Patents

Literature

1951results about How to "Avoid clutter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

System and method for CT scanning of baggage

InactiveUS7046761B2Overcome deficienciesAvoid clutterMaterial analysis by transmitting radiationNuclear radiation detectionComputed tomographyDual energy

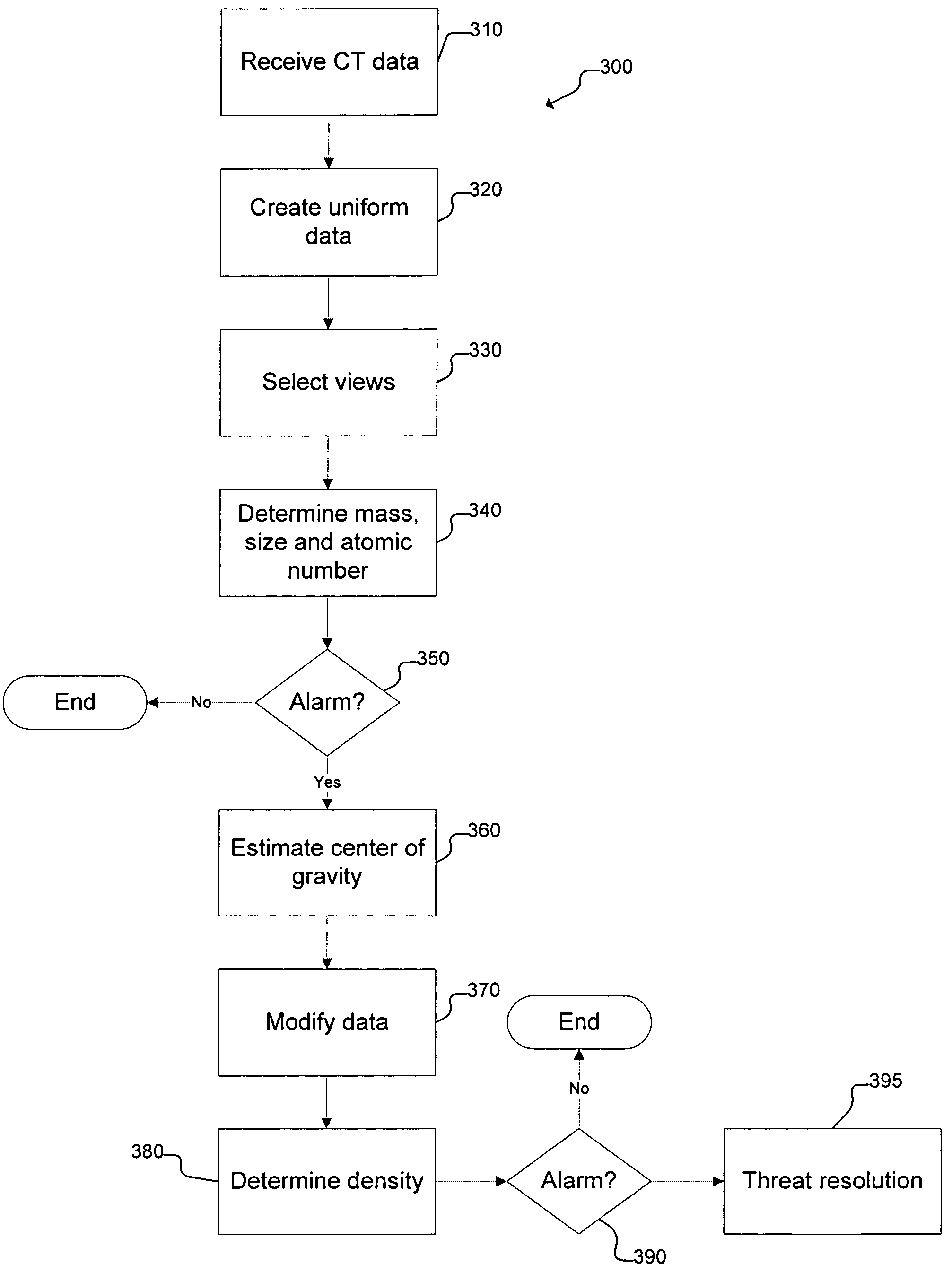

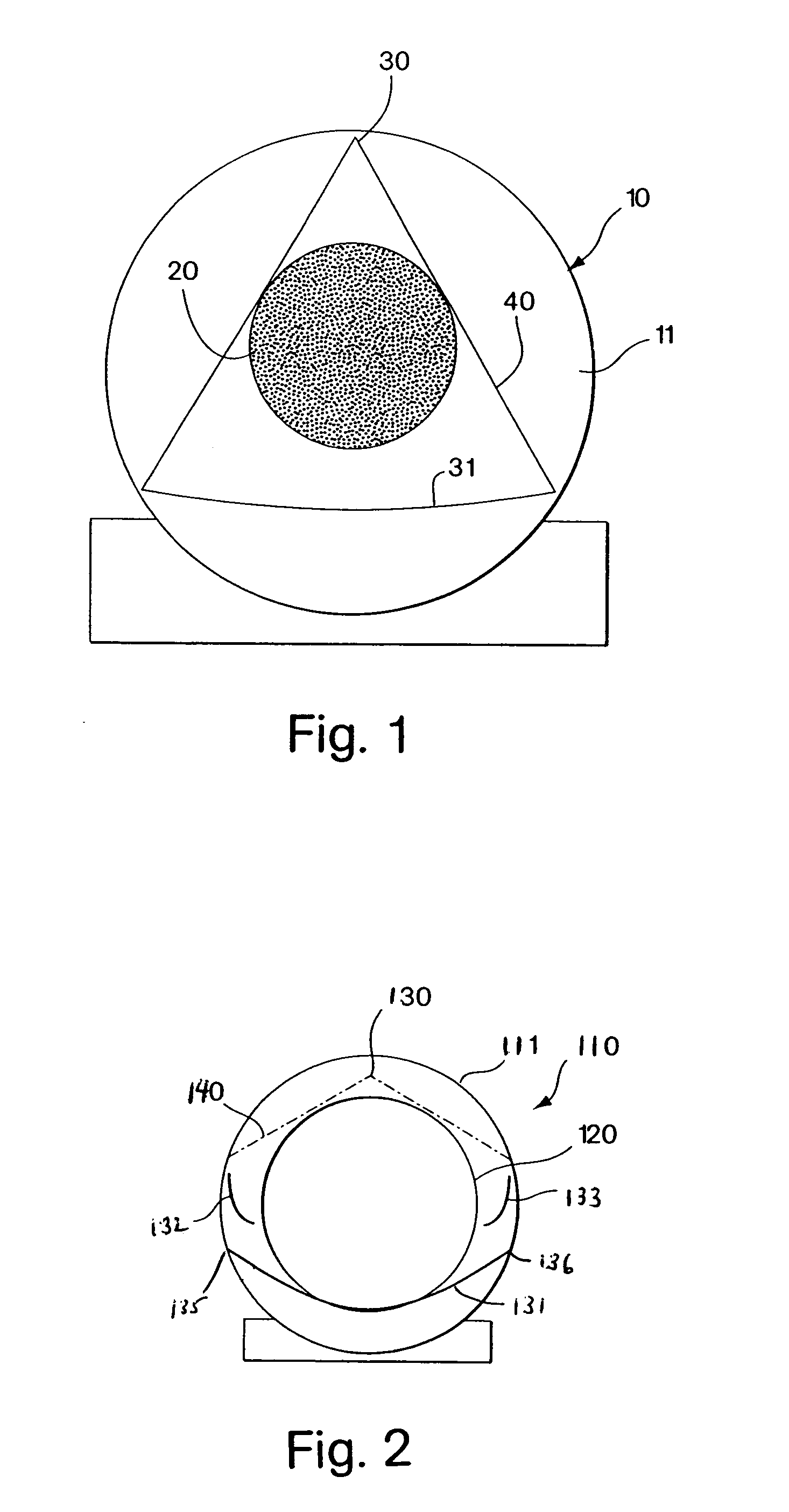

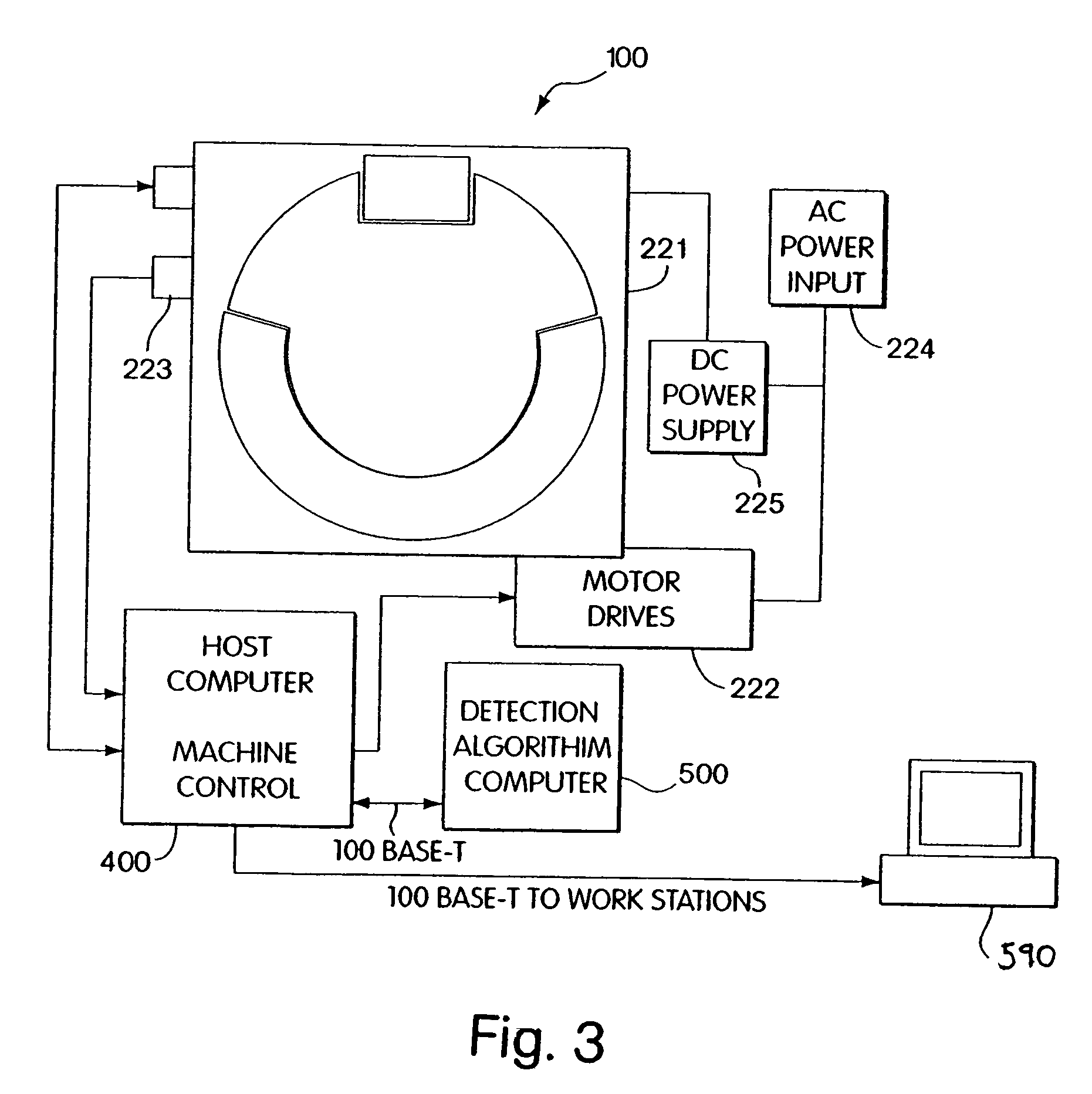

The threat determination process for CT scan of baggage eliminates the need for complete reconstruction the bag. The CT scan data is analyzed during scanning to locate potential threats. The analysis is based upon a lineogram representing objects in the bag. The mass, size, location and atomic number of objects are determined based upon the lineogram data. Any potential threats are further subjected to data modification and reconstruction to enhance the view of the potential threat. Dual energy scanning may also be used to determine density for resolution of potential threats.

Owner:REVEAL IMAGING TECH

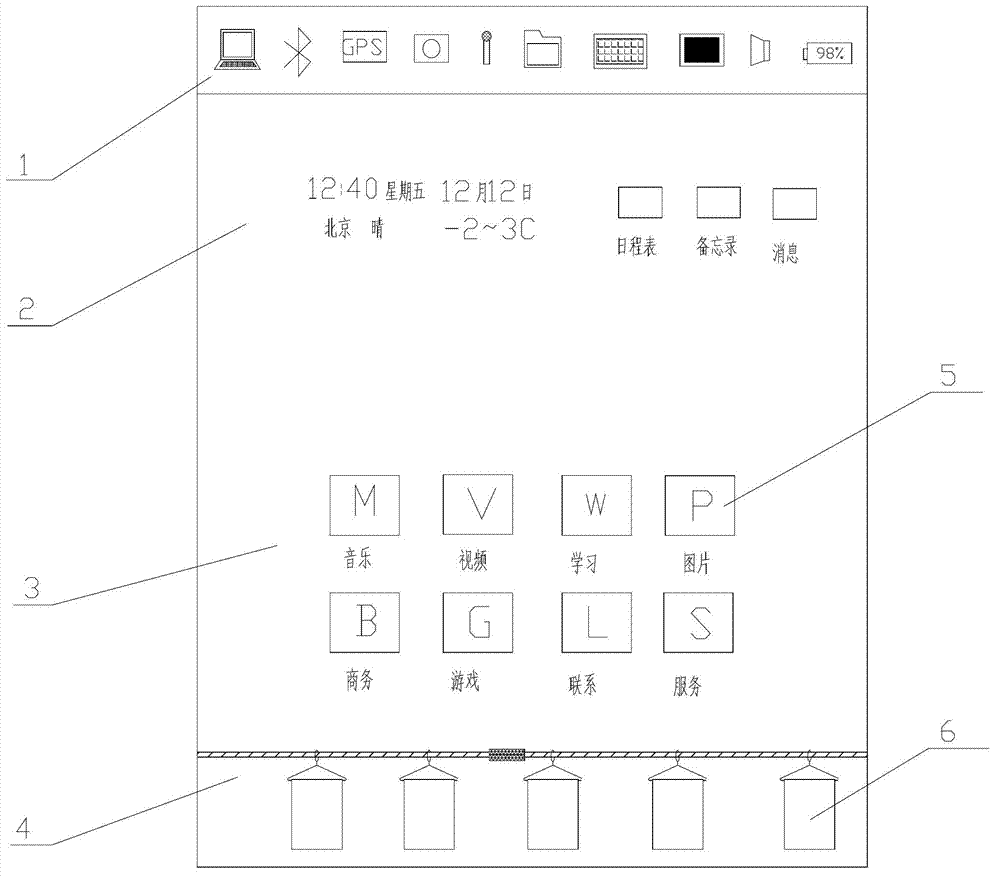

Icon displaying method and device

InactiveCN104063123AGuaranteed to stand outImprove operational efficiencyInput/output processes for data processingComputer graphics (images)Terminal equipment

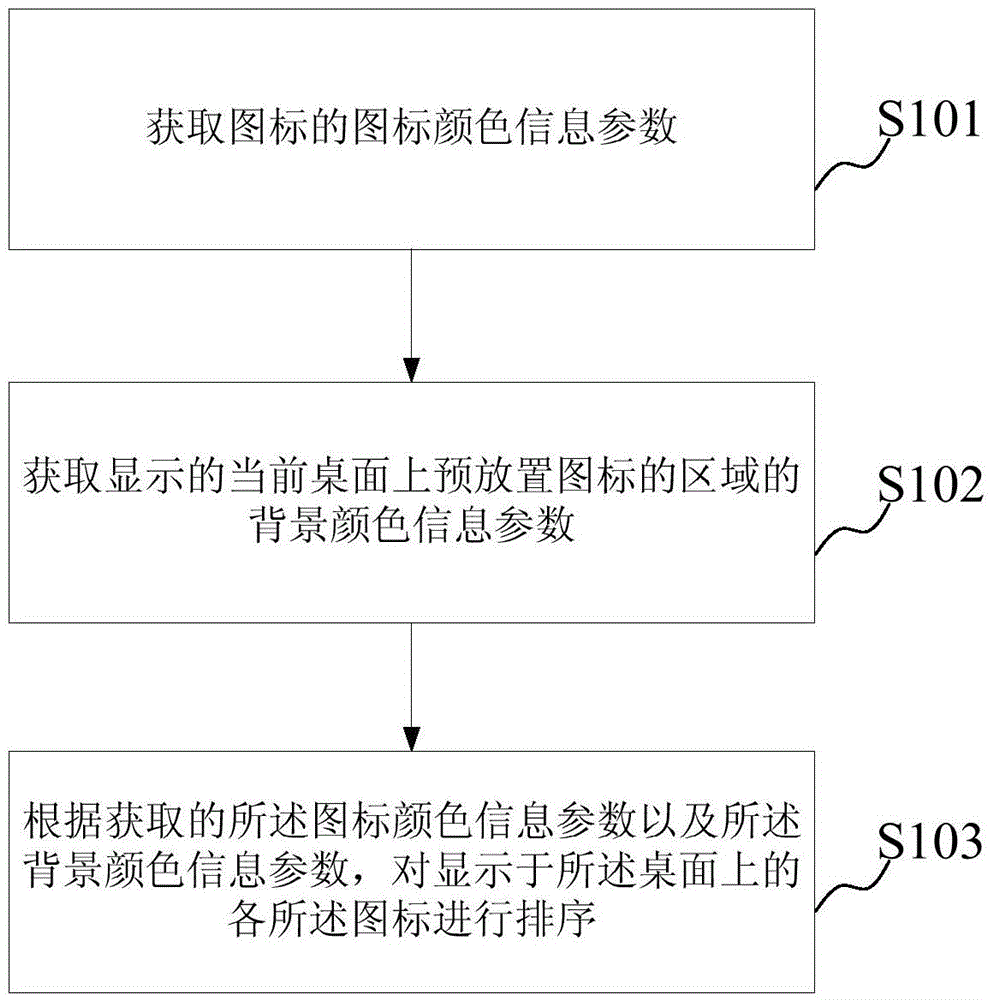

The embodiment of the invention discloses an icon displaying method and device. The method comprises the following steps: acquiring the icon color information parameters of icons and displayed information parameters of background color of areas used for pre-placing the icons on the current desktop; sorting the icons displayed on the desktop according to the acquired icon color information parameters and the background color information parameters. In the embodiment of the invention, the icons are not displayed on the desktop randomly, instead, the icon color information parameters of the icons and the background color information parameters of various areas of the desktop are acquired firstly, and then the icons are sorted (or arrayed) based on the two color information parameters, for example, the icons are enabled to be not placed on areas with the color similar to the icons through the sorting, so that the fact that the icons can be highlighted in a desktop background can be guaranteed, therefore, the speed for searching for icons can be increased, and further the operating efficiency of a terminal device is improved.

Owner:XIAOMI INC

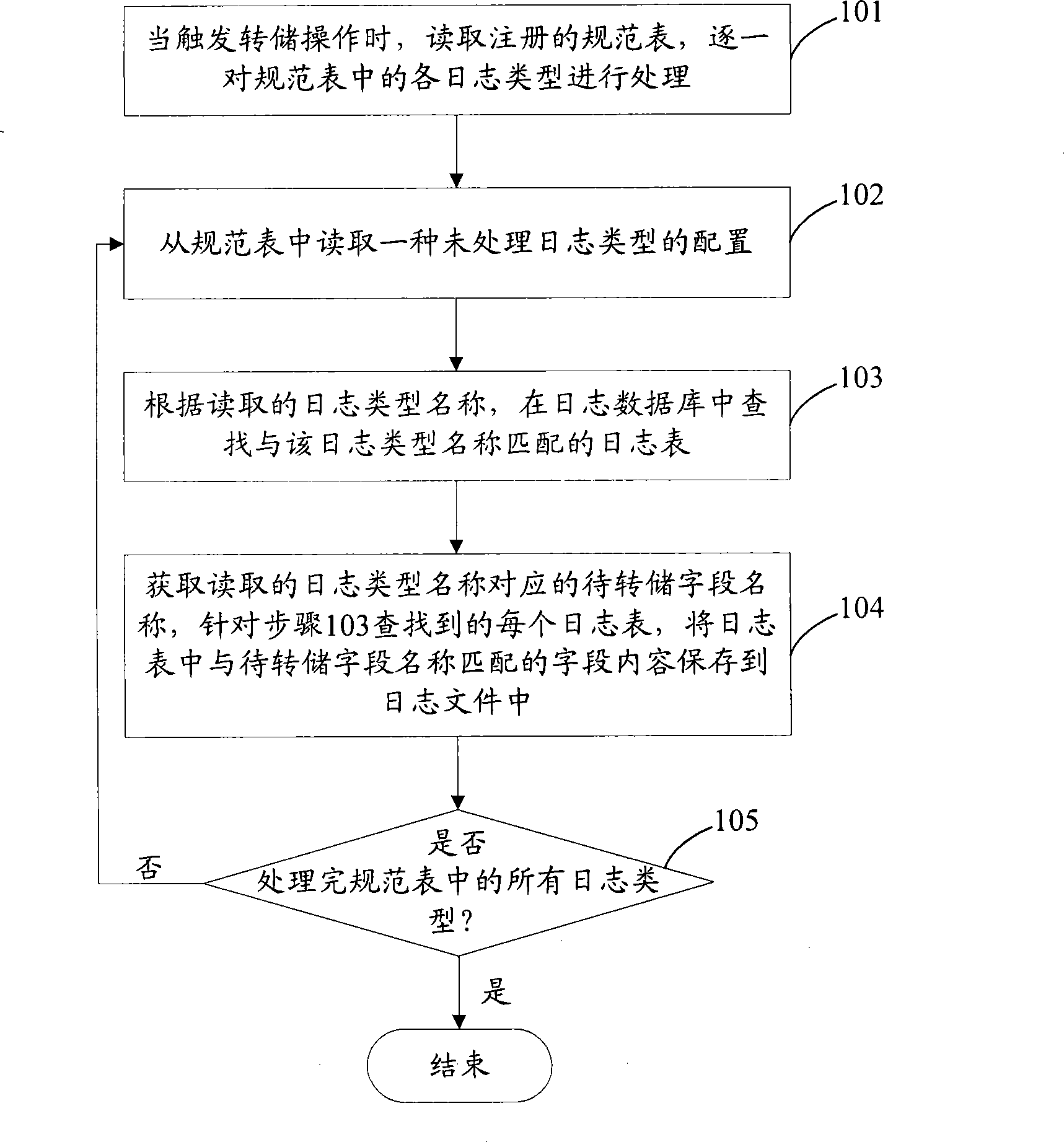

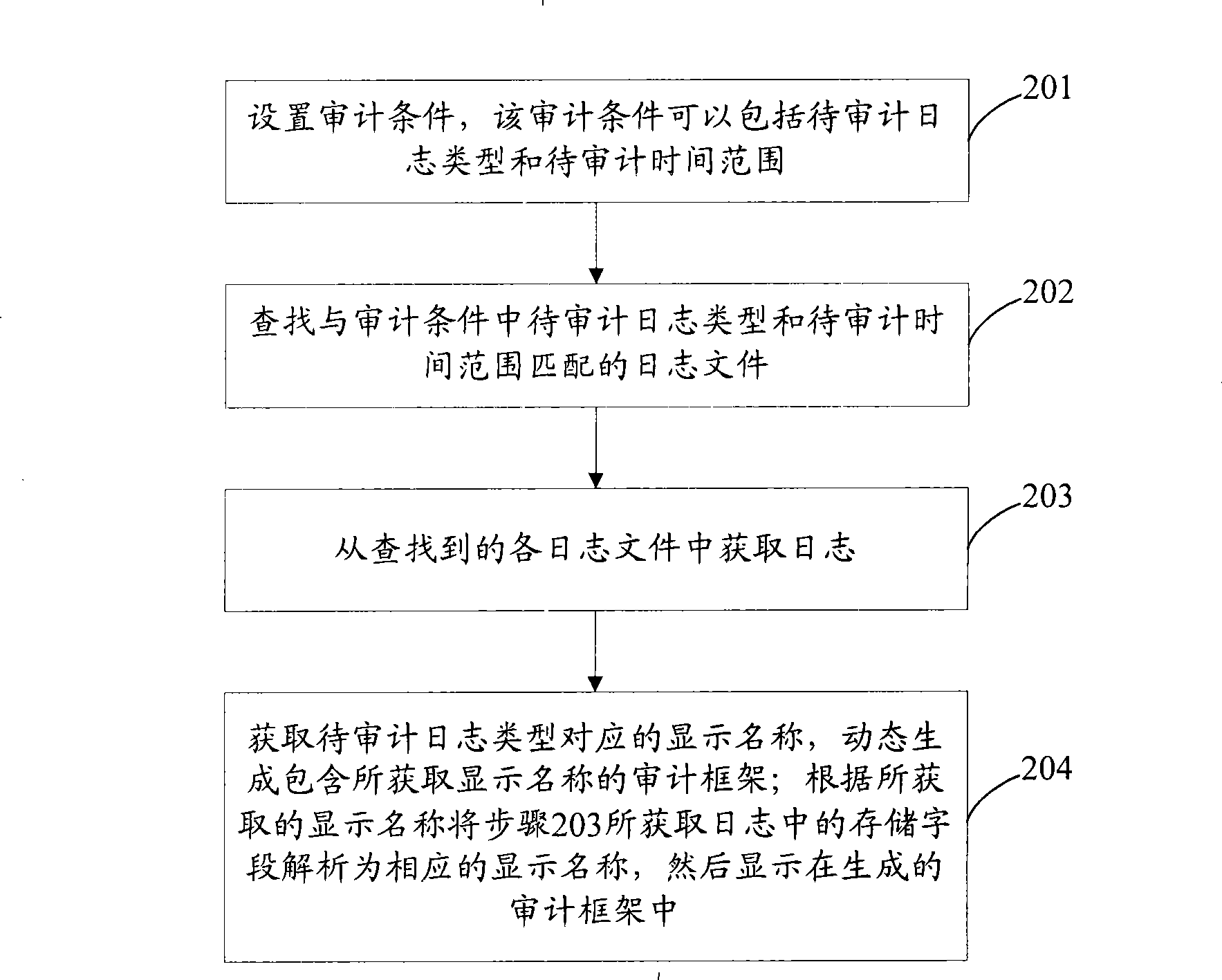

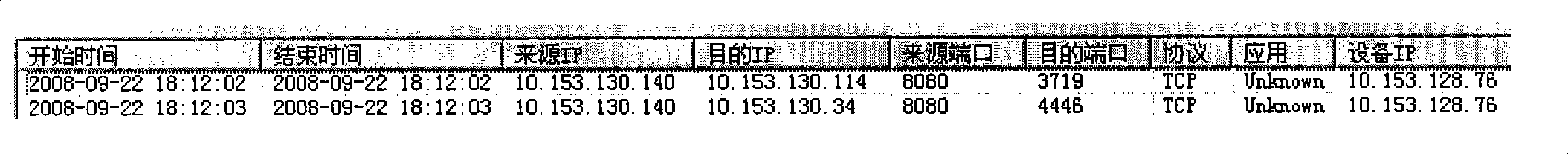

Method and system for log damp and audit

ActiveCN101453378ASolve the generality problemEasy to readData switching networksDisplay NameDatabase

The invention discloses a method and a system for dumping and auditing logs with strong universality and expansibility. The method comprises: establishing a profile, recording names of log types to be dumped, field to be dumped corresponding to each log type and display name of each field to be dumped in the profile; during dumping the logs, according to record of the profile, looking up a log list matched with the log type to be dumped, and storing the field to be dumped in the found log list into a log file; and during auditing the logs, looking up the log file matched with auditing conditions, and parsing and displaying the found log file according to the record of the profile.

