Flexible rule

A tape measure and shell technology, applied in the direction of a bendable ruler, etc., can solve the problems of difficulty in controlling the length, easy to cause tape expansion, tape measure impact, etc., to achieve accurate length control, prolong service life, and prevent tape expansion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

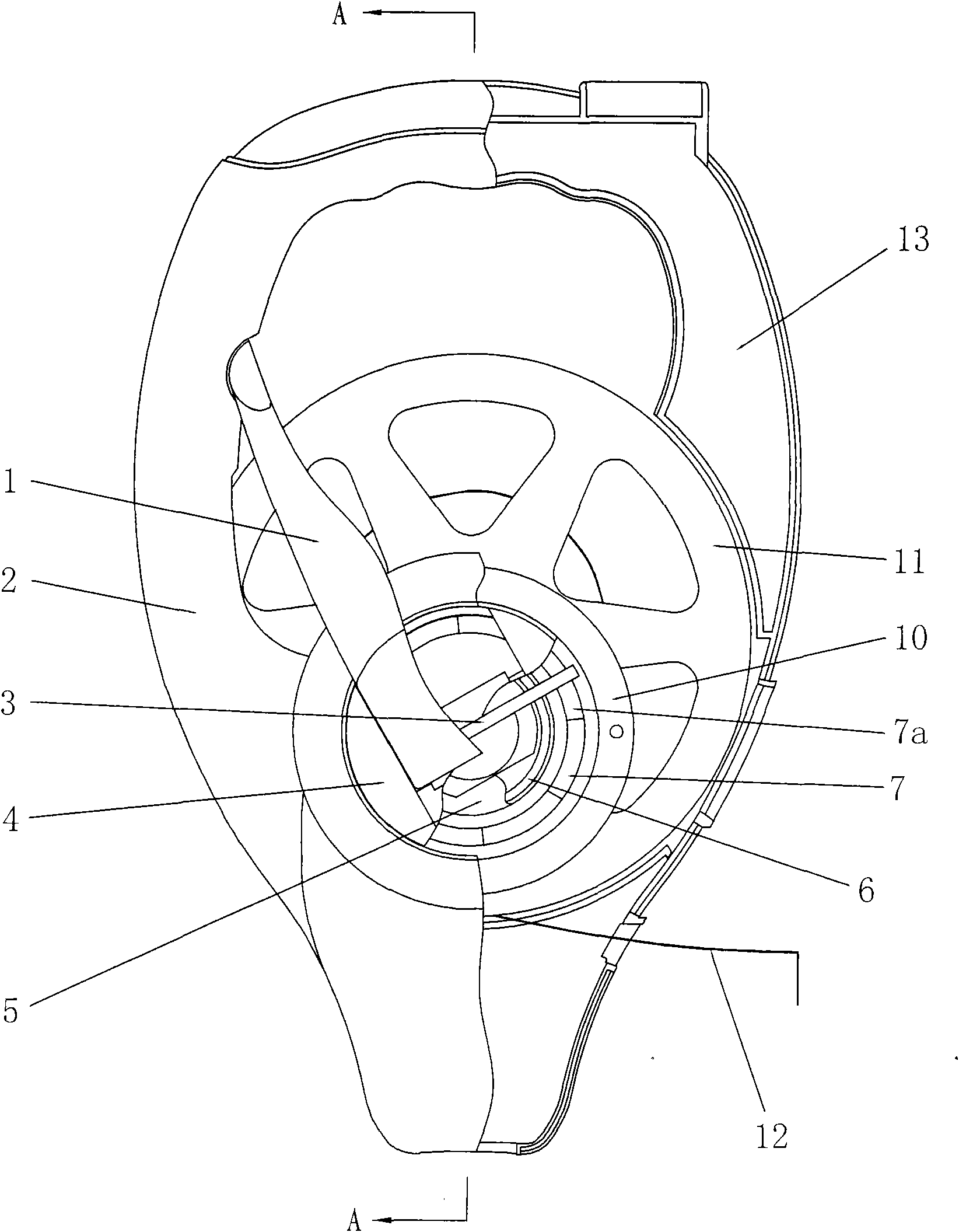

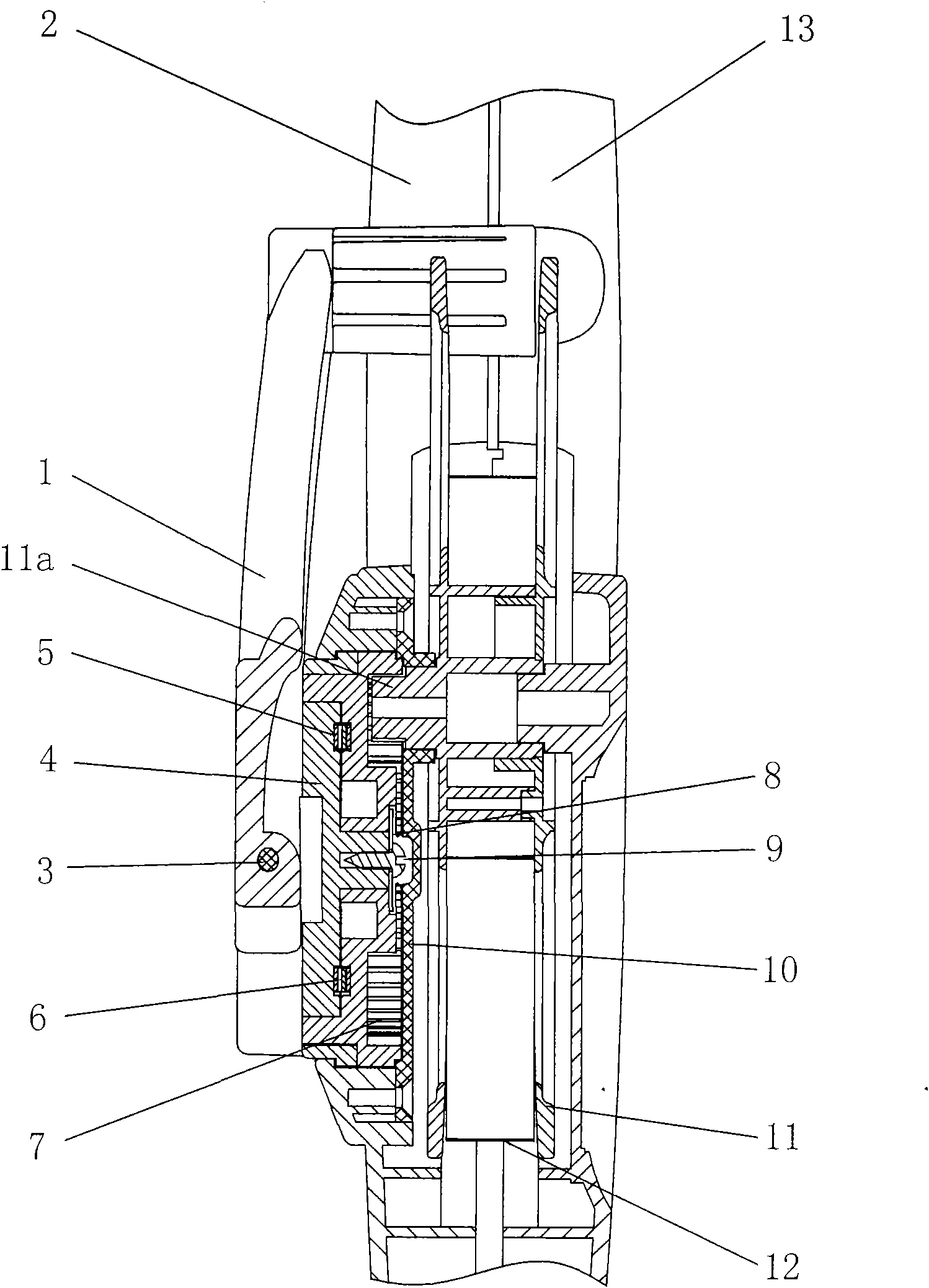

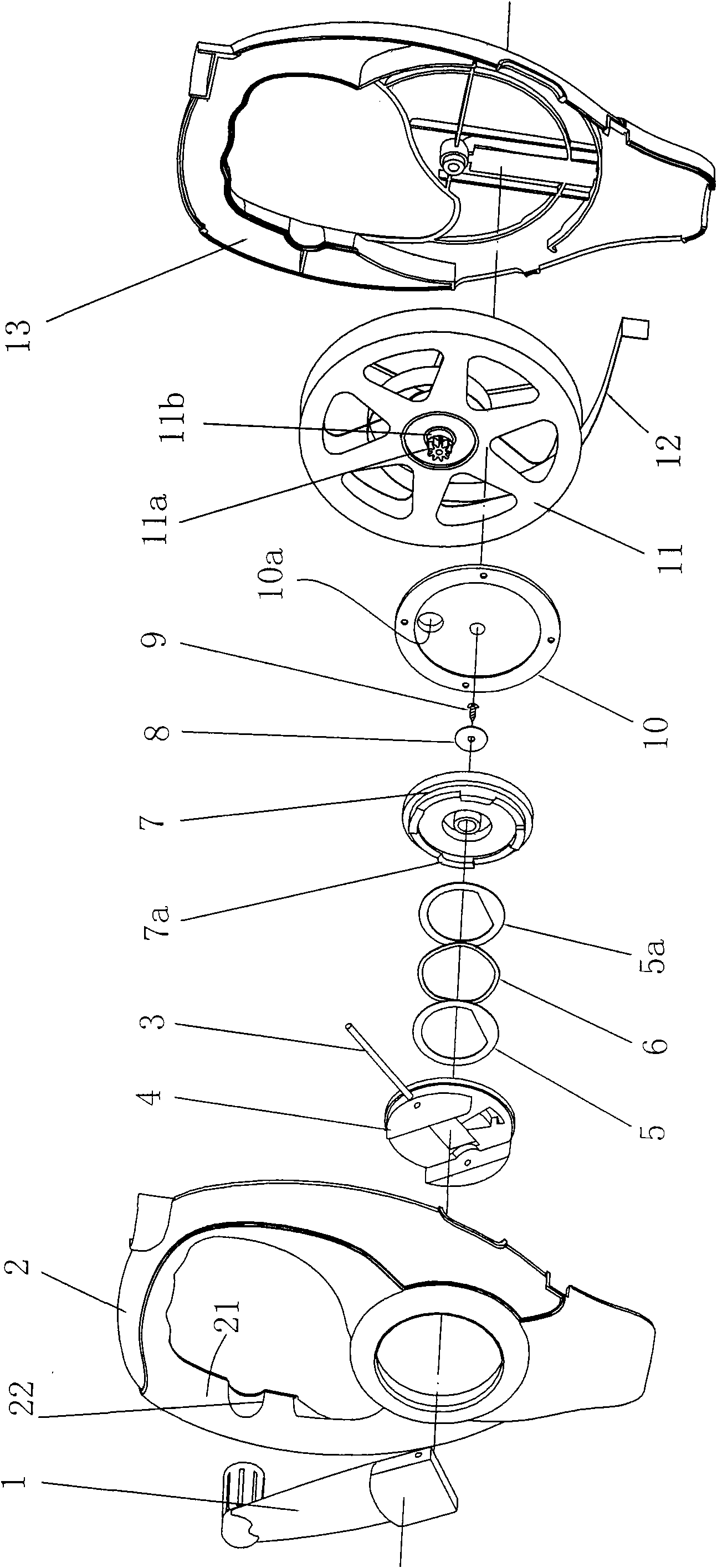

[0044] Embodiment 1, reference Figure 1 to Figure 4 As shown, the tape measure in this embodiment includes a housing, a rocker seat 4, a rocker handle 1, a core disc 11, a tape 12, a support plate 10, a transmission mechanism and a damping mechanism.

[0045] The casing is assembled from the upper first casing 2 and the second casing 13 , the casing has a handle portion 21 , and the tape 12 is coiled on the core disc 11 .

