Patents

Literature

924results about How to "Extended drying time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

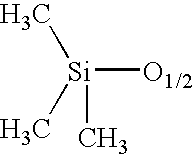

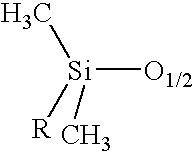

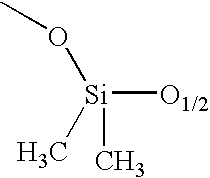

Compositions containing a silicone resin film former and a silicone-containing copolymer

Owner:LOREAL SA

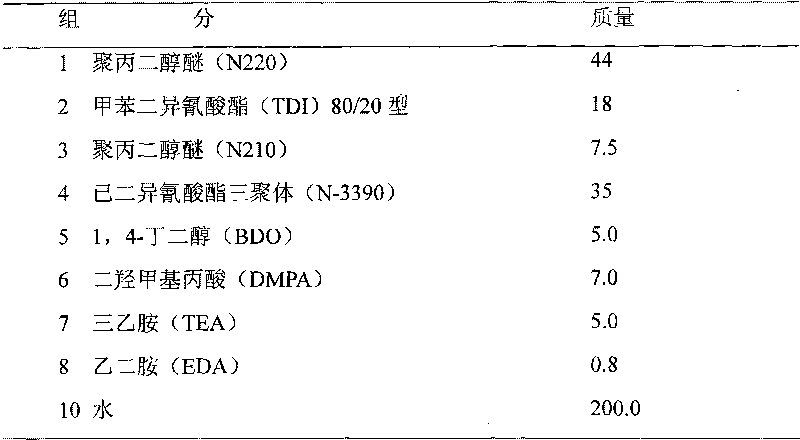

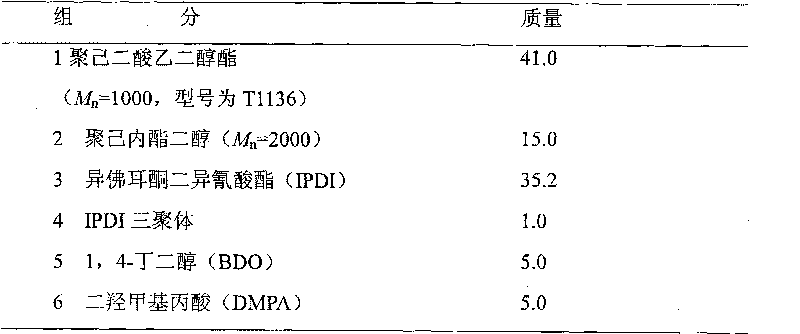

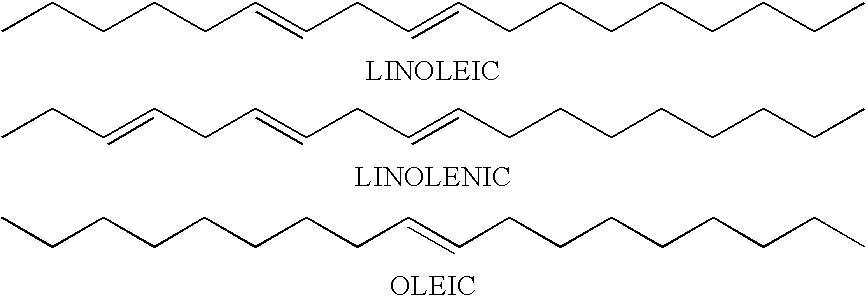

Preparation method and application of modified polyurethane aqueous dispersions of polyisocyanate curing agents

InactiveCN101696262ASimple processEasy to operatePolyurea/polyurethane coatingsLeather surface finishingPolyesterSolvent

The invention discloses a preparation method and application of modified polyurethane aqueous dispersions of polyisocyanate curing agents. The preparation method comprises the following steps of: carrying out prepolymerization reaction by using polyester polyol, vulcabond monomer and a polyisocyanate curing agent; reacting with a hydrophilic chain-extending agent and a micro-molecule chain-extending agent to obtain polyurethane prepolymer containing hydrophilic groups (carboxyl or sulfonic groups) and isocyanate(NCO)-terminated groups; neutralizing the polymer into salt, and then dispersing the salt into water; and preparing the modified polyurethane aqueous dispersions of the polyisocyanate curing agents by the chain extending of a polyamine chain-extending agent. The modified polyurethane aqueous dispersions of the polyisocyanate curing agents have self-crosslinking function at room temperature, and the self-crosslinking density is over 85%. Compared with non-modified polyurethane aqueous dispersions prepared under the same condition, the modified polyurethane aqueous dispersions have superior film forming property, water resistance, alcohol resistance, pollution resistance, cold resistance, dry / wet rubbing resistance and chemical solvent resistance; and coating films have especially high drying speed, high hardness increment speed and high final hardness.

Owner:SOUTH CHINA UNIV OF TECH

Water-based coating composition, preparation method thereof and method for taking water-based coating composition as strippable coating protective film

InactiveCN102127345AFast dryingImprove drying speed at room temperatureAnti-corrosive paintsPolyurea/polyurethane coatingsWater basedEmulsion

The present invention relates to a method for forming a strippable coating protective film using a water-based coating composition. The method comprises the following steps: the water-based coating composition is applied to a body surface to form a strippable coating protective film. The water-based coating composition takes synthesized resin emulsion as a substrate and takes water as a dispersion medium. When the water-based coating composition prepared by adopting the method is applied to the surface of an object, the strippable coating protective film can be formed. The formed strippable coating protective film has the advantages of excellent combination property, environmental friendliness, fast drying at normal temperature, wide strippable temperature range and high stripping property.

Owner:WUHAN JIHENG NEW MATERIAL TECH

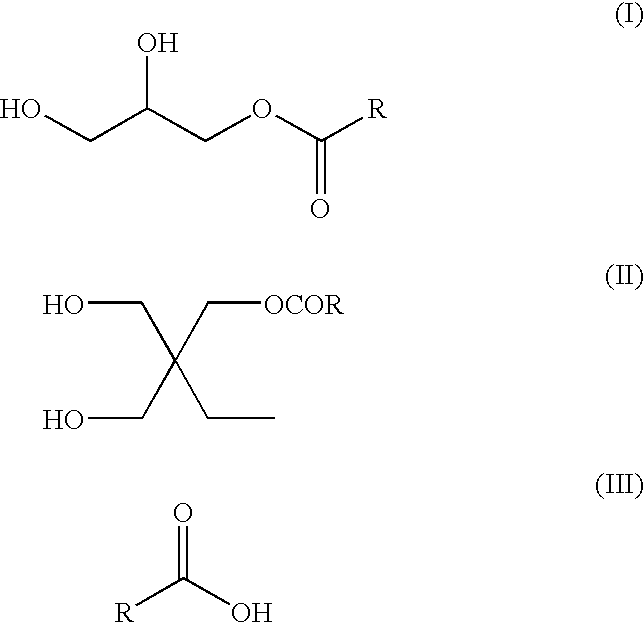

Acrylate-functional alkyd resins having improved dry time

InactiveUS6946509B2Extended drying timeHigh in calciumEngine sealsSynthetic resin layered productsDesiccantCalcium content

An acrylate-functionalized alkyd coating composition is disclosed having improved dry time. The compositon includes an acrylate-functionalized alkyd resin, a solvent, and a drier package that provides the composition with a cobalt content of at least 0.01 wt %, based on binder solids content, and a calcium content of from 0.15 wt % to 5 wt %, based on the binder solids content. The drier mixture disclosed results in the coating composition having improved dry time when compared with similar coating compositions using conventional drier packages.

Owner:PCCR USA

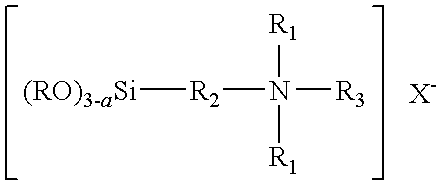

Stable aqueous solutions of silane quat ammonium compounds

InactiveUS20100028462A1Stable and long lifeEfficient use ofBiocideInorganic active ingredientsAmmonium compoundsSilanes

Stable aqueous compositions of silane quaternary ammonium compounds are provided by diluting an alkanol solution of the silane quaternary ammonium compound in water with at least one nonionic surfactant. The weight ratio of the silane quaternary ammonium compound and nonionic surfactant is provided to yield a composition which can remain stable in dilute aqueous compositions, can be applied to any surface and dry quickly to provide an anti-microbial film. The addition of an alkali metal bicarbonate salt to the composition improves the anti-microbial properties as well as the drying time of the composition.

Owner:CHURCH & DWIGHT CO INC

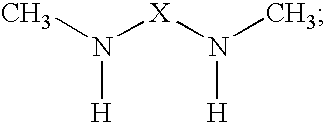

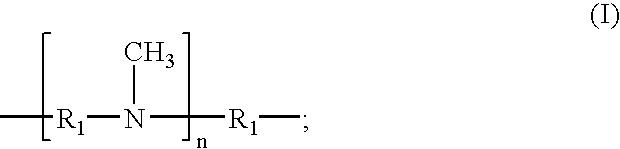

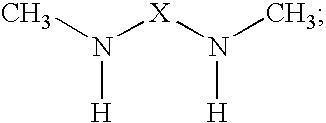

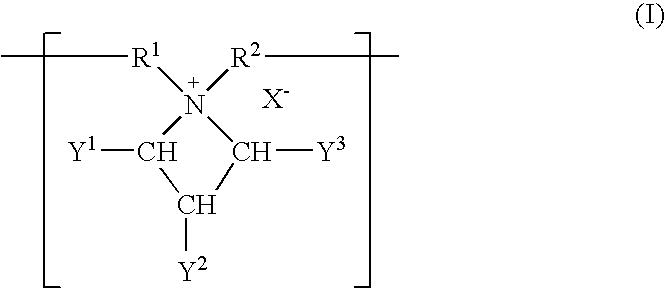

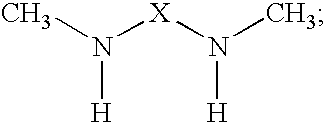

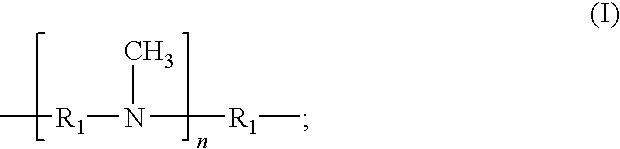

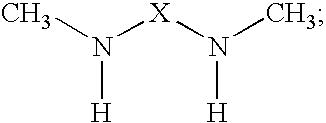

Curing agent for low temperature cure applications

InactiveUS20080194776A1Extended drying timeRapid hardness developmentThin material handlingEpoxyLow temperature curing

The present invention provides N,N′-dimethyl secondary diamine polymers including methylamine-terminated poly-(N-methylazetidine) and methylamine-terminated poly-(N-methylazacycloheptane). Amine compositions and amine-epoxy compositions comprising N,N′-dimethyl secondary diamine polymers are also disclosed.

Owner:EVONIK DEGUSSA GMBH

Inks containing glycol ethers and specific polymers for dry time and bleed improvements in ink-jet printing inks

InactiveUS6300391B2Faster rateImprove performanceDuplicating/marking methodsInksPH-sensitive polymersGlycol ethers

The ink set of this invention comprises at least two inks, one of which contains a pH sensitive polymer, a glycol ether, and preferably a self-dispersing pigment colorant. A second ink is provided which comprises incompatible inorganic or organic salts or has an appropriate pH. The polymer precipitates onto a medium upon contact with the second ink, thereby providing improved dry time as well as bleed and halo control.

Owner:HEWLETT PACKARD DEV CO LP

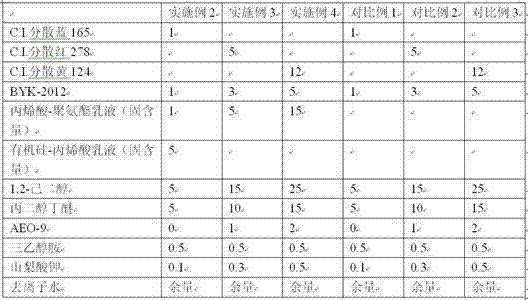

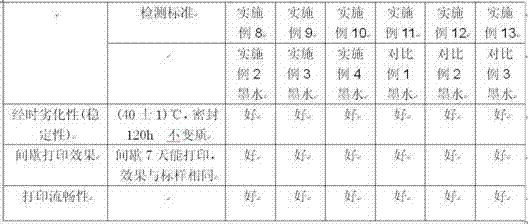

Water-based pigment ink for quality improvement

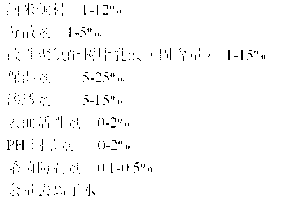

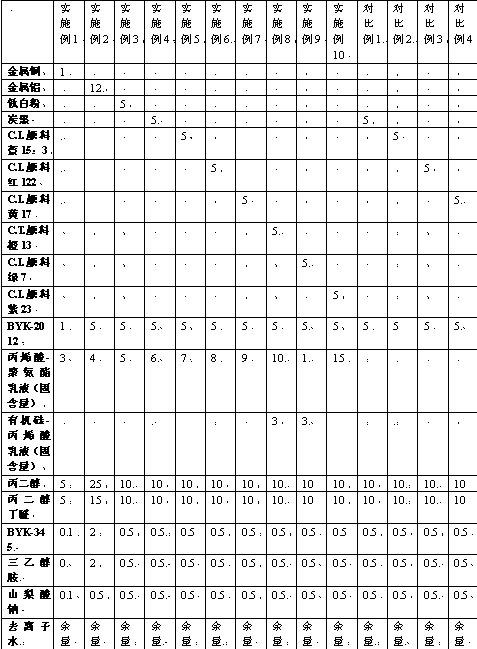

A water-based pigment jet ink comprises 1-12wt% of a nanopigment, 1-5wt% of a dispersant, 1-15wt% of a modified polyurethane resin emulsion (solid content), 5-25wt% of a humectant, 5-15wt% of an osmotic agent, 0-2wt% of a surfactant, 0-2wt% of a PH adjusting agent, 0.1-0.5wt% of a sterilization antiseptic, and the balance deionized water. The ink has the advantages of excellent preservation stability and printing smoothness, particle nanometer level, complete chromatogram, substantially increased comprehensive properties comprising the light resistance, the water resistance, the chemical resistance, the scratch resistance, high brightness, the high and low temperature resistances, the ageing resistance and the like, and application range enlargement.