Owner:NEW H3C TECH CO LTD

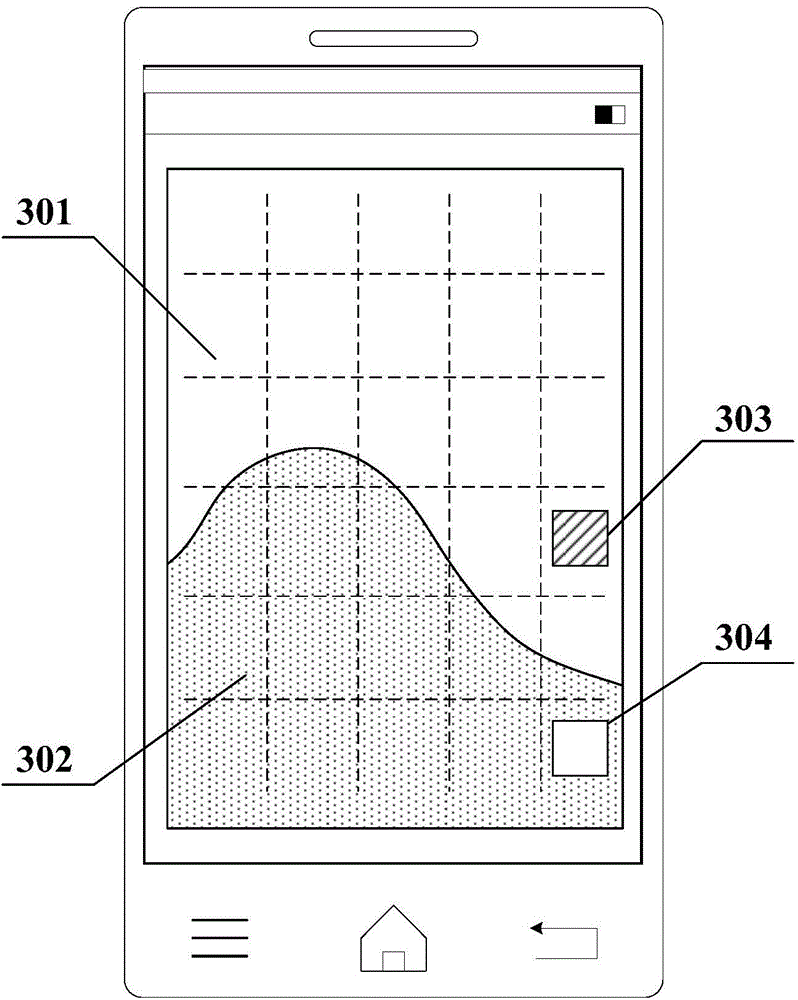

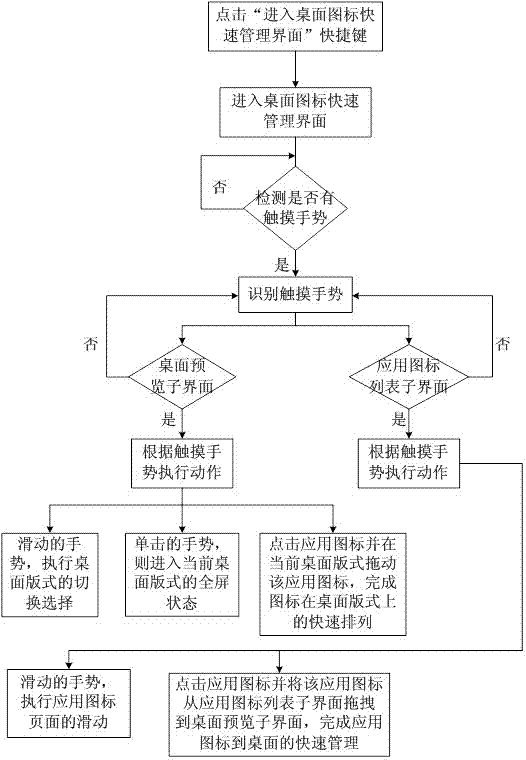

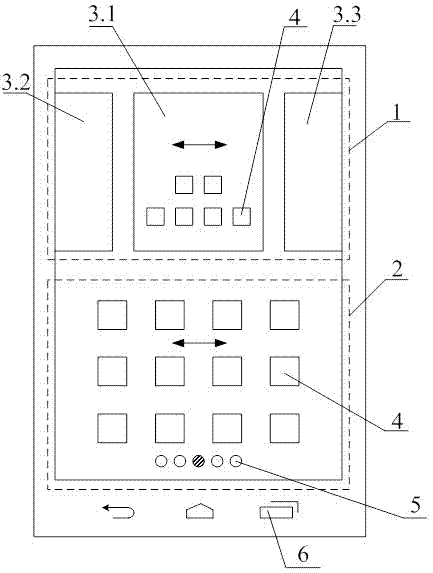

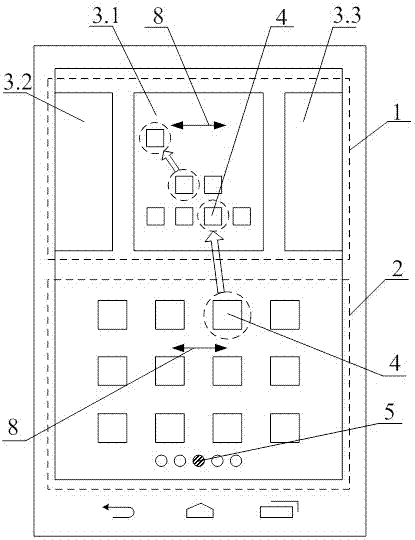

Rapid management method for moving application icon onto desktop

InactiveCN103577044AAvoid clutterEasy to operateInput/output processes for data processingKeyboard shortcut

The invention discloses a rapid management method for moving an application icon onto a desktop. The method comprises the following steps: S1: clicking a shortcut key of ''accessing a desktop icon rapid management interface''; S2: accessing the desktop icon rapid management interface, wherein the interface comprises a desktop preview sub-interface and an application icon list sub-interface; S3: detecting and identifying a user touch gesture; S4: performing corresponding operation according to the user touch gesture. According to the method, the desktop icon rapid management interface can be directly accessed through a shortcut icon or the shortcut key, the interface comprises the desktop preview sub-interface and the application icon list sub-interface, on the same display surface, an application icon on the application icon list sub-interface can be moved onto the desktop preview sub-interface, the operation is simple, the moving is rapid, the positioning is accurate, and the position of the application icon on the desktop format can be intuitively observed during the moving of the application icon, so that an icon disorder phenomenon can be effectively avoided.

Owner:CHENGDU CK SCI & TECH

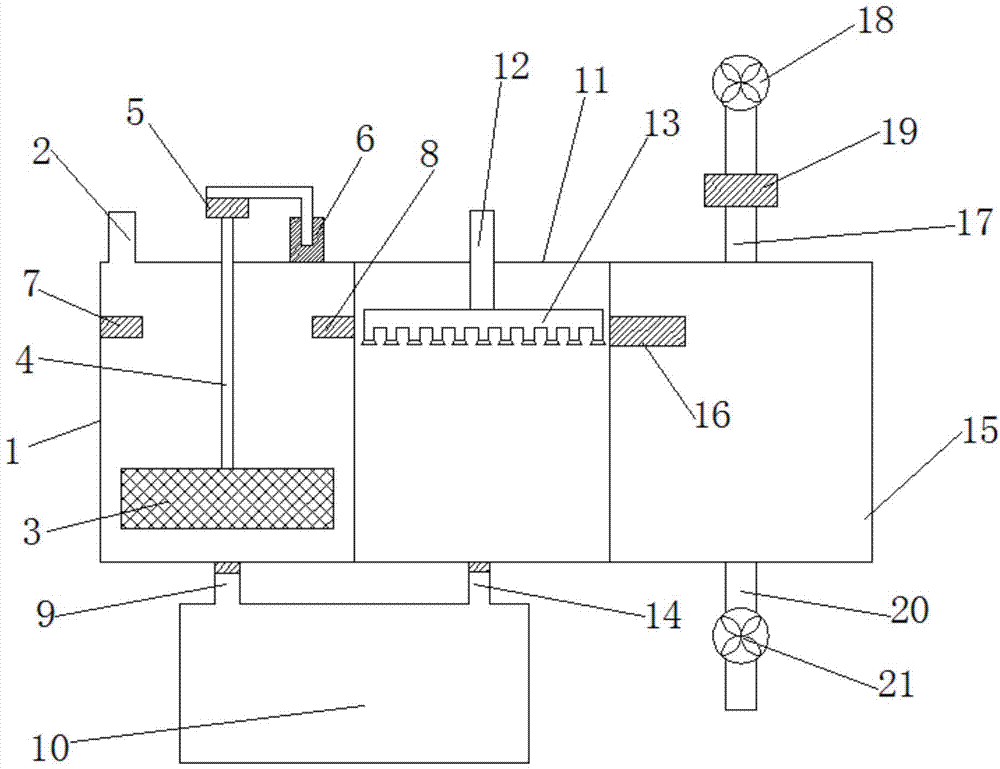

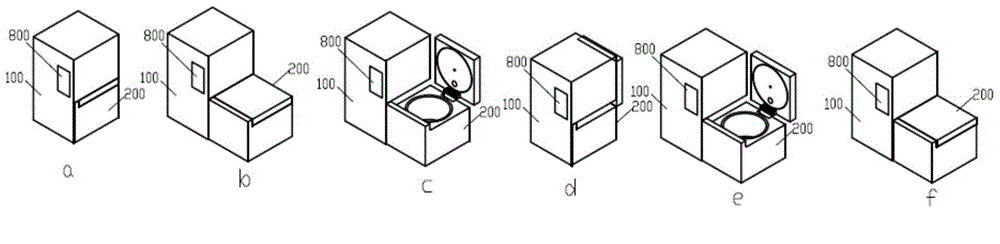

Efficient medical instrument disinfection and cleaning device

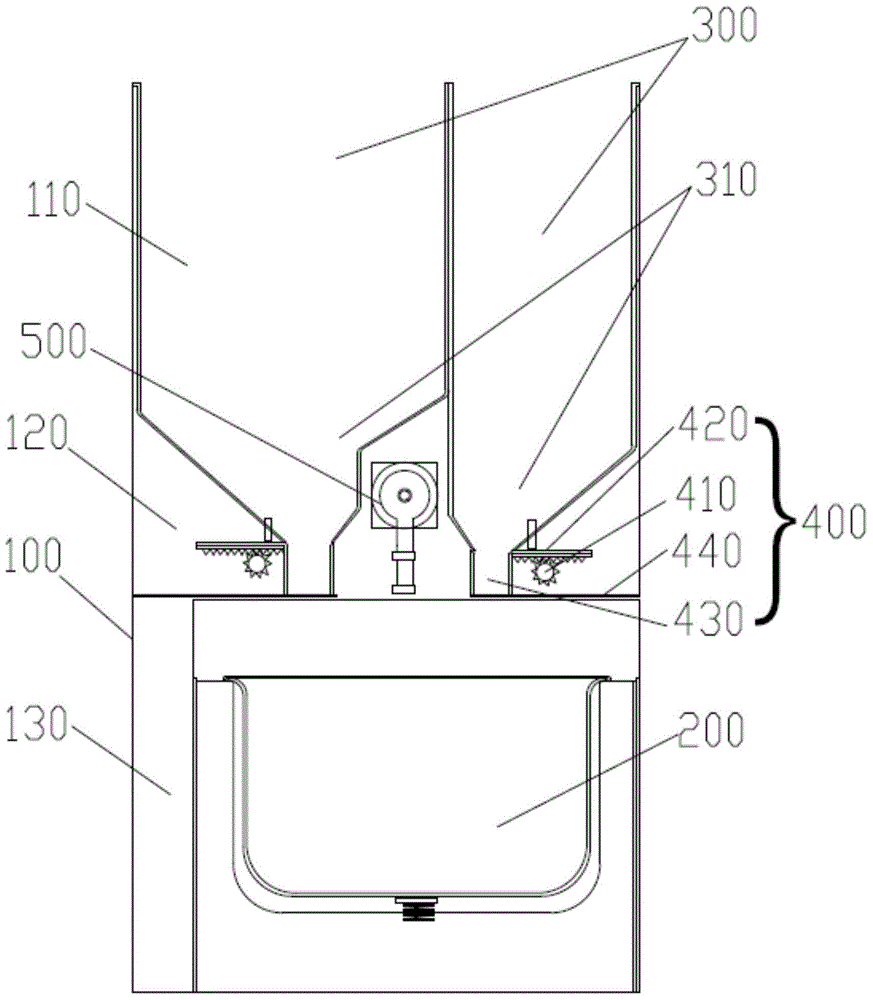

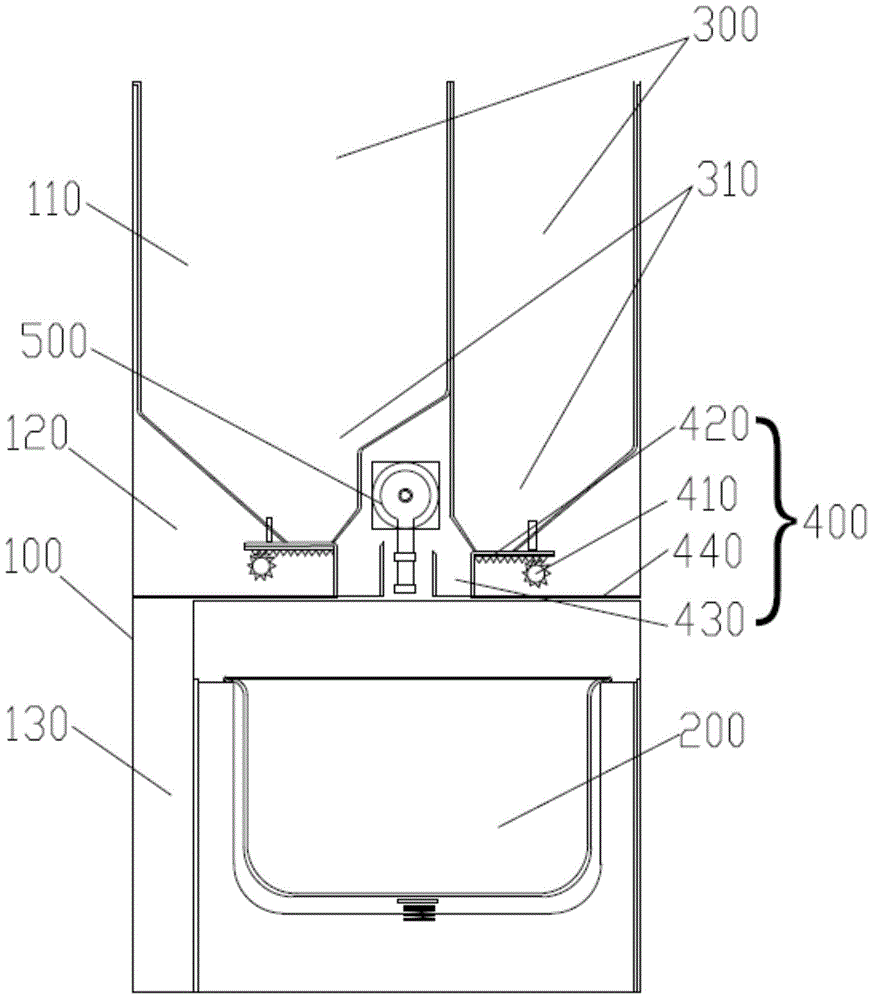

InactiveCN104840984AFully disinfectedImprove work efficiencyLavatory sanitoryHeatDisinfectantEngineering

The invention discloses an efficient medical instrument disinfection and cleaning device, which comprises a disinfection device, a cleaning device and a storage device, wherein a disinfectant inlet is formed in the upper part of the left side of the disinfection device; an instrument placement frame is arranged on the inner lower side of the disinfection device; a vertical rod is connected to the upper side of the instrument placement frame; a rotating motor is connected to the top end of the vertical rod, and is connected with a lifting device through a connecting rod; a heating probe is arranged on the upper inner wall of the left side of the disinfection device; an ultrasonic probe is arranged on the upper inner wall of the right side of the disinfection device. According to the efficient medical instrument disinfection and cleaning device, a medical instrument can be completely disinfected, cleaned, dried and stored; the lifting device can be rotated to spin-dry and drain the medical instrument after disinfection, so that the working efficiency of the device is greatly improved; waste liquor produced during working can be collected by a waste liquor tank, so that secondary pollution is reduced; in addition, a good hot air drying effect is achieved, so that the working efficiency of the device is further improved.

Owner:苏州福利恒电子科技有限公司

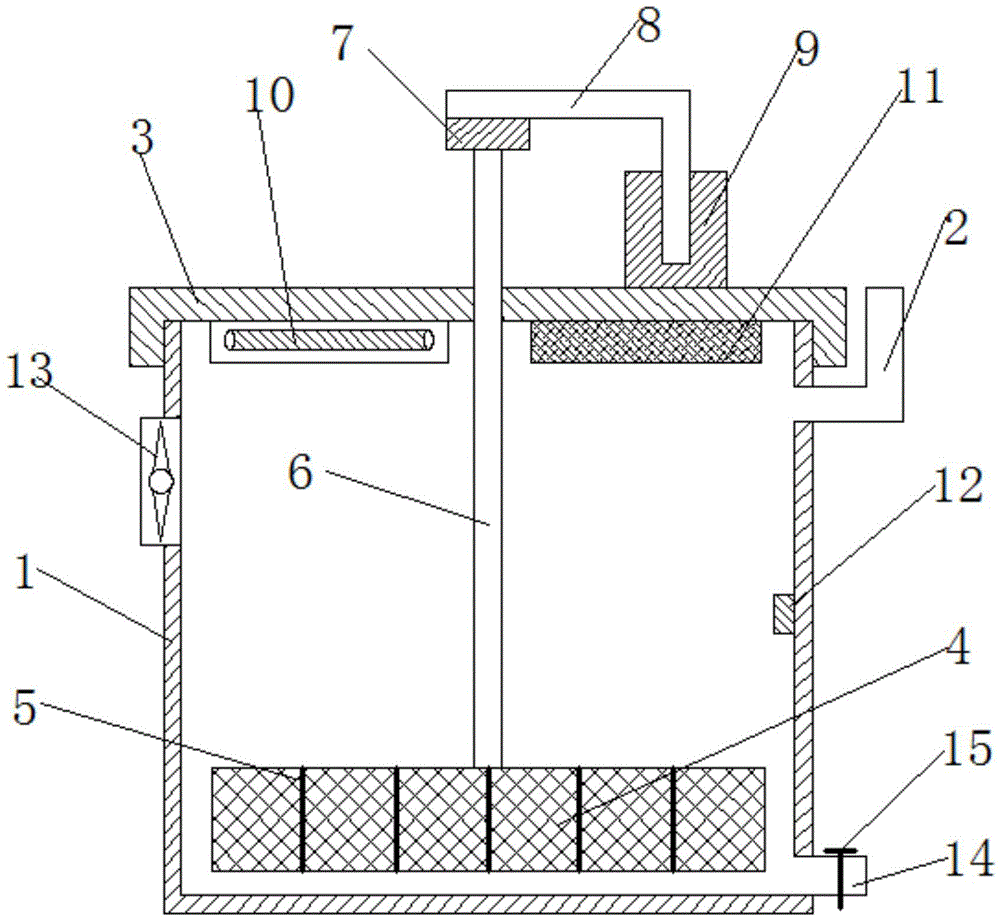

Medical apparatus cleaning and disinfecting device

The invention discloses a medical apparatus cleaning and disinfecting device, which comprises a main cleaning machine body, an upper cover and an apparatus placement rack, wherein a liquid inlet pipe is arranged above the right side of the main cleaning machine body; the upper cover board is arranged on the upper side of the main cleaning machine body; the apparatus placement rack is arranged on the lower side inside the main cleaning machine body; a partition plate is arranged on the apparatus placement rack; a rotating shaft is vertically arranged at the center of the apparatus placement rack; and the top end of the rotating shaft penetrates through the upper cover board and is connected with a rotary motor. According to the medical apparatus cleaning and disinfecting device disclosed by the invention, a medical apparatus can be fully disinfected, sterilized, cleaned and dried; draining of the apparatus is realized by adjusting the height of the apparatus placement rack; the apparatus can be spun by the rotary device in a rotating manner, and can be dried by a heating device at a high temperature; air convection in the device can be increased by a draught fan; and the drying effect and efficiency are improved.

Owner:苏州福利恒电子科技有限公司

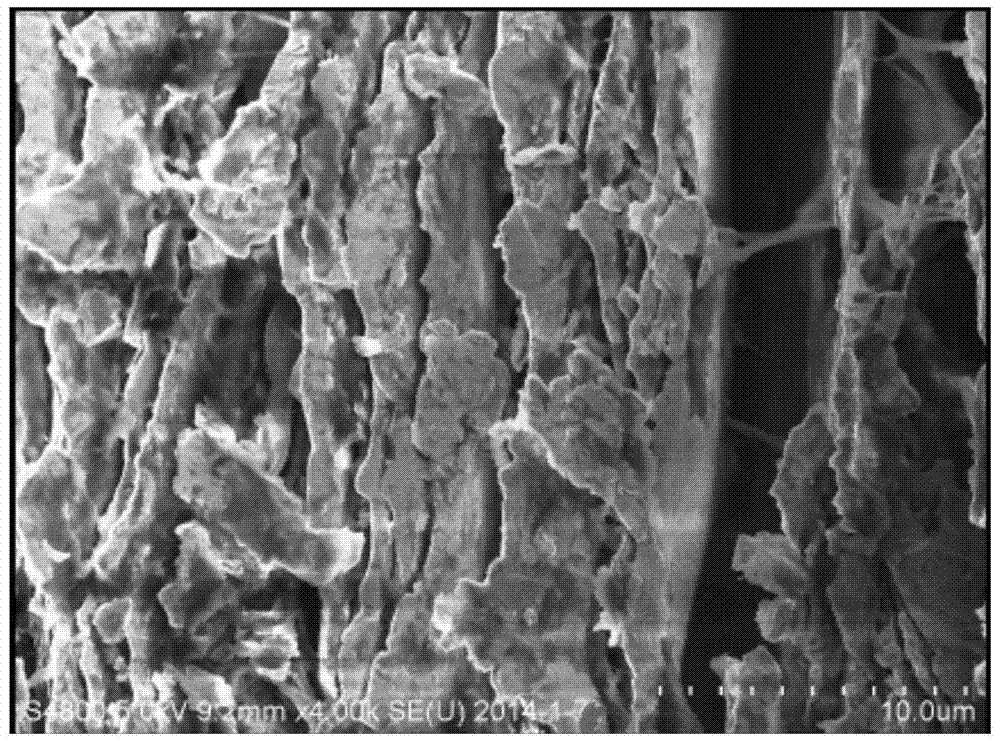

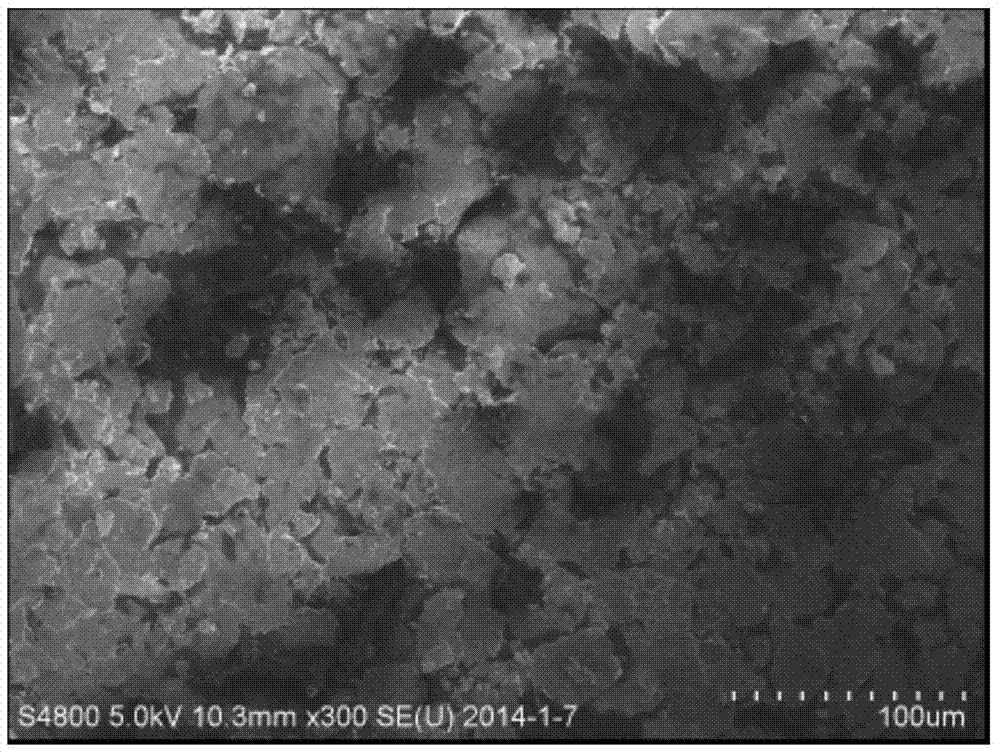

Plant straw novel lightweight wall body material and preparation method thereof

The invention discloses a plant straw novel lightweight wall body material. The plant straw novel lightweight wall body material is prepared by the following raw materials in parts by weight: 40-50 parts of fly ash, 20-30 parts of modified plant straw powder, 20-30 parts of sulphate aluminium cement, 10-20 parts of expanded perlite, 10-15 parts of silica powder, 10-15 parts of modified clay, 10-20 parts of glass fiber, 2-4 parts of foaming agent and 3-6 parts of water reducing agent. The plant straw novel lightweight wall body material disclosed by the invention is manufactured by utilizing an industrial waste material, namely the fly ash which is produced by abundant local coal mine resources and an agricultural waste, namely plant straw, so that the phenomena of disordered arrangement and disordered placement of the fly ash, excessive burning of the plant straw and the like can be effectively prevented, a natural environment can be protected, the production cost can be simultaneously greatly reduced, the cyclic utilization of the solid waste is realized and the energy-saving requirements of buildings can be also met. The produced wall body material has the advantages of higher compressive strength, smaller contractibility, light weight, heat preservation, heat insulation, sound insulation, fire resistance and the like.

