Patents

Literature

1252 results about "Flexural rigidity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flexural rigidity is defined as the force couple required to bend a fixed non-rigid structure in one unit of curvature or it can be defined as the resistance offered by a structure while undergoing bending.

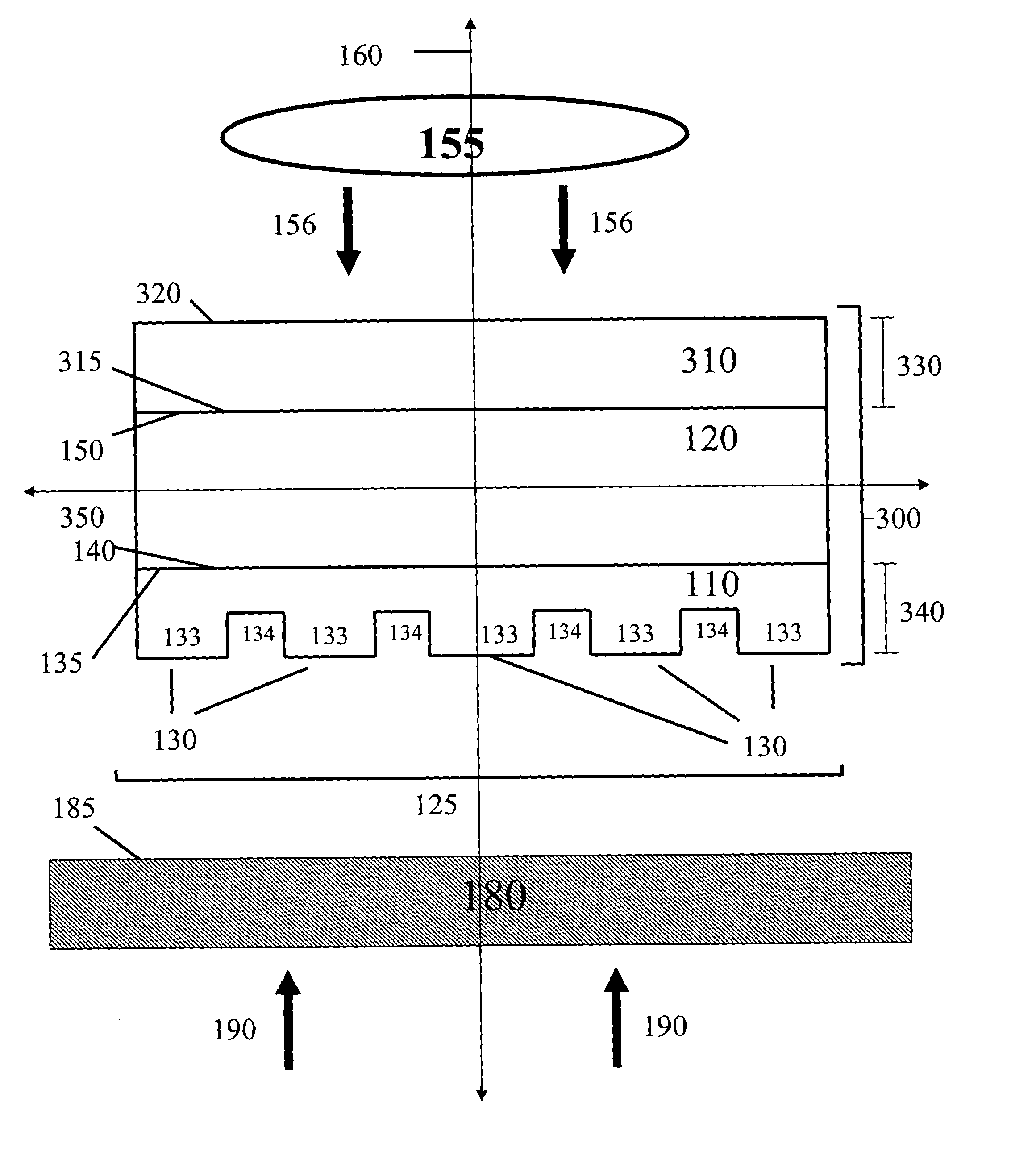

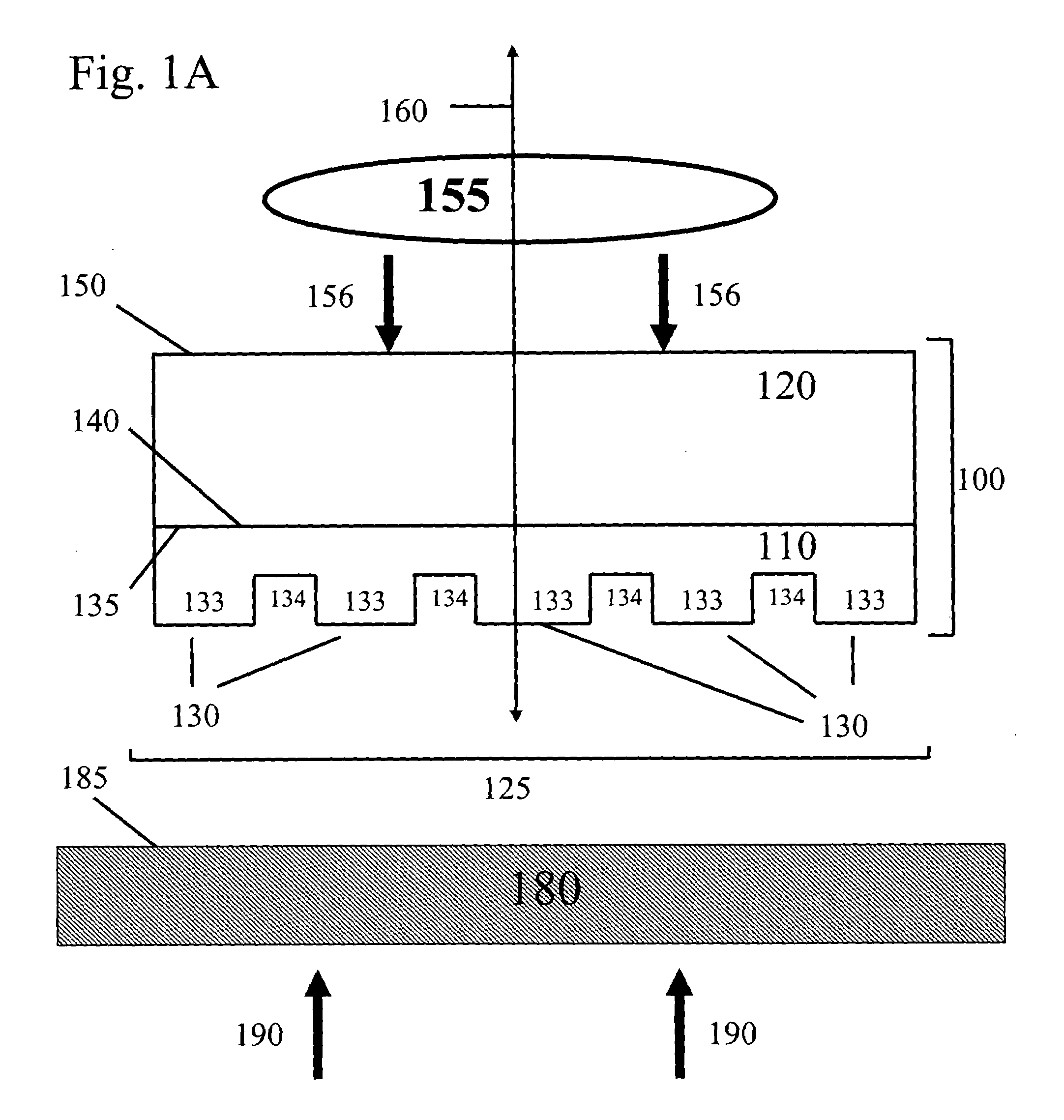

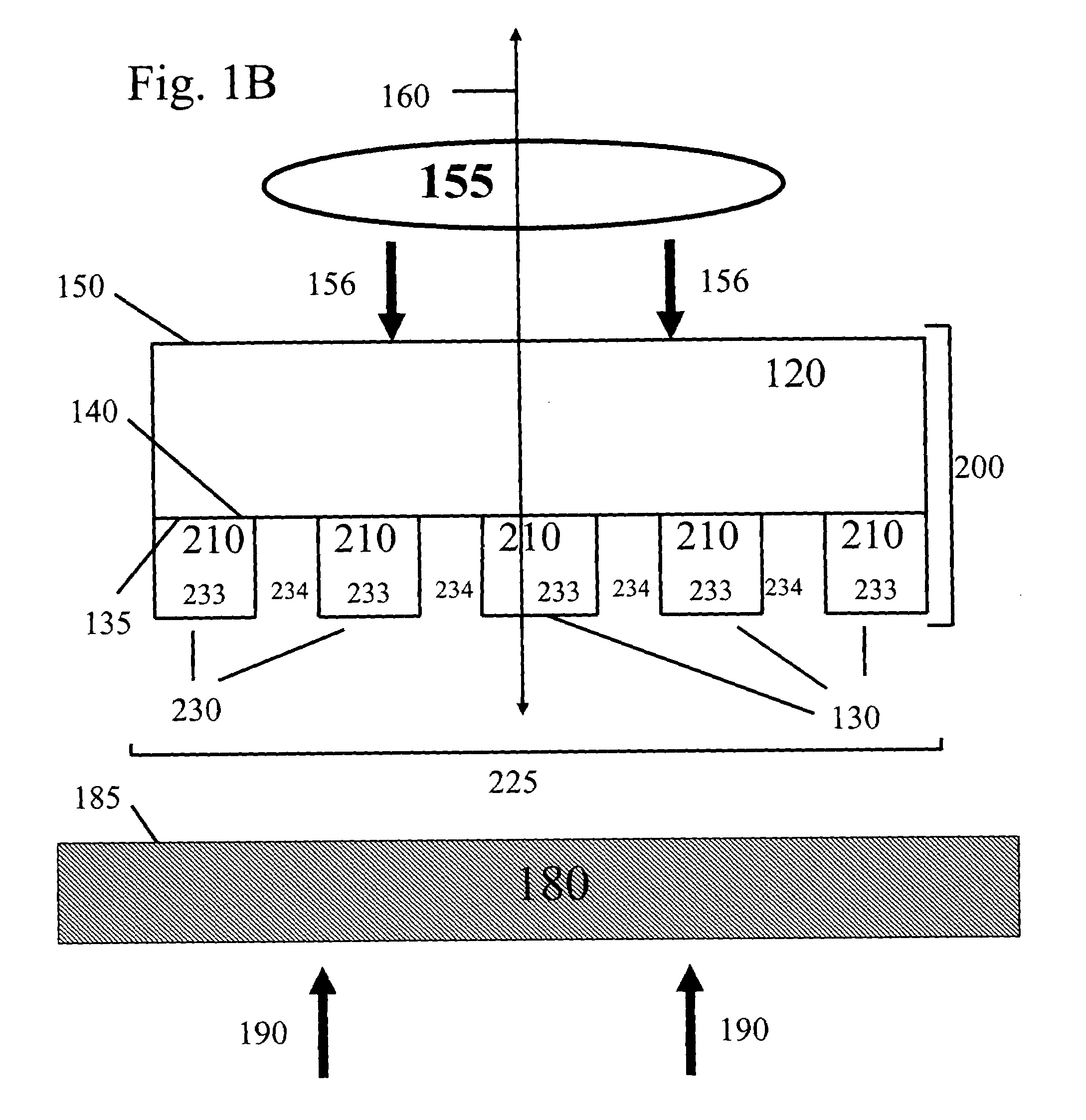

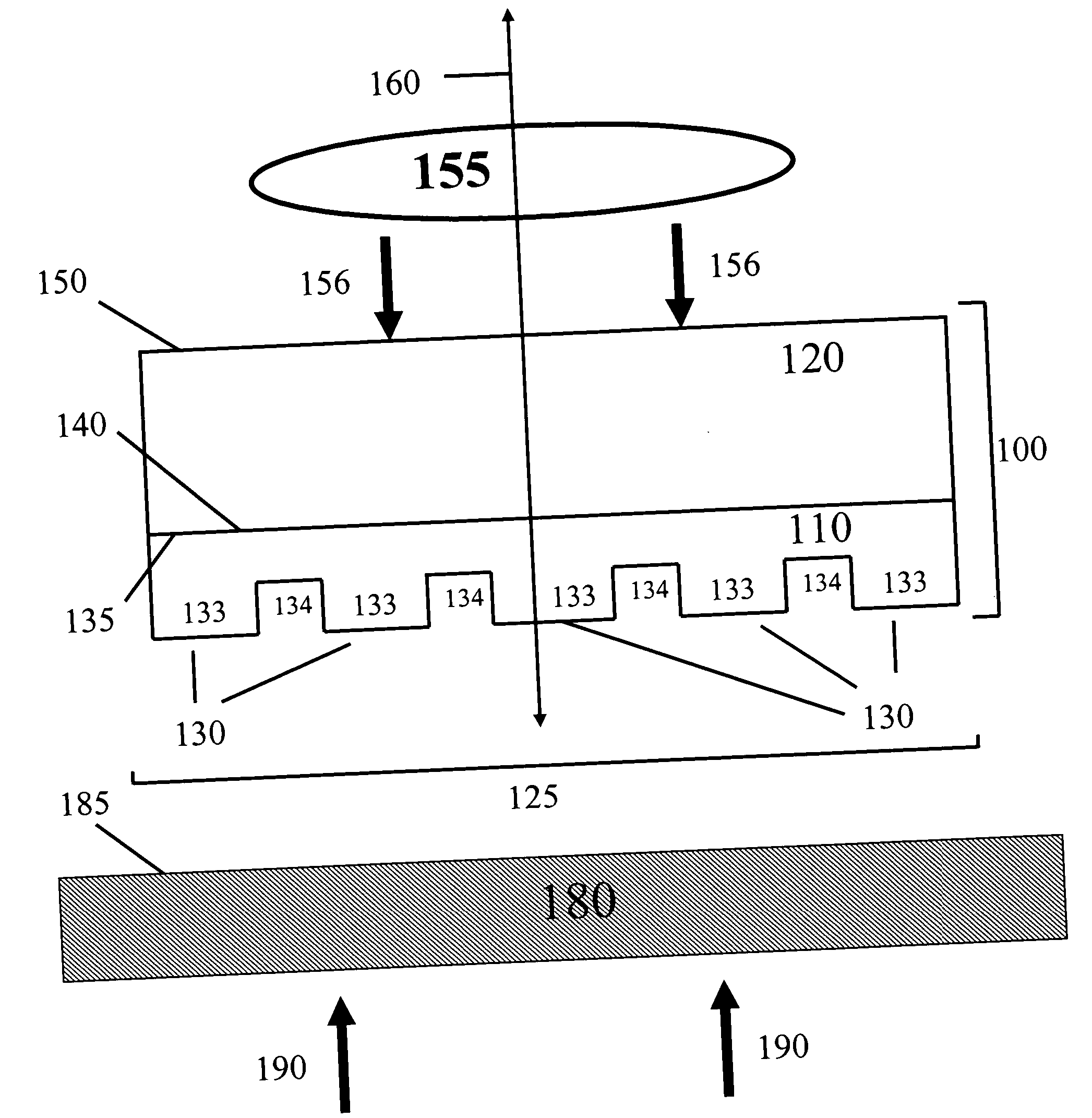

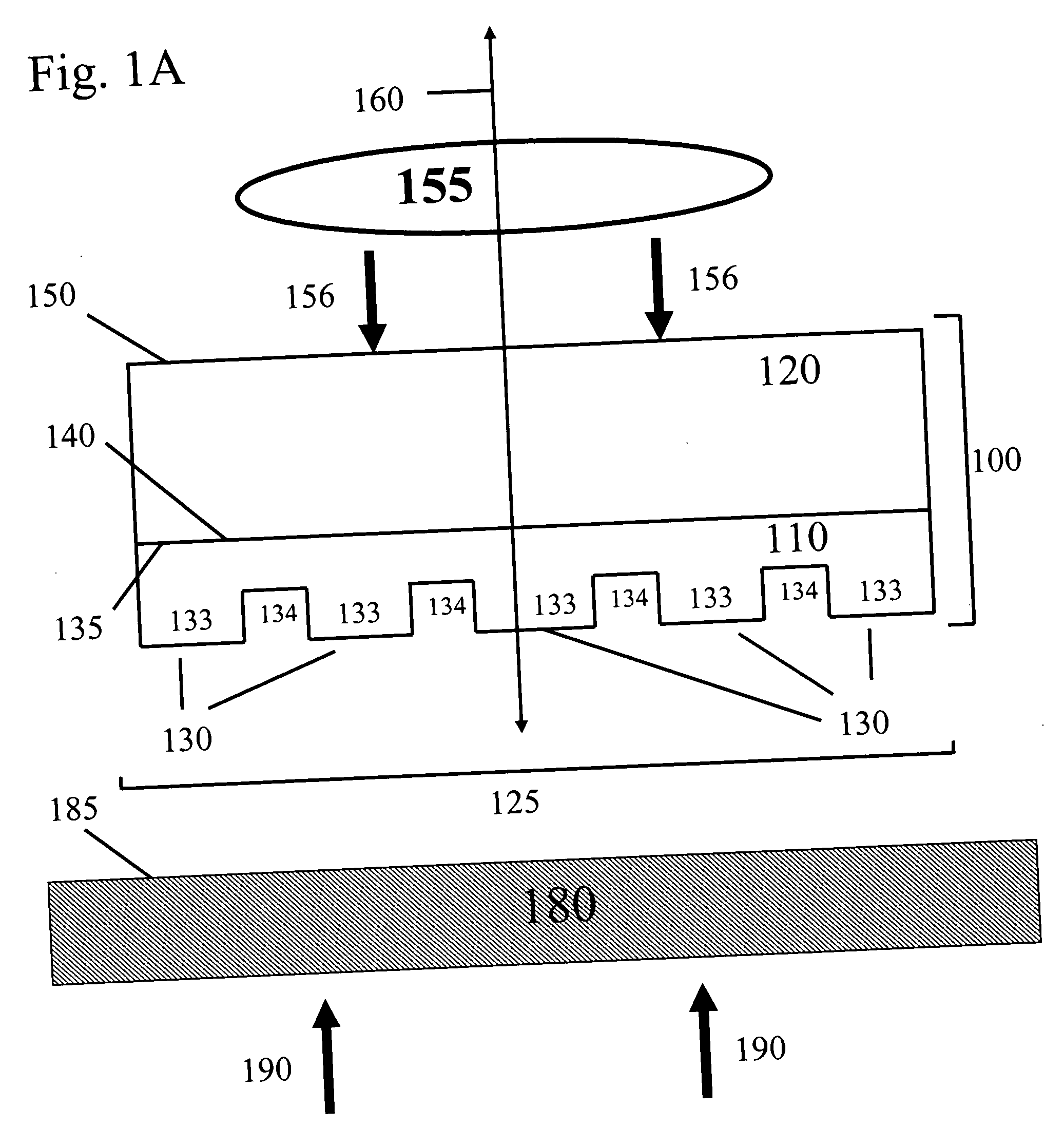

Composite patterning devices for soft lithography

ActiveUS7195733B2Improve fidelityIncrease resistanceMaterial nanotechnologyNanoinformaticsNano sizeYoung's modulus

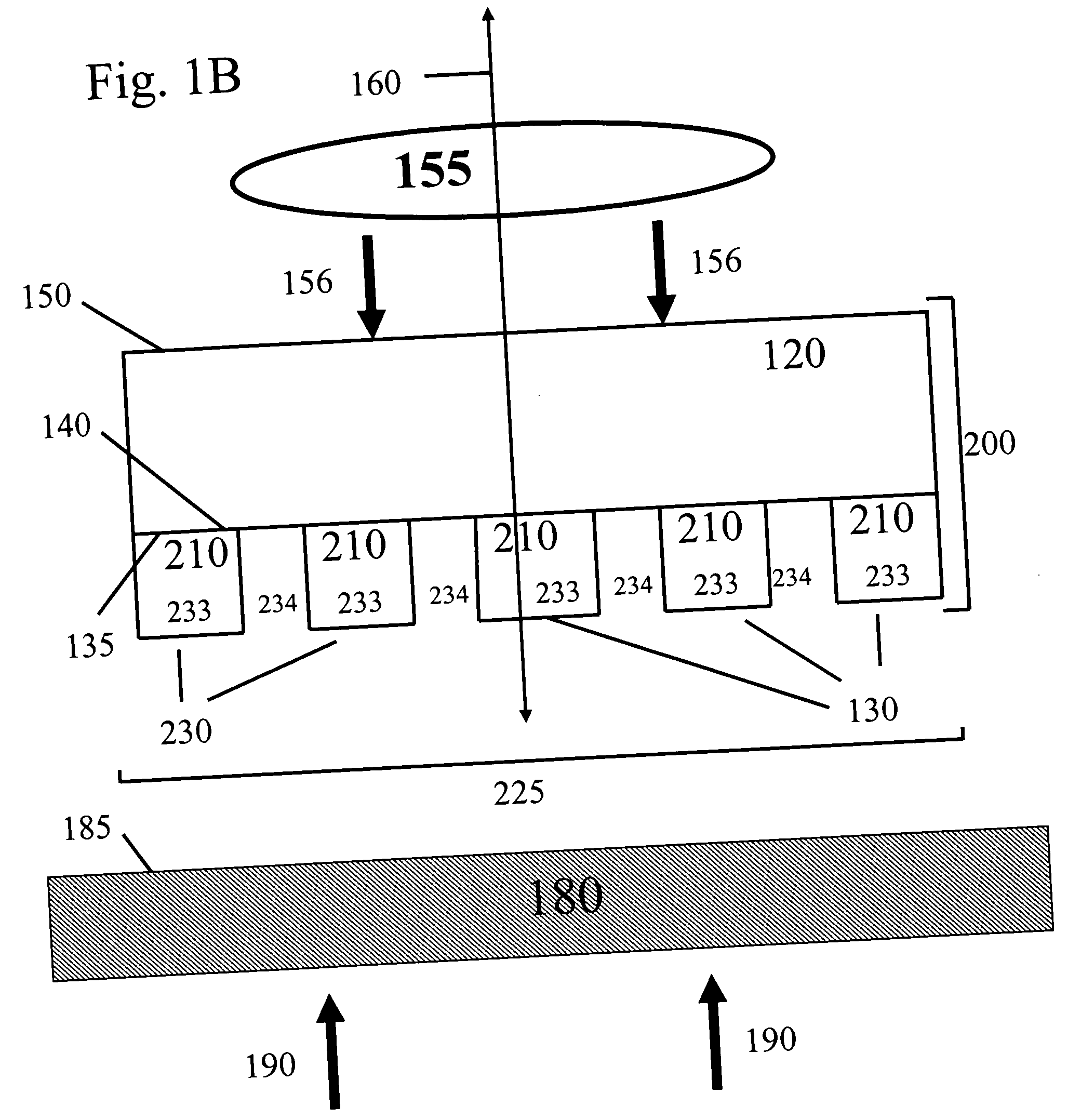

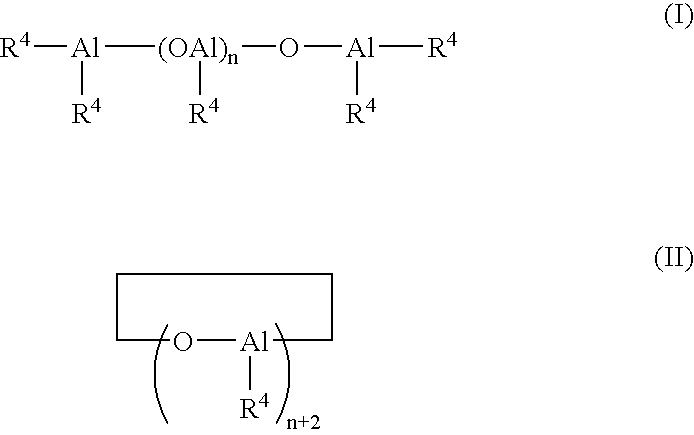

The present invention provides methods, devices and device components for fabricating patterns on substrate surfaces, particularly patterns comprising structures having microsized and / or nanosized features of selected lengths in one, two or three dimensions. The present invention provides composite patterning devices comprising a plurality of polymer layers each having selected mechanical properties, such as Young's Modulus and flexural rigidity, selected physical dimensions, such as thickness, surface area and relief pattern dimensions, and selected thermal properties, such as coefficients of thermal expansion, to provide high resolution patterning on a variety of substrate surfaces and surface morphologies.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

