Patents

Literature

63results about How to "Small feed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

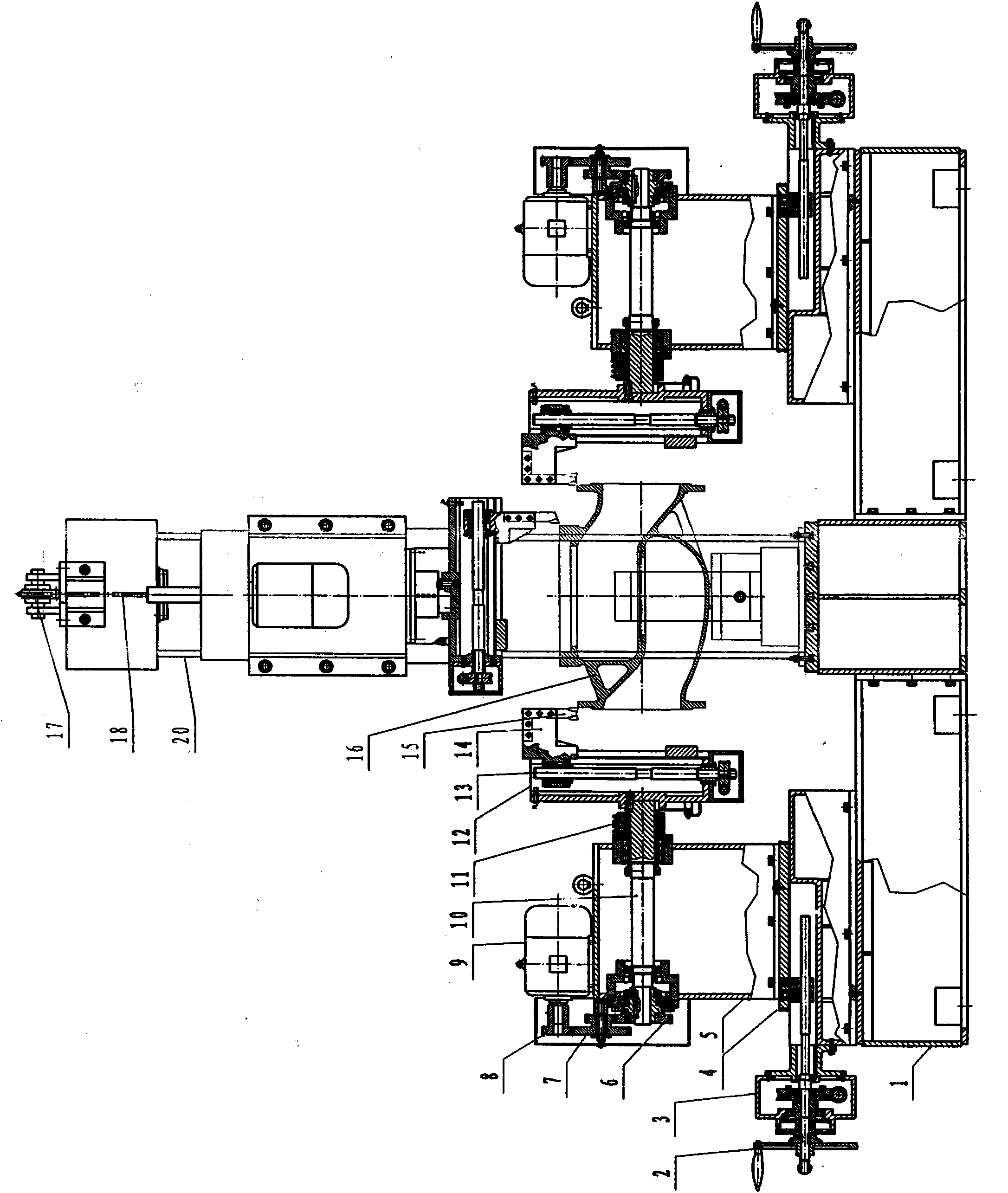

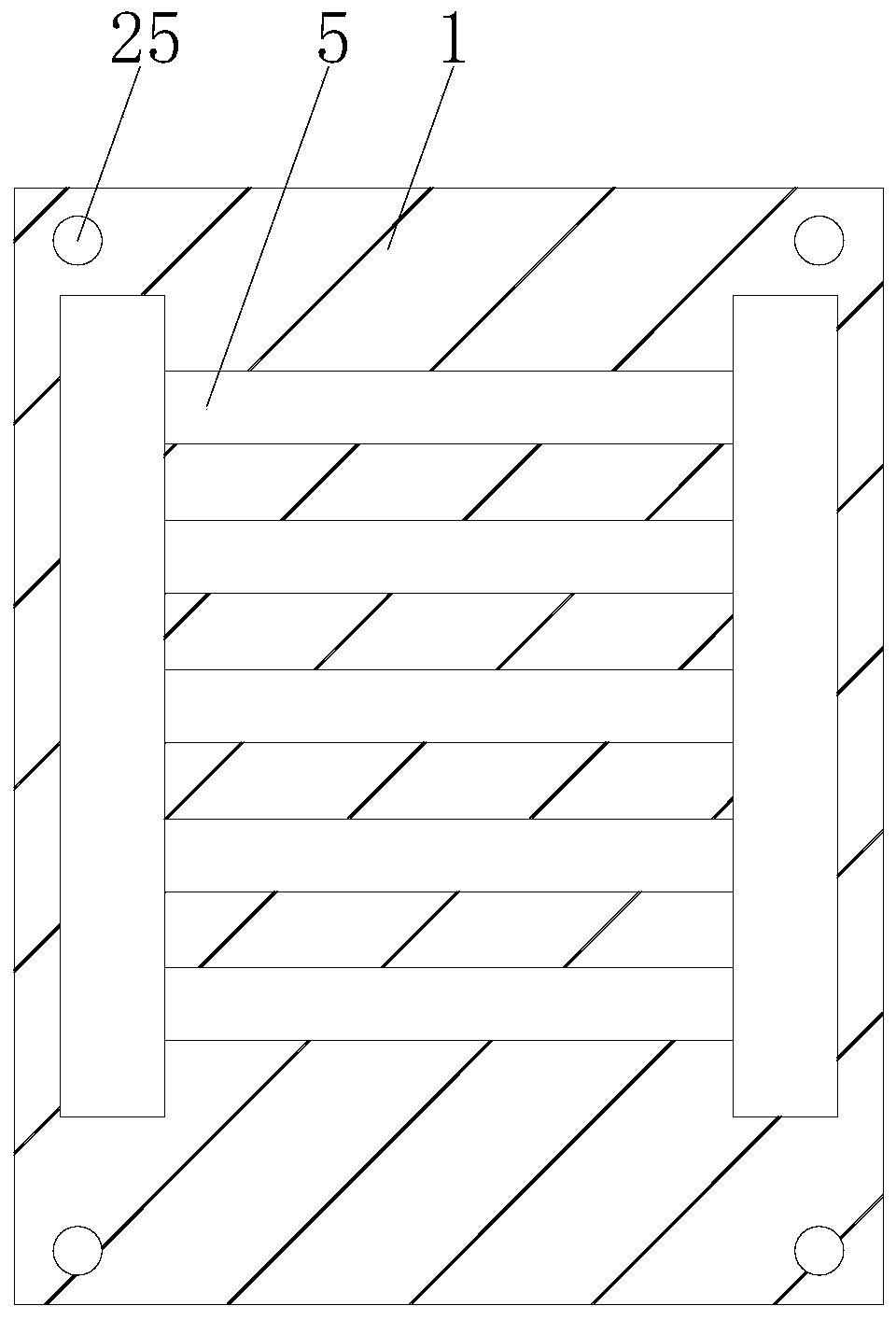

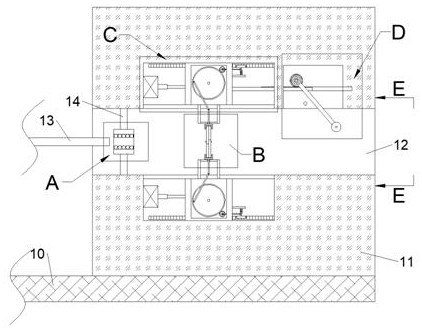

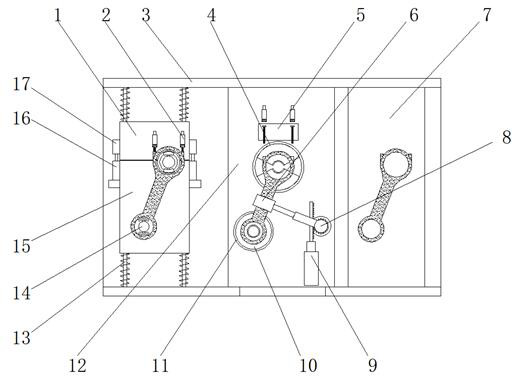

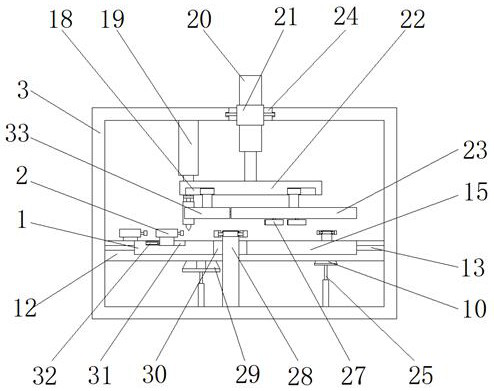

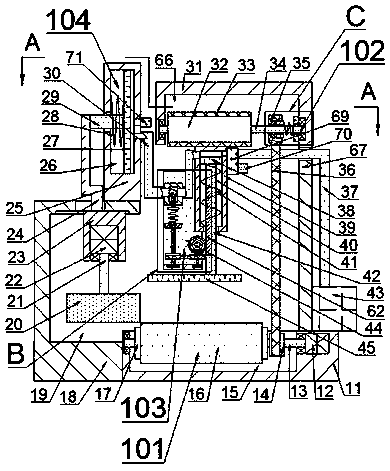

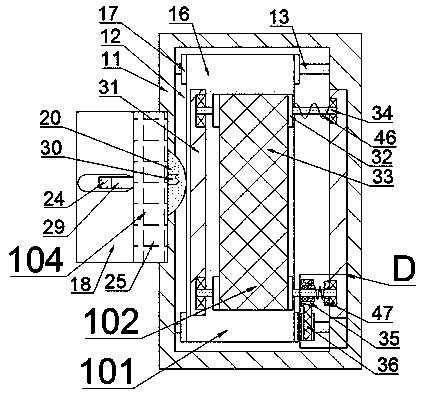

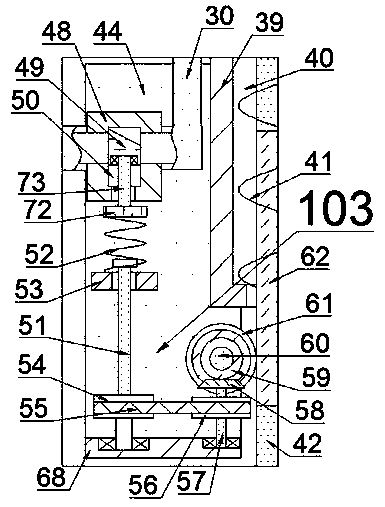

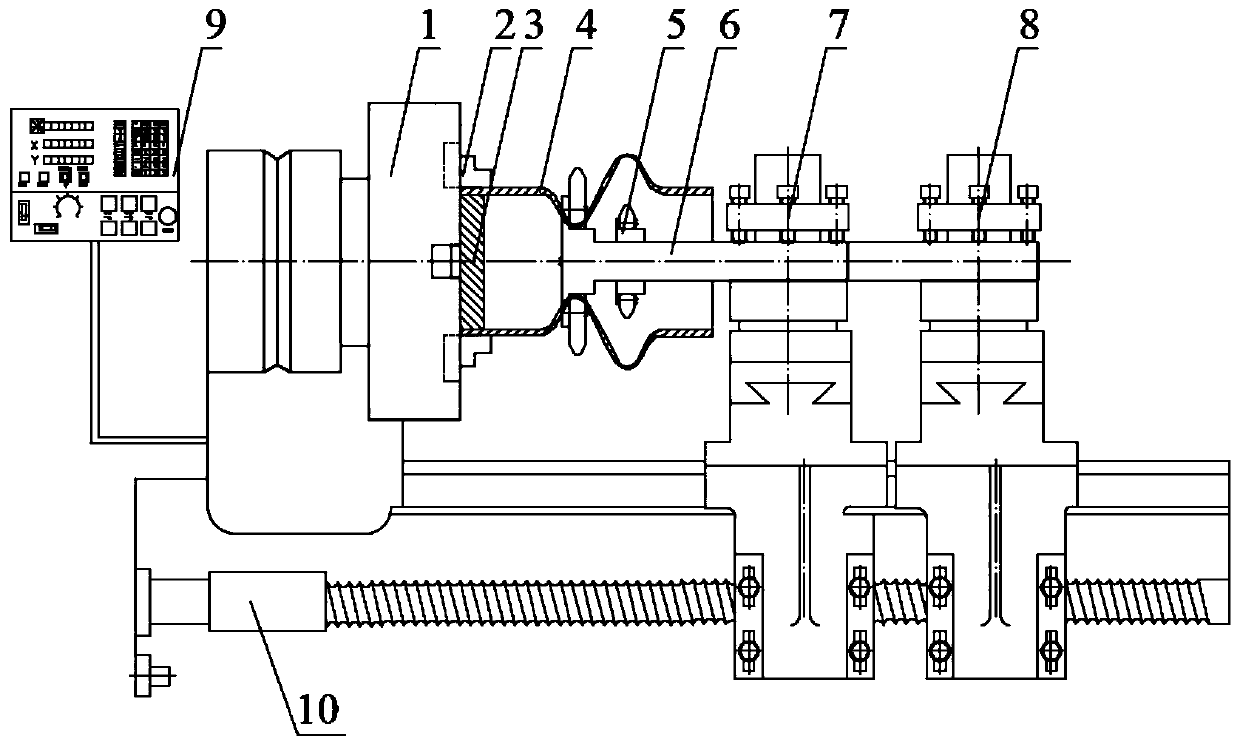

Three-station combined machining tool for valve body of valve

InactiveCN101869993APreserve machining accuracyReduce labor intensityFeeding apparatusTurning machinesControl systemEconomic benefits

The invention discloses a three-station combined machining tool for a valve body of a valve, which comprises a tool bed and three swivel stands, wherein each swivel stand mainly comprises a tool rest mechanism, a speed shifting mechanism, a main spindle box, a feeding mechanism and a control system, the tool bed is provided with a fixture, the three swivel stands are respectively arranged at the left part, the middle part and the right part of the tool bed to form a triangular structure, the left and the right swivel stands are arranged in opposite directions and are same in structure, and the middle swivel stand is vertically downwards arranged on a column. Only by single clamping and correcting, the three-station combined machining tool can simultaneously machine a left-end flange, a right-end flange and a rabbet (or a watermark trough) of a valve body workpiece of a valve as well as the surface rabbet, the inner hole and the like of a mount support at the upper end of the valve body in three three-dimensional directions, and therefore, the labor intensity of workers is reduced, time and labor are saved, the production efficiency and the product machining qualification rate are improved, and economic benefits of valve production enterprises are increased.

Owner:德阳市广泰机械科技有限公司

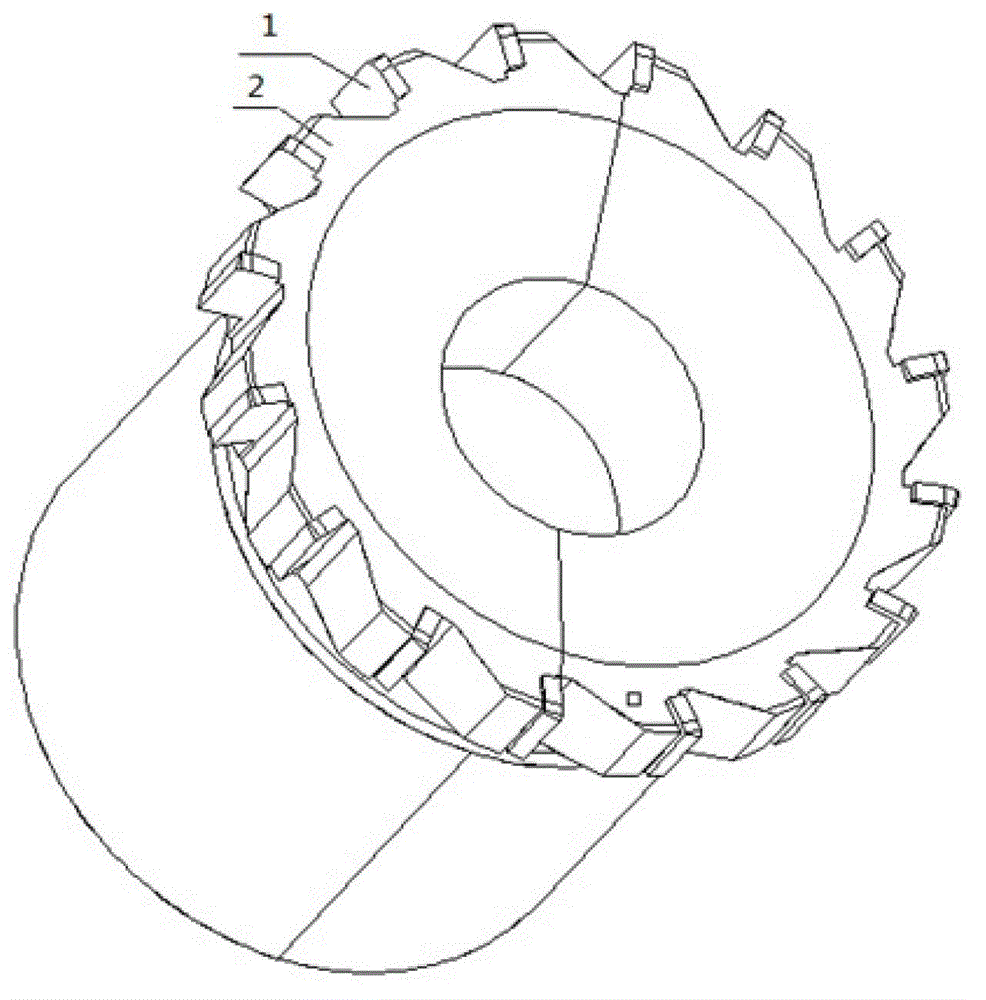

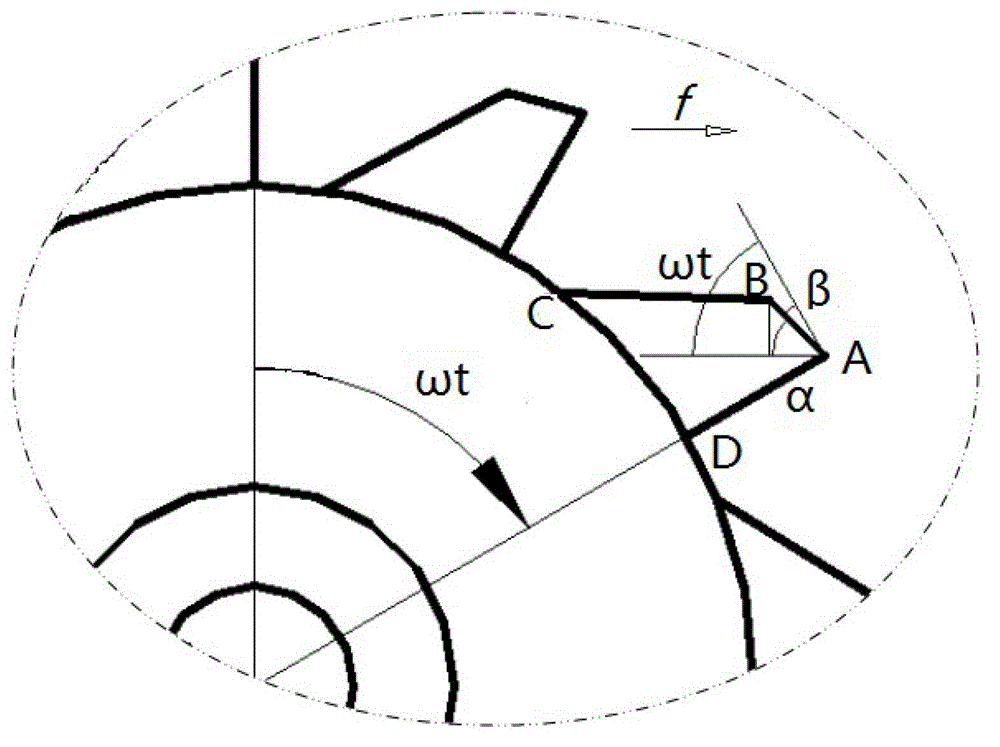

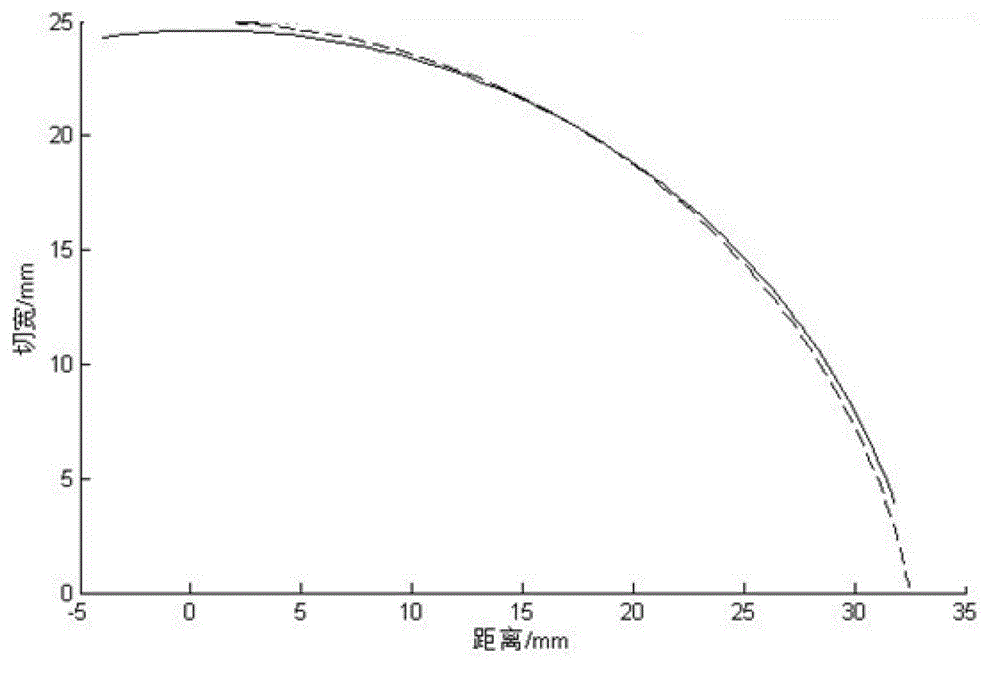

Ultra-dense tooth face milling cutter and design method thereof

The invention discloses an ultra-dense tooth face milling cutter and a design method thereof. The ultra-dense tooth face milling cutter can solve the problem that the existing milling cutter has low cutting efficiency and alow processing precision in processing on a material having high processing difficulty. In design, the number of milling teeth is used as an independent variable and according to influences of structure parameters and cutting parameters, under the premise of strength maintenance, the most appropriate number of the milling teeth of an ultra-dense tooth face milling cutter is obtained so that efficiency is improved, a loss is reduced and a processing precision is improved. The number of the milling teeth is greatly increased so that processing efficiency is greatly improved. Through appropriate decreasing of a feeding amount of each one of the milling teeth, the feeding amount adapts to the number of the ultra-dense milling teeth so that a cutting force on each one of the milling teeth is reduced, blade wear is reduced, and surface quality of a processed workpiece is improved. Under the two influences, the ultra-dense tooth face milling cutter obviously improves processing efficiency. The ultra-dense tooth face milling cutter has high cutting efficiency and precision, prolongs a milling cutter service life and reduces a processing cost.

