Patents

Literature

3148results about "Solder feeding devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

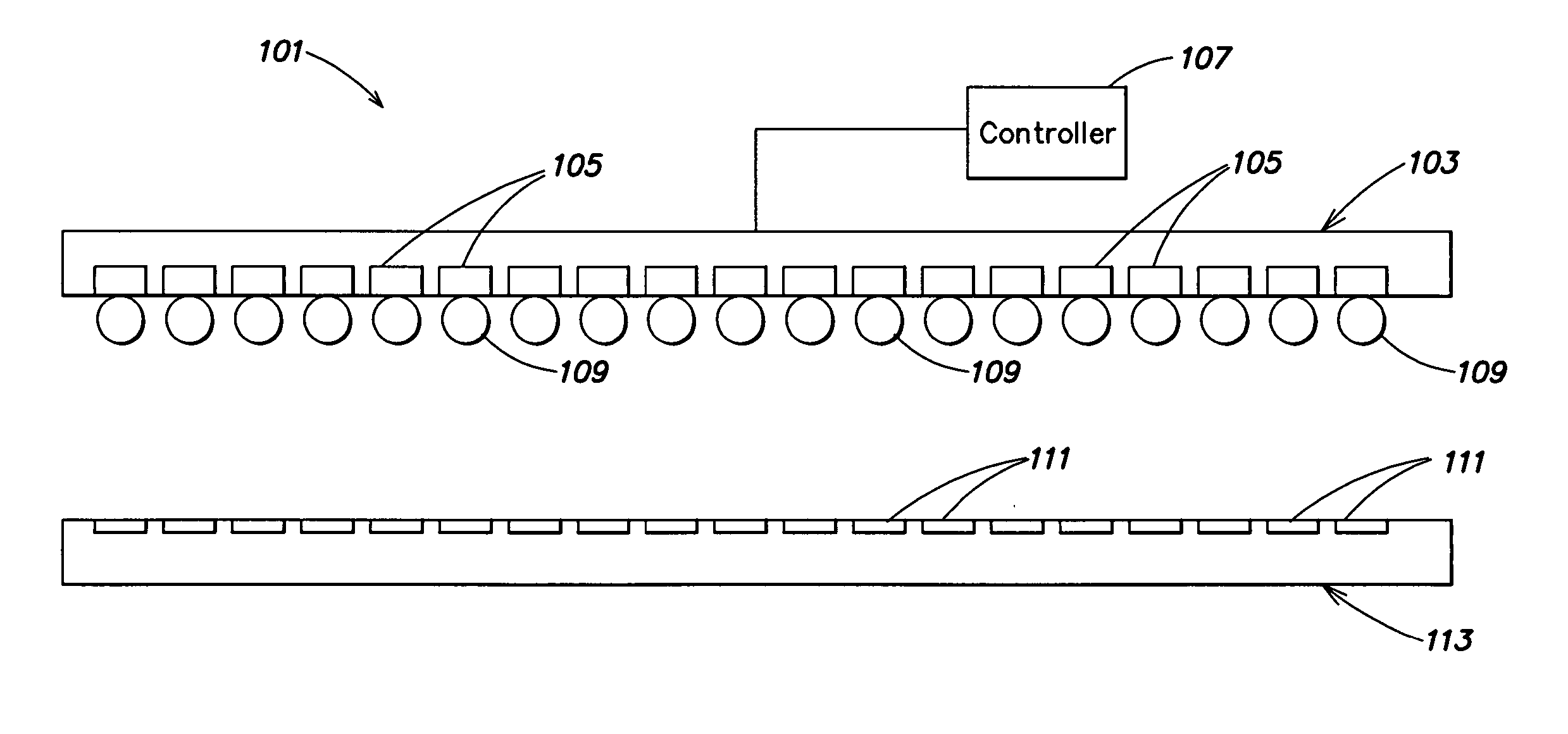

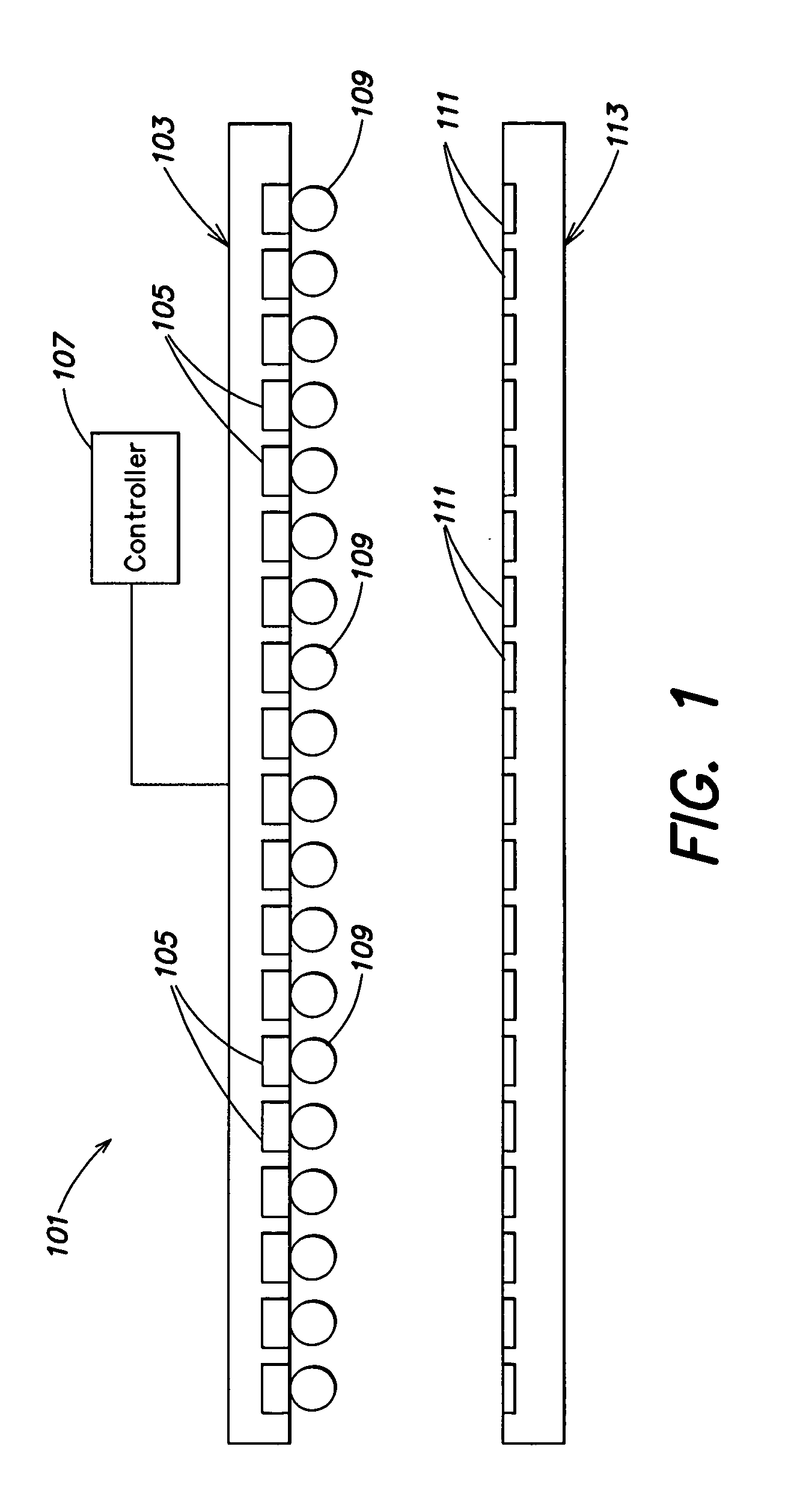

Methods and apparatus for transferring conductive pieces during semiconductor device fabrication

InactiveUS20050232728A1Semiconductor/solid-state device detailsSolid-state devicesSemiconductorSemiconductor device fabrication

In a first aspect, a programmable transfer device is provided for transferring conductive pieces to electrode pads of a target substrate. The programmable transfer device includes (1) a transfer substrate; and (2) a plurality of individually addressable electrodes formed on the transfer substrate. Each electrode is adapted to selectively attract and hold a conductive piece during transfer of the conductive piece to an electrode pad of a target substrate. Numerous other aspects are provided.

Owner:APPLIED MATERIALS INC

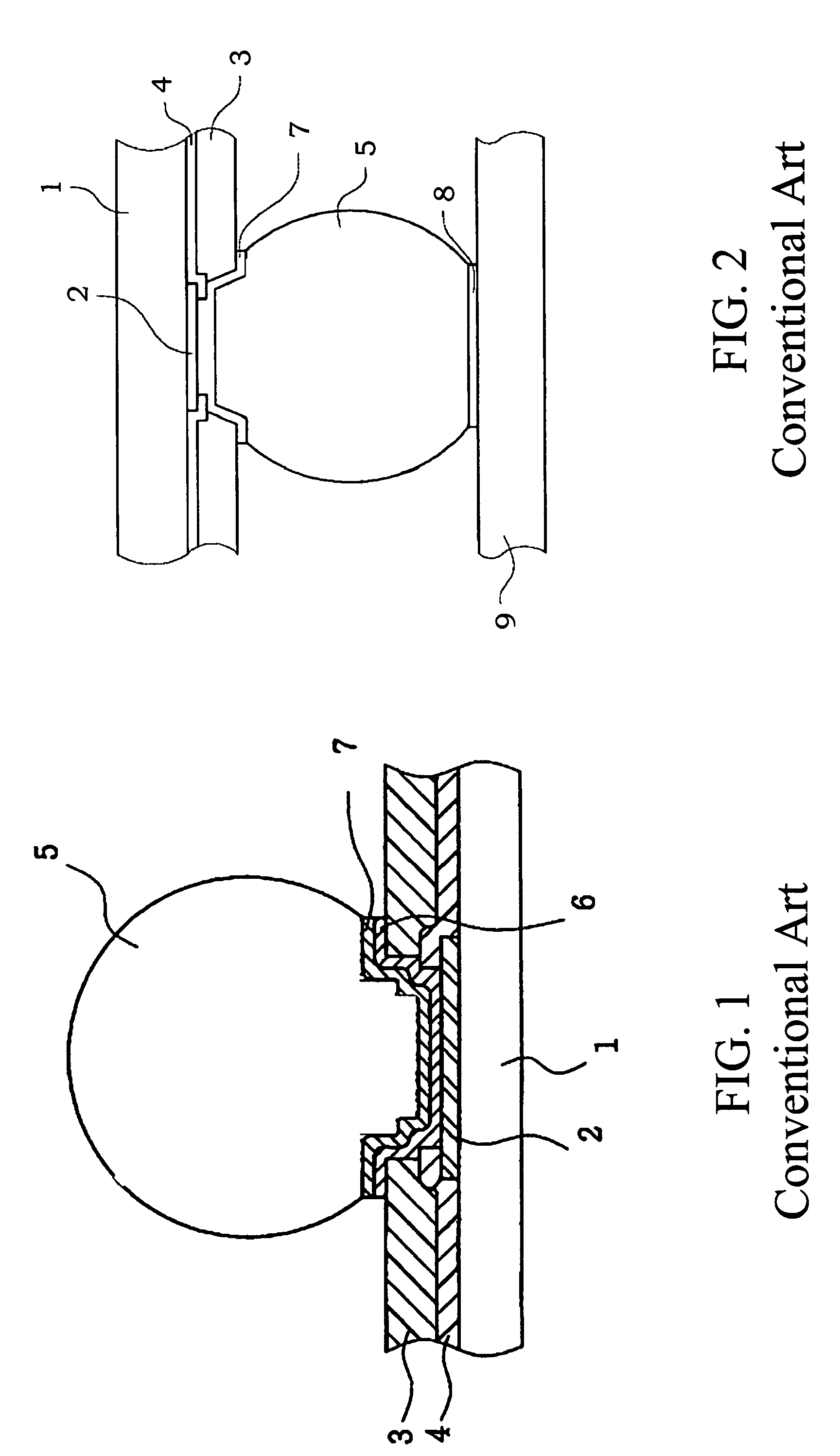

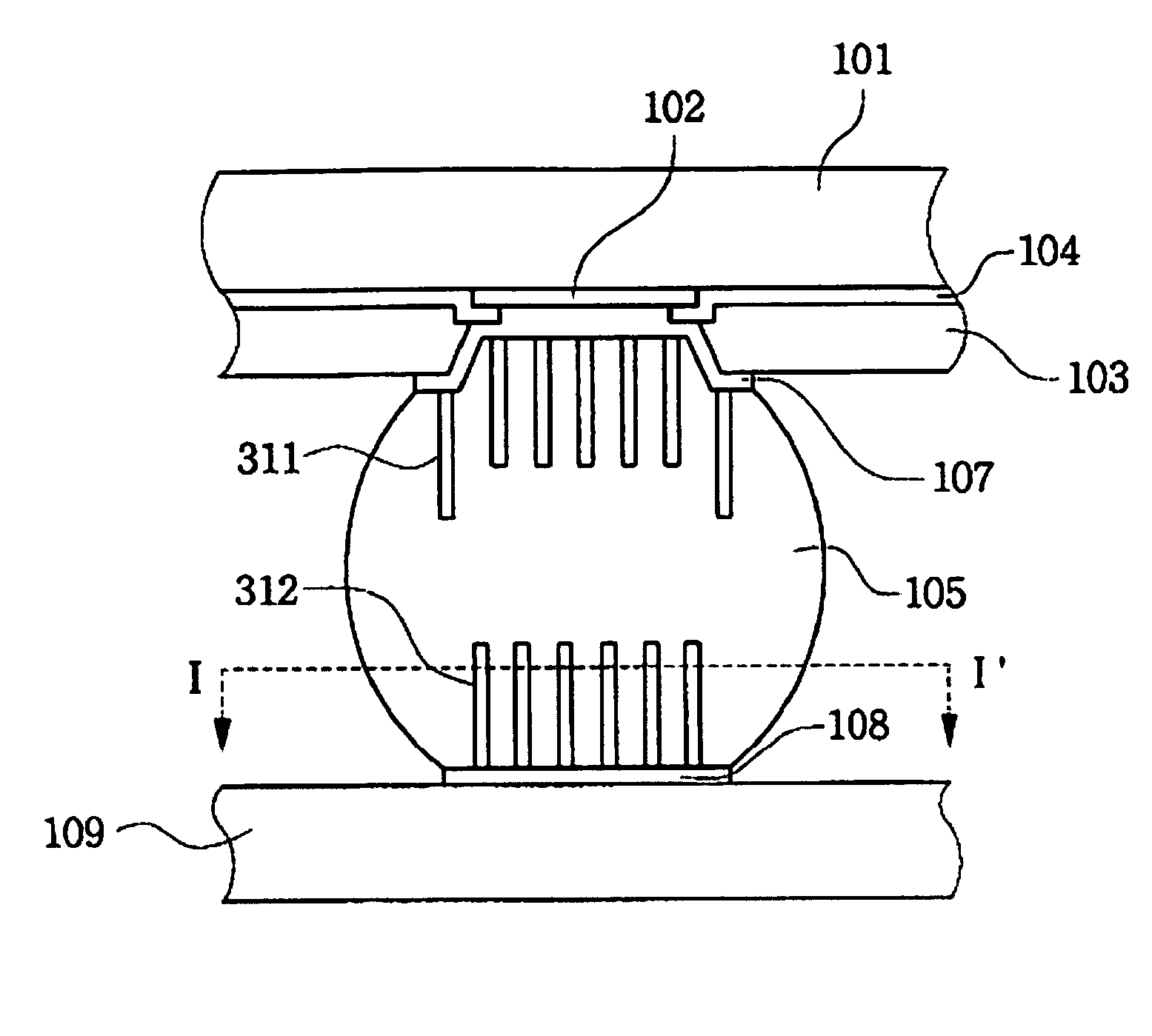

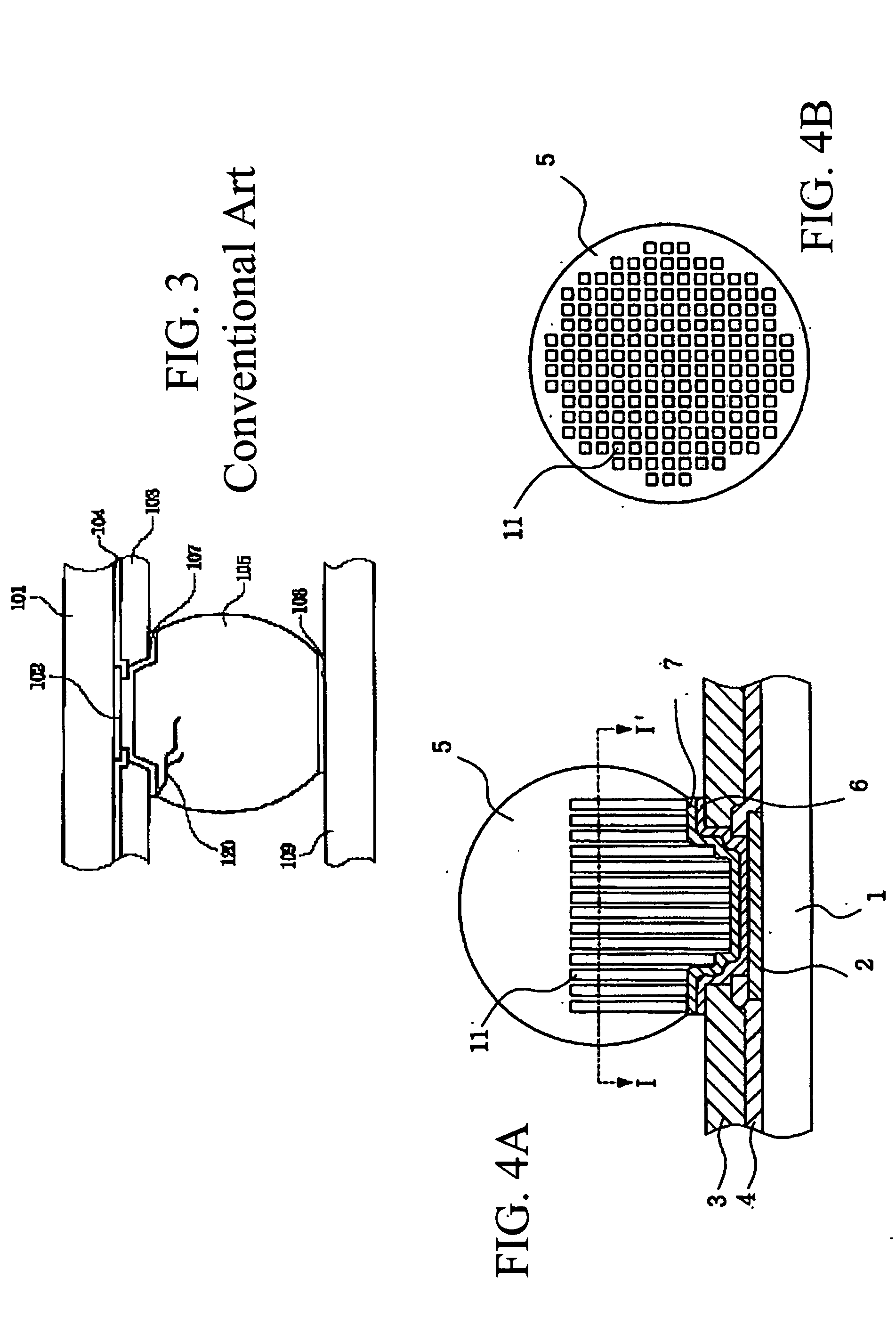

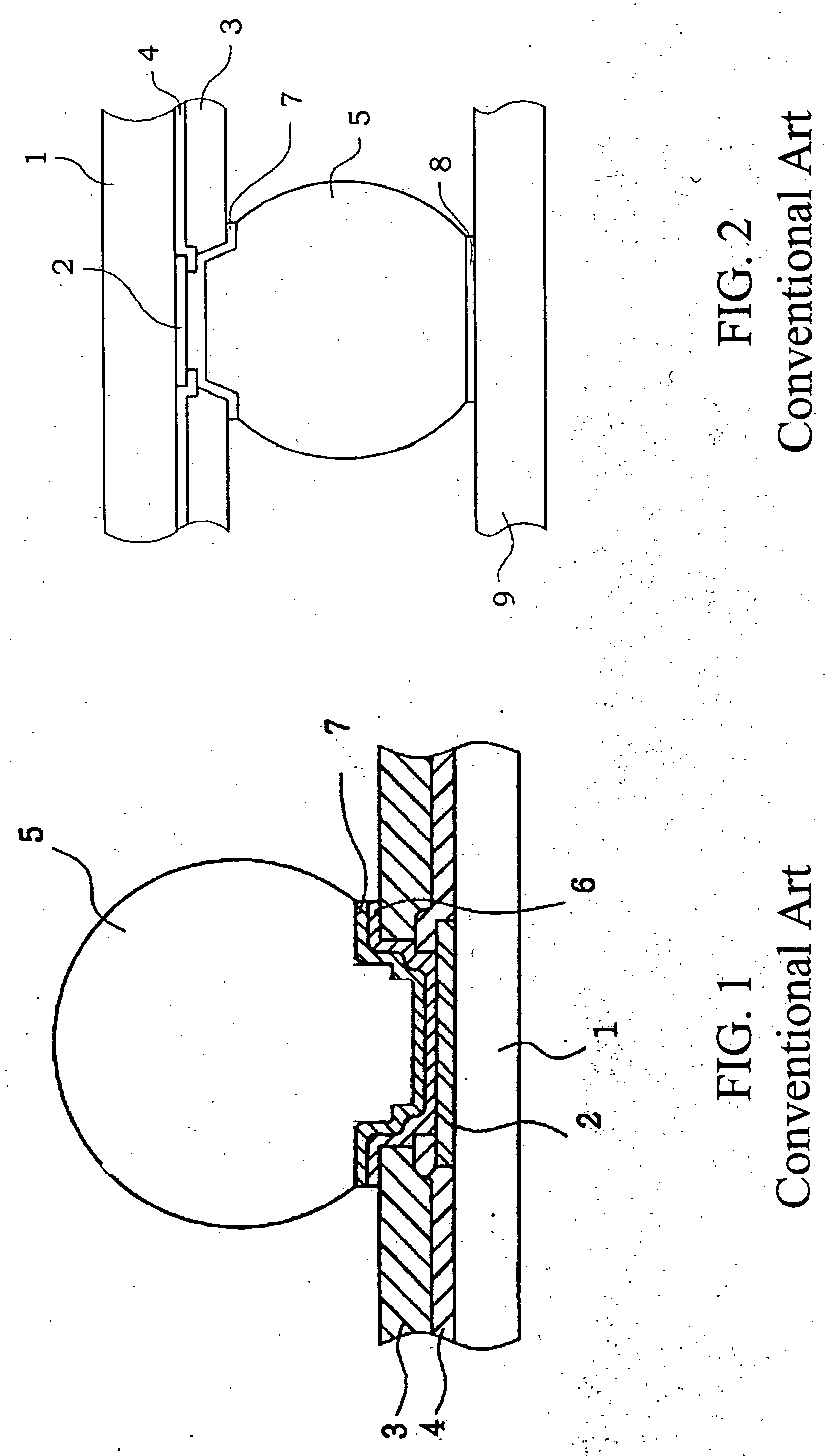

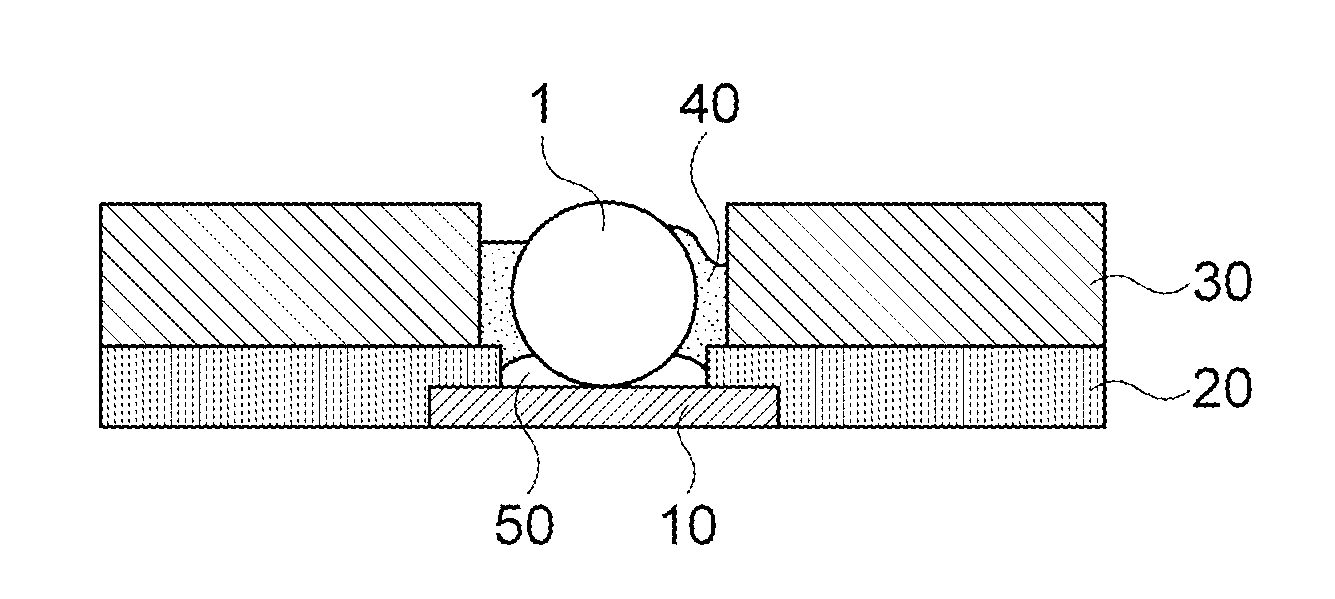

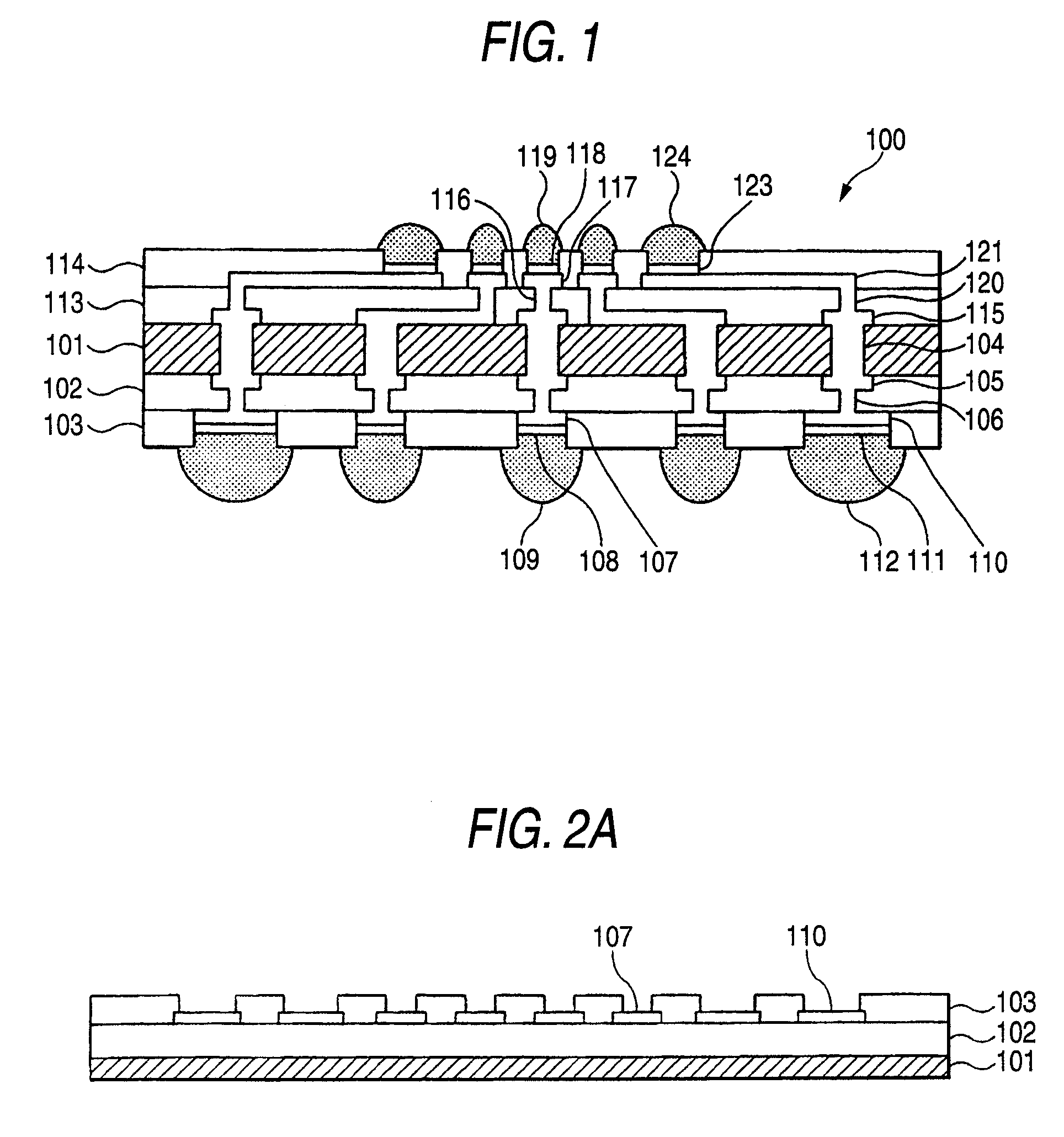

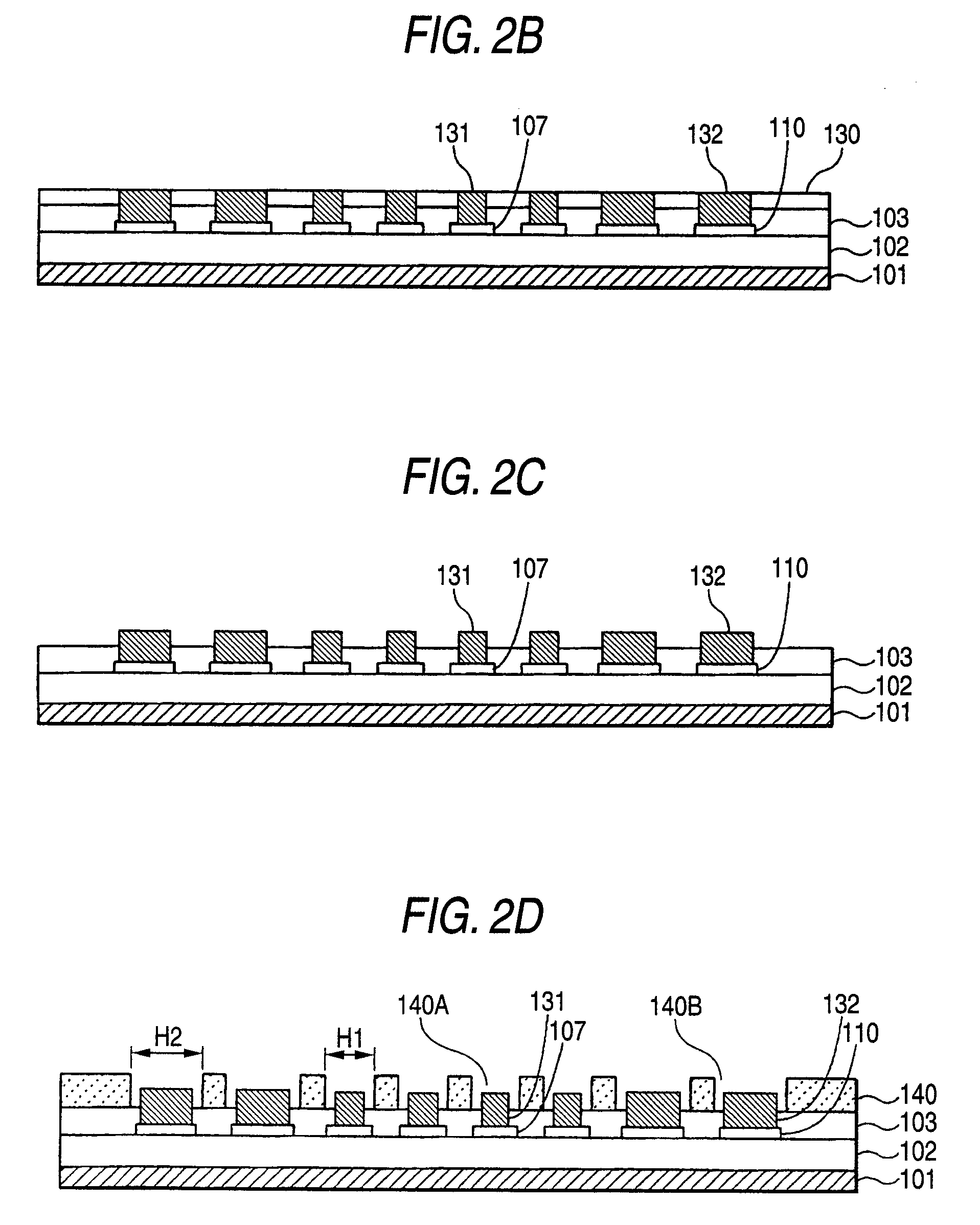

Reinforced solder bump structure and method for forming a reinforced solder bump

A reinforced solder bump connector structure is formed between a contact pad arranged on a semiconductor chip and a ball pad arranged on a mounting substrate. The semiconductor chip includes at least one reinforcing protrusion extending upwardly from a surface of an intermediate layer. The mounting substrate includes at least one reinforcing protrusion extending upwardly from a ball pad, the protrusions from both the chip and the substrate being embedded within the solder bump connector. In some configurations, the reinforcing protrusion from the contact pad and the ball pad are sized and arranged to have overlapping under portions. These overlapping portions may assume a wide variety of configurations that allow the protrusions to overlap without contacting each other including pin arrays and combinations of surrounding and surrounded elements. In each configuration, the reinforcing protrusions will tend to suppress crack formation and / or crack propagation thereby improving reliability.

Owner:SAMSUNG ELECTRONICS CO LTD

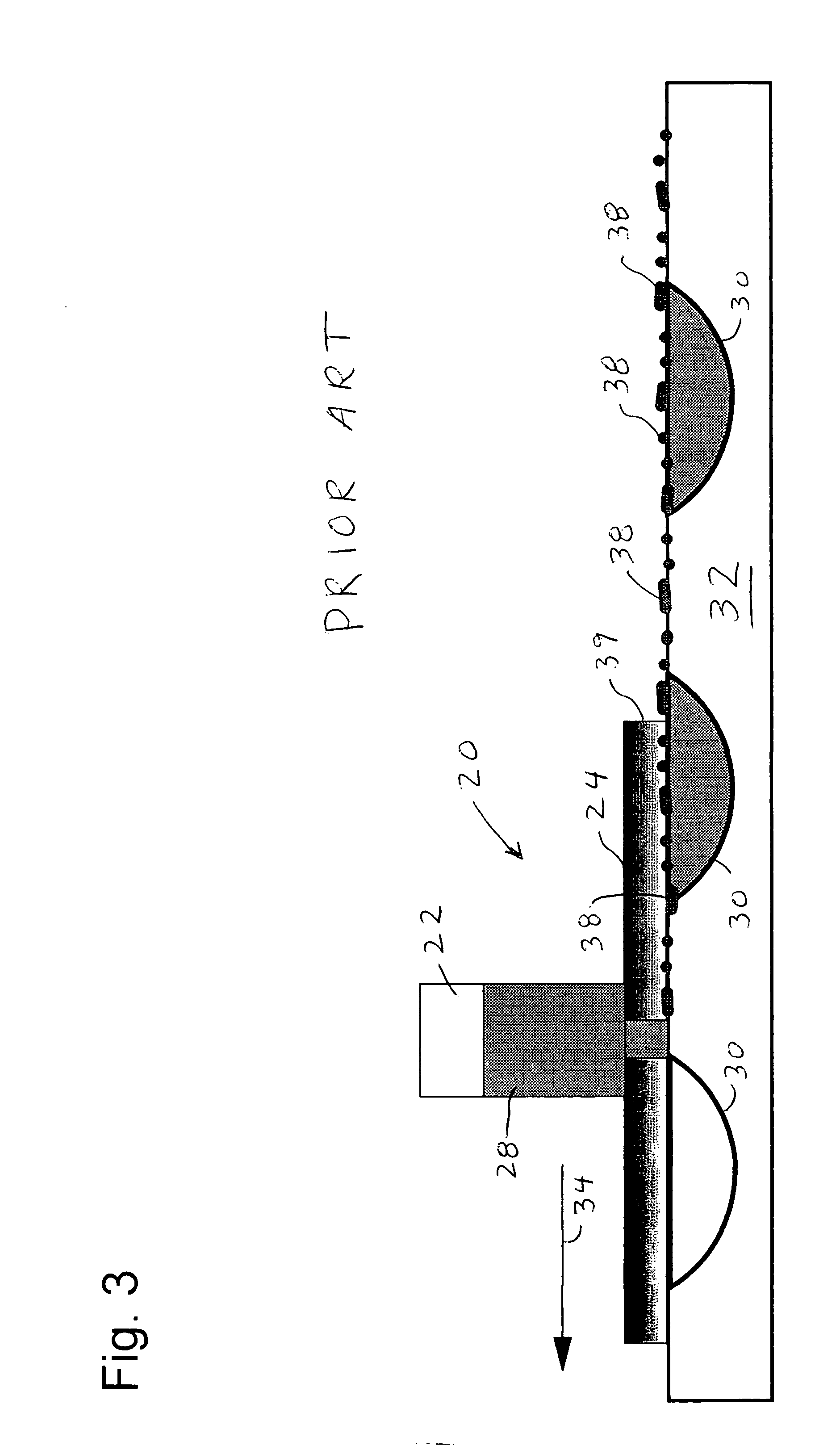

Tools and methods for forming conductive bumps on microelectronic elements

InactiveUS20060183270A1Easy to wetGood adhesionSolid-state devicesSemiconductor/solid-state device manufacturingContact padEngineering

A method of making a microelectronic assembly includes providing a microelectronic element having a front face and contact pads accessible at the front face, providing a dispensing tool containing a molten metal and having a discharge port for dispensing the molten metal, and aligning the discharge port of the dispensing tool with one of the contact pads of the microelectronic element. A mass of the molten metal is dispensed through the discharge port and onto the one of the contact pads of the microelectronic element; and ultrasonic waves are applied to the mass of molten metal during the dispensing step for facilitating wetting of the mass of molten metal with the one of the contact pads of the microelectronic element.

Owner:TESSERA INC

High performance multi-chip flip chip package

InactiveUS6992384B2Negligible resistanceImprove thermal performanceSemiconductor/solid-state device detailsSolid-state devicesElectrical resistance and conductanceCommon base

A structure and method of manufacture for an improved multi-chip semiconductor package that reduces package resistance to a negligible level, and offers superior thermal performance. Housing of multiple dies is facilitated by providing electrically isolated lead frames that are separated from a common base carrier by a non-conductive layer of laminating material. A silicon die is attached inside a cavity formed in each lead frame. Direct connection of the active surface of the silicon die to the printed circuit board is then made by an array of solder bumps that is distributed across the surface of each die as well as the edges of the lead frame adjacent to each die.

Owner:SEMICON COMPONENTS IND LLC

Substrate for producing a soldering connection

InactiveUS7271484B2Improve reliabilityReducing in fashionPrinted circuit assemblingSemiconductor/solid-state device detailsSolder maskEngineering

A solderable device includes a substrate and a soldering pad overlying the substrate. A solder mask overlies the substrate and portions of the soldering pad. The solder mask has an opening that exposes a portion of the soldering pad. The opening has at least two edges that symmetrically overlie portions of the soldering pad.

