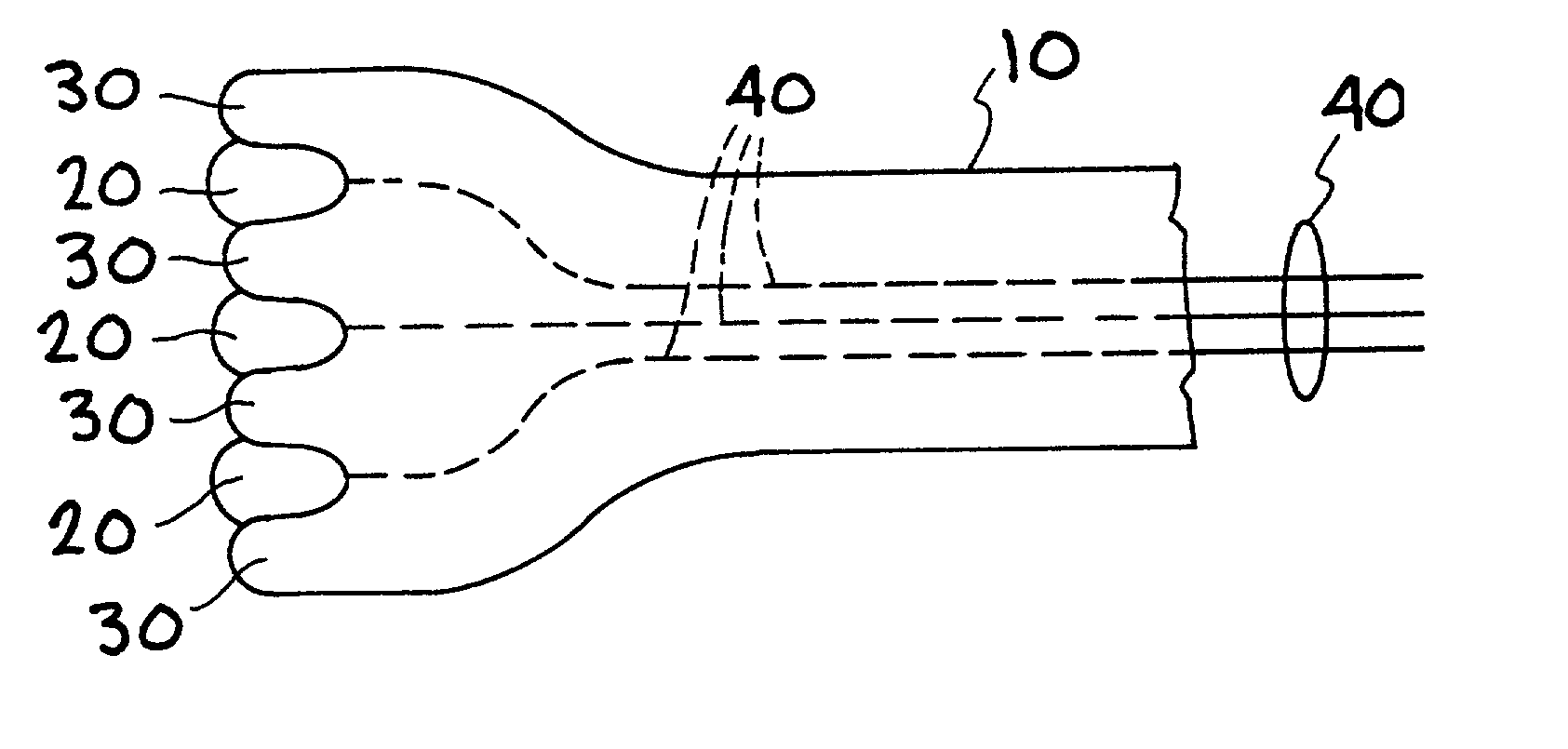

Percutaneous tissue removal apparatus comprises a flexible drill shaft, a cutting tip mounted on the shaft for placement adjacent a tissue mass for cutting the tissue, means for transmitting motion to the shaft to move the cutting tip against the tissue to cut tissue fragments from the tissue, and means for removing the tissue fragments along the shaft by suction to a location outside the tissue mass while cutting. The apparatus may include means for collecting one or more selected components of the harvested tissue fragments for implantation of the fragments preferably into the body of the patient from whom they were removed. Where the tissue to be cut is bone, a cutting tip is preferably made of a polymeric material which is softer than the cortical portion of the bone, although the cutting tip may be made of a ceramic or a composite material. A second flexible shaft may be provided either within or about the flexible drill shaft. The harvested tissue fragments may be implanted in the donor patient's body.

Owner:BONUTTI SKELETAL INNOVATIONS +2

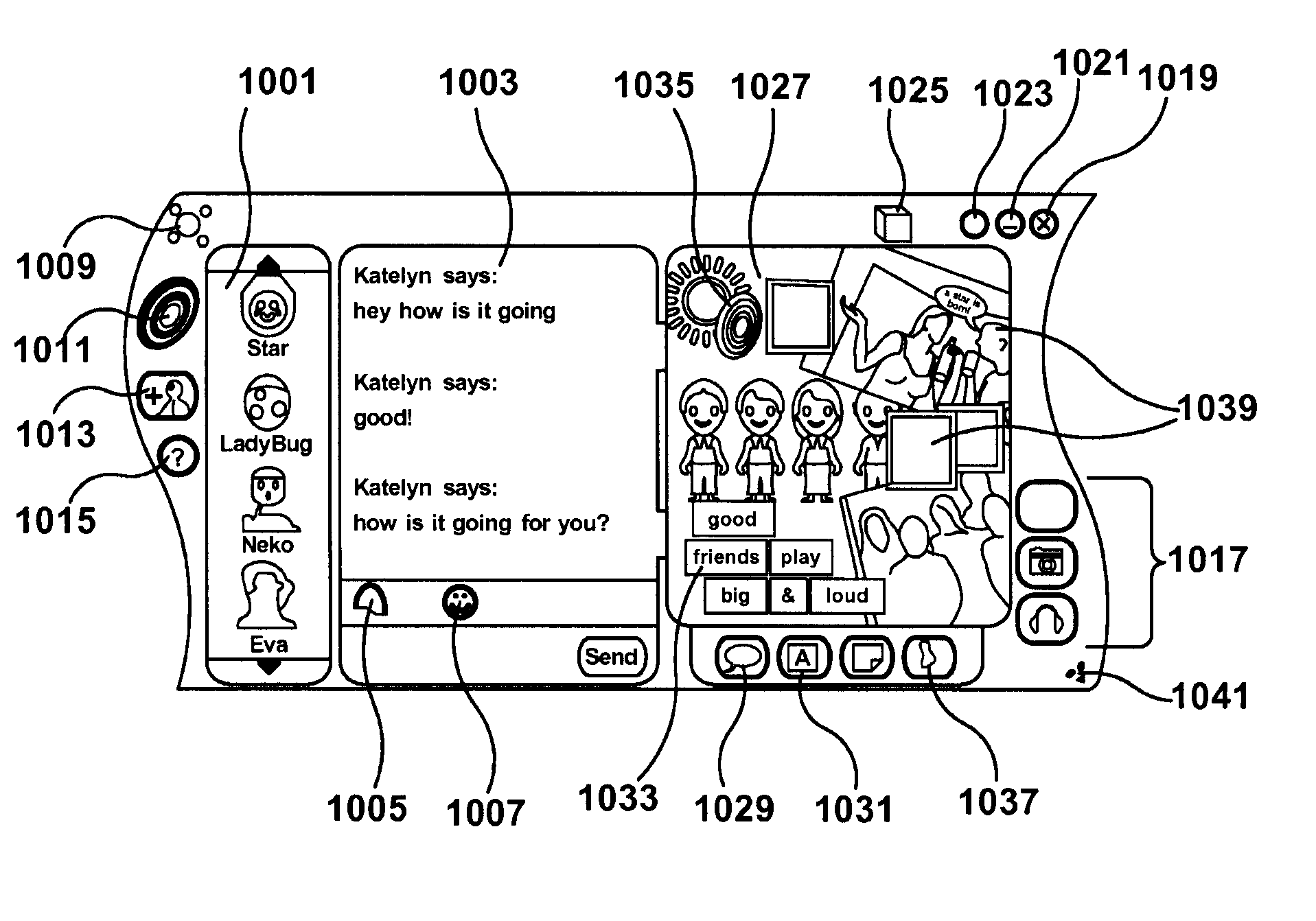

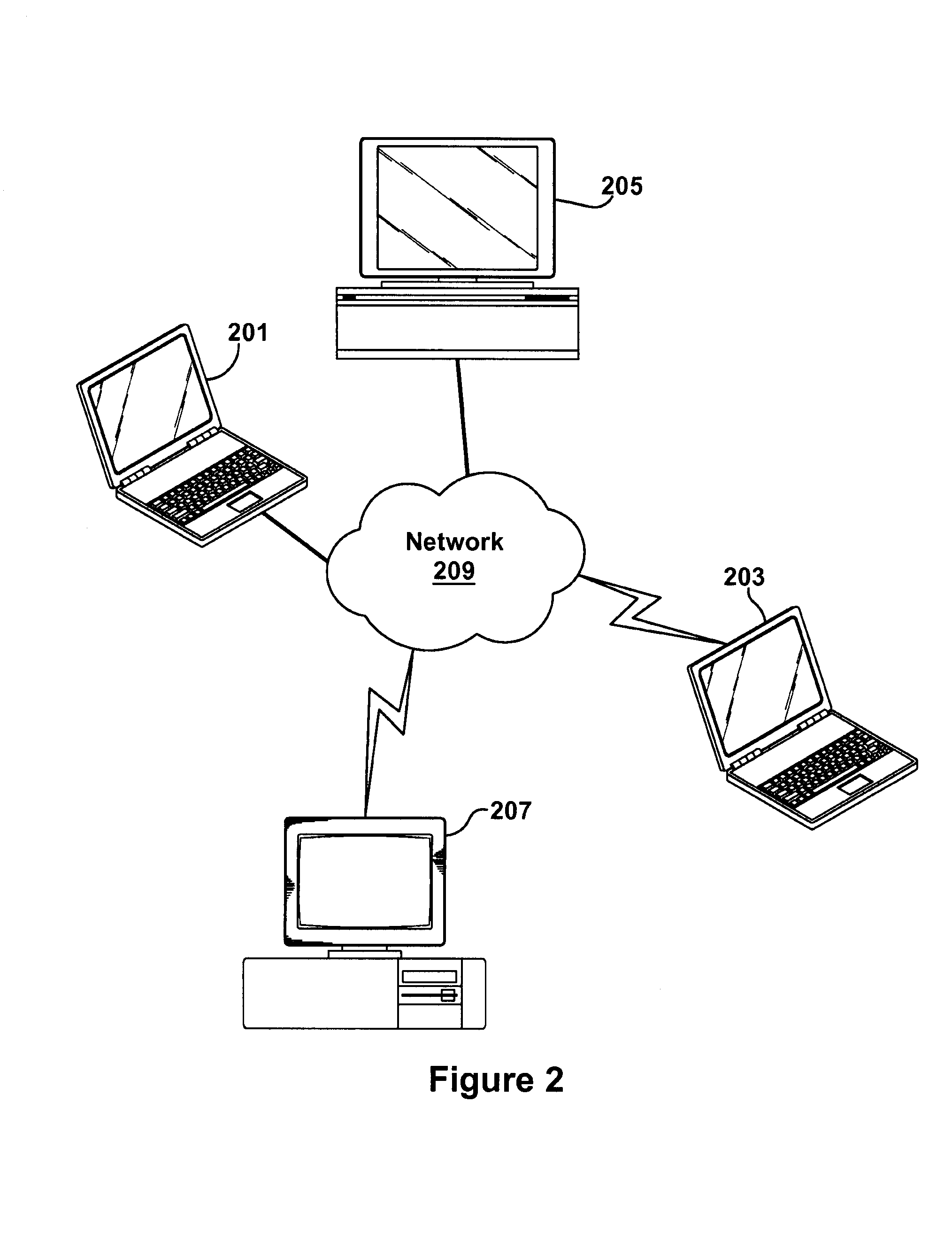

System and method for shared integrated online social interaction

InactiveUS7234117B2Enhanced interactionImprove identityOffice automationAnimationModularityNetwork communication

Owner:MICROSOFT TECH LICENSING LLC

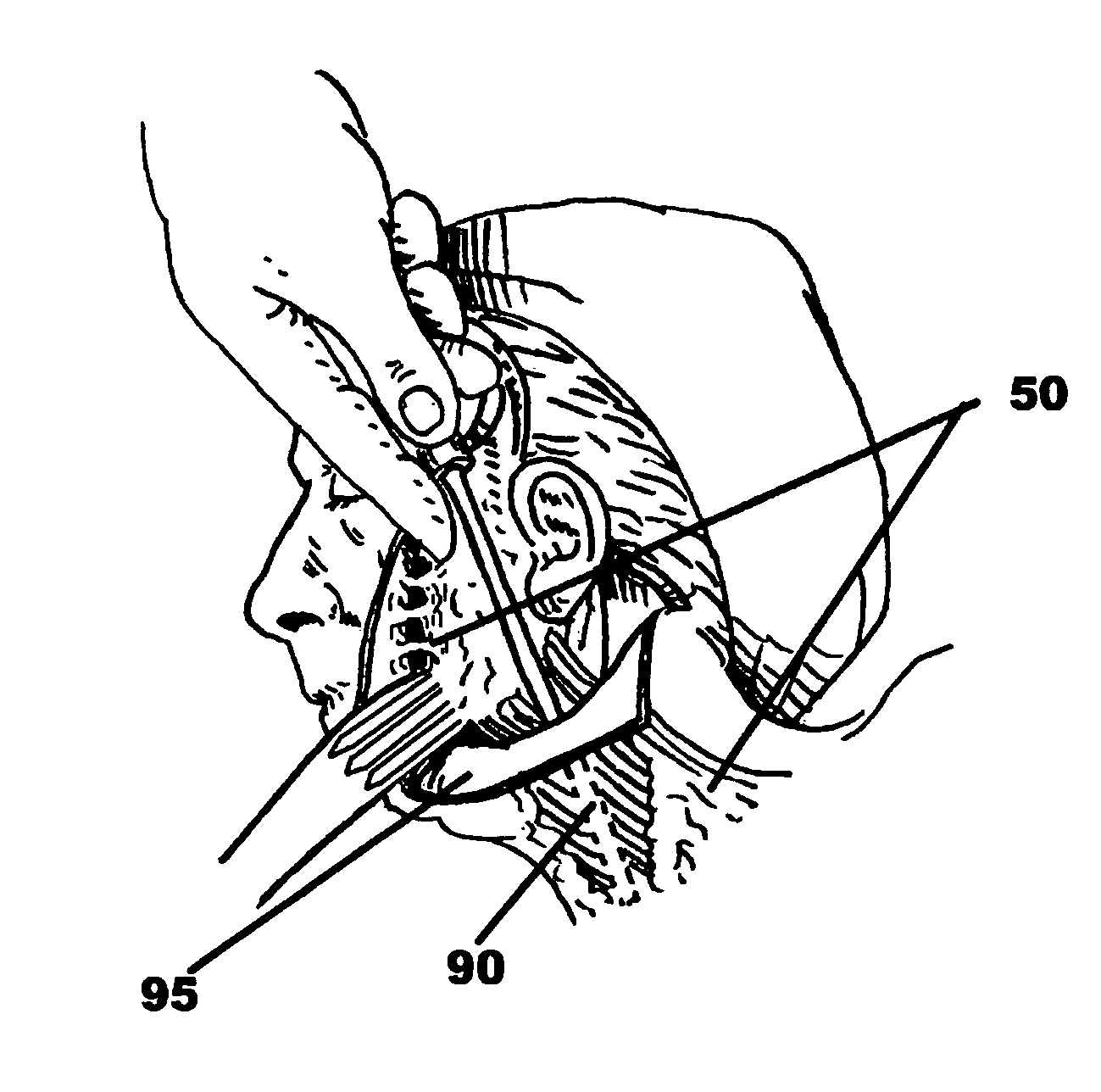

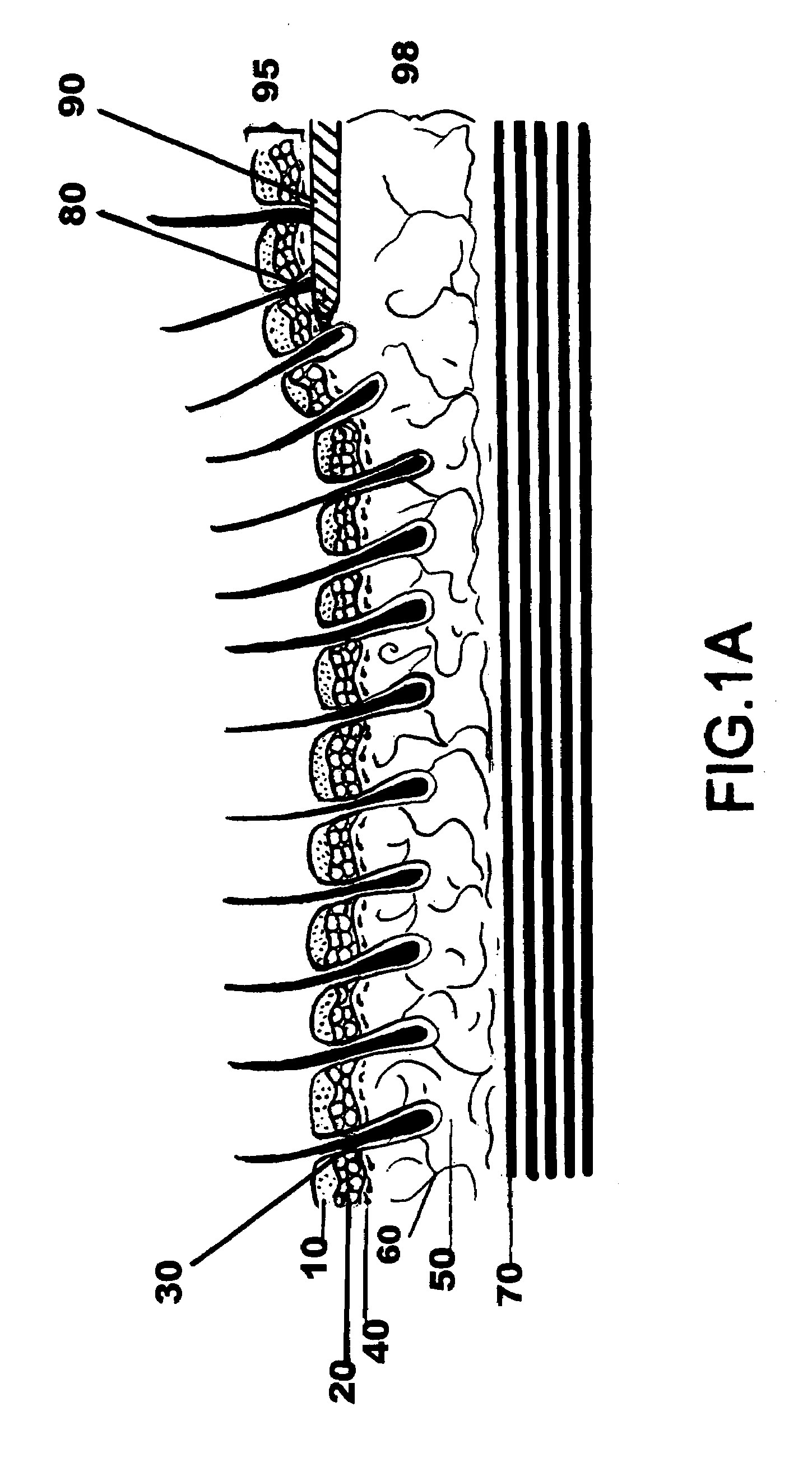

Facial tissue strengthening and tightening device and methods

InactiveUS7494488B2Improve efficacyImprove securityUltrasound therapyElectrotherapyForms of energyFacial tissue

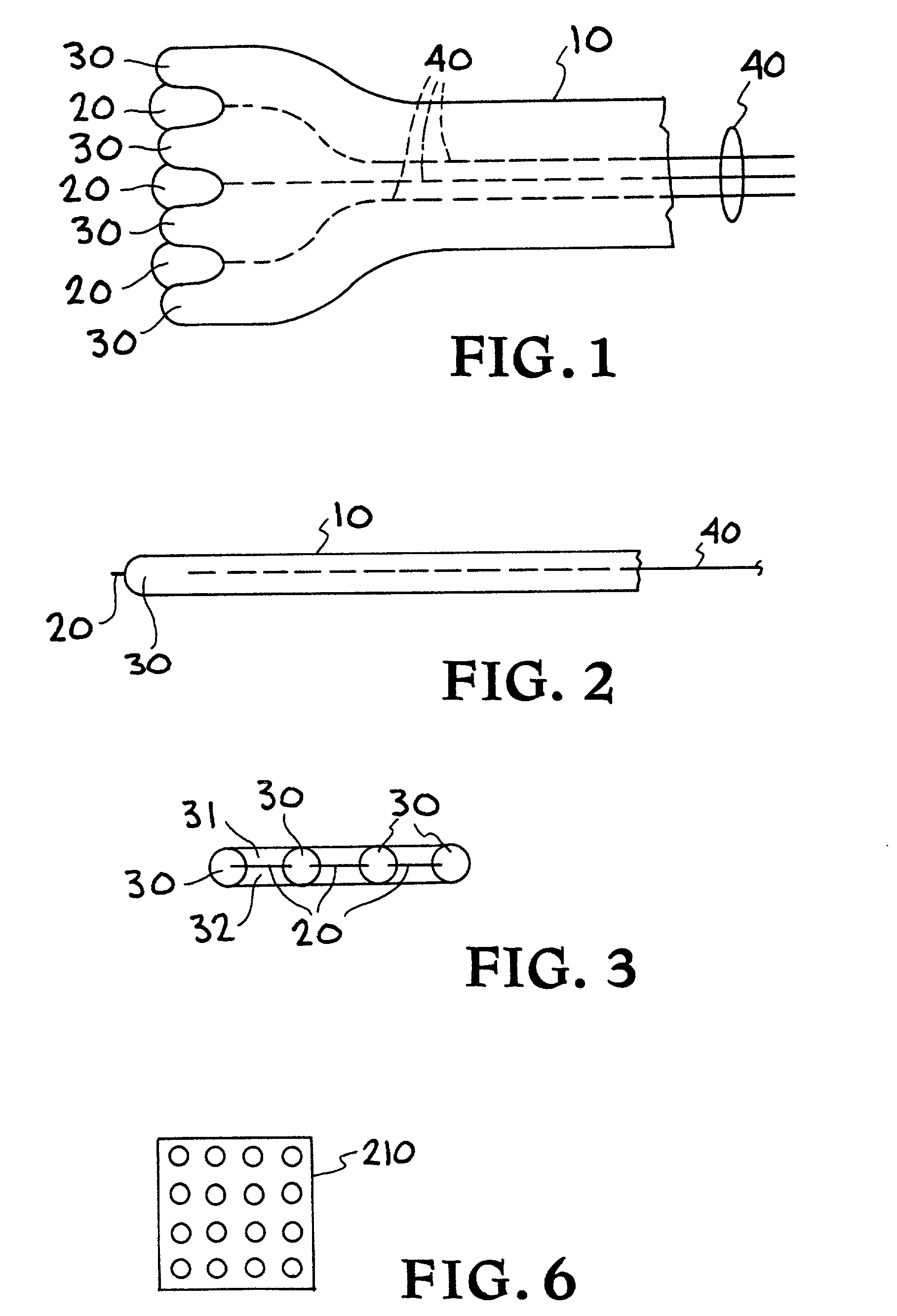

A device is described that can be used quickly and accurately by surgeons to provide uniform facial tissue planes that are tunnel-free and wall-free thus optimizing face lifting, tightening, and implant delivery. The device is comprised of a shaft with a substantially planar tip further comprised of relative protrusions and energized relative recession lysing segments. Forward motion of the device precisely divides and energizes various tissue planes causing contraction, especially via the fibrous tissues. Other forms of energy and matter can be delivered down the shaft to further enhance desirable tissue modification and contraction.

