Patents

Literature

31results about How to "Reduce and eliminate damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

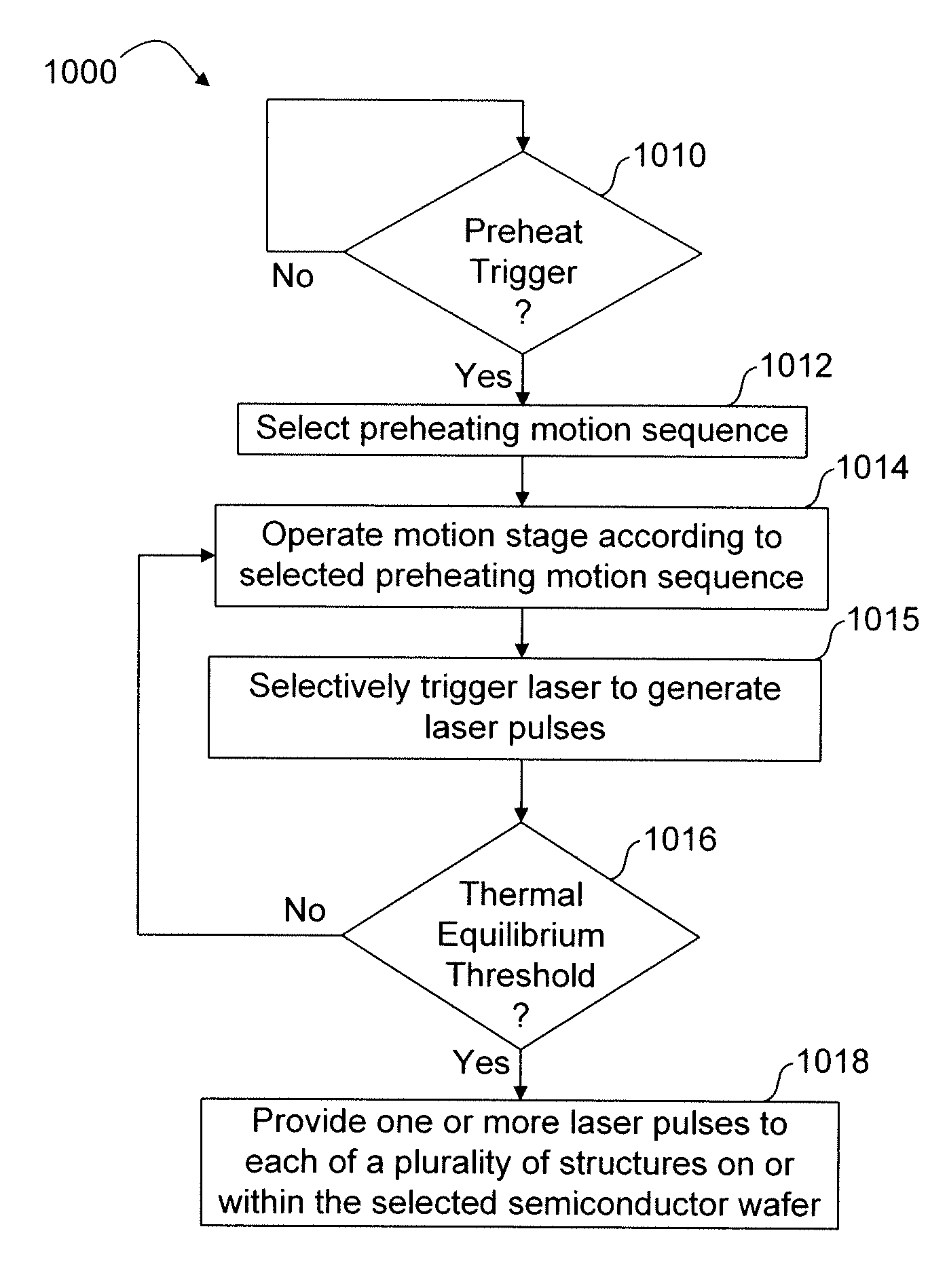

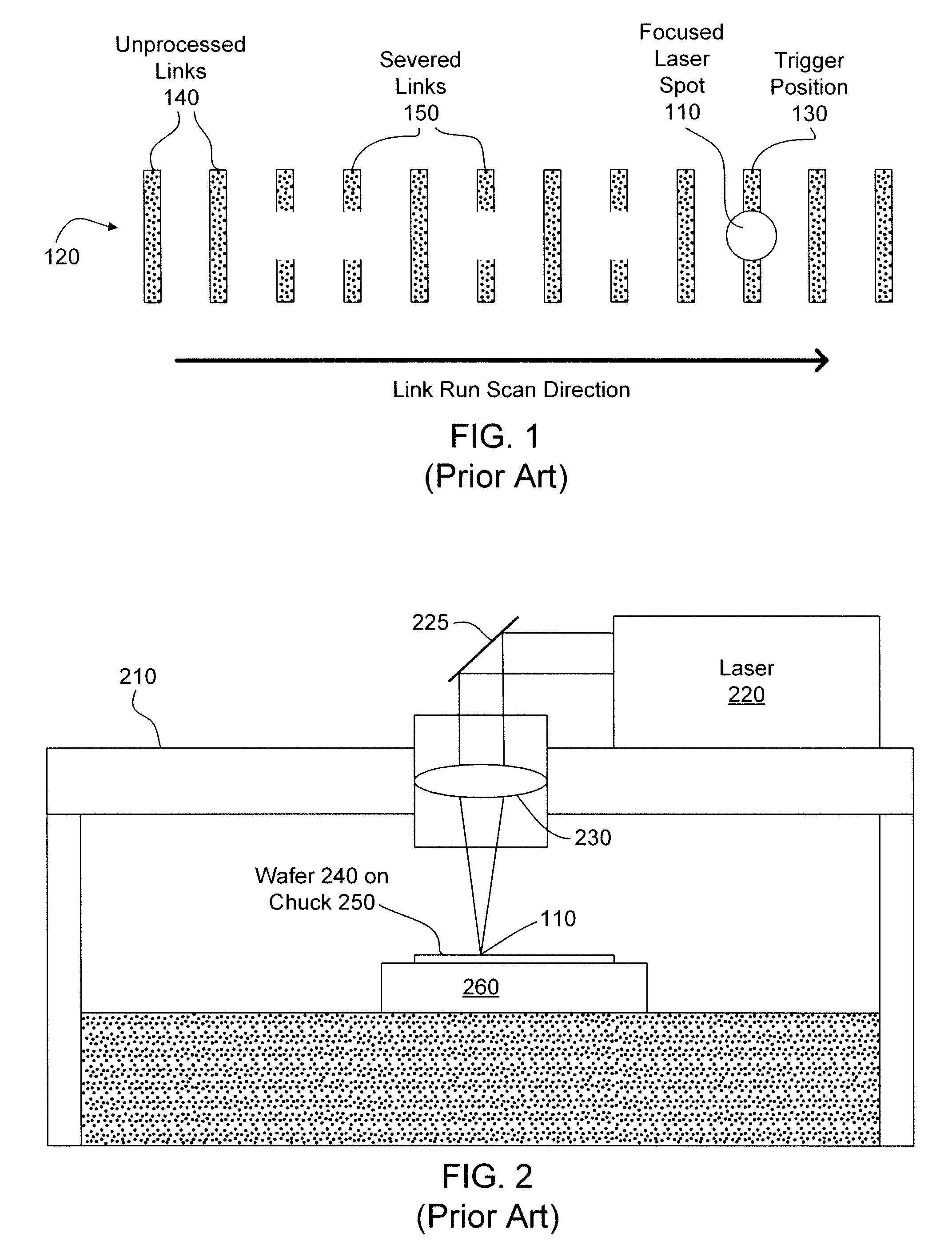

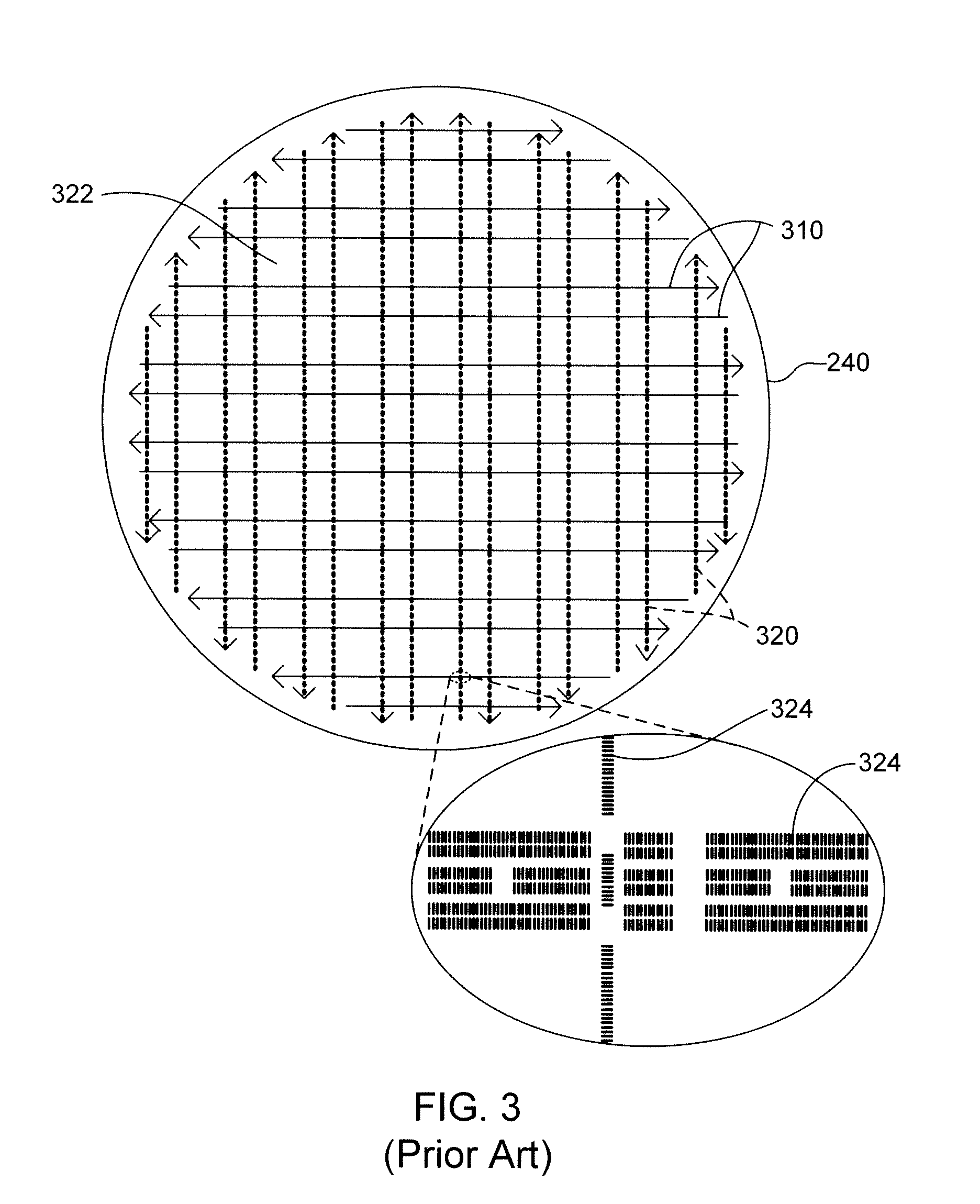

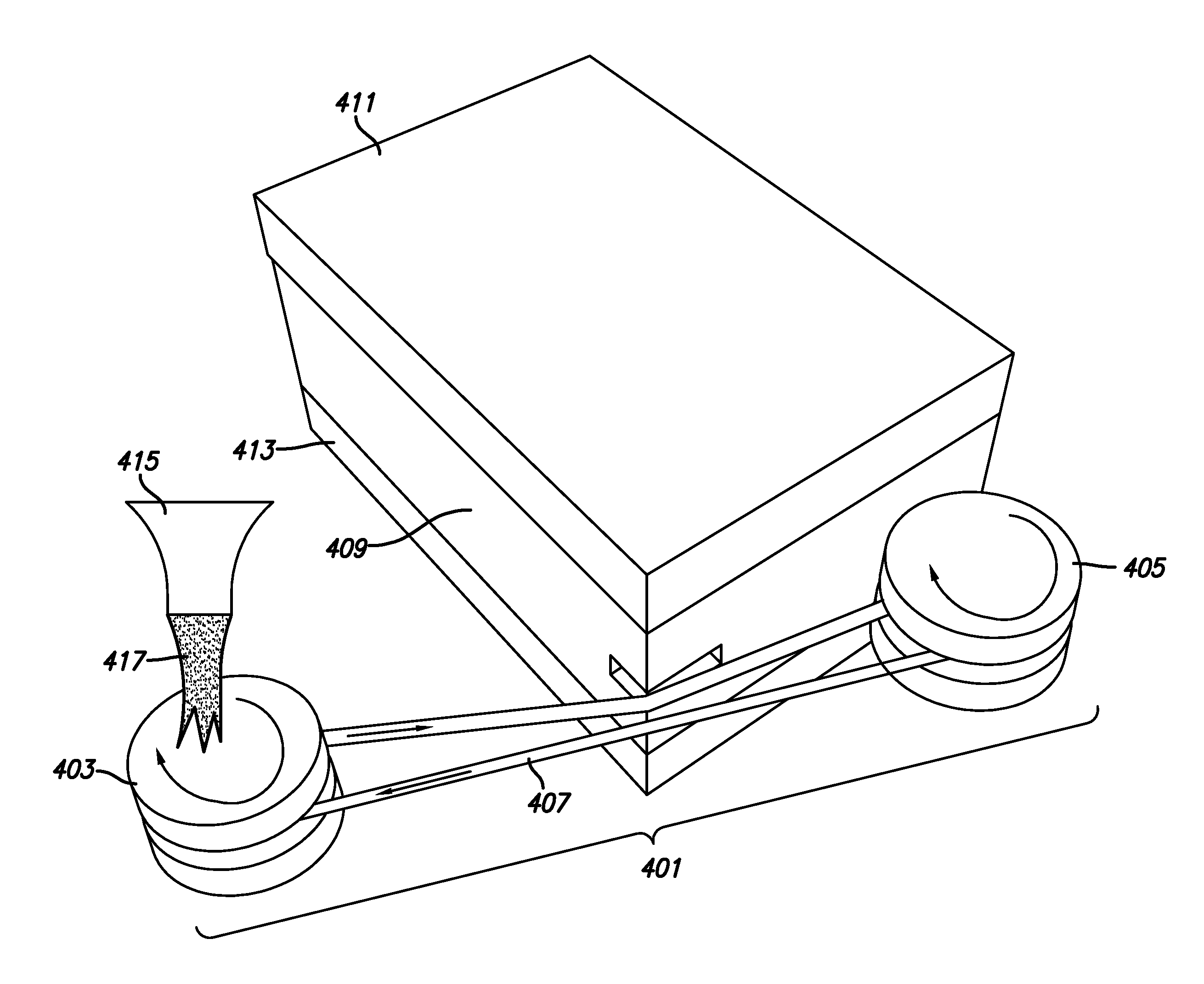

Systems and methods for adapting parameters to increase throughput during laser-based wafer processing

InactiveUS20080314879A1Reduce and eliminate damageRead-only memoriesSemiconductor/solid-state device manufacturingThermal stateEngineering

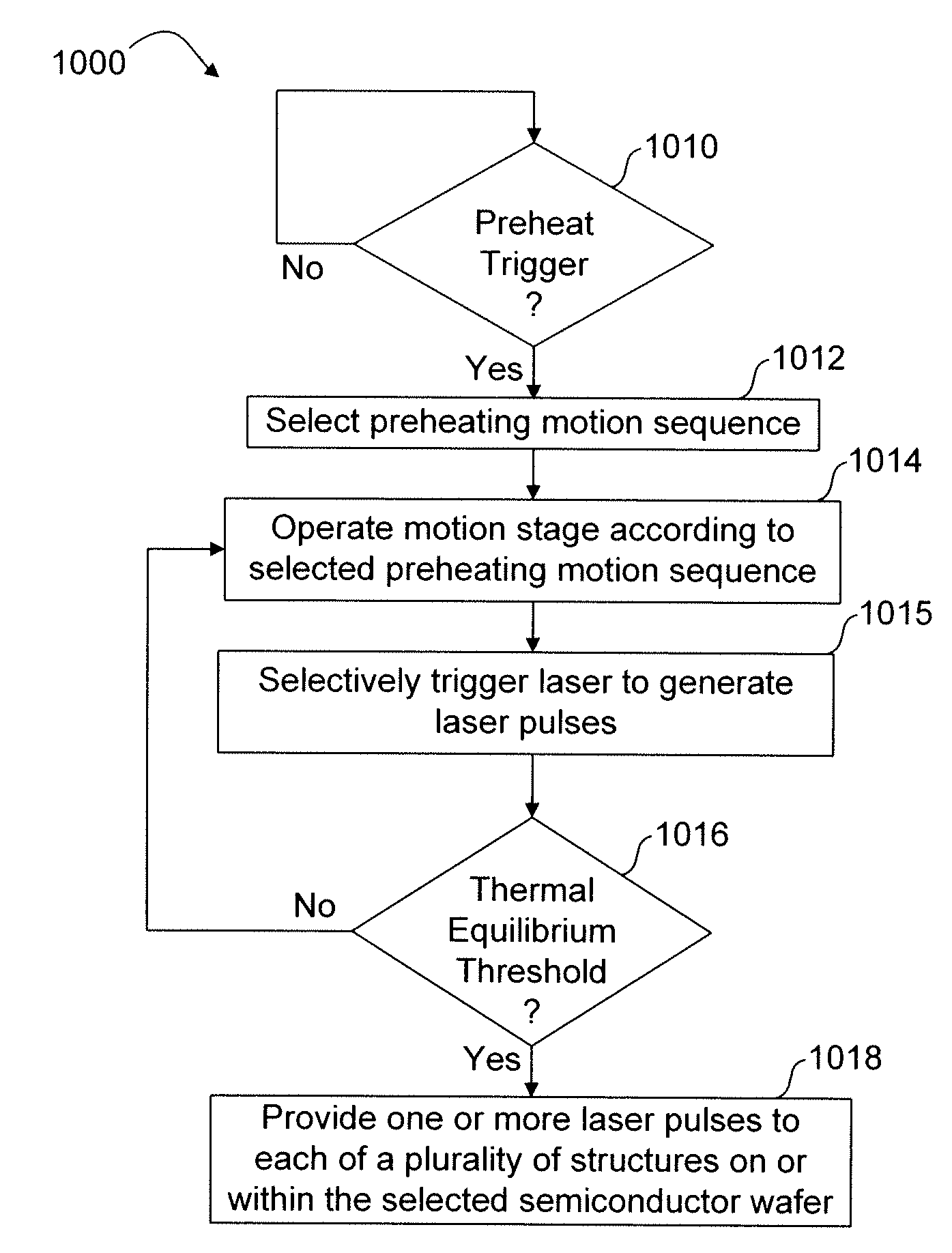

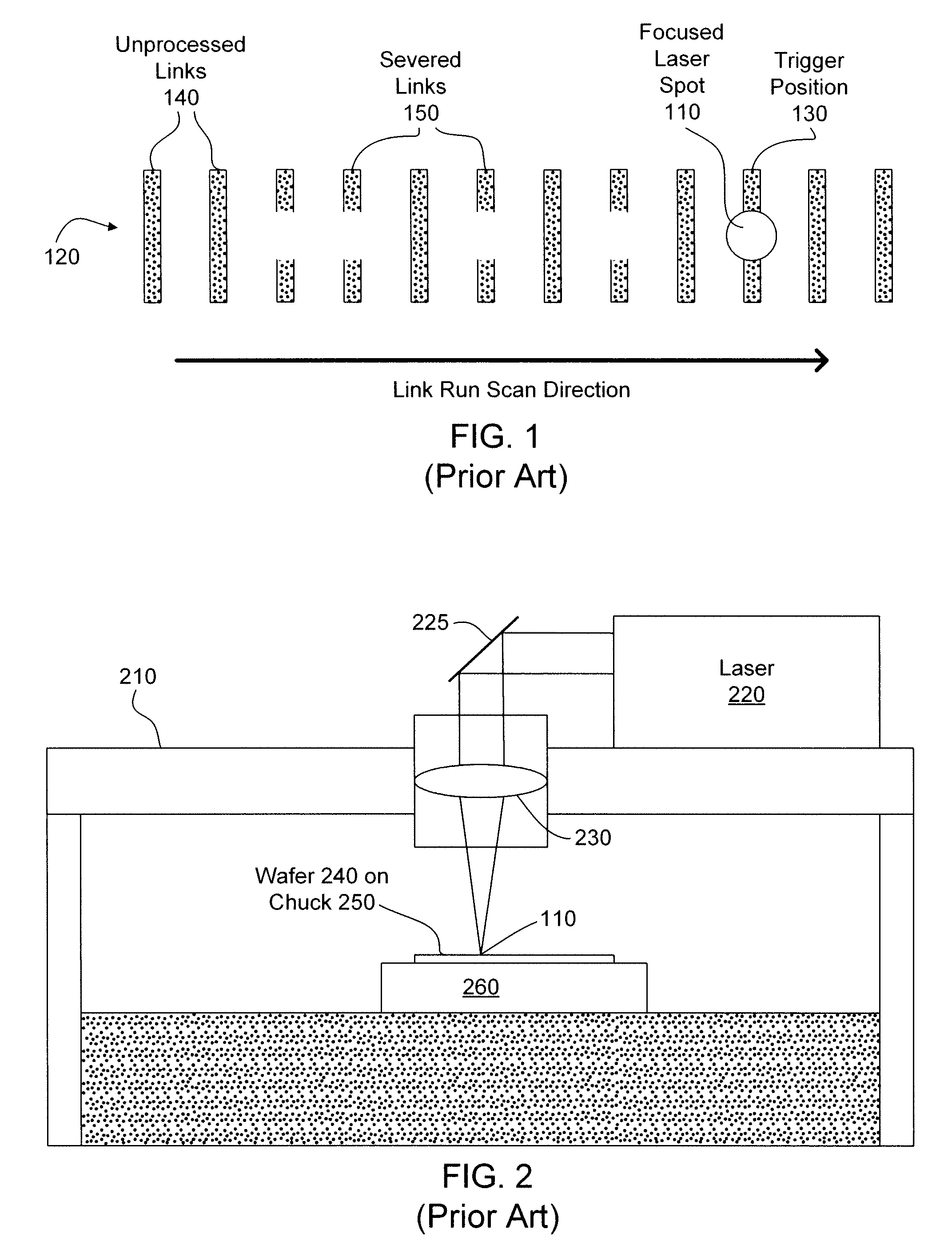

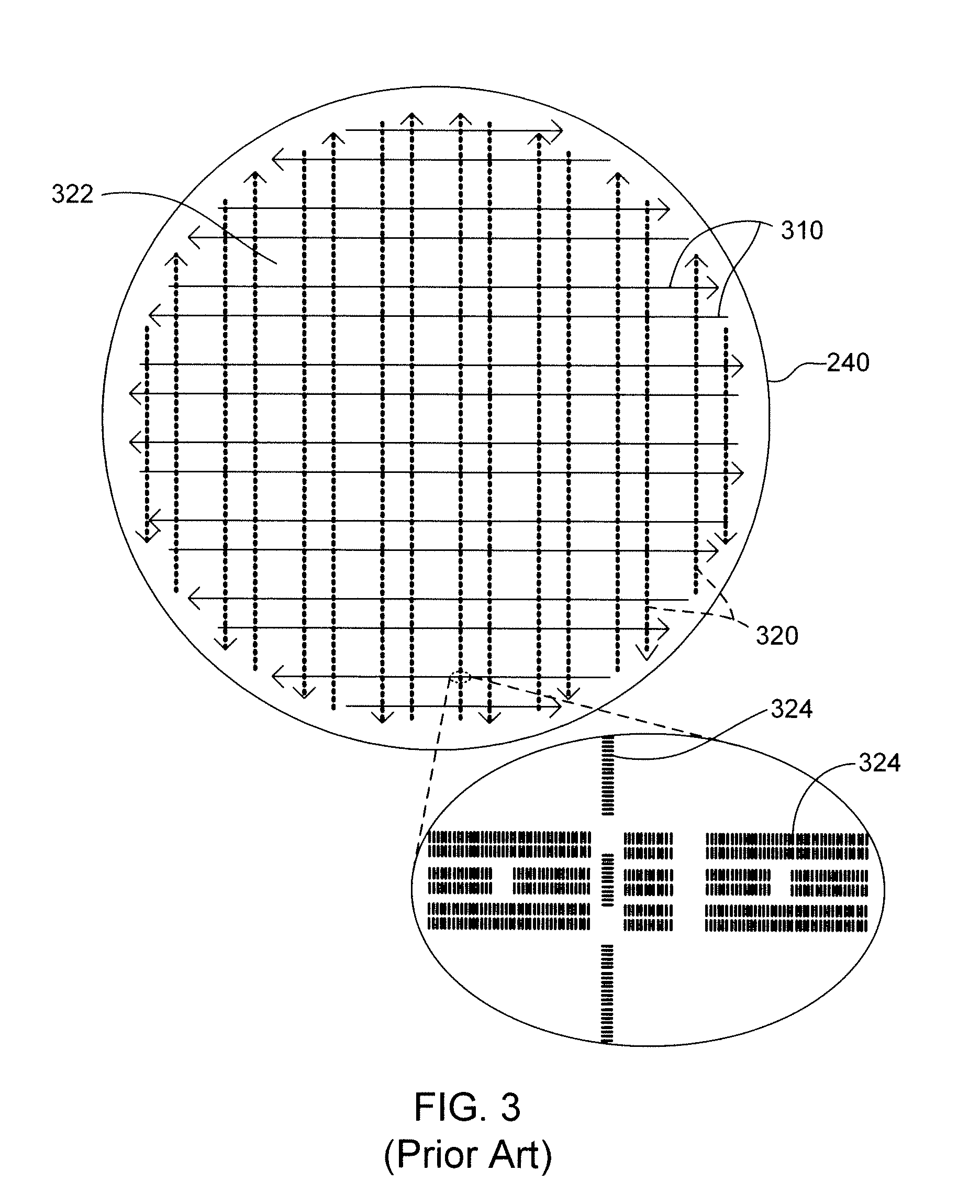

Systems and methods automatically modify a laser-based system for processing target specimens such as semiconductor wafers. In one embodiment, the laser-based system detects a trigger associated with a processing model. The processing model corresponds to a set of wafers. In response to the trigger, the system automatically adjusts one or more system parameters based on the processing model. The system then uses the modified system parameters to selectively irradiate structures on or within at least one wafer in the set of wafers. In one embodiment, the trigger includes variations in a thermal state related to a motion stage. In response to the variations in the thermal state, the system operates the motion stage in a series of movements until a thermal equilibrium threshold is reached. The sequence of movements may, for example, simulate movements used to process a particular wafer.