Owner:POLARIS INNOVATIONS LTD

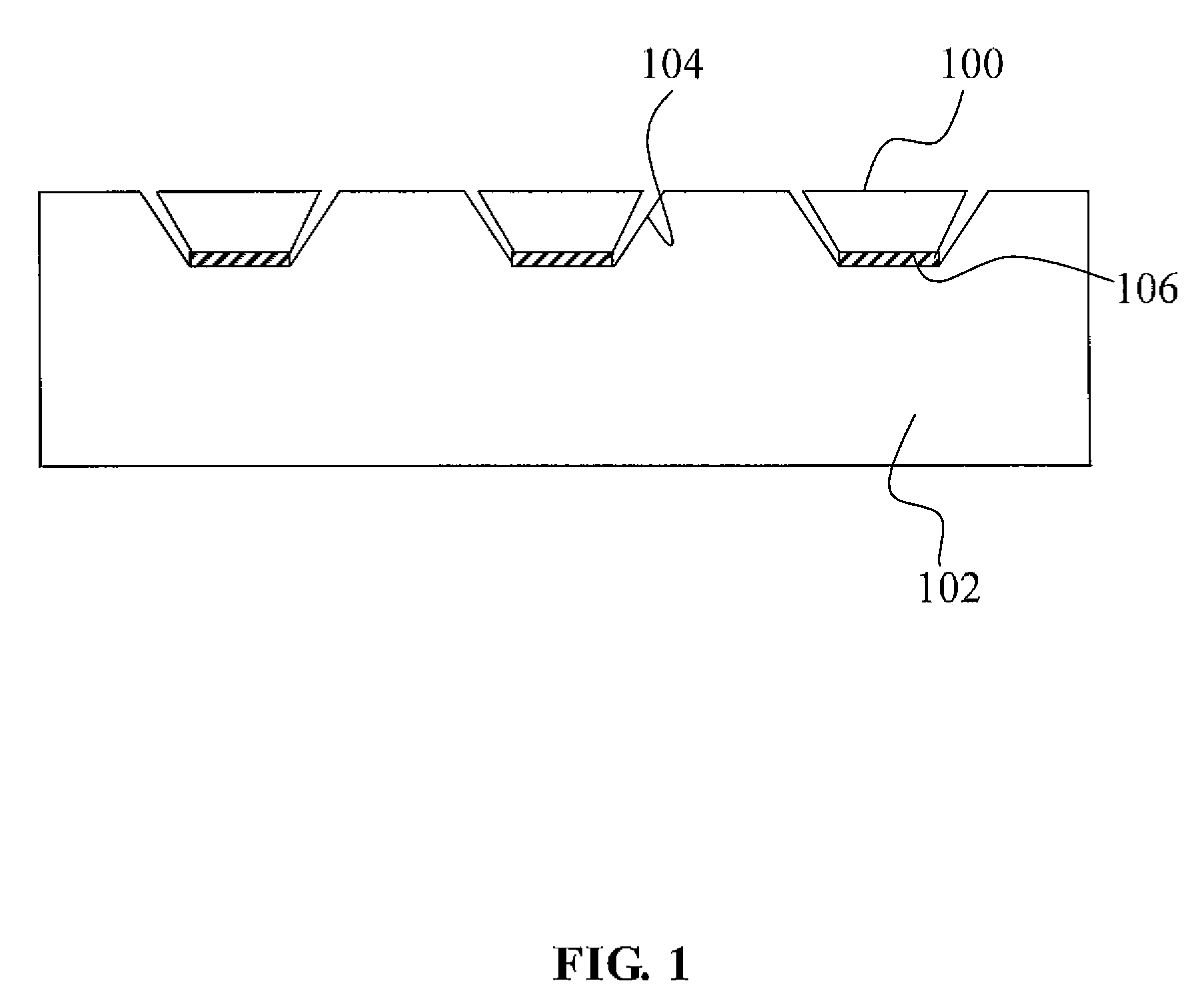

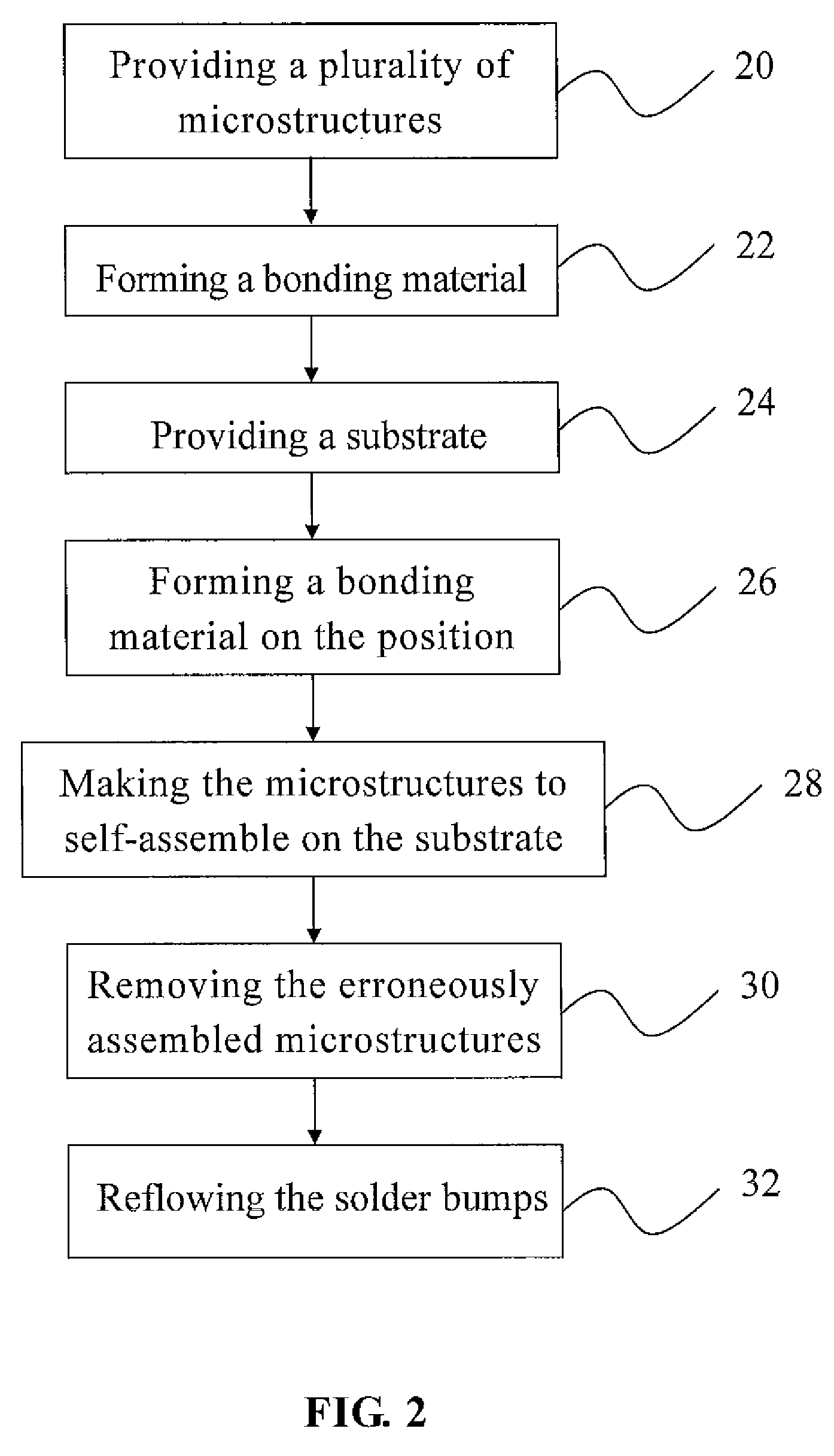

Method for self-assembling microstructures

InactiveUS20080023435A1Precise positioningImproved and easy processSolid-state devicesMicrostructural device assemblyPresent methodElectrical connection

A method for self-assembling a plurality of microstructures onto a substrate comprising using a bonding material to make the microstructure assembled onto the substrate by a physical attraction force The microstructures are self-aligned with the substrate, and further permanently fixed on and electrical connection with the substrate by the solder bumps between the microstructures and the substrate, which is formed by the solder bumps via reflow process. There is no need for the using of the conventional pick-and-place device in the present method. The present method could be applied to light emitting diodes, RFID tags, micro-integrated circuits or other types of microstructures.

Owner:NAT TAIWAN UNIV

Reinforced solder bump structure and method for forming a reinforced solder bump

A reinforced solder bump connector structure is formed between a contact pad arranged on a semiconductor chip and a ball pad arranged on a mounting substrate. The semiconductor chip includes at least one reinforcing protrusion extending upwardly from a surface of an intermediate layer. The mounting substrate includes at least one reinforcing protrusion extending upwardly from a ball pad, the protrusions from both the chip and the substrate being embedded within the solder bump connector. In some configurations, the reinforcing protrusion from the contact pad and the ball pad are sized and arranged to have overlapping under portions. These overlapping portions may assume a wide variety of configurations that allow the protrusions to overlap without contacting each other including pin arrays and combinations of surrounding and surrounded elements. In each configuration, the reinforcing protrusions will tend to suppress crack formation and / or crack propagation thereby improving reliability.

Owner:SAMSUNG ELECTRONICS CO LTD

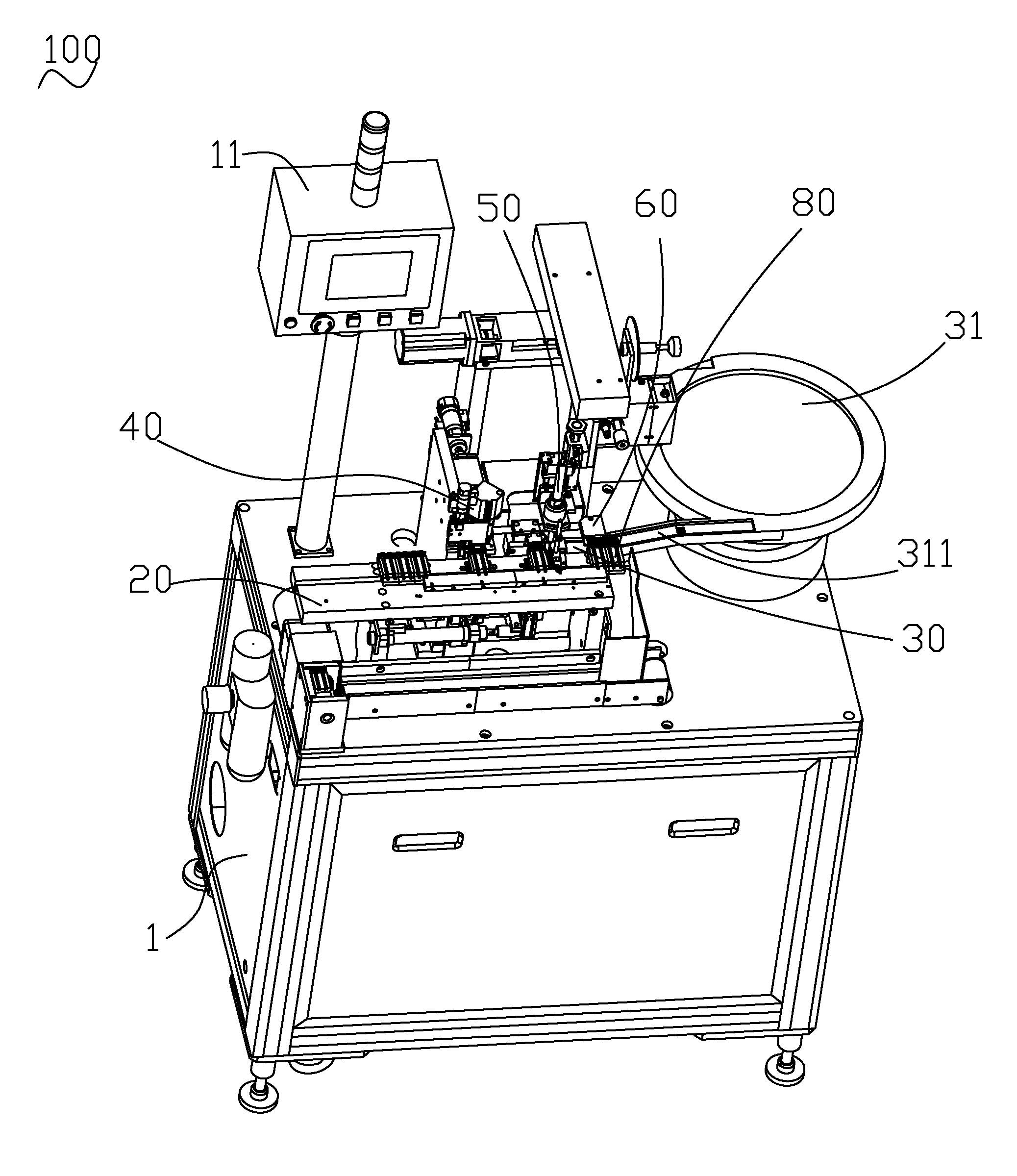

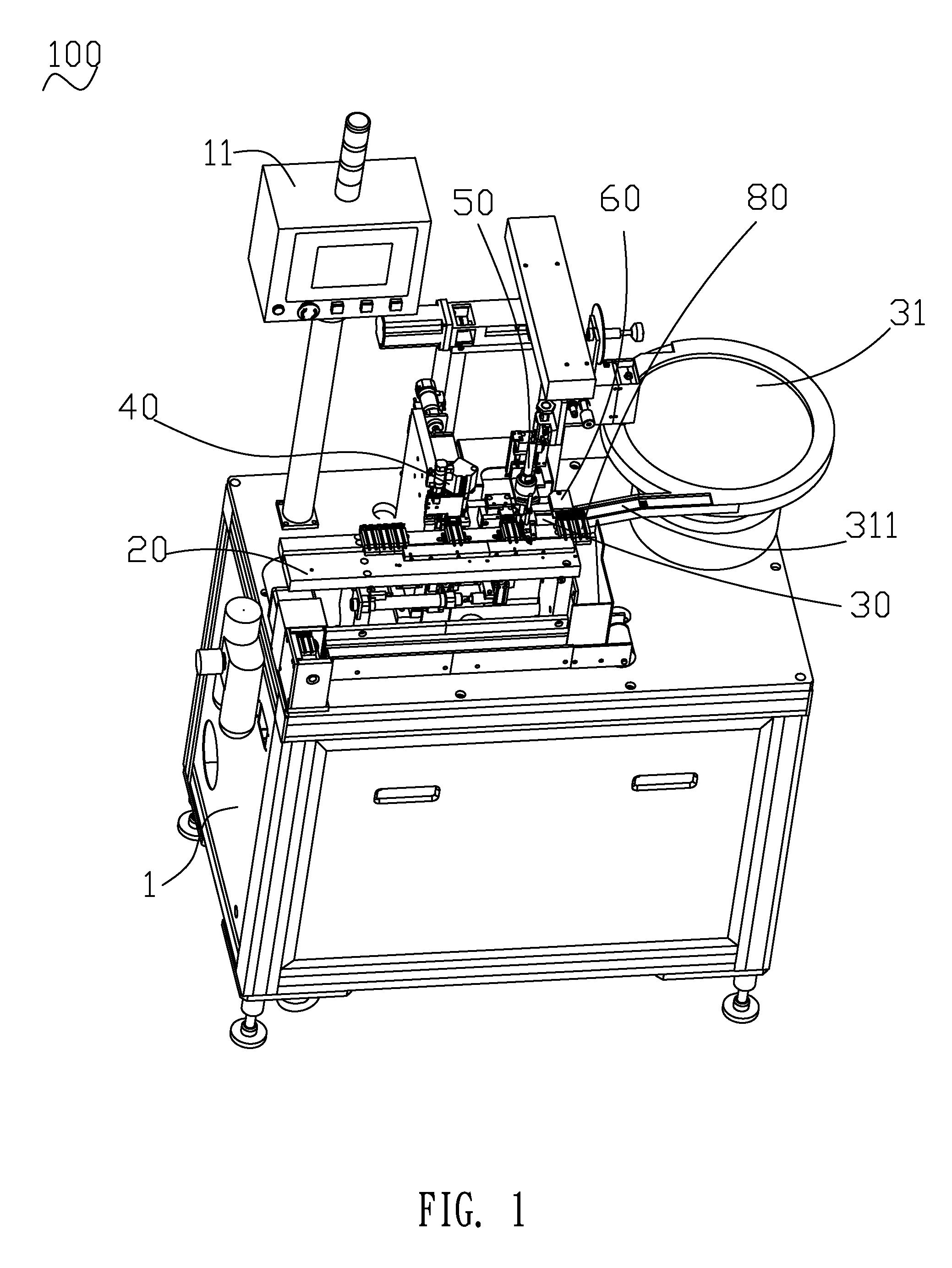

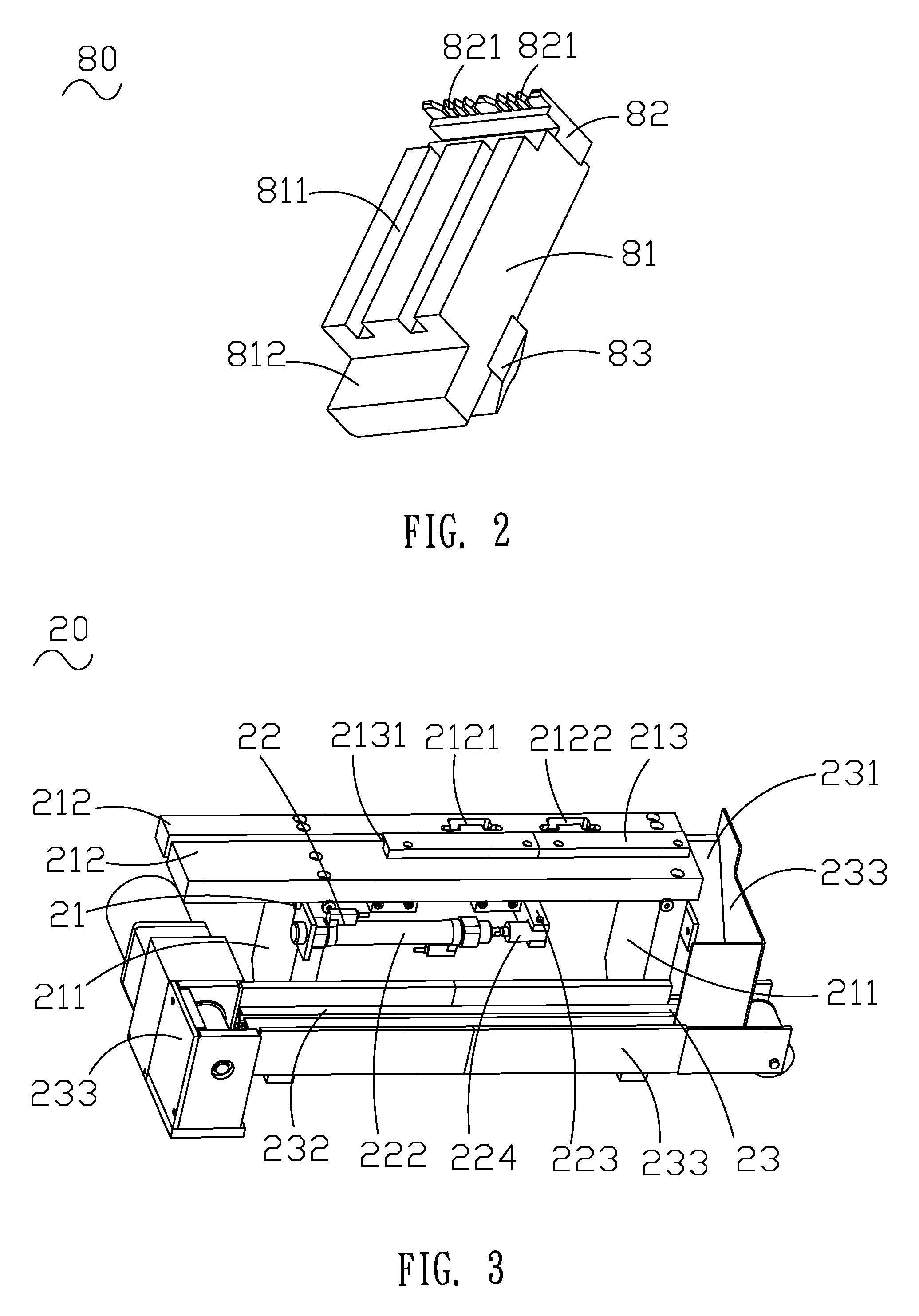

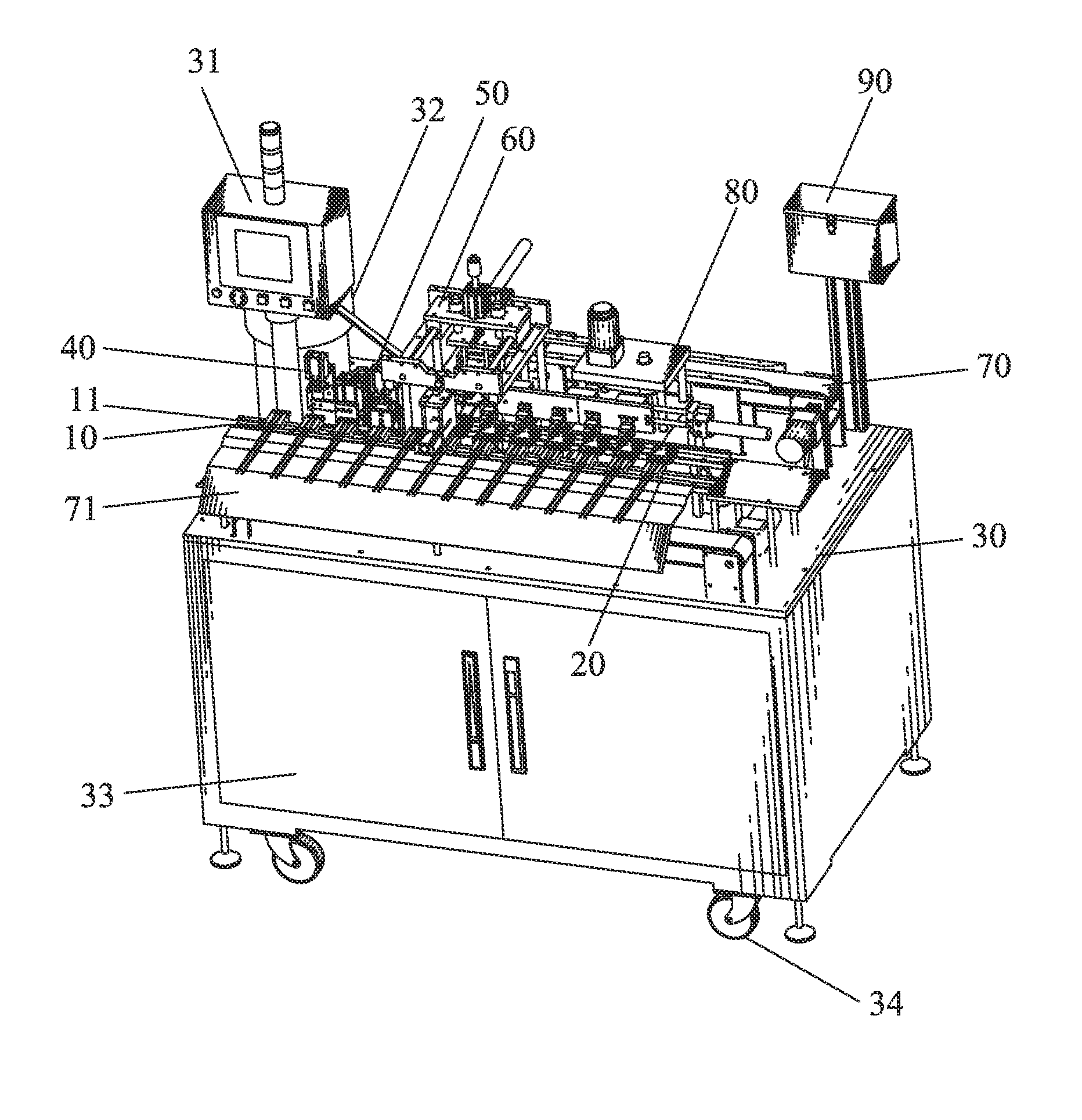

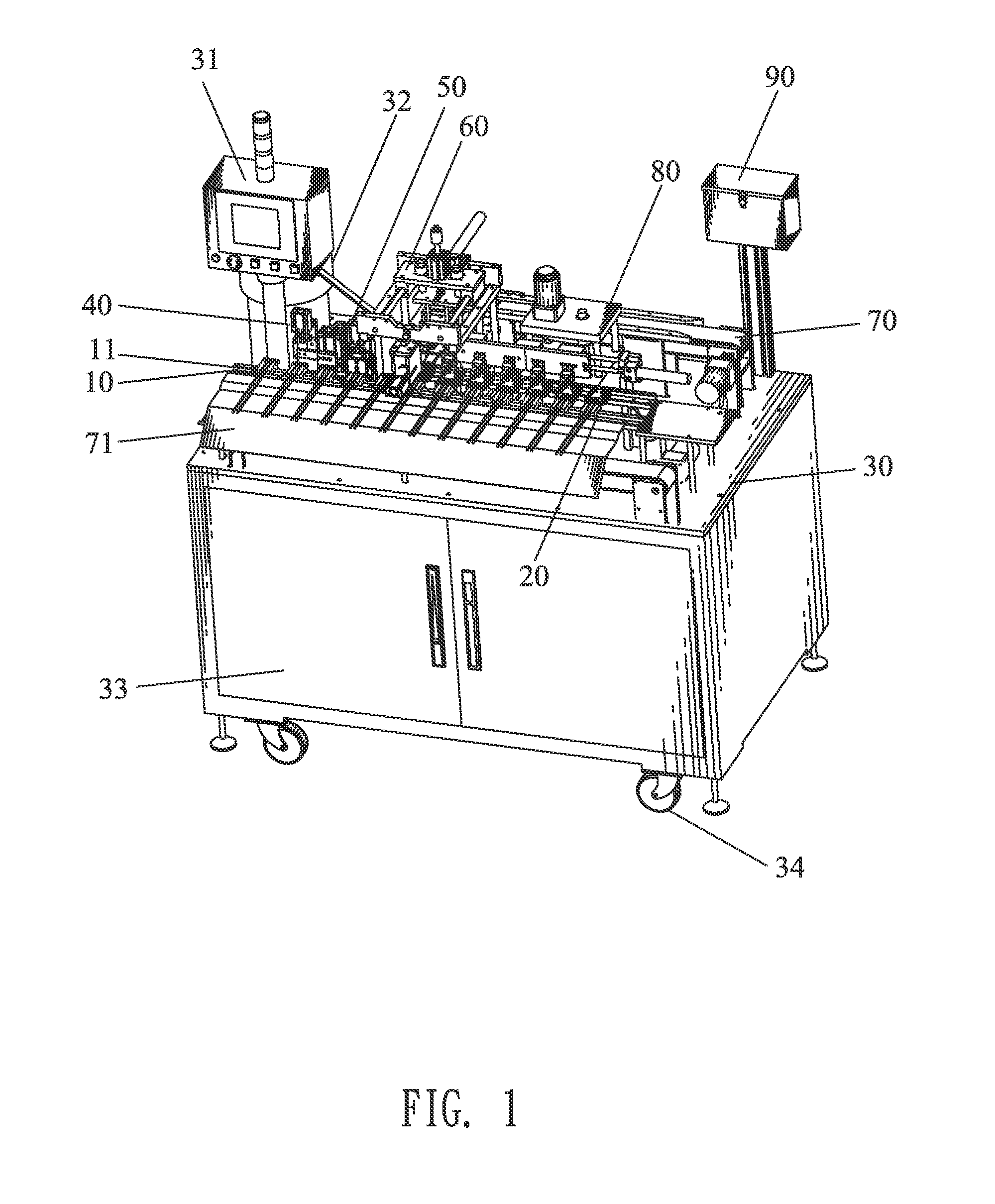

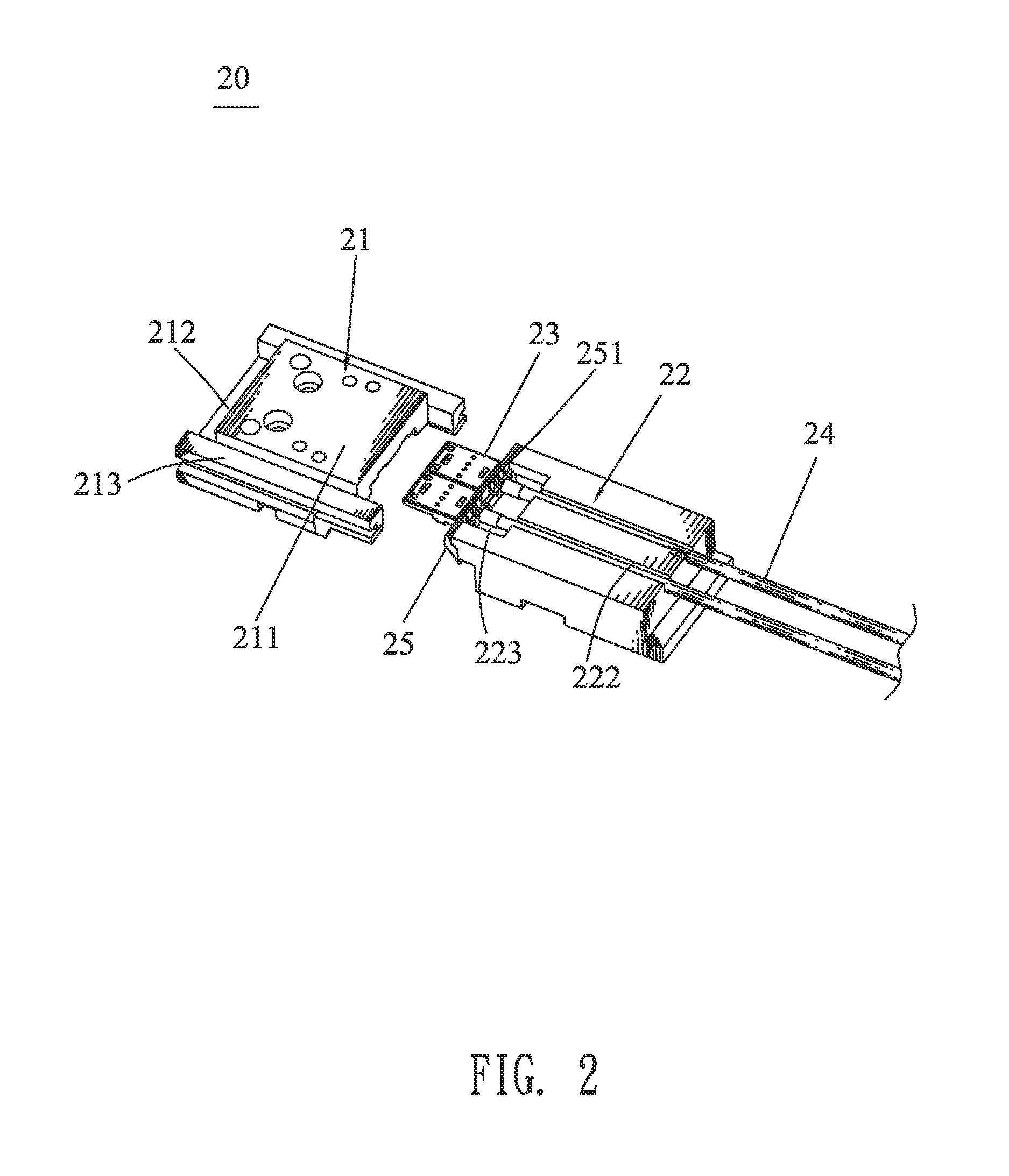

Automatic soldering machine

InactiveUS8011557B1High production efficacyImprove product qualityWelding/cutting auxillary devicesFeeding apparatusControl systemEngineering

An automatic soldering machine for soldering wires, each exposing at least one core wire and electronic components with at least one soldering portion respectively is disclosed. The automatic soldering machine comprises an equipment, a delivery mechanism, a plurality of clamps, a feeding mechanism, an insulation removing mechanism, a soldering mechanism, an unloading mechanism and a programmable control system. The delivery mechanism delivers the wires. The clamps locate the wires. The feeding mechanism conveys the electronic components. The insulation removing mechanism cuts the core wires and strips insulations at tops of the core wires. The soldering mechanism solders the core wires and the soldering portions of the electronic components. The unloading mechanism separates the soldered electronic components and core wires off from the clamps. The programmable control system is connect to the aforesaid mechanisms and controls thereof with high production efficacy and stable production quality.

Owner:CHENG UEI PRECISION IND CO LTD

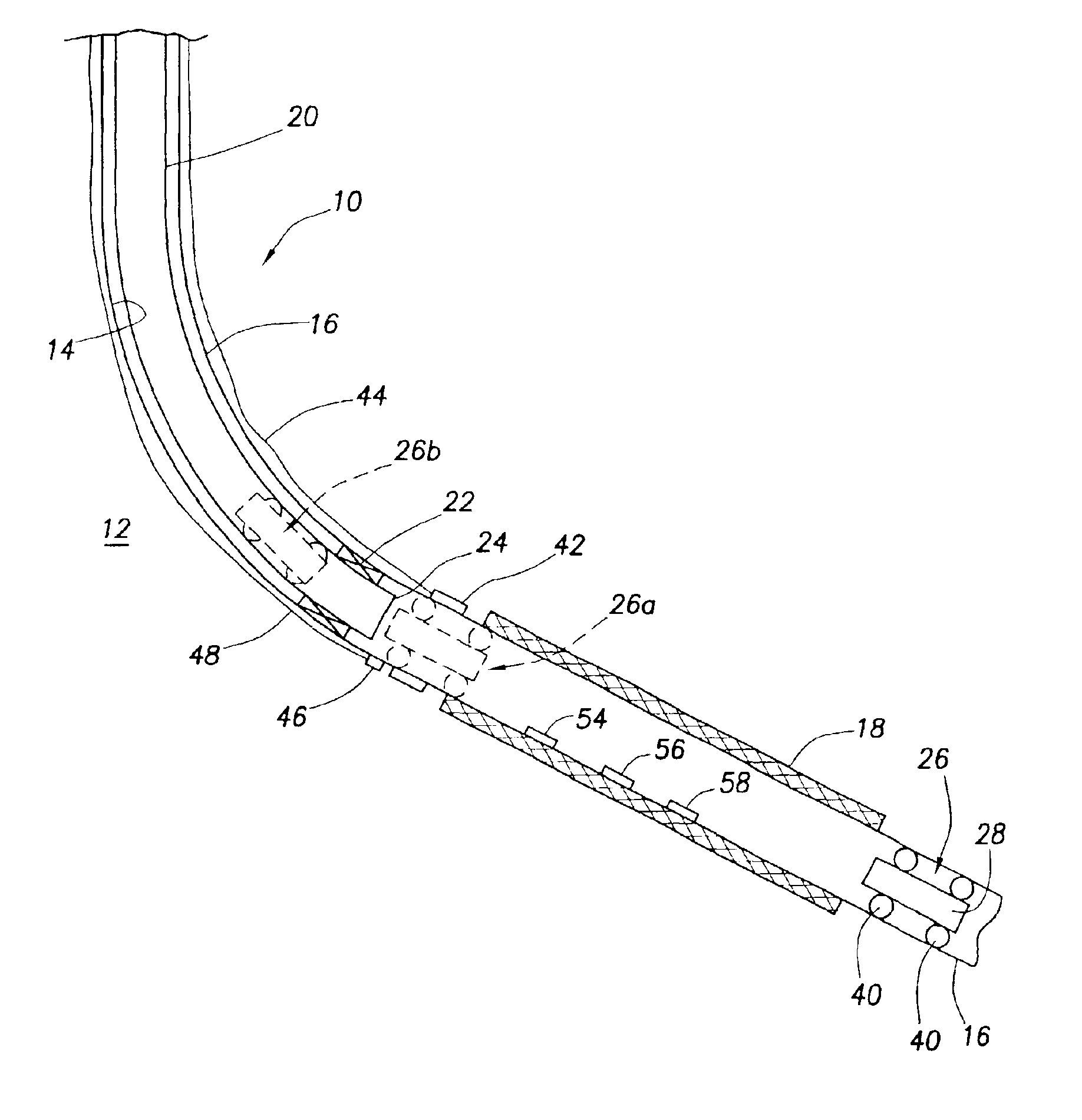

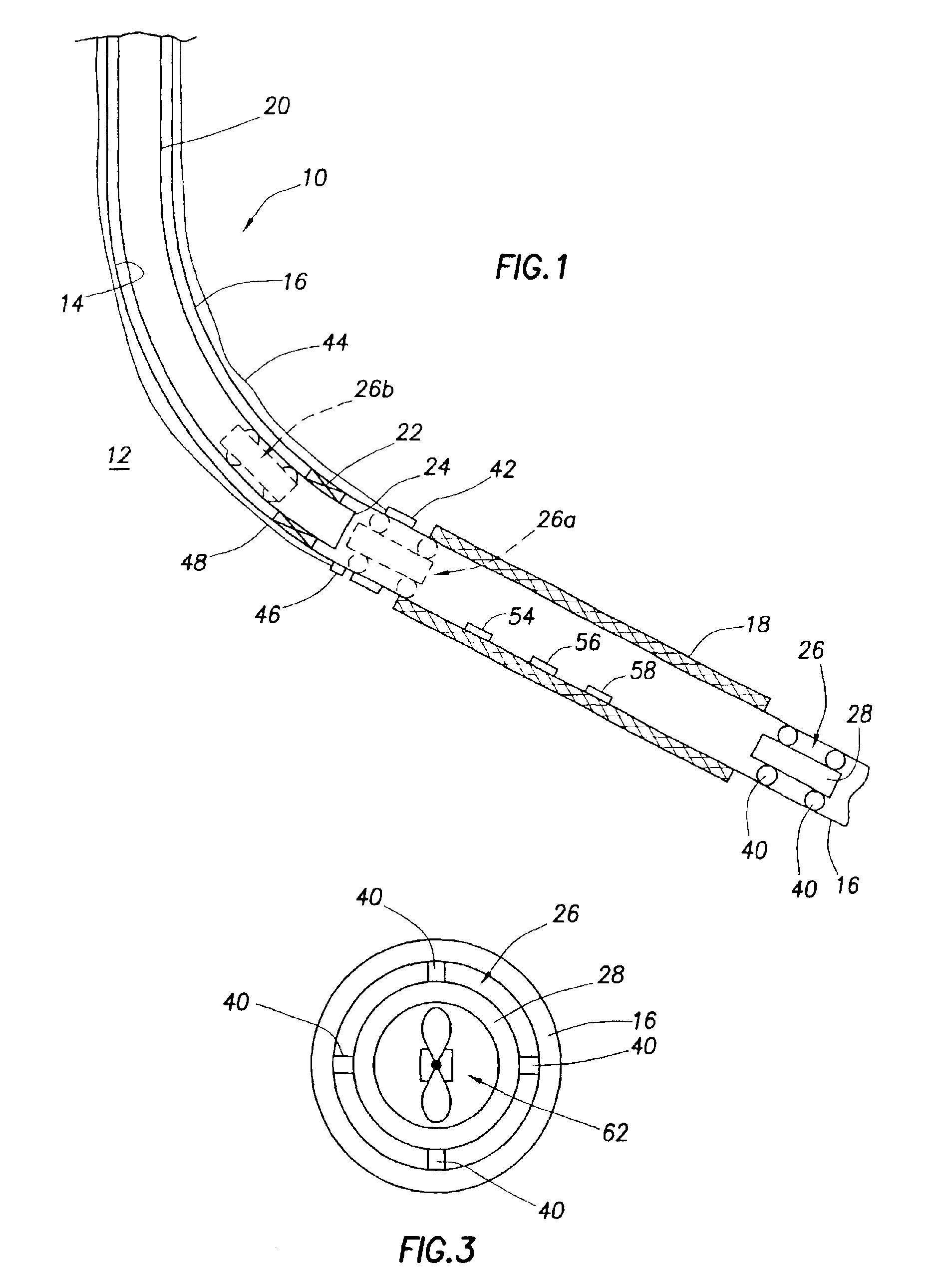

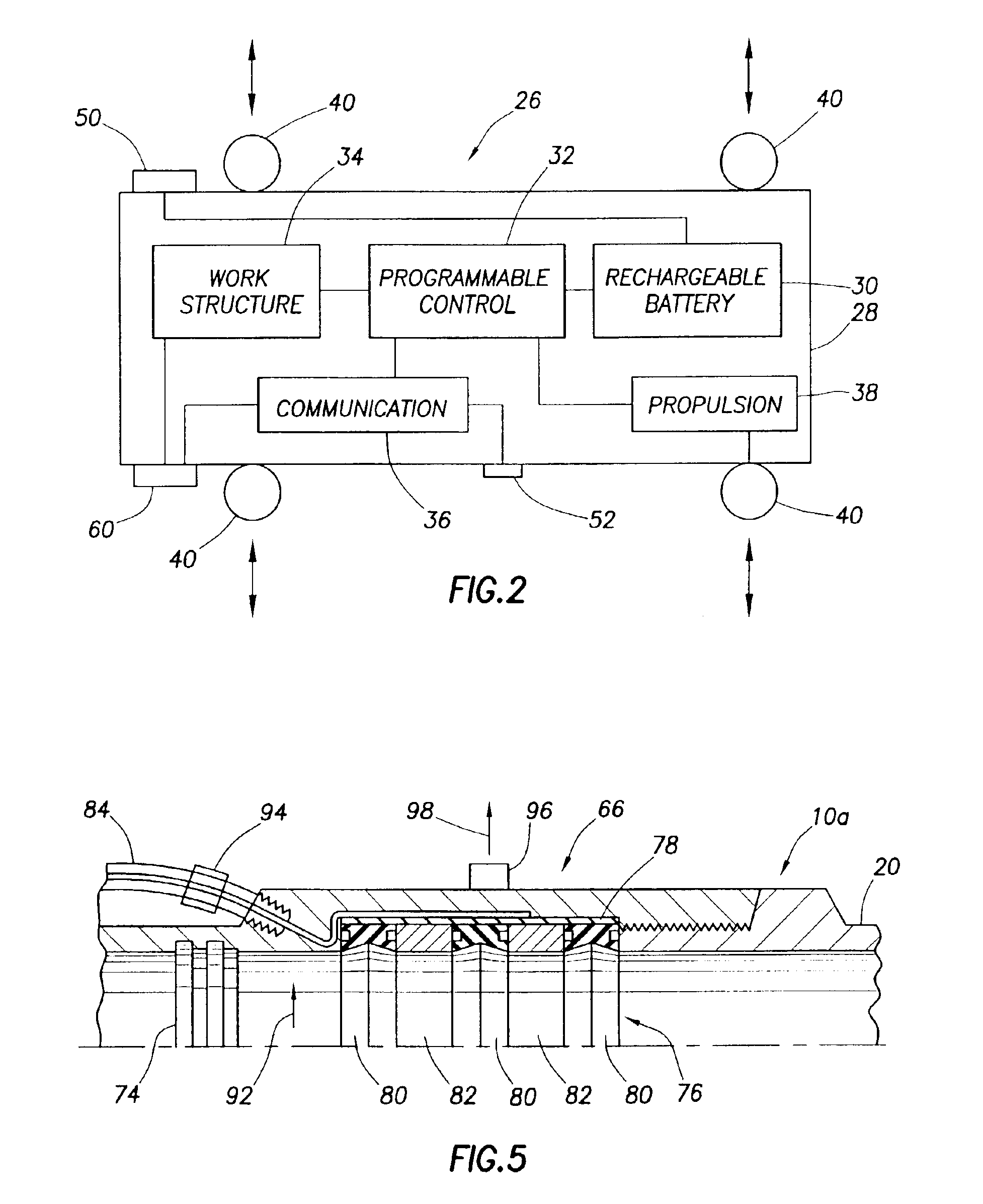

Subterranean well completion incorporating downhole-parkable robot therein

InactiveUS6953094B2Help positioningImprove fluid flowSurveyFluid removalRemote controlTeleoperated robot

A subterranean well completion has a tubular structure in which a remote controlled robot is permanently disposed. The robot is self-propelled, programmable, receives instructions from and communicates data to the surface, and is adapted to receive power from a downhole source and perform a variety of well tasks such as, for example, positioning valves and other well tools and sensing the values of predetermined downhole parameters and relaying the sensed information to the surface. The robot, which is operable without physical intervention through the tubular structure to the robot, propels itself to a location in the tubular structure at which a desired well task is to be performed, performs the task and then parks itself in the tubular structure until another well task is to be performed by the robot.