Owner:XI AN JIAOTONG UNIV

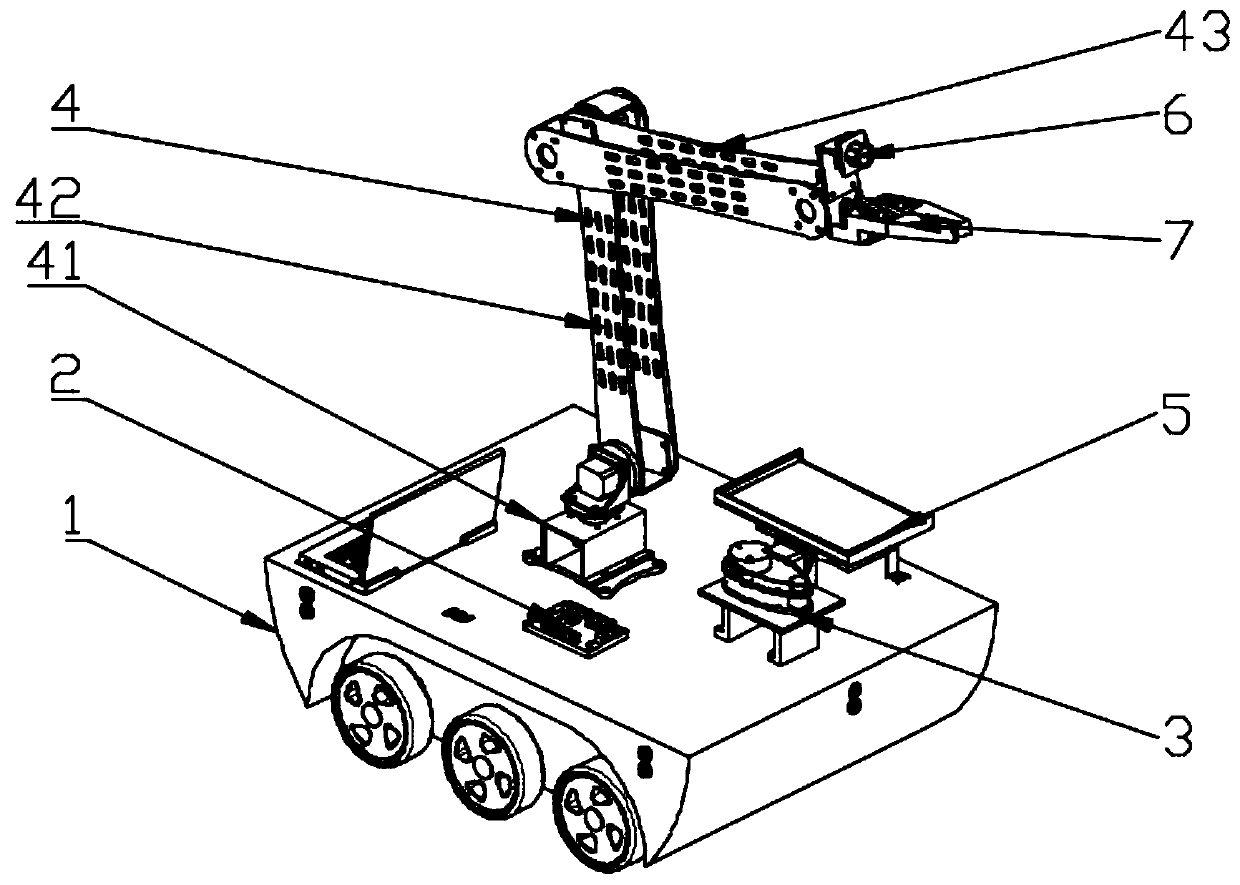

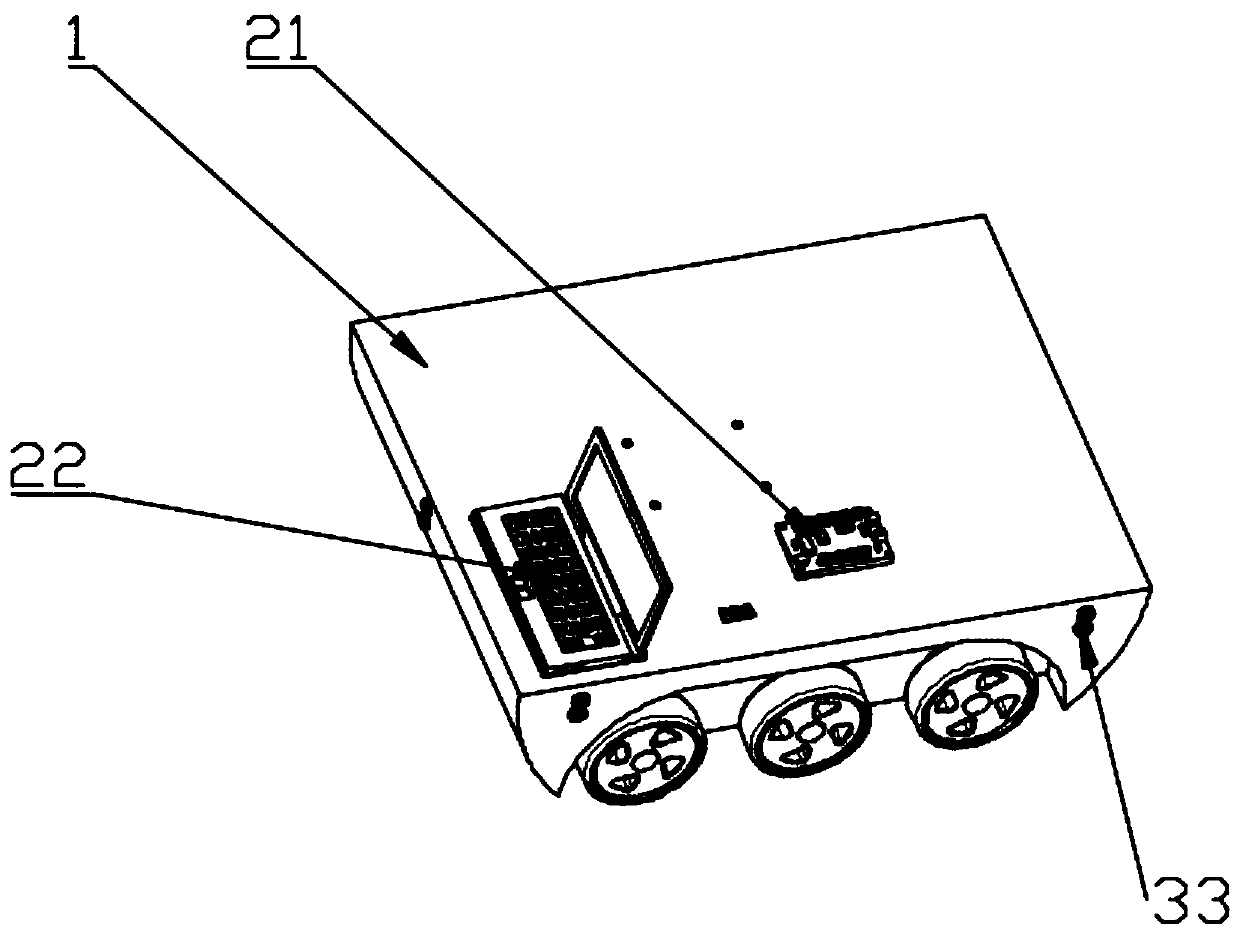

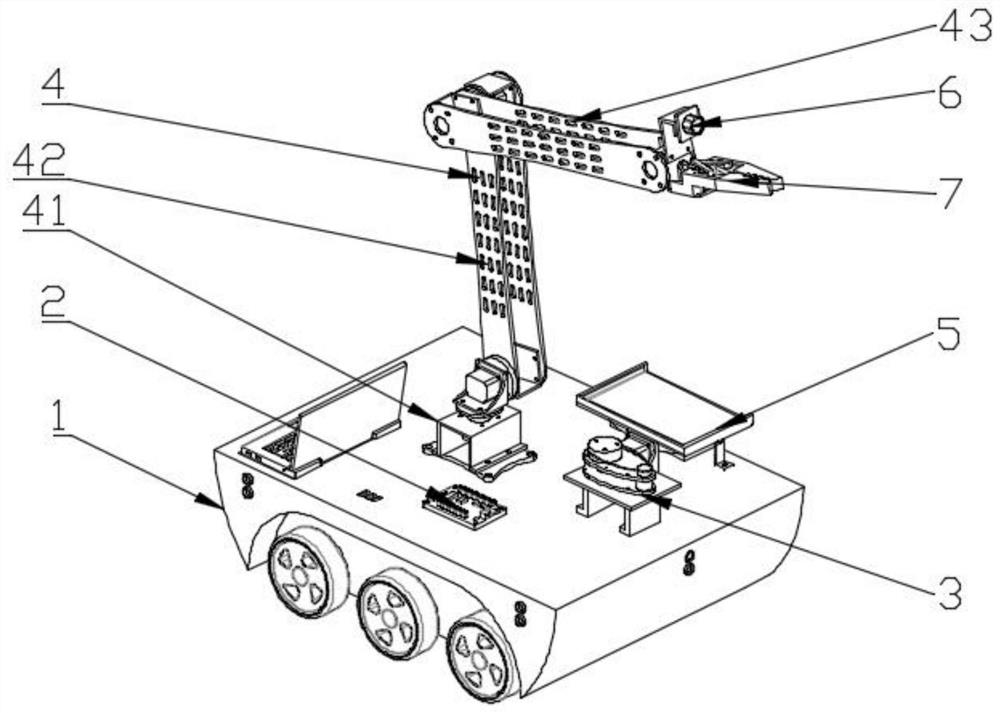

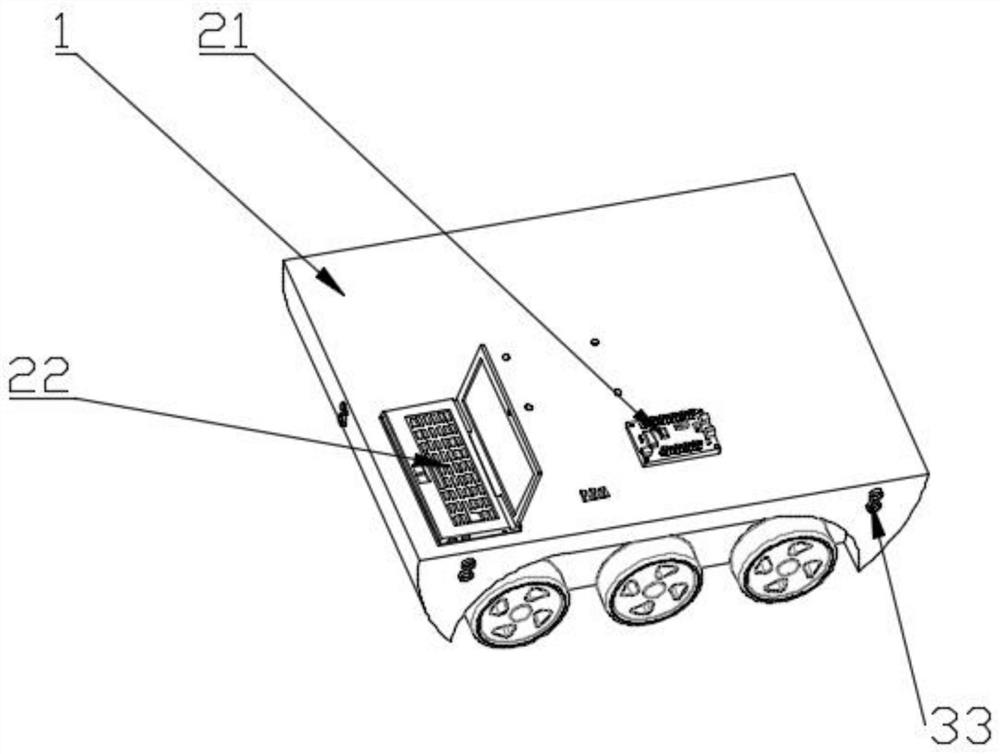

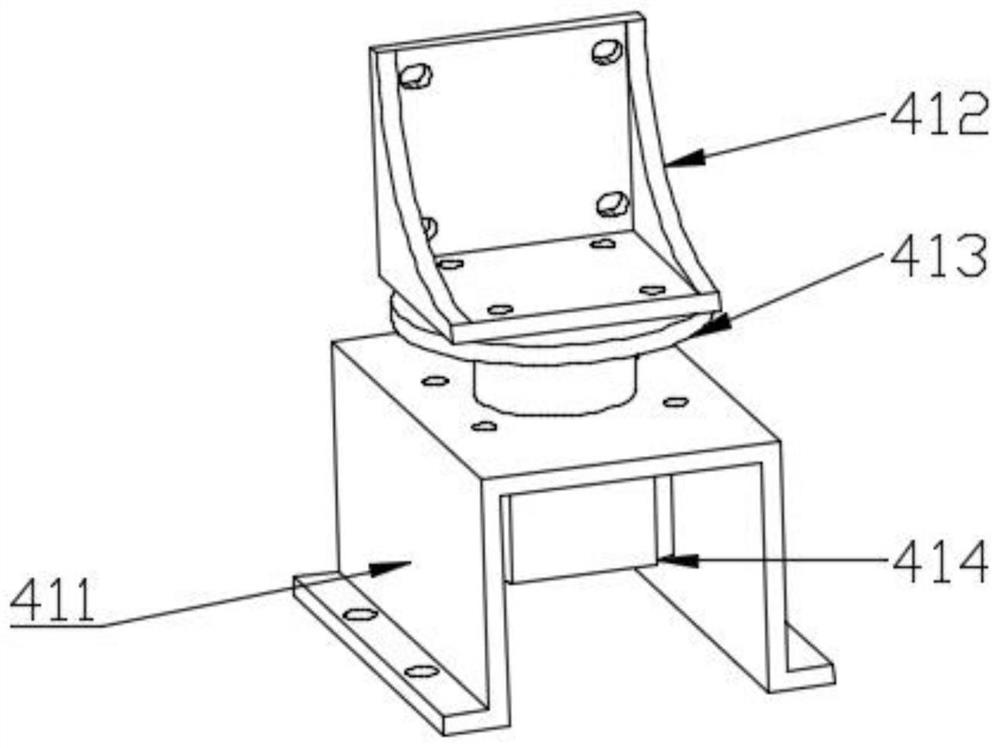

Moving platform for taking and placing stored goods and route planning method of moving platform

ActiveCN110465928AImprove reliabilitySmall feedProgramme-controlled manipulatorGripping headsModularityRoute planning

The invention discloses a moving platform for taking and placing stored goods and a route planning method of the moving platform. The moving platform comprises a moving platform body, an obstacle avoiding device, a mechanical arm device, a goods placing device, a goods recognition device and a goods grabbing device. The obstacle avoiding device, the mechanical arm device and the goods placing device are installed on the moving platform body. The goods grabbing device is installed at the tail end of the mechanical arm device. The goods recognition device is installed on the goods grabbing device. The mechanical arm device comprises a rotating mechanism and multiple mechanical arms. The multiple mechanical arms are mutually connected in a rotating manner. The multiple mechanical arms form one modularized mechanical arm. One end of the first mechanical arm is fixed to the rotating mechanism. The tail end of the last mechanical arm is fixed to the goods grabbing device. According to the method, the improved dynamic window method is adopted for adjusting three weights for evaluating a function in real time, the adaptation ability of the moving platform to the environment is improved, and the success rate of the moving platform reaching the designated position point is ensured.

