Patents

Literature

459results about How to "Fast print" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

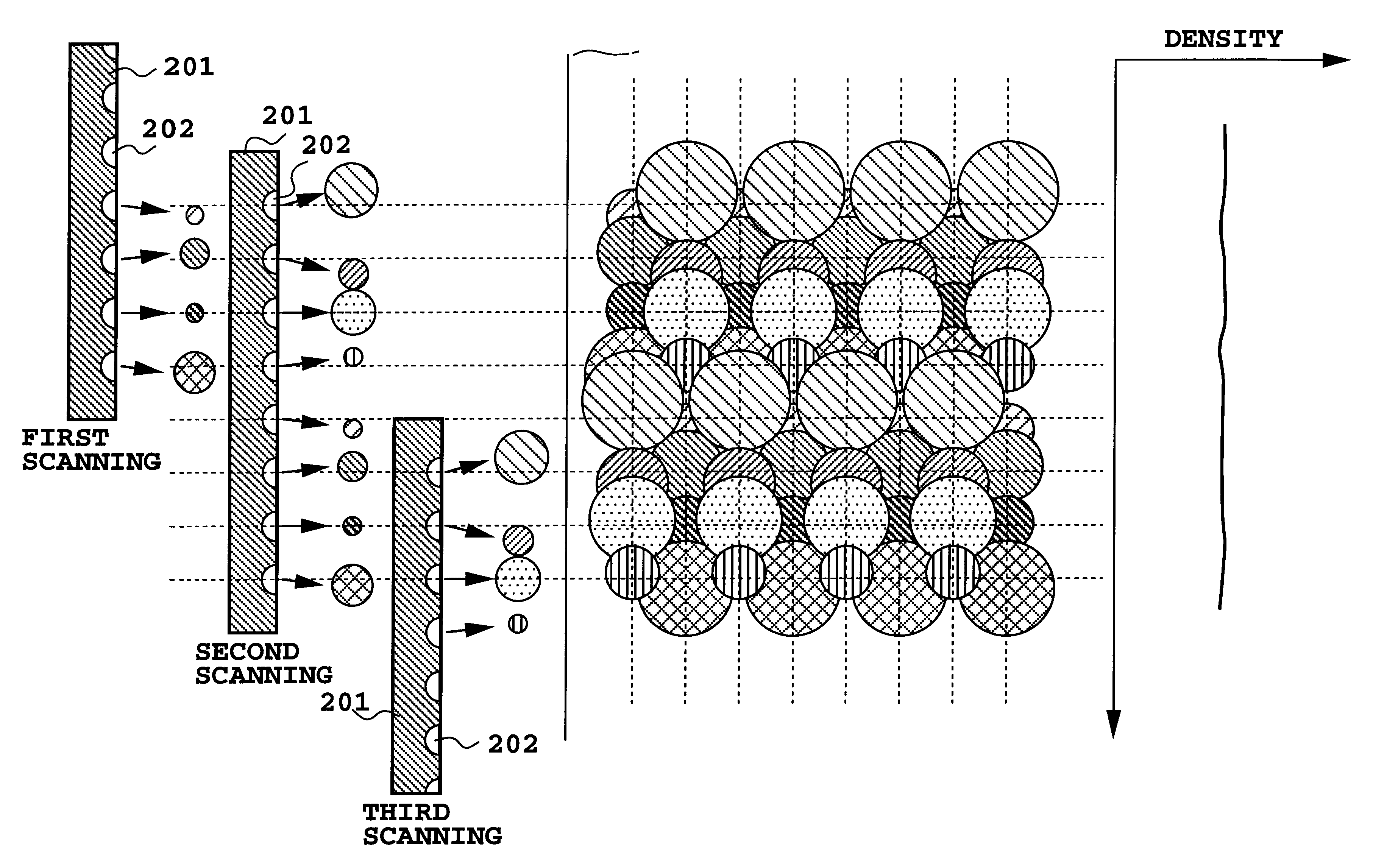

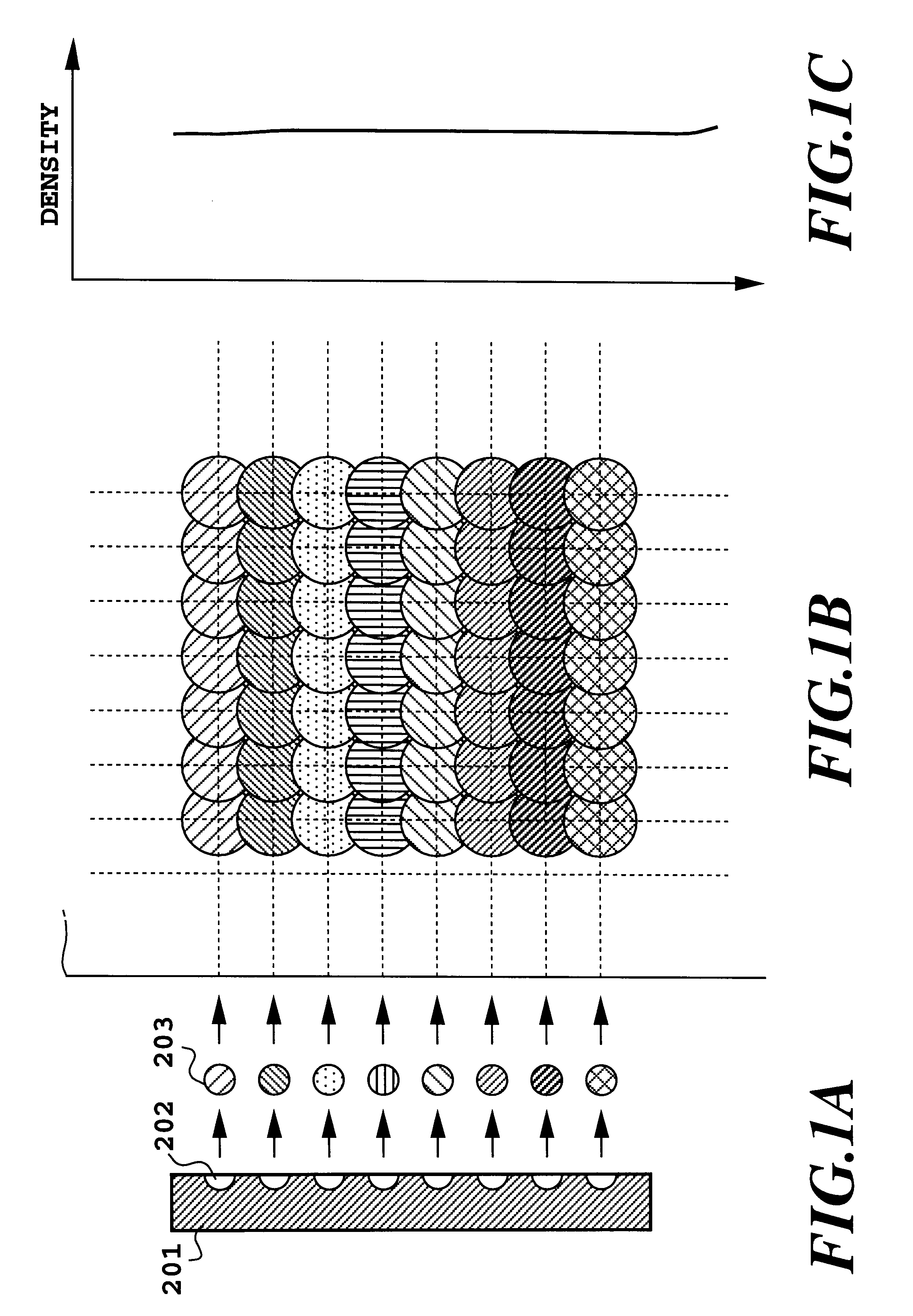

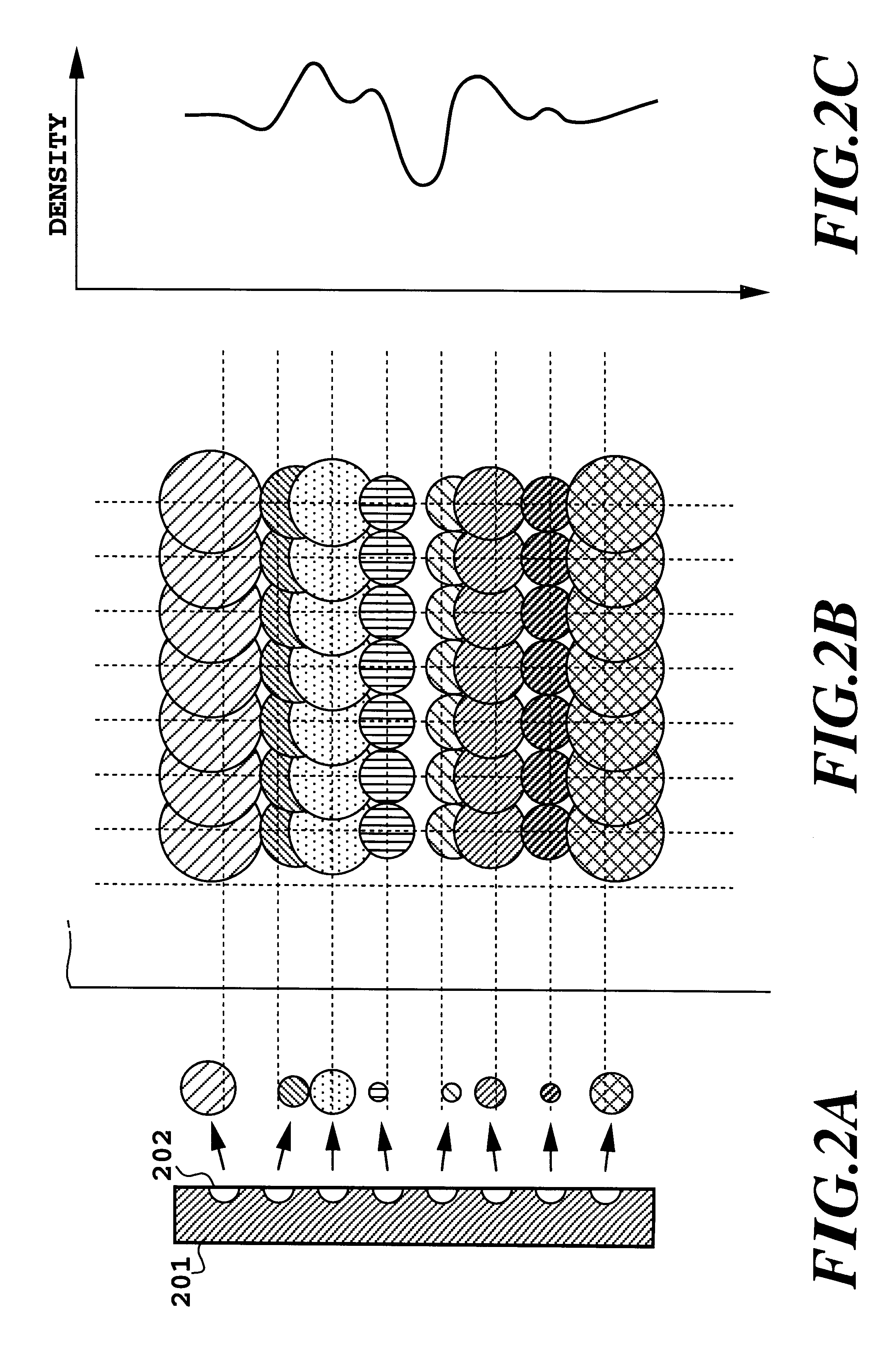

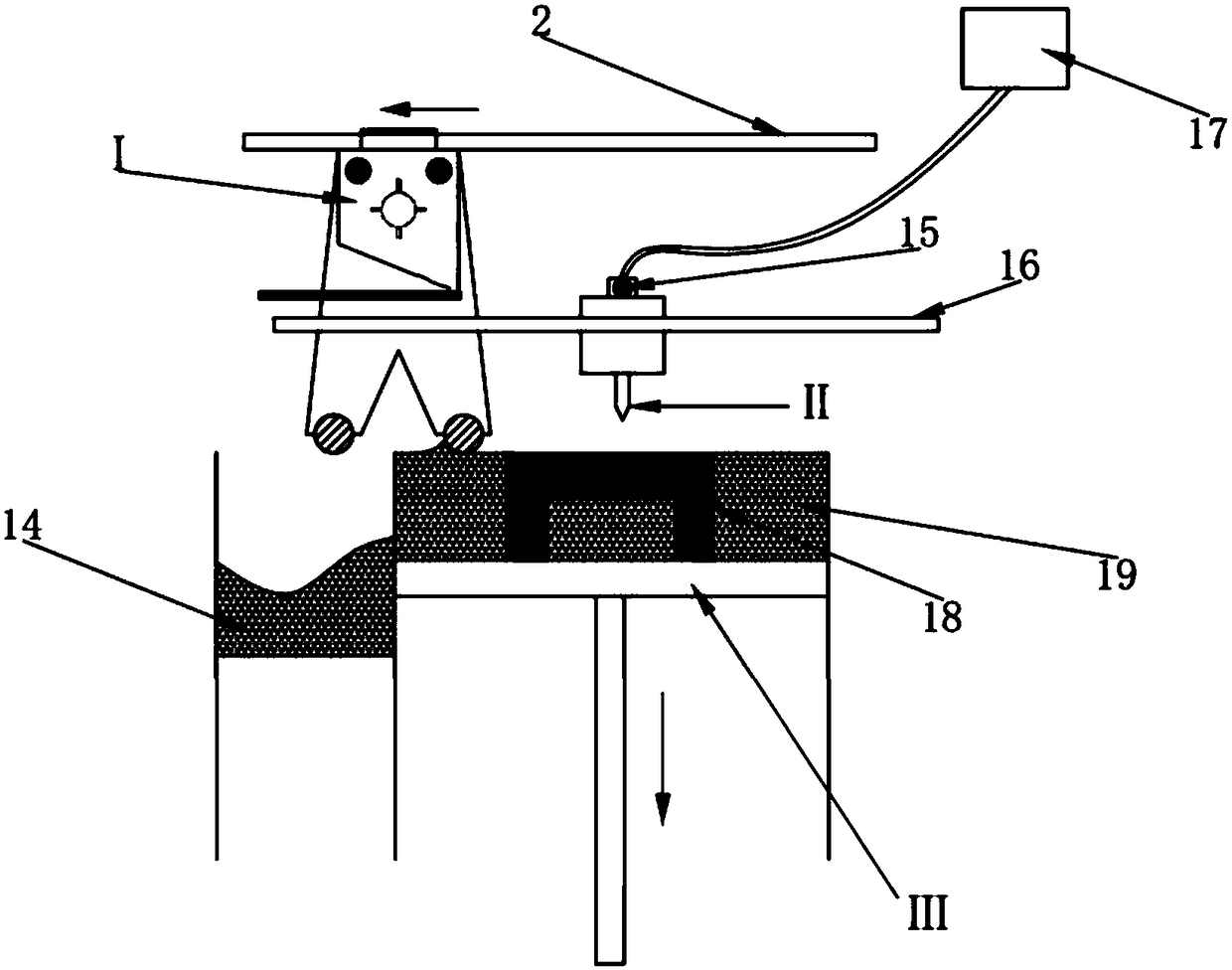

Adjustment method of dot printing positions and a printing apparatus

InactiveUS6257143B1Guaranteed uptimeLow costCylinder pressesPlaten pressesEngineeringPrinting registration

A plurality of patterns respectively having different area factor of dot formation area are formed by forward and reverse scanning printing of a print head, and then optical characteristics of the plurality of formed patterns are measured. A function representing the relationship between the printing position offset between the forward and reverse printings is determined from the optical characteristics. Then, respective pattern having a predetermined area factor of dot formation area is formed by means of forward and reverse scanning where the speed is differentiated according to the mode of a printing apparatus, and then the optical characteristics of this pattern is measured. By applying this measured optical characteristics to the function, an adjustment value of the dot formation position conditions between the forward and reverse scans is obtained for each mode. This makes it easy to perform printing registration in a printing apparatus in the case of printing by a forward and reverse scan of a printing head or in the case of printing by means of a plurality of printing heads. In this case, operations by a user etc. are also unnecessary and are easily performed.

