Patents

Literature

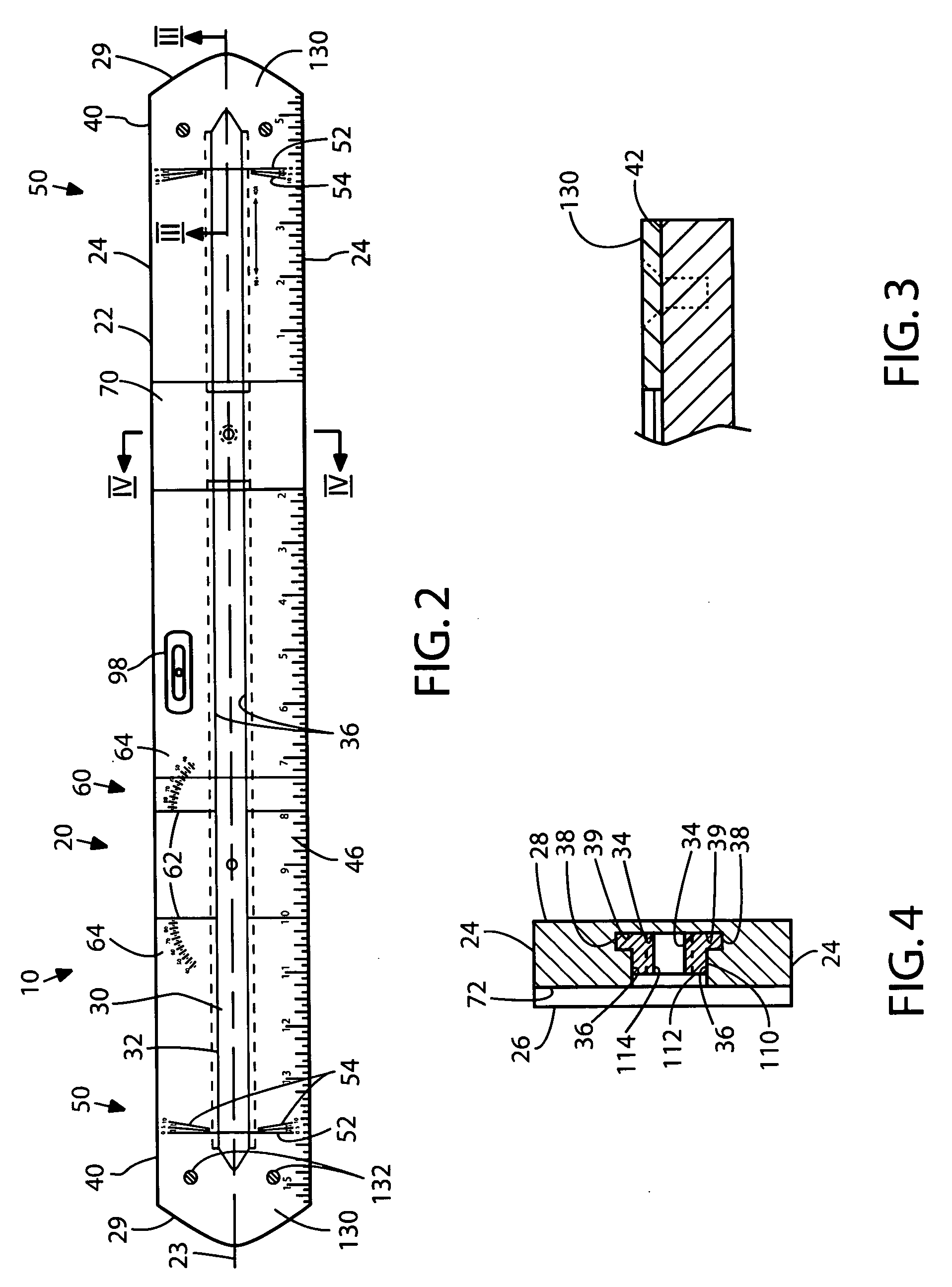

1541 results about "Woodworking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Woodworking is the activity or skill of making items from wood, and includes cabinet making (cabinetry and furniture), wood carving, joinery, carpentry, and woodturning.

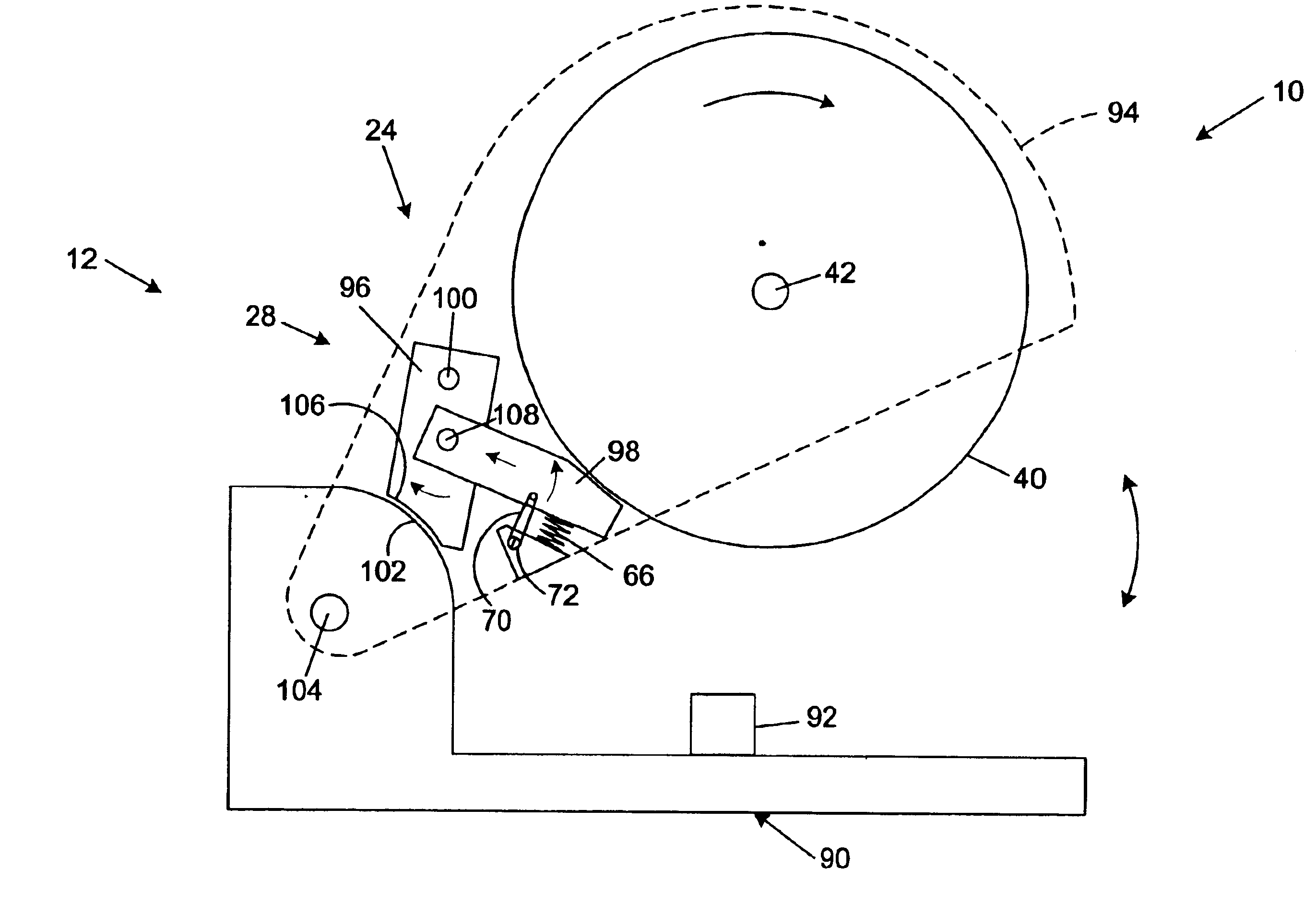

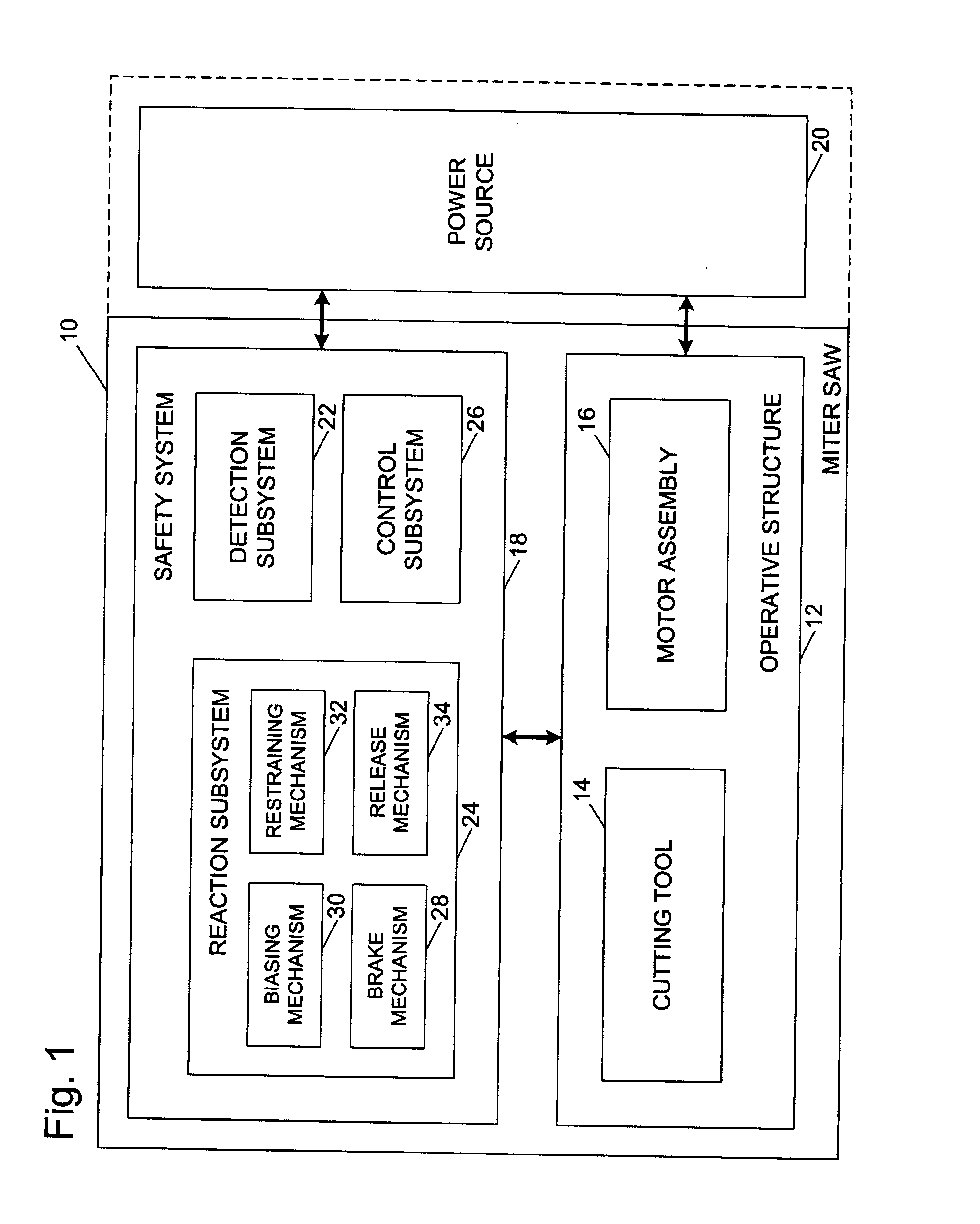

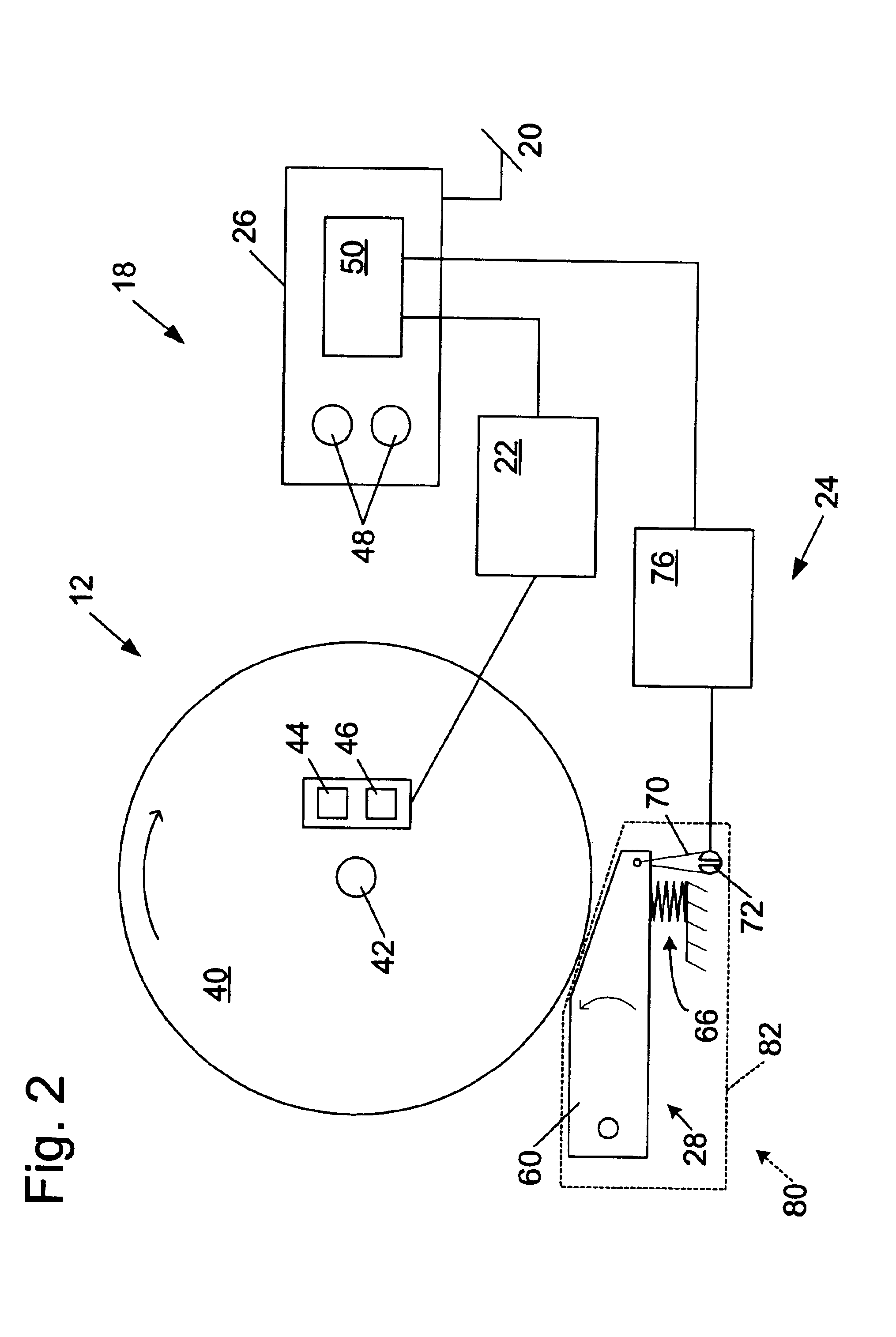

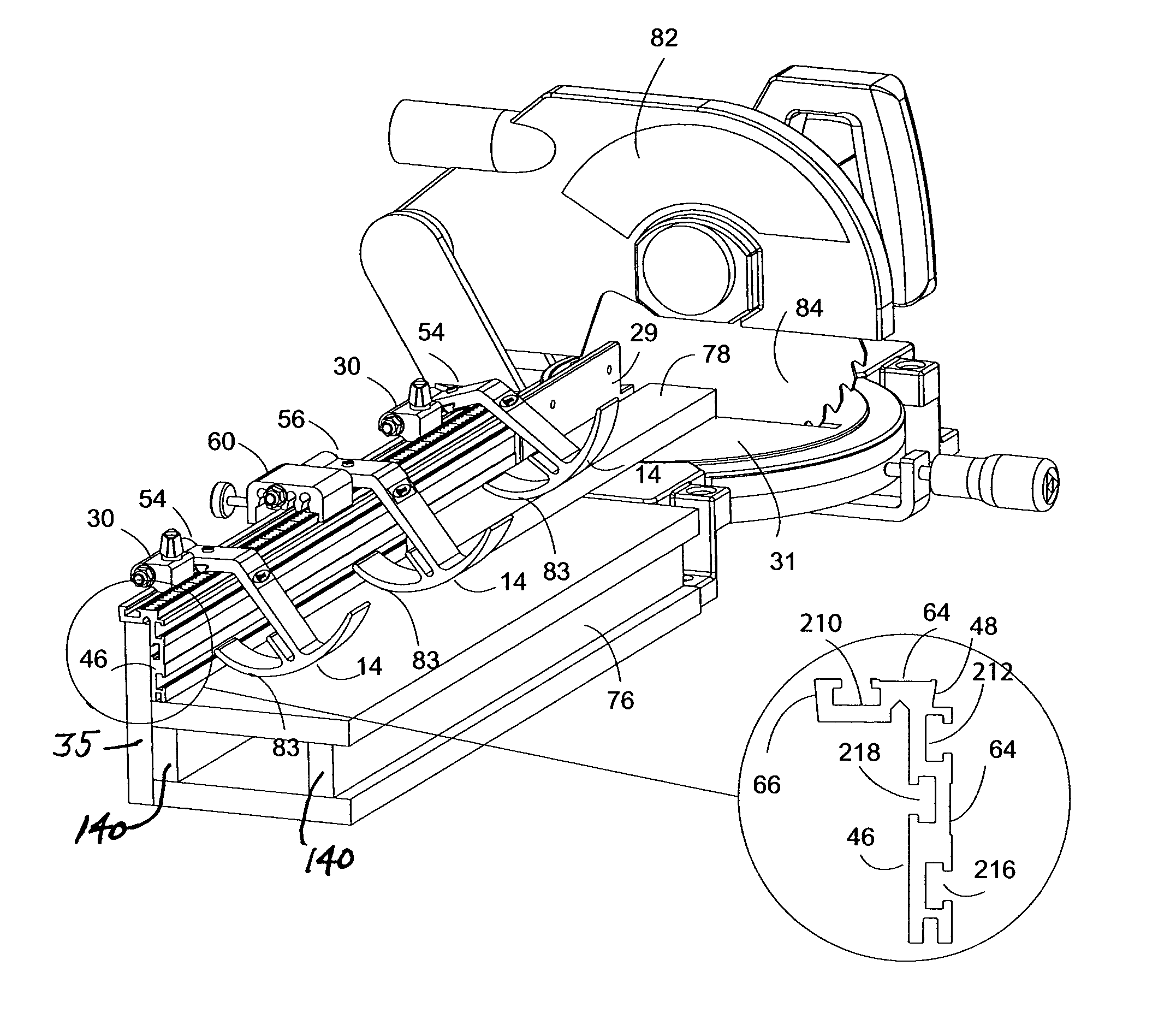

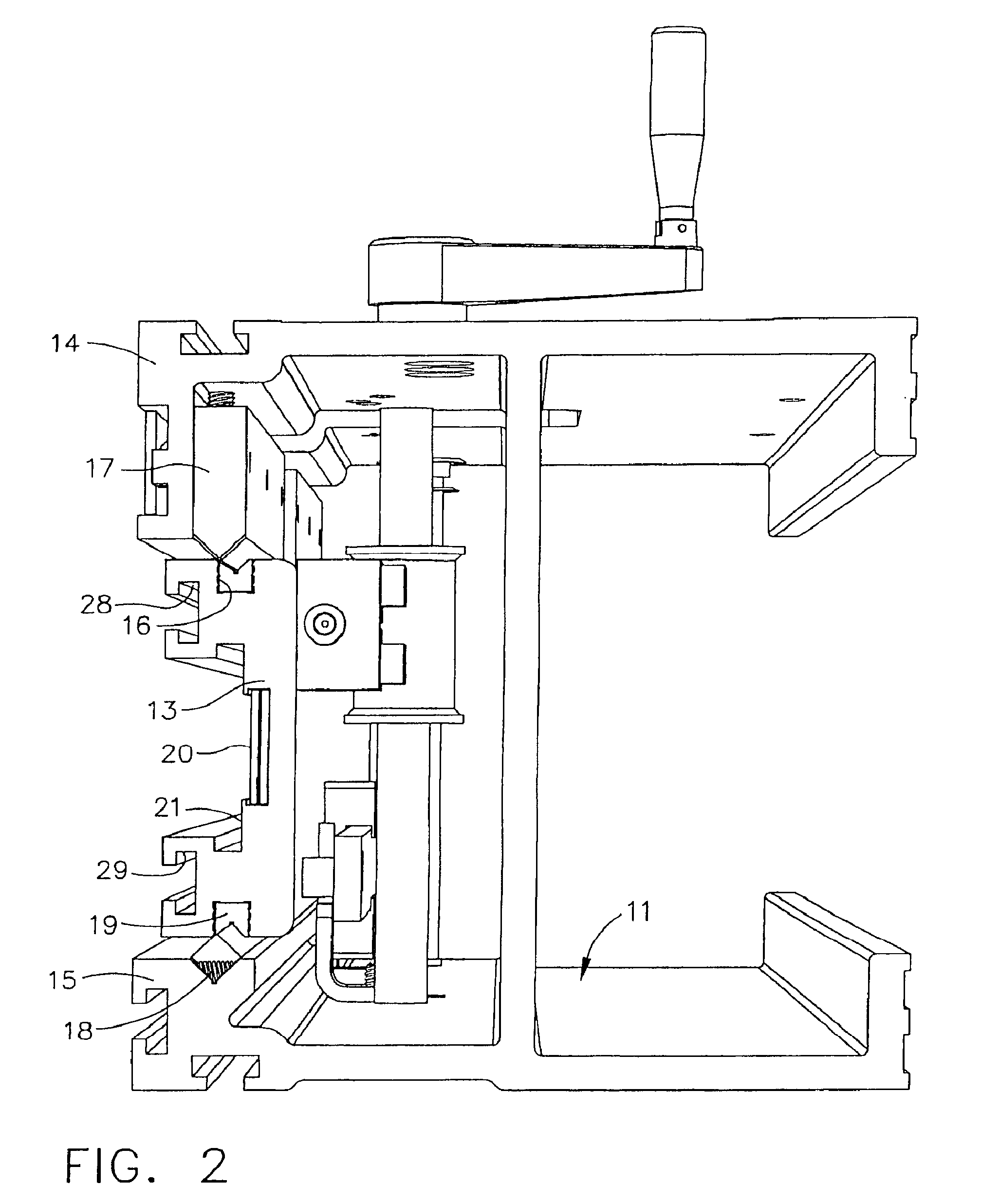

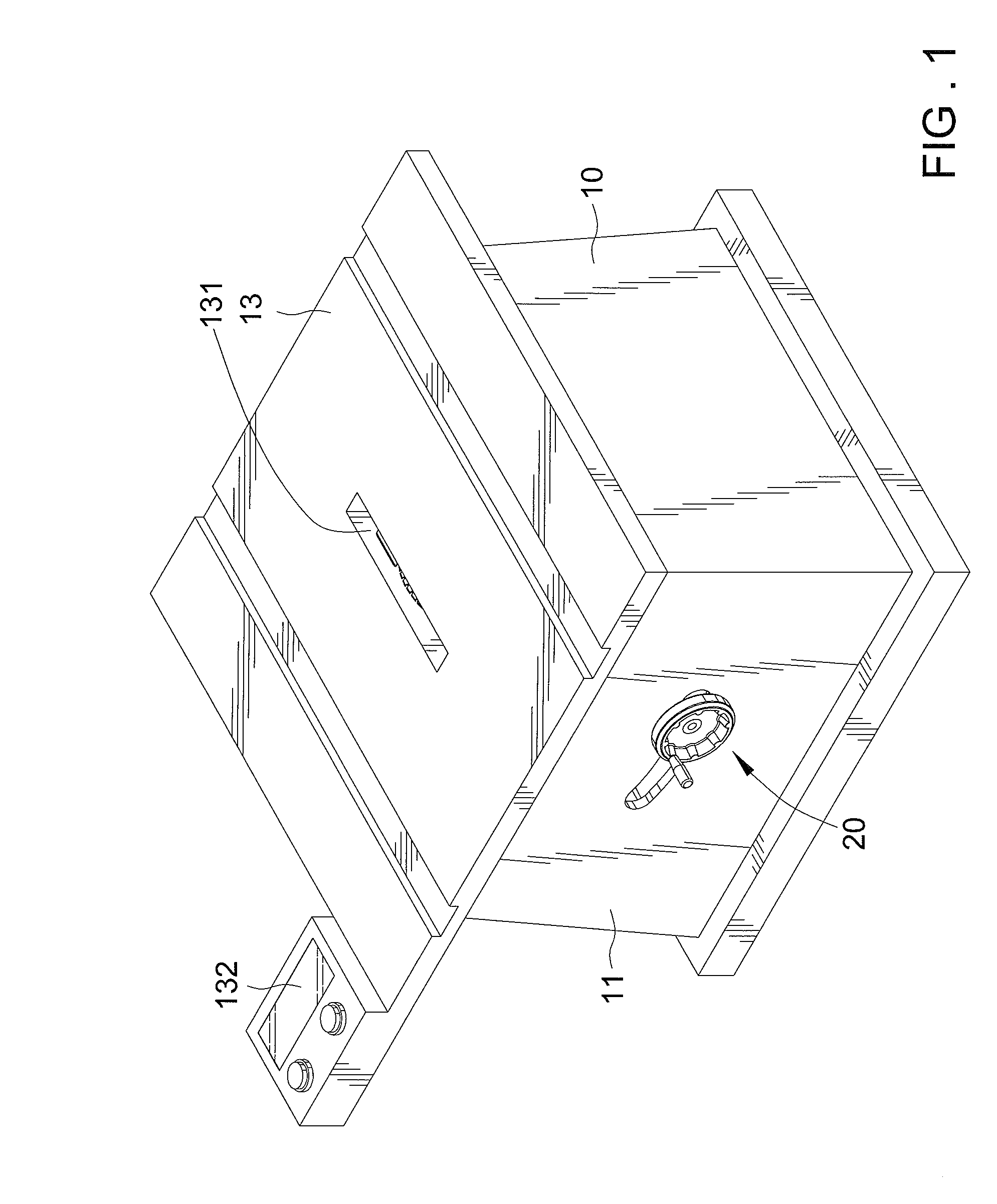

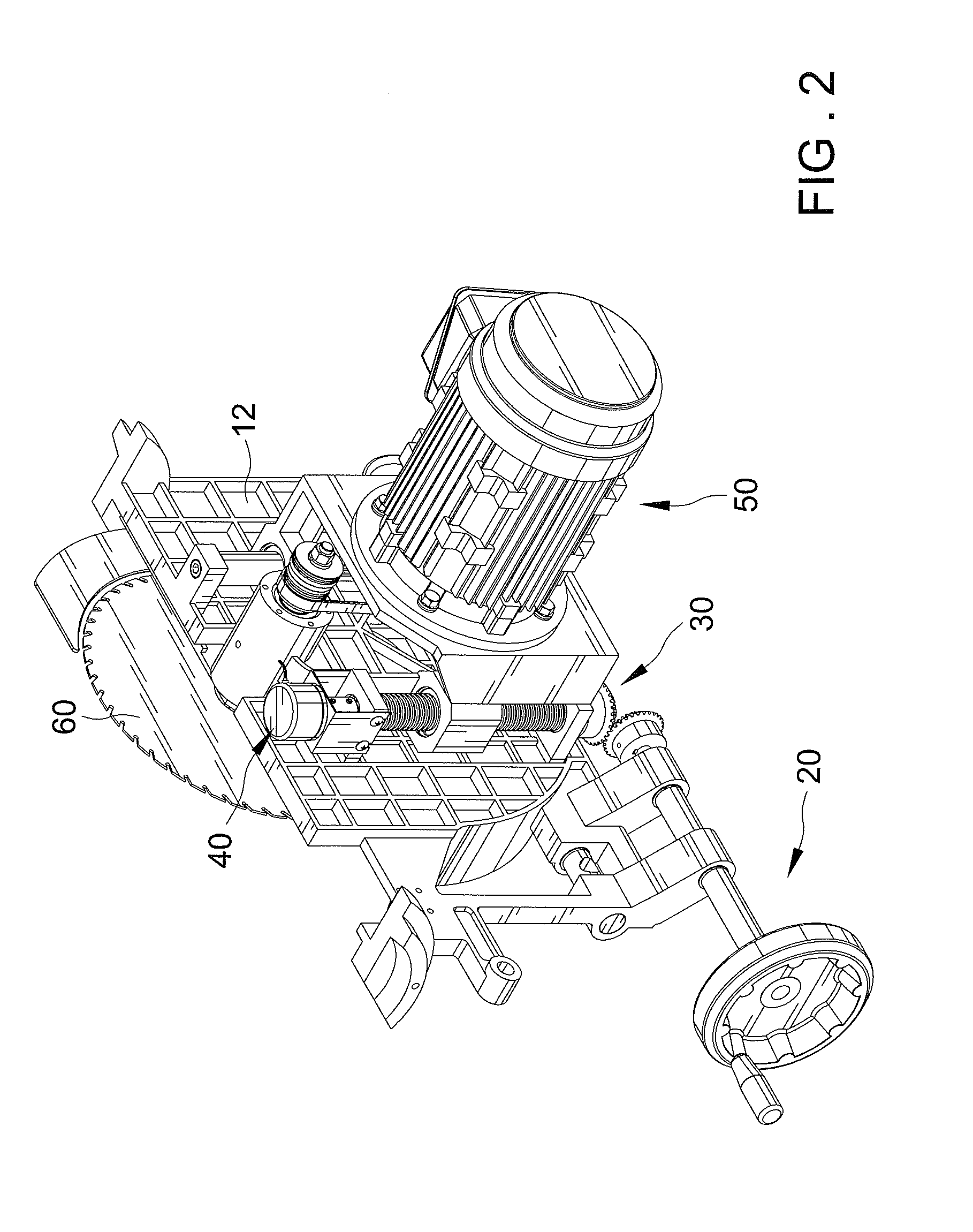

Miter saw with improved safety system

InactiveUS6826988B2Increase opportunitiesLimit and even prevent injuryEmergency protective circuit arrangementsEngineering safety devicesEngineeringWoodworking machine

A woodworking machine is disclosed having a base, a blade, a detection system adapted to detect a dangerous condition between a person and the blade, and a reaction system associated with the detection system to cause a predetermined action to take place upon detection of the dangerous condition. The blade is rotatable, and moves into a cutting zone to cut a workpiece. The predetermined action may be to stop the blade from rotating and / or to stop movement of the blade toward the cutting zone.