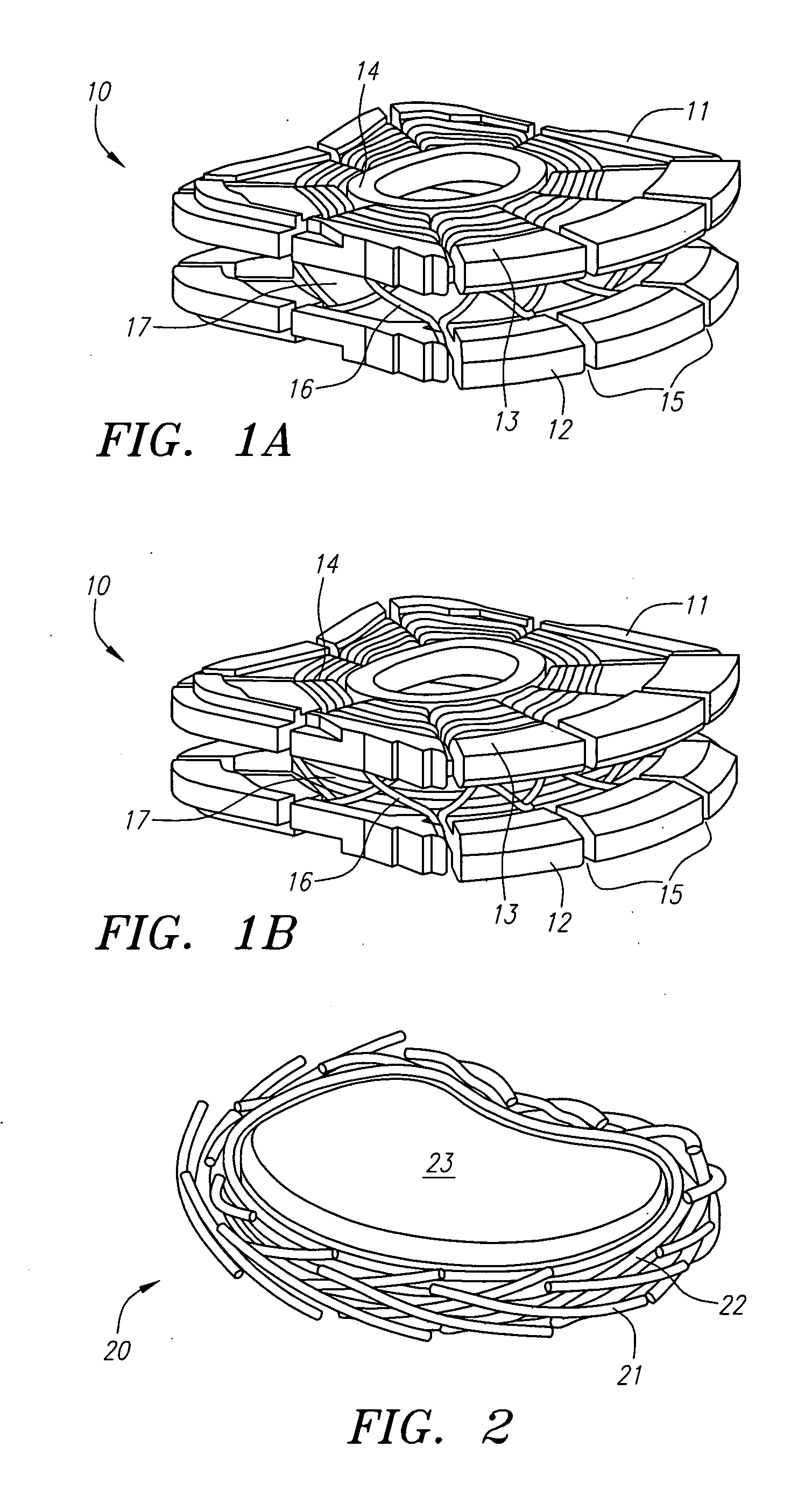

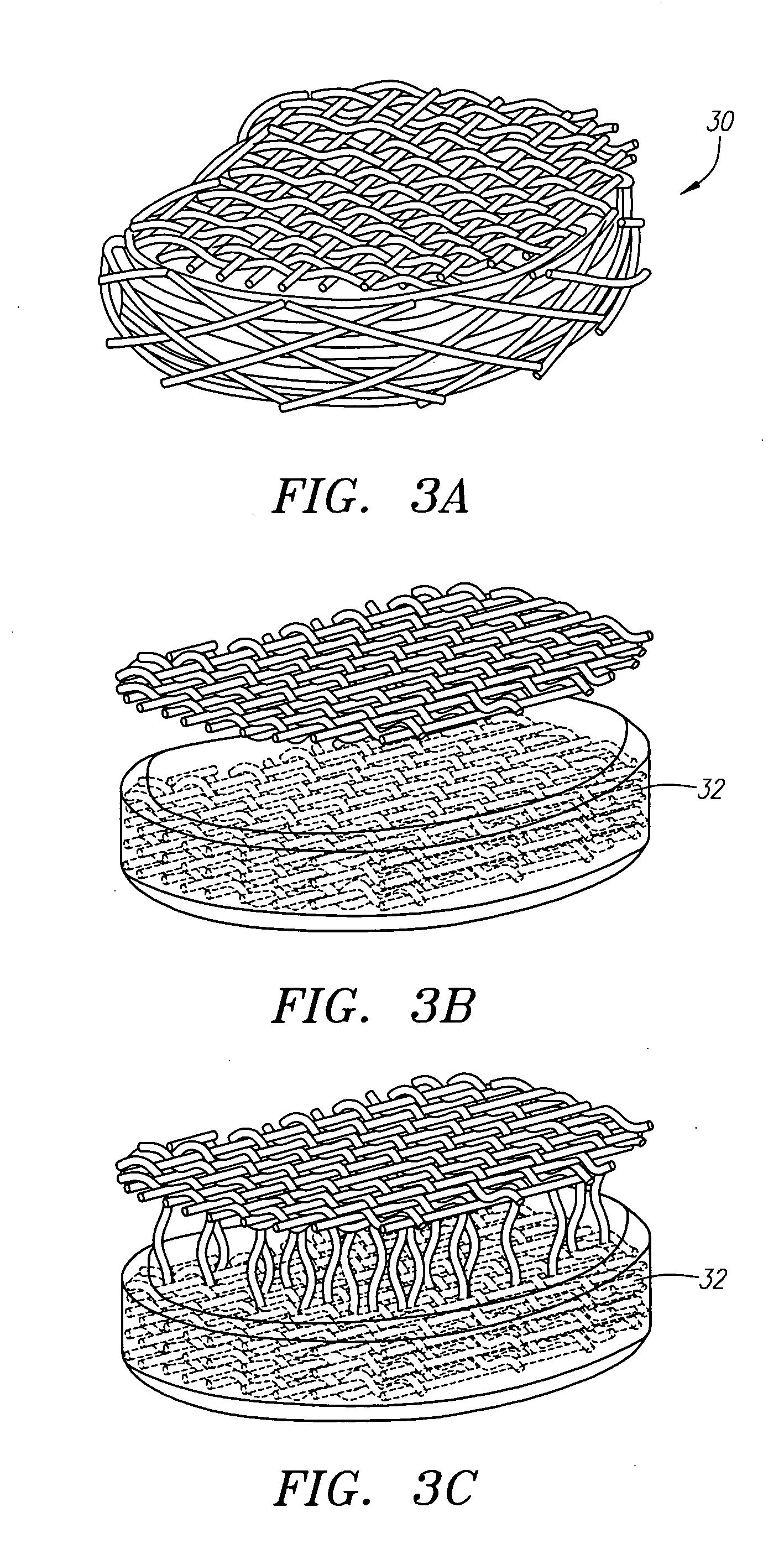

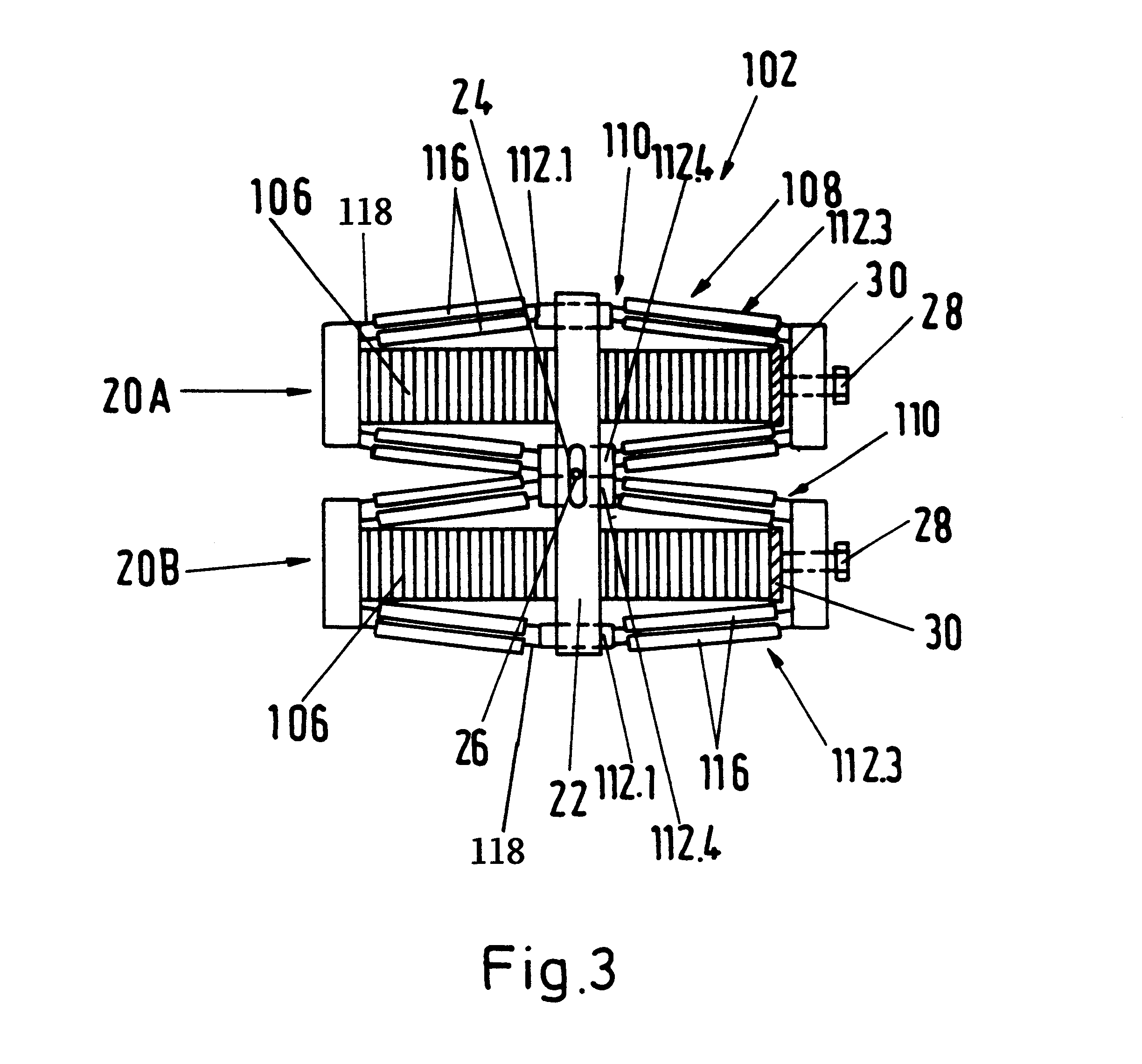

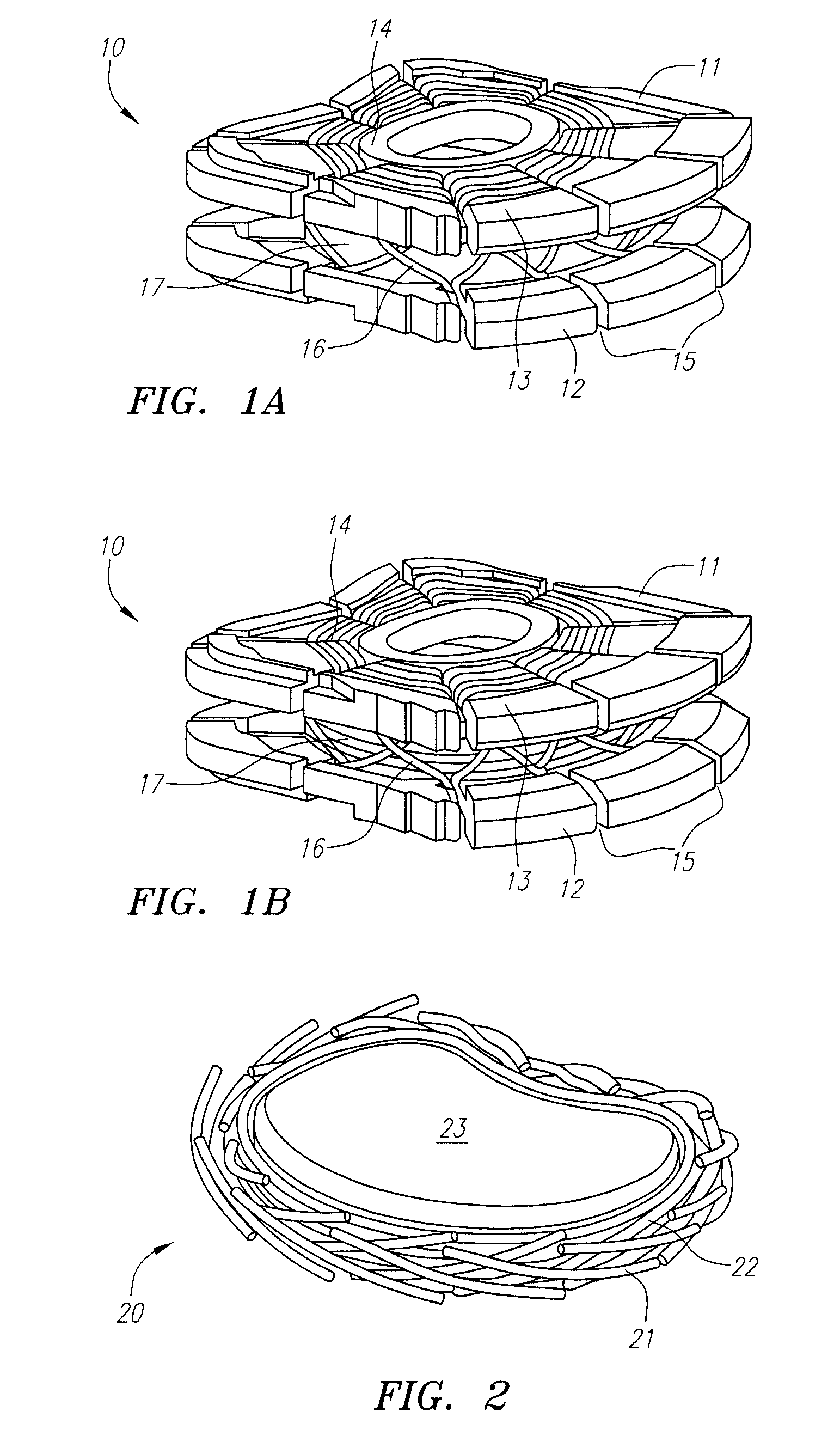

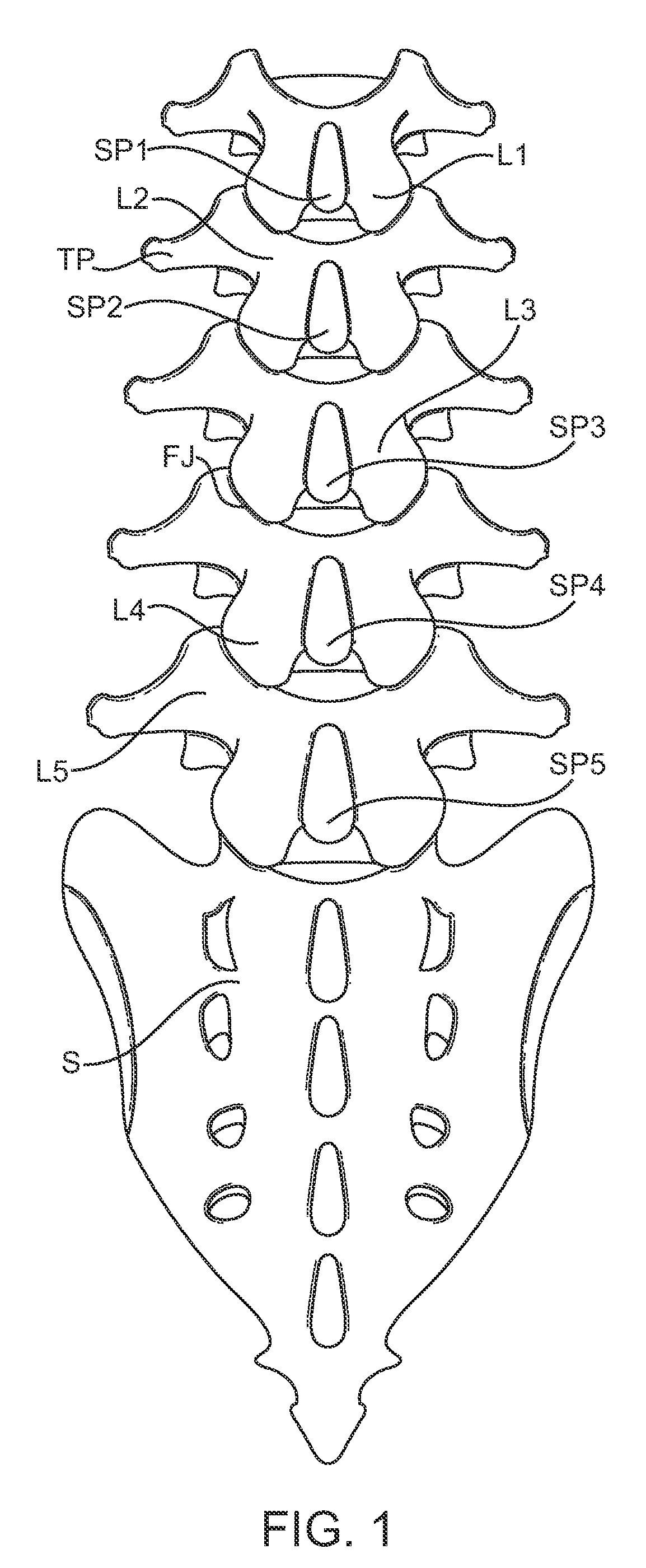

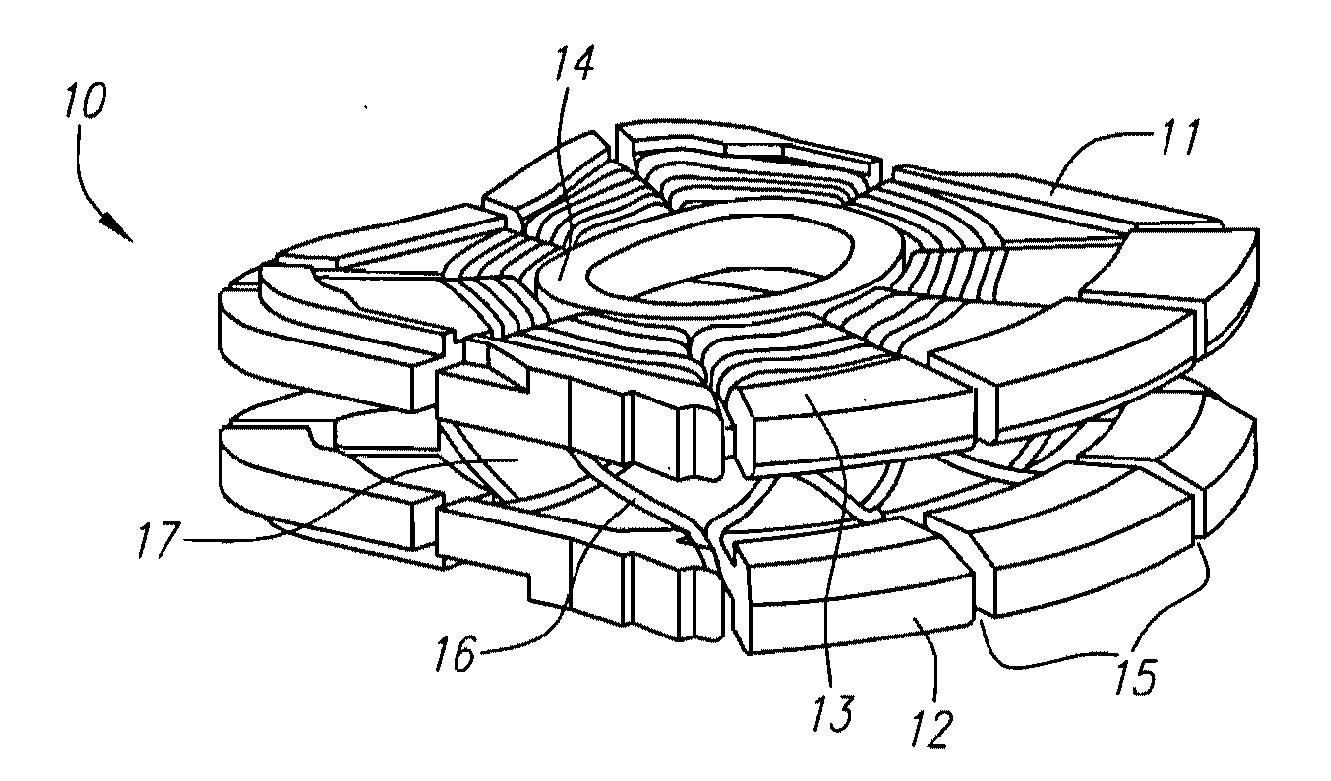

Prosthetic intervertebral disc and methods for using same

InactiveUS20050228500A1Improve toughnessHigh modulusJoint implantsSpinal implantsSurgical operationIntervertebral disc

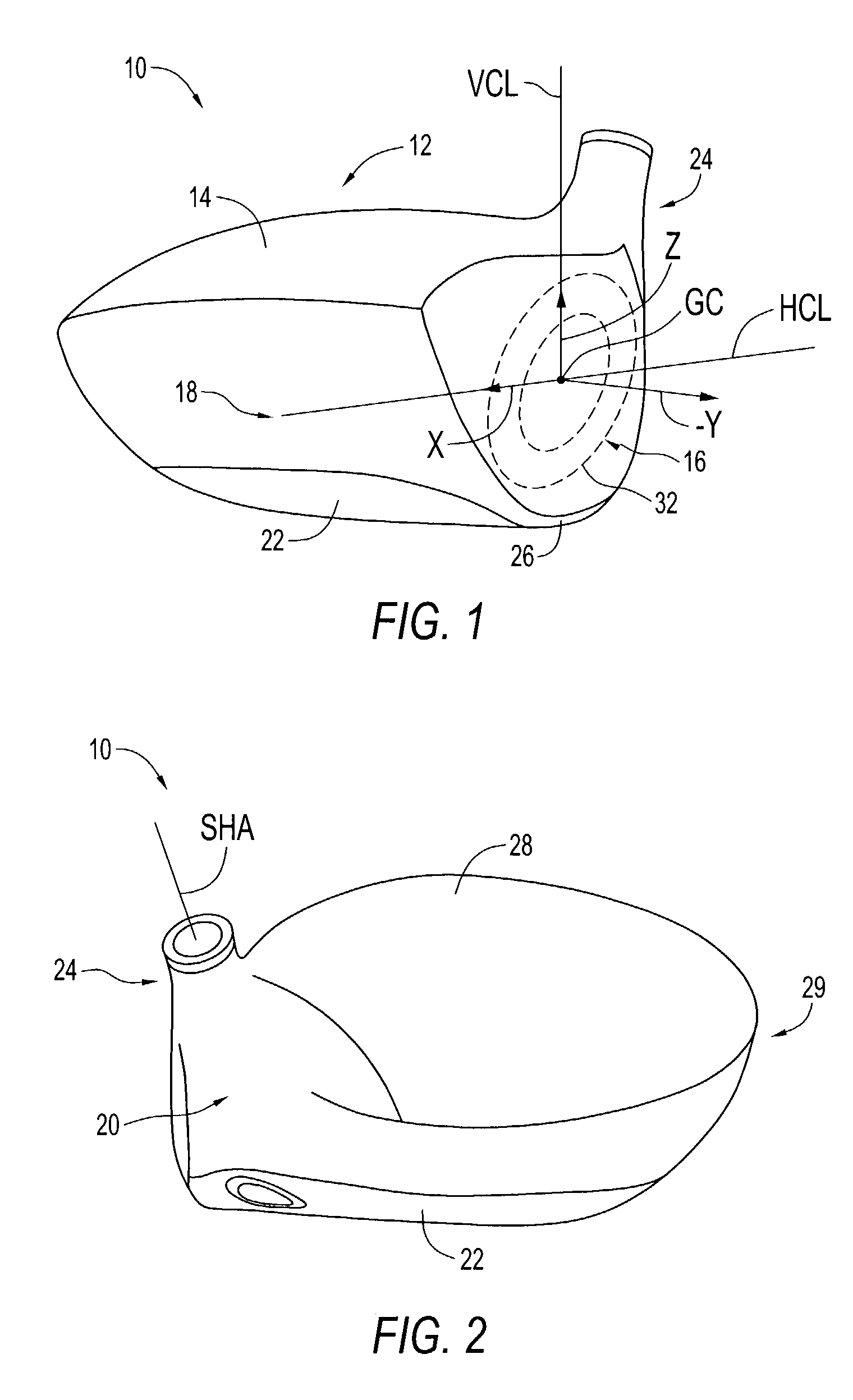

Prosthetic intervertebral discs and methods for using the same are described. The subject prosthetic discs include upper and lower endplates separated by a compressible core member. The prosthetic discs described herein include one-piece, two-piece, three-piece, and four-piece structures. The subject prosthetic discs exhibit stiffness in the vertical direction, torsional stiffness, bending stiffness in the saggital plane, and bending stiffness in the front plane, where the degree of these features can be controlled independently by adjusting the components of the discs. The interface mechanism between the endplates and the core members of several embodiments of the described prosthetic discs enables a very easy surgical operation for implantation.

Owner:SPINAL KINETICS

Composite patterning devices for soft lithography

ActiveUS20050238967A1High resolutionImprove placement accuracyMaterial nanotechnologyNanoinformaticsEngineeringThermal expansion

The present invention provides methods, devices and device components for fabricating patterns on substrate surfaces, particularly patterns comprising structures having microsized and / or nanosized features of selected lengths in one, two or three dimensions. The present invention provides composite patterning devices comprising a plurality of polymer layers each having selected mechanical properties, such as Young's Modulus and flexural rigidity, selected physical dimensions, such as thickness, surface area and relief pattern dimensions, and selected thermal properties, such as coefficients of thermal expansion, to provide high resolution patterning on a variety of substrate surfaces and surface morphologies.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