Owner:CANON KK

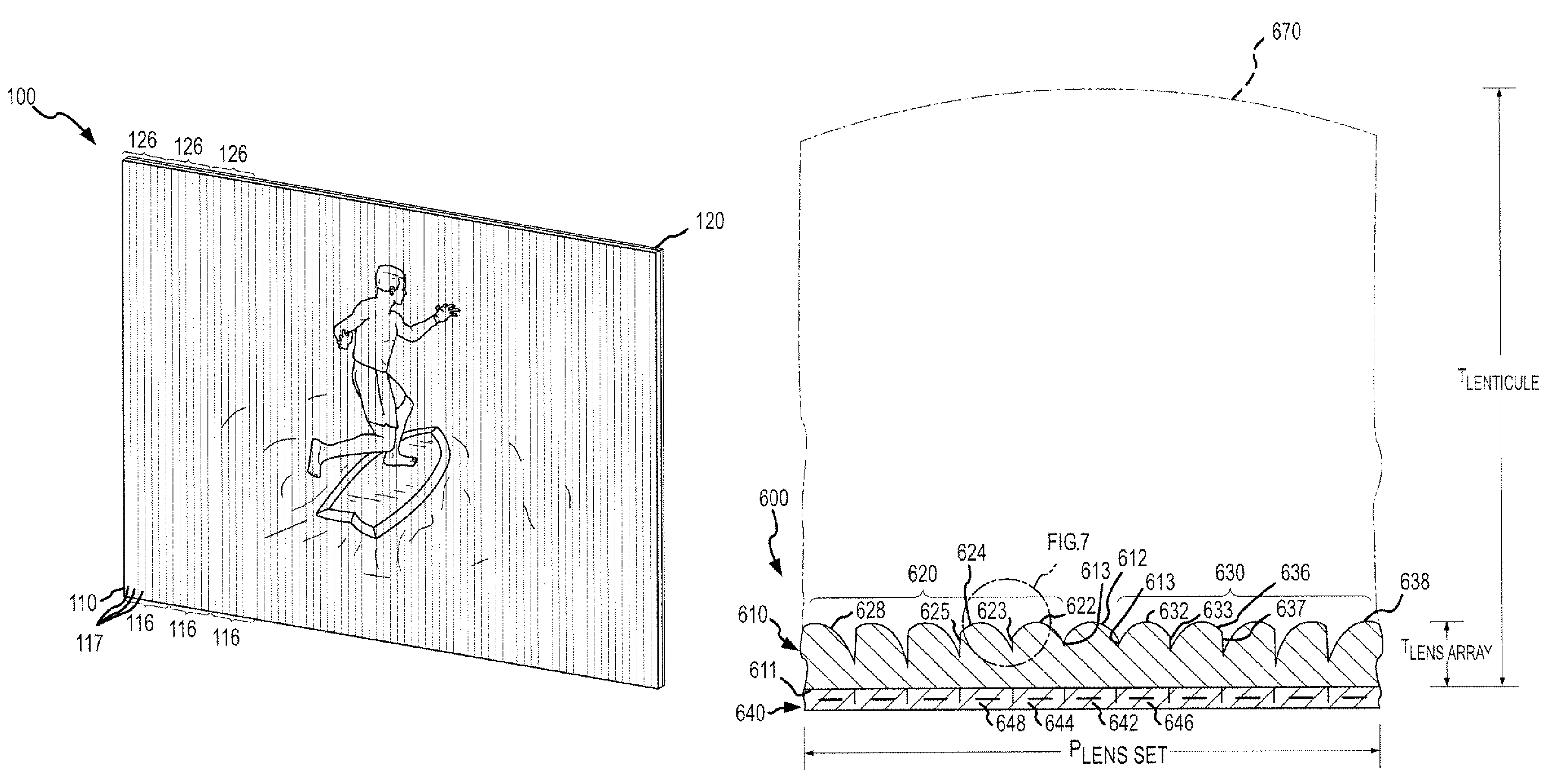

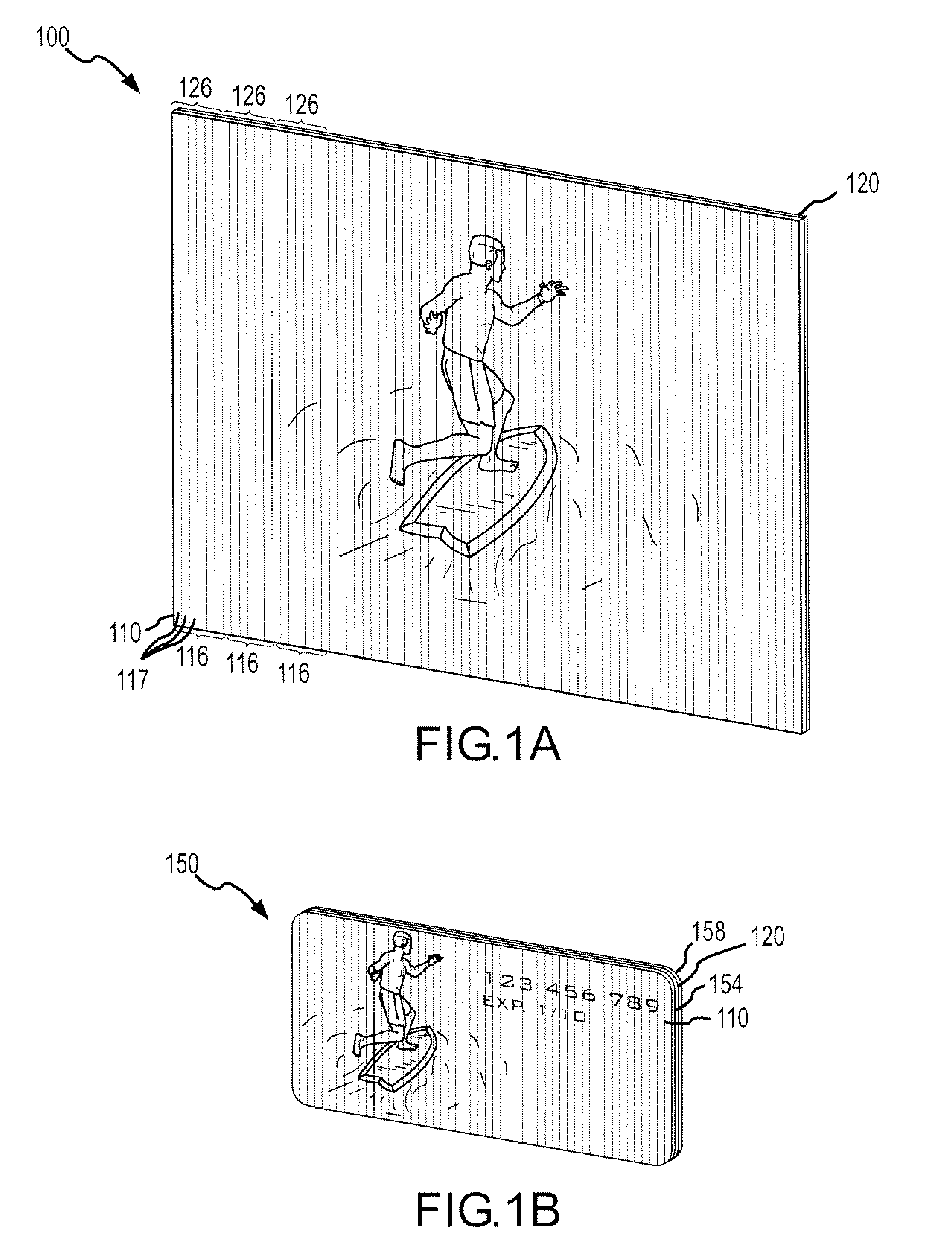

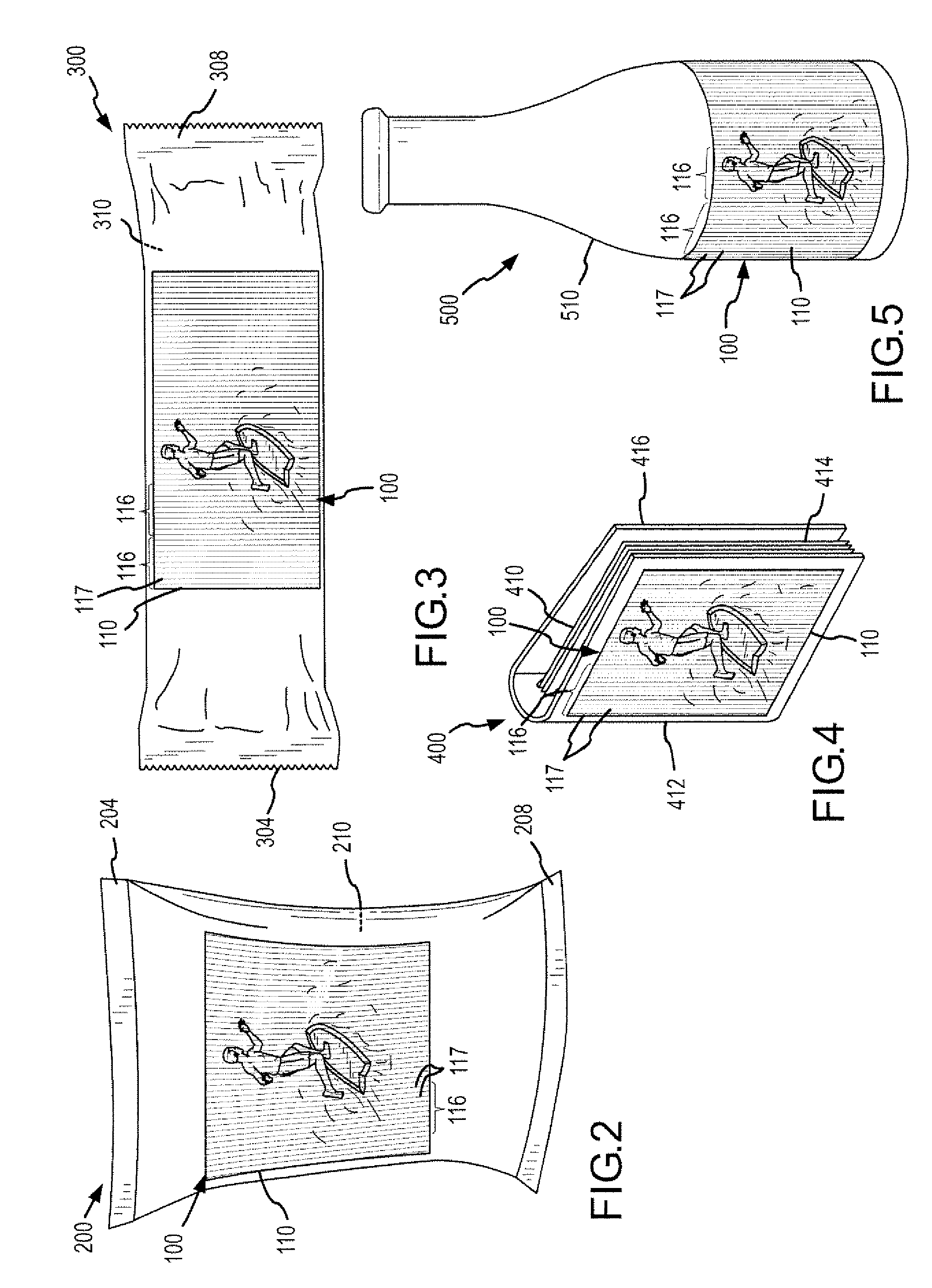

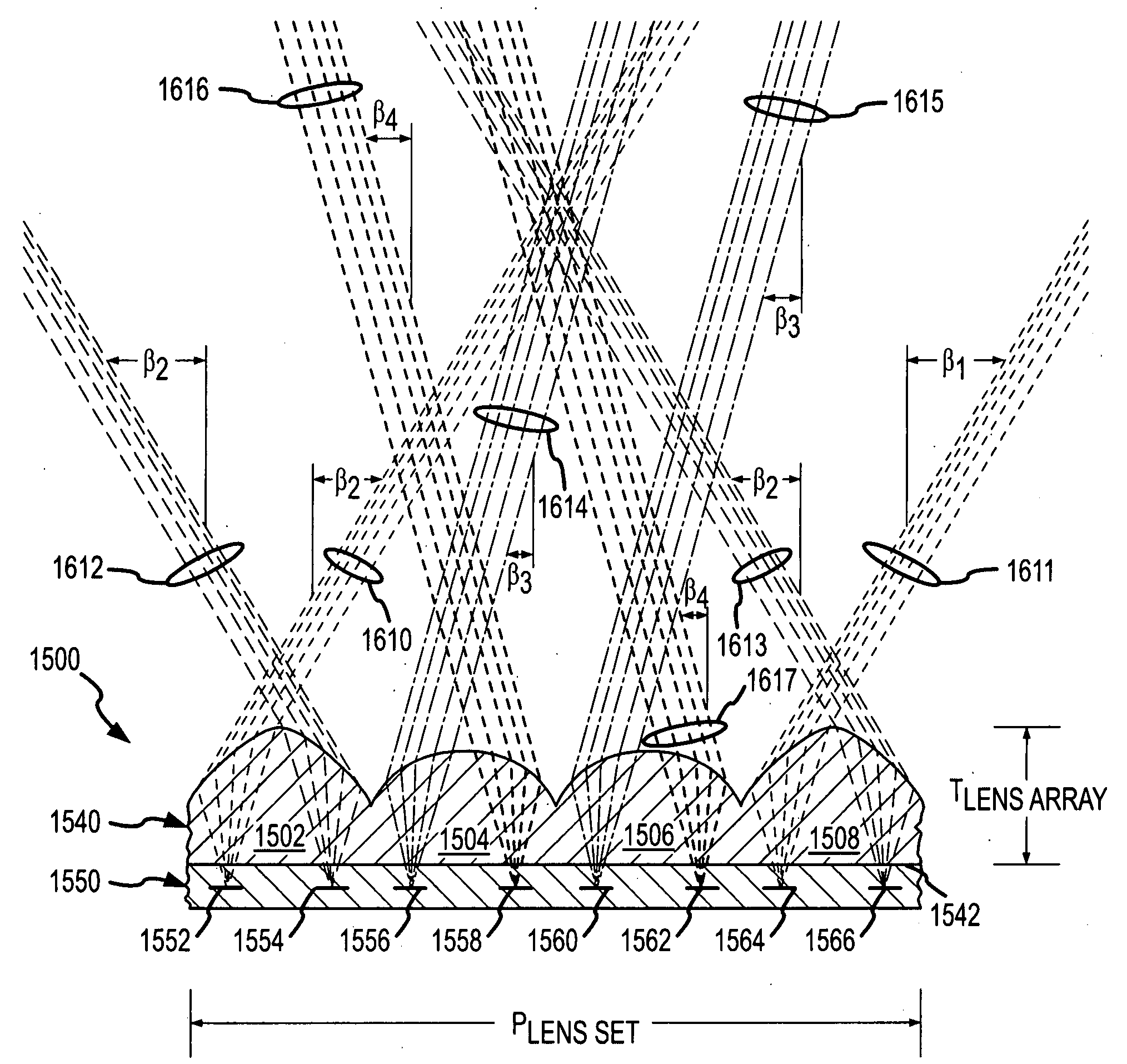

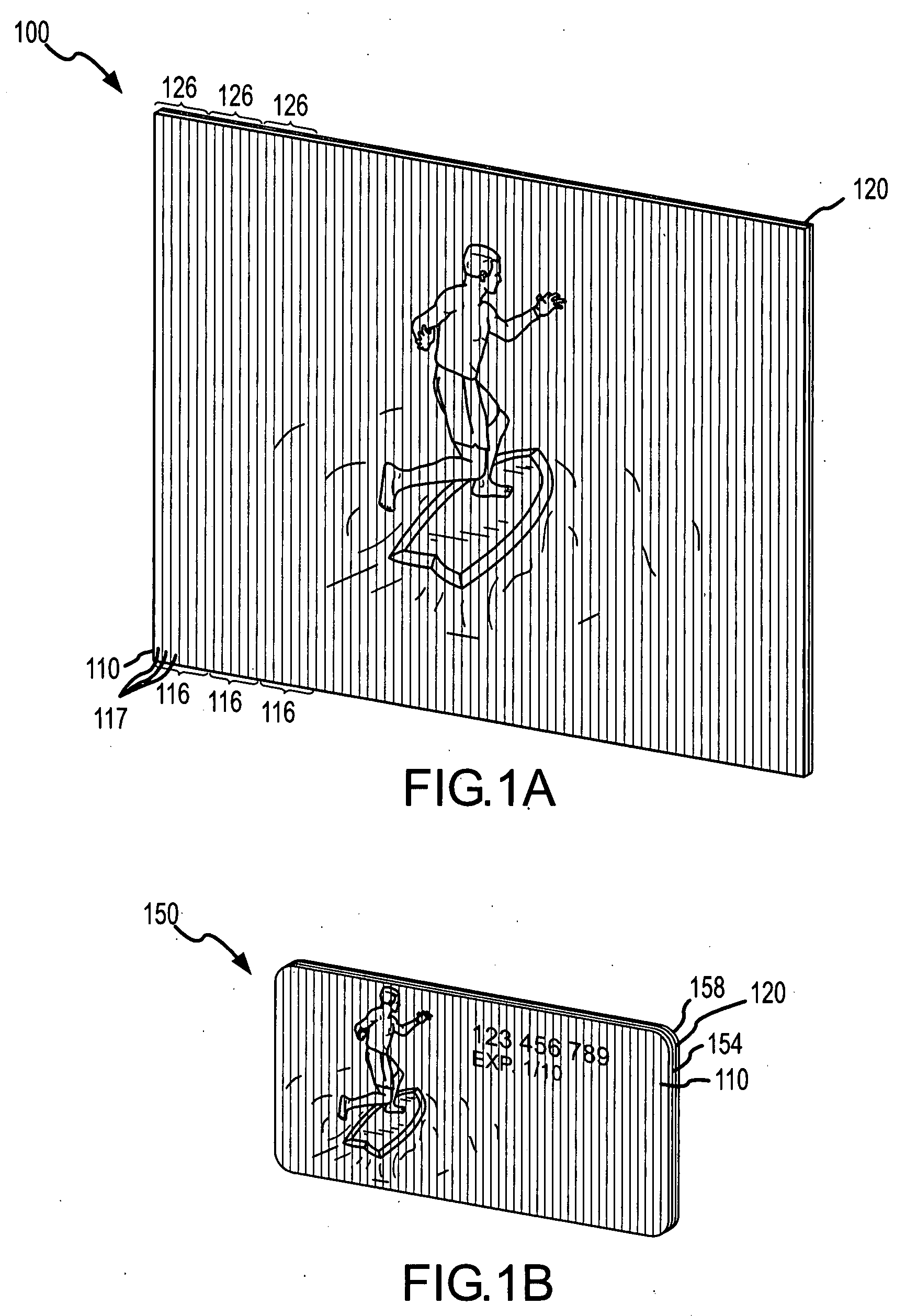

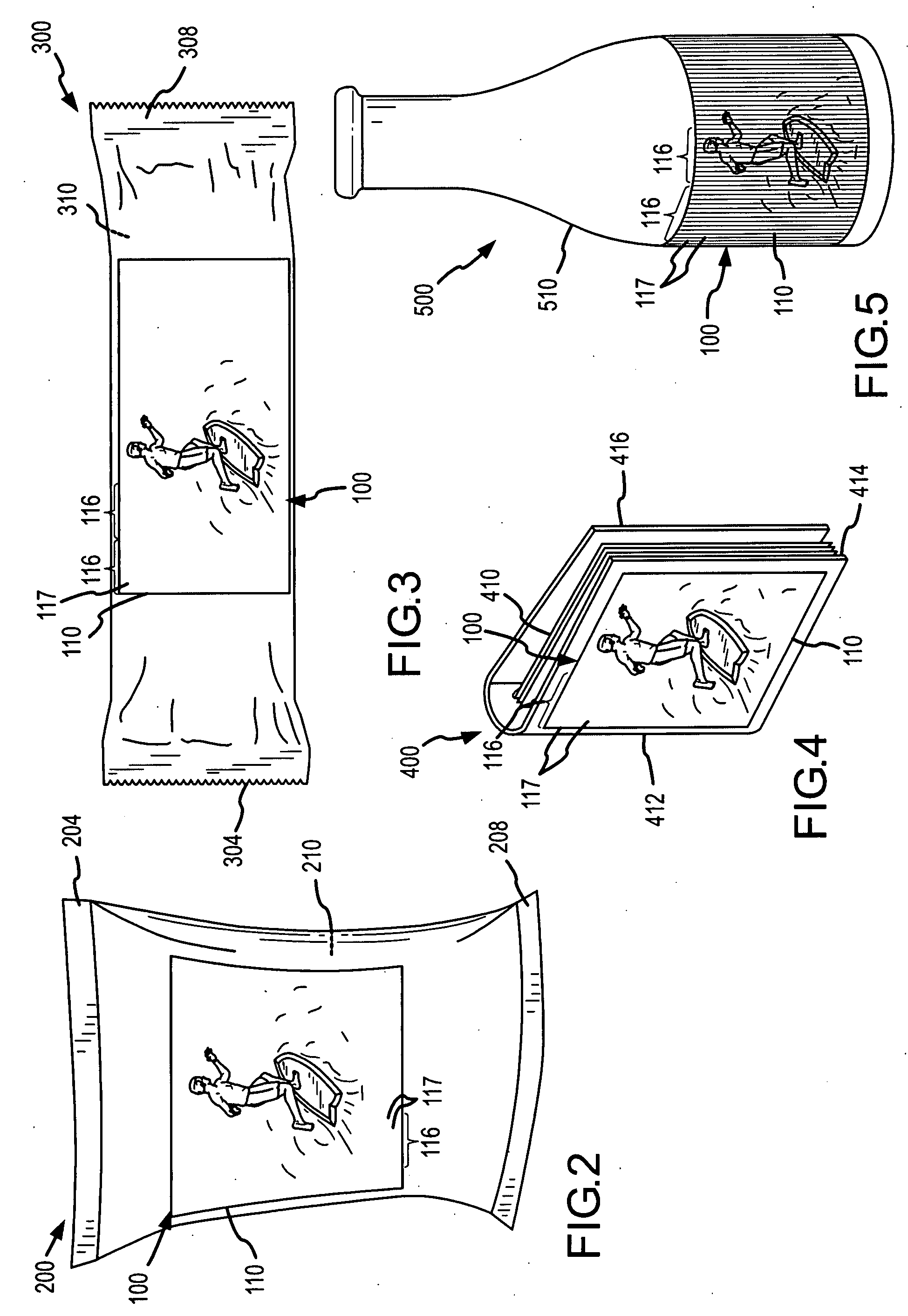

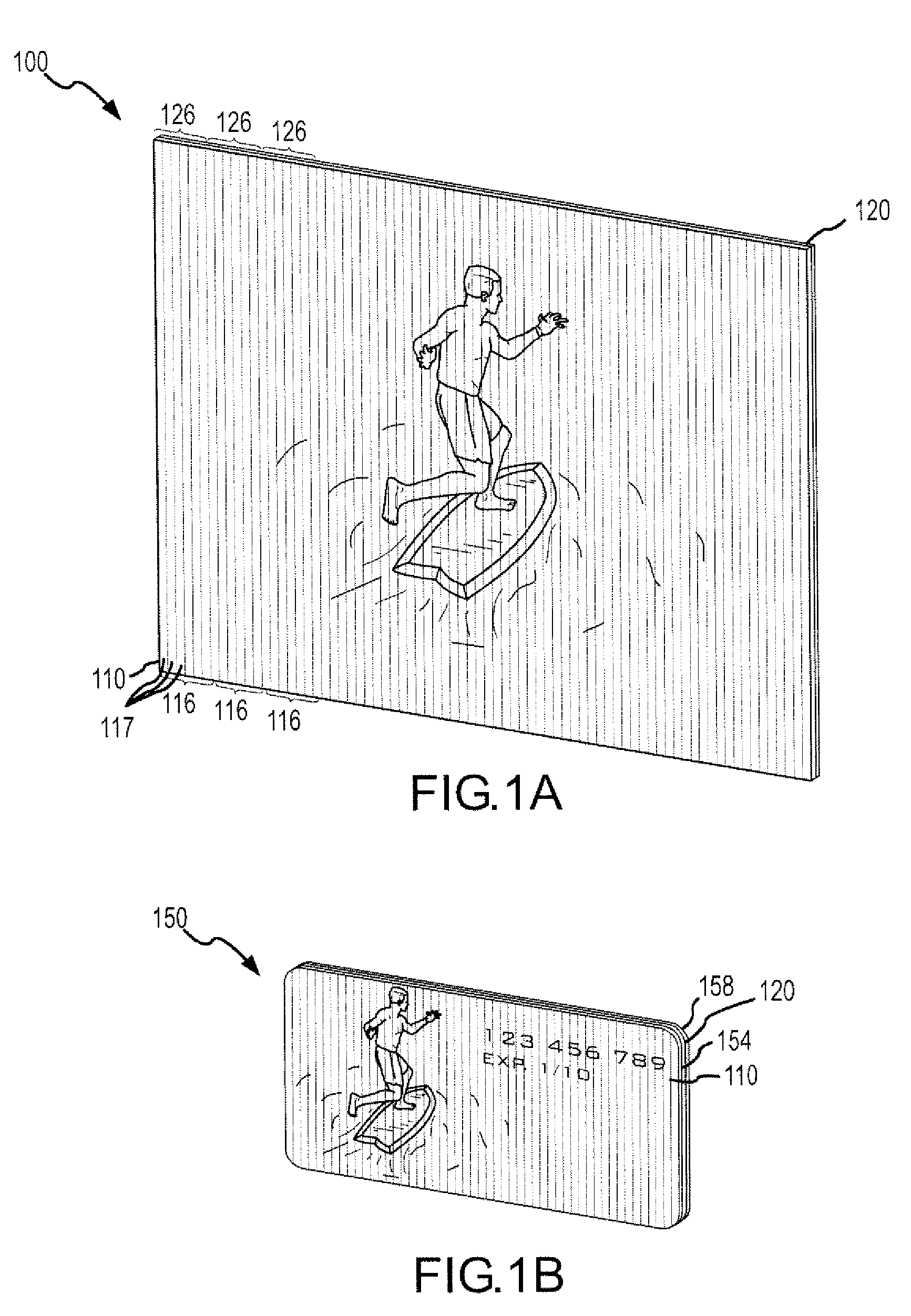

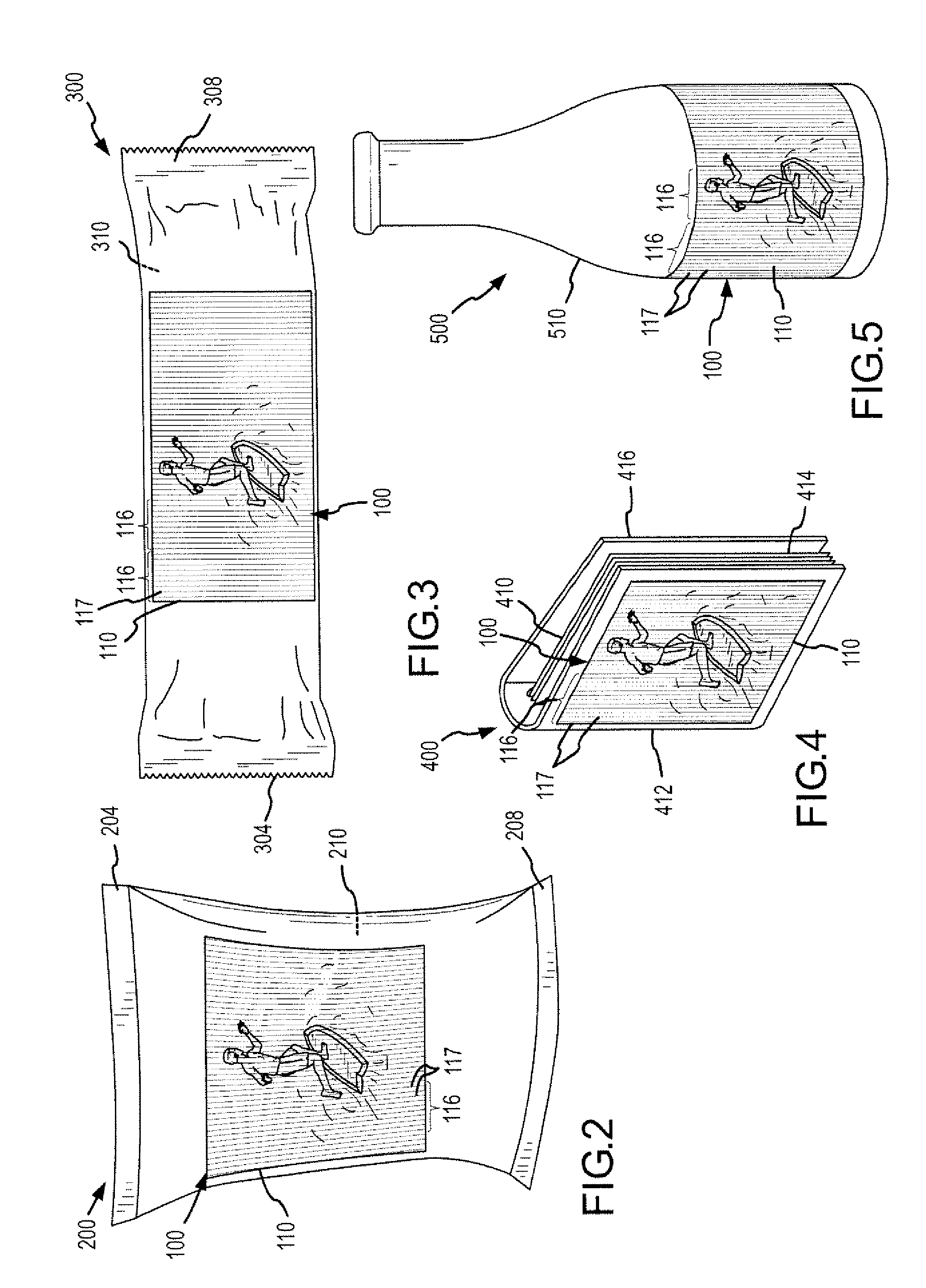

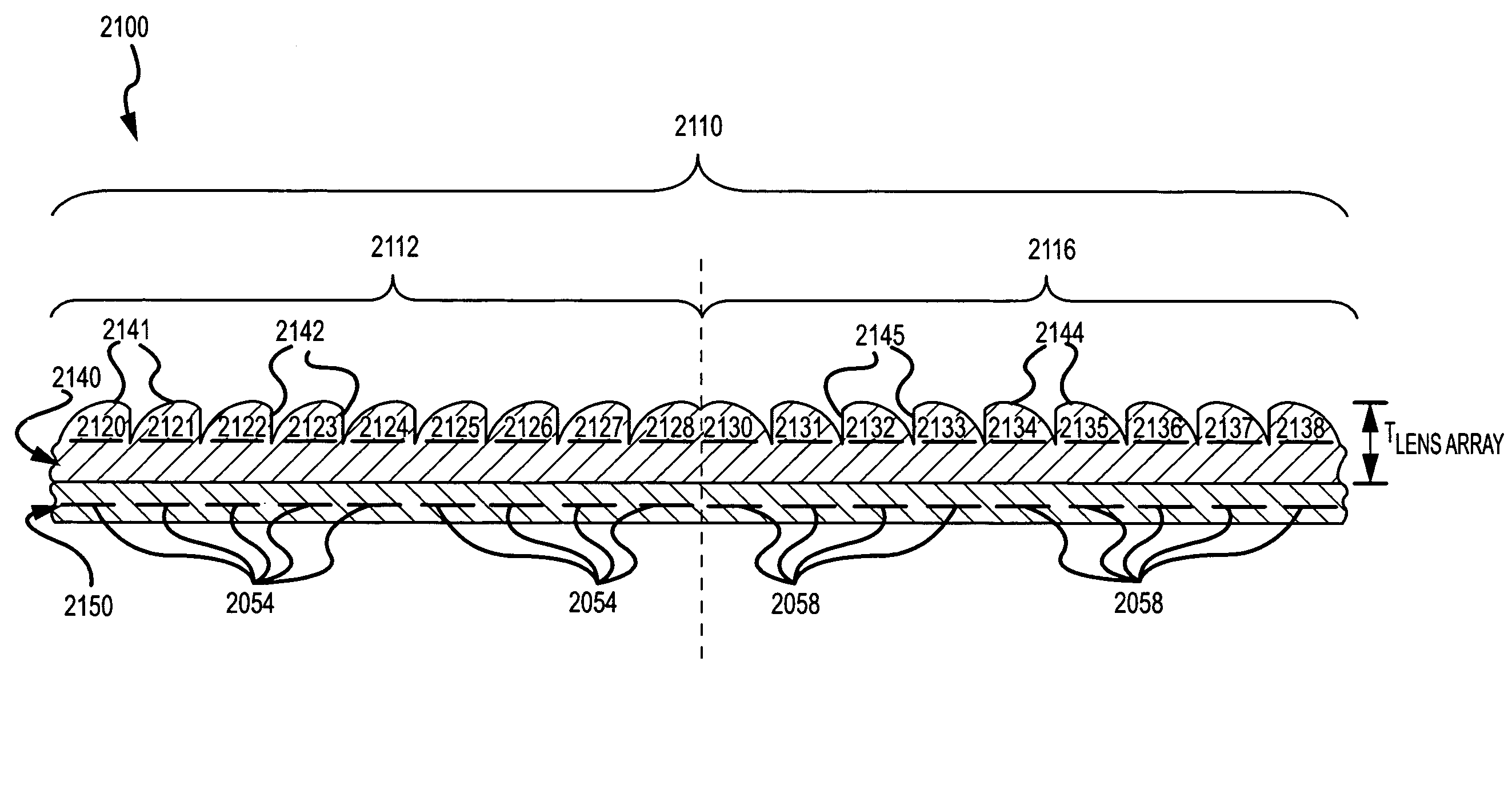

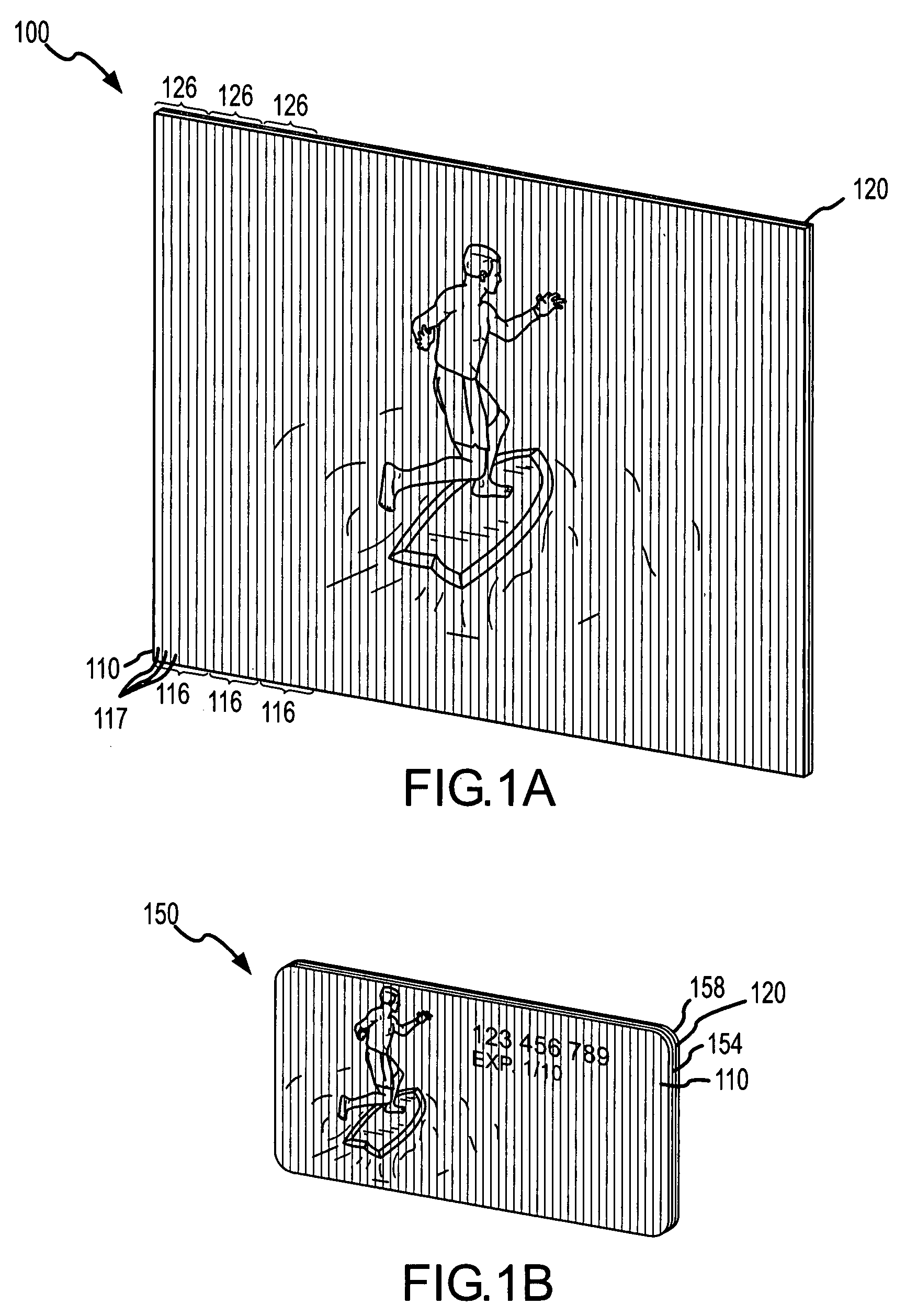

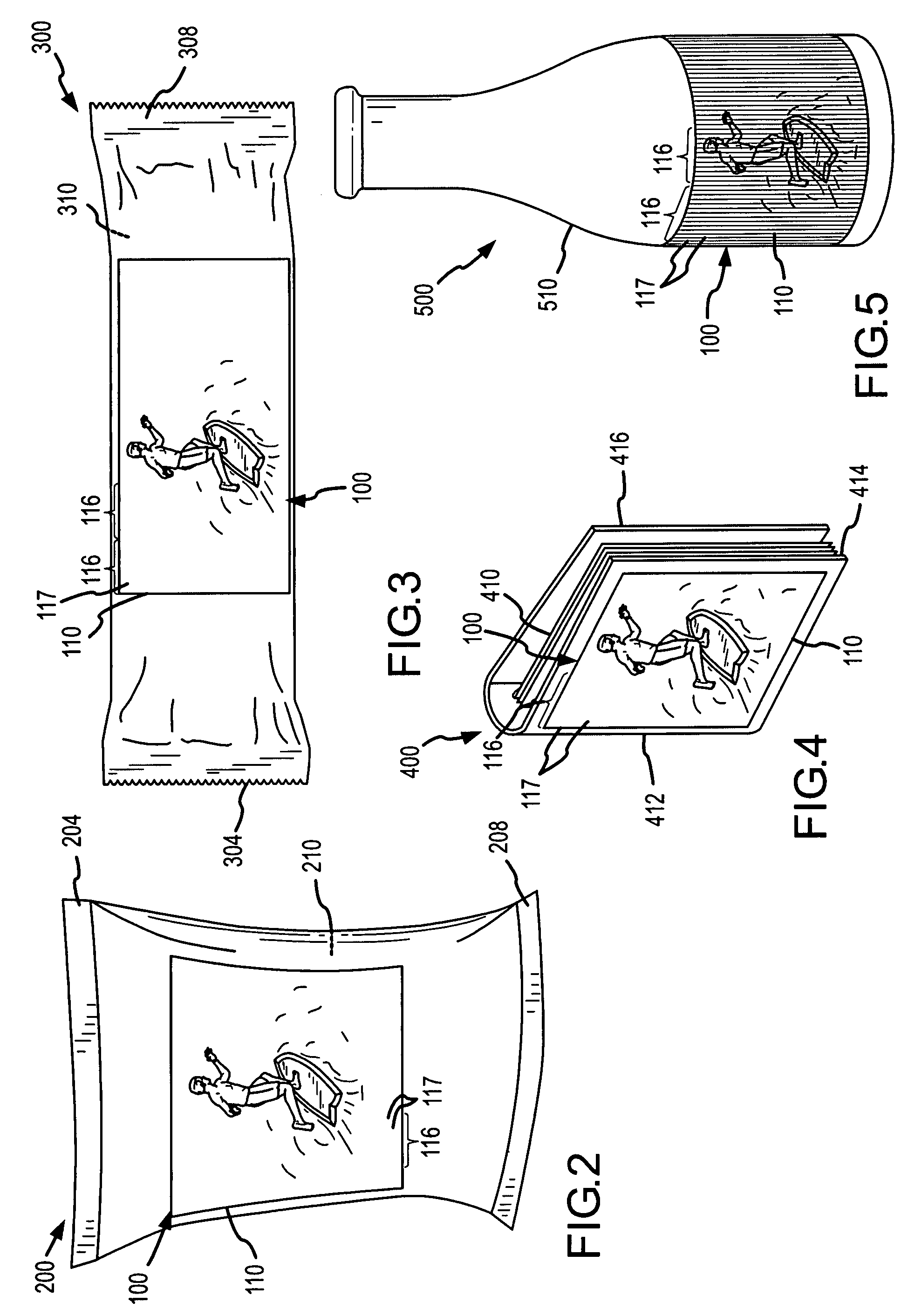

Manufacture of display devices with ultrathin lens arrays for viewing interlaced images

InactiveUS7359120B1Reduction in lens thicknessReduce thicknessViewersAdhesivesPicture booksSmall lens

Owner:GENIE LENS TECH

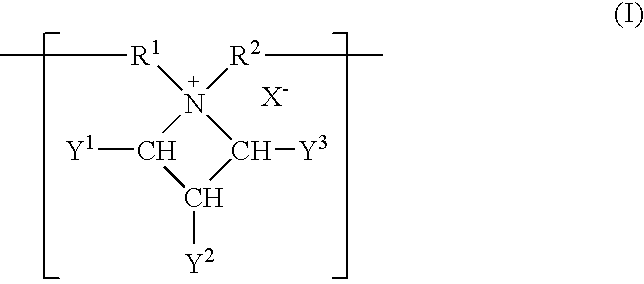

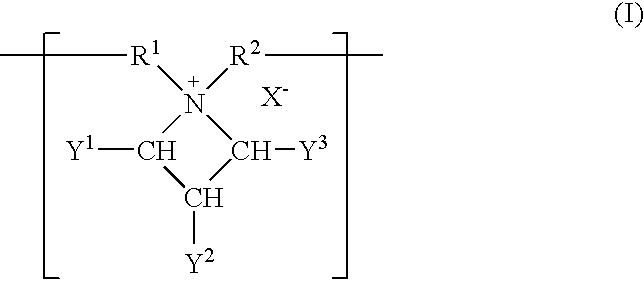

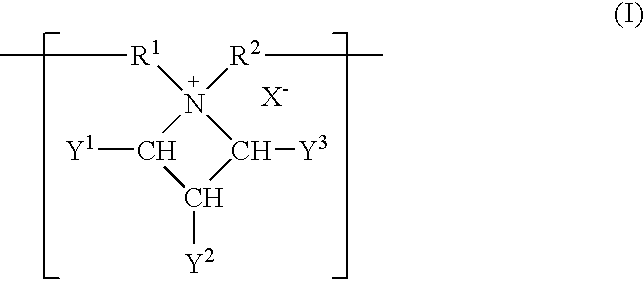

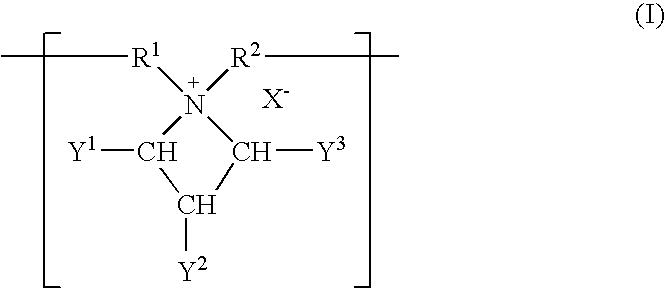

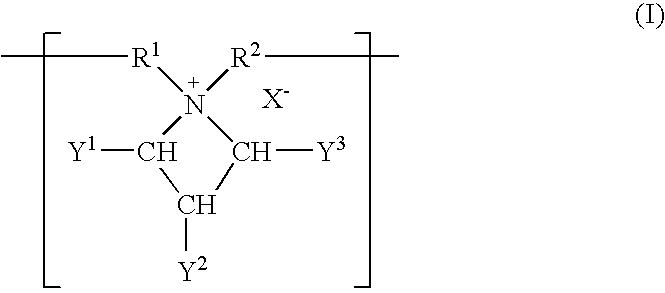

Ink-jet recording medium with an opaque or semi-opaque layer coated thereon, method for recording an image, and a recorded medium with at least one layer rendered clear or semi-opaque

InactiveUS20040109958A1Extended drying timeAvoid excessive adhesionLayered productsCoatingsAziridineCross linker

The present invention features a multi-layer ink-jet recording medium, suitable for recording images with dye and pigmented inks and thereby providing light-emitting, reflective, glossy, metallic-looking or holographic images, comprising a substrate coated with at least two layers comprising: (a) a first transparent ink-receptive layer comprising a polymeric binder and a cross-linker and optionally having a plasticizer and pigment particles such as alumina and silica coated over the substrate, wherein the cross-linker comprises and azetidinium polymer or a salt thereof, and / or a polyfunctinal aziridine or a salt thereof or a polyfunctional oxazoline or a salt thereof; and (b) a second ink-receptive layer comprising an opaque or semi-opaque coating composition, wherein the opaque or semi-opaque coating composition is capable of accepting a printed image and thereby becoming semi transparent or clearly transparent from application of ink-jet printing ink or similar inks, while presenting a light-emitting, reflective, glossy, metallic-looking or holographic image of high clarity and quality, wherein said first layer is located between said second layer and the substrate in said recording medium and the first and second layers are chemically coupled.