Owner:深圳市凌普鑫科技有限公司

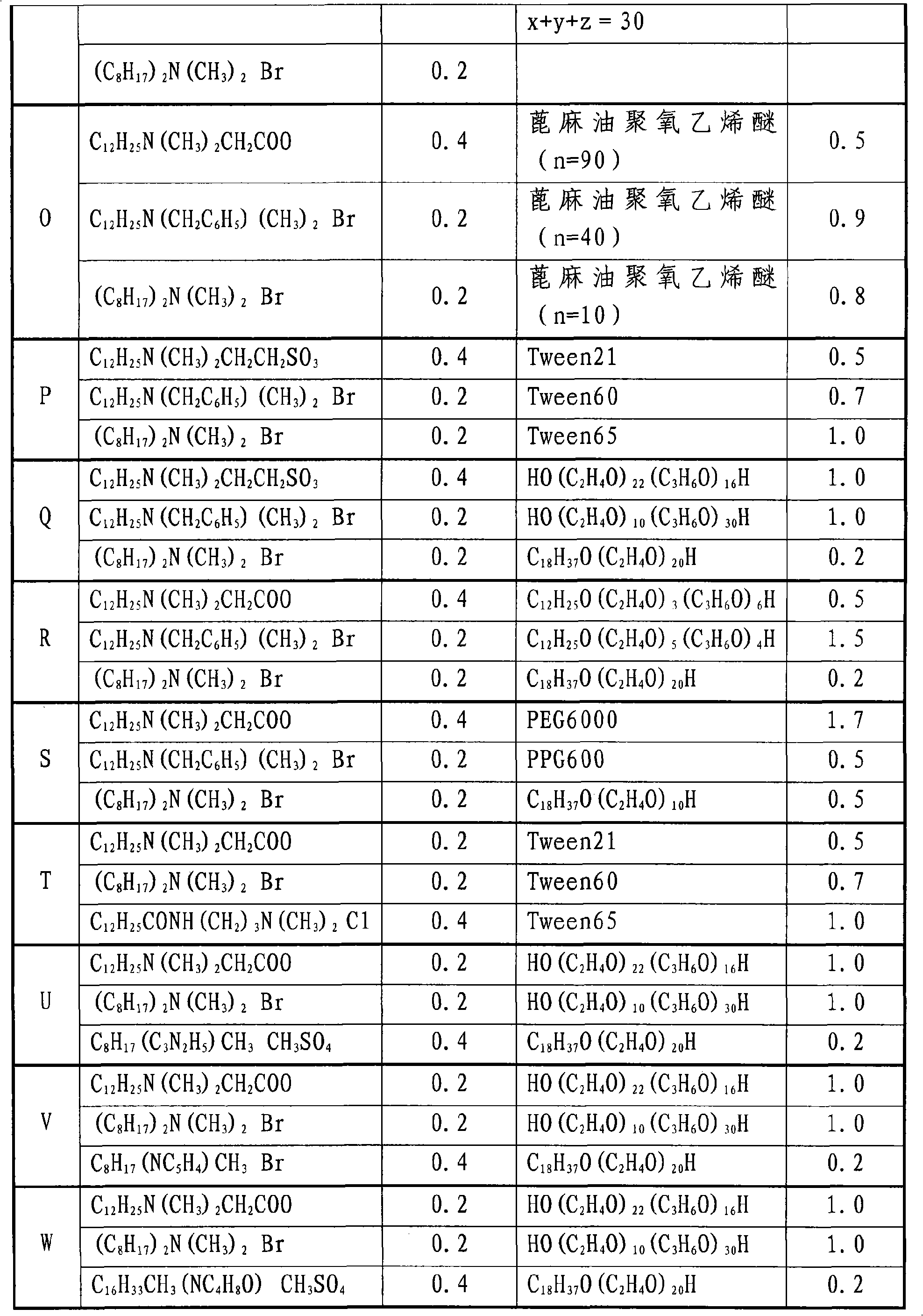

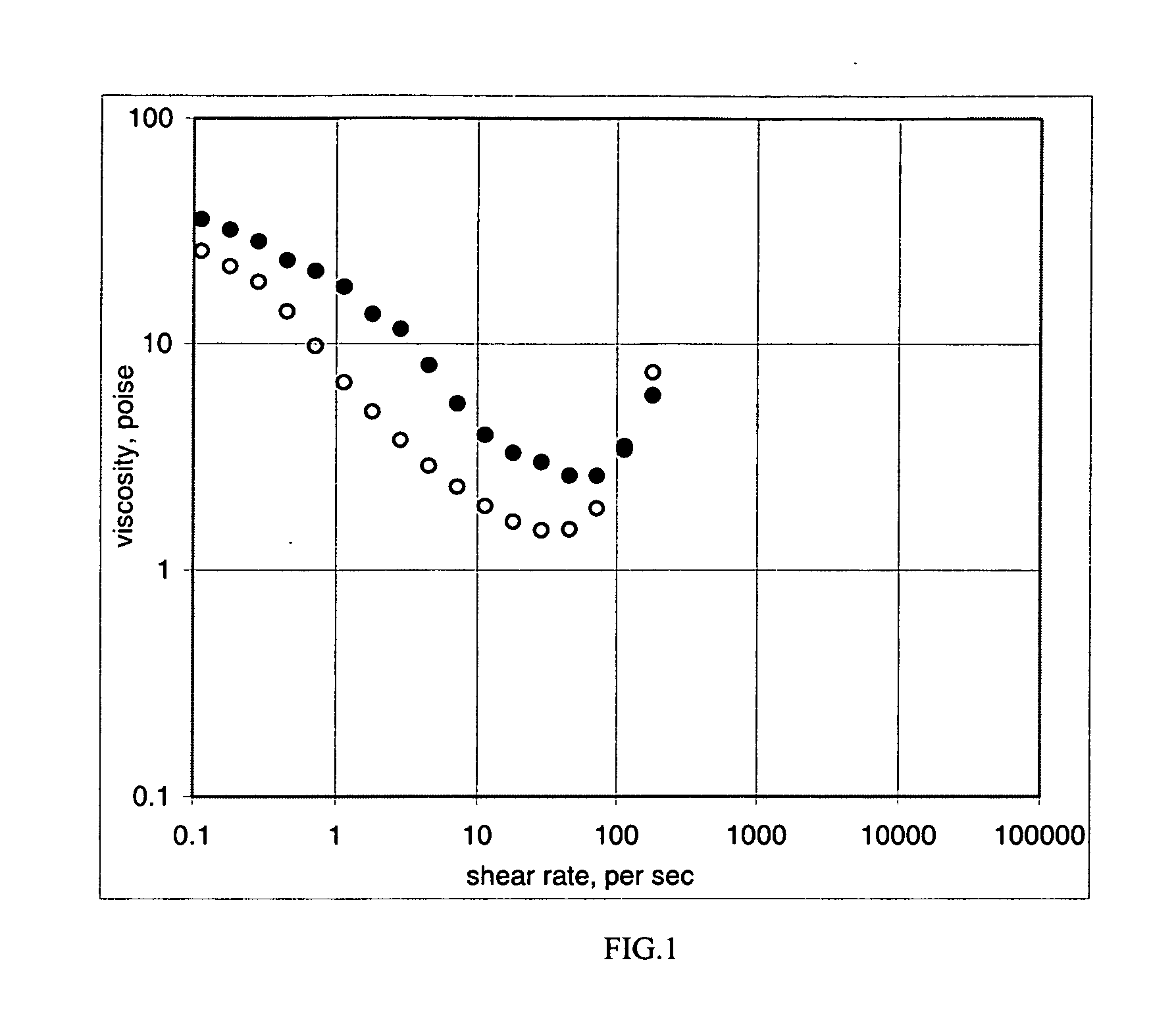

Multifunctional assistant plating additive for hot dip plating process, preparation and use method thereof

ActiveCN101328568AReduce lossImprove stabilityHot-dipping/immersion processesDissolutionLiquid metal

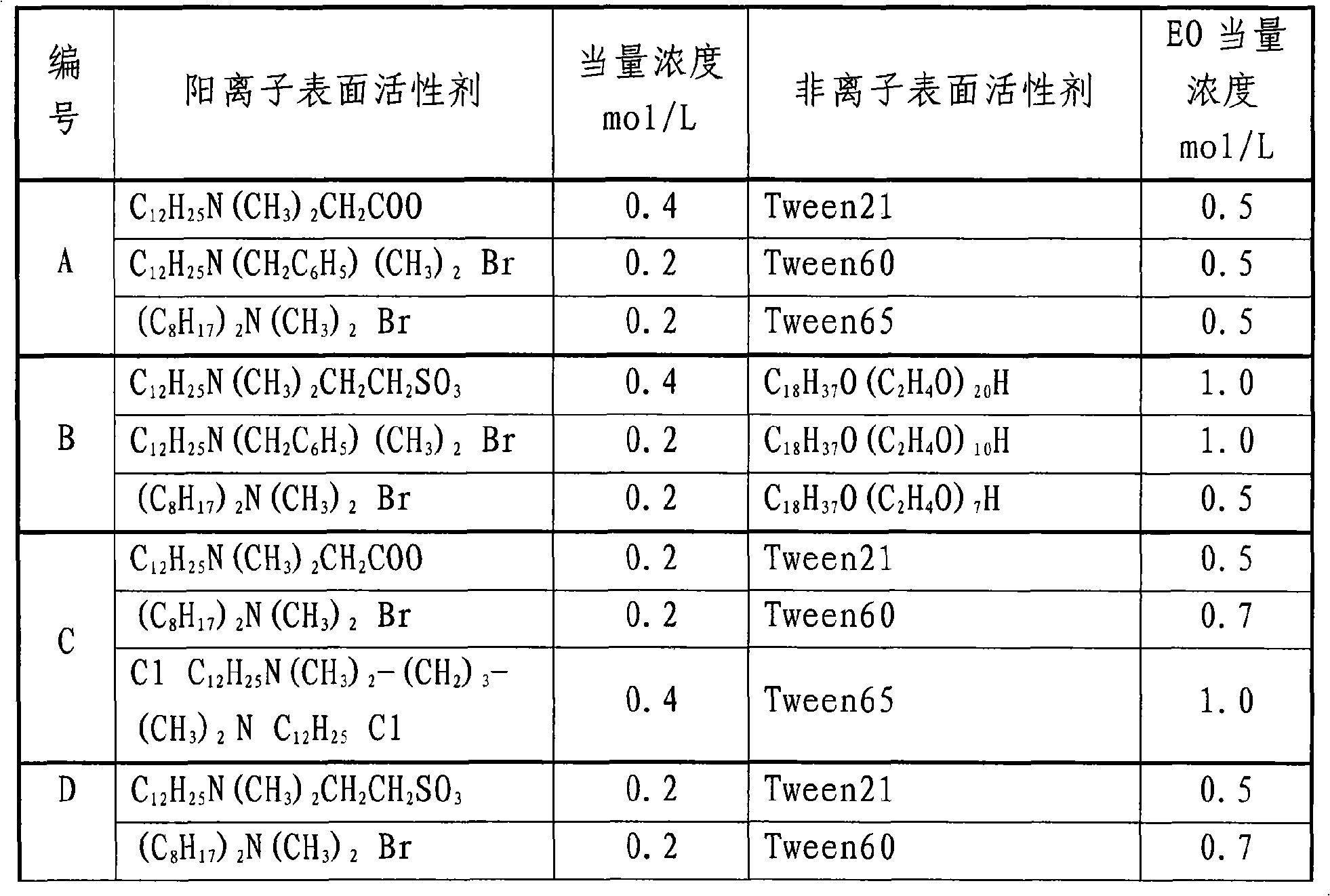

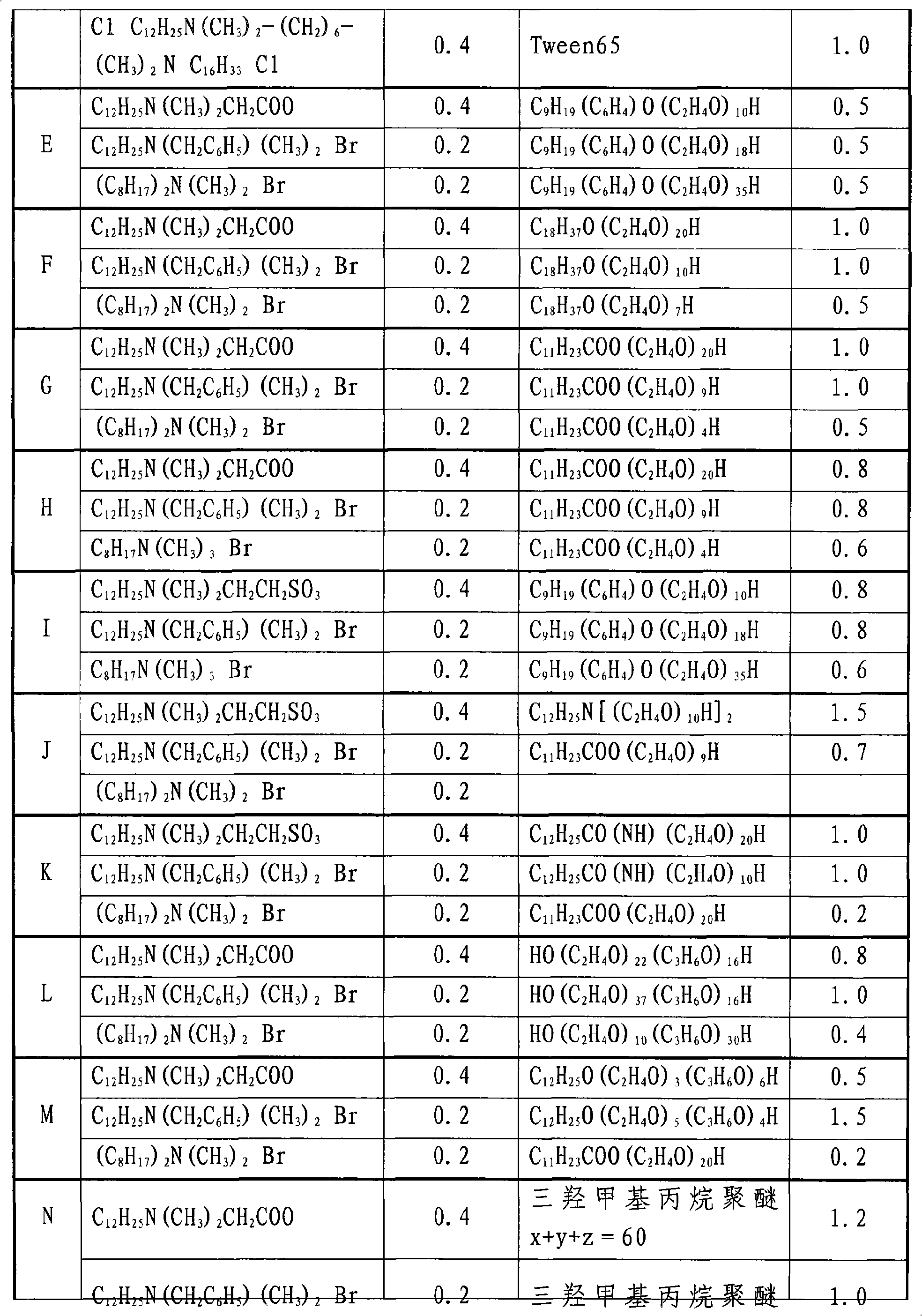

The invention relates to a multifunctional plating assisting additive for a hot dipping metallization process and a preparation and application method thereof, and belongs to the metal material anticorrosive technical field for providing multiple plating assisting efficacy. The technical proposal of the invention comprises that: a plurality of cations or an amphoteric surfactant ( an equivalent concentration of a quaternary ammonium group is between 0.1 and 2 mol / L) and nonionics (an equivalent concentration of a polyoxyethylene group is between 0.5 and 5 mol / L) are dissolved in deionized water. The method can improve the wetting quality between a liquid-state metal and a workpiece, and the adhesive uniformity and continuity of the plating assisting additive, reduces the drying time, prevents the liquid-state metal from falling and splashing, shortens the dipping and plating time, saves raw materials, improves a residue form, reduces an ash content, increases an ash discharge speed, isolates air, stops oxidation, disperses residual dirt and is suitable for a plurality of processes of hot galvanizing, hot plating zinc-aluminum alloy, hot plating aluminum, etc. The preparation steps comprise dissolution, cubage determination, cooling, keeping stand and filling; when the multifunctional plating assisting additive is used, the multifunctional plating assisting additive is directly added into a plating assisting additive solution and is evenly stirred.

Owner:JIANGSU FEITUO INTERFACE ENG TECH CO LTD

Inkjet recording media

InactiveUS20070218222A1Increase ink capacityExtended drying timeDuplicating/marking methodsPrecipitated calcium carbonateRecording media

The invention relates generally to the field of inkjet recording media and inkjet printing methods. More specifically, the invention relates to a porous base layer of an inkjet recording element, the base layer comprises precipitated calcium carbonate having scalenohedral morphology and ground calcium carbonate.