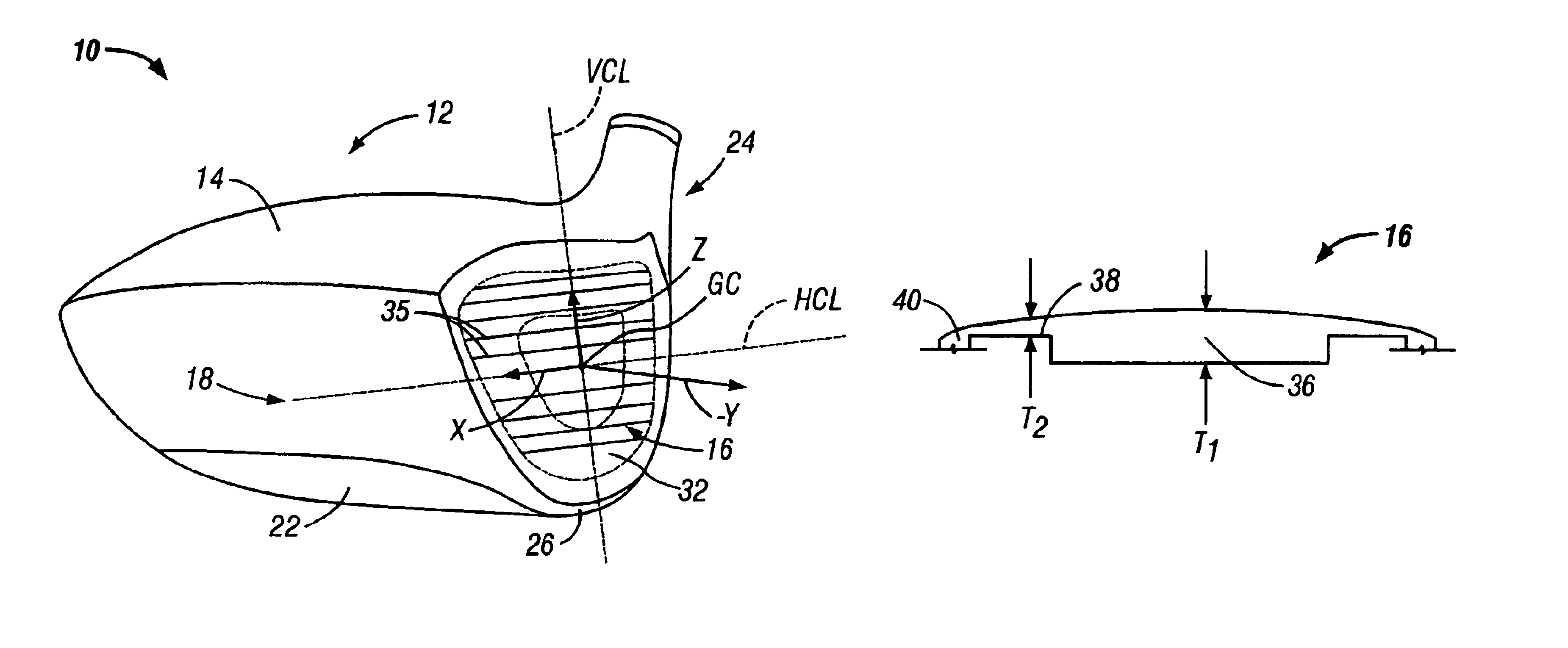

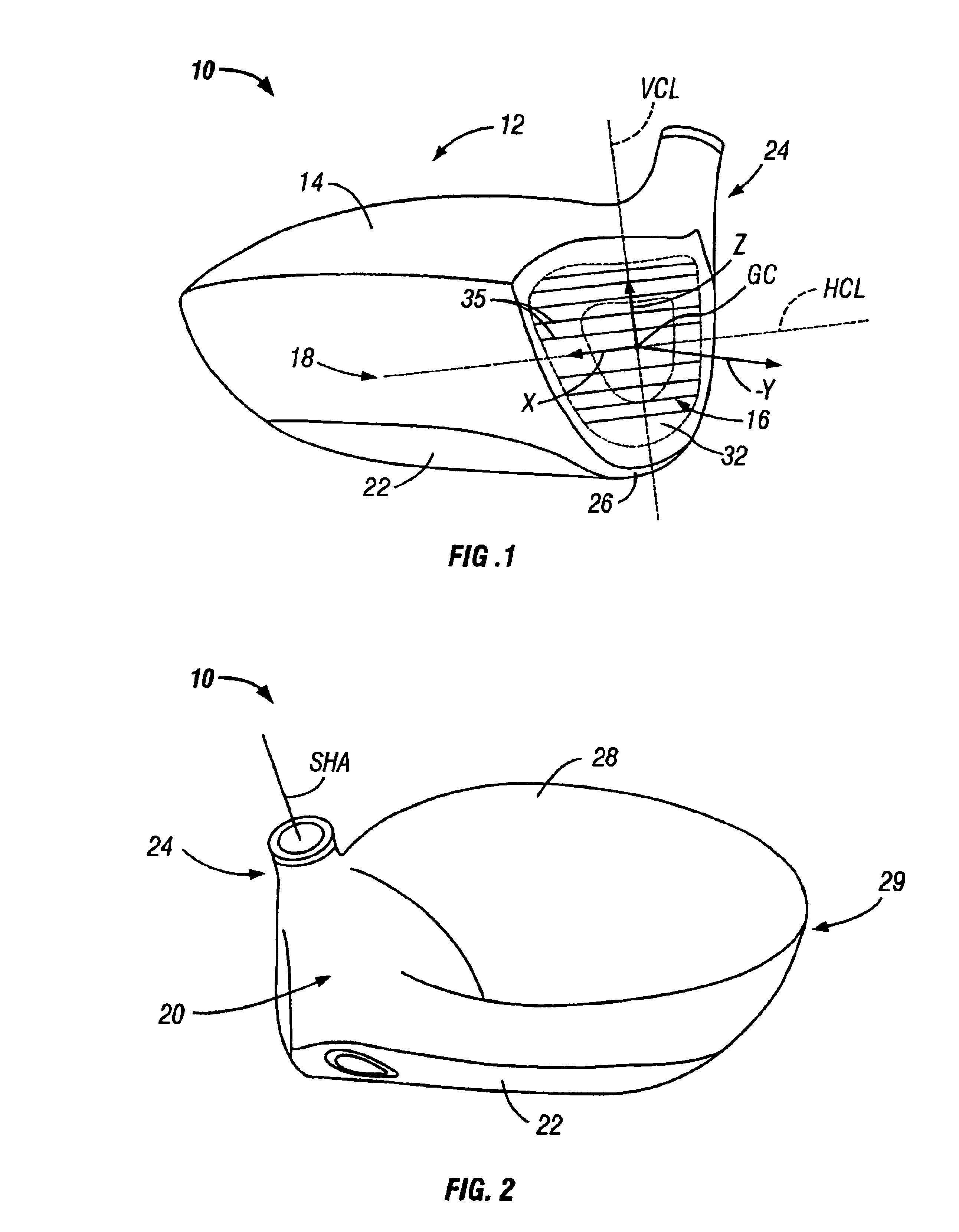

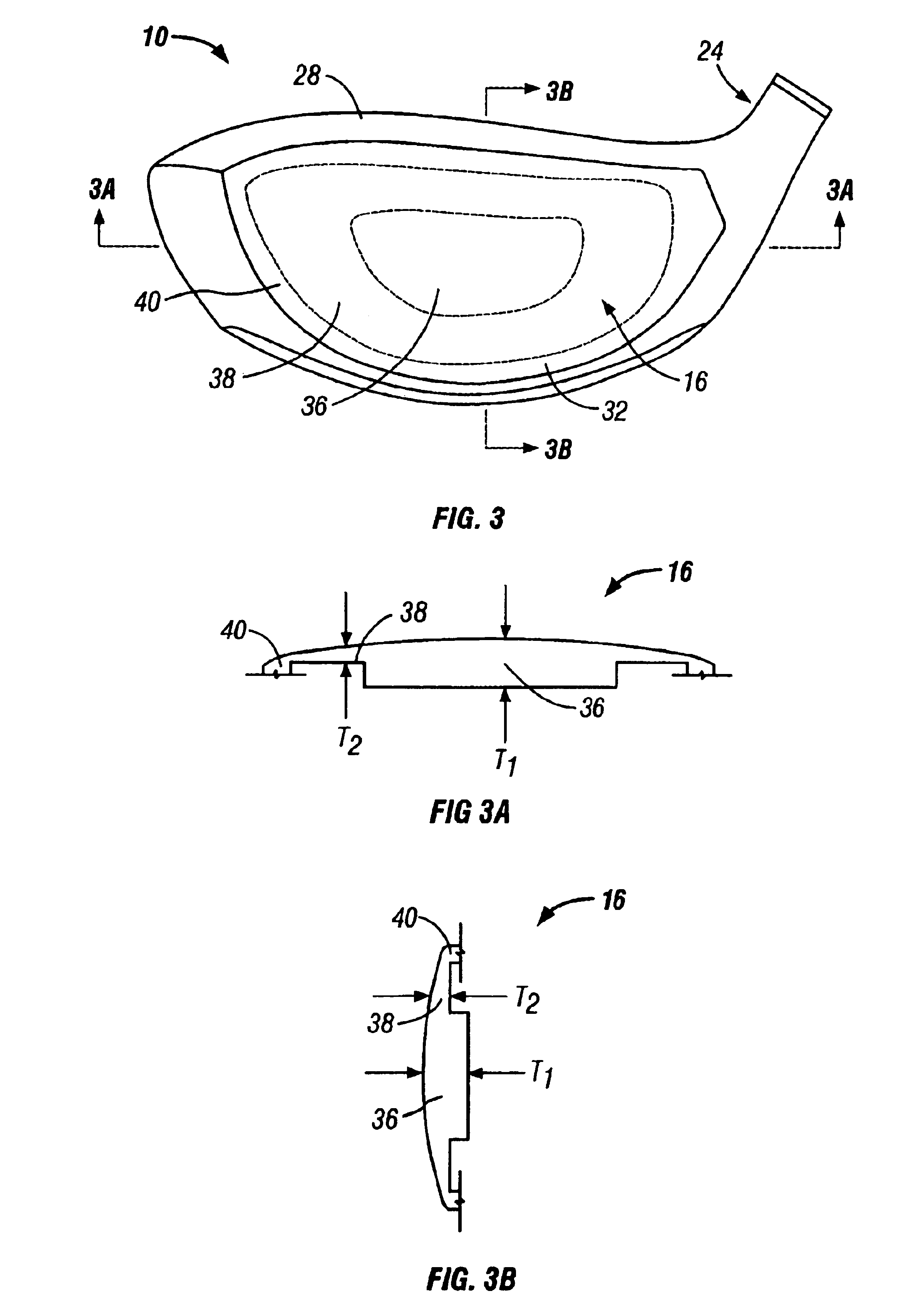

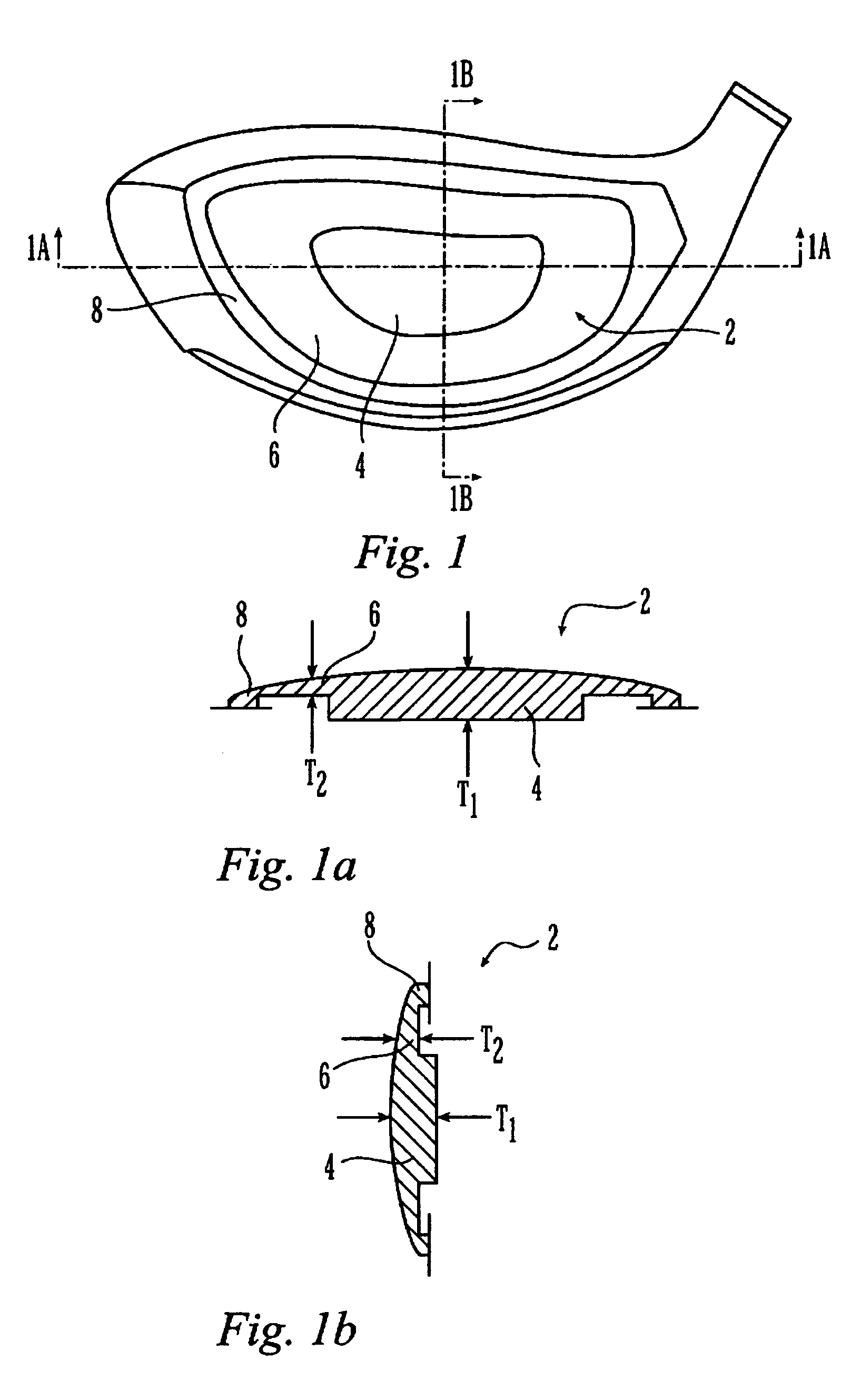

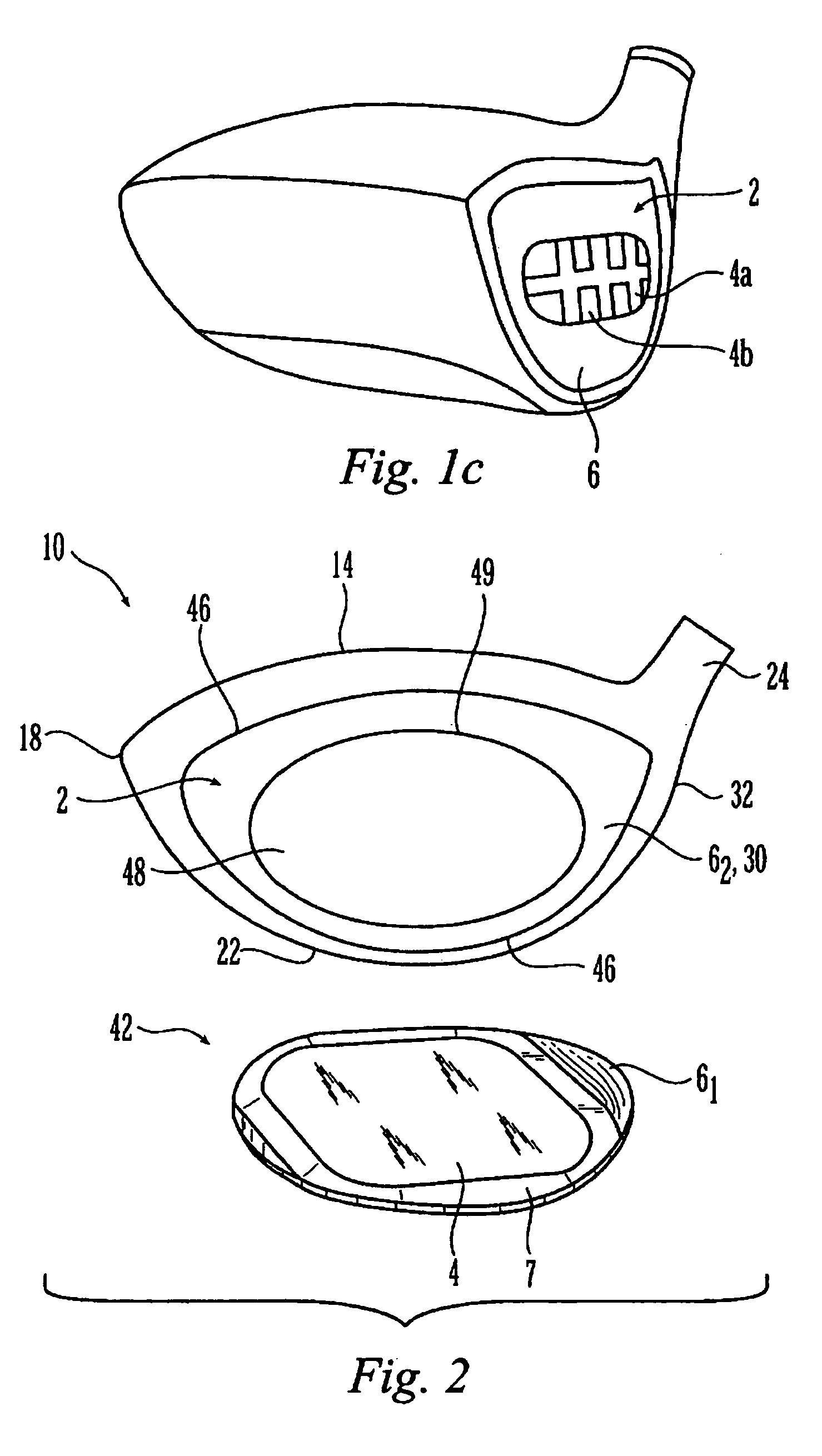

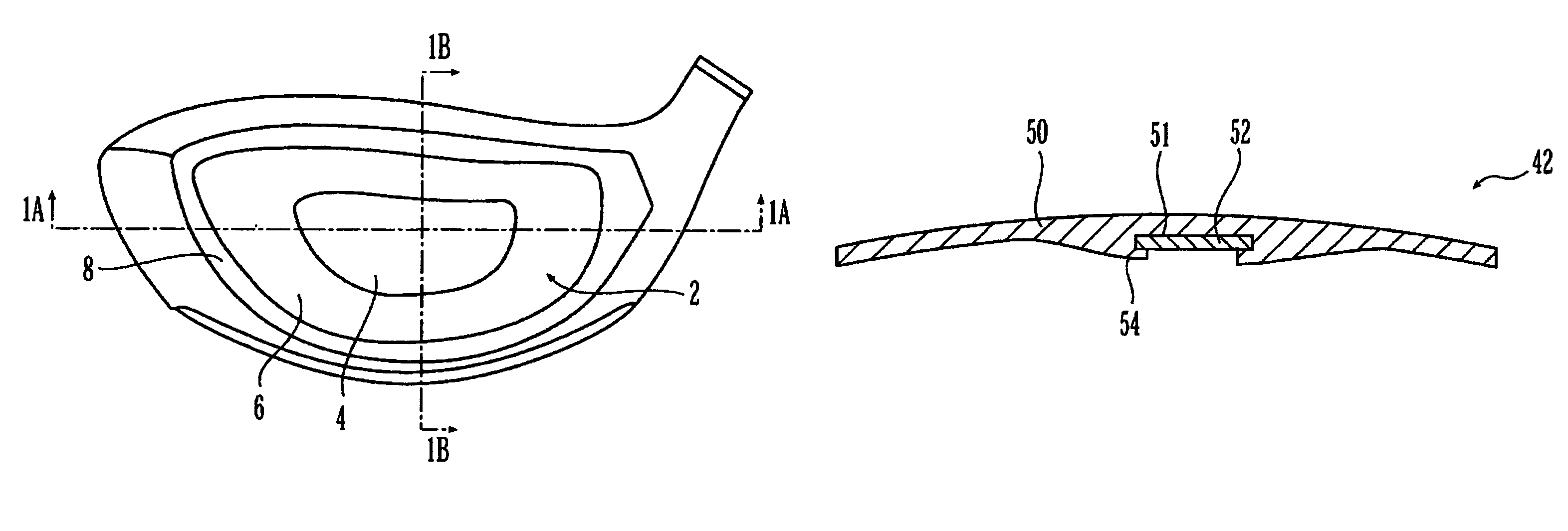

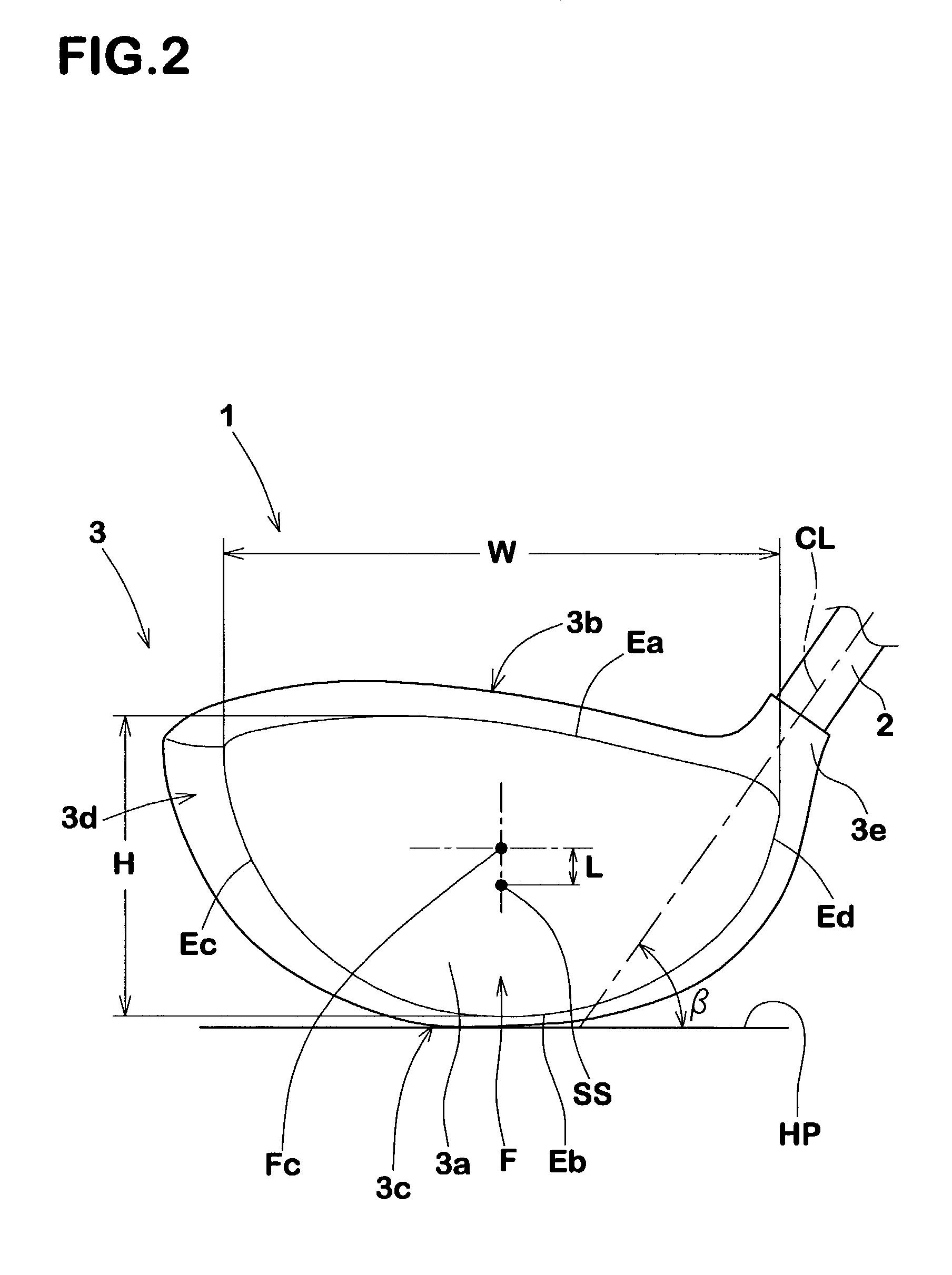

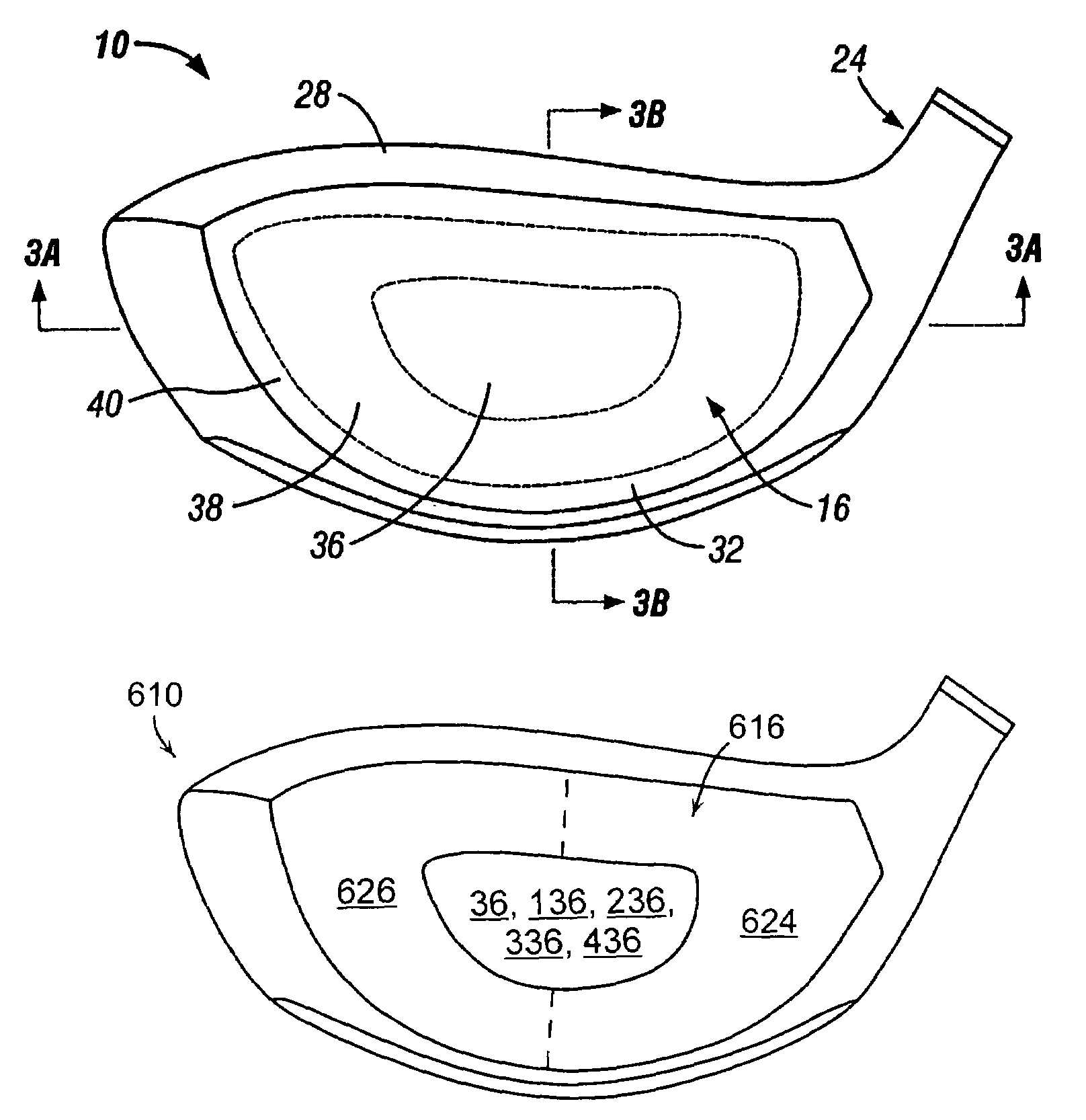

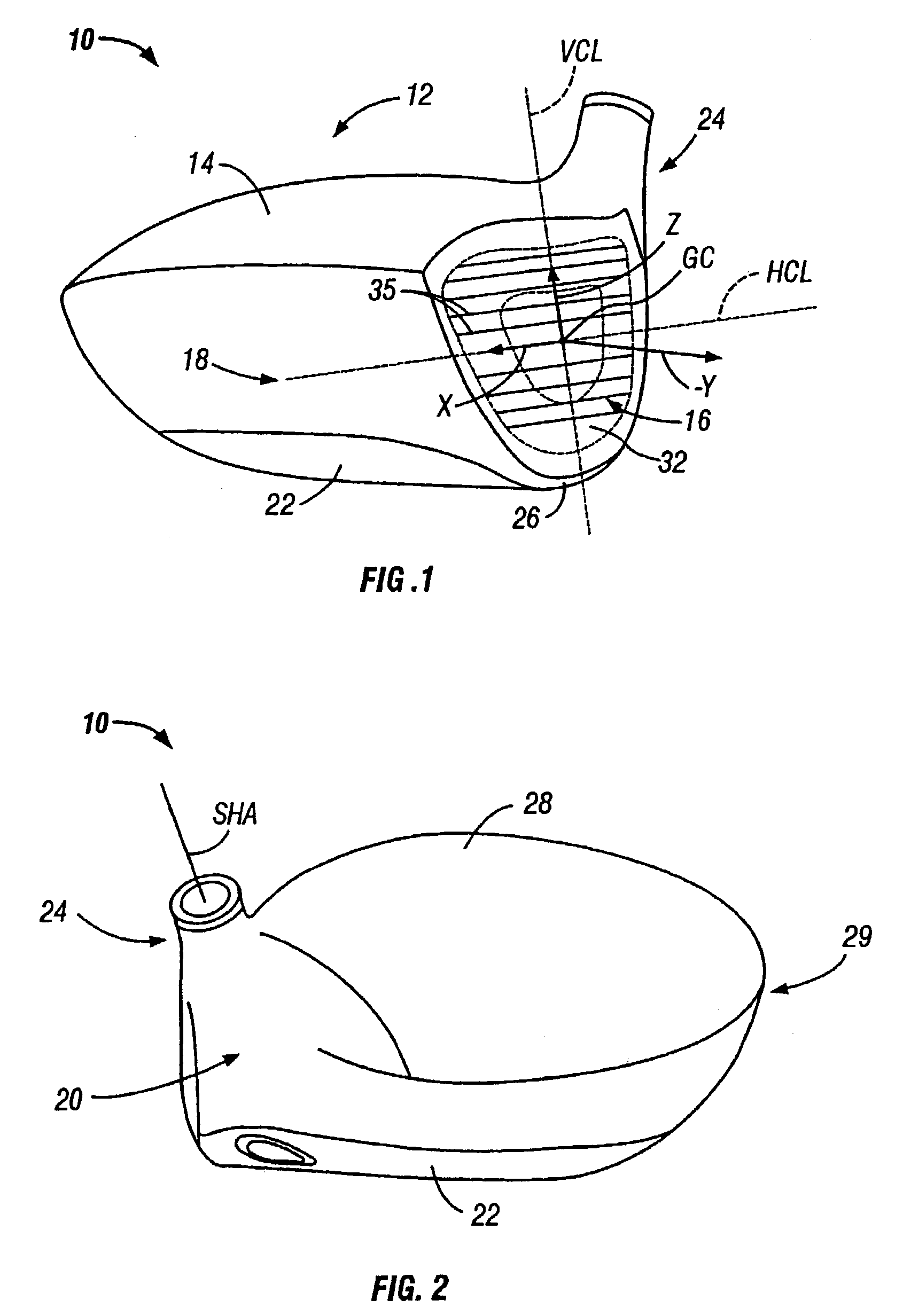

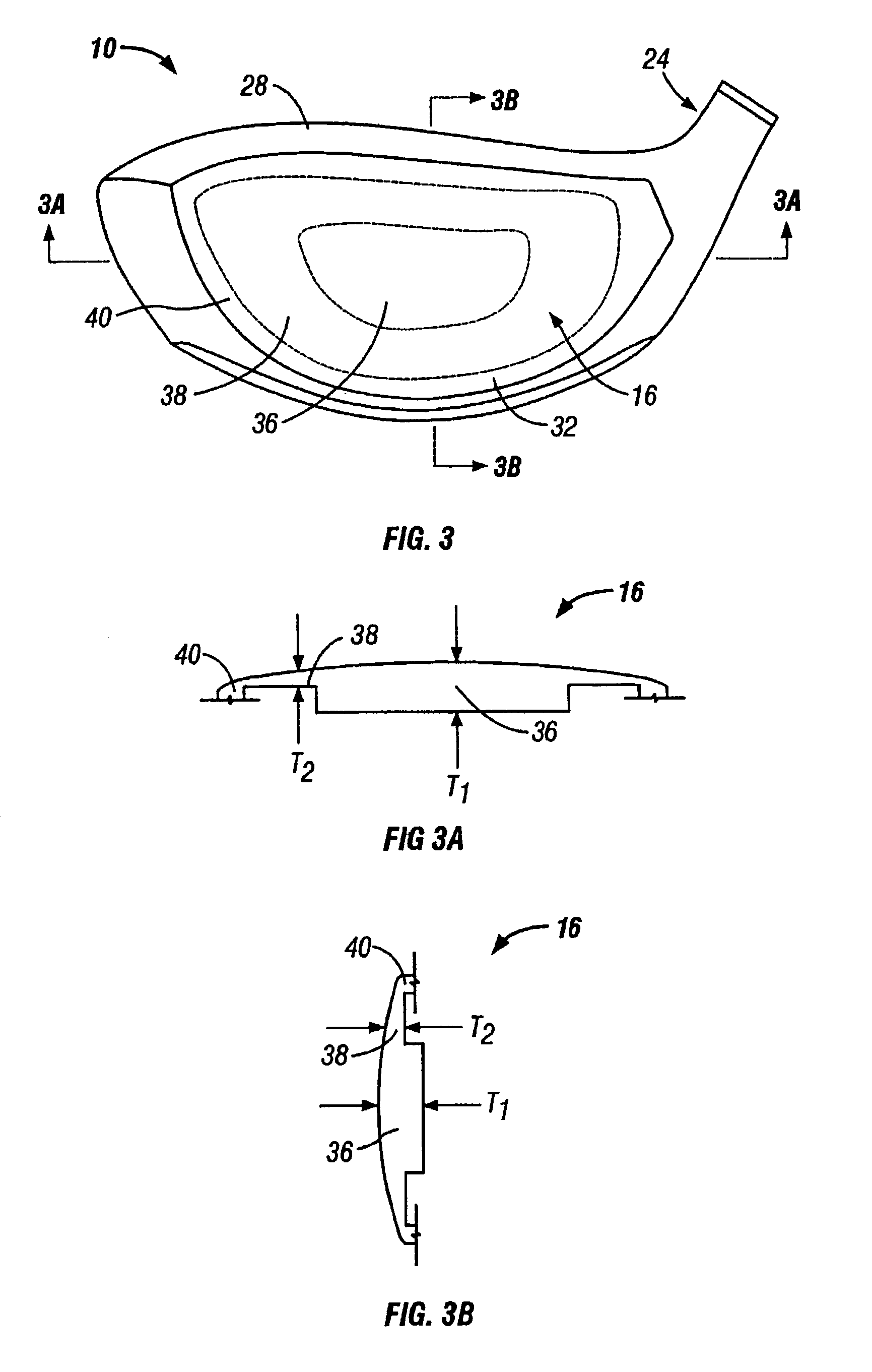

Metal wood club with improved hitting face

InactiveUS7029403B2Increased bending stiffnessIncrease elasticityAnalysing solids using sonic/ultrasonic/infrasonic wavesGolf clubsEllipseBall impact

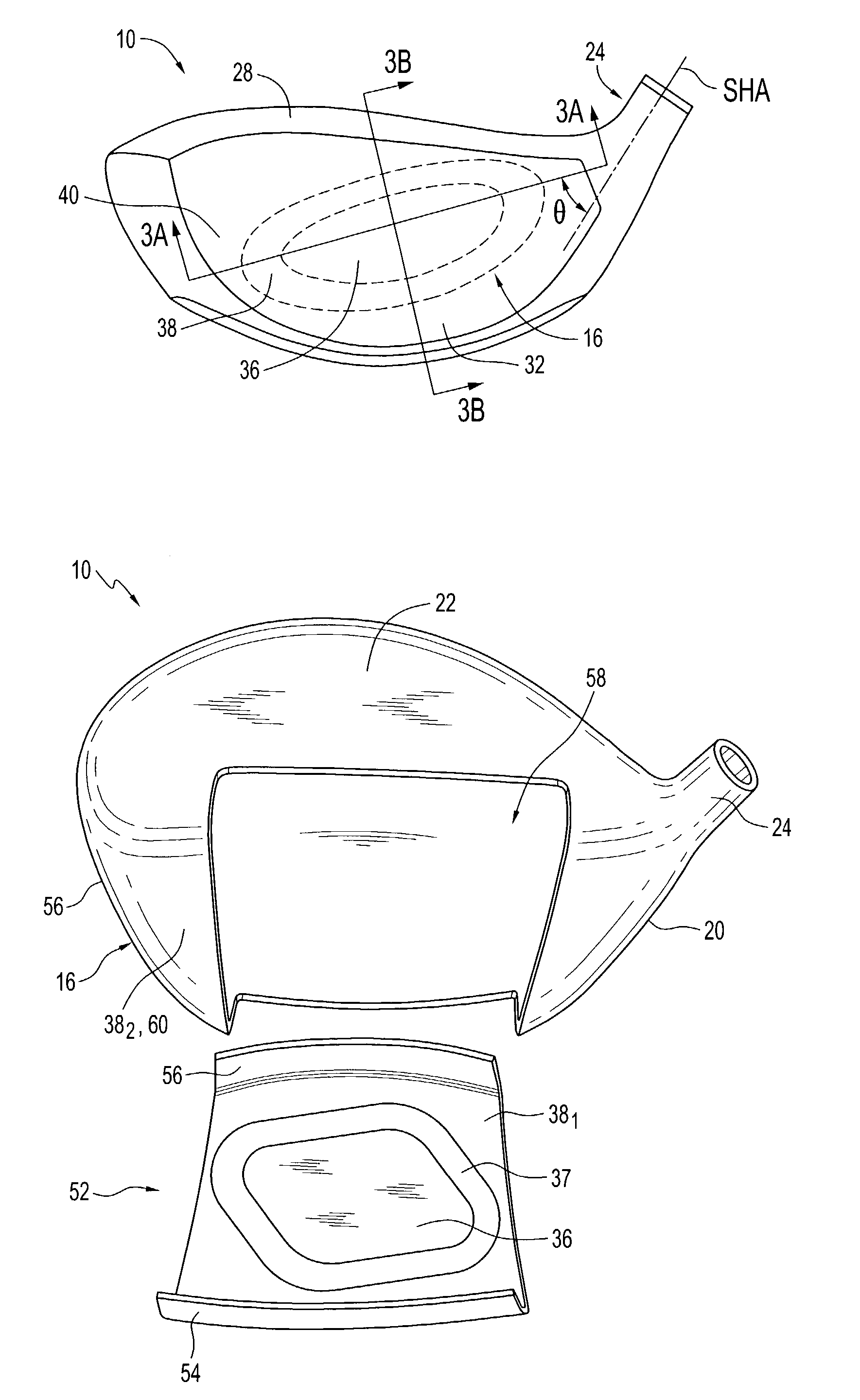

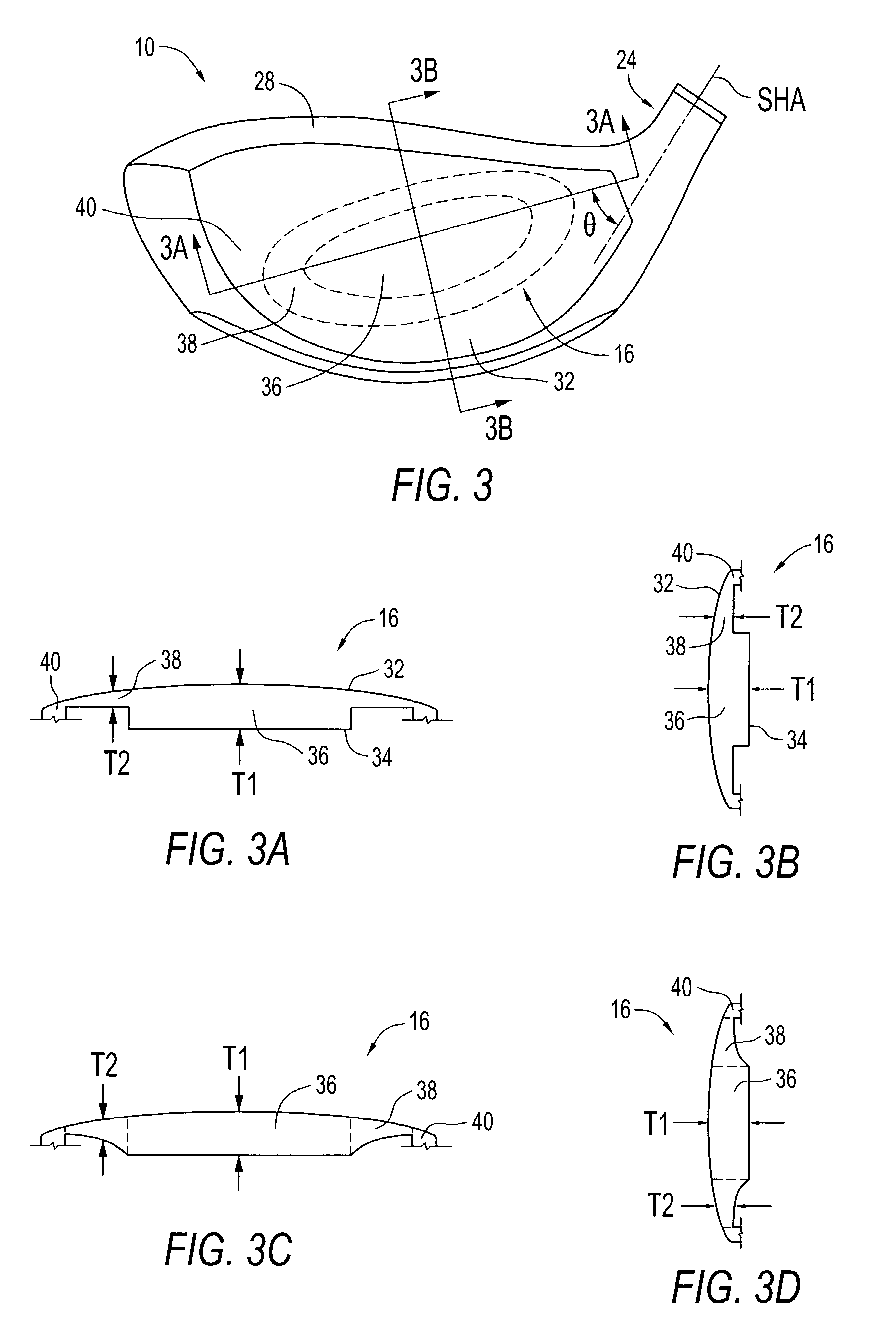

A golf club head having selectively oriented zones of relatively high flexural stiffness is disclosed. The hitting face is configured and dimensioned so that it includes an inner zone and a concentric intermediate zone. The inner zone has relatively high flexural stiffness and the intermediate zone has relatively lower flexural stiffness. The inner zone may have an elliptical shape or a substantially parallelogram shape. Preferably, the inner zone has a shape that comprises a major axis and a minor axis and the major axis aligns substantially in the direction of high heel to low toe. This arrangement of inner and intermediate zones creates a gradient of flexural stiffness in the direction of high toe to low heel and produces a desirable manipulation COR in that direction. This area of high coefficient of restitution advantageously coincides with the ball impact pattern that golfers typically make on the hitting face. The hitting face also comprises a measurement zone wherein the lowest COR is at least 93% of the highest COR.

Owner:ACUSHNET CO

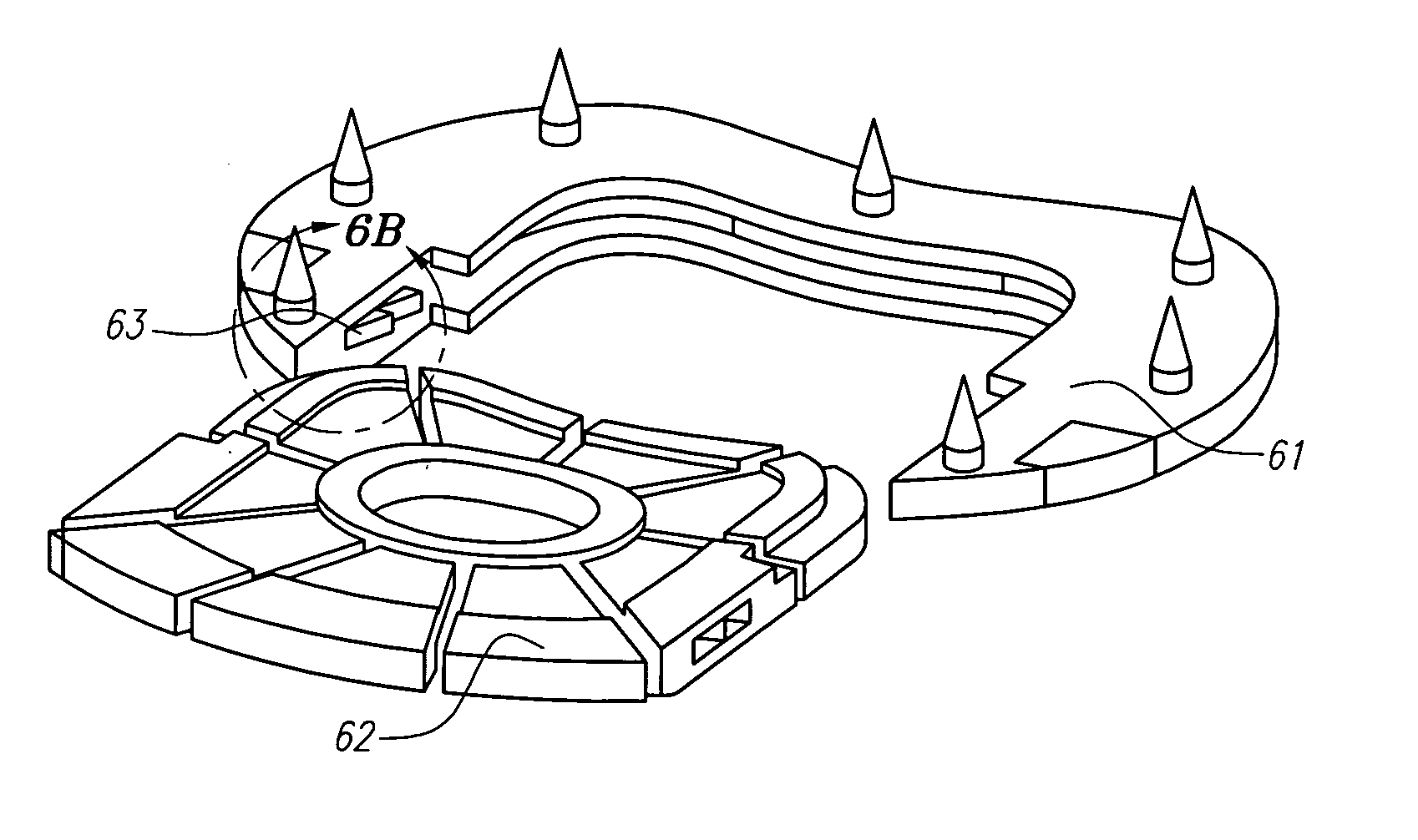

Appendage Mountable Electronic Devices COnformable to Surfaces

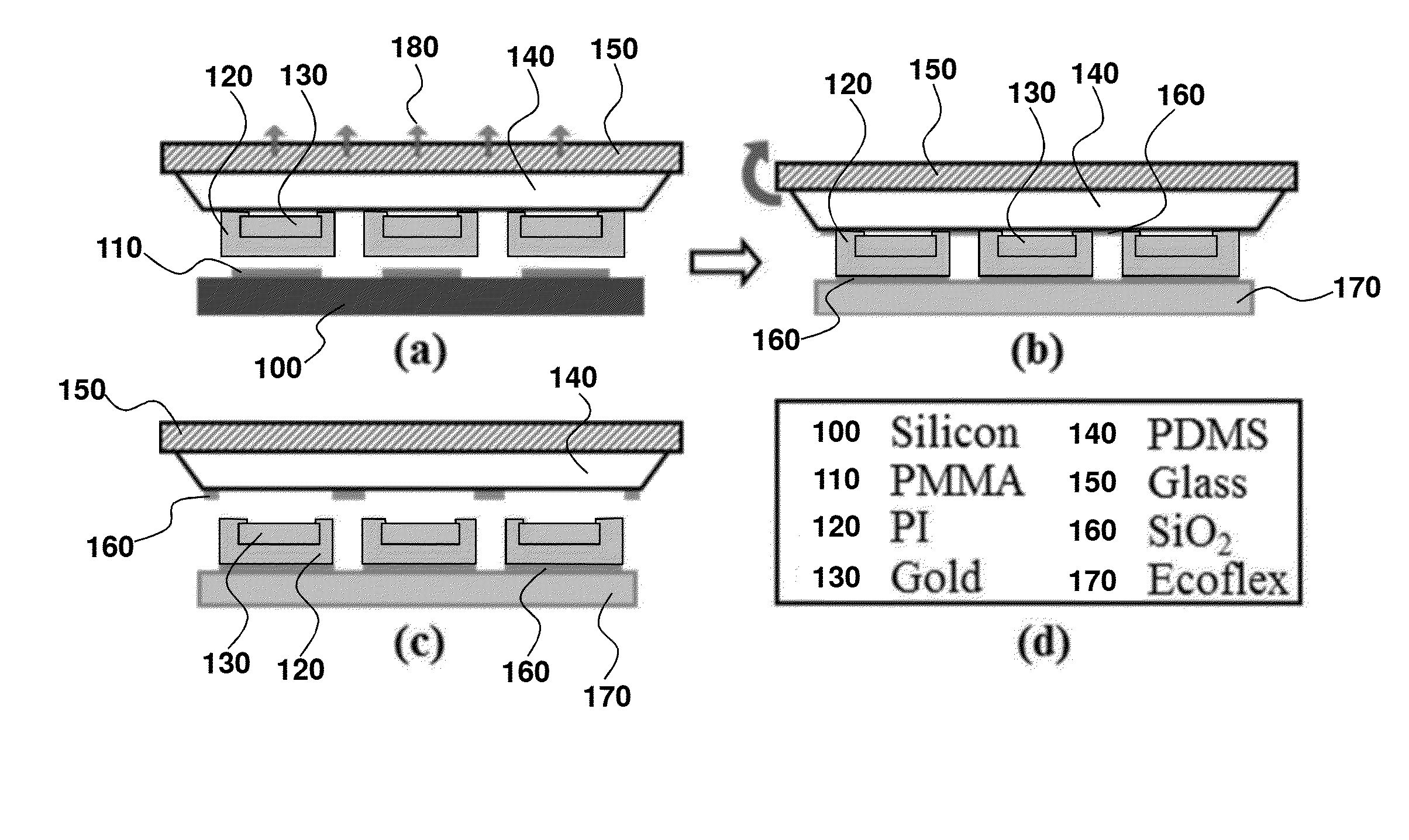

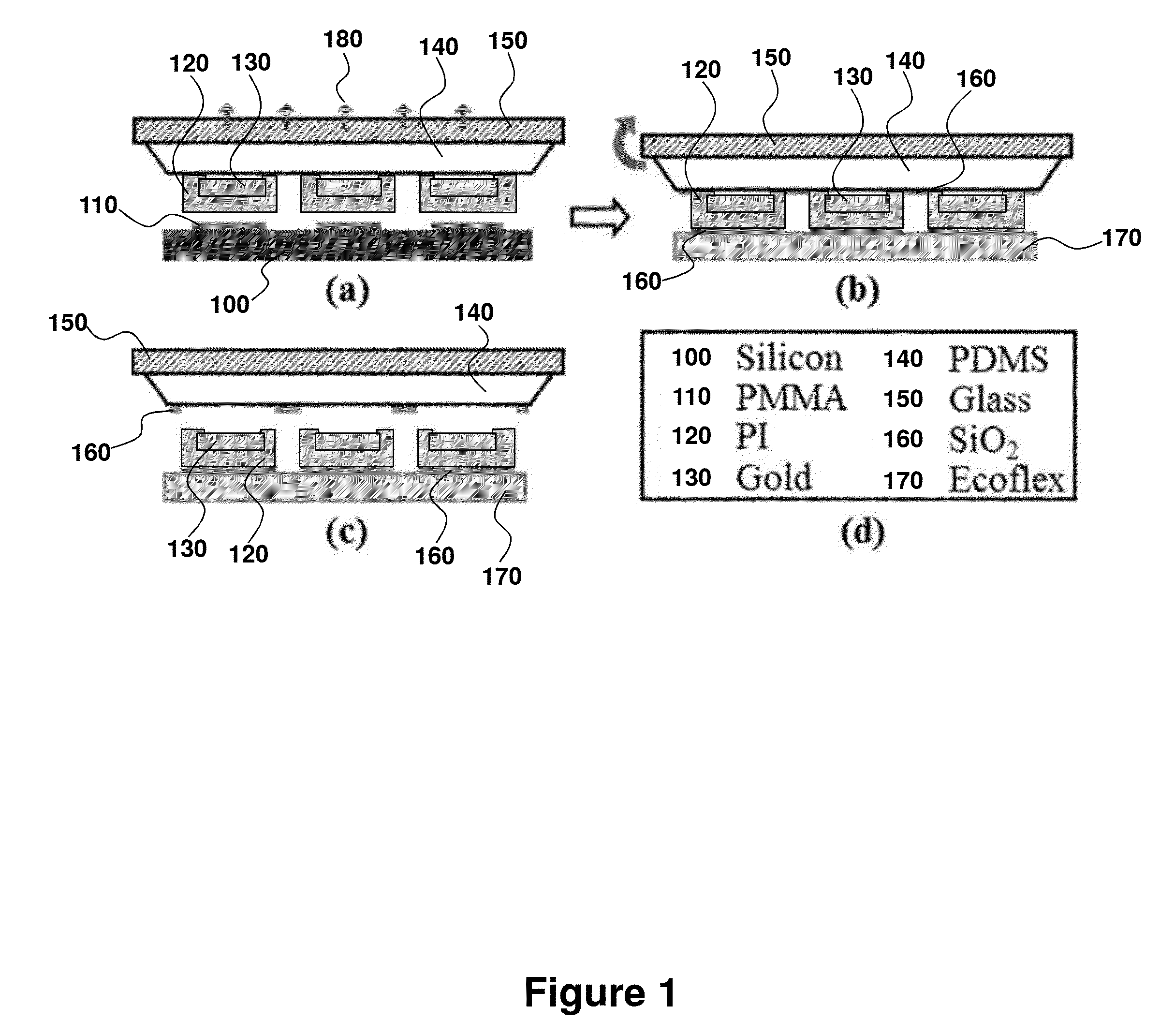

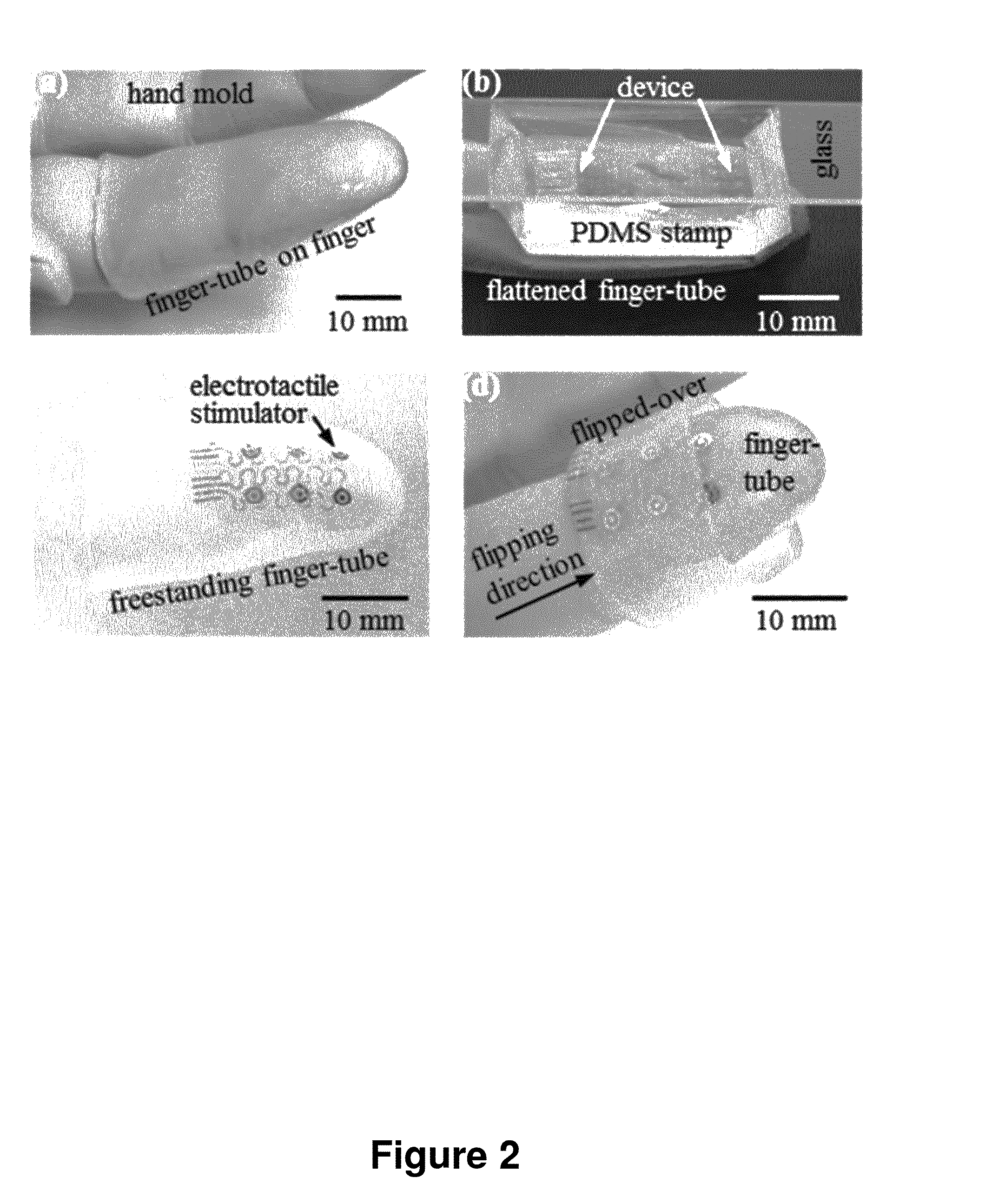

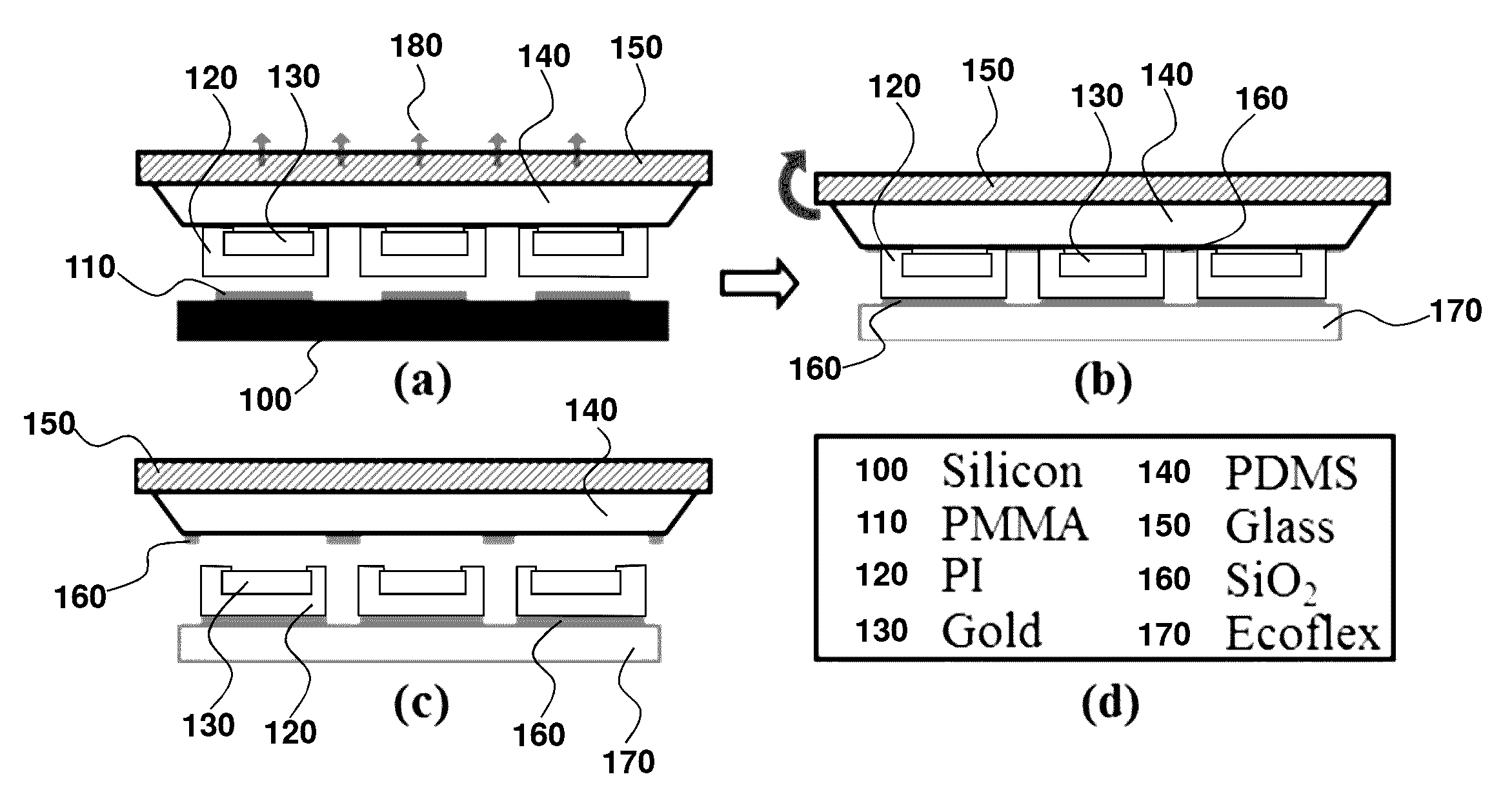

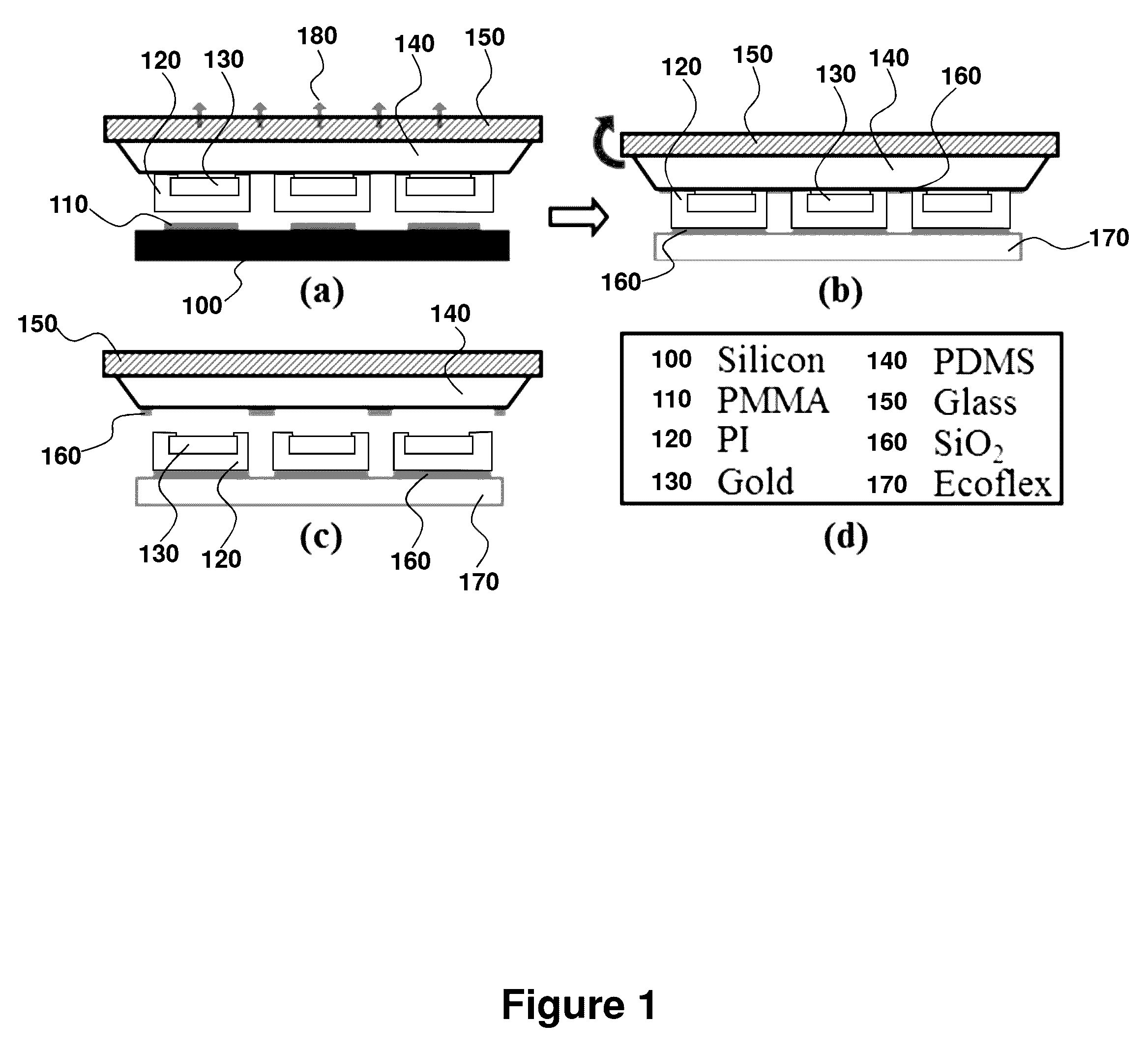

ActiveUS20130333094A1Lower the volumeReduce the overall diameterDigital data processing detailsSolid-state devicesSensor arrayElectronic systems