Owner:PIXTERRA

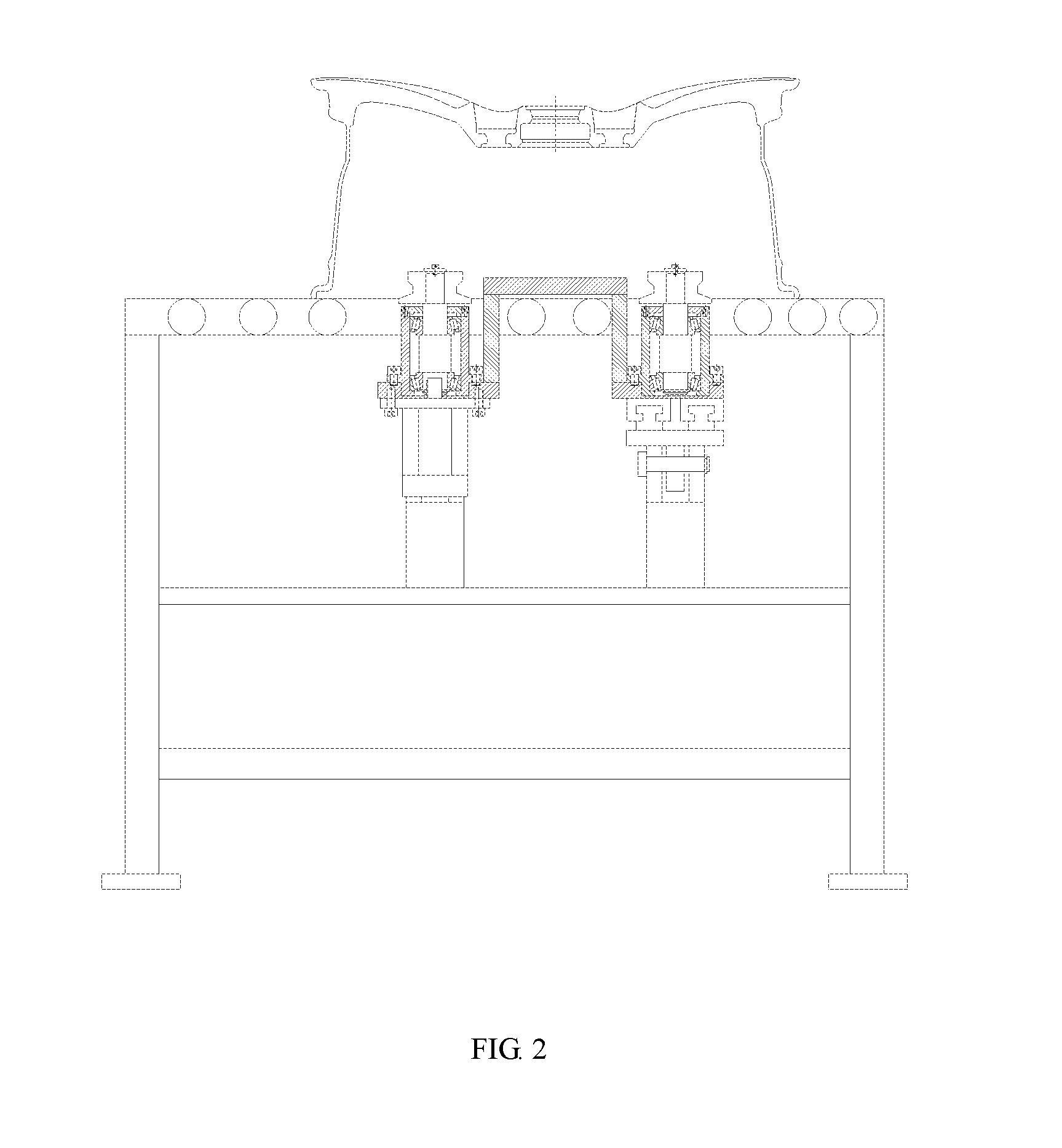

Ultrathin lens arrays for viewing interlaced images with dual lens structures

An assembly for displaying an interlaced image. The assembly includes an interlaced image, which may be digitally or web printed for example, with sets of elongate image elements or slices. A lens arrays is provided with a first side proximate the interlaced image such as a planar surface and a second side distal the image with numerous lens sets. Each of the lens sets is paired with one of the sets of the image elements and includes a number of linear or elongate lenses that are each mapped to one to three image elements. The lenses are each configured to focus light from the subset of image elements to a viewer along a focus direction or line. The lenses are configured to provide a lens-specific viewing angle with a focus line, and the focus line to the paired image element subset differs from other lenses or is unique.

Owner:GENIE LENS TECH

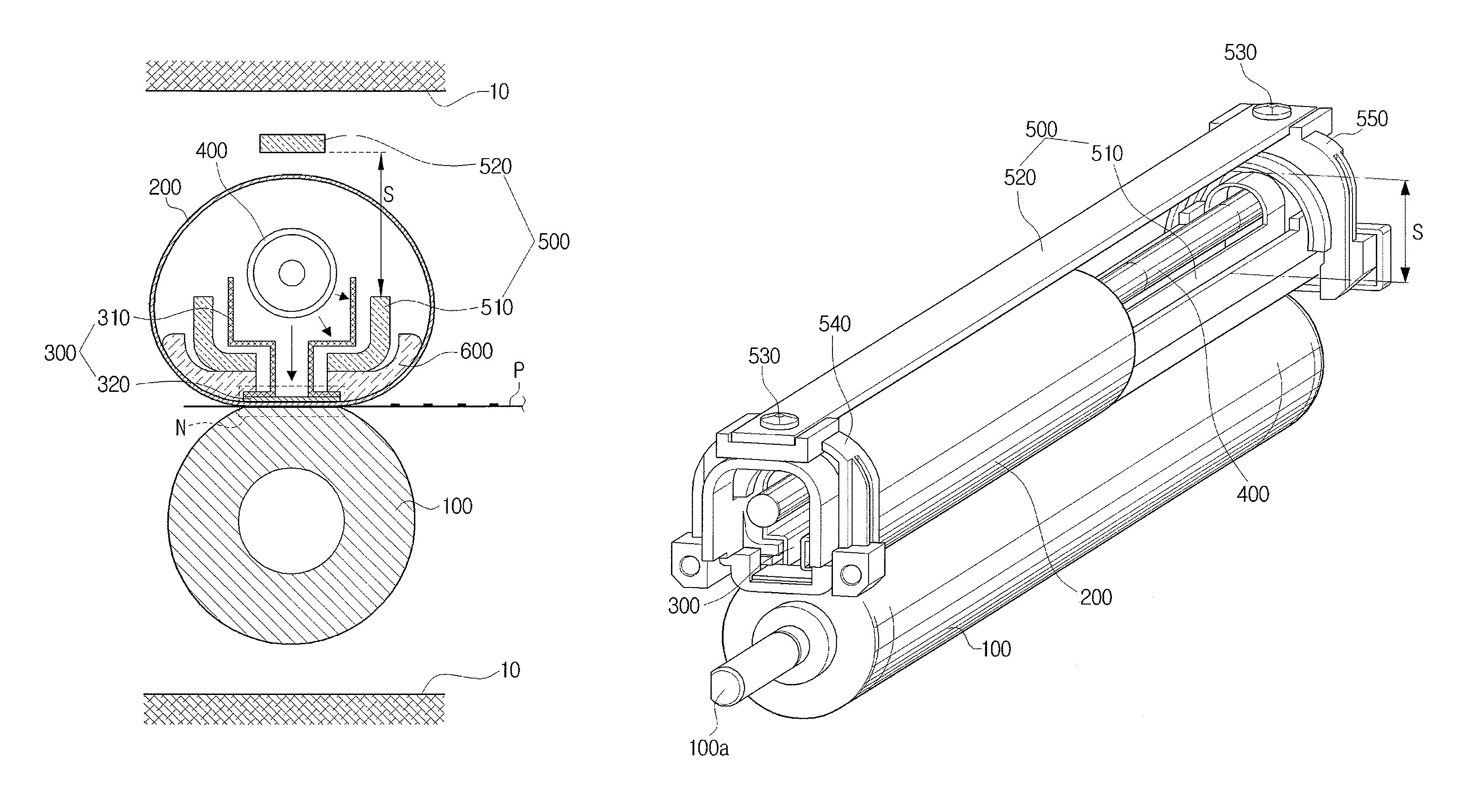

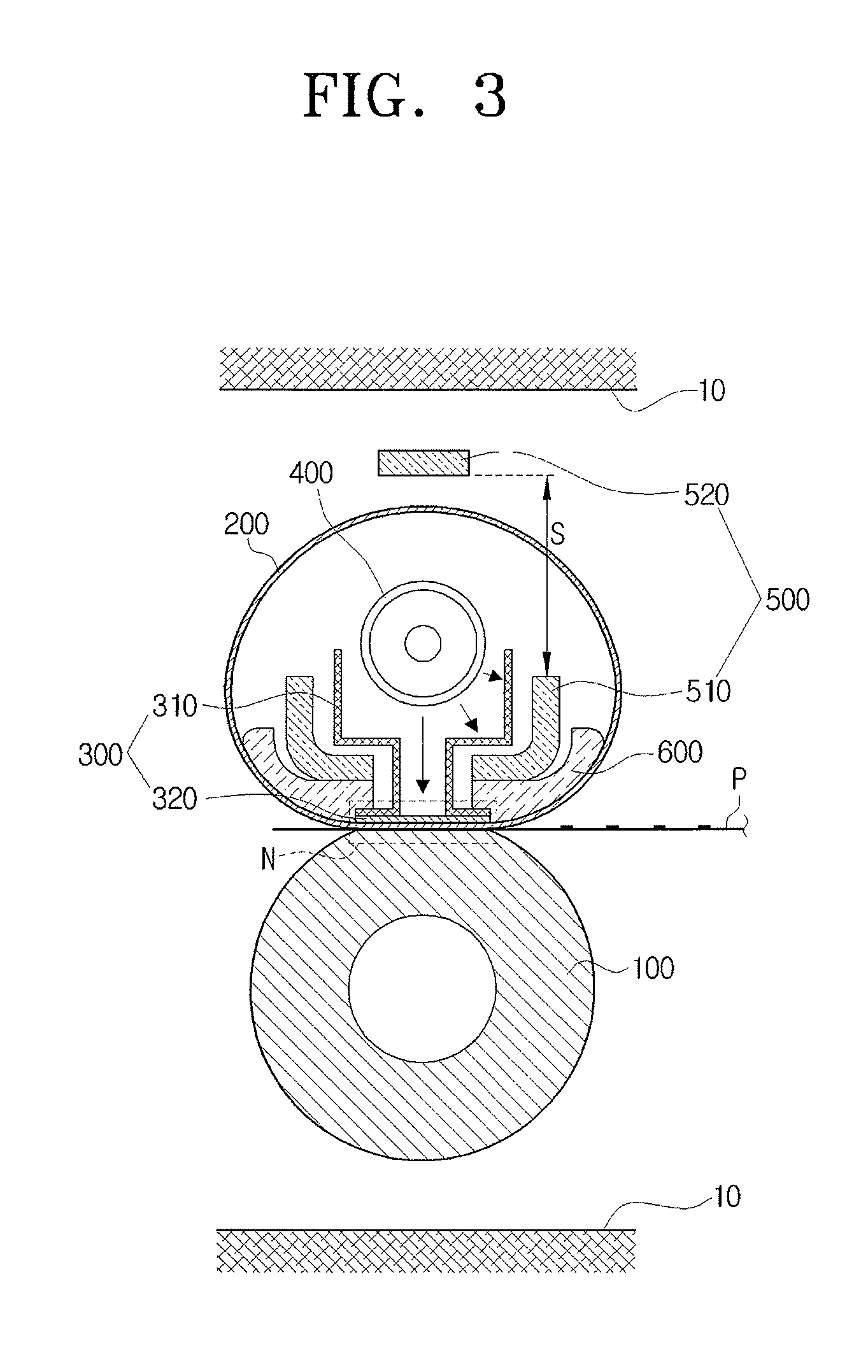

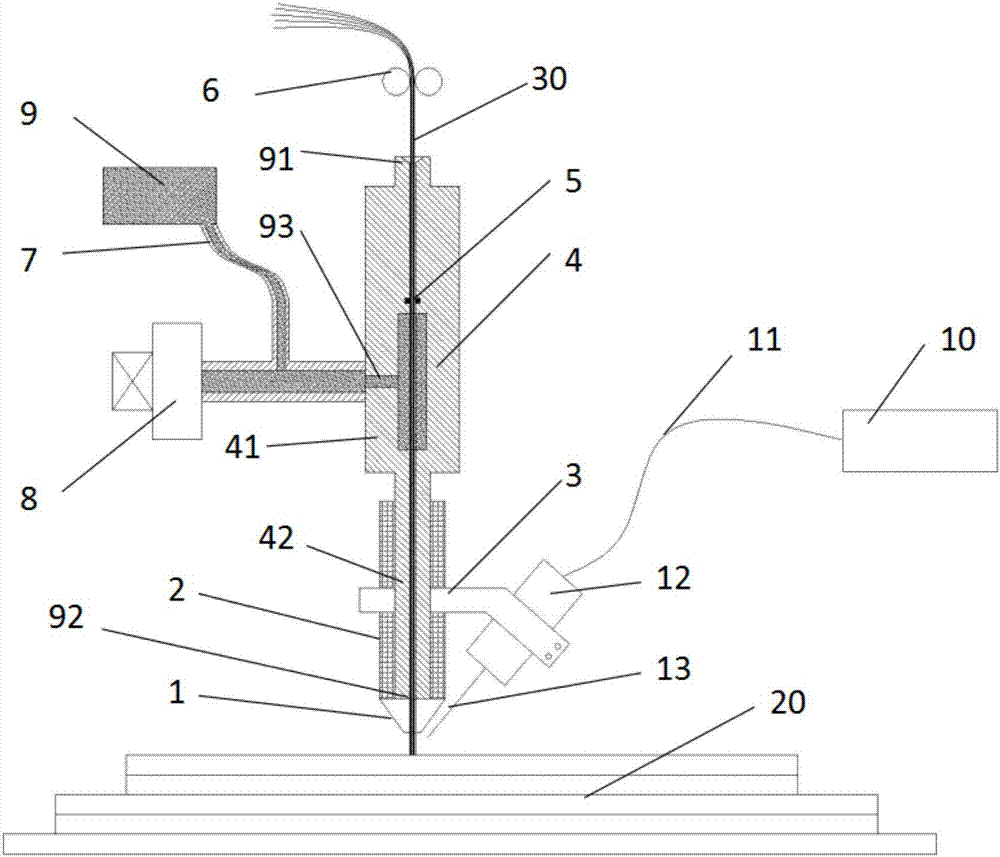

Fusing device and image forming apparatus having the same

ActiveUS7881650B2Shorten warm-up timeFast printElectrographic process apparatusImage formationEngineering

A fusing device includes a rotatable pressing roller, a fusing belt to rotate by a rotational force transmitted from the rotatable pressing roller, a nip forming member to contact an inner surface of the fusing belt to form a nip on a contact area between the rotatable pressing roller and the fusing belt, a heating member formed in approximately an internal central portion of the fusing belt to heat the nip forming member and the fusing belt, an inner support member formed within the fusing belt to press a nip part of the nip forming member toward the rotatable pressing roller, and an outer support member formed outside the fusing belt, and both ends of the outer support member being engaged with the inner support member to thereby reinforce the strength of the inner support member and form a path for radiation heat to disperse. The support unit includes an inner support member placed within the belt unit, and an outer support member placed outside the belt unit, both ends of the outer support member being engaged with the inner support member to reinforce the strength of the inner support member and to form a path for a radiation heat to disperse.

Owner:HEWLETT PACKARD DEV CO LP

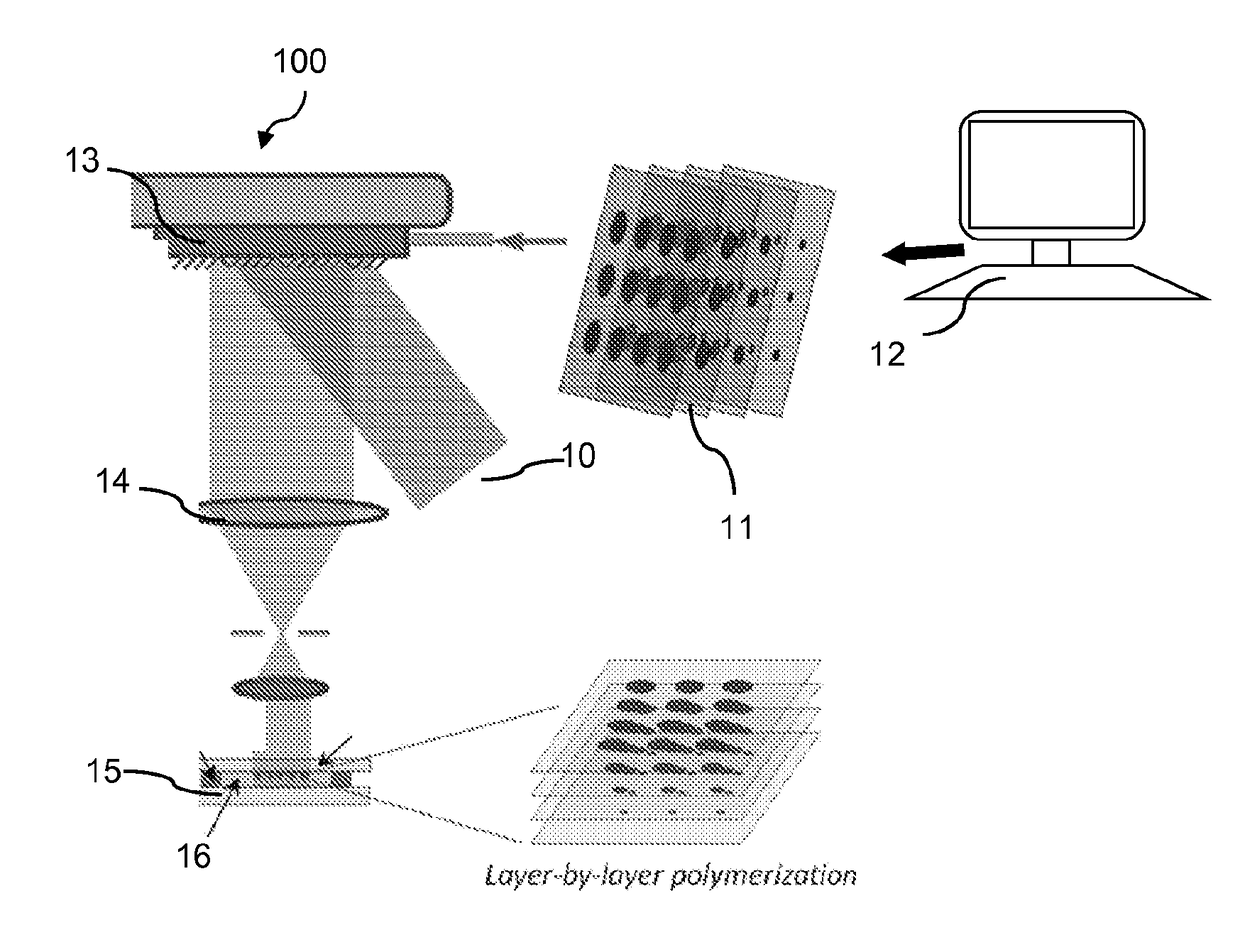

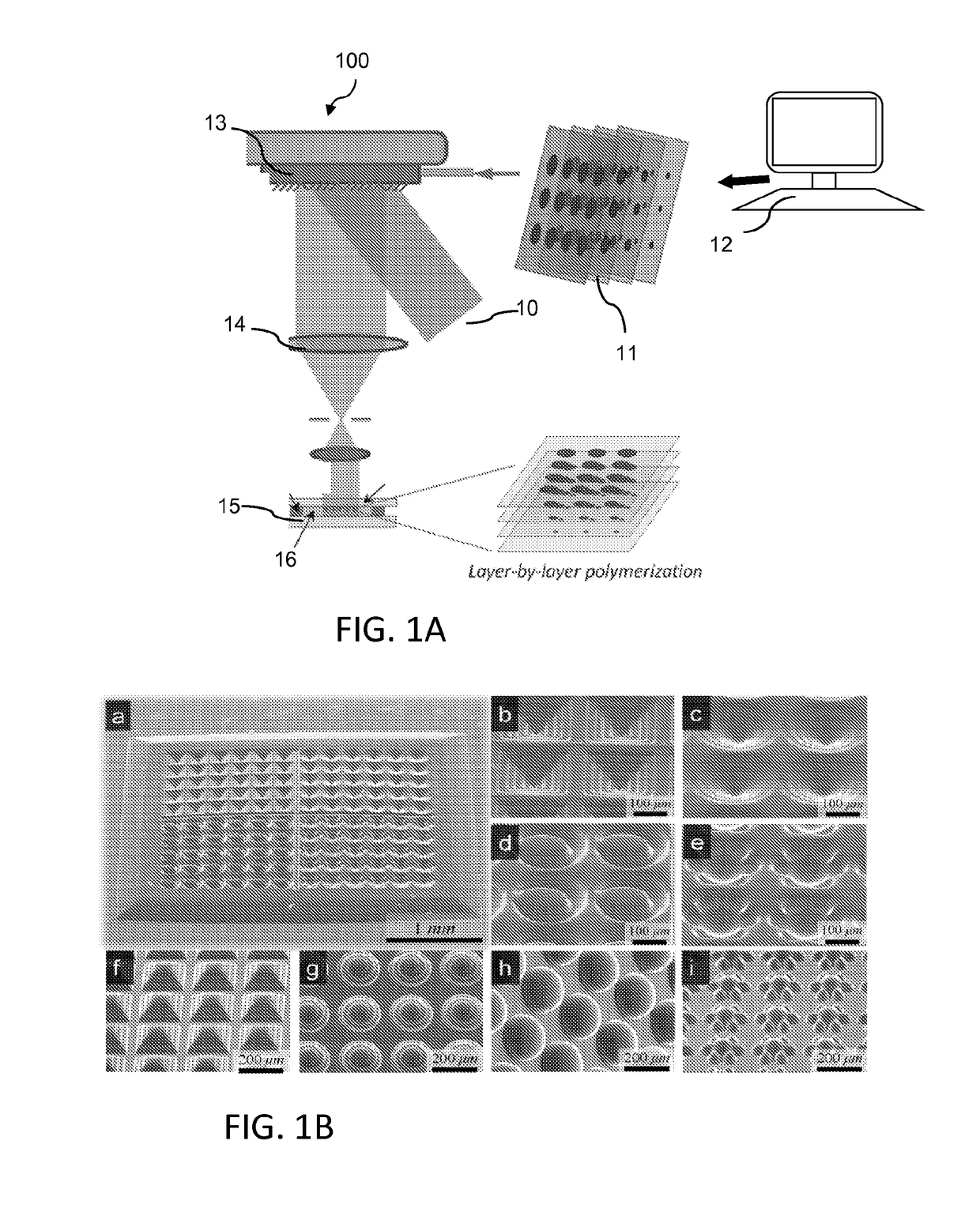

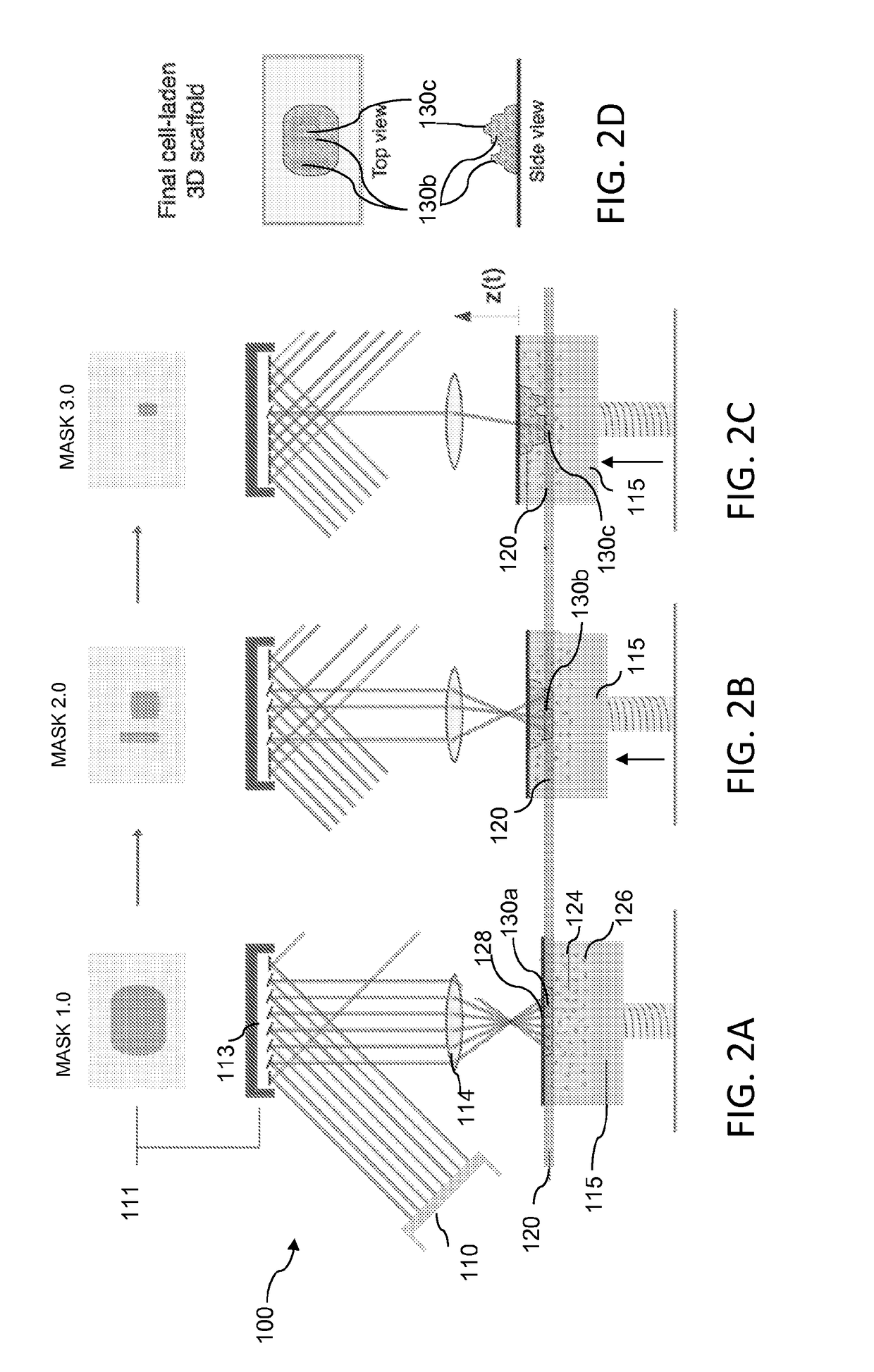

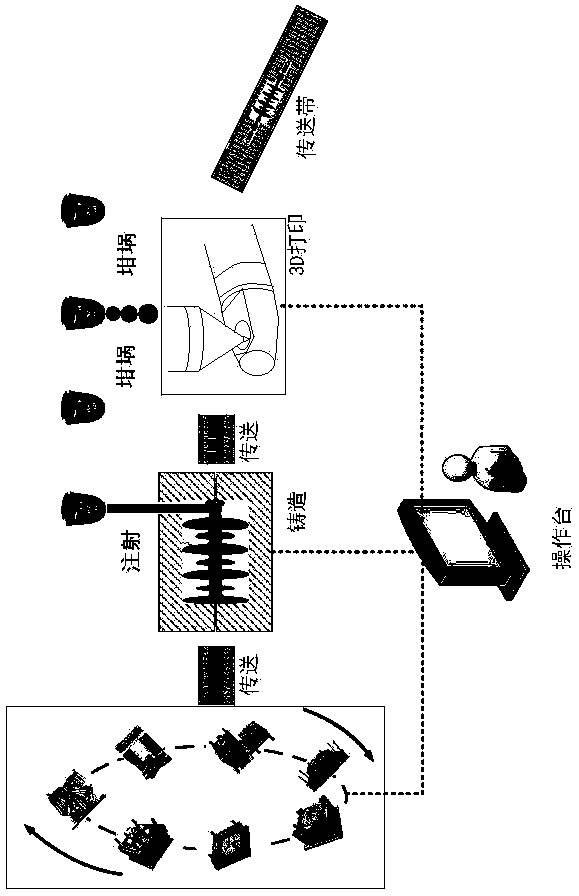

Layerless bioprinting via dynamic optical projection and uses thereof

ActiveUS20170087766A1Quick buildHigh resolutionAdditive manufacturing apparatusBiological testingProjection opticsSpatial light modulator

A system and method for 3D microfabrication projects light capable of initiating photopolymerization toward a spatial light modulator that modulates light responsive to digital masks corresponding to layers of the structure. Projection optics focus the modulated light onto an optical plane within a photopolymerizable material supported on a stage. A computer controller causes the spatial light modulator to project a sequence of images corresponding to the digital masks while coordinating movement of the stage to move a position of the optical plane within the photopolymerizable material to sequentially project each image of the sequence to generate the structure by progressively photopolymerizing the photopolymerizable material.

