Method for rapidly peeling and transferring graphene oxide leaching film to substrate

A graphene film and graphene technology, which is applied in the field of rapid peeling of graphene oxide suction filter membrane and transfer to the substrate, can solve the problem that the film shape cannot be kept flat, the film cannot be peeled off from the substrate, and the graphene oxide film peels off and other problems, to achieve the effect of good shape, easy attachment, and shortened time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

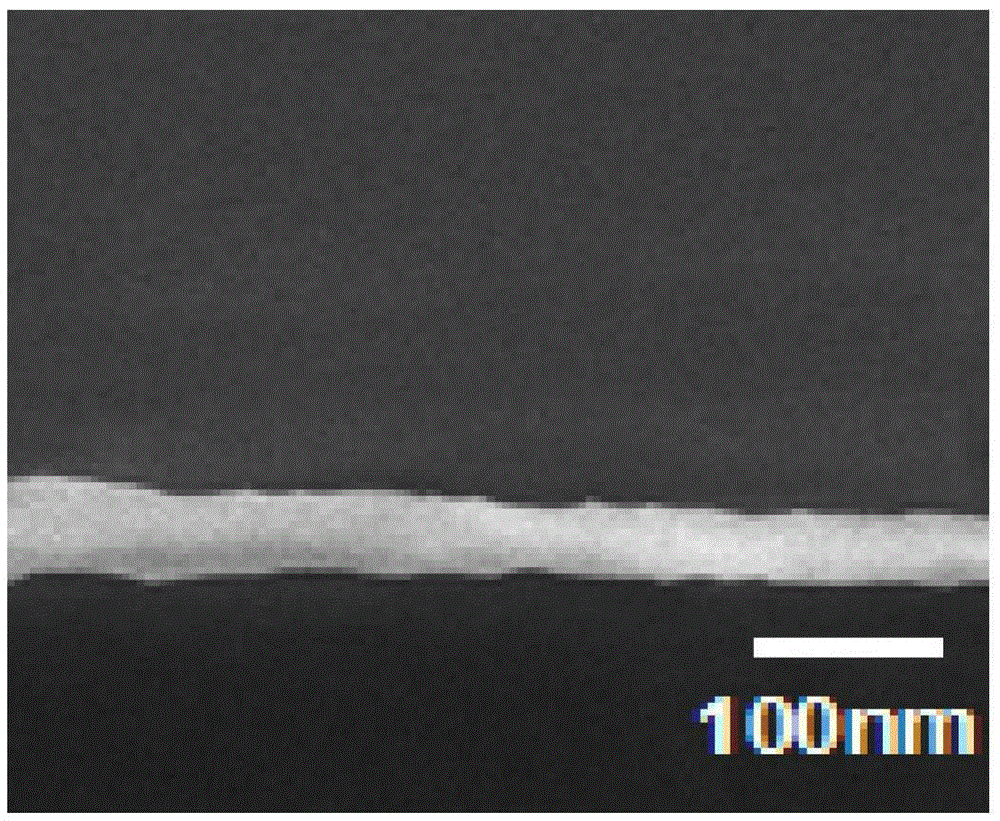

[0024] In the first step, take 10ul of 1mg / ml graphene oxide aqueous dispersion and add it into 100ml of water.

[0025] In the second step, the polycarbonate substrate with a pore size of 0.4um is fixed in the suction filtration device.

[0026] In the third step, the graphene oxide dispersion is poured into a suction filter bottle to start suction filtration.

[0027] In the fourth step, after the suction filtration is completed, the obtained film is quickly put into an ethanol solution to obtain an exfoliated graphene oxide film.

[0028] In the fifth step, the graphene oxide film floating in the ethanol solution is combined with the silicon substrate.

Embodiment 2

[0030] The control method is basically the same as that in Example 1, except that: 4 ml of 1 mg / ml graphene oxide aqueous dispersion is taken and added to 100 ml of water.

Embodiment 3

[0032] The control method is basically the same as that in Example 1, except that: 10 ml of 1 mg / ml graphene oxide aqueous dispersion is taken and added to 100 ml of water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com