Patents

Literature

11136results about "Actuators" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

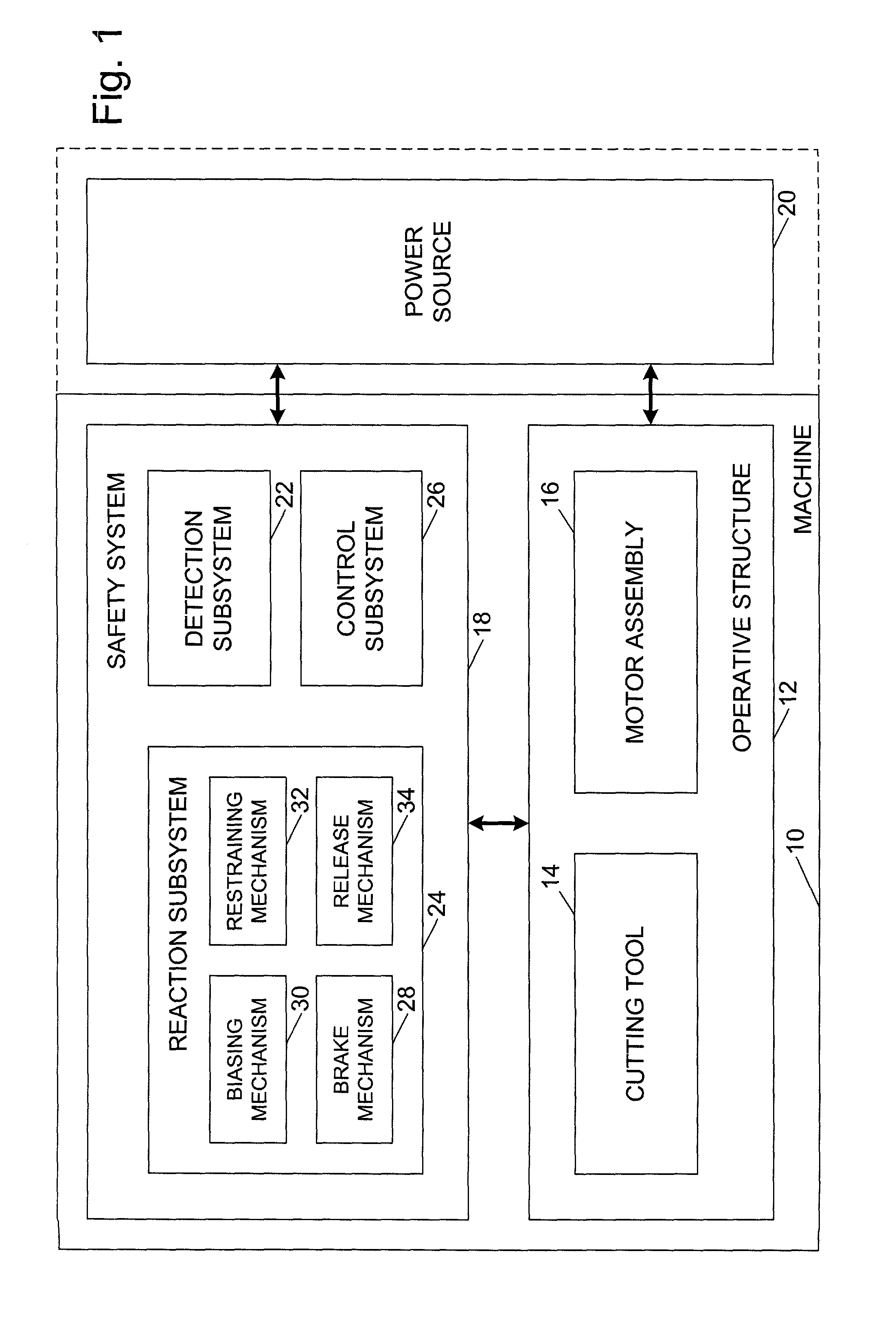

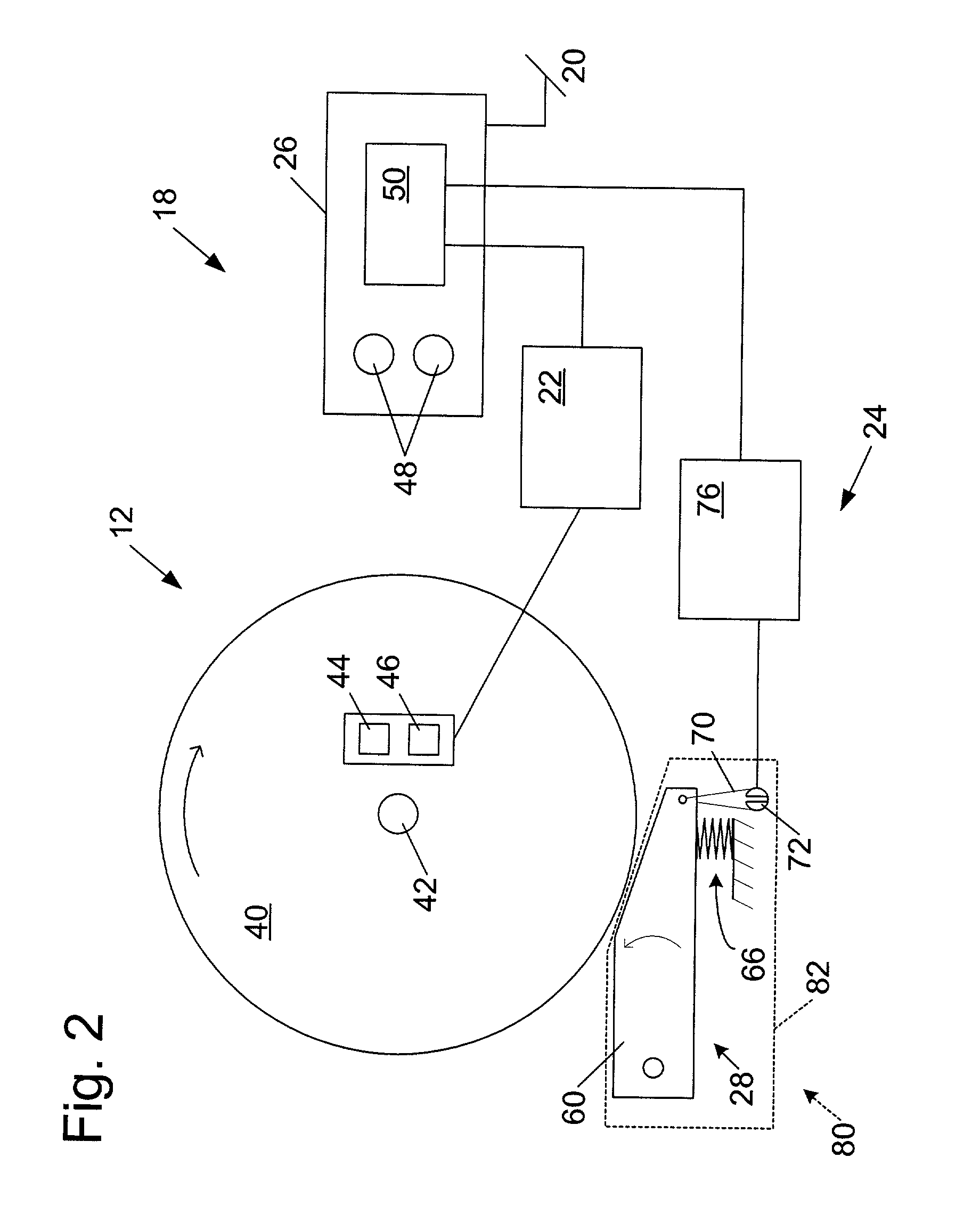

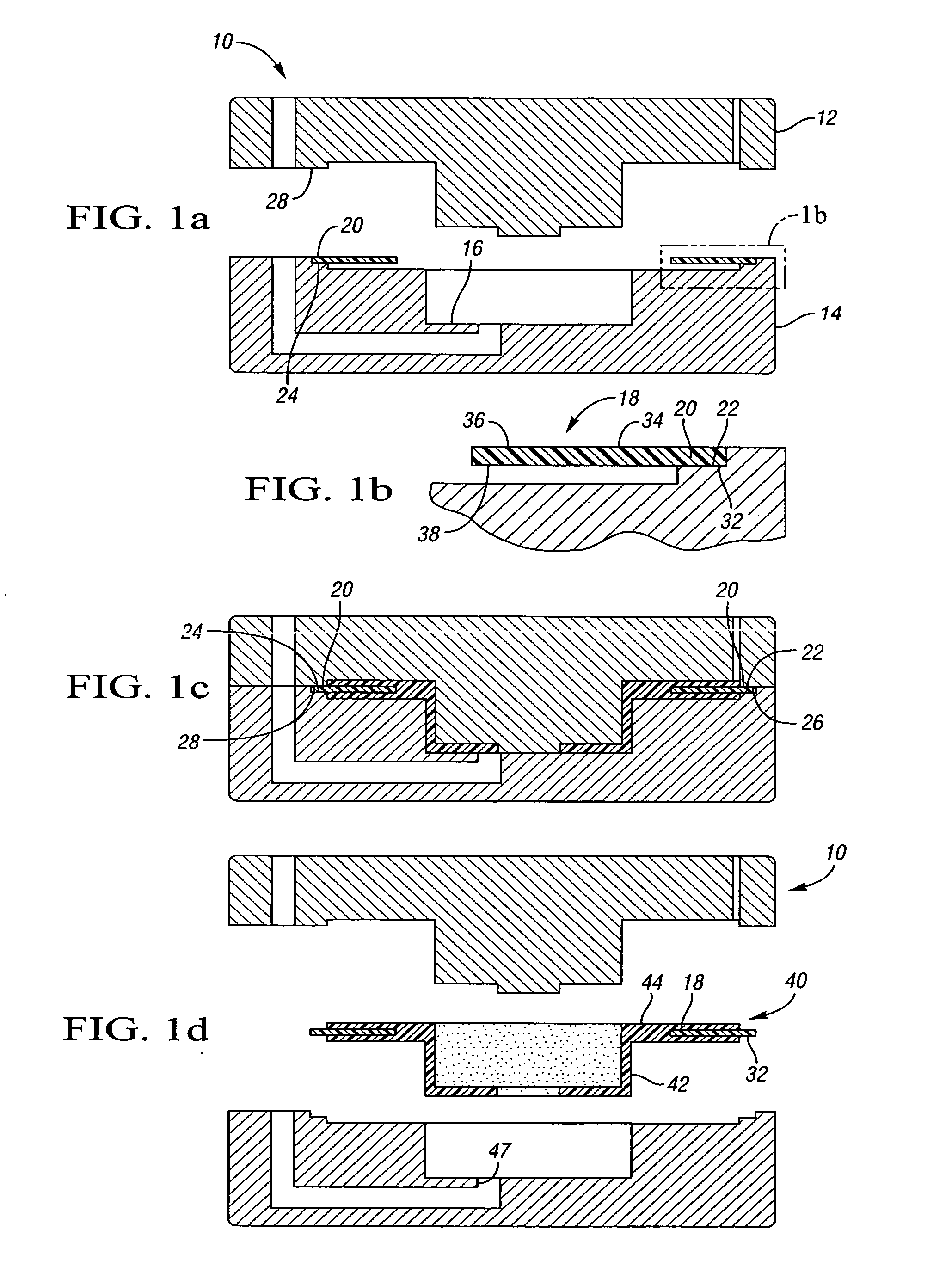

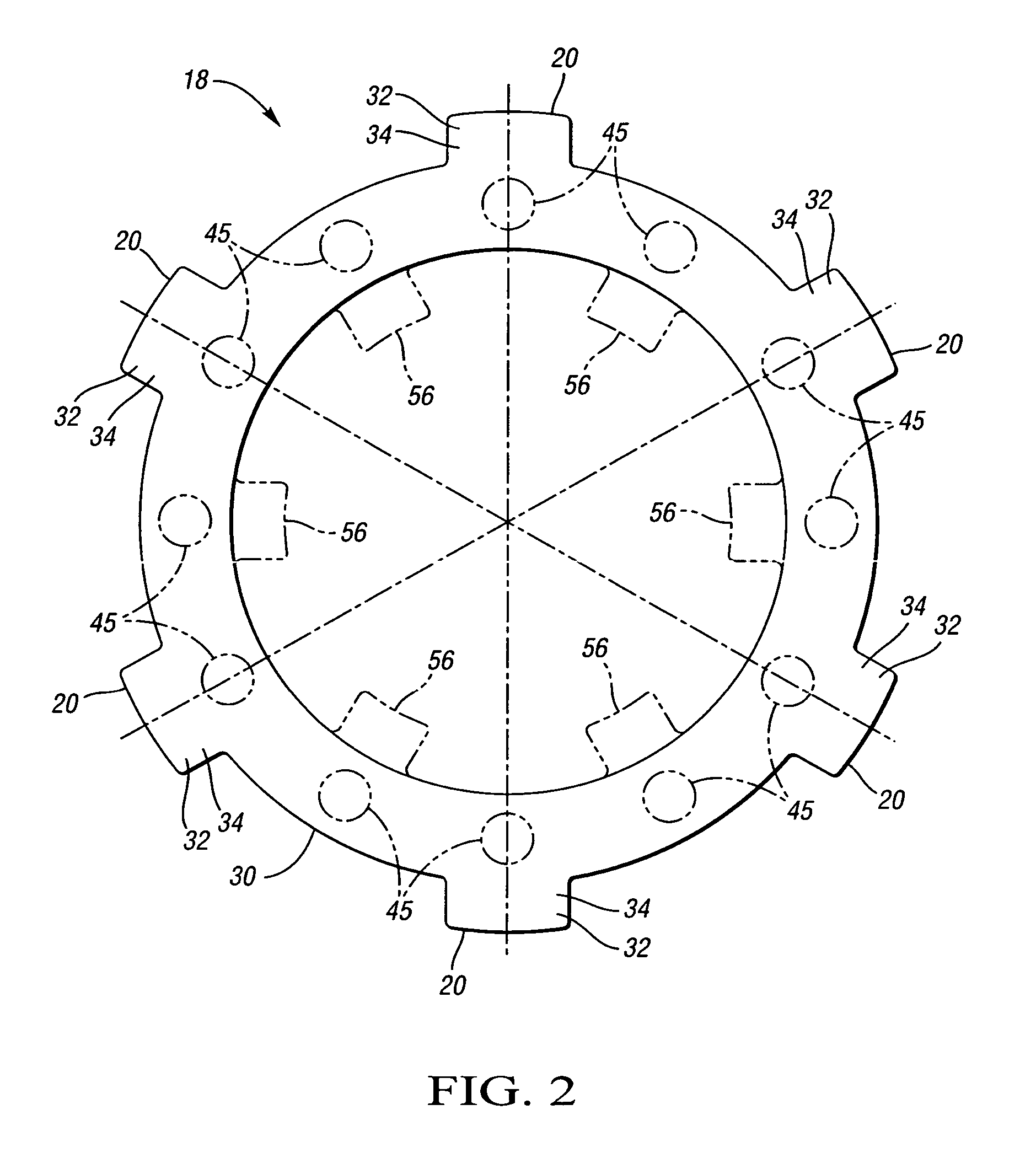

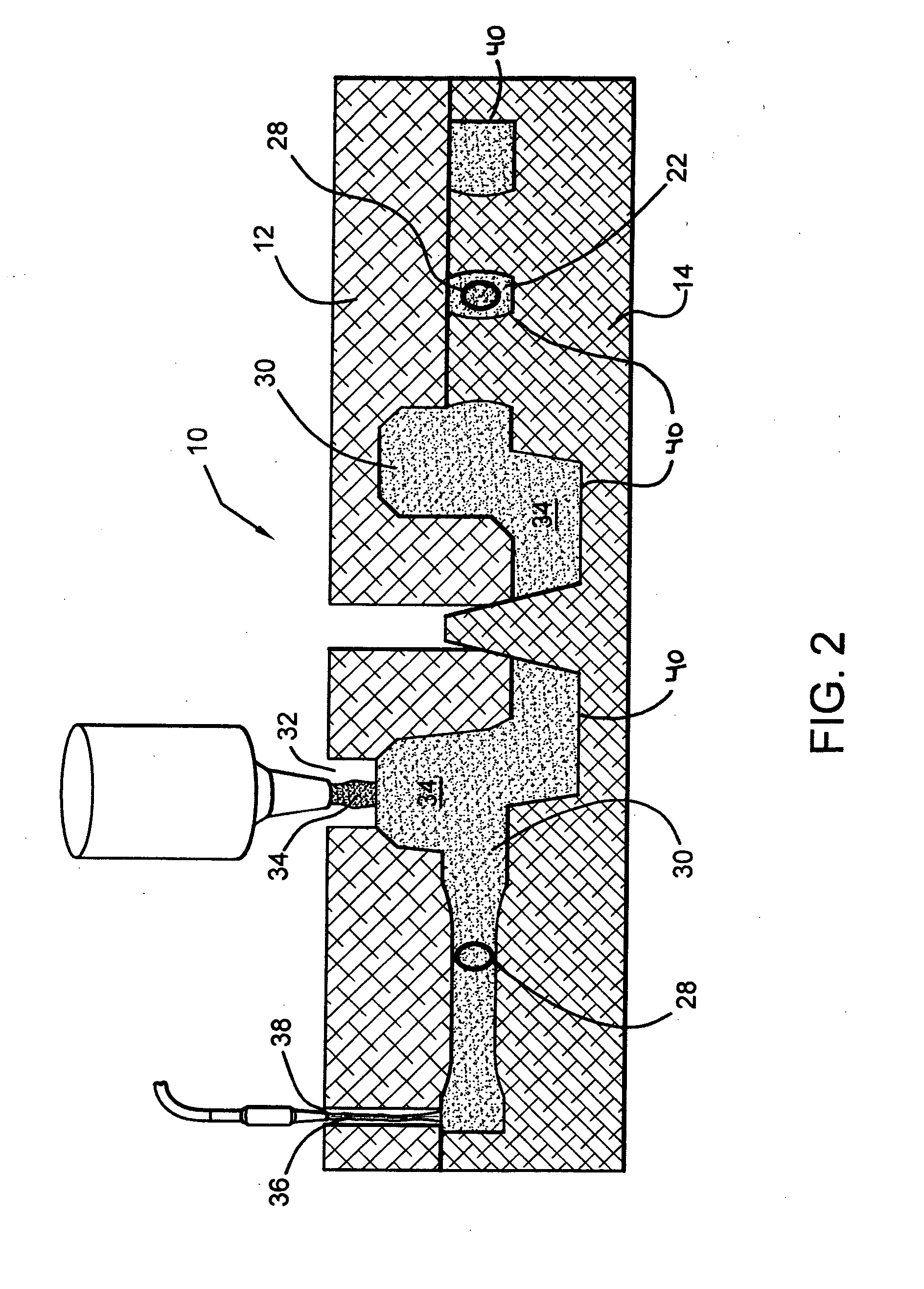

Safety systems for power equipment

Machines with safety systems are disclosed. The machine may take the form of woodworking machines including table saws, band saws, miter saws, hand-held circular saws, pneumatic chop saws, radial-arm saws, jointers, planars, routers and shapers. The machines may include an operative structure configured to perform a task, where the operative structure includes a cutting tool adapted to move in at least one motion, and a safety system adapted to detect the occurrence of an unsafe condition between a person and the cutting tool and for mitigating the unsafe condition. The safety system may include a detection subsystem and a reaction subsystem.

Owner:SAWSTOP HLDG LLC

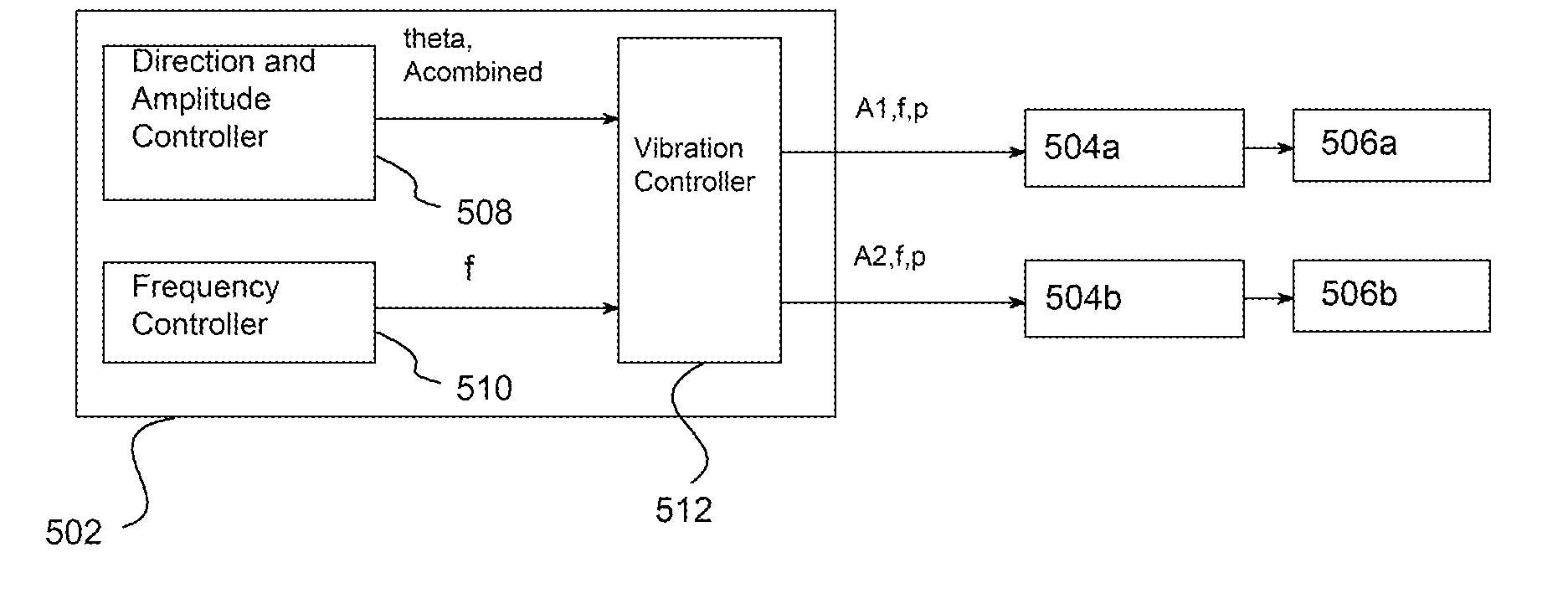

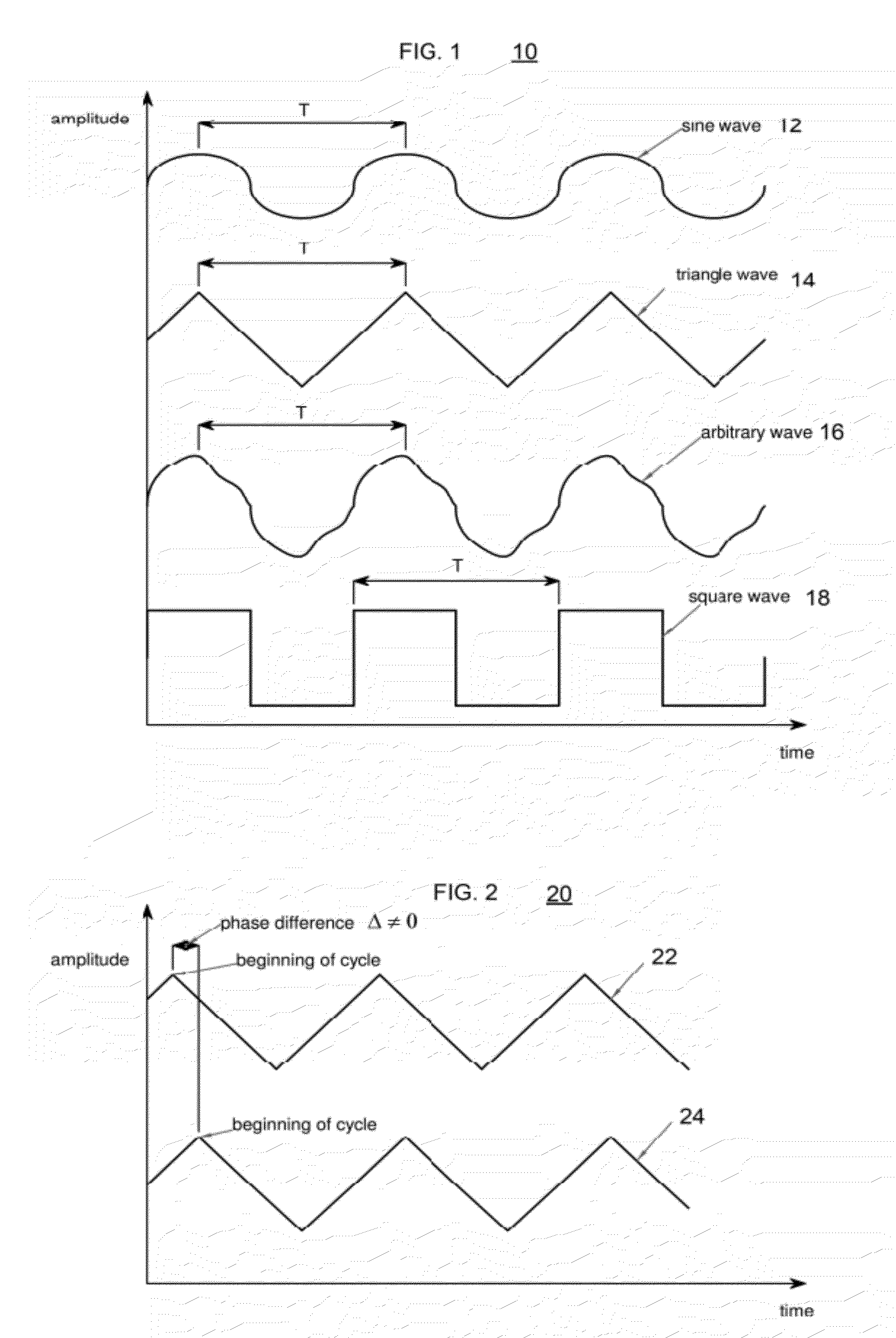

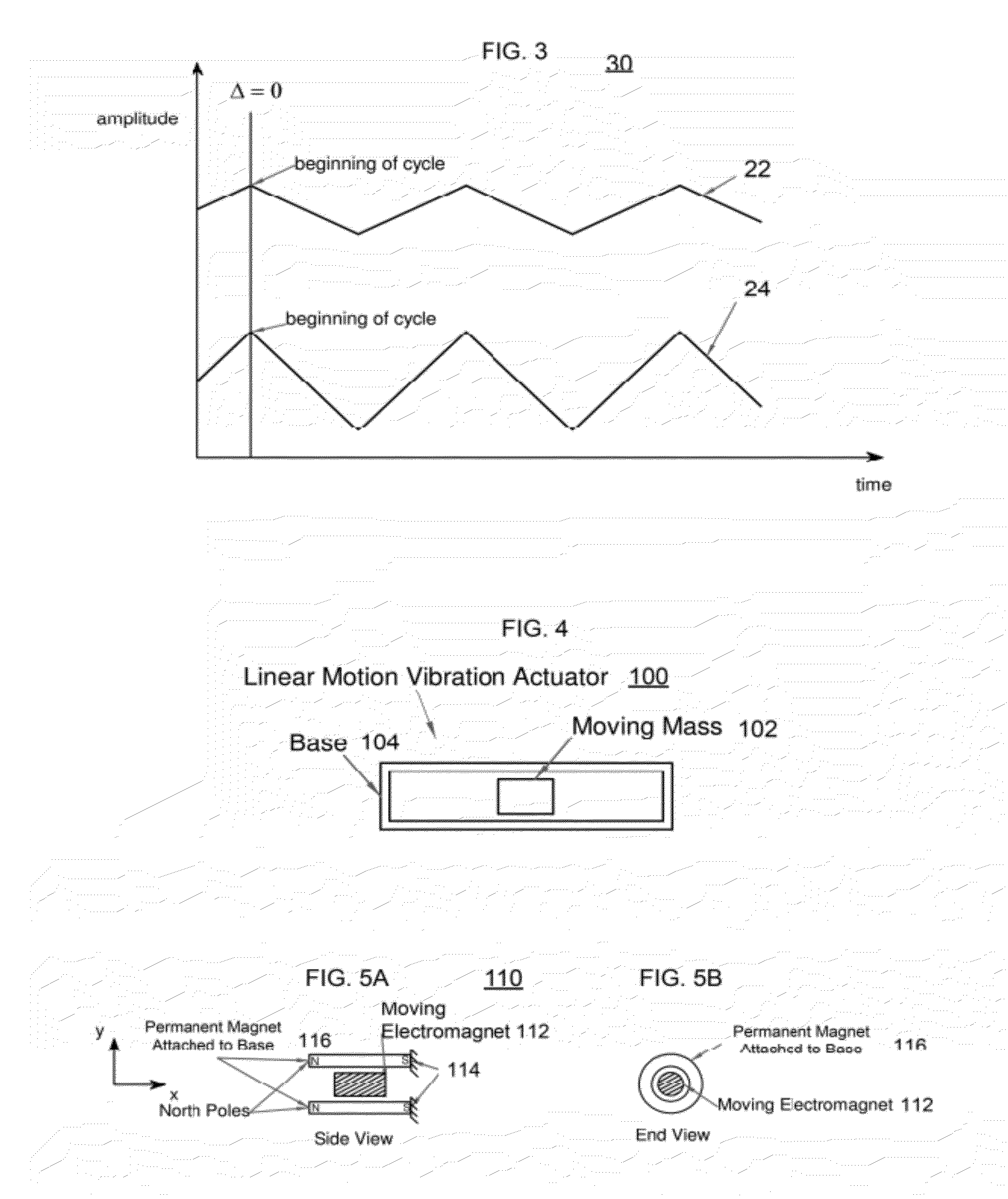

Asymmetric and general vibration waveforms from multiple synchronized vibration actuators

InactiveUS20120232780A1Low costImprove responsivenessDC motor speed/torque controlEmergency protective circuit arrangementsDriver circuitPeak value

The disclosure relates to General Synchronized Vibration devices that provide haptic feedback to a user and improve the performance of existing vibratory devices. Different actuator types may be employed to provide synchronized vibration, including linear rotary actuators, rotating eccentric mass actuators including interleaved rotating mass actuators, and rocking mass actuators. A controller sends signals to one or more driver circuits to provide adjustment of vibration magnitude, frequency, and direction of the actuators. The system may apply forces onto an object, and a sensor measures a feature(s) of the object. This information is provided to a vibration device controller, which can then modify the vibration waveform to improve overall system performance. Fourier synthesis can be used to approximate arbitrarily shaped waveforms by controlling the phase and frequency of vibration actuators. These waveforms can include asymmetry where the peak force in one direction is higher than the peak force in another direction.

Owner:COACTIVE DRIVE CORP

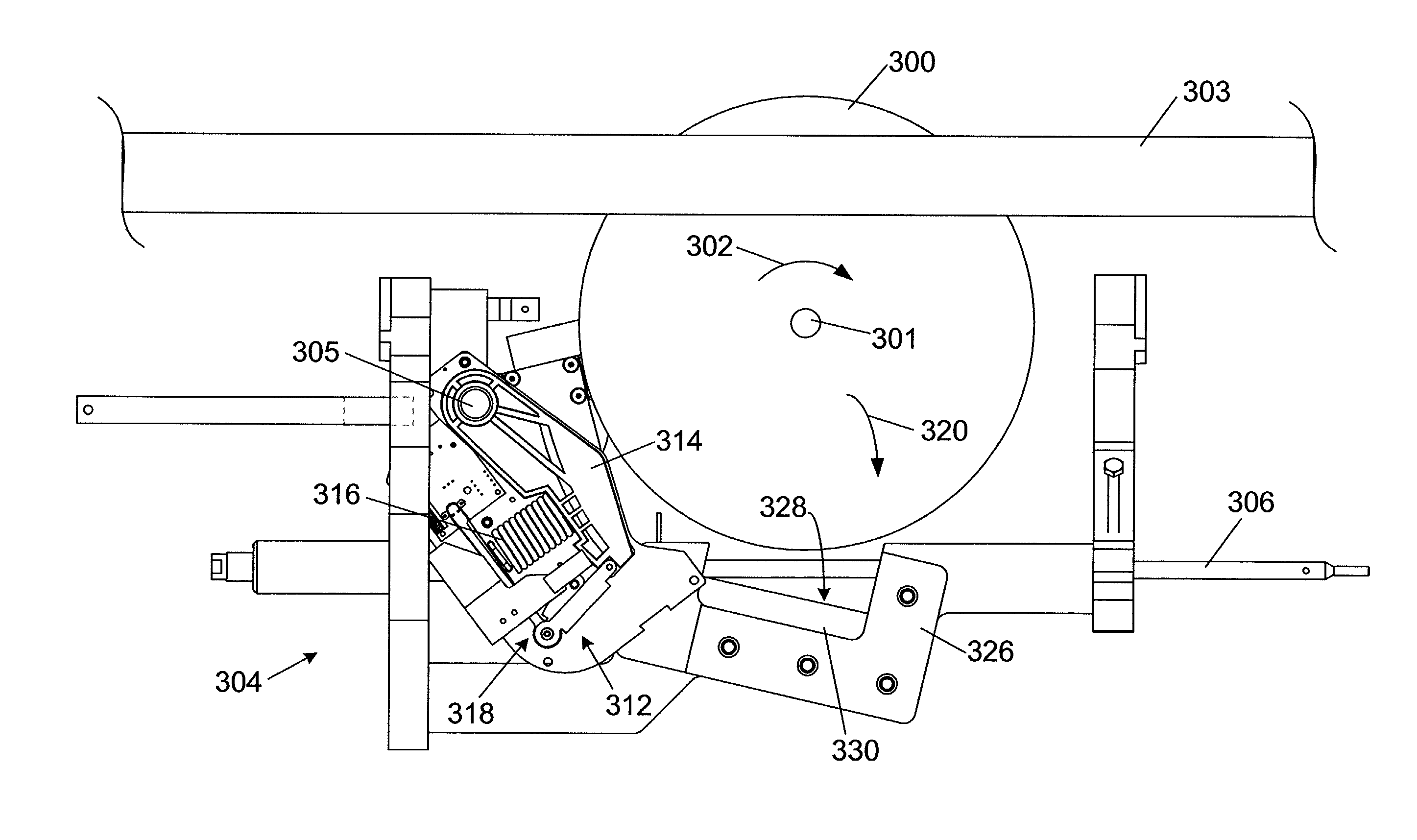

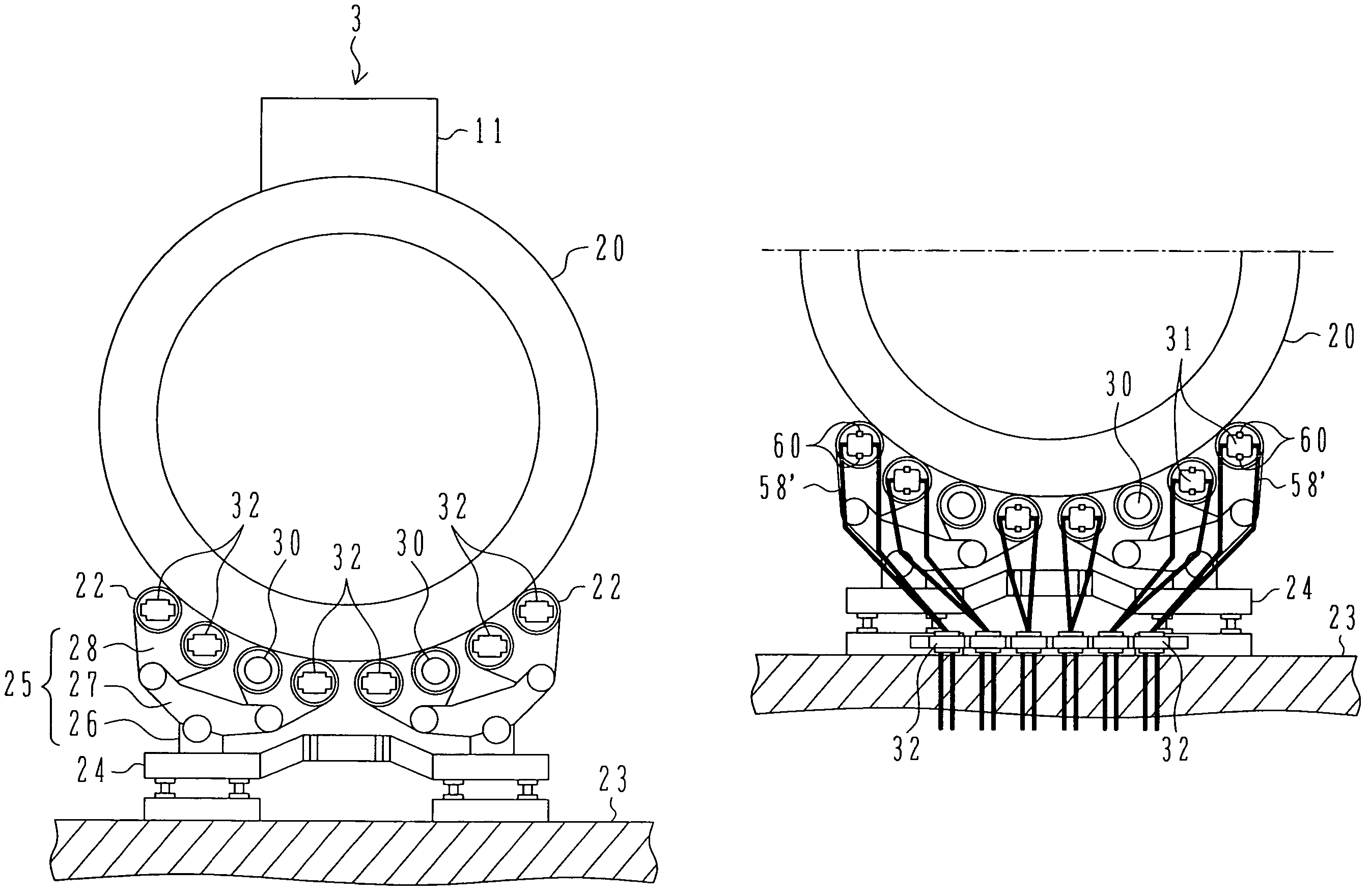

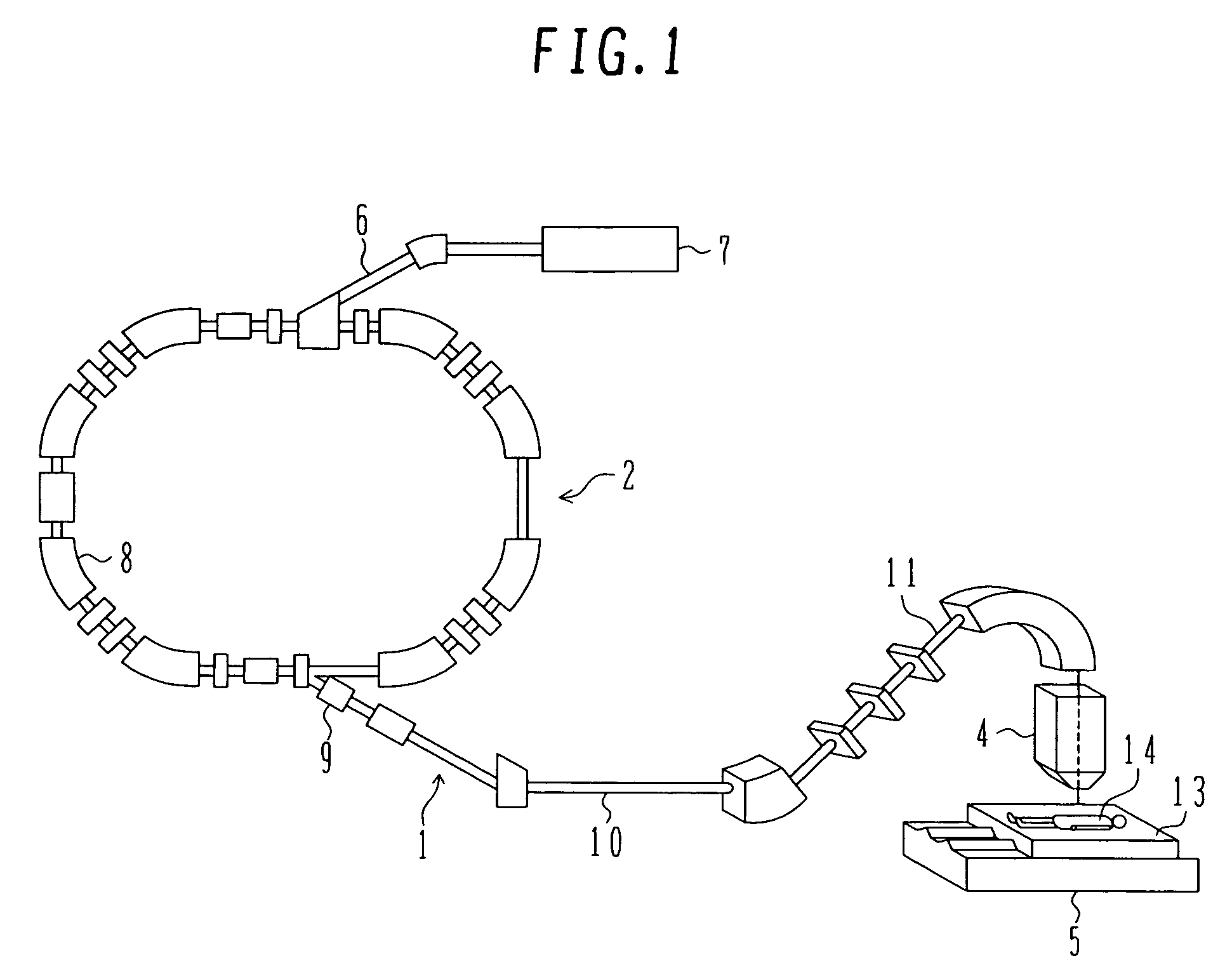

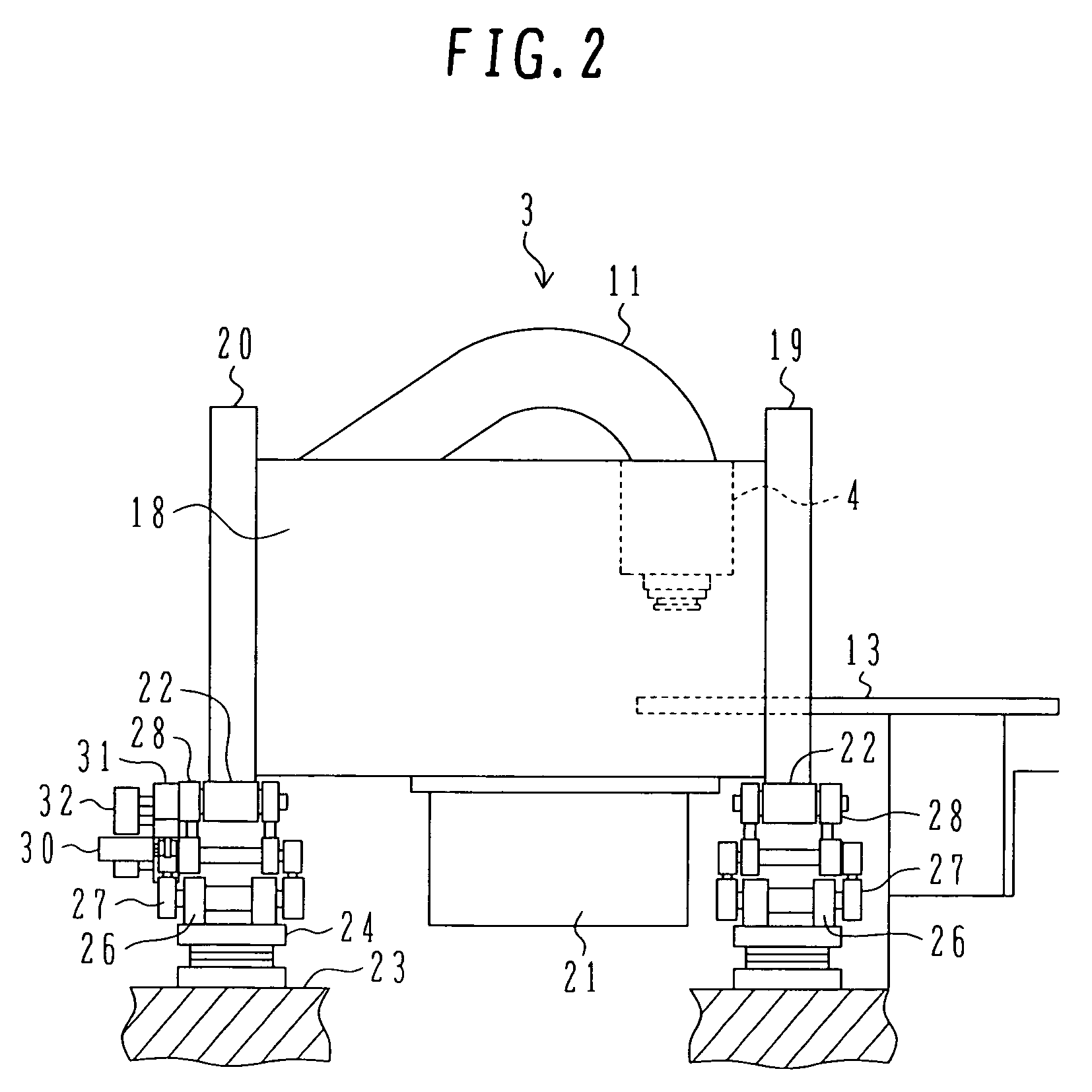

Rotating gantry of particle beam therapy system

ActiveUS7372053B2Improve rigidityVariation can be suppressedThermometer detailsFluid actuated brakesSolenoid valveParticle beam

A rotating gantry includes a link frame for supporting a plurality of rollers which rotatably support the rotating gantry, a brake for releasing a braking force applied to at least one of the rollers upon supply of air and applying the braking force to the one roller upon discharge of air, and a solenoid valve for sealing the supplied air in the brake when closed, and discharging the air from the brake when opened. The solenoid valve is supported by a solenoid valve support member mounted to the link frame such that the solenoid valve is positioned just near the brake. The rotating gantry can be more quickly braked and stopped while maintaining high irradiation accuracy.

