Patents

Literature

31results about How to "Increase ball speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

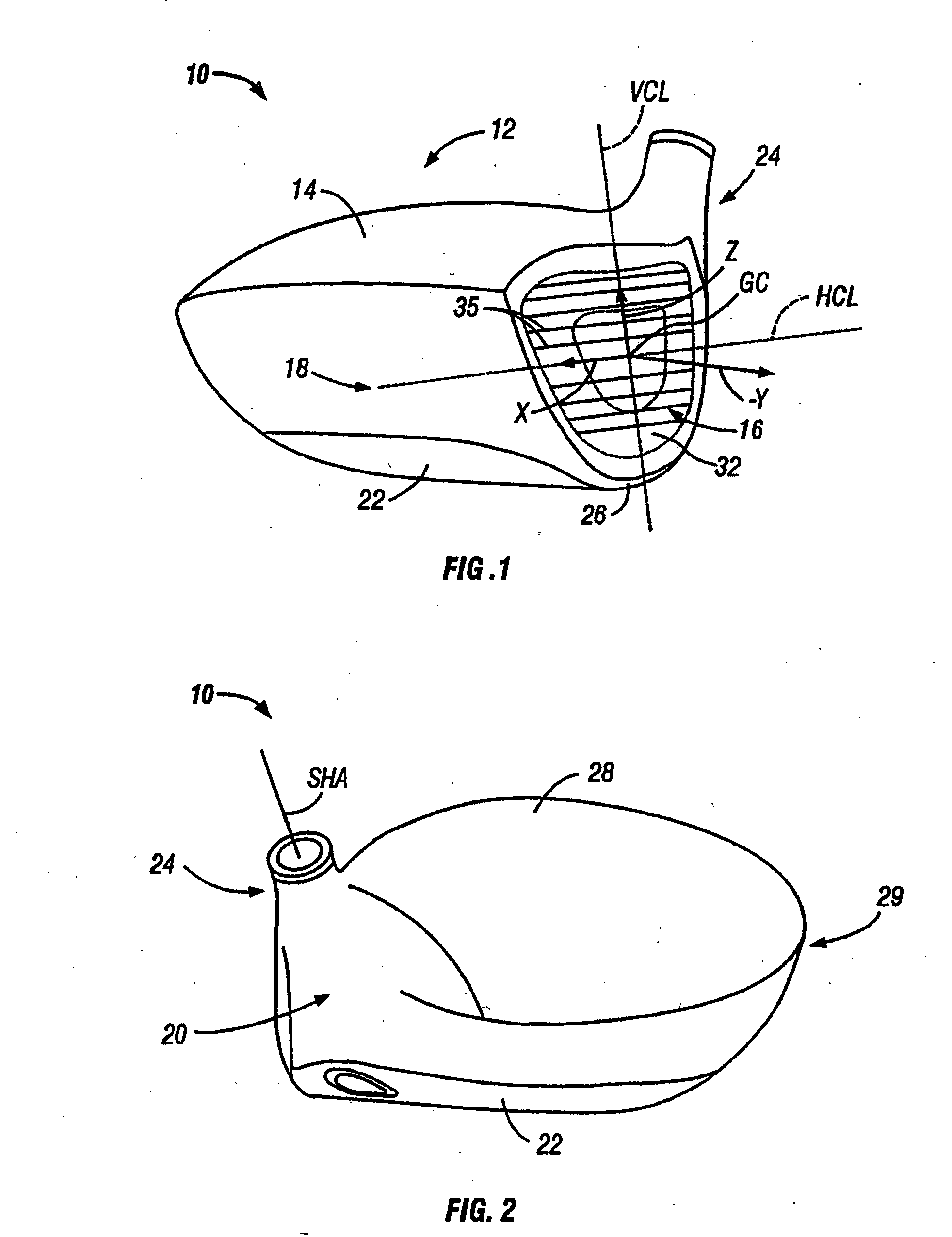

Golf club head with a high coefficient of restitution

InactiveUS6960142B2Increase ball speedAnalysing solids using sonic/ultrasonic/infrasonic wavesGolf clubsBall impactCoefficient of restitution

