Patents

Literature

5237results about "Layered product treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

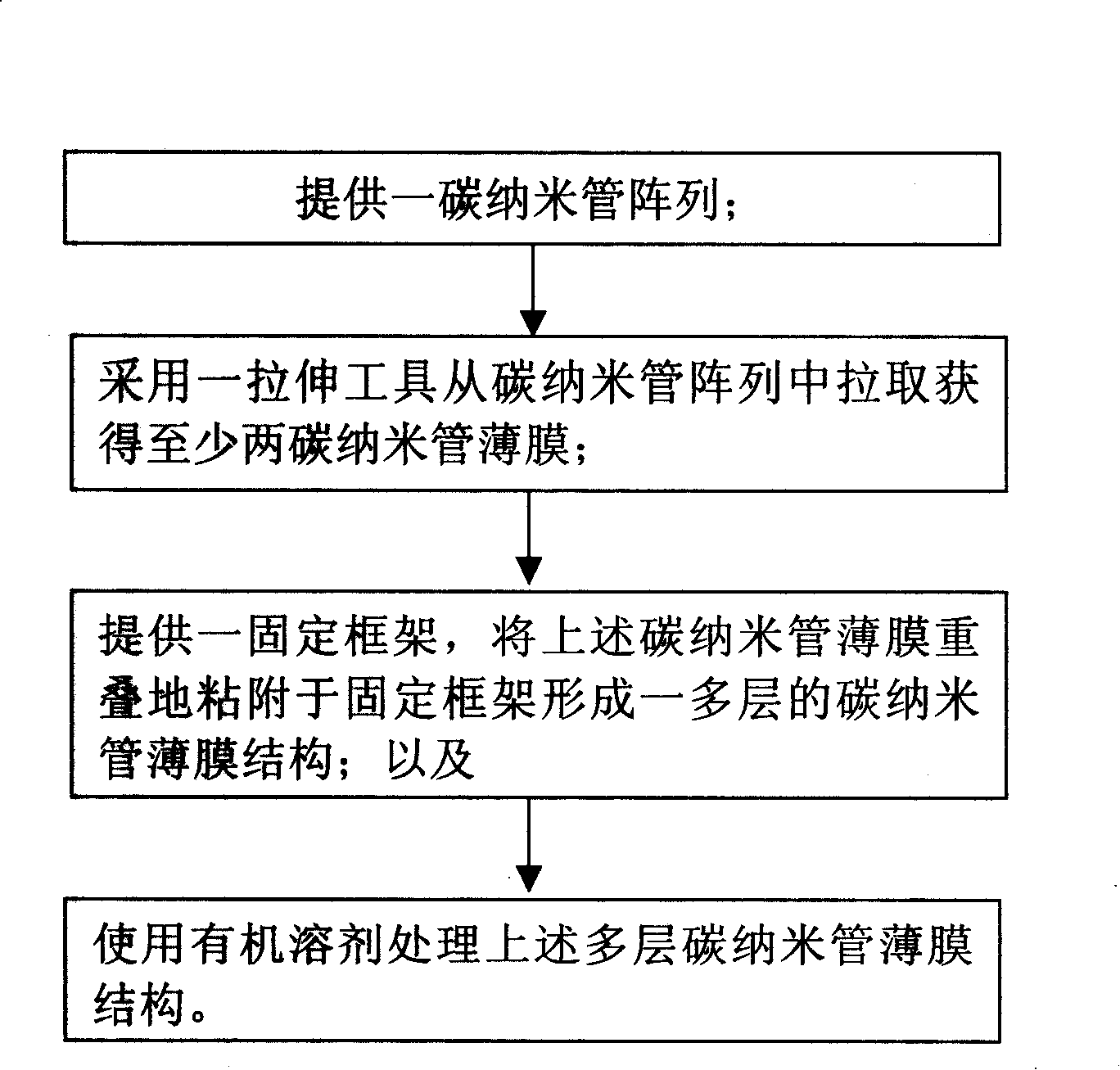

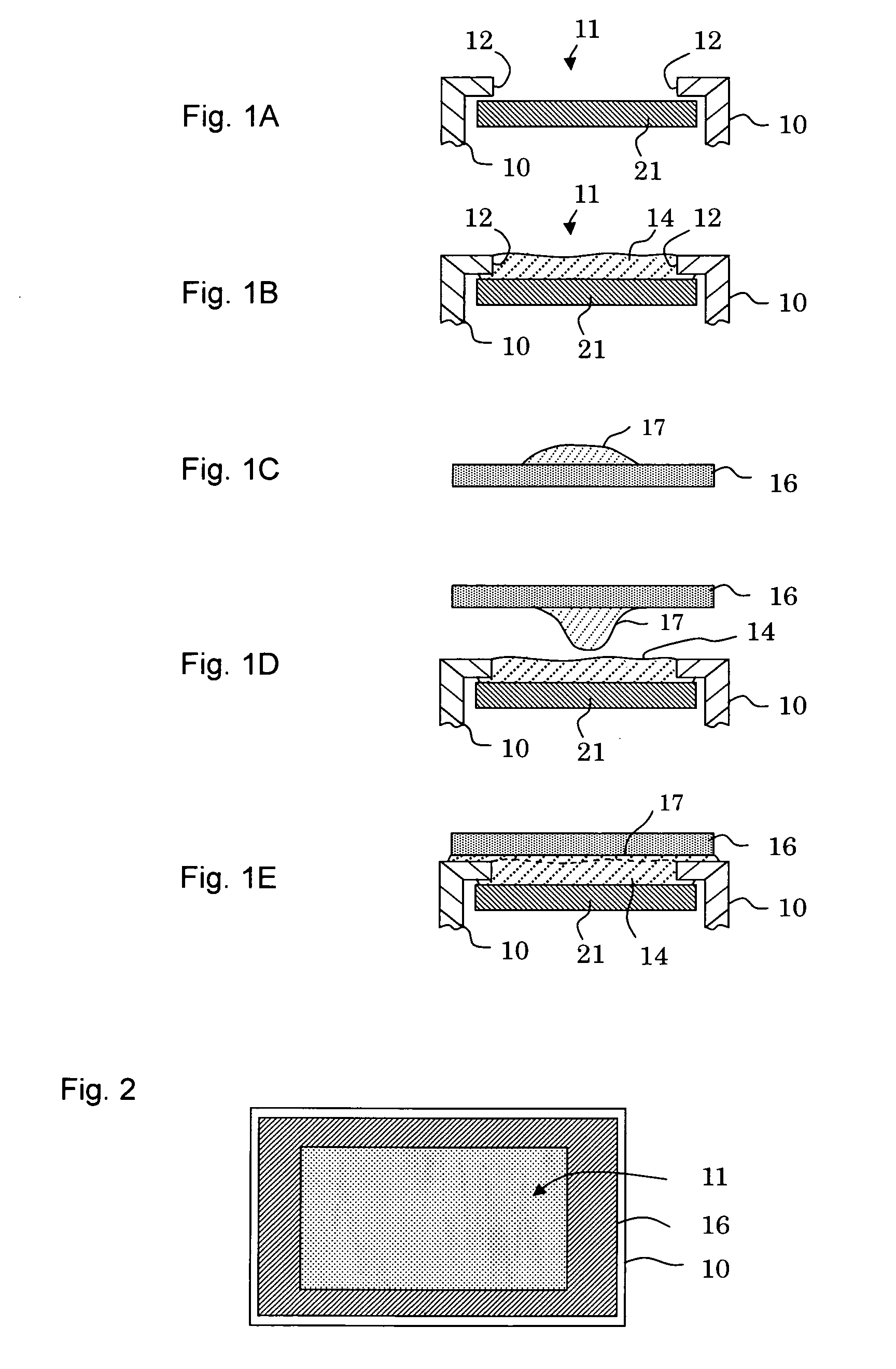

Carbon nano-tube thin film structure and preparation method thereof

ActiveCN101239712ASmall surface to volume ratioNon stickyMaterial nanotechnologyLamination ancillary operationsOrganic solventFixed frame

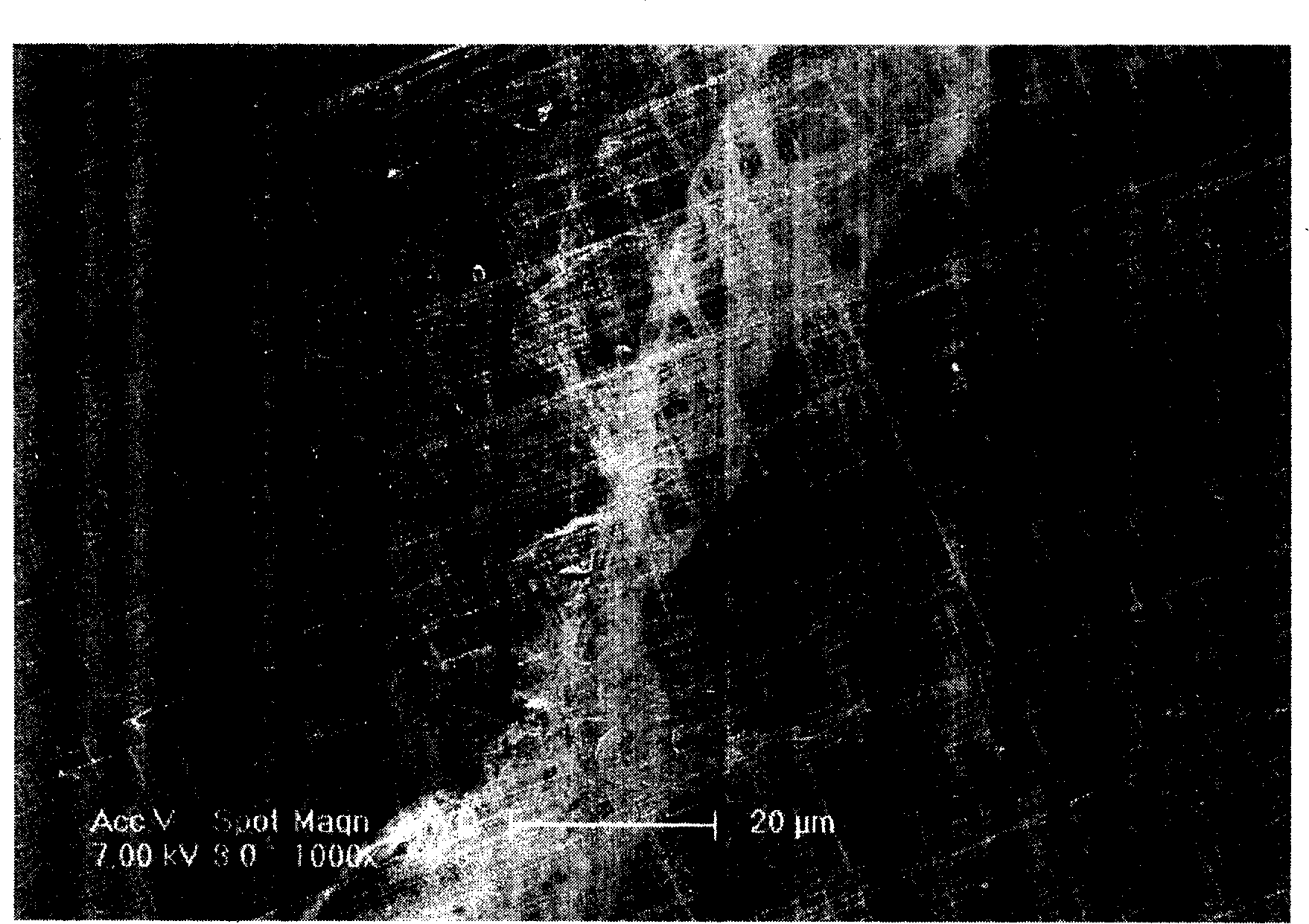

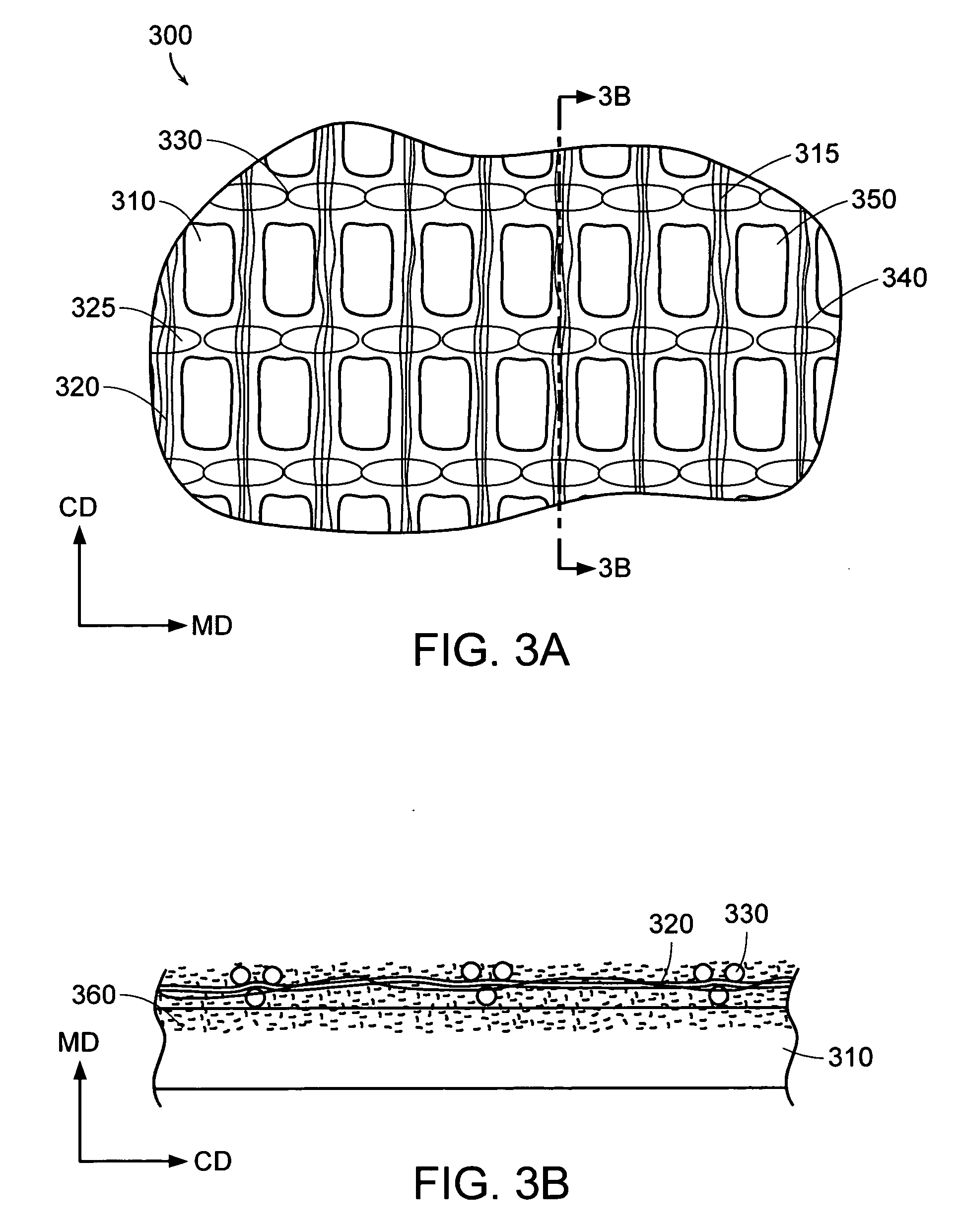

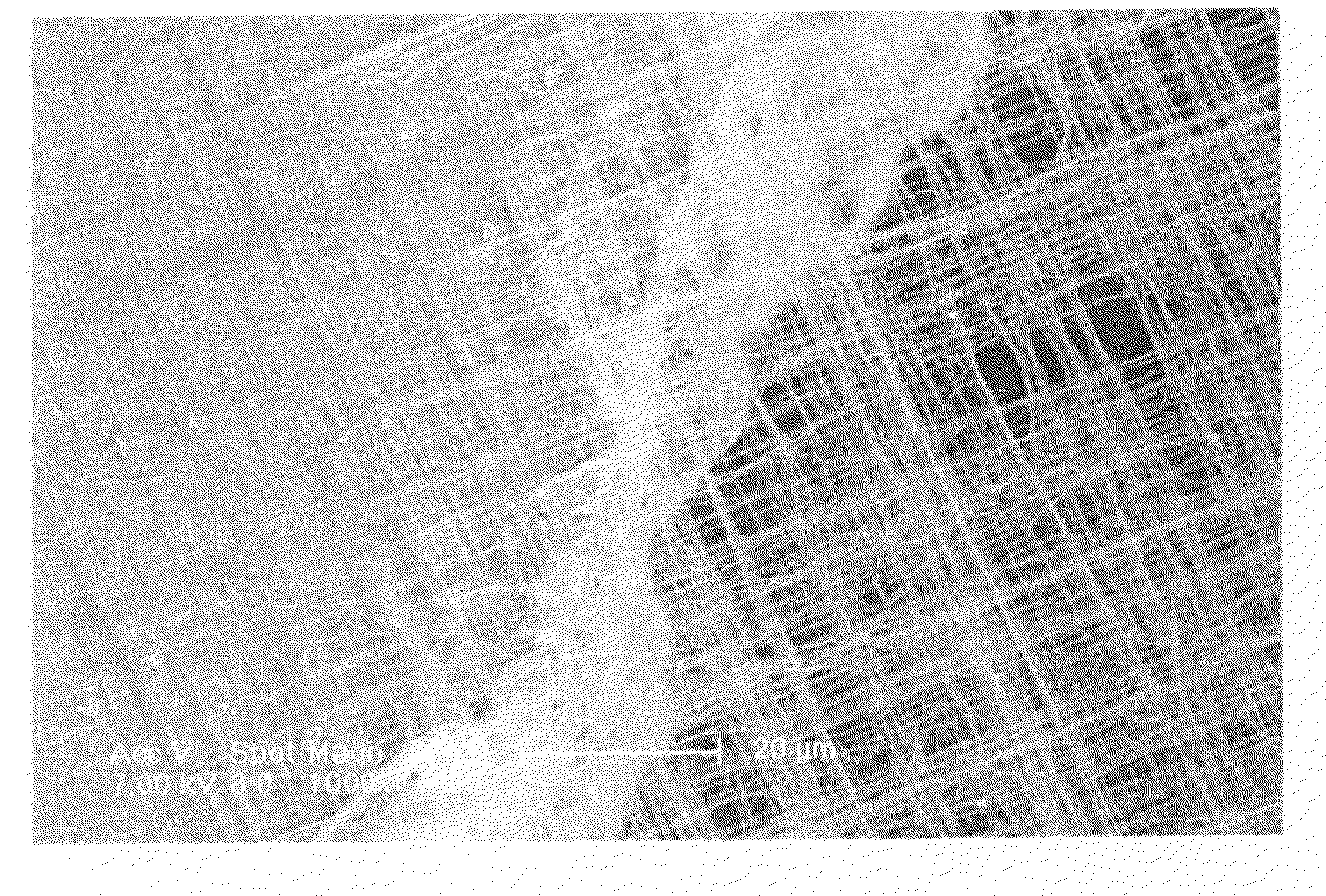

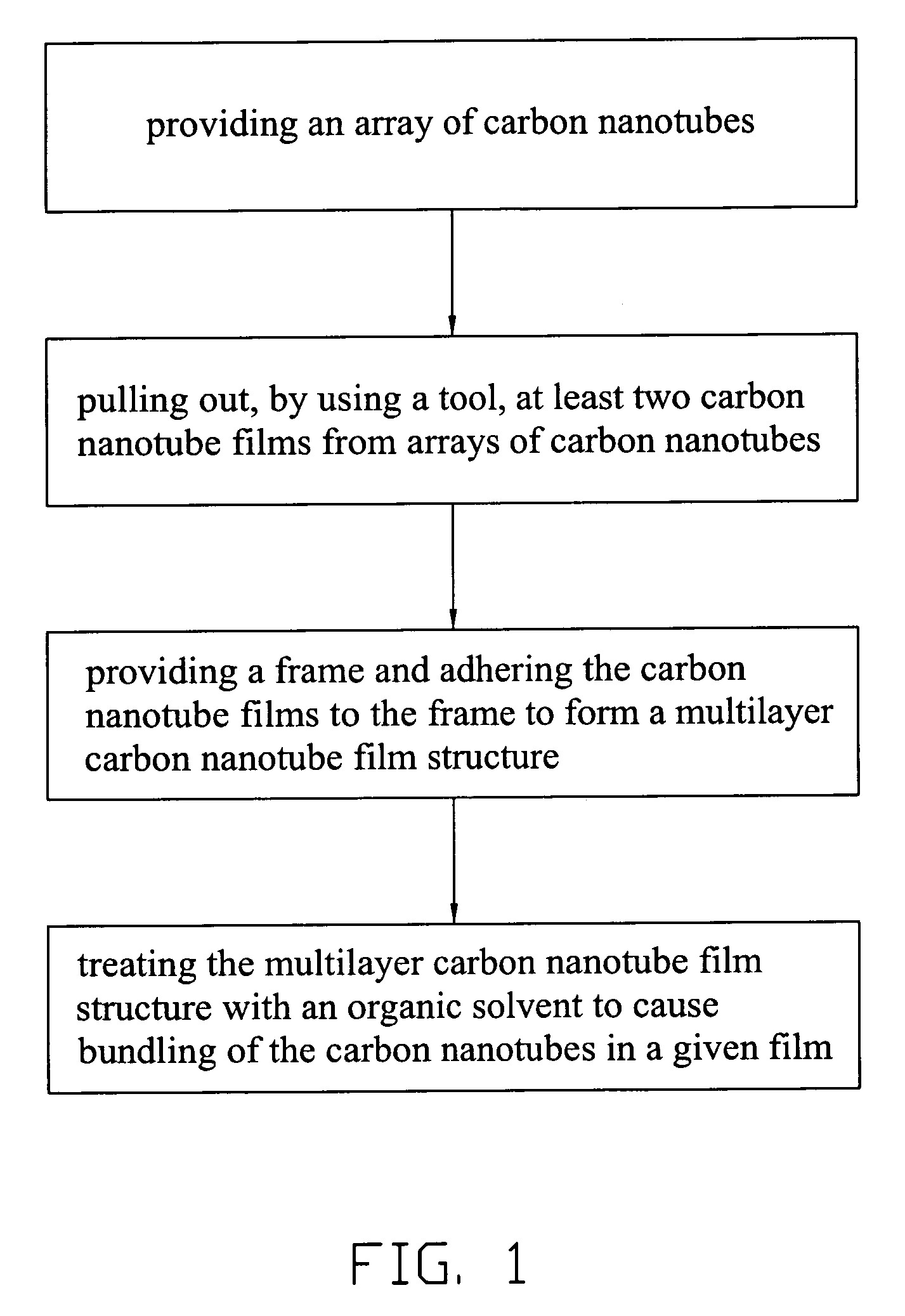

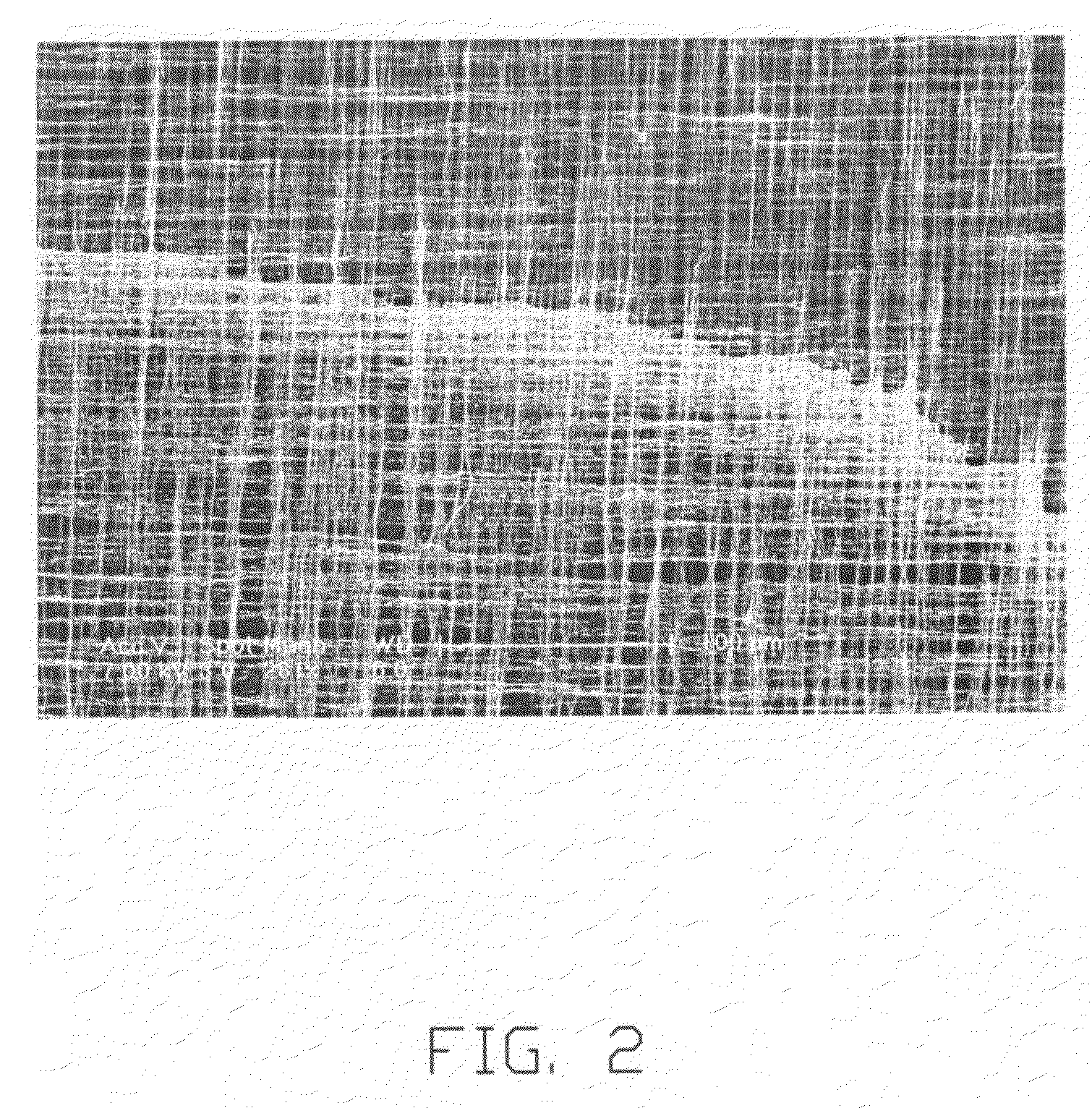

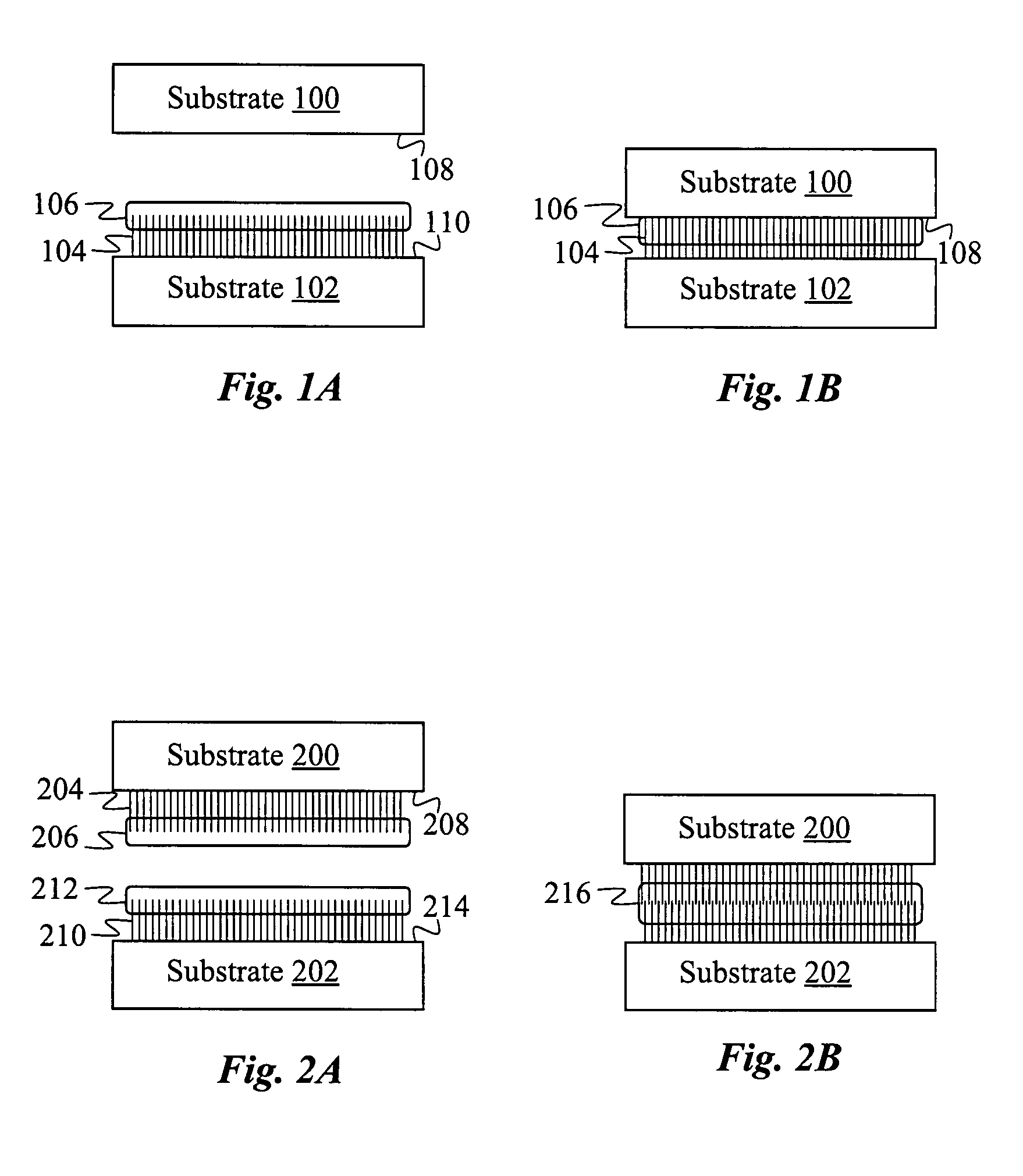

The present invention provides a preparing method of carbon nanotube film structure, including following steps: providing a carbon nanotube array; adopting a pulling tool to acquire at least two carbon nanotube films from the carbon nanotube array; providing a fixed frame, forming a multiple-layer carbon nanotube film structure by overlap adhereing the carbon nanotube film in the fixed frame; and treating the multiple-layer carbon nanotube film by an organic solvent. The carbon nanotube film structure prepared by the method includes at least two layers overlapped and cross-over installed carbon nanotube film, which includes multiple carbon nanotube bundle end to end and arranged in the direction, the multiple-layer carbon nanotube film further includes millipore crosswise formed by multiple carbon nanotube bundles.