Owner:HITACHI LTD +1

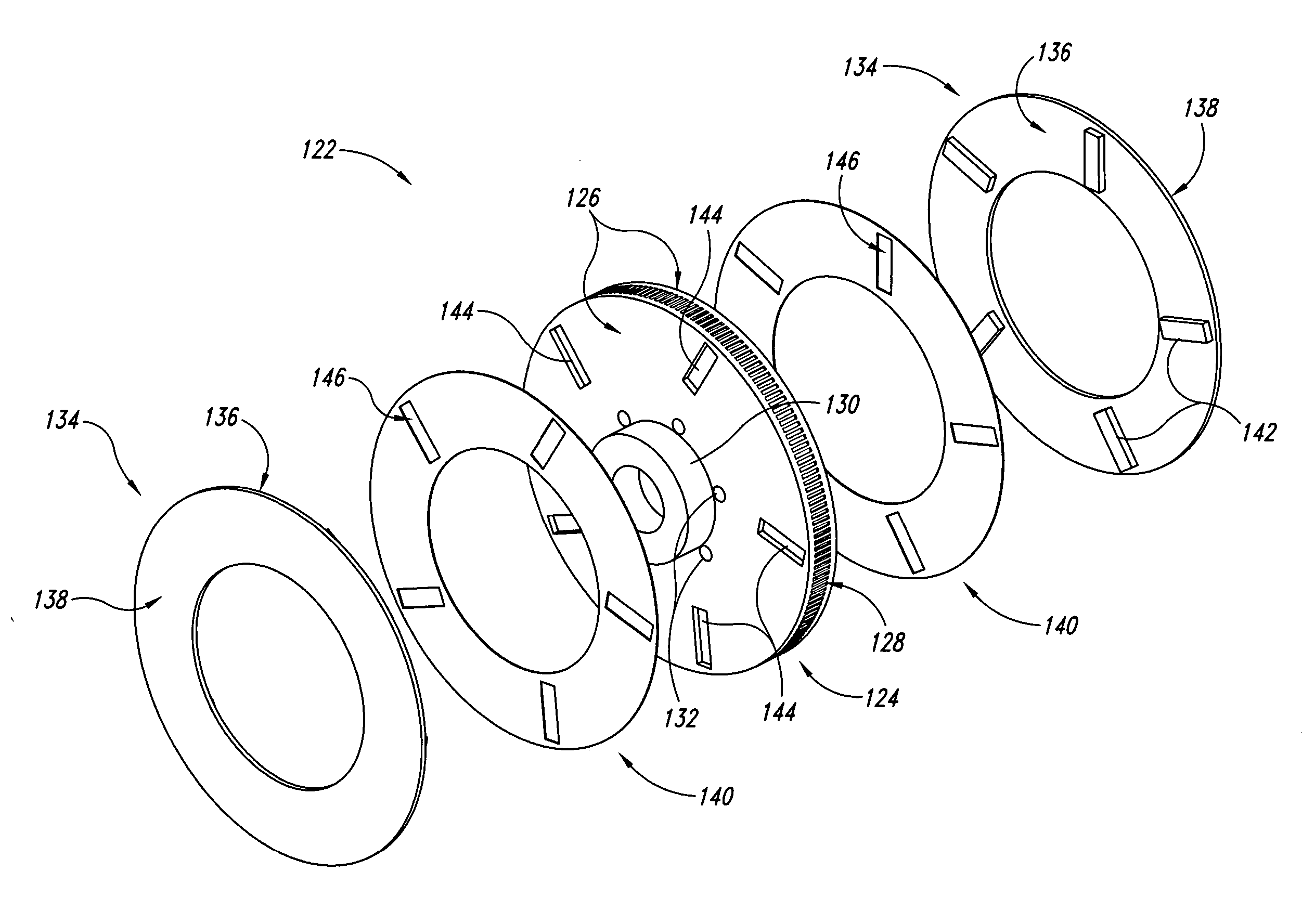

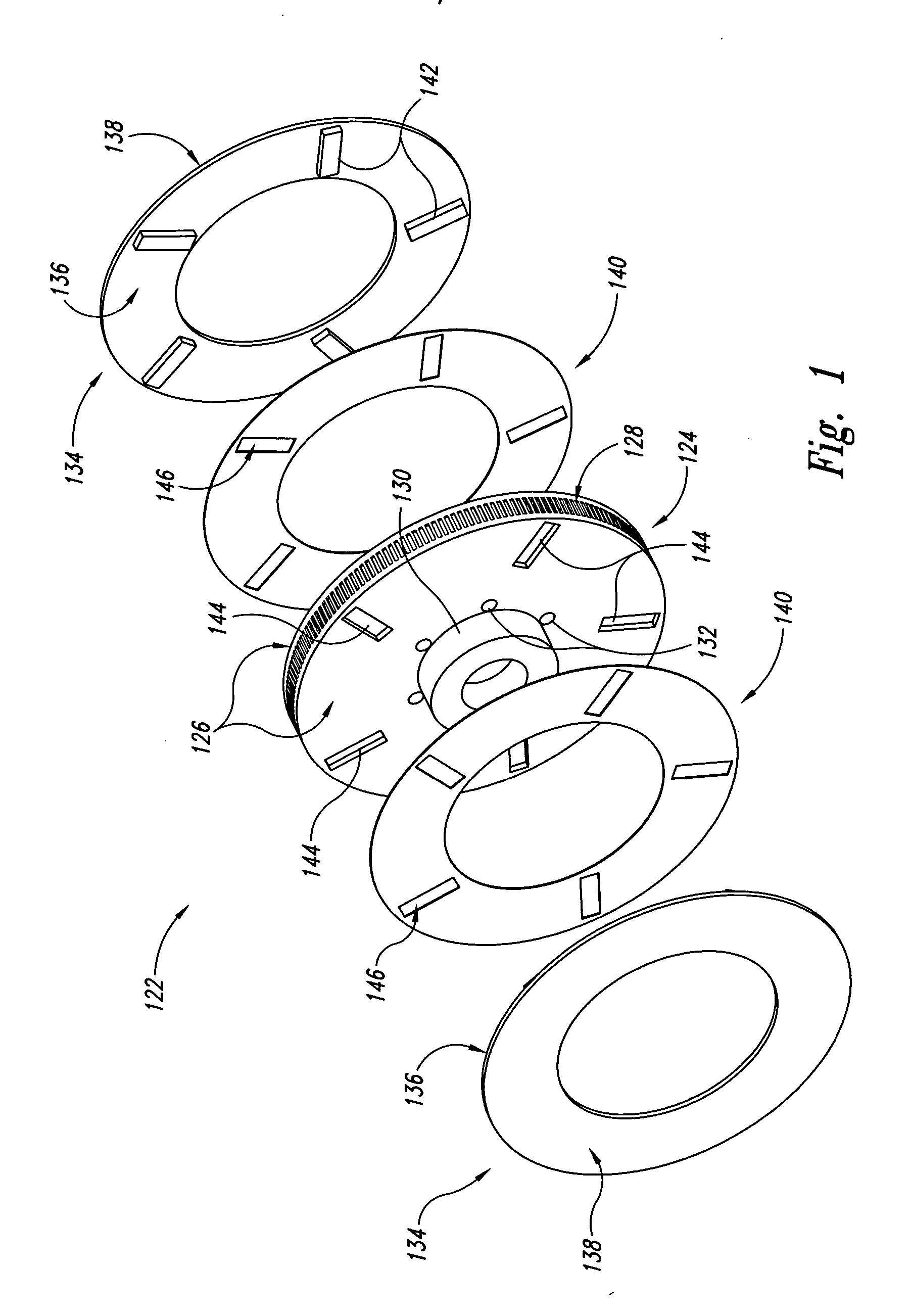

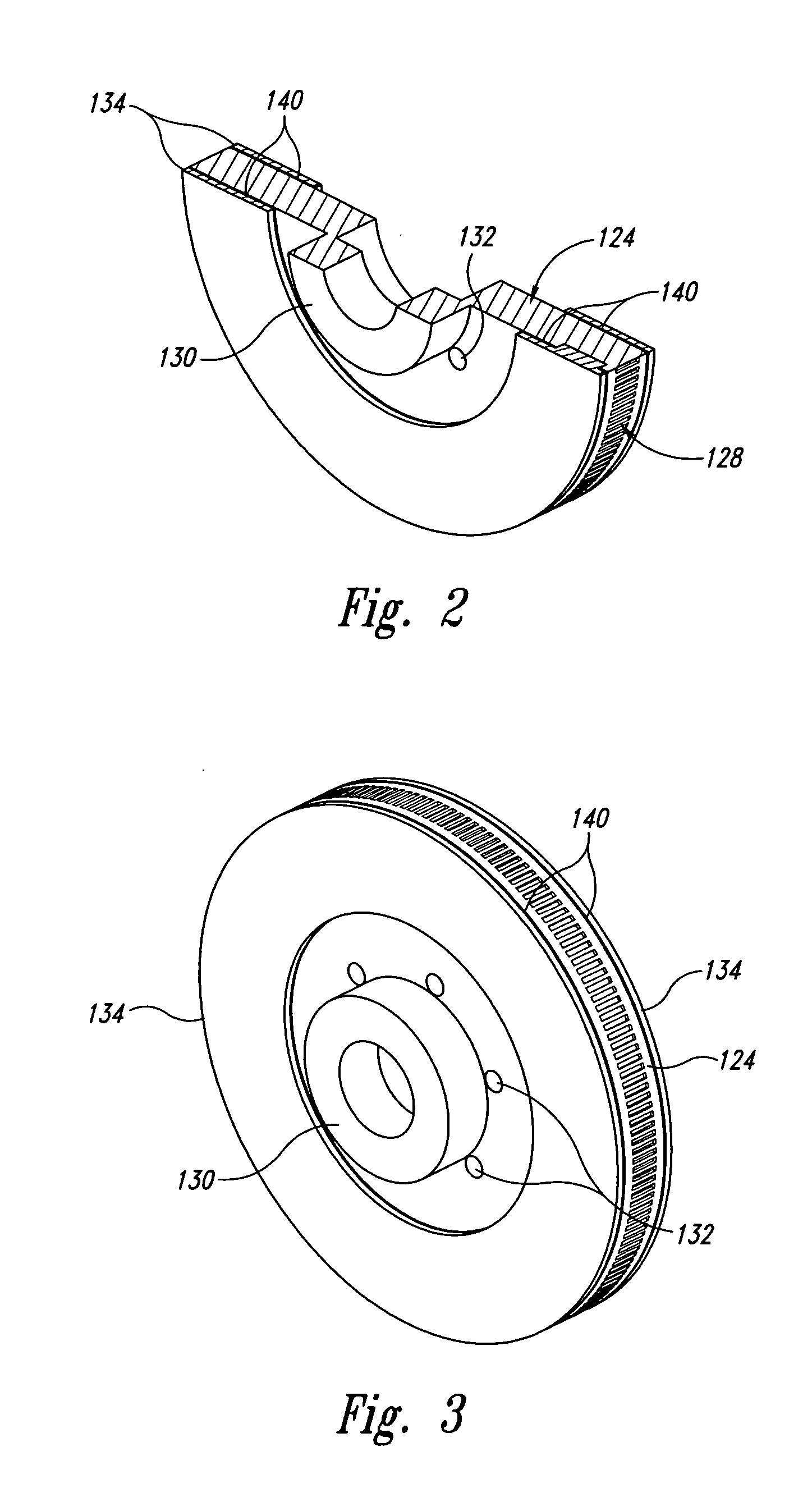

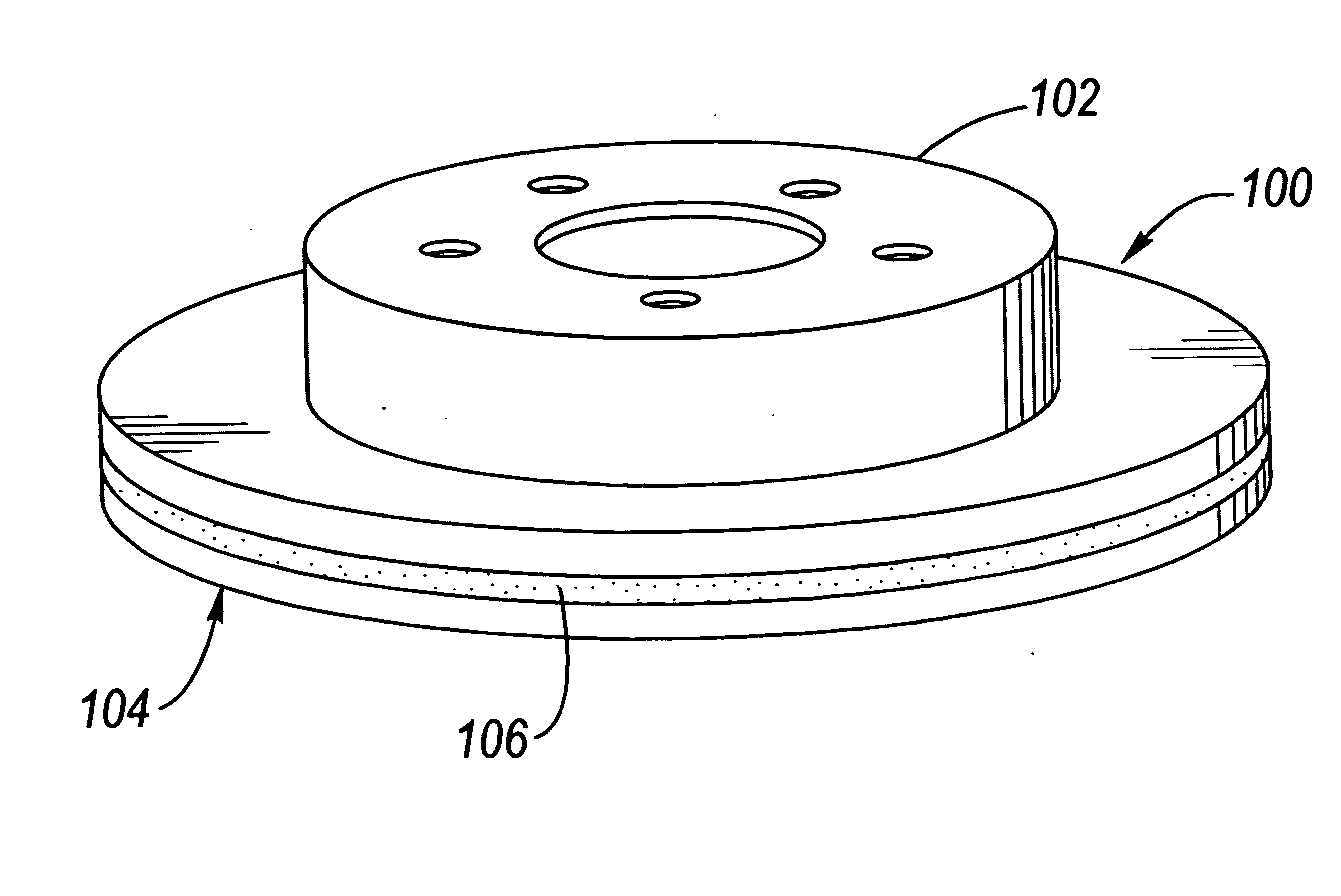

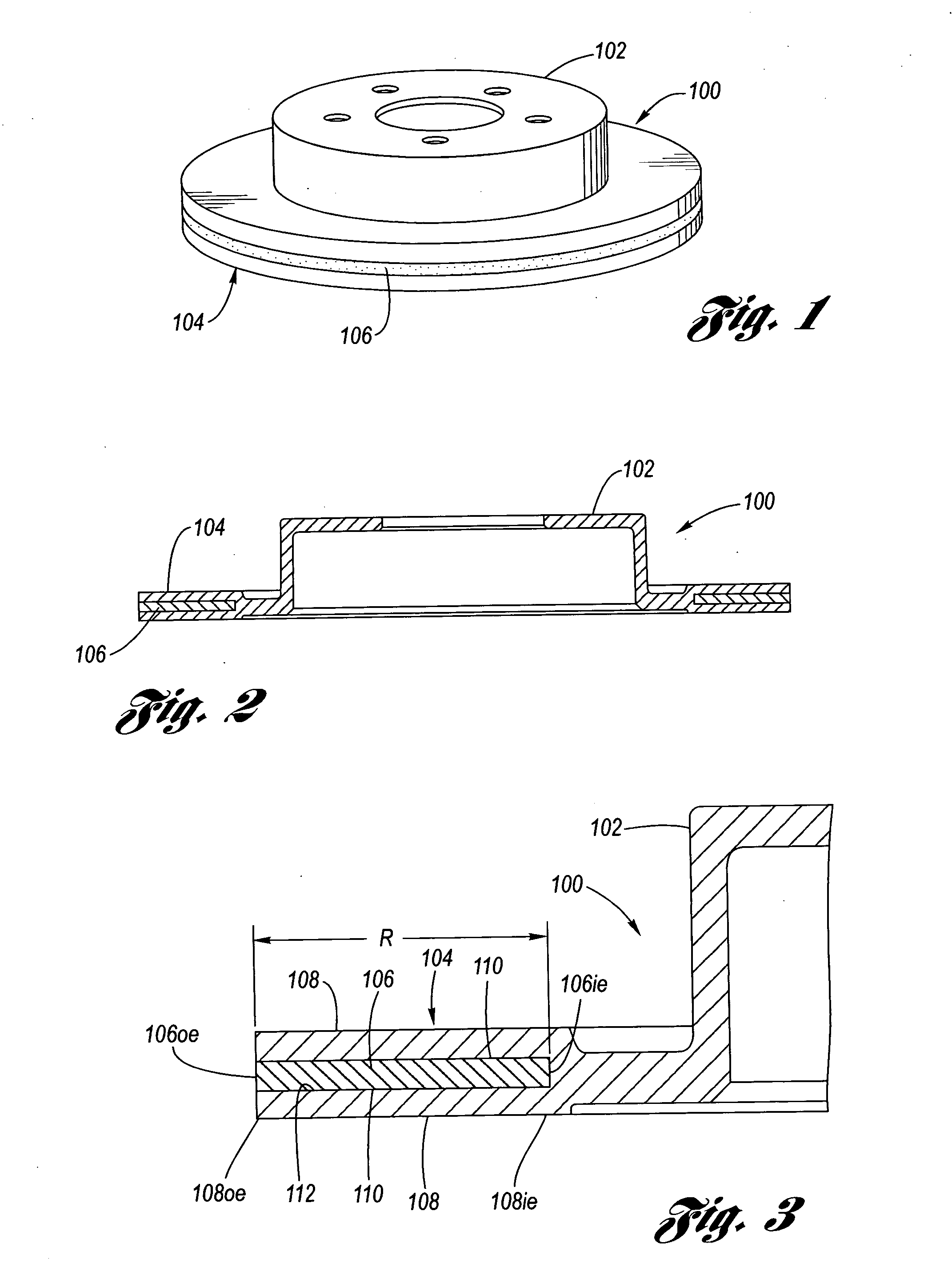

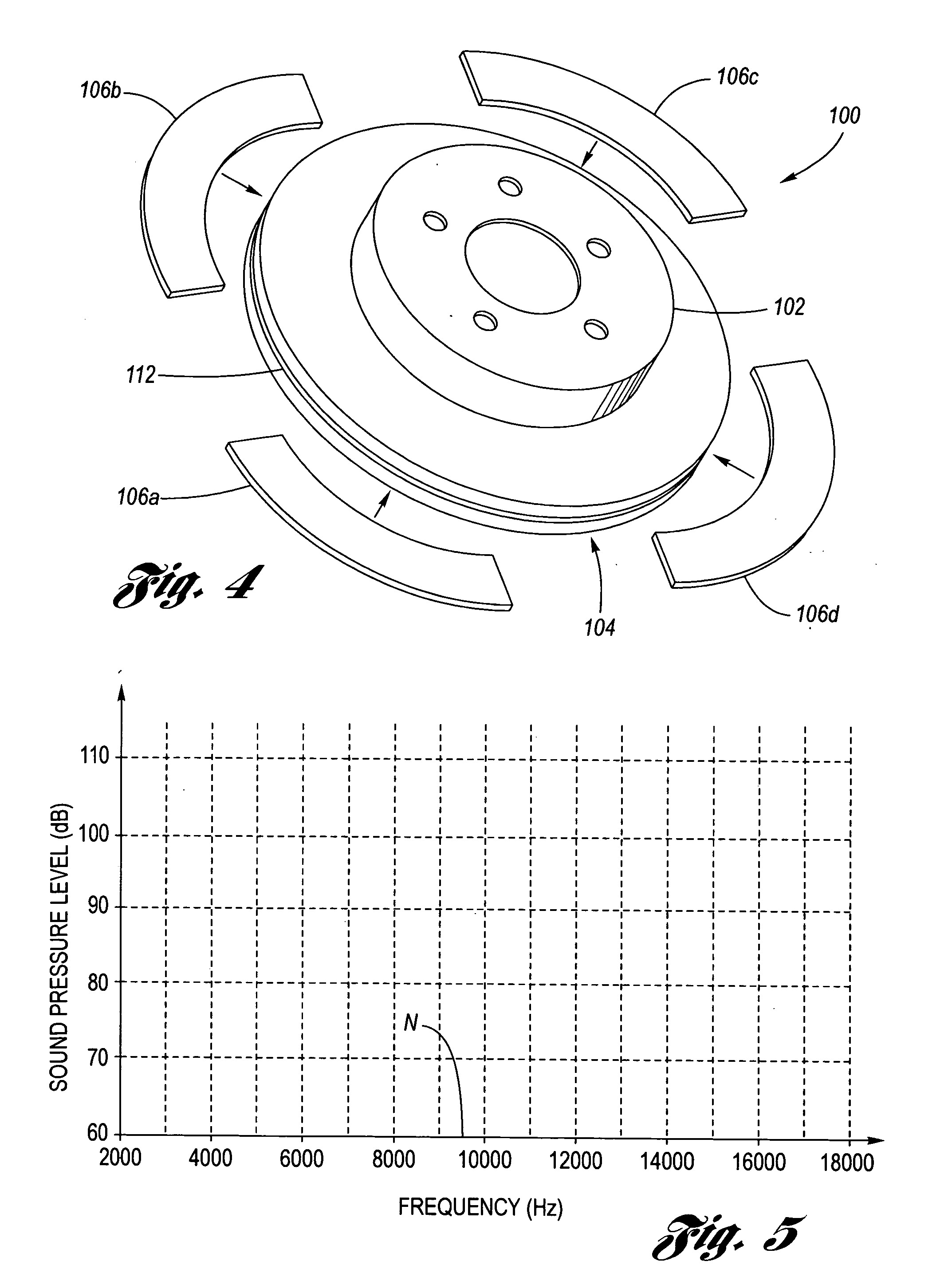

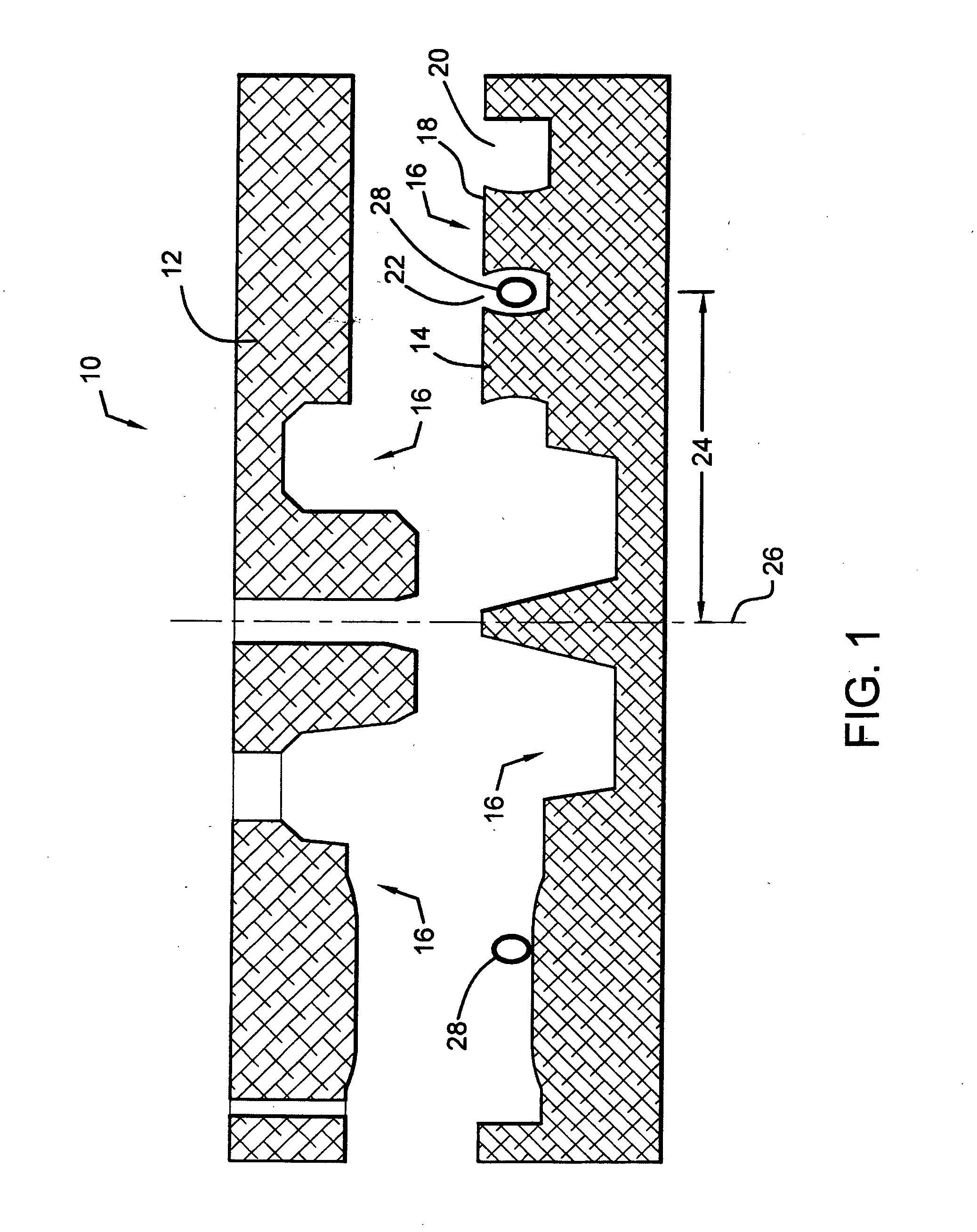

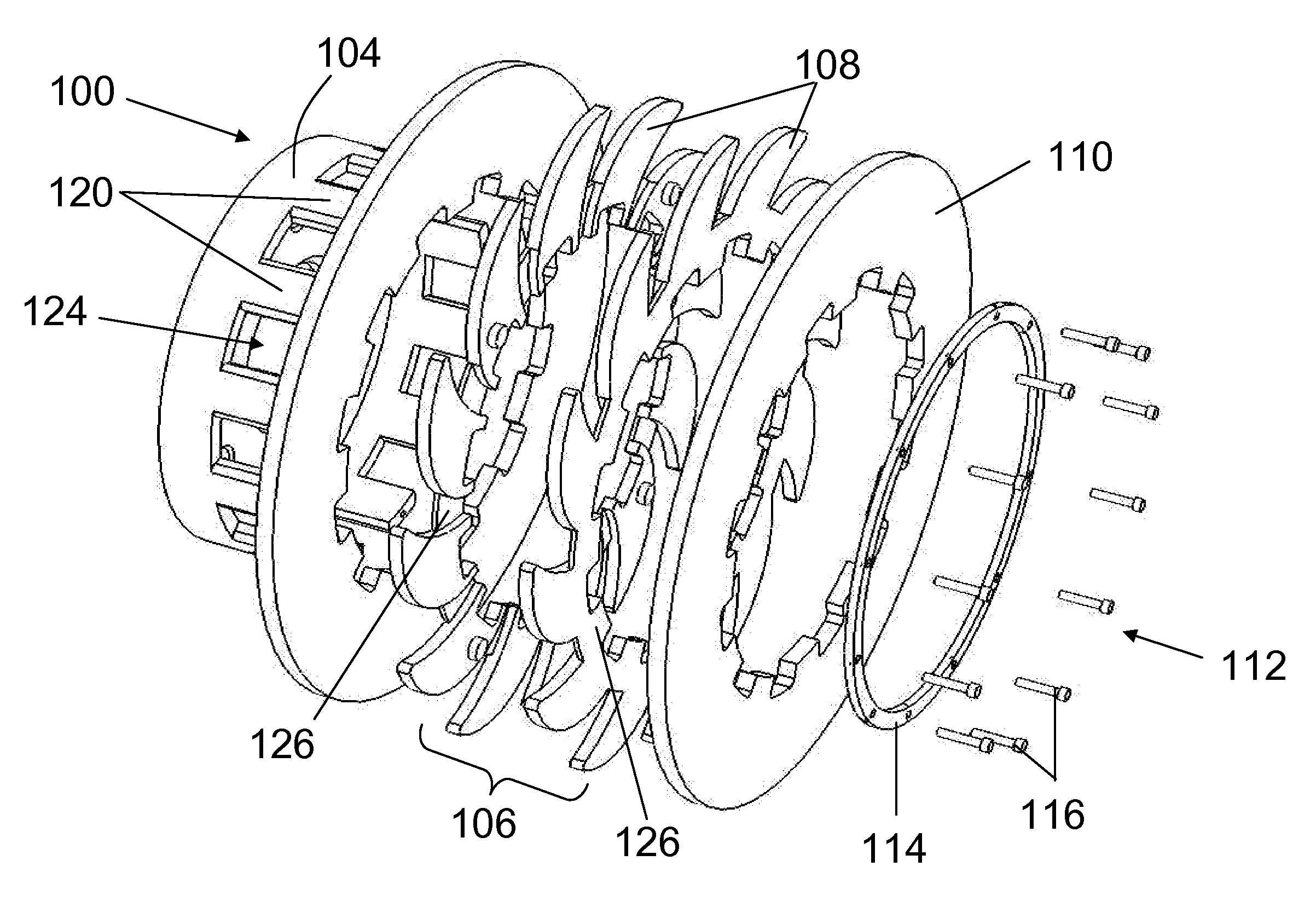

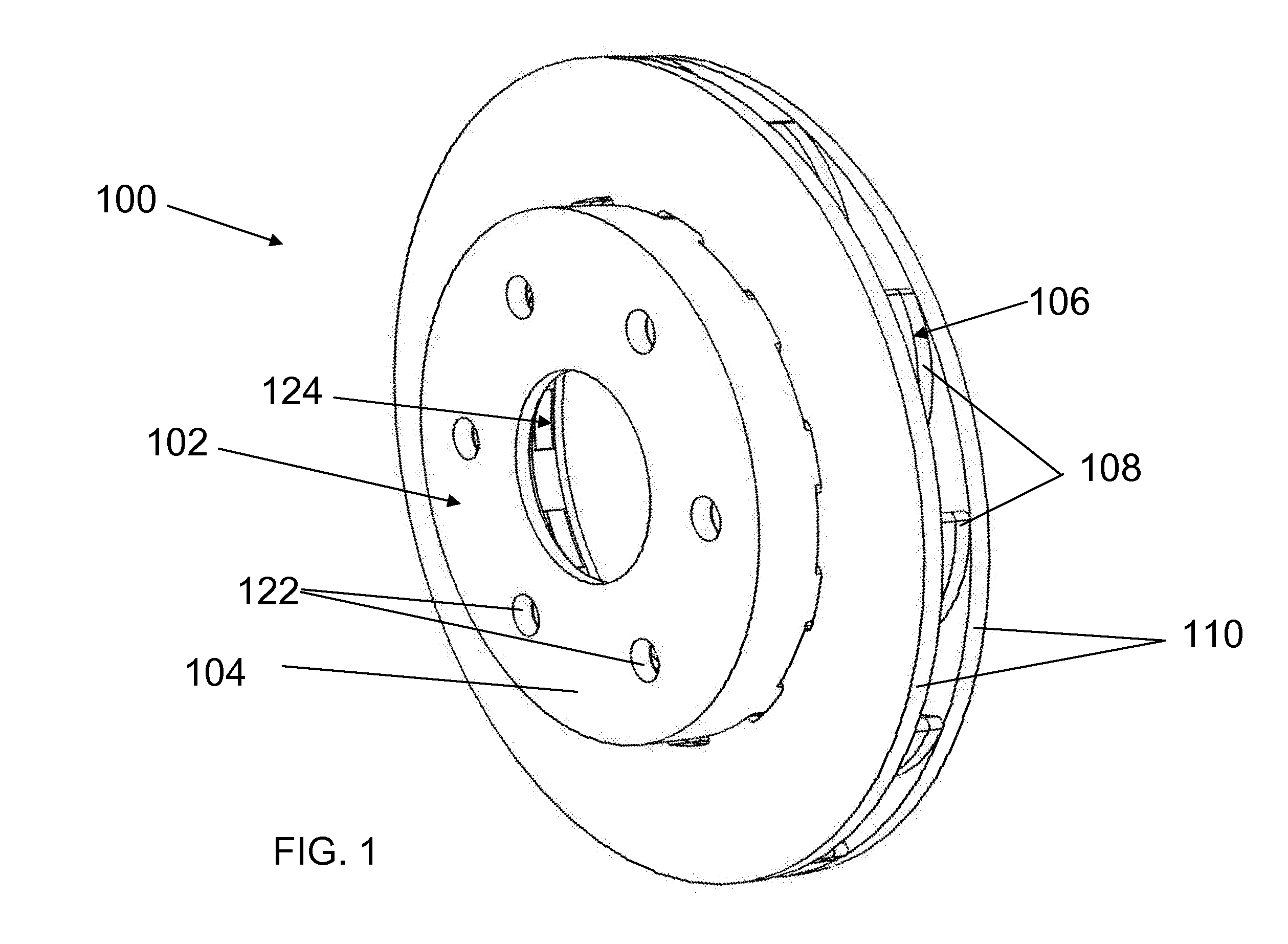

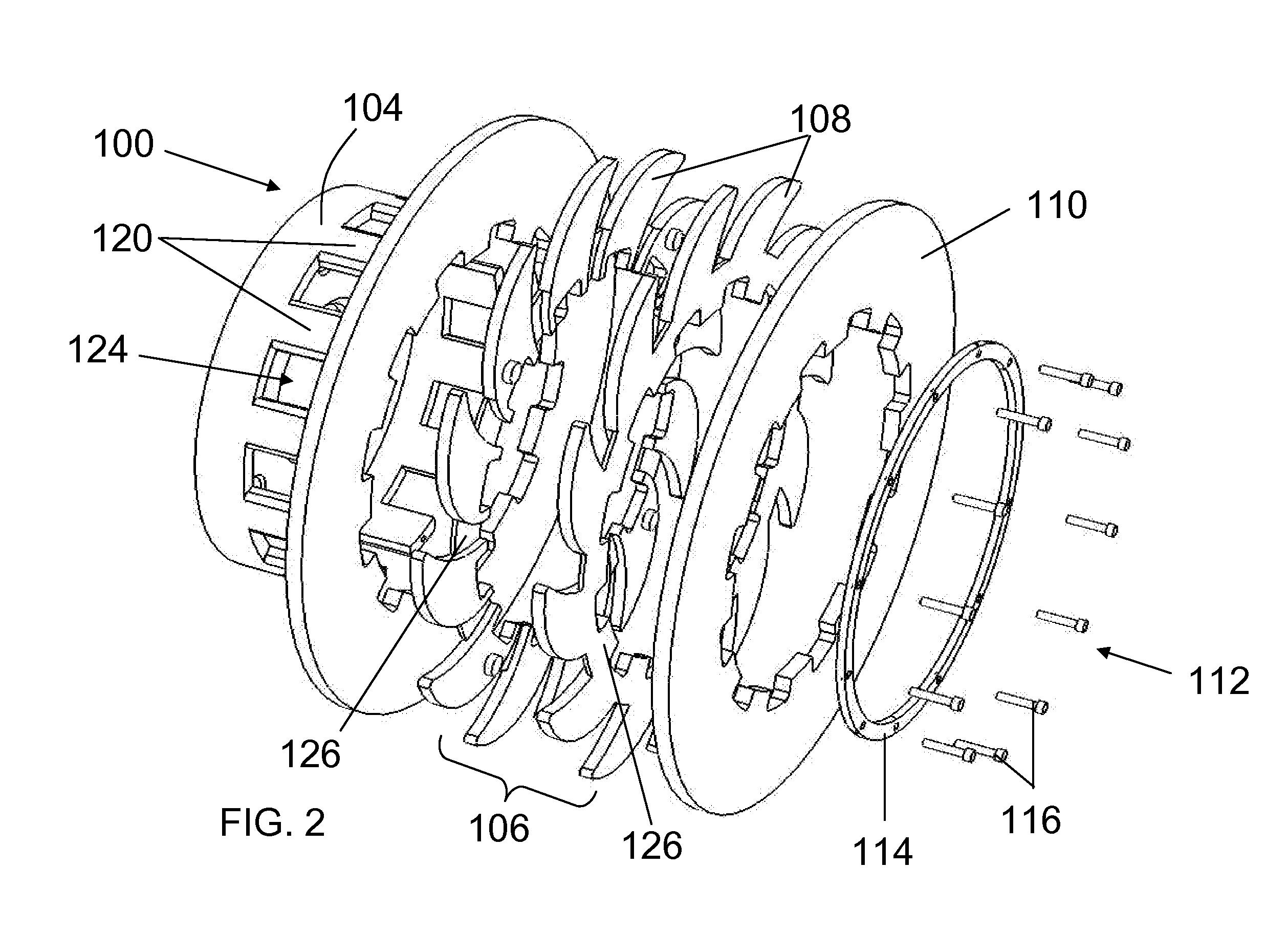

Disc brake rotor assembly and method for producing same

InactiveUS20050183909A1Improve thermal conductivityOptimize acoustic frequency transferBraking element arrangementsNoise/vibration controlAdhesiveMetal alloy

Novel composite disc brake rotor assemblies are provided, along with novel and efficient methods for manufacturing them. Preferably, the rotor assemblies comprise annular wear plates formed of particle reinforced aluminum-based metal matrix composite (MMC), ceramic matrix composite (CMC), or of ‘carbon graphite foam.’ The wear plates, made of a first material, are attached to annular surfaces of a central rotor, made of a second material, by fusing bonding layers between the wear plates and the rotor surfaces. The bonding layers are comprised of at least one of a metal alloy having a melting temperature lower than that of either the first or second materials, and a high-temperature adhesive. Preferably, the wear plates comprise projections that are positioned within adjacent receiving recesses in the center rotor. The bonding layers and projections enhance thermal and acoustical transference between the wear plates and the center rotor section. Carbon graphite foam provides for substantially enhanced heat transference. Use of the fusable binding layer, or adhesive provides for an efficient, low cost method of manufacturing for composite disc brake rotor assemblies.

