Patents

Literature

259results about How to "Precise length control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

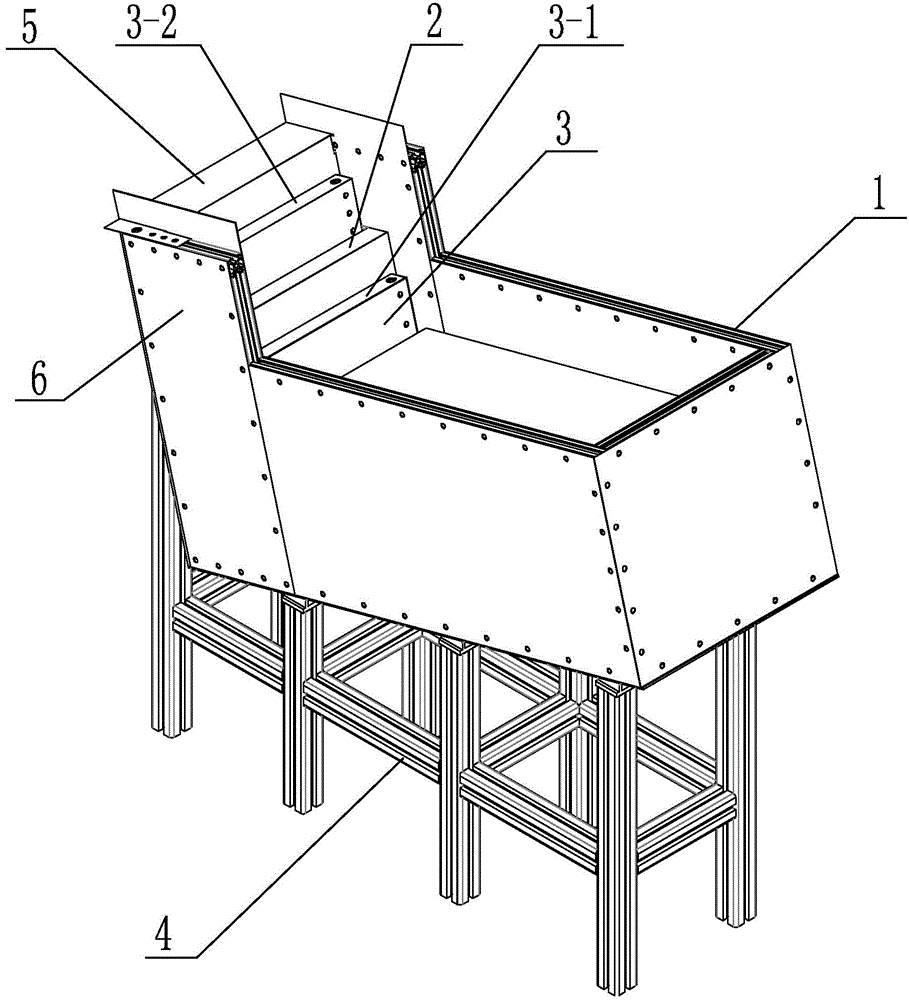

Automatic tin staining device

ActiveCN102601482ASimple structurePrecise length controlSolder feeding devicesSoldering auxillary devicesStainingAutomatic control

The invention discloses an automatic tin staining device for a connection line, which comprises a conveying mechanism, a tin furnace and a controller. The controller is used for coordinating the work of a pneumatic or / and electric device; the conveying mechanism is provided with a fixed guide rail mechanism matched with a connection line fixing mechanism, a connection line drive mechanism and a movable guide rail mechanism smoothly connected with the fixed guide rail mechanism; the movable guide rail mechanism is movably connected with a frame and is in transmission connection with a turning mechanism; and the tin furnace is movably arranged on the frame at one side of the movable guide rail mechanism. When the connection line fixed mechanism is moved to a tin staining position during the work, the movable guide rail is turned by the movable guide rail turning mechanism, so that the connection line on the connection line fixed mechanism is reset after being contacted with soldering tin in the tin furnace. The automatic tin staining device is simple in structure, and can accurately control the tin staining length through properly controlling the liquid surface of the soldering tin; simultaneously, the staining of the tin is automatically controlled, so that the efficiency of the staining of the tin can be improved, the low efficiency of the manual staining of the tin is avoided so as not to easily cause scalding phenomenon.

Owner:刘光辉

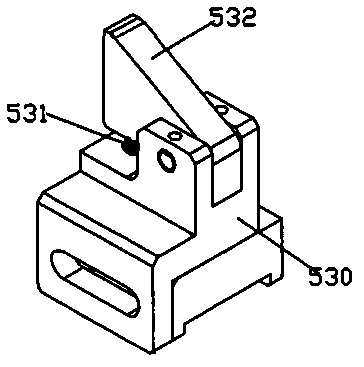

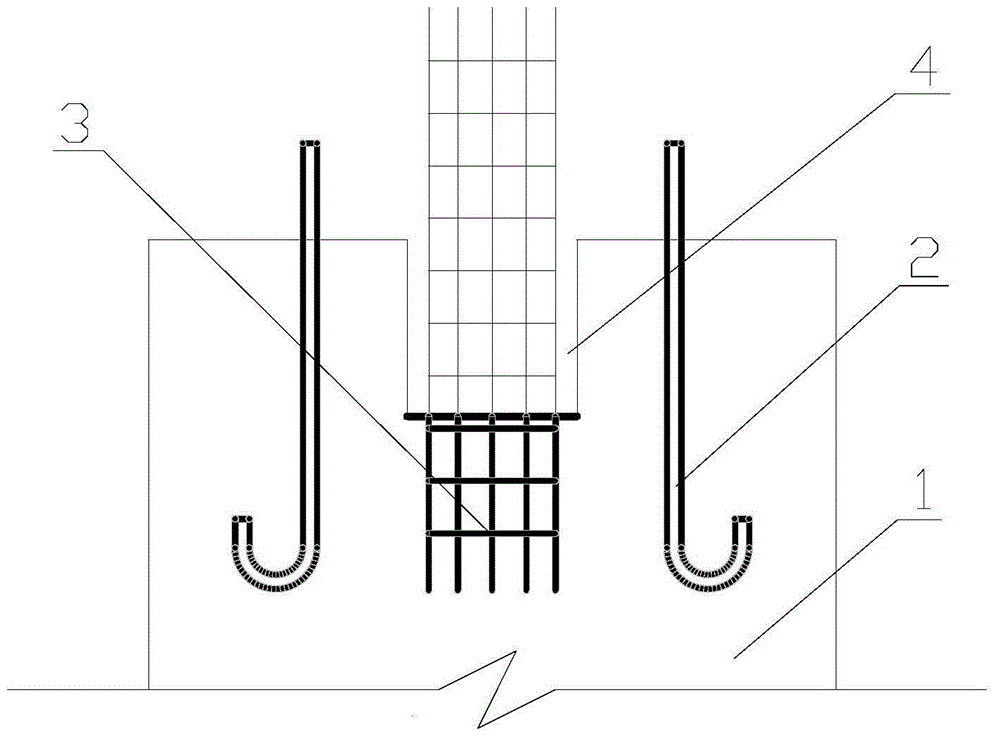

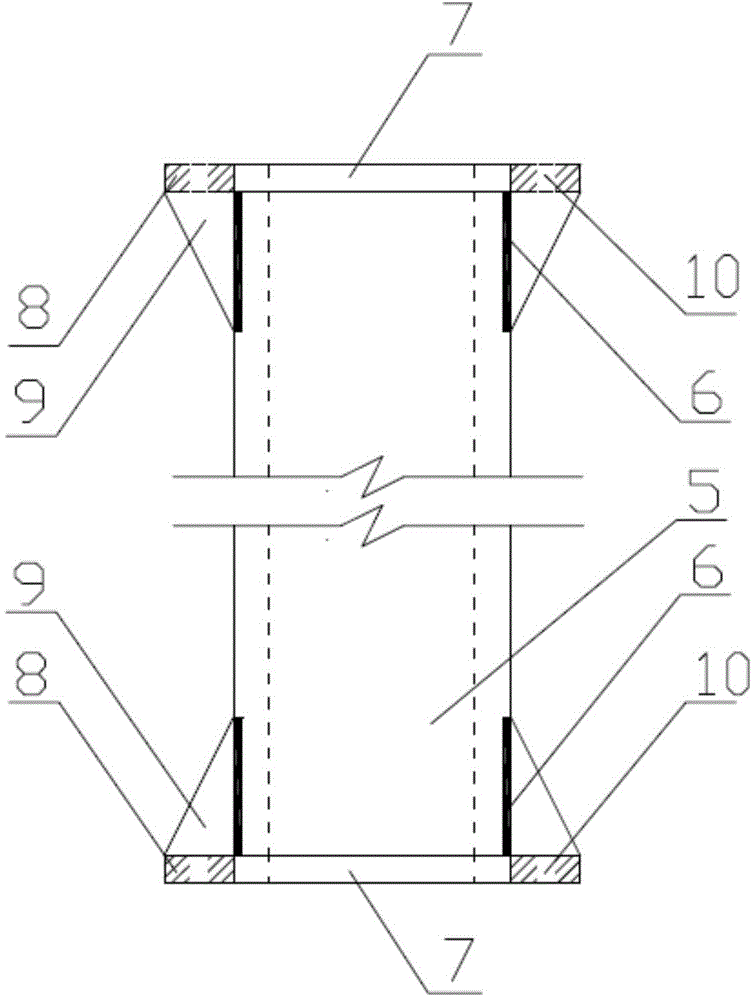

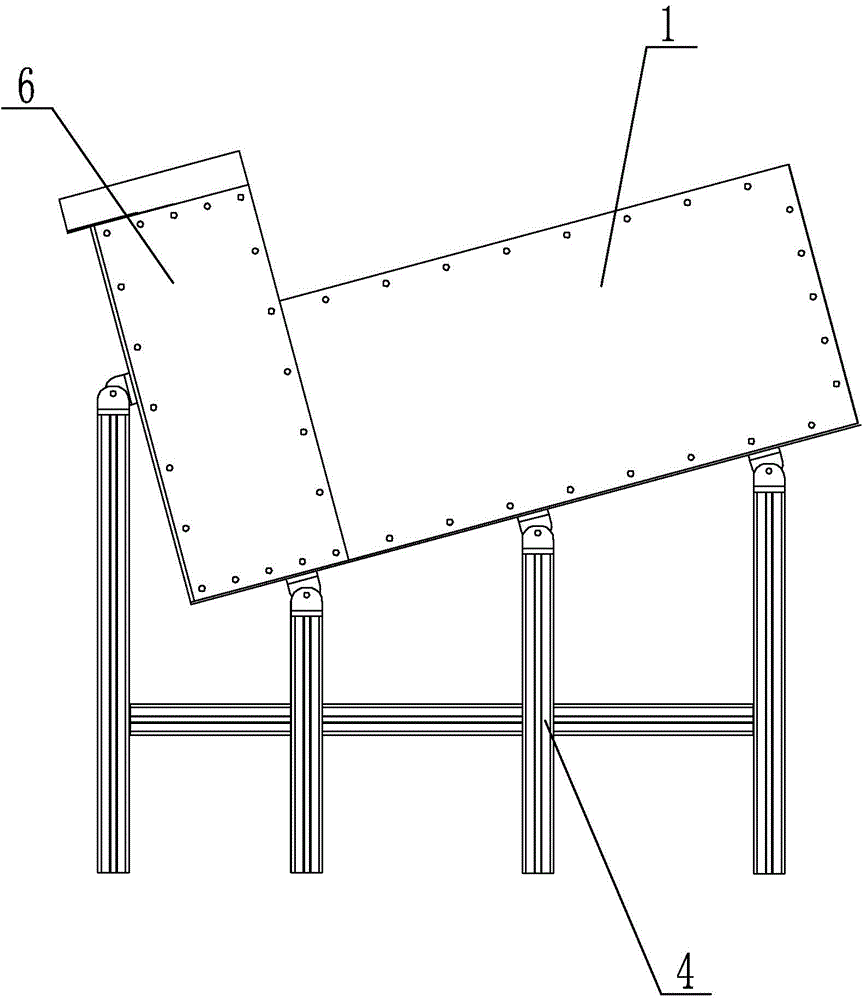

Pile column type concrete hollow pile pier structure

InactiveCN104404869APrecise length controlImprove bearing capacityBridge structural detailsFoundation engineeringEngineeringUltimate tensile strength

The invention relates to a pile column type concrete hollow pile pier structure. The pile column type concrete hollow pile pier structure is characterized by comprising a concrete hollow pile pier, a bridge support, a pier cover beam and a base bearing platform, a flange disc is arranged at the lower end of the concrete hollow pile pier, a reserved bolt hole is formed in the flange disc, the flange disc is connected with the base bearing platform, the flange disc and the base bearing platform are arranged in cast-in-place concrete, an upper bridge support steel plate is arranged at the upper surface of the bridge support while a lower bridge support steel plate is arranged at the lower surface of the bridge support, a flange disc is arranged at the upper end of the concrete hollow pile pier and connected with the lower bridge support steel plate, and the upper bridge support steel plate is connected with the pier cover beam. The pile column type concrete hollow pile pier structure has beneficial effects that the concrete hollow pile pier can be prefabricated in a factory, the pier length can be controlled precisely, the bearing ability of the pier is improved, the concrete hollow pile pier is connected with the base bearing platform through using the flange discs and an insert core reinforcing cage and casting concrete in place, the connecting intensity of the pier can be guaranteed, and the stability thereof is improved.

