Method and apparatus for mounting conductive balls

a technology of conductive balls and mounting methods, which is applied in the direction of soldering apparatus, manufacturing tools, non-printed masks, etc., can solve the problems of long time period needed for the mounting process, the speed of the ball cup cannot be increased to high speed, and the conductive balls leak from the gap between the ball cup and the arraying mask, so as to increase the speed of the ball suction body and the ball cup. , the effect of increasing the productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

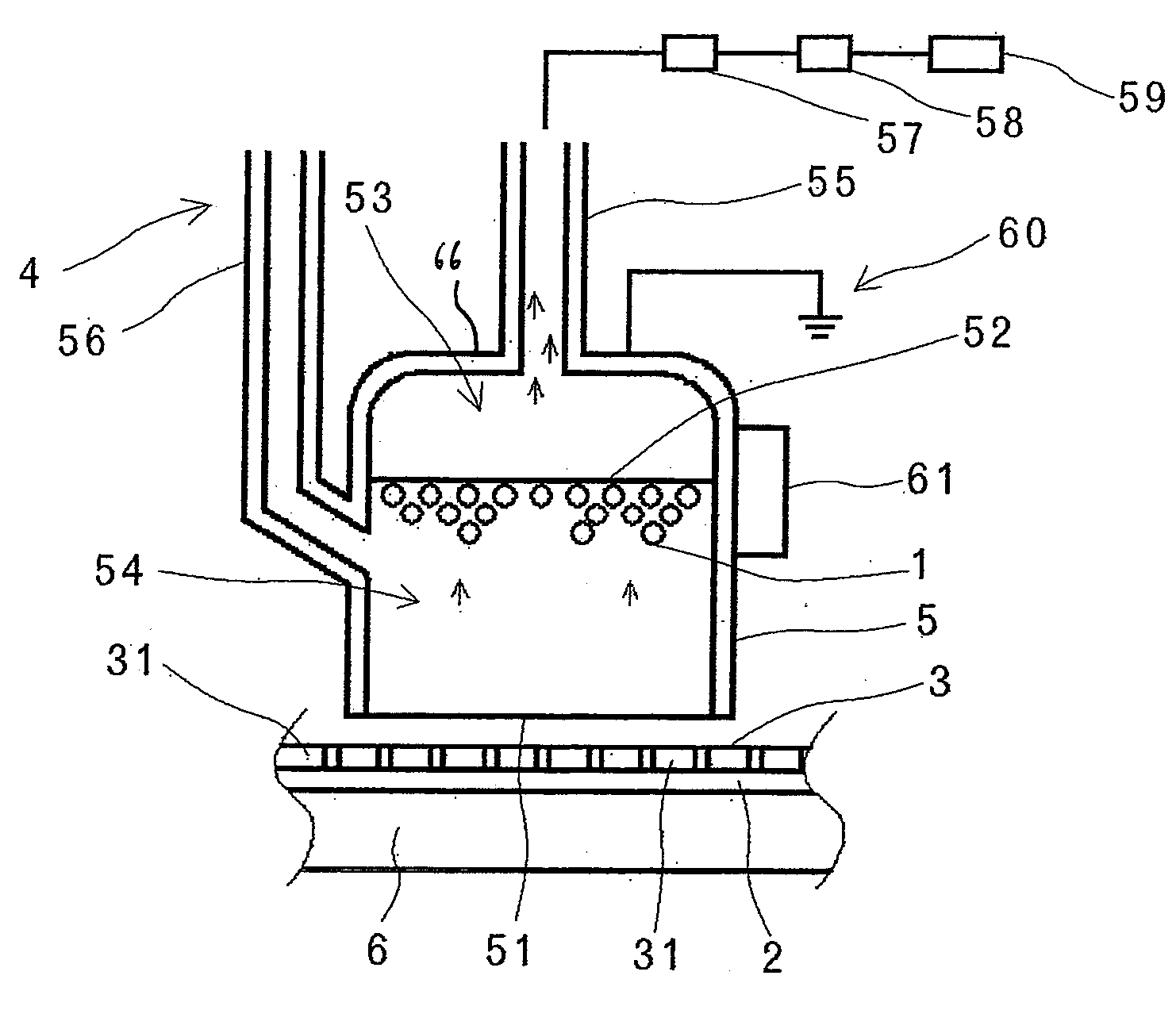

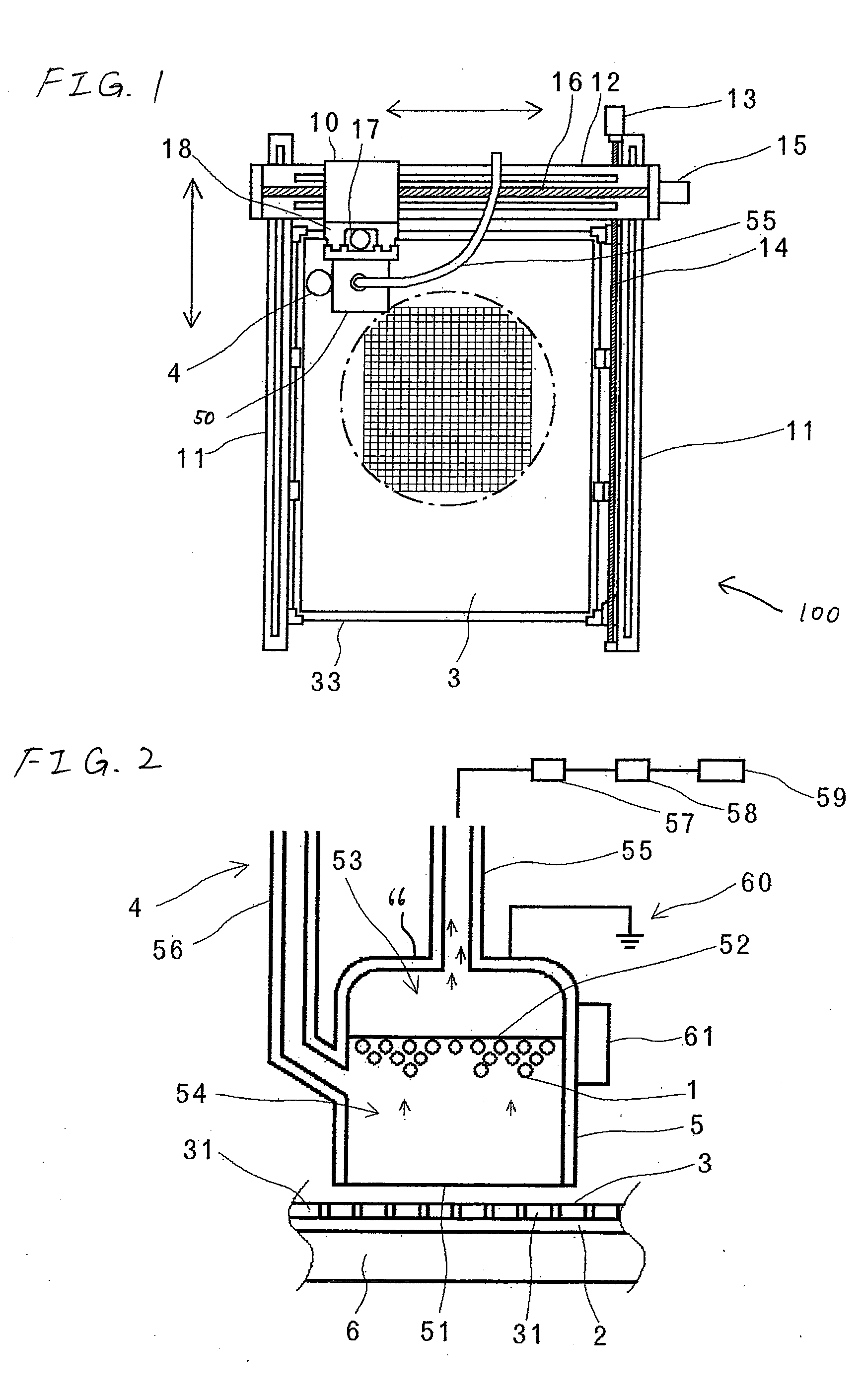

[0044]A first embodiment of the invention will be explained with reference to FIG. 2. As shown in FIG. 2, the ball cup 5 has interior space and is opened in a lower end face so as to define an opening 51, and the interior space is partitioned into an upper space 53 and a lower space 54 by a ball suction element 52 as an example of a ball holding member. Thus, an upper portion of the ball cup 5 which lies further upwards than the ball suction element 52 constitutes a casing 66 for the ball suction element 52. In other words, the ball suction element 52 is provided on a lower surface of the casing 66. In the first embodiment, the ball reservoir 50 as the ball suction unit is configured by the ball cup 5, the ball suction element 52 and the casing 66. The ball suction element 52 is made of a metallic net such as a stainless mesh which does not allow for the passage of the solder balls 1 but allows for the passage of gas. In addition, in the embodiment illustrated, although the ball cup...