Owner:BENMAXX

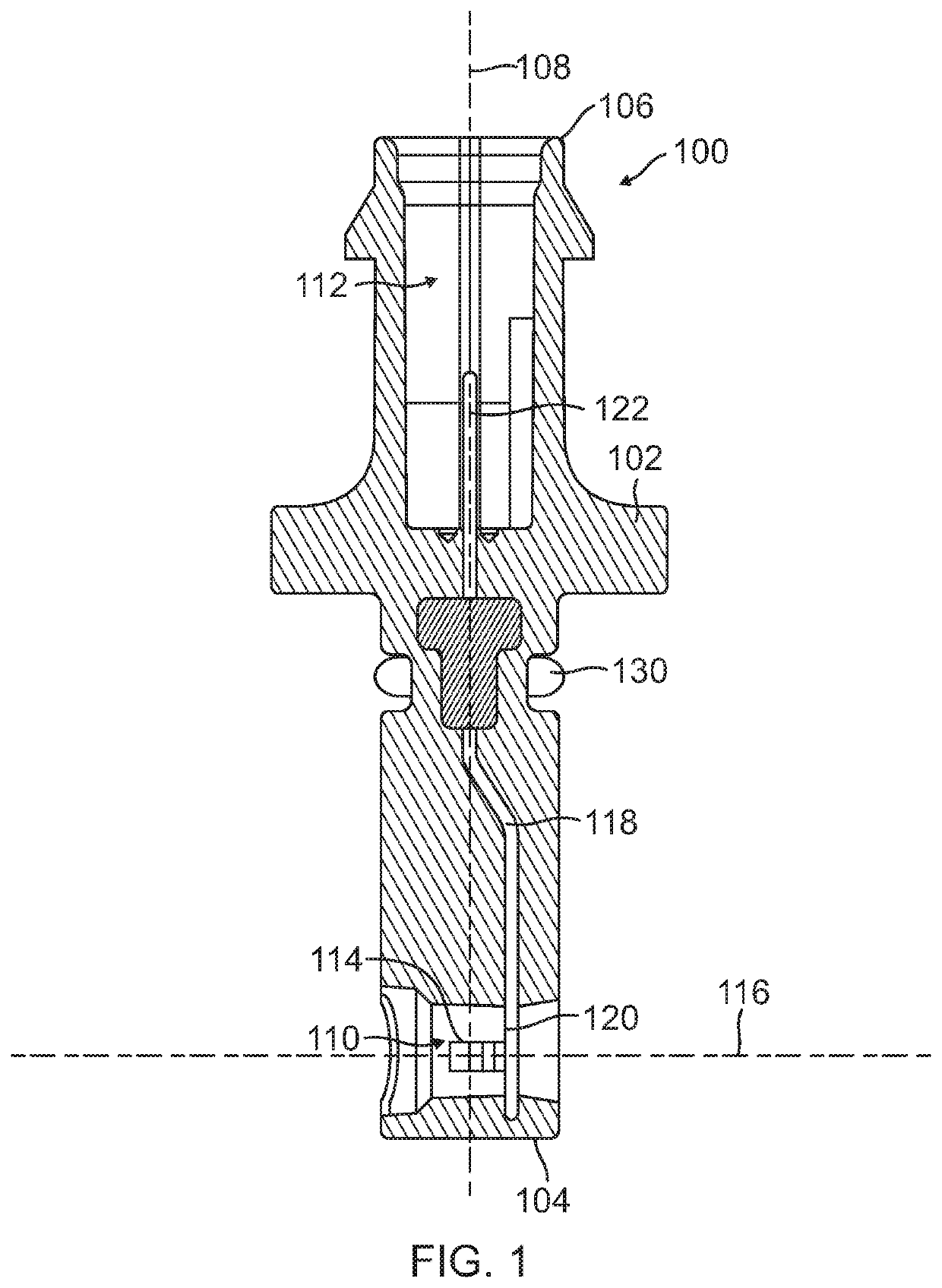

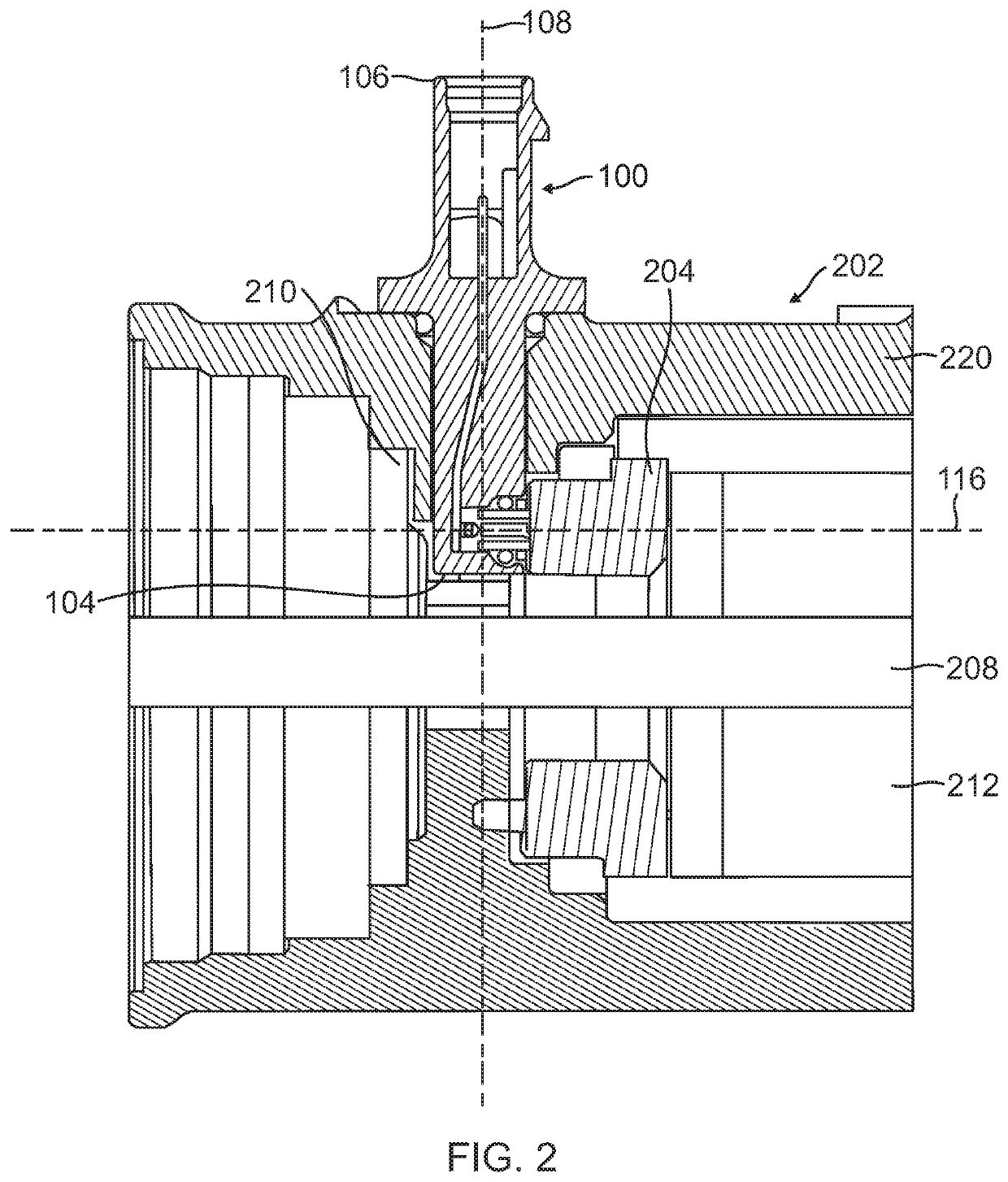

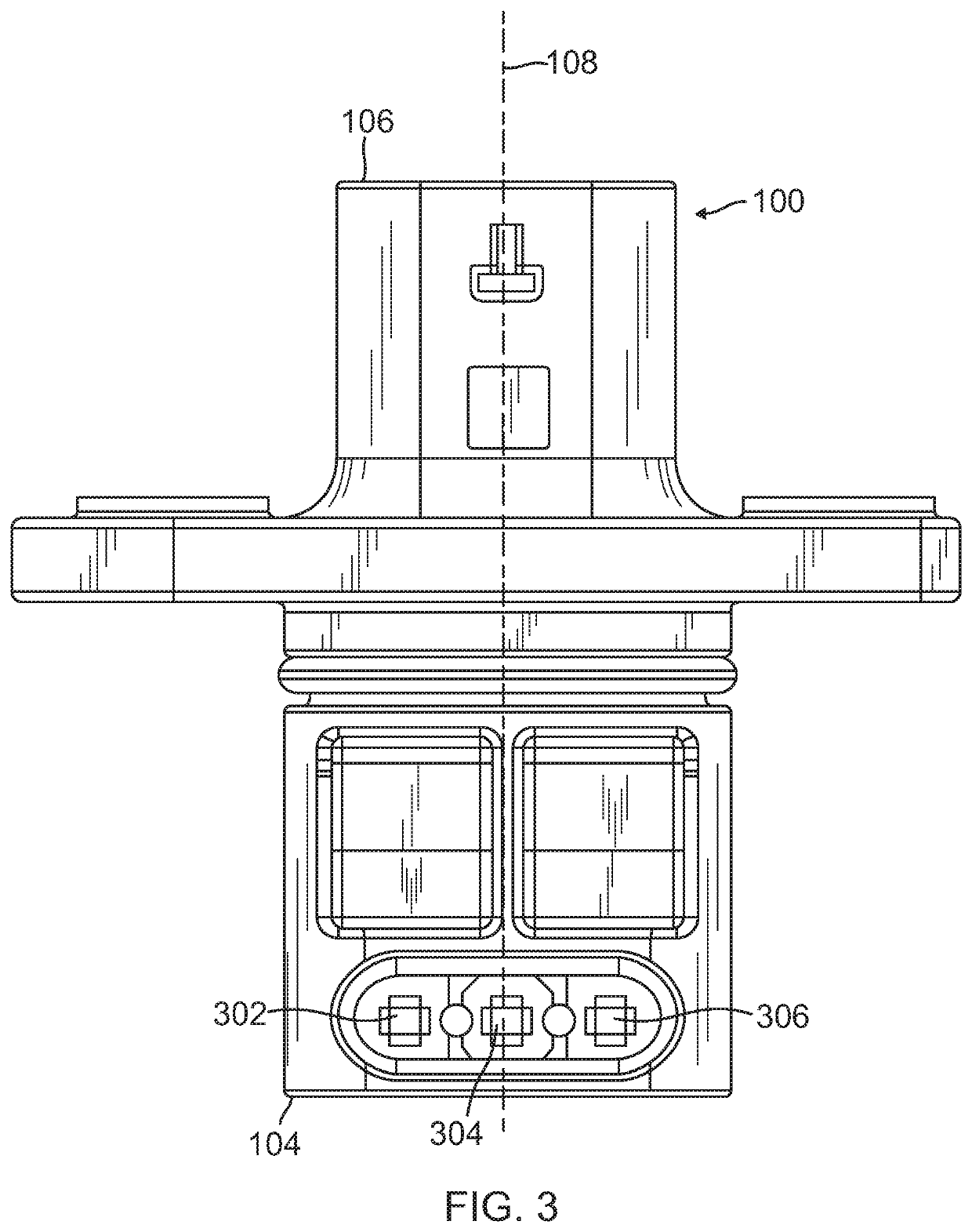

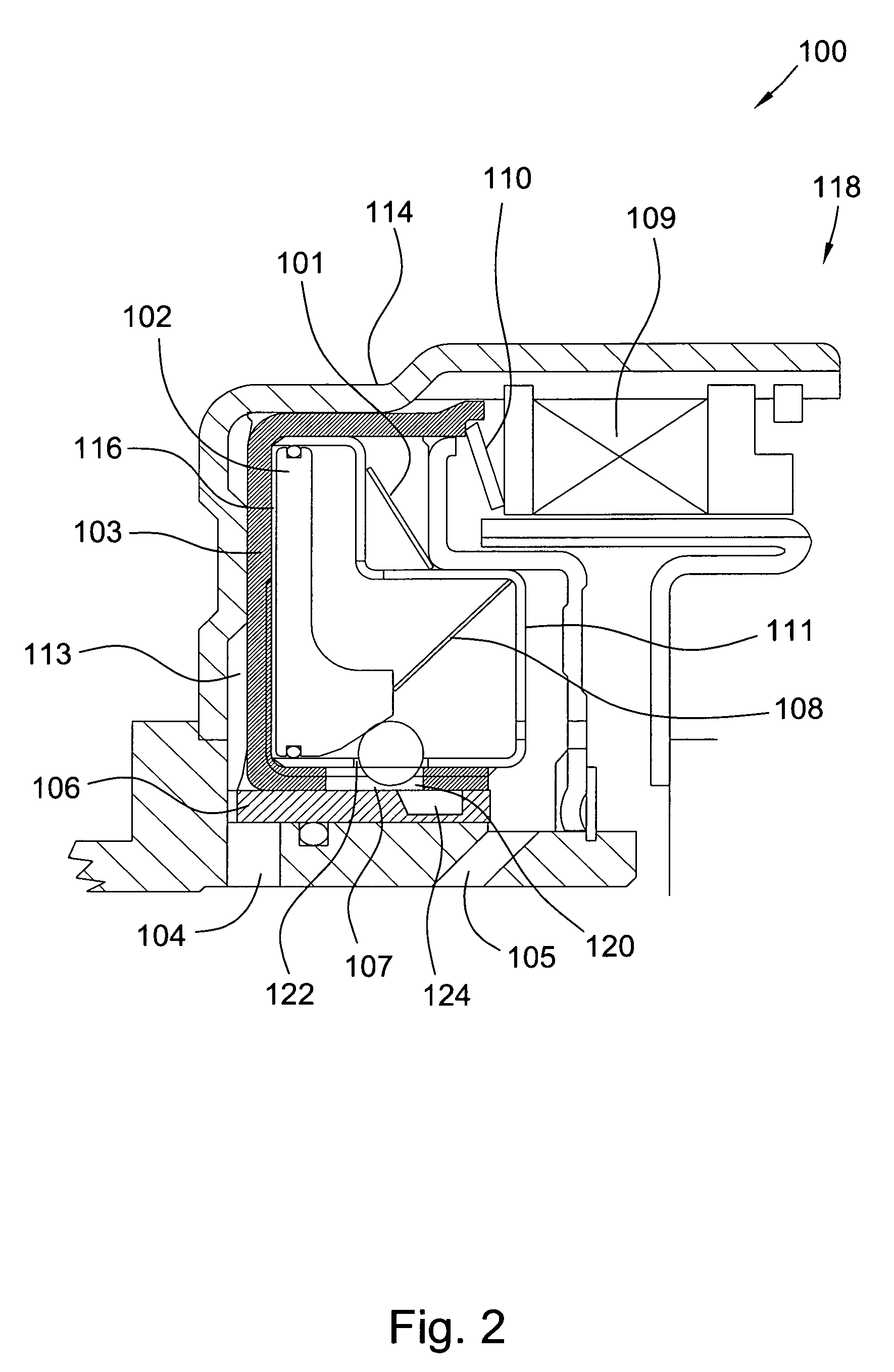

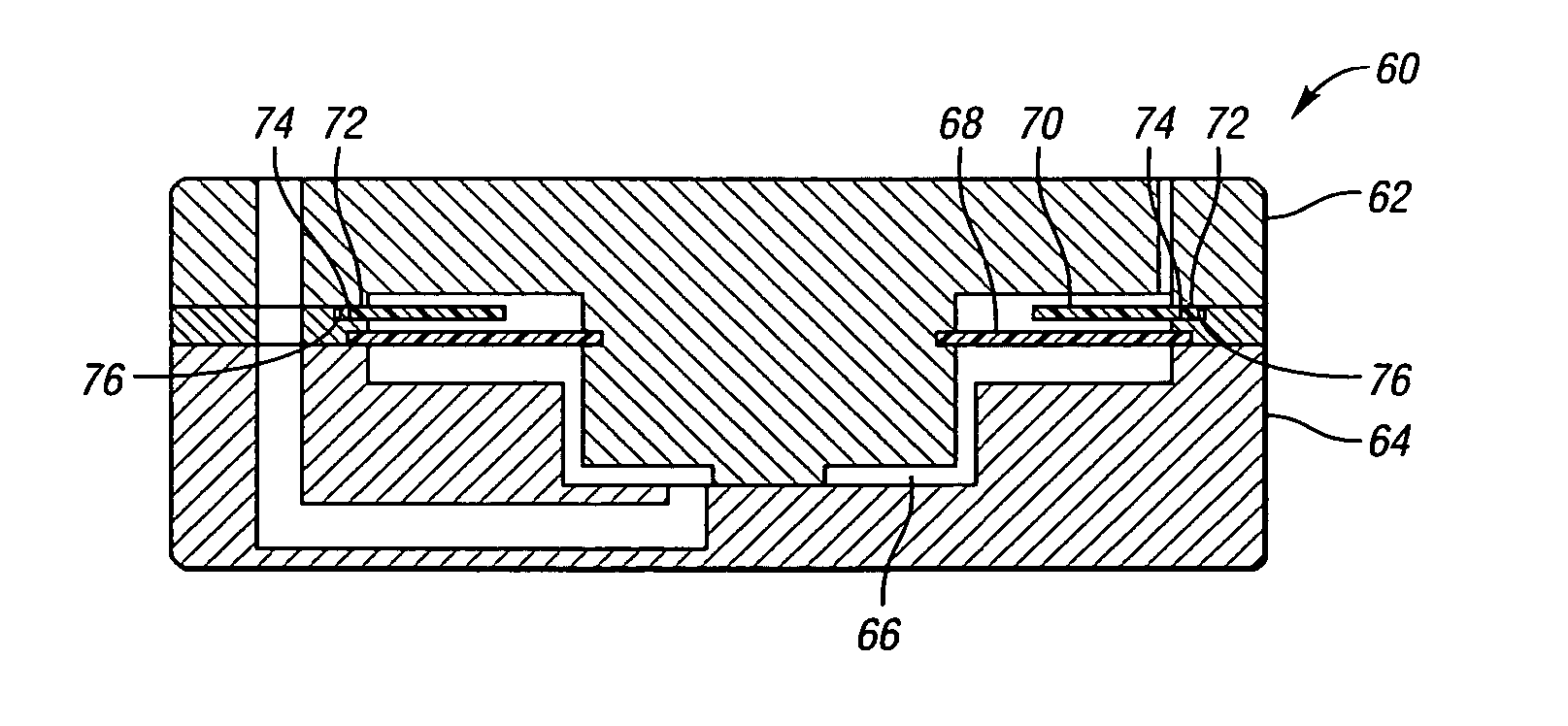

Electromechanical braking connector

ActiveUS20190375383A1Reduce excess spaceImprove the environmentBraking action transmissionCoupling device detailsBody axisElectrical connection

An electromechanical braking (EMB) connector for electrical communication between an interior of a brake caliper assembly and an exterior of the brake caliper assembly is disclosed. The EMB connector includes a body having a distal end for insertion into the interior of the brake caliper assembly and a proximal end for exposure on the exterior of the brake caliper assembly, with the distal end and the proximal end defining a body axis. The EMB connector also includes a load sensor connector for coupling with a load sensor disposed on the interior of the brake caliper assembly. The load sensor connector is compressible along a load sensor axis that is substantially perpendicular to the body axis. The EMB connector further includes a conductive component coupled to the load sensor connector. The conductive component enables electrical connection of the load sensor to the exterior of the brake caliper assembly.

Owner:SENSATA TECHNOLOGIES INC

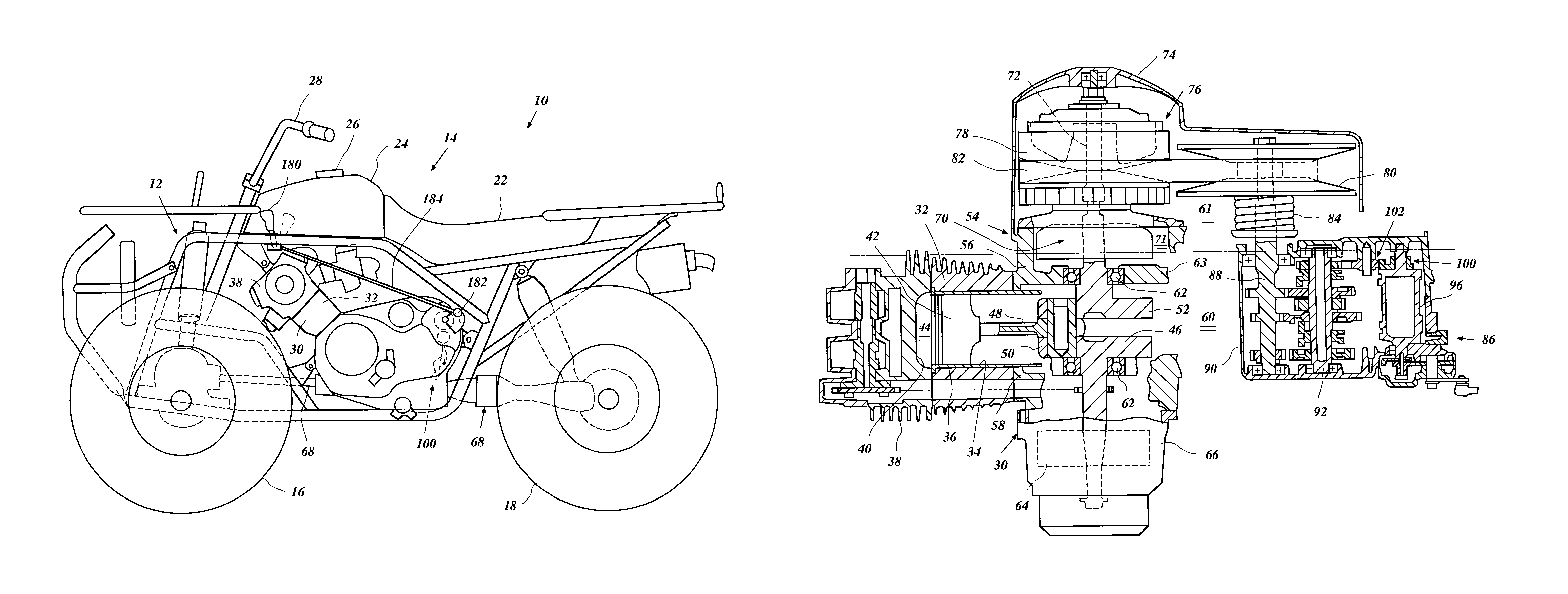

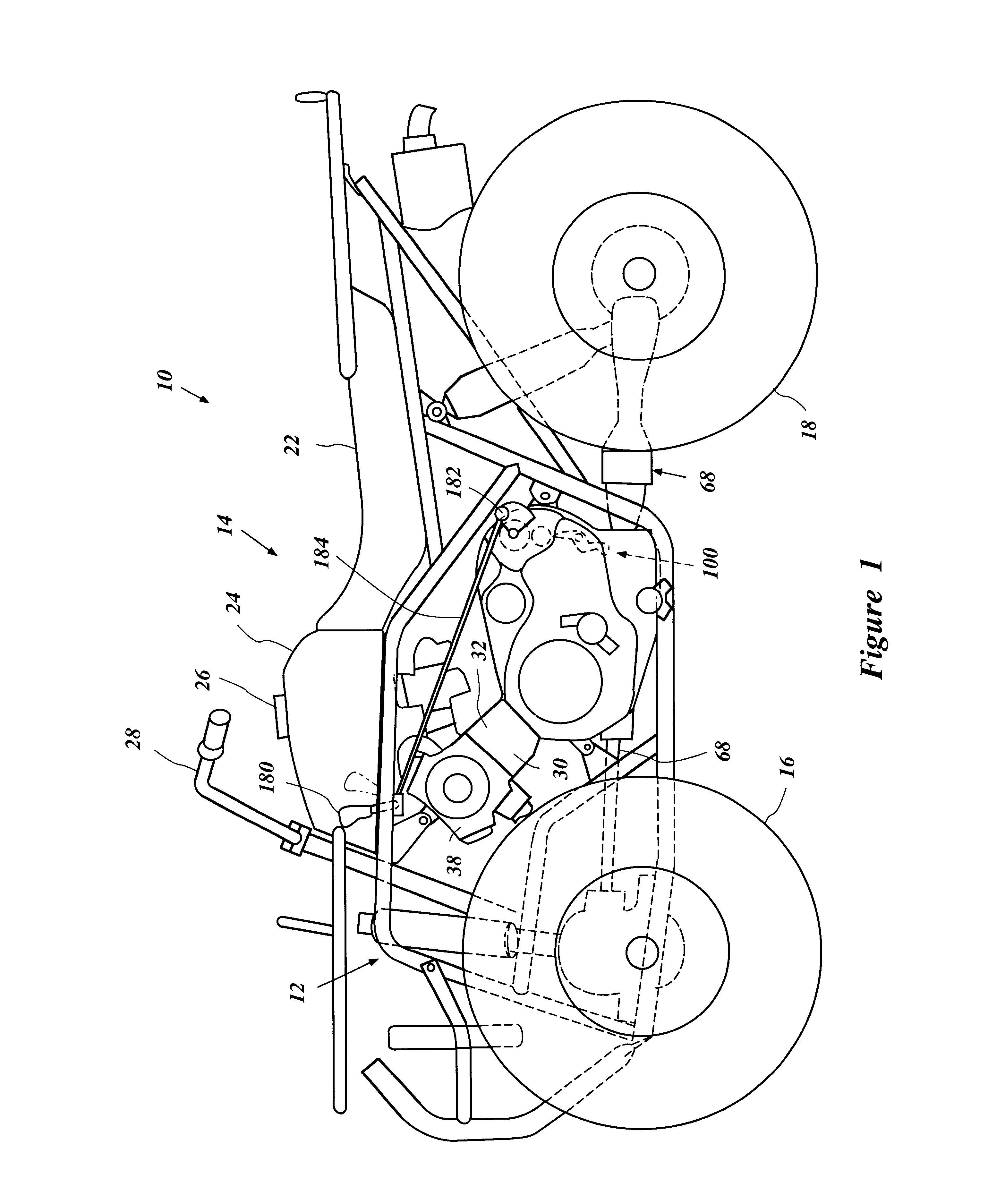

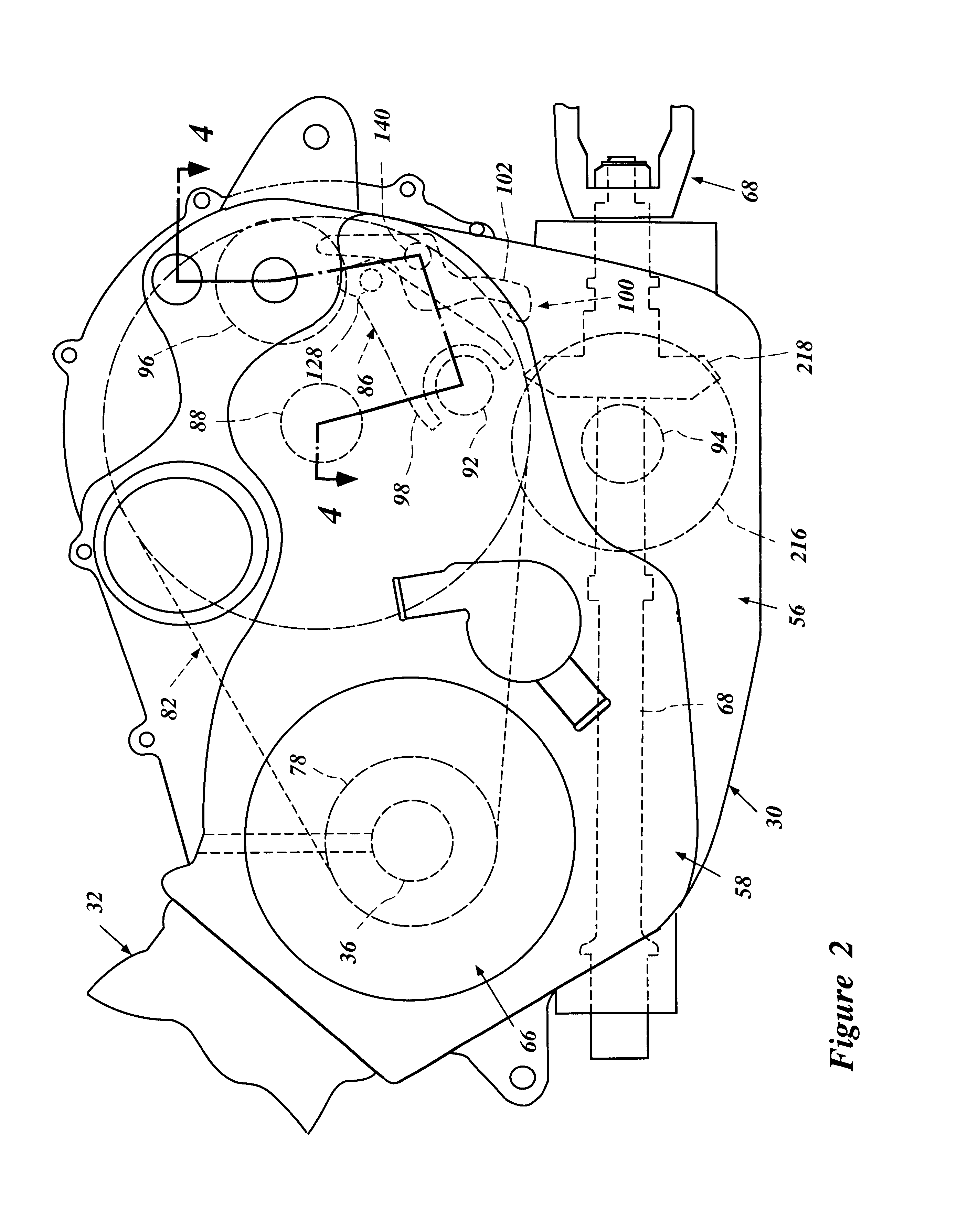

Transmission lock for all-terrain vehicle

InactiveUS6725962B1Braking element arrangementsElectric propulsion mountingCentrifugal clutchCrankshaft

All all-terrain vehicle has a shiftable transmission that is coupled to a variable speed V-belt transmission. The variable speed V-belt transmission is joined to a crankshaft through a centrifugal clutching arrangement. The shiftable transmission enables an operator to go between low, high, neutral, reverse, and park. In the park position, the transmission is locked from substantial rotation such that the engaged wheels of the all-terrain vehicle are also locked from substantial rotation, whether or not the engine speed is sufficient to allow the centrifugal clutch to be engaged with the variable speed transmission.

Owner:YAMAHA MOTOR CO LTD

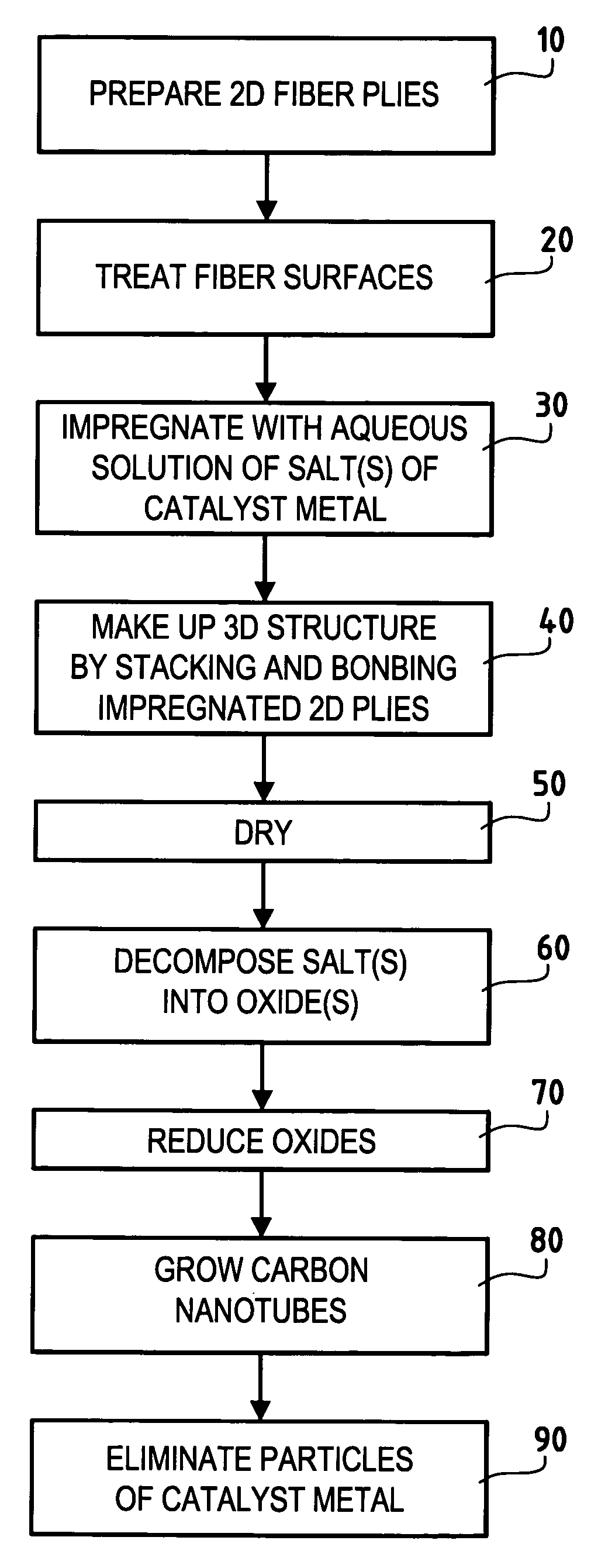

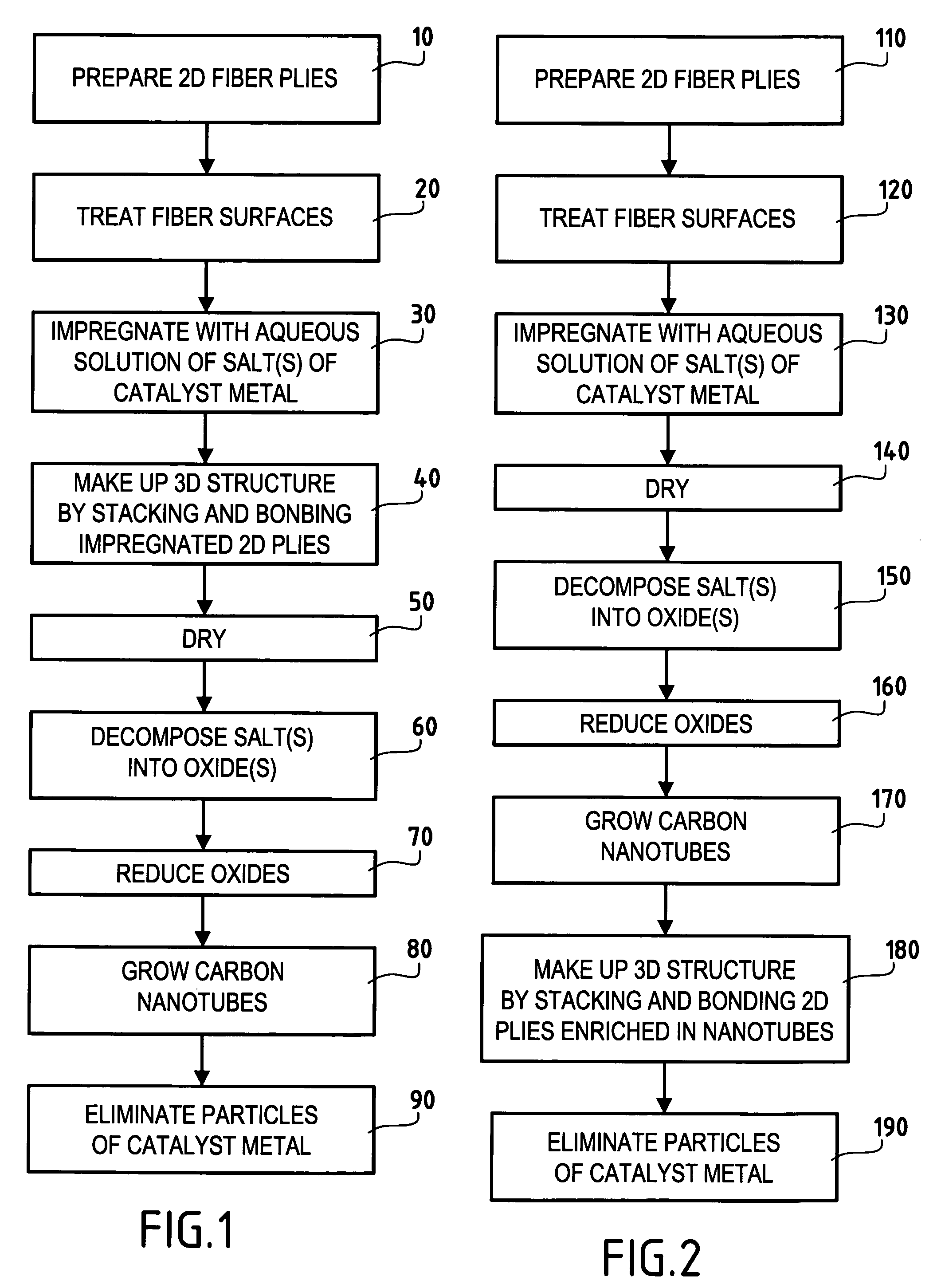

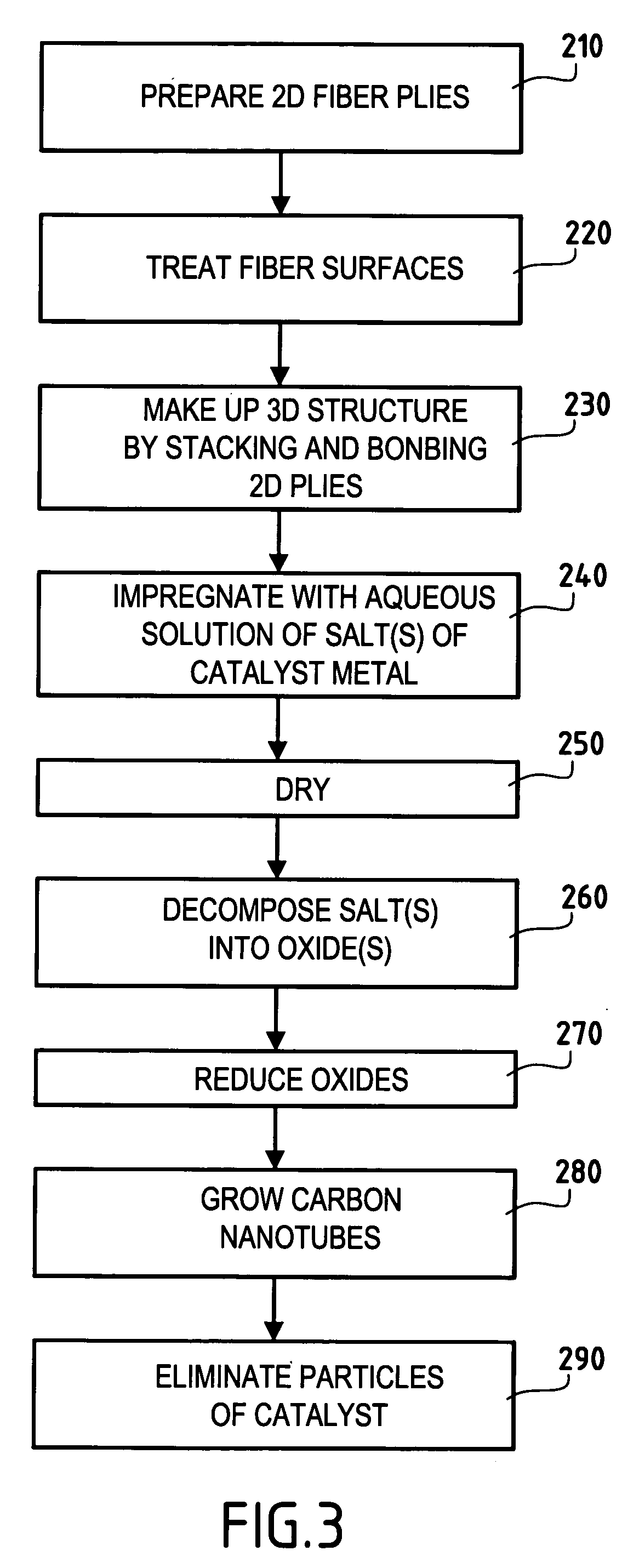

Three-dimensional fiber structure of refractory fibers, a method of making it, and thermostructural composite materials, in particular friction parts, made therefrom

ActiveUS20050176329A1Improve propertiesEasy to prepareMaterial nanotechnologyCarbon fibresMetallurgyCarbon nanotube

Carbon nanotubes are incorporated in the fiber structure by growing them on the refractory fibers of the substrate so as to obtain a three-dimensional substrate made of refractory fibers and enriched in carbon nanotubes. The substrate is densified with a matrix to form a part of composite material such as a friction part of C / C composite material.