Owner:SAWSTOP HLDG LLC

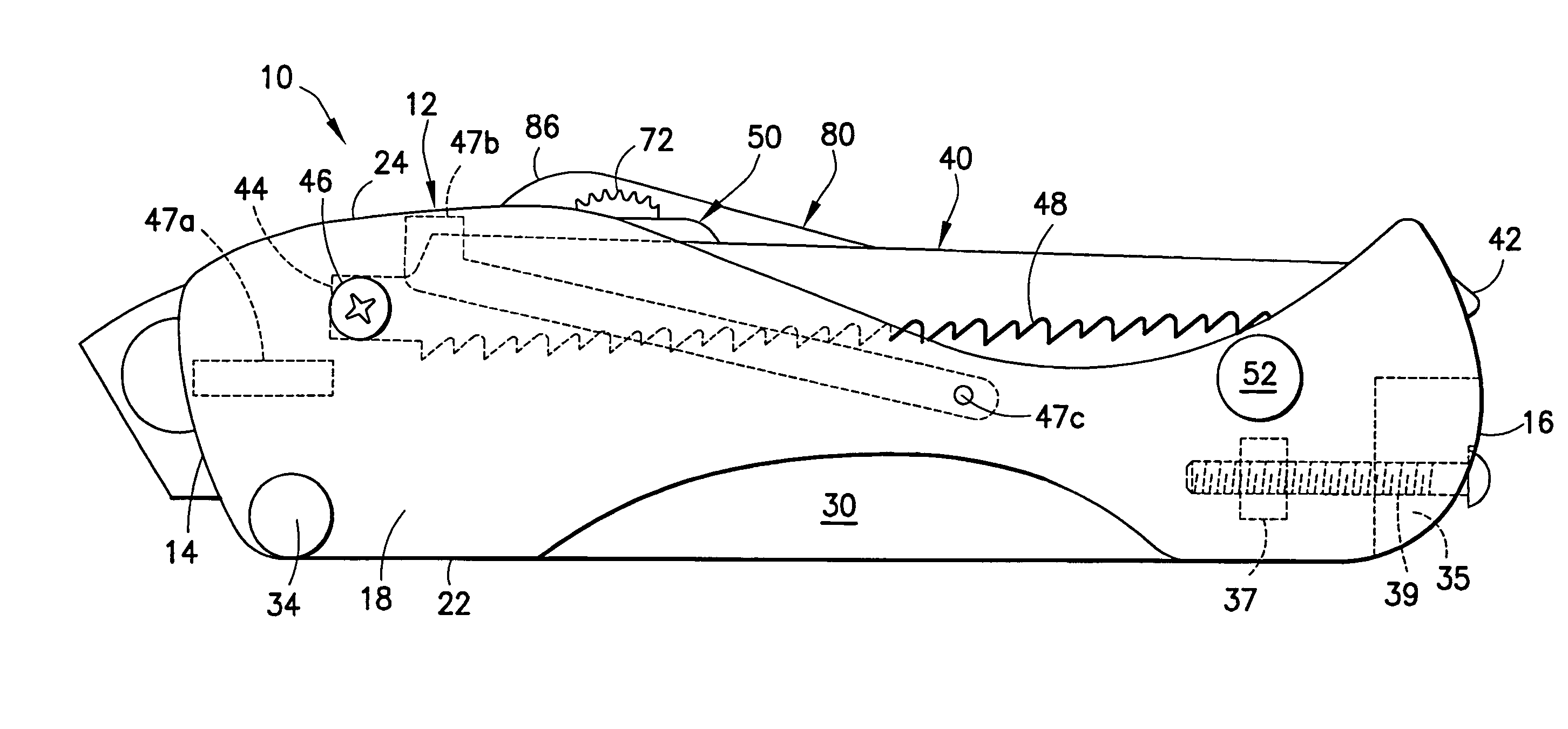

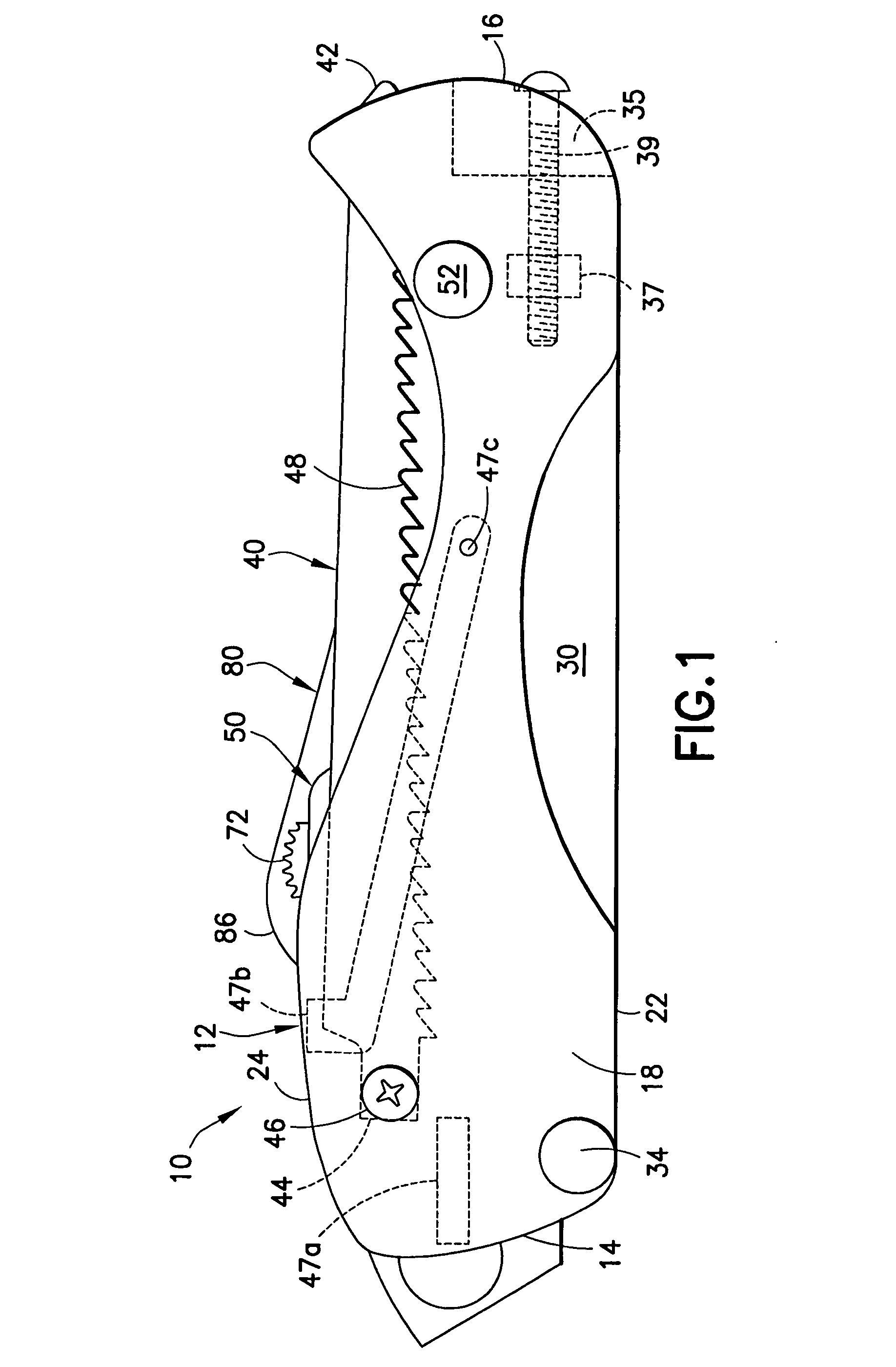

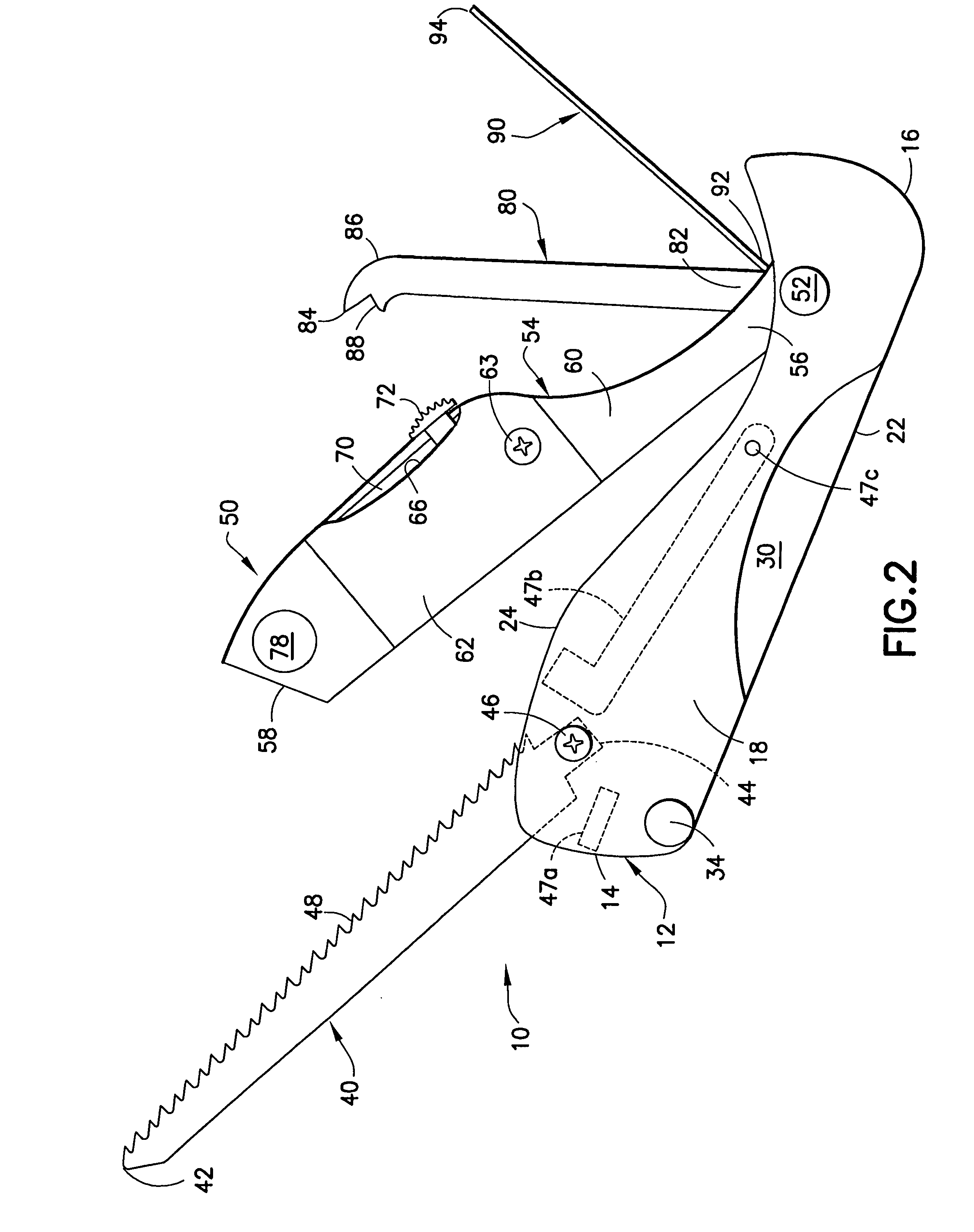

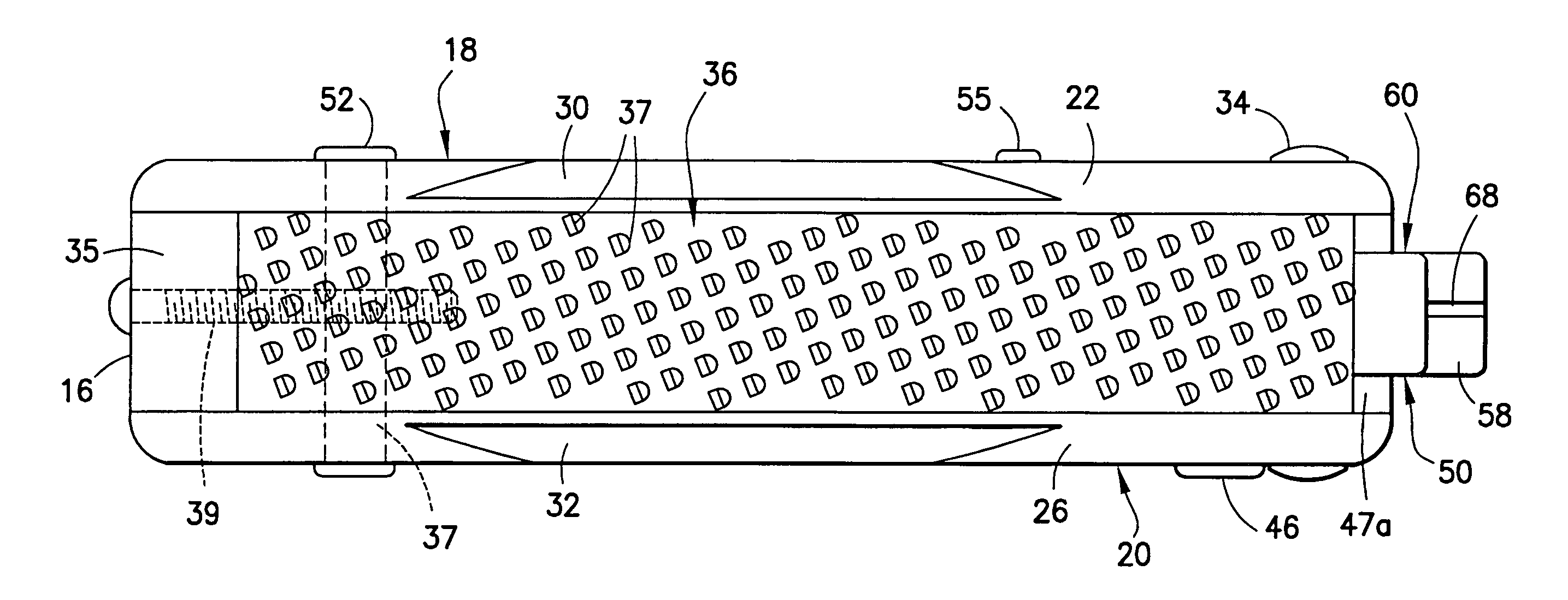

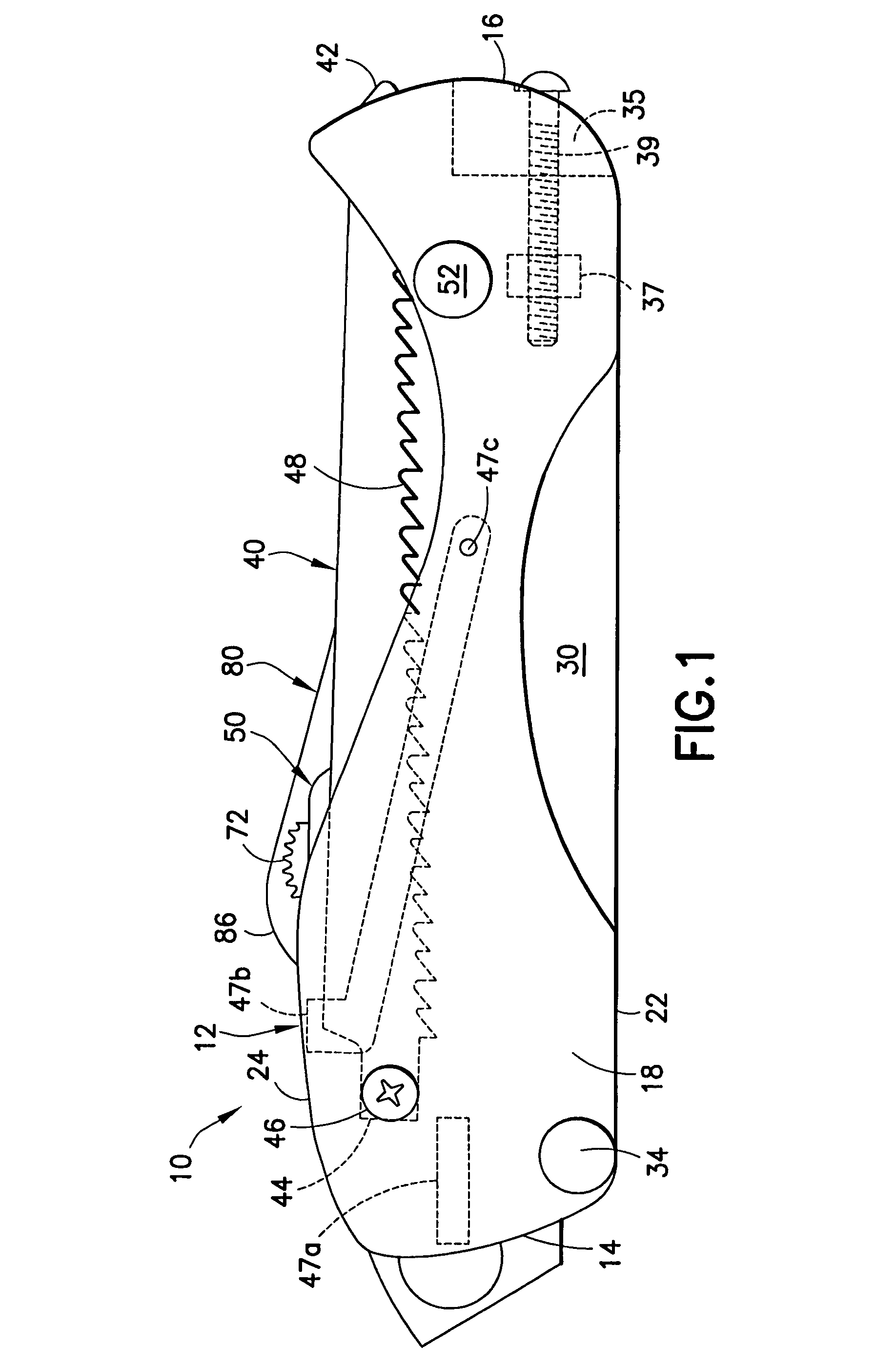

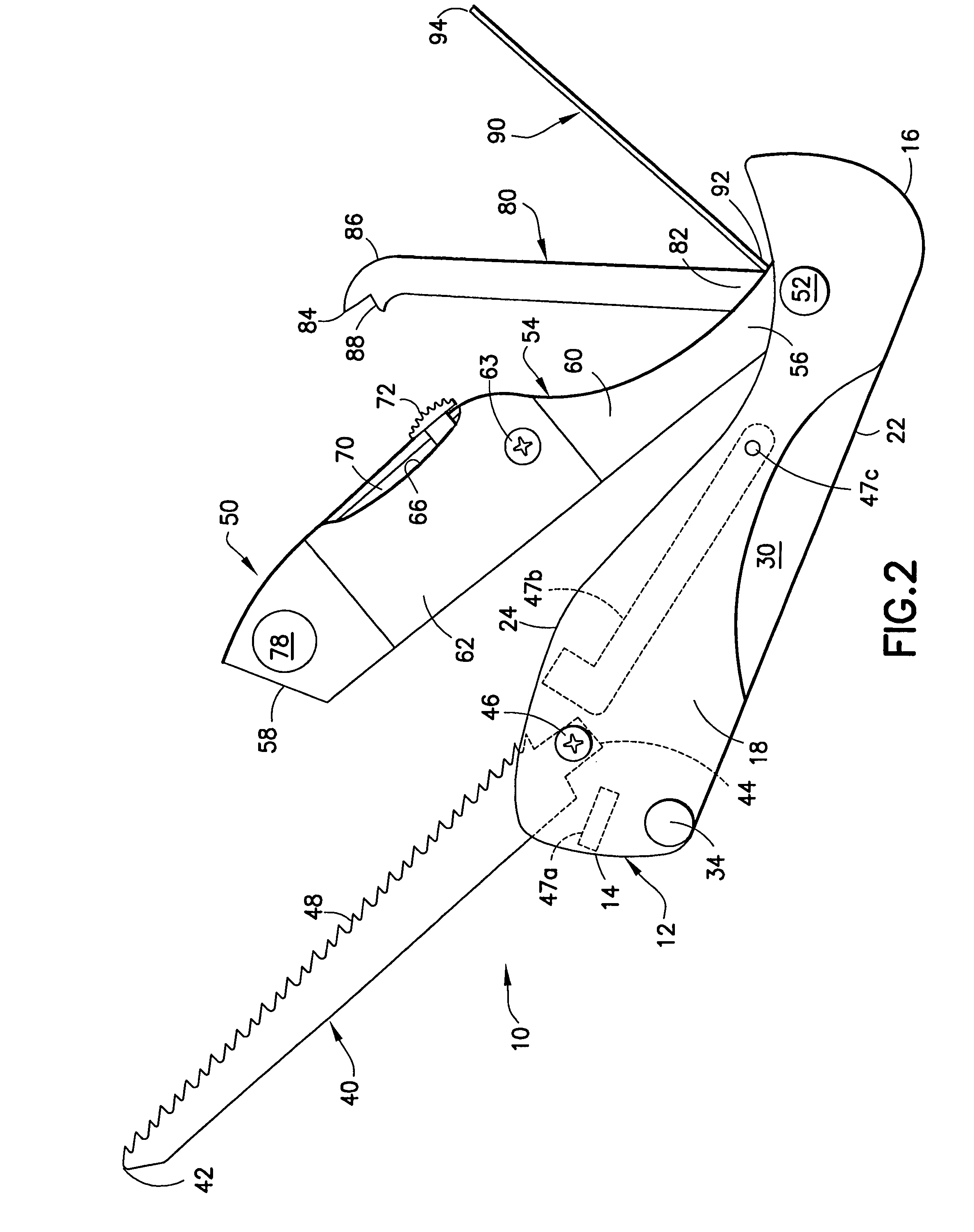

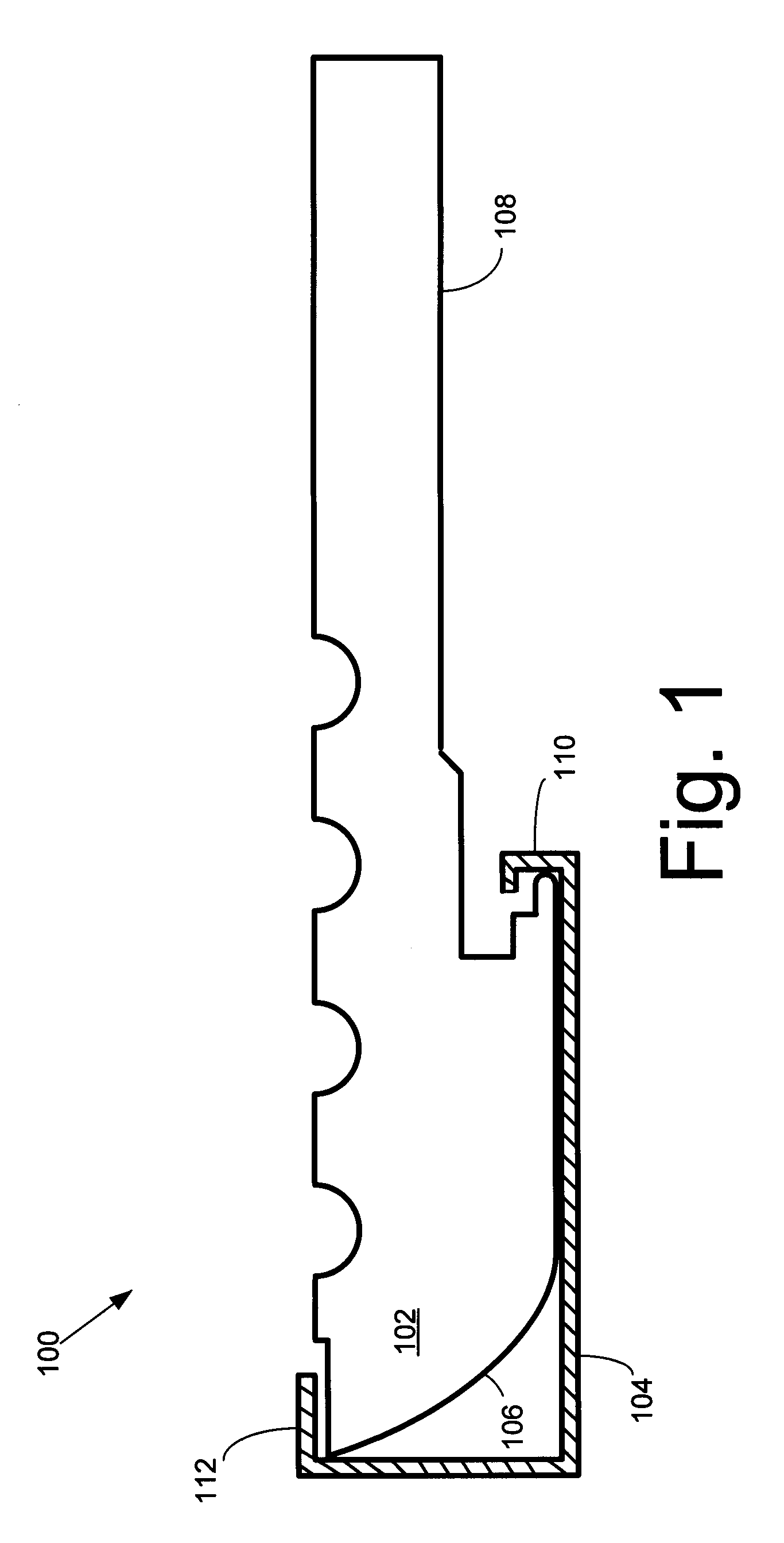

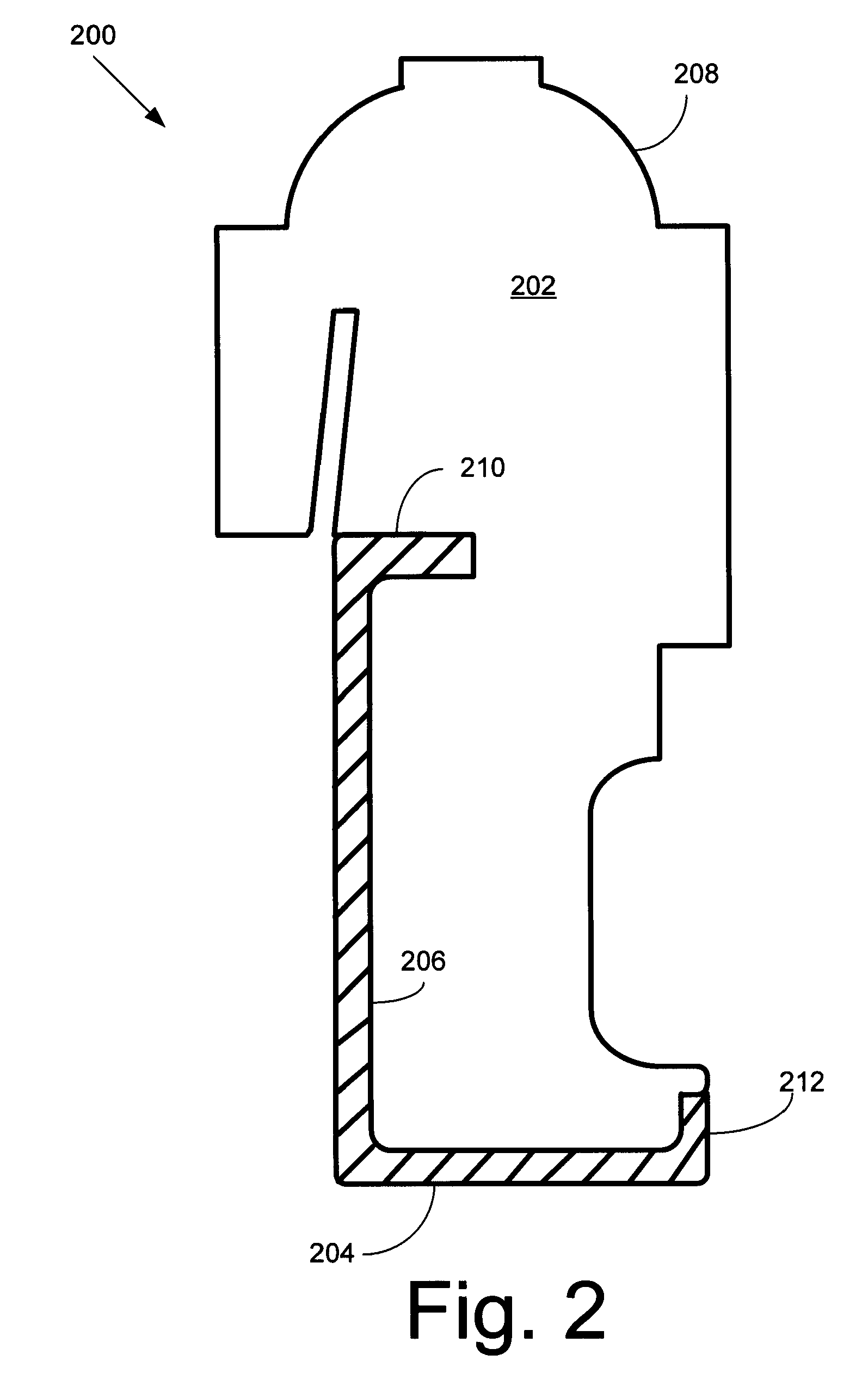

Hand-held carpenters tool

InactiveUS20050172416A1Easy to replaceEasy to disassembleSawing apparatusThrusting weaponsRaspHand held

A tool assembly includes a handle and a plurality of tools mounted to the handle. Several of the tools can be rotated between a closed position and an open position relative to the handle. The tools include a utility knife, a keyhole saw, a pry bar and a punch. Additionally, the tool assembly includes a recessed rasp for trimming an edge of a sheet of gypsum board.

Owner:FELICIANO PEDRO

Hand-held carpenters tool

A tool assembly includes a handle and a plurality of tools mounted to the handle. Several of the tools can be rotated between a closed position and an open position relative to the handle. The tools include a utility knife, a keyhole saw, a pry bar and a punch. Additionally, the tool assembly includes a recessed rasp for trimming an edge of a sheet of gypsum board.