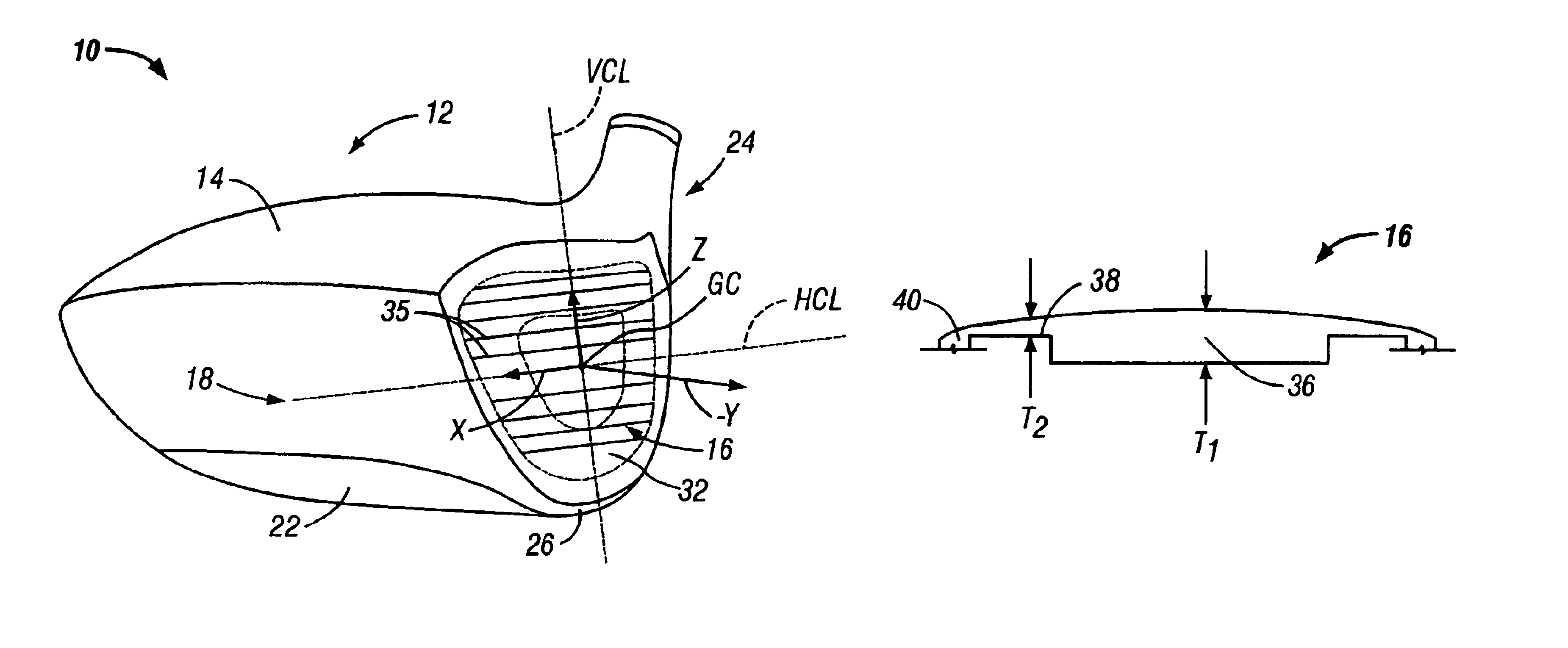

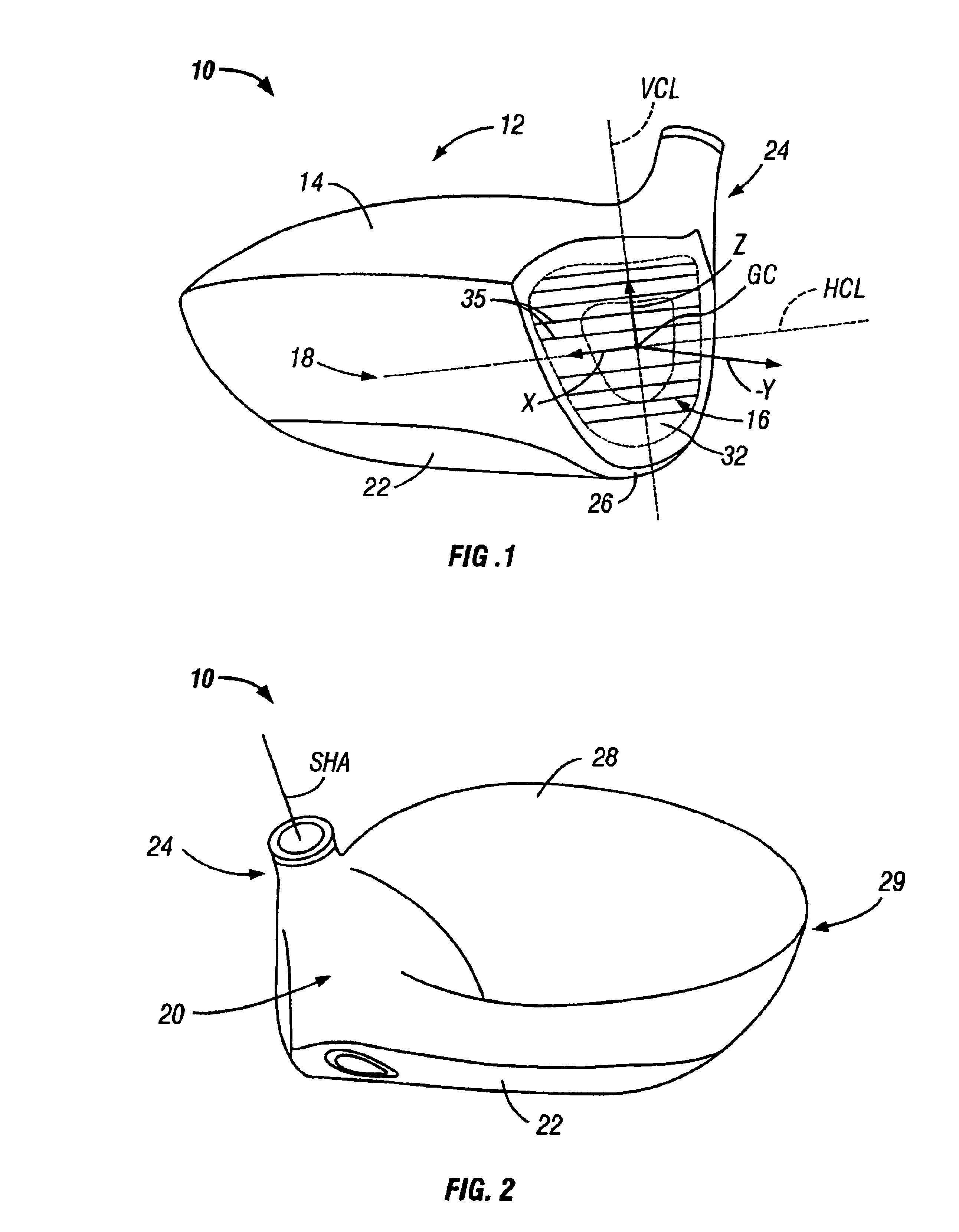

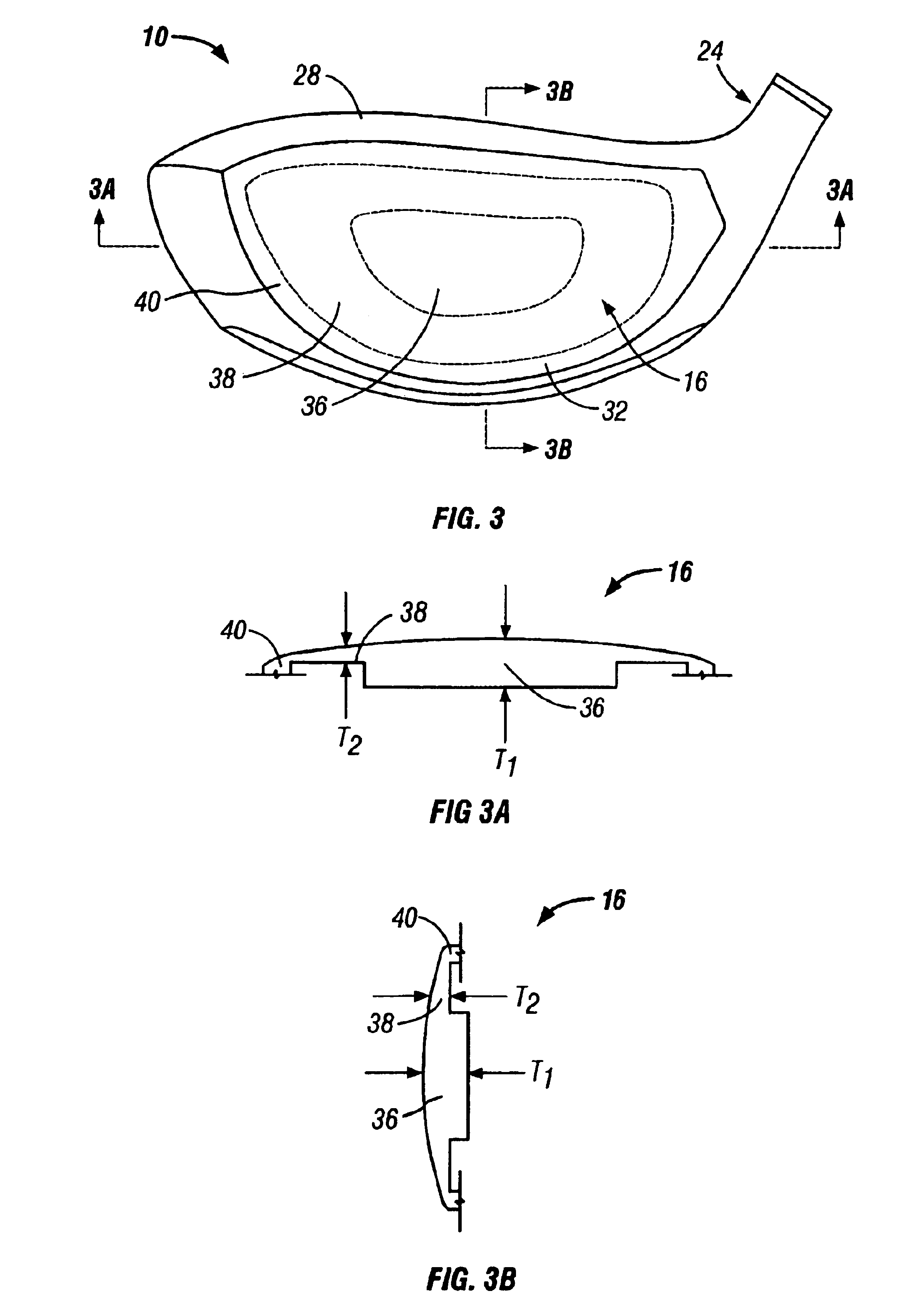

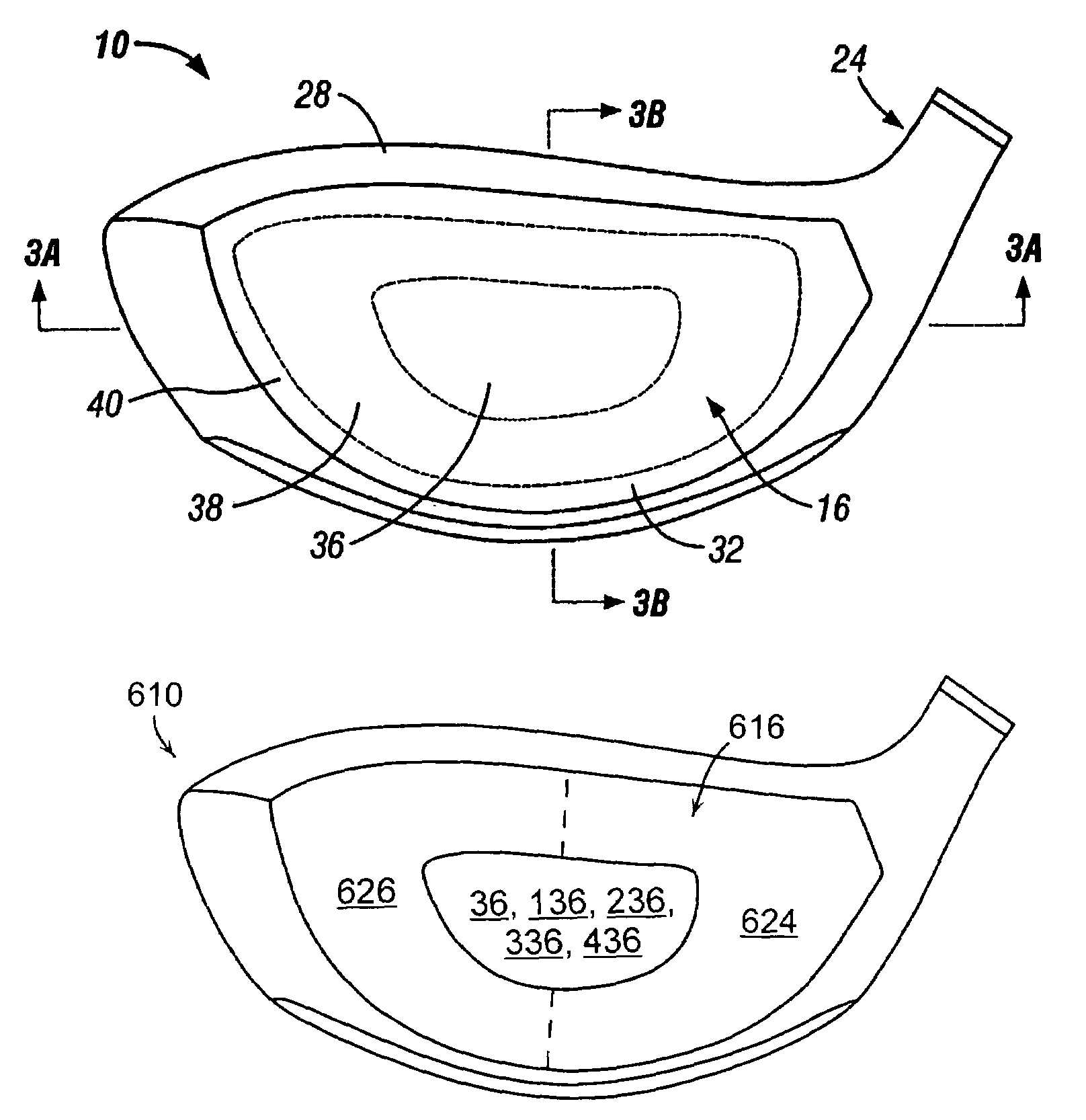

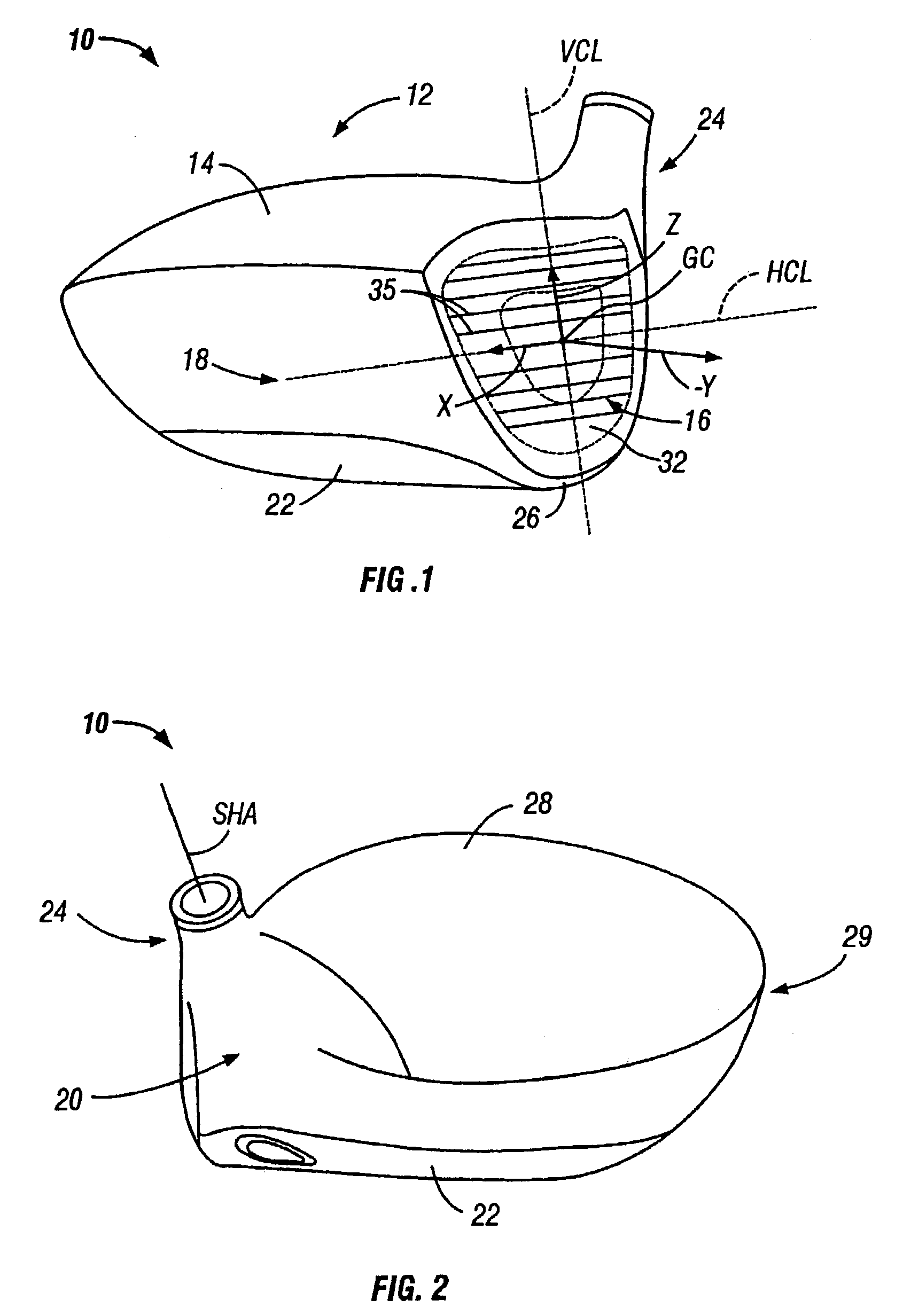

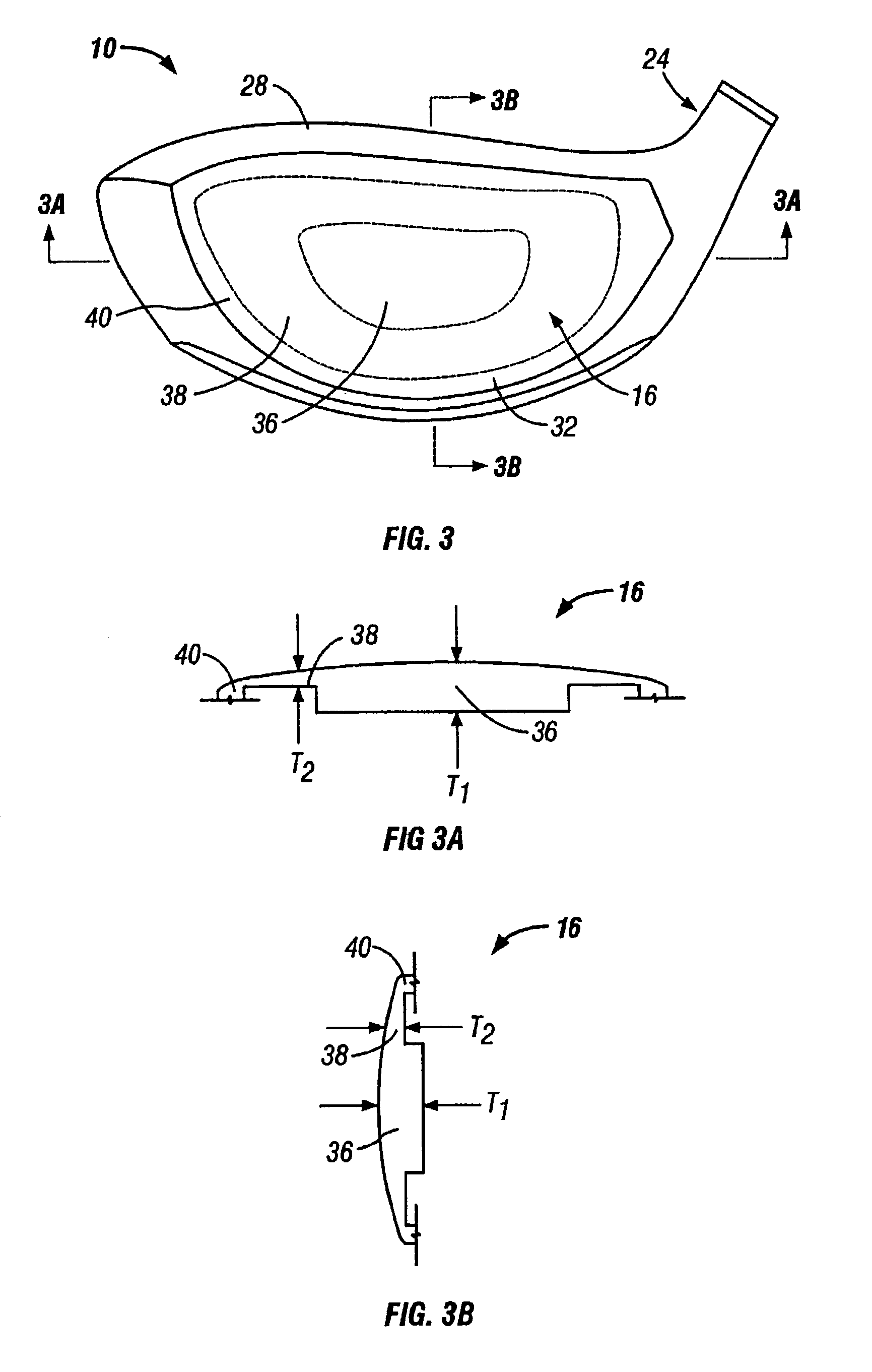

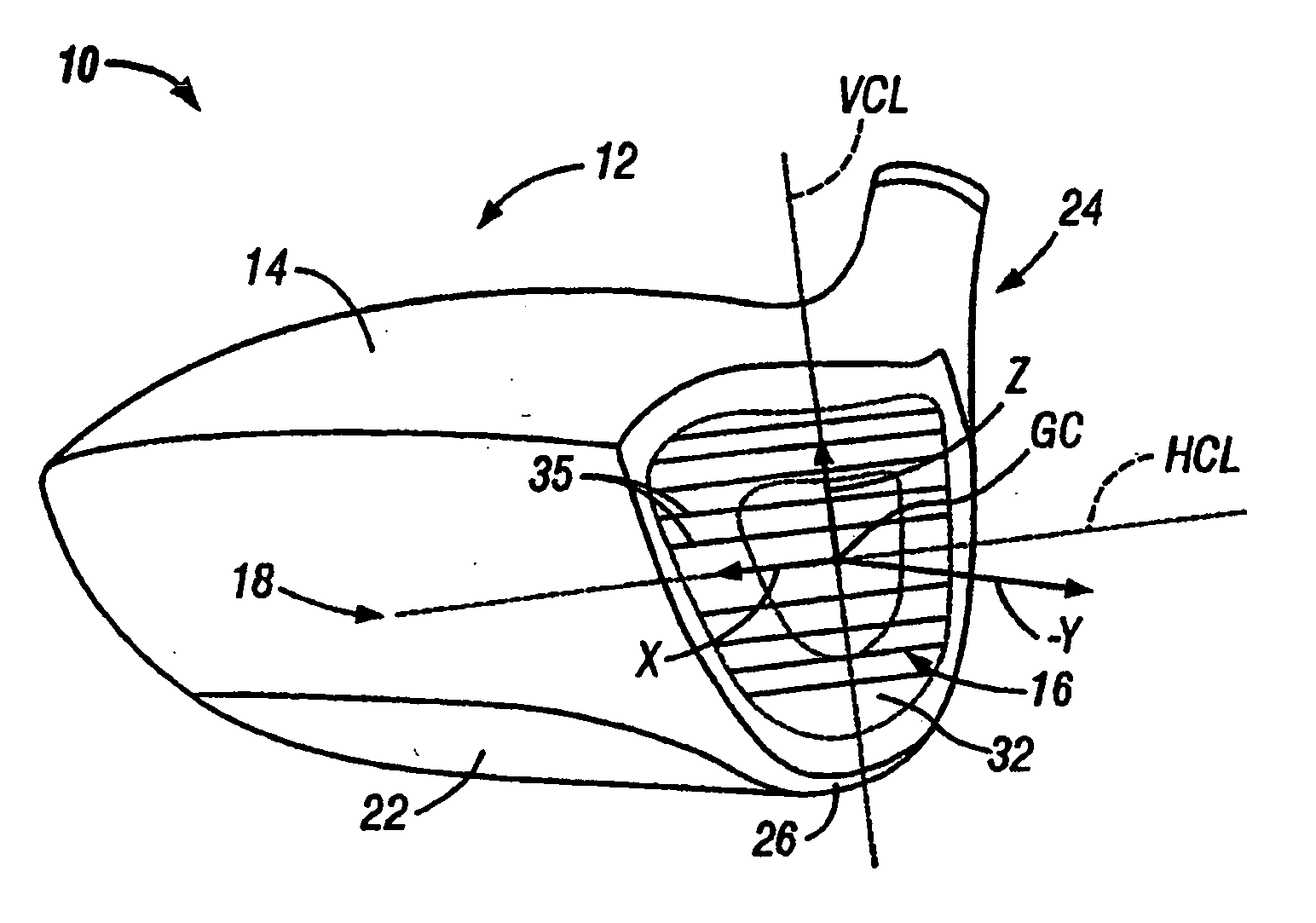

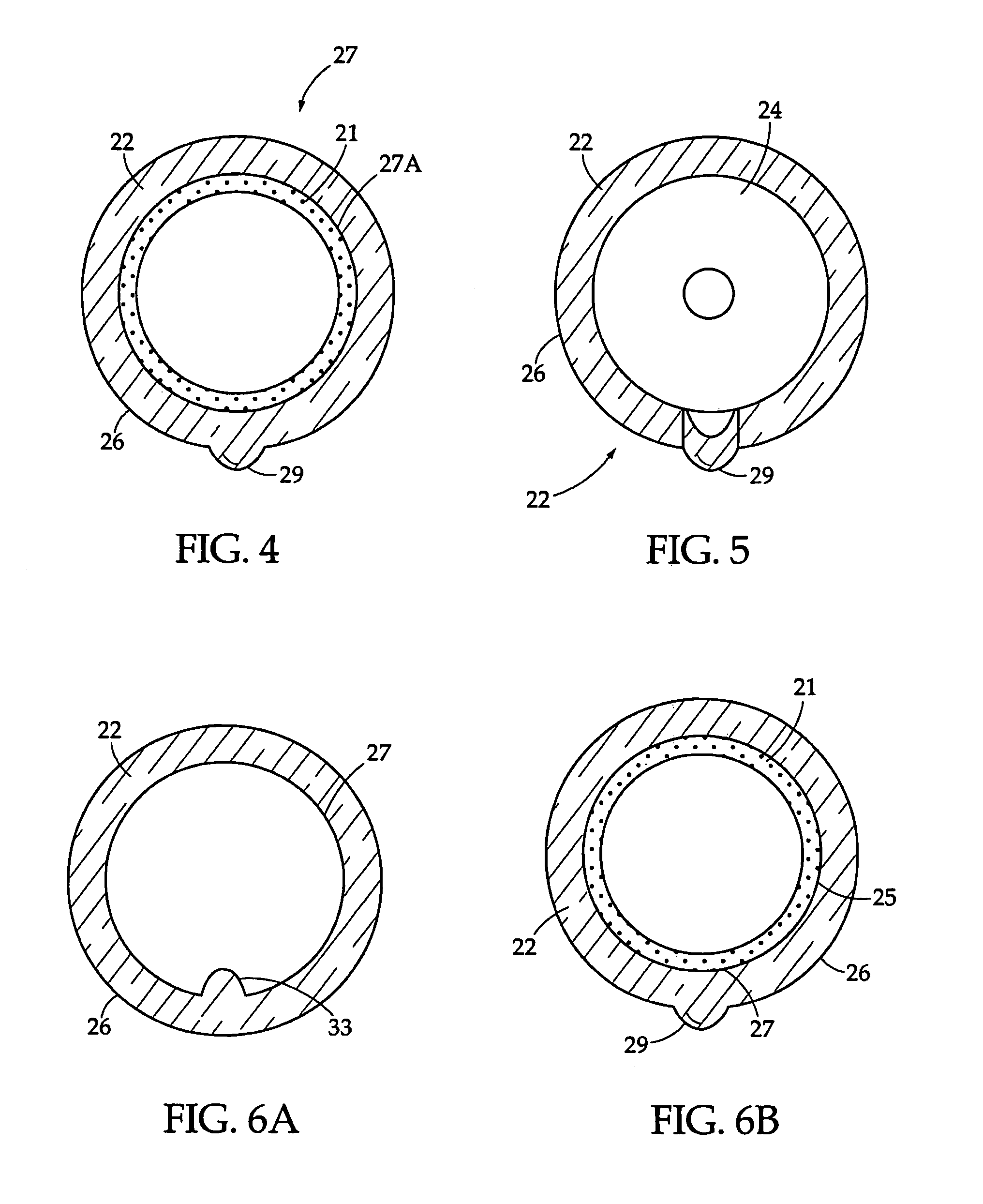

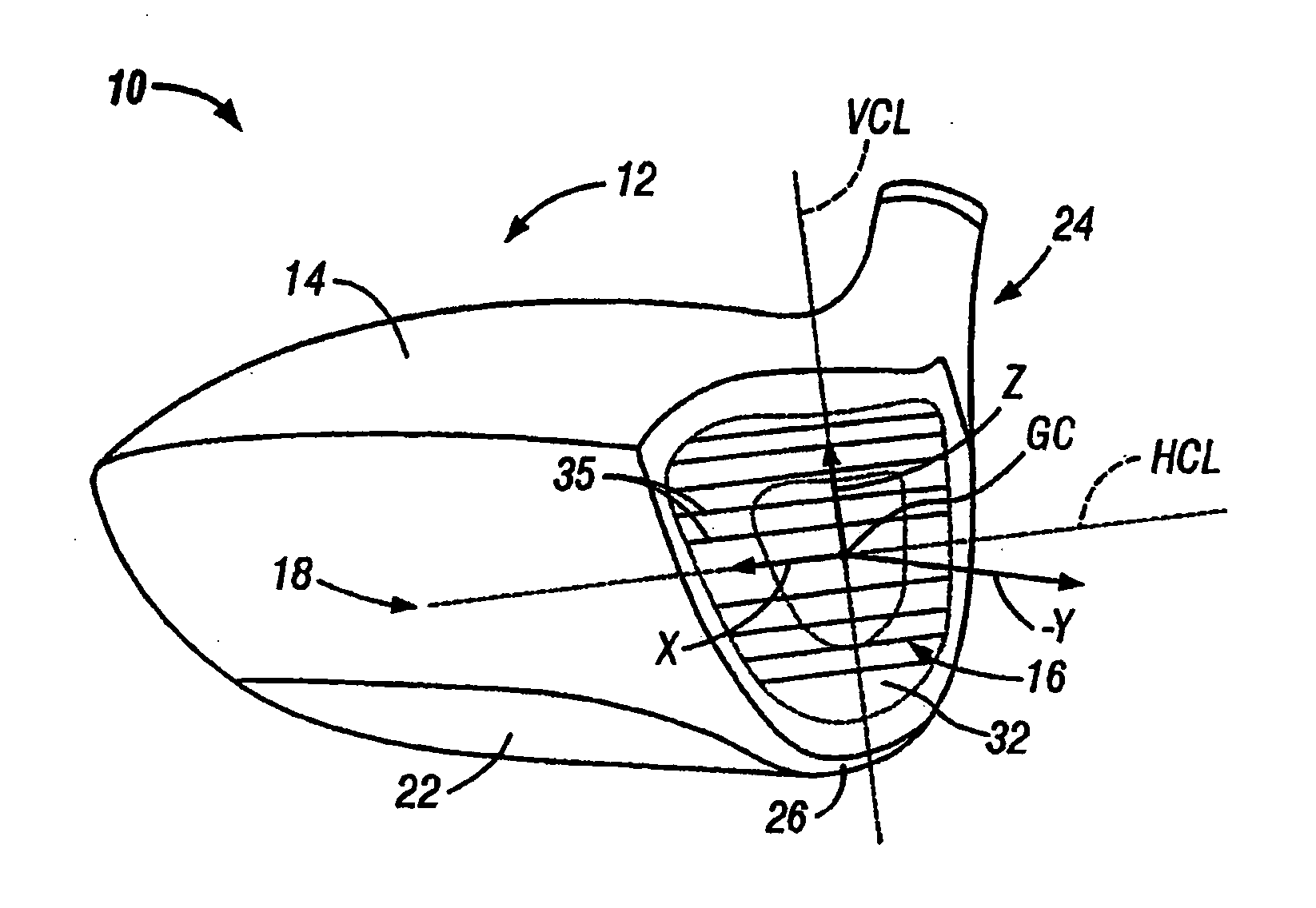

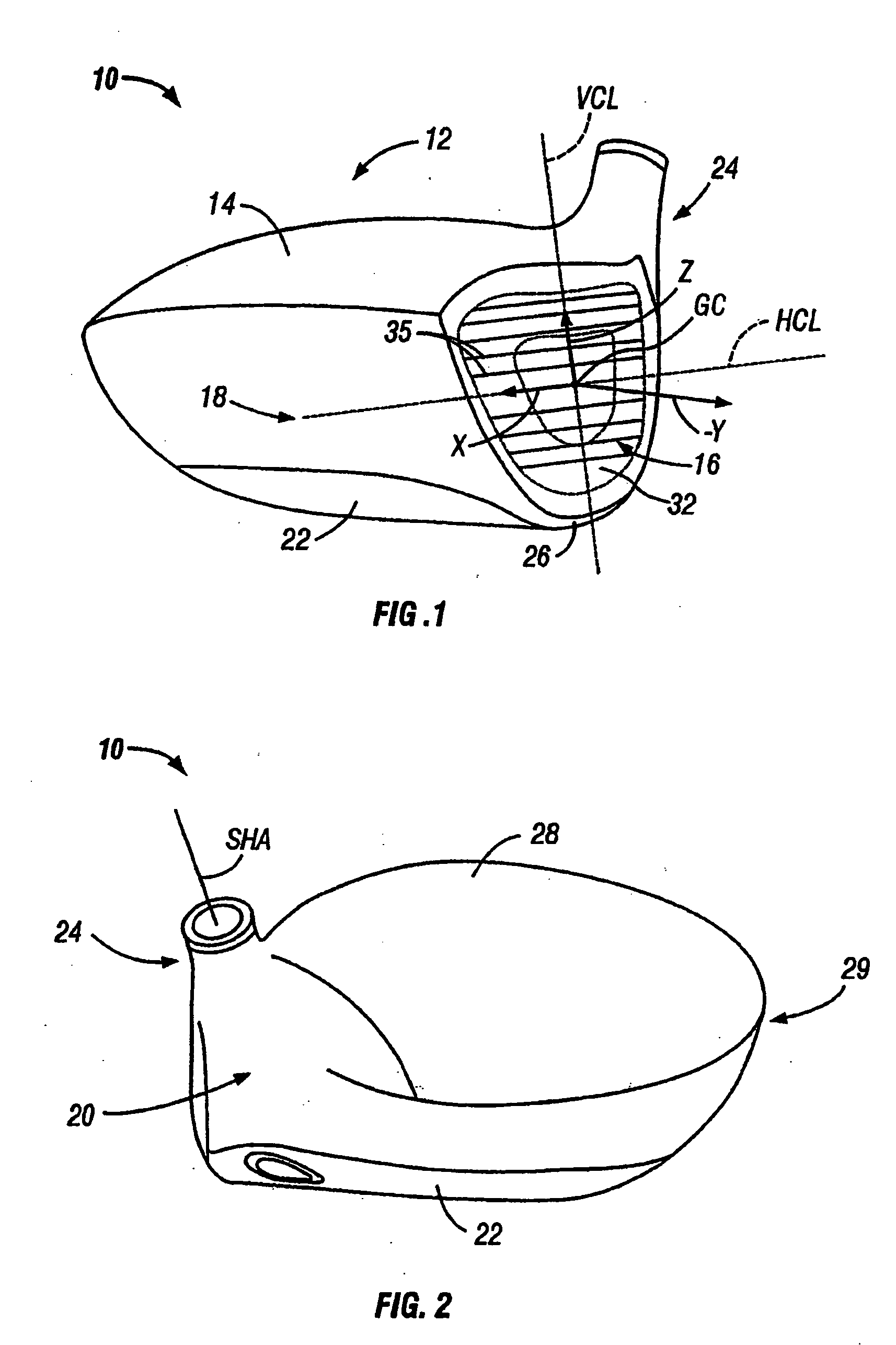

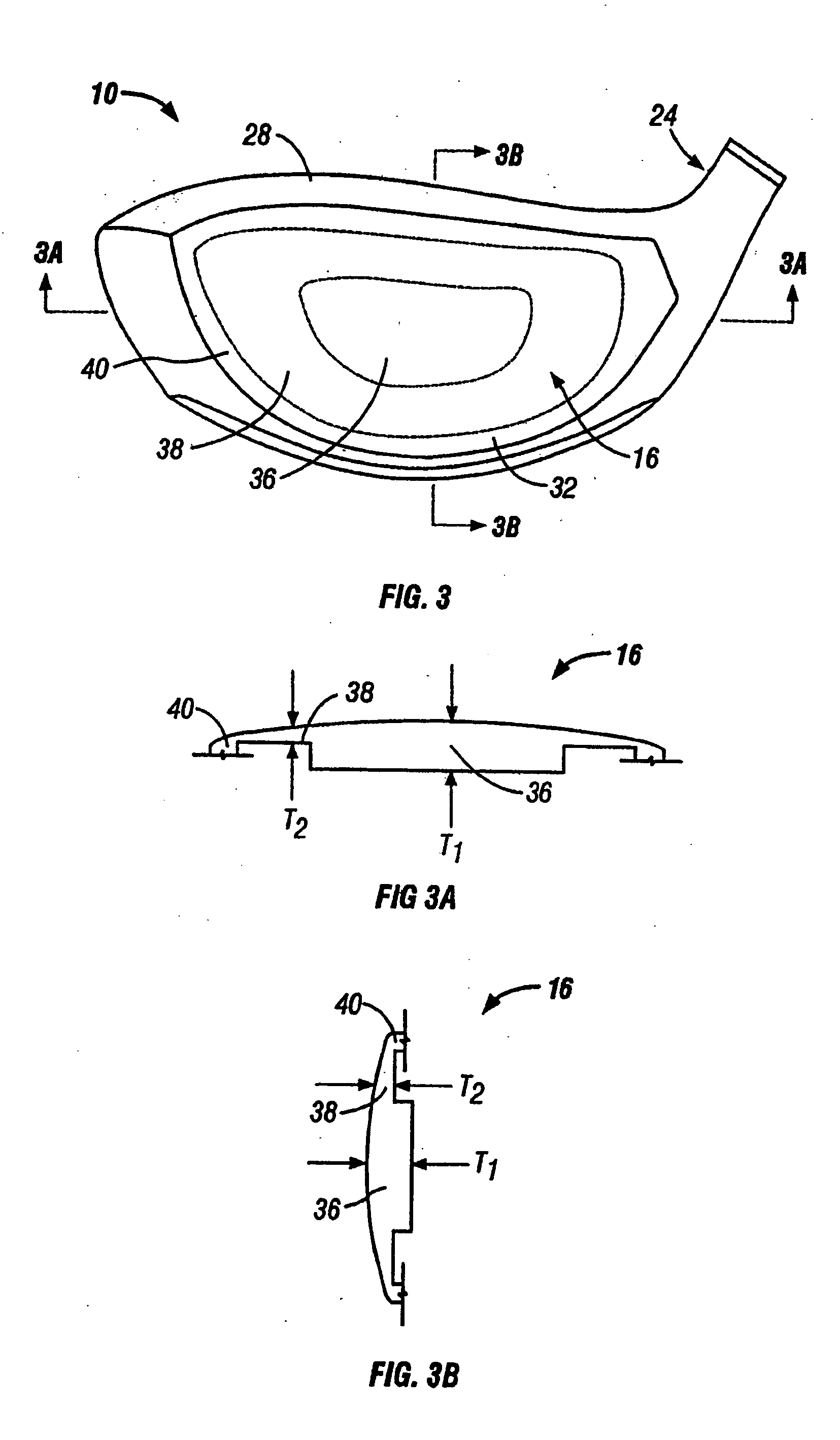

The present invention relates to a golf club head provided with a face and a body. The face has a central zone and a intermediate zone adjacent and surrounding the central zone. The central zone has a first flexural stiffness and the intermediate zone has a second flexural stiffness. The club head face is configured and dimensioned such that the first flexural stiffness is significantly greater than the second flexural stiffness such that upon ball impact with the face, the intermediate zone exhibits substantial deformation so that the central zone moves into the club head. At the same time, the central zone exhibits minimal deformation so that it moves into and out of the club head as a unit. Furthermore, the face exhibits a high coefficient of restitution.

Owner:ACUSHNET CO

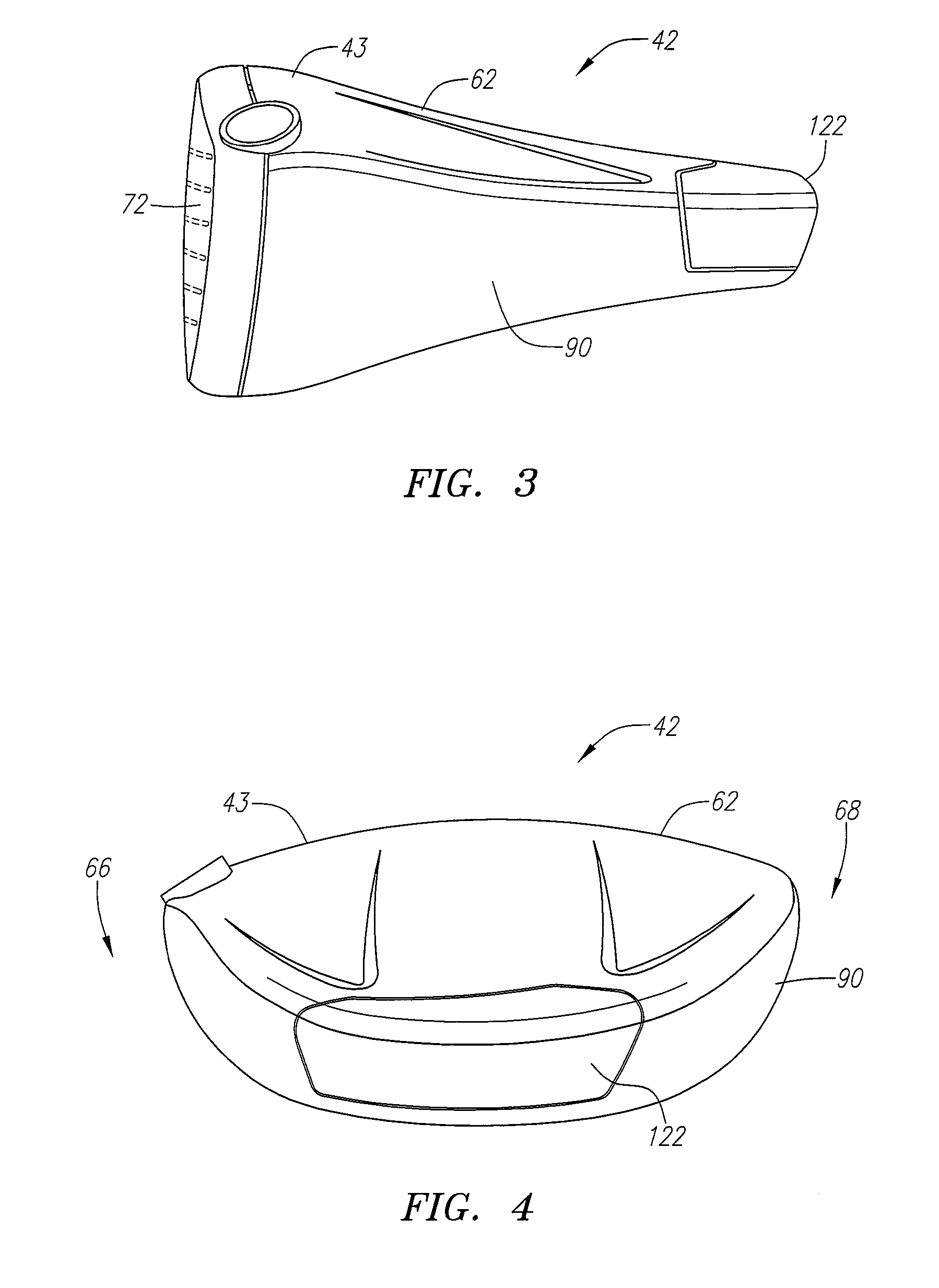

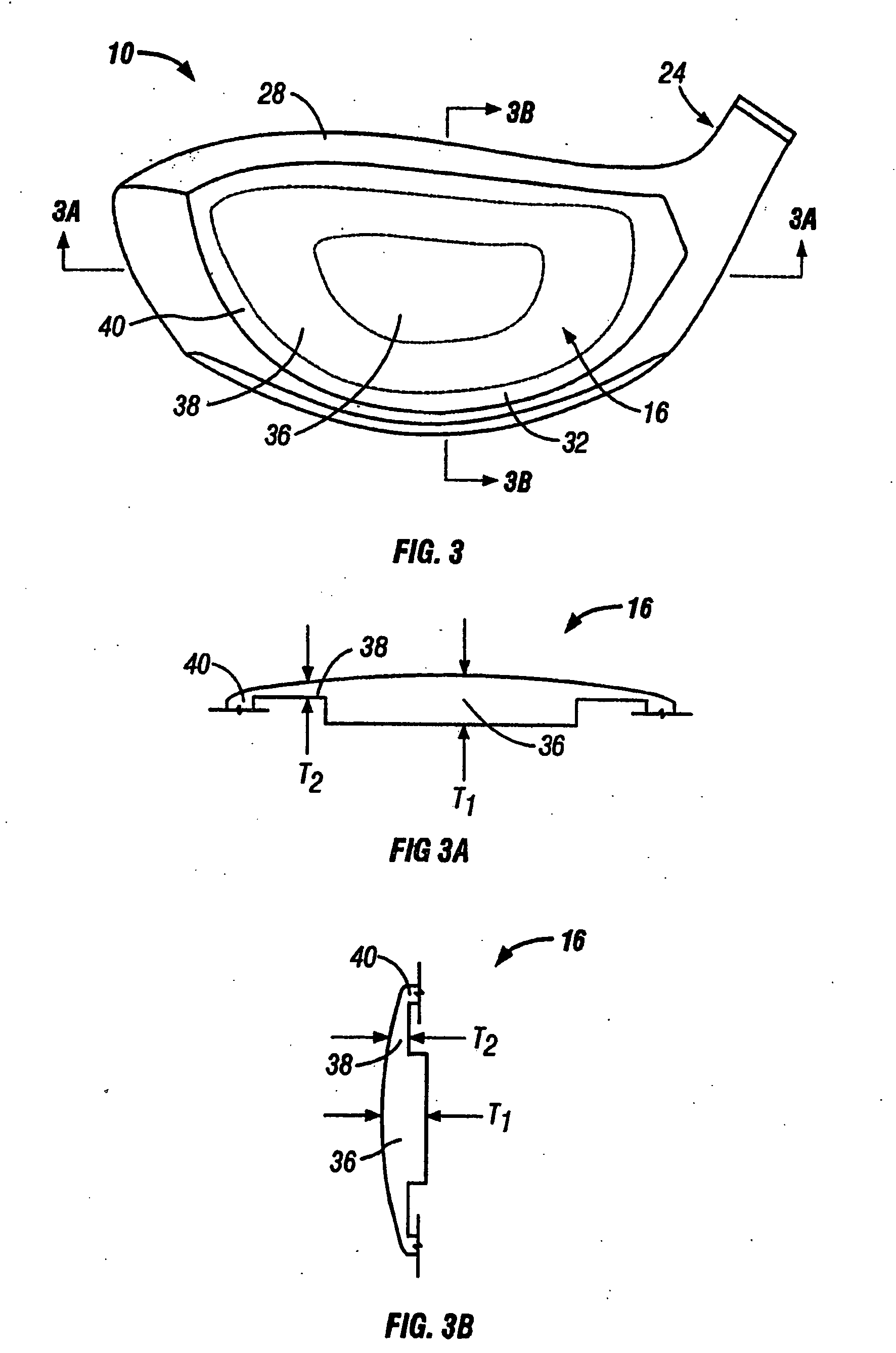

Golf club head with high moment of inertia

ActiveUS7413520B1Increase the areaHigh moments of inertiaGolf clubsRacket sportsMoment of inertiaGolf Ball