Owner:HALLIBURTON ENERGY SERVICES INC

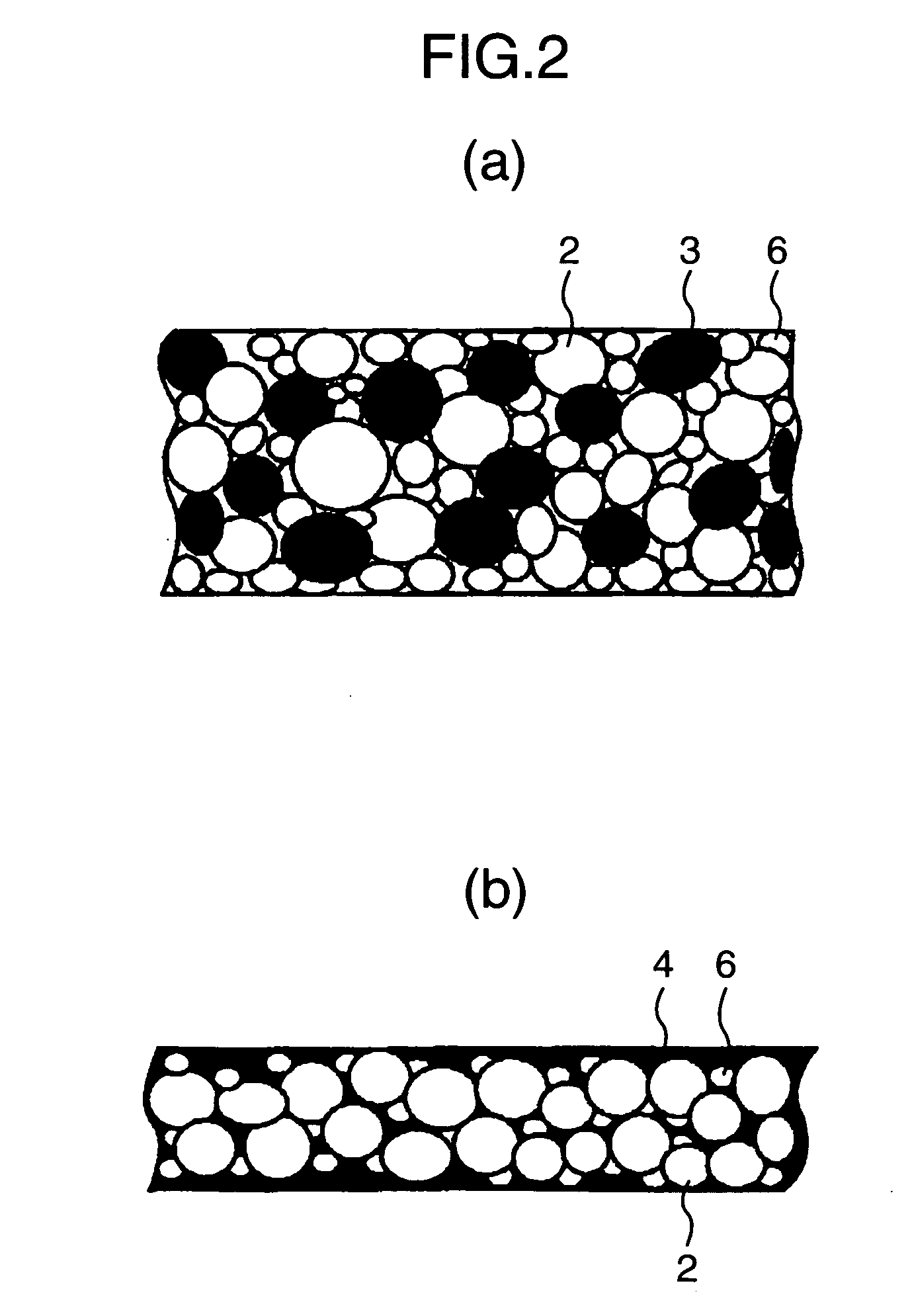

Solder foil semiconductor device and electronic device

InactiveUS20060061974A1NovelSemiconductor/solid-state device detailsSolid-state devicesDevice materialMetal particle

A solder foil formed from a material comprising particles of Cu, etc. as metal particles and Sn particles as solder particles by rolling is suitable for solder bonding at a high temperature side in temperature-hierarchical bonding, and semiconductor devices and electronic devices produced by use of such solder bonding have distinguished reliability of mechanical characteristics, etc.

Owner:RENESAS ELECTRONICS CORP

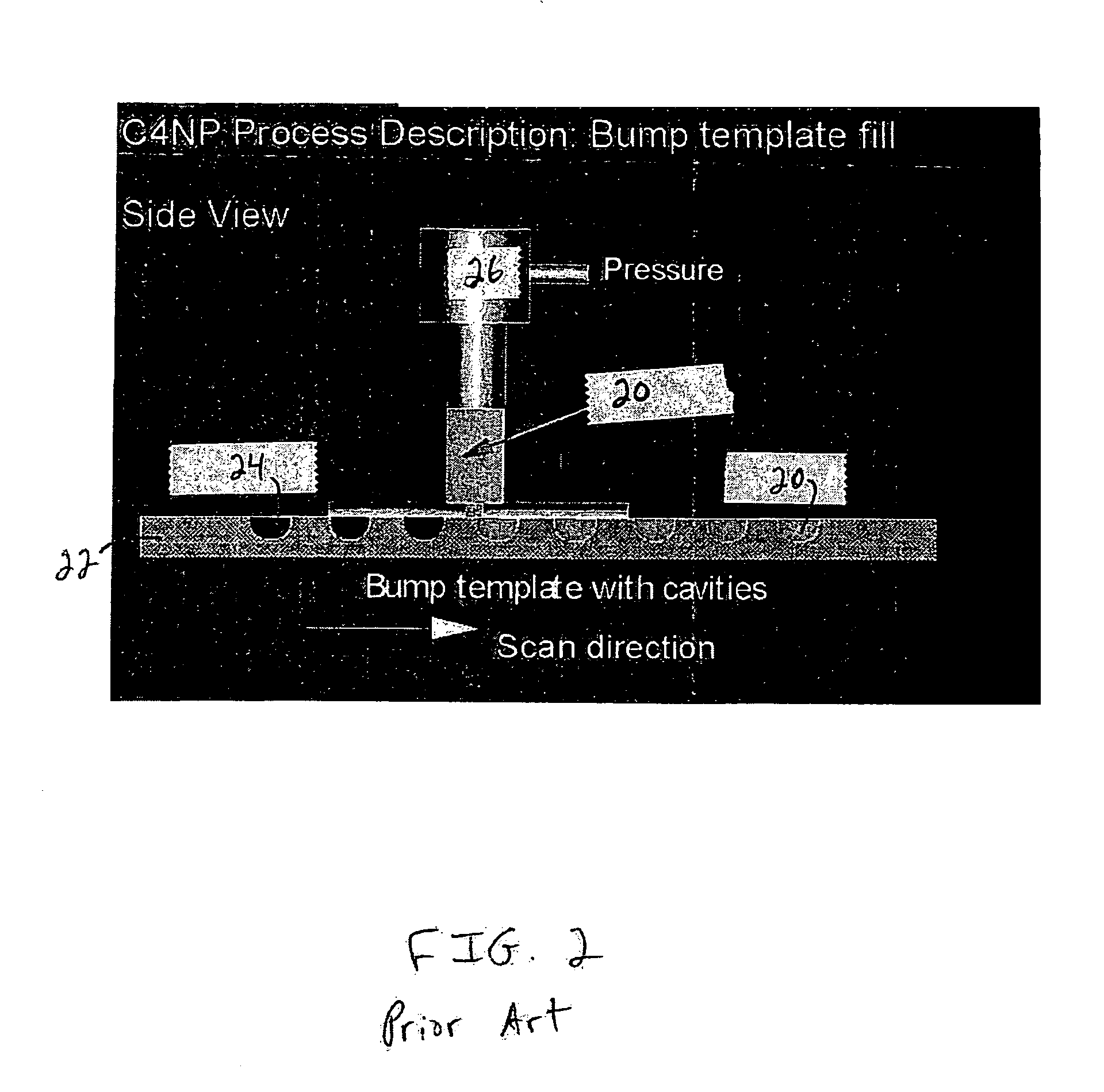

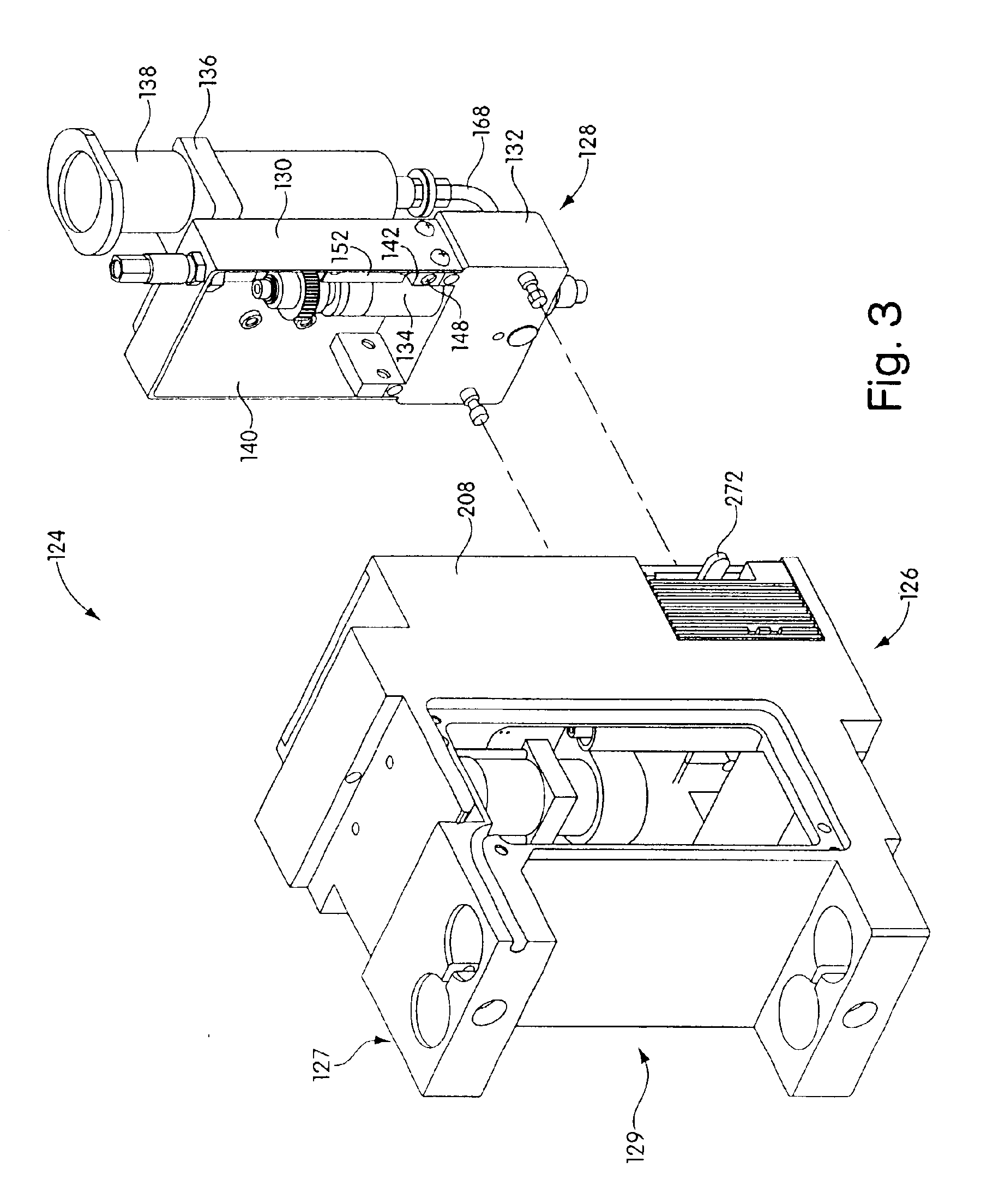

Injection molded continuously solidified solder method and apparatus

InactiveUS20050263571A1Accurate storageAccurately and completely fill the cavitiesPrinted circuit assemblingWelding/cutting media/materialsMetallurgyMaterials science

A method and apparatus for forming solder bumps by molten solder deposition into cavity arrays in a substrate immediately followed by solidification of molten solder such that precise replication of cavity volumes is consistently achieved in formed solder bump arrays. Various solder filling problems, such as those caused by surface tension and oxidation effects, are overcome by a combination of narrow molten Solder dispense slots and solidification of dispensed molten solder.

Owner:BELANGER LUC +12

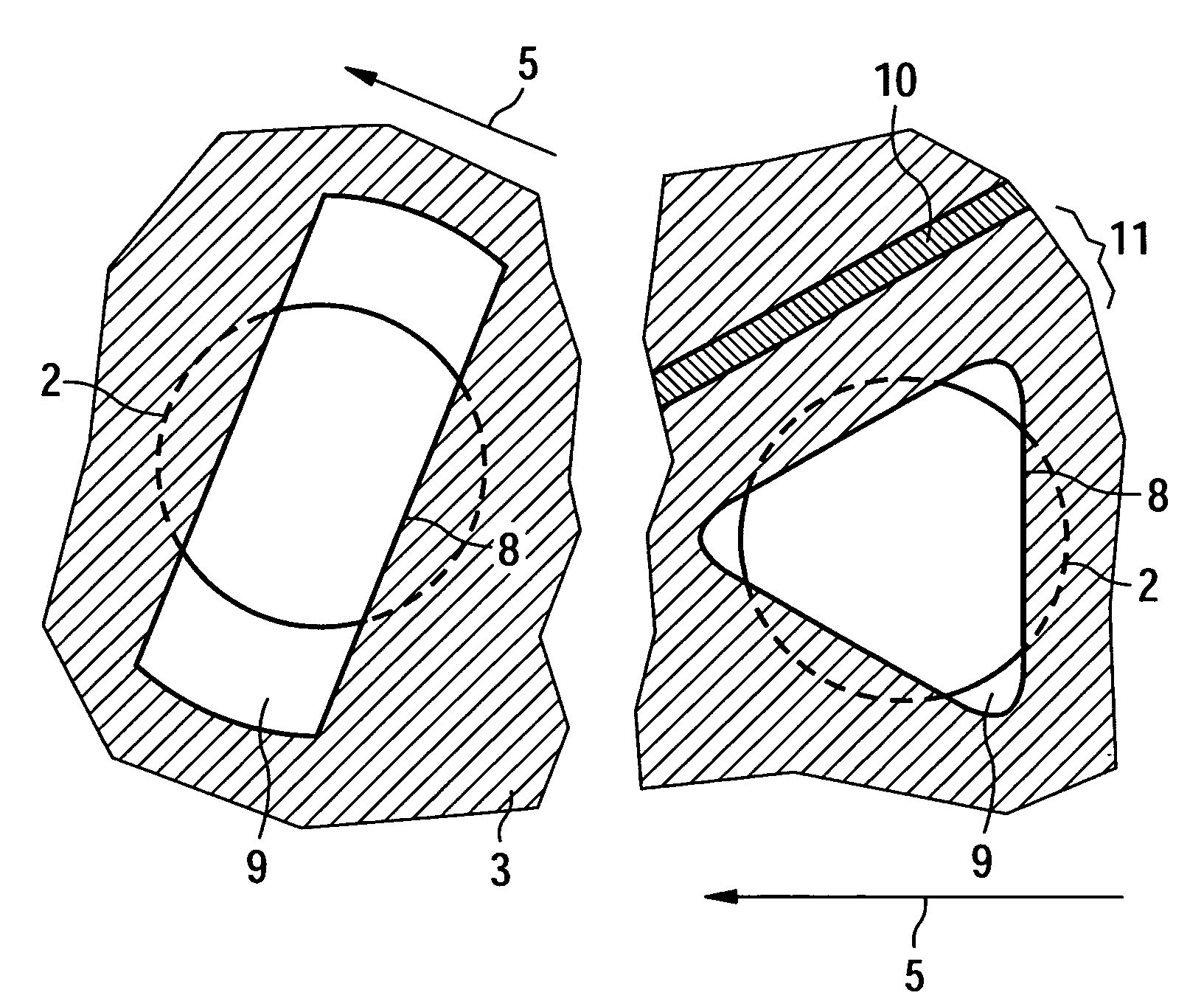

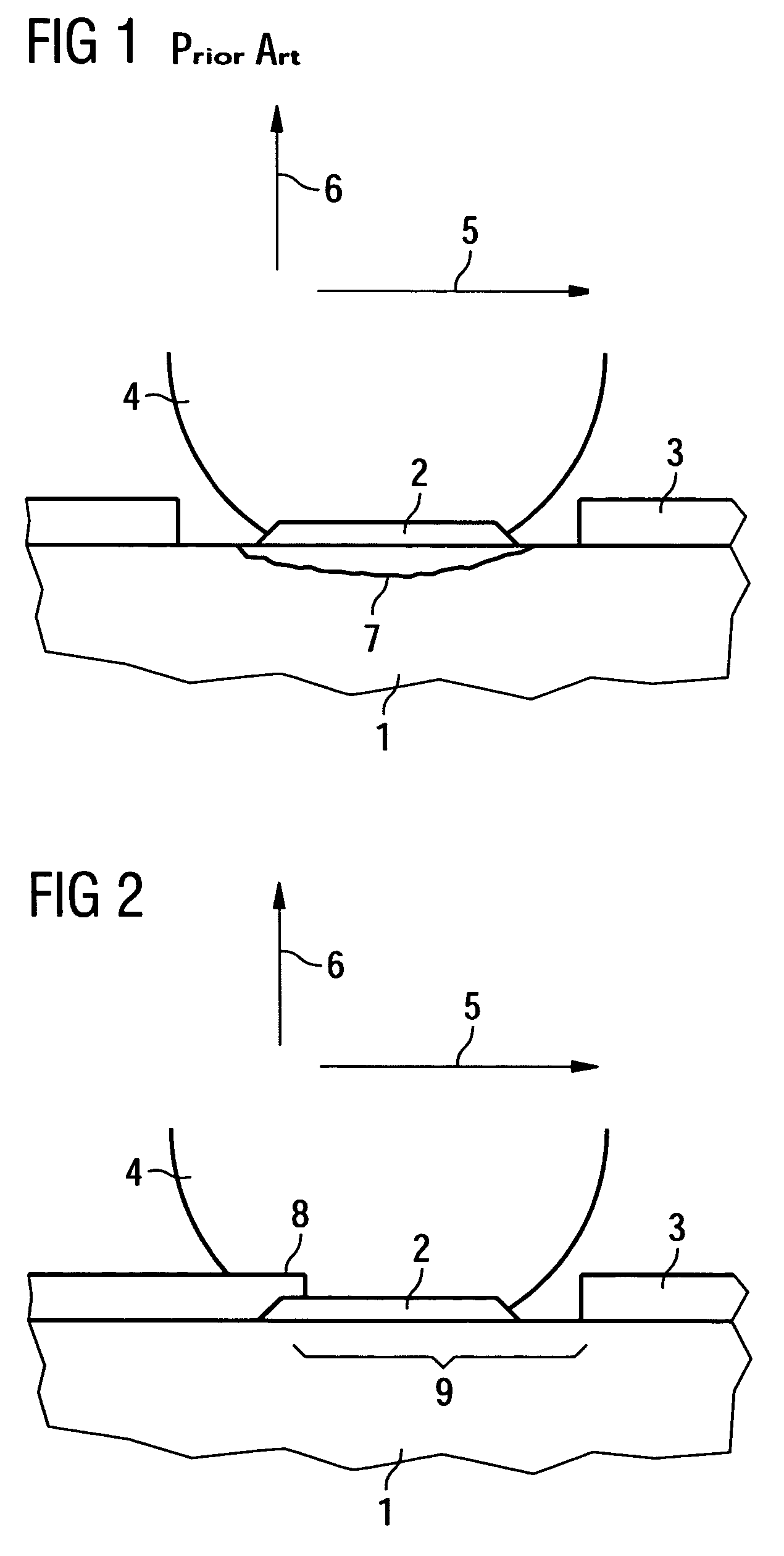

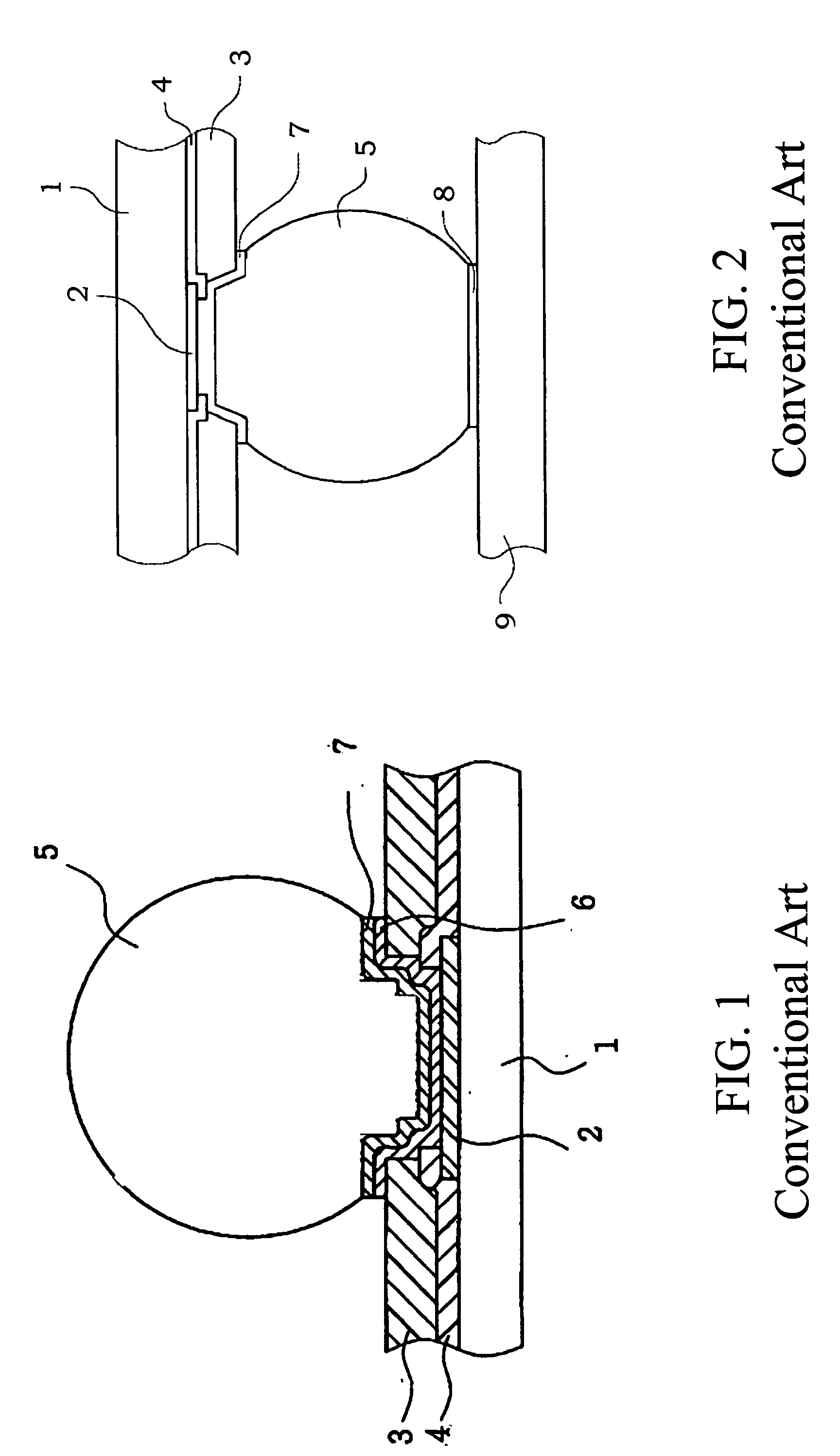

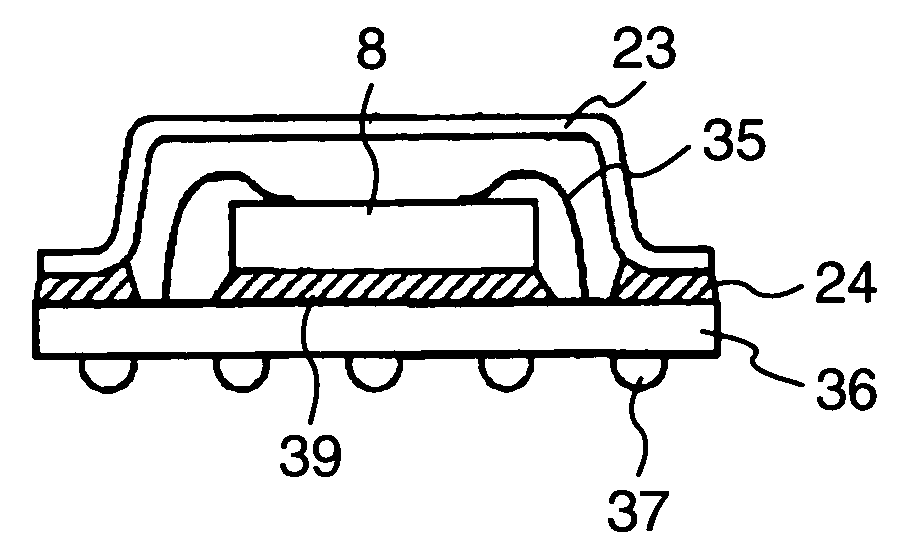

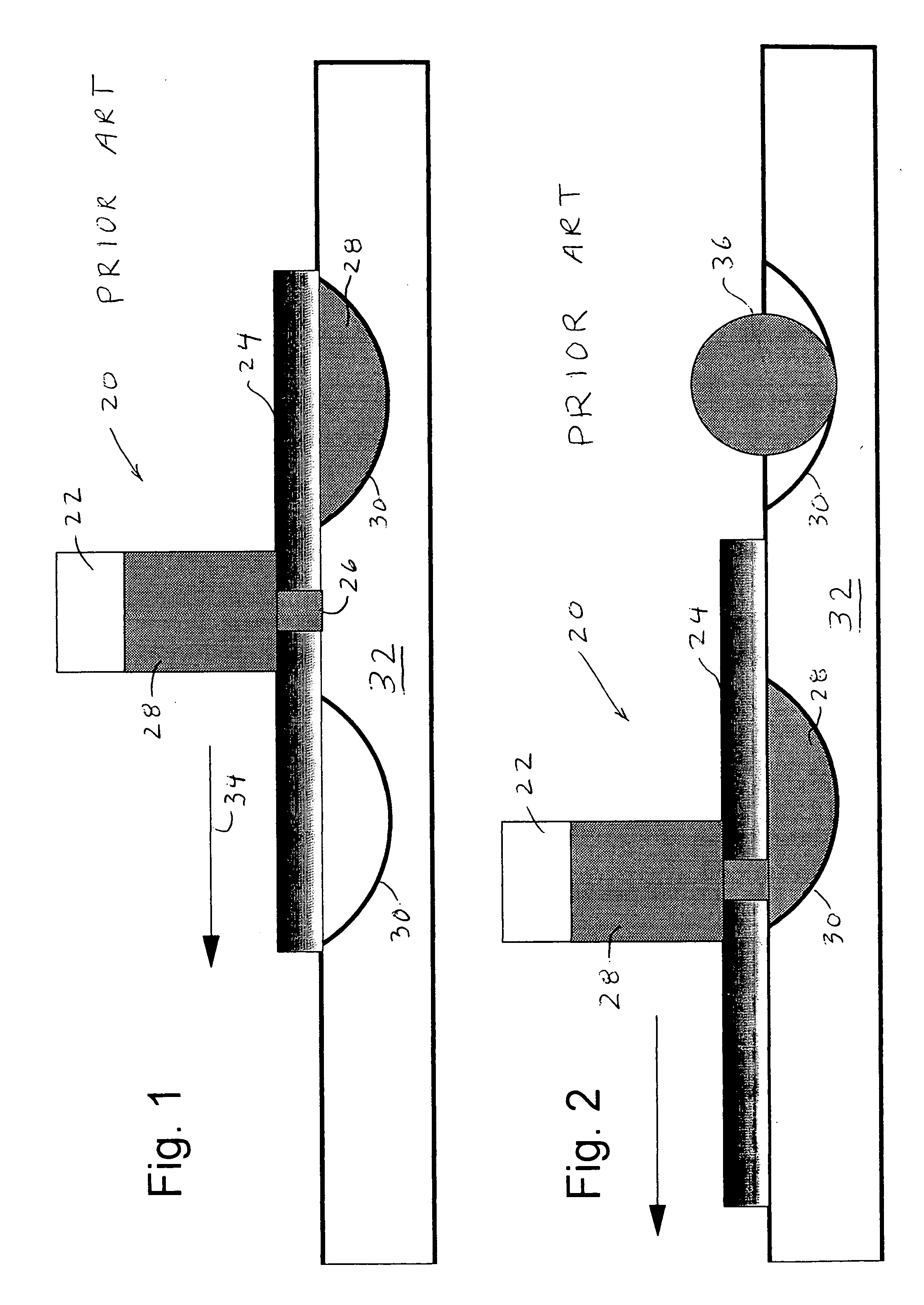

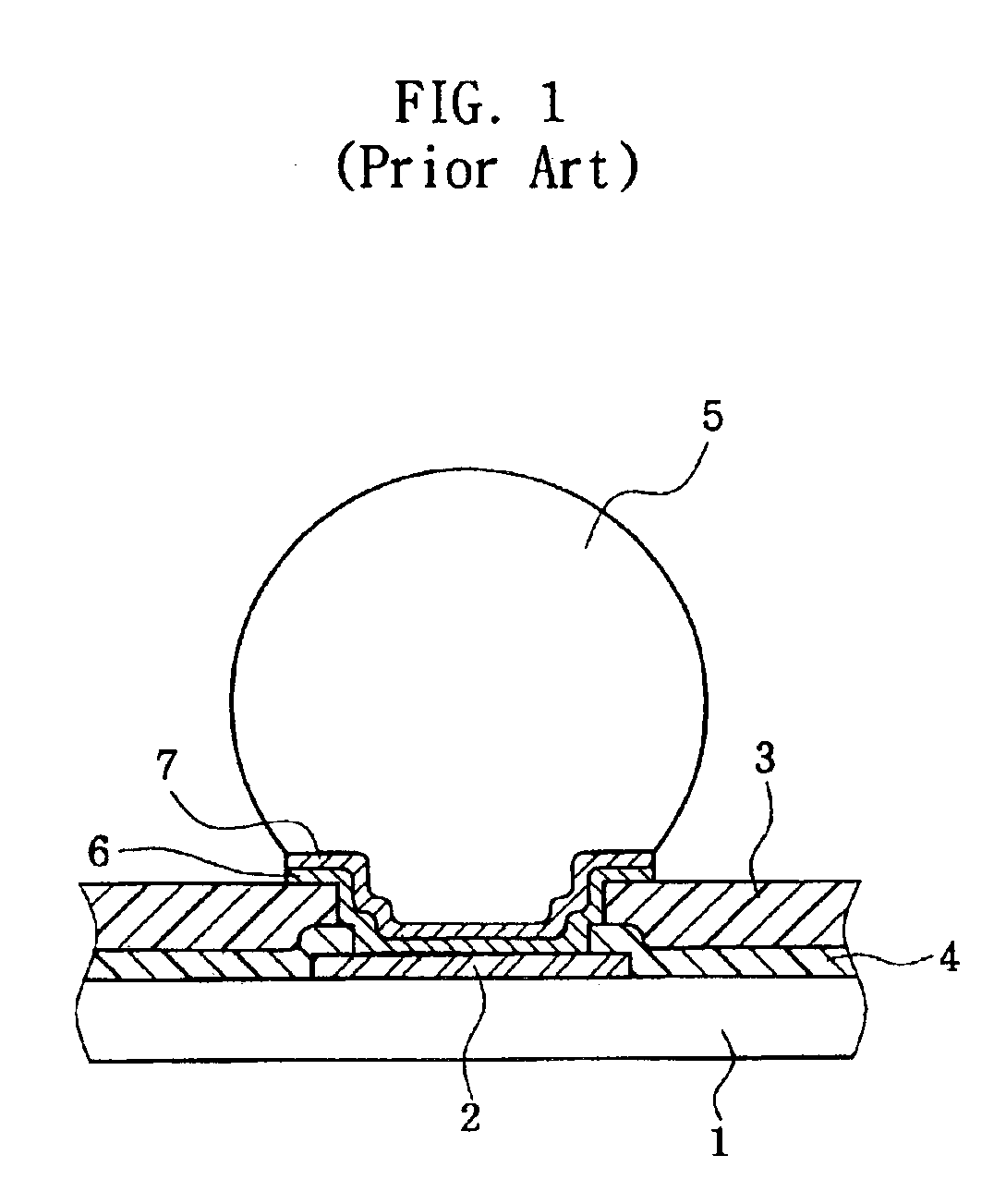

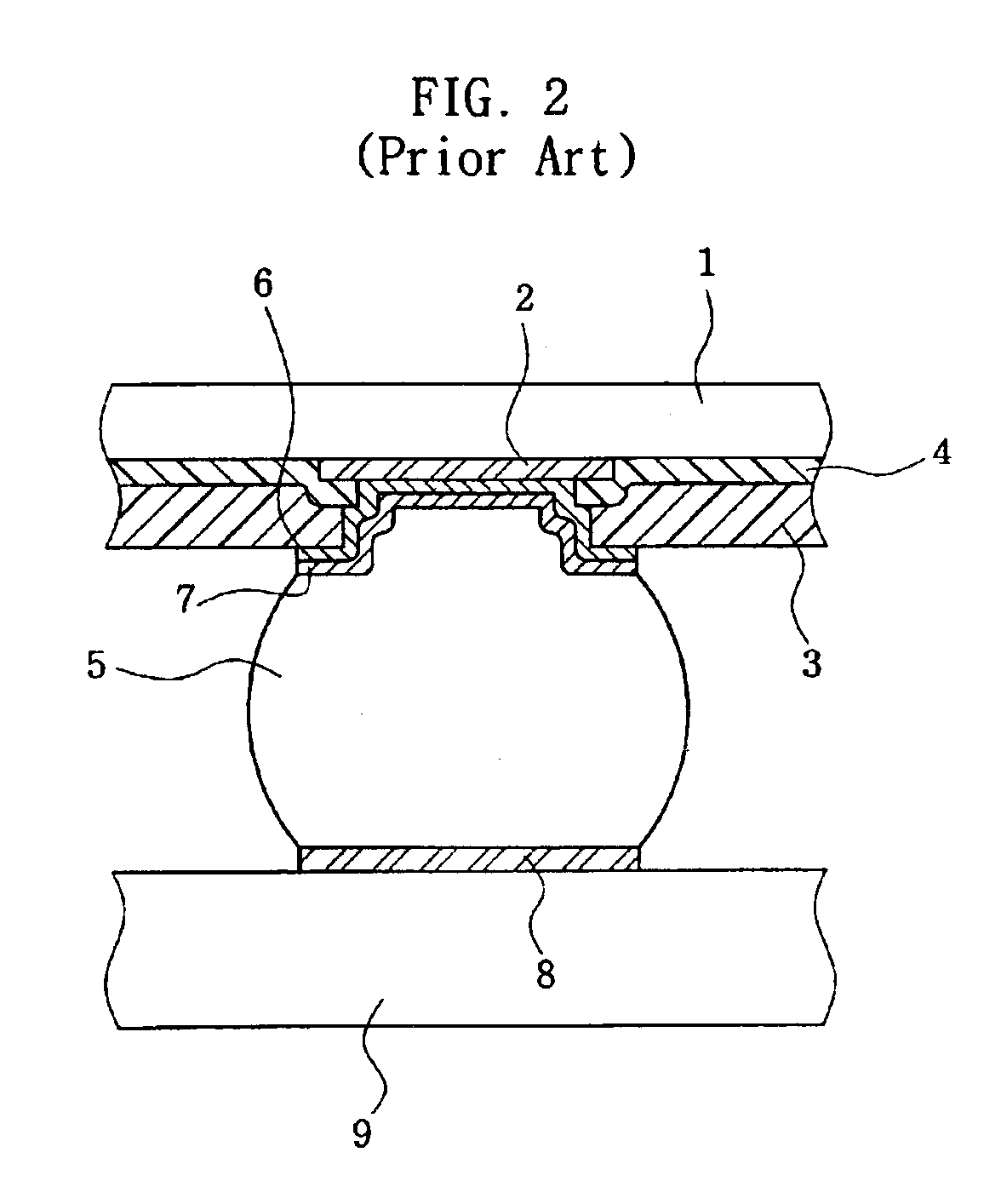

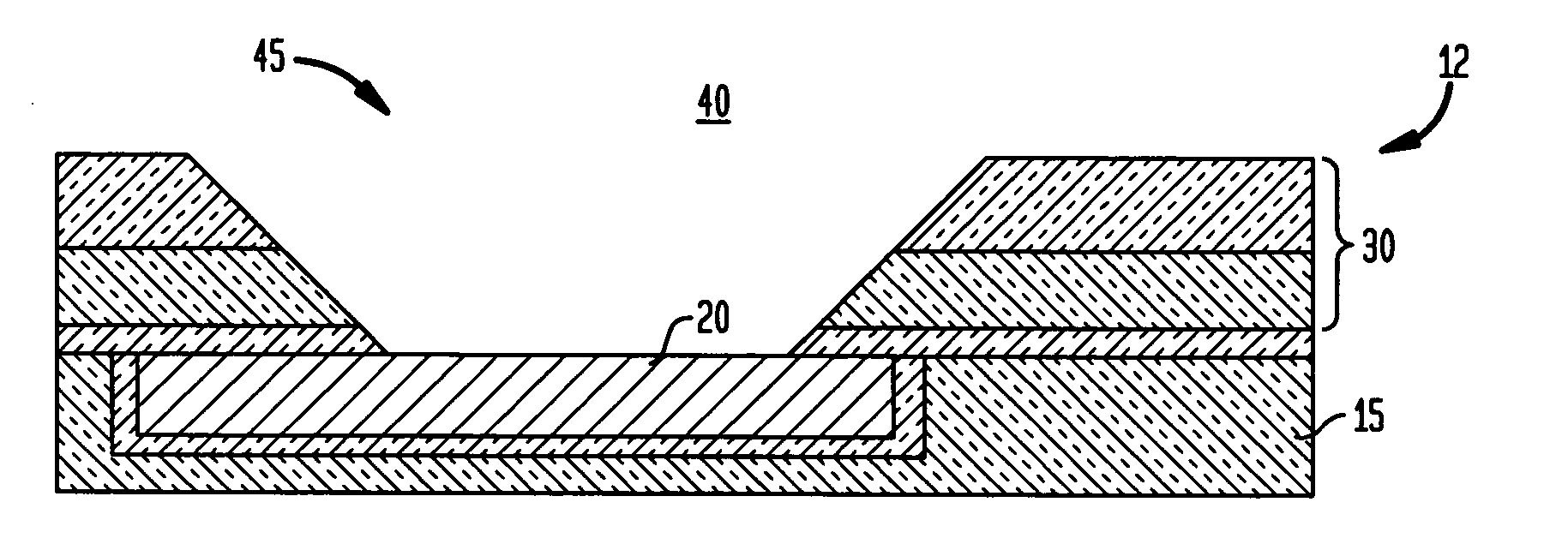

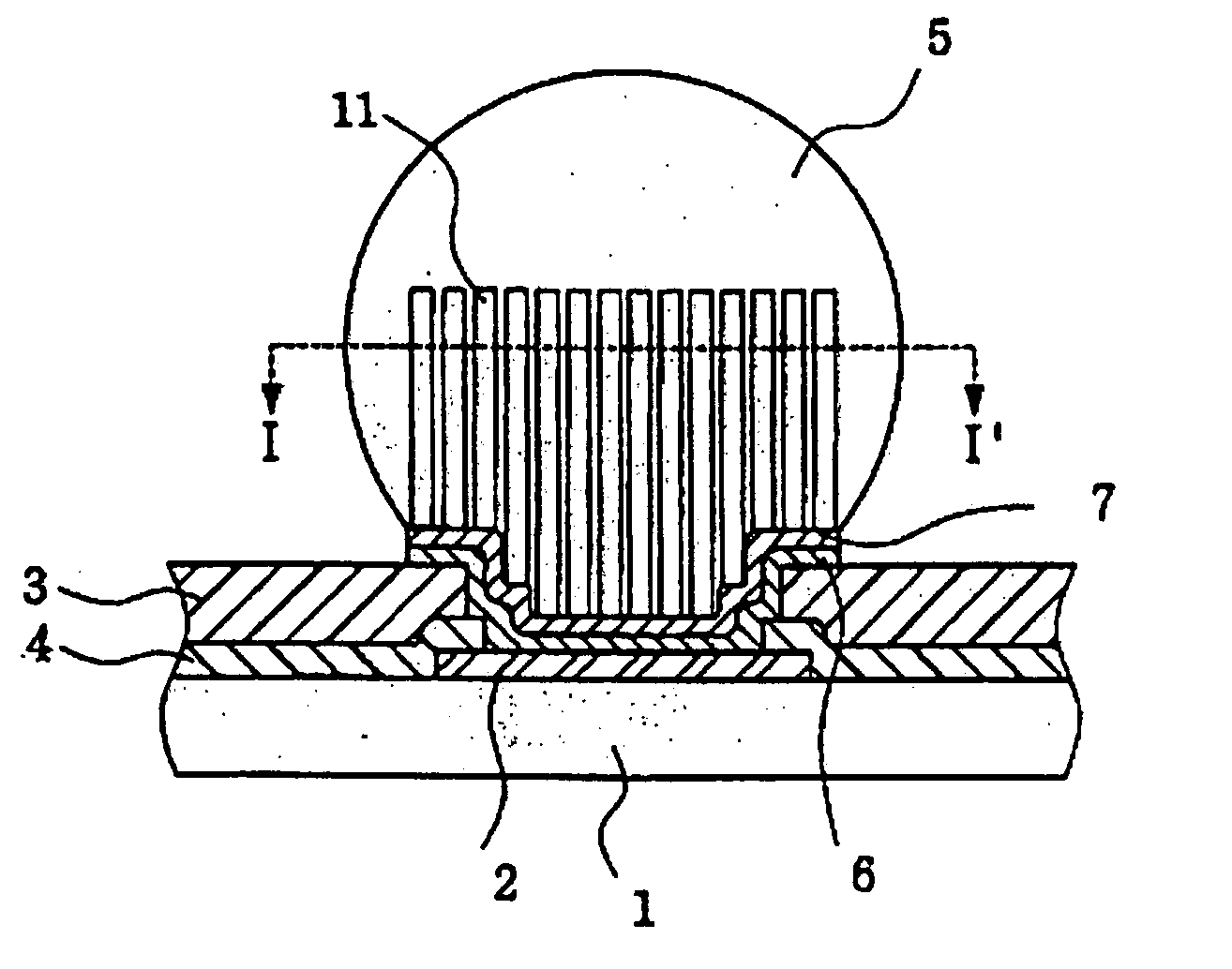

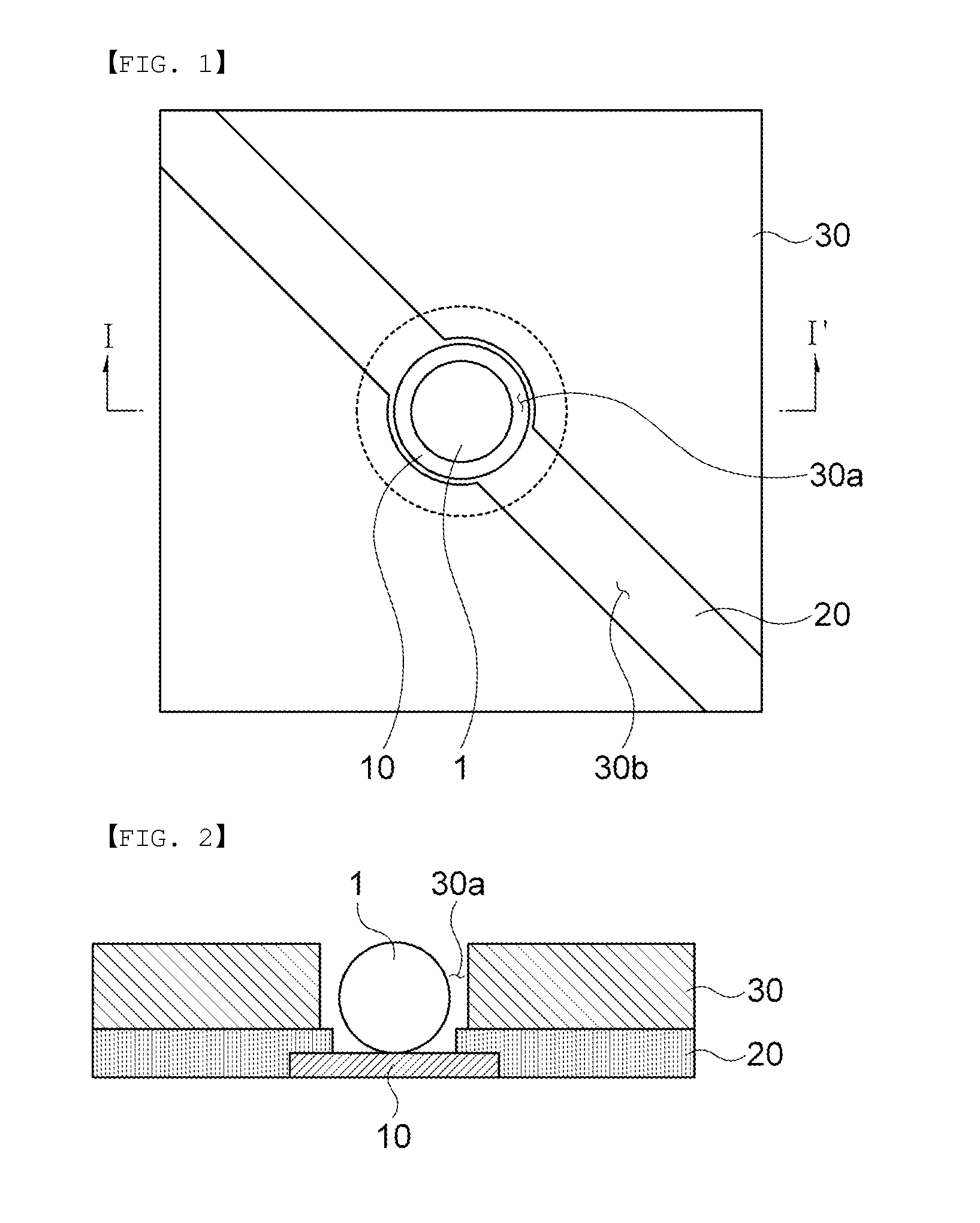

Solder bump structure and method for forming a solder bump

InactiveUS6959856B2Final product manufactureSemiconductor/solid-state device detailsCrack resistanceContact pad