Owner:WEBER PAUL J

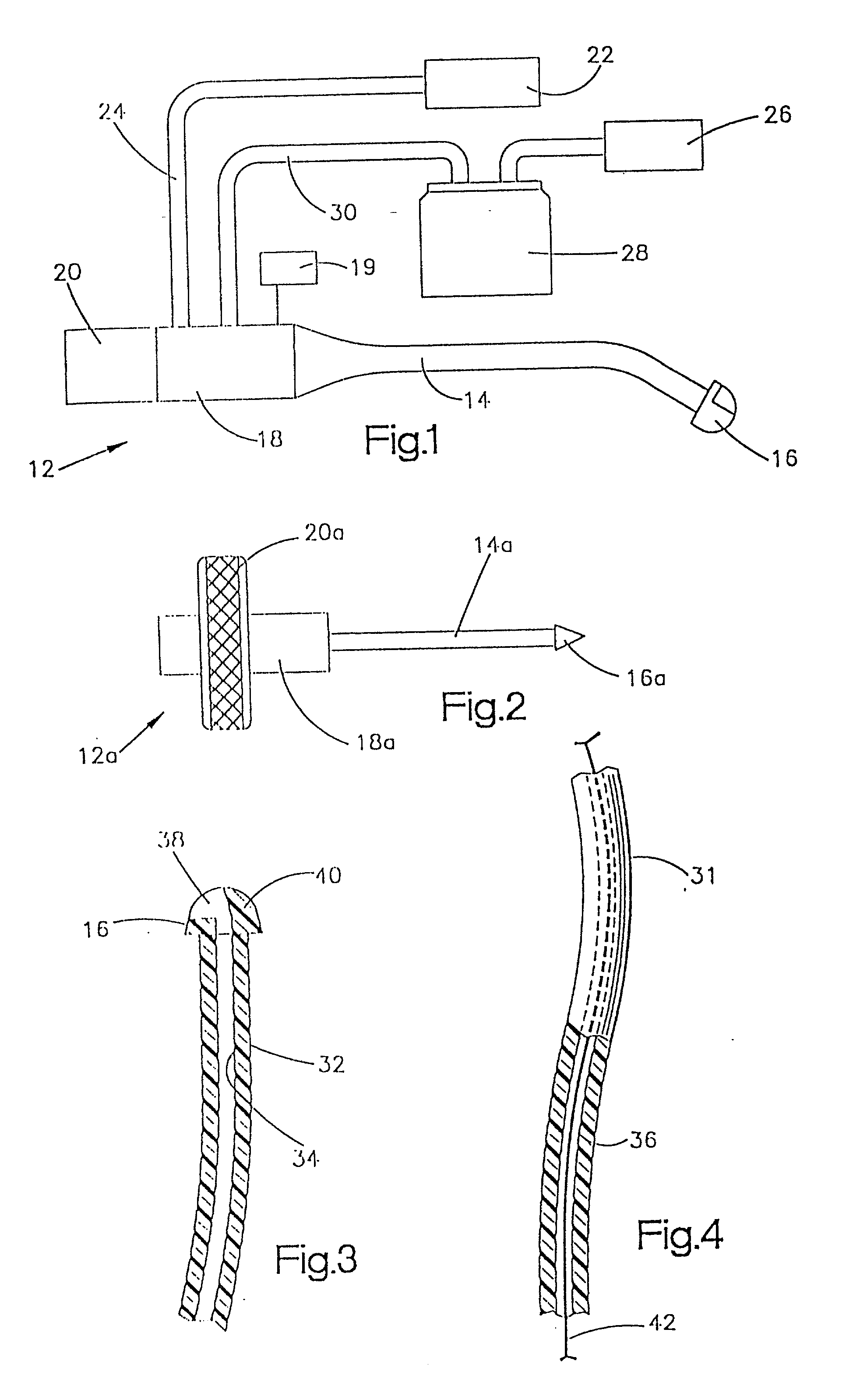

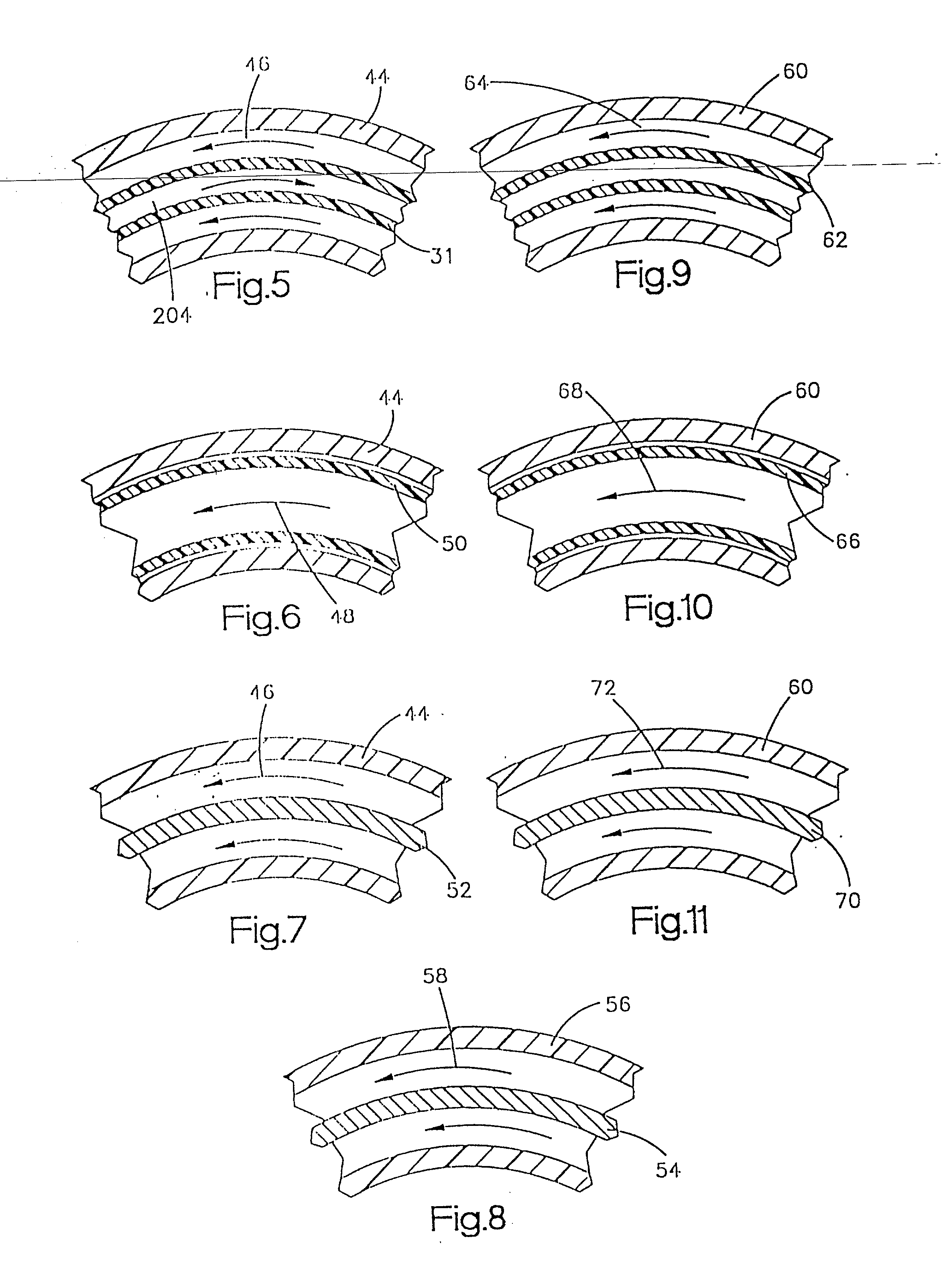

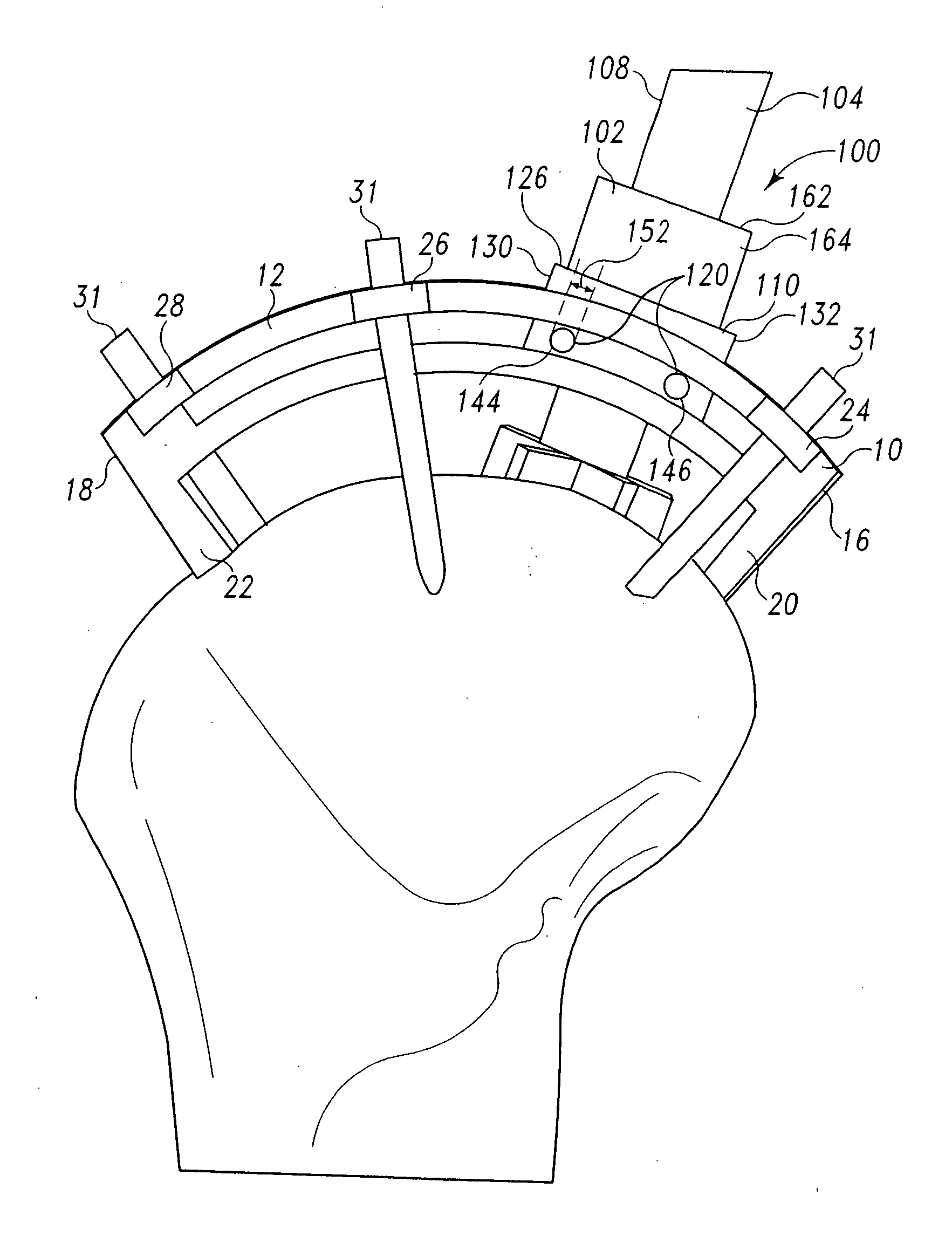

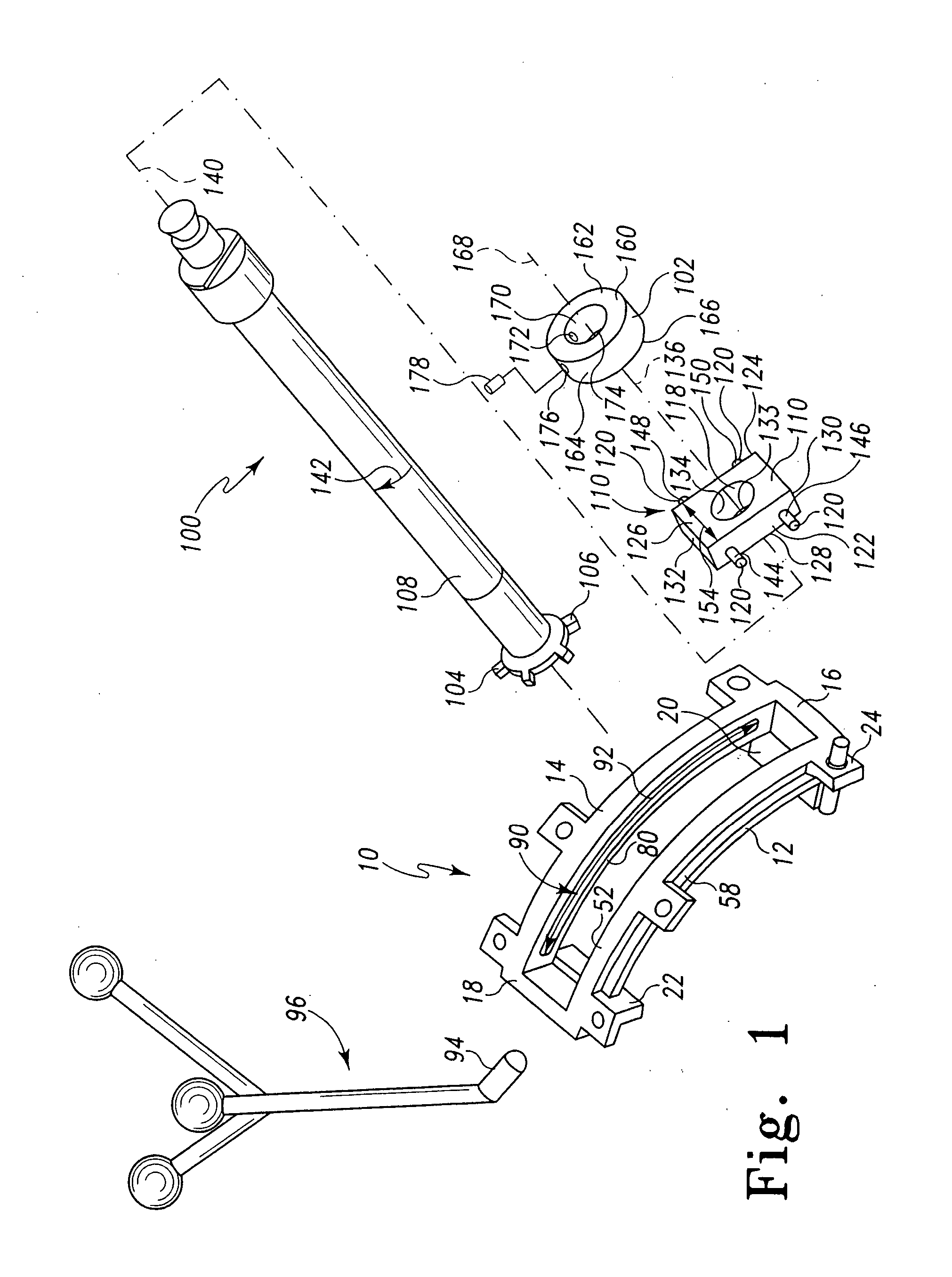

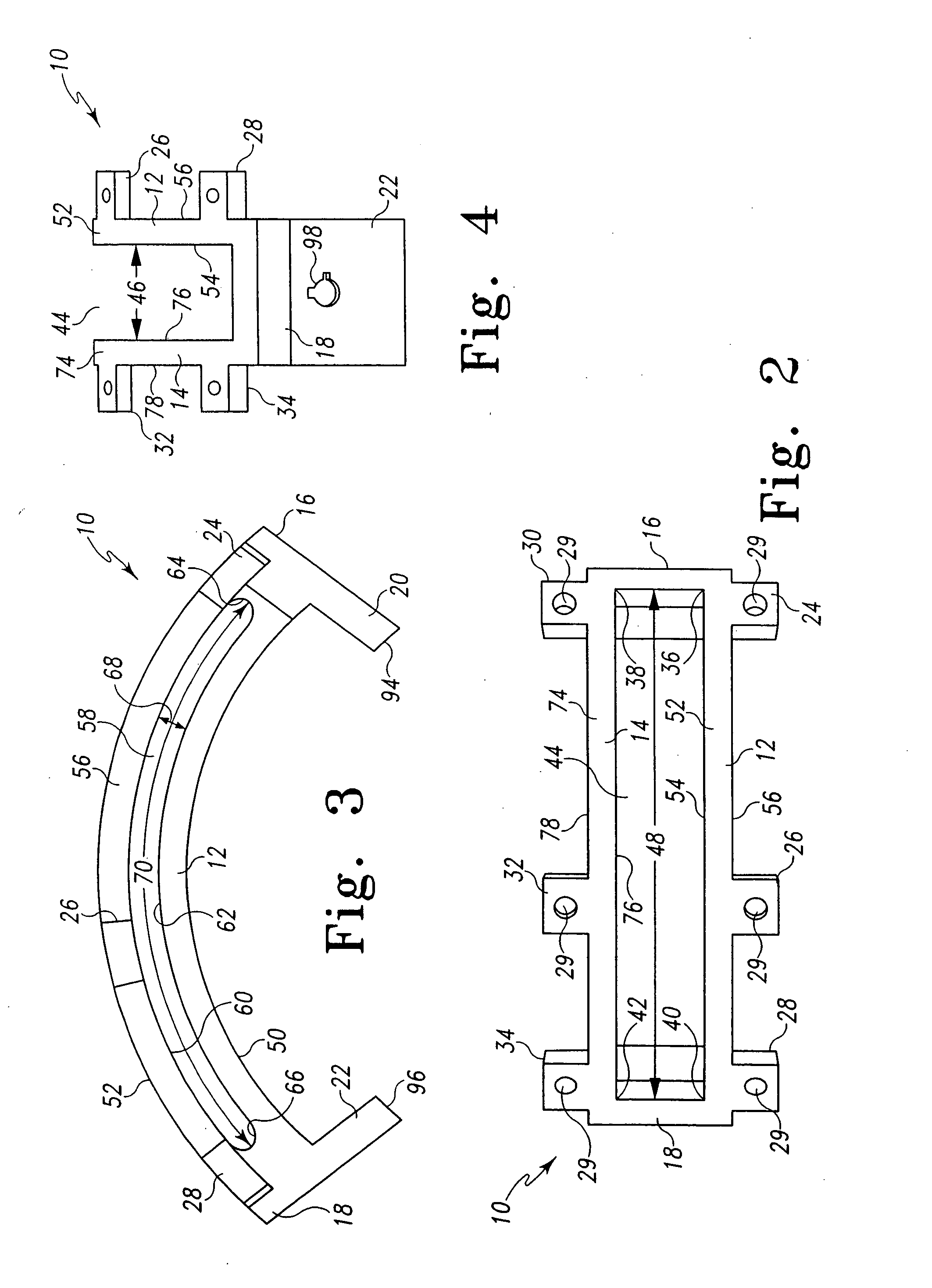

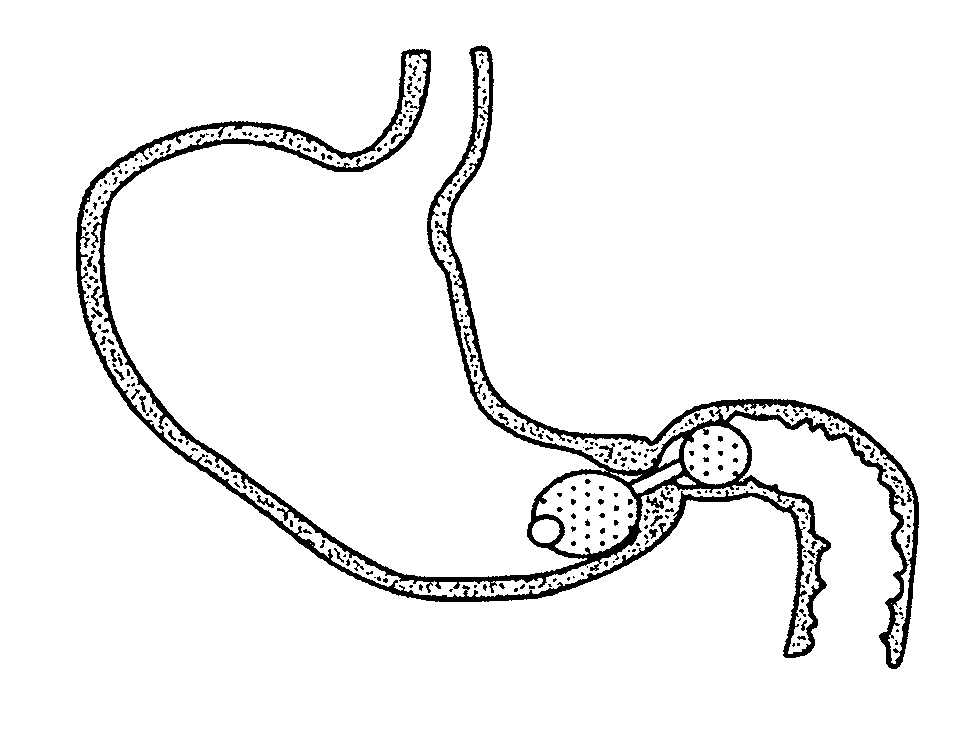

Bone shaping instrument and method for using the same

ActiveUS20060122616A1Small incisionGood functionNon-surgical orthopedic devicesSurgical sawsBone shapeProsthesis

A bone resection tool for resecting an end of a bone along a surface having a curvature comprises a guide, a cutting tool and a track follower. The guide is configured to be removably attached in a fixed position to the end of the bone. The guide is configured to include a track exhibiting a curvature generally corresponding to the curvature of the surface to be resected in the bone. The cutting tool includes a cutting face. The track follower is configured to couple to the cutting tool and cooperate with the track to facilitate reciprocation of the cutting tool relative to the guide to induce the cutting face to resect the bone along the surface having the curvature. A method for cutting a bone along a curved surface conforming to the curvature of a curved surface of the underside of a prosthetic component comprises the steps of incising the tissue surrounding the surface of the bone, positioning a guide alongside the surface of a bone to be cut, affixing the guide to the bone, interconnecting a cutter having a cutting face with the guide, maintaining the cutting face generally parallel to the tangent of the curved surface and traversing the cutting face along the bone while guiding the cutter along the track. The tissue incision incises the tissue surrounding the surface of the bone to be cut in a minimally invasive fashion. The positioned guide includes a track configured to assimilate the curvature of the curved surface of the underside of the prosthetic component.

Owner:DEPUY PROD INC

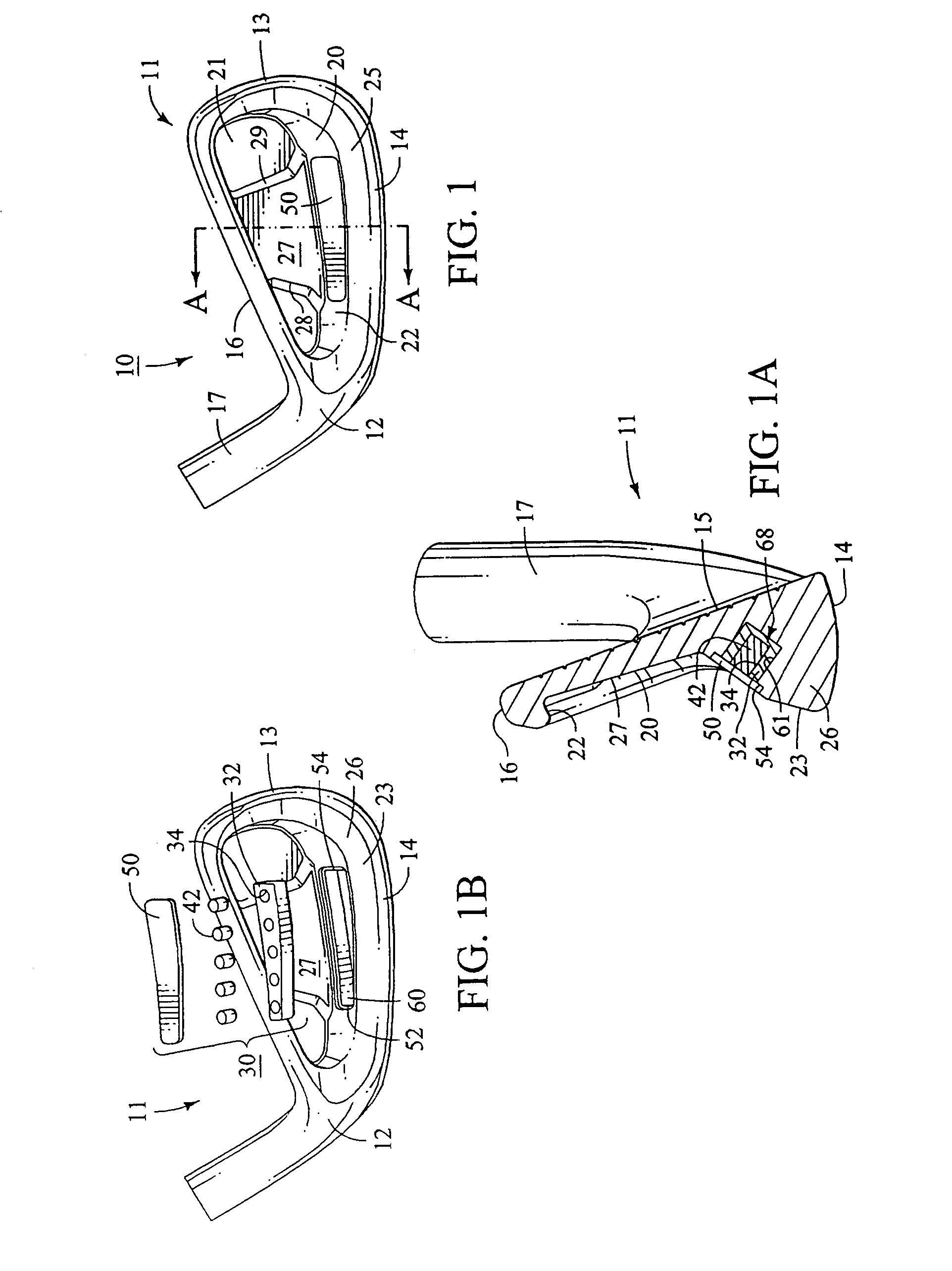

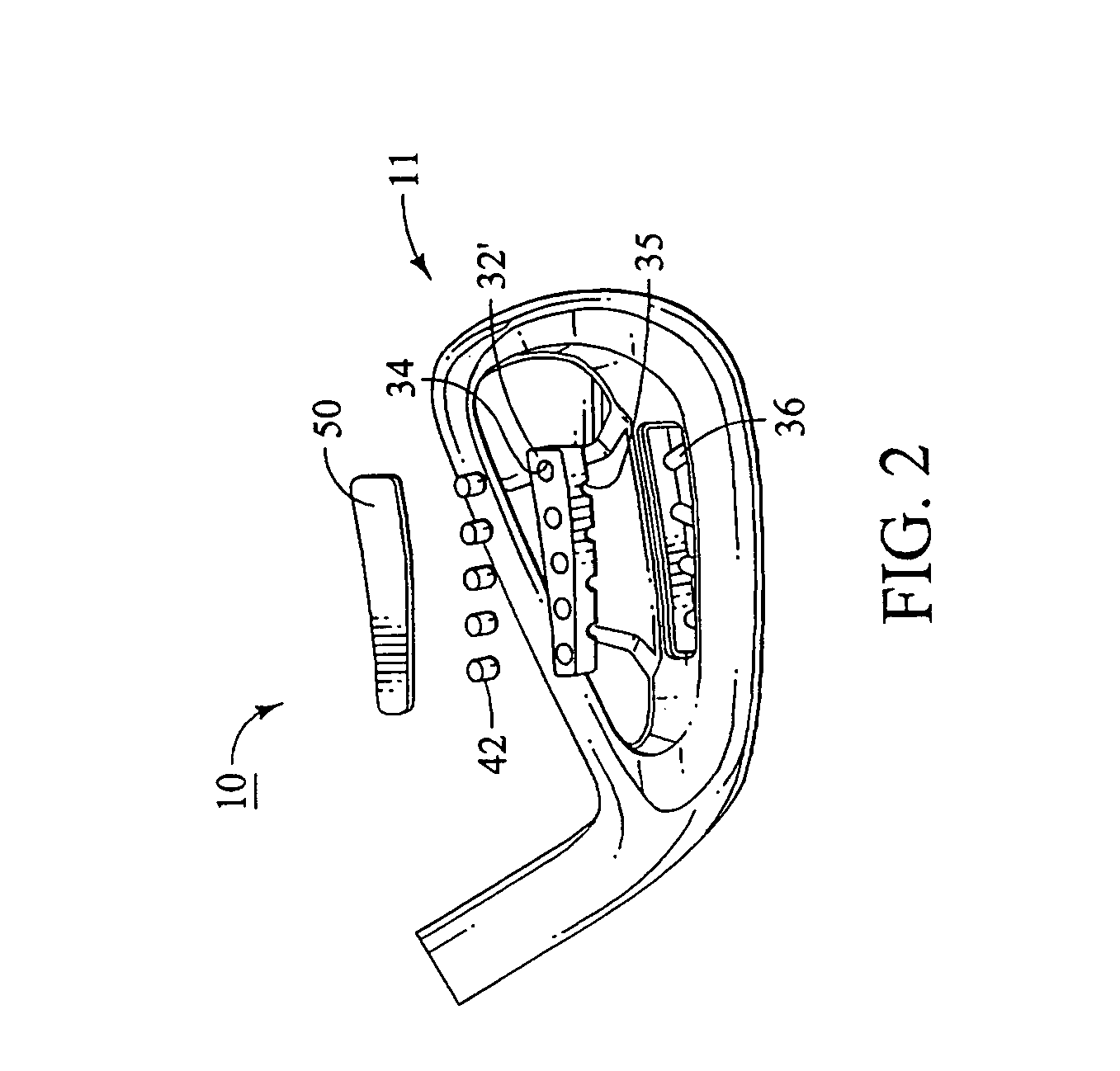

Tissue-lifting device

InactiveUS20020128648A1Quickly and safely separateEasy maintenanceUltrasound therapySurgical instruments for heatingForms of energyMedicine

A device is described that can be used by surgeons to provide accurate tissue-lifting and tightening maneuvers that uses minimal external incisions, enhances accuracy, reduces inadvertent consequences while speeding the procedure. The device is comprised of a shaft with a relatively planar but possibly lenticulate or even slightly curved tip that can divide and energize various tissue planes causing net contraction via the fibrous tissue modification. Various forms of energy can also be delivered to cause desirable tissue alterations.