Owner:EASTMAN KODAK CO

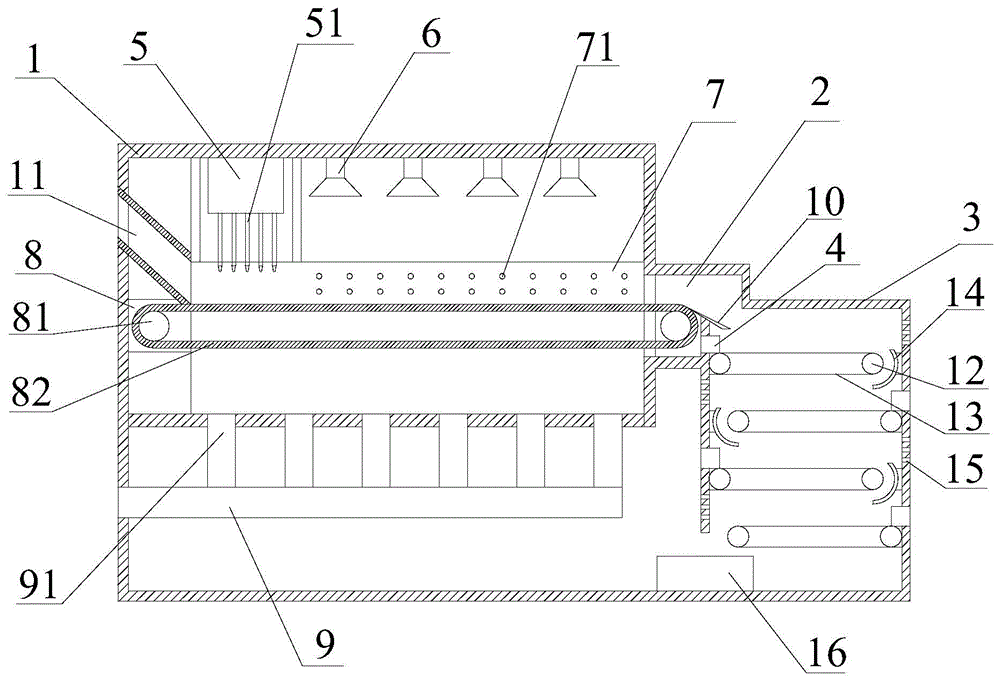

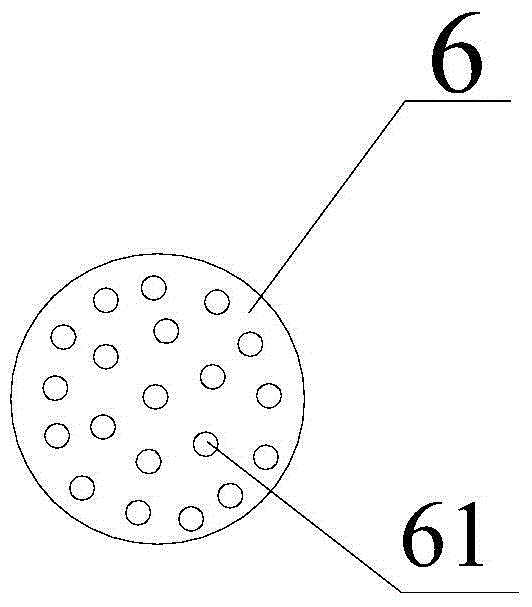

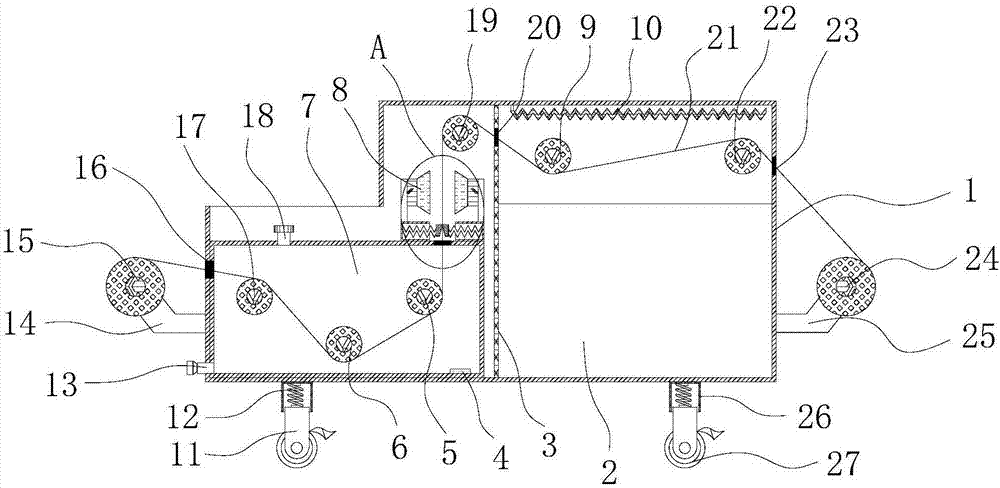

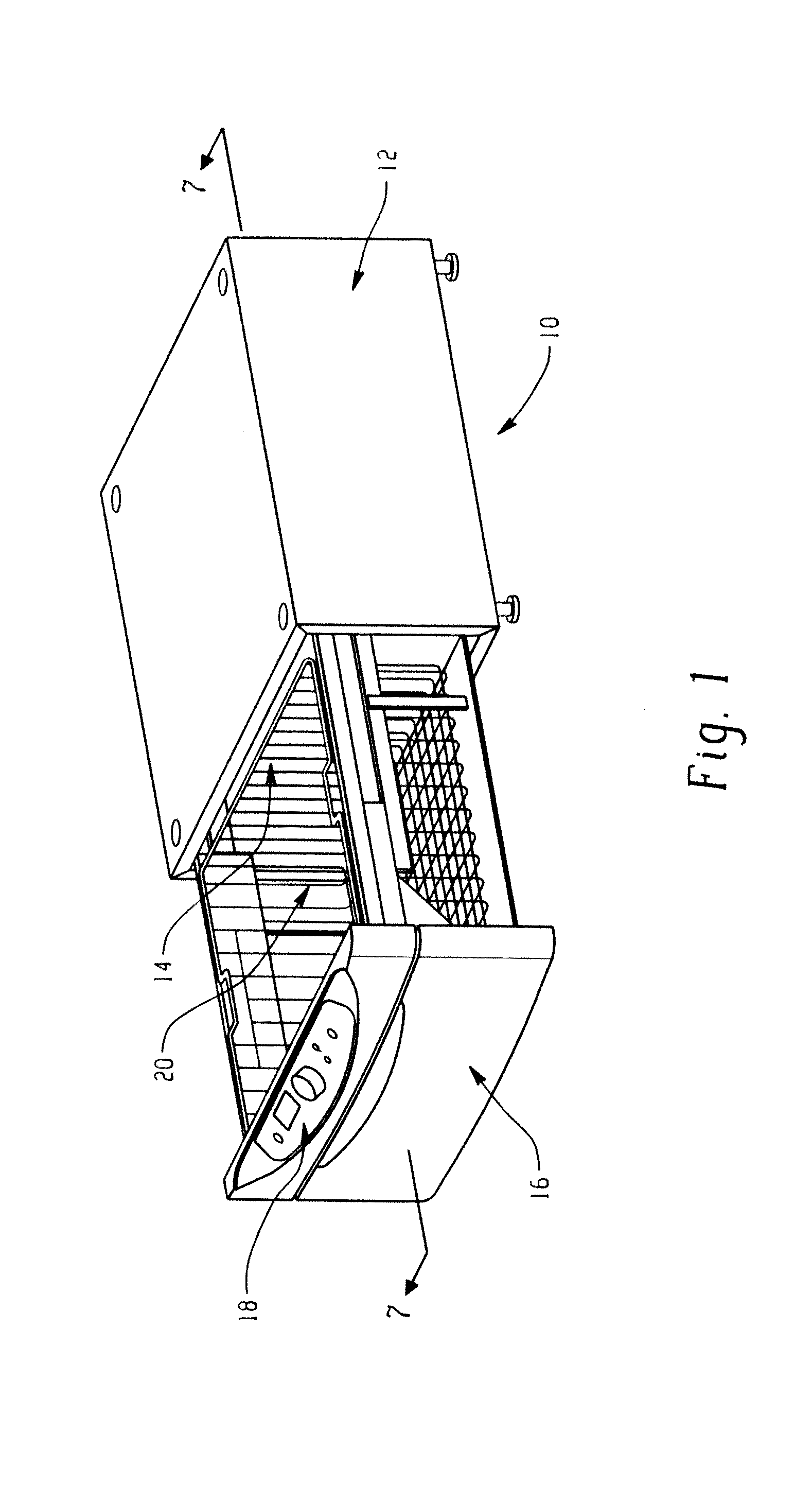

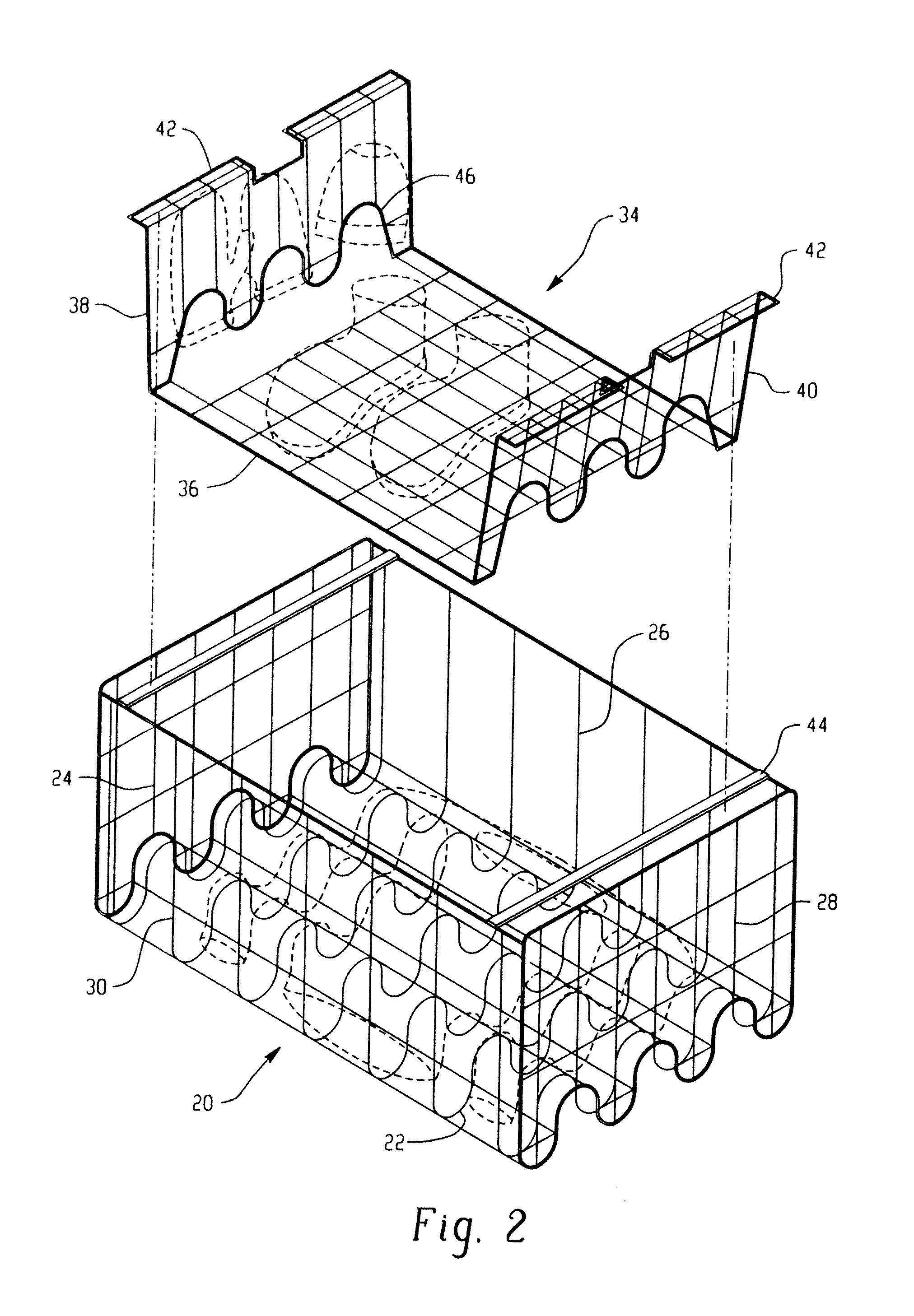

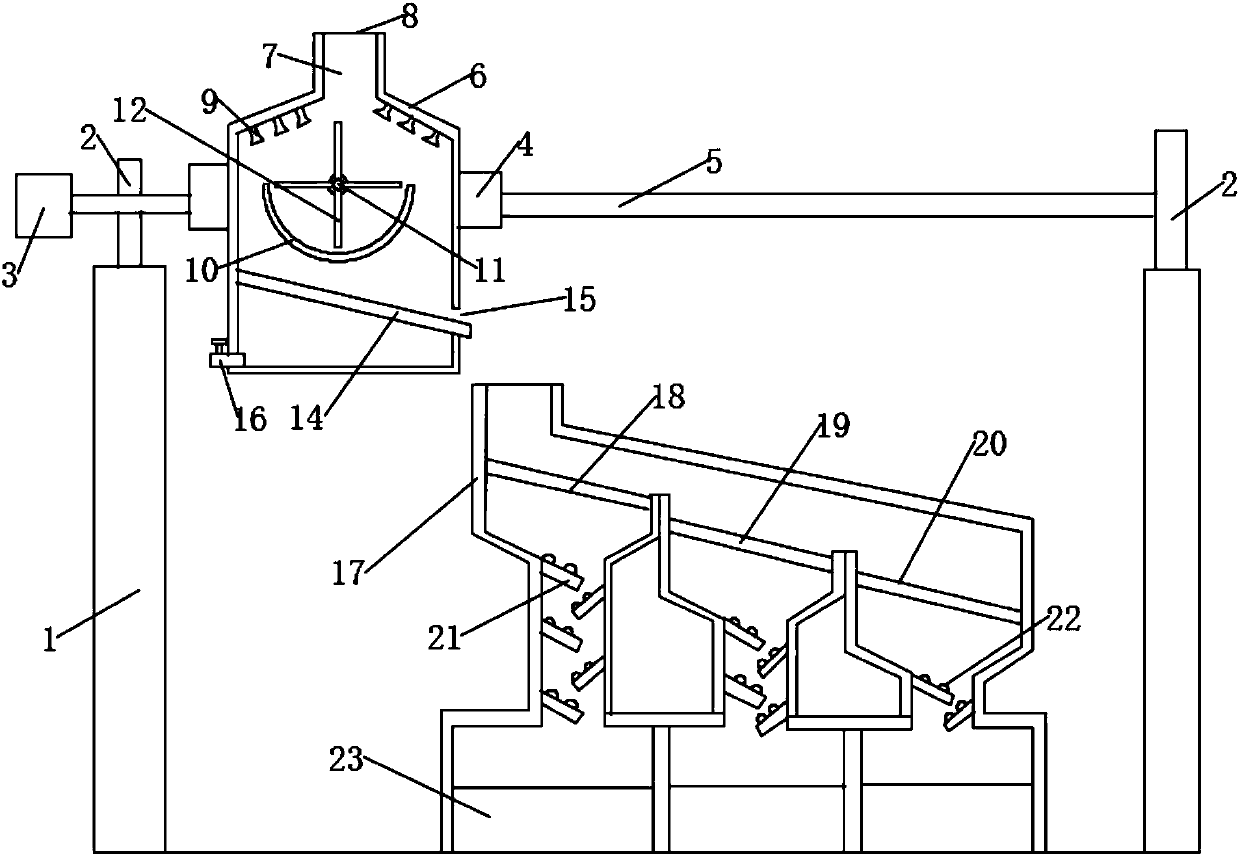

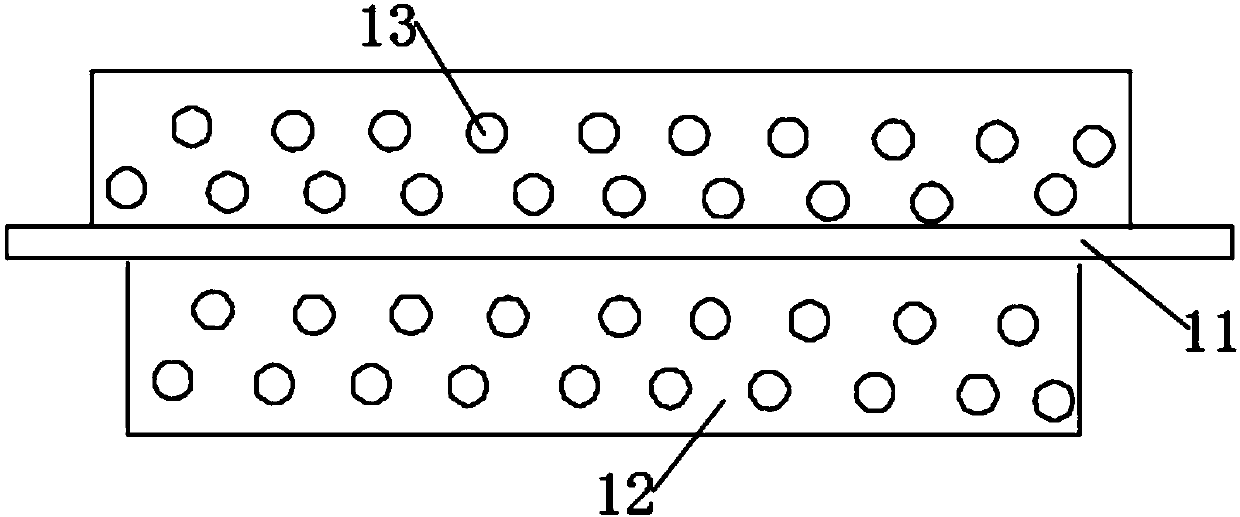

Bearing washing and drying integration device

InactiveCN104550087AReduce the intensity of manual operationImprove work efficiencyDrying gas arrangementsDrying machines with progressive movementsHigh pressureProduction effect

The invention discloses a bearing washing and drying integration device. The bearing washing and drying integration device comprises a washing machine body, a connecting part and a drying machine body, wherein the washing machine body and the drying machine body are communicated with each other through the connecting part to form a whole body, the washing machine body comprises a washing liquid storage box, a high pressure spray head, a baffle plate, a transmission device and a water discharge device, the transmission device is installed inside the washing machine body, the tail end of the transmission device is arranged on the junction of the connecting part and the drying machine body, a discharge baffle plate is arranged in the connecting part, the drying machine body comprises a drying device, conveyor belts, a roller, steering devices and a receiving box, four conveyor belts are arranged inside the drying machine body, each conveyor belt is installed on the roller, the drying device is correspondently installed on the junction of each conveyor belt and the drying machine body, and the steering device is arranged on the steering position of each conveyor belt. By adopting the bearing washing and drying integration device, the washing and drying of a bearing can be completed in one machine, so that the working efficiency is improved, the production effect of the bearing is guaranteed, and the floor occupation area of the machine is reduced.

Owner:XINCHANG LONG HAO BEARING CO LTD

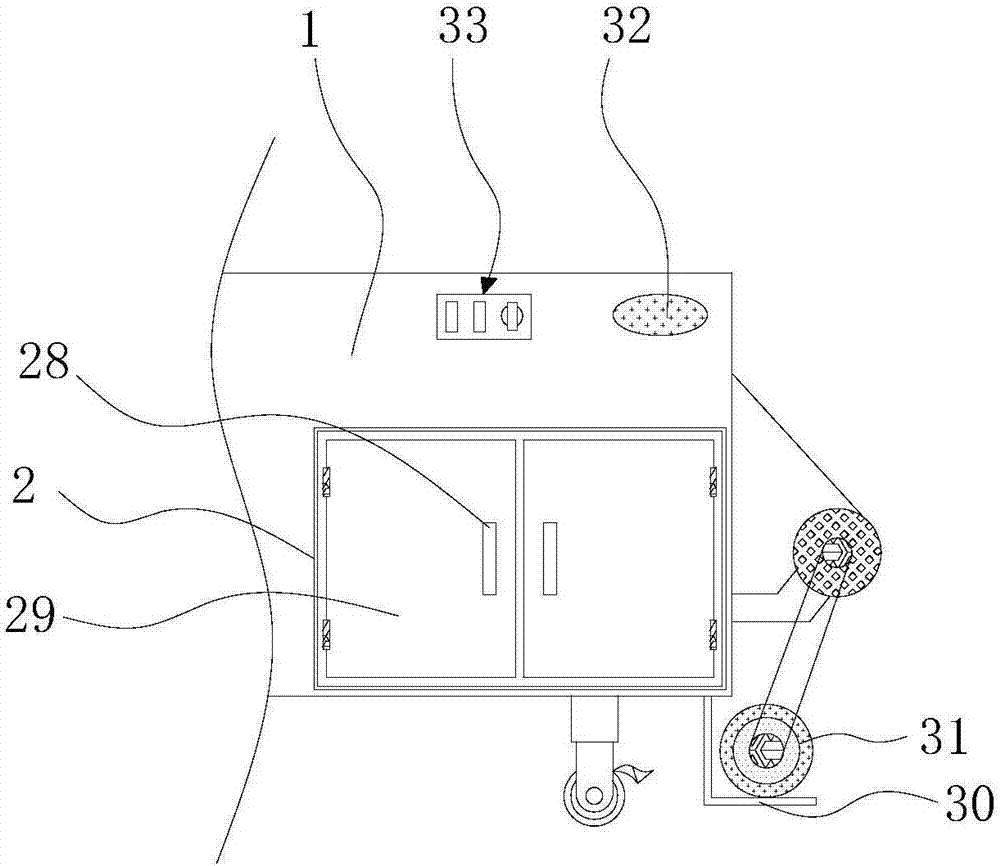

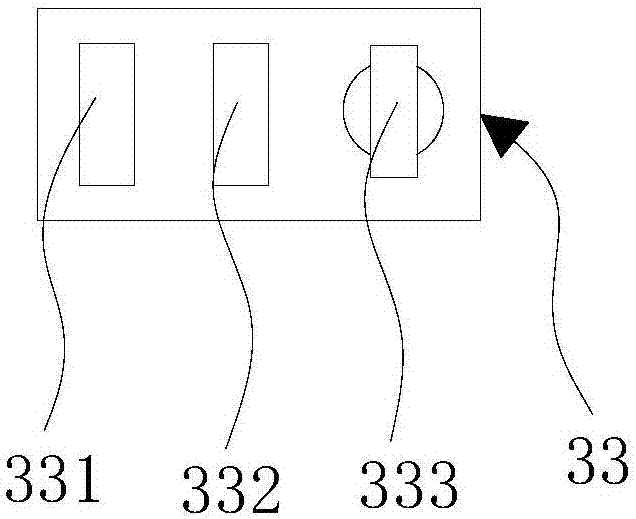

Textile dyeing device

InactiveCN106968069AExtended drying timeGuarantee normal dyeing workTextile treatment machine arrangementsLiquid/gas/vapor removal by gas jetsEngineeringDrying time

The invention discloses a textile dyeing device, comprising a box body, a dye box is fixedly installed at the left end of the bottom of the inner cavity of the box, and a first drive roller is movably installed at the upper left end of the inner cavity of the dye box. The lower end of the cavity is movably installed with a second transmission roller, the upper right end of the inner cavity of the dye box is movably installed with a third transmission roller, the right end of the upper surface of the dye box is provided with a second through hole, and the right end of the bottom of the inner cavity of the dye box is provided with a second through hole. A pressure sensor is fixedly installed. In the invention, the scraper is movably connected to the inner cavity of the second sleeve through the second spring, which can scrape off the dye adhering to the surface of the dyed fabric after dyeing. The fabric is air-dried, which solves the problem that a large amount of dye will adhere to the surface of the fabric during the dyeing process of the existing fabric dyeing machine, which not only prolongs the drying time of the fabric after dyeing, but also causes the waste of dye.