Owner:天津港航工程有限公司

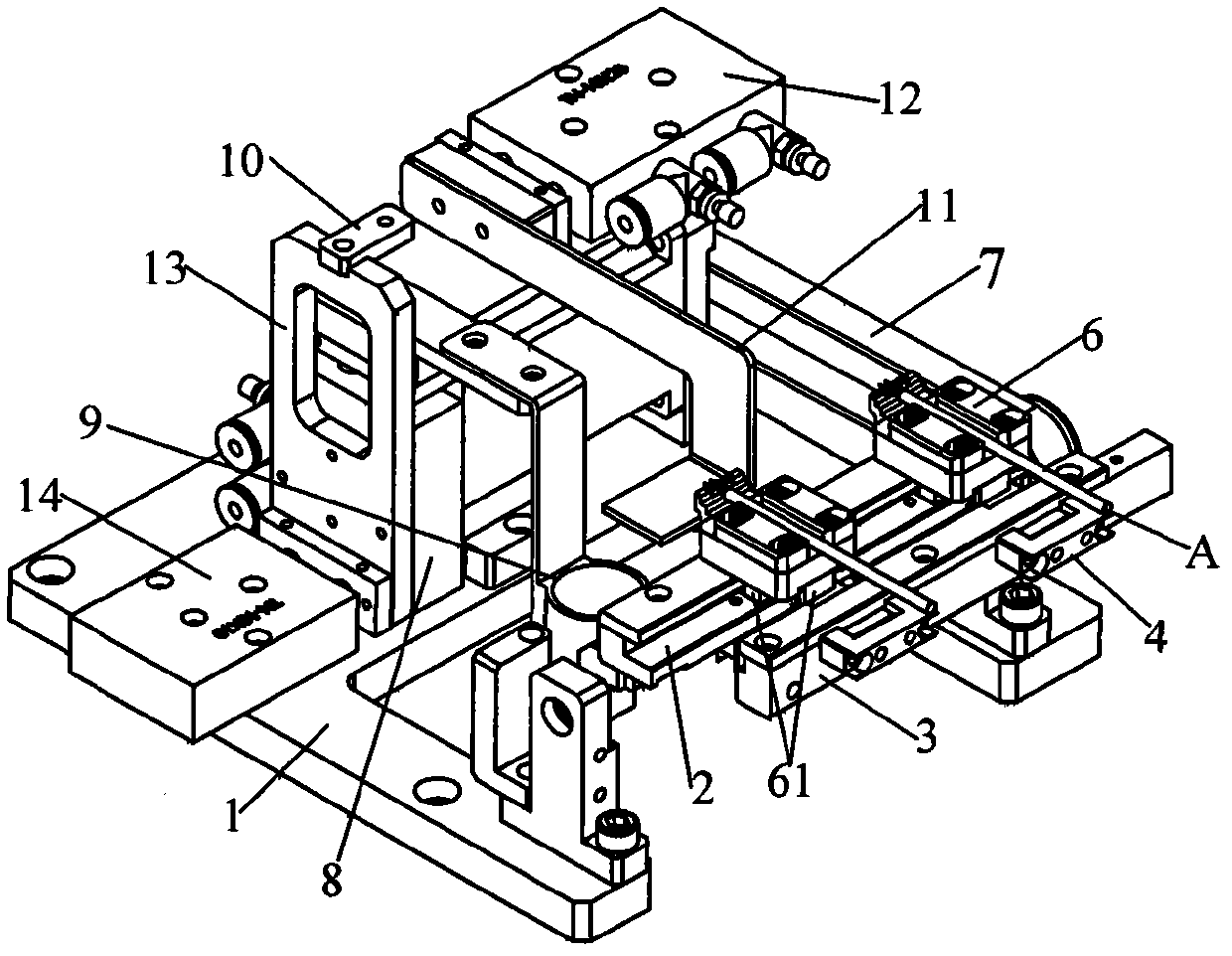

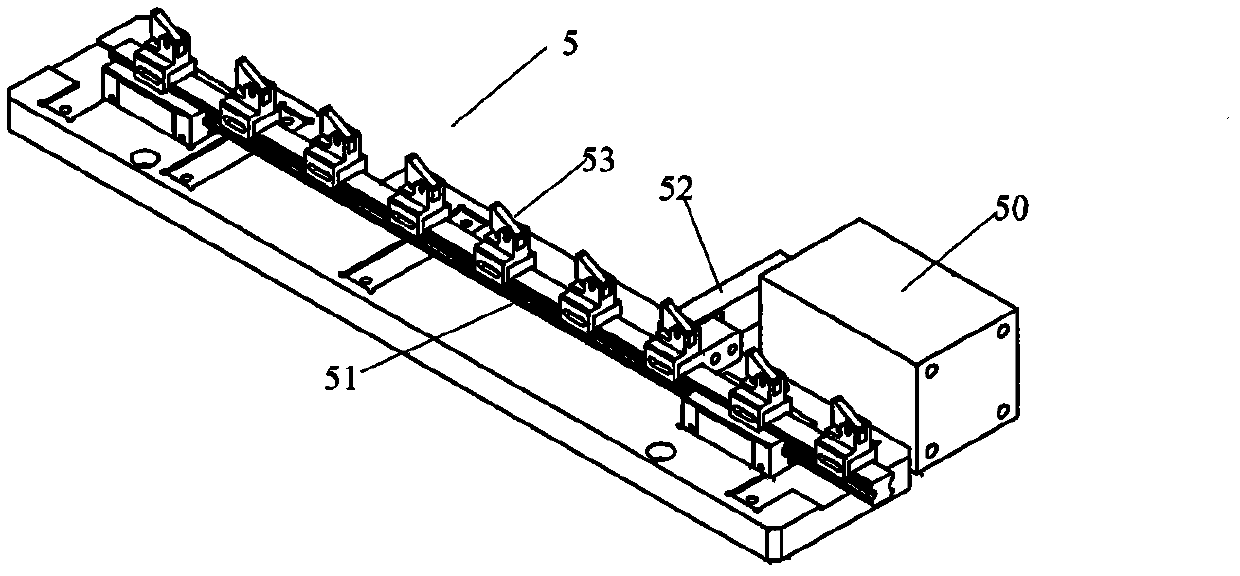

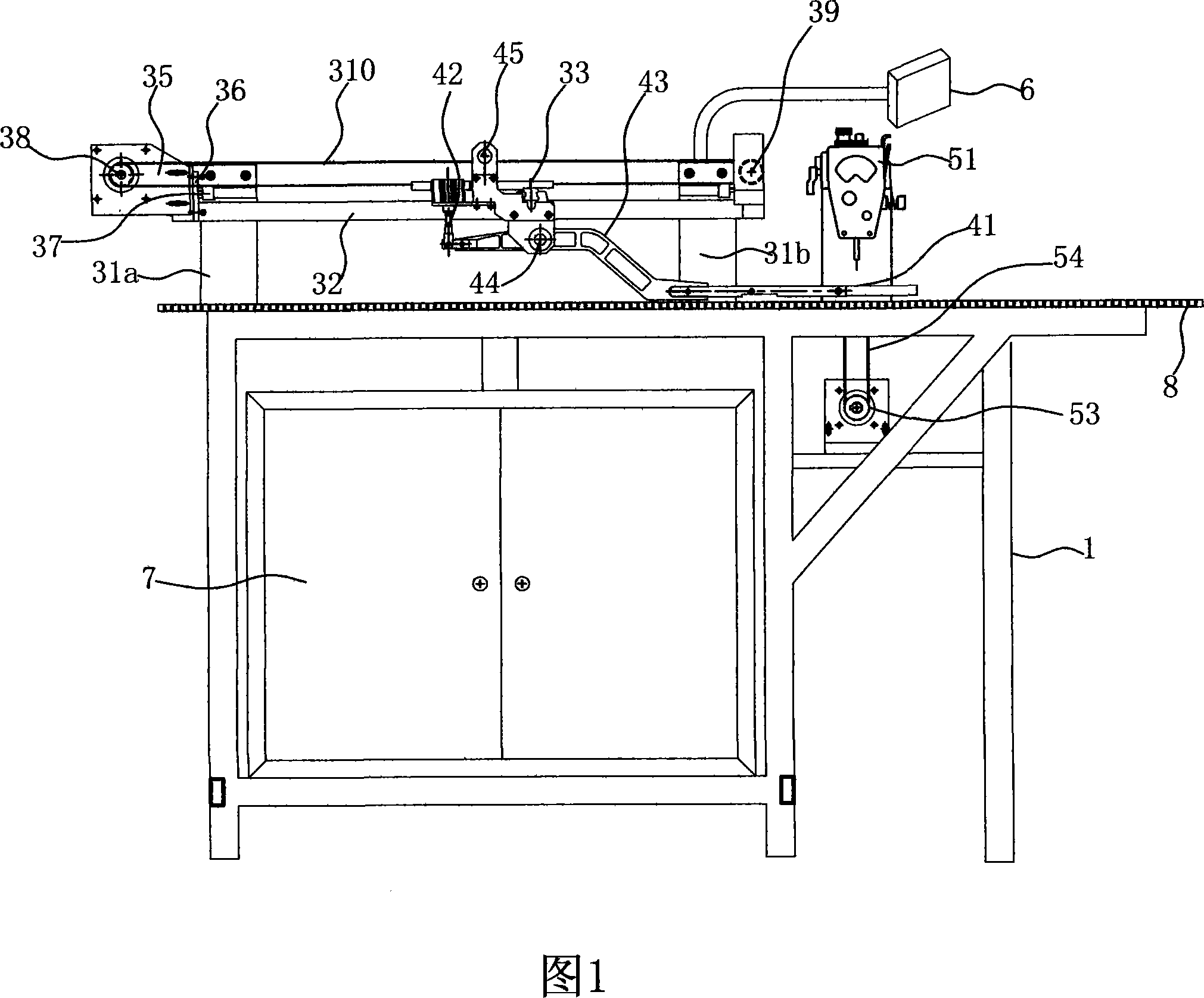

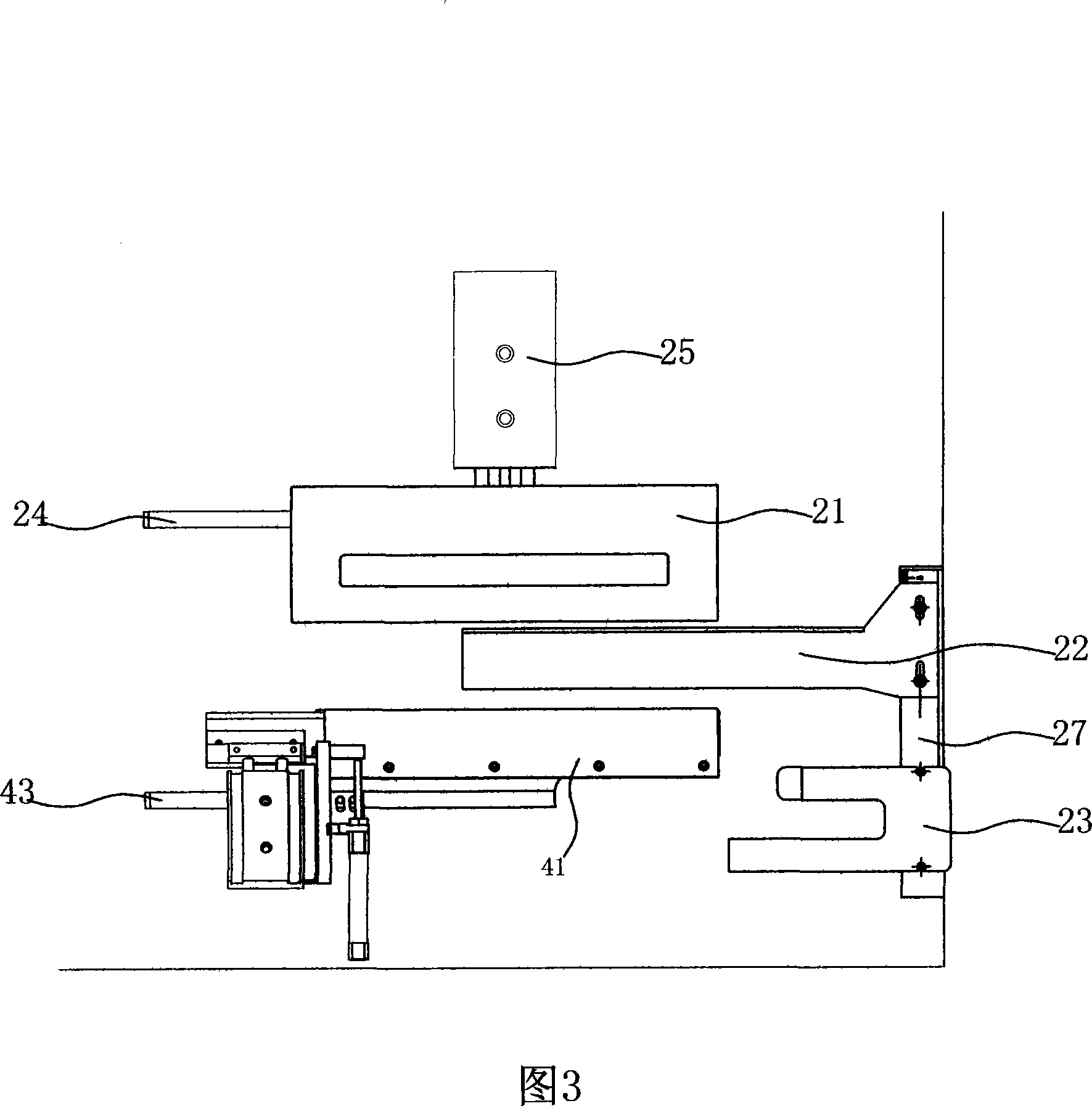

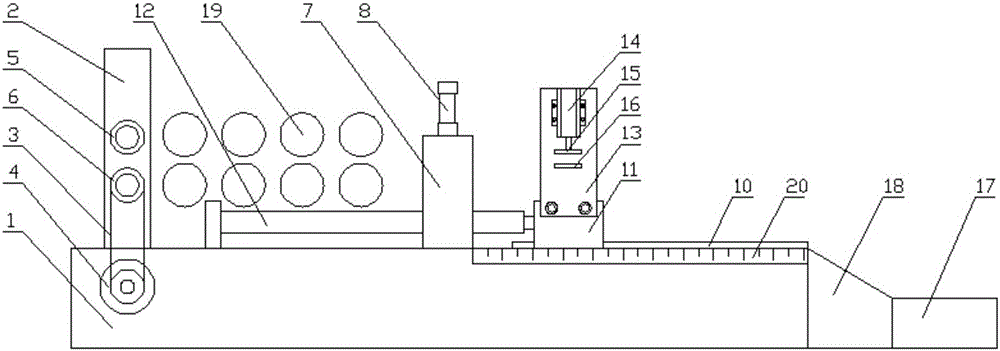

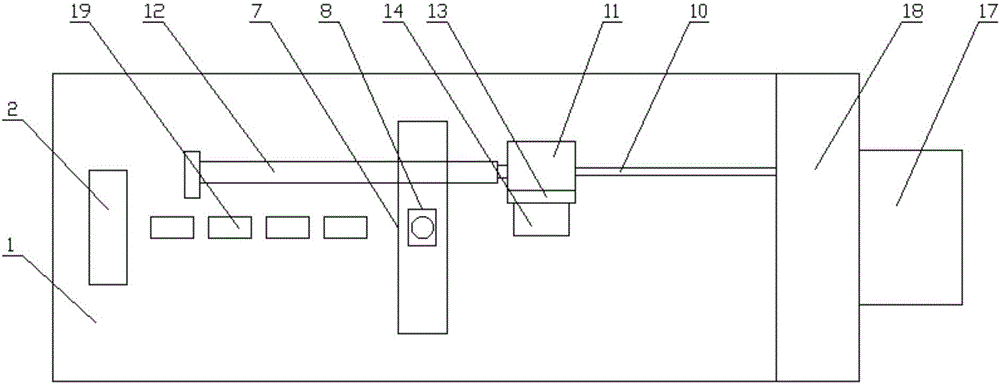

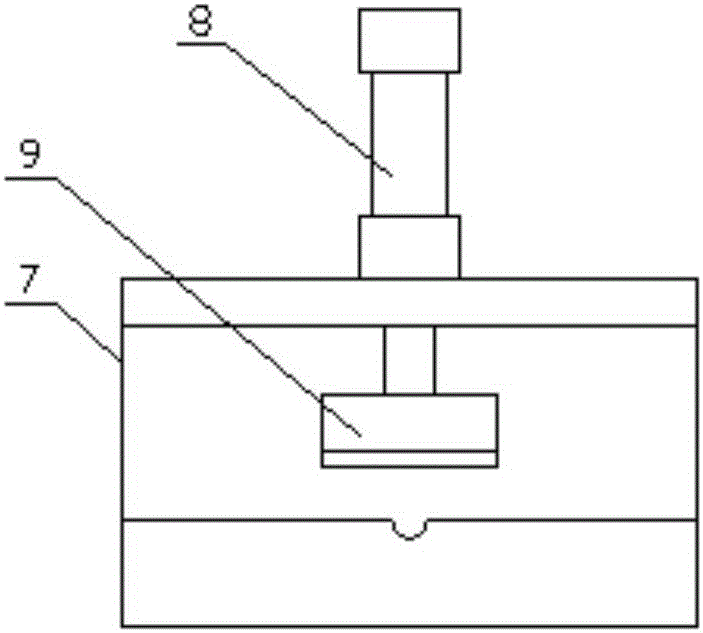

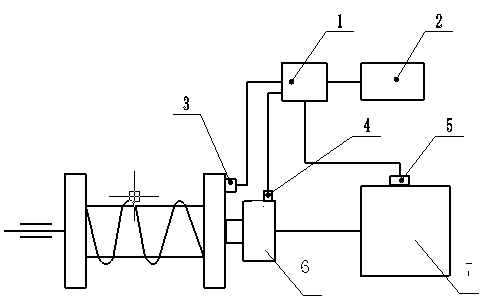

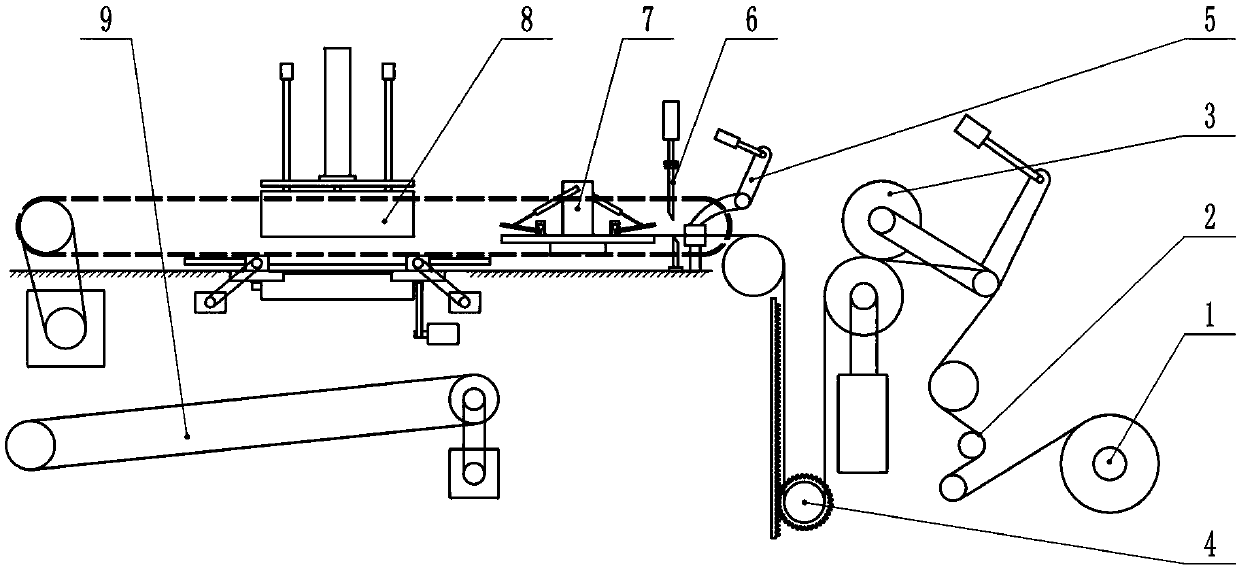

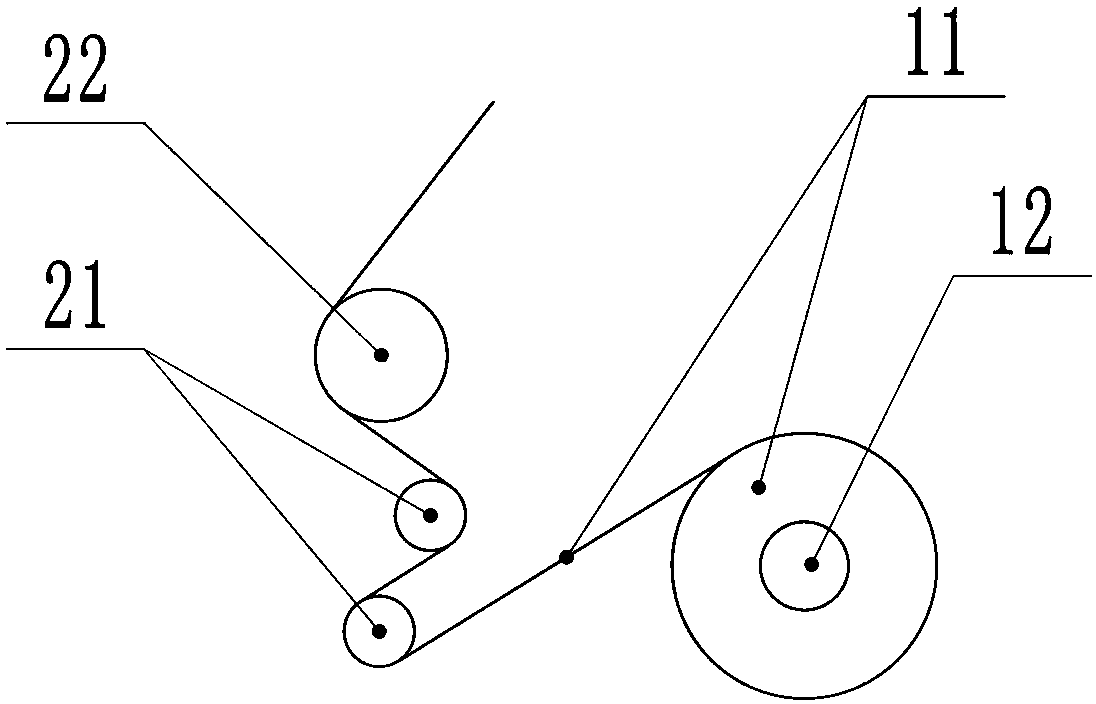

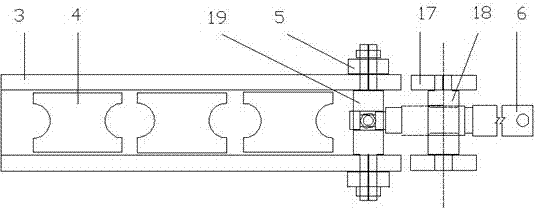

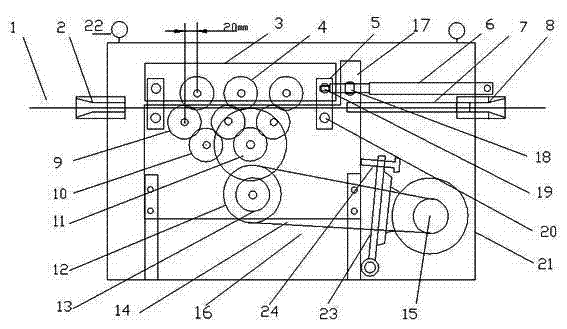

Single welding and series welding integrity device of solar cell slices

ActiveCN102699587AReduce wasteLow costFinal product manufactureWelding/cutting auxillary devicesFailure rateTemperature control

The invention discloses a single welding and series welding integrity device of solar cell slices. The provided single welding and series welding integrity device of the solar cell slices is good in positioning accuracy and compatible in the solar cell slices with different specifications, and can improve the single welding and series welding production efficiency of the solar cell slices. The device comprises a device rack, the device rack is provided with a feed mechanism, a transmission and positioning mechanism, a welding and temperature control mechanism, a blanking mechanism, a control mechanism and a power supply and control mechanism. According to the single welding and series welding integrity device of the solar cell slices, a full manual welding mode is replaced by a full automatic mechanical welding mode, the production efficiency is remarkably increased, the cell slice failure rate during a welding process is reduced, and the device is suitable for cell slice welding of the solar cells.

Owner:沈园众

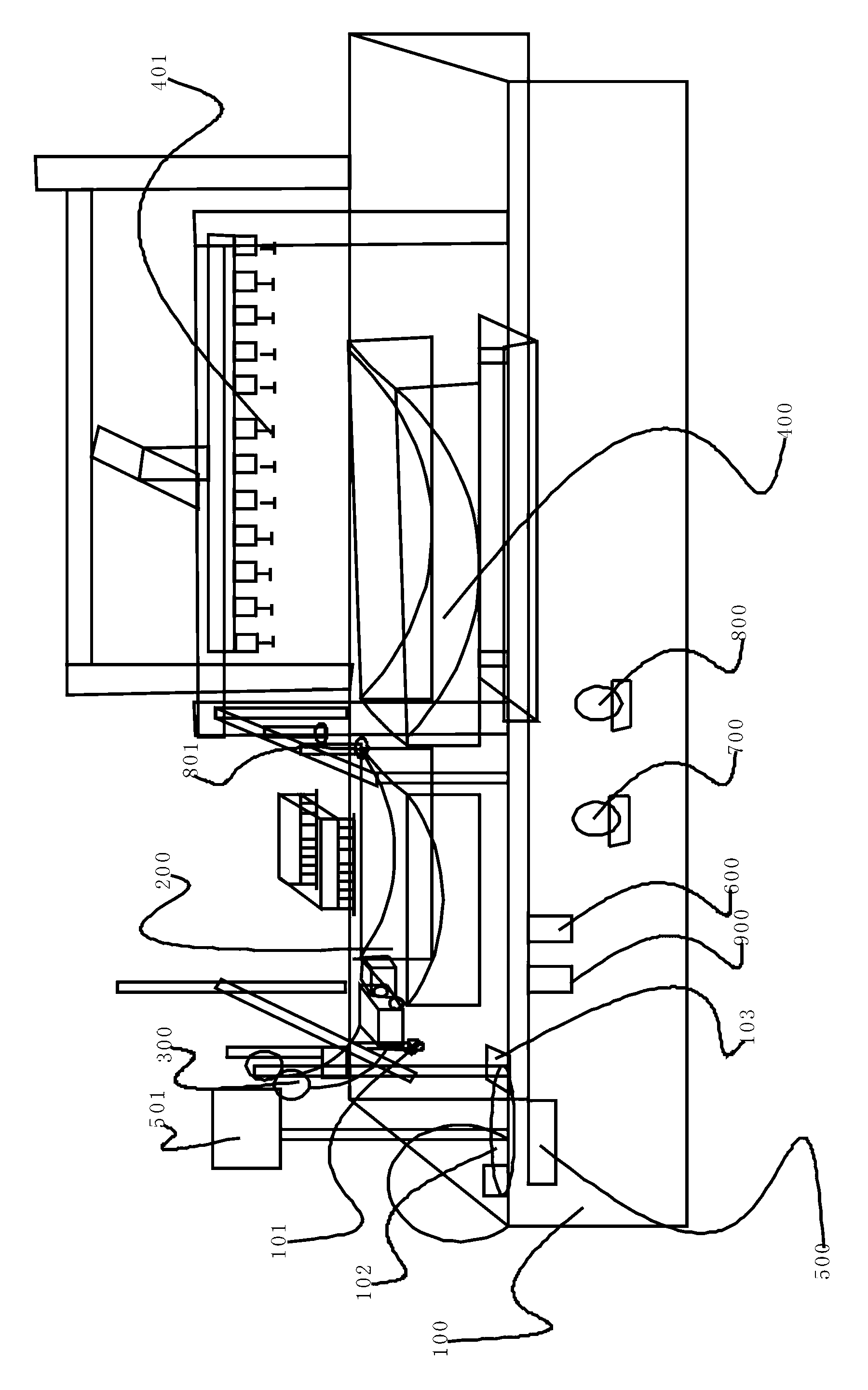

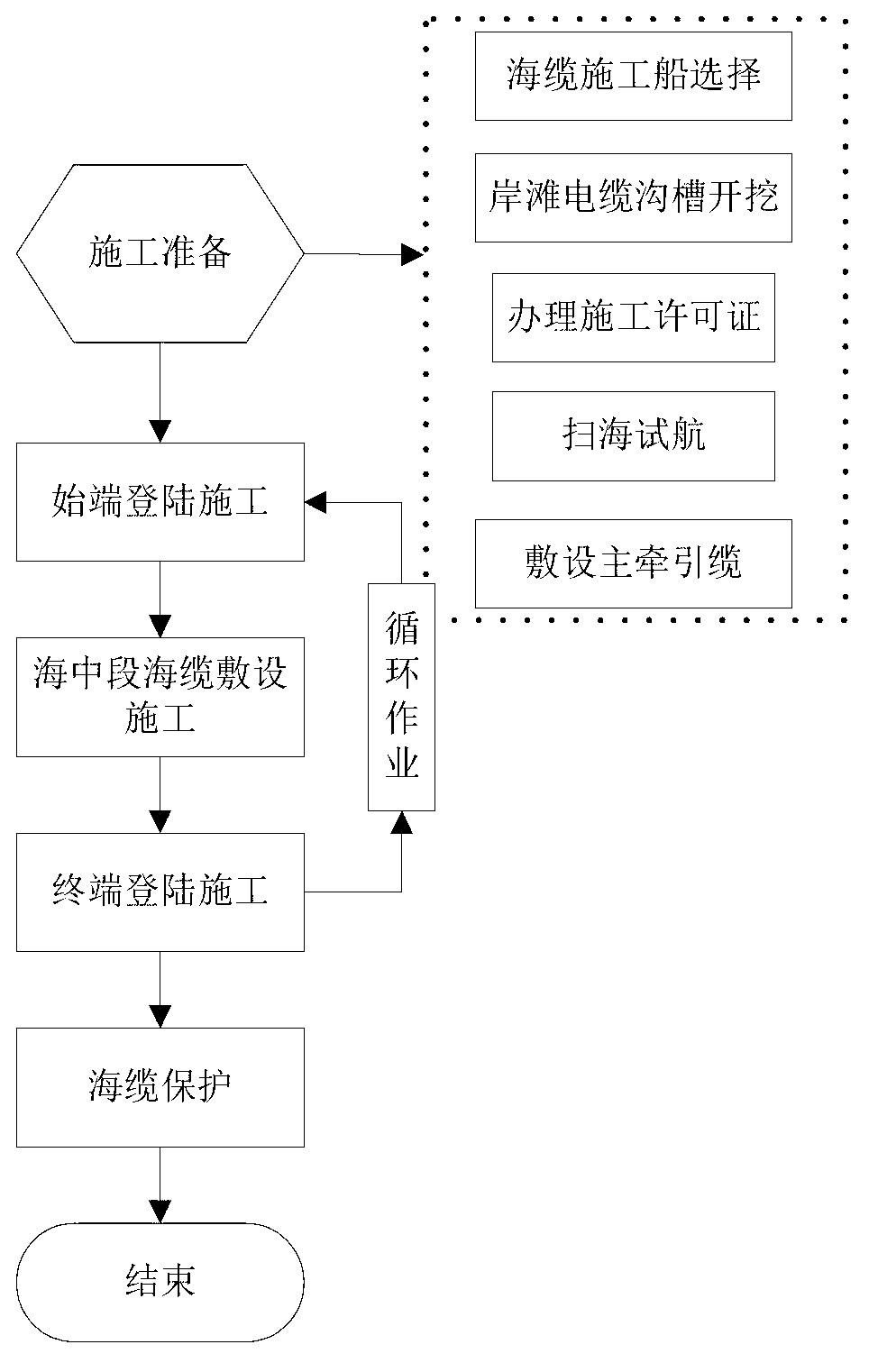

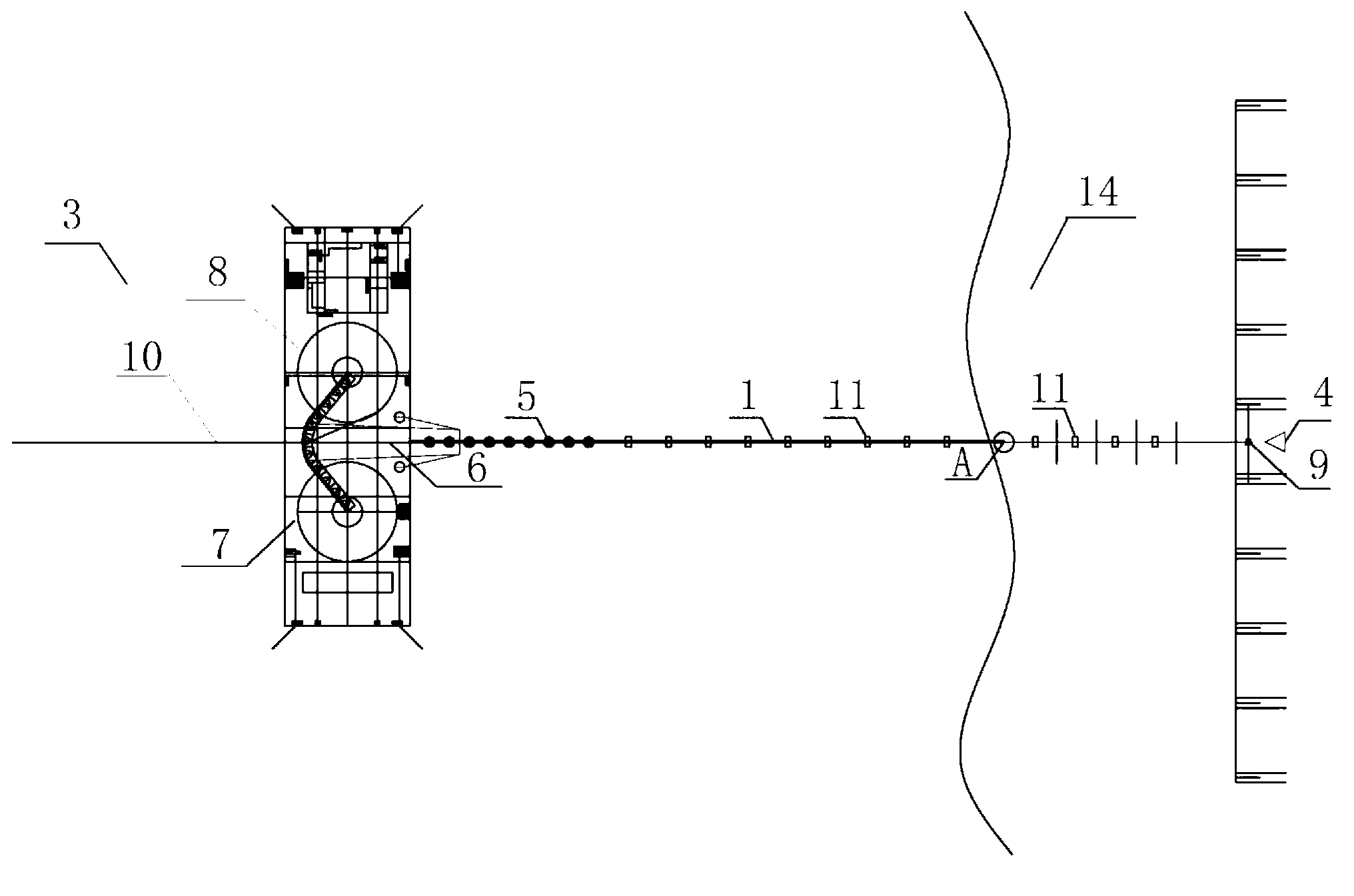

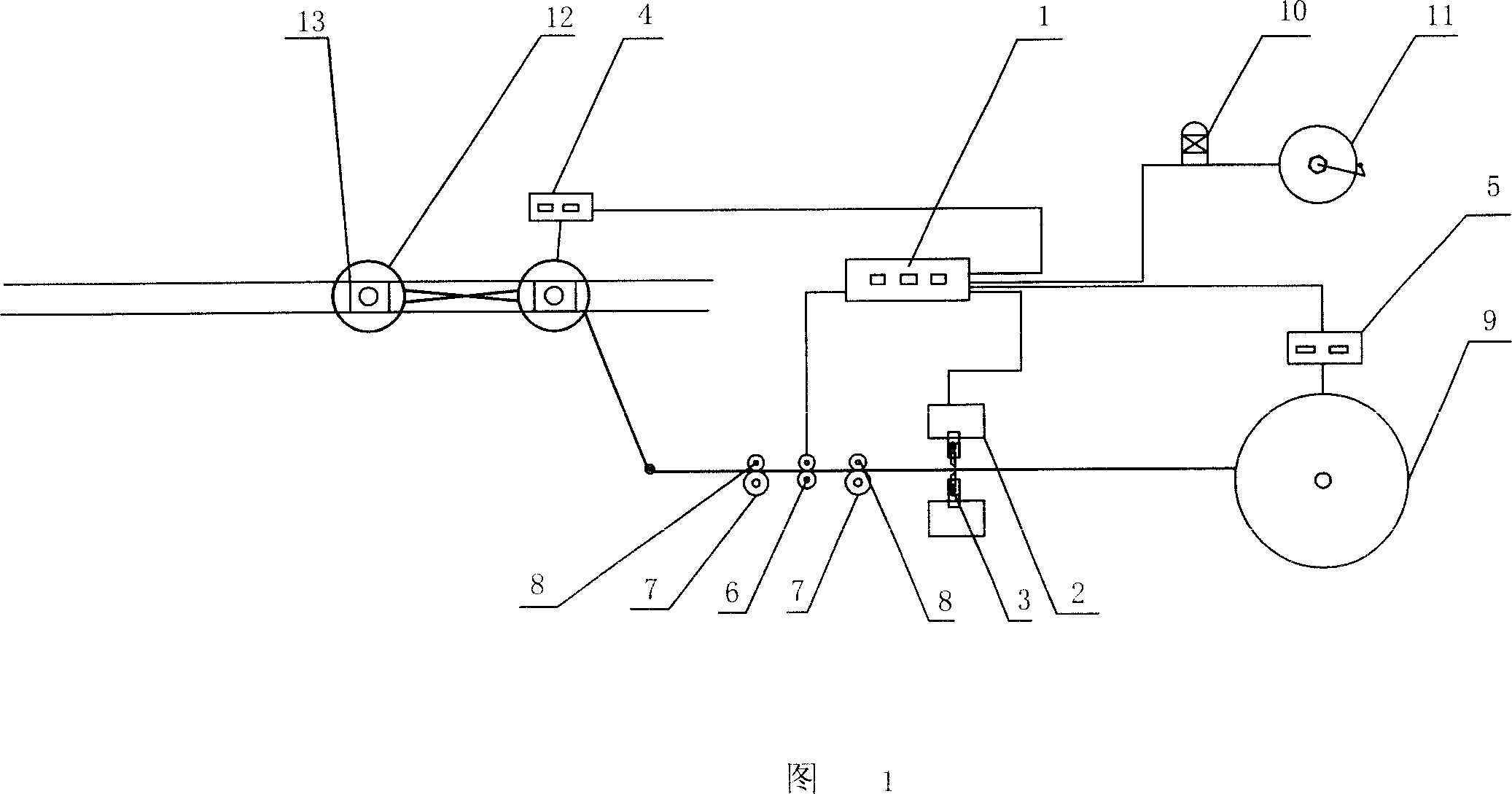

Multiphase submarine cable transversal arrangement circularly laying construction method

InactiveCN103247977AOptimize layoutIncreased effective working areaCable installations on groundApparatus for laying cablesArchitectural engineeringAutomation

The invention discloses a multiphase transversal arrangement circular laying construction method, which adopts a major engineering barge as a submarine cable laying ship, and adopts transversal arrangement of submarine cables, back-twist of a pi-shaped back-twist rack and transverse pull of heave away anchors of the barge, and comprises the concrete steps of construction preparation, top end landing construction, middle sea segment laying construction, tail end landing construction, circularly laying construction and submarine cable protection. The method has the advantages that the effective operation area is large, the adverse environmental impact can be effectively resisted, the laying and inclination adjustment efficiency is improved, measurement and control can be accurately performed, the routing deviation is avoided, the degree of automation is high, and the construction efficiency is high.