Owner:FELICIANO PEDRO

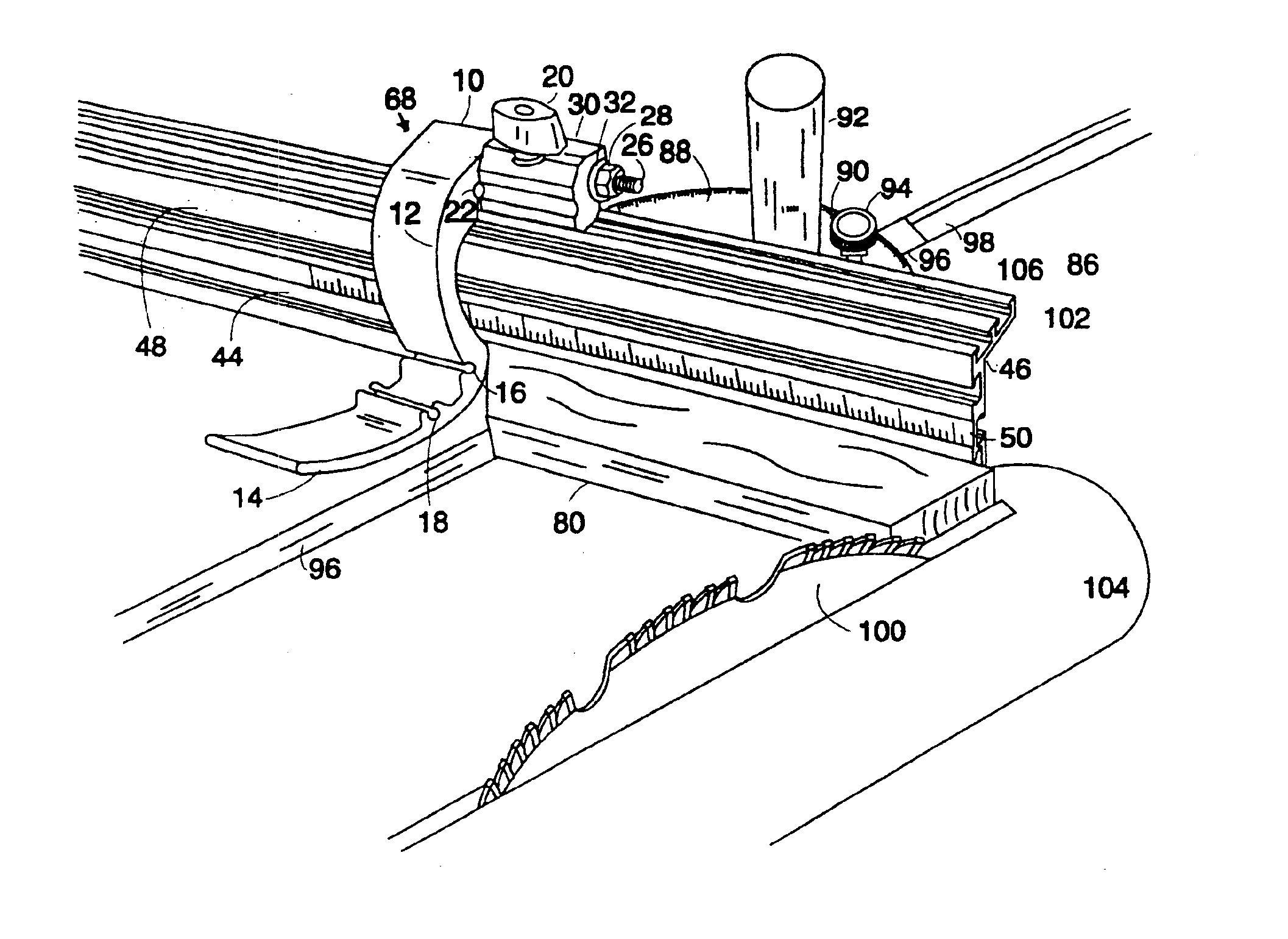

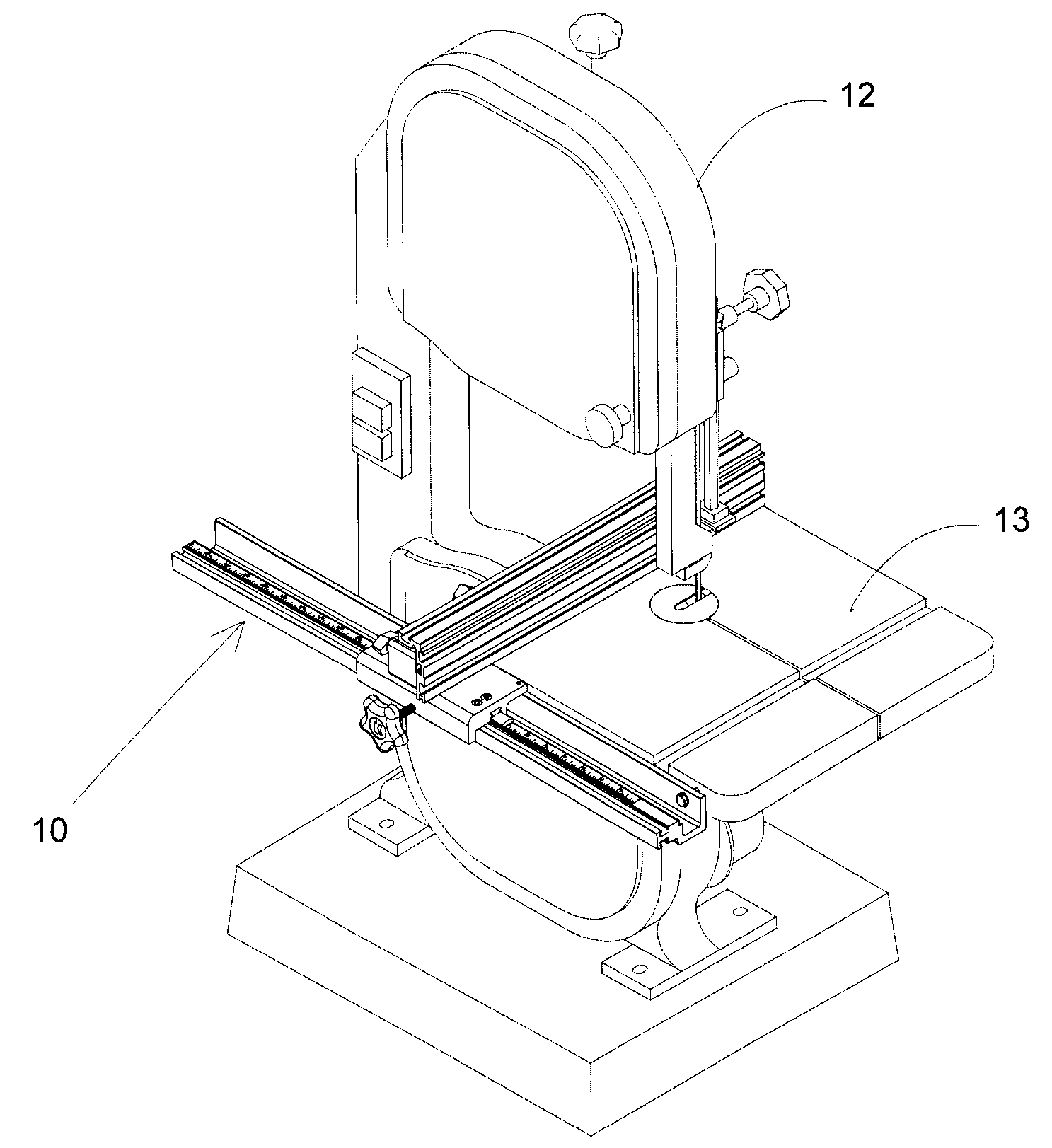

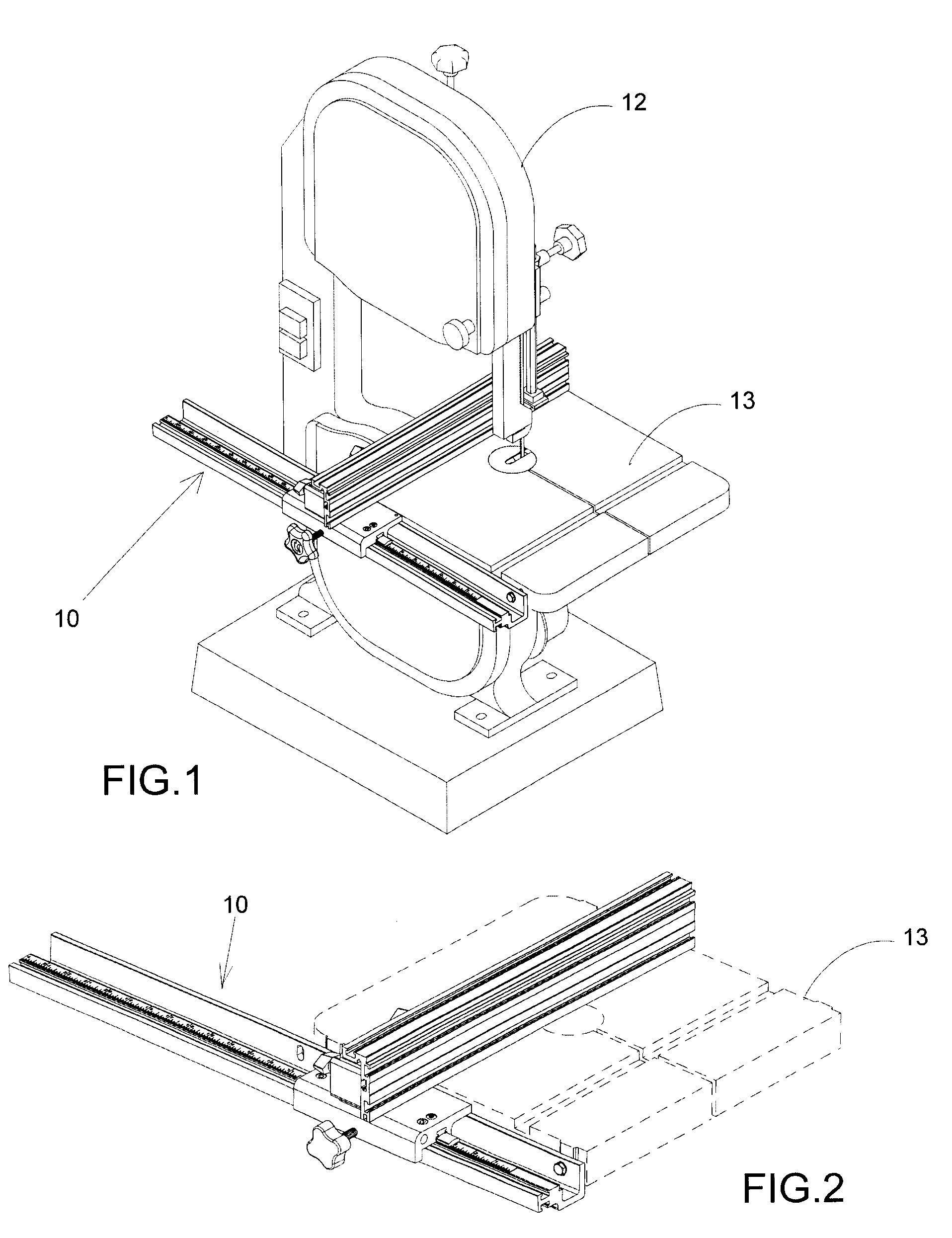

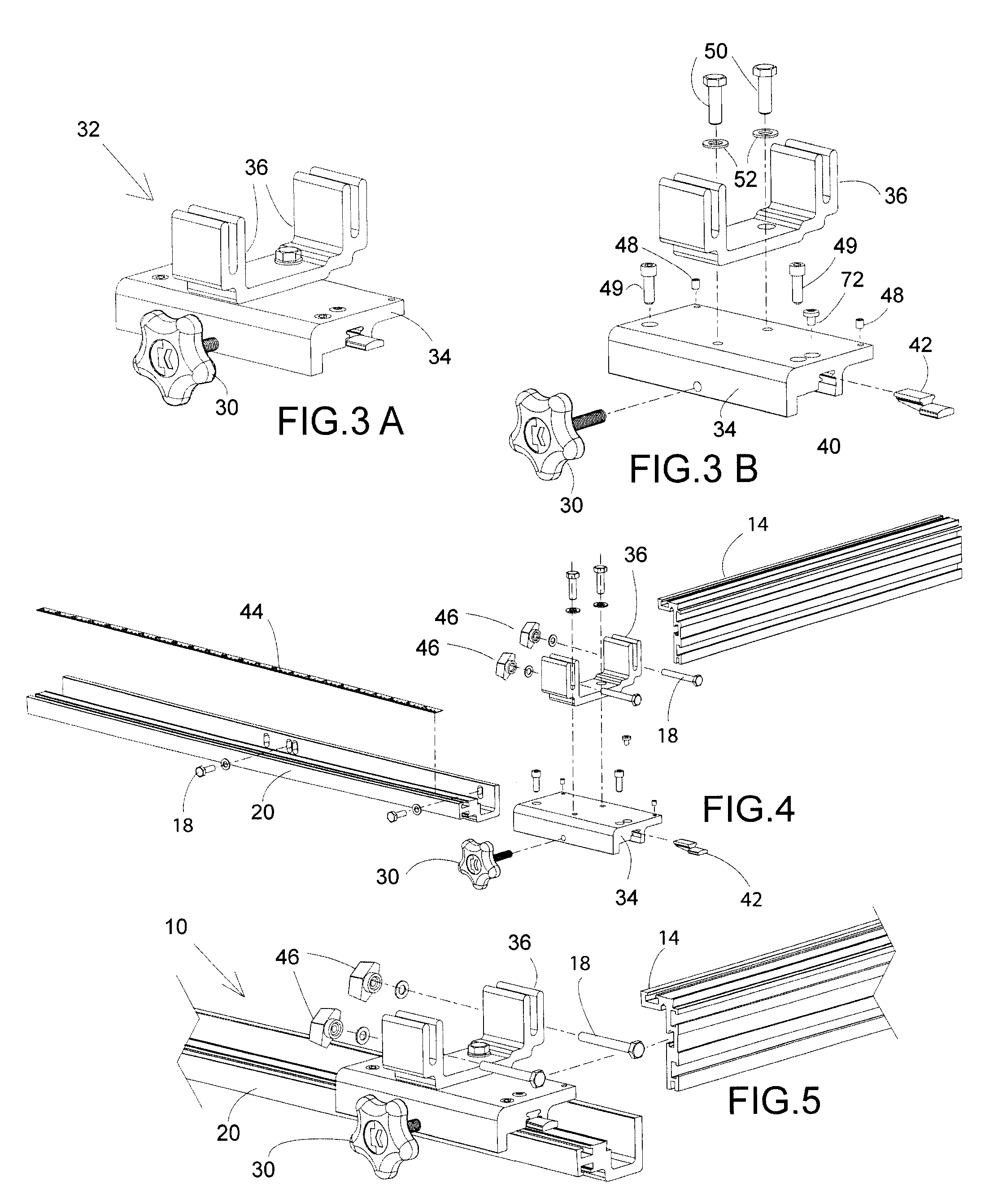

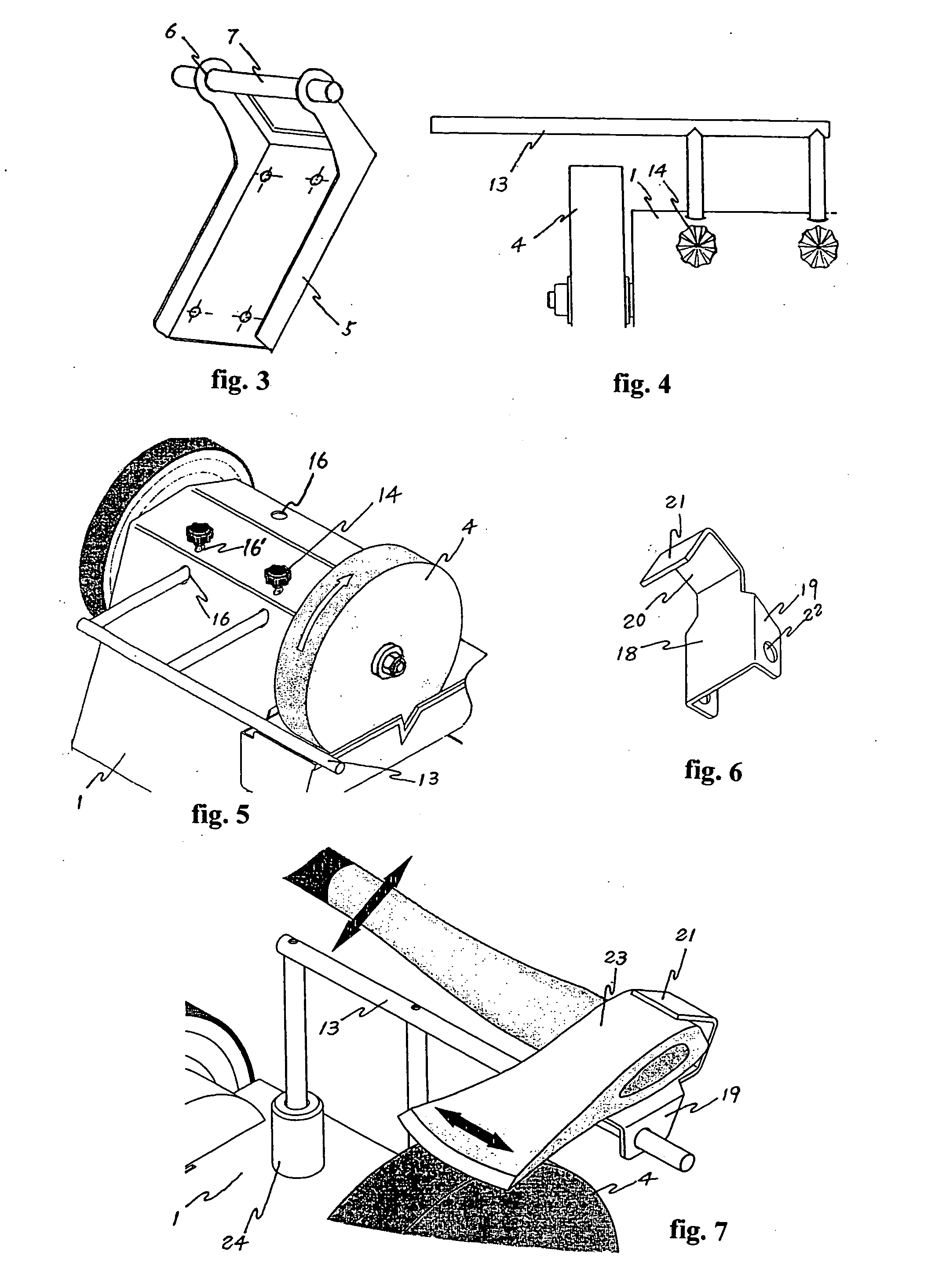

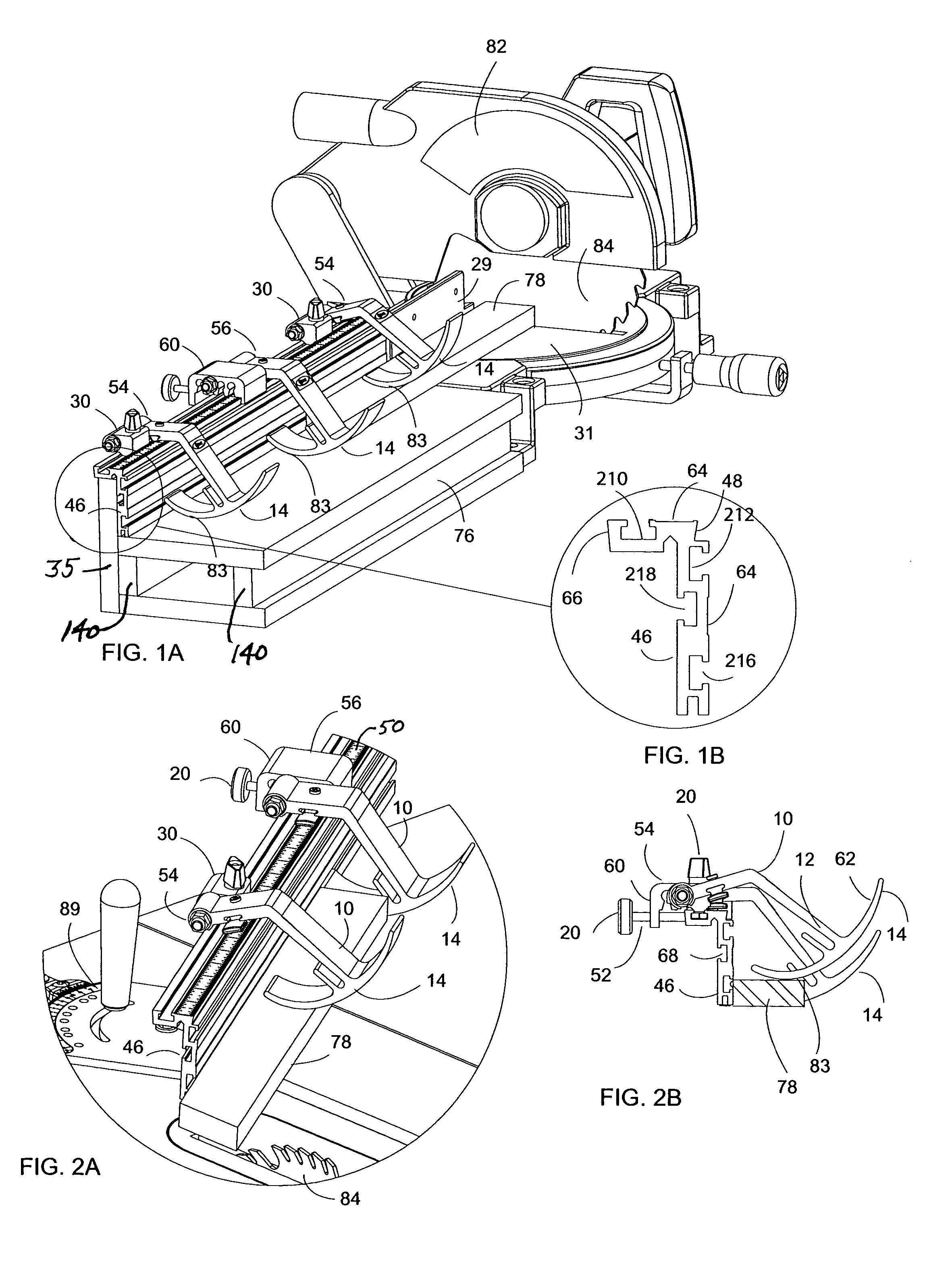

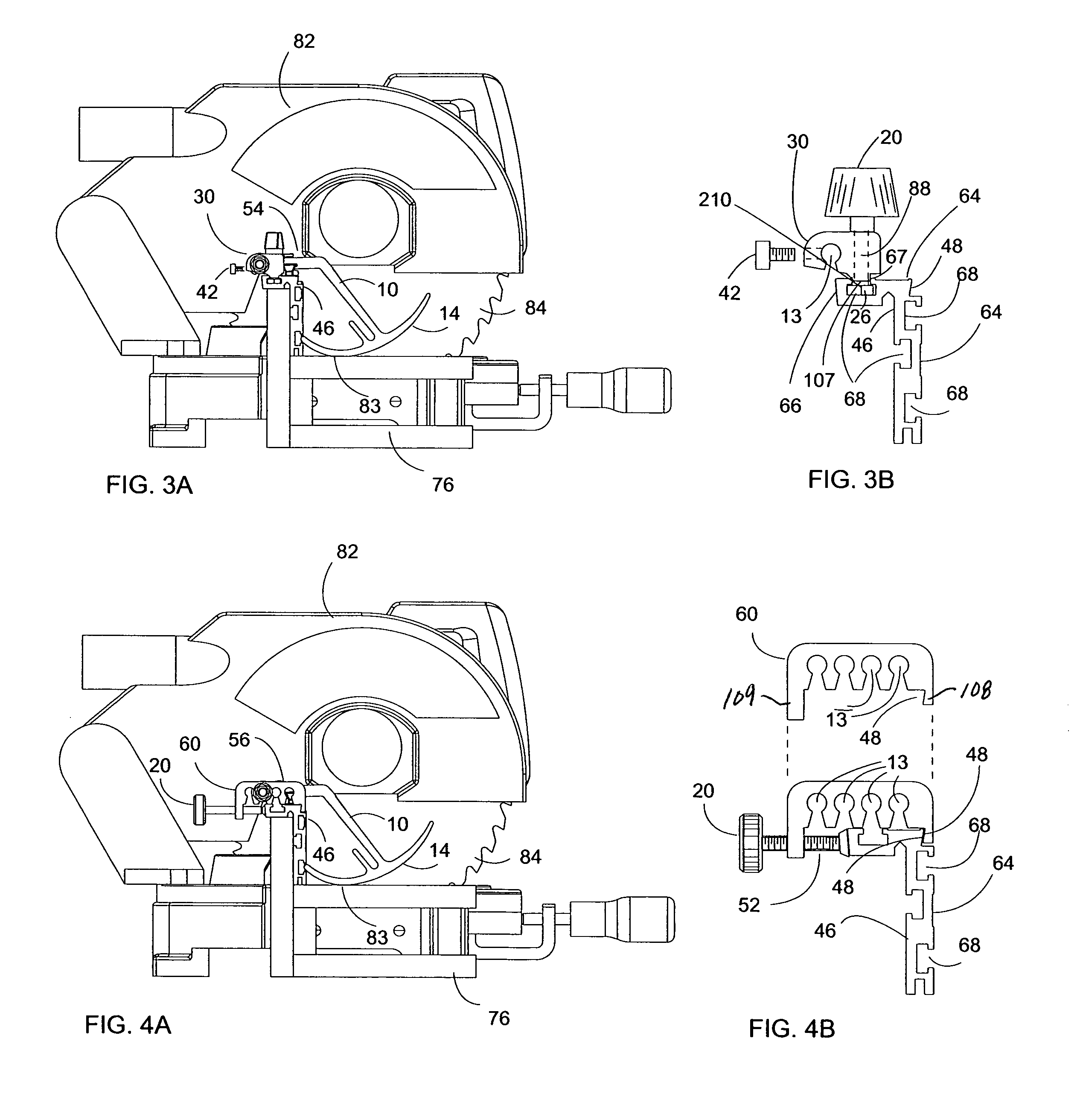

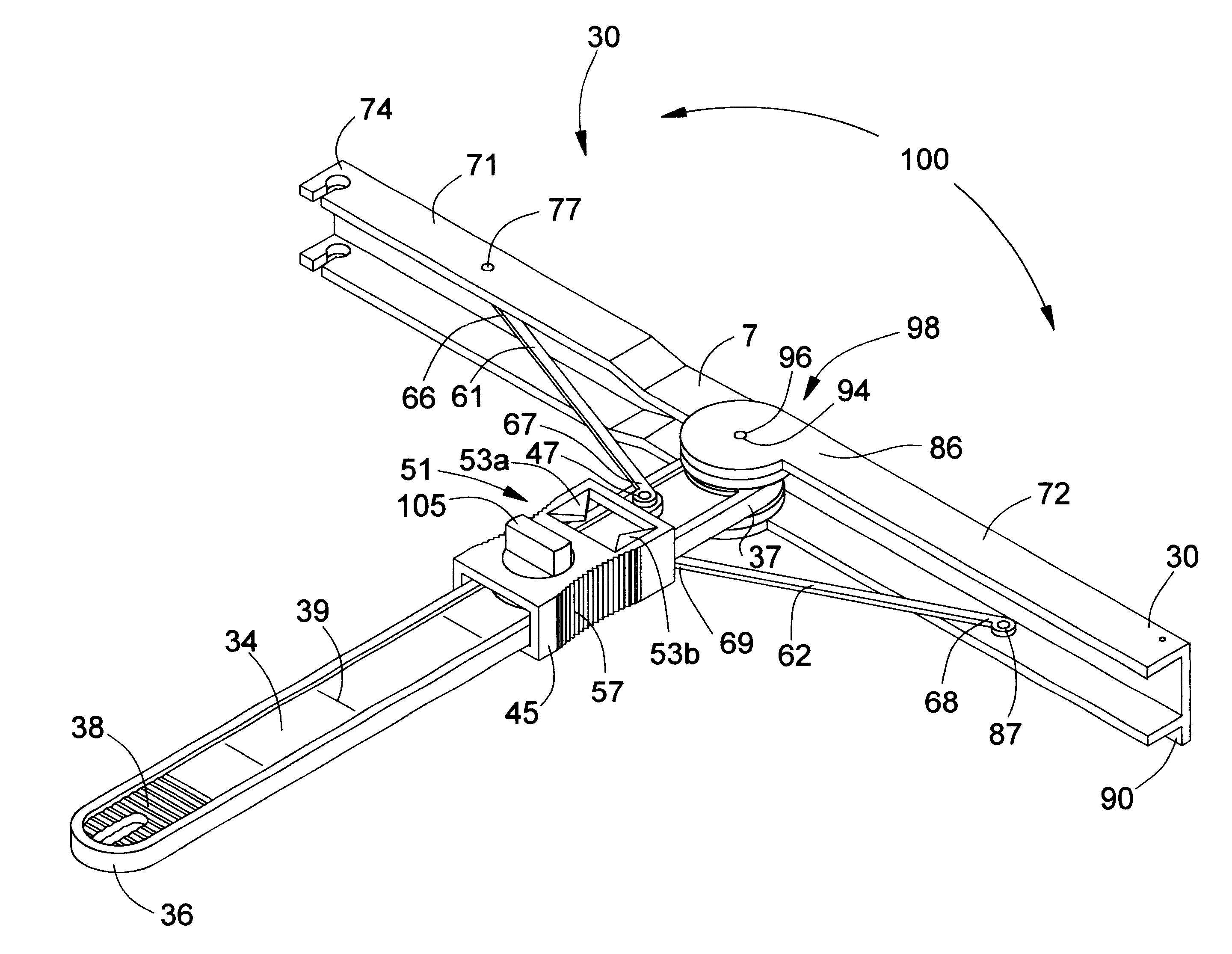

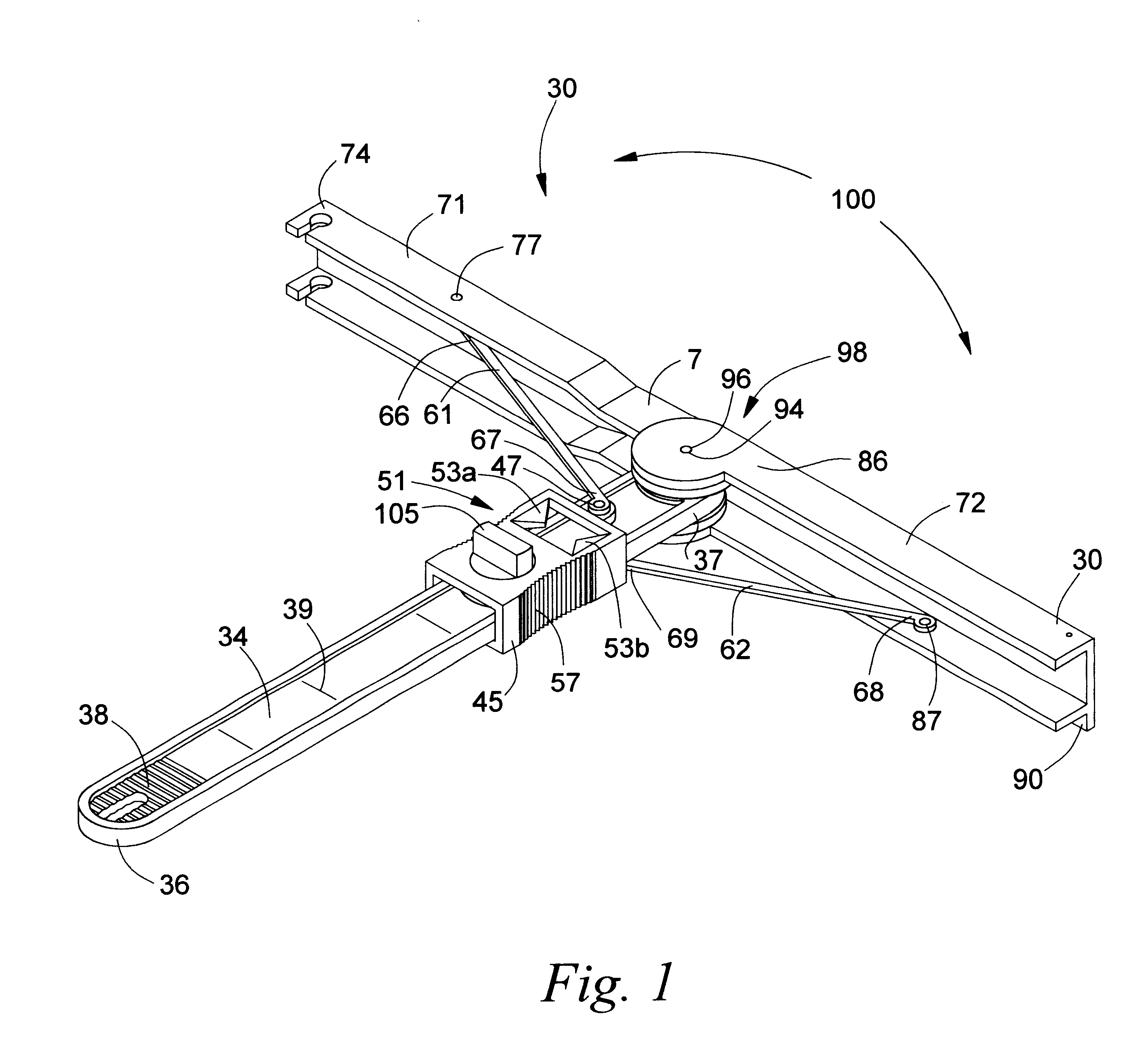

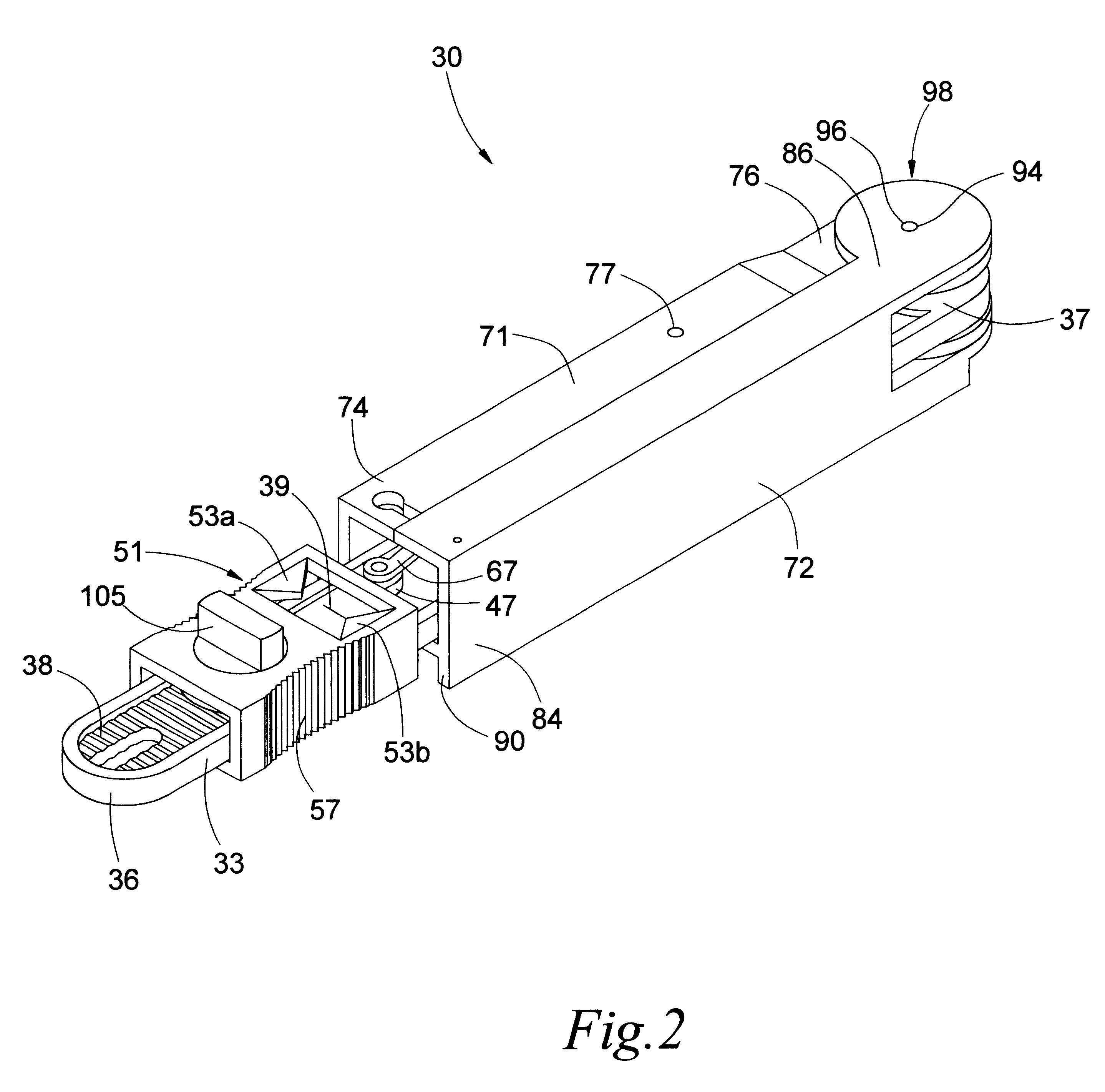

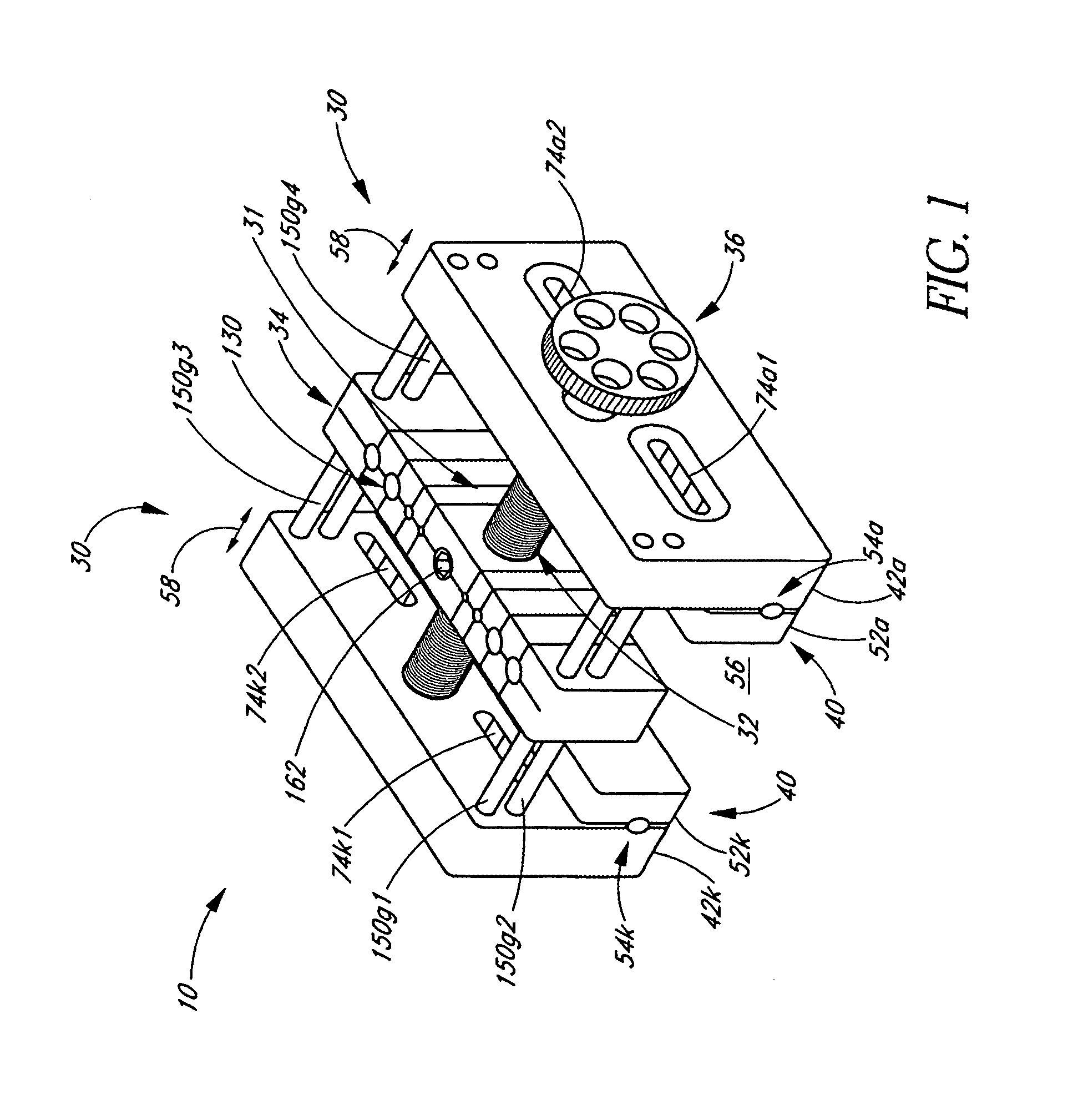

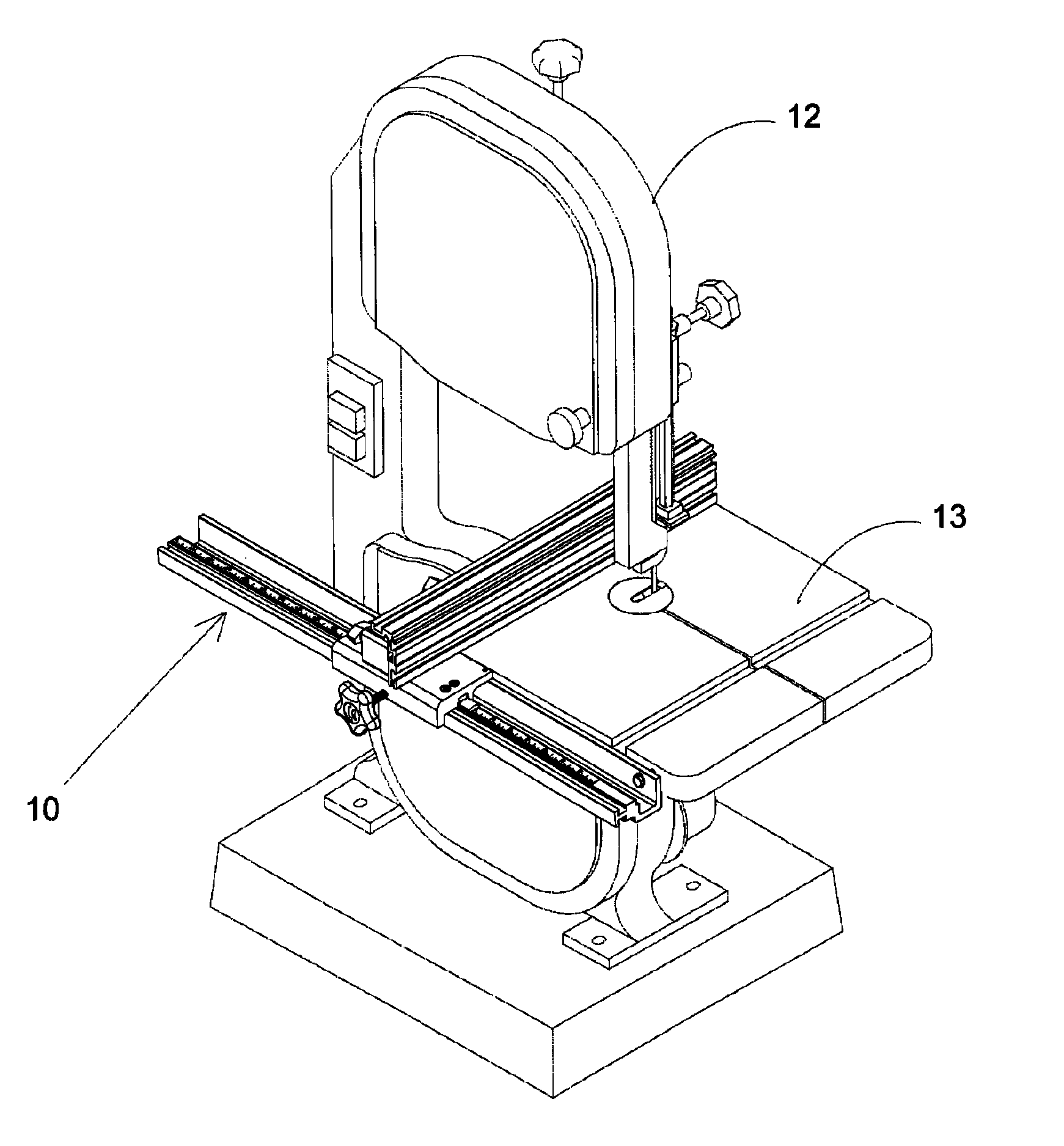

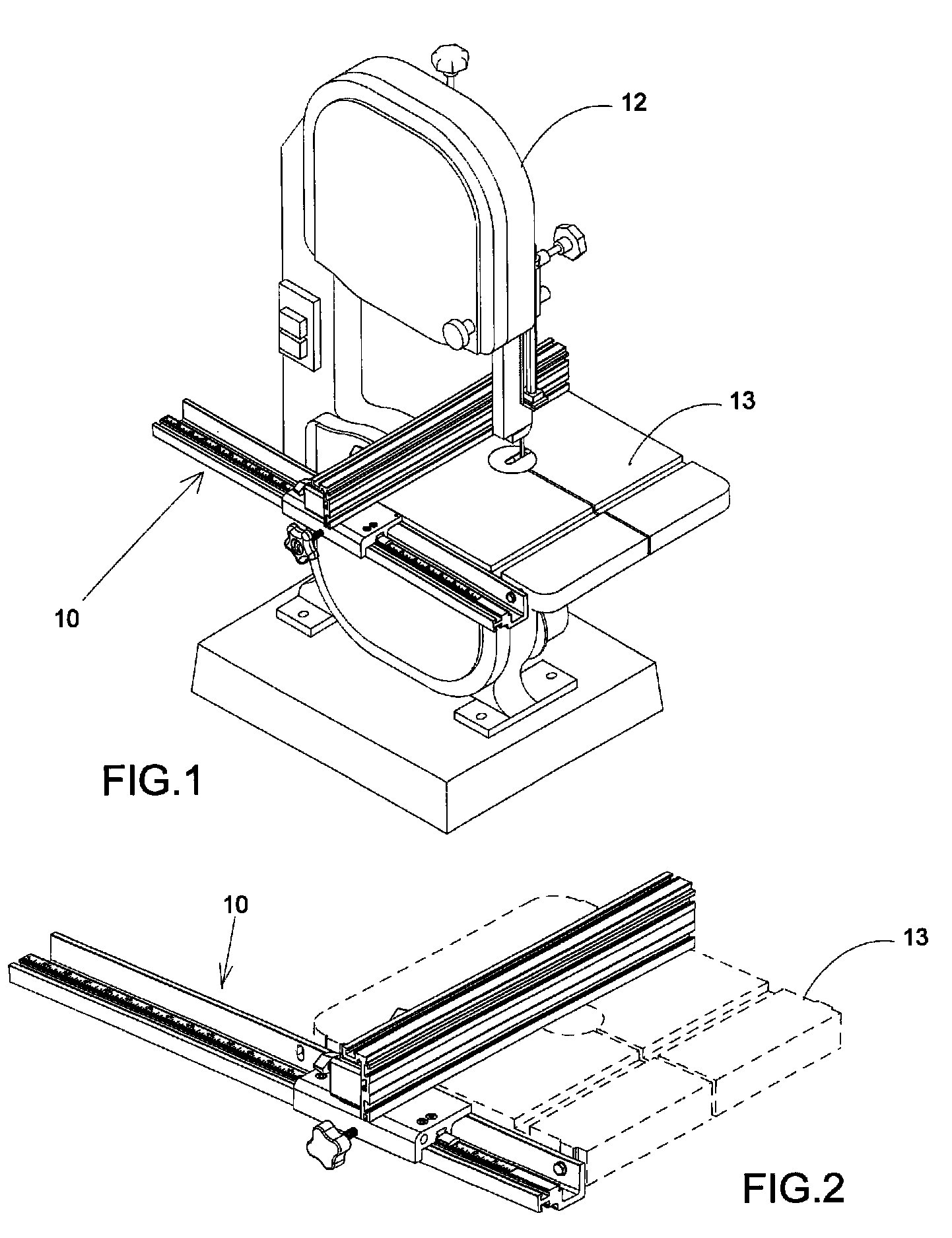

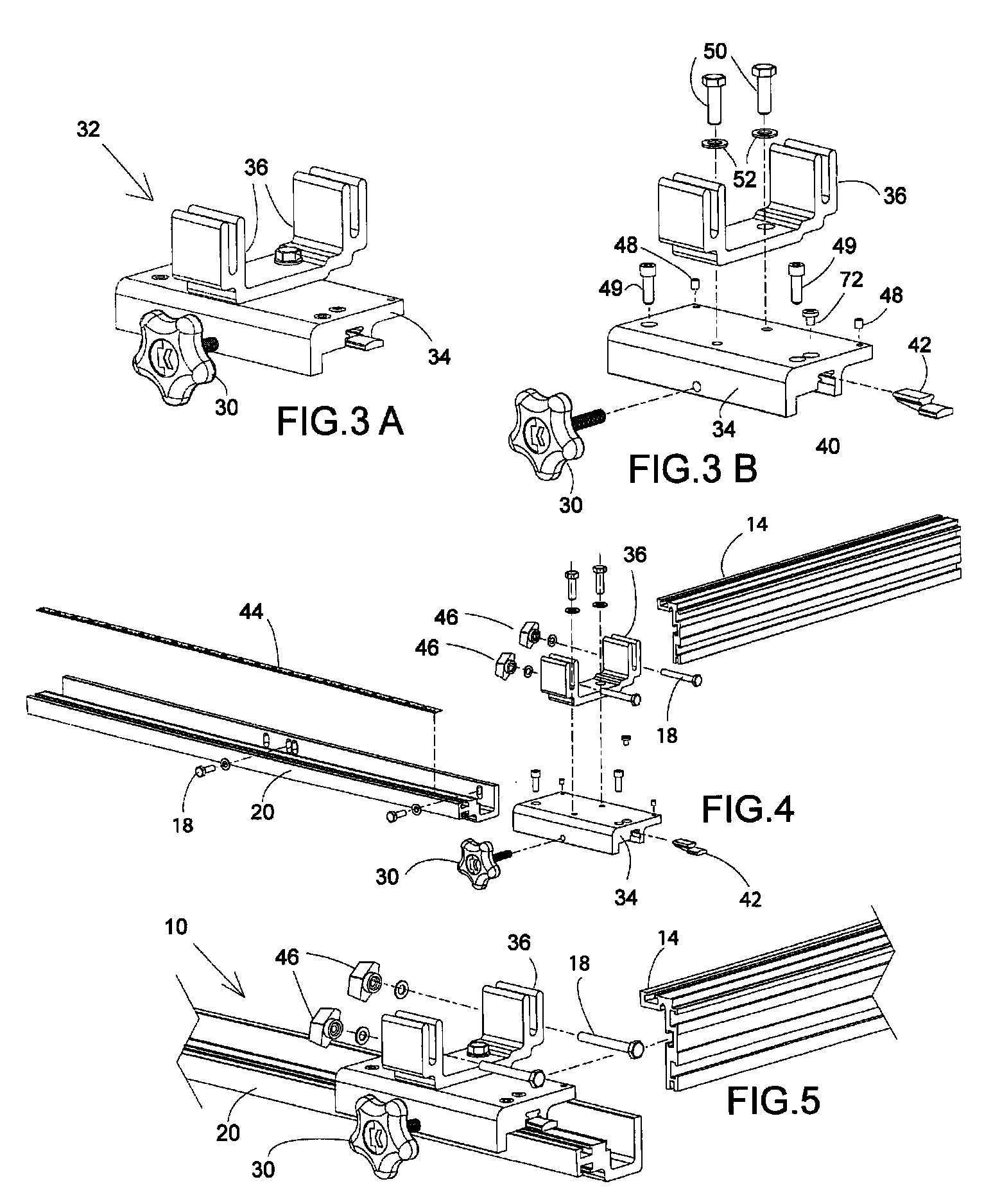

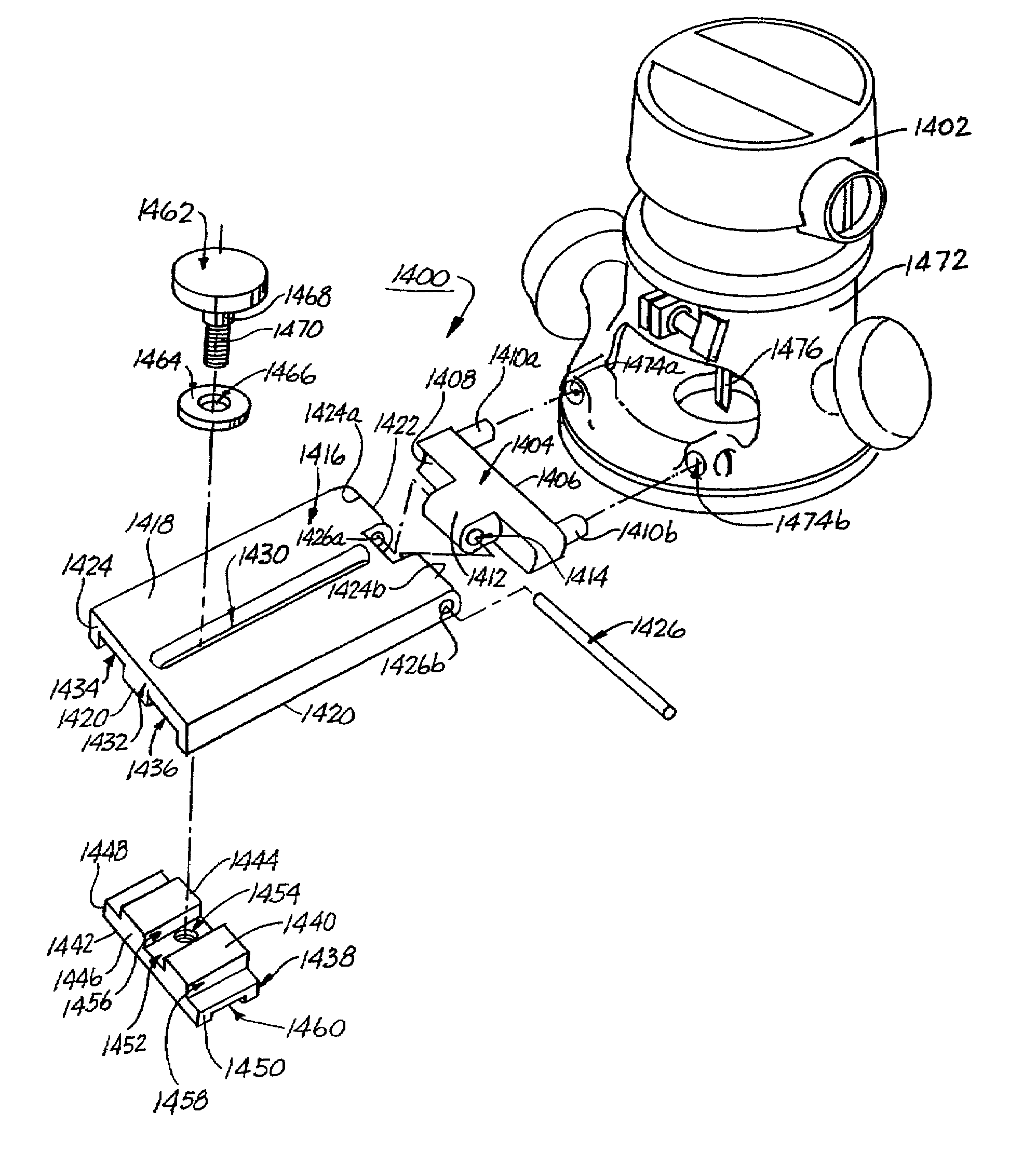

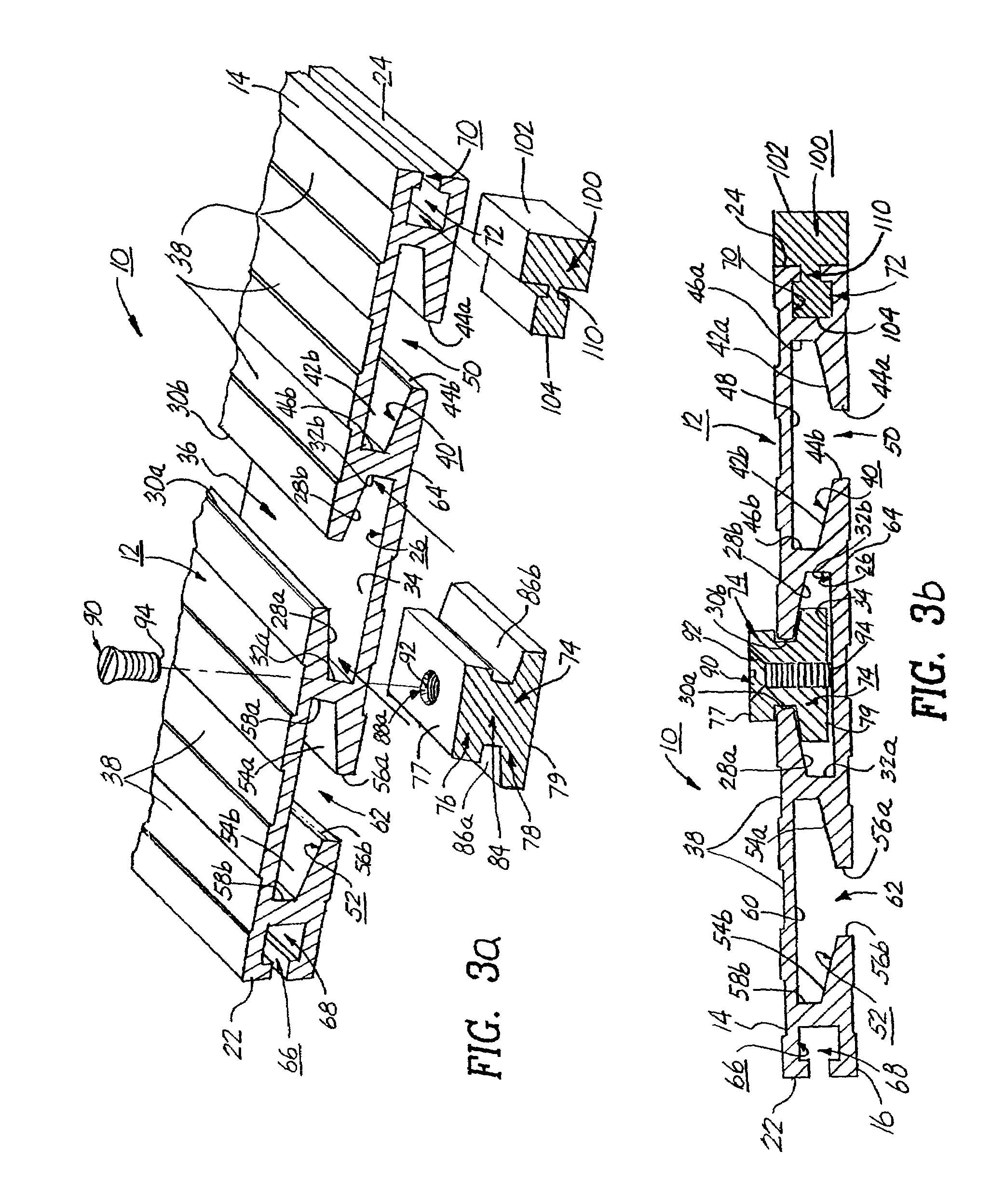

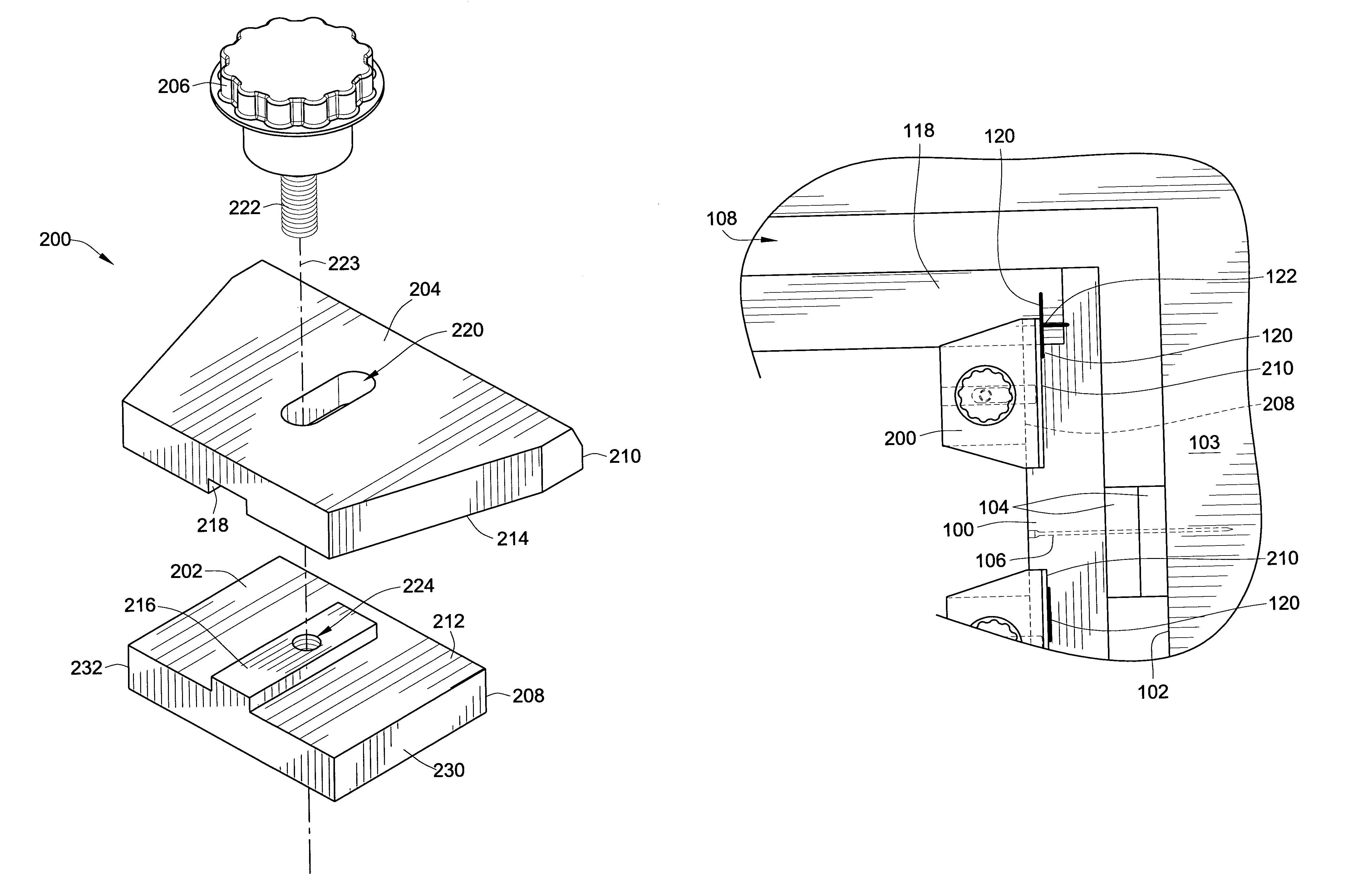

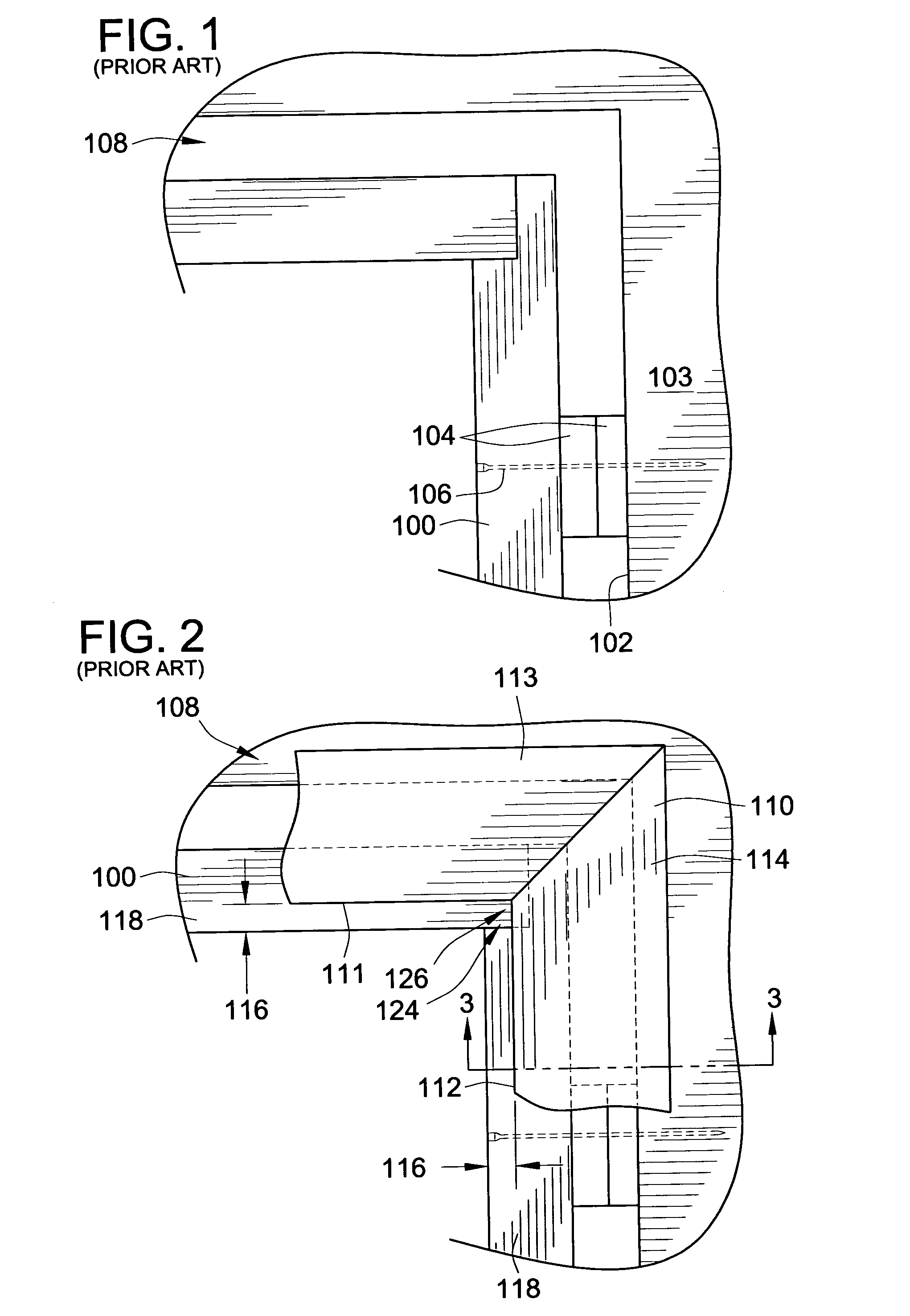

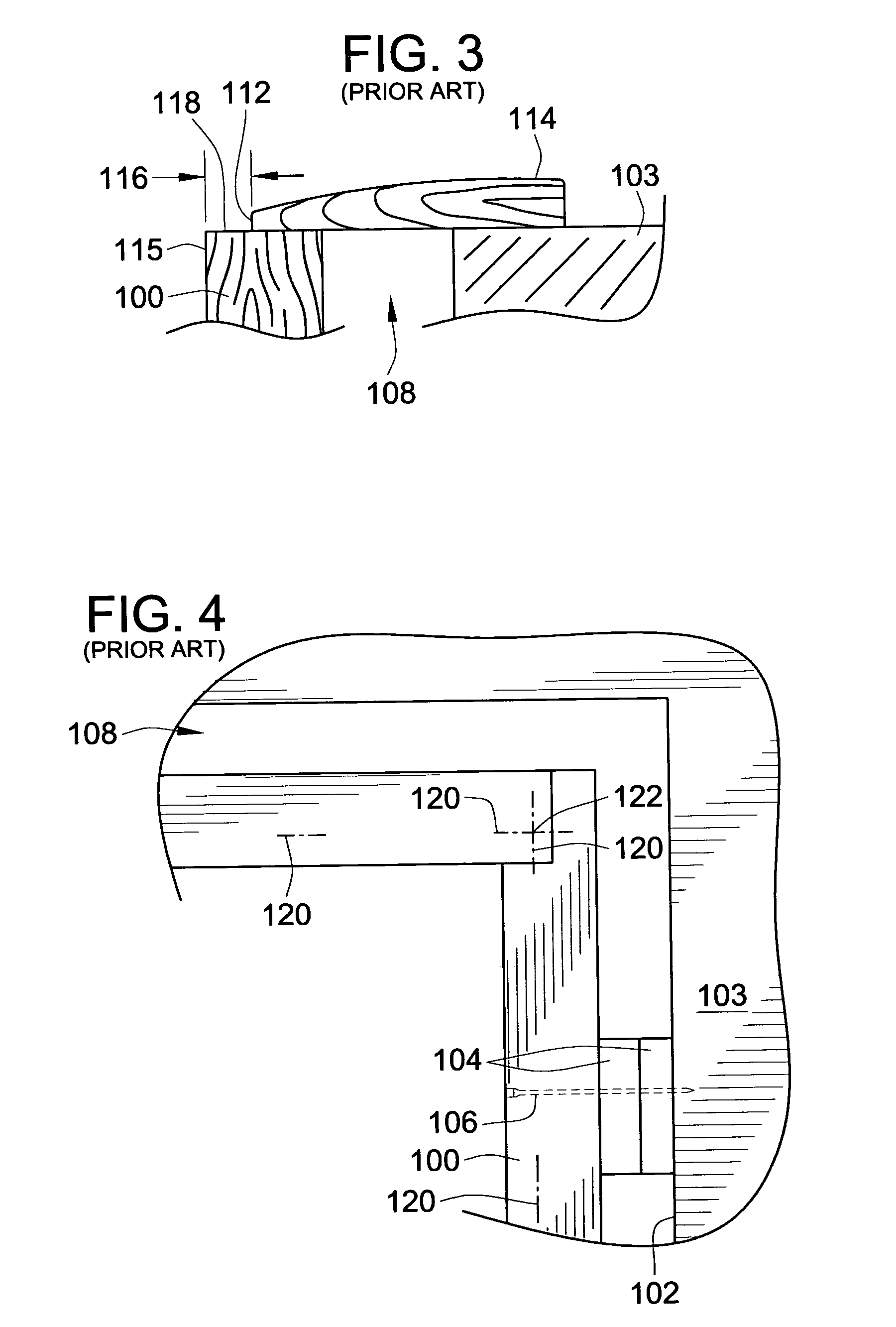

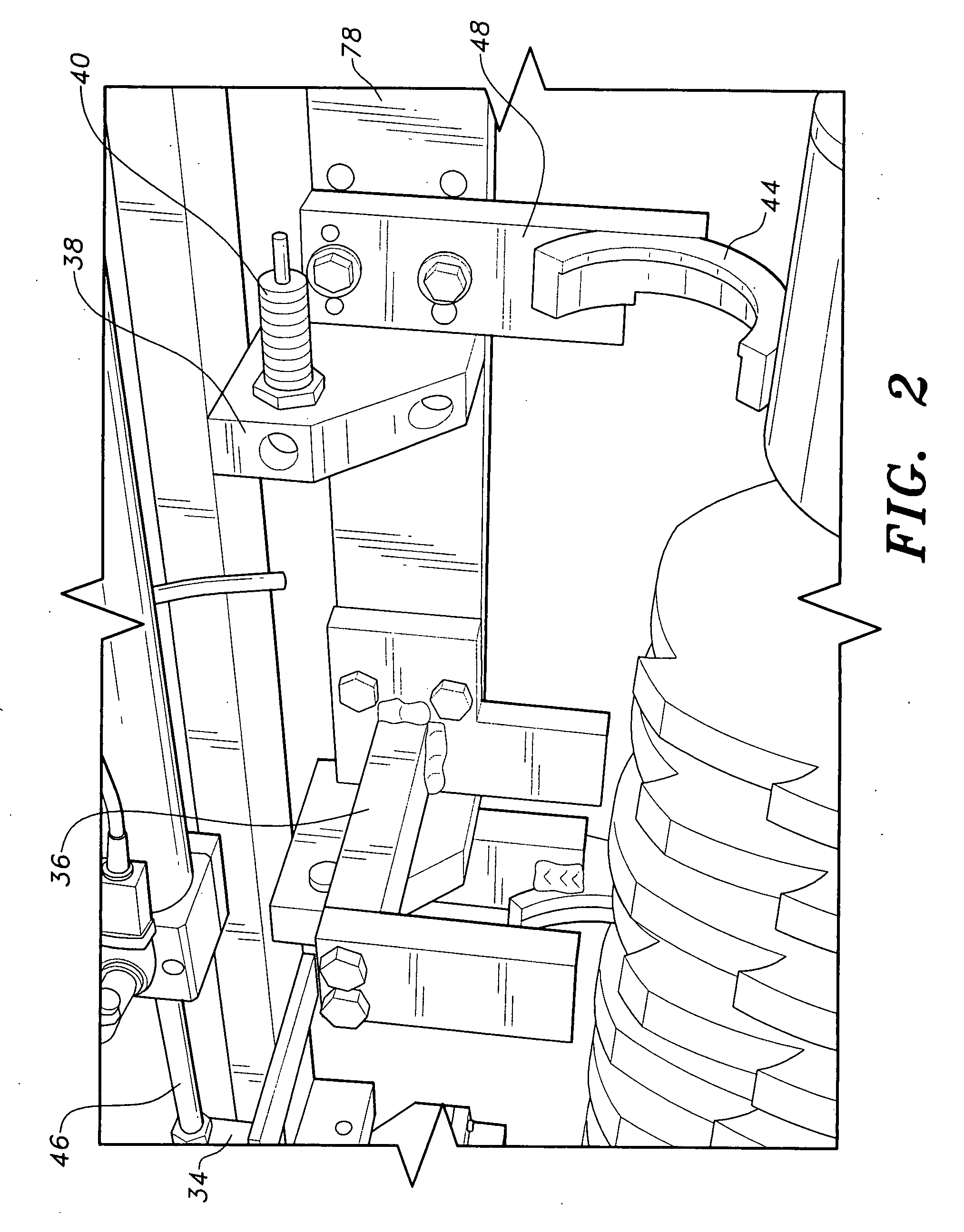

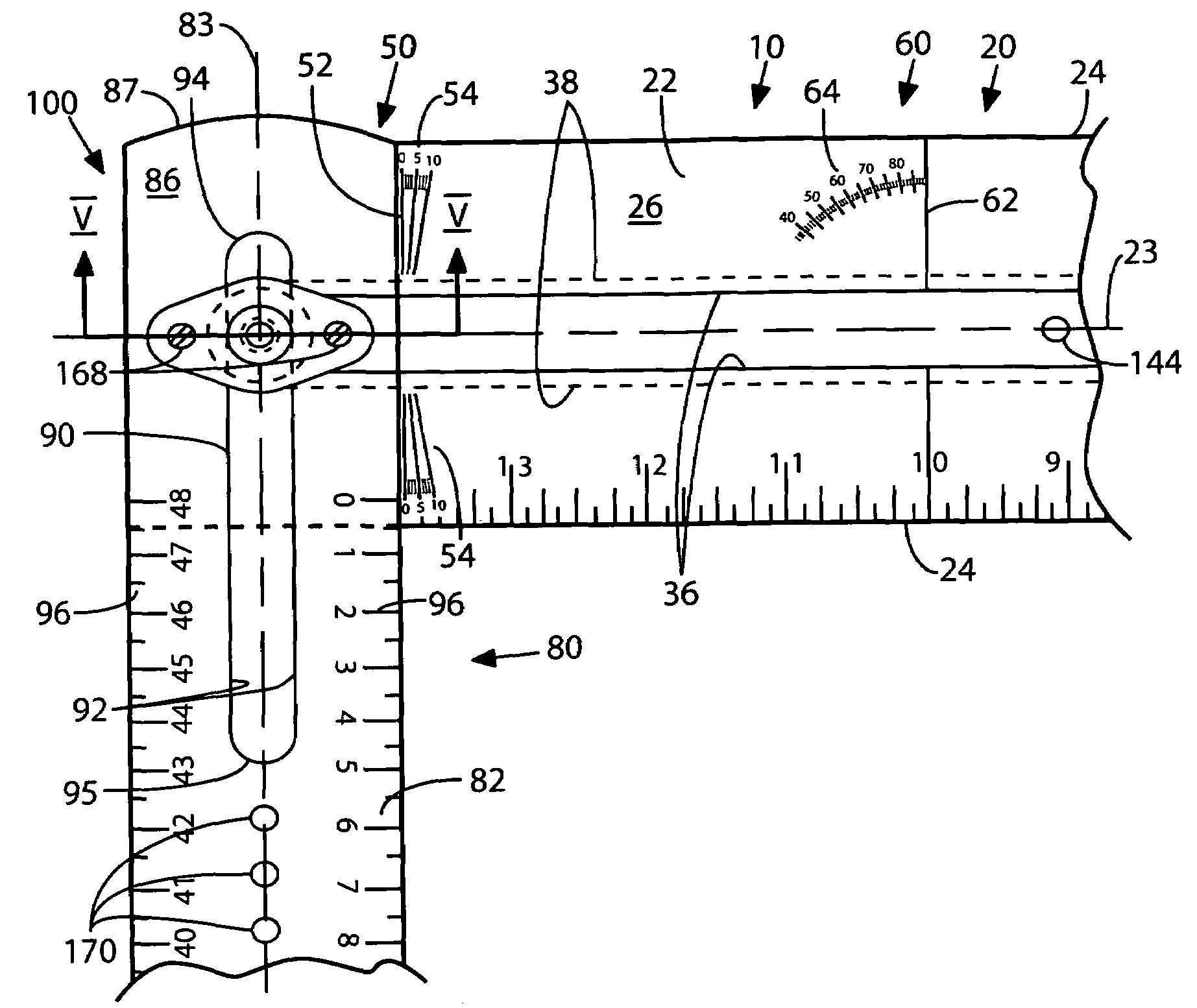

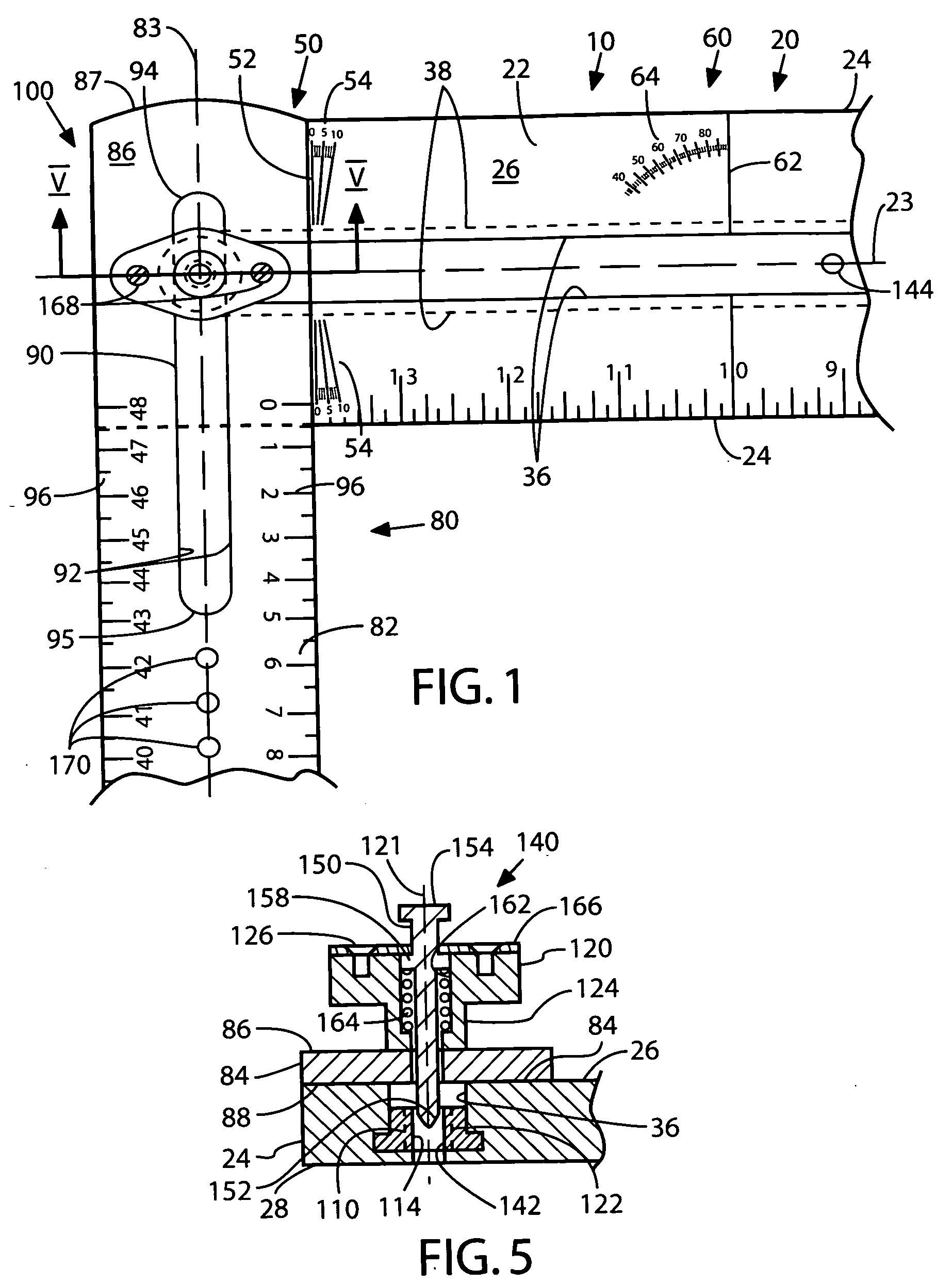

Woodworking machinery jig and fixture system

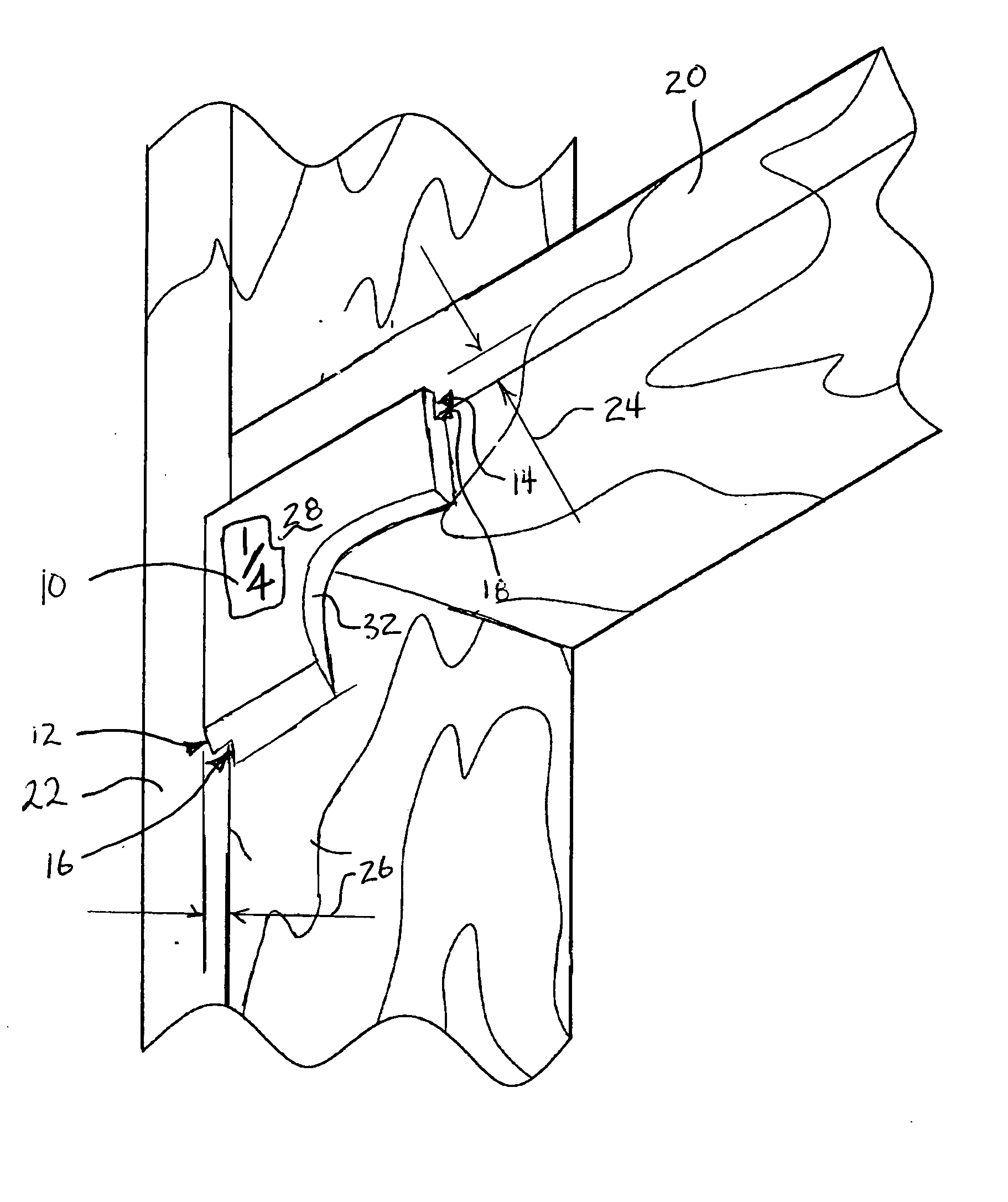

A woodworking machinery jig and fixture system includes a track which is or may be attached to a fence, a convex-concave curved flip stop and a base which mounts the stop to the track. The stop has a projecting portion which penetrates the plane of the fence so the stop isn't lifted by the point of a mitered board. The stop also has a lower convex surface which faces the work support surface and curves up at both ends. The top leg of the stop is concave toward the fence to allow clearance for a zero-clearance board and make the stop adaptable to different track and fence configurations. The base has opposite sides of different widths bordered by steps on one side and a ramp on the other side so the base can be used in a large range of T-track slot widths. The arm mounting hole of the base is offset from the base mounting so as to provide an offset to accommodate a ¾″ zero clearance board by turning the base a half turn relative to the slot. A two slot track is provided in which one of the slots can mount a sliding measurement tape or a base, and the other slot can also mount a base. In another track, a sidewall flange is provided which can be filed to accurately fit into a miter gauge slot of a cutting tool table.