Owner:TSINGHUA UNIV +1

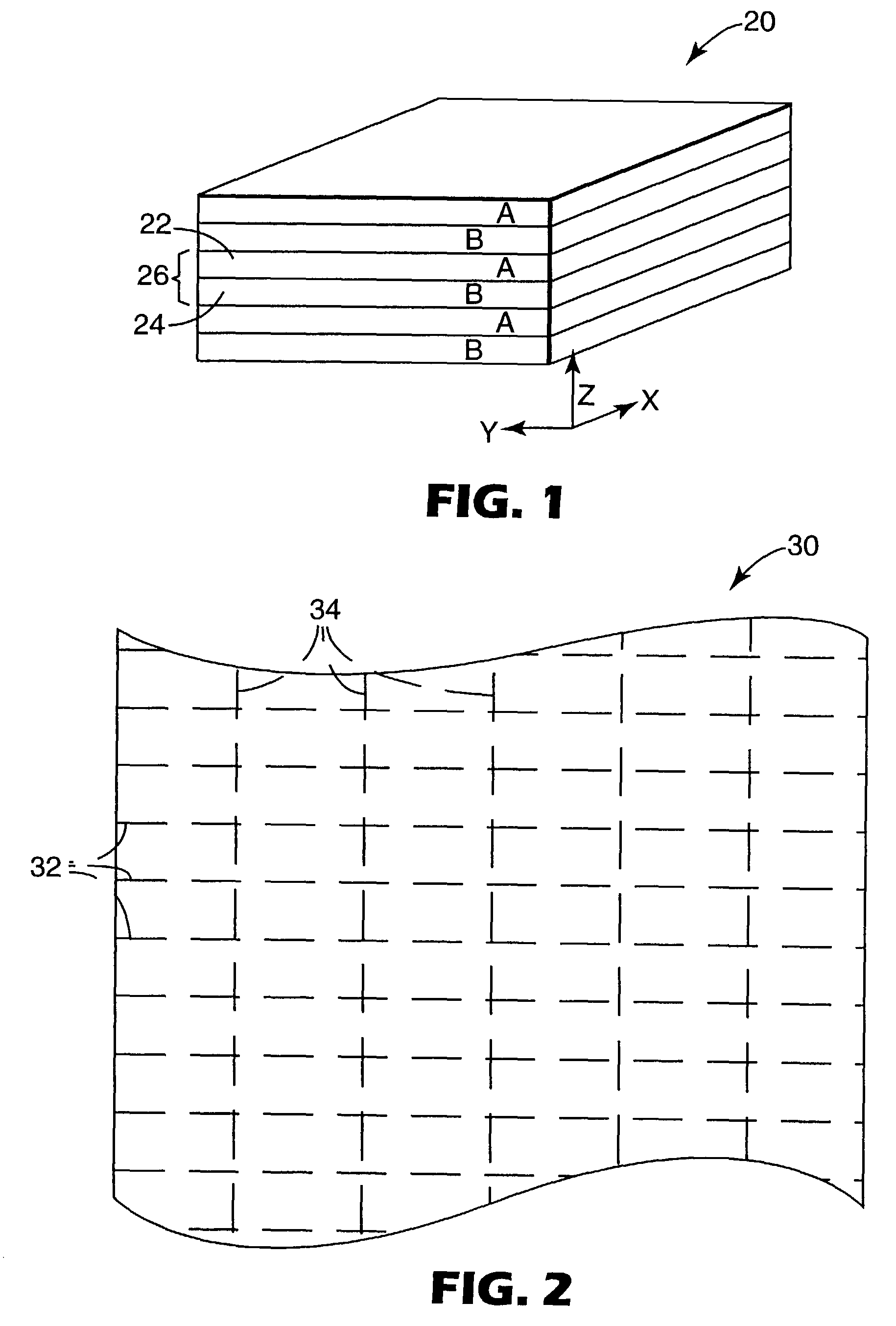

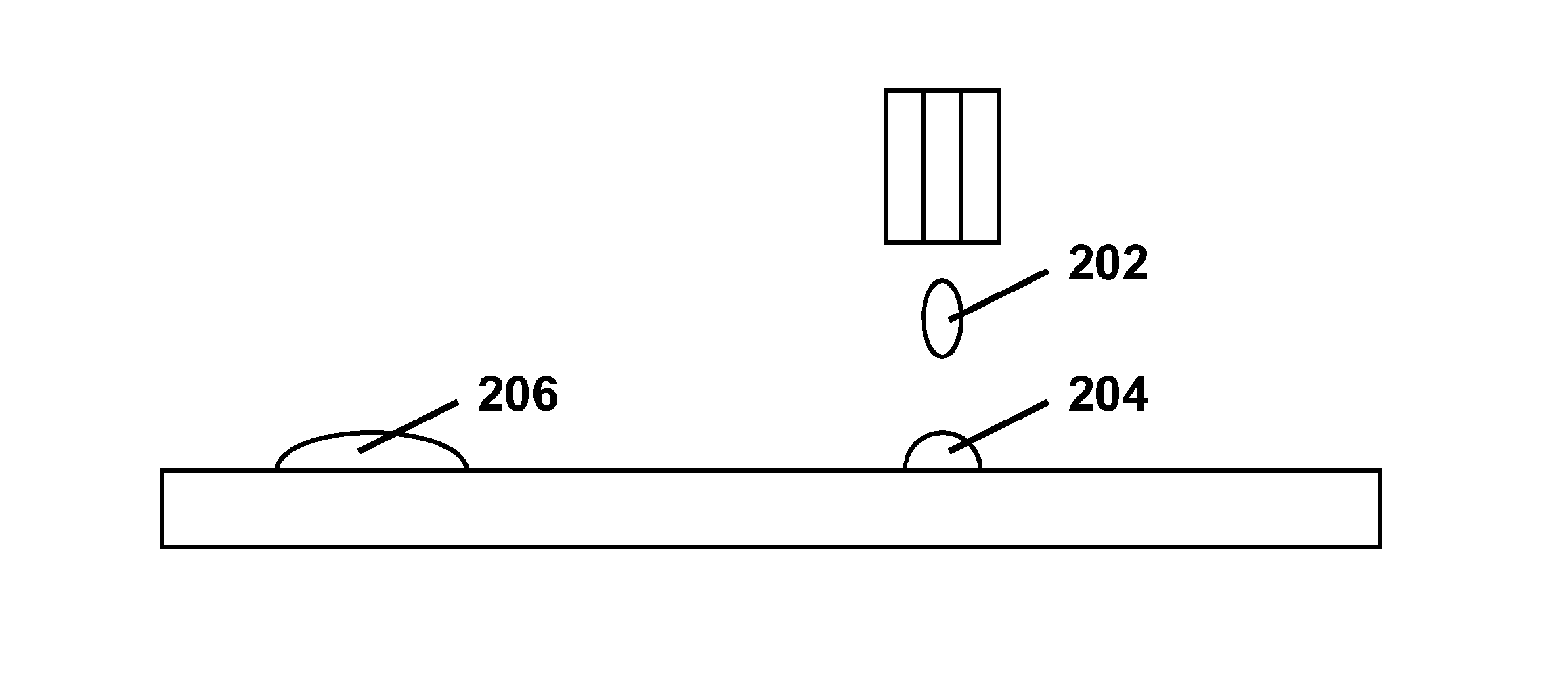

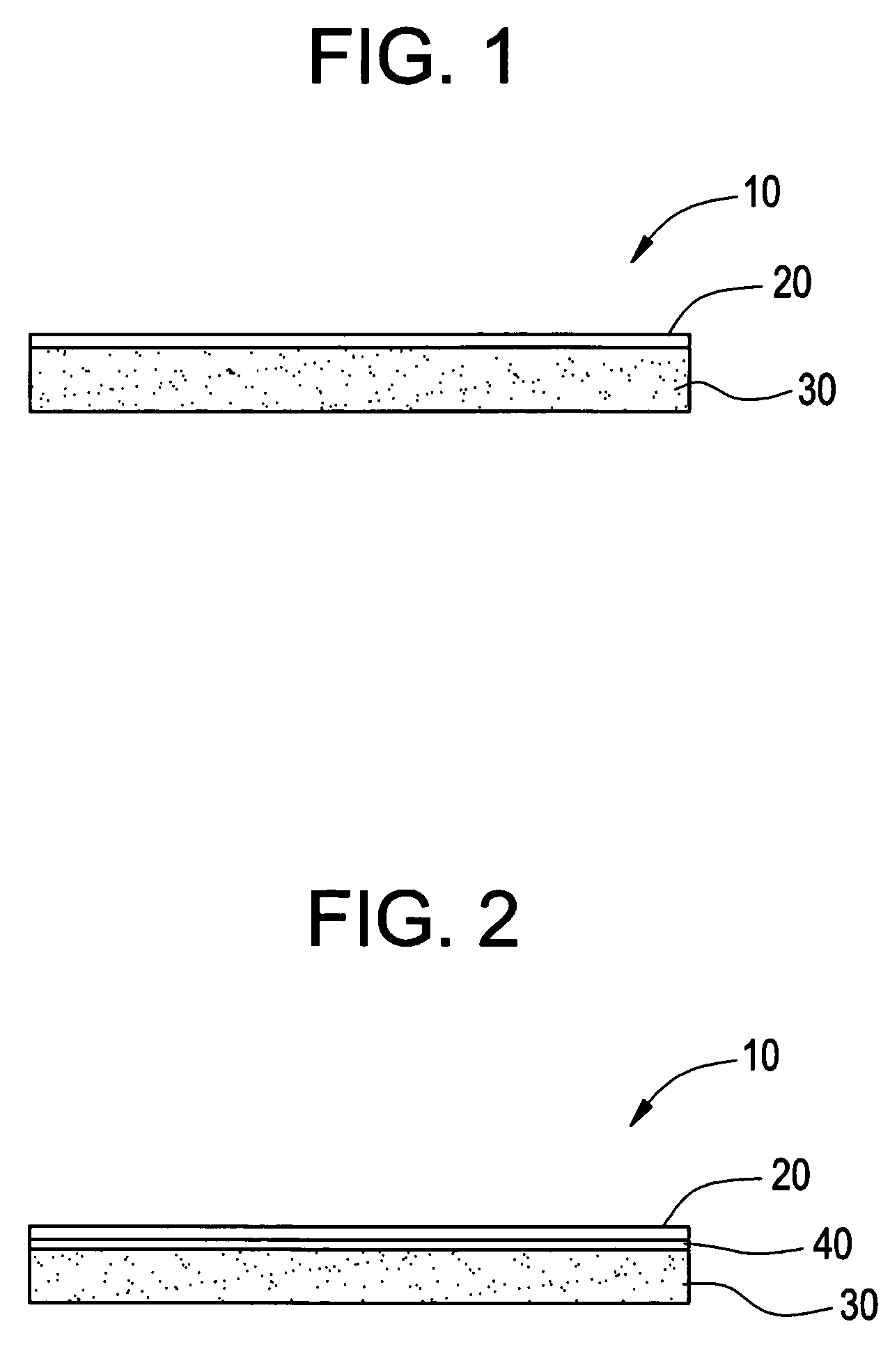

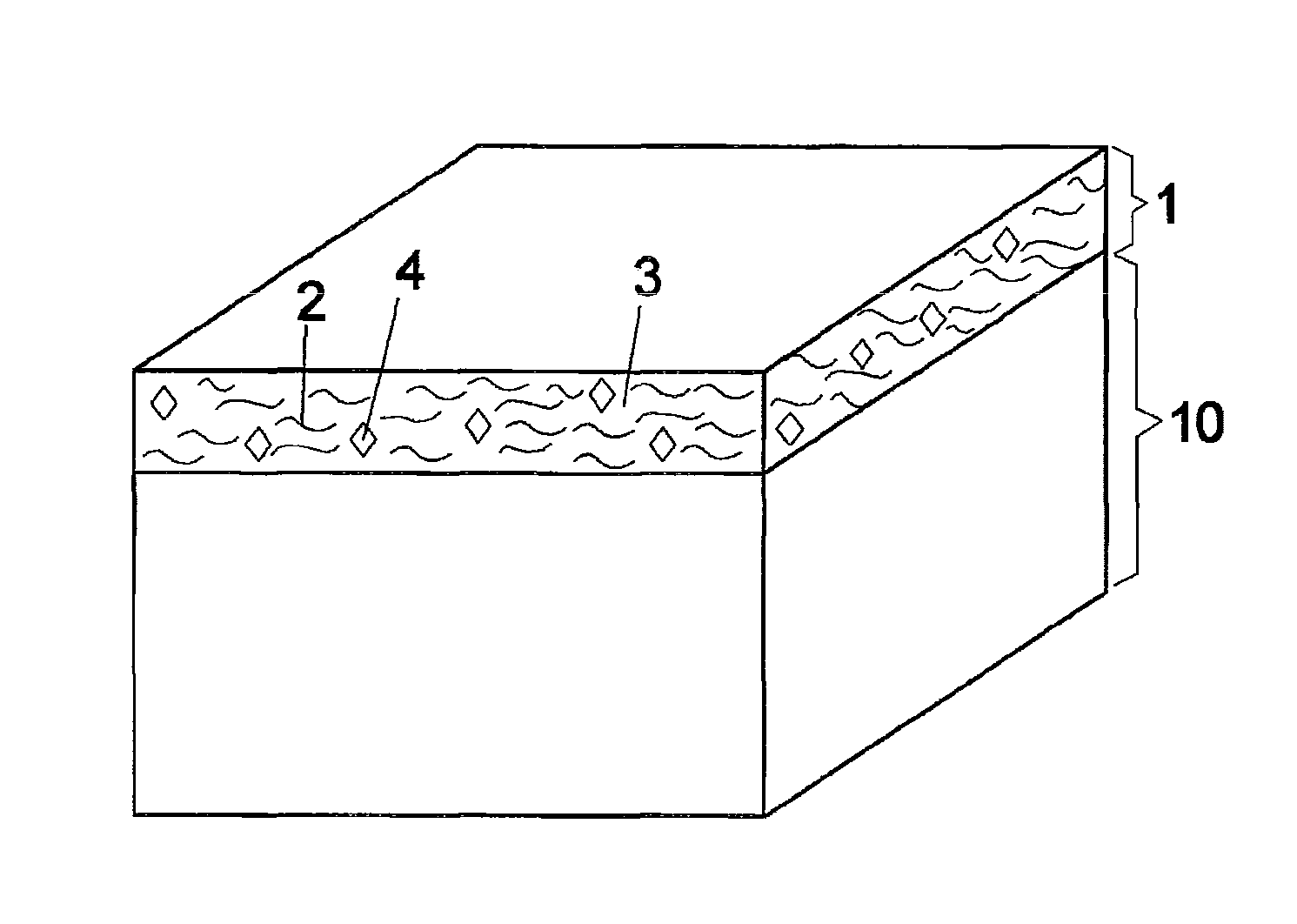

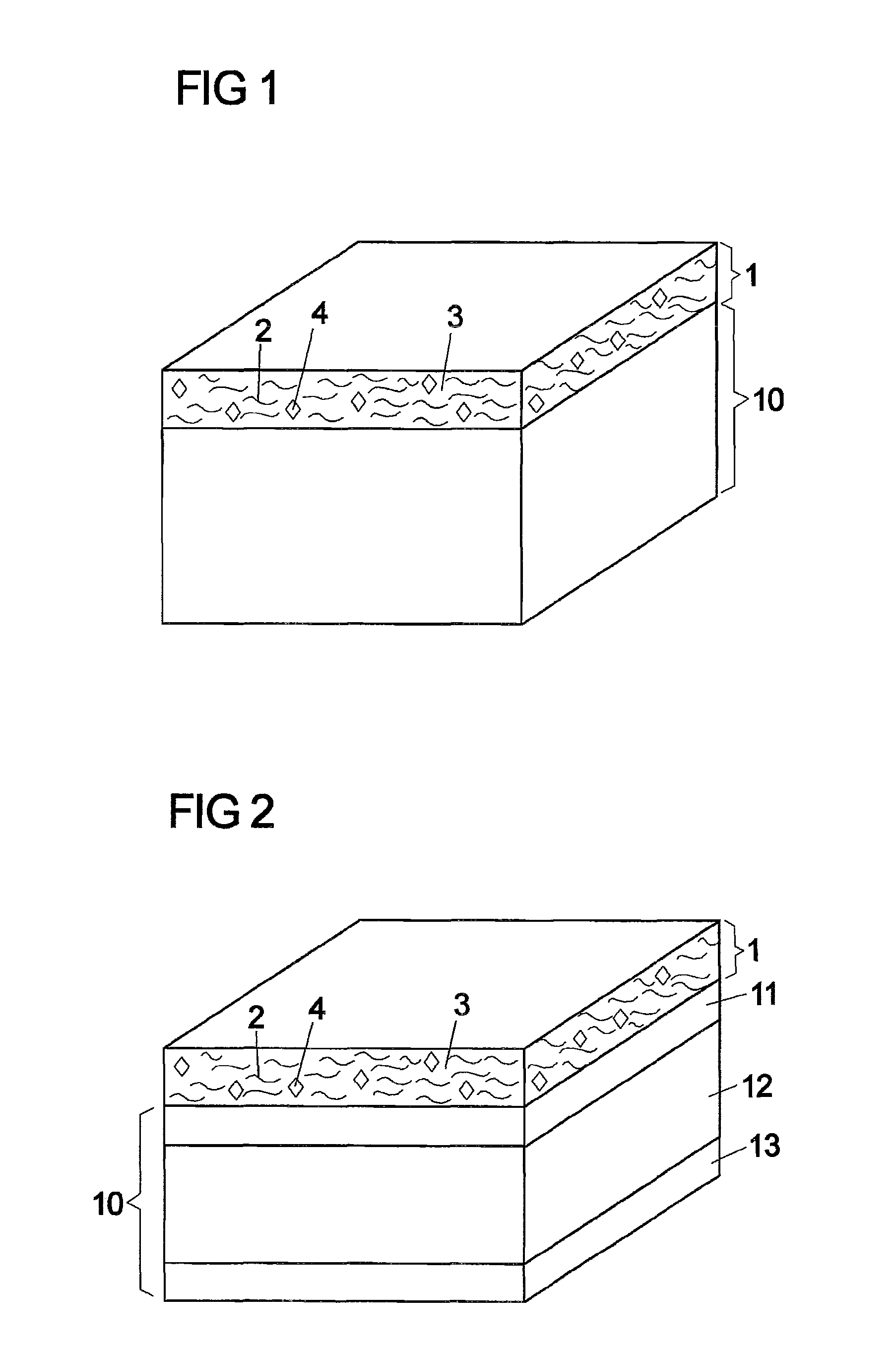

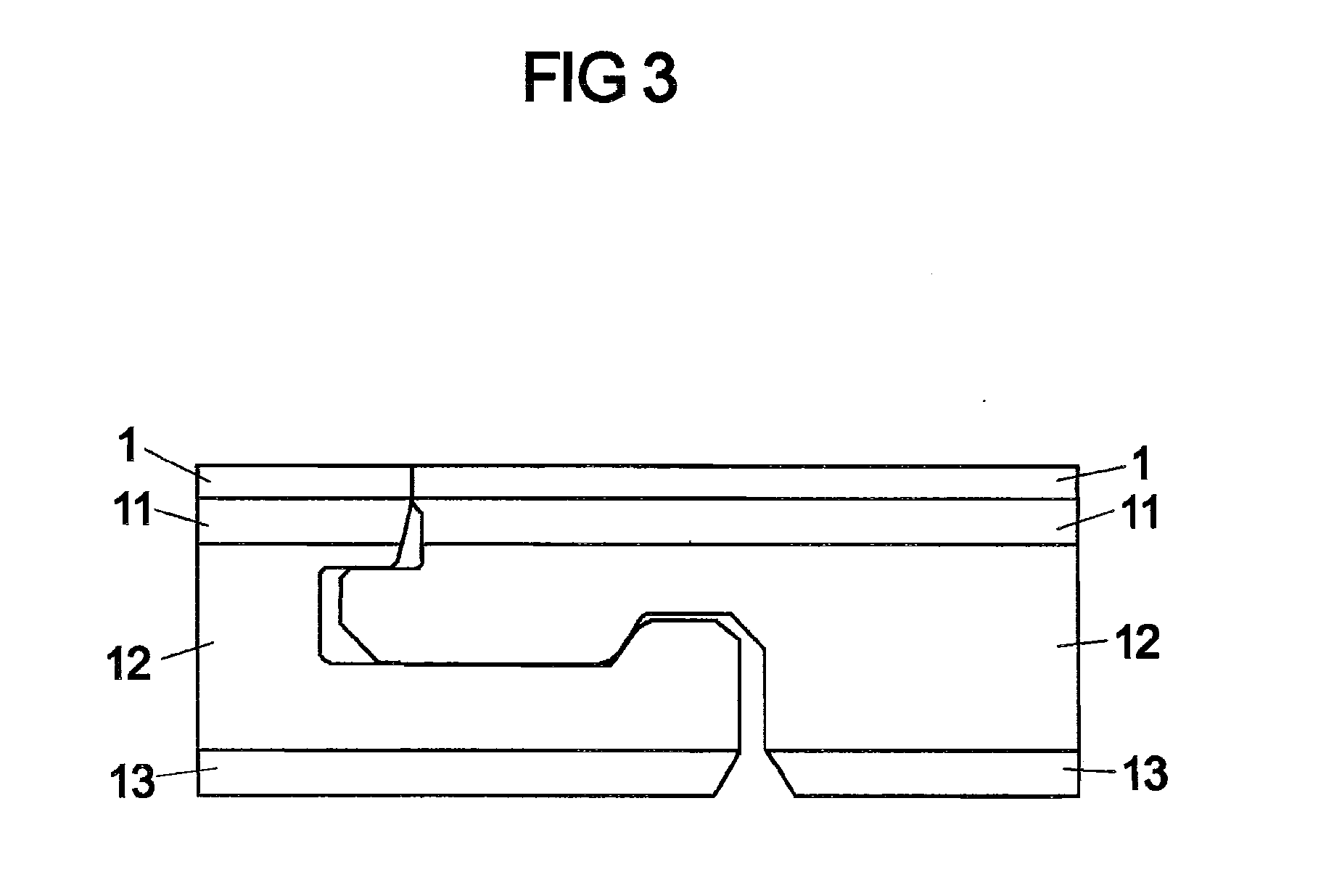

Disposable Absorbent Article With Substantially Continuously Distributed Absorbent Particulate Polymer Material And Method

A disposable absorbent core comprises first and second absorbent layers each comprising an absorbent particulate polymer material such that the absorbent particulate polymer material is substantially continuously distributed across an absorbent particulate polymer material area. A disposable absorbent article and method for making the absorbent core are also disclosed.

Owner:THE PROCTER & GAMBLE COMPANY

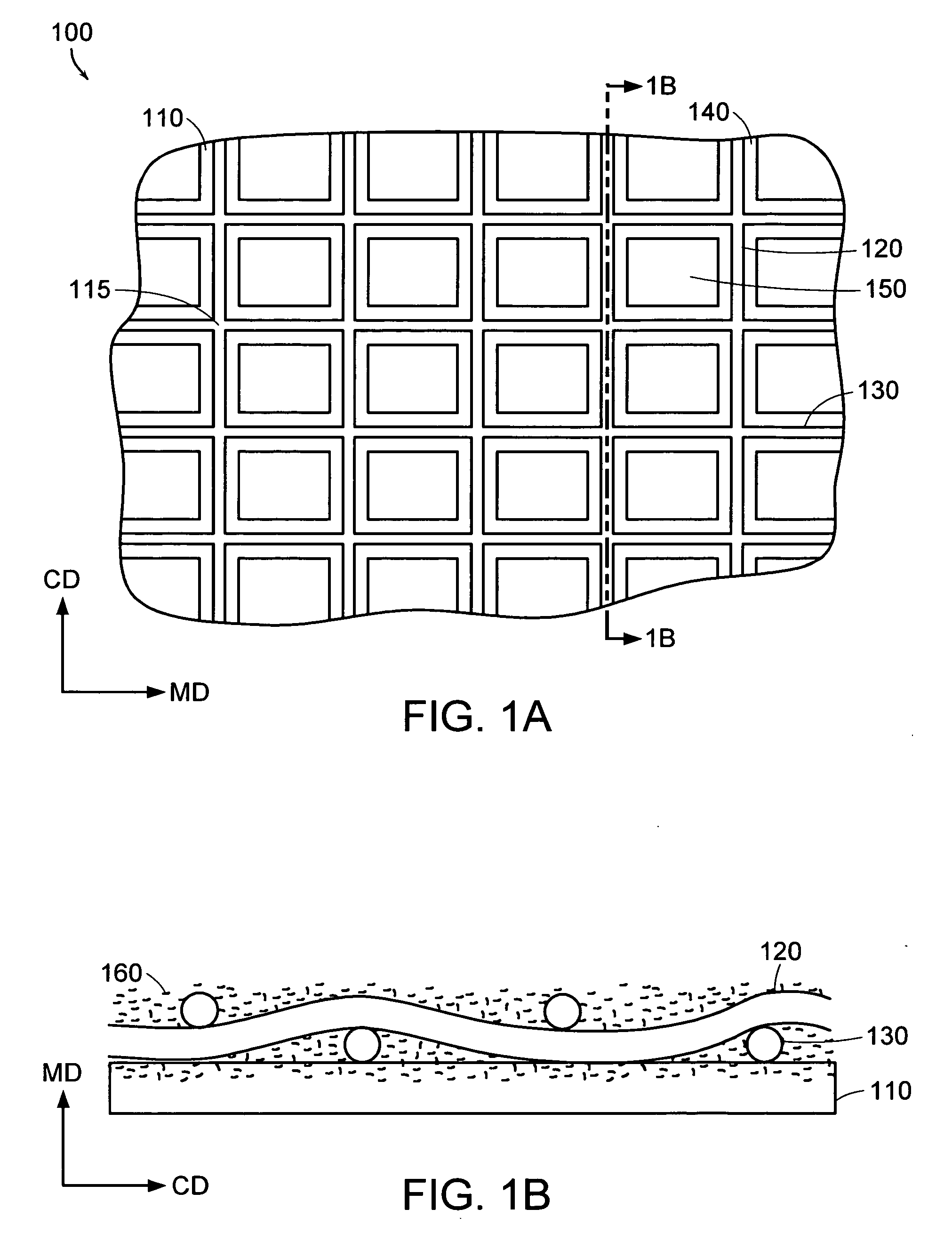

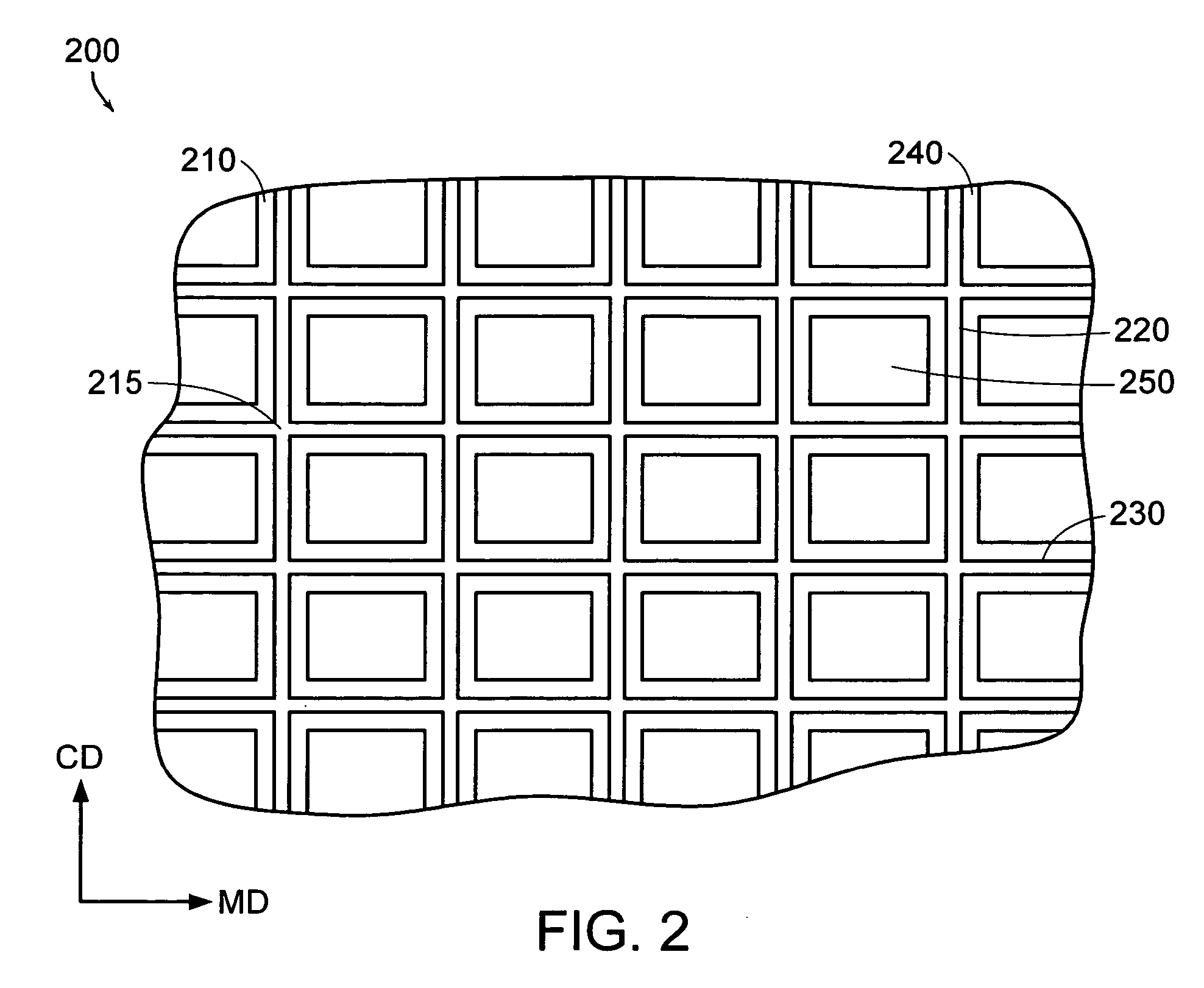

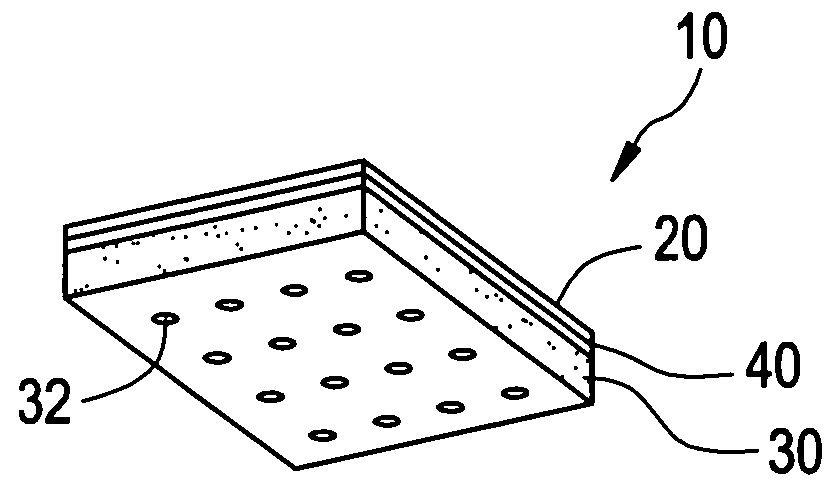

Air permeable pressure-sensitive adhesive tapes

InactiveUS20060154546A1Convenient to to manufactureEasy to useLamination ancillary operationsLayered product treatmentEngineeringPlastic film

A vapor permeable article includes a porous backing substrate and an open fabric applied to one surface of the backing substrate. The open fabric has a greater porosity than that of the backing substrate. The open fabric may be a woven fabric comprising warp (MD) yarns and weft (CD) yarns, and the warp yarns may be of a lower denier than the weft yarns, so as to facilitate hand-tear of the assembled article. The open fabric is coated with an adhesive in such a manner that the open fabric remains porous and vapor permeable. The backing substrate can be a woven, knit or non-woven fabric, or a porous film, such as an apertured plastic film.

Owner:ANDOVER HEALTHCARE

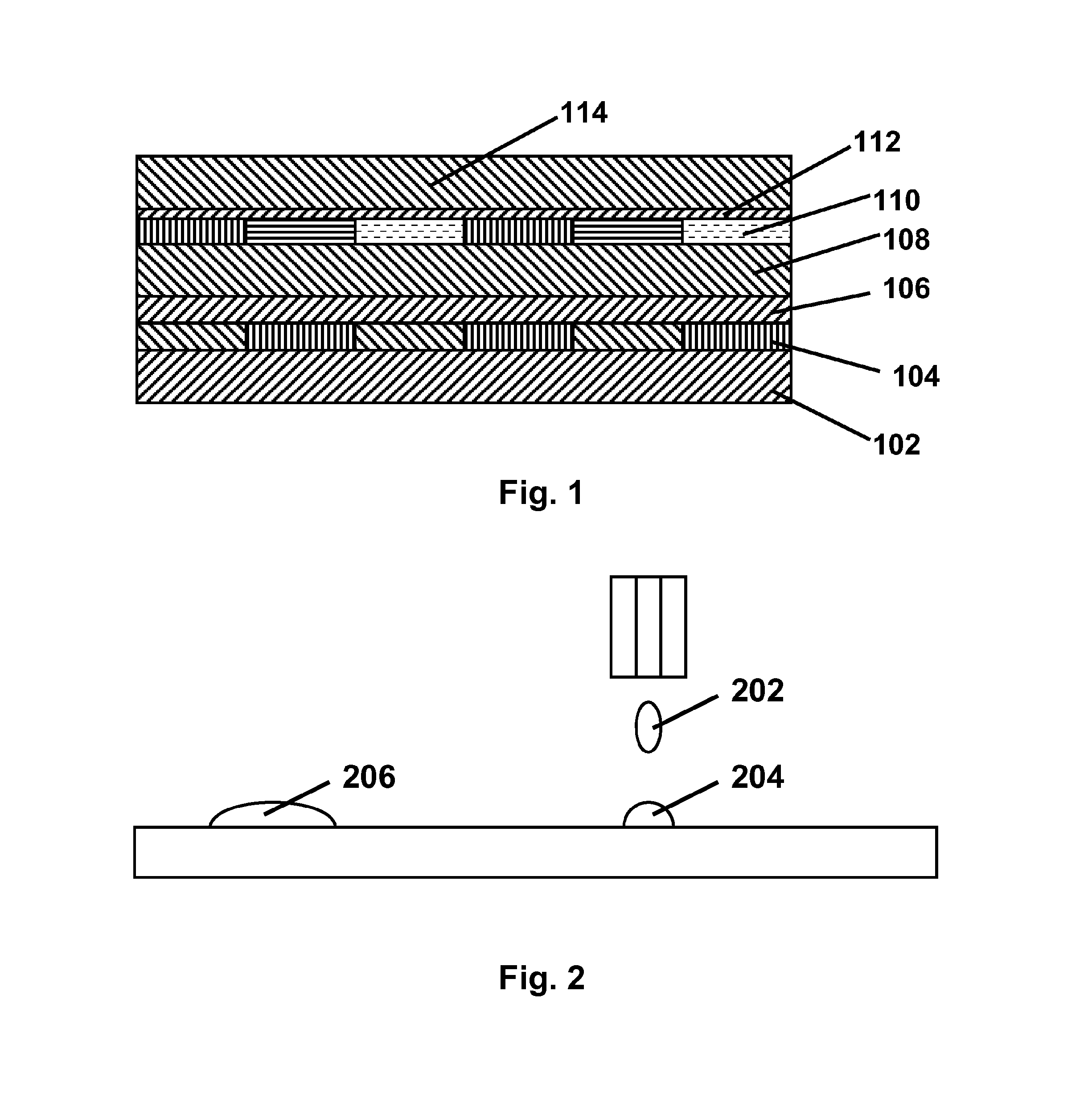

Carbon nanotube film structure and method for fabricating the same

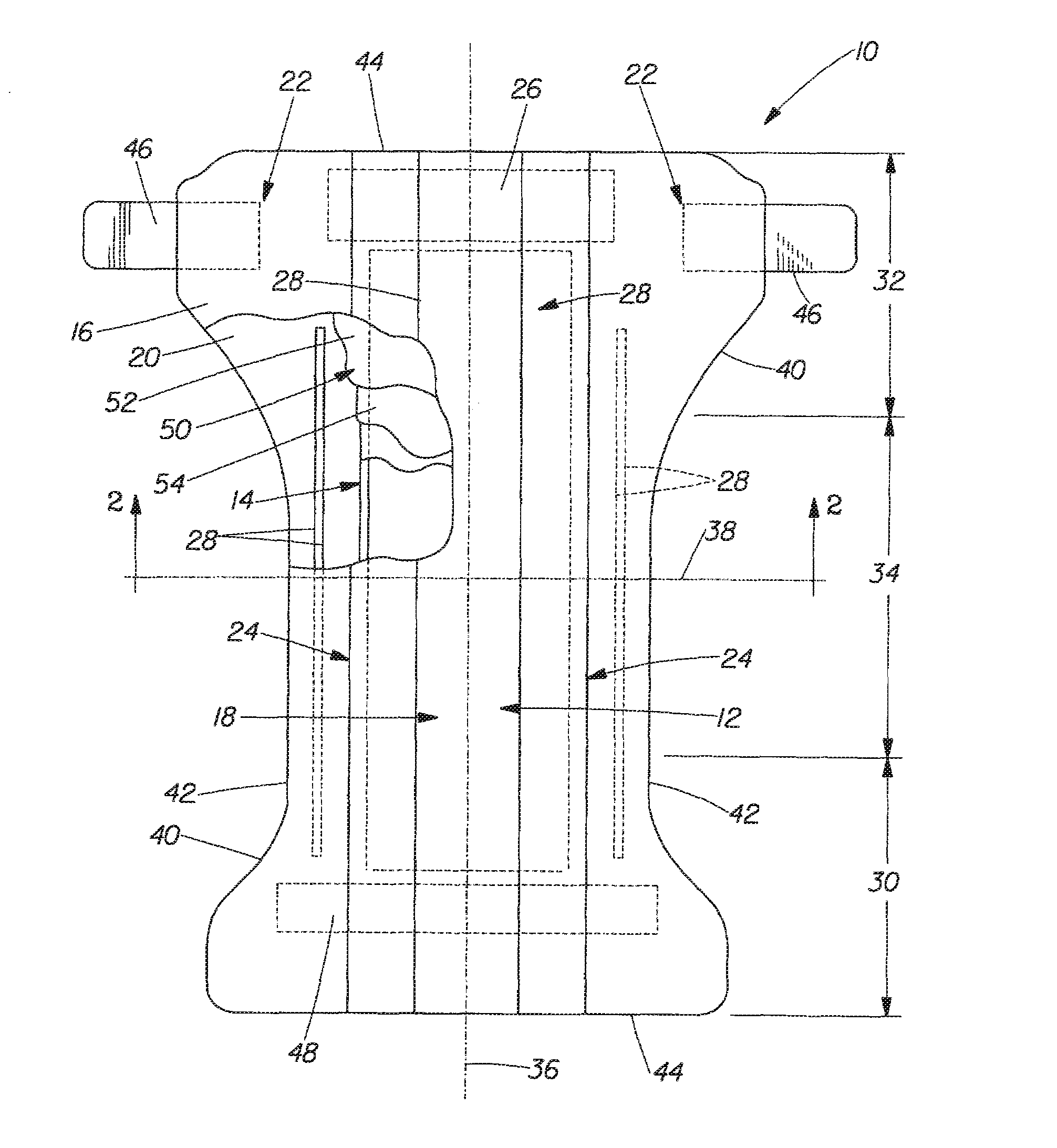

A carbon nanotube film structure includes at least two overlapped carbon nanotube films, with adjoining films being aligned in different directions. Each carbon nanotube film includes a plurality of successive carbon nanotube bundles aligned in the same direction. The carbon nanotube structure further includes a plurality of micropores formed by / between the adjoining carbon nanotube bundles. A method for fabricating the carbon nanotube film structure includes the steps of: (a) providing an array of carbon nanotubes; (b) pulling out, using a tool, one carbon nanotube film from the array of carbon nanotubes; (c) providing a frame and adhering the carbon nanotube film to the frame; (d) repeating steps (b) and (c), depositing each successive film on a preceding film, thereby achieving at least a two-layer carbon nanotube film; and (e) peeling the carbon nanotube film off the frame to achieve the carbon nanotube structure.