Owner:陶四新

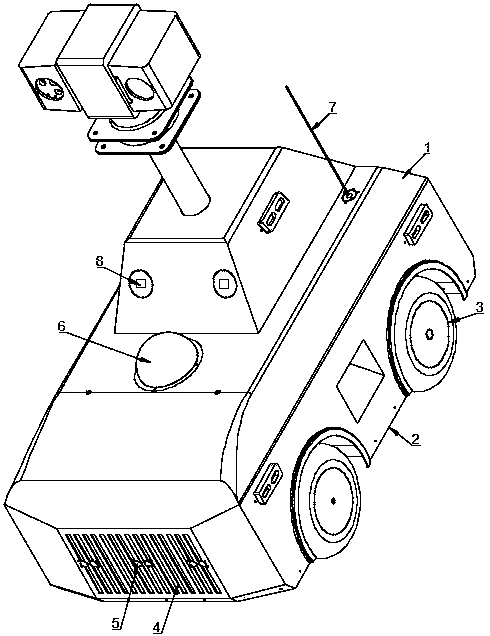

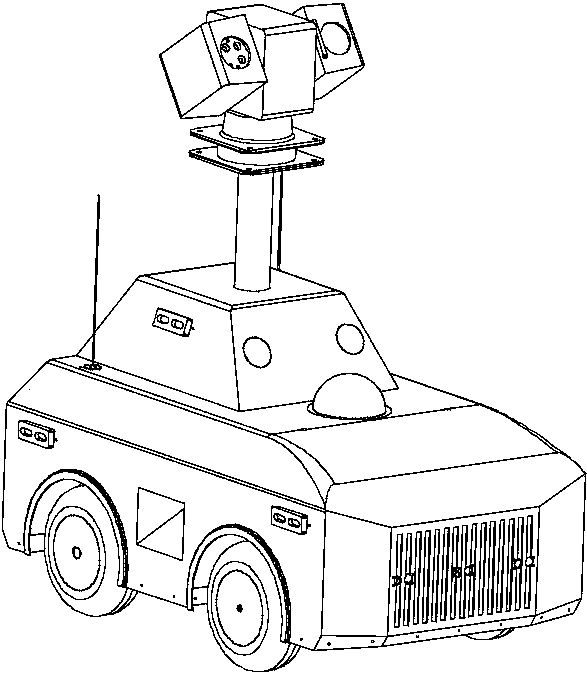

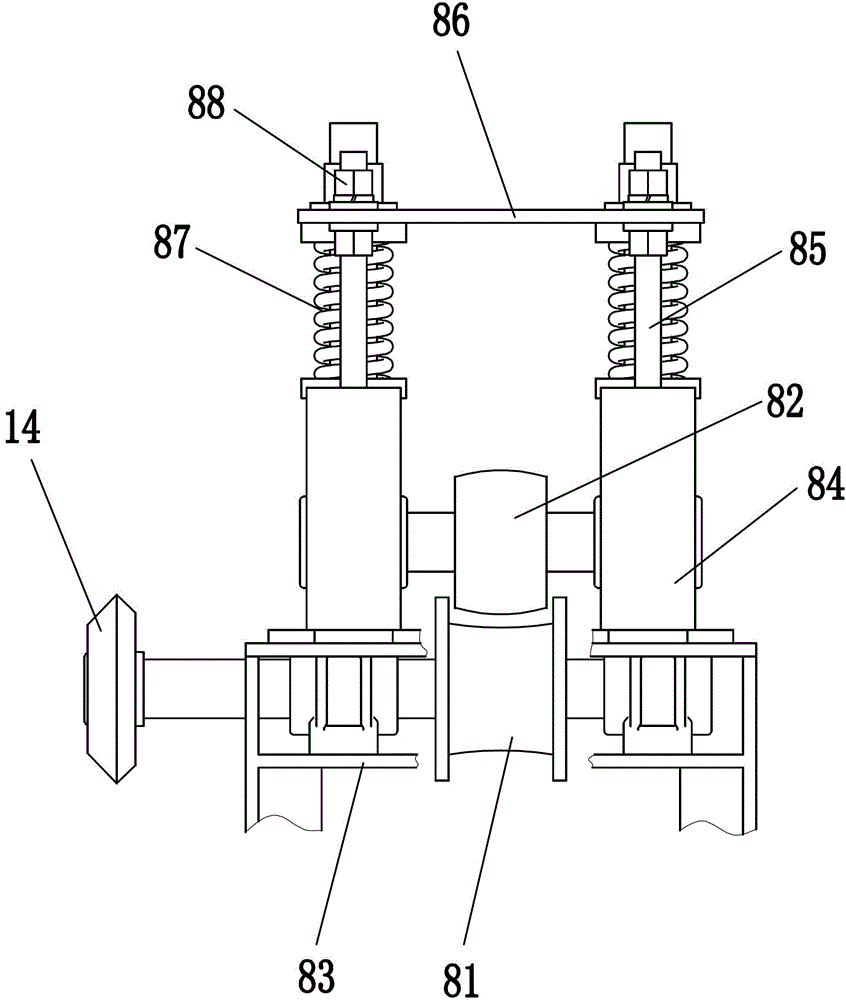

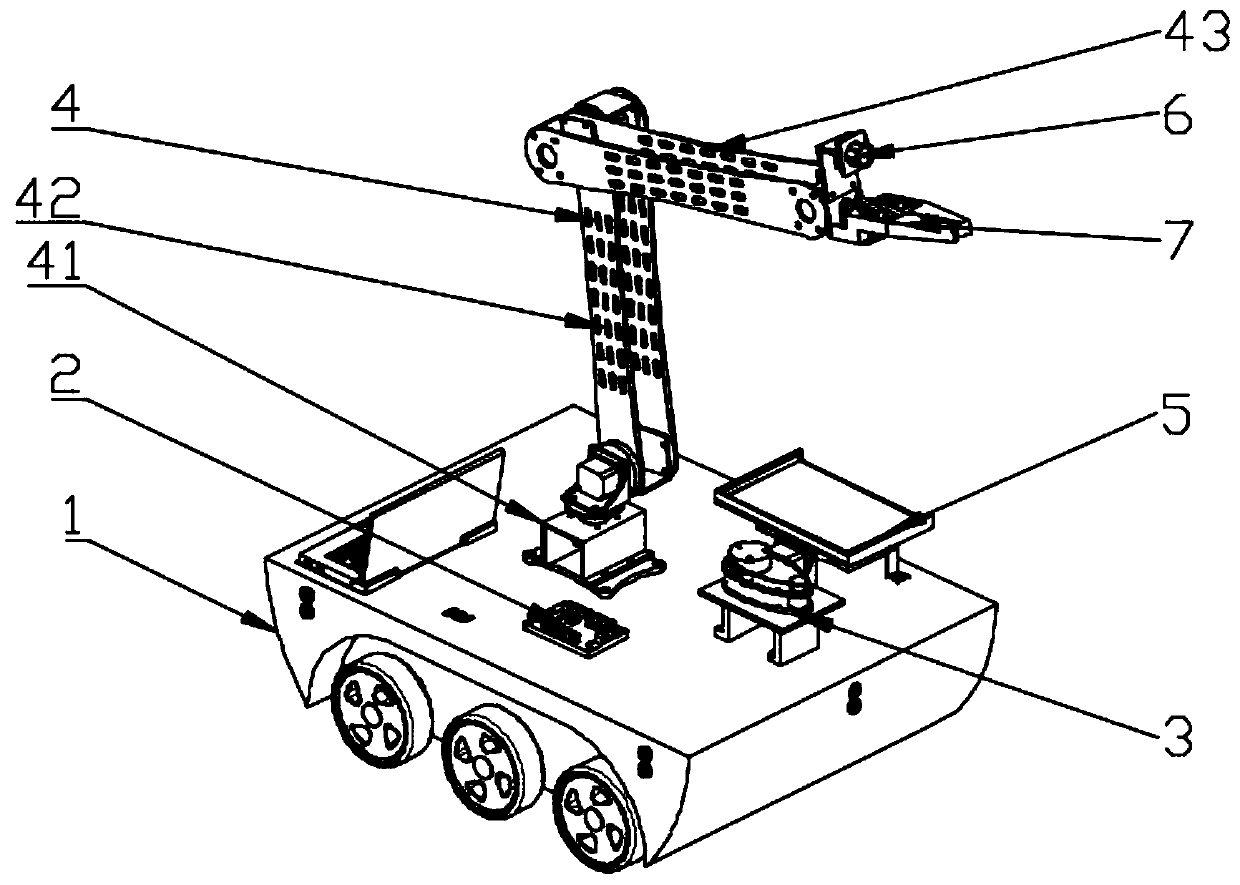

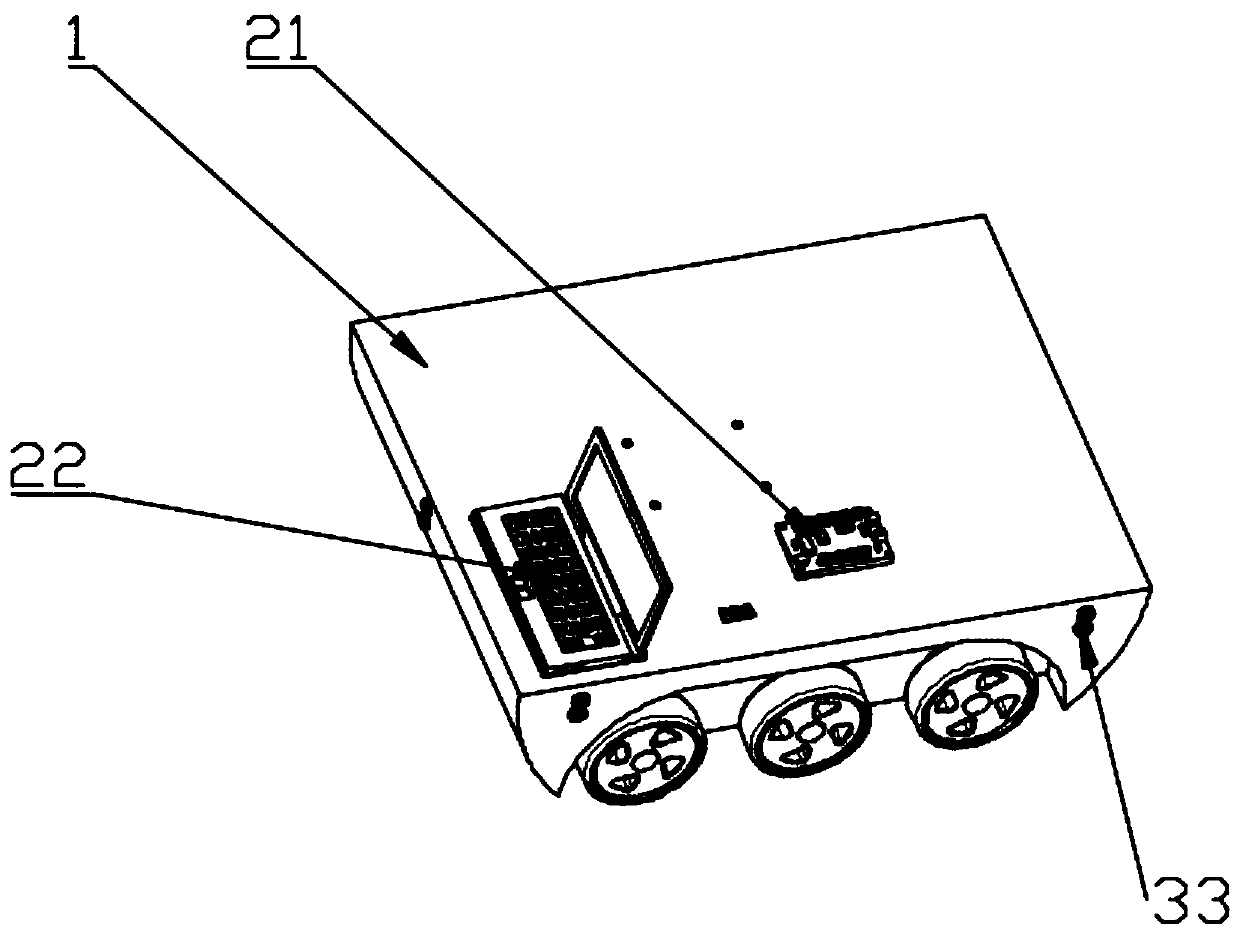

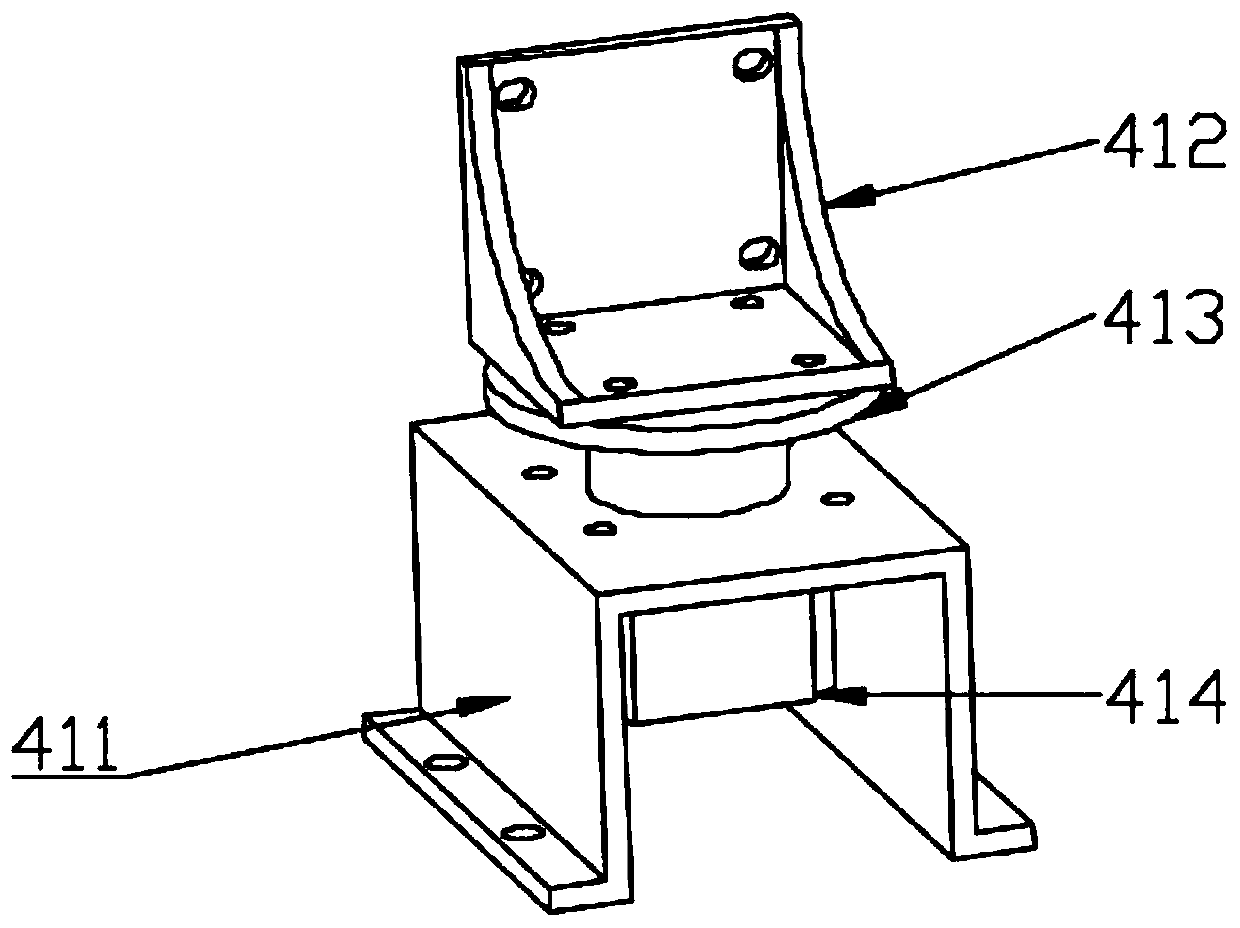

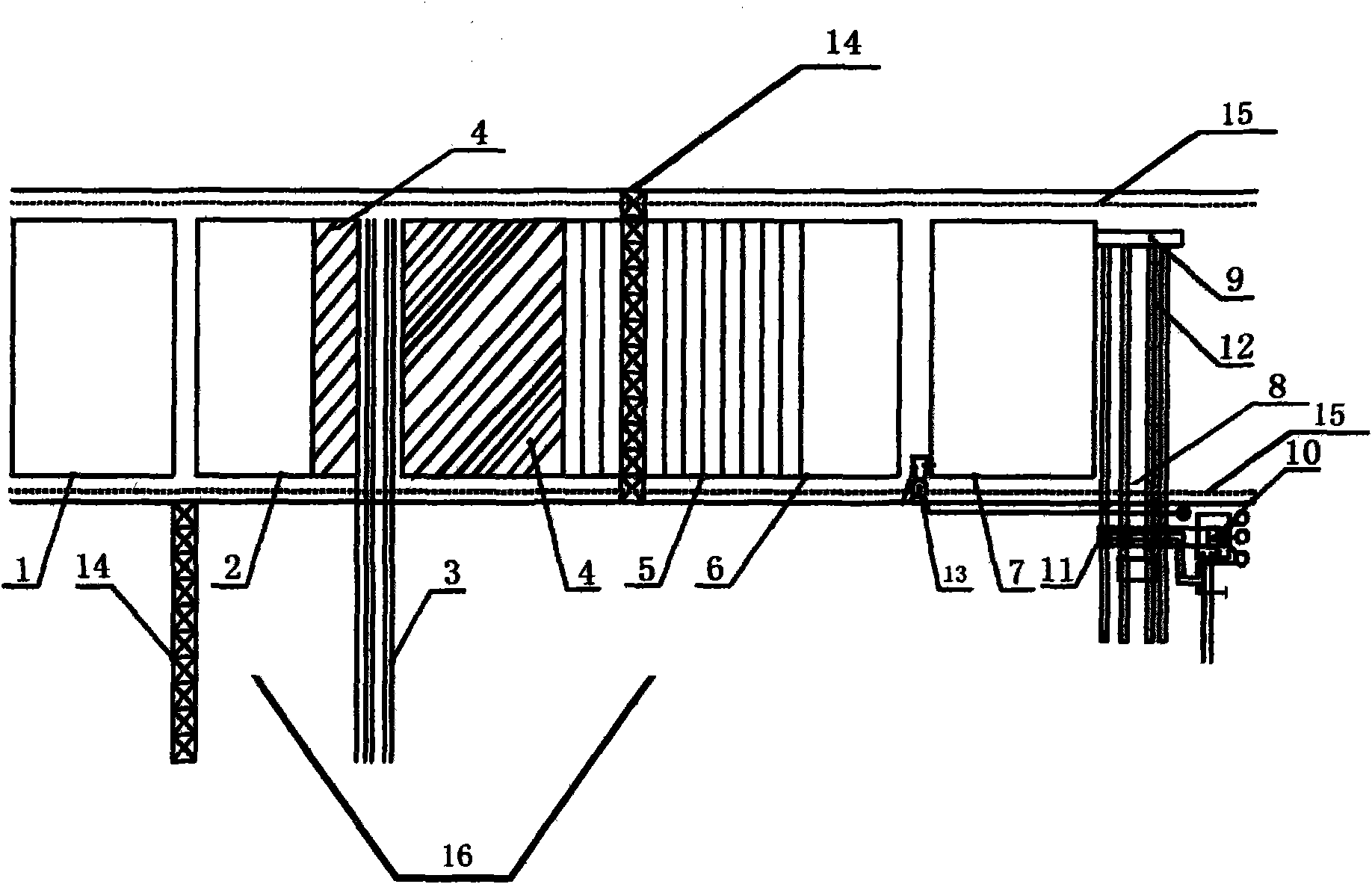

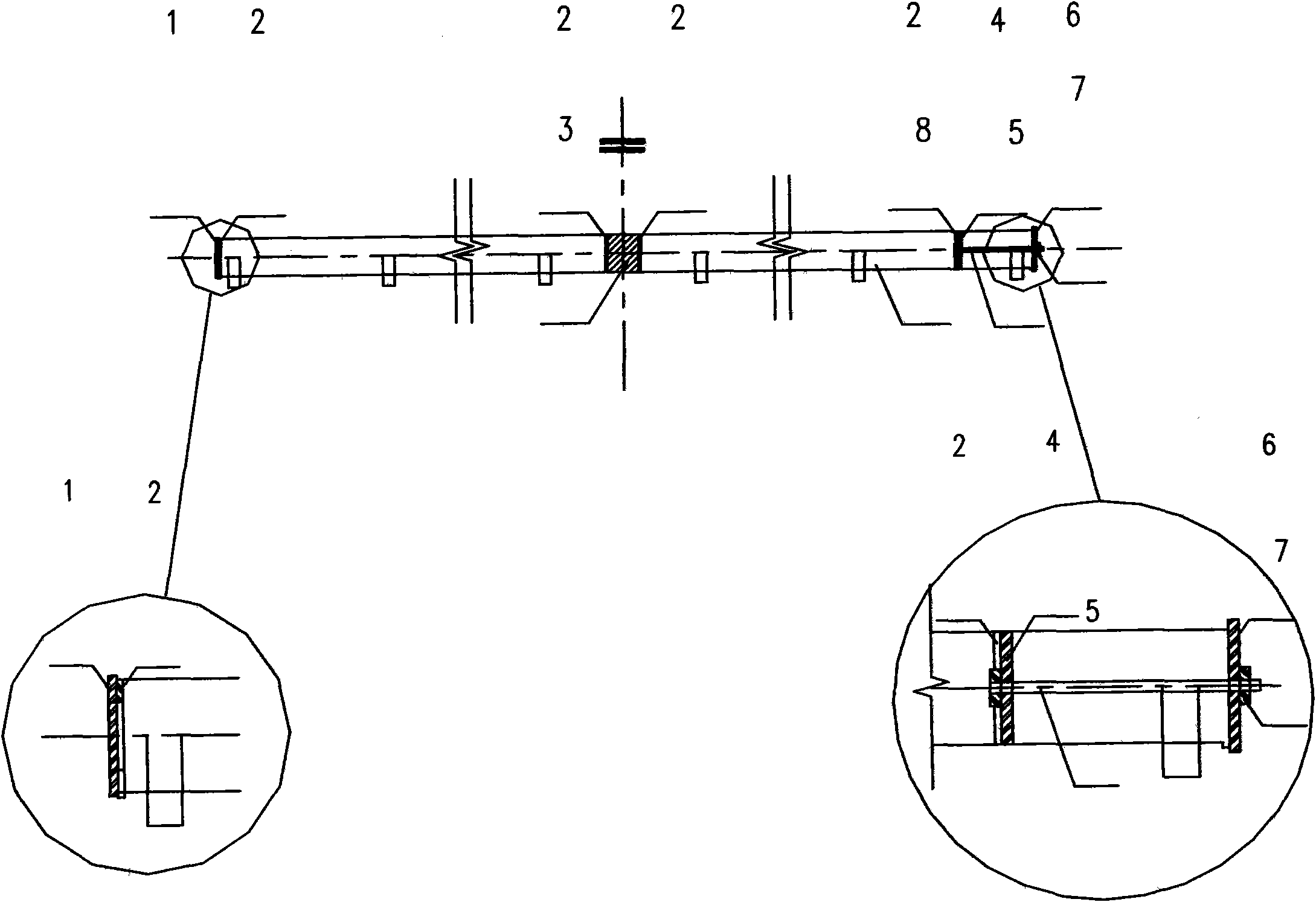

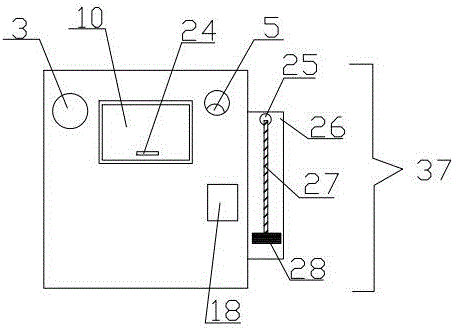

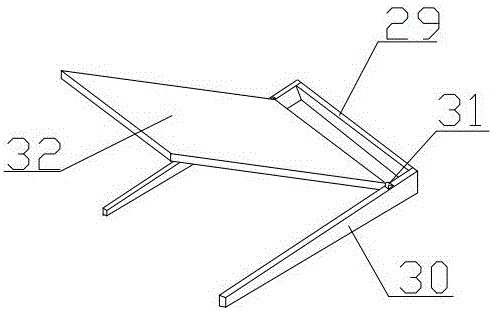

Security robot

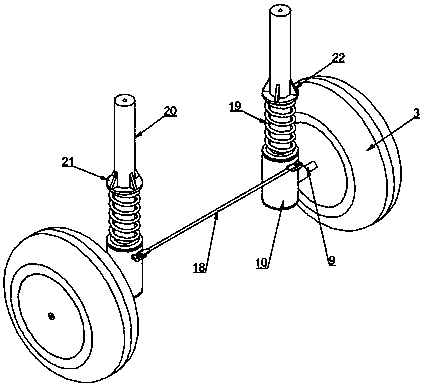

ActiveCN108500991AAvoid clutterGuaranteed stabilityClosed circuit television systemsManipulatorEngineeringMulti degree of freedom

The invention relates to a security robot, and belongs to the technical field of security robots. The security robot comprises a shell, a base plate, wheels, a front-wheel damping wrist set structure,a key grouping and locking structure, a multi-degree-of-freedom telescopic structure, a heat-dissipation system and a controller. According to the security robot, automatic monitoring can be achieved, and monitoring information can be transmitted in real time; all switches of a key box are effectively grouped, so that management is facilitated, and disorder of keys is effectively avoided; by adoption of the structural design of the front dual-damping wrist set structure, effective damping can be achieved, and steering is easy; through a multi-degree-of-freedom lifting adjustment structure, multi-degree-of-freedom adjustment of a camera of the security robot can be achieved, different work requirements are met, and patrolling information is effectively synchronized; and through the structural design of the circulating heat-dissipation system, the stability of the temperature and humidity of the internal environment of the security robot can be ensured, and the heat-dissipation efficiency is improved.