A solder bump structure includes a contact pad, an intermediate layer located over the contact pad, a solder bump located over the intermediate layer, and at least one metal projection extending upwardly from a surface of the intermediate layer and embedded within the solder bump. Any crack in the solder bump will tend to propagate horizontally through the bump material, and in this case, the metal projections act as obstacles to crack propagation. These obstacles have the effect of increasing the crack resistance, and further lengthen the propagation path of any crack as it travels through the solder bump material, thus decreasing the likelihood device failure.

Owner:SAMSUNG ELECTRONICS CO LTD

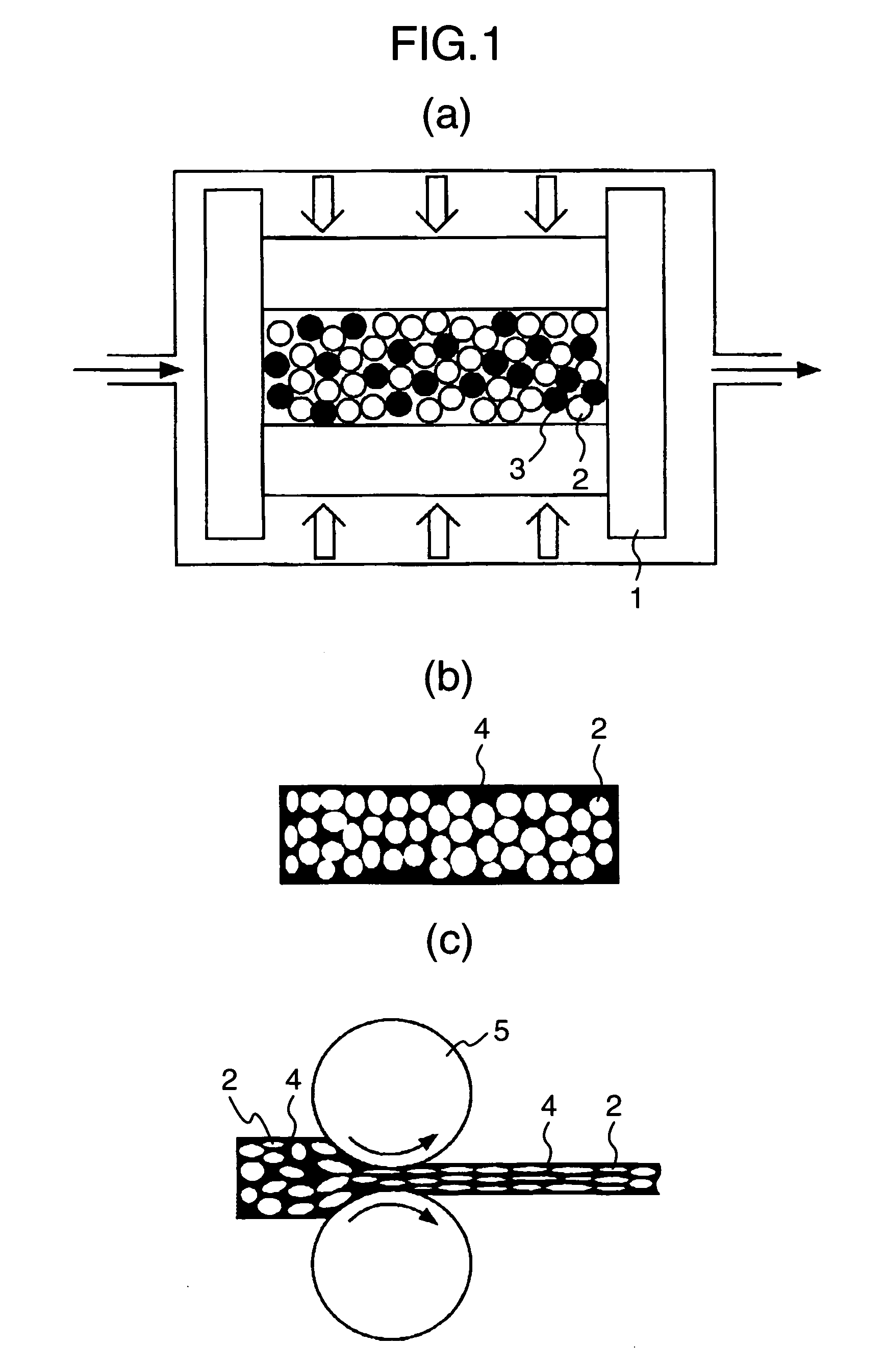

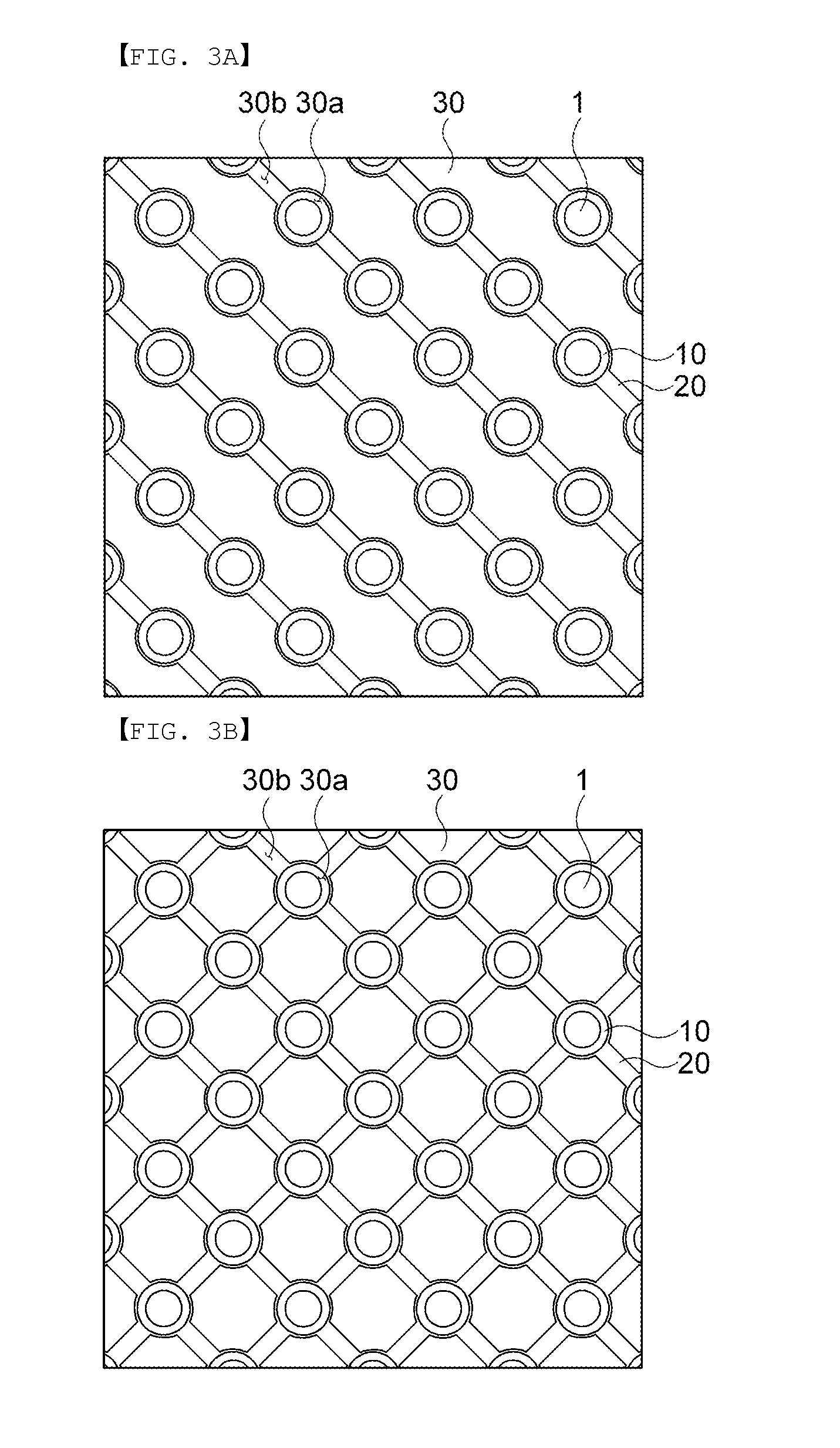

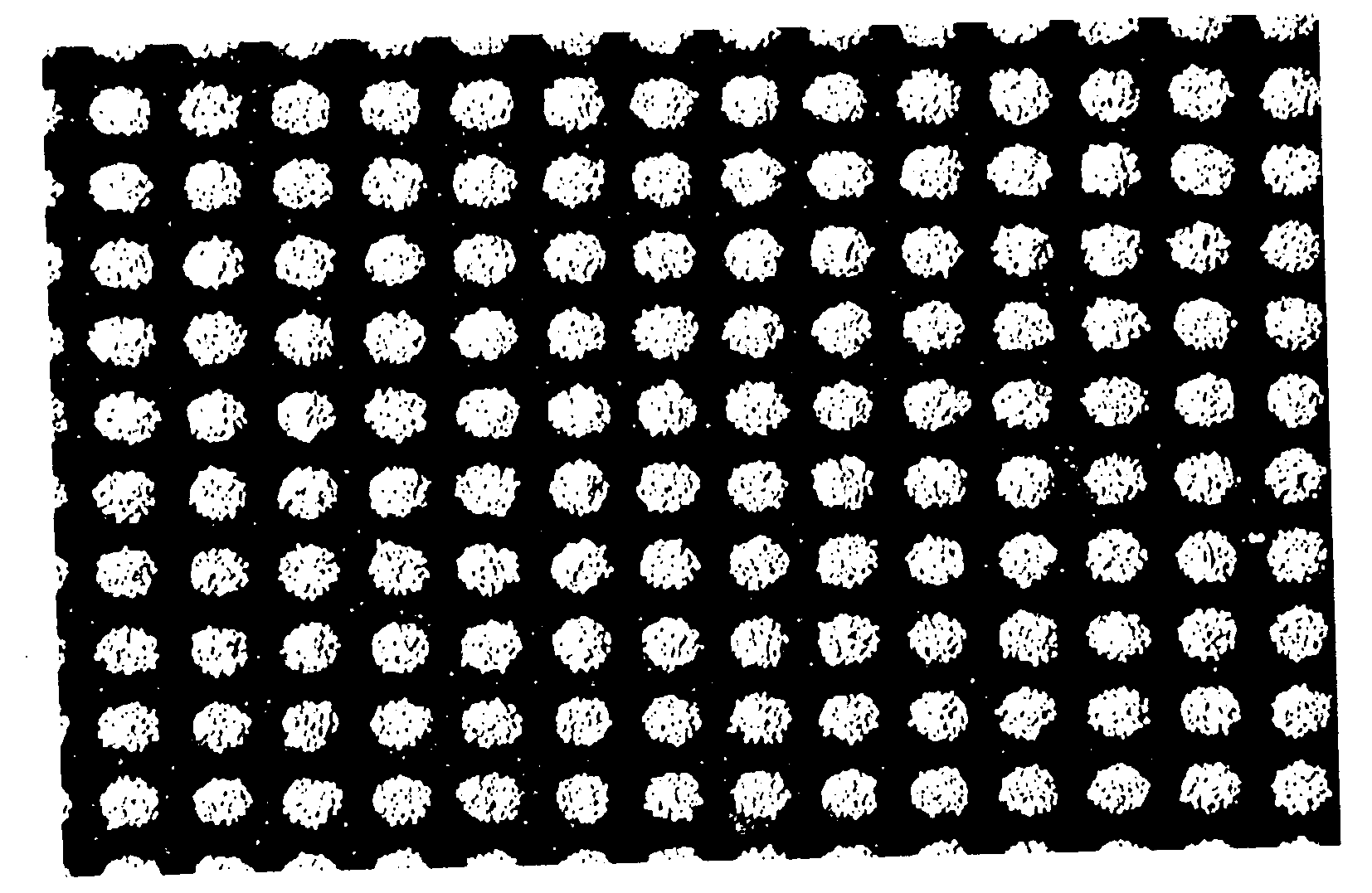

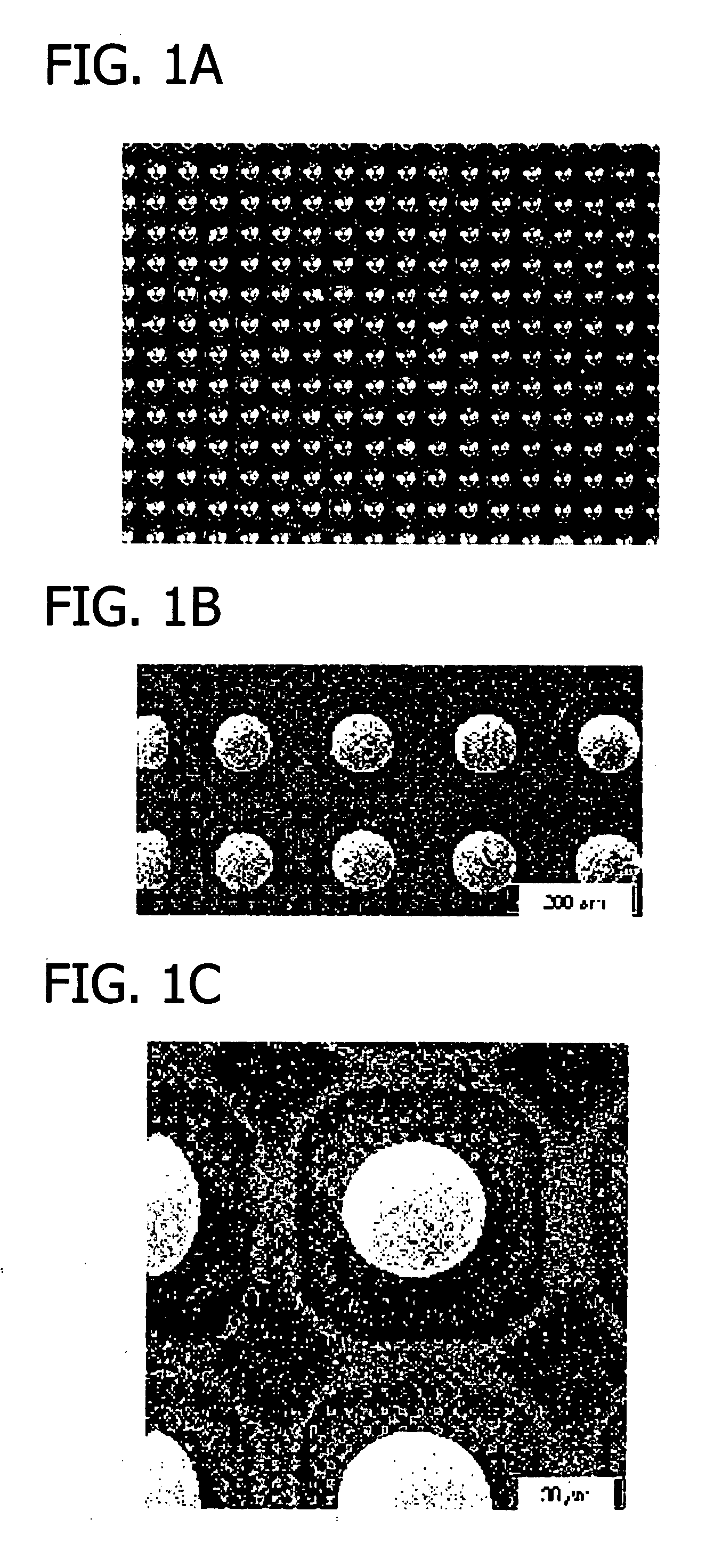

Microparticle arrangement film, electrical connection film, electrical connection structure, and microparticle arrangement method

InactiveUS20040106334A1Printed circuit assemblingNon-insulated conductorsElectricityElectrical connection

The present invention provides a method for disposing specific fine particles at arbitrary positions of a film with efficiency and ease, in just proportion and under a stable condition, and a fine particle-disposed film, that is to say, a method for disposing fine particles that basically disposes one particle in one hole, and fine particle-disposed film, as well as a conductively connecting film and a conductively connected structure, when opposite fine electrodes are connected, enabling to carry out easily an electric connection of high connecting reliability in a short time without causing leakage from neighbor electrodes by employing a film in which conductive fine particles are disposed at arbitrary positions thereof. The invention is a fine particle-disposed film, in which fine particles are disposed, the fine particles each having: an average particle diameter of 5 to 800 mum; an aspect ratio of less than 1.5; and CV value of 10% or less, wherein the film has holes at arbitrary positions in a surface thereof, the holes each having: an average hole diameter which is ½ to 2 times of the average particle diameter of the fine particle; the aspect ratio of less than 2; and the CV value of 20% or less, and the fine particles are disposed on the surface of the holes or inside the holes.

Owner:SUZUKI TATSUO +2

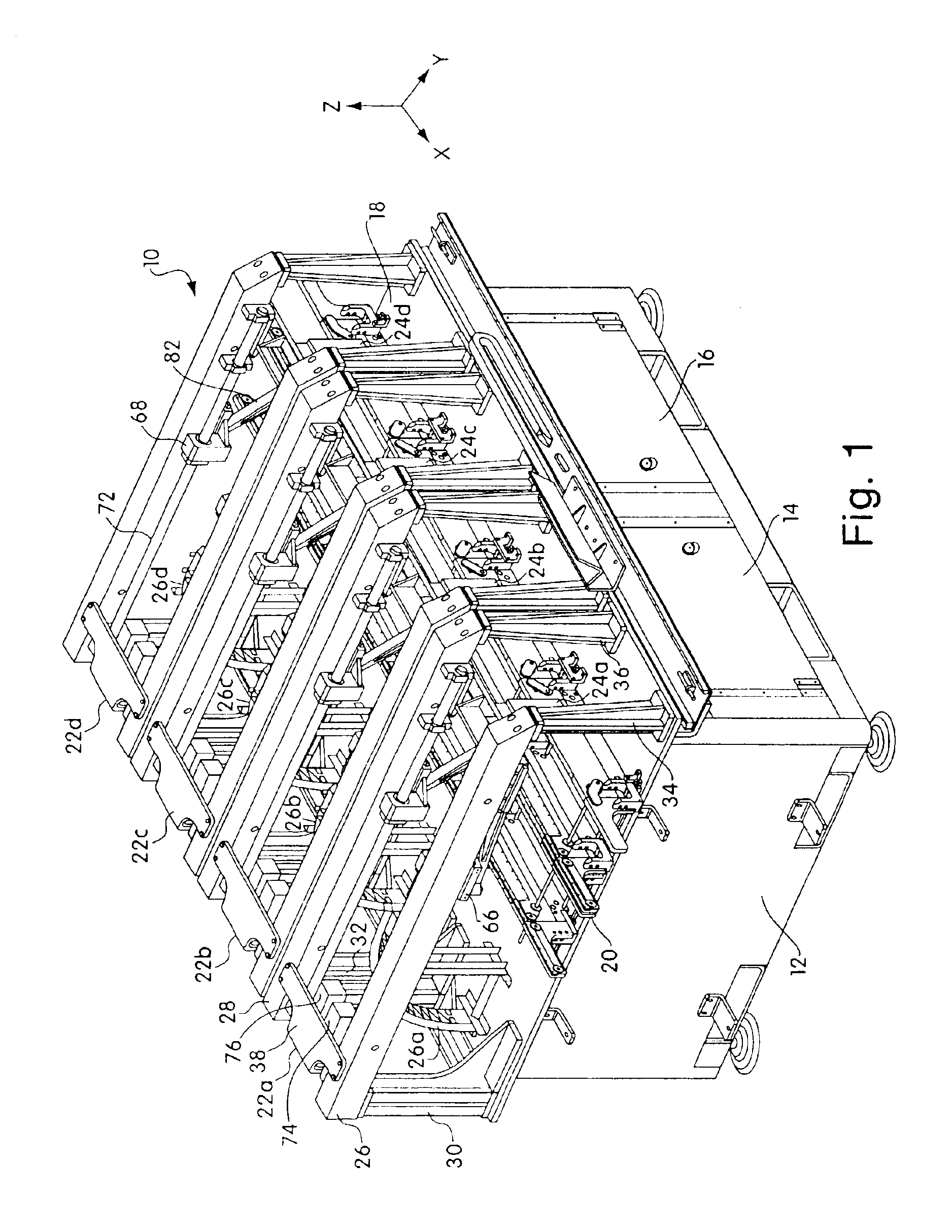

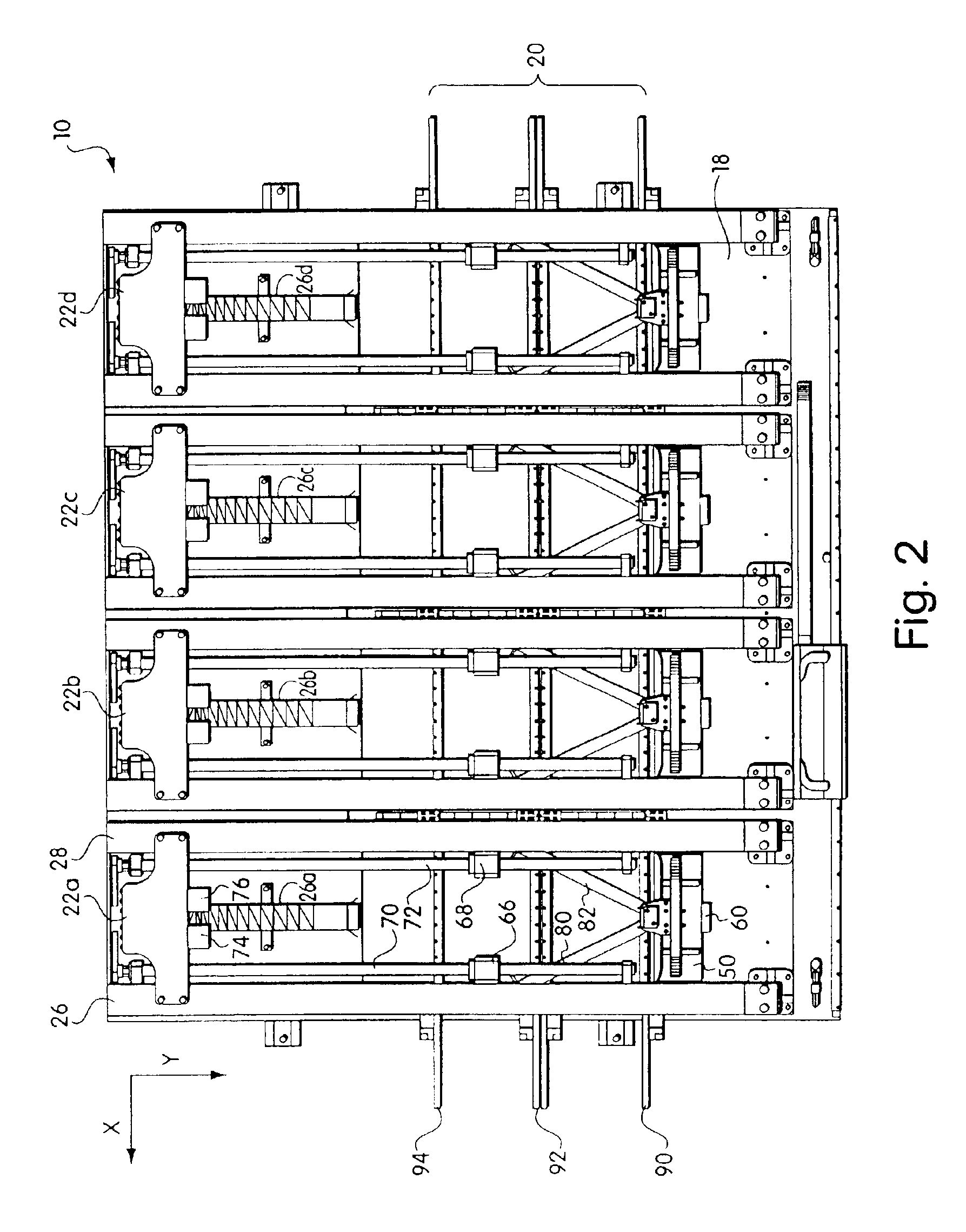

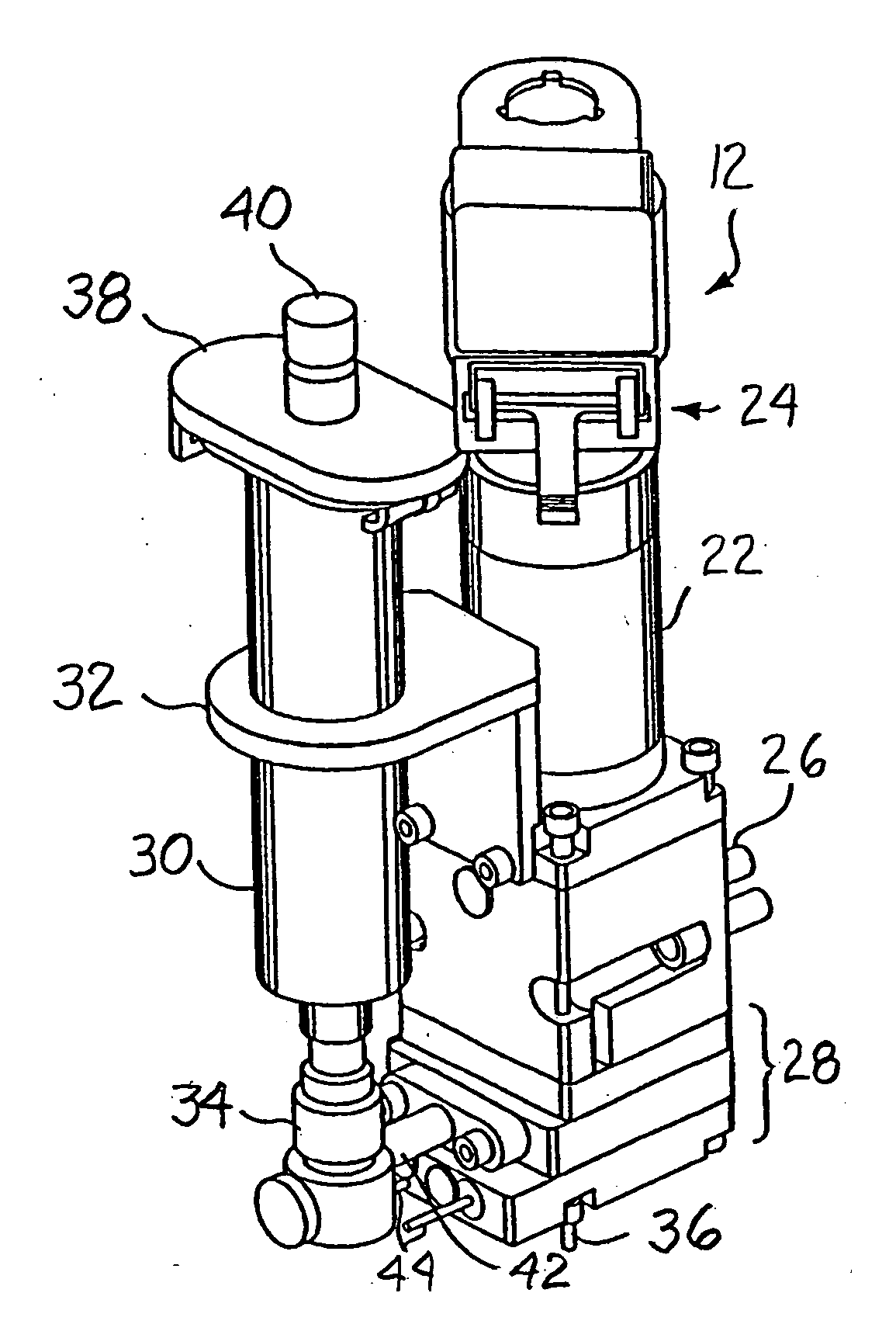

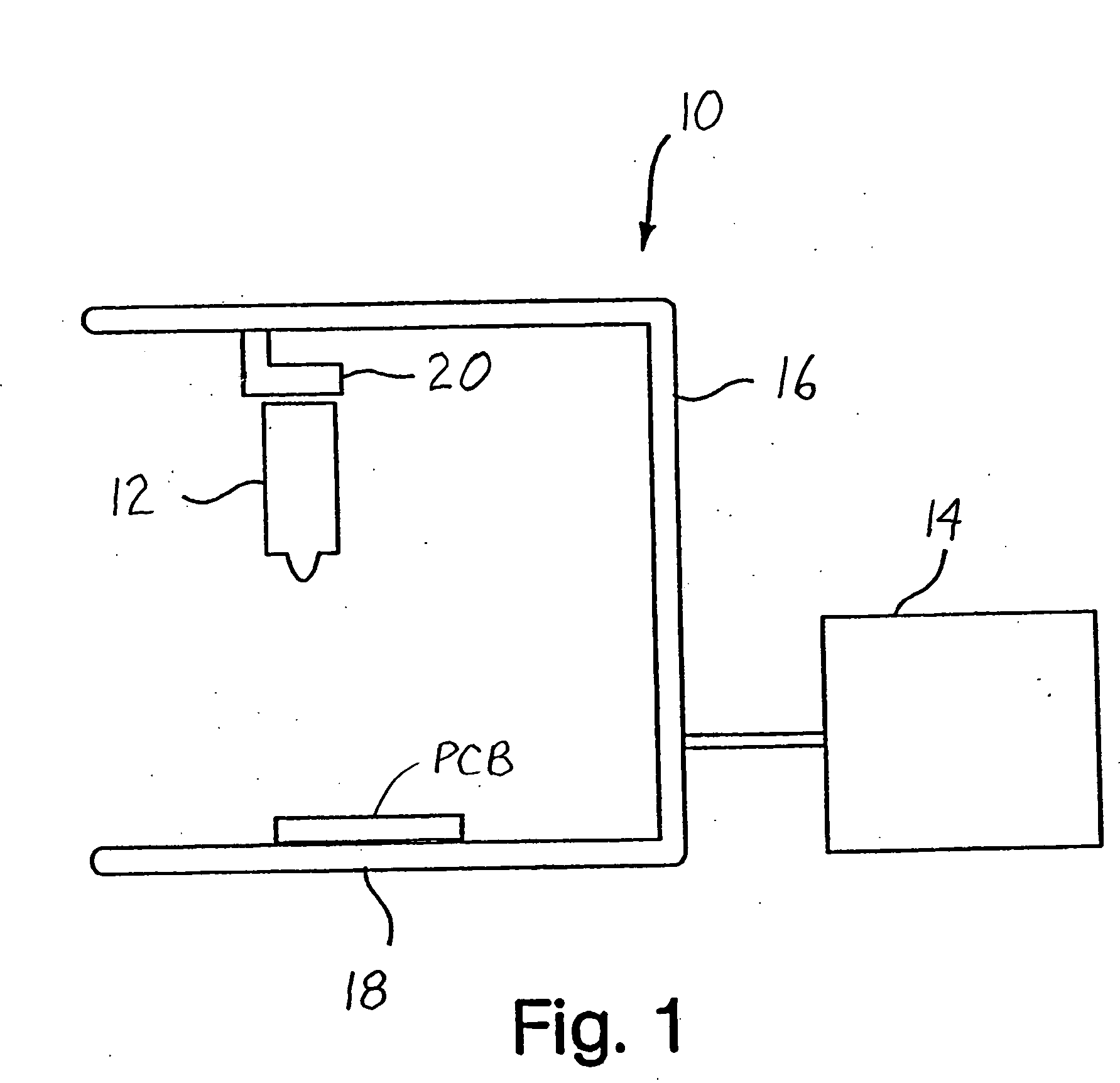

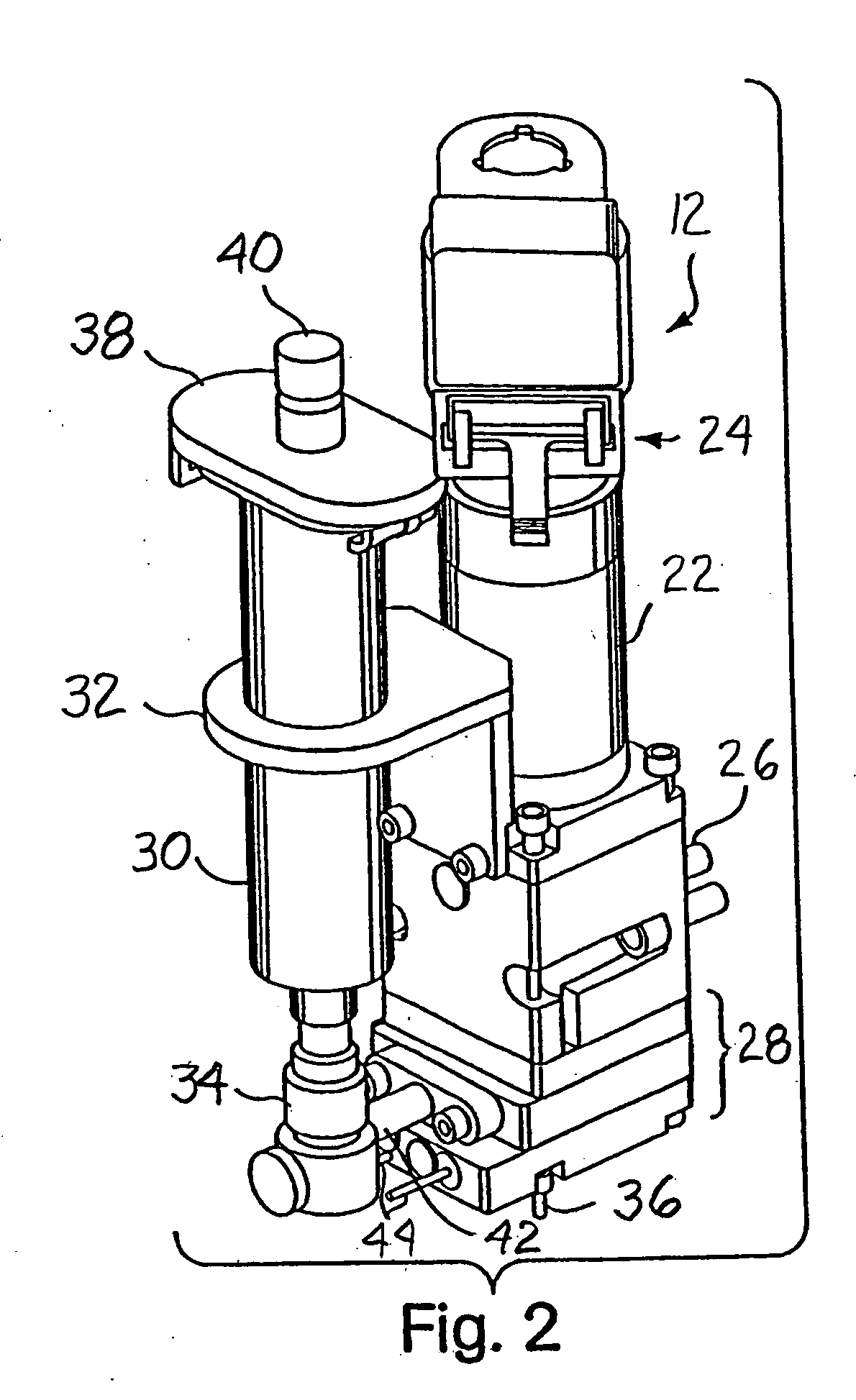

Dispensing system and method

InactiveUS6866881B2Increase the number ofReduce gear ratioLarge containersPretreated surfacesMotor unitElectric motor

A dispensing system and method for dispensing material onto a substrate. The dispensing system includes a frame, a support, coupled to the frame, that supports the substrate at a dispensing position in the dispensing system, and a dispensing head, coupled to the frame, that dispenses the material onto the substrate. The dispensing head includes a motor unit having a first motor coupled to an output drive mechanism, and a dispensing unit, removably coupled to the motor unit, having a material outlet from which the dispensing material is dispensed, the dispensing unit having a dispensing mechanism coupled to the material outlet and coupled to the output drive mechanism of the motor unit such that operation of the first motor causes the dispensing mechanism to dispense material through the outlet. The dispensing head may be controlled for deposition of dots of material having diameters smaller than a dispensing needle of the dispensing unit.