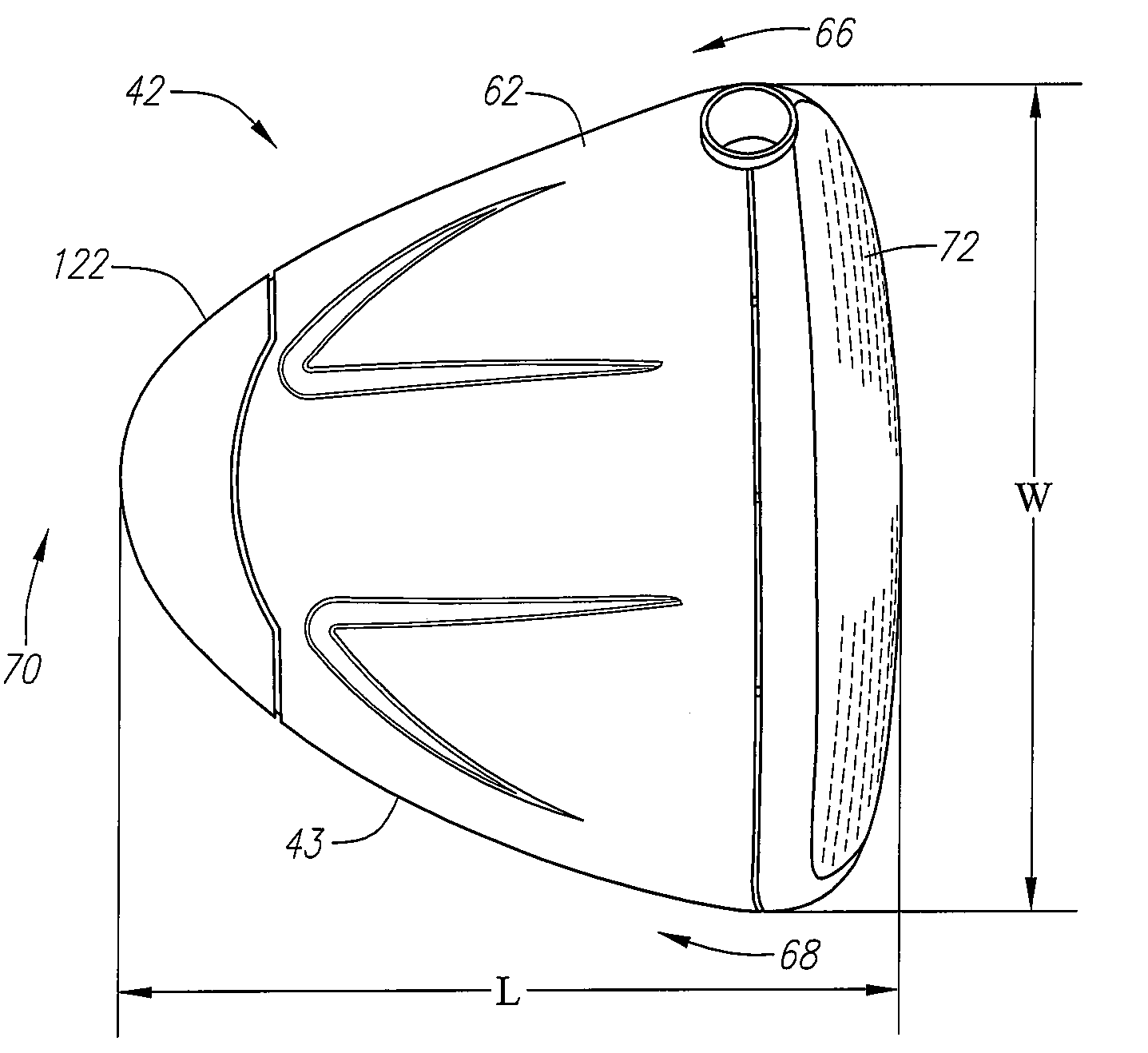

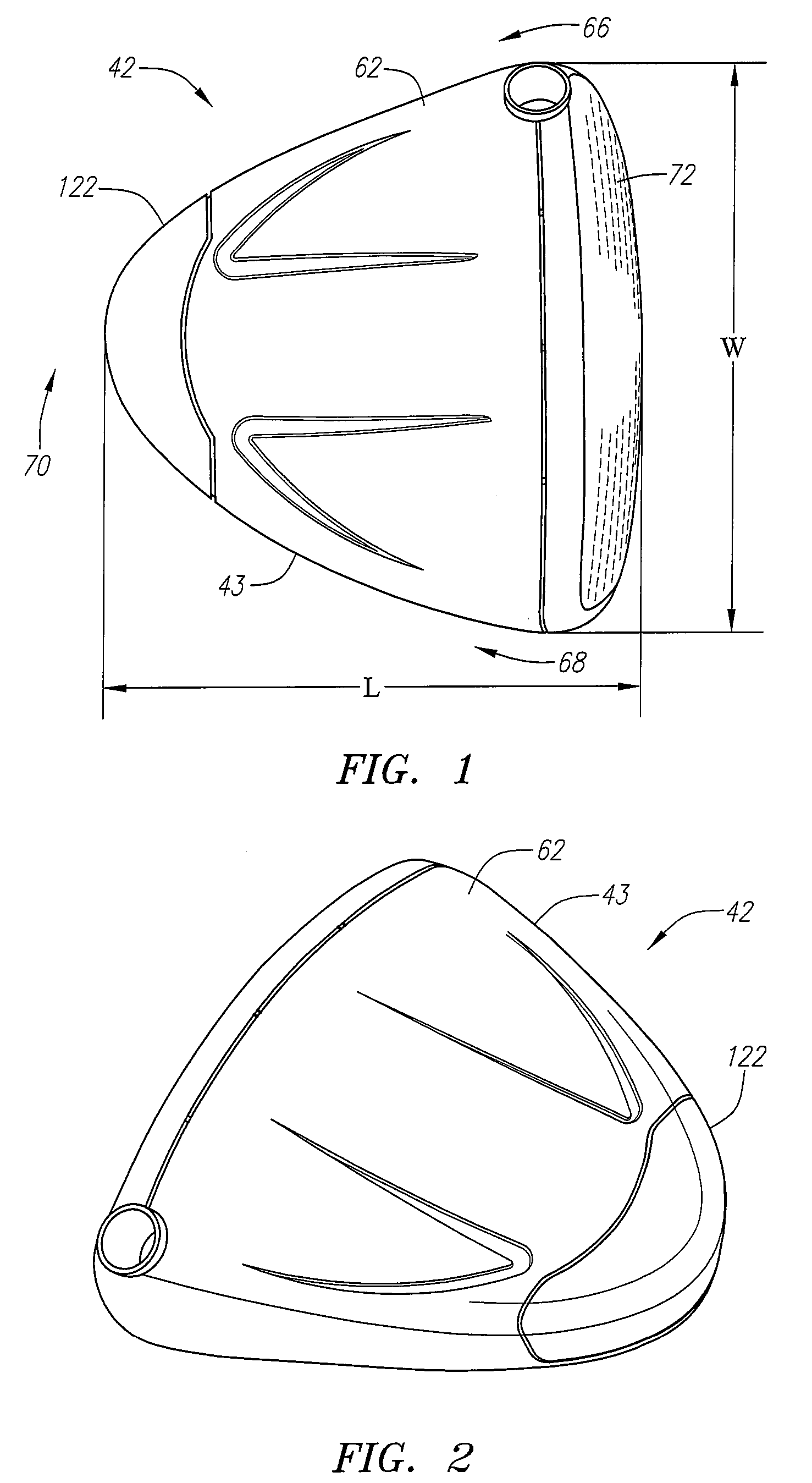

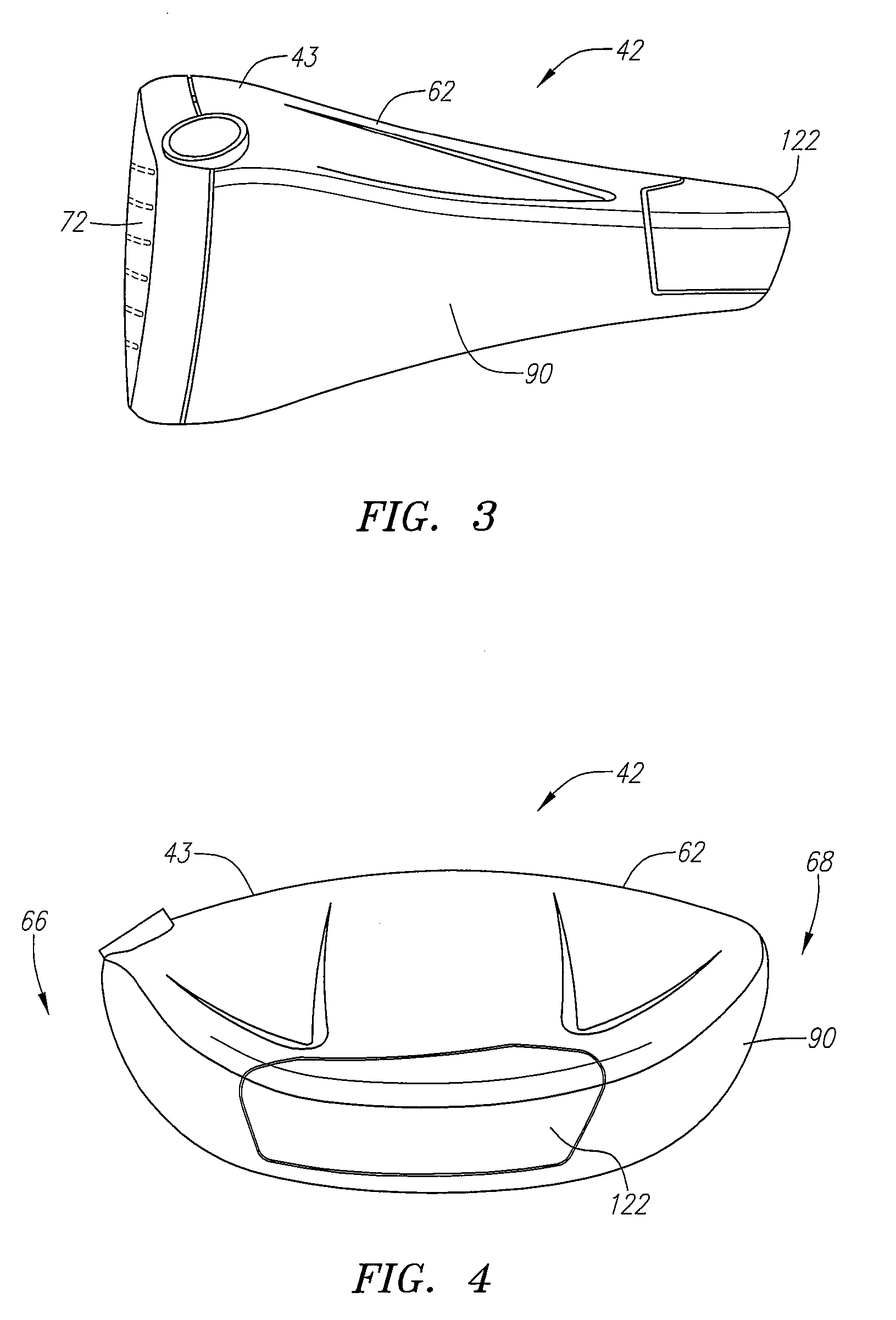

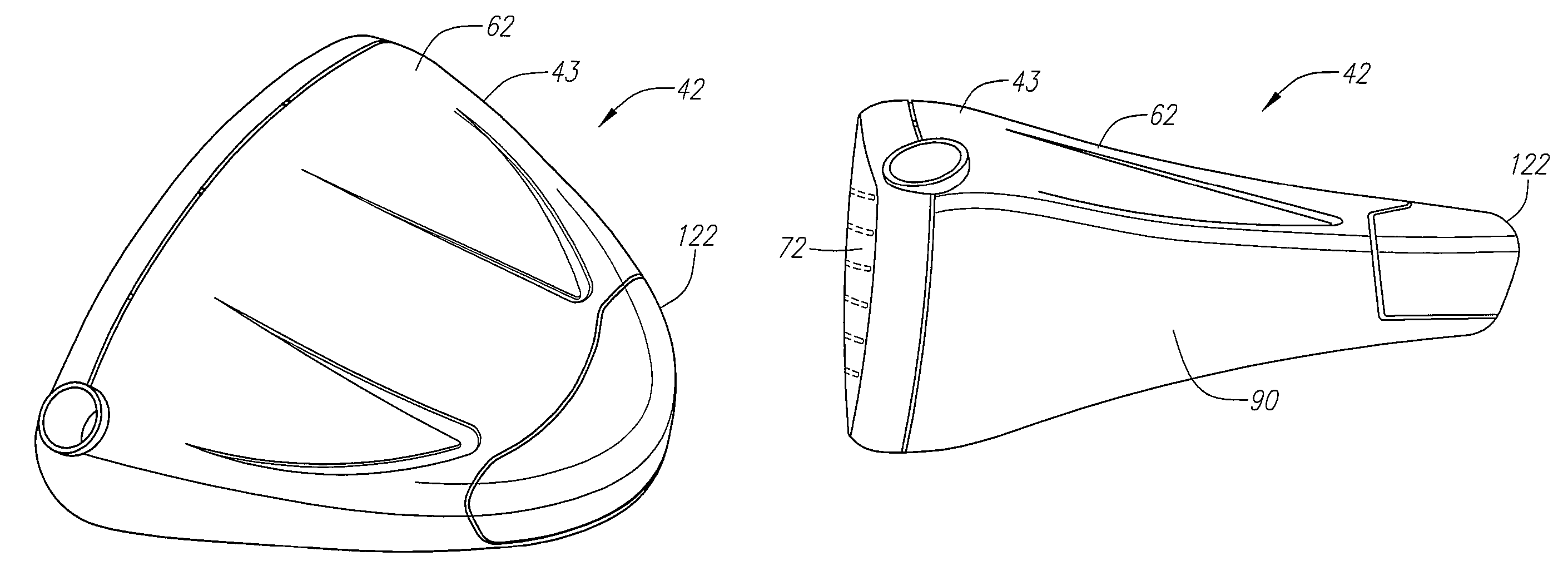

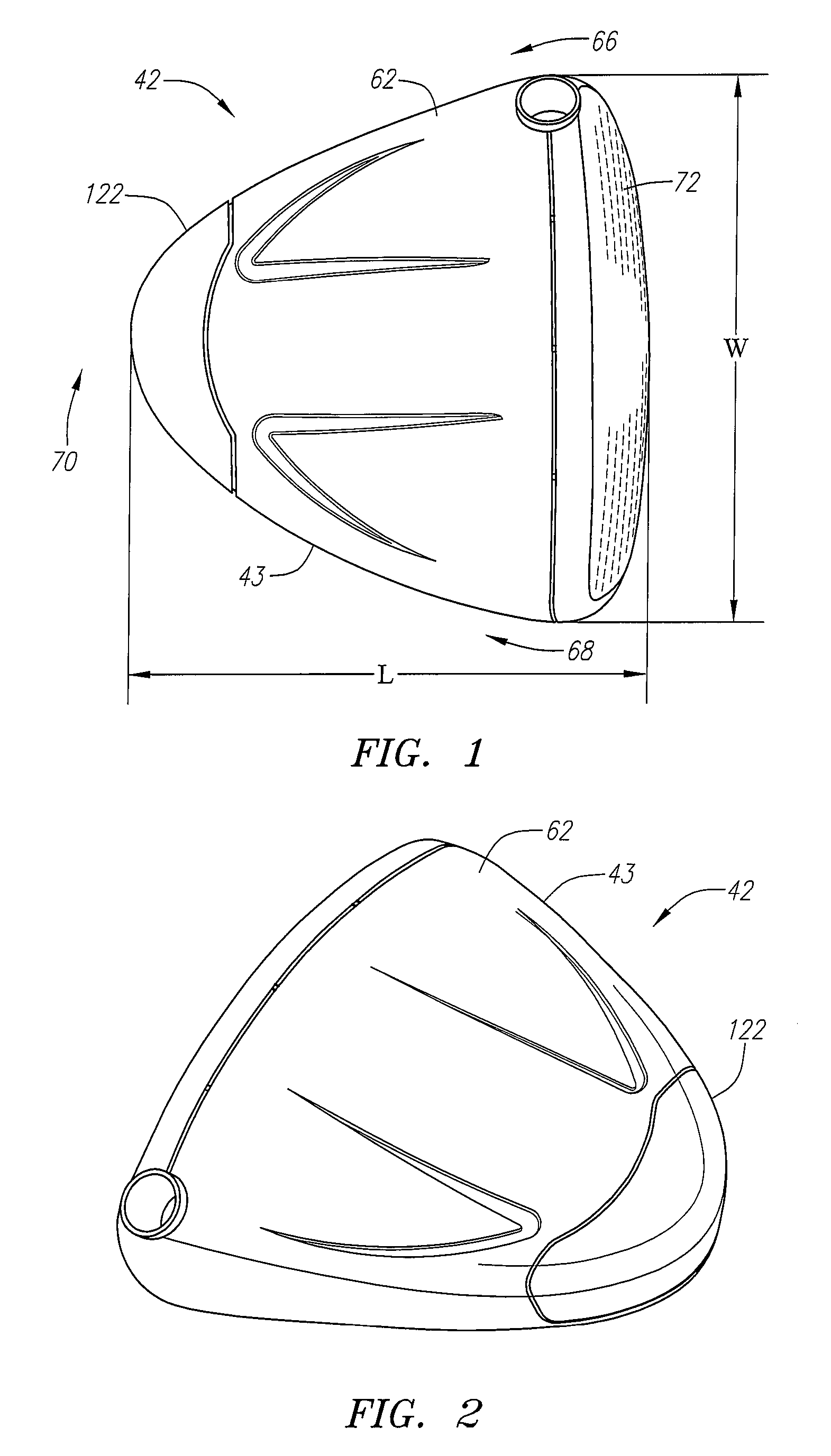

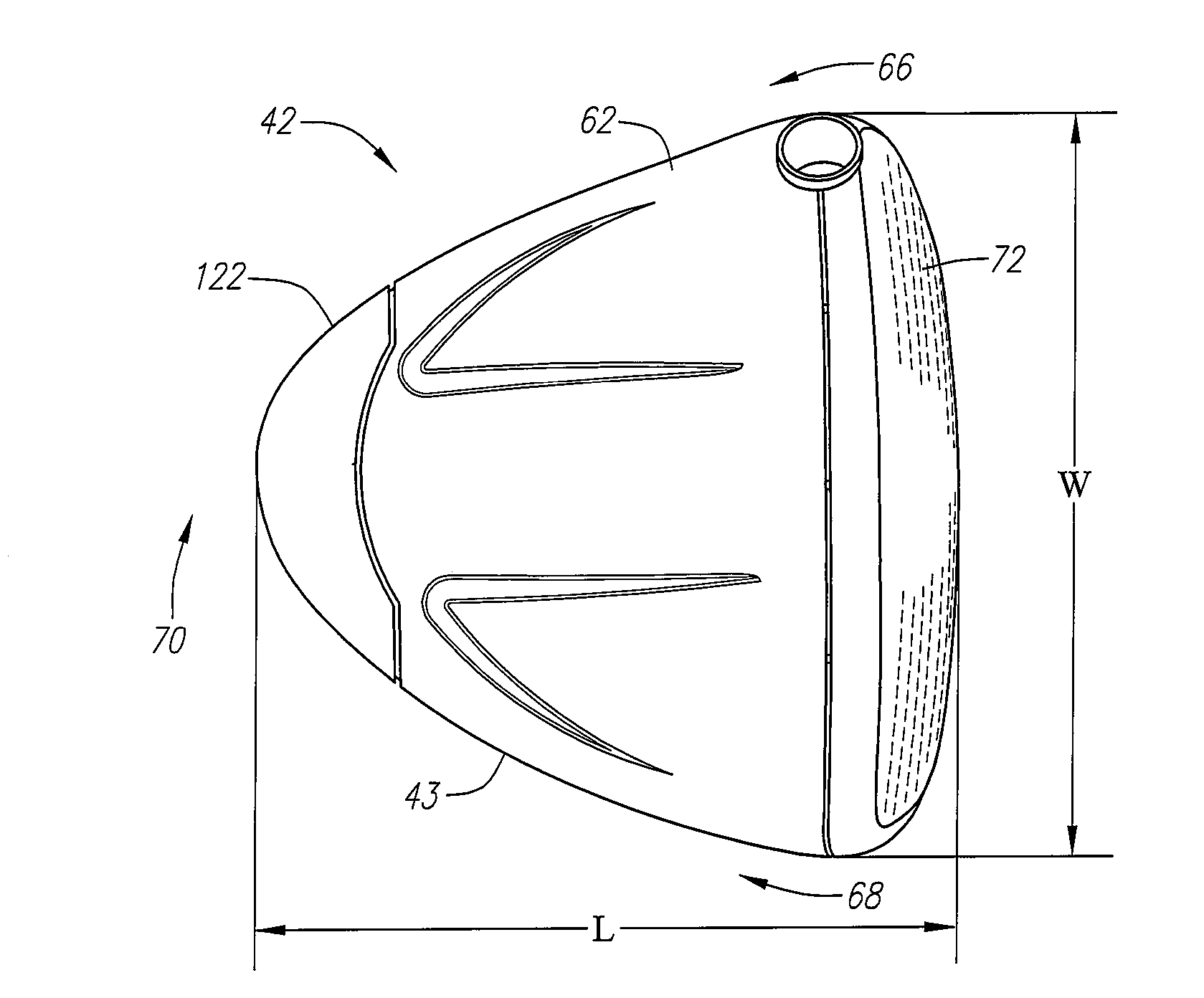

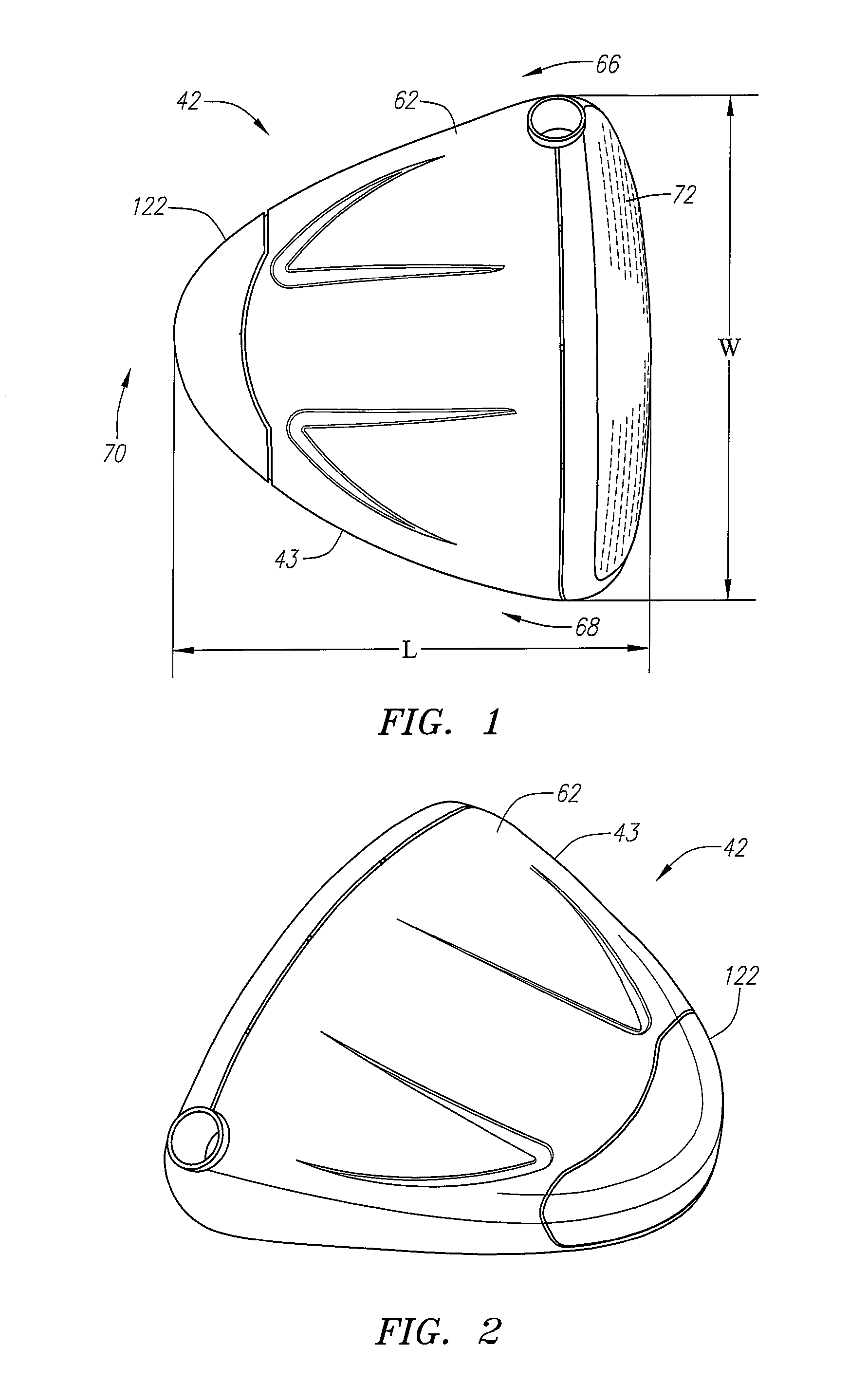

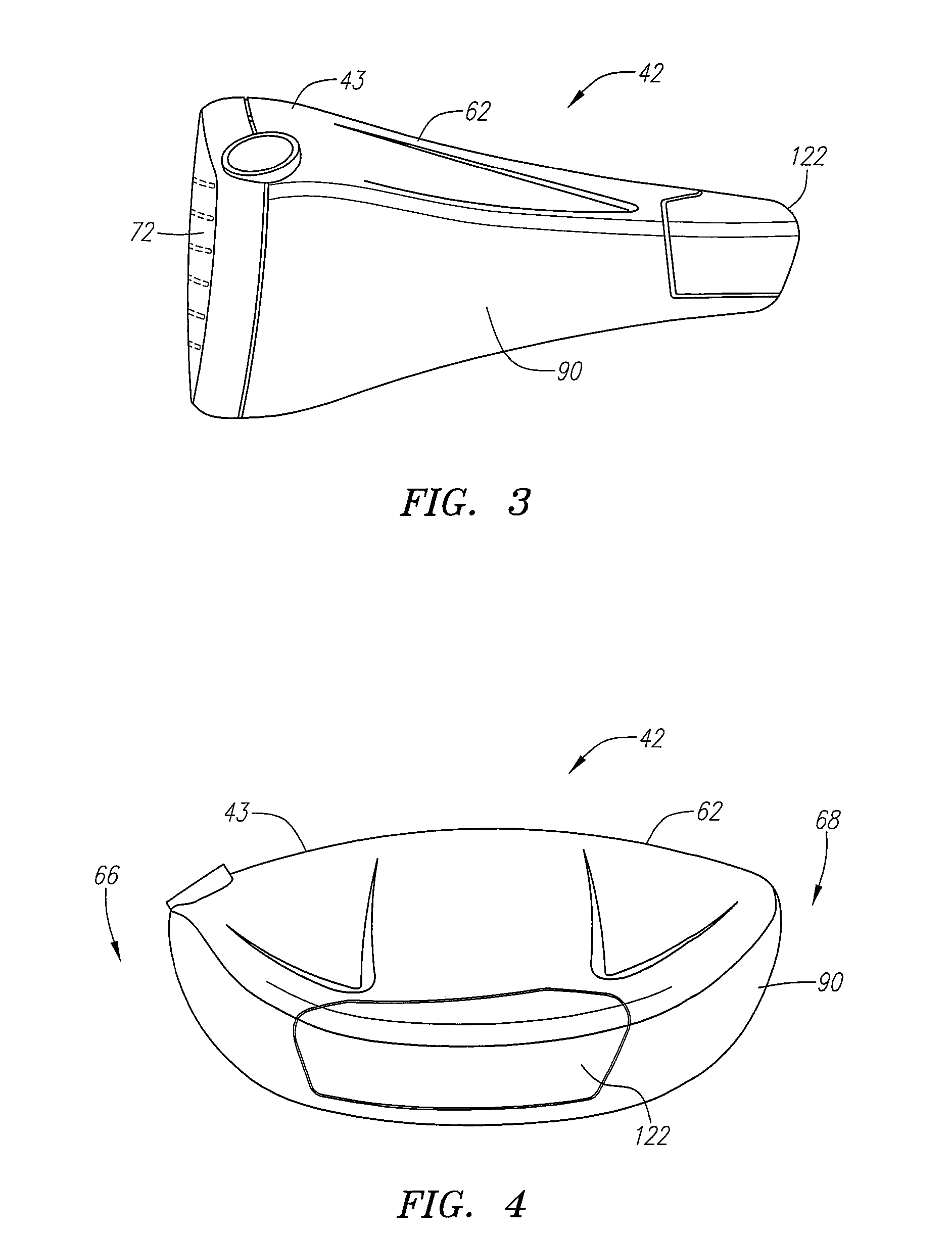

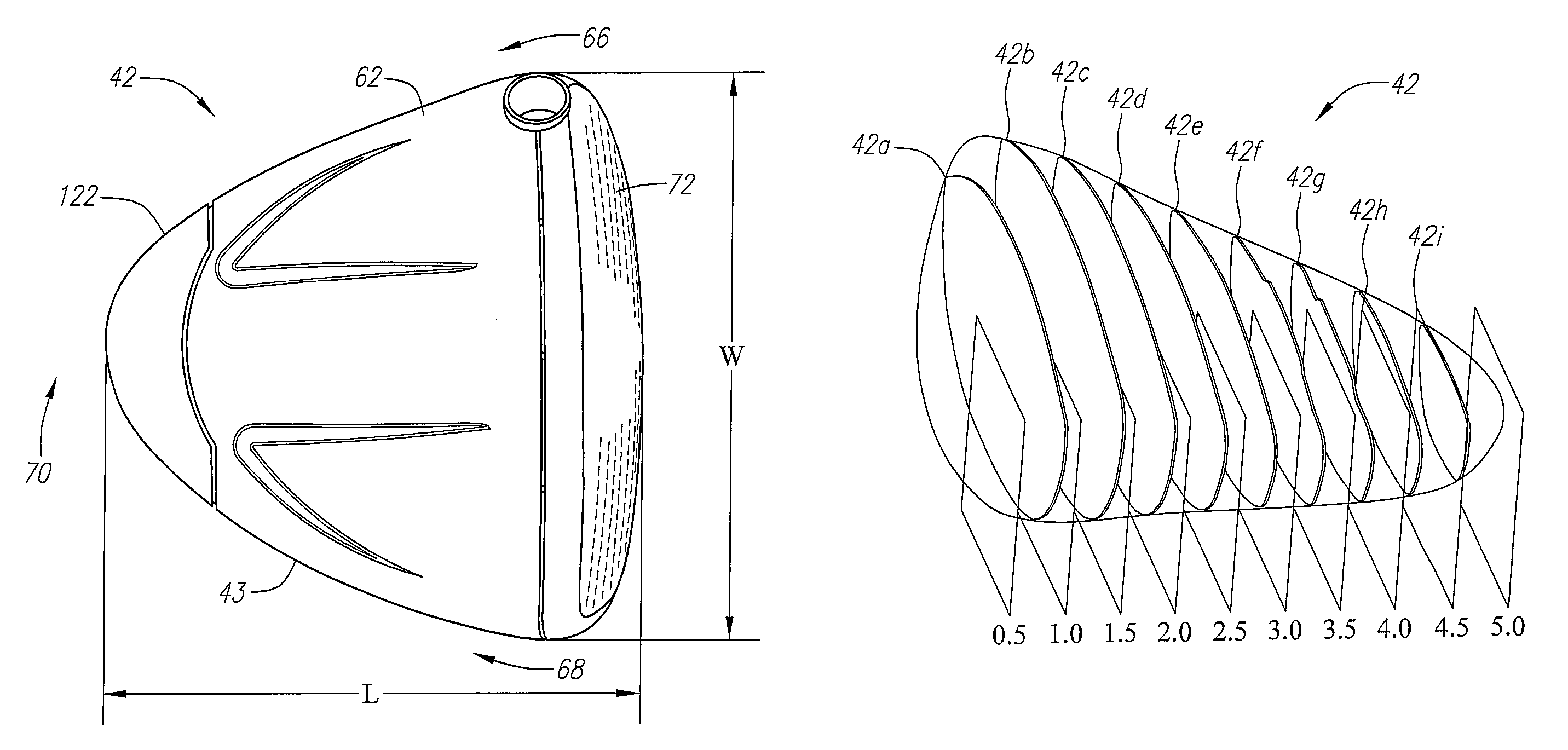

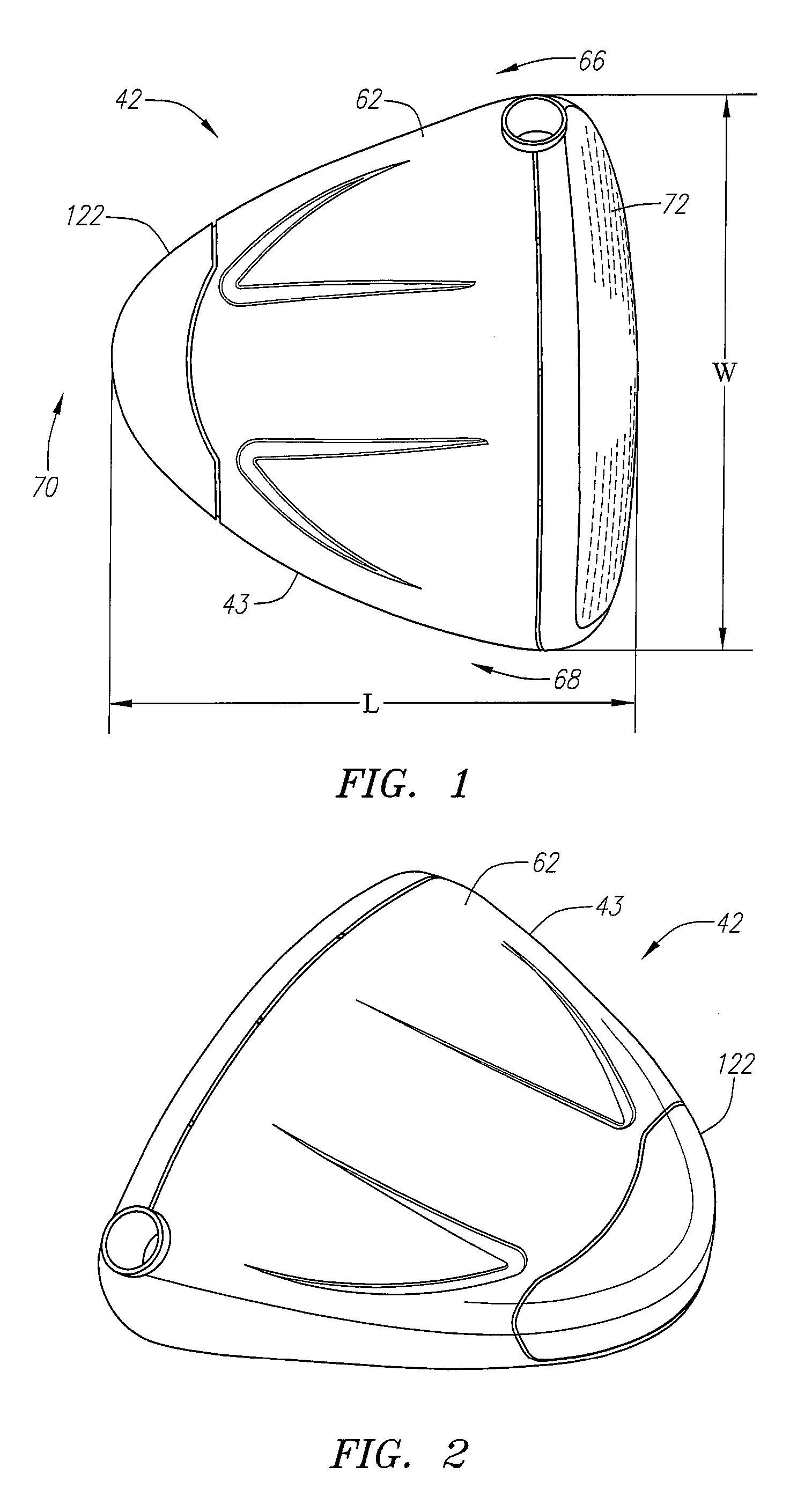

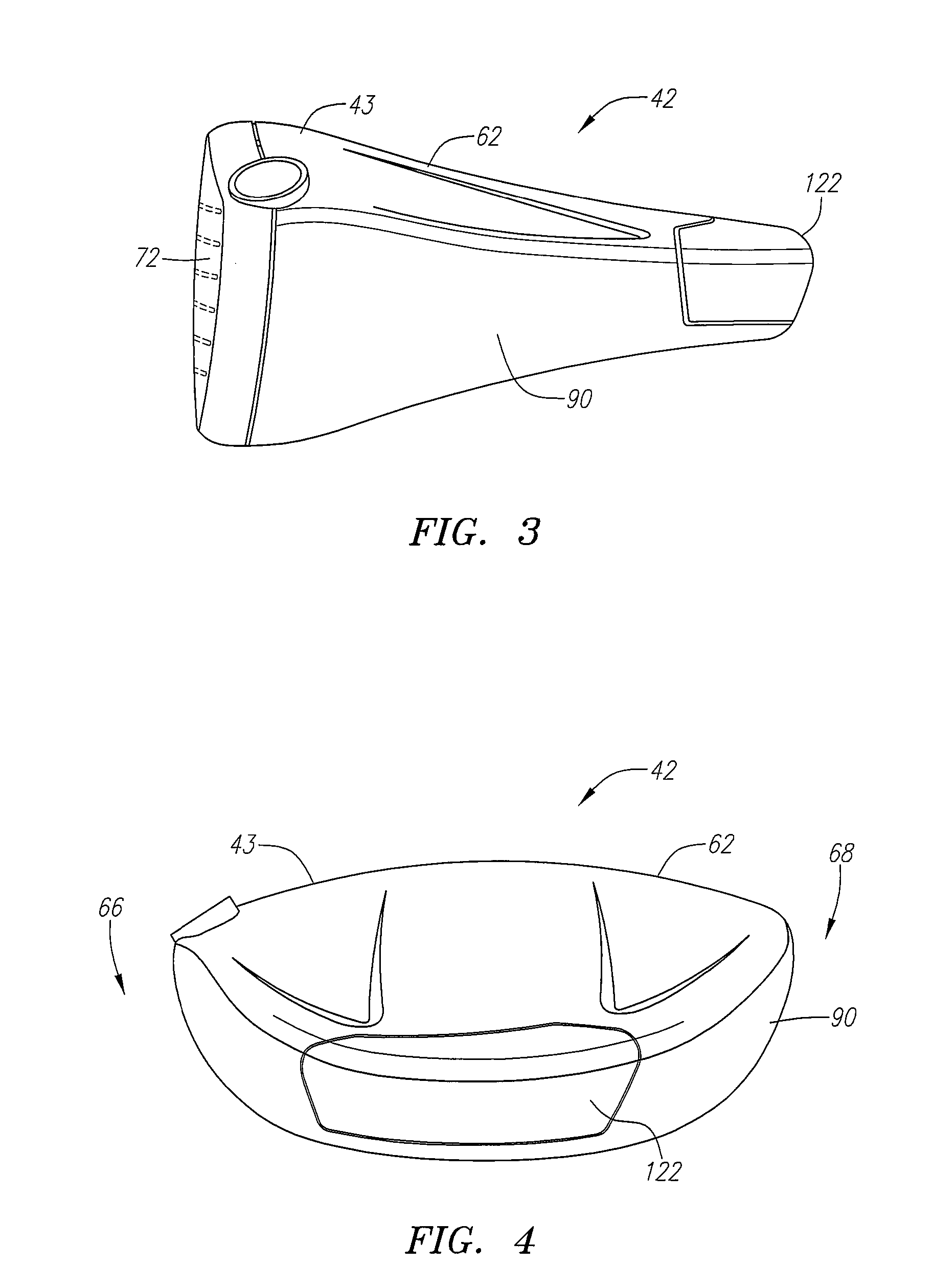

A golf club head having a high moment of inertia is disclosed herein. The golf club head preferably has a volume ranging from 450 cubic centimeters to 475 cubic centimeters, a mass ranging from 180 grams to 225 grams, and a length ranging from 4.0 inches to 5.0 inches. The golf club head preferably has a moment of inertia, Iyy, about the center of gravity of the golf club head greater than 4000 grams-centimeters squared. Preferably, the golf club includes a metal face component, a non-metal aft-body and a weight member attached to an inlaid portion of the non-metal aft-body.

Owner:TOPGOLF CALLAWAY BRANDS CORP

Golf club head with high moment of inertia

ActiveUS7410428B1Improved off center ball speedIncrease the areaGolf clubsRacket sportsMoment of inertiaGolf Ball

A golf club head having a high moment of inertia is disclosed herein. The golf club head preferably has a volume ranging from 450 cubic centimeters to 475 cubic centimeters, a mass ranging from 180 grams to 225 grams, and a length ranging from 4.0 inches to 5.0 inches. The golf club head preferably has a moment of inertia, Iyy, about the center of gravity of the golf club head ranging from 2000 grams-centimeters squared to 4000 grams-centimeters squared. Preferably, a middle section of the golf club head has less than 20% of the mass of the golf club head.