Owner:CENT NAT DE LA RECHERCHE SCI

Brake unit

InactiveUS6302246B1Prolong lifeImprove flatnessBraking element arrangementsNoise/vibration controlEngineeringCeramic metal

A brake unit comprising at least one brake and at least one brake pad having at least one friction lining is described. The brake has a disk brake with a brake rotor made of a ceramic-metal composite (CMC) whose outer surface or surfaces at least partially form a friction surface for the at least one friction lining, and a disk brake cup that is mounted on the disk brake by way of one or more mounting elements. The friction surface of the disk brake has a hardness of approximately 1600 to 2500 HV, and the at least one friction lining has a coefficient of friction of approximately 0.3 to 0.5. The disk brake cup and / or the mounting elements form a corrosion-inhibiting attachment to the disk brake. The brake unit can be operated in corrosion-free fashion over a service life of at least approximately eight to 10 years or approximately 200,000 to 300,000 km.

Owner:FRENI BREMBO SPA

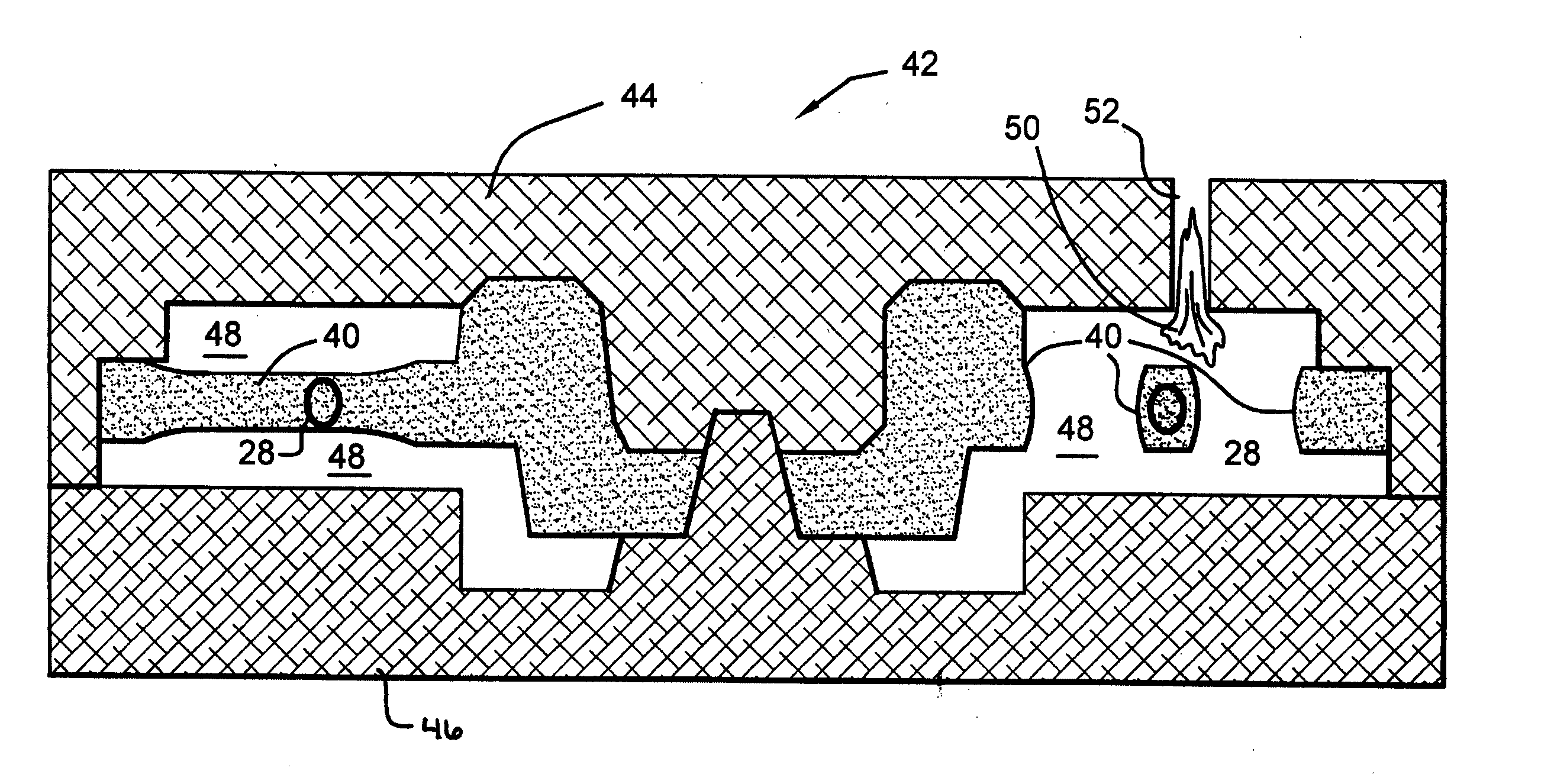

Coulomb friction damped disc brake rotors

InactiveUS20060076200A1Average thicknessSmall thicknessNoise/vibration controlBraking discsEngineeringMechanical engineering

A Coulomb friction damped disc brake rotor, wherein damping is provided Coulomb friction in generally coextensive relation with the braking surfaces of the one or more rotor cheeks. The Coulomb friction damped disc brake rotor has at least one interfacial boundary formed in at least one rotor cheek disposed in generally coextensive relation to the braking surface thereof. The interfacial boundary provides a mechanically distinguishable surface boundary between two surfaces which are in mutual contact such that a state of Coulomb friction exists therebetween.

Owner:GM GLOBAL TECH OPERATIONS LLC

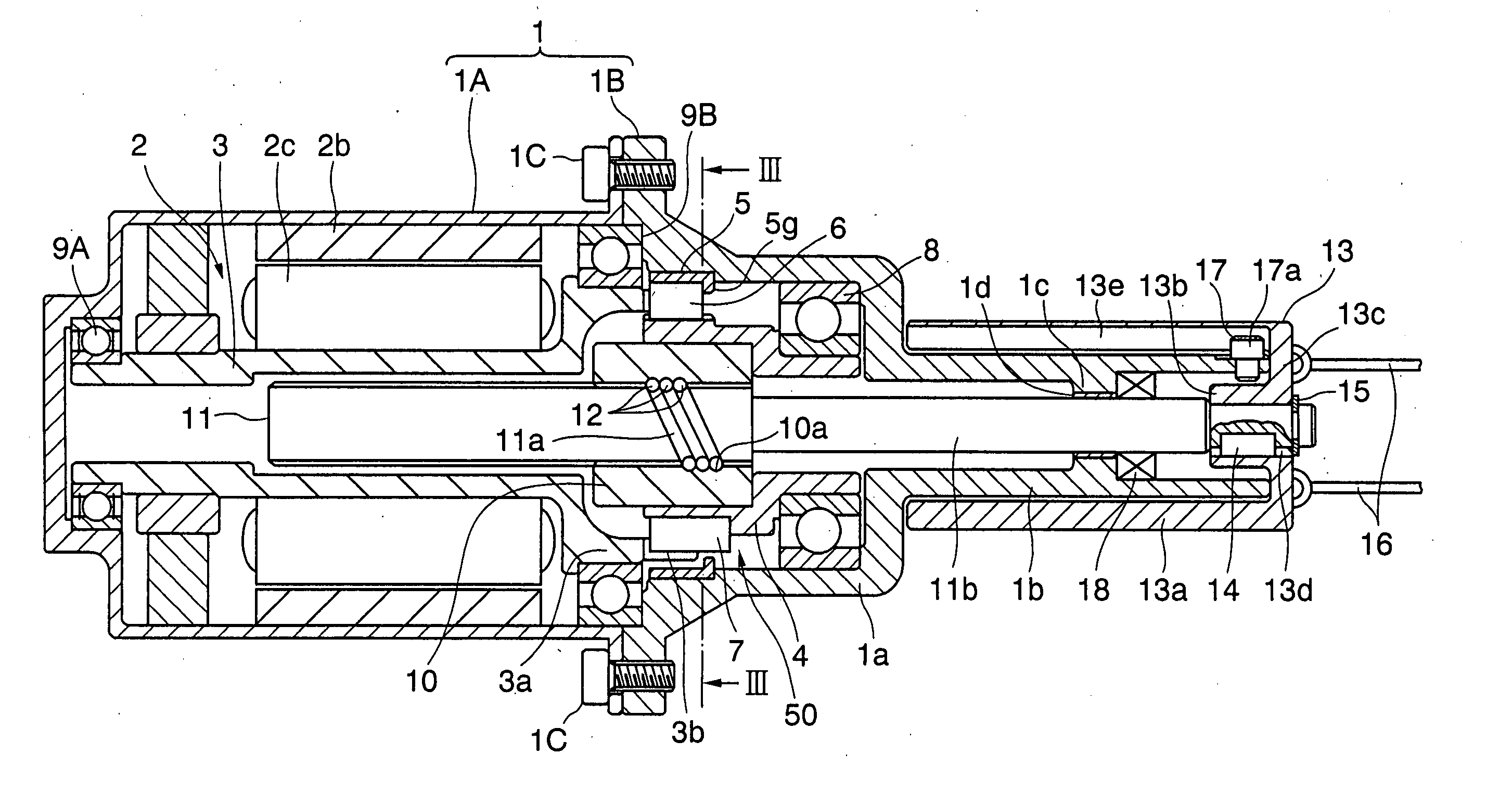

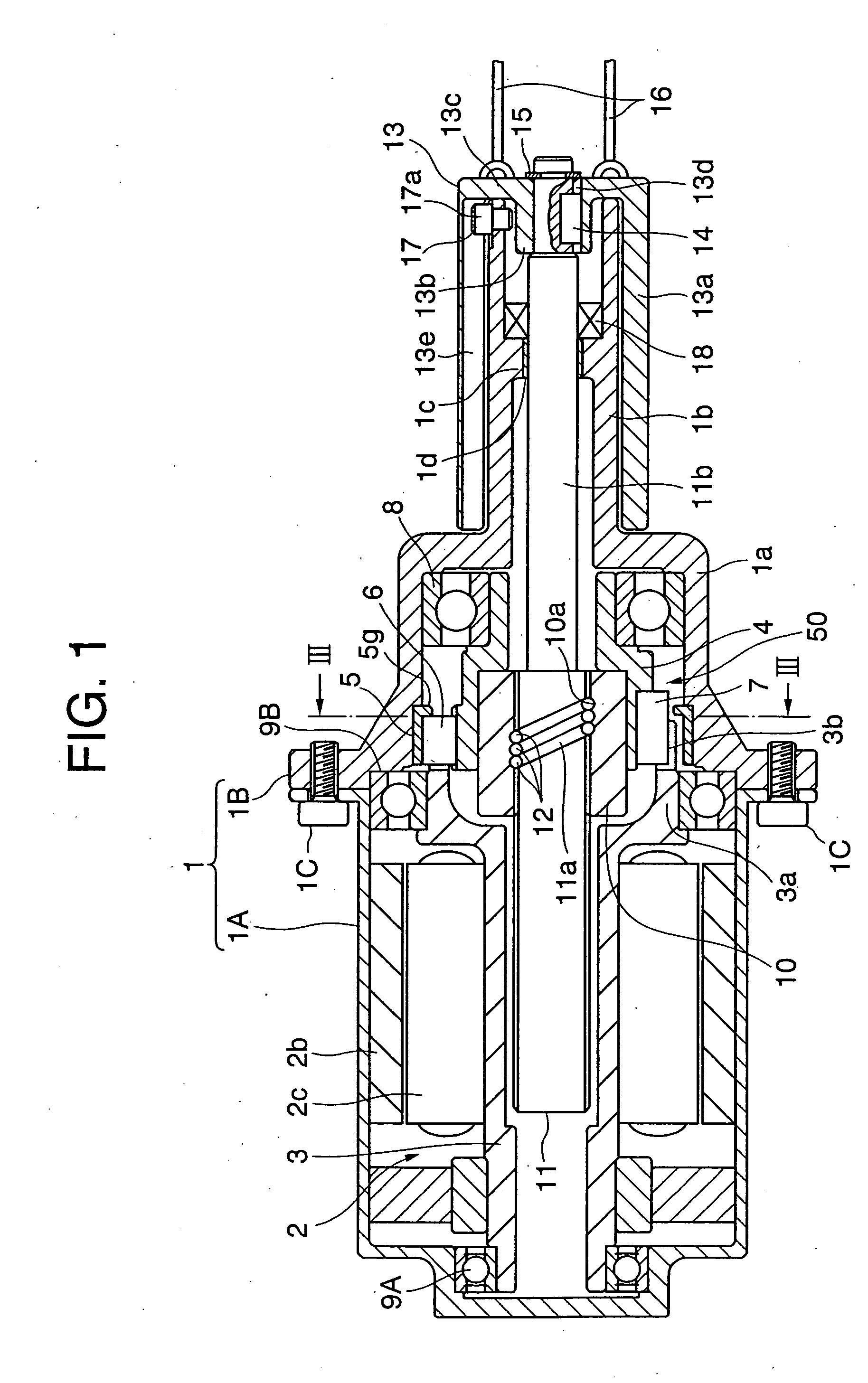

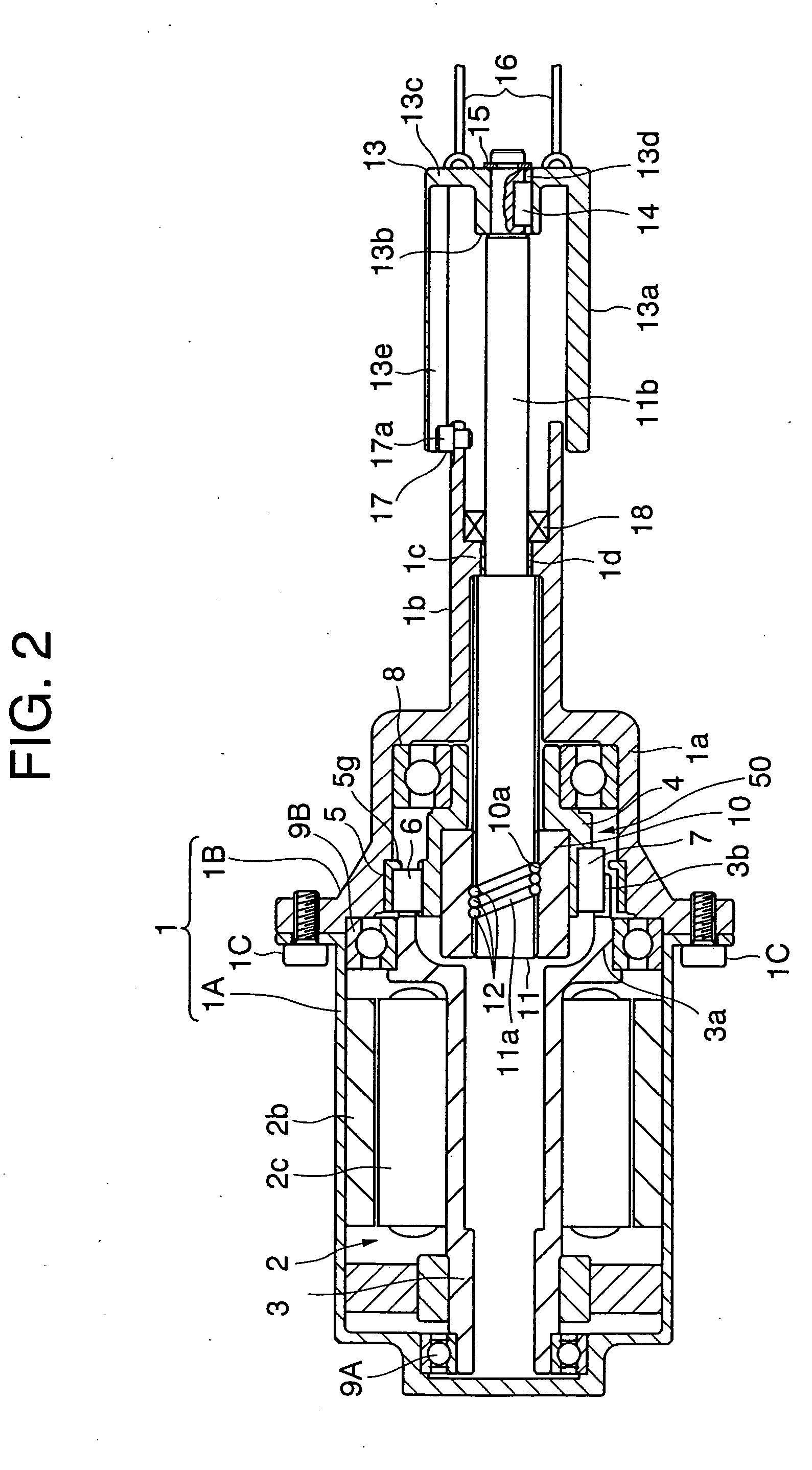

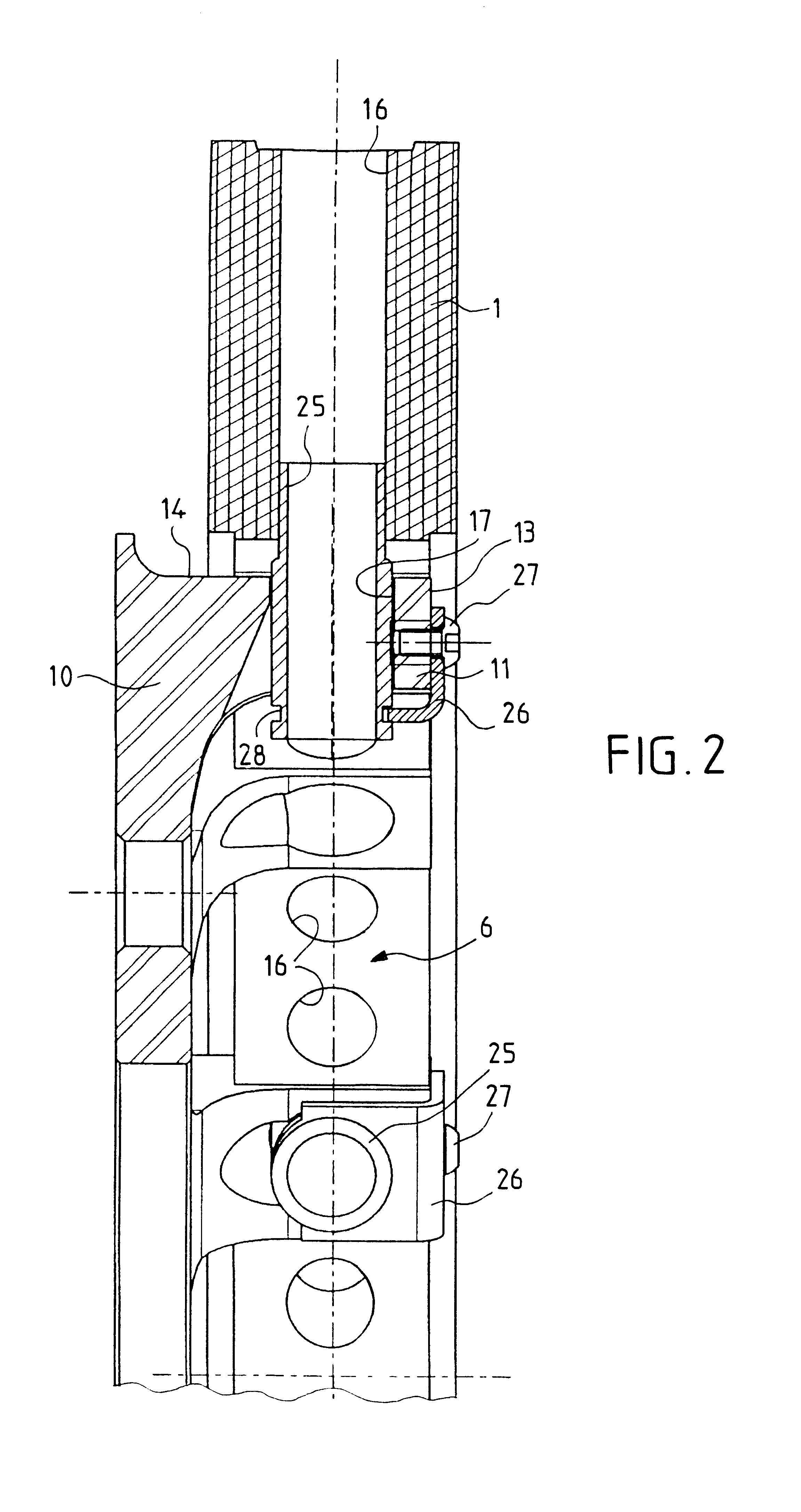

Linear actuator

ActiveUS20050155444A1Guarantee efficiencyGuaranteed normal transmissionToothed gearingsGearing controlEngineeringParking brake

A rotary shaft (3) and a rotation driven member (4) are so connected as to be capable of transmitting motive power when the rotary shaft (3) rotates relatively to the rotation driven member (4). A roller (6) gets displaced to a first position where a frictional force with an outer race (5) and the rotation driven member (4) decreases, thereby permitting transmission of a rotational force from the rotary shaft (3) to the rotation driven member (4). When the rotation driven member (4) rotates relatively to the rotary shaft (3), the roller (6) gets displaced to a second position where the frictional force with the outer race (5) and the rotation driven member (4) increases, thereby rotationally fixing the rotation driven member (4) with respect to the outer race (5). The power transmission from a brake apparatus (e.g., a parking brake apparatus) to an electric motor (2) can be hindered while permitting the power transmission to the brake apparatus from the electric motor (2) by using neither a worm exhibiting a relatively low transmission efficiency nor a worm wheel. In a state where the brake apparatus exhibits its braking force, the roller (6) receives the force from the brake apparatus and is thereby biased toward the second position, whereby a construction of a power transmission mechanism (50) can be simplified and costs can be reduced to such an extent.

Owner:NSK LTD

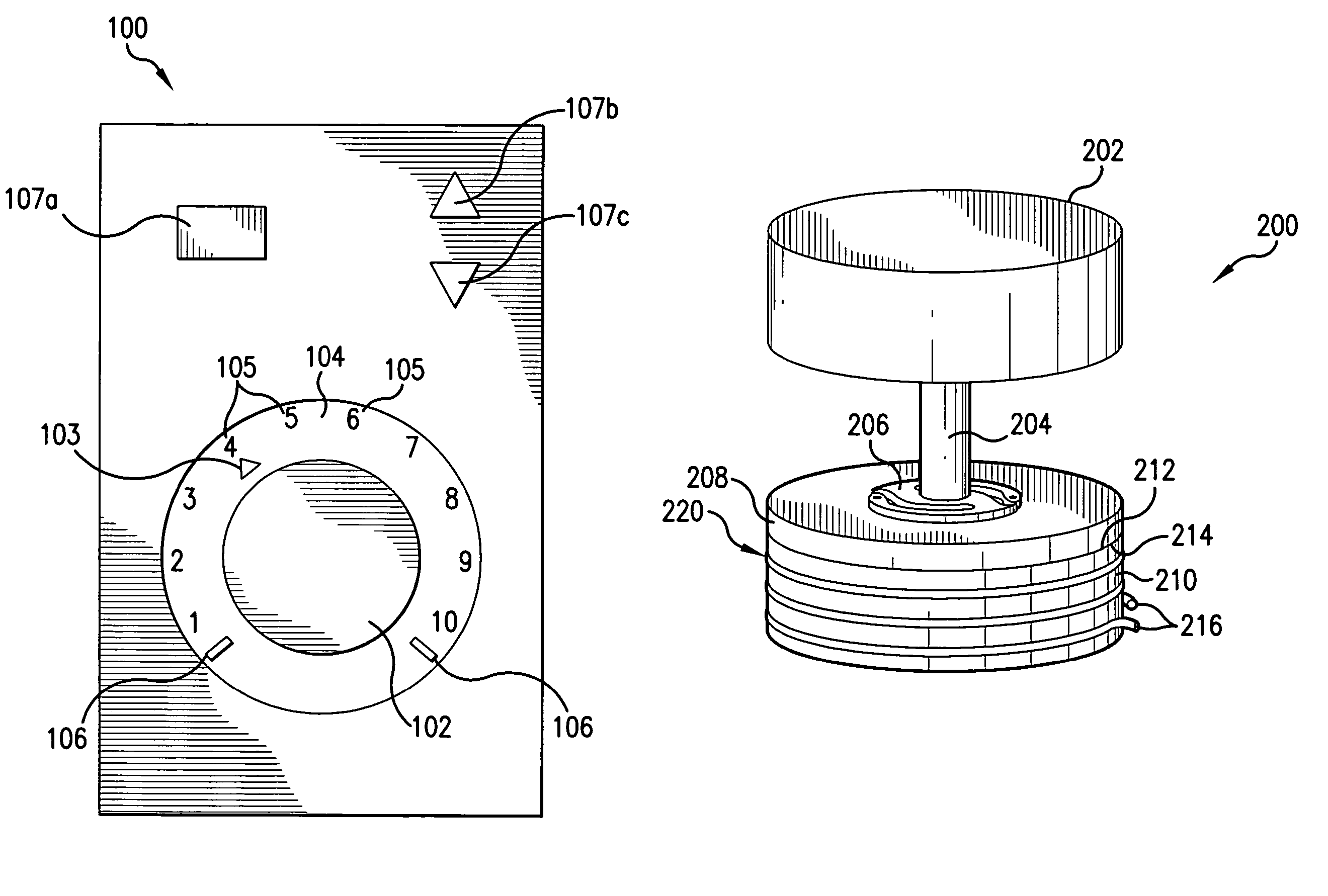

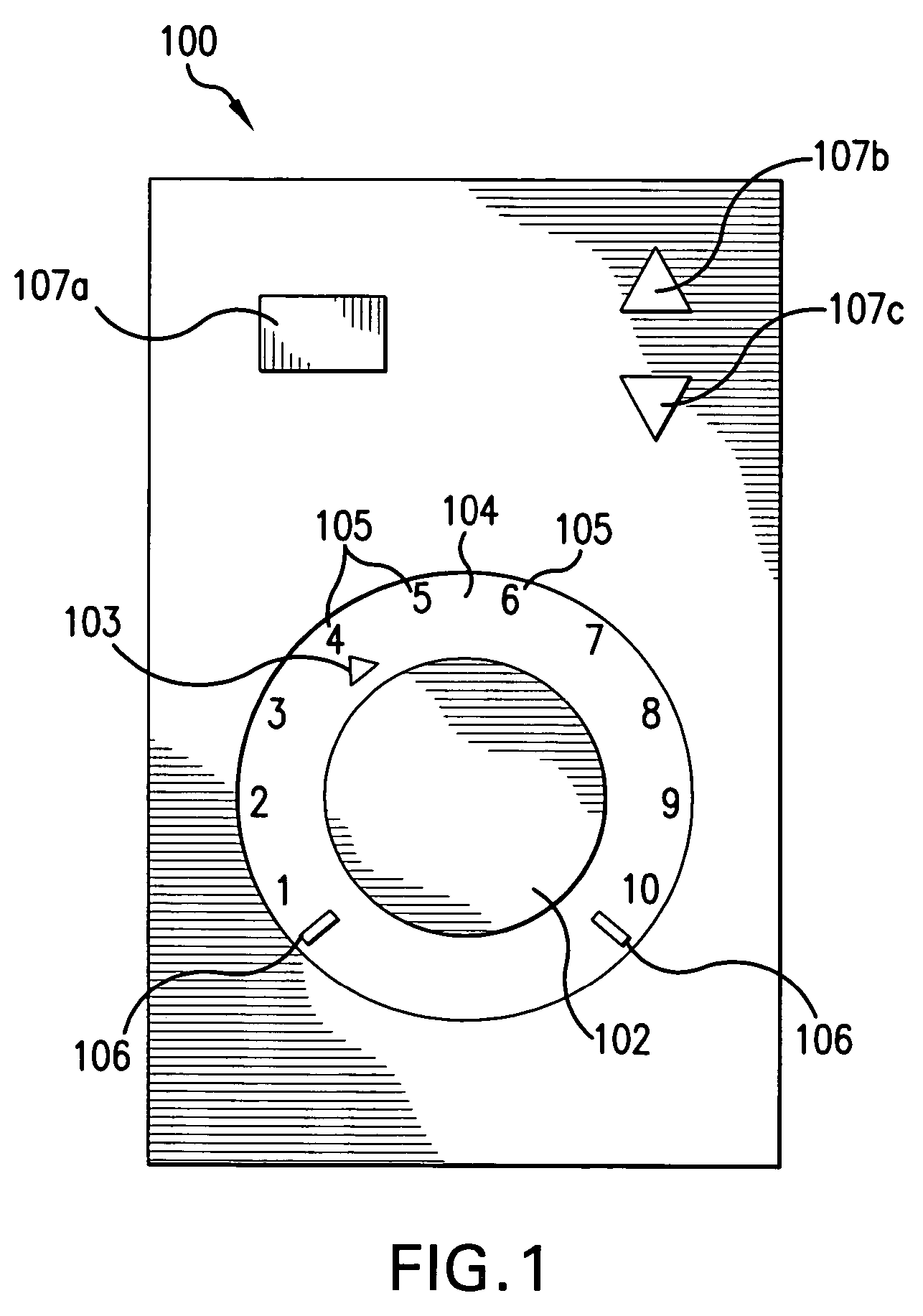

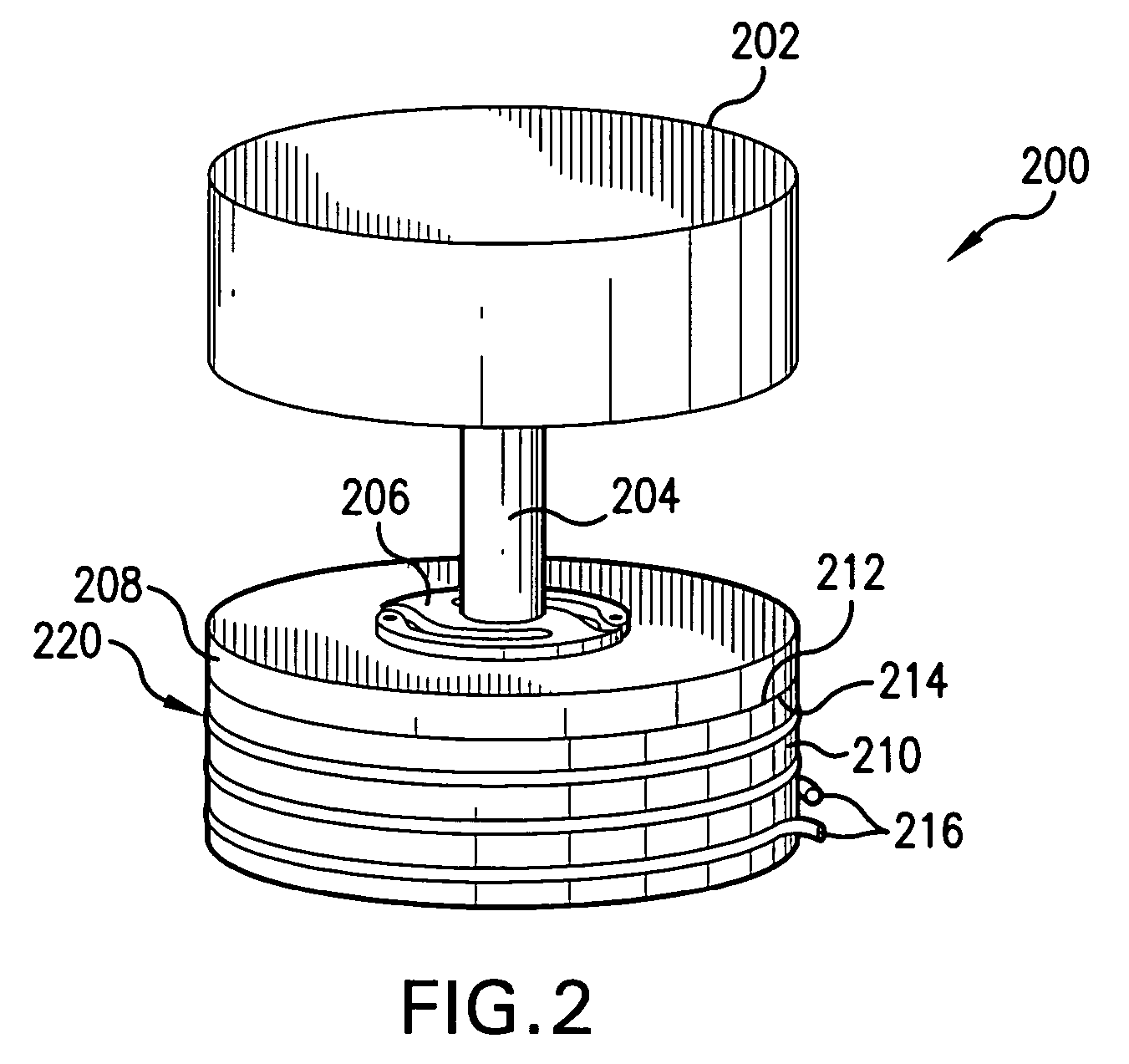

Systems and methods for providing a haptic device

ActiveUS8002089B2Degree of rotationControlling membersDynamo-electric brakes/clutchesEngineeringActuator

Systems and methods for providing a haptic device are described. In one described system, a first brake surface of a first element contacts a second brake surface of a second element. At least one actuator is configured to exert a force on at least one of the first and second elements. A flexure is coupled to at least one of the first element, the second element, a housing, a manipulandum, and a shaft coupled to the manipulandum. The flexure provides a degree of rotational flexibility to the manipulandum when the at least one actuator exerts the force. The described system may include a processor in communication with the at least one actuator for providing the haptic effects.