second embodiment

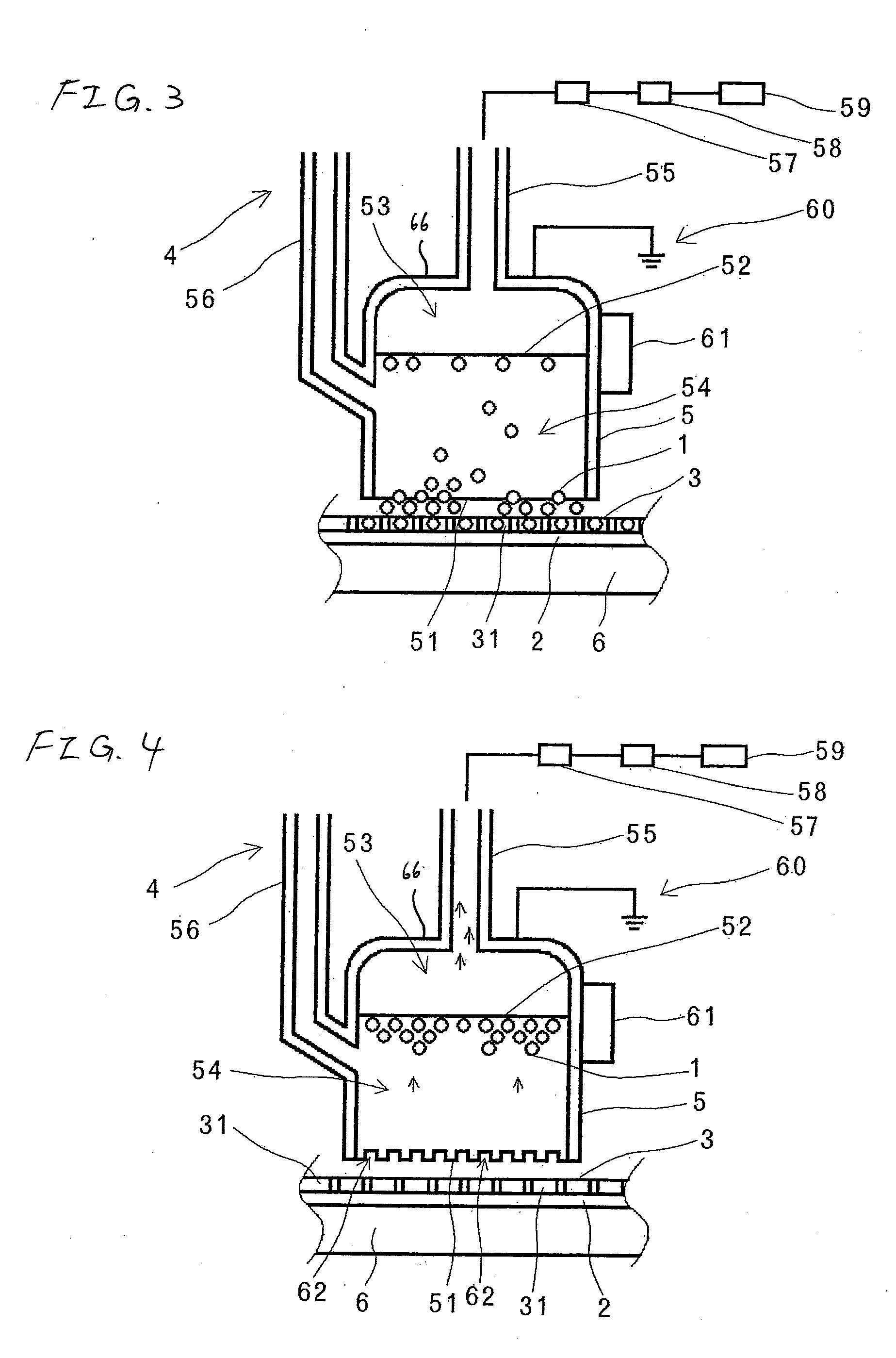

[0058]FIG. 4 shows a second embodiment of the invention. While in the first embodiment, the lower end face of the opening 51 of the ball cup 5 is formed into a planar shape which is in parallel with the ball arraying mask 3 and the ball cup 5 is disposed in such a position that the gap is formed the lower end face of the ball cup 5 and the upper surface of the ball arraying surface 3 in such a manner as to obtain the predetermined gas flow when the ball sucking operation is performed, in a second embodiment shown in FIG. 4, slits 62 are formed on a lower end face of an opening 51 of a ball cup 5 so that gas flows can be obtained. The slits 62 are preferably formed to be radiated in the opening 51 or preferably formed into spiral curves having directivity in one direction. By forming the slits 62 in this way, the flow of gas between the ball cup 5 and a ball arraying mask 3 can be controlled, thereby making it possible to prevent the floating of the ball arraying mask 3. Of course, d...

third embodiment

[0059]FIG. 5 shows a third embodiment of the invention. According to the third embodiment, in order to limit the range where the solder balls 1 drop from the ball suction element 52 down to the ball arraying mask 3, a ball guide 63, which is opened widely in an upper portion and is opened narrowly in a lower portion to match a mounting range, is provided below a ball suction element 52 of a ball cup 5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| conductive | aaaaa | aaaaa |

| diameters | aaaaa | aaaaa |

| speeds | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com