Owner:TOPGOLF CALLAWAY BRANDS CORP

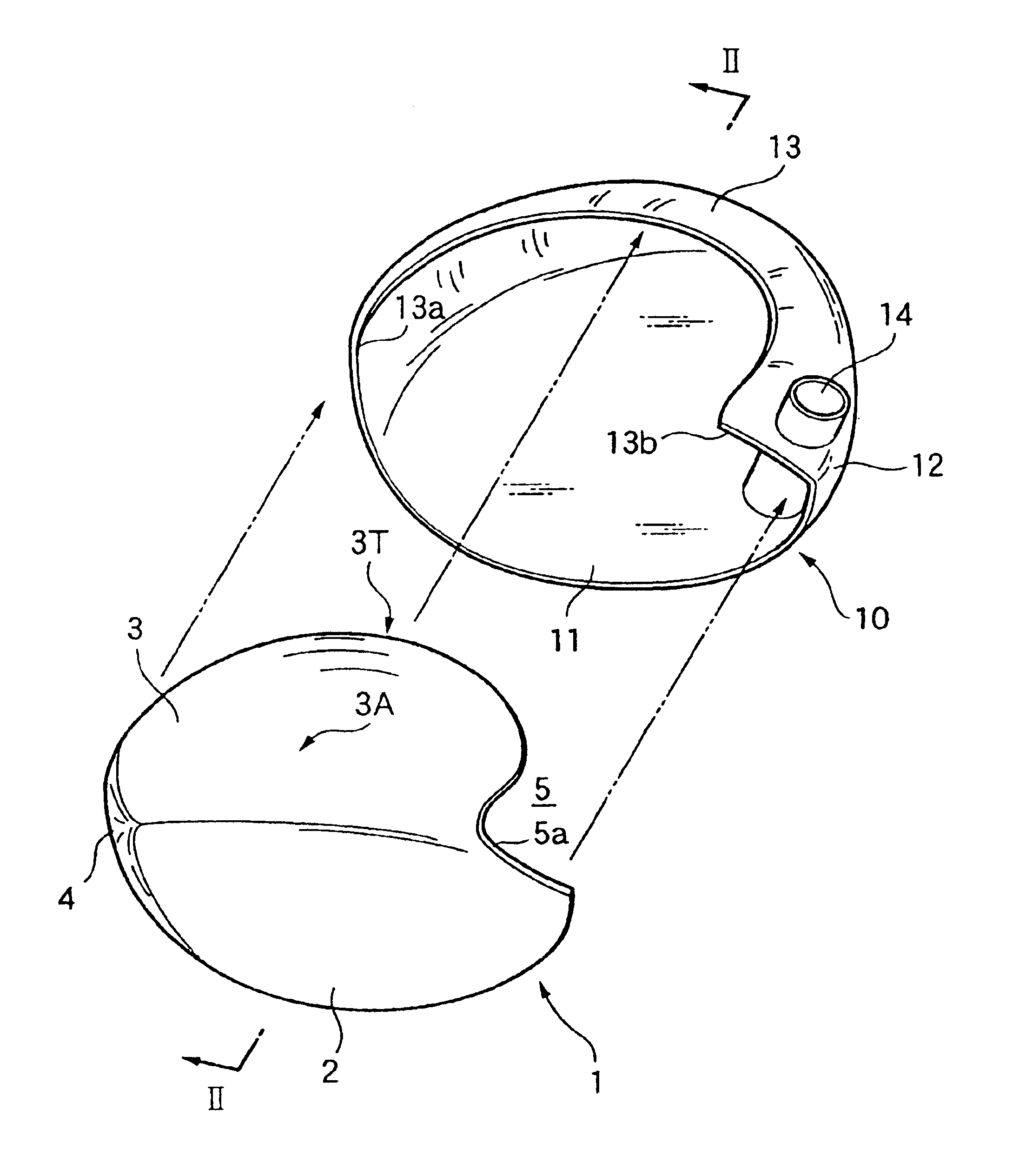

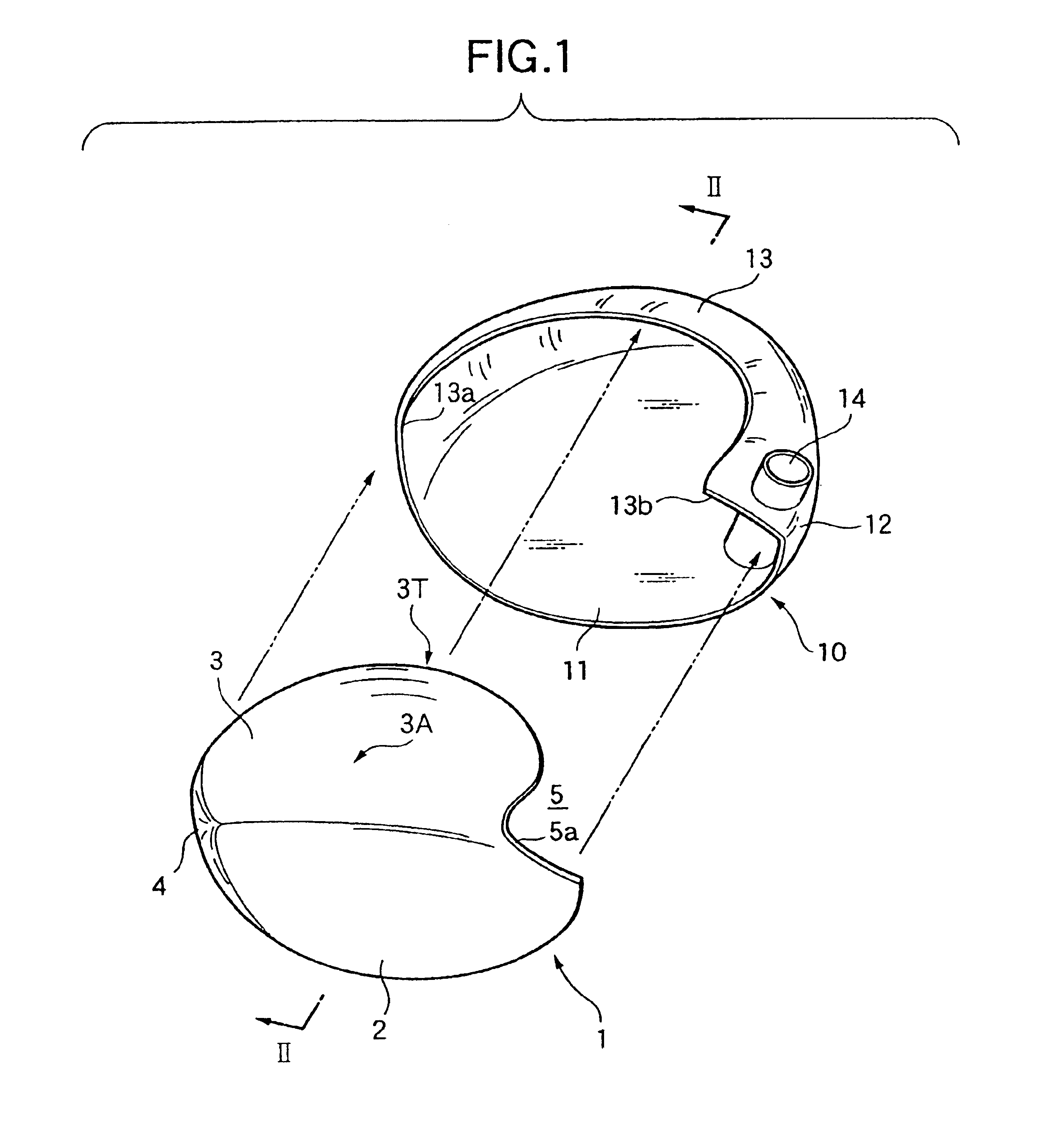

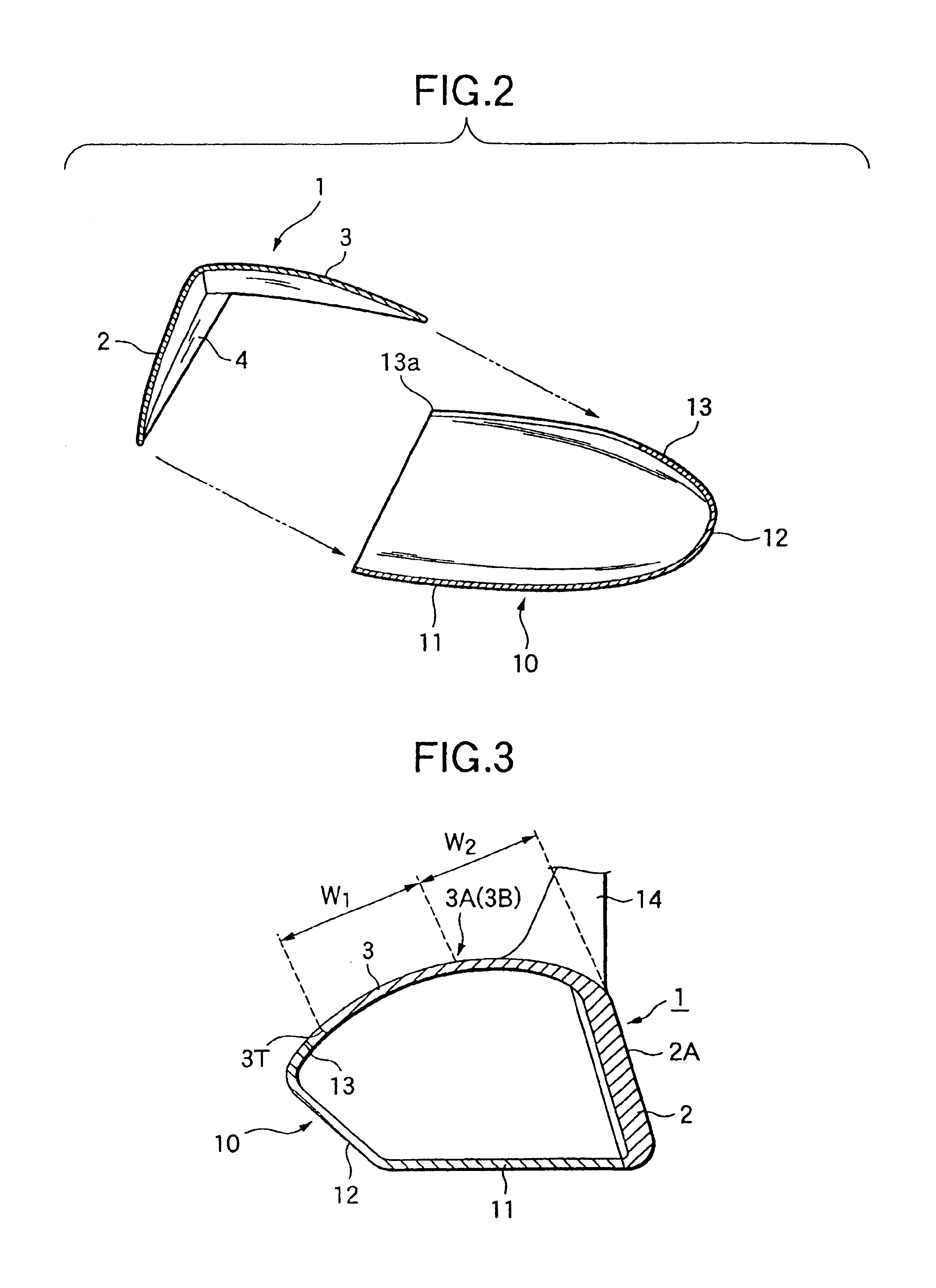

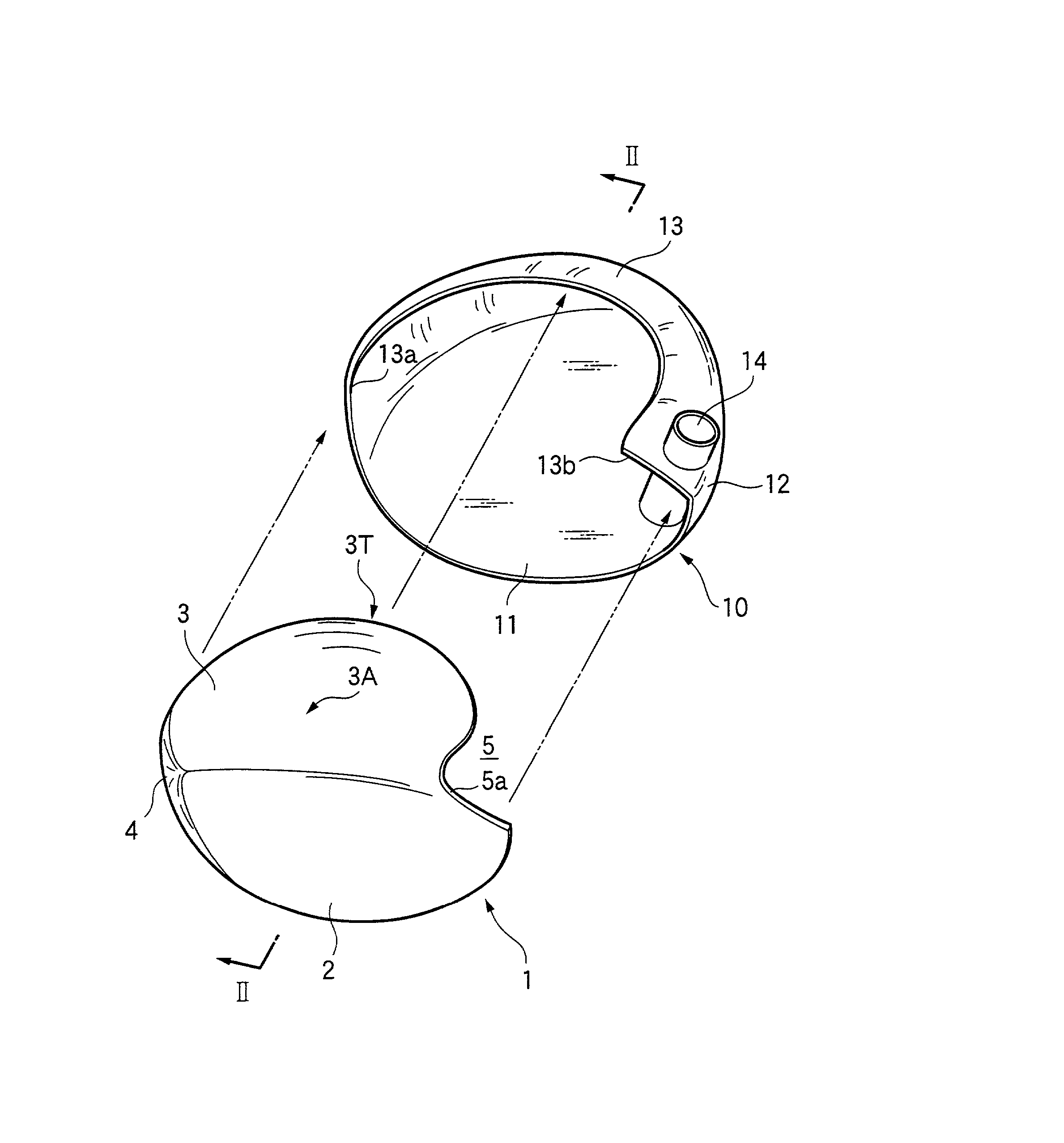

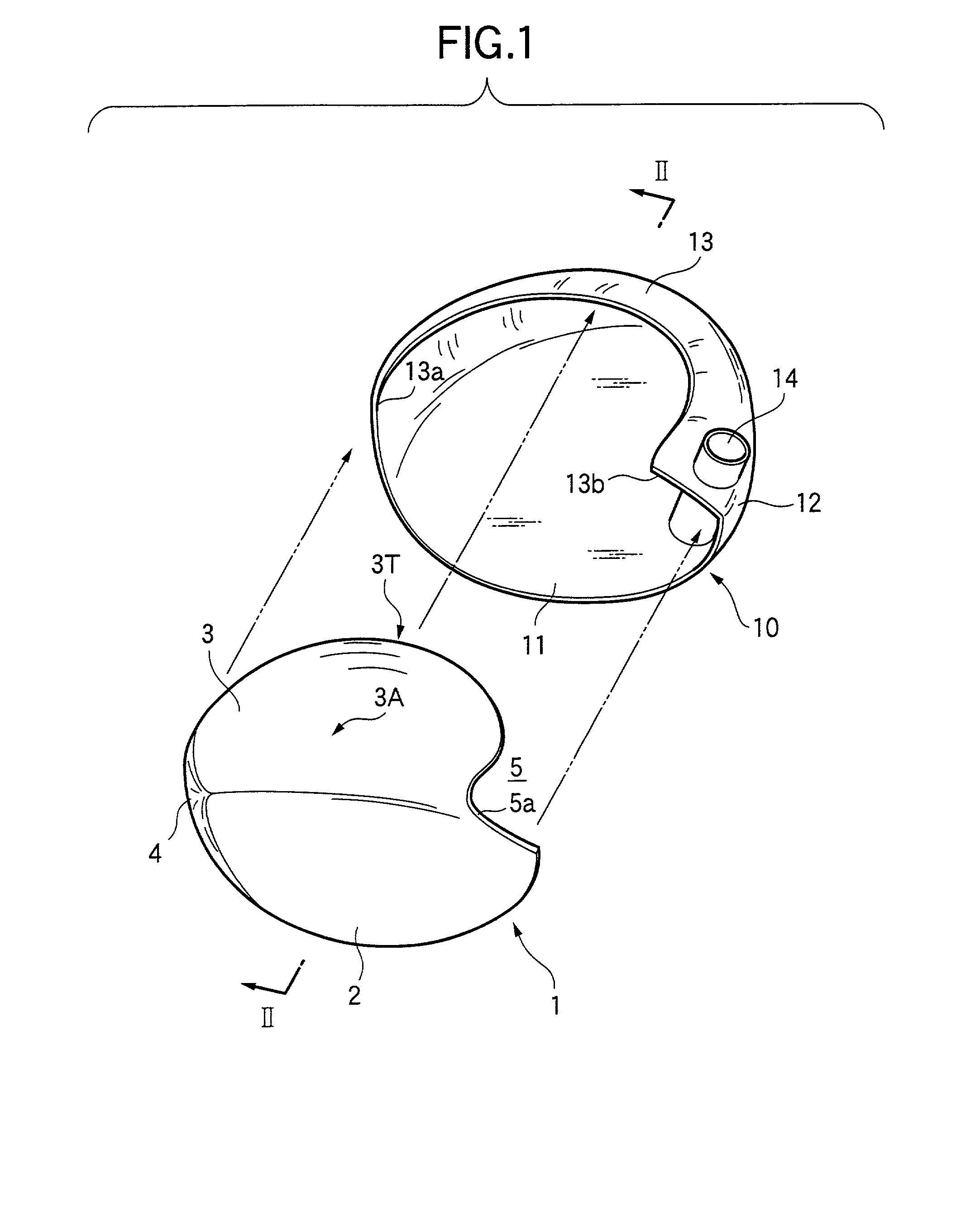

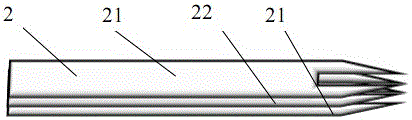

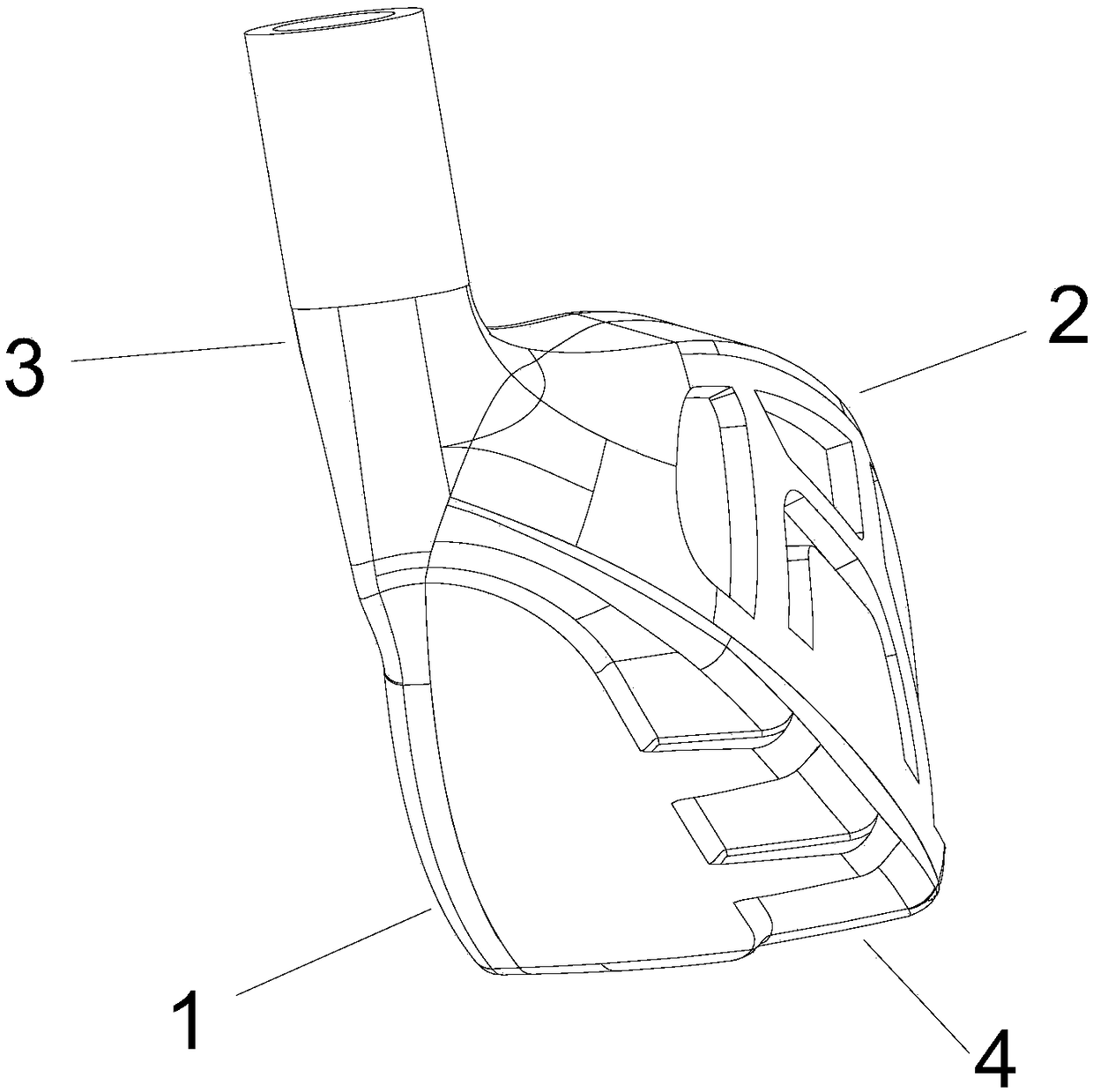

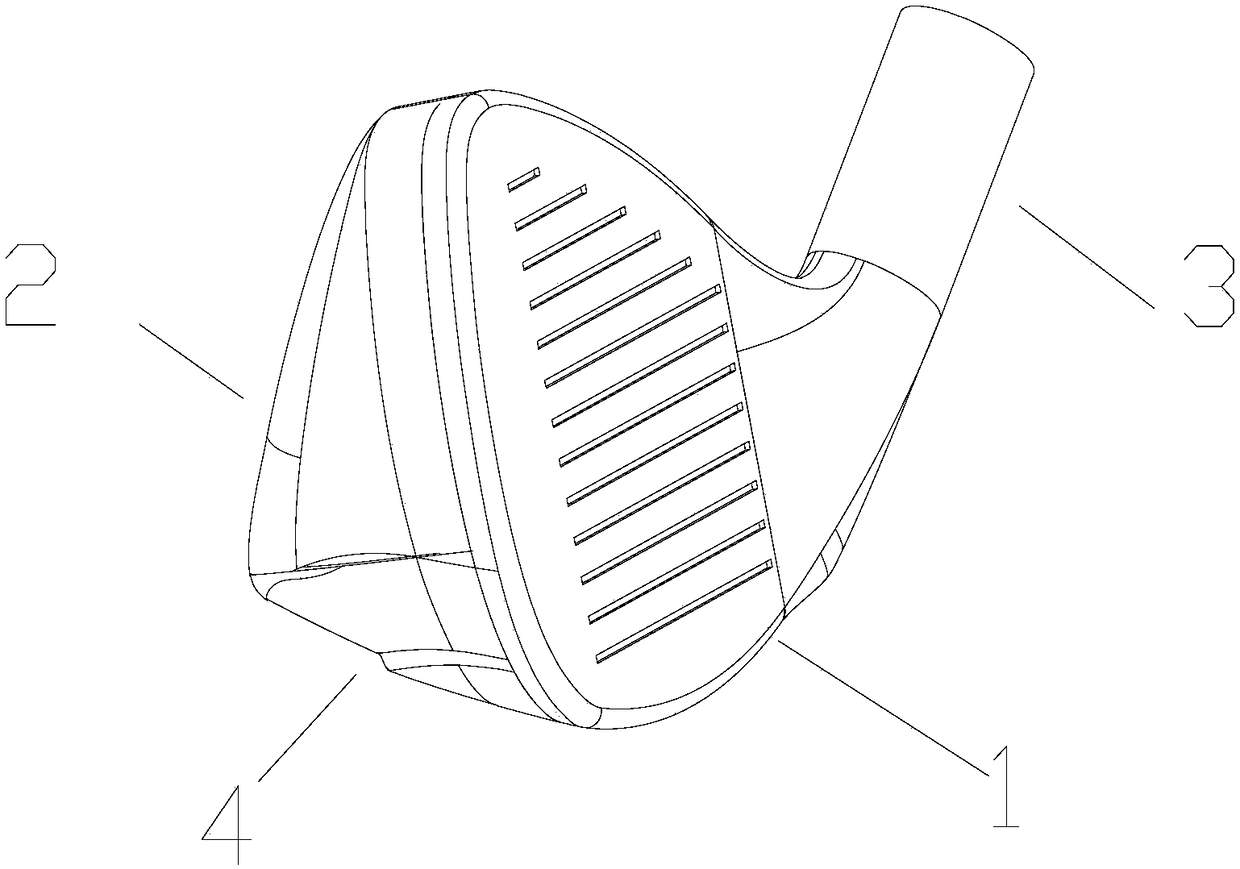

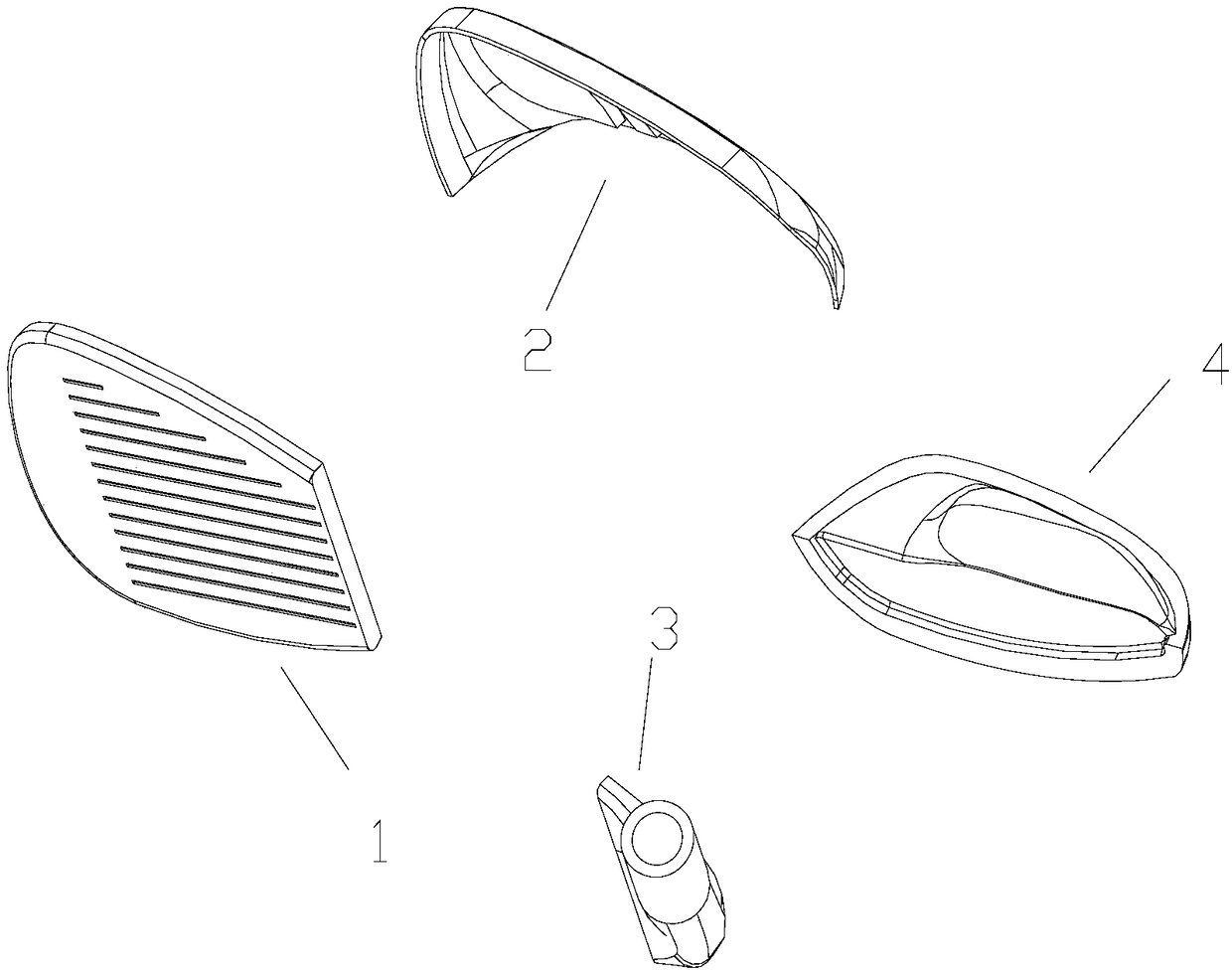

Golf club head

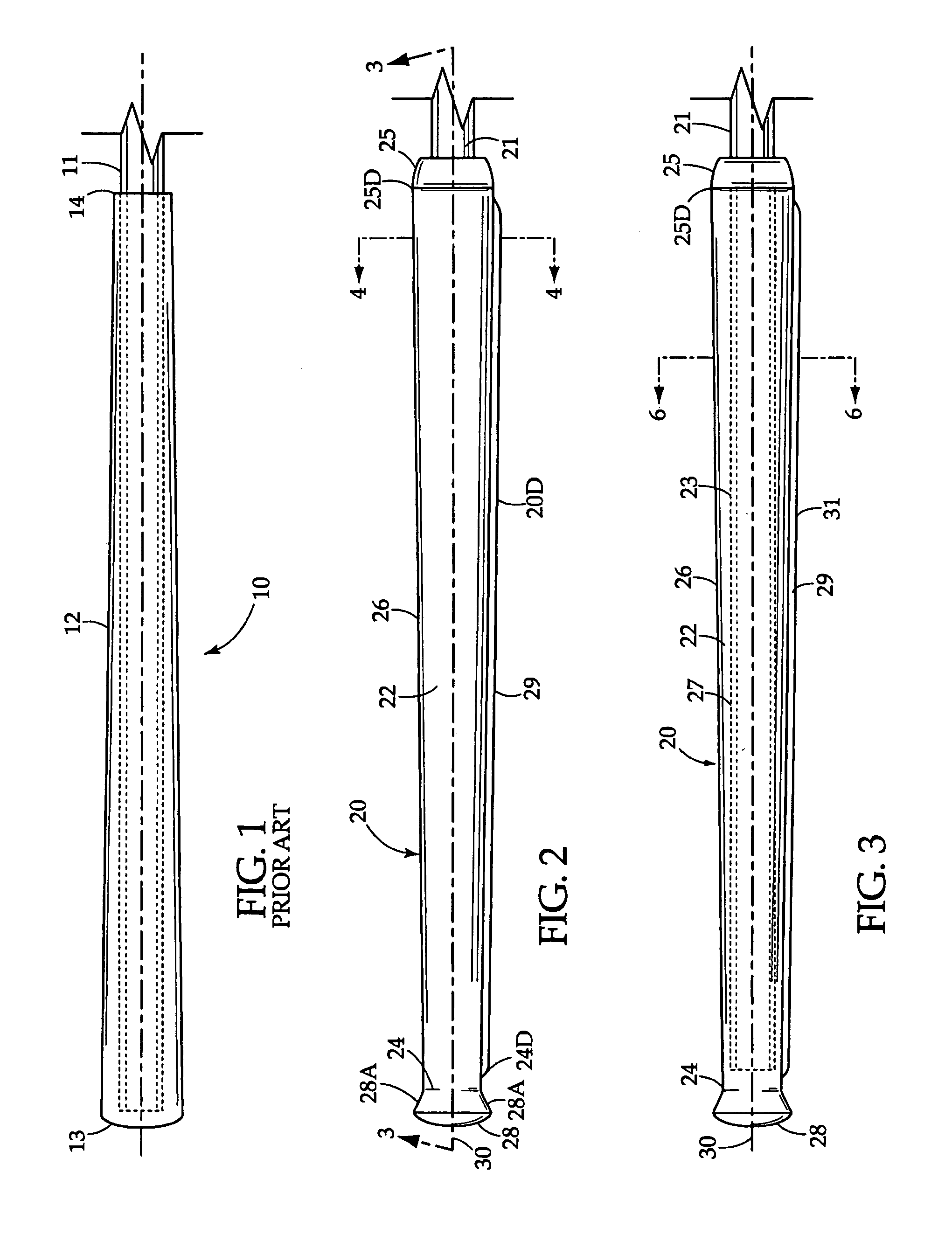

InactiveUS6783466B2Increase ball speedIncrease the number ofGolf clubsRacket sportsMetallic materialsYoung's modulus

This golf club head is constituted by a front part 1 including a face portion 2 and a crown main portion 3, and a back part 10 forming the remaining portion of the golf club head. A metal material forming the front part 1 has lower Young's modulus than that of a metal material forming the back part 10. The front part 1 and the back part 10 are welded. The thickness of the center of the face portion 2 is larger than the thickness of the periphery thereof. The thickness of the vicinity of a highest point 3A of the crown is small.

Owner:BRIDGESTONE SPORTS

Golf club head with variable flexural stiffness for controlled ball flight and trajectory

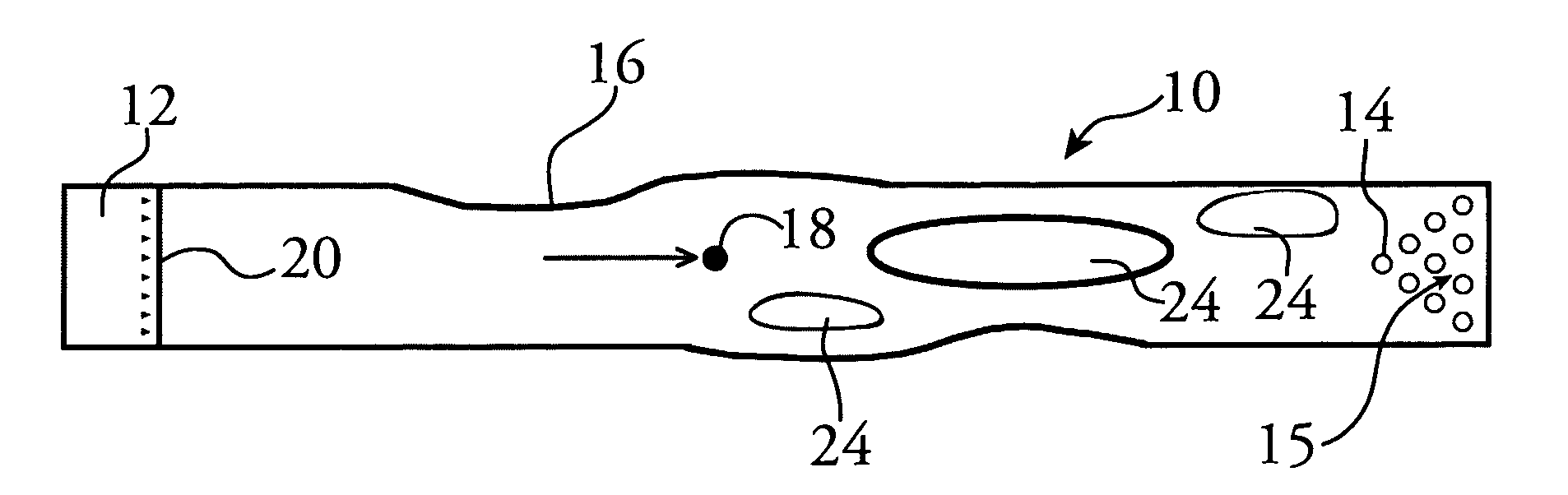

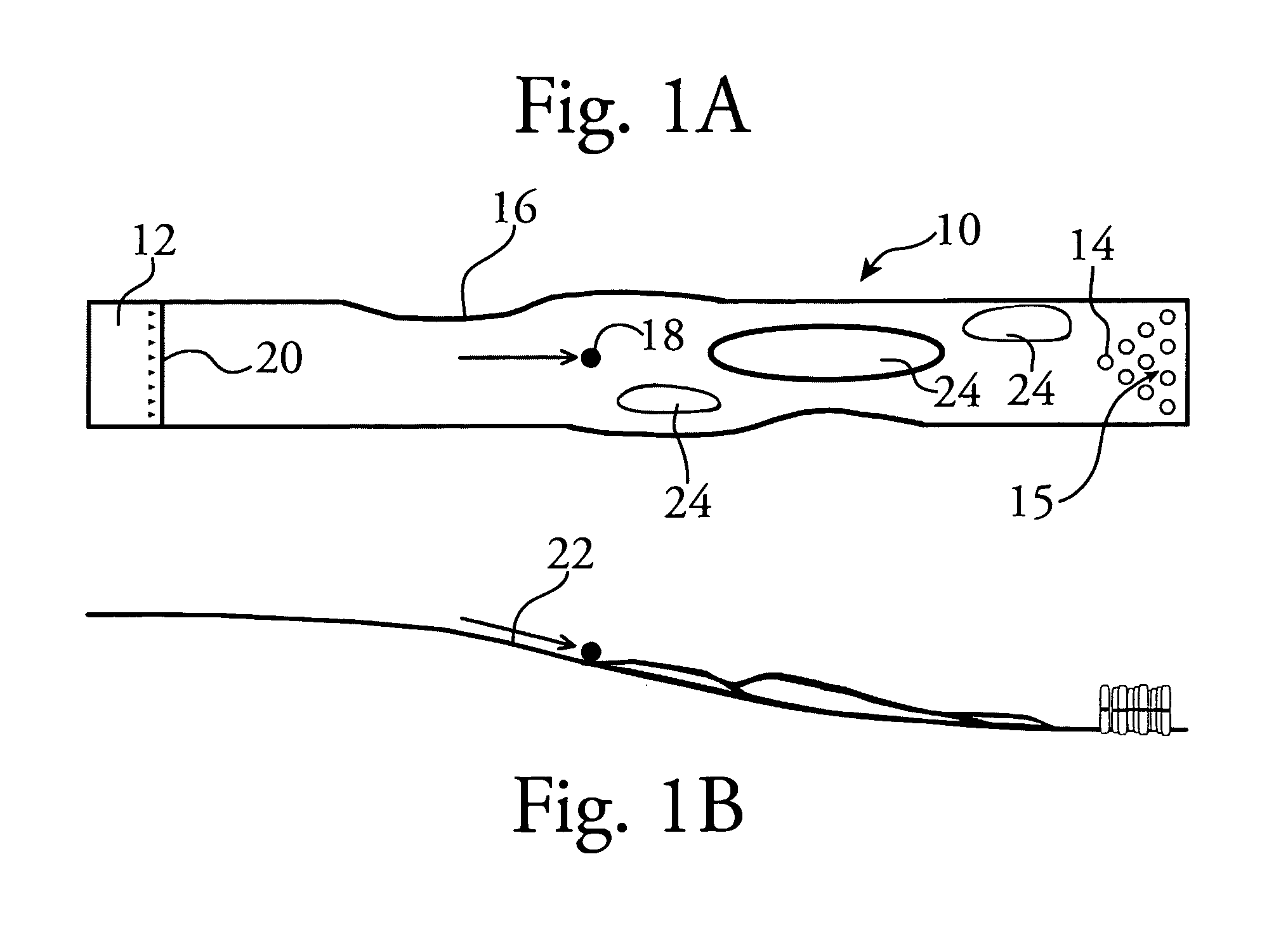

InactiveUS7041003B2Increase ball speedAnalysing solids using sonic/ultrasonic/infrasonic wavesGolf clubsEngineeringControl zone

The present invention relates to a golf club head with a hitting face. The hitting face comprises a directional control portion, which has at least two zones with different flexural stiffness, such that when the hitting face strikes a golf ball the two zones deform differently to selectively control the direction of the flight of the golf ball. The directional control portion may comprise an upper zone and a lower zone, where the upper zone has a lower flexural stiffness. Alternatively, the lower zone has a lower flexural stiffness. On the other hand, the directional control portion may comprise a left zone and a right zone, and either the left or right zone may have a lower flexural stiffness to selectively control the lateral launch angle either to the left of right. The hitting face may further comprise a central zone disposed within the directional control zone, wherein the central zone has a flexural stiffness of at least about three times greater than the flexural stiffness of the directional control zone.