Owner:IMMERSION CORPORATION

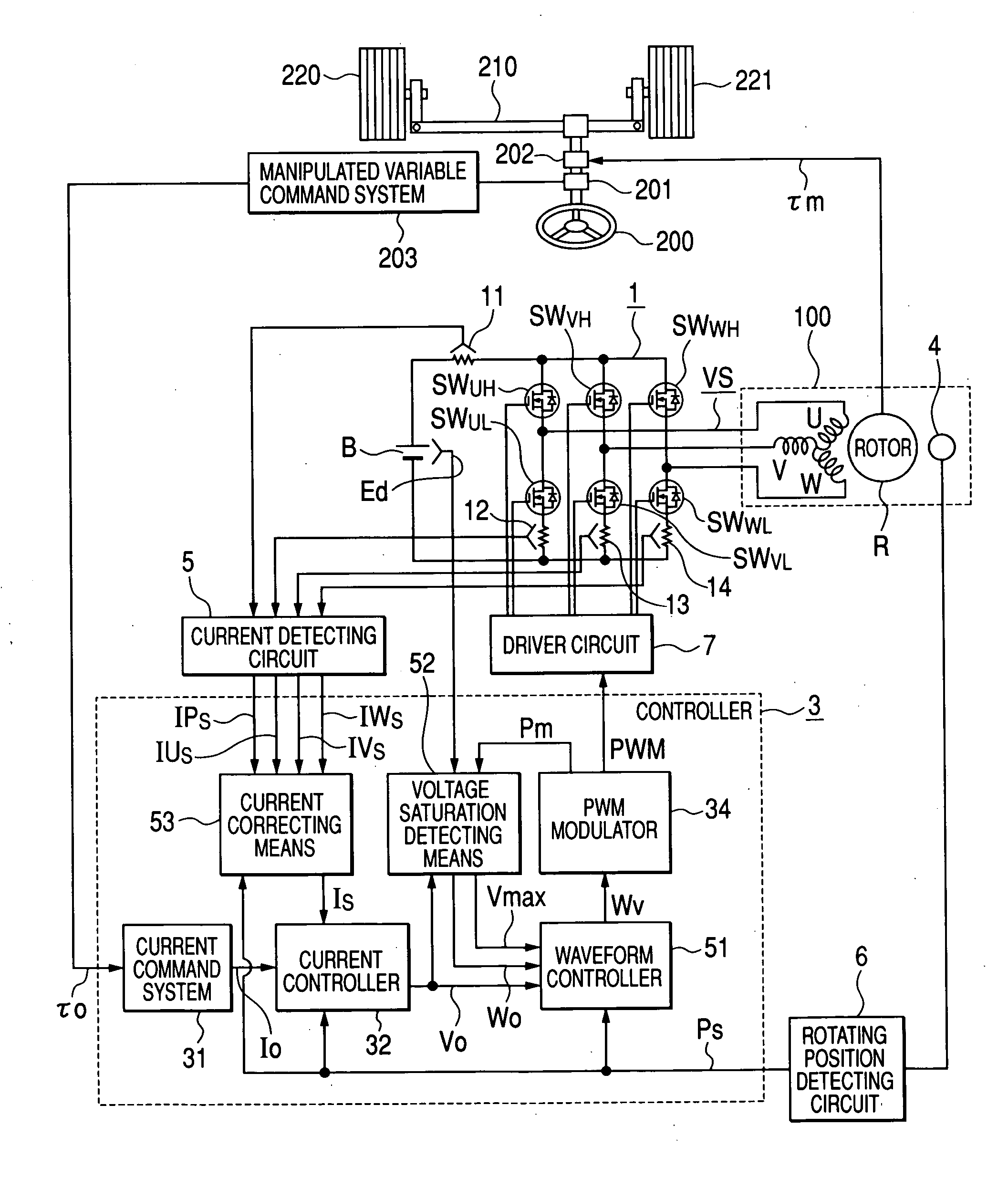

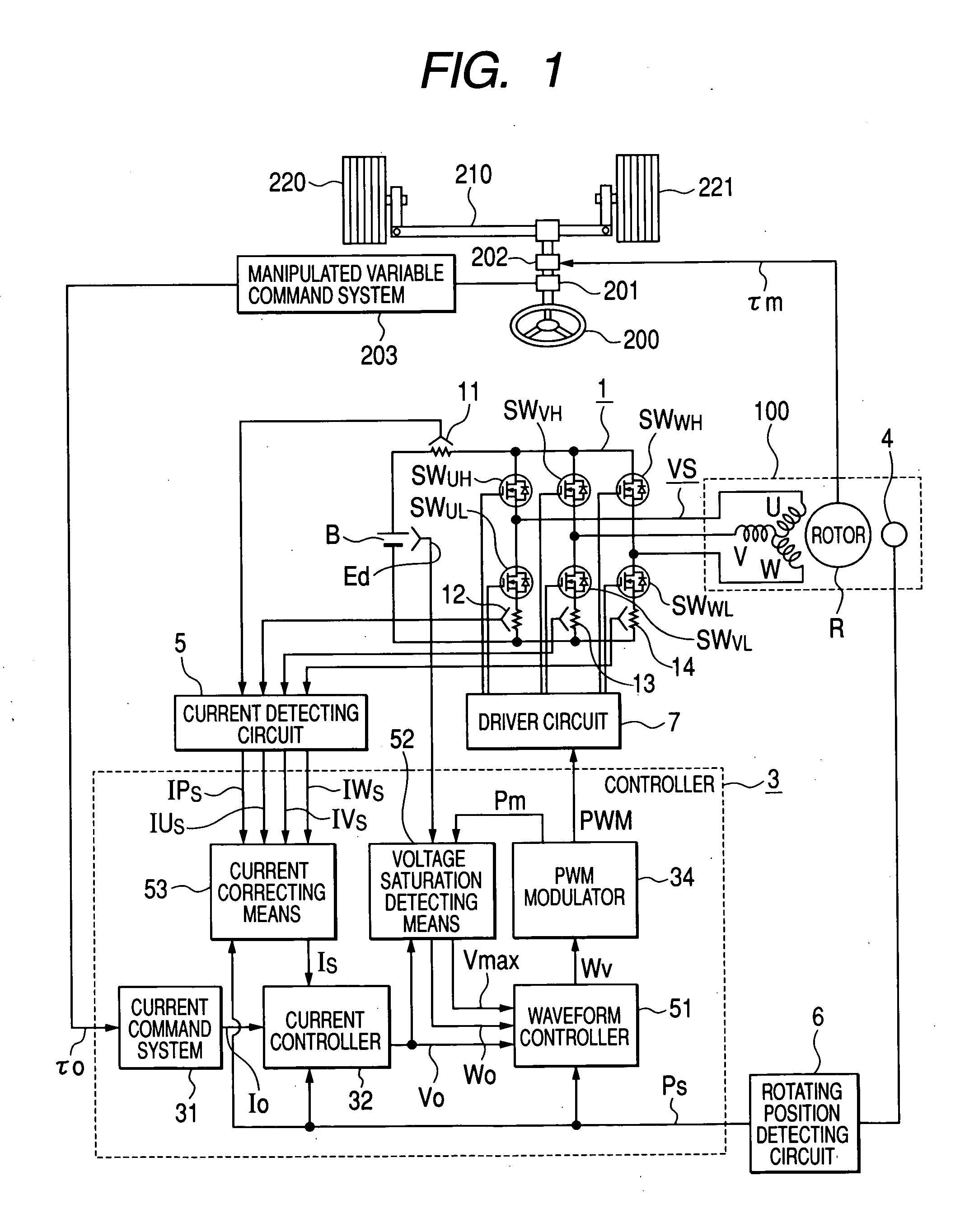

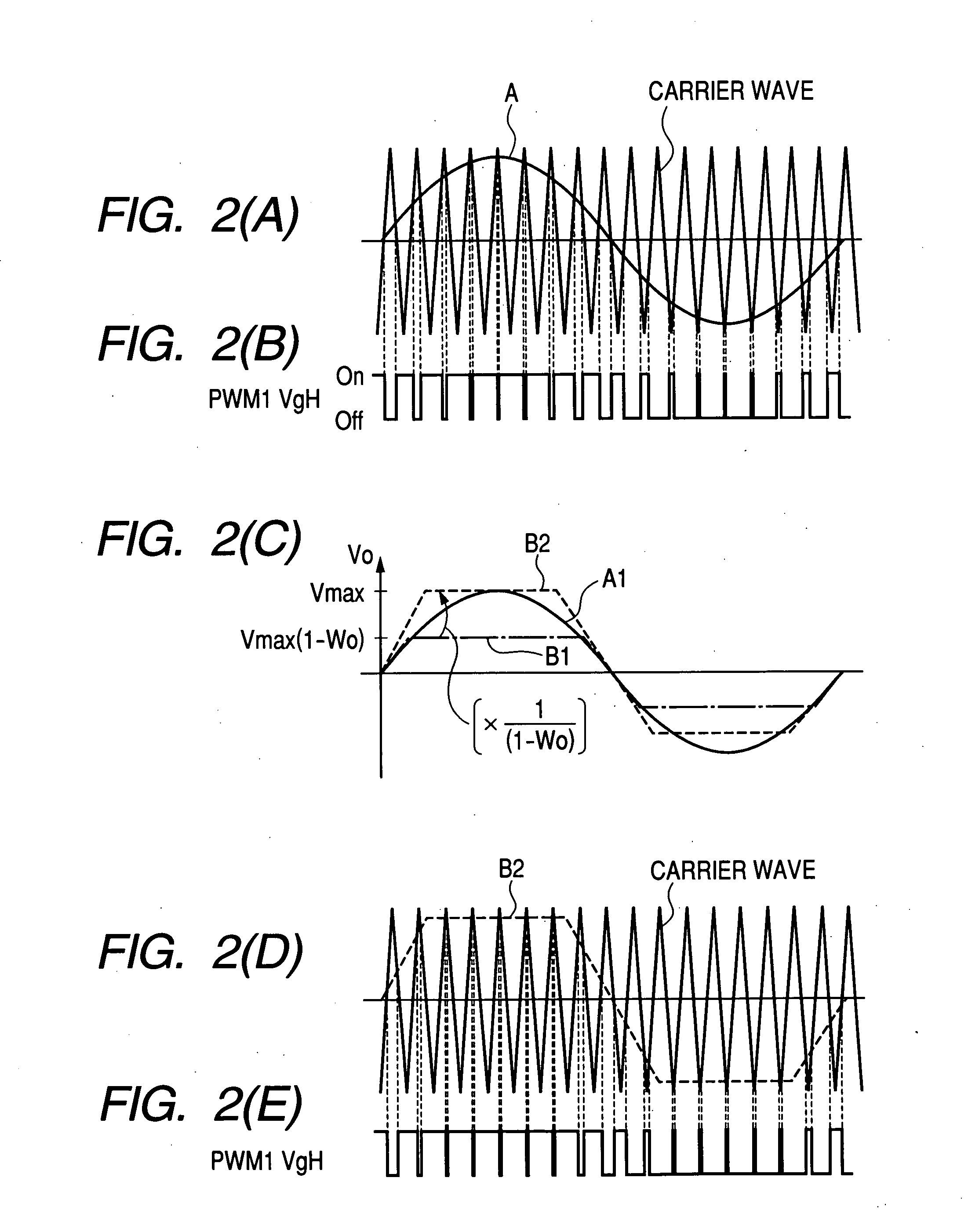

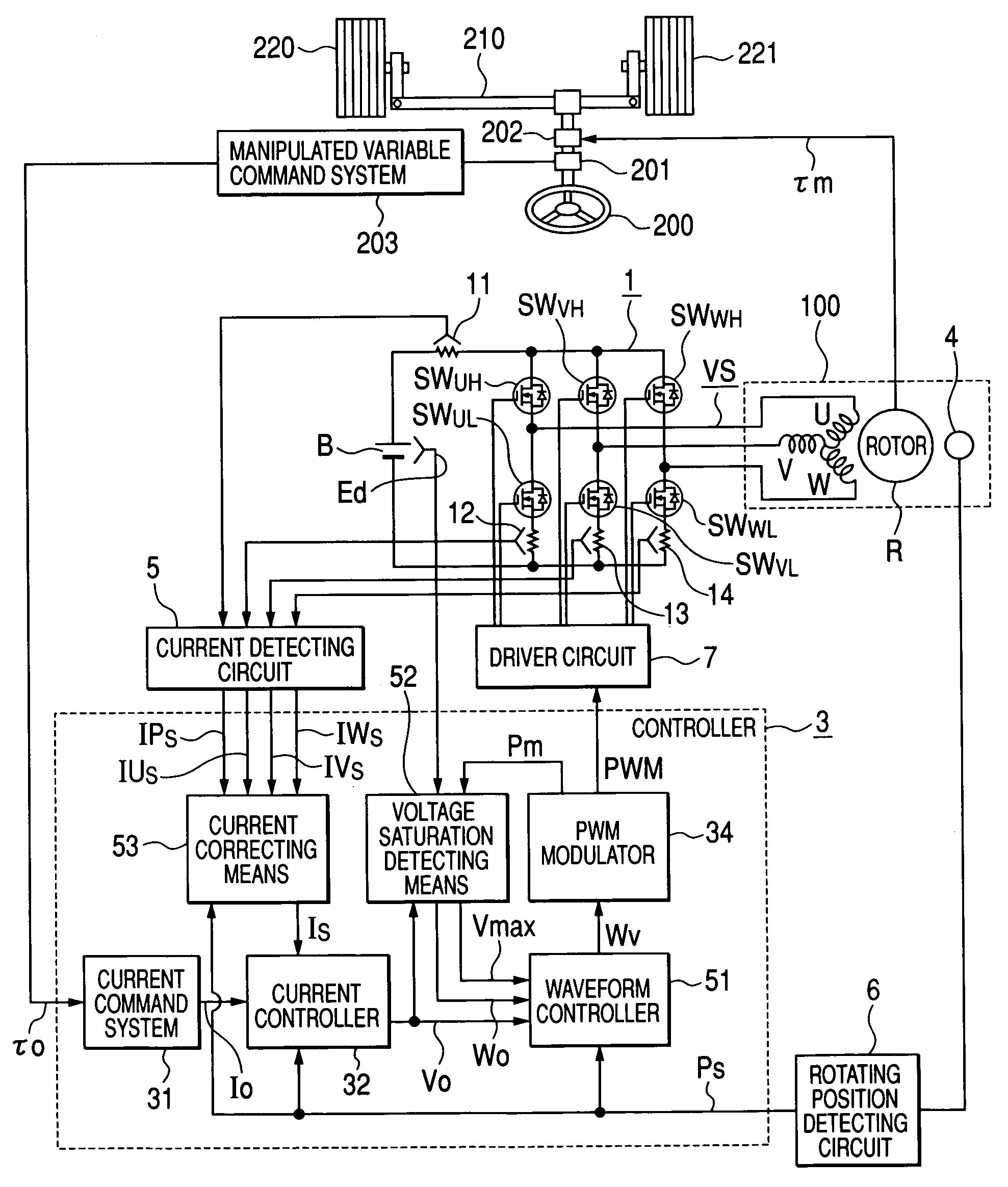

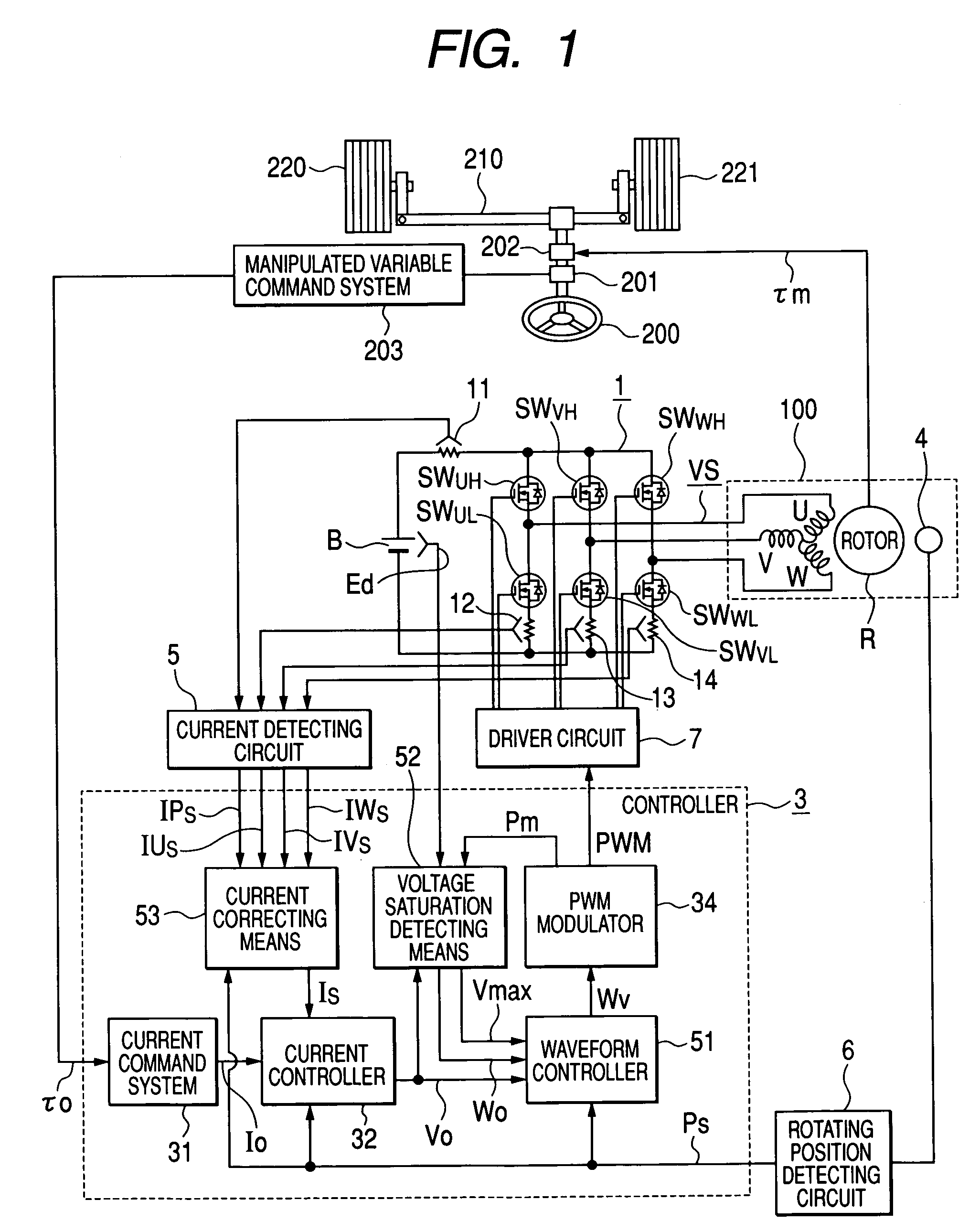

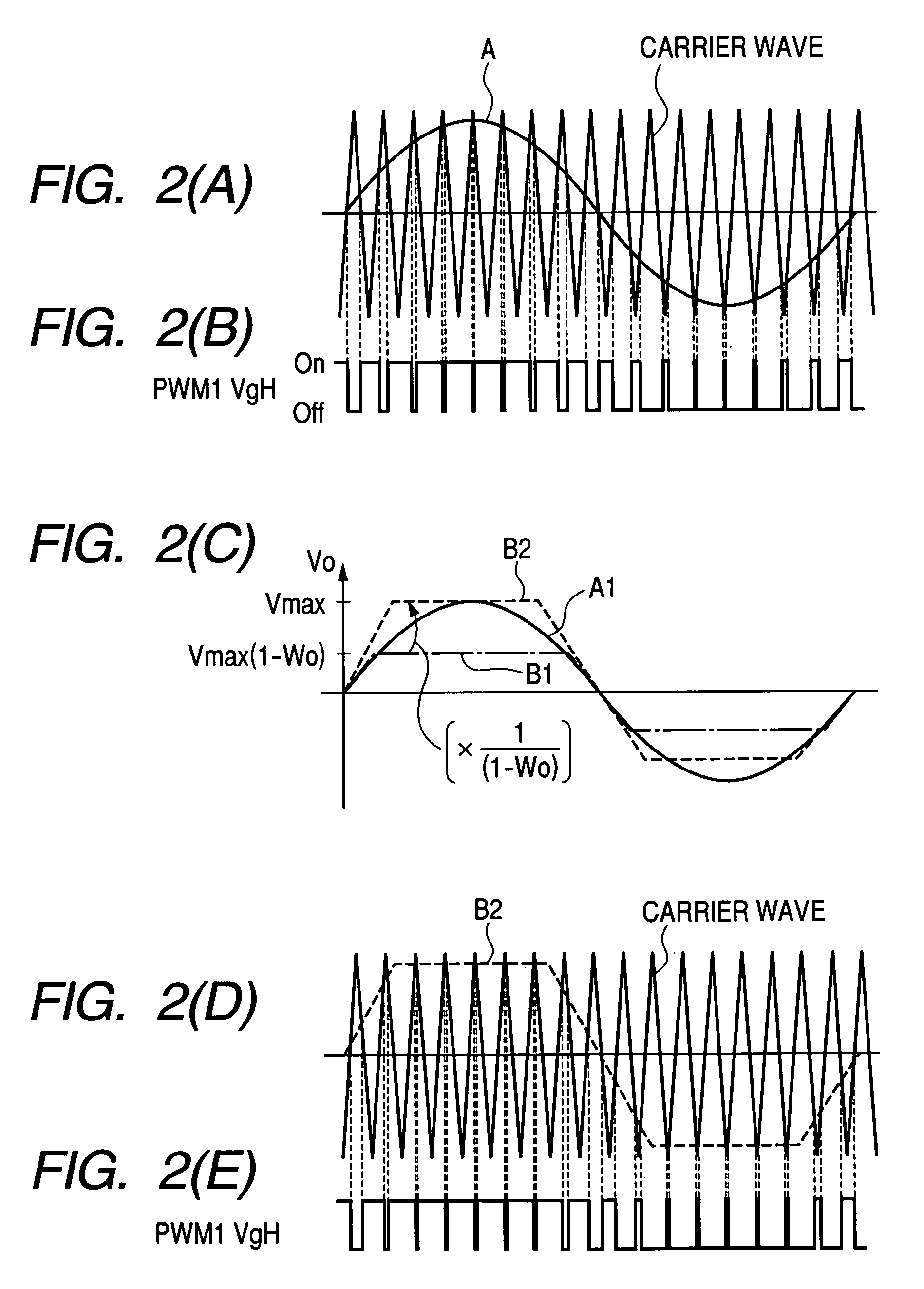

Motor drive apparatus, electric actuator and electric power steering apparatus

ActiveUS20060001392A1Increase driving speedHigh areaTorque ripple controlDC motor speed/torque controlElectric power steeringHigher order harmonics

In an operation range of an actuator subjected to quick acceleration and deceleration, a motor drive apparatus, an electric actuator and an electric power steering apparatus capable of continuous torque control up to the high drive speed and high torque area. A controller comprises a voltage saturation detecting means for detecting the voltage saturation of the output voltage of an inverter circuit, based on the battery voltage, and a waveform controller that converts the drive waveform of the inverter circuit into the waveform created by superimposing harmonics of high odd-numbered order on a sinusoidal wave as a fundamental wave of the modulated wave modulated by a PWN carrier wave; and continuously changes the ratio of superimposing the high-order harmonics in response to the voltage saturation detected by a voltage saturation detecting means. This arrangement allows the controller to continuously change the drive waveform of the inverter circuit.

Owner:HITACHI ASTEMO LTD

Motor drive apparatus, electric actuator and electric power steering apparatus

ActiveUS7161323B2Increase torqueTorque ripple controlDC motor speed/torque controlElectric power steeringMotor drive

The disclosure concerns a a motor drive apparatus, an electric actuator and an electric power steering apparatus capable of continuous torque control up to the high drive speed and high torque area, in order to enable quick acceleration and deceleration. A controller comprises a voltage saturation detecting apparatus for detecting the voltage saturation of the output voltage of an inverter circuit, based on the battery voltage, and a waveform controller that converts the drive waveform of the inverter circuit into the waveform created by superimposing harmonics of high odd-numbered order on a sinusoidal wave as a fundamental wave of the modulated wave modulated by a PWN carrier wave; and continuously changes the ratio of superimposing the high-order harmonics in response to the voltage saturation detected by a voltage saturation detecting means. This arrangement allows the controller to continuously change the drive waveform of the inverter circuit.

Owner:HITACHI ASTEMO LTD

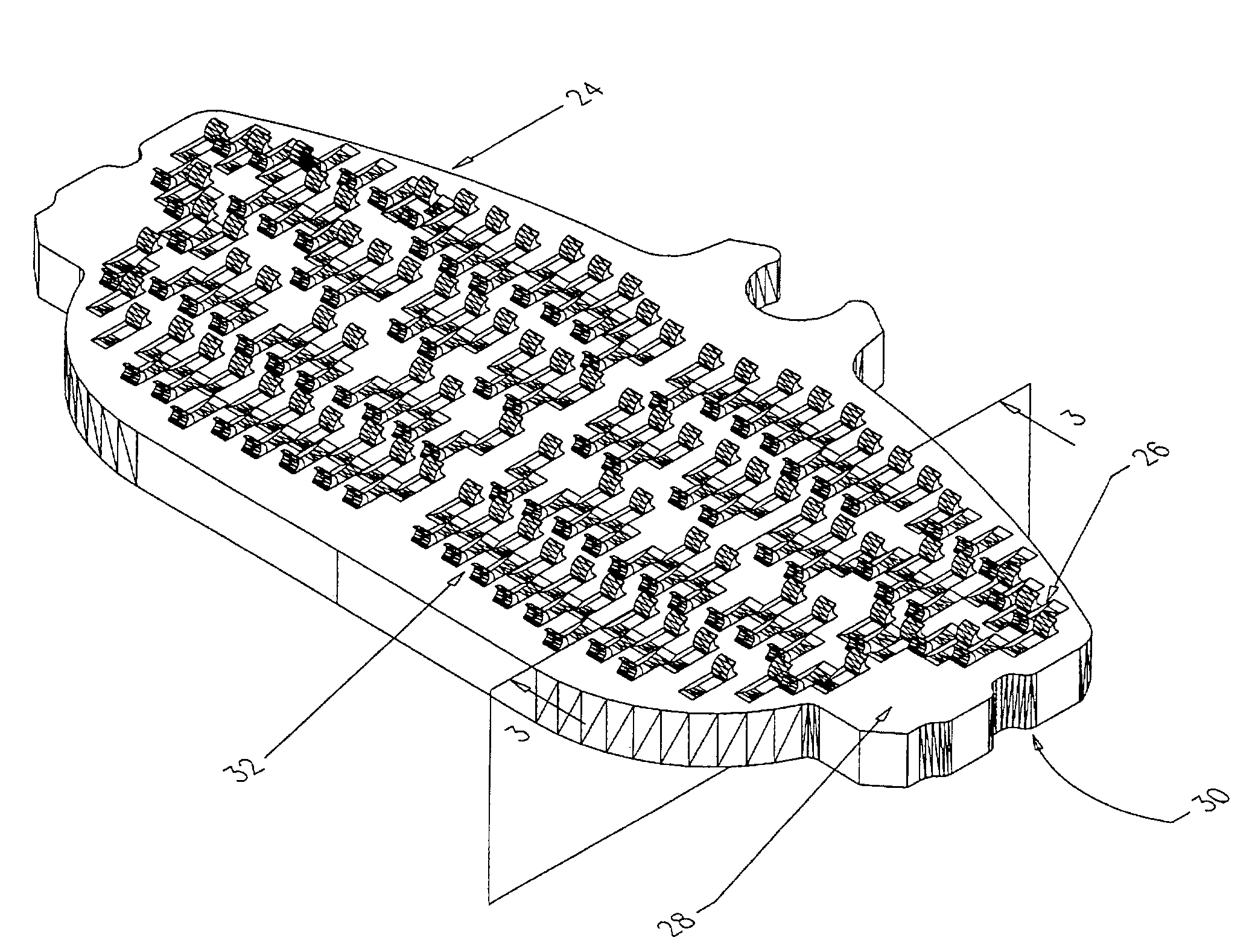

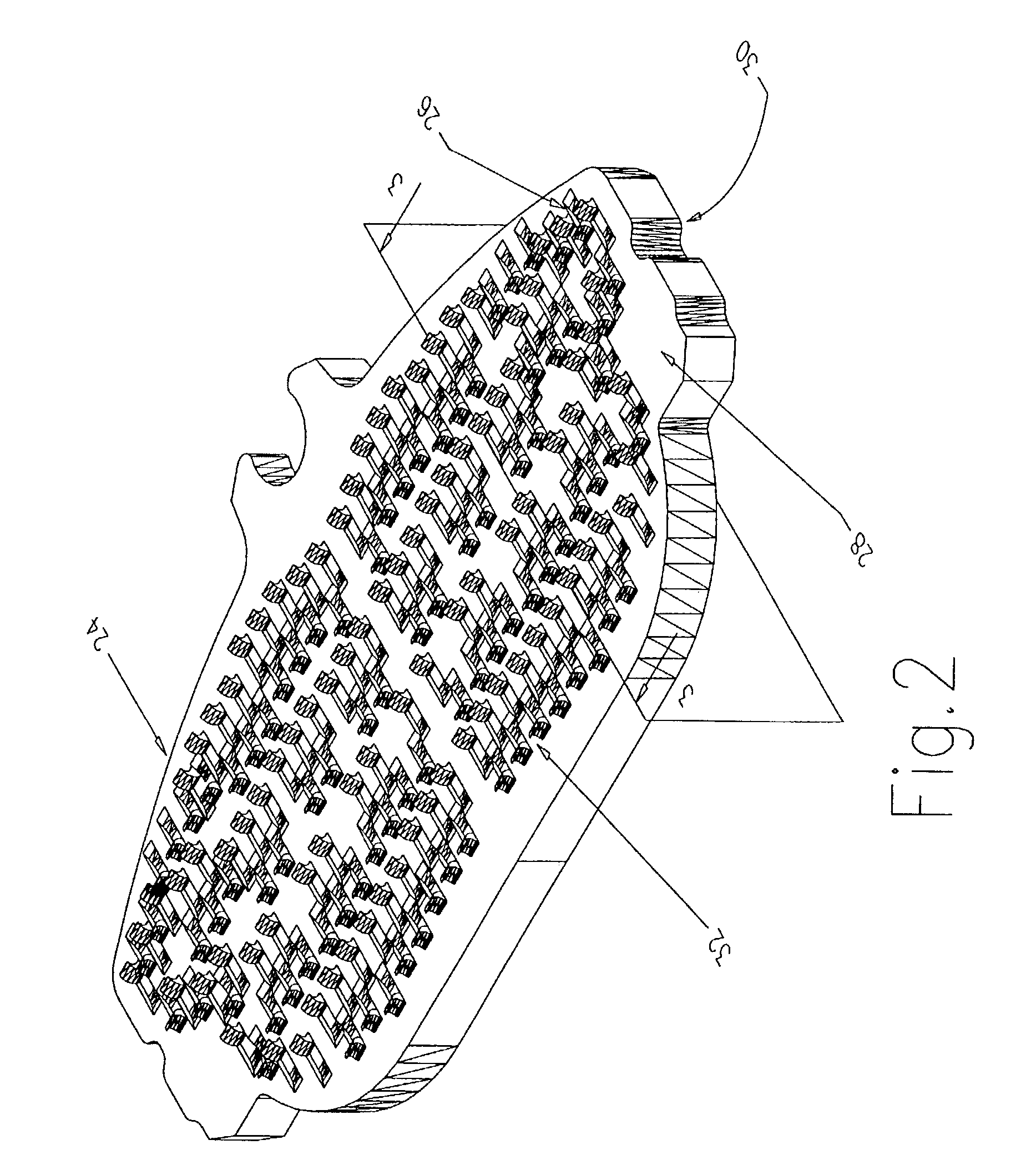

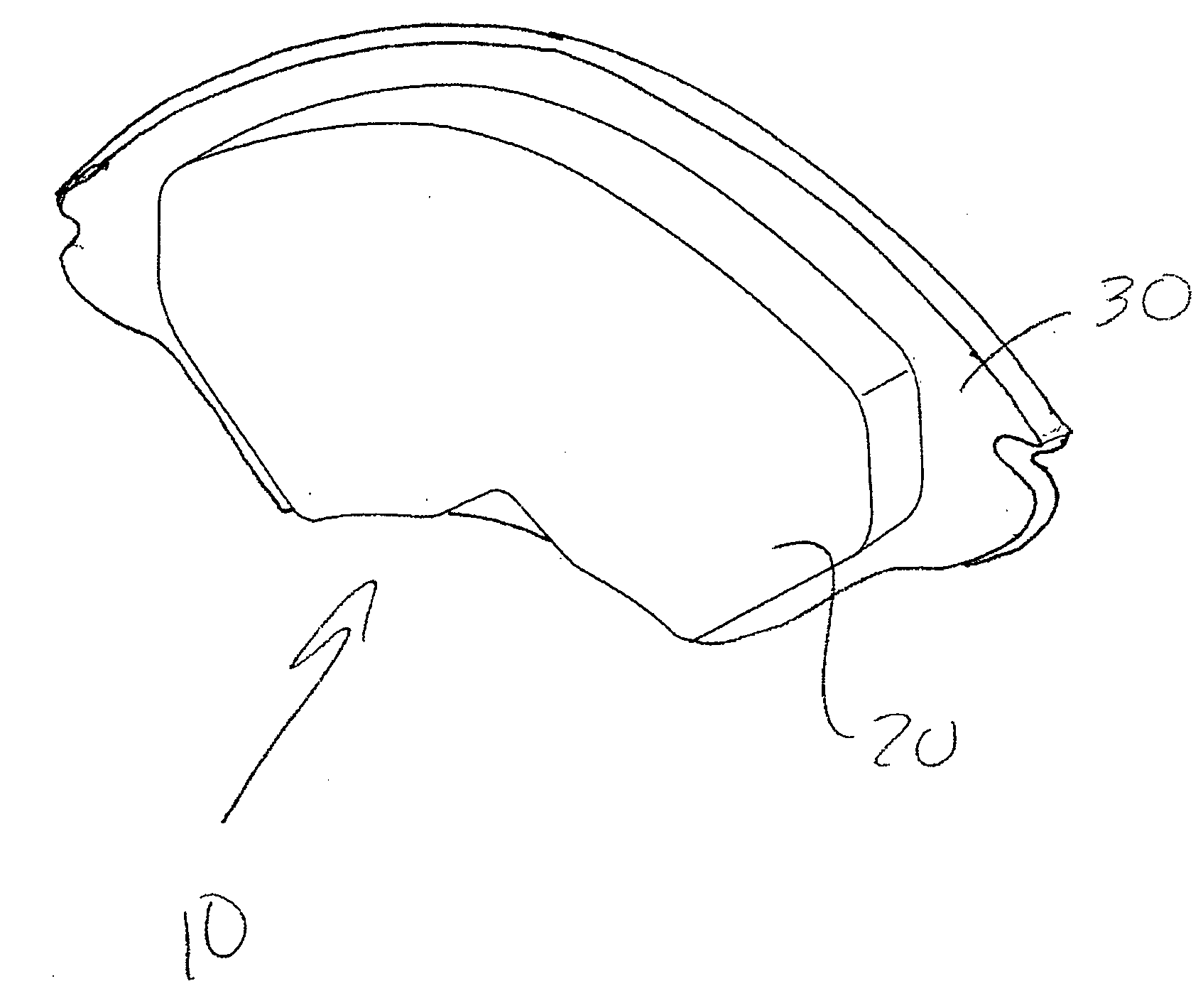

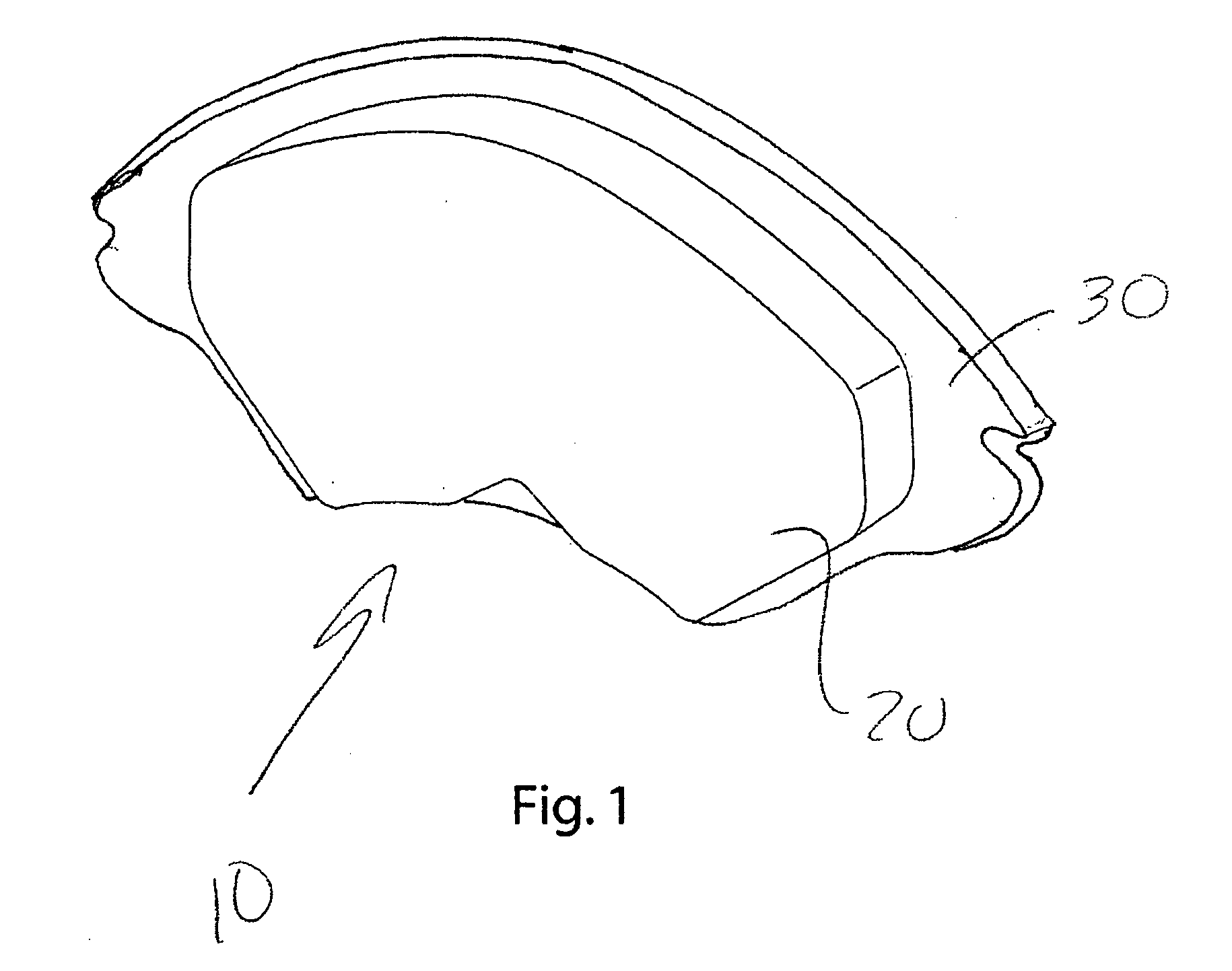

Backing plate with friction material retention members and method and apparatus for manufacturing same

A backing plate for a friction assembly includes a body having a first surface and a second surface and a thickness defined therebetween. One or more retention members are provided on the first surface for engaging a friction material mounted thereon. Each retention member has an extruded protrusion and an groove. The extruded protrusion has a generally constant width and a free curved distal end. The groove has a bottom wall having an inclined section and a flat section.