Owner:STATE GRID CORP OF CHINA +1

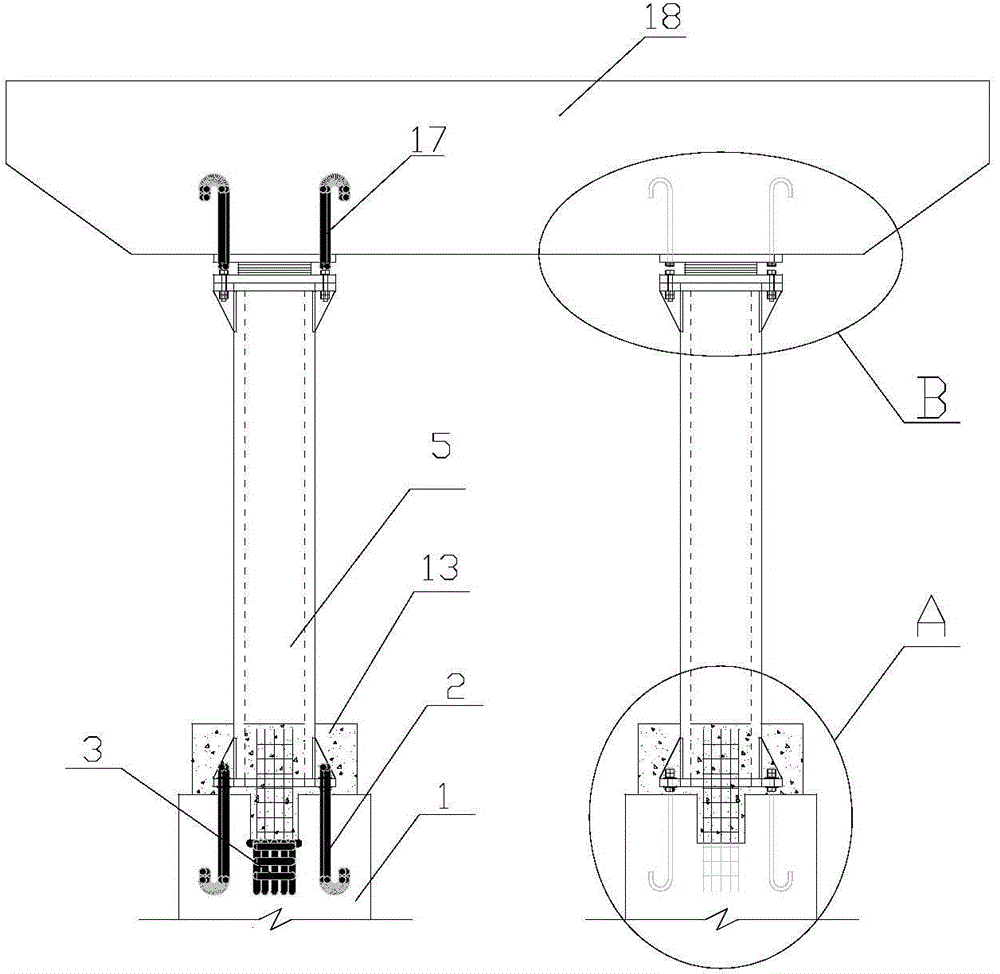

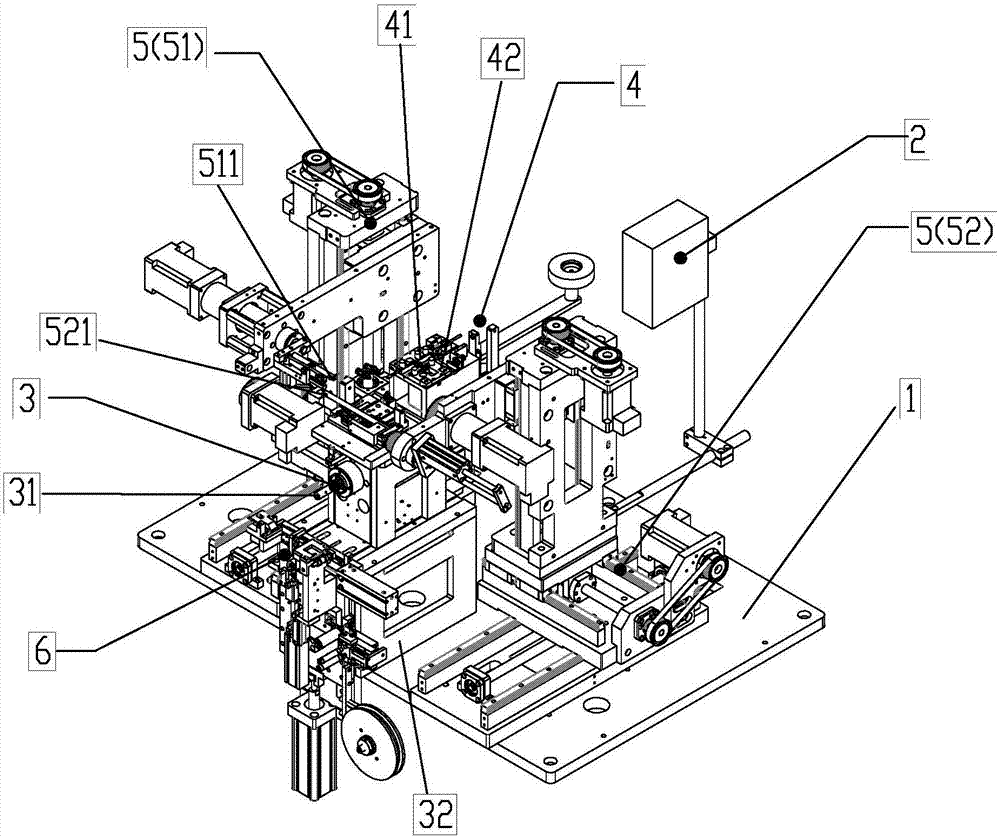

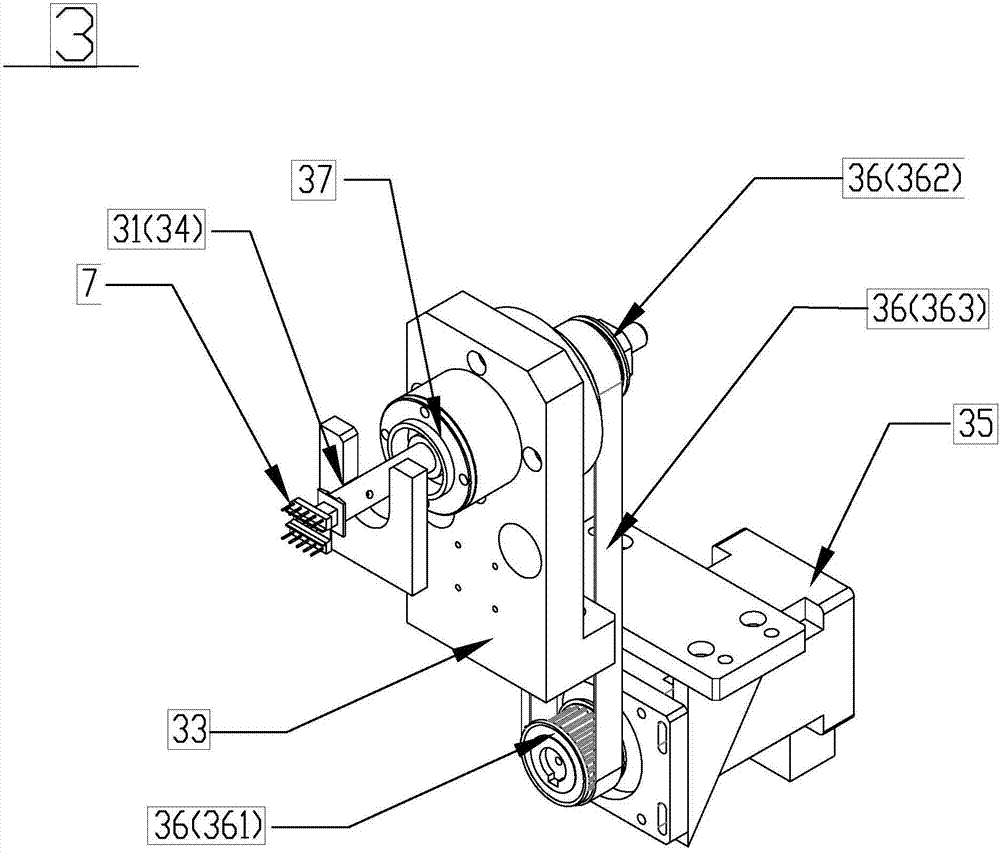

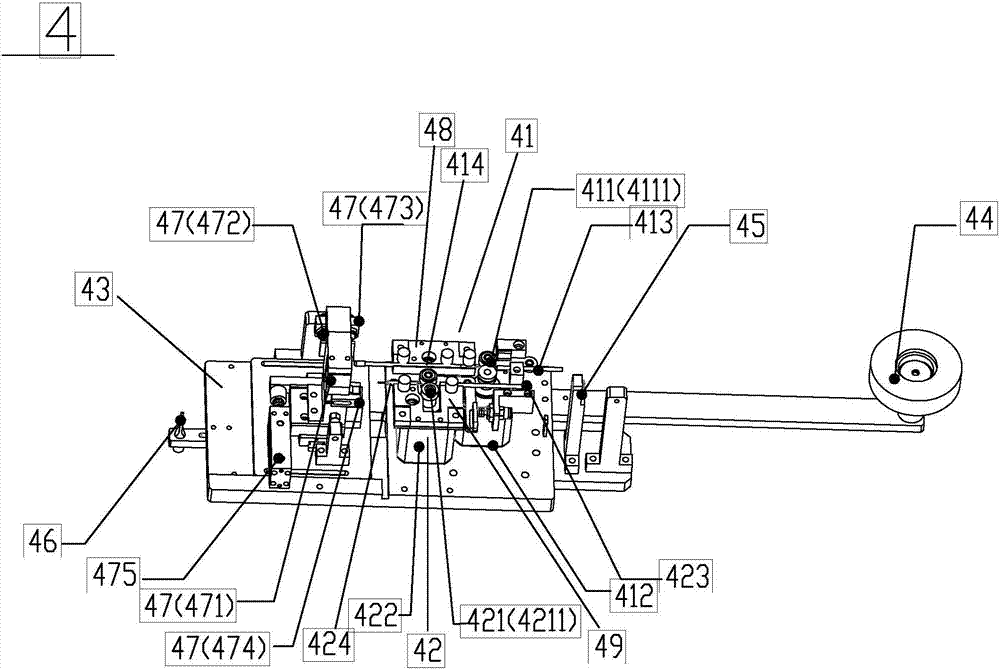

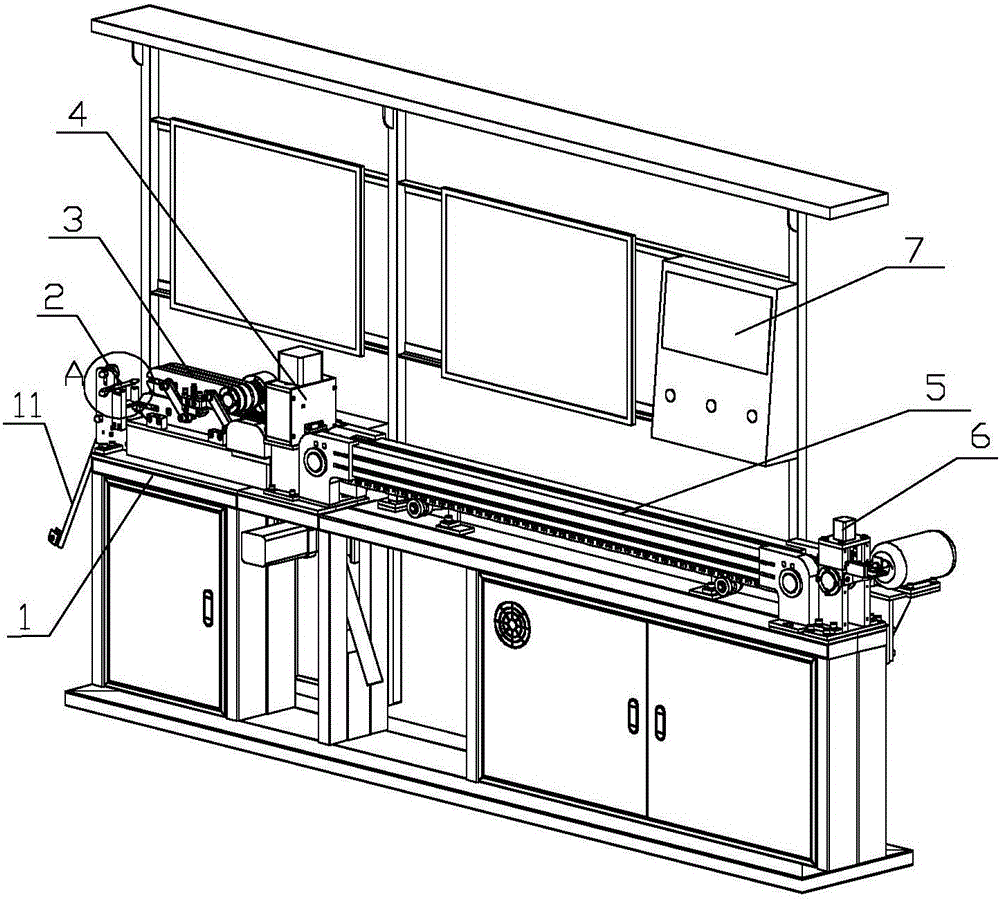

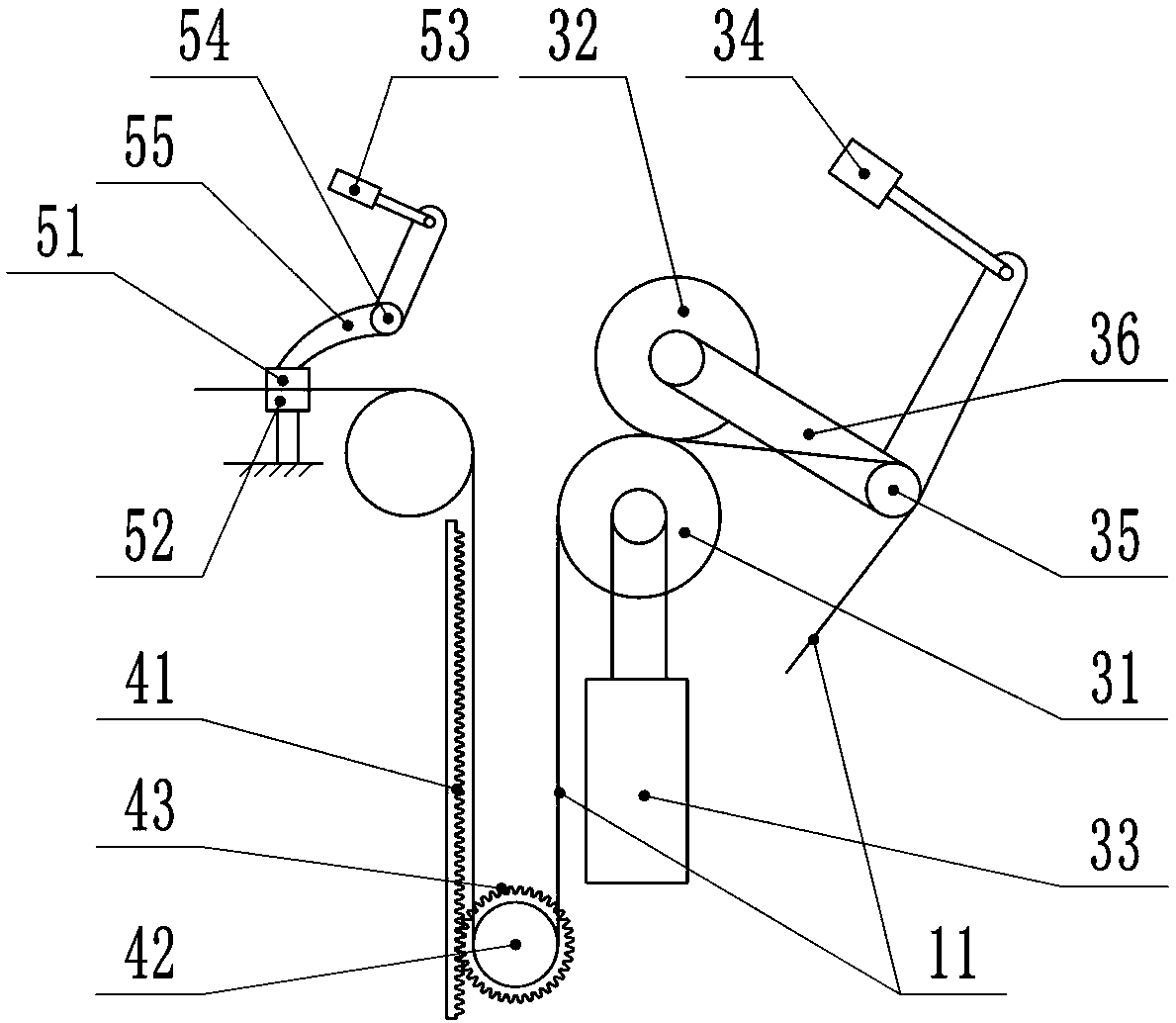

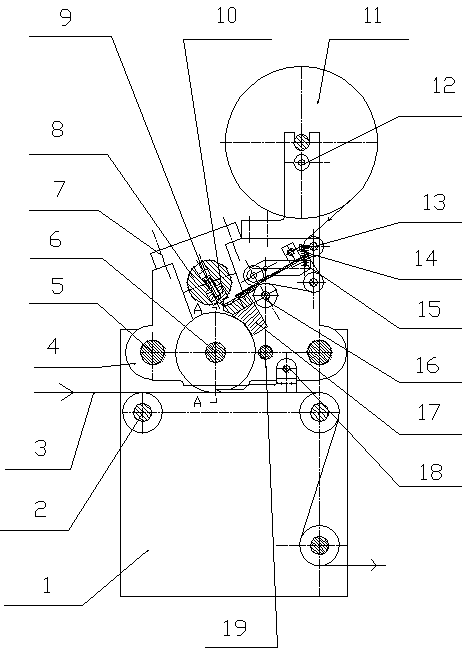

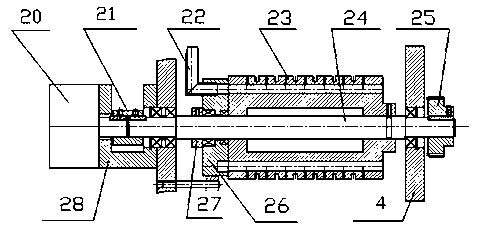

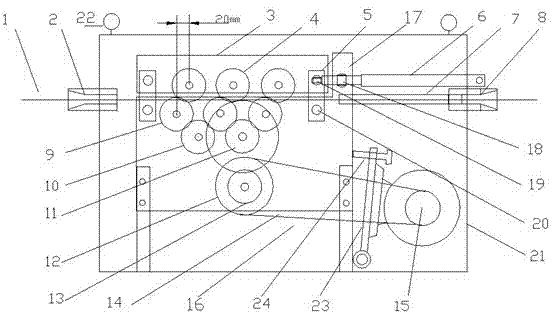

Full-automatic sleeve threading winding machine of electronic transformer

The invention discloses a full-automatic sleeve threading winding machine of an electronic transformer. The full-automatic sleeve threading winding machine comprises an installation platform, a tension mechanism, a main shaft mechanism, a sleeve threading winding mechanism, a winding device and an encapsulation mechanism, wherein the tension mechanism, the main shaft mechanism, the sleeve threading winding mechanism, the winding device and the encapsulation mechanism are arranged on the installation platform, a rotation product fixture is arranged at an end part of the main shaft mechanism, the sleeve threading mechanism comprises a sleeve feeding assembly and a line feeding assembly, the winding device comprises an initial winding mechanism and an end winding mechanism, an initial winding guide needle is movably arranged on the initial winding mechanism and extends to a side edge of the sleeve feeding assembly, and an end winding guide needle is movably arranged on the end winding mechanism and extends to a part above the sleeve threading mechanism. By the full-automatic sleeve threading winding machine, processes such as sleeve threading, sleeve assembled into a groove, twisting, pulling, winding, trimming and encapsulation are integrated on full-automatic equipment, the full-automatic operation process is achieved, action accuracy and precision are high, manual intervention is not needed any longer, and the production efficiency, the product yield and the product consistency are substantially improved.

Owner:SHENZHEN SUNLORD ELECTRONICS +1

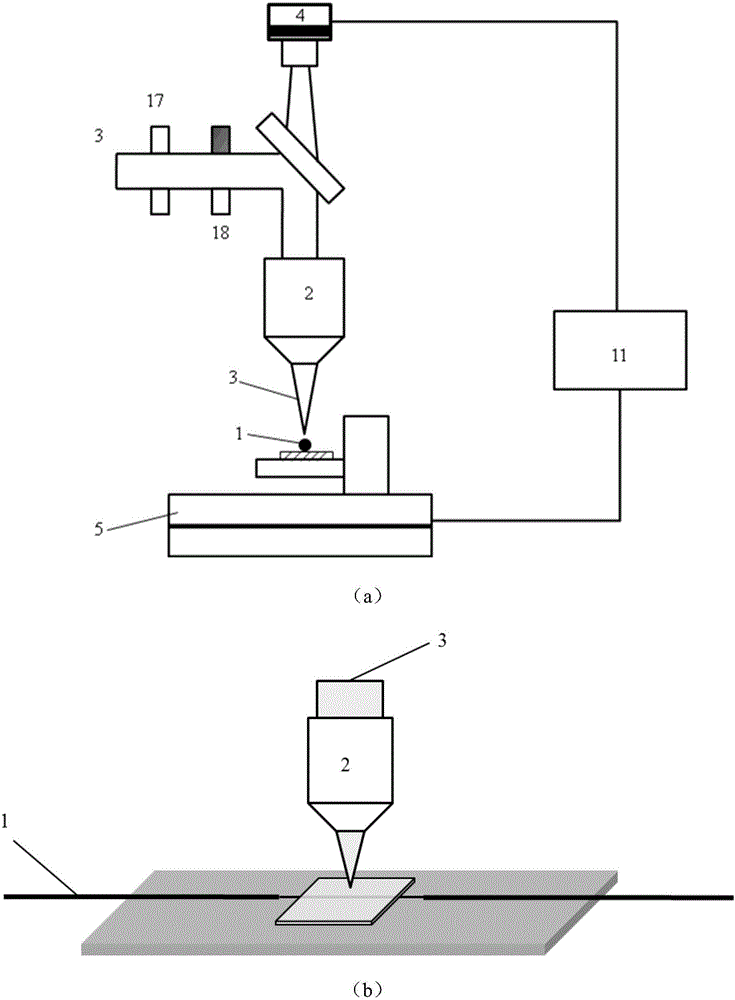

Method for preparing phase shift optical fiber bragg grating based on femtosecond laser direct writing

ActiveCN106291802AEasy to operatePrecise length controlCladded optical fibreOptical waveguide light guideGratingPhase shifted

The invention provides a method for preparing phase shift optical fiber bragg grating based on femtosecond laser direct writing. The method comprises the following steps: performing fixed point radiation or scanning in a fiber core area of the optical fiber bragg grating of an ordinary structure by using focused femtosecond laser, forming one or more areas with changed refractive indexes in the fiber core area of the optical fiber bragg grating of the ordinary structure, and forming a phase shift structure, thereby obtaining the phase shift optical fiber bragg grating. Compared with the prior art, the method is relatively simple in processing procedure, high in processing speed and applicable to optical fiber of different materials, and precision control of phase shift within 0-2pi can be achieved. The phase shift optical fiber bragg grating prepared by using the method provided by the invention can be applied to fields of sensation, optical fiber laser and the like.