Owner:湖州梦源环保科技有限公司

Method for preparing hydroxypropyl-beta-cyclodextrin

ActiveCN102040675AWill not cause decompositionLow impurity contentMacromolecular non-active ingredientsNanofiltrationPharmaceutic Adjuvant

The invention discloses a method for preparing hydroxypropyl-beta-cyclodextrin, which comprises the steps of etherification, neutralization, decoloring, nanofiltration, resin purification, and spray drying. The method of the invention is small in pollution, and the yield in weight is more than 80 percent; meanwhile, the product prepared by using the method of the invention is narrow in substituted ratio range and low in impurity content, and can be used as a pharmaceutic adjuvant.

Owner:石药集团中诺药业(石家庄)有限公司

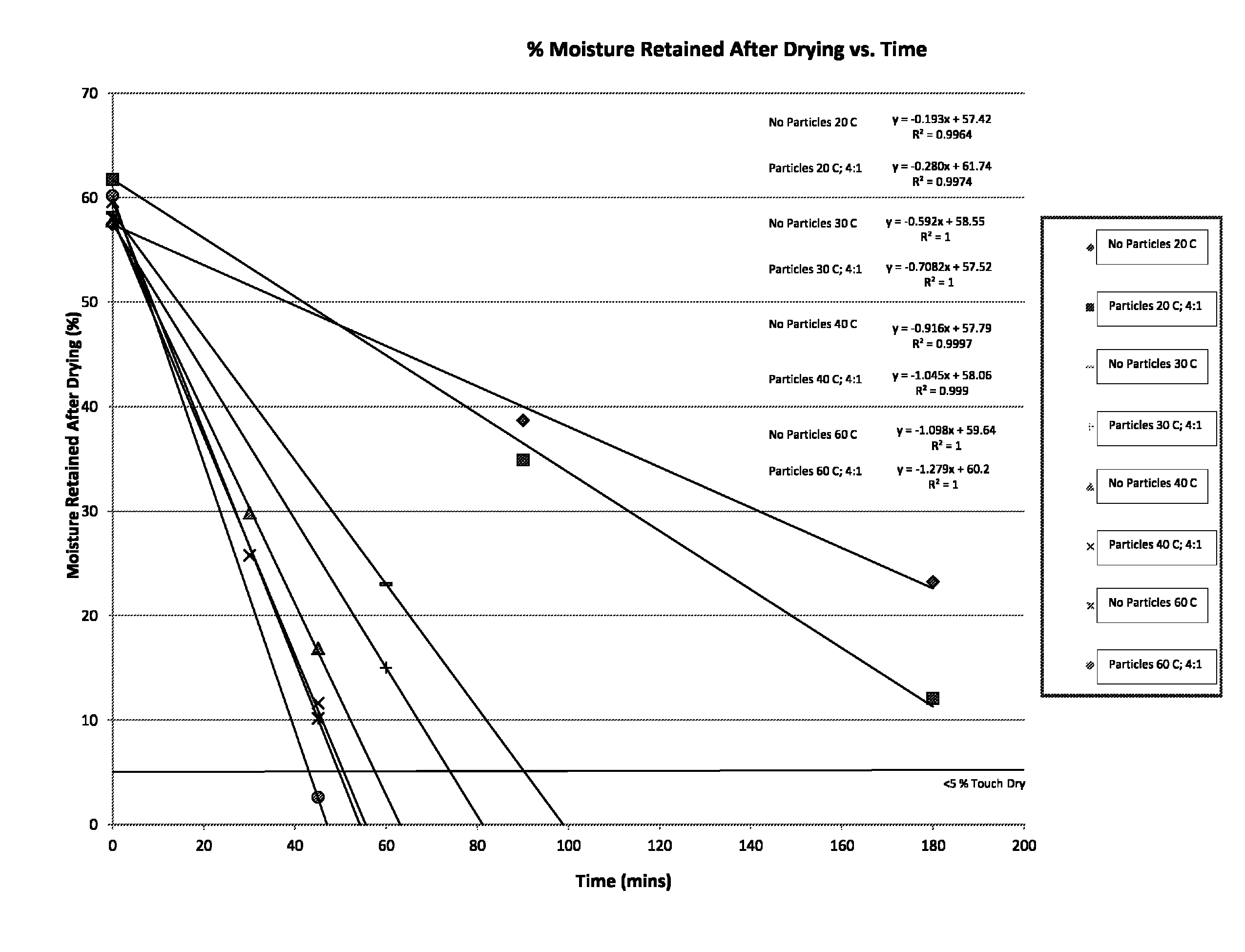

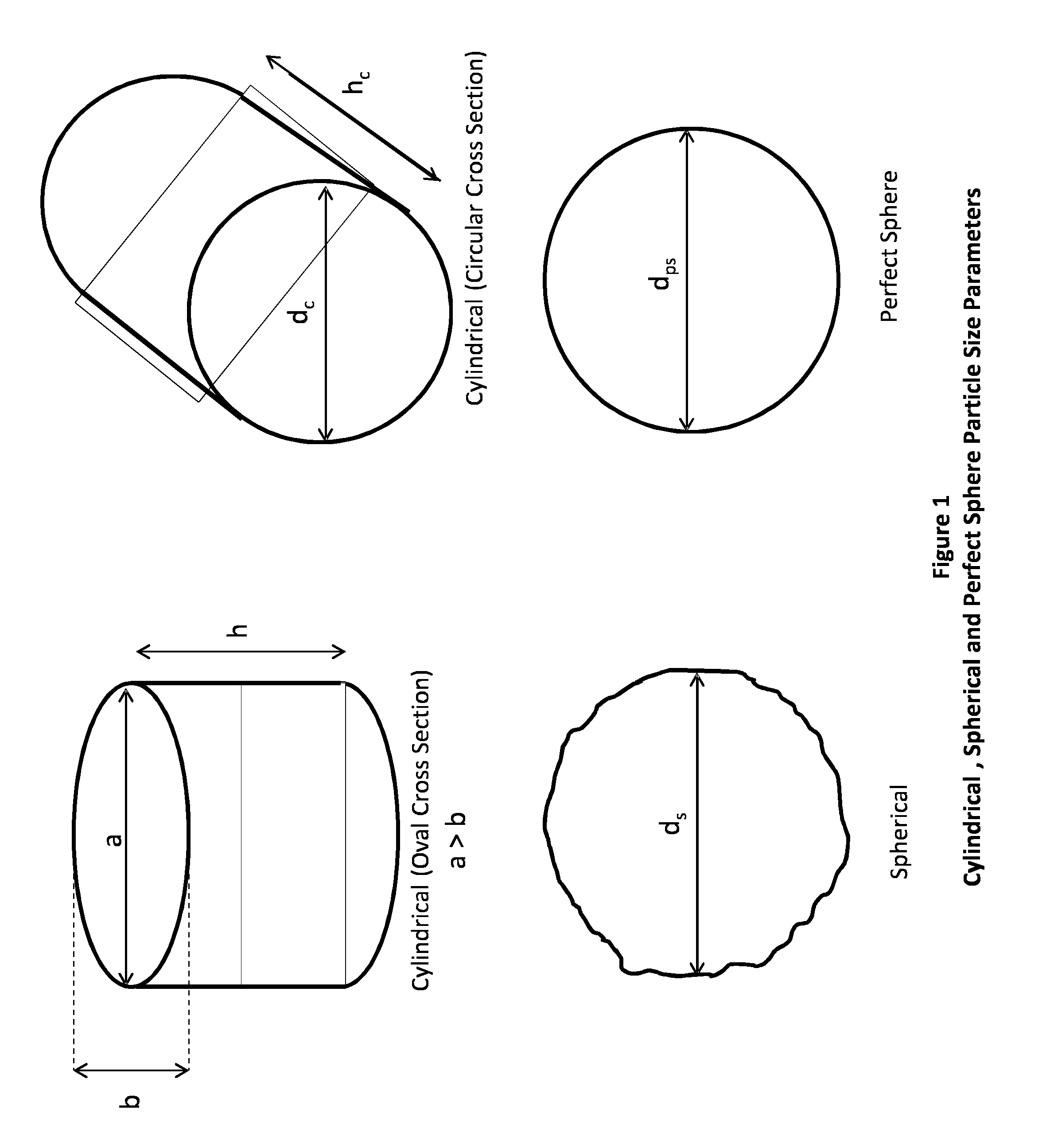

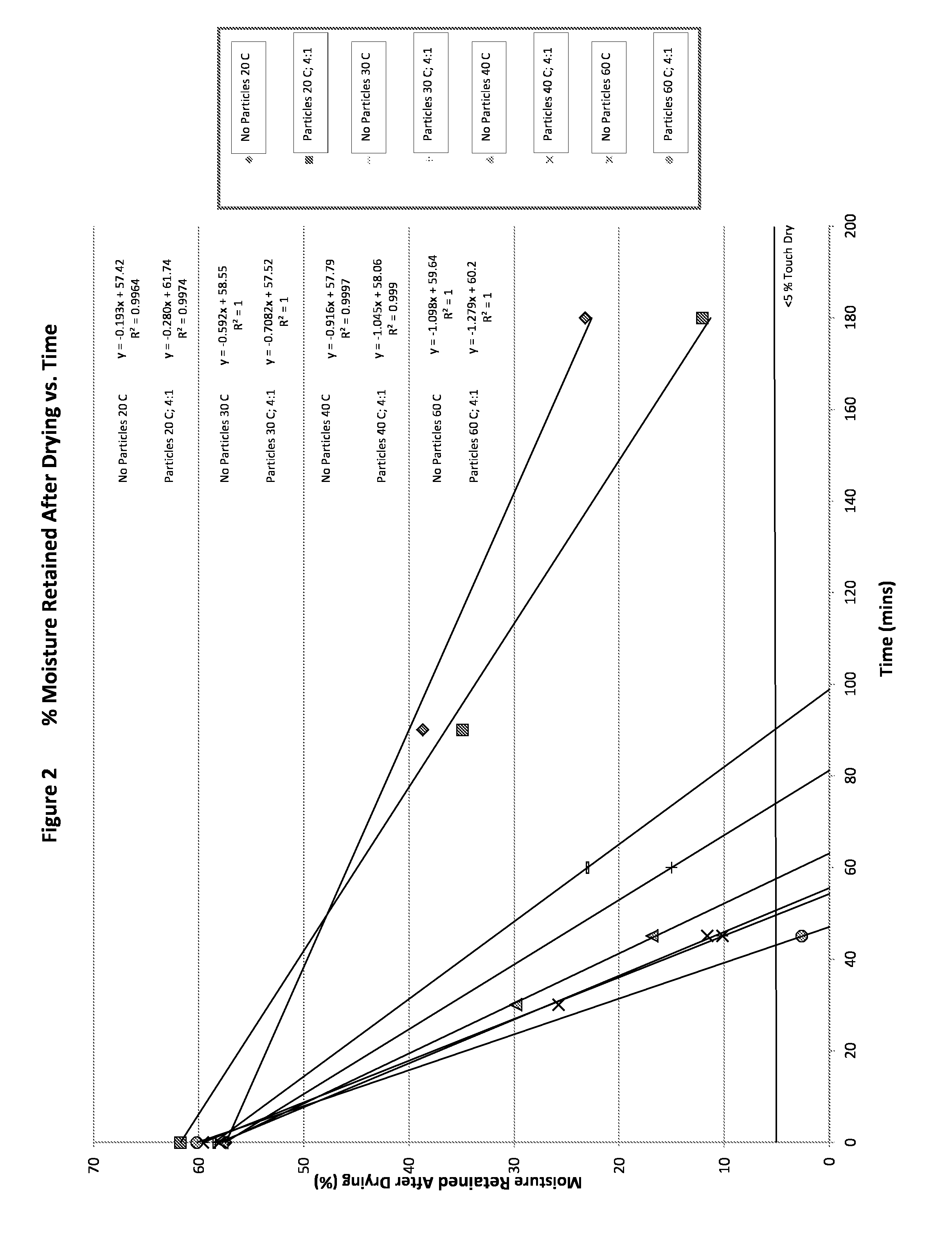

Drying method

InactiveUS9127882B2Facilitate increased mechanical actionKeep dryDrying solid materials with heatTextiles and paperSolid particleEngineering

The invention provides a method for the drying of a wet substrate, the method comprising treating the substrate with a solid particulate material at ambient or elevated temperature, the treatment being carried out in an apparatus comprising a drum comprising perforated side walls, wherein the drum comprising perforated side walls is rotated so as to facilitate increased mechanical action between the substrate and the particulate material. Preferably, the drum comprising perforated side walls has a capacity of between 5 and 50 liters for each kg of fabric in the load and is rotated at a speed which generates G forces in the range of from 0.05 to 0.99 G, and the method is carried out at a temperature of between 5° and 120° C. Preferably, the solid particulate material comprises a multiplicity of particles at a particle to fabric addition level of 0.1:1-10:1 by mass, wherein the particles comprise polymeric particles, non-polymeric particles, or mixtures of polymeric and non-polymeric particles. All particles may be solid or hollow in their structure, have smooth or irregular surface features, and are of such a shape and size as to allow for good flowability and intimate contact with the wet substrate. The invention provides optimum drying performance as a result of improved mechanical interaction between substrate and particulate media and is preferably used for the drying of textile fabrics. The method allows for significant reduction in the consumption of energy when compared with the conventional tumble drying of textile fabrics, and also facilitates reduced textile fabric damage.