Owner:ELECTRO SCI IND INC

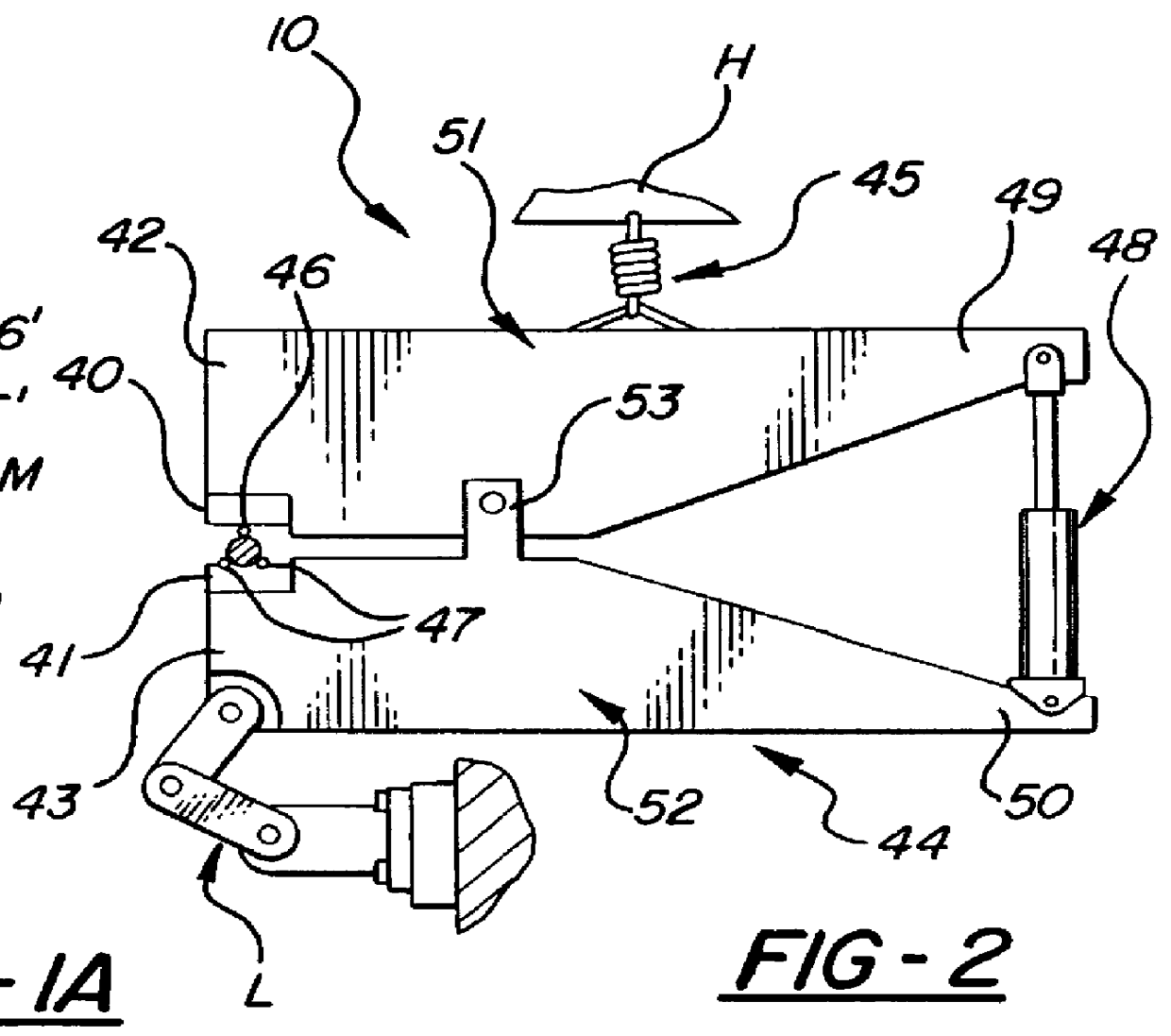

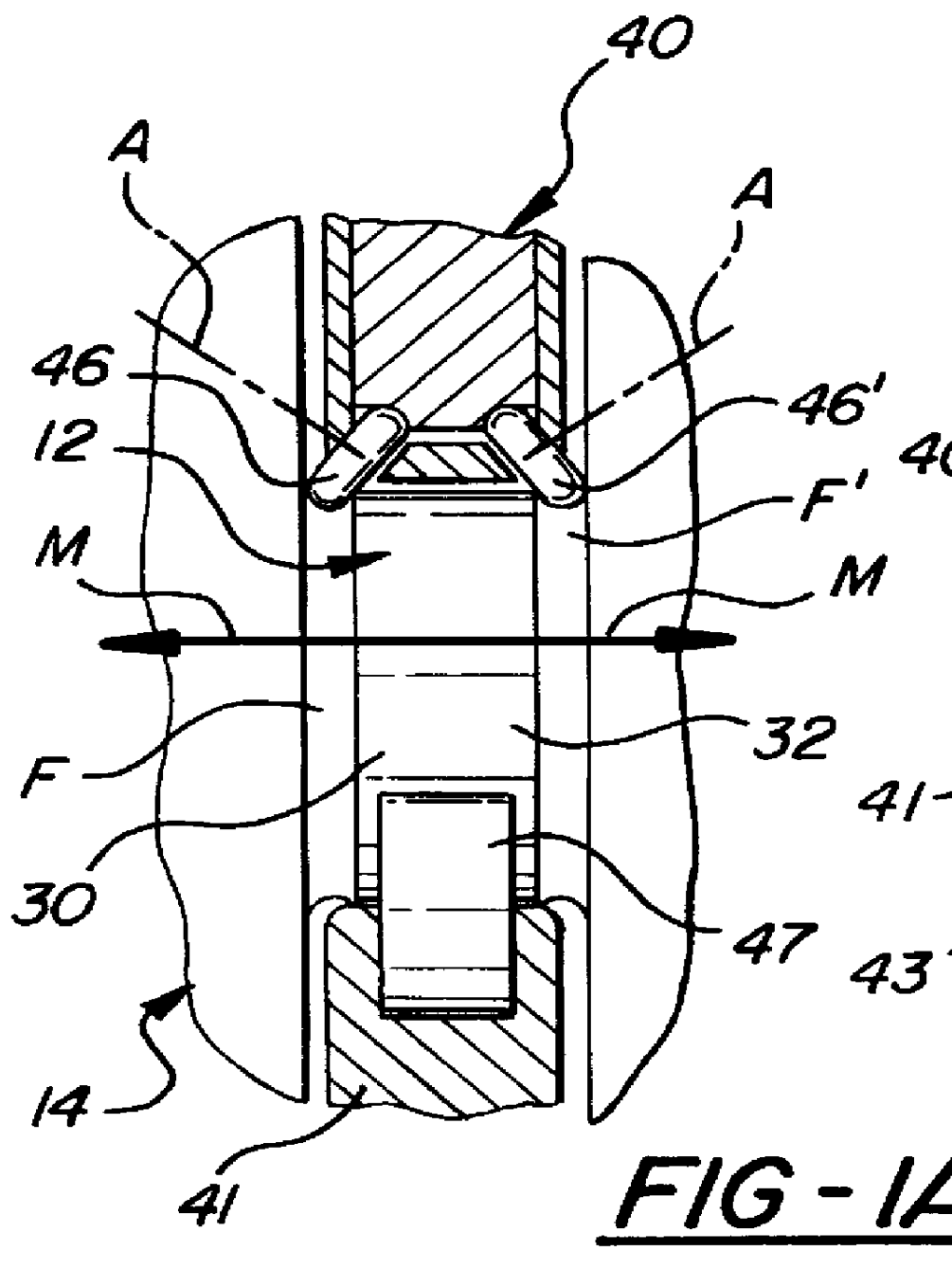

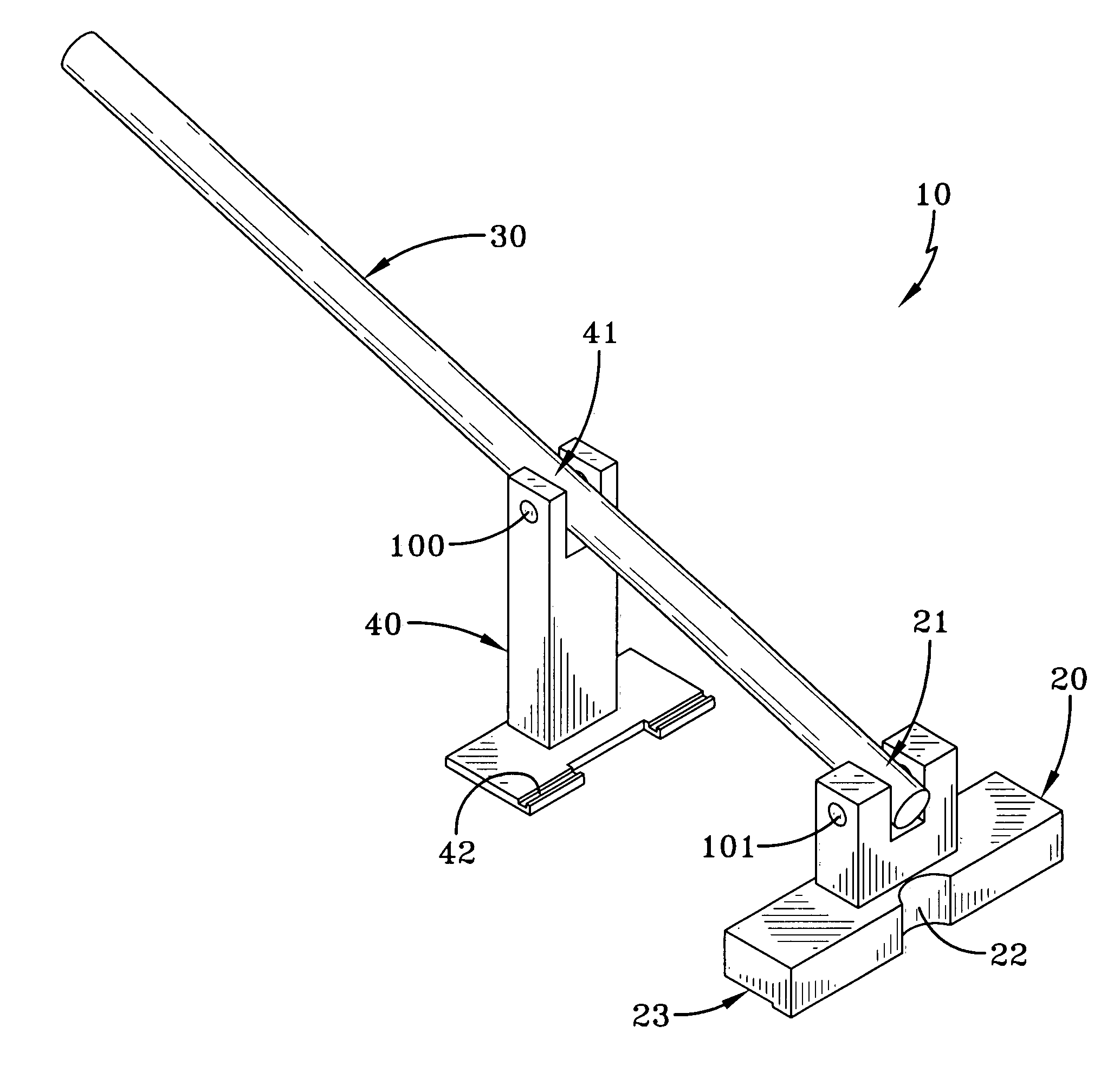

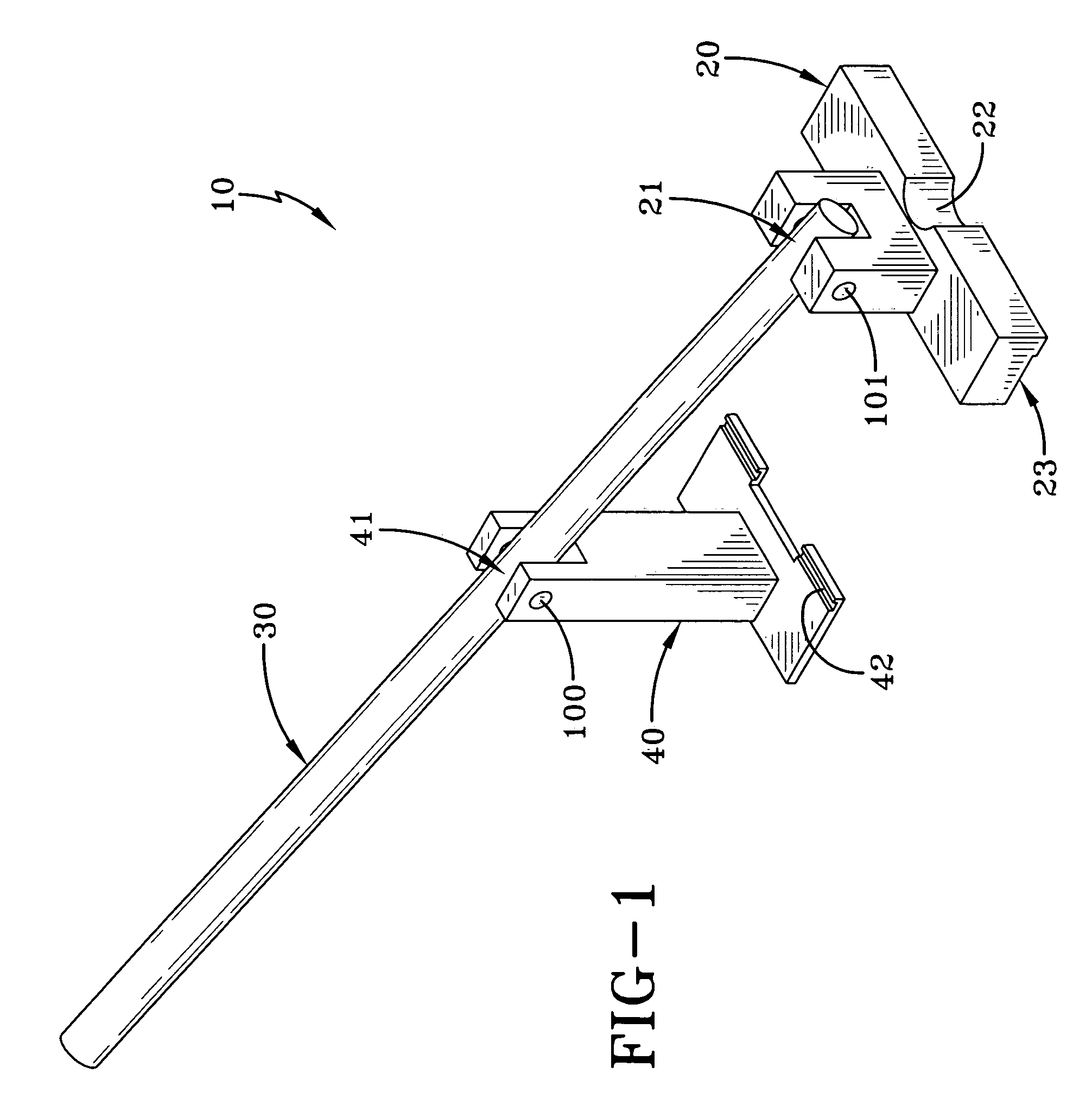

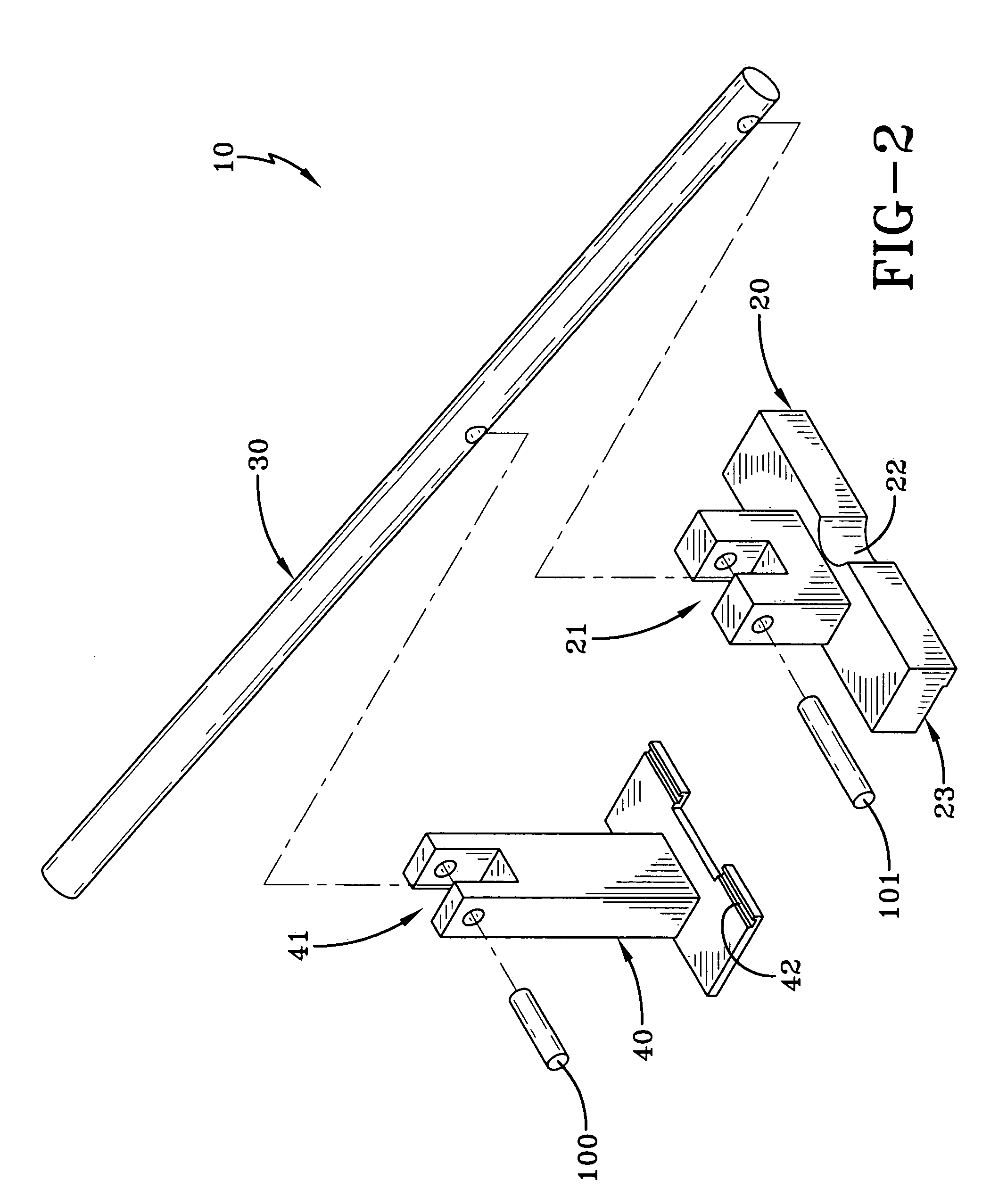

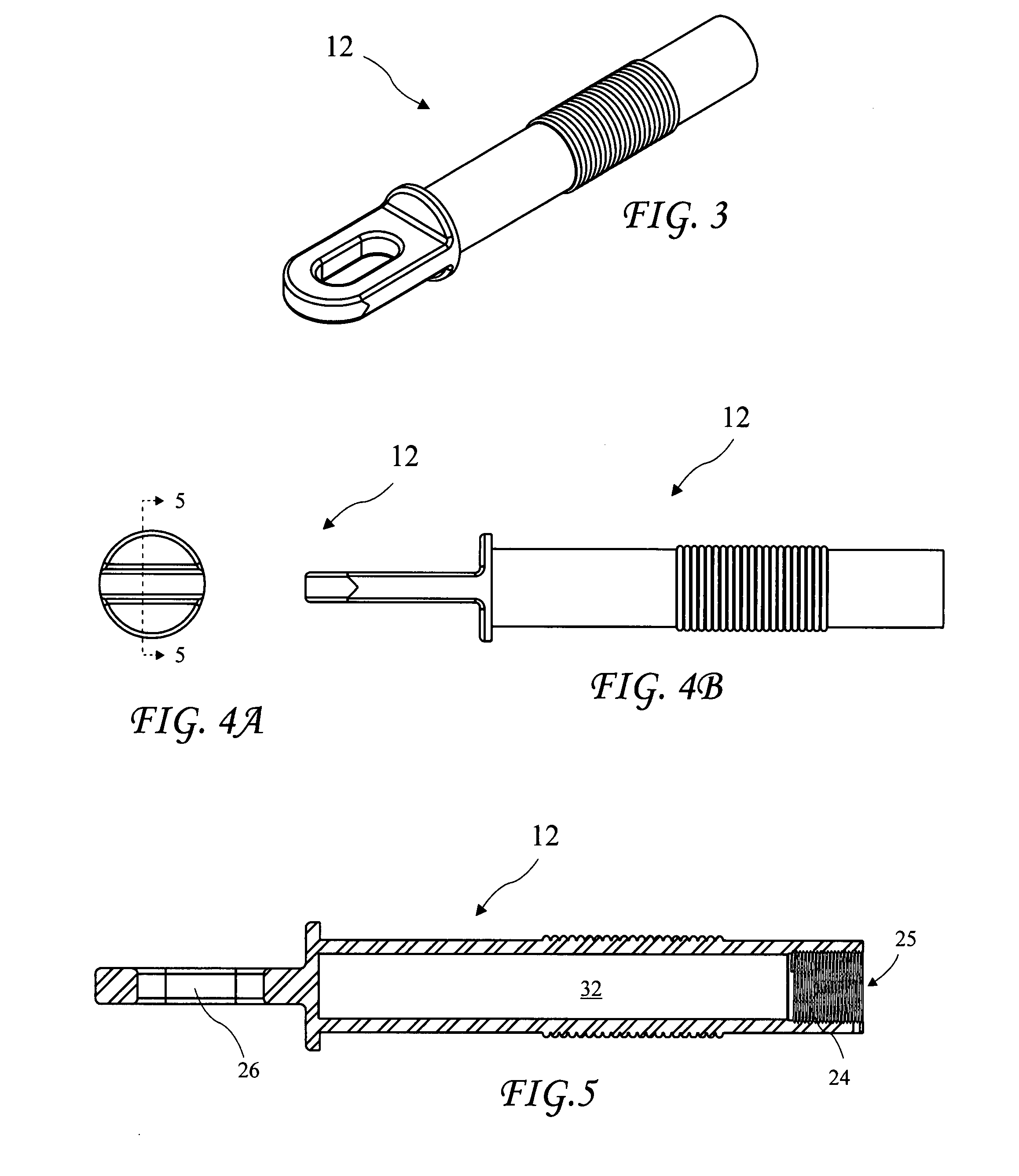

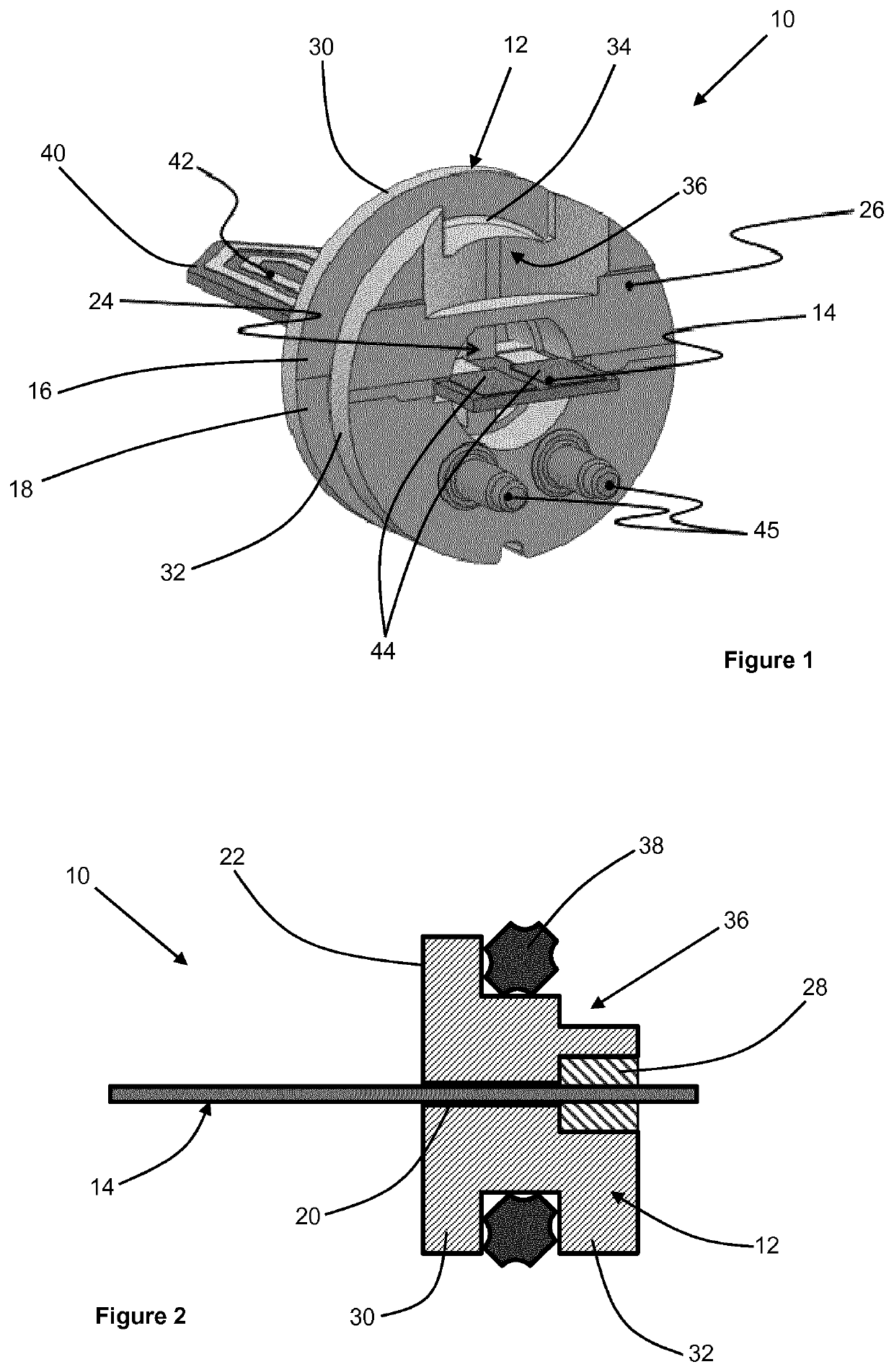

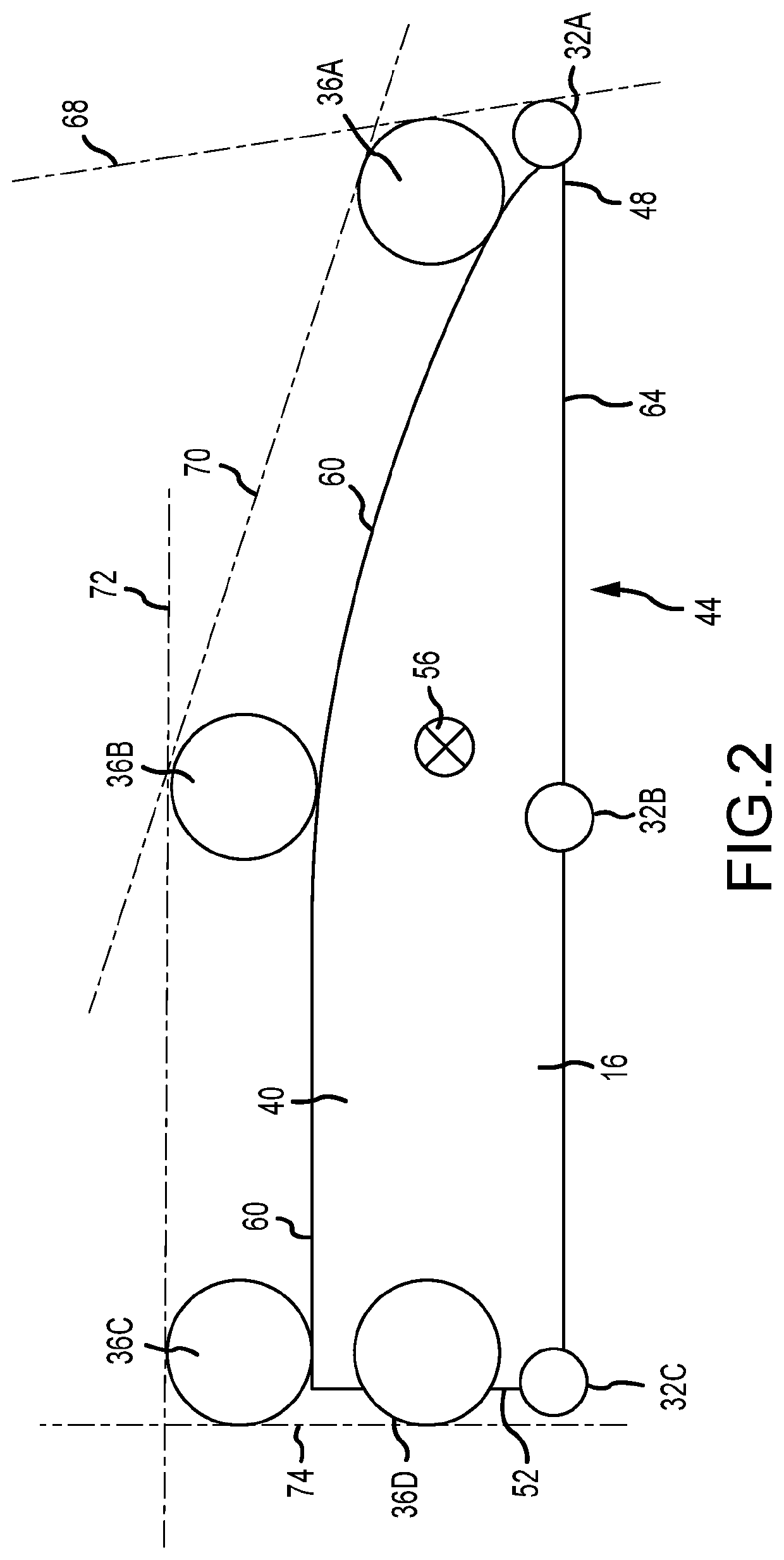

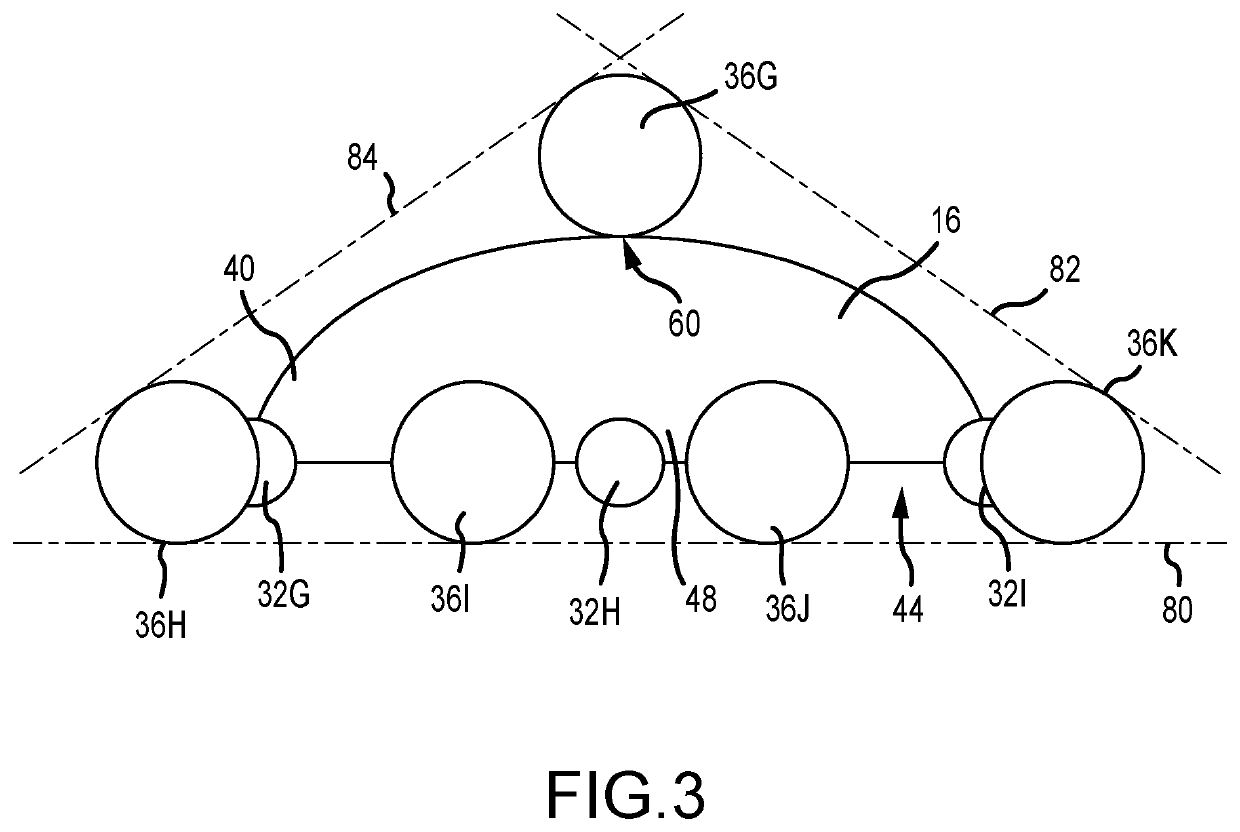

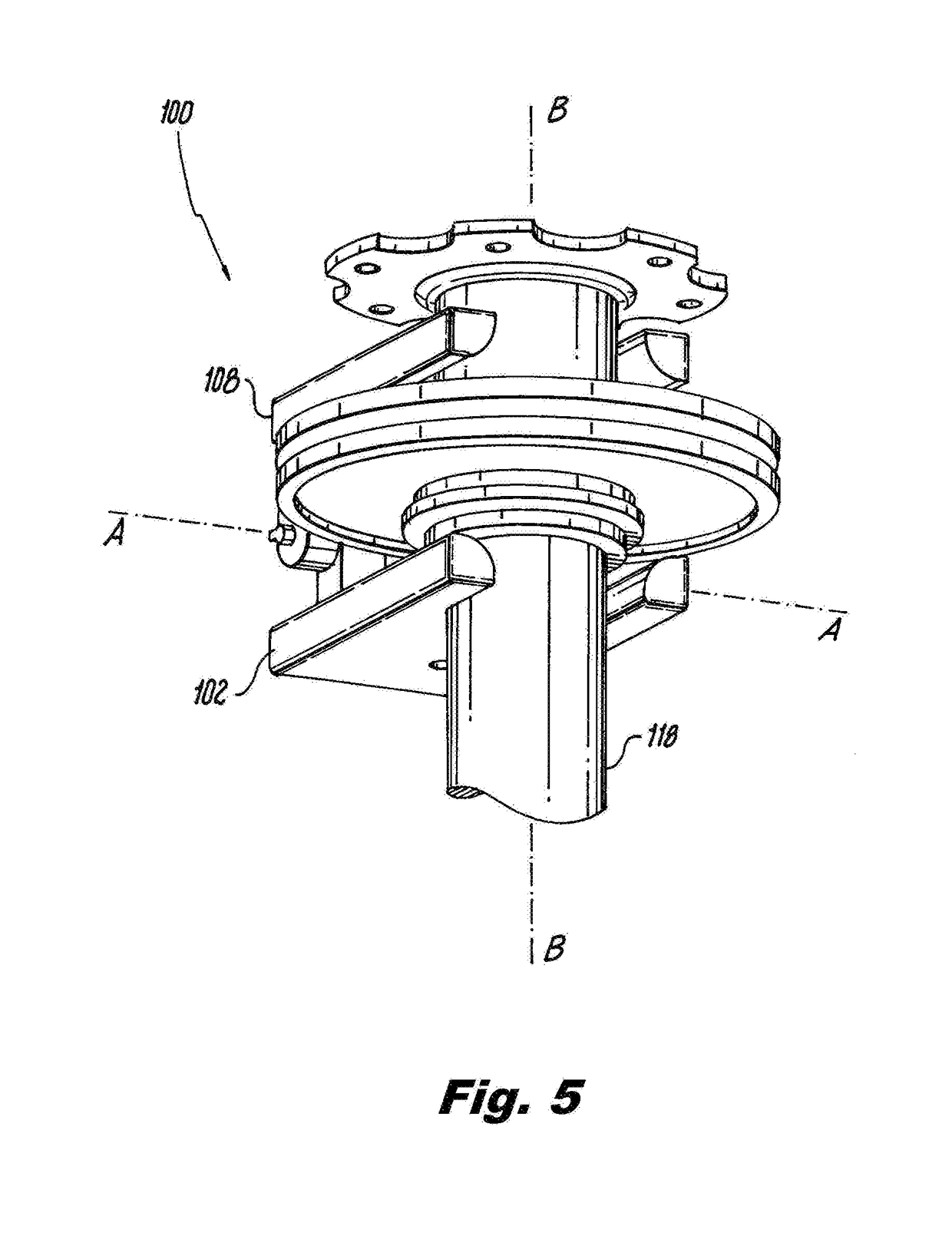

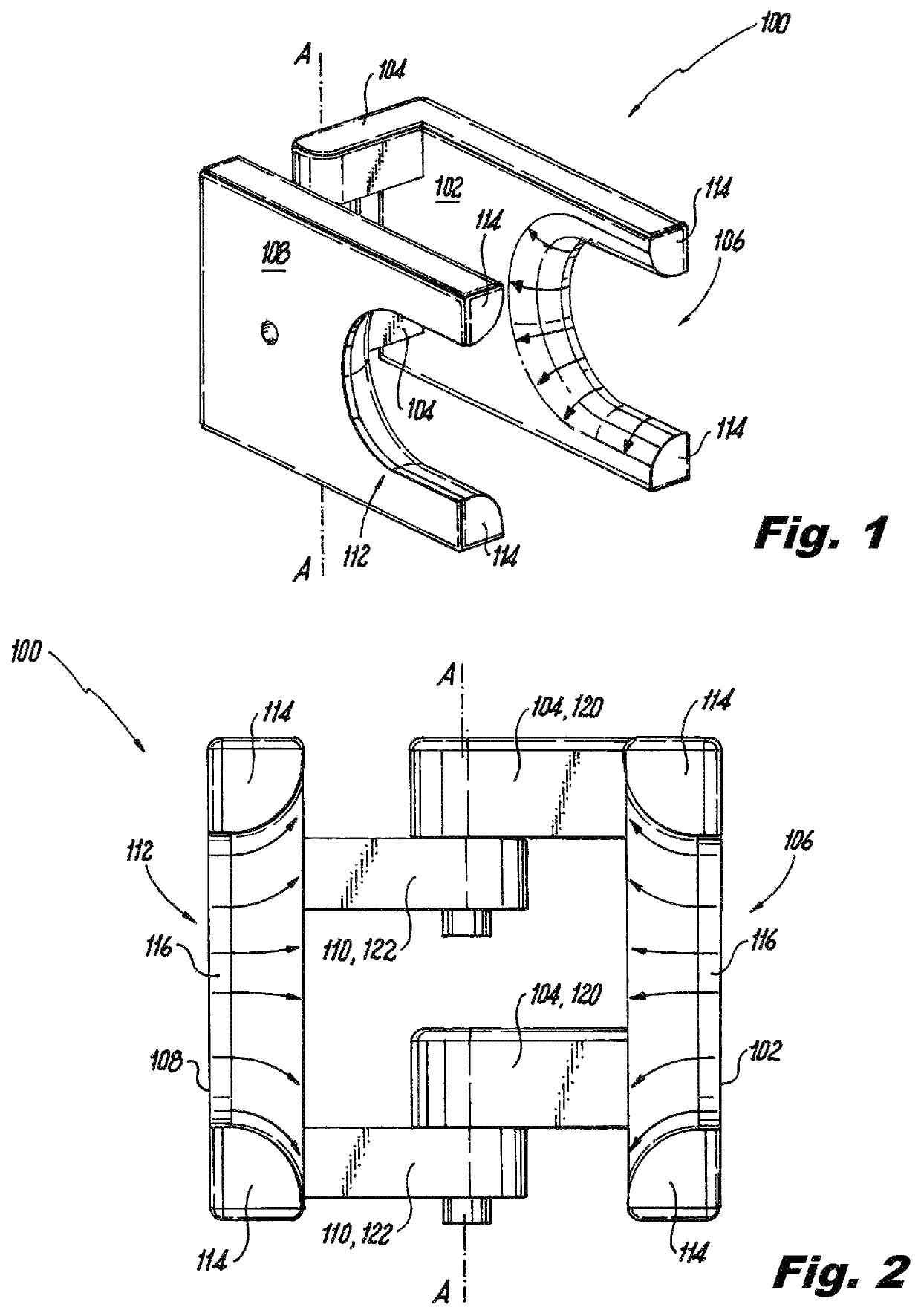

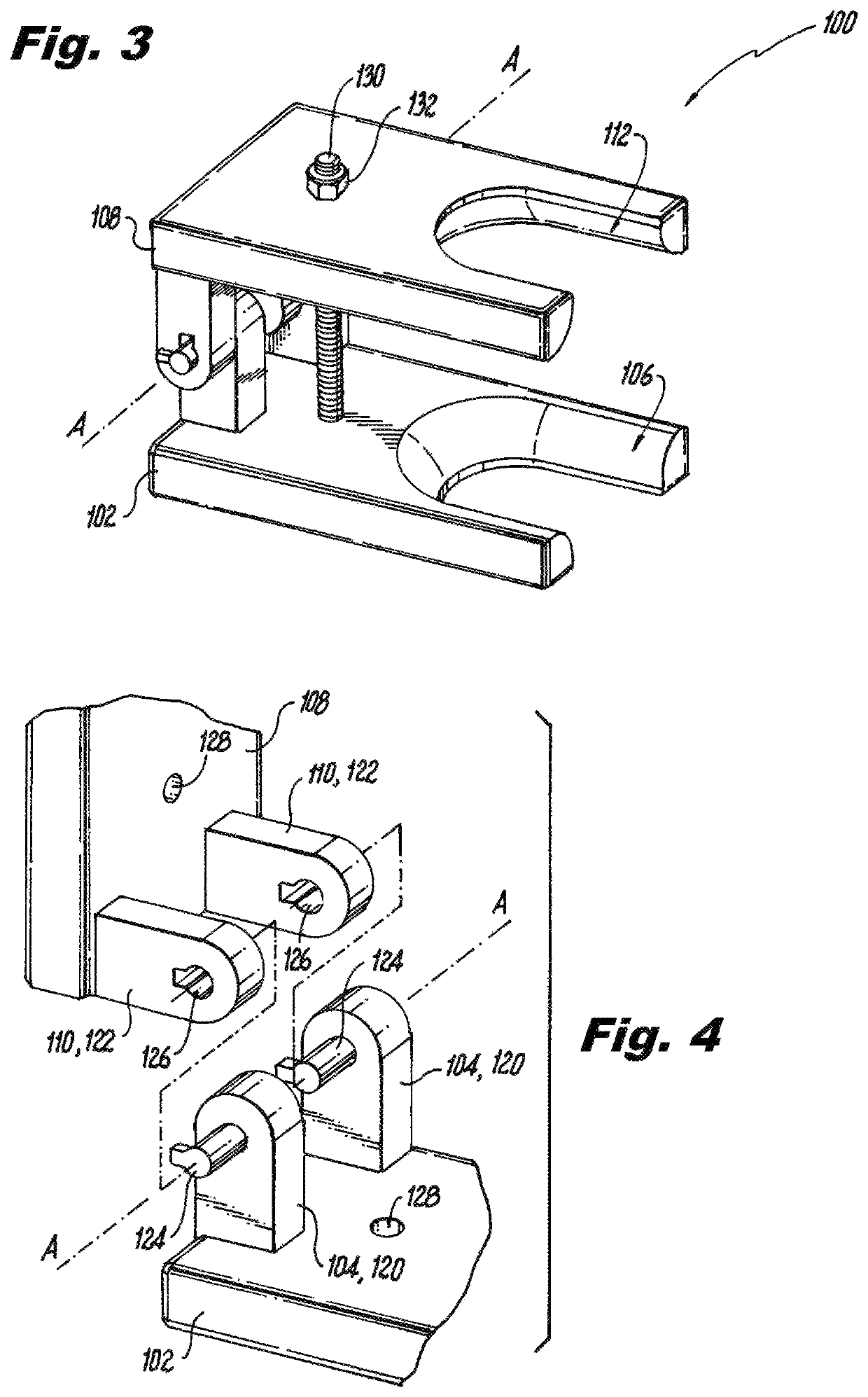

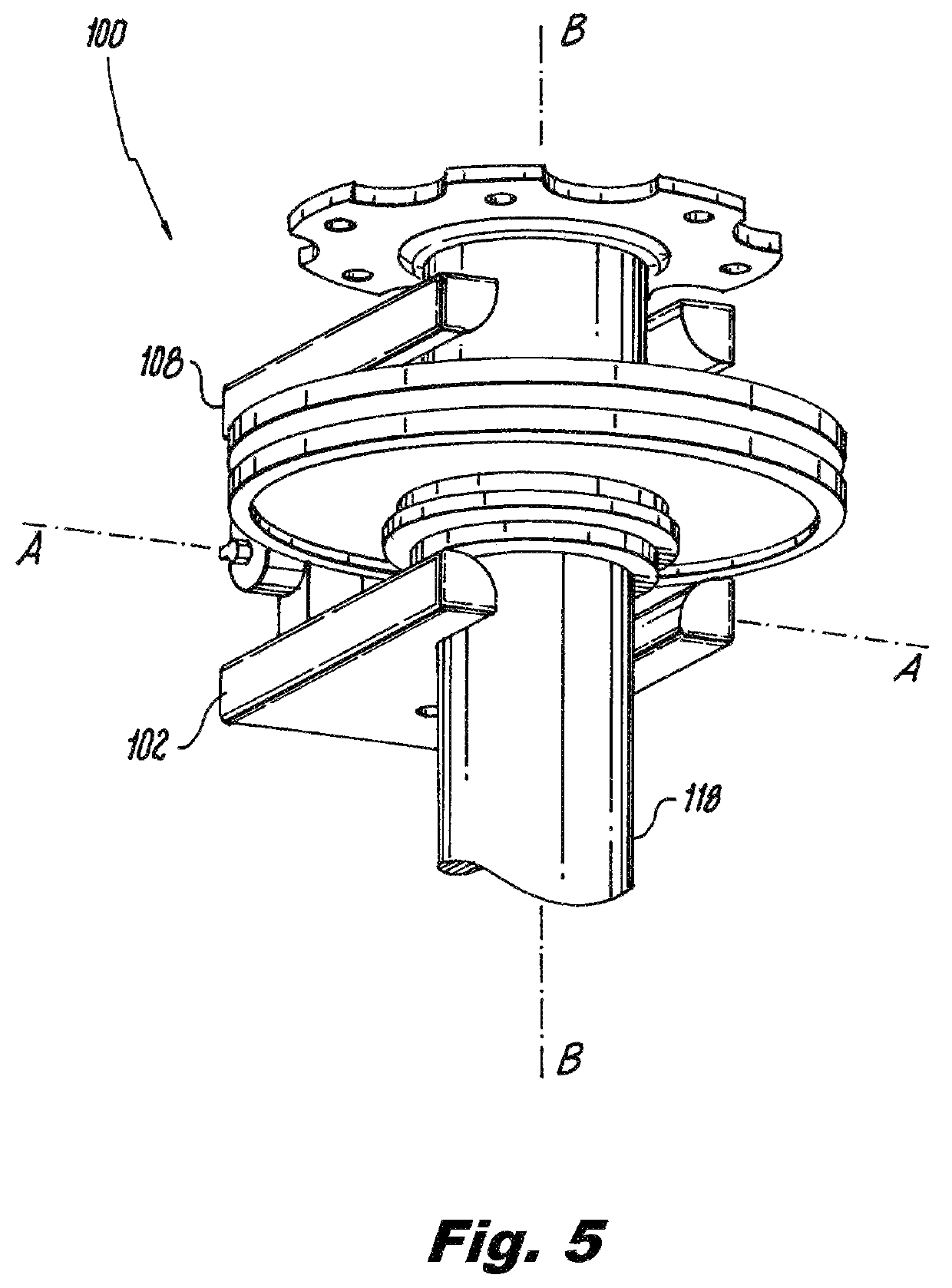

Support tool for deep rolling crankshaft fillets

InactiveUS6094956AEasy to controlLimit lateral shiftingRevolution surface grinding machinesBurnishing machinesEngineeringCrankshaft

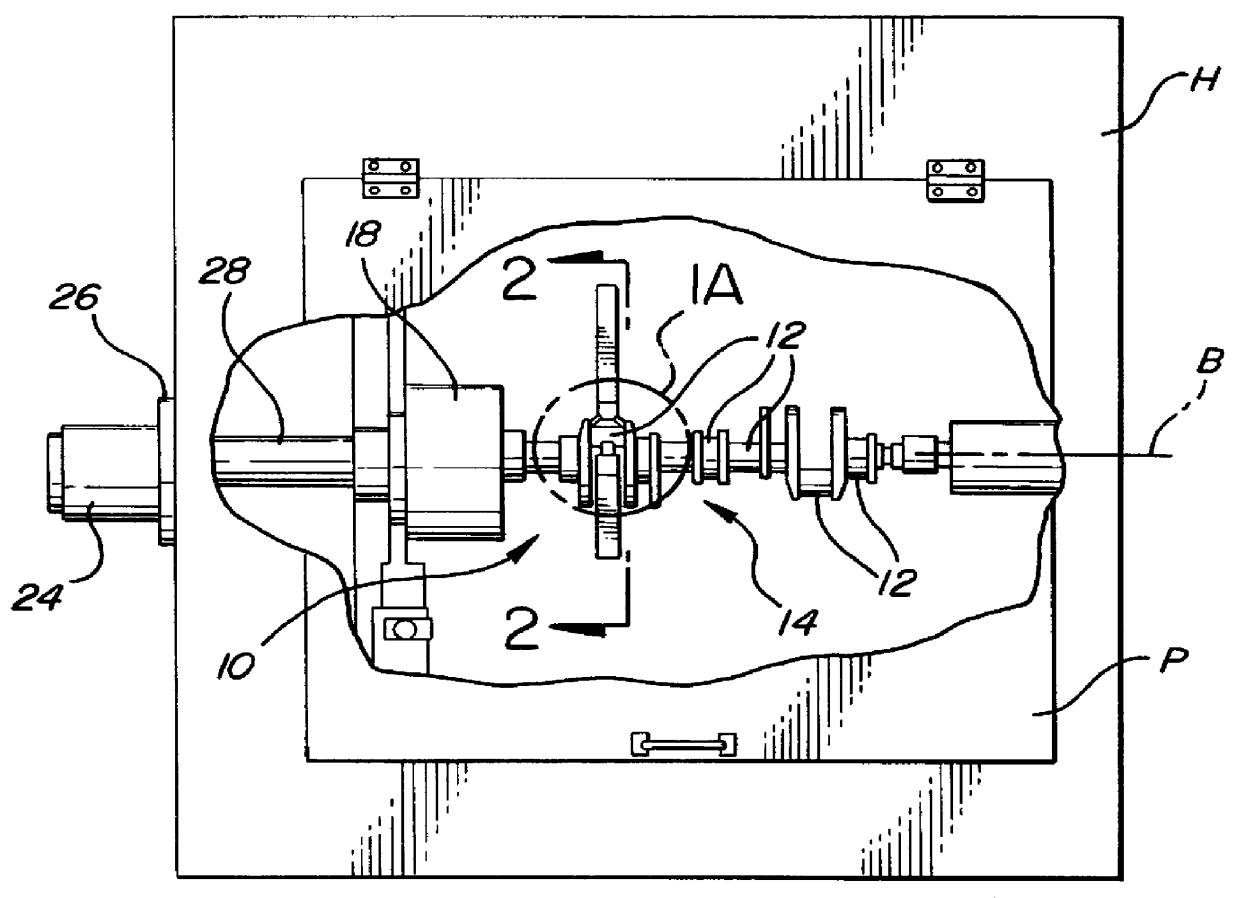

PCT No. PCT / US98 / 09524 Sec. 371 Date Jan. 15, 1999 Sec. 102(e) Date Jan. 15, 1999 PCT Filed May 13, 1998 PCT Pub. No. WO98 / 51432 PCT Pub. Date Nov. 19, 1998Deep rolling equipment for cold working fillet radii of annular undercuts on opposite sides of main bearing and crank pin journals of an engine crankshaft while being rotatably driven. The equipment has pairs of jaws movable between an open position for receiving the crankshaft journal and a closed position for rolling the fillets thereof. The upper jaw mounts fillet rolling tools for high load rolling engagement in the annular undercuts and a lower tool on the opposing lower jaw for support of the journal. The lower tool has a pair of support rollers with annular journal support portions which contact and support the journal while the fillet radii of the undercuts on either side of the journal are being rolled. These support rollers importantly have work stabilizing annular flanges outboard of the support portion with larger diameters that ride in the undercuts and limit lateral movement of the crankshaft with respect to the rolling and support tools so that the crankshaft is not abraded or otherwise damaged by side contact of the jaws and tools with portions of the crankshaft.