Owner:KREG ENTERPRISES

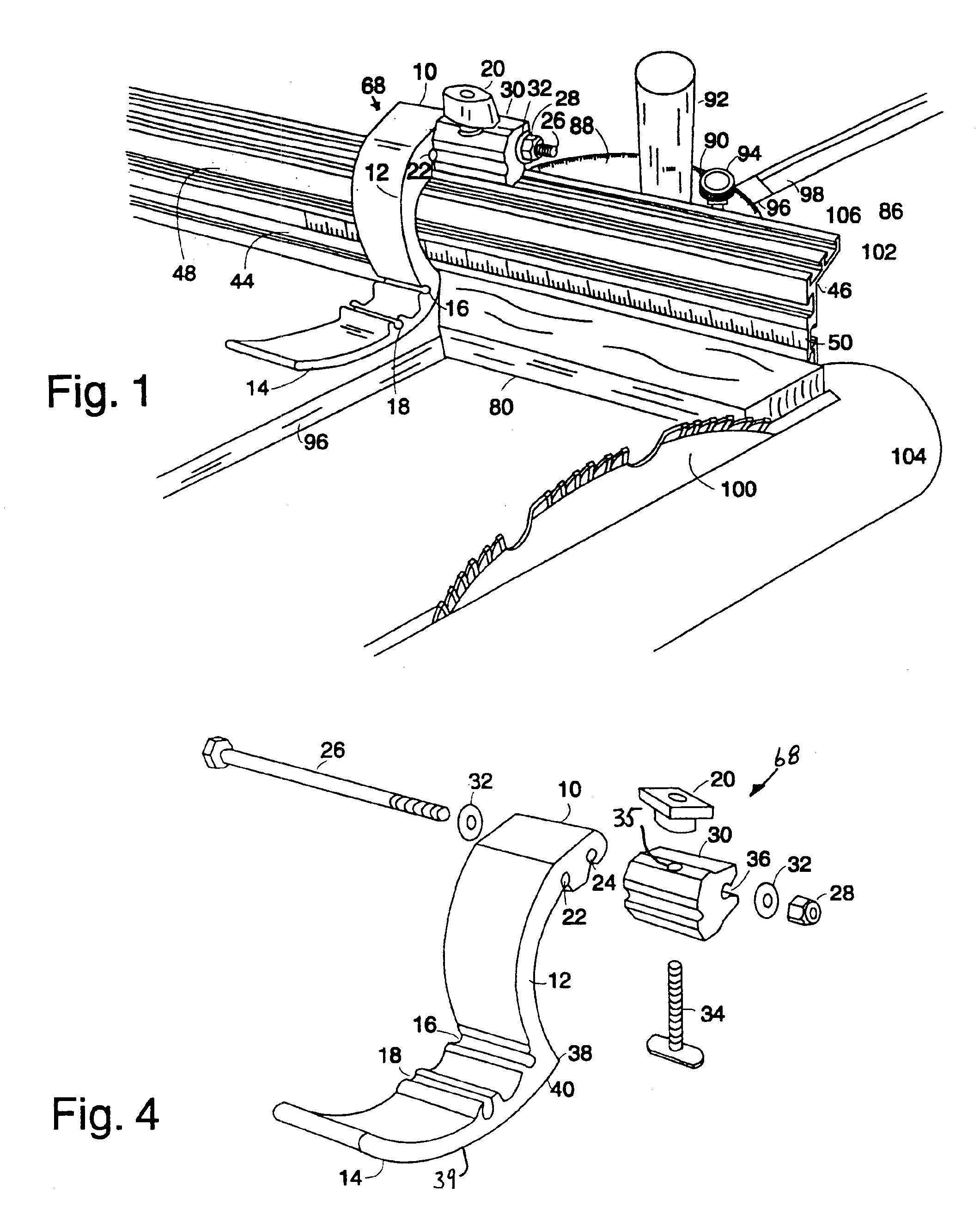

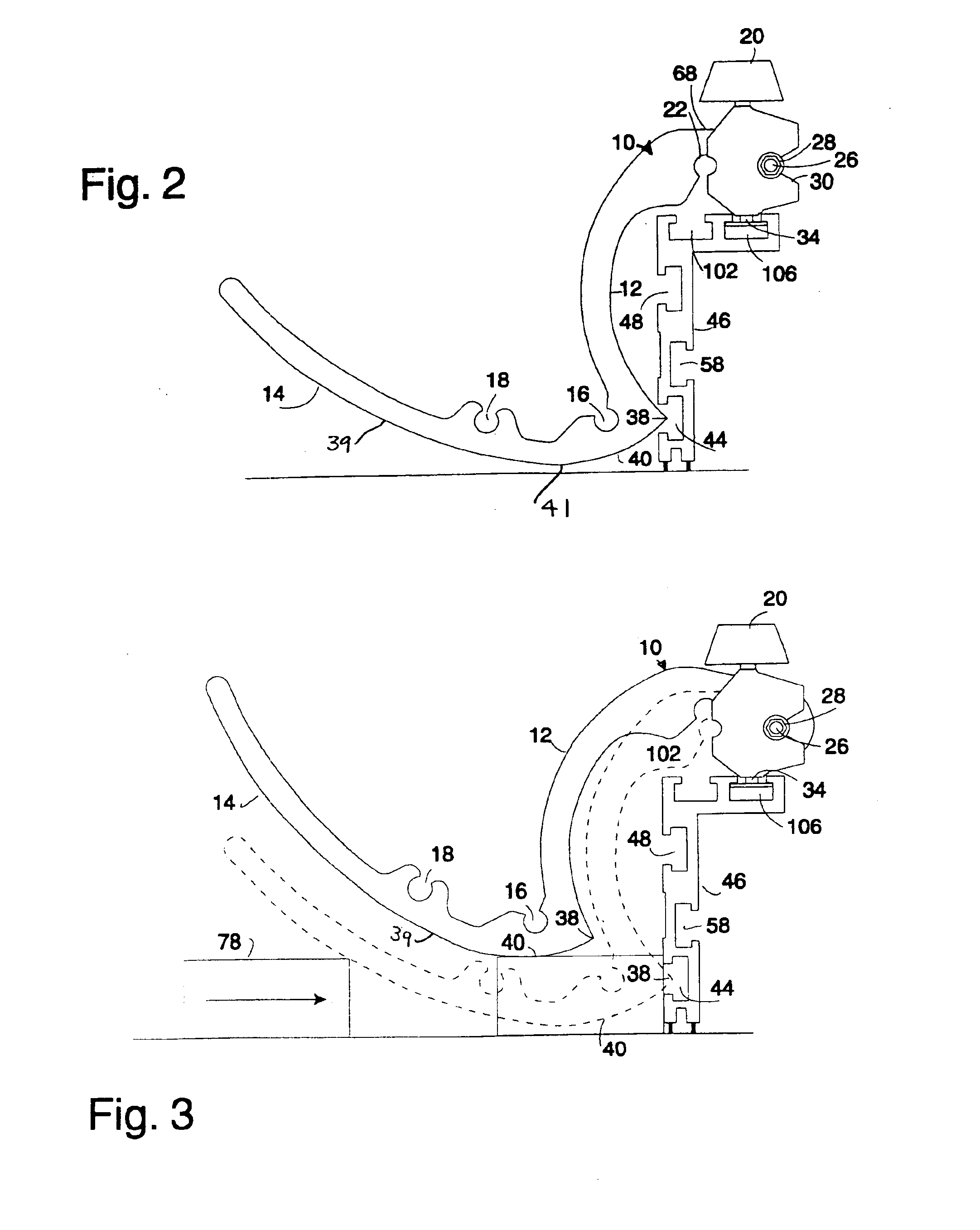

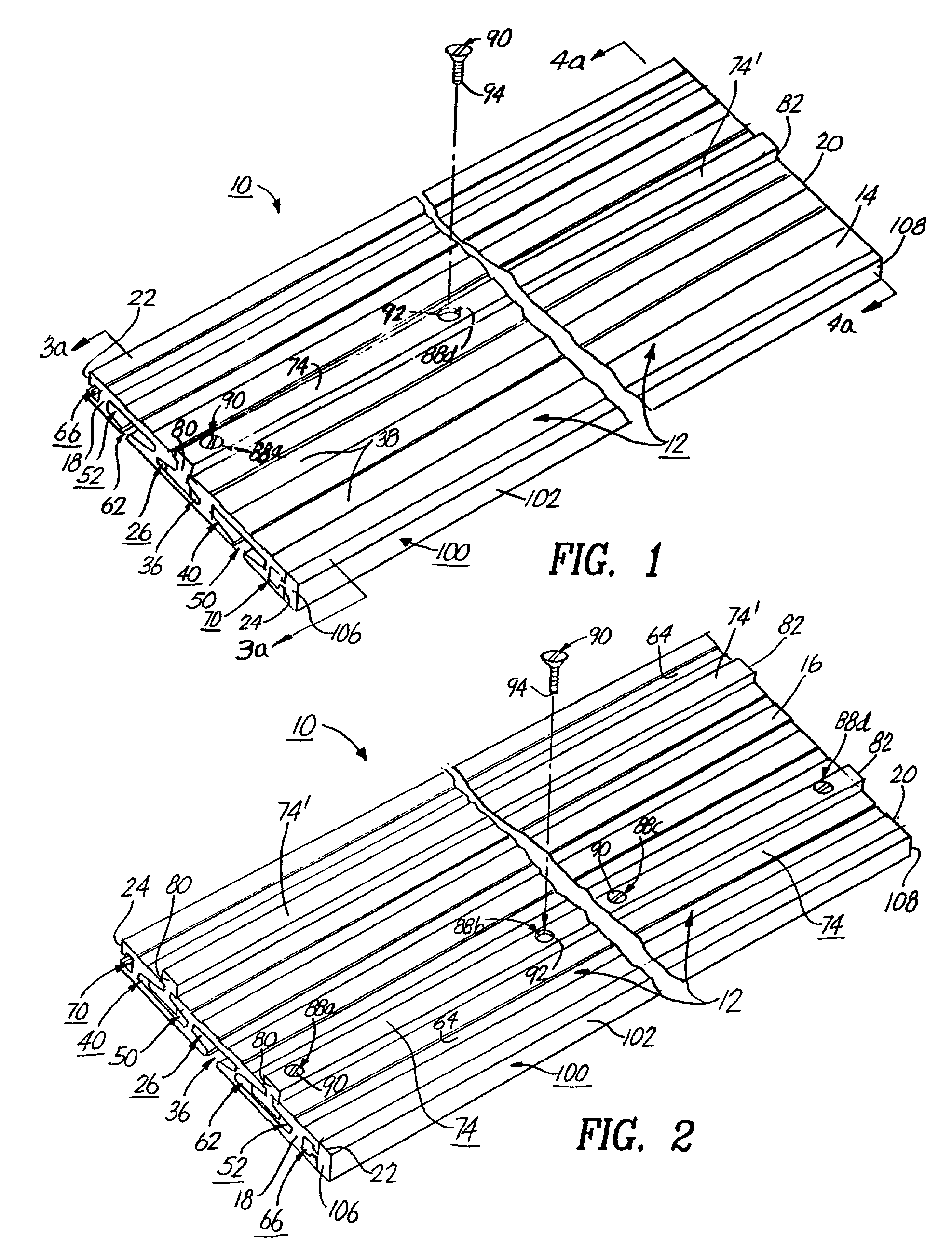

Improved Universal Machinery Fence System

A universal machinery fence system includes an L-shaped fence or a box shaped fence and clamp block which clamps to a rail extrusion with a half dovetail on the front on the edge of a table saw, band saw, shaper, router table, mortiser, or other woodworking or metal working machines. A U-shaped front rail is provided for attaching the fence to the cast iron table of a table saw, shaper, or band saw. The band saw fence U-shaped rail is predrilled to fit the table fence mounting holes of the most popular 14″ band saws. Optional extruded front rails are also provided for attaching the fence to shop made 0.750″ tables such as used on a drill press. Also provided is a fence rail extrusion for mounting the fence on the front and back of the popular 1.125″ size router table. An optional extruded front rail which is adjustable in height is also provided for attaching the fence to shop made tables between 0.750″ and 1.5″ in thickness. A re-saw guide fitted to the fence extrusion has a convex surface for supporting a workpiece on edge allowing the operator to easily adjust for blade drift. An optional micro-adjuster allows the fence to move accurately in small increments. A router table with holes and slots allows the fence to be used to guide the workpiece in the router table mode and then be used to guide the router or a saw on top of the workpiece.

Owner:KREG ENTERPRISES

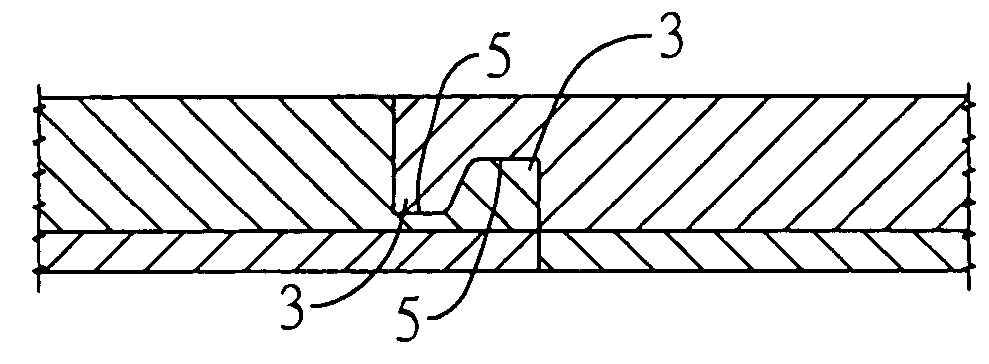

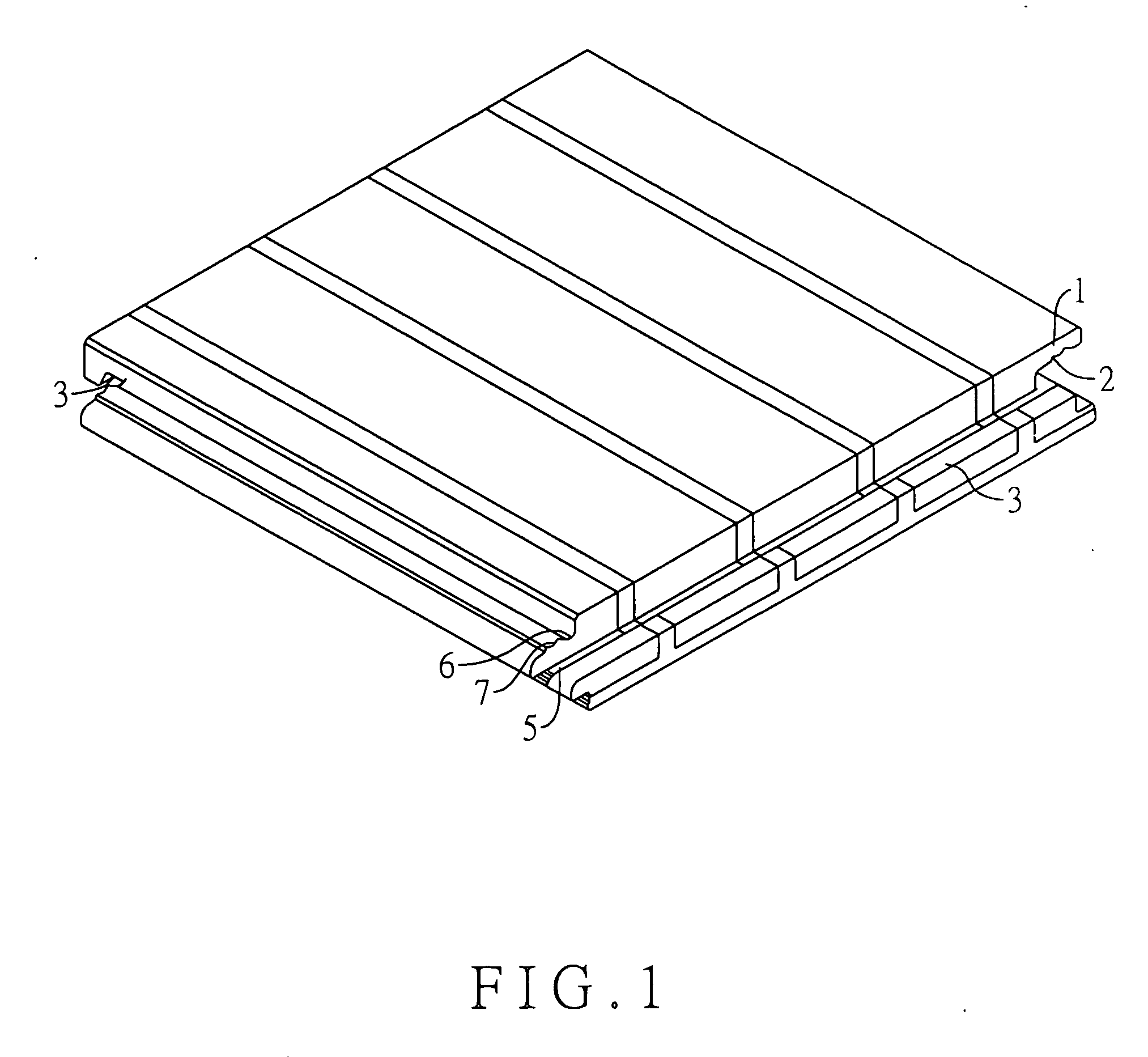

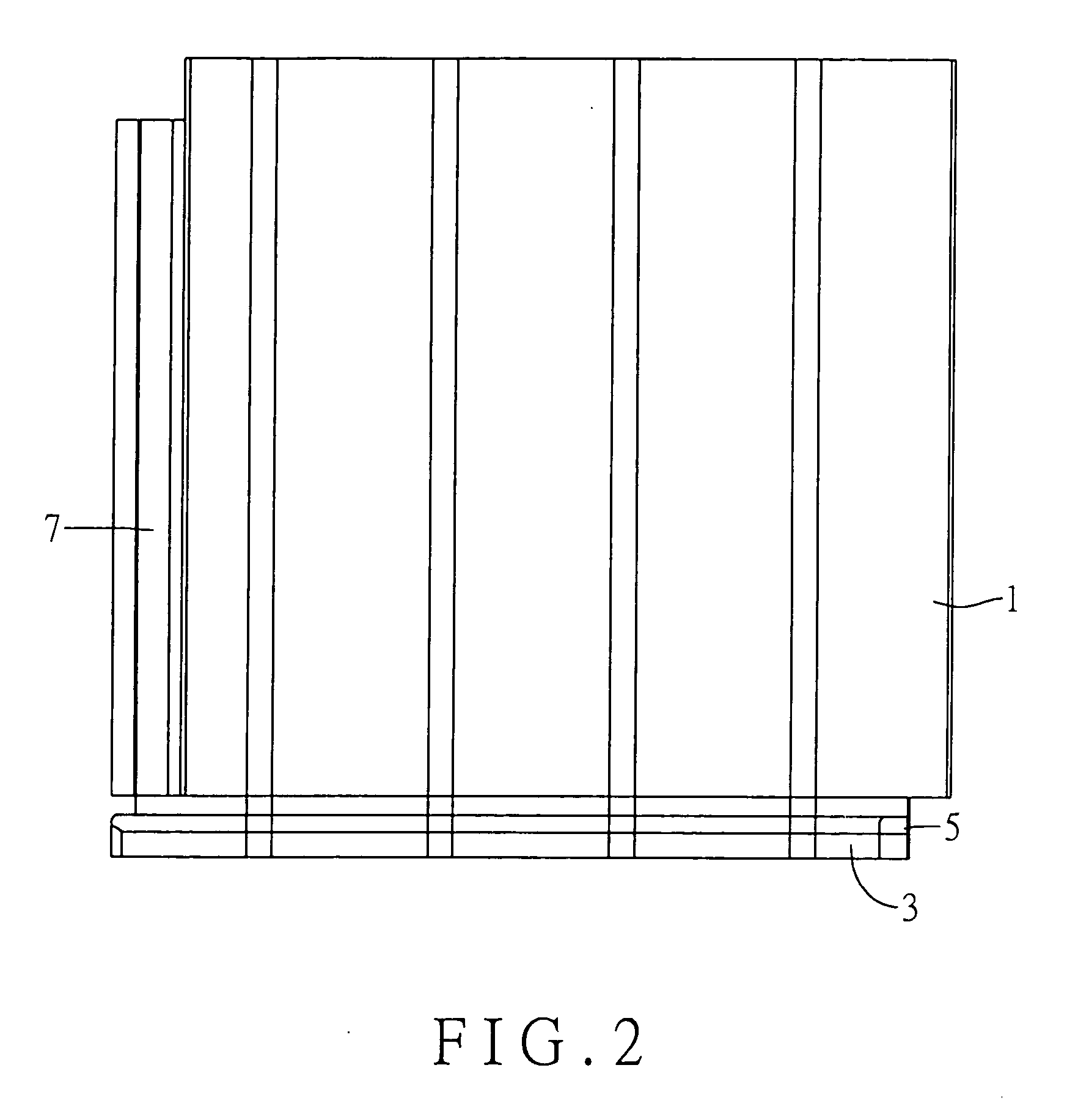

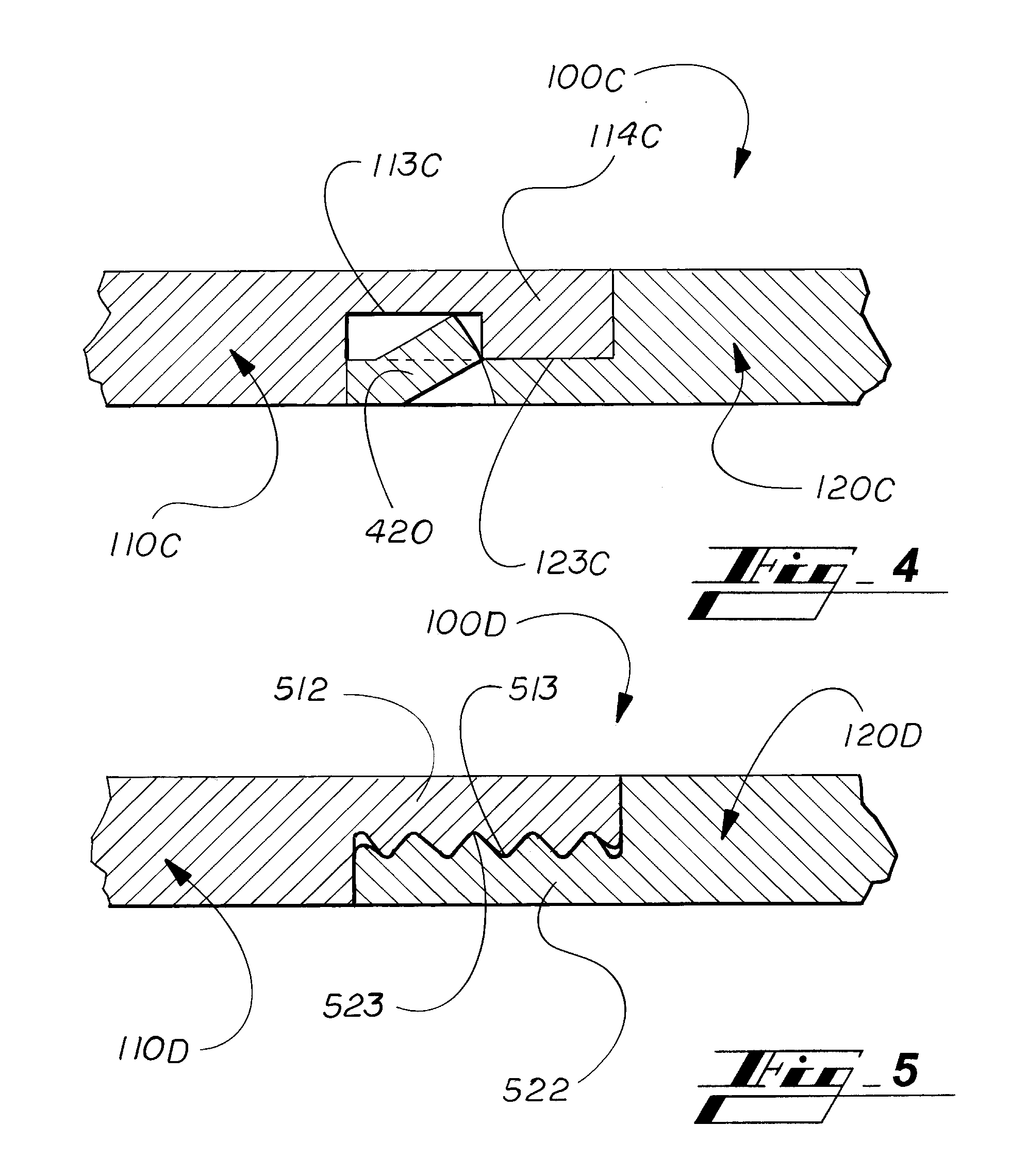

Parquet block with woodwork joints

A parquet block with a woodwork joint has two parallel abutting sides, a longitudinal notch, a longitudinal tongue, two transverse grooves and two transverse tongues. The longitudinal notch, the longitudinal tongue, the transverse grooves and the transverse tongues on adjacent parquet blocks interlock to hold the parquet blocks securely in the longitudinal and transverse directions.

Owner:LIU MEI LING

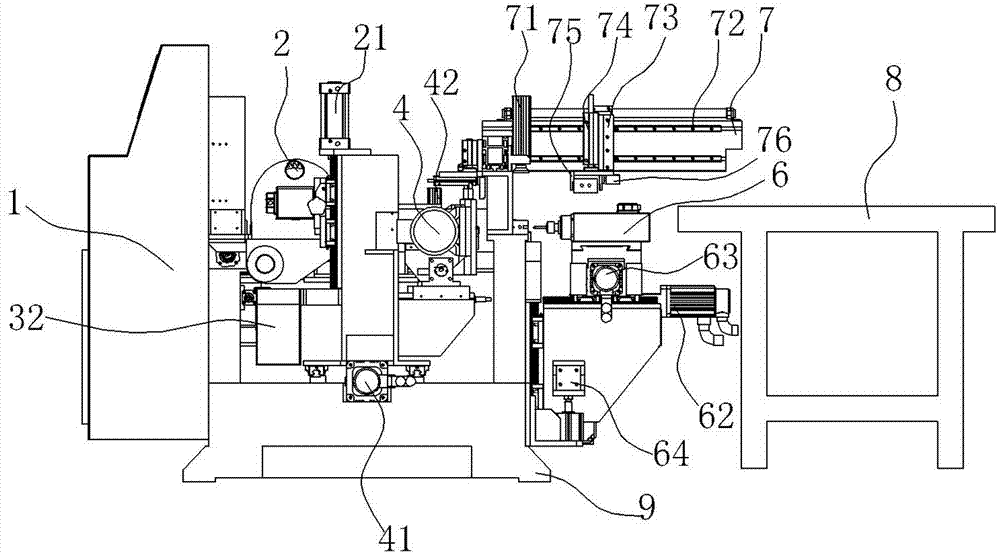

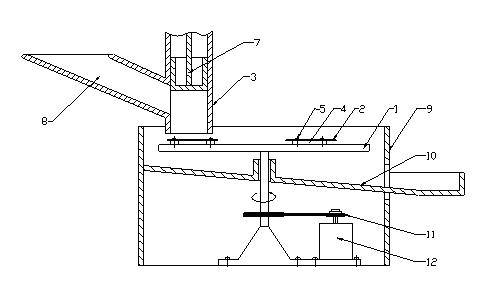

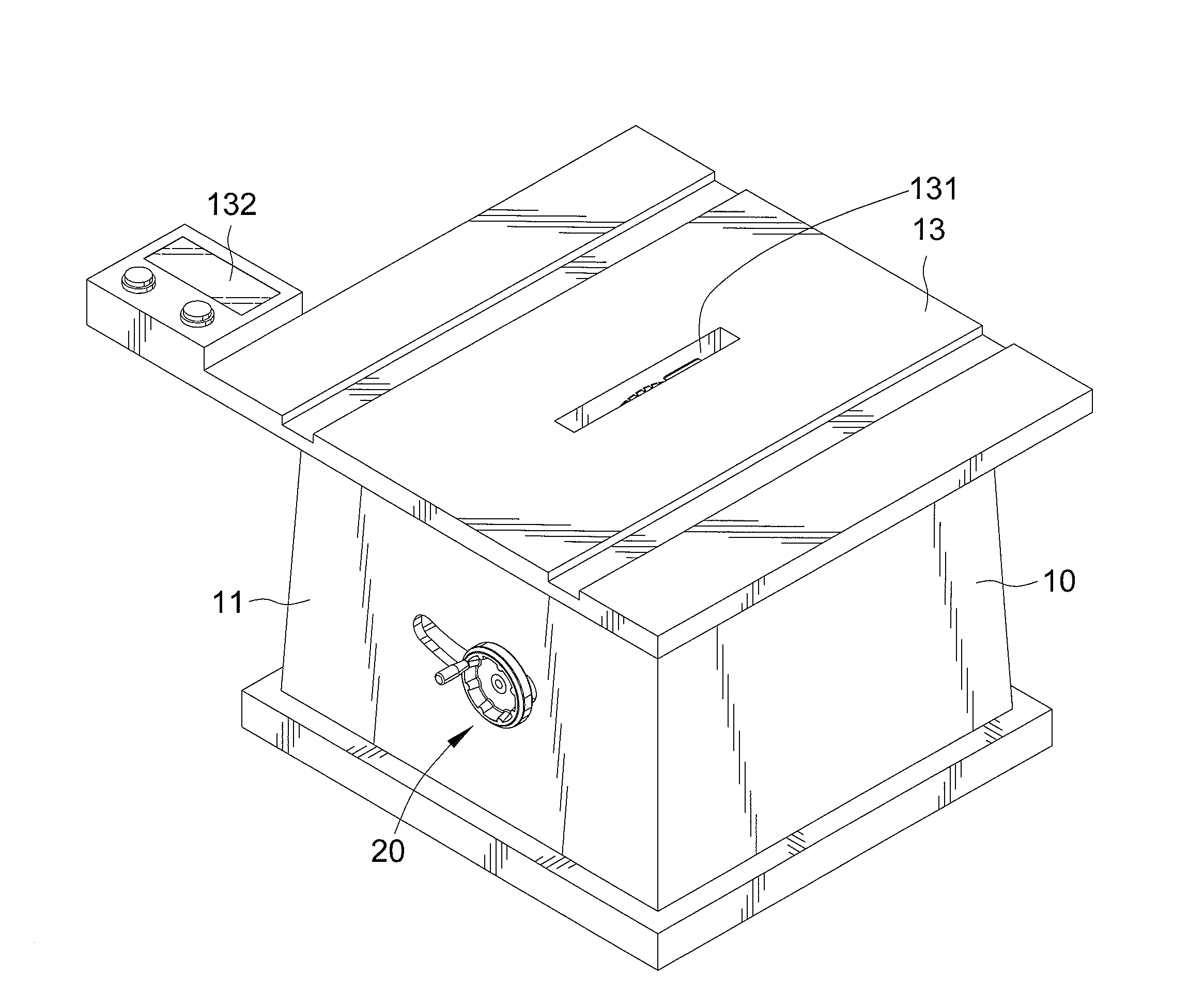

Automatic woodworking machine

InactiveCN103481335AImprove machining accuracyHigh degree of automationMulti-purpose machinesWoodworking machineServomotor

The invention provides an automatic woodworking machine, belongs to the technical field of woodworking machines, and solves the problems that a conventional woodworking machine is not high in processing efficiency and relatively low in product precision. The automatic woodworking machine comprises a machine frame, wherein a workpiece conveying mechanism is arranged on the machine frame; a feed hopper is arranged at the front end of the conveying mechanism; a cutting mechanism, a drilling mechanism and a groove milling mechanism are also arranged on the machine frame; the cutting mechanism comprises power heads respectively arranged at two ends of the machine frame, saw blades arranged on the output shafts of the power heads and lifting air cylinders for driving the saw blades to move up and down. According to the invention, a PLC system is adopted to control a servomotor, the cylinders, the power heads and other electric appliance mechanisms to act together, so that flush cutting, end-part drilling, side-surface groove milling and the like of sheet metal can be realized through one-time positioning, and the machining precision is high; end products can be grabbed and placed on a conveying line through an automatic reclaiming mechanism after the processing is finished, so that the degree of automation and the processing efficiency are high.

Owner:TAIZHOU EVOK MASCH CO LTD

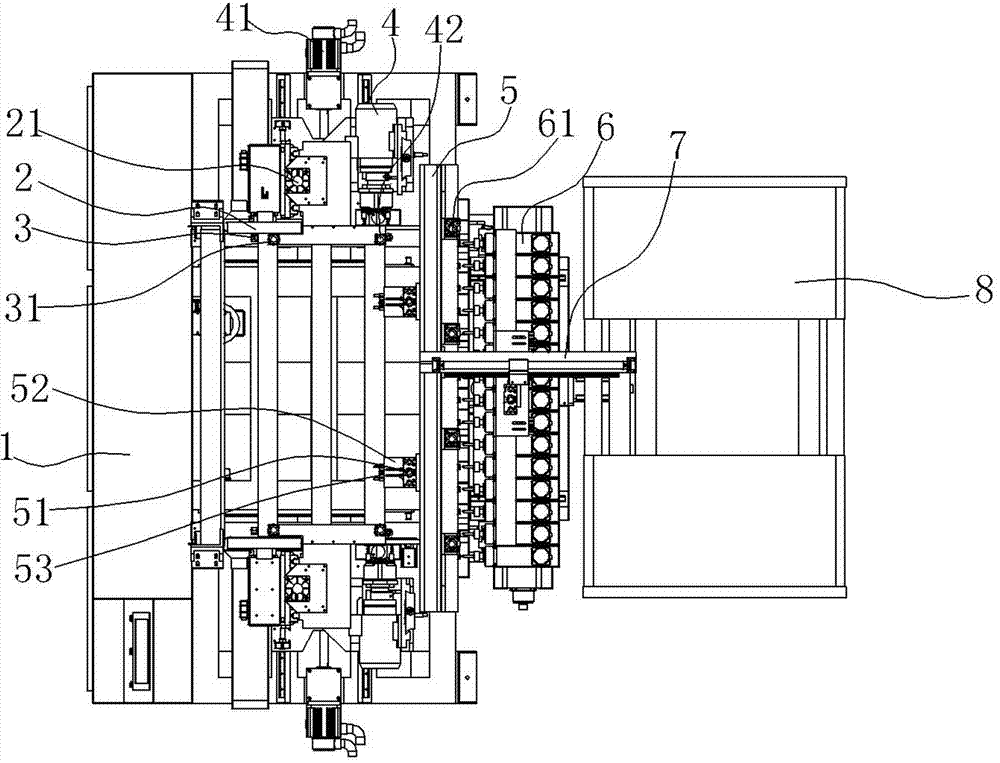

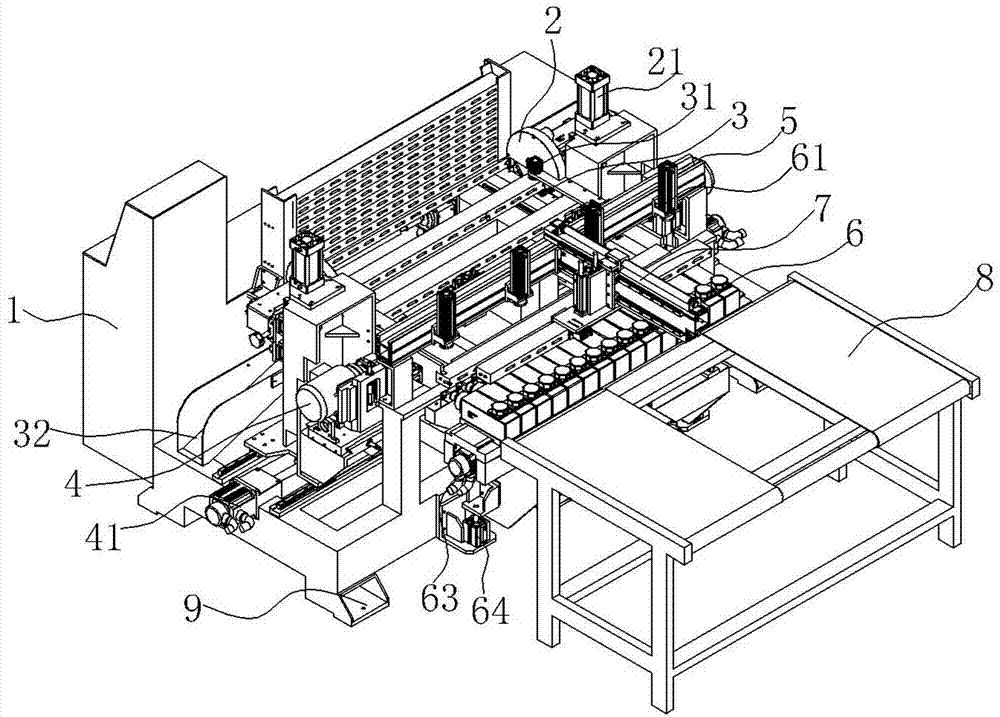

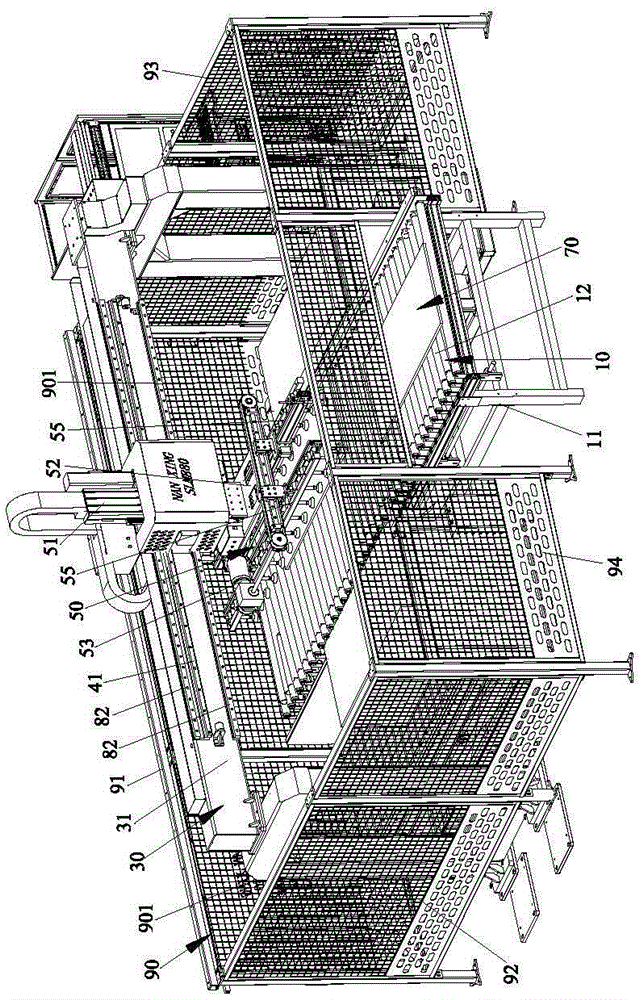

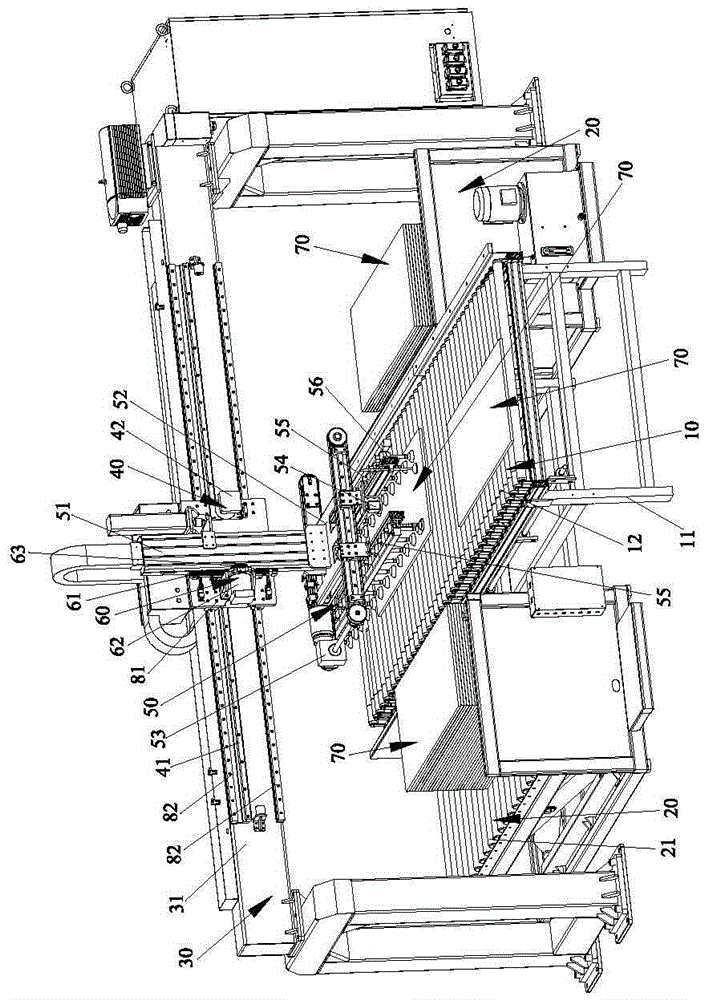

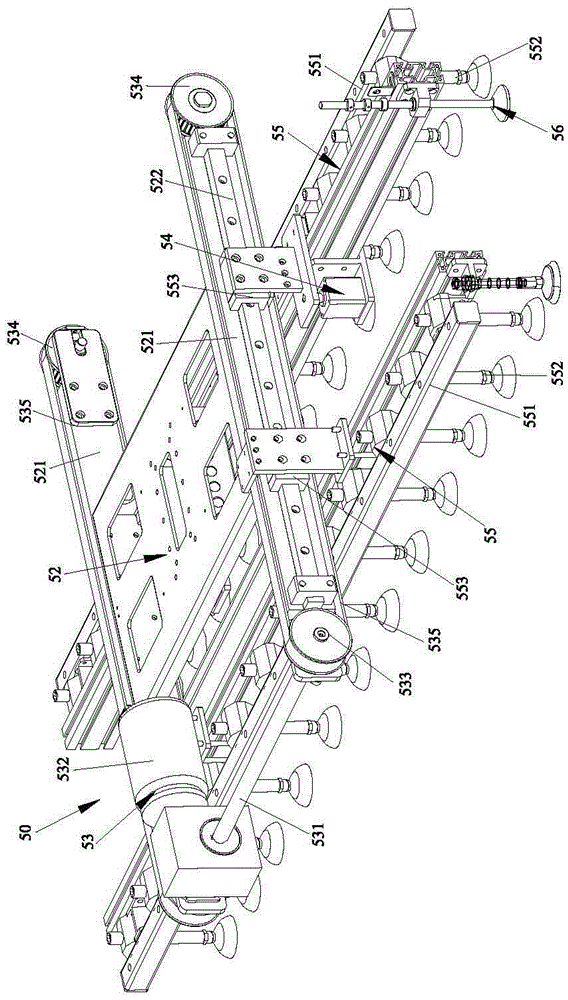

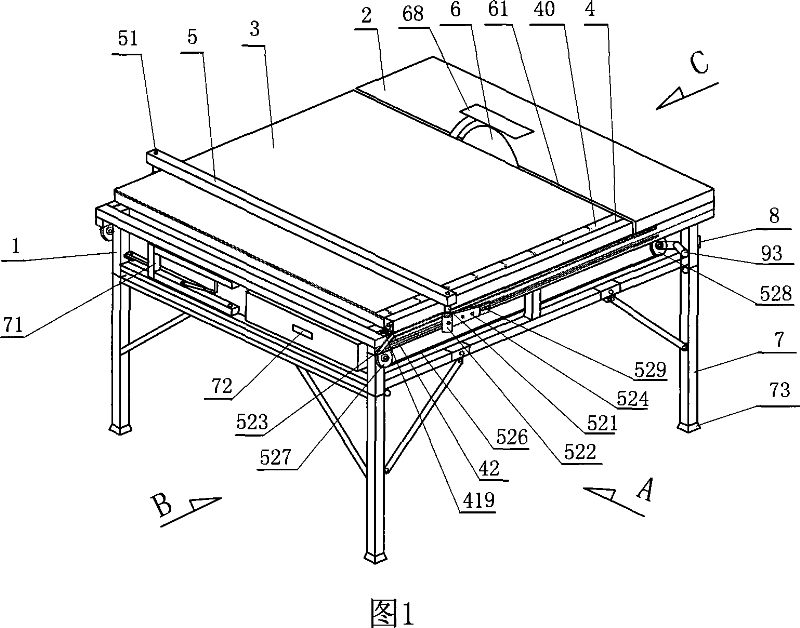

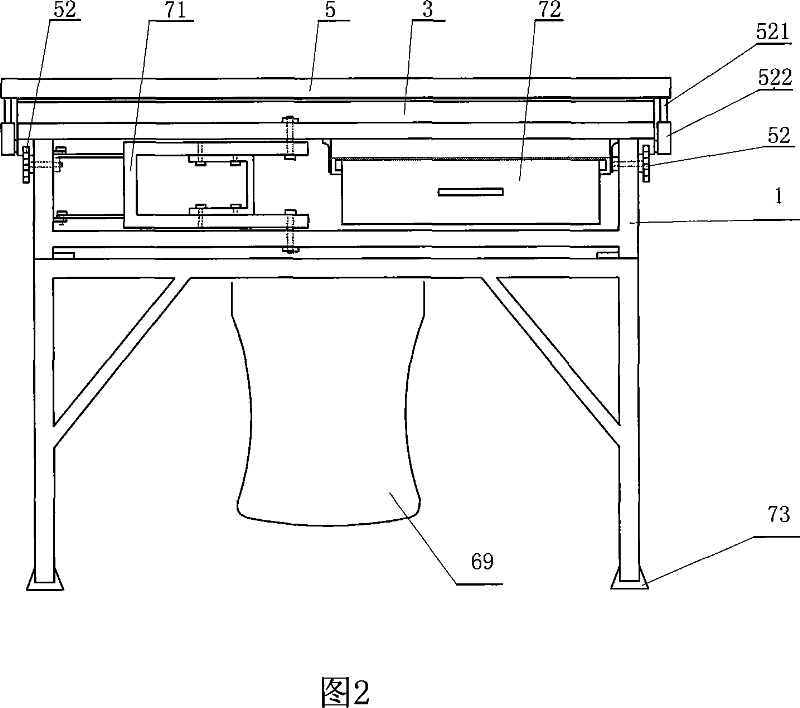

Gantry type sheet feeding and discharging manipulator for woodwork

ActiveCN105397872AShorten exercise distanceAvoid stickingGripping headsMulti-purpose machinesEngineeringStressed state

The invention discloses a gantry type sheet feeding and discharging manipulator for woodwork. The gantry type sheet feeding and discharging manipulator comprises a combined conveying table, a feeding device, a main support, a horizontal moving device, a grabbing device and a vertical moving device. The grabbing device comprises a stand column, a base, an opening and closing mechanism, an anti-adhesion shaking mechanism and at least two pressure maintaining type suction cup sets. Automatic feeding is achieved through the feeding device, the moving distance of the grabbing device in the vertical direction is reduced, and halt is not needed in the feeding process so that production efficiency can be effectively improved. The automatic opening and closing mechanism is adopted by the grabbing device, the distance between the pressure maintaining type suction cup sets can be automatically adjusted according to the sizes of sheets, and therefore abrasion of suction cups is reduced due to the fact that the suction cup sets are in a good stress state. The anti-adhesion shaking mechanism shakes after grabbing, so that adhesion of the sheets is effectively prevented; moreover, the grabbing device is made to firmly suck the sheets when a power supply is cut off, and the sheets are prevented from falling onto equipment; meanwhile, the situation that unnecessary harms are caused when operators enter a working zone after a power failure is prevented.