Owner:ACUSHNET CO

Golf club head with variable flexural stiffness for controlled ball flight and trajectory

InactiveUS20060094531A1Increase ball speedAnalysing solids using sonic/ultrasonic/infrasonic wavesGolf clubsEngineeringControl zone

Owner:ACUSHNET CO

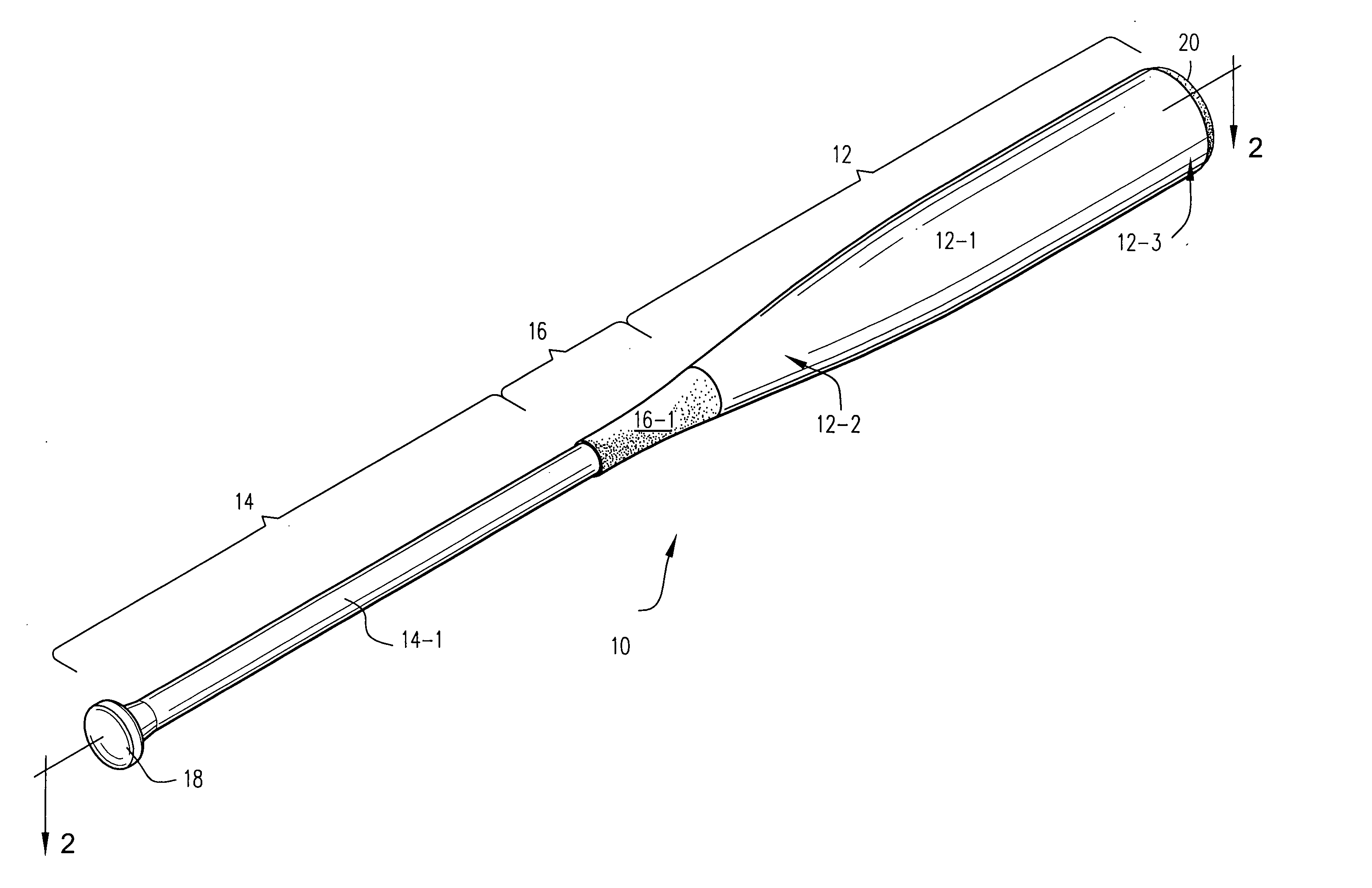

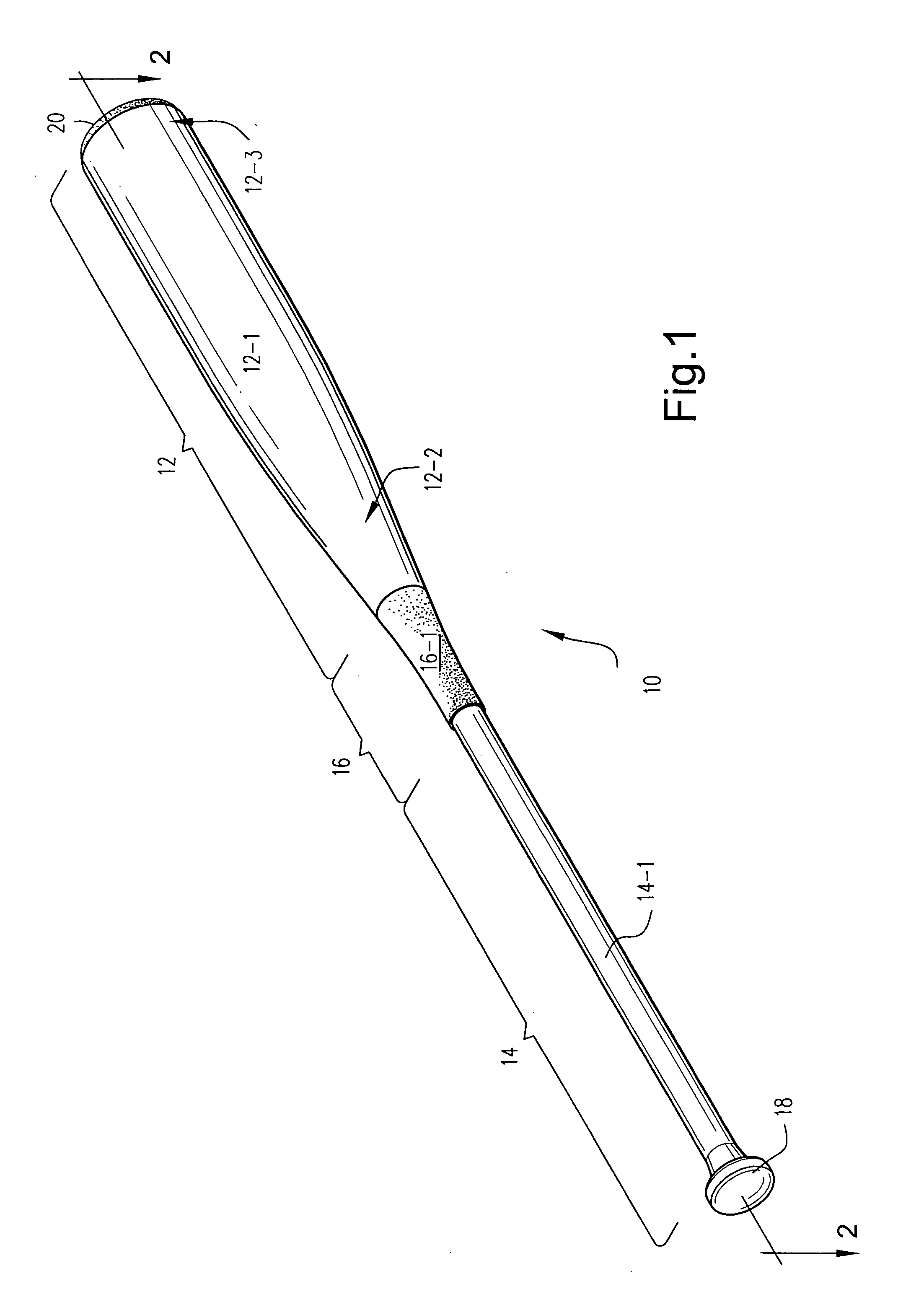

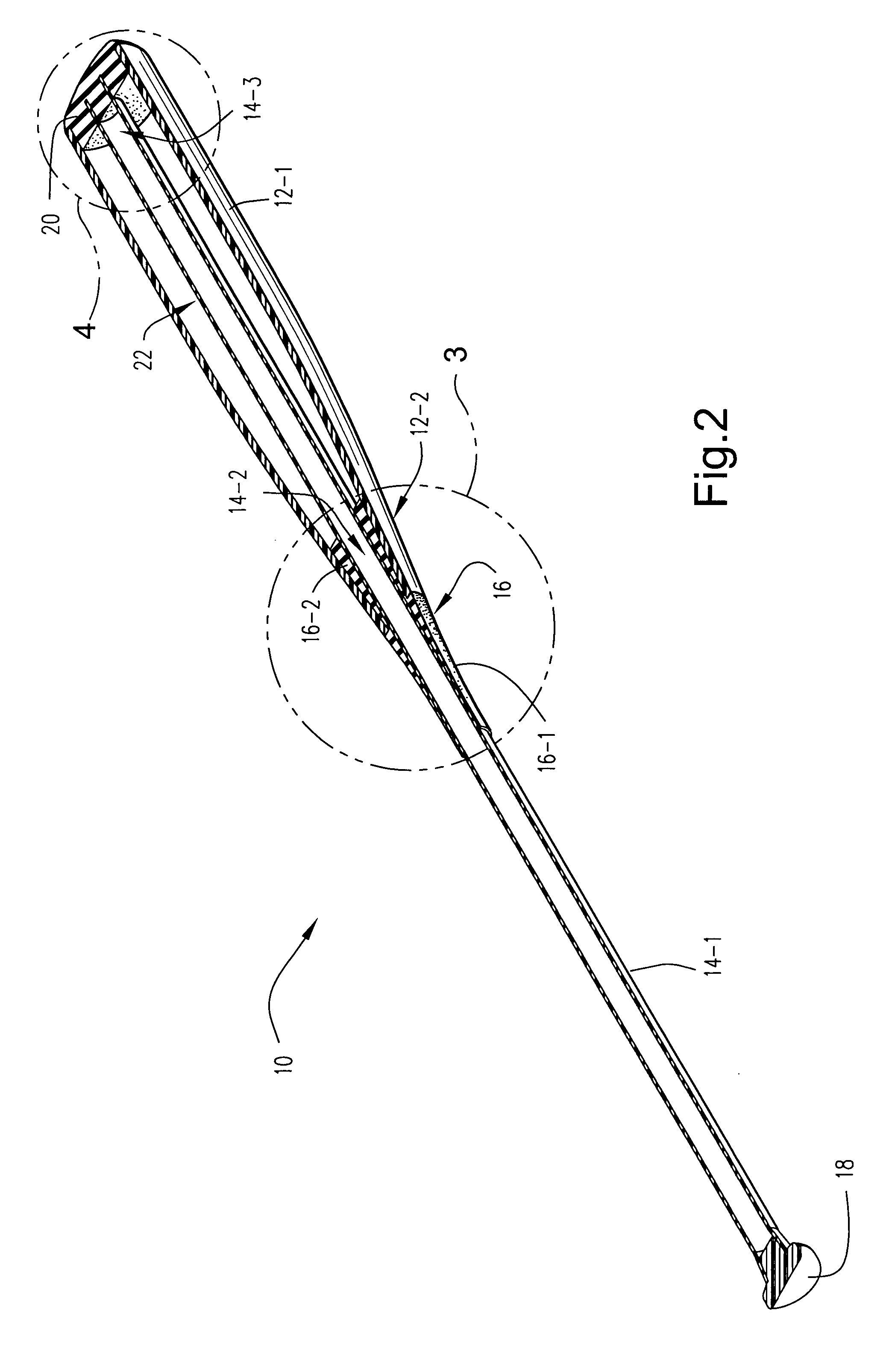

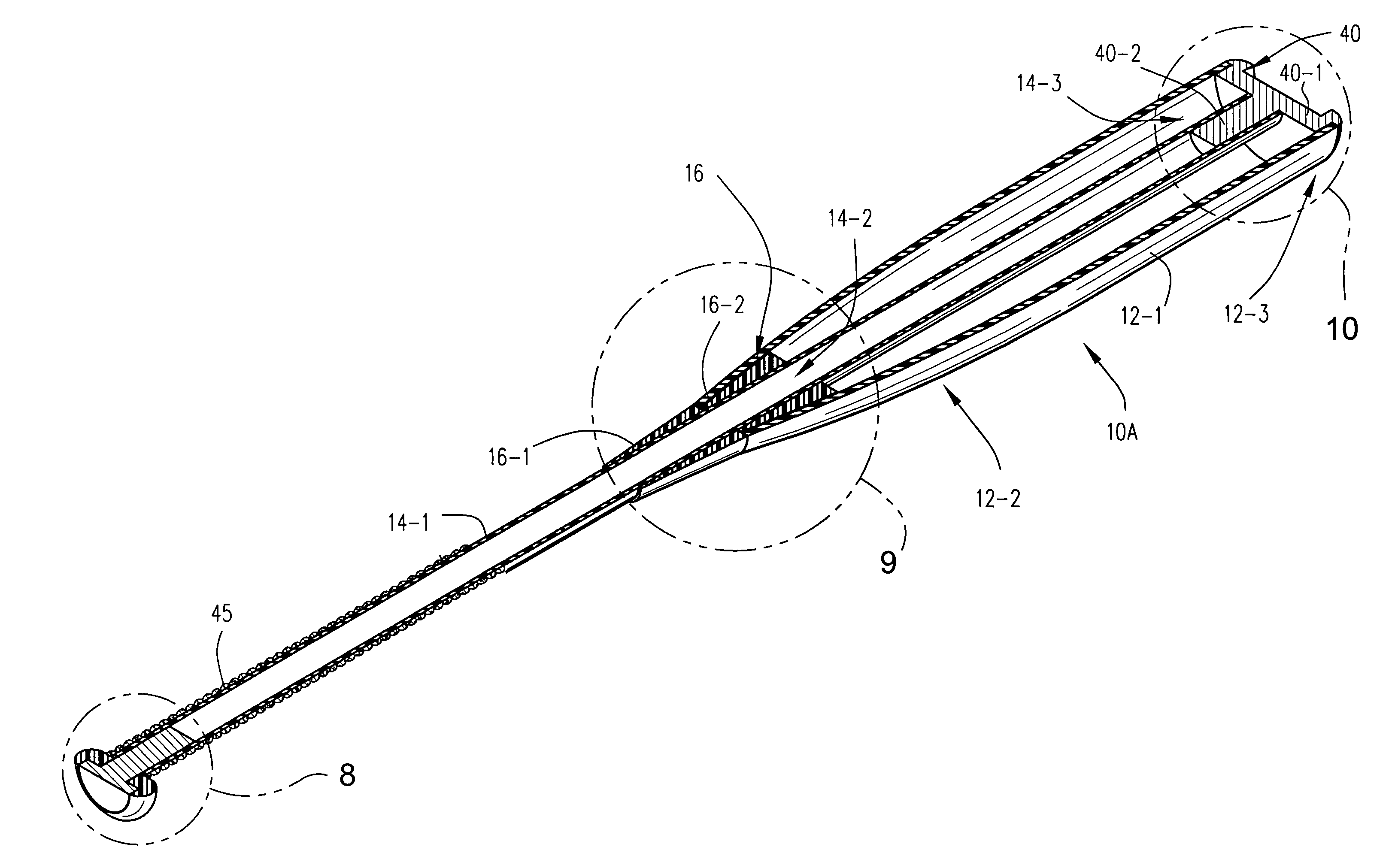

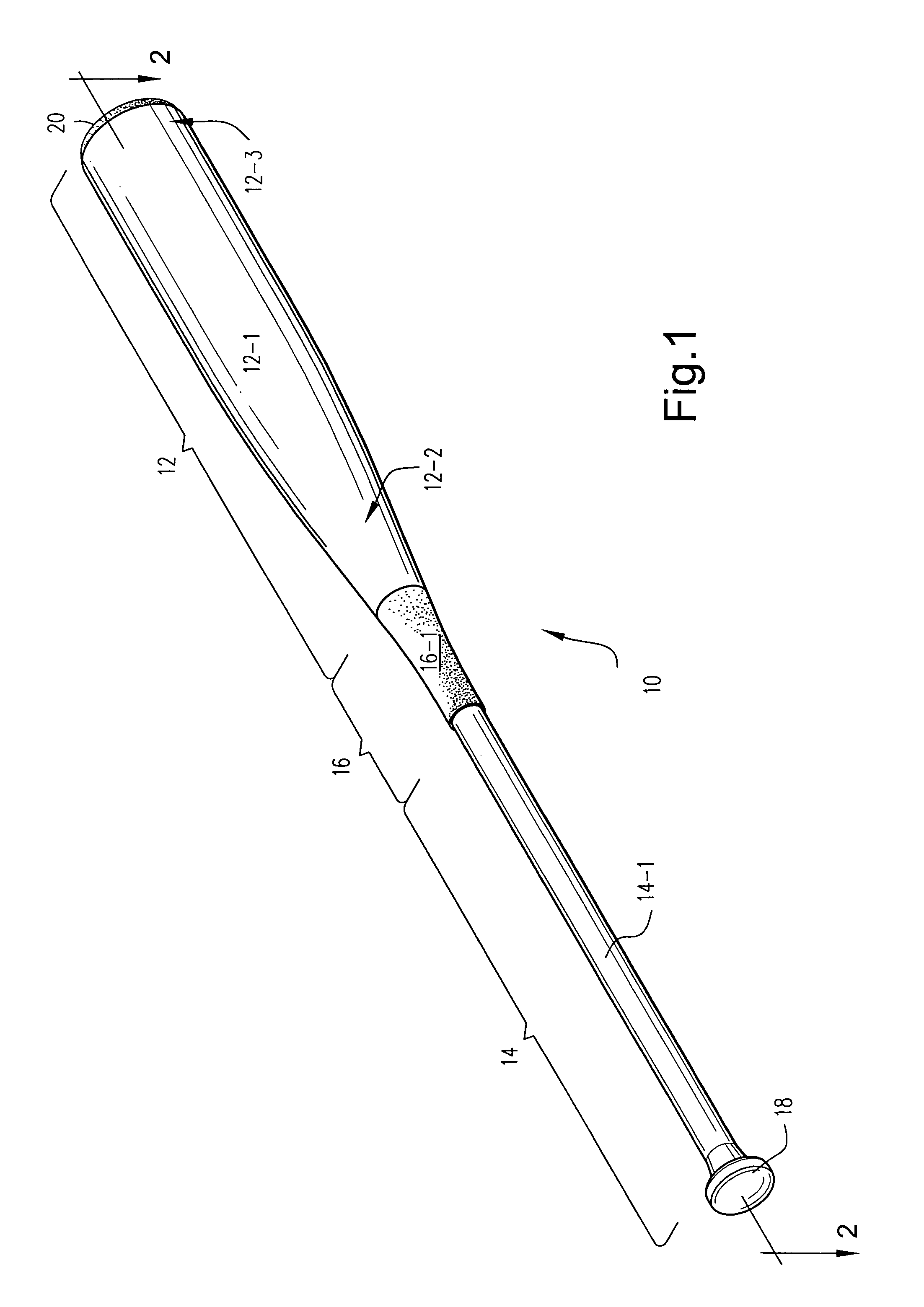

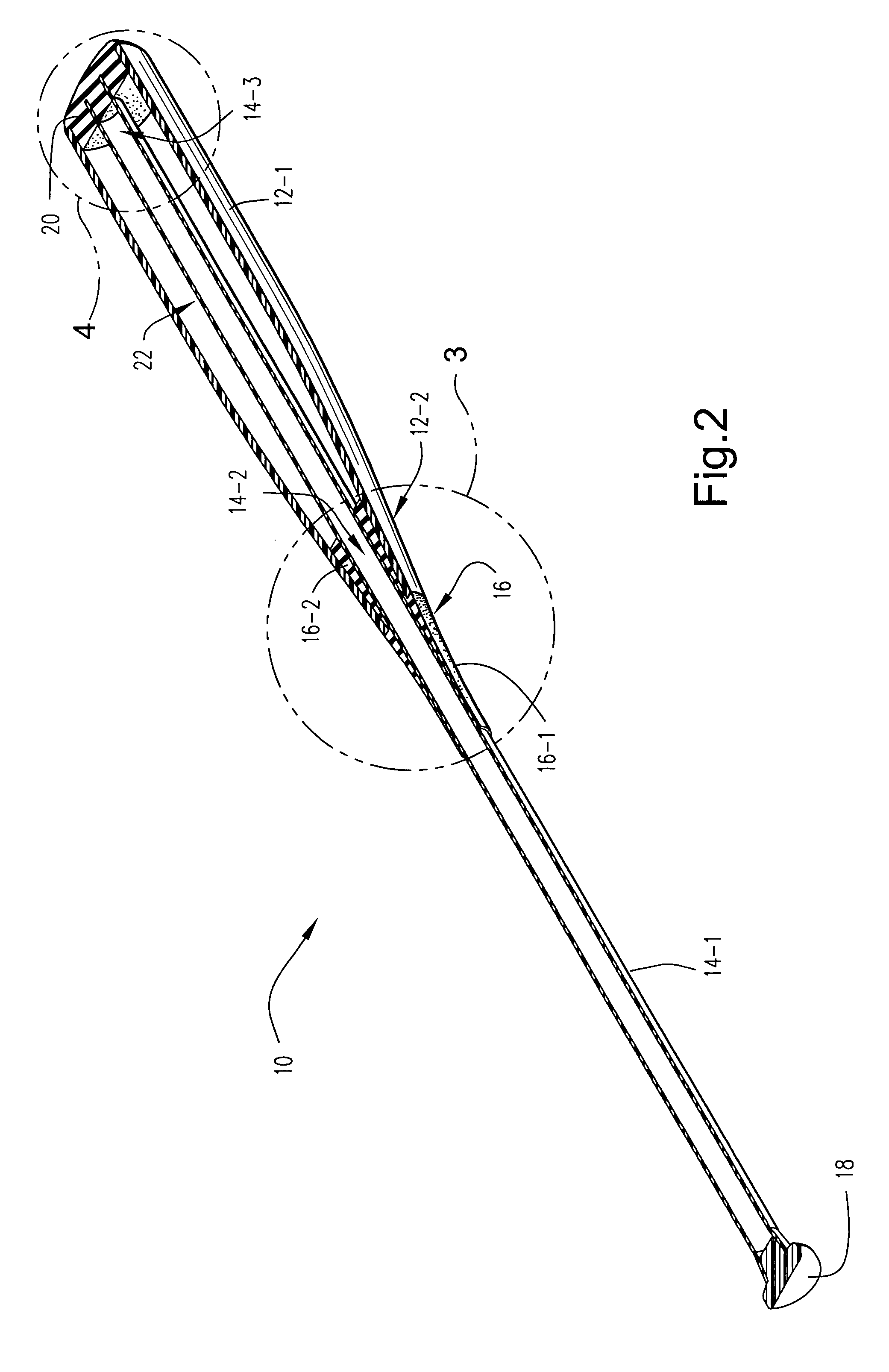

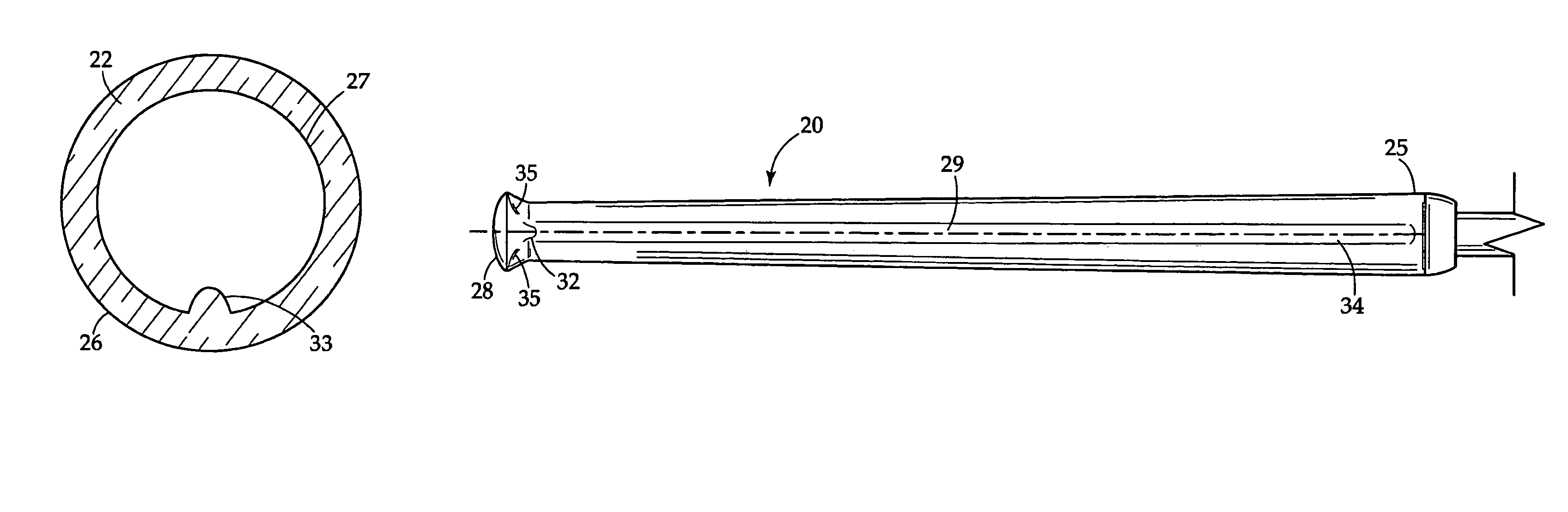

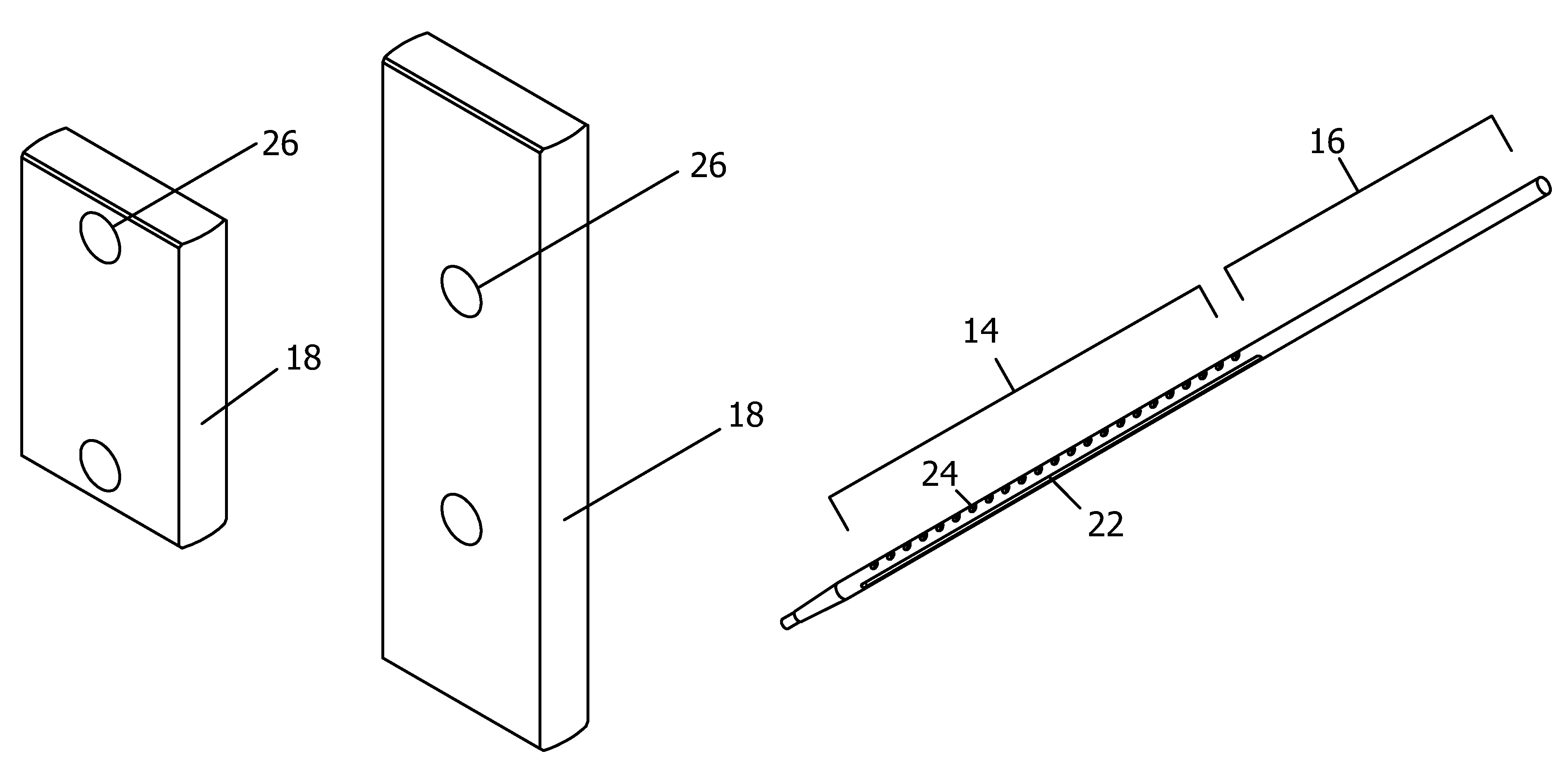

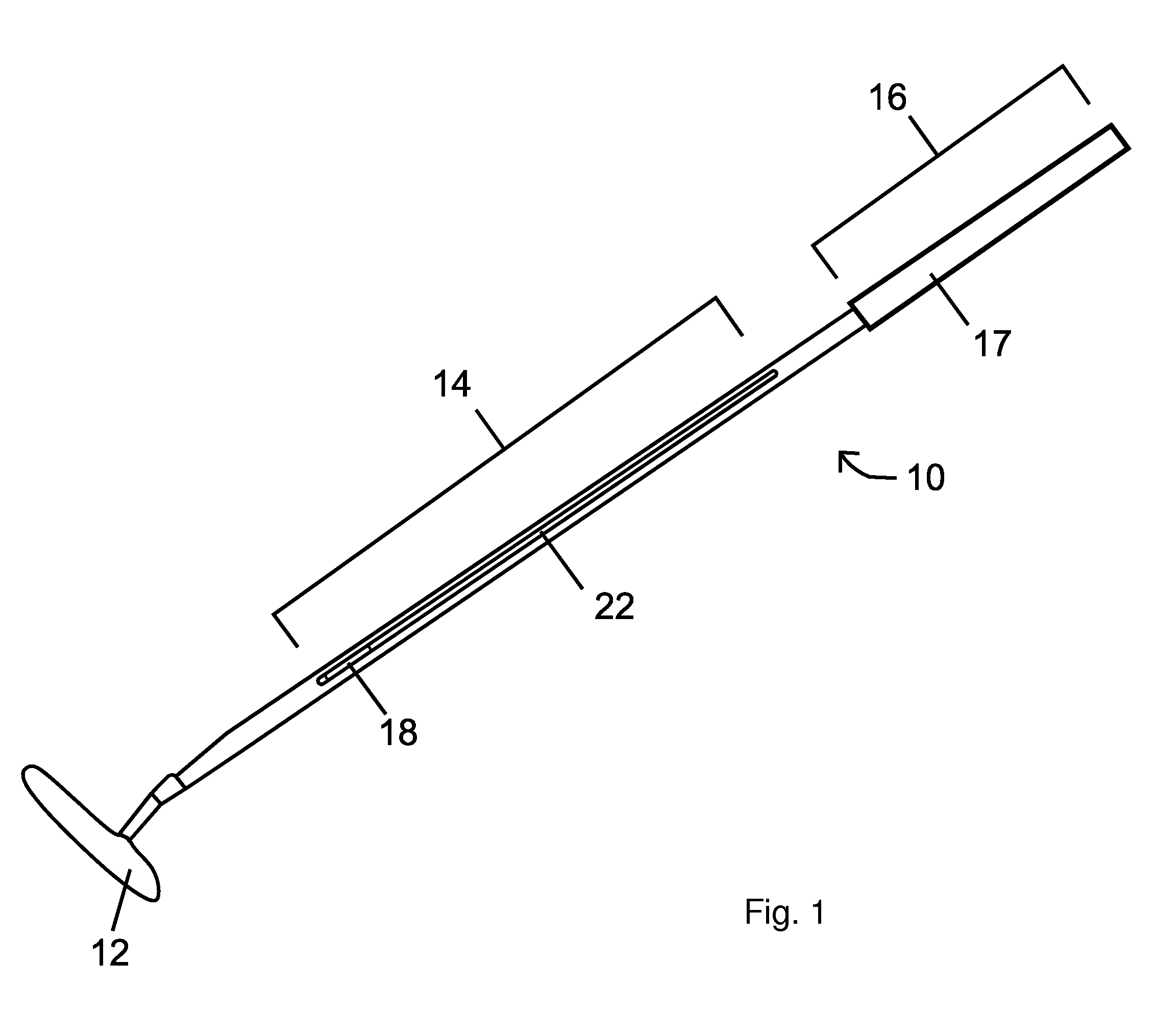

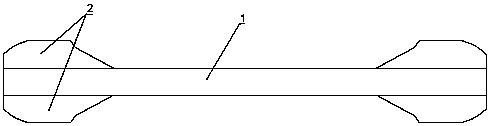

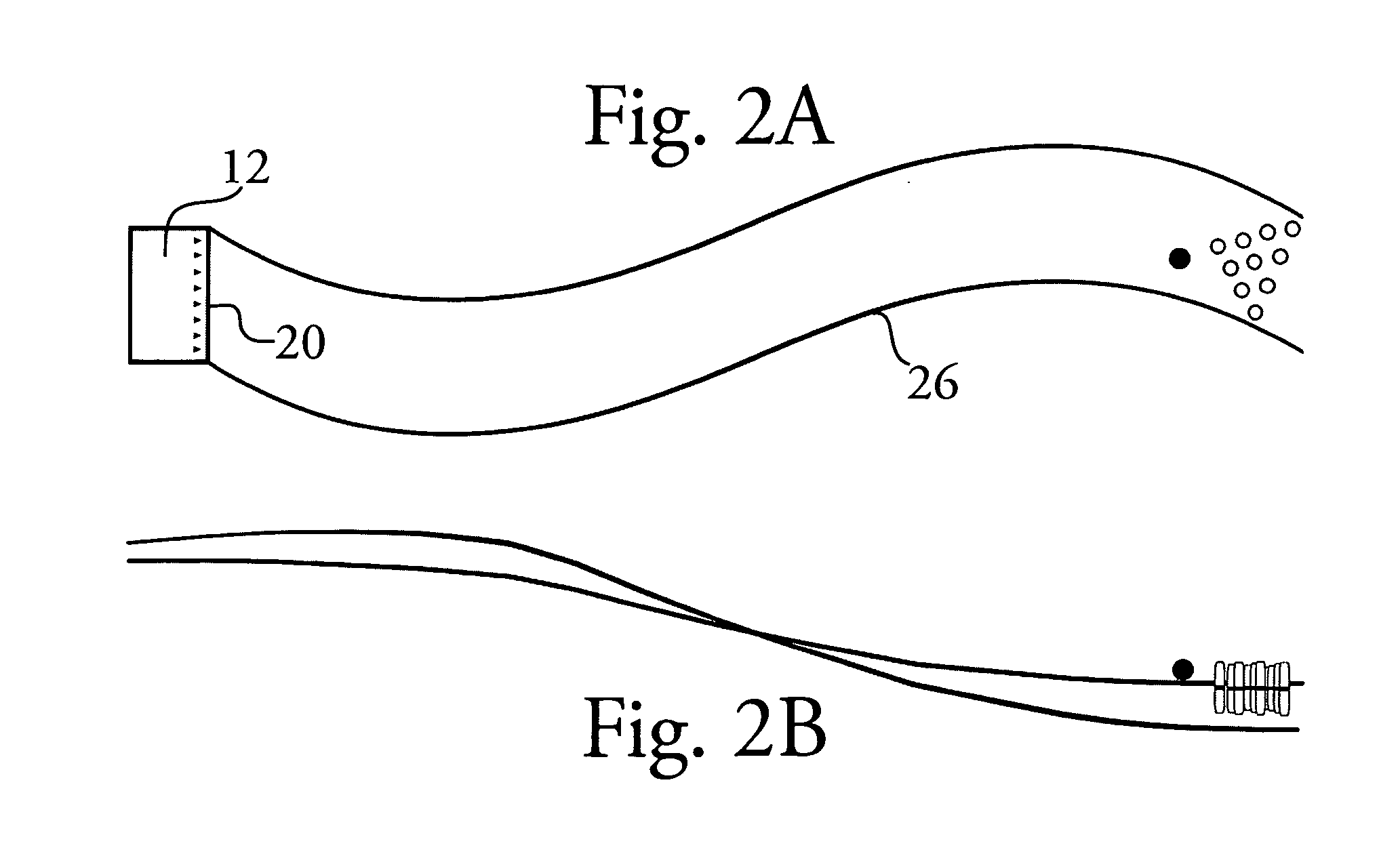

Ball bats and methods of making same

Ball bats and methods of making the same are disclosed whereby the handle and barrel members are separate structural components, and whereby the handle member is of sufficient length to extend through the hollow barrel member. The handle member is connected to the barrel member at its proximal and distal ends by proximal and distal connectors. The connection between the handle member at the proximal end of the barrel member is by means of an elastomeric proximal connector. The connection between the handle member and the distal end of the barrel member is accomplished by means of a rigid distal connector. The rigid connection of the handle member's distal end to the distal end of the barrel member and the elastomeric (flexible) connection between the handle member and the proximal end of the barrel thereby allows the handle member to flex substantially across its entire length during ball impact thereby improving ball speed and distance off the bat when struck.