Owner:HEGENSCHEIDT MFD

Systems and methods for adapting parameters to increase throughput during laser-based wafer processing

InactiveUS8076605B2Reduce and eliminate damageRead-only memoriesSemiconductor/solid-state device manufacturingThermal stateEngineering

Systems and methods automatically modify a laser-based system for processing target specimens such as semiconductor wafers. In one embodiment, the laser-based system detects a trigger associated with a processing model. The processing model corresponds to a set of wafers. In response to the trigger, the system automatically adjusts one or more system parameters based on the processing model. The system then uses the modified system parameters to selectively irradiate structures on or within at least one wafer in the set of wafers. In one embodiment, the trigger includes variations in a thermal state related to a motion stage. In response to the variations in the thermal state, the system operates the motion stage in a series of movements until a thermal equilibrium threshold is reached. The sequence of movements may, for example, simulate movements used to process a particular wafer.

Owner:ELECTRO SCI IND INC

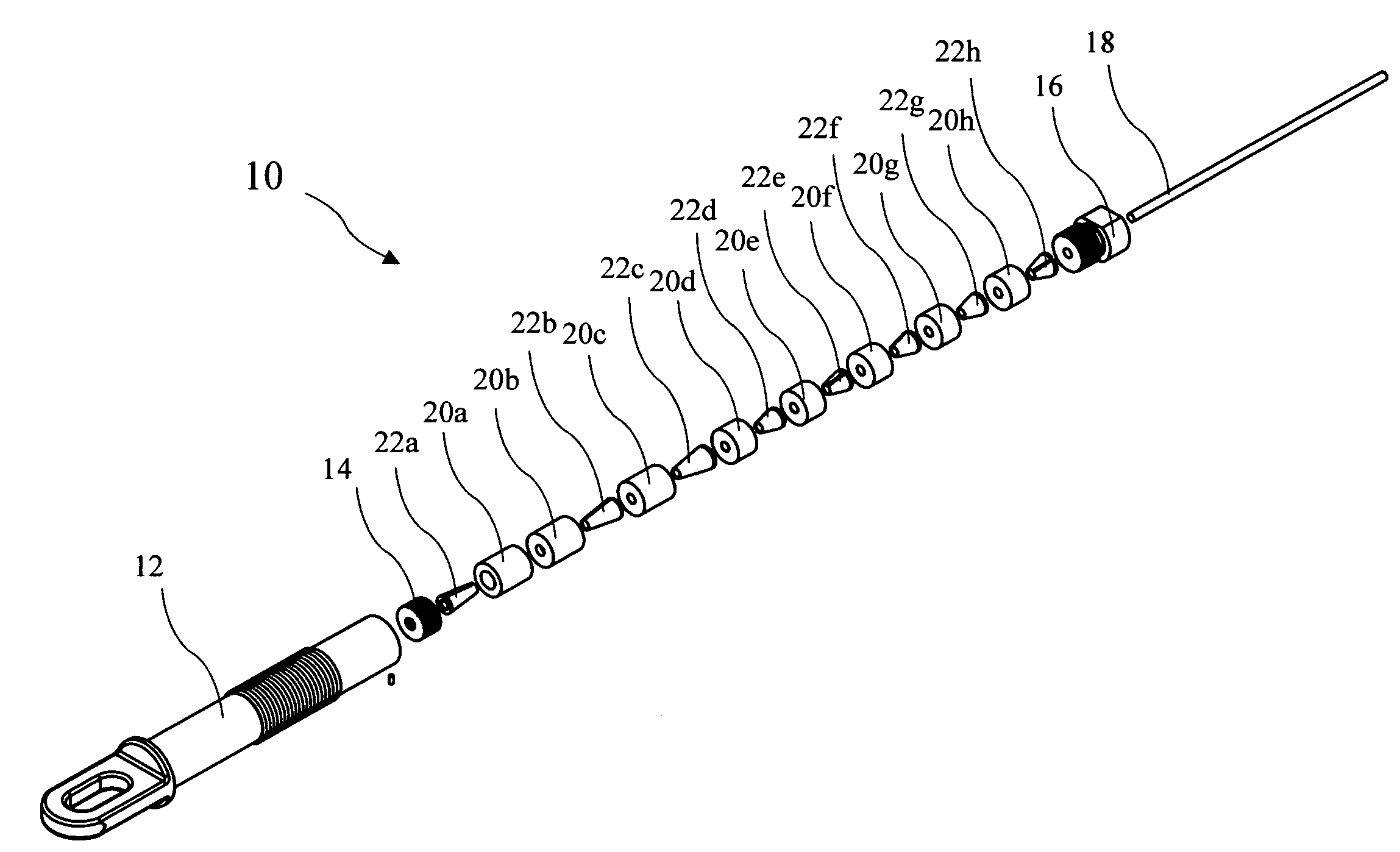

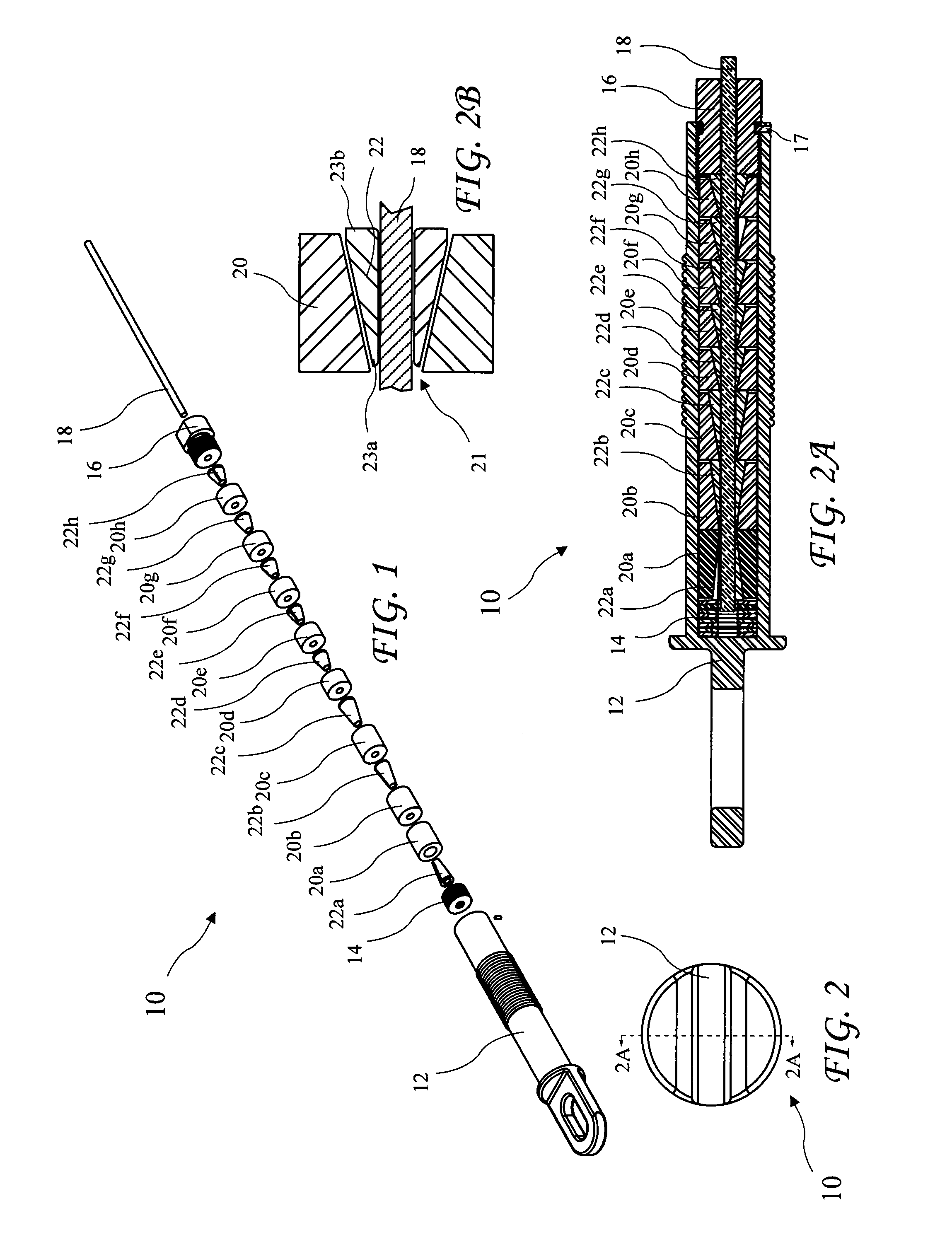

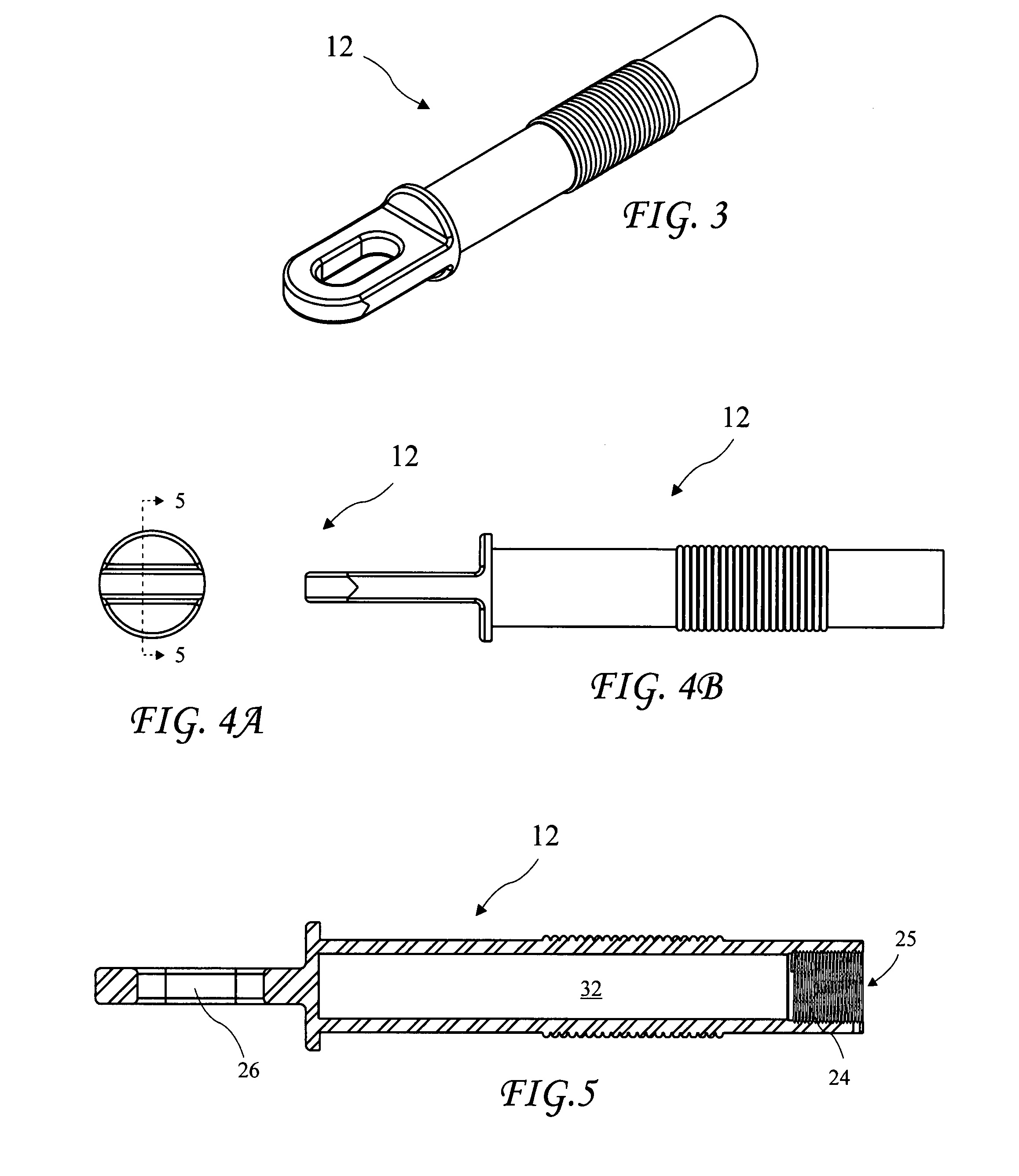

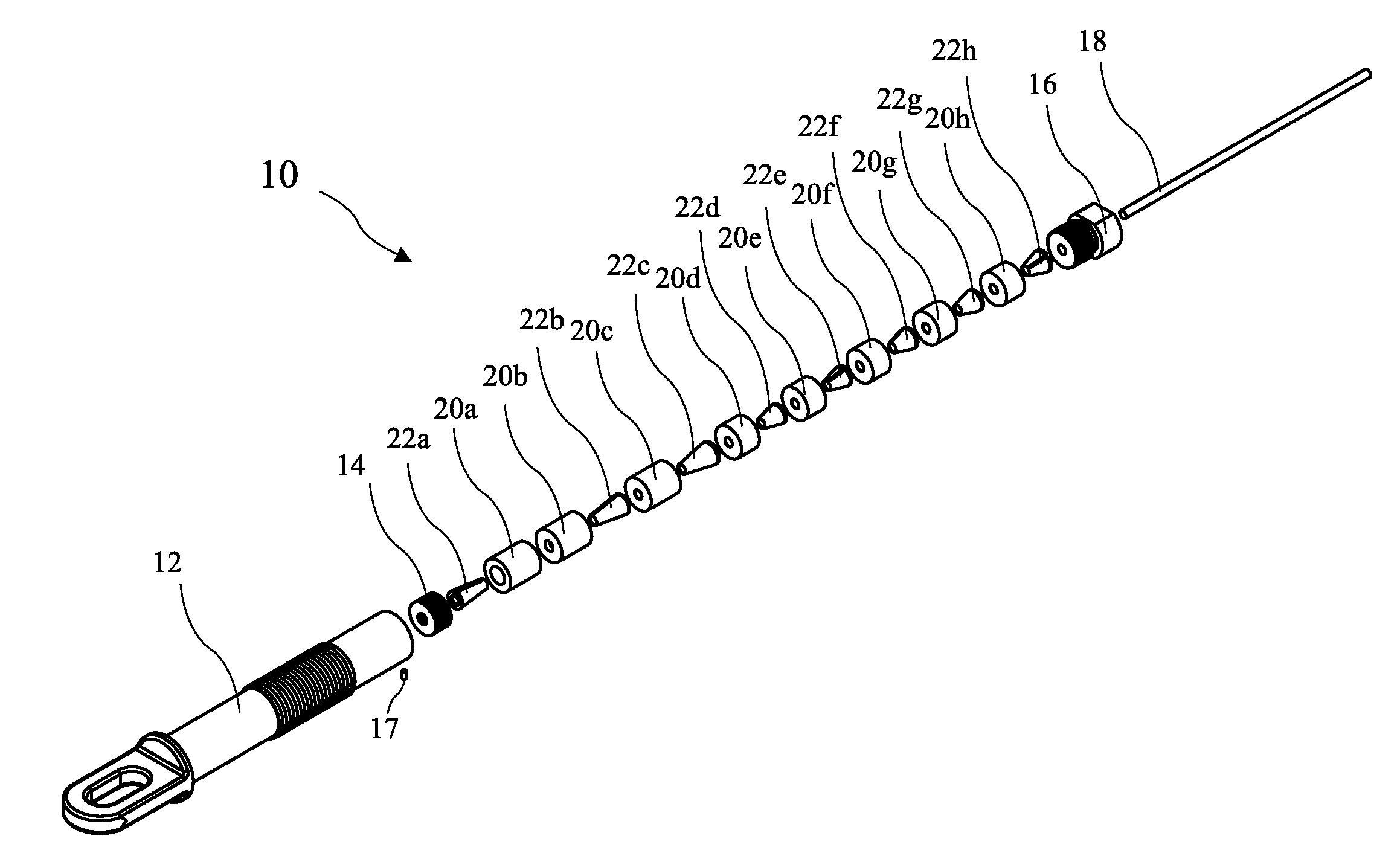

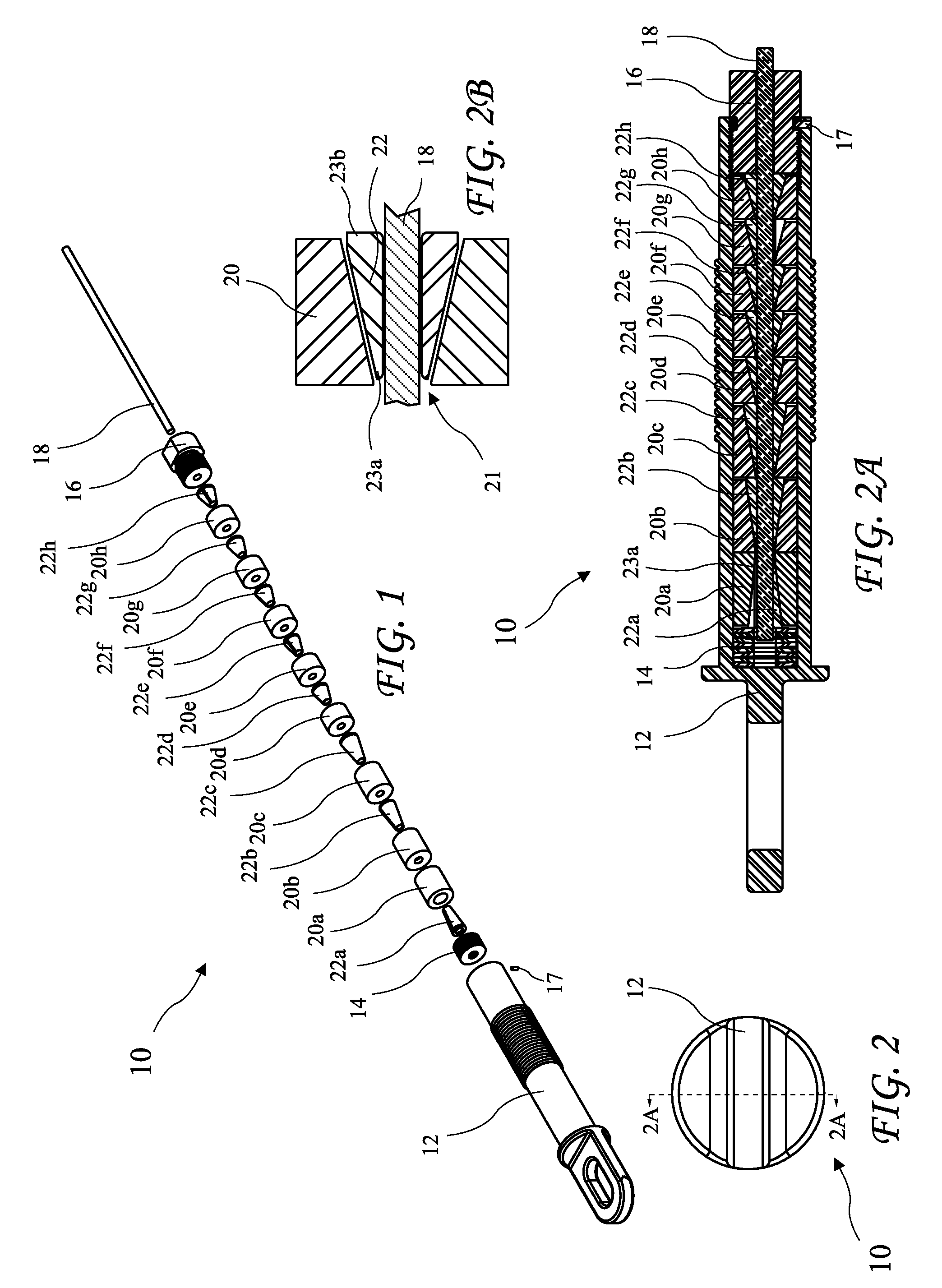

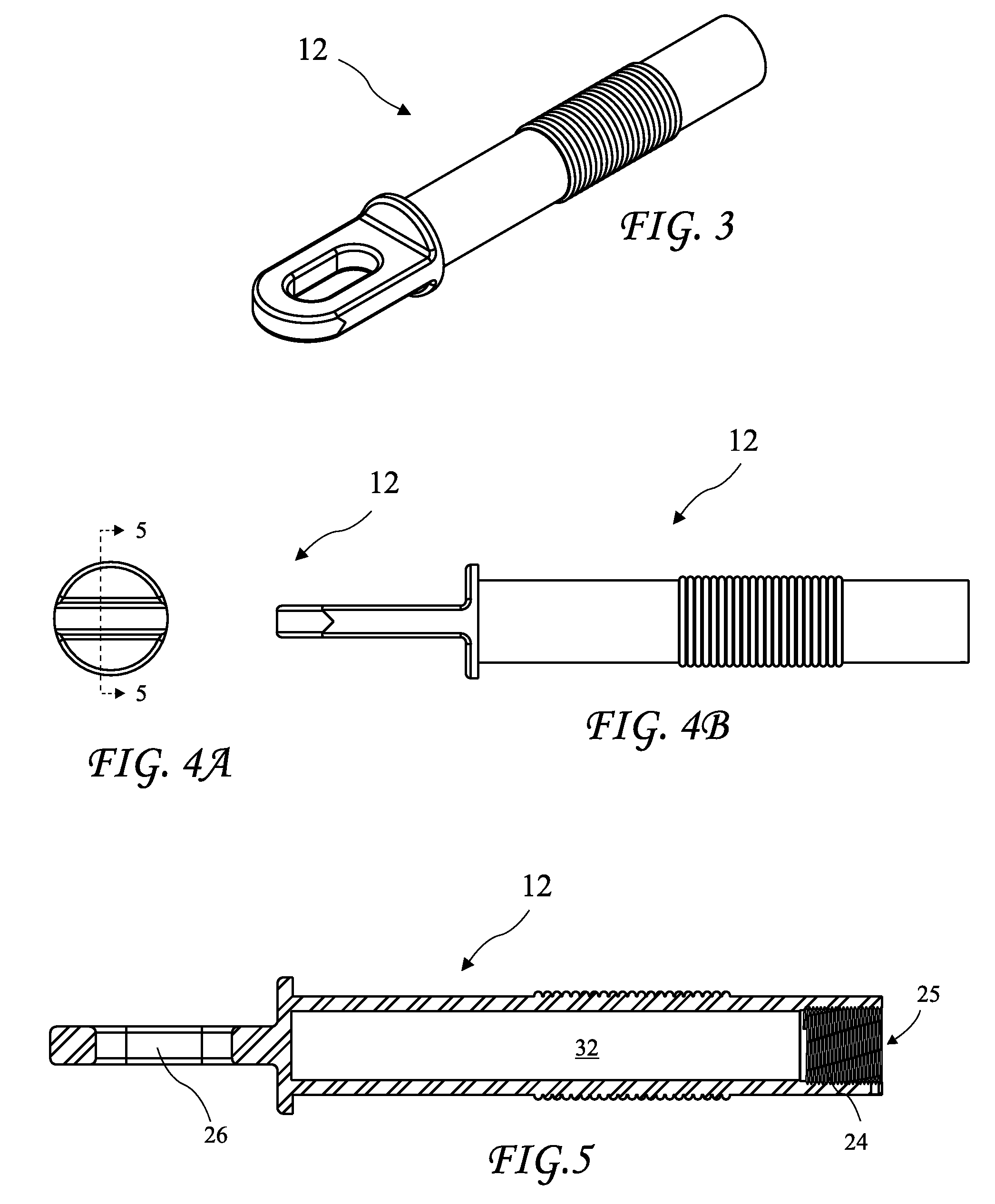

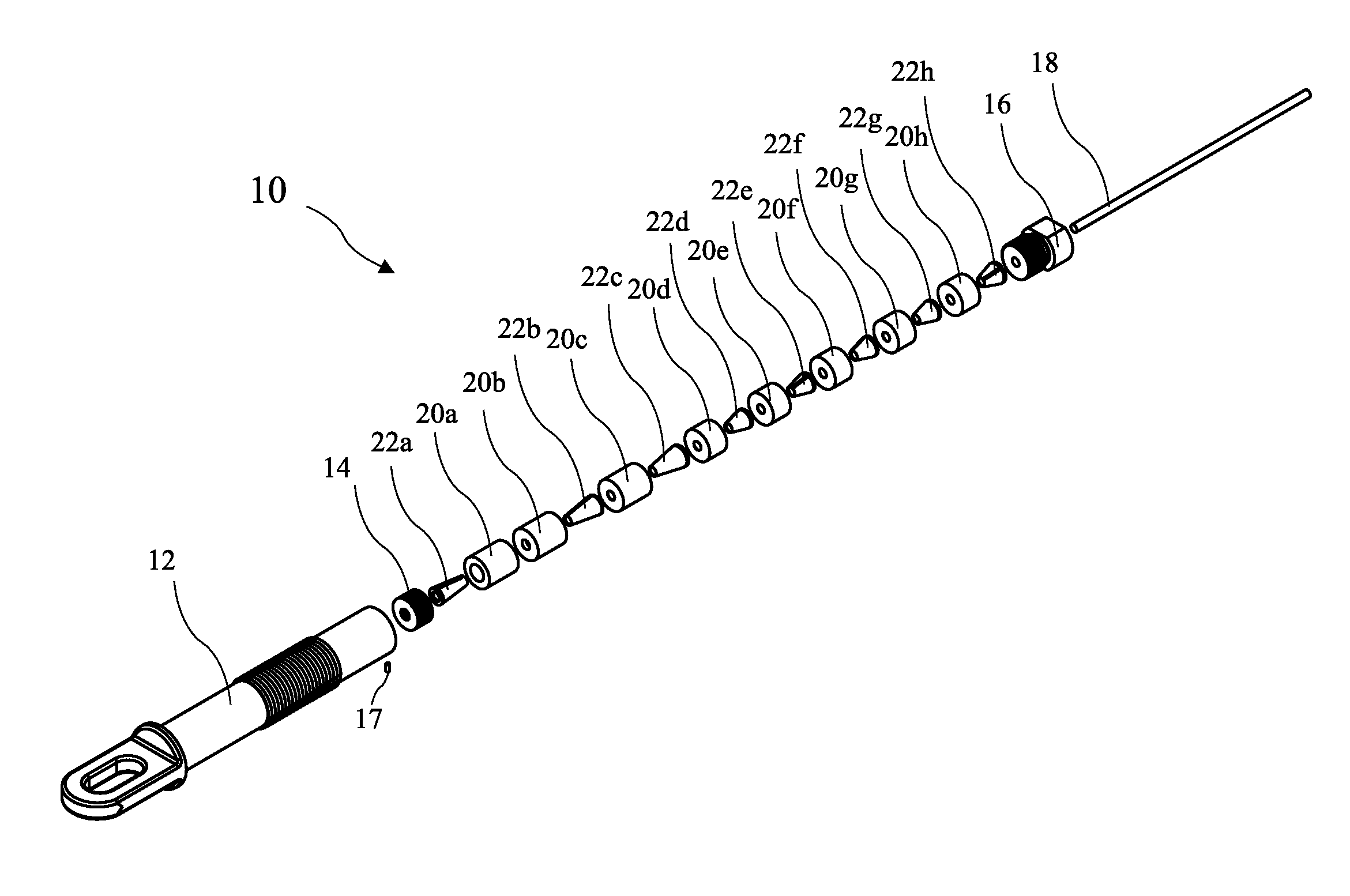

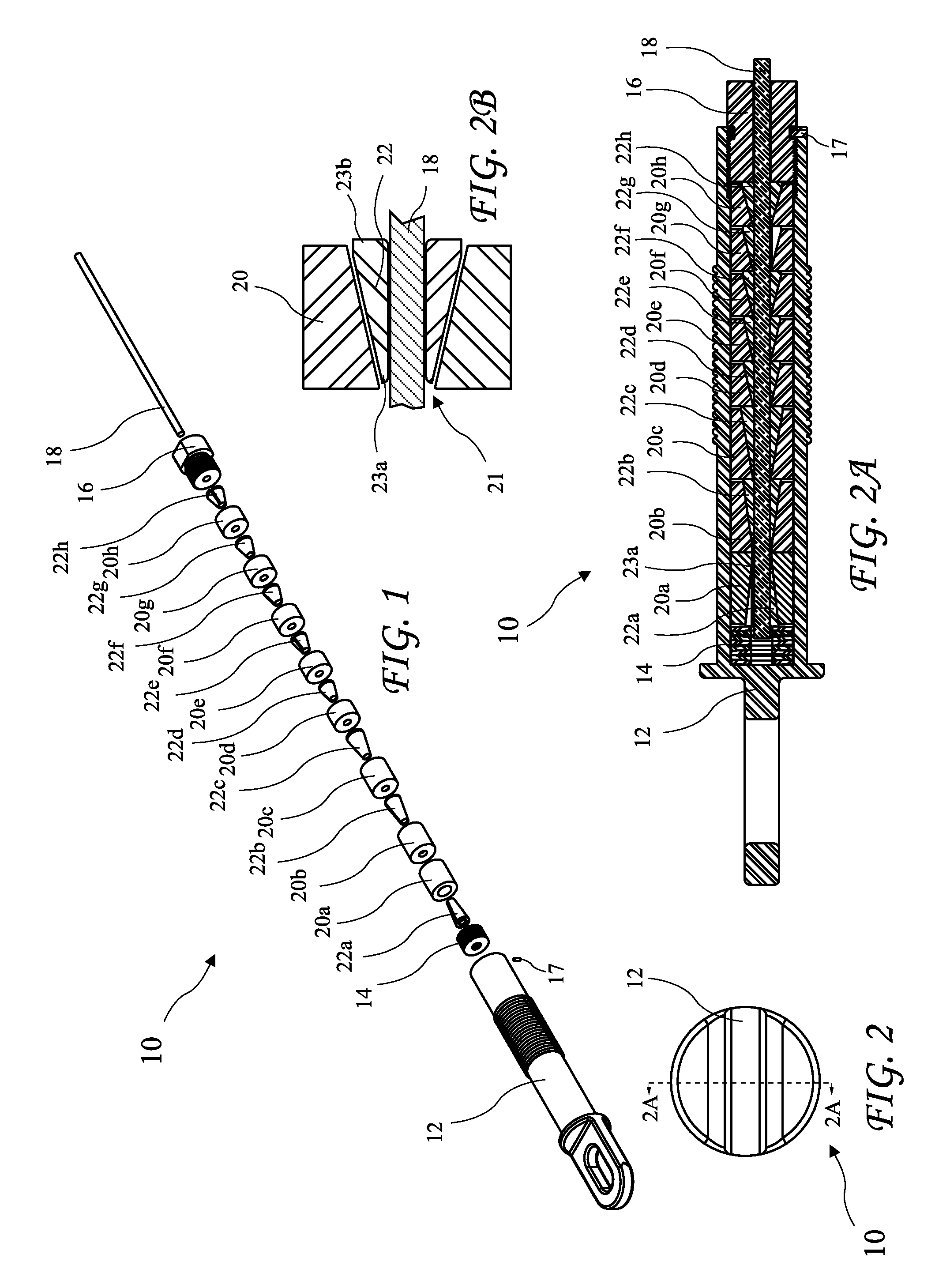

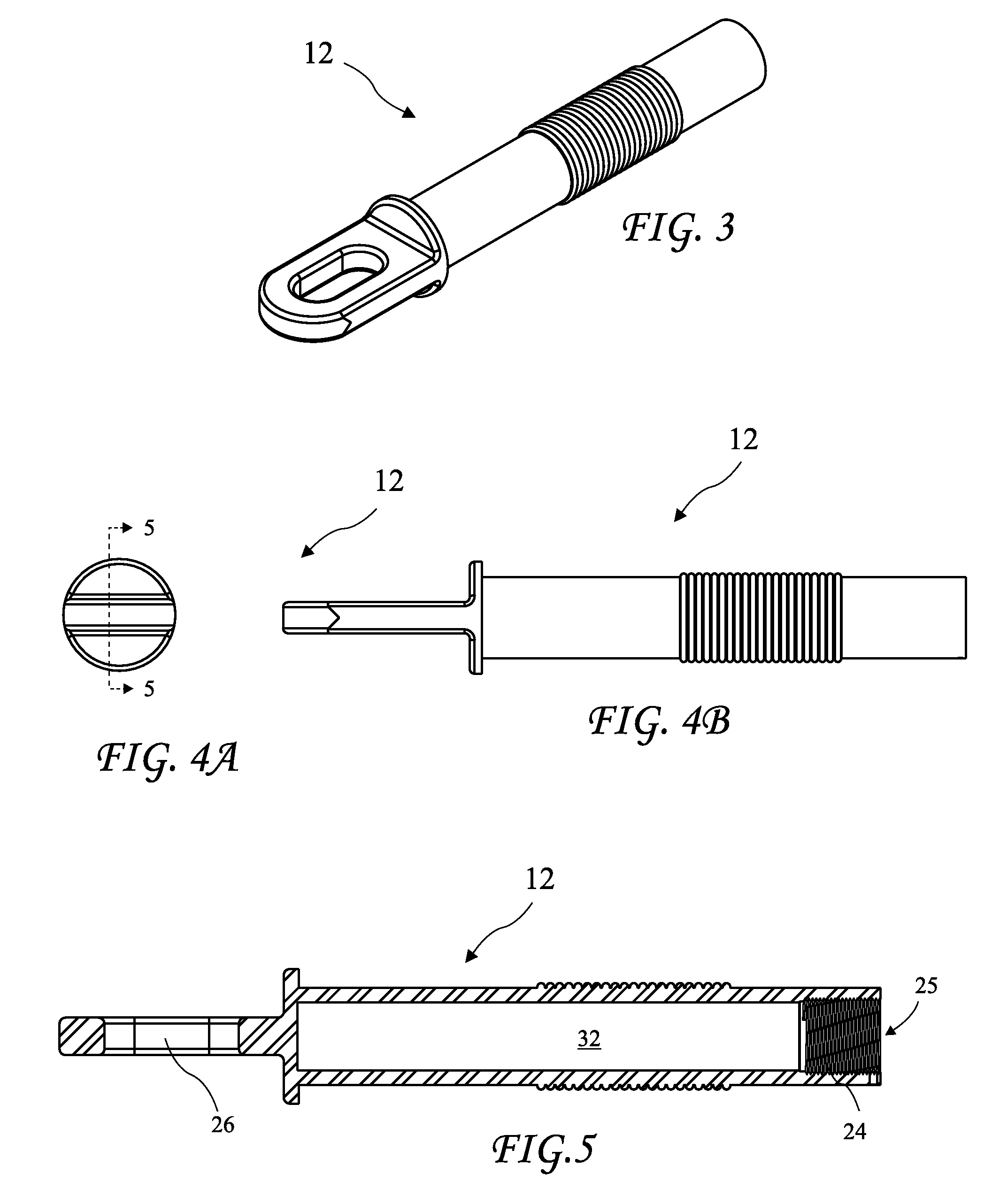

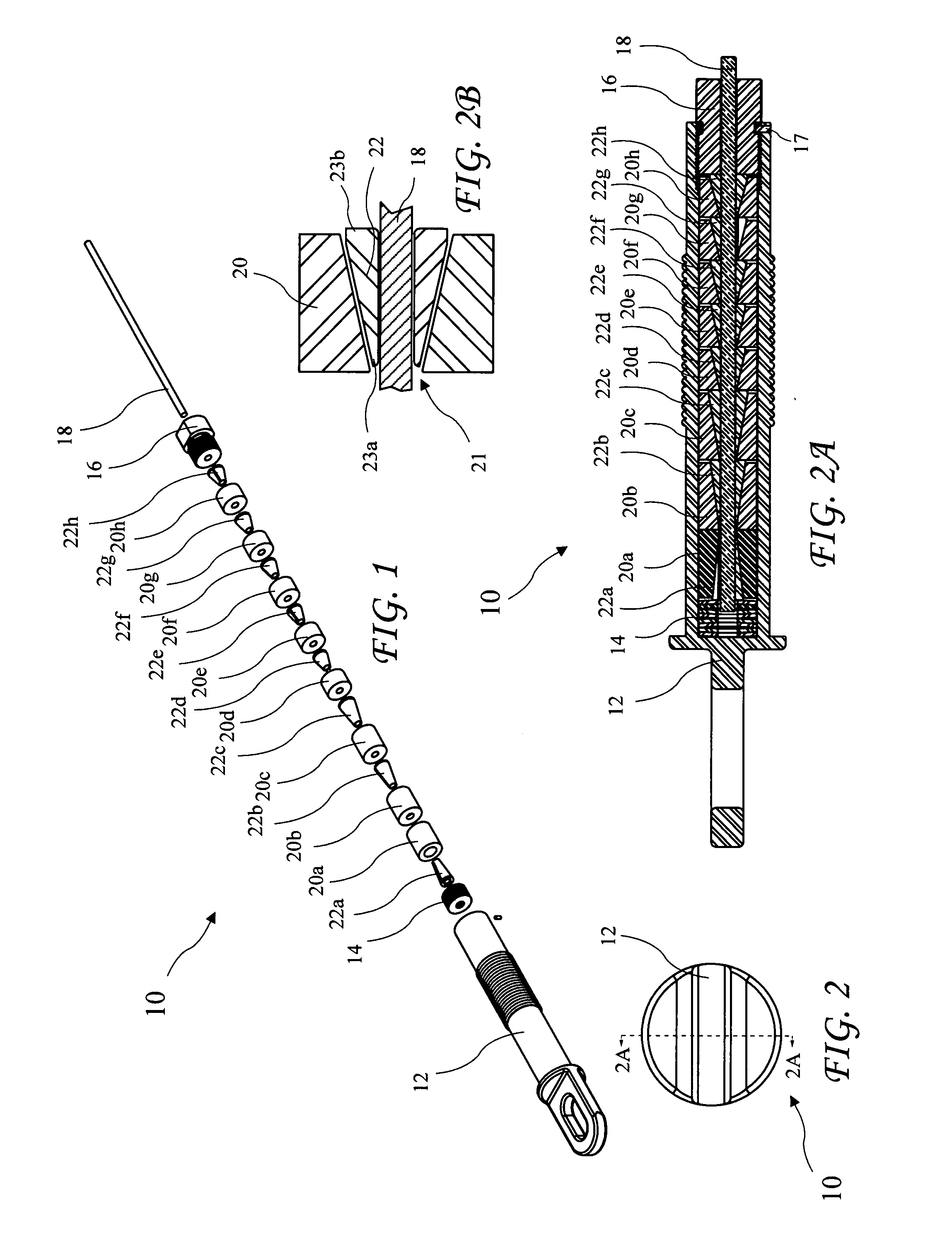

Dead cable end

InactiveUS7407411B2Reduce and eliminate damageAvoid damageOverhead installationElectrically conductive connectionsEngineeringCollet

A dead cable end distributes holding force over a length of a cable end to reduce or eliminate damage to cables. The dead cable end includes a housing containing a plurality of collets each residing in a collet receptacle. Each collet includes a conical exterior and a lengthwise collet gap and each collet receptacle includes a conical interior. The collets and collet receptacle are held inside the housing by a retaining nut, and the collet and collet receptacle pairs are compressed between the retaining nut and a spring inside the housing. The cable end resides inside the collets, and compressive force on each collet and collet receptacle pair causes each collet to compress radially and hold the cable end. The holding force is thereby distributed over the length of each collet and over the plurality of collet and receptacle pairs to avoid damage to the cable.