Owner:NANXING MACHINERY CO LTD

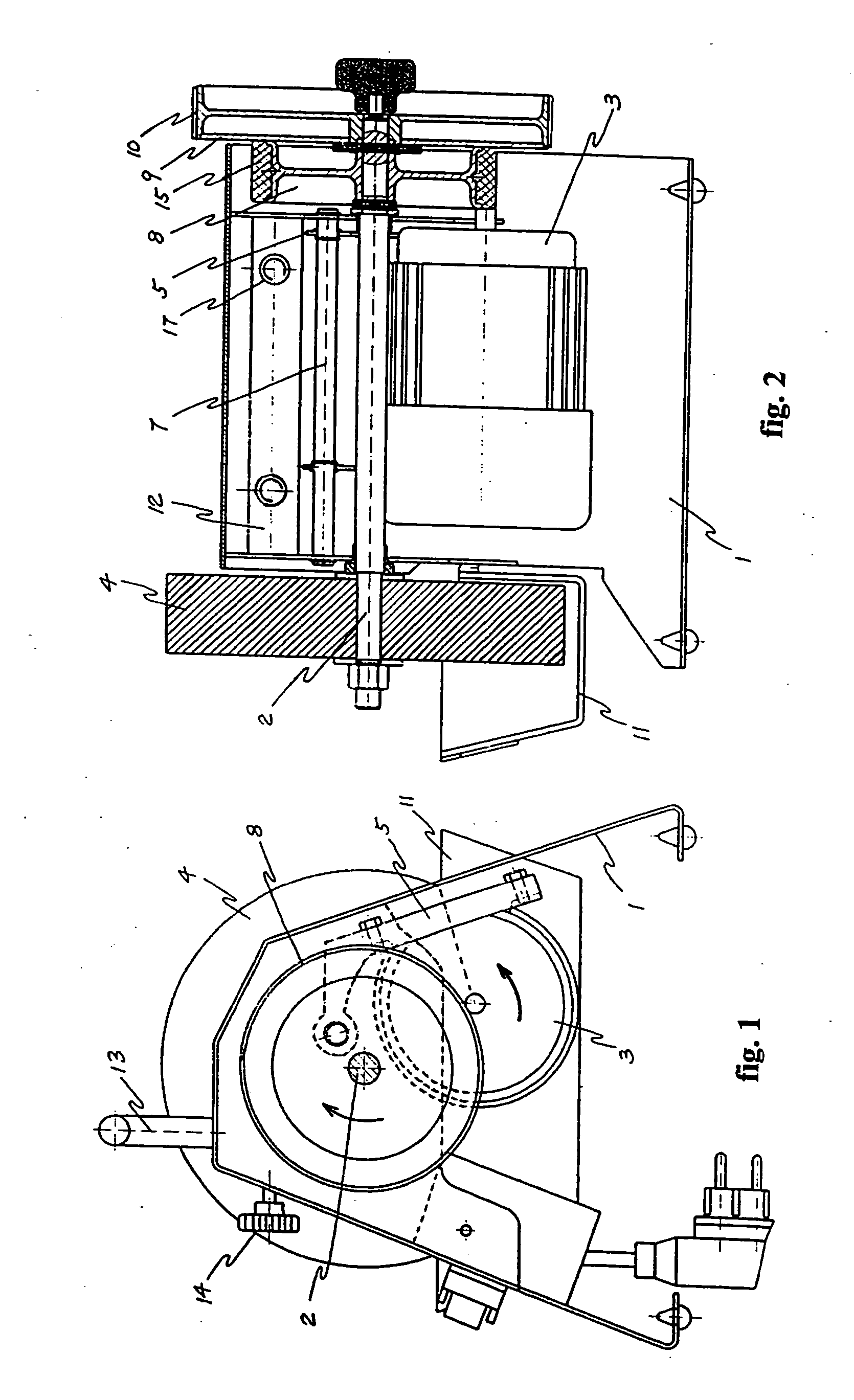

Electric sharpener

InactiveUS20050090184A1Simple and proper and compact and down-sized transmission systemImprove grinding efficiencyRevolution surface grinding machinesGrinding feed controlElectric machineryElectric control

The invention relates an electric sharpener, comprises a main frame, a main shaft, a motor, a transmission wheel, a grinding stone, and an electric control circuit. The motor is mounted on an angular frame which in turn is mounted on the main frame. The transmission wheel is fixed to an end of the main shaft, and the output shaft of the motor is tightly pressed against the periphery of the transmission wheel so as to drive it. A tool rest is fixed onto the main frame in a vertical or horizontal mounting orientation. A water vessel is fixed to the main frame, and the lower portion of the grinding stone dips into the water contained in the water vessel. Special clamps and attachments for grinding different tools are provided. The electric sharpener can be used for grinding various woodworking or household tools.

Owner:QINGDAO D&D ELECTRO MECHANCIAL TECH

Woodworking machinery stop and track system

Owner:KREG ENTERPRISES

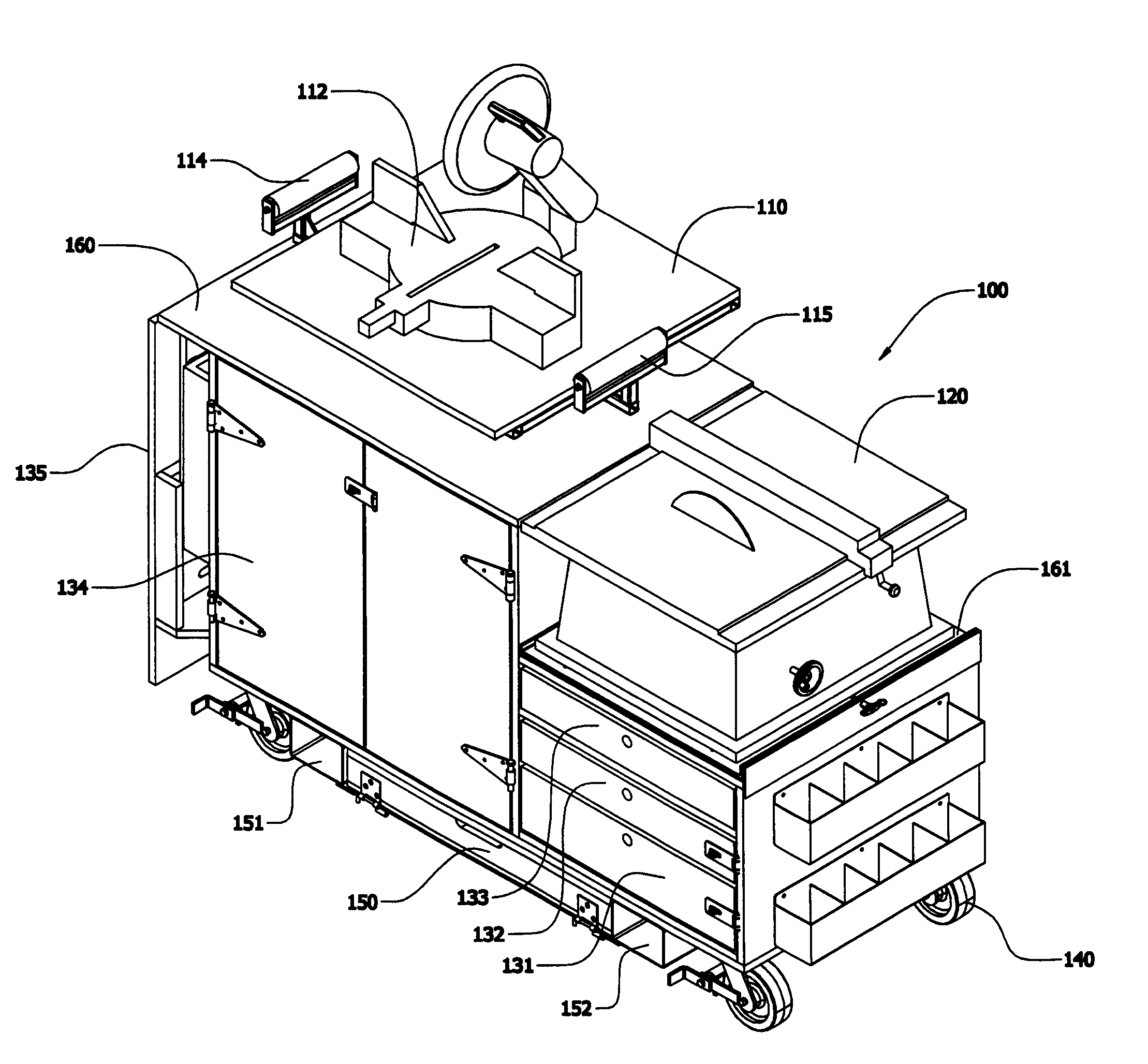

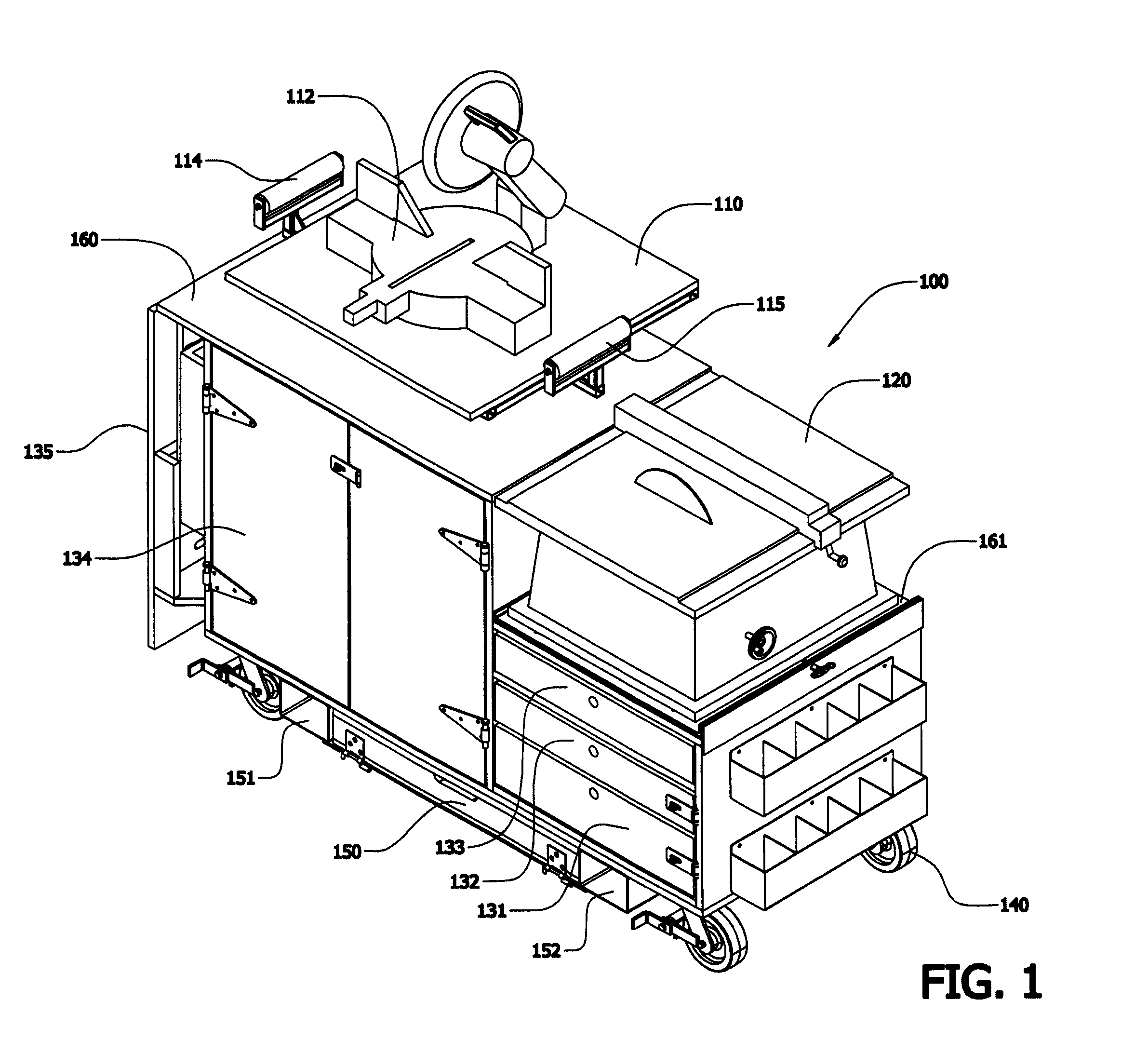

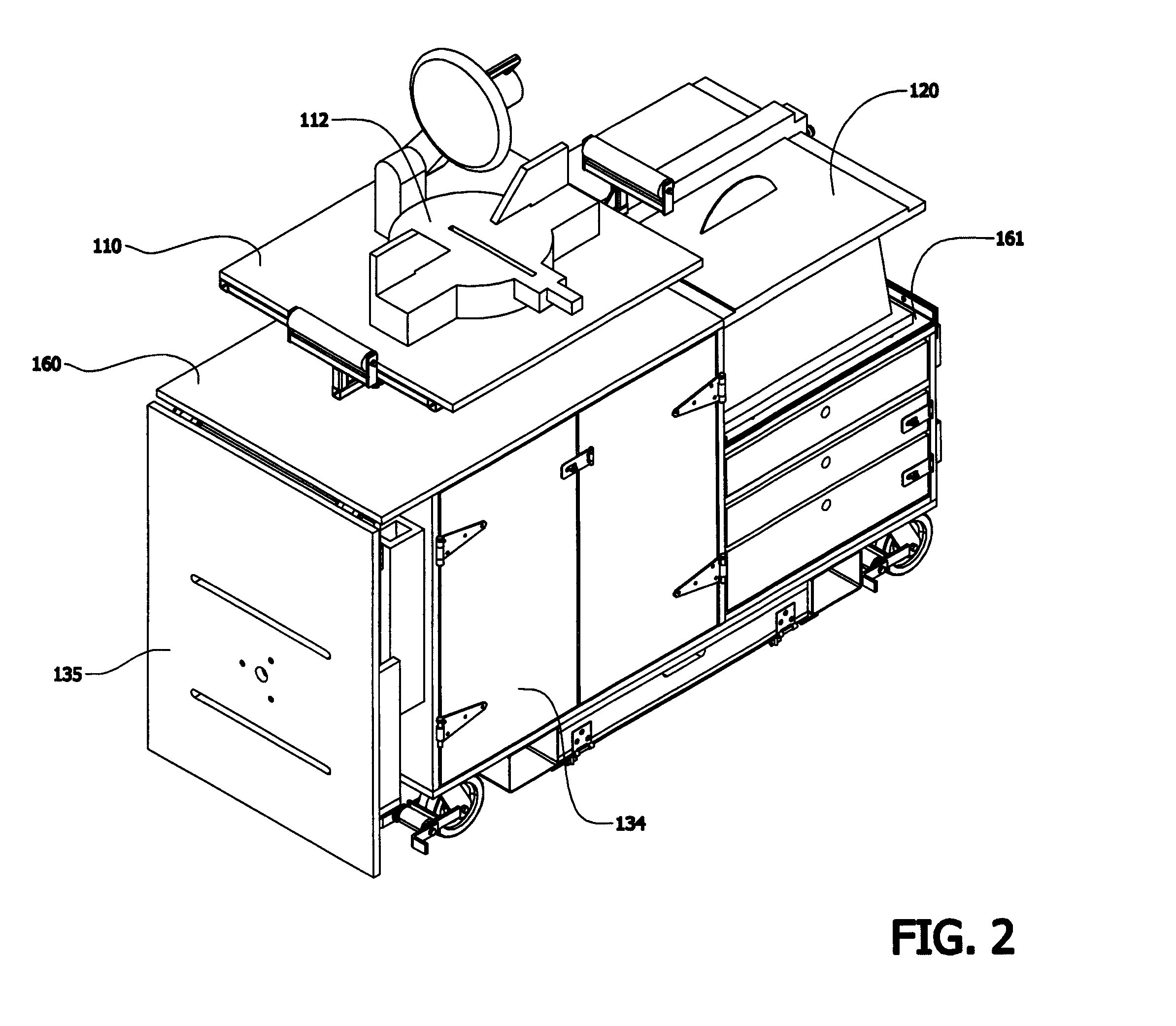

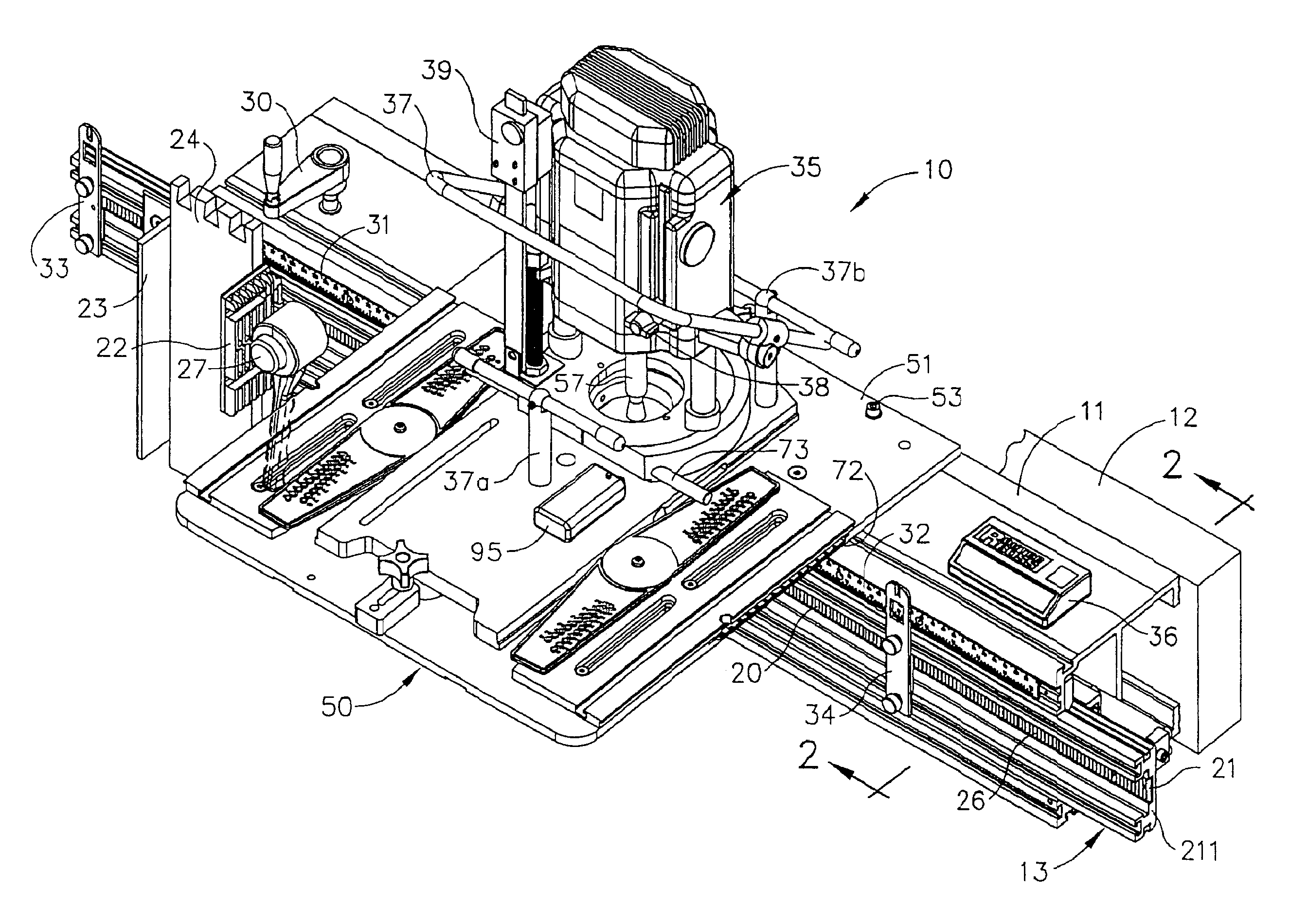

Portable carpentry workshop

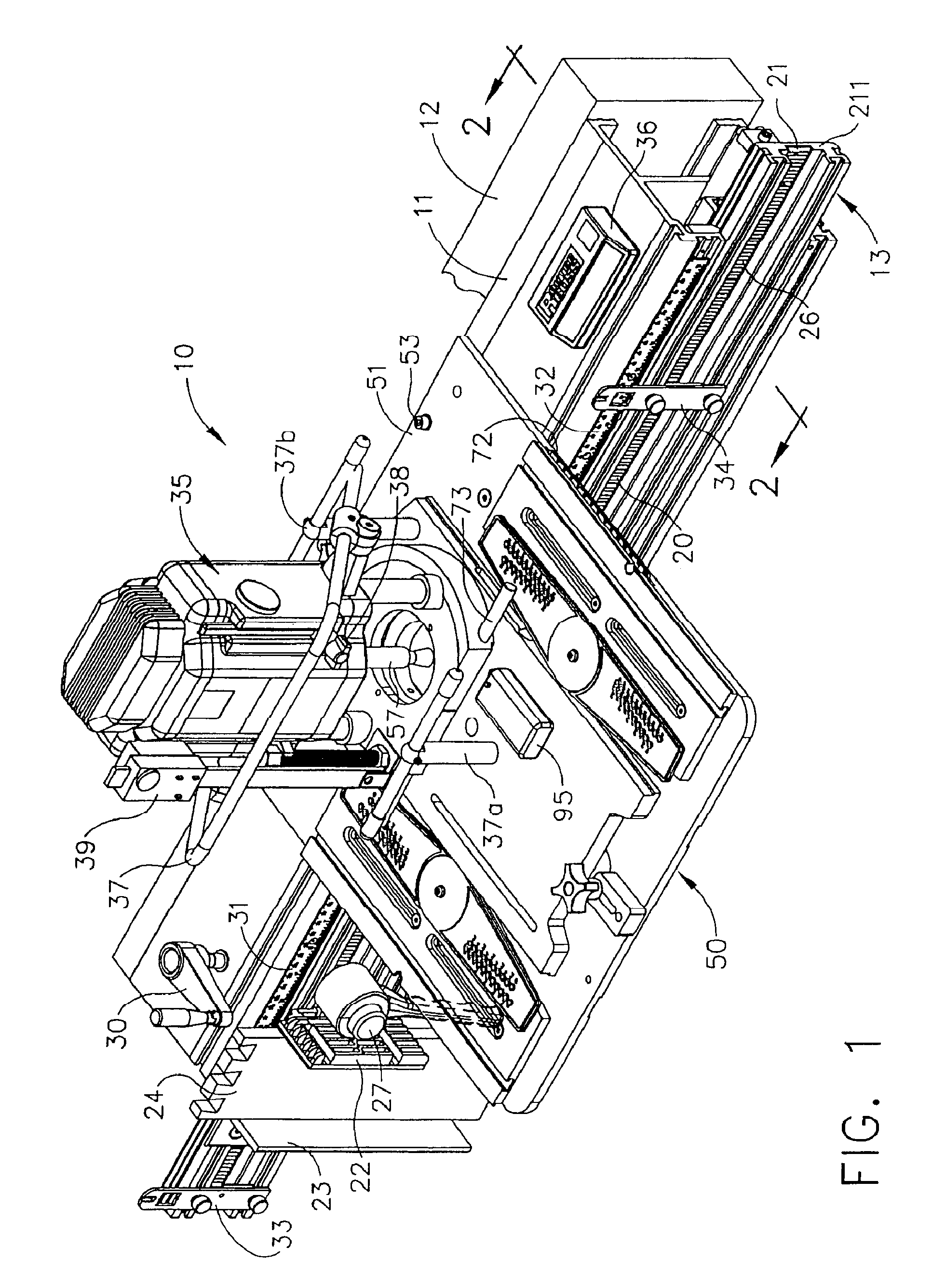

InactiveUS7647956B1Easy to transportImprove mobilityGuide fencesShearing machinesEngineeringPower tool

A portable rolling carpentry workshop includes a table saw mounted on a sliding means to allow the blade of the saw to be shifted to the left or to the right of the longitudinal centerline of the workshop so that more supporting surface is available on either side of the blade to allow cutting large workpieces on a relatively narrow tabletop surface. The workshop of the invention is sized to allow easy maneuvering through the narrow hallways of apartment buildings but affords the functionality of larger worktables due to this unique ability to slide the table saw. Also provided is an extendable miter saw table located above the main tabletop surface and allowing passing of the longer workpieces underneath thereof when ripping with table saw. Therefore the use of both the table saw and the miter saw can be accomplished at the same time without the need to rearrange the configuration of the power tools on the workshop.