Owner:TSINGHUA UNIV +1

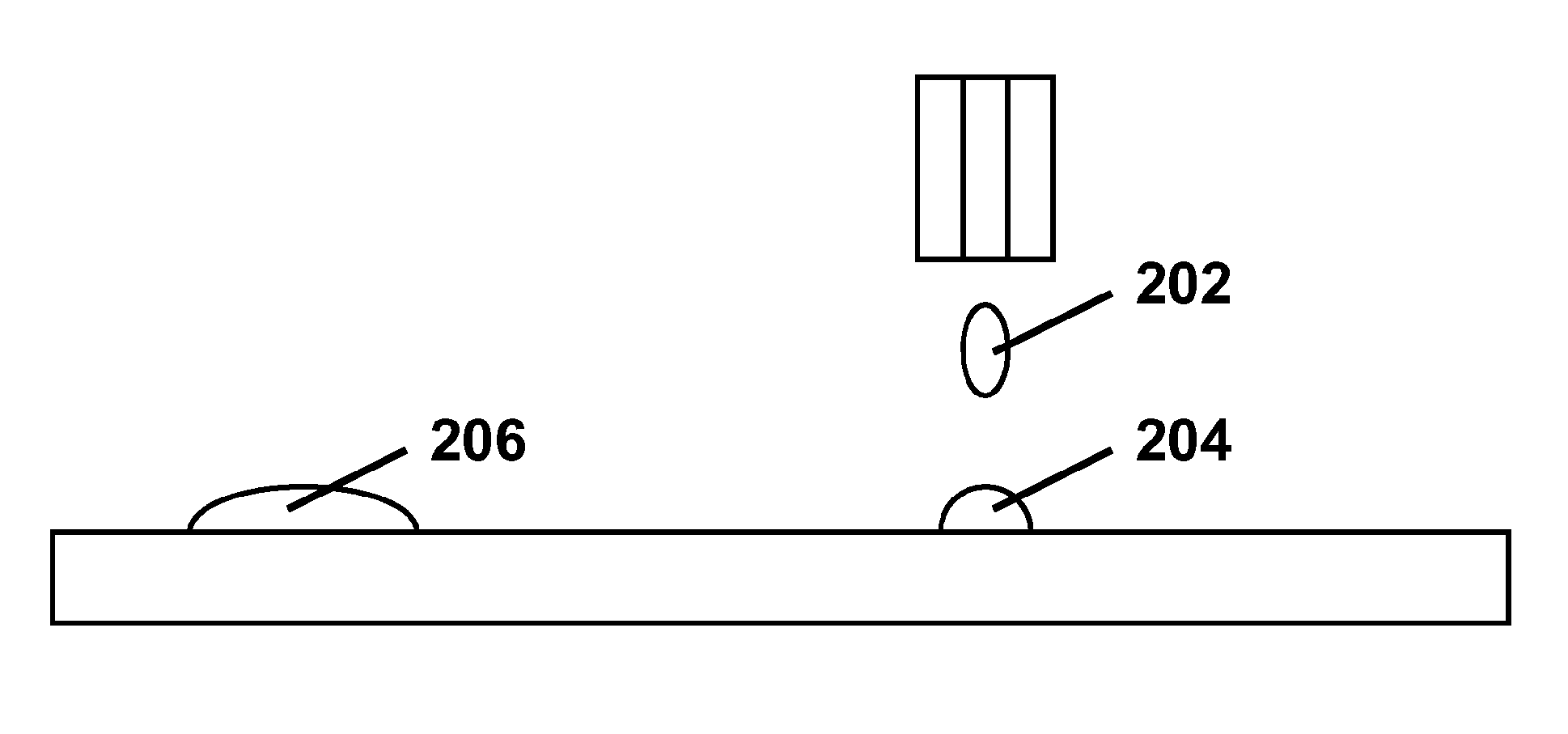

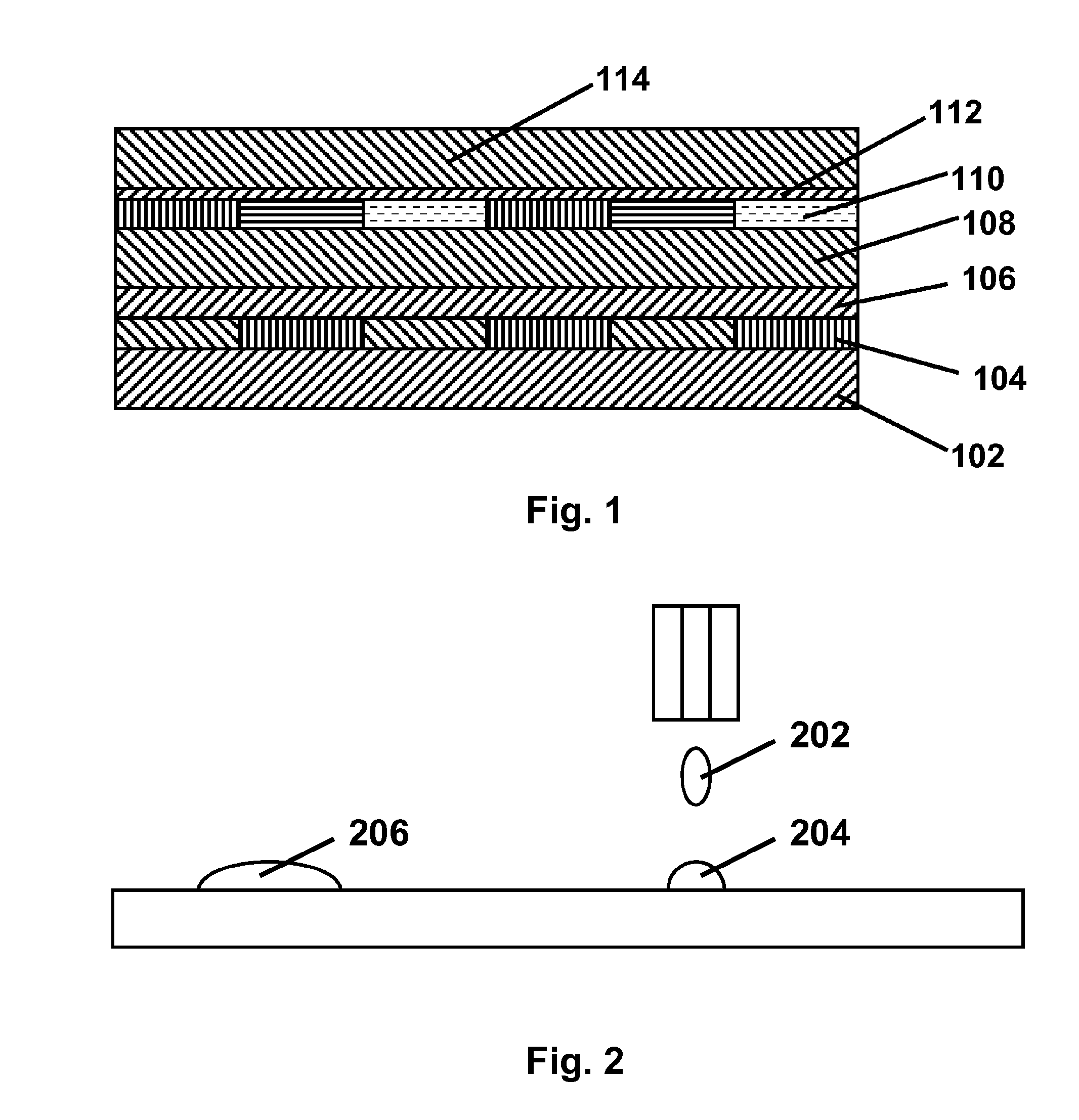

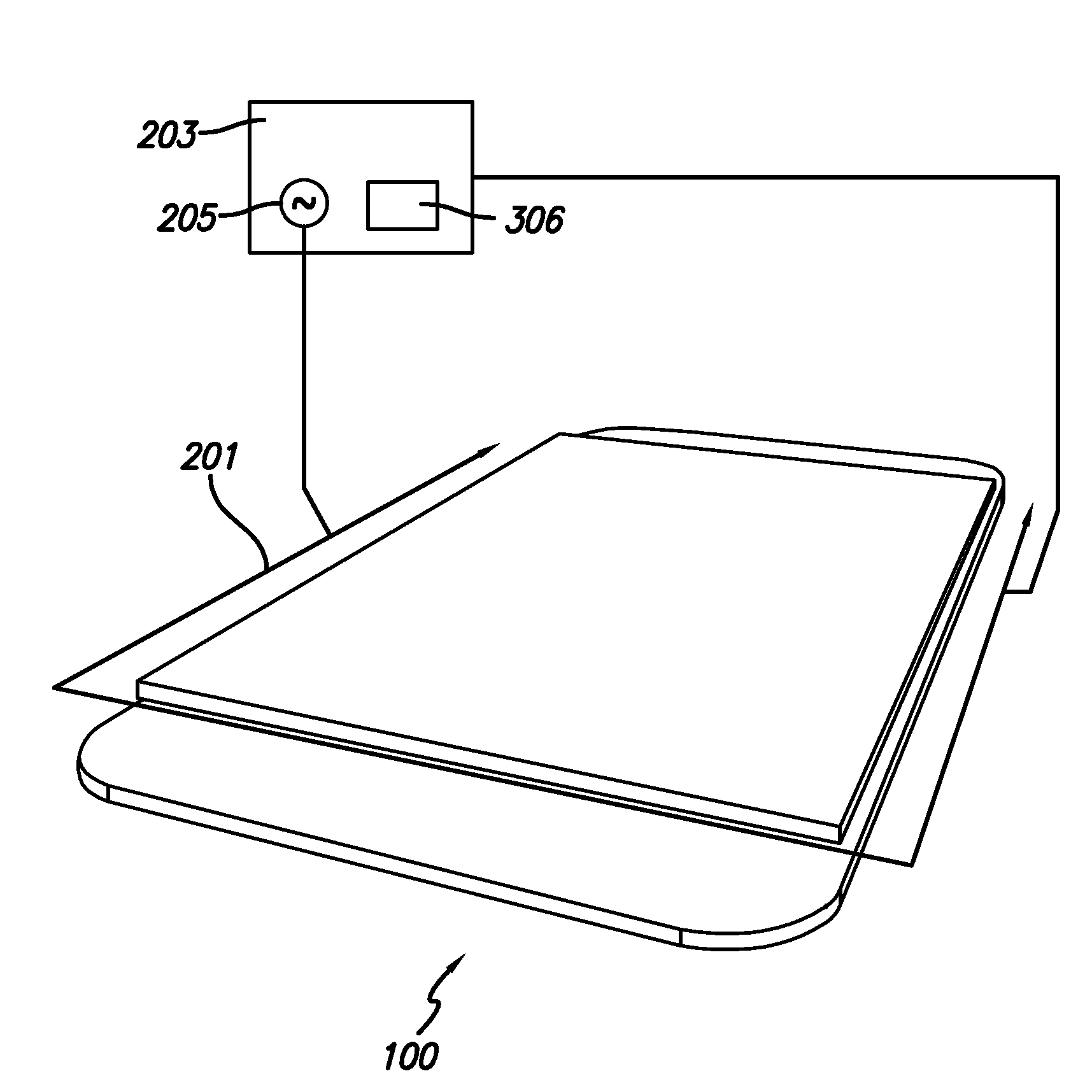

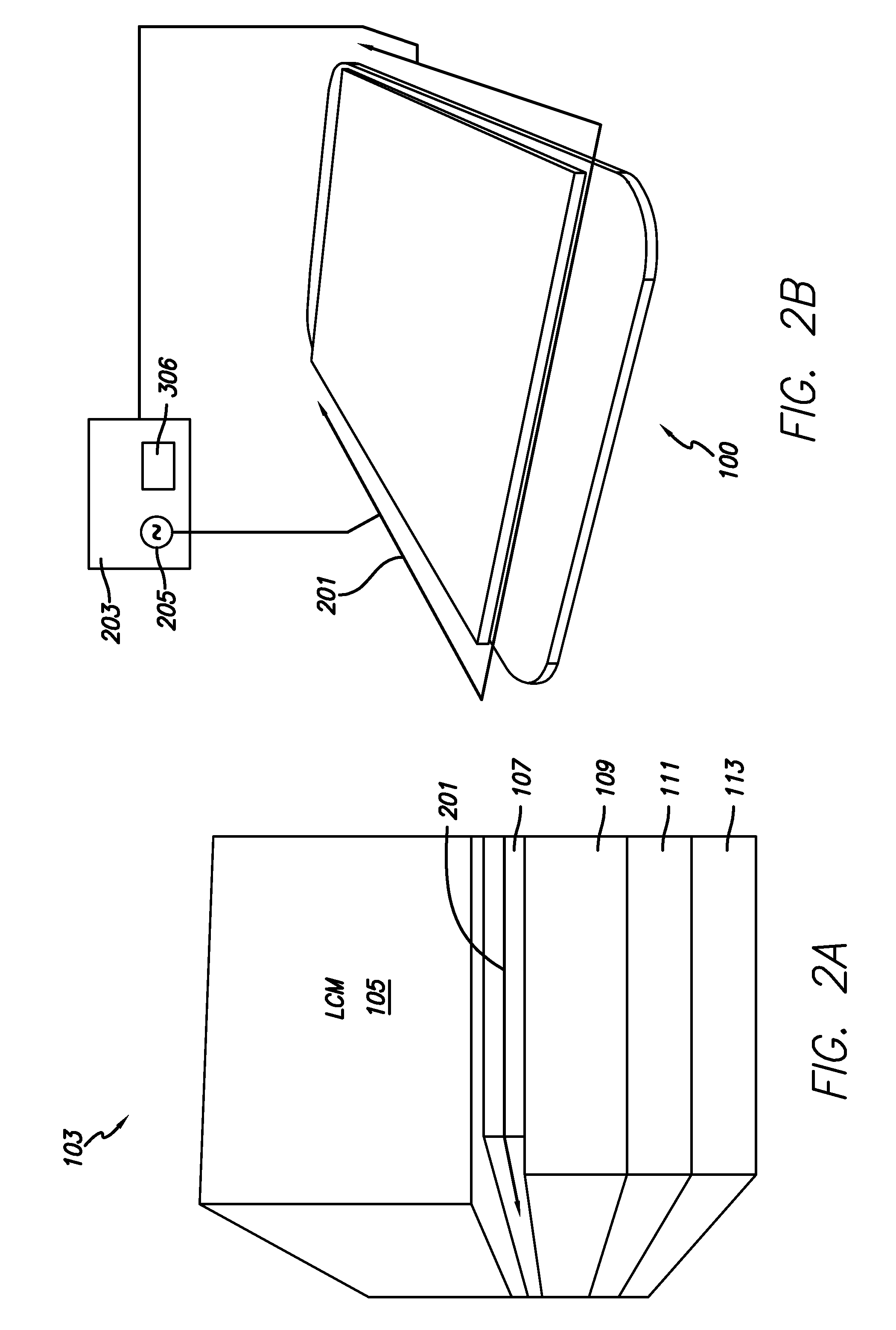

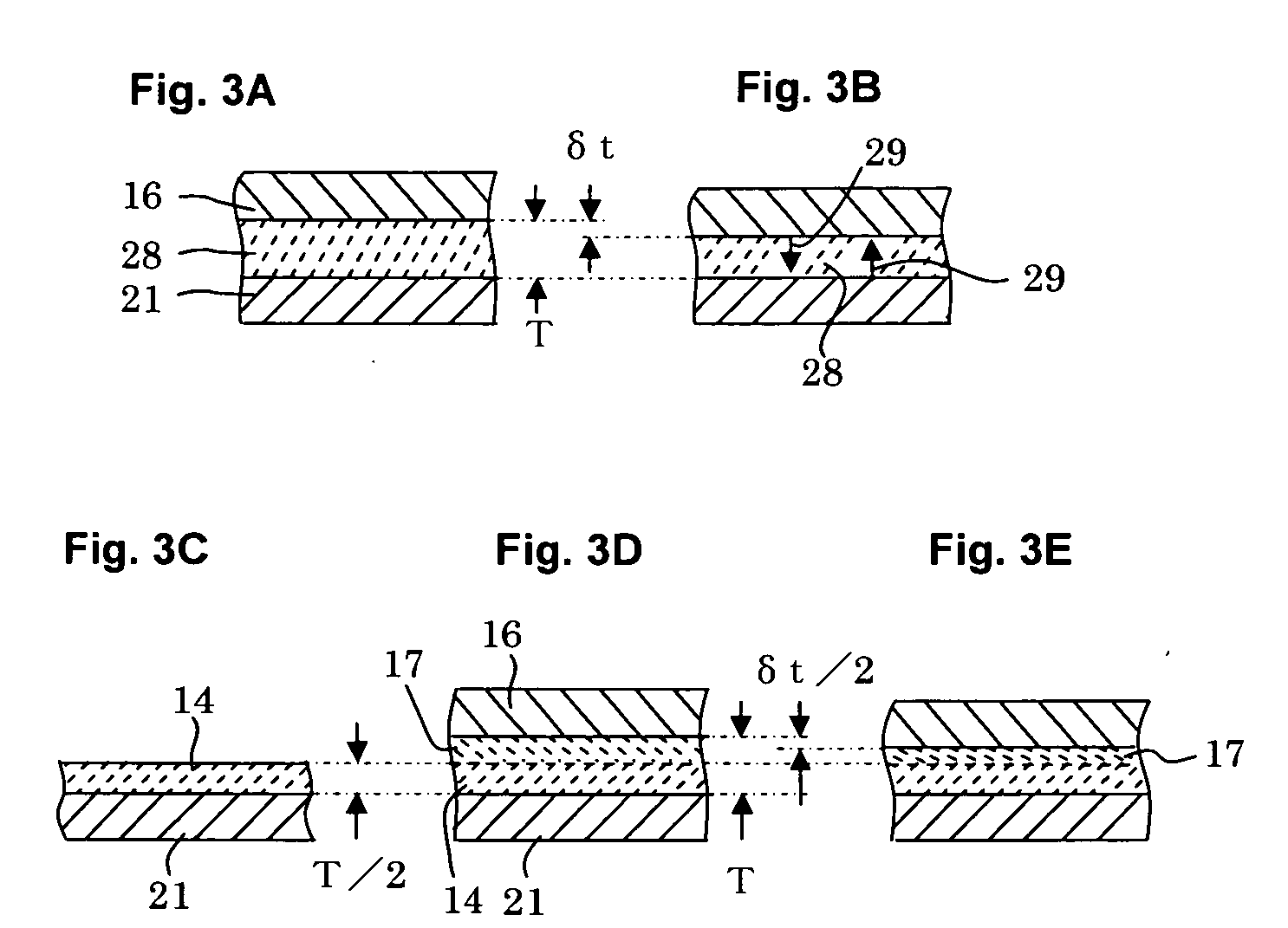

Electro-optic displays, and color filters for use therein

ActiveUS8098418B2Solve the lack of adhesionEliminate needLayered product treatmentStatic indicating devicesDisplay deviceColor filter array

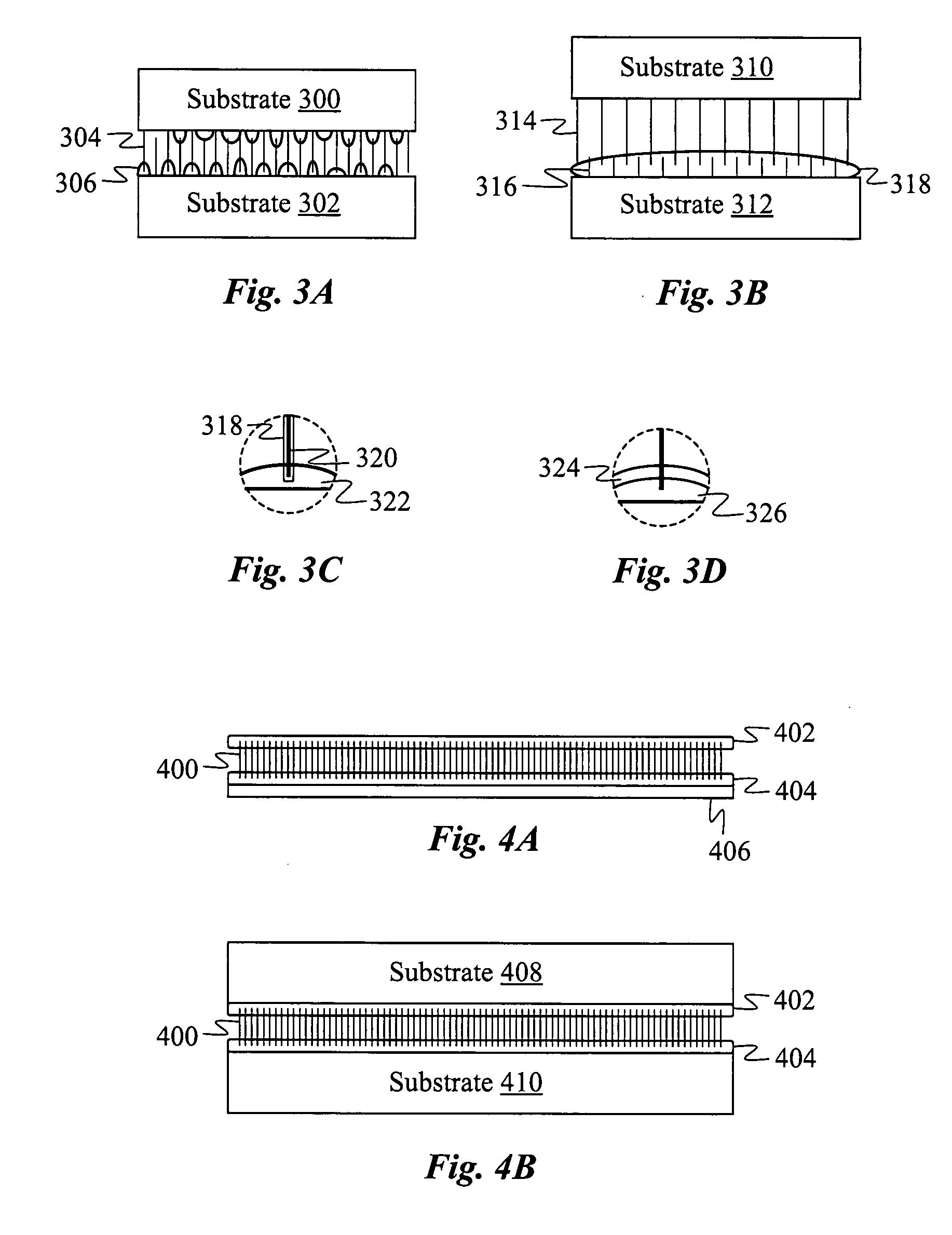

A process for producing a color electro-optic display uses an electro-optic sub-assembly comprising an electro-optic layer and a light-transmissive electrically-conductive layer. This sub-assembly is laminated to a backplane comprising a plurality of electrodes with the electro-optic layer disposed between the backplane and the electrically-conductive layer. A flowable material is placed over the sub-assembly and a color filter array is placed over the electrically-conductive layer and aligned with the electrodes of the backplane to form the color electro-optic display.