Owner:KPS SPECIAL SITUATIONS FUND II LP

Damascene patterning of barrier layer metal for C4 solder bumps

InactiveUS20060016861A1Reduce the amount presentReduce spacingPrinted circuit assemblingSemiconductor/solid-state device detailsEtchingCopper

A system and method for forming a novel C4 solder bump for BLM (Ball Limiting Metallurgy) includes a novel damascene technique is implemented to eliminate the Cu undercut problem and improve the C4 pitch. In the process, a barrier layer metal stack is deposited above a metal pad layer. A top layer of the barrier layer metals (e.g., Cu) is patterned by CMP. Only bottom layers of the barrier metal stack are patterned by a wet etching. The wet etch time for the Cu-based metals is greatly reduced resulting in a reduced undercut. This allows the pitch of the C4 solder bumps to be reduced. An alternate method includes use of multiple vias at the solder bump terminal.

Owner:GLOBALFOUNDRIES INC

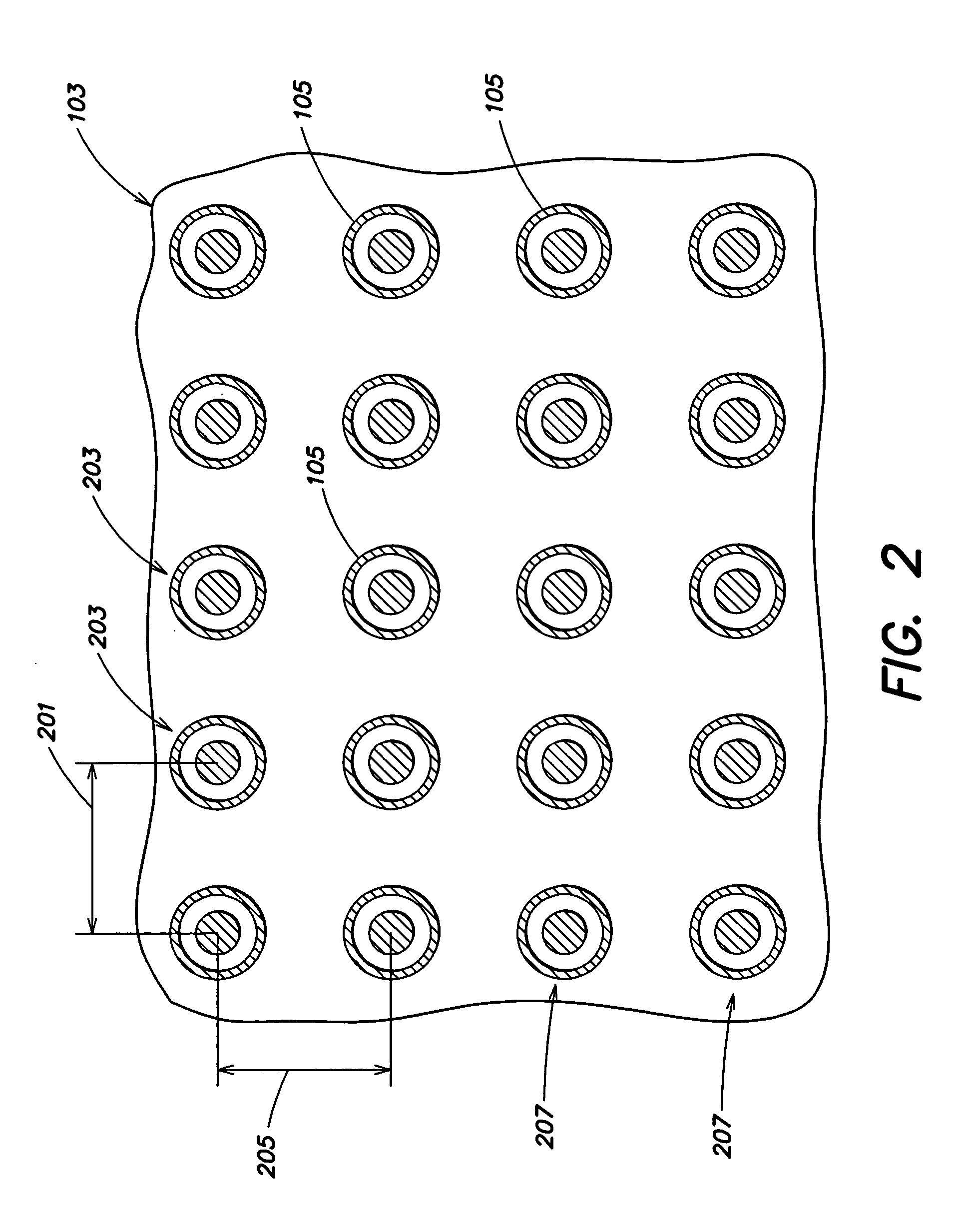

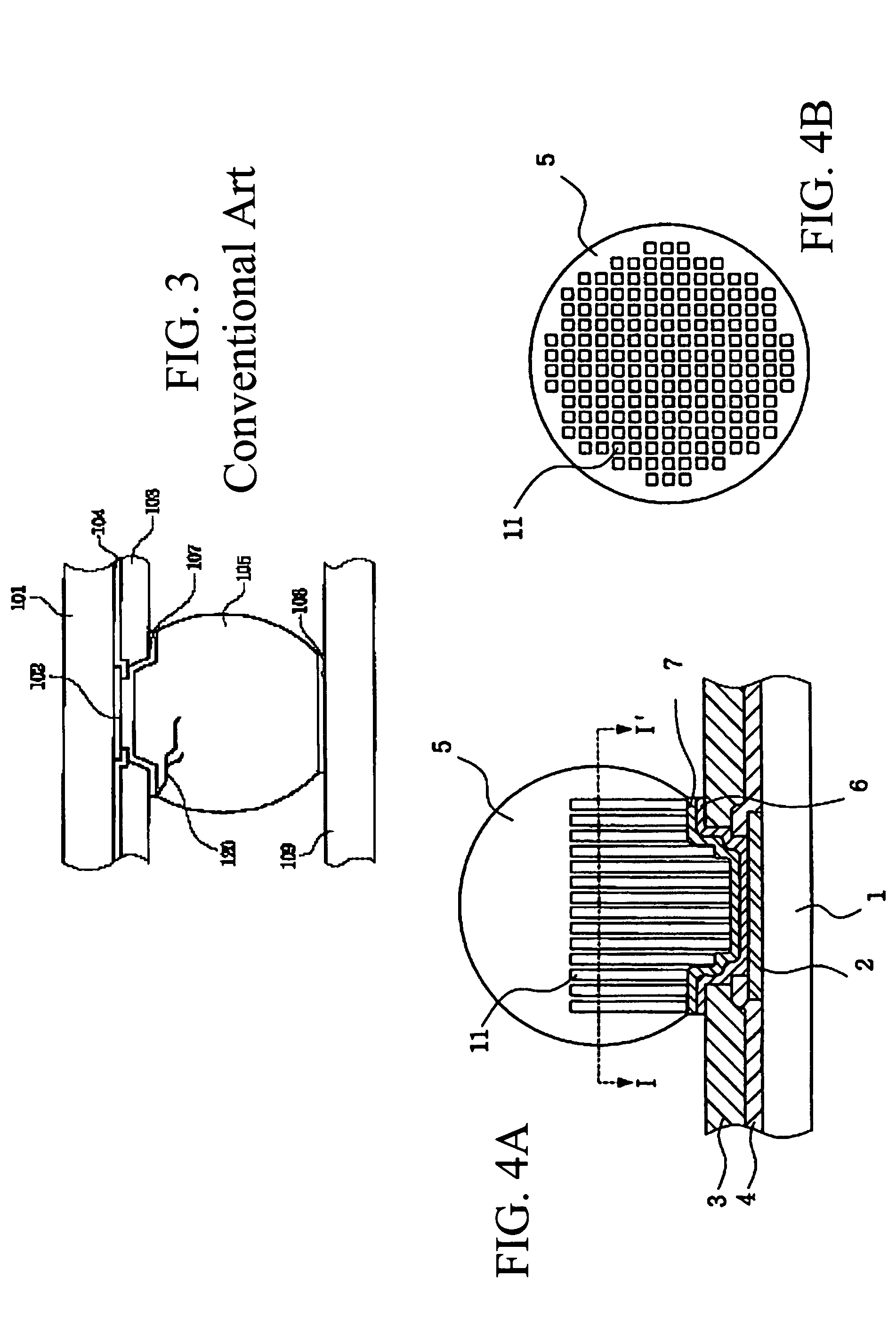

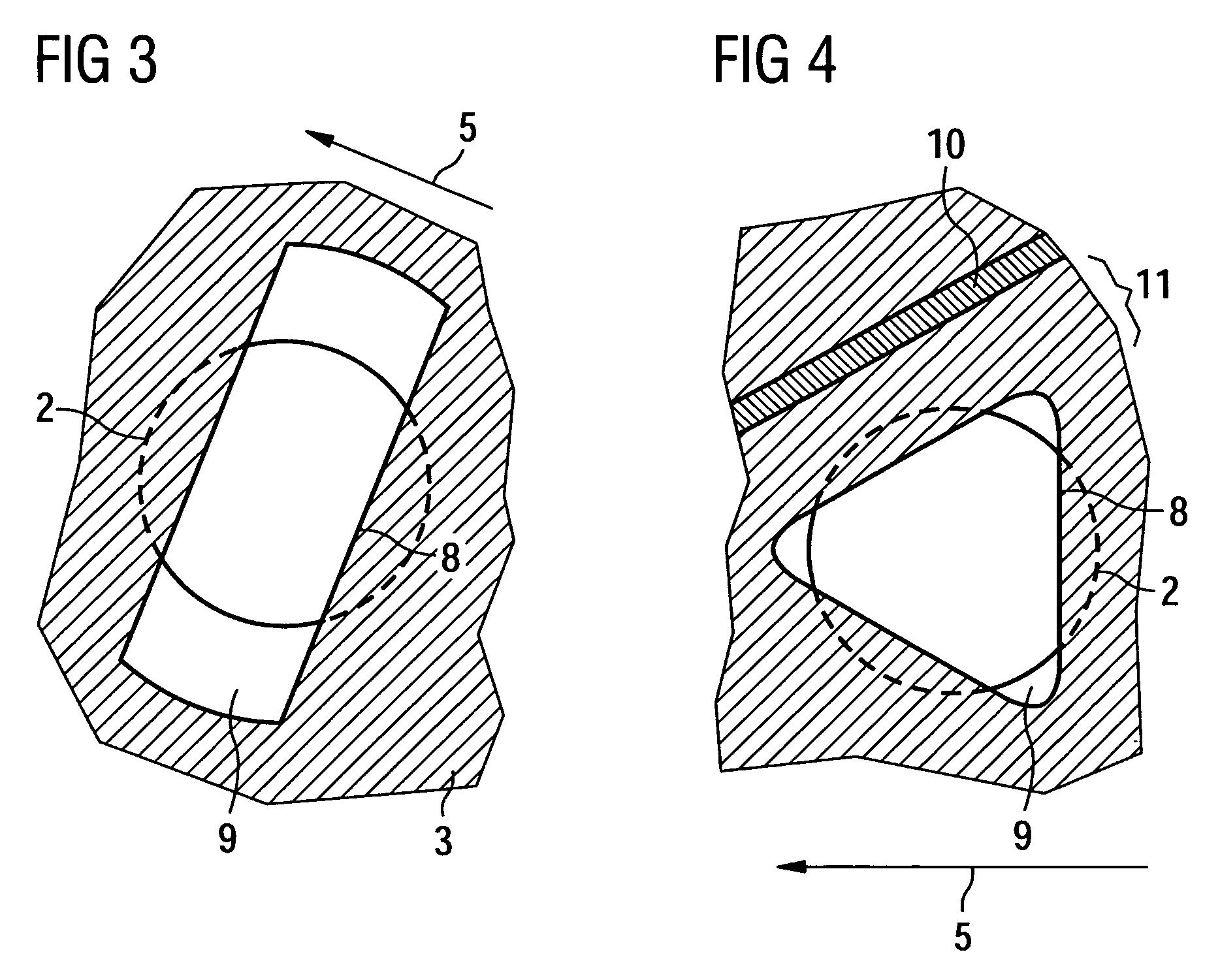

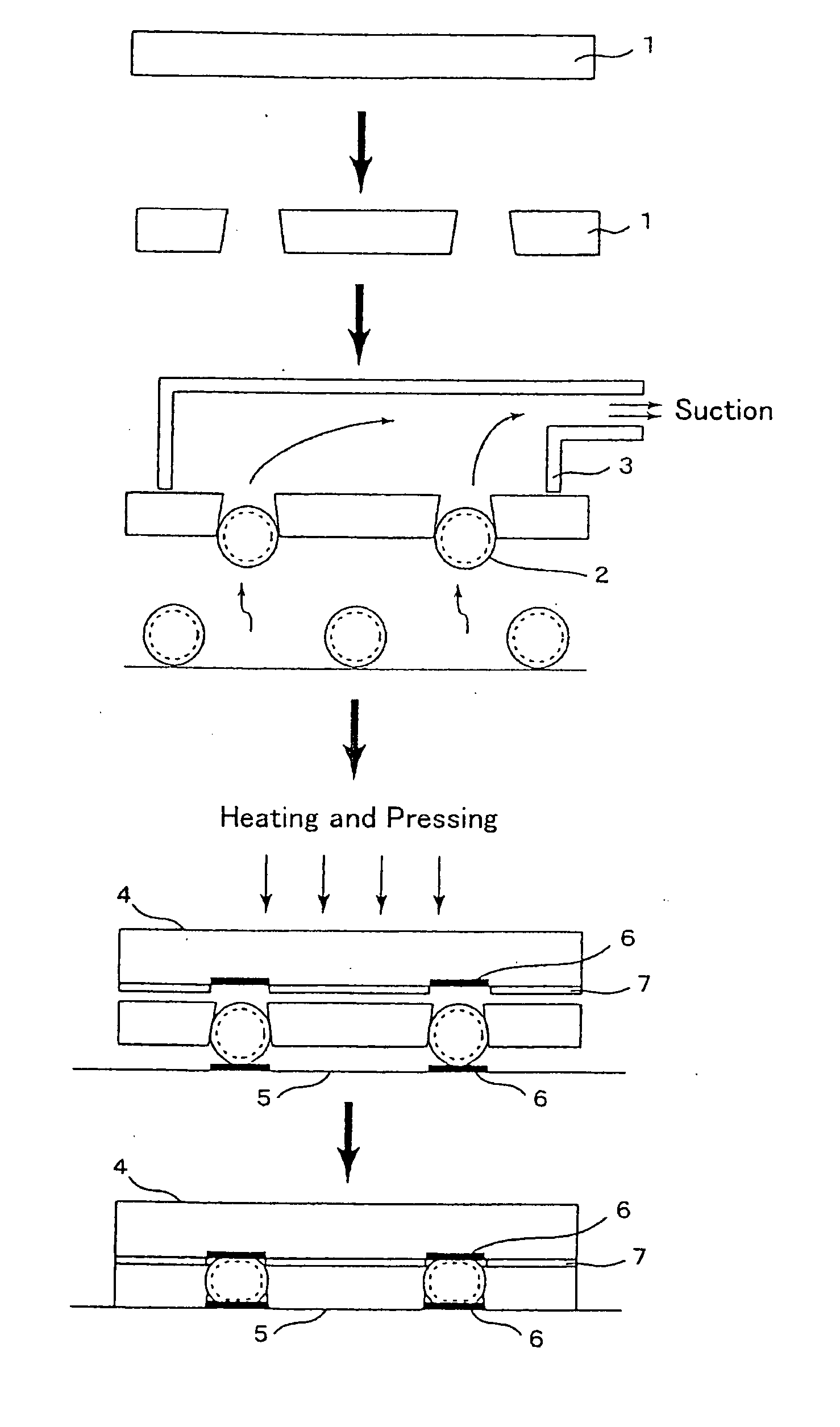

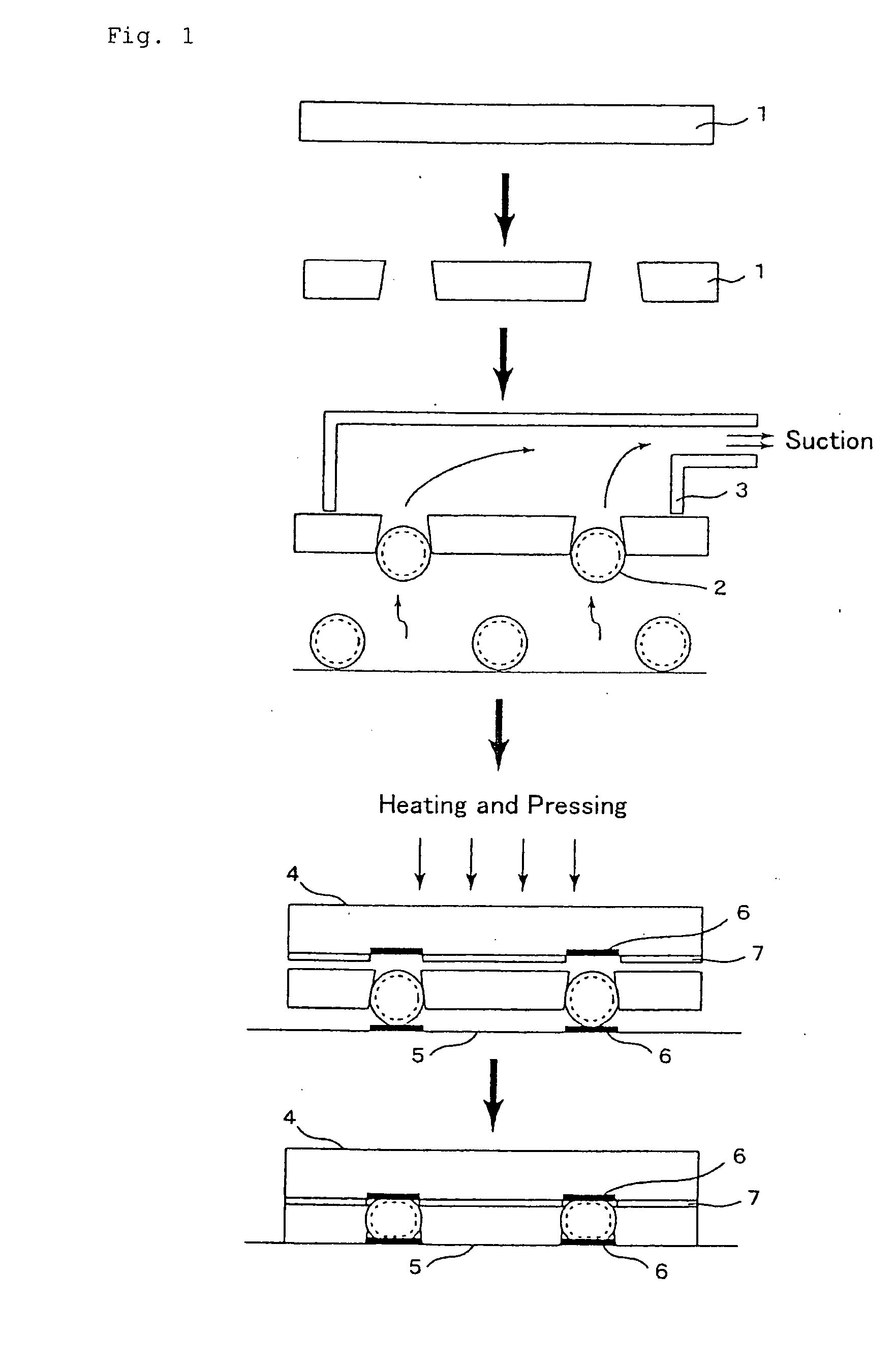

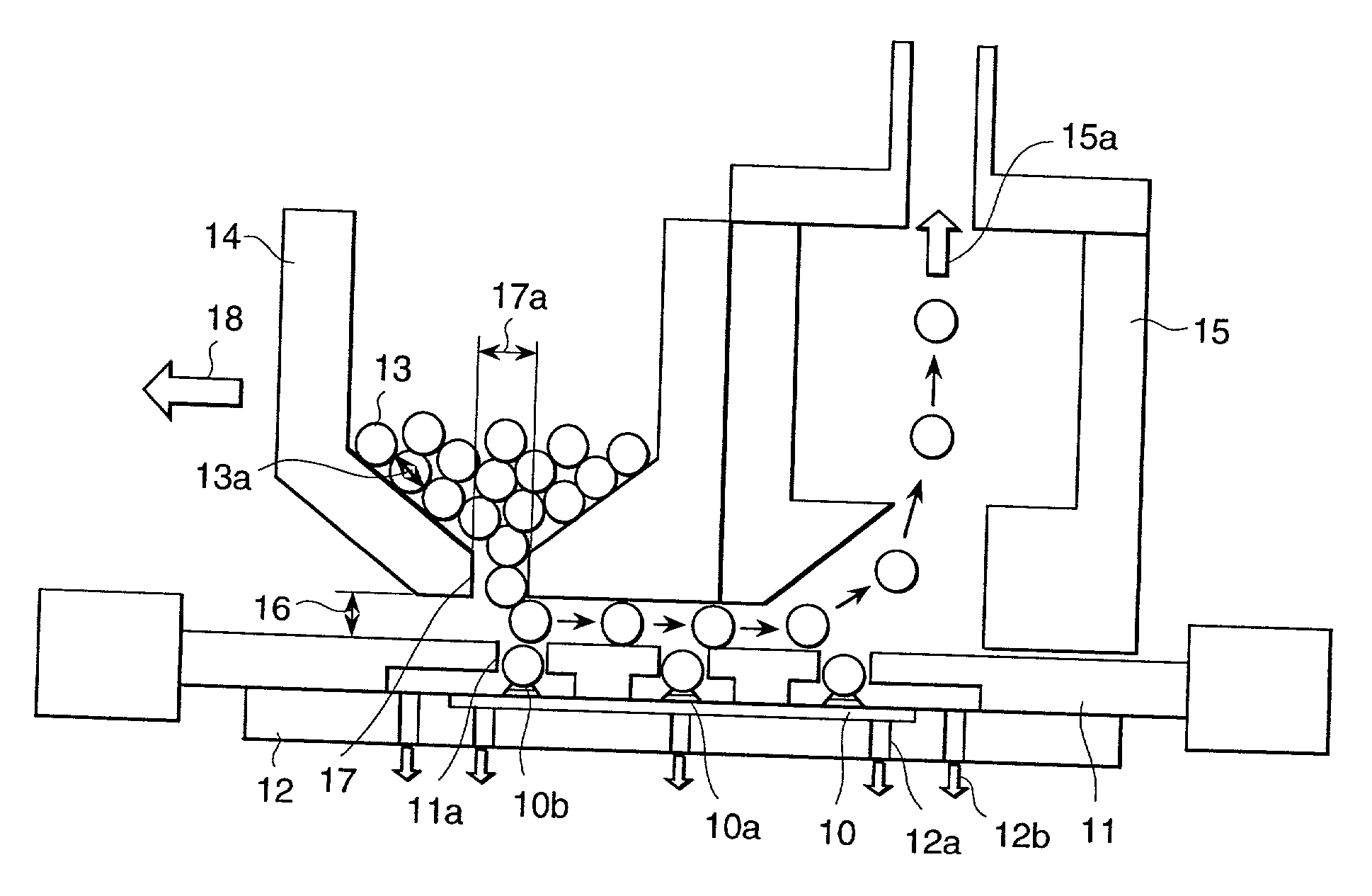

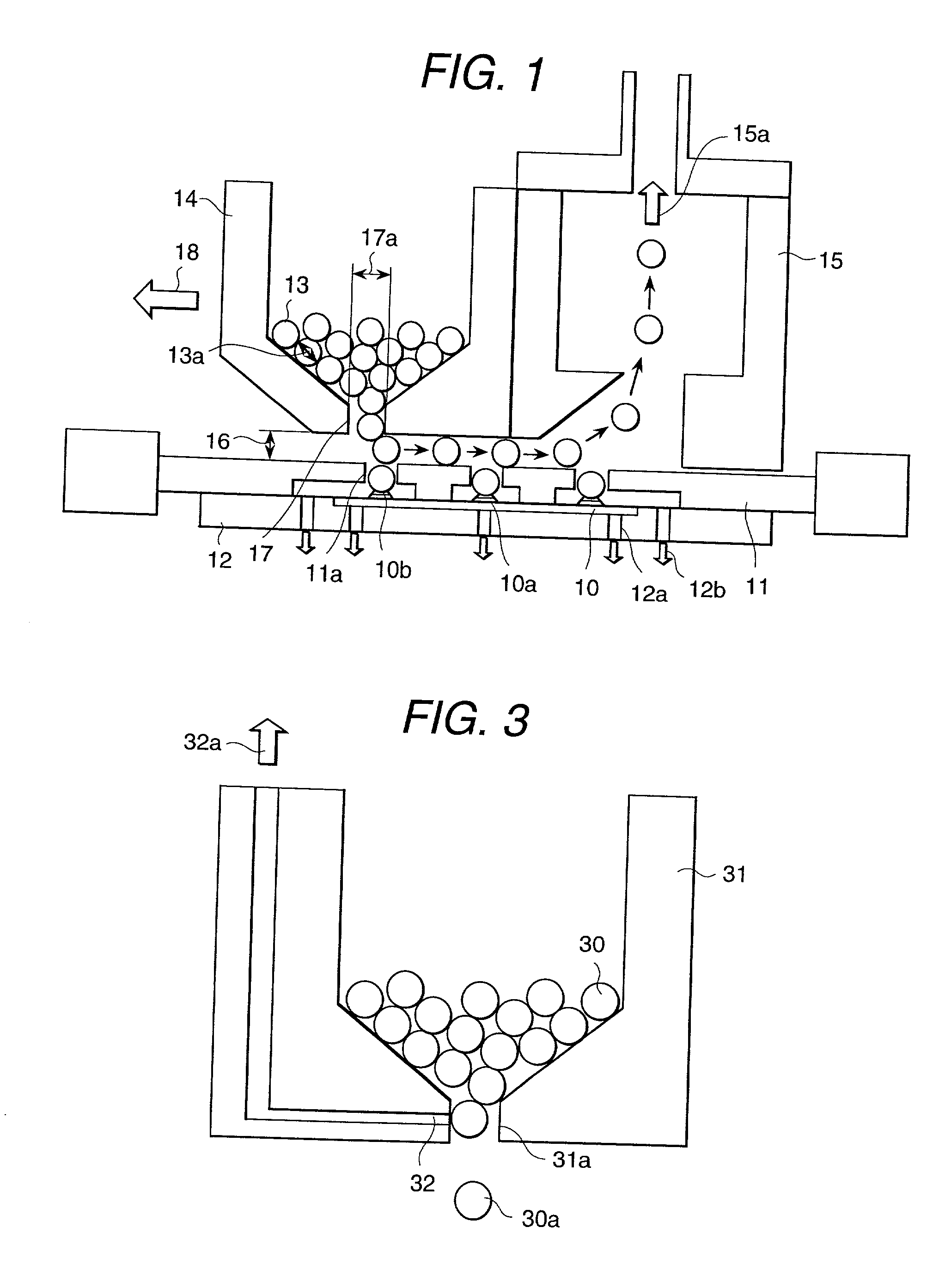

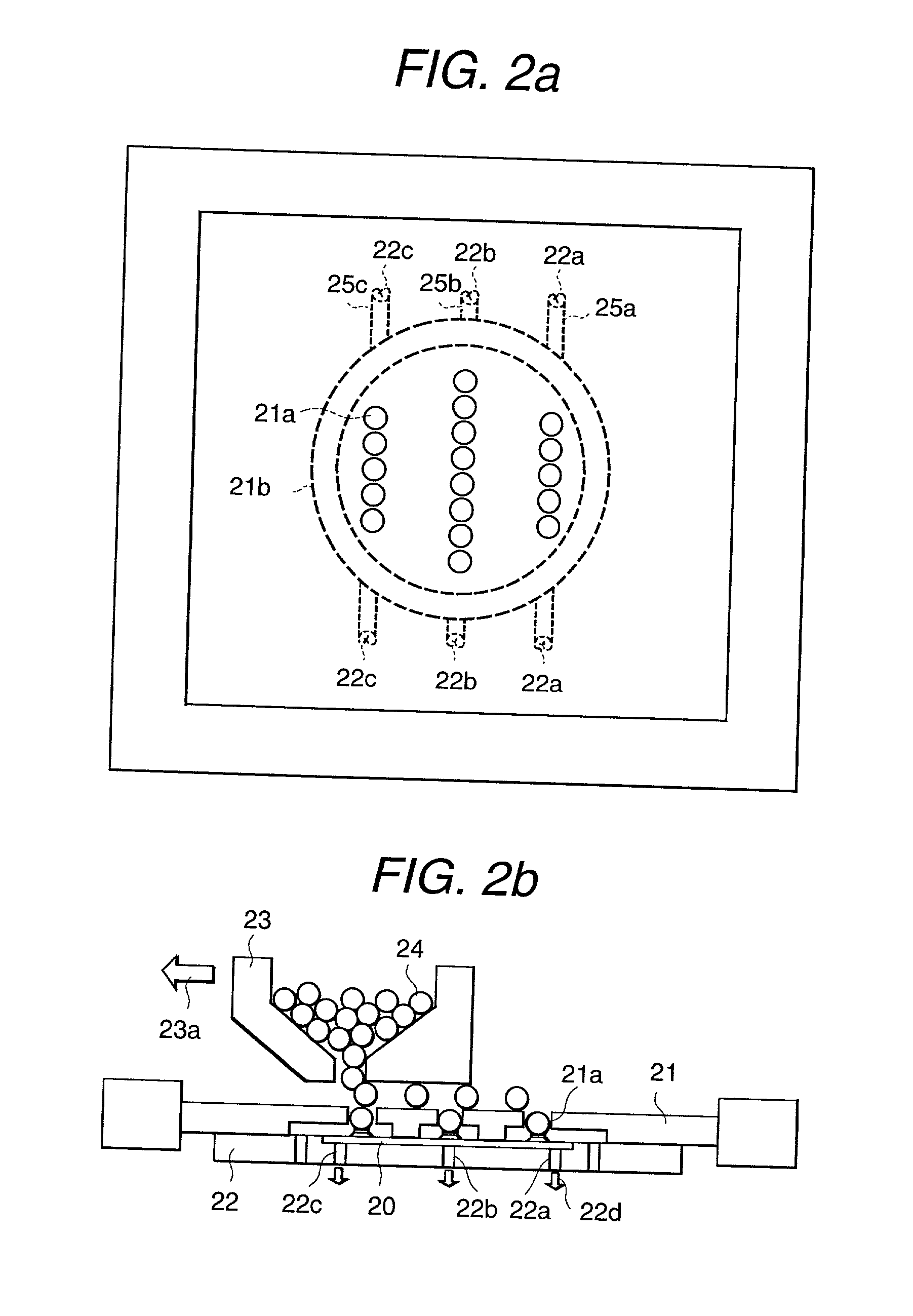

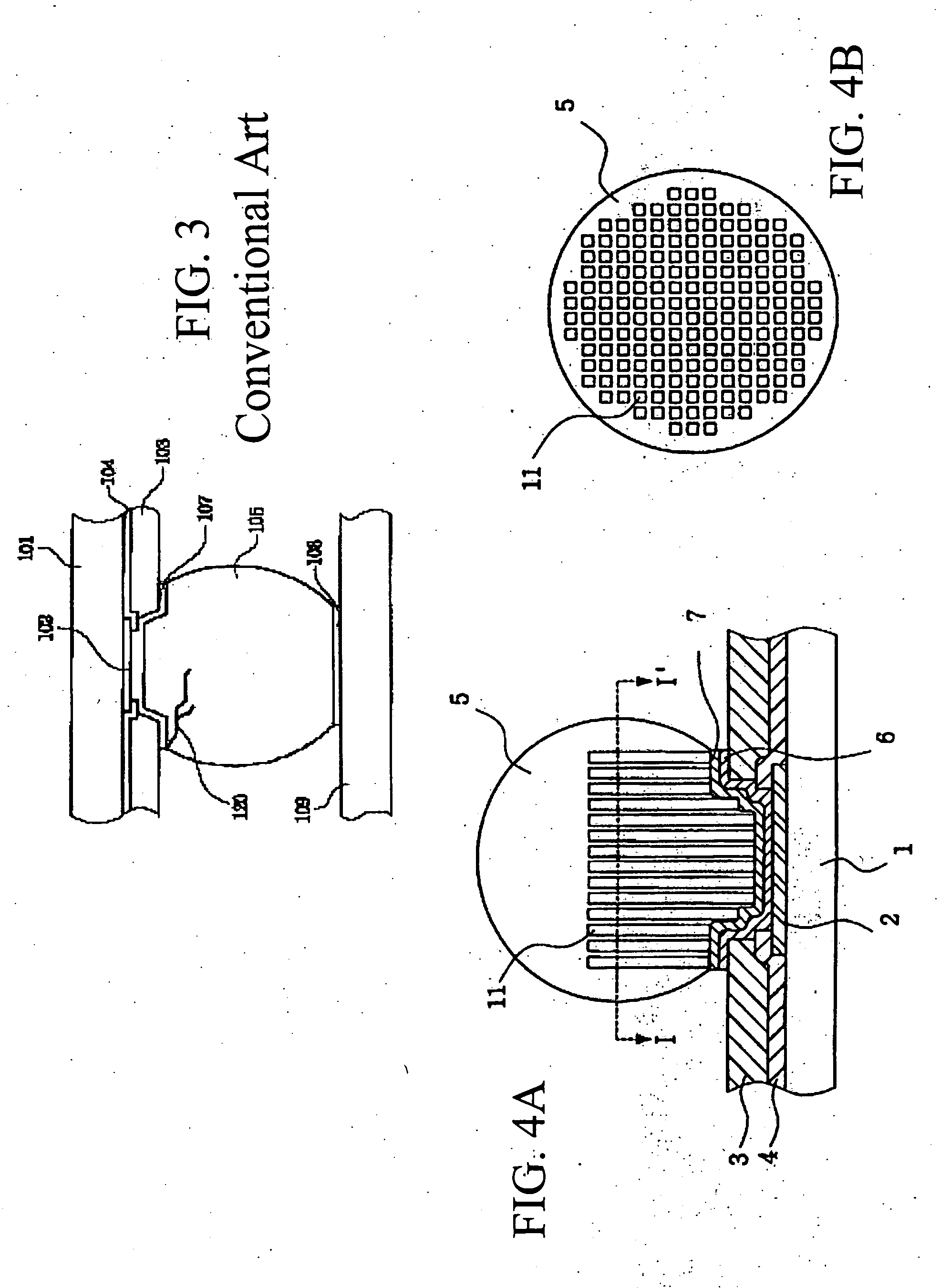

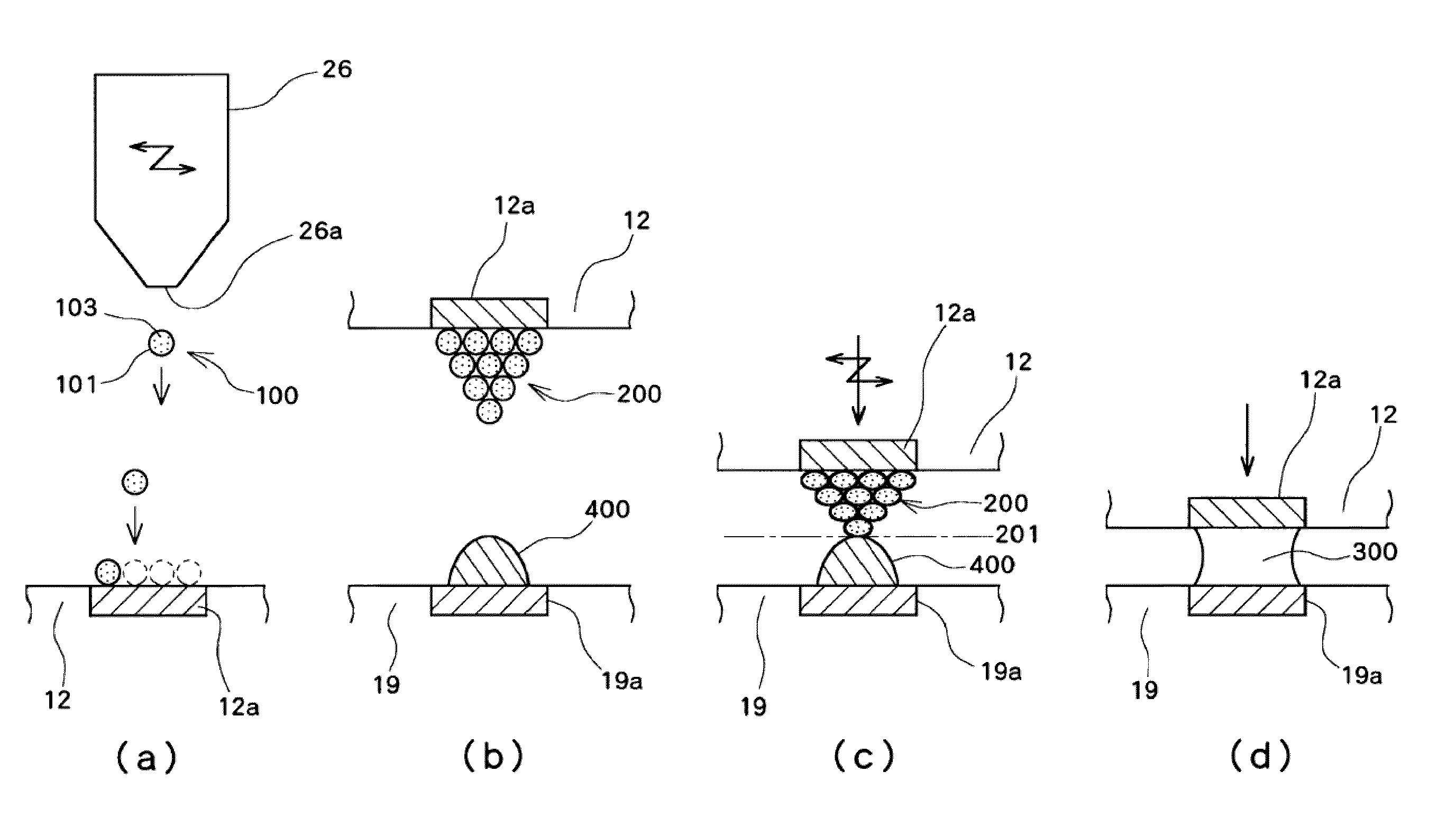

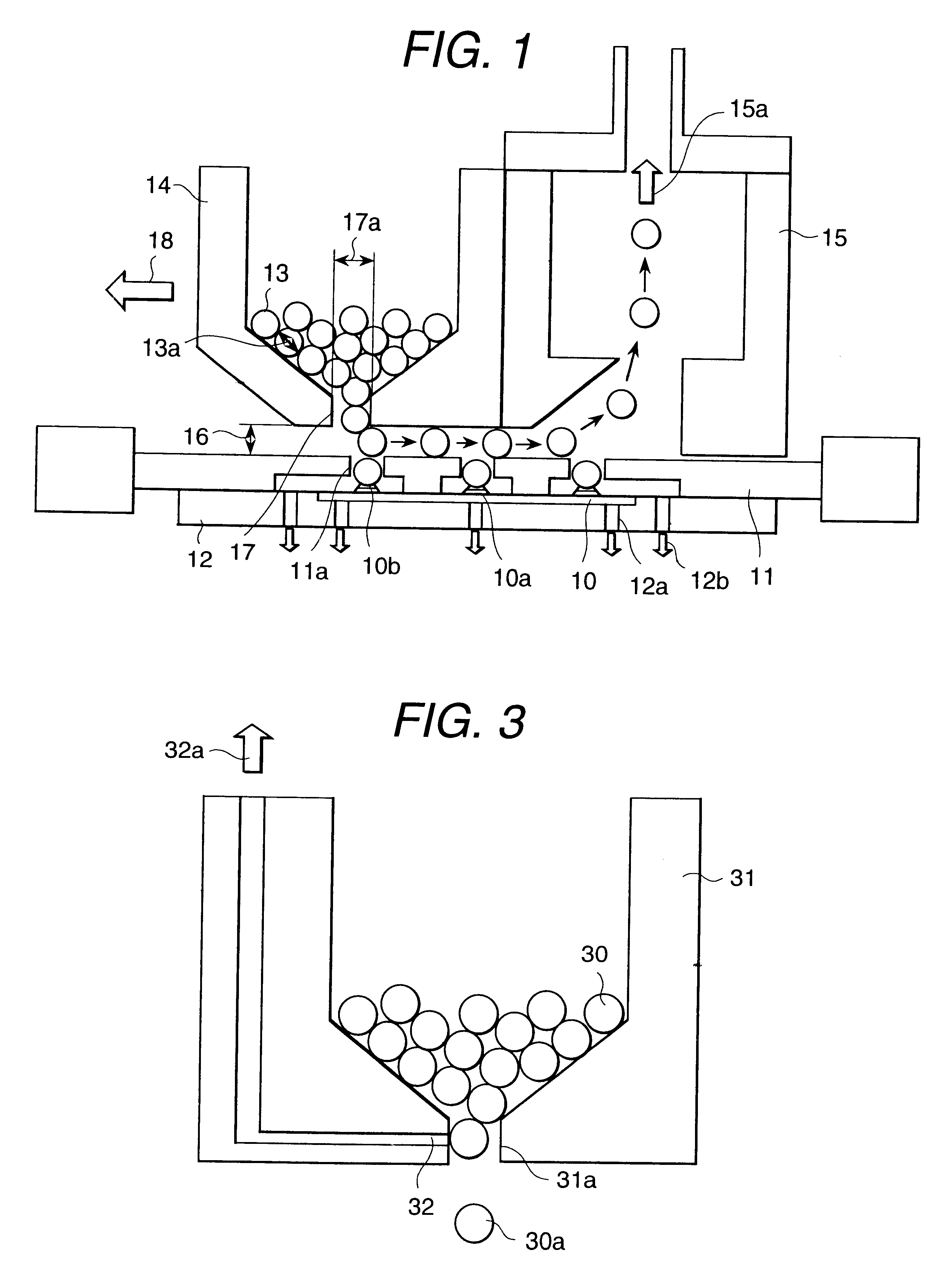

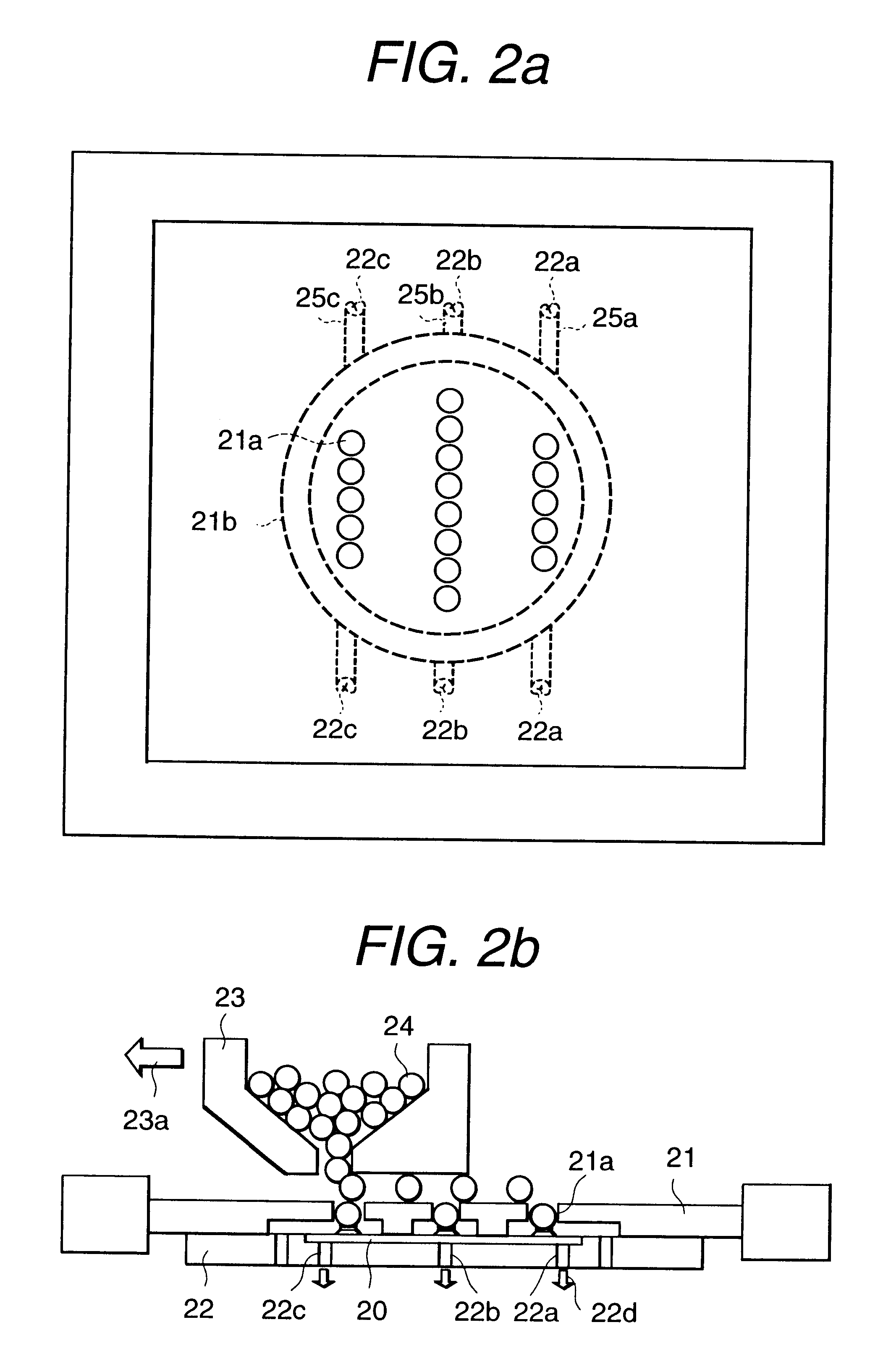

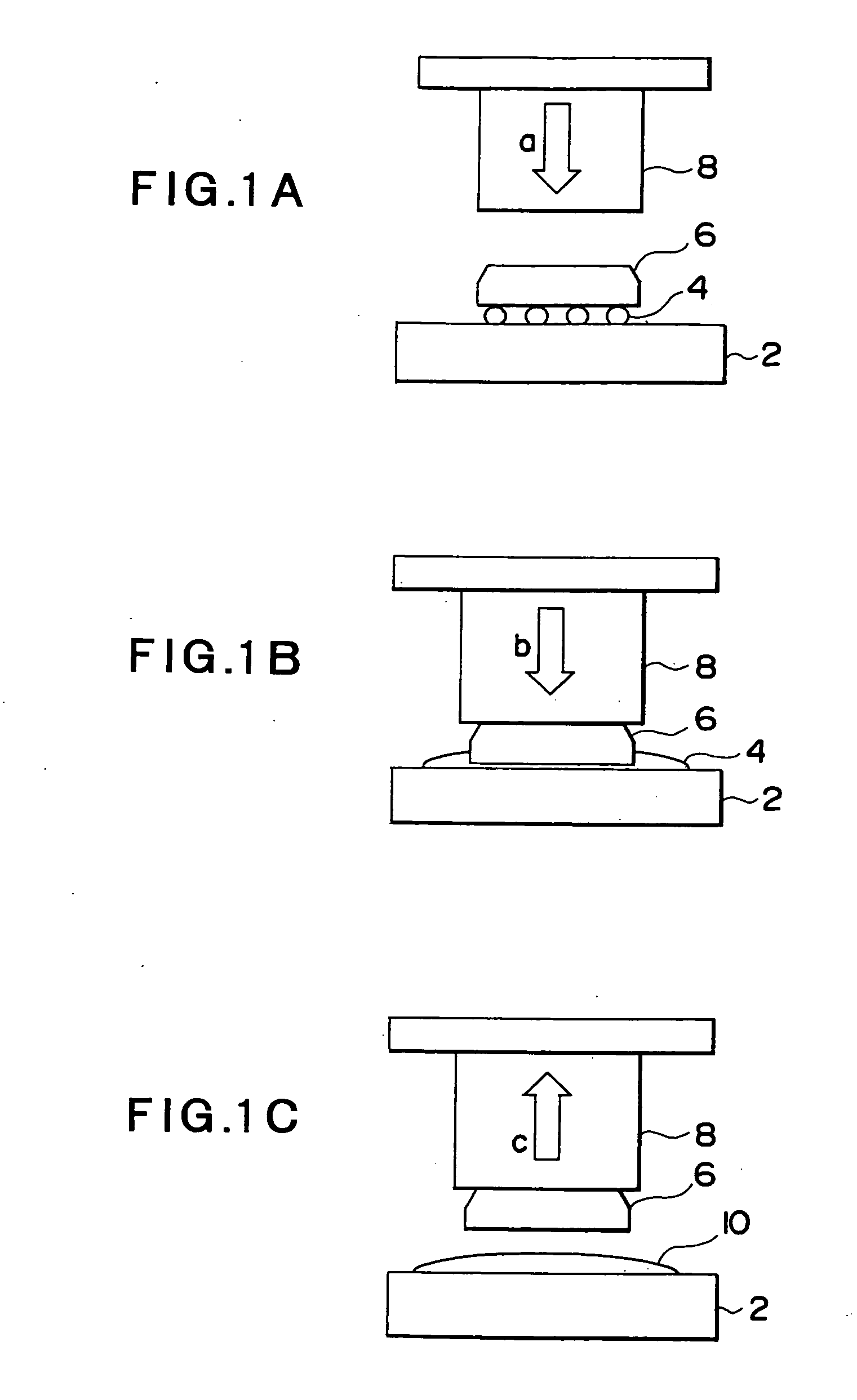

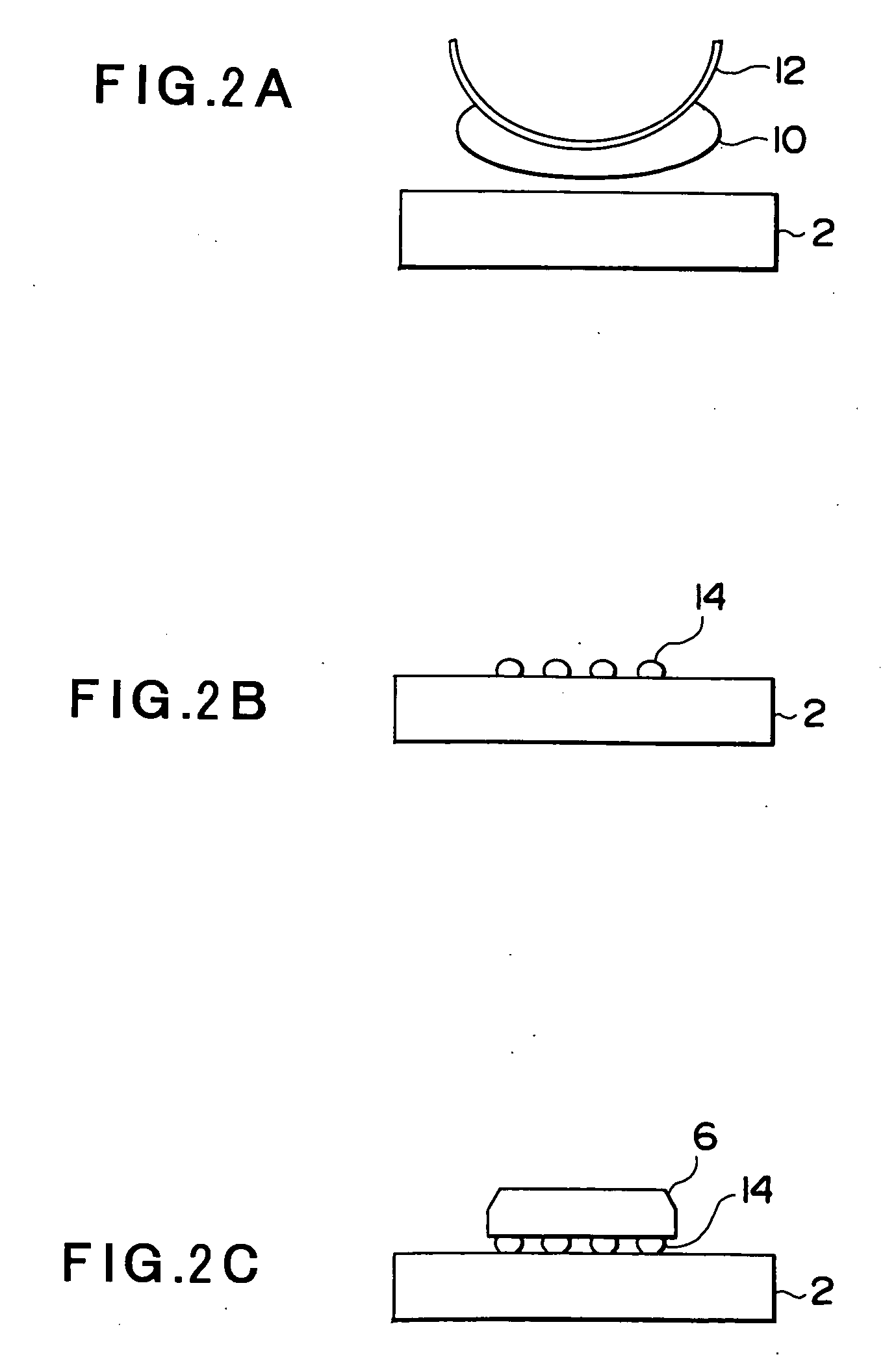

Bump forming method and bump forming apparatus

InactiveUS20020058406A1Easy to suckPrinted circuit assemblingSemiconductor/solid-state device manufacturingEngineeringSelf weight

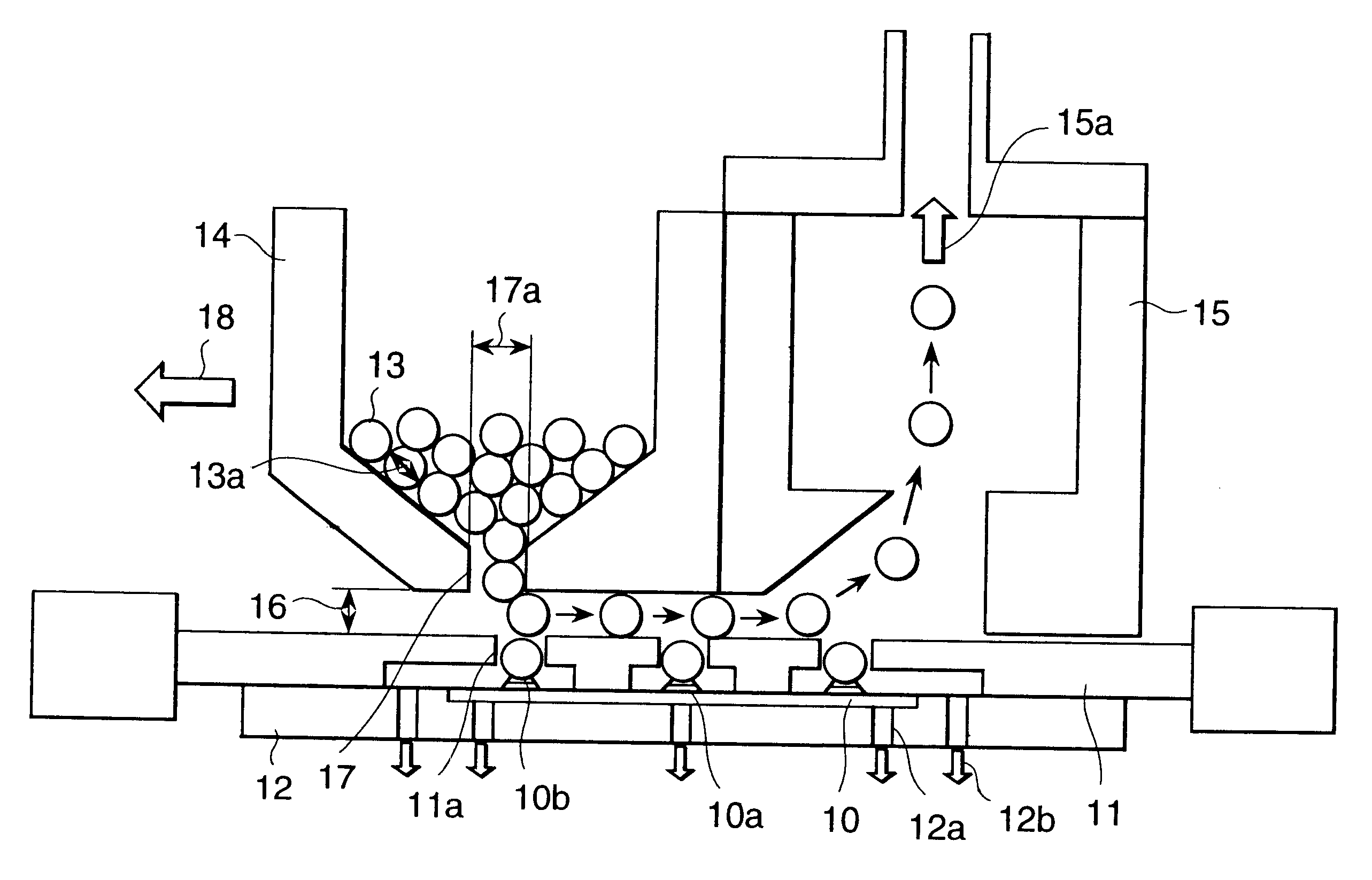

A mask 11 has a plurality of holes formed at positions corresponding to positions of a plurality of electrode portions 10a on one surface of an object to be processed 10 to mount thereon conductive particles 13, and the plurality of holes are opposite to the plurality of electrode portions 10a formed on the object to be processed. A table 12 has a plurality of holes 12a for sucking the object to be processed 10 from the other surface of the object to be processed 10, and for