Owner:UTIL CANADA LIMITED

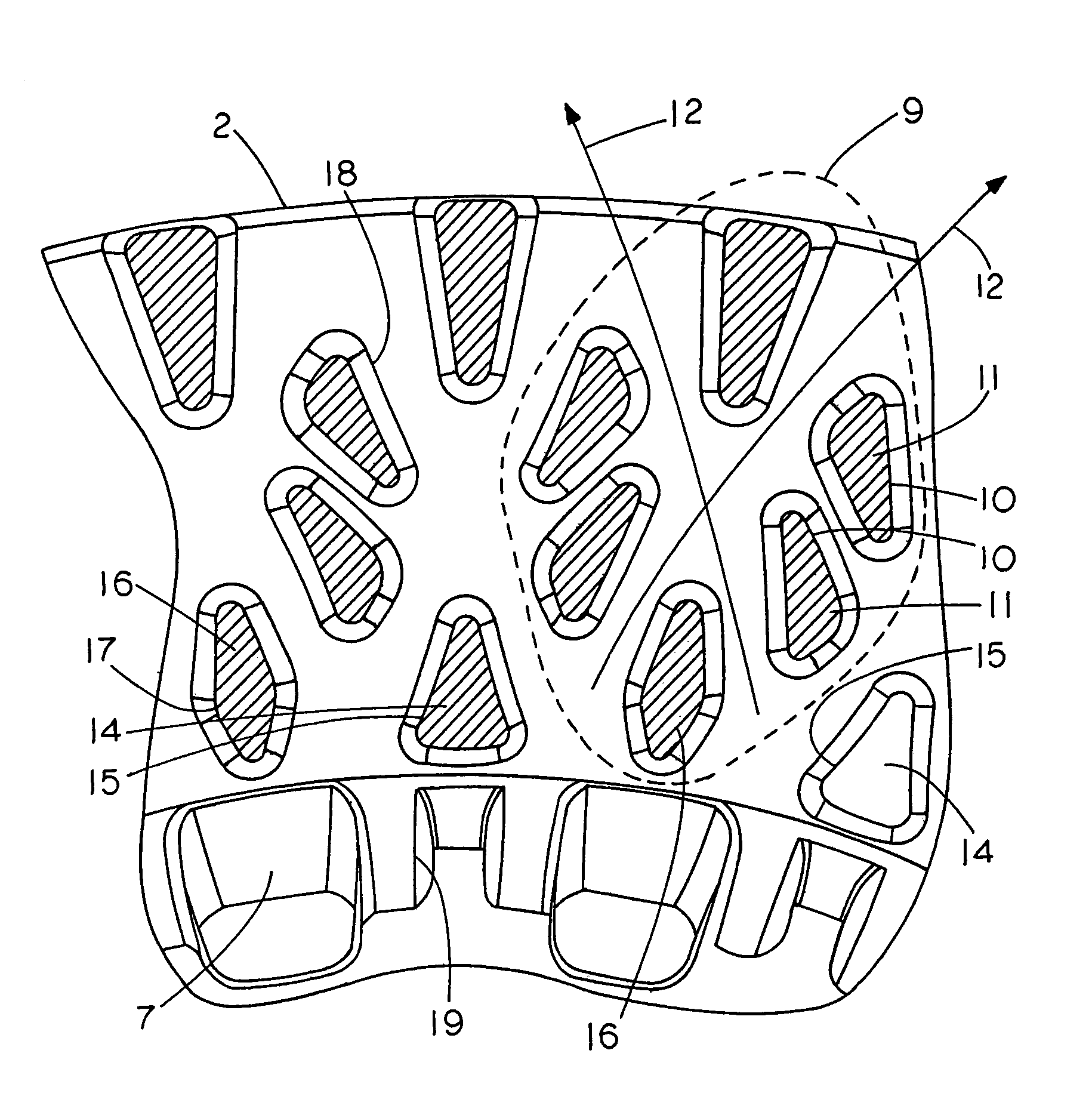

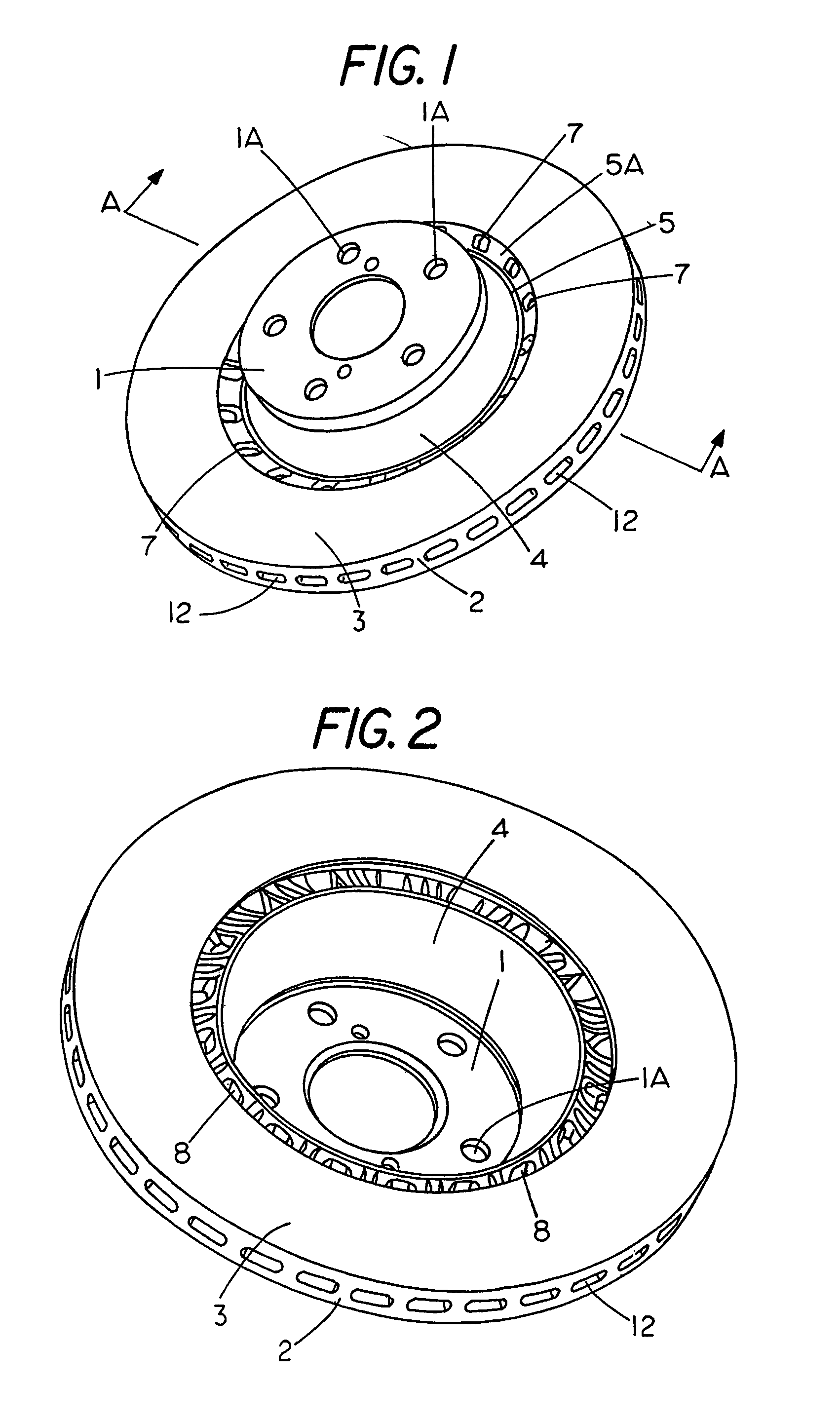

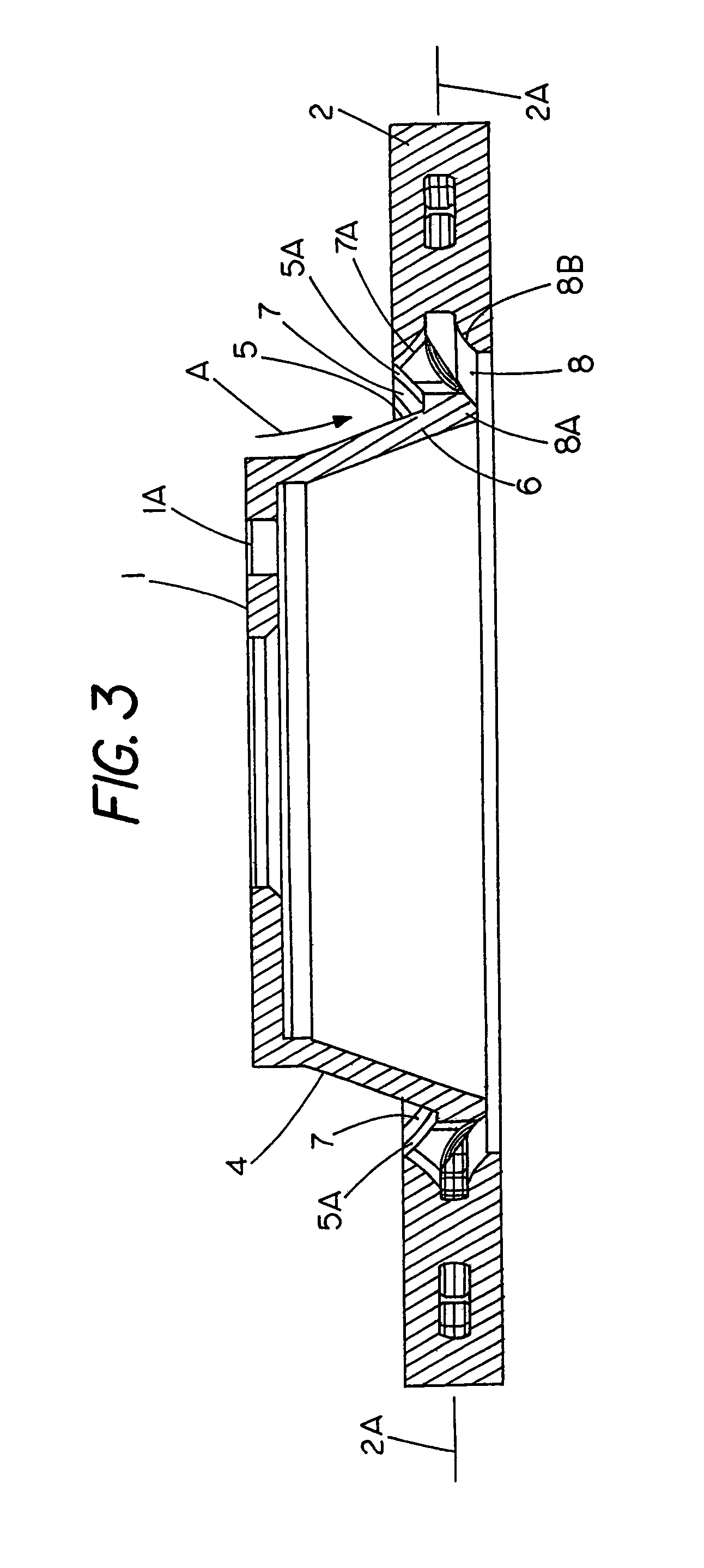

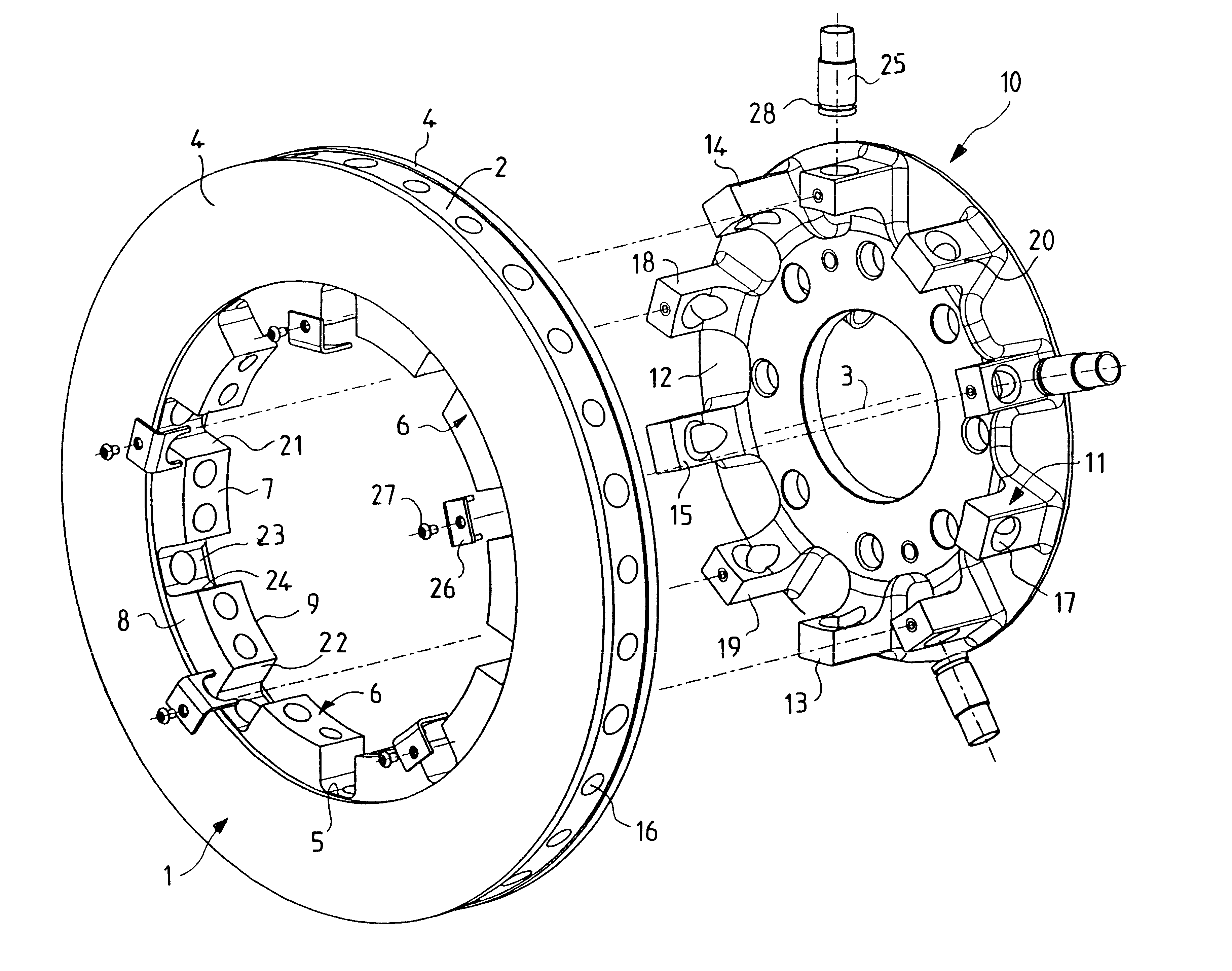

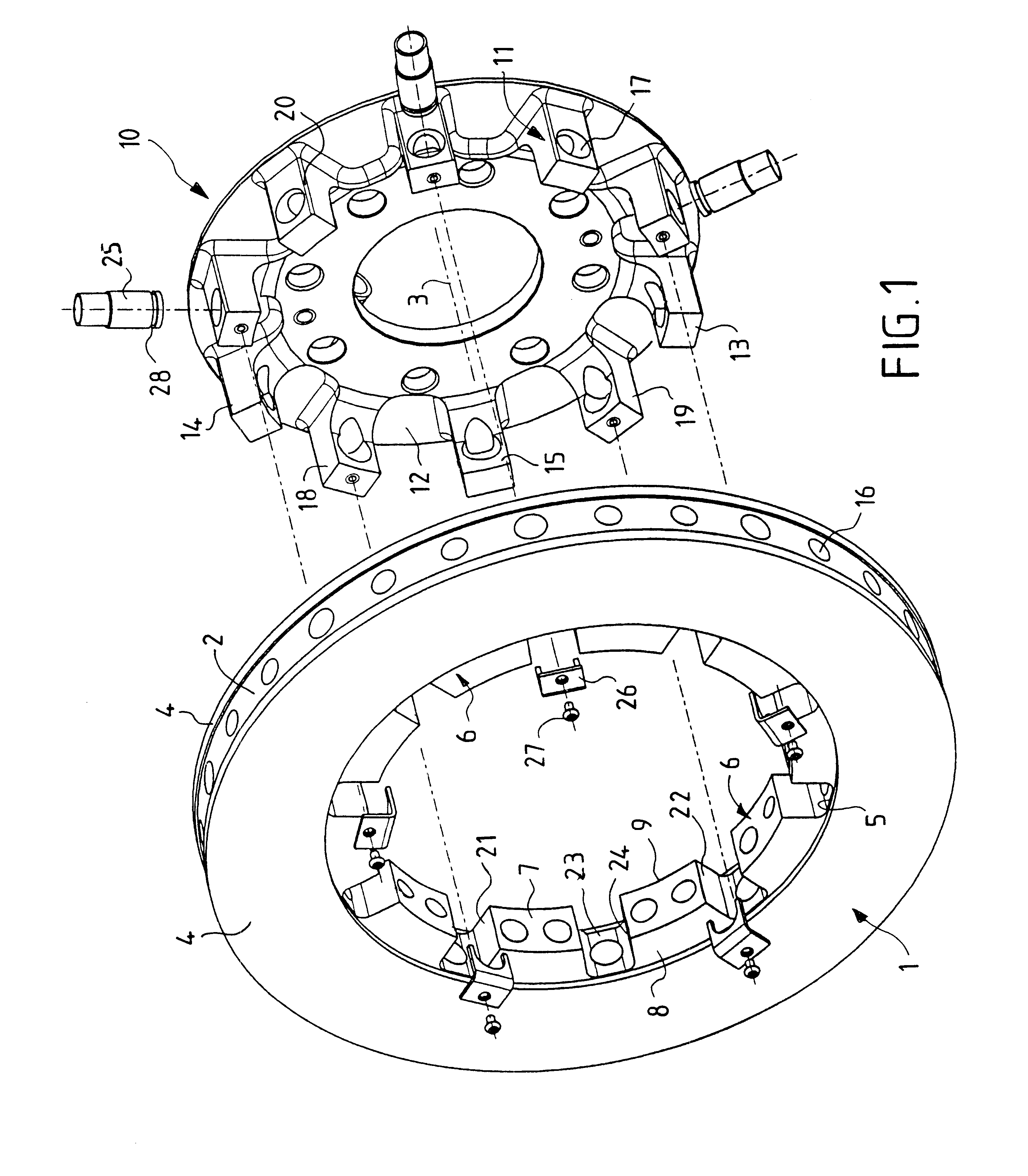

Self-ventilating disc brake rotor

There is a brake disc rotor having a central hub (1) co-axial with surrounding rings (2) which form brake bands (3) for engagement with brake pads. The rings (3) are supported in a spaced apart parallel configuration with channels (12) therebetween whereby in use of the rotor cooling air is drawn in through vent openings formed around the inner periphery of the rings (3) and then radially outwardly through the channels (12) as the rotor turns. The vent openings include inlet vent ports (7) on the outboard side of the rotor.

Owner:DISC BRAKES AUSTRALIA

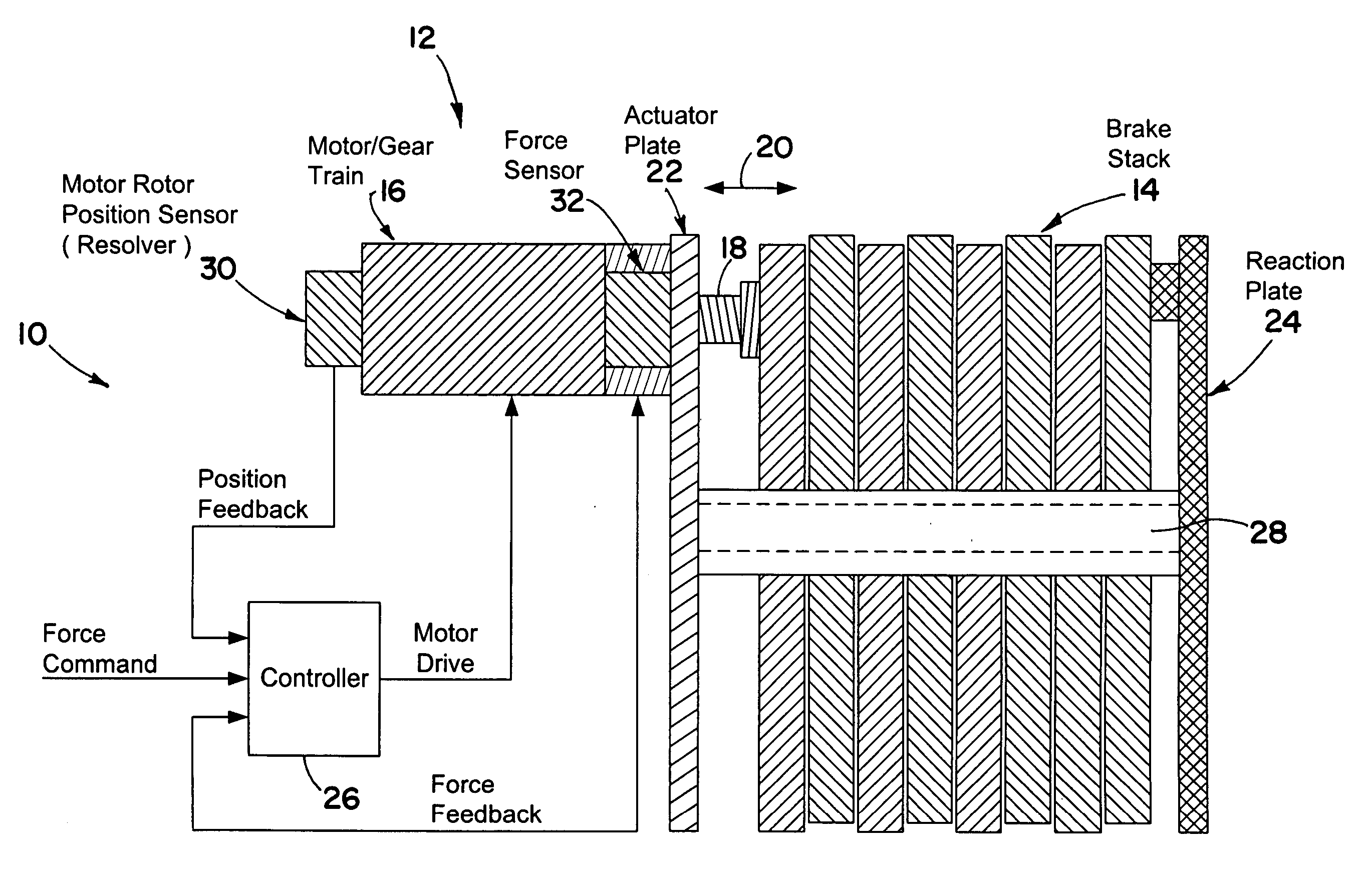

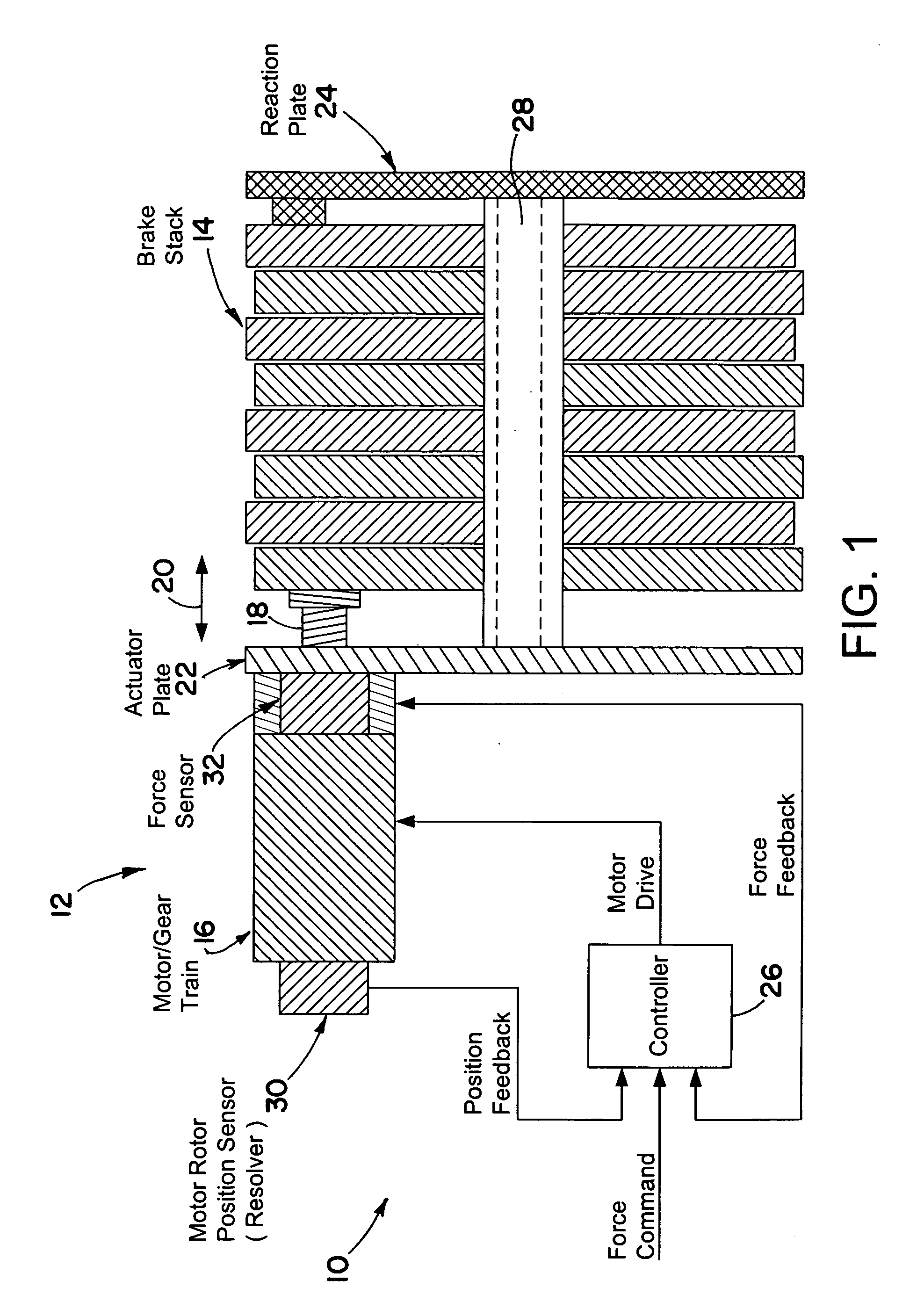

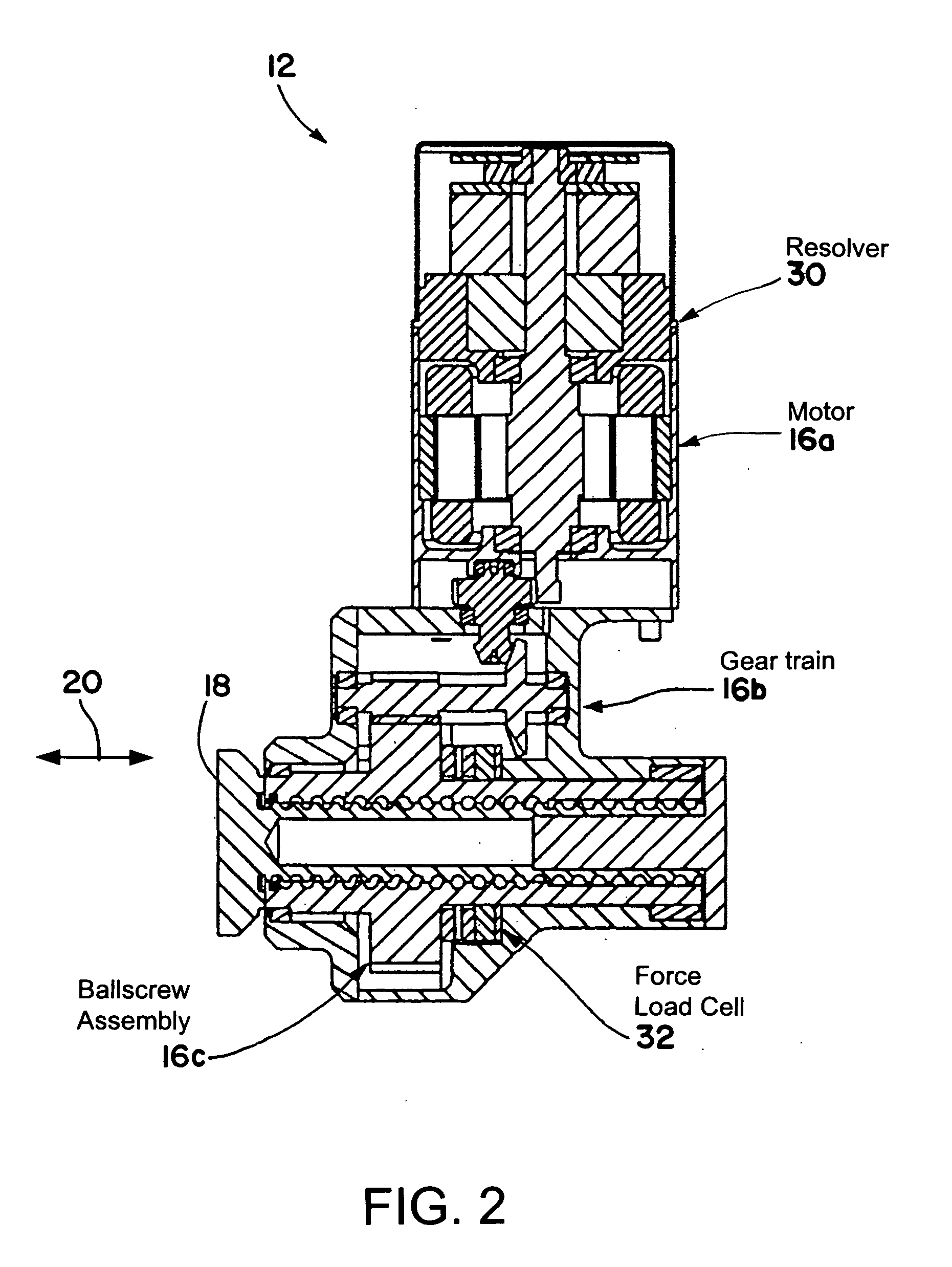

Electric brake position and force sensing and control

InactiveUS20050269872A1Braking action transmissionElectrodynamic brake systemsControl signalEngineering

A brake system including an electromechanical brake actuator having an actuator ram for exerting a brake force on a brake stack of a wheel to be braked in response to a control signal. In addition, the brake system includes a force sensor for sensing the brake force exerted on the brake stack by the actuator ram and outputting a force feedback signal based thereon; and a position sensor for sensing a position of the actuator ram and outputting a position feedback signal based thereon. Moreover, the brake system includes a controller for providing the control signal to the electromechanical brake actuator based on the force feedback signal and the position feedback signal.

Owner:THE BF GOODRICH CO

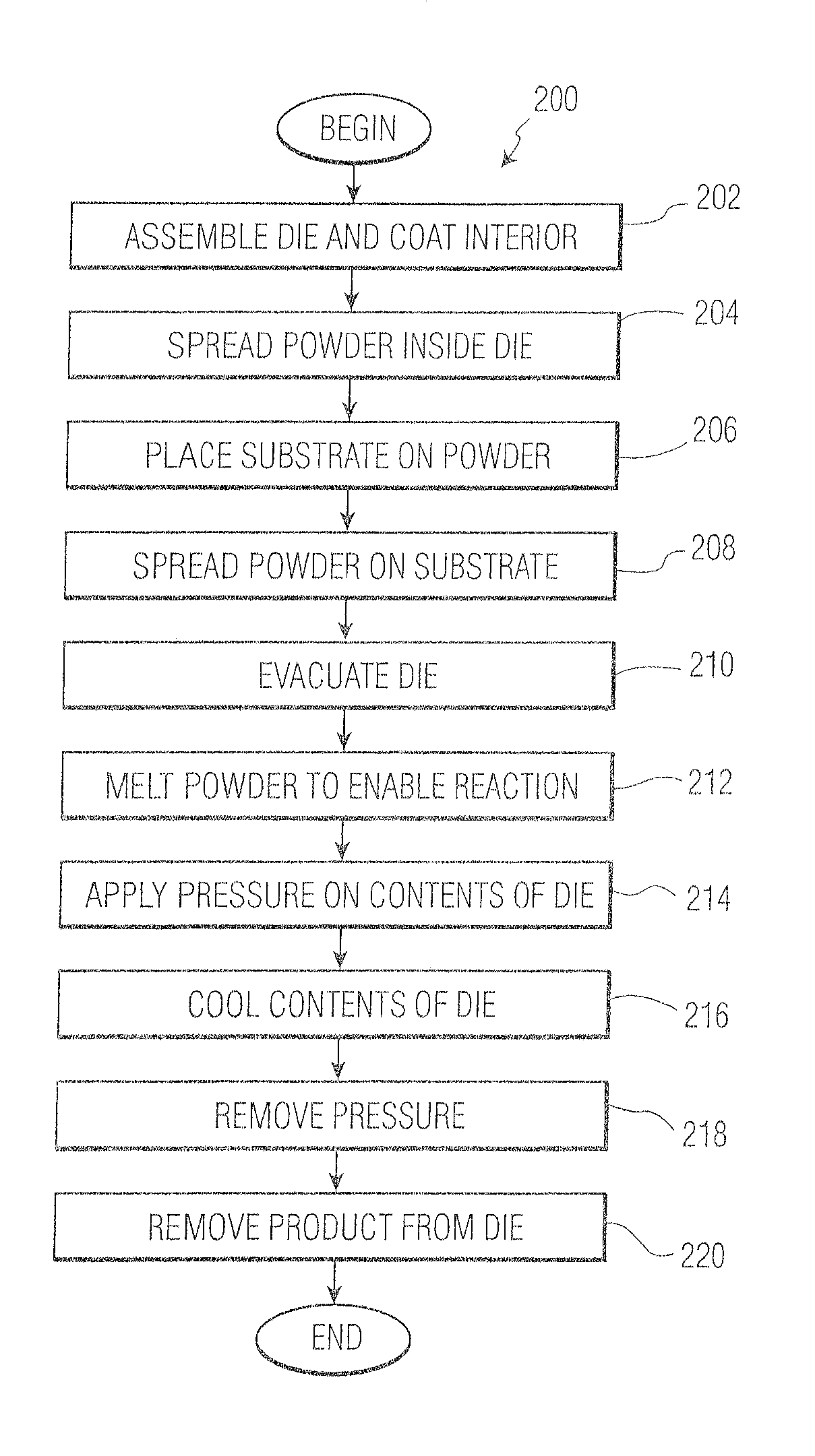

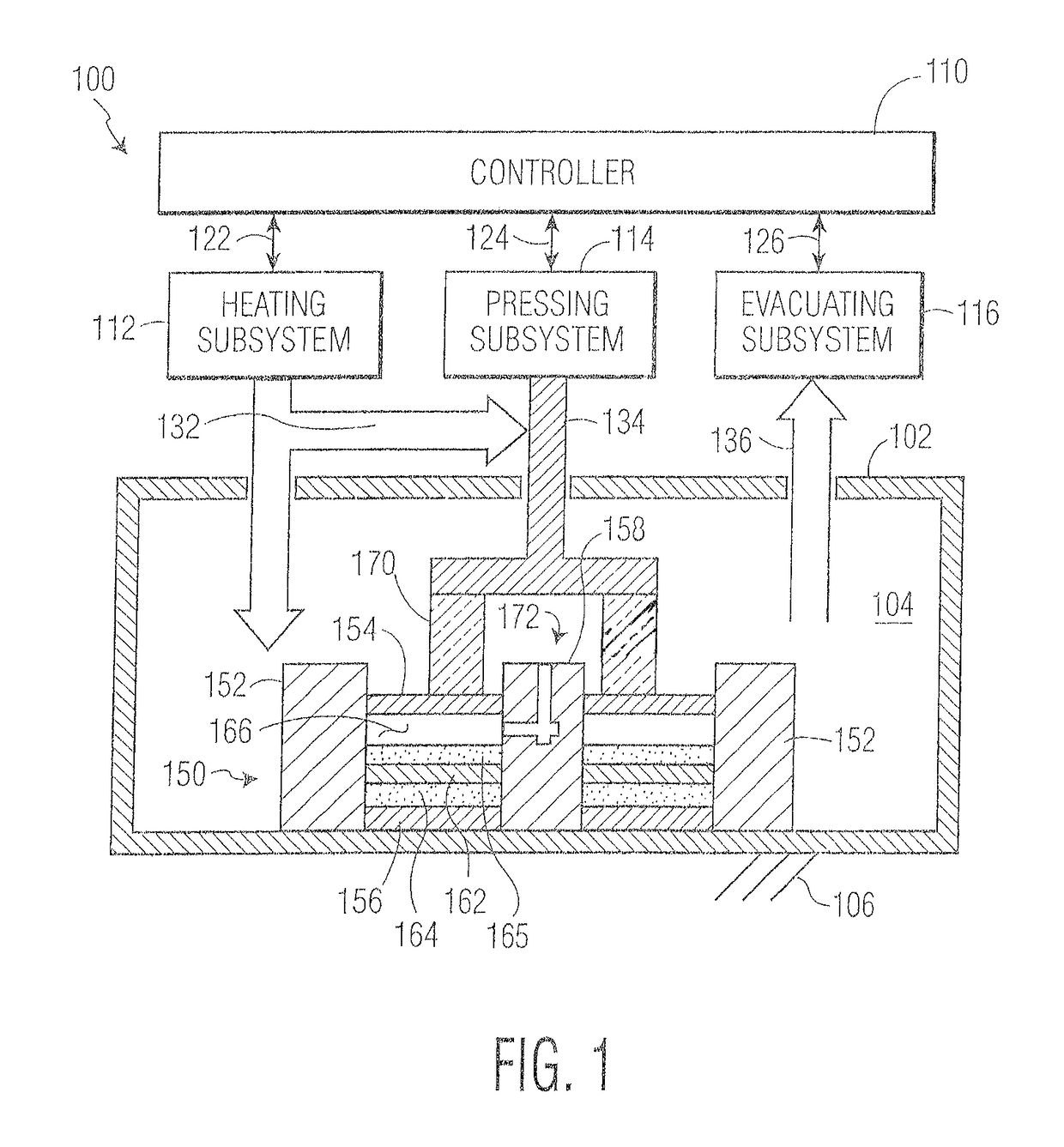

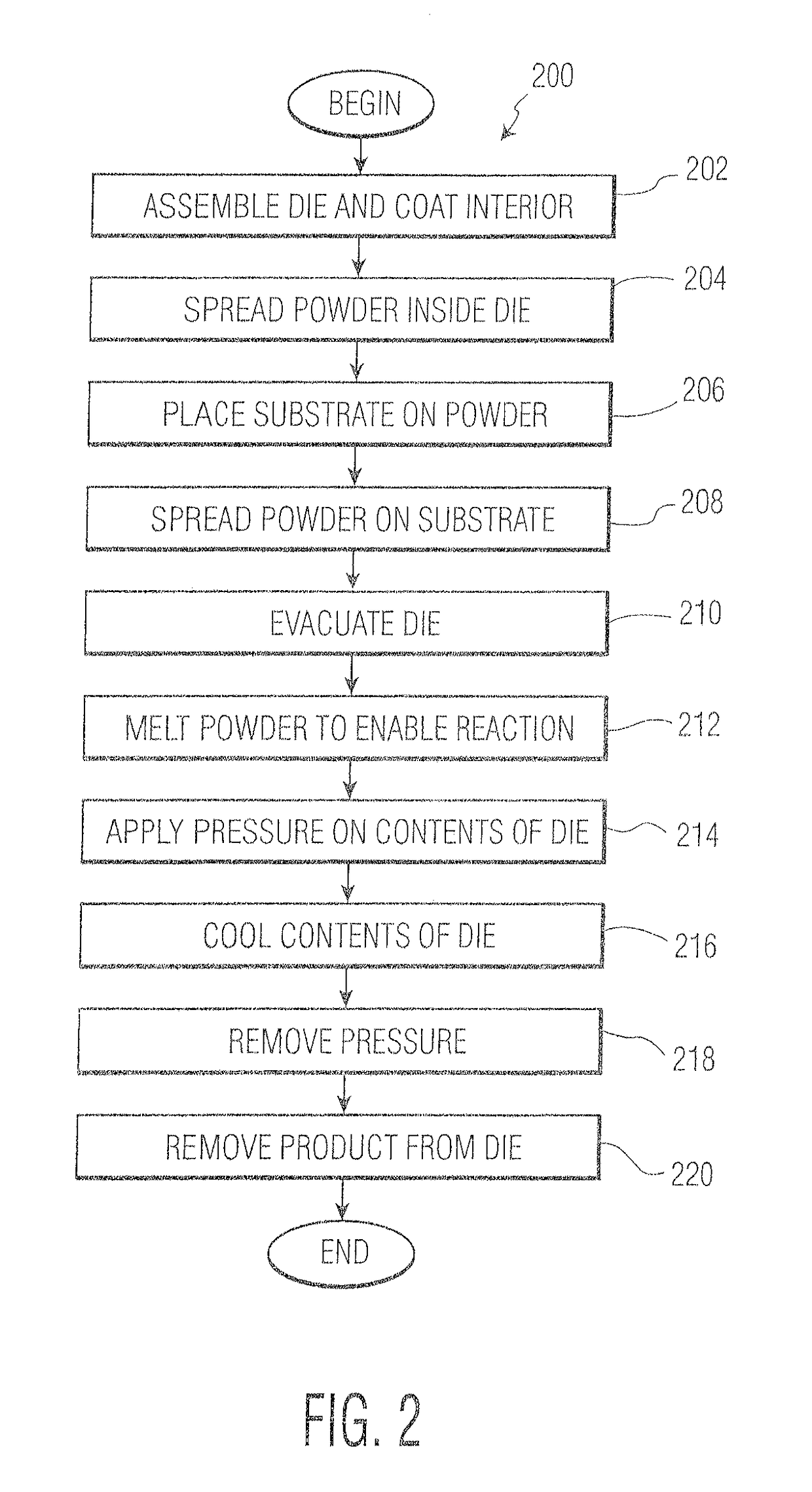

Systems and methods for forming a layer onto a surface of a solid substrate and products formed thereby

InactiveUS9933031B2Increase capacityImprove the overall coefficientBlade accessoriesBraking discsMetal matrix compositeSolid substrate

A method for forming a vehicular brake rotor involving loading a shaped metal substrate with a mixture of metal alloying components and ceramic particles in a dieheating the contents of the die while applying pressure to melt at least one of the metal components of the alloying mixture whereby to densify the contents of the die and form a ceramic particle-containing metal matrix composite coating on the metallic substrate; and cooling the resulting coated product.

Owner:ATS MER LLC

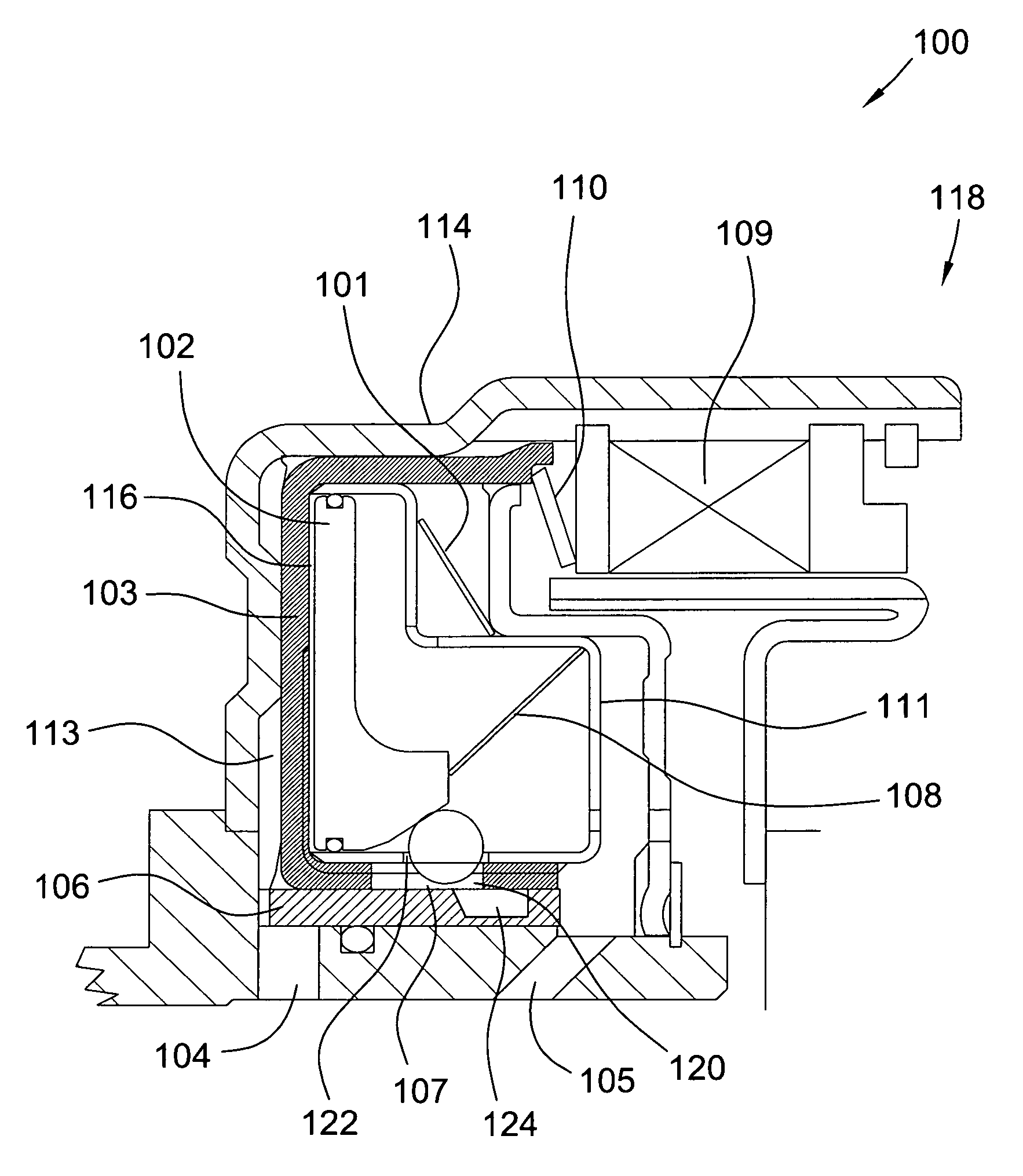

Clutch and brake latch mechanism

A clutch including: a first piston displaceable to operate a clutch pack; a second piston; a first fluid chamber partially formed by the pistons, wherein the second piston is displaceable by fluid pressure in the first fluid chamber; and a locking means fixable by the second piston to hold the pack closed. In a preferred embodiment, the locking means includes at least one displaceable ball. In another preferred embodiment, in response to a loss of fluid pressure in the first chamber, the second piston is displaceable to enable displacement of the locking means to open the pack. In a further preferred embodiment, the clutch includes a second chamber, separate from the first chamber and partially formed by the first piston. The first piston is displaceable in response to fluid pressure in the second chamber. The pack remains closed after a loss or reduction of fluid pressure in the second chamber.