Owner:WEBER PAUL J

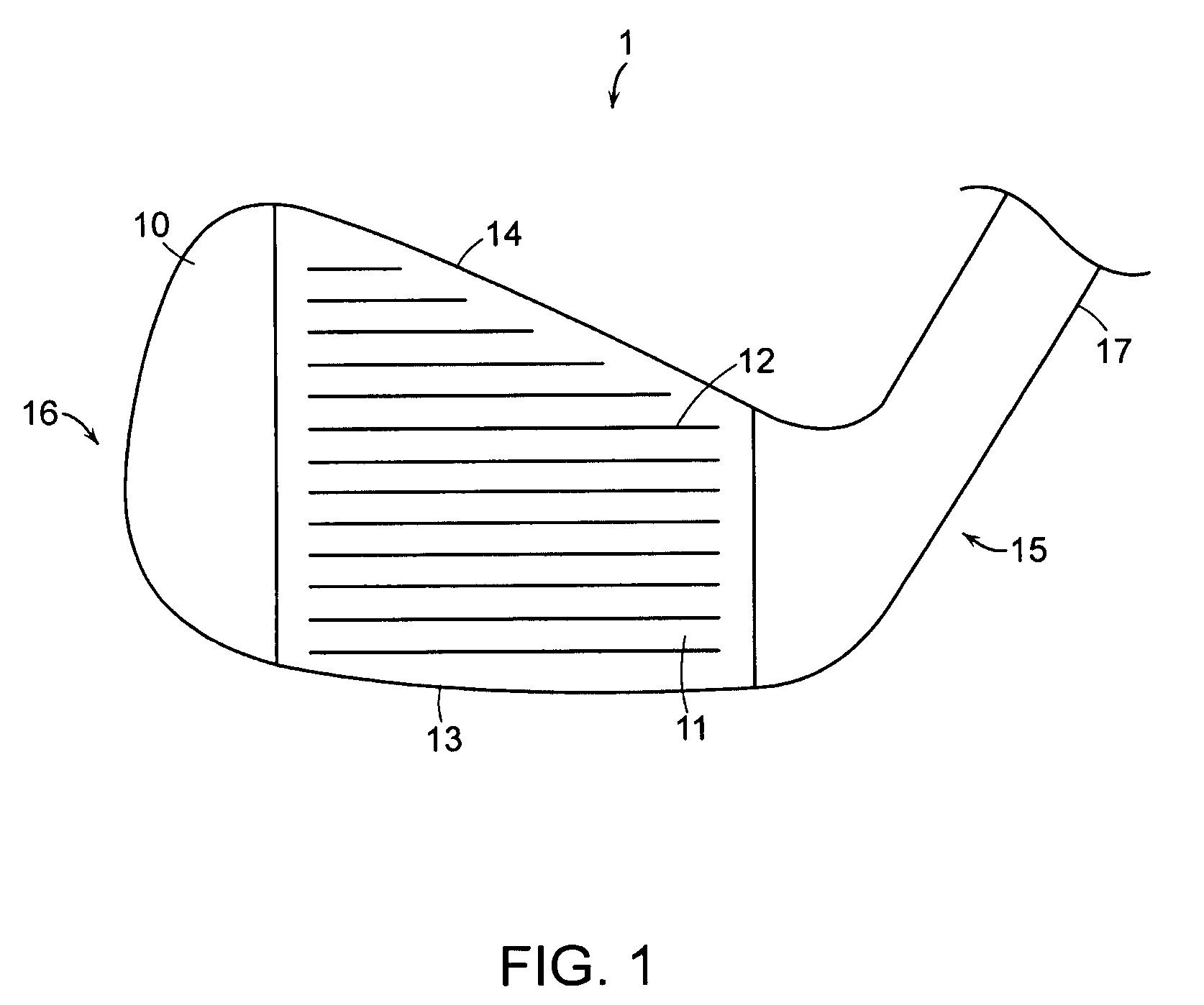

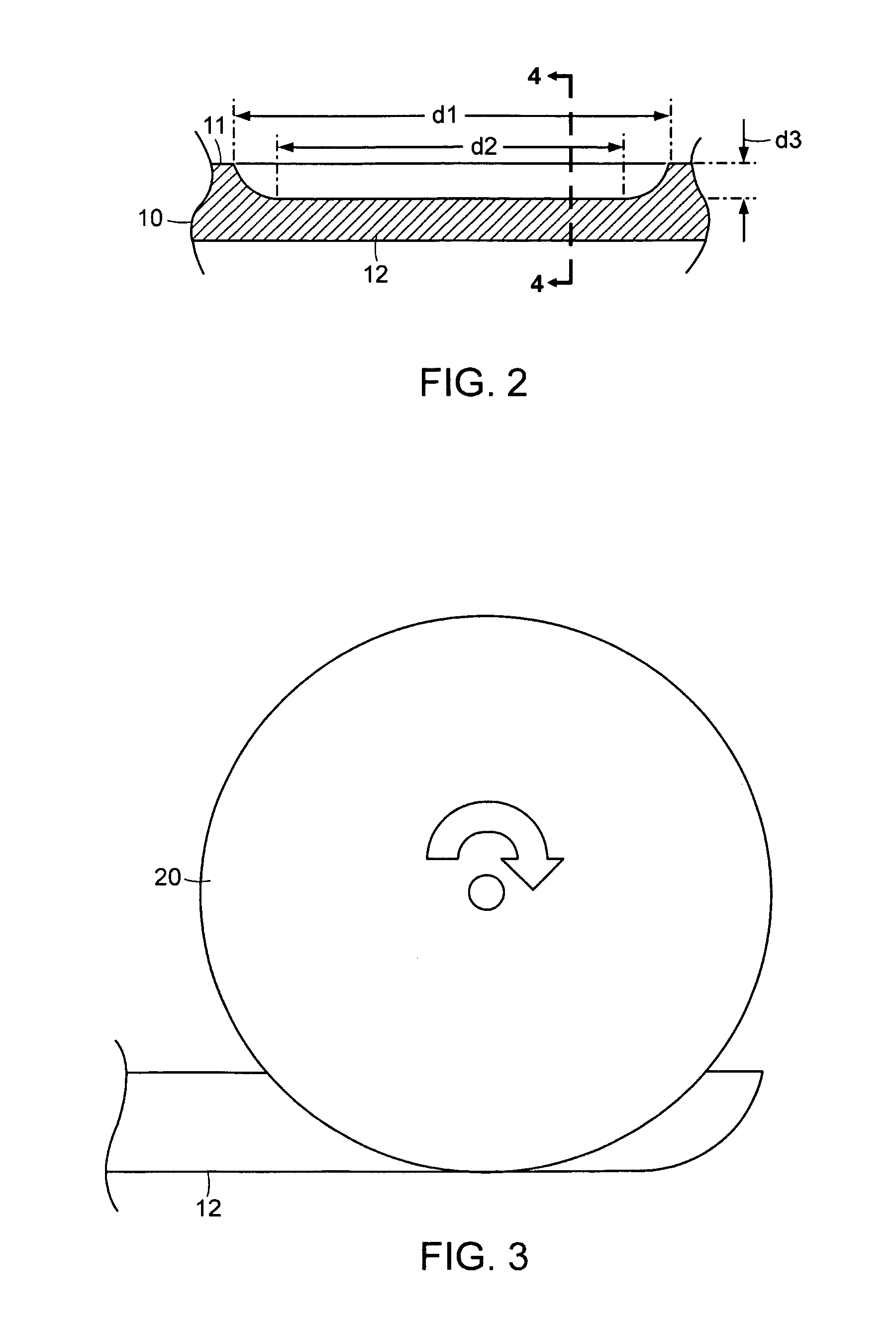

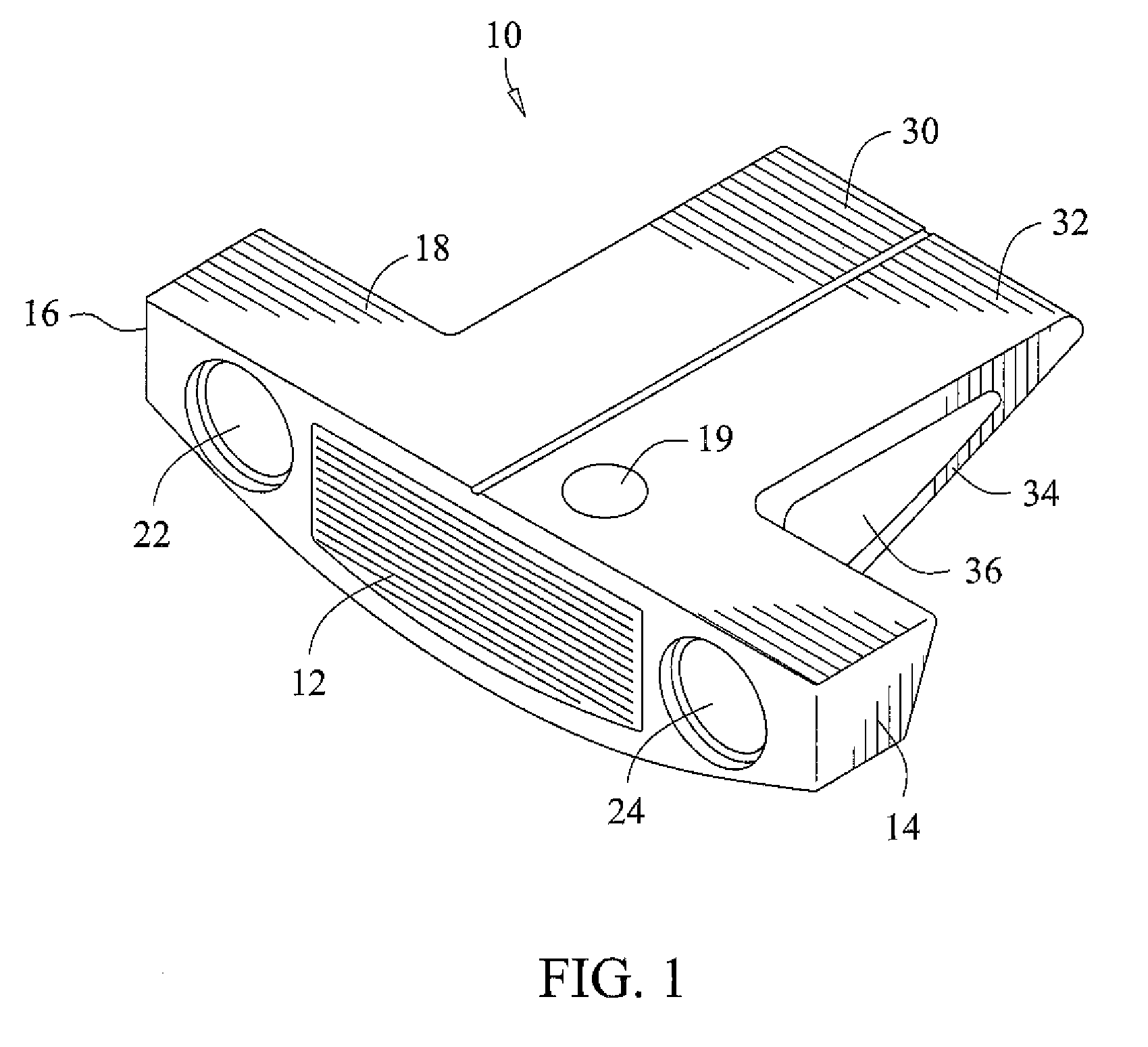

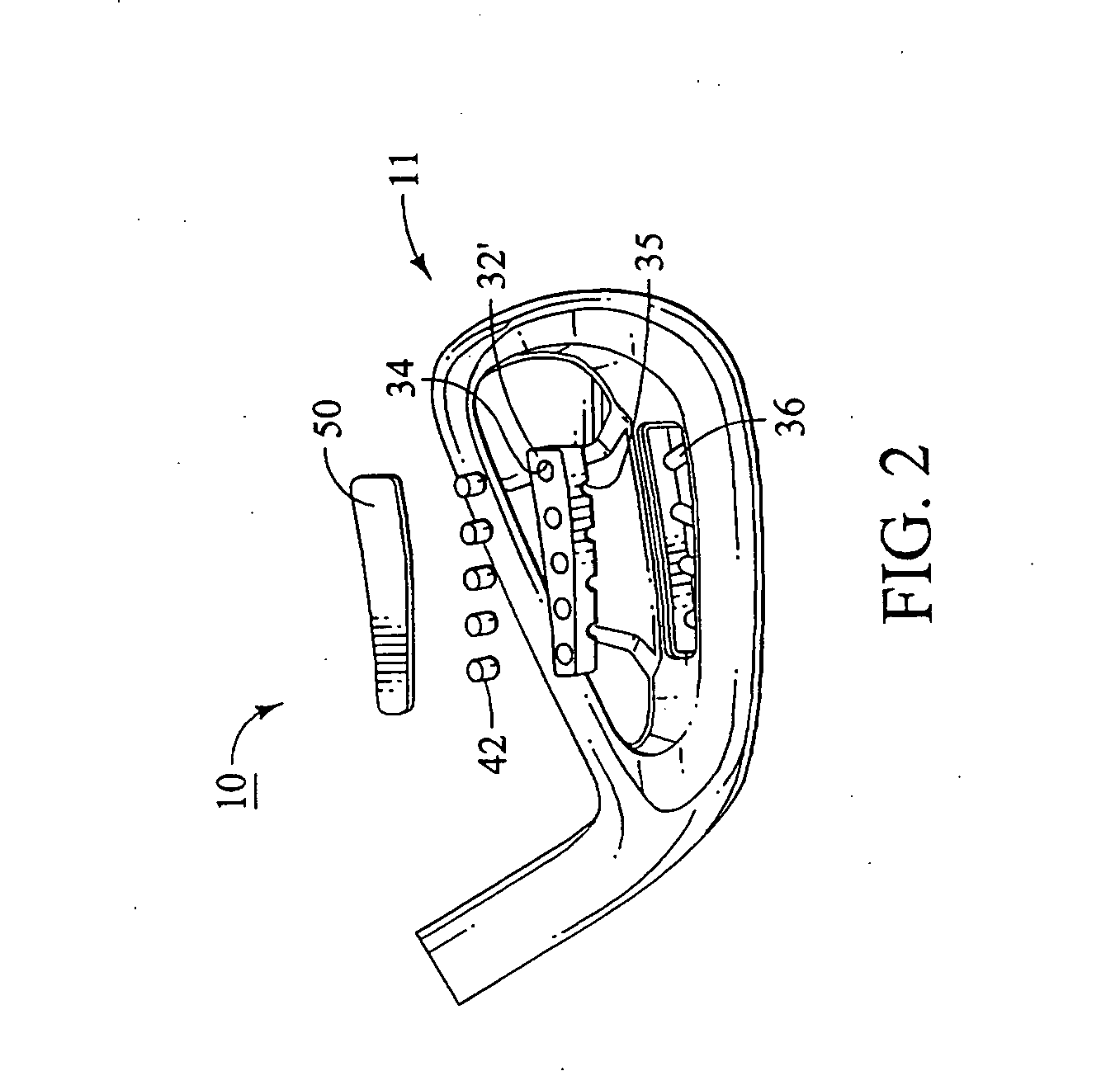

Golf club head

InactiveUS7083530B2Feel goodReduce stiffnessThermal switch detailsGolf clubsGolf BallBiomedical engineering

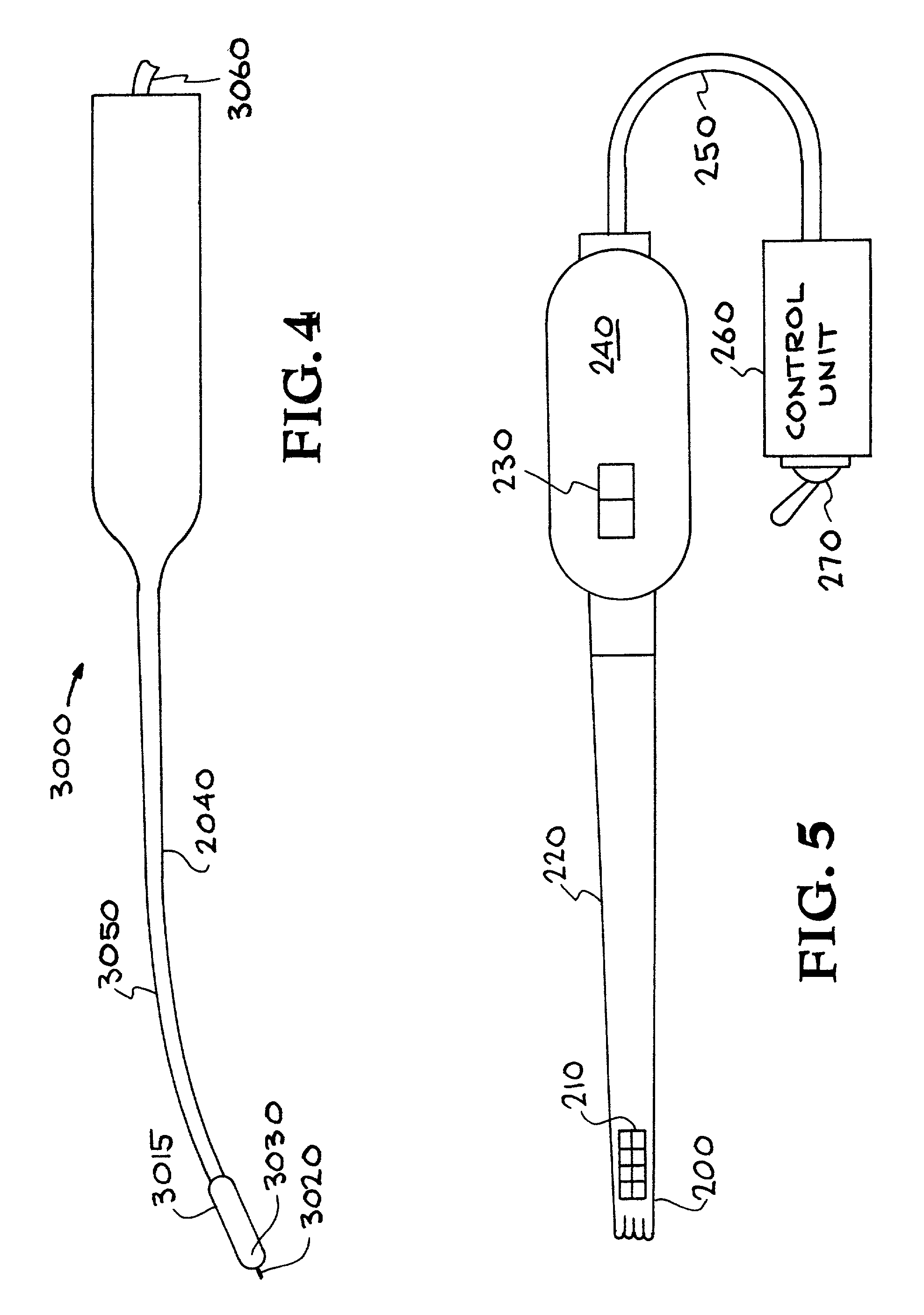

An iron-type golf club head is disclosed that comprises a striking face, a heel, a toe and a sole bar, wherein a recess is formed in the sole bar. A cartridge comprised of a first material at least partially disposed the sole recess, and at least one pin, comprised of a second material coupled to the cartridge. The first material has a modulus of elasticity that are less than that of the second material.

Owner:TAYLOR MADE GOLF

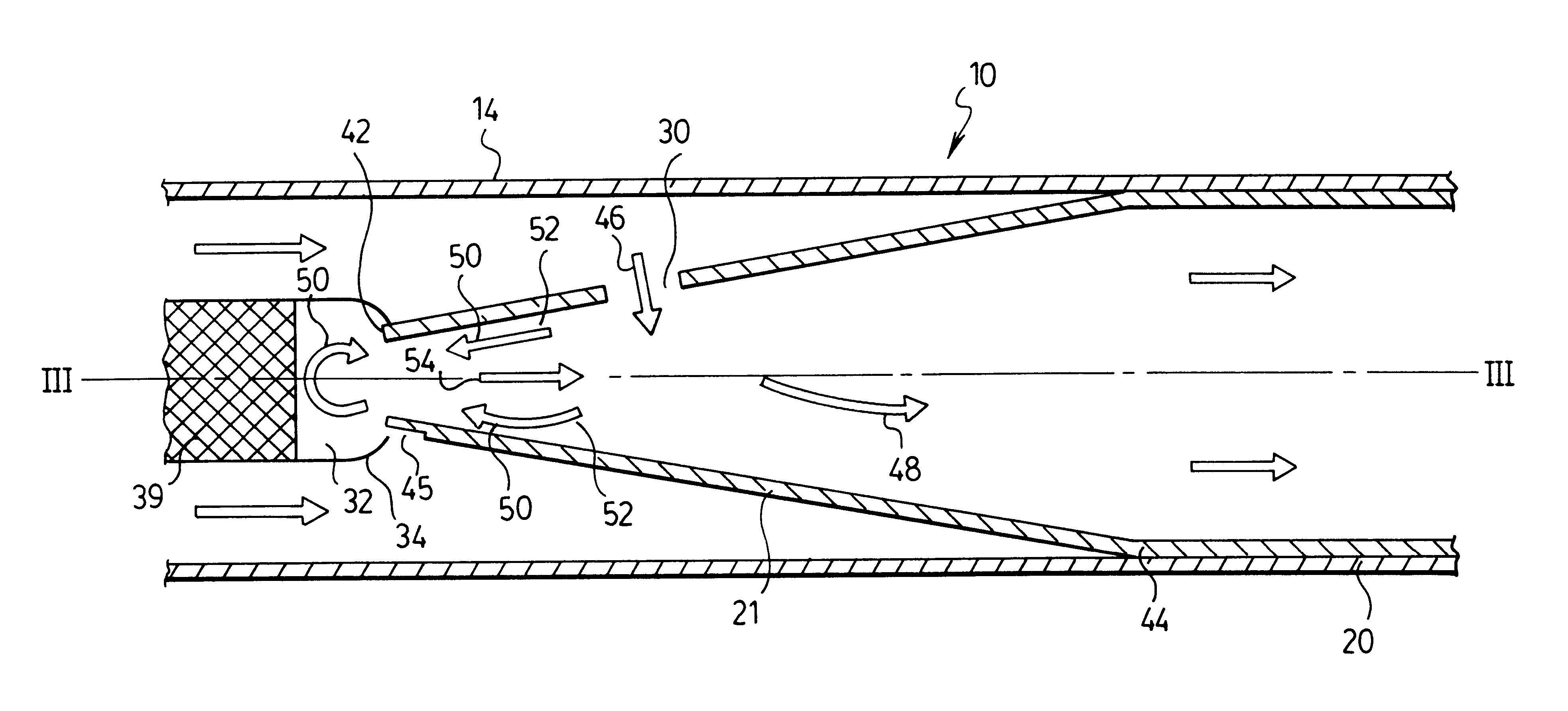

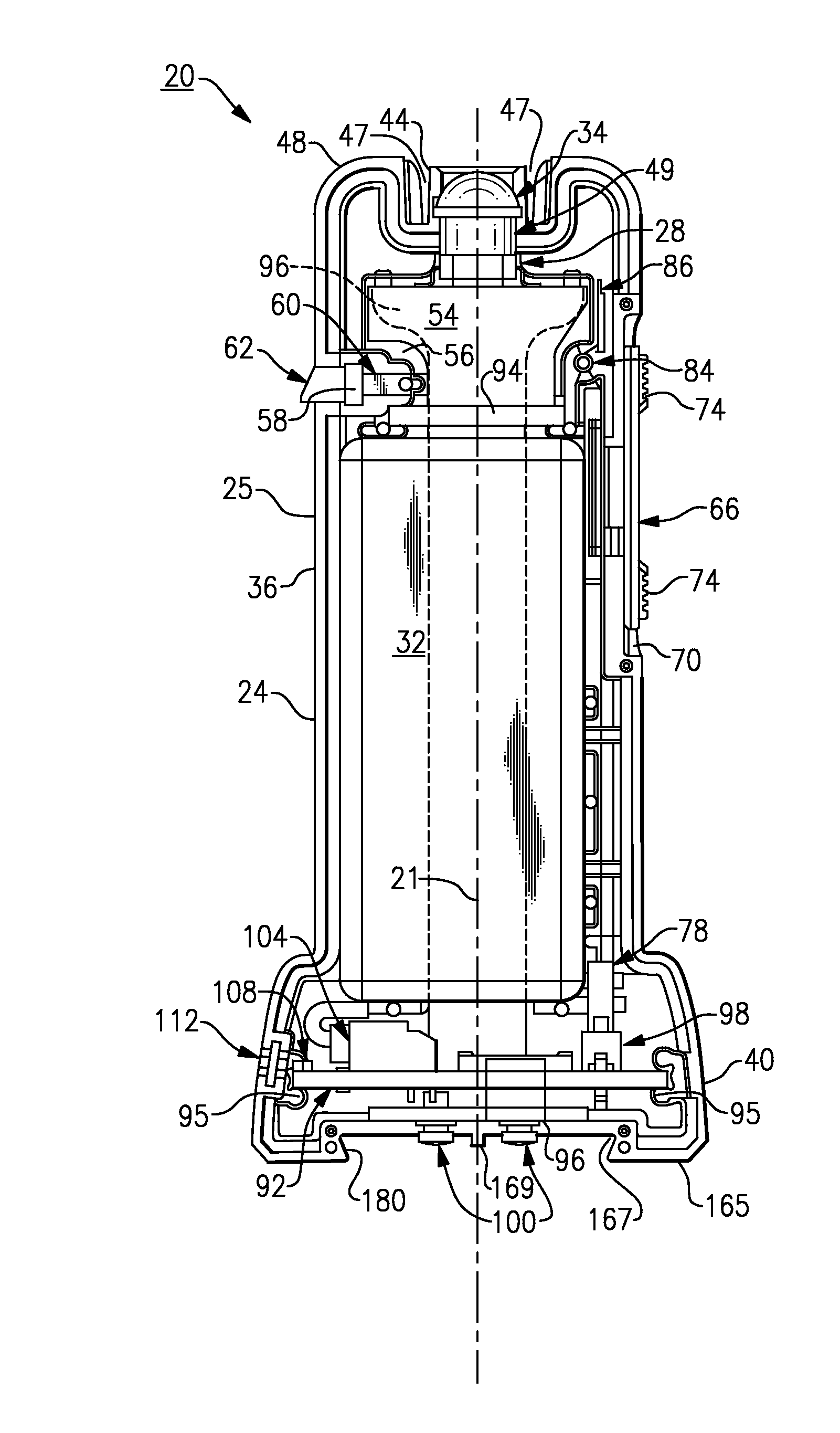

Inhaler

InactiveUS6234169B1Reduce negative impactHigh simulationRespiratorsLiquid surface applicatorsParticulatesInhalation

An inhaler for use by an individual to inhale a particulate medicament from a reservoir comprises a chamber having a first end connectable to the reservoir to be in air flow communication therewith, a second end for delivering the medicament to the individual upon inhalation and a conduit defining an air flow path extending between the first end and the second end; and, an orifice in the chamber between the first end and the second end, the orifice utilizing the Coanda Effect when the reservoir is in air flow communication with the chamber and upon inhalation by the individual to draw medicament from the reservoir into the air flow path.

Owner:SANSA BARBADOS

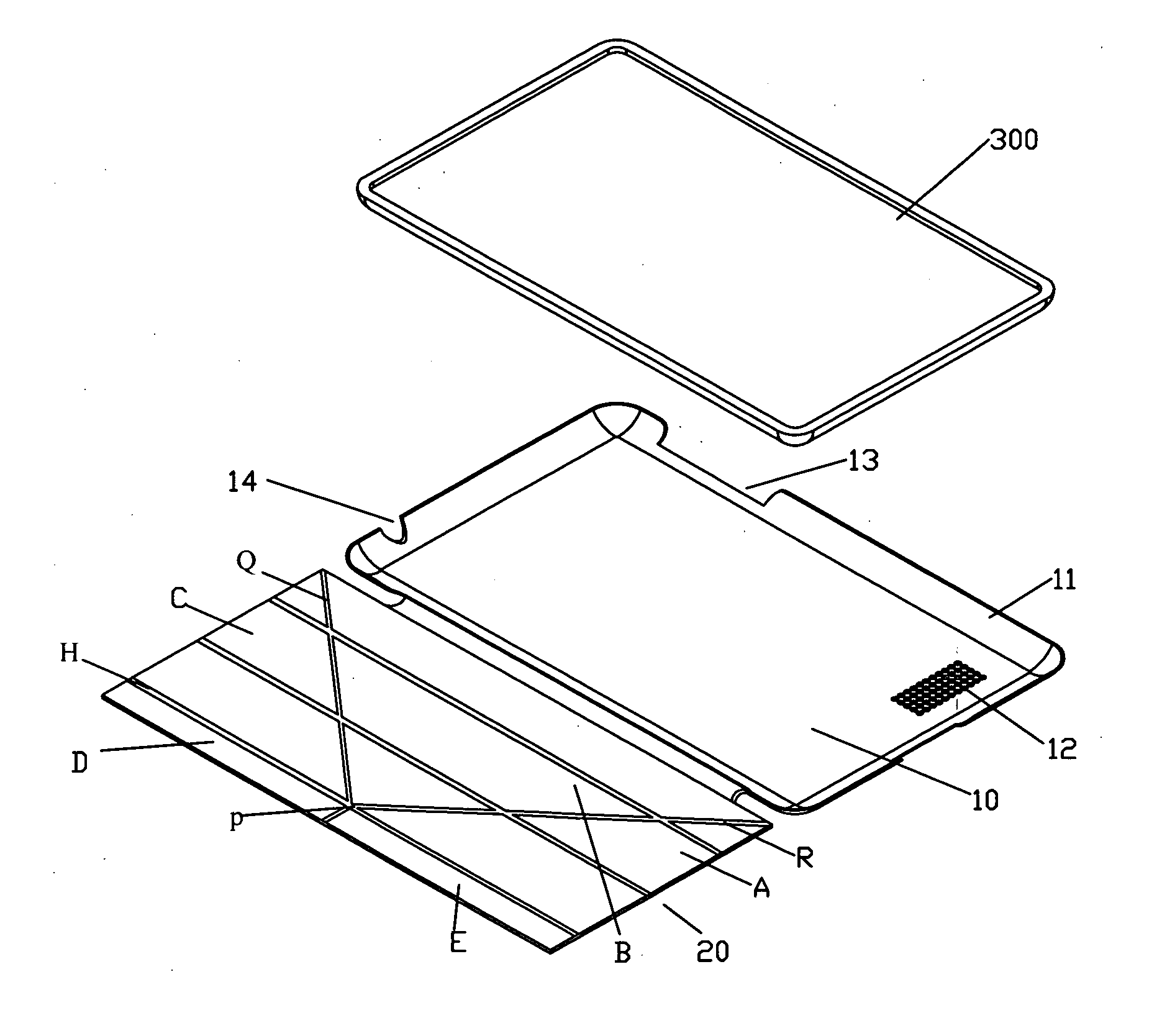

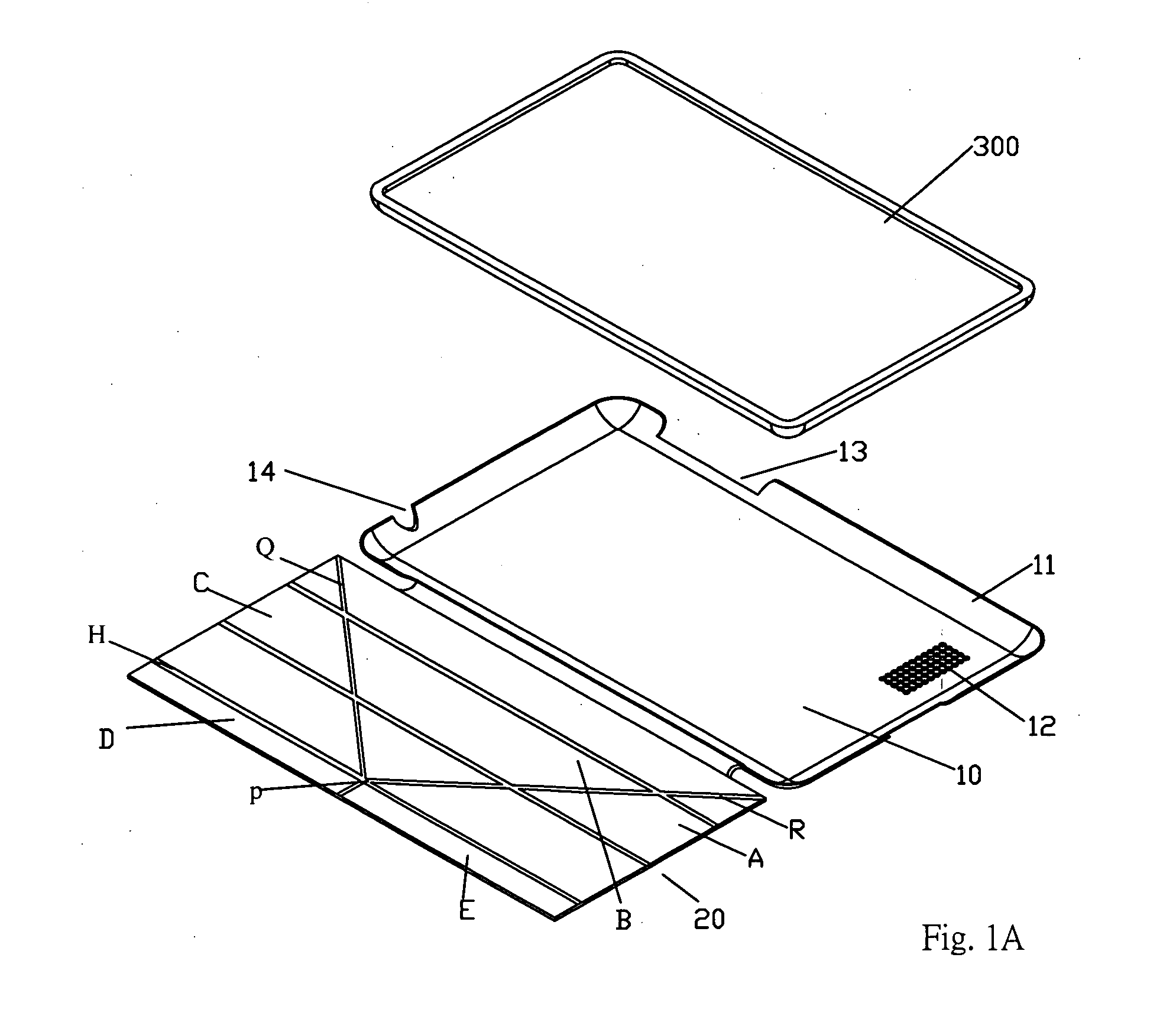

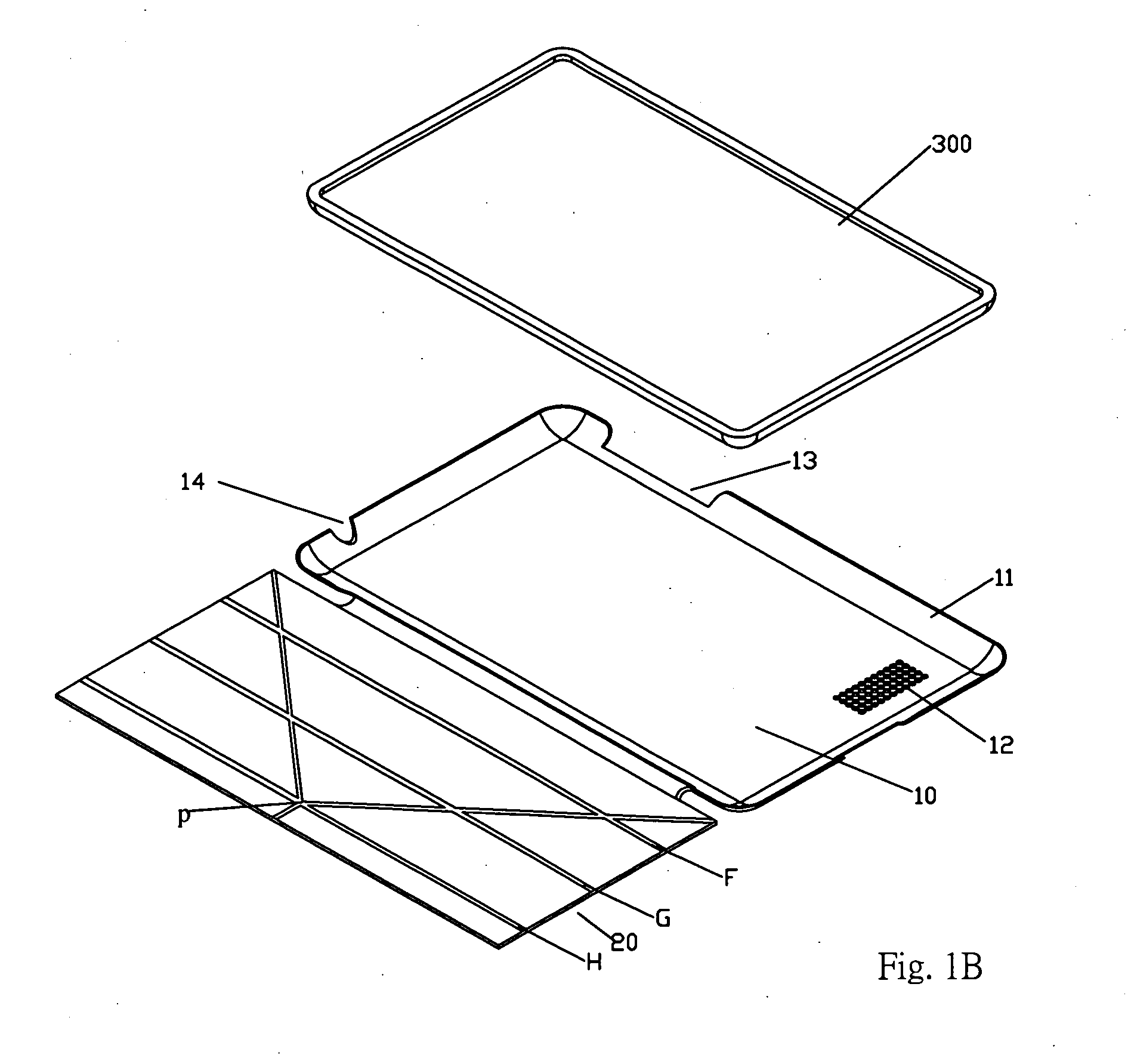

Tablet computer receiving housing with supporting function

InactiveUS20130020216A1Function increaseFeel goodDigital data processing detailsOther accessoriesEngineeringElectrical and Electronics engineering

A tablet computer receiving housing with supporting function includes a lower casing for protecting a tablet computer; an upper cover rotatably connected to the lower casing for protecting the screen of the tablet computer from damage; the lower casing being formed with a plurality of sections so that the upper cover can be folded along weak connection areas between different sections; the weak connection area forming as first folding lines which are not parallel to one another; wherein the upper cover is used as a cover and a supporter; the upper cover rotates along the lower casing; the lower casing is folded along the foldable lines so as to be formed as a supporter of the lower casing for supporting the tablet computer therein. Furthermore, the housing further has folding lines which are parallel to one another and transversally pass through a surface of the upper cover.