Owner:XI AN JIAOTONG UNIV +1

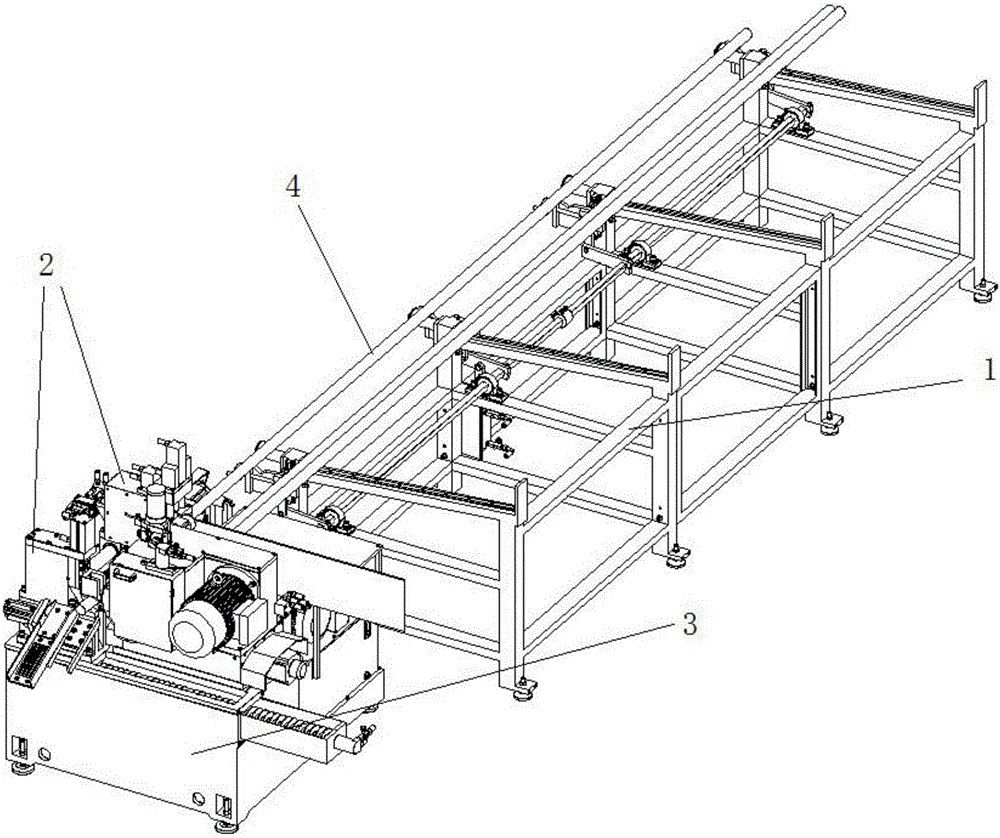

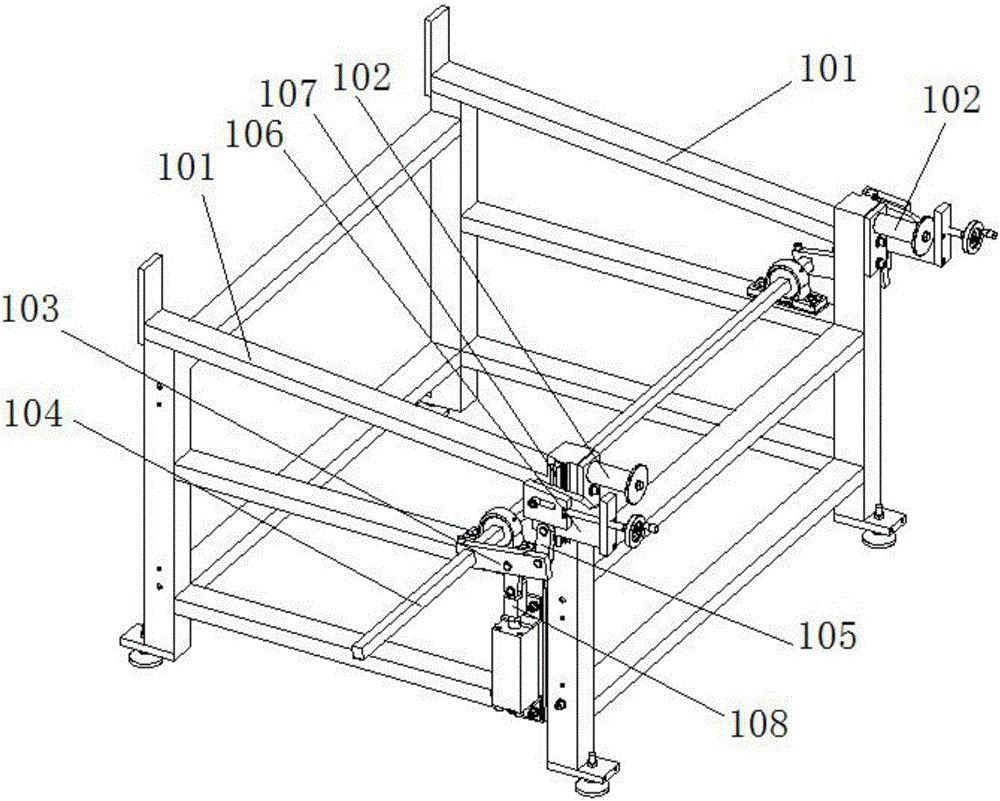

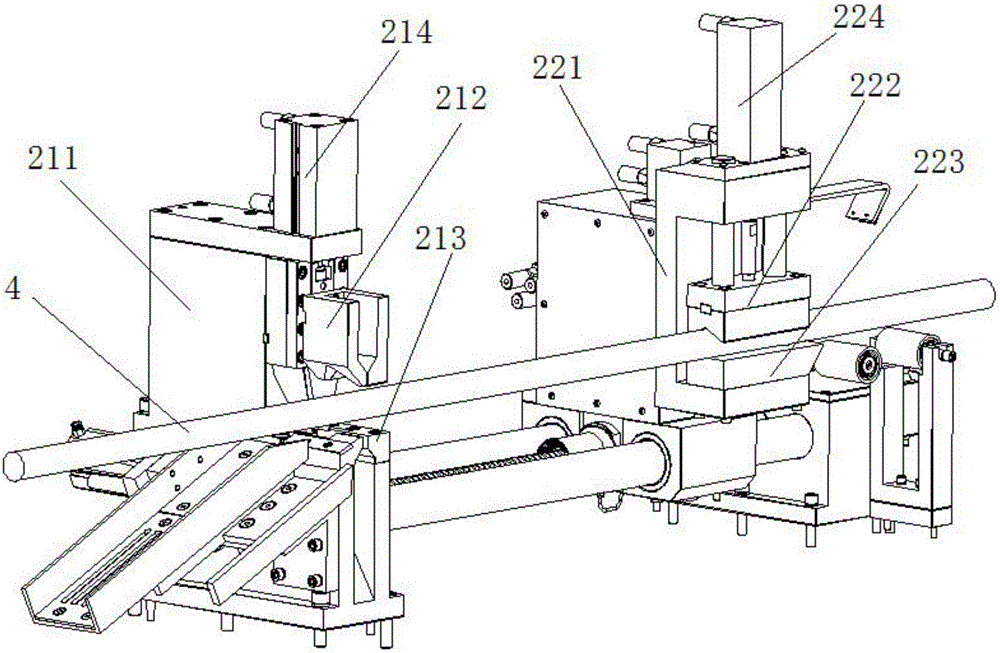

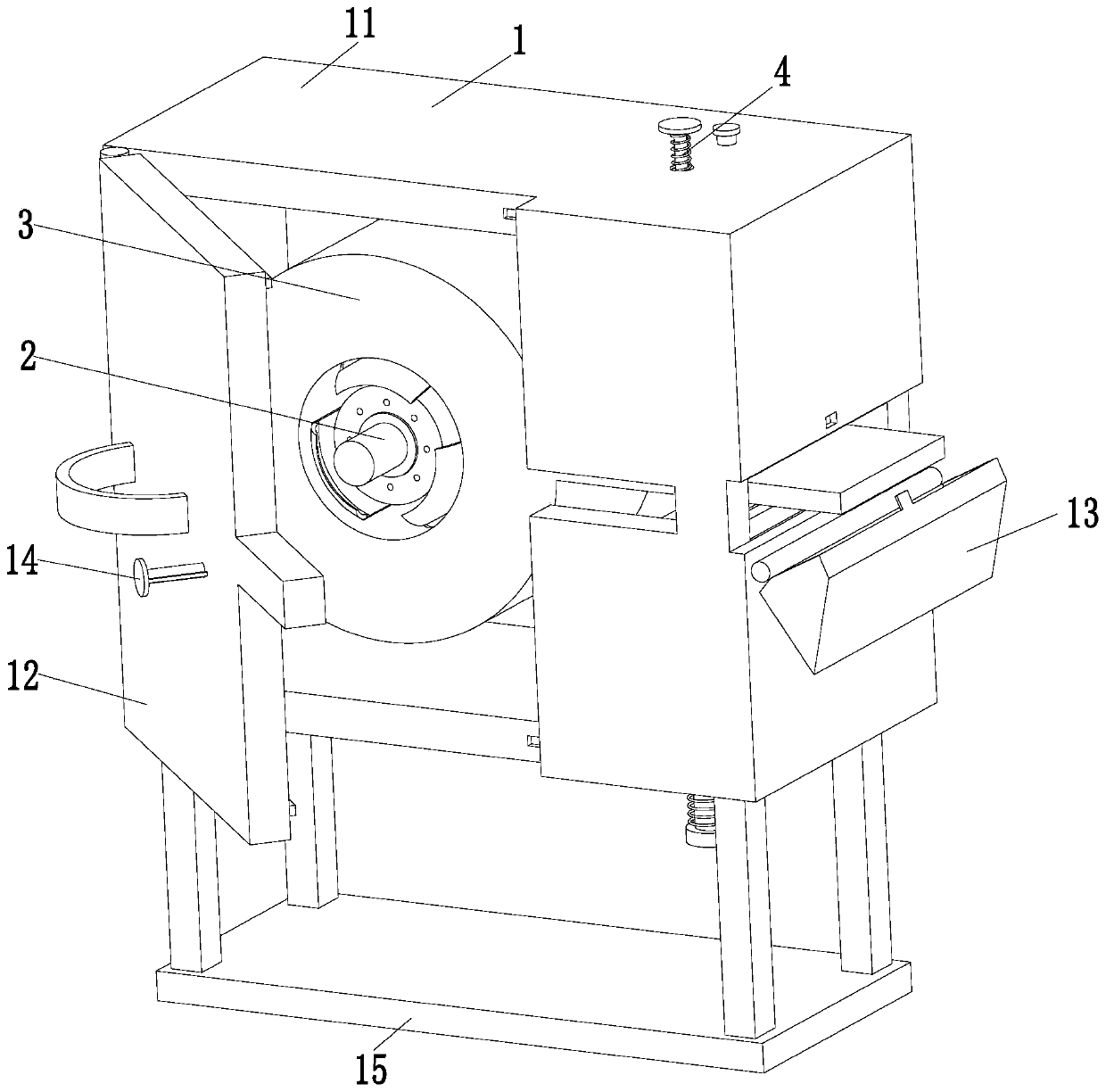

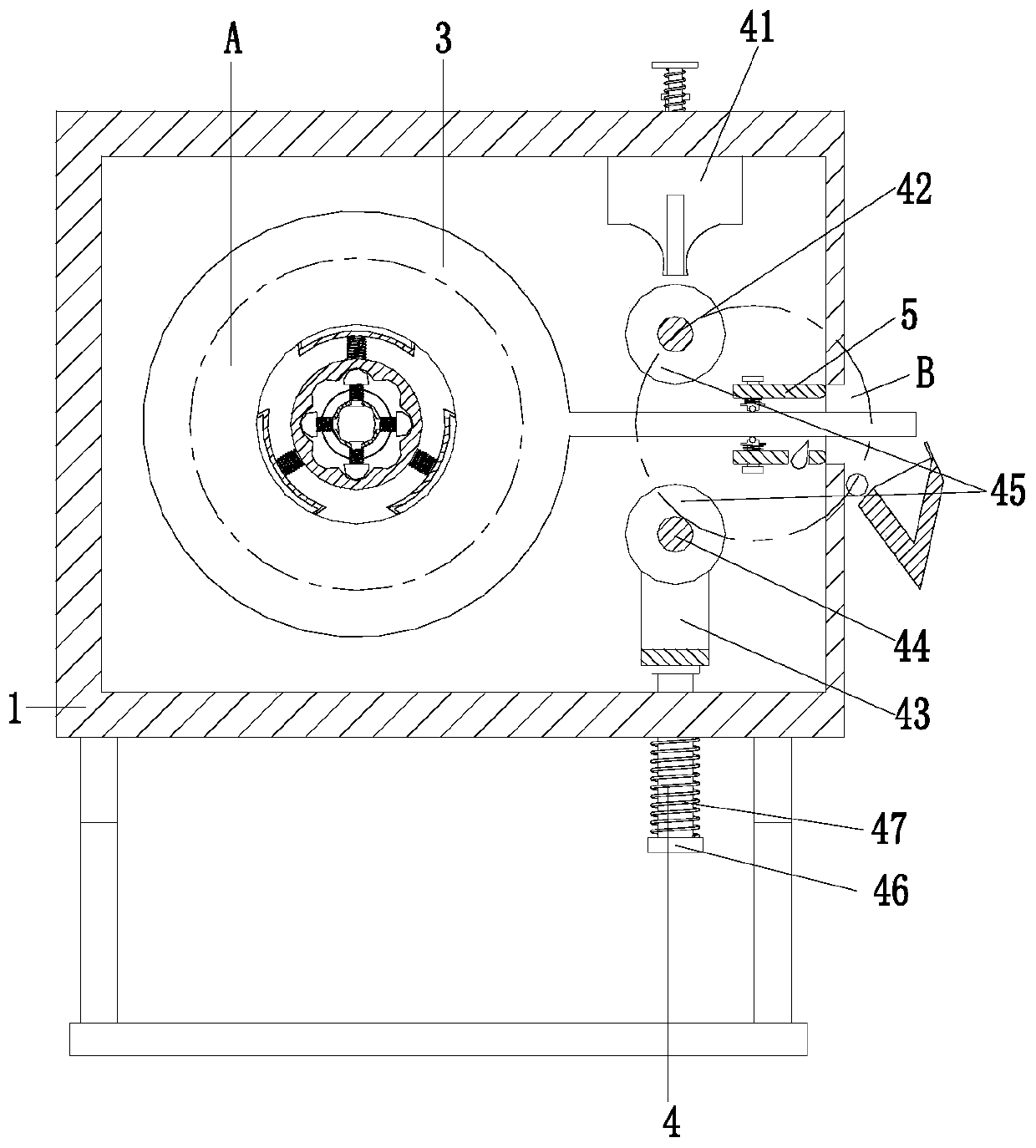

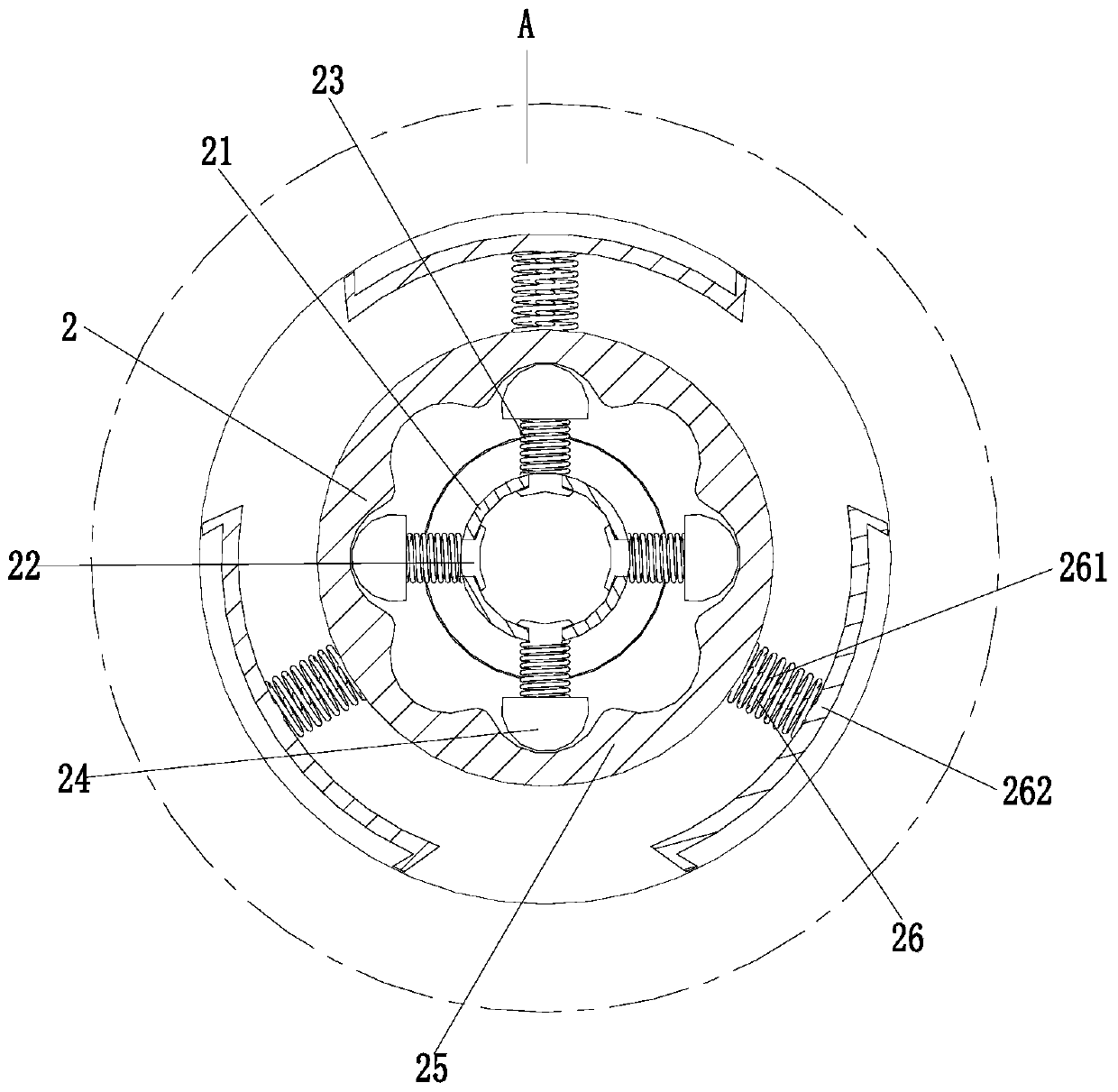

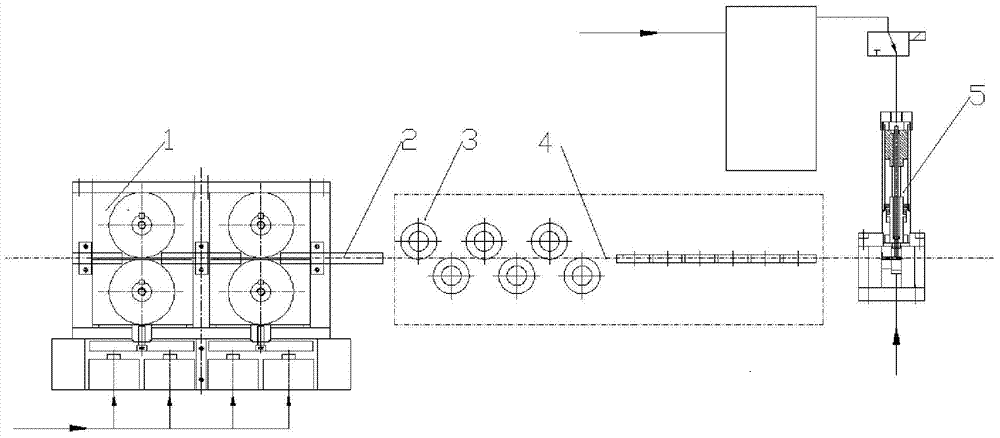

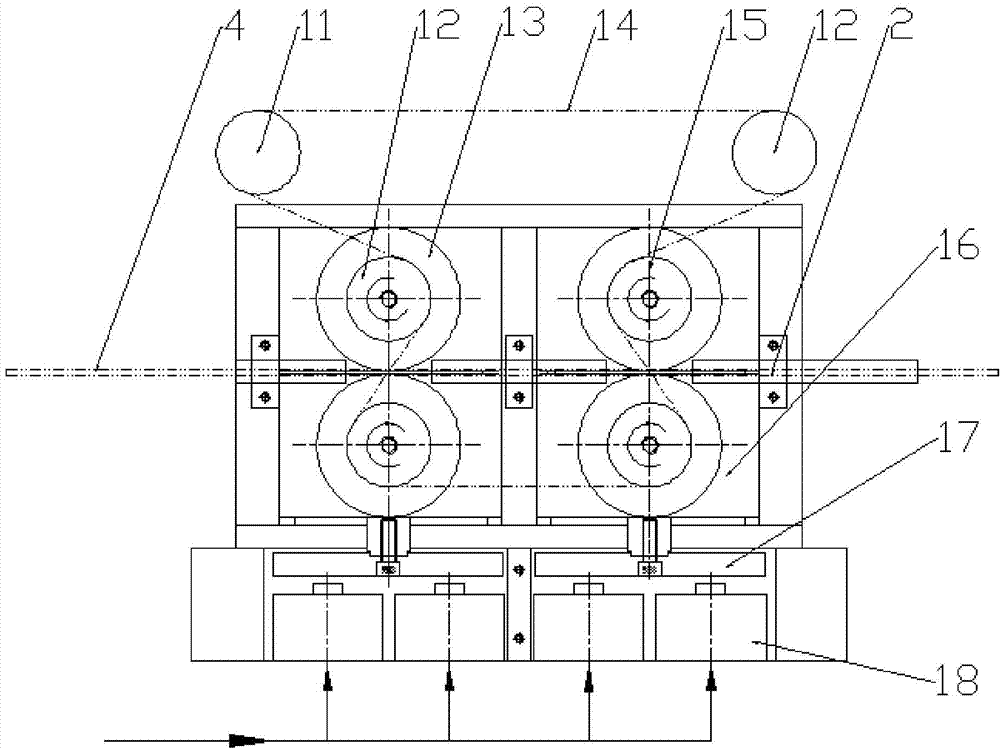

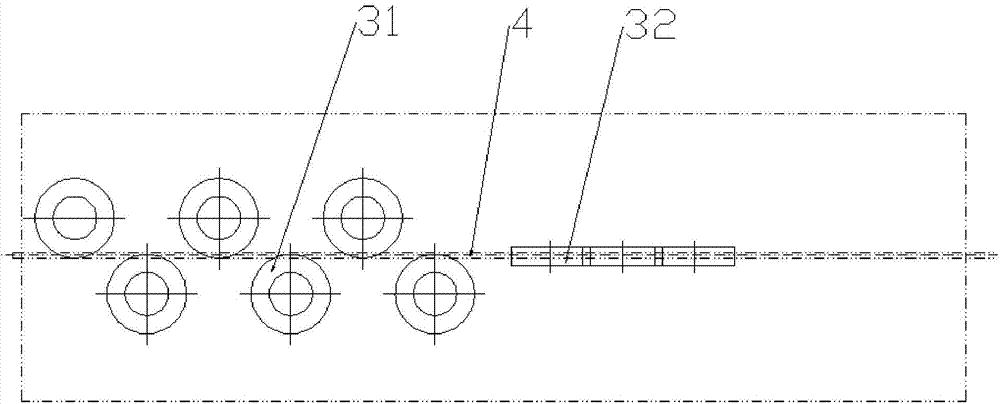

Full-automatic circular sawing machine

InactiveCN105689793AHigh degree of automationReduce labor costsMetal sawing devicesCircular sawEngineering

The invention discloses a full-automatic circular sawing machine which comprises a material feeding mechanism, a material conveying mechanism and a circular sawing machine body, wherein the circular sawing machine body is mounted on a sliding rail on a base; the material conveying mechanism is mounted on one side of the circular sawing machine body and matched with the circular sawing machine body to complete material conveying and cutting actions; the material conveying mechanism consists of front and rear two clamping mechanisms which are connected with each other through a guide column; clamping assemblies are arranged on the front and rear clamping mechanisms; the front clamping mechanism is fixed, and the rear clamping mechanism can move back and forth along the guide column; the material feeding mechanism comprises a material conveying frame and a material storage rack arranged on one side of the material conveying frame; a workpiece on the material storage rack is transferred to the material conveying frame through a jacking mechanism; the material conveying mechanism is arranged at the end part of the material storage rack of the material feeding mechanism; the workpiece on the material storage rack is aligned to a clamping part of the rear clamping mechanism. The full-automatic circular sawing machine is high in automation degree; the labor cost can be greatly saved, and the production efficiency is improved. Meanwhile, the cutting length can be precisely controlled, and the disqualification rate of a product is reduced.

Owner:浙江百金机床制造有限公司

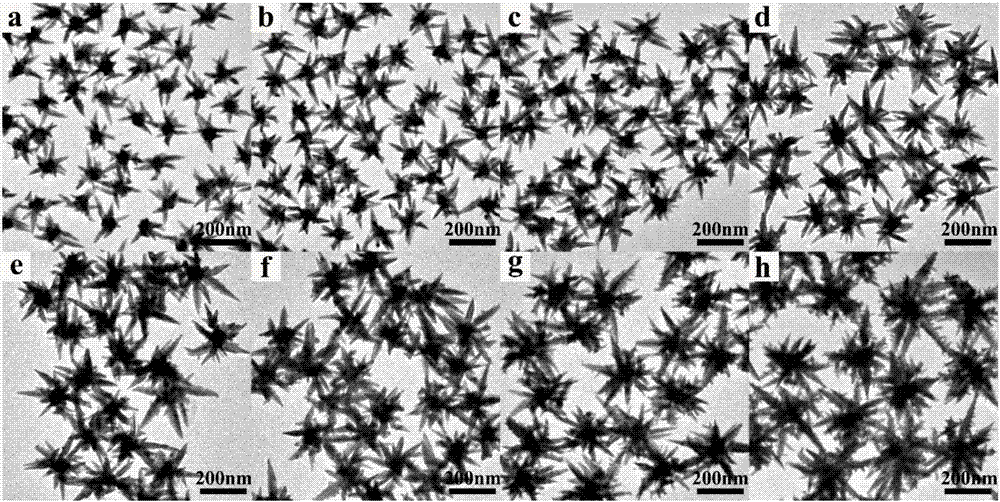

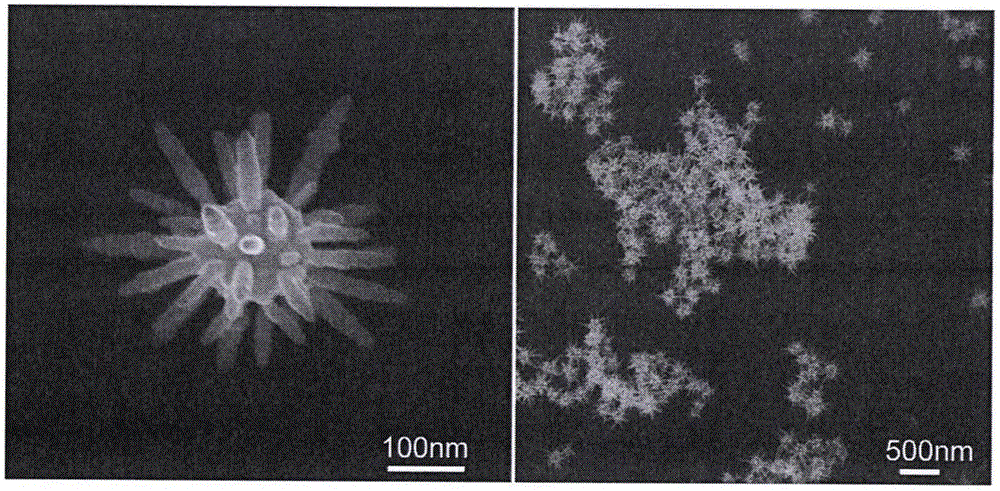

Synthetic method for monodisperse spinous gold nanoparticles

ActiveCN107252896APrecise control of the numberPrecise length controlMaterial nanotechnologyTransportation and packagingNanoparticleBiocompatibility Testing

The invention discloses a synthetic method for monodisperse spinous gold nanoparticles. The synthetic method comprises the following steps that (1) a first chloroauric acid solution, a second chloroauric acid solution, a first silver nitrate solution, a second silver nitrate solution, a glutathione solution, a sodium borohydride solution, a first ascorbic acid solution, a second ascorbic acid solution, a hexadecyl trimethyl ammonium bromide solution and a hexadecyl trimethyl ammonium chloride solution are prepared; (2) a growth solution is prepared; (3) an excessive growth solution is prepared; (4) rod-shaped gold nanoparticles are prepared; (5) a rod-shaped gold nanoparticle solution is prepared; and (6) the rod-shaped gold nanoparticle solution, the excessive growth solution and ultra-pure water are mixed and stirred, standing is conducted at the constant temperature, and the monodisperse spinous gold nanoparticles are obtained. According to the method, the monodisperse spinous gold nanoparticles which are high in yield and adjustable in size, number of surface thorns, length and width can be obtained, used ligand can be subjected to ligand exchange with other biocompatibility ligand, and application of the gold nanoparticles is further expanded.