Owner:HEBEI UNIV OF TECH

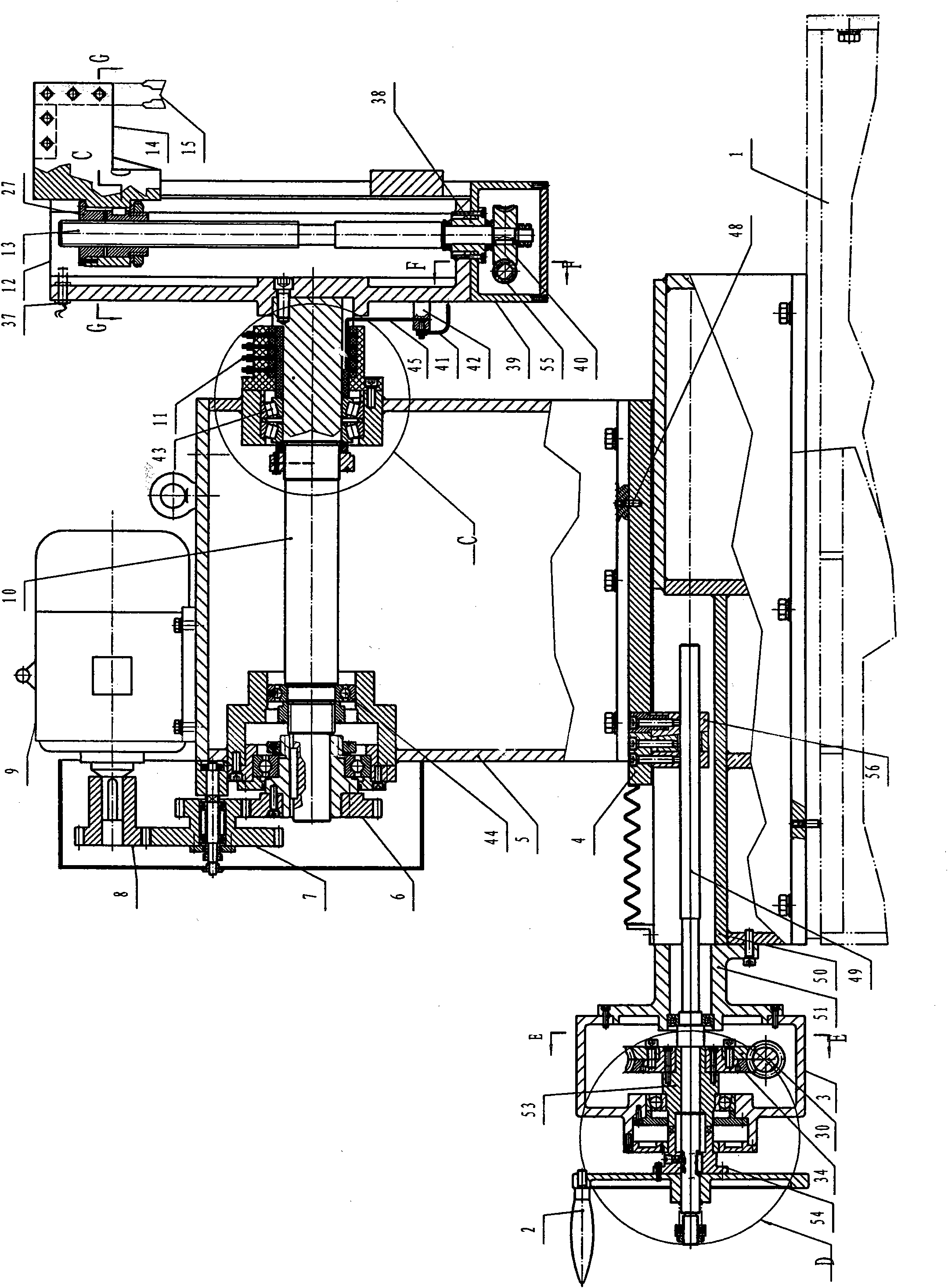

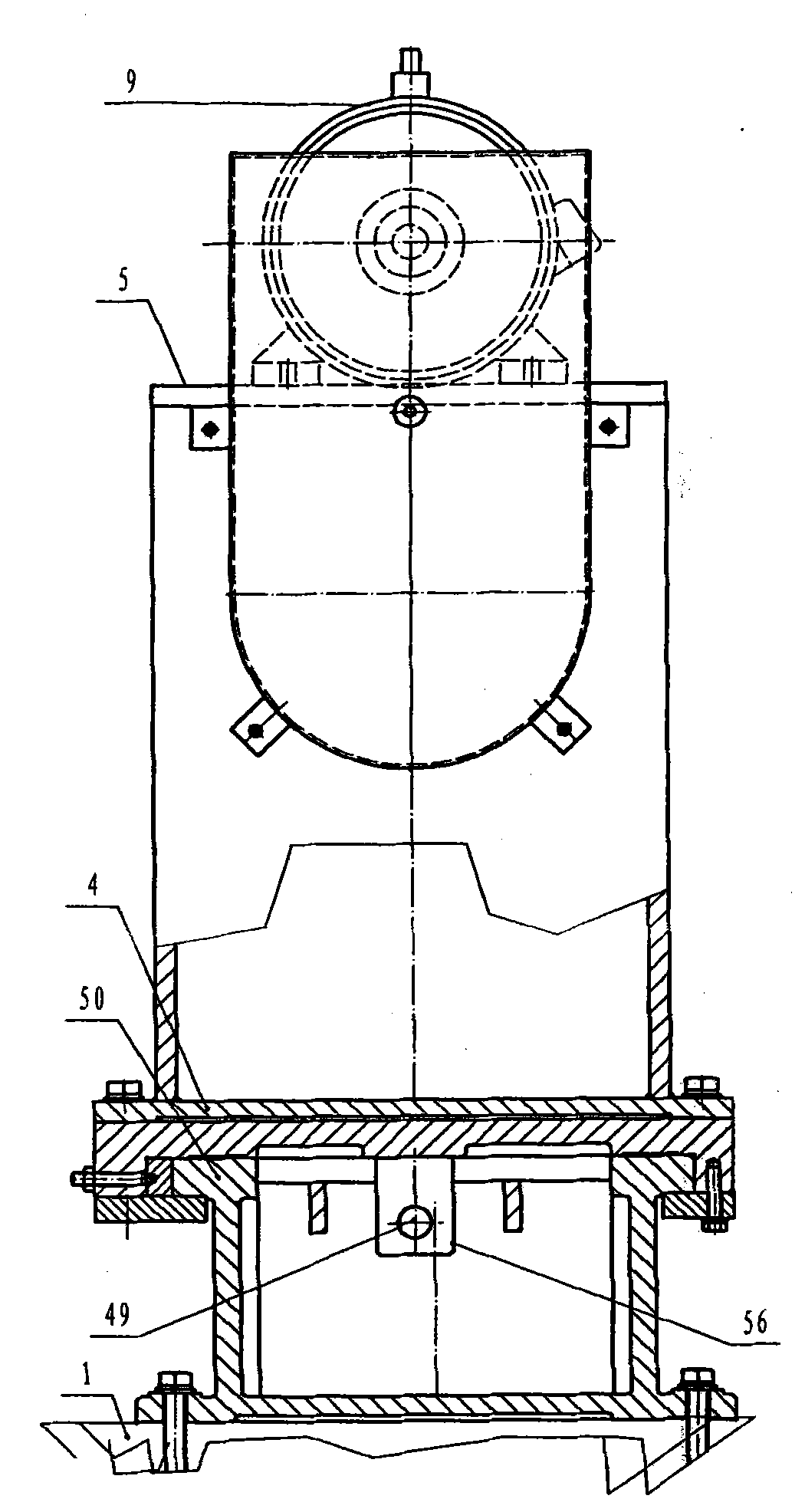

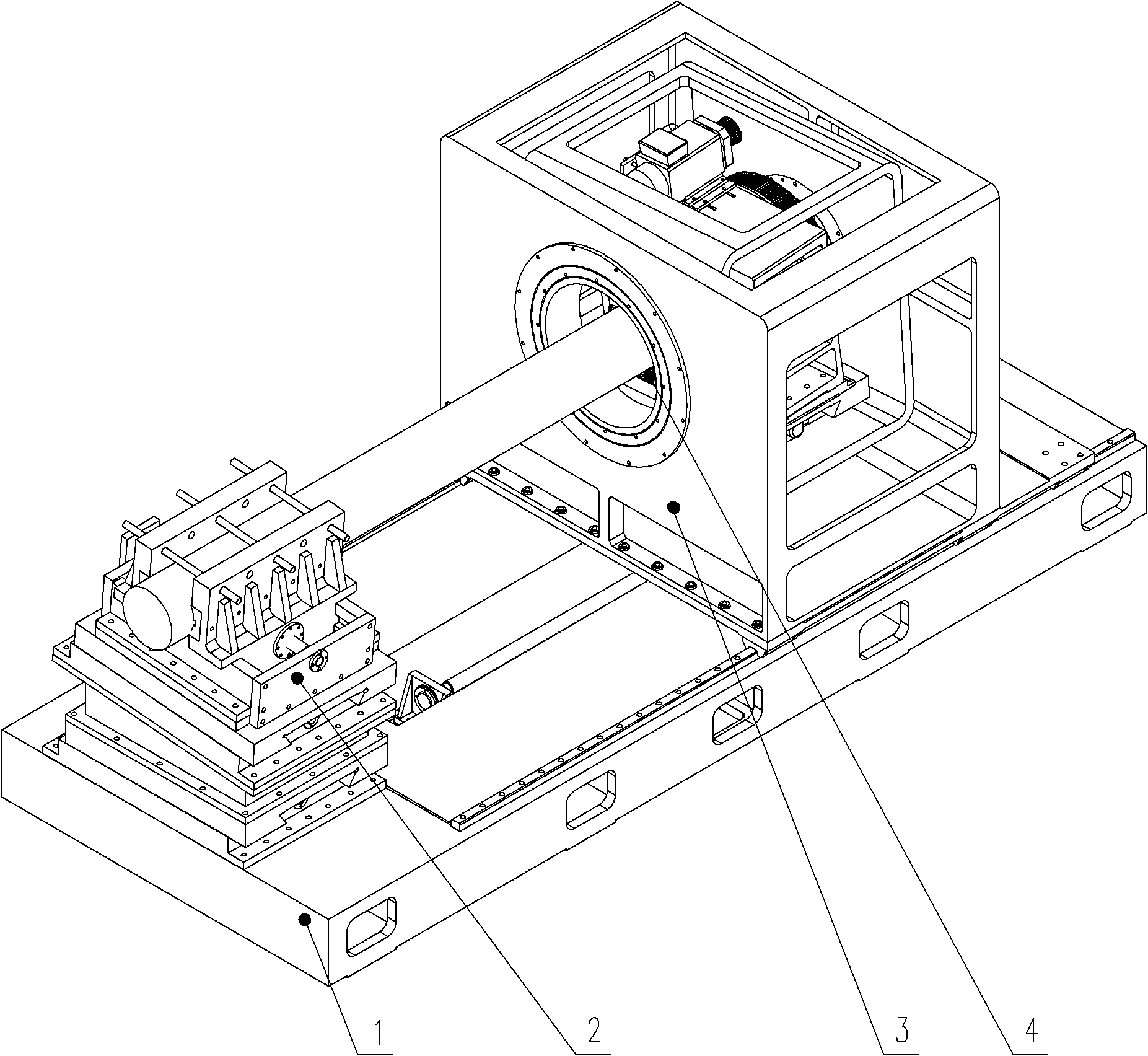

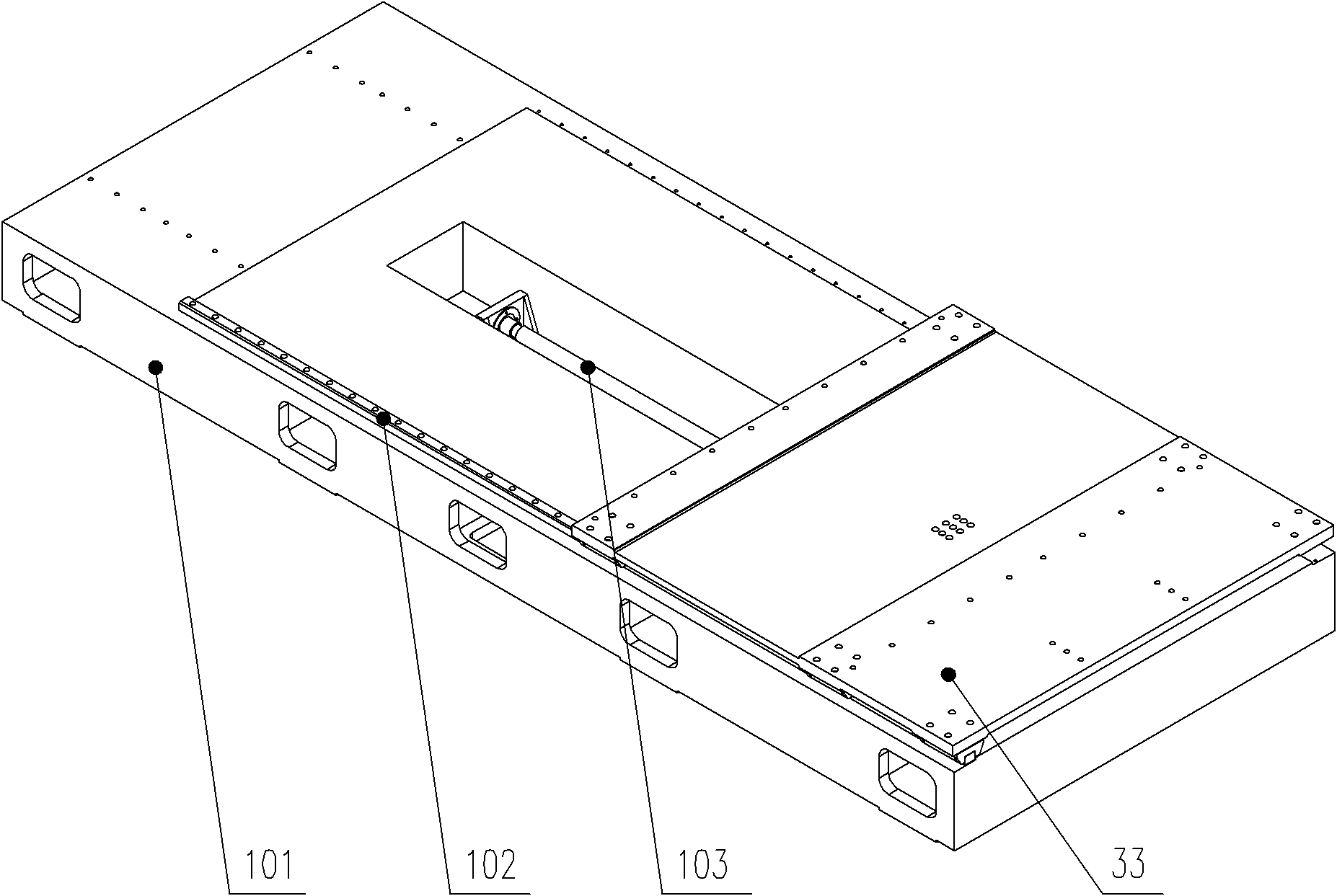

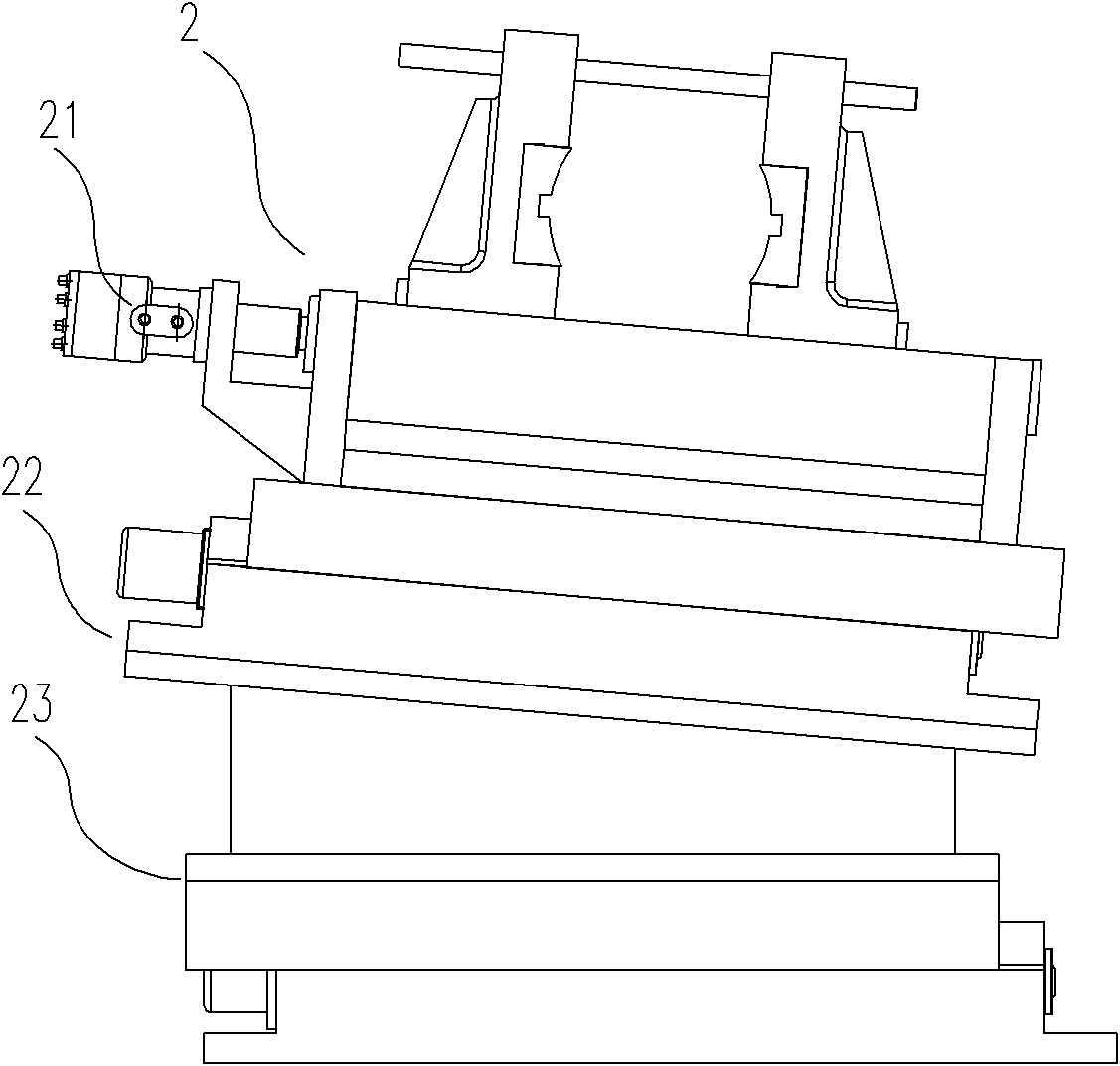

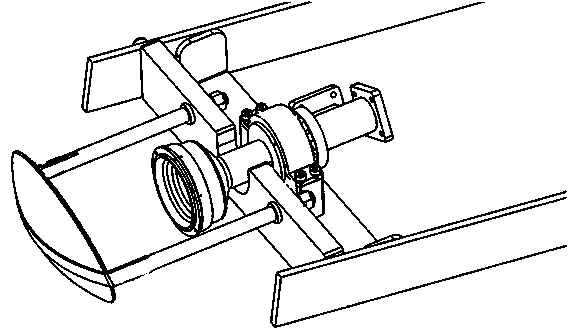

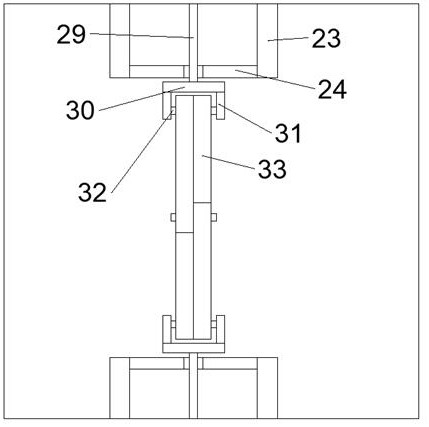

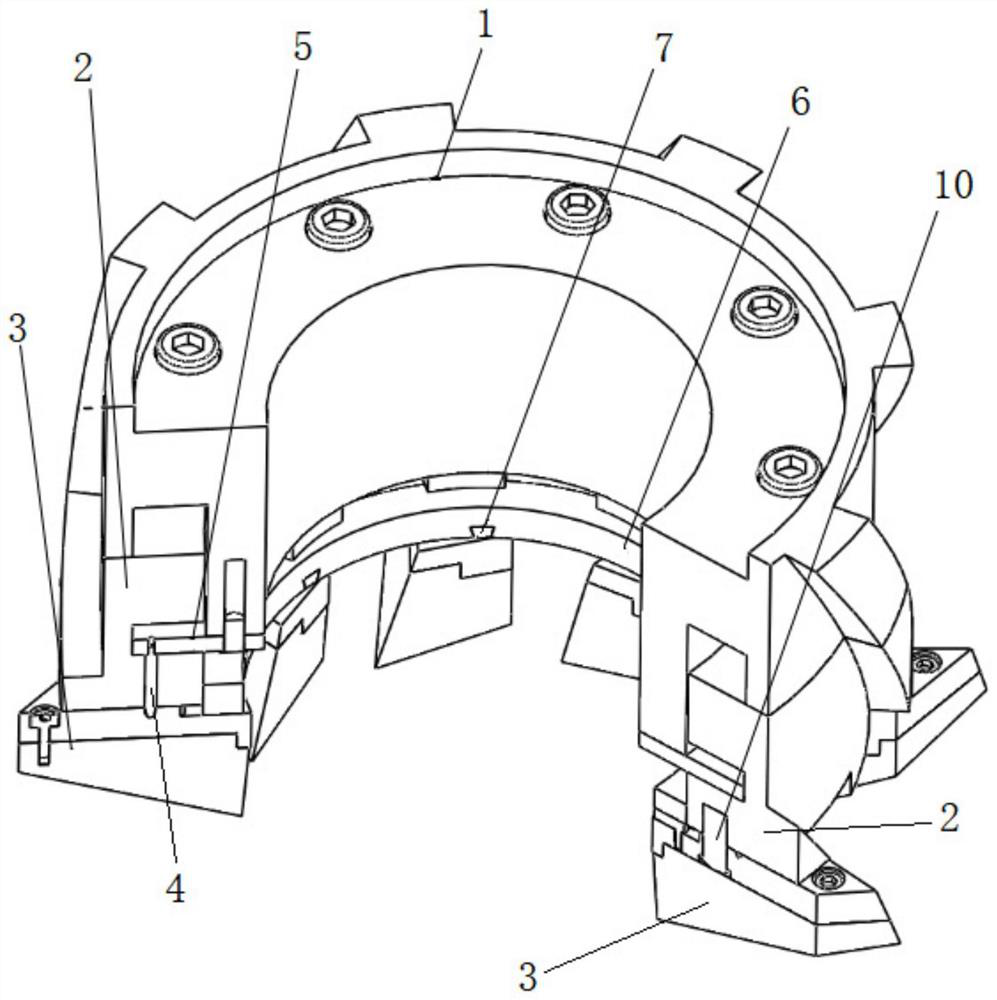

Shaft-like rotary workpiece static external round machining machine tool

ActiveCN101927374ARealize external machiningImprove processing efficiencyMilling equipment detailsEngineeringSmall tooth

The invention discloses a shaft-like rotary workpiece static external round machining machine tool and relates to a machine tool. The shaft-like rotary workpiece static external round machining machine tool comprises a machine tool body part, a workpiece clamping device, a cutter device and a cutter rotating device, wherein the machine tool body part comprises a machine tool body, linear guide rails arranged on the machine tool body and an axially feeding screw component, the cutter rotating device comprises a revolution part and a rotation part arranged in the revolution part, the cutter device is arranged on the rotation part, the revolution part is fixedly connected with a connecting plate, and the connecting plate is arranged on the linear guide rails on one end of the machine tool body and is fixedly connected with the axially feeding screw component; and the workpiece clamping device is arranged on the machine tool body on the other end of the machine tool body part. The machinetool can meet the requirements for shaft-like rotary workpiece static external round machining and realize thread whirling and has the advantages of high machining efficiency, high processing quality, large workpiece center adjusting range, small tooth machining amount, long tool service life, convenient tool replacement, low production cost, wide application range and the like.

Owner:LIUZHOU OVM MASCH CO LTD

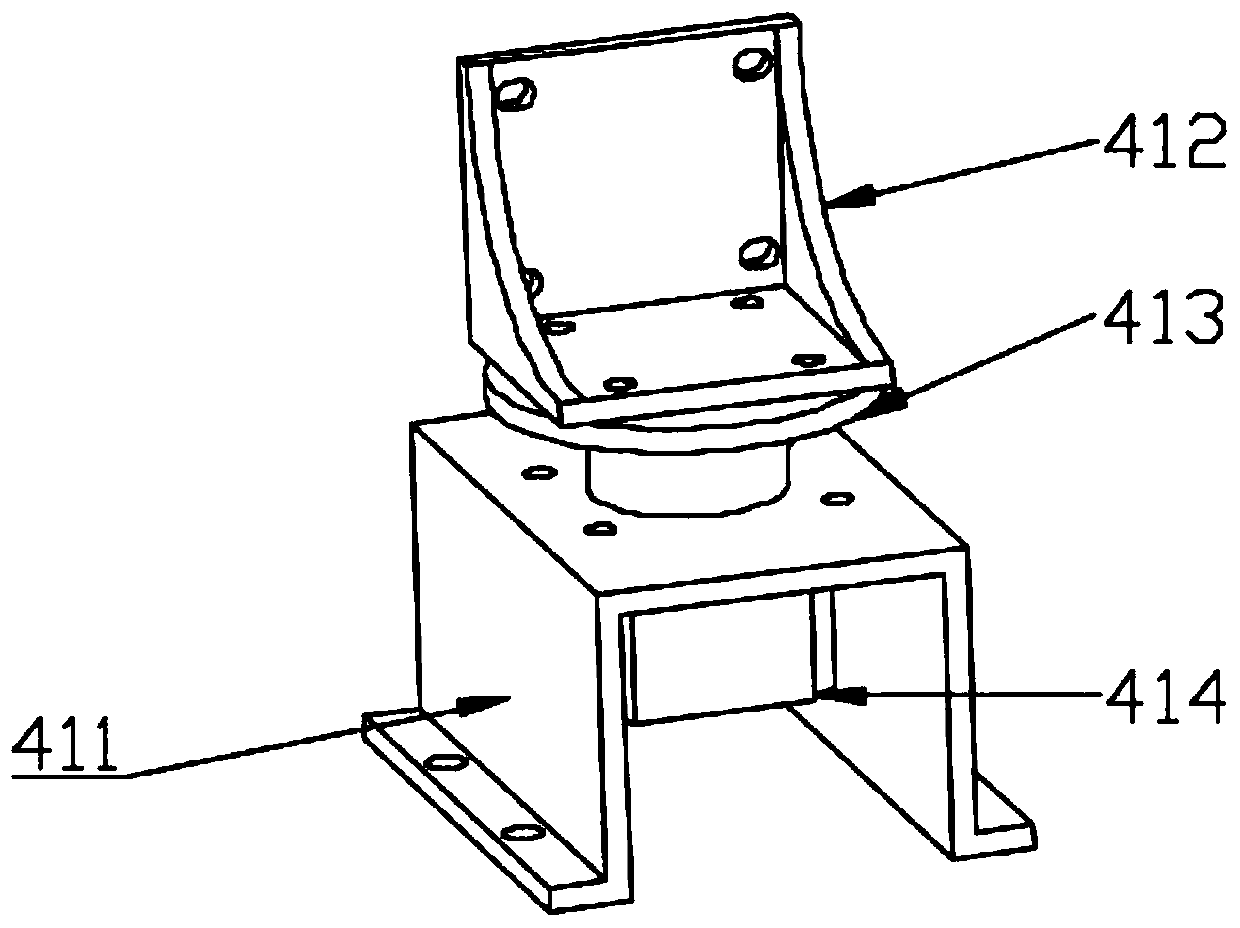

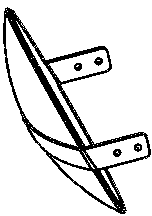

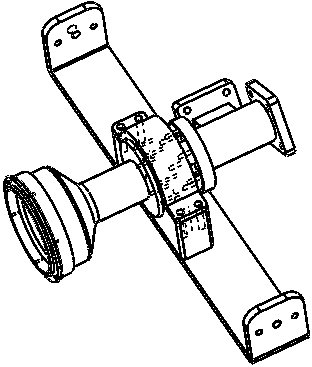

Portable double-offset-parabola antenna

InactiveCN104167612AGuaranteed performanceImprove performanceAntenna supports/mountingsEllipseEngineering

The invention discloses a portable double-offset-parabola antenna which comprises a main reflecting face, an auxiliary reflecting face, a main-reflecting-face supporting device, an auxiliary-reflecting-face fixing device, a feed source system, a feed source supporting device and a servo motor. The main reflecting face is fixed to the main-reflecting-face supporting device, the auxiliary reflecting face is fixed to the main-reflecting-face supporting device through the auxiliary-reflecting-face fixing device, the servo motor is fixed to the position below the main-reflecting-face supporting device, the feed source system is fixed to the main-reflecting-face supporting device through the feed source supporting device, and the main reflecting face is of a transverse elliptic structure, that is, the width of the main reflecting face is larger than the height of the main reflecting face. Compared with an existing Gregory antenna, the performance of the antenna is guaranteed; meanwhile, the portable double-offset-parabola antenna has the advantages that the focal length is small, the caliber is small, a feed source is small, and the performance is excellent; the portable double-offset-parabola antenna has the structural advantages of being simple in structure, light in weight, easy to machine and low in cost.

Owner:NANJING CHINA SPACENET SATELLITE TELECOM

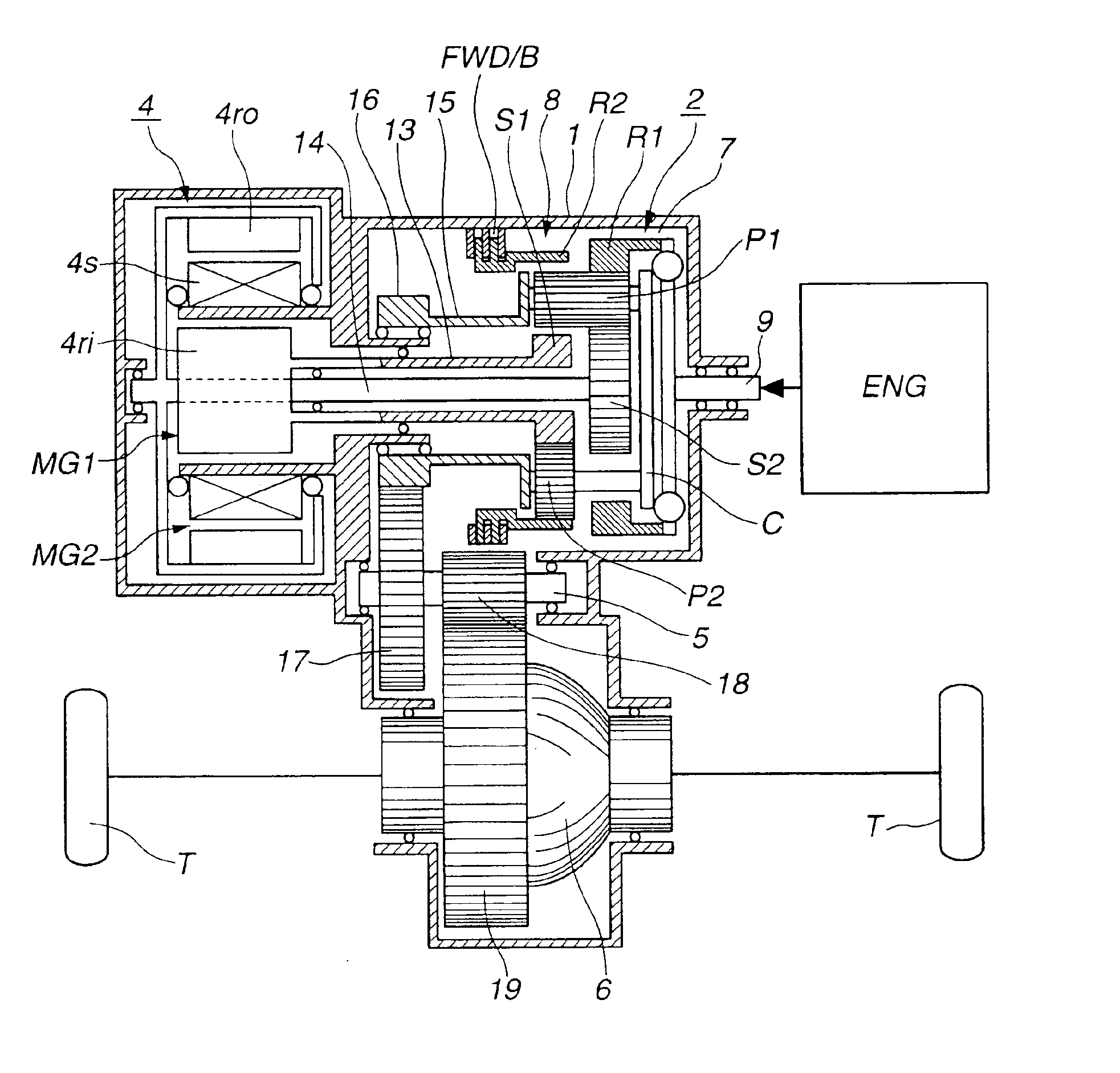

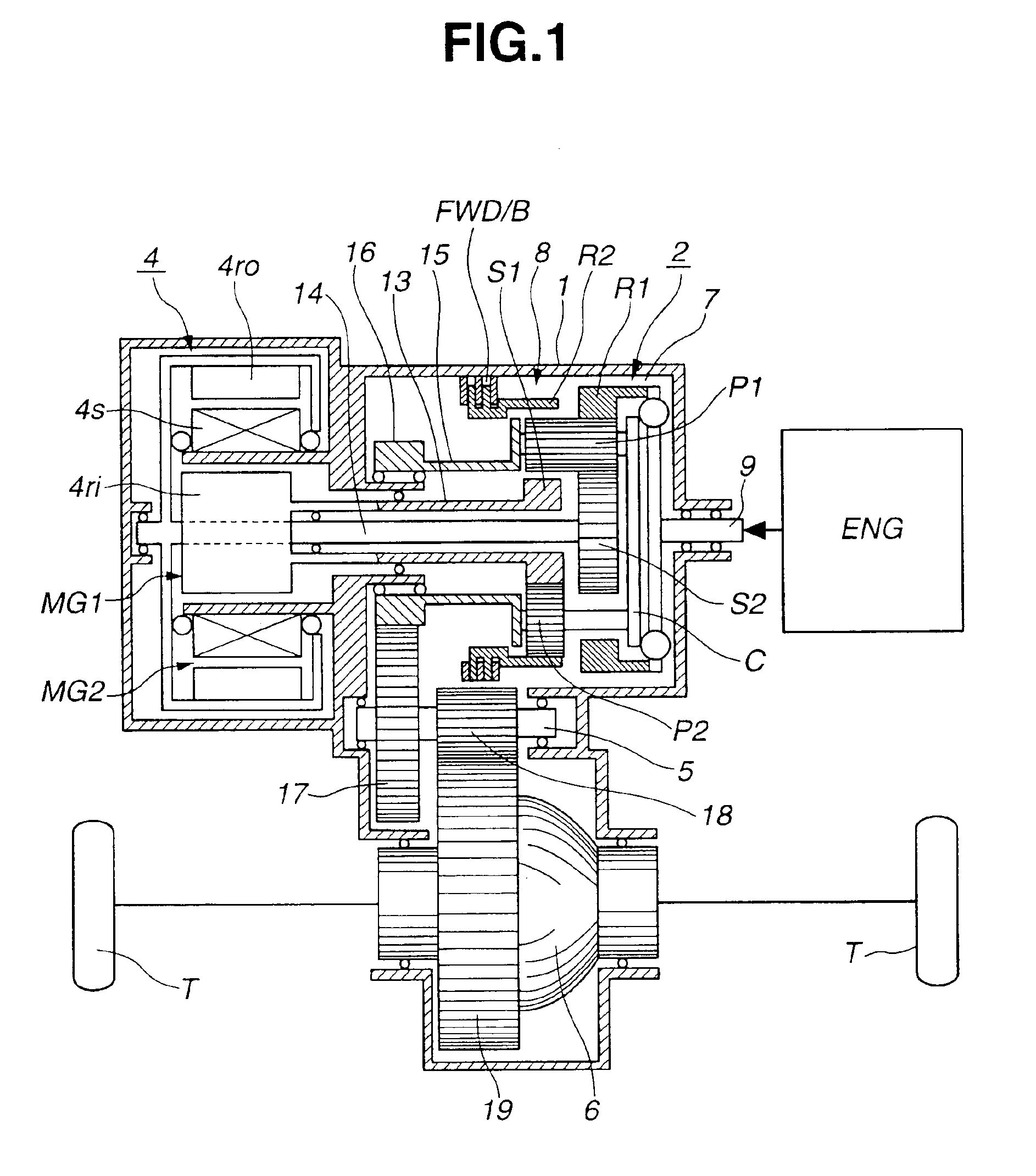

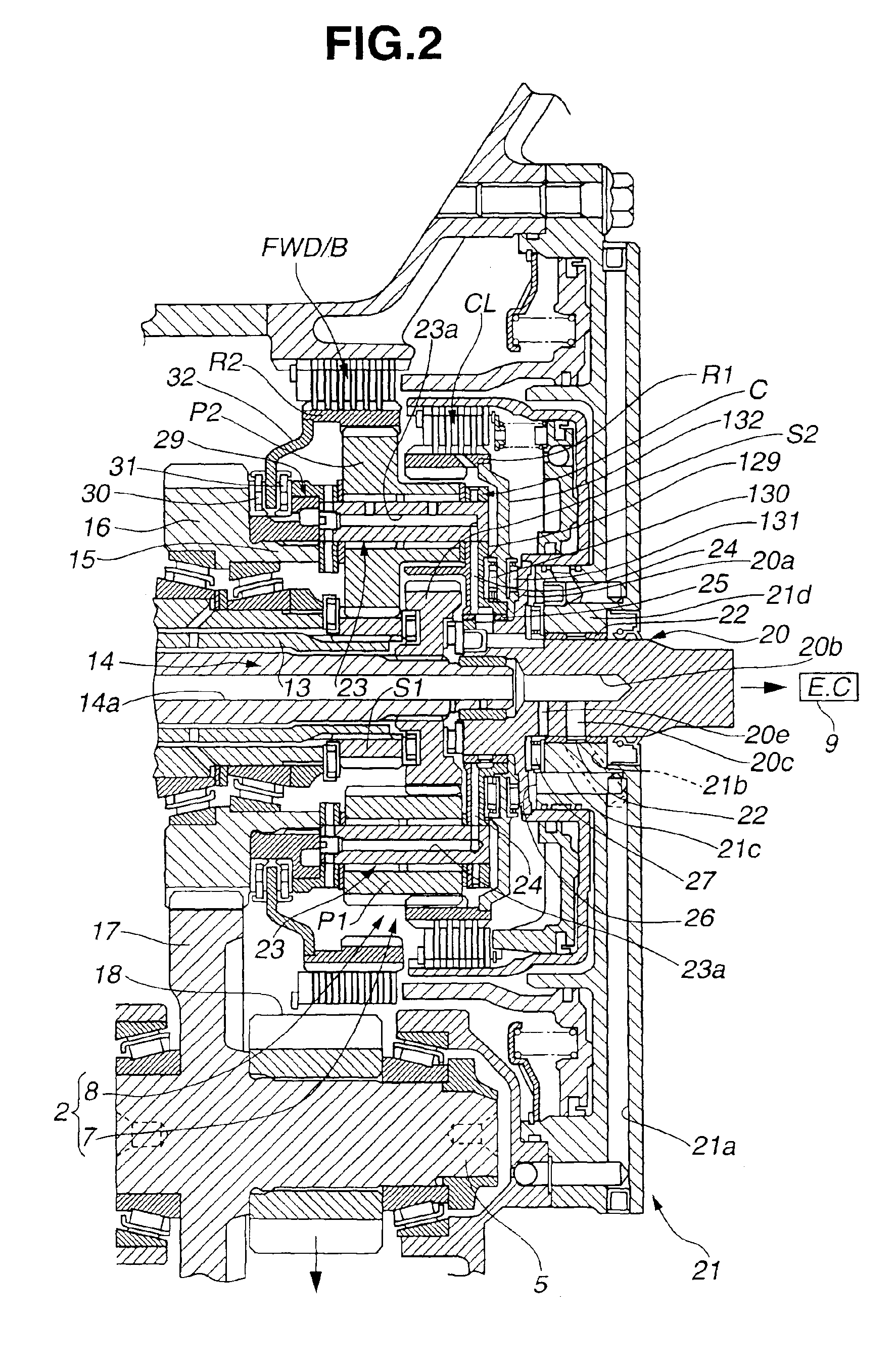

Lubricating device for automatic power transmission

An automatic power transmission to which a lubricating device of the invention is applied is of a type which has an operation mode wherein when, under rotation of an input shaft, a pinion carrier is prevented from making a revolution, pinions carried by the pinion carrier are rotated. The lubricating device comprises a first oil passage formed in a fixed wall of the transmission and connected with an oil supply source; a second oil passage formed in the input shaft, the input shaft being rotatably held by the fixed wall; a third oil passage formed in the pinion carrier to feed the pinions with the lubrication oil, the pinion carrier being concentrically disposed around an axis of the input shaft; a first connection passage connecting the first and second oil passages; and a second connection passage connecting the first and third oil passages. The first connection passage includes a first bore that is formed in the input shaft to lead the oil from the first oil passage to the second oil passage, and a second bore that is formed in the input shaft to lead the oil from the second oil passage to the first oil passage.