Owner:RGT UNIV OF CALIFORNIA

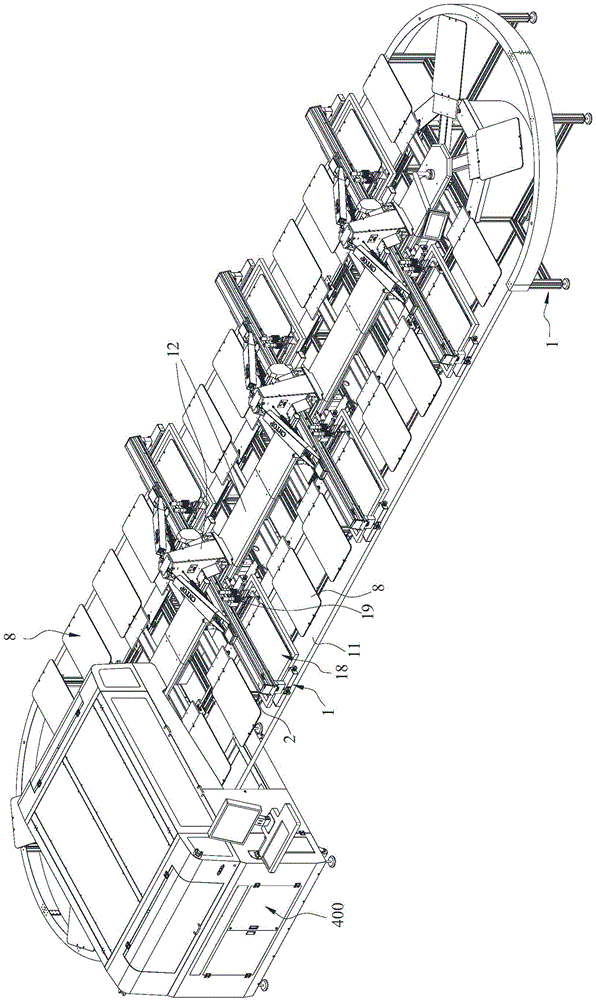

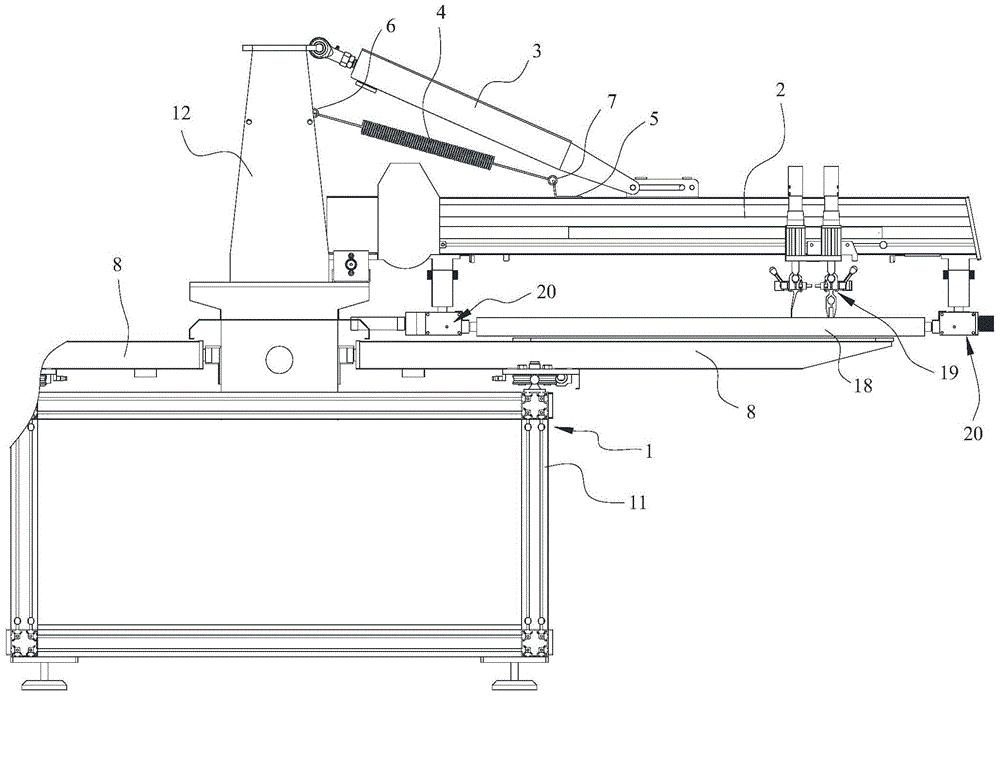

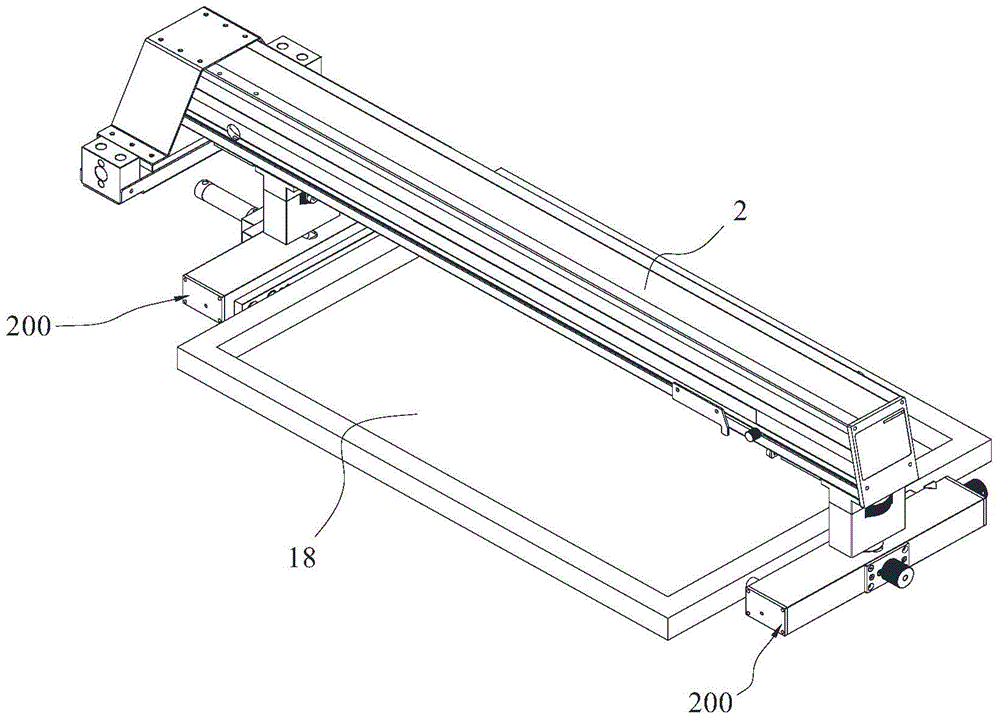

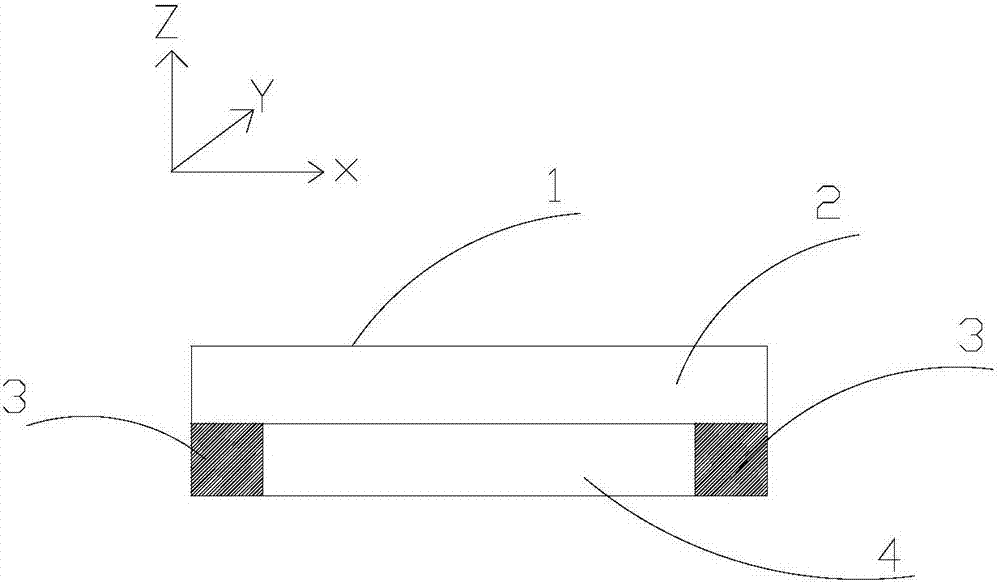

Novel decorating machine

The invention discloses a novel decorating machine. The novel decorating machine comprises a table rack, a printing arm, a cylinder, an extension spring, an elastic table plate, a screen frame, a scraper, and a screen frame fixing device, wherein the table rack comprises a rack leg and a fixed arm fixed on the rack leg, the fixed arm is linear, the rack leg wounds the periphery of the fixed arm, one end of the printing arm is hinged to the lower portion of the fixed arm, a piston rod of the cylinder extends out of one end of a cylinder body of the cylinder to be hinged to the upper end of the fixed arm, the other end of the cylinder body of the cylinder is hinged to the middle of the printing arm and is in sliding match with the printing arm in the direction of the length of the printing arm, one end of the extension spring is connected with the middle of the fixed arm, the other end of the extension spring is connected with the printing arm through a sliding plate, the sliding plate is in sliding match with the printing arm, and the bottom of the elastic table plate is in sliding match with the rack leg. The novel decorating machine is capable of buffering the action performed by the cylinder to lift or press the printing arm, greatly reducing vibration by the aid of an elastic force produced by the elastic table plate, and improving register accuracy.

Owner:SHENZHEN CNTOP DIGITAL EQUIP CO LTD

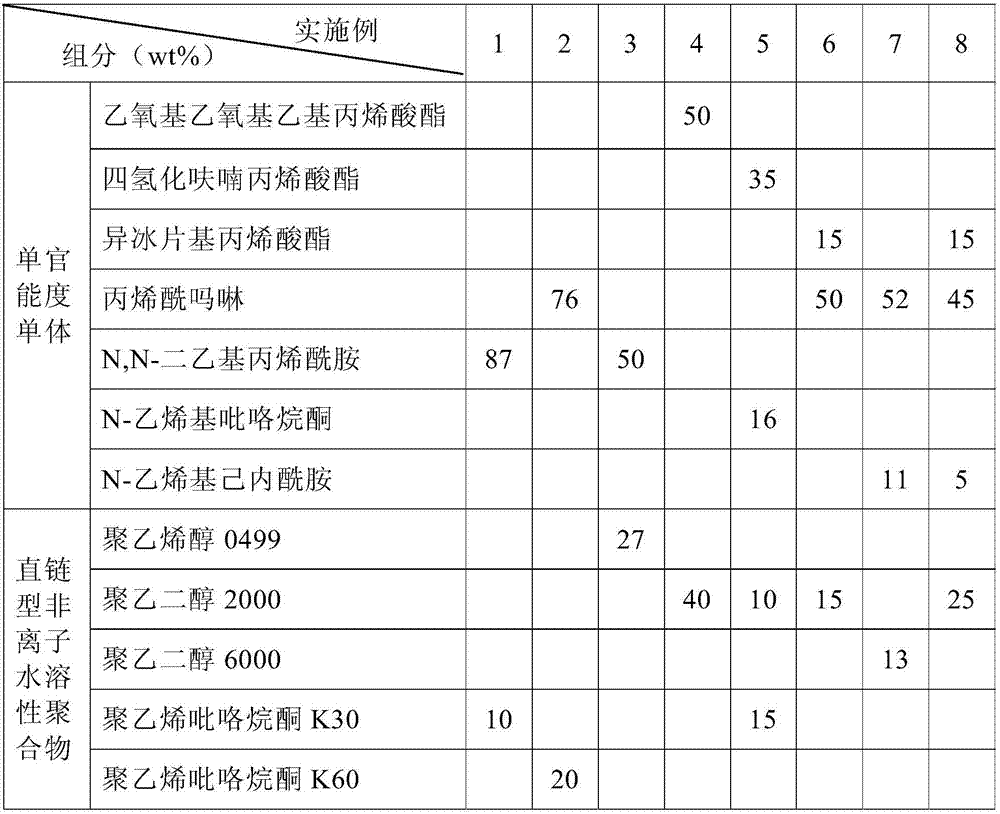

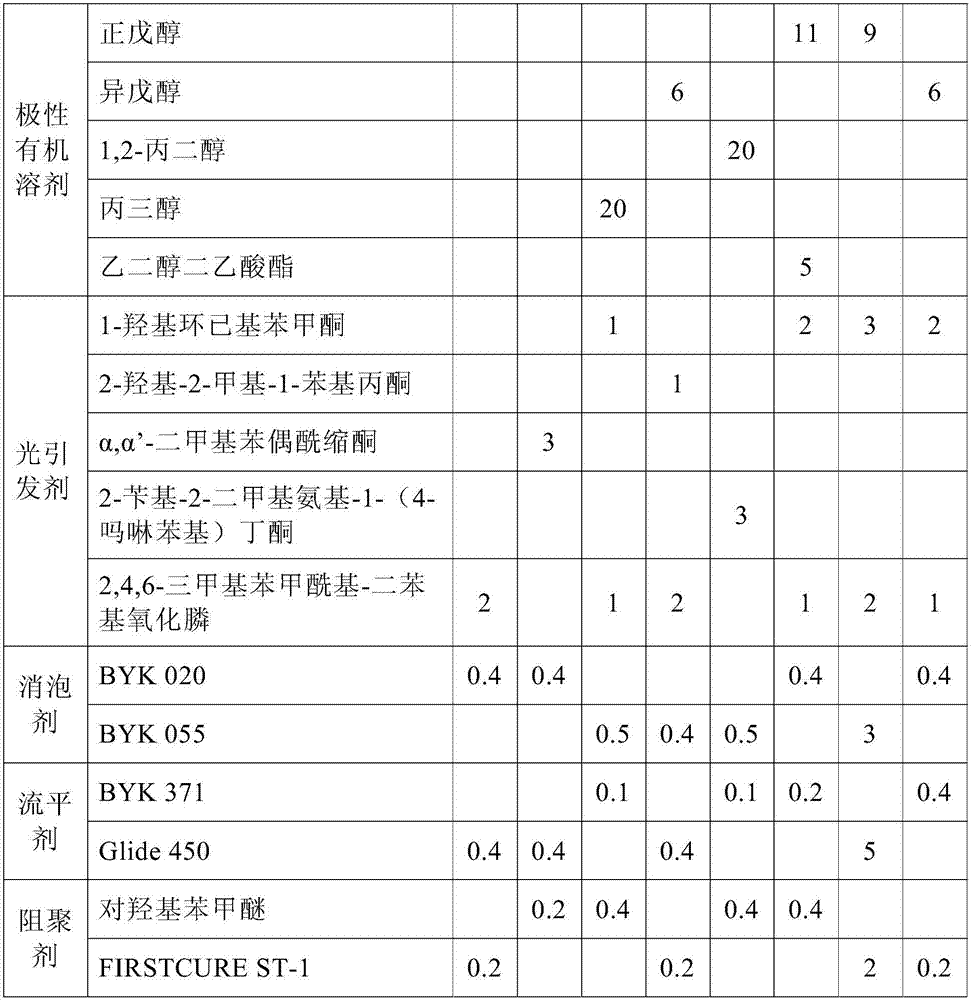

Photocurable material for 3D inkjet printing, and preparation method thereof, and printing method

ActiveCN107501477AMeet performance requirementsGood 3D inkjet printing effectAdditive manufacturing apparatusChemical industryOrganic solventPhotoinitiator

The present invention relates to a photocurable material for 3D inkjet printing, and a preparation method thereof, and a printing method, wherein the photocurable material comprises, by weight, 50-98 parts of a monofunctional monomer, 1-50 parts of a linear nonionic water-soluble polymer, 0-20 parts of a polar organic solvent, 0.1-5 parts of a photoinitiator, and 0.5-10 parts of an auxiliary agent. According to the present invention, the photocurable material can be used for 3D inkjet printing so as to print the support part, wherein the support part can be removed in the water or the aqueous liquid so as not to affect the precision of the target 3D object; and the 3D printing method has advantages of simple in operation, energy saving, and no harm to human body.

Owner:ZHUHAI SAILNER 3D TECH CO LTD

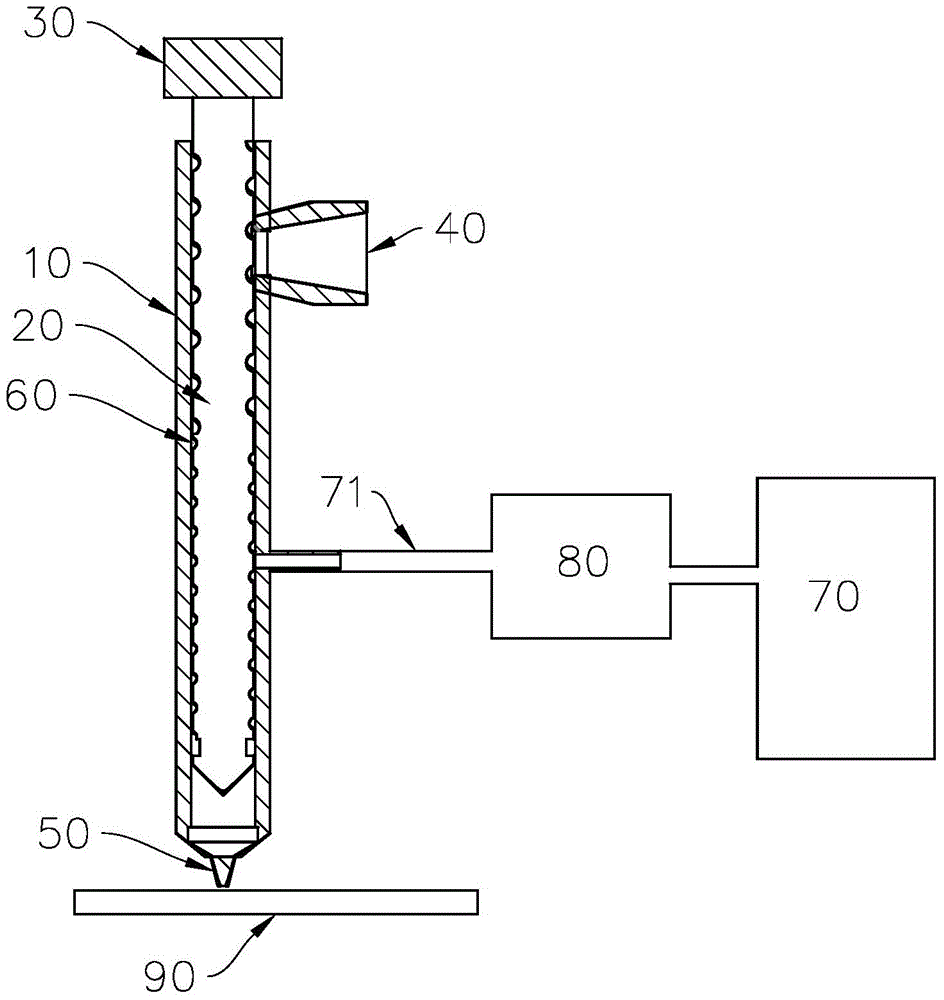

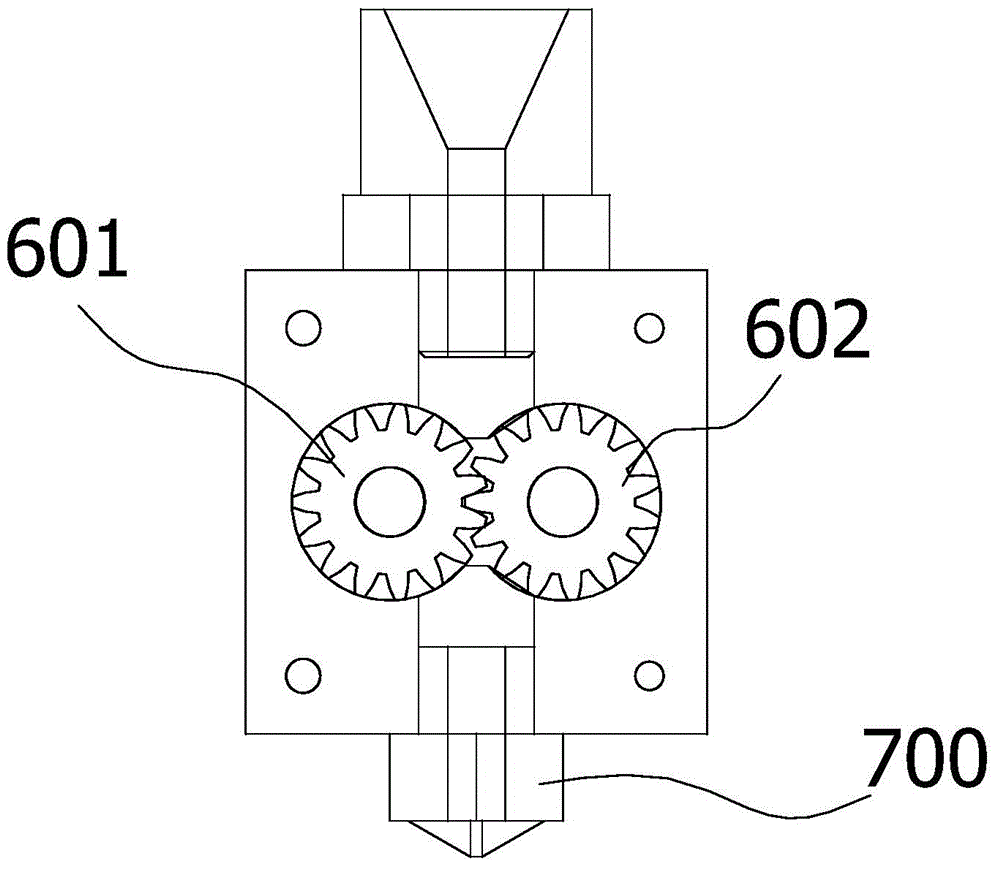

Three-dimensional printer and printing method and three-dimensional printing head

ActiveCN104875389ALow densityReduce the density valueAdditive manufacturing apparatusEngineeringVolumetric Mass Density

The invention relates to a three-dimensional printer, a three-dimensional printing head and a printing method. The three-dimensional printing head comprises a material volume cavity, wherein a screw rod is arranged in the material volume cavity, a motor is connected with the screw rod, a material supply device is communicated with the material volume cavity, a printing nozzle is arranged on the end part of the material volume cavity, a heater is arranged on the material volume cavity and positioned between the material supply device and the printing nozzle, and a supercritical fluid supply system is communicated with the material volume cavity. A molten printing material is mixed with supercritical fluid to generate a single-phase molten mixture under the mixing and stirring effect of the screw rod, and a uniform microporous bubble formation effect is formed, so that the density value of a printing object can be reduced, the size deviation of the three-dimensional printing object can be alleviated, the flatness and straightness of the three-dimensional printing object can be improved by more than 50 percent, the temperature for printing the molten printing material is effectively lowered, the energy is saved, and the operation personnel is prevented from being scalded.

Owner:PRINT RITE UNICORN IMAGE PROD CO LTD

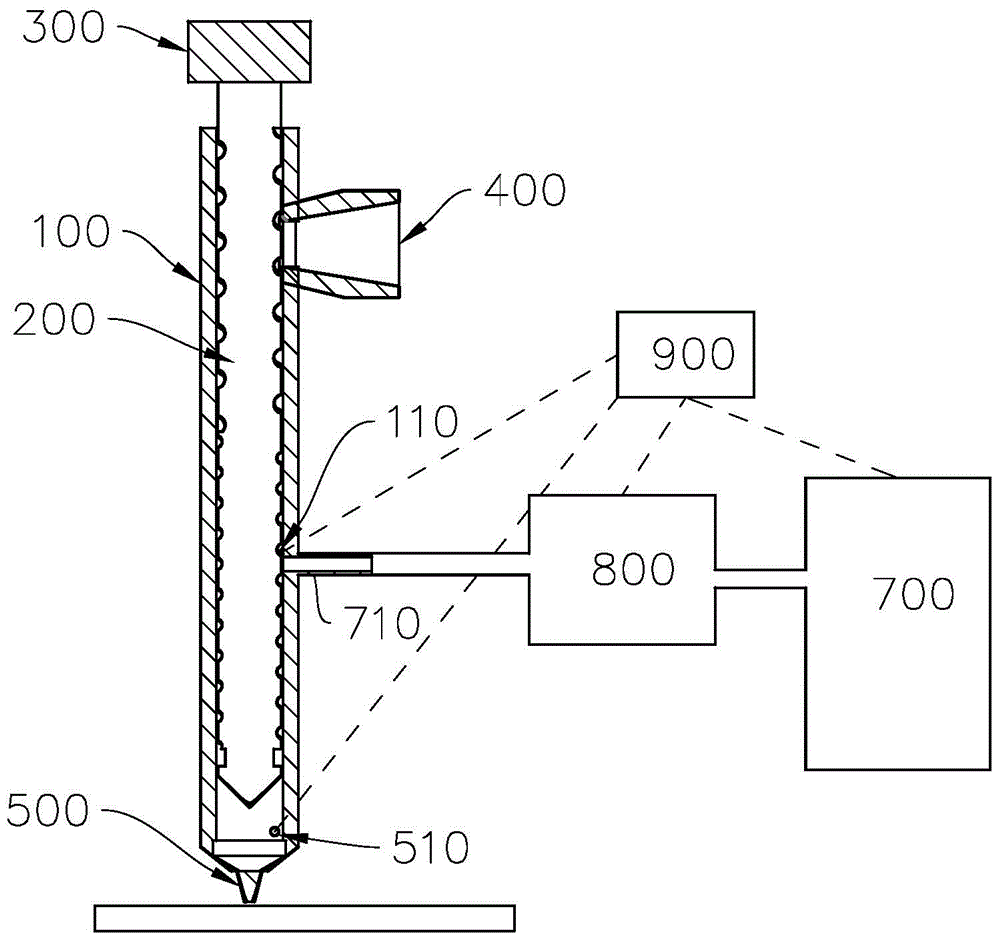

High-speed printing head of 3D printer

InactiveCN104552949AImprove liquidityInhibit refluxAdditive manufacturing apparatusHydraulic cylinderSpray nozzle

The invention discloses a high-speed printing head of a 3D (three-dimensional) printer. The printing head comprises a rack, wherein a hydraulic cylinder is fixed above the rack; a piston of the hydraulic cylinder is fixed with a feeding device capable of sliding up and down along the rack; an outlet of the feeding device is communicated with a nozzle structure through a volumetric metering pump; a feeding pipe is longitudinally arranged on the rack; the feeding device comprises a drive device and a screw rod driven by the drive device to rotate; the feeding pipe encircles the screw rod; a feeding hole is formed above the feeding pipe; a feeding hot-melting cavity is formed below the feeding pipe; the end of the screw rod is sleeved with a one-way valve; the nozzle structure comprises a nozzle pipe communicated with the volumetric metering pump; a multi-nozzle head is rotationally arranged at an outlet end of the nozzle pipe and provided with at least two nozzles with different pore diameters; when an opening, rotated to any nozzle, of the multi-nozzle head points to a workpiece, only the nozzle is communicated with the nozzle pipe; the multi-nozzle head is driven by a rotary power device to rotate. The printing head has the advantages that the printing speed can be increased while a high-precision printing effect is guaranteed.