Owner:CONA FRED MR

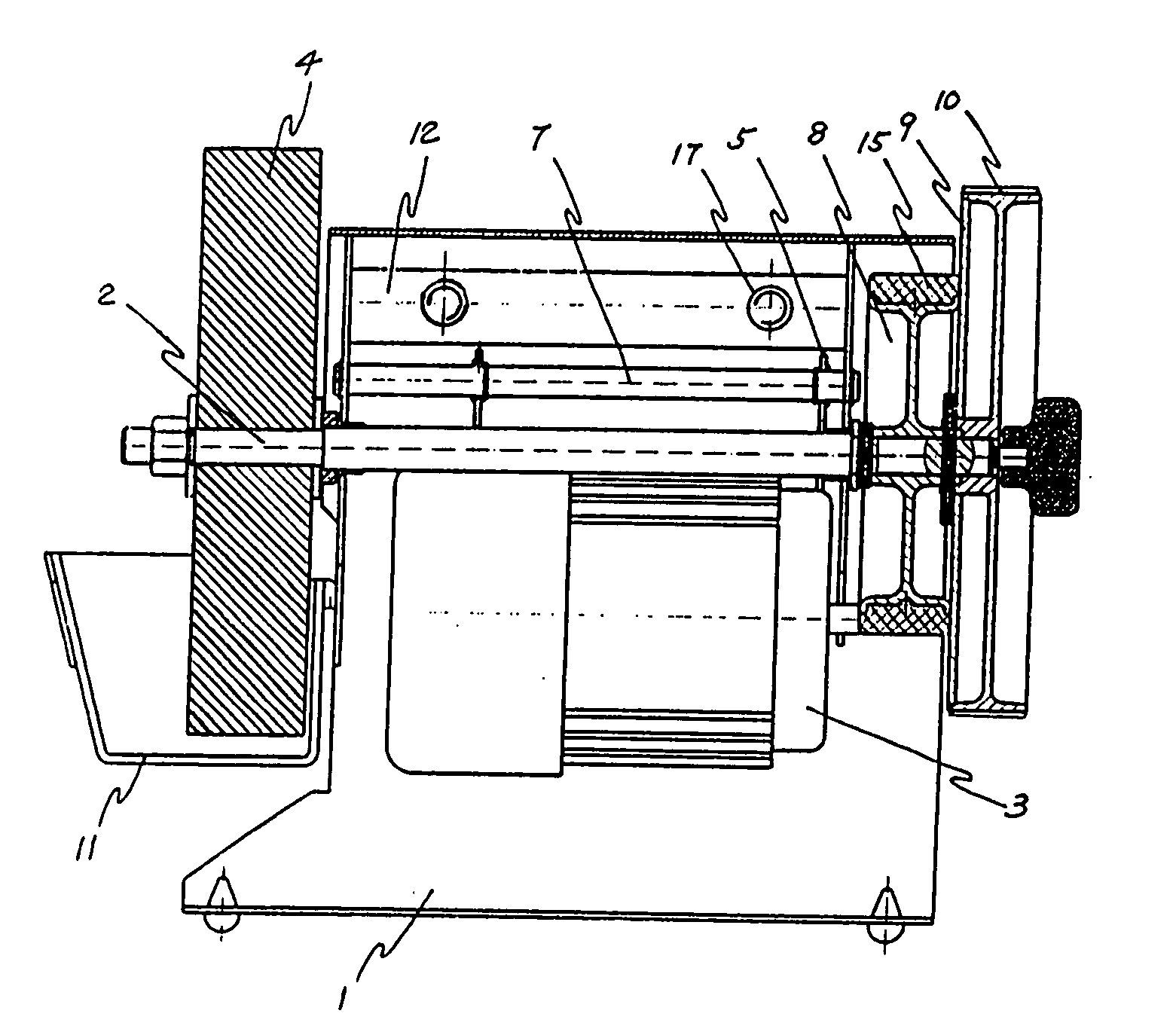

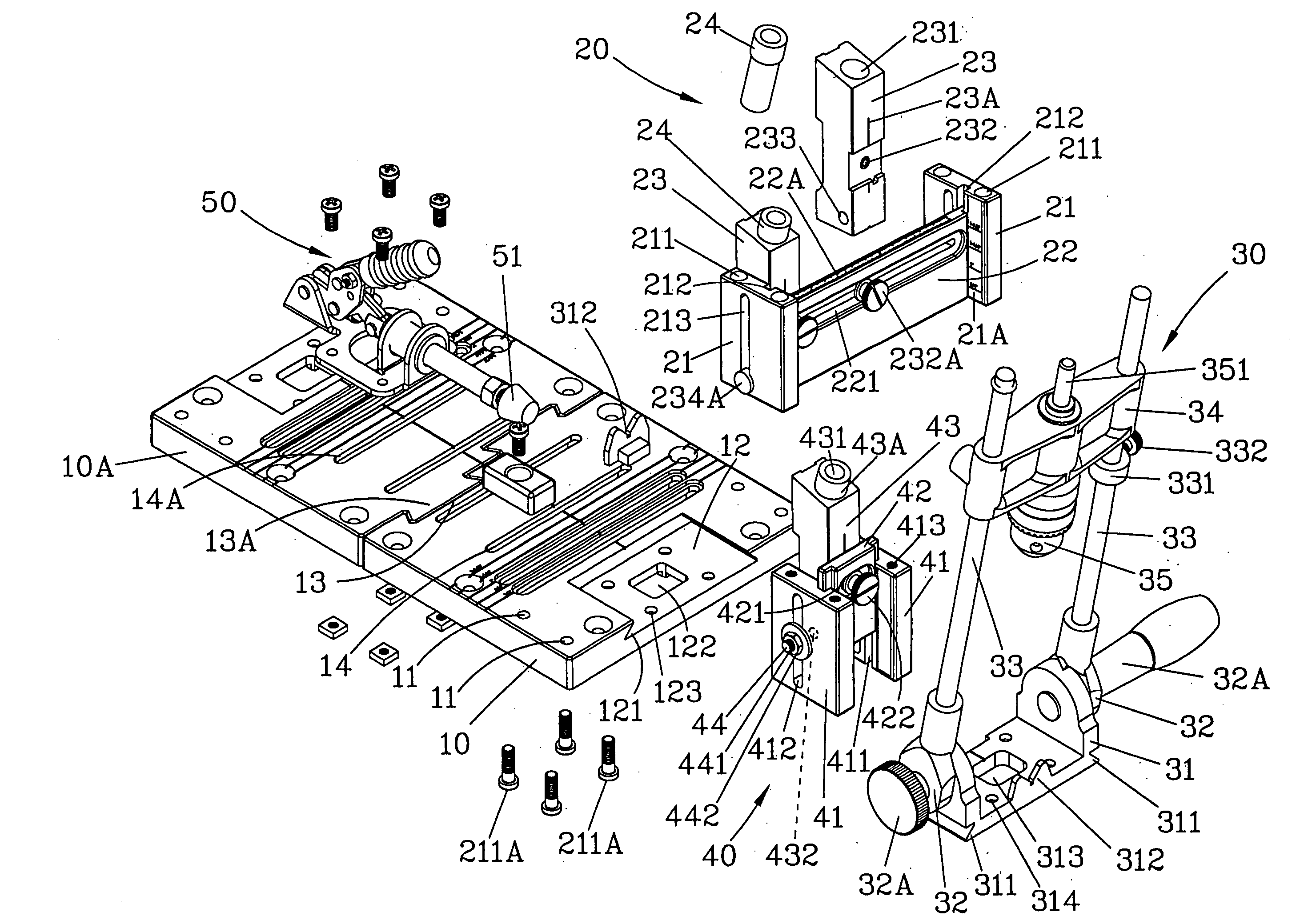

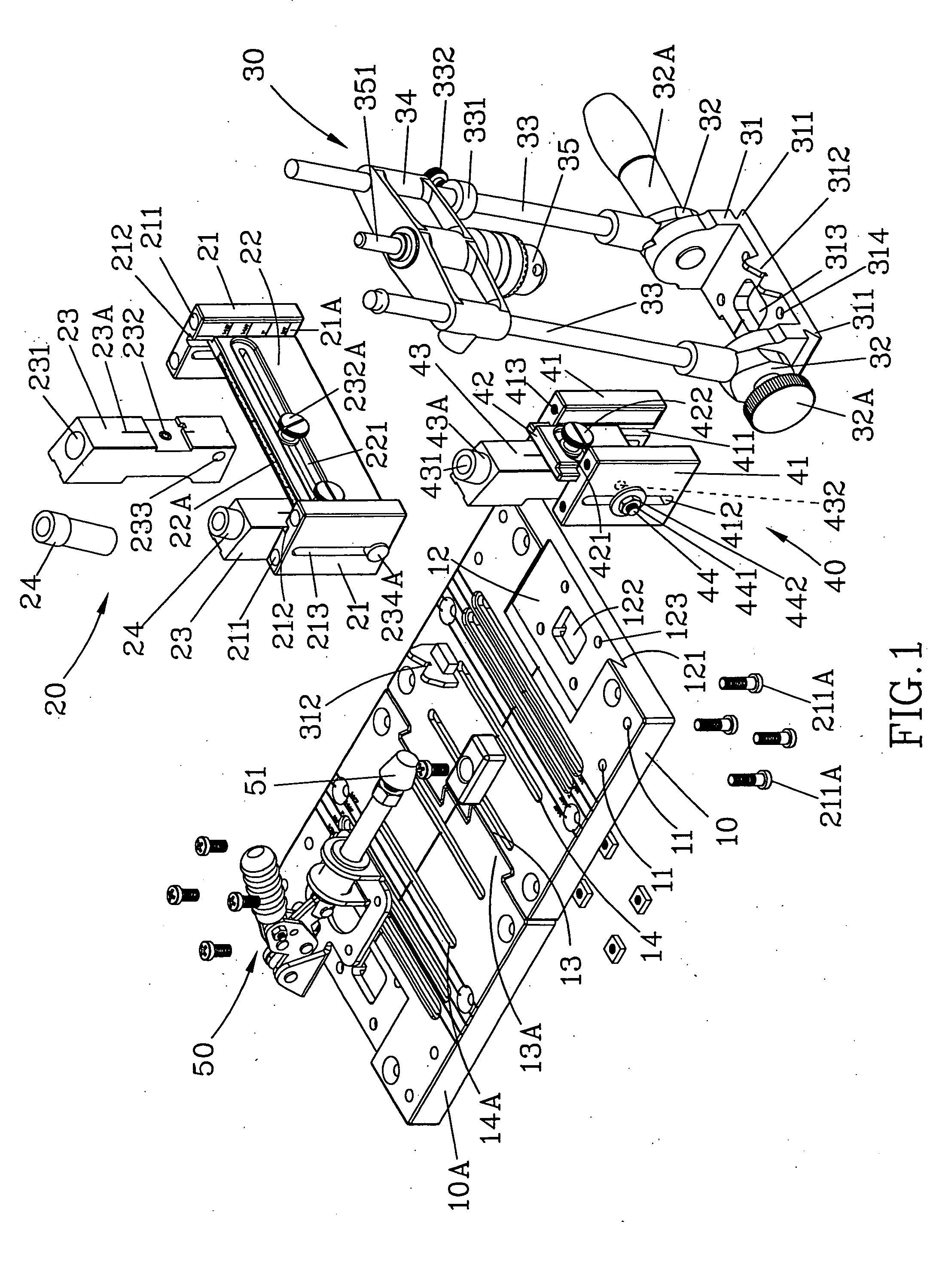

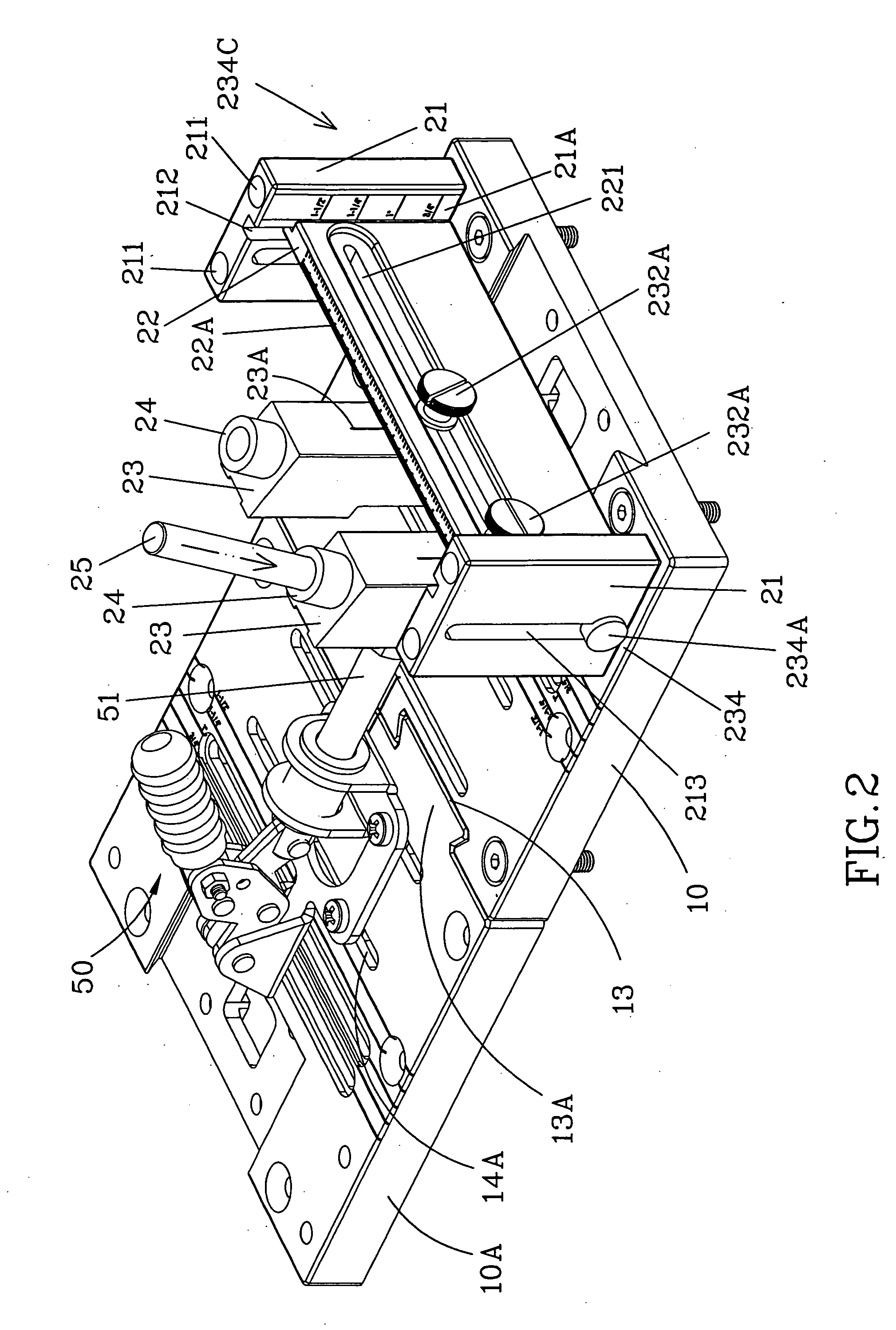

Holding fixture for all types of drilling concerning woodworking

InactiveUS20080099101A1Easy to adjustWooden sticks manufactureMulti-purpose machinesEngineeringFront edge

The invention proposes a holding fixture for use in all types of drilling concerning woodworking, comprised of at least one flat worktable having a set of dovetailing portions at the rear end for two flat worktables to dock together horizontally; a longitude-transverse adjustment module vertically arranged on the flat worktable, which secures the guide members for guiding the adjustments of height or latitude during drilling; an angle adjustment module being aligned at the front edge of said flat worktable, which guides the drilling operation on workpieces attached thereof; a height adjustment module vertically arranged at the front edge of flat worktable; a clamp member being secured on the flat worktable for securing workpieces to be worked on; as a result, the holding fixture is suitable for use in guiding the drilling operation on workpiece of all shapes and sizes.

Owner:CHIANG VANCE

Adjustable angle carpentry apparatus

Owner:QUICK ANGLE

Wood Working Machine

InactiveUS20090188584A1Economy of workspaceMany of characteristicTongue/grooves making apparatusDovetailed workWoodworking machineLaser source

A wood working machine is described that includes a mounting plate assembly for supporting a cutting tool, the mounting plate assembly including a base plate, first and second spaced apart intermediate plates on the base plate, and first and second guide plate elements pivotally supported on respective first and second intermediate plates, and a cutting tool support plate slidably disposed between the first and second guide plate elements, the guide plate elements including means defined therein for positioning each of the guide plate elements at selected angular intervals with respect to the respective first and second intermediate plates, whereby the cutting tool support plate is slidably movable on the base plate between the guide plate elements at a prescribed angle. The mounting plate assembly may include laser sources providing crossed laser beams for accurately positioning the tool bit of the cutting tool near a work piece, and light sources for illuminating the tool bit. A digital sensor may be included for precise positioning of the work piece held beneath the base plate on a movable carrier.

Owner:STEPP LEWIS E

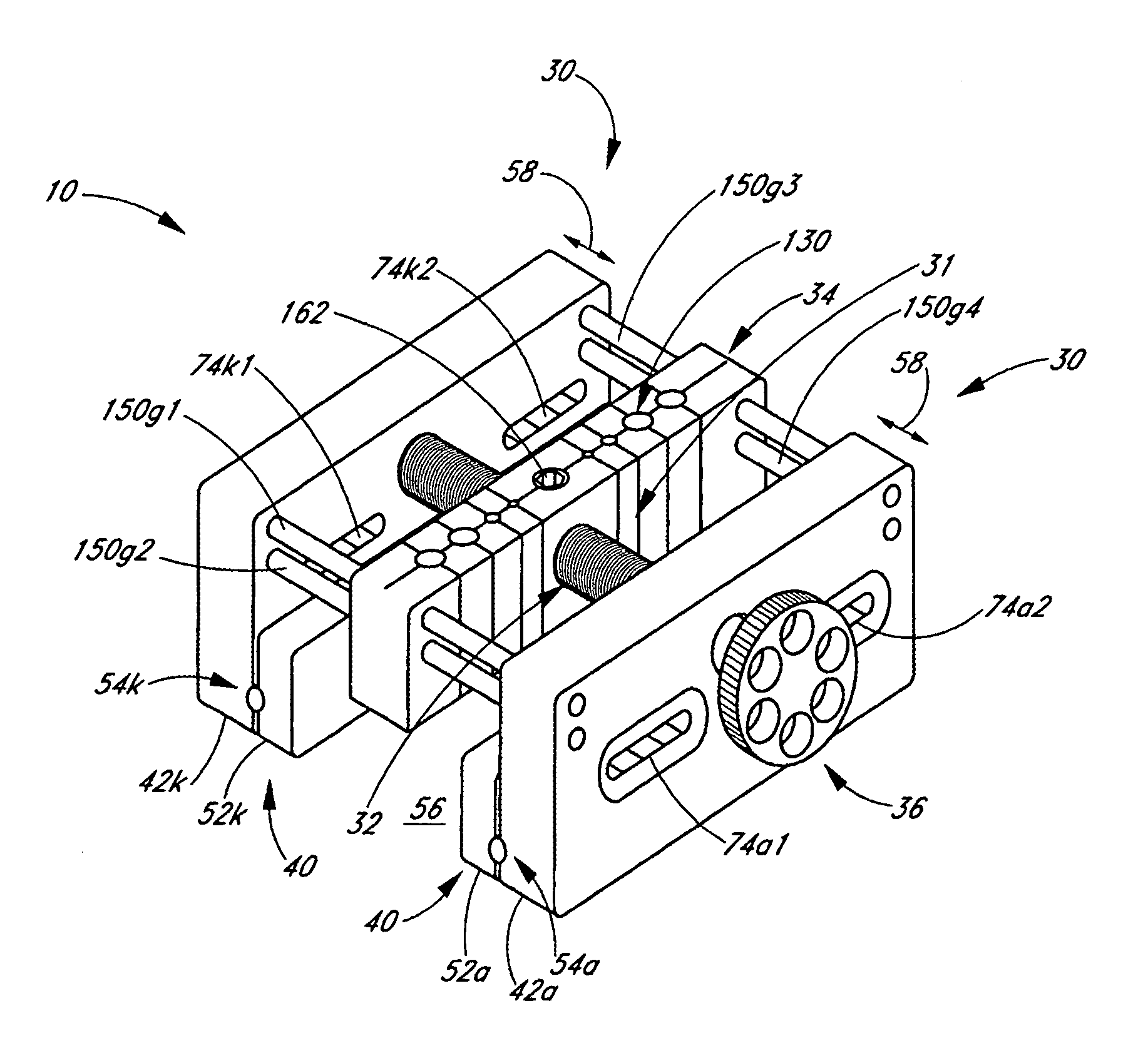

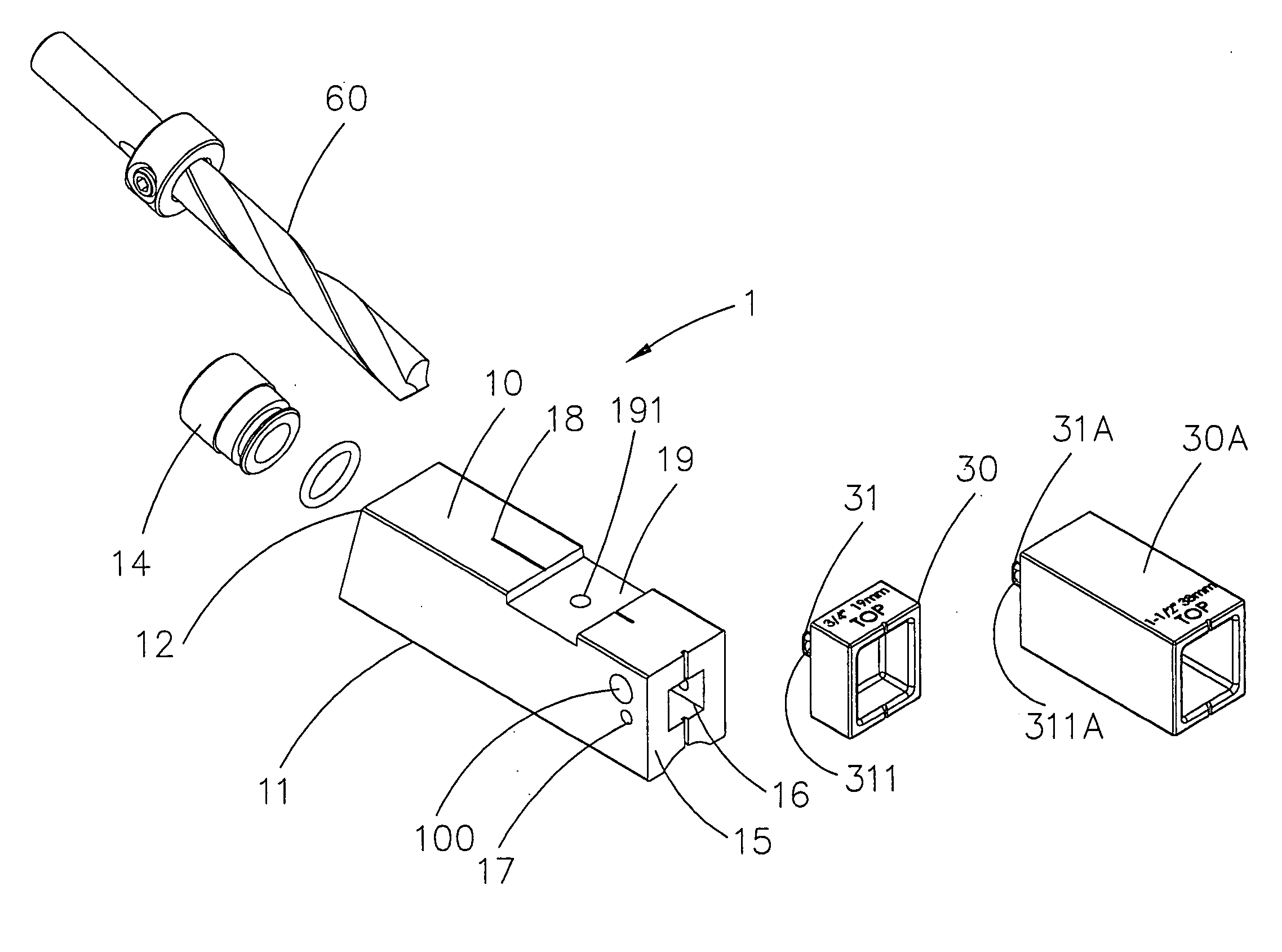

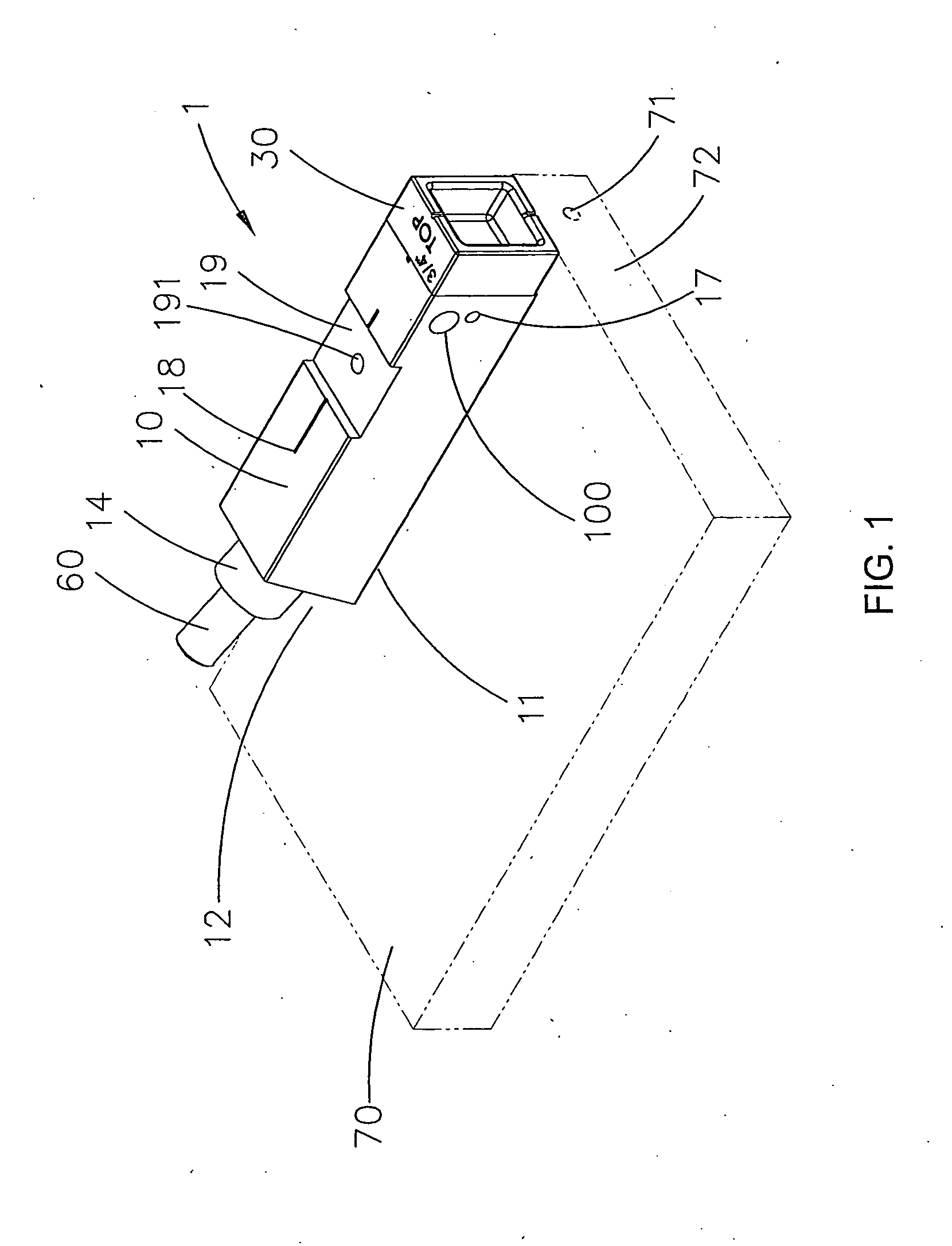

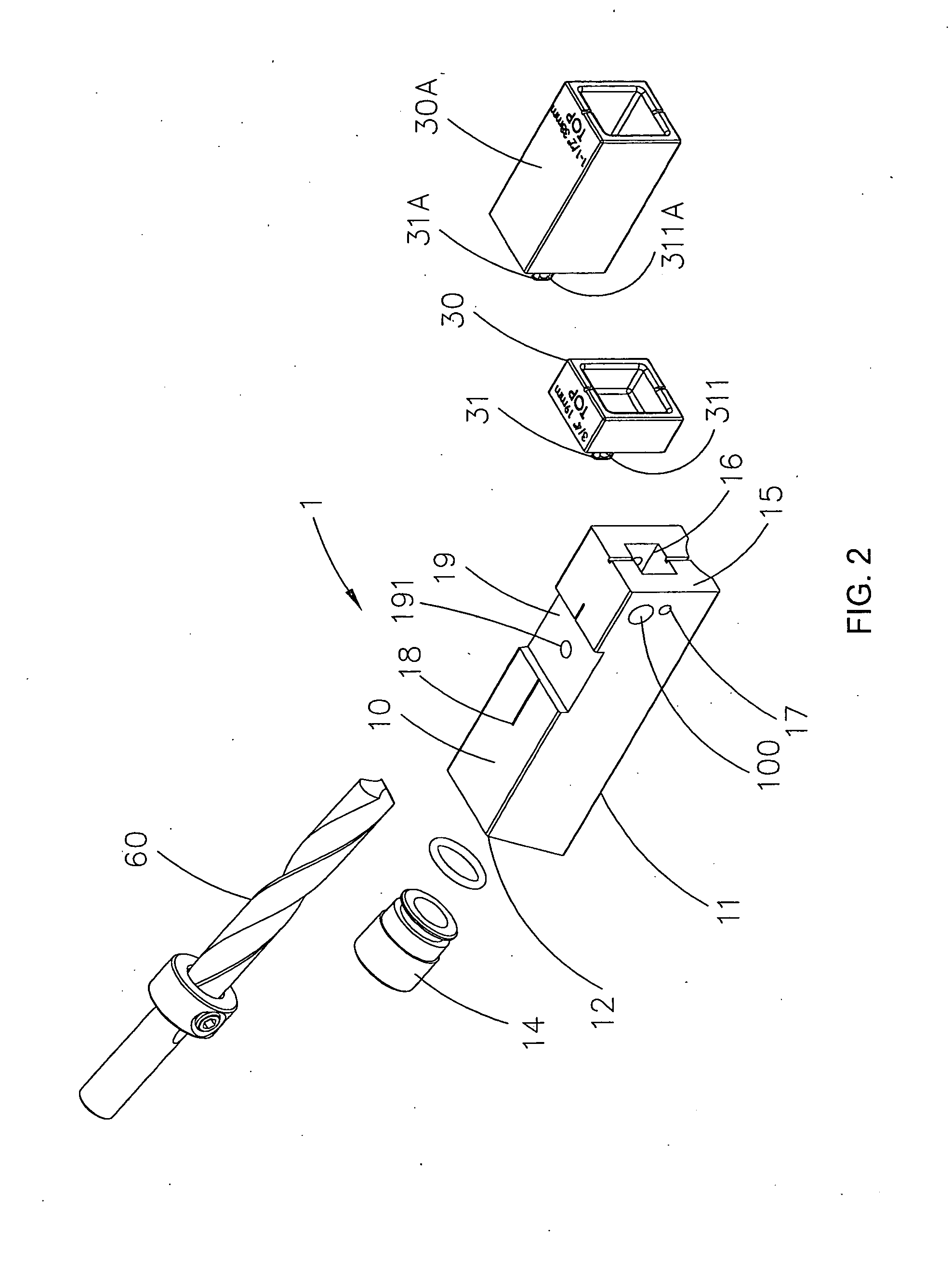

Doweling jig for woodworking

InactiveUS7147412B2Versatile and accurate couplingEasy clampingDrilling/boring measurement devicesThread cutting machinesEngineeringAngular variation

Owner:DAVIS ROBERT L

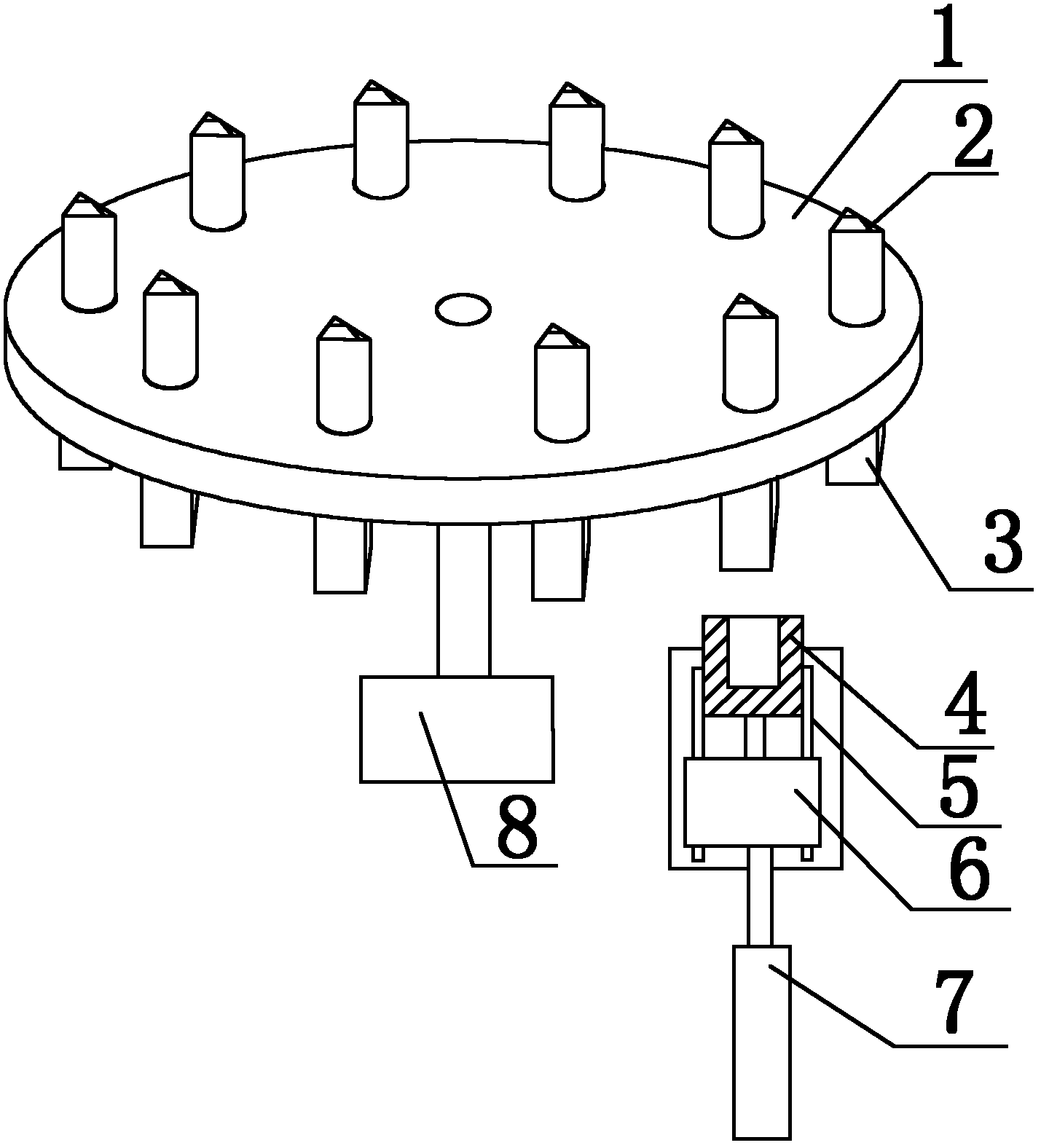

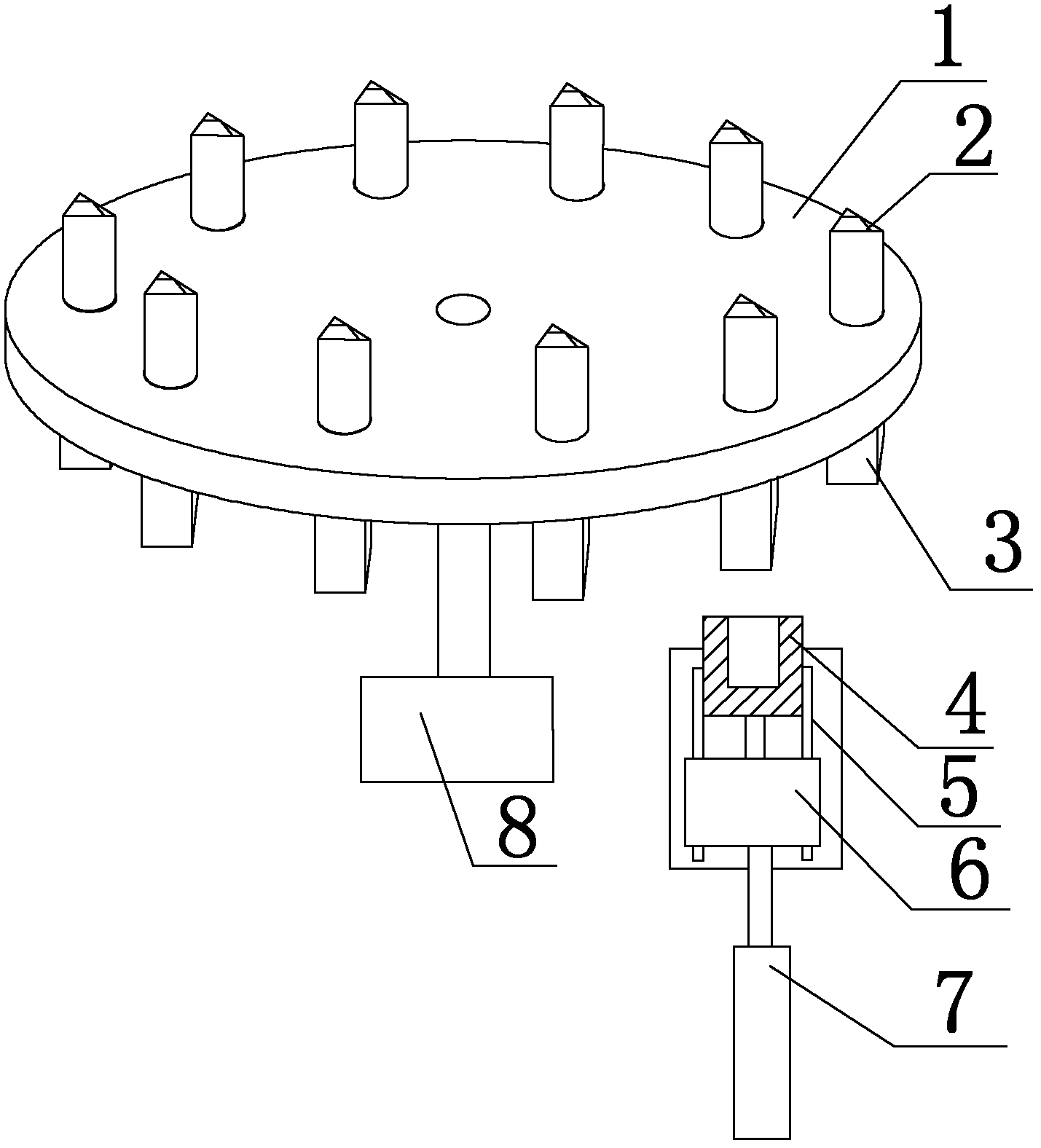

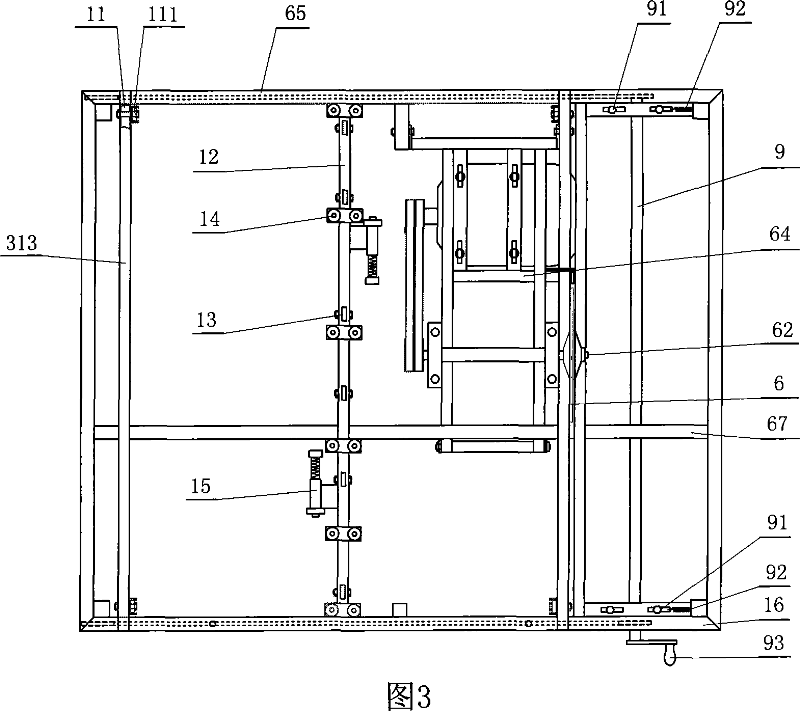

Automatic tool changing device for woodworking vertical type milling machine

InactiveCN102581886AIncrease production capacityAutomate replacementProfiling/shaping machinesPositioning apparatusEngineeringWoodworking

The invention discloses an automatic tool changing device for a woodworking vertical type milling machine. The automatic tool changing device comprises a rotary disc type tool magazine, wherein the rotary disc type tool magazine is arranged on a machine frame of the milling machine; the rotary disc type tool magazine is connected with a power control device; and a main shaft sleeve device matched with cutters on the tool magazine is arranged below the rotary disc type tool magazine. By adoption of the technology, the woodworking vertical type milling machine has high production efficiency, particularly can be clamped at one step when one profile needs to be machined by multiple sets of cutters, so that the machining precision is higher. The device can automatically replace multiple sets of cutters (mostly disc type forming cutters) required by the whole process and can realize replacement automation of the cutters of the woodworking vertical type milling machine, so that the whole processing flow is smooth and the work efficiency is high.

Owner:张承森

Universal machinery fence system

A universal machinery fence system includes an L-shaped fence or a box shaped fence and clamp block which clamps to a rail extrusion with a half dovetail on the front on the edge of a table saw, band saw, shaper, router table, mortiser, or other woodworking or metal working machines. A U-shaped front rail is provided for attaching the fence to the cast iron table of a table saw, shaper, or band saw. The band saw fence U-shaped rail is predrilled to fit the table fence mounting holes of the most popular 14″ band saws. Optional extruded front rails are also provided for attaching the fence to shop made 0.750″ tables such as used on a drill press. Also provided is a fence rail extrusion for mounting the fence on the front and back of the popular 1.125″ size router table. An optional extruded front rail which is adjustable in height is also provided for attaching the fence to shop made tables between 0.750″ and 1.5″ in thickness. A re-saw guide fitted to the fence extrusion has a convex surface for supporting a workpiece on edge allowing the operator to easily adjust for blade drift. An optional micro-adjuster allows the fence to move accurately in small increments. A router table with holes and slots allows the fence to be used to guide the workpiece in the router table mode and then be used to guide the router or a saw on top of the workpiece.

Owner:KREG ENTERPRISES

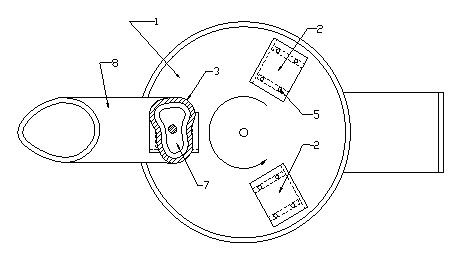

Finger citron slicing machine

InactiveCN101898368AReasonable designEasy to operateMetal working apparatusSlice thicknessSurface mounting

The invention relates to a finger citron slicing machine which comprises a rotary disc. The finger citron slicing machine is characterized in that the upper surface of the rotary disc is provided with a rotary cutting blade, and a feed guide sleeve is arranged above the station of the rotary cutting blade. The slicing machine has simple structure, the continuous slicing of finger citron can be easily realized, the thickness of slices is adjustable, and the uniformity of the thickness of the finger citron slices is ensured, which is beneficial to next processing procedure. In addition, another embodiment of the invention adopts the structural form of an inverted woodworking plane, and the finger citron slices cut by the structural form can meet food processing requirements and can have any thickness, which is beneficial to food processing and development and is also beneficial to the development of new application fields of finger citron besides medicinal application.

Owner:福建承天农林科技发展有限公司

Drill guide used in woodworking for preparing pocket joints

A drill guide used in woodworking for preparing pocket joints includes a guide member with a cuboid body. The cuboid body has an inclined plane formed on a front end thereof and a cavity defined in the front end thereof. The cavity has two opposite ends respectively and slantingly extending to the inclined plane and the first datum plane. A guide sleeve is longitudinally and detachably mounted in the front end of the cuboid body and abuts the inclined plane. The guide sleeve extends into the cavity for guiding a drill bit into the cavity and drilling an inclined hole in the workpiece. The cuboid body has a second datum plane formed on a rear end thereof. An axis of the drill bit passes through a central plane of the workpiece on a rear distal edge when the second datum plane aligns with the rear distal edge.