Owner:HONOR LIFE

Golf club head

InactiveUS20020091015A1Increase ball speedIncrease the number ofGolf clubsRacket sportsMetallic materialsYoung's modulus

This golf club head is constituted by a front part 1 including a face portion 2 and a crown main portion 3, and a back part 10 forming the remaining portion of the golf club head. A metal material forming the front part 1 has lower Young's modulus than that of a metal material forming the back part 10. The front part 1 and the back part 10 are welded. The thickness of the center of the face portion 2 is larger than the thickness of the periphery thereof. The thickness of the vicinity of a highest point 3A of the crown is small.

Owner:BRIDGESTONE SPORTS

Golf club head with high moment of inertia

ActiveUS7413519B1Increase the areaHigh moments of inertiaGolf clubsRacket sportsMoment of inertiaEngineering

A golf club head having a high moment of inertia is disclosed herein. The golf club head preferably has a volume ranging from 450 cubic centimeters to 475 cubic centimeters, a mass ranging from 180 grams to 225 grams, and a length ranging from 4.0 inches to 5.0 inches. The golf club head preferably has a moment of inertia, Iyy, about the center of gravity of the golf club head ranging from 2000 grams-centimeters squared to 4000 grams-centimeters squared. Preferably, the first 10% of the golf club head has at least 40% of the mass of the golf club head.

Owner:TOPGOLF CALLAWAY BRANDS CORP

Ball bats and methods of making same

Ball bats and methods of making the same are disclosed whereby the handle and barrel members are separate structural components, and whereby the handle member is of sufficient length to extend through the hollow barrel member. The handle member is connected to the barrel member at its proximal and distal ends by proximal and distal connectors. The connection between the handle member at the proximal end of the barrel member is by means of an elastomeric proximal connector. The connection between the handle member and the distal end of the barrel member is accomplished by means of a rigid distal connector. The rigid connection of the handle member's distal end to the distal end of the barrel member and the elastomeric (flexible) connection between the handle member and the proximal end of the barrel thereby allows the handle member to flex substantially across its entire length during ball impact.

Owner:HONOR LIFE

Golf club head with high moment of inertia

ActiveUS7419442B1Increase the areaHigh moments of inertiaGolf clubsRacket sportsMoment of inertiaGolf Ball

A golf club head having a high moment of inertia is disclosed herein. The golf club head preferably has a volume ranging from 450 cubic centimeters to 475 cubic centimeters, a mass ranging from 180 grams to 225 grams, and a length ranging from 4.0 inches to 5.0 inches. The golf club head preferably has a moment of inertia, Iyy, about the center of gravity of the golf club head ranging from 2000 grams-centimeters squared to 4000 grams-centimeters squared. Preferably, a middle section of the golf club head has less than 20% of the mass of the golf club head.

Owner:TOPGOLF CALLAWAY BRANDS CORP

Golf club grip

InactiveUS7435186B1Repeatable and increased controlImprove accuracyGolf clubsRacket sportsEngineeringGolf Ball

An improved golf club grip, adaptable to a golf club shaft, which promotes a more correct grip positioning, having a grip body, having a longitudinal axis, a top end with a first diameter and a flared cap with outwardly disposed sides attached thereto, a shaft end with a second diameter, an internal surface, an external surface with a uniformly and progressively increasing diameter from the first diameter to the second diameter, and at least one reminder rib, preferably y-shaped in configuration, extending from the external surface, aligned with the longitudinal axis of the grip body and intersecting with the outwardly sides of the flared cap that allows the golfer to carry or hold the grip more loosely in the fingers because of the reverse taper feature.

Owner:MILLER R LEE

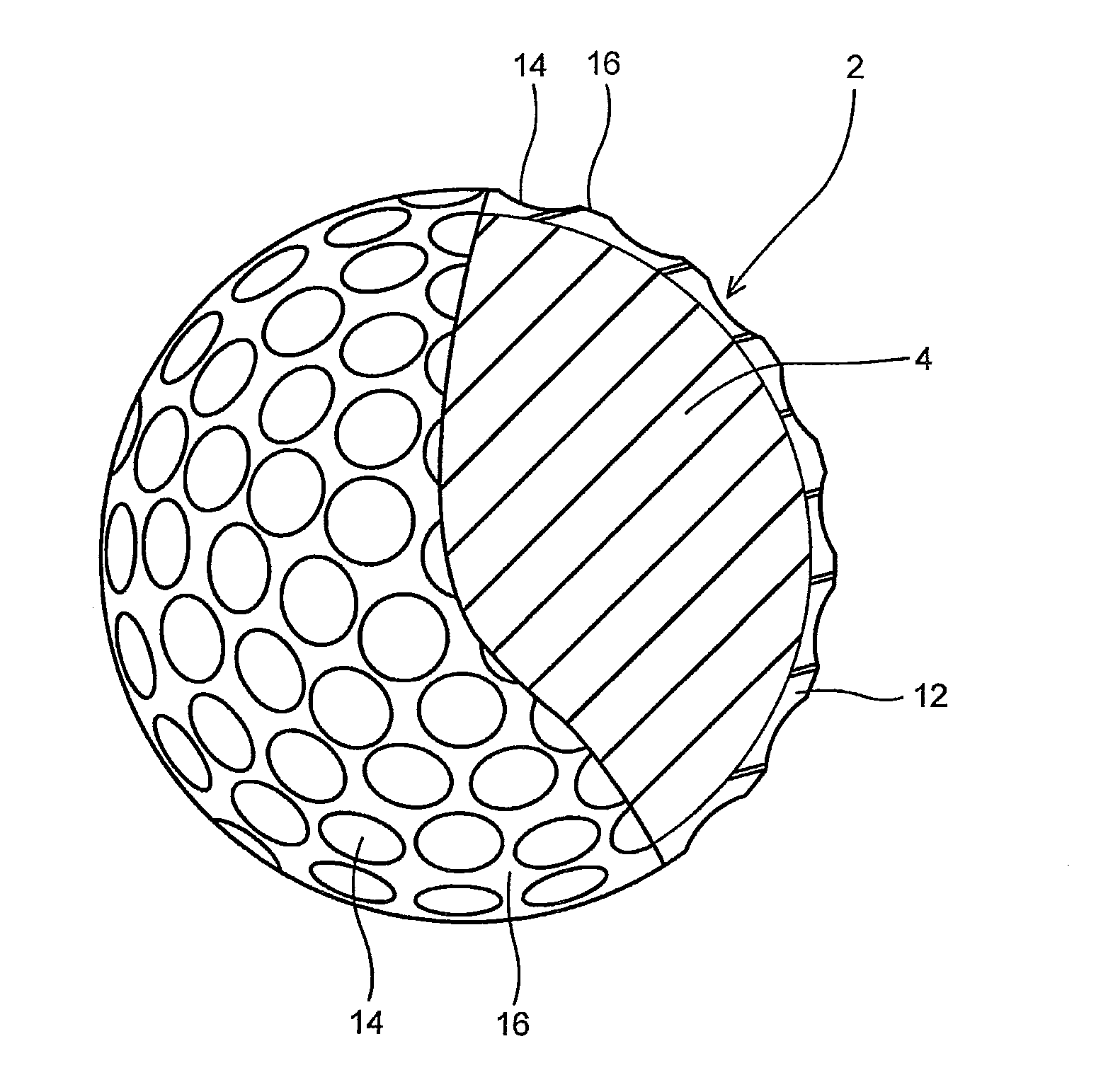

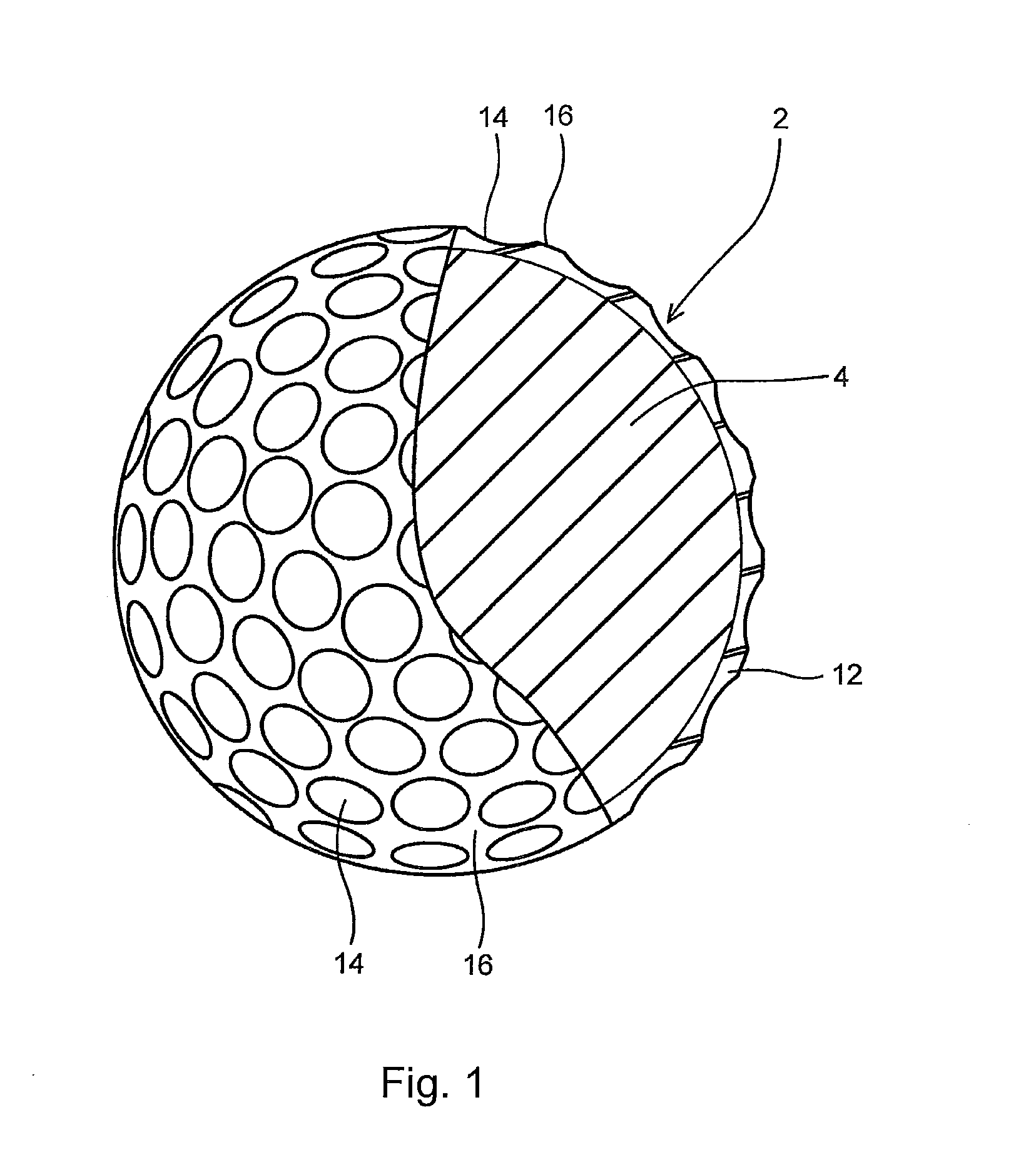

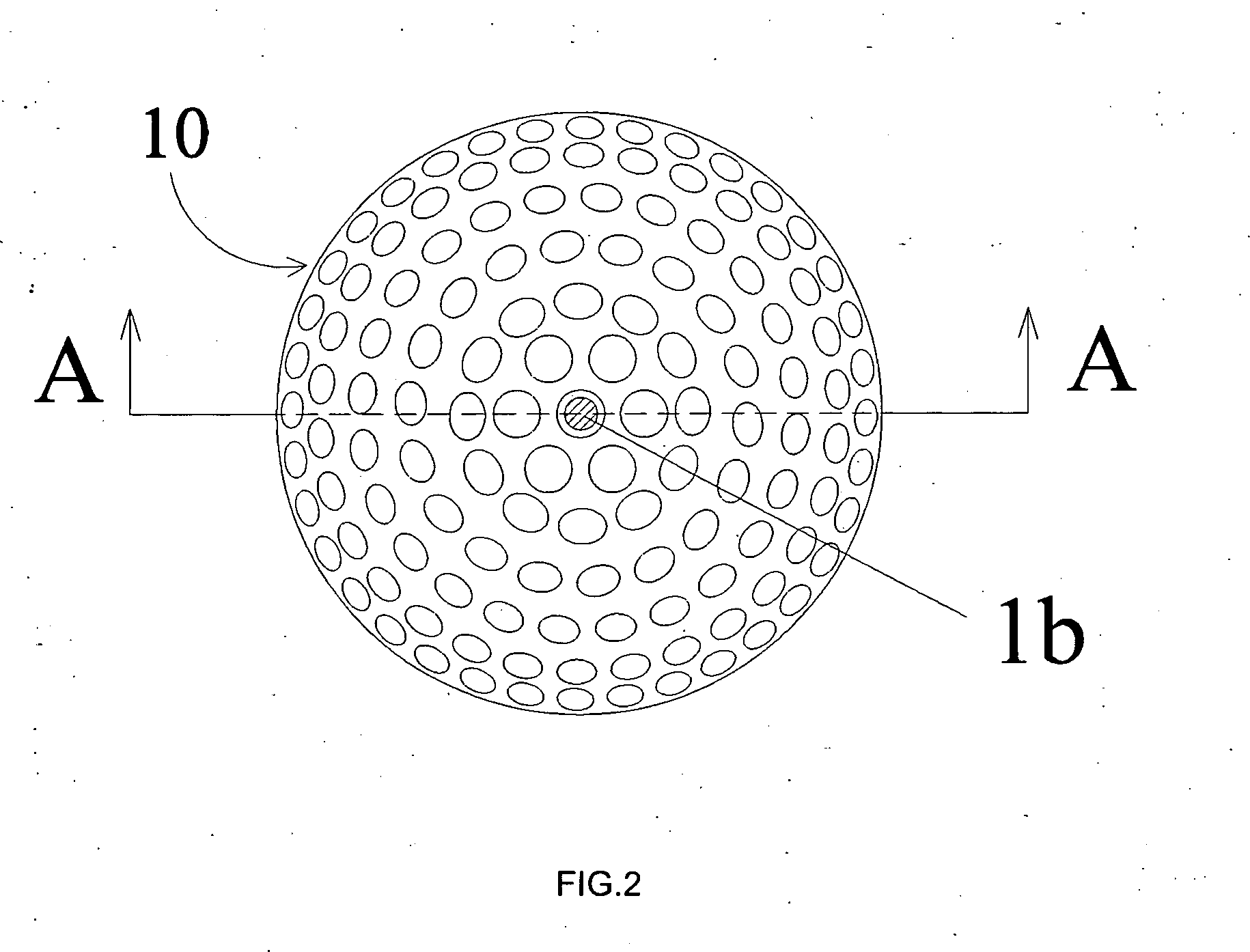

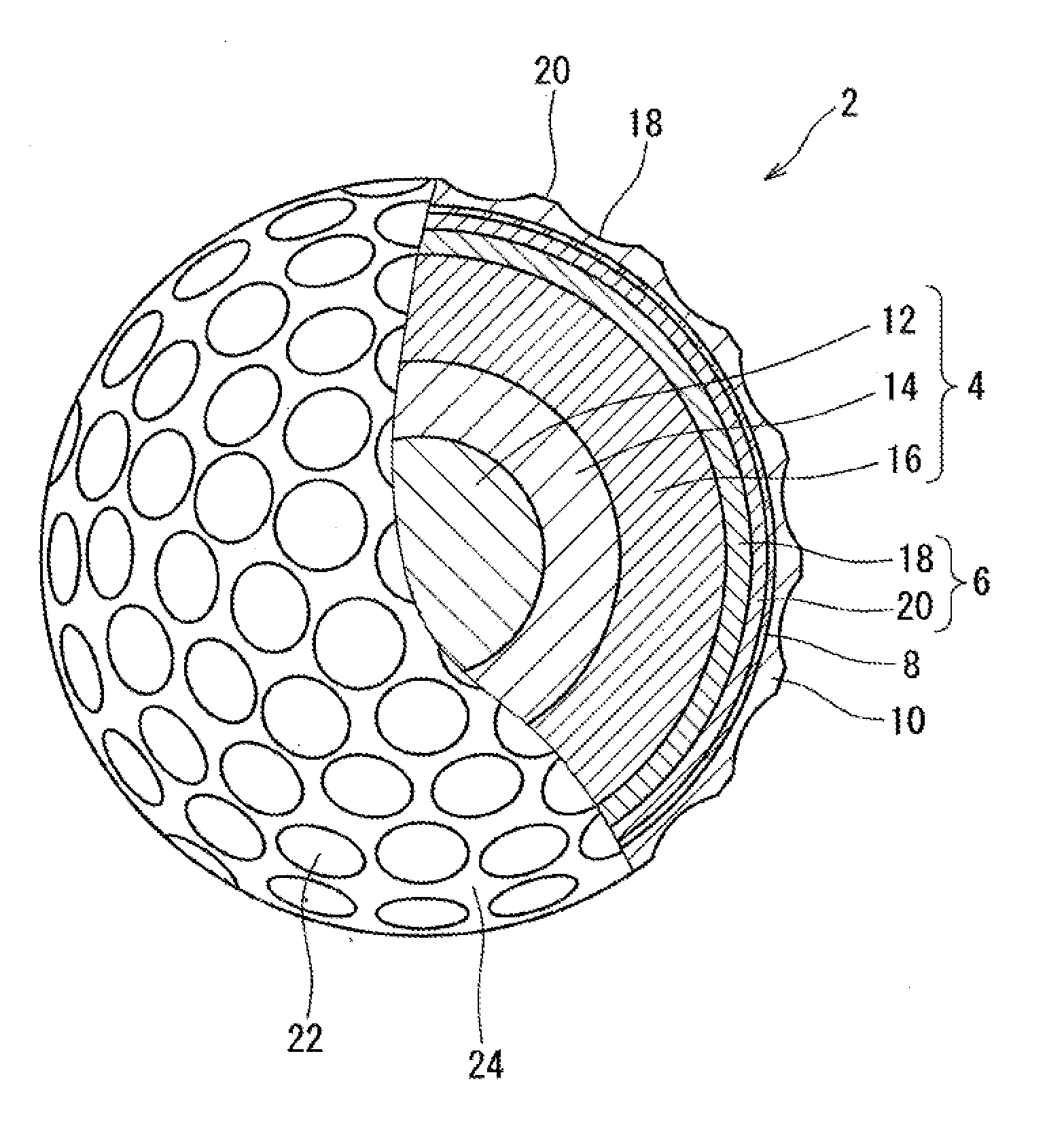

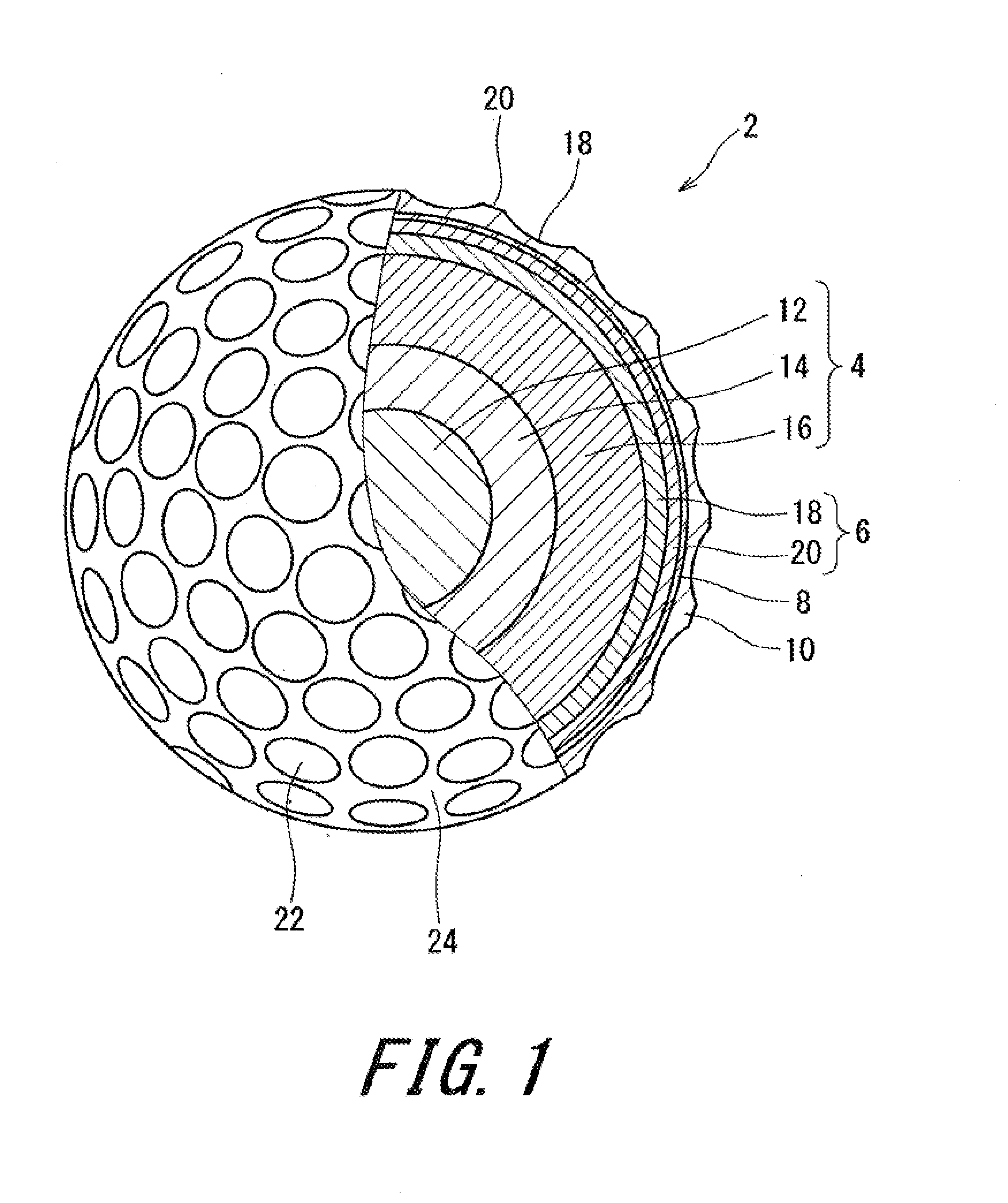

Golf ball

An object of the present invention is to provide a golf ball traveling a great flight distance on driver shots. The present invention provides a golf ball comprising a spherical core and at least one cover layer covering the spherical core, wherein the spherical core is formed from a rubber composition containing (a) base rubber, (b) an α,β-unsaturated carboxylic acid having 3 to 8 carbon atoms and / or a metal salt thereof as a co-crosslinking agent, (c) a crosslinking initiator, (d) a carboxylic acid having 1 to 14 carbon atoms and / or a salt thereof, and (e) a halogen-substituted thiophenol and / or a metal salt thereof as an organic sulfur compound, provided that the rubber composition further contains (f) a metal compound in the case of containing only (b) the α,β-unsaturated carboxylic acid having 3 to 8 carbon atoms as the co-crosslinking agent.

Owner:SUMITOMO RUBBER IND LTD

Golf ball-forming composition, golf balls prepared from the composition and the process for preparing thereof

InactiveUS20100248861A1Good water solubilityReduces ball speedHollow non-inflatable ballsHollow wall articlesCelluloseSubstance use

A golf ball-forming composition, golf balls prepared from the composition and the process for preparing thereof. The golf ball-forming composition is composed of the following: polyvinyl alcohol resin 5-80 wt %; filler 0-90 wt %, natural high polymer material 0-60 wt %, and plasticizer 5-50 wt %. The filler is the common filler known by the skilled person in the art; the natural high polymer material is celluloses or amyloses; the plasticizer is the common substances used by the skilled person in the art. The golf ball-forming composition is water soluble and biodegradable. The water soluble and biodegradable golf ball has a hollow inside, and has a surface which is disposed with at least one through hole communicated with the hollow. When the golf ball is hit into water, water will enter the hollow via the through hole, thereby increases the contact area between water and the ball and accelerates the dissolution of the ball, so that the ball may eventually completely biodegraded in the environment.

Owner:PROUDLY ECO FRIENDLY PRODS

Golf club

ActiveUS7686705B1Moment of inertia is maximally alteredLittle effectGolf clubsStringed racketsMoment of inertiaWeight management

An improved design for a golf club shaft and method increases stroke accuracy by significantly reducing stroke take-back distance. A ball traveling at a set initial velocity will travel a different distance on different parts of the course due to the friction of the grass on the ball which varies in response to height and moisture level. An inline weight management system that allows the moment of inertia of the club to be adjusted in a predictable manner. An increase in the moment of inertia translates into an increase in force which is in turn proportional to club velocity and resulting ball velocity. As green speed decreases, moment of inertia can be increased so that a stroke with a uniform take-back distance will deliver a shot that travels as far as the same stroke would deliver on a fast green.