Owner:中山火炬高新企业孵化器有限公司

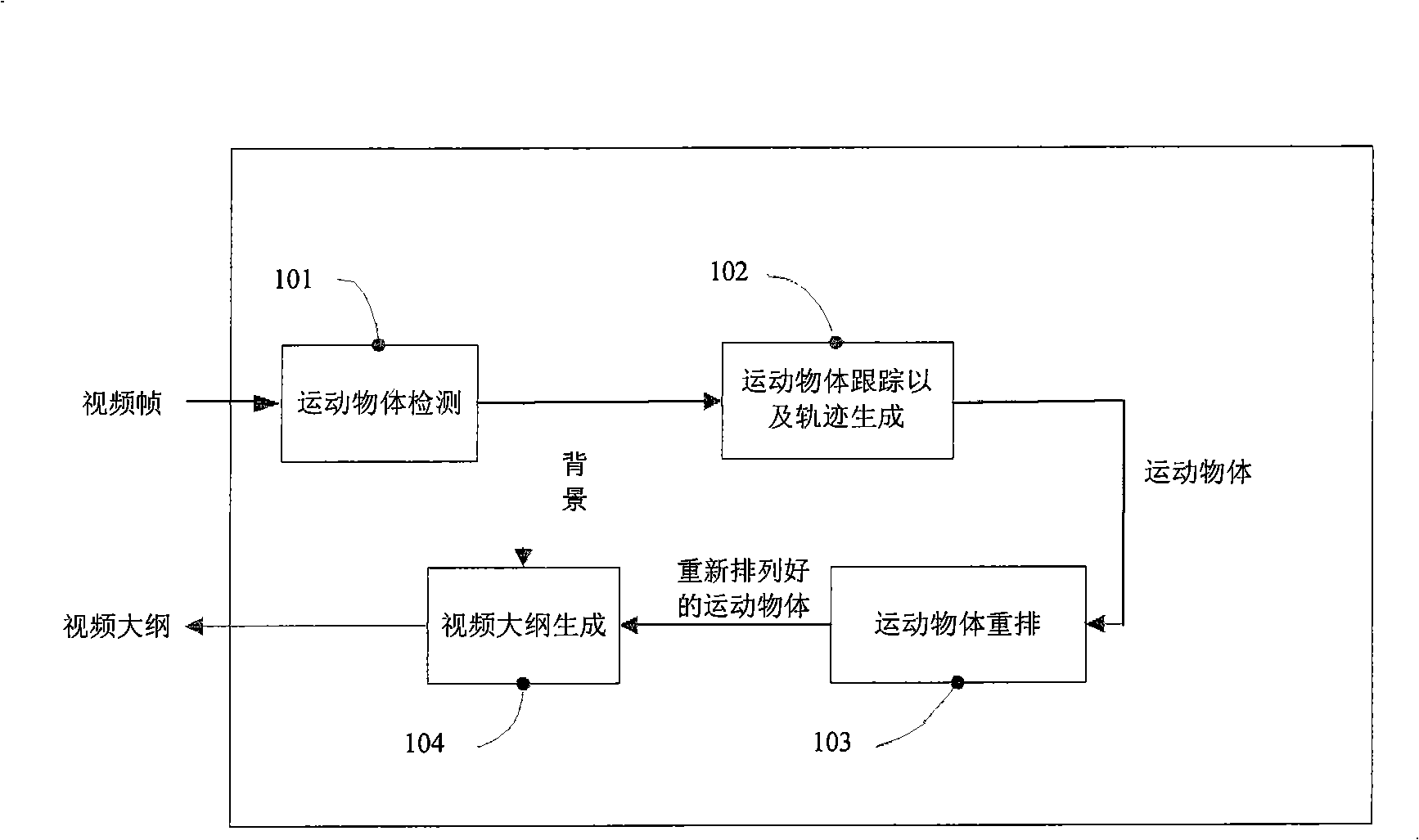

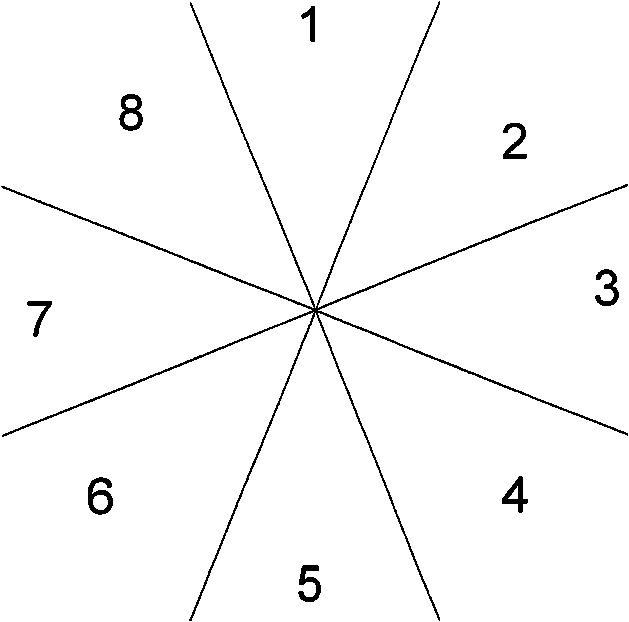

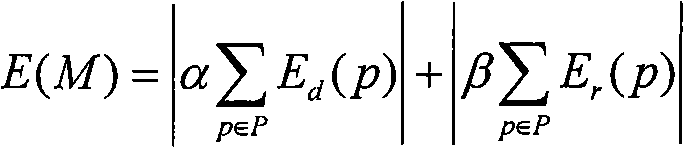

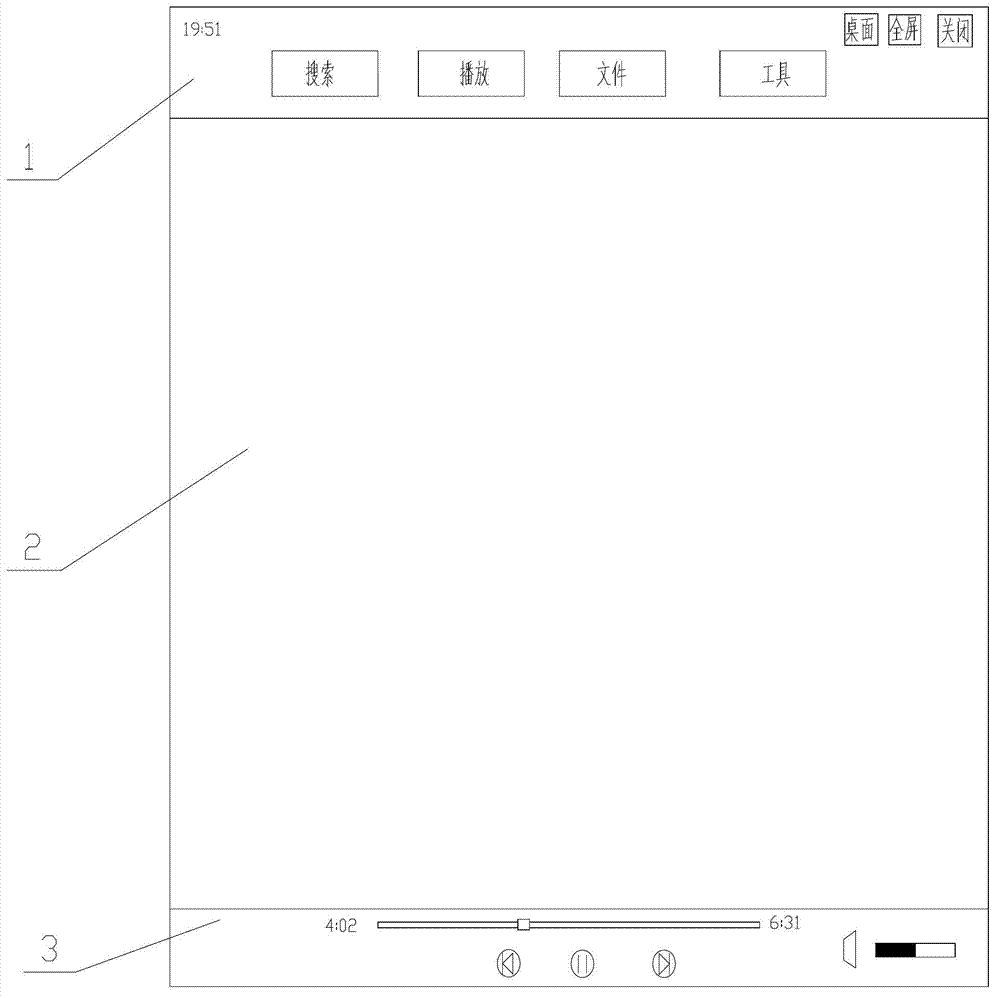

A method and system for generating video outline

ActiveCN101262568AAvoid clutterAvoid collisionTelevision system detailsColor television detailsObject detection

The invention provides a method for producing a video outline and the method comprises the steps as follows: carrying out moving object detection to a video frame to obtain a moving object and a background; tracking the moving object and producing the track of the moving object; calculating the video outline on the basis of the knowledge of cognitive psychology and re-arranging the track of the moving object accordingly; combining the background and the re-arranged track of the moving object to produce the video outline. The method of the invention avoids the disorder of the moving object in the output video outline so as to be suitable for observation for human eyes and provide convenience for customers to observe effective information in an original video as well as further avoids the collision of the moving object when being re-arranged and maintains the original timing sequence consistency of the object as far as possible.

Owner:INST OF COMPUTING TECH CHINESE ACAD OF SCI

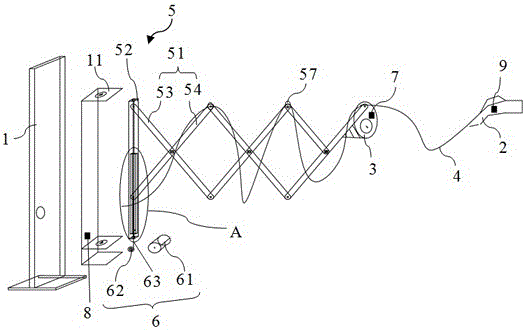

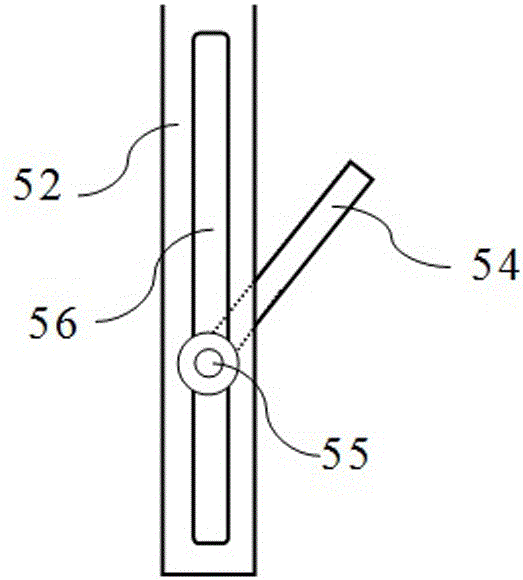

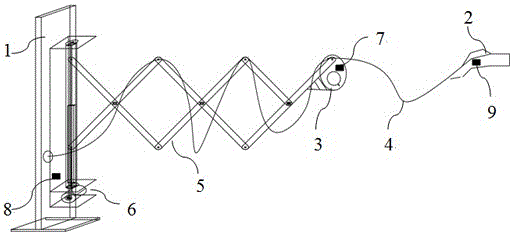

Charging pile with take up and pay off functions and control method of charging pile

PendingCN106740184AFunctionalNeat and orderly displayCharging stationsElectric vehicle charging technologyElectrical and Electronics engineering

The invention discloses a charging pile with take up and pay off functions and a control method of the charging pile. The charging pile with the take up and pay off functions comprises a charging pile body, a charging gun, a charging gun socket, a charging wire and an extension and retraction device, wherein one end of the charging wire is connected with the charging pile body, and the other end of the charging wire is connected with the charging gun; one end of the extension and retraction device is arranged on the charging pile body; the charging gun socket is arranged at the other end of the extension and retraction device; the charging wire is wound on the extension and retraction device; the charging gun is detachably plugged into the charging gun socket. The charging pile with the take up and pay off functions can take up and pay off the charging wire; when charging is needed, the charging gun is unplugged from the charging gun socket, and the extension and retraction device extends out to pay off the charging wire; after the charging is completed, the charging gun is plugged into the charging gun socket, and the extension and retraction device retracts to take up the charging wire.

Owner:QINGDAO TELD NEW ENERGY TECH CO LTD

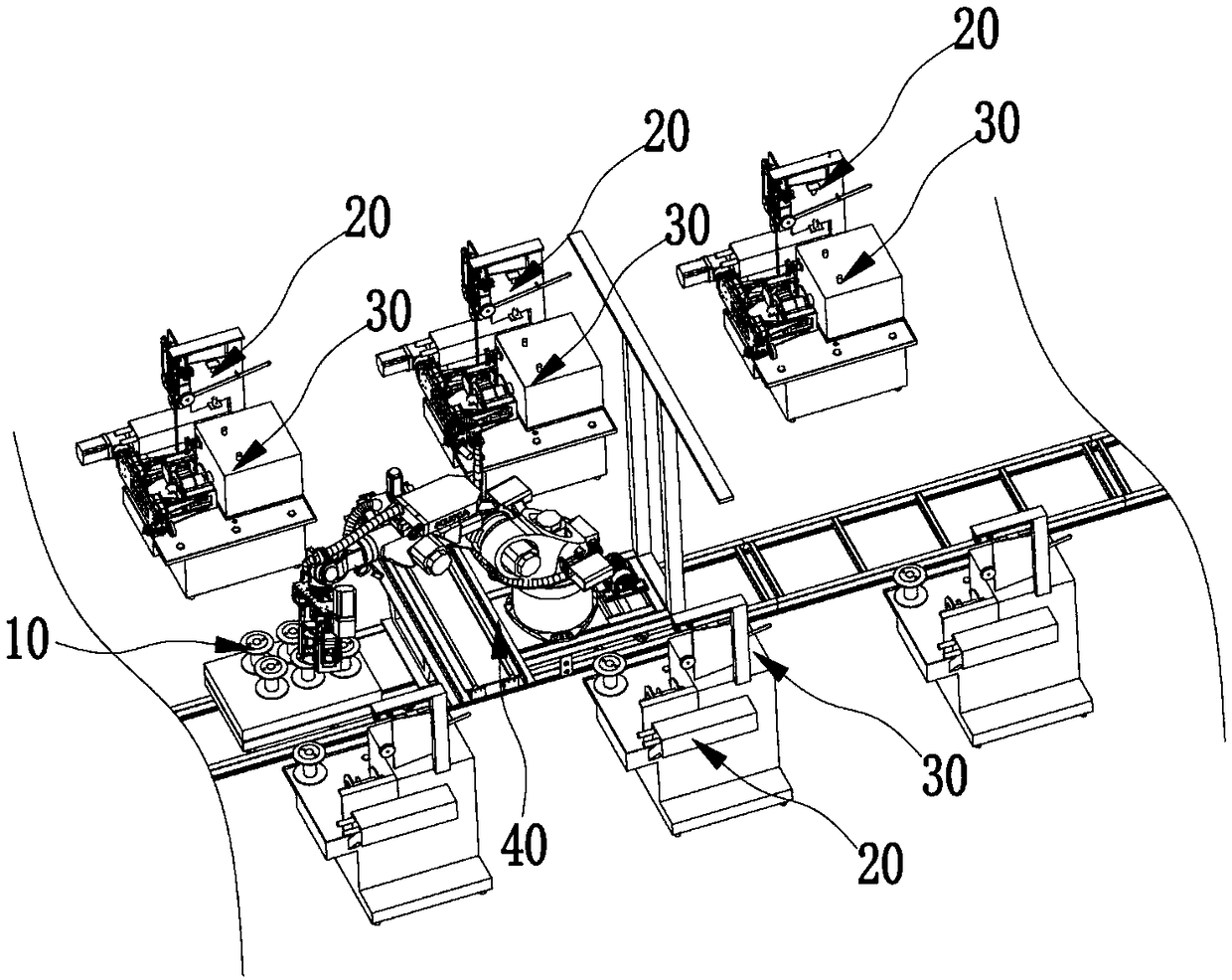

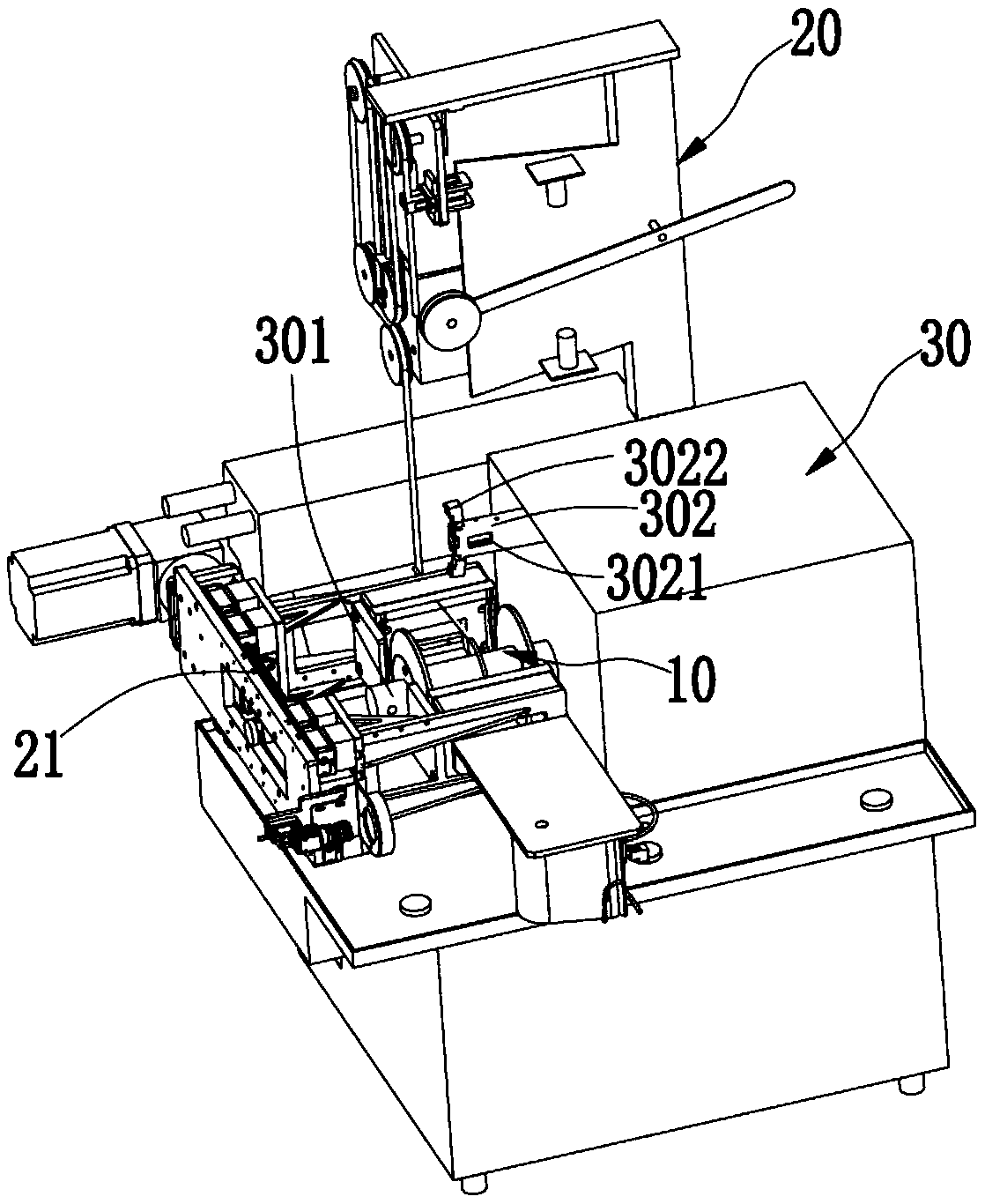

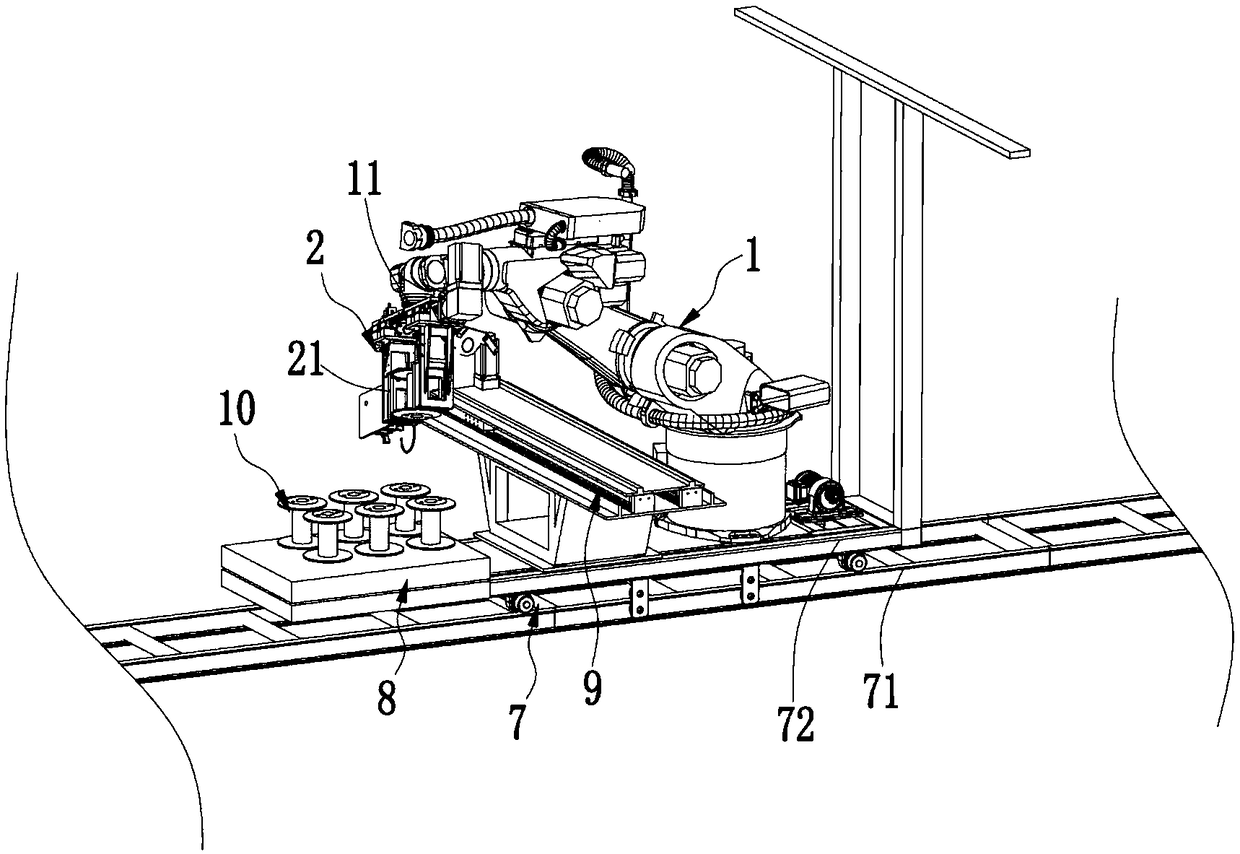

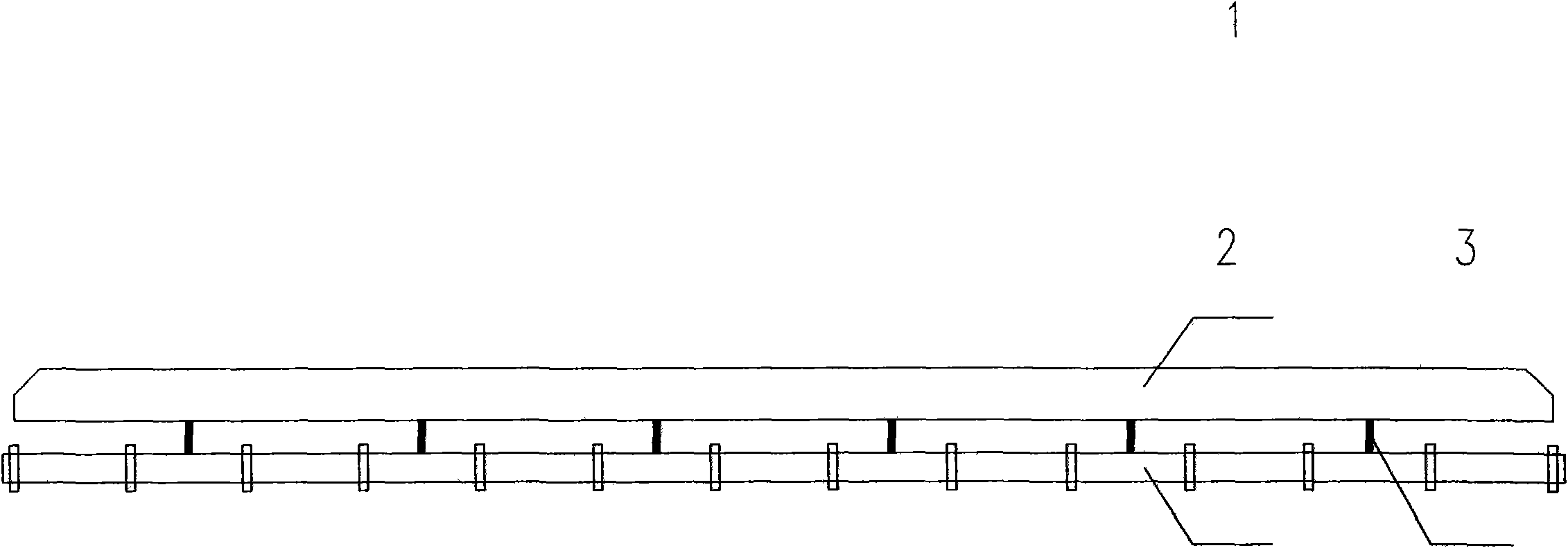

Full-automatic winding production line and processing method thereof

PendingCN109436951ASimple structureIncrease flexibilityFilament handlingProduction lineWinding machine

The invention discloses a full-automatic winding production line and a processing method thereof. The full-automatic winding production line comprises at least one automatic feeding machine, at leastone winding machine and an automatic winding disc feeding and discharging robot, wherein the automatic feeding machine is used for supplying a filament-shaped body; the winding machine is used for fixing a winding disc and driving the winding disc to rotate; and the automatic winding disc feeding and discharging machine can move the winding disc onto the winding machine and taking the winding discdown from the winding machine, and the position of the filament-shaped body can be determined visually when the filament-shaped body is grabbed and cut off. According to the scheme, the automatic winding disc feeding and discharging robot cooperates with the automatic feeding machine and the winding machine, so that the whole process of feeding, winding and discharging is achieved automatically,and the novel full-automatic winding production line which is simple in structure and capable of controlling the winding process easily is provided; in addition, the visual positioning technique can effectively and accurately determine the position of the filament-shaped body, so that automatic grabbing and shearing are made possible; and the visual positioning technique is good in flexibility andhigh in accuracy and efficiency, so that the winding efficiency is improved.