Owner:E INK CORPORATION

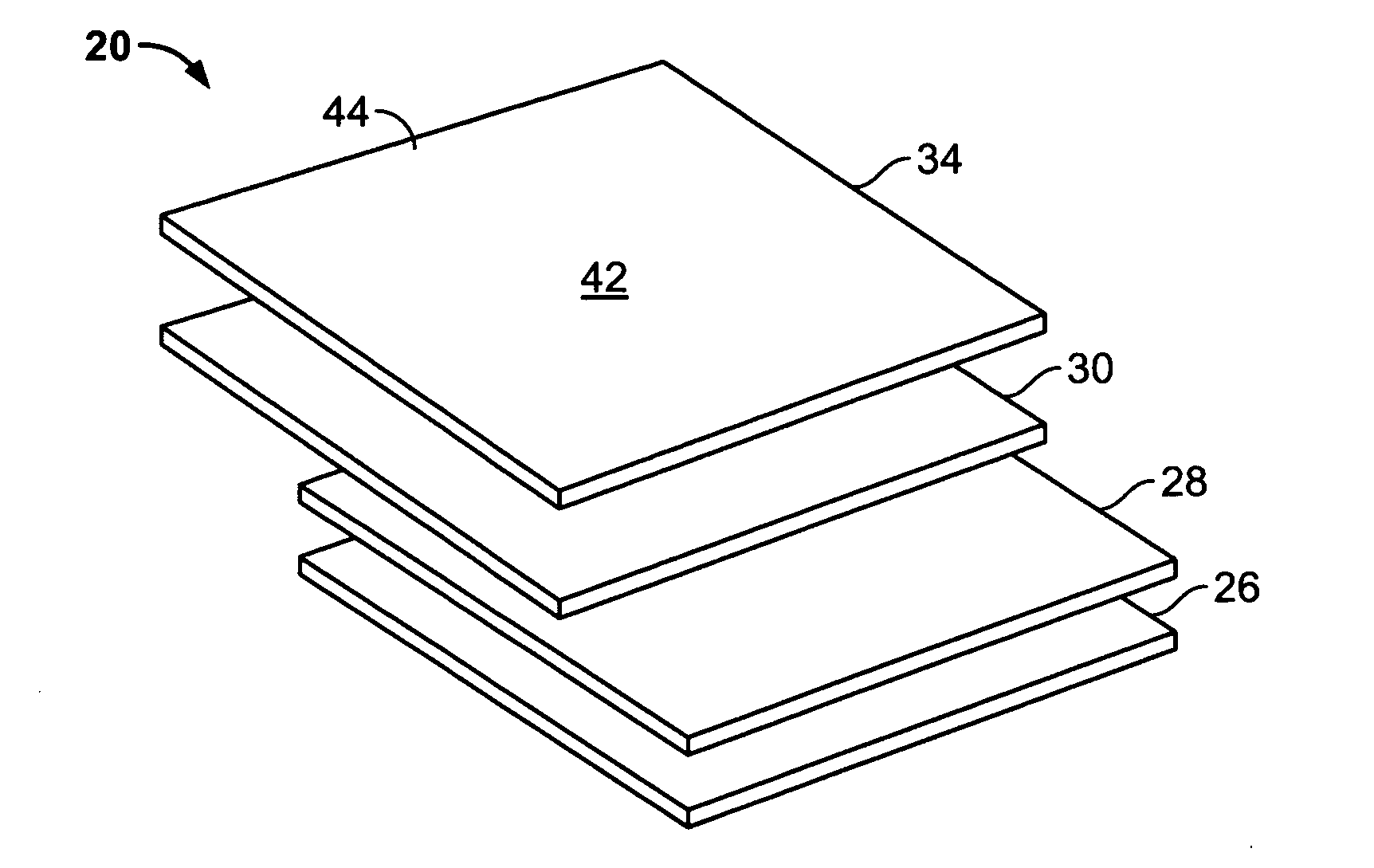

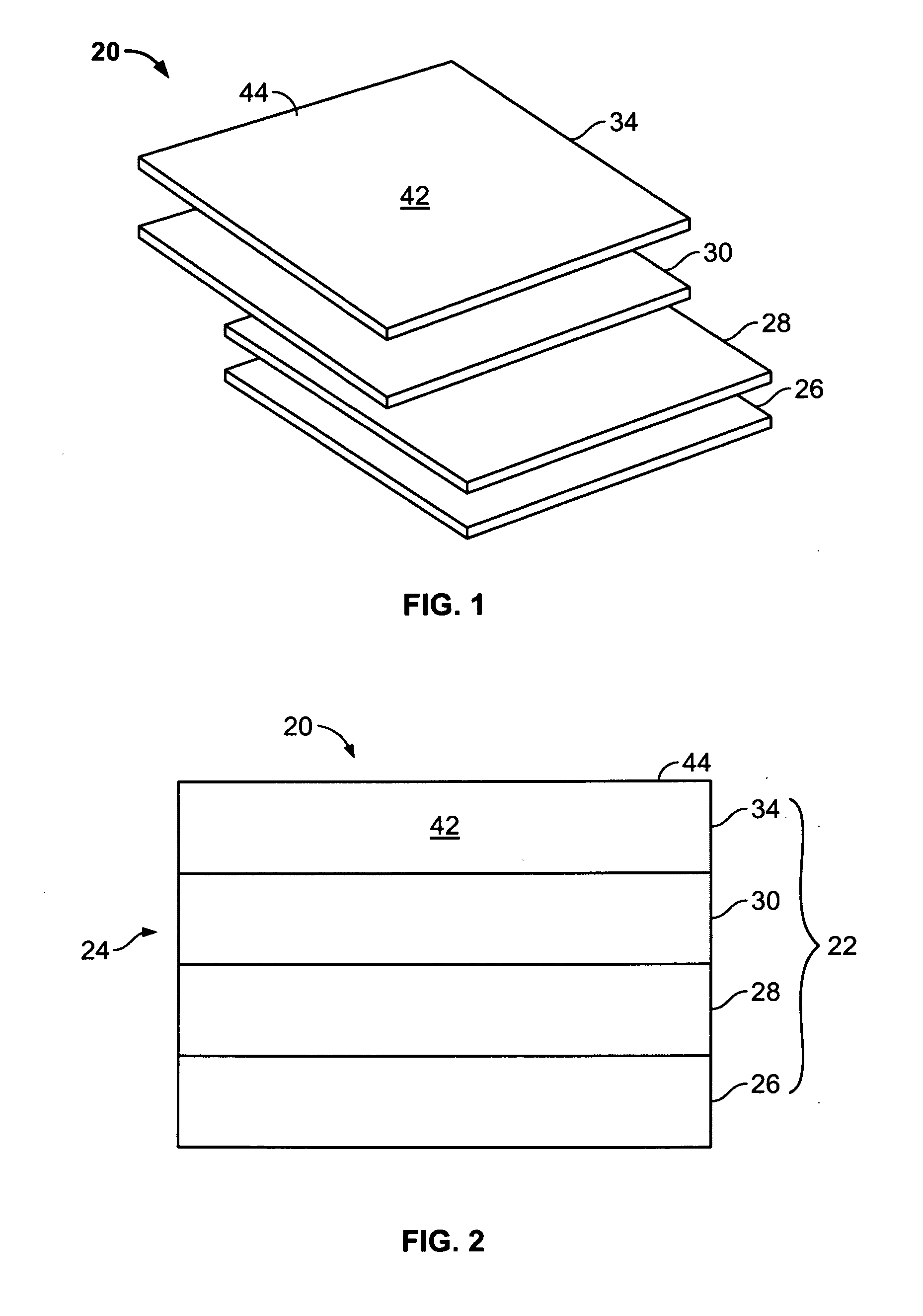

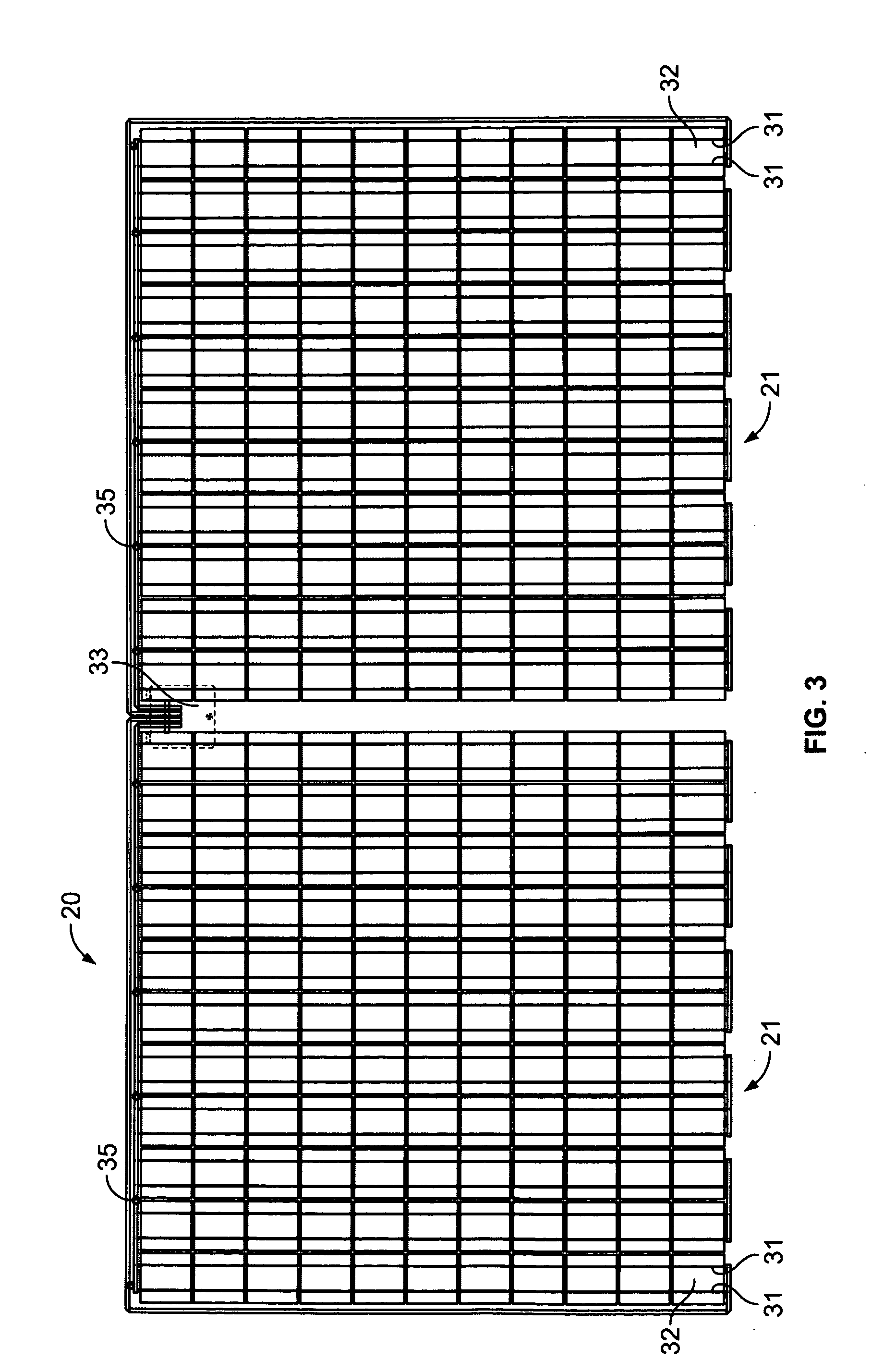

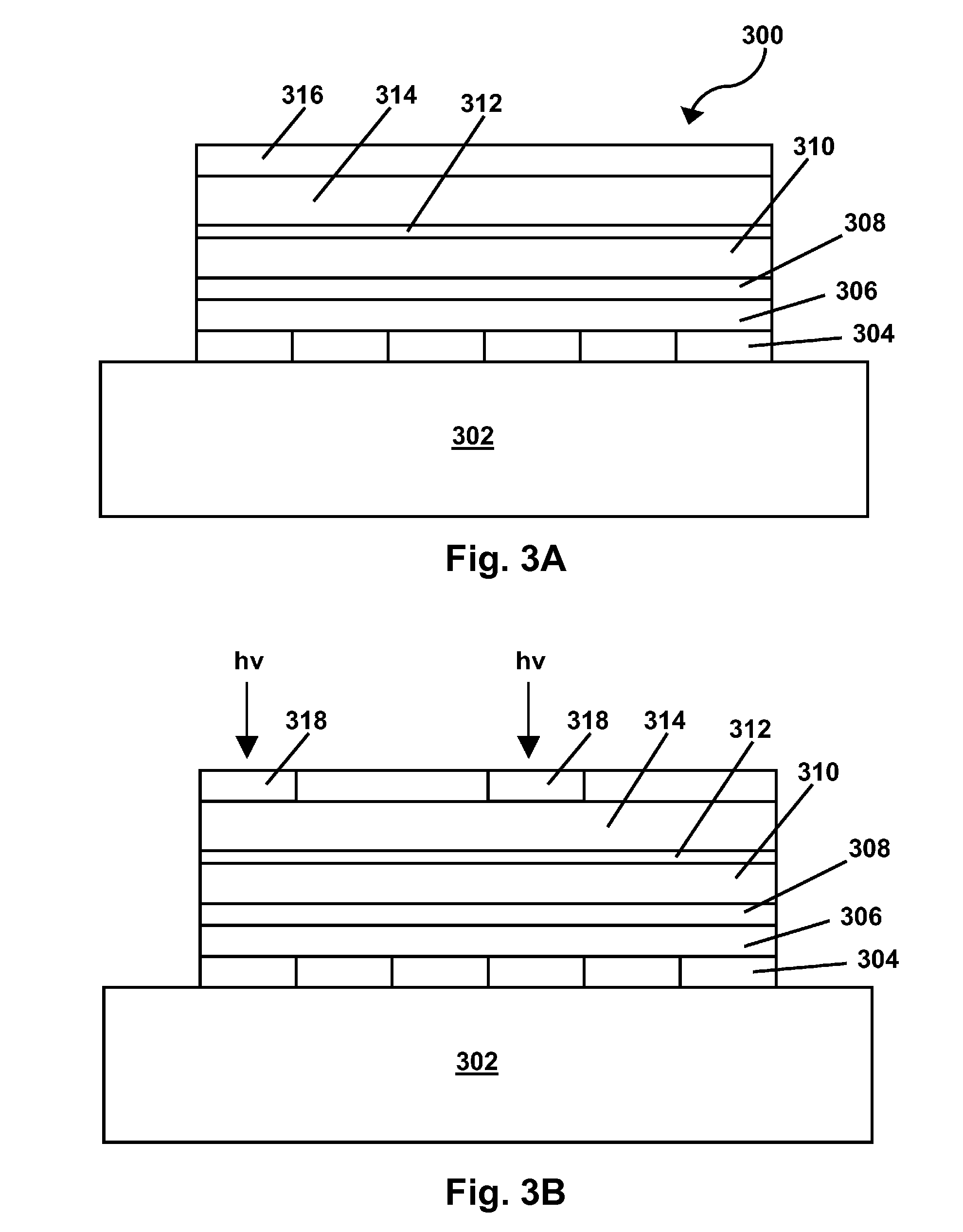

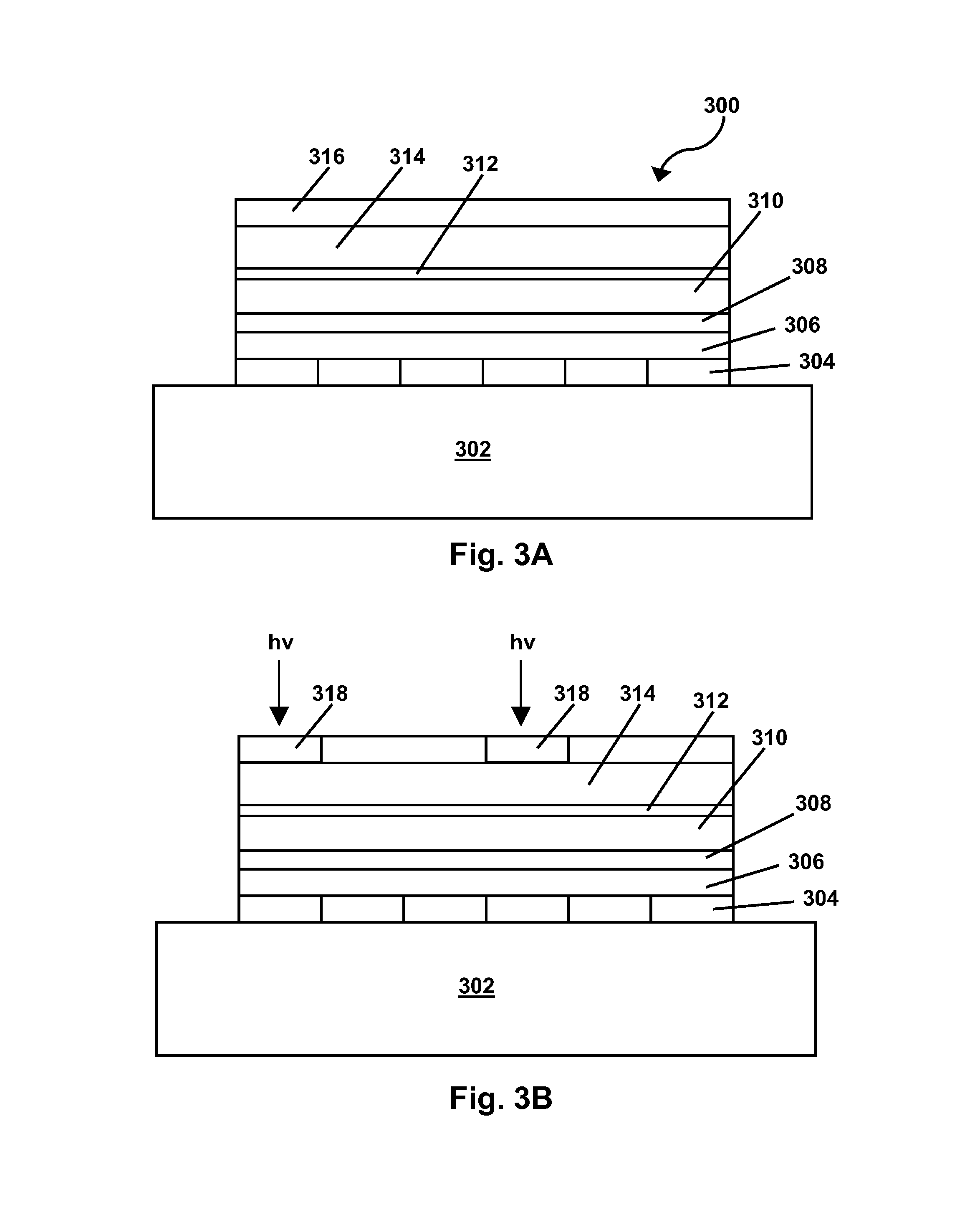

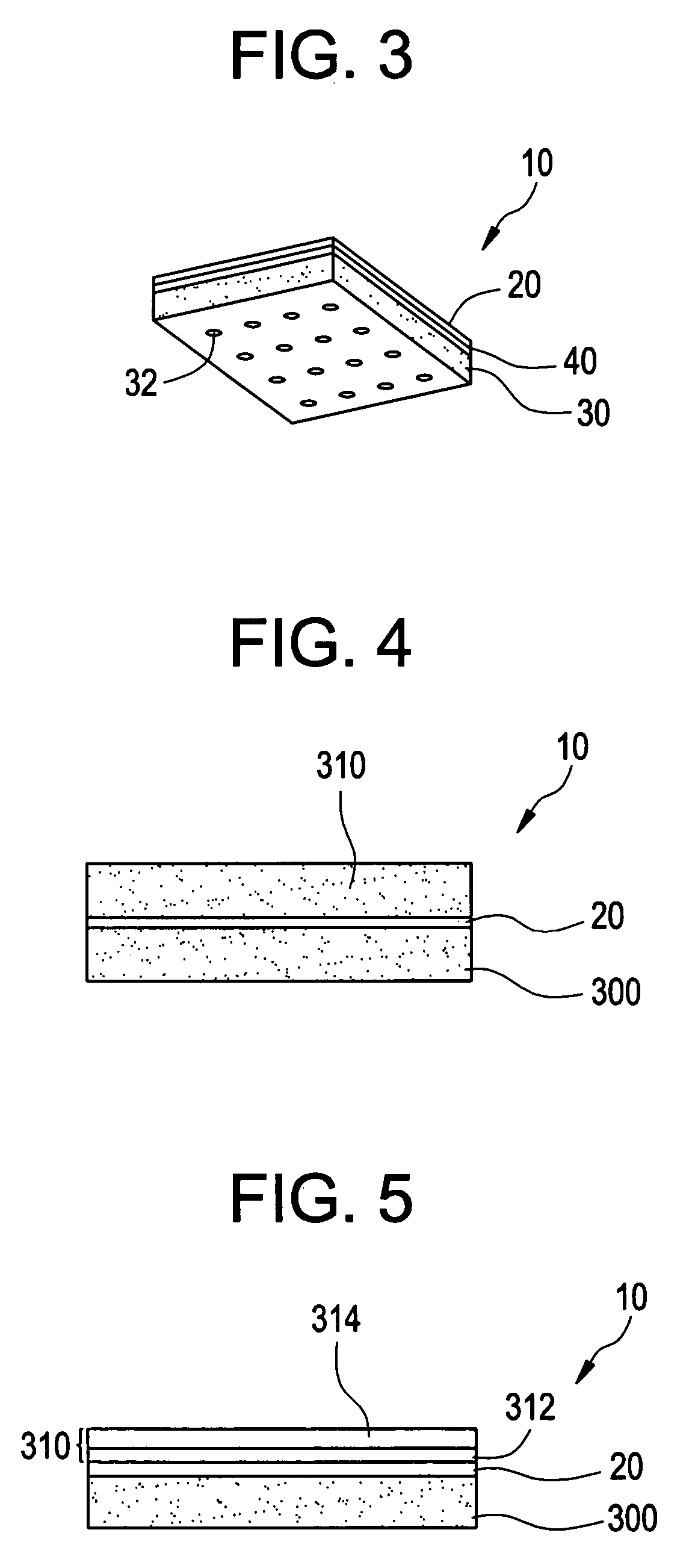

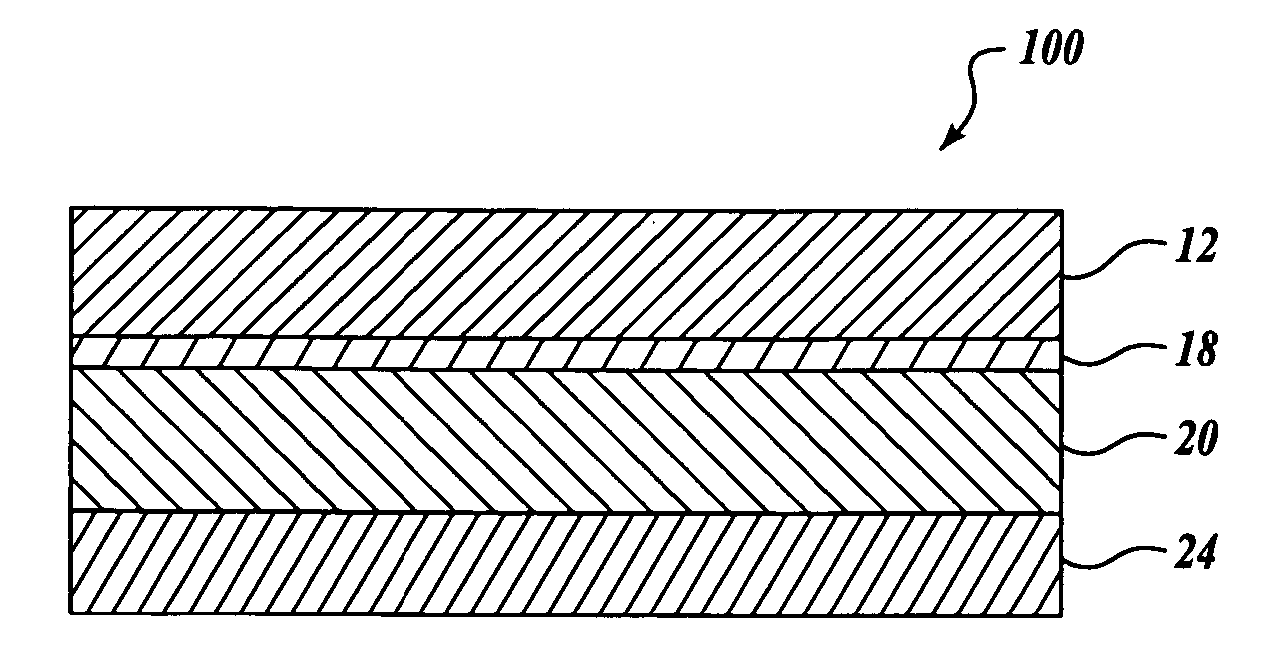

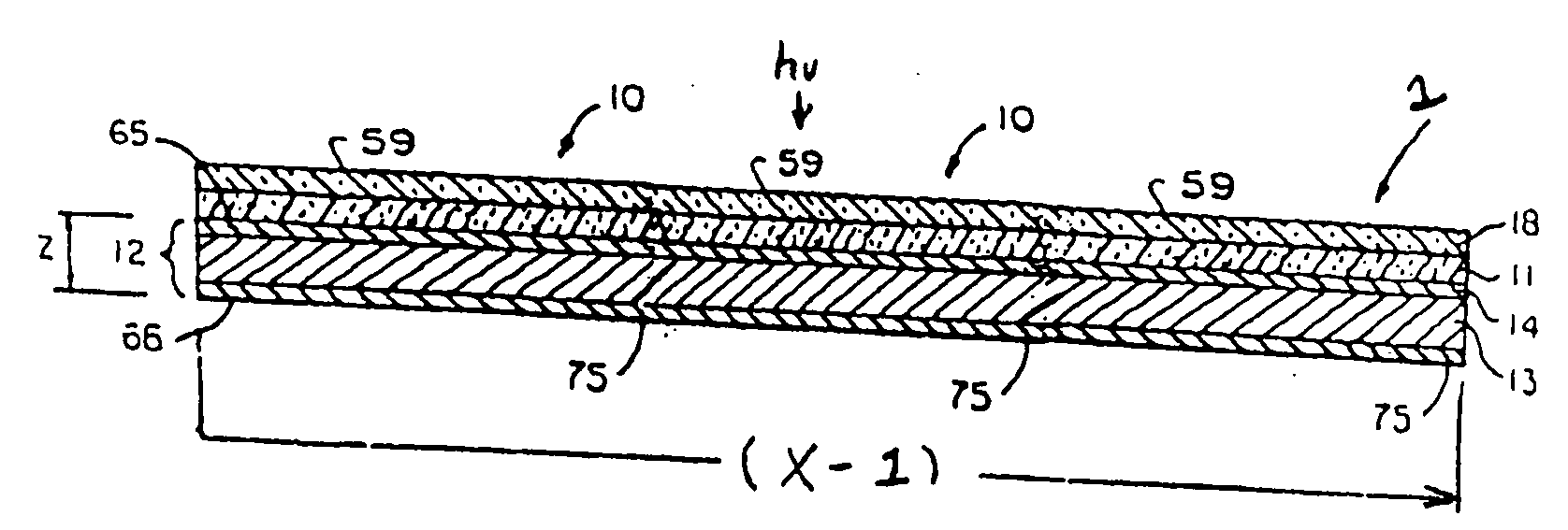

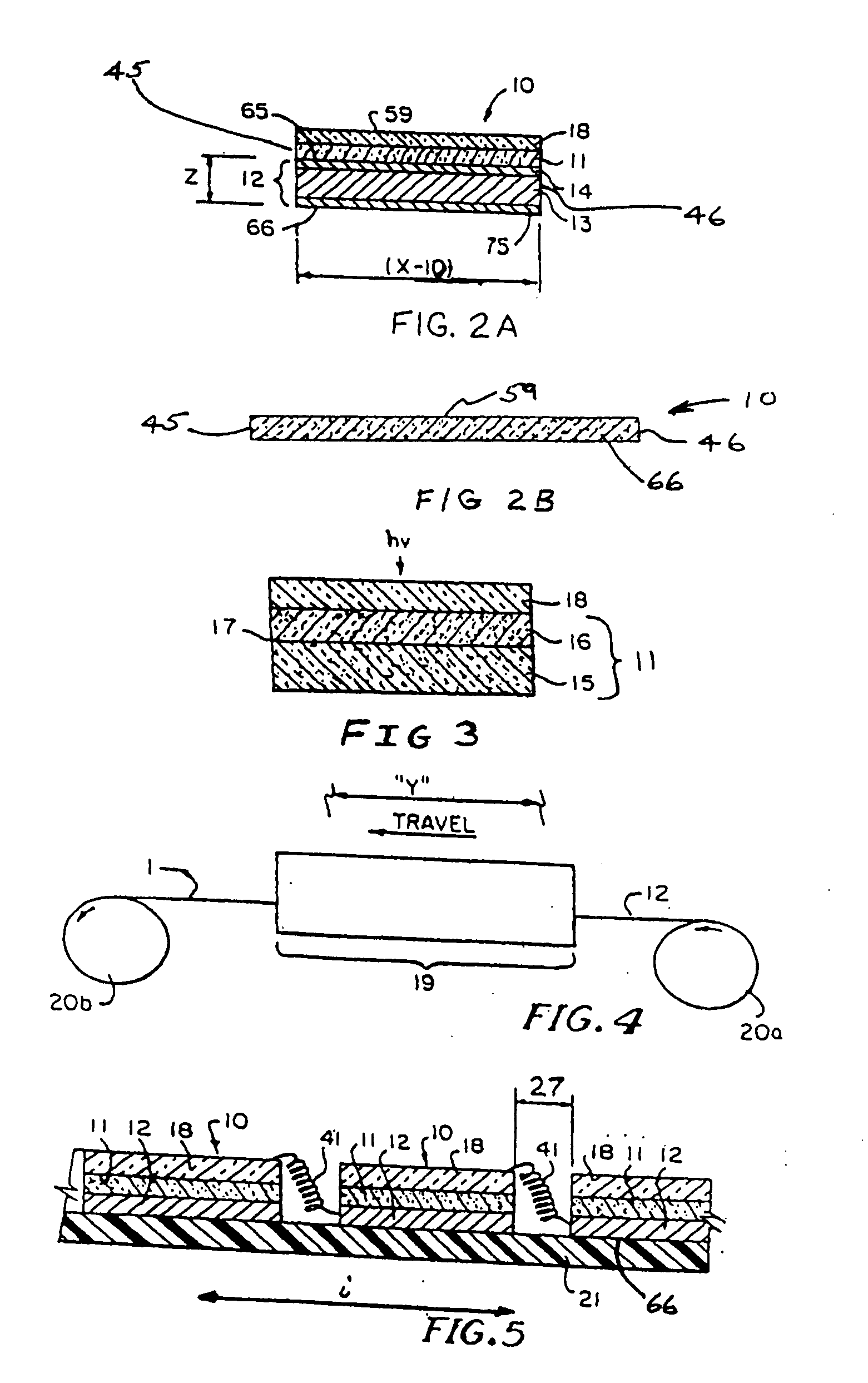

Photovoltaic system and method of making same

The present invention relates to a photovoltaic system and methods of making same. The photovoltaic system has a plurality of layers attached to each other to form a unitary structure. More specifically, the photovoltaic system includes: a base, flexible membrane layer; a photovoltaic layer having at least one photovoltaic cell associated therewith; a semi-rigid layer for supporting the photovoltaic layer and imparting rigidity thereto; and a top, transparent, protective layer for protecting the base, flexible membrane layer, the semi-rigid layer and the photovoltaic layer from exposure to the environment. The photovoltaic layer and the semi-rigid layer are disposed between the base, flexible membrane layer and the top, protective layer. Additional layers of adhesive may be disposed between the various layers to facilitate bonding thereof.

Owner:OPEN ENERGY CORP

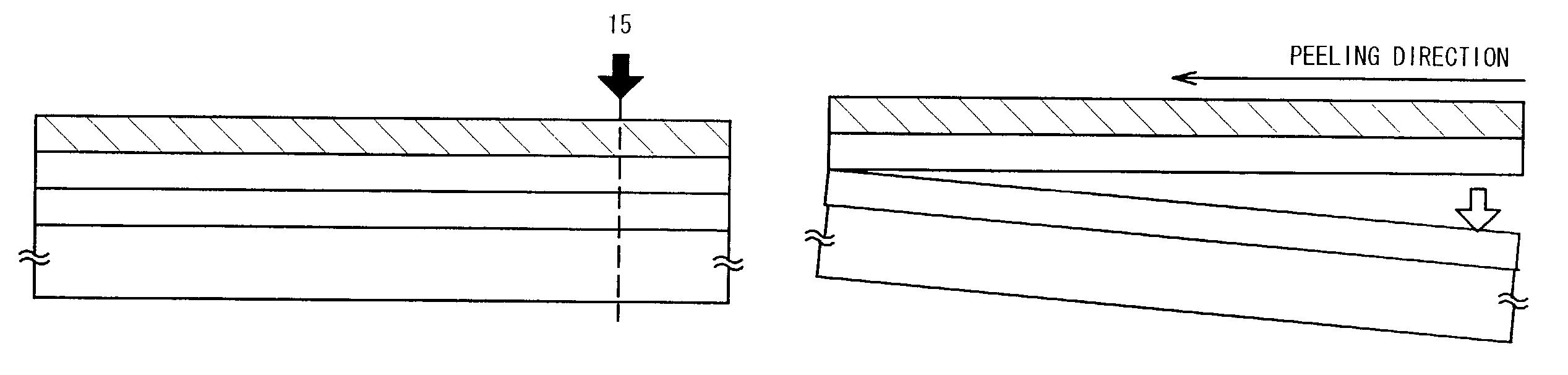

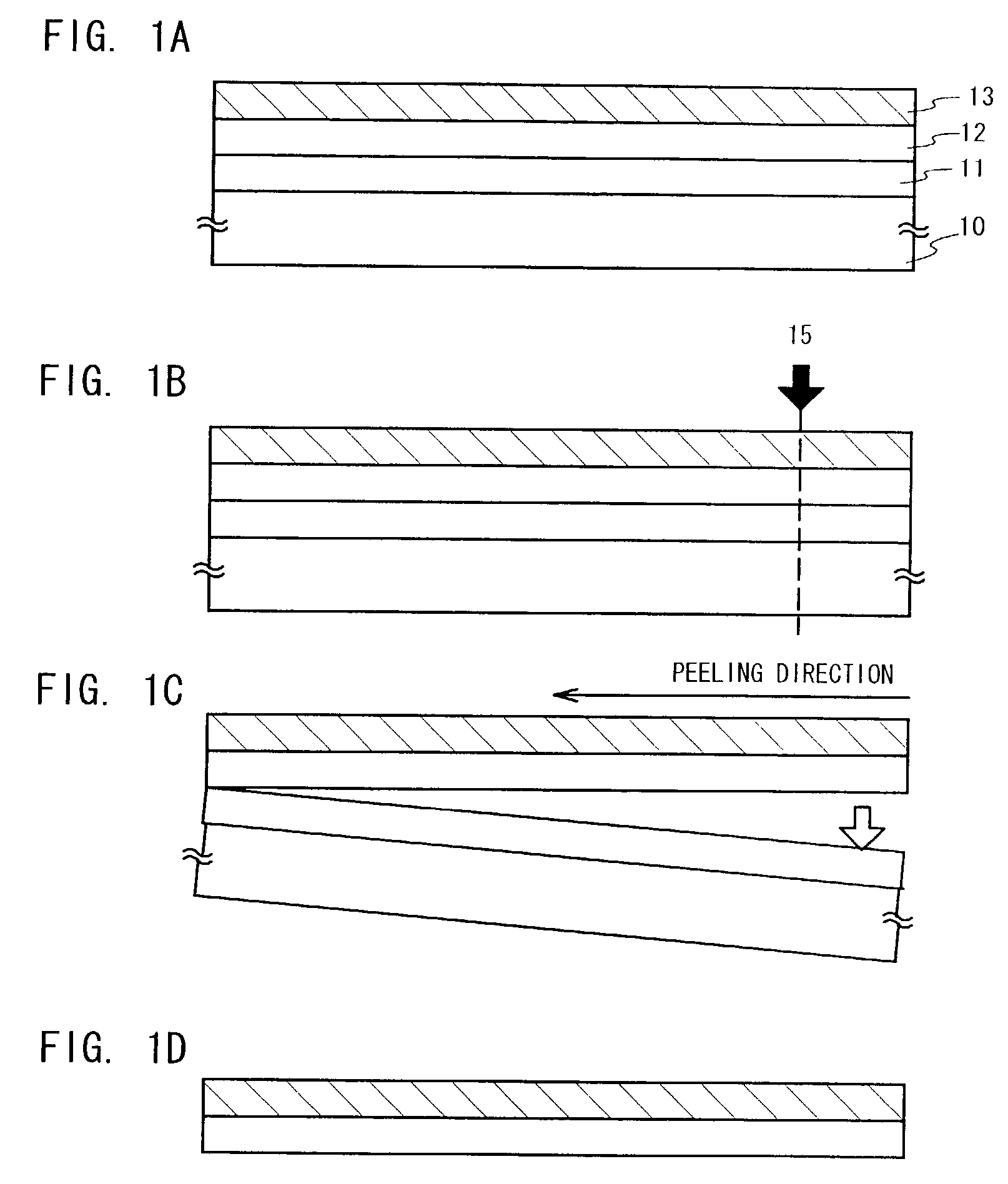

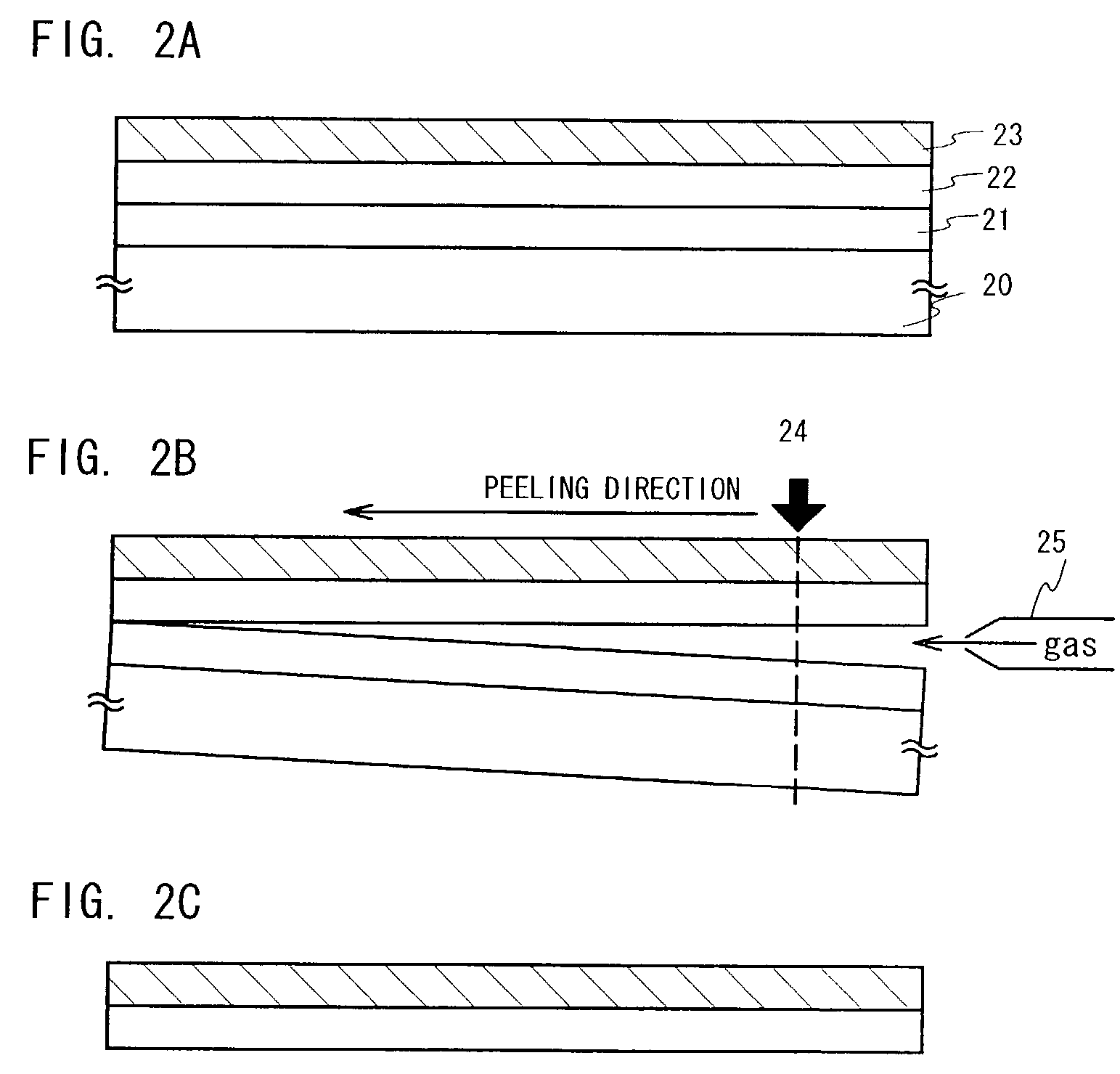

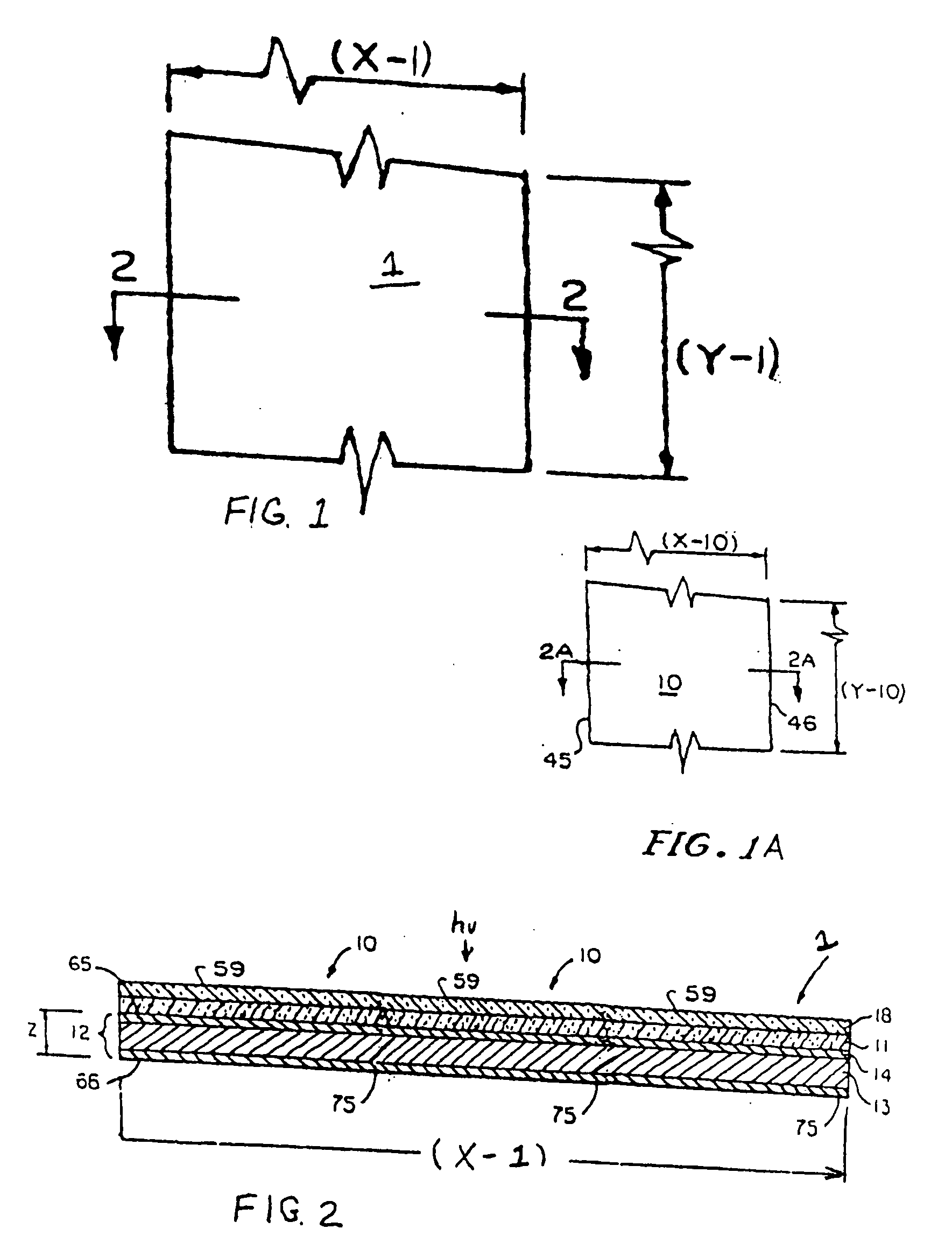

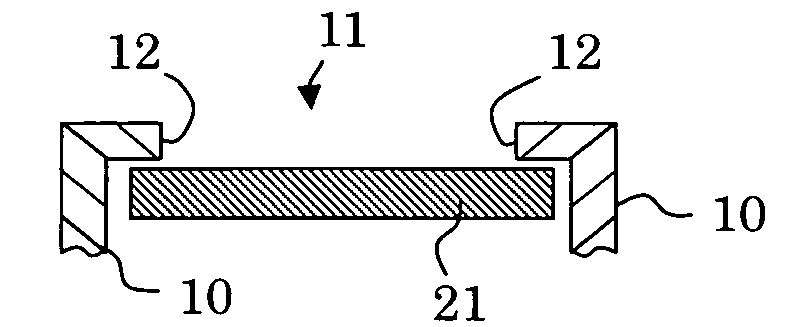

Peeling method and method of manufacturing semiconductor device

InactiveUS7351300B2Not to damageFinal product manufactureDecorative surface effectsLaser lightIrradiation

There is provided a peeling method capable of preventing a damage to a layer to be peeled. Thus, not only a layer to be peeled having a small area but also a layer to be peeled having a large area can be peeled over the entire surface at a high yield. Processing for partially reducing contact property between a first material layer (11) and a second material layer (12) (laser light irradiation, pressure application, or the like) is performed before peeling, and then peeling is conducted by physical means. Therefore, sufficient separation can be easily conducted in an inner portion of the second material layer (12) or an interface thereof.

Owner:SEMICON ENERGY LAB CO LTD

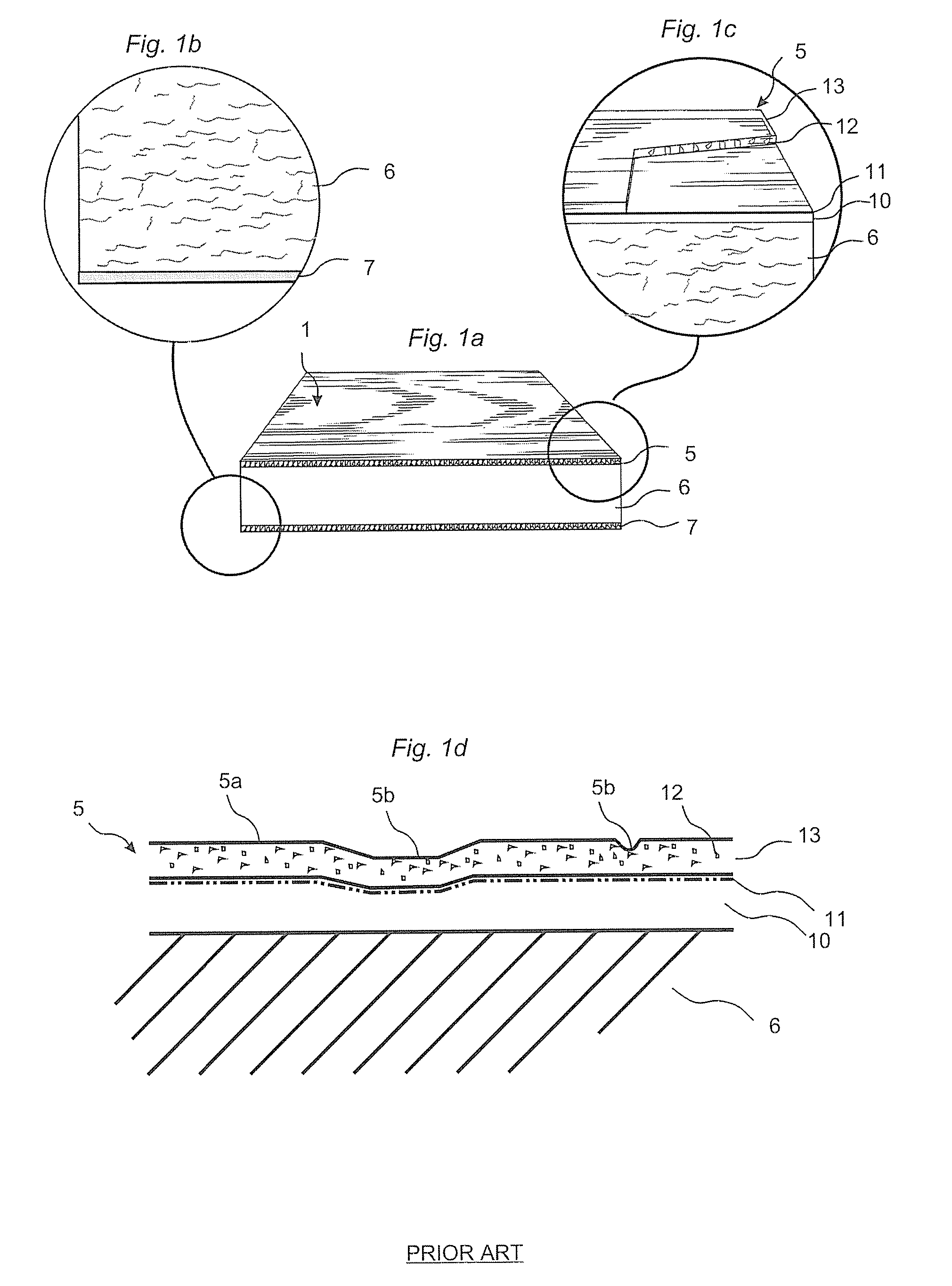

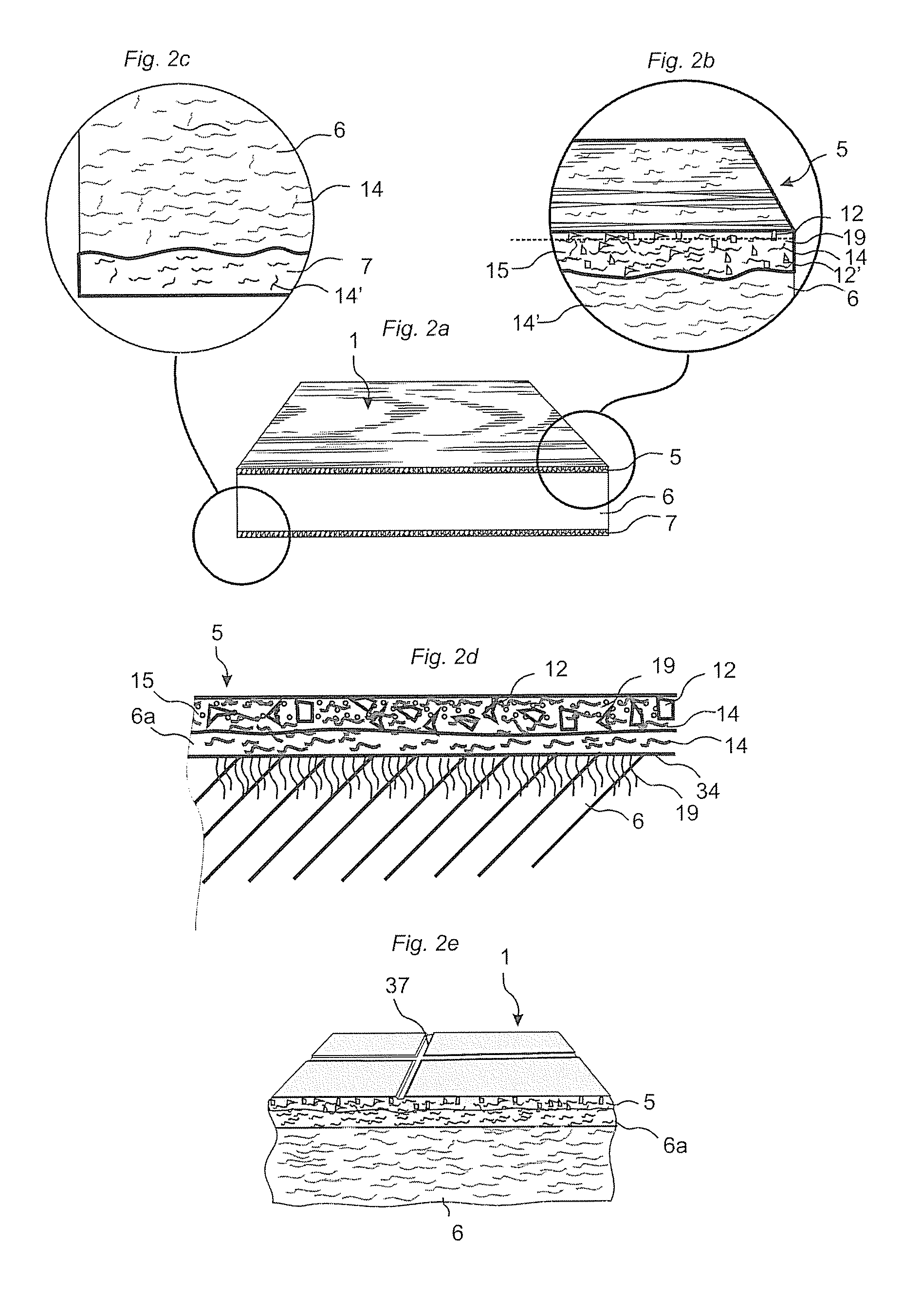

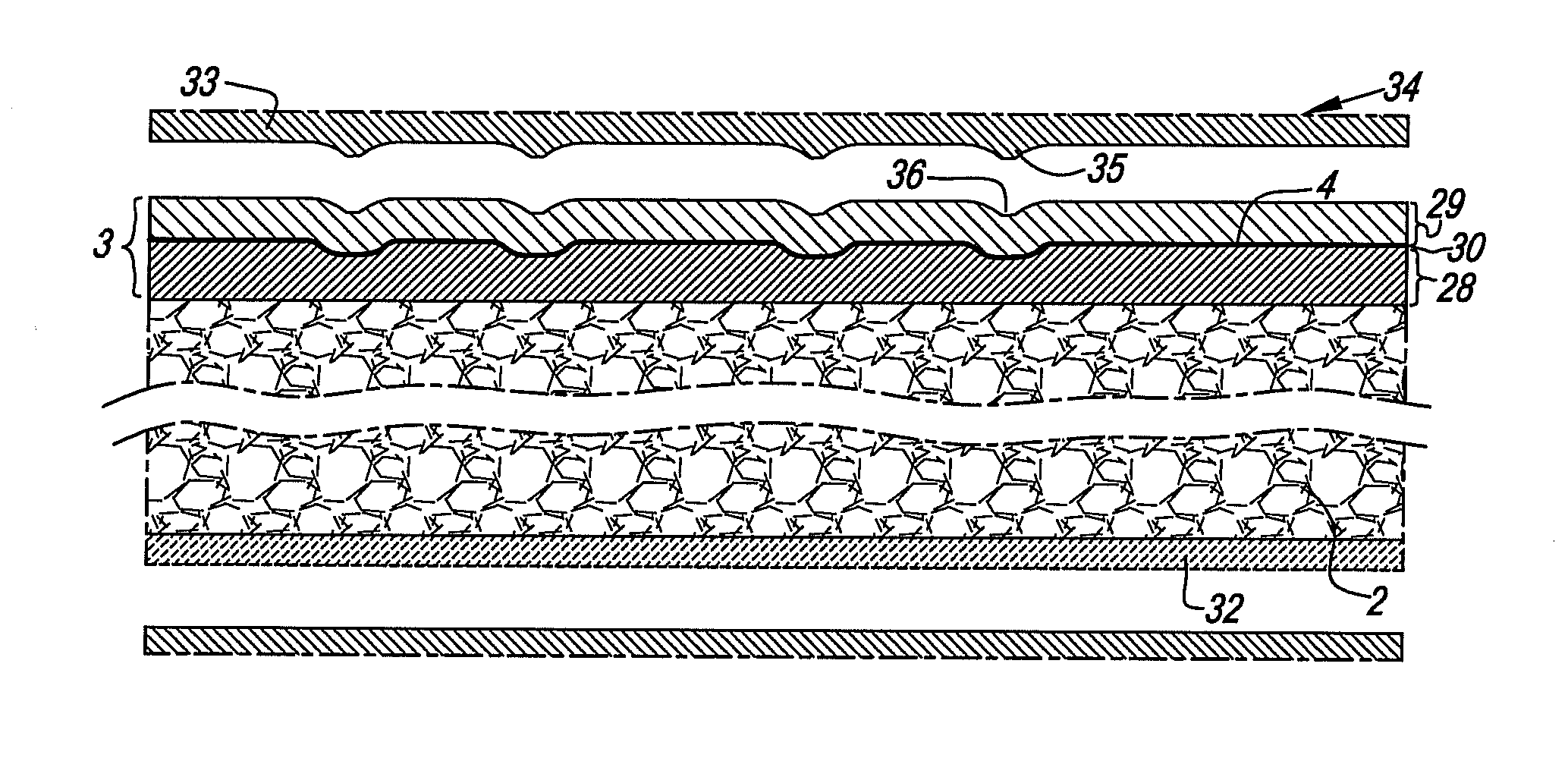

Wood fibre based panels with a thin surface layer

ActiveUS20100092731A1Large market shareImprove impact resistanceLiquid surface applicatorsCovering/liningsSurface layerWood fibre

Building panels with a thin and embossed surface layer and a sub layer between a surface layer and a core.