Owner:FOLEY DENNIS L

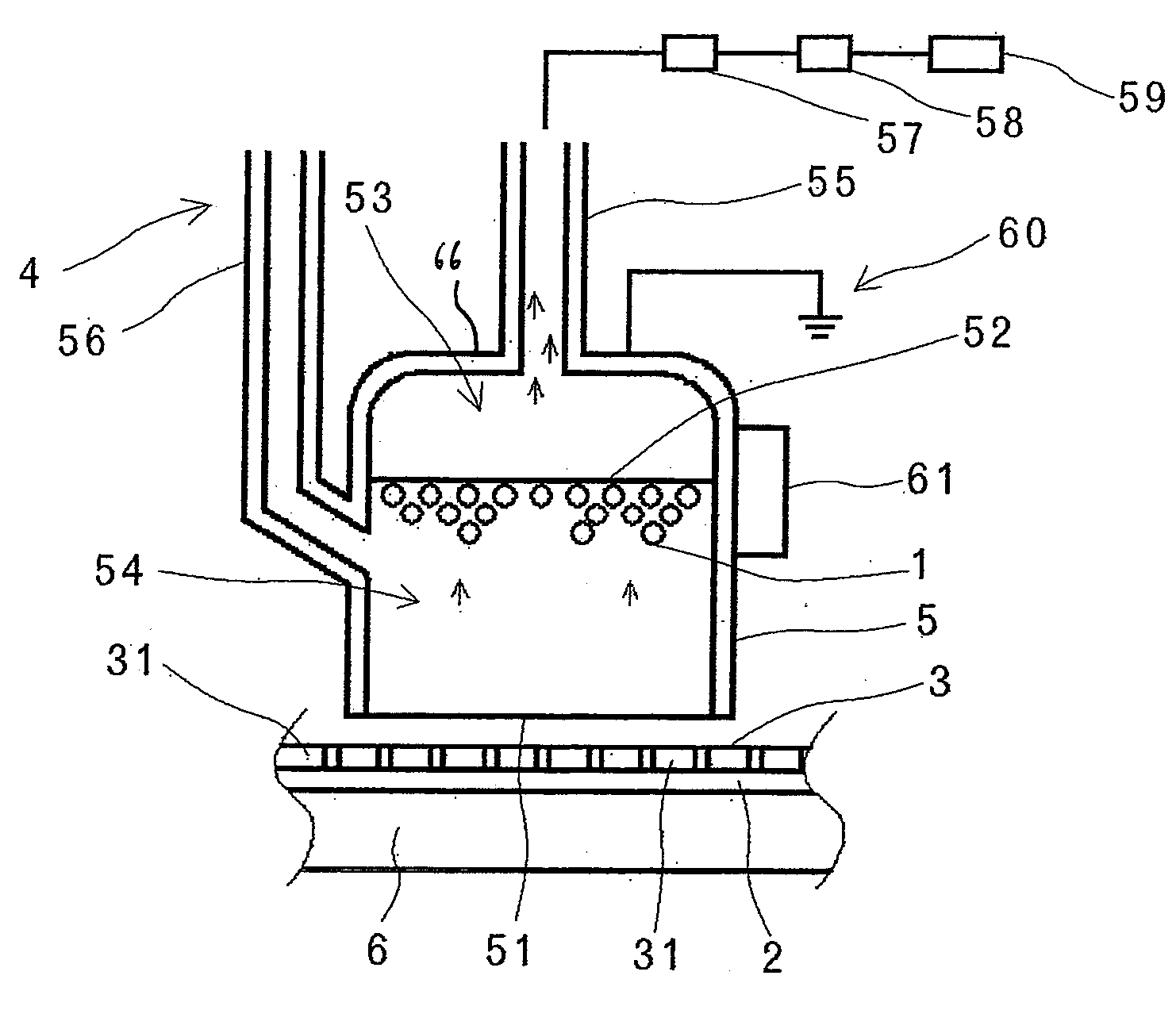

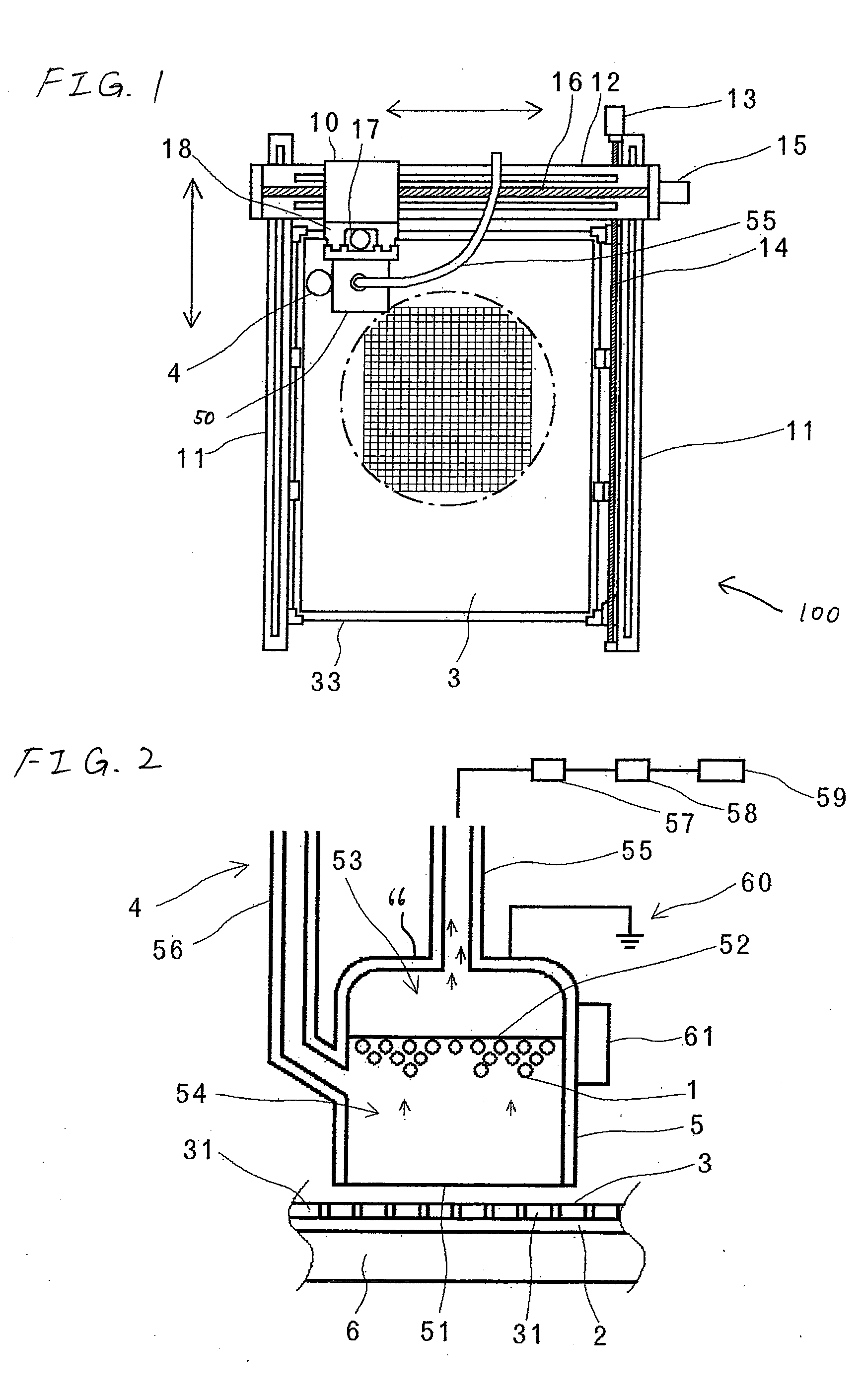

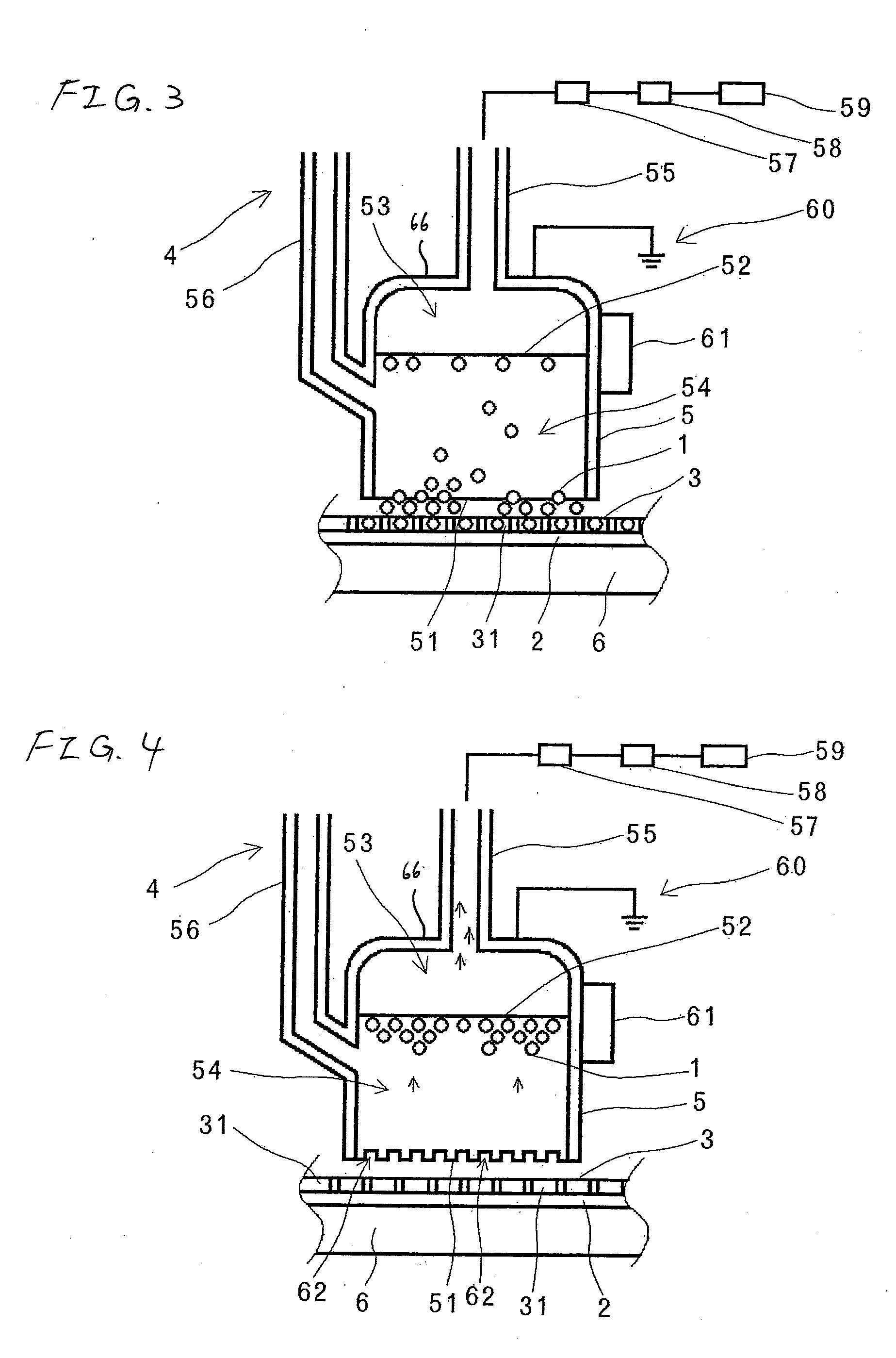

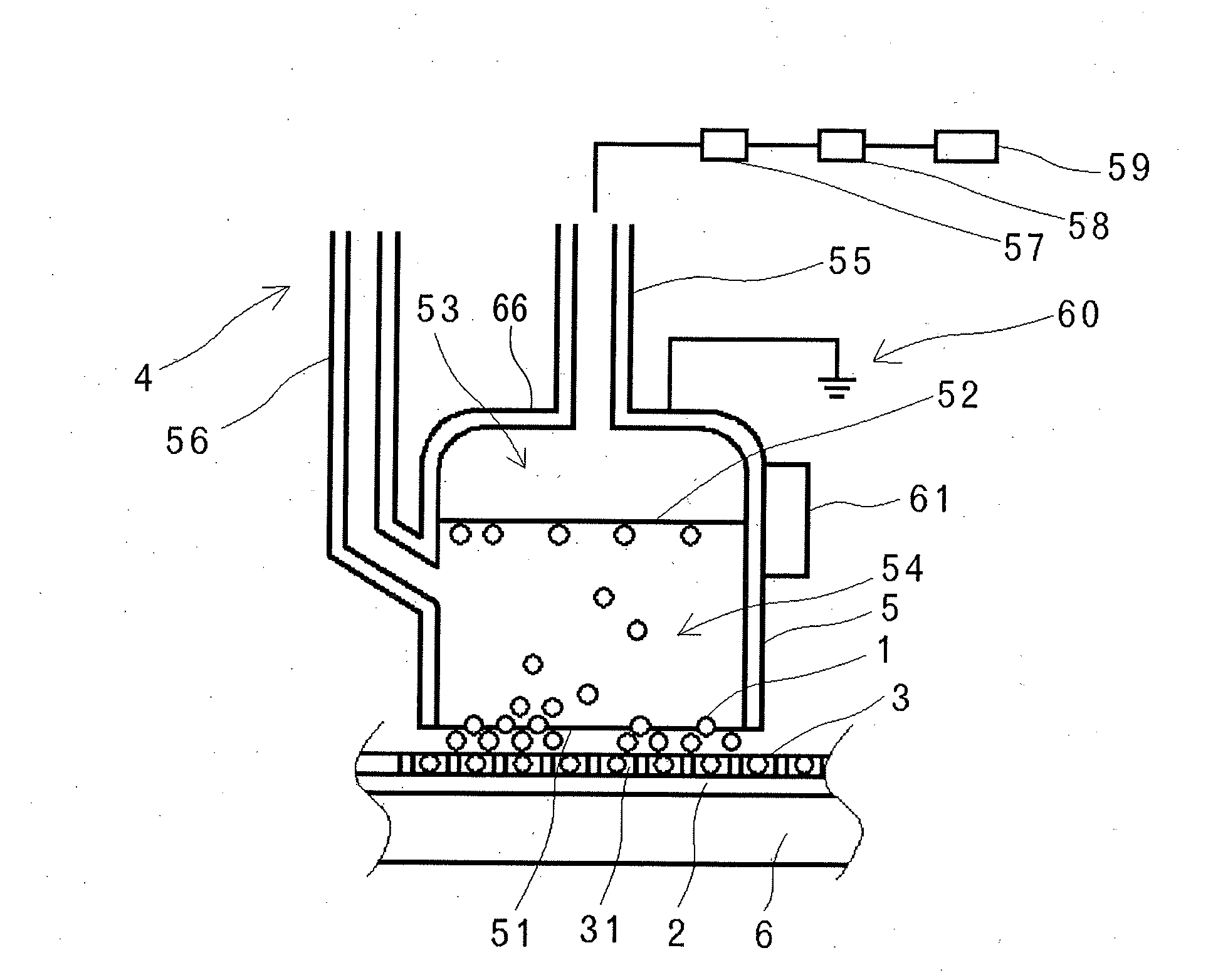

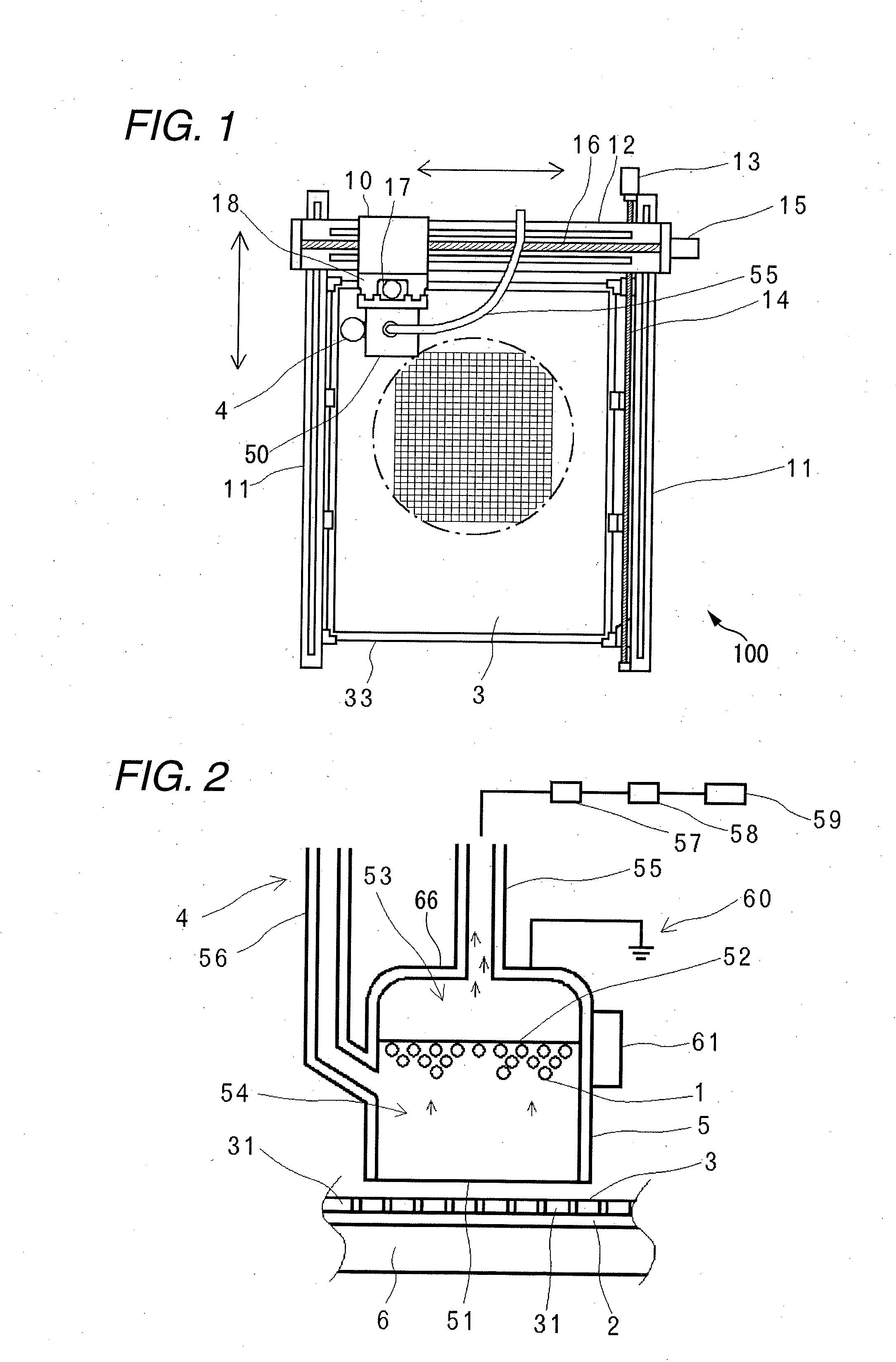

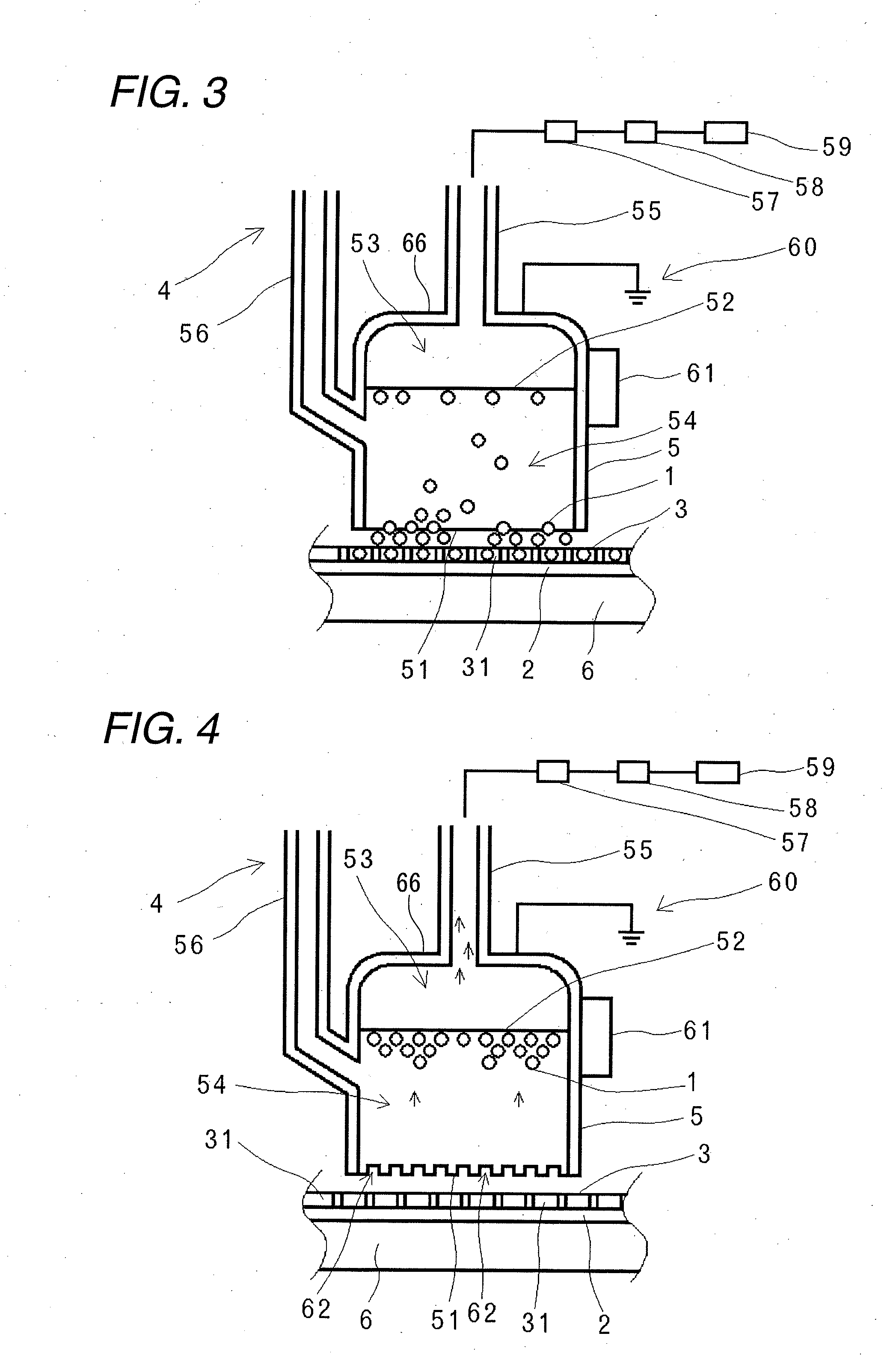

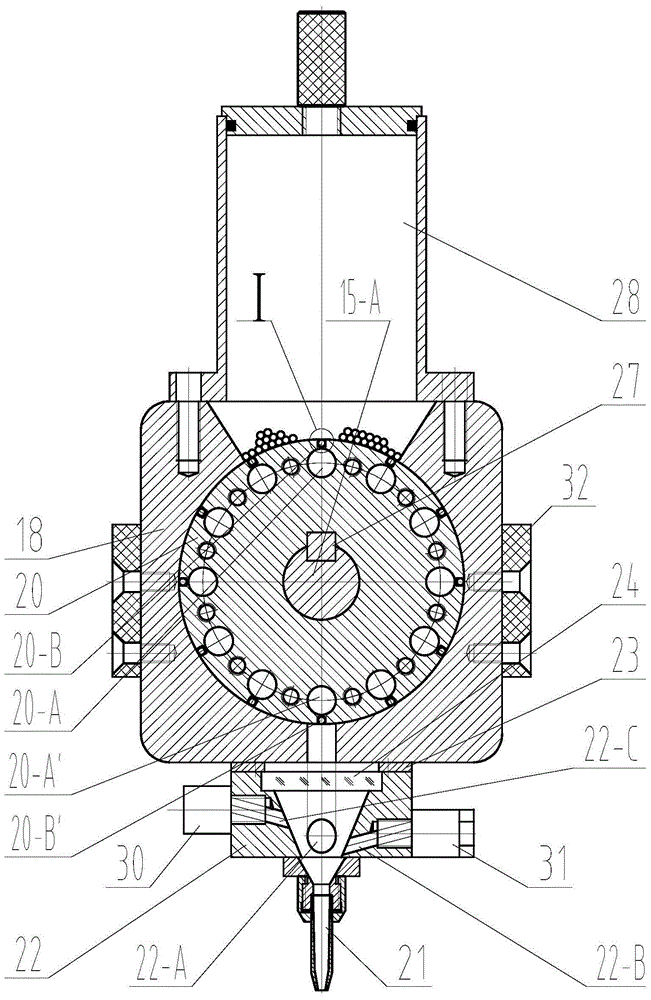

Method and apparatus for mounting conductive balls

InactiveUS20090307900A1Increase ball speedImprove productivityLine/current collector detailsSoldering apparatusSolder ballEngineering

A conductive ball mounting method for mounting conductive balls on a mount using an arraying mask, in which the mount includes mounting positions formed in a predetermined pattern, and the arraying mask is provided above the mount and includes through holes provided in positions corresponding to the mounting positions. The method includes providing a ball suction unit for sucking solder balls, the ball suction unit including a ball holding member capable of holding the conductive balls, sucking up the conductive balls below the ball suction unit, holding the conductive balls on a lower surface of the ball holding member while sucking up the conductive balls, and after the holding the conductive balls, falling the conductive balls held by the ball holding member to the mount.

Owner:SHIBUYA IND CO LTD

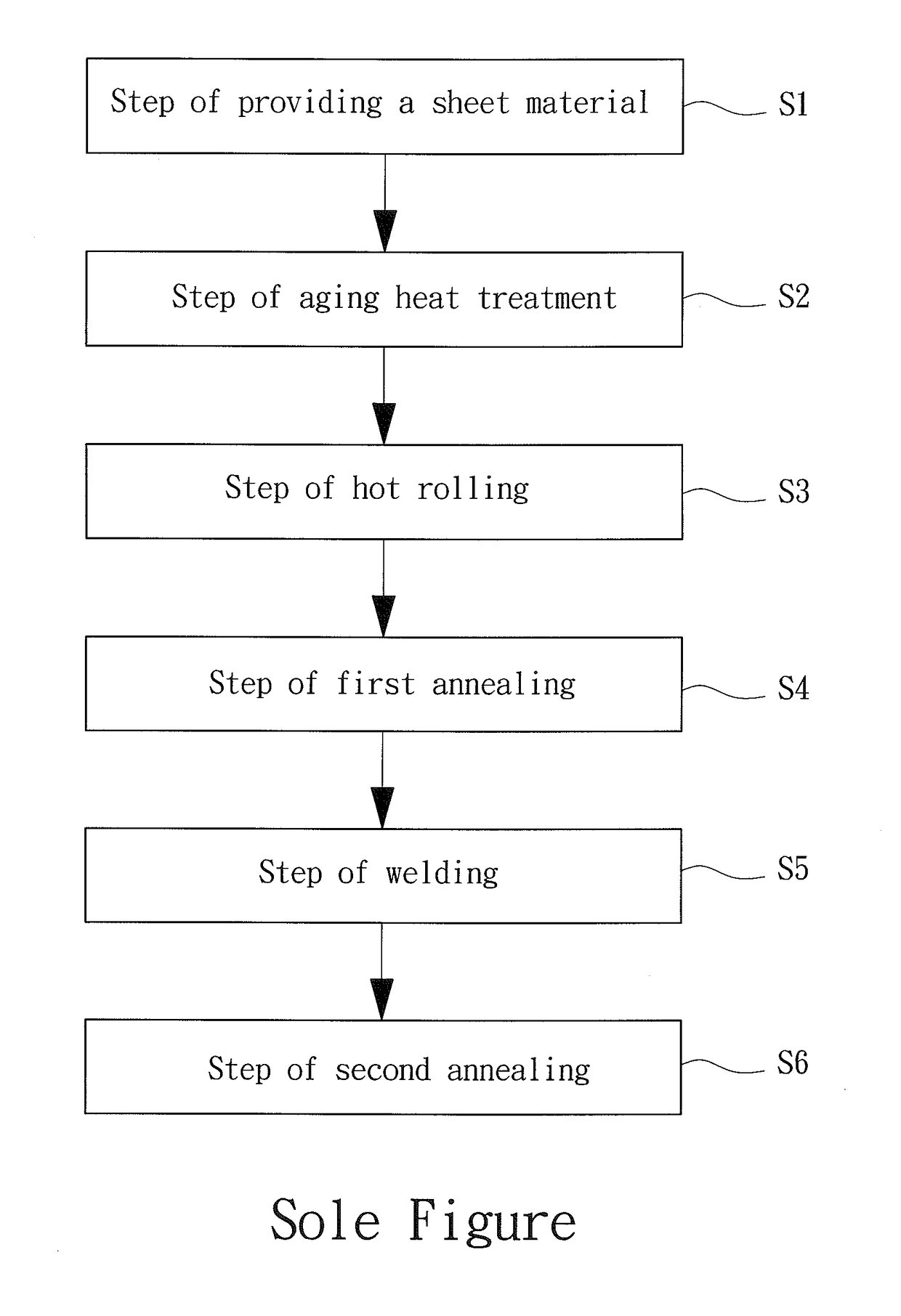

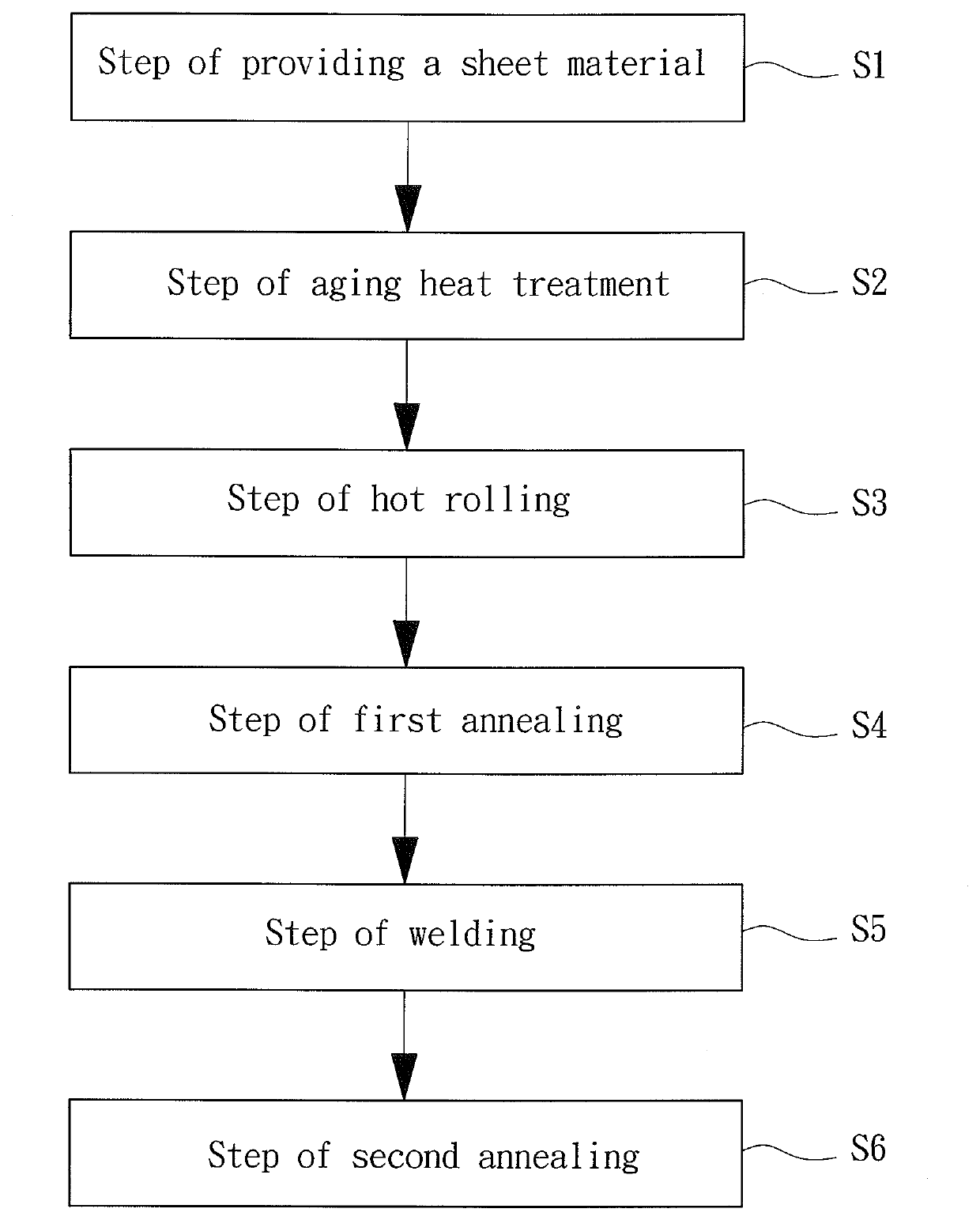

Method for Manufacturing a Golf Club Head

ActiveUS20180340247A1High Young 's modulusIncrease ball speedWelding/soldering/cutting articlesGolf clubsYoung's modulusTitanium alloy

A method for manufacturing a golf club head includes aging heat treat a sheet material made of a titanium alloy at 650-750° C. for 10-12 hours to obtain an aging heat treated sheet material. The aging heat treated sheet material is hot rolled to form a striking plate. The striking plate is annealed at 700-800° C. for 30-60 minutes to obtain an annealed striking plate. The annealed striking plate is welded to a club head body made of the titanium alloy to form a semi product. The semi product of the golf head is annealed at 500-700° C. for 30-240 minutes to obtain the golf club head. Thus, the golf club head with a Young's modulus higher than 119 GPa can be manufactured.

Owner:FUSHENG PRECISION

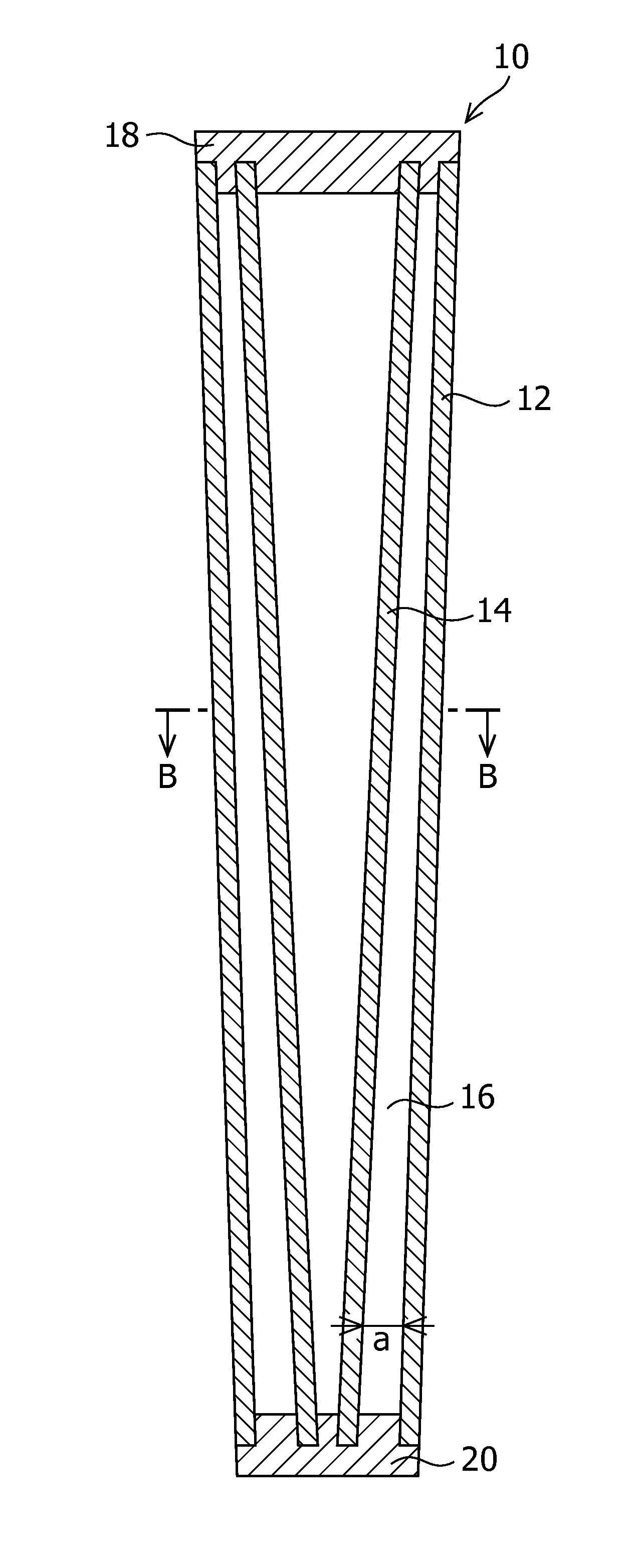

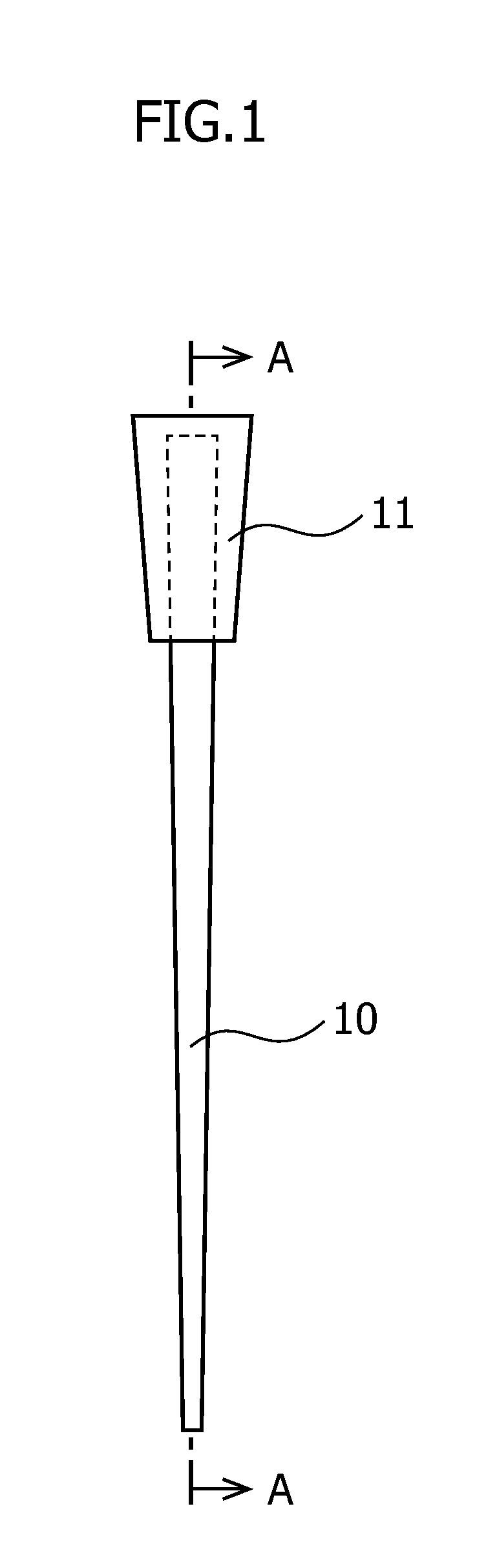

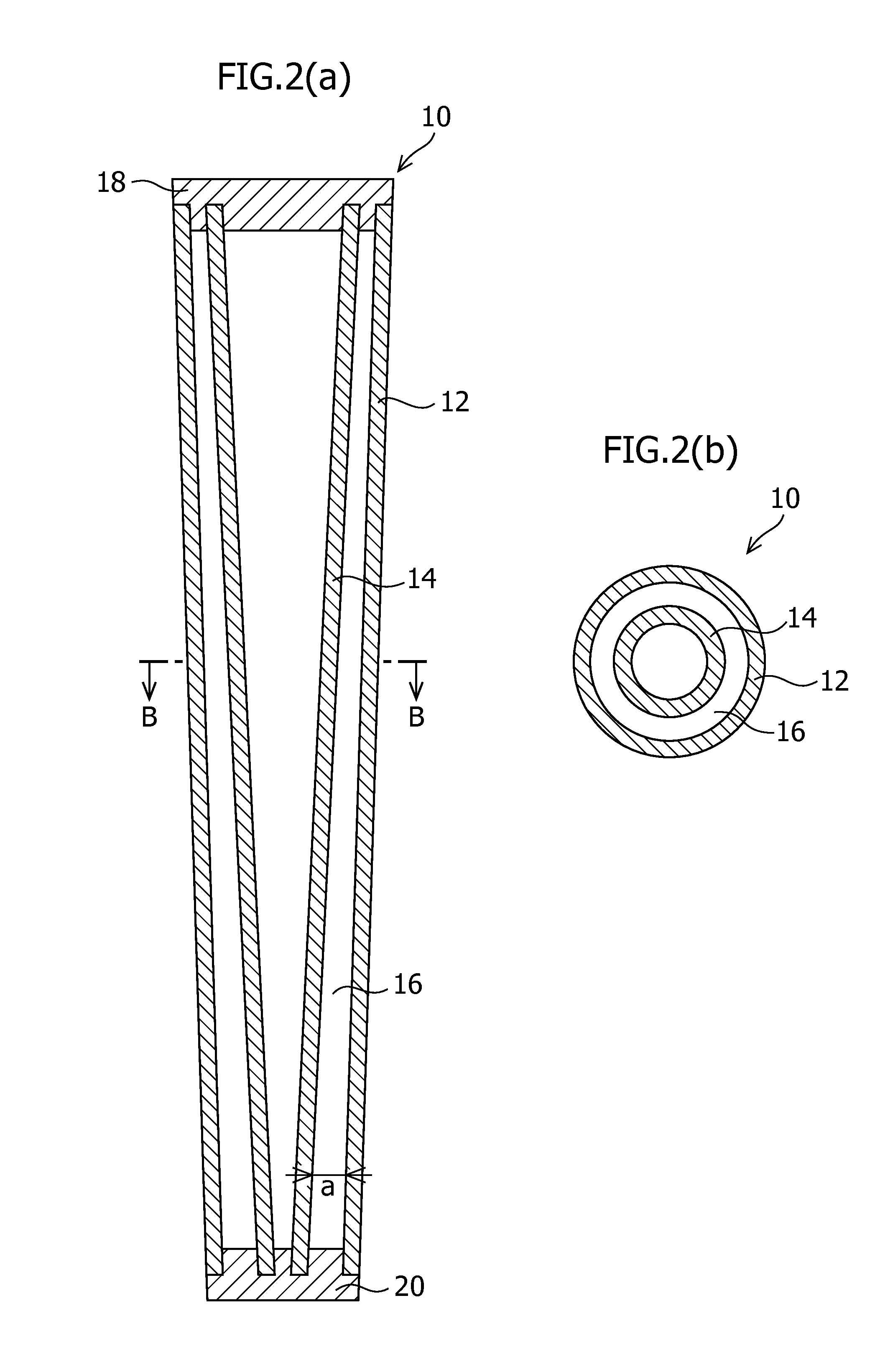

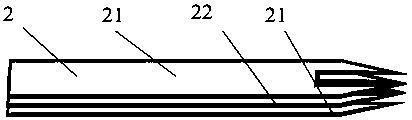

Golf club shaft and golf club

InactiveUS20110172025A1Extended driving distanceIncrease ball speedGolf clubsRacket sportsEngineeringGolf Ball

A golf club shaft includes an outer shaft and an inner shaft disposed in a hollow portion of the outer shaft. A void portion is formed between the outer shaft and the inner shaft. The golf club shaft has a double structure including the outer shaft and the inner shaft. This allows both of the shafts to integrally operate and also allows one of the shafts to primarily operate.