Disclosed are appendage mountable electronic systems and related methods for covering and conforming to an appendage surface. A flexible or stretchable substrate has an inner surface for receiving an appendage, including an appendage having a curved surface, and an opposed outer surface that is accessible to external surfaces. A stretchable or flexible electronic device is supported by the substrate inner and / or outer surface, depending on the application of interest. The electronic device in combination with the substrate provides a net bending stiffness to facilitate conformal contact between the inner surface and a surface of the appendage provided within the enclosure. In an aspect, the system is capable of surface flipping without adversely impacting electronic device functionality, such as electronic devices comprising arrays of sensors, actuators, or both sensors and actuators.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

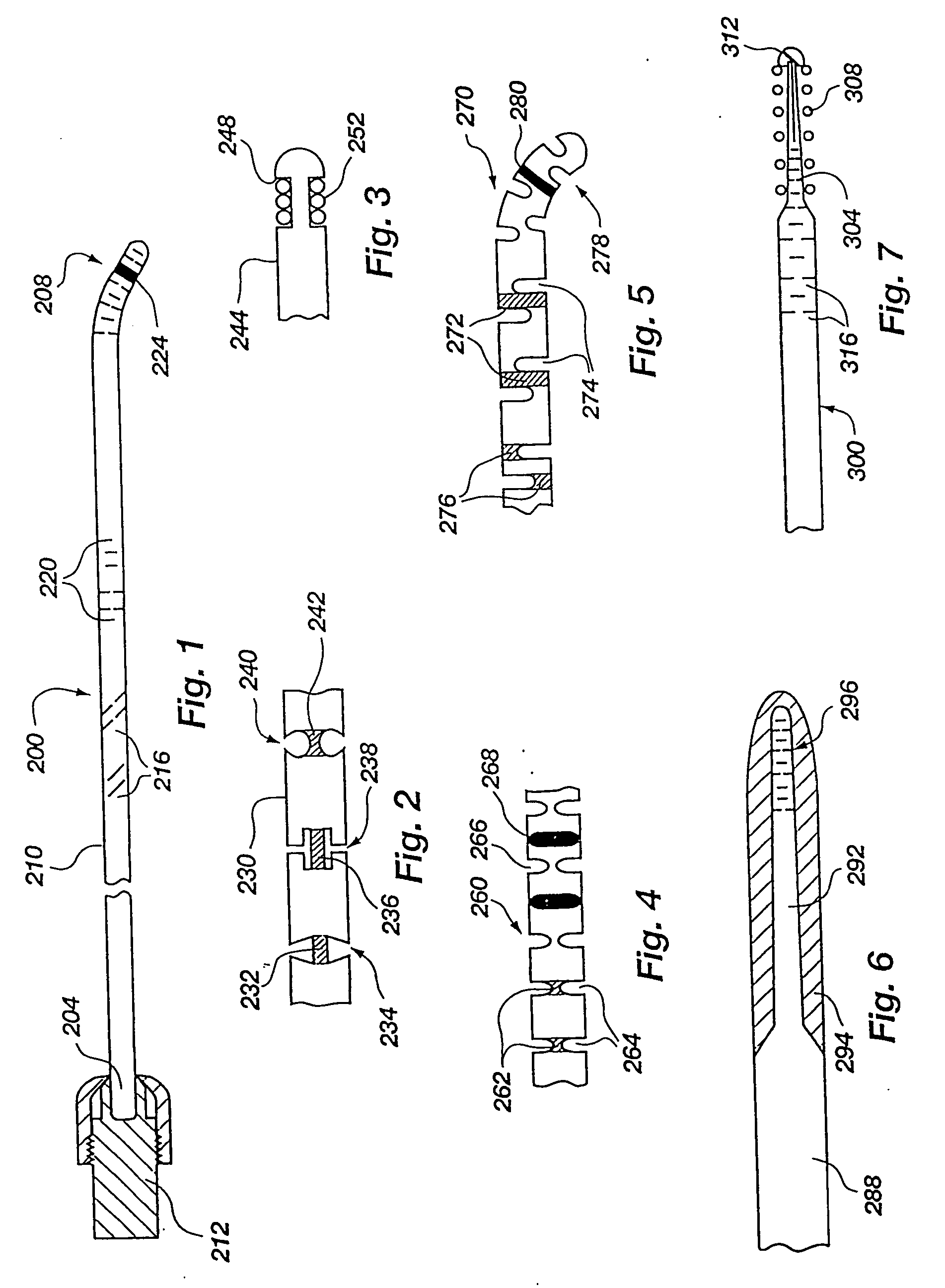

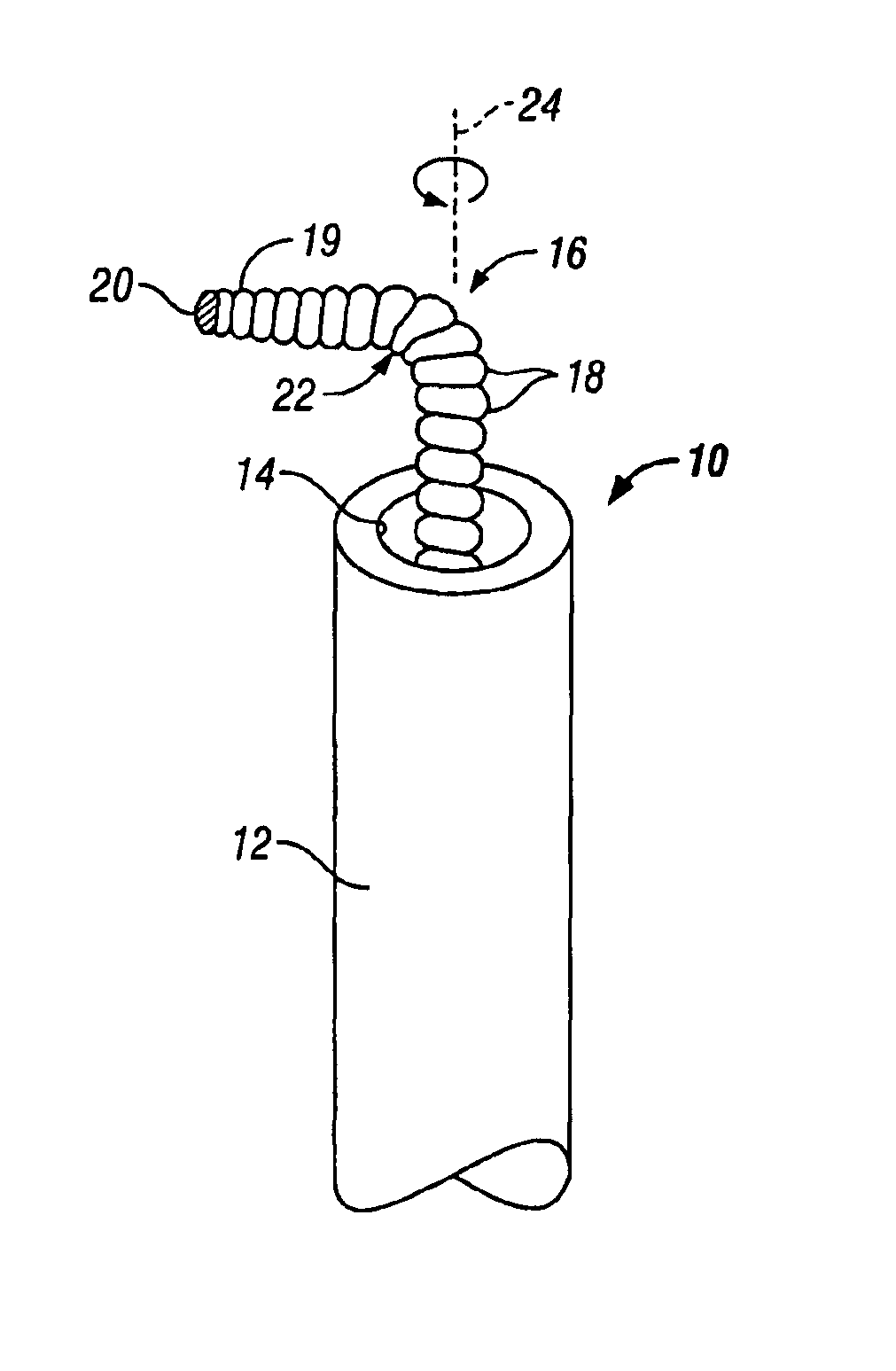

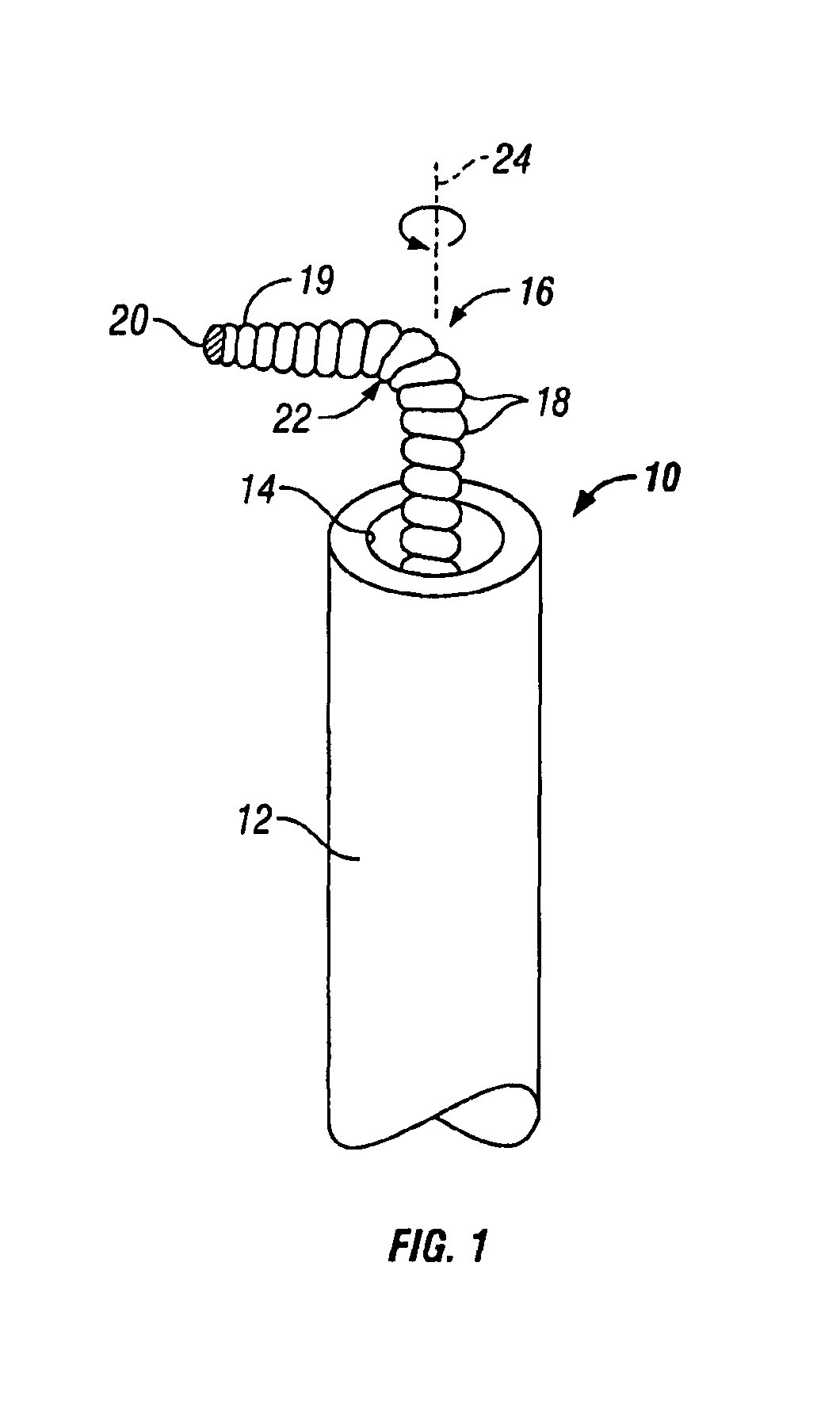

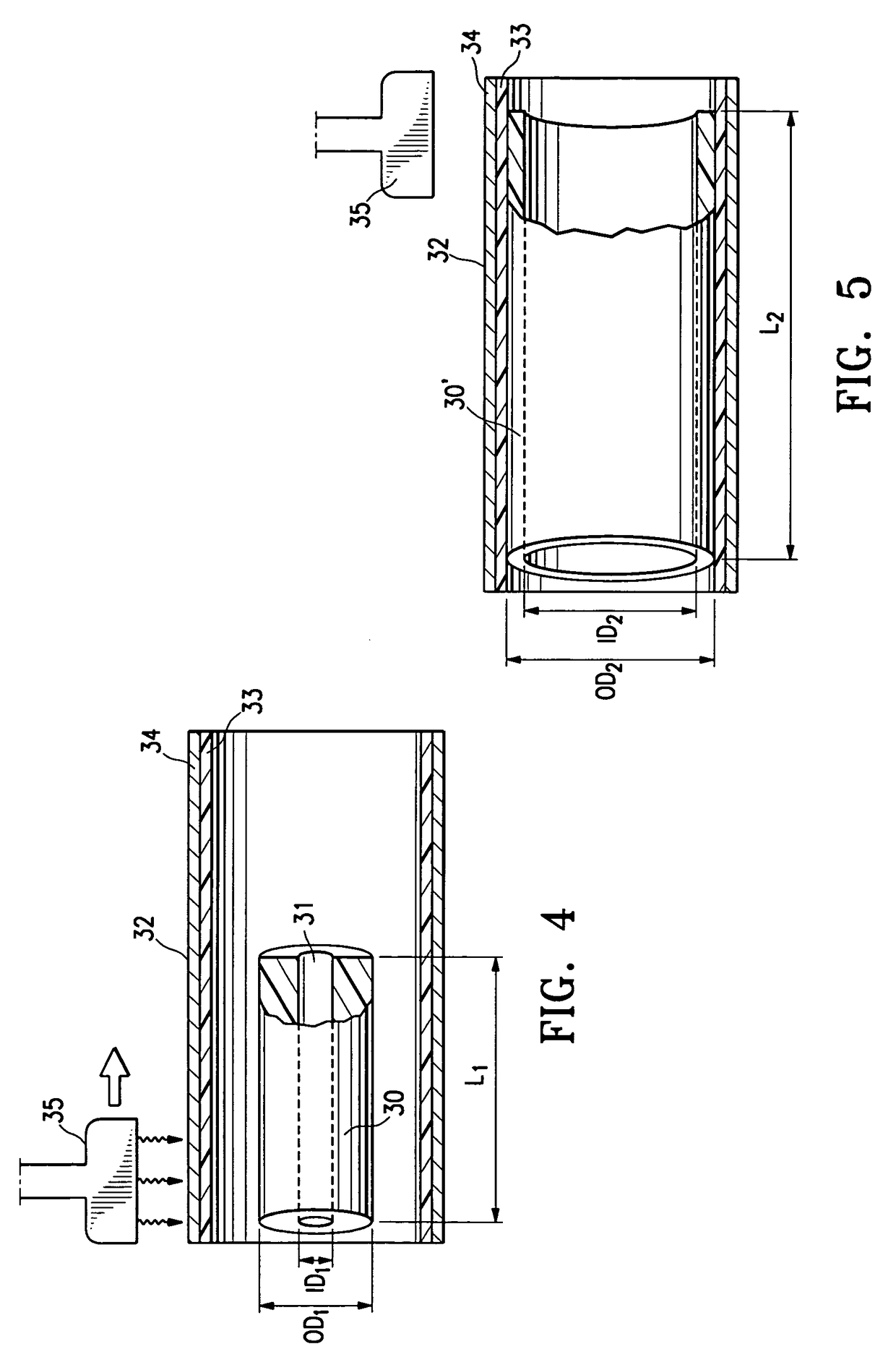

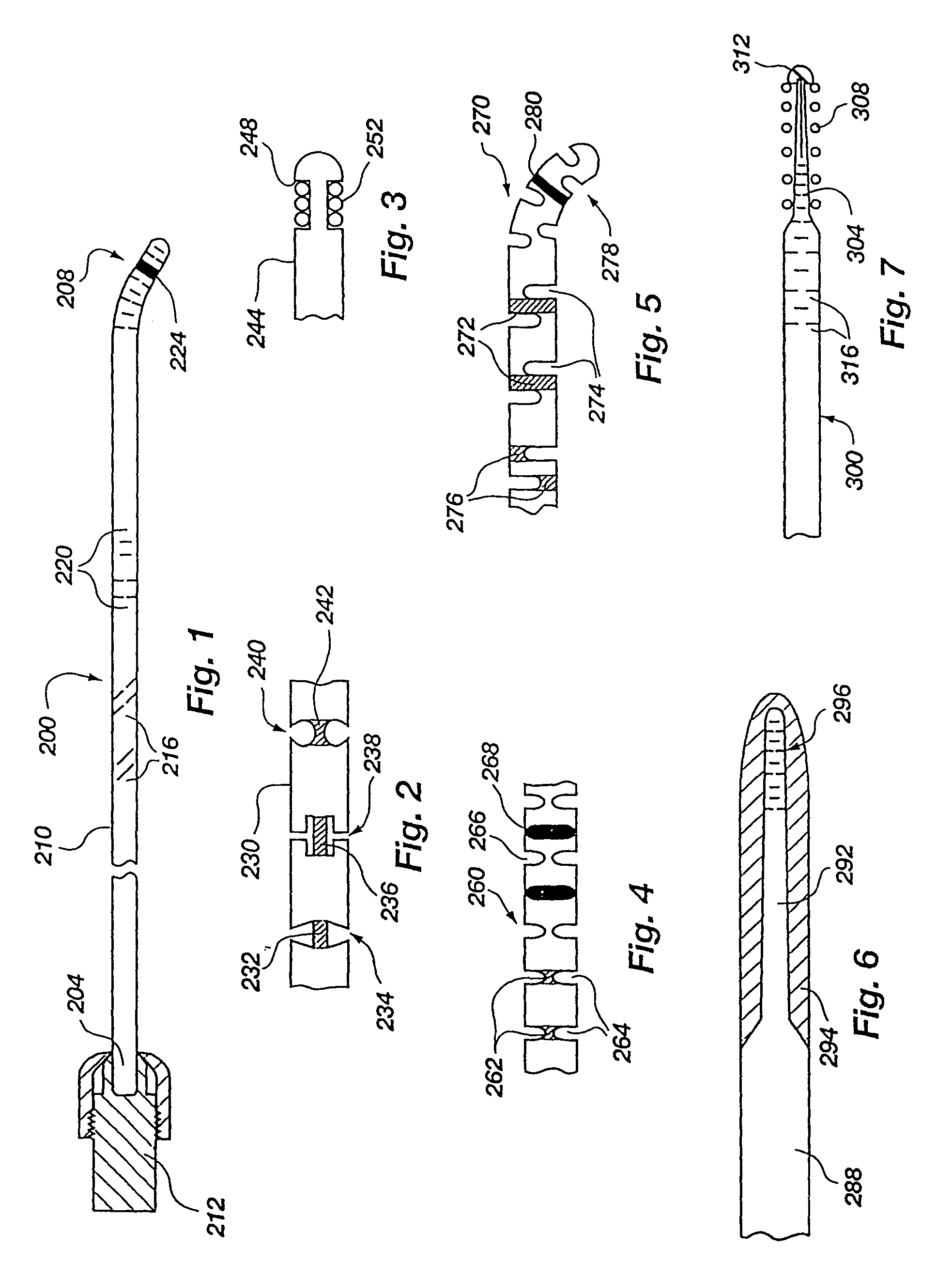

Medical device with collapse-resistant liner and mehtod of making same

InactiveUS20060189896A1Desired flexibility in bendingIncrease stiffnessGuide wiresDiagnostic recording/measuringBand shapeMedical device

A medical device for guiding through anatomy, such as a catheter or guidewire, with a tubular body that has been slotted to enhance bending flexibility, and a polymer liner with an anti-collapsing structure, and a method of making a medical device with a kink-resistant corrugated tubular member and an anti-collapsing structure. Anti collapsing structures may be helical or annular, and may be wire, such as ribbon wire, grooves in the liner, corrugations, or a braid. Liners may be bonded to the anti-collapsing structure, or may have two layers, with the anti-collapsing structure between the layers. Corrugations may be formed between sections of the anti-collapsing ‘structure with heat, pressure, stretching, compression, a mold, or a combination thereof, and may extend inward or outward. Shape or wall thickness may vary along the length to provide a varying bending stiffness. Slots may be formed in groups of two, three, or more, and adjacent groups may be rotated about the axis forming a helical pattern.

Owner:PRECISION VASCULAR SYST

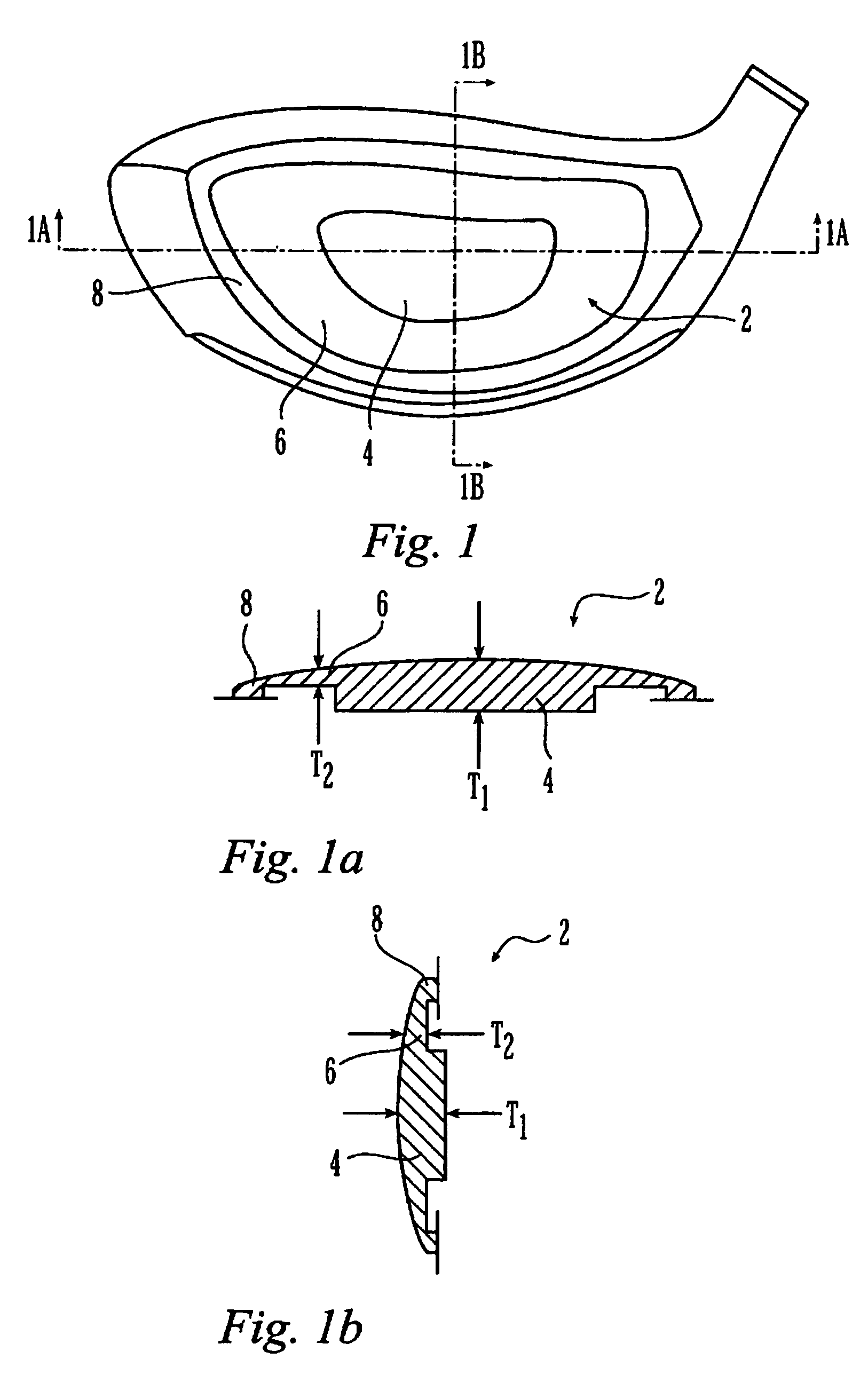

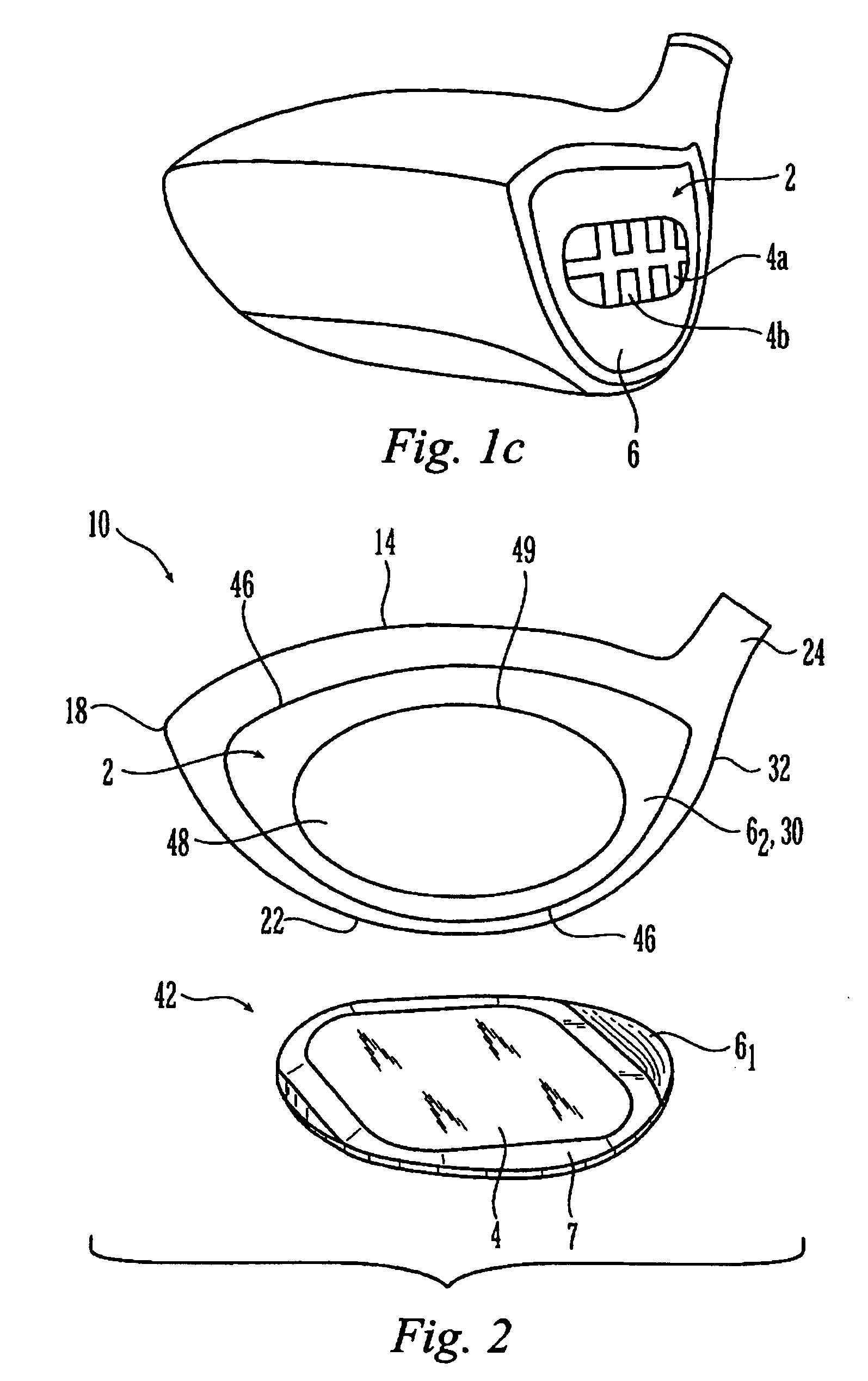

Golf club head with a high coefficient of restitution

InactiveUS6960142B2Increase ball speedAnalysing solids using sonic/ultrasonic/infrasonic wavesGolf clubsBall impactCoefficient of restitution

The present invention relates to a golf club head provided with a face and a body. The face has a central zone and a intermediate zone adjacent and surrounding the central zone. The central zone has a first flexural stiffness and the intermediate zone has a second flexural stiffness. The club head face is configured and dimensioned such that the first flexural stiffness is significantly greater than the second flexural stiffness such that upon ball impact with the face, the intermediate zone exhibits substantial deformation so that the central zone moves into the club head. At the same time, the central zone exhibits minimal deformation so that it moves into and out of the club head as a unit. Furthermore, the face exhibits a high coefficient of restitution.

Owner:ACUSHNET CO

Dust filter bag including a highly porous backing material ply

InactiveUS6706086B2Simple and cost-effective productionCleaning filter meansCombination devicesBursting strengthCellulose fiber

A dust filter bag having a highly porous backing material ply and a method for producing the dust filter bag. The dust filter bag includes at least one filter material ply and at least one backing material ply, the backing material ply possessing an air permeability of at least 900 l / m<2 >x s, a burst strength of at least 70 kPa, a rupture strength longitudinally better than 10 and transversely better than 3 N, a flexural rigidity longitudinally better than 0.5 cN cm<2 >and transversely better than 0.25 cN cm<2>, a basis weight of 30-80 g / m<2 >and a droplet sink-in time of less than 10 minimum. The dust filter bag can be produced by the following steps: mixing fibers including cellulose fibers and fusible fibers into a homogenous fiber mix, processing the fiber mix into a fiber web by wet laying, drying the fiber web, curing the dried fiber web by thermofusion into a backing material ply, processing the backing material ply with a filter material ply into a raw bag, and finishing the raw bag into a dust filter bag.