Owner:NISSAN MOTOR CO LTD

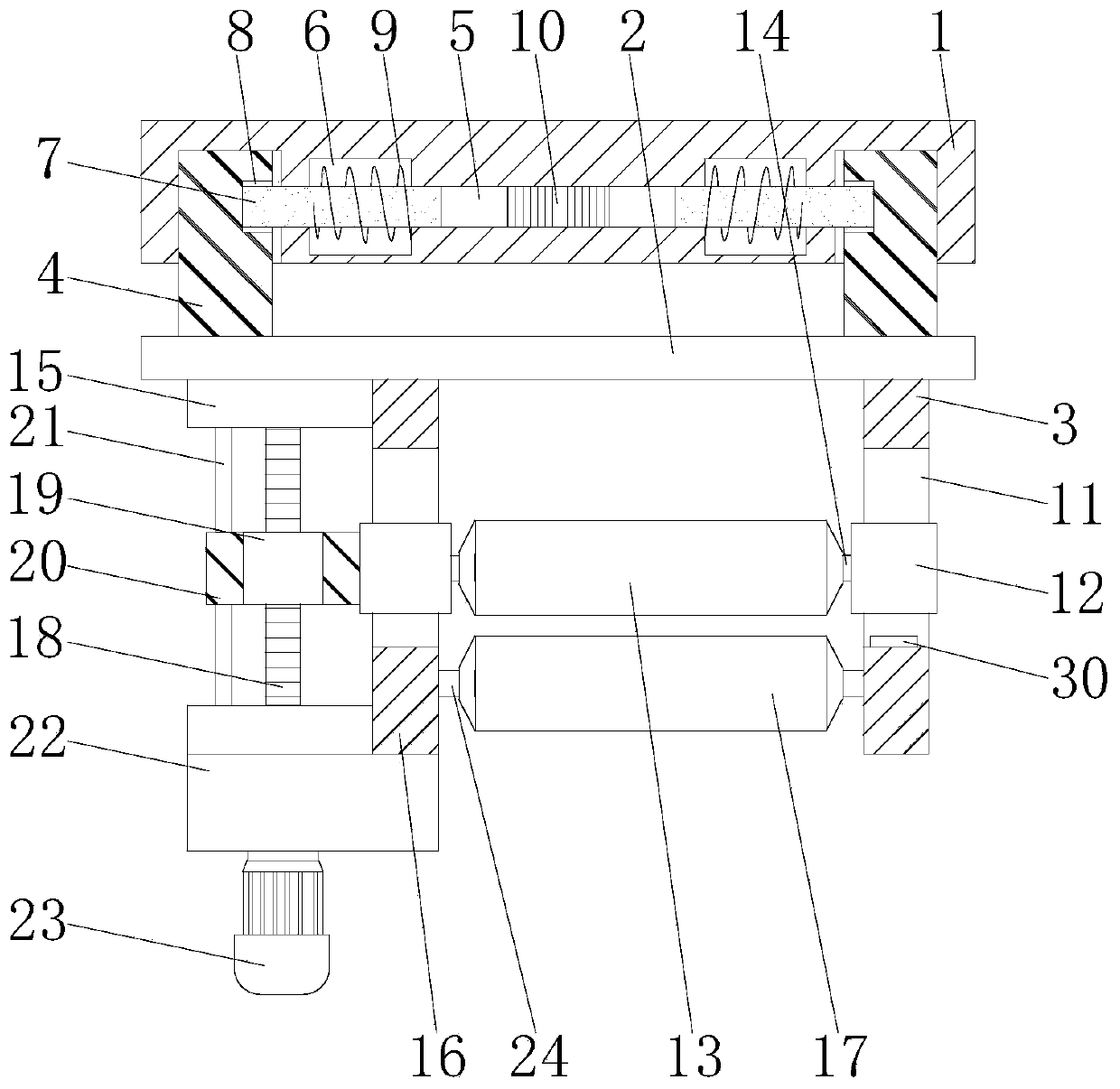

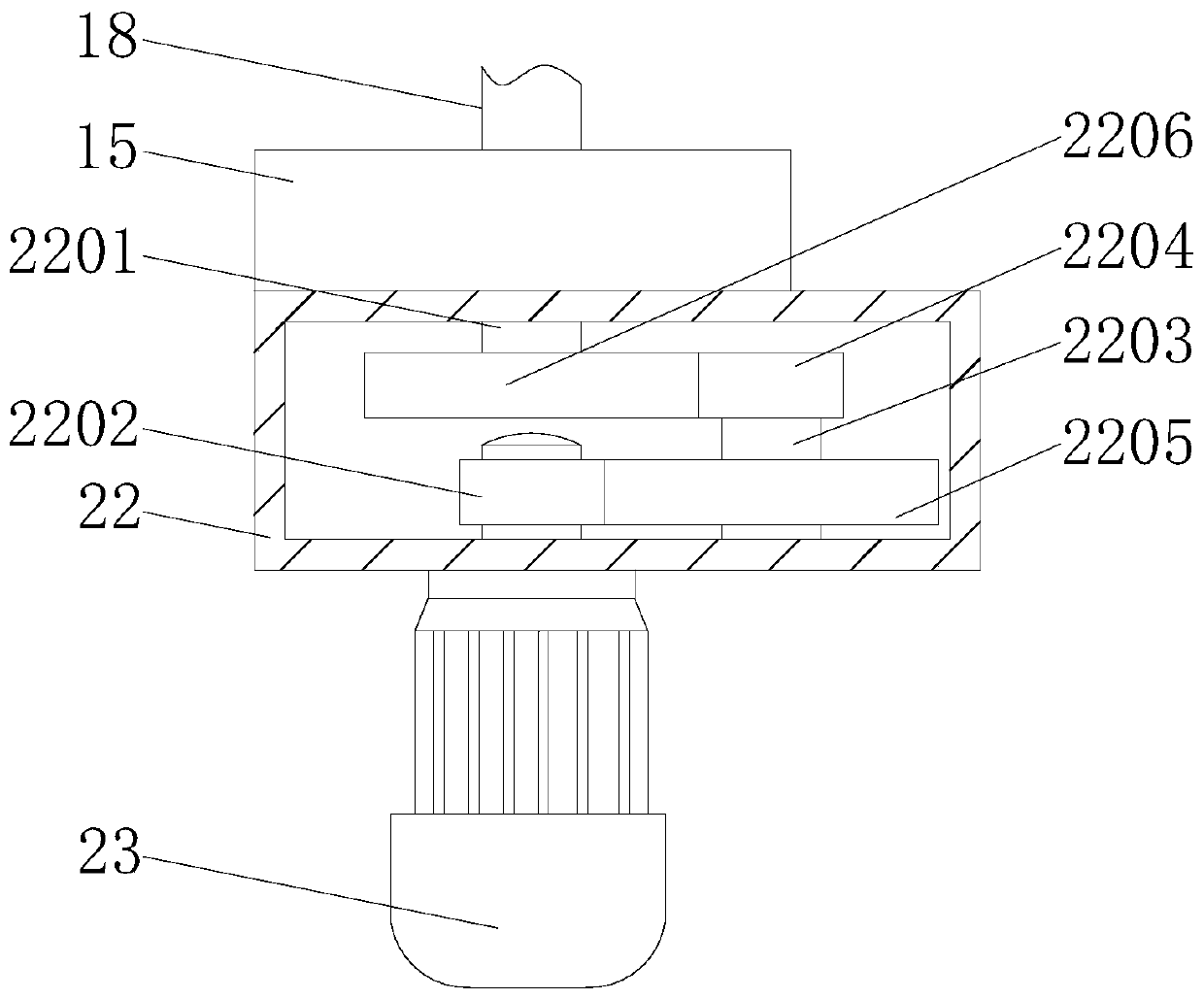

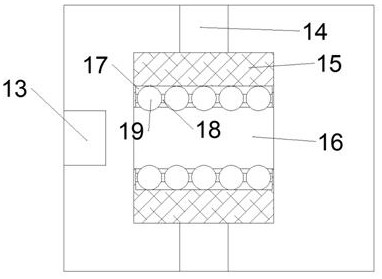

Pole piece cold-pressing device for lithium battery production

InactiveCN109786671AEffective liftingDeceleration is effectiveElectrode manufacturing processesImpellerMicrocomputer

The invention discloses a pole piece cold-pressing device for lithium battery production. The device comprises an installing plate, a flat plate, a first vertical plate, fixed strips, round holes, concave holes, iron rods, mating holes, springs, an electromagnet, sliding slots, sliding blocks, a first roller, a first connecting shaft, fixed plates, a second vertical plate, a second roller, a screw, a ball nut, a lantern ring, a guide rod, a reduction box, a first rotary shaft, a first gear, a second rotary shaft, a second gear, a third gear, a fourth gear, a servo motor, a second connecting shaft, installing holes, straight pipes, suction nozzles, connecting rods, fixed covers, distance sensors, connecting pipes, T-pipes, suction motors, a display screen, a single-chip microcomputer and centrifugal impellers. According to the device, through a lifting structure and the internal structure of the reduction box, ascending and descending of the first roller in the vertical direction can beeffectively realized, therefore, the distance between the first roller and the second roller can be adjusted, a pole piece can be pressed into a required thickness, and meanwhile the adjusted numbercan be displayed on the display screen in real time.

Owner:NANJING CHUQING ELECTRONICS TECH CO LTD

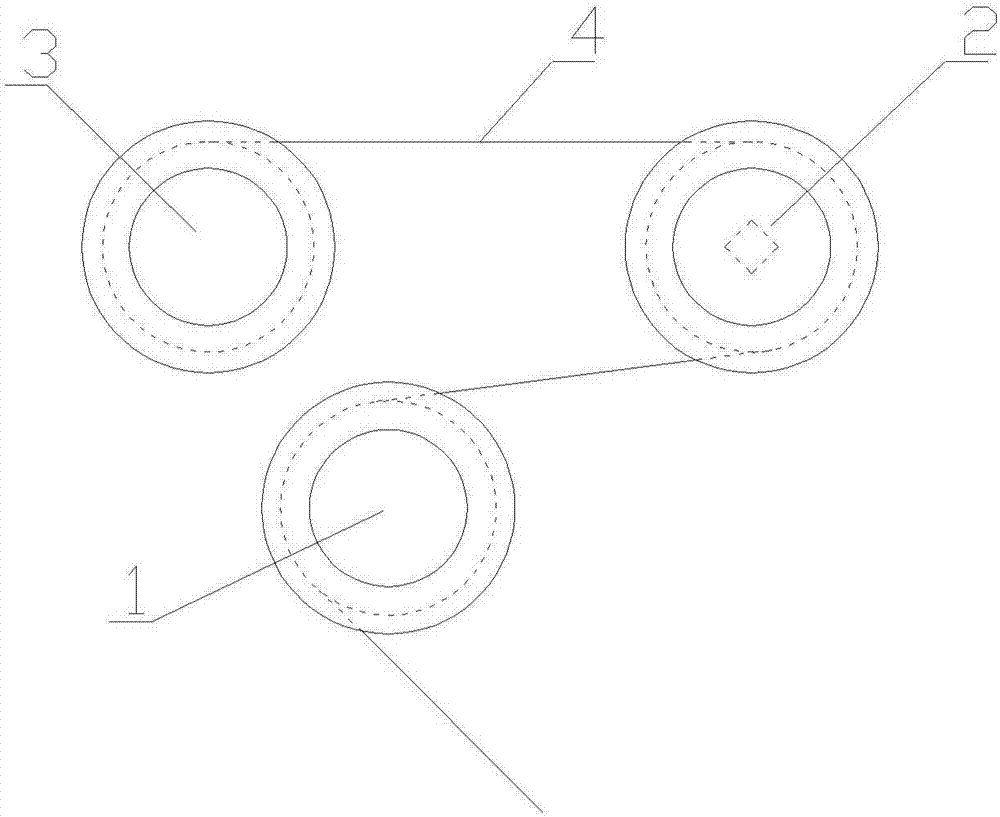

Method of cutting and squaring single crystal silicon round rod by utilizing diamond line

ActiveCN107415067ALow costEasy to operateWorking accessoriesGrinding machinesDiamond cuttingSingle crystal

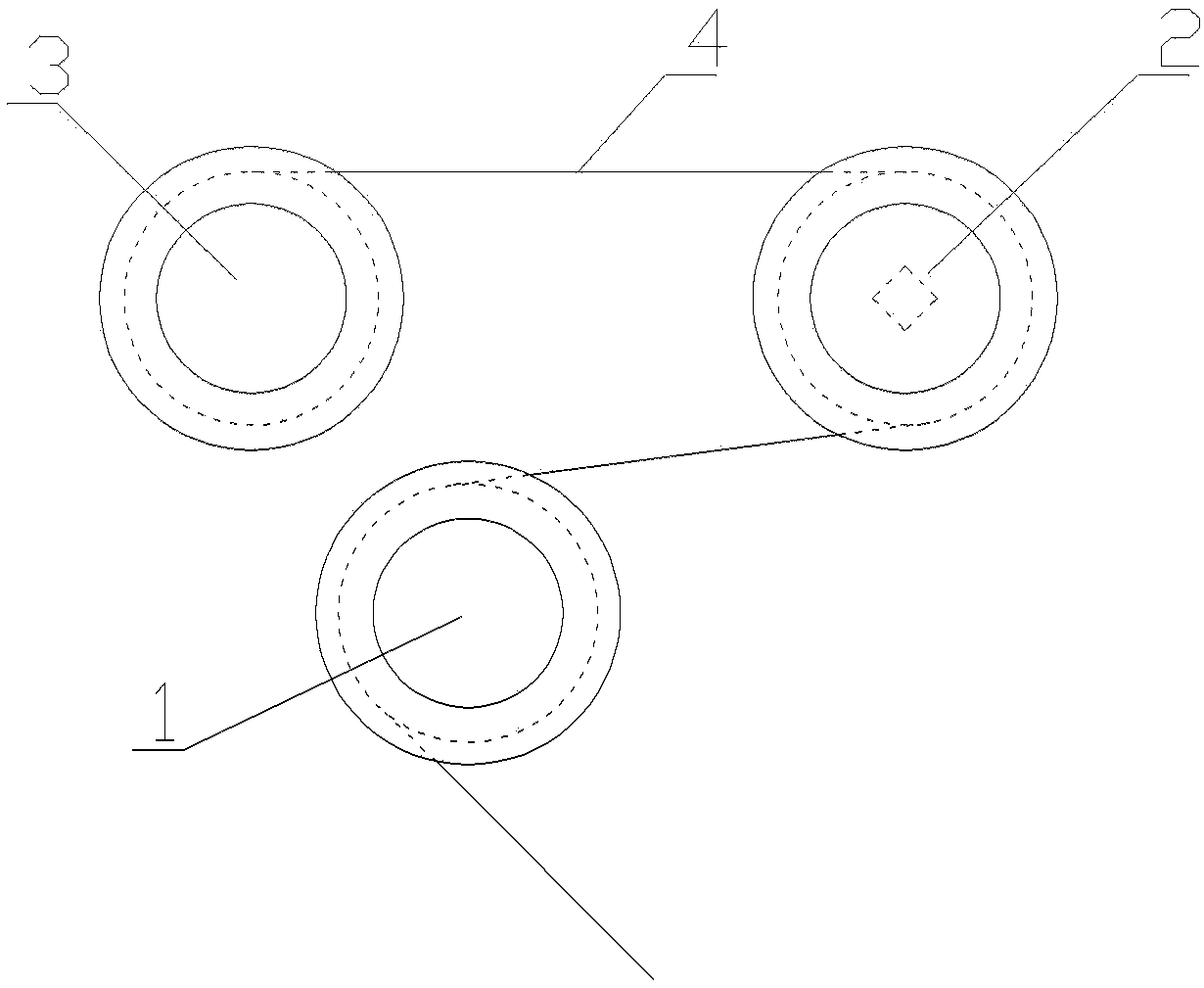

The invention provides a method of cutting and squaring a single crystal silicon round rod by utilizing a diamond line. The method utilizes high-speed feeding of the diamond line to cut the single crystal silicon round rod and comprises the following concrete steps of (1) wire winding: winding a diamond wire to form a wire net of a well-shaped structure after the diamond passes through a cutting wheel and guide wheels; (2) crystal rod mounting: mounting a crystal rod on a workbench, enabling the diamond cutting wire to form a field angle between the crystal rod and each of the guide wheels at the front, the back, the left and the right of the crystal rod; (3) parameter setting: setting a line tension, a feeding speed and a new wire feeding quantity according to the diameter of the crystal rod; (4) cutting: carrying out continuous cutting through relative movement of the diamond cutting wire and the single crystal round rod to be cut; and (5) finishing cutting, and ending a program. The method has the advantages that the feeding speed is increased, the new wire feeding quantity and the steel wire consumption quantity are reduced, and the quality of a quasi-square rod subjected to squaring is in a controlled state.