Owner:BRIDGESTONE SPORTS

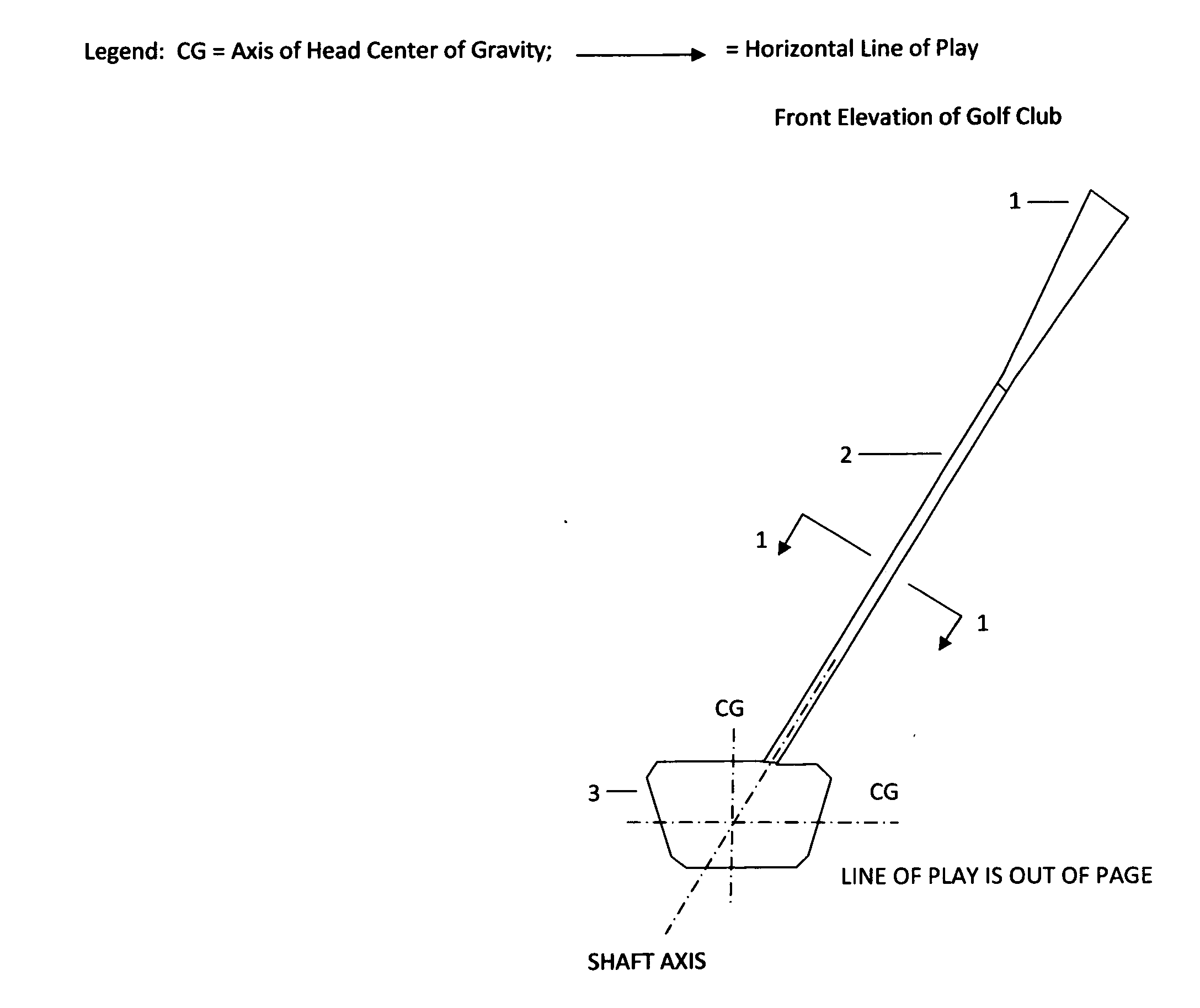

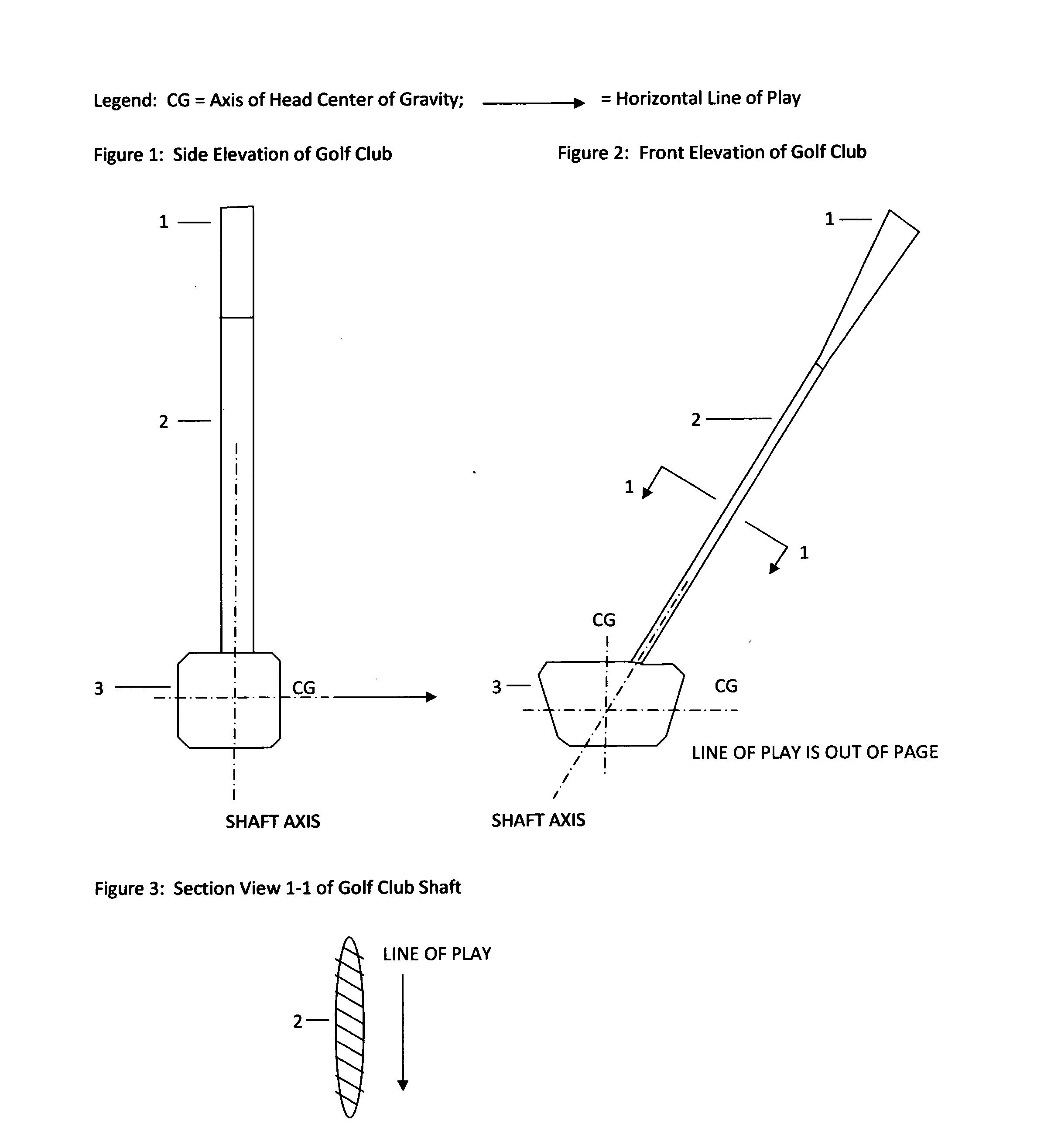

Aerodynamic balanced wood form and/or iron form golf club

InactiveUS20120015756A1Reduce widthLess aerodynamic dragGolf clubsRacket sportsHigh momentumMomentum transfer

The wood or iron golf club has a reduced shaft width transverse to the direction of motion and a greater shaft depth parallel to the direction of motion, therefore, has a reduced frontal area that creates less aerodynamic drag and a higher resistance to bending opposite the direction of motion, respectively. The low drag rigid shaft allows higher head velocity, higher momentum transfer to the ball, higher ball velocity, and longer more accurate drives then current clubs with elongated cone shaped symmetrical shafts.The wood or iron gulf club shaft-head configuration has the shaft axis intersecting the common axis of the horizontal component of the line of play and the head center of gravity. The club therefore does not create a torque about the shaft axis during the swing motion or ball impact and facilitates greater accuracy and consistency in hitting the optimum point on the ball with the optimum point on the club head.

Owner:MELLON MILTON THOMAS

Method and apparatus for mounting conductive balls

ActiveUS20130098975A1Increase movement speedImprove productivitySoldering apparatusSemiconductor/solid-state device manufacturingSolder ballEngineering

A conductive ball mounting method for mounting conductive balls on a mount using an arraying mask, in which the mount includes mounting positions formed in a predetermined pattern, and the arraying mask is provided above the mount and includes through holes provided in positions corresponding to the mounting positions. The method includes providing a ball suction unit for sucking solder balls, the ball suction unit including a ball holding member capable of holding the conductive balls, sucking up the conductive balls below the ball suction unit, holding the conductive balls on a lower surface of the ball holding member while sucking up the conductive balls, and after the holding the conductive balls, falling the conductive balls held by the ball holding member to the mount.

Owner:SHIBUYA IND CO LTD

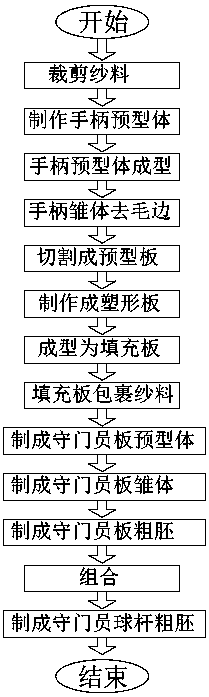

Novel hockey stick of hockey goalkeeper and manufacturing method of novel hockey stick

ActiveCN106390402AImprove shock absorptionImprove durabilityWood working apparatusRacket sportsFiberEpoxy

The invention relates to the technical field of sports goods and manufacturing thereof and particularly relates to a novel hockey stick of a hockey goalkeeper. The novel hockey stick comprises a front-section filling plate, a middle-section filling plate, a bolt filling block and a handle; a plurality of layers of glass fiber yarns or carbon fiber yarns cover the outer part of the connected front-section filling plate, middle-section filling plate, bolt filling block to form a goalkeeping plate, wherein the middle-section filling plate is formed by compounding three layers of materials including EPOXY, balsa wood and EPOXY in sequence; and the bolt filling block in the goalkeeping plate is inserted into the handle and the bolt filling block is fixedly connected with the handle. A manufacturing method of the novel hockey stick of the hockey goalkeeper comprises the following steps: manufacturing the front-section filling plate, the middle-section filling plate and the bolt filling block, and connecting the goalkeeping plate with the handle. The novel hockey stick of the hockey goalkeeper and the manufacturing method of the novel hockey stick, provided by the invention, have the beneficial effects that (1) the flexibility of kicking is increased; (2) the hockey control speed is improved; (3) the vibration resistance is improved; (4) the bounce of the goalkeeping plate is increased; (5) the goalkeeping plate is not easy to break, bend and deform when receiving a certain impact force; and (6) the service life is long.

Owner:TONGXIANG BONNY SCI & TECH COMPOSITE

Method for manufacturing a golf club head

ActiveUS10781511B2High Young 's modulusIncrease ball speedWelding/soldering/cutting articlesGolf clubsYoung's modulusTitanium alloy

A method for manufacturing a golf club head includes aging heat treat a sheet material made of a titanium alloy at 650-750° C. for 10-12 hours to obtain an aging heat treated sheet material. The aging heat treated sheet material is hot rolled to form a striking plate. The striking plate is annealed at 700-800° C. for 30-60 minutes to obtain an annealed striking plate. The annealed striking plate is welded to a club head body made of the titanium alloy to form a semi product. The semi product of the golf head is annealed at 500-700° C. for 30-240 minutes to obtain the golf club head. Thus, the golf club head with a Young's modulus higher than 119 GPa can be manufactured.

Owner:FUSHENG PRECISION

Novel hockey goaltender stick and method of making the same

ActiveCN106390402BImprove shock absorptionImprove durabilityWood working apparatusRacket sportsEpoxyYarn

The invention relates to the technical field of sports goods and manufacturing thereof and particularly relates to a novel hockey stick of a hockey goalkeeper. The novel hockey stick comprises a front-section filling plate, a middle-section filling plate, a bolt filling block and a handle; a plurality of layers of glass fiber yarns or carbon fiber yarns cover the outer part of the connected front-section filling plate, middle-section filling plate, bolt filling block to form a goalkeeping plate, wherein the middle-section filling plate is formed by compounding three layers of materials including EPOXY, balsa wood and EPOXY in sequence; and the bolt filling block in the goalkeeping plate is inserted into the handle and the bolt filling block is fixedly connected with the handle. A manufacturing method of the novel hockey stick of the hockey goalkeeper comprises the following steps: manufacturing the front-section filling plate, the middle-section filling plate and the bolt filling block, and connecting the goalkeeping plate with the handle. The novel hockey stick of the hockey goalkeeper and the manufacturing method of the novel hockey stick, provided by the invention, have the beneficial effects that (1) the flexibility of kicking is increased; (2) the hockey control speed is improved; (3) the vibration resistance is improved; (4) the bounce of the goalkeeping plate is increased; (5) the goalkeeping plate is not easy to break, bend and deform when receiving a certain impact force; and (6) the service life is long.

Owner:TONGXIANG BONNY SCI & TECH COMPOSITE

Hockey goalie club and manufacturing method thereof

The invention relates to the technical field of sports goods manufacturing, in particular to a hockey goalie club. The hockey goalie club comprises a handle and a goalie plate; the goalie plate consists of a front section part and a middle section part; a manufacturing method of the hockey goalie club comprises the following steps: (1) cutting a yarn material; (2) manufacturing a handle preform; (3) moulding the handle preform; (4) performing deburring on a handle green body; (5) cutting the handle green body into a preform plate; (6) manufacturing the preform plate into a shaping plate; (7) moulding the shaping plate into a filling plate; (8) wrapping the filling plate with the yarn material; (9) manufacturing into a goalie preform; (10) manufacturing a goalie plate green body; (11) manufacturing a goalie plate coarse blank; (12) combining; (13) manufacturing a goalie club coarse blank. The hockey goalie club has the beneficial effects that: (1) the weight is reduced; (2) the manufacturing cost of a material is reduced; (3) the batting flexibility is improved; (4) the ball control speed is increased; (5) the rebound force is higher.

Owner:TONGXIANG BONNY SCI & TECH COMPOSITE

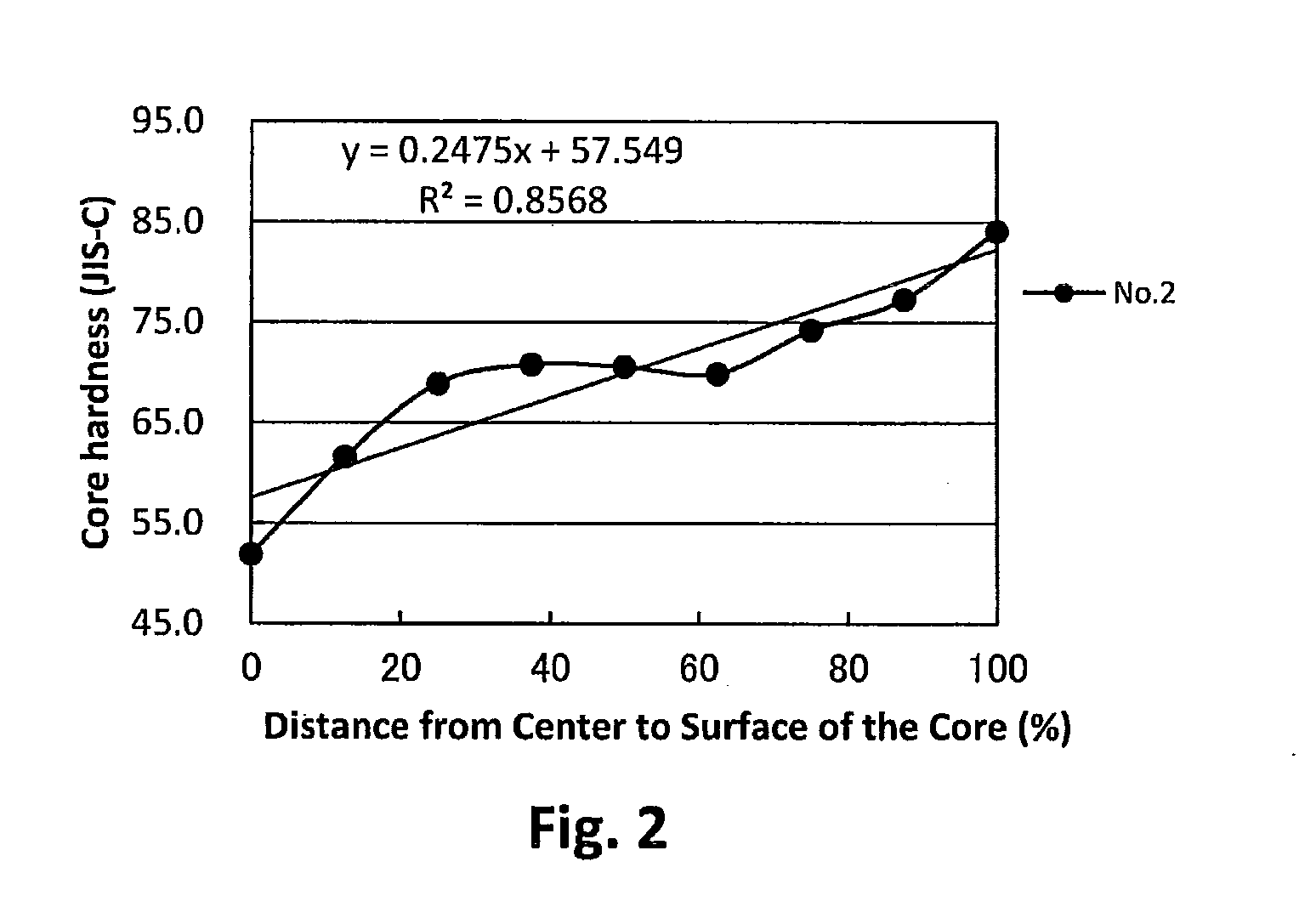

Golf ball

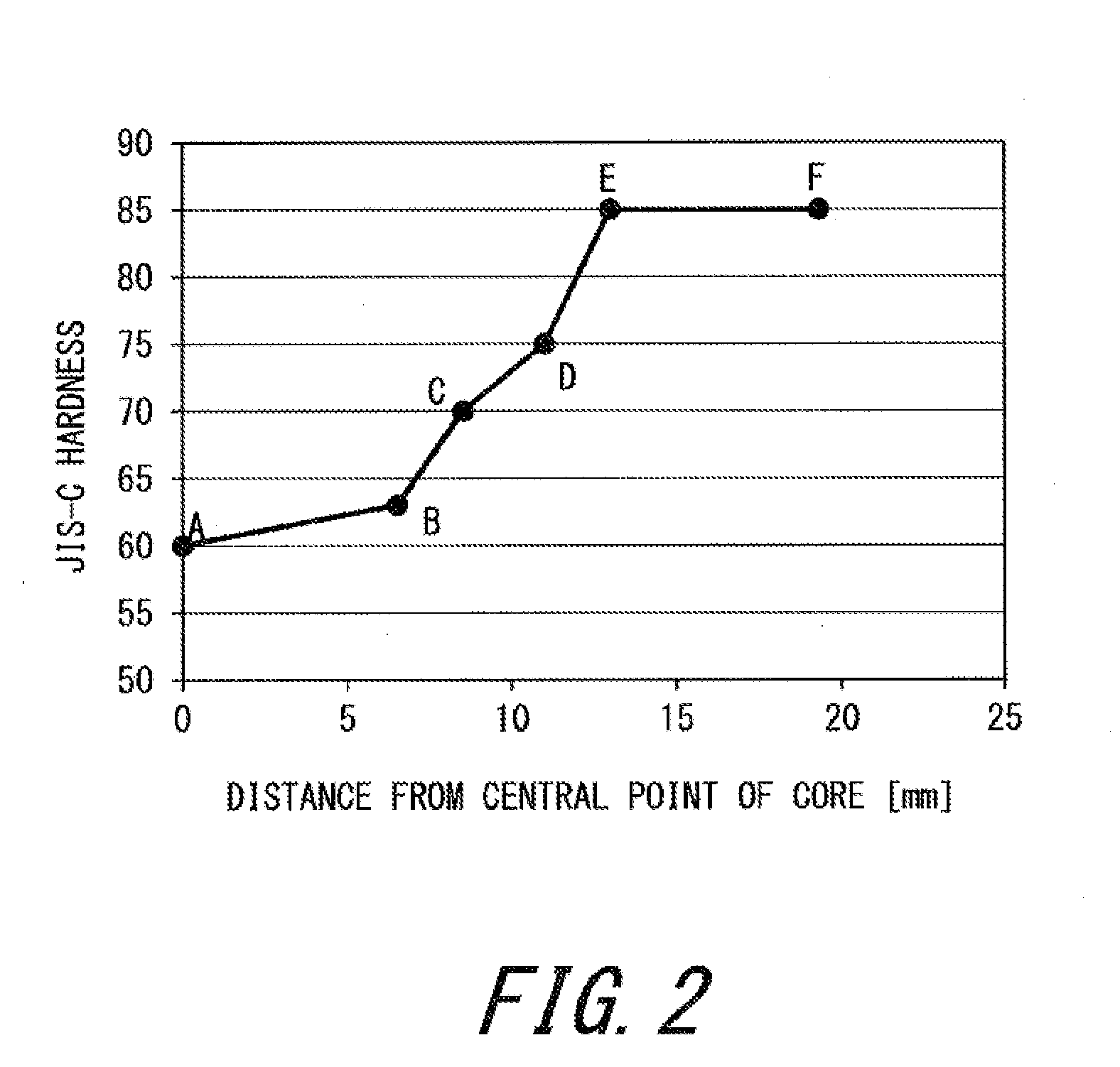

A golf ball includes a core, a mid layer, and a cover. The core includes an inner core, a mid core, and an outer core. The mid layer includes an inner mid layer and an outer mid layer. A hardness H(C) is equal to or greater than a hardness H(B). A hardness H(E) is equal to or greater than a hardness H(D). An angle α is calculated by (Formula 1). An angle β is calculated by (Formula 2). The angle α is 0° or greater. A difference (α−β) is 0° or greater. A hardness Hm2 of the outer mid layer is less than a hardness Hm1 of the inner mid layer. A hardness Hc of the cover is less than the hardness Hm2.α=(180° / π)*a tan [{H(D)−H(C)} / Y] (Formula 1)β=(180° / π)*a tan [{H(F)−H(E)} / Z] (Formula 2)

Owner:SUMITOMO RUBBER IND LTD

Golf club head with variable flexural stiffness for controlled ball flight and trajectory

InactiveUS20050101409A1Increase ball speedAnalysing solids using sonic/ultrasonic/infrasonic wavesGolf clubsControl zoneEngineering

The present invention relates to a golf club head with a hitting face. The hitting face comprises a directional control portion, which has at least two zones with different flexural stiffness, such that when the hitting face strikes a golf ball the two zones deform differently to selectively control the direction of the flight of the golf ball. The directional control portion may comprise an upper zone and a lower zone, where the upper zone has a lower flexural stiffness. Alternatively, the lower zone has a lower flexural stiffness. On the other hand, the directional control portion may comprise a left zone and a right zone, and either the left or right zone may have a lower flexural stiffness to selectively control the lateral launch angle either to the left of right. The hitting face may further comprise a central zone disposed within the directional control zone, wherein the central zone has a flexural stiffness of at least about three times greater than the flexural stiffness of the directional control zone.

Owner:ACUSHNET CO

Bowling game apparatus

A bowling game apparatus that combines some of the features of Bowling, Miniature Golf and Pinball concepts into an integrated game of skill and chance that can be played indoors. The game apparatus is played on lanes such that each lane is distinctly different such as Miniature Golf holes wherein ten lanes are played sequentially, as Miniature Golf, such that each lane comprises a frame and the ten played lanes comprises a single game or string. The game apparatus is scored the same as Candlepin and Duckpin bowling. Each unique lane is not like a bowling alley but can be free formed in different shapes, lengths and proximity to one another as found in Miniature Golf. The game apparatus can be installed in a center where more than one 10 lane set can be located. In addition, the each ten lanes of the apparatus can be set up in the same or differing themes such as pirates, jungle, western, etc. The bowling game apparatus can be accomplished without the need for expensive wooden or synthetic lanes that must be critically leveled and assiduously maintained. Further, there is no need for special shoes for the players to prevent damage to the playing surfaces. Other features found in Miniature Golf and Pinball machines make the game more fun, faster and exciting. The game can be challenging for adults but permits children to compete on a equal footing with adults; and gives the players the feeling that they playing a bowling type of game while standing inside a Pinball machine.

Owner:MACHARDY SCOTT

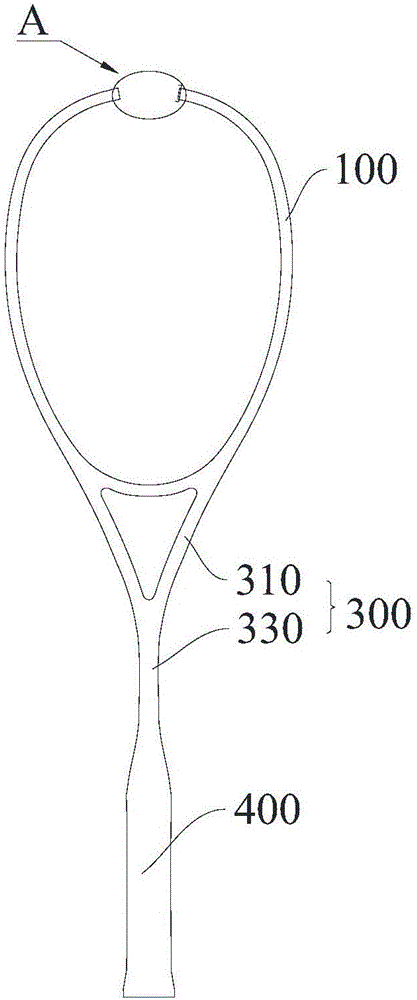

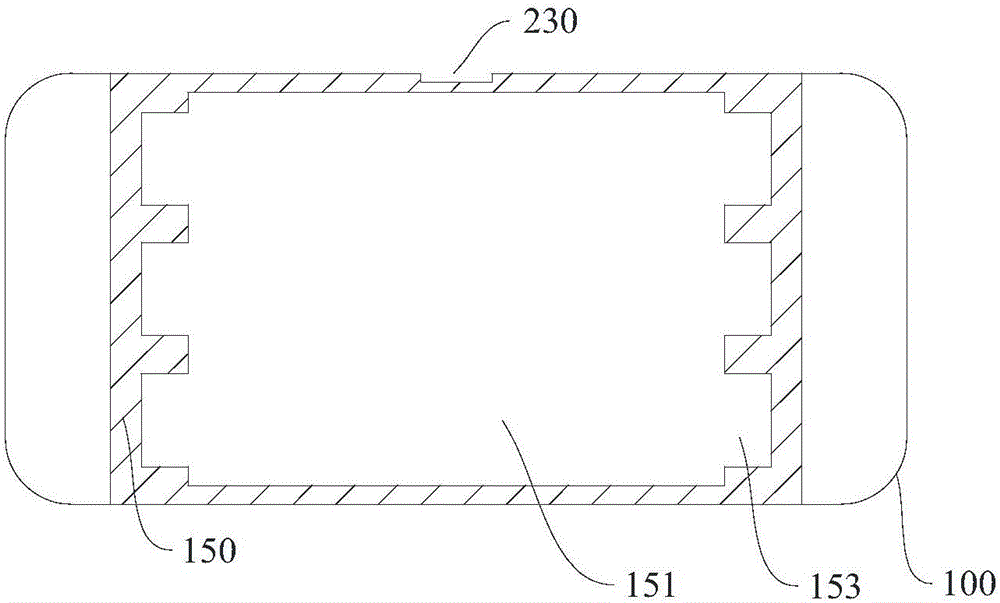

Tennis racket frame and tennis racket

The invention provides a tennis racket frame and a tennis racket, and belongs to the field of tennis appliances. The tennis racket frame comprises a racket body and a rebound block, the racket body comprises a racket head body, a racket throat and a racket handle, the rebound block is arranged at the top end of the racket head body and can flexibly move towards two surfaces of the racket head body, and a weighting block is arranged on the rebound block. The sweet spot area of the tennis racket frame can be enlarged by the aid of the rebound block, the return strength of the sweet spot area is enhanced, and the impact force of a tennis ball contacting with the sweet spot area is buffered. The tennis racket comprises the tennis racket frame and tennis racket lines. The tennis racket lines are mounted on the tennis racket frame to form a racket face, the return strength can be enhanced by hitting the ball through the racket face, and the impact force of the tennis ball contacting with the sweet spot area can be buffered.

Owner:YANCHENG INST OF TECH

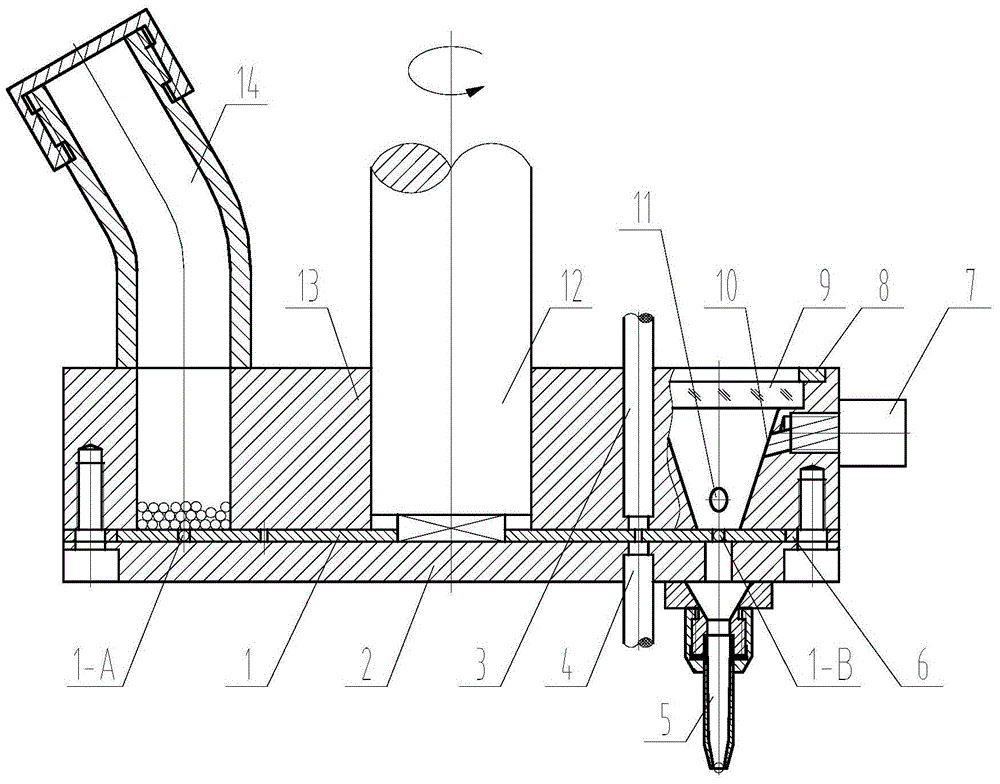

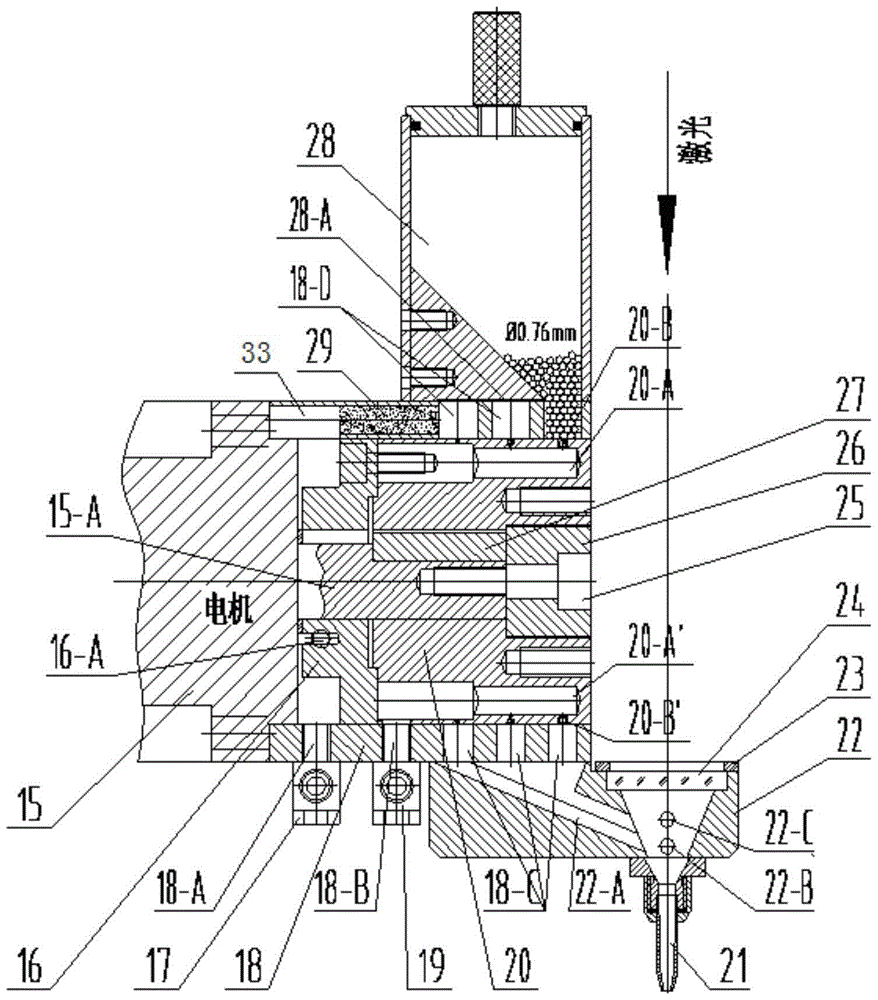

A solder ball pump head for laser soldering

ActiveCN105108264BReduce manufacturing costIncrease manufacturing costSolder feeding devicesLongitudinal planeSpray nozzle

Owner:WUHAN LINGYUN PHOTOELECTRONICS SYST

Hollow and smooth titanium-mass forging golf iron head

PendingCN108553852AImprove stabilityIncrease ball speedGolf clubsRacket sportsGravity centerTitanium

The invention relates to a hollow and smooth titanium-mass forging golf iron head. The golf iron head is provided with a striking face body, an upper cover body, a head and a weight block which are directly contacted with the golf. One side of the contact with the golf at the time of striking the golf is defined as the front, the ground is below, and the density of the weight block is greater thanthe density of the face body or the upper cover body. The upper cover body and the weight block are arranged up and down and are welded seamlessly, the head is firstly welded on the striking surfacebody. The welded upper cover body and the weight block are integrally connected with the striking face body, the head seamless welding, the weight block, the upper cover body, the head and the striking face body form a closed body. The golf iron head can adjust the center of gravity of the whole ball head with the weight block to be downward and backward, and then the center of gravity is more stable, so that the stability, the ball speed and the accuracy of the flying of the Golf body can be improved. At the same time, the cavity inside the golf iron head can generate a large sound to improvethe user's experience feeling when the ball is hit. The face body, the upper cover body and the head body is made of an effectively anti-corrosive titanium alloy material.

Owner:郭松

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com