Owner:NEENAH GESSNER GMBH

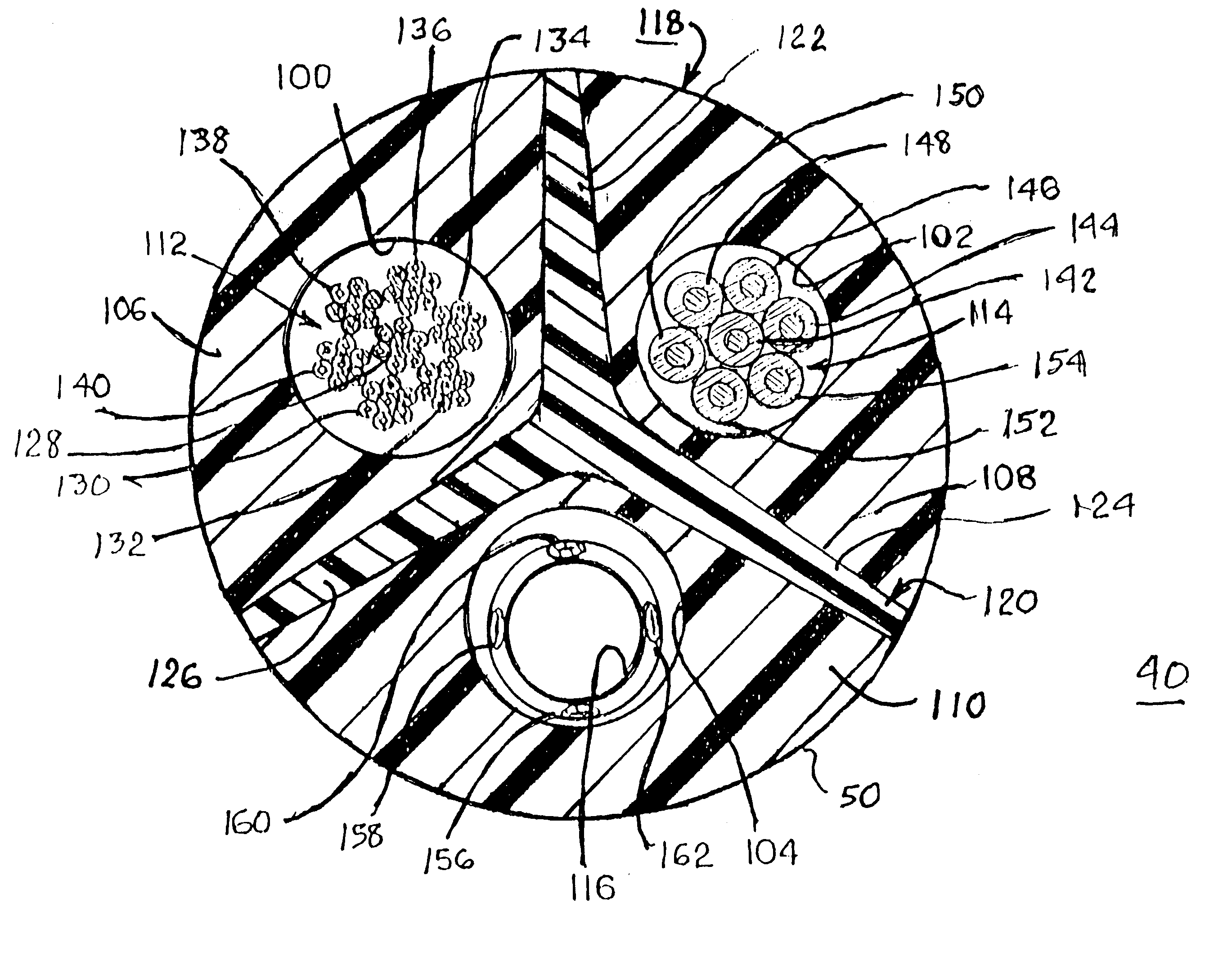

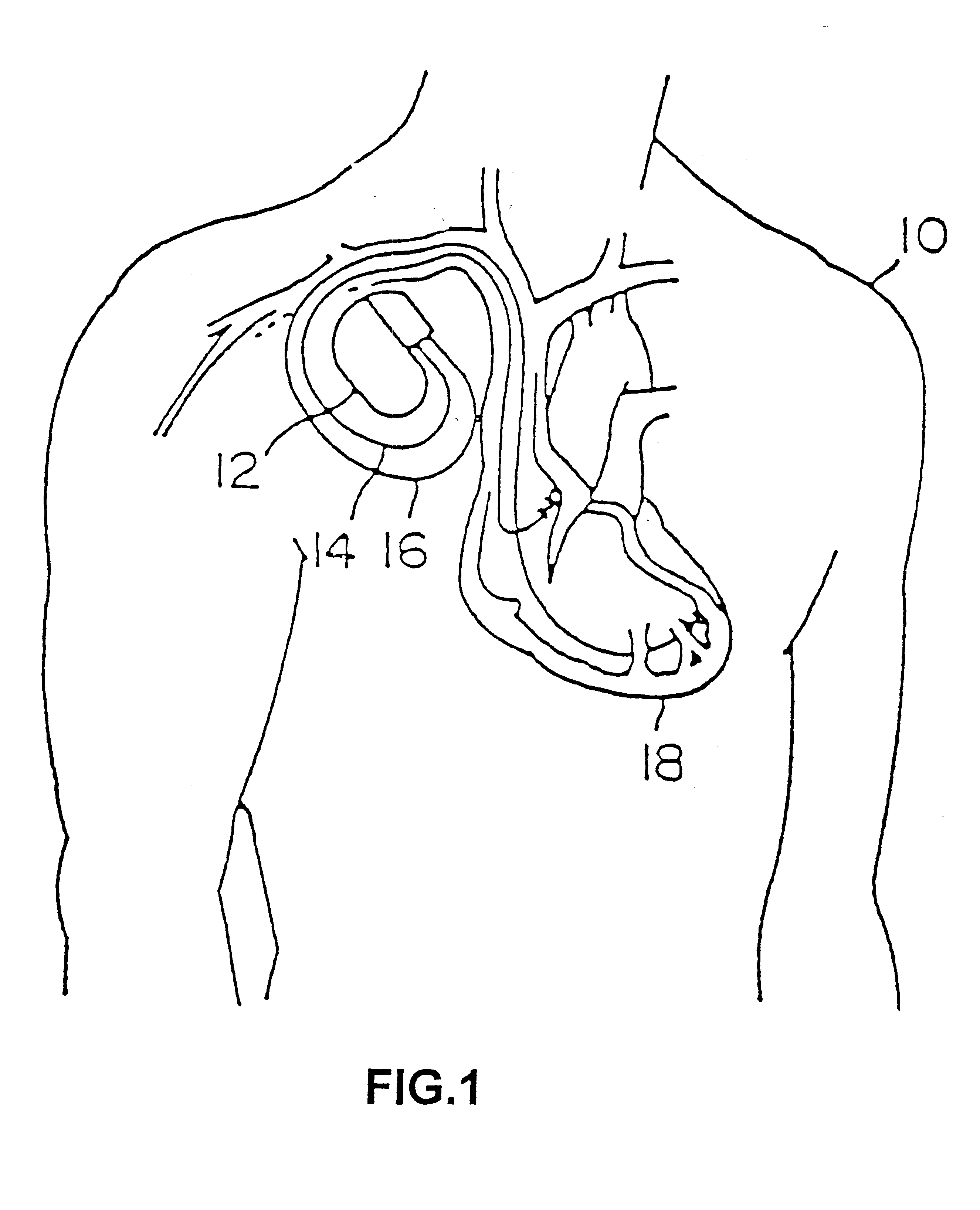

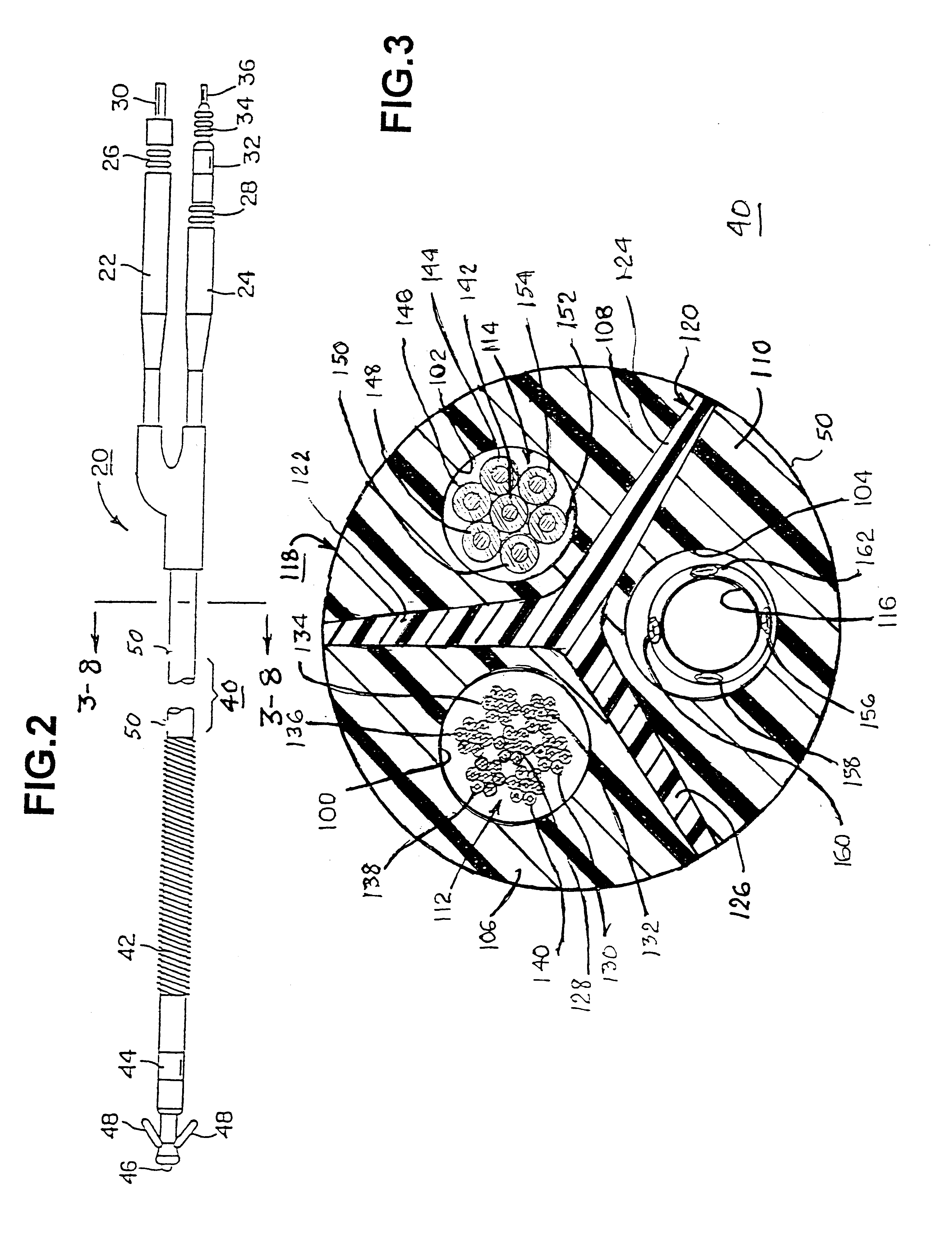

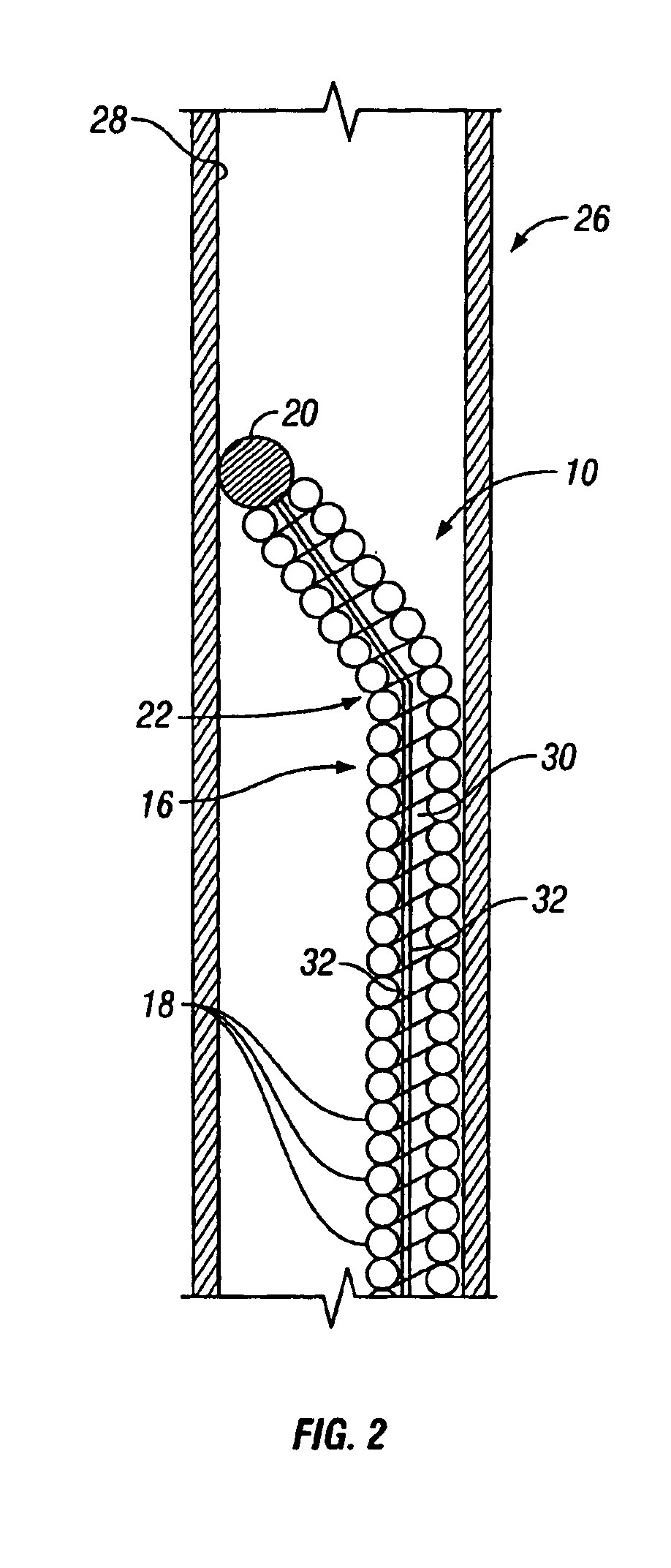

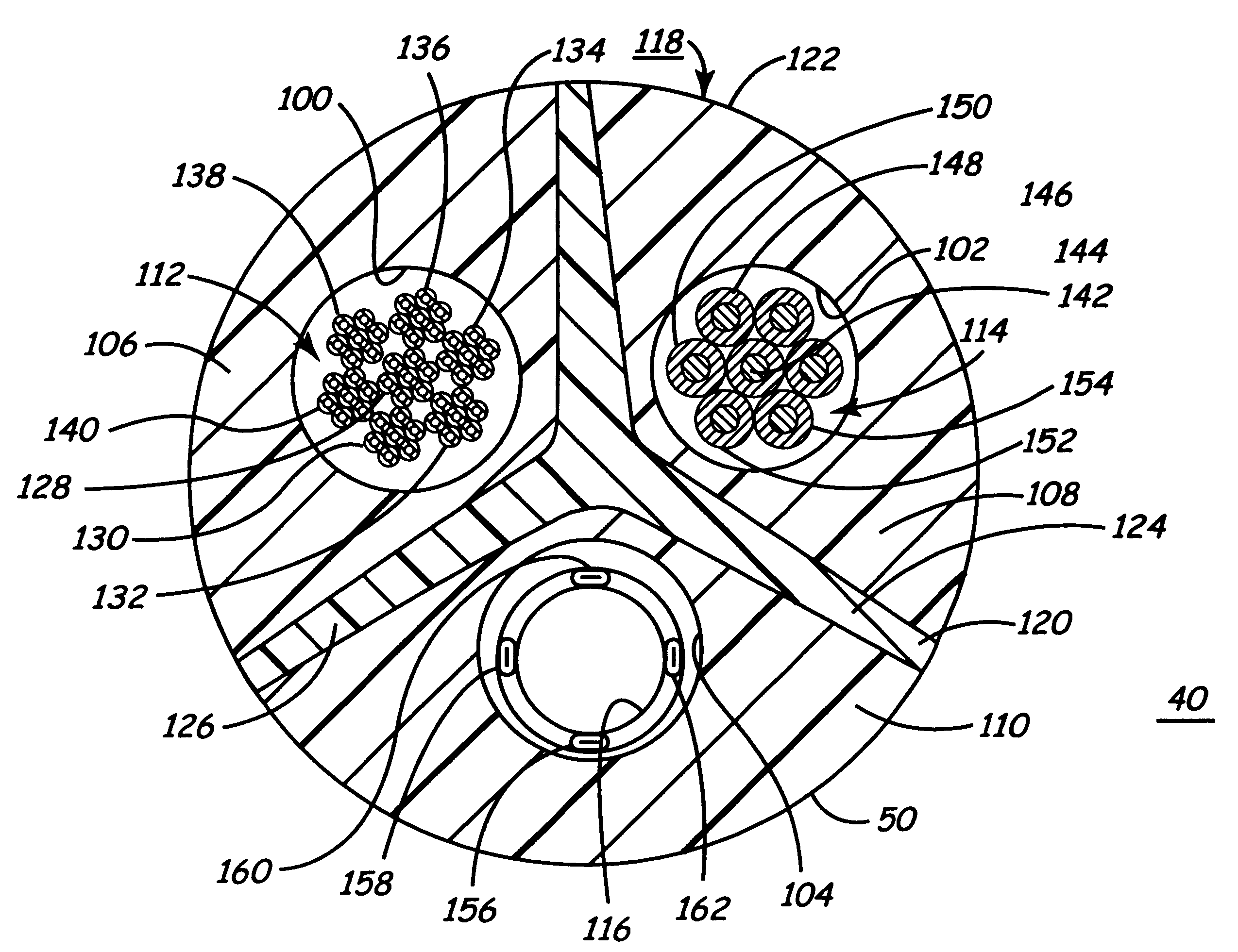

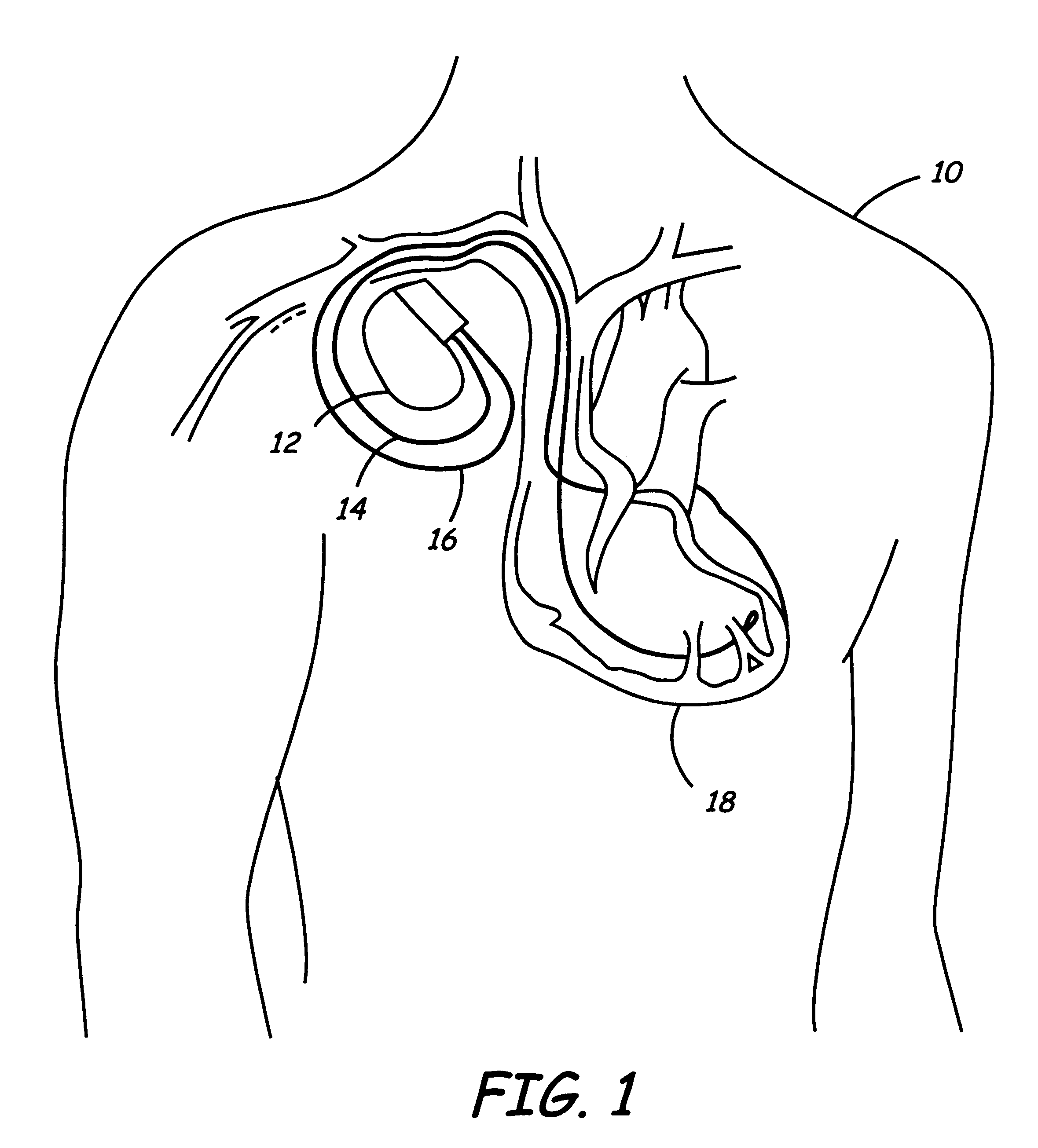

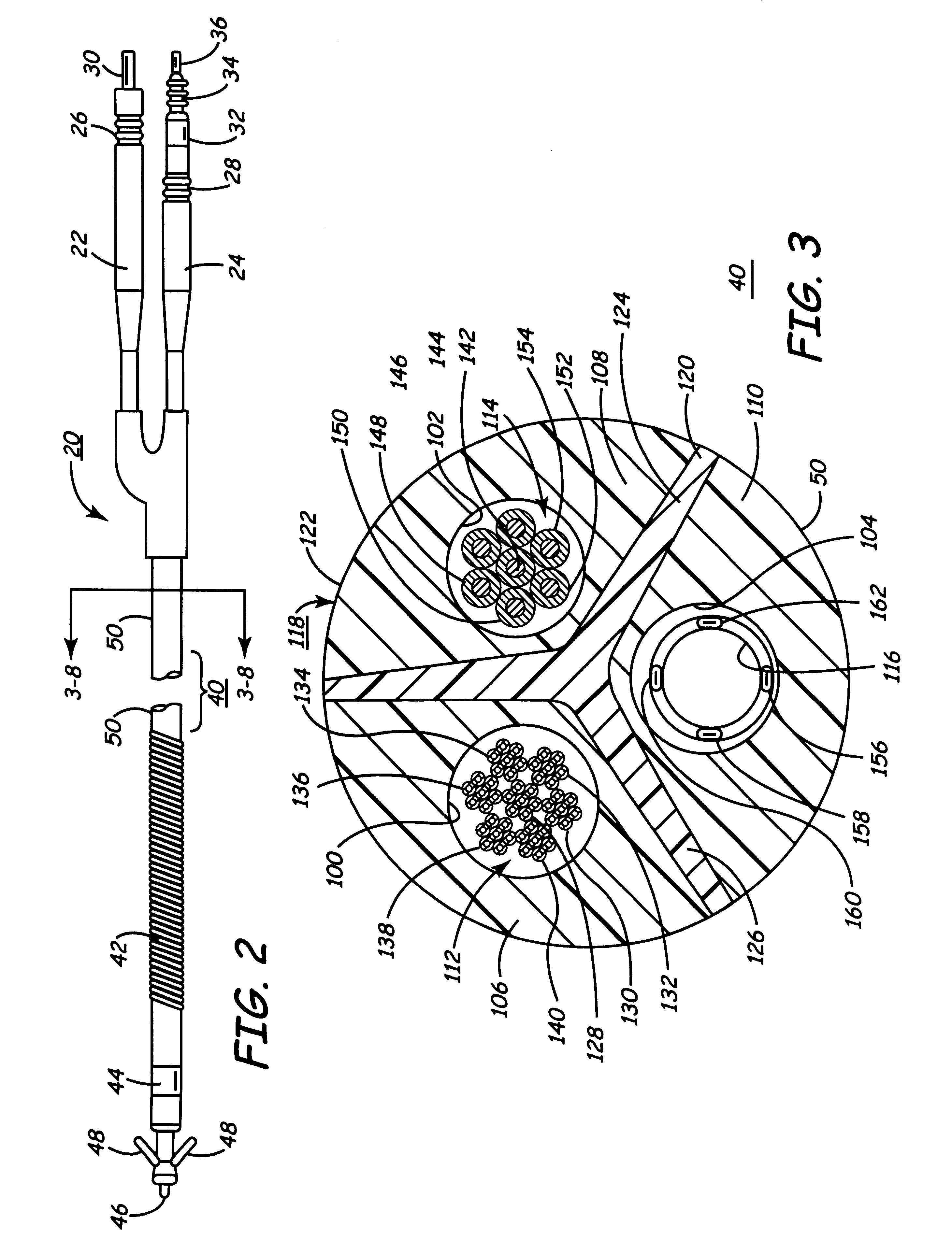

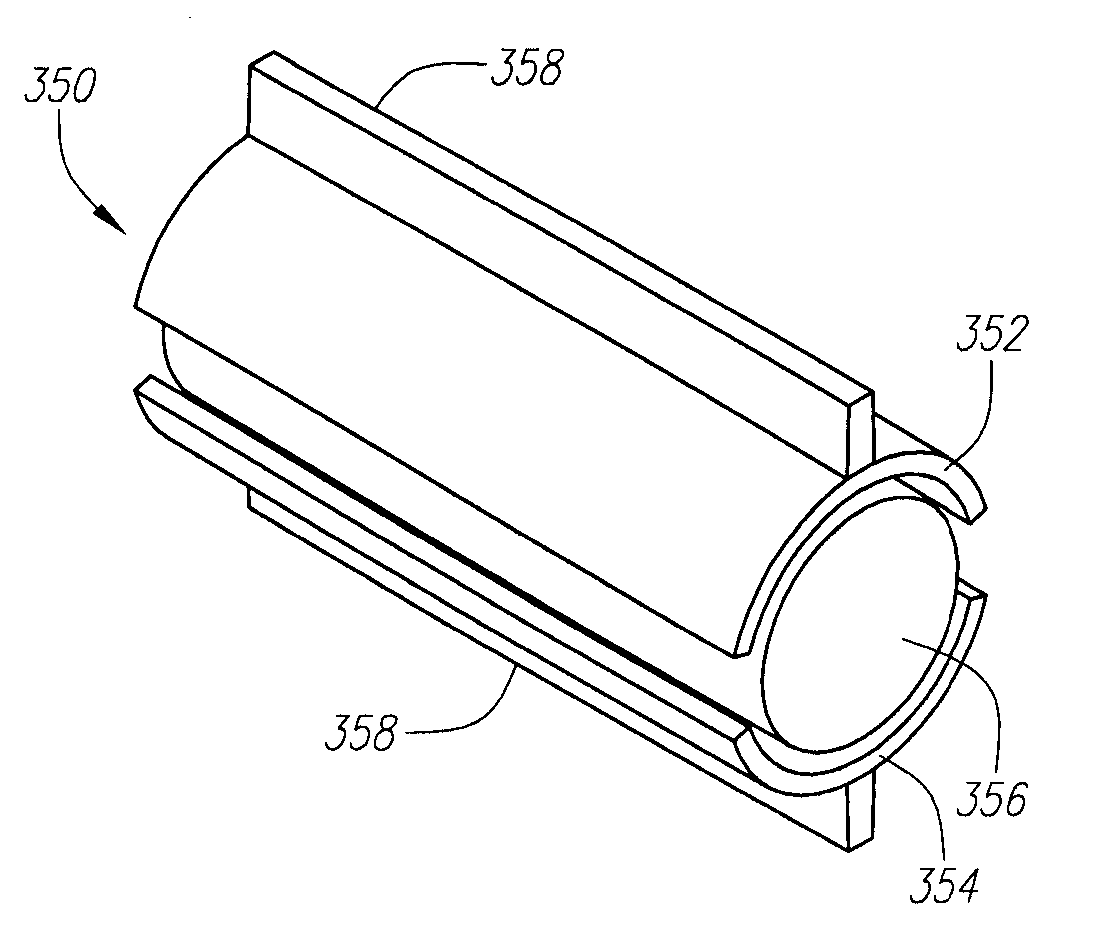

Co-extruded, multi-lumen medical lead

InactiveUS6434430B2Transvascular endocardial electrodesDiagnostic recording/measuringElectrical stimulationsBending stiffness

Owner:MEDTRONIC INC

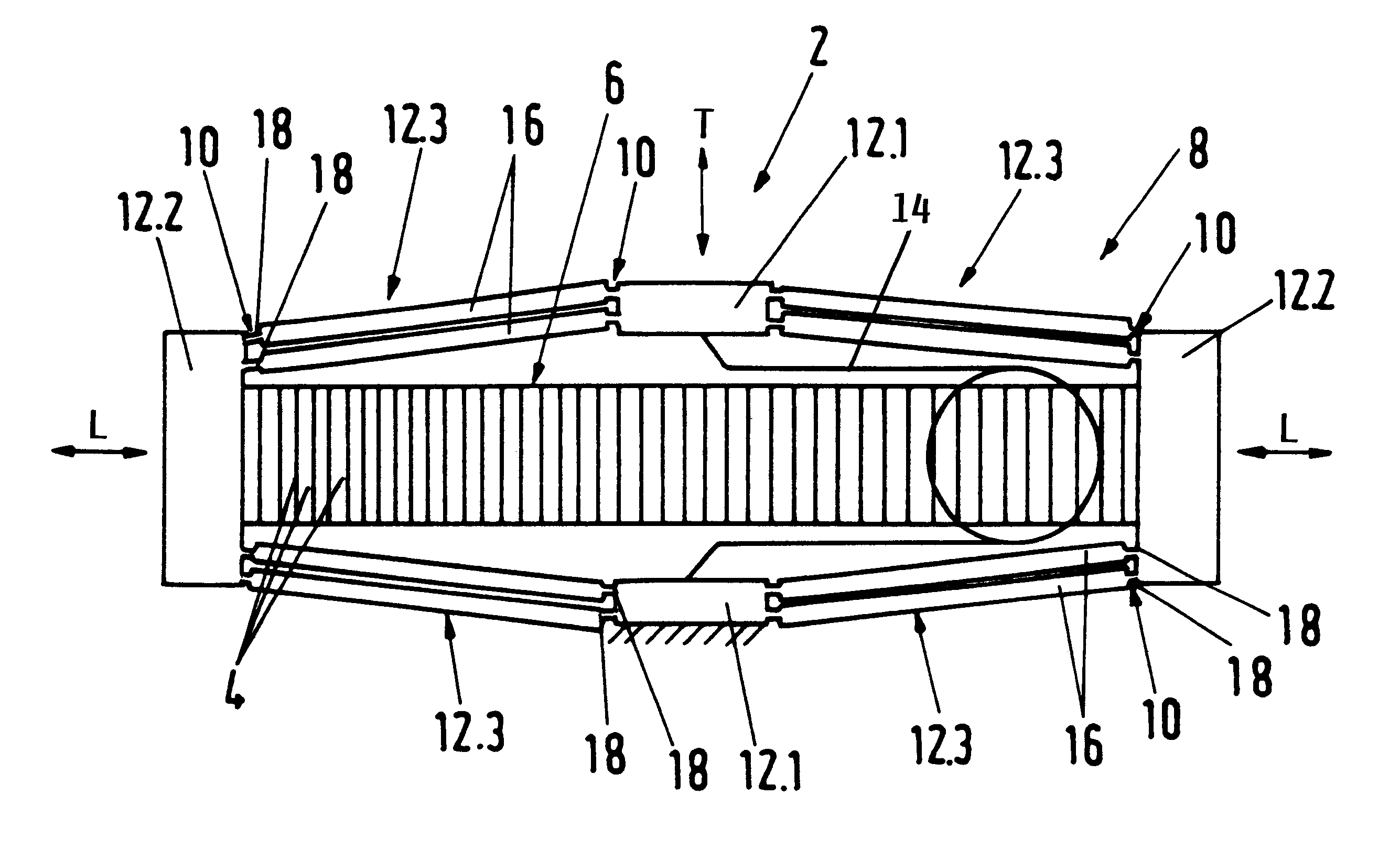

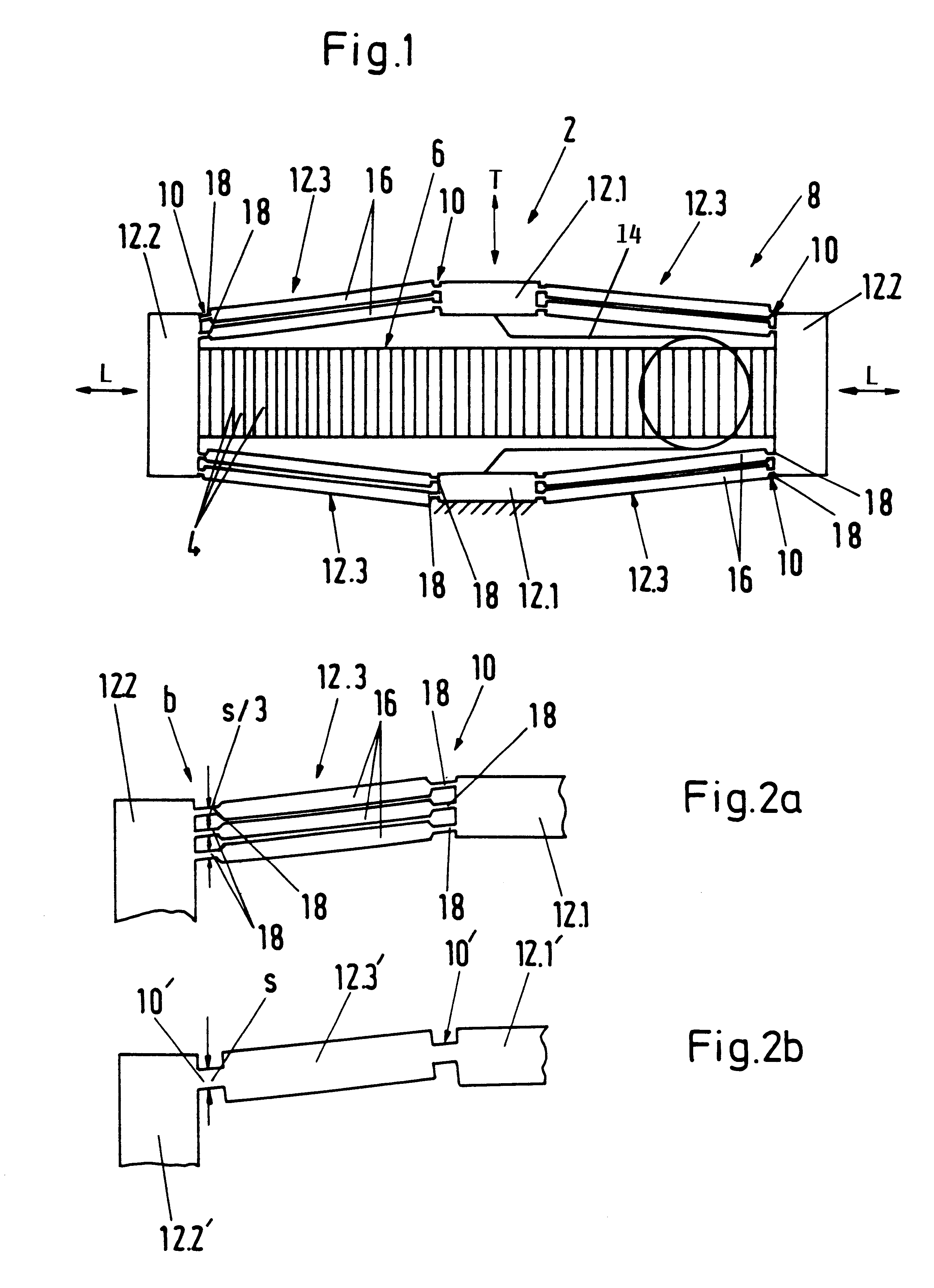

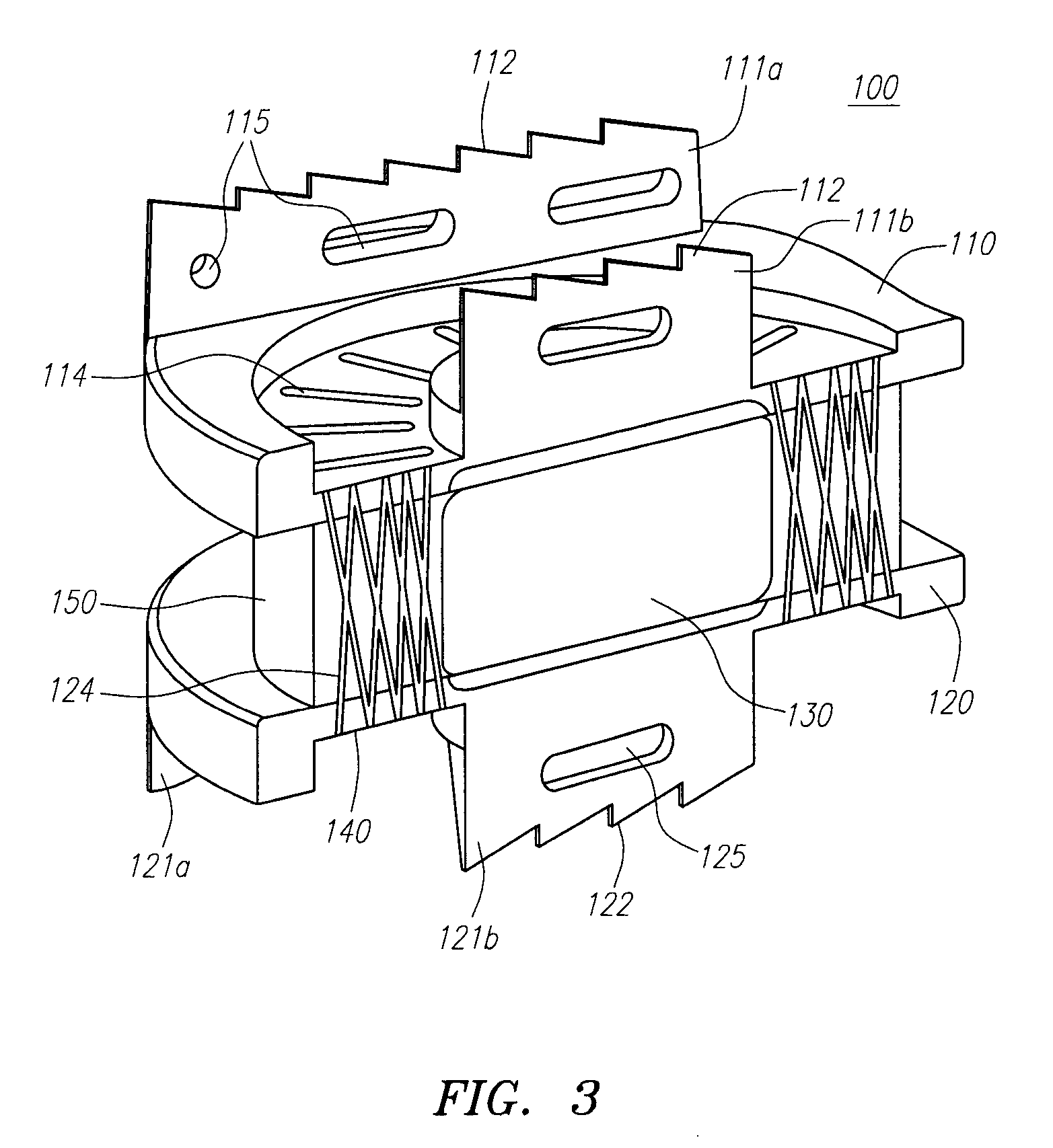

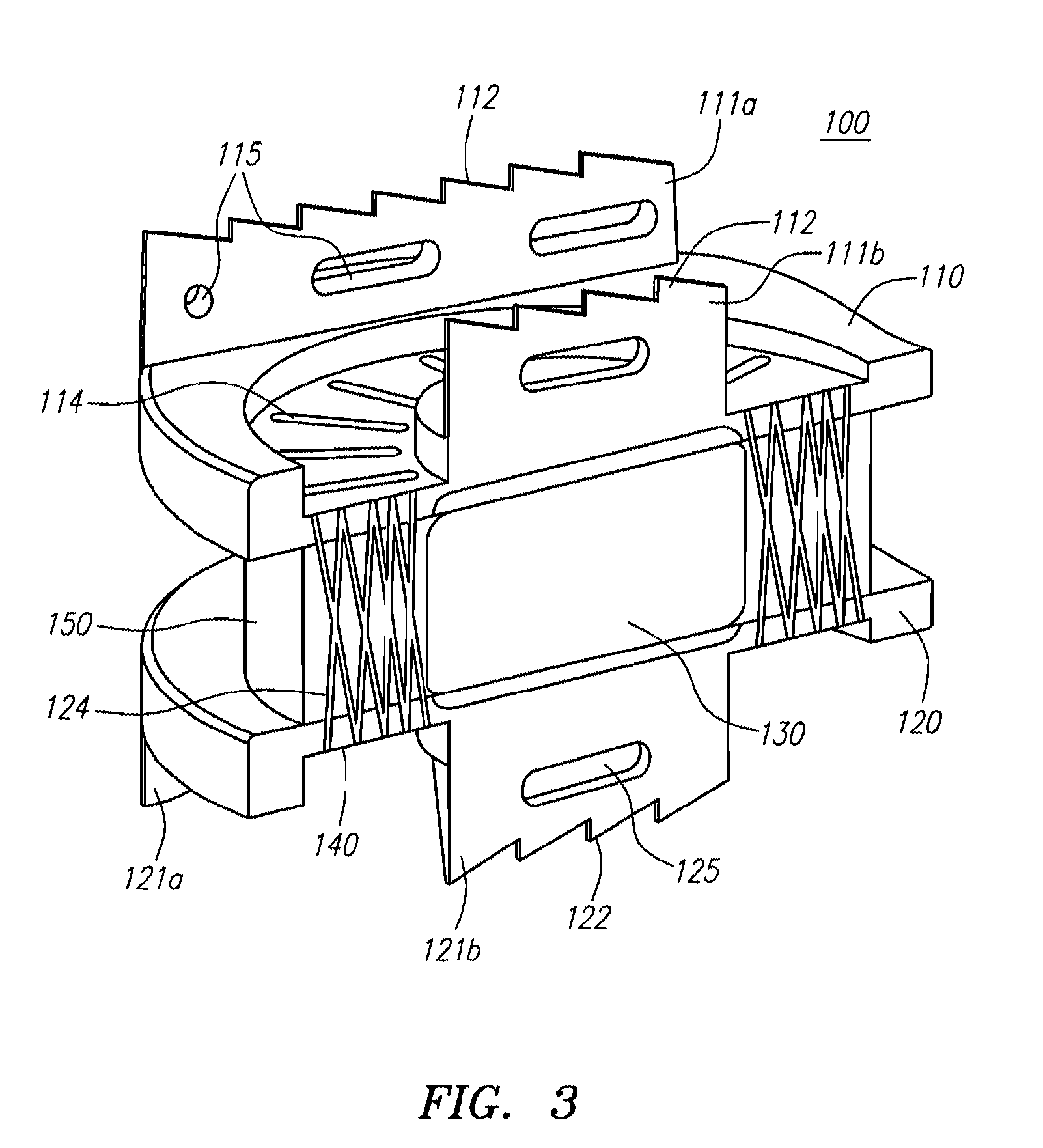

Electrostrictive or piezoelectric actuator device with a stroke amplifying transmission mechanism

InactiveUS6294859B1Low bending stiffnessReduce joint stiffnessPiezoelectric/electrostriction/magnetostriction machinesGearingFiber strainPiezoelectric actuators

An actuator device (2) includes a piezoelectric or electro-strictive solid state actuator element (6) that is elongated upon application of an electric voltage thereto, and a transmission mechanism (8) that amplifies the stroke displacement of the actuator element. The transmission mechanism (8) includes a plurality of rigid frame members (12), including unitary frame members (12.1, 12.2) and divided frame members (12.3), and elastically flexible joints (10) that respectively interconnect the frame members. Each one of the divided frame members (12.3) is made up of a plurality of separate parallel link rods (16). Each flexible joint (10) is made up of a plurality of individual parallel hinge members (18) that respectively connect an end of each one of the link rods (16) to the adjacent unitary frame member (12.1, 12.2). By this division of the flexible joints and of the divided frame members into parallel sub-components, the cross-sectional thickness of each individual hinge member is reduced, and thereby the bending stiffness and the outer fiber strain of the material of the hinge members is significantly reduced while providing the same total tensile strength and tensile stiffness. The link rods of each divided frame member effectively form a parallelogram linkage for moving and guiding the output members (12.1) in a parallel manner.