Owner:SCHAEFFLER TECH AG & CO KG

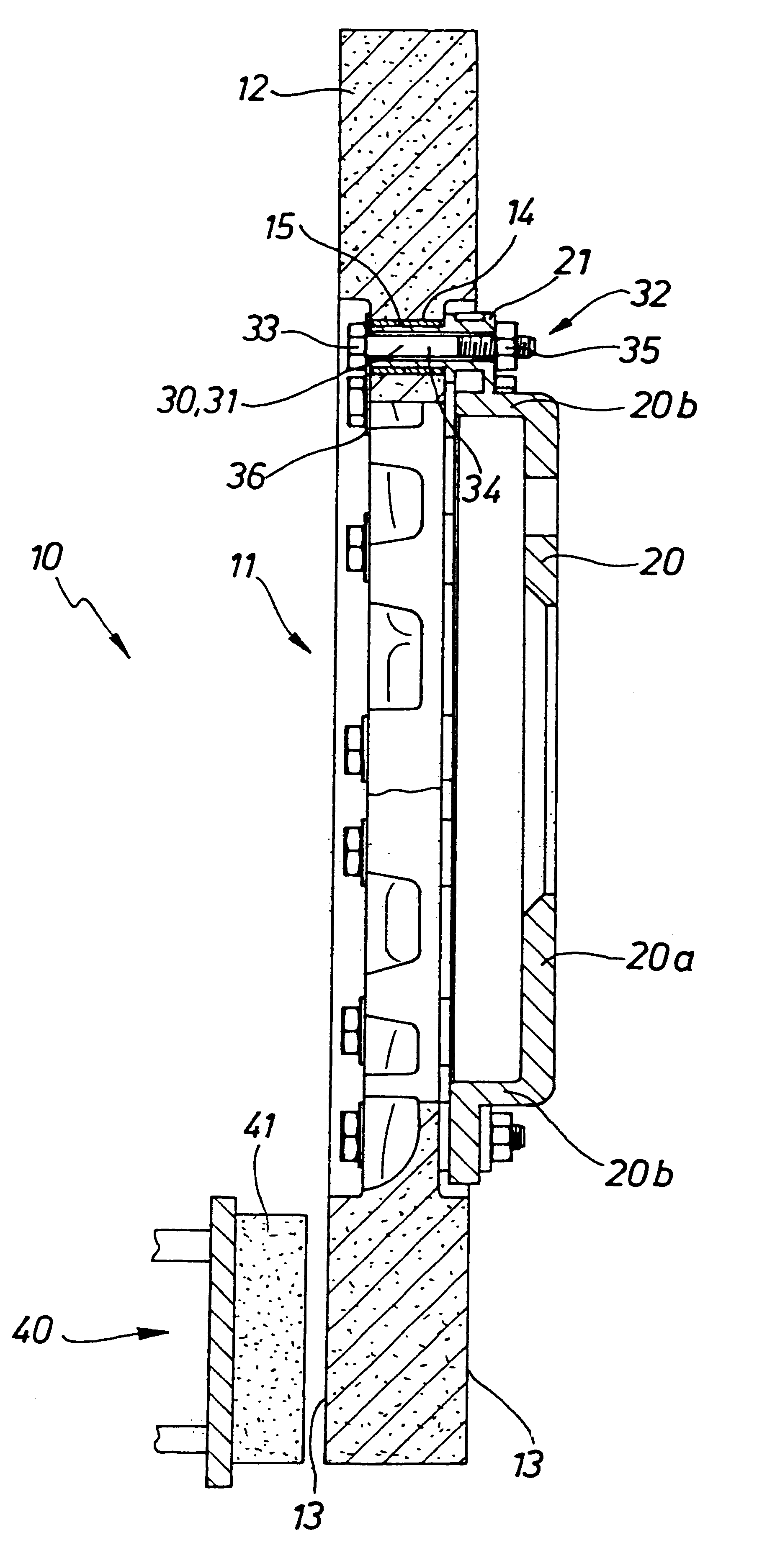

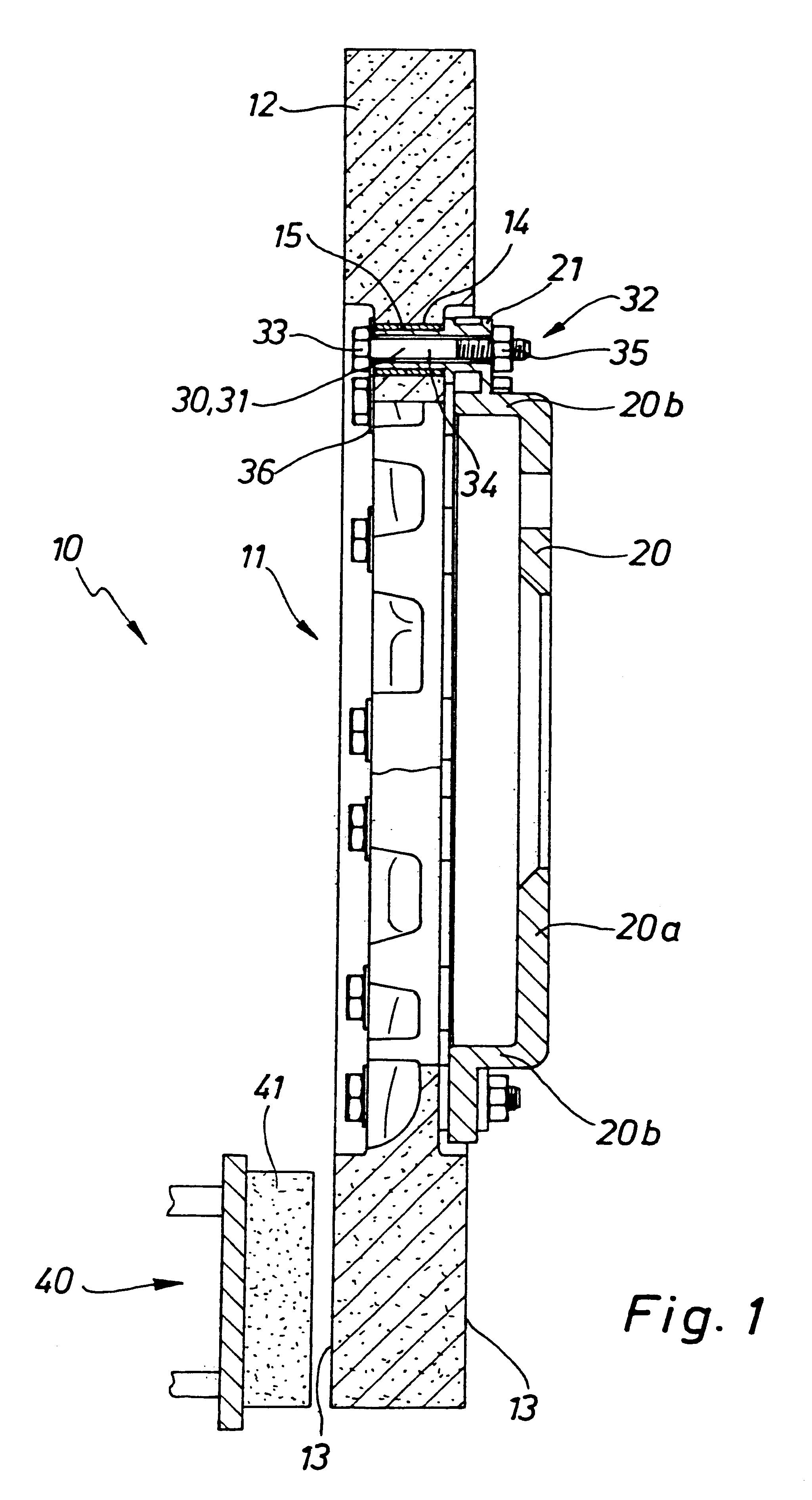

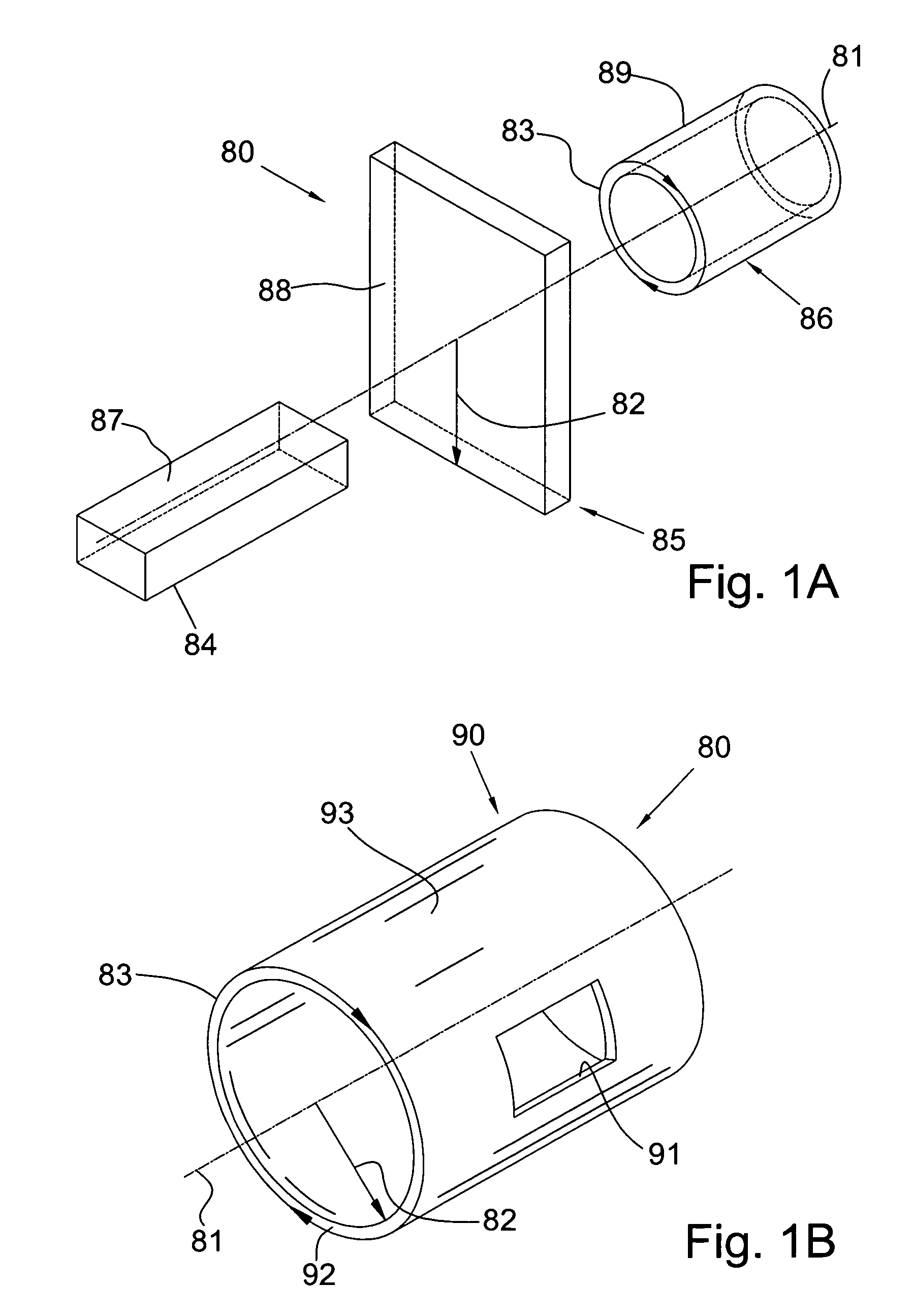

Device for fixing a ventilated brake disk axially on the hub of a motor vehicle wheel

InactiveUS6446765B1Easy to controlHigh speed usBraking element arrangementsAxially engaging brakesEngineeringMechanical engineering

An axial fixing device for axially fixing an annular brake disk on a wheel hub of a motor vehicle, the annular brake disk having the same axis of rotation as the hub and including radial ventilation ducts regularly distributed about its periphery. According to the invention, the hub has axial guide pieces in relief, or "lugs", for co-operating with fluting in an inner peripheral edge of the disk to center the disk, to lock it angularly, and to guide it axially relative to the hub, each lug of the hub having a radial through channel for co-operating with a corresponding ventilation duct of the disk, and the disk is held axially in the hub with play by axial holding means disposed between the disk and the hub.

Owner:MESSIER BUGATTI INC

Bi-metal disc brake rotor and method of manufacturing

InactiveUS20070062768A1Avoid problemsImprove bindingNoise/vibration controlMetal rolling stand detailsCeramic coatingMaterials science

The invention provides a method for manufacturing a friction damped disc brake rotor, including the steps of: (A) providing a ceramic coating on an insert, wherein the insert has a body with tabs extending therefrom to hold the insert in a desired position within a mold; (B) washing the ceramic coating off of the tabs; (C) positioning the insert into the mold; and (D) casting a rotor cheek of the disc brake rotor in the mold around the insert such that a portion of each tab is bonded with the rotor cheek, and such that the coating is substantially non-bonded with the rotor cheek so that the coating provides a proper interfacial boundary between the body and the cheek for damping, and the at least partial bonding of each tab with the rotor cheek prevents corrosion-causing exterior elements from reaching the interfacial boundary when the friction damped disc brake rotor is in use.

Owner:GM GLOBAL TECH OPERATIONS LLC

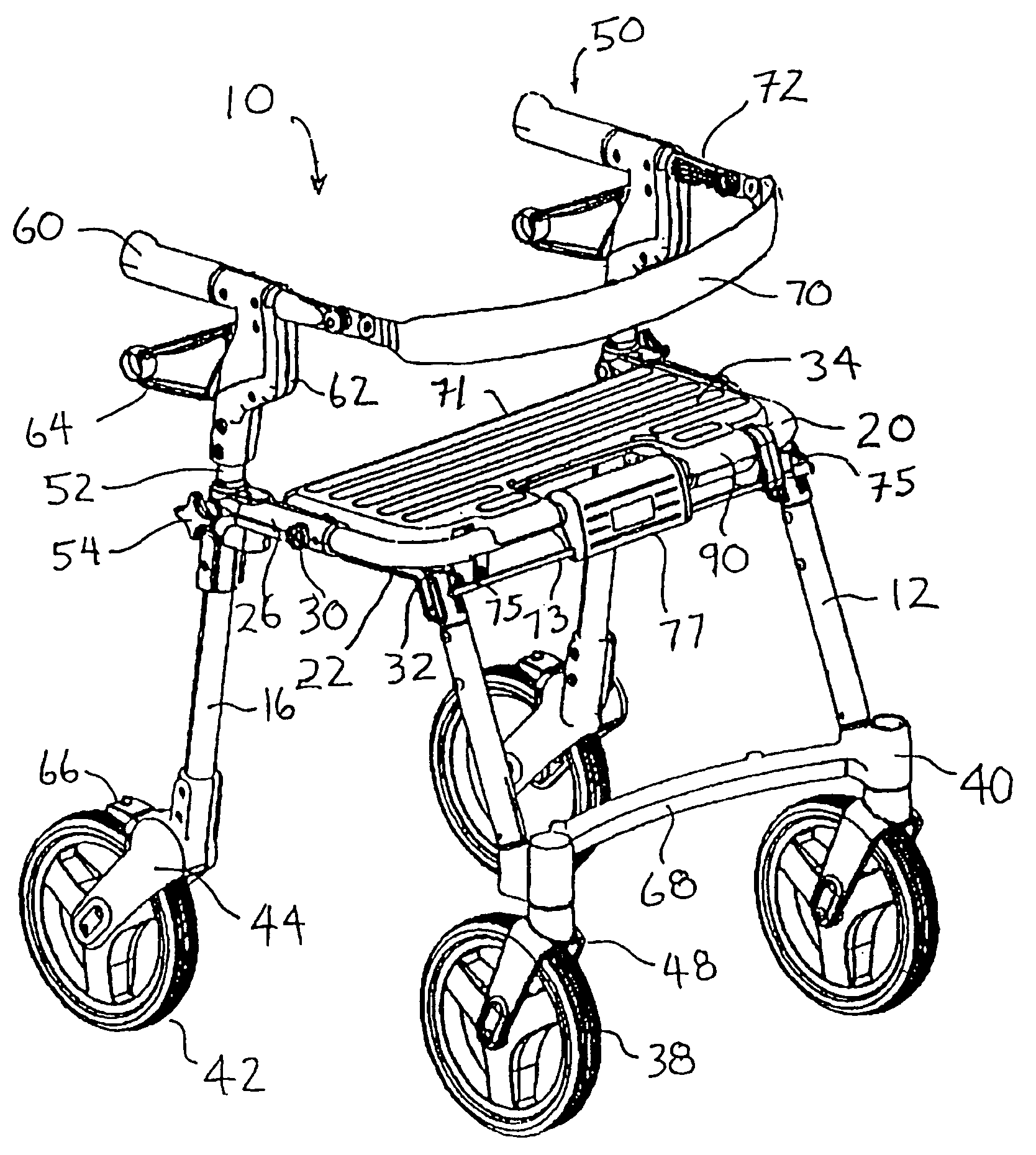

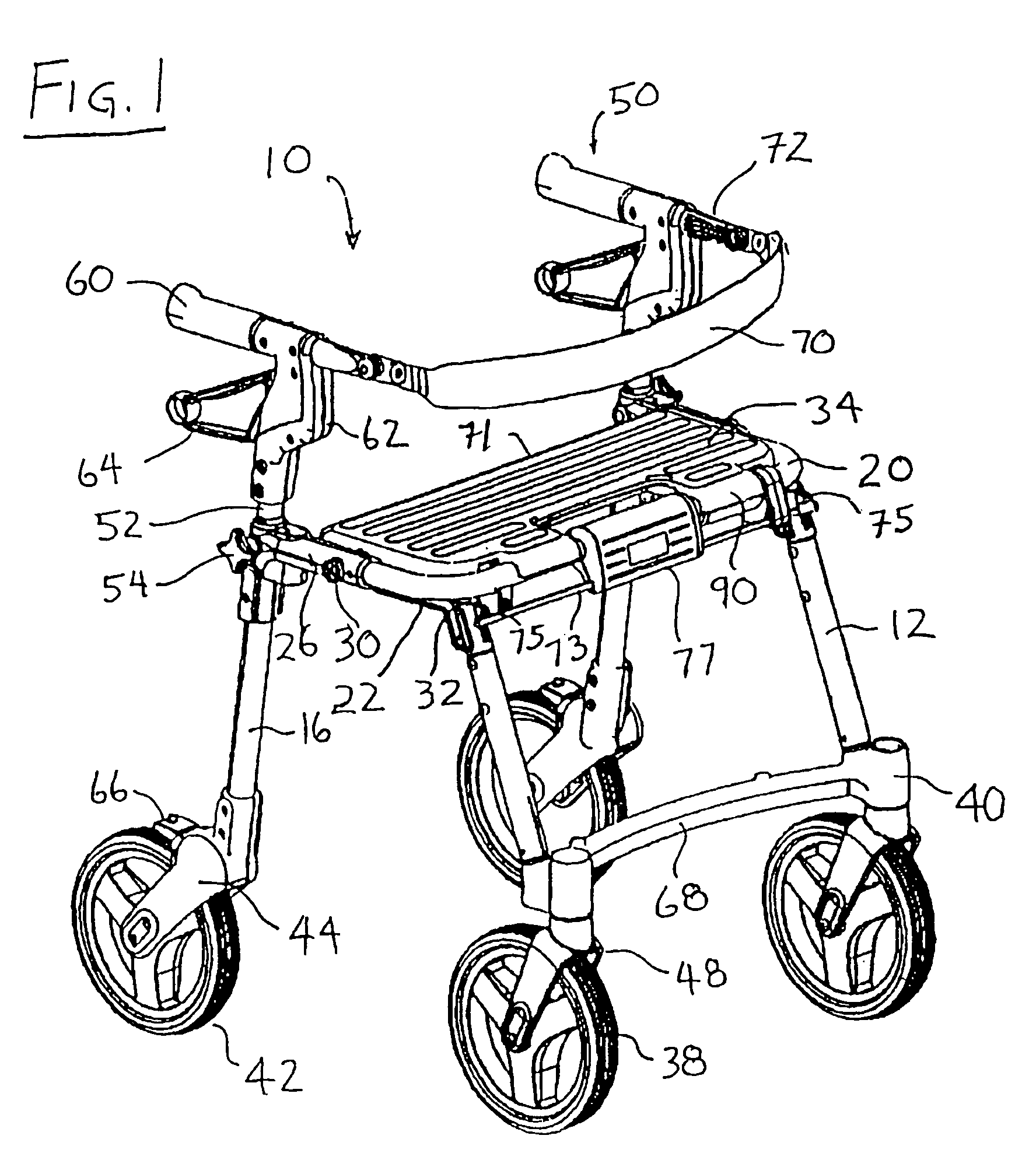

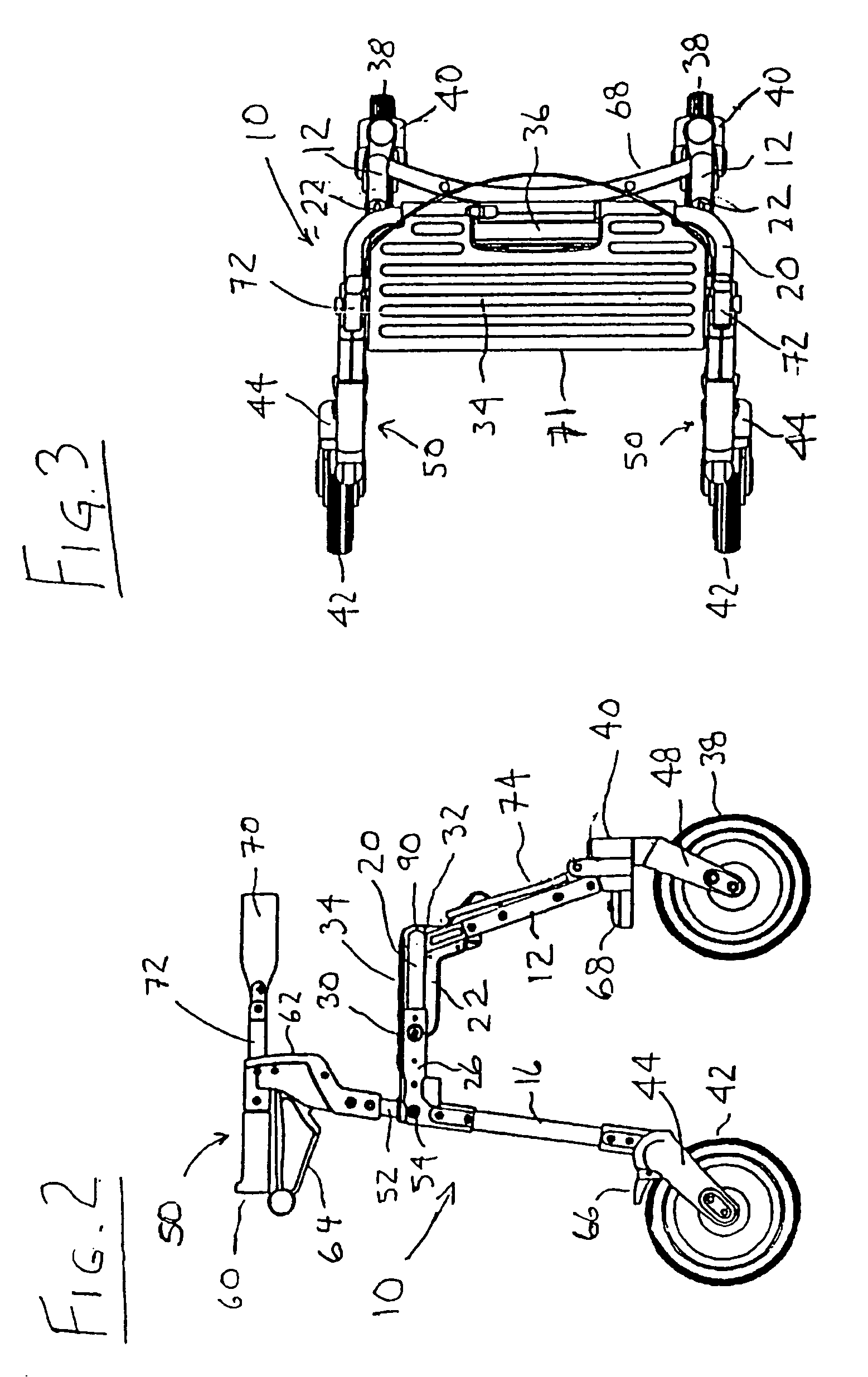

Height-adjustable cordless brake

InactiveUS7219906B2Avoid actionSmooth rollingBraking element arrangementsWheelchairs/patient conveyanceEngineeringAids walking

The present invention relates to a cordless braking system for a mobility-aiding device, such as a wheeled walker (a rollator) or a transport chair. The cordless braking system includes a brake actuating linkage, disposed inside the leg and handlebar members of the mobility-aiding device, which extends during height adjustment of the handlebars. The brake-actuating linkage and the leg / handlebar of the mobility-aiding device are designed to enable a locking pin or bolt to extend all the way therethrough to ensure that all of the height-adjustable members are secured together during use.

Owner:RANDOM PRODS TRUST +1

Method and apparatus for forming a part with dampener

InactiveUS20050011628A1Effectively and efficiently constructedDampening structureNoise/vibration controlFoundry mouldsMaterials scienceShock absorber

Owner:FRENI BREMBO SPA

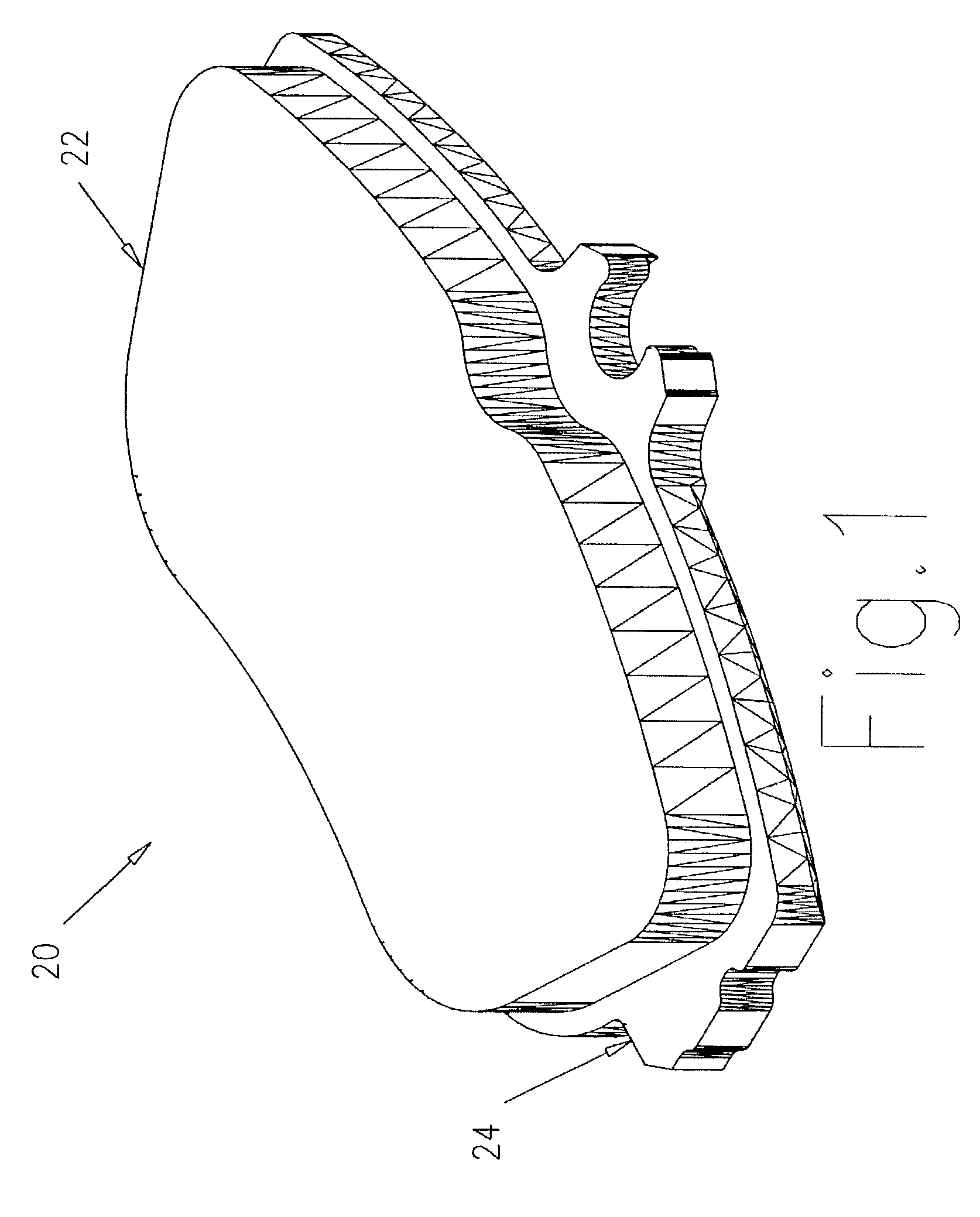

Brake rotor with ceramic matrix composite friction surface plates

The disclosure relates to structures and a method for providing an air cooled rotor with ceramic-metal composite friction surface plates, and in particular to a brake rotor including a rotor hat; a ventilation disc having a plurality of cooling vanes extending therefrom; a ceramic matrix composite (CMC) friction surface plate on each side of the ventilation disc; and a fastener for holding the CMC friction surface plates and the ventilation disc to the rotor hat.

Owner:STARFIRE SYST

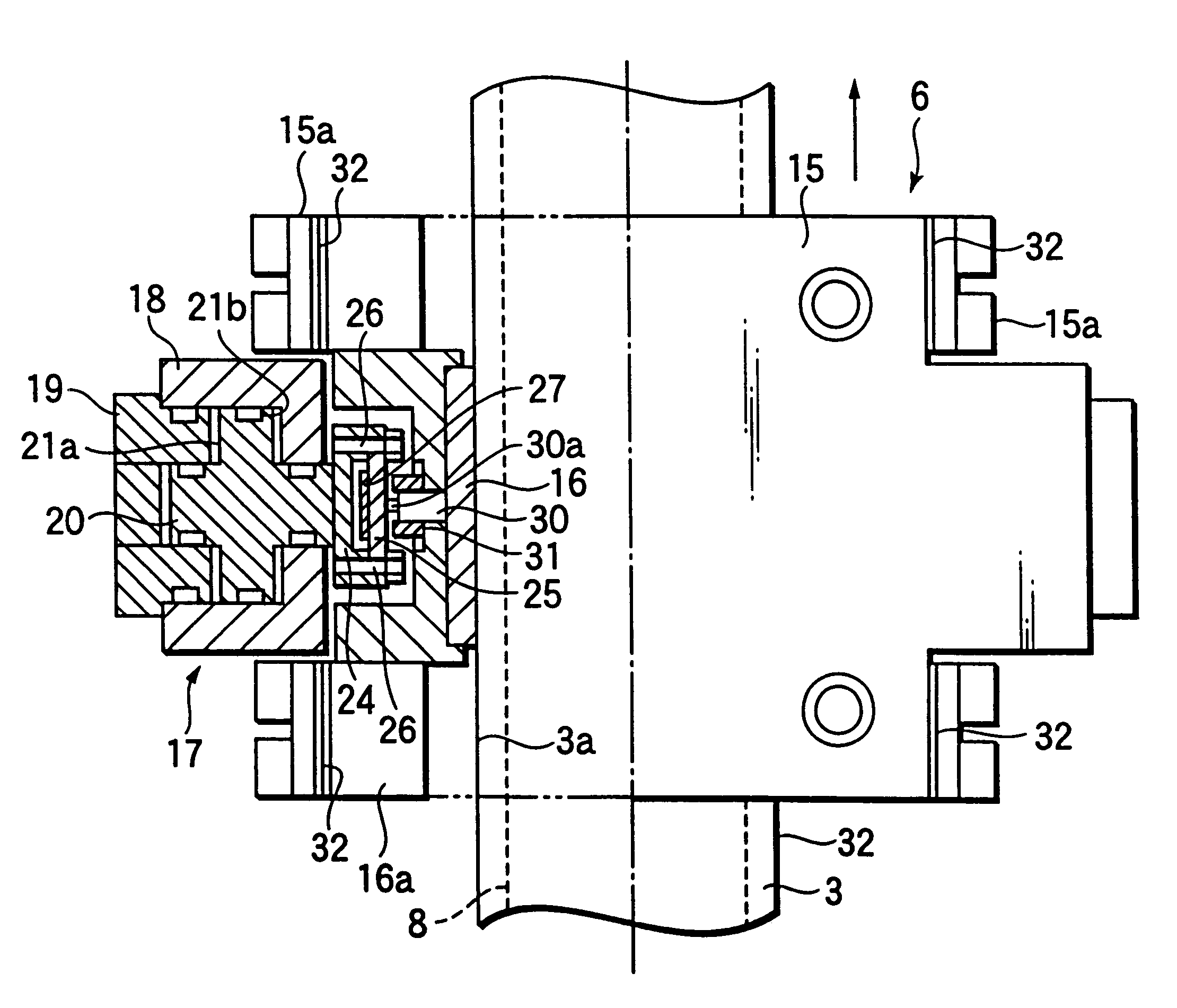

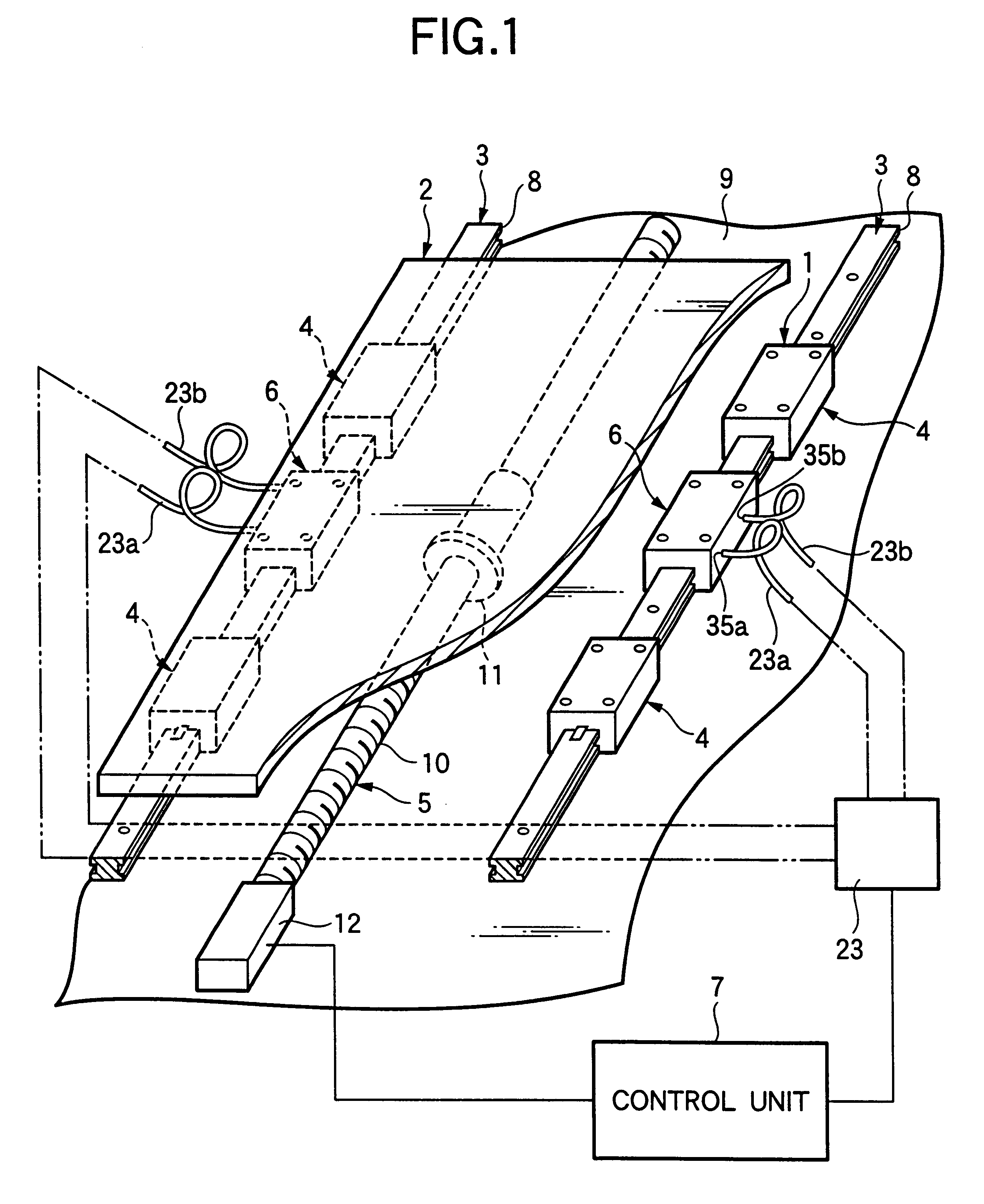

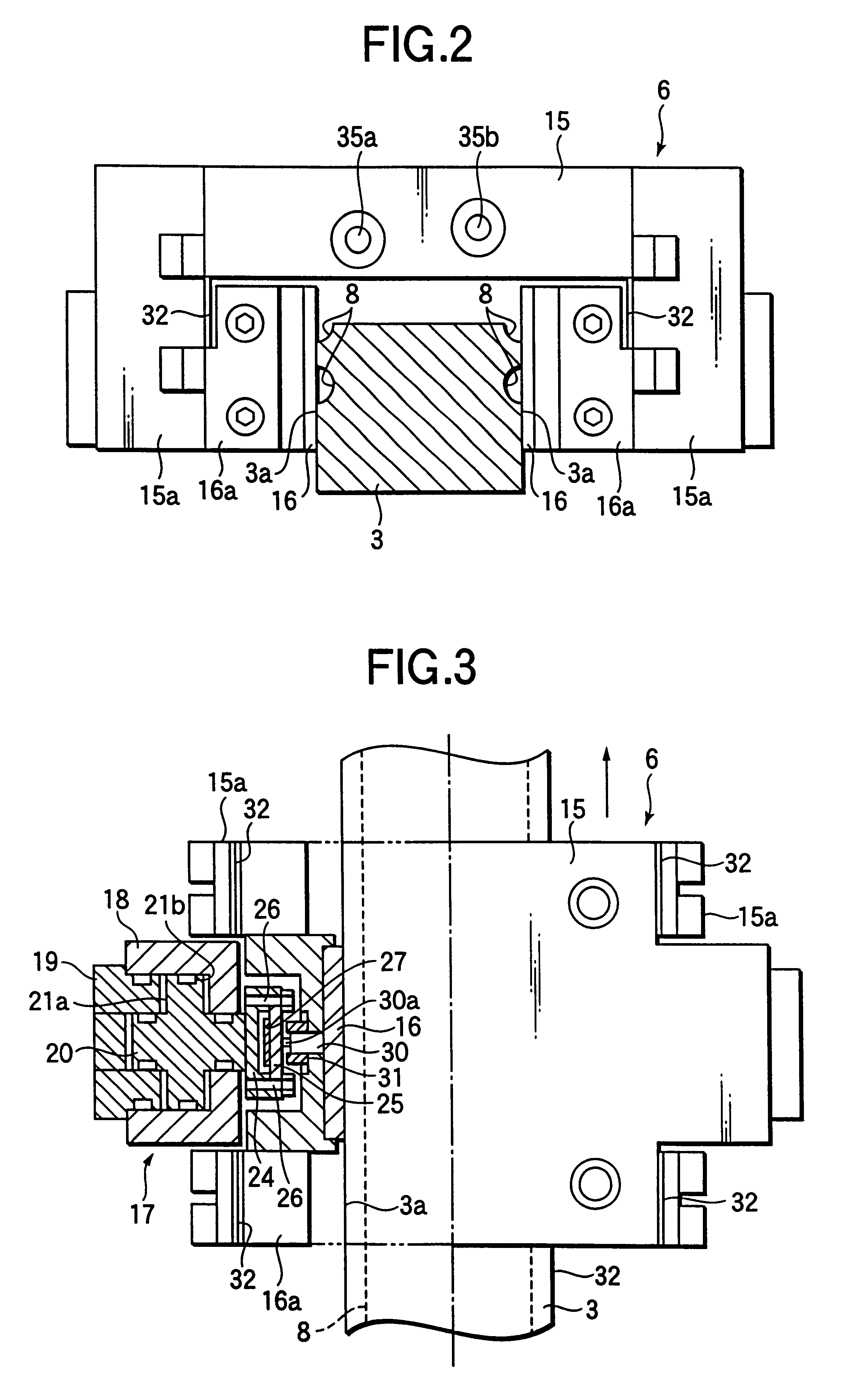

Linear guide apparatus

The linear guide apparatus includes a guide rail 3 including a rolling body rolling groove 8 and a friction apply unit 6 assembled to the guide rail 3. The friction apply unit 6 includes a unit main body 15, a brake member 16, an oil pressure cylinder 17 and a plate spring 32. The brake member 16 is disposed so as to face the side surface 3a of the guide rail 3 and can be contacted with the other portions of the side surface 3a than the rolling body rolling groove 8 thereof. The oil pressure cylinder 17 includes a piston member 20 which is structured to be driven in a positive direction to thereby press the brake member 16 against the side surface 3a of the guide rail 3 and also the piston member 20 can be driven in the opposite direction to thereby remove the pressure of the brake member 16 from the side surface 3a.

Owner:NSK LTD

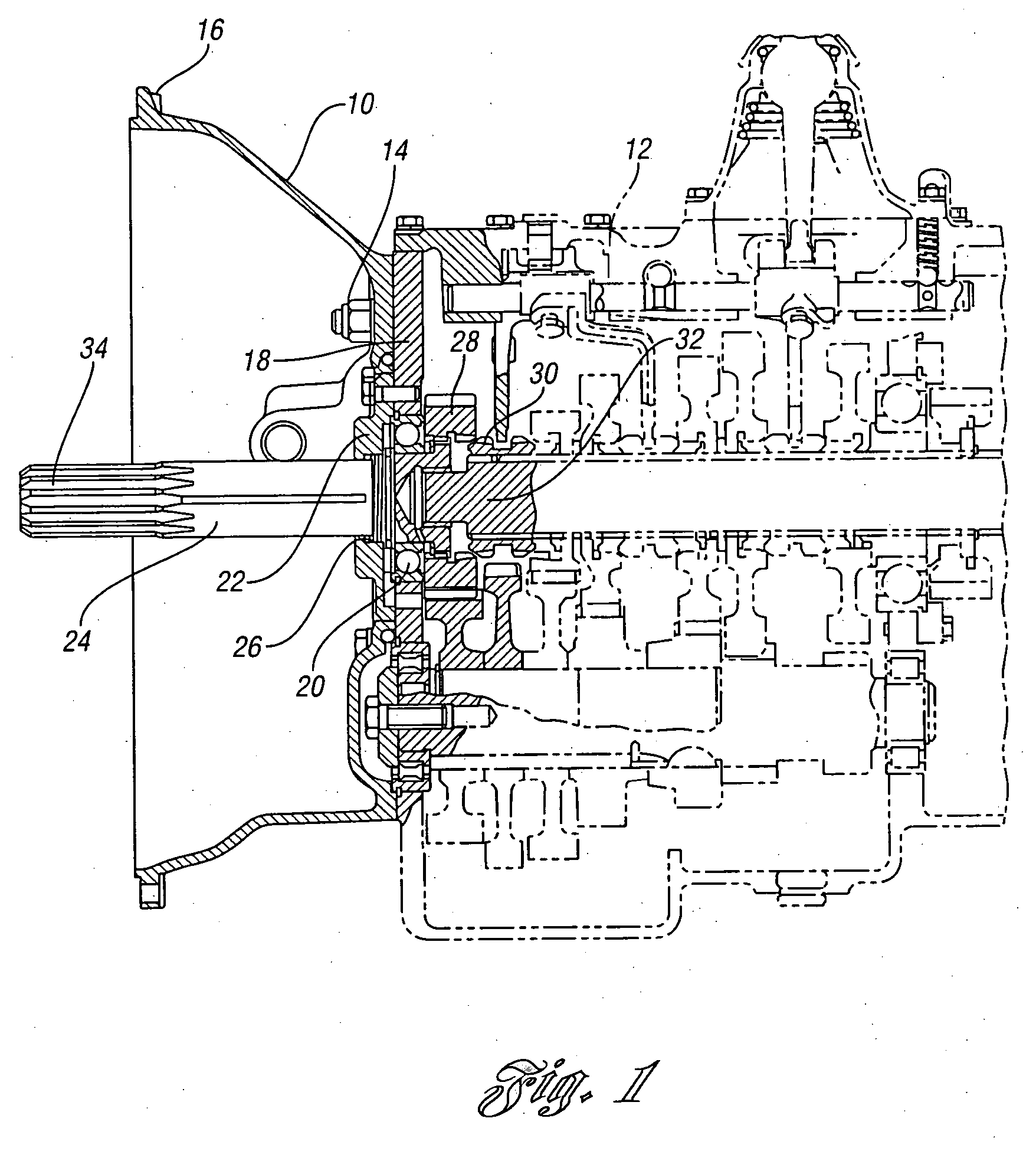

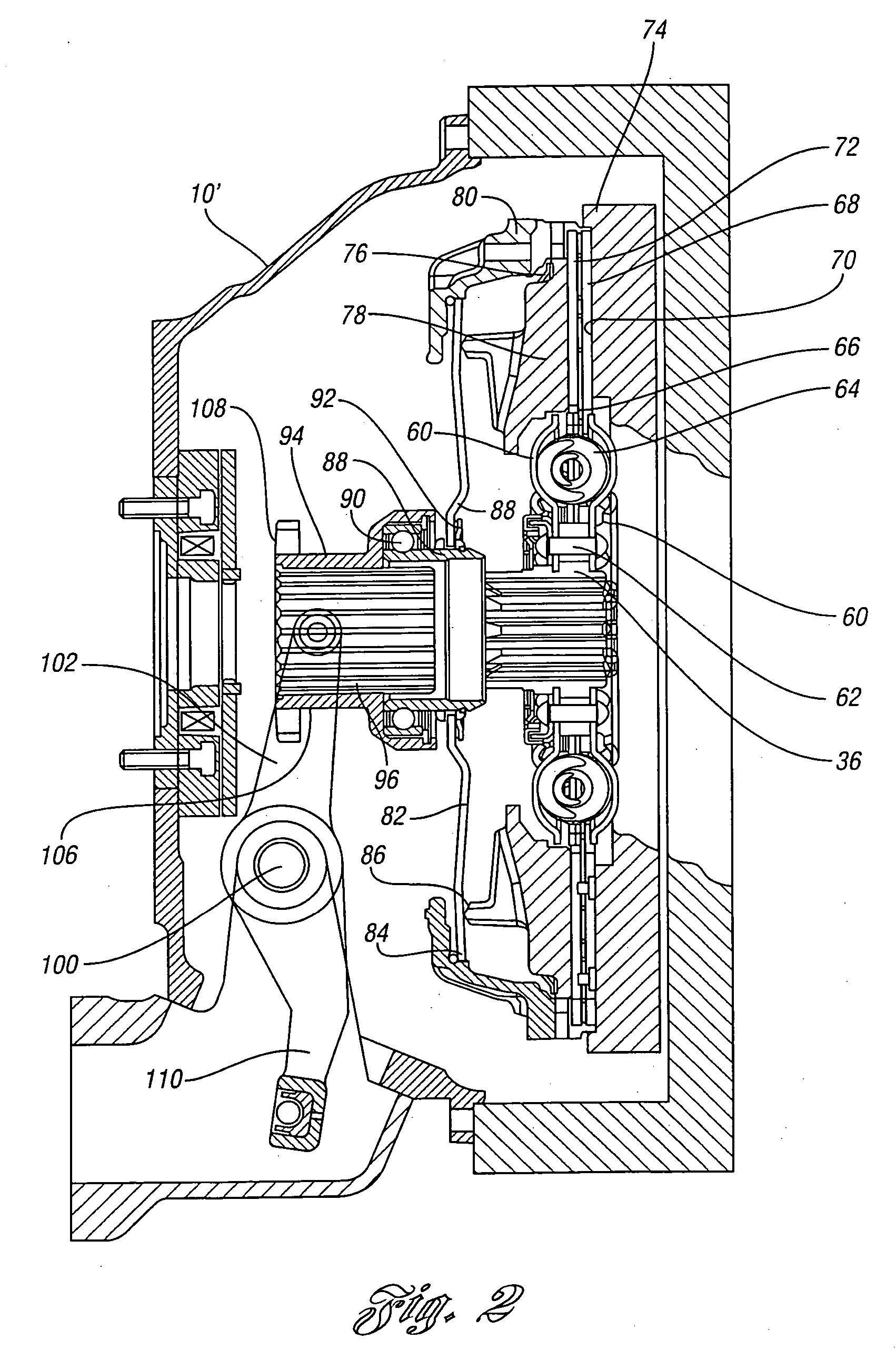

Electromagnetic brake for a multiple-ratio power transmission in a vehicle powertrain

InactiveUS20050217966A1Reduce the cross-sectional areaLimited amountBraking element arrangementsToothed gearingsActuatorControl theory

An electromagnetic brake, including an electromagnetic brake actuator coil surrounding a power input shaft for a multiple-ratio transmission in a vehicle powertrain, is disclosed. An electromagnetic flux flow path for the actuator coil is electromagnetically isolated from the power input shaft and other elements of the powertrain thereby avoiding residual magnetization.