Owner:XEROS LTD

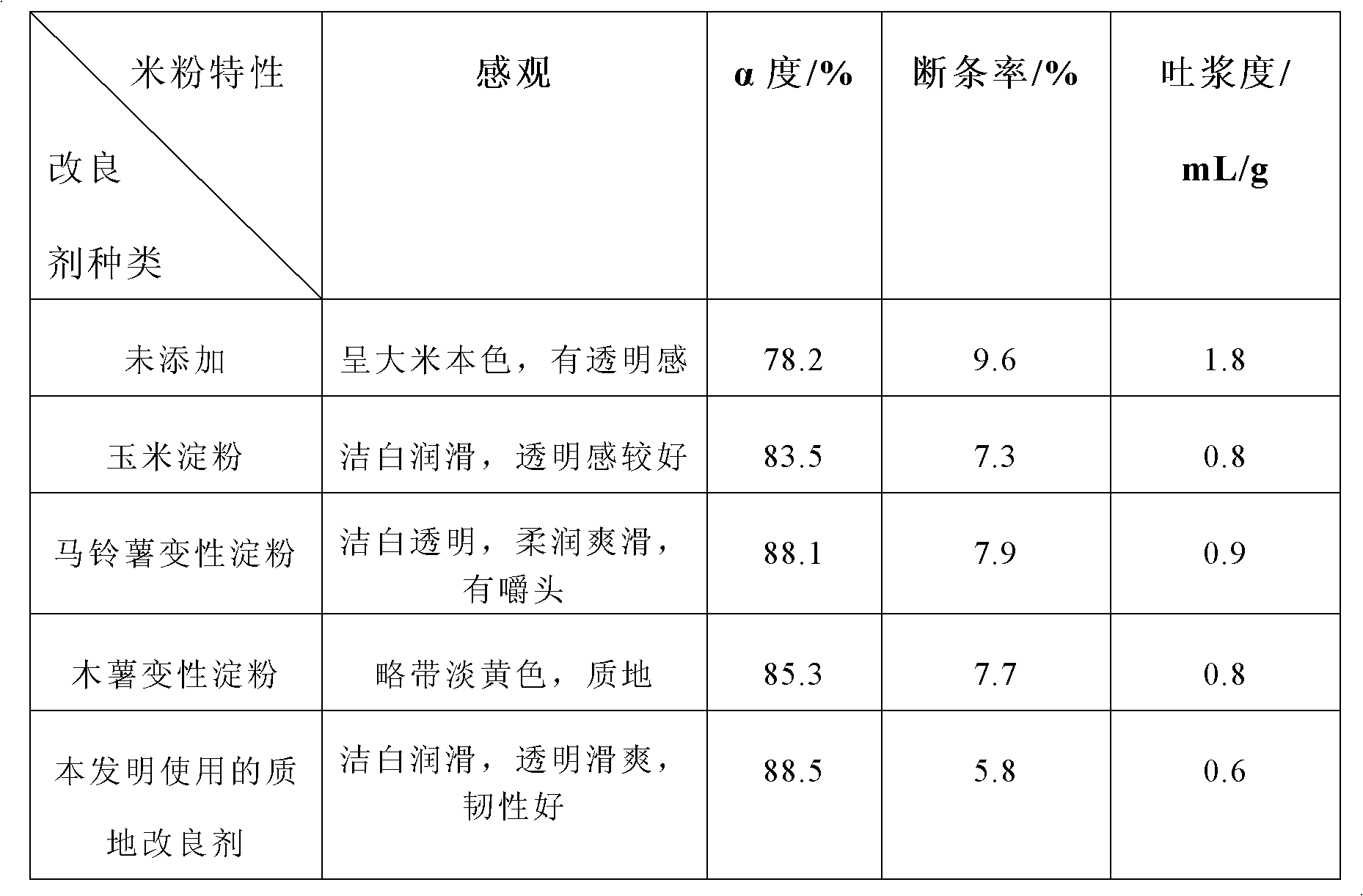

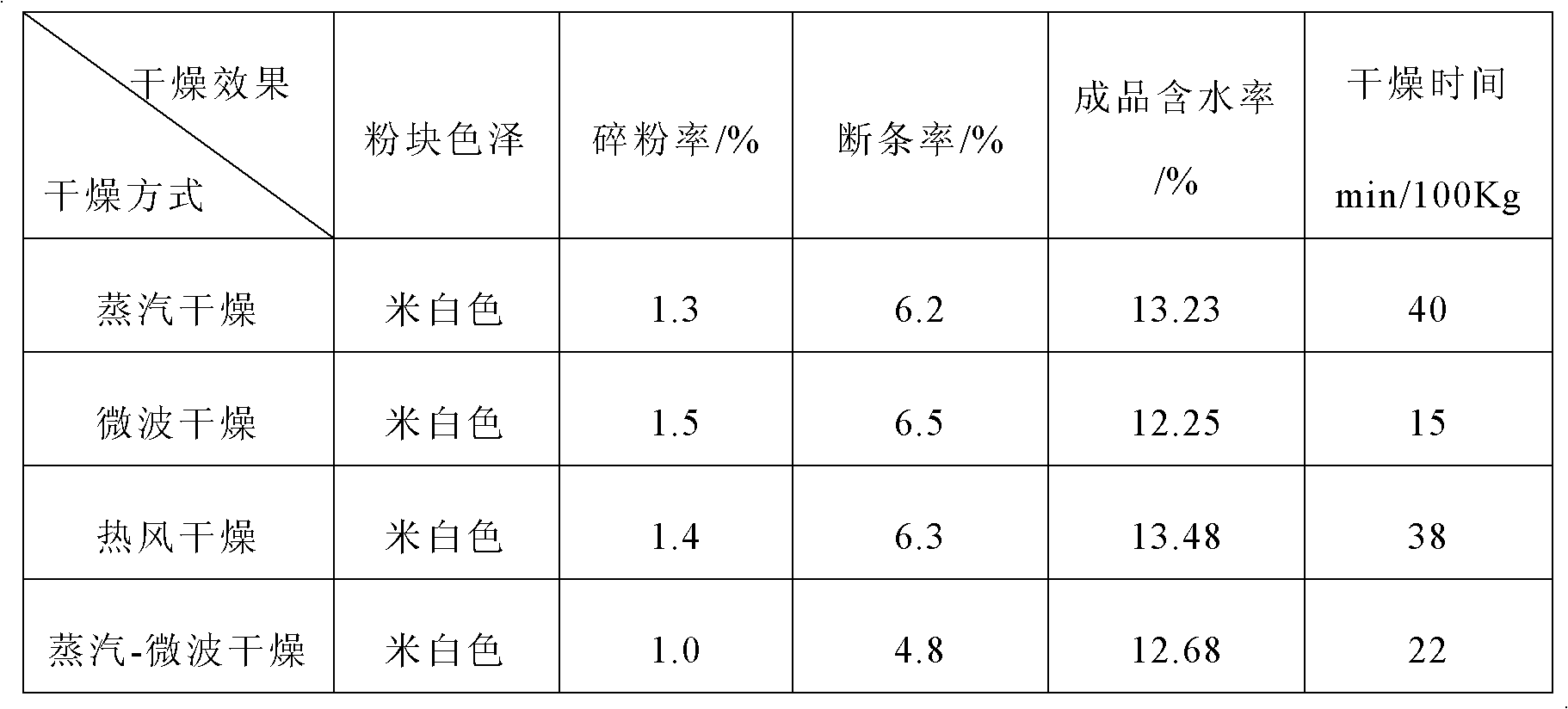

Preparation method of rice flour noodles with low noodle breaking rate and quality modifying agent thereof

ActiveCN102125222AImprove toughnessIncrease stickinessFood preparationProcess engineeringCorn starch

The invention discloses a preparation method of rice flour noodles with a low noodle breaking rate, which comprises the following steps of: (1) removing the impurity of a rice raw material, and whitening; (2) soaking, and grinding into a thick liquid; (3) dehydrating; (4) mixing: pouring rice powder into a powder stirring and steaming machine, adding the quality modifying agent with 4-10wt% of the total weight of the rice powder, and evenly mixing to obtain the powder material; (5) firstly steaming till that the gelatinization degree of the powder material reaches 75%-85%; (6) forming by means of piece extruding and noodle extruding; (7) repeatedly steaming and cutting off; (8) drying: drying the obtained power blocks till that the water content is less than 13.5wt%; and (9) packing in a cooling way. By adopting a novel natural quality modifying agent and a steam-microwave drying method, the invention can remarkably reduce the noodle breaking rate, the stripe breaking rate and the pulp discharging degree of the rice flour noodles, and can improve the perception of the rice flour noodles, thereby being high in popularization and application values and good in market potential. The invention further discloses the quality modifying agent for preventing the rice flour noodles from being broken, wherein the quality modifying agent comprises corn starch, vine root starch and carrageenan.

Owner:GUANGDONG BAWANGHUA FOOD

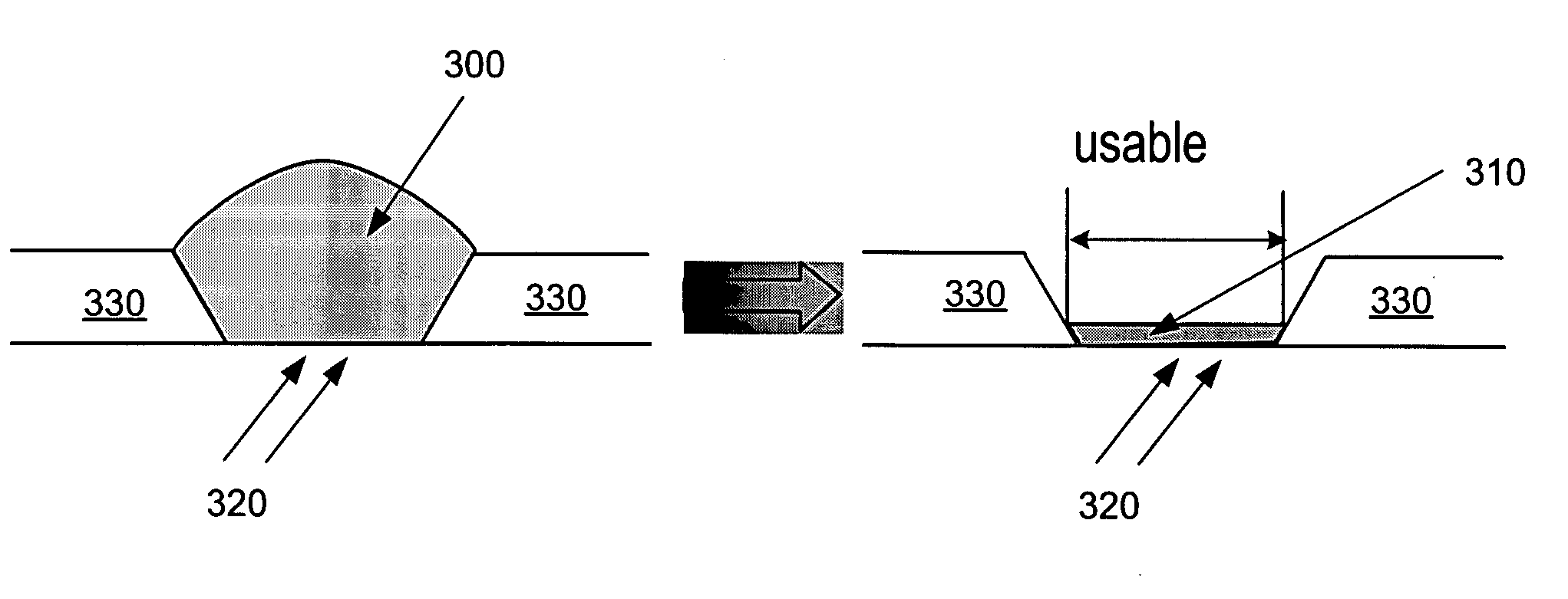

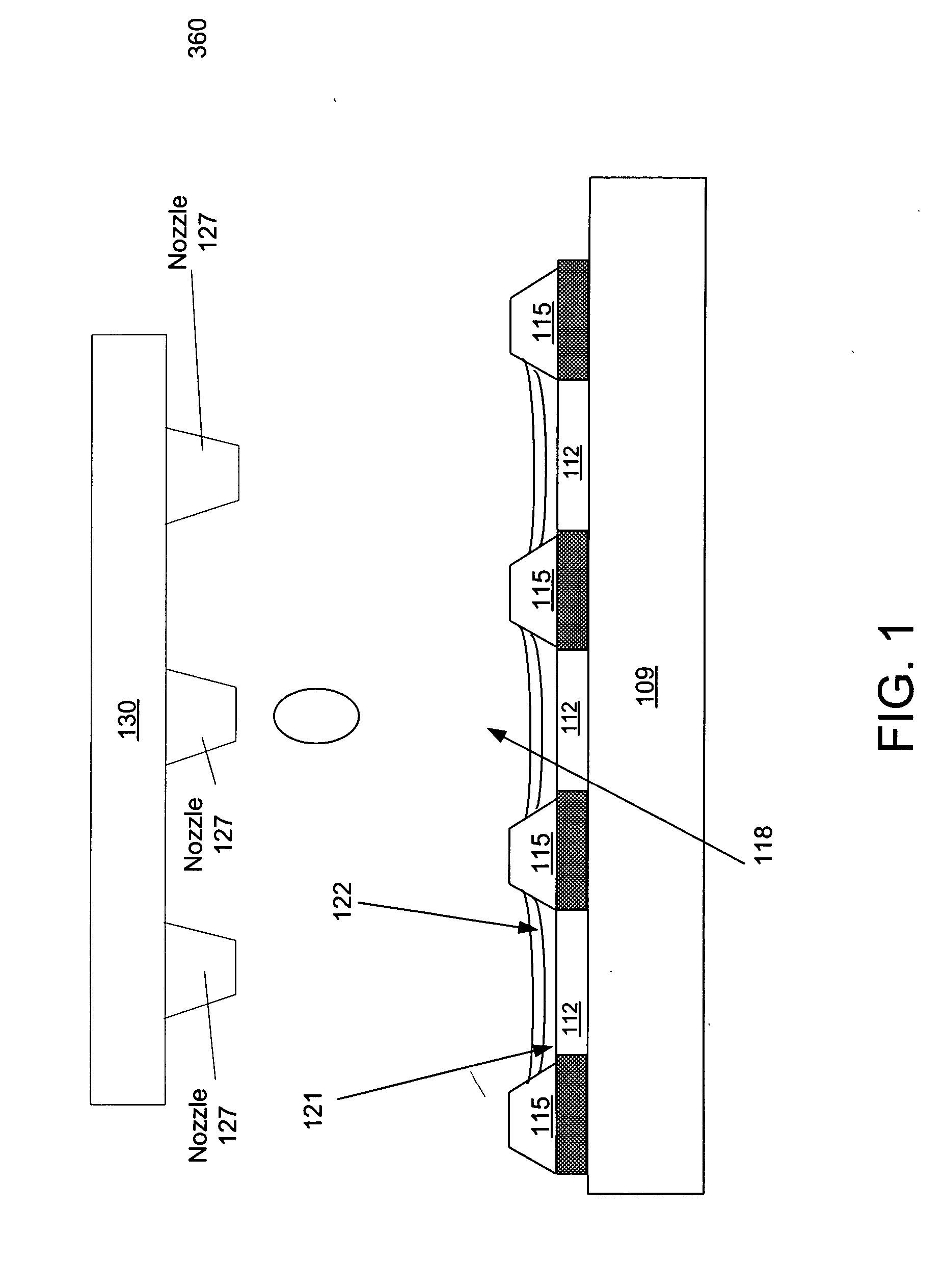

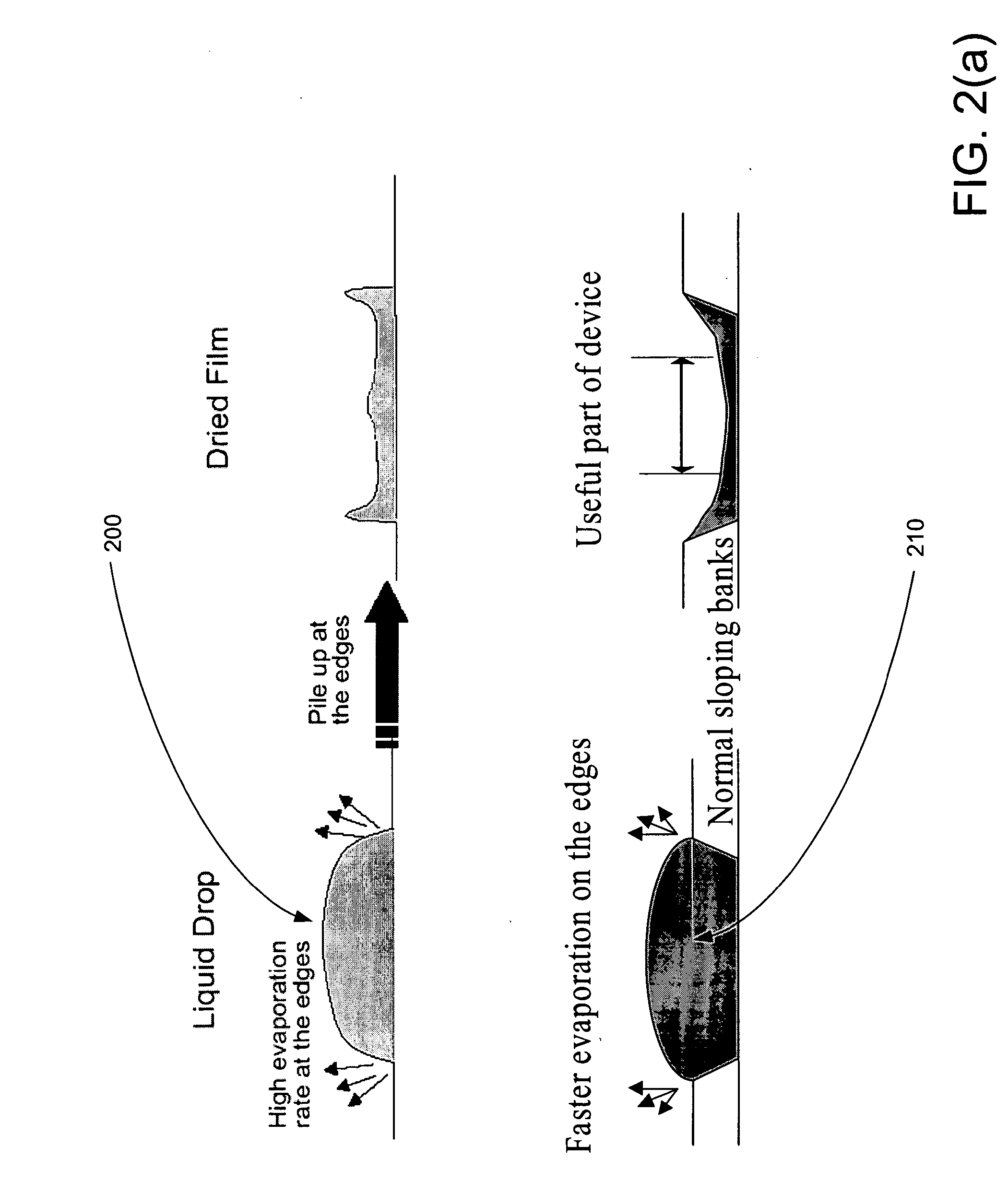

Printing of organic electronic devices

InactiveUS20050153114A1Uniform and flatter profileExtended drying timeDecorative surface effectsSolid-state devicesConductive polymerInorganic chemistry

The composition of a organic (e.g. conducting polymer) solution is reformulated and the device upon which the organic solution is to be deposited is plasma treated to provide a more uniform and flat drying profile for the resulting dried film. This reformulation and treatment induces a more uniform and flatter profile when the reformulated organic solution is allowed to dry into a film on the treated device.