Owner:SHENZHEN WANWEI IM TECH CO LTD

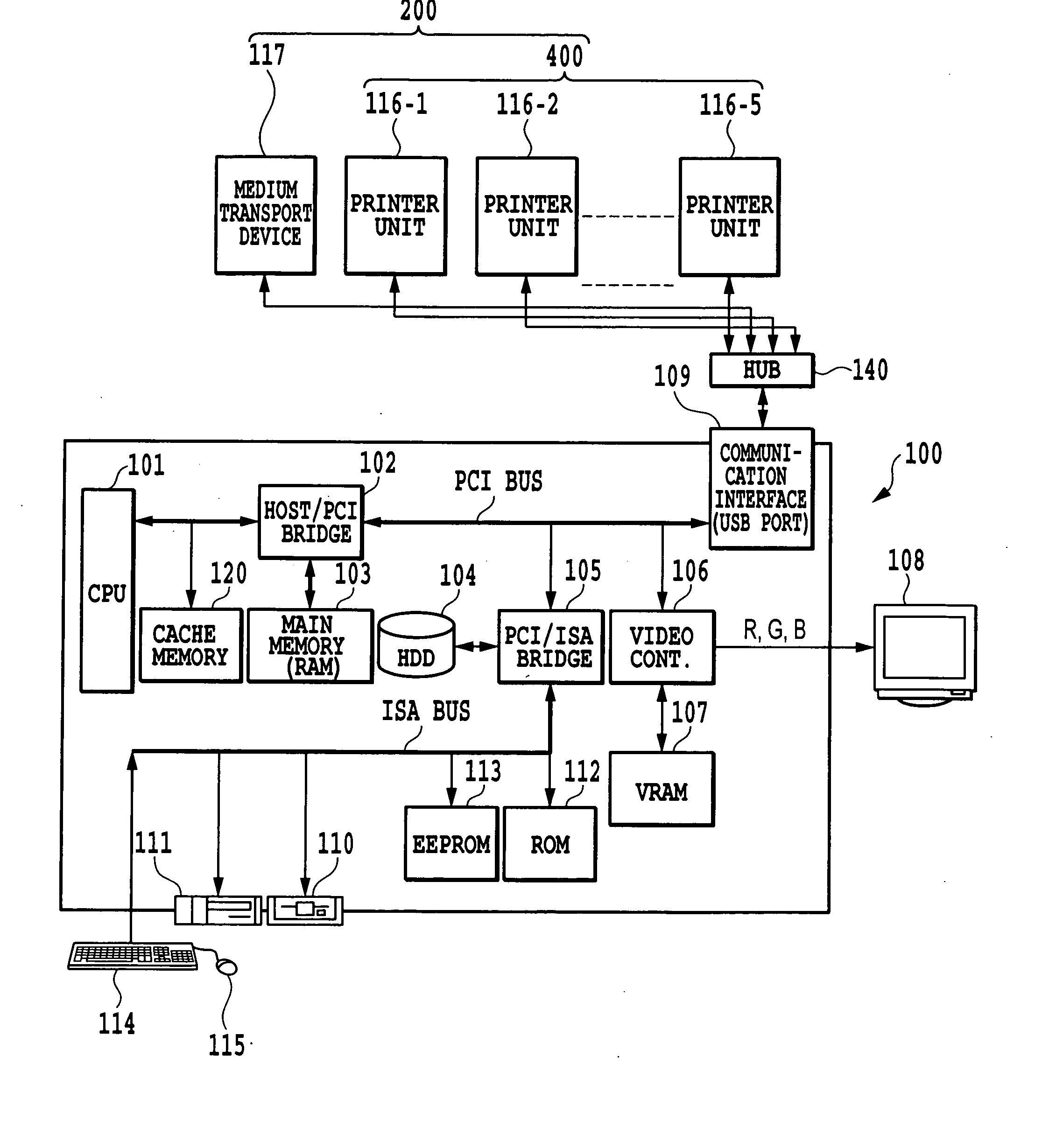

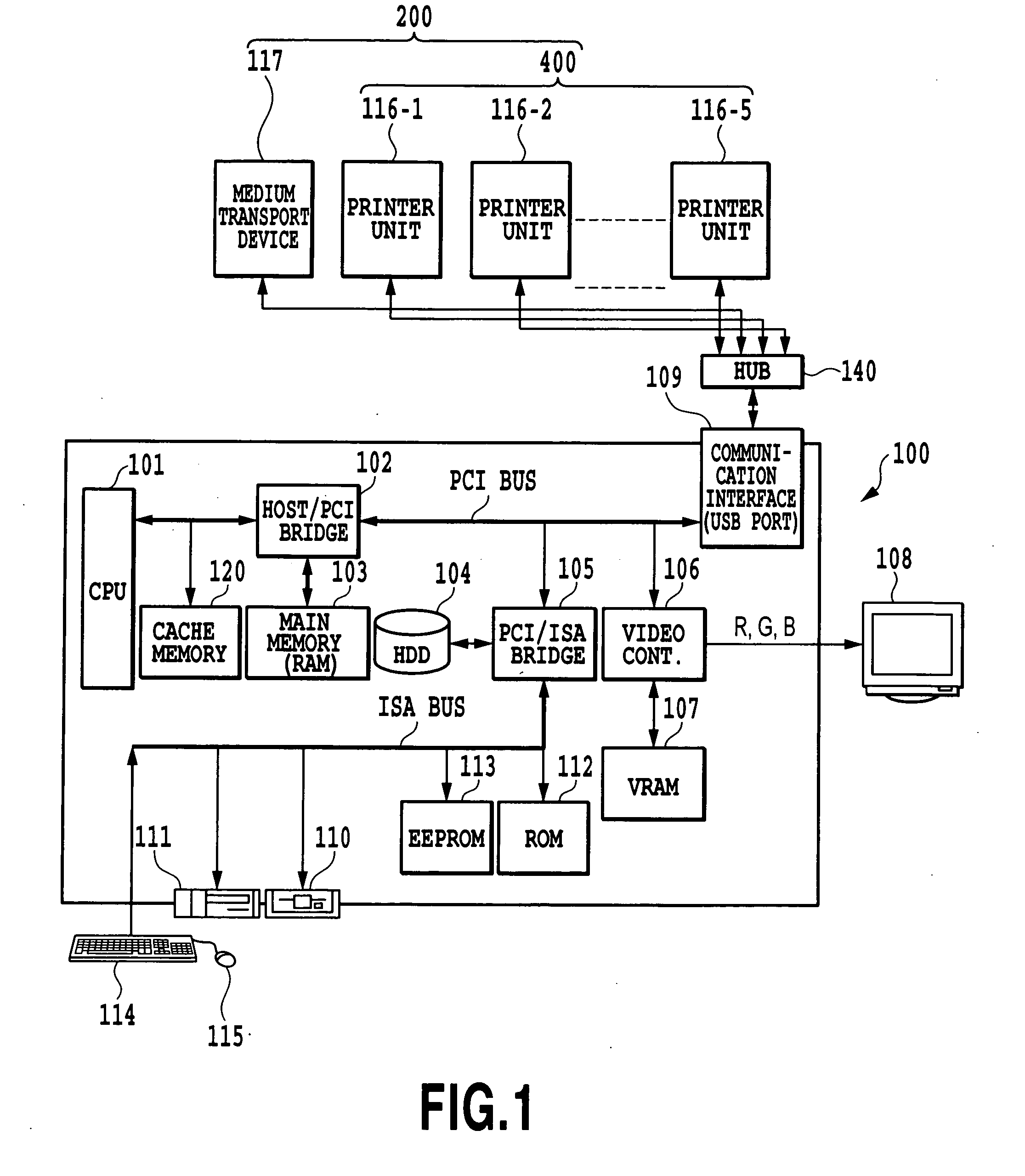

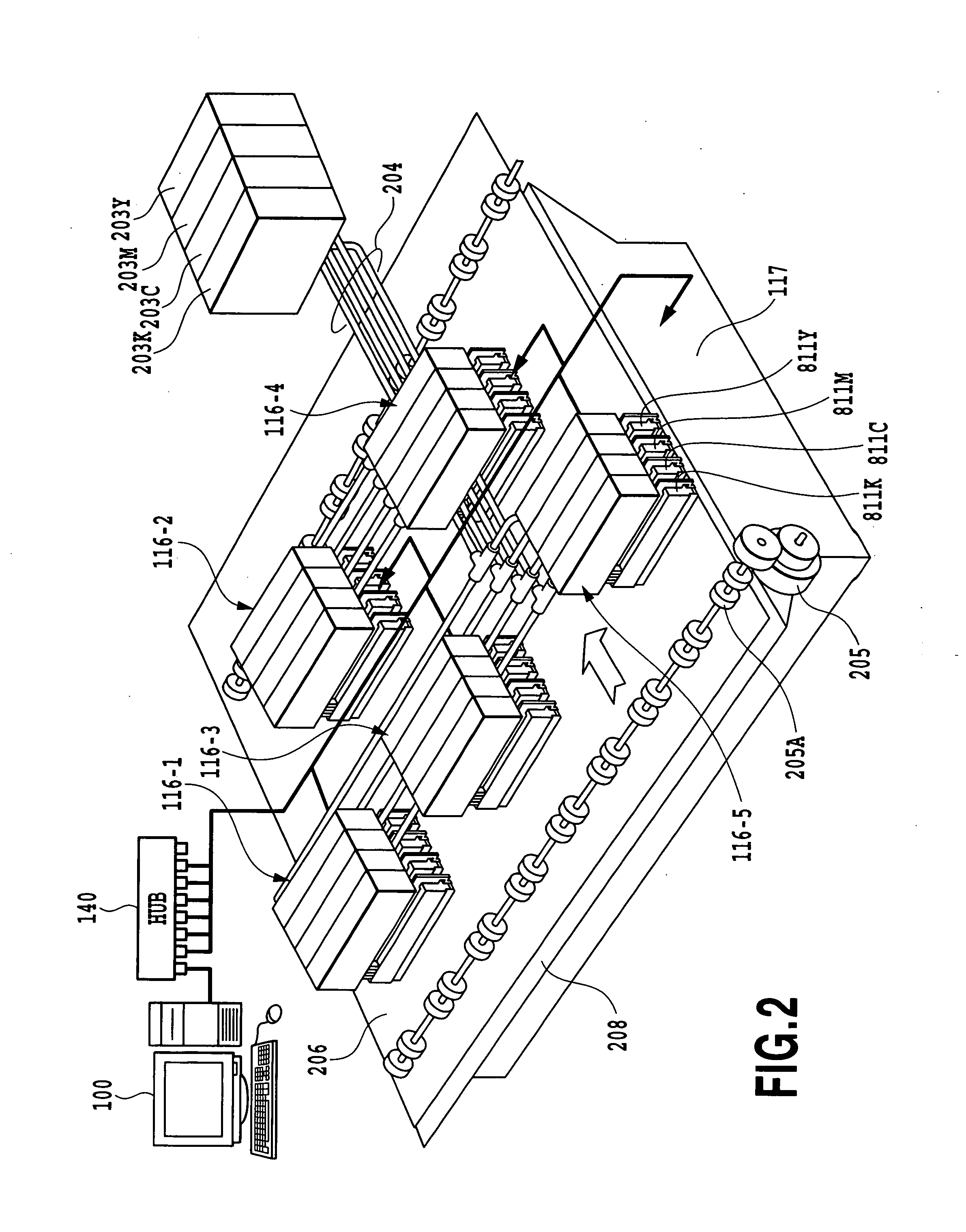

Image Forming Device, Printer Complex System and Medium Conveying Device for the Device, Information Processing Unit for Supplying Image Data to the Image Forming Device, and Image Forming System and Image Forming Method Provided with These

InactiveUS20070263244A1Quickly and easily copeFast printingTypewritersOther printing apparatusImage segmentationEngineering

To meet a demand for changing a print medium size, particularly for increasing the size of print medium while at the same time satisfying the demand for higher printing speed. To that end, a plurality of printer units (116), which are spatially independent of each other (separate from each other) and also independent in the signal system and the ink system, are arranged in an appropriate layout to allow for a line-sequential printing. An information processing device (100) divides a generated image into a plurality of pieces of print data and transfers them to the plurality of printer units. A transport device (117) is installed to feed a large-sized print medium to an area where the plurality of printer units are arranged. The transport device transfers to each of the plurality of printer units a print timing signal corresponding to the position of each printer unit.

Owner:COPYER

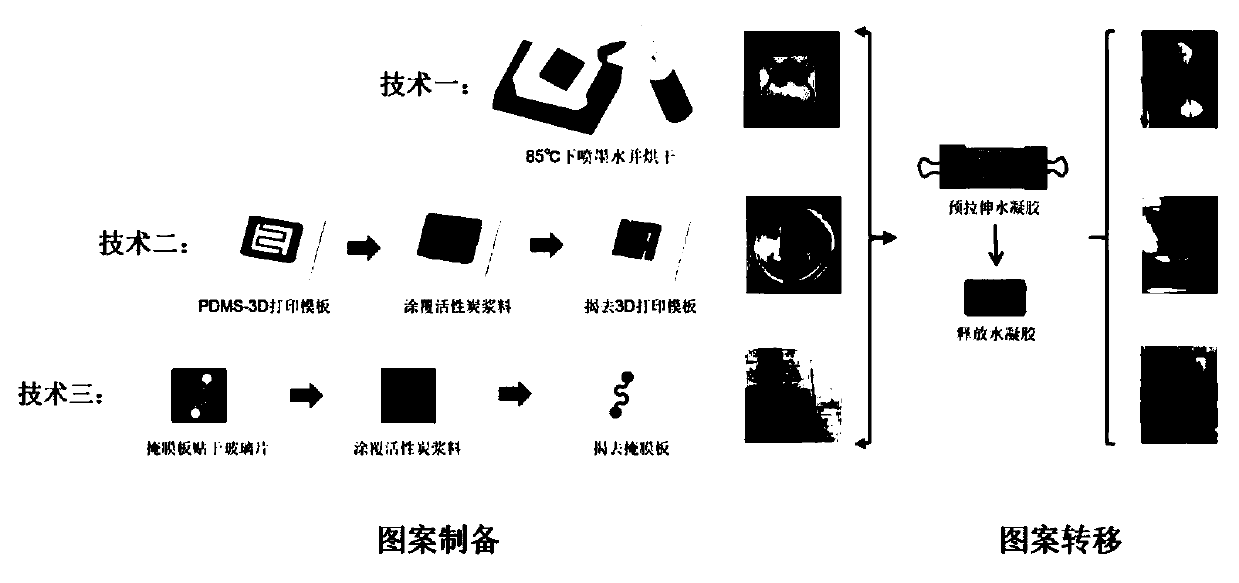

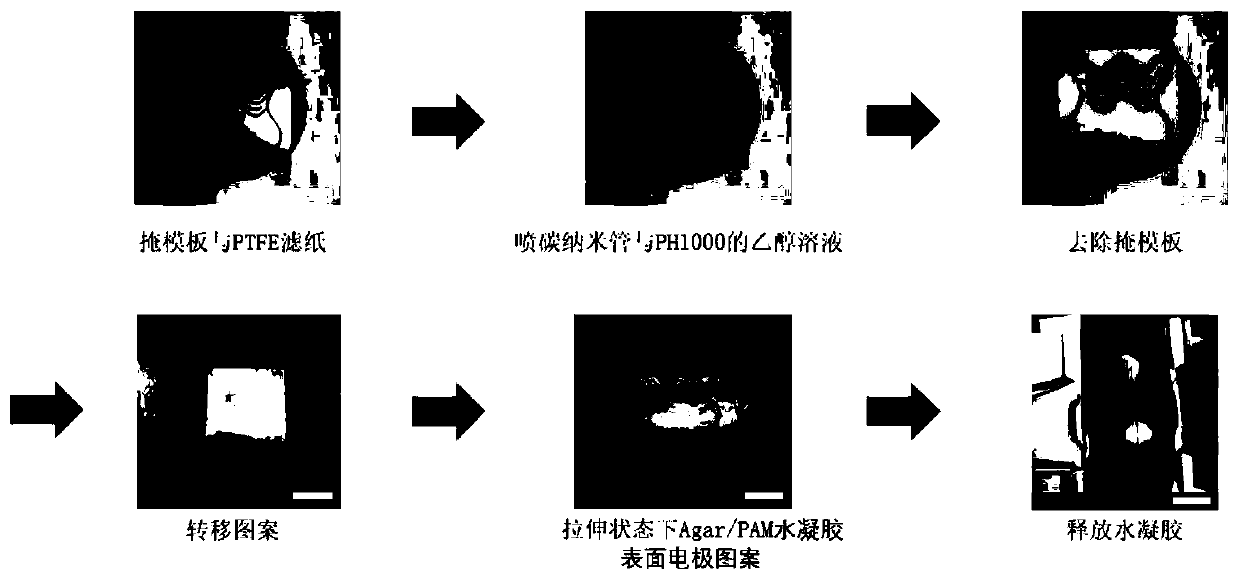

Stretchable microelectronic device taking hydrogel as substrate and preparation method

ActiveCN110970232AFast printEasy to printHybrid capacitor electrolytesHybrid capacitor electrodesTetrafluoroethyleneSupercapacitor

The invention provides a stretchable microelectronic device taking hydrogel as a substrate and a preparation method of the stretchable microelectronic device. The preparation method comprises: the step 1, obtaining an intermediate product with a preset electrode pattern; the step 2, pre-stretching the tough hydrogel, and fitting the pre-stretched hydrogel with the intermediate product in the step1 to transfer the electrode pattern to the surface of the hydrogel; and the step 3, slowly releasing the hydrogel to recover the hydrogel to an unstretched state, so as to obtain the stretchable microelectronic device taking the hydrogel as the substrate. According to the invention, 3D printing, a template printing technology, a transfer printing technology and the like are combined, a flexible polytetrafluoroethylene (PTFE) filter membrane, polydimethylsiloxane (PDMS) silicone rubber or glass and the like are used as intermediary materials and matched with specially-made electrode slurry, anda stretchable micro device can be obtained through rapid and convenient printing on the surface of a tough hydrogel electrolyte represented by agar / polyacrylamide (Aar / PAM) and the like. The preparedmicro device comprises a micro sensor, a micro super capacitor and the like.

Owner:SUN YAT SEN UNIV

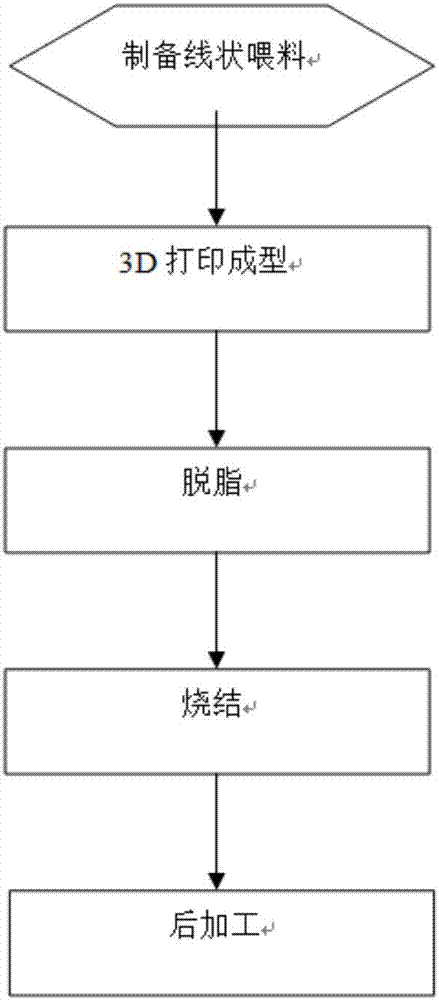

Feed for 3D printing as well as preparation method thereof and application thereof

ActiveCN106984805AAvoid wastingControl precisionAdditive manufacturing apparatusTransportation and packagingEconomic benefitsEngineering

The invention relates to feed for 3D printing as well as a preparation method thereof and an application thereof. The feed is metal powder packaged by a high-molecular binder, and is linear. After being printed into raw blank with a preset shape through a 3D printer, the linear feed is sequentially degreased and sintered, so that a metal product with a complex structure and high precision can be obtained. Compared with the prior art, the linear feed is applied to 3D printing, so that waste of raw materials can be avoided; precision of a product surface is controlled and quality of a product is improved by selecting different linear diameters of the feed and controlling a heating temperature; and melting treatment can be performed by a simple thermocouple, and complex and dear laser heating equipment does not need, so that production cost is reduced. A powder injection molding technology and a 3D printing technology are combined, so that the complex product can be quickly printed and manufactured, development flow is shortened, and mass production popularization is realized. The feed has good economic benefits and a wide application prospect.

Owner:KUNSHAN KADAM NEW MATERIAL TECH CO LTD

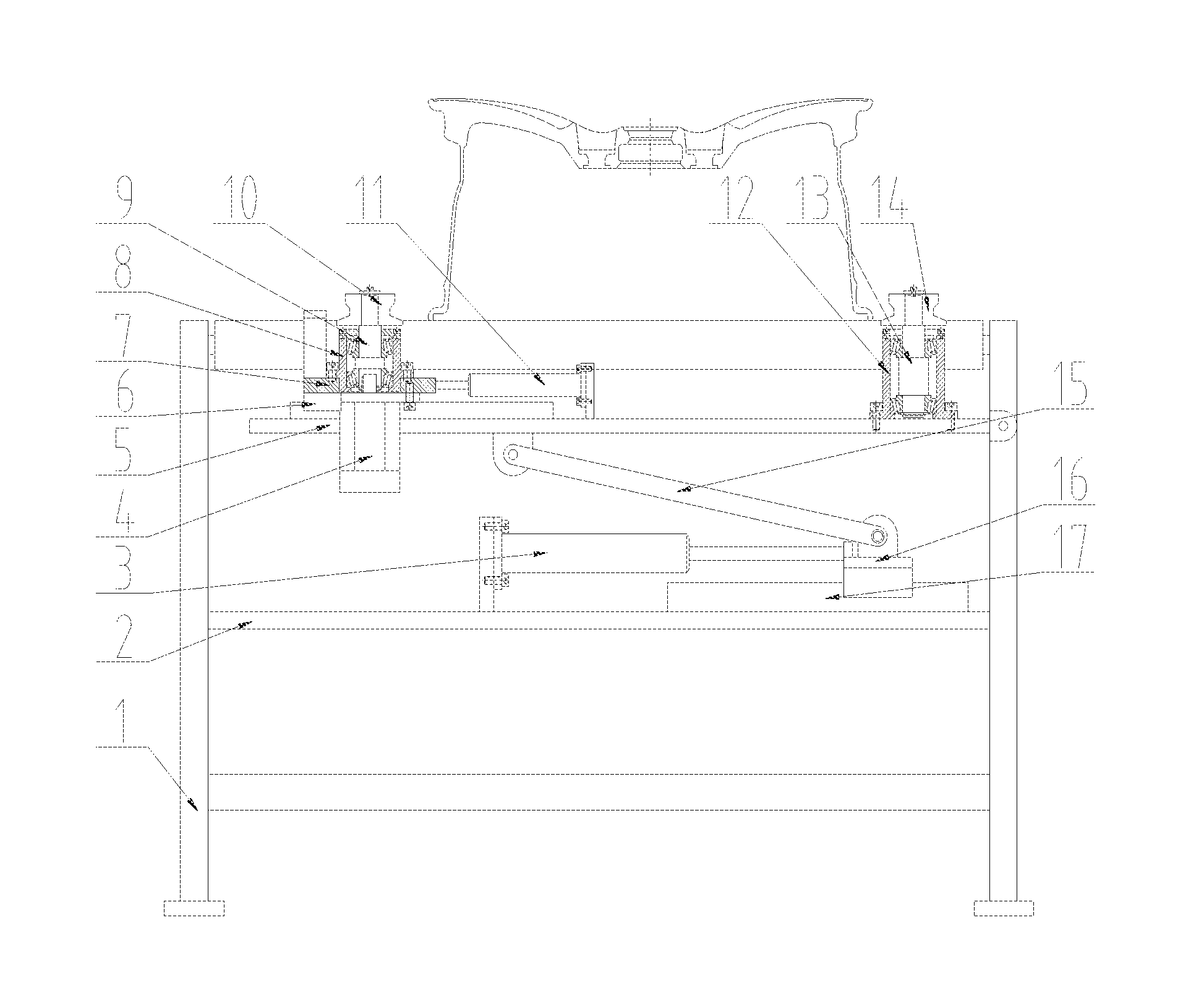

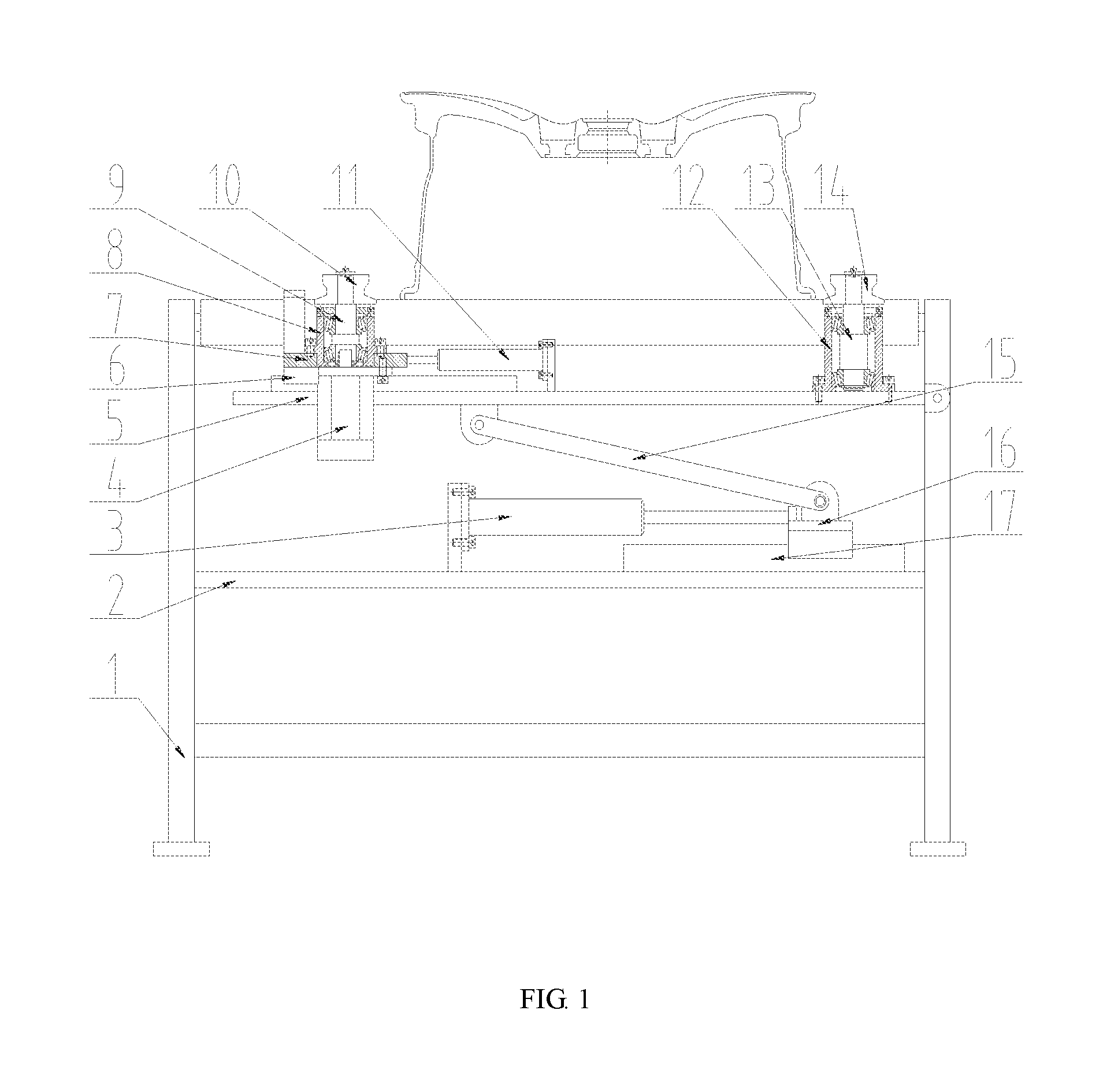

Fixture for on-line wheel printing

ActiveUS20160311215A1High degree of automationImprove performanceRotary pressesWheel protectionEngineeringAutomation

The present invention relates to a fixture for on-line wheel printing, which is composed of a stand, a servo motor, a flip plate, air cylinders and the like. When in use, the fixture provided by the present invention can meet the requirement for quickly printing a pattern on a fixed window of wheel on line, and meanwhile, has the characteristics of advanced technology, high automation degree, safe and stable performance.

Owner:CITIC DICASTAL

Ultrathin lens arrays for viewing interlaced images

An assembly for displaying an interlaced image. The assembly includes an interlaced image, which may be digitally or web printed for example, with sets of elongate image elements or slices A lens arrays is provided with a first side proximate the interlaced image such as a planar surface and a second side distal the image with numerous lens sets. Each of the lens sets is paired with one of the sets of the image elements and includes a number of linear or elongate lenses that are each mapped to one to three image elements. The lenses are each configured to focus light from the subset of image elements to a viewer along a focus direction or line. The lenses are configured to provide a lens-specific viewing angle with a focus line, and the focus line to the paired image element subset differs from other lenses or is unique.

Owner:GENIE LENS TECH

Ink-jet recording medium with an opaque or semi-opaque layer coated thereon, method for recording an image, and a recorded medium with at least one layer rendered clear or semi-opaque

InactiveUS6936316B2Avoid excessive adhesionExtended drying timeCoatingsThermographyAziridineCross linker

The present invention features a multi-layer ink-jet recording medium, suitable for recording images with dye and pigmented inks and thereby providing light-emitting, reflective, glossy, metallic-looking or holographic images, comprising a substrate coated with at least two layers comprising:(a) a first transparent ink-receptive layer comprising a polymeric binder and a cross-linker and optionally having a plasticizer and pigment particles such as alumina and silica coated over the substrate, wherein the cross-linker comprises and azetidinium polymer or a salt thereof, and / or a polyfunctinal aziridine or a salt thereof or a polyfunctional oxazoline or a salt thereof; and(b) a second ink-receptive layer comprising an opaque or semi-opaque coating composition, wherein the opaque or semi-opaque coating composition is capable of accepting a printed image and thereby becoming semi transparent or clearly transparent from application of ink-jet printing ink or similar inks, while presenting a light-emitting, reflective, glossy, metallic-looking or holographic image of high clarity and quality,wherein said first layer is located between said second layer and the substrate in said recording medium and the first and second layers are chemically coupled.

Owner:PIXTERRA

Light-weight concrete for 3D printing, and preparation method and application thereof

ActiveCN105948668AShort initial setting timeSolve the problem of special-shaped formworkAdditive manufacturing apparatusPortland cementUltimate tensile strength

The invention provides a light-weight concrete for 3D printing, and a preparation method and application thereof. The light-weight concrete is prepared from the following raw materials in parts by weight: 100 parts of 52.5R ordinary Portland cement, 6-12 parts of quick-setting sulfoaluminate cement with the strength level of not less than 42.5, 7-10 parts of fly ash, 100-250 parts of composite inert light-weight filler, 1.2-6.5 parts of polypropylene fiber, 0.06-0.2 part of viscosity modifier, 0.5-1.5 parts of flexibility modifier and 25-40 parts of water. Compared with the traditional concrete material, the dead weight of the material is obviously lowered by 25-40%, the pressure deformation from the upper layer material to the lower layer material in the printing process is greatly reduced, and the number of layers of one-step continuous printing can be further increased, thereby shortening the construction period. Besides, the material has certain heat-shielding and heat-insulating properties, so that the light-weight concrete is more energy-saving and environment-friendly when being applied to the field of buildings.