Owner:BYRNE JOSEPH +1

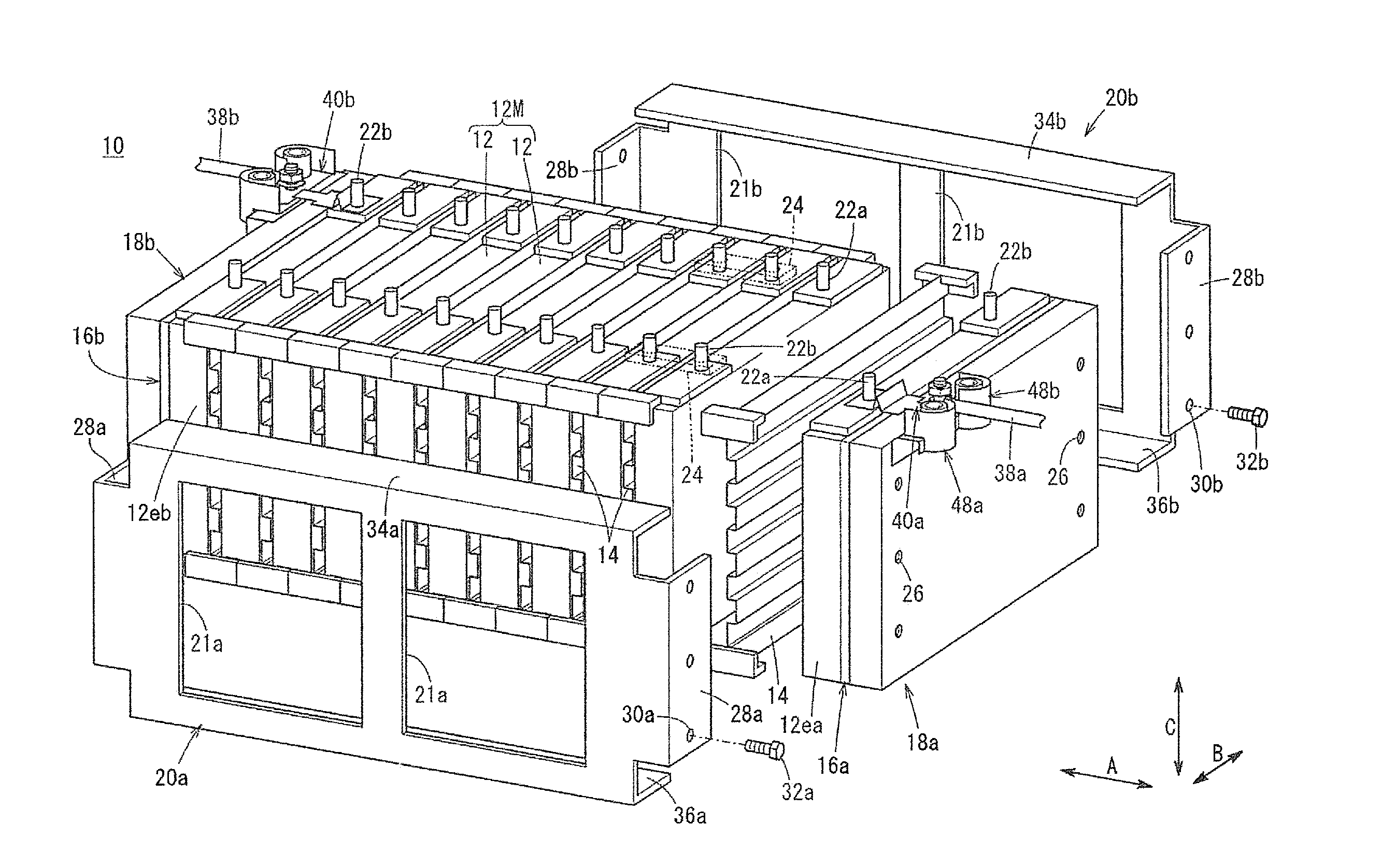

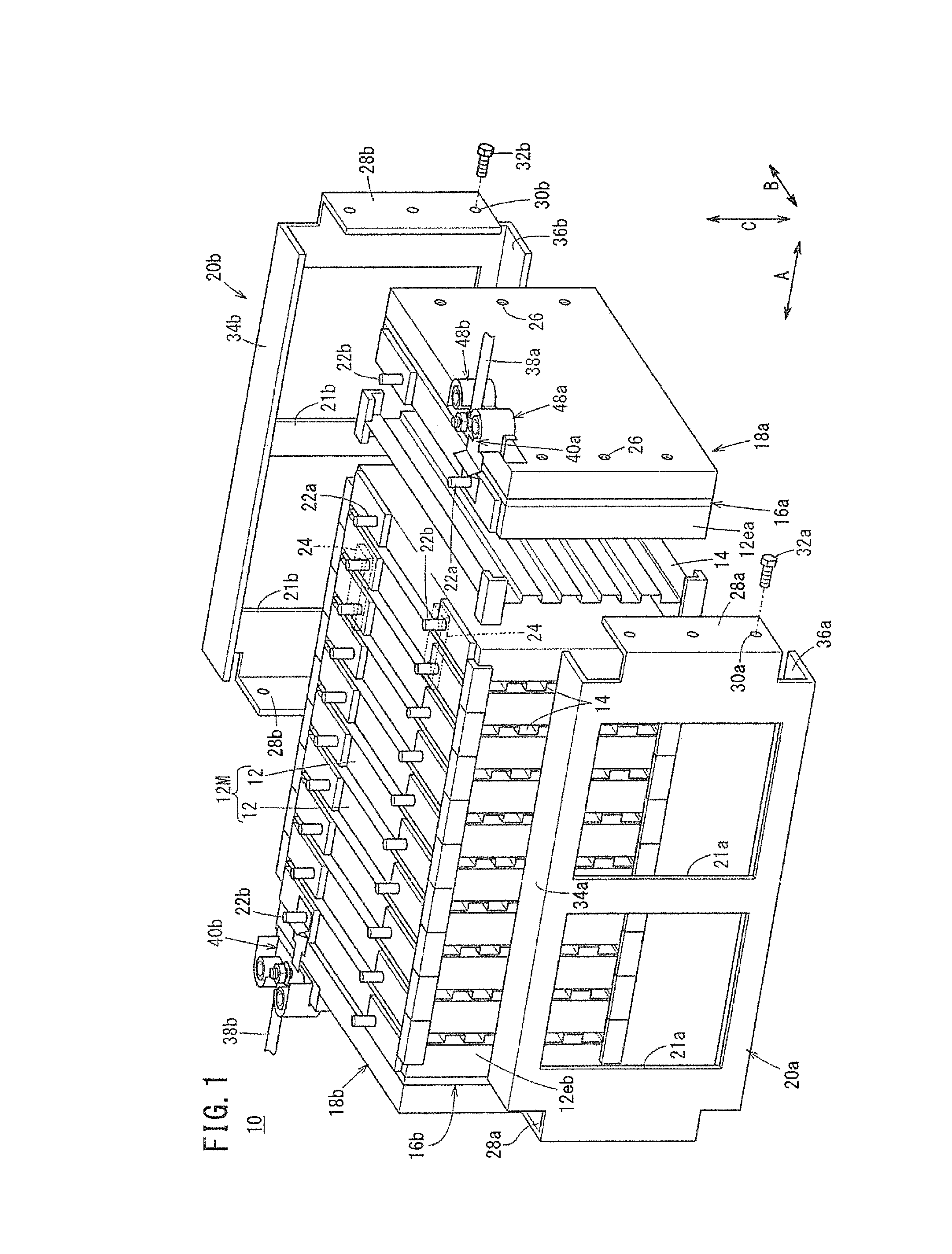

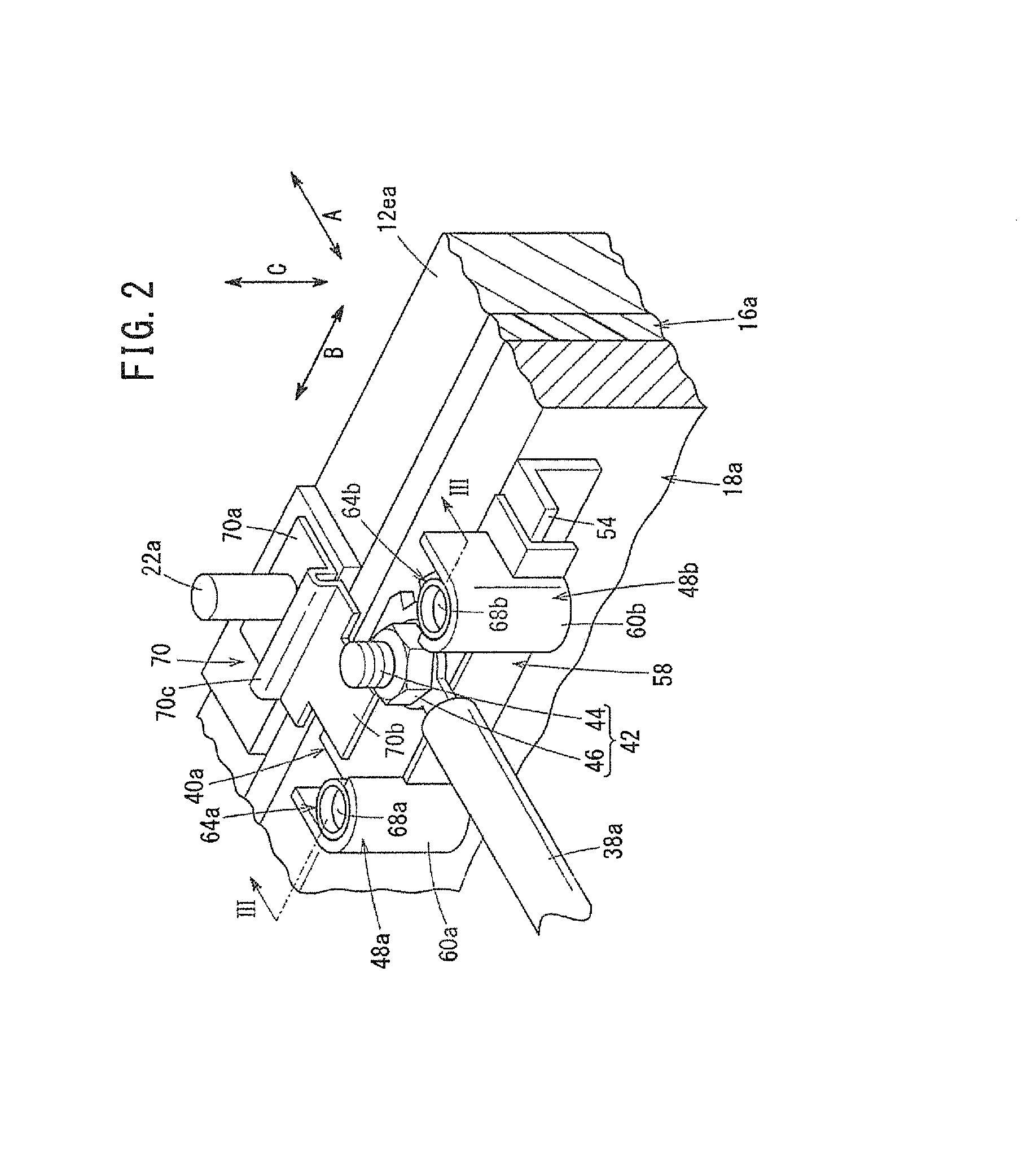

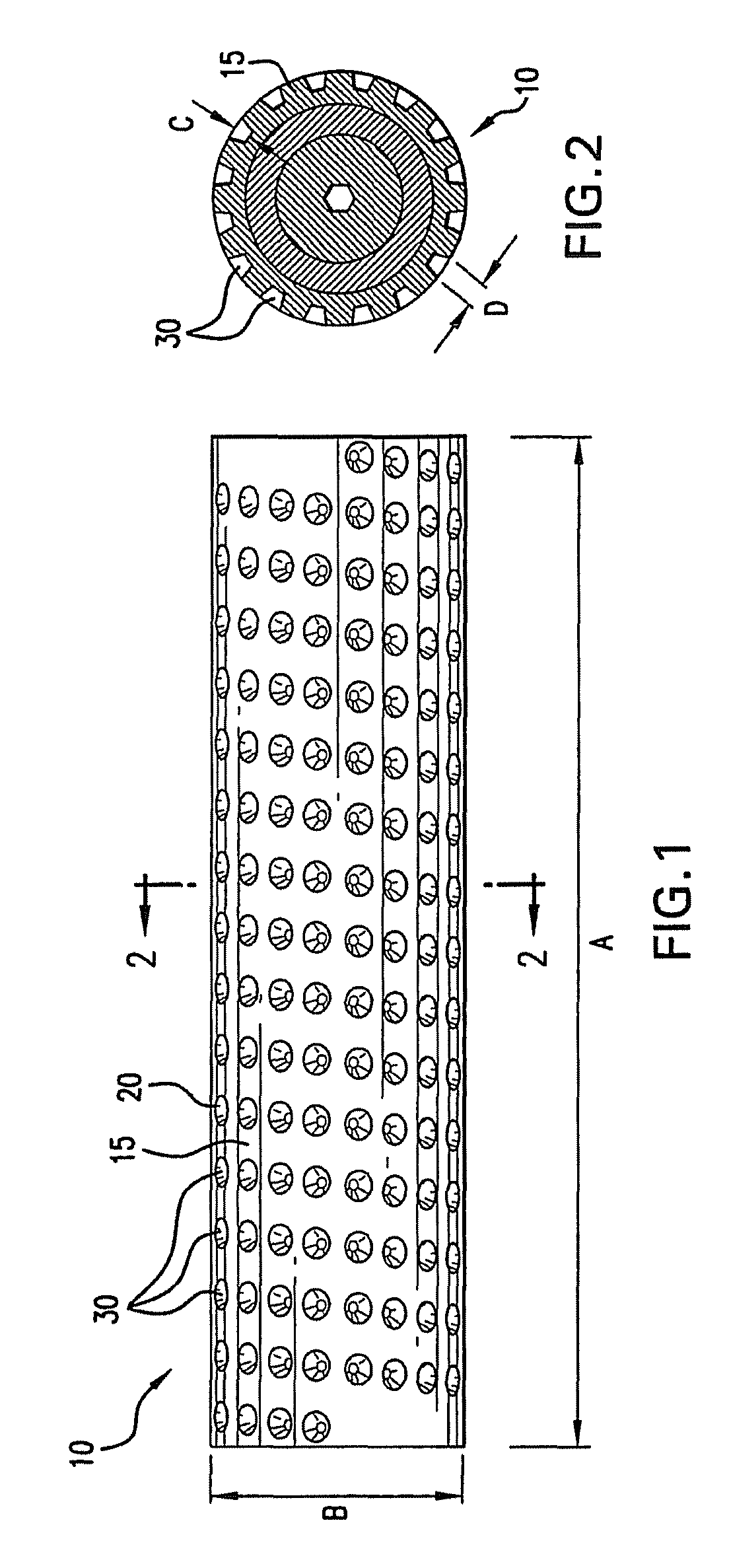

Energy storage module

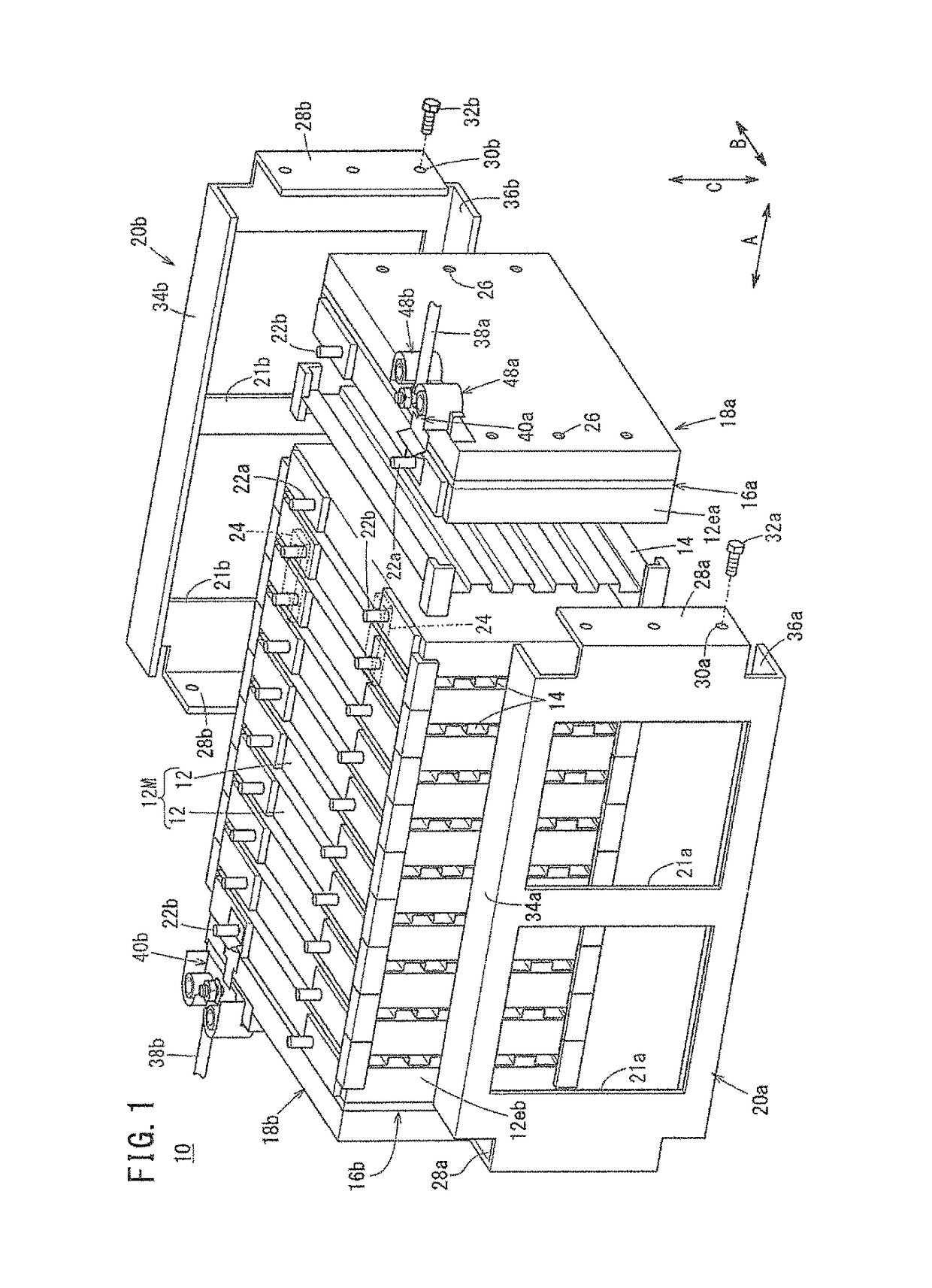

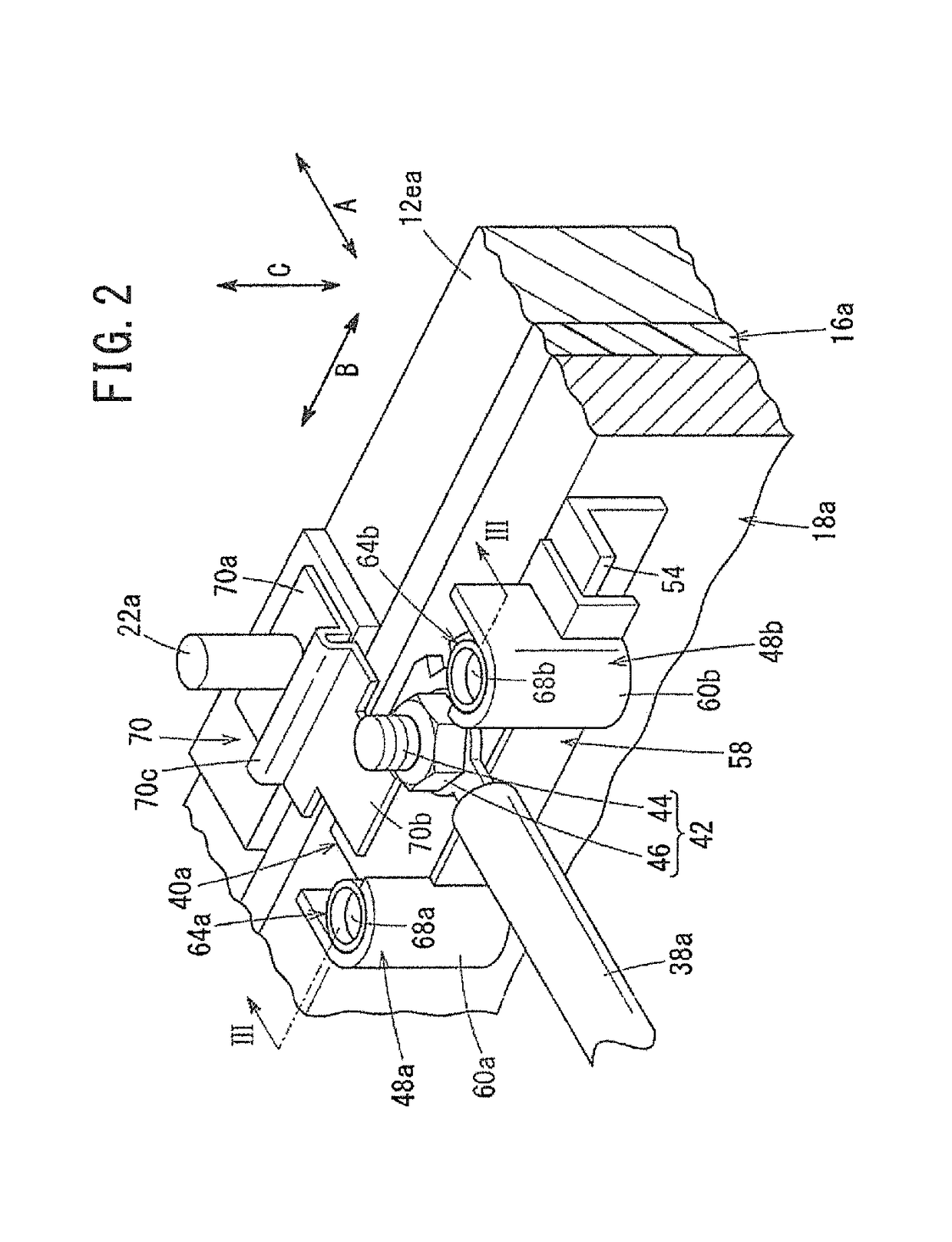

ActiveUS20160013467A1Avoiding torque induced damageAvoid damagePrimary cell to battery groupingFinal product manufactureEngineeringEnergy storage

An energy storage module includes an energy storage cell group containing a plurality of energy storage cells stacked in a stacking direction, and a pair of end plates provided at both ends of the energy storage cell group in the stacking direction. A terminal frame is provided at the end plate in order to electrically connect an electrode terminal of the energy storage cell provided at an end in the stacking direction and an output line. The terminal frame is fixed to the end plate by fixing points.

Owner:HONDA MOTOR CO LTD

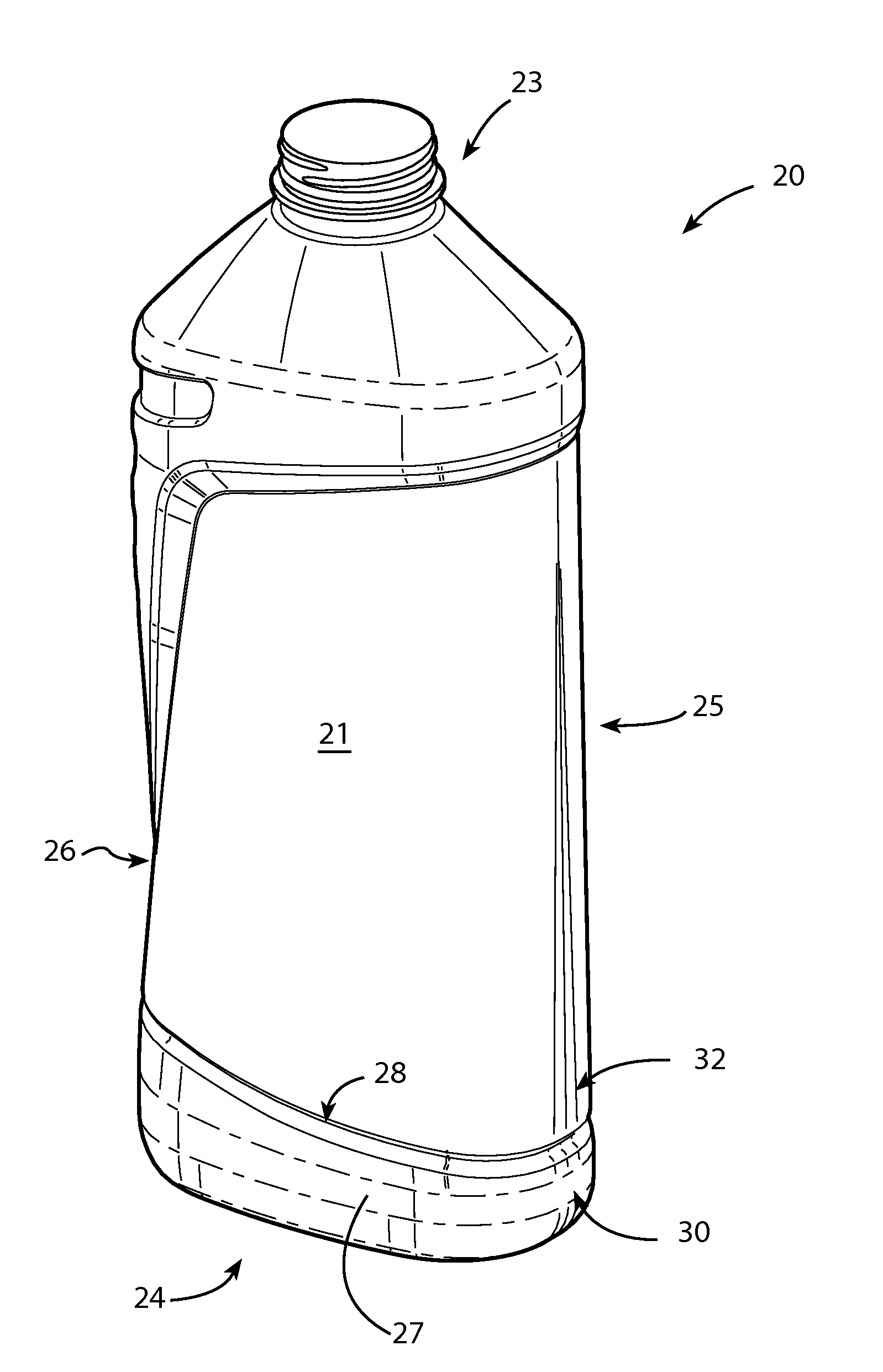

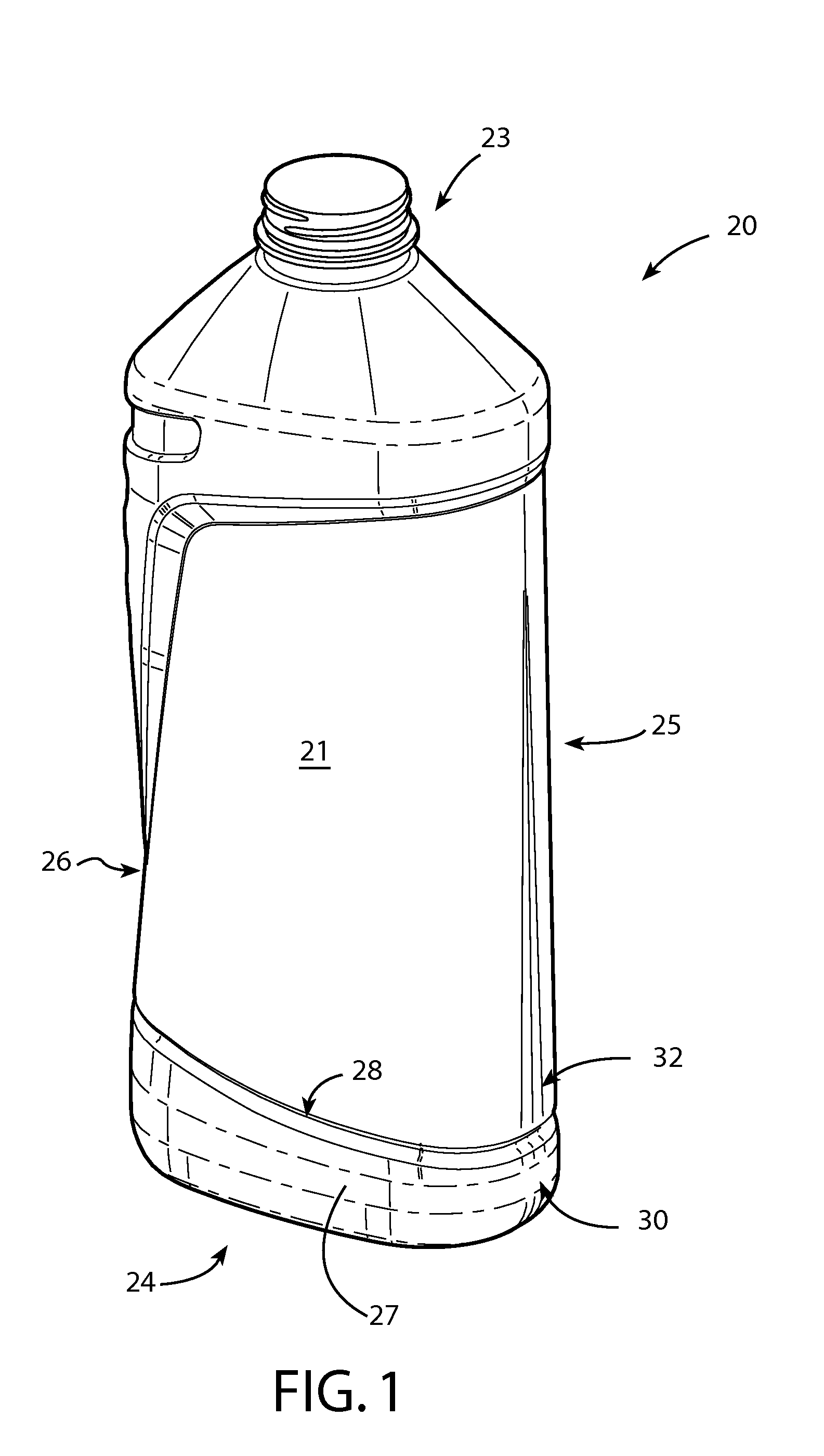

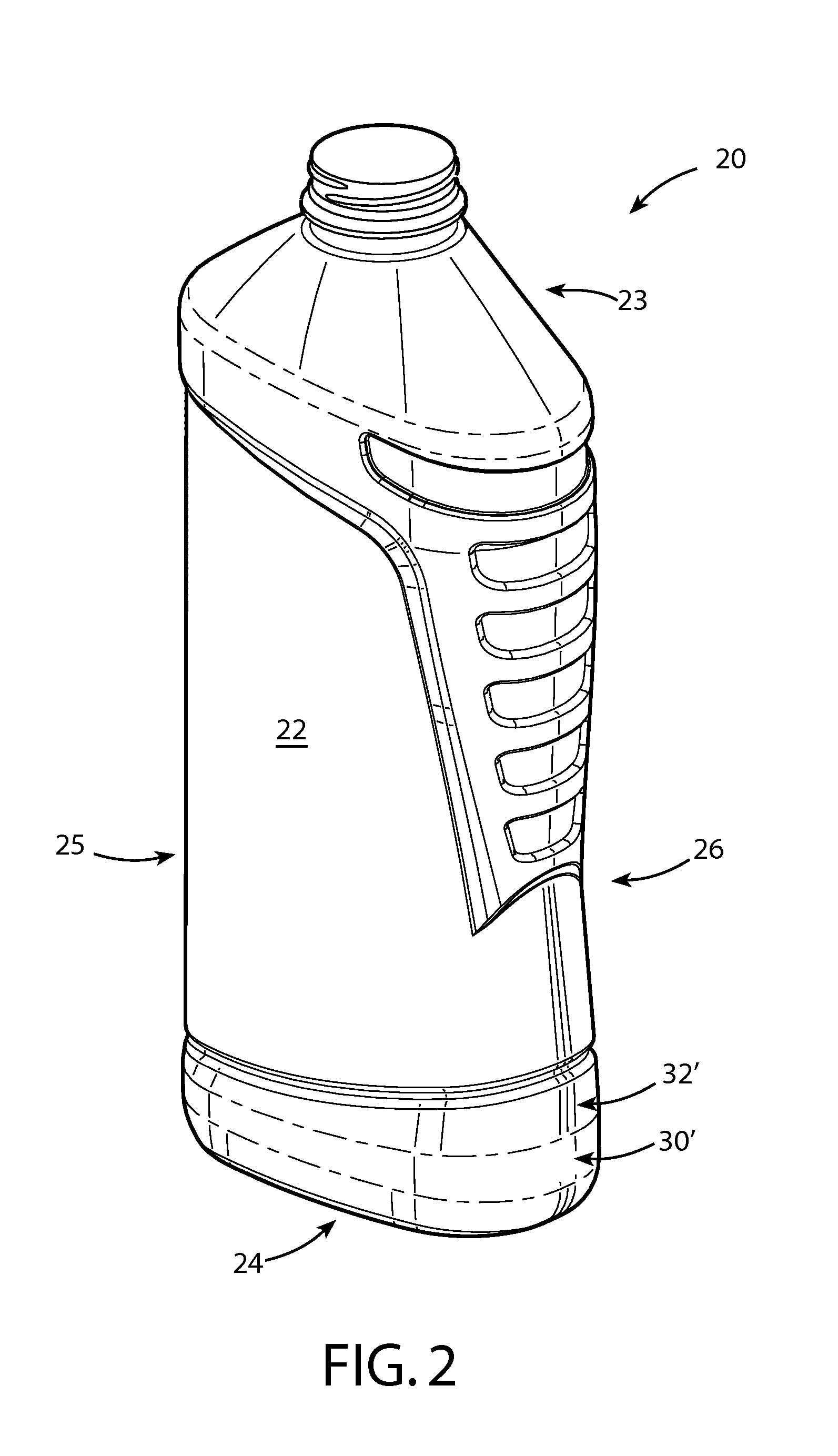

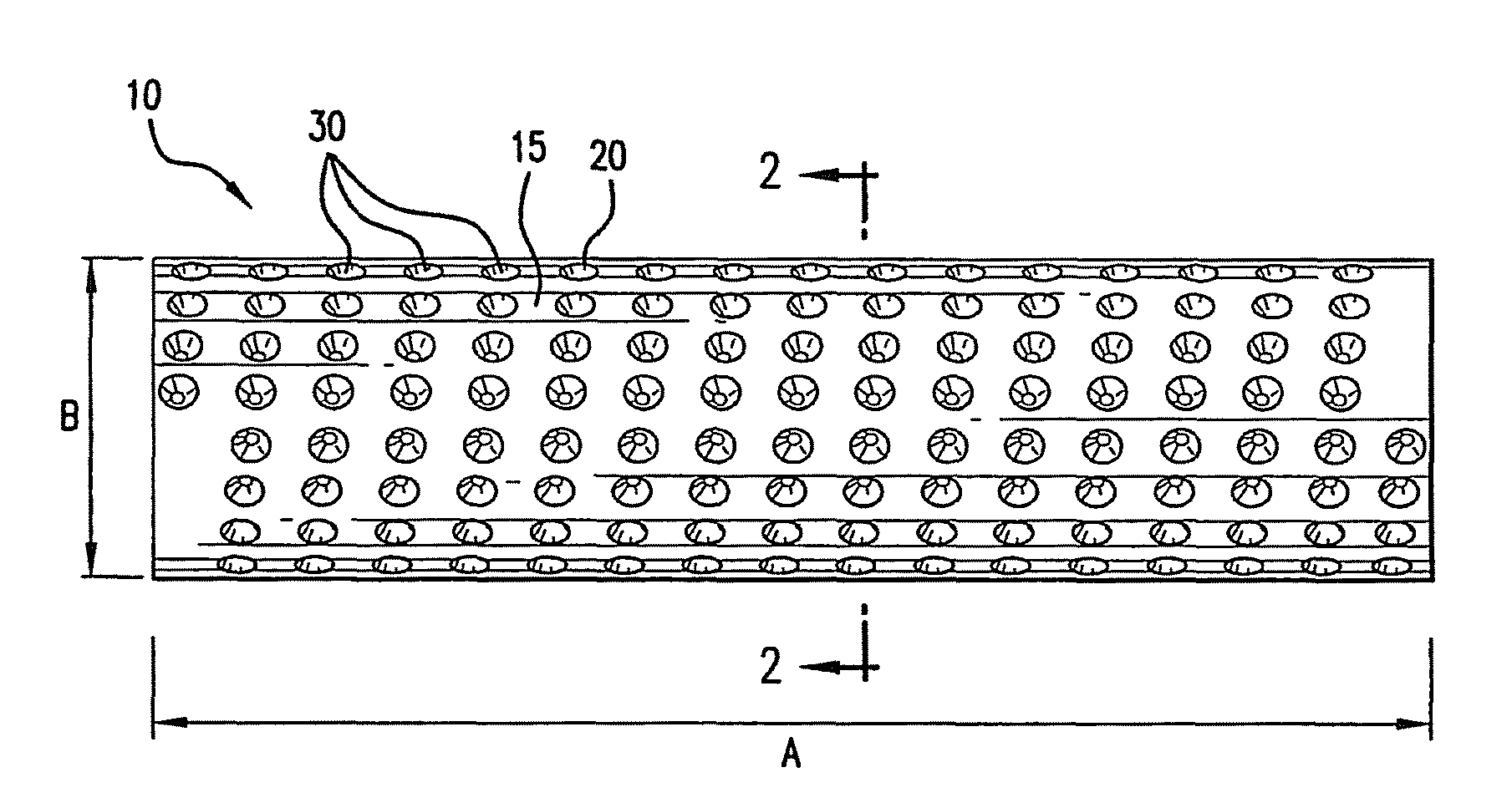

Plastic bottle

InactiveUS20120103929A1Reducing and eliminating damageImprove impact resistanceLarge containersRigid containersPlastic materialsEngineering

A light weight flat container such as a bottle (20) formed of an elastically deformable plastic material and having a staged load bearing system including primary and secondary load bearing surfaces. The bottle includes two op posing wide sides (21, 22) and two opposing narrow sides (25, 26) on which the load bearing surfaces may be disposed. A base (27) is provided which protrudes beyond the narrow sides (25, 26) in some embodiments. During processing of the bottles on a conveyor fill line, mating primary load bearing surfaces (30, 30′) on adjacent bottles initially engage and begin to deform under contact forces. The mating secondary load bearing surfaces (32, 32′) next engage to better distribute the contact forces and control deformation of the bottles to below the elastic limit of the plastic material to avoid plastic deformation or crazing damage to the bottles when the contact forces subsides. A bottle processing method is also provided.