Owner:EADS DEUT GMBH

Metal wood club with improved hitting face

InactiveUS7207898B2Analysing solids using sonic/ultrasonic/infrasonic wavesGolf clubsMulti materialGolf Ball

A hitting face of a golf club head having improved flexural stiffness properties. In one embodiment, the hitting face is made from multiple materials. The main portion of the hitting face is a plate-like face made from a first material having a first density. A dense insert made from a second material having a second density that is greater than the first density is attached directly or indirectly to the plate-like face at or near the geometric center thereof. The dense insert increases the flexural stiffness of in a central zone of the hitting face so that a golf club head that has a larger zone of substantially uniform high initial ball speed. In another embodiment, the hitting face includes an insert that includes main plate and at least one wing extending therefrom. The insert is welded to the golf club head so that the main plate does not deflect separately from the remainder of the hitting face. The geometry of the insert controls the stiffness in the axial directions.

Owner:ACUSHNET CO

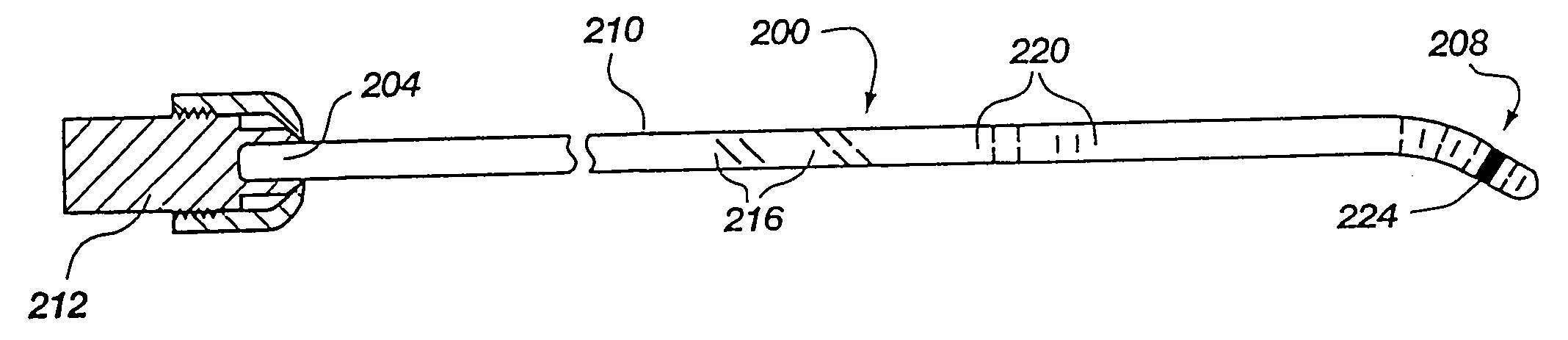

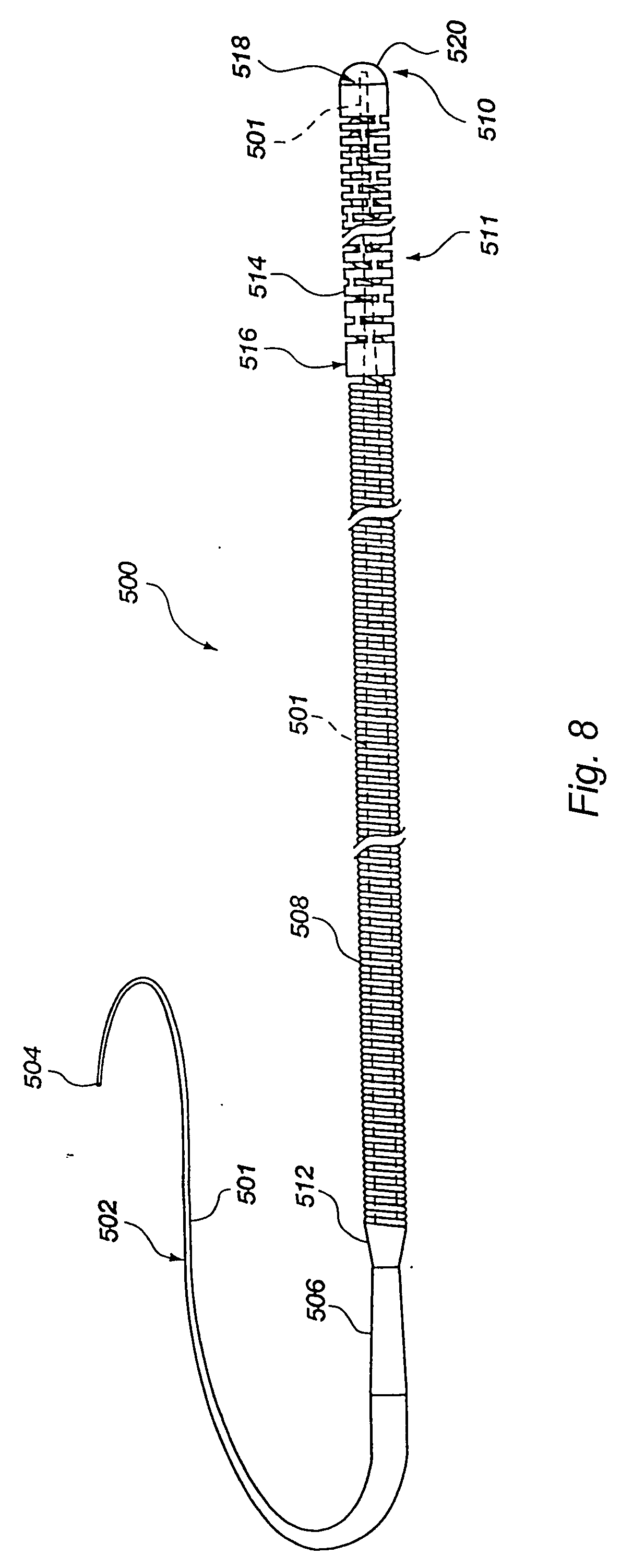

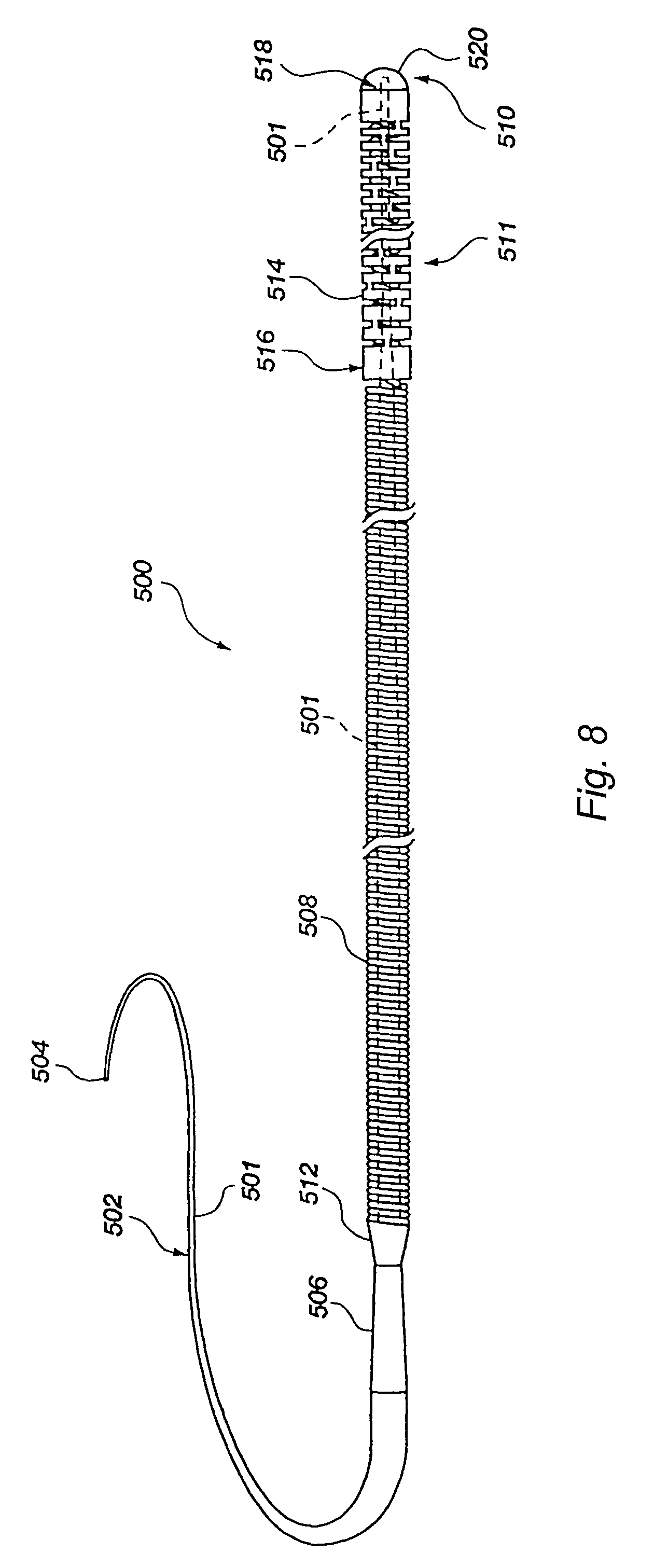

Device for sensing parameters of a hollow body organ

A device for sensing the profile of a hollow body organ includes a hollow guidewire or probe carrying a sensor. The hollow probe includes a distal coiled end tube with a tip bent at an angle between about 10° to 90° relative to the probe longitudinal axis and having a torque response of no more than about 0.4 ozf in. The flexural rigidity of the distal end tube relative to the mid and proximal end tubes forming the probe is generally in the range of about 1:(4 to 4,400):(110 to 13,000), respectively. An actuator is detachably secured to the probe and includes one or several motors which allow the sensor to travel in a rotational and axial path through the body organ.

Owner:SAADAT VAHID

Co-extruded, multi-lumen medical lead

InactiveUS6400992B1Transvascular endocardial electrodesExternal electrodesElectrical stimulationsBending stiffness

Medical electrical leads for sensing or electrical stimulation of body organs or tissues, particularly implantable cardiac leads for delivering pacing pulses and cardioversion / defibrillation shocks, and / or sensing the cardiac electrogram (EGM) or other physiologic data and their methods of fabrication are disclosed. A lead body sheath is co-extruded in a co-extrusion process using bio-compatible, electrically insulating, materials of differing durometers in differing axial sections thereof, resulting in a unitary lead body sheath having differing stiffness sections including axial segments or webs or lumen encircling rings or other structures in its cross-section. The lead body sheath is co-extruded to have an outer surface adapted to be exposed to the environment or to be enclosed within an outer sheath and to have a plurality of lead conductor lumens for receiving and enclosing a like plurality of lead conductors of the same or differing types. The lead body sheath can be co-extruded of a plurality of sheath segments containing a lead conductor lumen and formed of a first durometer material or of differing durometer materials. A web of a further durometer material can be co-extruded extending between the adjoining boundaries of the axial sheath segments and bonding the adjacent segments together. The lead body sheath can be tailored to exhibit differing bending stiffnesses away from the lead body sheath axis in selected polar directions around 360° circumference of the sheath body.

Owner:MEDTRONIC INC

Metal wood club with improved hitting face

InactiveUS7261643B2Analysing solids using sonic/ultrasonic/infrasonic wavesGolf clubsMulti materialEngineering

A hitting face of a golf club head having improved flexural stiffness properties. In one embodiment, the hitting face is made from multiple materials. The main portion of the hitting face is a plate-like face made from a first material having a first density. A dense insert made from a second material having a second density that is greater than the first density is attached directly or indirectly to the plate-like face at or near the geometric center thereof. The dense insert increases the flexural stiffness of in a central zone of the hitting face so that a golf club head that has a larger zone of substantially uniform high initial ball speed. In another embodiment, the hitting face includes an insert that includes main plate and at least one wing extending therefrom. The insert is welded to the golf club head so that the main plate does not deflect separately from the remainder of the hitting face. The geometry of the insert controls the stiffness in the axial directions.

Owner:ACUSHNET CO

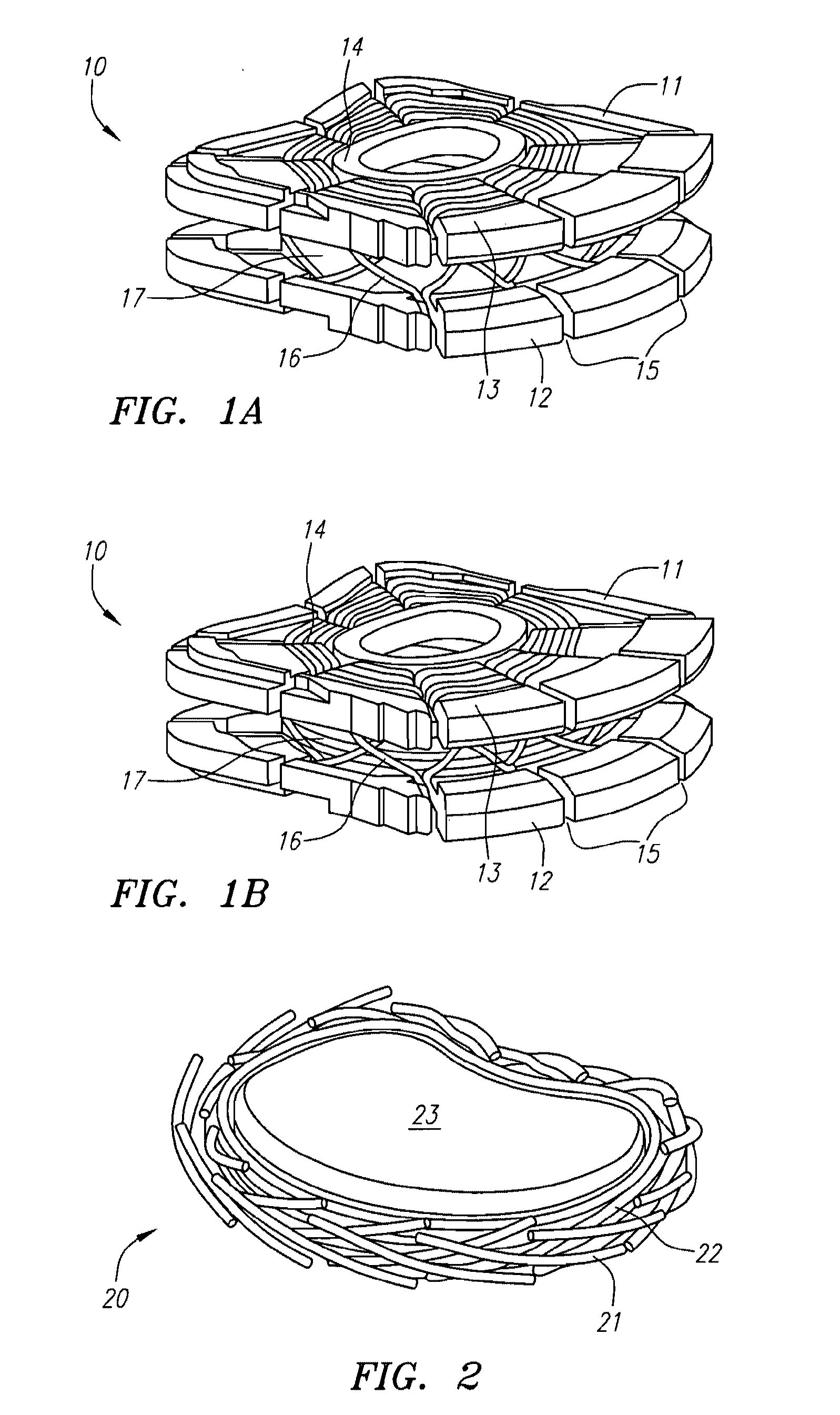

Prosthetic intervertebral discs

ActiveUS20070050033A1Improve wear resistanceHigh modulusInternal osteosythesisSpinal implantsIntervertebral discProsthesis

Prosthetic intervertebral discs, systems including such prosthetic intervertebral discs, and methods for using the same are described. The subject prosthetic discs include upper and lower endplates separated by a compressible core member. The subject prosthetic discs exhibit stiffness in the vertical direction, torsional stiffness, bending stiffness in the saggital plane, and bending stiffness in the front plane, where the degree of these features can be controlled independently by adjusting the components, construction, and other features of the discs.

Owner:SPINAL KINETICS

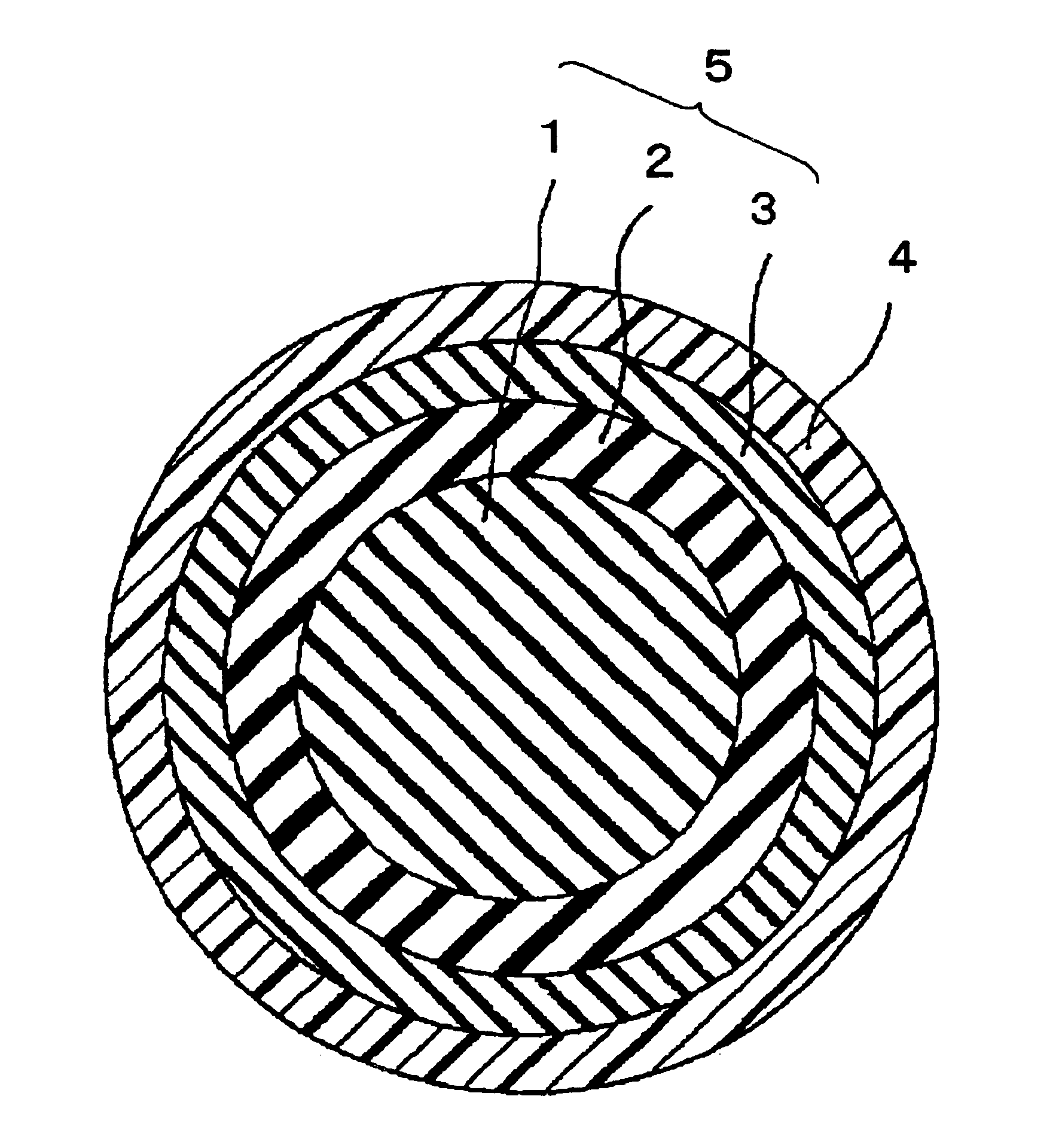

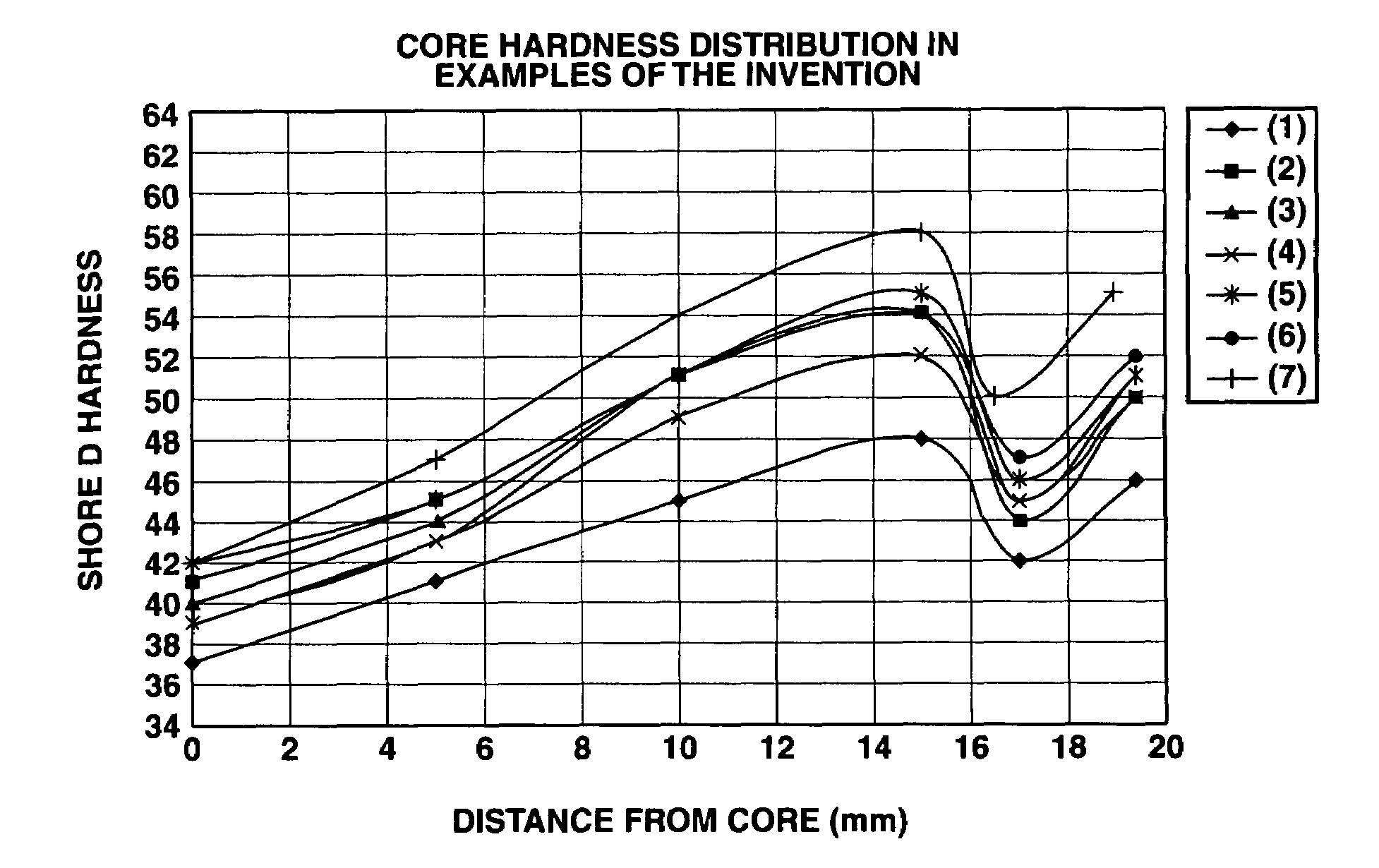

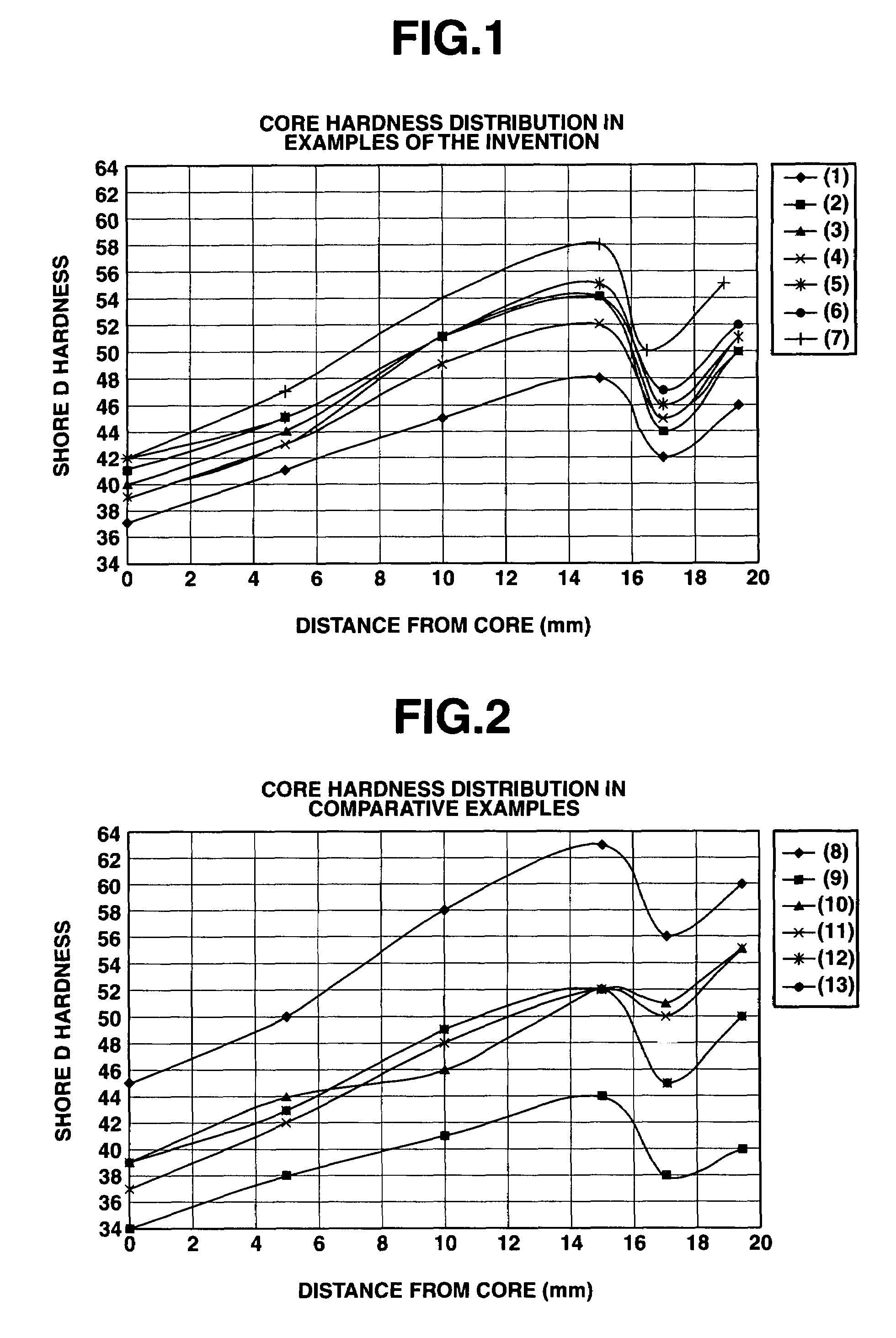

Multi-piece solid golf ball

InactiveUS6913548B2High trajectoryImprove flight performanceGolf ballsSolid ballsEngineeringGolf Ball

The present invention provides a multi-piece solid golf ball having excellent flight performance and good shot feel. The present invention relates to a multi-piece solid golf ball comprising a core consisting of an inner core, an intermediate layer and an outer layer, and a cover, wherein the inner core has a flexural rigidity (RI) of 20 to 80 MPa, a ratio (RM / RI) of a flexural rigidity of the intermediate layer (RM) to the (RI) is from 0.6 to 1.4, a flexural rigidity of the outer layer is higher than the (RI) by 70 to 500 MPa, and the intermediate layer is placed such that the a radius of the golf ball (rG), a radius of the inner core (rI) and a radius of a two-layer structured core obtained by forming the intermediate layer on the inner core (rT) satisfy the following two formulae:rI / rG≧0.70rT / rG≦0.83.

Owner:SUMITOMO RUBBER IND LTD

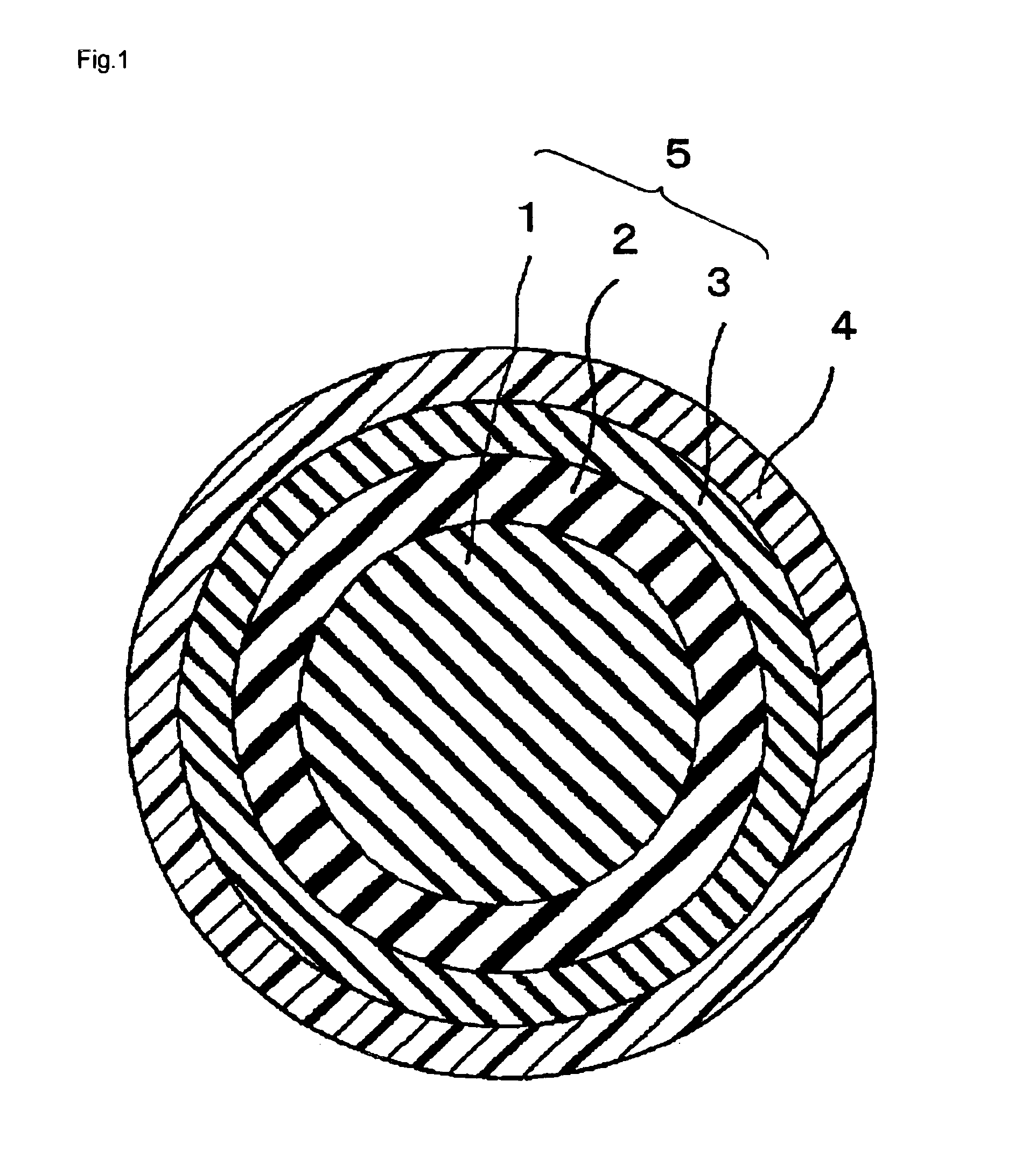

Solid golf ball

InactiveUS20080194357A1Improve spin performanceIncrease distanceGolf ballsSolid ballsThermoplasticPolymer science

The invention provides a solid golf ball having a solid core and a cover layer that encases the core and has an outermost layer on an outside surface of which are formed a plurality of dimples. The solid core is formed of a rubber composition composed of 100 parts by weight of a base rubber that includes 60 to 100 parts by weight of a polybutadiene rubber having a cis-1,4 bond content of at least 60% and synthesized using a rare-earth catalyst, 0.1 to 5 parts by weight of an organosulfur compound, an unsaturated carboxylic acid or a metal salt thereof, and an inorganic filler. The solid core has a deformation, when compressed under a final load of 130 kgf from an initial load of 10 kgf, of 2.0 to 4.0 mm, and has a specific hardness distribution. The cover layer is formed primarily of a thermoplastic or thermoset polyurethane material and has a thickness of 0.5 to 2.5 mm, a Shore D hardness at the surface of 50 to 70 and a flexural rigidity of 50 to 300 MPa. The golf ball has a deformation, when compressed under a final load of 130 kgf from an initial load of 10 kgf, of 2.0 to 3.8 mm. The solid golf ball is advantageous overall in competitive use.

Owner:BRIDGESTONE SPORTS

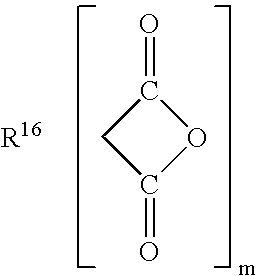

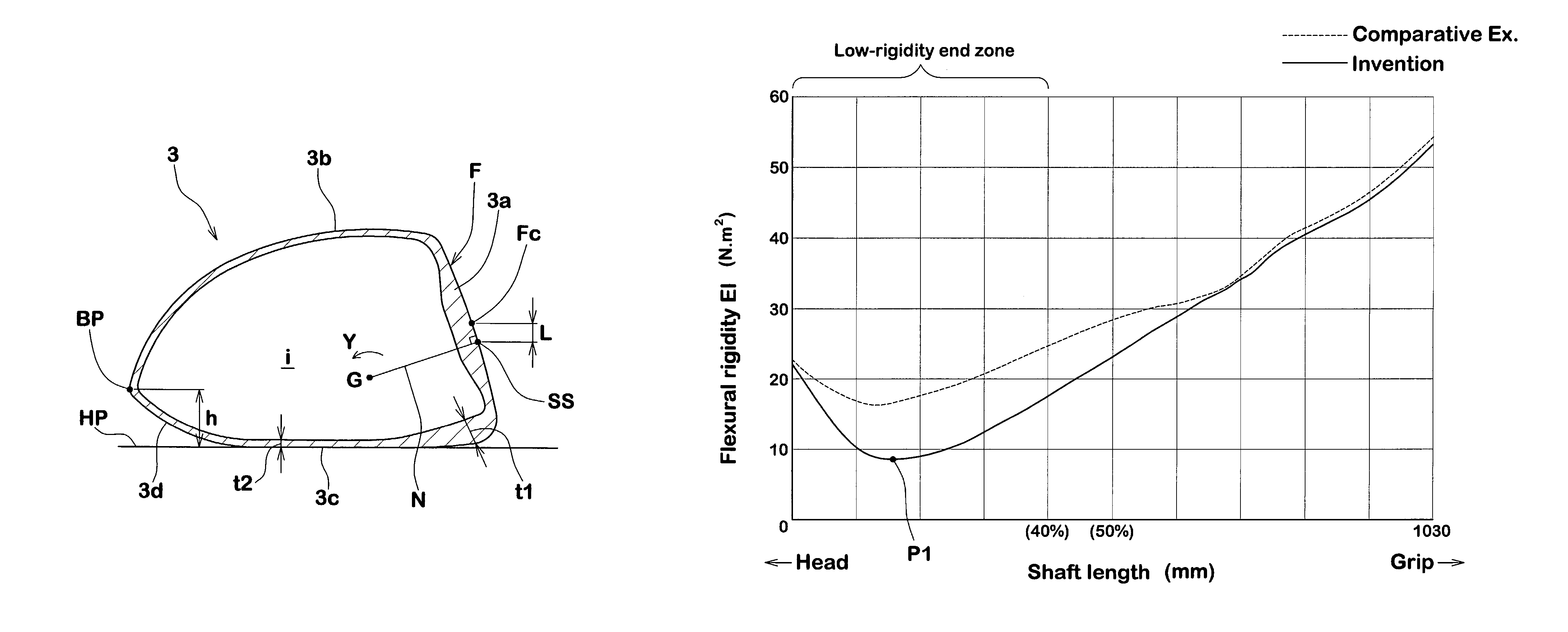

Golf club

Owner:DUNLOP SPORTS CO LTD

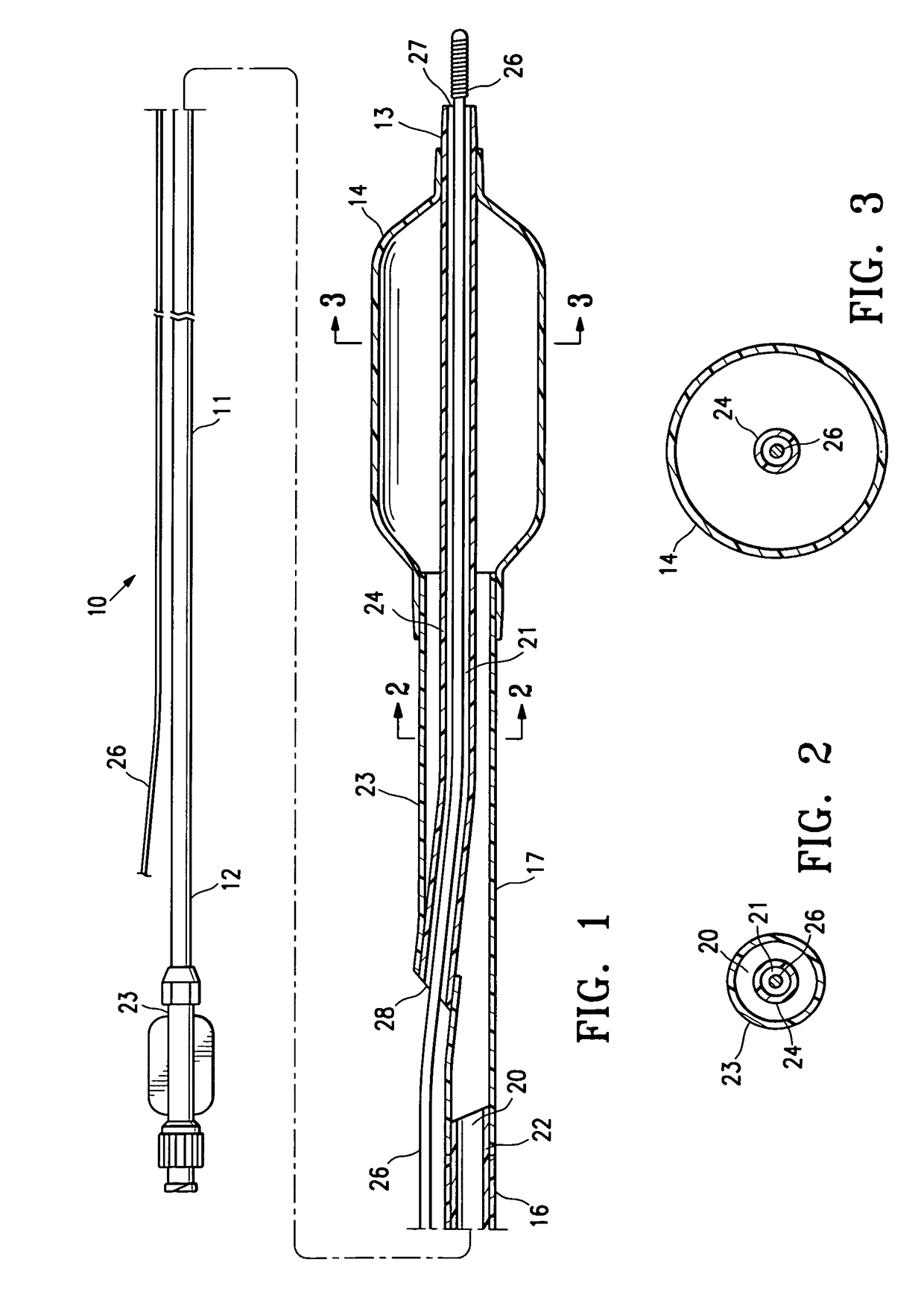

Method of making a balloon catheter shaft having high strength and flexibility

A catheter having an elongated shaft with a tubular member which forms at least a portion of the shaft and which is formed of a biaxially oriented thermoplastic polymeric material, and a method of forming the catheter shaft by radially and longitudinally expanding the tubular member to biaxially orient the polymeric material. A catheter of the invention has an improved combination of low bending stiffness, high rupture pressure, and high tensile strength, for improved catheter performance.