Owner:SHANDONG UNIV

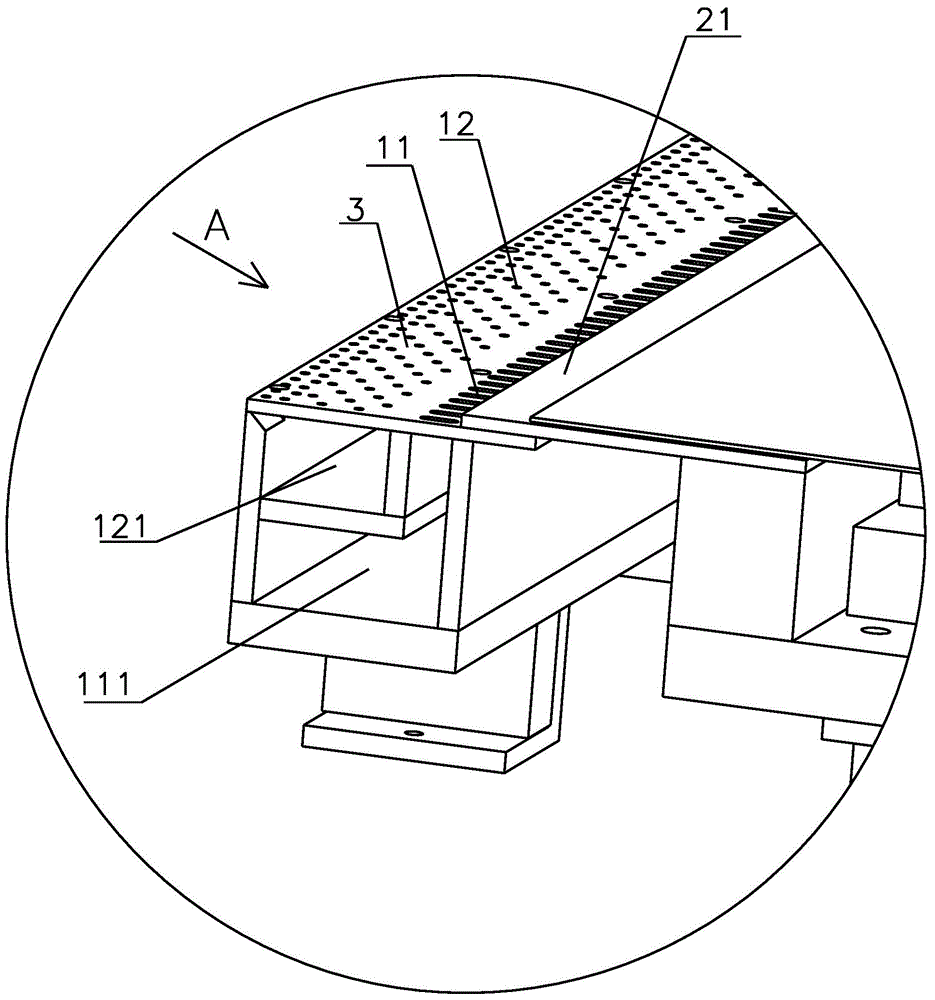

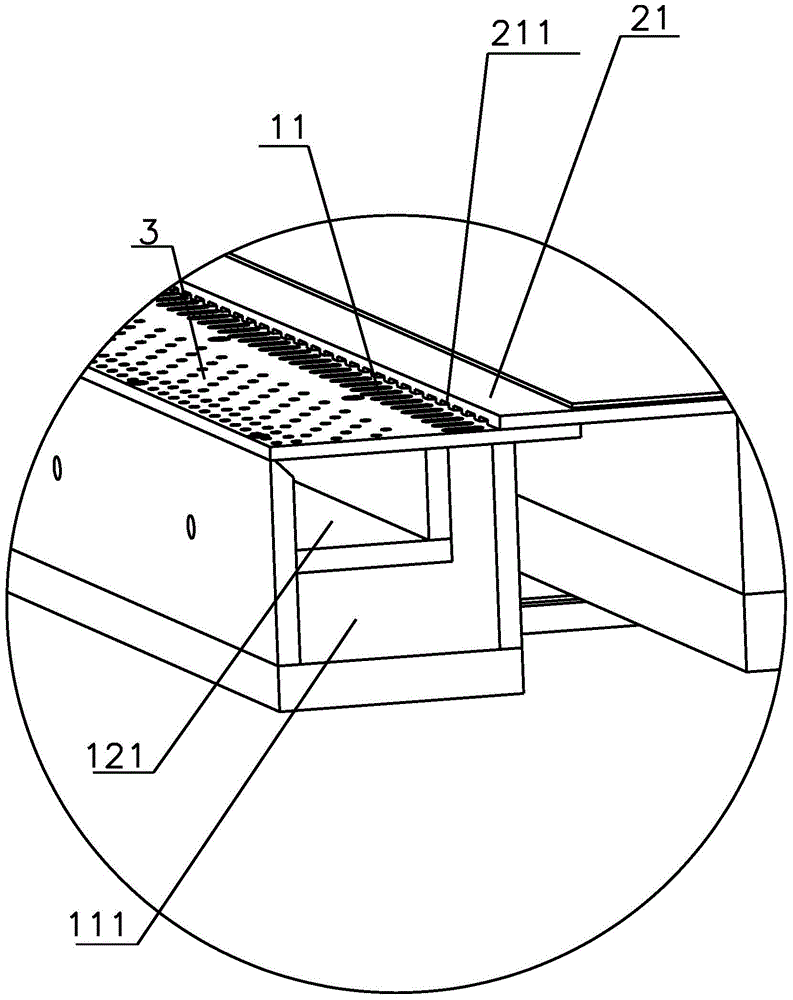

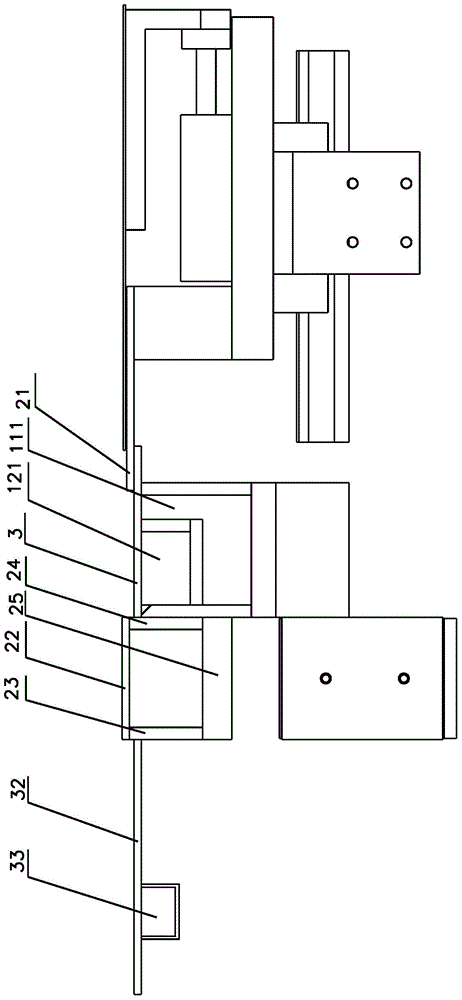

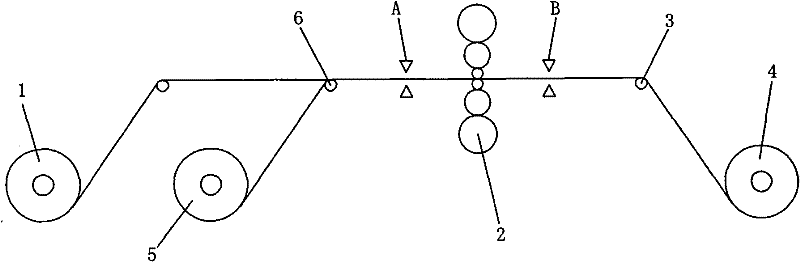

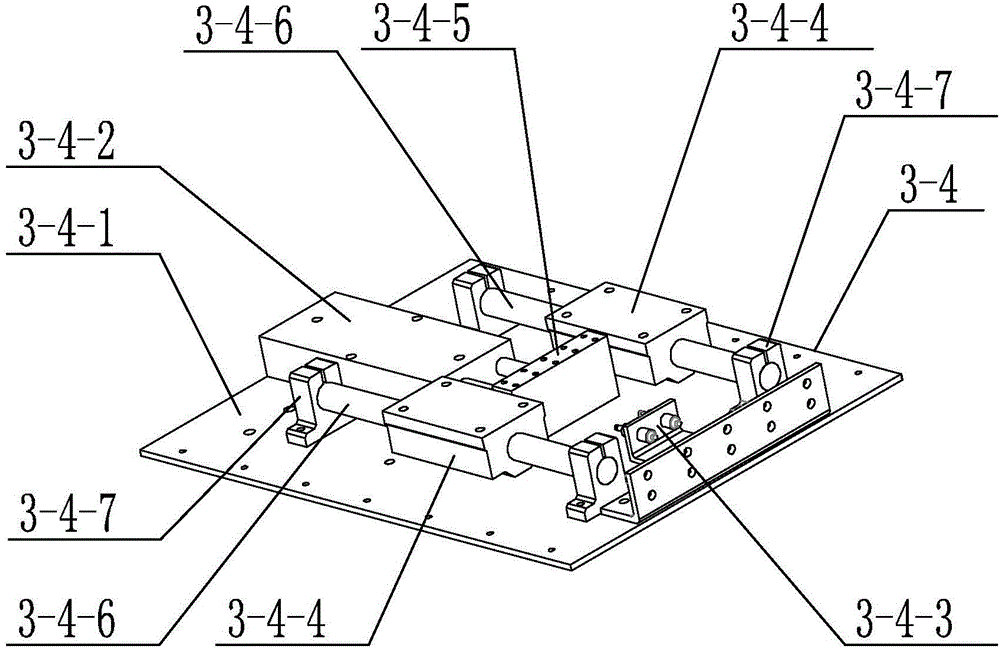

Automatic shirt under fly sewing machine

ActiveCN105177875ASolve the positioning problemSolving Sewing DifficultiesWorkpiece carriersWork-feeding meansSewing machineSurface plate

The invention relates to an automatic shirt under fly sewing machine which comprises a worktable and an edge folding mechanism. The edge folding mechanism comprises a table top plate, the table top plate is provided with a first low air suction area formed by multiple lower air suction through holes, a column of side air suction through holes is formed in the right side of the first low air suction area on the face plate, a cover plate capable of covering the side air suction through holes is arranged on the upper surface of the table top plate, grooves are formed in the lower surface of the cover plate, the groove openings of the grooves face the side air suction through holes and cover the side air suction through holes, one end of each groove extends to the edge of the cover plate close to the center of the table face plate, and a transverse cloth dragging device and a sewing machine head are further installed on the worktable. The automatic shirt under fly sewing machine is provided with the cover plate with the grooves formed in the lower surface on the table with the holes, so that lower air suction is changed into side air suction, the edge of a fabric is folded, and the fabric is erected at the position provided with the grooves at the edge position of the cover plate to form a folded edge.

Owner:中山市阿米达机电设备有限公司

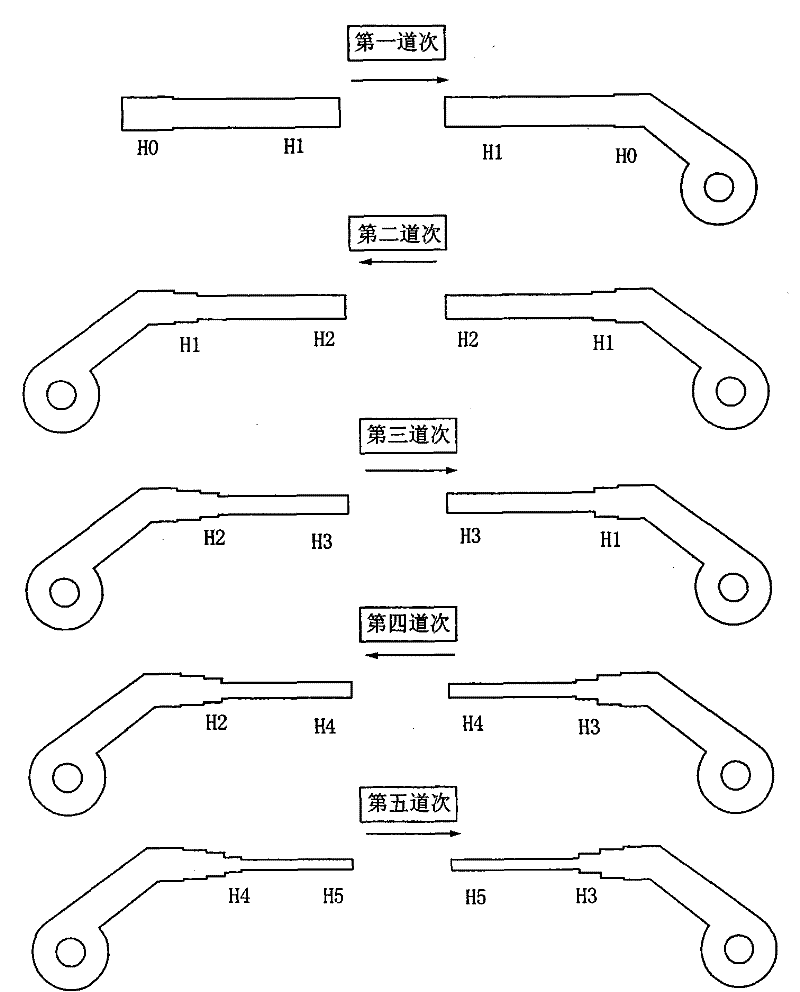

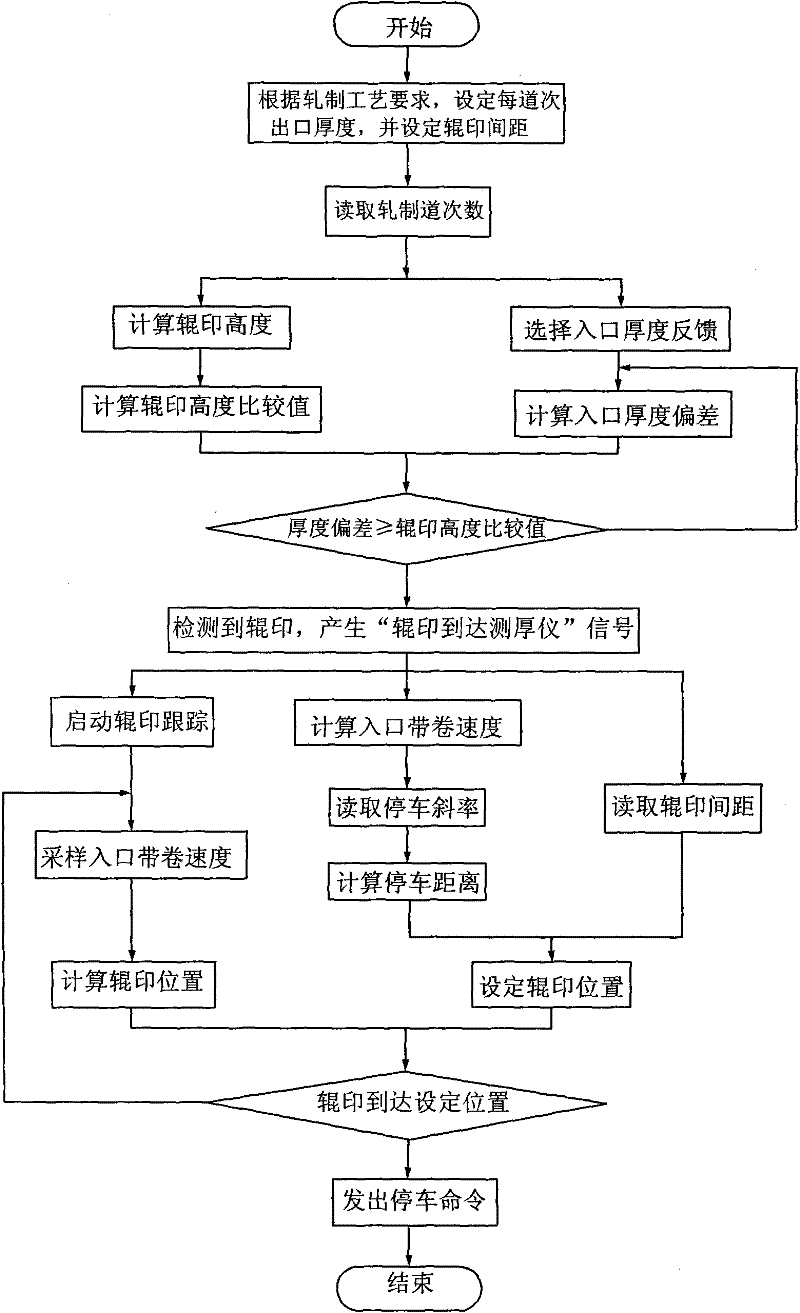

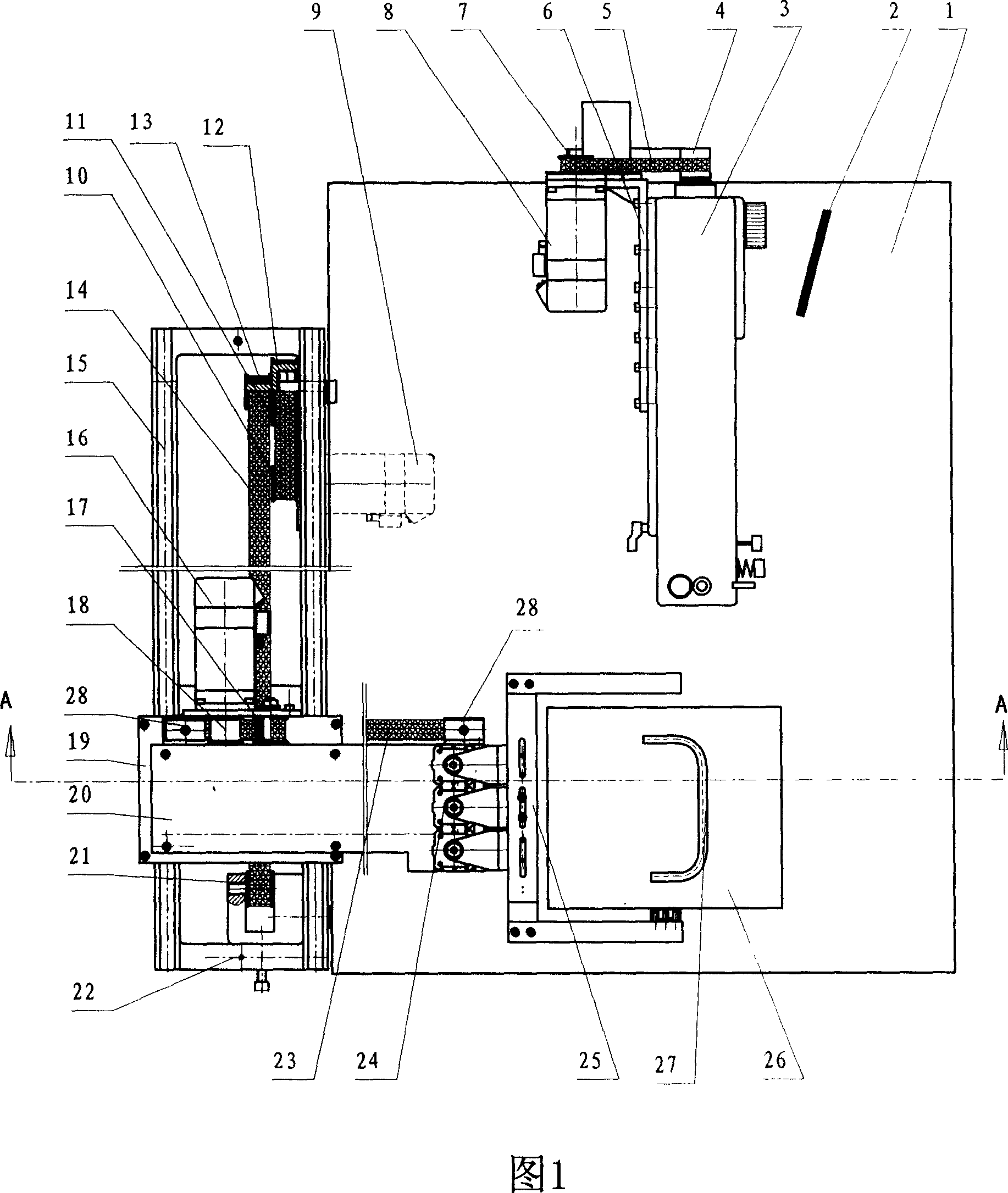

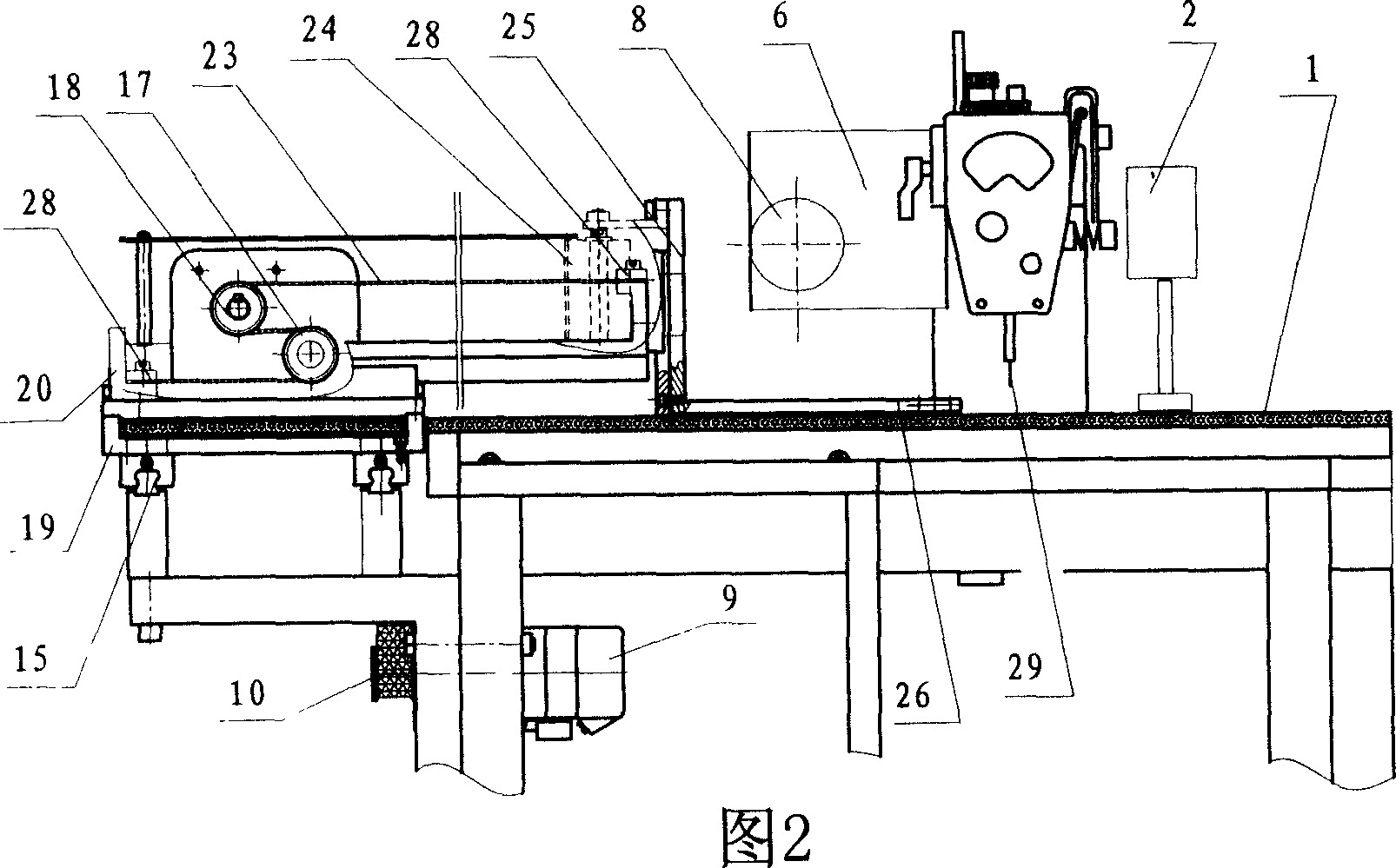

Control method for stopping reversible cold-rolling mill

InactiveCN102205348APrecise length controlHigh yieldRare end control deviceMetal rolling arrangementsControl systemRolling mill

The invention relates to a control method for stopping a reversible cold-rolling mill and belongs to the technical field of automation control for rolling. The method comprises the following steps: setting a strip coil outlet thickness and a rolling mark distance for each-pass rolling; by starting from the second-pass rolling, calculating a rolling mark height and a comparison value of the rolling mark height for each-pass rolling; by starting from the second-pass rolling, reading the strip coil outlet thickness and an actual value of the strip coil outlet thickness for each-pass rolling by arolling control system, and after comparing, acquiring a strip coil outlet thickness deviation for each-pass rolling; after comparing the strip coil outlet thickness deviation and the comparison value of the rolling mark height, calculating an actual displacement of the rolling mark at real time or starting the parking timing by the rolling control system; calculating a rolling mark parking displacement or a parking delay at real time by the rolling control system; and when the actual displacement of the rolling mark is equal to the rolling mark parking displacement or the parking timing reaches the parking delay, controlling the rolling mill to park at each pass by the rolling control system. The method can be used for precisely positioning the strip tail position of each pass rolling strip coil of the reversible cold-rolling mill, so as to increase the yield of strip coil rolling.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Digitally controlled multifunctional sewing machine

InactiveCN1932115ASimple mechanical structureEasy to operateSewing-machine control devicesControl systemElectric machinery

The digitally controlled multifunctional sewing machine belongs to the field of automatic sewing apparatus technology. The digitally controlled multifunctional sewing machine includes mainly one sewing machine body with control system on the working platform and motor, one X-Y skid platform mechanism and one presser foot mechanism. The X-Y skid platform mechanism consists of one Y skid platform pedestal with Y guide track, one Y skid platform motor with Y transmission mechanism, one Y skid platform connected to the Y transmission mechanism, one X skid platform motor with X transmission mechanism, one X skid platform connected to the X transmission mechanism, etc. The presser foot mechanism consists of one outer presser foot, presser foot, cylinder and other part. The digitally controlled multifunctional sewing machine can grasp fabric and move fabric automatically for sewing.