Owner:COMTEC SOLAR JIANGSU

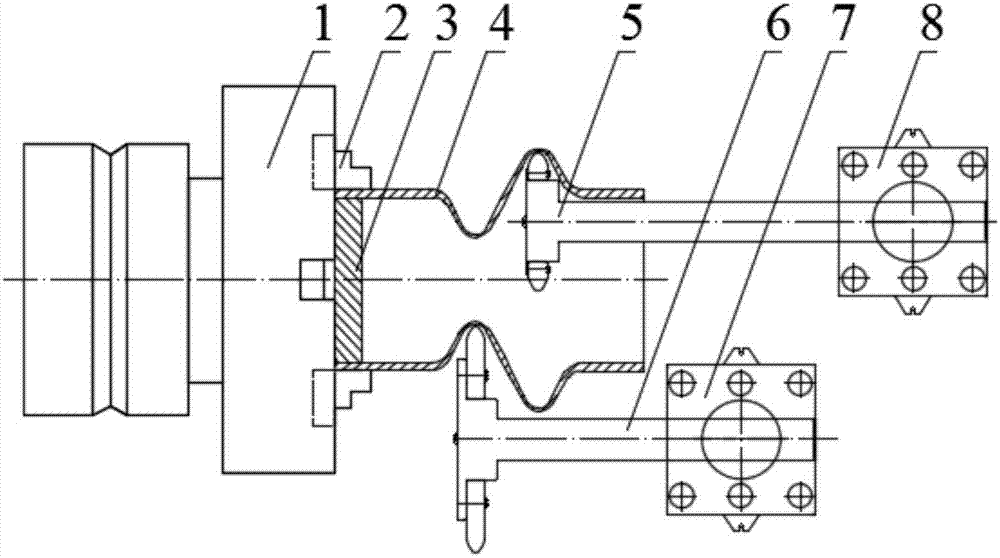

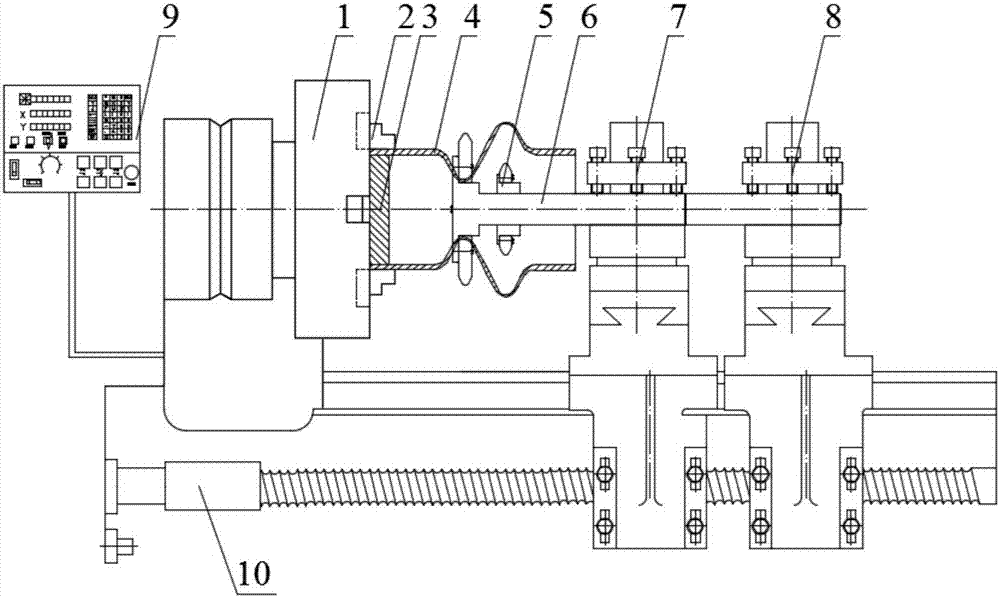

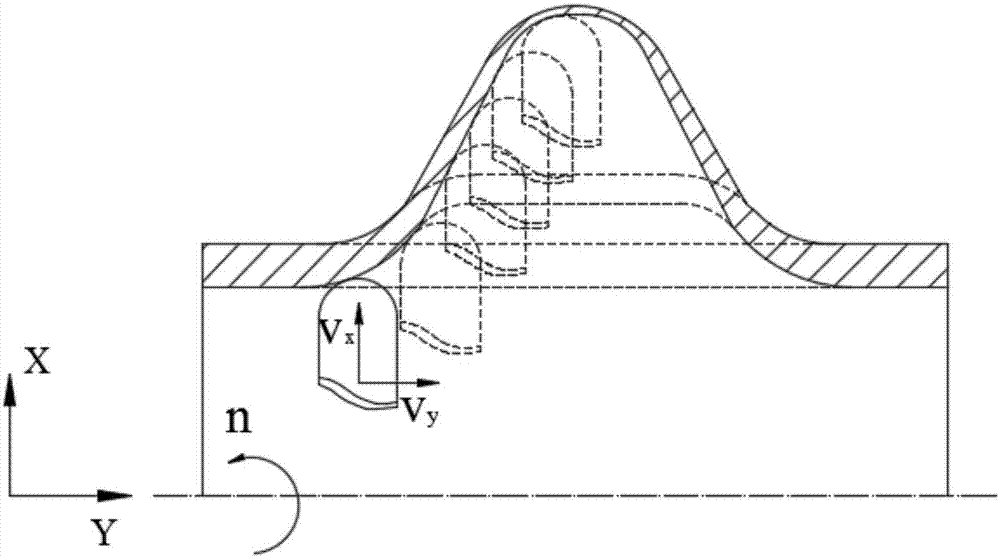

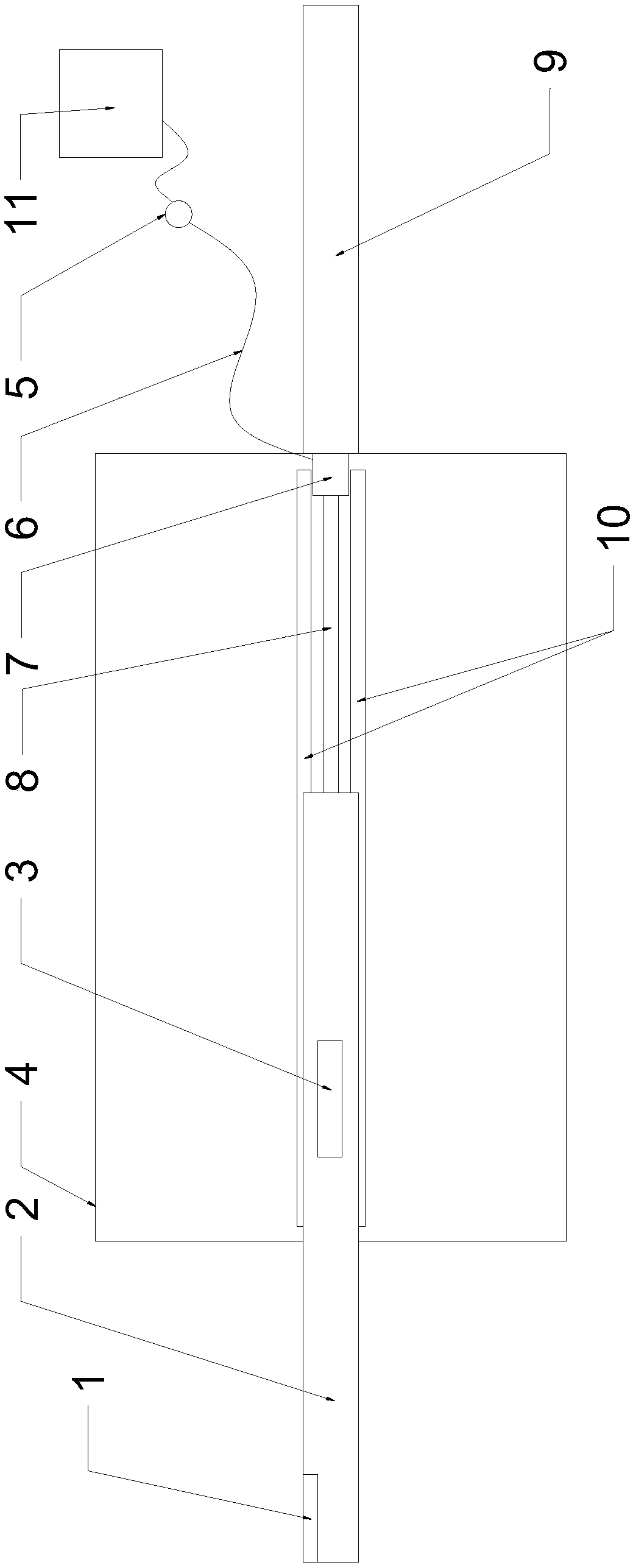

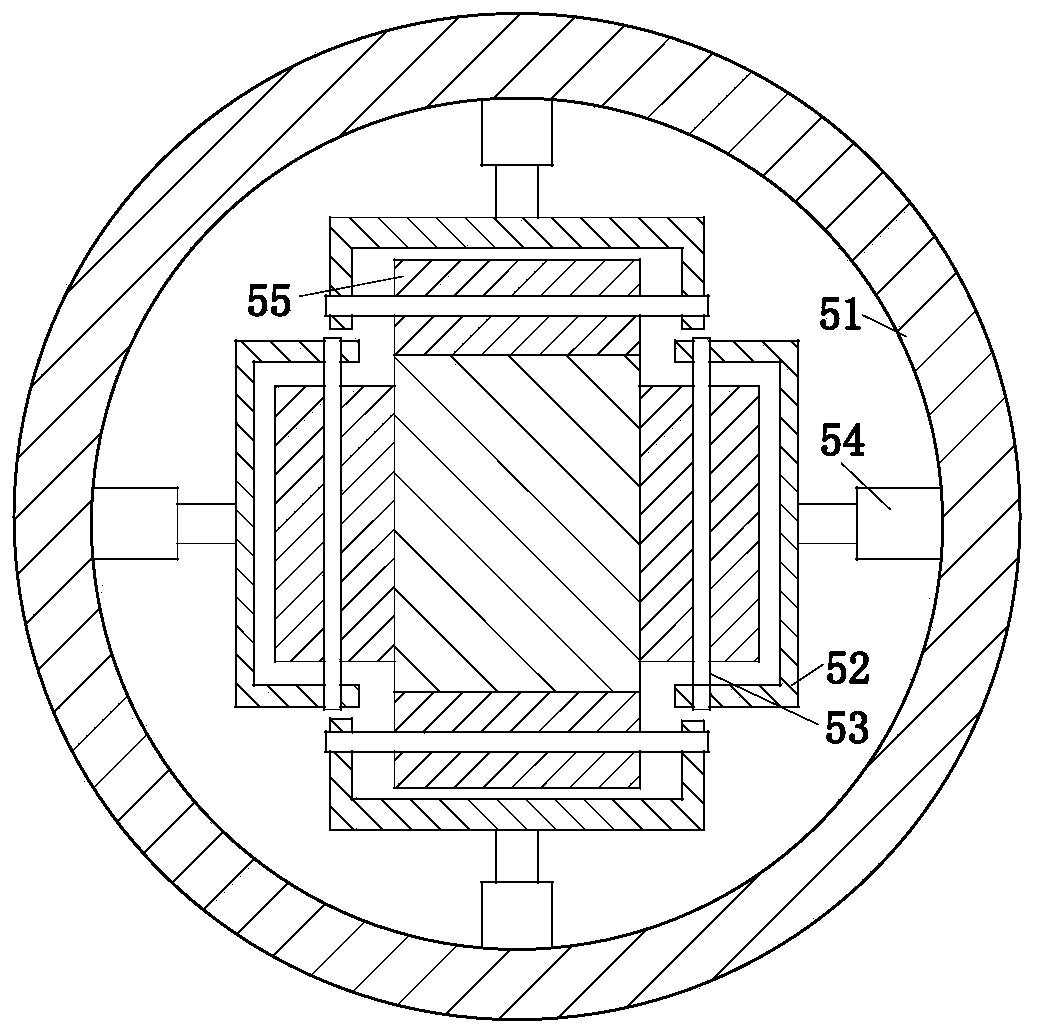

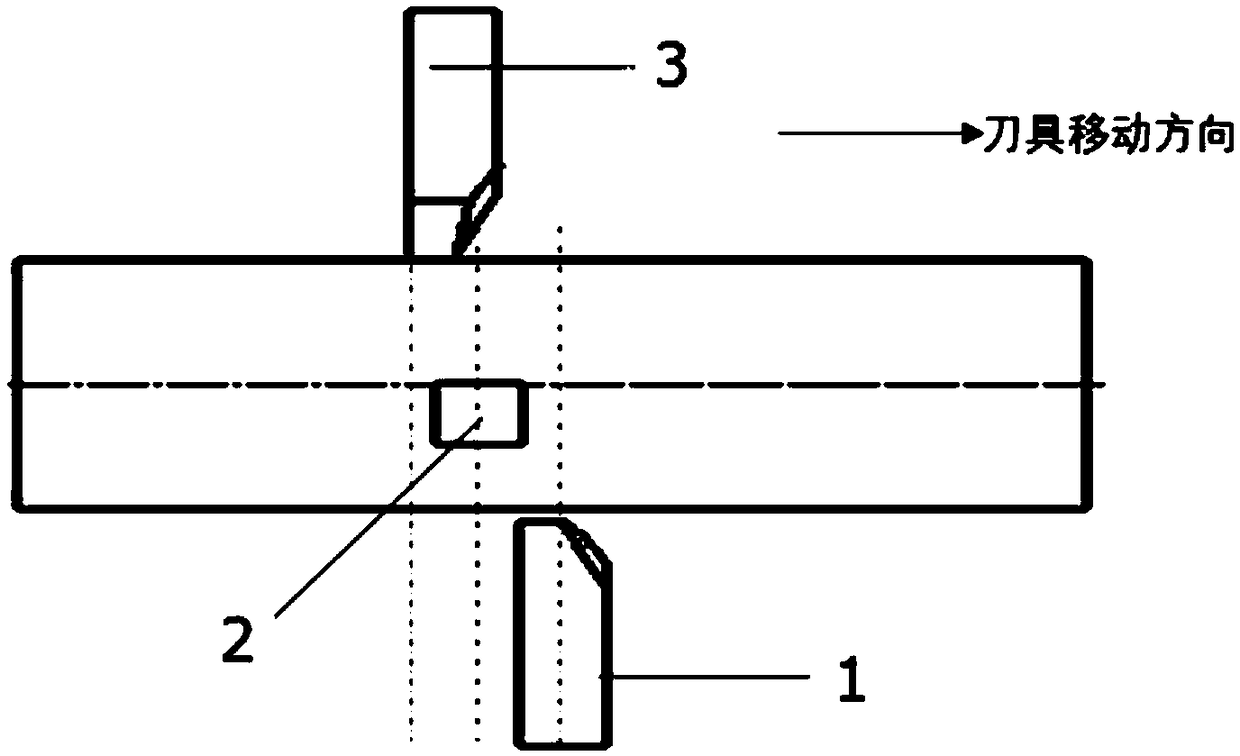

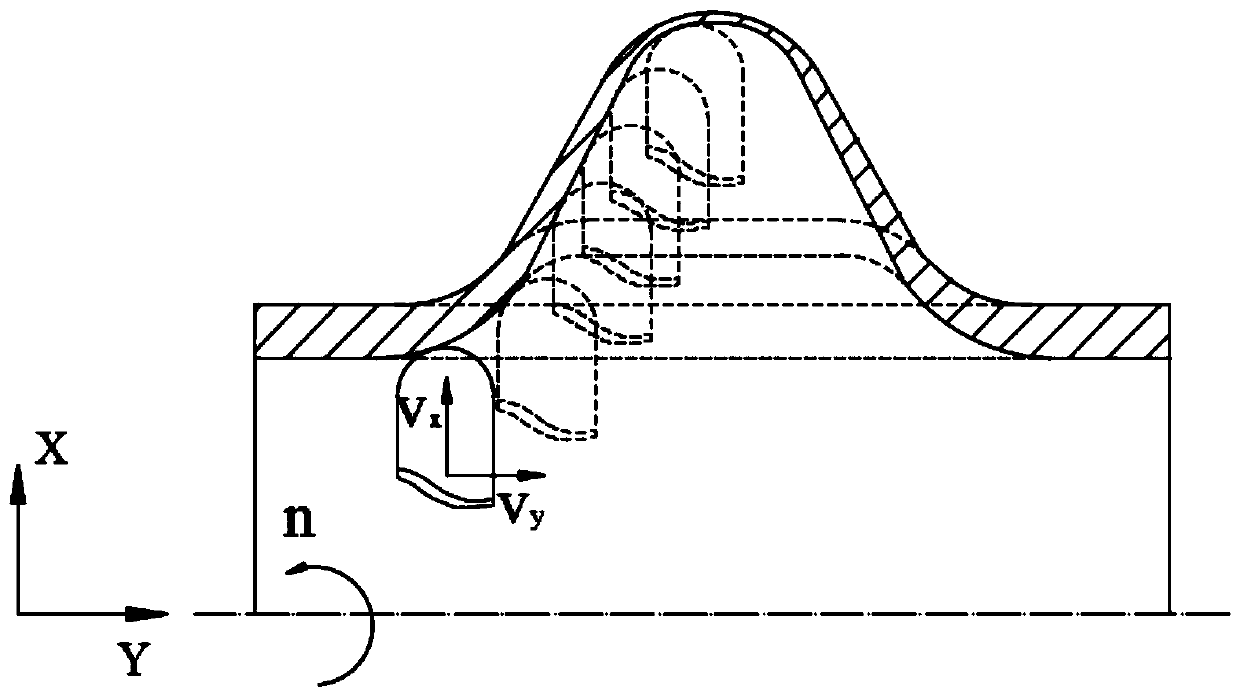

Interior and exterior incremental forming device for metal corrugated pipe

The invention discloses an interior and exterior incremental forming device for a metal corrugated pipe. The interior and exterior incremental forming device for the metal corrugated pipe comprises a forming system and a numerical control device which are connected to a machine tool. The forming system comprises a centering chuck which is connected with a spindle of the machine tool. A mandrel is perpendicularly connected to the center of the centering chuck. A clamping claw is further arranged in the center of the centering chuck. The forming system further comprises a crest interior incremental forming tool wheel and a trough exterior incremental forming tool wheel, wherein a tool rod of the crest interior incremental forming tool wheel is connected with a crest forming cutter rest; a tool rod of the trough exterior incremental forming tool wheel is connected with a trough forming cutter rest; the crest forming cutter rest and the trough forming cutter rest are connected with the numerical control device and arranged on a guide rail of the machine tool; and the trough forming cutter rest is arranged close to the centering chuck relative to the crest forming cutter rest. By means of the interior and exterior incremental forming device for the metal corrugated pipe, the forming quality of the formed metal corrugated pipe can be improved.

Owner:XIAN UNIV OF TECH

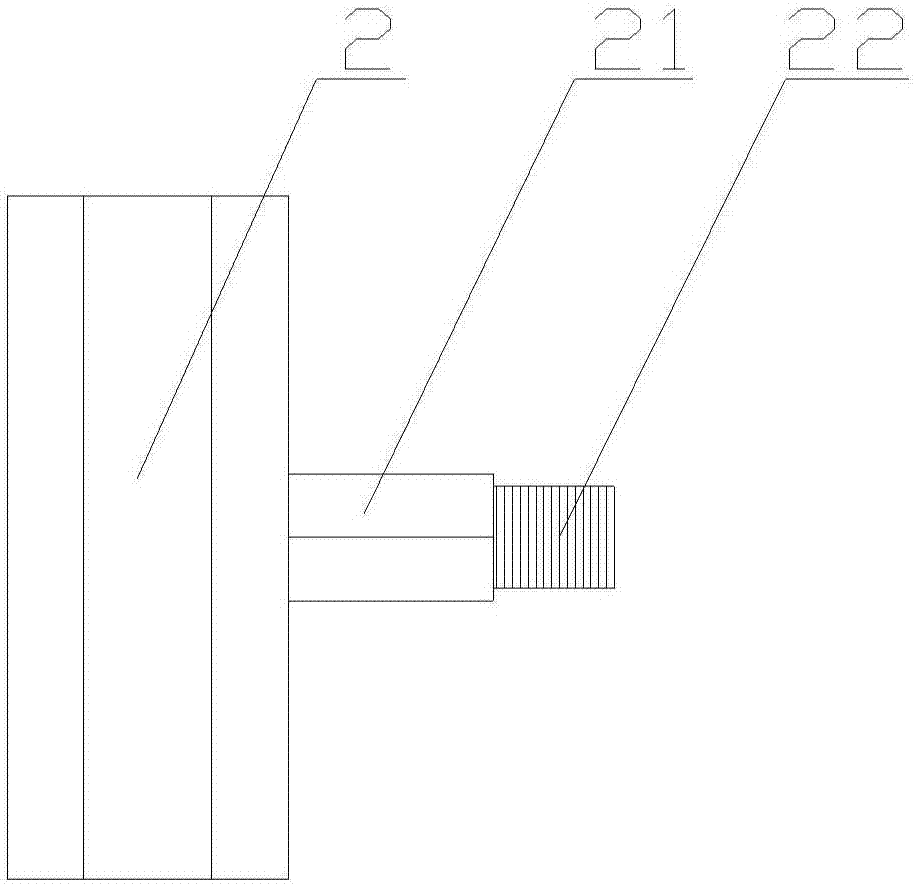

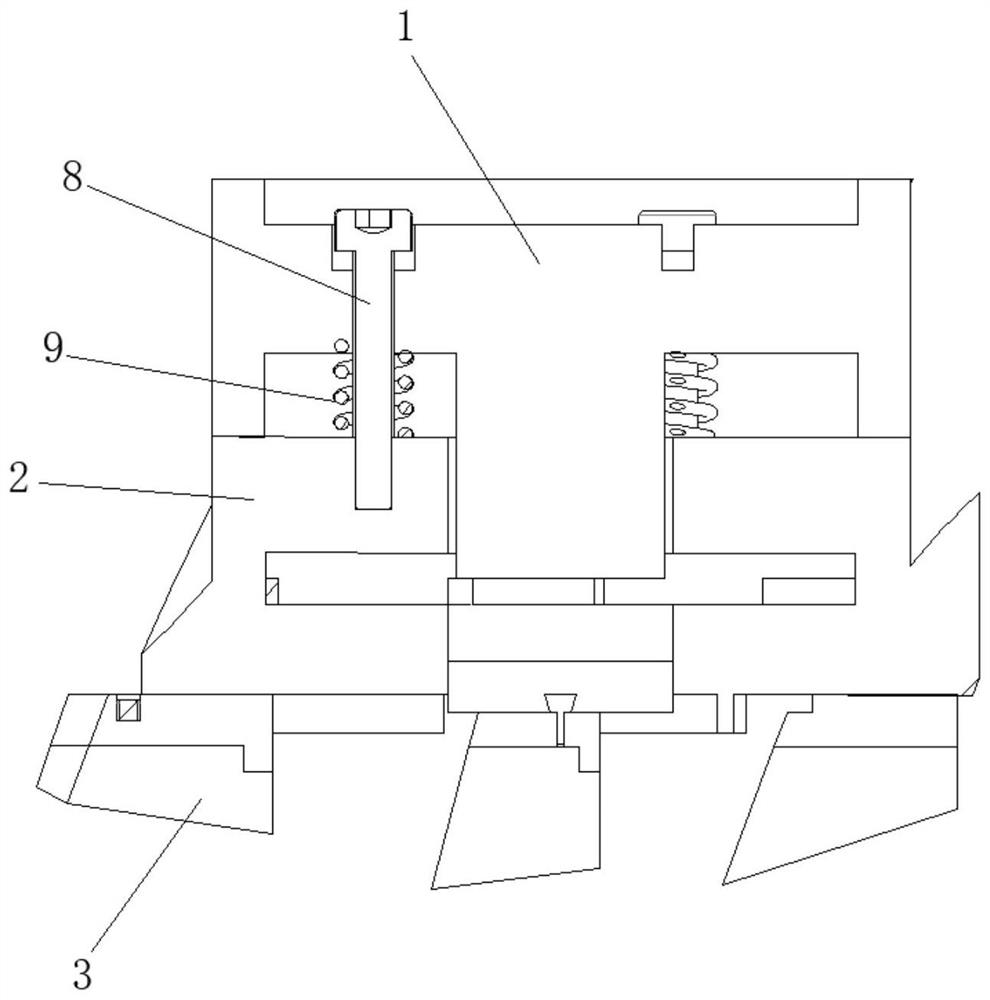

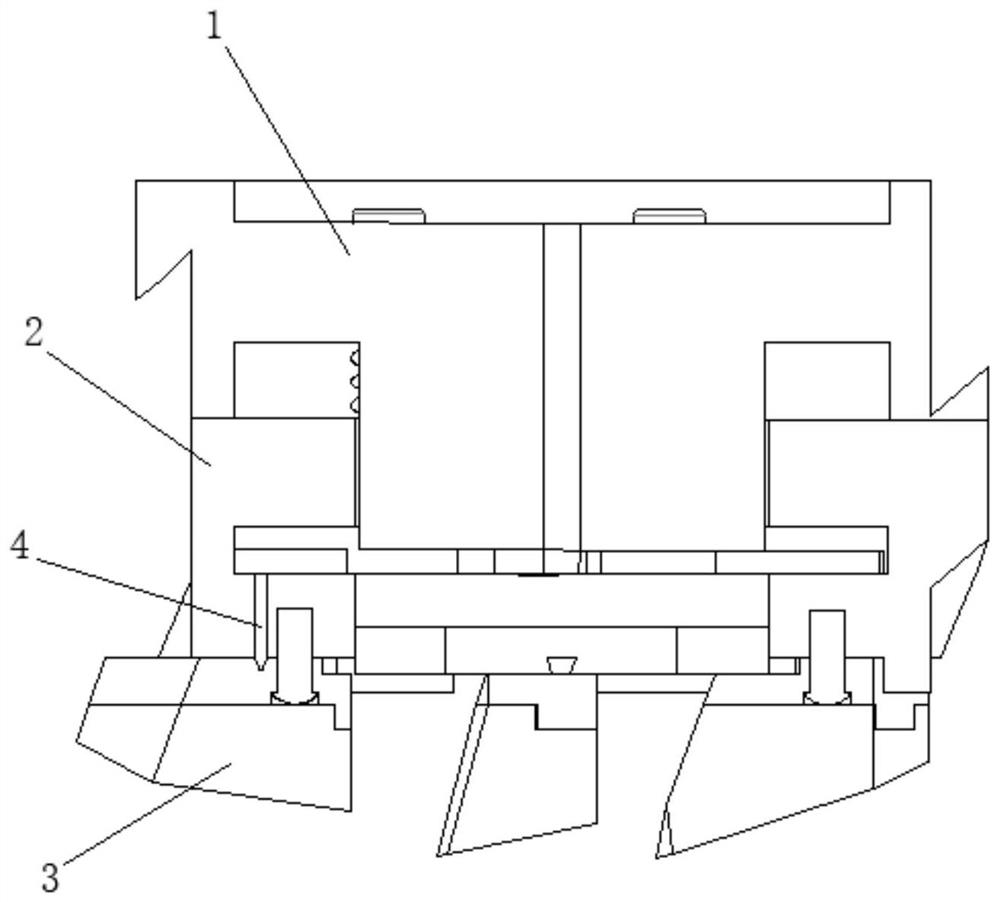

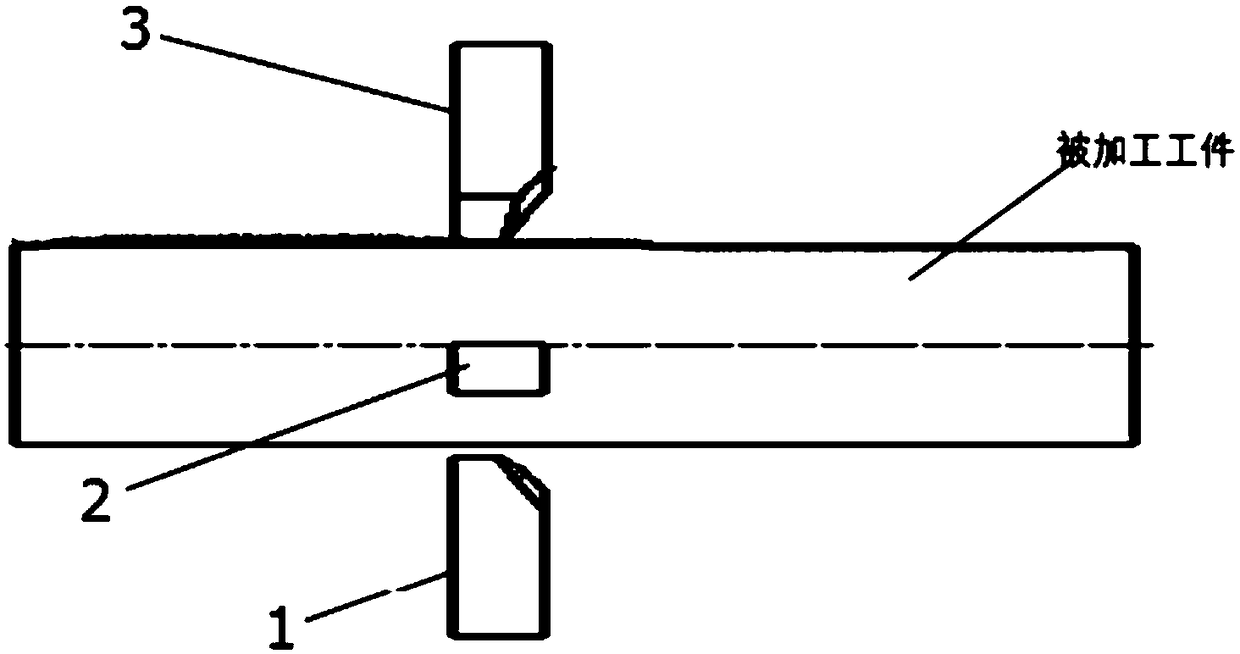

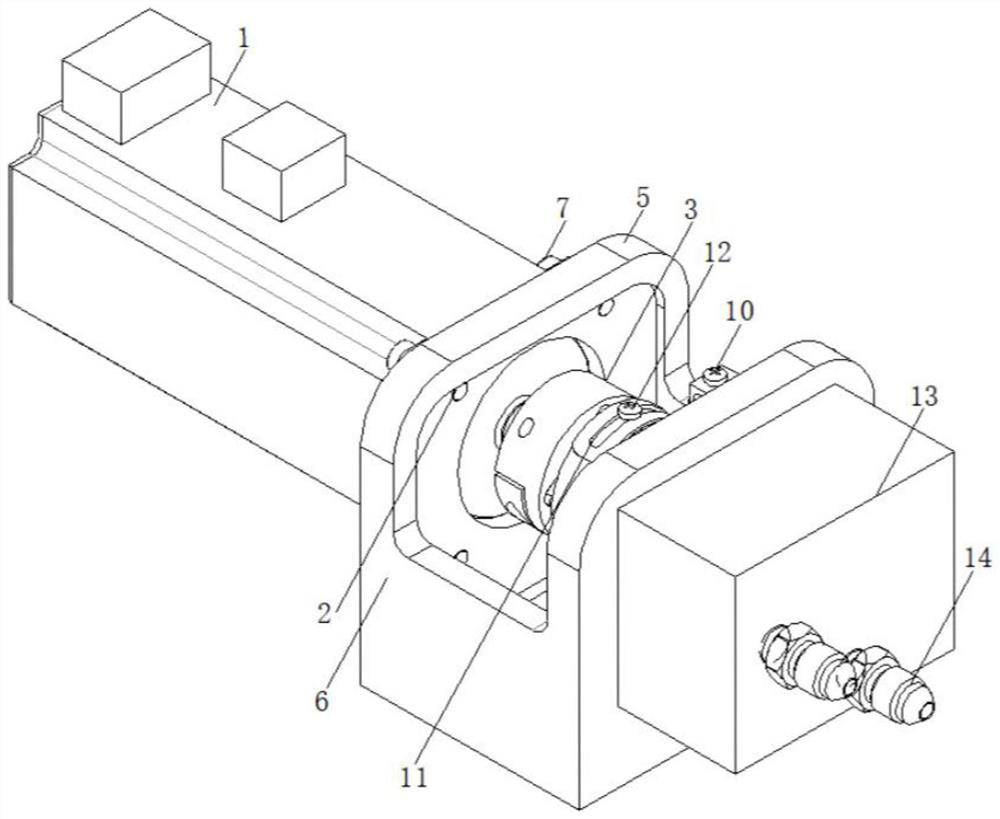

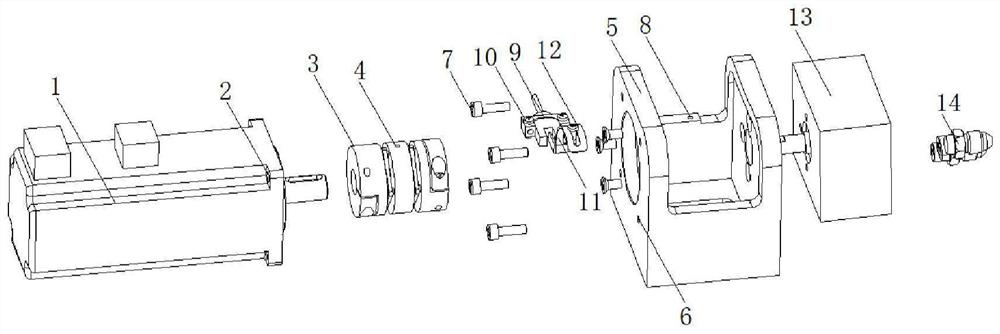

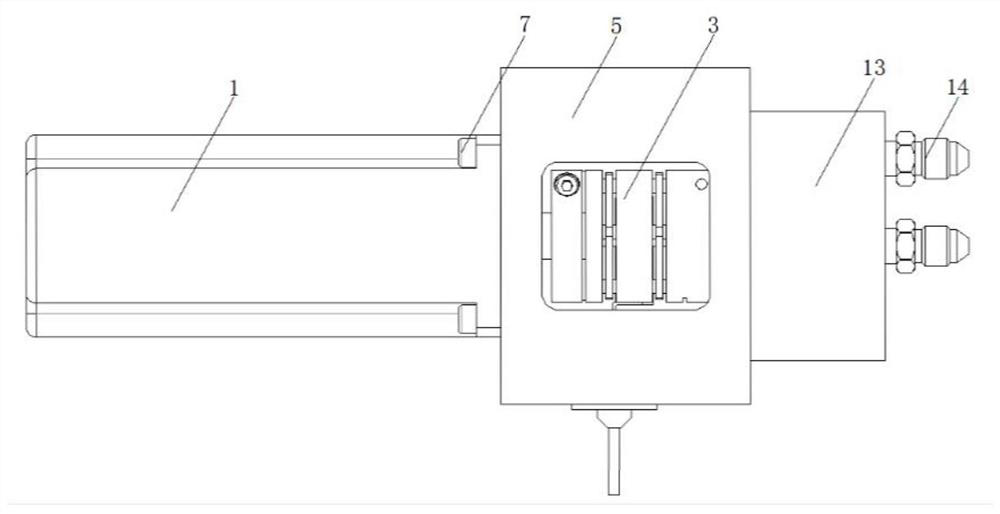

Cutting-force-adjustable turning tool and turning lathe with same

InactiveCN108526499AAvoid damageSmooth cuttingMeasurement/indication equipmentsTurning toolsStress conditionsReciprocating motion

The invention discloses a cutting-force-adjustable turning tool and a turning lathe with the same. The turning tool comprises a blade, a turning tool rod and a cutting force adjusting device. The blade is mounted at the first end of the turning tool rod. The cutting force adjusting device comprises a controller, a cutting force detecting mechanism and a cutting force adjusting mechanism, wherein the cutting force detecting mechanism and the cutting force adjusting mechanism are in signal connection with the controller; the cutting force detecting mechanism is mounted on the turning tool rod soas to detect the counter-acting force of the blade during cutting; the cutting adjusting mechanism comprises a turning tool rod feeding amount adjusting power unit and a turning tool rod fixing rack;the turning tool rod fixing rack is fixed to the second end of the turning tool rod; and the turning tool rod fixing rack reciprocates in the axis direction of the turning tool rod under driving of the turning tool rod feeding amount adjusting power unit. The cutting-force-adjustable turning tool and the turning lathe with the same have the beneficial effects that the stressing condition of the blade and the turning tool rod is detected dynamically in real time, the stress of the blade and the turning tool rod is controlled to be within a certain range, then the damage to the blade and the turning tool rod is avoided, the cost is reduced, and cutting is finished smoothly.