Owner:COLGATE PALMOLIVE CO

Engine cover puller

InactiveUS7114233B1Easy to separateEasy to removeBottle/container closureCrowbarsEngineeringAutomotive engineering

Owner:HONDA MOTOR CO LTD

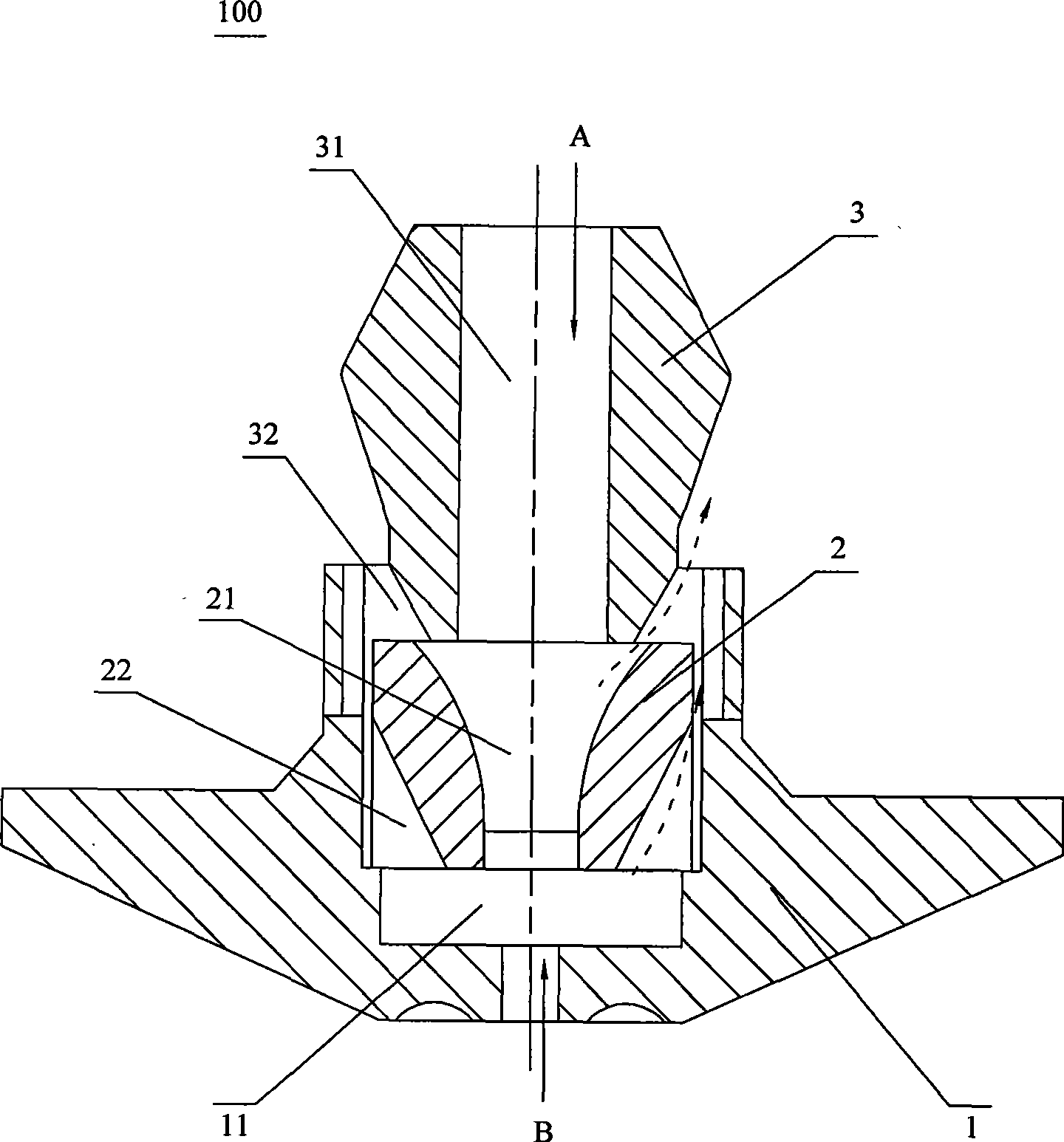

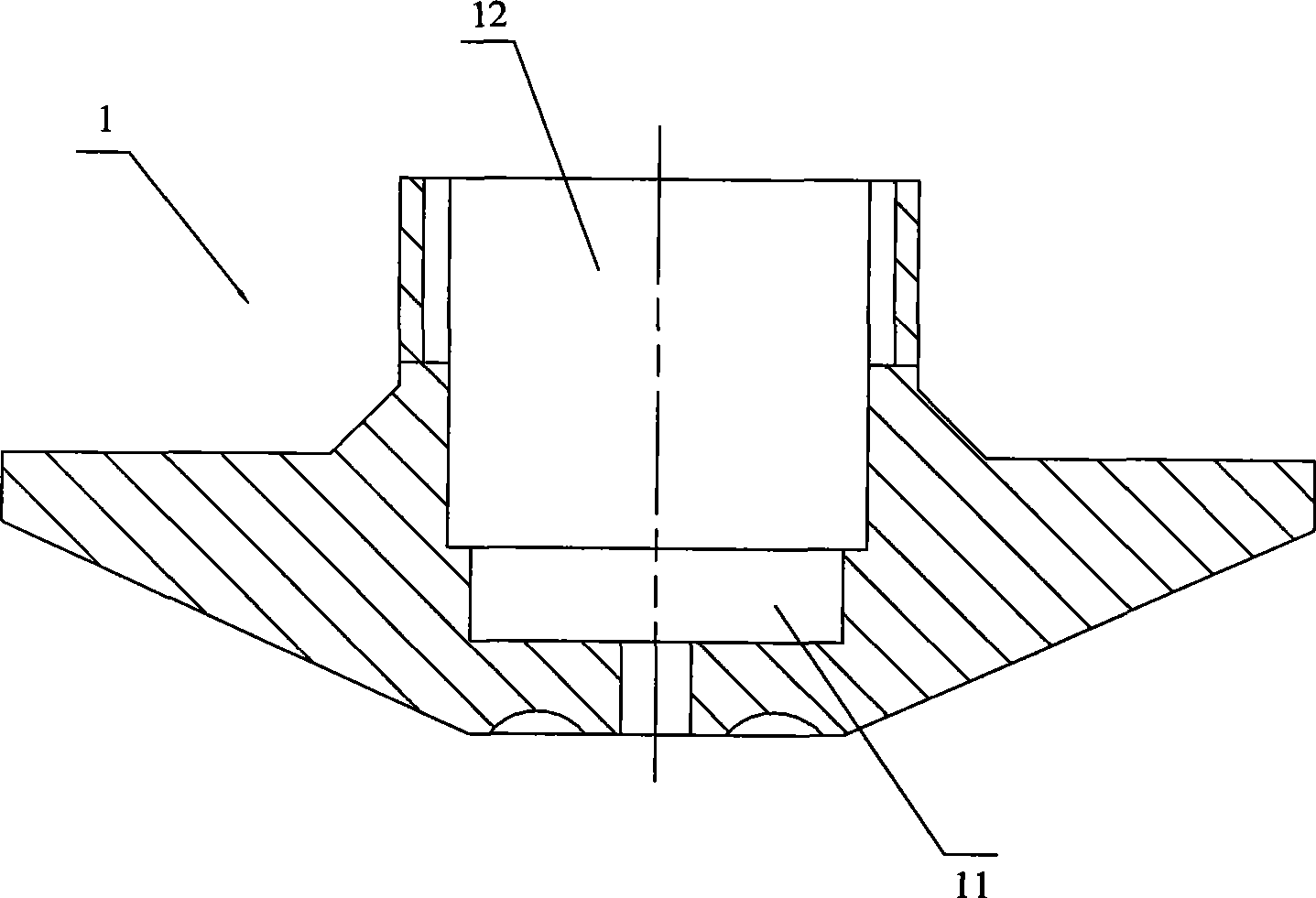

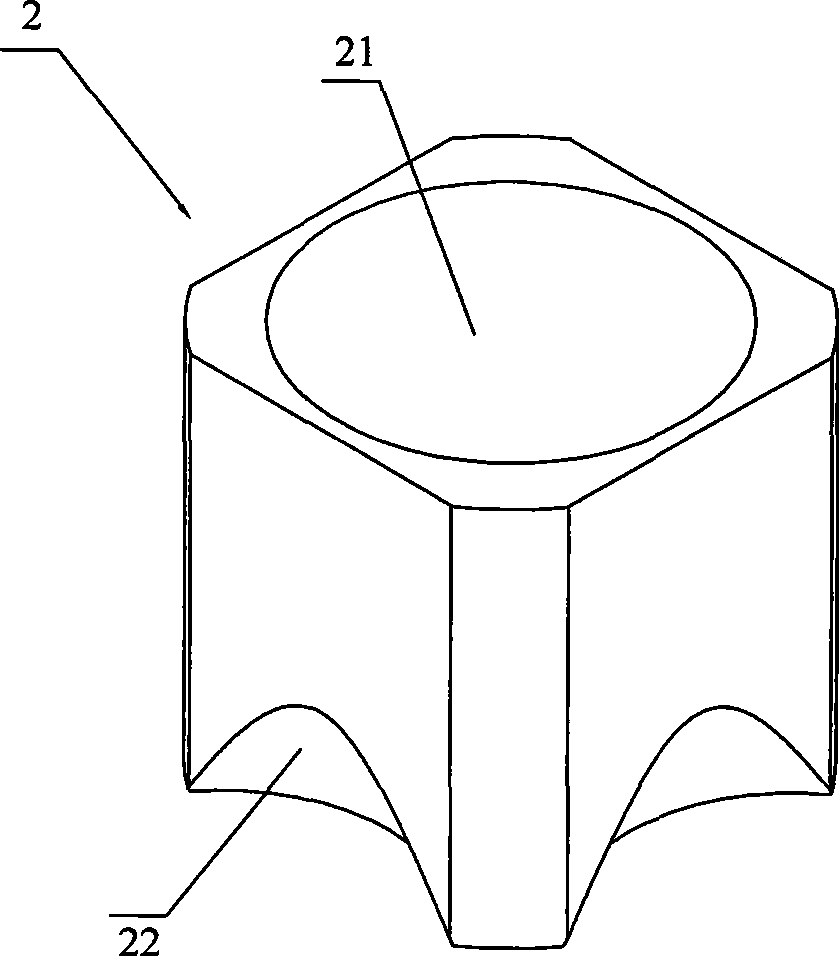

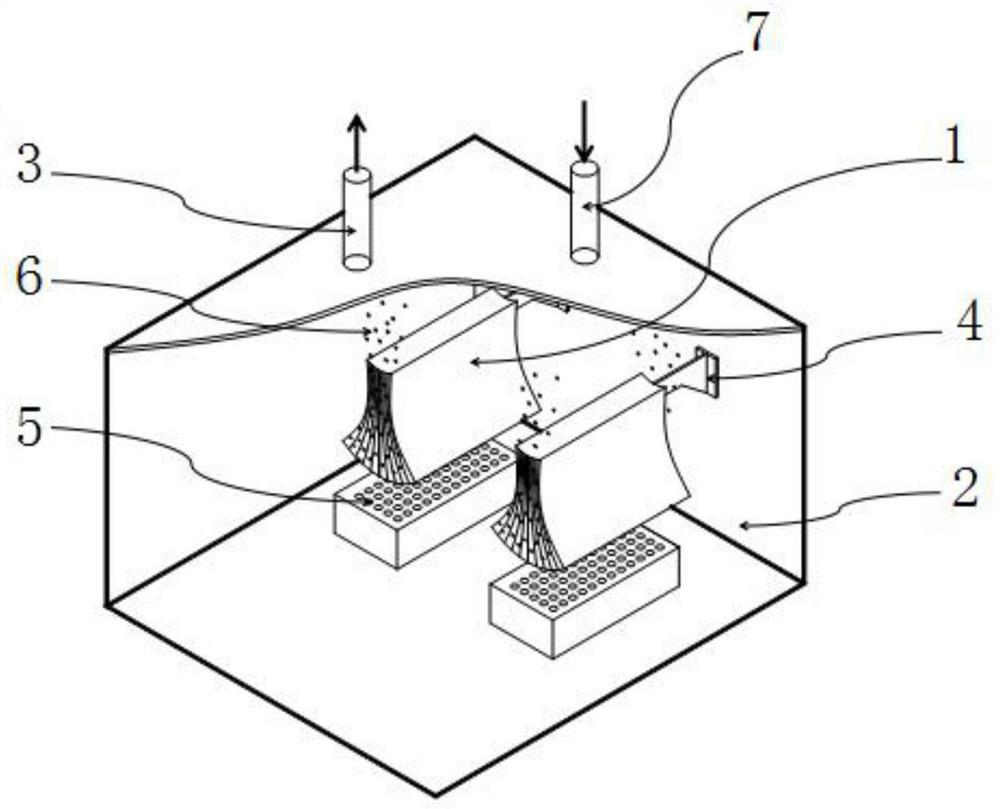

Laser cutting nozzle

InactiveCN101508059ALimited movement spaceBlocking motion abilityLaser beam welding apparatusSlagProduct gas

The invention provides a laser cutting nozzle, which consists of a cutting nozzle main body, a fluid collector and a slag returner, wherein the laser cutting nozzle has a first accommodating chamber, a second accommodating chamber and a third accommodating chamber; the bottom of the slag returner is provided with a plurality of slag returning ports adjacent to the second accommodating chamber; and when gases flow, fluid in different accommodating chambers has different flow rates to generate different pressures so as to generate pressure difference, and all motion vectors are consistent. When the cutting nozzle works, generated oxidizing slag is splashed into the chambers, the different pressure differences in the chambers force the oxidizing slag to change motion direction to move toward the direction of the slag returning ports; the slag returner is arranged in a chamber to limit the motion space of the oxidizing slag and resist the motor ability of the oxidizing slag; and the vectors of the gases consistently move towards the nozzle, so the oxidizing slag is cut down or stopped and cannot move to the section of a lens so as to achieve the aims of reducing and stopping lens damage.

Owner:HANS LASER TECH IND GRP CO LTD

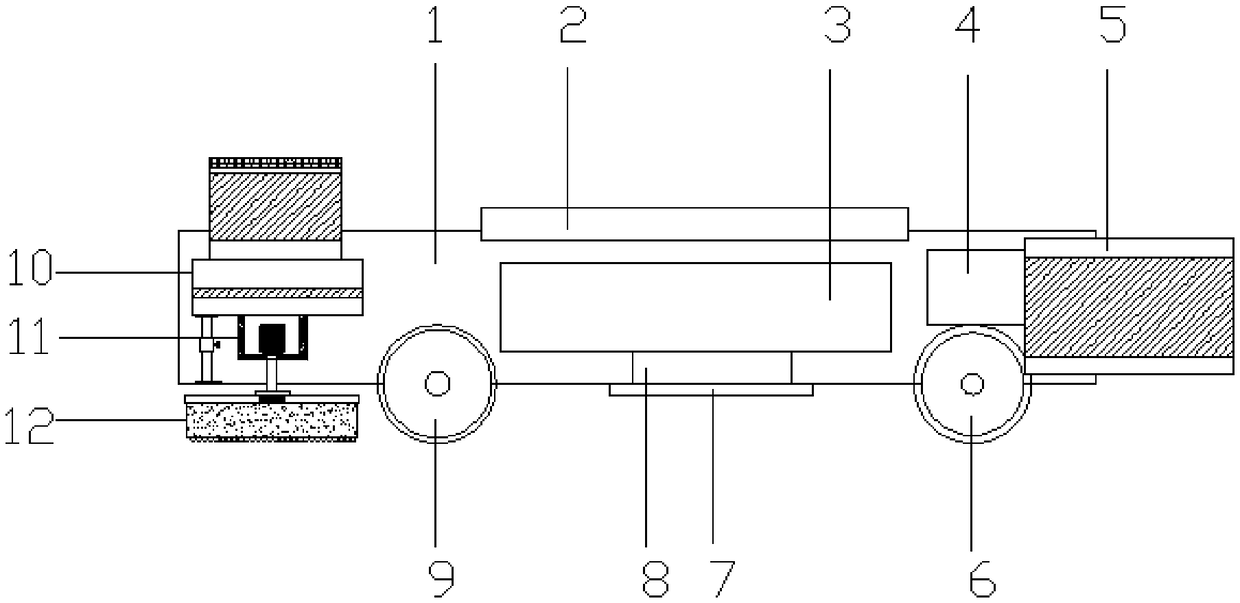

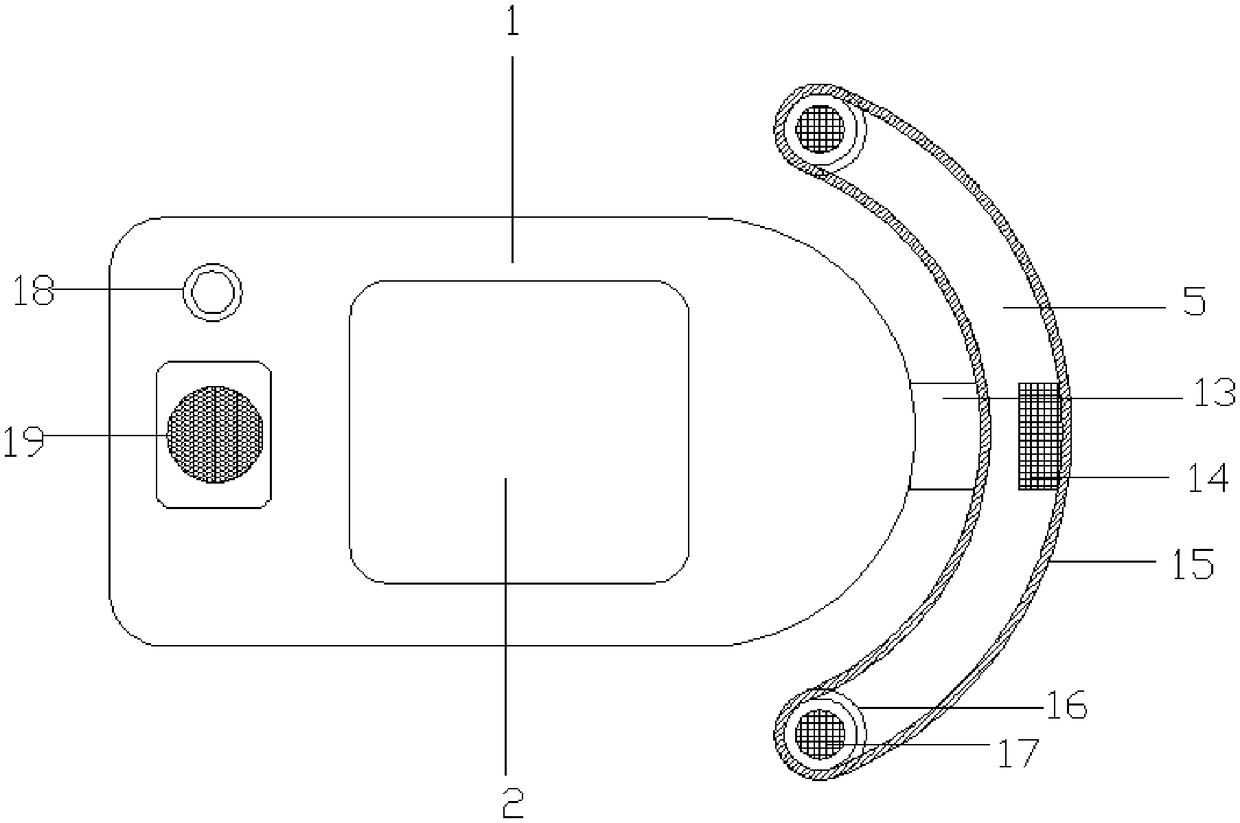

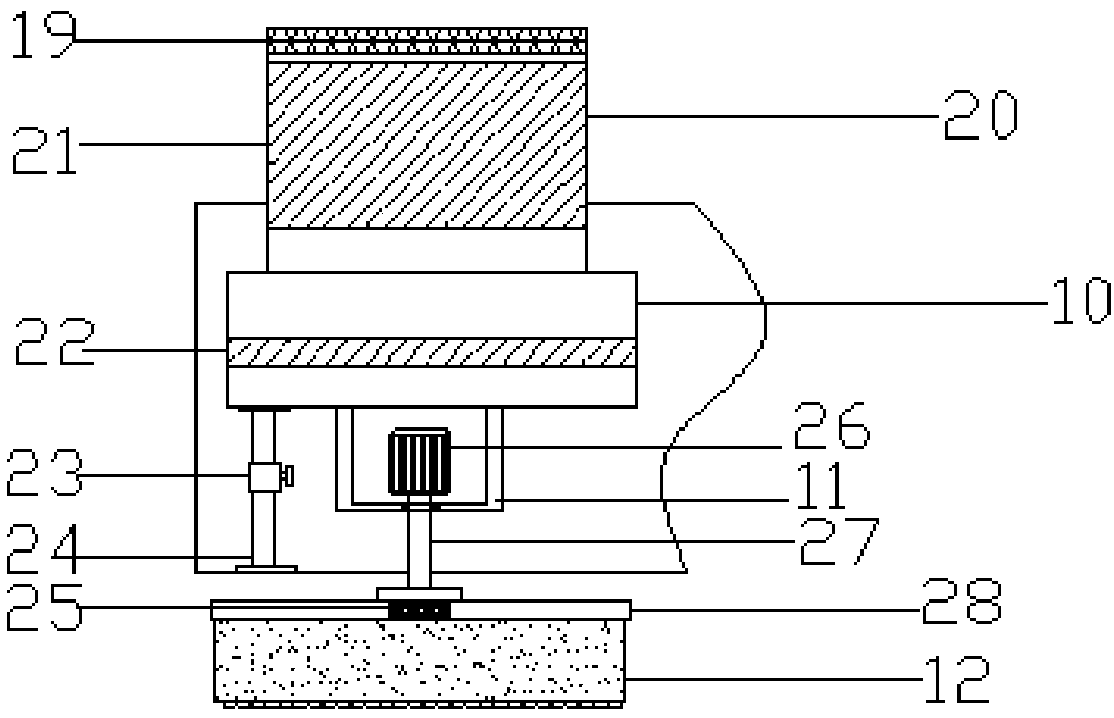

Intelligent floor sweeping robot

InactiveCN108814456AExpand the scope of workImprove functionalityCarpet cleanersFloor cleanersWorking rangeEngineering

The invention discloses an intelligent floor sweeping robot. The intelligent floor sweeping robot comprises a machine body, an anti-collision beam and sponge erasers, wherein the anti-collision beam is an arc beam, and the front end of the machine body is wrapped with the anti-collision beam; an intelligent washing device is arranged on the anti-collision beam, and shaking damage suffering when the floor sweeping robot is collided is reduced through the anti-collision beam and a spring column; the bottoms of the wall and furniture can be effectively cleaned through the intelligent washing device on the anti-collision beam, the working range of the floor sweeping robot is widened, and the functionality of the intelligent floor sweeping robot is effectively reinforced; multiple sponge eraserare arranged at the other end, connected with the spring column, of the machine body, and are driven by a rotating device to rotate for effectively and rotationally wiping the floor passing through the intelligent floor sweeping robot, strains, ink marks and the like on floors and tiles are efficiently removed, the floor cleaning efficiency of the intelligent floor sweeping robot is improved, anddifferent cleaning requirements of multiple floors are met. The intelligent floor sweeping robot is simple in structure, high in practicability and easy to apply and popularize.

Owner:苏州洋紫瑞信息科技有限公司

Dead cable end

InactiveUS7607954B2Reduce and eliminate damagePrevent internal rotationOverhead installationCoupling device detailsEngineeringInternal rotation

A dead cable end distributes holding force over a length of a cable end to reduce or eliminate damage to cables. The dead cable end includes a housing containing a plurality of collets each residing in a collet receptacle. Each collet includes a conical exterior and a lengthwise collet gap, and each collet receptacle includes a conical interior. The collets and collet receptacle are held inside the housing by a screw-in retaining nut, and the collet and collet receptacle pairs are compressed between the retaining nut and a spring inside the housing. The cable end resides inside the collets, and axial compressive forces on each collet and collet receptacle pair cause each collet to compress radially and hold the cable end. Anti-rotation pins are inserted through the housing into slots in the collet receptacle next to the screw-in retainer to prevent internal rotation during tightening.

Owner:BYRNE JOSEPH +1

Dead cable end

InactiveUS20080318471A1Reduce and eliminate damagePrevent internal rotationOverhead installationCoupling device detailsInternal rotationEngineering

A dead cable end distributes holding force over a length of a cable end to reduce or eliminate damage to cables. The dead cable end includes a housing containing a plurality of collets each residing in a collet receptacle. Each collet includes a conical exterior and a lengthwise collet gap, and each collet receptacle includes a conical interior. The collets and collet receptacle are held inside the housing by a screw-in retaining nut, and the collet and collet receptacle pairs are compressed between the retaining nut and a spring inside the housing. The cable end resides inside the collets, and axial compressive forces on each collet and collet receptacle pair cause each collet to compress radially and hold the cable end. Anti-rotation pins are inserted through the housing into slots in the collet receptacle next to the screw-in retainer to prevent internal rotation during tightening.

Owner:BYRNE JOSEPH +1

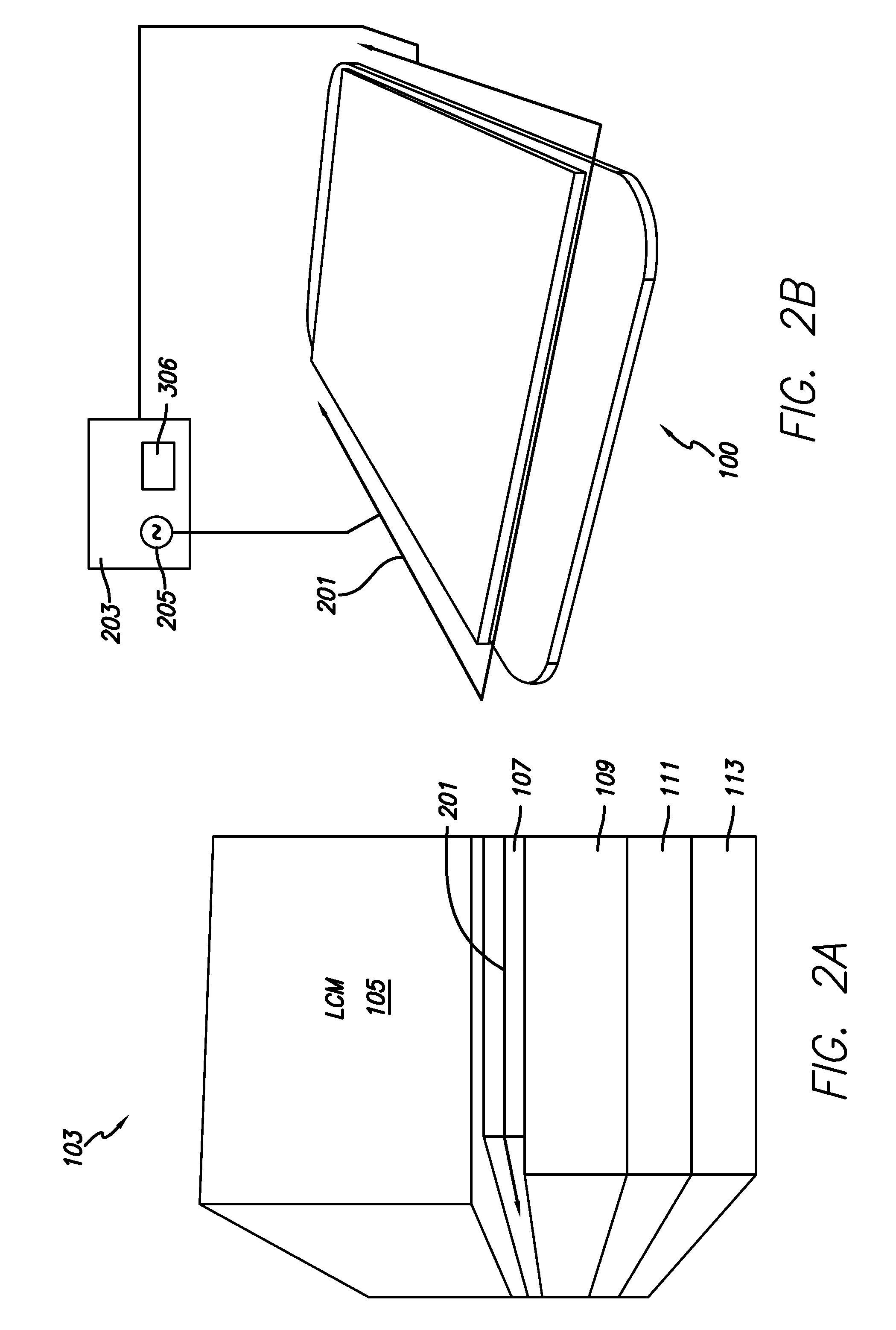

Layer-specific energy distribution delamination

InactiveUS9409383B2Reduce and eliminate damageEfficient and fast processingLamination ancillary operationsLayered product treatmentEnergy transferThermal energy

Delamination of a laminated multilayer stack is provided by generating a layer-specific energy distribution in the stack during delamination. A localized energy transferrer can generate localized heating, cooling heating, cooling, or other form of energy absorption or transmission, in a bonding layer of a multilayer stack. Localized energy transfer can include thermal energy transfer, such as heating and / or cooling, acoustic energy transfer, such as applying ultrasonic energy, electromagnetic energy transfer, such as applying laser light, directed microwaves, etc. Localized energy transfer can generate a layer-specific energy distribution that can weaken the bonding layer while reducing damage to other layers of the stack.

Owner:APPLE INC

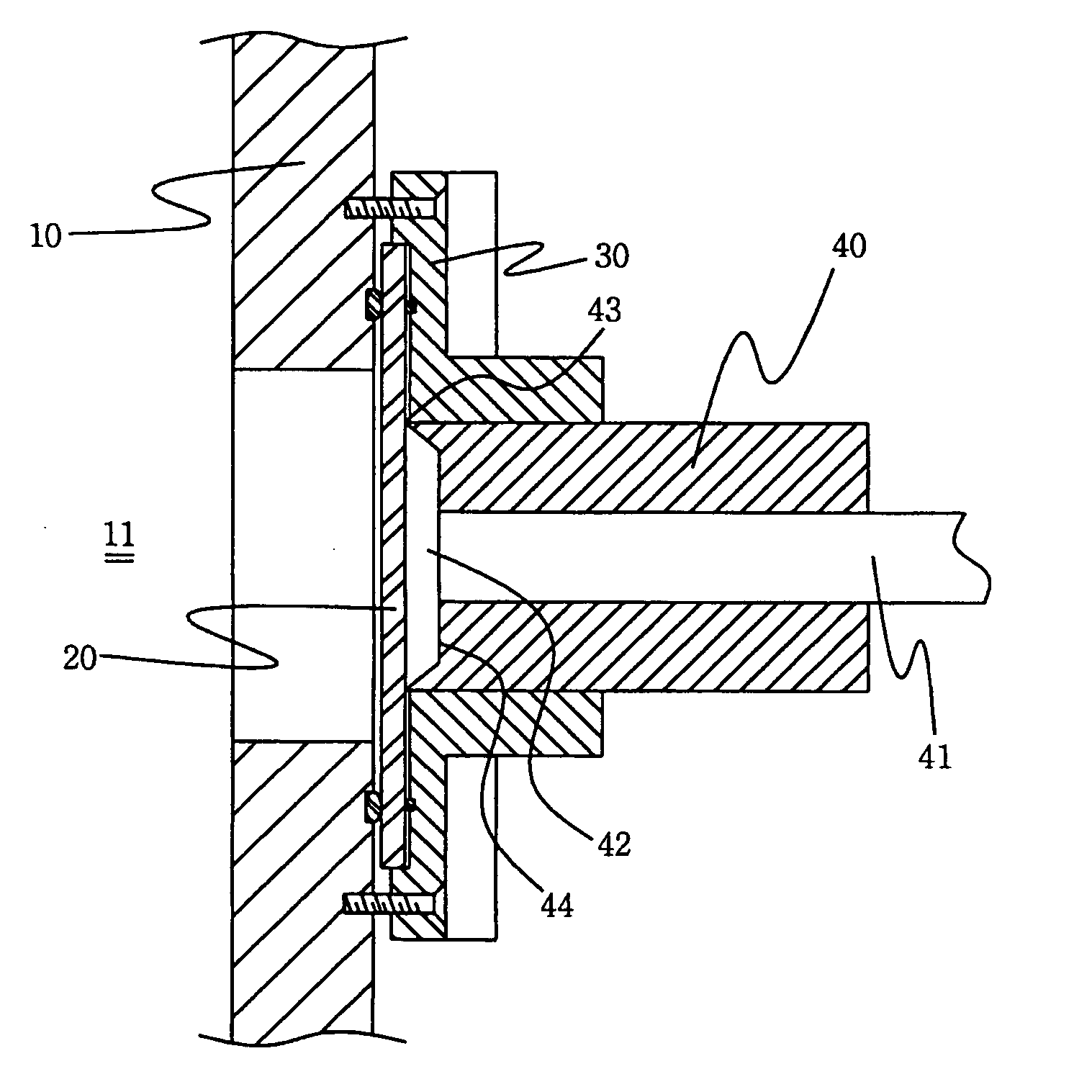

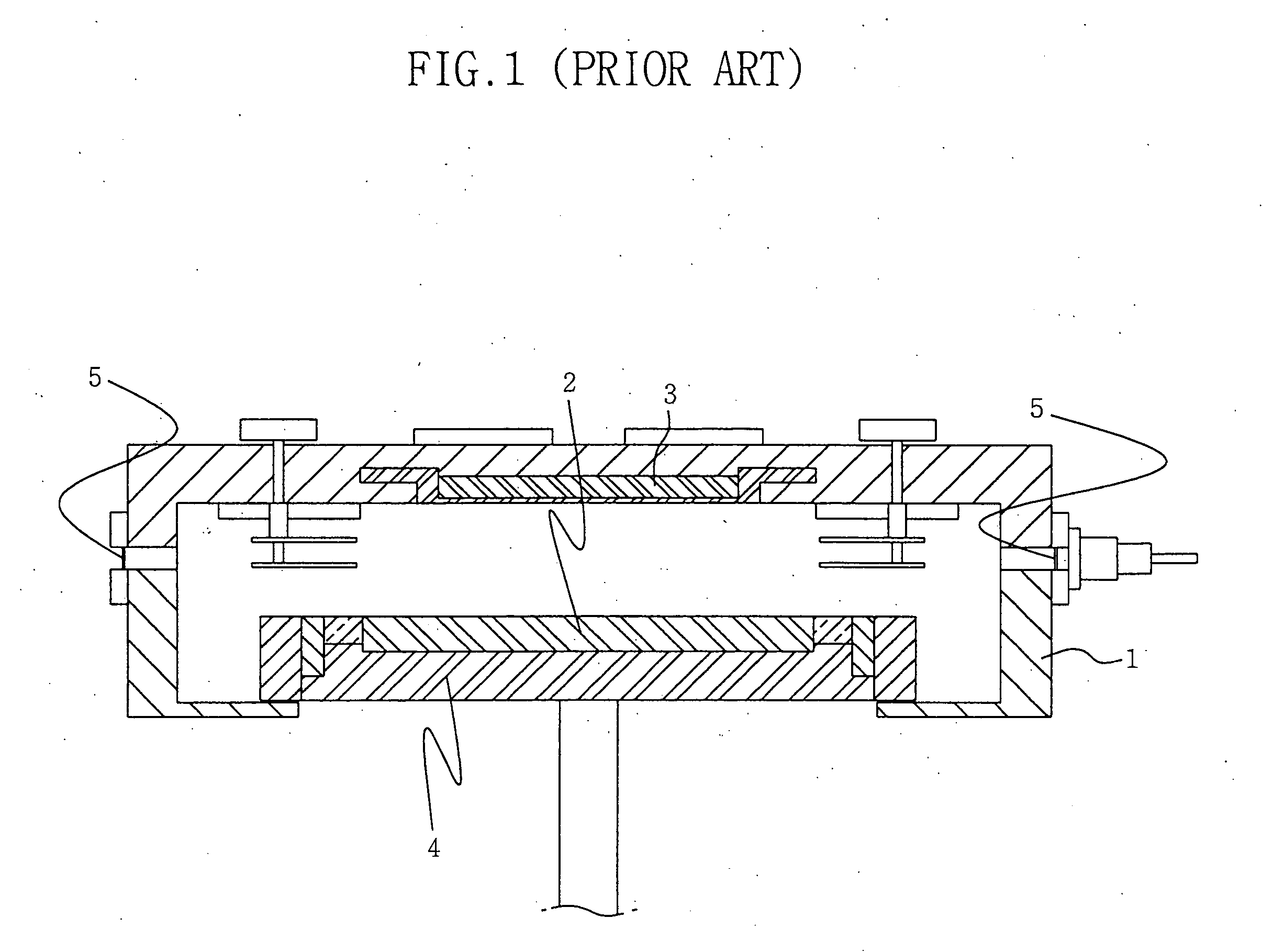

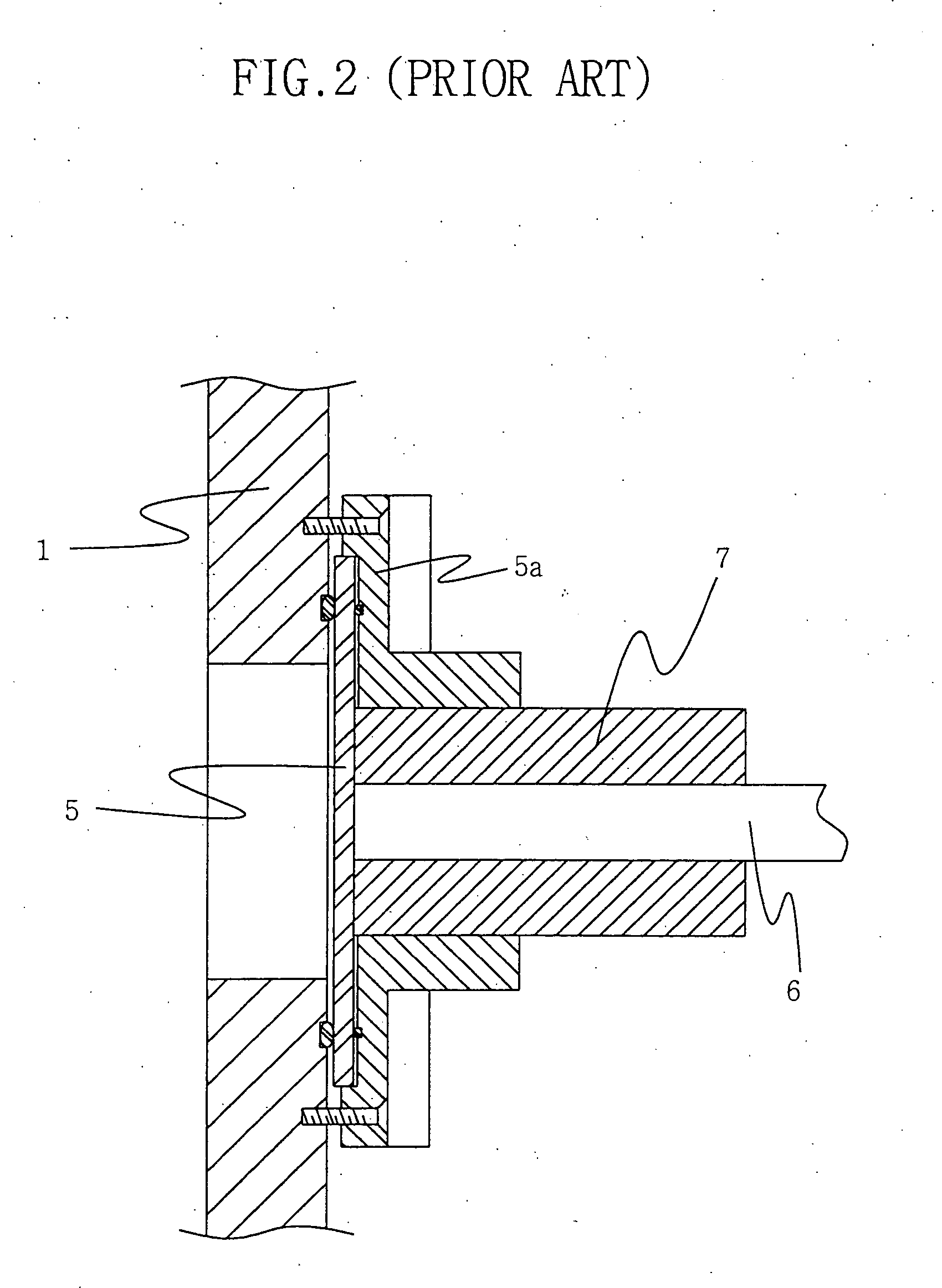

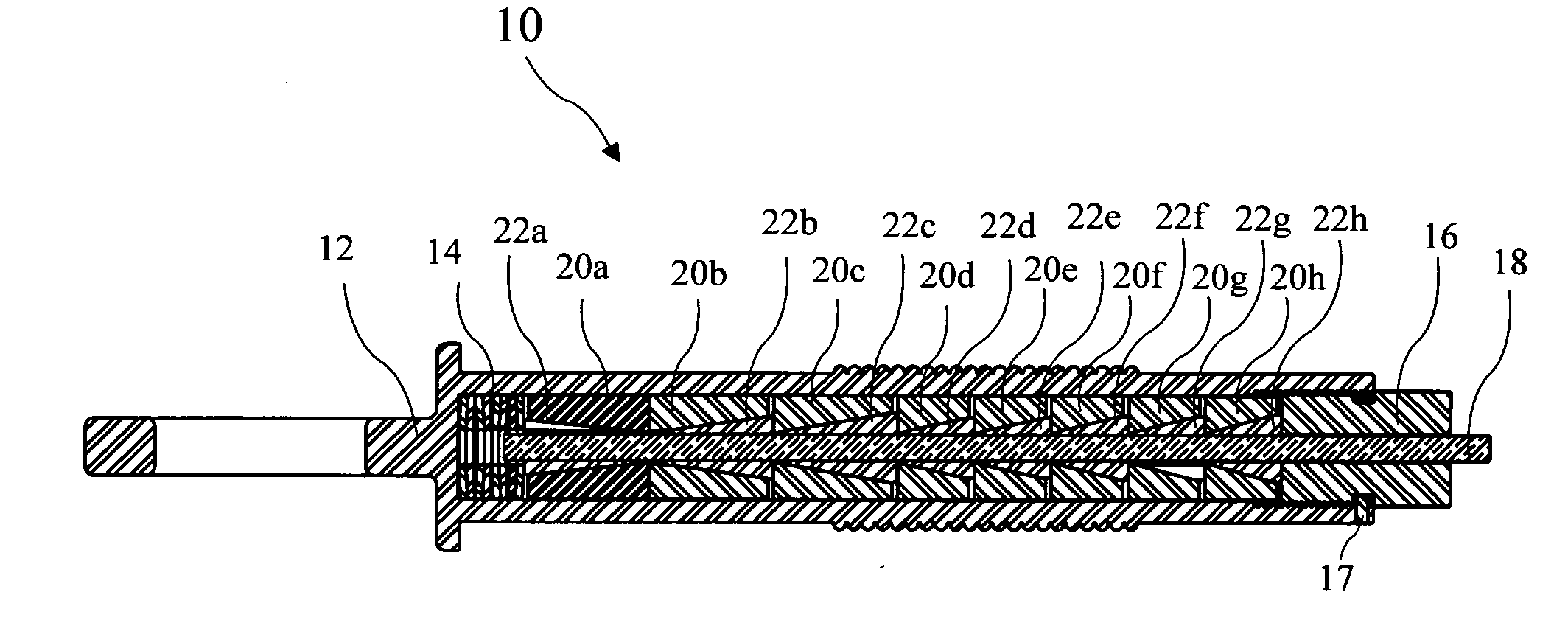

End point detector for etching equipment

InactiveUS20050109728A1Reduce and eliminate damageElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringPoint detector

The present invention relates to an end point detector for etching equipment. The embodiment of the present invention has a unique feature which allows for a minimal contact between a connector and viewing window. This feature prevents scratches on the surface of the viewing window when the connector is removed or replaced.