Owner:ABBOTT CARDIOVASCULAR

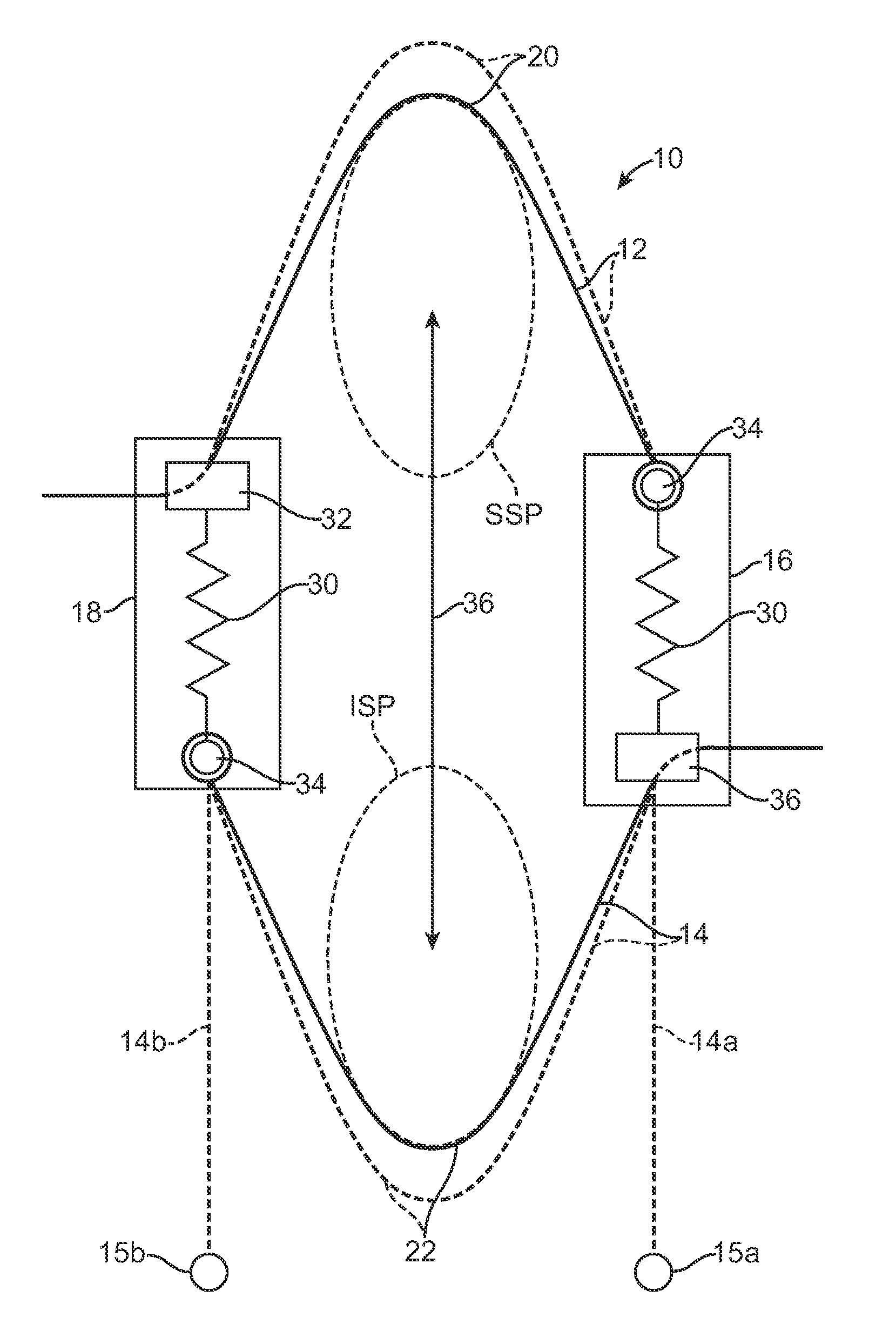

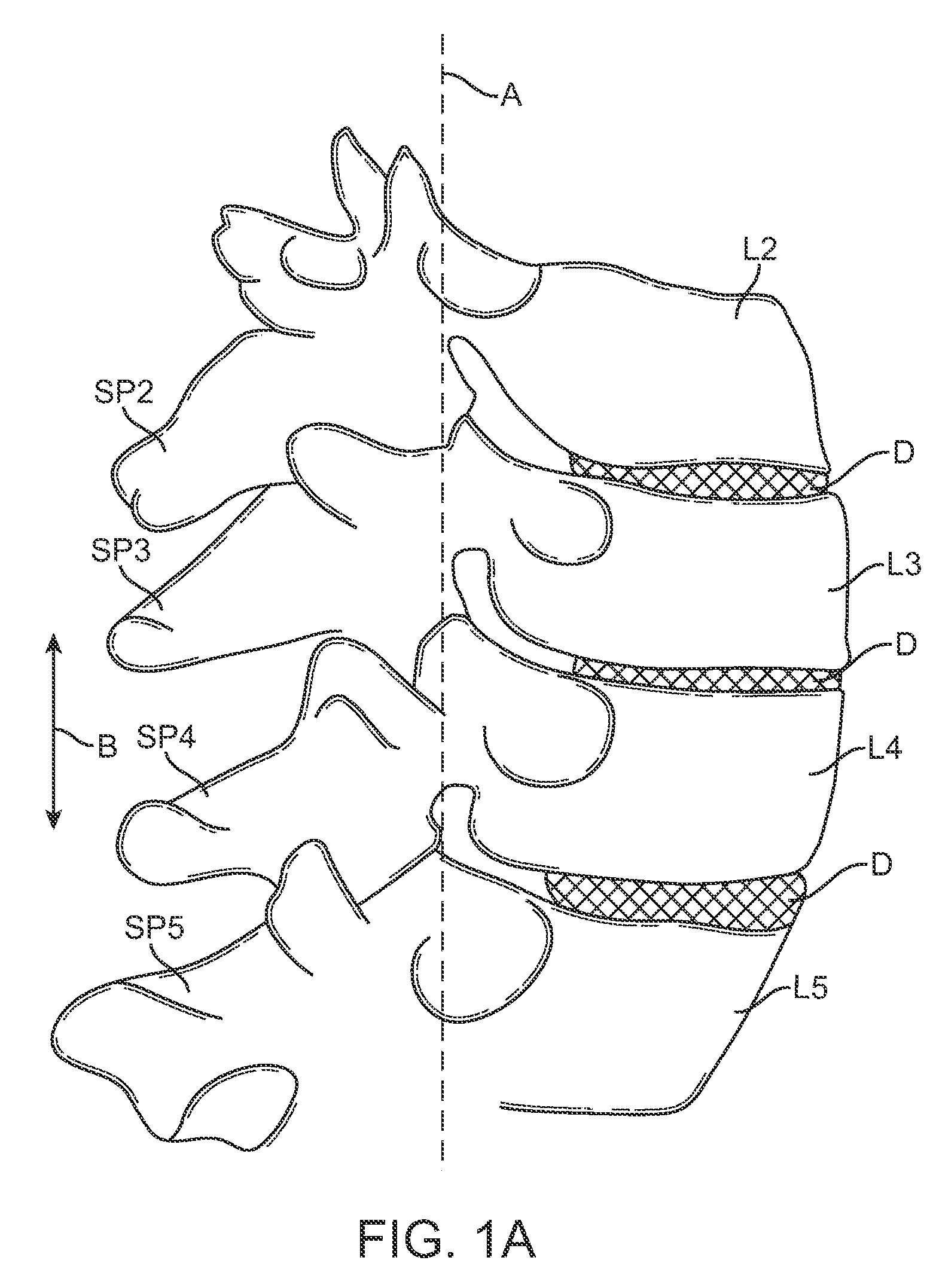

Methods and systems for increasing the bending stiffness and constraining the spreading of a spinal segment

InactiveUS20100036424A1Increased bending stiffnessRelieve instabilityInternal osteosythesisDiagnosticsMedicineTension member

A system for restricting spinal flexion includes superior and inferior tether structures joined by a pair of compliance members. Compliance members comprise tension members which apply a relatively low elastic tension on the tether structures. By placing the tether structures on or over adjacent spinous processes, flexion of a spinal segment can be controlled in order to reduce pain.

Owner:SIMPIRICA SPINE

Solid golf ball

InactiveUS7344455B1Reduce rigidityImprove performanceGolf ballsSolid ballsPolymer scienceAntioxidant

The invention provides a solid golf ball having a solid core and a cover layer that encases the core and has an outermost layer on an outside surface of which are formed a plurality of dimples. The solid core is formed of a rubber composition composed of 100 parts by weight of a base rubber that includes 60 to 100 parts by weight of a polybutadiene rubber having a cis-1,4 bond content of at least 60% and synthesized using a rare-earth catalyst, 0.1 to 5 parts by weight of an organosulfur compound, an unsaturated carboxylic acid or a metal salt thereof, an inorganic filler, and an antioxidant. The solid core has a deformation, when compressed under a final load of 130 kgf from an initial load of 10 kgf, of 2.0 to 4.0 mm, and has a specific hardness distribution. The cover layer is formed primarily of a polyurethane material and has a thickness of 0.5 to 2.5 mm, a Shore D hardness at the surface of 50 to 70 and a flexural rigidity of 50 to 300 MPa. The golf ball has a deformation, when compressed under a final load of 130 kgf from an initial load of 10 kgf, of 2.0 to 3.8 mm. The solid golf ball is advantageous overall in competitive use.

Owner:BRIDGESTONE SPORTS

Golf club head with variable flexural stiffness for controlled ball flight and trajectory

InactiveUS7041003B2Increase ball speedAnalysing solids using sonic/ultrasonic/infrasonic wavesGolf clubsEngineeringControl zone

The present invention relates to a golf club head with a hitting face. The hitting face comprises a directional control portion, which has at least two zones with different flexural stiffness, such that when the hitting face strikes a golf ball the two zones deform differently to selectively control the direction of the flight of the golf ball. The directional control portion may comprise an upper zone and a lower zone, where the upper zone has a lower flexural stiffness. Alternatively, the lower zone has a lower flexural stiffness. On the other hand, the directional control portion may comprise a left zone and a right zone, and either the left or right zone may have a lower flexural stiffness to selectively control the lateral launch angle either to the left of right. The hitting face may further comprise a central zone disposed within the directional control zone, wherein the central zone has a flexural stiffness of at least about three times greater than the flexural stiffness of the directional control zone.

Owner:ACUSHNET CO

Appendage mountable electronic devices conformable to surfaces

ActiveUS9554484B2Increase contactDigital data processing detailsSolid-state devicesElectronic systemsEngineering

Disclosed are appendage mountable electronic systems and related methods for covering and conforming to an appendage surface. A flexible or stretchable substrate has an inner surface for receiving an appendage, including an appendage having a curved surface, and an opposed outer surface that is accessible to external surfaces. A stretchable or flexible electronic device is supported by the substrate inner and / or outer surface, depending on the application of interest. The electronic device in combination with the substrate provides a net bending stiffness to facilitate conformal contact between the inner surface and a surface of the appendage provided within the enclosure. In an aspect, the system is capable of surface flipping without adversely impacting electronic device functionality, such as electronic devices comprising arrays of sensors, actuators, or both sensors and actuators.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

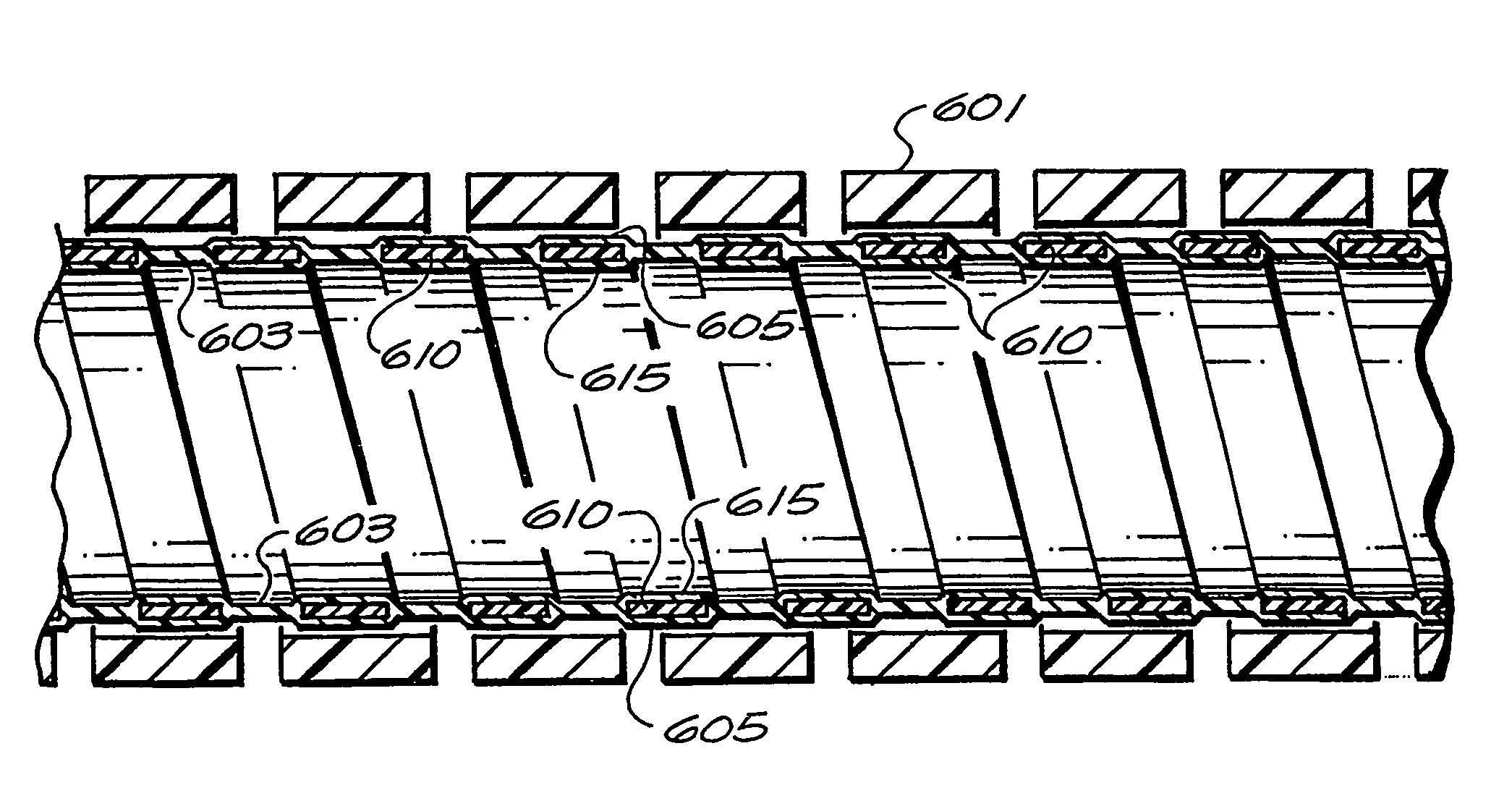

Medical device with collapse-resistant liner and method of making same

InactiveUS7914466B2Desired flexibility in bendingIncrease stiffnessGuide wiresDiagnostic recording/measuringCatheterMedical device

A medical device for guiding through anatomy, such as a catheter or guidewire, with a tubular body that has been slotted to enhance bending flexibility, and a polymer liner with an anti-collapsing structure, and a method of making a medical device with a kink-resistant corrugated tubular member and an anti-collapsing structure. Anti collapsing structures may be helical or annular, and may be wire, such as ribbon wire, grooves in the liner, corrugations, or a braid. Liners may be bonded to the anti-collapsing structure, or may have two layers, with the anti-collapsing structure between the layers. Corrugations may be formed between sections of the anti-collapsing ‘structure with heat, pressure, stretching, compression, a mold, or a combination thereof, and may extend inward or outward. Shape or wall thickness may vary along the length to provide a varying bending stiffness. Slots may be formed in groups of two, three, or more, and adjacent groups may be rotated about the axis forming a helical pattern.

Owner:PRECISION VASCULAR SYST

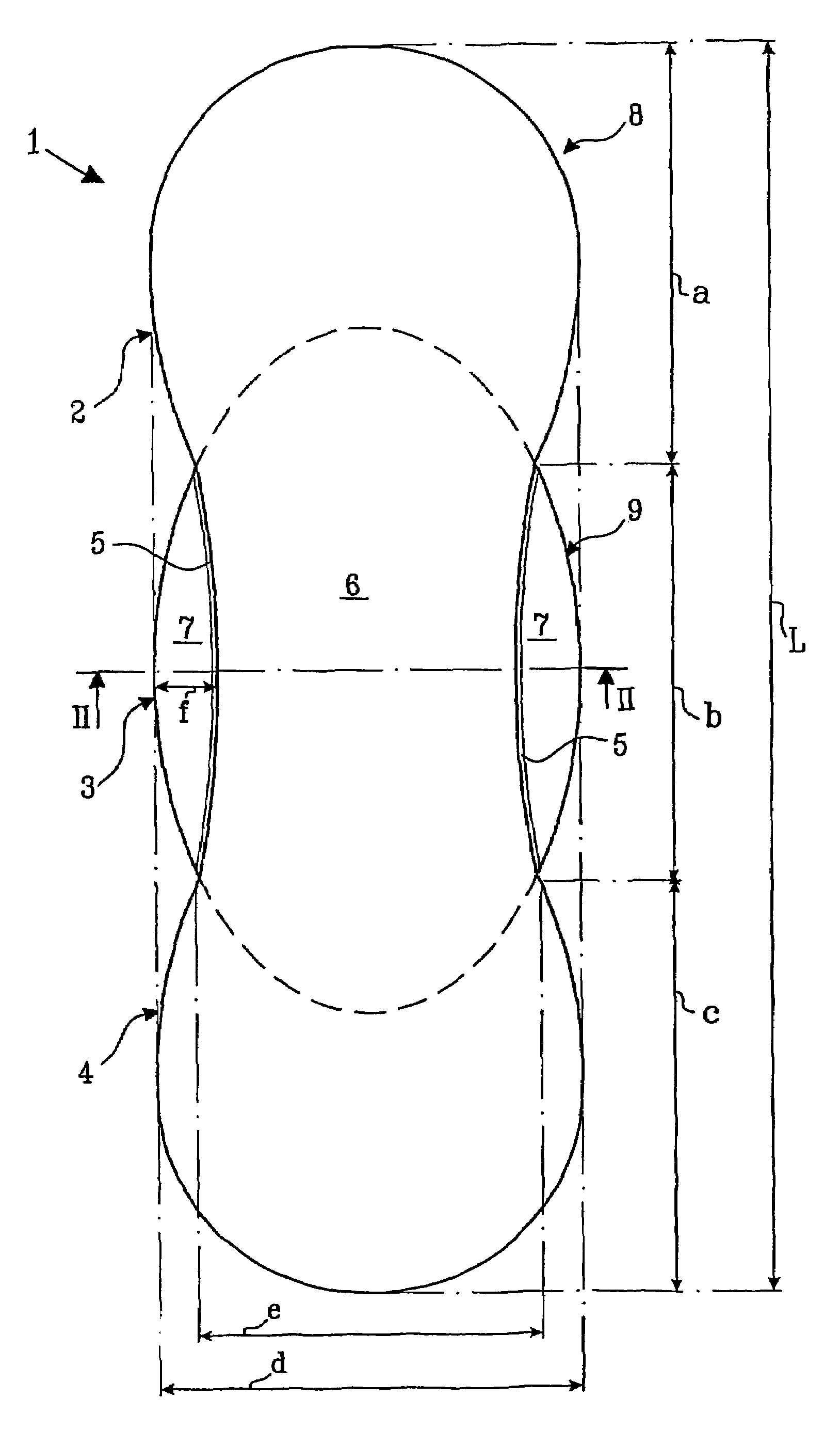

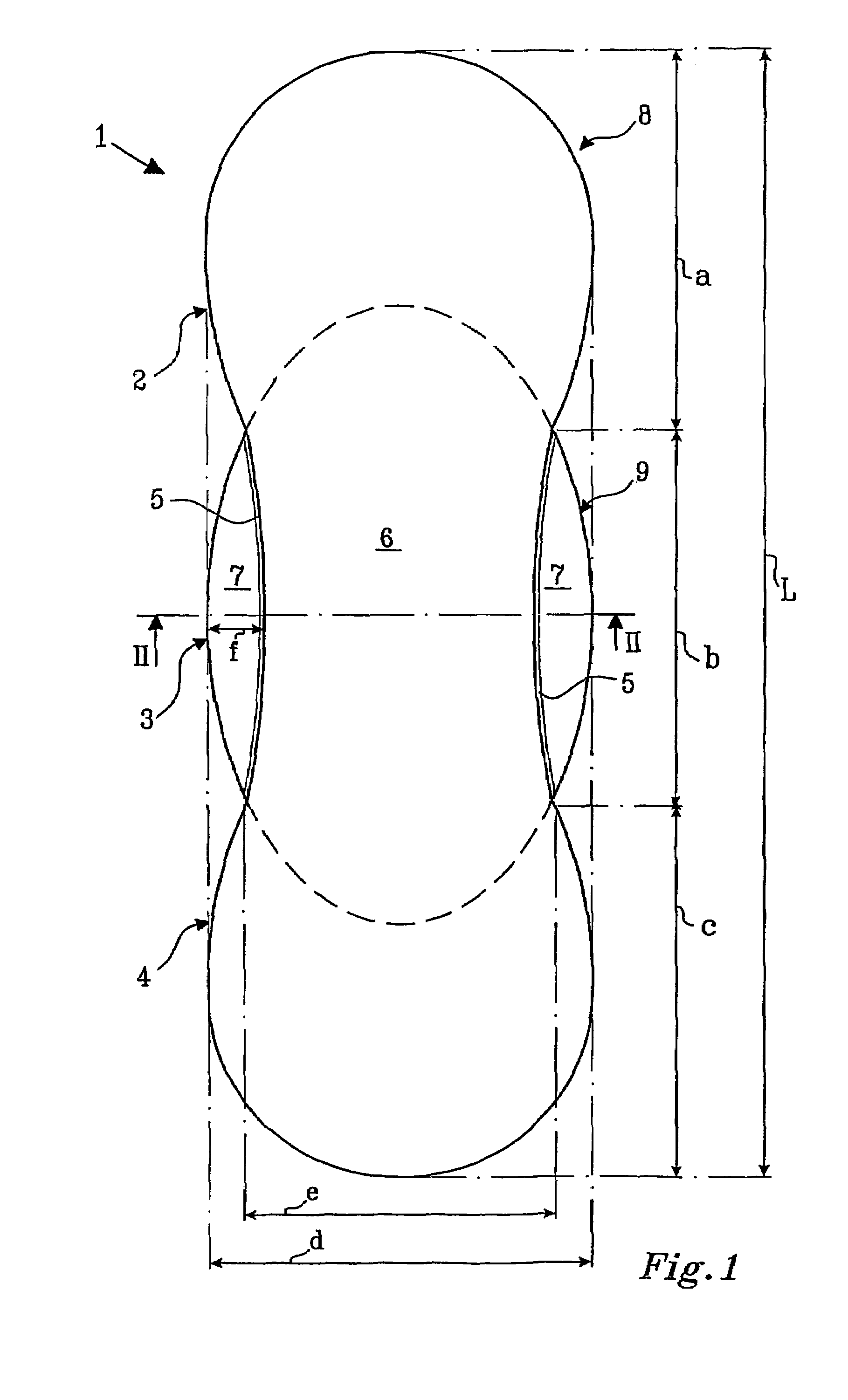

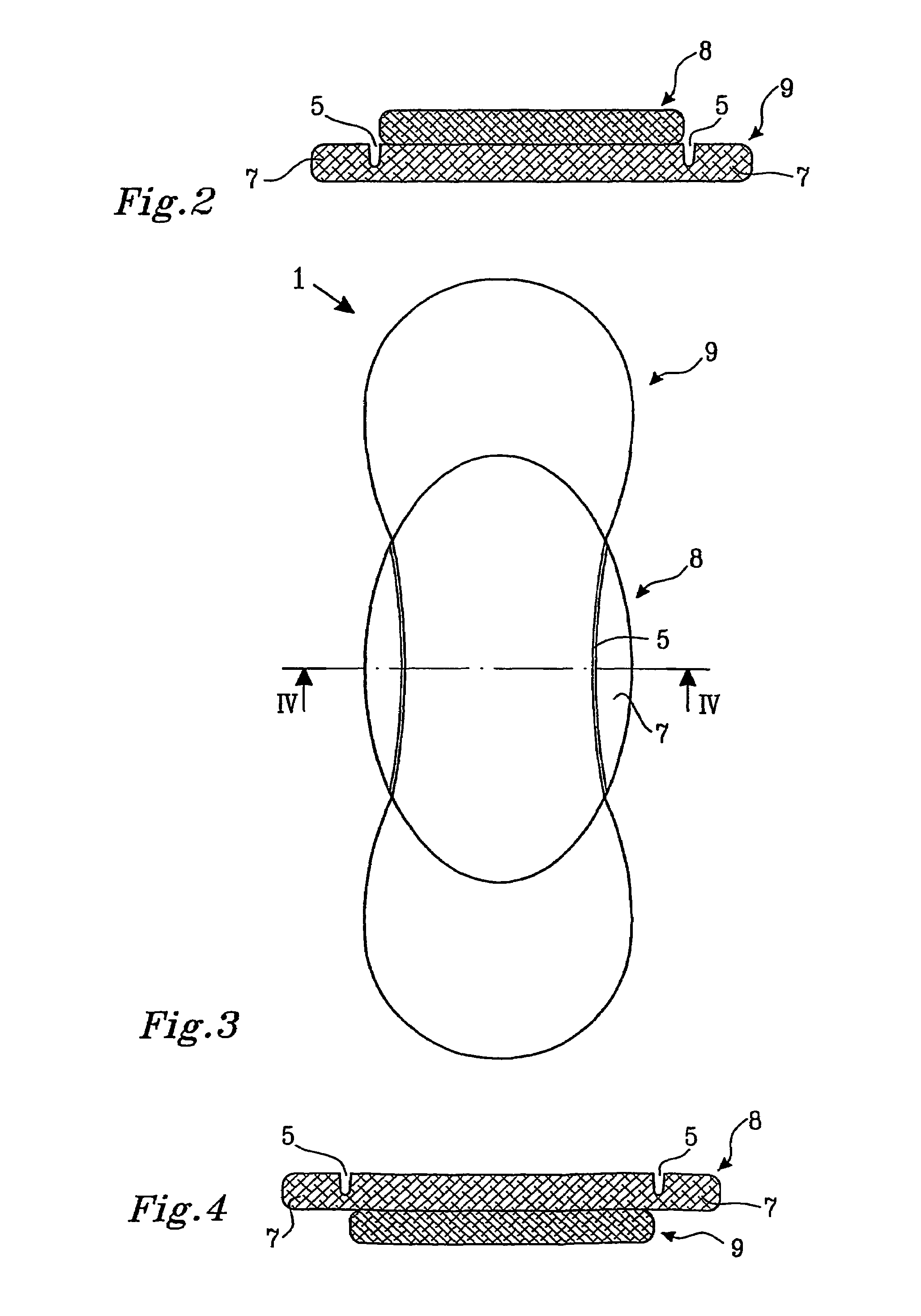

Absorbent article

An absorbent article, especially an incontinence pad, having a length and a width extension, the length being greater than the width, and including absorbent core material, wherein the absorbent core material forms a central portion (6) and a pair of longitudinally extending side portions (7), the flexural rigidity of the article (1) at the side portions (7) is between 3 and 20% of the flexural rigidity of the article (1) of the central portion (6) at a location opposite the side portions (7), preferably between 4 and 15%, most preferred between 4 and 10%.