Owner:WUXI MINGONG TECH

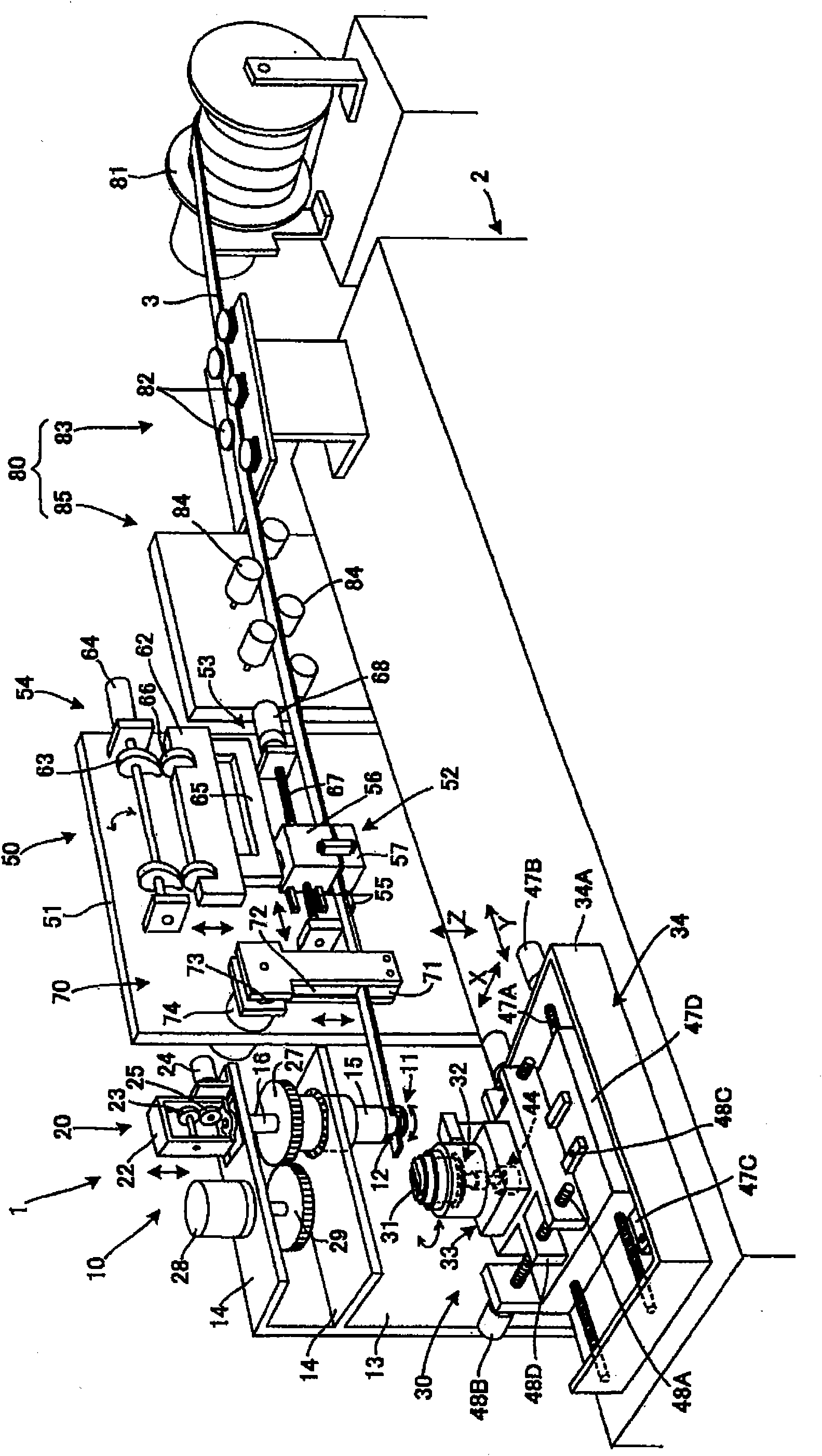

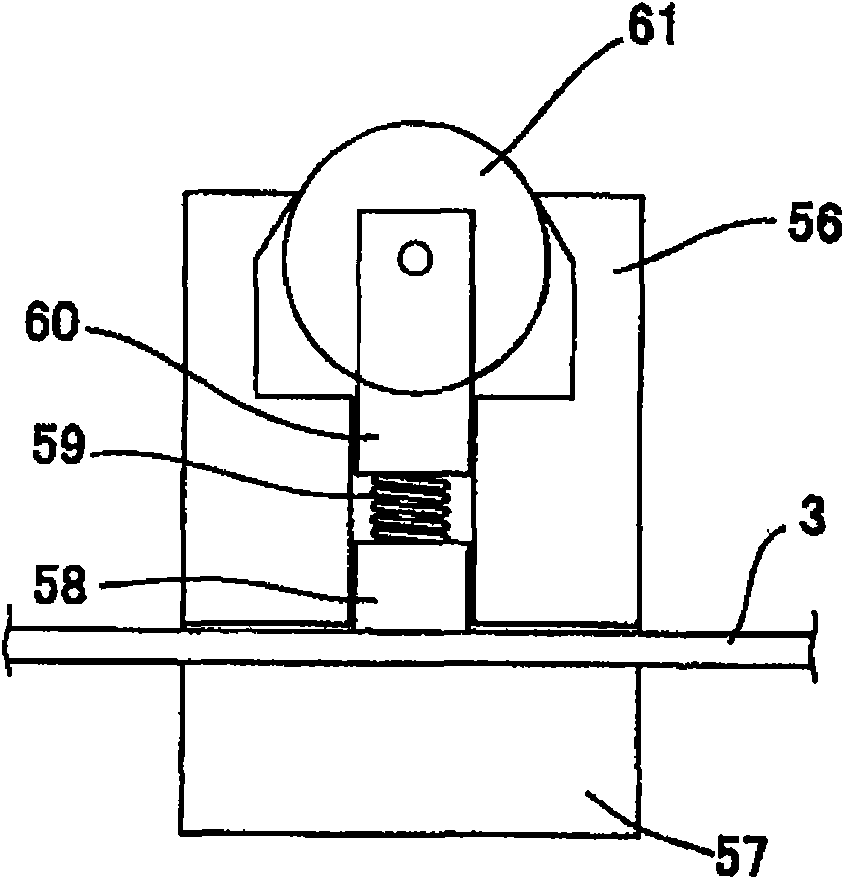

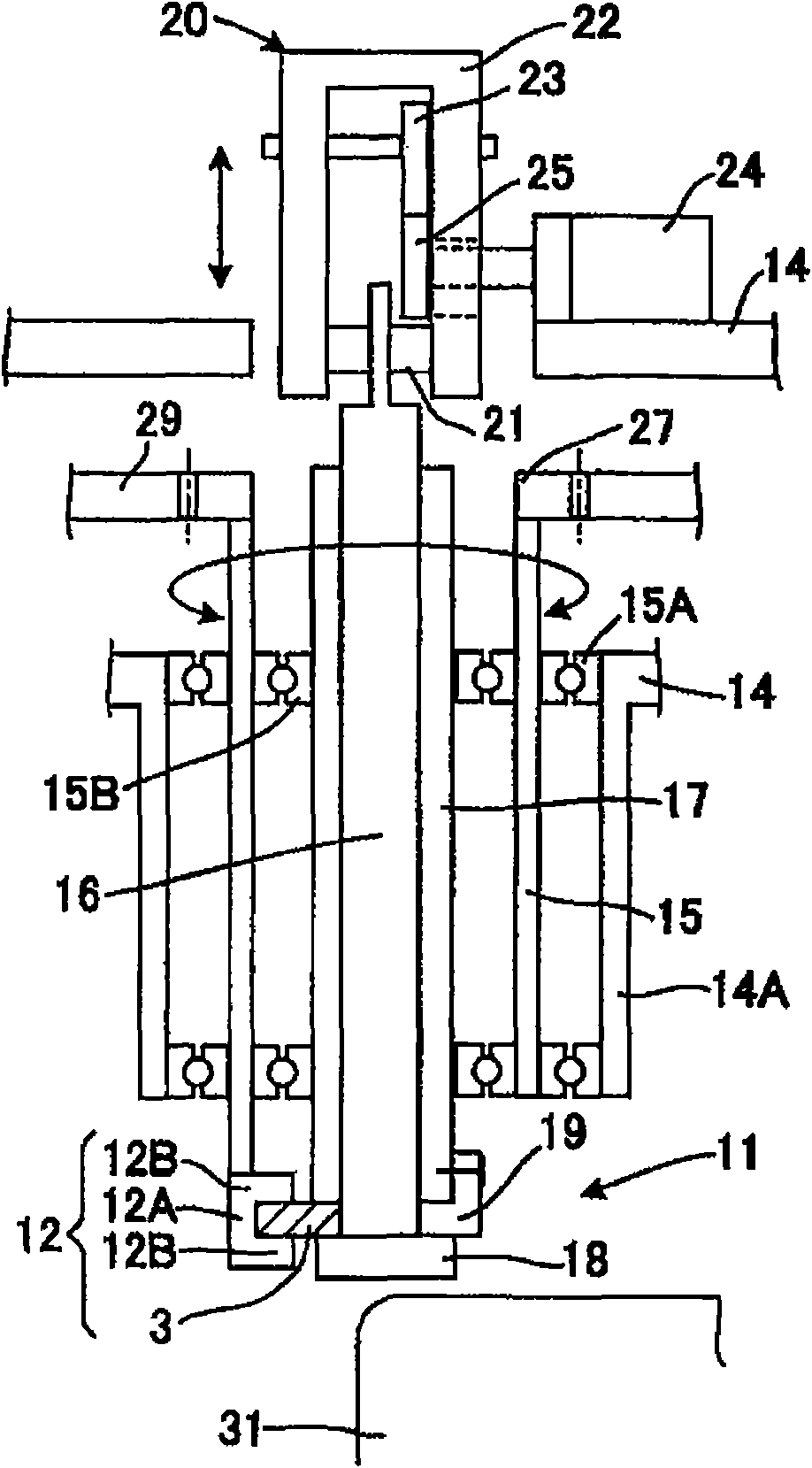

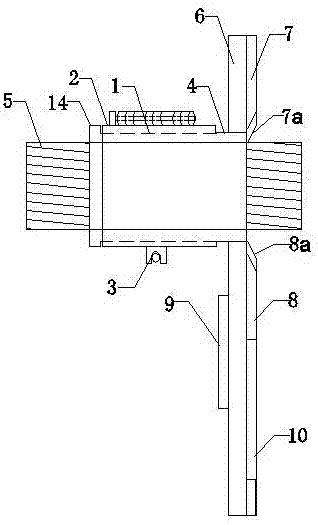

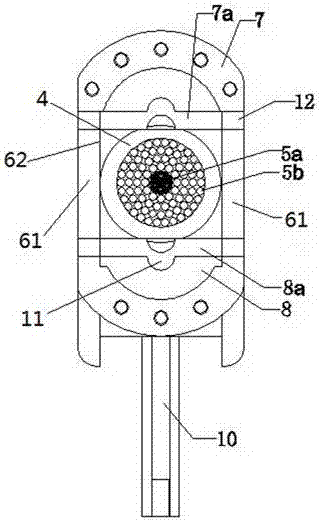

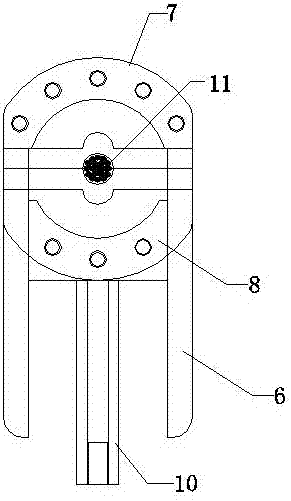

Winding method of edgewise coil and bobbin winder

ActiveCN101615508AAvoid clutterNo deformation of shape will occurManufacturing dynamo-electric machinesCoils manufactureEngineeringBobbin

The invention provides a winding method of an edgewise coil and a bobbin winder suitable for a coil being capable of keeping completion of winding. The winding method of an edgewise coil adopts a pivot part of a main plate (11) used as a joggling machine and a bending mechanism (12) to keep a bent part of a flat wire (3) that is conveyed by a given length; enables the bending mechanism (12) to rotate around the pivot part when a supply side of the flat wire (3) connected with the joggling machine is fixed; then bends the kept flat wire (3) to form the edgewise coil (4). An inner periphery side or an outer periphery side of the edgewise coil (4) is buckled with a coil guider (31). The coil guider (31) is moved following movement of the edgewise coil (4) driven by a submission action of the flat wire (3), and the coil guider (31) is rotated side to side following movement of the edgewise coil (4) driven by rotation side to side of the joggling action.

Owner:NITTOKU ENG CO LTD

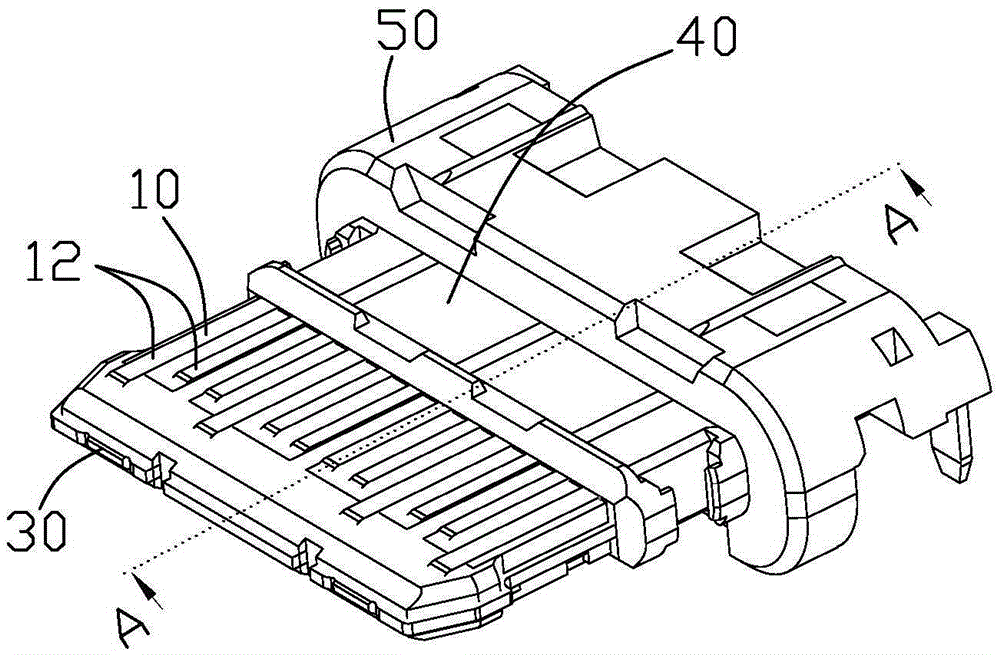

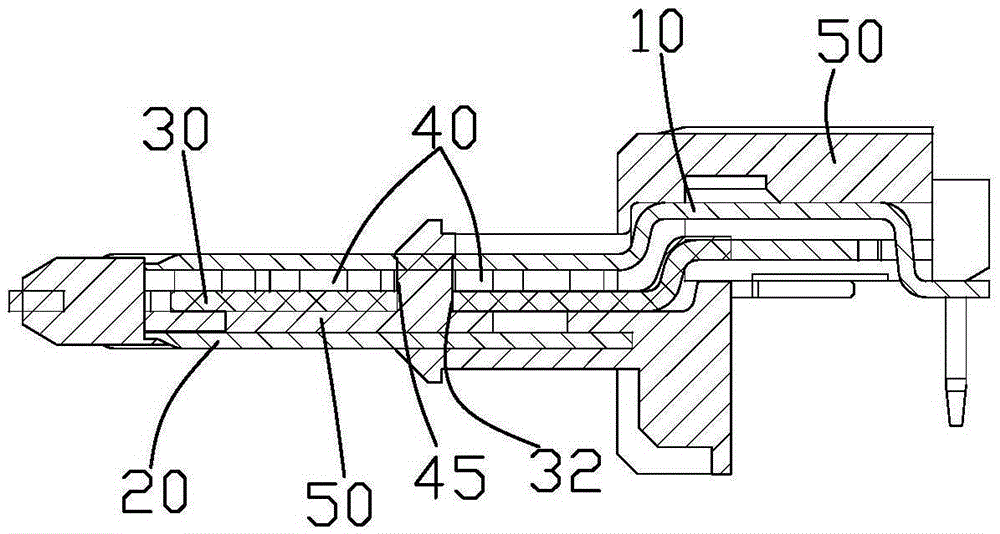

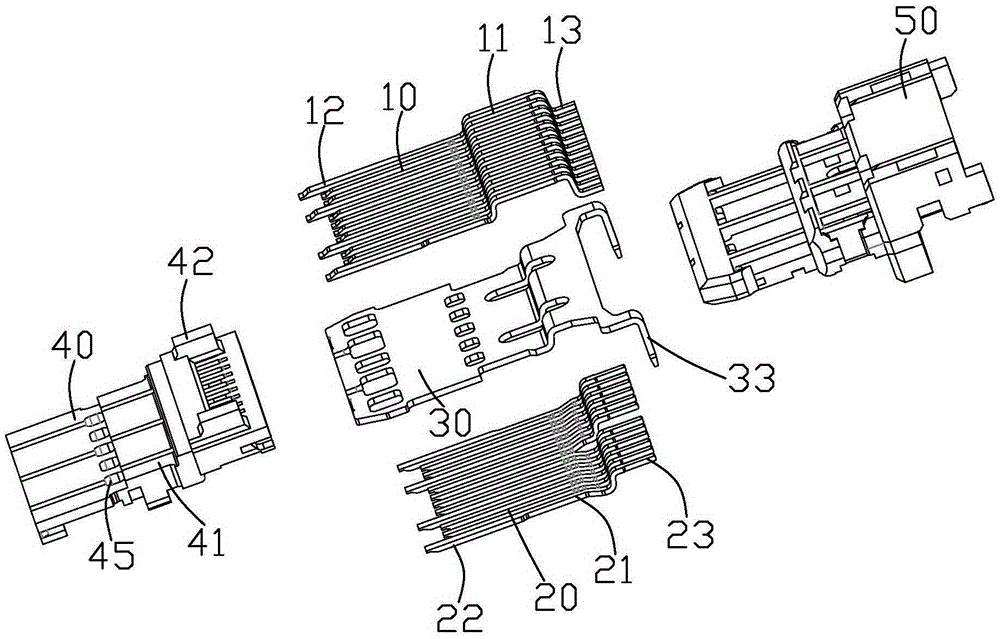

Twice-molded type reversible-plug USB connector and manufacturing method thereof

ActiveCN105305132AAvoid clutterAvoid shortingContact member assembly/disassemblyCoupling contact membersWhole bodyEngineering

A twice-molded type reversible-plug USB connector comprises a first terminal unit, an isolation middle plate, a first insulator which is formed by injection molding and is superposed on the first terminal unit and the isolation middle plate in a spacing manner in a vertical direction, a second terminal unit installed on one side of the first insulator on the isolation middle plate, and a second insulator that enables the first insulator and the second terminal unit to be formed as a whole body through injection molding. The first insulator is provided with terminal positioning slots and spacing bosses close to one side of the isolation middle plate. The second terminal unit is positioned in the terminal positioning slots of the first insulator. Second contact parts abut against the surfaces of the spacing bosses and then undergo injection molding to form the second insulator. According to the invention, the problem that a conventional product is low in efficiency because of undergoing injection molding too frequently is effectively solved.

Owner:SHENZHEN EVERWIN PRECISION TECH

Wave-absorbing material and preparation method thereof

ActiveCN103881245AImprove permeabilityExcellent electromagnetic wave absorption performanceElastomerMagnetic poles

The invention provides a wave-absorbing material and a preparation method thereof. The wave-absorbing material is prepared from the following raw materials in parts by mass: 5-15 parts of thermosetting elastomer, 60-80 parts of flaky wave-absorbing agent, 0.1-2 parts of curing agent, 0.1-0.5 part of accelerator and 20-30 parts of solvent. The preparation method comprises the following steps: (1) dissolving a matrix; (2) mixing the matrix with the wave-absorbing agent; (3) scraping the base material; and (4) flattening the surface by a double-roller calender, and passing through a tunnel furnace to perform high-temperature curing, thereby obtaining the product. The method prevents the calendering from crushing the flaky wave-absorbing agent, and maintains the completeness of the flaky wave-absorbing agent particles. The magnetic poles are added to well orient the flaky wave-absorbing agent, thereby avoiding unordered arrangement of the particles in the high-polymer matrix due to calendering. The wave-absorbing material has the advantages of very high magnetic permeability and favorable electromagnetic wave absorption property, and can be prepared into a material of which the minimum thickness is 0.03mm.

Owner:重庆市鸿富诚电子新材料有限公司

Full-automatic rice cooking device

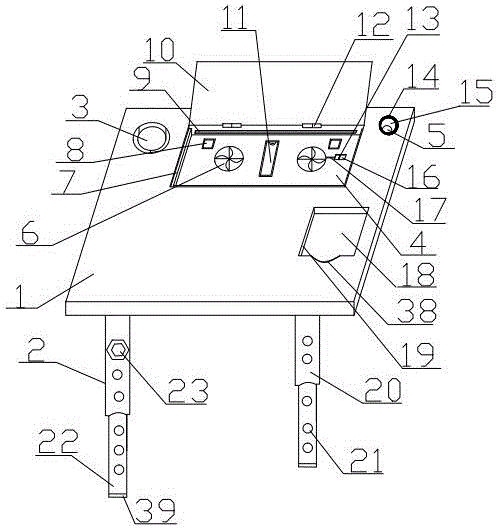

The invention discloses a full-automatic rice cooking device. The full-automatic rice cooking device comprises a frame, an electric cooker, a rice storage bin, a rice taking device, a rice washing device, a water conveying system, a transmission system and a controller, wherein the rice storage bin is disposed in the upper machine position of the frame, the rice taking device and the rice washing device are disposed in the middle machine position of the frame, the transmission system is disposed in the lower machine position of the frame, the electric cooker accesses the lower machine position through the transmission system, the rice washing device comprises a second drive machine, a rocker, a hollow-shaft motor and a stirring rod, the water conveying system comprises a water conveying pipeline, the stirring rod and the second end of the water conveying pipeline extends into the electric cooker, the active end of the rocker is driven by the second drive machine to drive the hollow-shaft motor to swing , and the hollow-shaft motor leaves the electric cooker. The full-automatic rice cooking device has the advantages that automatic rice taking, rice washing, water adding and rice cooking can be achieved, artificial interference is not needed in the whole process, rice can be directly washed in the electric cooker, and the full-automatic rice cooking device is compact in overall structure and convenient to operate.