Owner:CHIOU SHIH HSUN

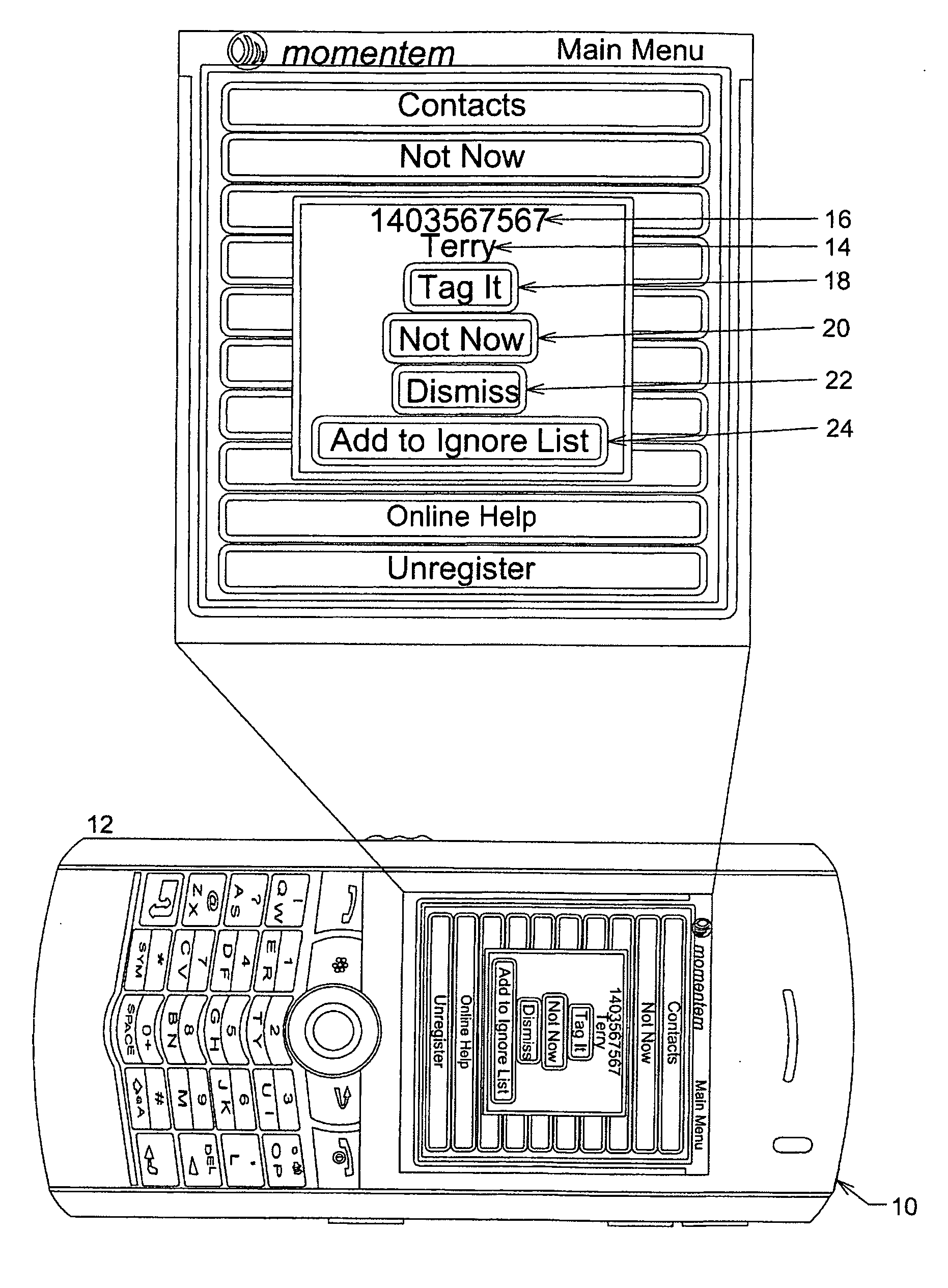

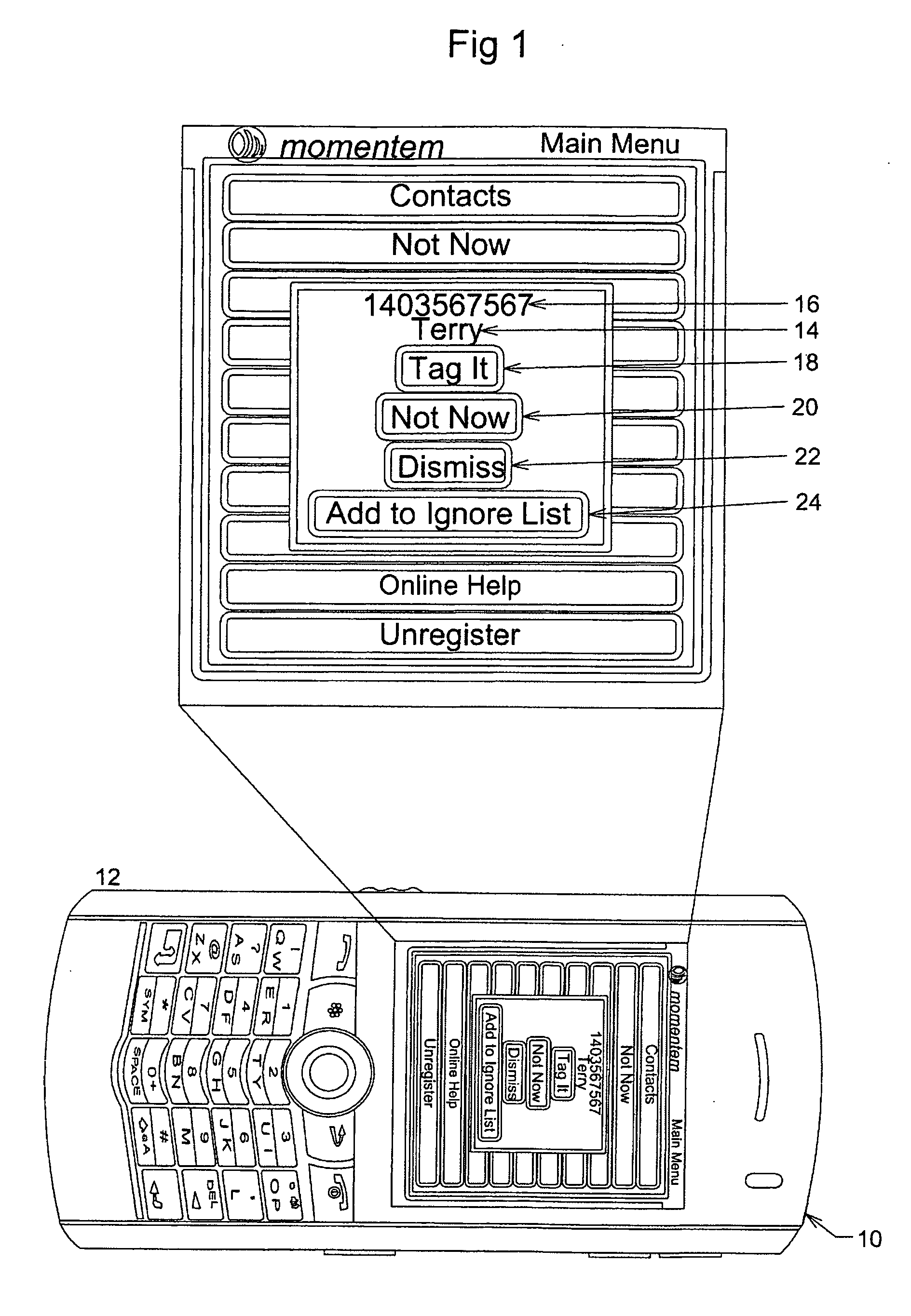

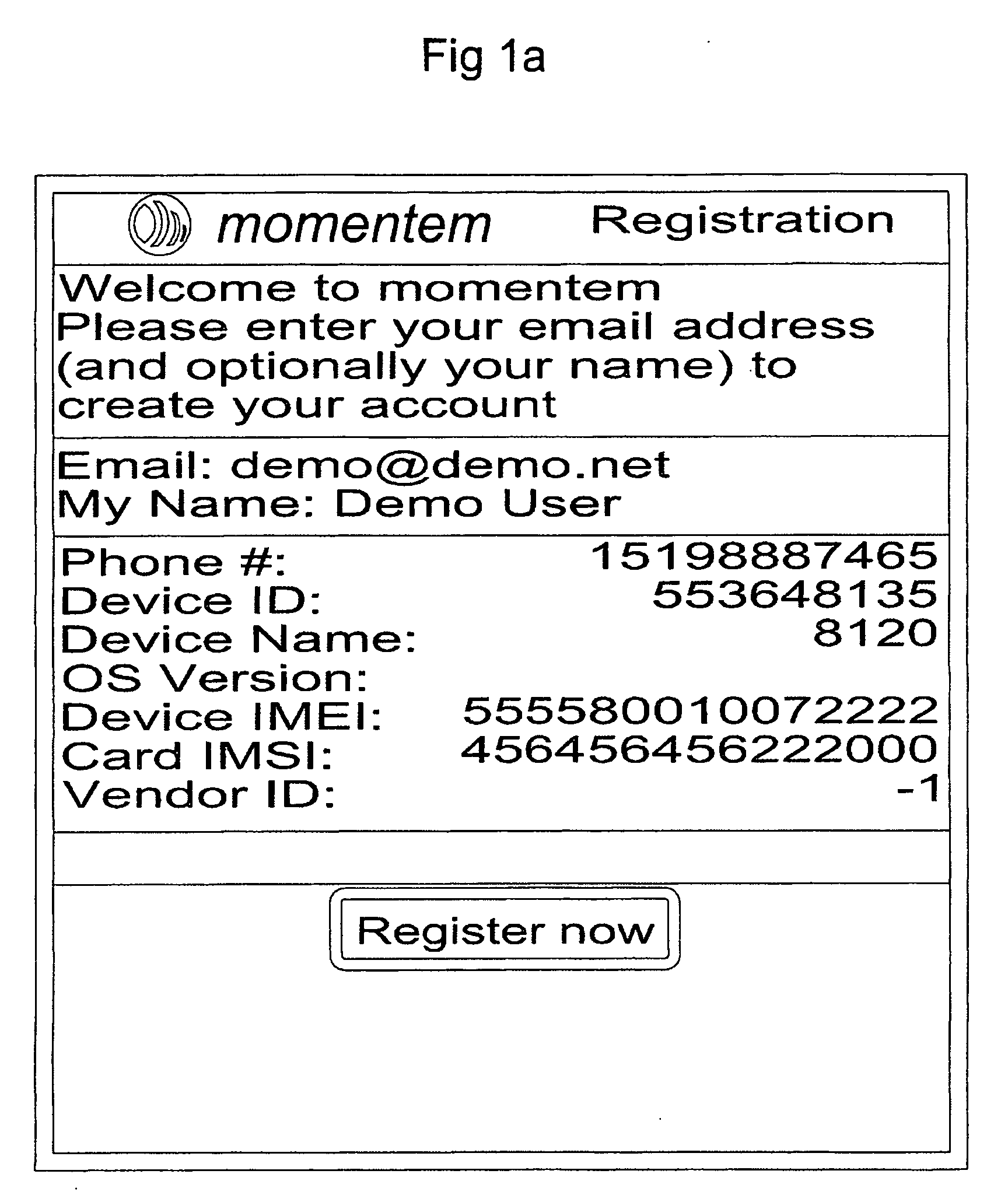

Method and apparatus for telecommunication expense management

ActiveUS20090291665A1Avoid over useSimple mannerMetering/charging/biilling arrangementsAccounting/billing servicesExpense managementManagement system

The user of a handheld wireless communicator, for example a cell phone or so-called smartphone completes a call or email or other communication event. The event is timed by the device or the duration is calculated, or otherwise the event is quantified and the information is stored in for example a log within the device. At the end of the communication event, the telecommunication expense management system provides a pop up user interface asking the user to decide whether to capture the communication event so as to assist in billing the event, to delay capturing the communication event to a future time, to dismiss the communication event as if it had not occurred, or to add the communication event to a list which is of personal interest to the user but which is not in the user's opinion billable or the costs not recoverable or otherwise of a business nature that requires capturing.

Owner:WMODE

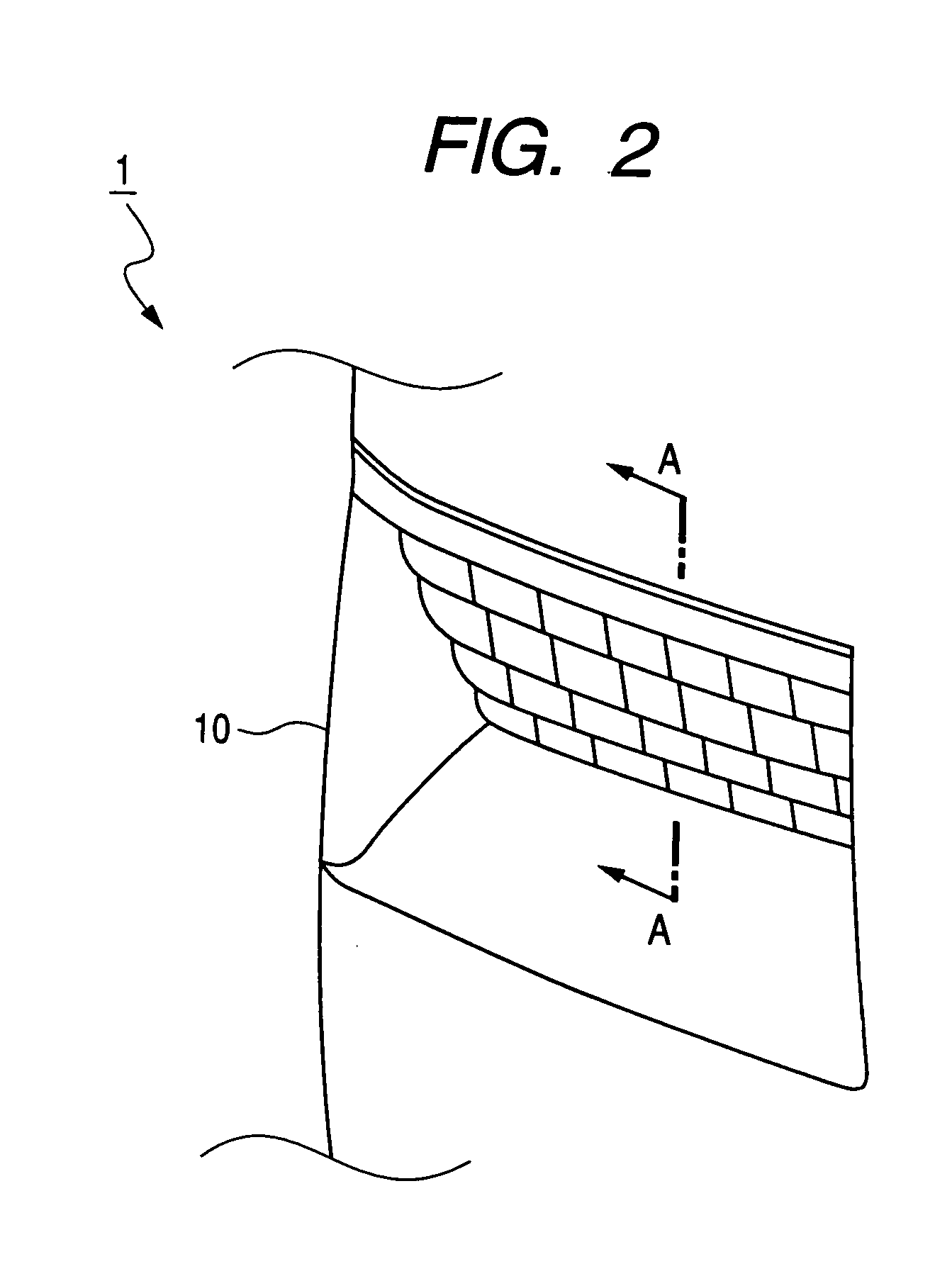

Golf club head

InactiveUS7594862B2Feel goodImprove wear resistanceGolf clubsRacket sportsMulti materialWear resistant

A golf club head having a multi-material face. The golf club head has a hard, wear resistant material as the ball-impacting face surface coupled to a softer material, allowing the multi-material face to be joined to a soft body material such that the body can be bent and customized. The multi-material face allows for improved playing characteristics by allowing the club designer to use a thinner face and lighter body material while still providing improved face wear resistance and durability.

Owner:ACUSHNET CO

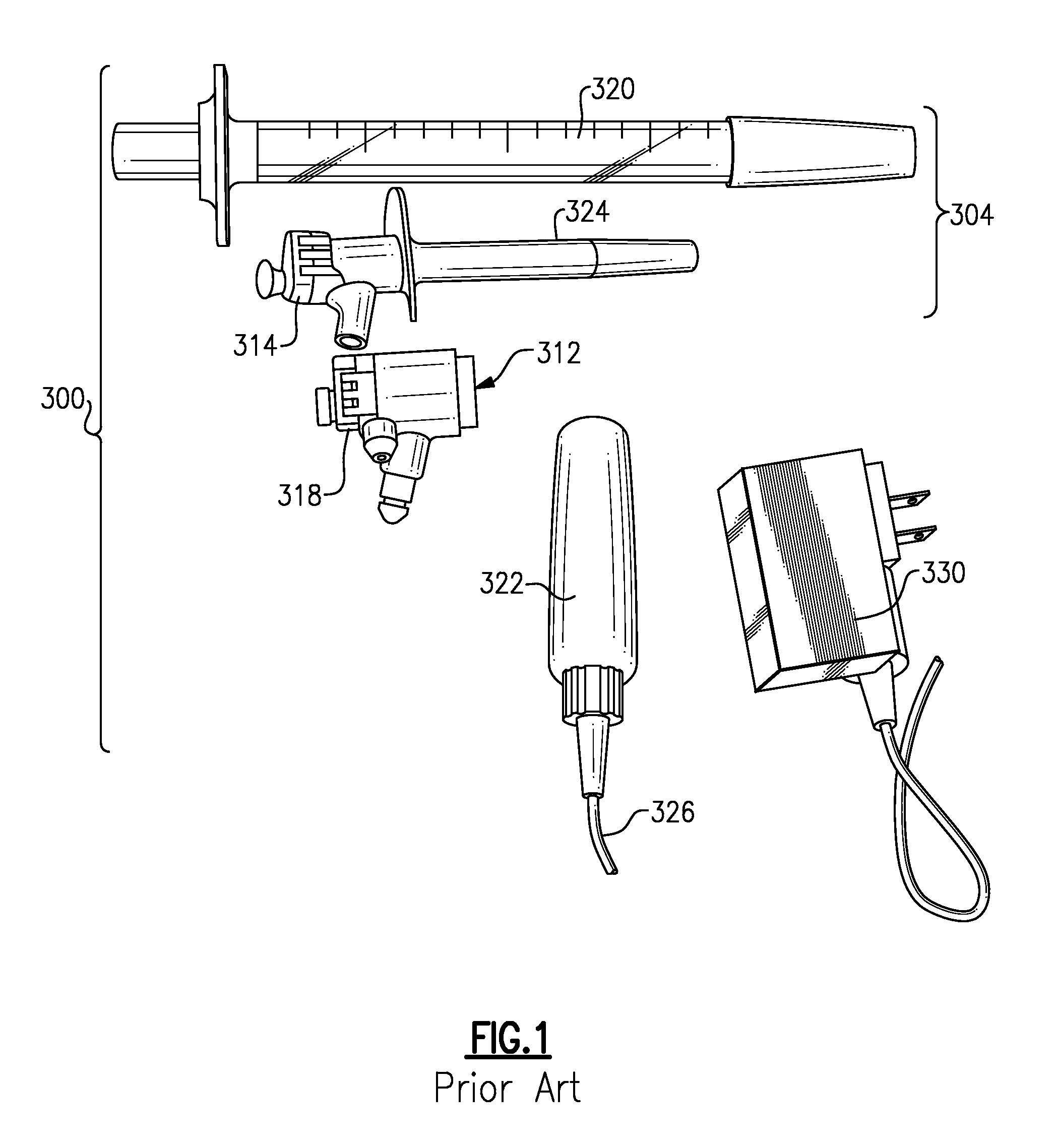

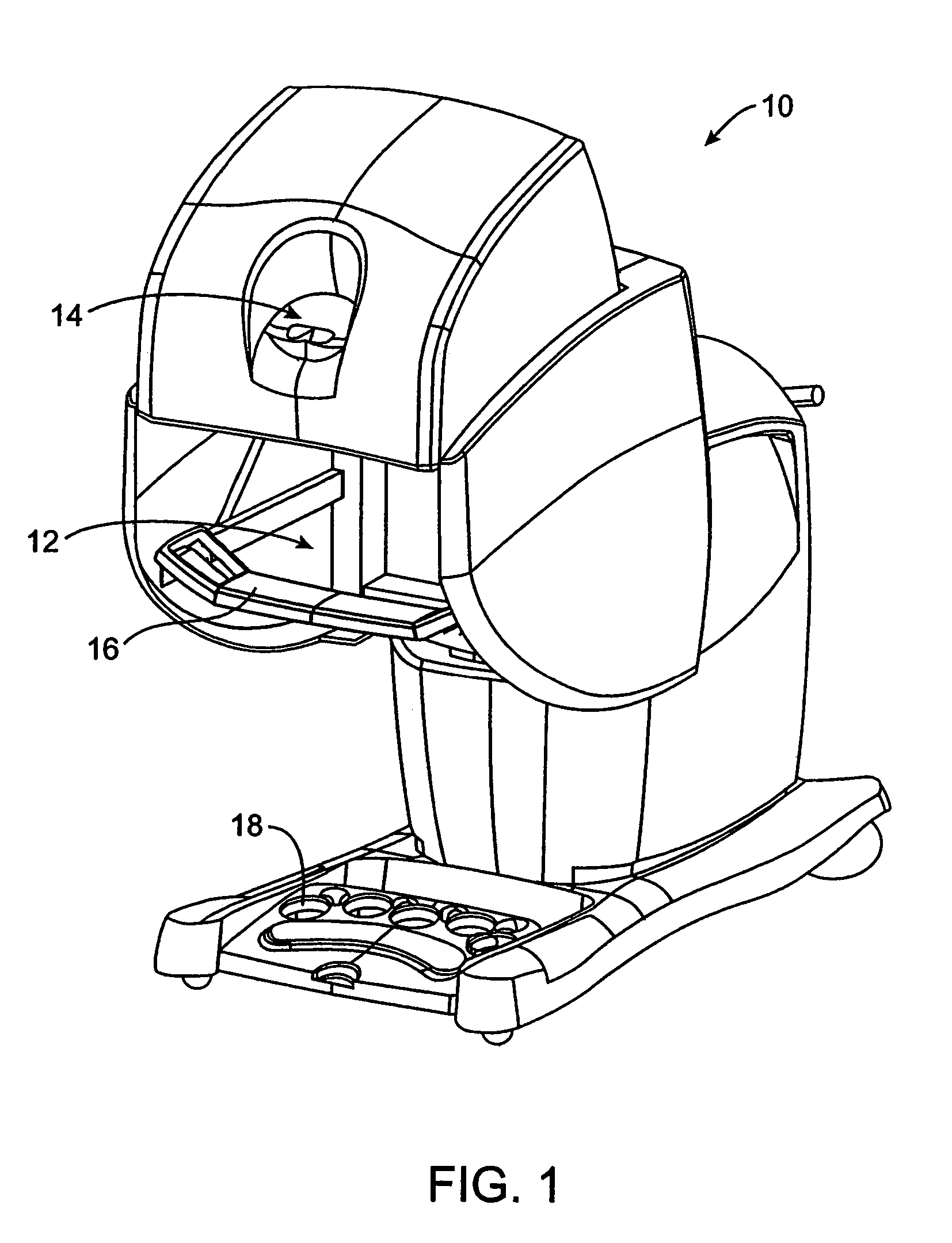

Medical diagnostic instrument having portable illuminator

ActiveUS20090287192A1Great degreeExcellent ease of useBronchoscopesLaryngoscopesEngineeringBiomedical engineering

A portable medical diagnostic instrument includes an instrument head and a handle portion having an open-ended receiving cavity. A compact illuminator defined by a housing retaining a miniature light source and a power supply is releasably fitted within the open-ended receiving cavity of the handle portion wherein the light source of the illuminator is optically coupled with the instrument on assembly therewith. The handle portion can be integral with the instrument or releasably attached. The handle portion according to at least one version is made from a plastic or other suitable material, permitting disposability and / or single patient use. In one version, the handle portion is flexibly deformable, at least partially, to facilitate release of the portable illuminator.