Owner:CHONGQING CONSTR ENG NEW BUILDING MATERIALS +1

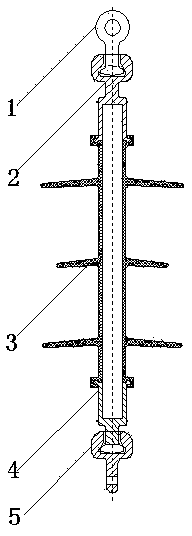

Overhung composite insulator string and method for printing same by using 3D

ActiveCN104103385AHigh degree of manufacturing flexibilitySave timeSuspension/strain insulatorsComputer Aided DesignComposite insulators

The invention discloses an integrated overhung composite insulator string and a method for printing a composite insulator string connecting metal tool by using 3D. The method comprises the following steps of: firstly, generating a three-dimensional CAD (Computer-Aided Design) model of a part in a computer, and printing the three-dimensional CAD model by utilizing a 3D molten-drop printing machine; then slicing up and layering the model according to a certain thickness, converting the three-dimensional information of the part into a series of two-dimensional profile information; melting down metal by using a crucible, and enabling the molten metal to flow out of a nozzle to form molten drops; then accumulating the molten drops layers by layer according to the two-dimensional profile information under the control of the computer so as to obtain a three-dimensional entity part or a part in similar shape. After the method is adopted, a ball-socket series of metal tools is shaped for once directly through the molten-drop 3D printing machine, the connecting cooperation is more reliable and more stable, secondary installation is unnecessary, and the production efficiency is improved; meanwhile, the efficiency of the site construction is provided, and a great influence to the construction of a high-voltage overhead power line is generated.

Owner:STATE GRID CORP OF CHINA +3

Ultrathin lens arrays for viewing interlaced images with dual lens structures

An assembly for displaying an interlaced image. The assembly includes an interlaced image, which may be digitally or web printed for example, with sets of elongate image elements or slices. A lens arrays is provided with a first side proximate the interlaced image such as a planar surface and a second side distal the image with numerous lens sets. Each of the lens sets is paired with one of the sets of the image elements and includes a number of linear or elongate lenses that are each mapped to one to three image elements. The lenses are each configured to focus light from the subset of image elements to a viewer along a focus direction or line. The lenses are configured to provide a lens-specific viewing angle with a focus line, and the focus line to the paired image element subset differs from other lenses or is unique.

Owner:GENIE LENS TECH

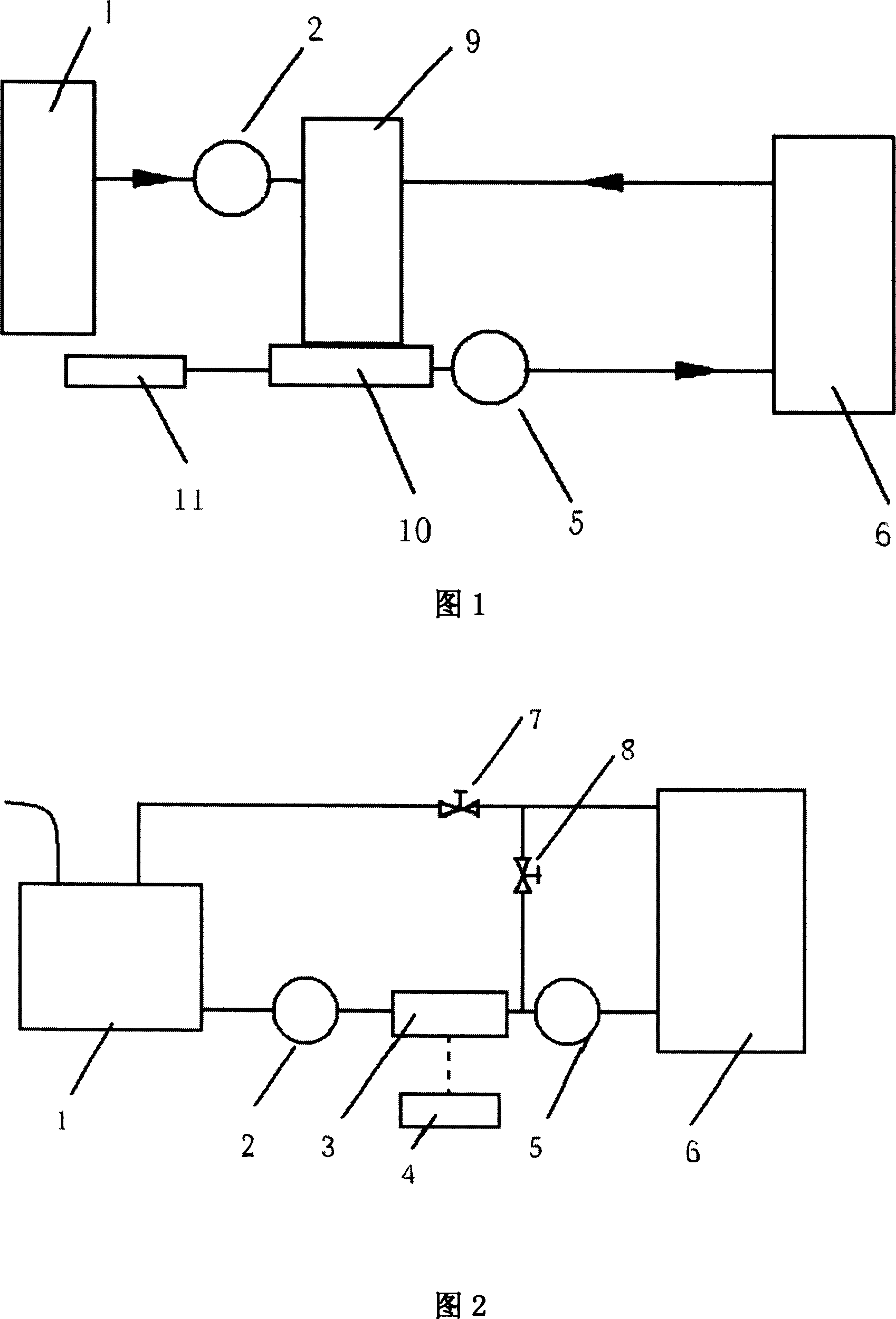

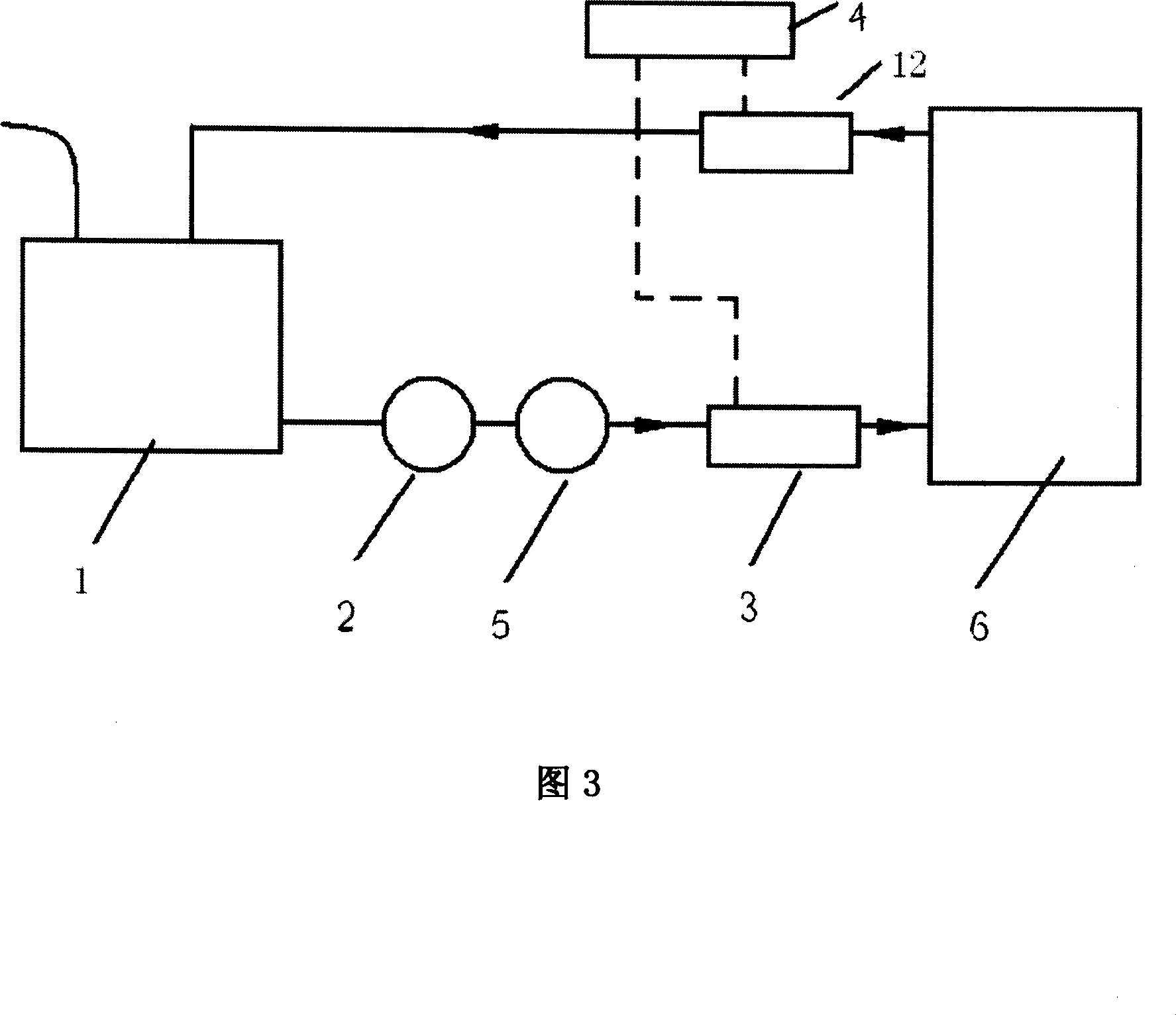

Diesel engine fuel consumption measuring apparatus

ActiveCN101013064AEasy to measureHigh precisionMass flow measurement devicesInternal-combustion engine testingMeasurement deviceFuel oil

The invention relates to a diesel engine fuel consumption measurement device, and the device installs mass flow meter on the original fuel system, and transmits the signals of the mass flow meter output and the signals of the original diesel engine output power to the fuel oil consumption device to conduct operations, and outputs the diesel engine output power, fuel consumption volume and fuel consumption rate. The diesel engine fuel consumption measurement device of the invention greatly enhances the measurement precision, and it can real-time monitor the diesel fuel consumption status, applied to the diesel on the land or water.

Owner:HUDONG HEAVY MACHINERY

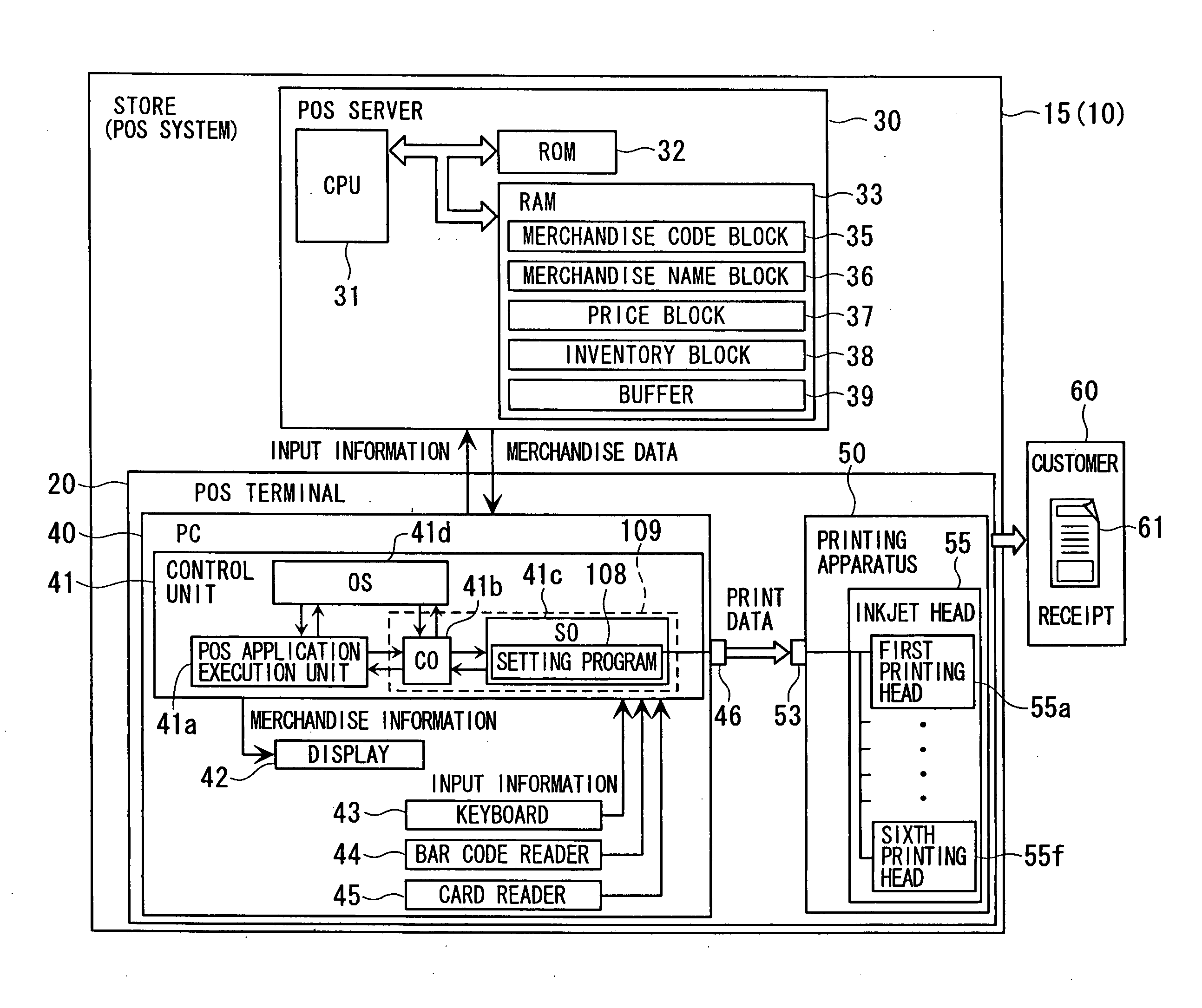

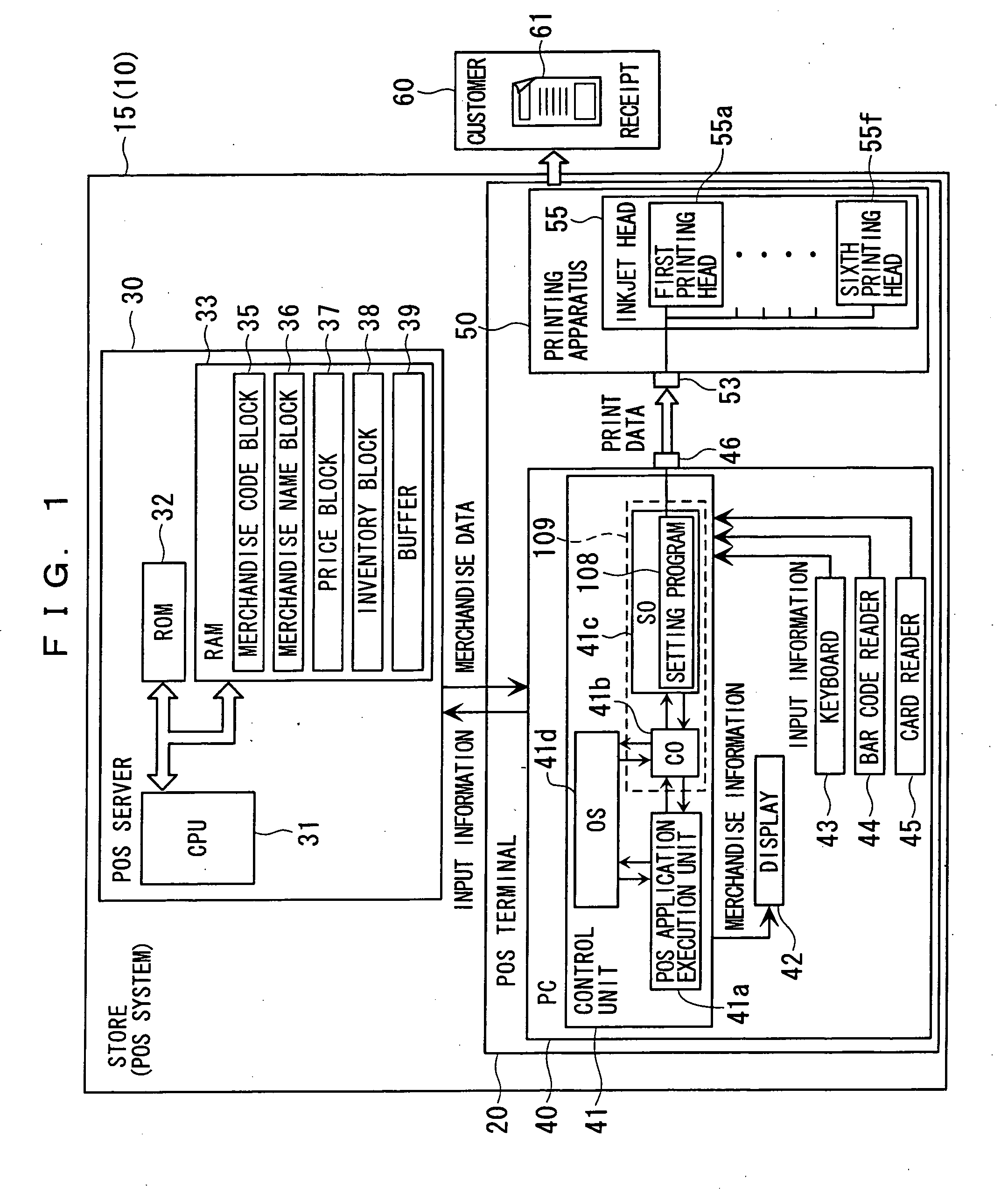

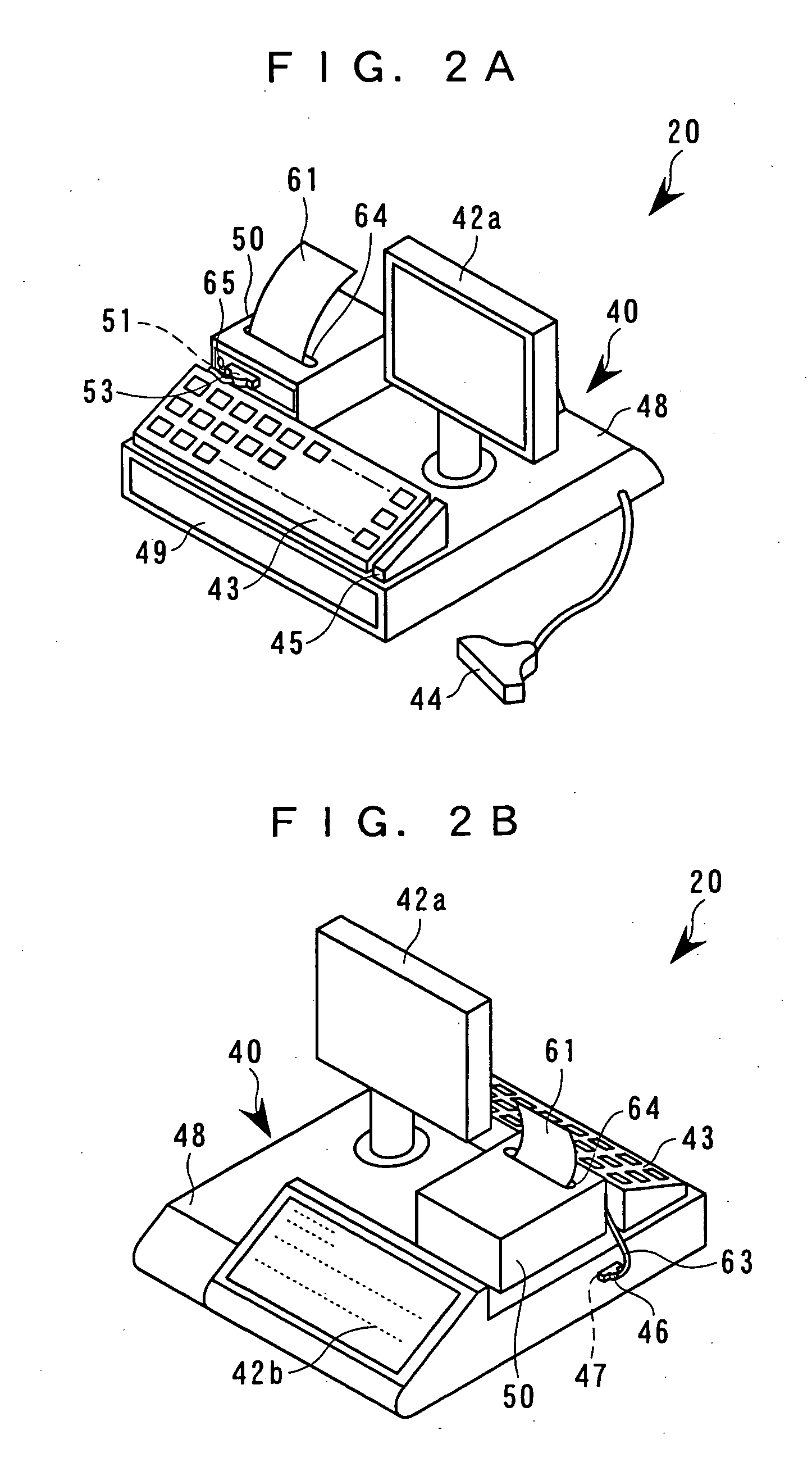

Method of controlling printing apparatus, method of generating receipt print data, program, printer driver, printing apparatus, merchandise sales data processing apparatus and POS system

InactiveUS20050275894A1Easily determine print positionImage data can be rapidlyDigital computer detailsApparatus for meter-controlled dispensingLow speedPayment transaction

In a method of controlling a printing apparatus which performs printing by adding image data already stored in the printing apparatus to payment transaction print data generated on the basis of input information concerning merchandise sales, a predetermined character string indicating a print position of the image data is retrieved from the payment transaction print data and the predetermined character string is extracted. A line number specified by the extracted predetermined character string is obtained and an image addition setting command is generated on the basis of the line number. The payment transaction print data and the image addition setting command are transmitted to the printing apparatus. Even if a low-speed interface is used as an interface between a PC and the printing apparatus, the image data can be printed rapidly.

Owner:SEIKO EPSON CORP

Environment-friendly powder 3D printer

InactiveCN108357101AEasy to printFast printManufacturing platforms/substratesManufacturing enclosuresPeristaltic pumpEngineering

The invention discloses an environment-friendly powder 3D printer, and belongs to the field of 3D printing. According to the environment-friendly powder 3D printer, during fallen leaf powder printing,the designed powder 3D printer and a binder are utilized, and a printing spray head is controlled to freely move in the XY direction in a belt drive manner; and a printing bottom plane is controlledto move up and down in the Z-axis direction in a lead screw drive manner. In addition, the spray head is driven by a peristaltic pump, and uniform spraying of the binder is achieved through start-stopand speed adjustment of the peristaltic pump. A designed powder spreading tank and designed powder pavement rollers control the powder spreading process during movement in the Y direction. Accordingto the overall working sequence, the spray head carries out binder spraying on the current layer of section according to a designed 3D printing model, the axis Z descends by a printing height, the powder spreading tank and the powder pavement rollers complete one-time back and forth powder pavement in the Y direction, and the printing spray head works again to start to print the next layer. According to the environment-friendly powder 3D printer, fallen leaves can be utilized for printing meal boxes, and extremely high economic value and environment value are achieved.

Owner:ZHEJIANG UNIV

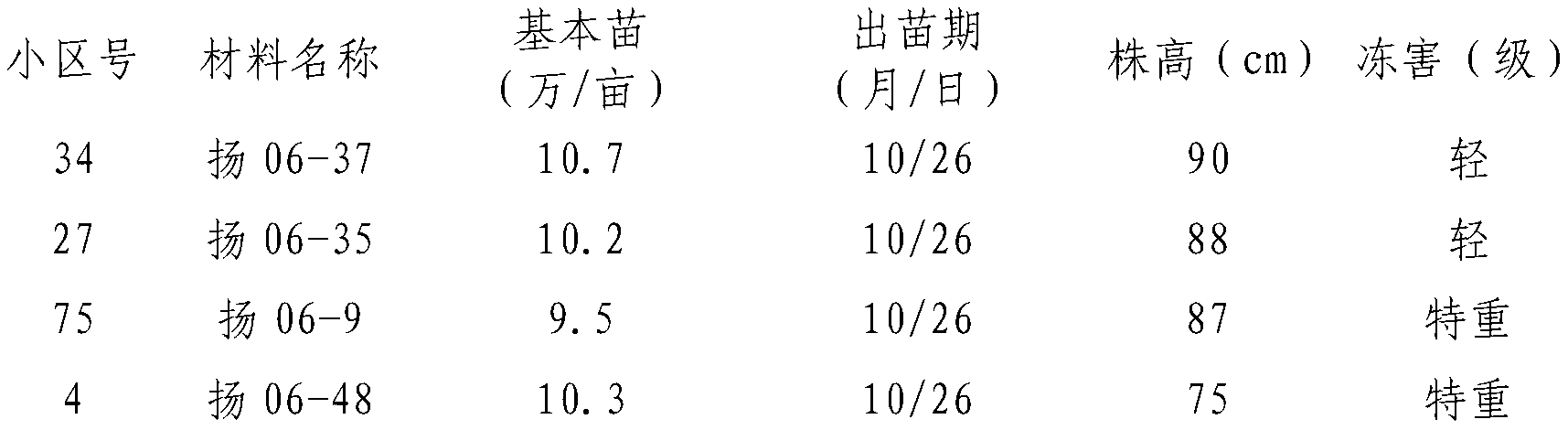

Investigation method for crop breeding field characters

ActiveCN103164777AImprove collection efficiencyImprove transmission efficiencySensing record carriersResourcesInvestigation methodsData acquisition

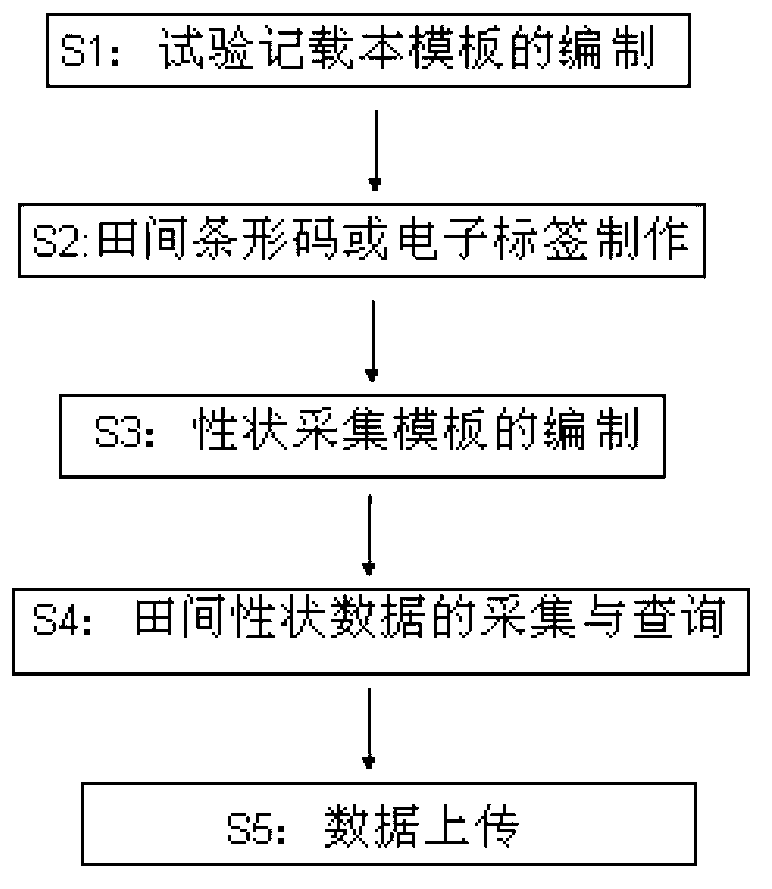

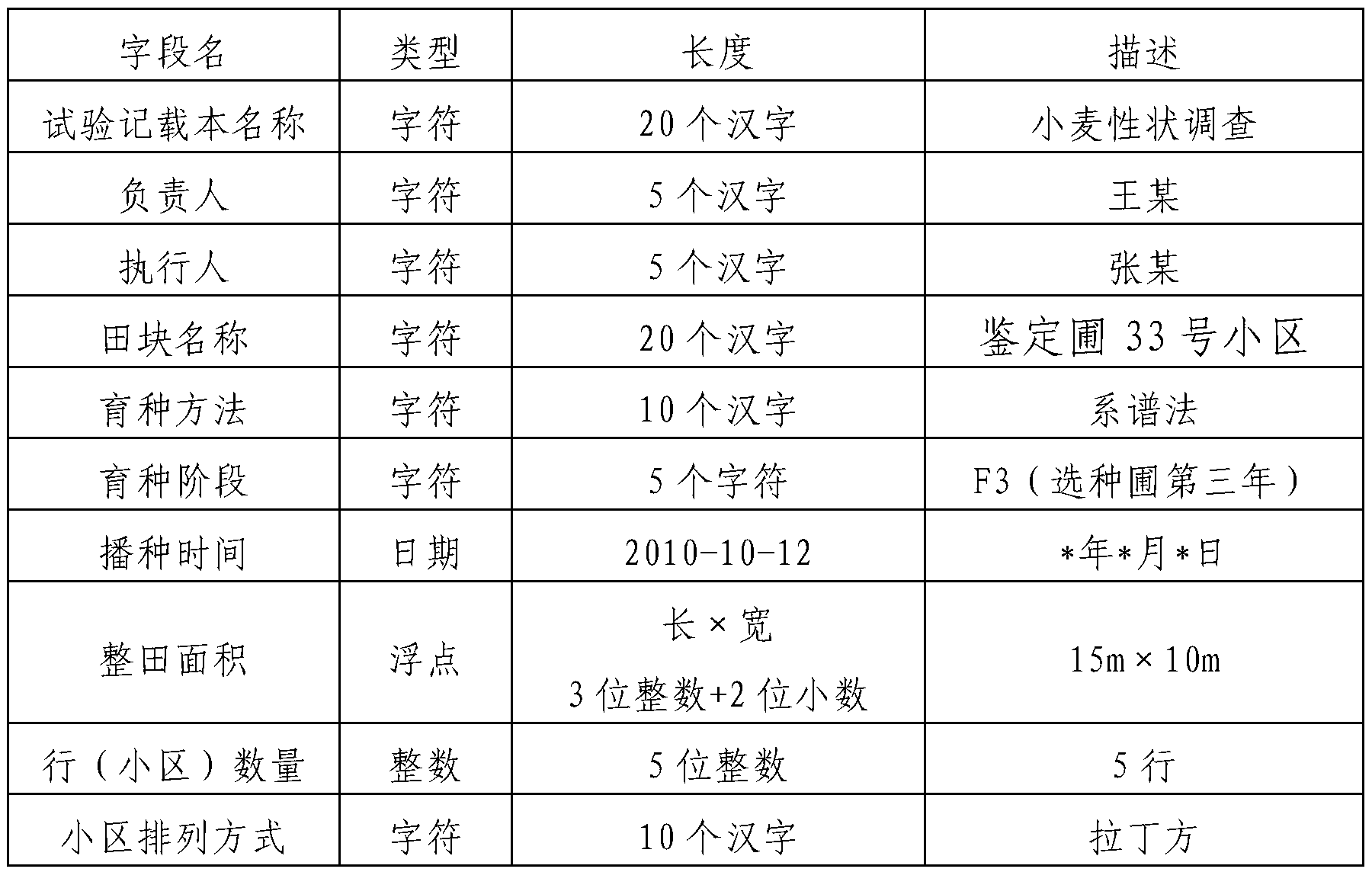

The invention relates to an investigation method for crop breeding field characters. The method includes the steps: S1, establishing a test recording book template, entering a test recording book establishing module to establish basic information in a test recording book, and storing the basic information in a database; S2, making a field bar code or an electronic tag containing crop field position information, and hanging the field bar code or the electronic tag on a crop stem or inserting the field bar code or the electronic tag into a field to facilitate recognition when in field investigation; S3, establishing a character acquisition module containing various crop character parameters, and storing the crop character parameters in the database; S4, acquiring and inquiring field character data by recording the basic information of the test recording book and the crop character parameters through an acquisition terminal device held by a breeding investigator; and S5, uploading the data. By the aid of the method, data acquisition and transmission efficiency is greatly improved, the link of manual entry is omitted, mistakes and the like caused by secondary data reduction are avoided, and the labor intensity of a breeder is reduced.