Owner:SAMSUNG ELECTRONICS CO LTD

Dead cable end

InactiveUS20070202740A1Reduce and eliminate damageAvoid damageOverhead installationElectrically conductive connectionsEngineeringCollet

A dead cable end distributes holding force over a length of a cable end to reduce or eliminate damage to cables. The dead cable end includes a housing containing a plurality of collets each residing in a collet receptacle. Each collet includes a conical exterior and a lengthwise collet gap and each collet receptacle includes a conical interior. The collets and collet receptacle are held inside the housing by a retaining nut, and the collet and collet receptacle pairs are compressed between the retaining nut and a spring inside the housing. The cable end resides inside the collets, and compressive force on each collet and collet receptacle pair causes each collet to compress radially and hold the cable end. The holding force is thereby distributed over the length of each collet and over the plurality of collet and receptacle pairs to avoid damage to the cable.

Owner:BYRNE JOSEPH +1

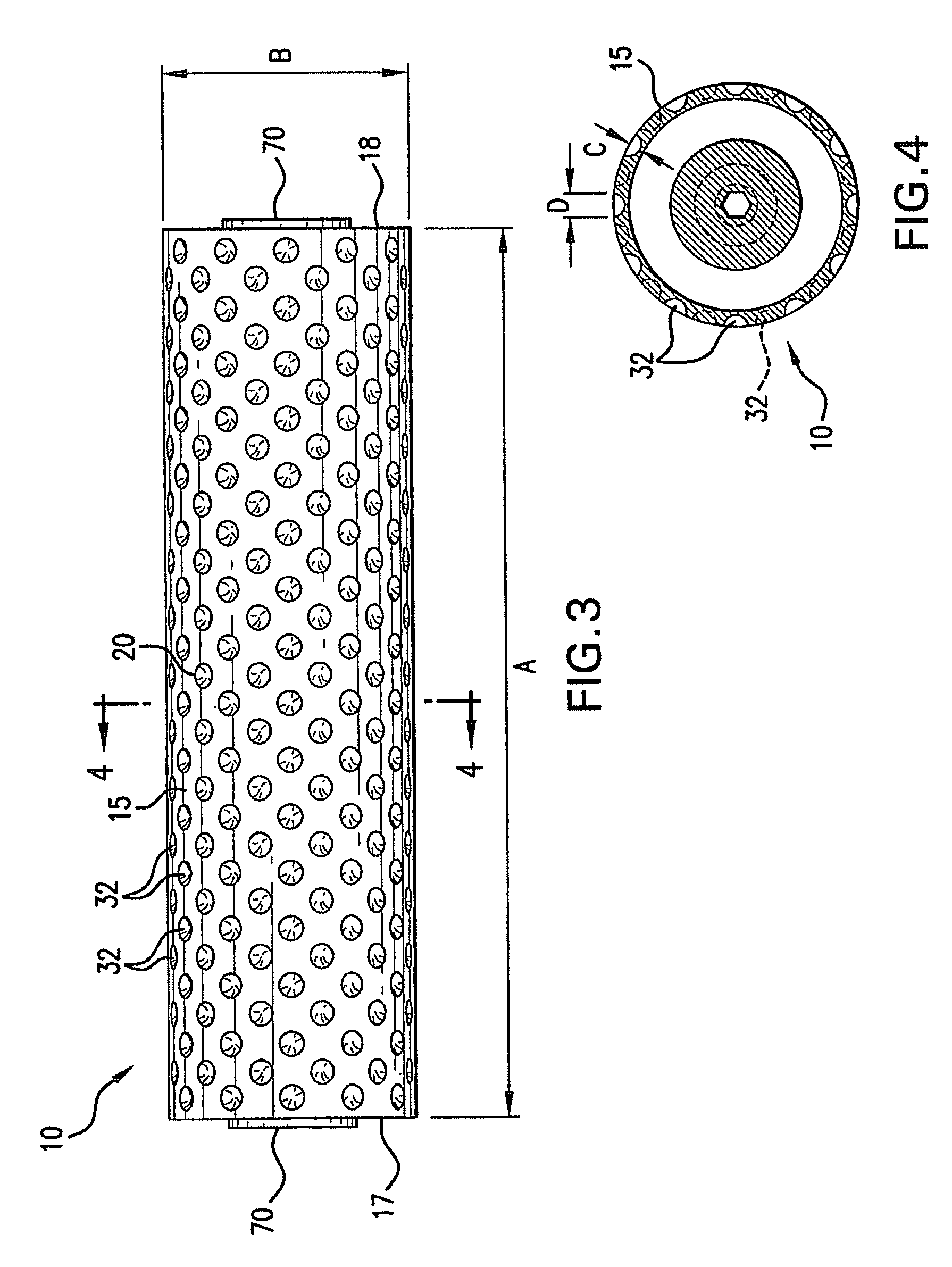

Rollers and disks for carpet cleaning

ActiveUS7814613B1Prolong useful economic lifeFree from damageCarpet cleanersBrush bodiesForeign matterCircular disc

Owner:WHITTAKER CLEANING SYST

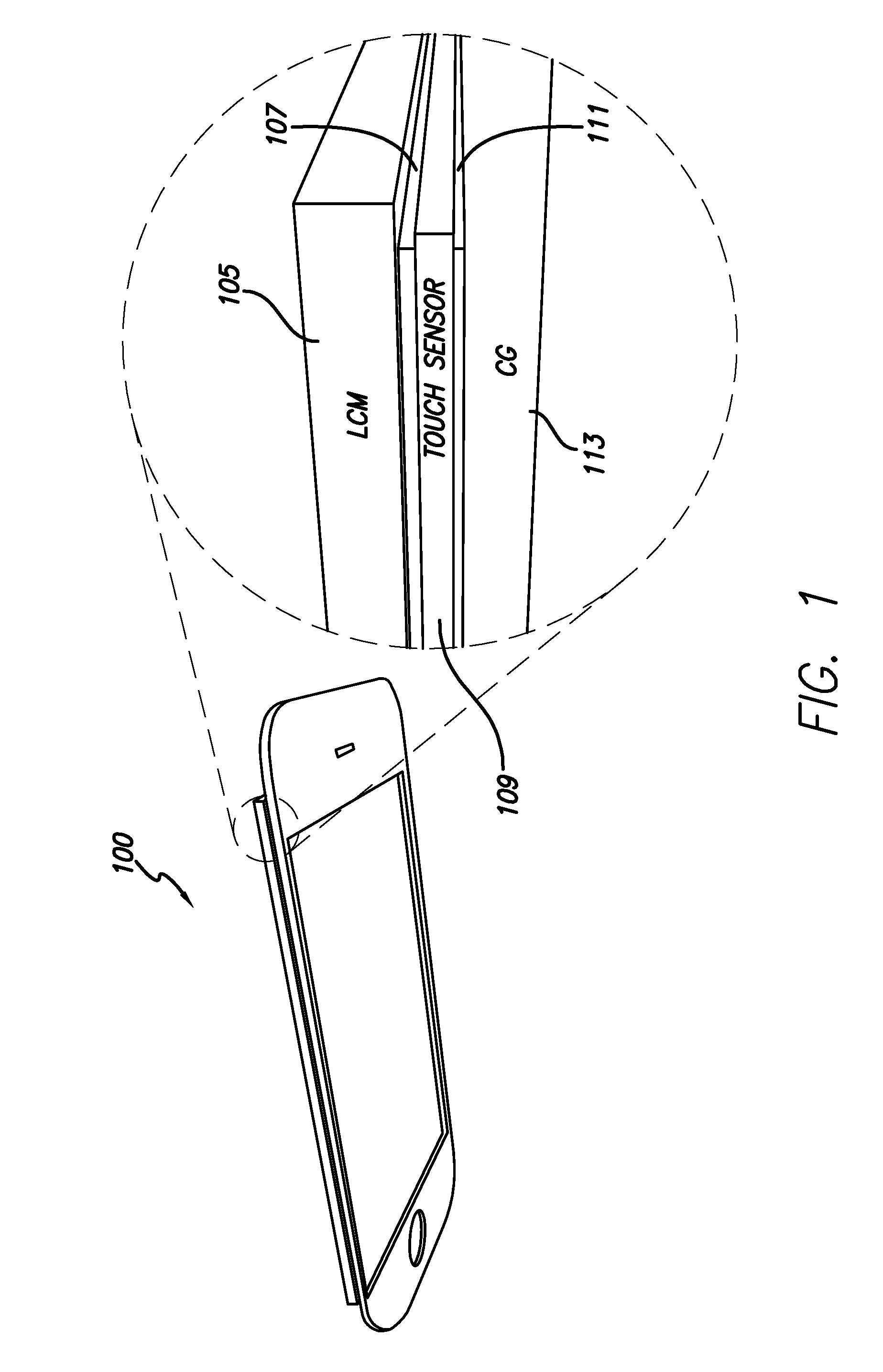

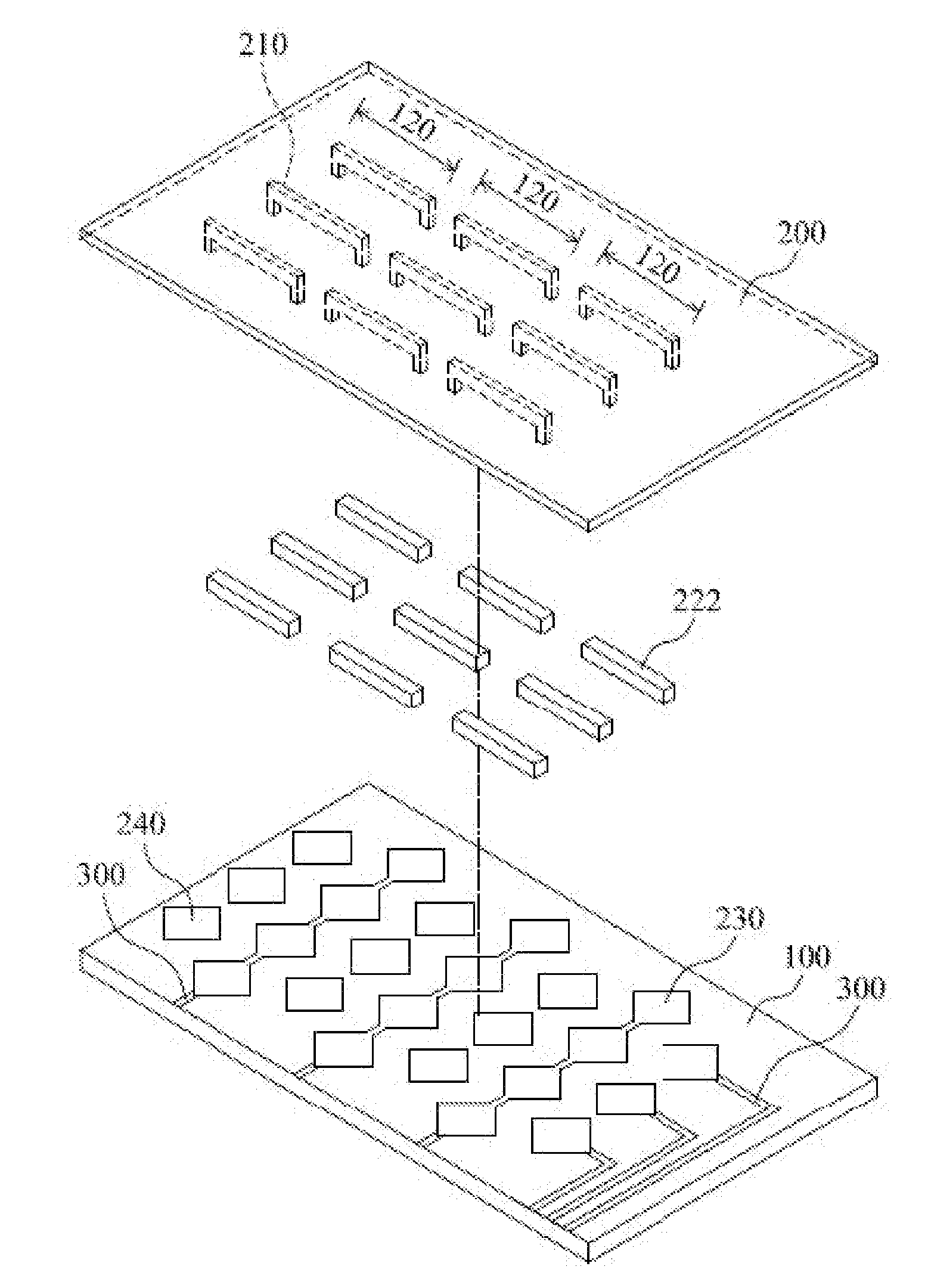

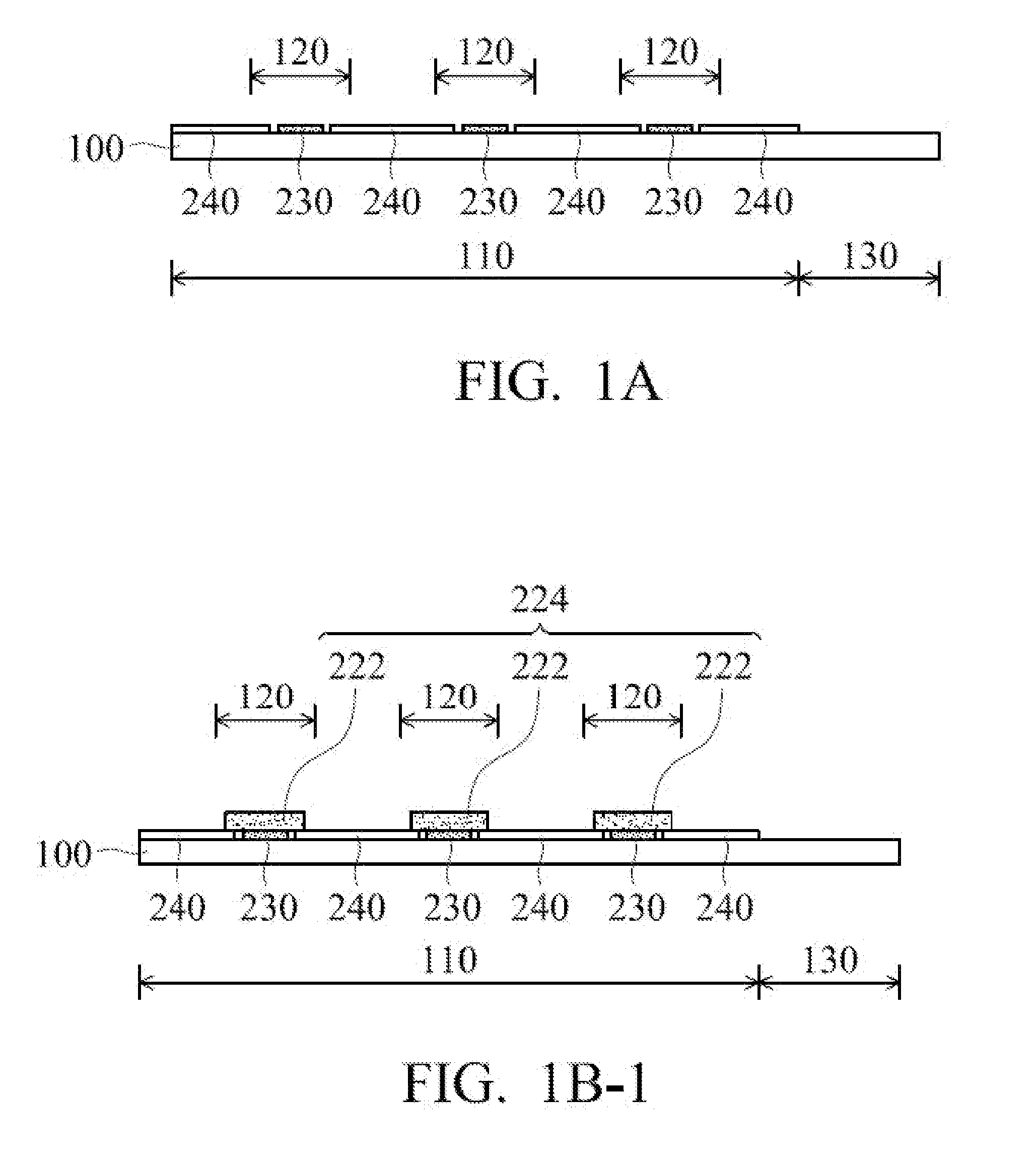

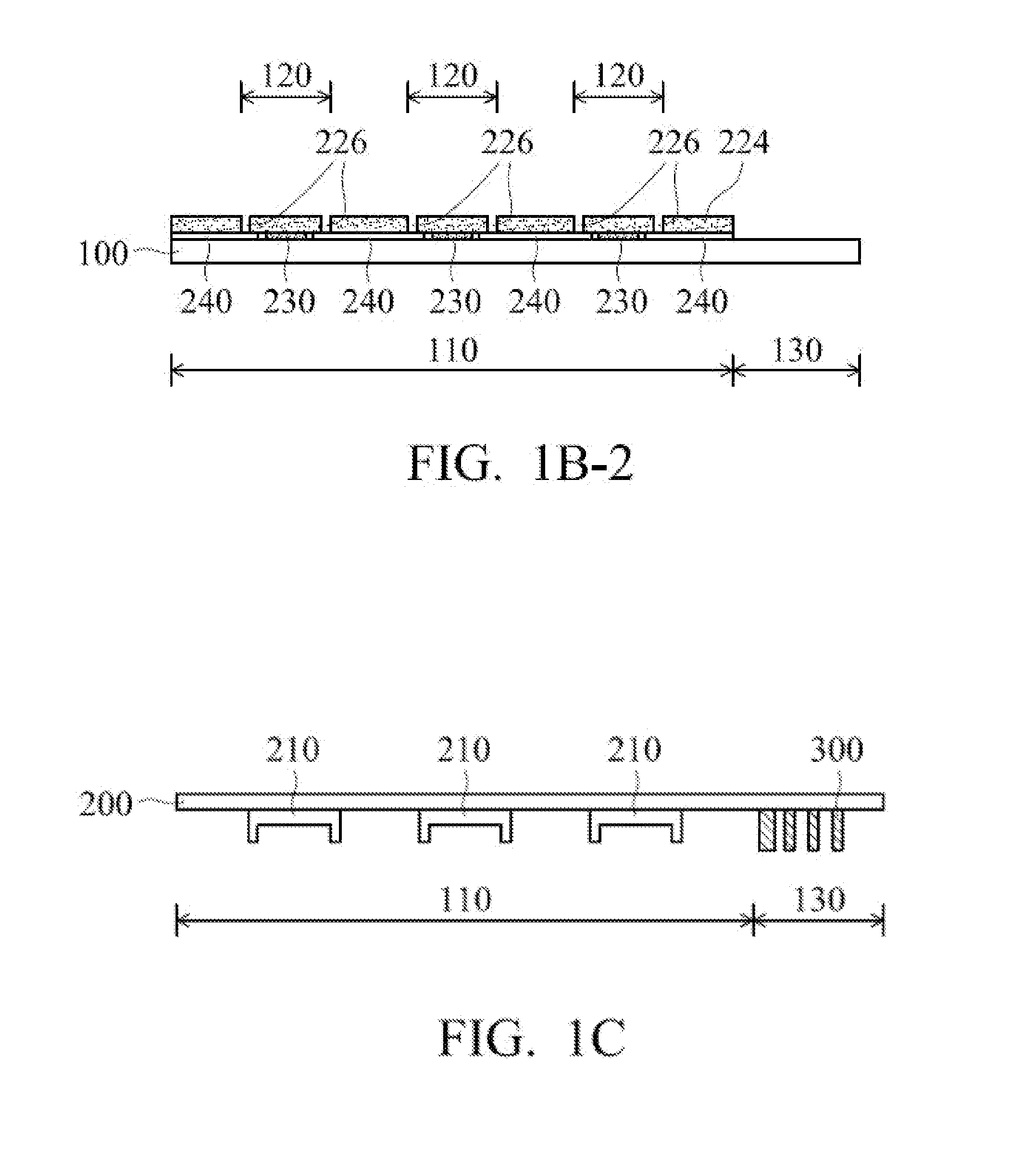

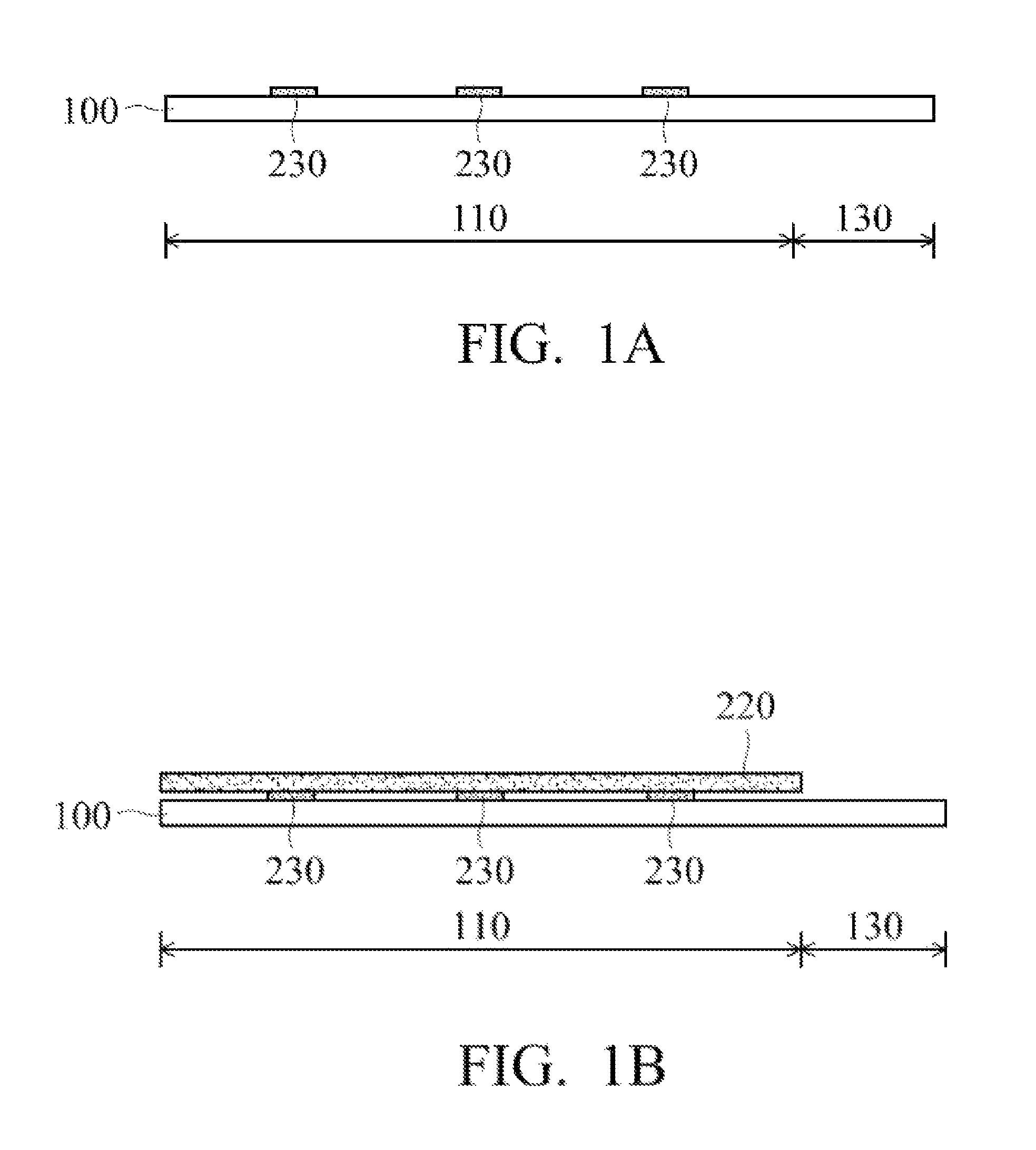

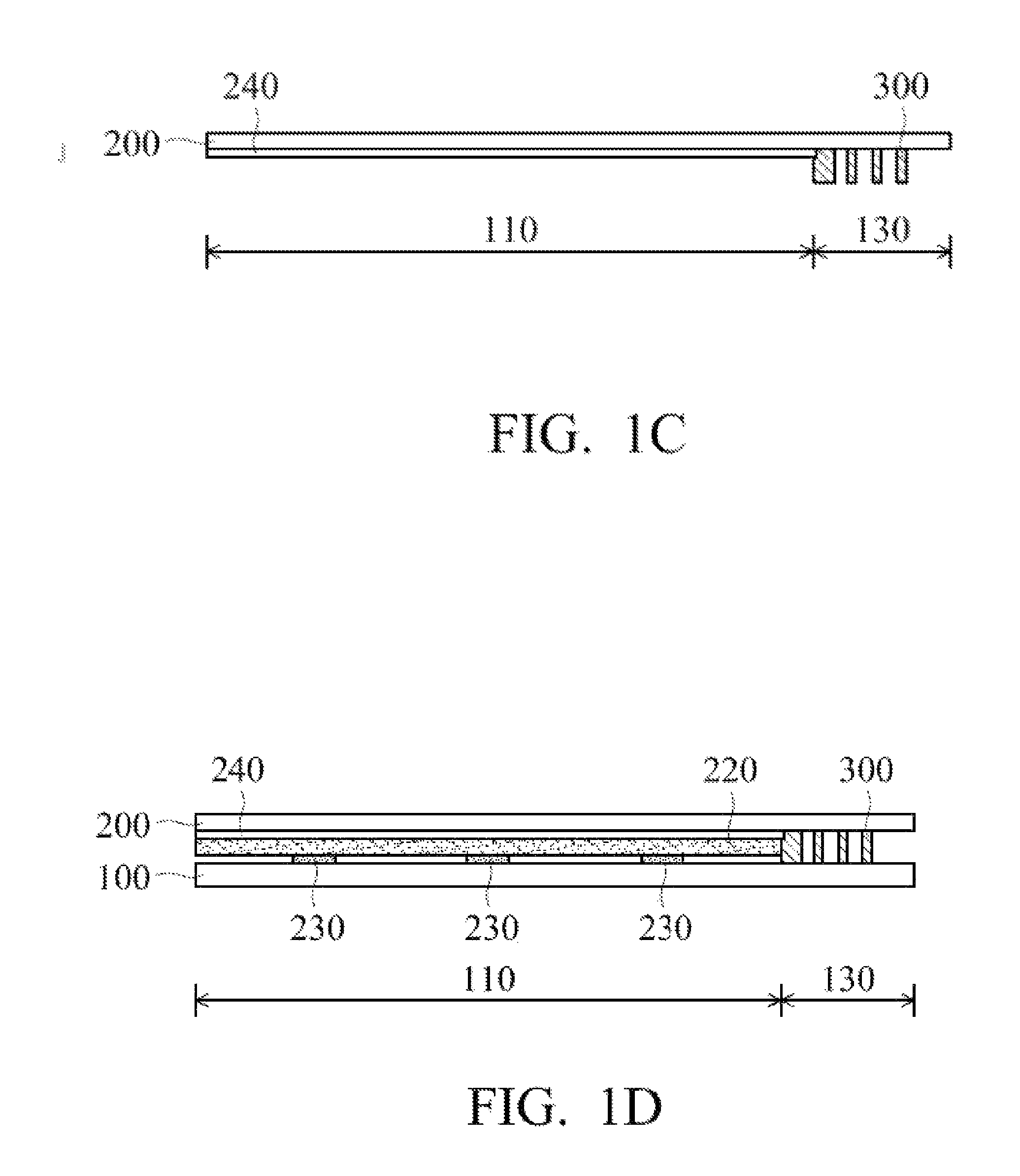

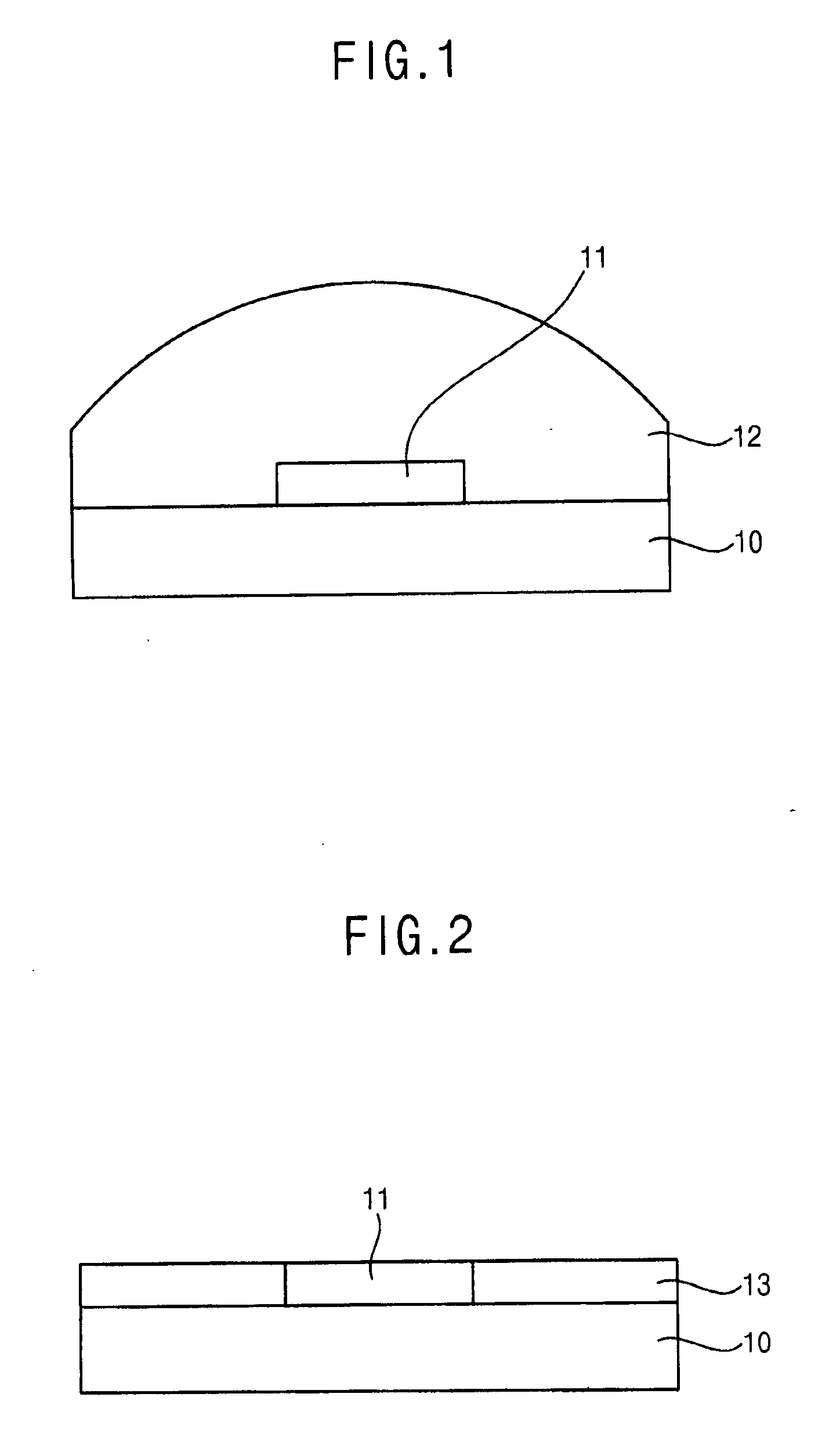

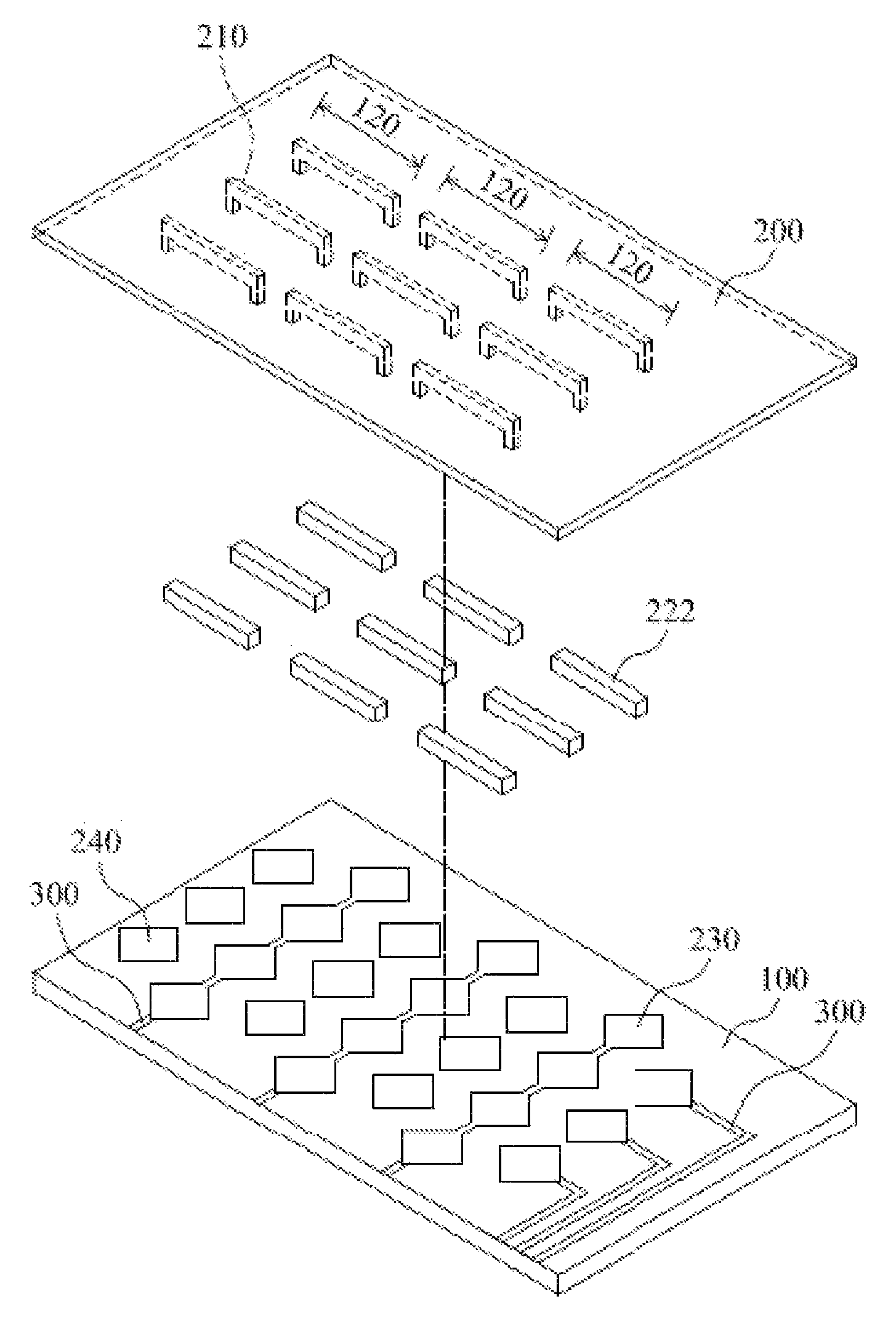

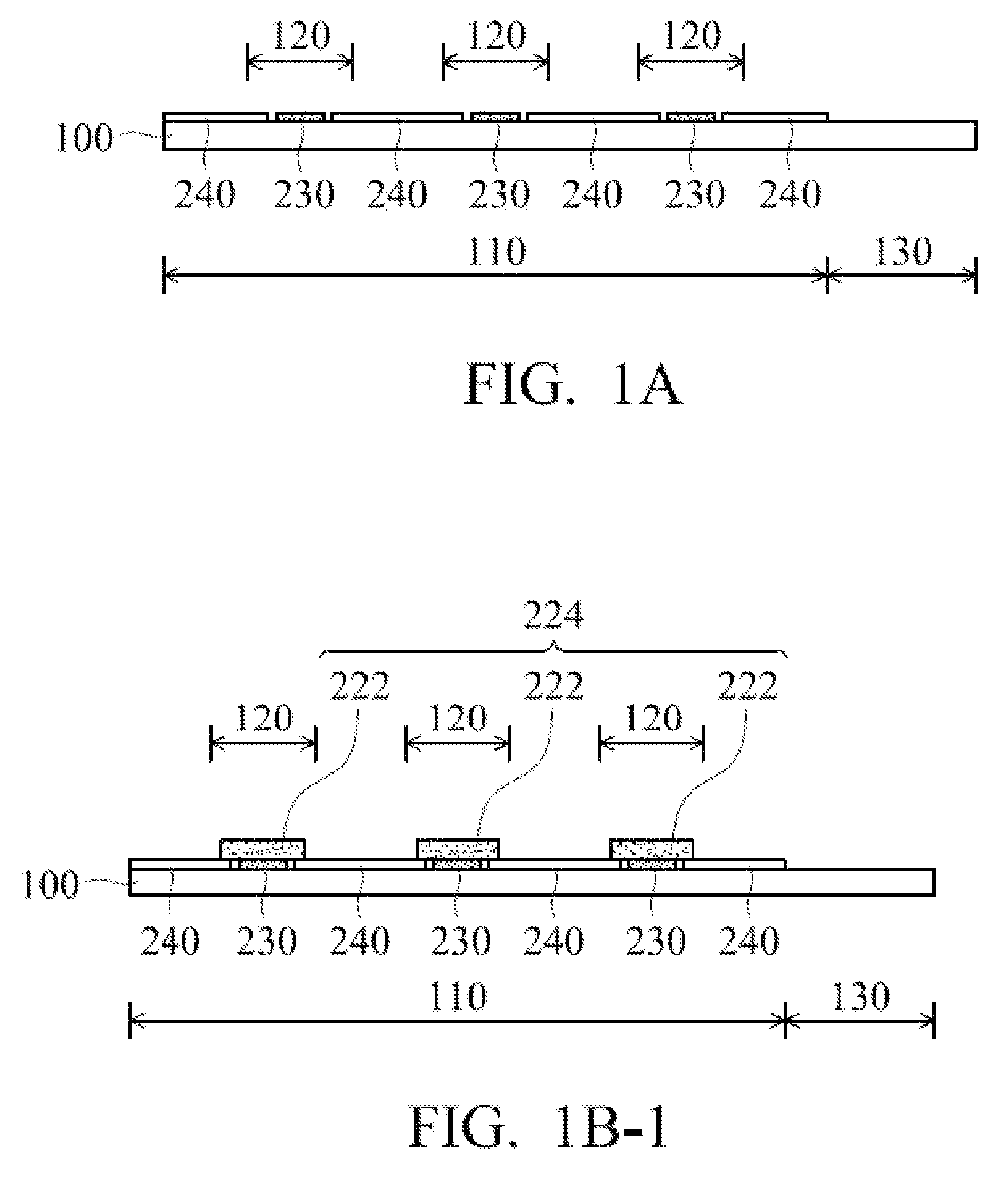

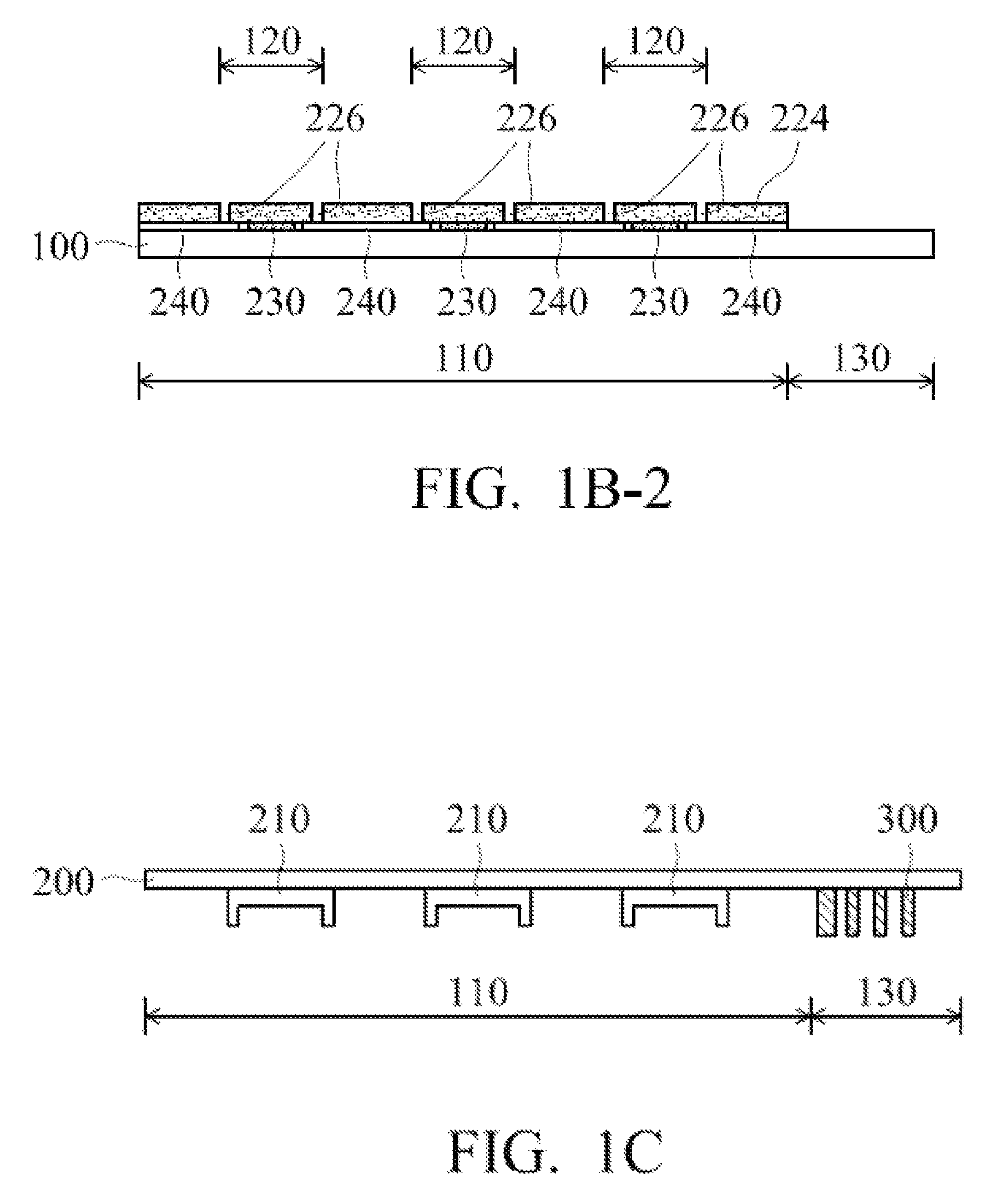

Touch device and manufacturing method thereof

ActiveUS20140224635A1Simple manufacturing processIncrease productionElectronic switchingElectric switchesBiomedical engineeringElectrode

A manufacturing method of a touch device is disclosed. A substrate having a viewing region is provided. A plurality of first sensing electrodes and a plurality of second sensing electrodes insulated from and in a staggered arrangement with the plurality of first sensing electrodes are formed on the substrate corresponding to the viewing region, wherein a plurality of jumper regions are defined between the adjacent second sensing electrodes. An insulating layer is formed on the plurality of first sensing electrodes and the plurality of second sensing electrodes. A plurality of jumpers is transfer-printed onto the insulating layer, wherein the plurality of jumpers is electrically connected to the adjacent second sensing electrodes and insulated from the first sensing electrodes by the insulating layer. A touch device is also disclosed.