Owner:WELCH ALLYN INC

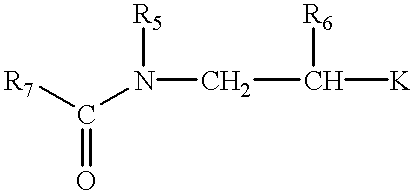

Personal care formulations

InactiveUS20020034489A1Good lookingFeel goodCosmetic preparationsNon-ionic surface-active compoundsPersonal careChemical composition

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

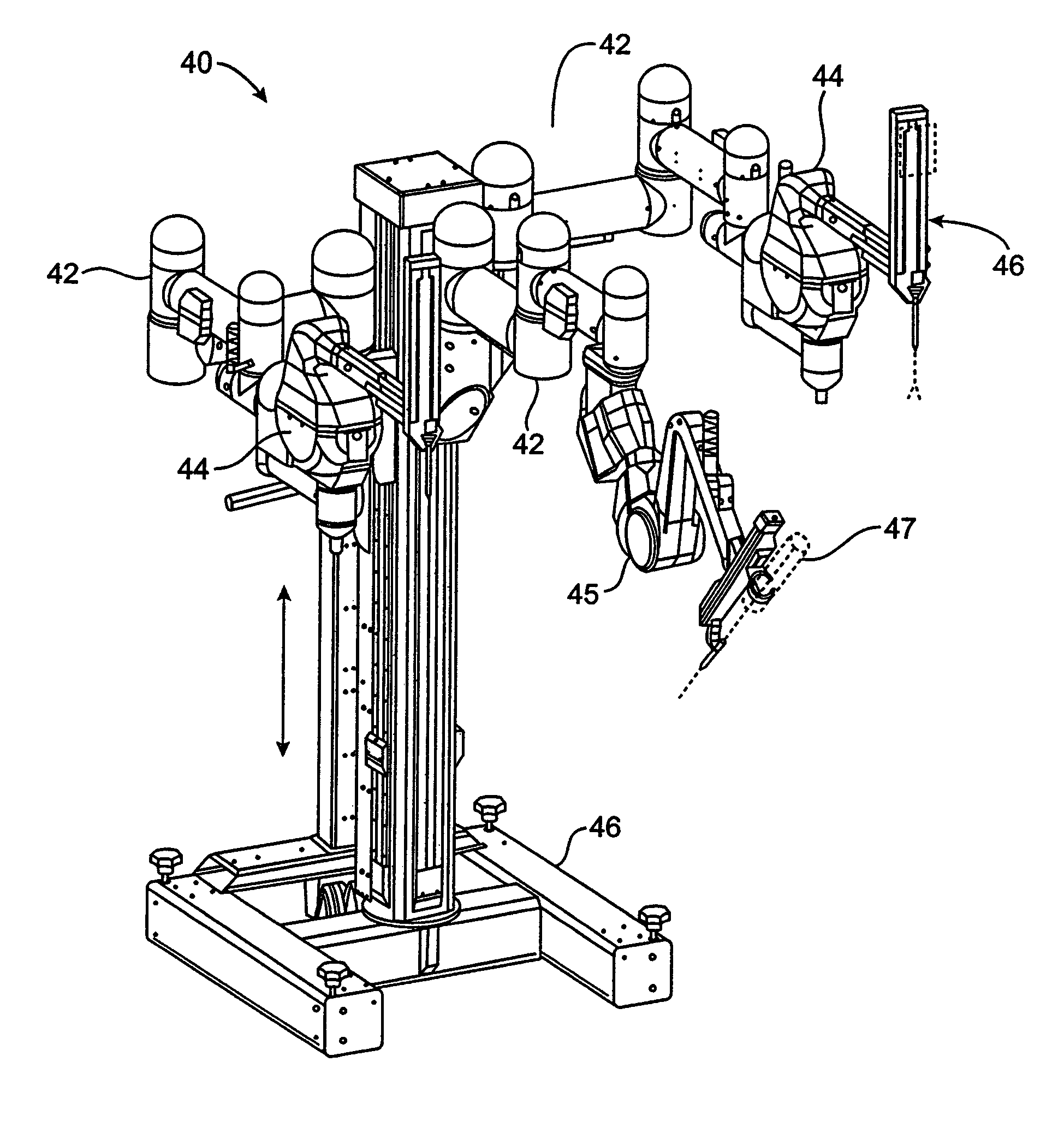

Grip strength with tactile feedback for robotic surgery

InactiveUS7373219B2Enhanced telepresenceImprove grip strengthProgramme-controlled manipulatorDigital data processing detailsSurgical robotEngineering

Surgical robots and other telepresence systems have enhanced grip actuation for manipulating tissues and objects with small sizes. A master / slave system is used in which an error signal or gain is artificially altered when grip members are near a closed configuration.

Owner:INTUITIVE SURGICAL OPERATIONS INC

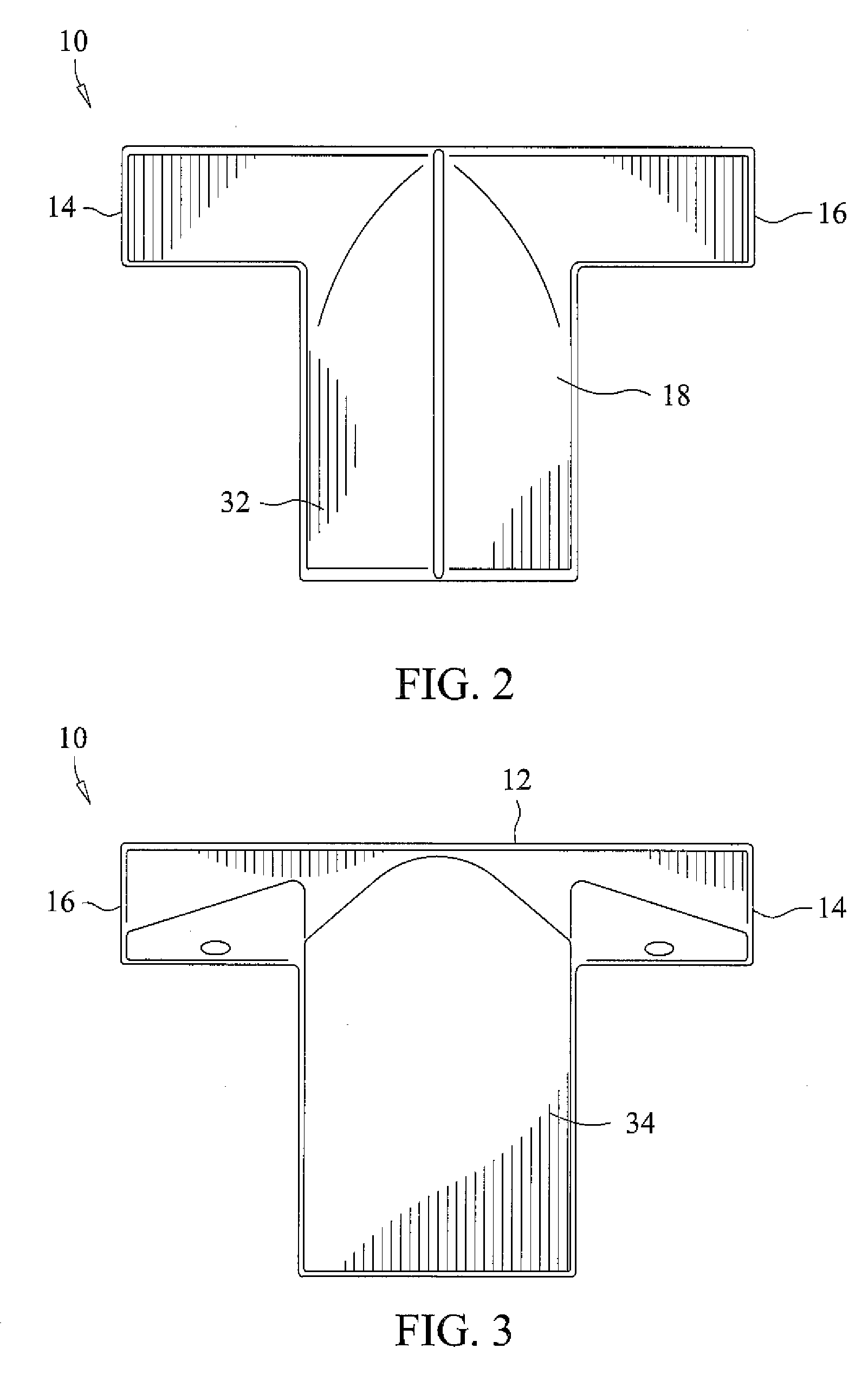

Golf putter incorporating swing analysis module

InactiveUS20100255922A1Enhance sound transmissionSuppress energyGymnastic exercisingBall sportsHead movementsWeight management

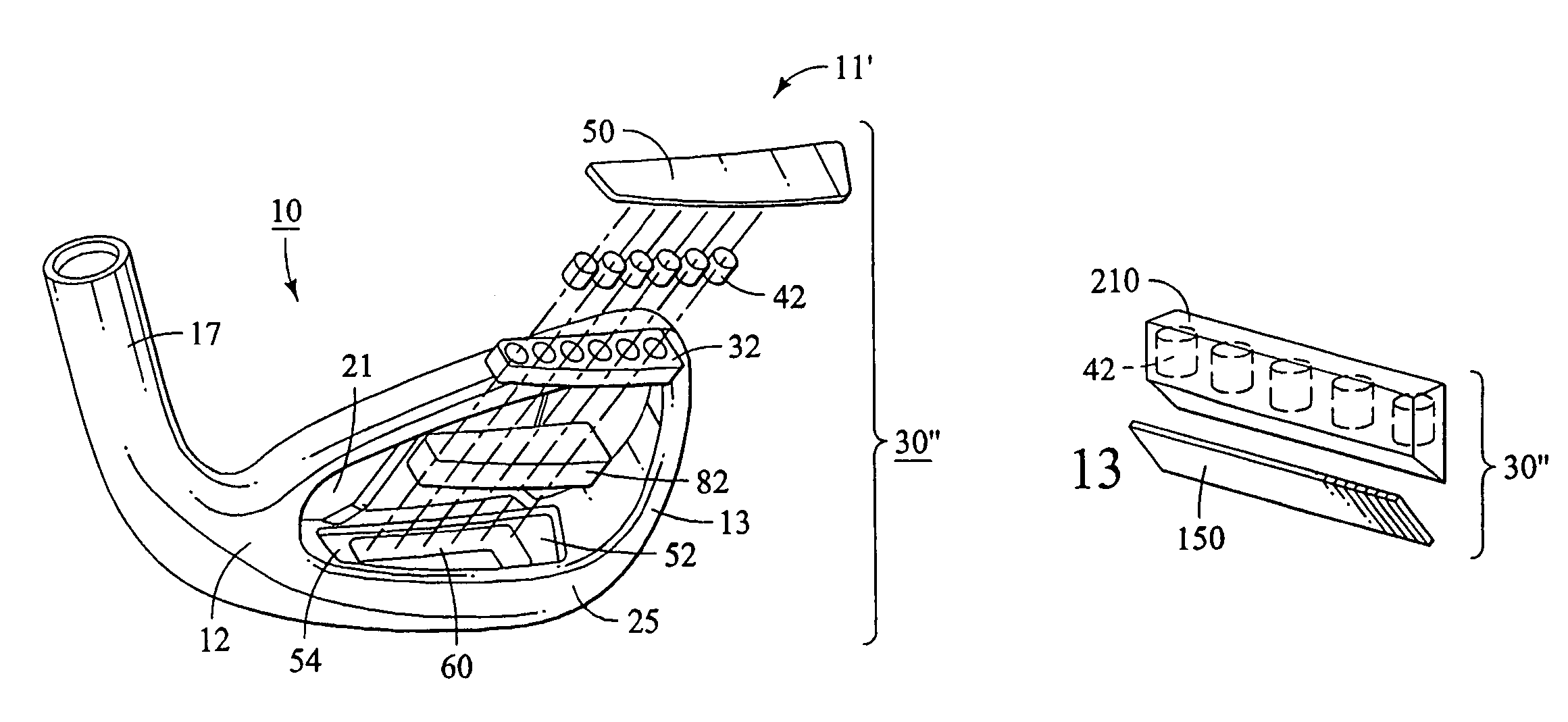

An improved golf putter incorporating a weight management system that allows for adjustment of a golf club head weighting by incorporating an adjustable weight system wherein weights may be removed and replaced quickly and easily without requiring a specialized tool is disclosed. Weights received within weight ports formed in the heel and toe portions of the putter are maintained securely affixed within the club head body. While the preferred golf club embodiment disclosed is a putter, the present invention contemplates incorporating any of the features and / or advancements disclosed herein into any golf club. In addition, the present invention further includes novel aspects relating to overall design, including mass distribution and a rearwardly projecting portion having an upwardly sloped sole that prevents the club from snagging the turf. Furthermore a hollowed out area formed within the rearwardly projecting portion is sized and shaped to receive a correspondingly sized and shaped sensing module adapted to measure club head movement and wirelessly transmit data to a remote graphical user interface.

Owner:LUEDERS ROBERT

Apparatus and method for tissue removal

InactiveUS6174313B1Various locationsReduce frictionSurgical needlesVaccination/ovulation diagnosticsWood splinterMotion transfer

Percutaneous tissue removal apparatus comprises a flexible drill shaft, a cutting tip mounted on the shaft for placement adjacent a tissue mass for cutting the tissue, means for transmitting motion to the shaft to move the cutting tip against the tissue to cut tissue fragments from the tissue, and means for removing the tissue fragments along the shaft by suction to a location outside the tissue mass while cutting. The apparatus may include means for collecting one or more selected components of the harvested tissue fragments for implantation of the fragments preferably into the body of the patient from whom they were removed. Where the tissue to be cut is bone, a cutting tip is preferably made of a polymeric material which is softer than the cortical portion of the bone, although the cutting tip may be made of a ceramic or a composite material. A second flexible shaft may be provided either within or about the flexible drill shaft. The harvested tissue fragments may be implanted in the donor patient's body.

Owner:BONUTTI SKELETAL INNOVATIONS +1

Method for a driver assistance system for autonomous longitudinal and/or lateral control of a vehicle

ActiveUS9604652B2Reduce effortEasy to operateDashboard fitting arrangementsCruise controlDriver/operatorEngineering

A driver assistance system and an operating method thereof are configured and adapted to perform autonomous longitudinal and / or lateral control of a vehicle. At least one control task for longitudinal and / or lateral control of the vehicle can be transferred from the driver to the driver assistance system. This involves informing the driver that a control task can be transferred to the system, and then transferring the control task from the driver to the system in response to the driver ceasing a manual control of this control task.

Owner:CONTINENTAL TEVES AG & CO OHG

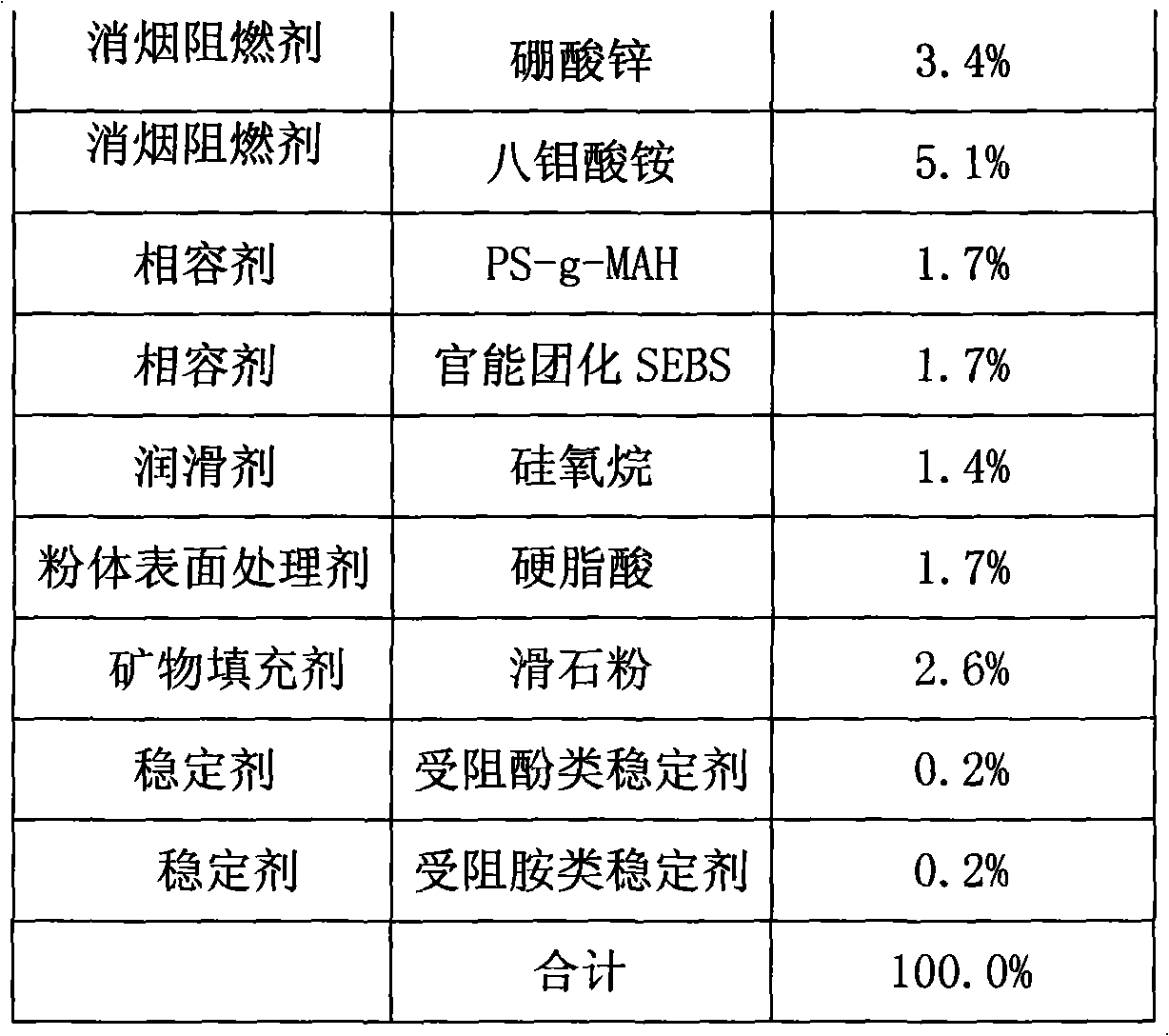

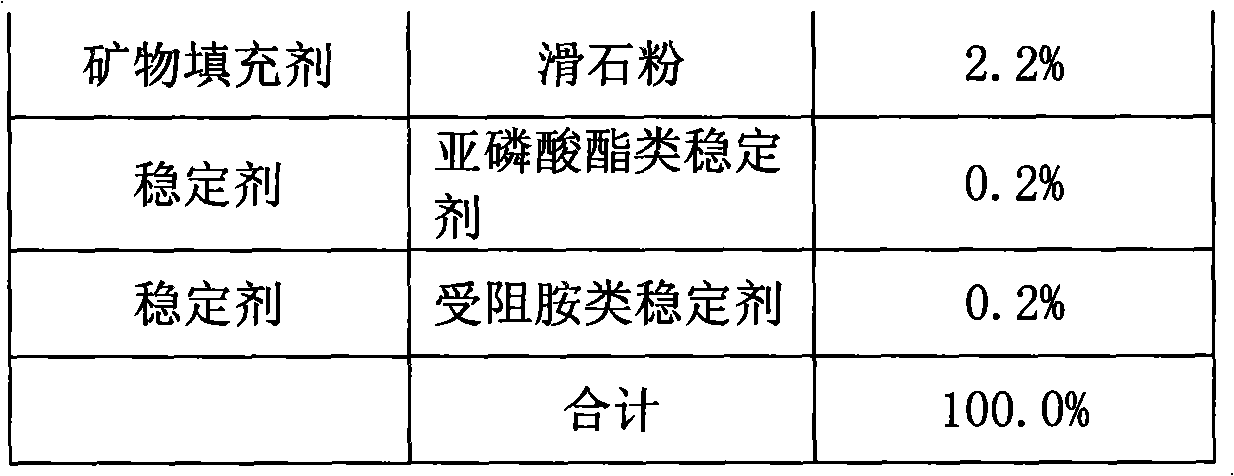

Halogen-free flame-retardant thermoplastic elastomer electrical cable material using polyphenylene ether as base material and preparation method thereof

InactiveCN101358028AGood compatibilityReduce stratificationInsulated cablesInsulated conductorsElastomerPolyphenylene oxide

The invention discloses a halogen-free flame-retardant thermoplastic elastomer cable material with polyphenylether as the base materials and a preparation method thereof. The raw material of the cable material contains the components with the following weight percentage: 10 to 35 percent of matrix resin A; 5 to 15 percent of matrix resin B; 10 to 25 percent of elastomer; 5 to 25 percent of softening plasticizer; 8 to 15 percent of flame-retardant plasticizer; 20 to 40 percent of smoke-suppression flame retardant; 3 to 10 percent of compatilizer; 1 to 5 percent of lubricant; 1 to 5 percent of powder surface conditioner; 0 to 10 percent of mineral filler; 0.1 to 1 percent of stabilizing agent. The invention adds matrix resin, polyphenylether of strong polarity and functional group of styrene-ethylene / butylene-styrene segmented copolymer, which effectively improves the compatibility of non-polar elastomer with polyphenylether; the invention also adds plasticizer, which reduces the hardness of the material and increases the flexibility; and through the optimization and interaction of the softening plasticizer and the flame-retardant plasticizer, the invention reduces the hardness and improves the tactility of the material, and the flame retardant performance is excellent.

Owner:NINGBO SHIP PLASTIC CO LTD

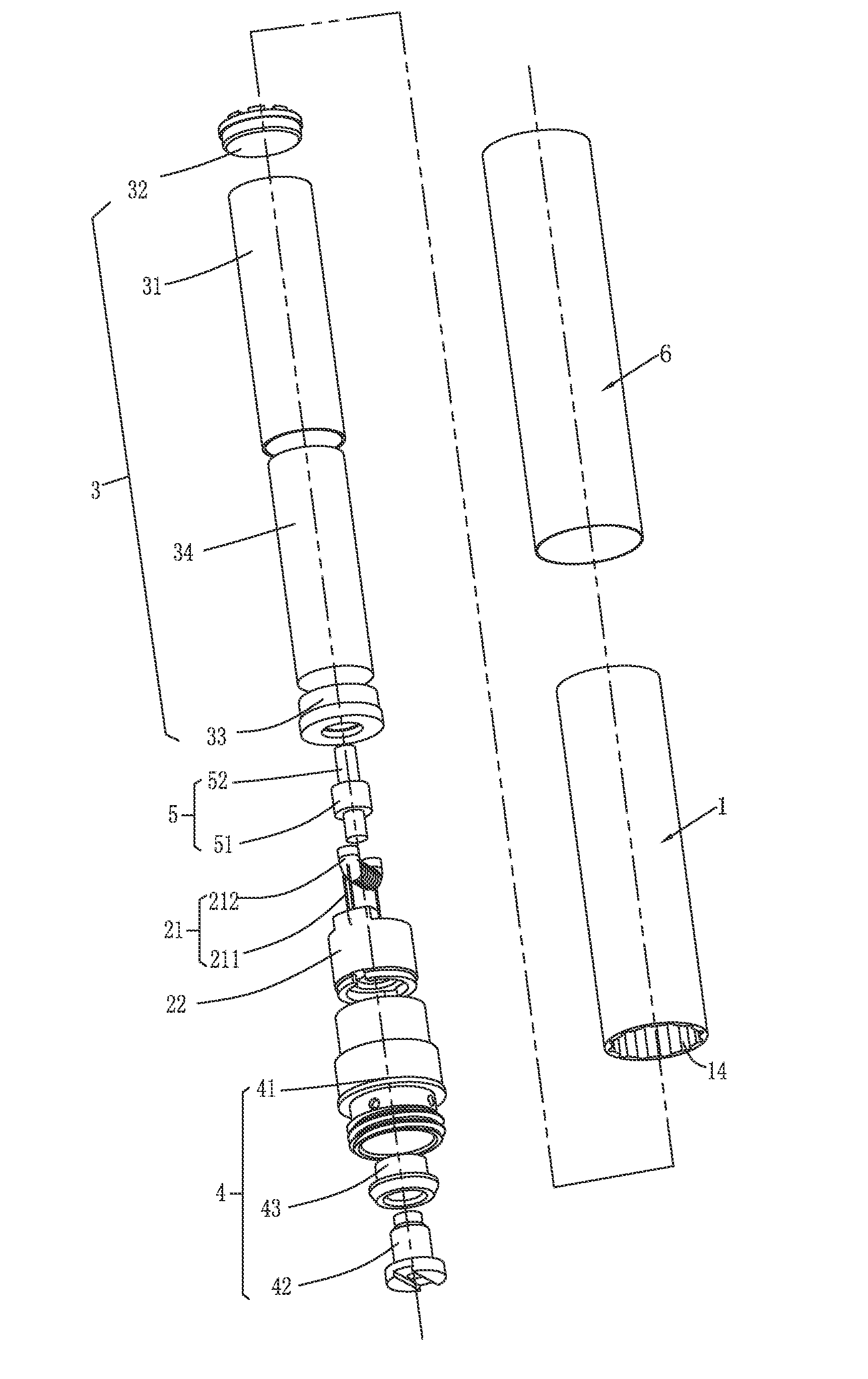

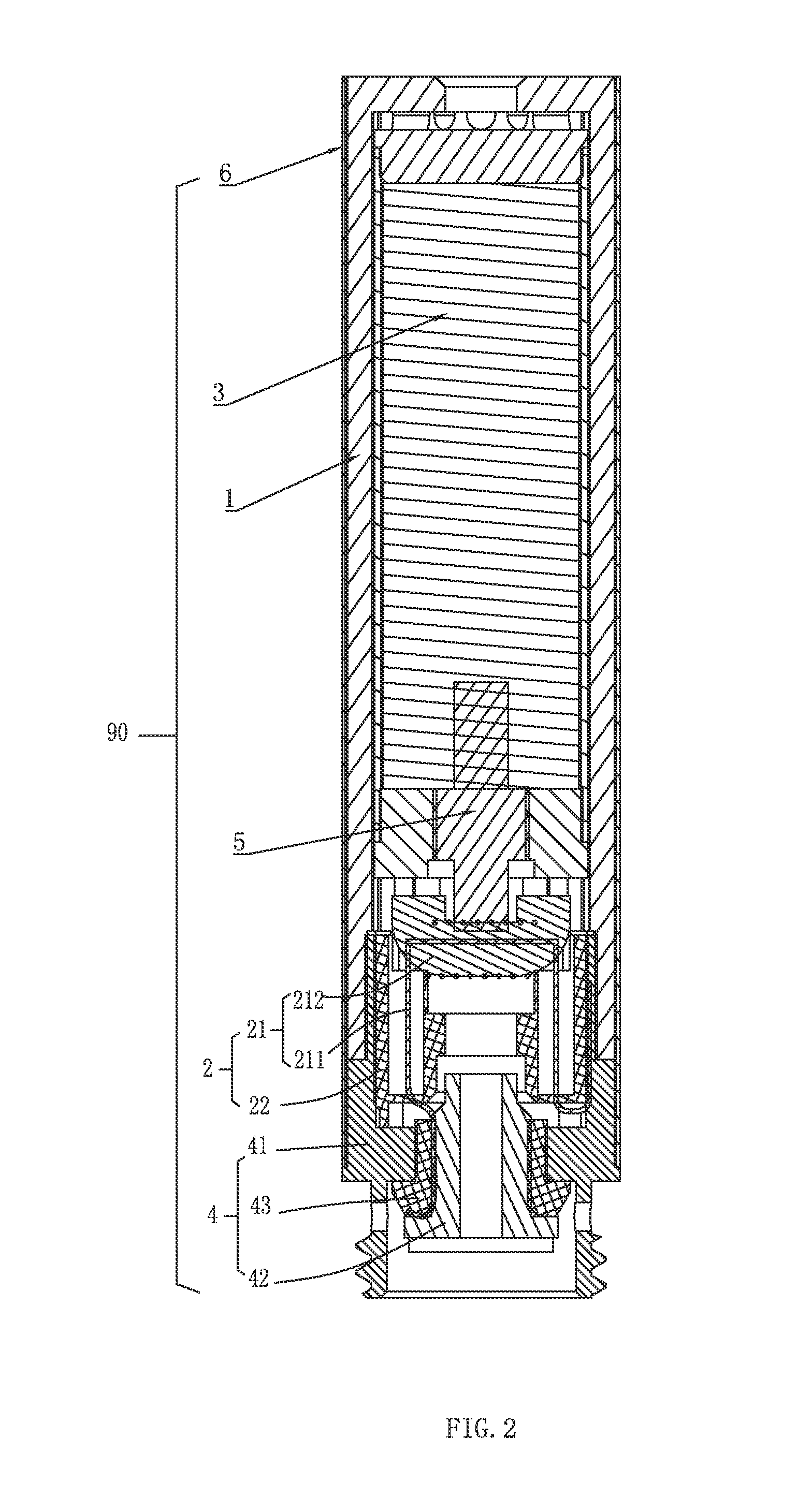

Electronic Cigarette and Soft Absorption Stem Thereof

InactiveUS20140182610A1Compact internal structureUnique smoke pathTobacco pipesTobacco devicesElectronic cigaretteSoft materials

A soft absorption stem for an electronic cigarette is provided, comprising a sleeve, a cigar liquid tank disposed inside the sleeve, an atomization device and a liquid guiding component. The sleeve is made of soft material; a plurality of venting slots is extended axially from one end of the sleeve to the other end thereof and disposed on an inner wall of the sleeve; the sleeve includes a mouthpiece end and a connection end; a suction hole communicating with the venting slots is provided on the mouthpiece end; smoke produced by atomization of the atomization device flows out of the sleeve from the venting slots across the suction hole. The electronic cigarette makes the user more comfortable when holding the sleeve in hand and containing in mouth, having more compact internal construction, having unique smoke path, and having increased cigar liquid storage capacity.

Owner:HUIZHOU KIMREE TECH

Solid golf ball

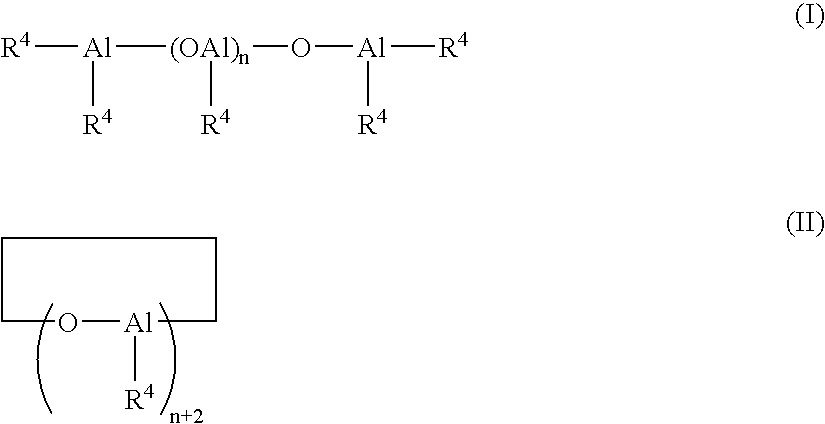

InactiveUS20080194357A1Improve spin performanceIncrease distanceGolf ballsSolid ballsThermoplasticPolymer science

The invention provides a solid golf ball having a solid core and a cover layer that encases the core and has an outermost layer on an outside surface of which are formed a plurality of dimples. The solid core is formed of a rubber composition composed of 100 parts by weight of a base rubber that includes 60 to 100 parts by weight of a polybutadiene rubber having a cis-1,4 bond content of at least 60% and synthesized using a rare-earth catalyst, 0.1 to 5 parts by weight of an organosulfur compound, an unsaturated carboxylic acid or a metal salt thereof, and an inorganic filler. The solid core has a deformation, when compressed under a final load of 130 kgf from an initial load of 10 kgf, of 2.0 to 4.0 mm, and has a specific hardness distribution. The cover layer is formed primarily of a thermoplastic or thermoset polyurethane material and has a thickness of 0.5 to 2.5 mm, a Shore D hardness at the surface of 50 to 70 and a flexural rigidity of 50 to 300 MPa. The golf ball has a deformation, when compressed under a final load of 130 kgf from an initial load of 10 kgf, of 2.0 to 3.8 mm. The solid golf ball is advantageous overall in competitive use.