Owner:绍兴县奇功数控机械有限公司

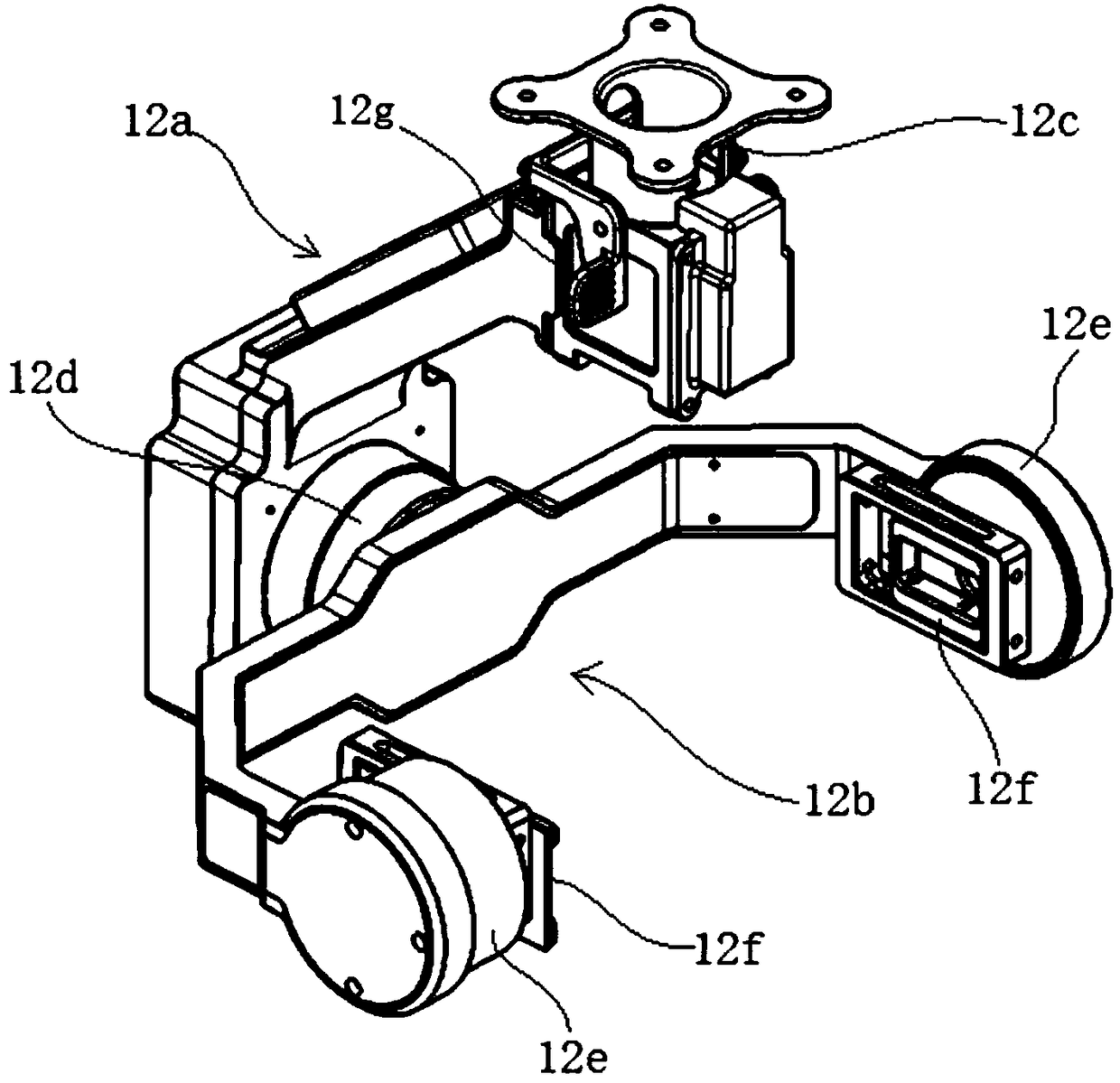

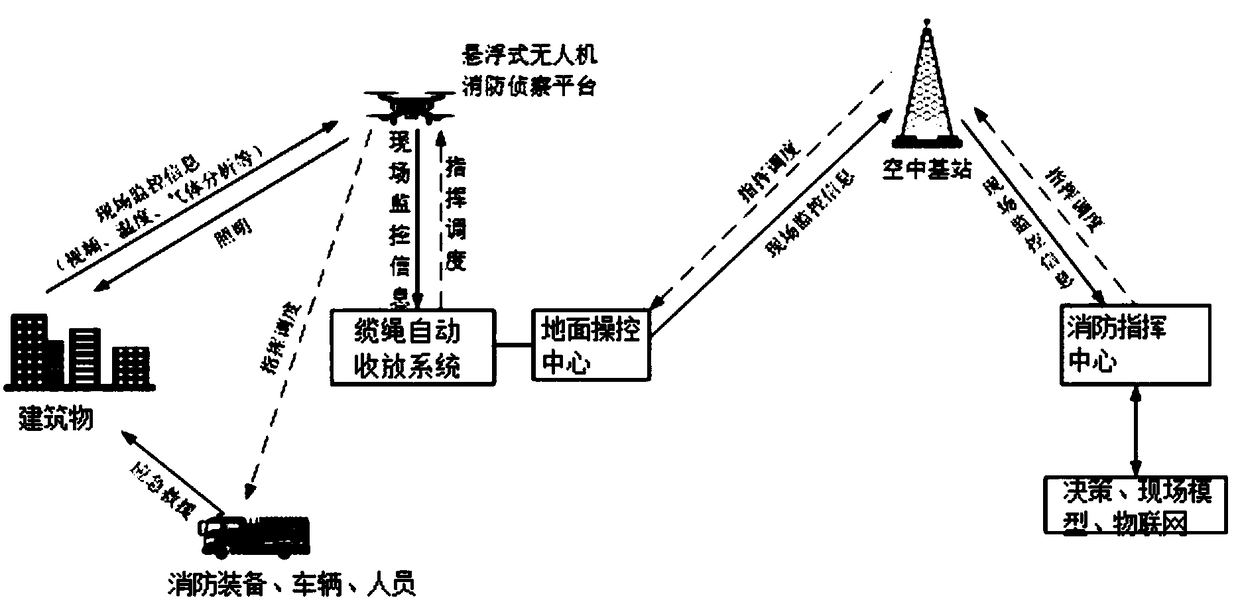

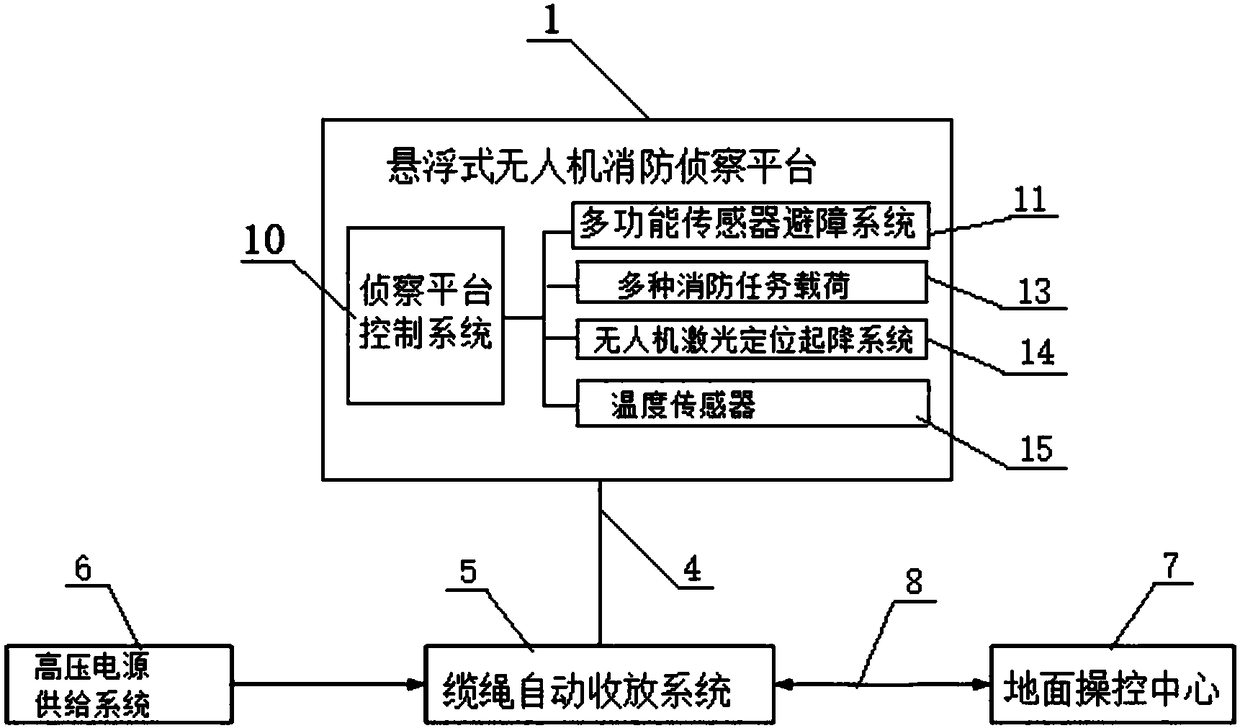

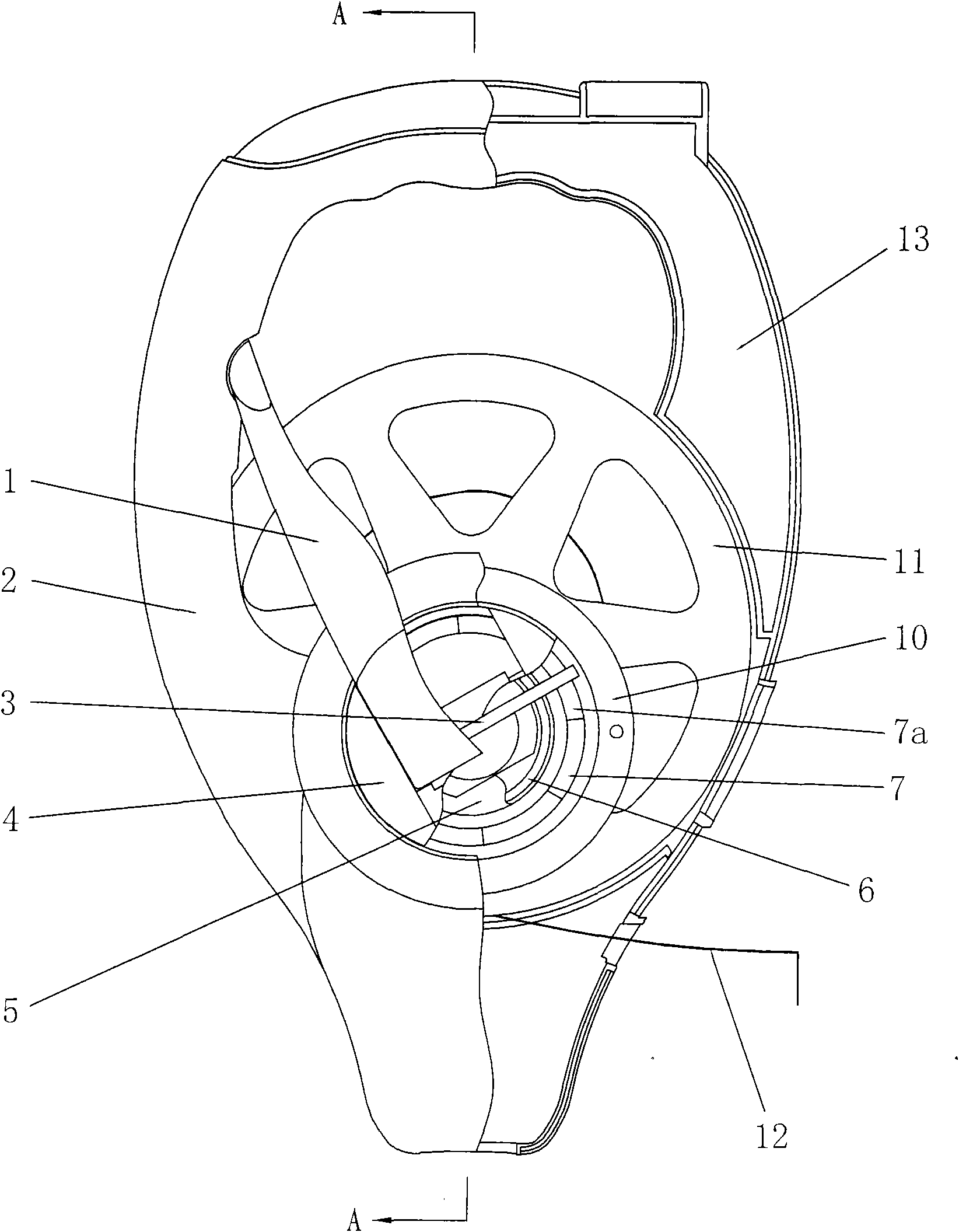

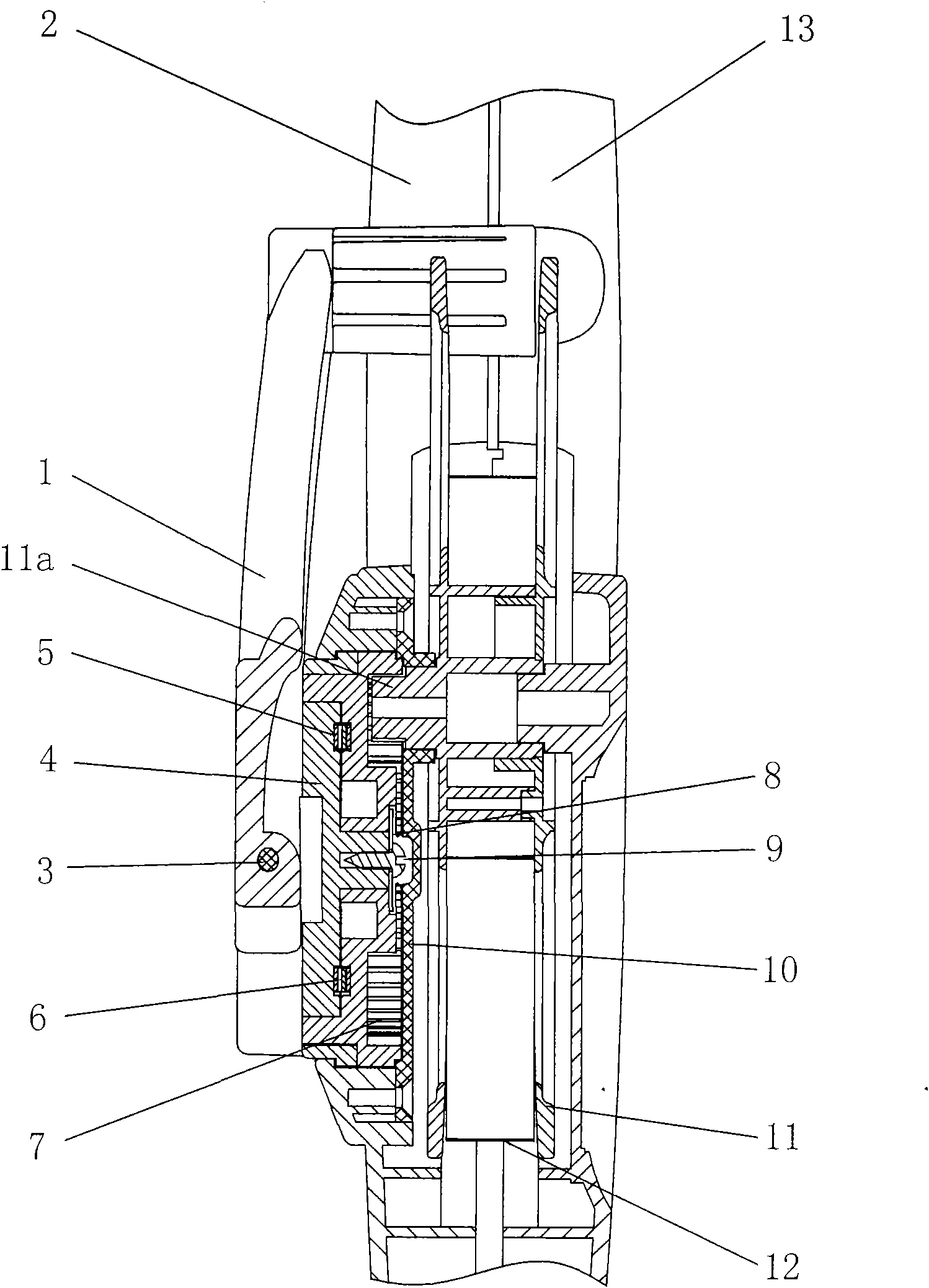

Mooring-type firefighting aerial reconnaissance platform

PendingCN108528753AHigh precisionImprove reliabilityTethered aircraftCharging stationsFirefightingWork ability

The invention relates to a mooring-type firefighting aerial reconnaissance platform which comprises a suspended unmanned aerial vehicle firefighting reconnaissance platform, a mooring cable, a cable automatic release and retraction system, a high-voltage power source supply system and a ground control center. A reconnaissance platform control system, a multifunctional sensor obstacle-avoiding system, an unmanned aerial vehicle laser positioning takeoff and landing system, a temperature sensor and a load mounting platform are mounted on the suspended unmanned aerial vehicle firefighting reconnaissance platform, and various firefighting task loads are mounted on the load mounting platform. The high-voltage power source supply system comprises a ground power supply system and an onboard powersupply system, the mooring cable is connected between the onboard power supply system and the cable automatic release and retraction system, and the ground control center is connected with the cableautomatic release and retraction system through an optical cable. The mooring-type firefighting aerial reconnaissance platform can constantly work for 24h, so that working ability is improved greatly.The platform can carry more than 5 firefighting task loads for simultaneous working and can complete various firefighting work tasks, so that functions are expanded greatly.

Owner:SHANGHAI FIRE RES INST OF THE MIN OF PUBLIC SECURITY +1

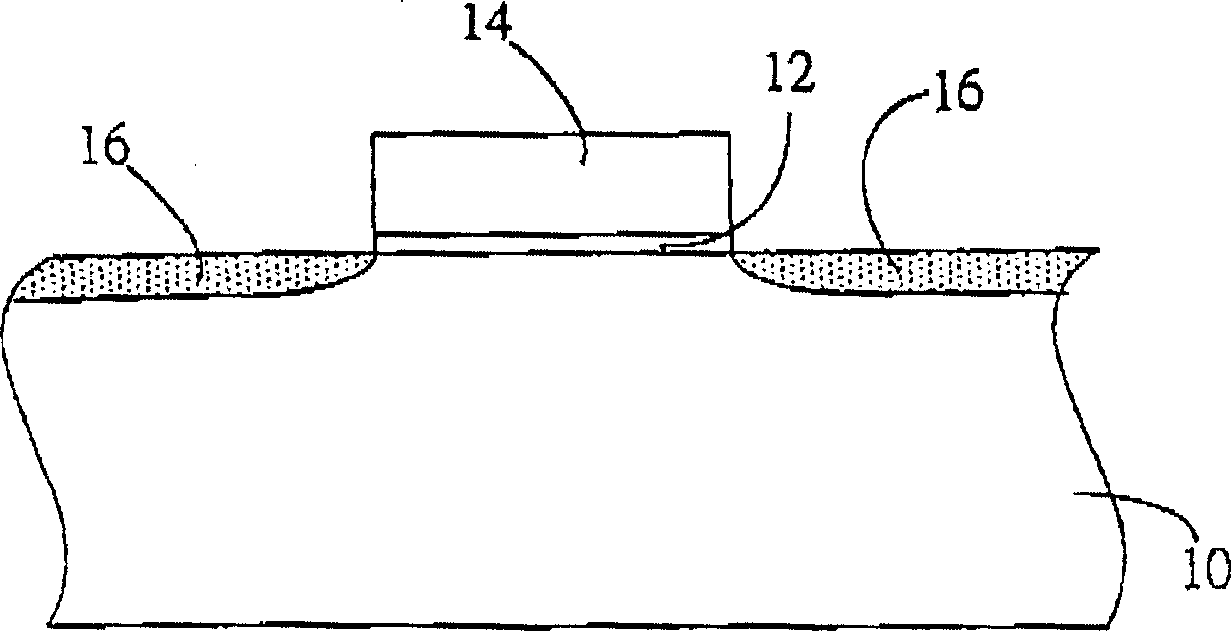

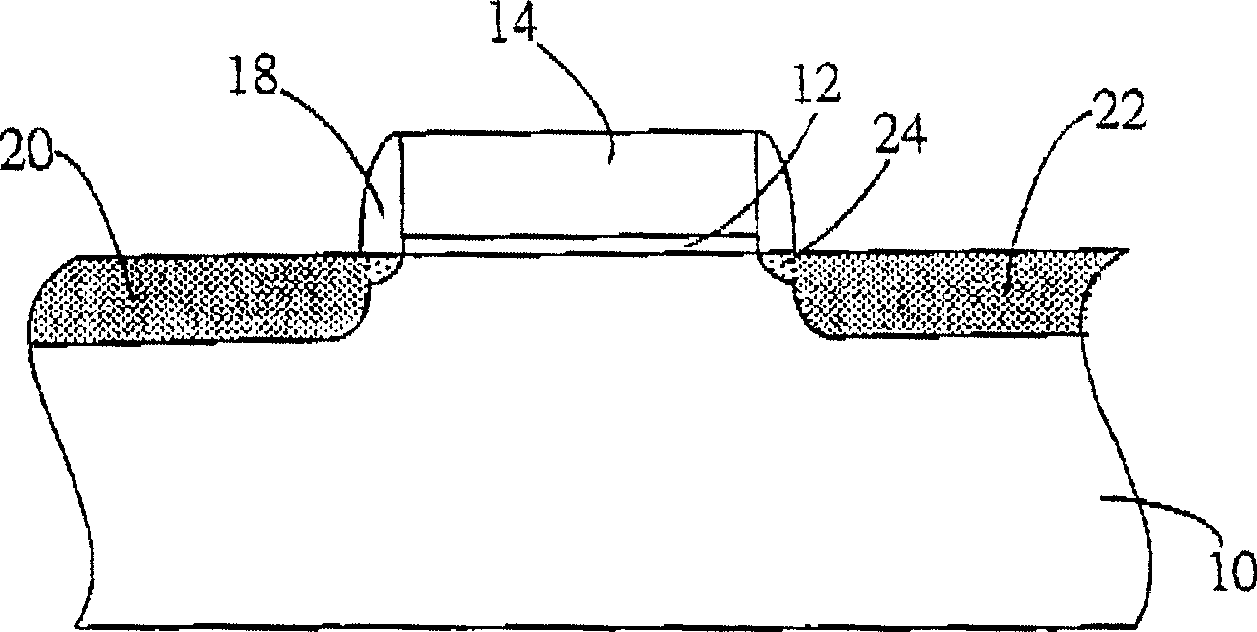

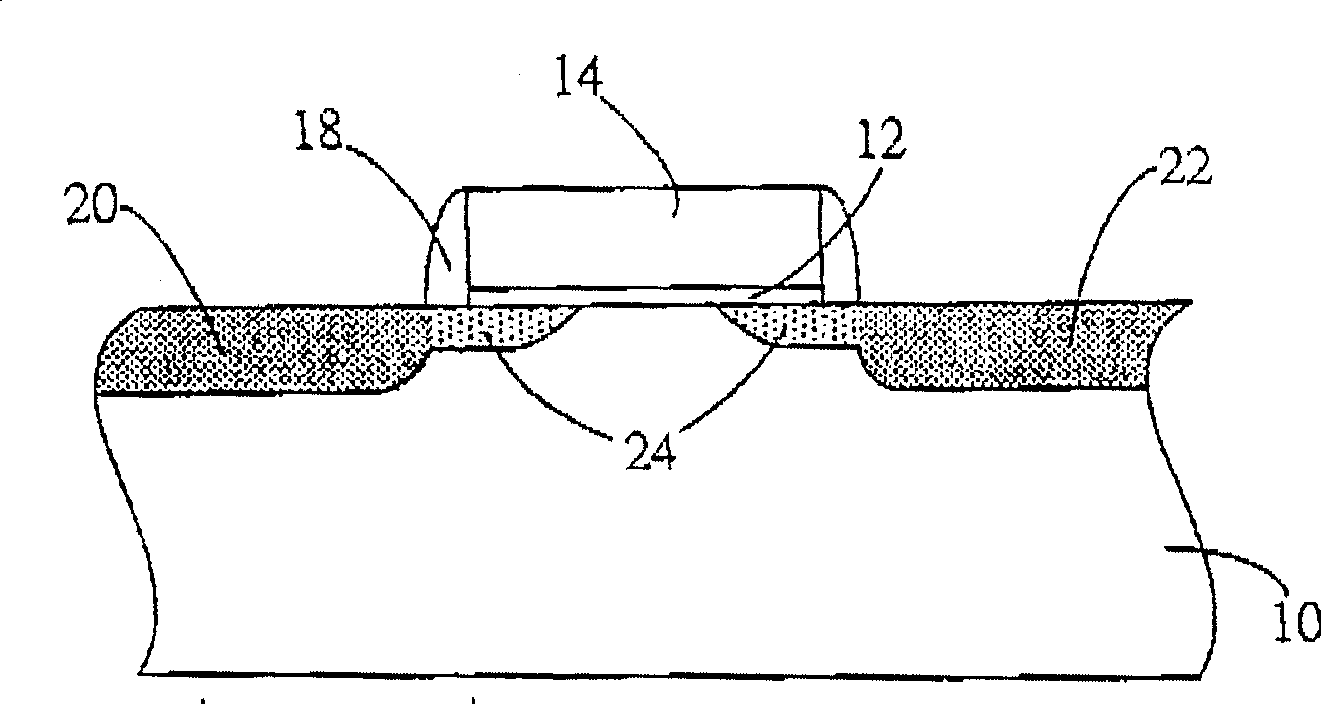

Method of forming light doped drain electrode using inverse taper grid structure

InactiveCN1476064APrecise length controlImprove featuresSemiconductor/solid-state device manufacturingSemiconductor devicesOptoelectronicsGate oxide

In the method, a counter-trapeziodal structure with wide top edge and narrow bottom edge is formed by utilizing etching technique to etch grid stack structure after a gate oxide layer and grid stack structure of polysilicon layer are formed at the surface of a substrate. A vertical implanting step of shallow ion doping is carried on by utilizing the grid stack structure as shield to form a shallow ion doping region in the substrate at two sides of the grid stack stracture so the shallow ion doping region can be diffused horizontally to substrate under bottom periphery of the grid stack structure to form lightly doped drain structure in the following heat preparation process.

Owner:GRACE SEMICON MFG CORP

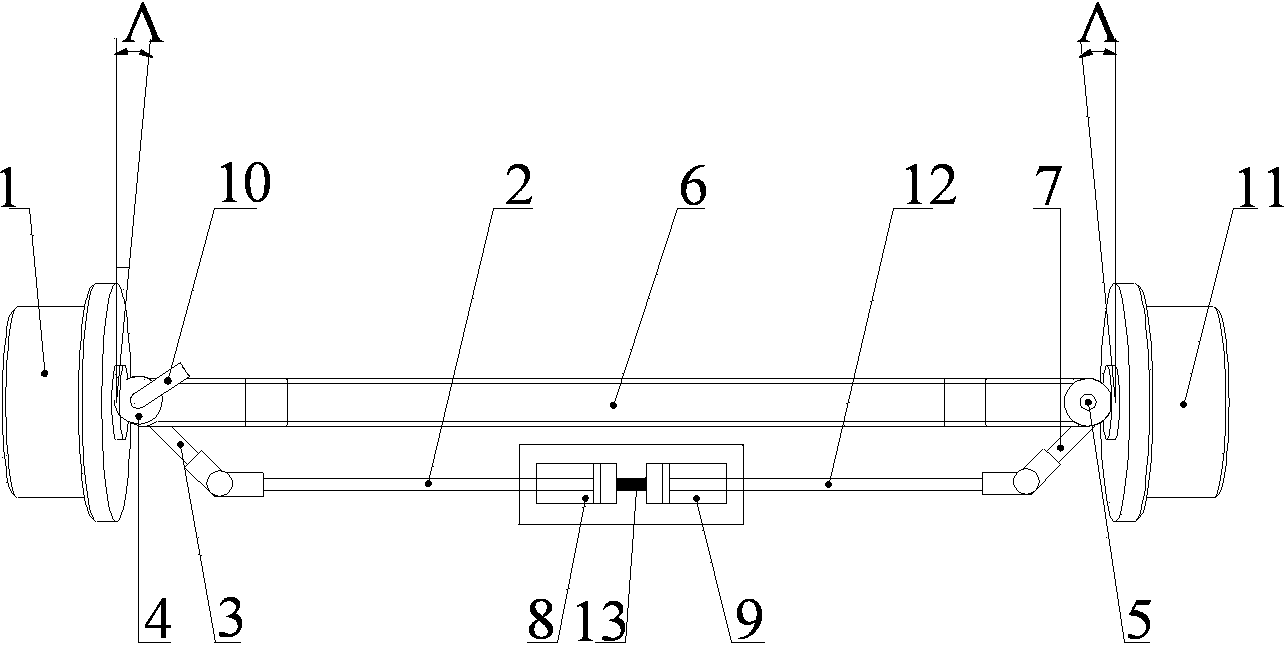

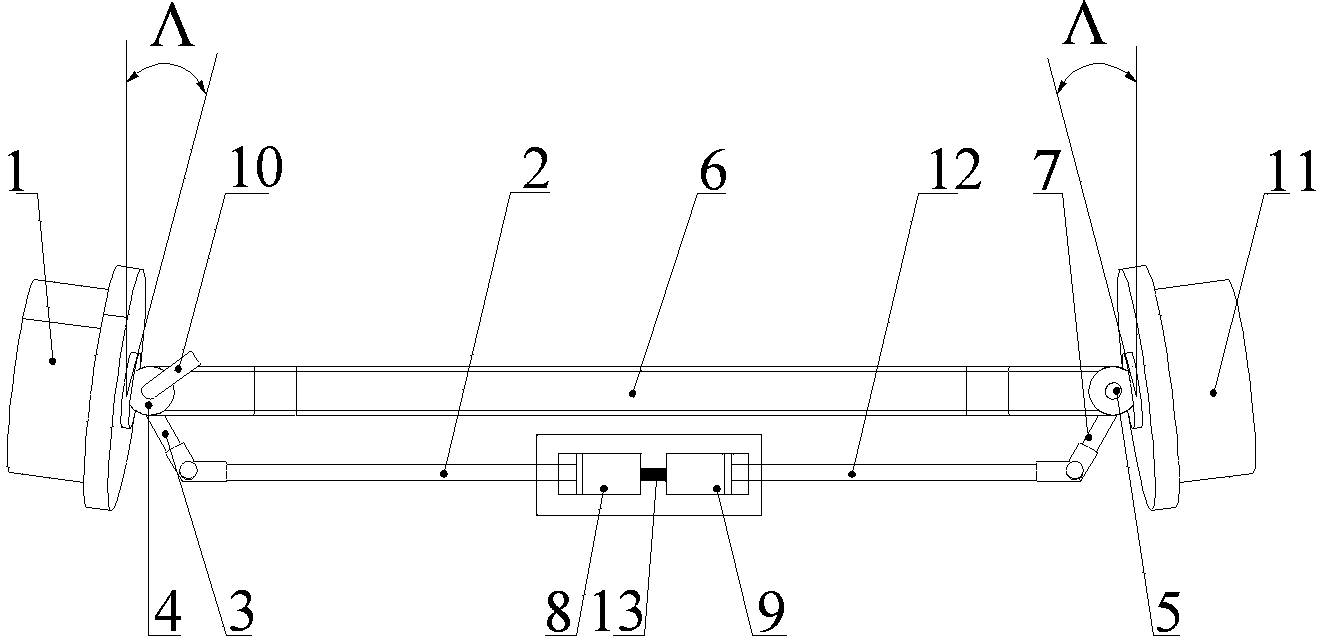

Hydraulic toe-in value adjusting mechanism for steering wheels

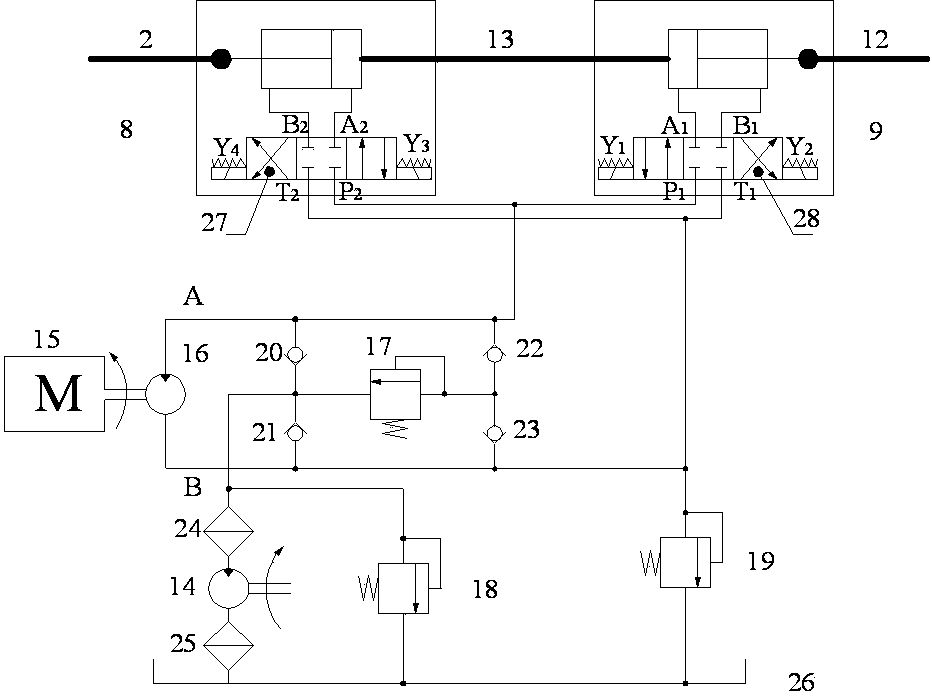

ActiveCN104290814AAvoid the pitfalls of length adjustment toe-inReduce adjustment errorSteering partsSteering wheelCamber angle

The invention discloses a hydraulic toe-in value adjusting mechanism for steering wheels. The hydraulic toe-in value adjusting mechanism for the steering wheels comprises a front axle, a transverse draw bar, the left steering wheel, the right steering wheel and a steering wheel toe-in value adjusting mechanism, wherein the adjusting mechanism comprises the transverse draw bar and a hydraulic mechanism; the transverse draw bar comprises a left transverse draw bar body, a right transverse draw bar body, a left electro-hydraulic servo cylinder and a right electro-hydraulic servo cylinder; and the hydraulic mechanism comprises a constant displacement pump, a stepping motor, a variable pump, a first overflow valve, a second overflow valve, a third overflow valve, four one-way valves and an oil tank. In a running process of a vehicle, the lengths of two ends of the transverse draw bar can be automatically adjusted, so that a toe-in value can be adjusted to be matched with a camber angle, the shortcoming that the lengths of two sides of the transverse draw bar are required to be respectively adjusted manually when the vehicle stops so as to adjust the toe-in value is overcome, and adjustment errors caused by artificial reasons are reduced. The length of the transverse draw bar can be accurately controlled by the electro-hydraulic servo cylinders with MR (magnetic resonance) displacement sensors, linear movement accuracy can be controlled to reach 0.1mm, and the toe-in value adjustment accuracy is improved.