Owner:VÄLINGE INNOVATION AB

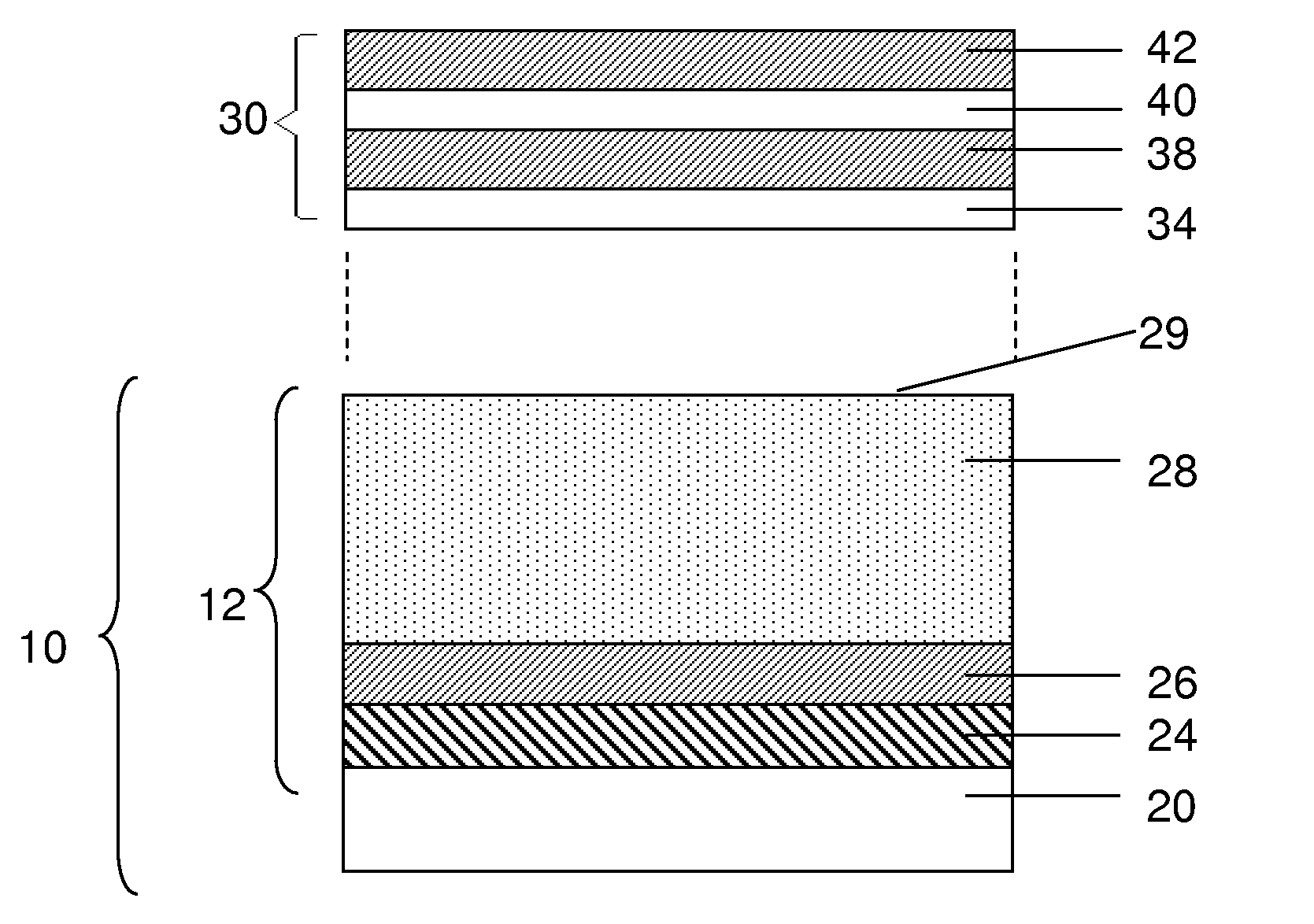

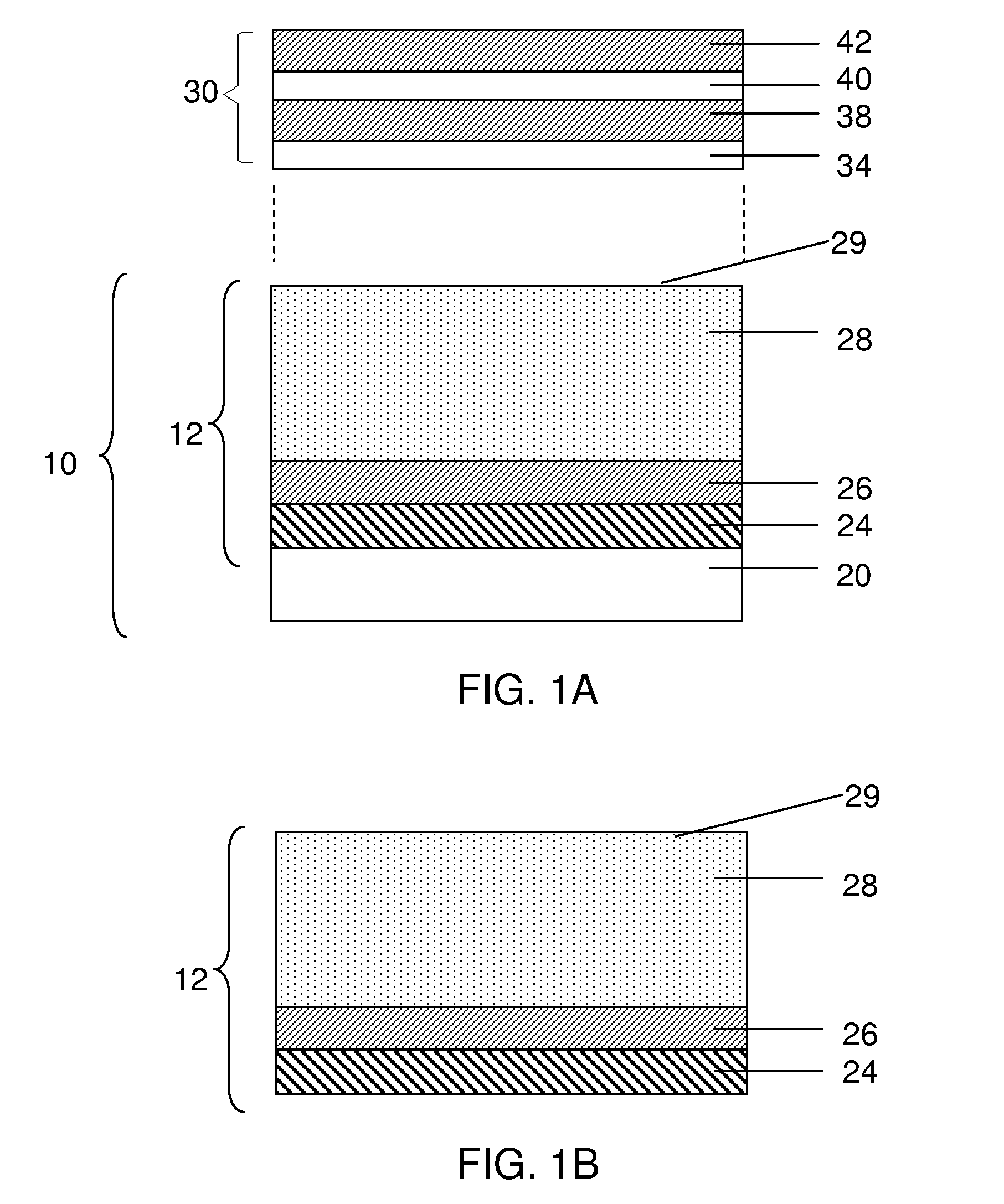

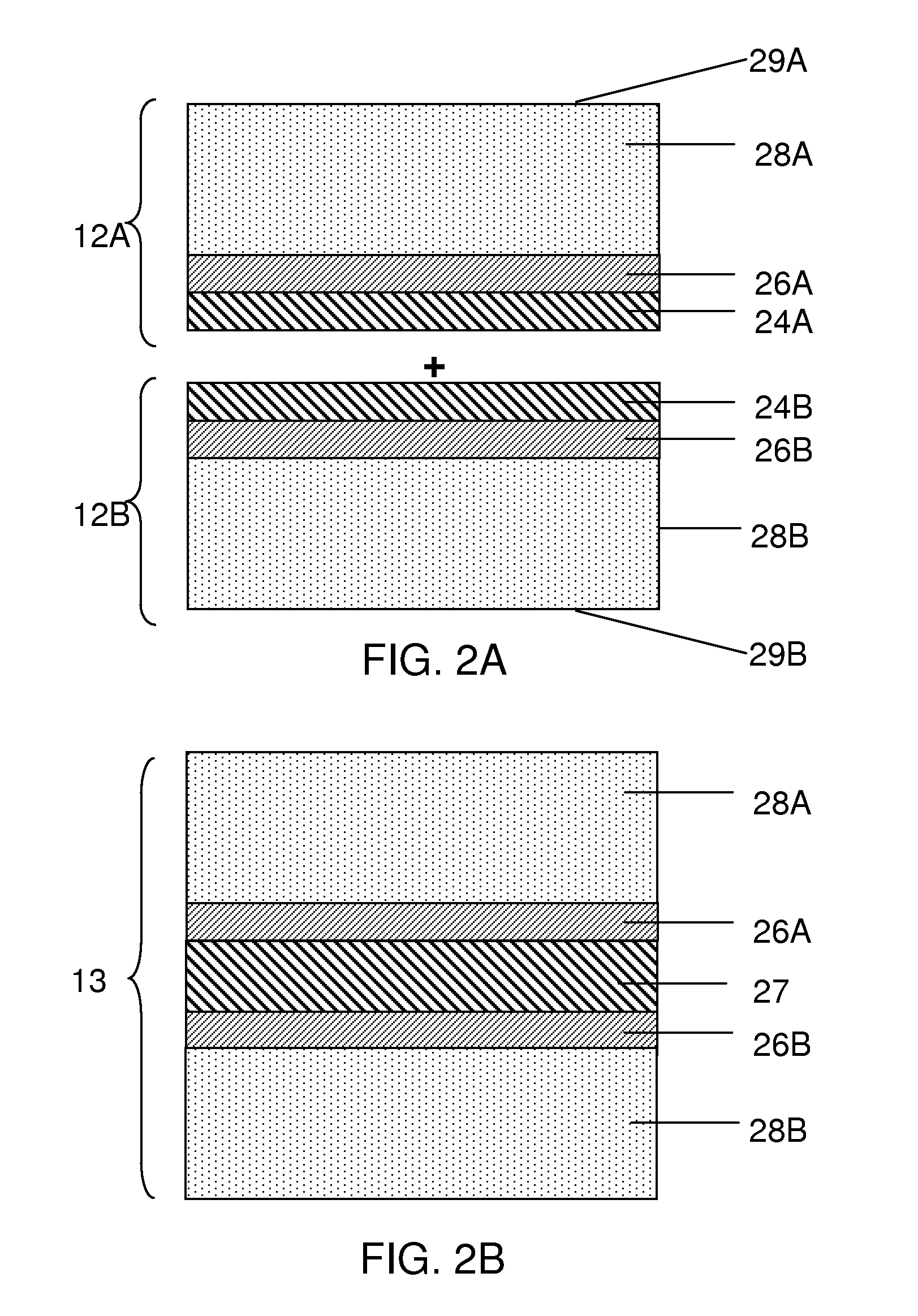

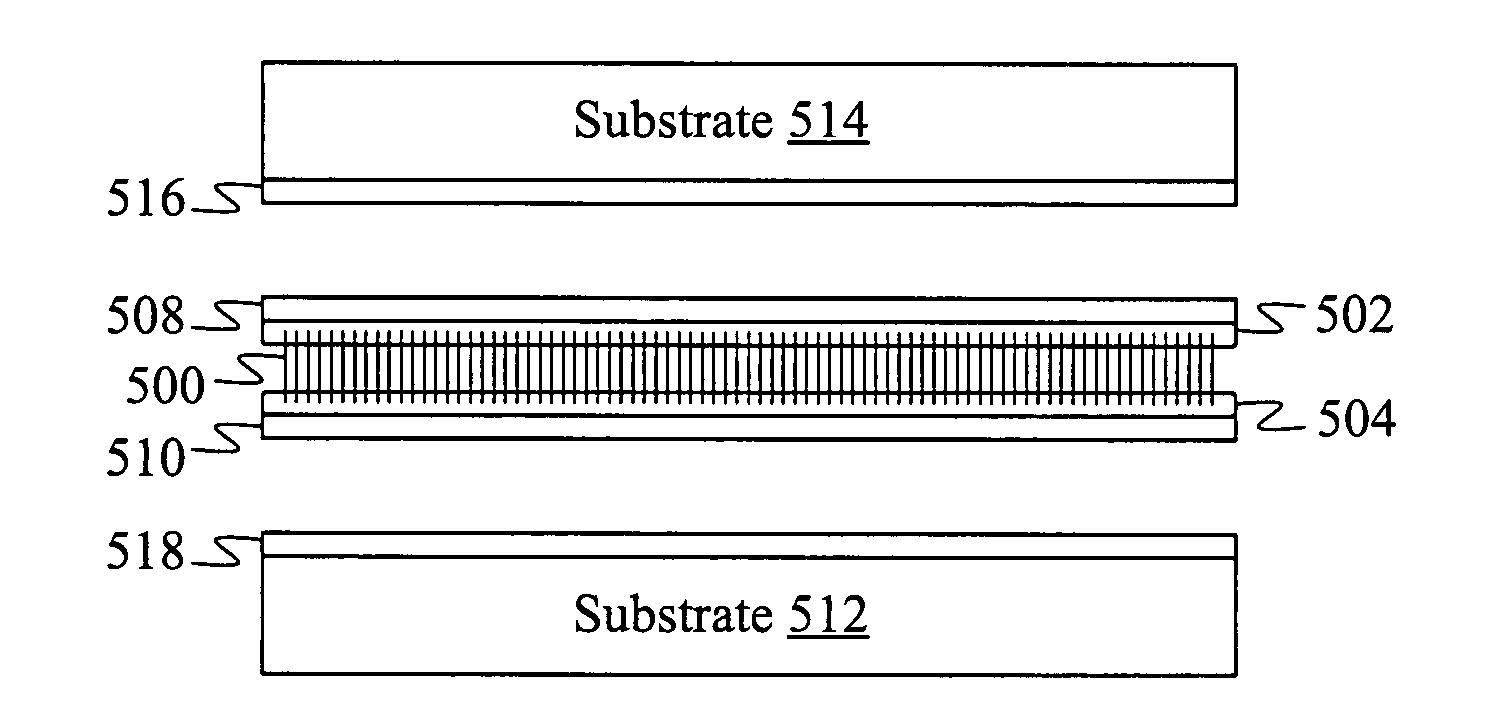

Release system for electrochemical cells

InactiveUS20110068001A1Active material electrodesElectrical-based machining electrodesEngineeringElectrochemical cell

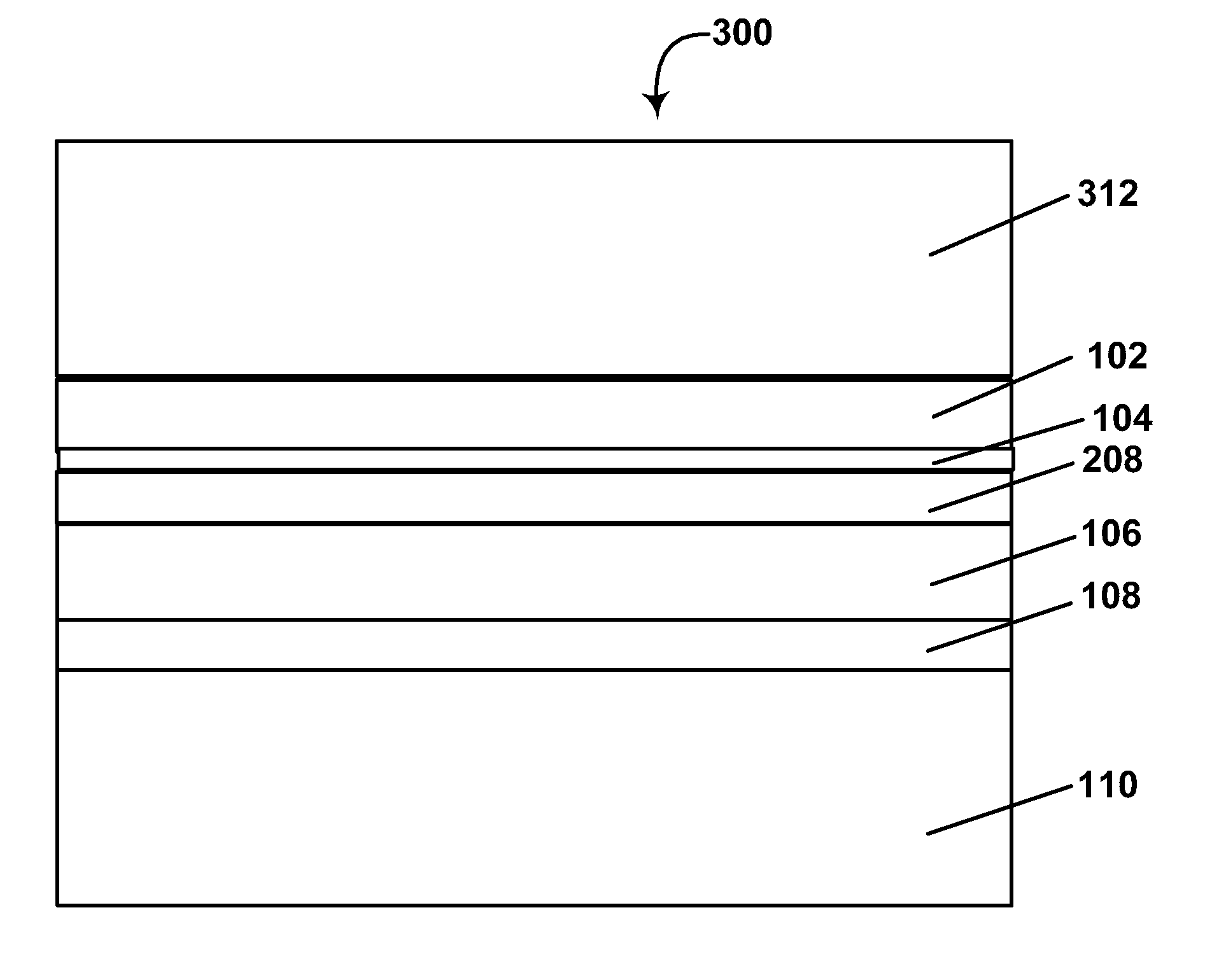

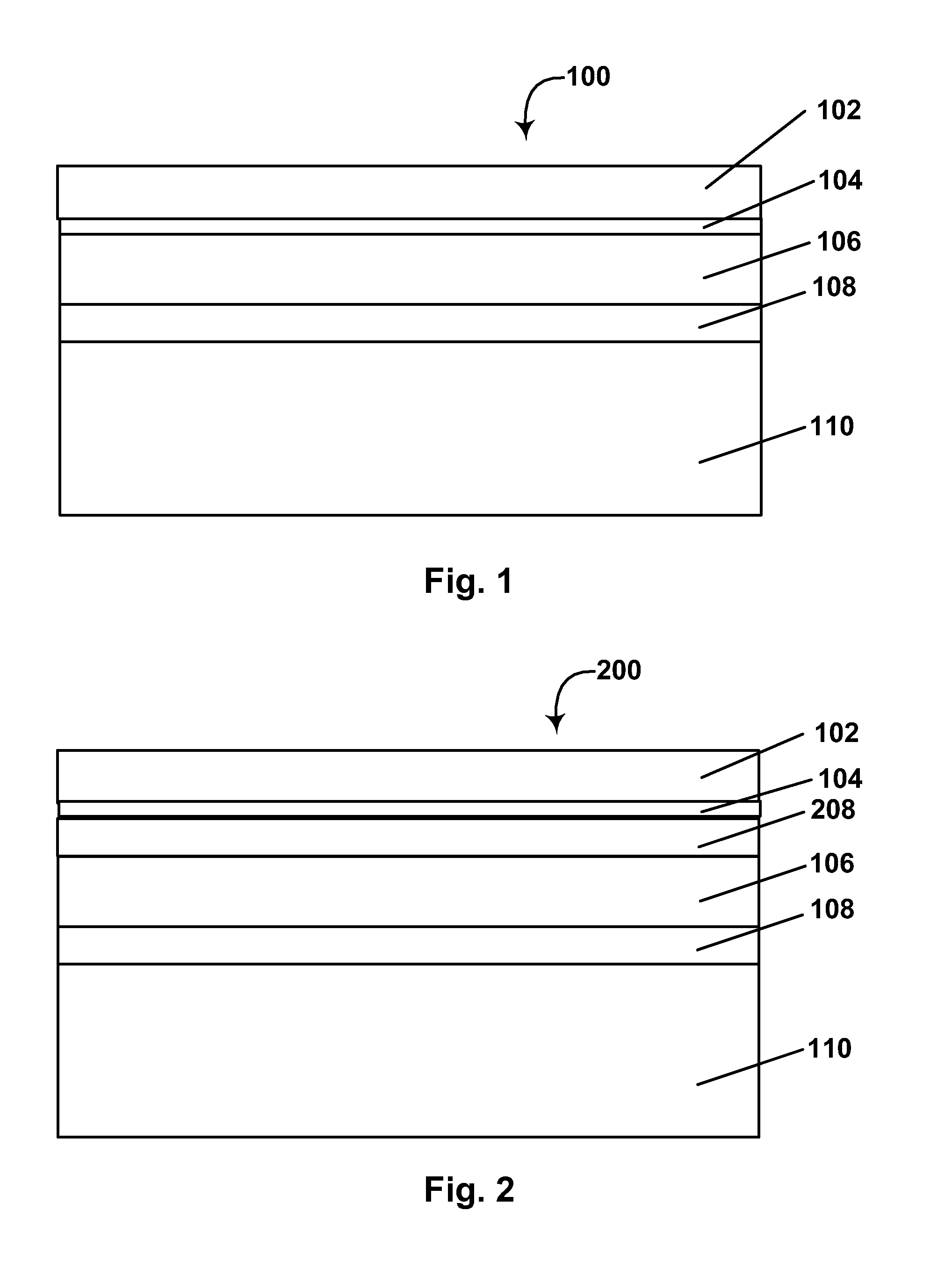

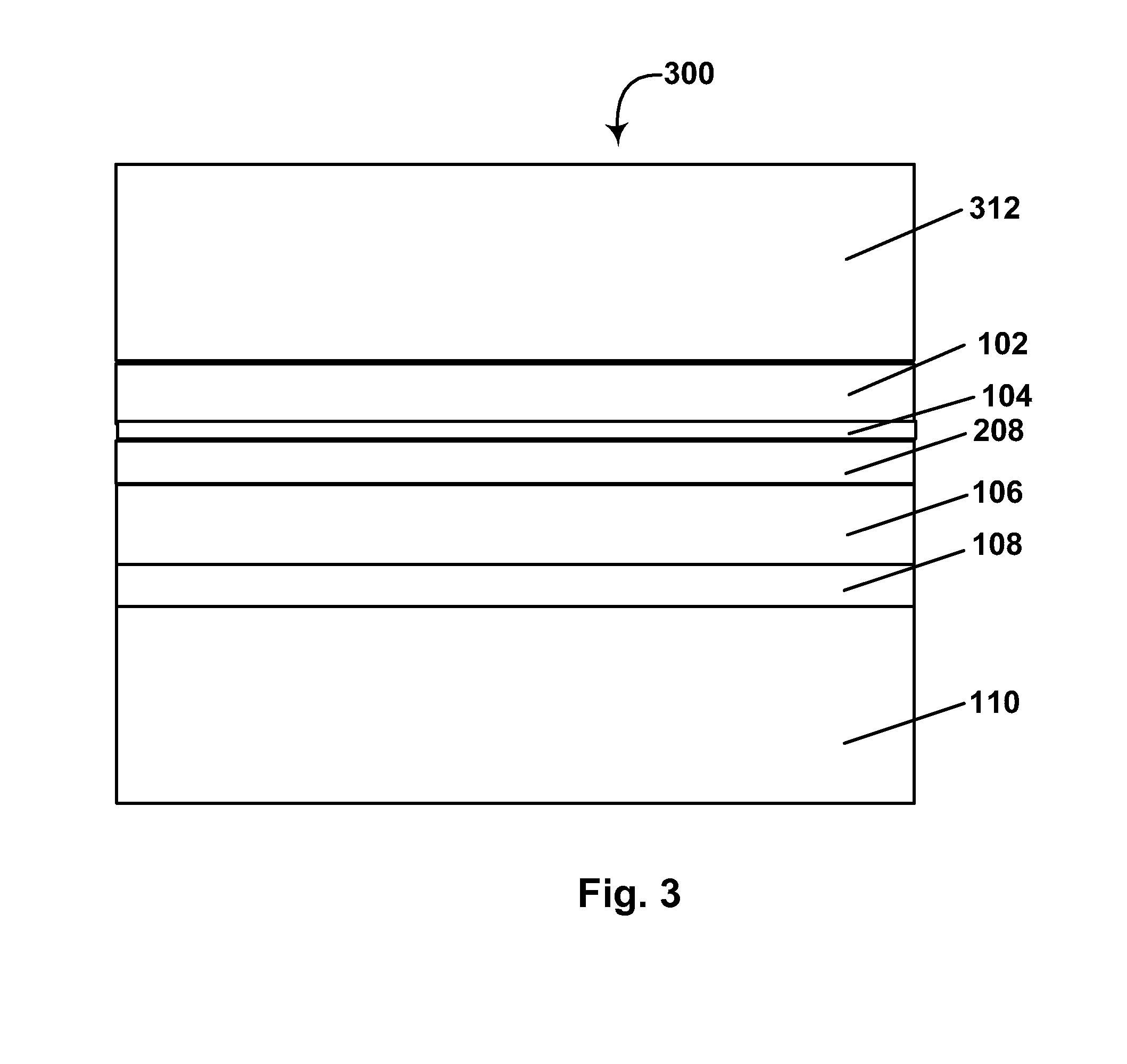

Electrochemical cells, and more specifically, release systems for the fabrication of electrochemical cells are described. In particular, release layer arrangements, assemblies, methods and compositions that facilitate the fabrication of electrochemical cell components, such as electrodes, are presented. In some embodiments, methods of fabricating an electrode involve the use of a release layer to separate portions of the electrode from a carrier substrate on which the electrode was fabricated. For example, an intermediate electrode assembly may include, in sequence, an electroactive material layer, a current collector layer, a release layer, and a carrier substrate. The carrier substrate can facilitate handling of the electrode during fabrication and / or assembly, but may be released from the electrode prior to commercial use.

Owner:SION POWER CORP

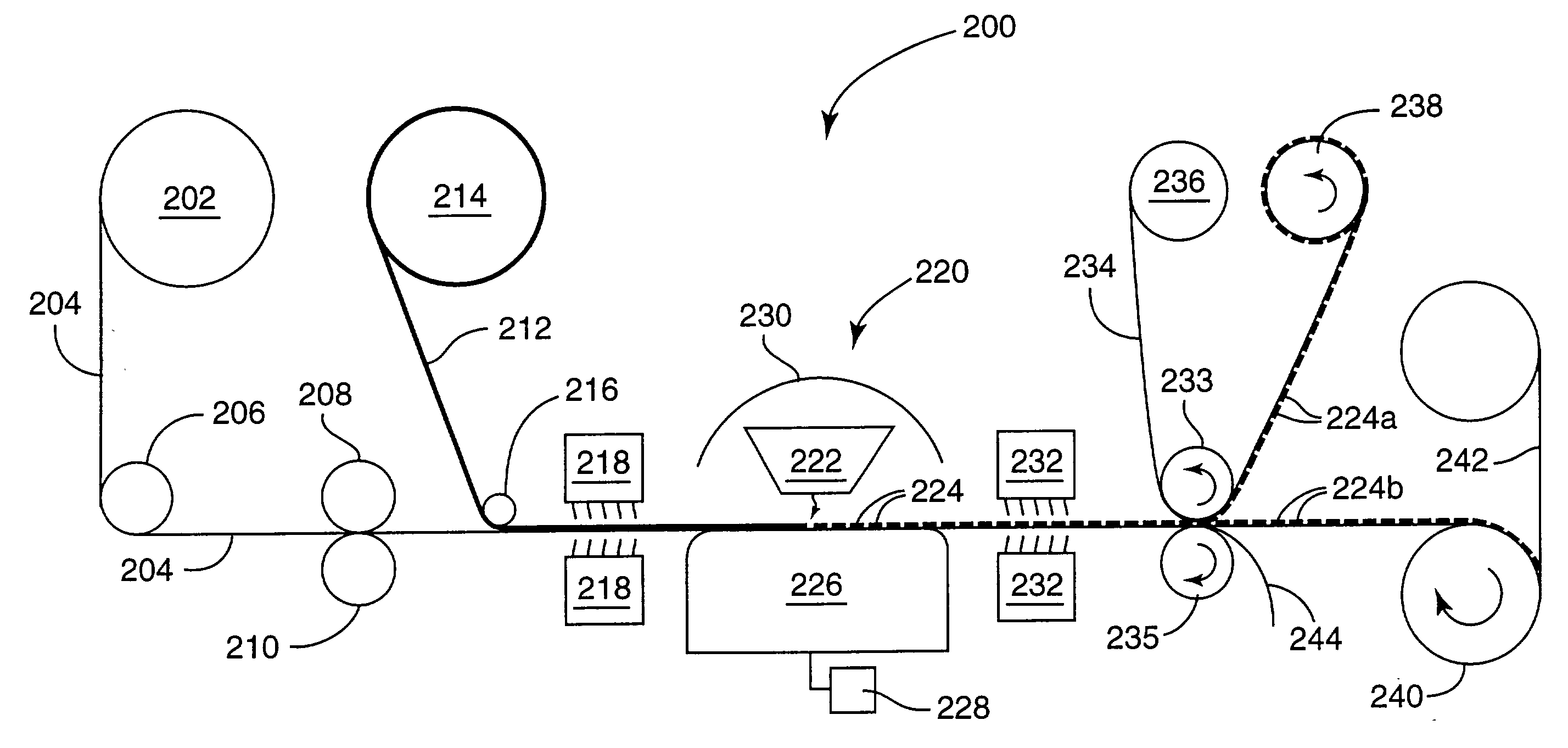

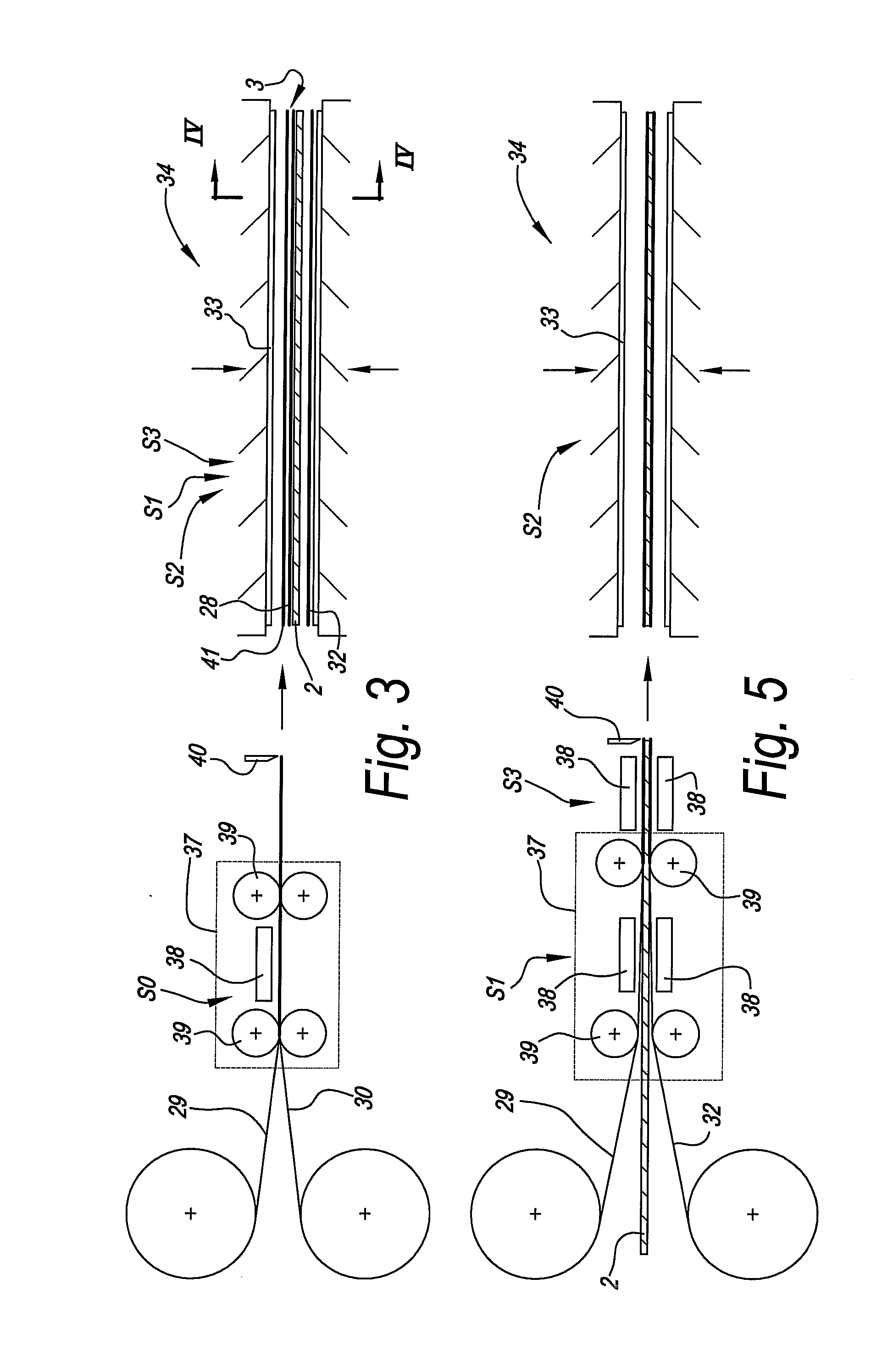

Method for subdividing multilayer optical film cleanly and rapidly

InactiveUS6991695B2Reduce electrostatic attractionPaper/cardboard articlesOptical articlesPolymerLaser

Owner:3M INNOVATIVE PROPERTIES CO

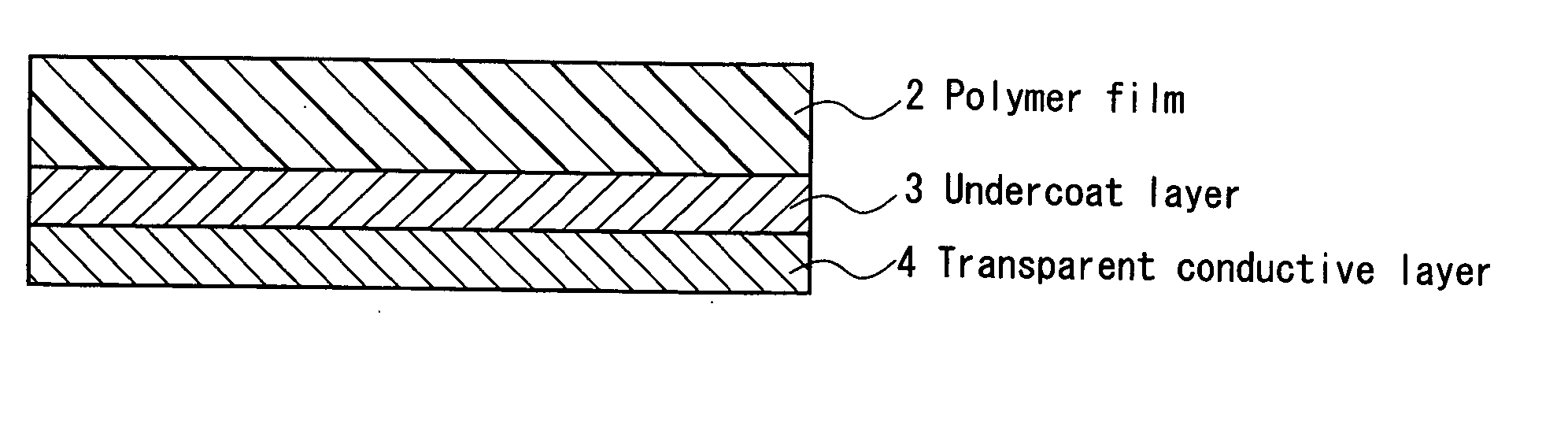

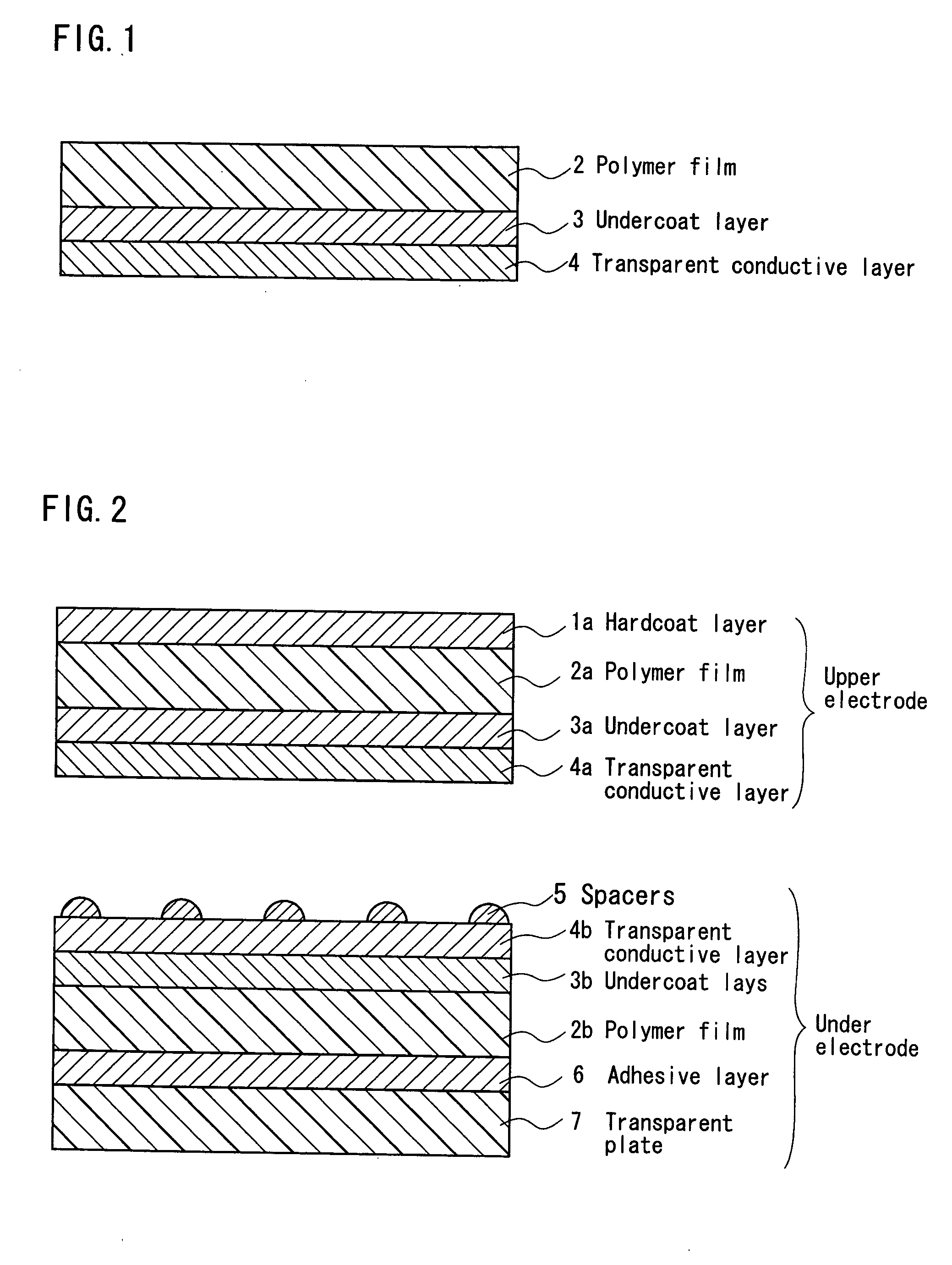

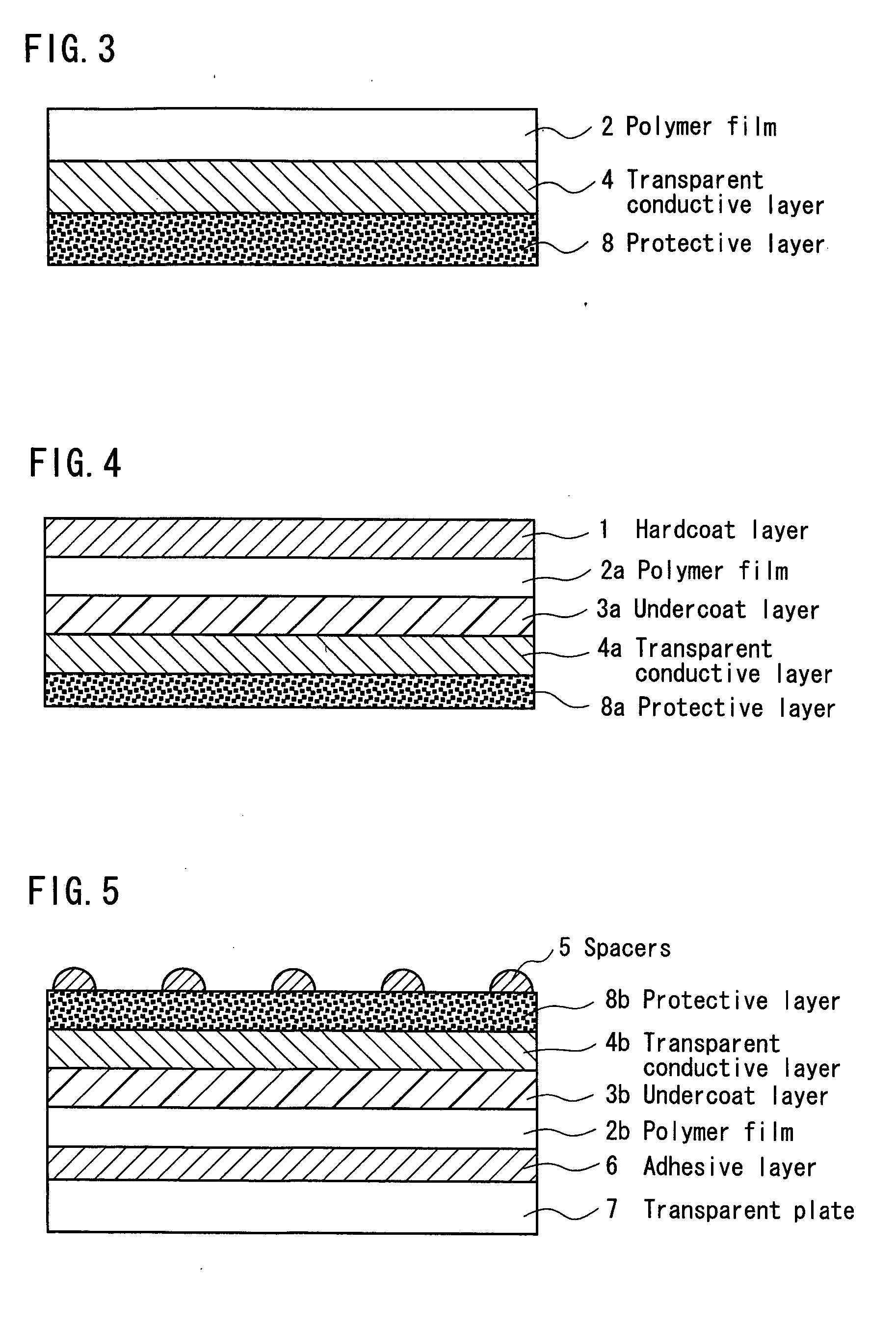

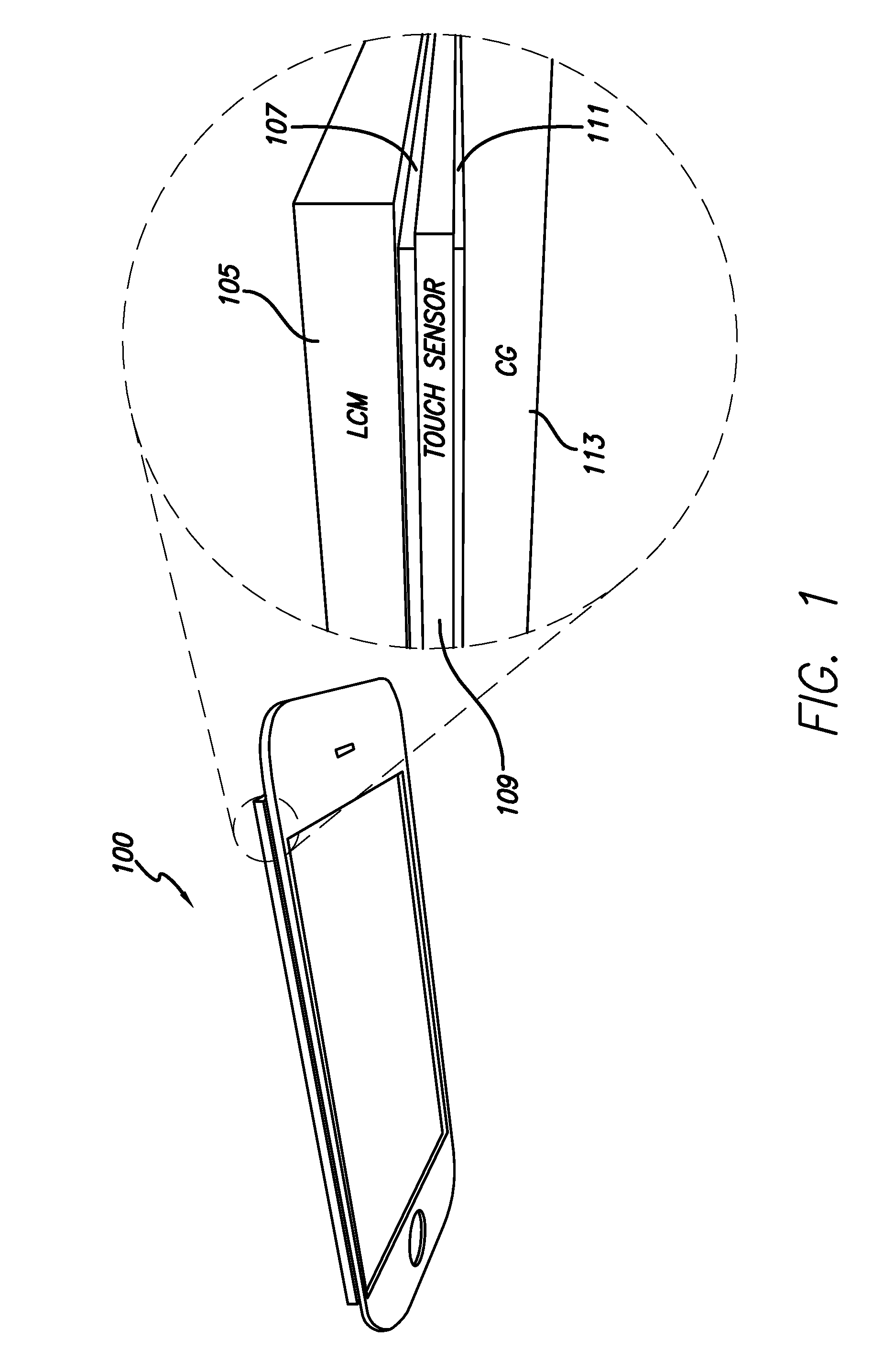

Transparent electroconductive film, method for manufacture thereof, and touch panel