[0046] The rocker seat 4 is arranged on the first shell, and the rear end has a clutch groove. One end of the rocker handle 1 is hinged to the rocker seat 4 through a cylindrical pin 3, and the other end is a free end for use by shaking operation. The ruler core plate 11 It is arranged in the housing and is used to drive the measuring tape 12 to be pulled out and rolled up.

[0047] The transmission mechanism is also arranged in the housing and located between the rocker seat 4 and the core plate 11 for transmitting the driving force of the rocker handle ...

Embodiment 2

[0055] Embodiment 2, refer to Figure 5 As shown, the damping mechanism of the tape measure in this embodiment includes a compression spring 6a and a marble 5b arranged at one end against the rear end surface of the handle seat 4. The front end surface of the internal gear 7 has a groove, and the front end of the compression spring 6a is in contact with the marble 5b. contact, and the rear end is against the bottom of the internal gear 7 grooves. Other structures and working principles are the same as in Embodiment 1.

Embodiment 3

[0056] Embodiment 3, refer to Figure 6 As shown, the damping mechanism of the tape measure in this embodiment includes a compression spring 6a and a toothed spring 5c that is arranged at one end to resist the rear end surface of the handle seat 4. The front end surface of the internal gear 7 has a groove, and the front end of the compression spring 6a is connected to the toothed spring. 5c contacts, and the rear end is against the bottom of the internal gear 7 grooves. Other structures and working principles are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com