sucking the particles 13 through the plurality of holes 11a in the mask 11 so that the particles 13 may be mounted on the electrode portions 10a formed on the object to be processed 10. A hopper 14 contains therein the plurality of conductive particles 13, prevents the plurality of conductive particles 13 from adhering to each other, and has a slit portion 17 for dropping the plurality of conductive particles 13 by the self-weight. A slit portion 17 in the hopper 14 is moved, facing the upper surface of the mask 11 with a gap between the slit portion 17 and the upper surface of the mask 11 larger than a diameter of the particle 13, and the hopper 14 is arranged in the front side in the moving direction, and the unit 15 is arranged in the rear side, and the particles 13 not dropped into the holes of the mask being collected by the collecting unit 15.

Owner:HITACHI LTD +1

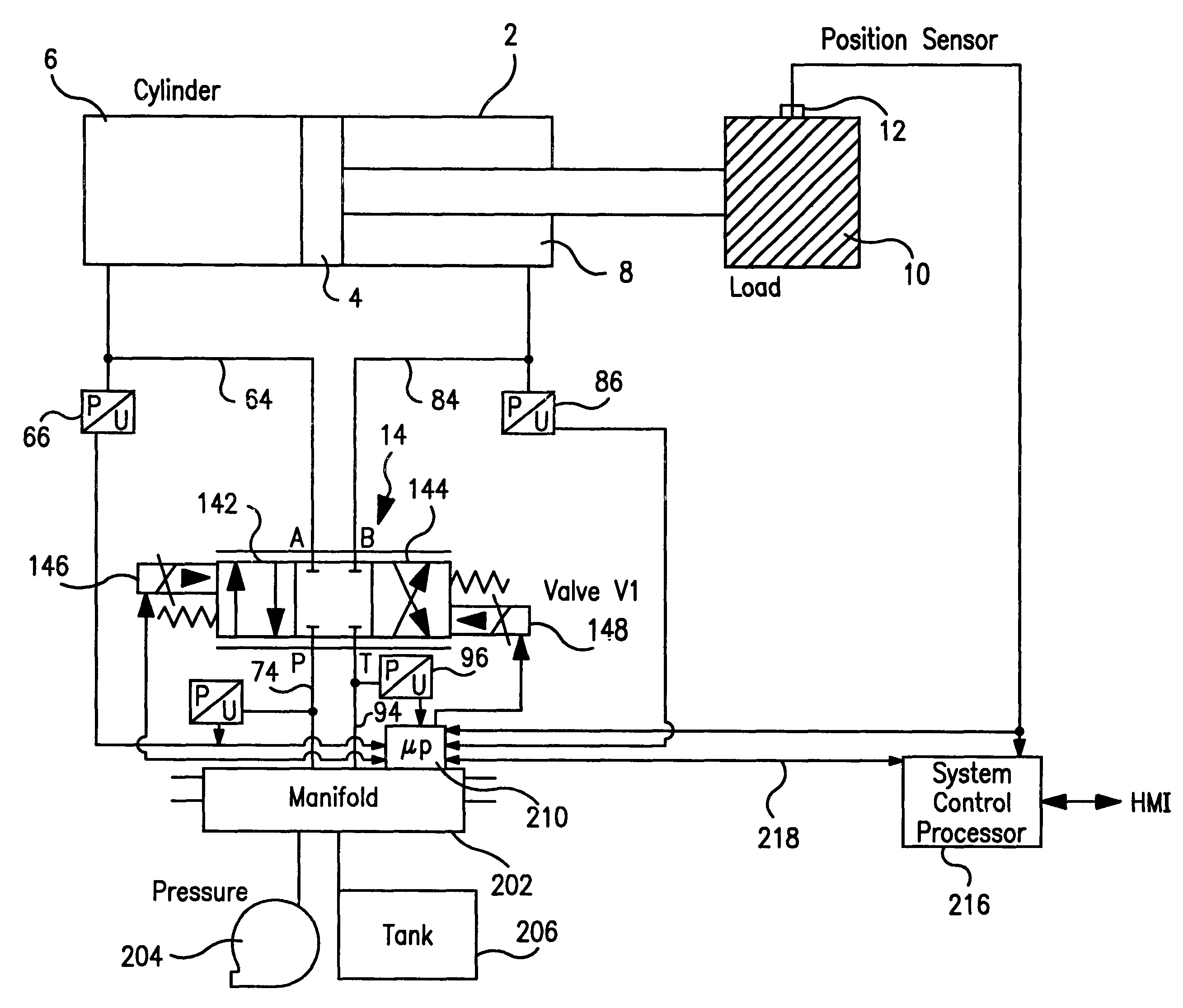

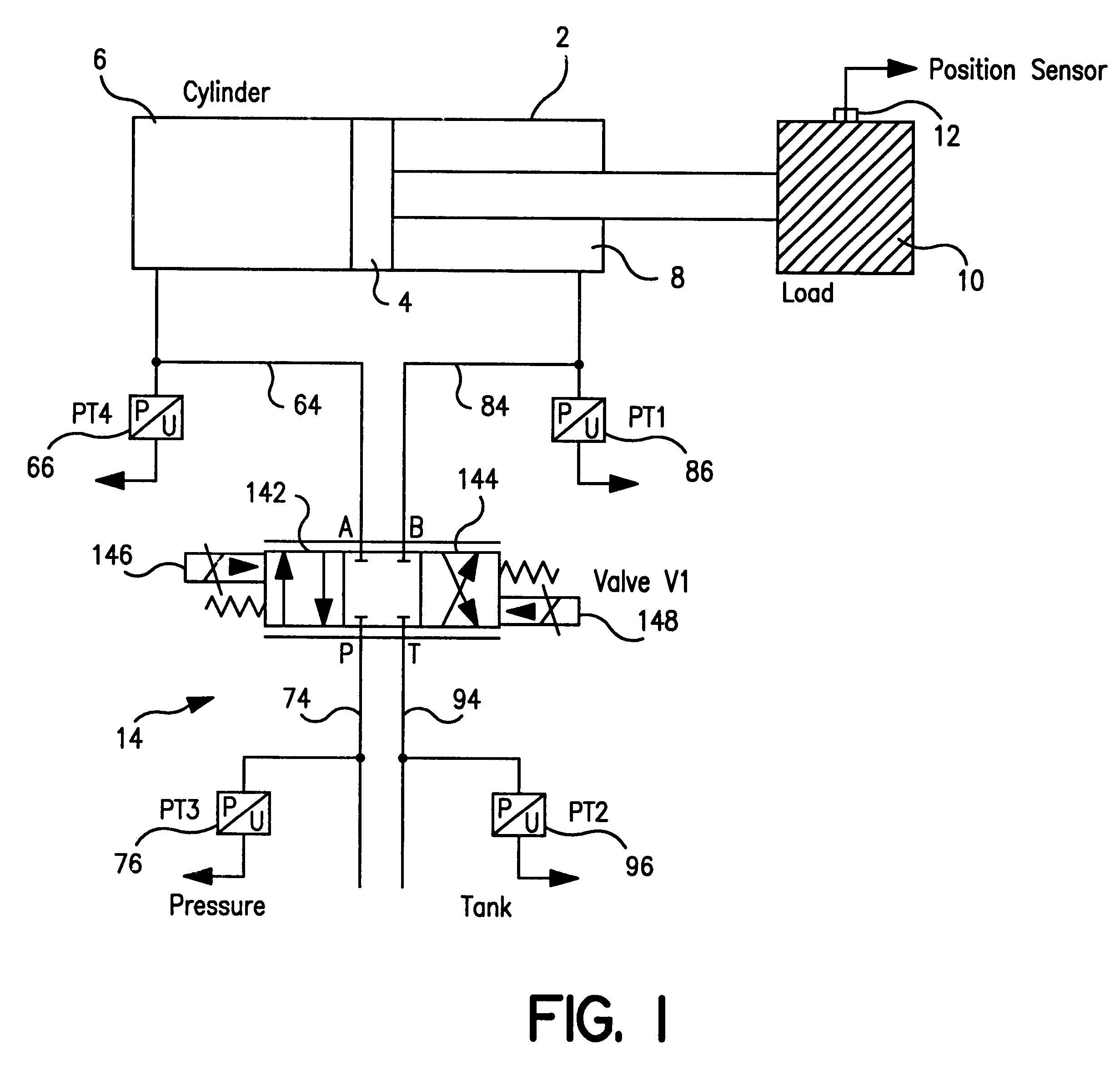

Intelligent hydraulic manifold used in an injection molding machine

Apparatus and method for controlling a hydraulic actuator in an injection molding machine, where the hydraulic actuator moves in a linear or rotary manner to effect movement of an injection molding device, such as a mold clamp. A microcontroller is locally disposed adjacent to the actuator or the hydraulic fluid distribution manifold to cause the actuator to drive the device. The microcontroller is electrically coupled to the system control processor. This distributed control architecture increases system processing throughput, enhances reliability, and permits easier upgrades / repair. Preferably, the microcontroller is mounted on the manifold and controls all of the actuators supplied from that manifold.

Owner:HUSKY INJECTION MOLDING SYST LTD

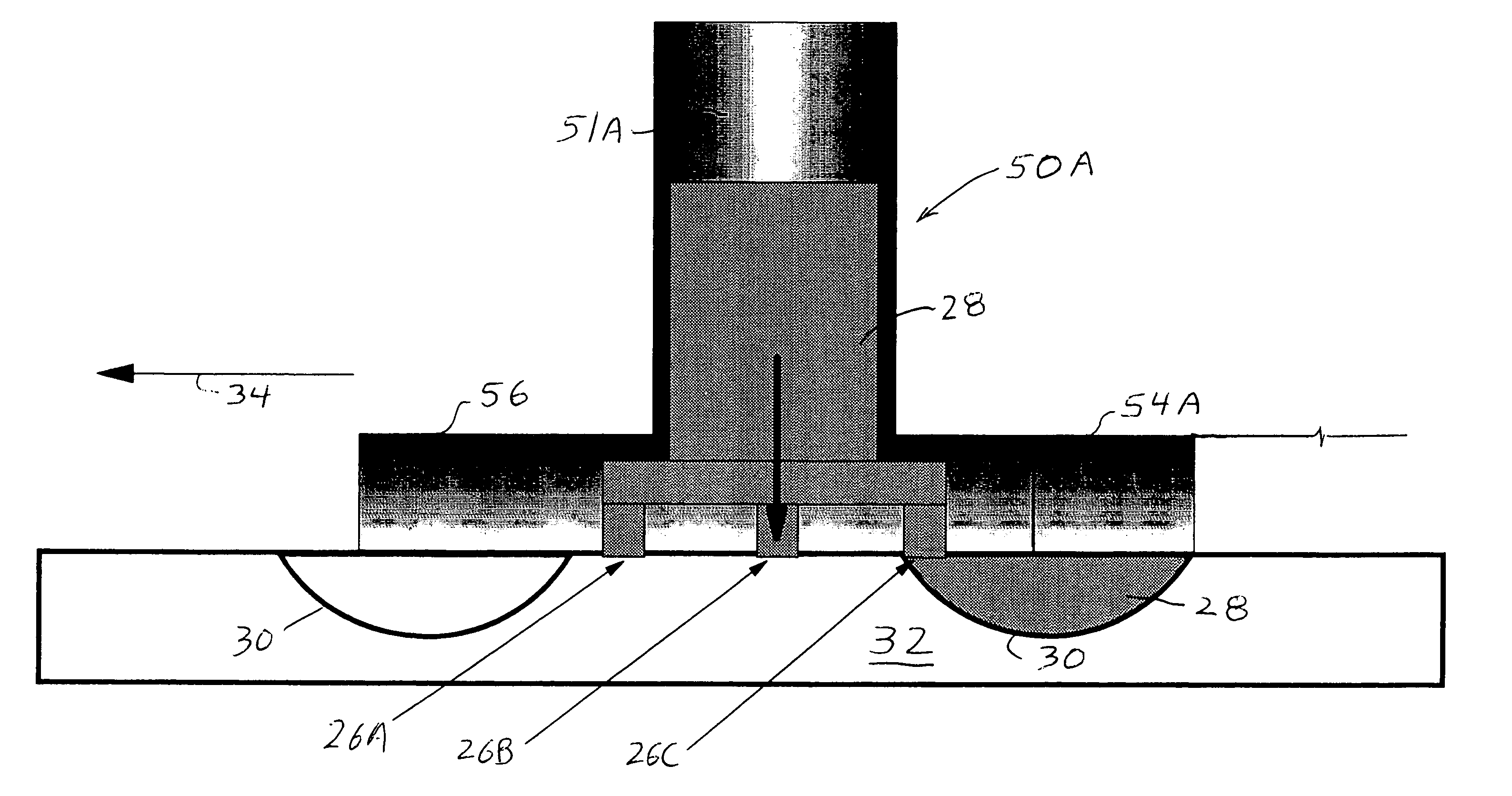

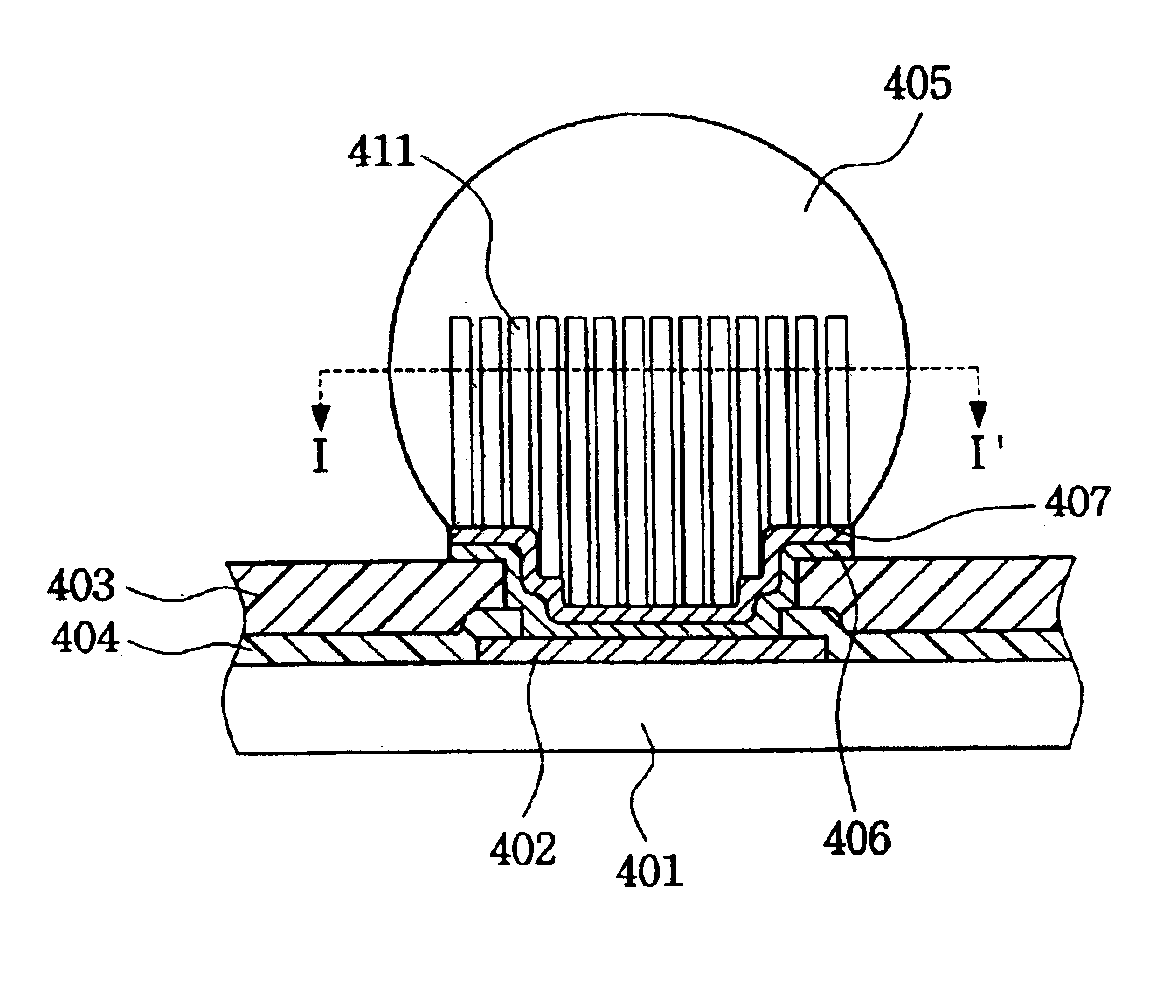

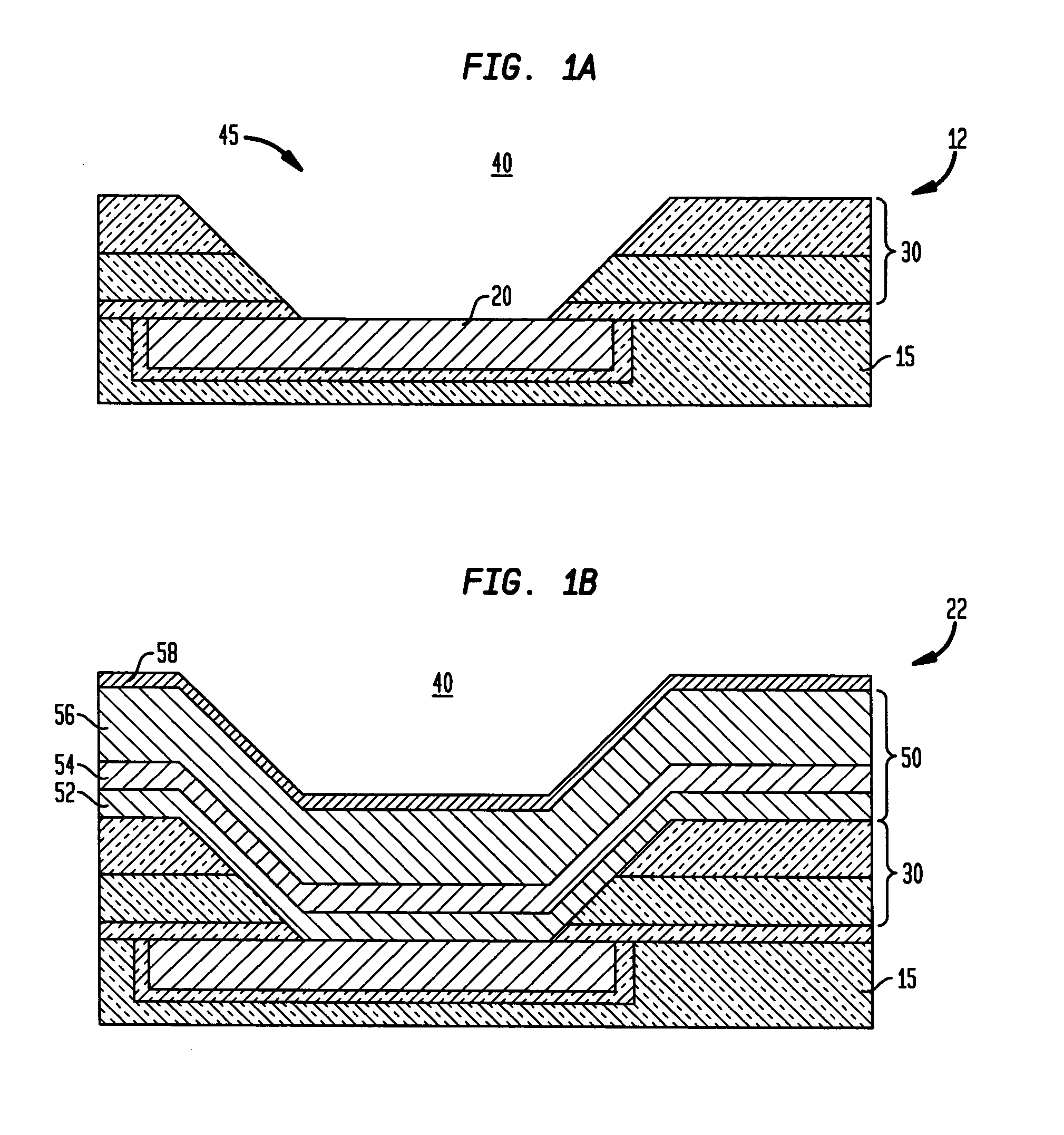

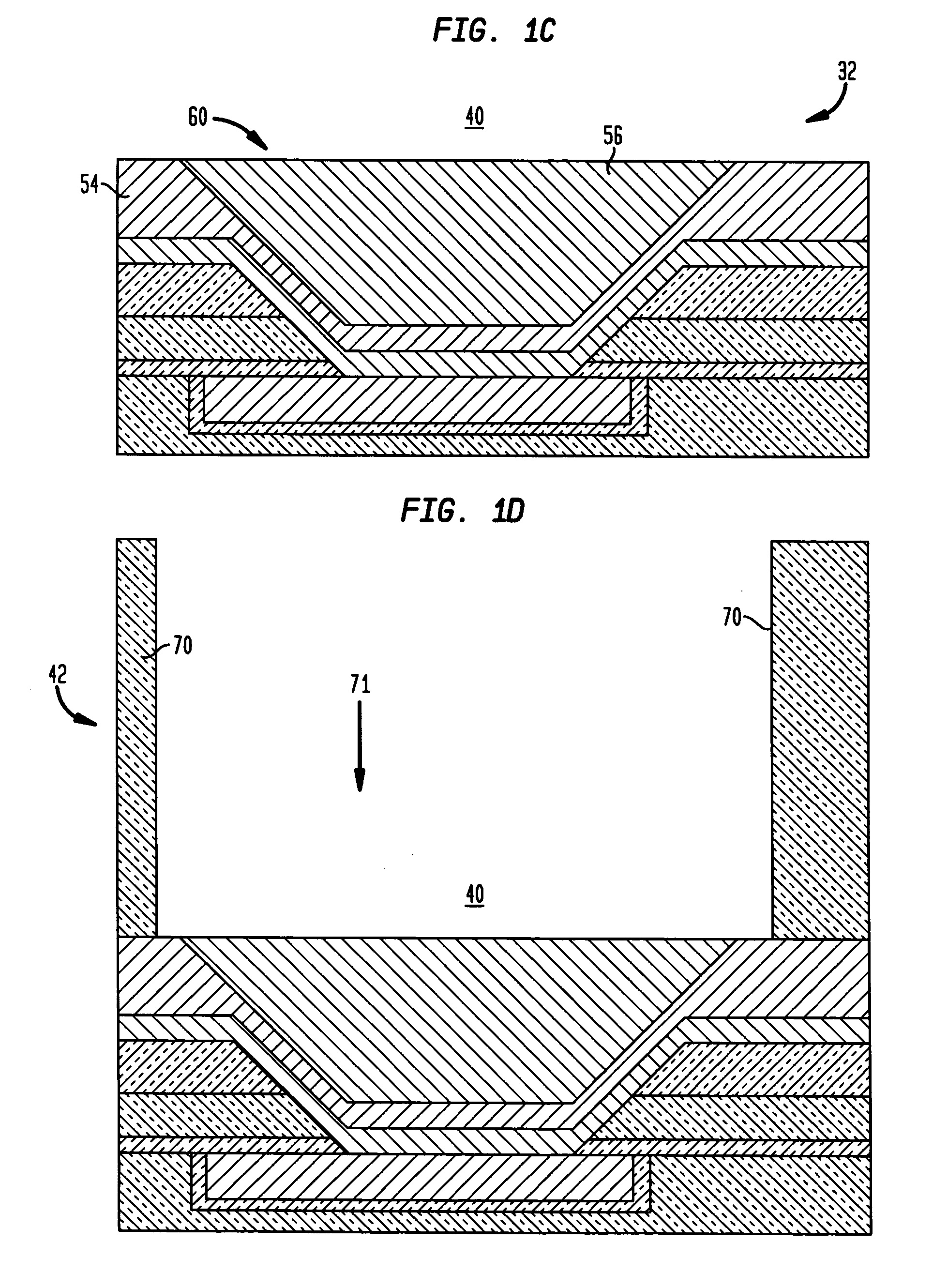

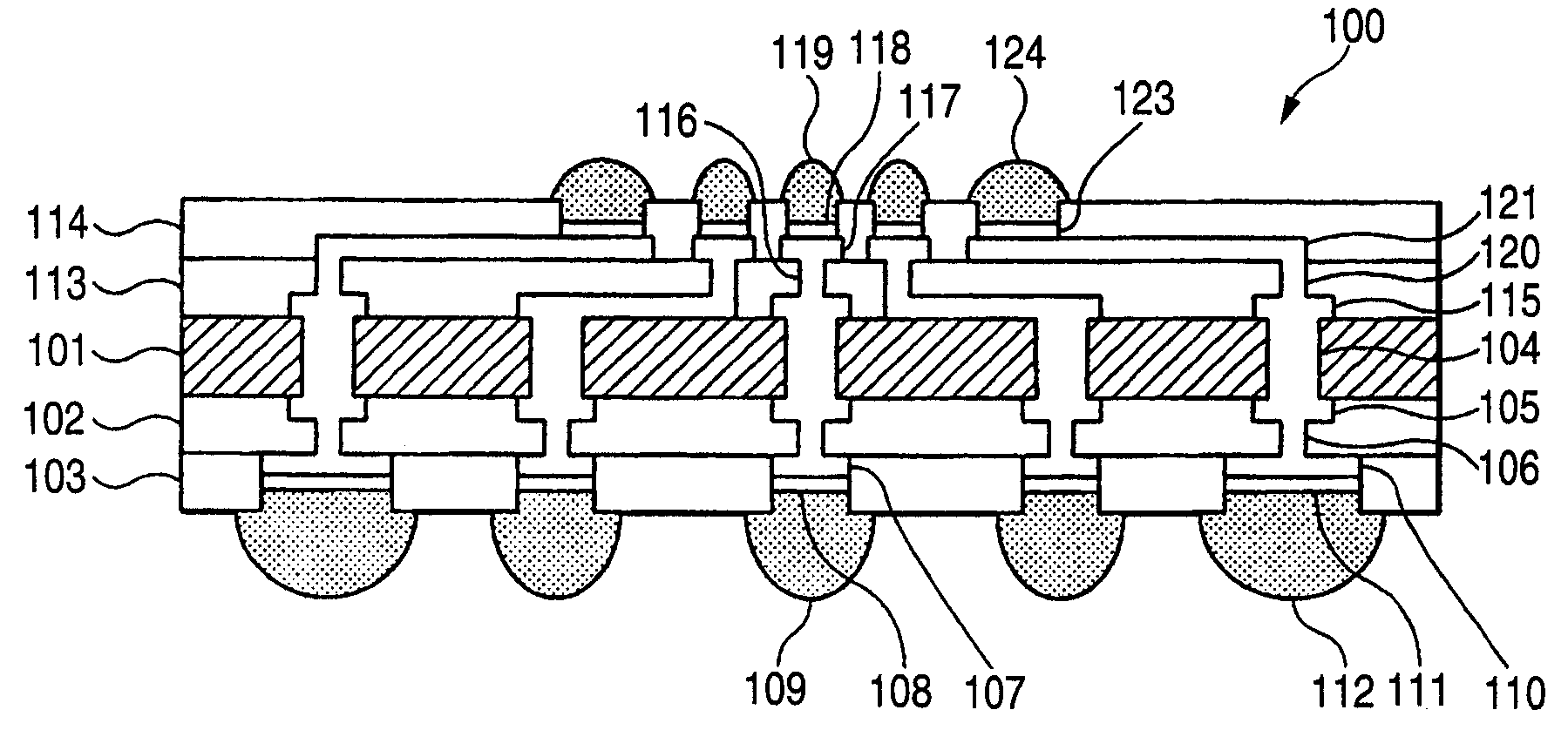

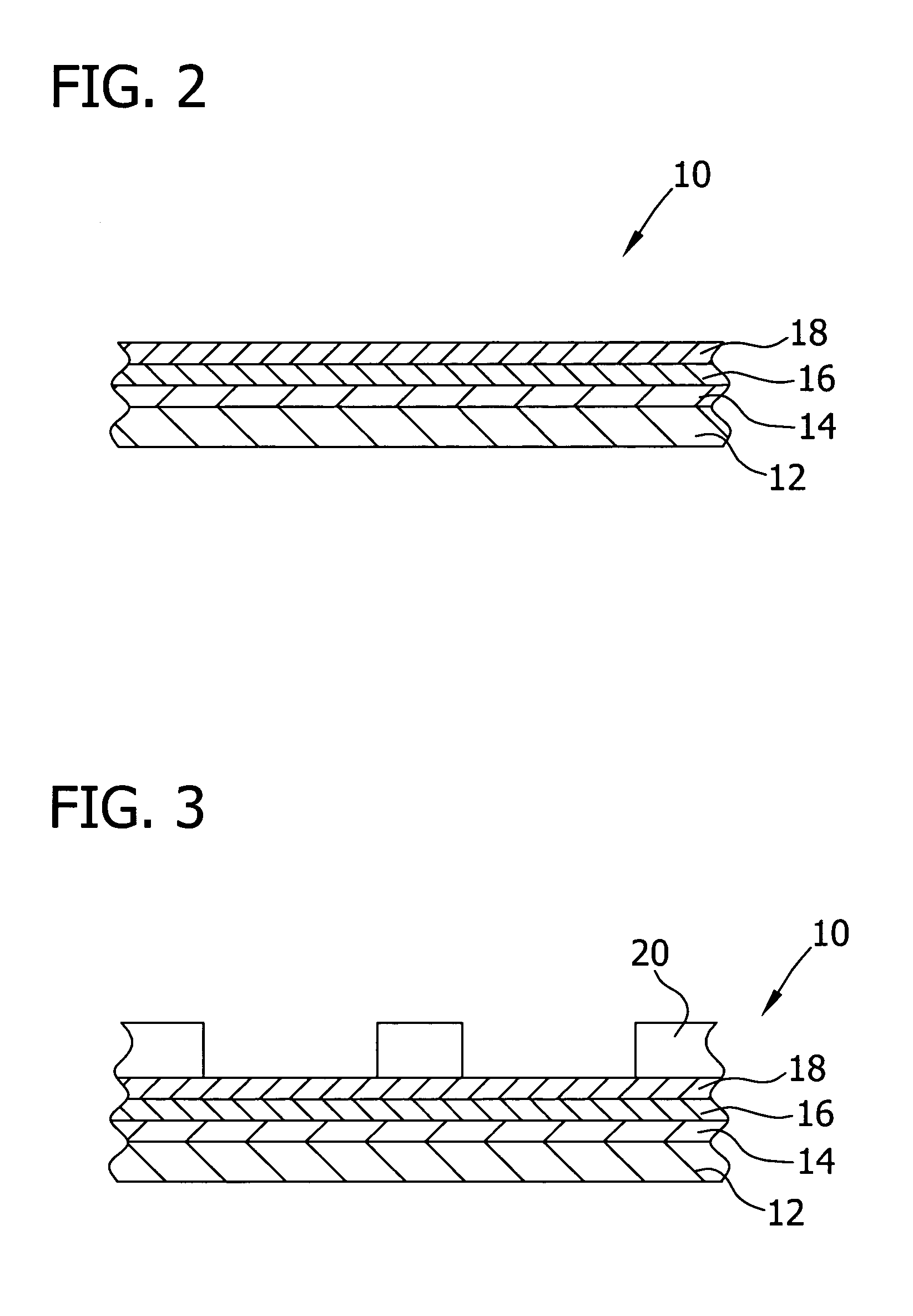

Reinforced solder bump structure and method for forming a reinforced solder bump

InactiveUS20060113681A1Printed circuit assemblingFinal product manufactureContact padSemiconductor chip