InactiveUS20040265602A1Easy to prepareIncreased durabilityConductive layers on insulating-supportsContact surface shape/structurePhosphoric acidTransparent conducting film

A transparent conductive film comprising a polymer film and a transparent conductive layer provided thereon, especially a transparent conductive film improved in durability and mechanical and electrical properties, a process for the preparation thereof, and a touch panel provided with the transparent conductive film, as well as transparent conductive plate and the process for the preparation thereof. The transparent conductive film comprising a polymer film, an undercoat layer and a transparent conductive layer which are superposed in this order, and the undercoat layer contains a compound having at least one selected from an amino group and a phosphoric acid group.

Owner:BRIDGESTONE CORP

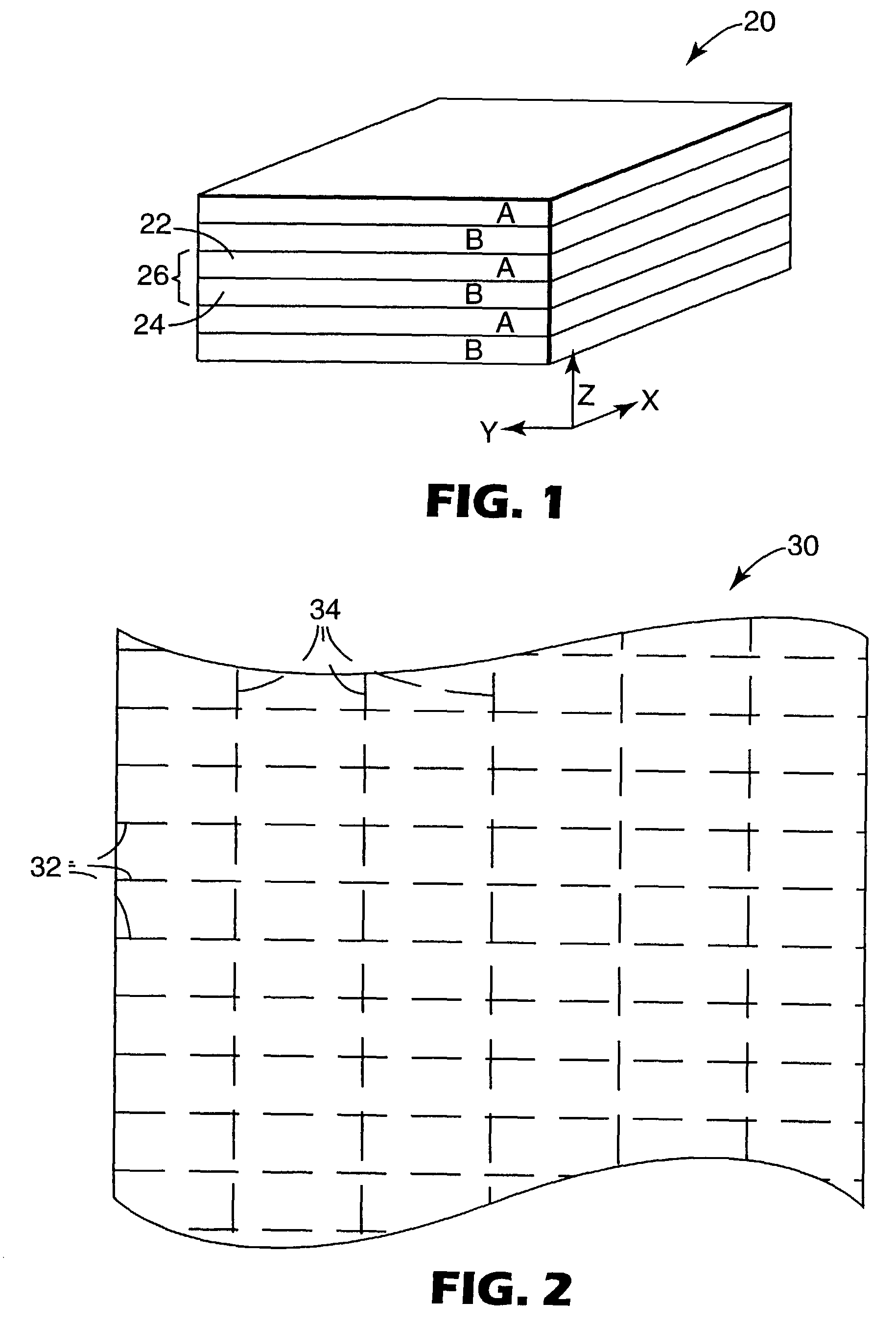

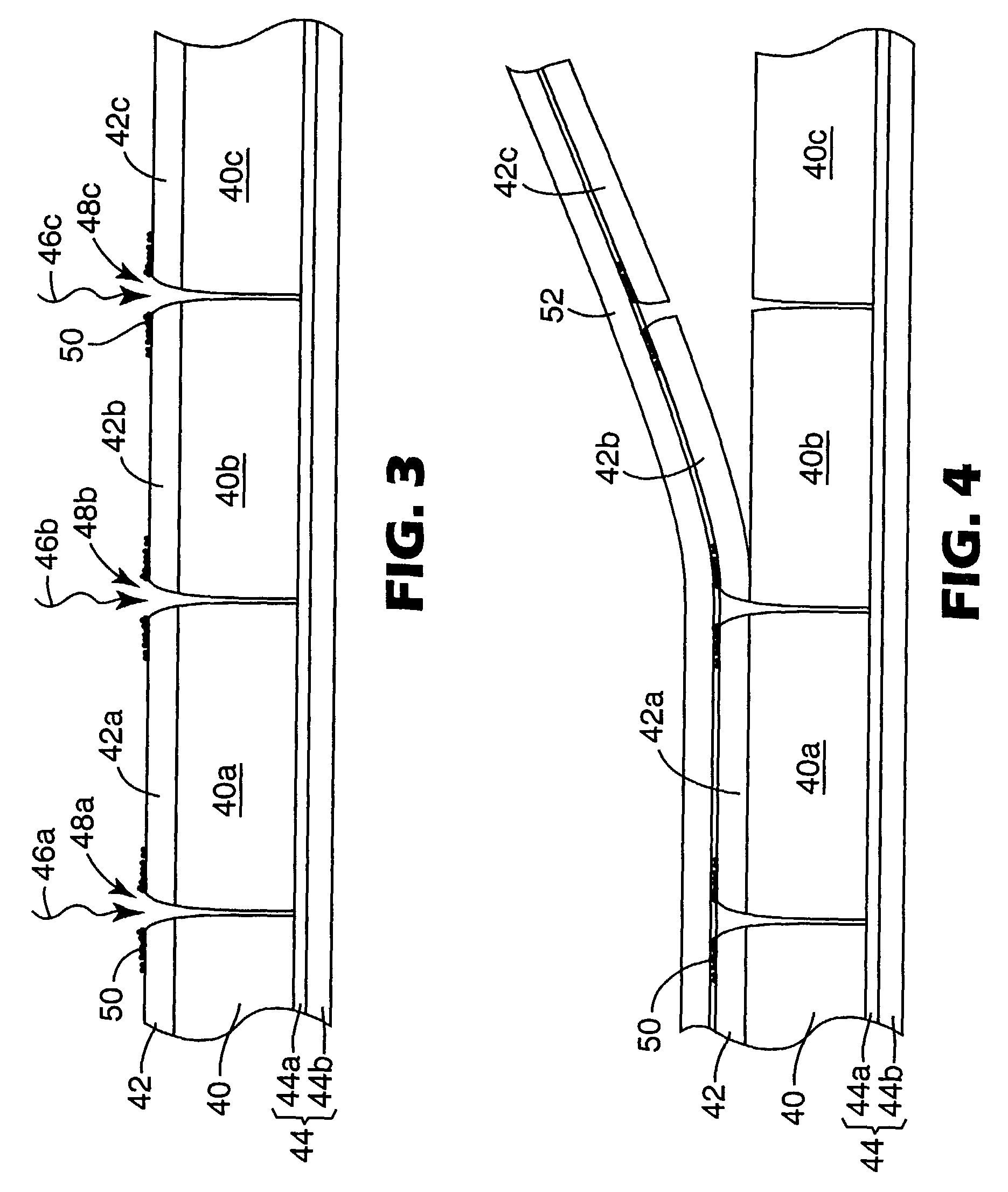

Method for subdividing multilayer optical film cleanly and rapidly

Polymeric multilayer optical films, and laminate bodies that include such films, are cut or subdivided into one or more discrete pieces by removably applying a first and second liner to opposed major surfaces of the multilayer optical film. Laser radiation is then directed at the multilayer optical film through the first liner in such a way as to produce cut lines that define a plurality of pieces of the first liner and of the multilayer optical film. Thereafter, the plurality of pieces of the first liner are removed from the plurality of pieces of the multilayer optical film while the pieces of multilayer optical film are supported by the second liner. Application of the first liner to the multilayer optical film can be accomplished with electrostatics.

Owner:3M INNOVATIVE PROPERTIES CO

Panel and methods for manufacturing panels

InactiveUS20130062006A1Realized more smoothly and/or economicallyAcceptable soundCovering/liningsDecorative surface effectsSynthetic materialsEngineering

Owner:FLOORING IND LTD

Processes for the production of electro-optic displays, and color filters for use therein

ActiveUS20090004442A1Decorative surface effectsPhotomechanical apparatusRadiative transferEngineering

Processes are provided for depositing multiple color filter materials on a substrate to form color filters. In a first process, the surface characteristic of a substrate is modified by radiation so that a flowable form of a first color filter material will be deposited on a first area, and converted to a non-flowable form. A second color filter material can then be deposited on a second area of the substrate. In a second process, first and second color filter materials are deposited on separate donor sheets and transferred by radiation to separate areas of the substrate. A third process uses flexographic printing to transfer the first and second color filter materials to the substrate.

Owner:E INK CORPORATION

Composite thermal interface material including aligned nanofiber with low melting temperature binder

ActiveUS20090068387A1Improve thermal conductivityMaterial nanotechnologyLamination ancillary operationsFiberAdhesion process

A thermal interface material includes a mechanically compliant vertically aligned nanofiber film and a binder material for joining the nanofibers of the film to the surfaces of two substrates. Preferably, the binder material comprises a non-hydrocarbon-based material such as a metallic eutectic with a melting temperature below a nanofiber thermal damage threshold temperature of the film. The film is grown on a substrate which is then bonded to another substrate by the binder material in an adhesion process that may include pressure and heat. Alternatively, the film may be released from the substrate to produce a stand-alone thermal tape which may later be placed between two substrates and bonded.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

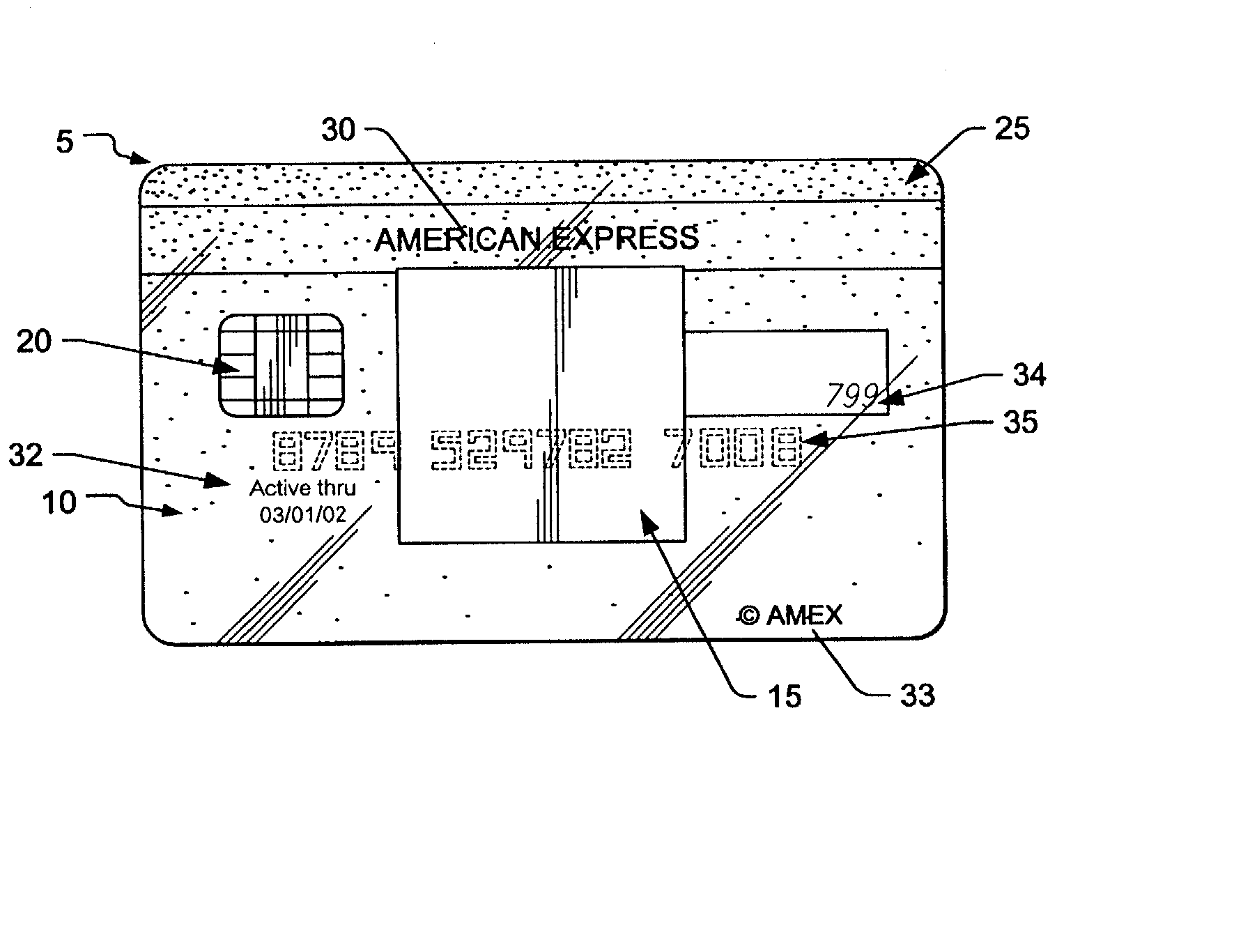

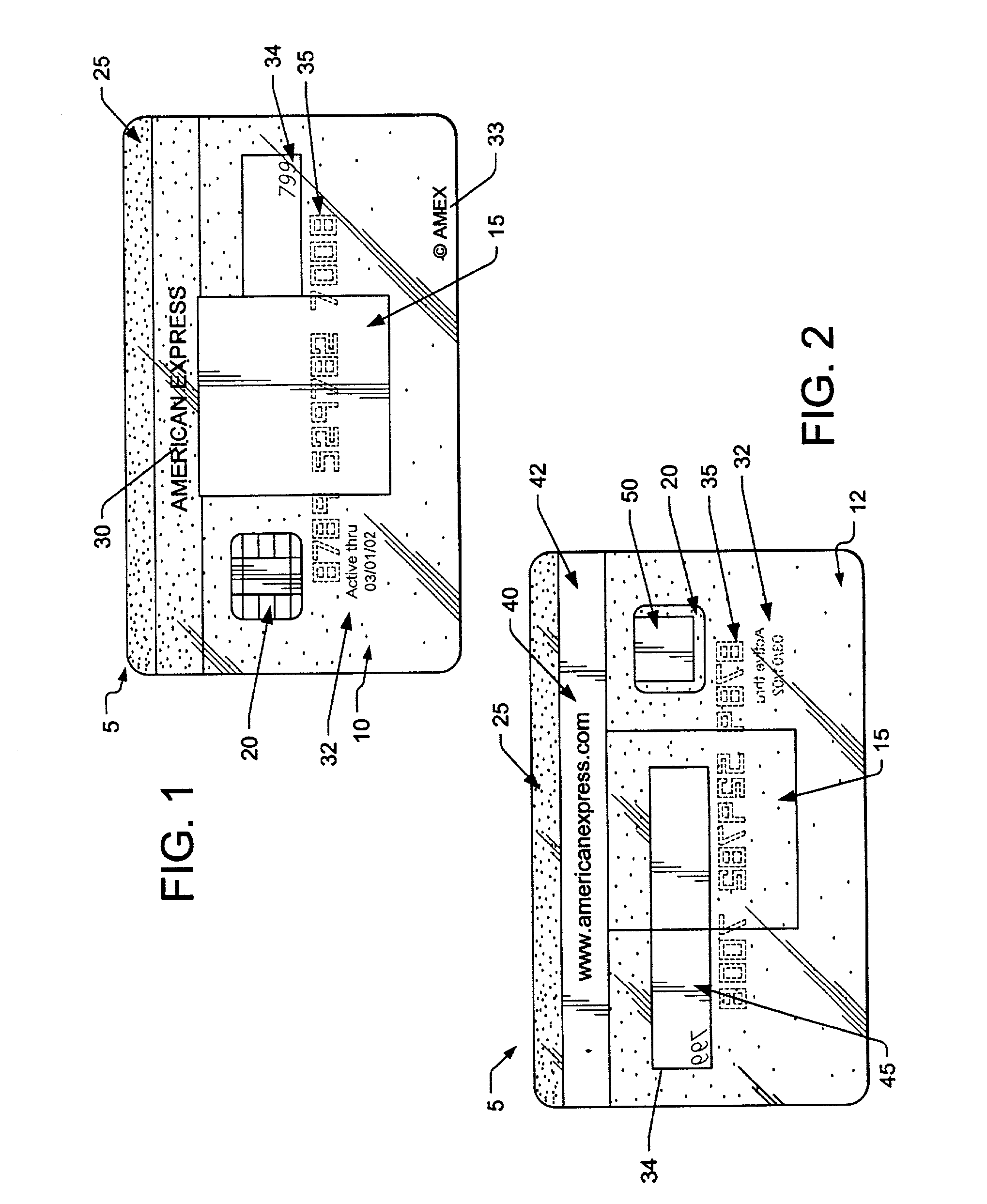

Transaction card

The present invention relates to a process for producing an opaque, transparent or translucent transaction card having multiple features, such as a holographic foil, integrated circuit chip, silver magnetic stripe with text on the magnetic stripe, opacity gradient, an invisible optically recognizable compound, a translucent signature field such that the signature on back of the card is visible from the front of the card and an active thru date on the front of the card. The invisible optically recognizable compound is an infrared ink and / or film, which can be detected by a sensor found in an ATM or card assembly line.

Owner:LIBERTY PEAK VENTURES LLC

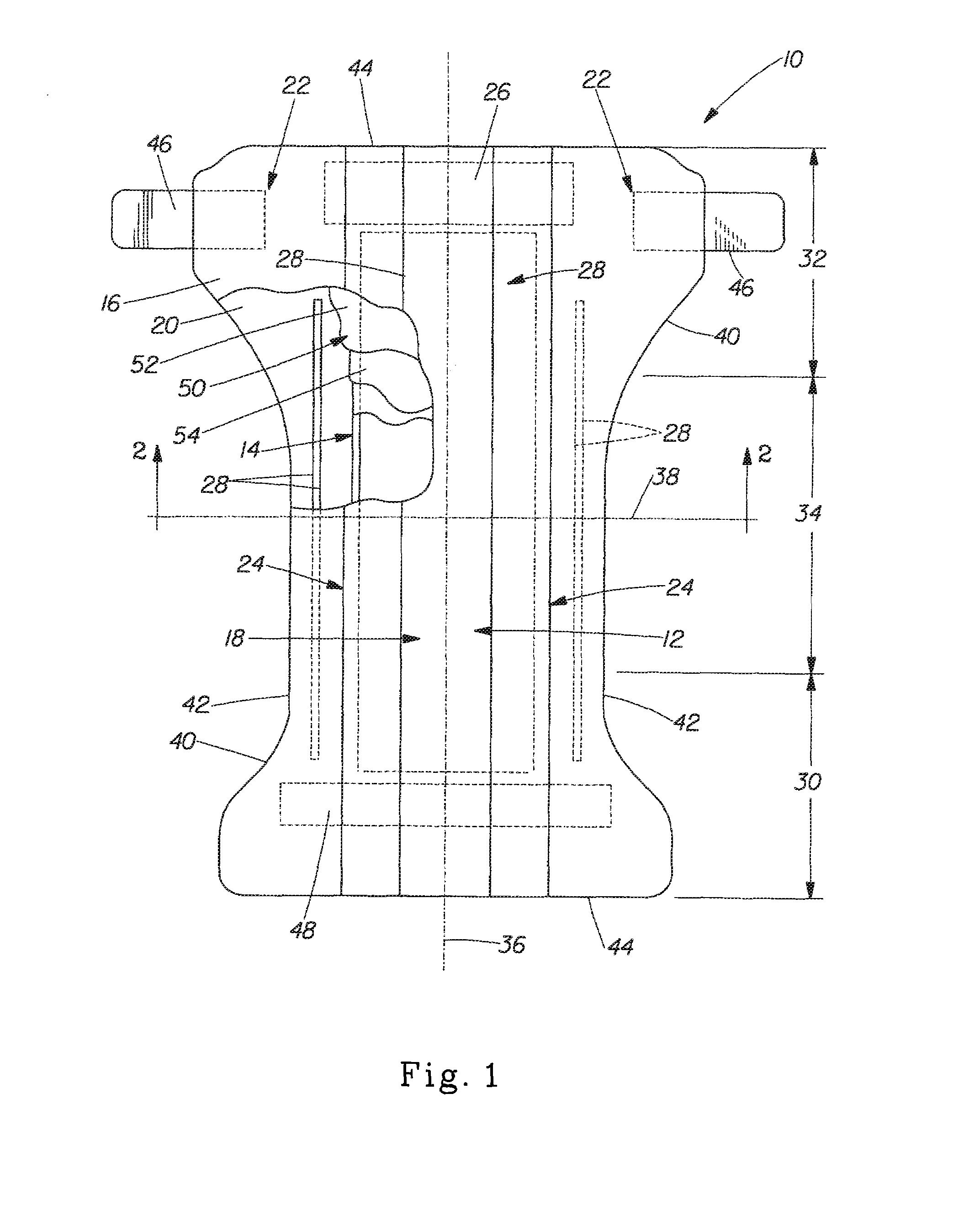

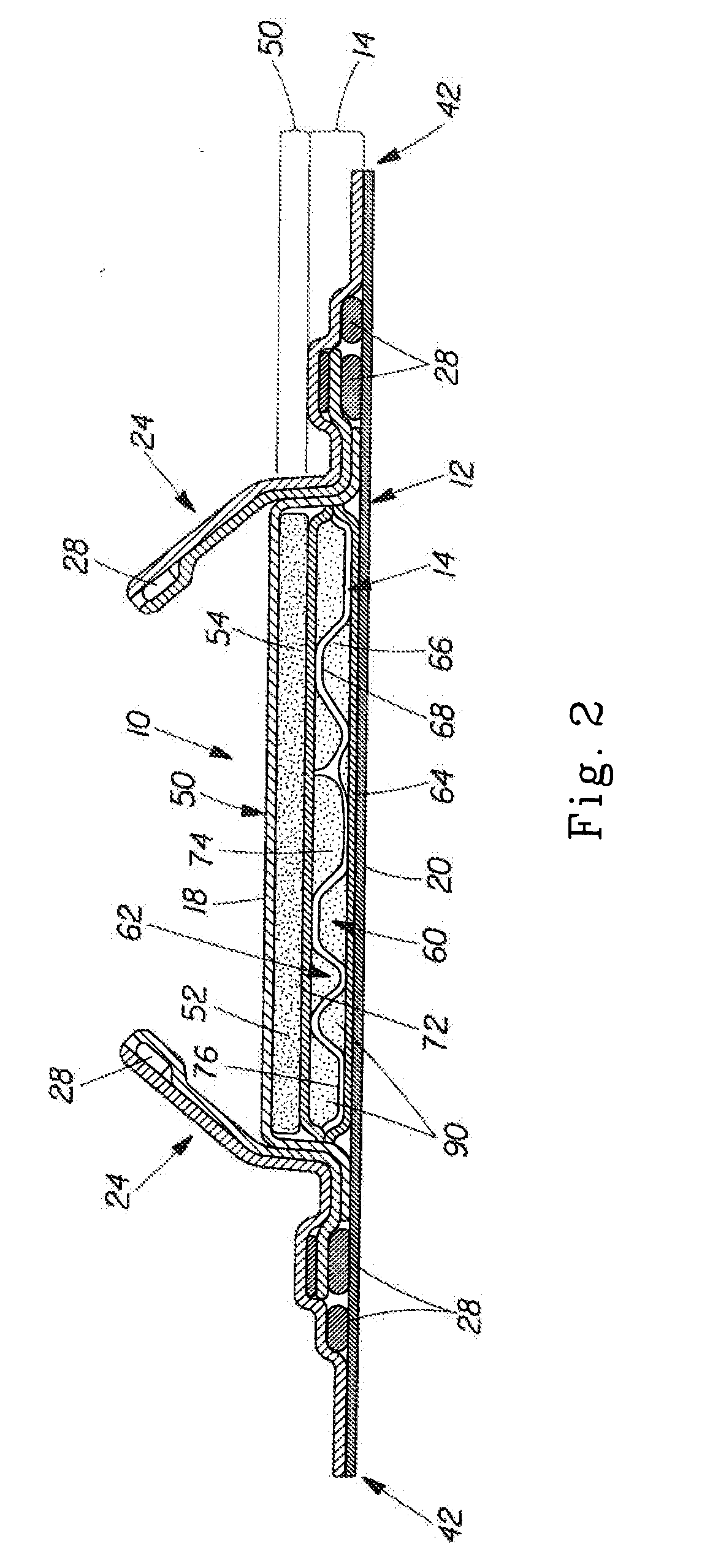

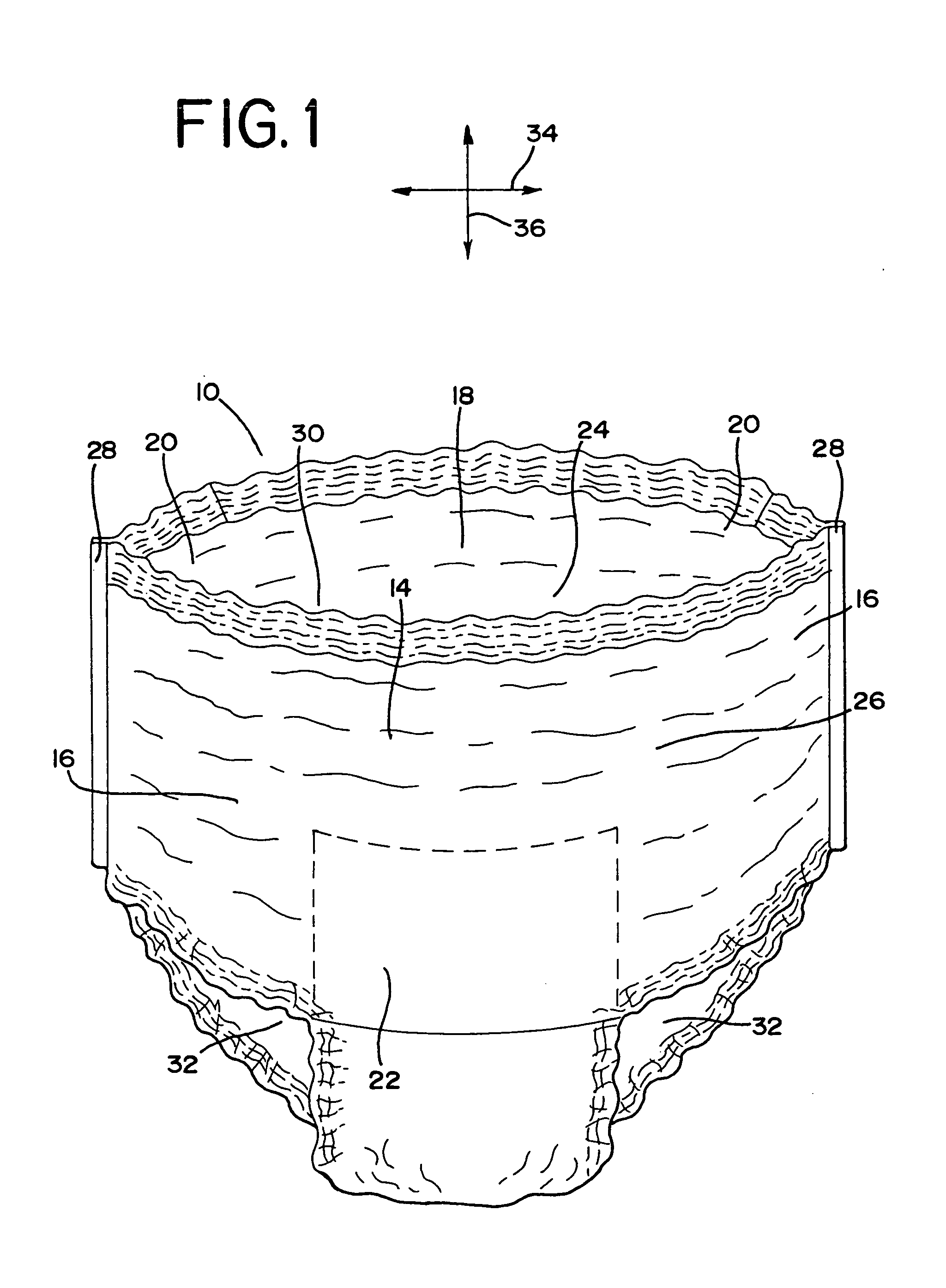

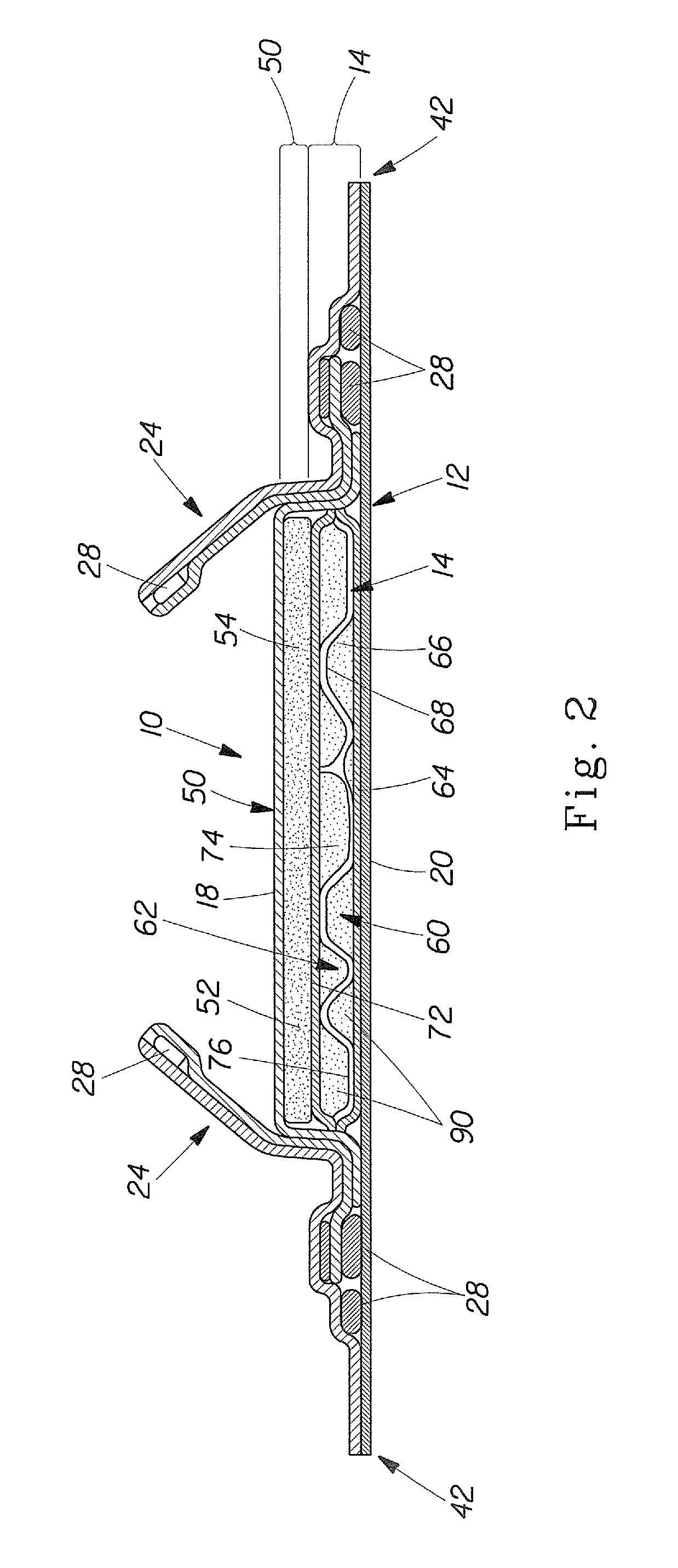

Thin and dry diaper

ActiveUS8187240B2Lamination ancillary operationsLayered product treatmentEngineeringAbsorbent material

An absorbent article, preferably a disposable absorbent article such as a diaper, is disclosed having an absorbent core which imparts increased wearing comfort to the article and makes it thin and dry. The absorbent core useful for an absorbent article comprises a substrate layer, a discontinuous layer of absorbent material, and a layer of thermoplastic material. A second surface of the discontinuous layer of absorbent material is in at least partial contact with a first surface of the substrate layer. Portions of a second surface of the layer of thermoplastic material are in direct contact with the first surface of the substrate layer and portions of said second surface of the layer of thermoplastic material are in direct contact with a first surface of the discontinuous layer of absorbent material. A process for providing a storage layer for an absorbent core useful in an absorbent article is further disclosed.