Owner:ESSITY HYGIENE & HEALTH AB

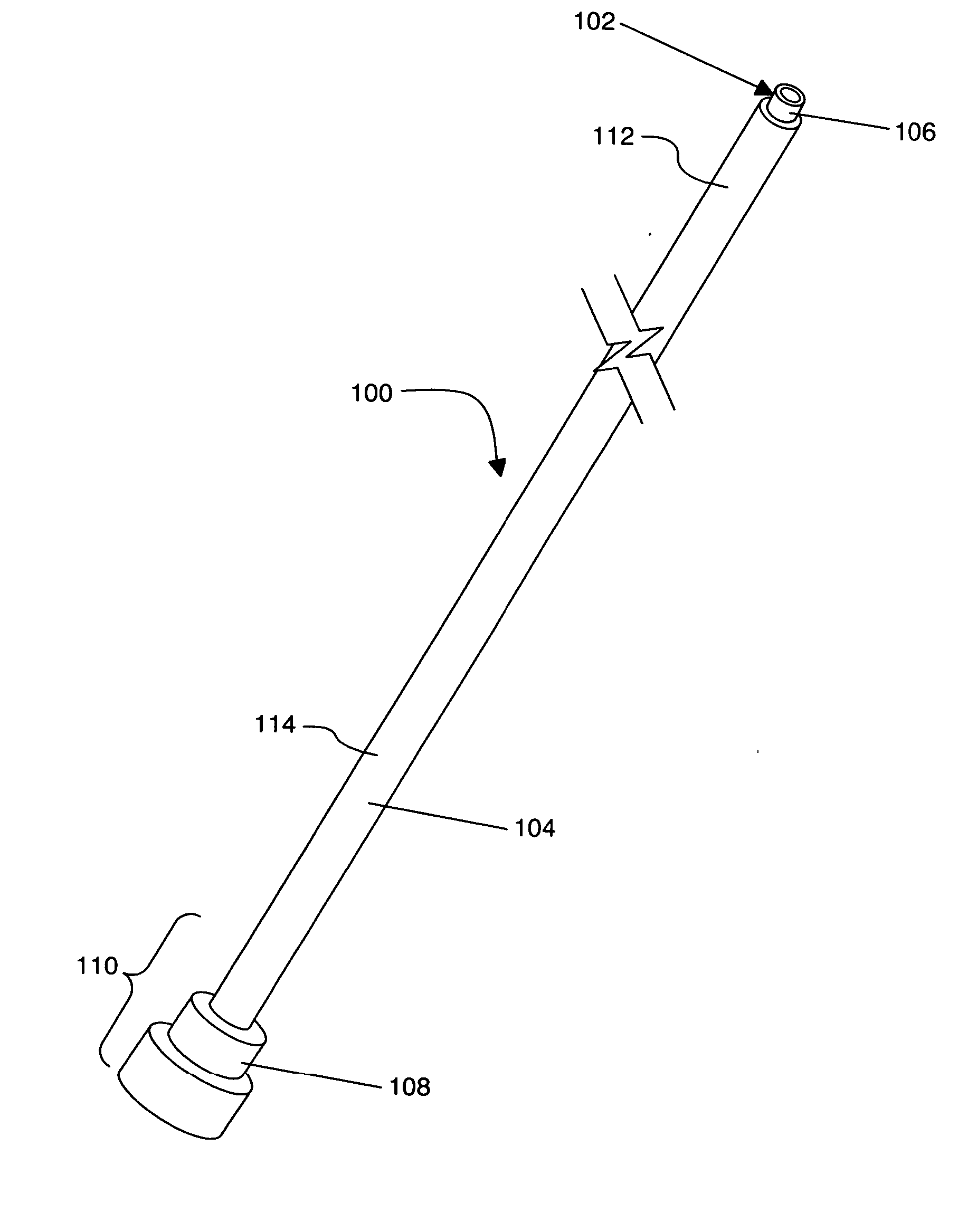

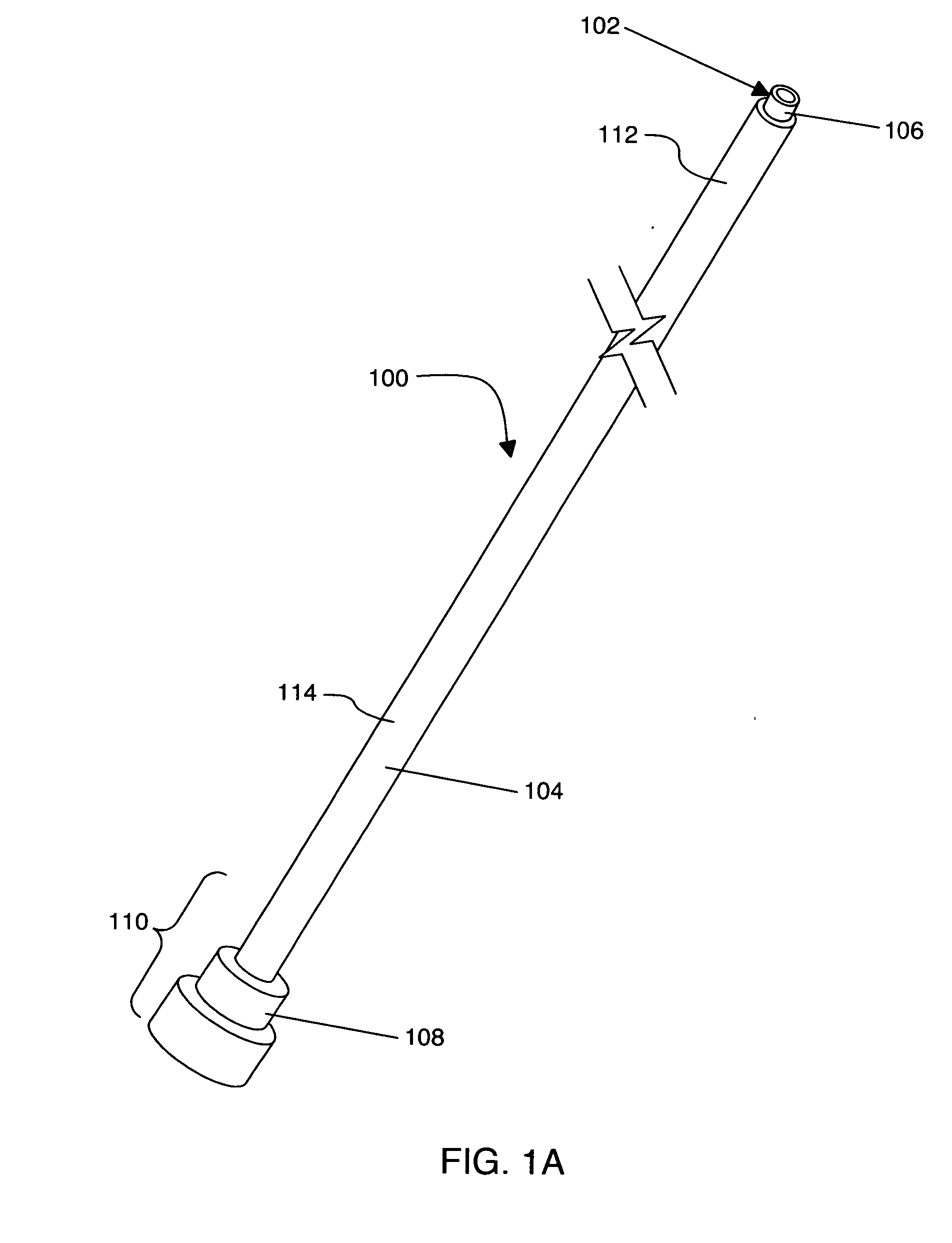

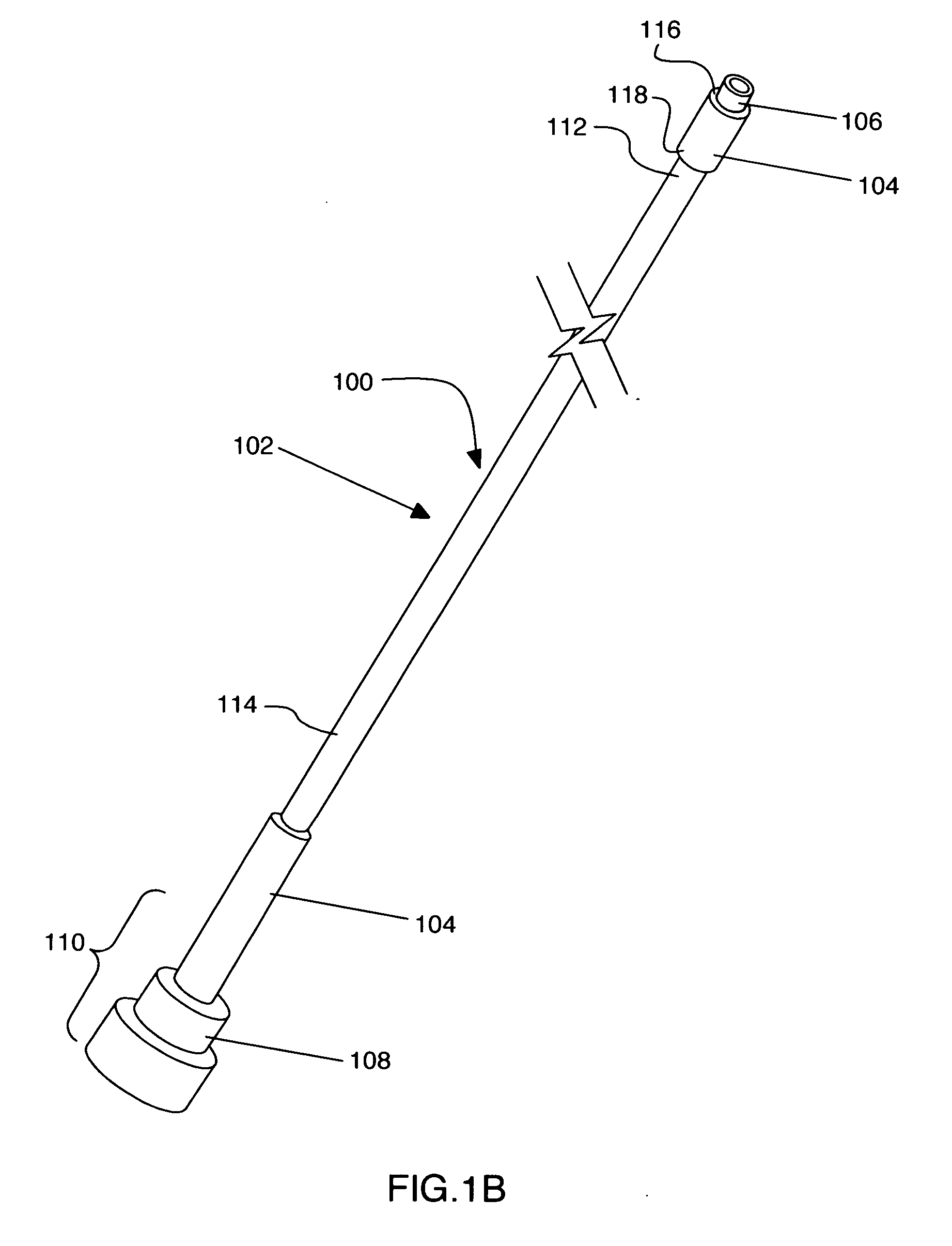

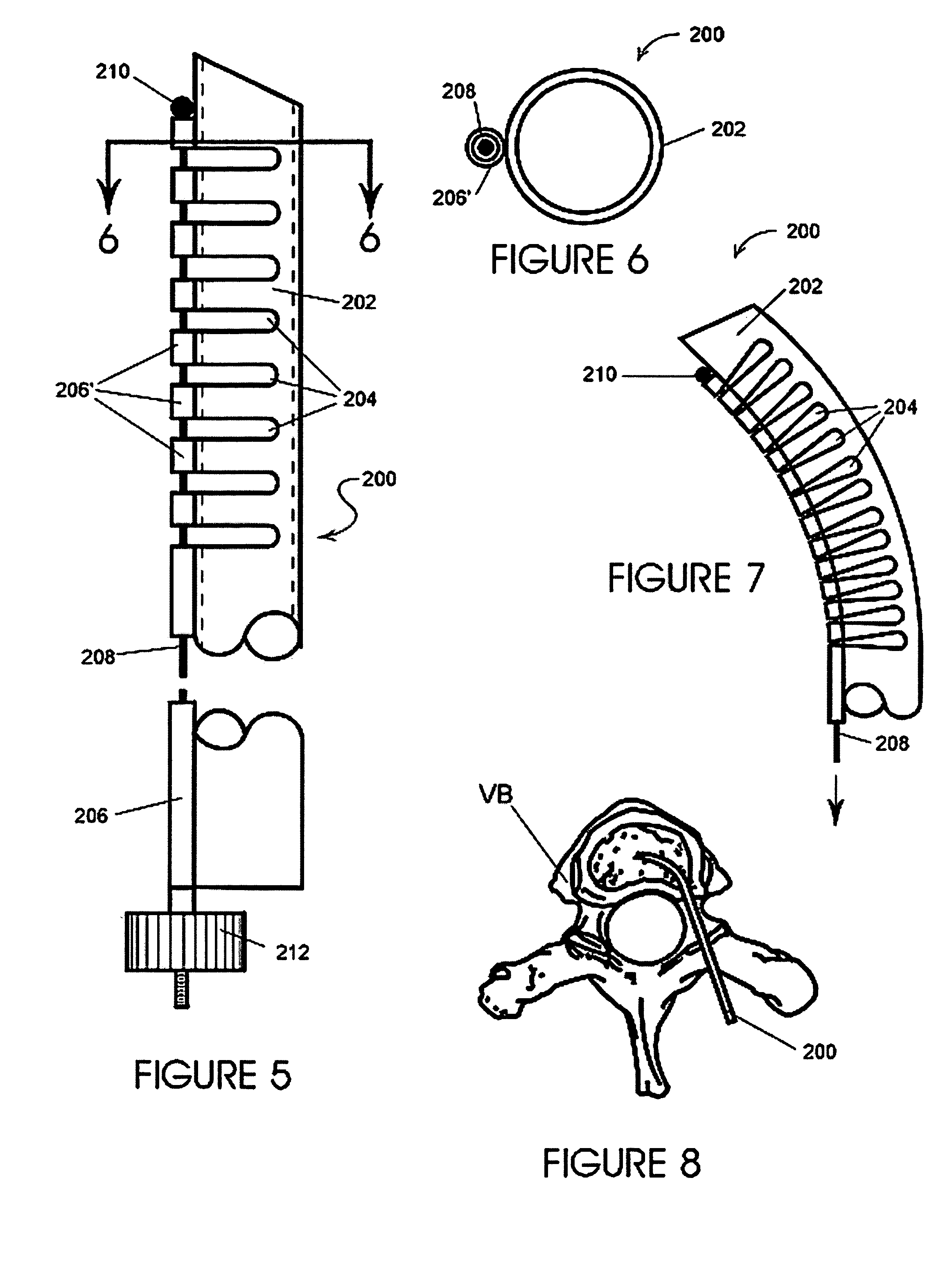

Radiofrequency perforation apparatus

ActiveUS20080086120A1Improves rapidity and precisionReduce the risk of injuryDiagnosticsSurgical instruments for irrigation of substancesDistal portionContact force

A radiofrequency perforation apparatus for creating a channel at a target location in a body of a patient, the radiofrequency perforation apparatus being usable by an intended user having a hand, the radiofrequency perforation apparatus comprising: a handle graspable by the hand; a distal portion, the distal portion defining a distal portion length, the distal portion including an electrode and an electrical insulator extending from the electrode; and a force transmitting portion extending between the distal portion and the handle, the force transmitting portion defining a force transmitting portion length, the force transmitting portion length being larger than the distal portion length, the force transmitting portion having a force transmitting portion flexural rigidity of at least about 0.016 Nm2; whereby the force transmitting portion has a force transmitting portion flexural rigidity allowing the transmission to the handle of contact forces exerted on the distal portion when the distal portion contacts the target location to provide tactile feedback to the intended user.

Owner:BOSTON SCI MEDICAL DEVICE LTD

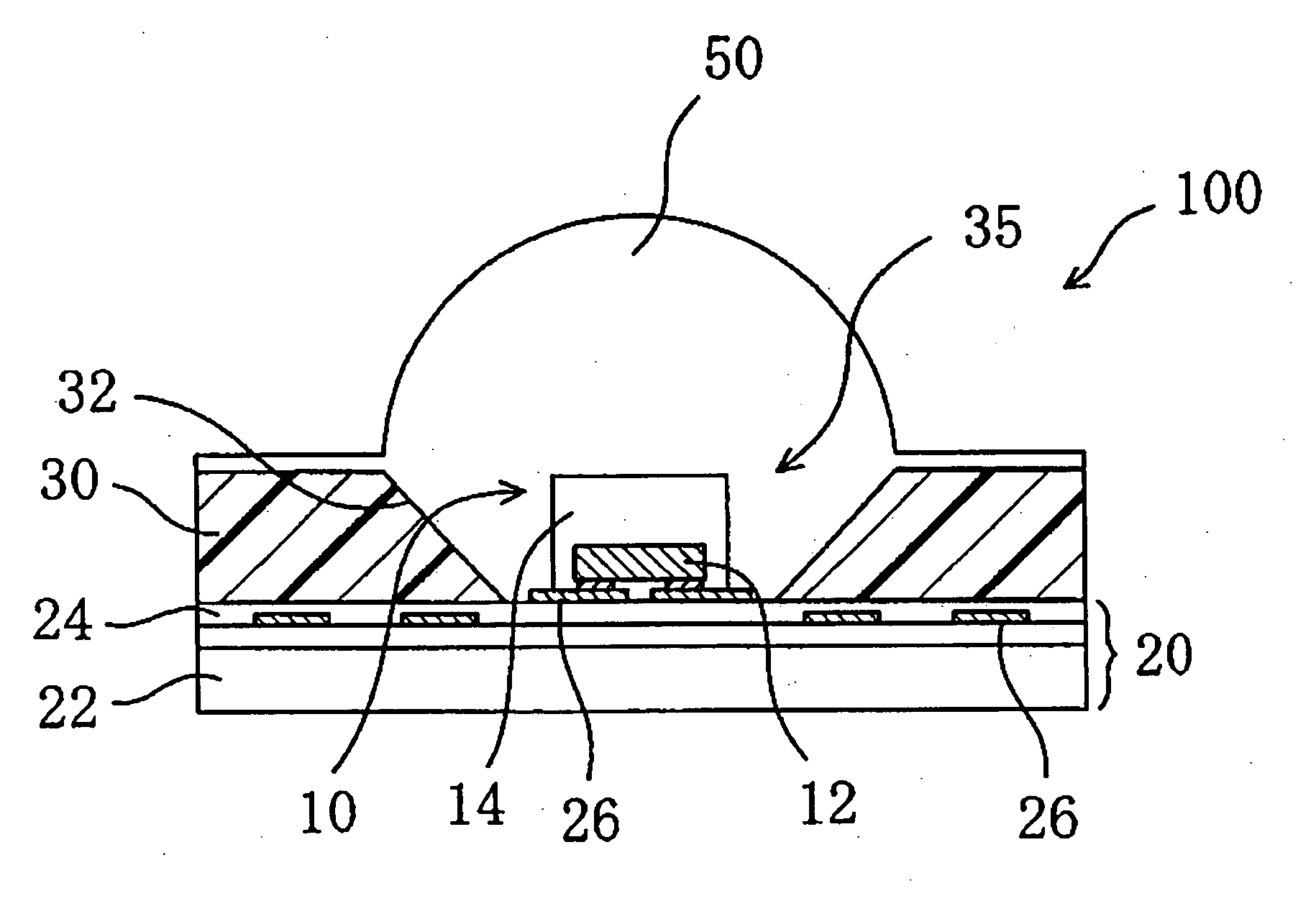

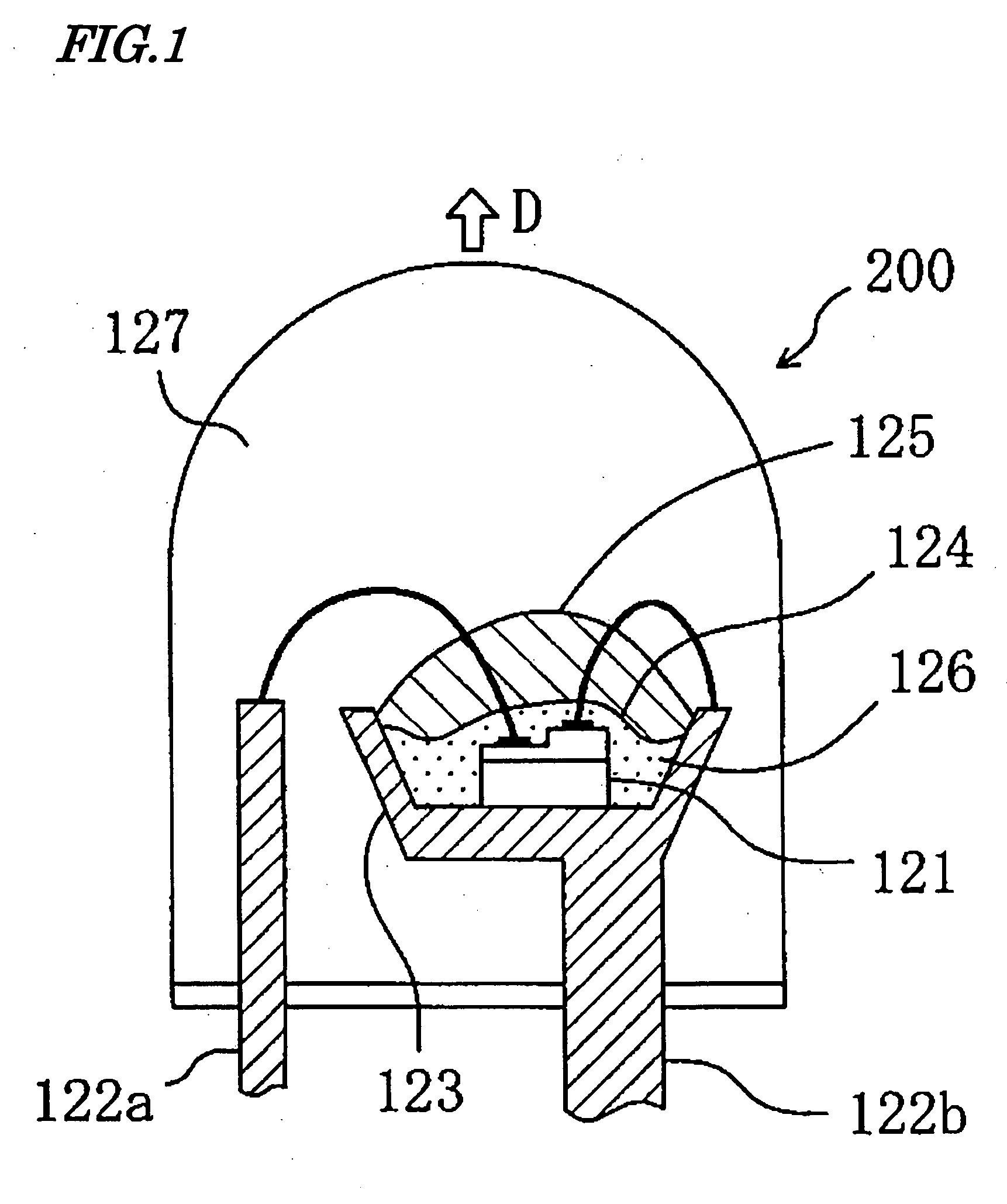

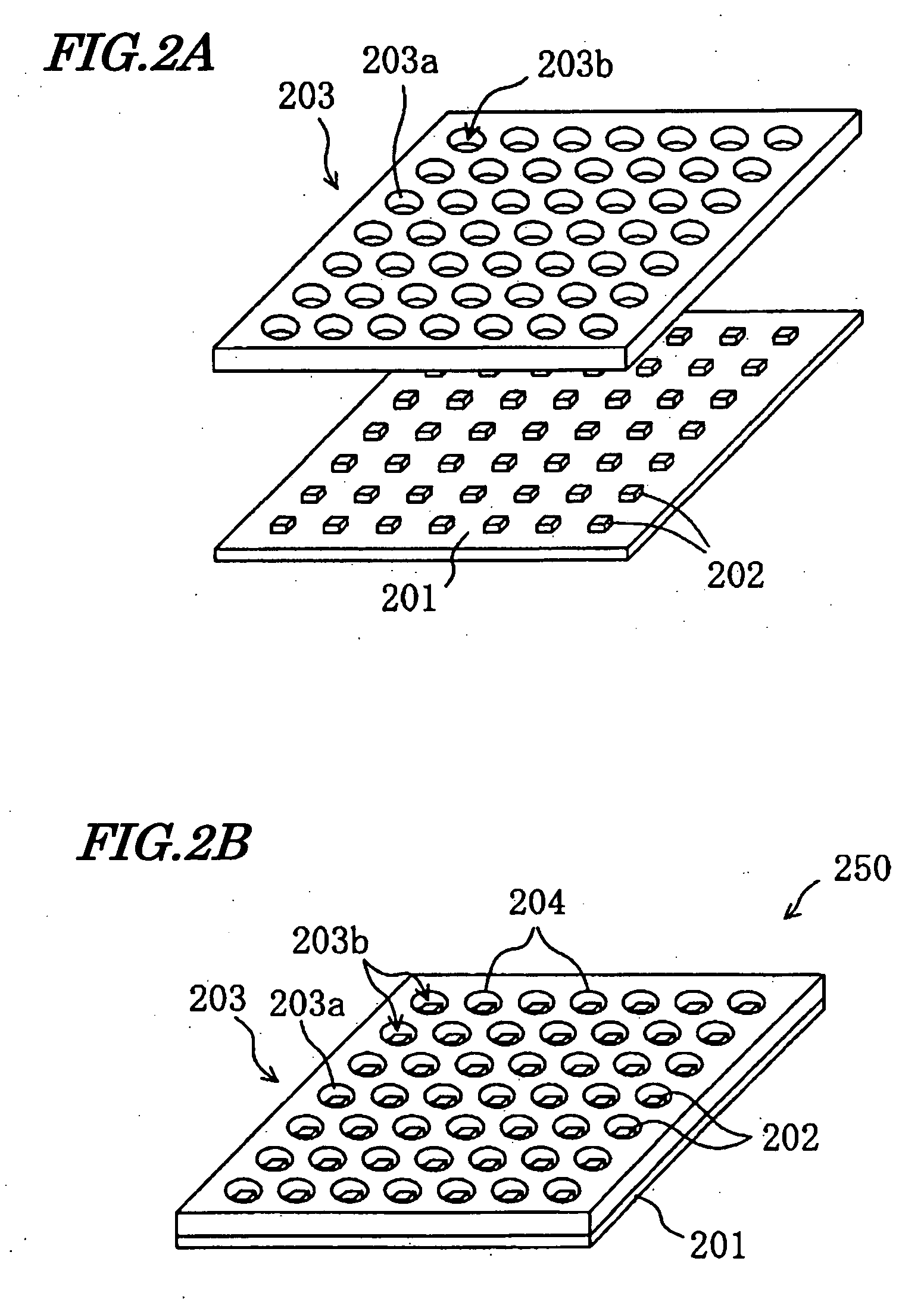

LED lamp

InactiveUS20060186425A1Increased bending stiffnessImprove rigidityPlanar light sourcesPoint-like light sourceEngineeringLED lamp

An LED lamp 100 according to the present invention includes: a substrate 20 with an upper surface; a plurality of LED chips 10, which are arranged on the upper surface of the substrate 20; and a reflector 30, which has reflective surfaces that reflect emissions of the respective LED chips 10 at least partially. The reflector 30 includes a resin and a framework that is made of a material having a higher flexural rigidity than the resin.

Owner:PANASONIC CORP

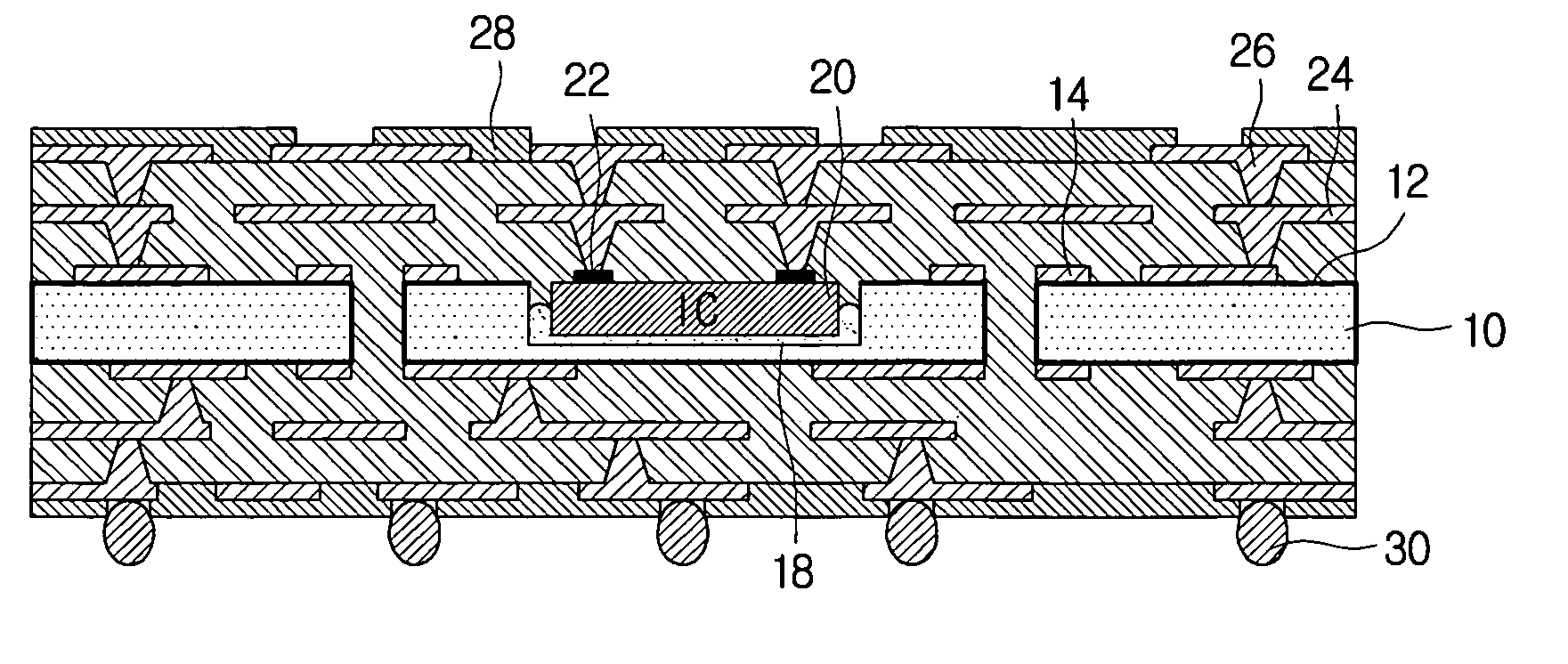

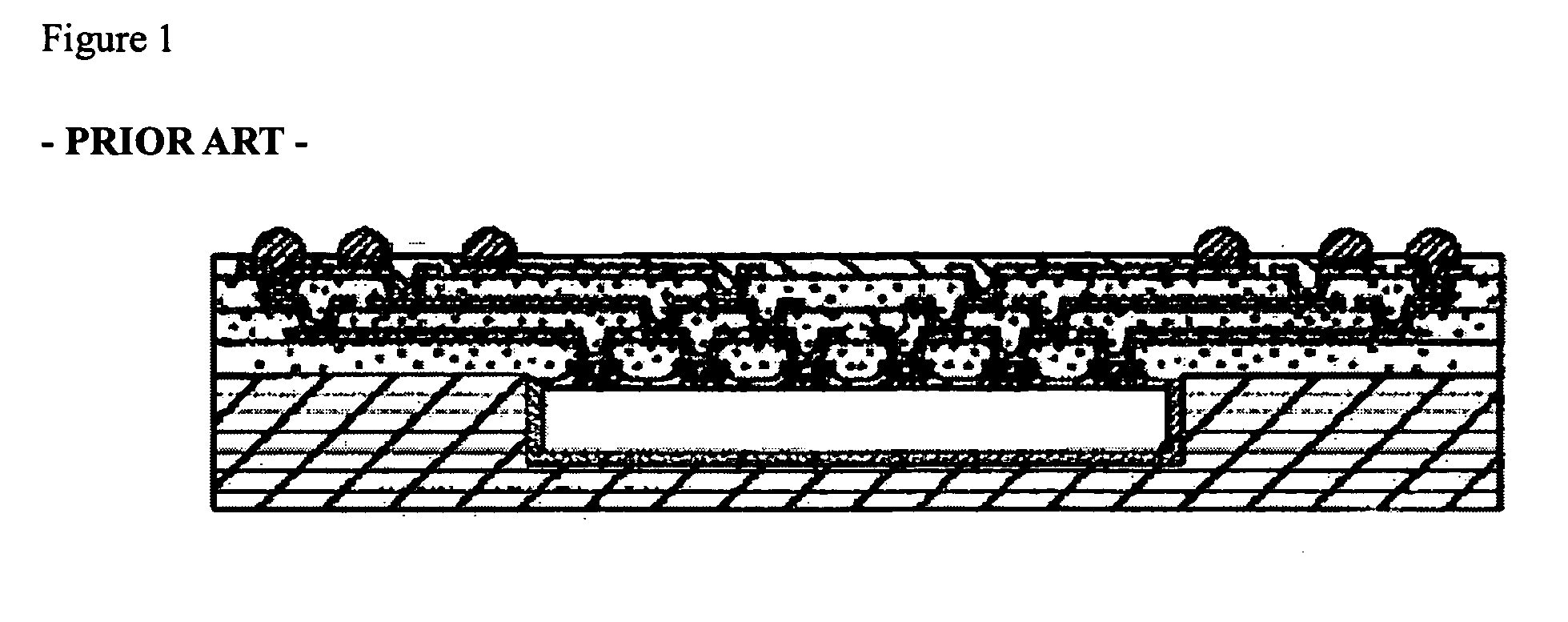

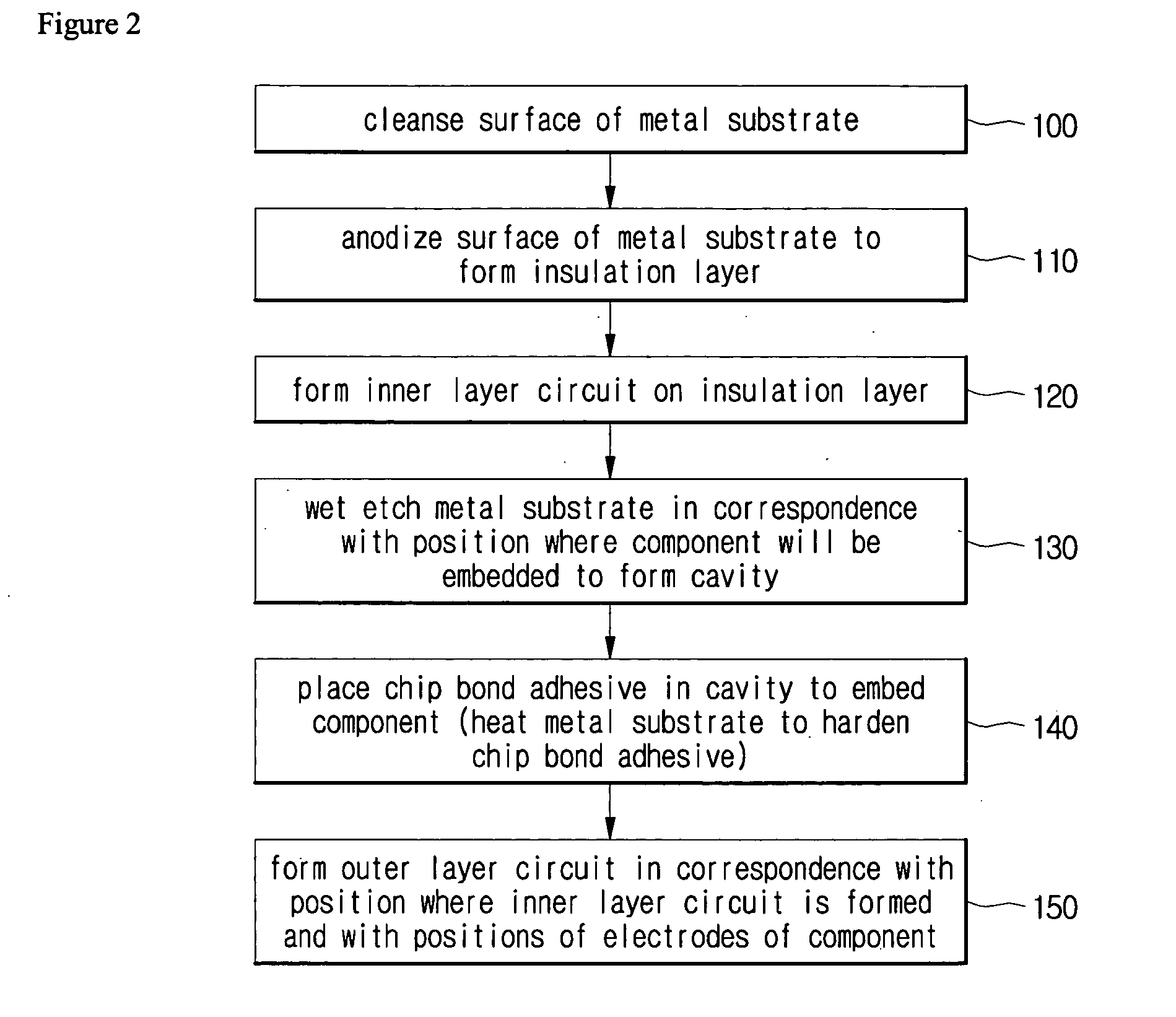

Printed circuit board and manufacturing method thereof

InactiveUS20070074900A1Increase stiffnessImprove heat-releasing propertyPrinted circuit assemblingPrinted electric component incorporationManufacturing cost reductionEtching

A printed circuit board and manufacturing method thereof are disclosed. By use of a method of manufacturing a printed circuit board, which uses a metal substrate as a core member and has an electronic component embedded in the metal substrate, mainly comprising: (a) anodizing at least one surface of the metal substrate to form at least one insulation layer, (b) forming an inner layer circuit on the at least one insulation layer, (d) placing chip bond adhesive in correspondence with a position where the electronic component is to be embedded and mounting the electronic component, and (e) forming an outer layer circuit in correspondence with a position where the inner layer circuit is formed and with positions of the electrodes of the electronic component, and which may further comprise an operation (c) of etching the metal substrate to form a cavity in correspondence with a position where the electronic component is to be embedded between the operations (b) and (d), a metal substrate, such as that of aluminum, etc., is rendered electrically insulating by applying an anodizing process and is used as a core member in a printed circuit board, so that bending stiffness and heat-releasing property are improved; wet etching can be applied, so that manufacturing costs are reduced; and a chip bond adhesive, die attach film, or nonconductive paste, etc., that is high in thixotropy is used in embedding the electronic component, so that the degree of precision may be increased for the position and height of the electronic component when embedding the electronic component.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

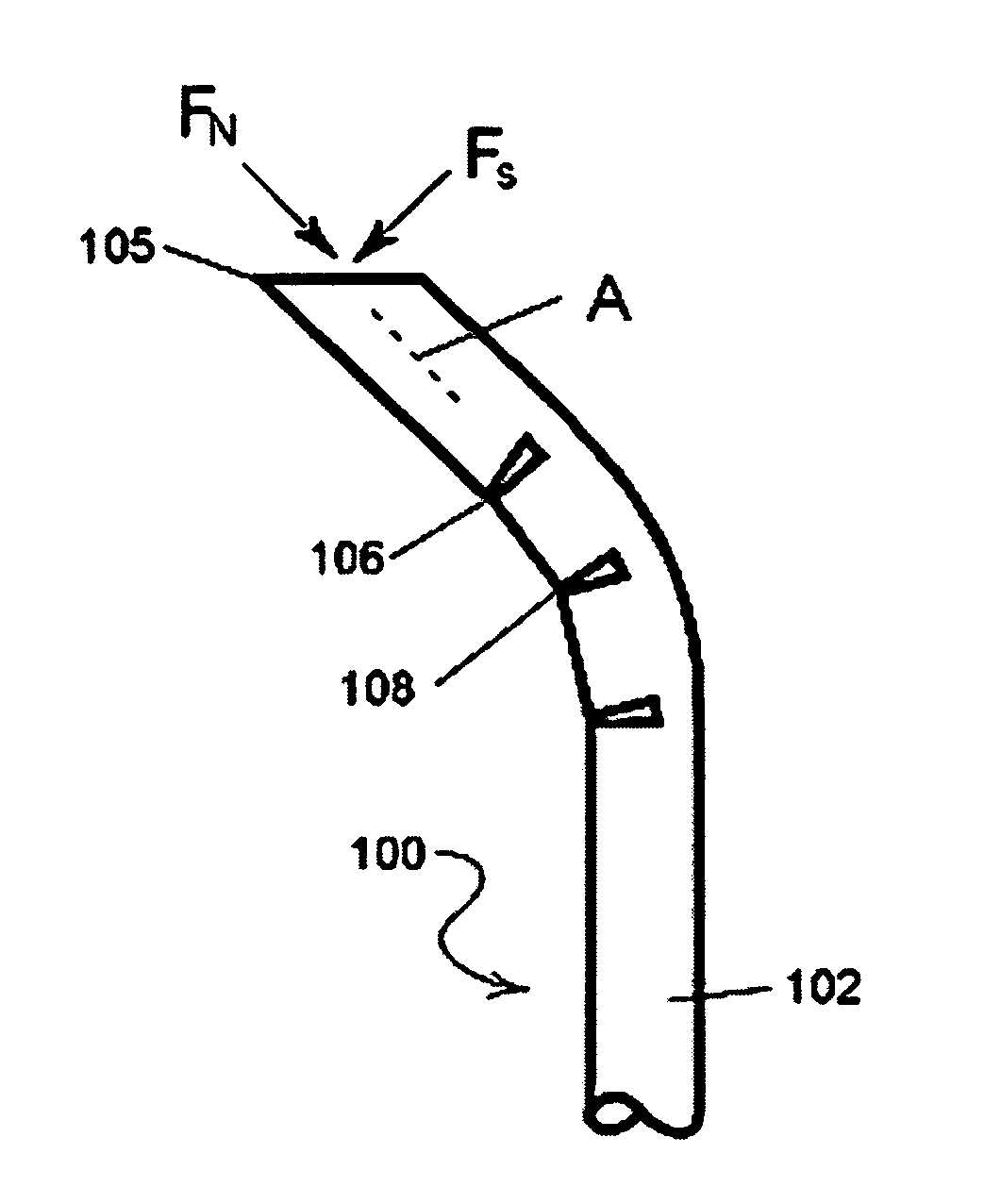

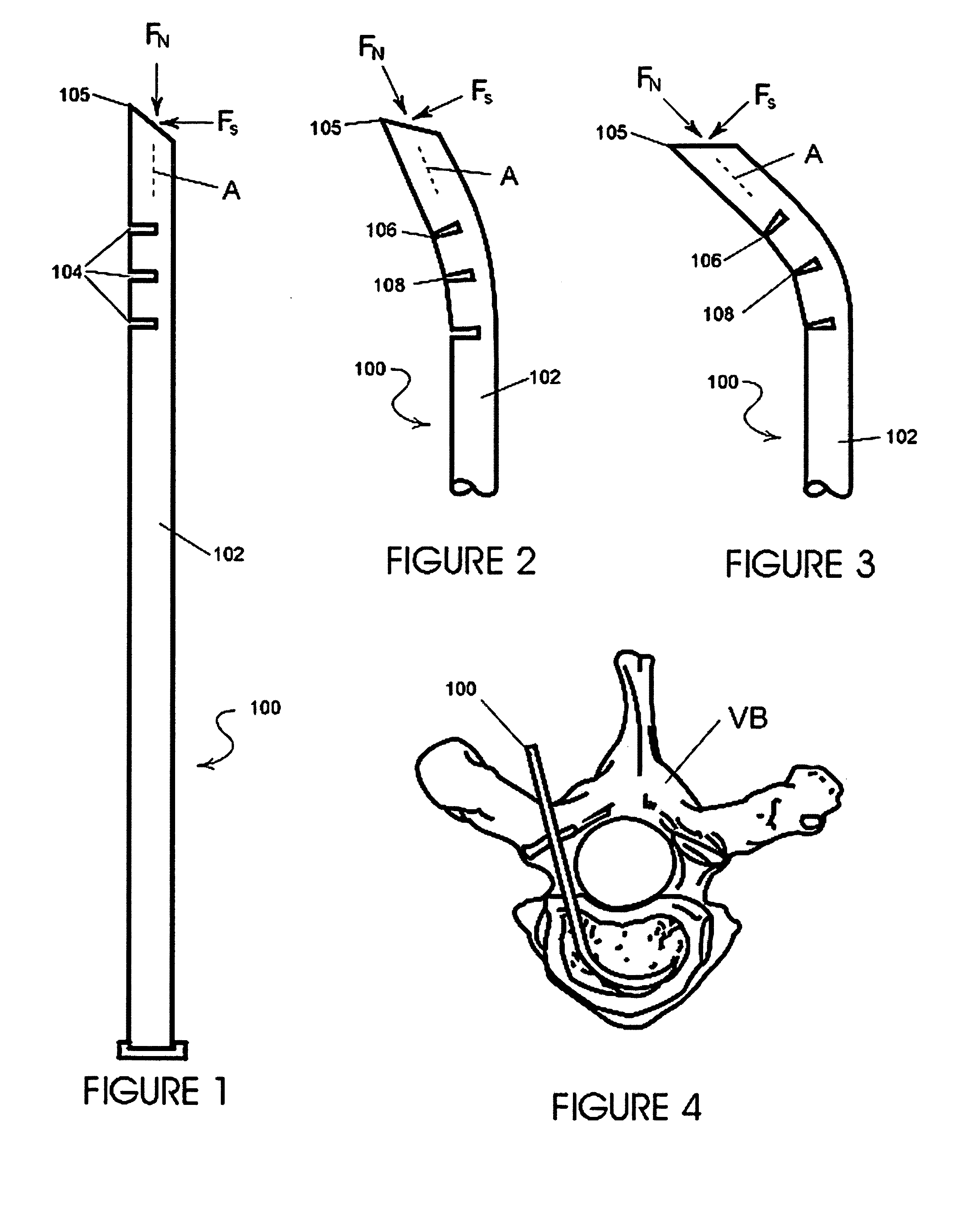

Orthopedic surgery access devices

InactiveUS7959634B2Easy accessLow bending stiffnessCannulasOsteosynthesis devicesCancellous boneBending stiffness

The present invention provides instrumentation that facilitates access to both sides of the vertebral body from a single access point. More particularly, the present invention provides bendable access devices that can be steered so as to traverse the vertebral body from the point of entry into the vertebral body, through the cancellous bone within the vertebral body, and to the contralateral side of the vertebral body. This steerability is provided by forming the access device with a series of slots, grooves, or notches in the side of the access device near the distal end of the access device, which slots, grooves, or notches reduce the bending stiffness of the access device. As a result, the distal end of the access device bends as it is being advanced into the vertebral body.

Owner:GLOBUS MEDICAL INC

Prosthetic Intervertebral Discs

Prosthetic intervertebral discs, systems including such prosthetic intervertebral discs, and methods for using the same are described. The subject prosthetic discs include upper and lower endplates separated by a compressible core member. The subject prosthetic discs exhibit stiffness in the vertical direction, torsional stiffness, bending stiffness in the sagittal plane, and bending stiffness in the front plane, where the degree of these features can be controlled independently by adjusting the components, construction, and other features of the discs.

Owner:SPINAL KINETICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com