Owner:范伟伟

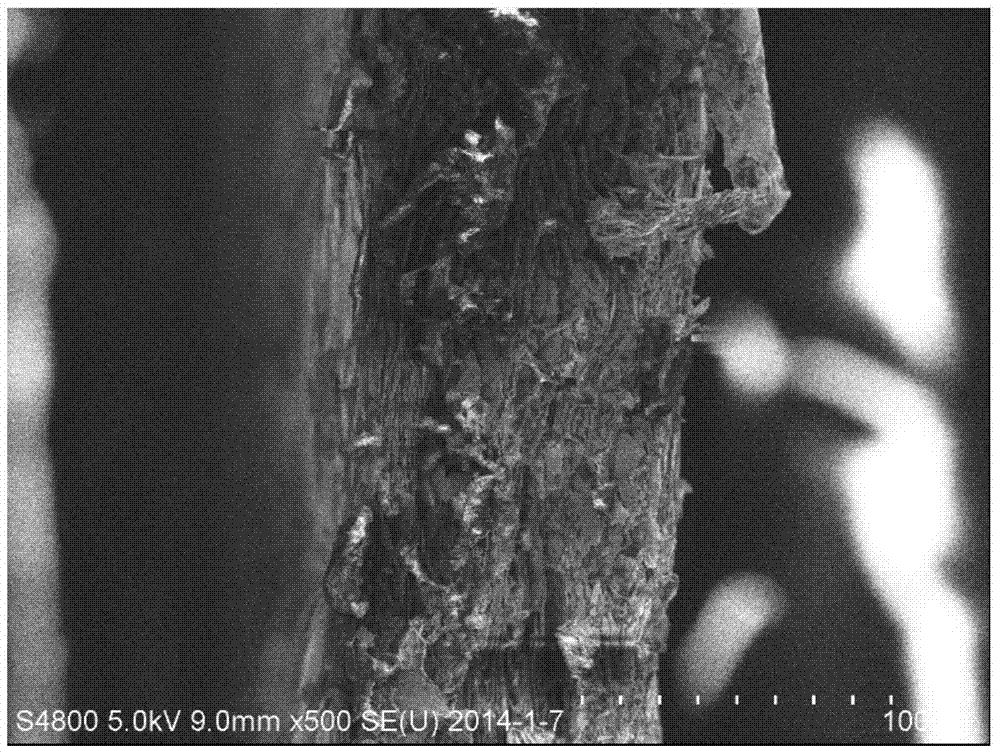

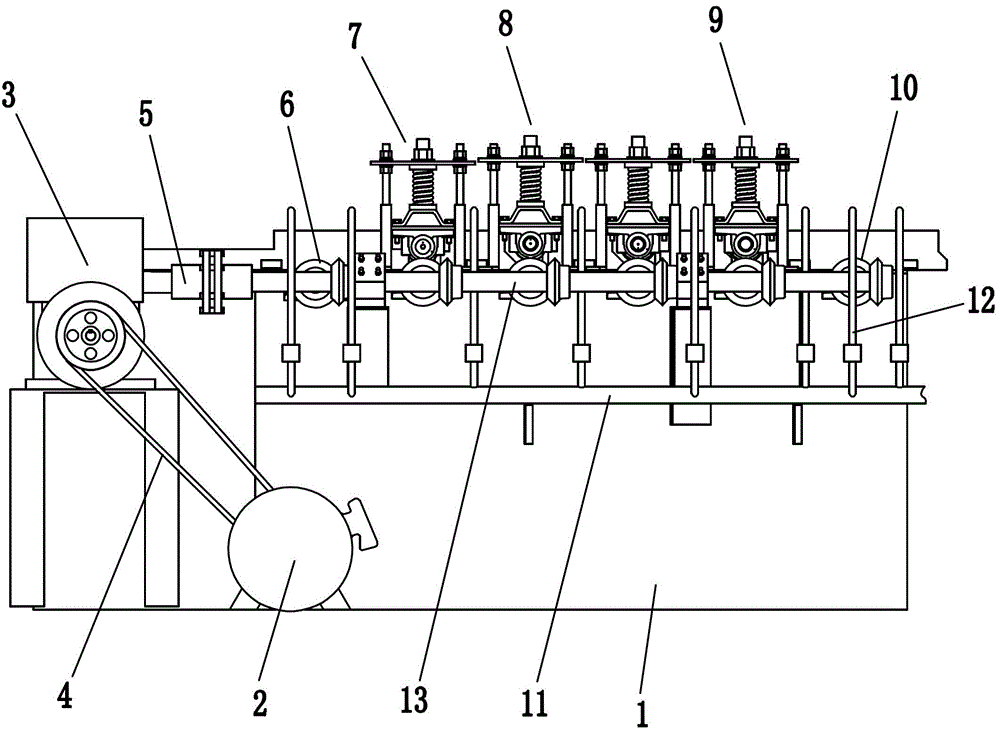

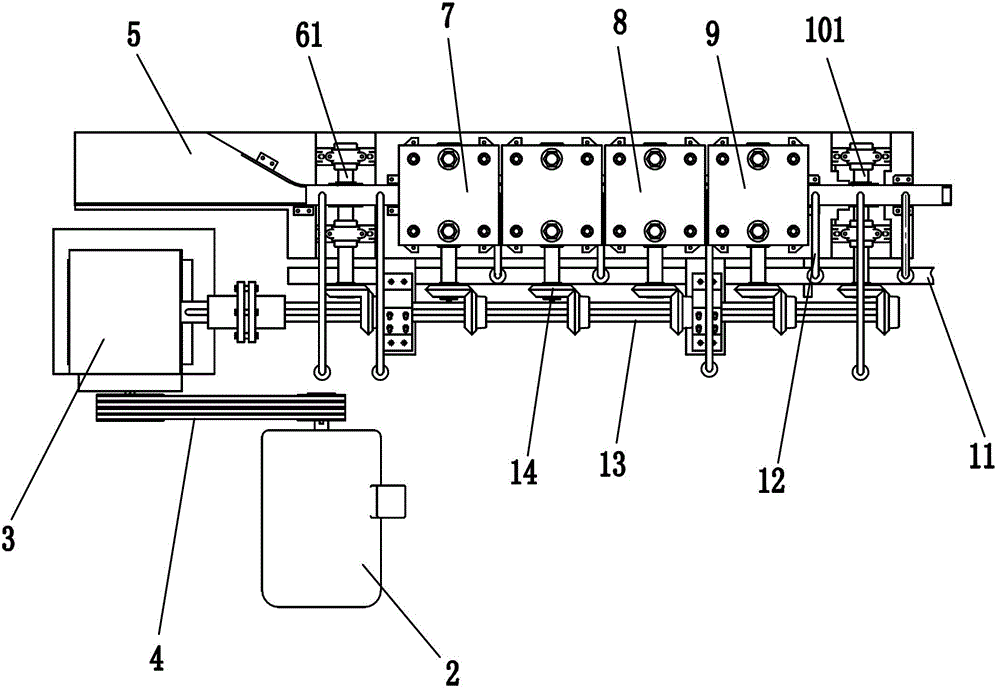

Continuous processing device for bamboo filament bundle

InactiveCN103331794ARolling effect is goodImprove efficiencyWood working apparatusContinuous productionEngineering

The invention relates to a processing device for bamboo wood, in particular to a continuous processing device for a bamboo filament bundle. The continuous processing device for the bamboo filament bundle comprises a rack, a motor and a reducer, wherein a feed groove, at least one grinding roll mechanism and a blanking groove are sequentially arrayed on the rack from one end close to a charging groove; the feed groove comprises a feed conveying roll; the grinding roll mechanism comprises a driving roll and a driven compression roll with pretightening force; the diameter of a section of the driving roll ascends uniformly from the middle part to the two ends; the shape of the external surface of the driven compression roll is matched with that of the external surface of the driving roll; the blanking groove comprises a feed output roll with the same structure as the feed conveying roll; a steam conveying pipe is horizontally arranged below the feed groove, the grinding roll mechanism and the blanking groove; and a plurality of steam spray pipes which are arranged at intervals and used for heating bamboos are connected with the steam conveying pipe. The continuous processing device has the benefits that the continuous processing device can process and separate the bamboo wood into the bamboo filament bundle, can be continuously produced, and can effectively prevent the bamboo wood from rupture.

Owner:ZHEJIANG FORESTRY UNIVERSITY

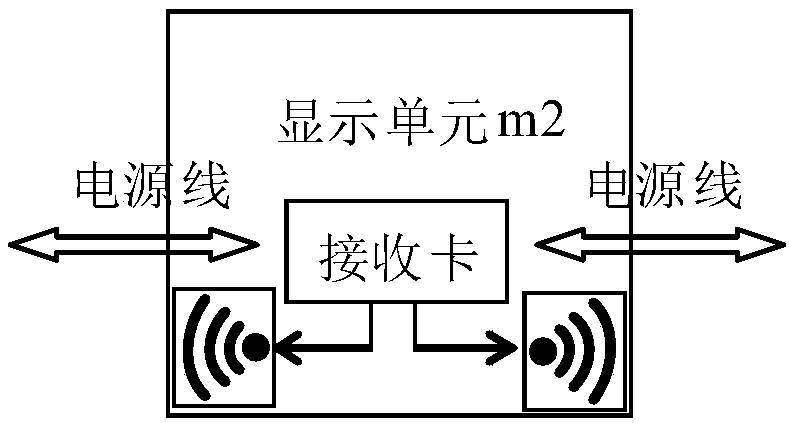

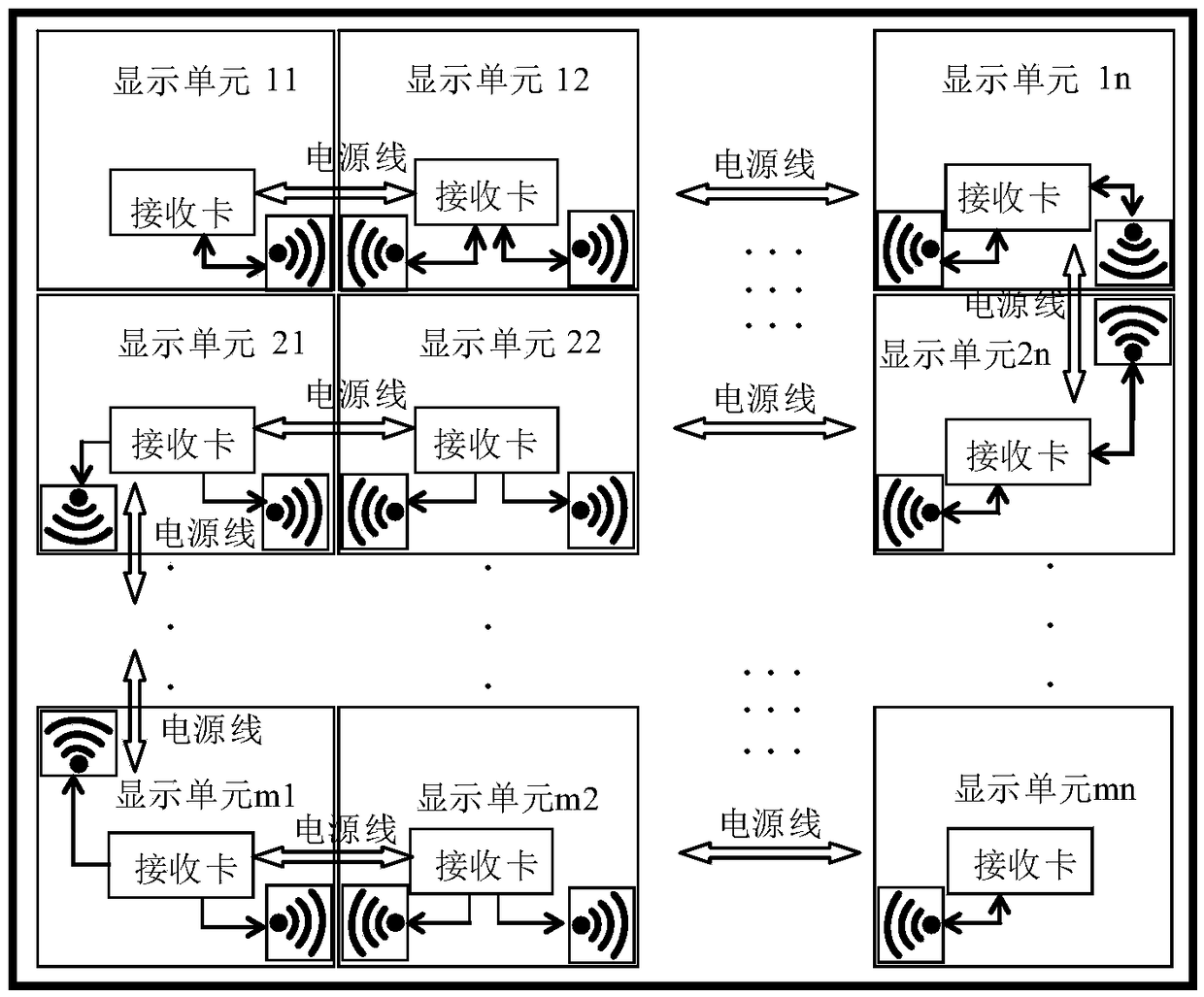

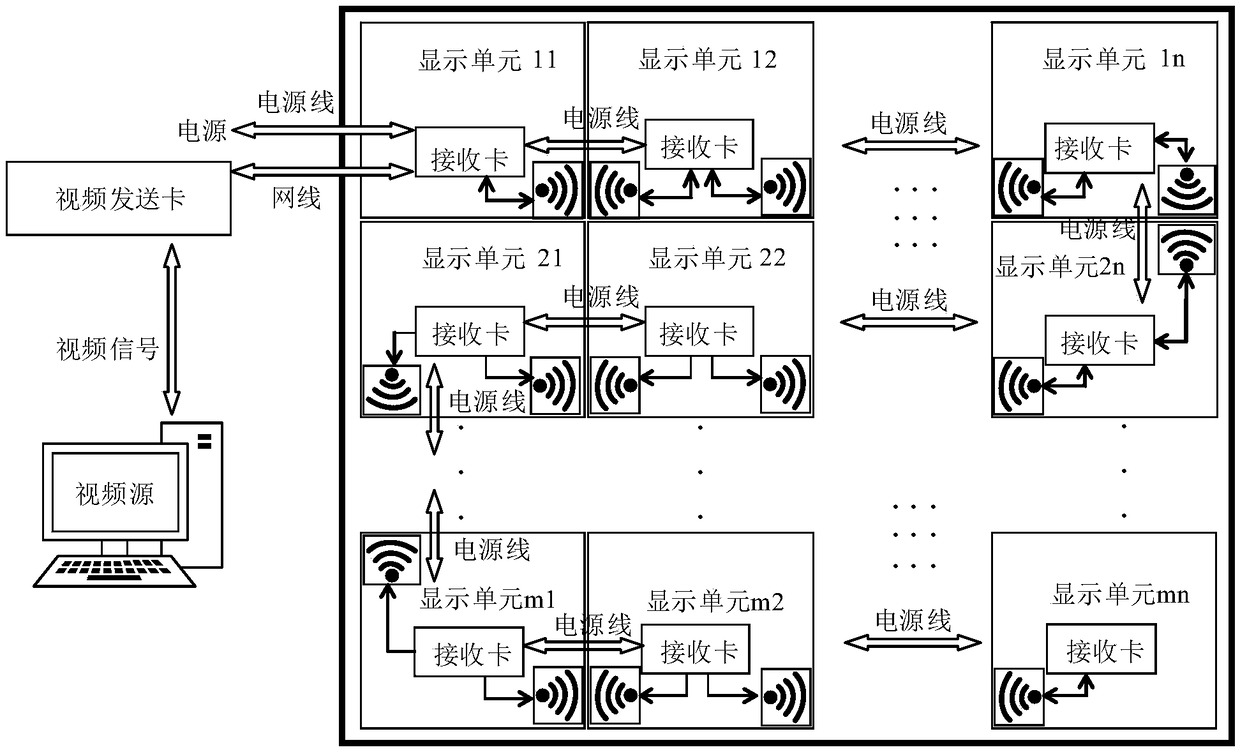

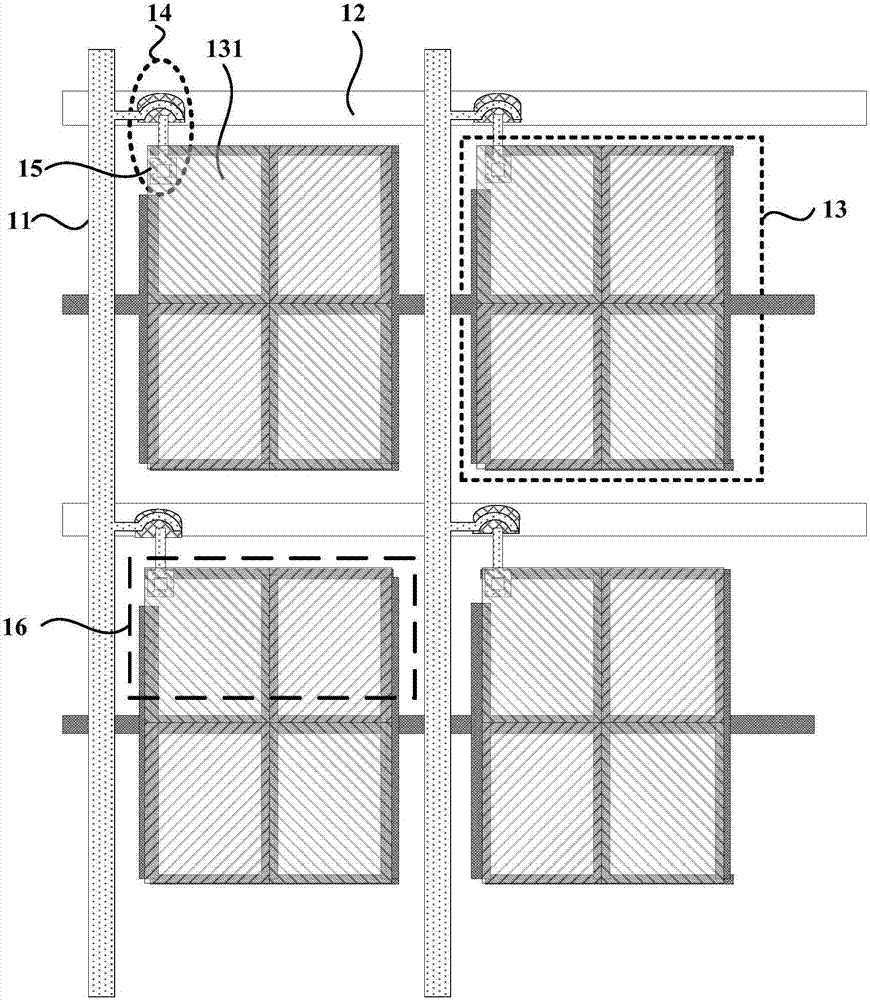

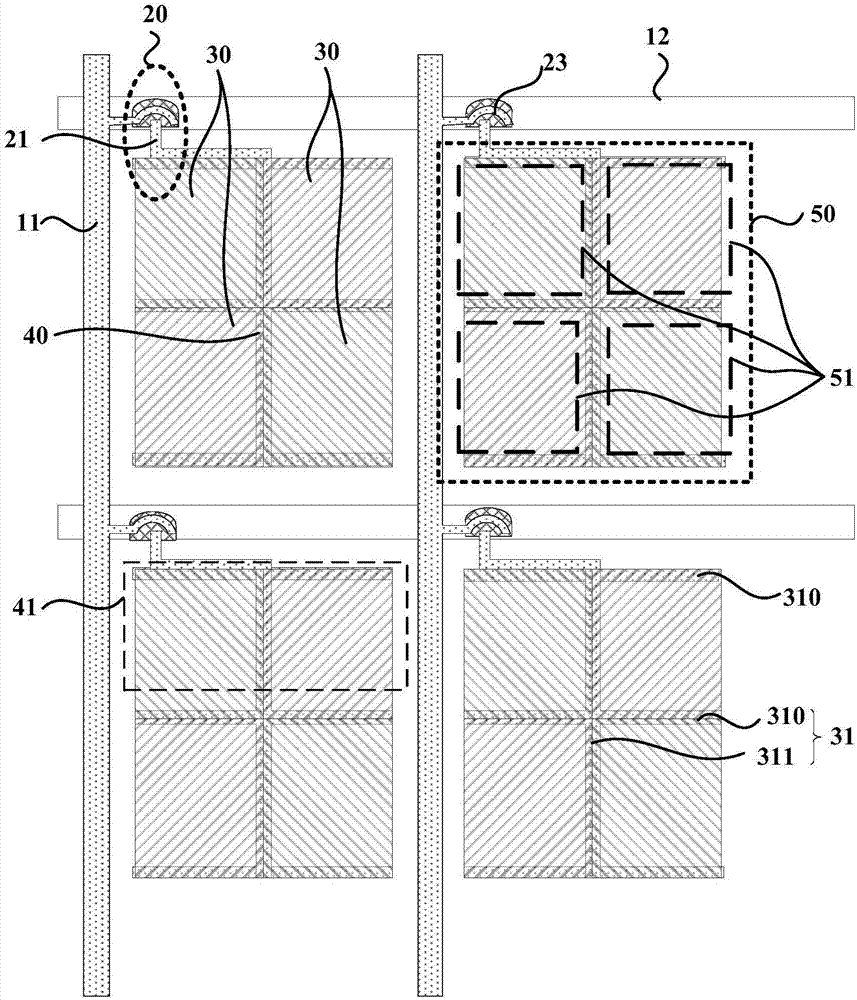

Display unit, spliced display device and spliced display system

ActiveCN109358828AAvoid clutterReduce transmission lossDigital output to display deviceWireless transmissionDisplay device

The invention relates to a display unit, which is characterized in that the display unit comprises a first wireless transmission module, a receiving card, a display screen and a second wireless transmission module. Wherein the first transmission module is configured to receive the first video data; The receiving card is connected with the first wireless transmission module. The display screen is connected with the receiving card; The second wireless transmission module is connected with the receiving card. A display unit receives or transmits video data through a first wireless transmission module and a second wireless transmission module by using a wireless transmission mode, thereby avoiding the clutter of wired transmission lines. At the same time, the VHF wireless transmission mode isadopted between the display units, which reduces the transmission loss and interference, and has good waterproof effect at the same time.

Owner:西安触点电子科技有限公司

Integrated circuit, film removing method of integrated circuit and film removal arranging device of integrated circuit

InactiveCN110422416ASmooth peelingAvoid clutterSemiconductor/solid-state device manufacturingArticle unpackingIntegrated circuit manufacturingEngineering