Owner:BRIDGESTONE SPORTS

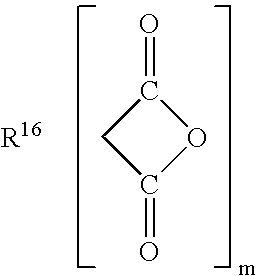

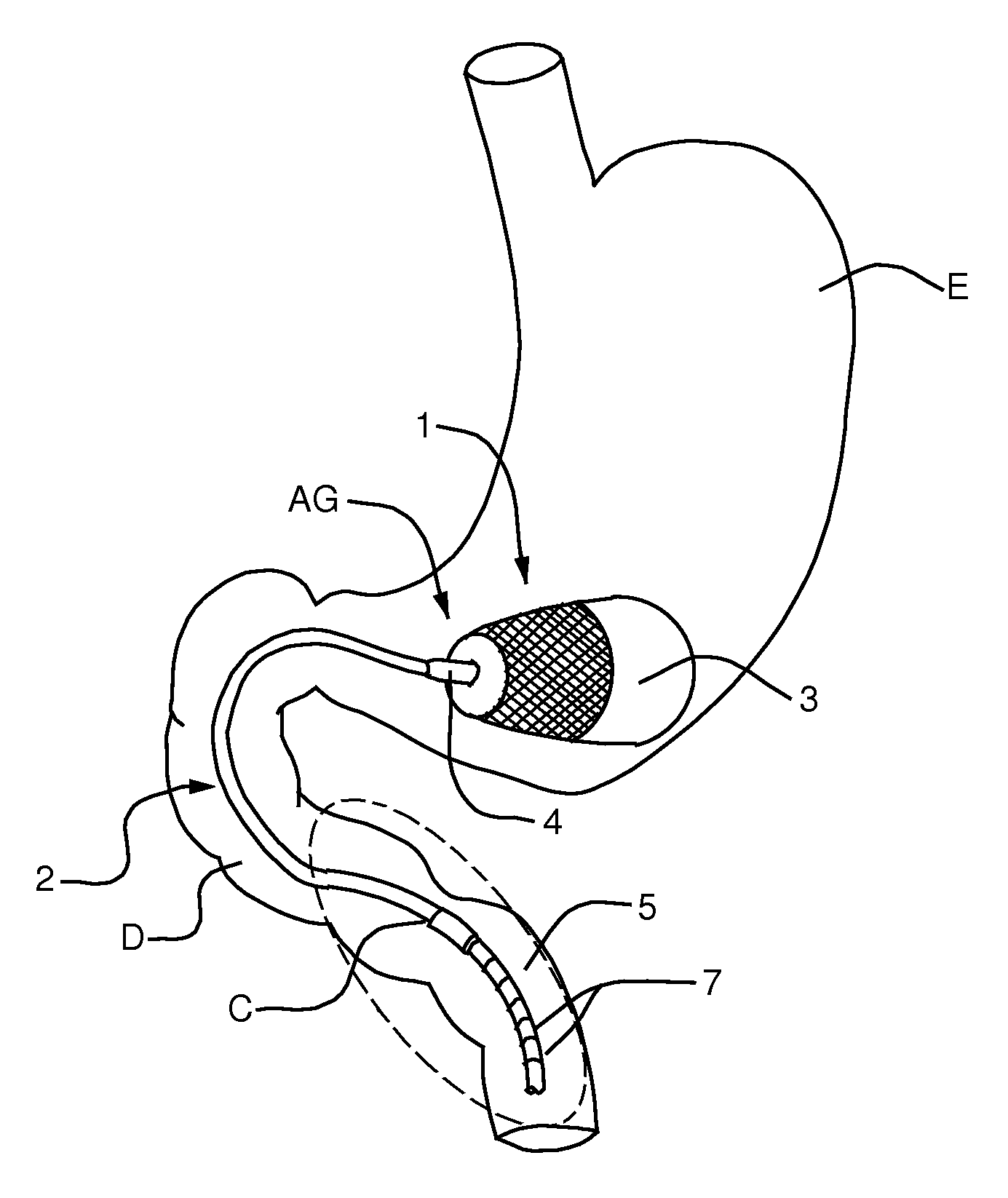

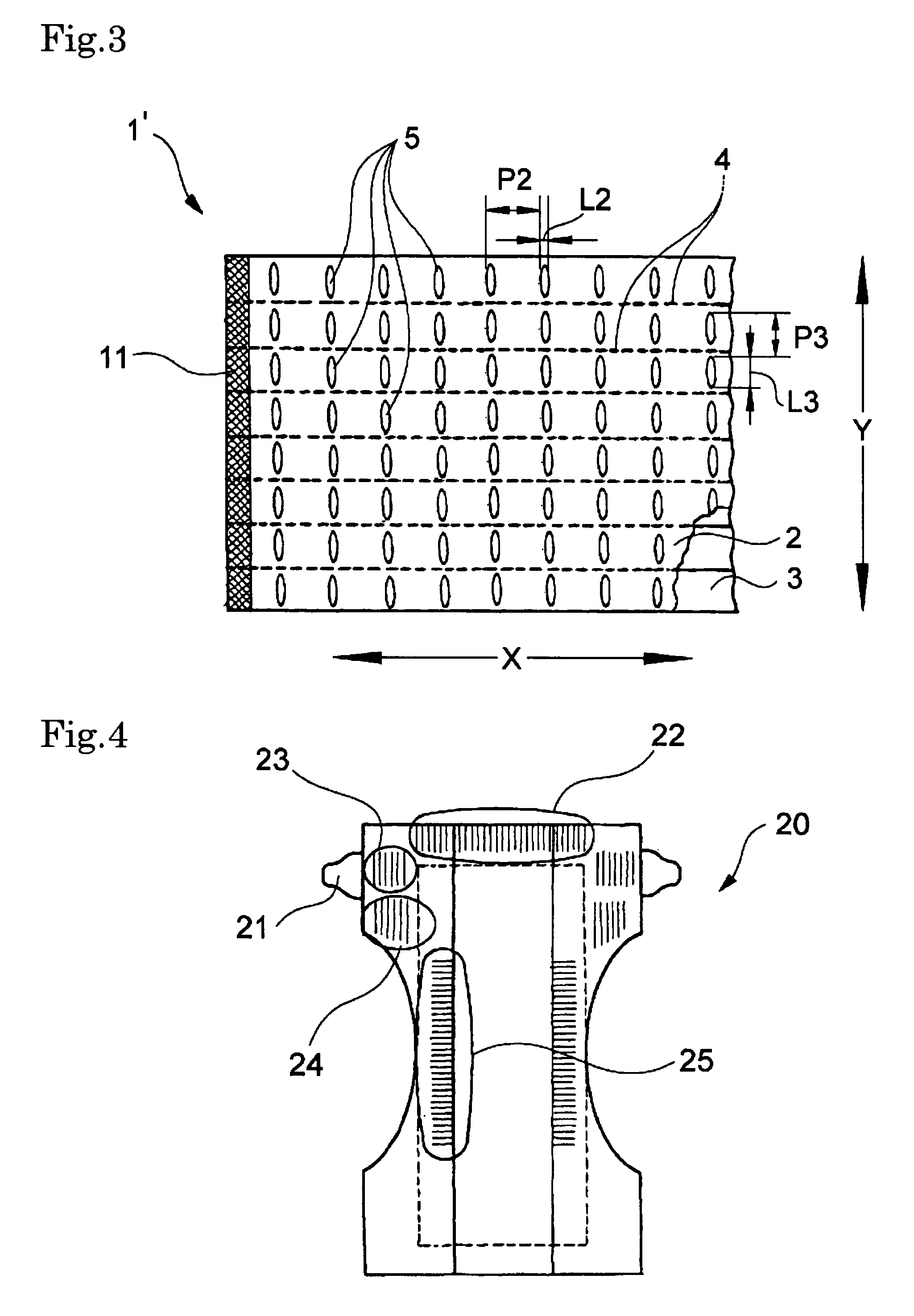

Semi-stationary balloon in the gastric antrum provided with connecting an anchoring rod for inducing weight reduction in human beings

A semi-stationary balloon in the gastric antrum provided with an anchoring rod for inducing weight reduction in human beings is disclosed, a device for inducing a lesser appetite and early prandial satiety, said balloon being made of inflatable per-os medical grade silicone having a volume of up to 240 ml, with an average space of 120 ml to be filled with non-elastic fluid provided with radio-opaque contrast and dye, preferably methylene blue, so that the maximum diameter of 8 cm is reached after it is filled up with a volume of up to 240 ml and the average diameter of 6 cm with a volume of 120 ml, to be endoscopically placed inside the stomach (E); said intra-gastric balloon (1) being positioned in a semi-stationary way in the gastric antrum (GAC) and provided with an anchoring or duodenal rod (2) having a distal counter-weight (5) installed in the duodenum (D); particularly, the inner face of the pear-shaped medium portion of lesser diameter is coated with a malleable ribbon (f) that provides said balloon (1) with resistance and flexibility.

Owner:GAZI BASHIR MUSSA +2

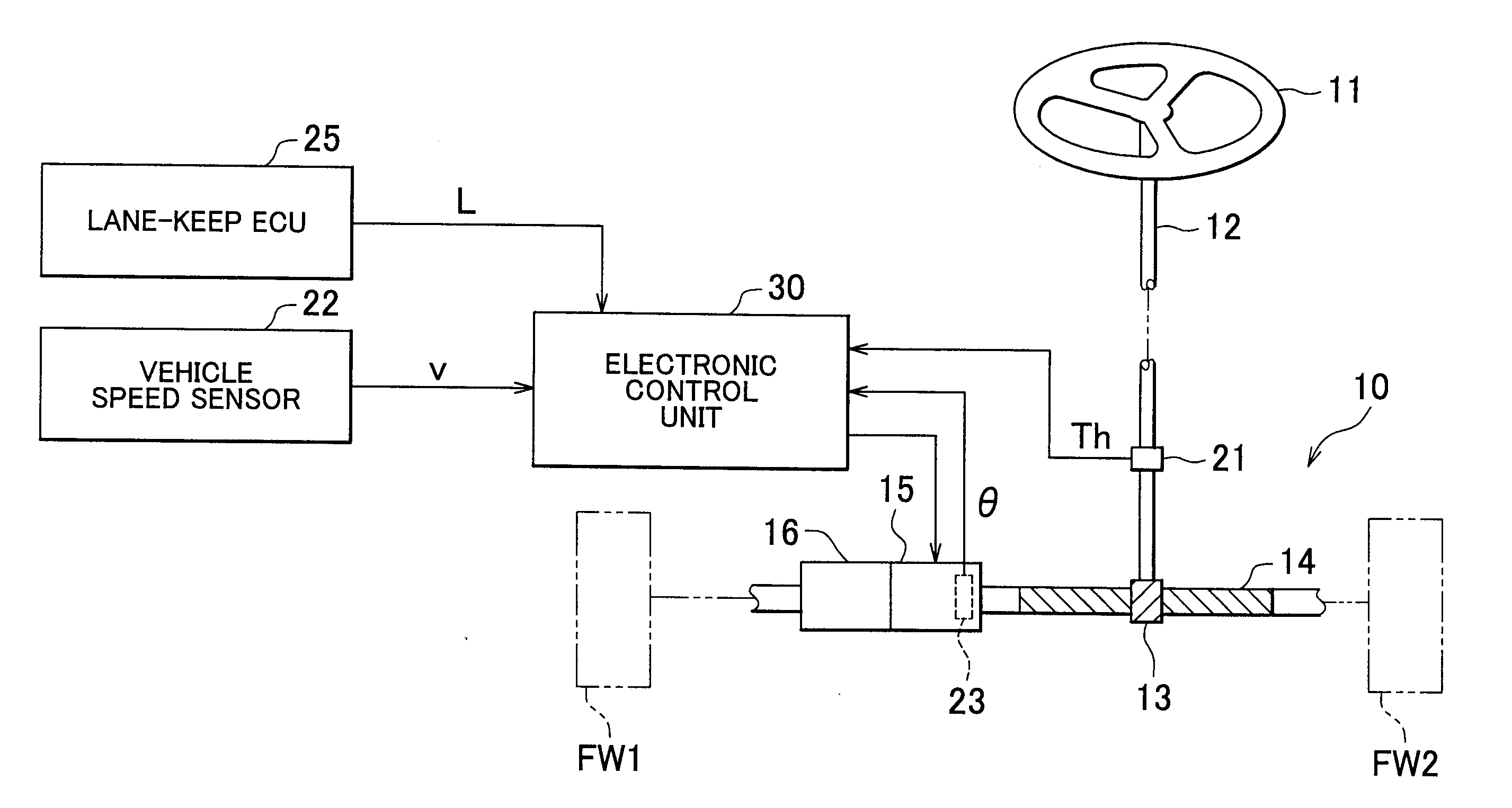

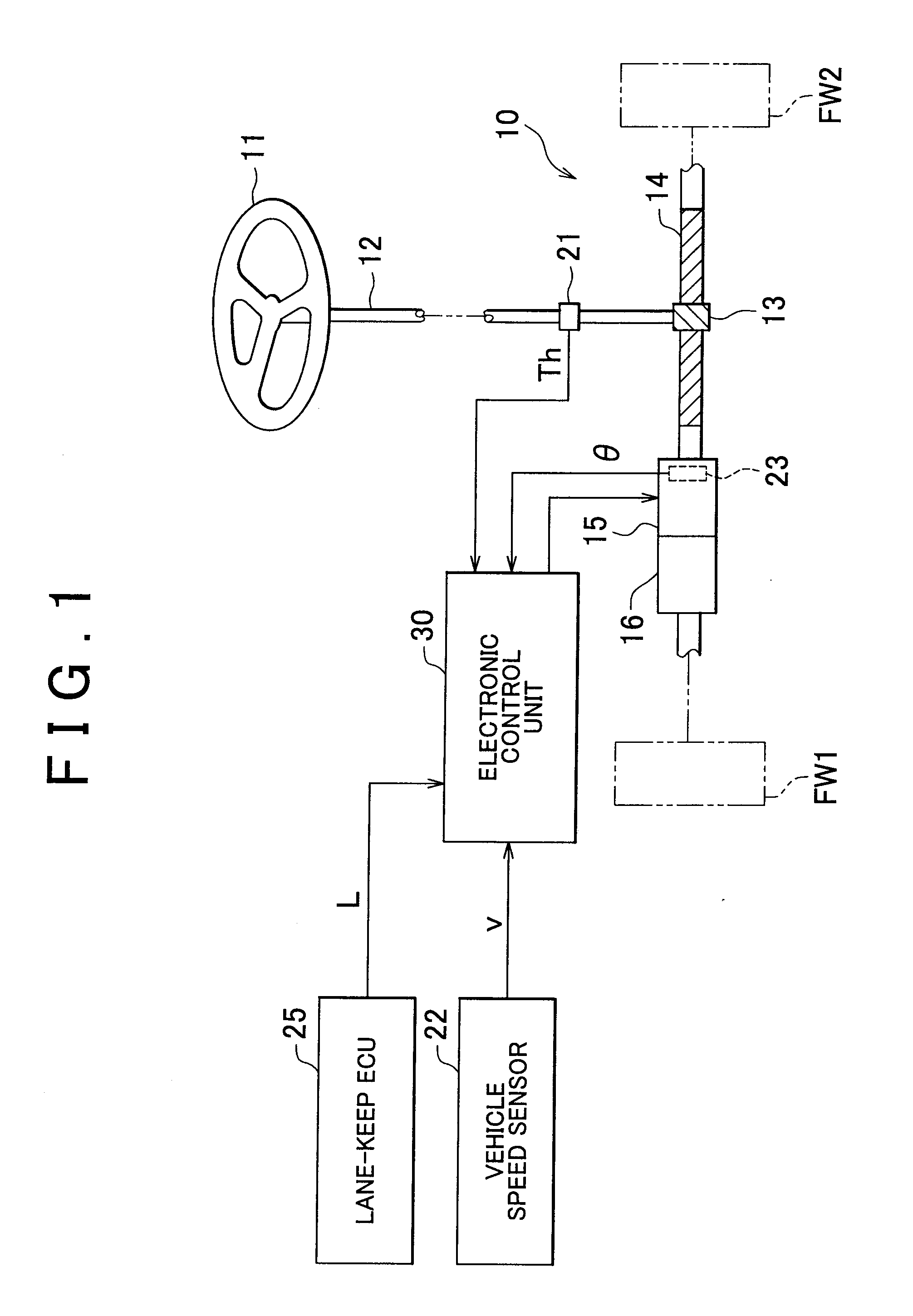

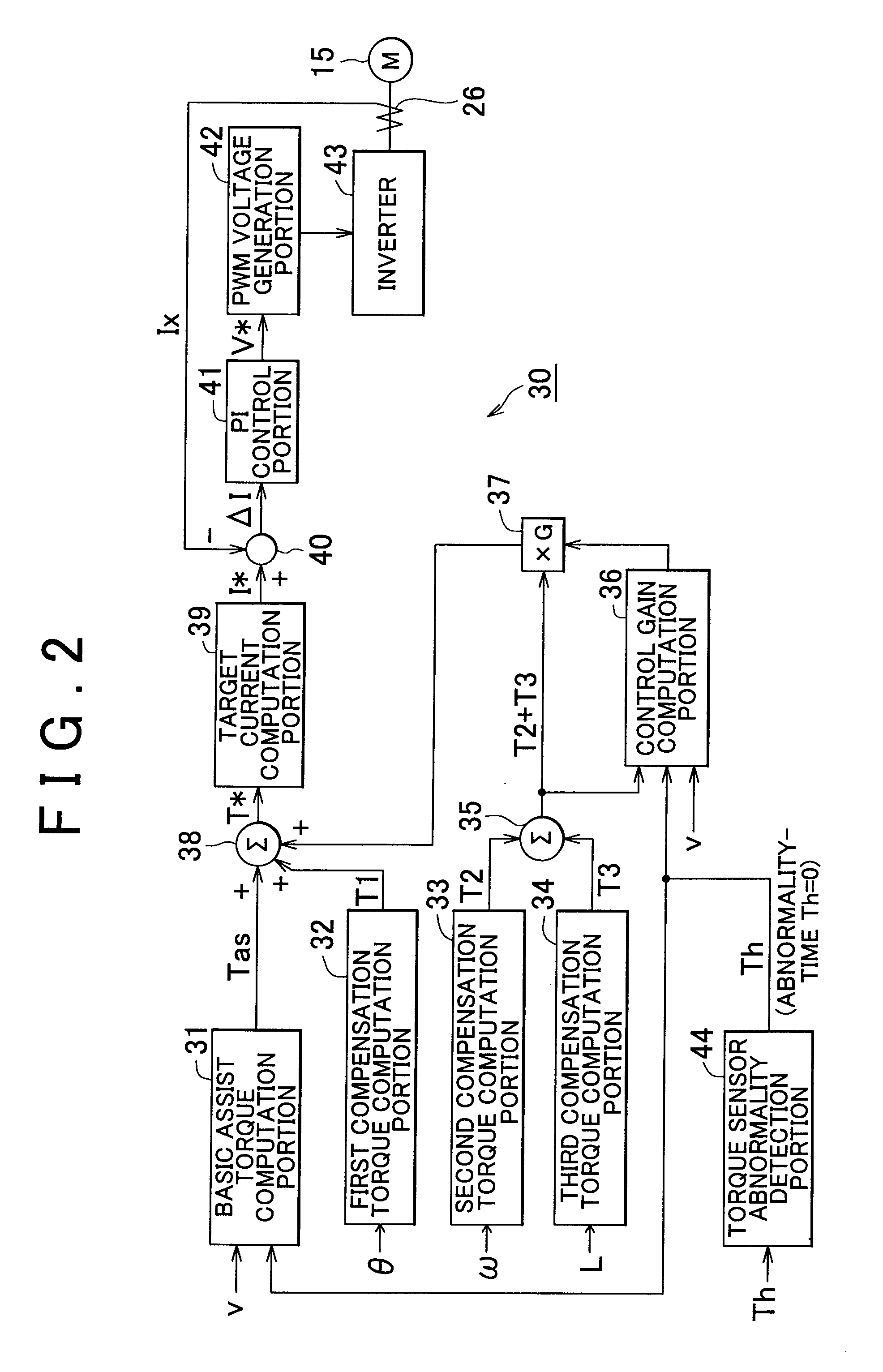

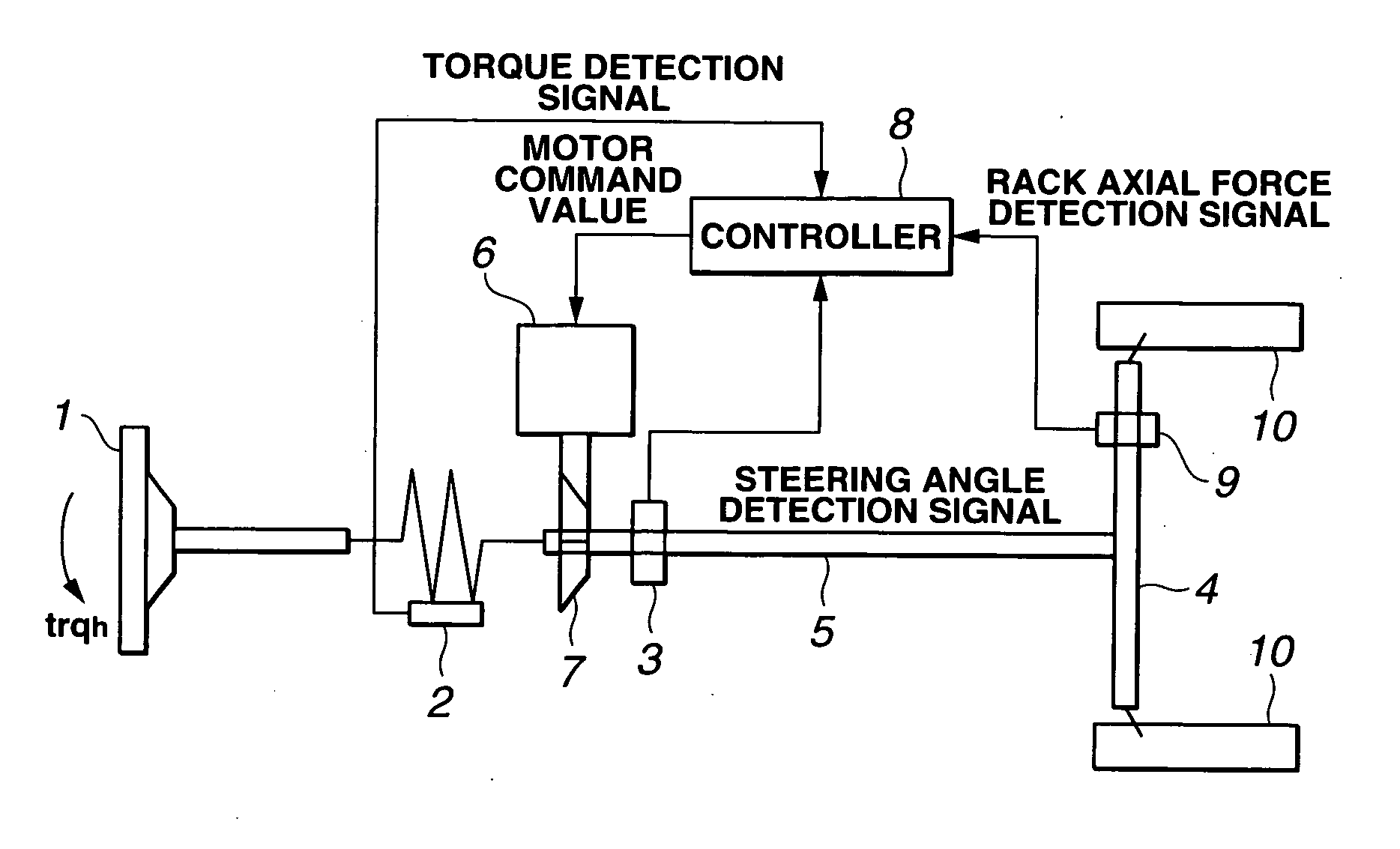

Electric power steering device, and control method thereof

InactiveUS20080047775A1Steering feeling can be improvedMan-hours for the conformation can be reducedSteering initiationsDigital data processing detailsElectric power steeringControl theory

A first compensation torque T1, a second compensation torque T2 and a third compensation torque T3 are added to a basic assist torque Tas. In this case, the second compensation torque T2 and the third compensation torque T3 are corrected by multiplying them by a common control gain G that is determined by the steering torque Th and the vehicle speed v. Therefore, since the two compensation control amounts are corrected through multiplication by the common control gain G, no interference occurs between the compensation controls. Besides, when the direction in which the total (T2+T3) of the pre-correction second compensation torque T2 and the pre-correction third compensation torque T3 acts is the same direction as the steering torque Th, the multiplication by the control gain G is avoided.

Owner:TOYOTA JIDOSHA KK

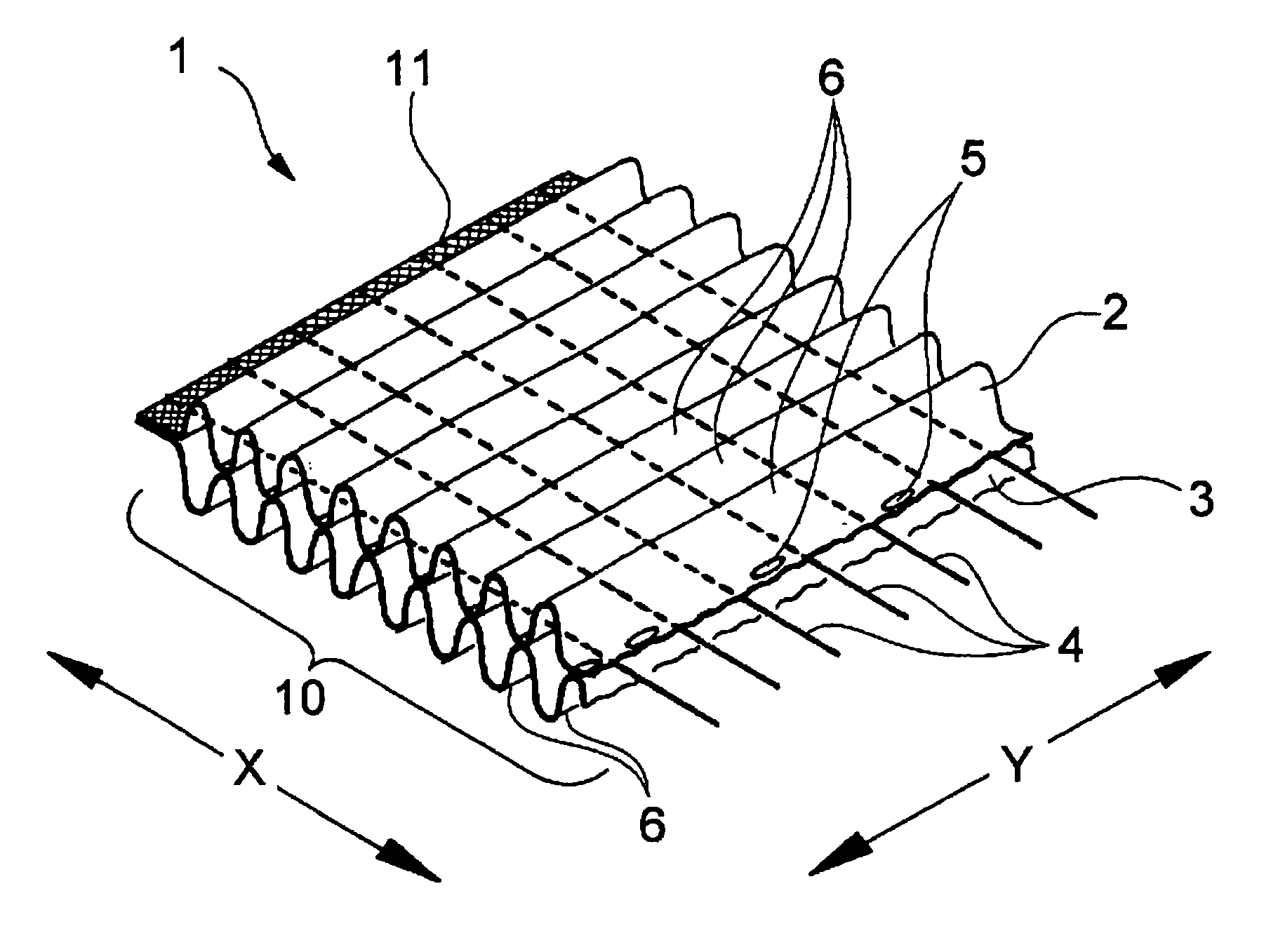

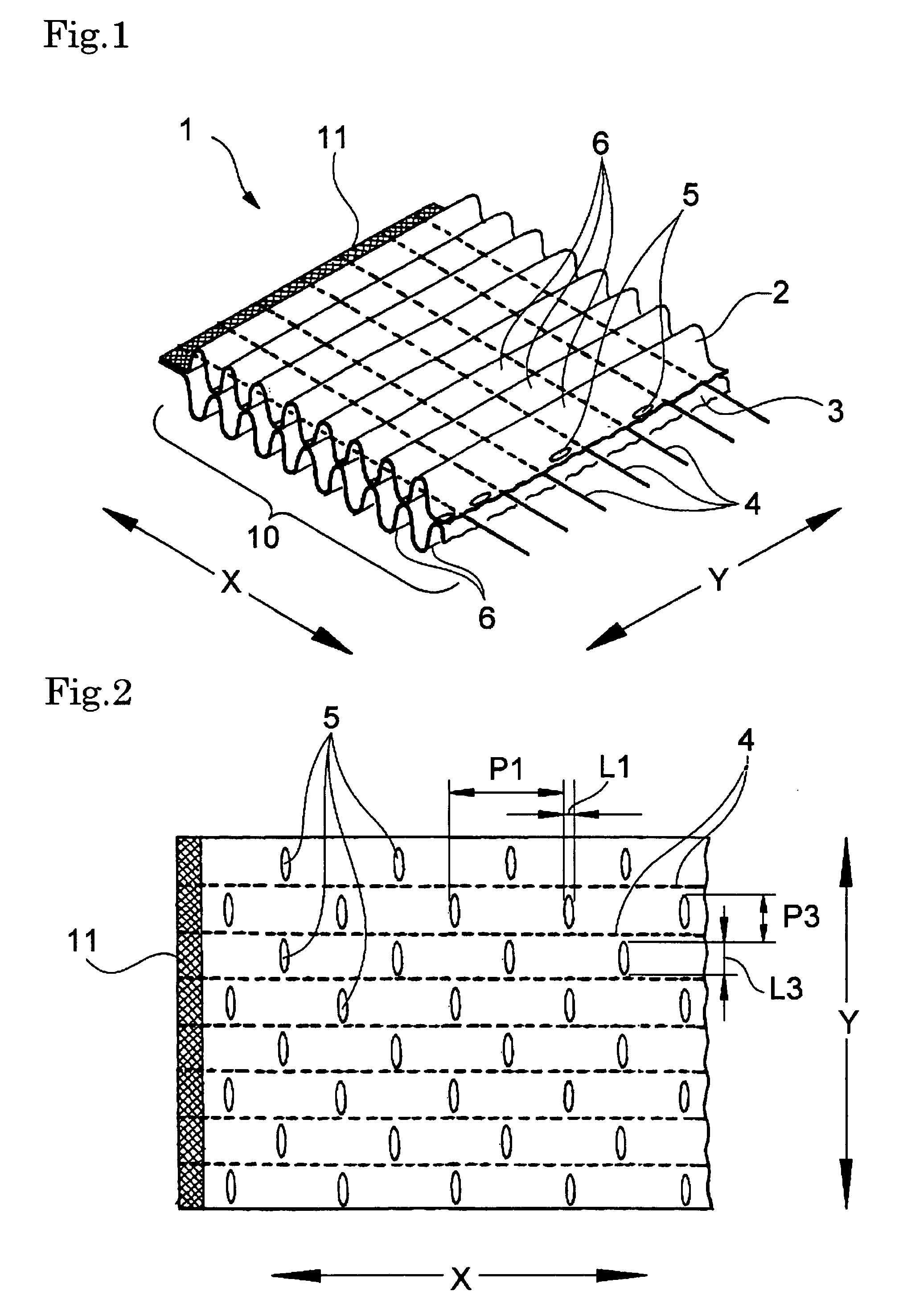

Composite extensible member and method of manufacturing the same

ActiveUS20060270302A1Good flexibilityFeel goodPersonal careSynthetic resin layered productsEngineeringSheet material

Owner:KAO CORP

Embossed rod medicinal health-care bathing-mud powder

InactiveCN1850026AFull of nutritionSoft textureCosmetic preparationsToilet preparationsDendranthema borealeBathing

The present invention discloses an attapulgite medicine health-care bath mud powder. Its composition contains the following components: attapulgite clay, active attapulgite clay, Chinese angelica root, salvia root, licorice, mint, lonicera flower, carthamus flower, wild chrysanthemum flower and others. Said health-care bath mud powder contains lots of Chinese medicine components, several minerals, rich trace elements and organic substances. Said invention also provides its preparation method.