Owner:PROCTER & GAMBLE CO

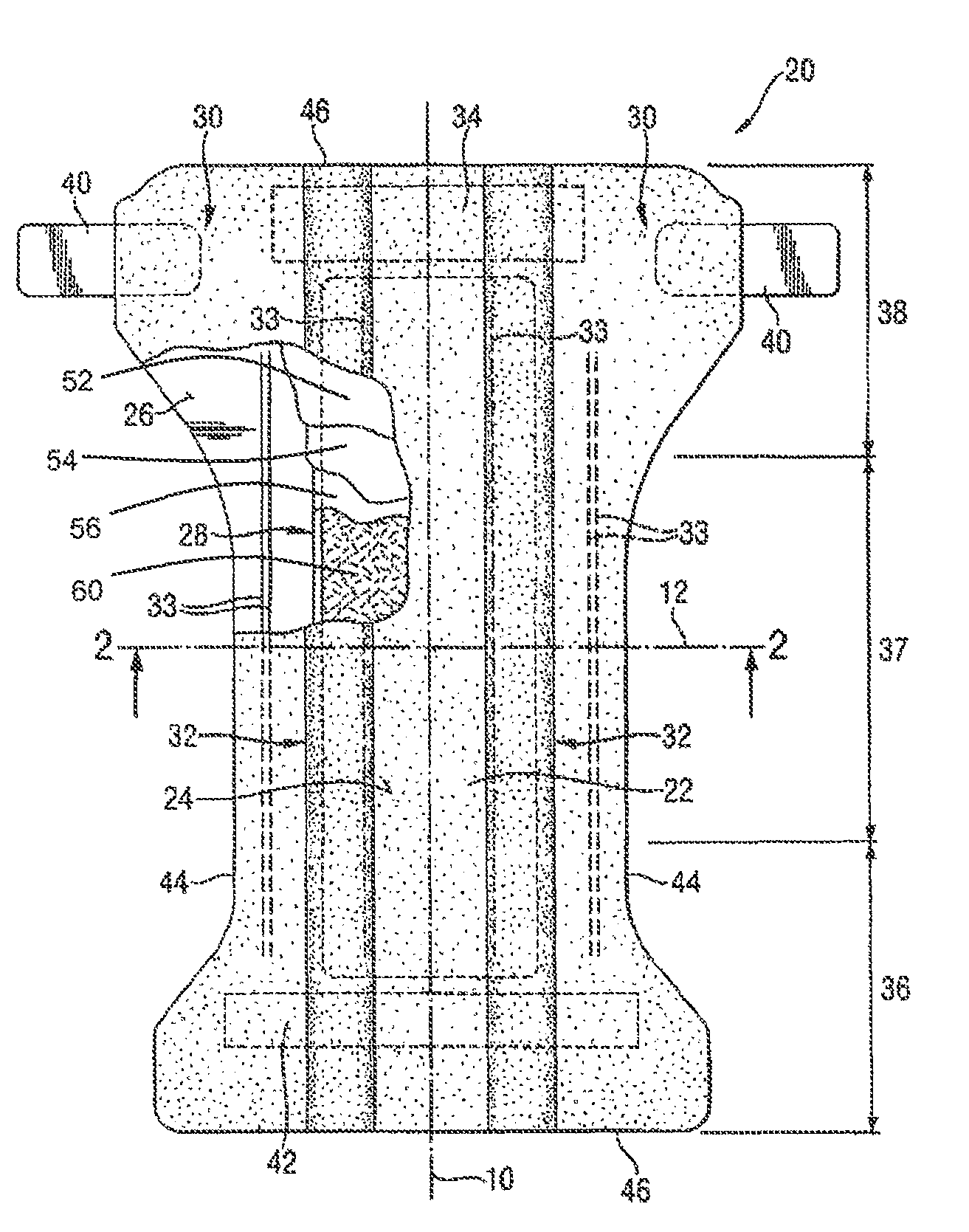

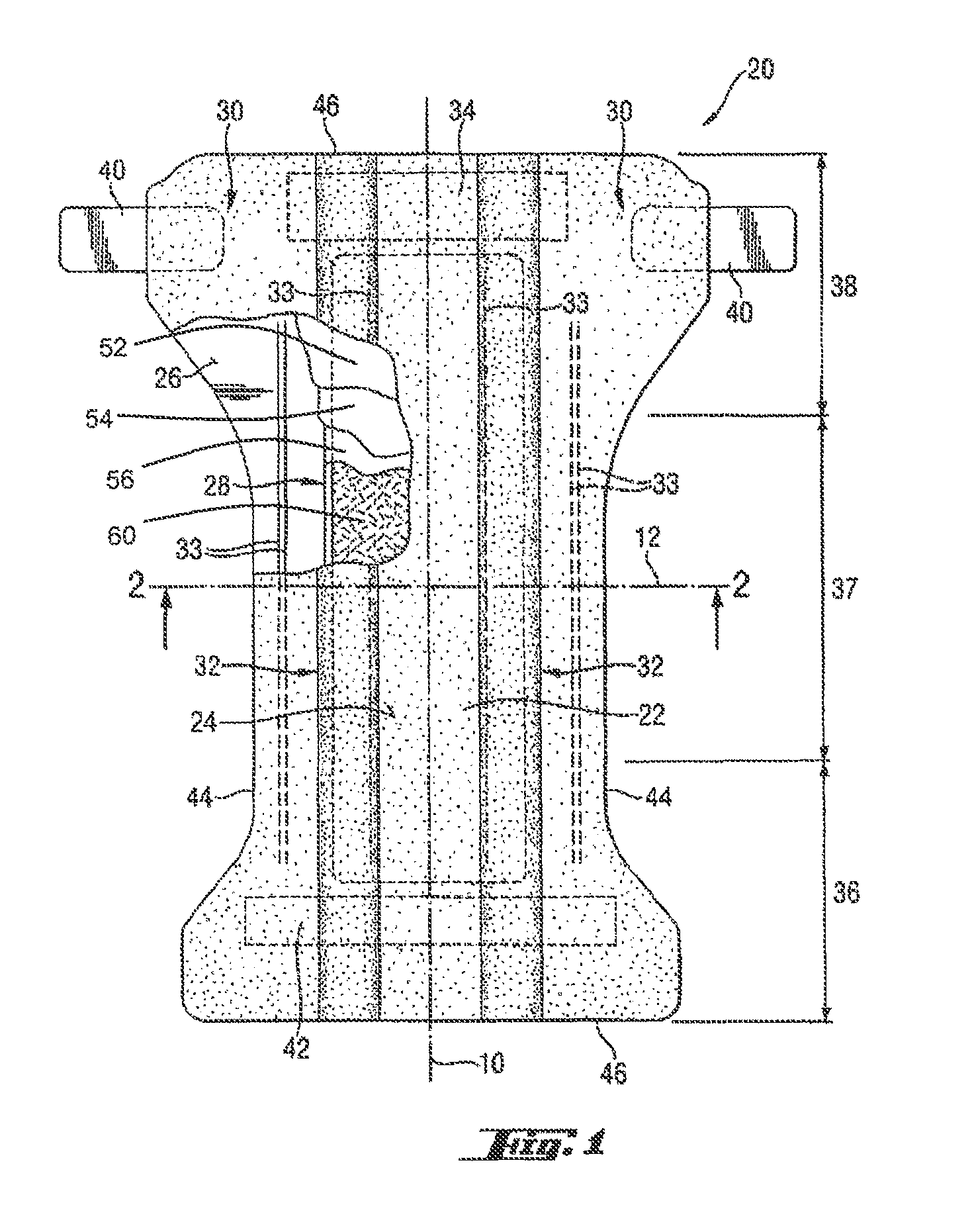

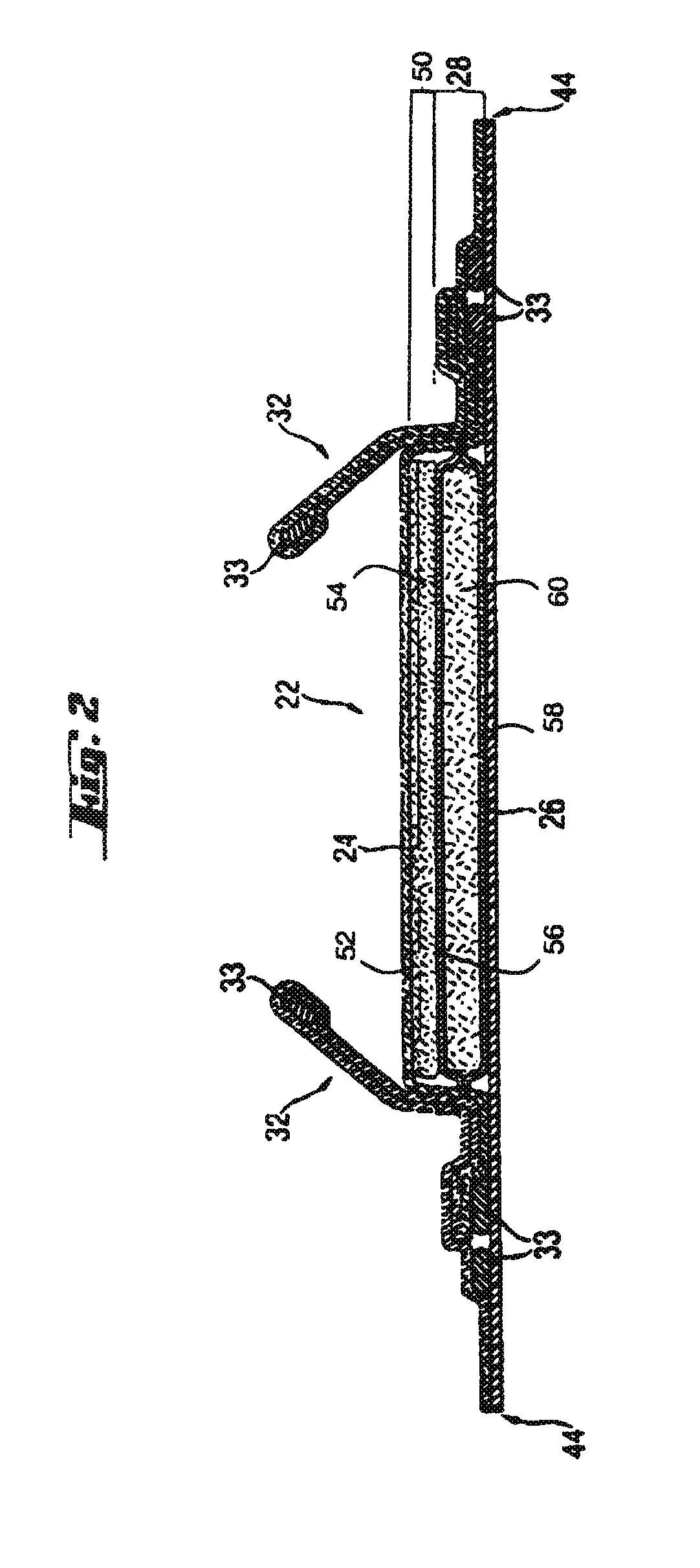

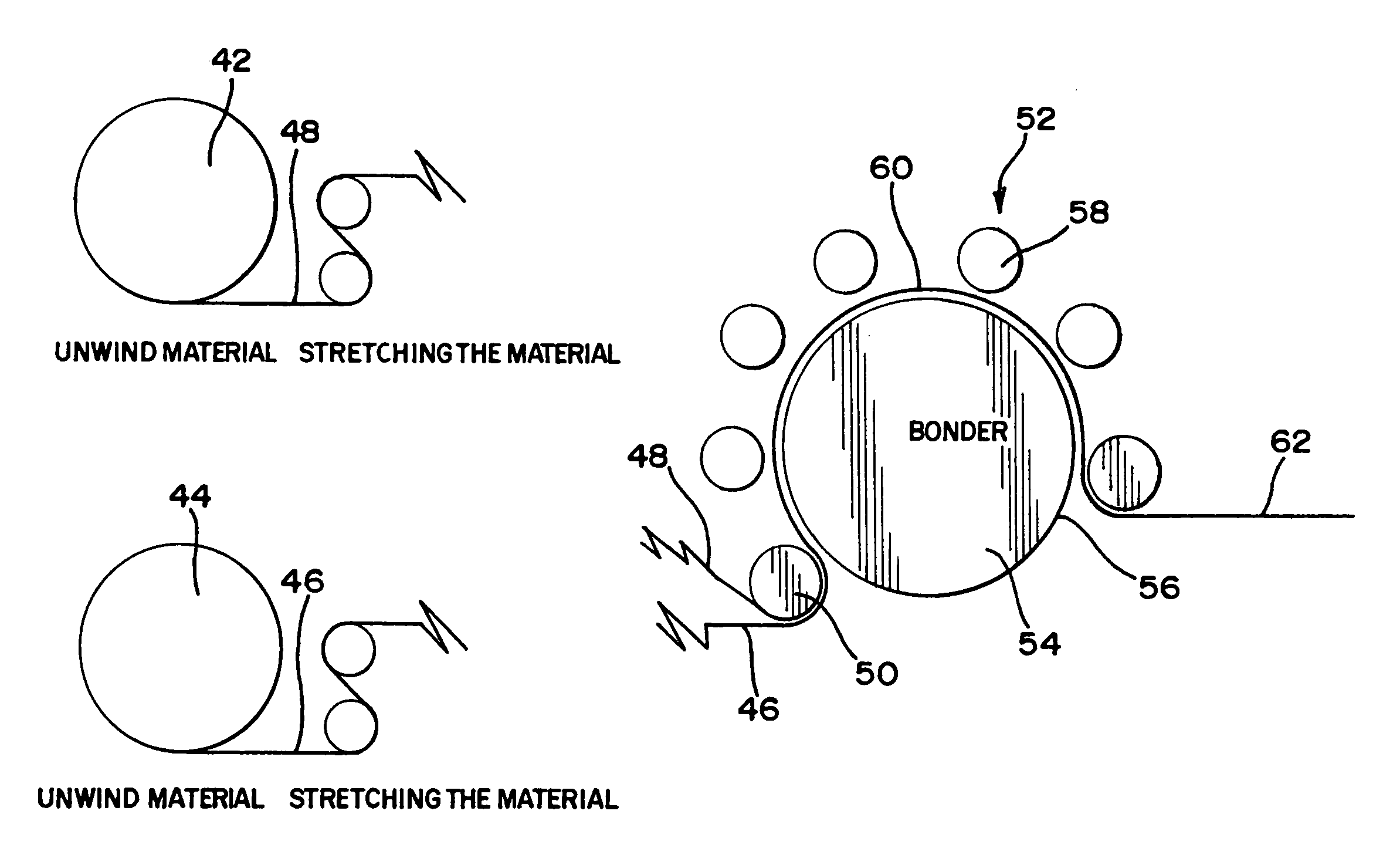

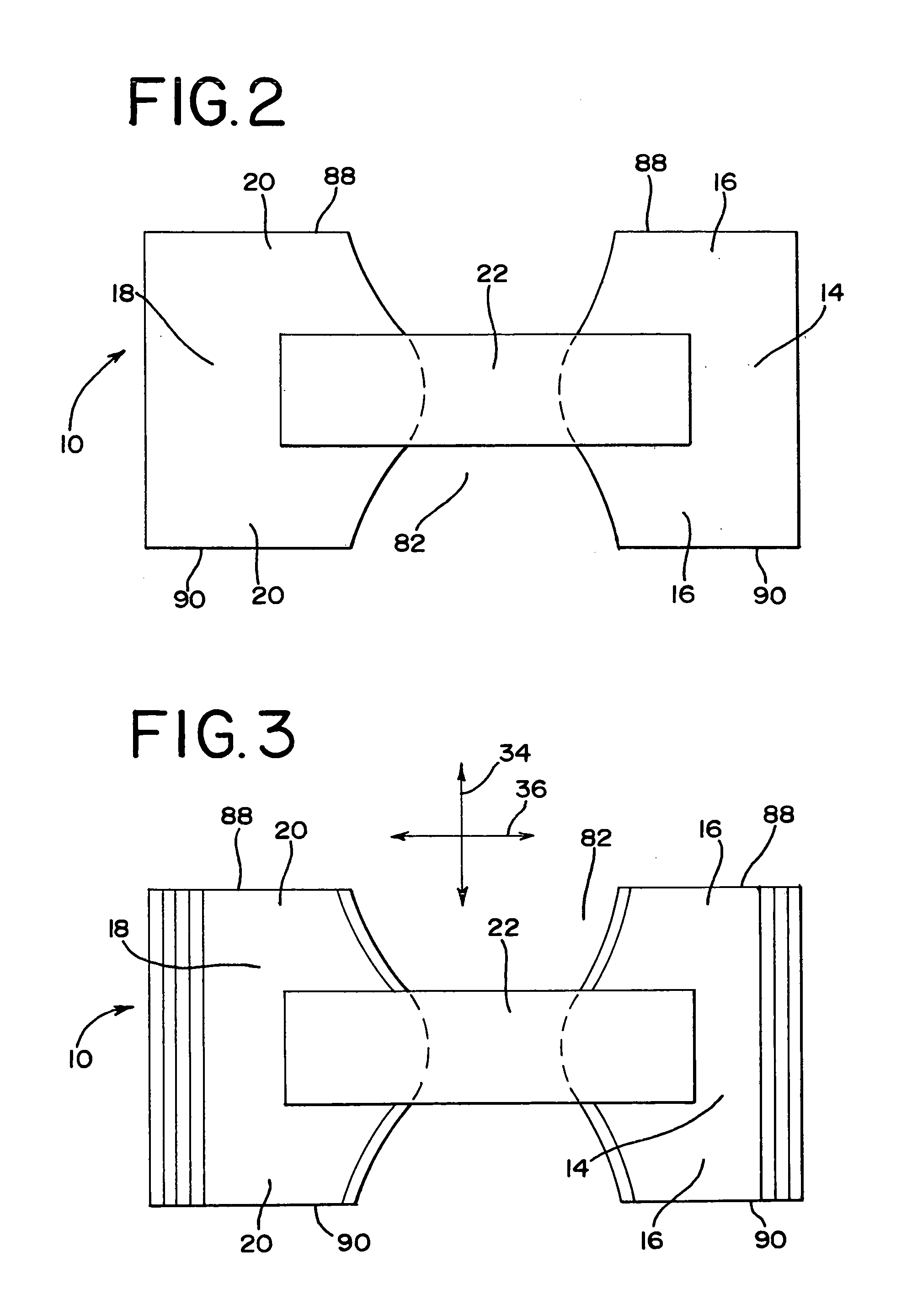

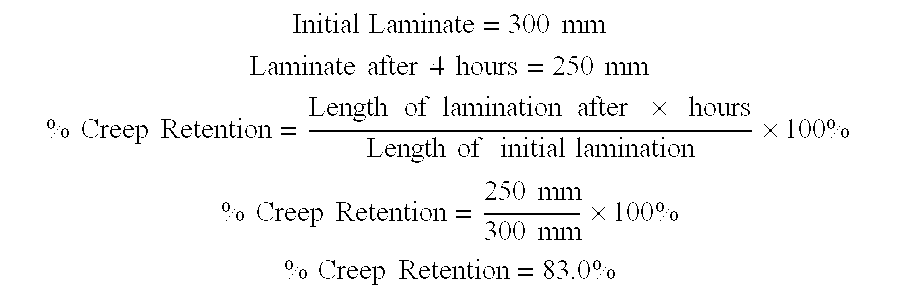

Method for improved bond strength in an elastomeric material

ActiveUS7108759B2High strengthIncreasing ultrasonic bond strengthPersonal careLayered product treatmentElastomerUltimate tensile strength

A method for increasing the bond strength of ultrasonic bonds in elastomeric materials comprising elongating the elastomeric materials prior to ultrasonically bonding the materials.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Hot Melt Adhesive Based on Olefin Block Copolymers

ActiveUS20110021103A1Improve spray characteristicsGood viscosity stabilityPersonal careLayered product treatmentCardboardCrystallinity

A hot melt adhesive composition, comprising a blend of components including about 5% to about 50% by weight of an olefin block copolymer; about 10% to about 70% by weight of a first tackifying resin having a softening point of at least about 95° C.; about 0 to 65% of a second tackifying resin that is different than the first tackifying resin; about 0% to about 60% by weight of a plasticizer; about 0% to about 20% by weight of an aromatic reinforcing resin having a softening point equal to or higher than 115° C.; about 0.1% to about 5% by weight of a stabilizer; and about 1% to about 40% by weight of a secondary polymer that is different from the olefin block copolymer, the first and second tackifying resins and the reinforcing resin, having relatively low crystallinity, which low crystallinity is equal to or less than 250 Joules / gram, wherein the components total 100% by weight of the composition, and the viscosity of the composition is equal to or less than about 20,000 mPa·s at 163° C. Laminates, especially those used in disposable soft goods, and methods of making such laminates using the hot melt adhesive composition are also described. The adhesive composition and / or laminate may be used in making a variety of end products such as a disposable diaper, a sanitary napkin, a bed pad, a bandage, a surgical drape, a tape, a label, a plastic sheet, a nonwoven sheet, a paper sheet, a cardboard, a book, a filter, or a package.

Owner:BOSTIK INC

Processes for the production of electro-optic displays, and color filters for use therein

ActiveUS9199441B2Lamination ancillary operationsLayered product treatmentRadiative transferEngineering

Processes are provided for depositing multiple color filter materials on a substrate to form color filters. In a first process, the surface characteristic of a substrate is modified by radiation so that a flowable form of a first color filter material will be deposited on a first area, and converted to a non-flowable form. A second color filter material can then be deposited on a second area of the substrate. In a second process, first and second color filter materials are deposited on separate donor sheets and transferred by radiation to separate areas of the substrate. A third process uses flexographic printing to transfer the first and second color filter materials to the substrate.

Owner:E INK CORPORATION

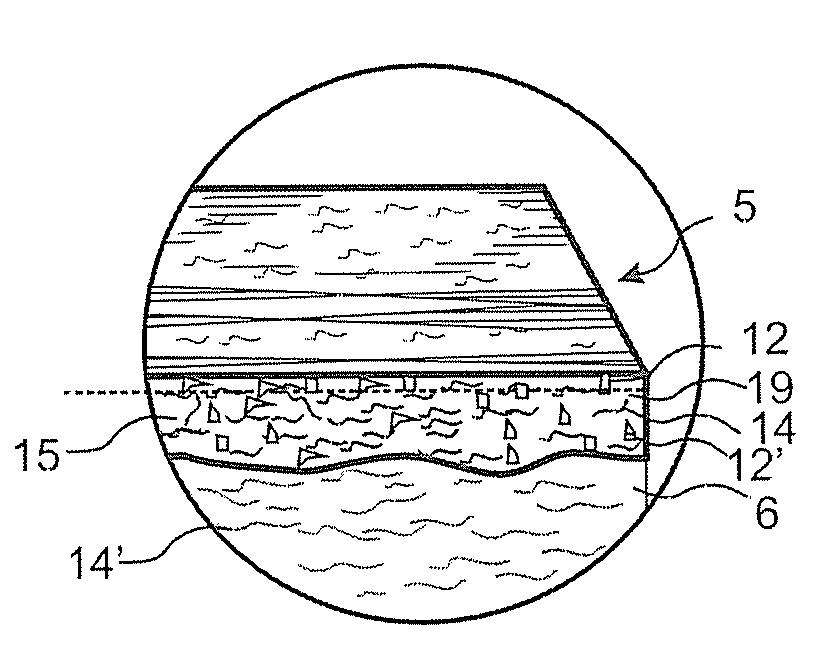

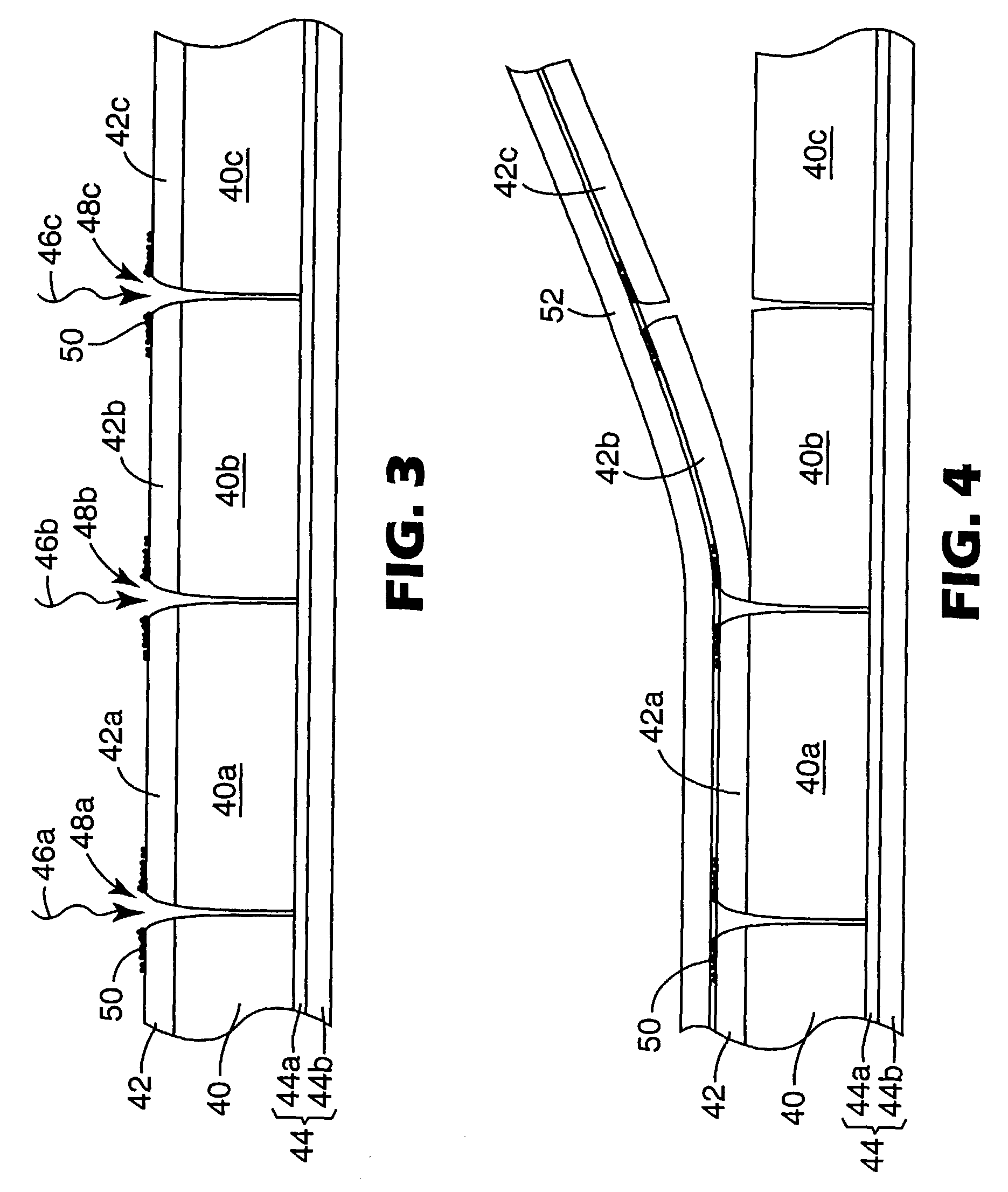

Layer-Specific Energy Distribution Delamination

InactiveUS20100154992A1Faster and efficient delamination processReduce and eliminate damageLamination ancillary operationsLayered product treatmentEnergy transferMicrowave

Delamination of a laminated multilayer stack is provided by generating a layer-specific energy distribution in the stack during delamination. A localized energy transferrer can generate localized heating, cooling heating, cooling, or other form of energy absorption or transmission, in a bonding layer of a multilayer stack. Localized energy transfer can include thermal energy transfer, such as heating and / or cooling, acoustic energy transfer, such as applying ultrasonic energy, electromagnetic energy transfer, such as applying laser light, directed microwaves, etc. Localized energy transfer can generate a layer-specific energy distribution that can weaken the bonding layer while reducing damage to other layers of the stack.

Owner:APPLE INC

Glass product for use in ultra-thin glass display applications

InactiveUS20050001201A1Liquid crystal compositionsLayered product treatmentActive-matrix liquid-crystal displayAlkali free

The present invention is directed to a substrate product for use in the manufacture of active matrix liquid crystal display panels. The product includes a display substrate suitable for use as a display panel. The display substrate has a thickness less than or equal to 0.4 mm, a composition that is substantially alkali free, and a surface smoothness that allows the direct formation of thin-film transistors thereon without a prior processing step of polishing and / or grinding. The product also includes at least one support substrate removably attached to the display substrate.

Owner:CORNING INC

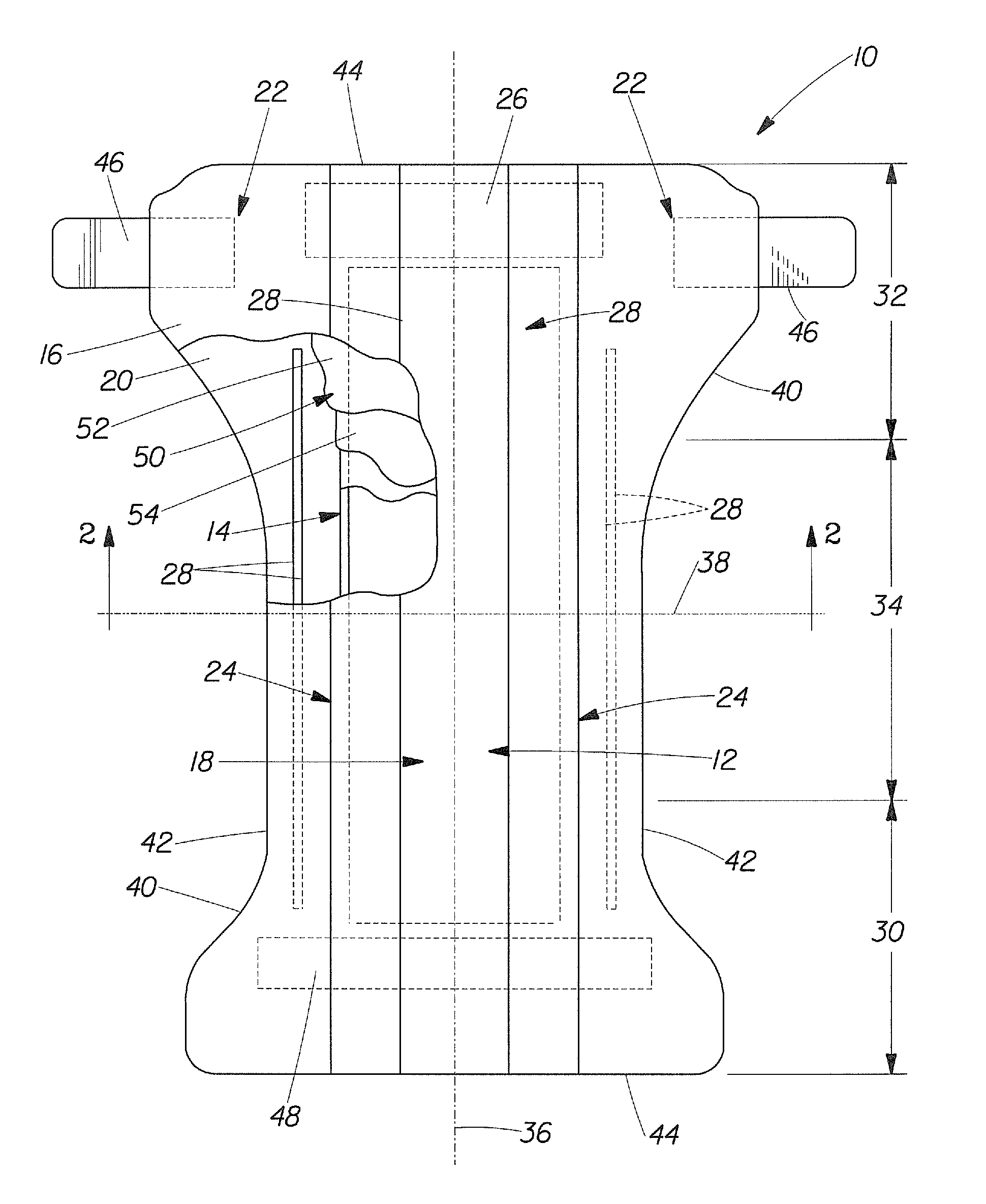

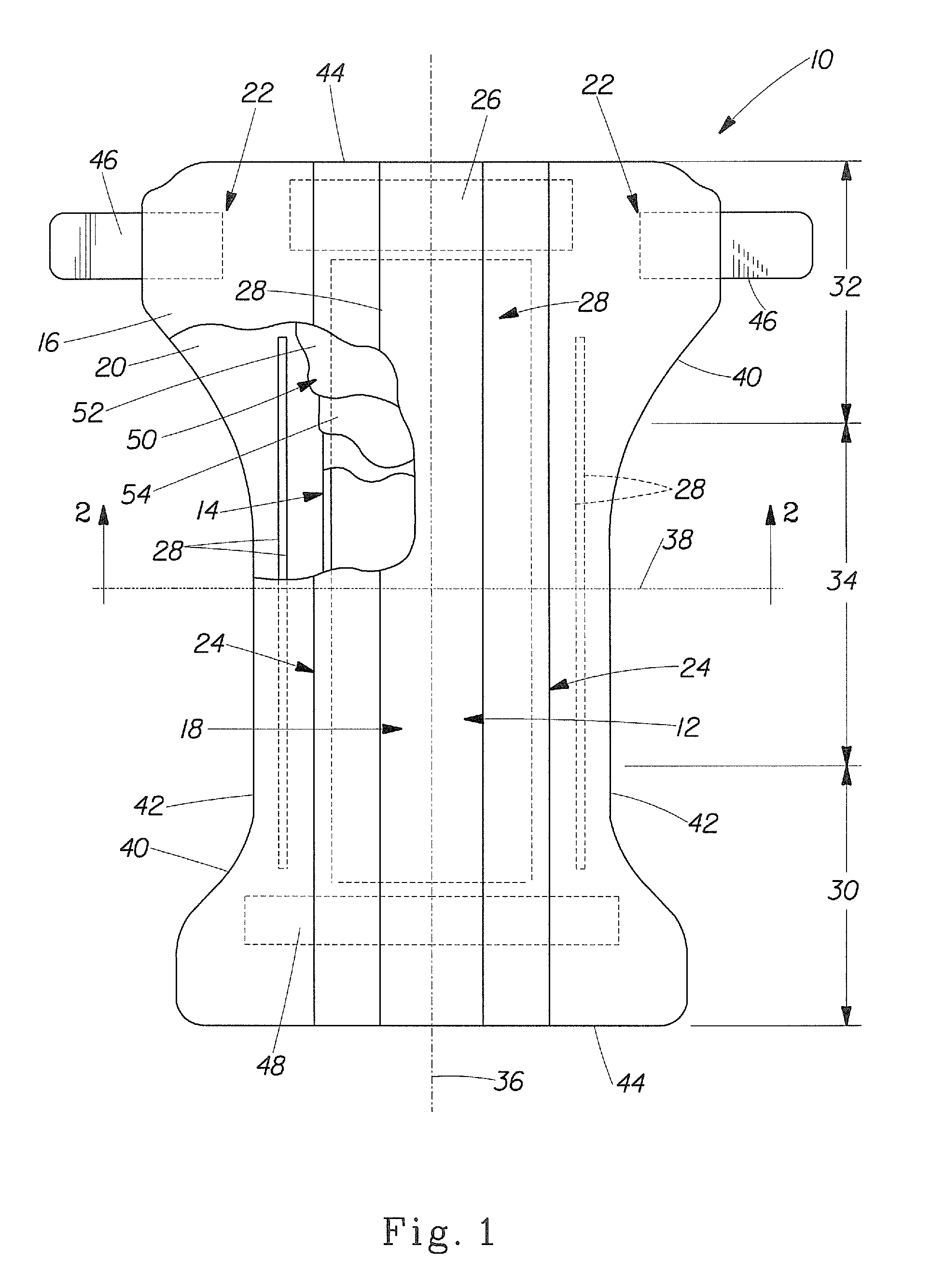

Disposable Absorbent Article With Substantially Continuously Distributed Absorbent Particulate Polymer Material And Method

A disposable absorbent core comprises first and second absorbent layers each comprising an absorbent particulate polymer material such that the absorbent particulate polymer material is substantially continuously distributed across an absorbent particulate polymer material area. A disposable absorbent article and method for making the absorbent core are also disclosed.