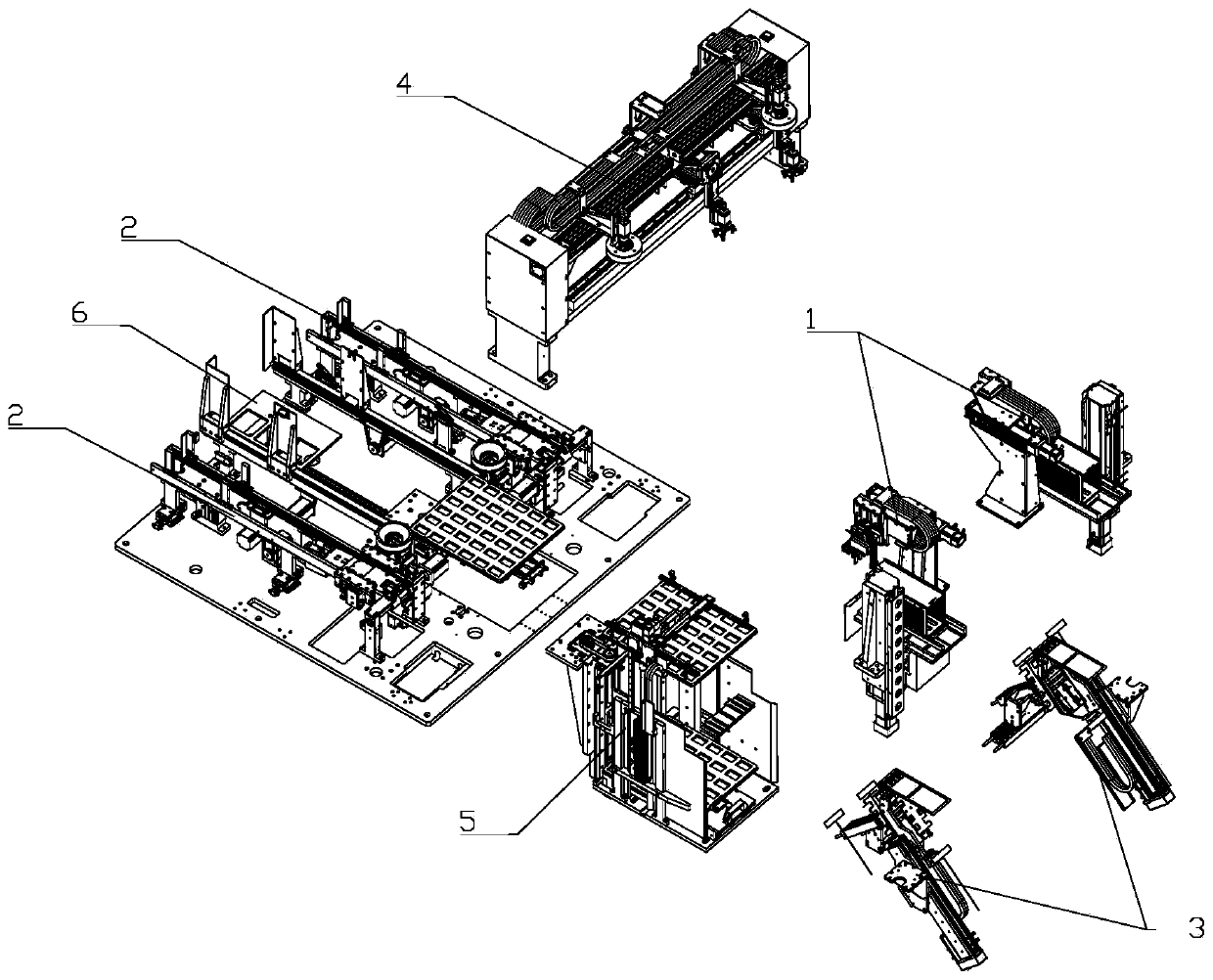

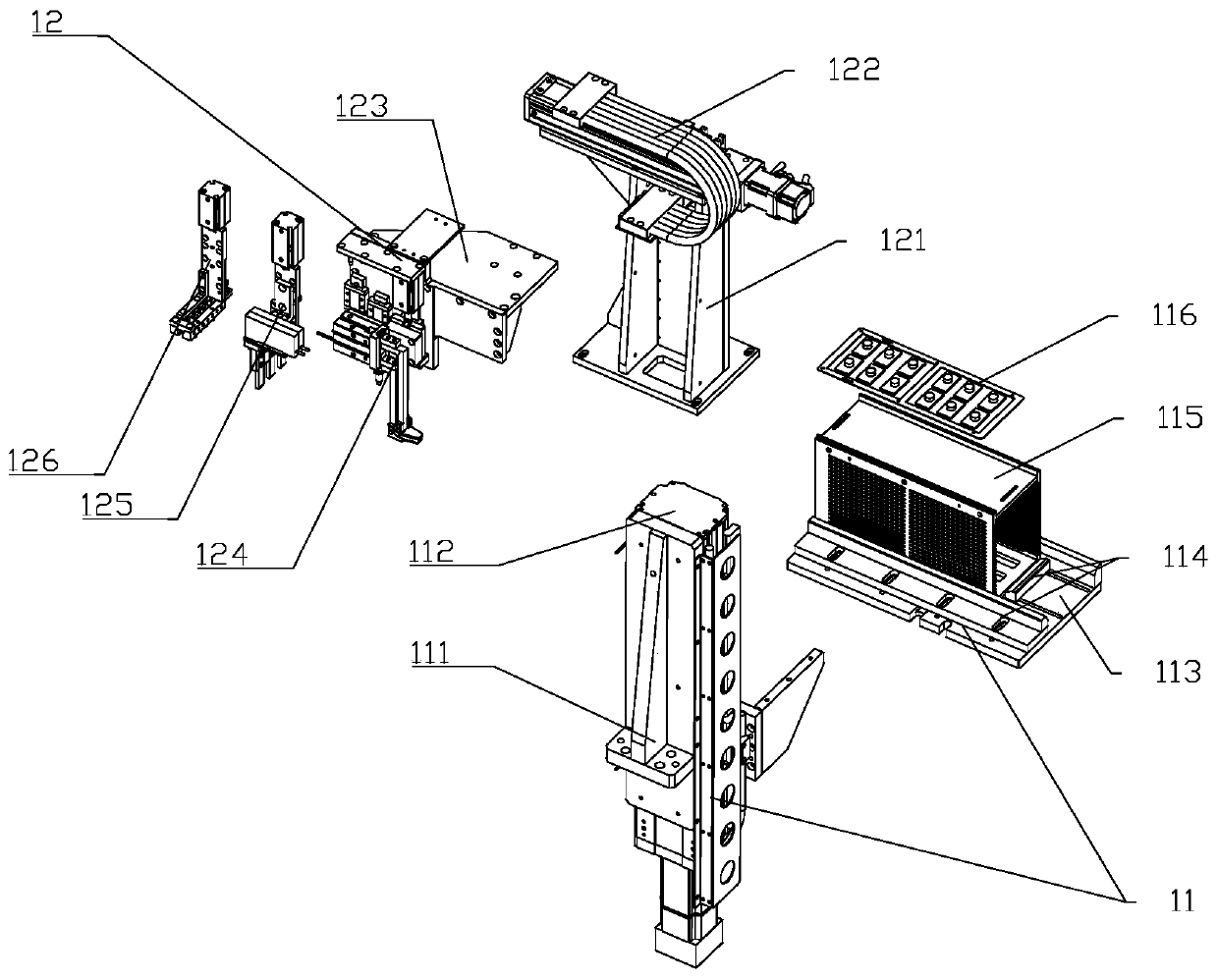

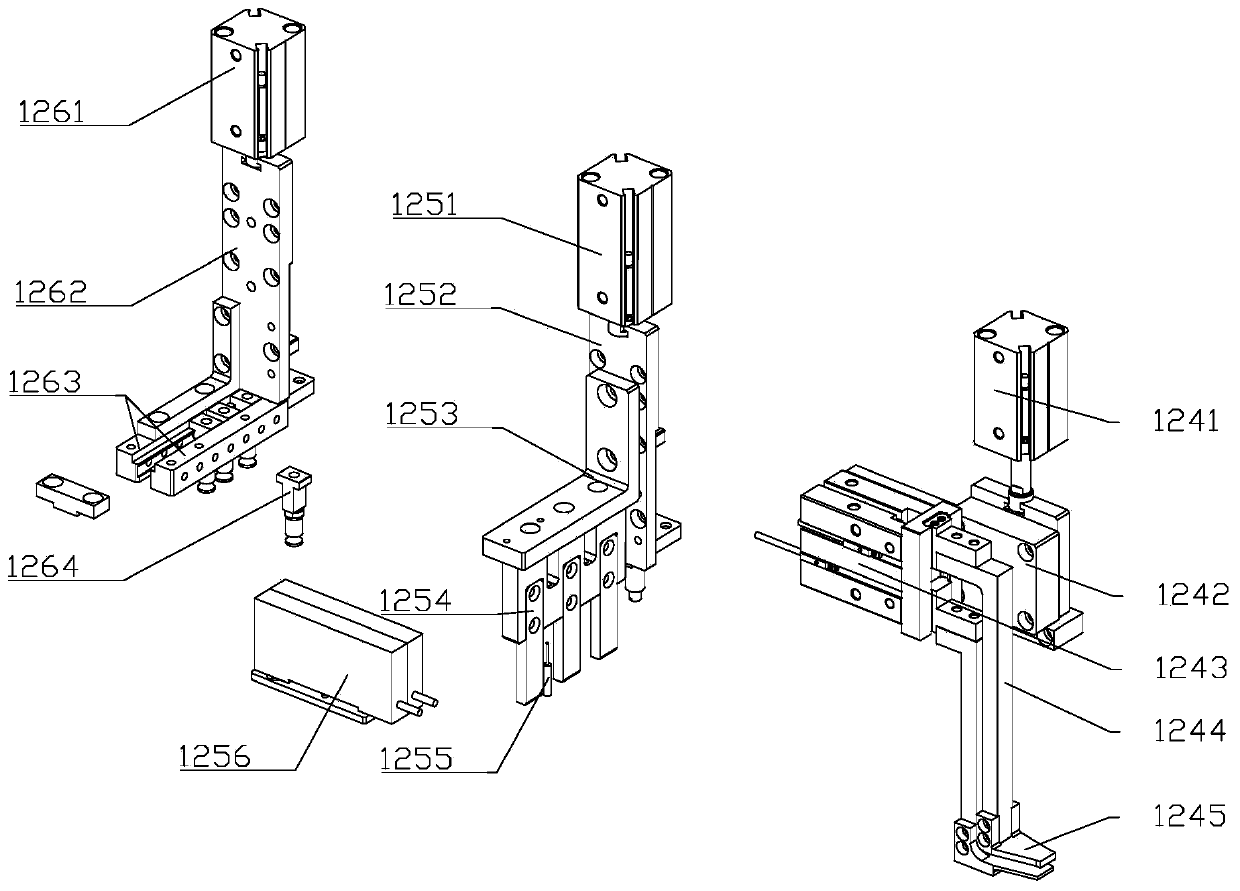

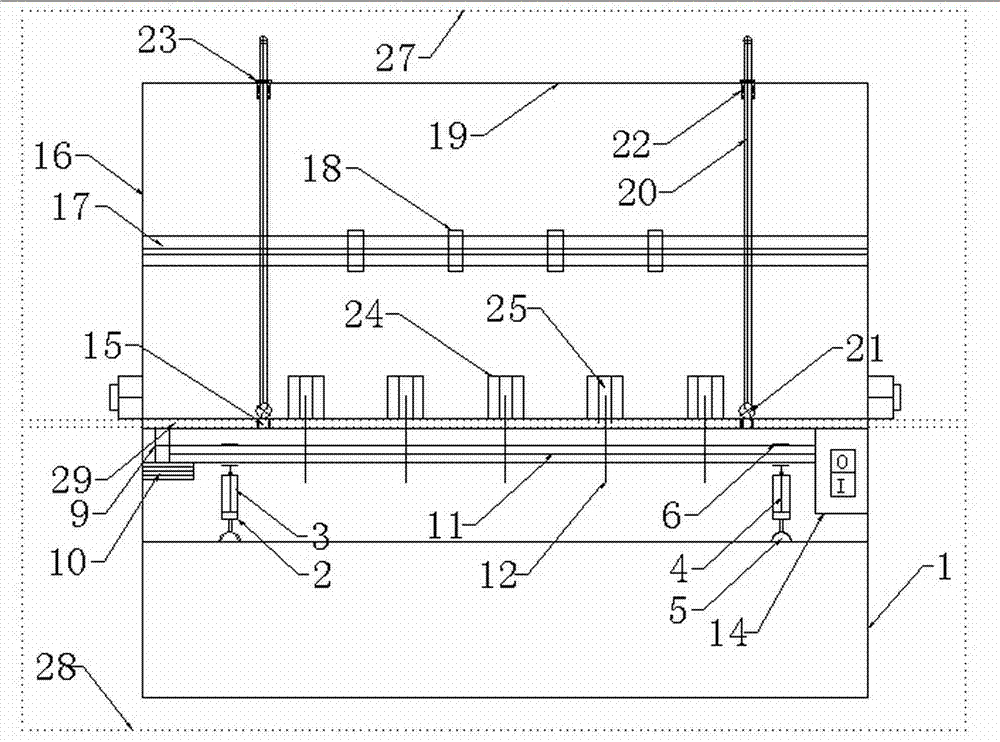

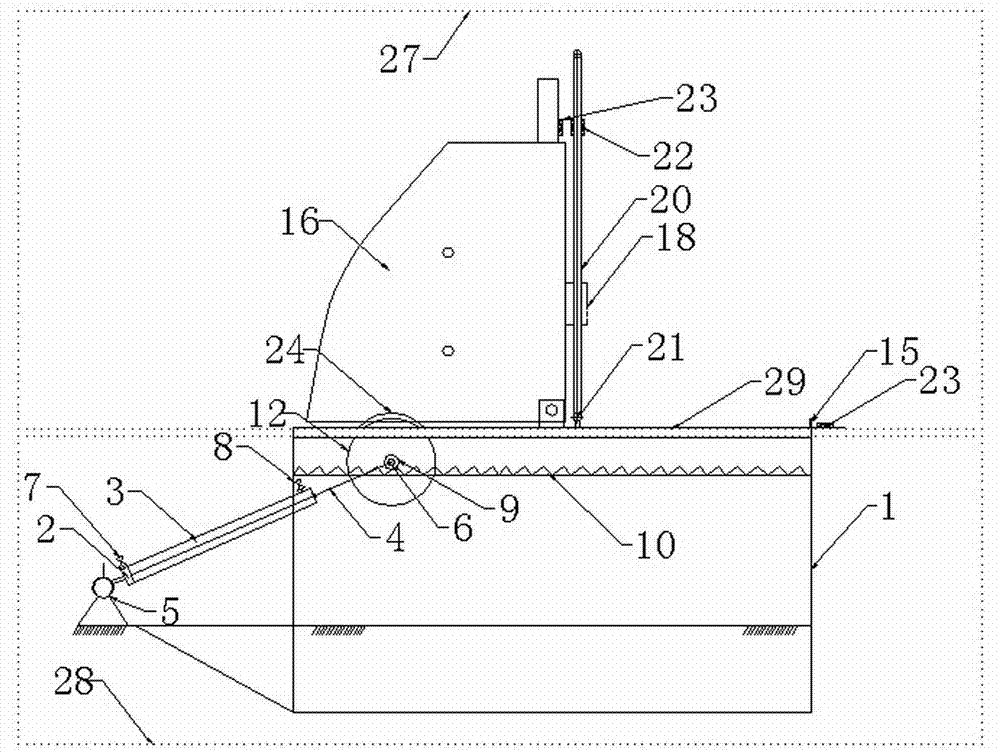

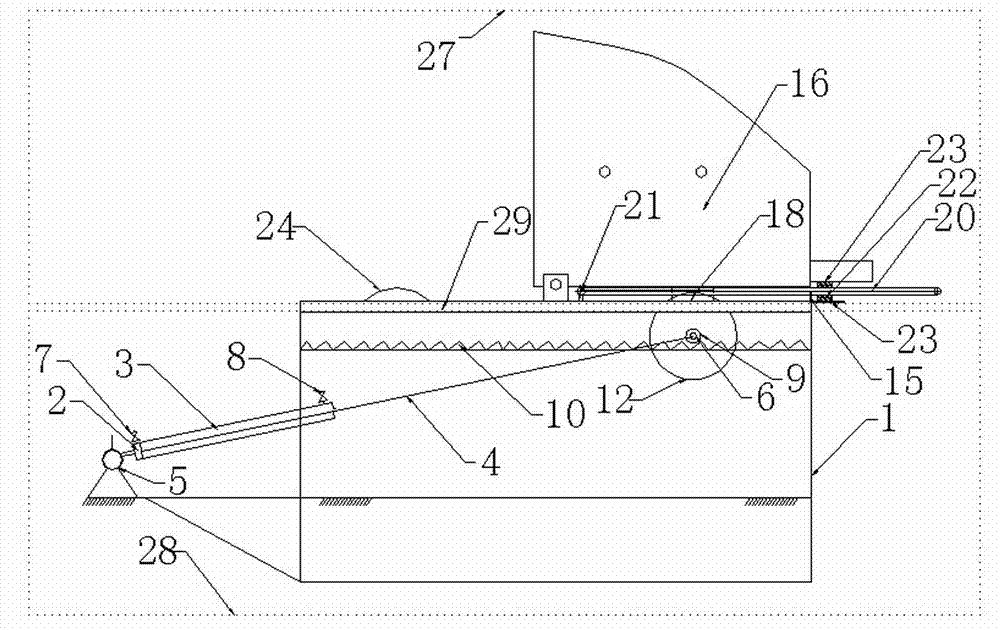

The invention relates to the technical field of integrated circuit manufacturing, and discloses a film removal arranging device of an integrated circuit. The film removal arranging device comprises aframe, two symmetrically arranged carrier plate feeding devices, two symmetrically arranged carrier plate conveying line devices, two symmetrically arranged film removing devices, a carrying manipulator, a visual detection device, a tray feeding device and a tray conveying line device, wherein the carrier plate feeding devices, the carrier plate conveying line devices, the film removing devices, the carrying manipulator, the visual detection device, the tray feeding device and the tray conveying line device are arranged on the frame; the film removing devices are positioned below the carrier plate feeding devices; the carrier plate conveying line devices are connected with the carrier plate feeding devices; the tray feeding device is positioned between the two carrier plate feeding devices; the tray conveying line device is positioned between the two carrier plate conveying line devices and is connected with the tray feeding device; and the carrying manipulator and the visual detectiondevice are arranged on the frame and are positioned above the carrier plate conveying line devices and the tray conveying line device. The film removal arranging device has the advantages of being efficient and accurate in glue removing, automatic in feeding and discharging, high in processing efficiency and capable of collecting and arranging the integrated circuit.

Owner:NINGBO YINZHOU TEERFEI ELECTRONICS CO LTD

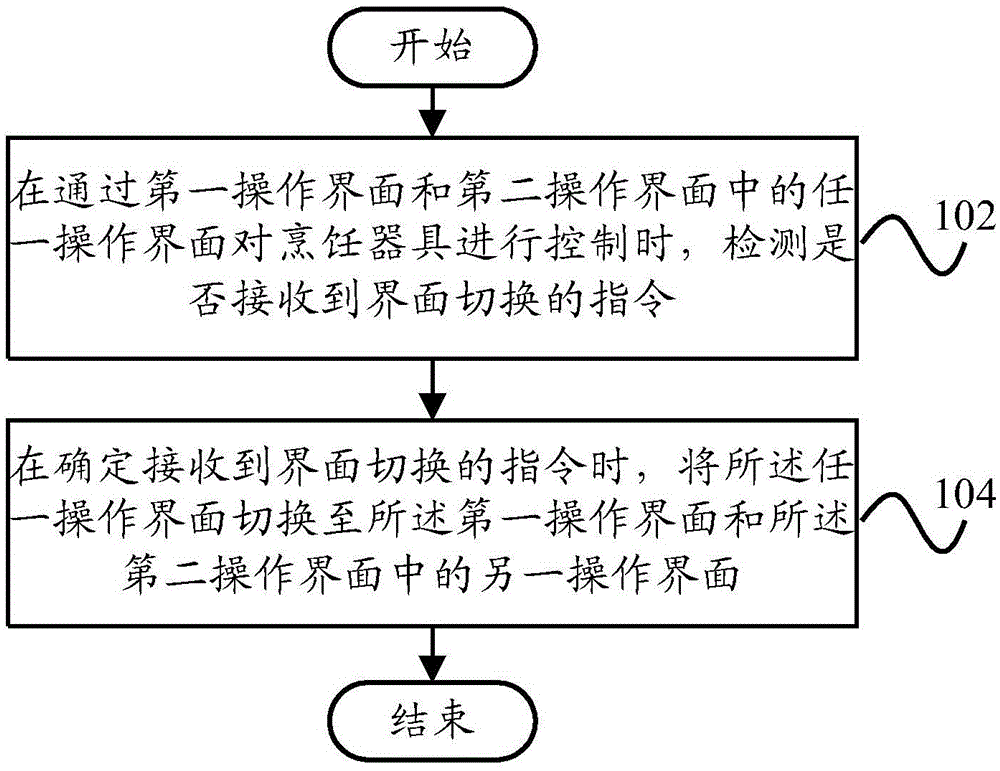

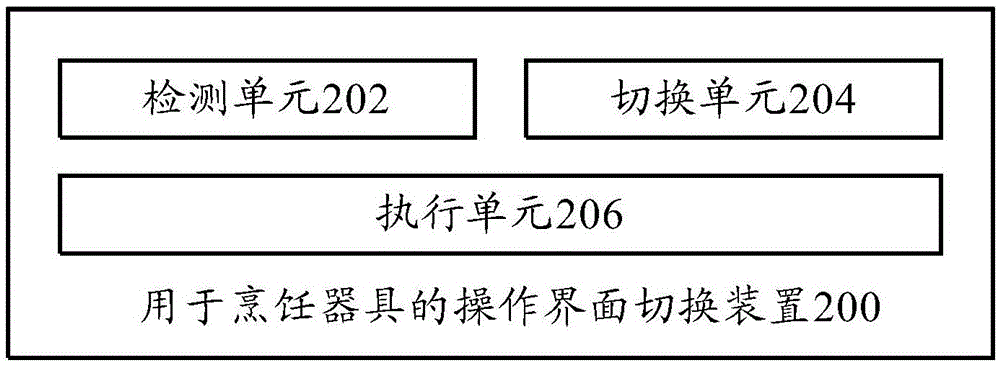

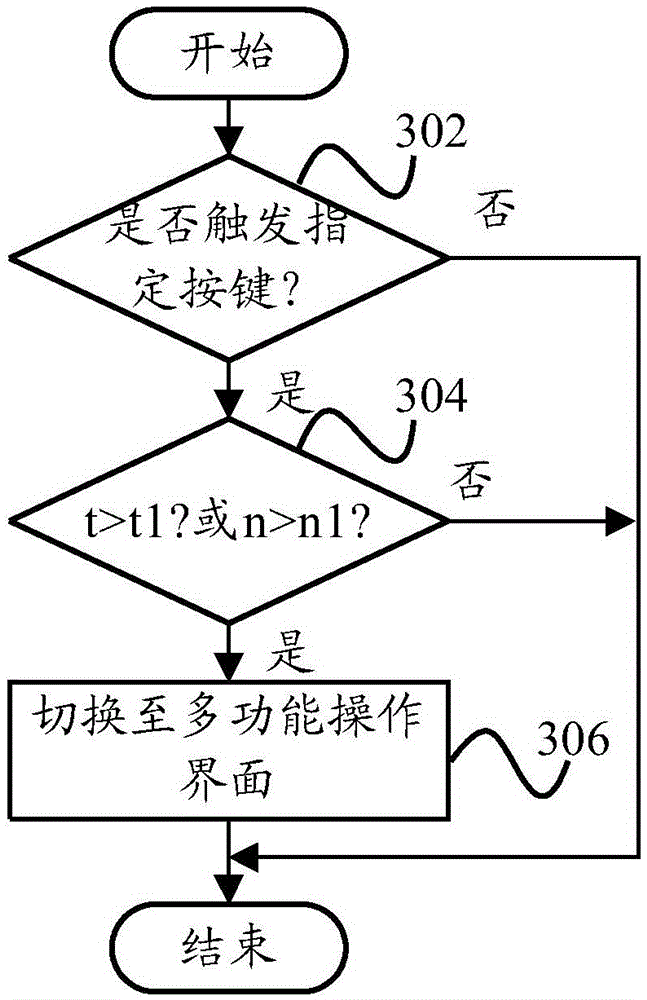

Operation interface switching method and device for cooking utensil and cooking utensil

ActiveCN106293378AImprove user experienceSatisfy switching needsCooking vesselsInput/output processes for data processingOperations management

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD +1

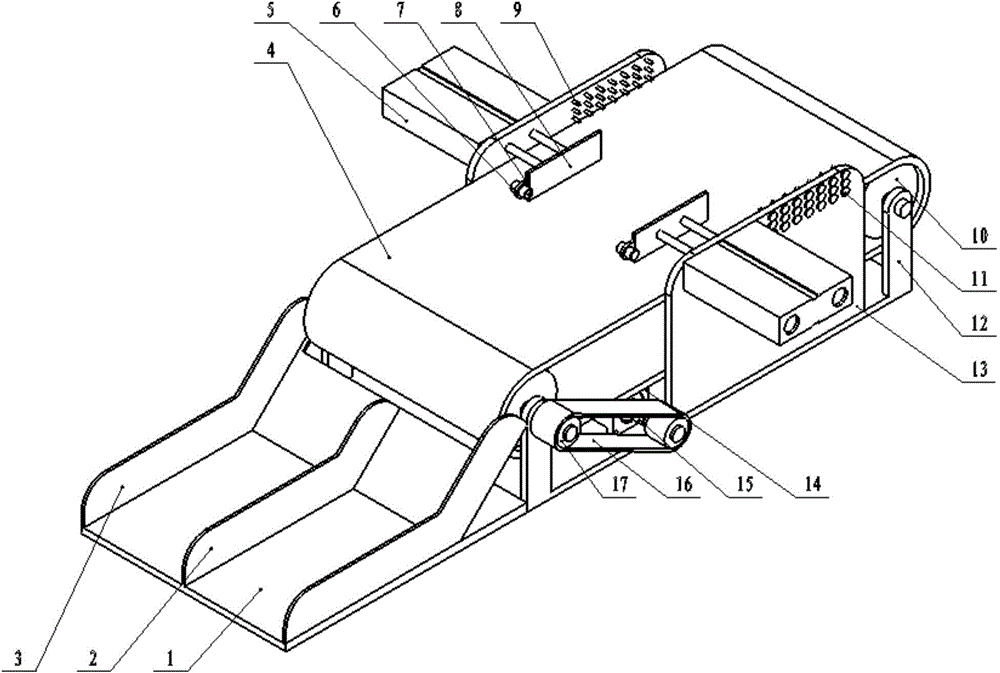

Device for picking outside diameter dimension of bearing

The invention relates to a device for picking an outside diameter dimension of a bearing, and belongs to the mechanical manufacturing field. The device consists of a classification support, a classification ribbed plate, edge baffles, a conveyer belt, air cylinders, ultrasonic distance sensors, sensor mounting plates, bearing clamping plates, detection head emitters, rollers, detection head receivers, a main fixing frame, vertical mounting plates, a motor, a coupler, a belt and belt pulleys, wherein the classification support is welded on the rear end of the fixing frame; the vertical mounting plates are welded on the middle part of the main fixing frame; the rollers are installed on the both ends of the main fixing frame, the conveyer belt is arranged outside the rollers, one side of one roller is connected with one belt pulley, and the belt is arranged outside the belt pulleys; the motor is connected with the coupler, which is connected with the other belt pulley. The device has the advantages of being simple in design and easy to operate, combining the mechanical structure and modernized control, realizing automatic production, improving production efficiency and saving time and effort.

Owner:TAIZHOU HONGXIANG POWER MACHINERY

Moving platform for taking and placing stored goods and route planning method of moving platform

ActiveCN110465928AImprove reliabilitySmall feedProgramme-controlled manipulatorGripping headsModularityRoute planning

The invention discloses a moving platform for taking and placing stored goods and a route planning method of the moving platform. The moving platform comprises a moving platform body, an obstacle avoiding device, a mechanical arm device, a goods placing device, a goods recognition device and a goods grabbing device. The obstacle avoiding device, the mechanical arm device and the goods placing device are installed on the moving platform body. The goods grabbing device is installed at the tail end of the mechanical arm device. The goods recognition device is installed on the goods grabbing device. The mechanical arm device comprises a rotating mechanism and multiple mechanical arms. The multiple mechanical arms are mutually connected in a rotating manner. The multiple mechanical arms form one modularized mechanical arm. One end of the first mechanical arm is fixed to the rotating mechanism. The tail end of the last mechanical arm is fixed to the goods grabbing device. According to the method, the improved dynamic window method is adopted for adjusting three weights for evaluating a function in real time, the adaptation ability of the moving platform to the environment is improved, and the success rate of the moving platform reaching the designated position point is ensured.

Owner:HEBEI UNIV OF TECH

Method for producing precast concrete piles

The invention relates to a method for producing precast concrete piles, which comprises the following main steps of: manufacturing a reinforcement cage; placing the reinforcement cage into a die; pouring concrete into the die; centrifugally rotating; and carrying out steam curing. The method is characterized in that the die with the length of over 20 meters is adopted in the method; two or a plurality of precast concrete piles can be simultaneously produced by one die; upper and lower half dies of the die have a transporting mode of transversely moving in parallel in the direction vertical to the axis of a crane beam of a plant in the production process; and centrifugal equipment and a curing tank are transversely arranged in parallel in the direction vertical to the axis of the crane beam of the plant. Due to the adoption of the transverse flow production scheme of the long die, the production effect can be multiplied, the space occupied by the plant is greatly reduced, a great amount of lands are saved, the working efficiency is improved, and the production quality can be ensured.

Owner:NINGBO YIZHONG CONCRETE PILE +2

Wire stripping tool

ActiveCN107147050APrevent scurryingGuaranteed radial position relationshipApparatus for removing/armouring cablesEngineeringMechanical engineering

The invention relates to a wire stripping tool comprising a cutting mechanism and a cable locating sleeve, wherein the cable locating sleeve is provided with an inner hole having an axial line extending along the left and right direction and used for locating and penetrating through a corresponding cable, the cutting mechanism comprises a mechanism seat, a locating sleeve guide mechanism forming guide movement fit with the cable locating sleeve along a direction vertical to the left and right direction is arranged on the mechanism seat, two cutter bodies used for cutting an aluminum stranded wire on the outer side of a steel core are further arranged on the mechanism seat, wherein at least one cutter body is a movable cutter body in guide movement fit with the mechanism seat, the guide movement direction of the movable cutter body is consistent with the guide movement direction of the cable locating sleeve relative to the mechanism seat, and steel core evasion grooves used for evading the corresponding steel core are formed in the cutting edges of the fixed cutter body and the movable cutter body. The wire stripping tool provided by the invention solves the problem that a conducting wire or the wire stripping tool needs to be rotated, resulting in complex wire stripping operation in the prior art.

Owner:HENAN POWER TRANSMISSION & TRANSFORMATION CONSTR CO LTD +2

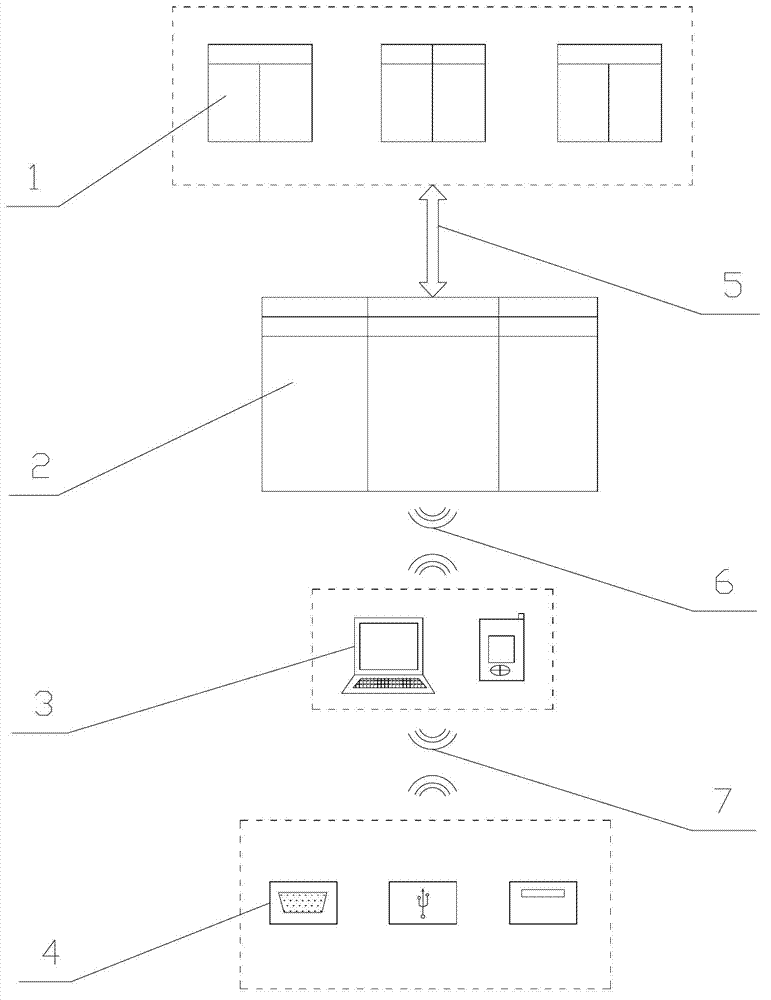

Personal information system based on cloud computing and formed by dependent special terminals

A personal information system based on the cloud computing and formed by dependent special terminals is mainly composed of a client device, a cloud end server and a corresponding connection network. The client device first needs to build connection with the cloud end server through the connection network to serve as a whole, and cannot visit other network serves alone or finish information processing and file storage tasks independently. Effect of the client device is similar to that of a browser in hardware level. The cloud end server finishes file storage and main information processing tasks of the whole system and can accept visit of client devices in different types of users as an information pivot. The whole system can respectively conduct software resource and hardware device expansion at the cloud end and the client. The system aims at resolving the problems of device performance, connection mode, file storage, information safety, manipulation experience, service provider profit, user using cost contradiction and the like in the field of personal information service.