Owner:EATON INTELLIGENT POWER LIMITED

Materials and methods for making ceramic matrix composites

Ceramic matrix composites and fiber reinforced ceramic matrix composite components of brake systems and other friction tolerant composite articles of this invention are made by providing a fiber preform, coating the fibers with an interface layer of carbon or ceramic, infiltrating the coated fiber preform with a composition comprising a liquid ceramic forming polymer including friction controlling additives, and pyrolyzing the polymer in the infiltrated preform to form a ceramic matrix around the fibers of the preform.

Owner:SHERWOOD WALTER J +1

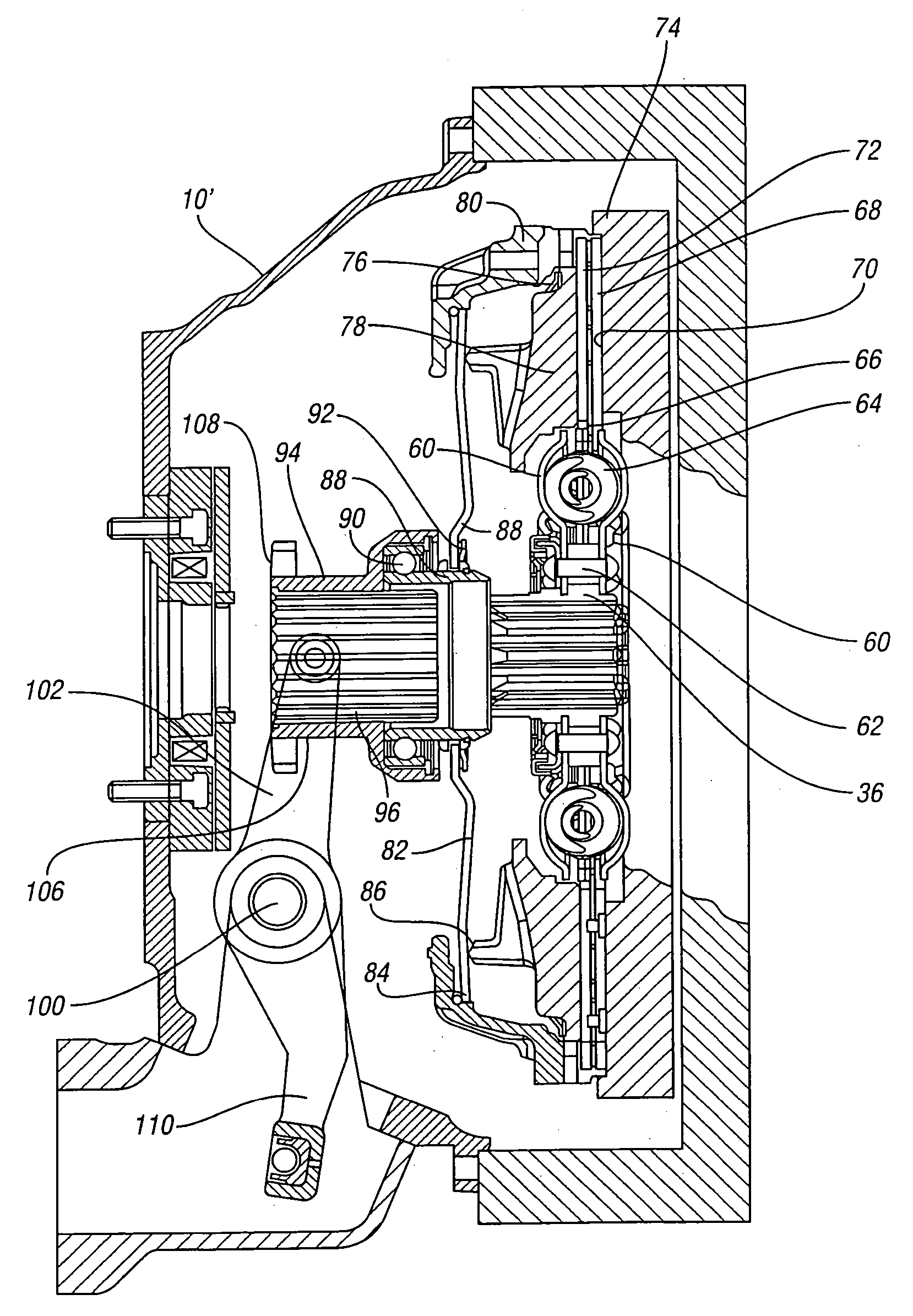

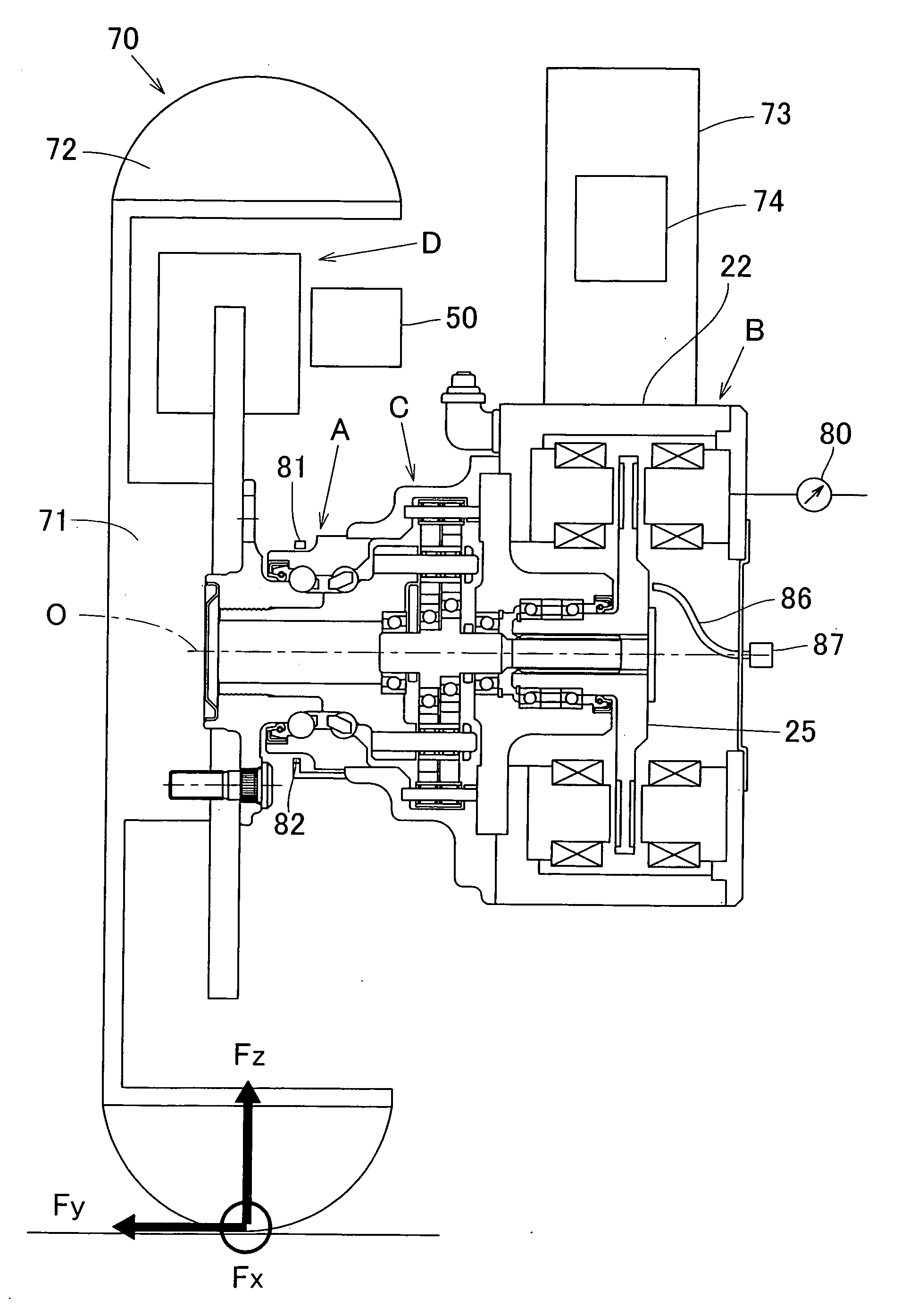

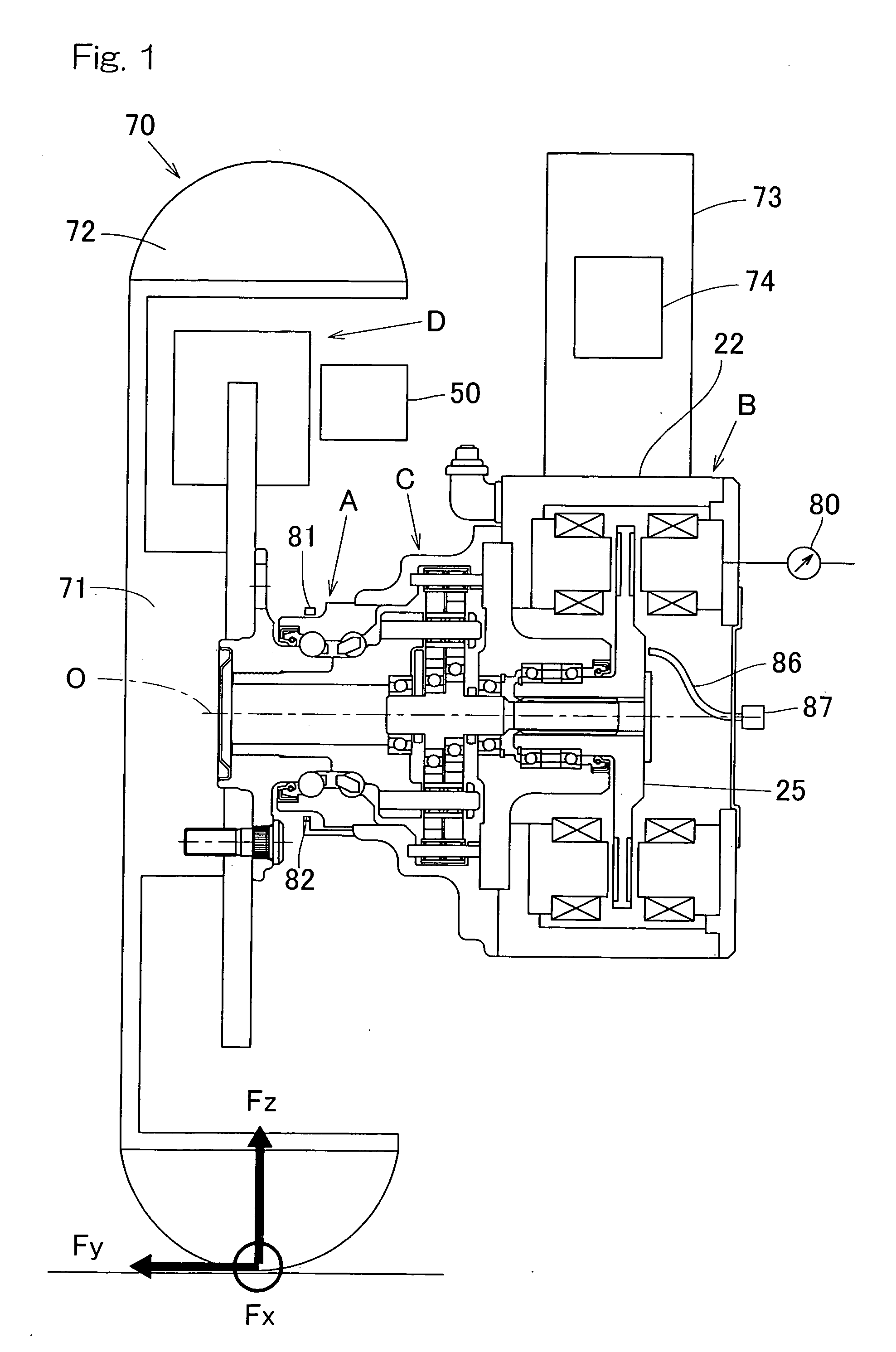

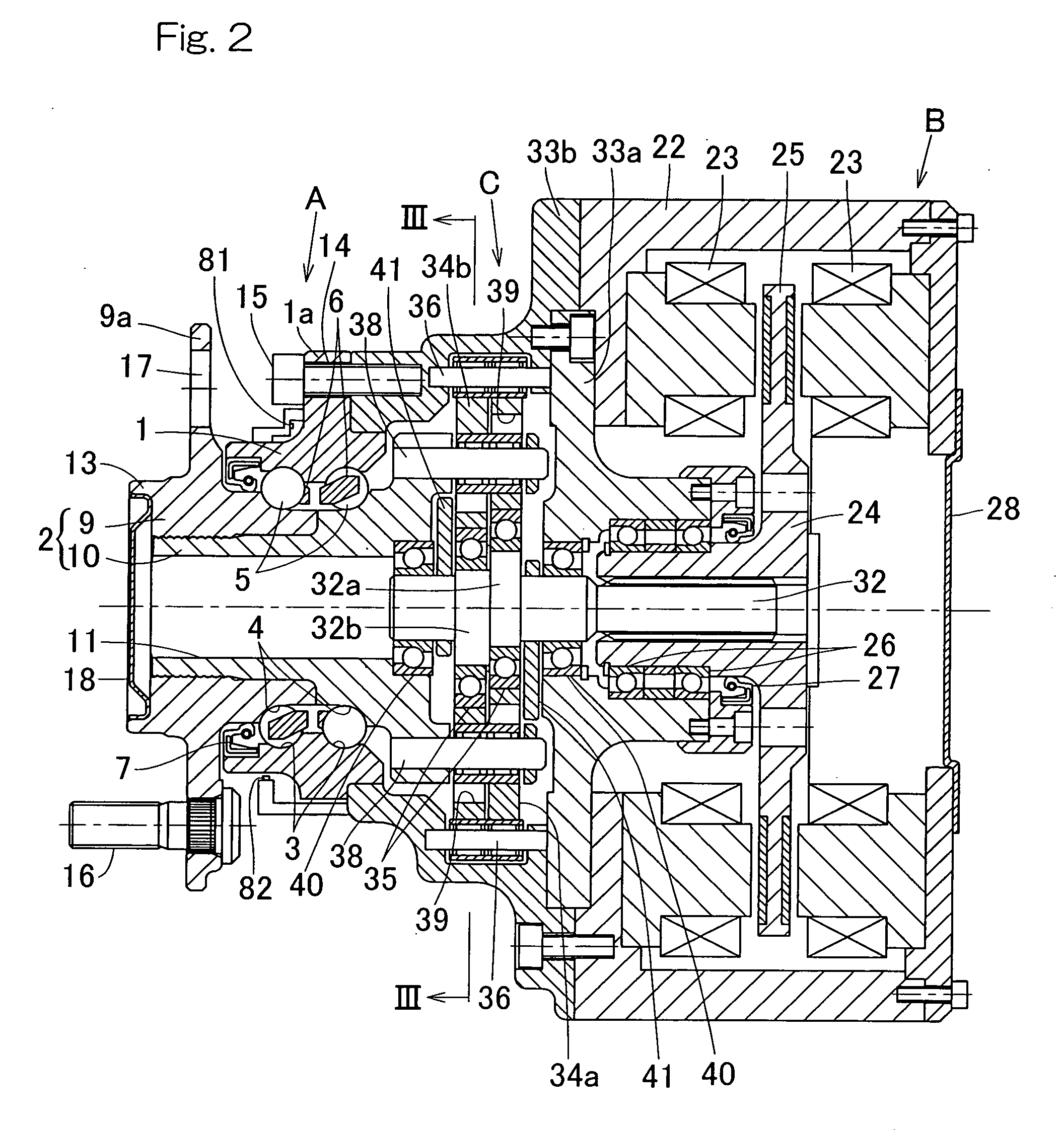

Sensor-equipped axle unit having a built-in motor of in-wheel type

ActiveUS20090236157A1Improve accuracyHigh sensitivityHybrid vehiclesMotor depositionDrive wheelElectric machine

A sensor equipped axle unit having an in-wheel type motor built therein, in which a hub bearing assembly (A), an electric motor (B), a reduction gear unit (C) and a brake assembly (D) are arranged coaxially on a center axis of a vehicle drive wheel. Sensors (80, 81 and 82) are provided for measuring forces Fx, Fy and Fz acting at a point of contact of the vehicle drive wheel (70) and a road surface in three axis directions perpendicular to each other, respectively, from the status of at least one of the hub bearing assembly (A), the electric motor (B), the reduction gear unit (C) and the brake assembly (D). Results of such measurement are utilized for a suspension control, an ABS control and any other control.

Owner:NTN CORP

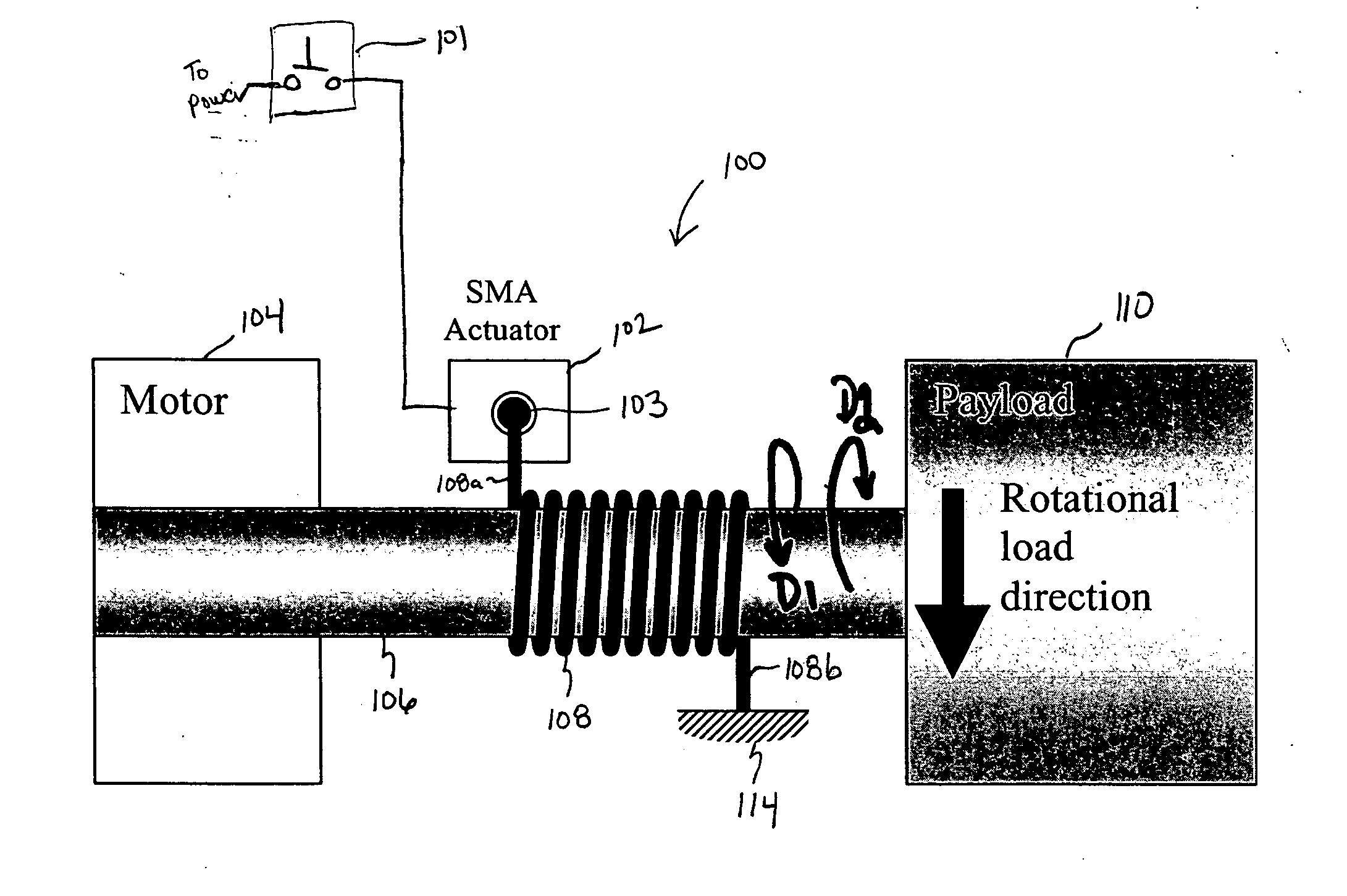

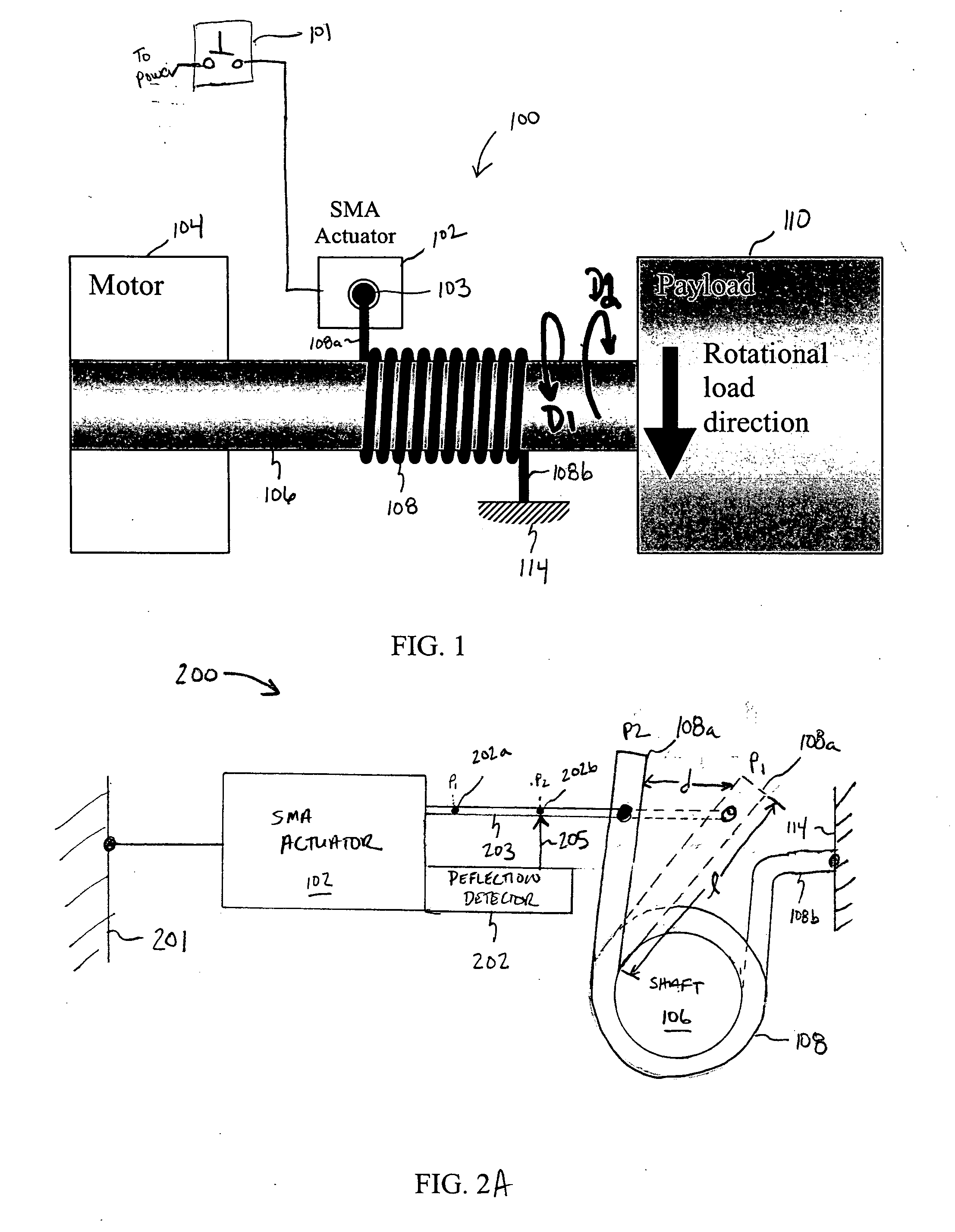

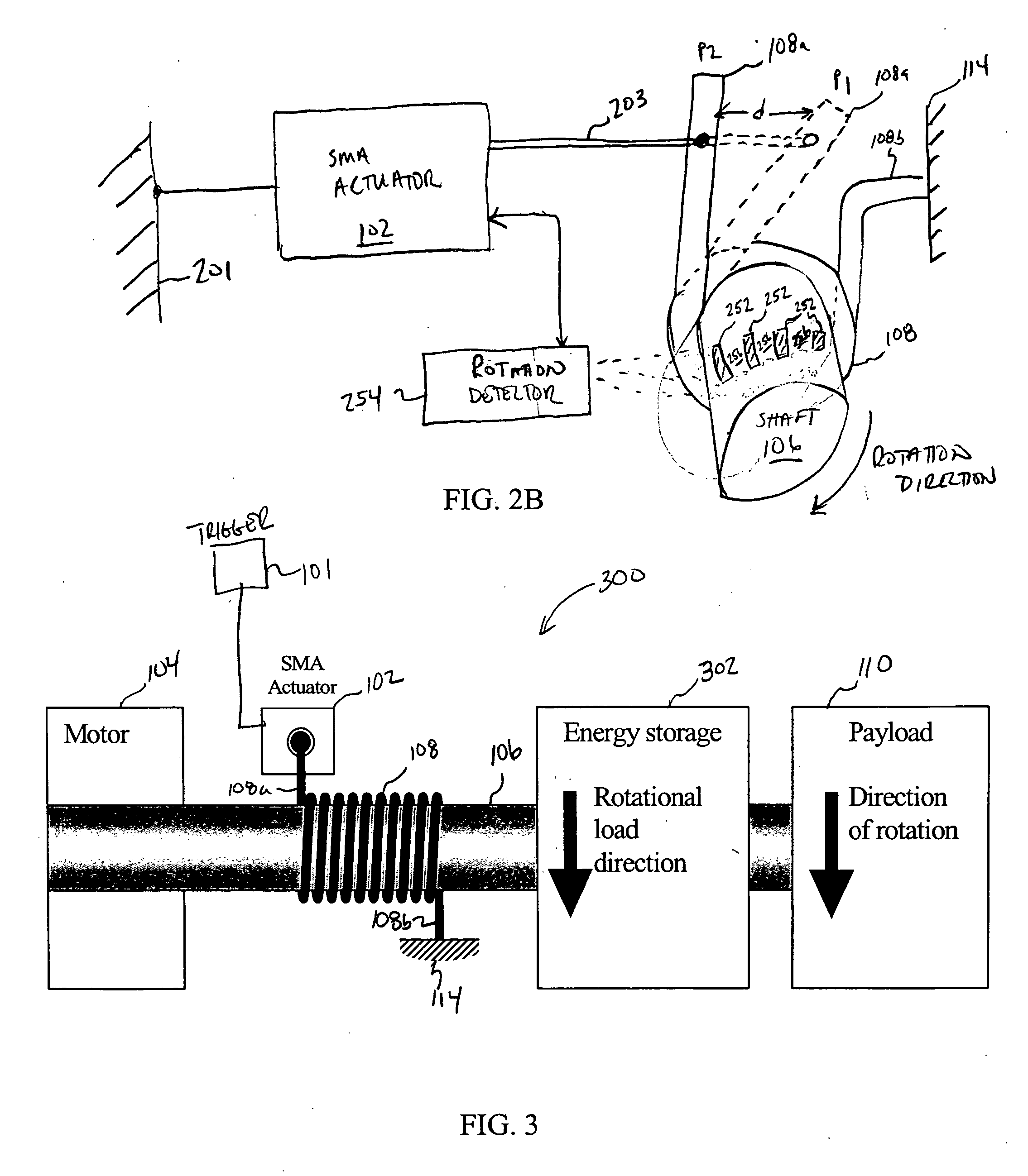

Shape memory alloy-actuated and bender-actuated helical spring brakes

In one embodiment of the present invention, a shape memory alloy (“SMA”)-actuated helical spring brake comprises a rotatable member and a helical wrap spring arranged concentrically about the rotatable member. The spring has a first spring end and a second spring end and includes a number of turns that are based radially inward and are configured to frictionally engage the rotatable member. The turns permit rotation of the rotatable member in a first direction and inhabit rotation in a second direction. The SMA-actuate helical spring brake also include an anchor point coupled to the second spring end, and an SMA actuator having an output drive member coupled to the first spring end. The SMA actuator is configured to, for example, deflect the first spring end to permit the rotatable member to rotate.

Owner:ALFMEIER PRAZISION BAUGRUPPEN & SYSTLOSUNGEN

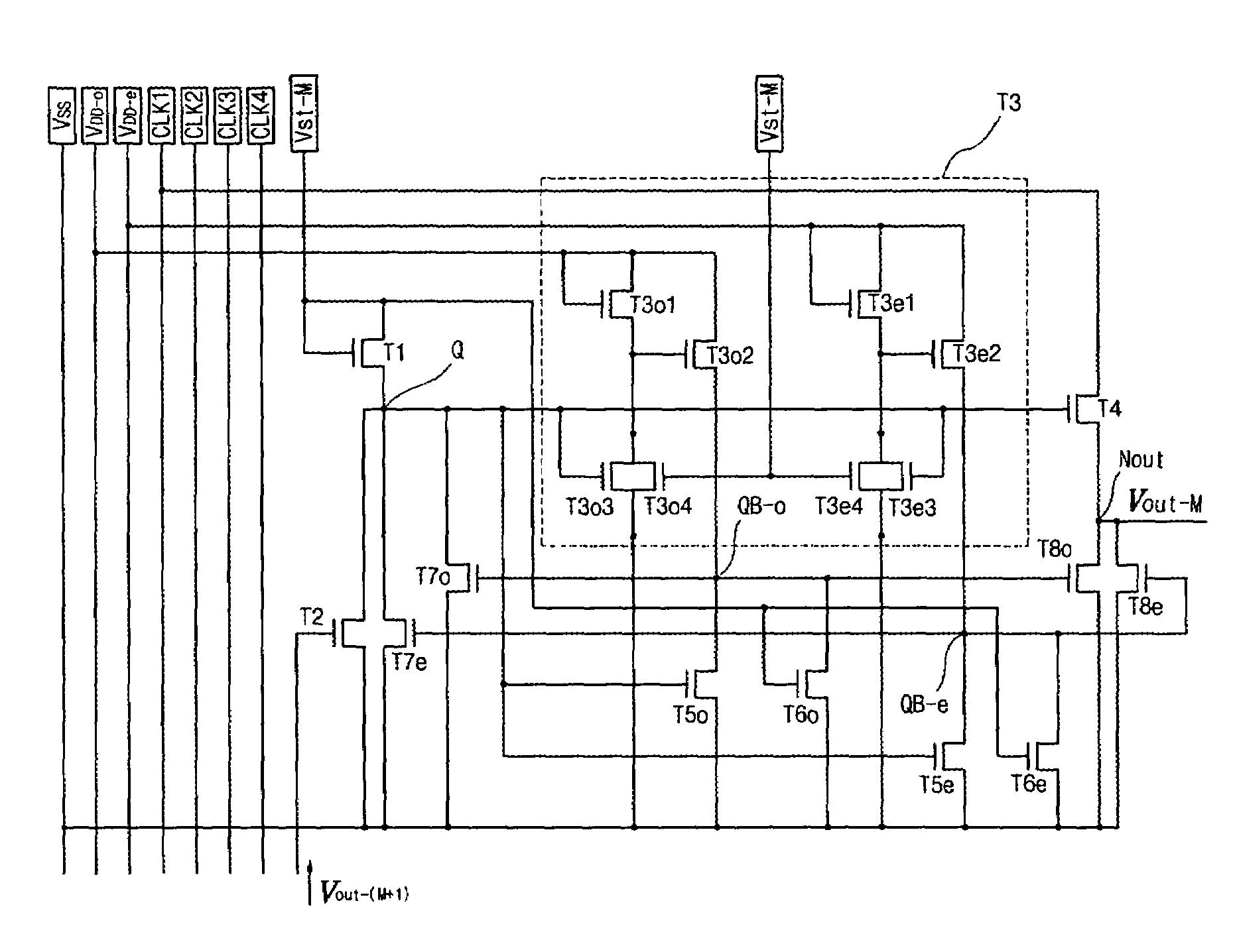

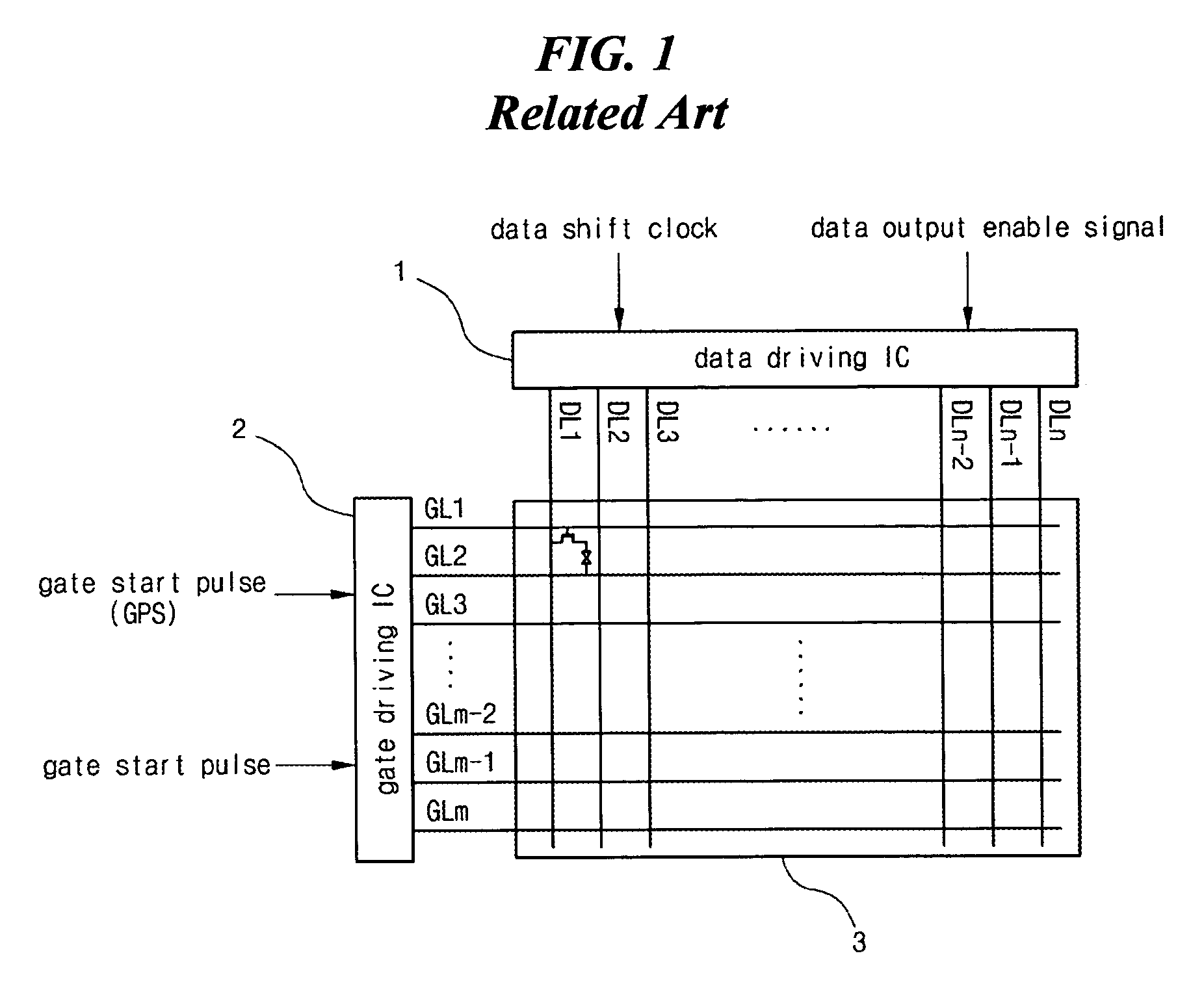

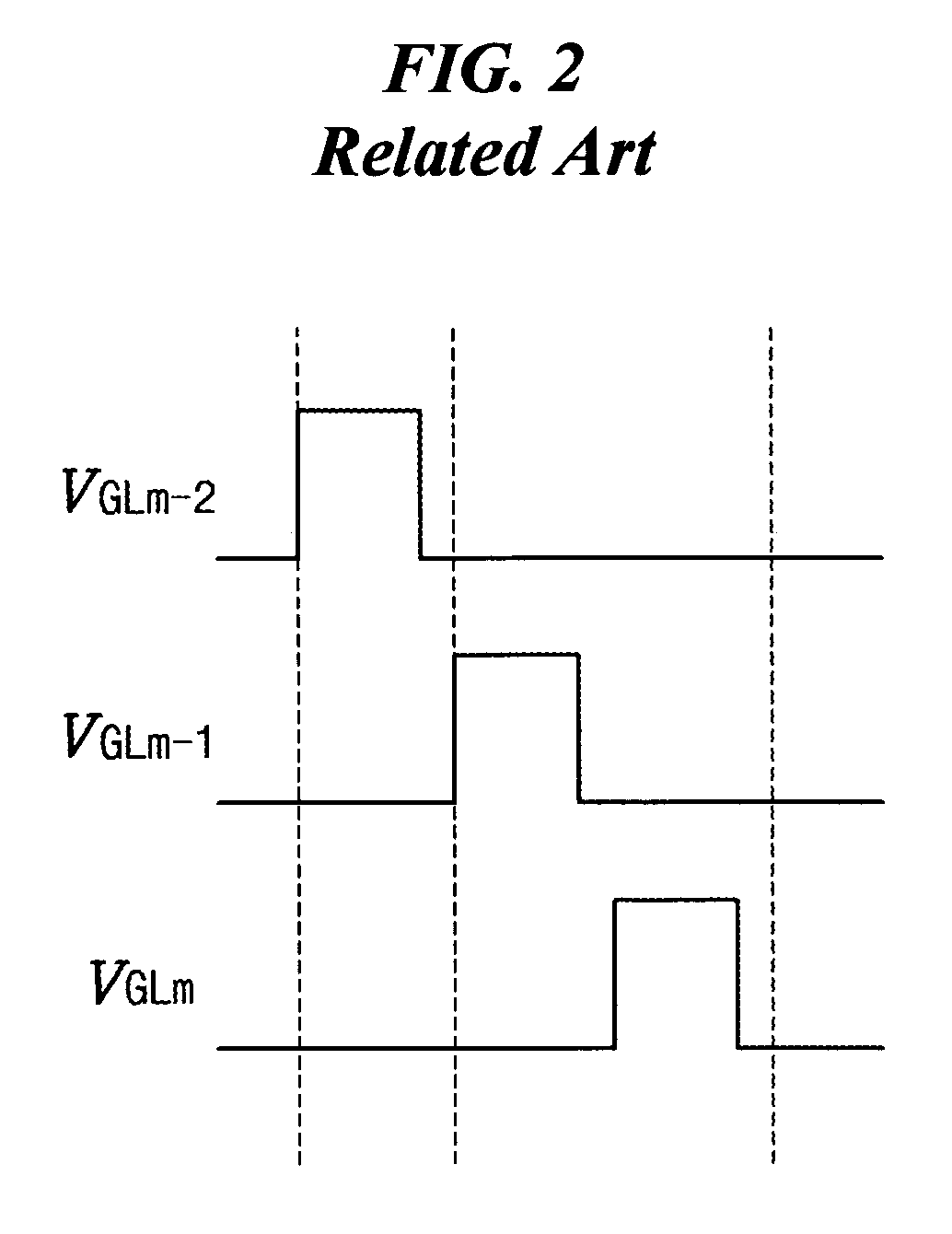

Driving circuit including shift register and flat panel display device using the same

ActiveUS7528820B2Increase contrastImprove display qualityAxially engaging brakesStatic indicating devicesShift registerEngineering

A driving circuit for a flat panel display device includes shift register stages, each containing: a first TFT charging a Q node according to a start signal; a second TFT discharging the Q node according to an output voltage of a next shift register stage; a pull-up unit increasing an output voltage according to the Q node voltage; an odd pull-down unit decreasing the output voltage in an odd frame according to a QB-o node voltage; and an even pull-down unit decreasing the output voltage in an even frame according to a QB-e node voltage. A gate and drain of a third odd TFT connected to the QB-o node are connected to each other and receive an odd source voltage. A gate and drain of the third even TFT connected to the QB-e node are connected to each other and receive an even source voltage.

Owner:LG DISPLAY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com