A reinforced solder bump connector structure is formed between a contact pad arranged on a semiconductor chip and a ball pad arranged on a mounting substrate. The semiconductor chip includes at least one reinforcing protrusion extending upwardly from a surface of an intermediate layer. The mounting substrate includes at least one reinforcing protrusion extending upwardly from a ball pad, the protrusions from both the chip and the substrate being embedded within the solder bump connector. In some configurations, the reinforcing protrusions from the contact pad and the ball pad are sized and arranged to have overlapping upper portions. These overlapping portions may assume a wide variety of configurations that allow the protrusions to overlap without contacting each other including pin arrays and combinations of surrounding and surrounded elements. In each configuration, the reinforcing protrusions will tend to suppress crack formation and / or crack propagation thereby improving reliability.

Owner:SAMSUNG ELECTRONICS CO LTD

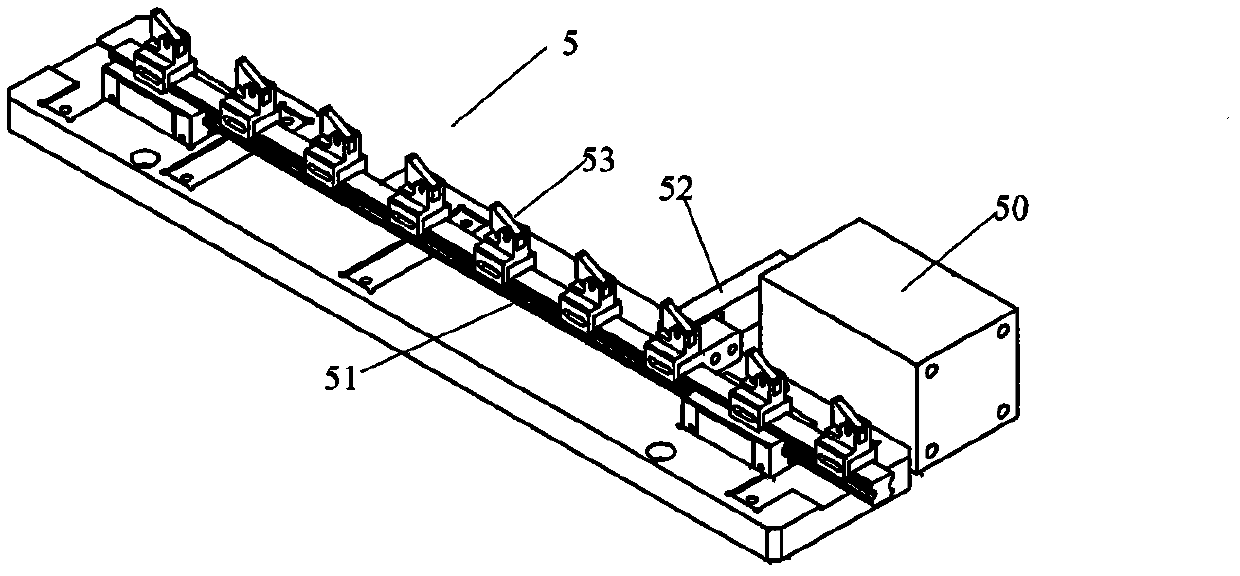

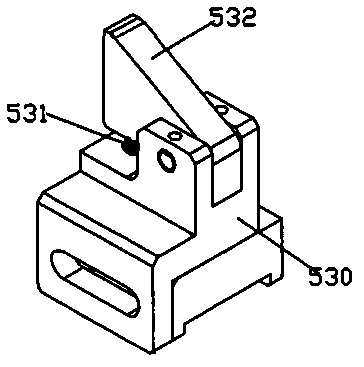

Automatic tin staining device

ActiveCN102601482ASimple structurePrecise length controlSolder feeding devicesSoldering auxillary devicesStainingAutomatic control

The invention discloses an automatic tin staining device for a connection line, which comprises a conveying mechanism, a tin furnace and a controller. The controller is used for coordinating the work of a pneumatic or / and electric device; the conveying mechanism is provided with a fixed guide rail mechanism matched with a connection line fixing mechanism, a connection line drive mechanism and a movable guide rail mechanism smoothly connected with the fixed guide rail mechanism; the movable guide rail mechanism is movably connected with a frame and is in transmission connection with a turning mechanism; and the tin furnace is movably arranged on the frame at one side of the movable guide rail mechanism. When the connection line fixed mechanism is moved to a tin staining position during the work, the movable guide rail is turned by the movable guide rail turning mechanism, so that the connection line on the connection line fixed mechanism is reset after being contacted with soldering tin in the tin furnace. The automatic tin staining device is simple in structure, and can accurately control the tin staining length through properly controlling the liquid surface of the soldering tin; simultaneously, the staining of the tin is automatically controlled, so that the efficiency of the staining of the tin can be improved, the low efficiency of the manual staining of the tin is avoided so as not to easily cause scalding phenomenon.

Owner:刘光辉

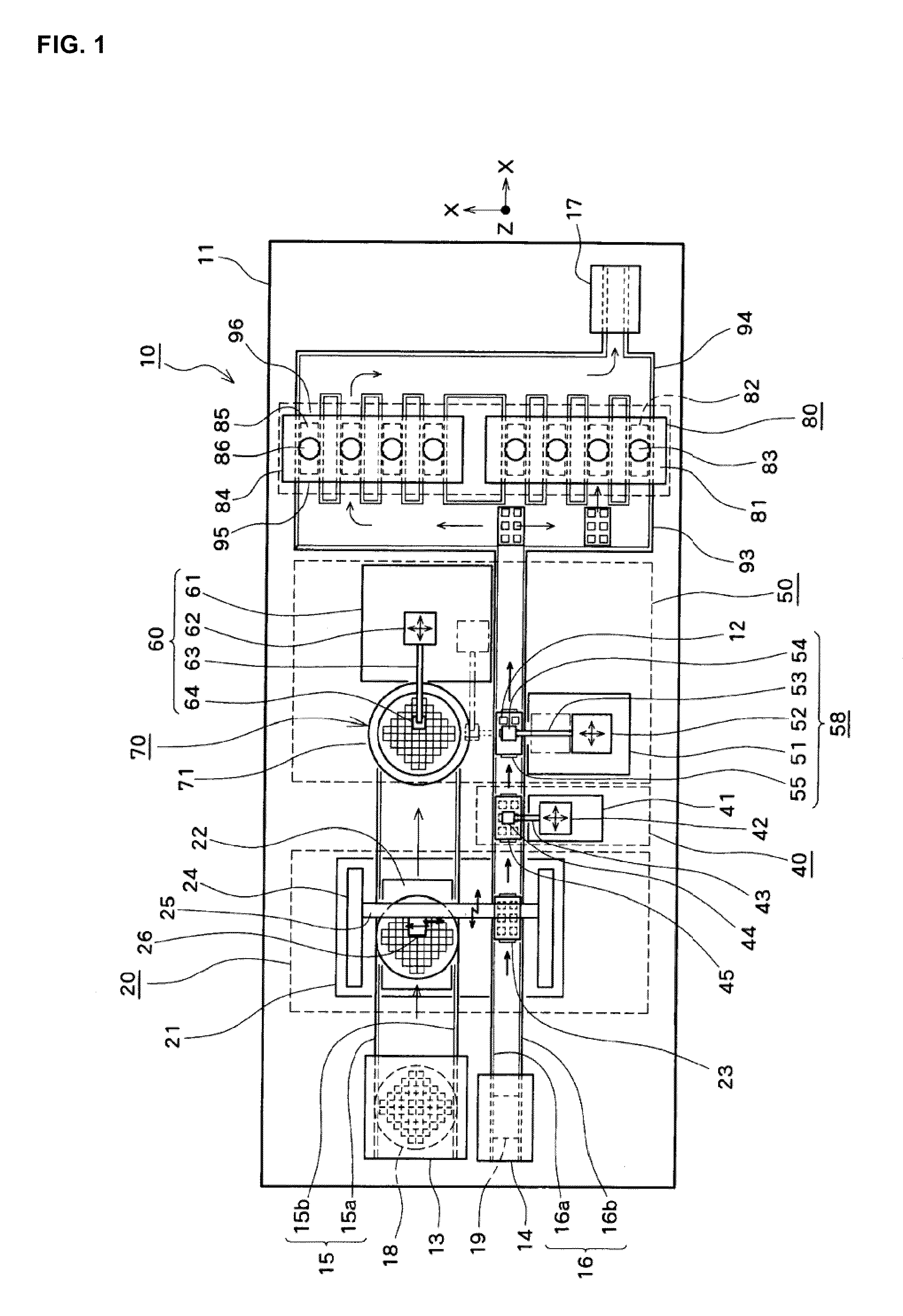

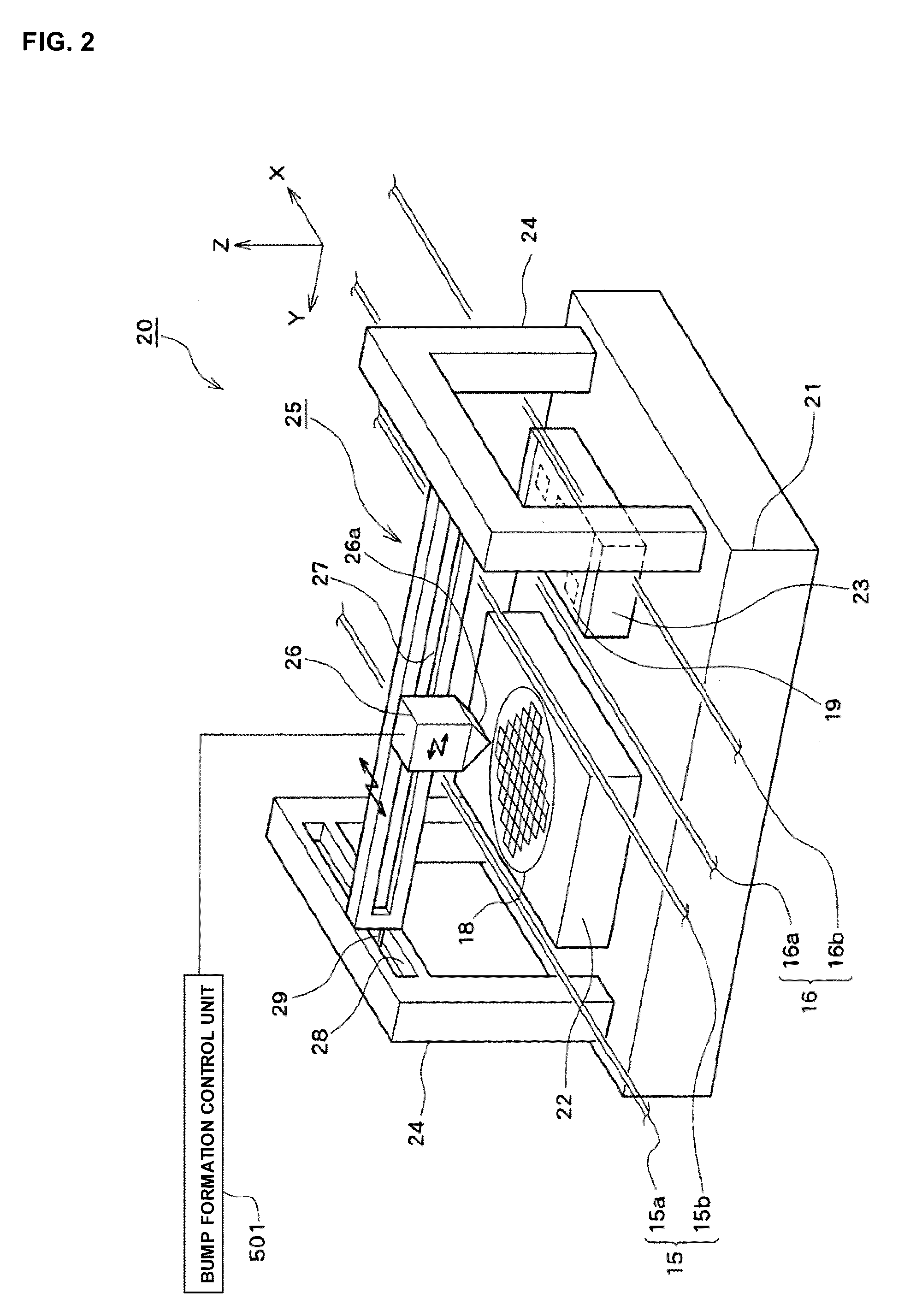

Bonding apparatus and bonding method

InactiveUS20100093131A1Improve bindingEffective combinationMaterial nanotechnologySemiconductor/solid-state device detailsEngineeringSecondary bonding

A bonding apparatus (10) that bonds an electrode of a semiconductor die (12) and an electrode of a circuit board (19) using a metal nano paste includes a bump formation mechanism (20) that forms bump by injecting microdroplets of a metal nano paste on each electrode, a primary bonding mechanism (50) that carries out primary bonding to the electrodes in a non-conductive state by pressing the bump of the semiconductor die (12) against the bump of the circuit board (19), and a secondary bonding mechanism (80) that carries out secondary bonding so that the electrodes become conductive by pressurizing the primary bonded bump in bonding direction and by heating the bump to pressurize and sinter the metal nanoparticles in the bump. With this, it is possible to efficiently bond the electrodes with a simple and easy way while reducing a bonding load.

Owner:SHINKAWA CO LTD

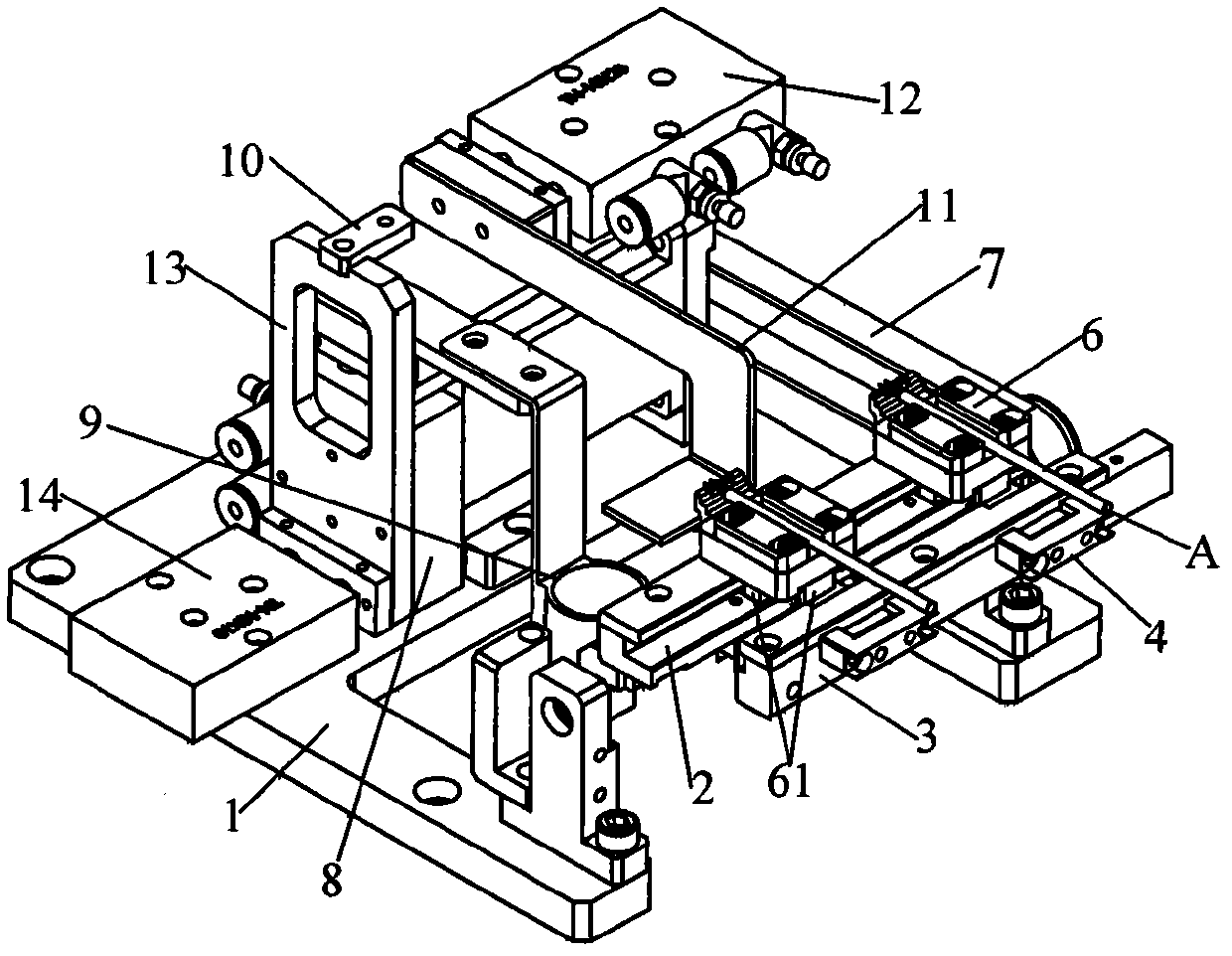

Full-automatic inductor tin dipping device and control method

InactiveCN104526104AReduce adverse effectsNo manual operationMetal working apparatusSolder feeding devicesFree coolingInductor

The invention discloses a full-automatic inductor tin dipping device and a control method. The full-automatic inductor tin dipping device comprises an operating platform, an attracting device, a discharging device, an overturning device, a moving device, a soldering flux device, a tin dipping device body and a tin scraping device, wherein the attracting device is arranged on the discharging device, the discharging device is arranged on the left side of the operating platform, one end of the overturning device is connected with the attracting device, the other end of the overturning device is arranged on the moving device, the moving device is arranged on the operating platform, the soldering flux device is located on the right side of the discharging device, the tin dipping device is located on the right side of the soldering flux device, the moving device can move to the tin dipping device from a feeding position, and the tin scraping device is arranged on the right side of the tin dipping device body. By arranging the rod overturning device, a previous batch of workpieces can be naturally cooled while a current batch of workpieces are moved and dipped with tin, so that it is guaranteed that the workpieces will not be too hot when entering the discharging device, and the quality of the workpieces is guaranteed.

Owner:SHENYANG INST OF AUTOMATION GUANGZHOU CHINESE ACAD OF SCI +1

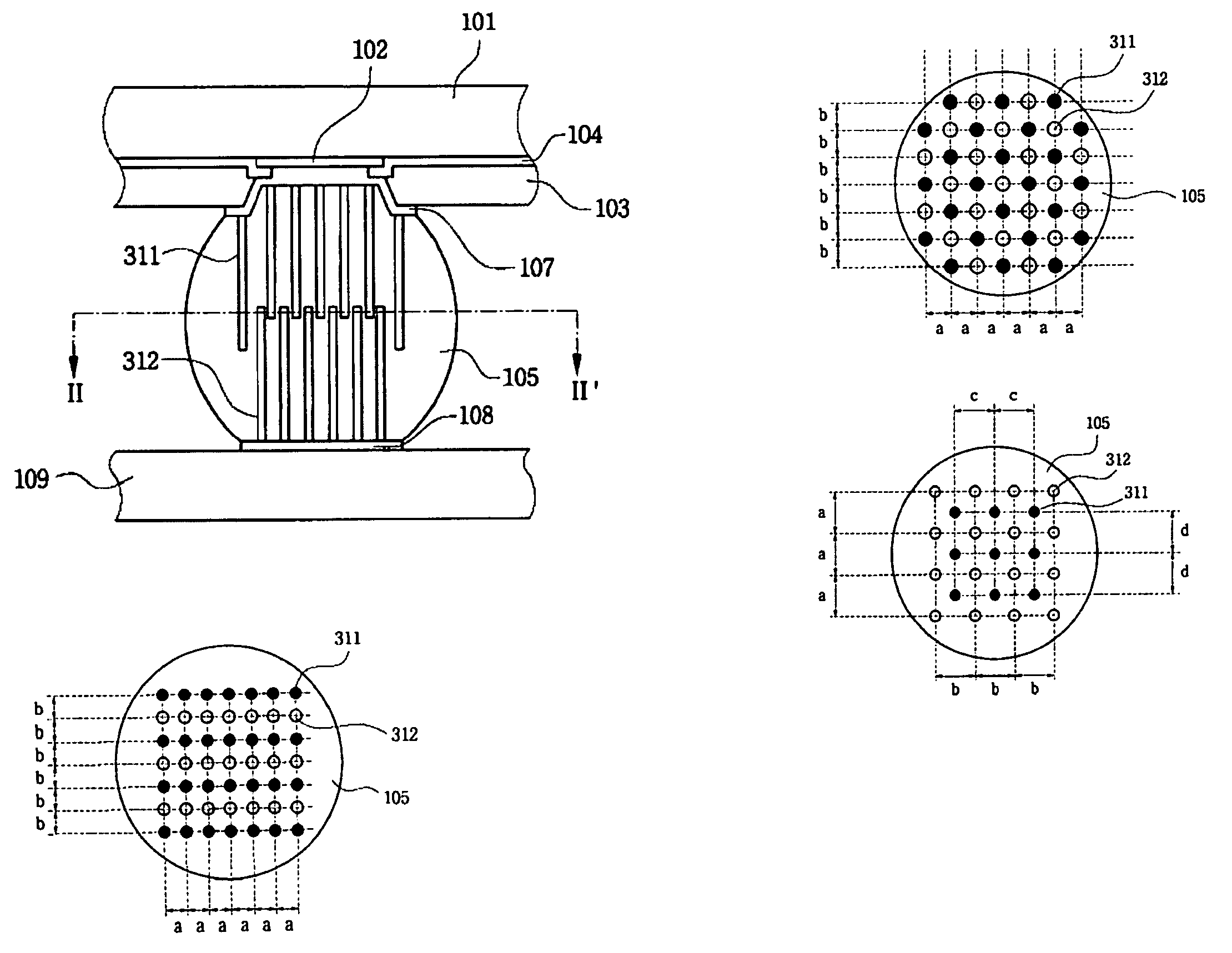

Mask for bumping solder balls on circuit board and solder ball bumping method using the same

Disclosed herein are a mask for bumping solder balls on a circuit board and a solder ball bumping method using the same. The mask includes: a plurality of openings providing spaces into which the solder balls are inserted to thereby be seated on solder pads; and trenches providing introduction spaces for spreading a flux to portions at which the solder balls are seated on the solder pads and extended from at least one side of circumferences of the openings.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Method and apparatus for streaming a viscous material on a substrate

InactiveUS20060193969A1Liquid surface applicatorsMovable spraying apparatusStream flowViscous material

A method for streaming a viscous material onto an electronic substrate using a dispensing system having a dispenser includes positioning a nozzle of the dispenser at a nominal clearance height above the substrate, dispensing a continuous stream of viscous material from the nozzle to dispense an amount of material on the substrate, controlling the volumetric flow rate of the viscous material being dispensed by the dispenser, moving the nozzle over areas of the substrate requiring viscous material, and terminating the continuous stream of viscous material. A dispensing system for performing methods of streaming viscous material is further disclosed.

Owner:SPEEDLINE TECH

Method of forming solder connection portions, method of forming wiring substrate and method of producing semiconductor device

ActiveUS20070234563A1Improve reliabilitySemiconductor/solid-state device detailsSolid-state devicesSolder ballSemiconductor

A method of forming solder connection portions on first electrode pads and on second electrode pads, comprises a first step of arranging solder balls on the first electrode pads by arranging a first mask on a base mask; a second step of arranging solder balls on the second electrode pads by arranging a second mask on the base mask; and a third step of melting the solder balls. The base mask has first opening portions corresponding to the first electrode pads and second opening portions corresponding to the second electrode pads and having a size different from that of the first opening portions. The first mask has opening portions corresponding to the first opening portions and covering the second opening portions. The second mask has opening portions corresponding to the second opening portions and covers the first opening portions.

Owner:SHINKO ELECTRIC IND CO LTD

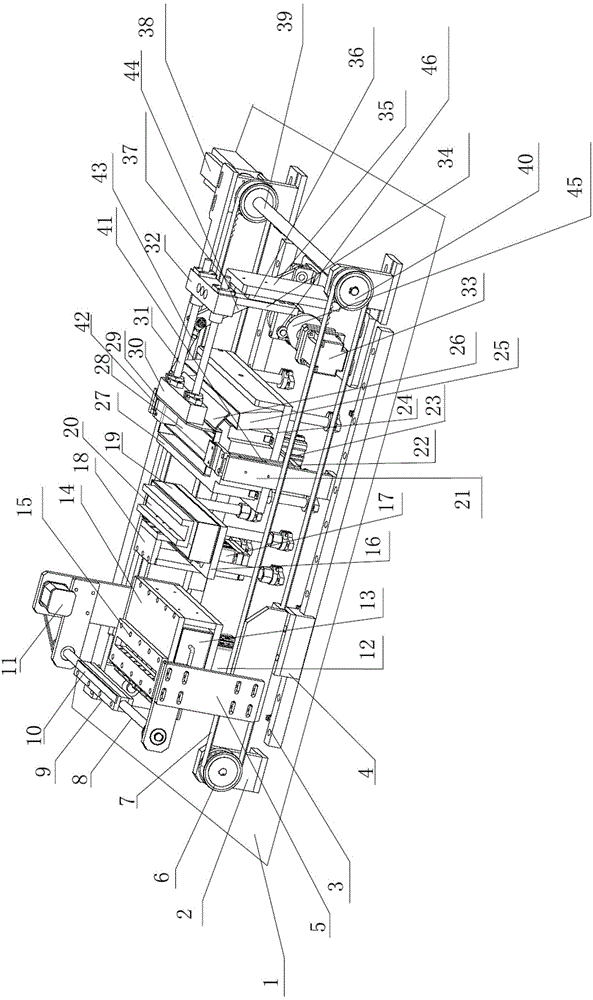

Automatic soldering machine

InactiveUS8517245B1Solve low manufacturing efficiencyQuality improvementWelding/cutting auxillary devicesAuxillary welding devicesMan machineEngineering

An automatic soldering machine adapted for soldering cables with electronic products includes a main frame module, a man-machine control interface, a sliding tray located in front of the man-machine control interface, a loading tool slidably disposed in the sliding tray, a feeding module close to a bottom of the sliding tray, a removing module located between the man-machine control interface and a reforming module, a container, a loading tool combination module located above the sliding tray, a spraying module located in rear of the sliding tray, and a loading tool reflow module mounted on a rear of the main frame module. The man-machine control interface is connected with and controls the loading tool, the feeding module, the removing module, the reforming module, the loading tool combination module, the spraying module and the loading tool reflow module for realizing an automatic soldering process of the electronic products and the cables.

Owner:CHENG UEI PRECISION IND CO LTD

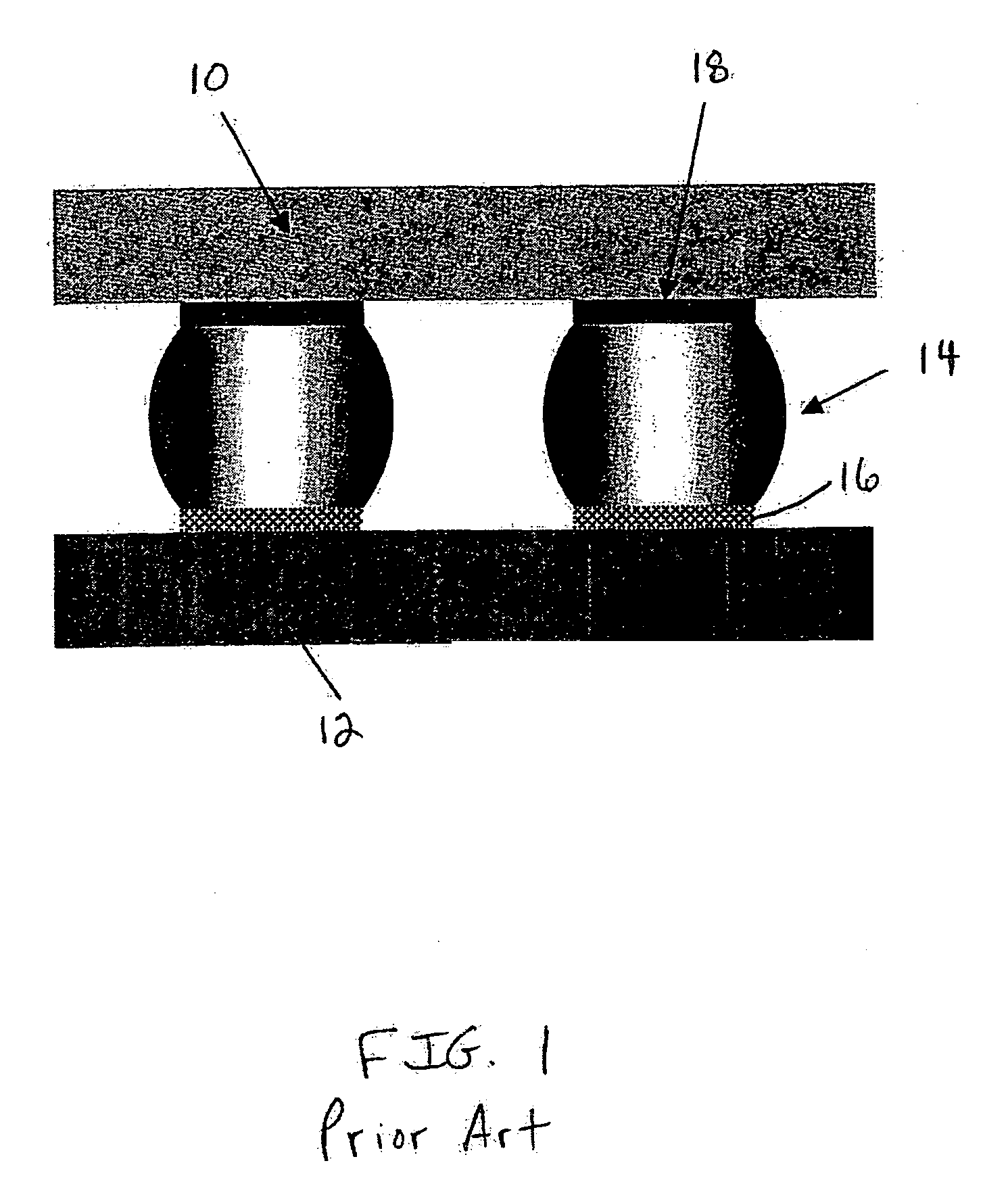

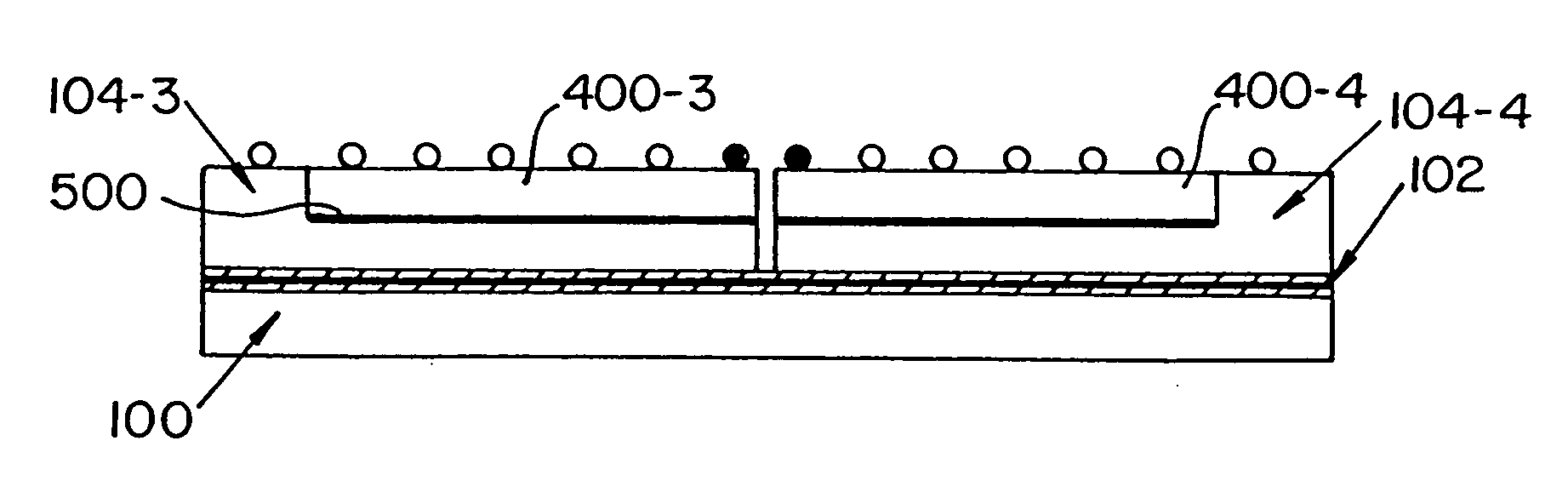

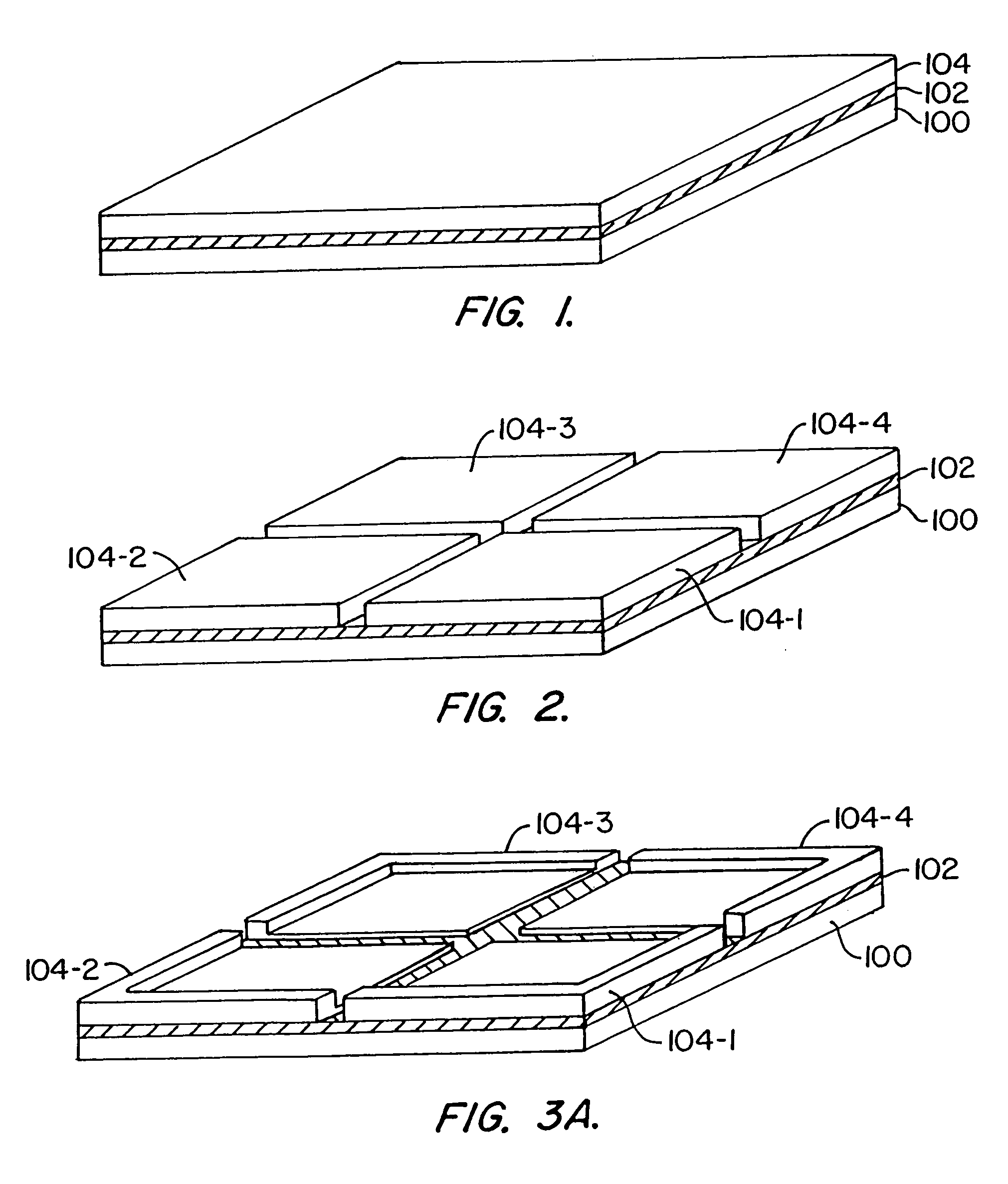

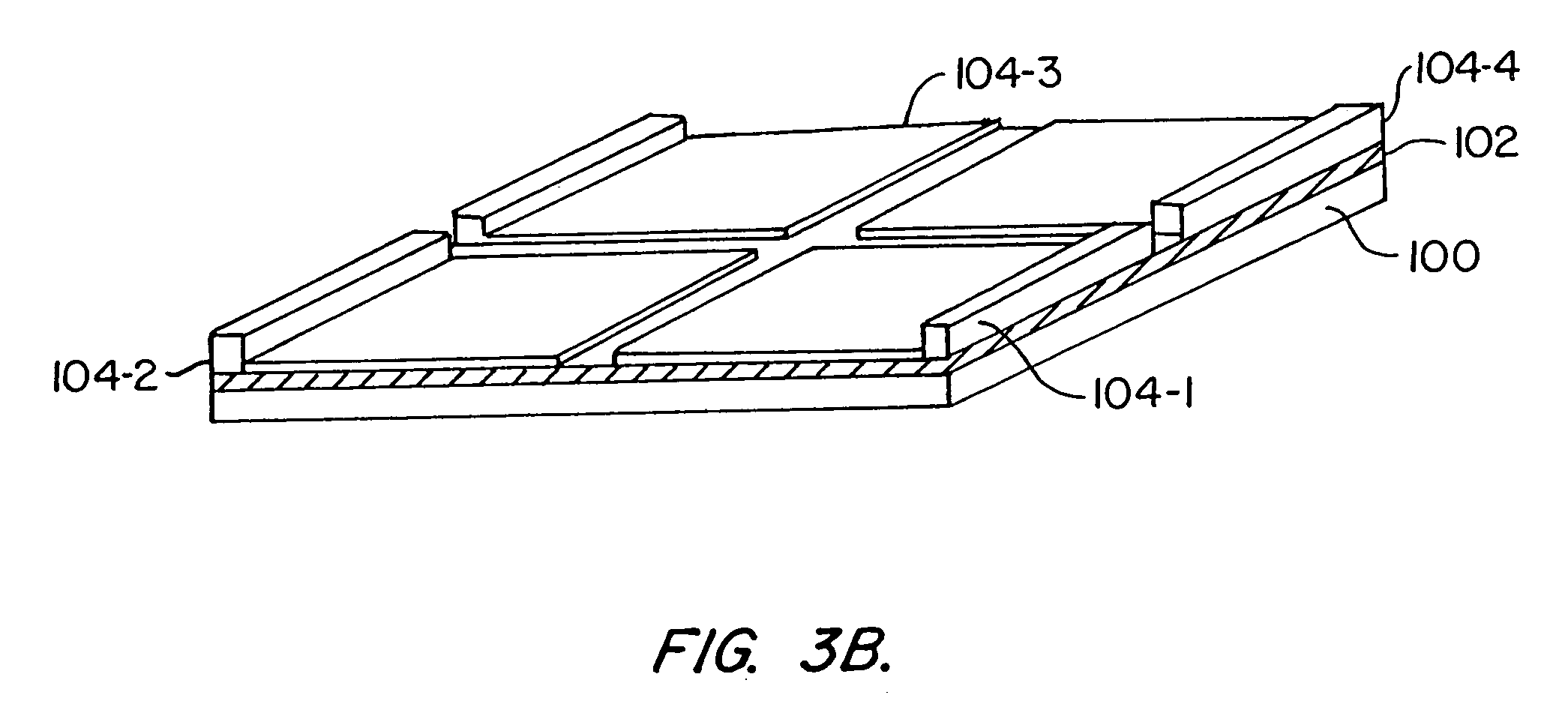

Methods for forming solder balls on substrates

InactiveUS6293456B1Reduce effective thermal massPromote wettingPrinted circuit assemblingPrinted circuit aspectsSolder ballMechanical engineering