Owner:马青川

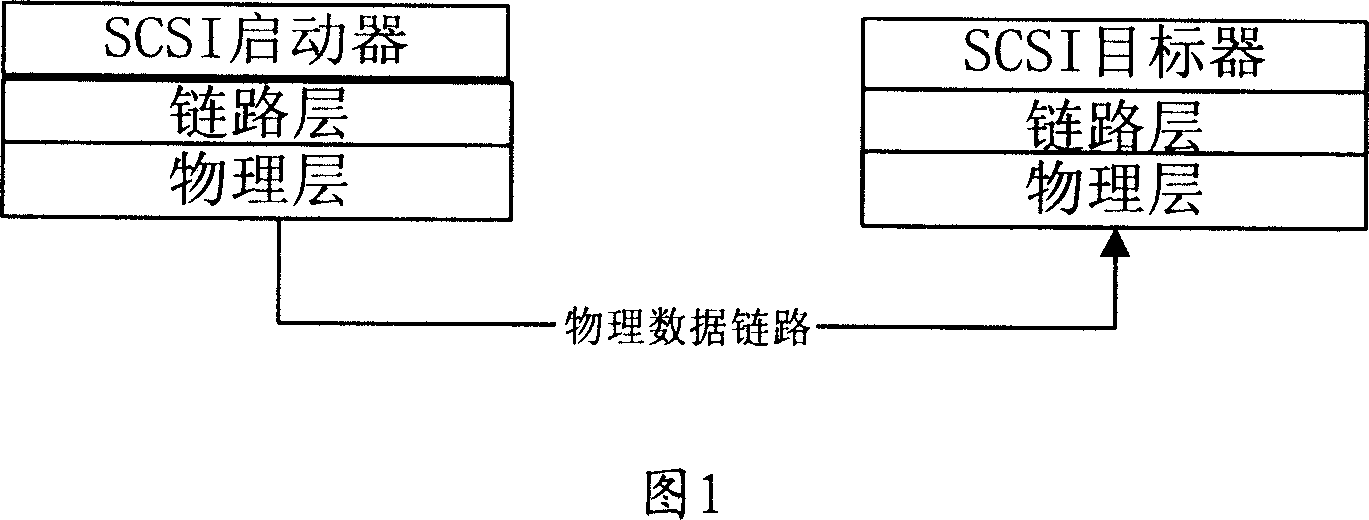

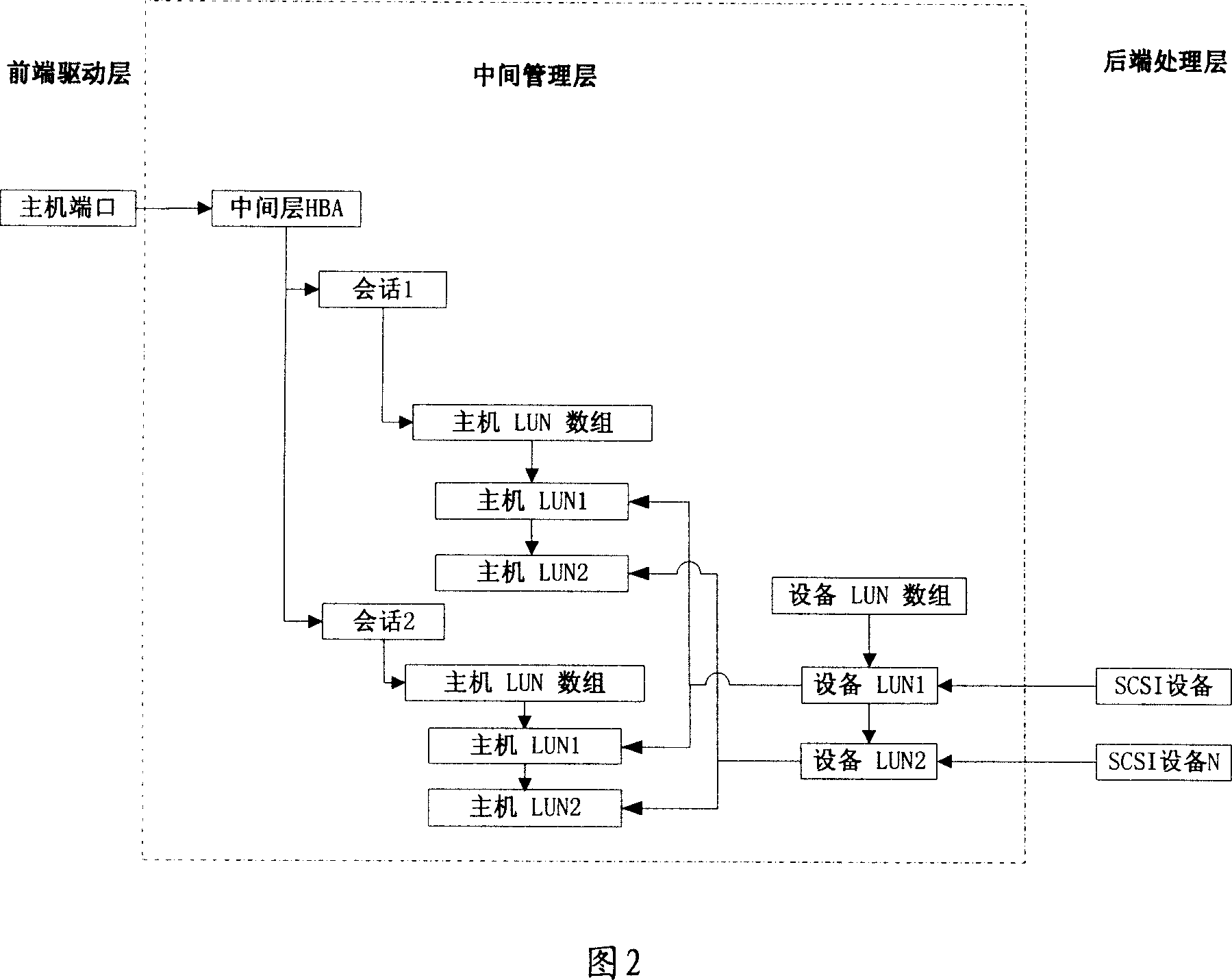

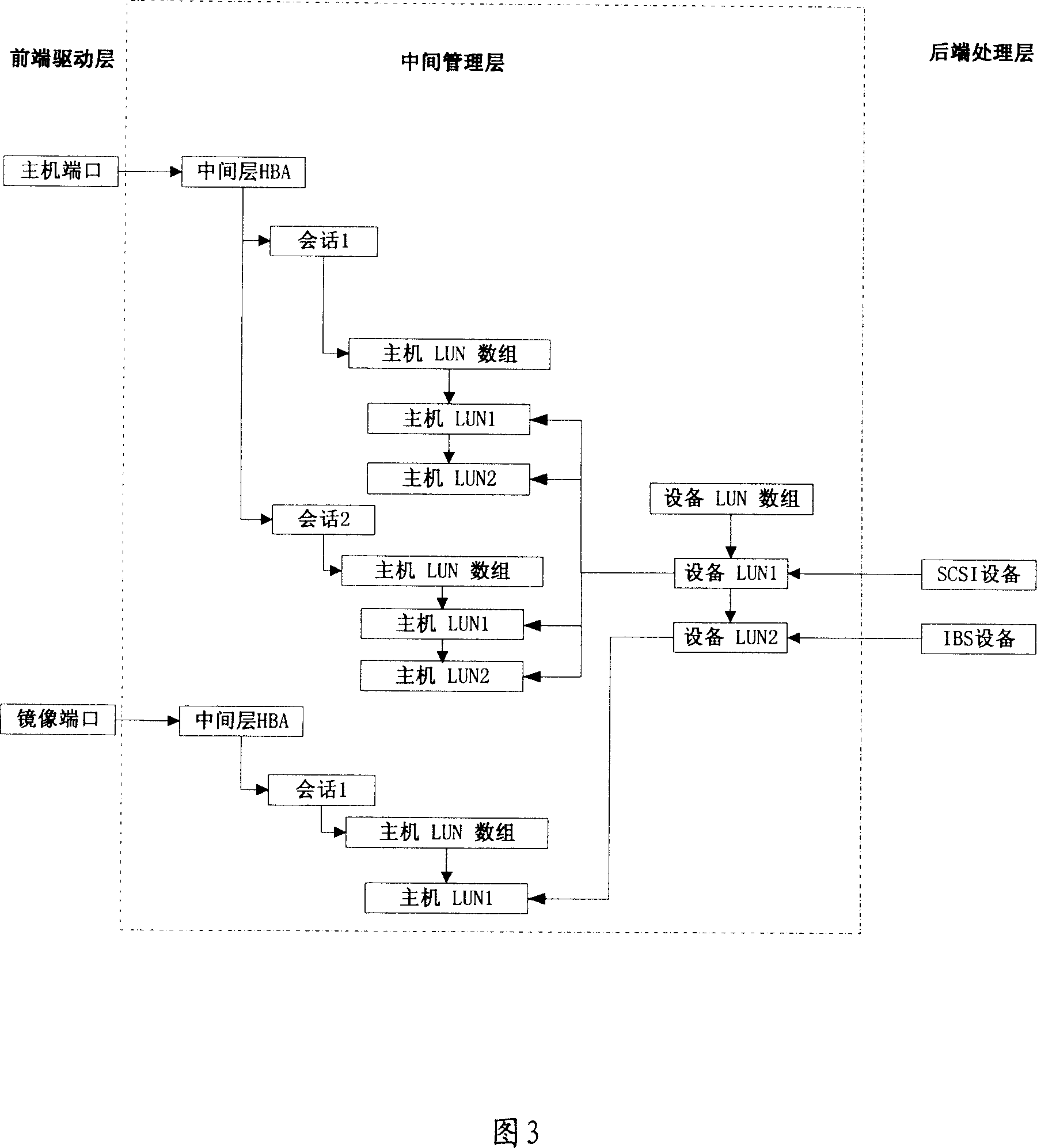

Architecture of interface target machine for miniature computer system and data transmitting method

ActiveCN1949203AEasy to execute and manageEasy to manageInput/output to record carriersData transmissionData processing

The invention supply small computer system interface target machine framework and data transmitting method. The framework includes front end drive layer used to receive SCSI request from host computer starter and transmit to middle managing layer and receive processed response back from the middle managing layer and transmit to host computer starter, middle managing layer used to receive SCSI request from the front end drive layer, generate SCSI command, manage the SCSI command, and transmit to back end processing layer receive processed response back from back end processing layer and transmit to front end drive layer, back end processing layer used to store configuration data, process SCSI command, return processed response to the middle managing layer. The invention can be used to keep SCSI target machine configuration data synchronizing with back end processing layer data, unify different SCSI target machine back end processing flow.

Owner:HUAWEI TECH CO LTD

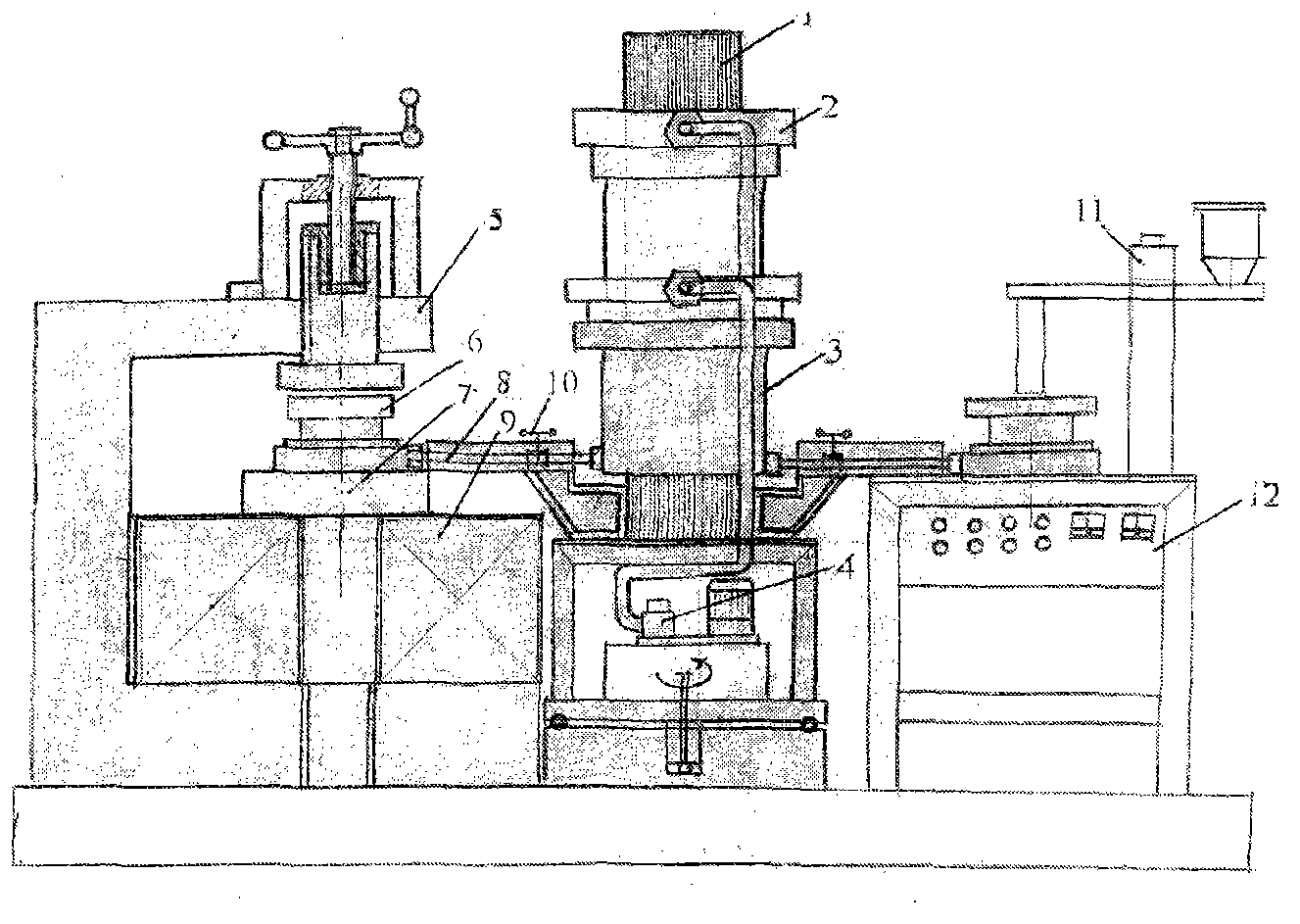

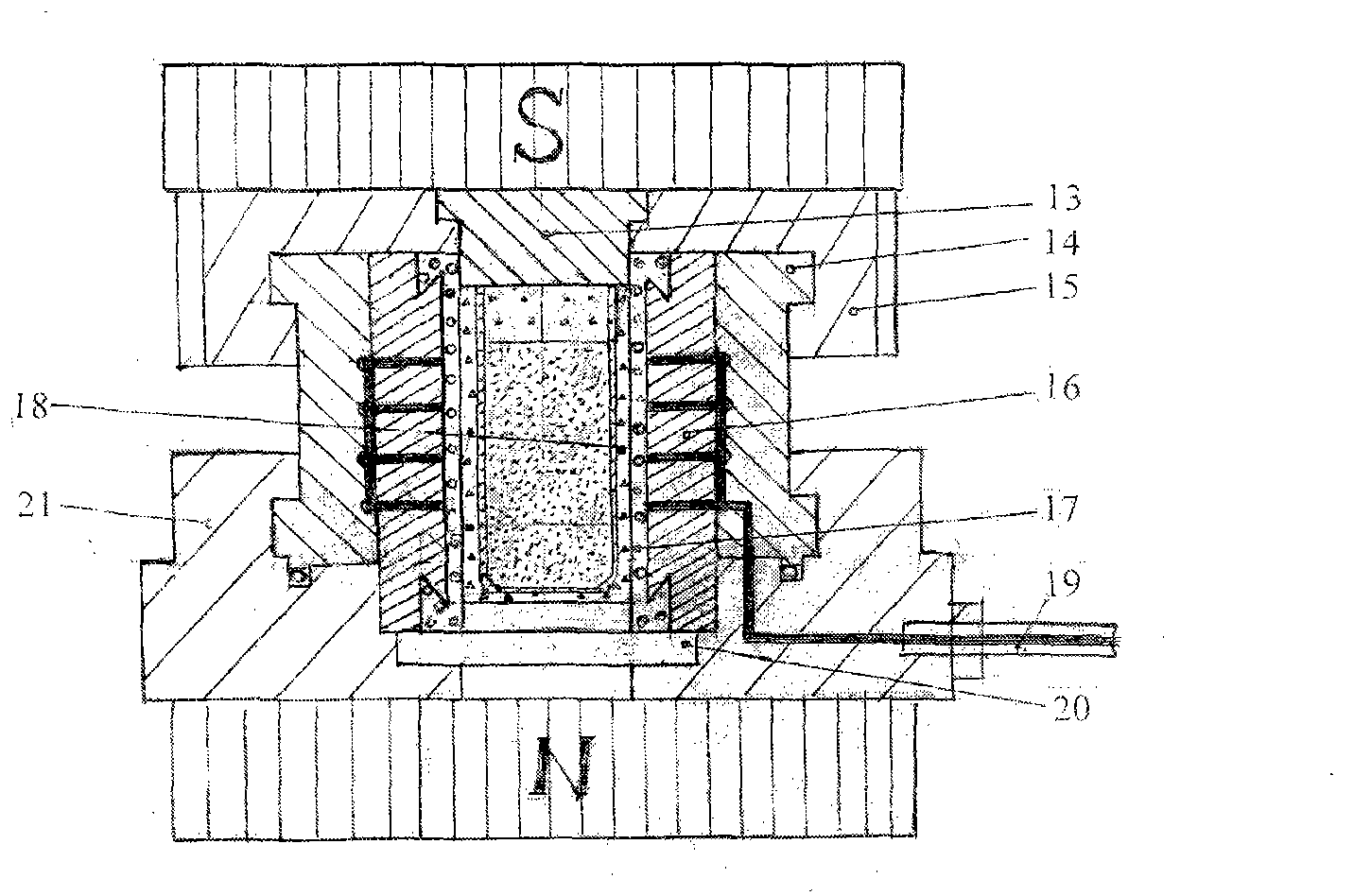

Technology and device for forming dry bag quick isostatic pressing in oriented magnetic fields

InactiveCN103878368AImprove automationIncrease the level of mechanizationInorganic material magnetismInductances/transformers/magnets manufactureResource utilizationMagnetic poles

The invention belongs to the field of technologies for manufacturing magnetic materials, and provides a technology and a device for forming dry bag quick isostatic pressing in oriented magnetic fields. The technology and the device have the advantages that an oriented magnetic field technology is ingeniously and organically combined with the technology and the device for forming dry bag isostatic pressing by the aid of a novel design concept, so that dry bag isostatic pressing can be formed in the oriented magnetic fields which have optional directions and optional magnetic field intensities by the aid of the novel technology and the novel device; orientation degrees of products can be obviously upgraded; two necessary working procedures in existing neodymium, iron and boron magnet production can be combined with each other to form one working procedure by the novel technology and the novel device, and the automation and mechanization levels are high; powder is not in contact with pressing blanks and oil in production procedures, and accordingly a latex sheath for binding the corresponding pressing blank can be omitted; the pressing blanks are quite uniform in density distribution and internal stress distribution; the pressing blanks can be machined, and original powder can be recycled; single-hole and multi-hole thin-walled pipes, sleeves and multi-magnetic-pole products which are heavy and are in complicated shapes or have large length-diameter (L / d) ratios can be produced by the aid of the technology and the device, the rare earth mineral resource utilization rate can be greatly increased, and the neodymium, iron and boron magnet industrial production level of China can be upgraded to the world leading level.

Owner:吴庆华 +2

Sliding roll-cutting type semiautomatic film cutting machine for fruit film bags

InactiveCN102756391ARealize semi-automatic film cuttingImprove efficiencyMetal working apparatusReciprocating motionPlastic film

The invention discloses a sliding roll-cutting type semiautomatic film cutting machine for fruit film bags. The film cutting machine comprises a rack, and a film cutting device and a fixing and pressing device, which are arranged on the rack. The film cutting device comprises a film cutting working tabletop, guide-track grooves, cylinders and roll-cutting discs, wherein the guide-track grooves are formed in the film cutting working tabletop; and the roll-cutting discs are driven by the cylinders to rotate, and reciprocally move in the guide-track grooves. The fixing and pressing device comprises pressing handles, wherein the pressing handles are arranged above a plastic film bag strip to be cut, and are used for fixing and pressing the plastic film bag strip. The fixing and pressing device for pressing the plastic film bag strip and a plurality of roll-cutting discs are arranged, a plurality of parts of the plastic film bag strip formed by stacking plastic fruit film bags with the film thicknesses of 0.003 to 0.01mm are subjected to semiautomatic film cutting at the same time, and a maximum thickness of the plastic film bag strip to be cut can reach 15cm, so that the aim of improving the film cutting efficiency and the quality of a product is fulfilled.

Owner:徐世慧

Multifunctional computer desk

InactiveCN106213801APrevent fallingPrevent rolloverOffice tablesVariable height tablesTablet computerUSB

The invention discloses a multifunctional computer desk. The multifunctional computer desk comprises a desk top and supporting legs. A first groove, a second groove, a through hole and a sixth groove are formed in the desk top, and a drawer is arranged on one side of the desk top. A lighting device is arranged in the drawer. Fans, a supporting frame and two supports are arranged at the bottom of the second groove, first supporting plates are arranged on the two side faces and the front face of the second groove respectively, a third groove is formed in the rear face of the second groove, and a cover plate is arranged on the upper face of the second groove. The through hole is communicated with the interior of one side of the second groove. A connecting line and a USB plug are arranged on one fan. A mouse pad is arranged in the sixth groove, and a wrist protecting groove is formed in the front end of the sixth groove. Each supporting leg comprises an upper sleeve and a lower sleeve. The multifunctional computer desk is good in heat dissipating effect and high in university, the height of the computer desk can be adjusted, and the inclination of a notebook computer or a tablet computer can be adjusted; meanwhile, the computer desk can serve as a study desk and is wide in application range and high in practicality.

Owner:XUCHANG UNIV

Array substrate and display device

InactiveCN107238990AAvoid clutterIncrease opening ratioSolid-state devicesNon-linear opticsVertical projectionDisplay device

The embodiment of the invention provides an array substrate and a display device. The array substrate comprises a substrate body, a switch component, metal wirings, a pixel electrode and a plurality of pixel units, wherein the switch component is arranged on the substrate body; the switch component comprises a plurality of transistors; the pixel electrode comprises a plurality of strip-shaped main lines, the main lines comprise horizontal main lines and vertical main lines which are perpendicular to each other, and drain electrode wirings of the transistors are located below the horizontal main line closest to the transistors; each pixel unit comprises a plurality of display domain areas, and the display domain areas of each pixel unit are symmetric about the horizontal main lines or the vertical main lines; the projection of the metal wirings on the array substrate coincides with the vertical projection of the horizontal main lines or the vertical main lines on the array substrate. According to the embodiment, the aperture ratio of the display device is increased, and the display effect is obviously improved.

Owner:HKC CORP LTD +1

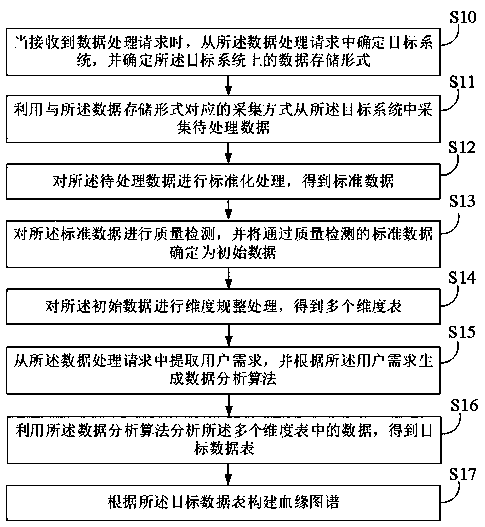

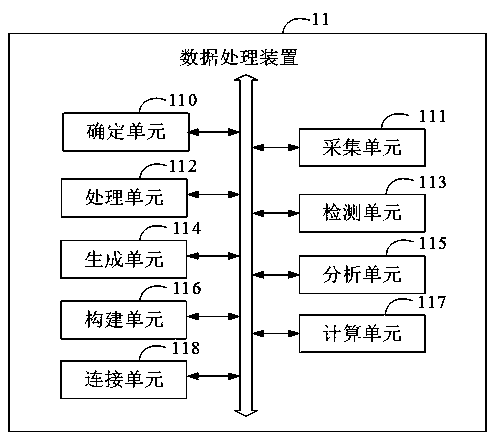

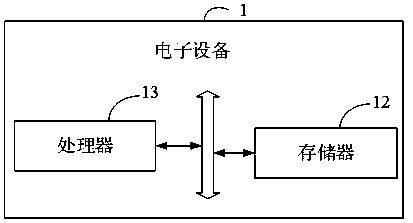

Data processing method and device, electronic equipment and medium

ActiveCN111488363AEnsure complianceReduce difficultyDatabase management systemsFinanceDatasheetEngineering

The invention relates to big data, and provides a data processing method and device, electronic equipment and a medium. The method includes: determining a target system from a data processing request;determining a data storage form on the target system; acquiring to-be-processed data from the target system by utilizing an acquisition mode corresponding to the data storage form, standardizing theto-be-processed data; obtaining standard data, performing quality detection on the standard data; determining the standard data passing the quality detection as initial data; carrying out dimension normalization processing on the initial data; obtaining a plurality of dimension tables; extracting the user demand from the data processing request, generating the data analysis algorithm according tothe user demand, analyzing the data in the multiple dimension tables by using the data analysis algorithm to obtain the target data table, and constructing the blood relationship map according to thetarget data table. The problem that the data is difficult to collect is solved, and the data analysis efficiency is also improved. The invention also relates to a blockchain technology, and the bloodrelationship map is stored in the blockchain.

Owner:PINGAN INT SMART CITY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com