Owner:GUIZHOU INST OF TECH

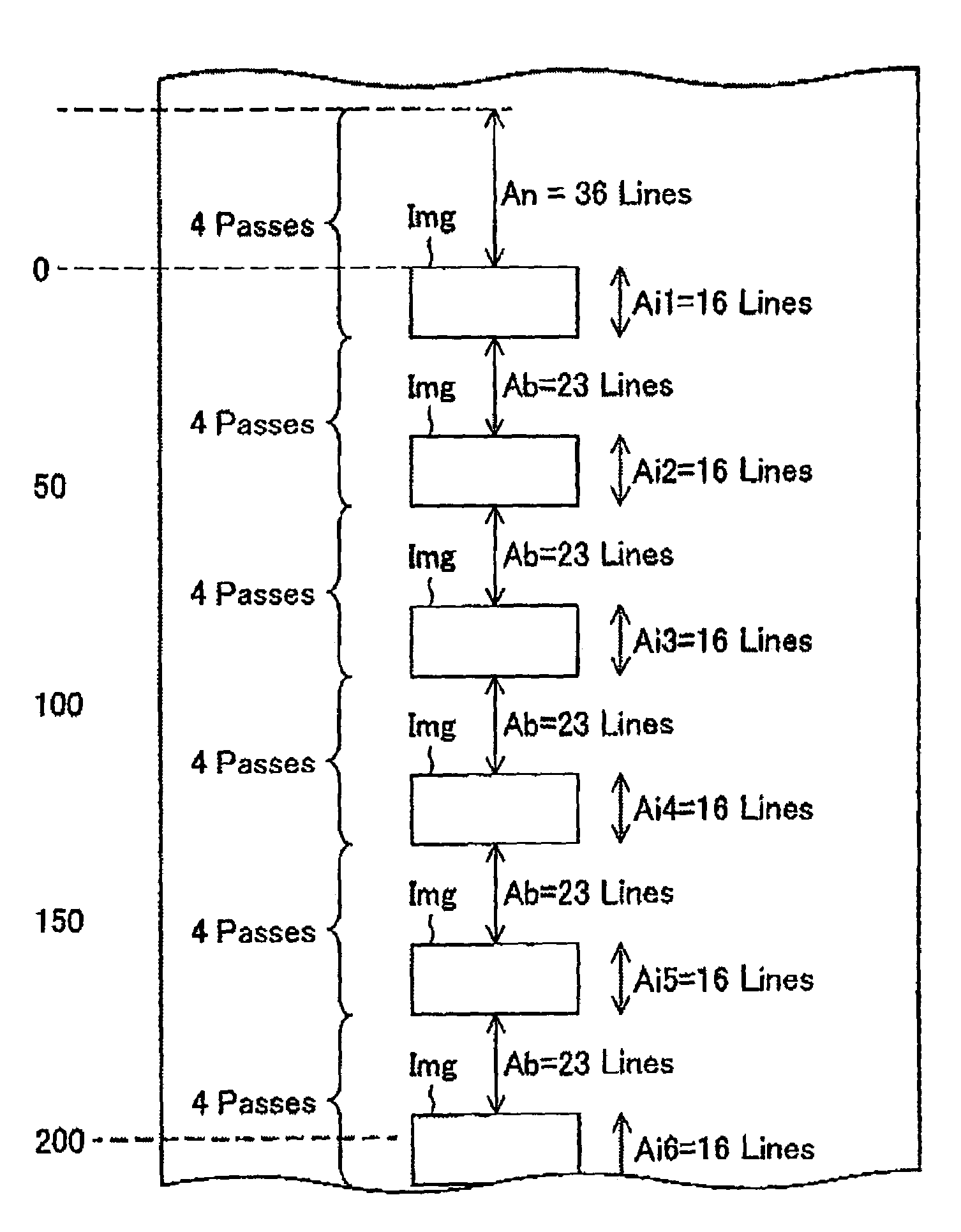

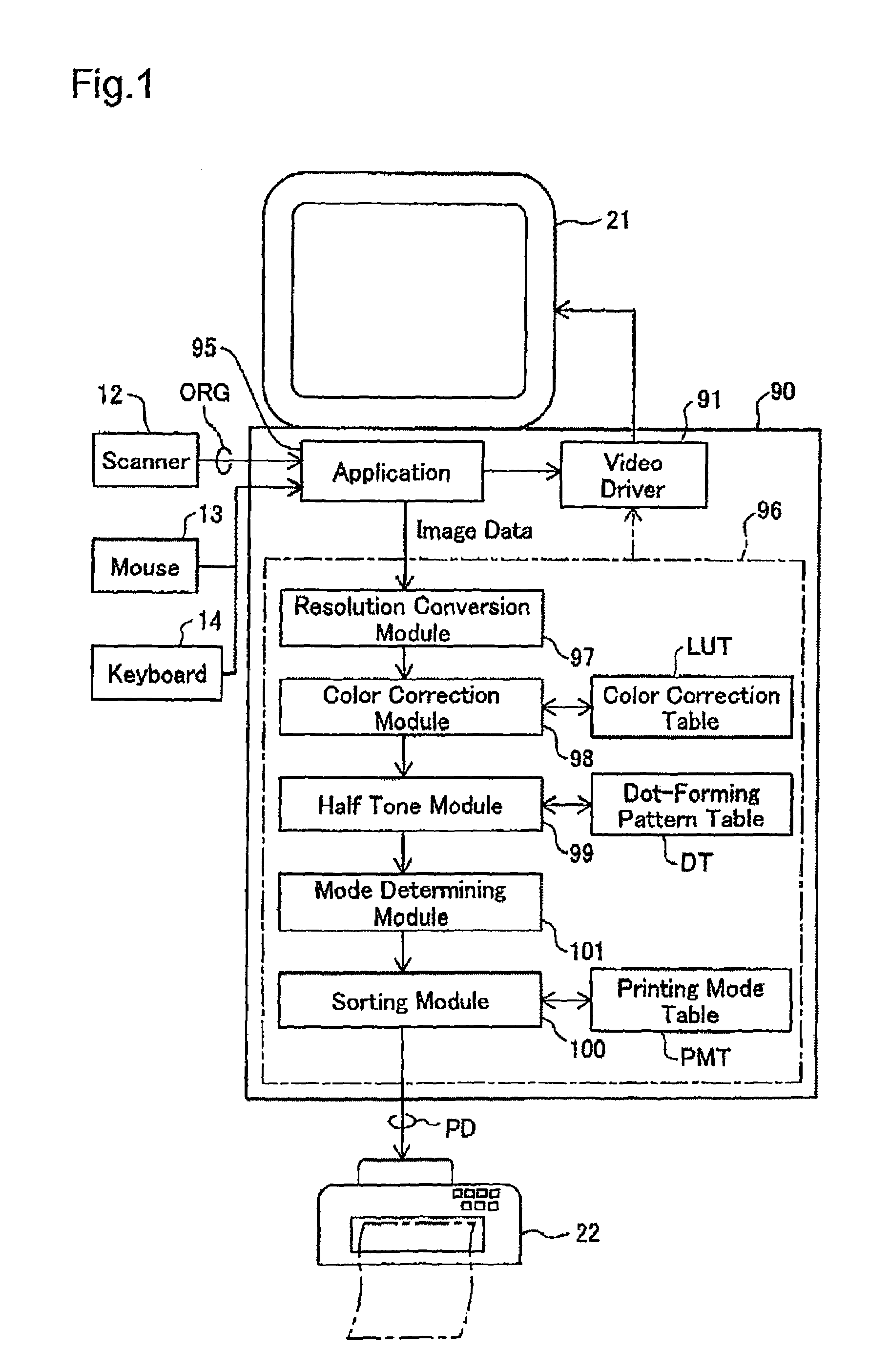

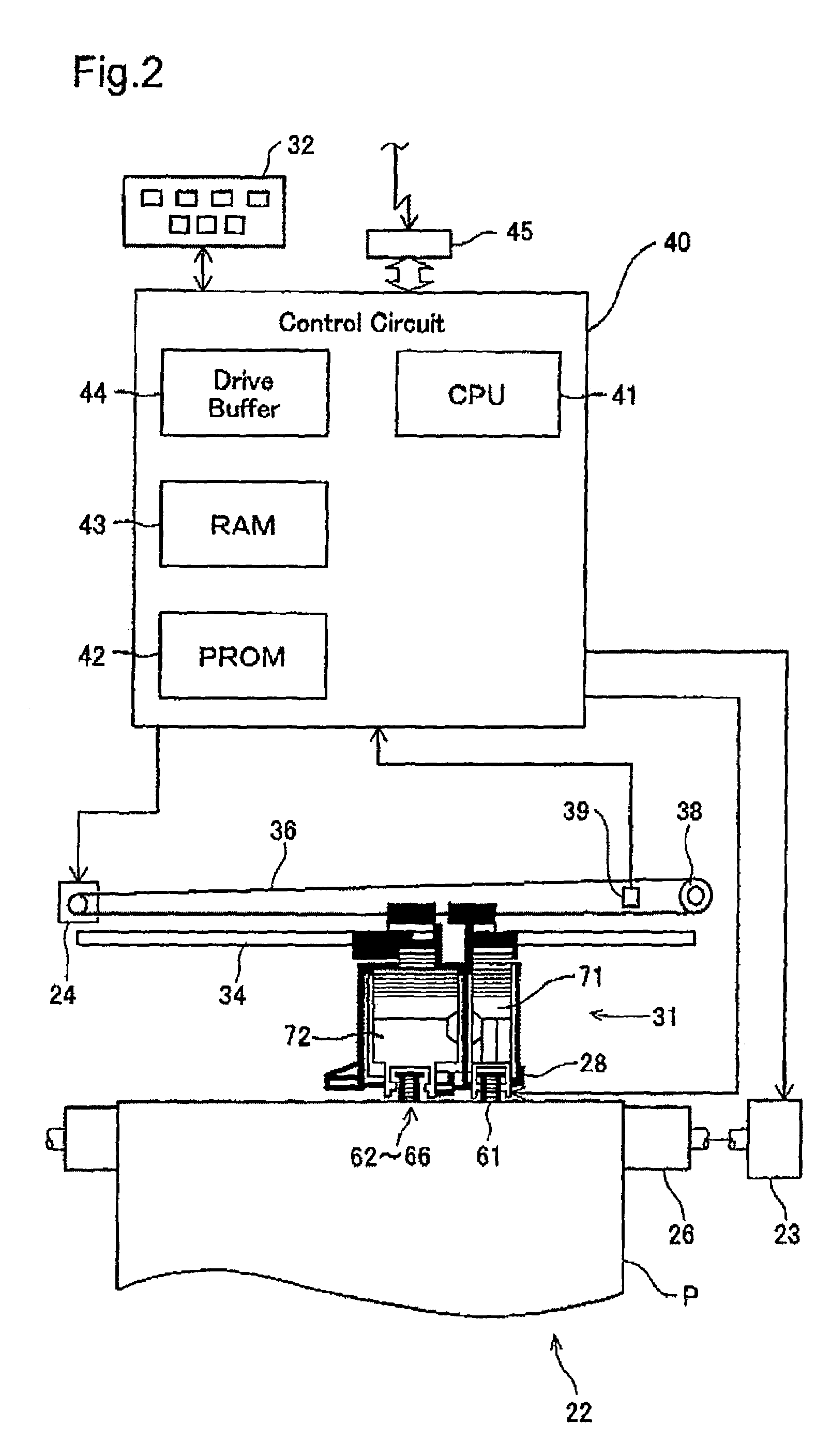

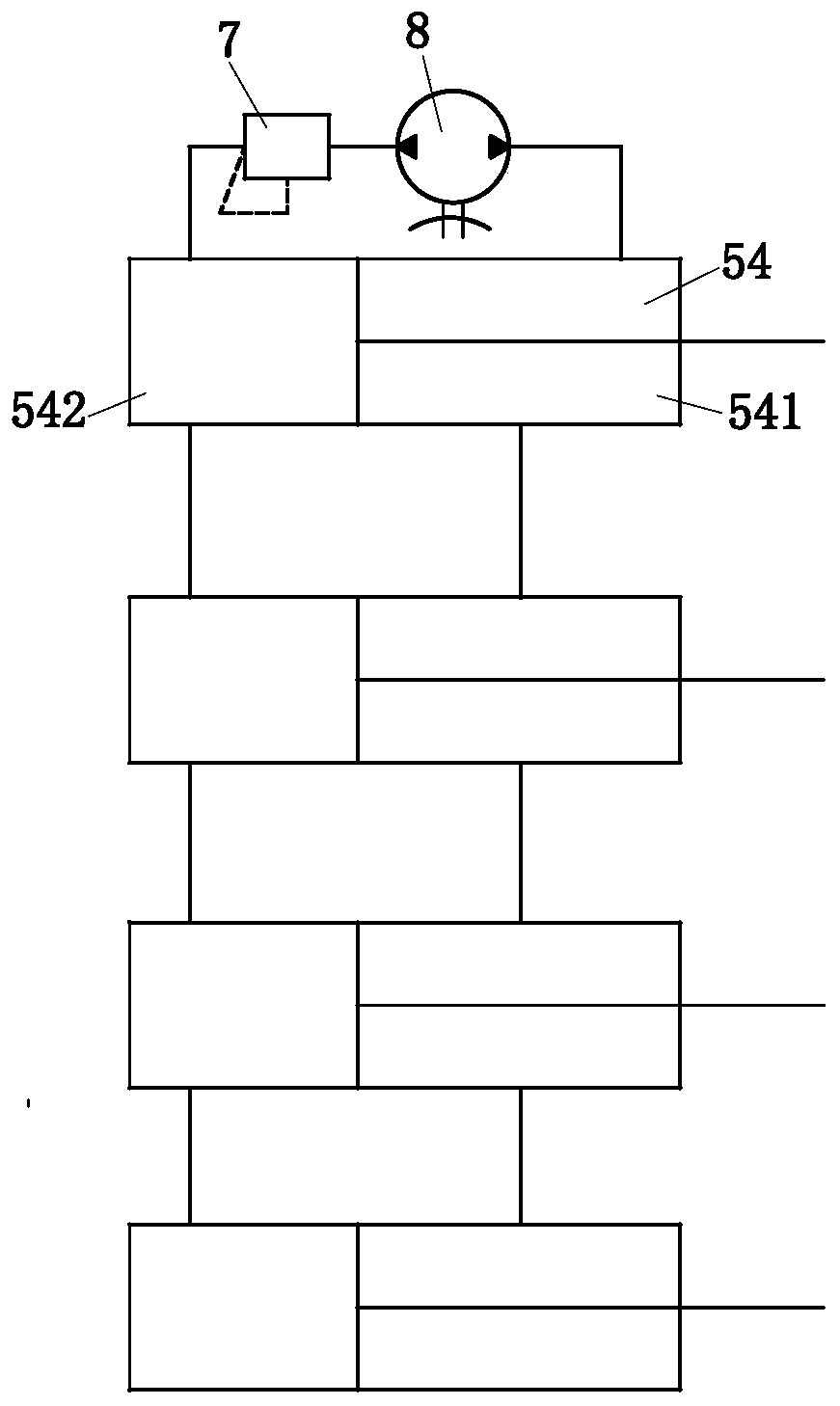

Printing in different modes according to image size

InactiveUS7377606B2Fast printEfficiently printed on printing paperDigitally marking record carriersDigital computer detailsComputer science

Owner:SEIKO EPSON CORP

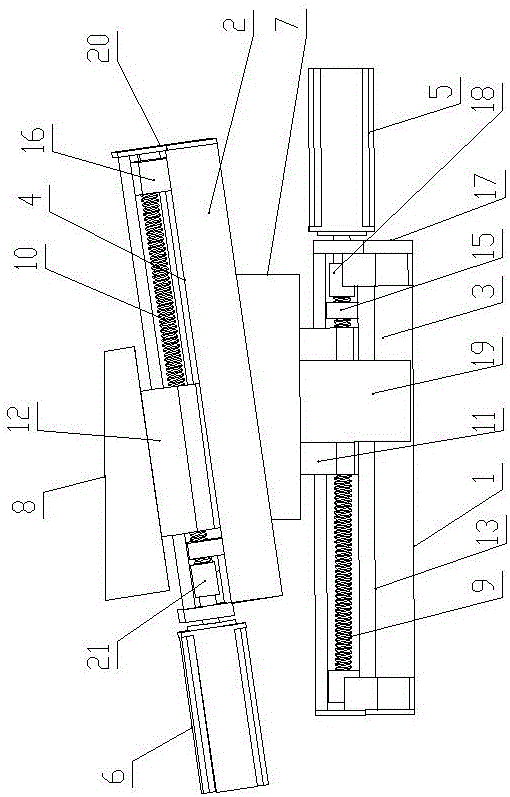

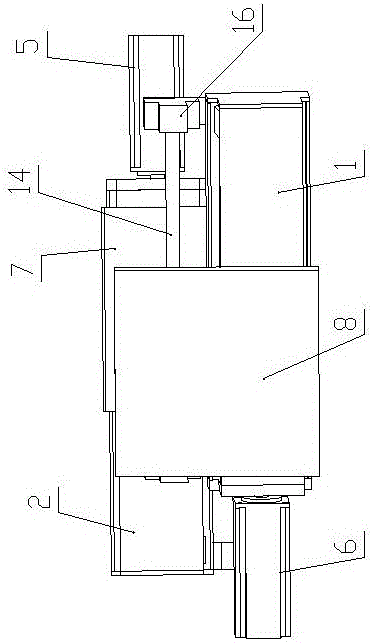

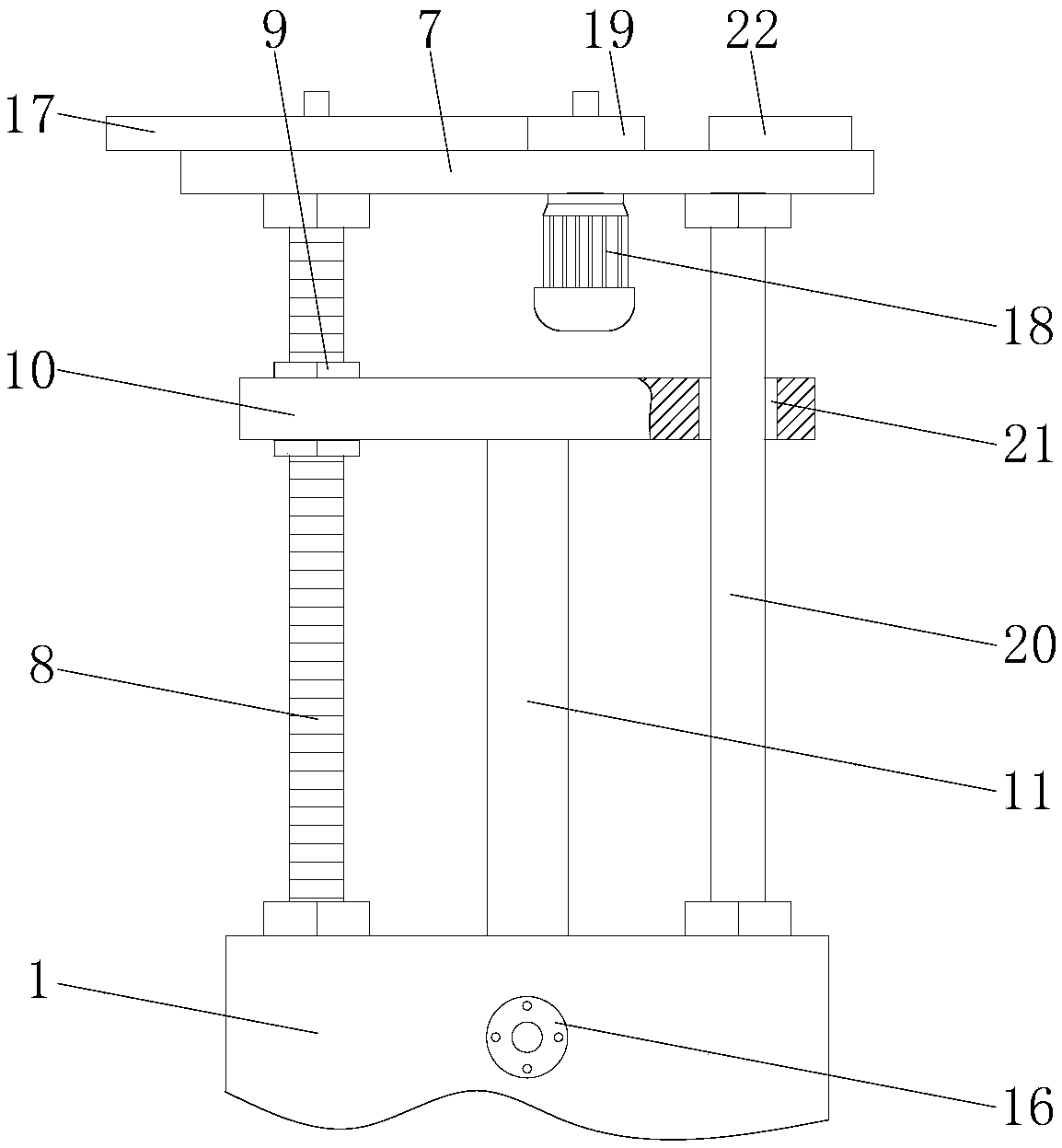

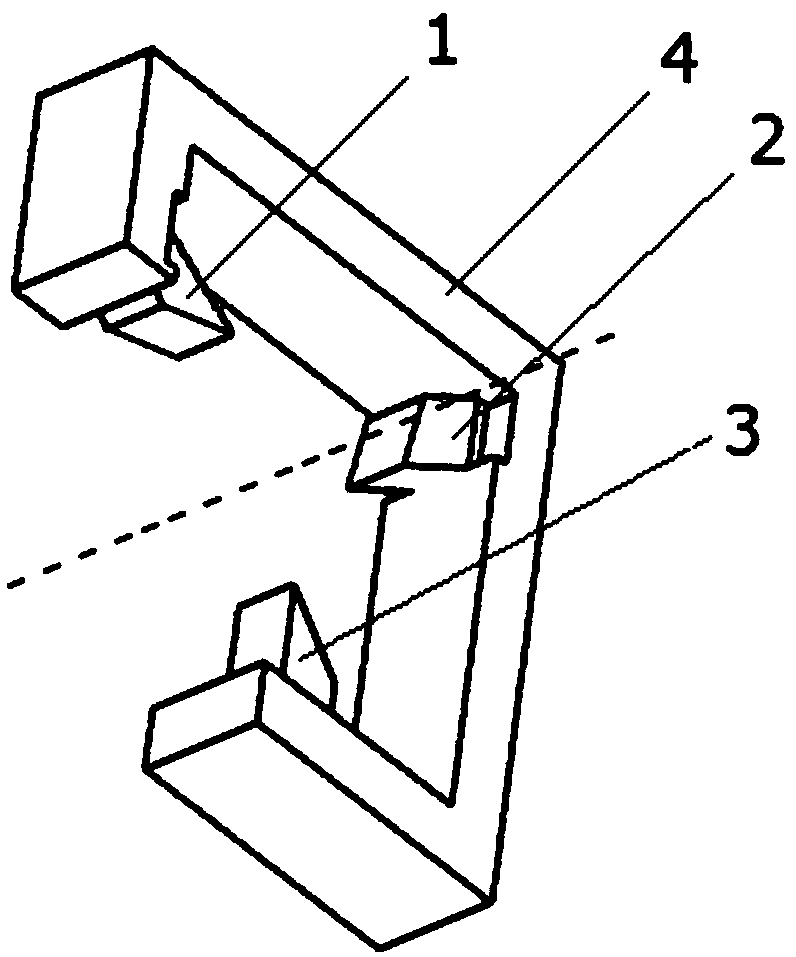

Z-direction micro displacement structure based on wedge feeding horizontal compensation

The invention discloses a Z-direction micro displacement structure based on wedge feeding horizontal compensation. The structure mainly comprises two servo motors, linear sliding rails, a sliding table base, a ball screw, a supporting base, a polished rod guide rail and wedge blocks. One linear sliding rail is fixed to a platform, and the sliding table base is connected with one wedge block; the other linear sliding rail is fixed to the first wedge, a linear table base is connected with the second wedge block, and the polished guide rail is connected with the outer bottom of the linear sliding rail. Besides, by means of the wedge blocks, an included angle can be formed between displacement in the horizontal direction and displacement in the vertical direction. The structure can meet the Z-direction micro-feeding requirement during large-load precise and ultra-precise processing, a closed-loop control system can be built through a horizontal displacement measurement method by means of the wedge right-angle relation, the displacement amount in the horizontal direction is compensated for, feeding at the precision of the micron level is achieved, and the problems that an existing micro displacement mechanism is low in loading capacity and the feeding amount in the Z-axis direction is small are solved.

Owner:HENAN POLYTECHNIC UNIV

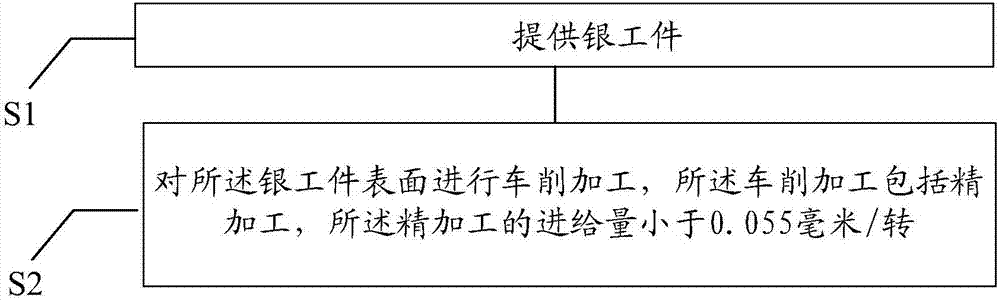

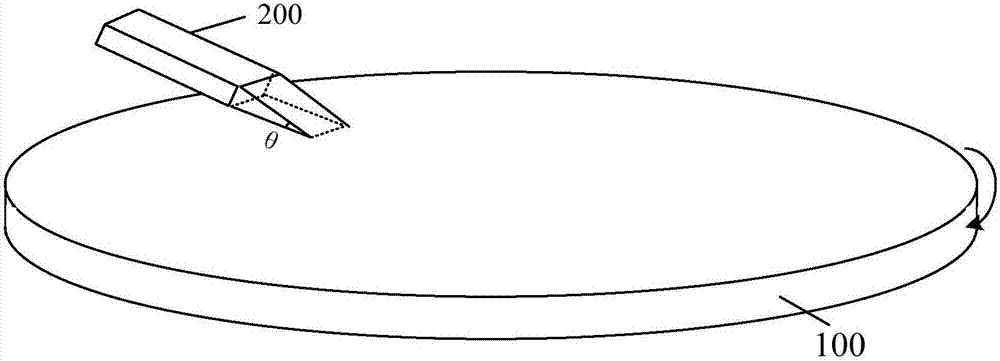

Machining method of silver target material

InactiveCN107470650AReduce wearExtended service lifeVacuum evaporation coatingCutting insertsSurface patternFeeding force

The invention provides a machining method of a silver target material. The machining method comprises the steps of providing a silver workpiece; and carrying out turning machining on the surface of the silver workpiece, wherein turning machining comprises finish machining, and the feed amount of finish machining is smaller than 0.055 mm / turn. According to the machining method, the cutter penetration amount of turning machining is relatively small, feeding force of a cutter for the silver workpiece is relatively small, patterns are not liable to generate on the surface of the silver workpiece, the surface patterns of the silver workpiece can be decreased, and surface roughness of the silver workpiece is reduced; and besides, the feed amount is relatively small, cut chips are not liable to crimp, friction between the chips and the silver workpiece can be reduced, and surface roughness of the silver workpiece is further reduced.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Efficient paper straw cutting device

InactiveCN112677198AAvoid stickingSmall feedMetal working apparatusAgricultural engineeringEngineering

The invention discloses an efficient paper straw cutting device which comprises a base, a cutting box is fixedly arranged at the upper end of the base, a cutting cavity penetrating left and right is formed in the cutting box, four working sliding grooves are formed in the cutting box in a front-back and up-down symmetrical mode, working sliding blocks are arranged in the working sliding grooves in a left-right sliding mode, a rotating disc cavity with downward opening is formed in each working sliding block, and the lower ends of working sliding grooves communicate with the cutting cavity and are provided with sliding rod sliding grooves. According to the efficient paper straw cutting device, four cutting knives are driven by rhombic knife rests which are hinged together, the cutting speed is adjusted according to the conveying speed of paper straws, the feeding amount of the knives is small, and when the paper straws are cut, only the displacement distance of the length of one section of straw needs to be moved, so that the occupied size of equipment is small, the equipment can automatically knock the cut paper straws after cutting is finished, and the cut paper straws are prevented from being still adhered together.

Owner:洛阳美思凯家具有限公司

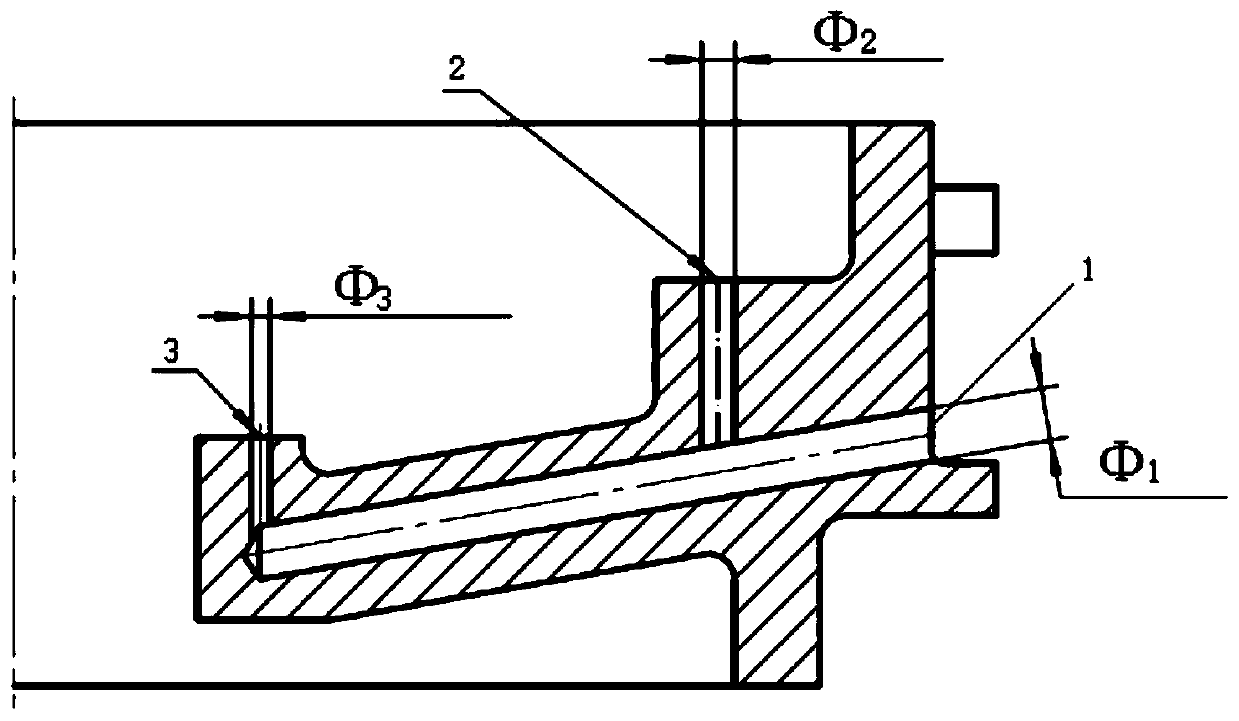

Processing method for improving flow precision of oil injecting ring

The present invention discloses a processing method for improving the flow precision of an oil injecting ring. Drilling and reaming processes are adopted for forming oil injecting holes and oil feeding holes of an oil path, a single-oil-path flow process test is performed, and the diameter phi 1 of one oil feeding hole and the diameters phi 2 and phi 3 of two oil injecting holes, which meet the median flow requirements under the processing precision level of the reaming process are determined; then the oil feeding holes and the oil injecting holes are formed according to the drilling and reaming processes, after all the oil feeding holes and oil injecting holes are formed, the oil path test is performed, a reamer is adopted for polishing the oil injecting holes when the flow test is not qualified, the smaller feeding amount is adopted in polishing, and the whole oil path of the oil injecting holes is completely polished, so that polishing of only the oil path near oil discharging holesof the oil injecting holes is avoided; the better inner hole surface roughness and the smaller geometric tolerance in the oil path are improved, the flow test frequency is greatly reduced, and the problem of part scrapping caused by flow out-of-tolerance is eliminated; and on-time on-demand delivery of the oil injecting ring is ensured.