Owner:OSRAM OPTO SEMICONDUCTORS GMBH & CO OHG

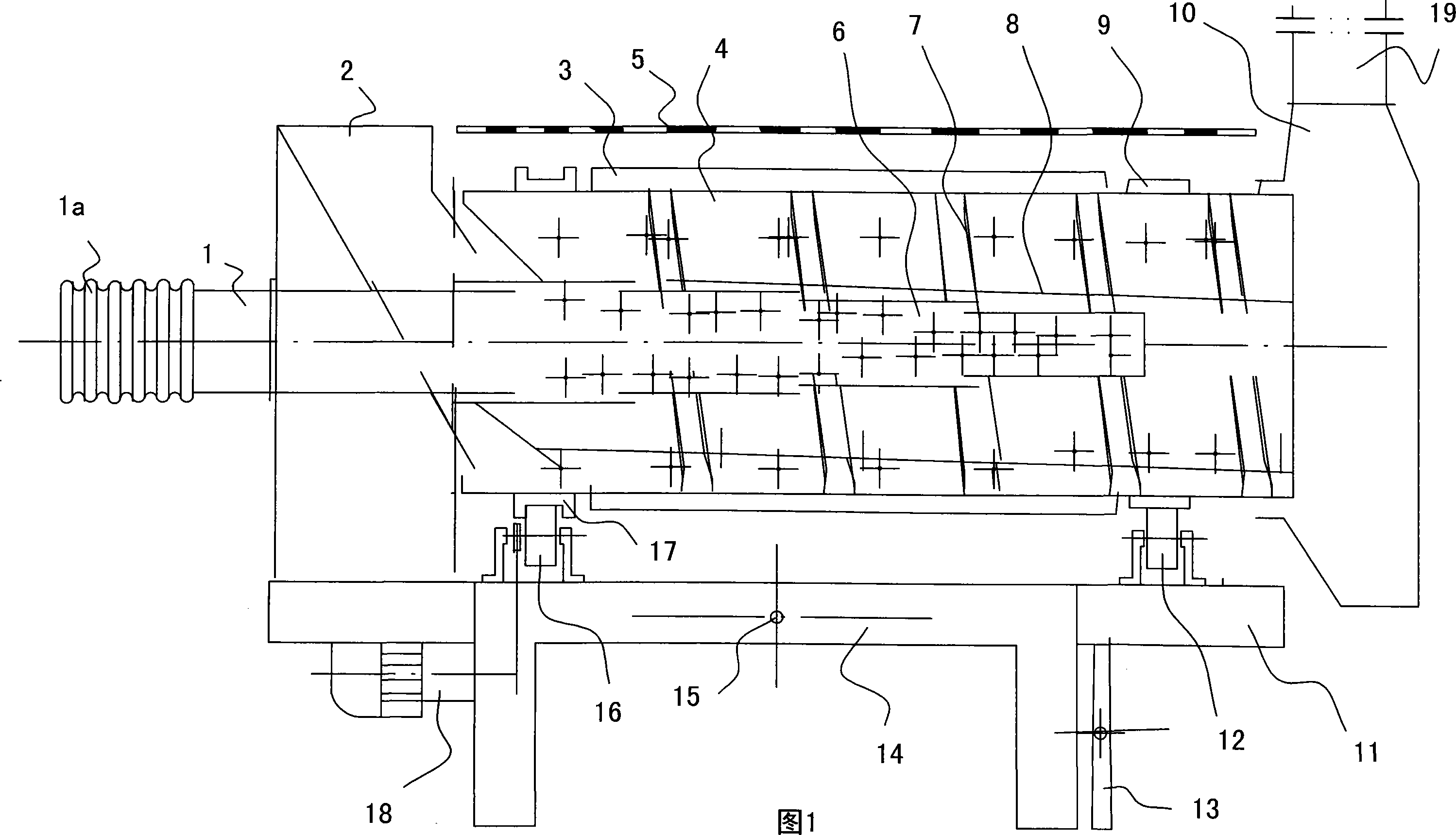

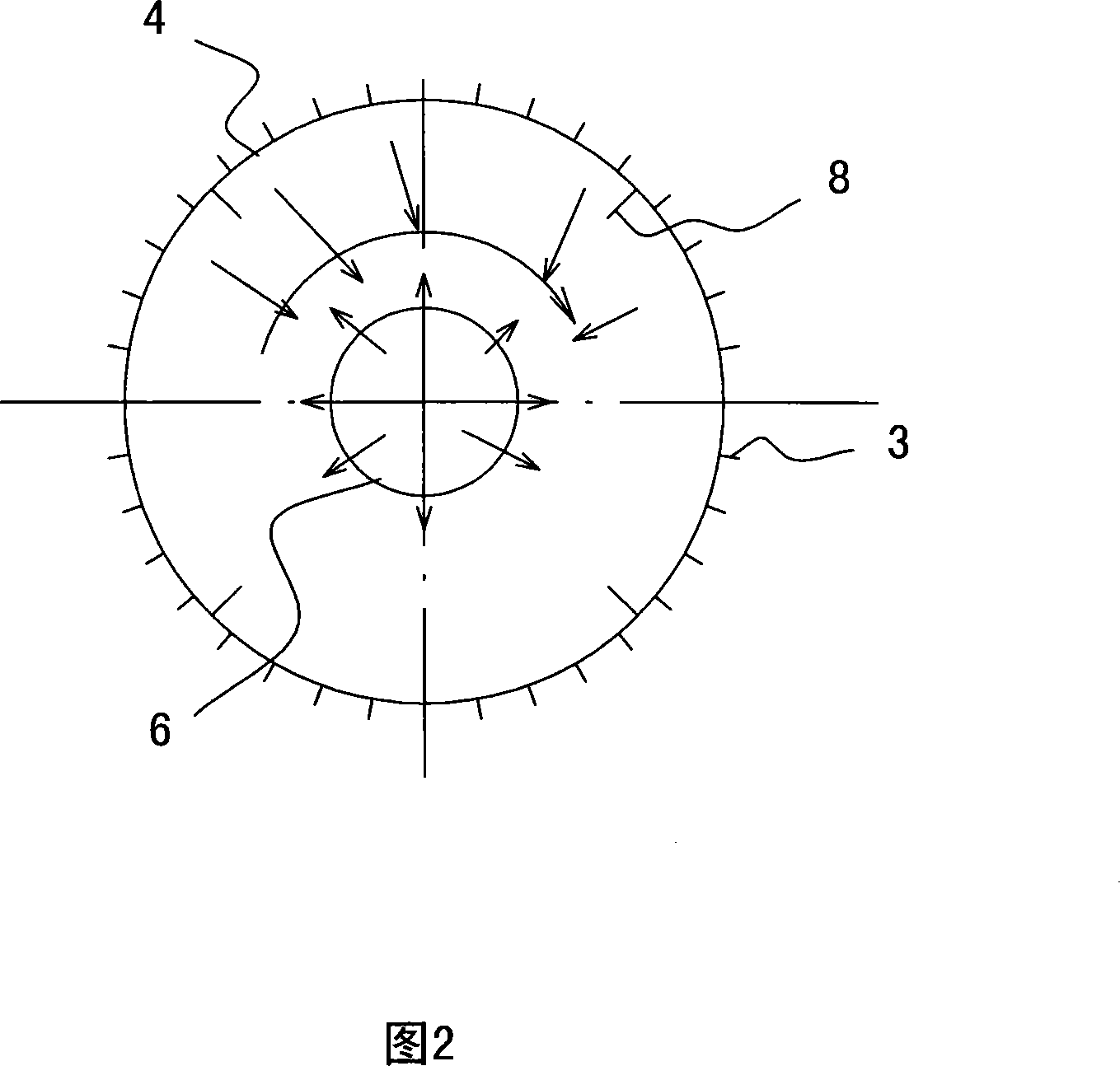

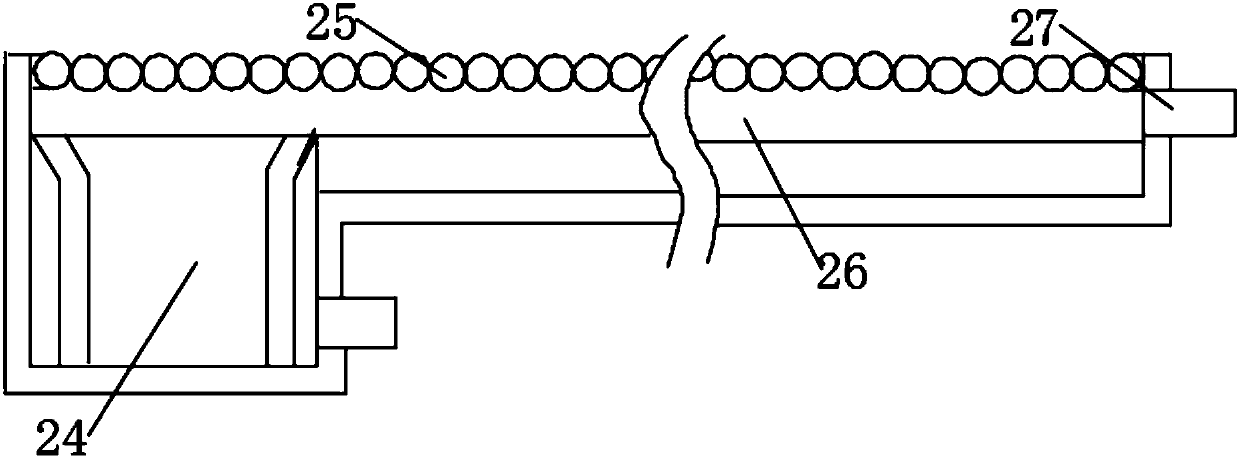

Tea dynamic drying machine

ActiveCN101238839AImprove space utilizationReasonable drying processPre-extraction tea treatmentAgricultural engineeringRunning time

The invention provides a tea dynamic dryer, the structure includes machine rack, drum, outer cover shell, tea inlet bucket, the drum upon the machine rack is placed on the friction wheel and supporting wheel, the lower part of the tea inlet bucket is adapted to one end of the drum tea inlet dynamic-static interval, which is characterized in that: the other end of the air inlet pipe is connected to the hot air transmitting pipe through the floating pipe; the cross sectional area of the central air pipe is gradually reduced from the air inlet end; outer ring surface of the drum is longitudinally equipped with many bar shaped plates; the machine rack is equipped on the machine rack through the swivel-pin, the machine rack horizontal angle modulation mechanism is equipped between the machine base and the machine rack. Under the conditions that the tea is in dynamic, suspending state and is desiccated, the machine has the advantages as follows: the utilization rate of equal diameter drum useful space is high, the waste hot wind is not easy to resort around the drum, the hot efficiency is high, the running time of tea in the drum can be effectively controlled according to the processing demand.

Owner:浙江上洋机械股份有限公司

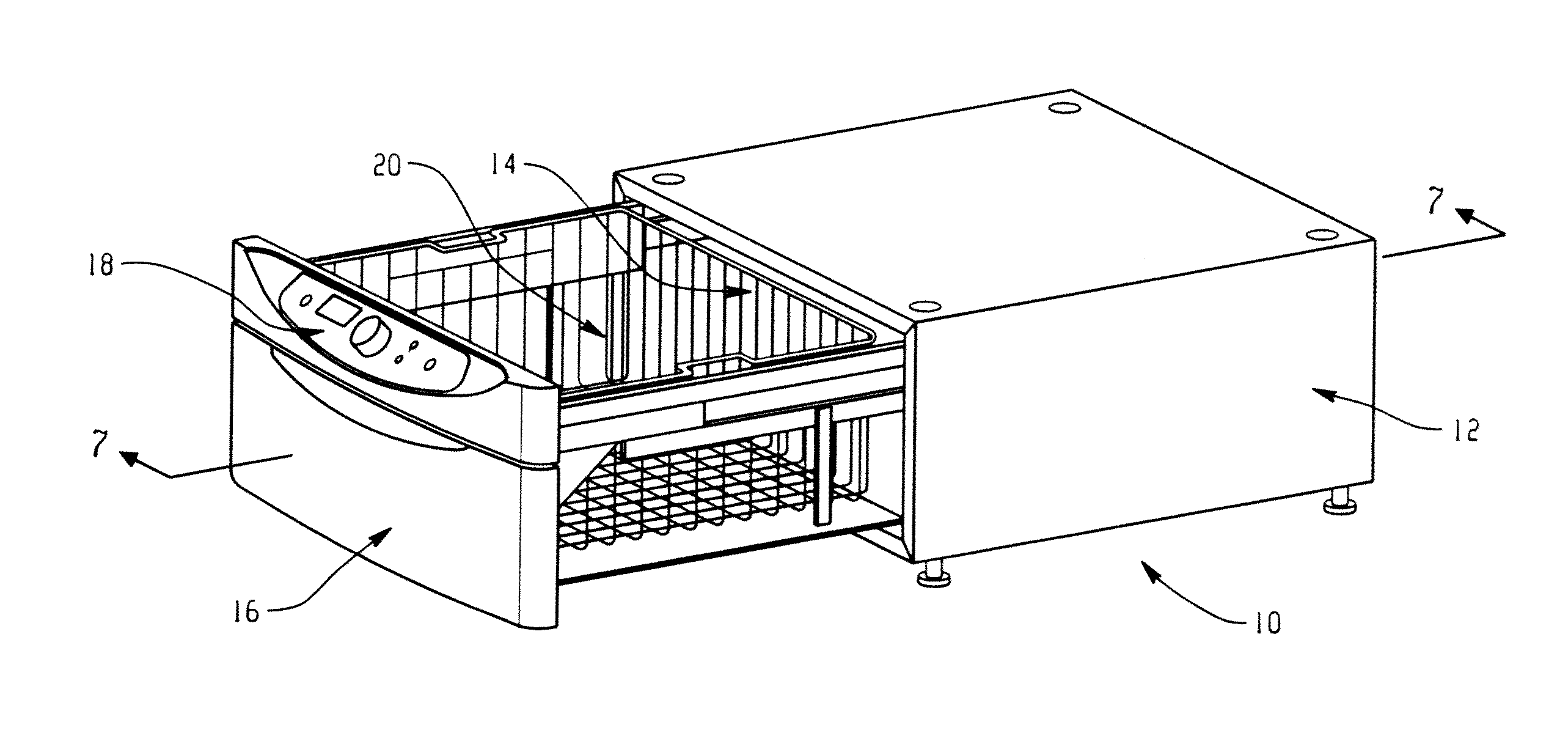

Drying and warming appliance

InactiveUS20120055039A1Extended drying timeEfficient dryingOther washing machinesDrying chambers/containersAir cycleEngineering

An appliance for drying or warming associated laundry items includes a housing having a wall forming a stationary cavity dimensioned to receive the associated laundry items. At least one article support member is preferably contained within the cavity. A heater increases a temperature of associated air within the cavity and a fan circulates the heated air within the cavity. A vent is dimensioned to allow air to exit the housing cavity, and a controller regulates circulation of the associated heated air within the cavity.

Owner:GENERAL ELECTRIC CO

Aqueous disperse dye ink-jet printing ink

The invention aims at providing an aqueous disperse dye ink-jet printing ink with excellent comprehensive performance capable of overcoming the defects of the traditional disperse dye ink-jet printing ink, and a preparation method of the aqueous disperse dye ink-jet printing ink. The aqueous disperse dye ink-jet printing ink has good ink storage stability and good printing fluency; the service time of a disperse dye ink-jet product is greatly prolonged; the aqueous disperse dye ink-jet printing ink can be cured under the irradiation of ultraviolet light (UV); the comprehensive performances of the ink, such as light resistance, water tolerance, chemical resistance, high and low-temperature resistance, rubbing scratch resistance, high brightness and ageing resistance of the ink are improved; the aqueous disperse dye ink-jet printing ink is applicable to an uncoated and non-printing coating medium and is applied to the fields such as digital printing, digital calico printing, digital images, office documents, outdoor inkjet, ceramic tile wallpapers, glass plastics and surface decoration.

Owner:鲁继烈

Ink-jet recording medium with an opaque or semi-opaque layer coated thereon, method for recording an image, and a recorded medium with at least one layer rendered clear or semi-opaque

InactiveUS6936316B2Avoid excessive adhesionExtended drying timeCoatingsThermographyAziridineCross linker

The present invention features a multi-layer ink-jet recording medium, suitable for recording images with dye and pigmented inks and thereby providing light-emitting, reflective, glossy, metallic-looking or holographic images, comprising a substrate coated with at least two layers comprising:(a) a first transparent ink-receptive layer comprising a polymeric binder and a cross-linker and optionally having a plasticizer and pigment particles such as alumina and silica coated over the substrate, wherein the cross-linker comprises and azetidinium polymer or a salt thereof, and / or a polyfunctinal aziridine or a salt thereof or a polyfunctional oxazoline or a salt thereof; and(b) a second ink-receptive layer comprising an opaque or semi-opaque coating composition, wherein the opaque or semi-opaque coating composition is capable of accepting a printed image and thereby becoming semi transparent or clearly transparent from application of ink-jet printing ink or similar inks, while presenting a light-emitting, reflective, glossy, metallic-looking or holographic image of high clarity and quality,wherein said first layer is located between said second layer and the substrate in said recording medium and the first and second layers are chemically coupled.

Owner:PIXTERRA

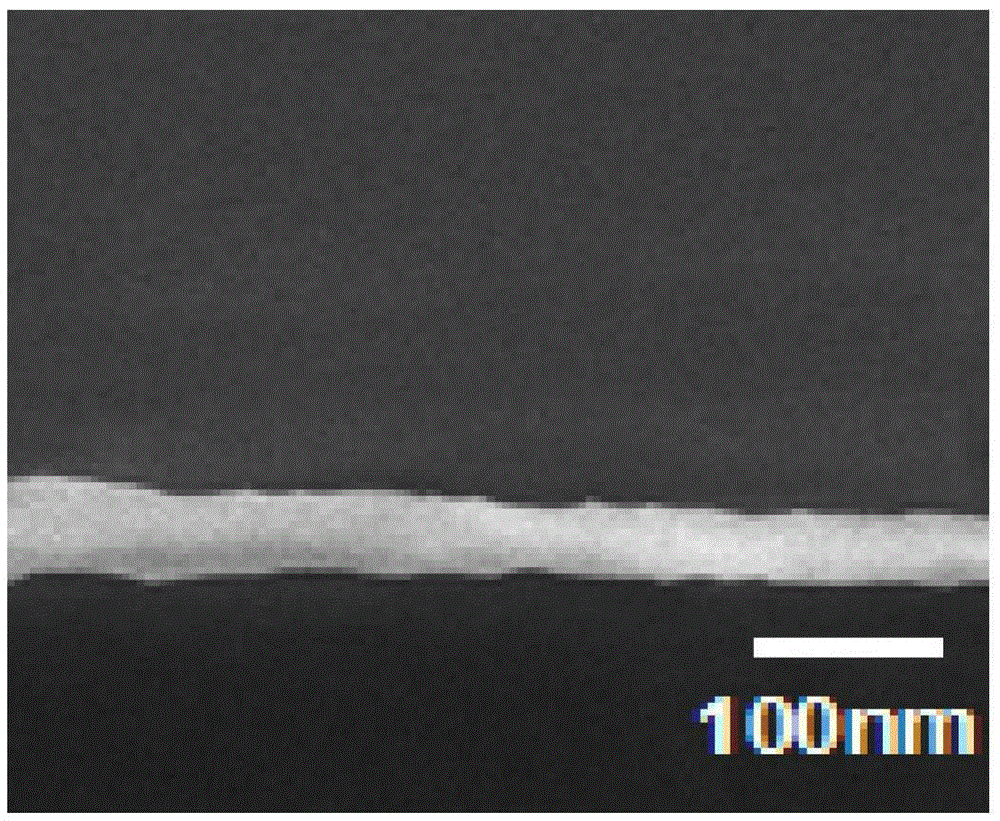

Method for rapidly peeling and transferring graphene oxide leaching film to substrate

The invention discloses a method for rapidly peeling and transferring a graphene oxide leaching film to a substrate. The method specifically comprises the steps of firstly adding graphene oxide in water, forming graphene oxide dispersion liquid in an ultrasonic dispersion way, arranging the substrate on a sand core of a leaching flask, installing a leaching device, then pouring the prepared graphene oxide dispersion liquid into the leaching device, and starting leaching; then taking out the substrate which is attached with a leached graphene oxide film, and putting the substrate into an organic solvent, enabling the graphene oxide film to be rapidly formed through dewatering, and enabling the graphene oxide film to fall off the substrate; enabling the smooth substrate to be in direct contact with the floated graphene oxide film in the organic solvent, and enabling the graphene oxide film to transfer to be attached onto the substrate. Through the method disclosed by the invention, the drying time is not needed at all, and the time for peeling a thick film is greatly shortened; meanwhile, a thin film can also be peeled, a smooth graphene oxide film can be obtained, and the shape can be well maintained.