Owner:HUNDORF HARALD HERMANN +6

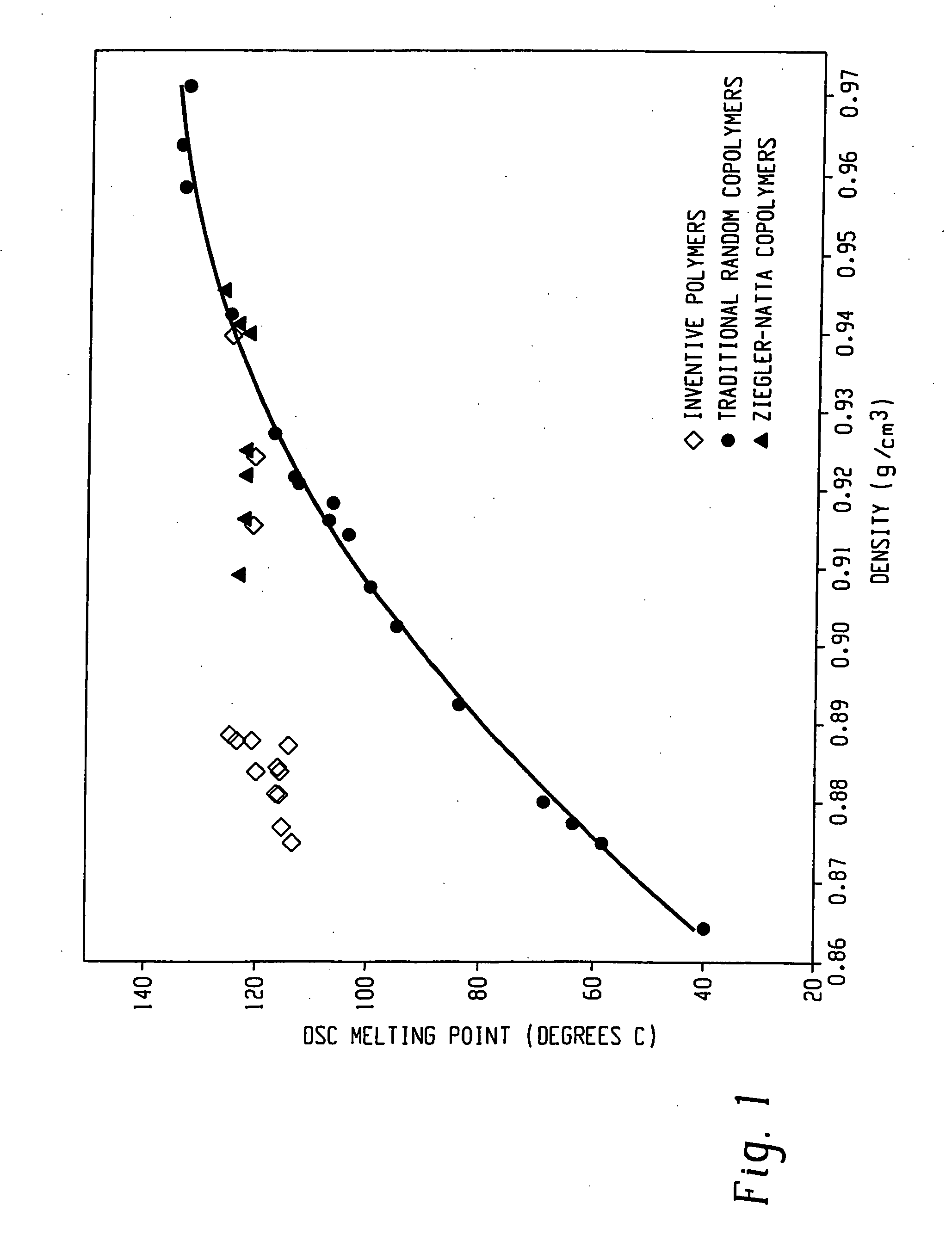

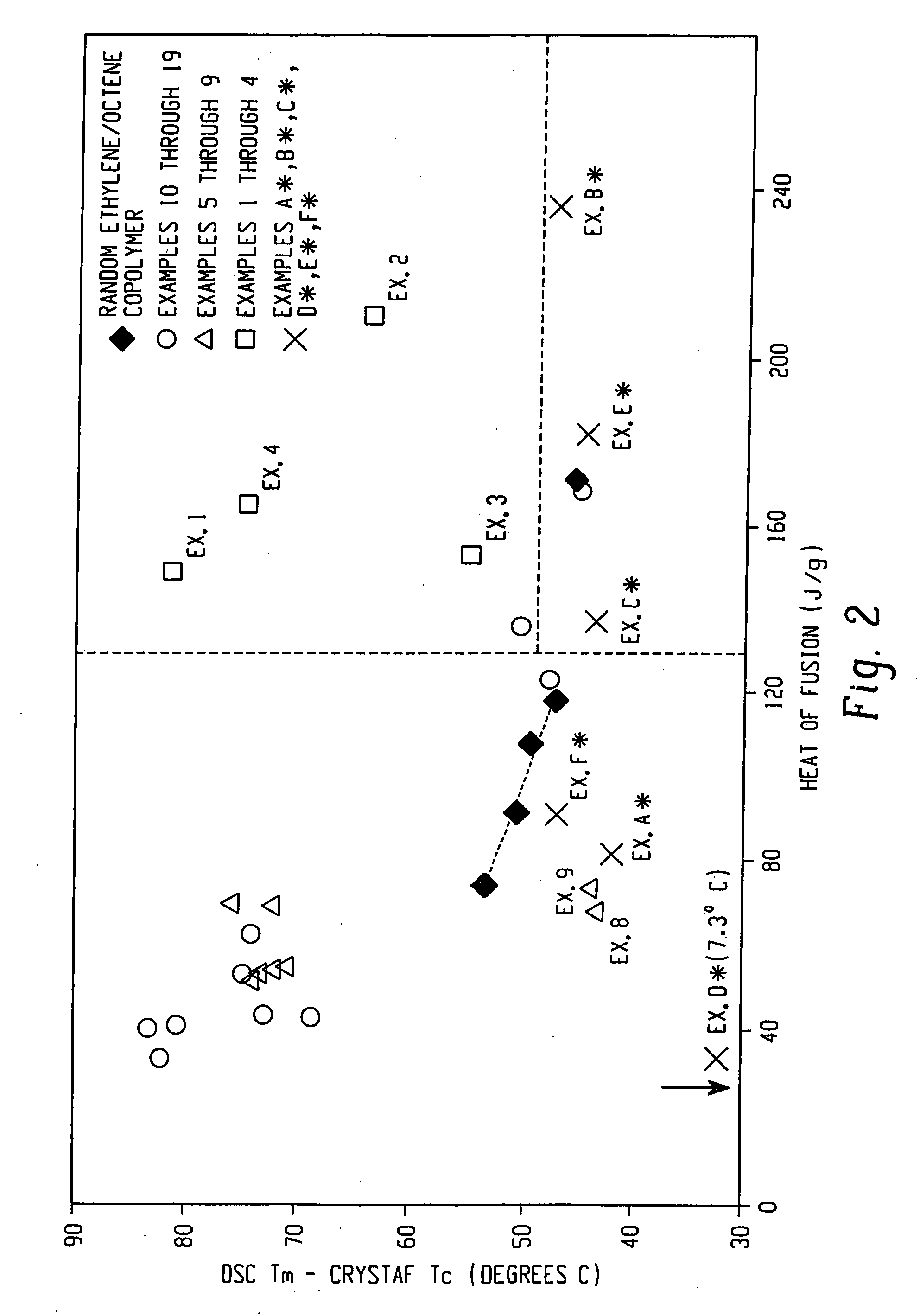

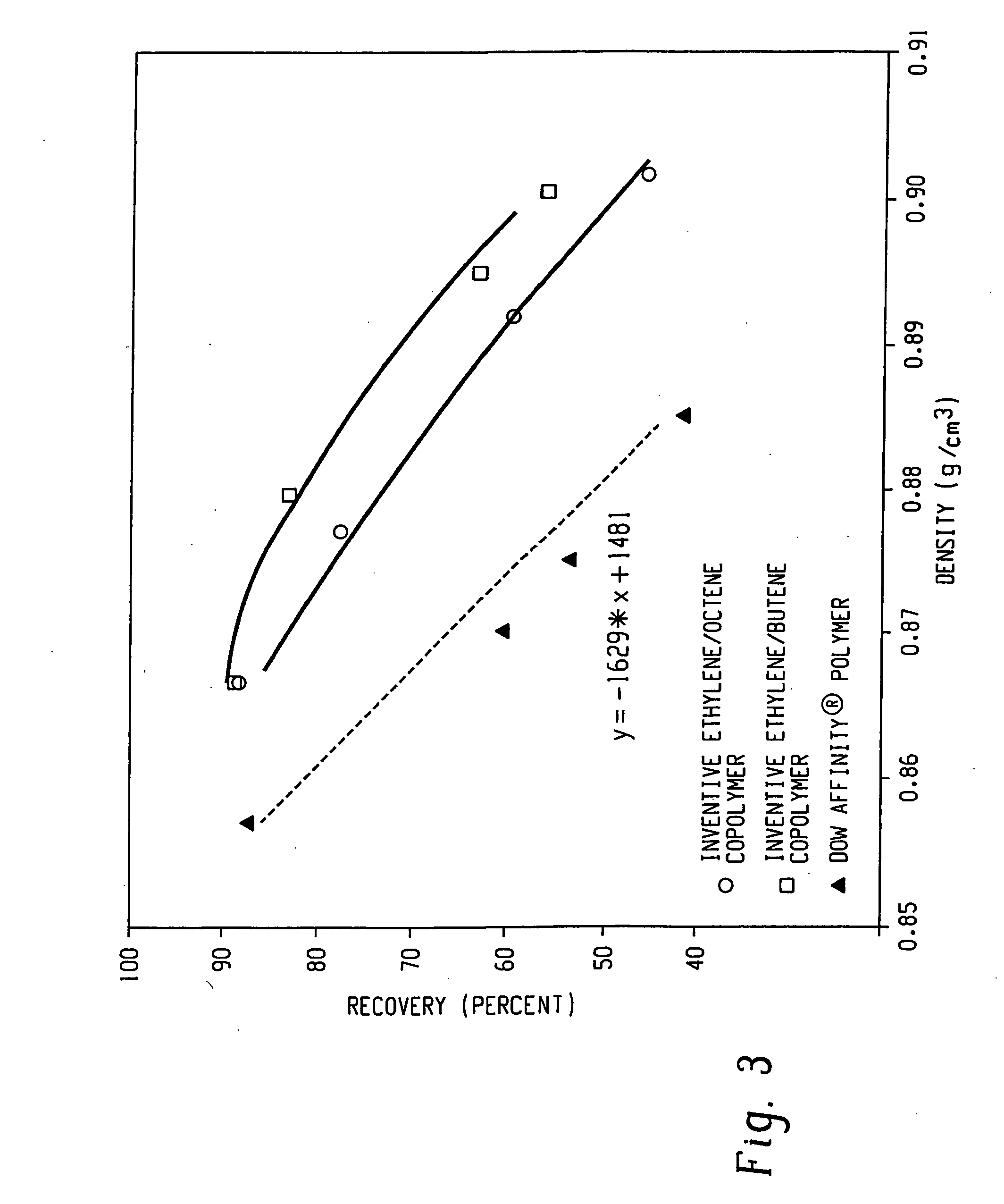

Compositions of ethylene/alpha-olefin multi-block interpolymer for elastic films and laminates

ActiveUS20070155900A1Easy to processHigh tensile strengthPersonal careLayered product treatmentProduction linePolyolefin

This invention relates to polyolefin compositions. In particular, the invention pertains to elastic polymer compositions that can be more easily processed on cast film lines, extrusion lamination or coating lines. The compositions of the present invention preferably comprise an elastomeric polyolefin resin and a high pressure low density type resin.

Owner:DOW GLOBAL TECH LLC

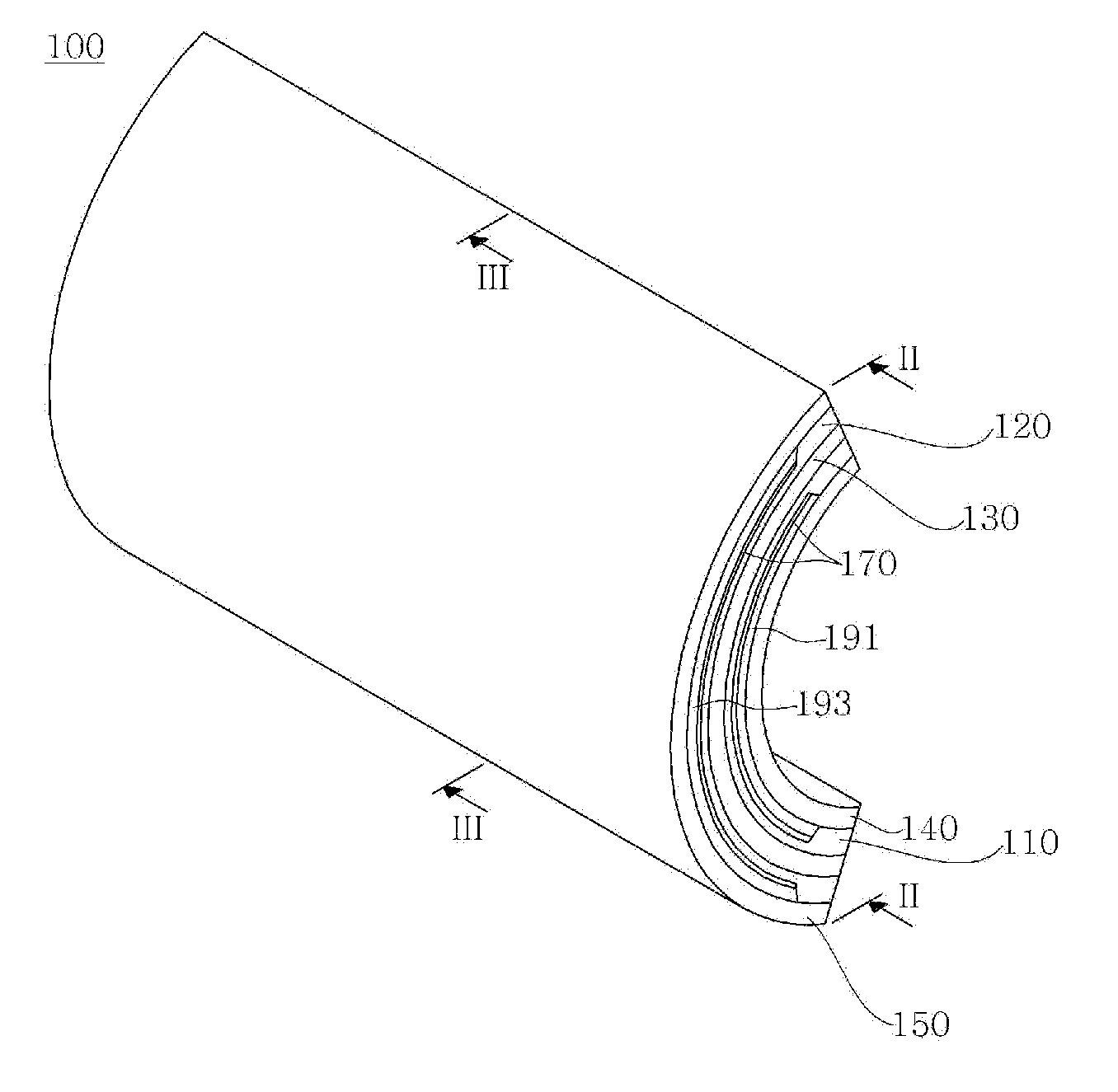

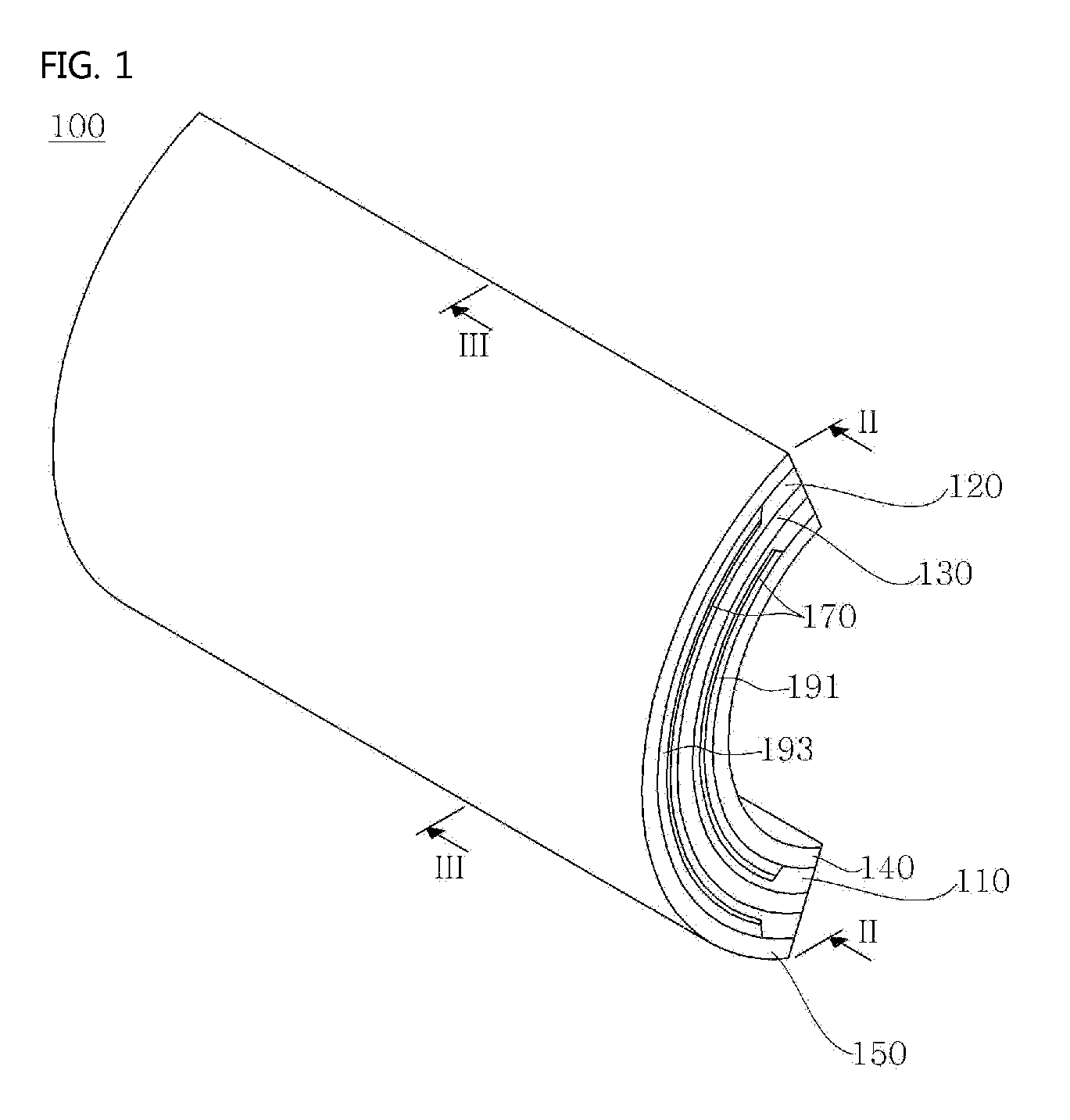

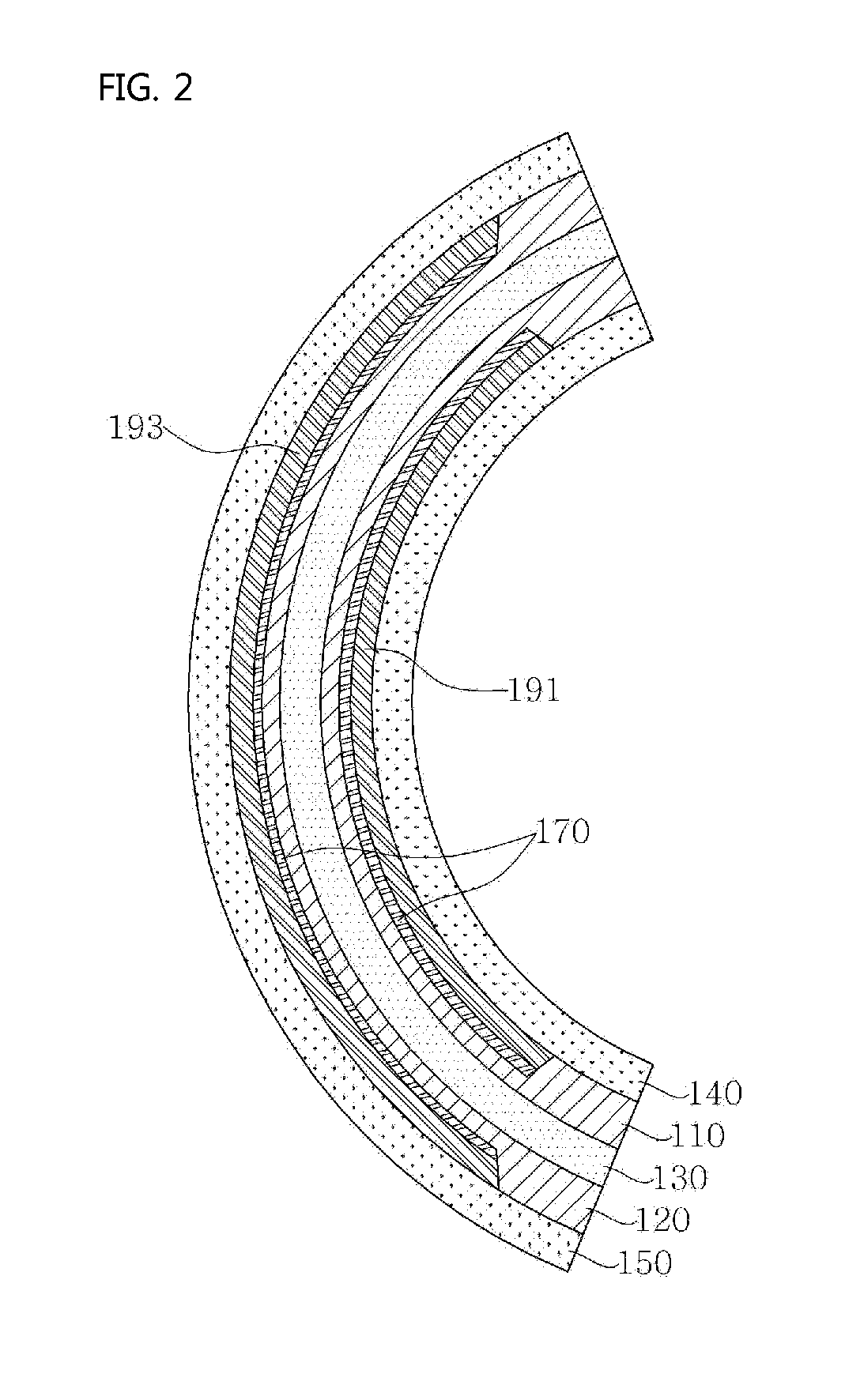

Method for fabrication of curved-surface display panel

ActiveUS20130180653A1Reduce thicknessSimple processLamination ancillary operationsLayered product treatmentSurface displayCurve shape

A curved-surface display panel fabrication method for fabricating a curved display panel having a desired curved shape using a flat display panel having a first substrate and a second substrate, includes: paring partially outer surfaces of the first substrate and the second substrate so as to reduce thicknesses thereof to a predetermined thickness; and attaching a reinforcing plate having the same shape with the desired curved shape and light transmitting characteristics to the display panel using an adhesive layer which is formed on at least a portion of edge portions of the display panel in a state that the pared flat display panel is bent to the desired curved shape.

Owner:TOVIS

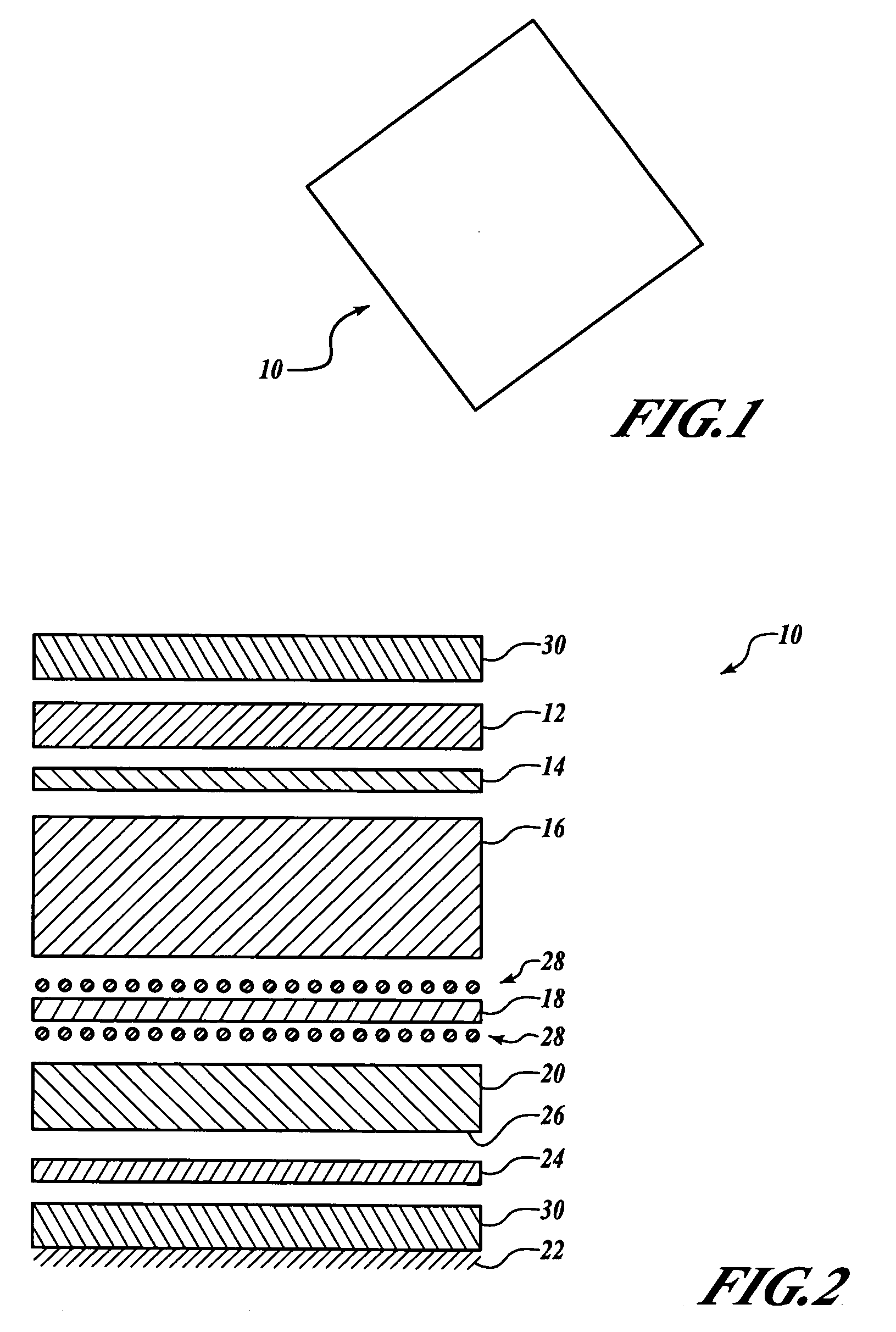

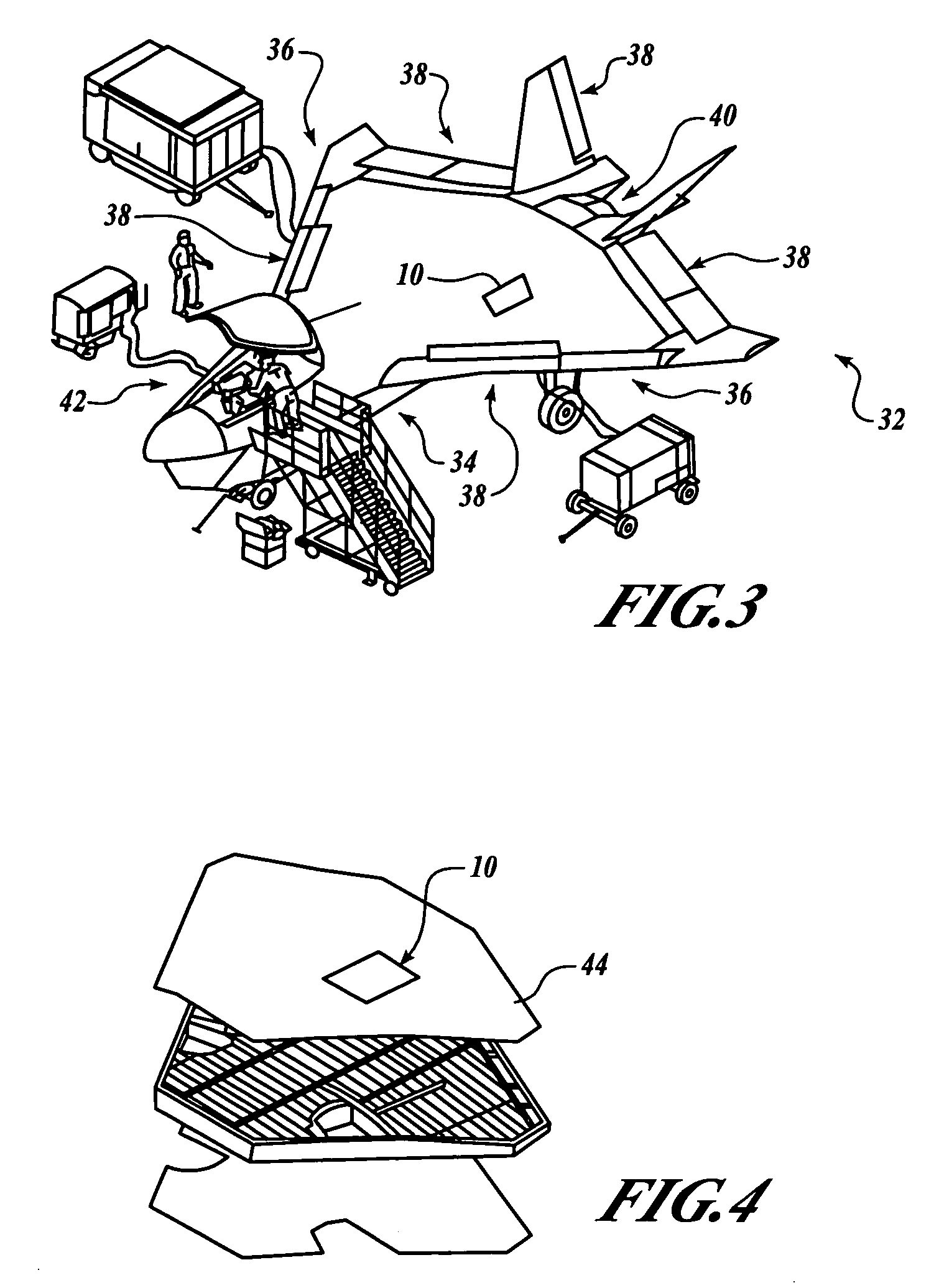

Applique

ActiveUS20050181203A1High porosityEnhancing static charge migrationDecorative surface effectsWingsFiberPolymer science

According to a non-limiting embodiment of the present invention, an appliqué coating is provided for a substrate. The appliqué coating includes a metal foil and a first polymer film underlying the metal foil. A topcoat overlying the metal foil may be provided as a layer of paint or as a second polymer film. An adhesive, such as a pressure sensitive adhesive, underlying the first polymer film may be provided to affix the appliqué coating to the substrate. If desired, fibers may be dispersed throughout the second polymer film to provide anti-static properties. Also, an ink layer may be provided between the metal foil and the second polymer film, if desired, for aesthetic and / or anti-static purposes.

Owner:THE BOEING CO

Panel, Use of a Panel, Method for Manufacturing a Panel and a Prepreg

InactiveUS20100323187A1Improve light fastnessSpecial ornamental structuresWood working apparatusSurface layerWear resistant

Described are panels including a surface layer on a substrate. The surface layer includes a) cellulose fibers, b) at least one binder and (c) wear resistant particles. The use of different panels and a method for manufacturing is also described.

Owner:VÄLINGE INNOVATION AB

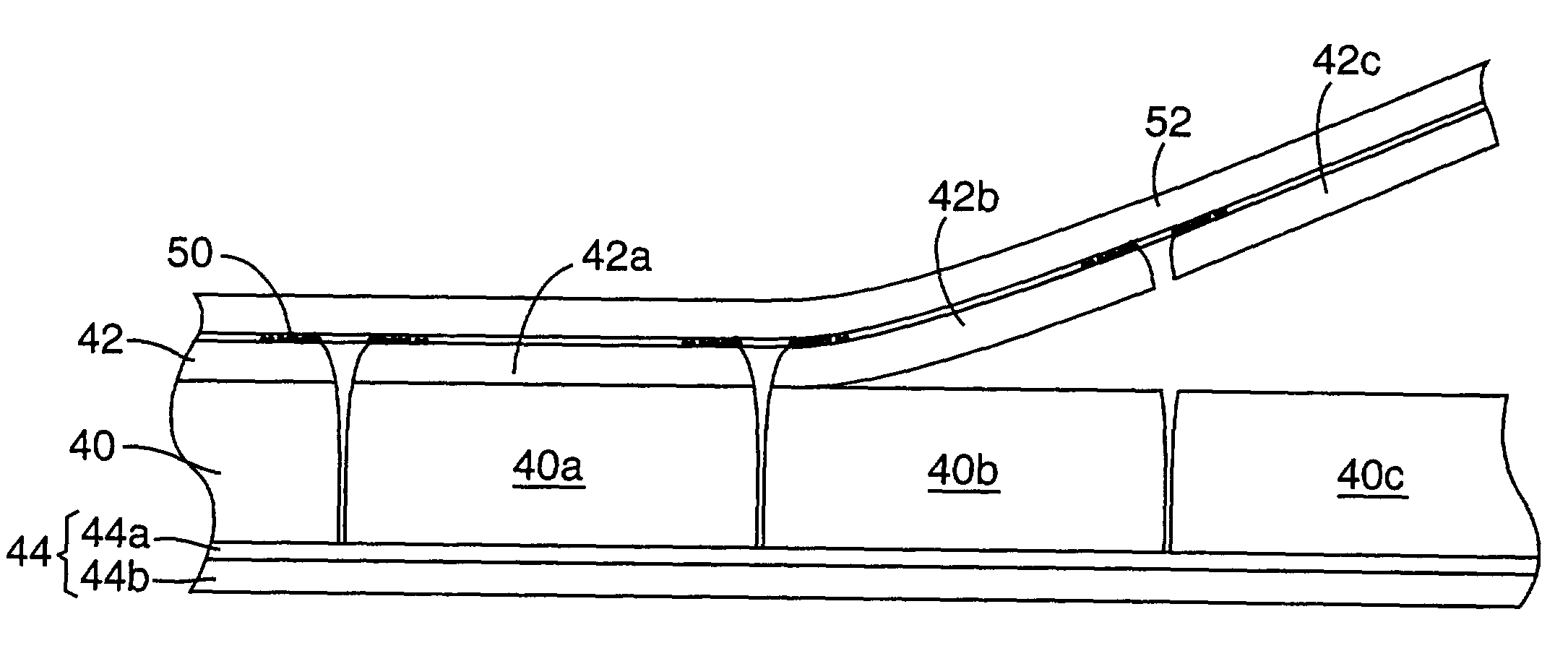

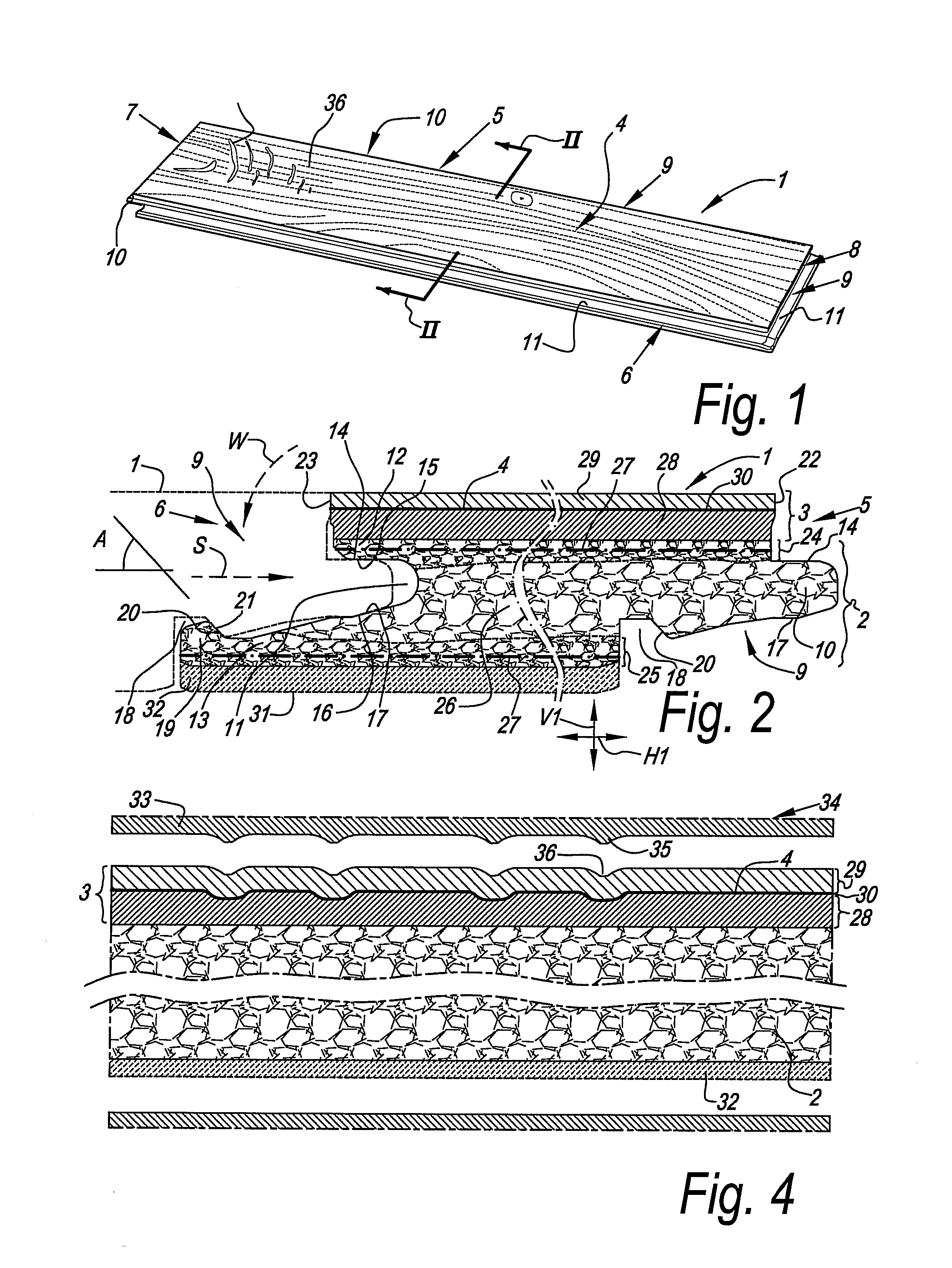

Collector grid and interconnect structures for photovoltaic arrays and modules

InactiveUS20090107538A1Ease of mass productionLamination ancillary operationsLayered product treatmentPhotovoltaic arraysEngineering

An interconnected arrangement of photovoltaic cells is achieved using laminating current collector electrodes. The electrodes comprises a pattern of conductive material extending over a first surface of sheetlike substrate material. The first surface comprises material having adhesive affinity for a selected conductive surface. Application of the electrode to the selected conductive surface brings the first surface of the sheetlike substrate into adhesive contact with the conductive surface and simultaneously brings the conductive surface into firm contact with the conductive material extending over first surface of the sheetlike substrate. Use of the laminating current collector electrodes allows facile and continuous production of expansive area interconnected photovoltaic arrays.

Owner:SOLANNEX

Floor panel and methods for manufacturing floor panels

ActiveUS20130067842A1High densityHigh sensitivityCovering/liningsDecorative surface effectsPanellingEngineering

In a method for manufacturing floor panels that have at least a substrate and a top layer provided on the substrate, the top layer including a thermoplastic layer that is translucent or transparent, the method may involve providing the top layer, including the thermoplastic layer, on the substrate. The method may also involve heating at least the thermoplastic layer, and structuring the thermoplastic layer using a mechanical press element.

Owner:FLOORING IND LTD

Manufacturing method for a display device

InactiveUS20090183819A1Avoid it happening againReduce stressLayered product treatmentLaminationAdhesiveDisplay device

It is aimed to, in a manufacturing method for a display device including a translucent substrate bonded to a display panel using a translucent adhesive, realize a bright display screen free from an air layer formed between the display panel and the translucent substrate. For this purpose, a first adhesive layer made of a first adhesive is formed between a frame body and an exposed surface of an upper portion of the display panel, a second adhesive is next applied onto a surface of the translucent substrate, and the surface applied with the second adhesive is faced downward and is bonded to a top surface of the display panel including the first adhesive layer formed thereon, to thereby cure the second adhesive. Accordingly, the adhesive can be filled between the top surface of the display panel and a bottom surface of the translucent substrate without trapping bubbles or voids therebetween.

Owner:SEIKO INSTR INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com