Owner:AECC AVIATION POWER CO LTD

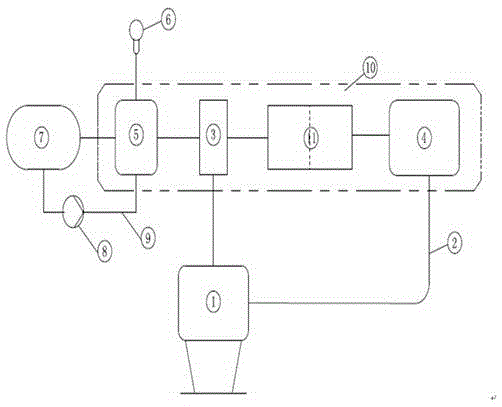

Automatic coating control method and automatic coating control system

InactiveCN104668162ASimple structureReasonable designPretreated surfacesCoatingsProduction lineAutomatic control

The invention discloses an automatic coating control method and an automatic coating control system. The automatic coating control system comprises a coating production line control system, a data transmission network, a coating steel roller, a double-side-penetrating beta sensor, a coating cavity, a pressure detection sensor, a feeding tank, a feeding pump, a feeding pipeline, a coating pipeline and a drying box. The coating production line allows a battery pole piece to pass, the coating production line control system controls production, the battery pole piece is produced through the coating cavity, the coating steel roller and the drying box, the pressure detection sensor is mounted on the coating cavity, data after detection are transmitted to the coating production line control system through the data transmission network after the double-side-penetrating beta sensor is mounted on the drying box, and the feeding tank feeds slurry to the coating cavity through the feeding pump and the feeding pipeline. The automatic coating control system is simple in structure and reasonable in design, slurry feeding quantity in the process of manual intervening and adjusting of coating is reduced, and automatic adjusting is realized; lag of surface density adjusting in the process of coating is reduced.

Owner:ZHONGTIAN ENERGY STORAGE TECH

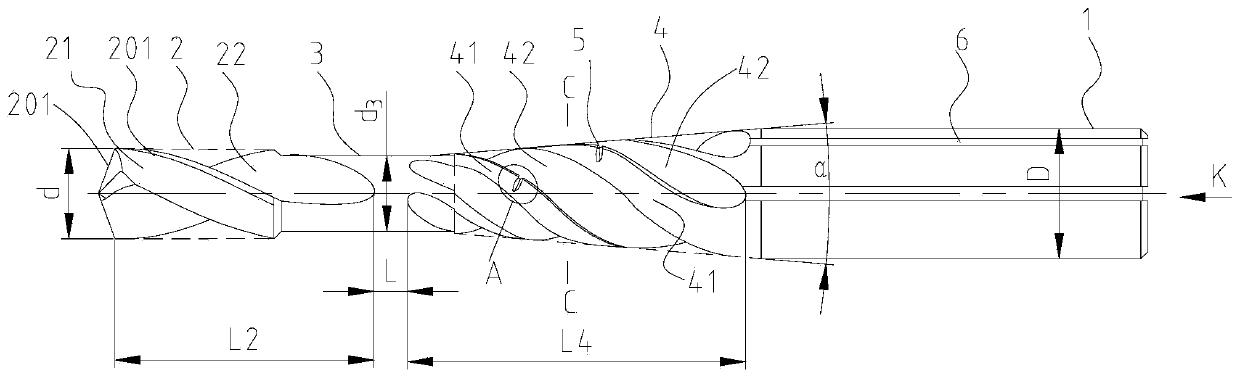

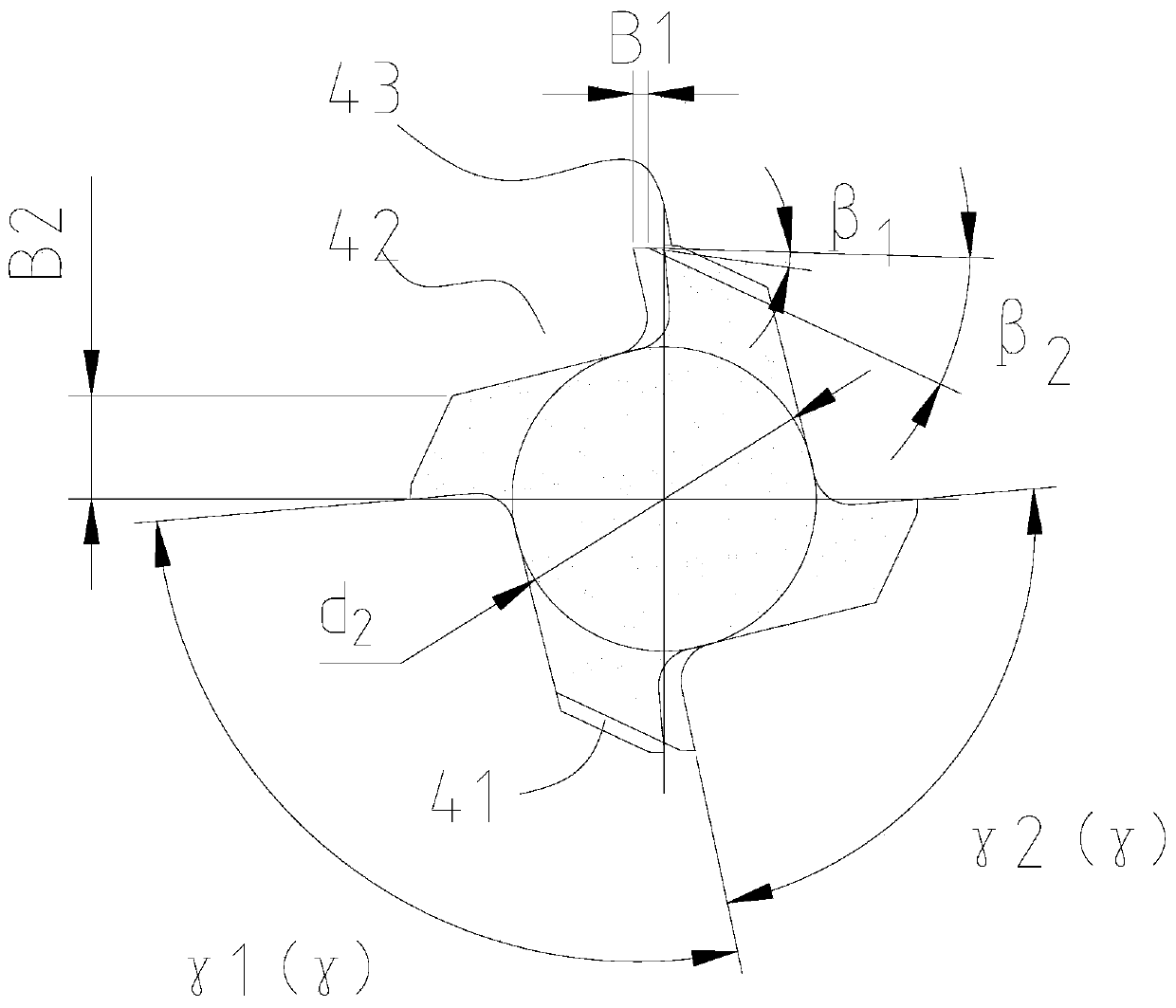

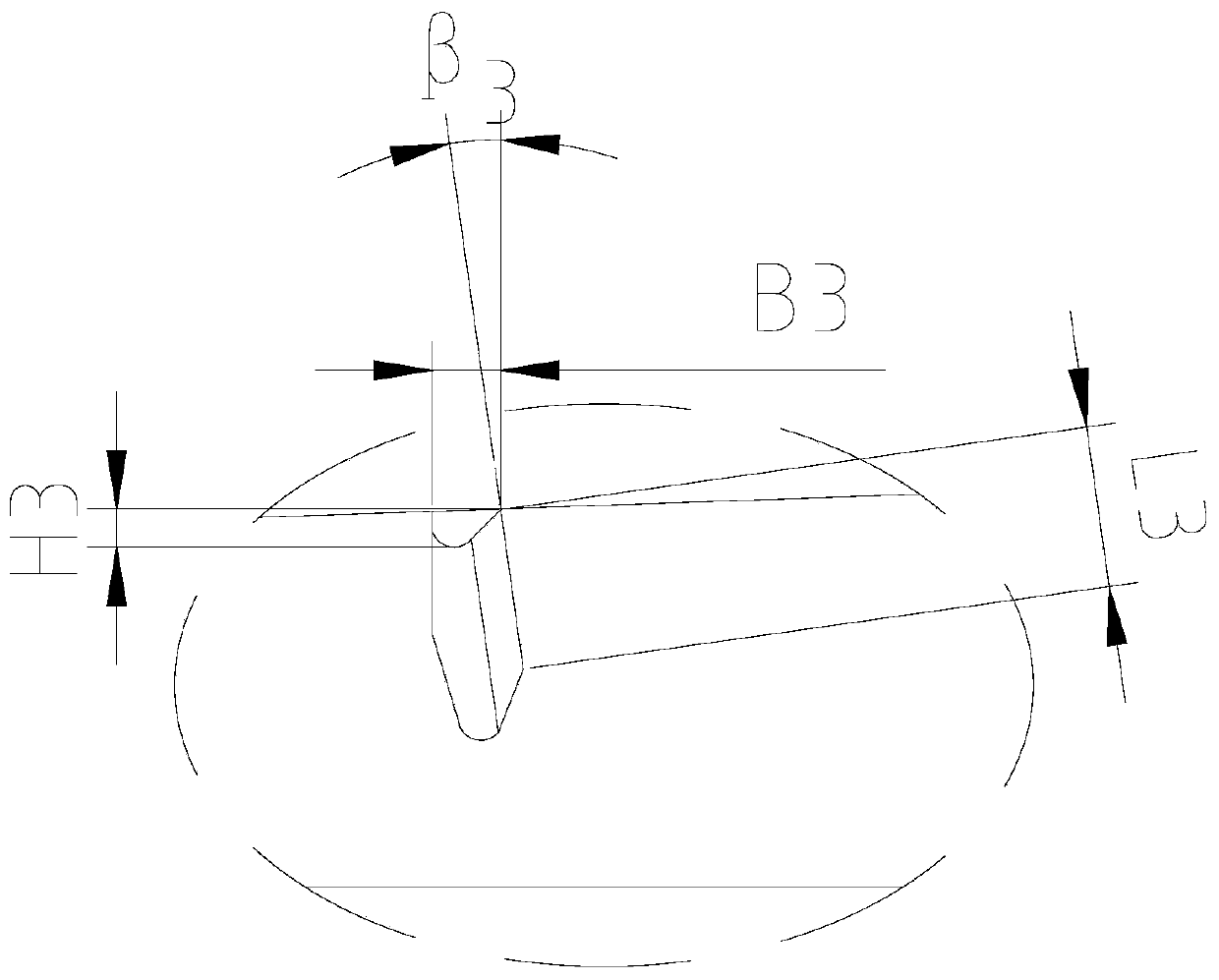

Taper drill reamer

InactiveCN110405258ACore thickIncreased core thicknessTransportation and packagingTrepanning drillsNeck partsReamer

The invention discloses a taper drill reamer. The taper drill reamer comprises a cutting part and a handle part, wherein the cutting part comprises a drilling part, a neck part and a taper cutting part which are sequentially arranged, and the taper cutting part is connected with the handle part; the drilling part comprises two drilling blades and two drilling chip removal grooves arranged betweenthe two drilling cutting blades, a drill tip is arranged on the end face of each drilling blade, and an auxiliary blade is arranged on the circumferential surface of each drilling blade; the taper cutting part comprises at least three taper blades and three taper chip removal grooves; the drilling chip removal grooves and the taper chip removal grooves extend to the neck part; and the axial distance between the drilling chip removal grooves and the taper chip removal grooves are L, wherein L is larger than 0. According to the taper drill reamer, the drilling part and the taper cutting part areseparated through the neck part, the taper cutting part can provide with more than three taper chip removal grooves and does not need to correspond to the drilling part, on the basis that the core thickness of the taper cutting part is increased, the chip removal requirement is met by increasing the number of the taper chip removal grooves, so that the strength of the taper cutting part is increased, the anti-seismic capability of the cutter is increased, and generation of vibration grains is reduced.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

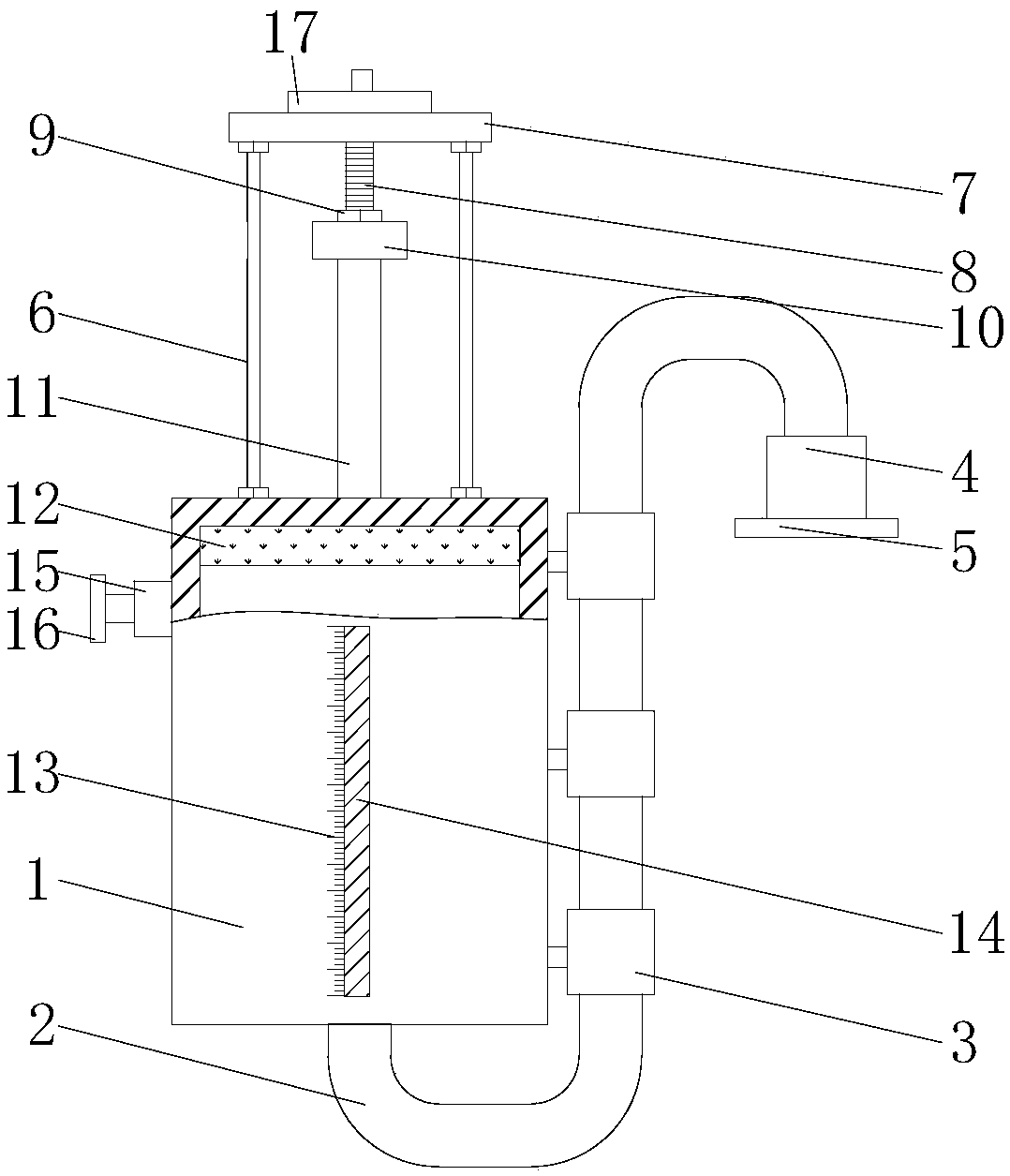

Feeding device used for resin treatment

The invention discloses a feeding device used for resin treatment. The feeding device comprises a round resin storage can, a discharge tube, piping supports, a first electromagnetic valve, a first flange, supporting bars, a top plate, a screw, a movable block, a connecting block, a compression bar, a piston, a containing mark, a glass strip plate, a second electromagnetic valve, a second flange, afirst gear, a stepping motor, a second gear, a square guide bar, a square through hole and a stepping motor driver. The feeding device disclosed by the invention is reasonable in structure; during resin treatment, feeding can be effectively performed through a feeding structure; after the stepping motor is driven, angular velocity after transmission can be effectively lowered through transmissionof the first gear and a second piston gear, and therefore, each time of feed rate of the movable block and displacement distance of the piston can be reduced; and further, under the matching action between the glass strip plate and the containing mark, feeding accuracy is increased.

Owner:YANGZHOU ZHENGXING RESIN

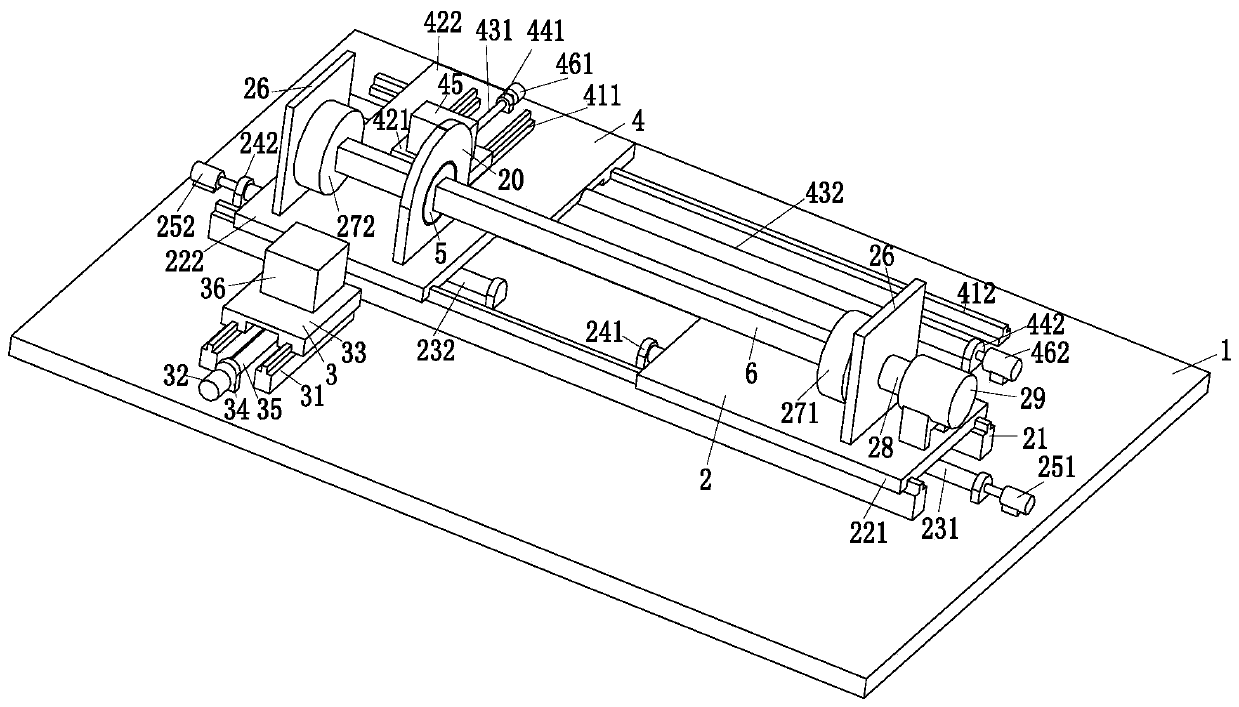

A wire cutting device with grinding technology

ActiveCN107297625BHigh precisionSmooth rotationElectrical-based machining electrodesOther manufacturing equipments/toolsWire cuttingMachining process

The invention belongs to the field of machining, and particularly relates to a wire-cutting device with a grinding process. The wire-cutting device comprises a supporting plate, a clamping module, a wire-cutting module, a grinding module and a controller, and the controller is placed on the supporting plate; the clamping module is fixed to the supporting plate, and the wire-cutting module is located in front of the clamping module; the grinding module is located behind the clamping module; under the cooperative work of a slide supporting mechanism, the vibration generated when a wire-cutting mechanism or a grinding mechanism conducts wire cutting or grinding on a workpiece can be reduced, and thus the wire cutting precision or grinding precision is improved; in the wire cutting machining process, the workpiece is in a rotation state, the feeding amount of the wire-cutting mechanism can be reduced, the heat generated on machining surfaces is also reduced, and thus the service life of the wire-cutting mechanism is prolonged; the grinding mechanism grinds two cut machining surfaces simultaneously, and in this way, the grinding efficiency can be improved; meanwhile, the grinded surfaces serve as the criterion, and thus the wire cutting precision next time can be improved.

Owner:泰州市江南机械制造有限公司

Drilling coring device with flexible drill bits

The invention relates to the technical field of drilling devices, and provides a drilling coring device with flexible drill bits. The device comprises a mounting seat, the drill bits mounted on the mounting seat in a manner of floating up and down and drilling tools hinged to the drill bits through hinge mechanisms. Therefore, the drilling tools can rotate between the folded positions where the drilling tools are folded inwards and the unfolded positions where the drilling tools are unfolded outwards, positioning mechanisms are arranged on the mounting seat, and can be matched with the drilling tools to limit rotation of the drilling tools when the drilling tools move to the unfolded positions. The actual working feed amount of the drilling tools can be adjusted by changing the positions of the drilling tools, so that the drilling coring device can cope with an unknown geological environment, and the coring efficiency is improved. Meanwhile, in the lifting process after coring is completed, the drilling tools rotate to the folded position, so that damage to a coring hole and the requirement for lifting force are reduced, the possibility of drill jamming is reduced, and the continuity of the coring process is improved.