Owner:TPK TOUCH SYST XIAMEN

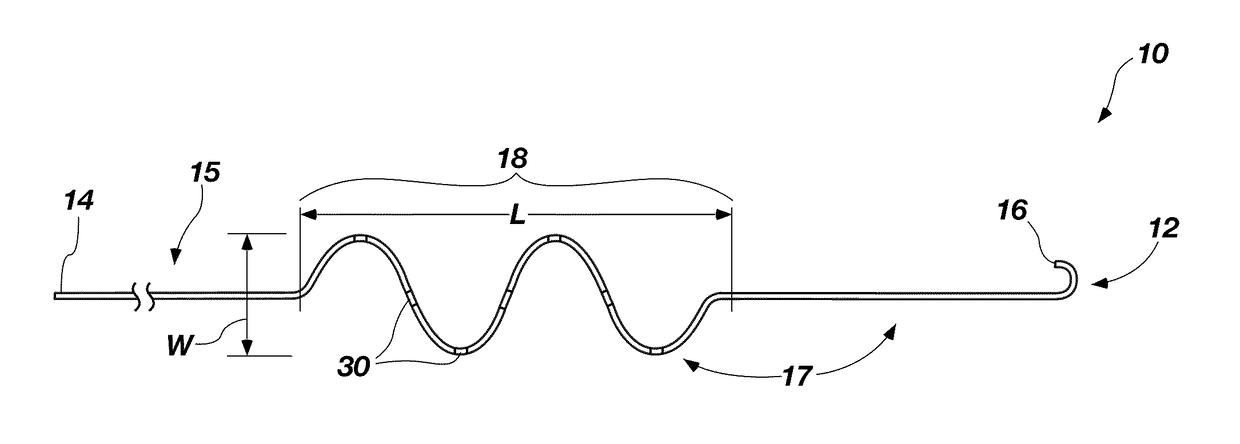

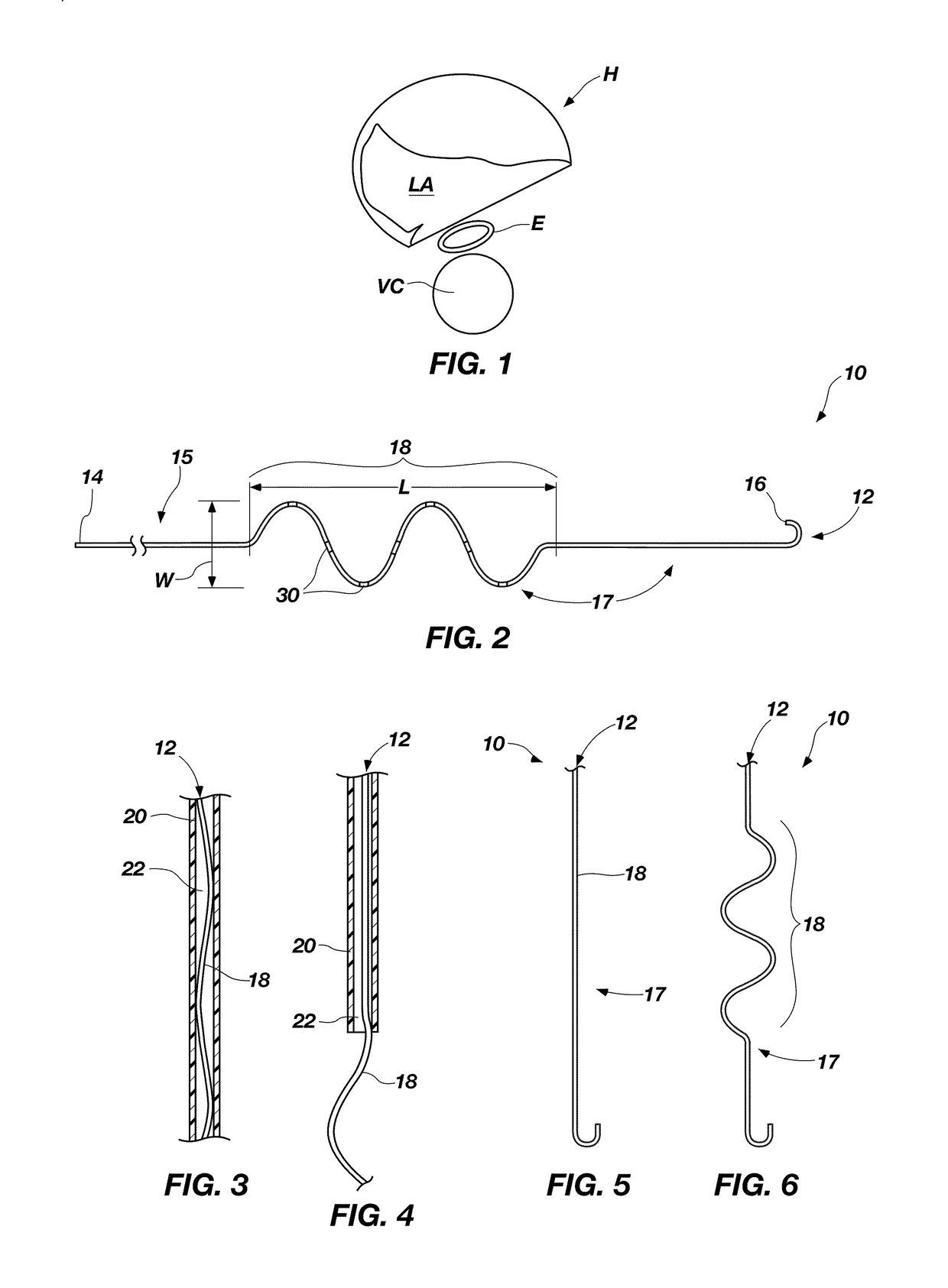

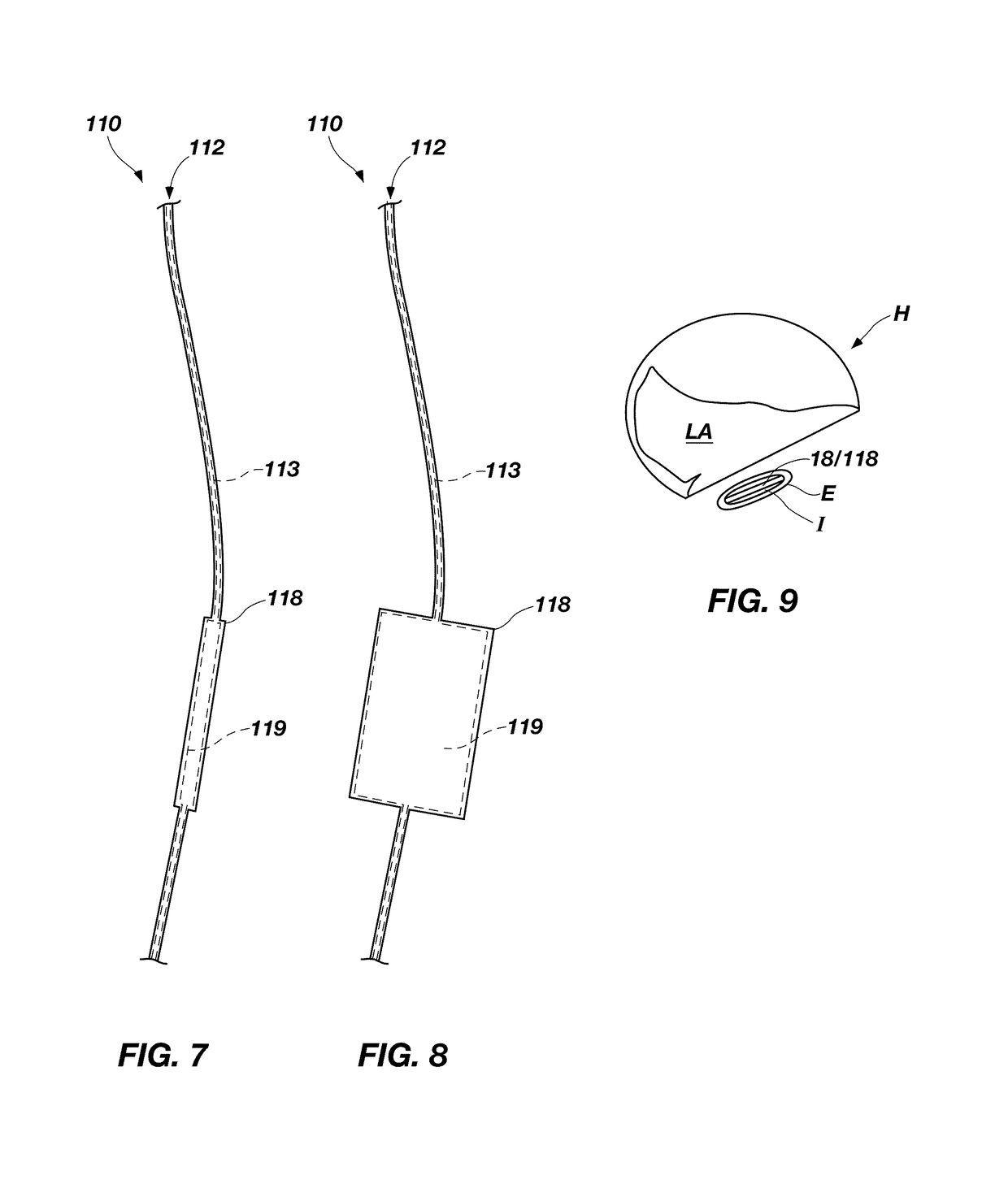

Apparatus for manually manipulating hollow organs

An apparatus for mechanically manipulating hollow organs within the body of a subject, or an organ manipulation apparatus, includes a manipulation section. The manipulation section may include a substantially two-dimensional element, which may have a width that exceeds a distance across a portion of the interior of a hollow organ within which the manipulation section is to be positioned. The manipulation section is configured to manipulate at least a portion of a hollow organ from within, which may modify at least one of a shape, orientation, or location of at least part of the hollow organ. Methods for manipulating hollow organs are also disclosed, as are operating techniques, such as left atrial ablation, in which the shapes, orientations, and / or locations of hollow organs are manipulated to move the hollow organs away from the site of the medical procedure, reducing the potential for damage to the hollow organs.

Owner:CIRCA SCI INC

Touch device and manufacturing method thereof

ActiveUS20140085550A1Simple manufacturing processIncrease productivityElectric switchesLiquid/solution decomposition chemical coatingBiomedical engineeringElectrode

Owner:TPK TOUCH SYST XIAMEN

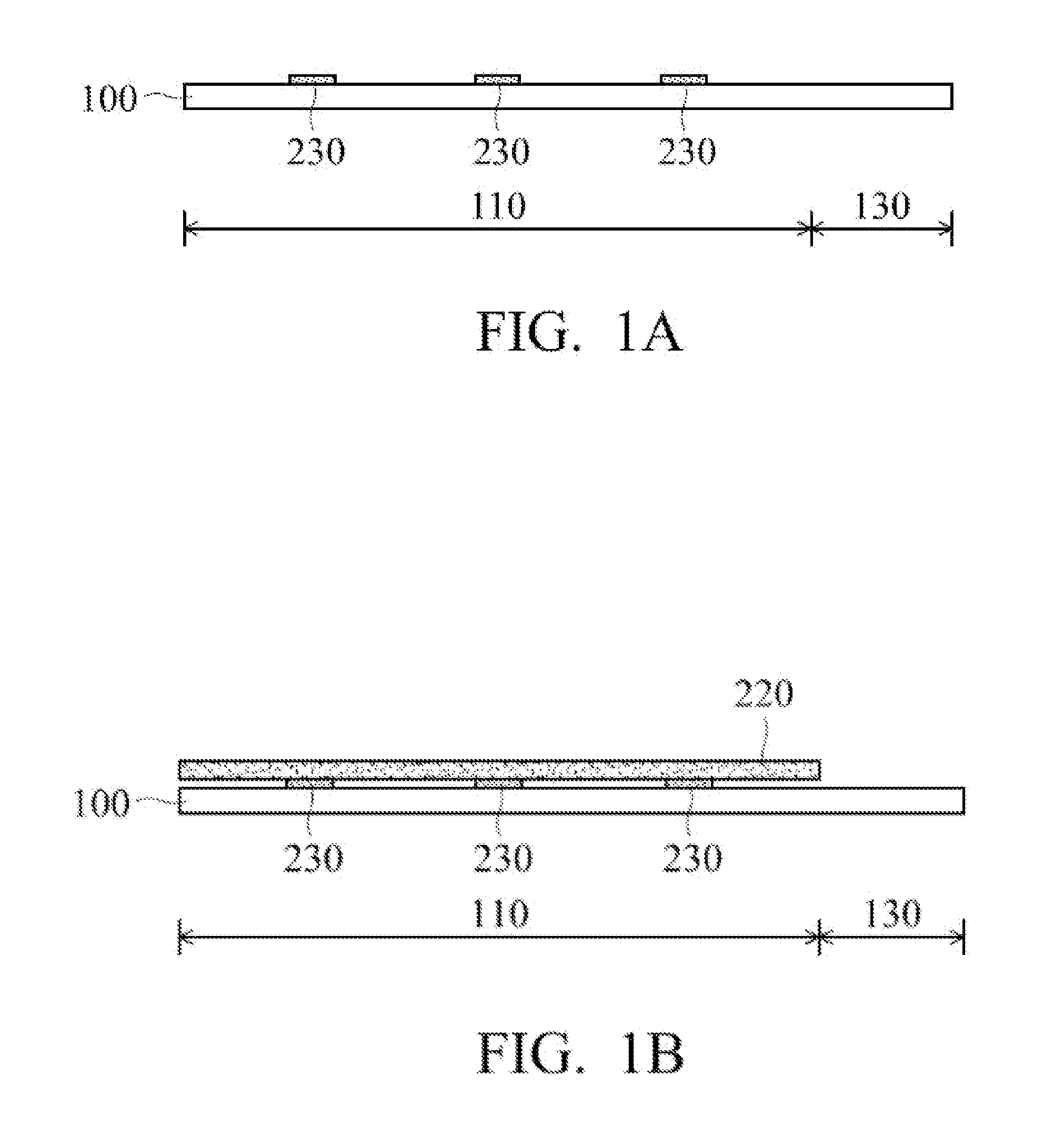

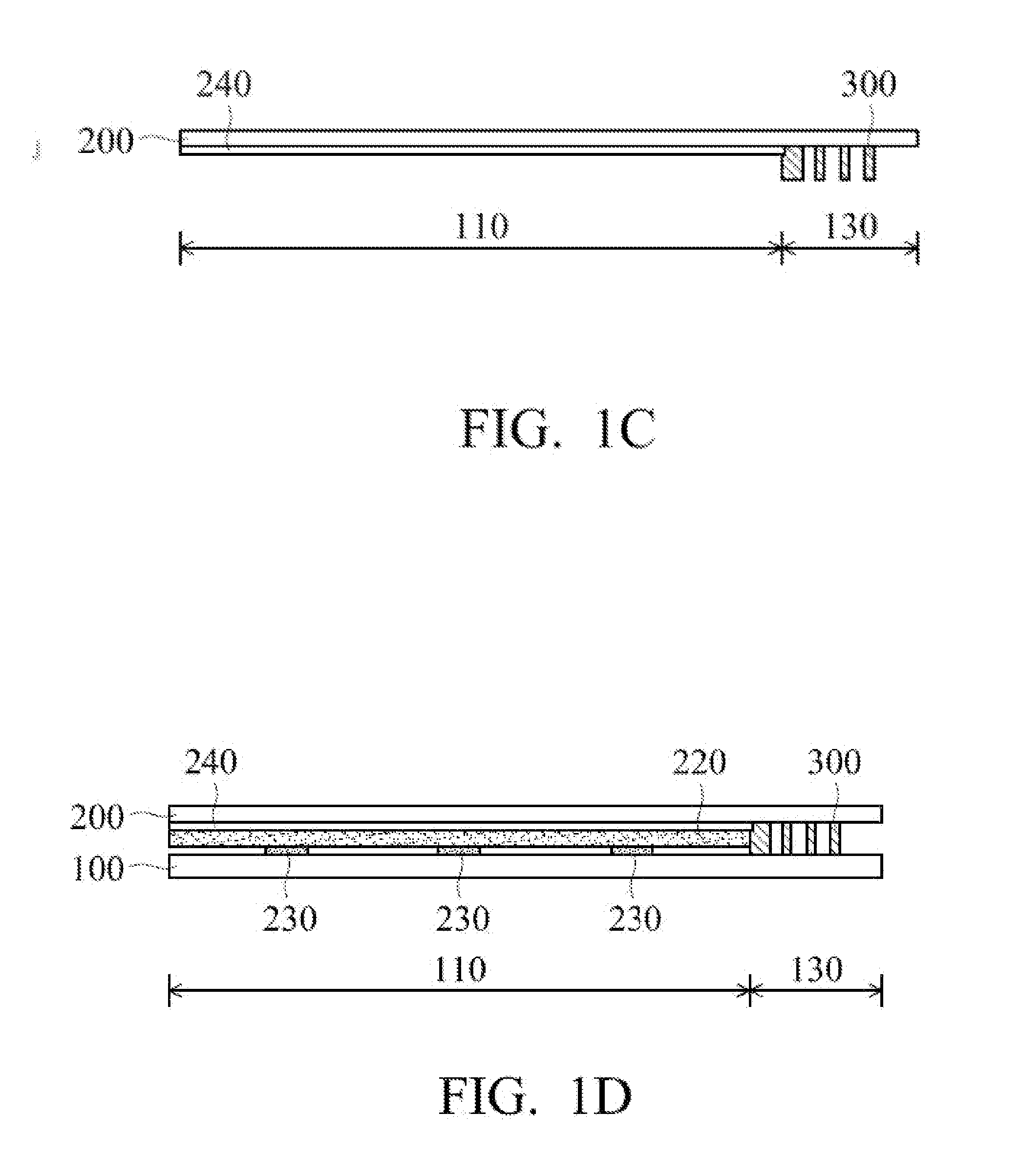

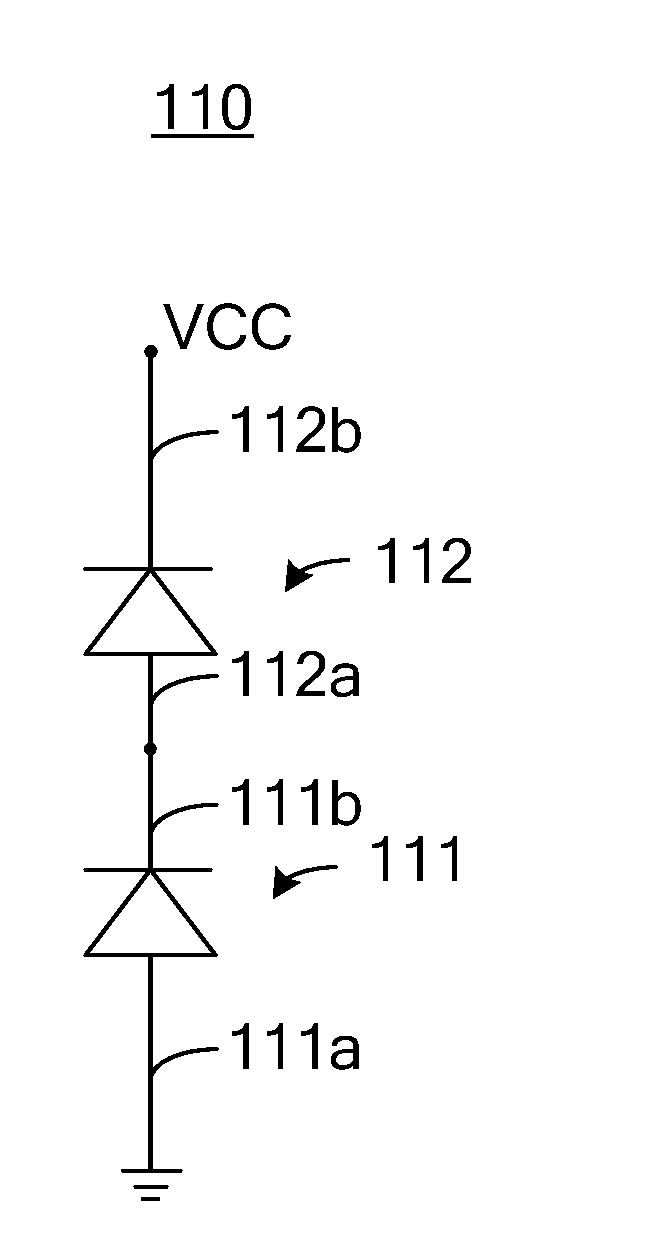

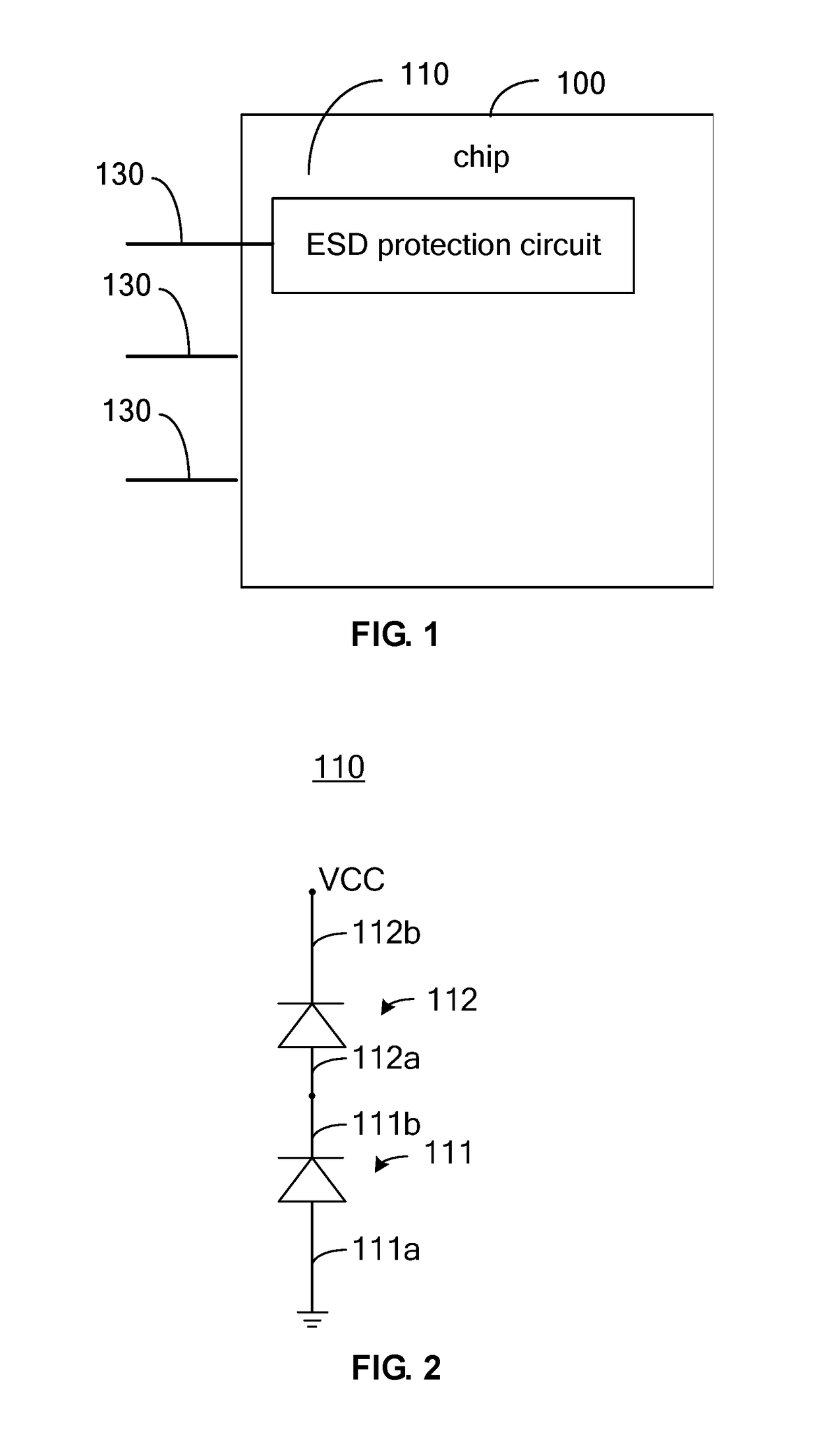

Chip and electronic device

InactiveUS20170187183A1Reduce eliminate damageEnsure stabilitySolid-state devicesDiodeElectrostatic dischargeElectrical and Electronics engineering

The present invention provides a chip and an electronic device. The chip comprises at least one pin, and the chip comprises at least one ESD (Electrostatic Discharge) protection circuit inside, and the ESD protection circuit is employed to reduce or eliminate a damage of electrostatic to other elements or circuit inside the chip, and the ESD protection circuit is located corresponding to a pin, and the ESD protection circuit is electrically coupled to the pin. The electronic device comprises the aforesaid chip.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

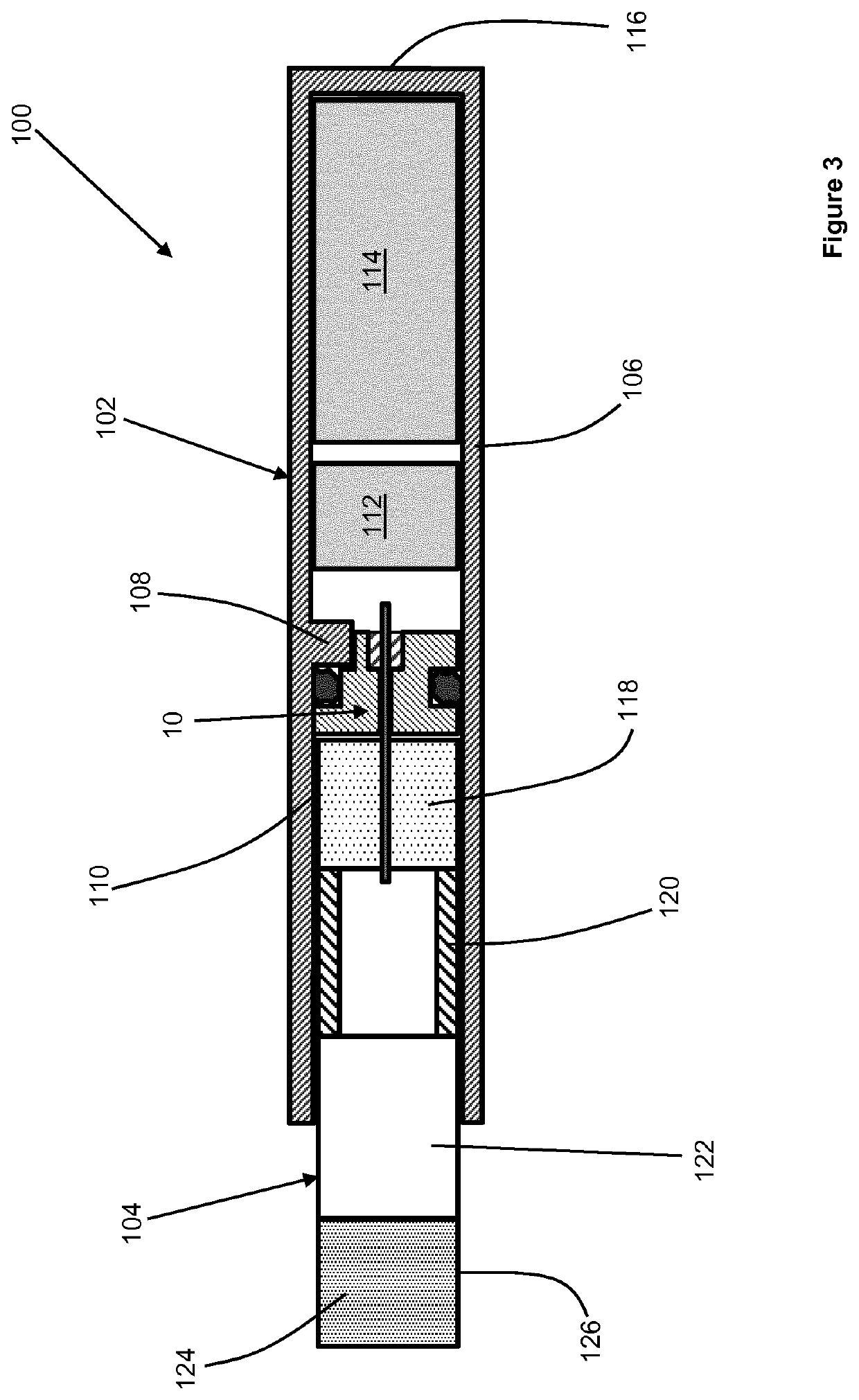

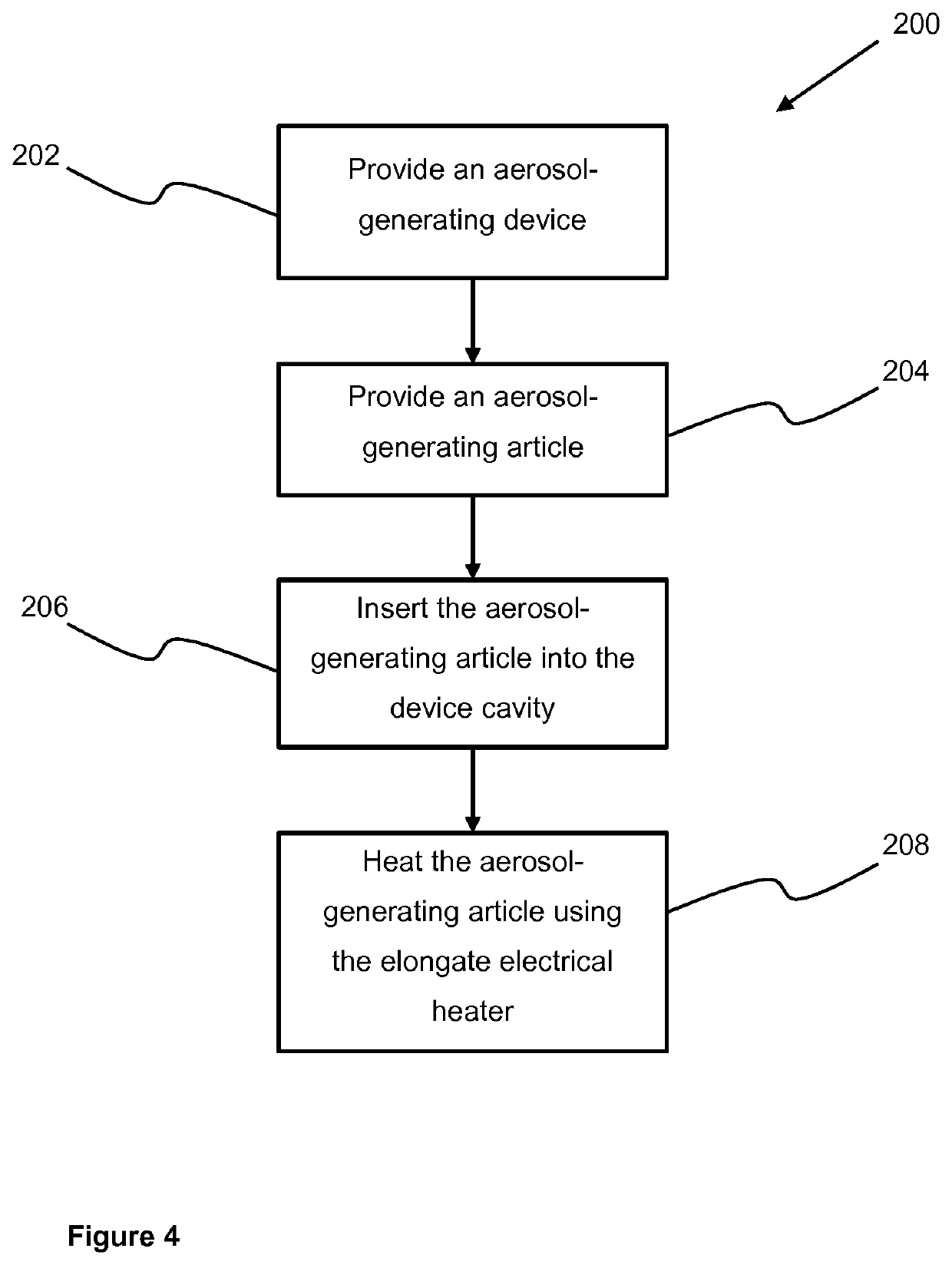

Heater assembly with cavity filled with a potting compound

ActiveUS11413411B2Easy to installEasy to assembleRespiratorsOhmic-resistance electrodesEngineeringPhysics

A heater assembly for an aerosol-generating device is provided, the heater assembly including a bushing defining an aperture at a first end of the bushing and a cavity at a second end of the bushing; a potting compound disposed within the cavity; and an elongate electrical heater extending from the first end of the bushing, where a portion of the elongate electrical heater extends through the aperture and into the cavity. An aerosol-generating device, an aerosol-generating system, and a method of assembling a heater assembly for an aerosol-generating device are also provided.