Owner:CHANGZHOU XIAOGUO INFORMATION SERVICES

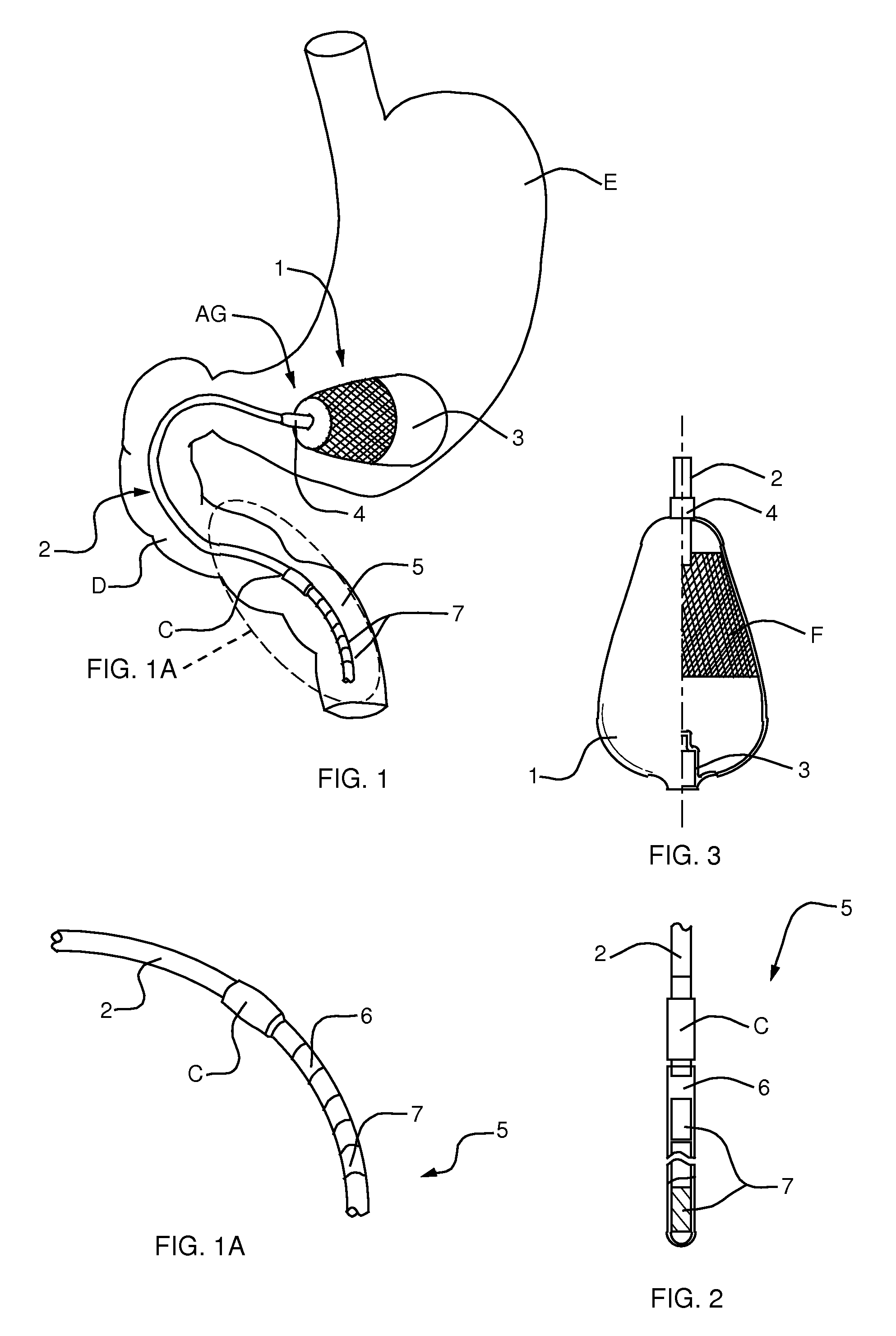

Device for intermittently obstructing a gastric opening and method of use

The present invention relates to a device for intermittently obstructing a bodily opening, such as a gastric opening, and includes a proximal member connected to a distal member by a tether. The proximal member includes an apron member surrounding a first occluding member, which is formable from an elongated and narrower configuration to a contracted or expanded but wider configuration. When employed in the stomach, the device of the present invention is arranged transluminally, with the distal member disposed in the duodenum and the proximal member disposed against the pyloric valve, intermittently occluding the pyloric valve and preventing or delaying the flow of gastric contents through the pyloric valve. In certain embodiments, a reservoir may be included for releasing a substance of interest, for example for releasing insulin from a reservoir disposed in the distal member. Sensors, actuators, and data transmission devices may also be included.

Owner:BARONOVA

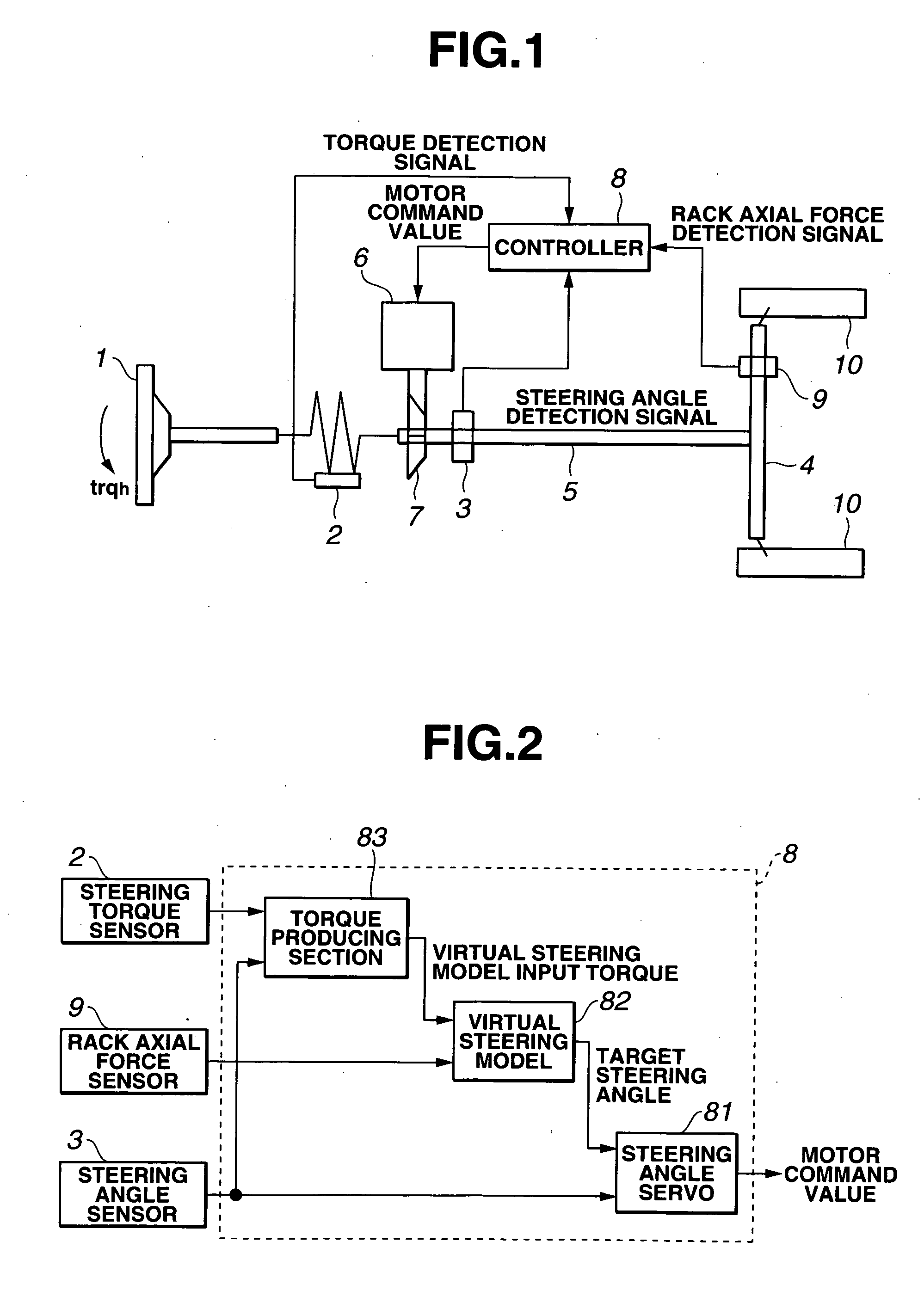

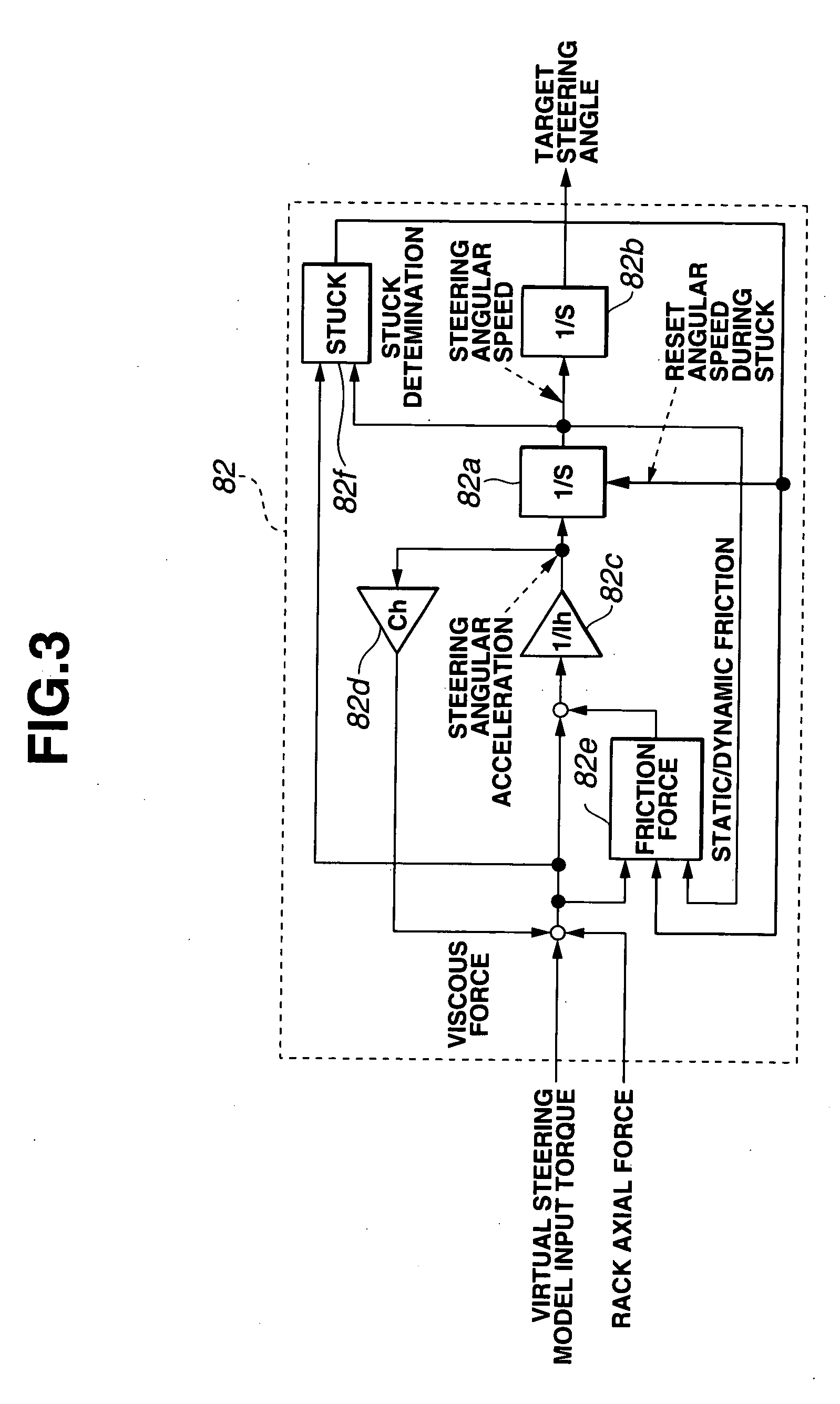

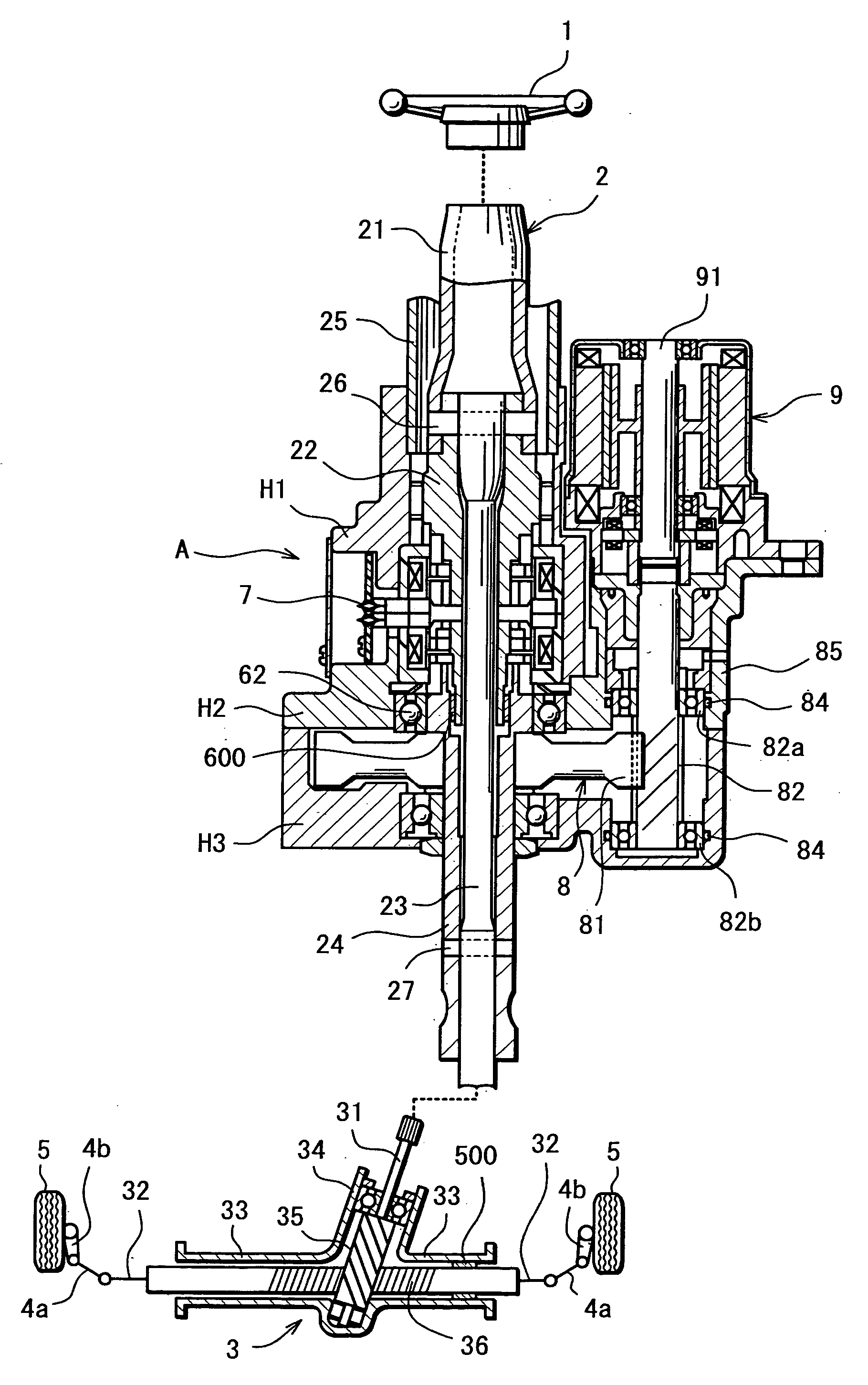

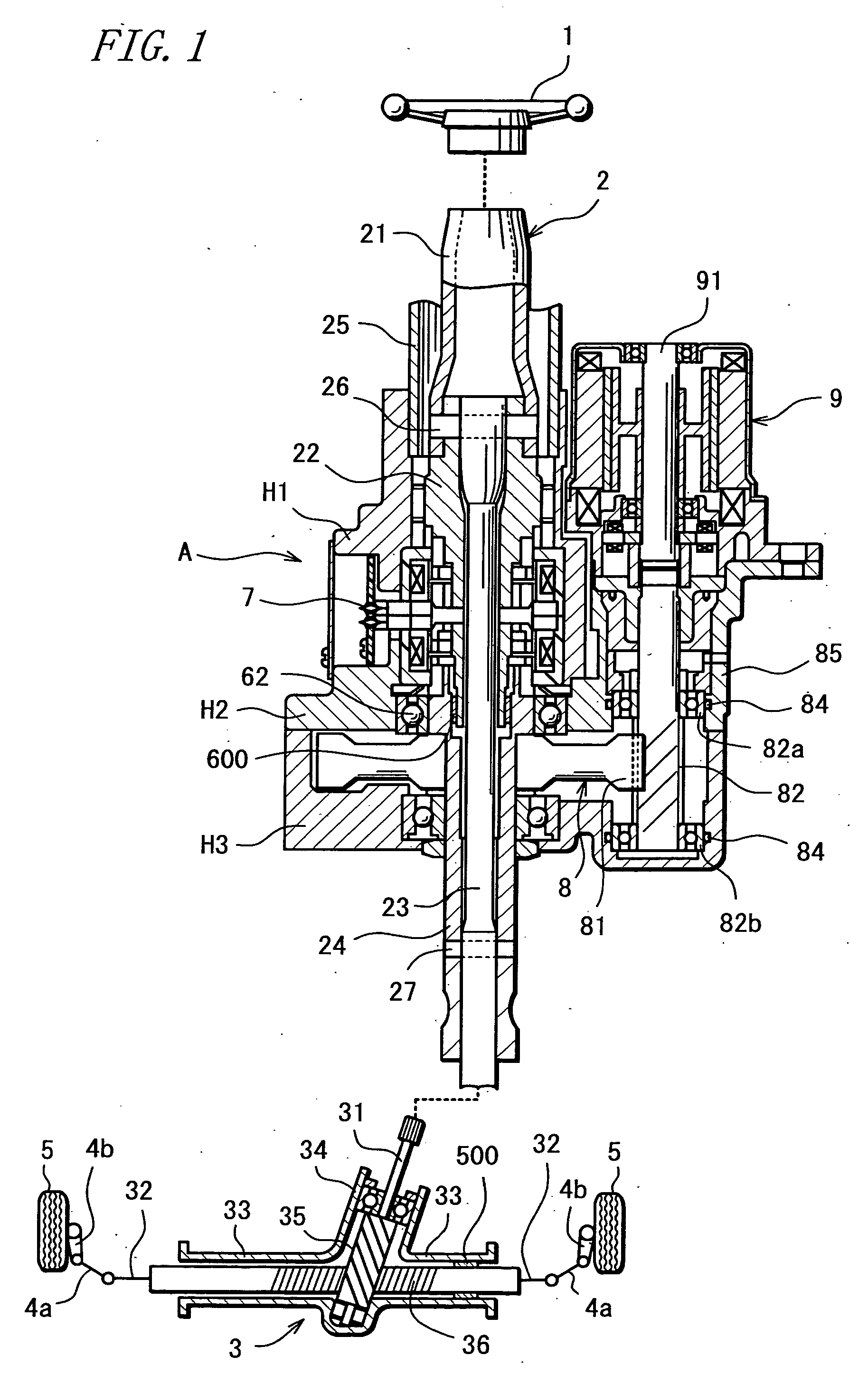

Vehicle steering apparatus

InactiveUS20060086560A1Reduce impactFeel goodDigital data processing detailsSteering initiationsSteering columnSteering angle

A vehicle steering apparatus is comprised of an assist motor, a steering torque sensor, a steering angle sensor, and a controller. The controller has a torque producing section for estimating a virtual steering model input torque from a torque sensor detection value and a steering angle detection value, a virtual steering model of representing a desired steering characteristic which receives the virtual steering model input torque and outputs a target steering angle of a steering column shaft, and a steering angle servo for controlling an output of the assist motor so that the steering angle detection angle follows the target steering angle.