Owner:HEFEI UNIV OF TECH

Constant length wire cutter

InactiveCN1931533APrecise length controlReduce lossesMeasurement devicesFilament handlingMeasuring instrumentLength measurement

The constant length wire cutter includes a length measuring instrument, a power set, a shearing unit, a non-return unit, a wire storing unit and a wire collecting unit. The length measuring instrument measures the length of wire or cable, and when the measured length is equal to the set value, it outputs one signal to the power set, the wire storing unit and the wire -collecting unit. The power set, after receiving the signal, drives the shearing unit to cut the wire or the cable, the wire -storing unit receiving the signal stores the wire or cable, and the wire collecting unit receiving the signal stops collecting. The present invention can cut wire or cable in constant length.

Owner:何仁

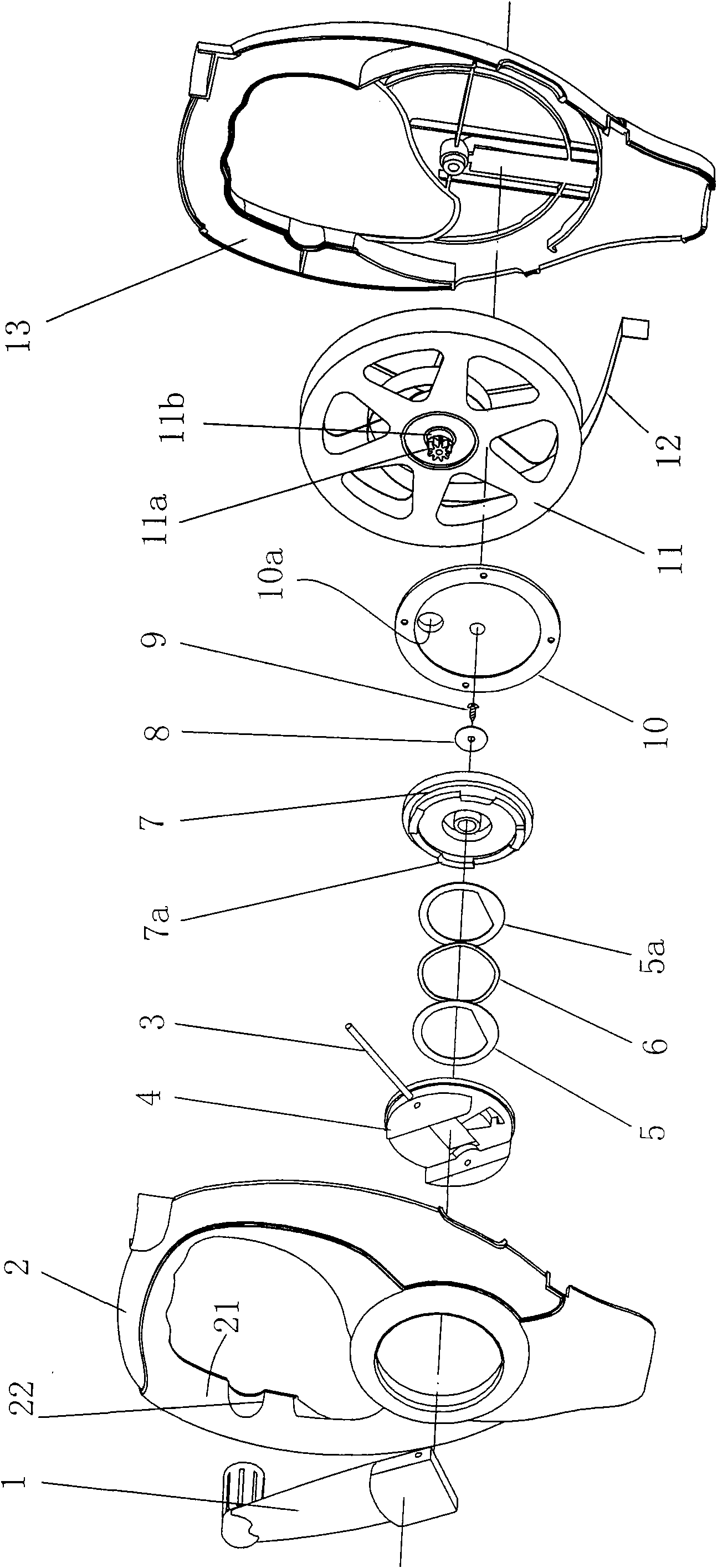

Full-automatic assembling system for adjusting pin of cupboard

InactiveCN104526339AScientific and reasonable structure designFast assemblyMetal working apparatusCouplingEngineering

The invention provides a full-automatic assembling system for an adjusting pin of a cupboard, relates to an assembling system, and aims at solving the problems that when an existing adjusting pin is assembled by a manual manner, the manual assembling is low in efficiency, costs lots of time and force and is high in cost, and meanwhile, a large length difference occurs when manually assembling and screwing a T-shaped part into a cylindrical part, the standardization and unification cannot be reached, and as a result, the packaging and transportation are difficult. The full-automatic adjusting system for the adjusting pin of the cupboard is characterized in that a cylindrical part lifting machine is positioned at one side of an overturning mechanism; a discharging opening in the cylindrical part lifting machine is formed above a conveyor belt in the overturning mechanism; a four-shaft coupling assembling device is positioned at the other side of the overturning mechanism, and a clearance exists between the four-shaft coupling assembling device and the overturning mechanism; two conveyor belts of a T-shaped part arranging machine are positioned at one side of the double-shaft coupling assembling device and a clearance exists between the conveyor belts and a rotating plate mechanism in the four-shaft coupling assembling device; the overturning mechanism and the four-shaft coupling assembling device are respectively electrically connected with a system controller. The full-automatic adjusting system for the adjusting pin of the cupboard is used for assembling the T-shaped part and the cylindrical part.

Owner:HARBIN INST OF TECH

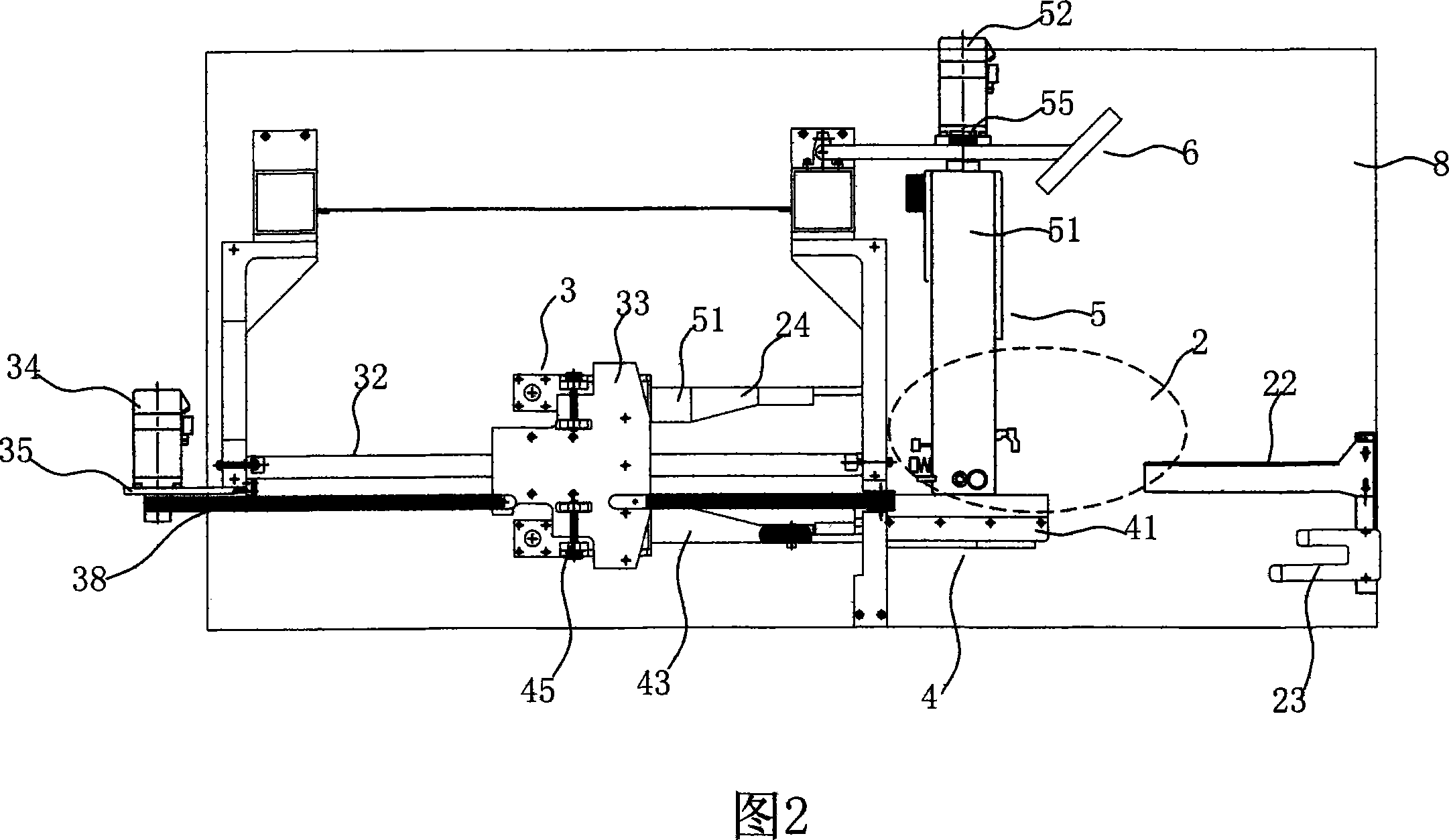

Digital control edgefold sewing machine

InactiveCN101067261APrecise length controlSave unloading timeProgramme-controlled sewing machinesWork-feeding meansEngineeringDigital control

The present invention discloses one kind of numerically controlled hemming sewing machine, which includes a sewing assembly, a driving mechanism, a presser foot mechanism, and a hemming mechanism. The hemming mechanism consists of mainly a pushing cutter, a locating cutter and a locating rod. The pushing cutter and its driving cylinder are mounted on a link rod, which is mounted on the driving mechanism; and the locating cutter is mounted on a seat, which is fixed on the work platform; with one locating clip being mounted beside the locating cutter. The present invention has the integrated automatic functions of seizing cloth, shifting cloth, hemming and sewing and thus high production efficiency.

Owner:龚培云

Novel automatic cable cutting device

InactiveCN106424463APrecise length controlNo need for secondary croppingMetal working apparatusDrive wheelEngineering

The invention provides a novel automatic cable cutting device. The novel automatic cable cutting device comprises a base, wherein a dragging device, a cutting device and a distance fixing device are successively arranged on the base; the dragging device comprises a fixed frame, a transmission belt and a motor; the fixed frame is fixed on the base; a driven wheel and a driving wheel are arranged at the top and the bottom of the fixed frame; the driving wheel is connected with the motor via the transmission belt; the cutting device comprises a bracket and a cutting cylinder arranged on a bracket top plate; the output end of the cutting cylinder passes through the bracket top plate and is connected with a cutter; the distance fixing device comprises a sliding rail, a sliding block and a distance fixing cylinder; the sliding rail is arranged on the base in the length direction of the base; the sliding block is slidably arranged on the sliding rail; the output end of the distance fixing cylinder is fixedly connected with the sliding block; a cable clamping mechanism used for clamping cables is fixedly arranged on the side of the sliding block. The novel automatic cable cutting device has the beneficial effects that data cables can be cut at a fixed distance, the novel automatic cable cutting device is convenient to operate, and the production efficiency of the data cables is improved.

Owner:TIANJIN OULIN ELECTRONICS

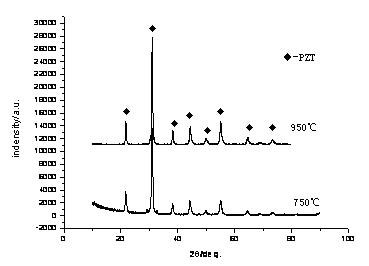

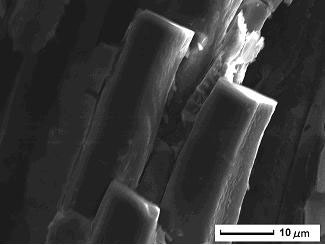

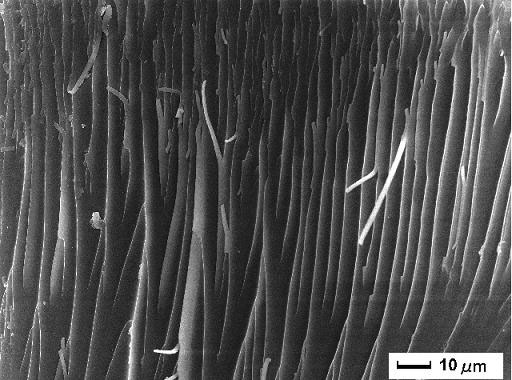

Method for manufacturing fine straight PZT piezoelectric fiber array

A method for manufacturing a fine straight PZT (Pbbased Lanthanumdoped Zirconate Titanates) piezoelectric fiber array relates to a method for manufacturing functional ceramic fiber. The method comprises the steps as follows: preparing PZT sol at first by taking plastic capillary tubes as reaction templates; then adding PZT millimicron powder to get suspending liquid after uniform blending; placing the plastic capillary tubes into a quartz tube with two ends opened; filling the gaps among the capillary tubes, as well between the quartz tube and the plastic capillary tubes with glue or paraffin, so as to form an array shape after solidification; submerging the quartz tube into the suspending liquid, and after full adsorption, pouring the remain suspending liquid into the quartz tube from one end and performing vacuum filtration at the other end, for ensuring that the suspending liquid enters into the plastic capillary tubes through vacuumize force until the capillary tubes are full of suspending liquid; and after the quartz tubes are dried to have no excess liquid, repeatedly performing dipping, vacuum filtration and drying to the withdrawn quartz tubes, then performing template removal and crystallization thermal treatment, and obtaining the PZT piezoelectric fiber array with a diameter ranging from several microns to hundreds of microns, a length ranging from 0.5cm to 3cm, as well as straight form and high density.

Owner:JIANGSU UNIV

Automatic cleaning and disinfecting disconnected gauze

ActiveCN109925128APrecise length controlGood dry and wet separation effectBandagesEngineeringActuator

The invention provides automatic cleaning and disinfecting disconnected gauze comprising an outer box, an actuator, a roll of gauze, a disinfecting mechanism and a limiting mechanism. The gauze can solve the problem that the gauze currently on the market is generally in a roll, when the current gauze is used, the cutting length is inaccurate to control, the material is wasted if the cut gauze is too long, or the dressing effect is not ideal if the cut gauze is short; the wet gauze or the dry gauze cannot be taken out conveniently according to the actual use when needed; when the gauze is cut,other tools such as scissors are required to assist the cutting, and the gauze is difficult to cut if the scissors are not available; if the gauze in a roll is not used out in time after unpacked, thesurface is easily contaminated by dust. The gauze can achieve automatic cleaning and disinfection disconnection during use and can be used both in the dry and wet states.

Owner:THE AFFILIATED HOSPITAL OF QINGDAO UNIV

Auto-control and auto-detection system for non-decoupled dynamic compaction machine

InactiveCN103309276APrecise length controlSafe and stable operationProgramme control in sequence/logic controllersAutomatic controlDynamic compaction

Owner:SHANDONG UNIV OF SCI & TECH +1

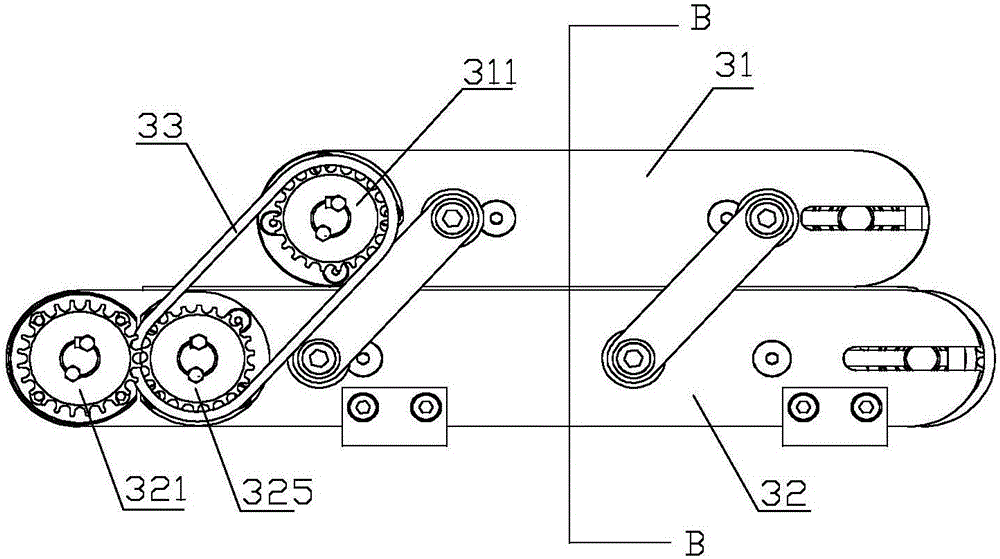

Automatic magnetic strip passing machine

The invention discloses an automatic magnetic strip passing machine. The automatic magnetic strip passing machine comprises a rack and a magnetic strip tractor, wherein the magnetic strip tractor is positioned on the rack, a magnetic strip passes through a guide rod, a pressing wheel and the magnetic strip tractor in sequence, the magnetic strip tractor comprises two conveying machines respectively including an upper conveying machine positioned on the top and a lower conveying machine positioned at the bottom, an upper guide groove is formed in one surface, which is opposite to the lower conveying machine, of the upper conveying machine, a lower guide groove which is opposite to the upper guide groove is formed in the lower conveying machine, a conveying belt of the upper conveying machine is arranged in the upper guide groove, a conveying belt of the lower conveying machine is arranged in the lower guide groove, the magnetic strip is positioned in a gap formed by the conveying belts of the upper conveying machine and the lower conveying machine and is clamped to move forward by the conveying belts of the upper conveying machine and the lower conveying machine, and the gap is positioned in the upper guide groove or the lower guide groove. According to the automatic magnetic strip passing machine, whether the magnetic force of the magnetic strip is qualified can be automatically detected, the traction of the magnetic strip does not slip, the cutting length of the magnetic strip is accurate, the qualified rate of products is increased, and the cost is reduced.

Owner:QINGDAO HENGJUN EQUIP MFG CO LTD

Abdominal pad folding machine

InactiveCN107857157ACompact structureSmall footprintFolding thin materialsAgricultural engineeringSmall footprint

The invention discloses a belly pad folding machine, which comprises a frame, a material discharging device, a material feeding device, a material cutting traction device and a folding and discharging device arranged on the frame in sequence; the folding and discharging device includes a transverse folding mechanism And the longitudinal folding mechanism, the horizontal folding mechanism includes two folding shafts parallel to each other, the folding shafts are provided with a plurality of folding rods, and the folding rods are perpendicular to the folding shaft; the longitudinal folding mechanism includes vertical The half-folding plate is set and perpendicular to the folding shaft, and the position corresponding to the horizontal platform and the half-folding plate is provided with a plate-passing groove, and two side-by-side double-folding transfer rollers are arranged below the plate-passing groove. The invention eliminates the labor cost, has the advantages of accurate material cutting, rapid folding and high efficiency, low equipment cost, compact structure and small occupied space.

Owner:宜昌麦迪科机电设备有限责任公司

Roll paper film sticking device

ActiveCN102700171APrecise length controlPrecise position controlContainer making machineryProduction lineRolling paper

The invention discloses a roller paper film sticking device. A wall plate is provided with a group of guide rollers; a guide rod is fixed on the wall plate; a rack is movably mounted on the guide rod through a screw rod; an upper cutter frame and a cutter roller are mounted on the rack; the cutter roller is provided with a mounting groove; the upper film cutter is movably mounted in the mounting groove through adjustable screws; a lower cutter adaptable to the upper film cutter is mounted on the rack; a film mounting frame is fixed on the rack; a film adjusting device is arranged on the film mounting frame; a film guide roller, a film pressing bar, a film upper pressing roller and a film lower roller are mounted on the rack and are located between the film mounting frame and a film sticking roller; the film upper pressing roller is adaptable to the film lower roller; the film lower roller is connected with a servo motor; and a shovel film for separating the film from the film stickingroller is arranged on the rack and is located at one side of the film sticking roller. The roller paper film sticking device, disclosed by the invention, adopts the servo motor to control the film cutting length and the film sticking position accurately; and the roller paper film sticking device is an independent unit which can be used on a production line of a paper bag machine.

Owner:上豪包装机械(镇江)有限公司

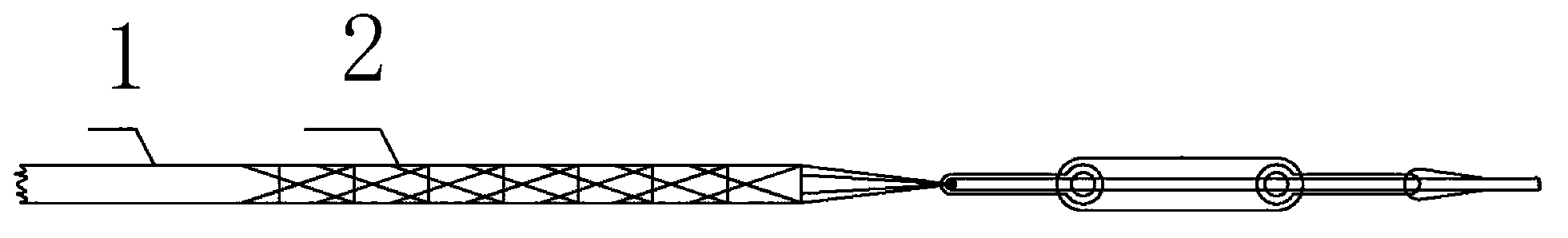

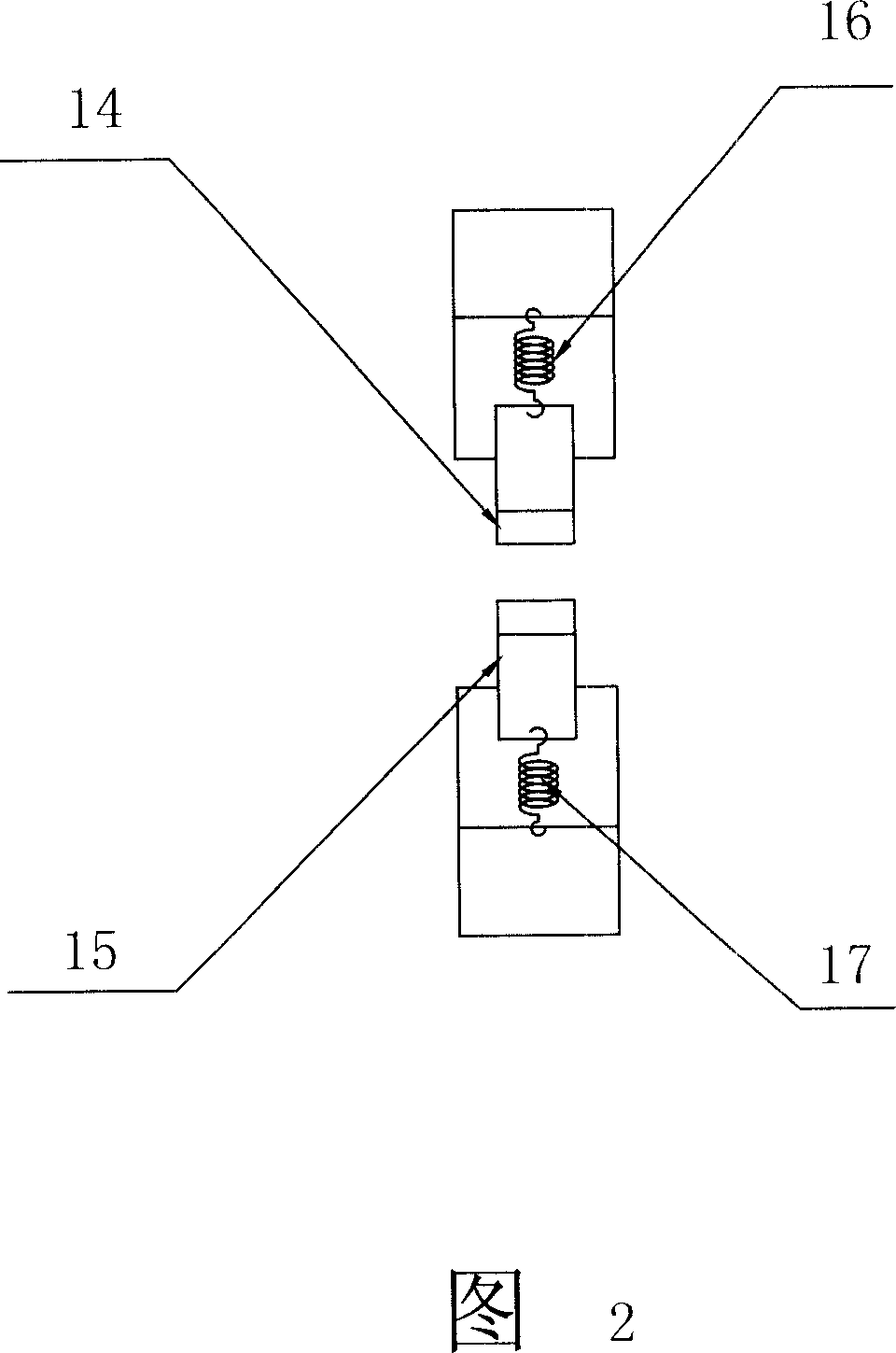

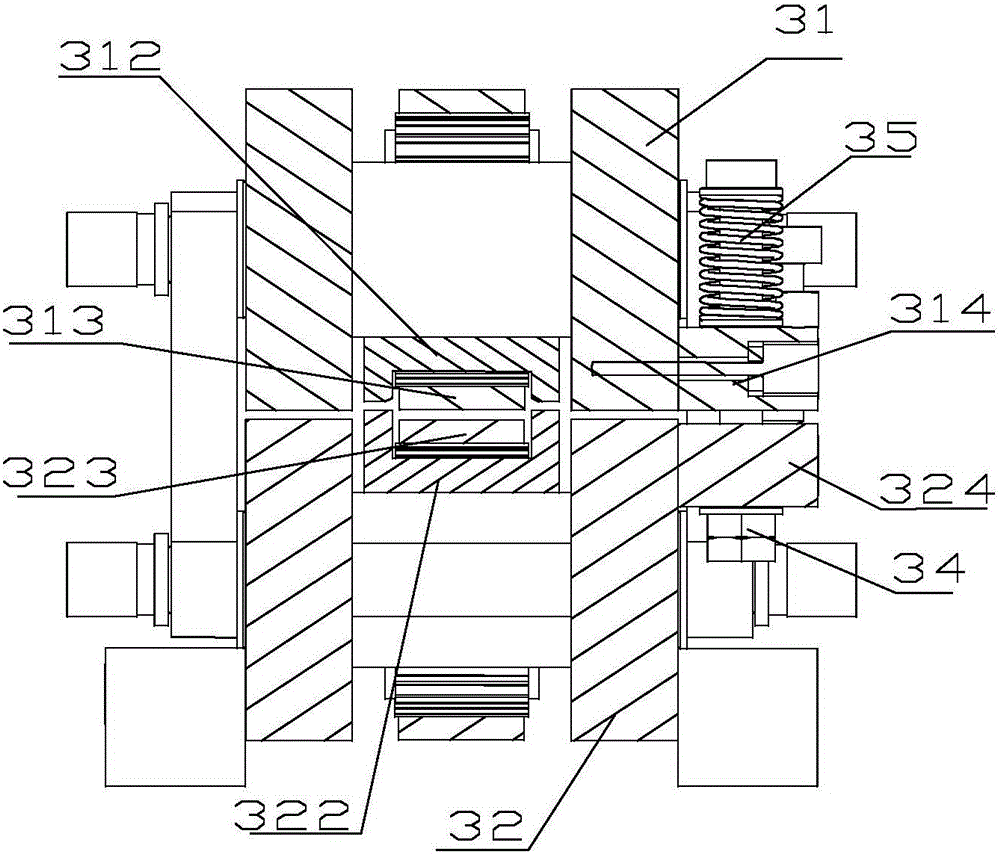

Variable frequency steel strand cable penetrating machine

InactiveCN102296544APrecise length controlAdvance and retreat freelyBridge erection/assemblyBridge materialsGear wheelMachine

The invention relates to a variable frequency steel strand cable penetrating machine. The machine comprises a machine shell, wherein a steel strand inlet pipe and a steel strand outlet pipe are arranged on two side plates of the machine shell; a driving mechanism, a clamping mechanism and an adjusting screw rod are arranged in the machine shell; the driving mechanism comprises a reduction gear set and a carrier gear; the clamping mechanism comprises two upper occupied plates and two lower occupied plates which are symmetrically arranged; movable connection plates are correspondingly arranged at the two sides of the upper and lower occupied plates; upper pressure gears are arranged on the upper occupied plates; lower pressure gears are arranged on the lower occupied plates; the upper pressure gears are meshed with the lower pressure gears; the reduction gear set and the carrier gear are simultaneously meshed with the lower pressure gears; semicircular slots are arranged in the middle of the outer edges of the teeth of the upper and lower pressure gears; one end of each of the lower occupied plates extends upwards to form a support plate of the adjusting screw rod; support shafts are arranged between the support plates; threaded holes are arranged in the middle of the support shafts; the adjusting screw rod penetrates through the threaded holes; and the end of the adjusting screw rod is movably connected with a locking pendulum shaft. The machine has the following beneficial effects: the machine can succeed in cable releasing and cable penetrating once, can proceed or step back freely, can accurately control the length of the steel strands conveyed into prestressed ducts and can solve the problem of long-distance cable penetrating.