Owner:PHILIP MORRIS PROD SA

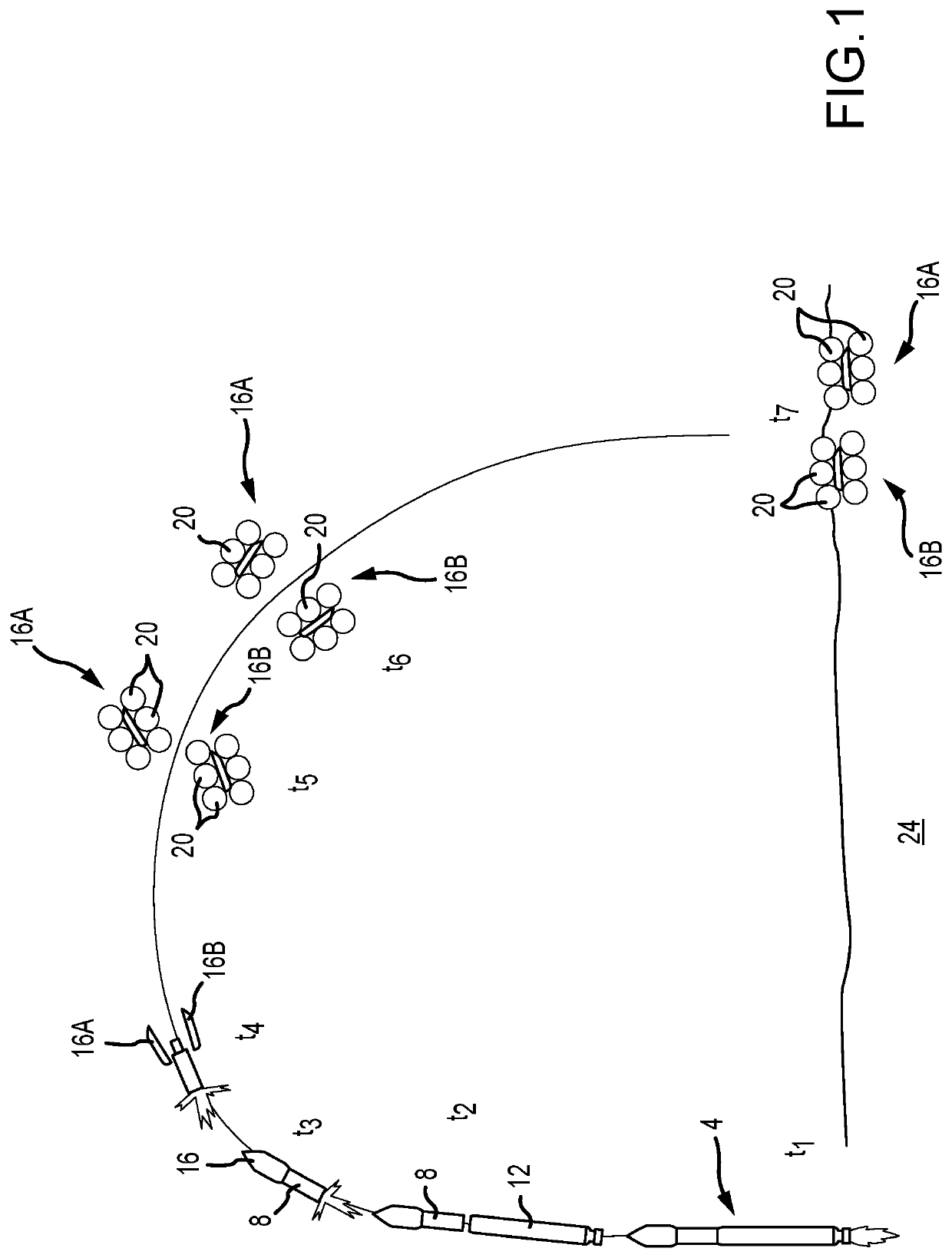

Inflatable bladder fairing recovery system with repositioning mechanisms and method

ActiveUS11066193B1Undermine potential savingMaximum cleaningCargo handling apparatusLaunch systemsAirbagHydraulic fluid

Embodiments of the present invention relate to a launch vehicle fairing recovery system and method using inflatable bags and fairing repositioning mechanisms. Embodiments of the present invention also relate to providing a system or mechanism to flip the fairing into the proper floating position. In some embodiments, the fairing has an inner surface and an outer surface, where the outer surface is exposed to the atmosphere when the fairing is interconnected to a spacecraft, and one or more inflatable bags interconnected to the outer surface of the fairing, where when the fairing is interconnected to the spacecraft the one or more inflatable bags is empty, and after the fairing separates from the spacecraft the one or more airbags are filled with pressurized gas and / or hydraulic liquids.

Owner:UNITED LAUNCH ALLIANCE

Touch device and manufacturing method thereof

ActiveUS9354671B2Reduce and eliminate damageImprove manufacturing yieldDetails for portable computersInput/output processes for data processingBiomedical engineering

Owner:TPK TOUCH SYST XIAMEN

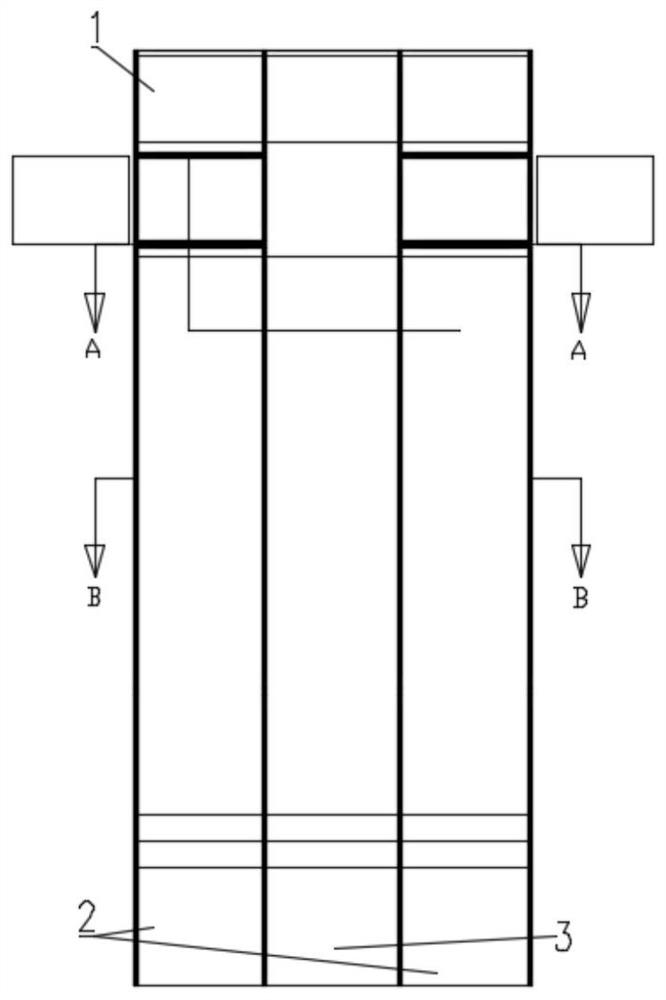

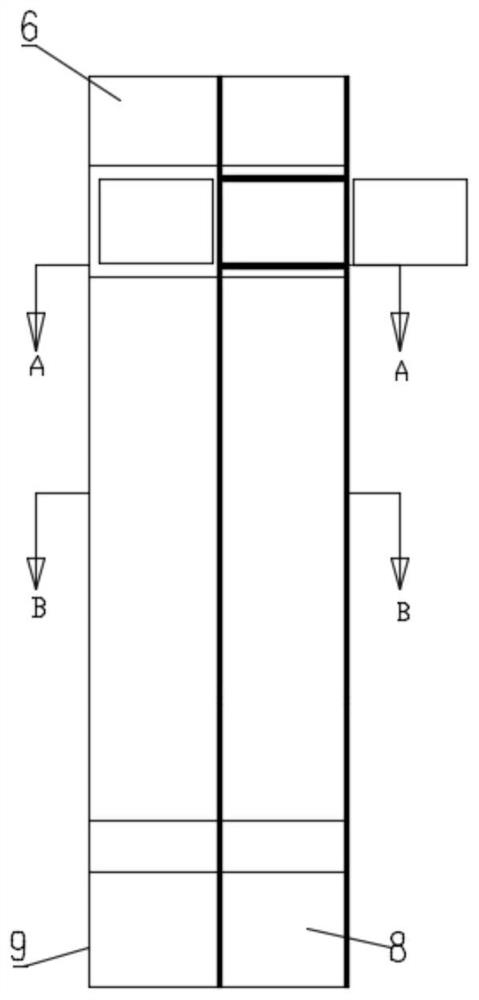

Manufacturing method of inner support steel structure special-shaped column

PendingCN112709371AReduce and eliminate damageImprove performanceStrutsFire proofingAxial compressionTorsional deformation

The invention discloses a manufacturing method of an inner support steel structure special-shaped column, belongs to the technical field of steel structure engineering, and well solves the problem of poorer torsional deformation resistance of an existing steel structure column at a high axial compression ratio by utilizing a self complete inner support and outer sealed structure form. The manufacturing method is technically characterized by comprising the following manufacturing steps that each column body in the inner support steel structure special-shaped column is assembled; the inner support steel structure special-shaped column comprises a middle column, side columns and corner columns; and a plurality of side columns are horizontally arranged in edge positions of a building. A building structure using the inner support steel structure special-shaped column in the embodiment of the invention realizes more reasonable stress and force transmission; the safety, stability and reliability of the whole building can be guaranteed to the maximum extent; the damage to the building under various load and natural disaster conditions is reduced and eliminated; the life and property safety of people is guaranteed; and the method is more suitable for assembled high-rise and super high-rise civil and public buildings.

Owner:姜博霖

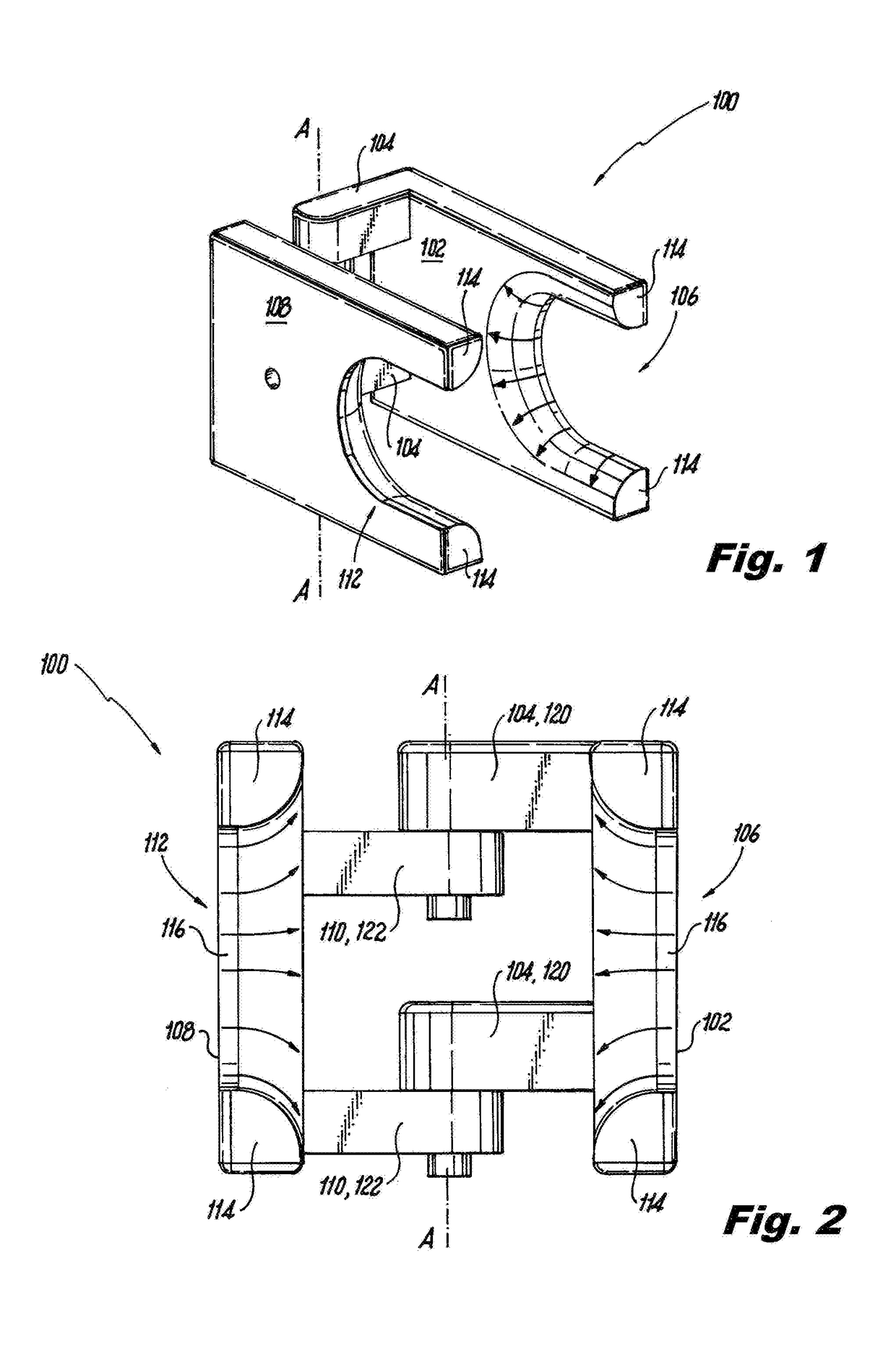

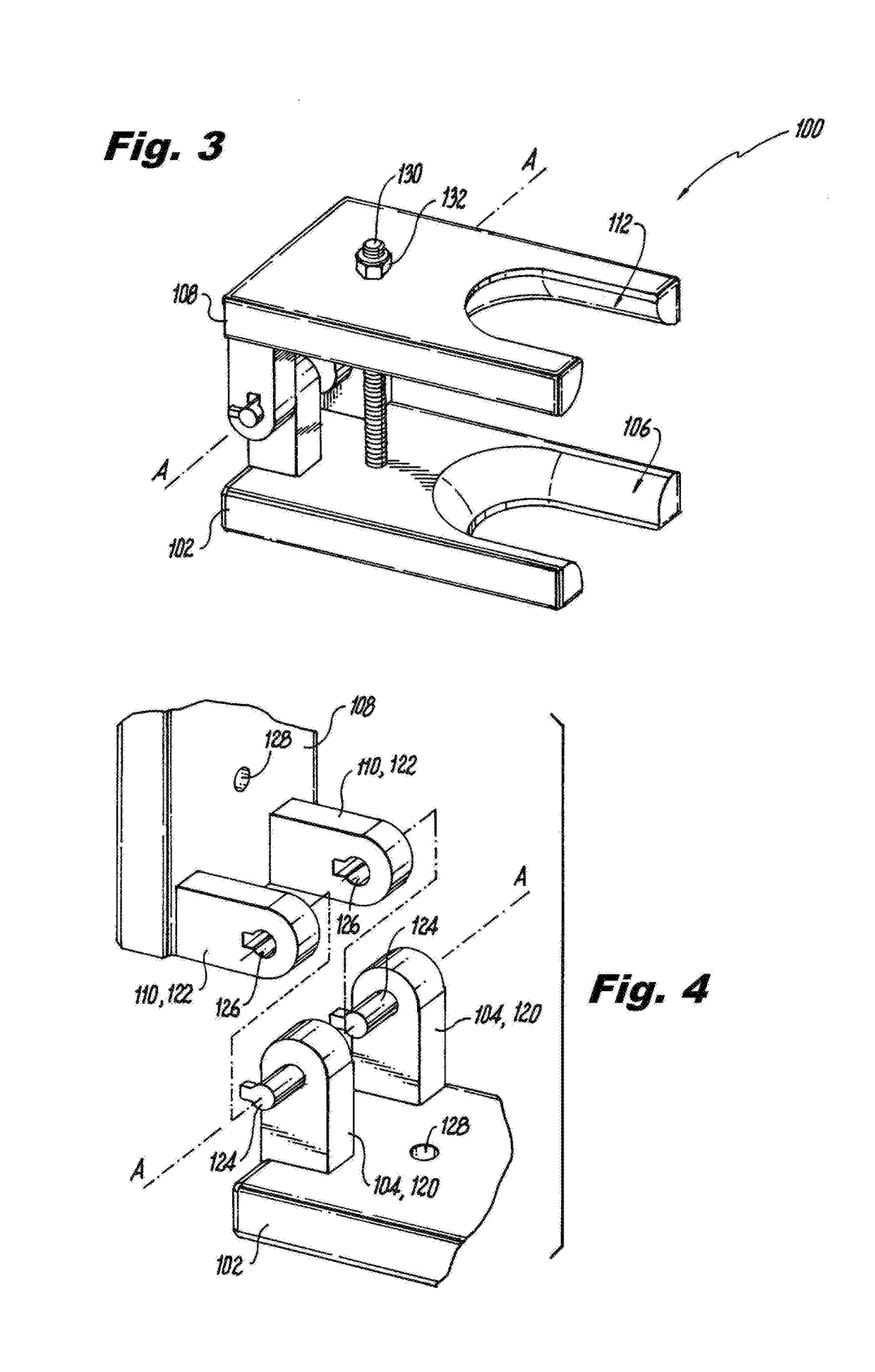

Diaphragm coupling tools

Owner:THE BF GOODRICH CO

Process and equipment for deacidifying whole paper document

PendingCN111851143AReduce damageEliminate damageOld paper after-treatmentPaper sheetProcess engineering

The invention discloses a process and equipment for deacidification protection of a whole paper document, belongs to the technical field of collection document protection, and can perform soaking typedeacidification protection on the acidified whole paper document, in particular to an acidified paper document with low paper stiffness. The process and the equipment have the advantages that the damage caused by bending and folding of the paper in the soaking and deacidifying process of the soft paper can be eliminated; an effective channel is provided for the deacidification liquid to flow in the paper literature page, the problem of directional flow of the deacidification liquid in the whole paper literature page is solved, an alkaline deacidification medium is promoted to be uniformly distributed on the paper page, the deacidification effect is good, and the practicability is high.

Owner:NANJING MUSEUM

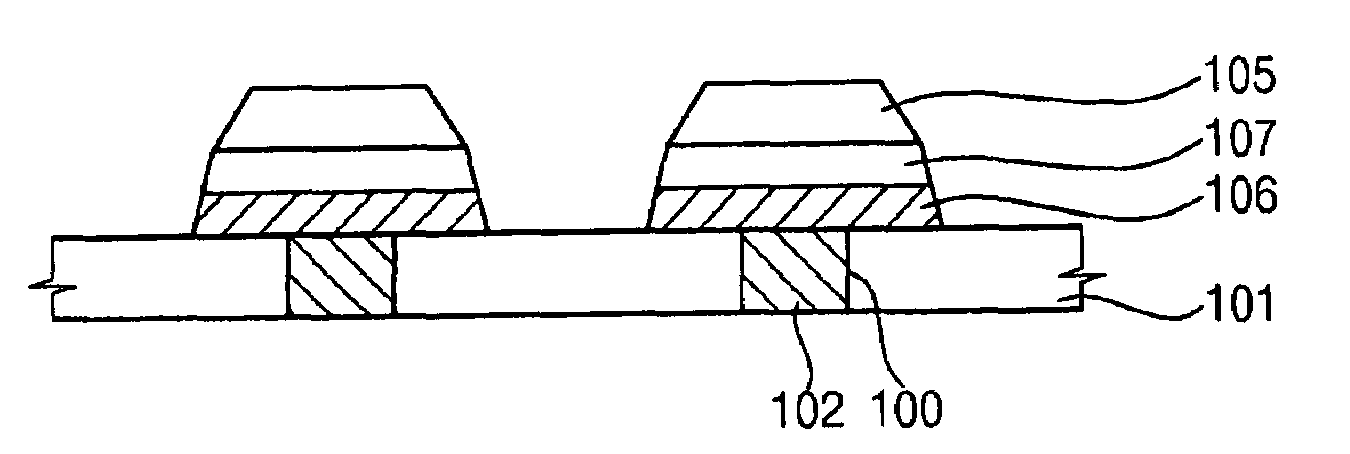

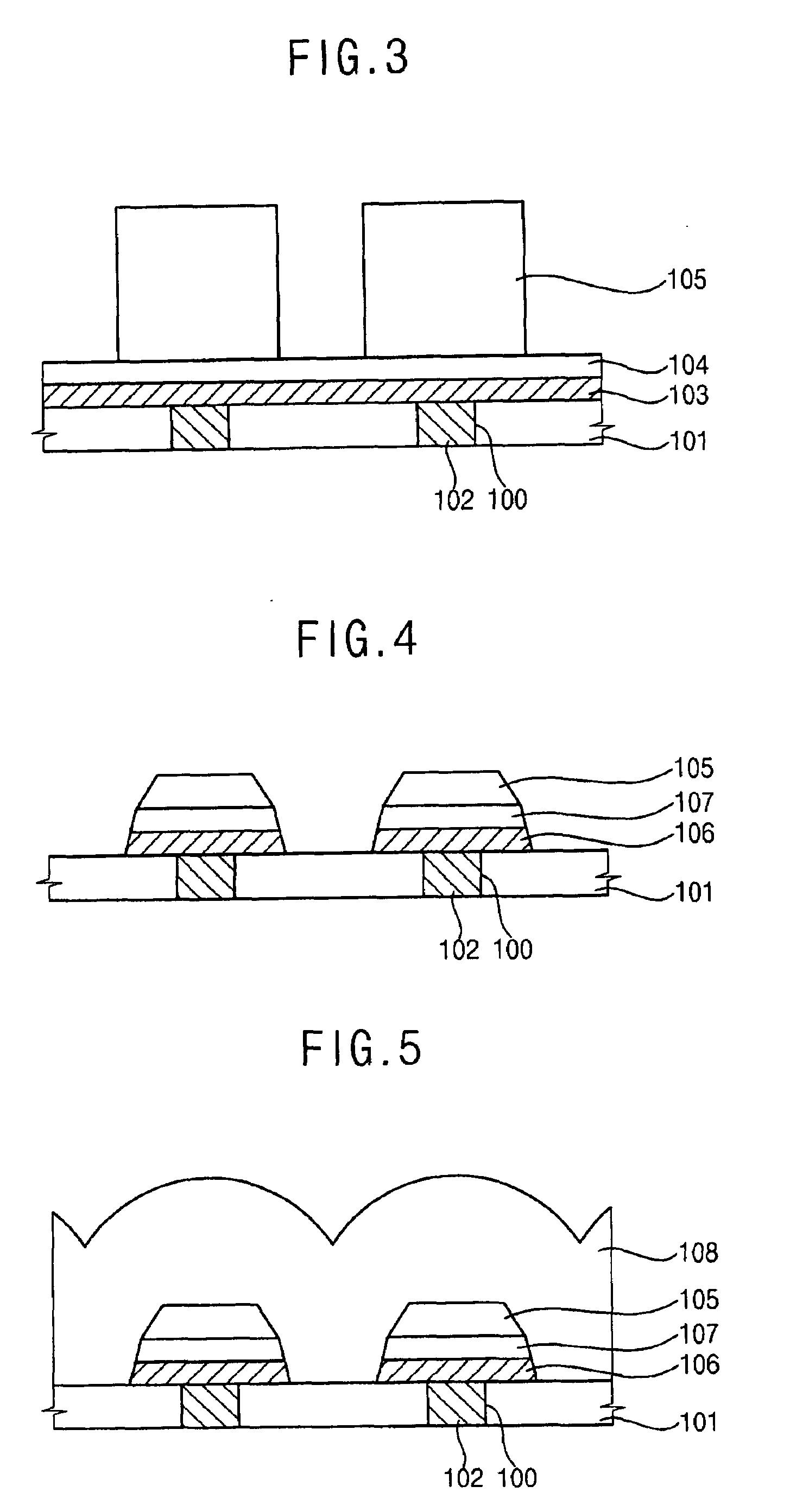

Method of forming a ferroelectric device

InactiveUS20070212797A1Low polishing rateReduce and eliminate damageSolid-state devicesSemiconductor/solid-state device manufacturingTitaniumSlurry

A method of forming a ferroelectric device includes forming a ferroelectric pattern on a substrate, the ferroelectric pattern including a ferroelectric material including titanium and oxygen, forming an insulating layer on the ferroelectric pattern, and planarizing the insulating layer using a slurry until the ferroelectric pattern is exposed, wherein the ferroelectric pattern serves as a polishing stop pattern and the slurry includes ceria.

Owner:SAMSUNG ELECTRONICS CO LTD

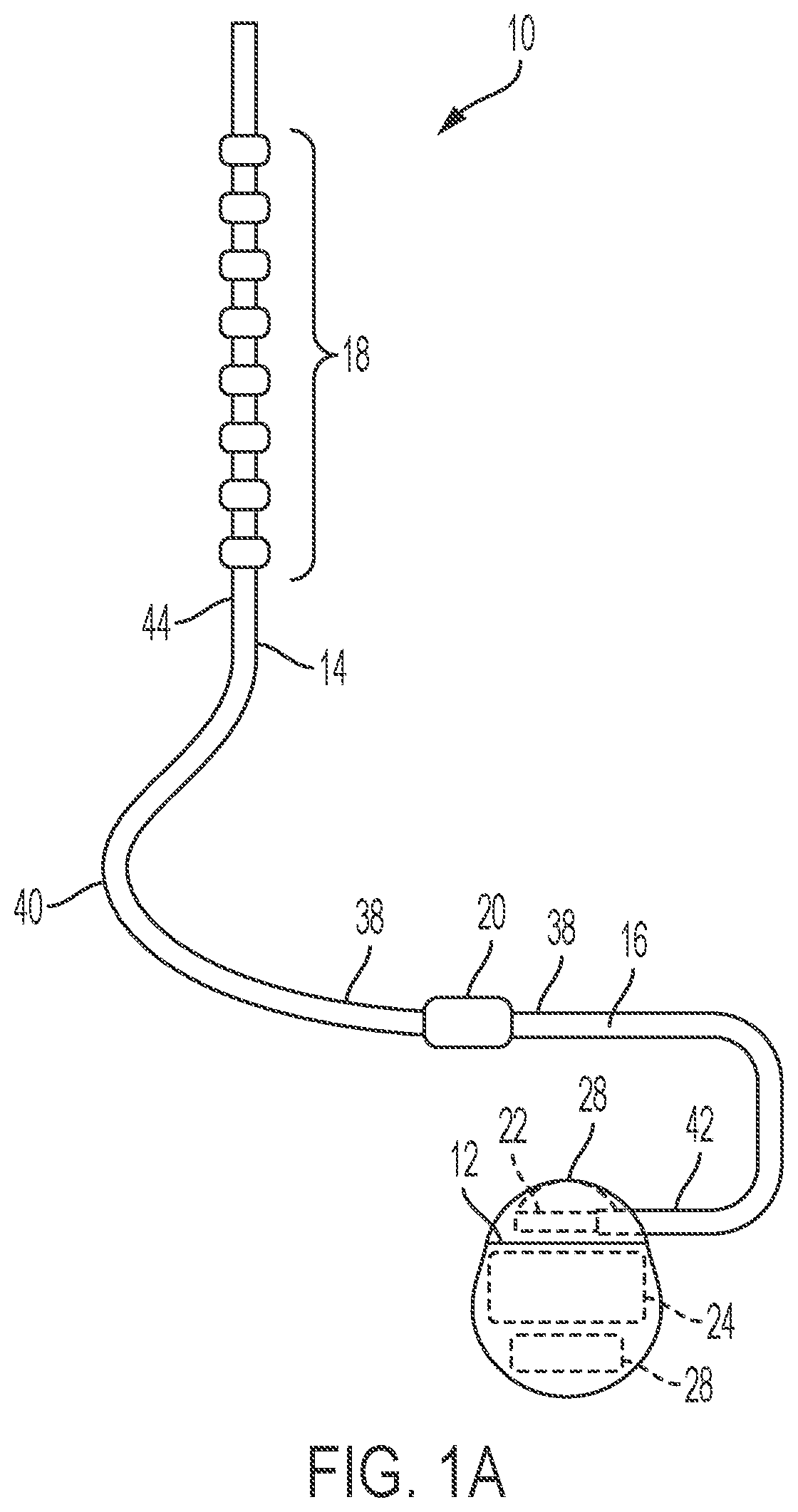

Bulkhead anchor for medical device leads

PendingUS20220161040A1Reduce and eliminate damageStrong anchoringSpinal electrodesTransvascular endocardial electrodesMedicineEngineering

Systems and methods which provide a bulkhead anchor configuration in which an anchor body includes flexure finger members and a radial bulkhead operable in cooperation to impart a radial compressive force to a corresponding lead body are described. A first portion of a bulkhead anchor body may comprise a plurality of flexure finger members disposed in a corolla configuration forming an anchor lumen through which a lead body may be inserted. A second portion of the bulkhead anchor body may comprise a radial bulkhead having a flexure profile configured to operatively engage the flexure finger members. A locking mechanism may be used to retain the first and second portions of the bulkhead anchor in their relative positions such that the radial compressive force is maintained upon the lead body indefinitely.

Owner:ADVANCED NEUROMODULATION SYST INC

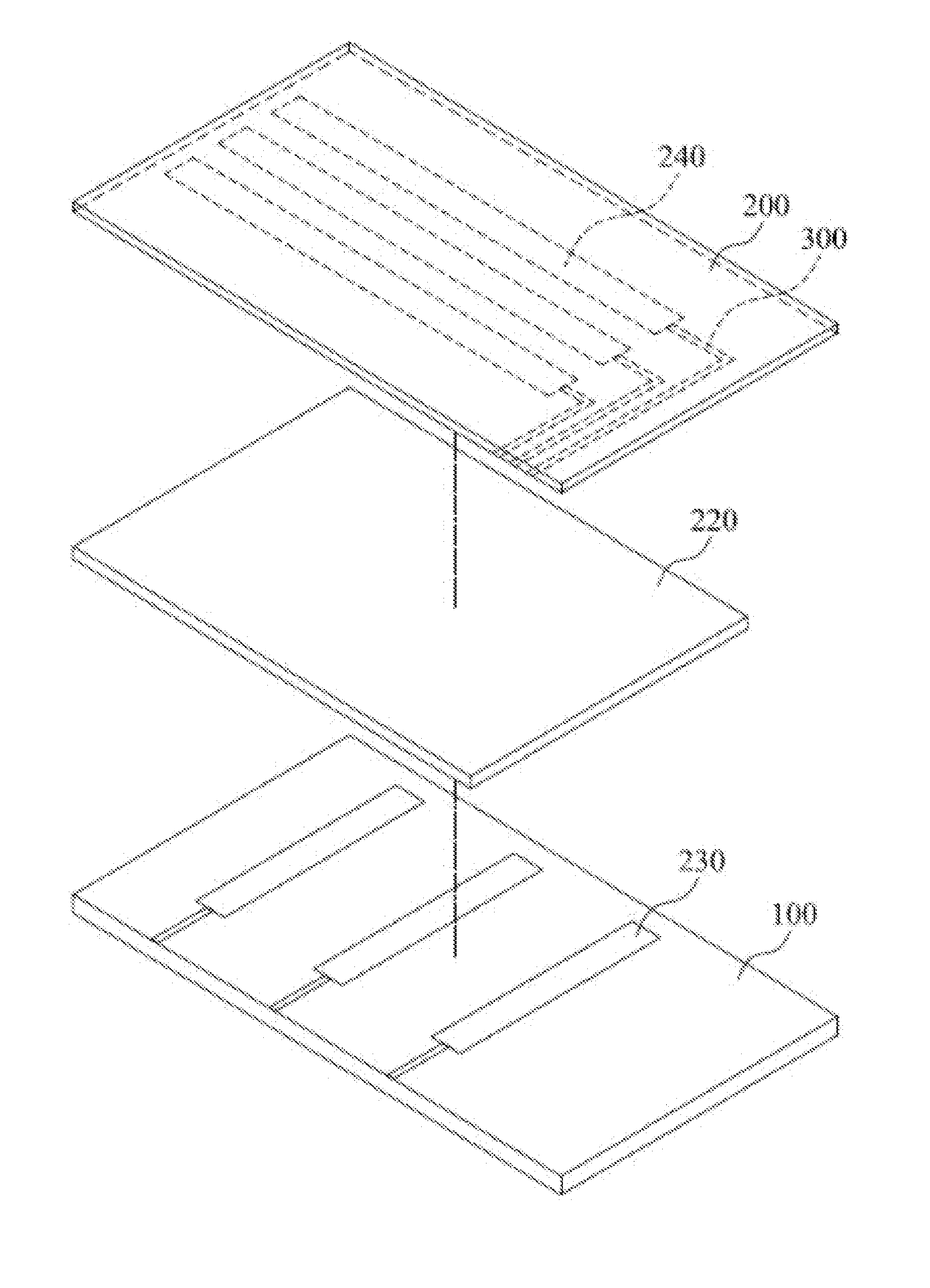

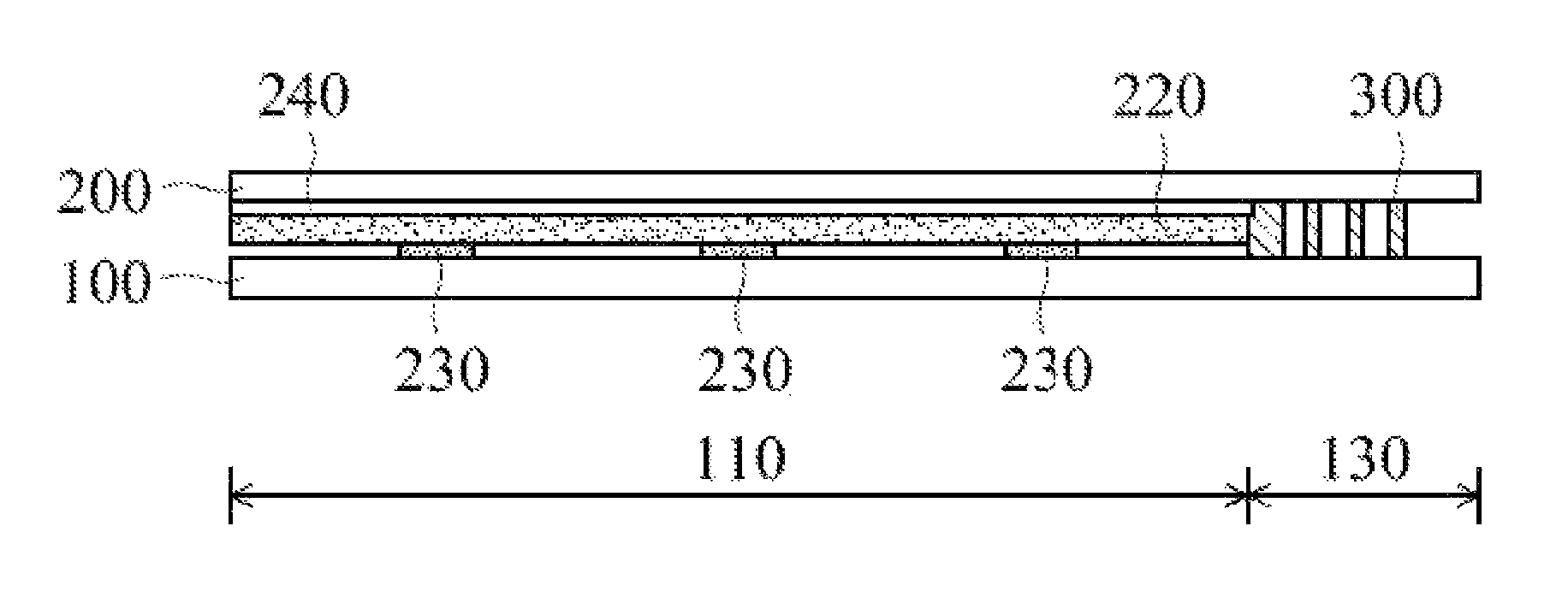

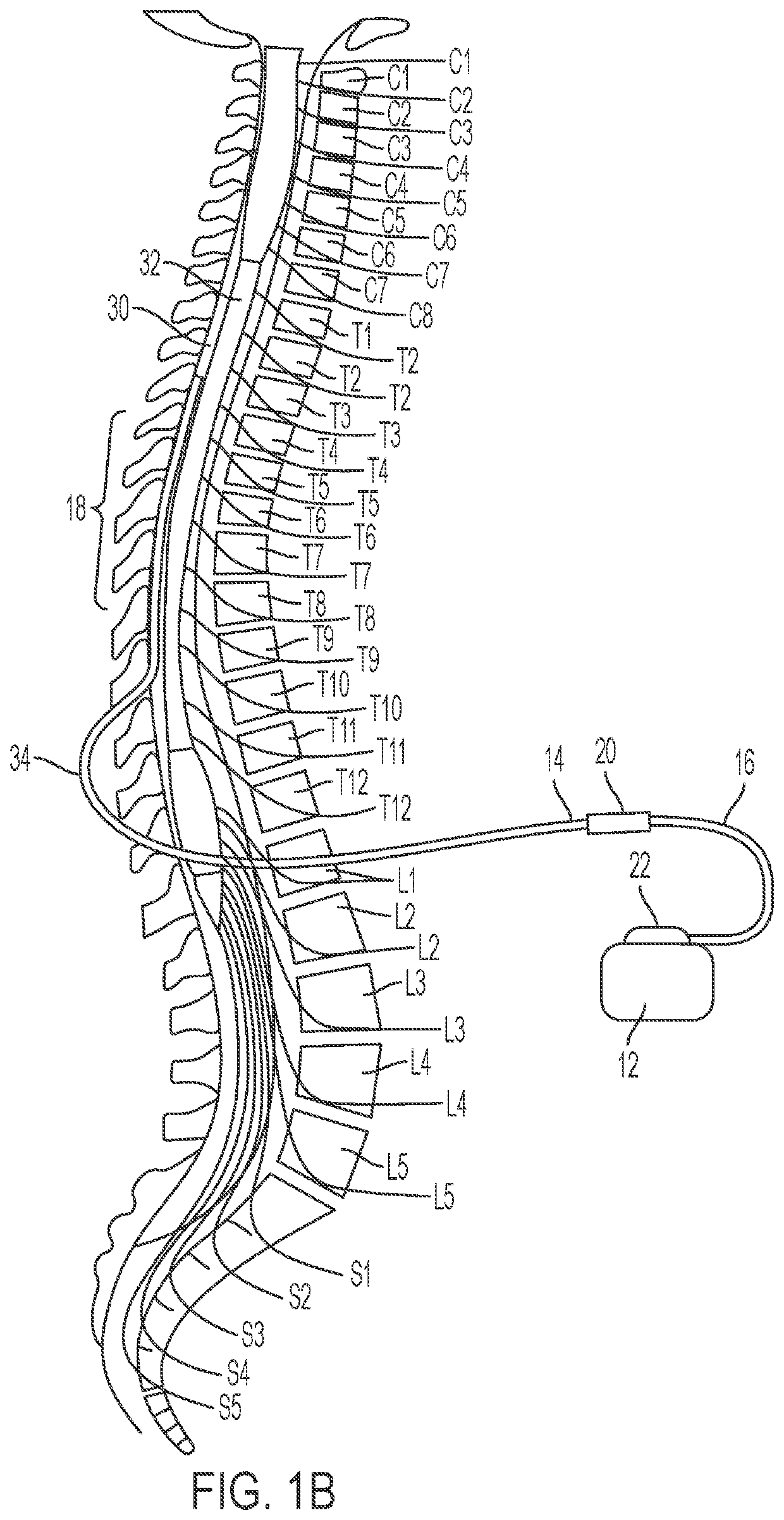

Energy storage module with reduced damage to electrode terminals

ActiveUS9786895B2Simplify and improve efficiencyReduce and eliminate damagePrimary cell to battery groupingFinal product manufactureElectricityEngineering

An energy storage module includes an energy storage cell group containing a plurality of energy storage cells stacked in a stacking direction, and a pair of end plates provided at both ends of the energy storage cell group in the stacking direction. A terminal frame is provided at the end plate in order to electrically connect an electrode terminal of the energy storage cell provided at an end in the stacking direction and an output line. The terminal frame is fixed to the end plate by fixing points.

Owner:HONDA MOTOR CO LTD

Diaphragm coupling tools

Owner:THE BF GOODRICH CO

Touch device and manufacturing method thereof

ActiveUS9148143B2Reduce and eliminate damageIncrease productionElectronic switchingElectric switchesEngineeringBiomedical engineering

A manufacturing method of a touch device is disclosed. A substrate having a viewing region is provided. A plurality of first sensing electrodes and a plurality of second sensing electrodes insulated from and in a staggered arrangement with the plurality of first sensing electrodes are formed on the substrate corresponding to the viewing region, wherein a plurality of jumper regions are defined between the adjacent second sensing electrodes. An insulating layer is formed on the plurality of first sensing electrodes and the plurality of second sensing electrodes. A plurality of jumpers is transfer-printed onto the insulating layer, wherein the plurality of jumpers is electrically connected to the adjacent second sensing electrodes and insulated from the first sensing electrodes by the insulating layer. A touch device is also disclosed.

Owner:TPK TOUCH SYST XIAMEN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com