Owner:SOUTHEAST UNIV

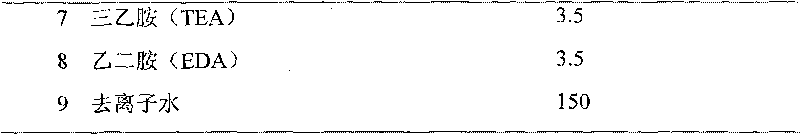

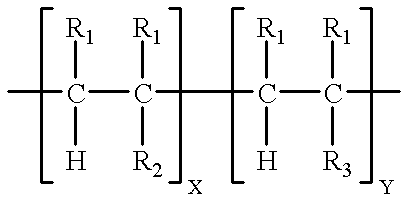

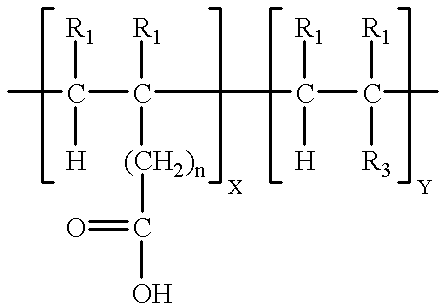

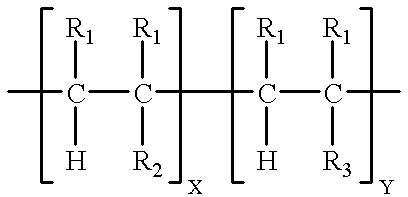

Method for preparing low VOC polyester-acrylic graft resin compositions

A method is disclosed for the preparation of a water-based graft copolymer of a carboxyl functional polyester and an ethylenically unsaturated monomer having a low level of volatile organic compounds.

Owner:BP CORP NORTH AMERICA INC

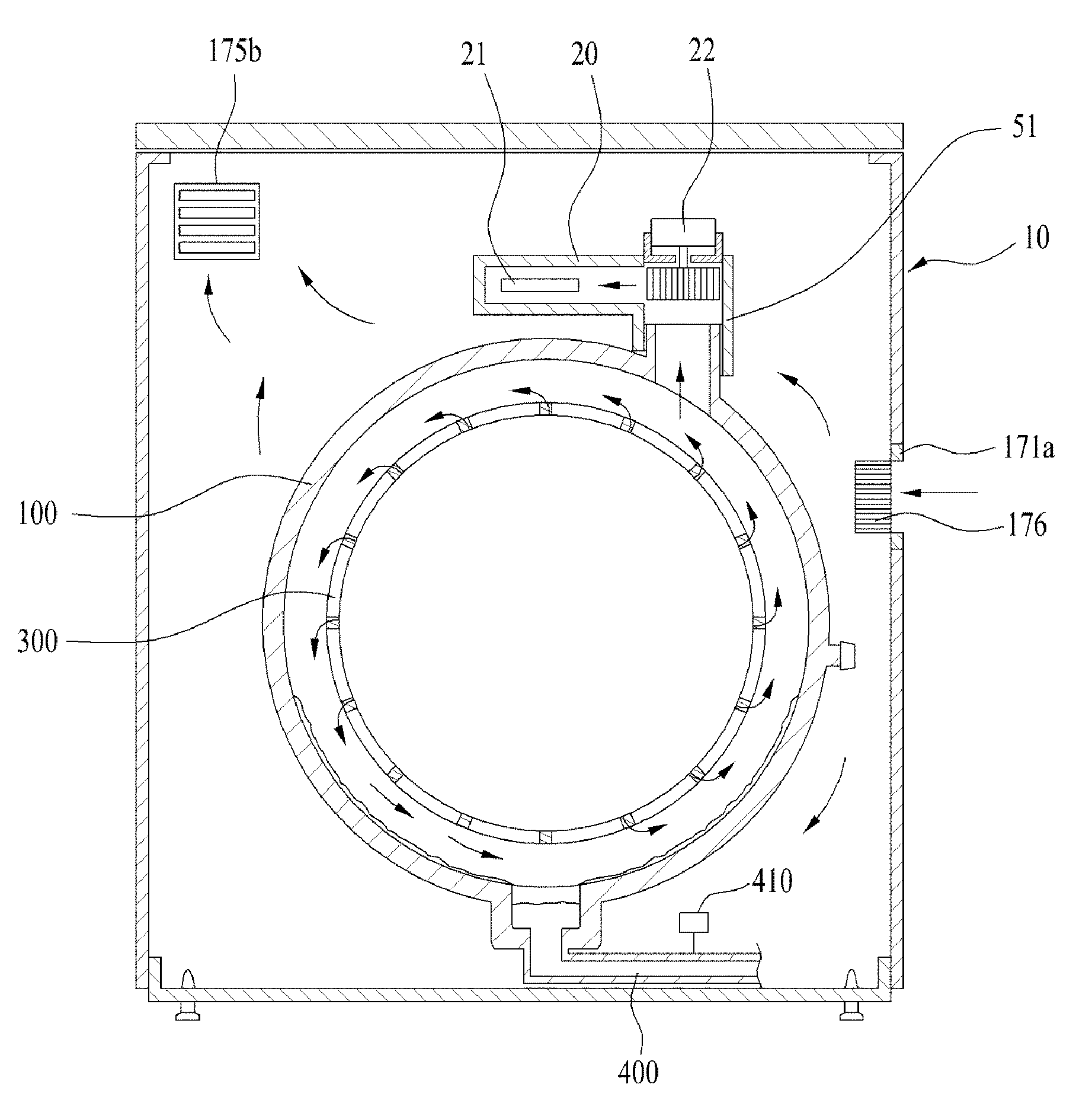

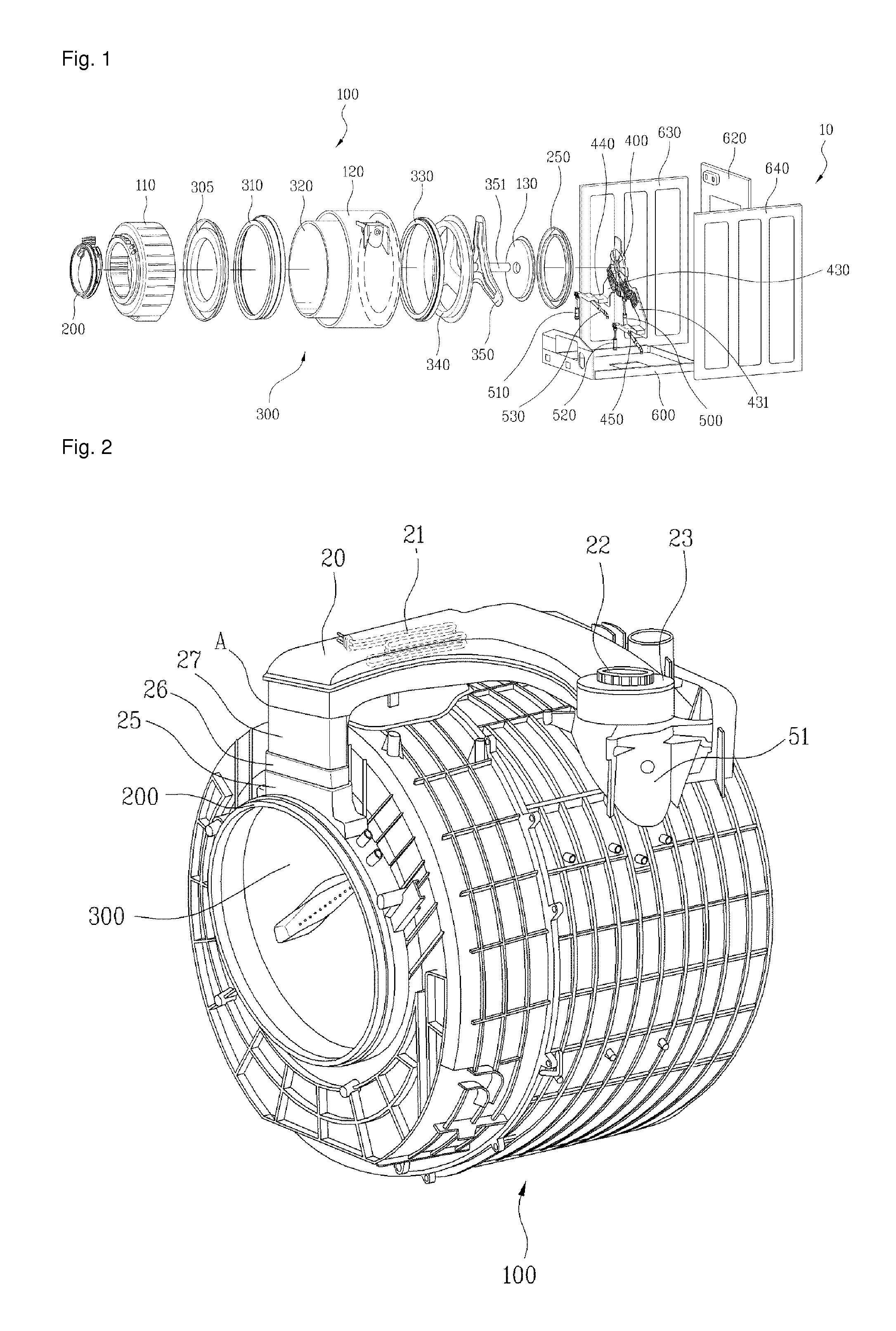

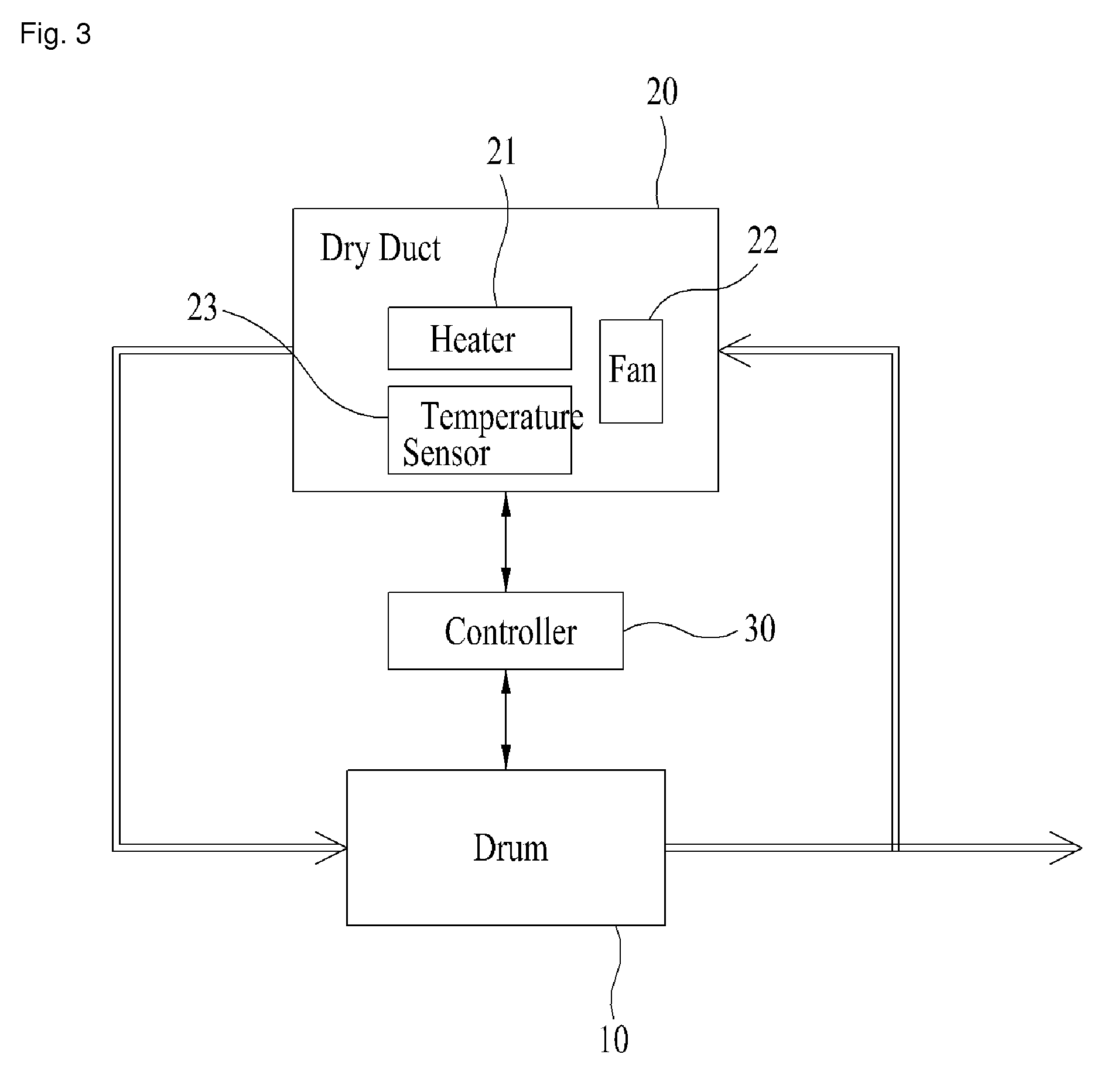

Washing machine and control method thereof

InactiveUS9133575B2Increase capacityAdd support structureDrying solid materials with heatOther washing machinesMechanical engineeringMoisture

A washing machine and a control method therefore are disclosed. The washing machine includes a cabinet (10); a tub (100) fixed to the cabinet (10); a drum (300) rotatably provided in the tub (100); a dry duct (20) which heats air exhausted from the tub (100) a predetermined temperature, to re-supply the heated air to the tub (100); condensation unit (170) which condenses moisture on at least a predetermined area of an inner circumferential surface of the tub (100) by heat-exchanging external air of the cabinet (10) with at least predetermined area of an outer circumferential surface of the tub (100); and sensing unit (410) which senses the amount of condensate generated in the tub (100). A washing machine and a control method thereof are disclosed. The washing machine includes a cabinet; a tub fixed to the cabinet; a drum rotatably provided in the tub; a dry duct which heats air exhausted from the tub a predetermined temperature, to re-supply the heated air to the tub; condensation unit which condenses moisture on at least a predetermined area of an inner circumferential surface of the tub by heat-exchanging external air of the cabinet with at least predetermined area of an outer circumferential surface of the tub; and sensing unit which sense the amount of condensate generated in the tub.

Owner:LG ELECTRONICS INC

Epoxy resin amine curing agent of N,N′-dimethyl secondary diamine polymer

InactiveUS7666954B2Extended drying timeRapid hardness developmentThin material handlingEpoxyEndcapping

The present invention provides N,N′-dimethyl secondary diamine polymers including methylamine-terminated poly-(N-methylazetidine) and methylamine-terminated poly-(N-methylazacycloheptane). Amine compositions and amine-epoxy compositions comprising N,N′-dimethyl secondary diamine polymers are also disclosed.

Owner:EVONIK DEGUSSA GMBH

Integrated cleaning, drying and screening device for red date

InactiveCN107660805AFast cleaningReduce falling speedSievingGas current separationMotor drivePulp and paper industry

The invention discloses an integrated device for cleaning, drying and screening jujube, which comprises a support column, a cleaning box, a screening box and a drying device. The upper ends of the support columns are all provided with bearing seats, and a bearing seat rotates on the A rotating shaft is connected, the other bearing seat is rotationally connected with the rotating shaft and the rotating shaft is connected with the rotating motor, both the rotating shaft and the rotating shaft are connected with the cleaning box, a nozzle is installed in the cleaning box, and a cleaning tank and a material guide plate are installed inside the cleaning box , the cleaning tank is provided with a stirring shaft and a brush is provided on the stirring shaft, the end of the material guide plate is connected with the discharge port, and the screening inlet of the screening box is located below the bottom end of the material guide plate. In this device, the rotating motor drives the cleaning box to rotate, while the stirring motor drives the stirring shaft and the brush to rotate, which can stir the jujubes in the cleaning tank and improve the cleaning speed of the jujubes. The screening box can screen jujubes of different specifications and is equipped with a drying device. , no need to transport red dates, reducing the work intensity.