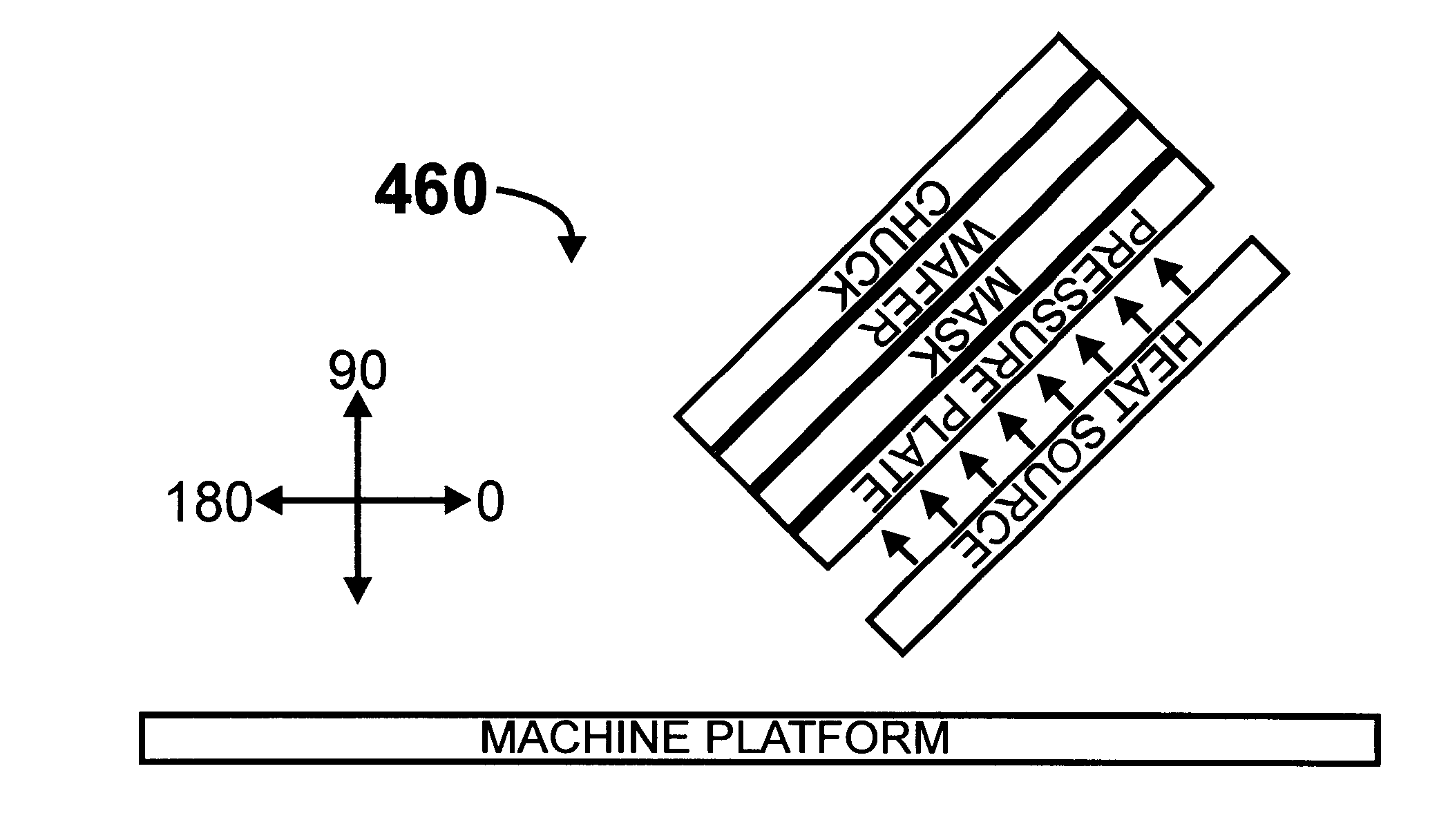

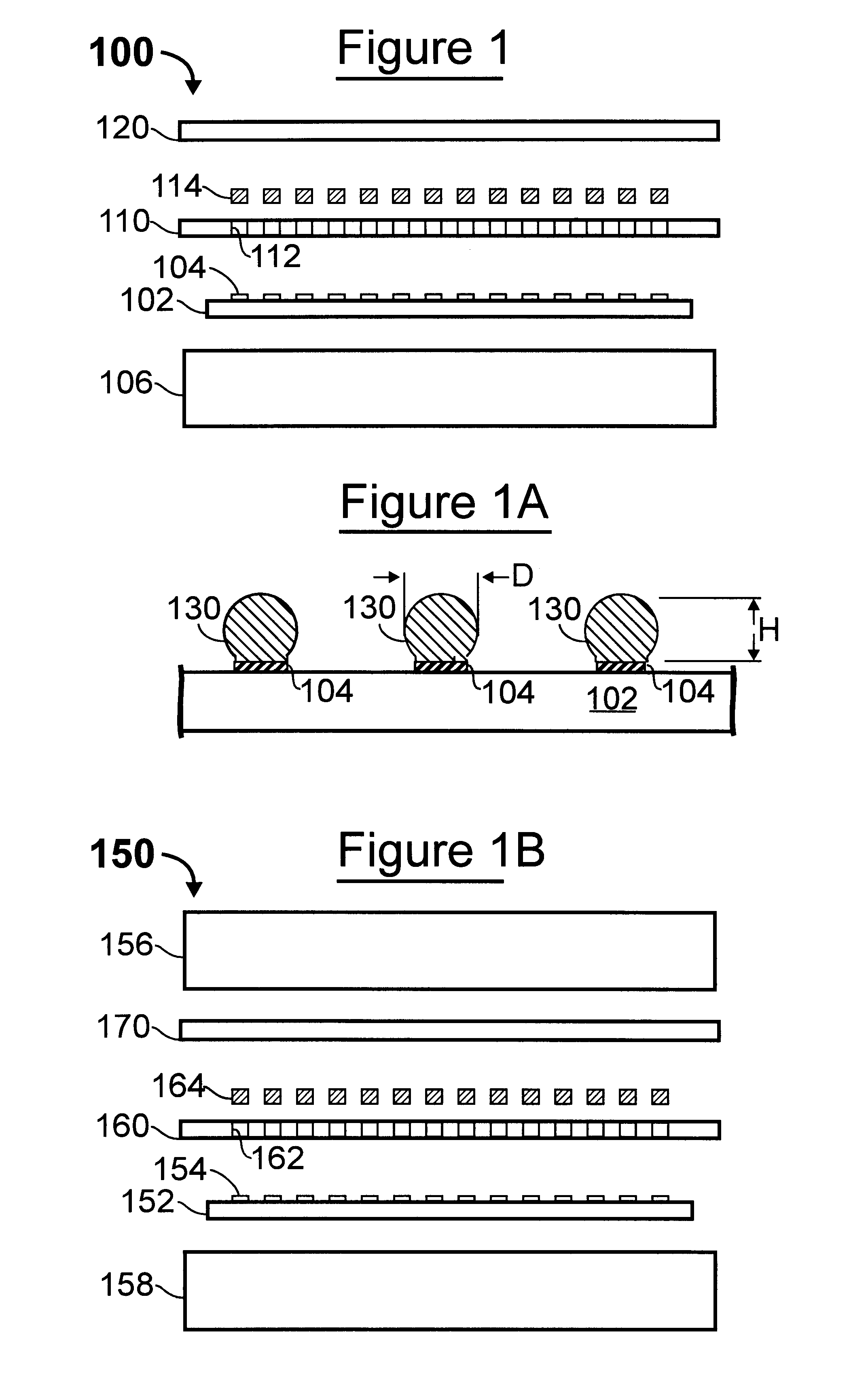

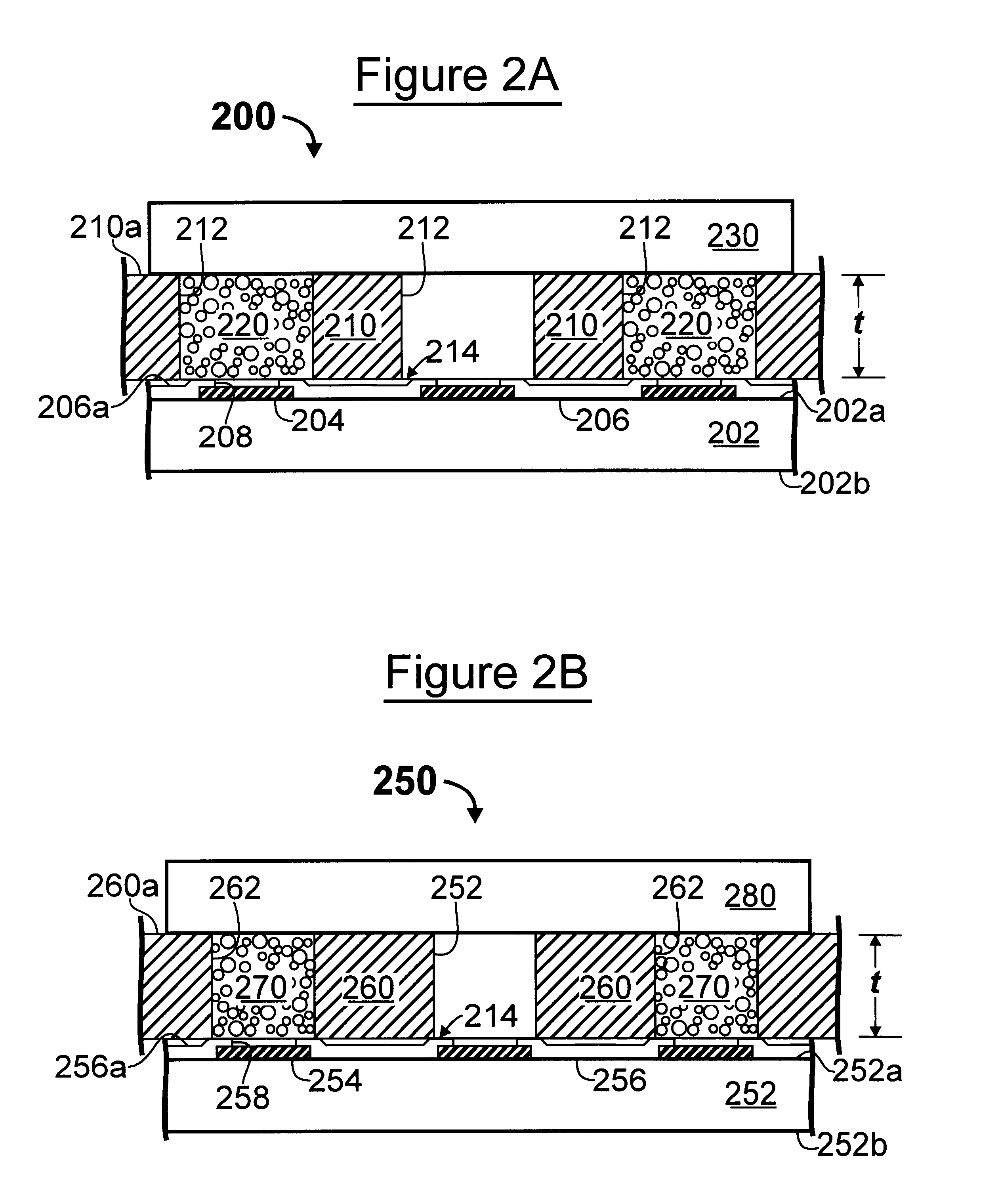

A mask (110; see also 160, 210, 260, 310, 408, 500, 702, 802, 904) having a plurality of openings (cells) is disposed on, or nearly on, the surface of a substrate (102), the openings (112) of the mask being aligned over a corresponding plurality of pads (104) on the substrate. The openings in the mask are filled with solder material (114). A pressure plate (120) is disposed over the mask to capture the solder material in the cells. Heat is directed at the mask (through the pressure plate) to reflow the solder. This is done in an inverted or partially inverted orientation. The stackup (assembly) of substrate / mask / pressure plate may be un-inverted prior to cooling. Mask configurations, methods of mounting the masks, and solder material compositions are described. The methods are robust, and are well suited to fine pitch as well as coarse pitch ball bumping of substrates.

Owner:SEMIPAC INC

Bump forming method and bump forming apparatus

InactiveUS6541364B2Easy to suckPrinted circuit assemblingSemiconductor/solid-state device manufacturingEngineeringSelf weight

A mask 11 has a plurality of holes formed at positions corresponding to positions of a plurality of electrode portions 10a on one surface of an object to be processed 10 to mount thereon conductive particles 13, and the plurality of holes are opposite to the plurality of electrode portions 10a formed on the object to be processed. A table 12 has a plurality of holes 12a for sucking the object to be processed 10 from the other surface of the object to be processed 10, and for sucking the particles 13 through the plurality of holes 11a in the mask 11 so that the particles 13 may be mounted on the electrode portions 10a formed on the object to be processed 10. A hopper 14 contains therein the plurality of conductive particles 13, prevents the plurality of conductive particles 13 from adhering to each other, and has a slit portion 17 for dropping the plurality of conductive particles 13 by the self-weight. A slit portion 17 in the hopper 14 is moved, facing the upper surface of the mask 11 with a gap between the slit portion 17 and the upper surface of the mask 11 larger than a diameter of the particle 13, and the hopper 14 is arranged in the front side in the moving direction, and the unit 15 is arranged in the rear side, and the particles 13 not dropped into the holes of the mask being collected by the collecting unit 15.

Owner:HITACHI LTD +1

Deposition and patterning process

ActiveUS20050106329A1Reduce and eliminate edge effectAvoid edge effectsSolid-state devicesSemiconductor/solid-state device manufacturingMetal particleMaterials science

A method for applying particles in a pattern to a substrate, either directly or by use of an intermediate tool, by electrokinetic or electrostatic means. A method for applying metal particles such as solder metal in a pattern to an electronic device substrate, either directly or by use of an intermediate tool, by electrokinetic or electrostatic means.

Owner:FRY S METALS INC

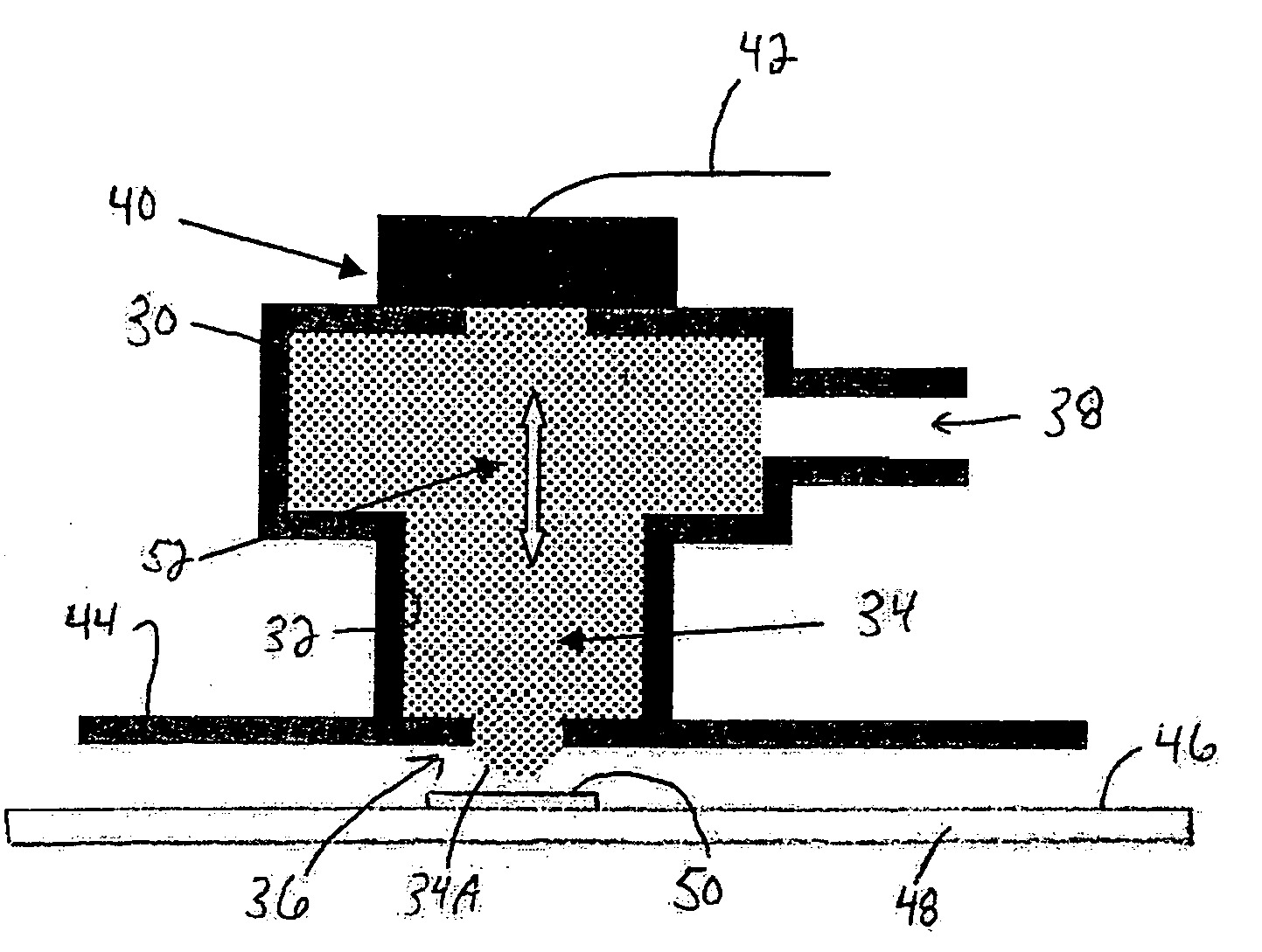

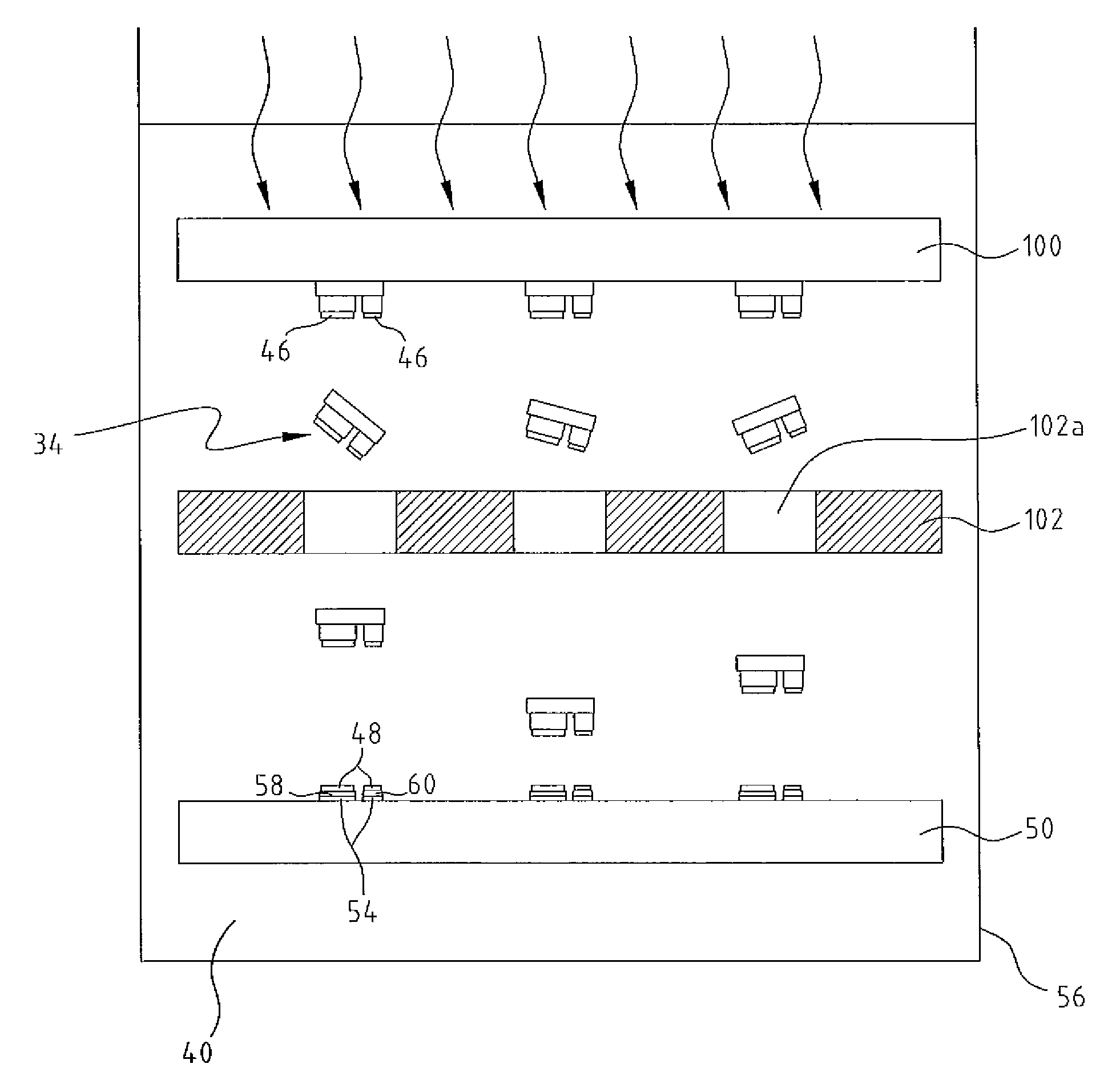

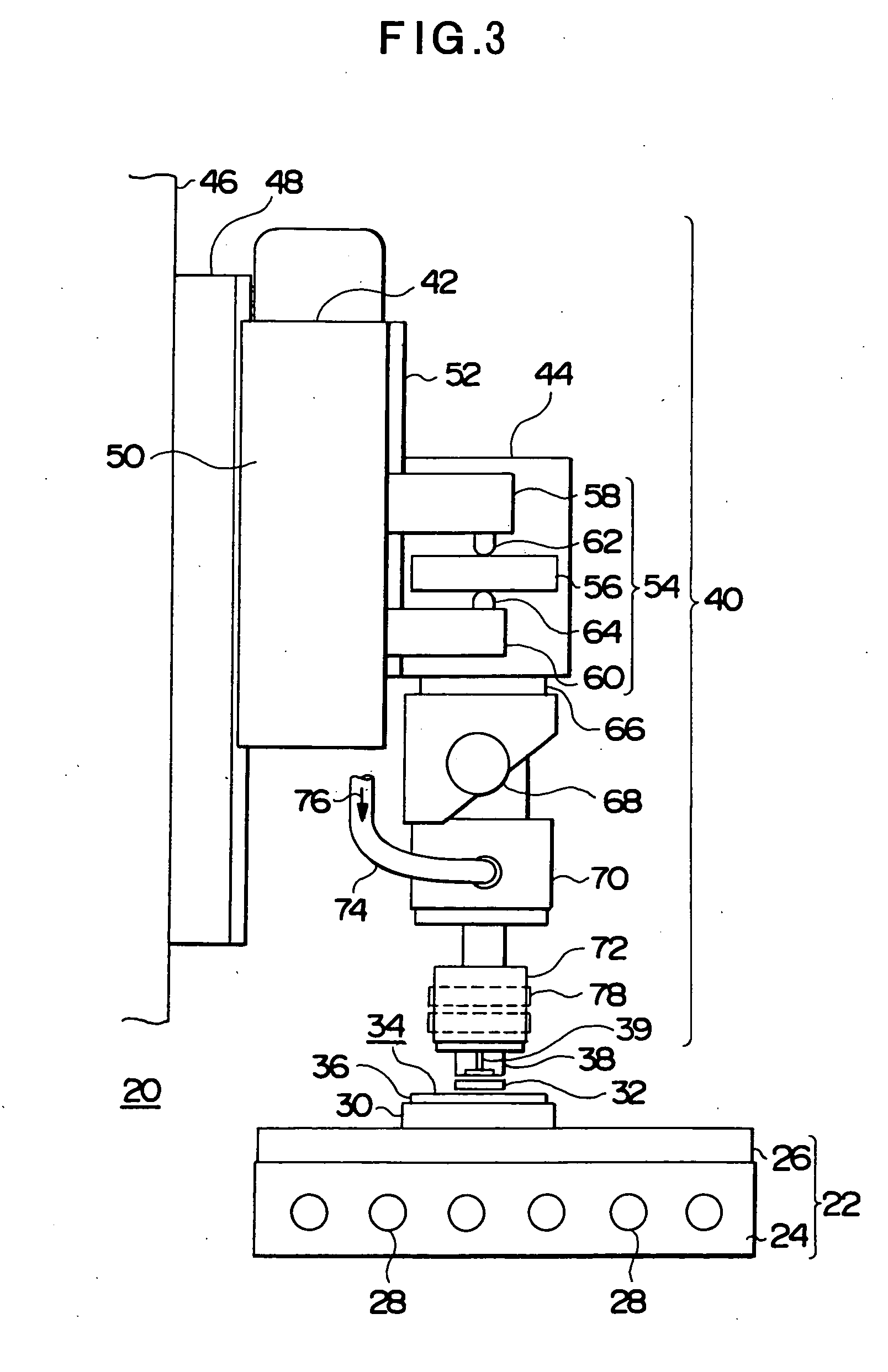

Method and apparatus for mounting and removing an electronic component

InactiveUS20060076388A1Low costReduce stressProgramme controlPrinted circuit assemblingElectronic componentHeating temperature

A method and an apparatus are provided for mounting and removing electronic components using solder bumps while constraining thermal stresses to a substrate. The method and apparatus for mounting and removing an electronic component (bear chip 32) to be soldered onto the substrate with solder bumps 114 is configured to move the electronic component to detect contact of the solder bumps with the substrate or contact of a tool (chuck unit 38) with the electronic component, to define the contact as an original point for raising a heating temperature of the electronic component and the substrate from the heating temperature to a maximum heating temperature HTm as well as move the electronic component in conformity with the temperature rising, and to move the electronic component from a position where the maximum heating temperature is achieved to a mounting height of the substrate.

Owner:FUJITSU LTD

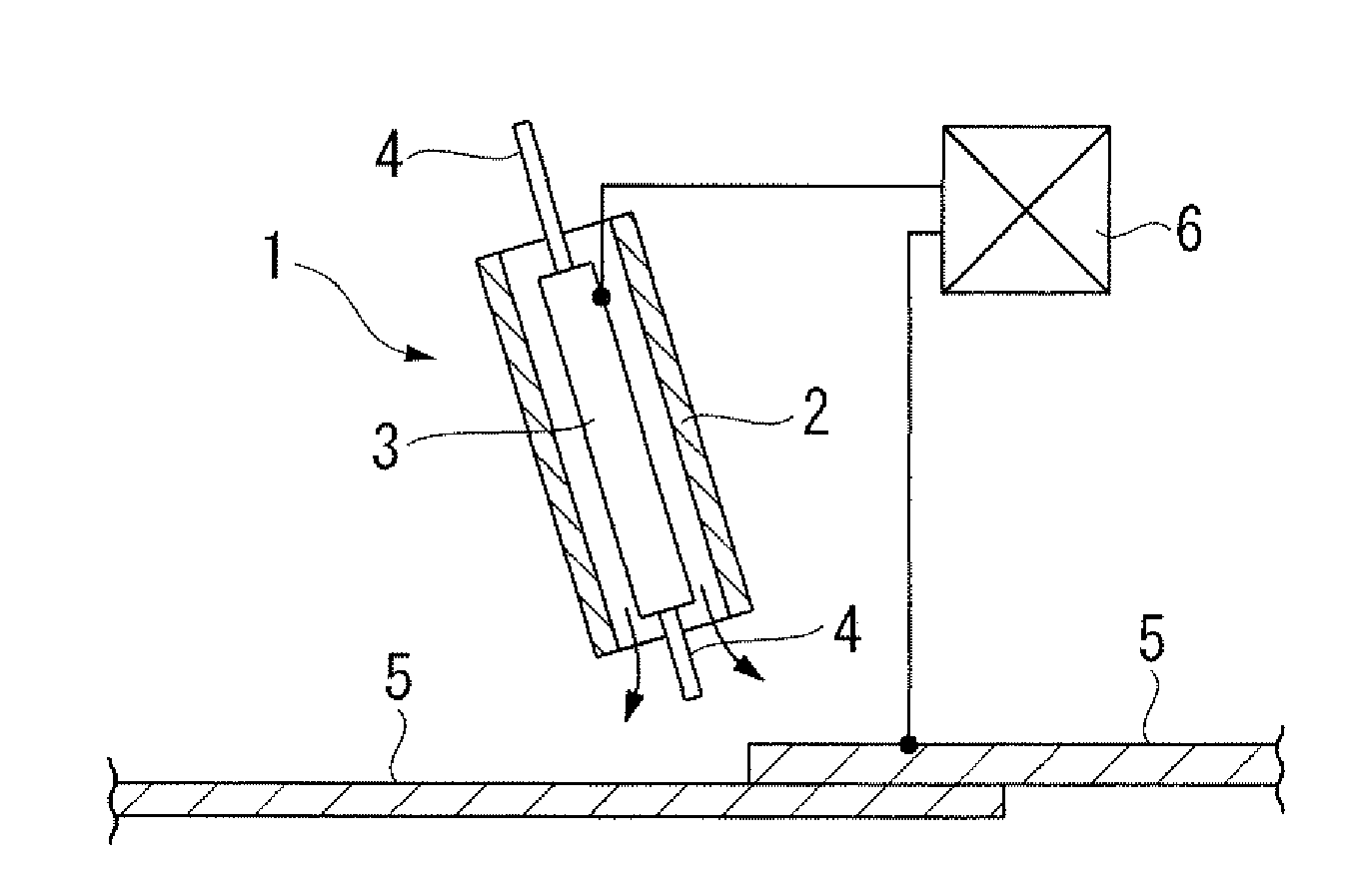

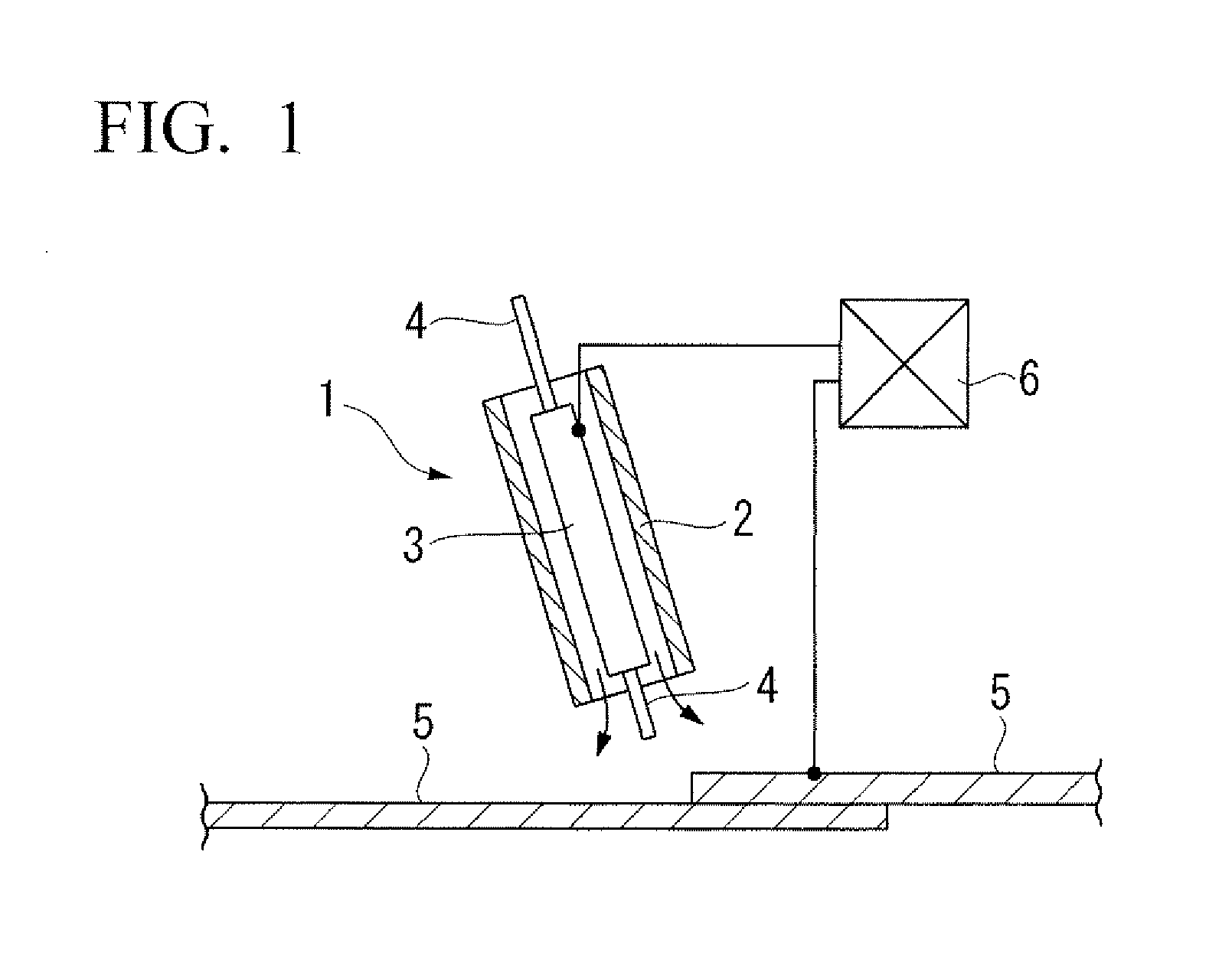

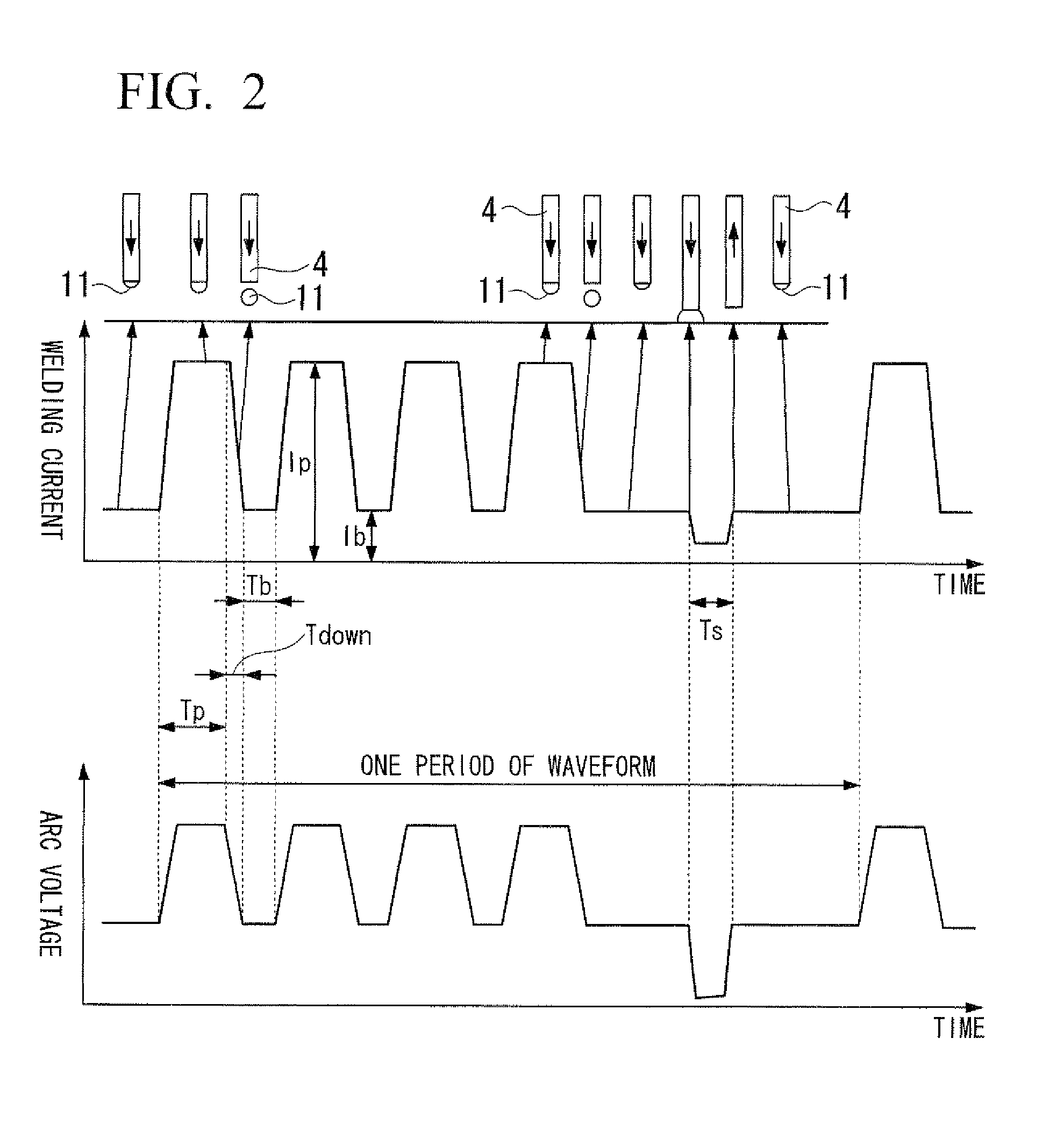

Method for gas-shielded arc brazing of steel sheet

InactiveUS20110174784A1Reduce generationReduce arc voltageArc welding apparatusWelding/cutting media/materialsSheet steelShielding gas

Owner:NIPPON SANSO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com