Owner:SHENZHEN UNIV

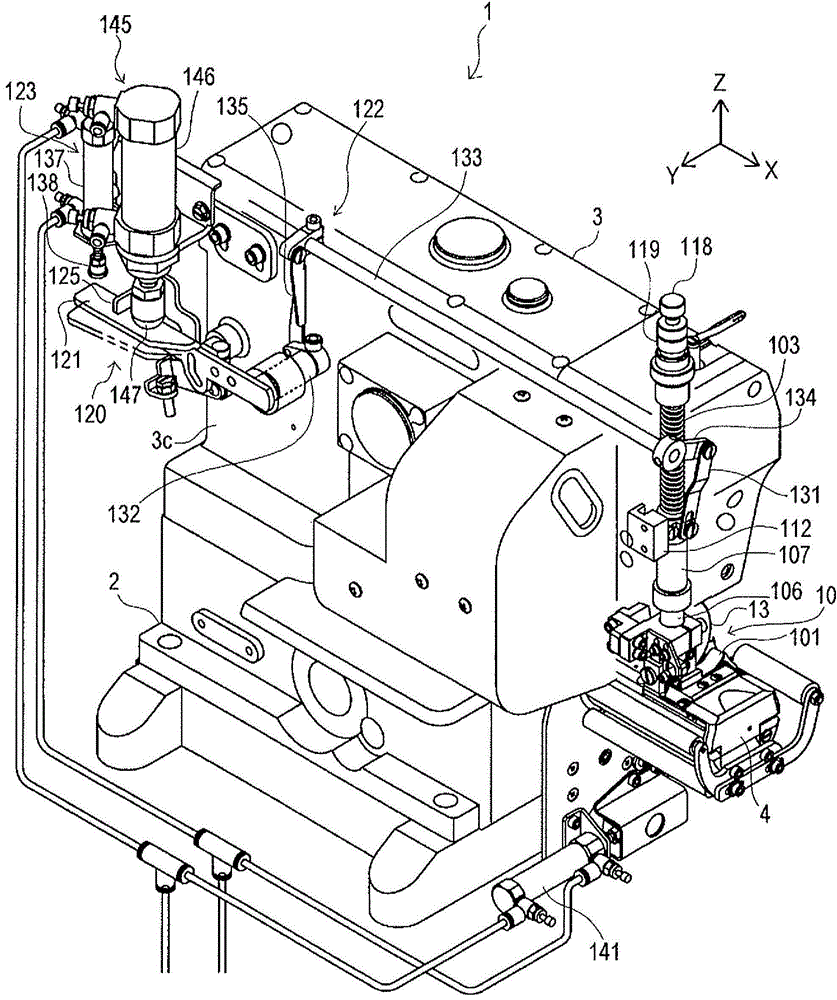

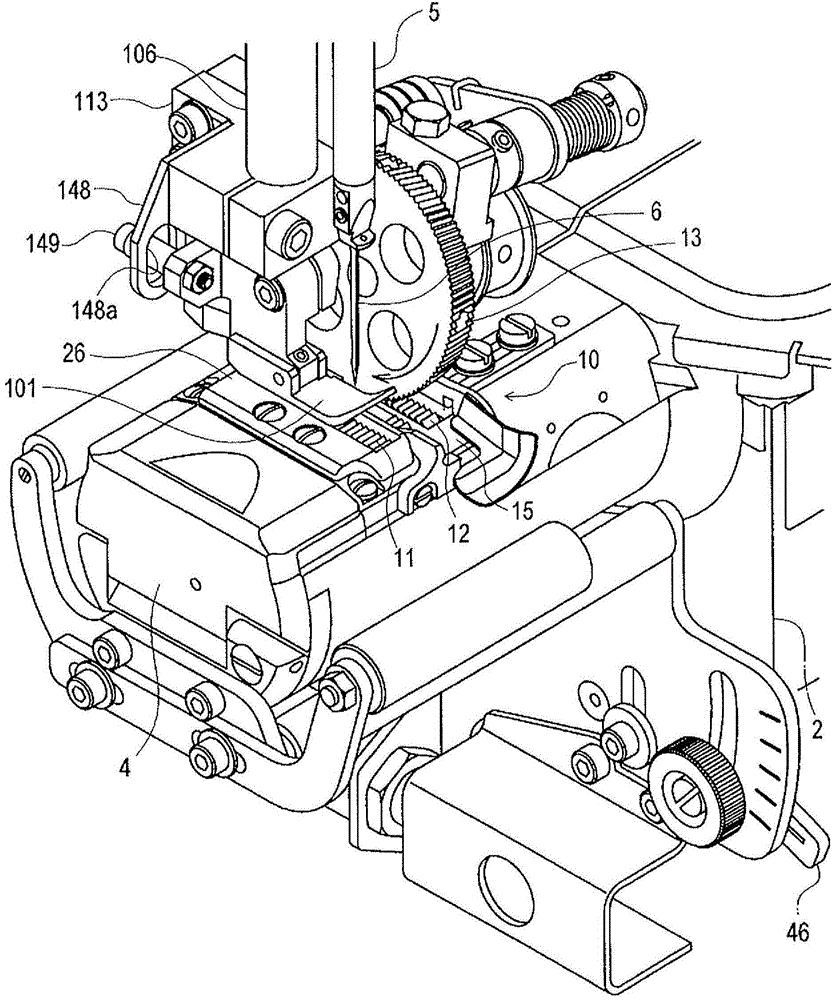

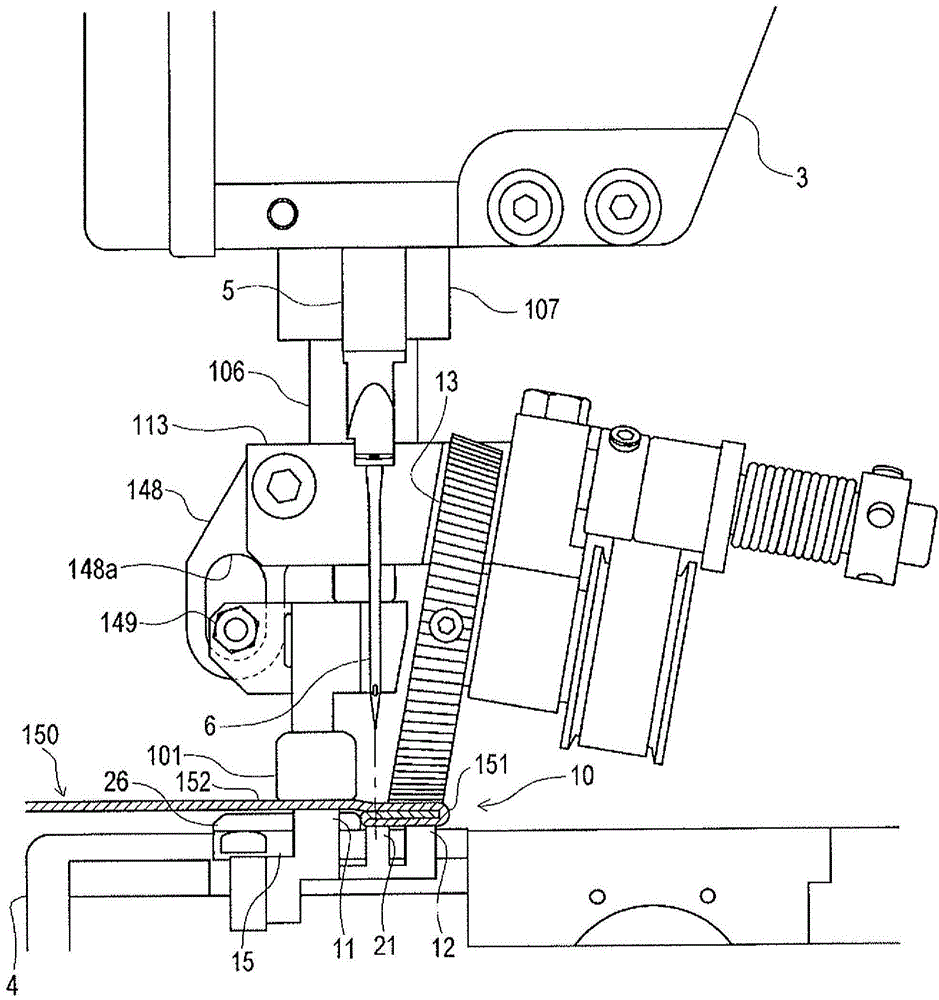

Gas cylinder type sewing machine

The invention provides a gas cylinder type sewing machine which is capable of obtaining fine processing in sewing of a barrel-shaped lower hem of a multi-layer folding clothing material. A clothing material feeding mechanism for the gas cylinder type sewing machine comprises a first feeding tooth which is arranged at one side of a needle dropping position of a sewing needle of a gas cylinder part and capable of conveying a sheet part along a clothing material feeding direction from one resisting side of the sheet body and the below, a second feeding tooth which is arranged at one side reverse to one side of the first feeding tooth opposite to the needle dropping position of the sewing needle and capable of conveying the lower hem along the clothing material feeding direction from one resisting side of the lower hem and below, and an intermittent feeding roller which is arranged at the side of the sewing needle in a mode of moving up and down and capable of intermittently conveying the lower hem in the clothing material feeding direction from the above and one resisting side of the lower hem; The gas cylinder type sewing machine can be regulated through the feeding amount of the sheet conveyed by the first feeding tooth, the feeding amount of the lower hem conveyed by the second feeding tooth and the feeding amount of the lower hem conveyed by the intermittent feeding roller.

Owner:MORIMOTO MFG

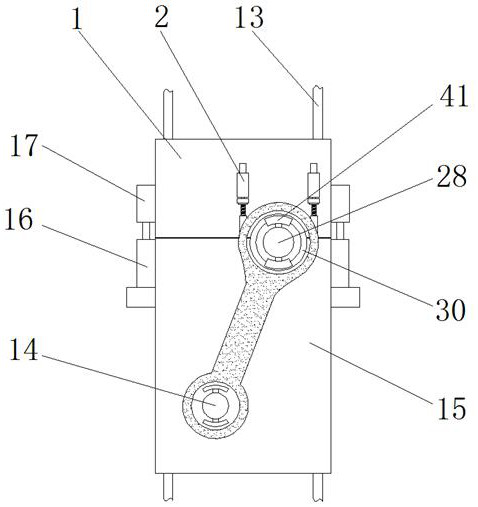

Connecting rod cracking equipment and technology

ActiveCN112222606AFacilitate step-by-step continuous productionIncrease productivityLaser beam welding apparatusEngineeringLaser cutting

The invention discloses connecting rod cracking equipment. The connecting rod cracking equipment comprises a shell and a laser grooving assembly; an inner wall laser cutting head is arranged on the laser grooving assembly; the two ends of the shell are both open; a feeding plate is arranged at one end in the shell; a hole wall pull-down plate and a rod wall pull-down plate which are aligned to each other are glidingly mounted at the other end in the shell; and two sliding rods which are arranged in parallel are arranged in the shell. According to the equipment, the feeding plate, an inspectionplate and the pull-down plates are arranged in the shell, a first suction cup, a second suction cup and a clamping plate are mounted on a mounting plate, step-by-step continuous production of a connecting rod is facilitated in the connecting rod cracking machining process, the mounting plate moves to drive the first suction cup, the second suction cup and the clamping plate to move simultaneously, the connecting rod is synchronously transferred in the steps of feeding, bolt assembling, grooving, cracking and discharging, the automation degree is high, and the production efficiency of connecting rod machining is improved.

Owner:济南吉隆锻造有限公司

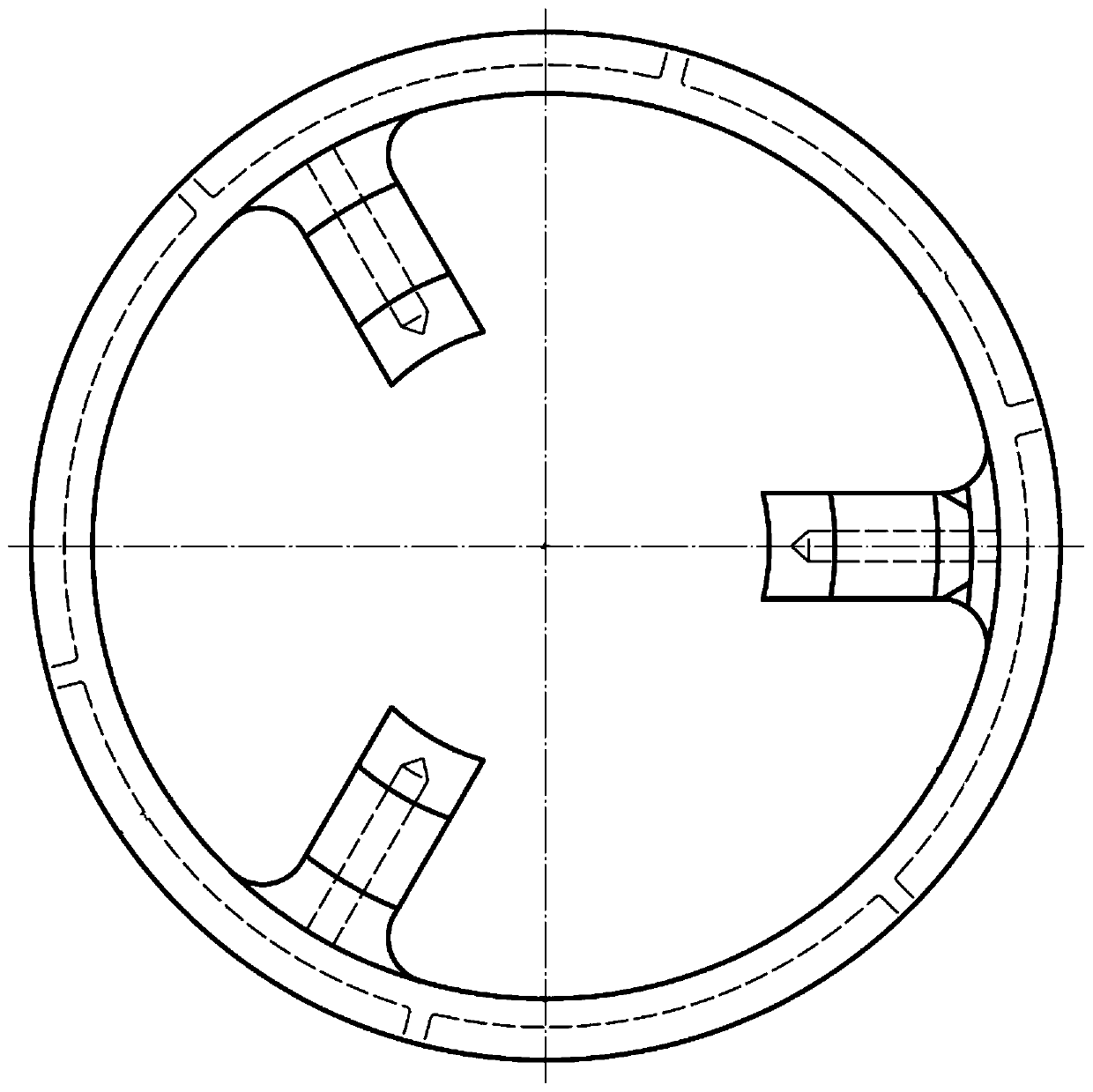

Cutter device for improving machining precision of thin and long shaft

The invention relates to a cutter device for improving the machining precision of a thin and long shaft. The cutter device comprises a cutter rest and three blades installed on the cutter rest, wherein the blades are uniformly installed on the cutter rest and are arranged in the radial direction at intervals of 120 degrees. Compared with the prior art, the flexible deformation of the machined thinand long shaft during cutting is decreased, the dynamic rigidity is improved, stress is uniform, and small-feed high-precision surface machining is achieved. In addition, efficient machining is completed while coarse machining is achieved by changing the arrangement mode of three blades in the axial direction and the cutting depth in the radial direction.

Owner:SHANGHAI JIAO TONG UNIV

Intelligent speed adjusting system for automatically adjusting feeding speed according to material saw cutting face

InactiveCN111618364ATime-consuming and laborious to solveSolve the problem that the speed cannot be adjusted accuratelyMetal sawing devicesAutomatic control devicesCouplingControl engineering

The invention discloses an intelligent speed adjusting system for automatically adjusting the feeding speed according to a material saw cutting face, and relates to the field of intelligent speed adjusting systems. For the problems that according to an existing turning sawing machine speed adjusting system, manual speed adjustment is manually conducted, time and labor are wasted, and accurate speed adjusting cannot be achieved, the following scheme is provided at present, the intelligent speed adjusting system comprises a servo motor, a plurality of first bolt holes are formed in the right side face of the servo motor, a coupler is fixedly connected to the output end of the servo motor, second bolt holes are formed in the upper surface of the coupler, a speed adjusting device installing base is arranged on the right side of the servo motor, the left side face of the speed adjusting device installing base is provided with a plurality of third bolt holes, first bolts are arranged on theright sides of the first bolt holes, a plurality of fourth bolt holes are formed in the upper side and the rear side of the speed adjusting device installing base, and a photoelectric sensor is arranged in the speed adjusting device installing base. According to the device, the service life of a saw belt is prolonged, and the saw cutting efficiency is improved.

Owner:浙江奥林发机床有限公司

A mobile platform for picking and placing warehouse commodities and a path planning method for the mobile platform

ActiveCN110465928BImprove reliabilitySmall feedProgramme-controlled manipulatorGripping headsRobotic armControl engineering

Owner:HEBEI UNIV OF TECH

A kind of preparation method of strontium aluminum alloy with high strontium content

The invention discloses a preparation method of a strontium aluminum alloy with a high strontium content, and belongs to the technical field of preparation of alloy materials. The preparation method specifically comprises the following steps: firstly, an aluminum block is preheated; then, under inert gas shielding, a strontium block is heated for melting to obtain strontium solution; a covering agent is added in the surface of the strontium solution; the strontium solution keeps the temperature; then, under inert gas shielding, the preheated aluminum block is pressed in the strontium solution for totally melting; the mass ratio of the pressed aluminum block to the strontium solution is 1: 14-1: 0.9; then, a refining agent is added for degassing, stirring and smelting to obtain strontium aluminum alloy liquid; and finally, under inert gas shielding, the strontium aluminum alloy liquid is heated for keeping the temperature at 700-900 DEG C, and is cast to obtain the strontium aluminum alloy. The strontium aluminum alloy, prepared by adding the preheated aluminum block in the strontium solution, is uniform in components, the content of effective component-strontium reaches 47-93%, and the melting point is only 580 DEG C, so that the production energy consumption of users can be reduced; and the strontium aluminum alloy is an excellent high-density modifying agent for casting an aluminum alloy.

Owner:GAOYOU HONGRUI SPECIAL METAL CO LTD

A Method for Cutting Squared Monocrystalline Silicon Rods Using Diamond Wire

ActiveCN107415067BSmall feedReduce consumptionWorking accessoriesGrinding machinesDiamond cuttingSingle crystal

The invention provides a method of cutting and squaring a single crystal silicon round rod by utilizing a diamond line. The method utilizes high-speed feeding of the diamond line to cut the single crystal silicon round rod and comprises the following concrete steps of (1) wire winding: winding a diamond wire to form a wire net of a well-shaped structure after the diamond passes through a cutting wheel and guide wheels; (2) crystal rod mounting: mounting a crystal rod on a workbench, enabling the diamond cutting wire to form a field angle between the crystal rod and each of the guide wheels at the front, the back, the left and the right of the crystal rod; (3) parameter setting: setting a line tension, a feeding speed and a new wire feeding quantity according to the diameter of the crystal rod; (4) cutting: carrying out continuous cutting through relative movement of the diamond cutting wire and the single crystal round rod to be cut; and (5) finishing cutting, and ending a program. The method has the advantages that the feeding speed is increased, the new wire feeding quantity and the steel wire consumption quantity are reduced, and the quality of a quasi-square rod subjected to squaring is in a controlled state.

Owner:德州倍力刀具有限公司

Back milling equipment of a wireless glue binding machine for books and periodicals

ActiveCN110696518BReduce air pressureIncrease the amount of downCasing-inBookbinding adhesiveMechanical engineeringEngineering

The invention discloses a back-milling equipment of a wireless glue binding machine for books and periodicals, which comprises a conveying box, in which a conveying chamber with an upward opening is provided, and a conveying belt device for conveying book blocks is arranged in the conveying chamber, so that A support plate is fixedly connected to the upper end surface of the delivery box, and a transmission box is fixedly connected to the upper end surface of the support plate. A transmission chamber with an opening facing downward is provided in the transmission box, and a moving device is provided in the transmission chamber. , the moving device is provided with a press-down fixing device, the moving device is used to transport the press-down fixing device, a milling back box is fixedly connected to the left end surface of the delivery box, and a milling back box is provided in the milling back box The back milling chamber with the opening facing the right, the milling back chamber is equipped with a back milling device for back milling, the invention can automatically adjust the feeding amount of the back milling and the clamping force on the book block according to the thickness of the book block, suitable for flexible Production.

Owner:曾镜炜

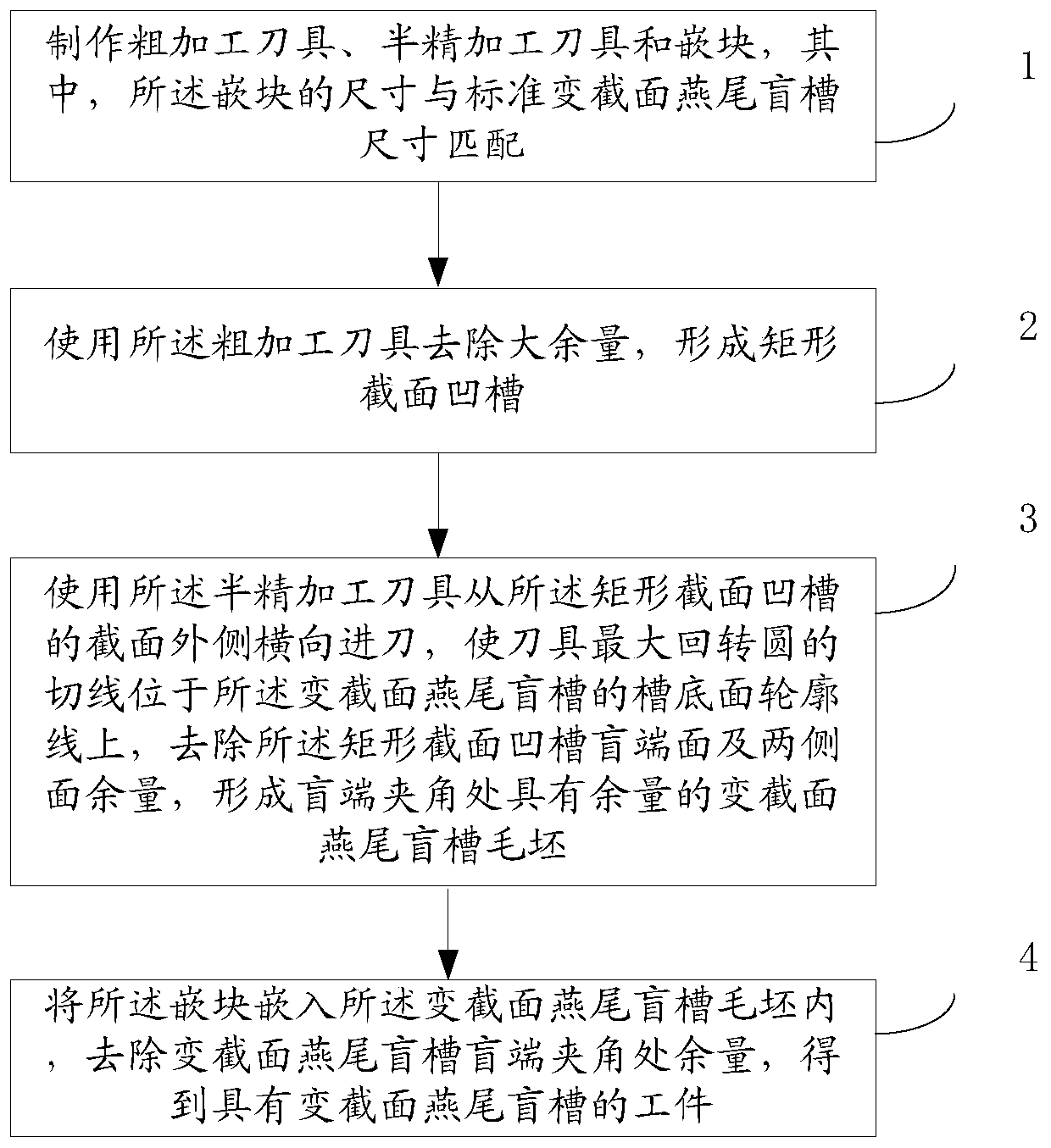

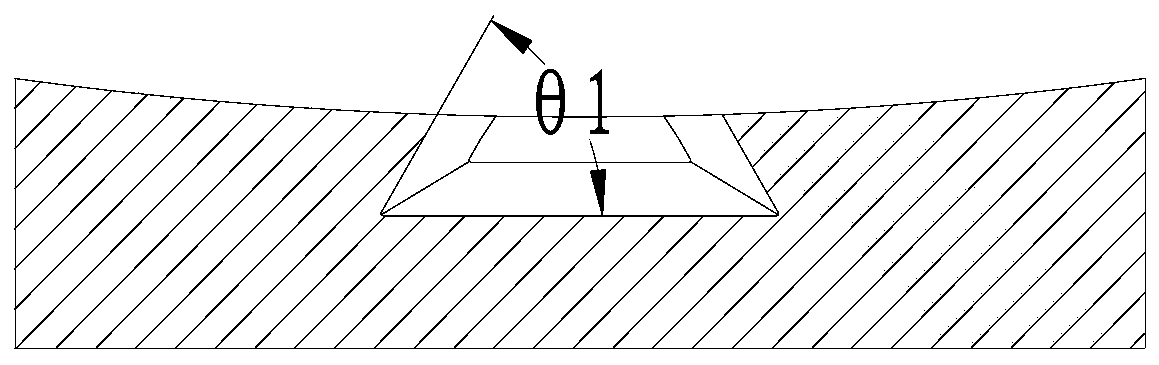

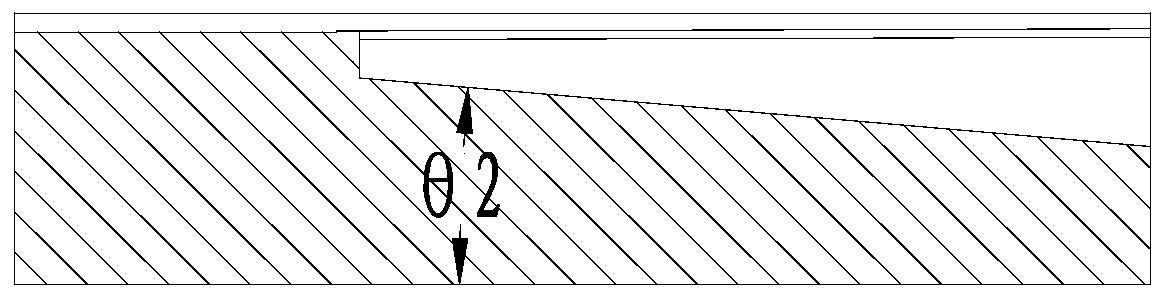

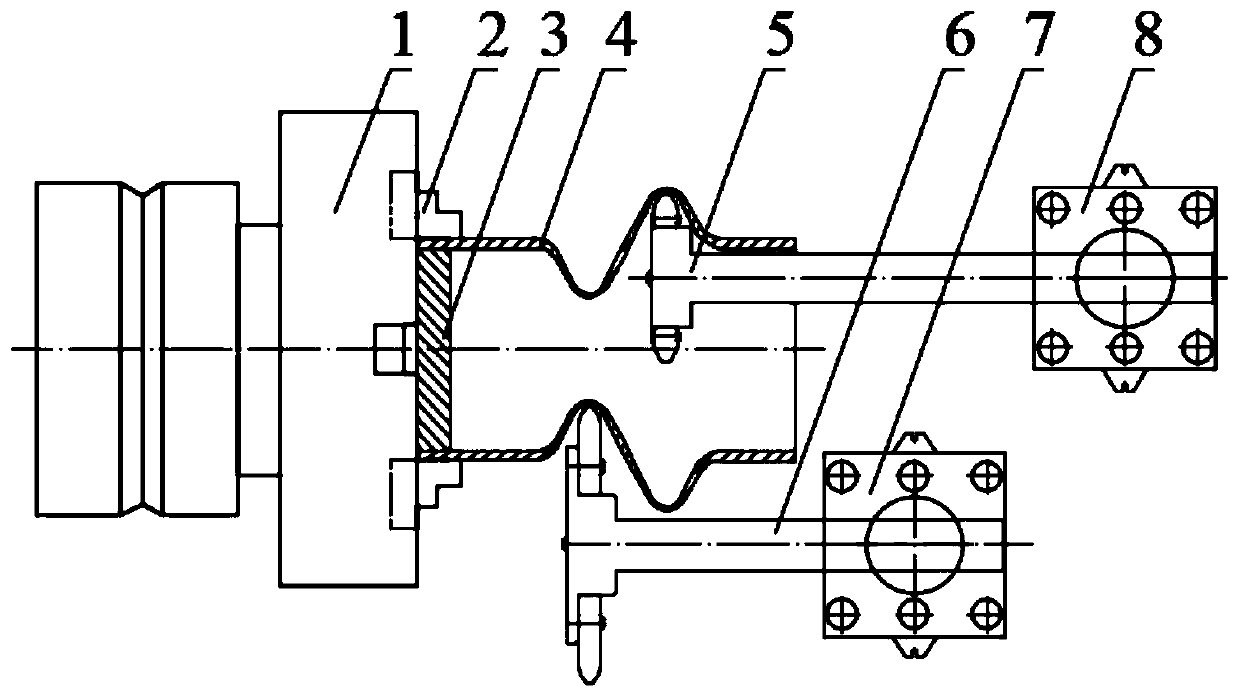

A kind of composite material variable-section dovetail blind groove machining method

The invention provides a method for machining a variable cross-section dovetail blind groove of a composite material, and belongs to the technical field of machining. The method includes the steps that a rough machining tool, a semi-finishing tool and an insert block are manufactured; the rough machining tool is used for removing the large allowance to form a rectangular cross-section groove; the semi-finishing tool is used for conducting transverse cutting feed from the outer side of the cross section of the rectangular cross-section groove, the tangent line of the maximal turning circle of the tool is located on the groove bottom face contour line of the variable cross-section dovetail blind groove, the allowances of the blind end face and the two side faces of the rectangular cross-section groove are removed, and accordingly a variable cross-section dovetail blind groove workblank with the allowance being reserved at the blind end included angle position is formed; and the insert block is embedded into the variable cross-section dovetail blind groove workblank, the allowance at the blind end included angle position of the variable cross-section dovetail blind groove is removed and a workpiece with the variable cross-section dovetail blind groove can be obtained. By the adoption of the machining method provided by the invention, overcut of the blind end is avoided; the tool durability is effectively improved, and production cost is reduced; and corner chipping happening in the machining process of the workpiece dovetail groove is prevented.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

A metal bellows inner and outer incremental forming device

The invention discloses an interior and exterior incremental forming device for a metal corrugated pipe. The interior and exterior incremental forming device for the metal corrugated pipe comprises a forming system and a numerical control device which are connected to a machine tool. The forming system comprises a centering chuck which is connected with a spindle of the machine tool. A mandrel is perpendicularly connected to the center of the centering chuck. A clamping claw is further arranged in the center of the centering chuck. The forming system further comprises a crest interior incremental forming tool wheel and a trough exterior incremental forming tool wheel, wherein a tool rod of the crest interior incremental forming tool wheel is connected with a crest forming cutter rest; a tool rod of the trough exterior incremental forming tool wheel is connected with a trough forming cutter rest; the crest forming cutter rest and the trough forming cutter rest are connected with the numerical control device and arranged on a guide rail of the machine tool; and the trough forming cutter rest is arranged close to the centering chuck relative to the crest forming cutter rest. By means of the interior and exterior incremental forming device for the metal corrugated pipe, the forming quality of the formed metal corrugated pipe can be improved.

Owner:XIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com