Owner:BEIJING RES CENT OF INTELLIGENT EQUIP FOR AGRI

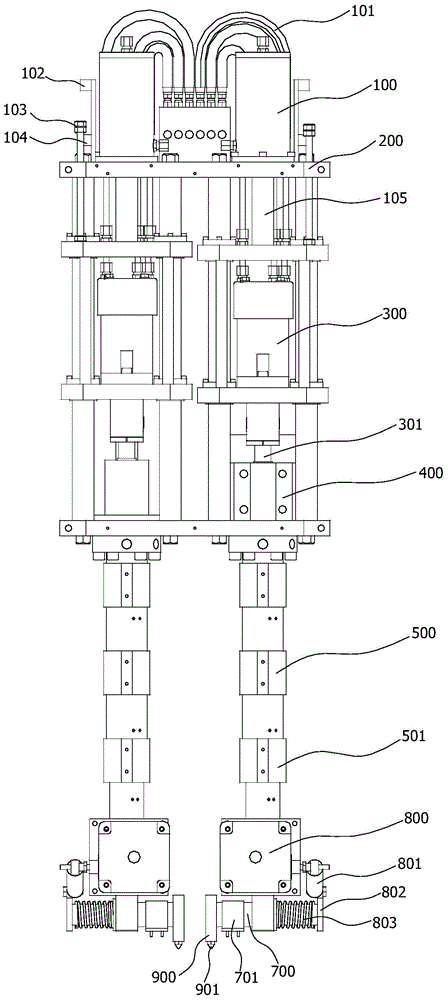

Continuous carbon fiber 3D printing device

InactiveCN106915079AFast printImprove adhesionManufacturing heating elements3D object support structuresSpray nozzleYarn

The invention discloses a continuous carbon fiber 3D printing device. The device comprises a spray cavity, a nozzle, fiber yarns, a liquid supplying pump, a resin tank and a laser device, wherein the spray cavity adopts a cylindrical structure with a cavity, and is provided with a first end and a second end; the diameter of the first end is larger than that of the second end; a first inlet is formed in the upper part of the first end; an outlet is formed in the lower part of the second end; a second inlet is formed in a lateral side of the first end; the second inlet communicates with the first inlet and the first outlet to form a three-way structure; the nozzle is connected with the outlet of the spray cavity; the fiber yarns penetrate through the spray cavity; the resin tank is connected with an inlet of a liquid supplying pump through a hose; the outlet of the liquid supplying pump is connected with the second inlet of the spray cavity; the second end of the spray cavity is coated with a heating coil; a supporting frame is also arranged at the second end of the spray cavity, near the nozzle; one end of the supporting frame is fixedly connected with the spray cavity, and the other end of the supporting frame is fixedly connected with a collimating mirror; and the laser device is connected with the collimating mirror through an optical fiber. Through the adoption of the device disclosed by the invention, rapid continuous printing can be realized.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

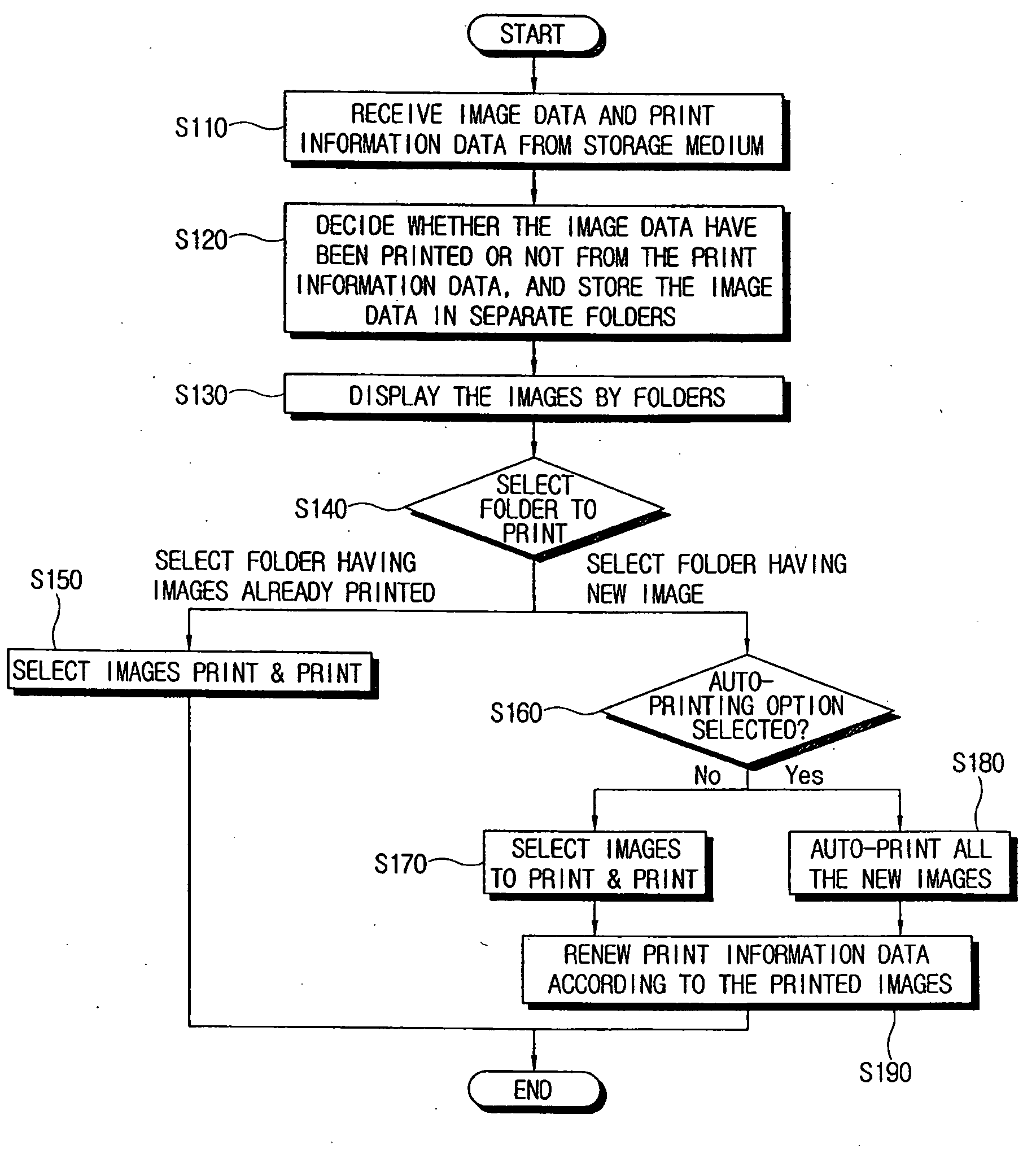

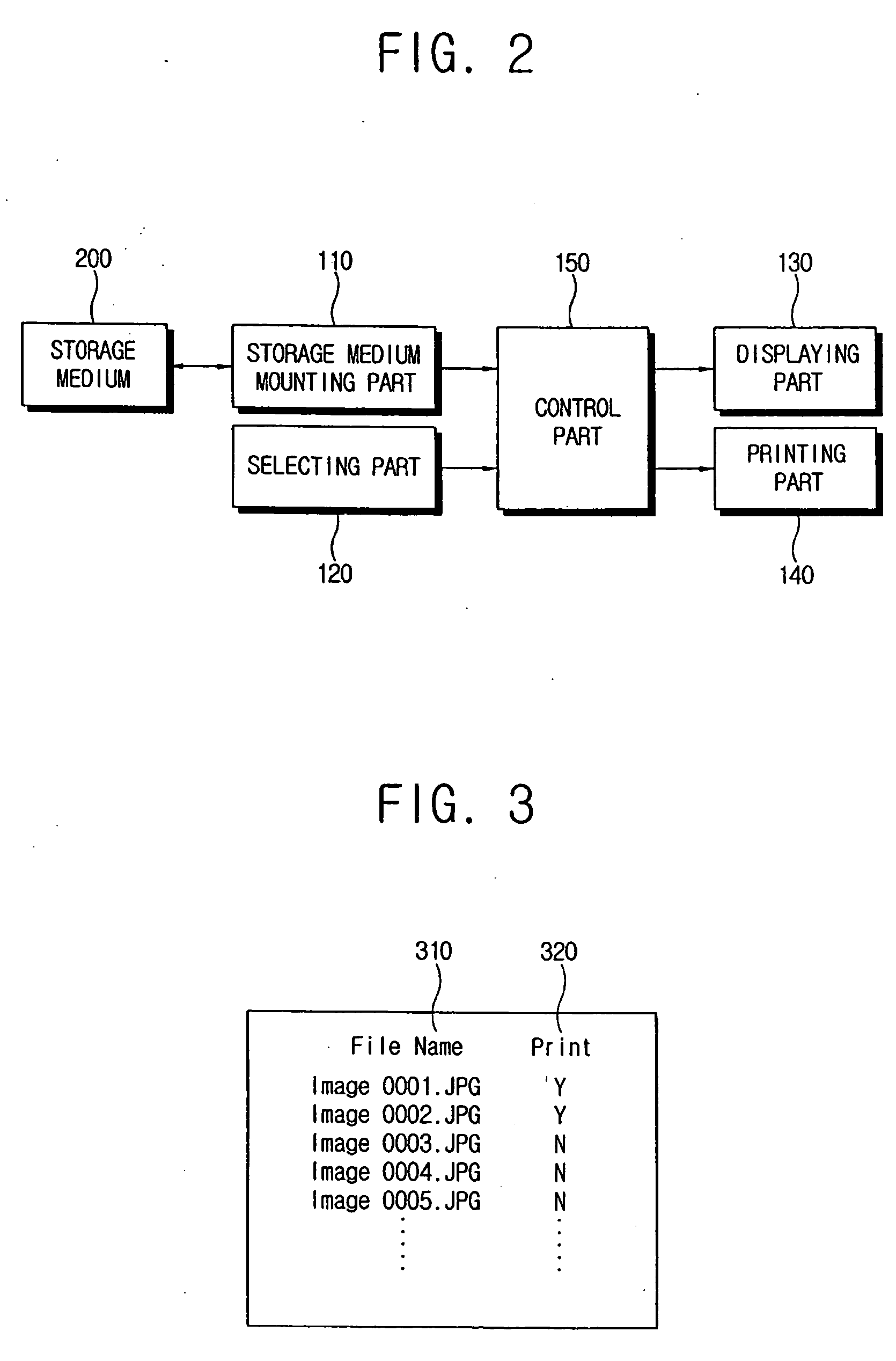

Image forming device and image forming method using the same

InactiveUS20060132841A1Easy to getFast printPictoral communicationDigital output to print unitsComputer graphics (images)Image formation

An image forming method usable with an image forming device includes a storage medium mounting part to receive image data from a storage medium connectable therein and a displaying part to images that correspond to the image data received from the storage medium. The image forming method includes: receiving the image data and print information data about whether the images that correspond to the image data received from the storage medium have been printed before, dividing the images into a first group and a second group according to whether the images have been printed before and displaying the images in at least one of the first and second groups, printing one or more images selected from among the displayed images, and updating the print information data that corresponds to the printed one or more images in the storage medium. Thus, the user may easily obtain information about whether the images stored in the storage medium have been printed or not.

Owner:SAMSUNG ELECTRONICS CO LTD

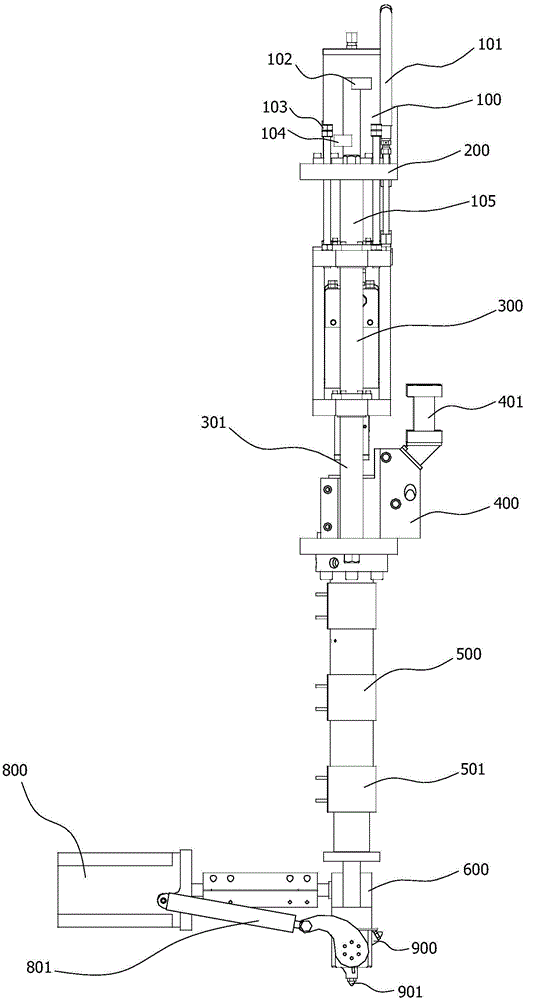

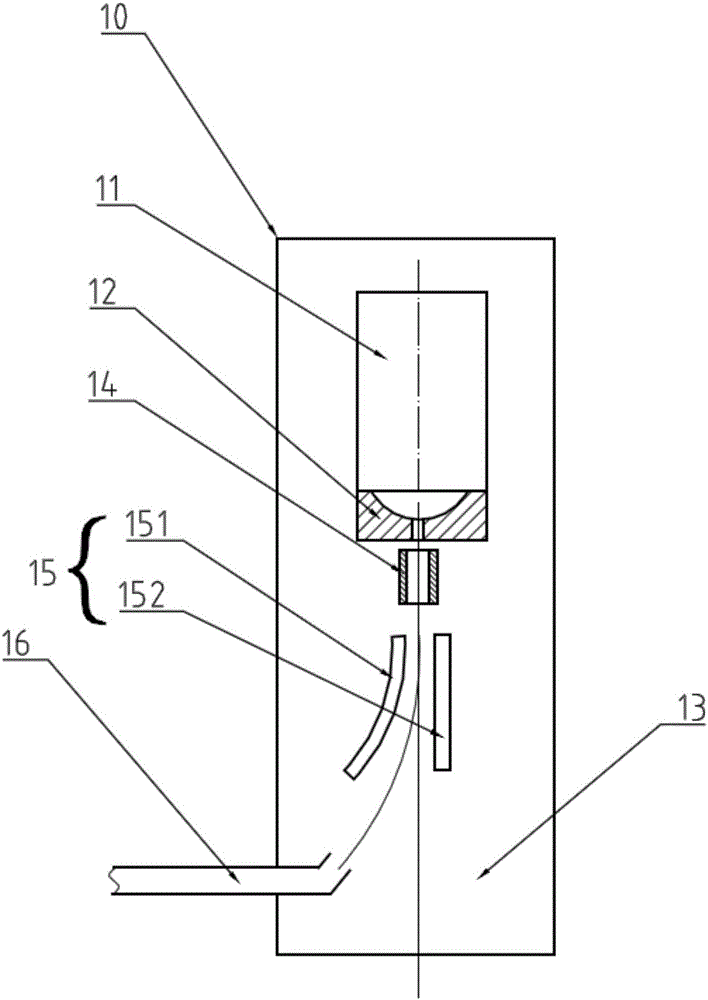

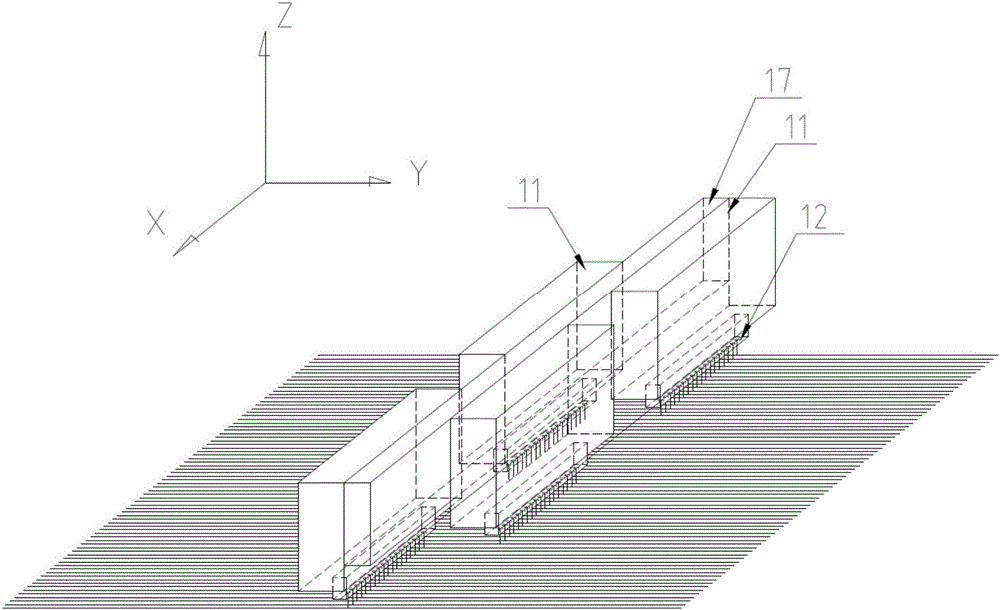

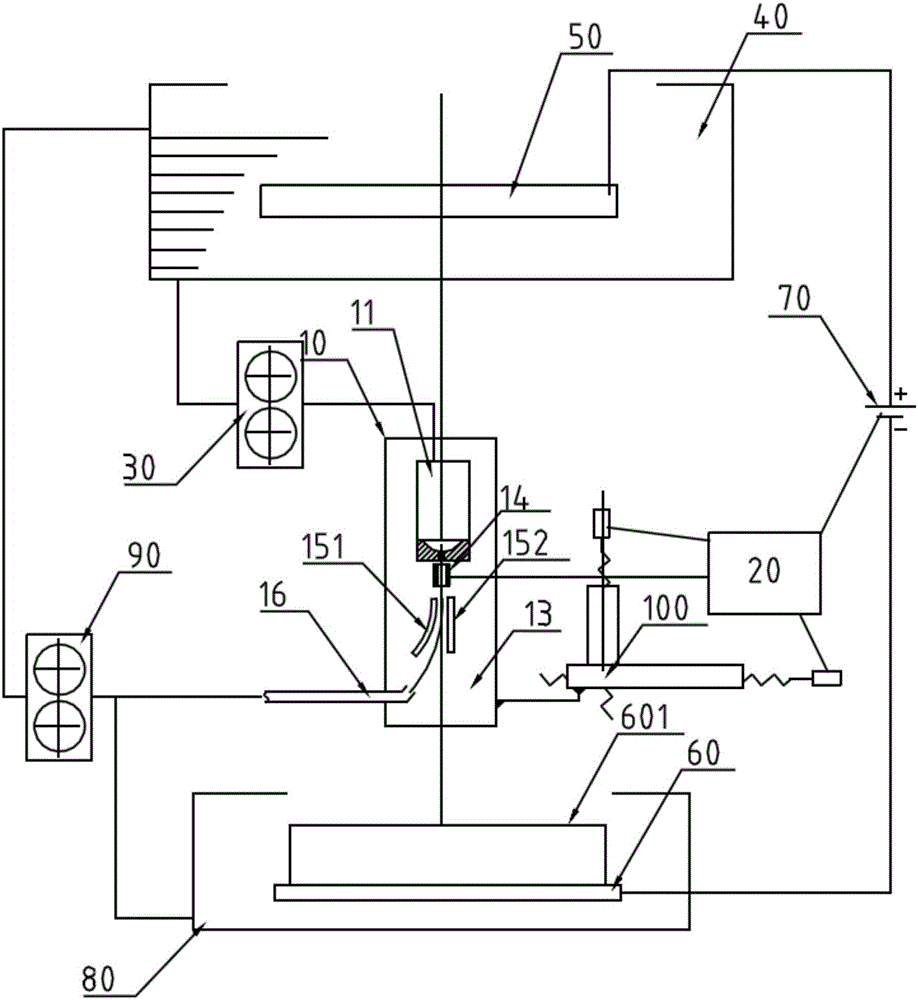

Printing head, printing device and printing method for rapid forming of metal piece

InactiveCN105112965ATo overcome the shortcomings of low printing efficiencyFast printAdditive manufacturing apparatusEtchingEngineering

The invention discloses a printing head, a printing device and a printing method for rapid forming of a metal piece. The printing head comprises a body, a plurality of nozzles, a first electrode and a second common electrode. When the printing head is in the working state, electroplate liquid is sprayed out through the multiple nozzles and sequentially passes through the first electrode and the second common electrode. The printing device is provided with the printing head. According to the printing method, when electrochemical deposition or electrolytic etching is conducted on the electroplate liquid, the electroplate liquid is electrified and is directly sprayed onto a position needing to be printed; in the position which does not need to be printed, the electroplate liquid deflects when flowing through a deflection electric field by changing the electrical characteristic of the electroplate liquid, and the electroplate liquid is prevented from being sprayed onto the position which does not need to be printed. By the adoption of the printing head, the printing device and the printing method for rapid forming of the metal piece, the defects that a three-dimensional (3D) printer for the metal piece in the prior art is low in printing efficiency and low in precision are overcome, and rapid, high-quality and high-precision printing of 3D metal pieces is achieved.