Owner:NISSAN MOTOR CO LTD

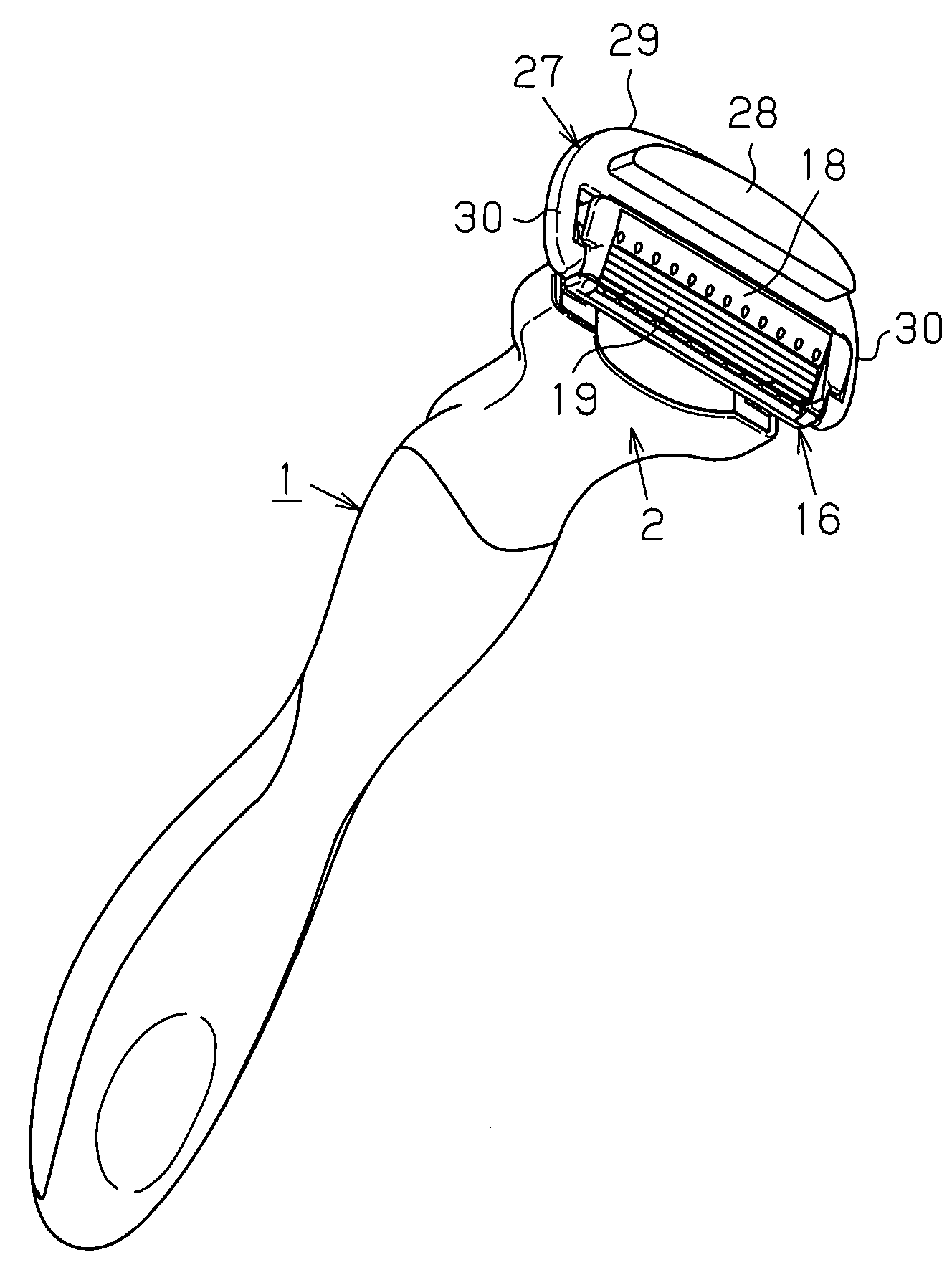

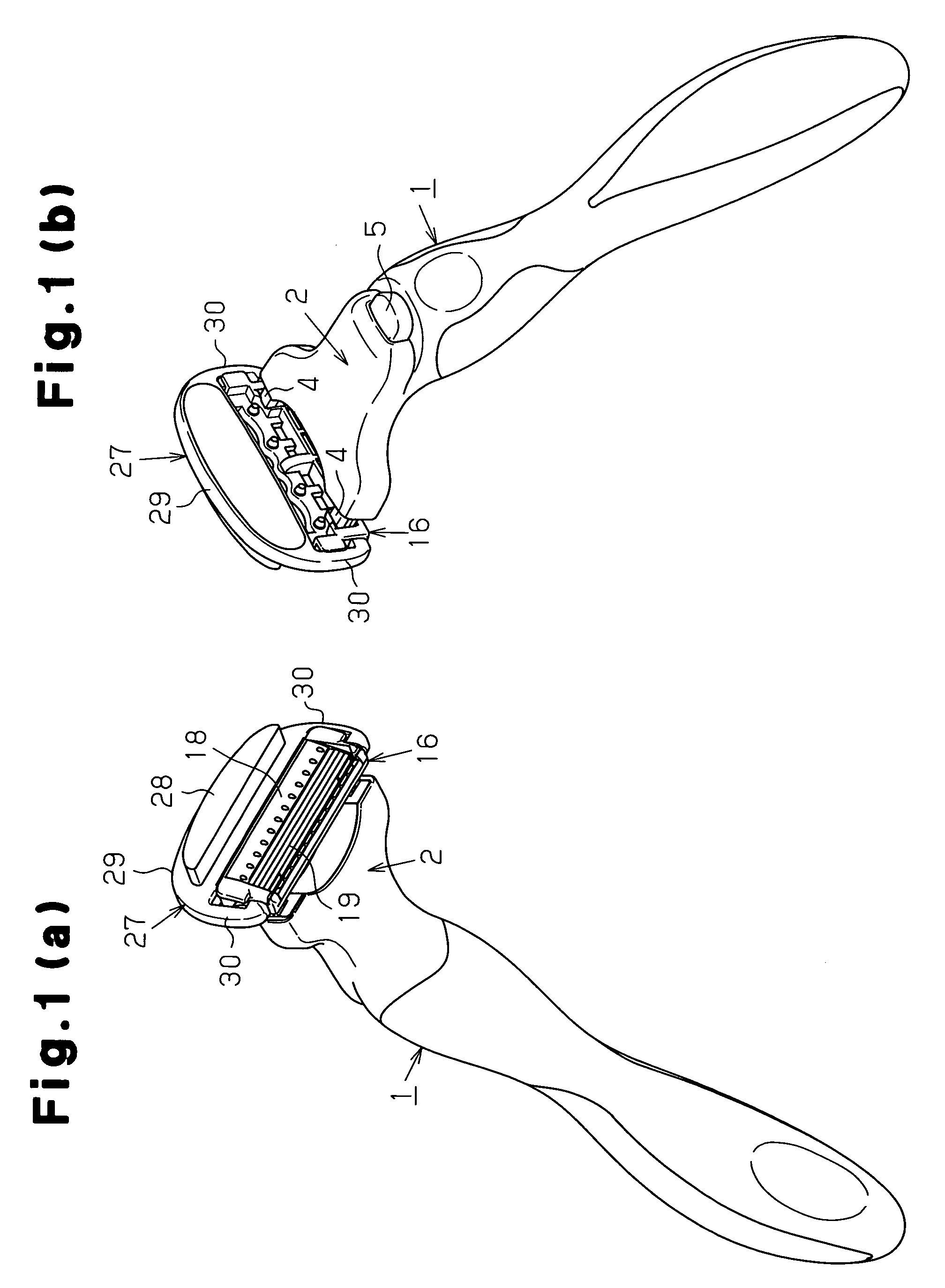

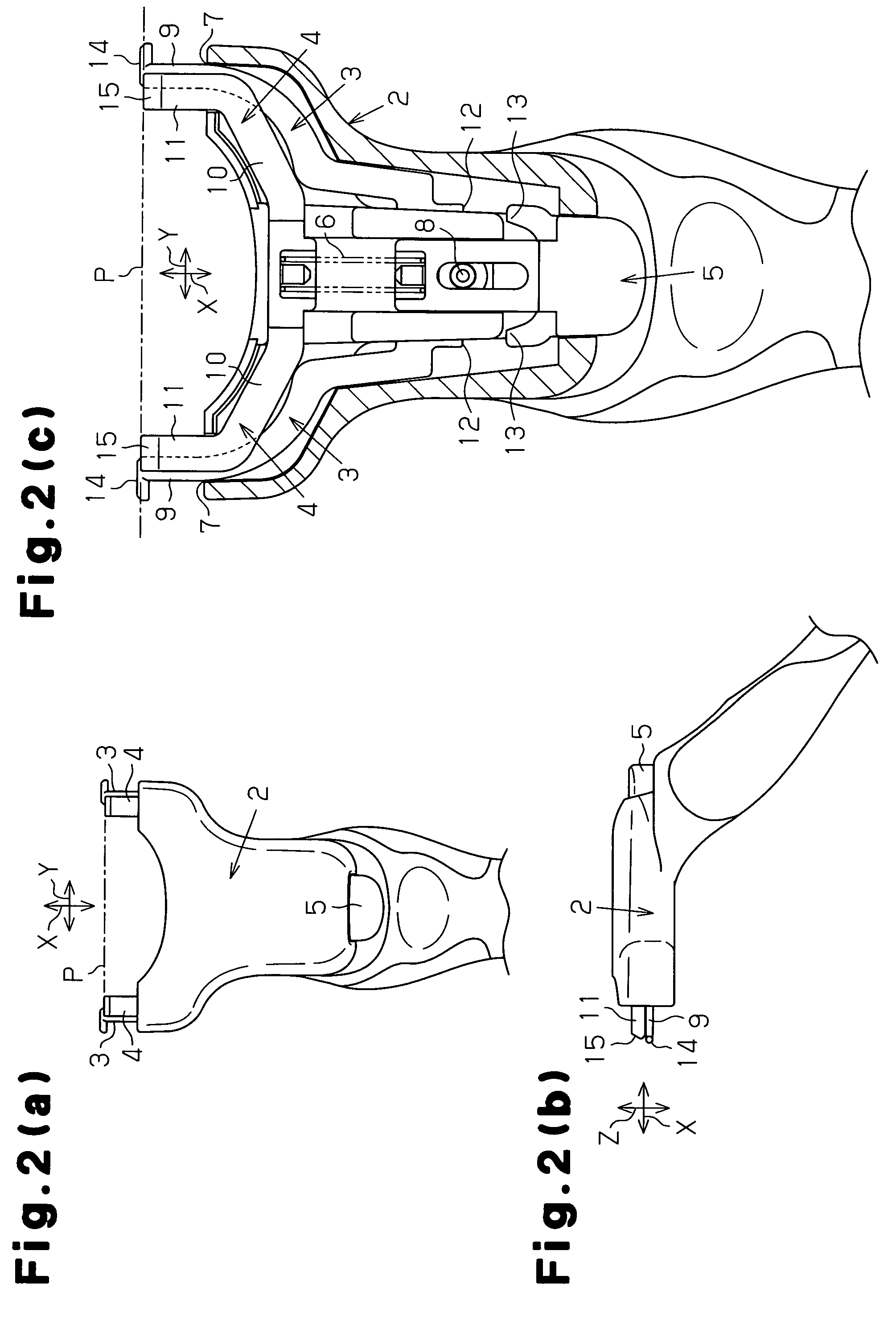

Razor

ActiveUS7877879B2Feel goodEasy to useMetal working apparatusEngineeringElectrical and Electronics engineering

Owner:KAI R&D CENT CO LTD

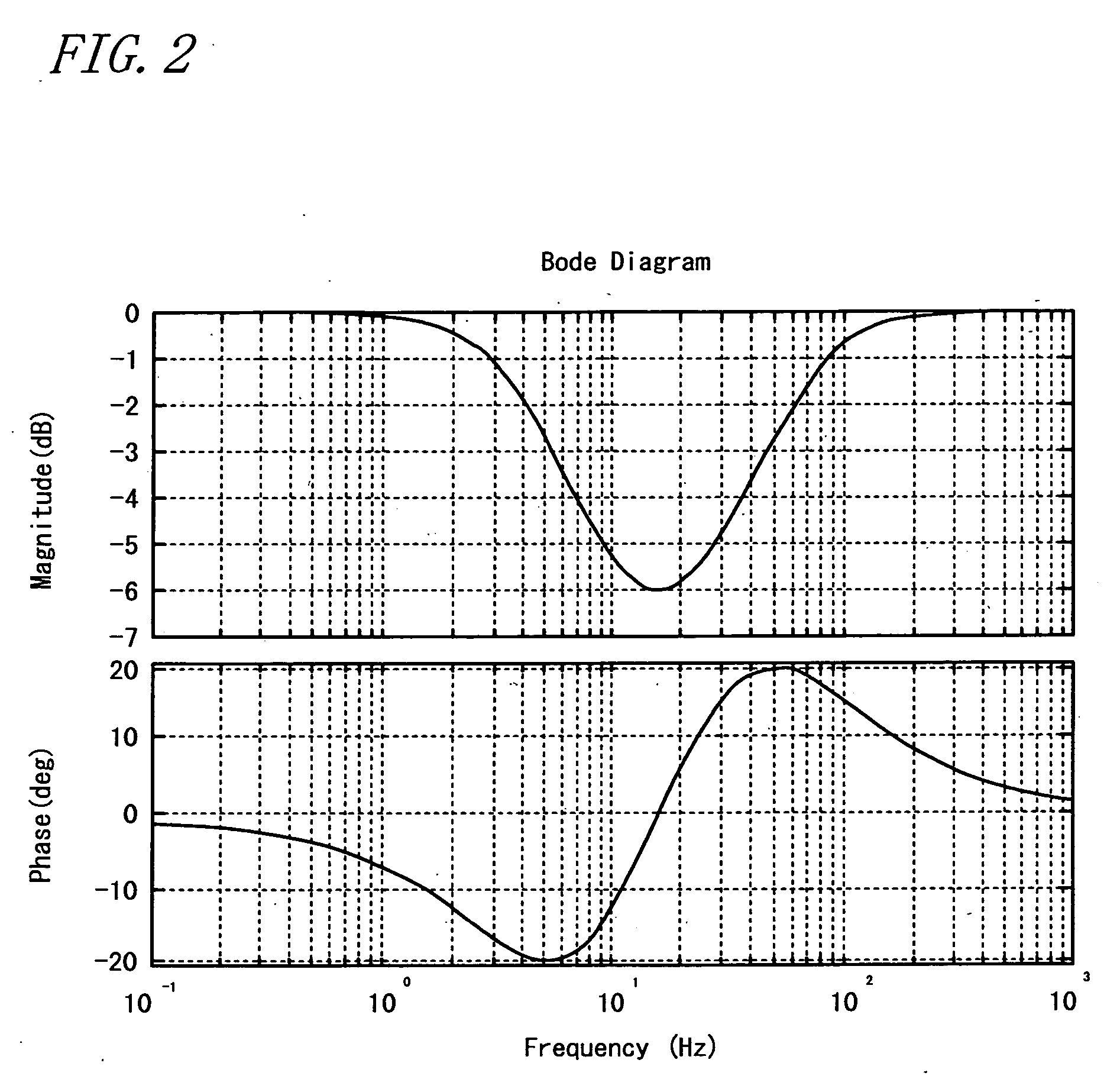

Electric Power Steering System

InactiveUS20070205041A1Favorable steering feelingLess inertia feelingSteering linkagesAutomatic steering controlElectric power steeringDamping torque

An electric power steering system is provided which is capable of providing a favorable steering feeling without using compensation logics such as of inertia compensation and friction compensation. The electric power steering system includes road-noise suppression control means (213) for controlling a steering assist motor (9) in a manner to damp torque transmission in a higher frequency region representing road noises than a frequency region representing road information. A friction value of a steering mechanism (A) is decreased enough to allow the intrinsic vibrations of the steering mechanism (A) to appear. Rotor inertia of the steering assist motor (9) is set to a value small enough to allow the frequencies of the intrinsic vibrations to be present in the frequency region where the torque transmission is damped by the road-noise suppression control means (213).

Owner:JTEKT CORP

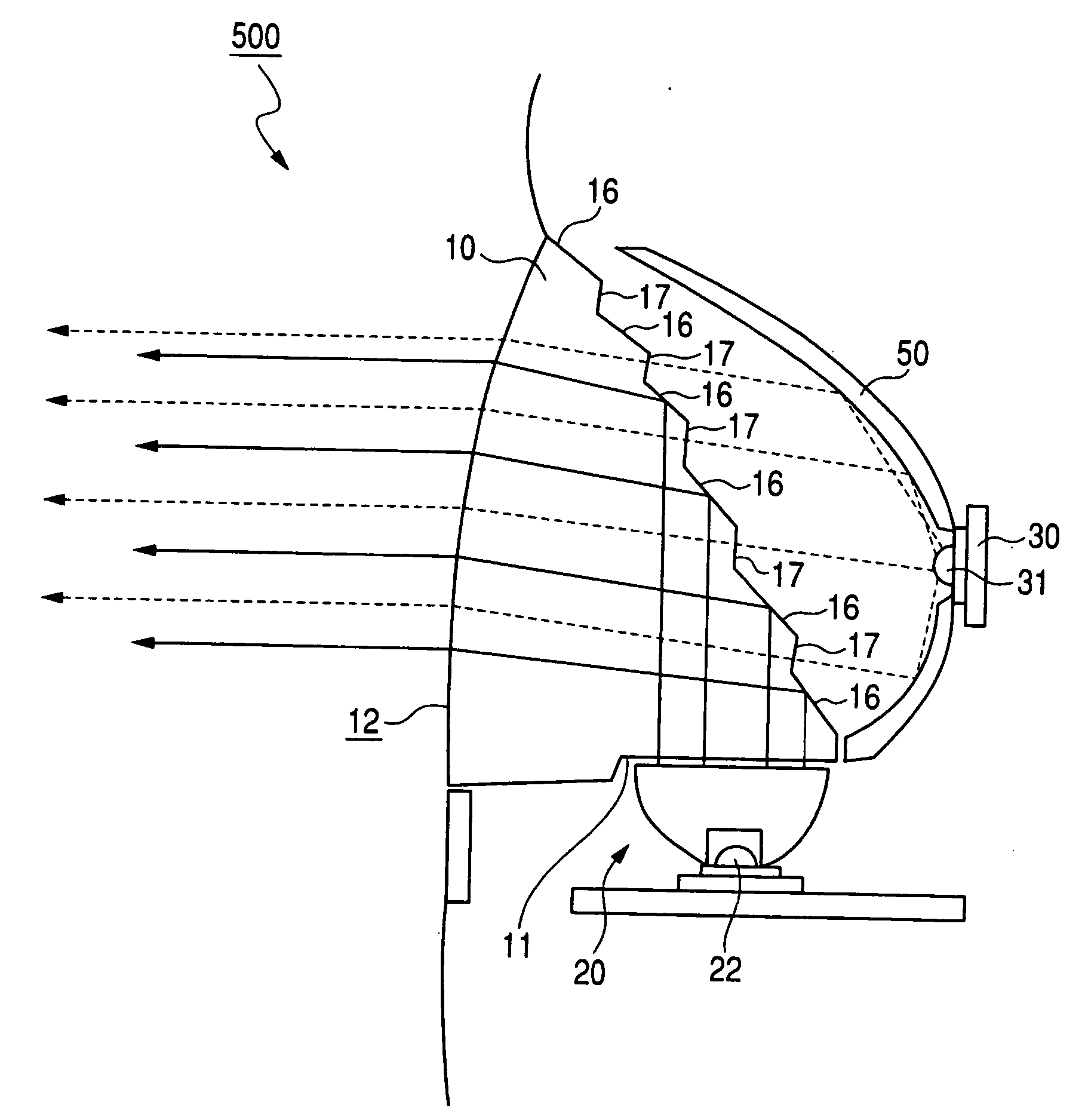

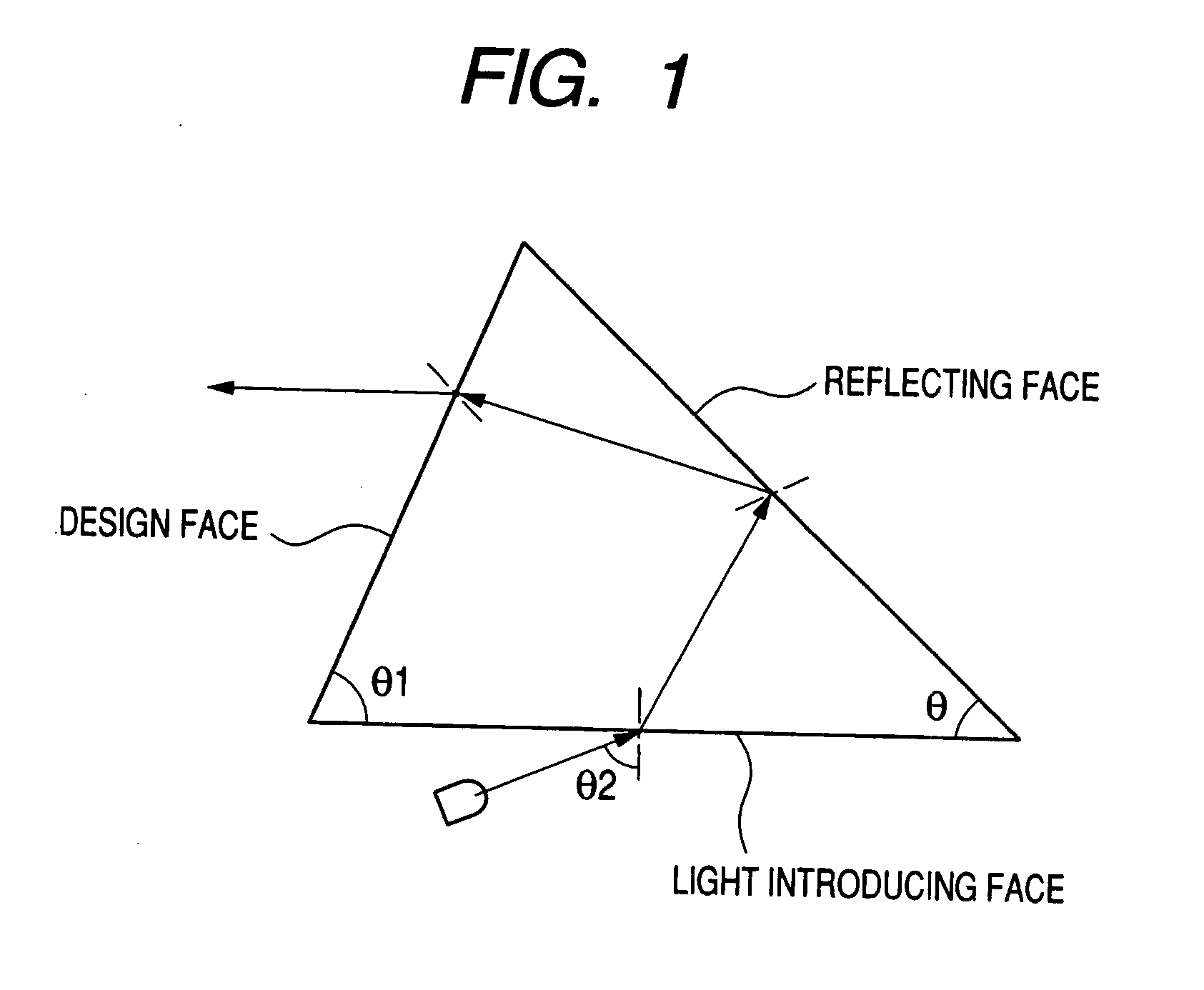

Vehicular lamp

InactiveUS20090027911A1Simplify manufacturing stepsReduce manufacturing costLighting support devicesPoint-like light sourceLight-emitting diodeLight source

The invention is constituted by a vehicular lamp characterized in a lens having a first light source, a second light source, a front light emitting face, a side end face to which the first light source is opposed, and a rear face, wherein the rear face includes a lens having pluralities of reflecting portions and transmitting portions consecutively aligned alternately in a direction of being remote from the side end face, and a reflecting face arranged on a rear side of the lens, light of the first light source is incident on the lens from the side end face of the lens, reflected by an interface of the reflecting portion, thereafter, radiated from the front light emitting face, and light of the second light source is reflected by the reflecting portion, thereafter, incident on the lens from the transmitting portion and radiated from the front light emitting face.

Owner:TOYODA GOSEI CO LTD

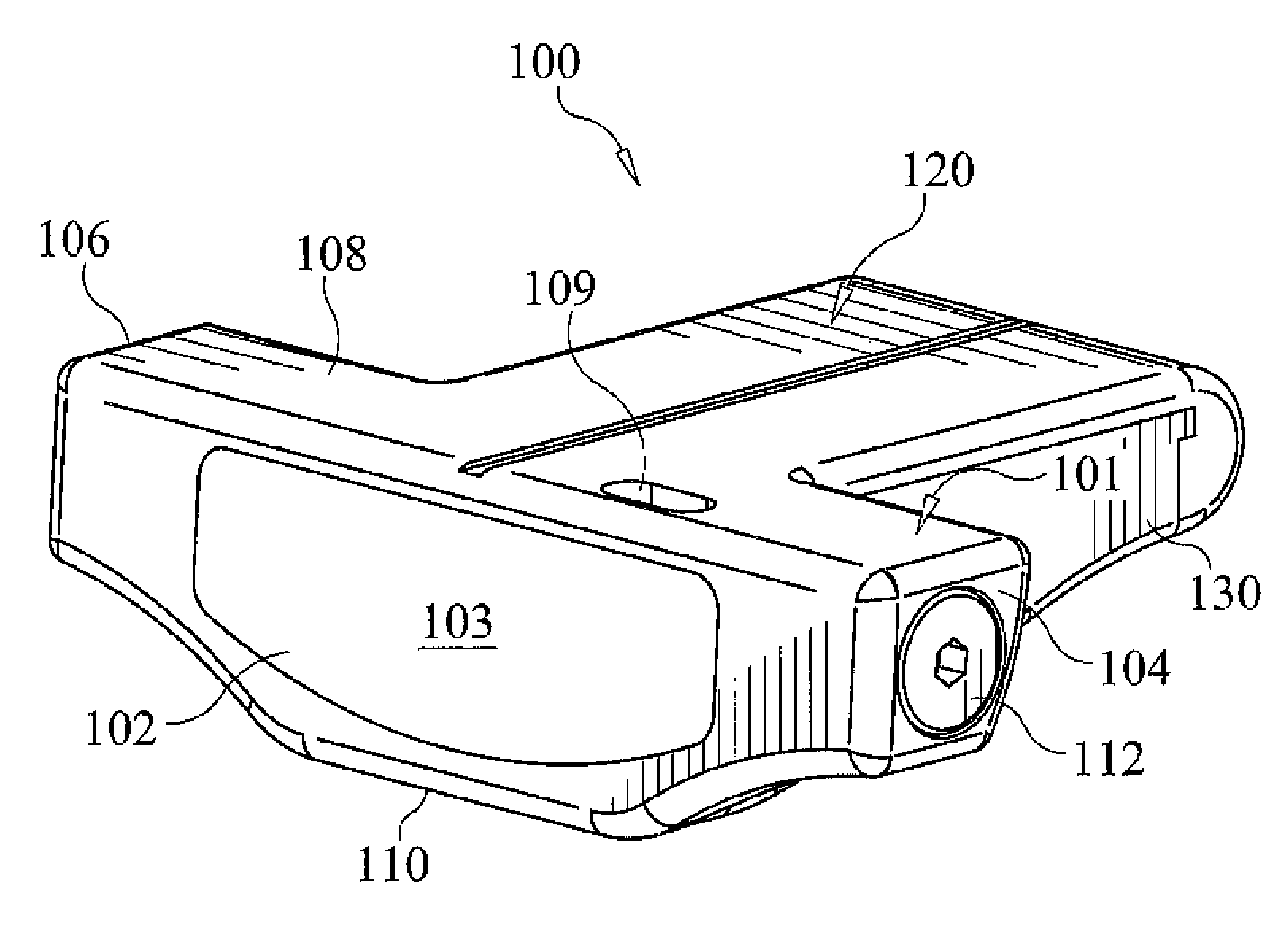

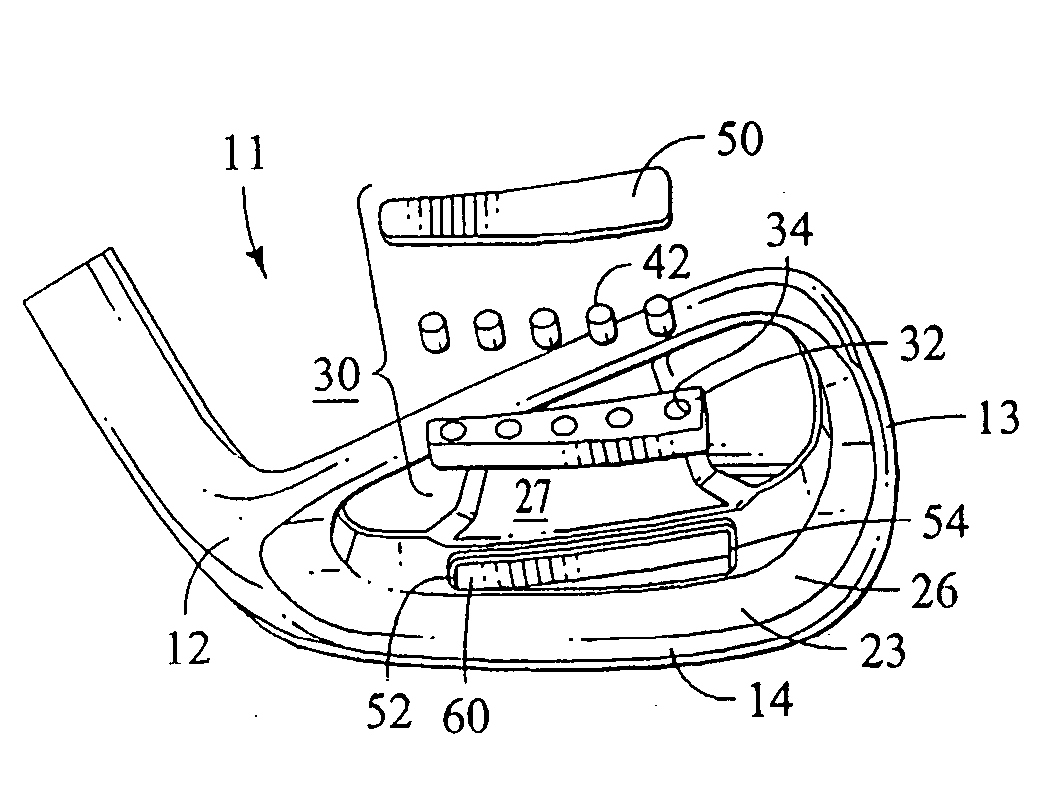

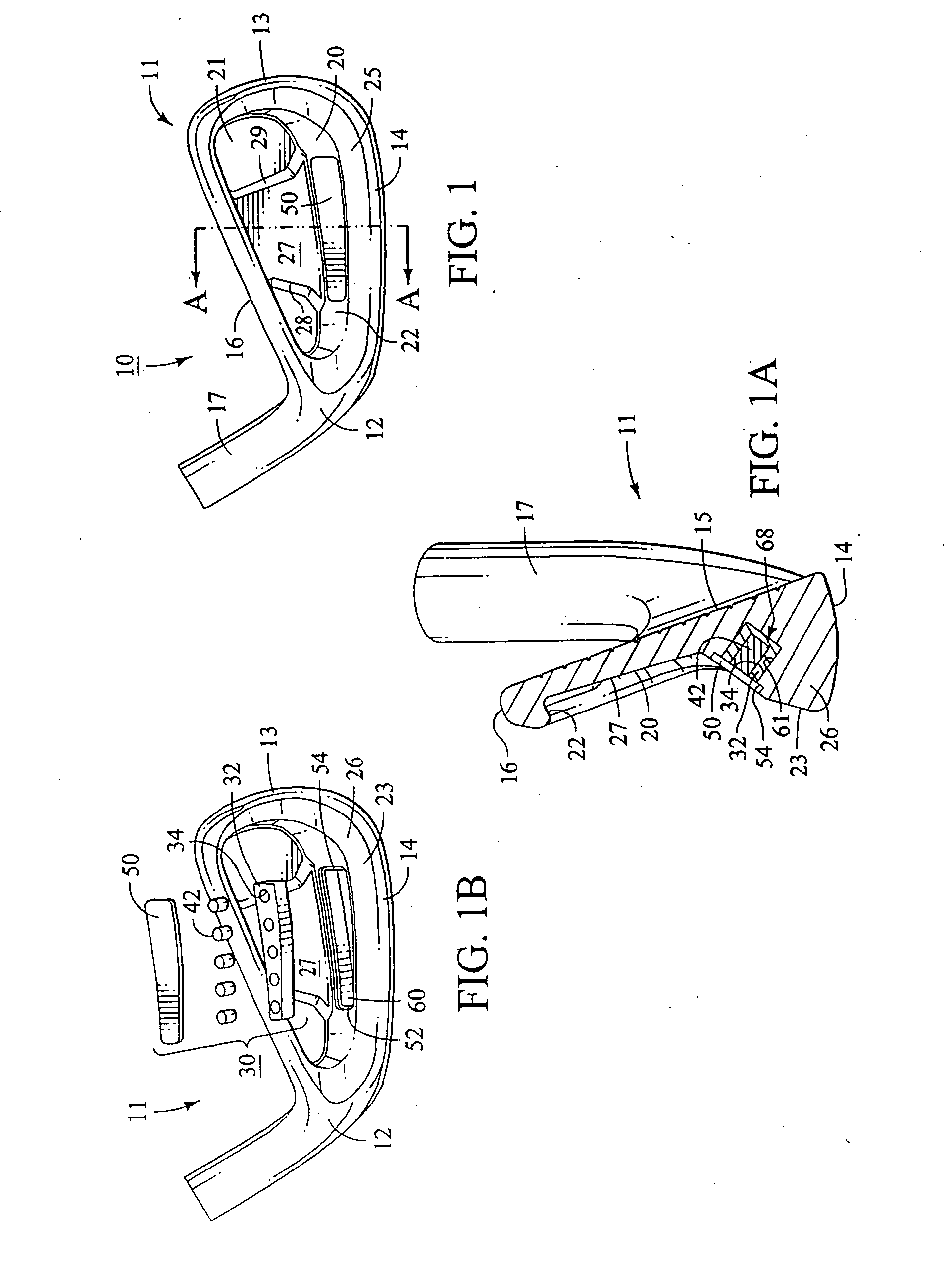

Golf club head

InactiveUS20050026716A1Feel goodReduce stiffnessIndoor gamesThermal switch detailsEngineeringGolf Ball

A golf club head is disclosed that comprises a body having a striking face, a rear cavity and a sole bar, wherein a recess is formed in the sole bar that extends generally from the rear cavity. An insert is located within the sole recess, the insert including a core and an intermediate layer that separates the core from the recess wall. The intermediate layer has a hardness and a modulus of elasticity that are less than that of the core, such that when the golf club head is used to strike a golf ball, the resulting vibrations are dissipated by compression of the intermediate layer and movement of the core with respect to the intermediate layer.

Owner:TAYLOR MADE GOLF

Tamper resistant bait station for rats

A bait station for containing rat poison contains a housing; at least one opening in the housing for a rat to enter; and a bait position in the housing for locating poisoned bait. A divider is provided between the bait position and each opening to prevent direct access to the bait from the opening, for example by a child. However, there are at least two different routes from the bait position leading to openings. Research has shown that rats, unlike mice, prefer not to eat in a confined space and it is believed that the choice of escape routes offered by the bait station of the invention encourages a rat to eat more of the bait. The bait station may include a hinged lid with locking means to prevent tampering with the bait.

Owner:DE SANGOSSE U S

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com