Owner:廖继春

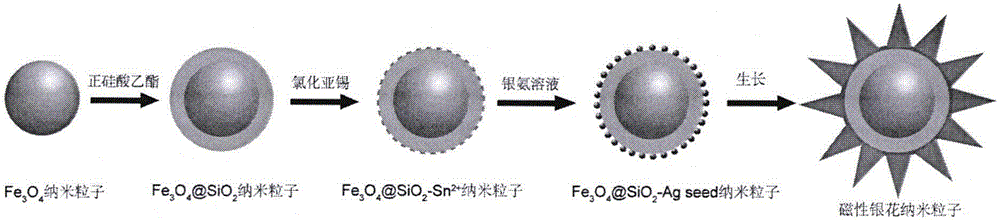

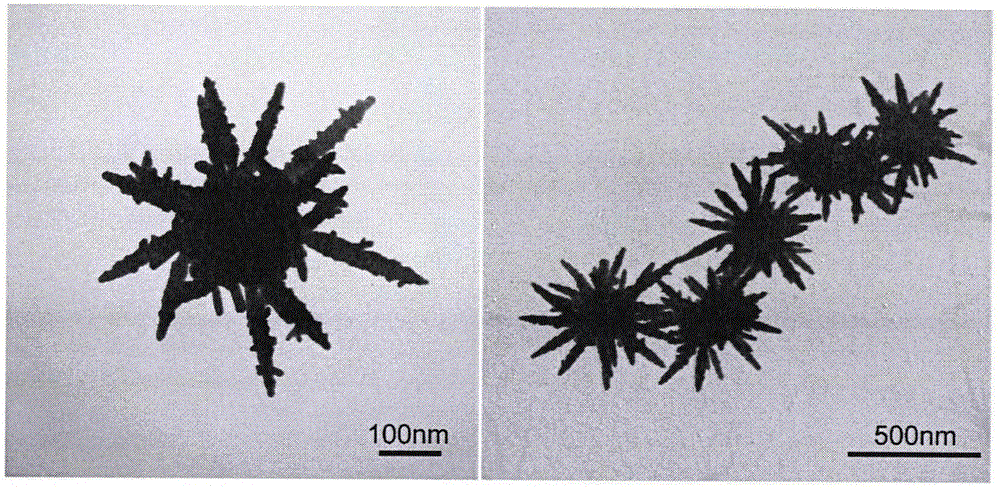

Structure and preparation method for magnetic sliver-flower nano-particles

InactiveCN106887295AMagnetically responsiveEasy to collectTransportation and packagingMetal-working apparatusAmmonium hydroxideSilicon dioxide

The invention discloses a structure and a preparation method for magnetic sliver-flower nano-particles. The structure takes magnetic nano-particles (Fe3O4) as the core and takes a silicon dioxide shell layer (SiO2) as a multi-functional layer. By formaldehyde reduction, flower-shaped sliver shells similar to needle points rapidly grow. The preparation method comprises the following steps: wrapping surfaces of 100-6000 nano Fe3O4 magnetic nanoparticles with an SiO2 layer and improving dispersion of magnetic nano-particles and providing position points of sliver seed growth; utilizing a chemical electroplating method with the assistance of ultrasonic wave to grow the surfaces of the Fe3O4@SiO2 magnetic particles with uniform and dense sliver particles as seeds for growth of flower-shaped sliver shells; finally, utilizing formaldehyde as a reduction agent and ammonium hydroxide as a catalyst to rapidly reduce magnetic sliver-flower nano-particles on the ultrasonic condition. The invention further discloses a magnetic SERS substrate prepared by the above method. The magnetic SERS substrate is made from magnetic sliver-flower nano-particles and is good in dispersion, high in magnetic induction, stable in structure and great in heart and can be directly used for SERS detection of small molecule pollutants, pesticide residuals and illegal additives of food.

Owner:ACADEMY OF MILITARY MEDICAL SCI

Novel wire cutting machine

ActiveCN103658811AGuarantee the quality of the sectionAccurate Wire Feeding LengthShearing machinesShearing machine accessoriesWire cuttingPneumatic pressure

The invention provides a novel wire cutting machine which comprises a wire feeding mechanism, a straightening mechanism, a wire cutting mechanism and a control system. The wire feeding mechanism, the straightening mechanism and the wire cutting mechanism are arranged in sequence. The control system controls the wire feeding mechanism and the wire cutting mechanism. The wire cutting mechanism comprises a pneumatic control device, an impact hammer, a spring, an air cylinder, a collision block, a fixed cutter, a moving cutter, a guide rod and a plate support. The impact hammer, the spring and the collision block are sequentially connected and are arranged in the air cylinder. The pneumatic control device is connected with the air cylinder. The moving cutter is arranged under the collision block. The fixed cutter is provided with a wire passing hole. The moving cutter is provided with a cutter hole. When the pneumatic control device is switched off, the wire passing hole and the cutter hole are coaxial. According to the novel wire cutting machine, the impact hammer in the wire cutting mechanism drives the cutter to move at a high speed under the action of air pressure, cut-off motion can be instantly completed, and the quality of cross sections is guaranteed. Meanwhile, wire feeding wheels in the wire feeding mechanism press metal wires tightly through the air cylinder and are driven by a servo motor to feed the metal wires. The control system is used for automatically and accurately controlling the feeding length of the wires.

Owner:TIANJIN GOLDEN BRIDGE WELDING MATERIALS GRP

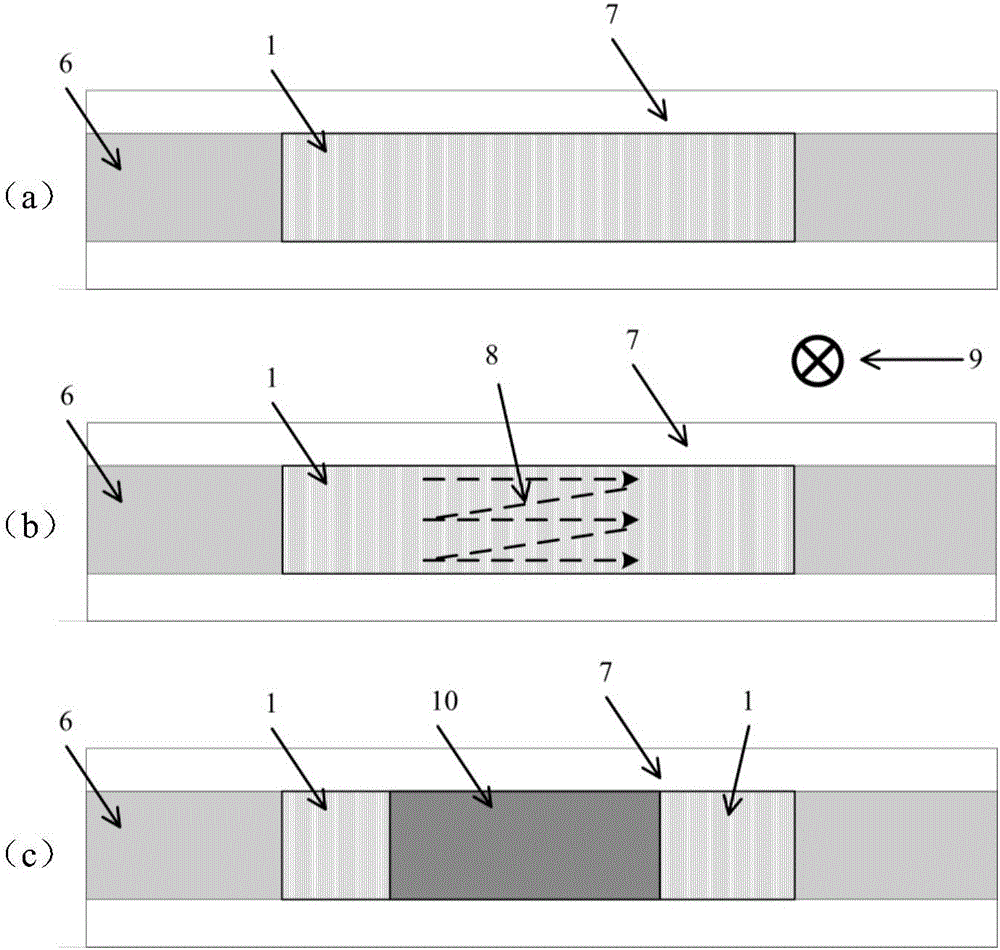

Vernier effect based optical fiber line intra-cascade Fabry-Perot cavity sensor induced by femtosecond laser

InactiveCN109974759ALow costEasy to makeConverting sensor output opticallySpectrum analyzerLight source

The invention puts forward an interferometer cascaded by two Fabry-Perot cavities on the basis of an optical fiber line. The interferometer comprises a broadband light source, a circulator, a sensinghead and a spectrum analyzer, wherein the sensing head is manufactured by a single-mode optical fiber or a multimode optical fiber. The interferometer is characterized in that femtosecond laser is used for inscribing four reflecting mirror surfaces which vertically penetrate through a fiber core and have the same size, wherein the end surface of the optical fiber is cut into a wedge shape to eliminate end surface reflection interference, and all reflecting mirrors and the optical fiber form the sensing head of the Fabry-Perot cavity interferometer. Light from the broadband light source is received by the circulator and is transmitted to the sensing head, then, the sensing head returns the light to the circulator, and the light is transmitted to the spectrum analyzer through the circulatorso as to form the cascade Fabry-Perot cavity interferometer. The interferometer has the characteristics of being simple in structure, simple in manufacture, low in cost, high in sensitivity and the like.

Owner:CHINA JILIANG UNIV

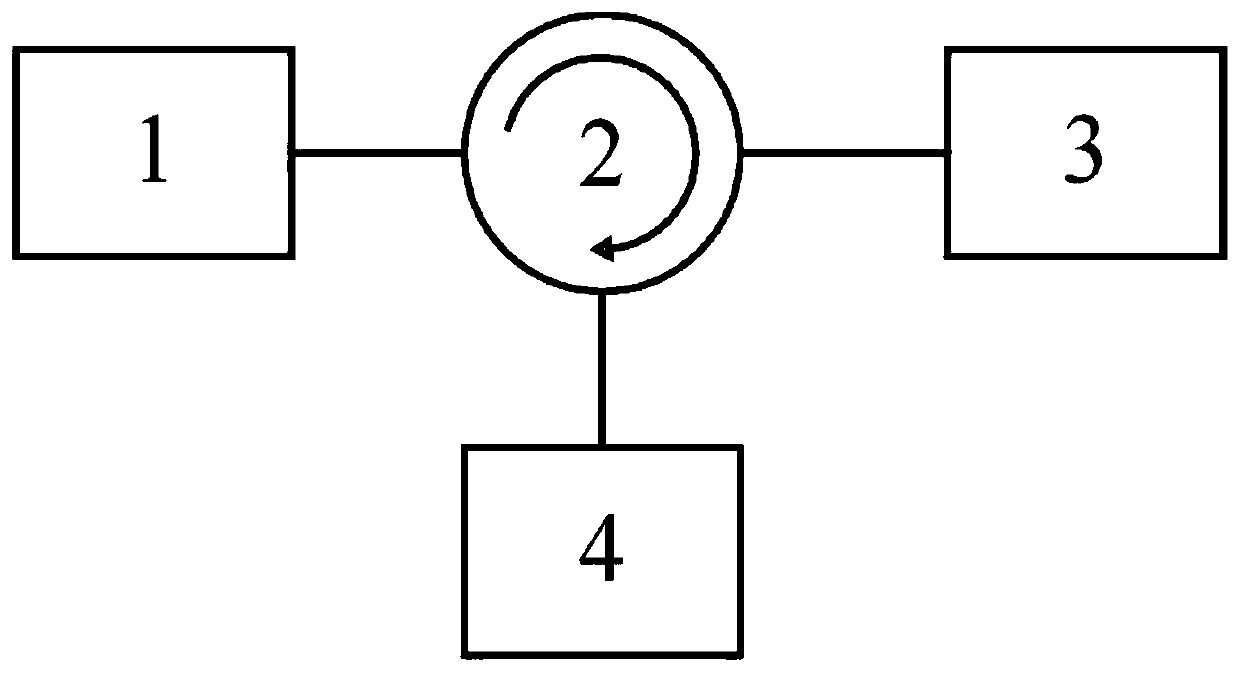

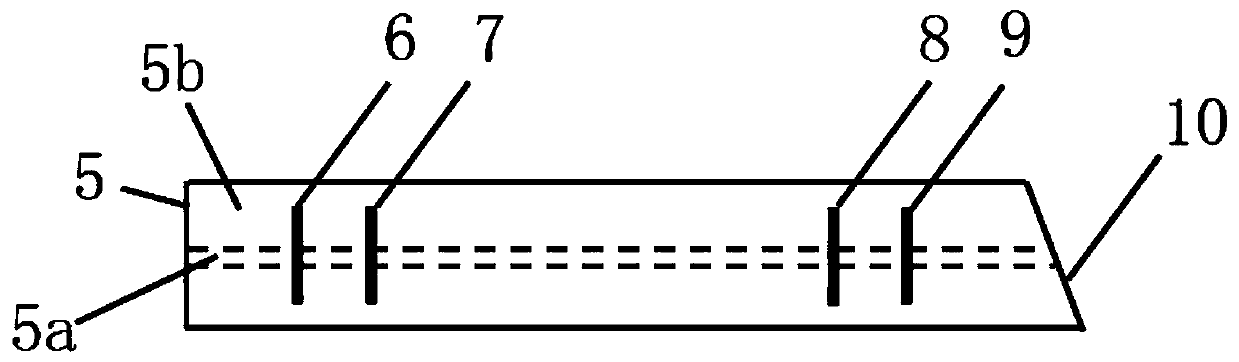

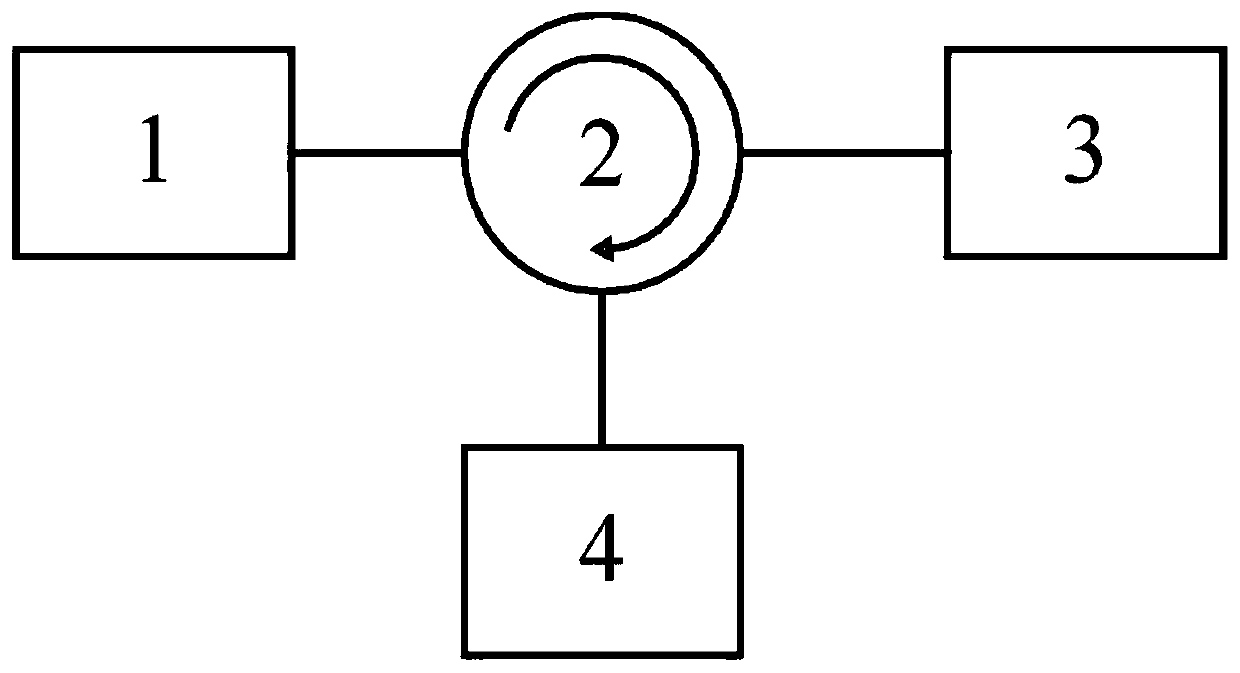

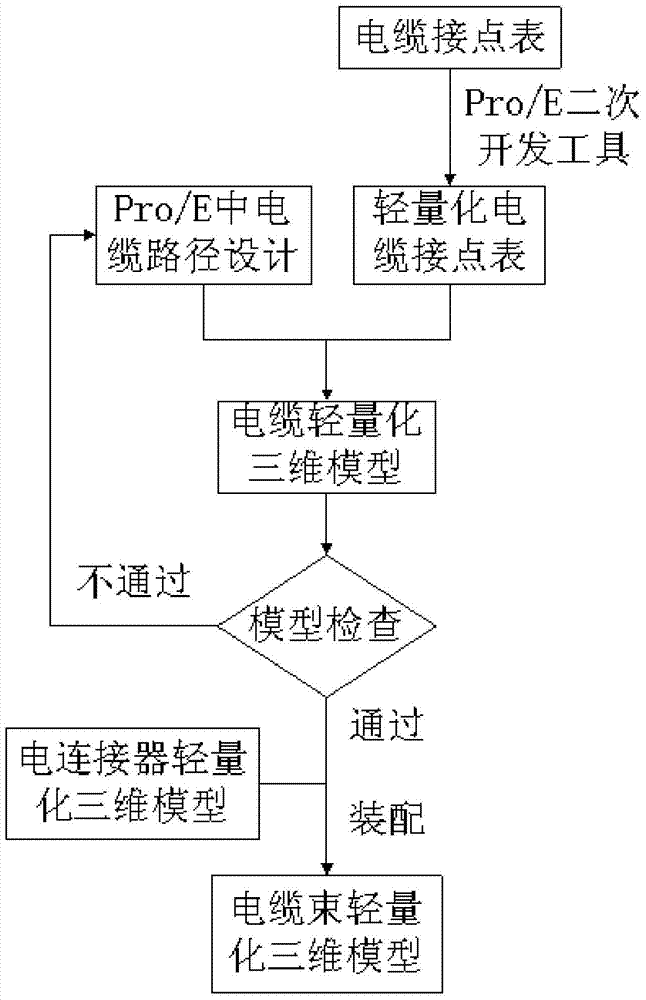

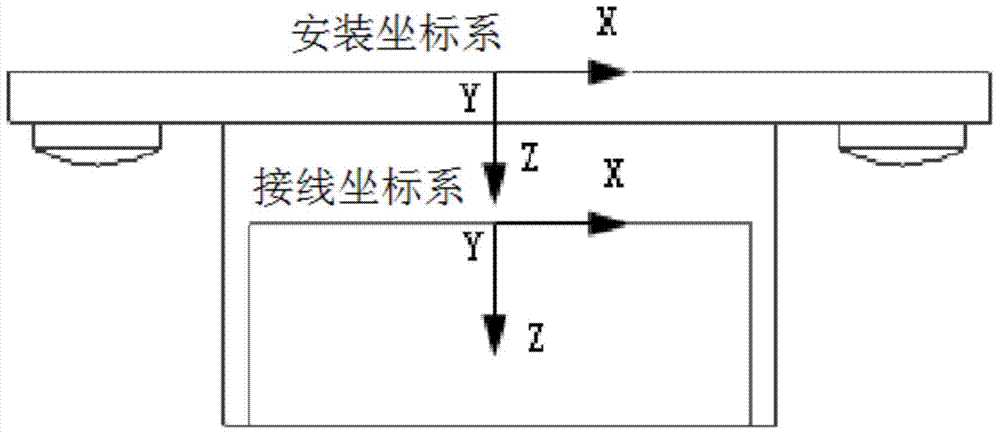

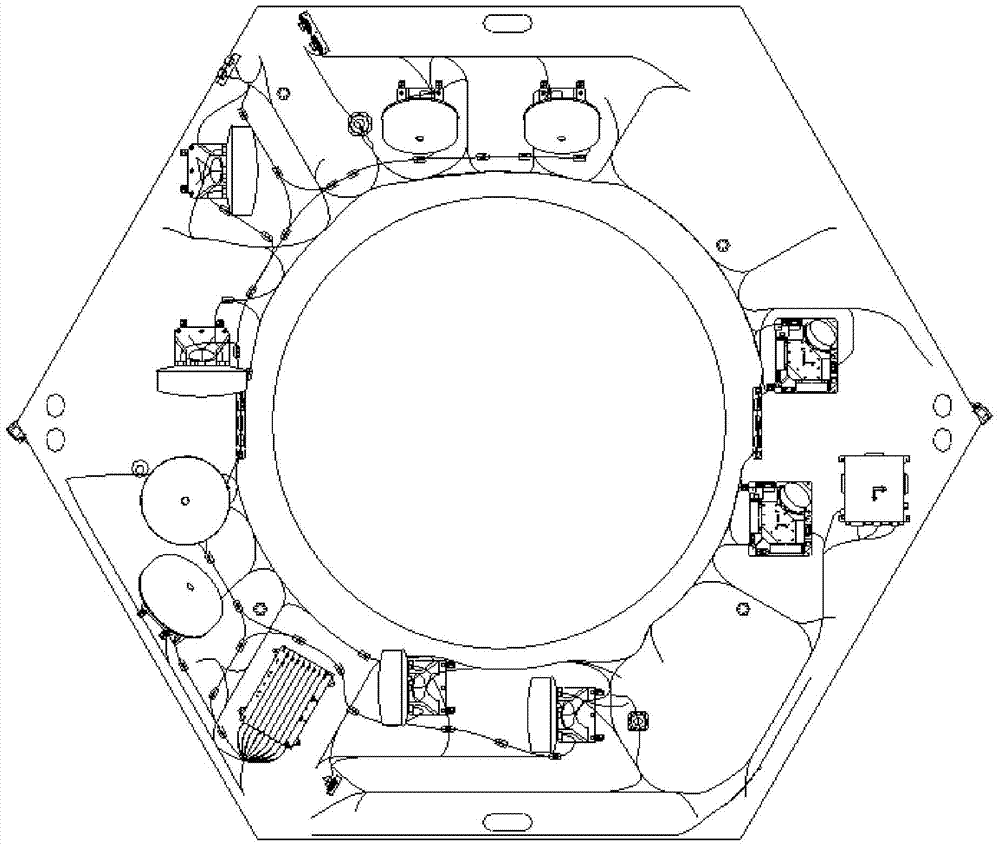

Lightweight modeling method of satellite cable

ActiveCN104268321ALow hardware performance requirementsAvoid path distortionSpecial data processing applications3D modellingPetroleum engineeringDesign technology

The invention discloses a lightweight modeling method of a satellite cable. Based on the computerized design technique and the Pro / E secondary development technology, the lightweight modeling method comprises the steps of 1, establishing a three-dimensional electrical connector lightweight model in Pro / E, 2, establishing a cable joint table in a computer system, 3, generating a lightweight cable joint table by use of a Pro / E secondary development tool, 4, designing a cable trend path in the Pro / E, 5, reading in the lightweight cable joint table in the Pro / E and creating a three-dimensional cable lightweight model, 6, performing model examination in the Pro / E, and 7, assembling the cable model and the electrical connector model in the Pro / E. The lightweight modeling method of the satellite cable has the advantages that the size of a three-dimensional cable model file can be greatly reduced, the three-dimensional modeling of the satellite cable can be improved, the length and the weight of the cable can be accurately controlled and the efficiency and the quality of the satellite cable design can be improved, based on the lightweight thought and by maintaining the major information of cable modeling and neglecting secondary and irrelevant information.

Owner:SHANGHAI SATELLITE ENG INST

Flexible rule

The invention relates to a flexible rule, which comprises the following parts: a shell; a handle seat (4) arranged on the shell; a handle handgrip (1) of which one end is connected with the handle seat (4); a rule core plate (11) for driving rule strip to be drawn out and coiled; and a driving mechanism which is used for transmitting the driving force of the handle handgrip (1) to the rule core plate (11) and is arranged in the shell and positioned between the handle seat (4) and the rule core plate (11). The flexible rule is characterized by further comprising a damping mechanism which can instantaneously stop the rule core plate (11) from rotating continuously when the rule strip is in the drawn out state or in the coiled state. Compared with the prior art, the flexible rule has the following advantages that: the increased damping mechanism can stop the rule core plate instantaneously without being influenced by the inertia force and the elastic force of the stretching of the rule strip so that the rule core plate stops rotating; the flexible rule not only can prevent expansible band and dispersion, but also can reduce the impacts caused by the self-rotation of the rule core plate, and prolong the service life of the flexible life; besides, when the rule strip is drawn out, the length can be controlled accurately.

Owner:吴其联

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com