Owner:SHANGHAI SHENGKUANG ELECTROMECHANICAL TECH

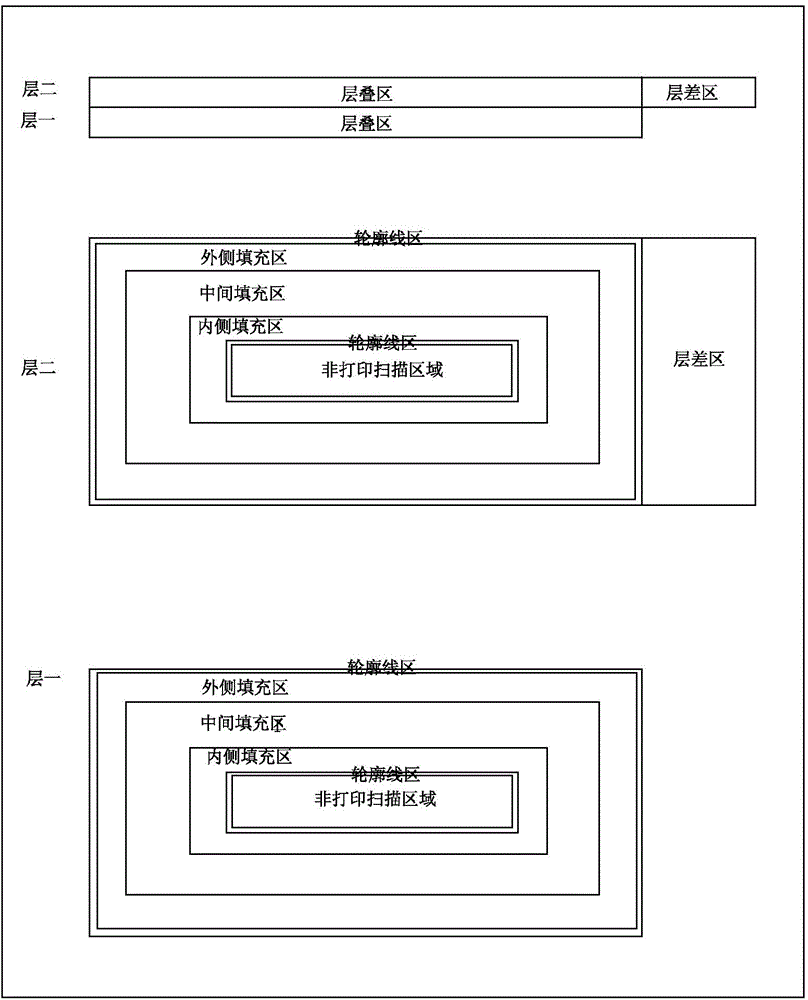

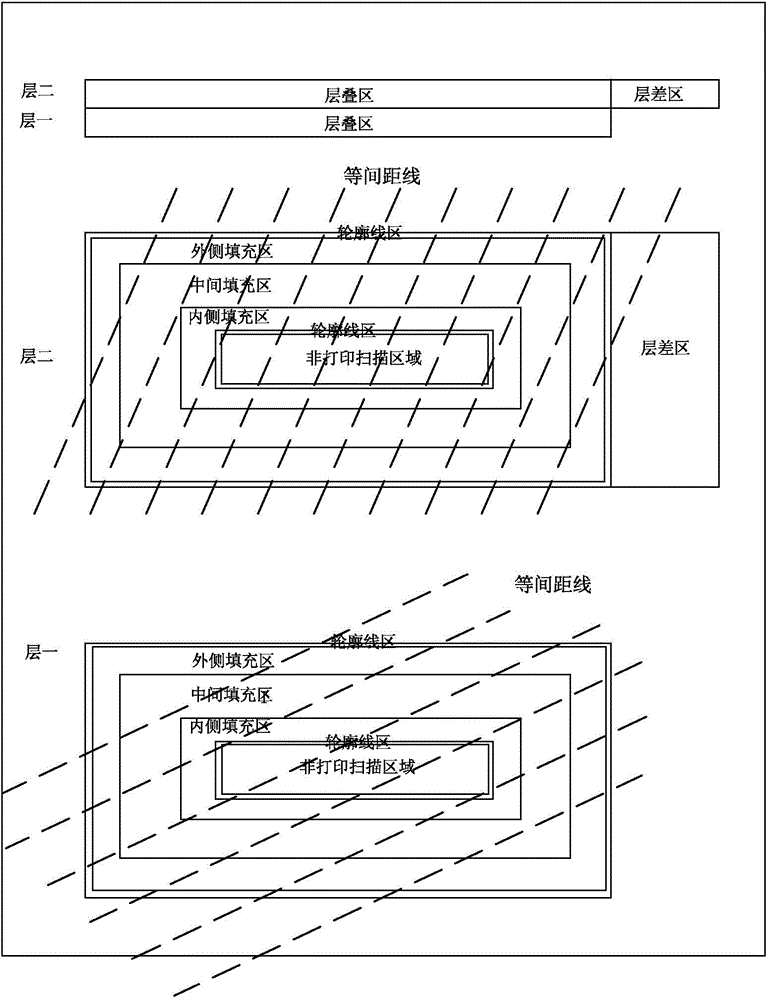

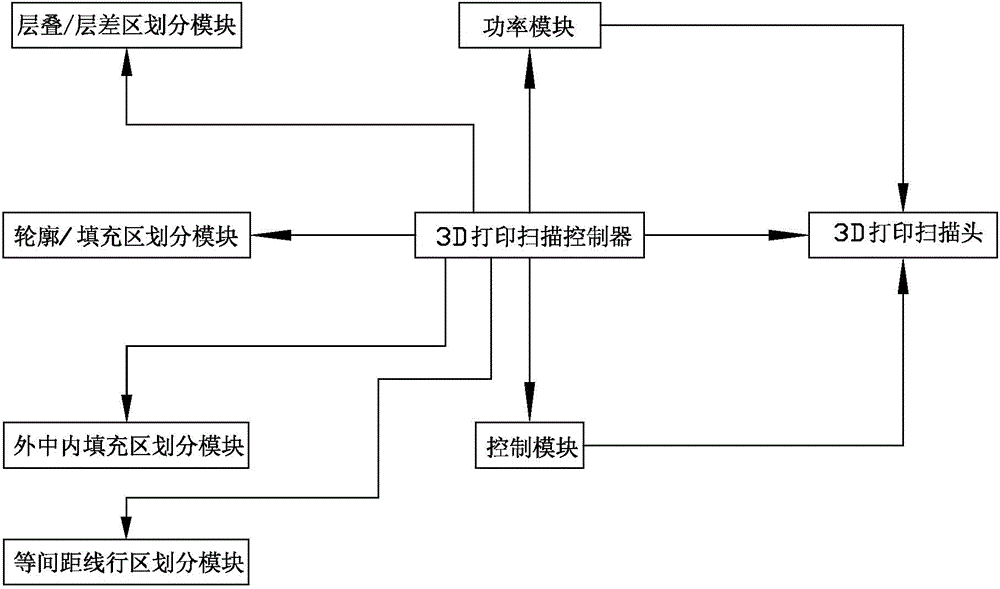

Control method and controller for 3D (three-dimension) printing and scanning

Owner:GUANGDONG HANBANG 3D TECH CO LTD

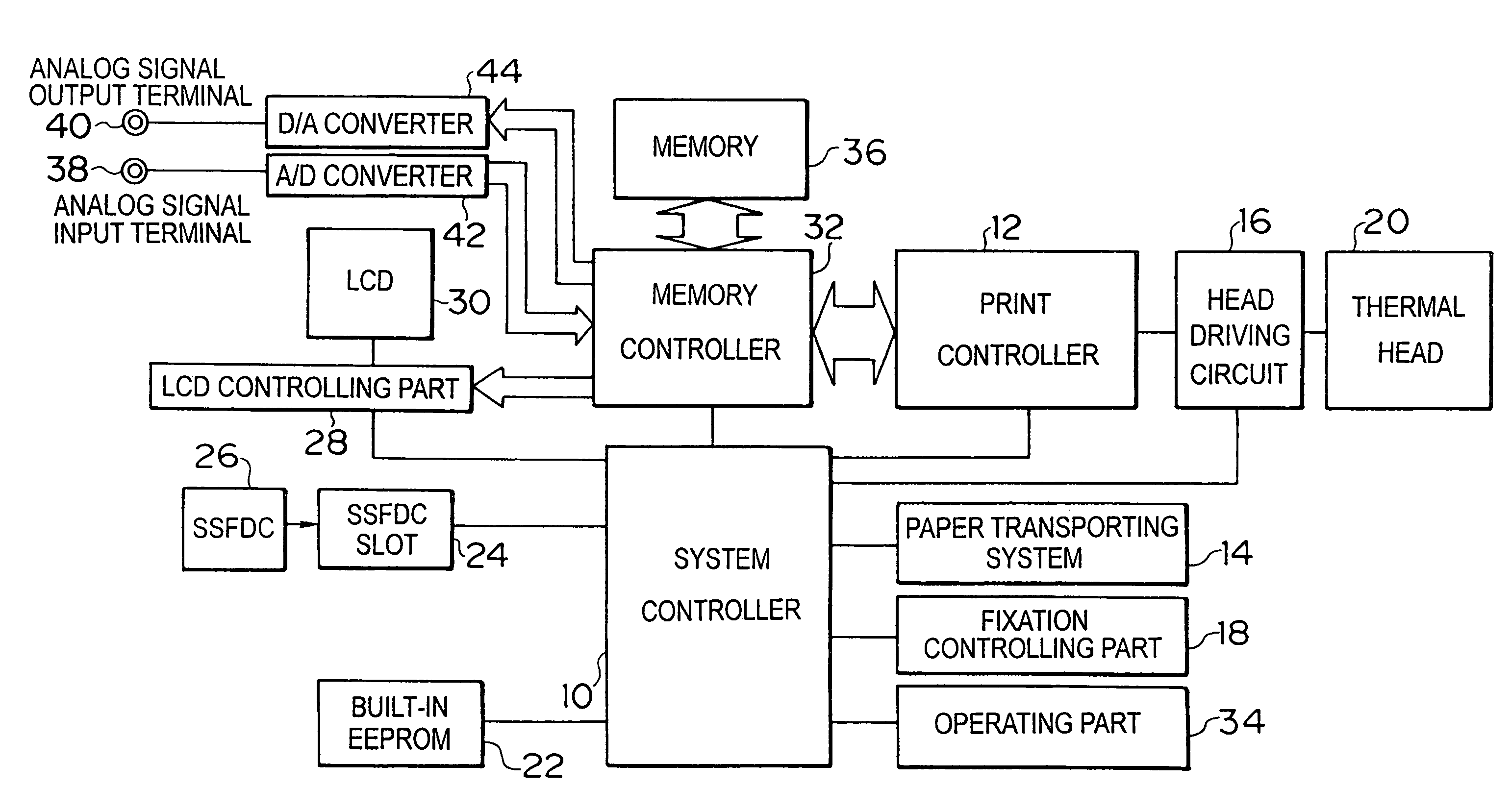

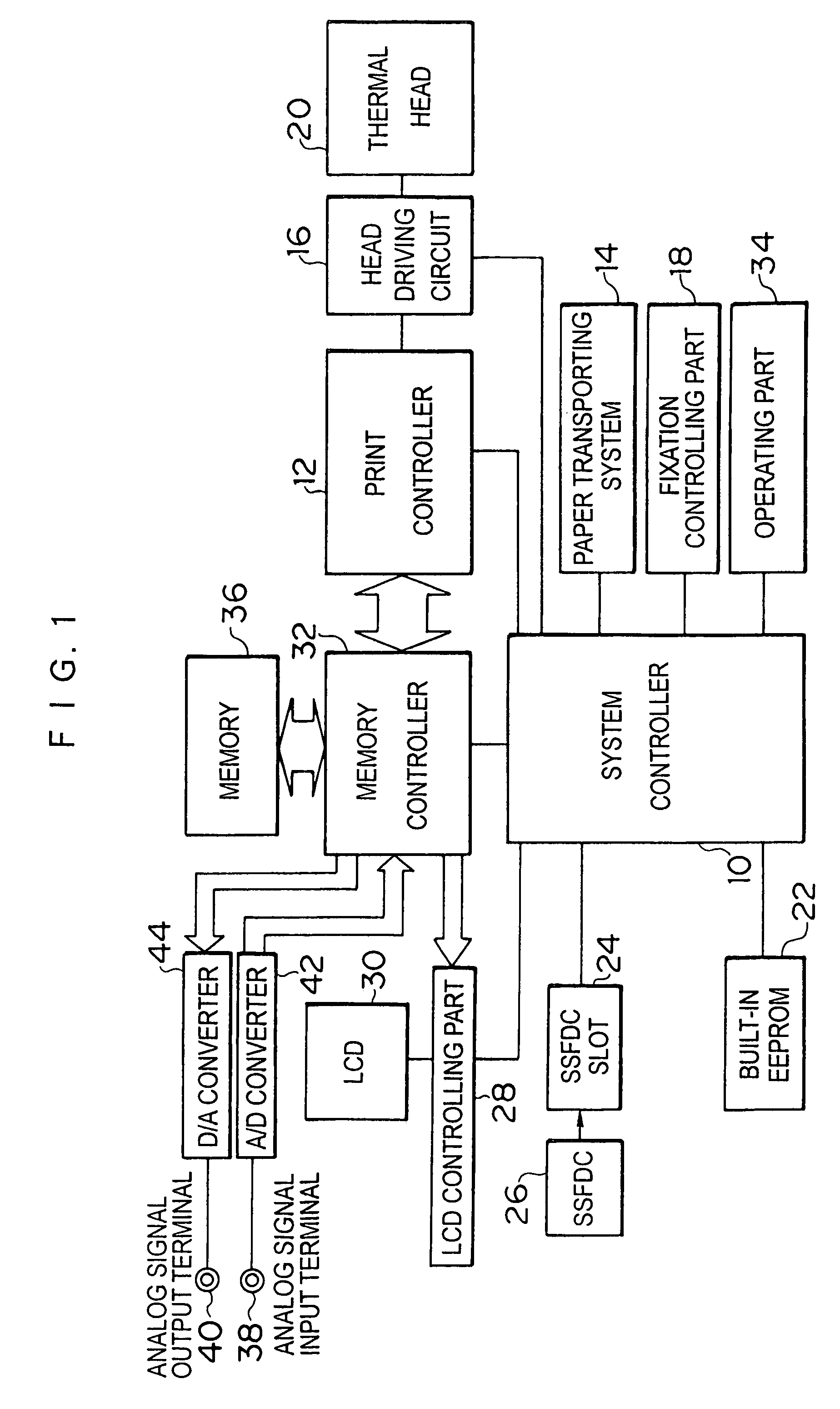

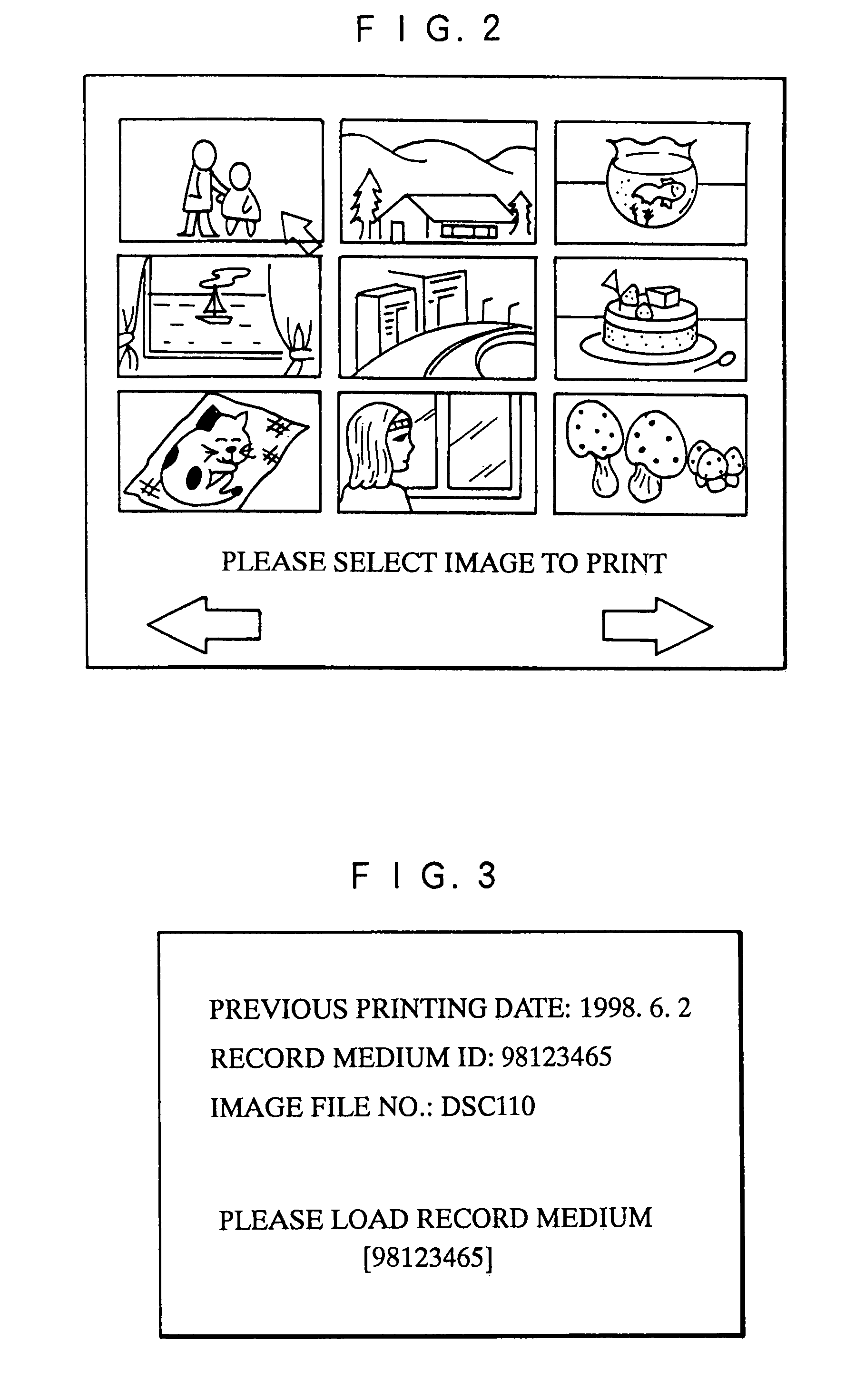

Printer

InactiveUS7031005B1Fast imagingEfficiently findDigitally marking record carriersDigital computer detailsComputer hardwareThumbnail Image

The present invention provides a printer which can efficiently find the desired image printed before and which can print the image quickly. The printer of the present invention has a memory installed, and the information related to the image printed before is recorded in the memory as job information. For example, a thumbnail image, a number of image files, an ID number for the SSFDC in which the image file is recorded, and so forth, are recorded as the job information. Referring to the job information, a user can efficiently find the image desired to be reprinted and the file in which the image is recorded, and quickly reprint the image.

Owner:FUJIFILM HLDG CORP +1

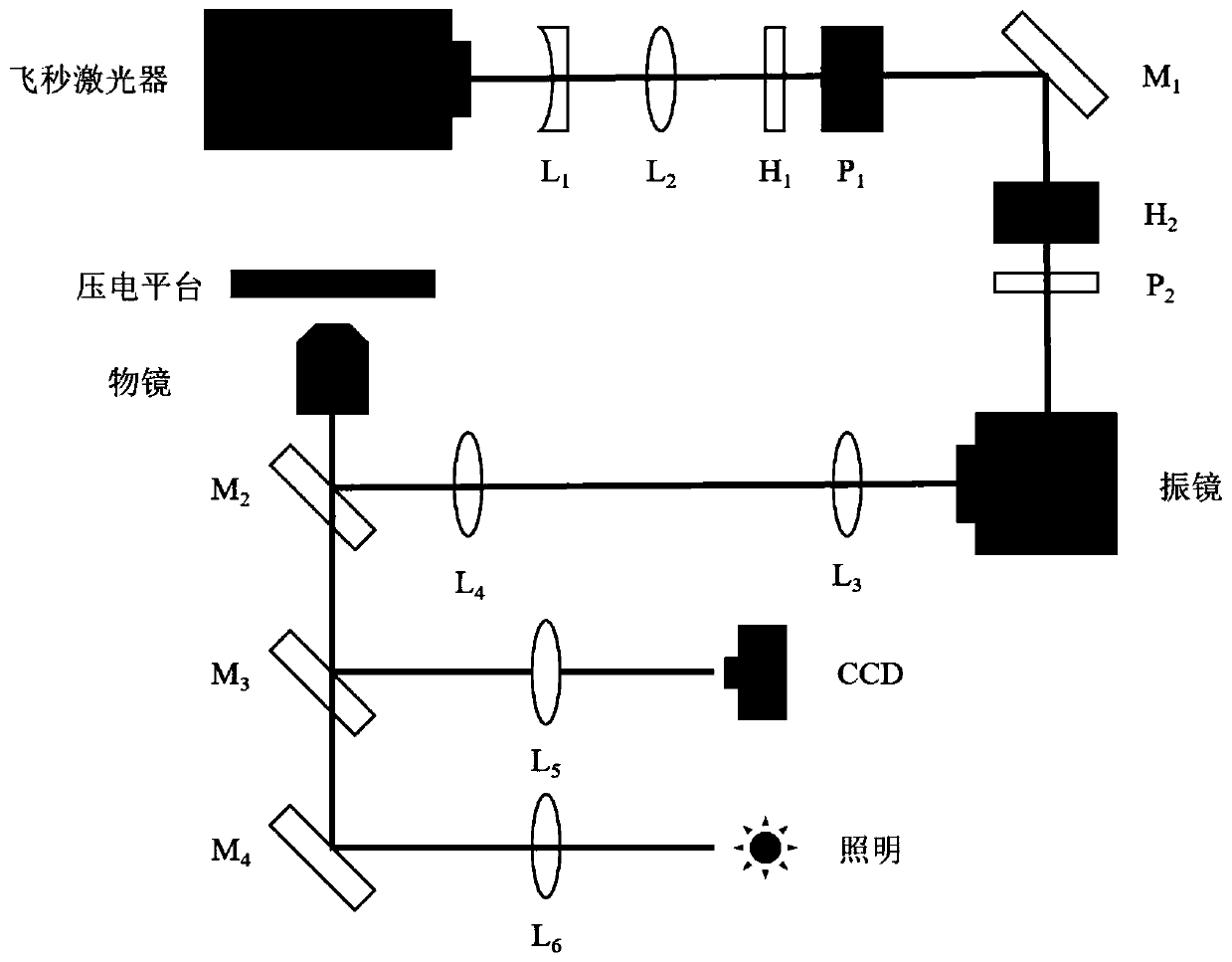

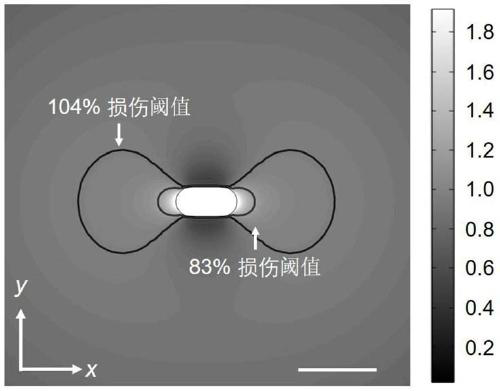

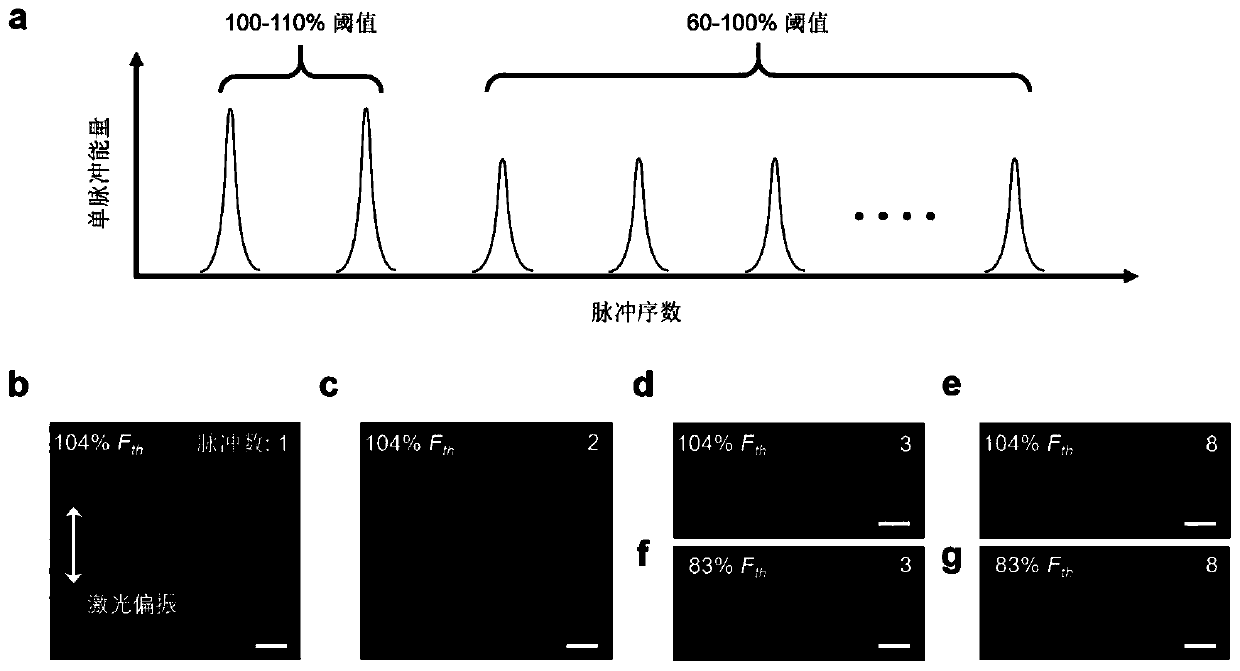

Method for carrying out nanometer precision preparation by using femtosecond laser

ActiveCN111168232AStrong processing compatibilityReduce manufacturing costLaser detailsPolarising elementsNano structuringGrating

The invention discloses a method for carrying out nanometer precision preparation by using femtosecond laser, and belongs to the technical field of laser processing. According to the method, an initial damage nanopore formed through femtosecond laser multi-photon excitation is taken as a seed structure, energy and polarization states of subsequent laser pulses are regulated in real time, uniform and directional optical near-field enhancement is generated near the seed structure, finally high-precision removal of processed material is achieved, and due to high localization of near-field light spot energy in space, femtosecond laser pulses with a wavelength of 800 nm are utilized to achieve the processing precision of the thinnest 18 nm line width, and a resolution ratio reaches 1 / 40 of thewavelength. According to the method for carrying out nanometer precision preparation by using the femtosecond laser, a vacuum environment is not needed, the method has good atmosphere / solution processing compatibility, and rapid printing of a large-area periodic micro-nano structure can be carried out by combining parallel deposition of the seed structure and grating scanning, so that the manufacturing cost of a device can be effectively reduced, and the method is more suitable for industrial production.

Owner:JILIN UNIV

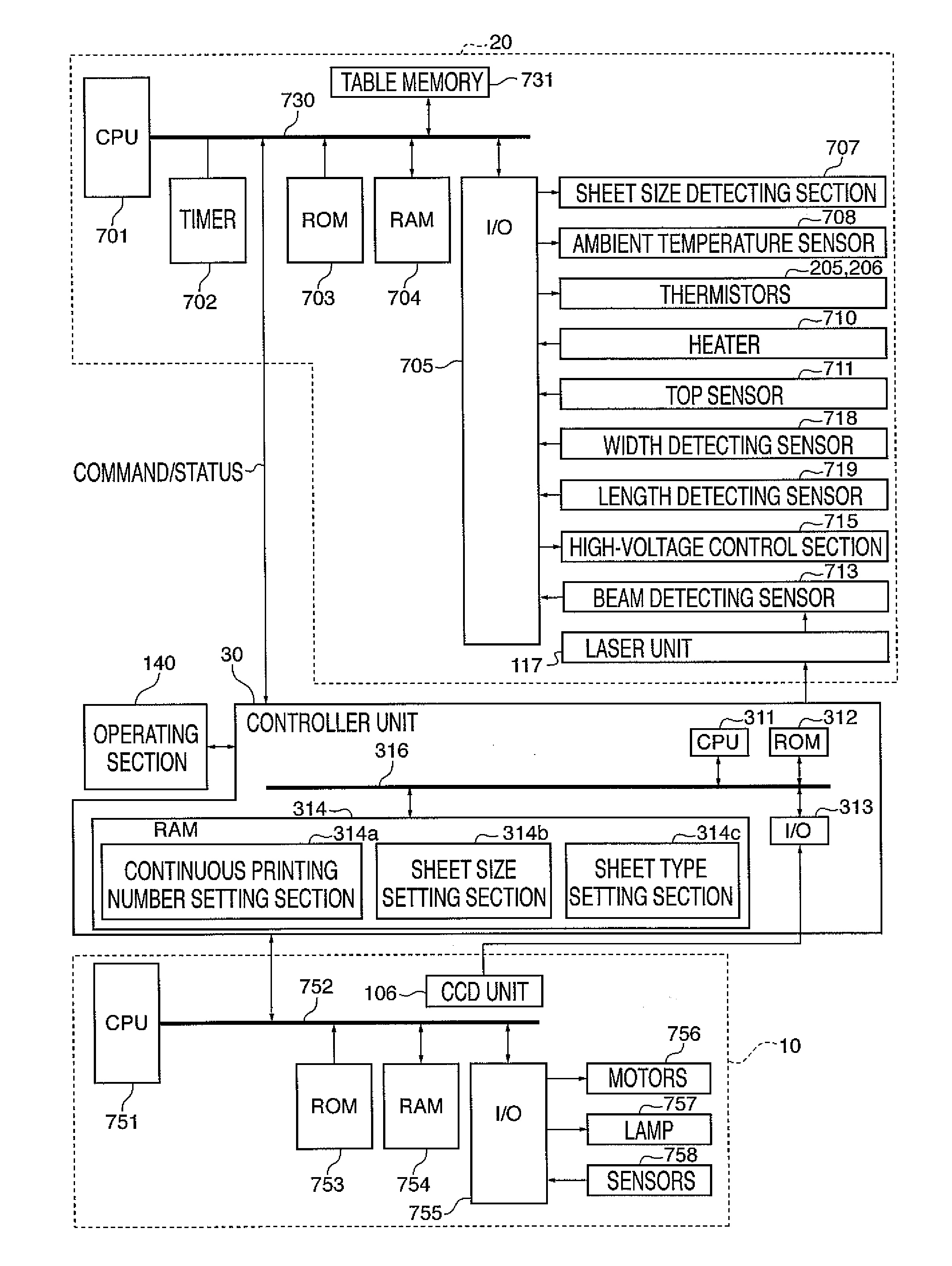

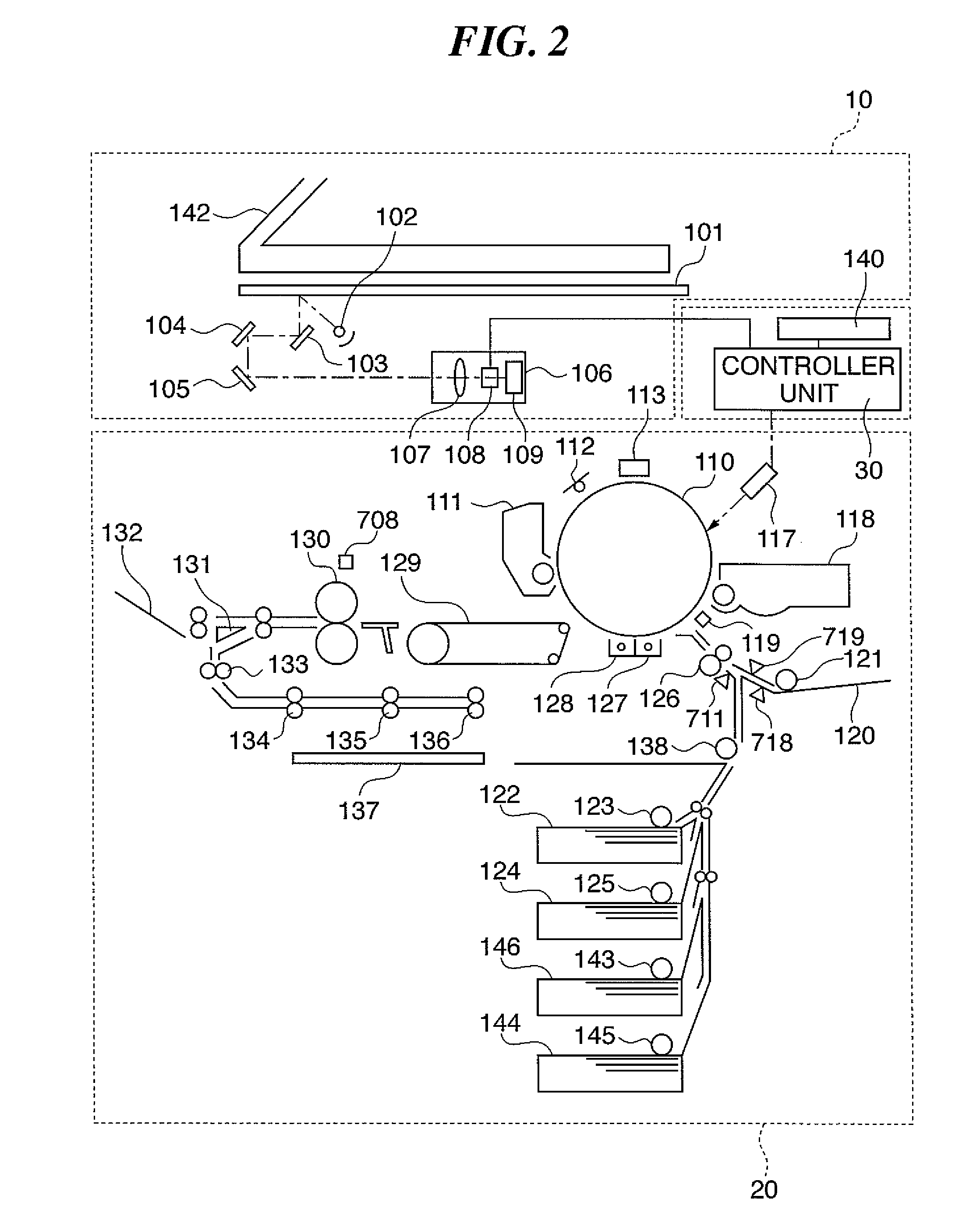

Image forming apparatus, recording material conveying method, program for implementing the method, and storage medium storing the program

InactiveUS20070071468A1Avoid temperature riseFast printElectrographic process apparatusImage formationThroughput

An image forming apparatus which can prevent a temperature increase at predetermined locations of a fixing unit and also realize the fastest printing with respect to each continuous printing number. The image forming apparatus includes a fixing unit that fixes an image supported on a recording material passing through the nip section, and a conveying unit that conveys the recording material to the fixing unit at a throughput representing the number of recording materials conveyed to the fixing unit per unit time. The printing number is set in continuous printing on the recording materials, and the size of the recording material is acquired. Nearly the highest throughput is set as the predetermined throughput based on the set printing numbers and the acquired size of the recording material so that the continuous printing is completed before a temperature at predetermined locations in the fixing unit reaches an upper limit.

Owner:CANON KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com