Owner:姜伟龙

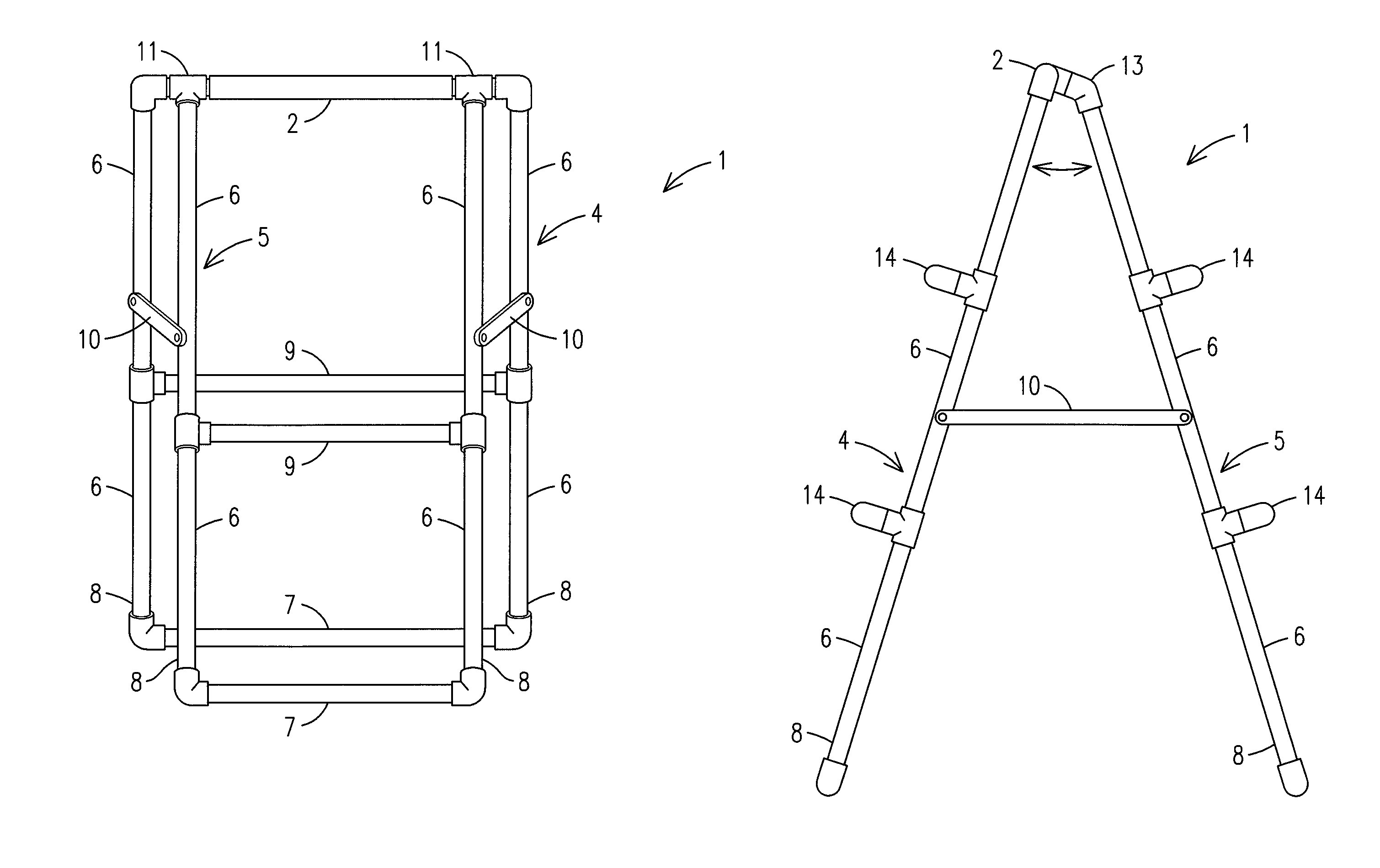

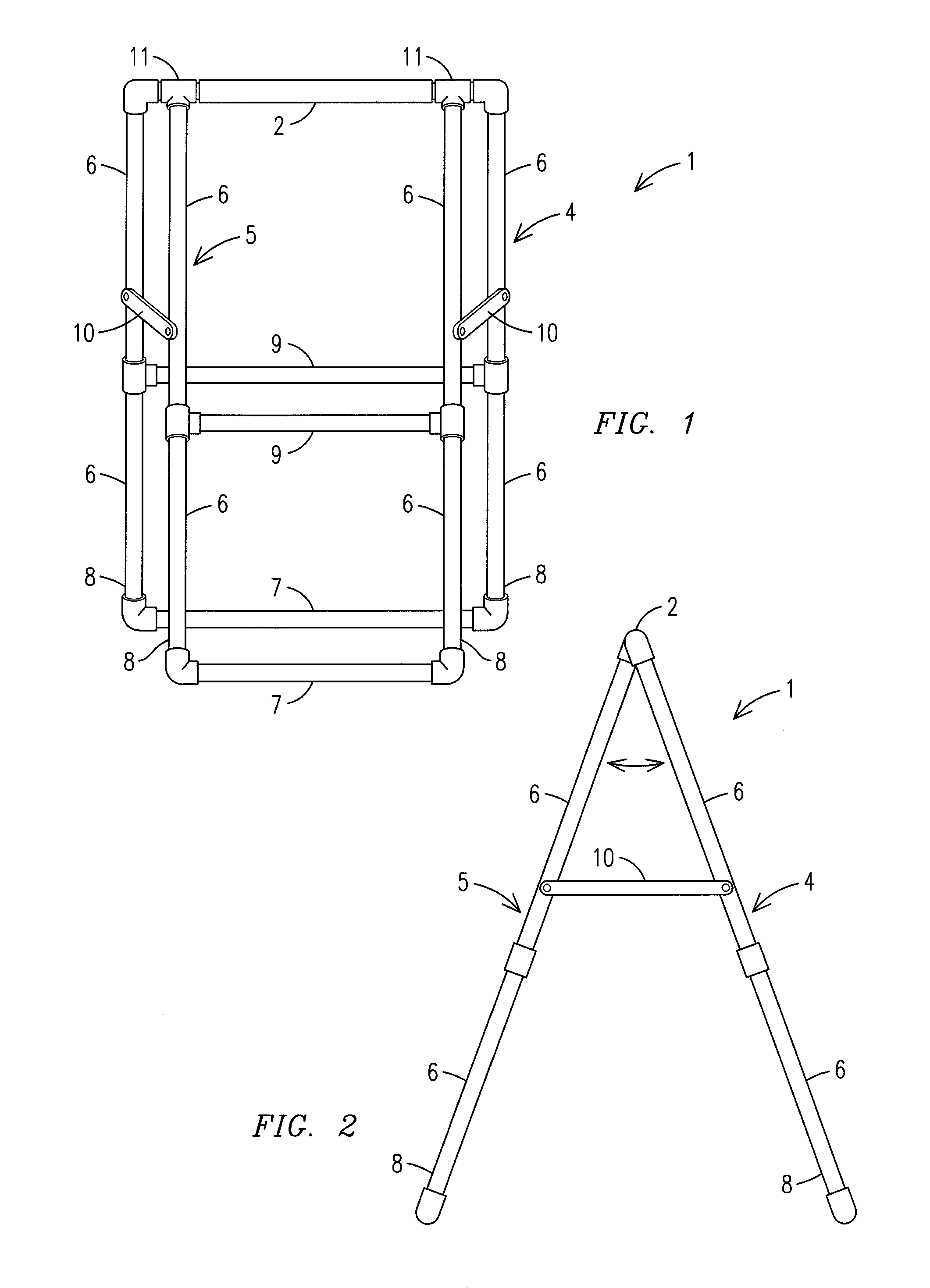

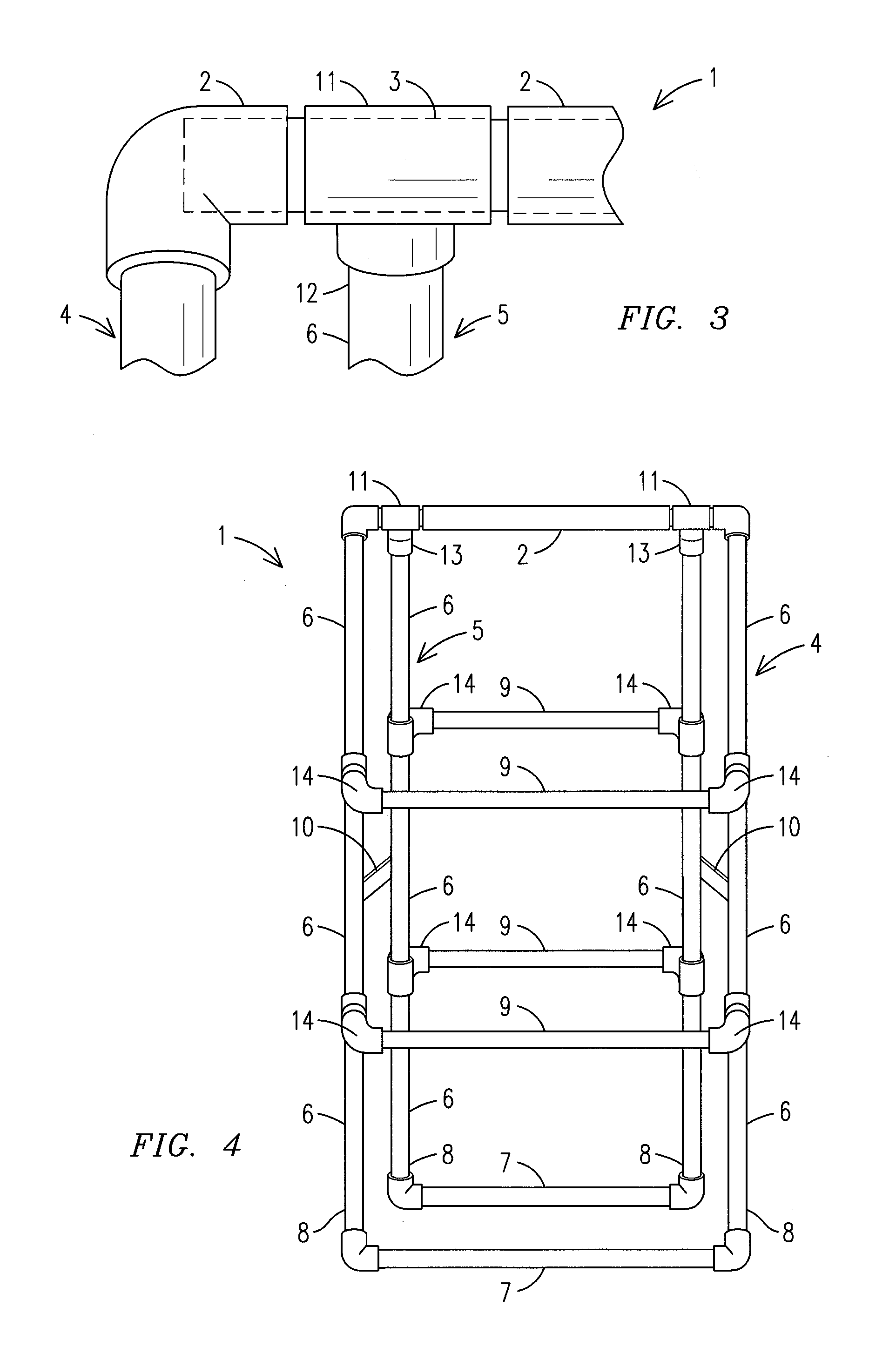

Folding clothes rack

InactiveUS8783473B1Sufficient air flowWithout taking up too much roomApparel holdersKitchen equipmentEngineeringAirflow

A triangular folding clothes rack (1) having a top tubular cross piece (2) with an inner axle (3) to allow a front frame (4) of the rack and a rear frame (5) of the rack to fold outward into an open position for drying articles of clothing and inward into a closed position for storing the rack. Clothes may be hung from the top tubular piece and / or hanging rods (9) either directly and / or by using conventional hangers. Offsets (13) located on the rear frame and extensions (14) located on hanging rods allow clothes to be hung without the clothes lying on top of each other, thereby providing maximum airflow between the clothes to allow for expedited drying.

Owner:SCHOSEK WILLIAM O

Energy-saving quality-keeping method in the dewatering course of high-water fruit vegetables or aquatic products

InactiveCN101138359ALow drying efficiencyExtended drying timeFood processingFruits/vegetable preservation by dehydrationFreeze-dryingEngineering

A method for saving energy and guaranteeing the quality in the process of dehydration of fruit and vegetable with high water content or water product; the method belongs to the food processing technical field of fruit and vegetable or water product. The present invention adopts the combined processing of hot air drying and hot pump drying or the combined processing of freeze drying and hot pump drying to dehydrate the fruit and vegetable with high water content or water product; with the present invention, energy can be saved by 45 to 60 percent and the appearance and quality of the product are near the simple ordinary dried products. The process is that the raw materials of vegetable and fruit or water product are cleaned, cut and burnt; and then the raw materials are cooled and centrifugally dehydrated; the dehydrated raw materials are seasoned and settled; the settled raw materials are dried by the method of hot pump combined drying and then cooled down for storage; and then metal-detecting process is implemented on the materials and the materials are packed. The present invention adopts the novel process of hot pump combined drying for dehydration; the fruit and vegetable or water product after being dehydrated with the hot pump combined drying are characterized by low heating temperature, short production time, excellent quality and low energy consumption.

Owner:NINGBO HAITONG FOOD SCI & TECH CO LTD +1

Graphene dispersion liquid and method for preparing graphene material power

The invention provides a graphene dispersion liquid which comprises an organic solvent and a graphene material dispersed in the organic solvent, wherein the graphene dispersion liquid is prepared by virtue of the following steps: S1, providing a graphene water-based slurry which comprises the graphene material and water; S2, adding the organic solvent once or multiple times into the graphene water-based slurry in an accumulated manner to obtain a mixed slurry, wherein the organic solvent and the water can form an azeotropic system; S3, heating the mixed slurry till all moistures in the mixed slurry are removed, so as to obtain the graphene dispersion liquid. The invention further provides a method for preparing graphene material power by using the graphene dispersion liquid.

Owner:NINGBO MORSH TECH +1

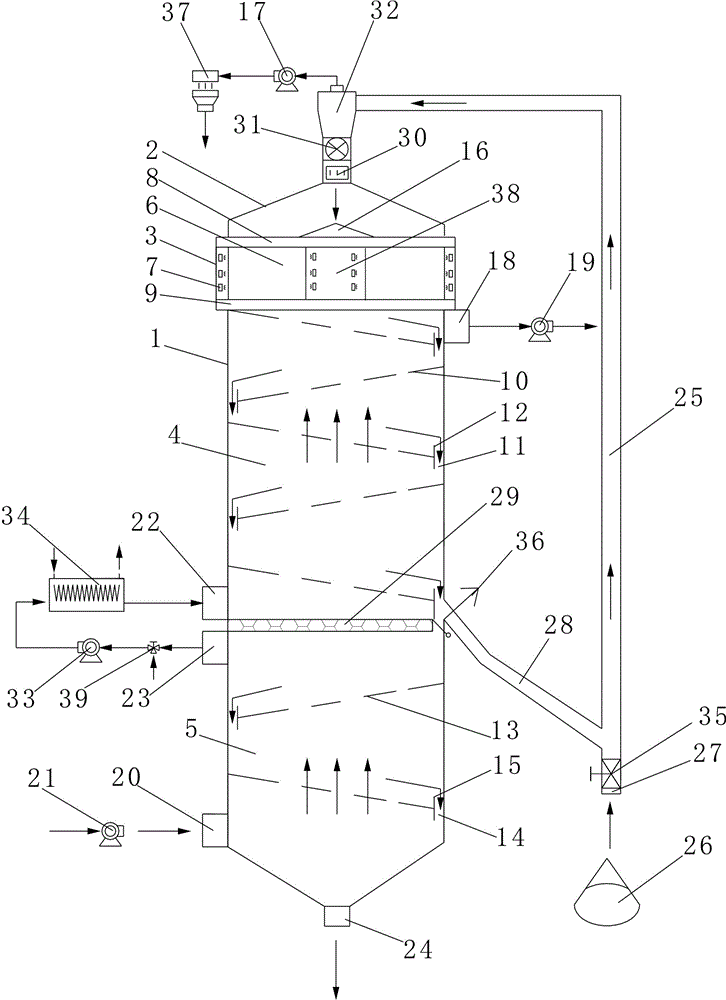

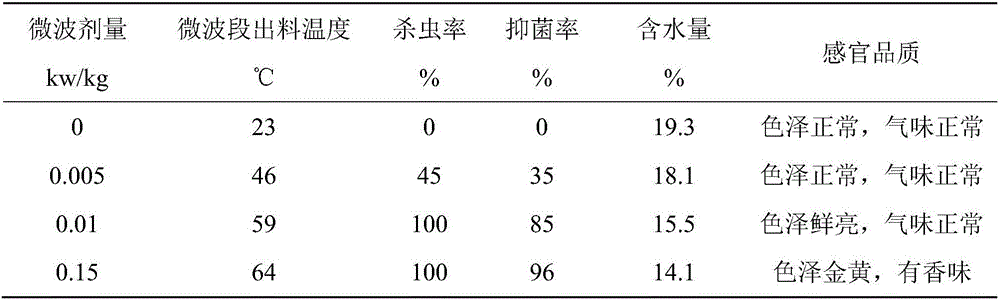

Grain microwave and fluidization combined drying equipment, drying method and application

ActiveCN105928323AReach killEfficient killingDrying solid materials with heatDrying gas arrangementsMicrowaveEngineering

The invention discloses grain microwave and fluidization combined drying equipment, a drying method and application. The equipment comprises a tower body; and the tower body is provided with a buffer bin, a microwave section, a drying section and a cooling section in sequence from top to bottom. The drying section and the cooling section respectively include multiple fluidization plates staggered on upper and lower layers; one ends of the fluidization plates are fixedly connected with the tower body, and baffle plates are mounted at the other ends; and overflow channels are formed between the baffle plates and the tower body. An exhaust port of the cooling section communicates with a hot air intake ports of the drying section via a hot air fan and a heat exchanger; hot air exhausted by the cooling section is leaded into the drying section; and afterheat thereof is fully used to save the energy. The drying method comprises three steps of microwave preheating, fluidization drying and fluidization cooling. The drying equipment and the drying method use the microwave and fluidization combined drying, have the characteristics of high drying efficiency and uniform drying, can realize functions of insecticide and bacteriostasis, and can be used for drying such grains with good fluidity as paddy, wheat and corn.

Owner:HUAZHONG AGRI UNIV

Protection method for rust removal, paint removal and anticorrosion of metal surface

InactiveCN102218386ASolve the work of rust removal and rust preventionReduce labor intensityPretreated surfacesCoatingsBenzeneKetone

The invention relates to a protection method for rust removal, paint removal and anticorrosion of a metal surface. The method comprises three steps of (1) metal surface lossless rust removal technology, (2) conversion of rust iron on a metal surface and antirust processing, (3) painting of anticorrosion paint on the metal surface. Compared with prior art, the protection processing on the metal surface of the invention employs a high-pressure water-sand blending technology to remove rust, so that rust removal efficiency is higher and the method is safe and environment-friendly. Free rust on the metal surface can be conversed into antirust priming paint when a rust removal transforming agent is being painted, so as to complete metal rust removal and rust prevention by one step, and solve problems, that harm antirust quality, such as local corrosion and free rust at one time. The rust transforming agent employed in the technology belongs to an aqueous system, is without harmful solvents of benzene, ketone, etc., or heavy metal compositions and is nontoxic and environmental-friendly, so that base materials with rust can be used in construction to save costs and raise efficiency. Anticorrosion coating on the metal surface employs a high-pressure air-free coating spraying, so that construction quality is more reliable and the efficiency is higher.

Owner:SHANGHAI FAHE BRIDGE & TUNNEL MAINTENANCE ENG TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com