Owner:CHIANG VANCE

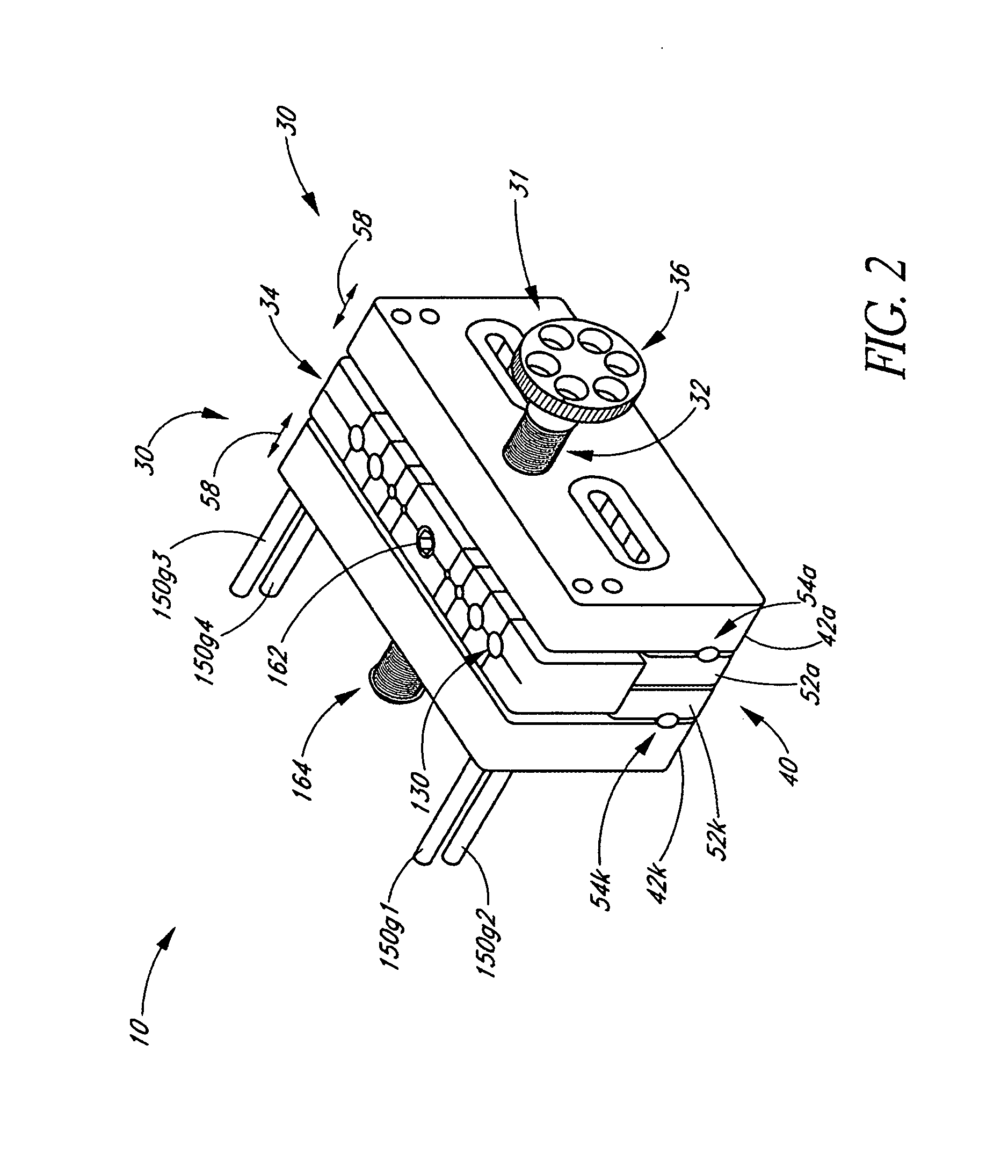

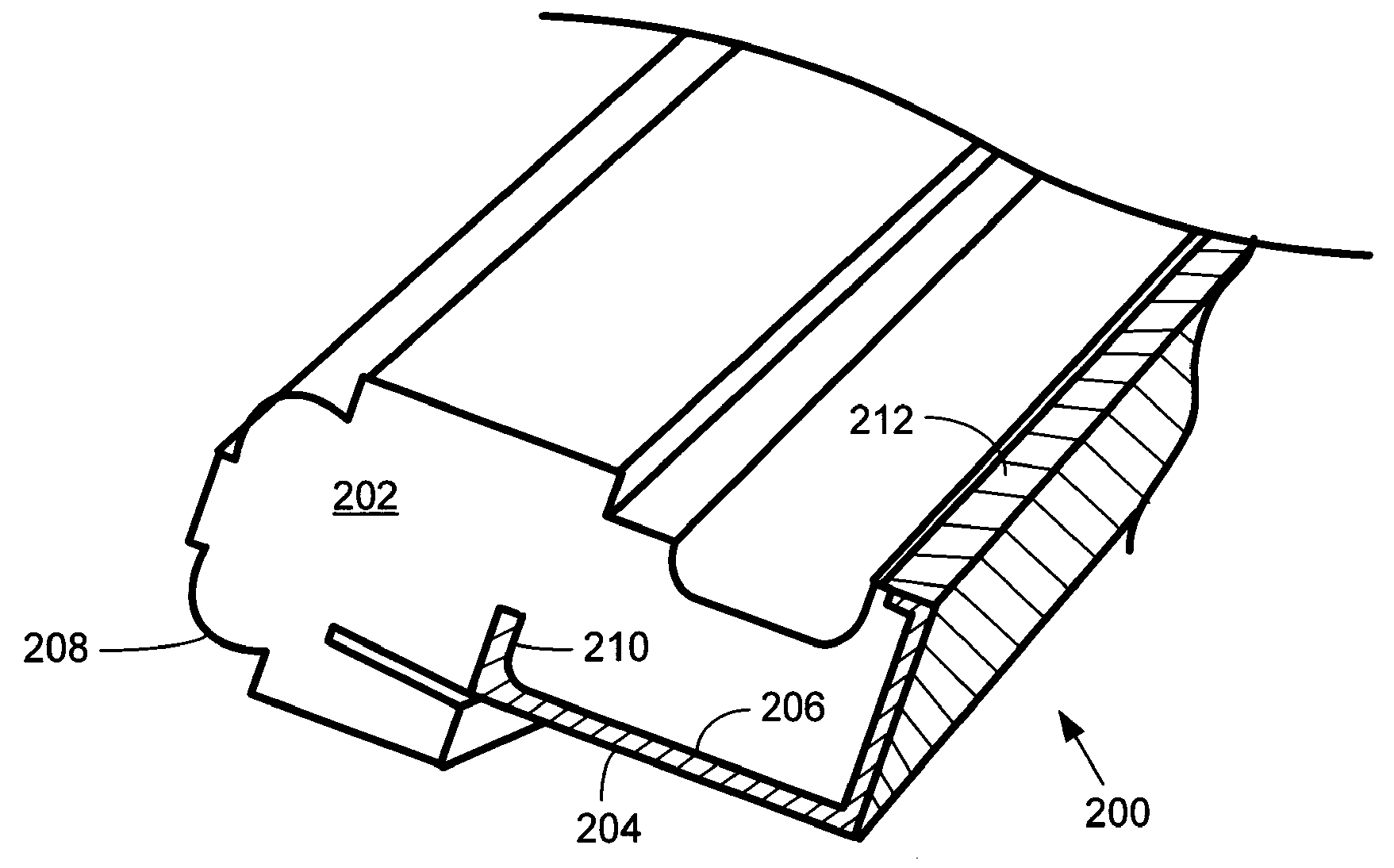

Multi-application wood working knife and clamping assembly

InactiveUS7159626B2Reduce riskAvoid prolonged useMulti-purpose machinesProfiling/shaping machinesWood processorEngineering

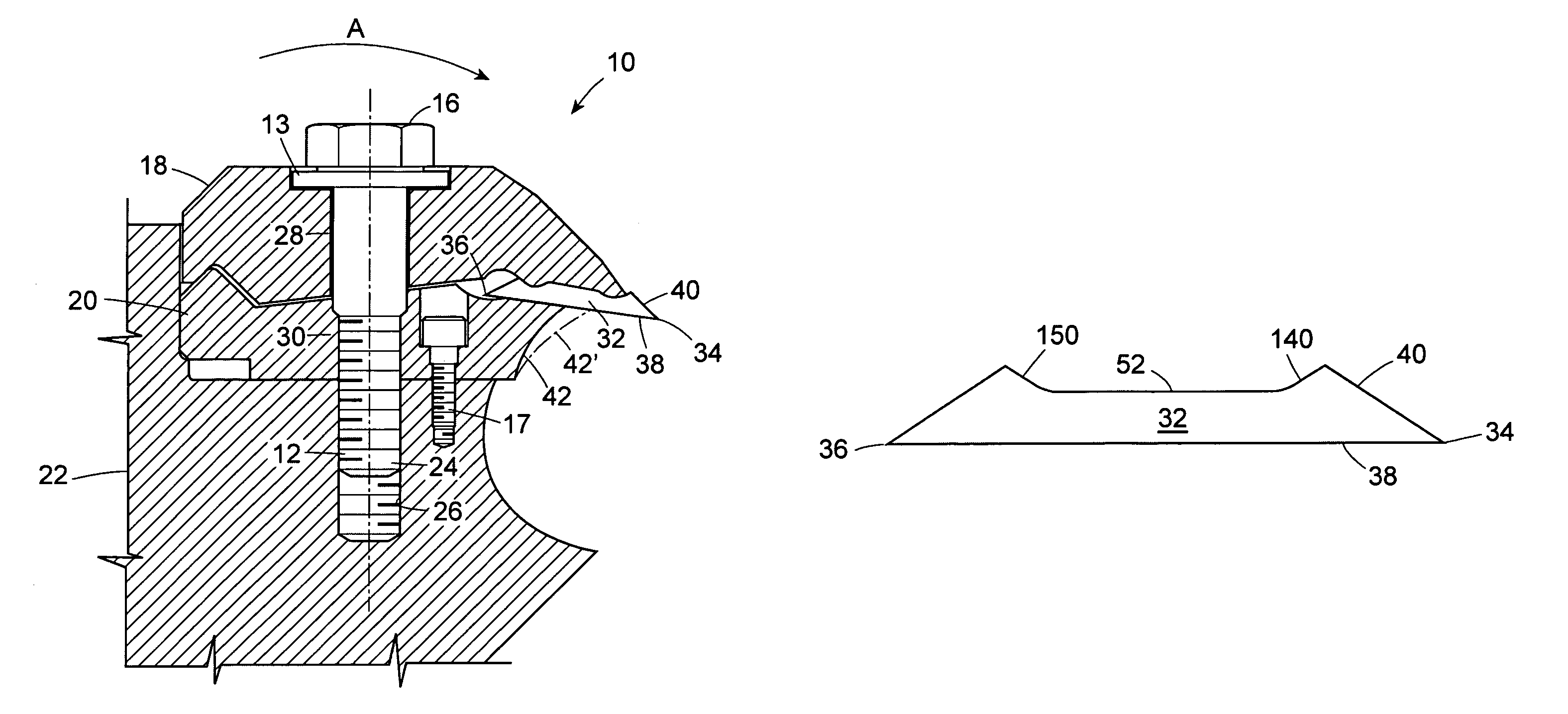

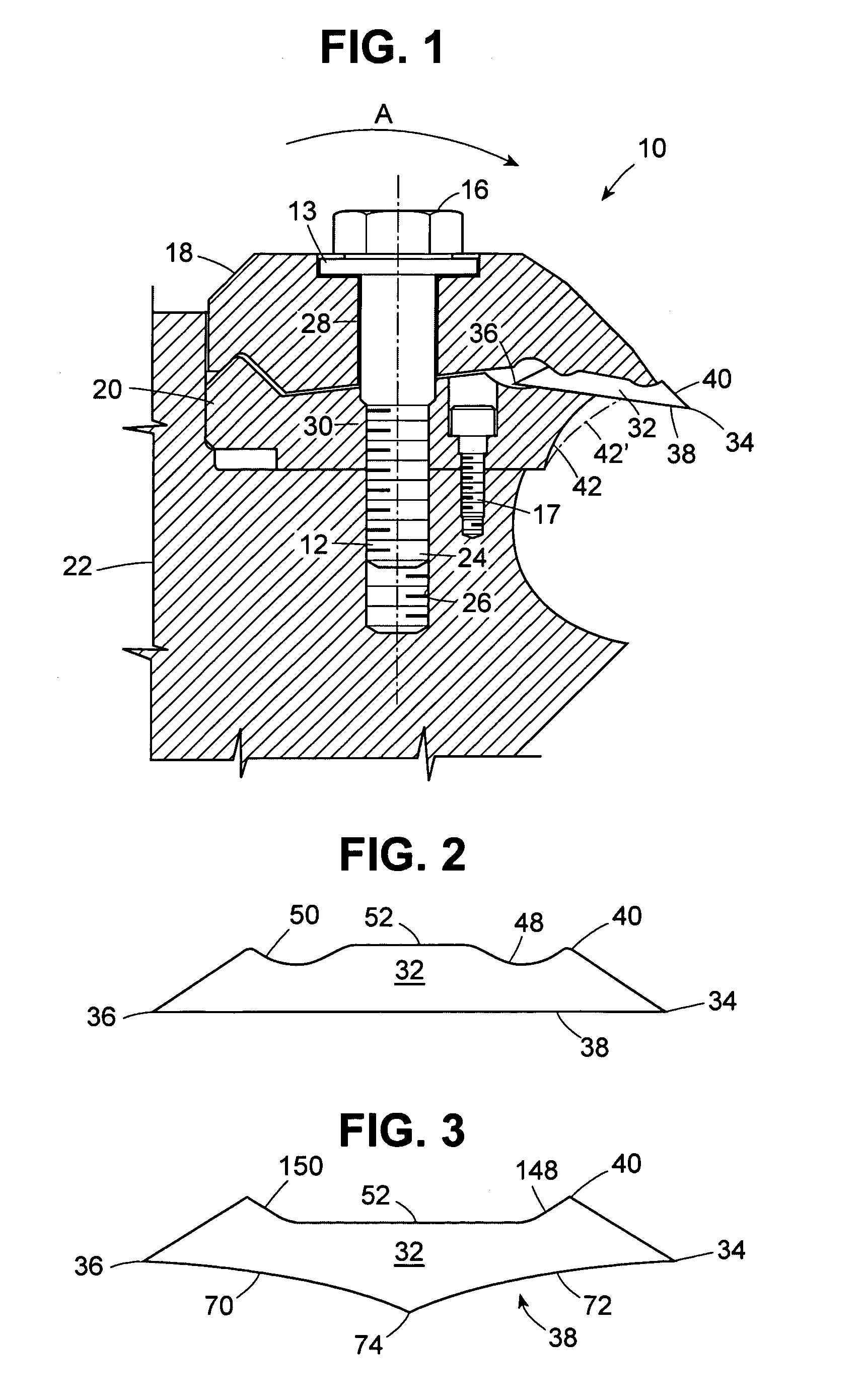

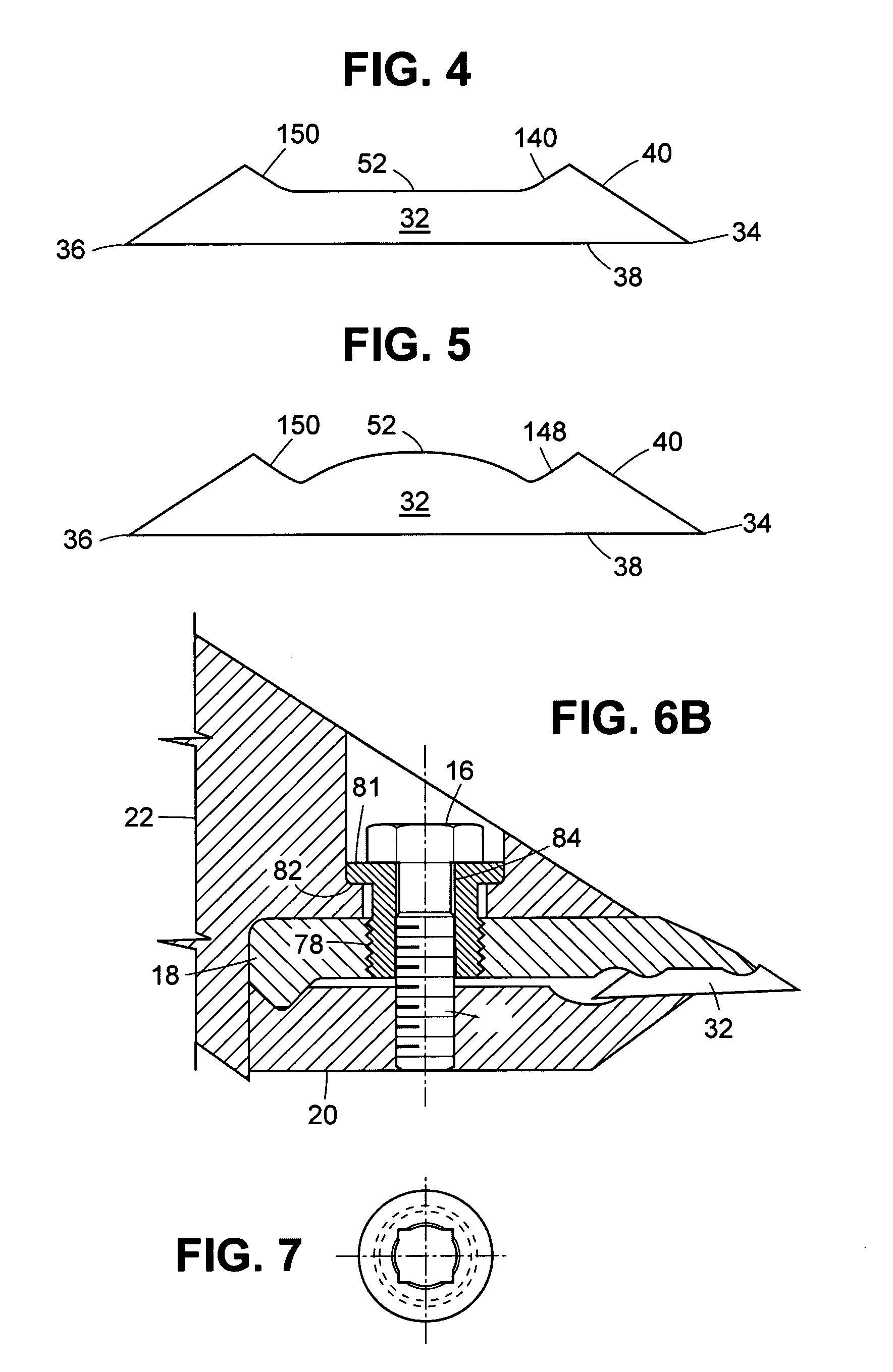

A wood working knife for use in a wood working machine, comprising a knife body having a first cutting edge and an opposed second cutting edge, the knife body having a first clamping surface and a second clamping surface. The first clamping surface has opposed clamping features separated by a middle section, the opposed clamping features and the middle section being sized and shaped such that, upon the knife body being inserted into a clamping assembly, the clamping forces are localized towards the opposed cutting edges and away from the middle section.

Owner:IGGESUND TOOLS

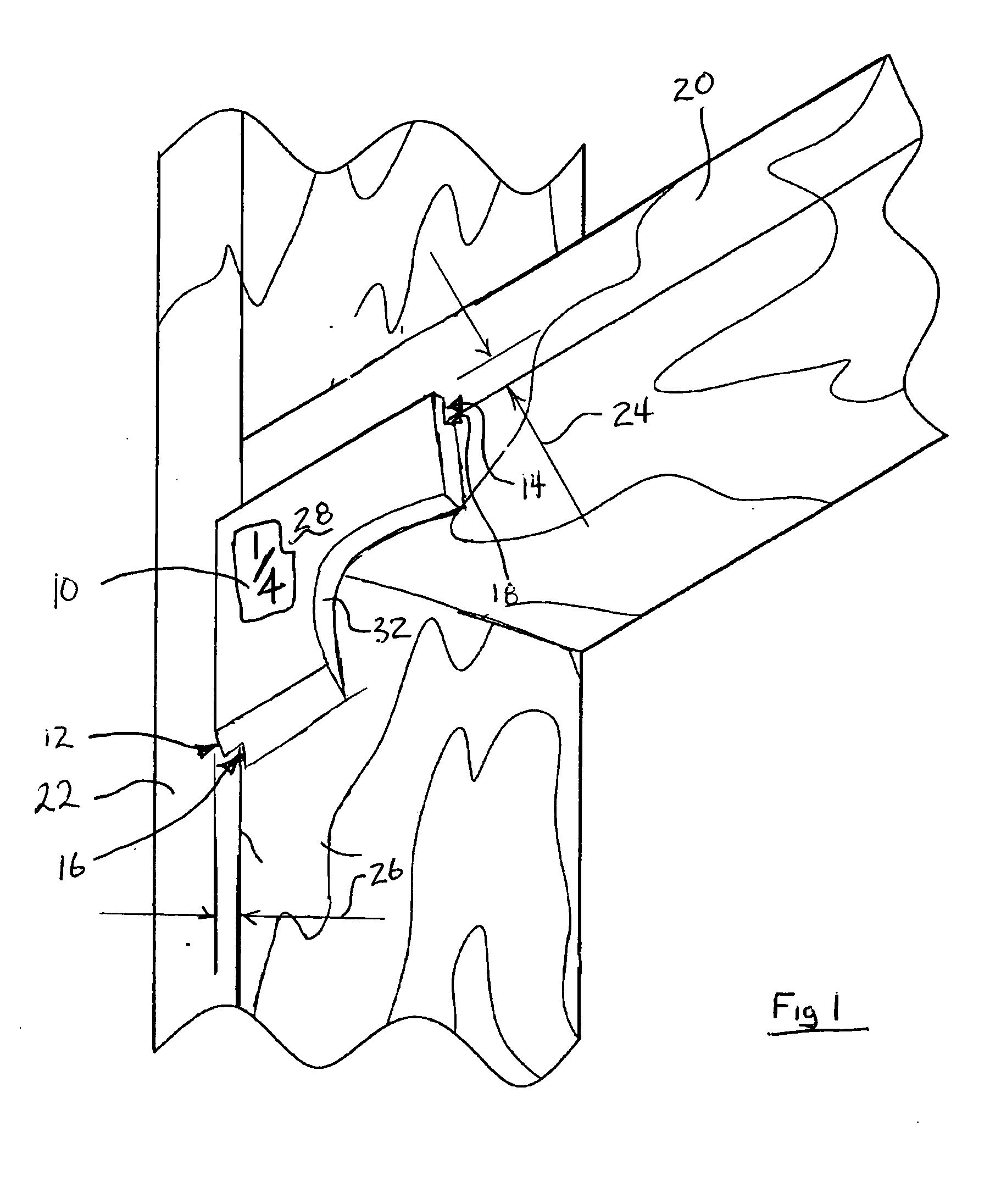

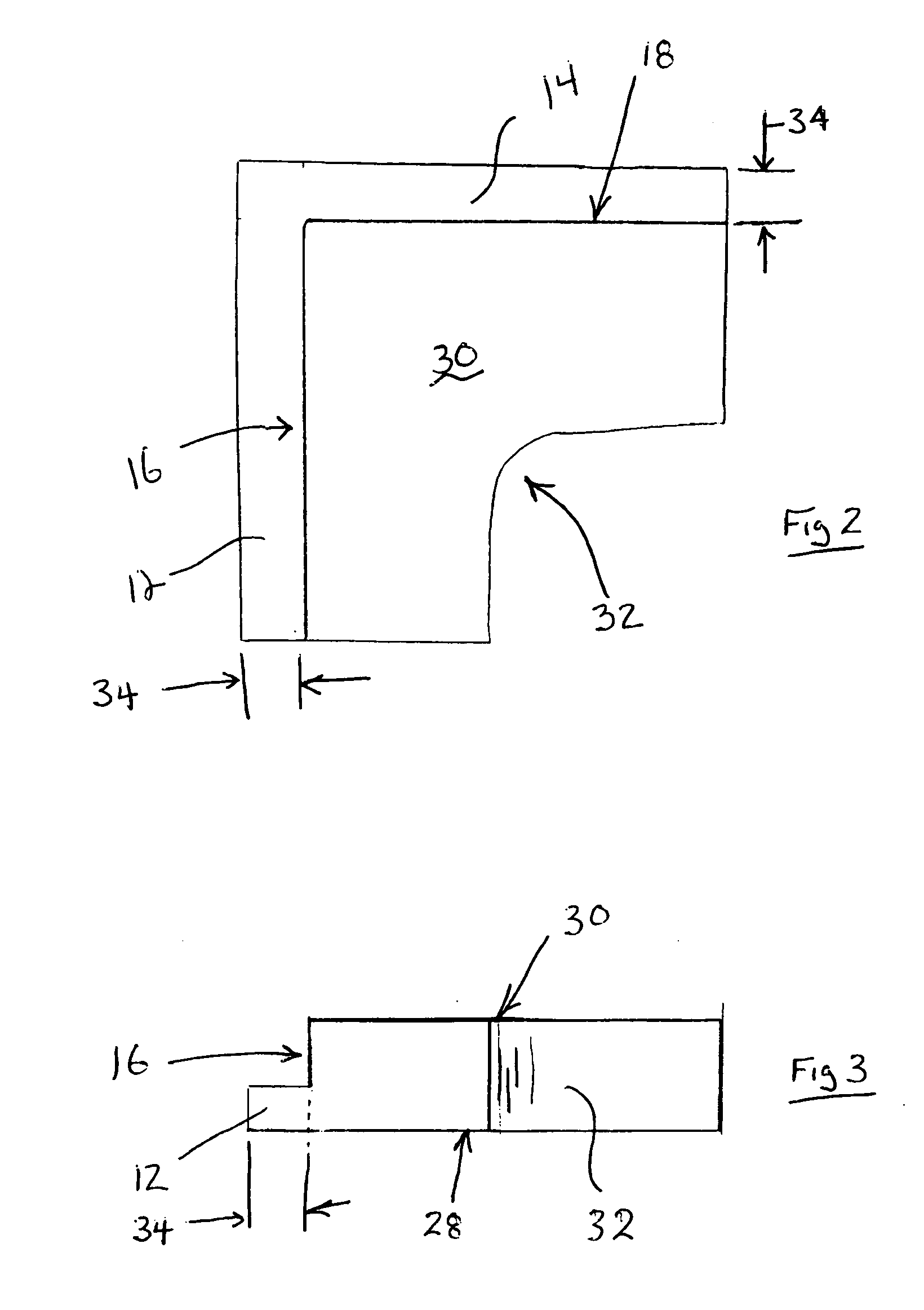

Finish carpentry trim gauge

InactiveUS20050022397A1Easy to carryEasy to placeMeasurement devicesDoors/windowsEngineeringConfusion

A carpentry gauge of this invention includes a first and second face surface that abut interior surfaces of vertical and horizontal frame members for the window or door opening. Extending from those faces are the lip portions. The lip portions overlap the outer surface of the vertical and horizontal members of the doorframe and provide the correct distance for a desired setback. The carpentry gauge of this invention is small, compact and easily placed and carried within a shirt pocket. No adjustments are required to be made to the gauge and only one dimension is provided in each gauge eliminating possible confusion during marking for a specific window or doorframe.

Owner:NEBLO RODNEY

Multi-function woodworking guide

InactiveUS7621206B2Easily extendable in lengthMulti-purpose machinesProfiling/shaping machinesHand heldEngineering

The multi-functional woodworking guide is a modular portable universal guide, adapted for guiding multiple hand held power tools, that is extendable with the use of multiple guide plates, side bars and edge bars in order to increase the size of the guide device to any length, thus being capable of cutting, grooving or sanding an unlimited length of material with the use of side extension clamps. The multi-functional woodworking guide is compact, portable and easy to transport, as it fits into the back seat or trunk of a car. The multi-functional woodworking guide is easy to secure to a work piece by various integrated clamps, which do not have to be move when cutting, grooving or sanding the material.

Owner:MAKROPOULOS DINO

Multifunctional folding saw table

A multifunctional folding saw bench, a fixing bench face is provided in the right side of the support body, a movable push plate is paralleled to the fixing bench face, a vertical locating bar moving horizontally is provided on the movable push plate, a self-elevating type horizontal locating bar is provided in the front edge of the push plate support of the movable push plate, the suspending guide bearings are provided on both sides of the push plate support, the push plate vertical guide is arranged opposite to the suspending guide bearing, the base part of the push plate vertical guide is fixed coupling with the support vertical square tube on the support body, a suspending support bearing is provided inside of the support vertical square tube, a push plate locating guide is provided in the middle of the push plate support base, a supporting guide of the push plate support is provided on the support body of the base of the push plate locating guide, a supporting bearing and a locating guide bearing are provided on the supporting guide rail, the technique project that the push plate locating guide is movable housed between the locating guide bearings on the supporting bearing of the supporting guide of the support settles the defect of existing saw bench with single function; which is widely adapted for finishing worksite, constructing worksite, furniture factory and packing case making and so on woodworking and spacious individual users.

Owner:朱健文

Carpentry trim marking gage

InactiveUS7240435B1Easy to installEasy to manufactureDoors/windowsMechanical clearance measurementsEngineeringWoodworking

An adjustable carpentry trim gage includes a scribing block adjustably attached to a guide block. The guide block includes a guide surface, adapted to be placed against a jamb. The scribing block includes a scribing surface along which a scribing instrument, such as a pencil or an awl, can be drawn to mark guidelines on the jamb, to facilitate installation of a casing on the jamb. The position of the guide block with respect to the scribing block is adjustable to allow the position of the scribing surface on the scribing block, with respect to the guide surface on the guide block, to be set in such a manner that the scribing surface will be placed to indicate a desired reveal on the jamb, when the guide surface is bearing against the jamb. The scribing surface extends beyond the maximum reveal setting of the gage, in a direction parallel to the face of the jamb against which the guide surface is bearing, to facilitate making intersecting guidelines indicating corners of the casing.

Owner:DOWDAKIN WILLIAM J

Fenestration Products Comprising Pultrusion Reinforced Vinyl Polymer Foam

InactiveUS20090255197A1Lamination ancillary operationsSynthetic resin layered productsPolymer scienceImproved method

The present application provides improved fenestration products and improved methods of making fenestration products. The product may include (a) an elongated vinyl polymer foam body having a length, a first surface extending the length of the foam body, and a second surface extending the length of the foam body; and (b) an elongated fiber reinforced polymer pultrusion support engaging the foam body and substantially entirely covering the first surface, wherein at least a portion of the second surface is exposed. The method may include (a) providing an elongated vinyl polymer foam body; (b) covering a first surface extending the length of the body with an elongated fiber reinforced polymer pultrusion support; and (c) applying traditional woodworking processes to a second exposed surface extending the length of the body.

Owner:GLOBAL PRODS

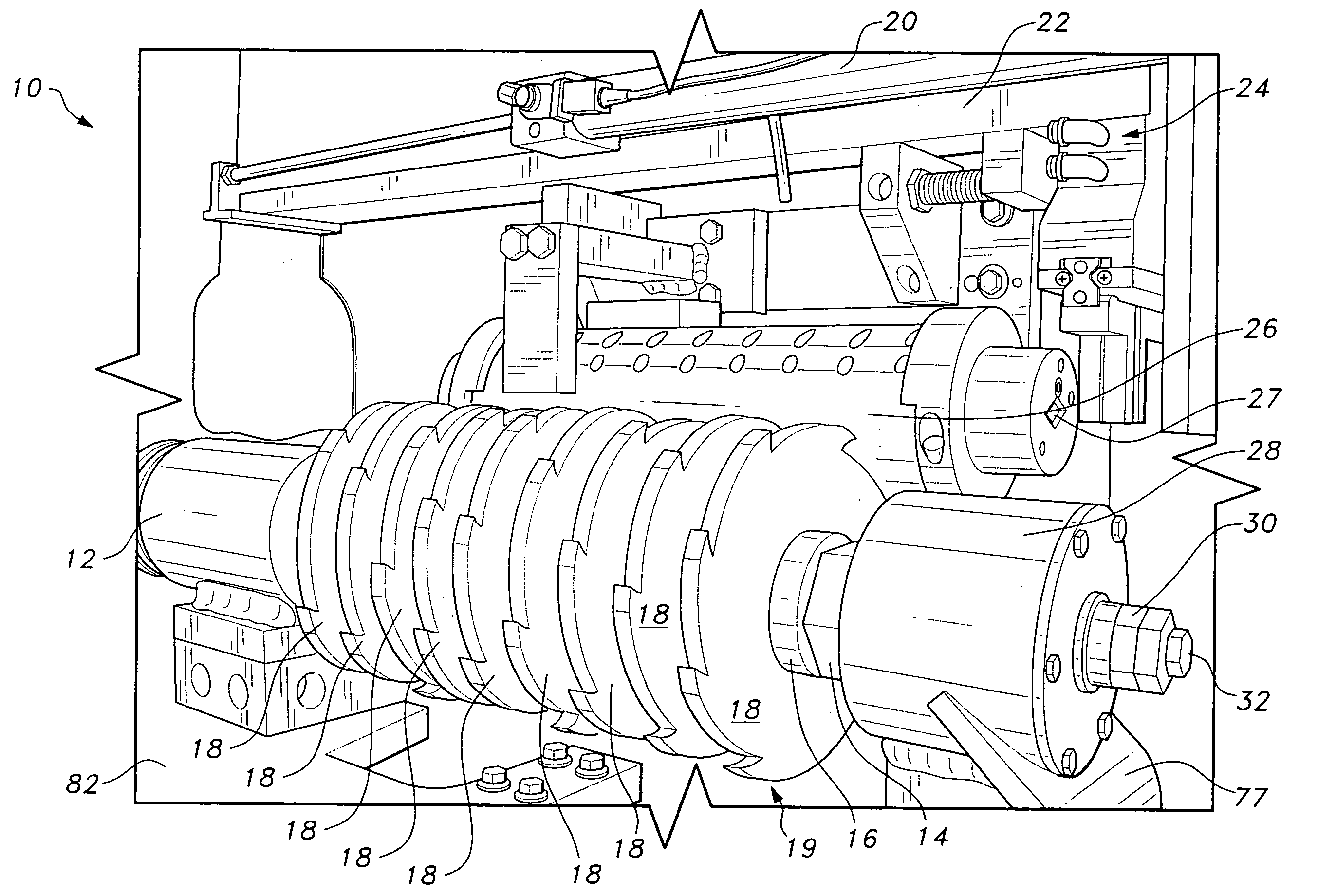

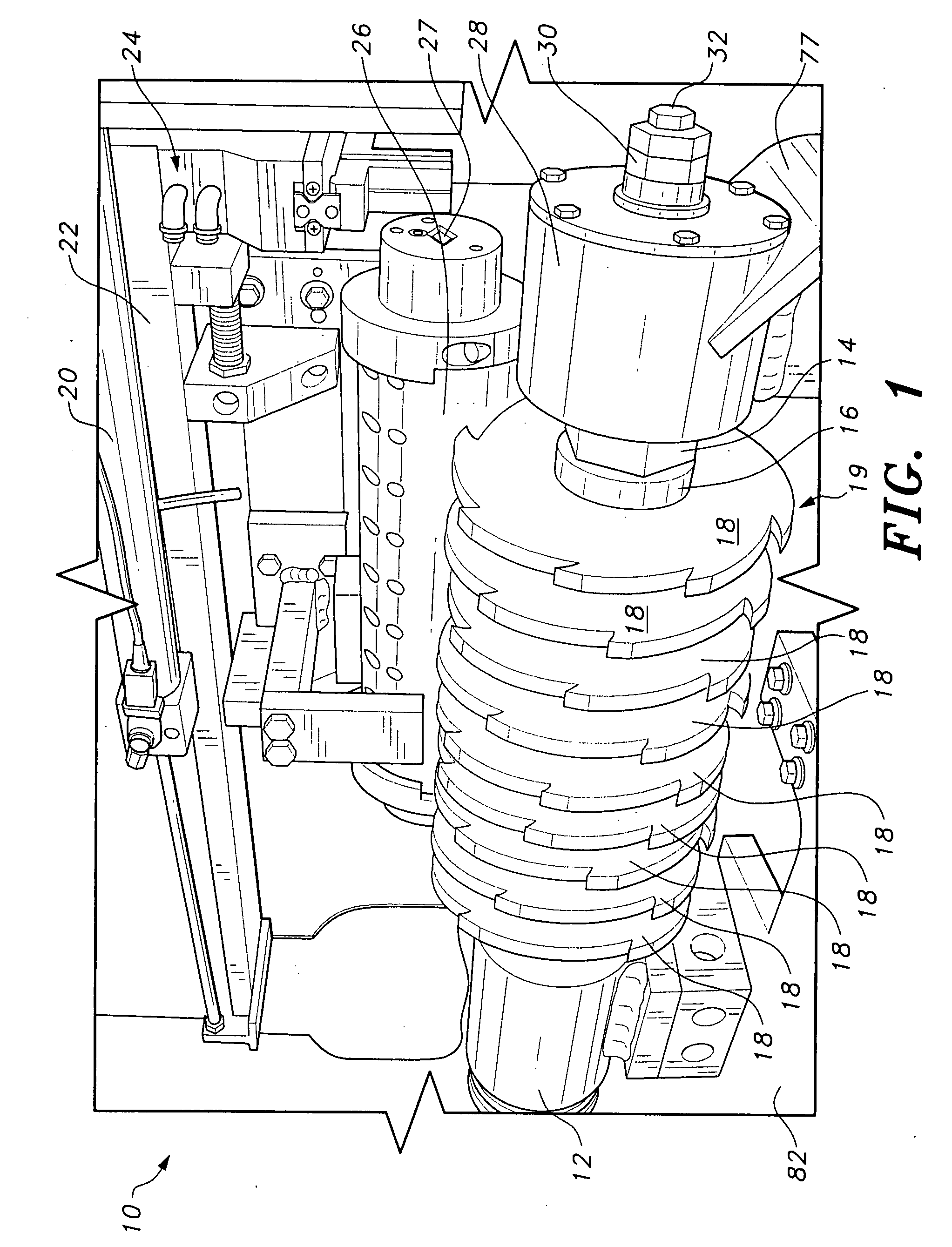

Woodworking machine for shaping molding

The woodworking machine for shaping molding has a hollow cylindrical cartridge with end caps having openings defined therein adapted for inserting a blank strip of molding through the cartridge. Robotic grippers advance the molding strip through the cartridge in indexed increments. A cutter assembly is mounted on a movable table, the cutter assembly having a plurality of spaced apart cutters. An electronic control system, preferably including a programmable logic controller, causes the grippers to grip the blank molding, insert the blank through the cartridge, actuate the cutter assembly and move the table so that the cutters simultaneously cut a plurality of notches in the molding, retract the cutter assembly, advance the molding the indexed distance, and automatically repeat the cycle, ejecting the strip when notches have been formed in the entire length of the molding. The machine may be used to form dental molding.

Owner:BURKHOLDER LEON R

Multi-functional carpentry tool

InactiveUS20090193670A1Reduce weightCircular curve drawing instrumentsStraightedgesWoodworkingShip's carpenter

A multi-functional carpentry tool includes a base member having a longitudinal T-shaped groove formed therewithin and a rule member. A T-shaped slide member is positioned within the groove and has a threaded aperture formed therewithin. A knob has a threaded stem operatively received within the threaded aperture for selectively securing the base member and the rule member together in frictional engagement maintaining the base member and the rule member in selected positions relative to one another and permitting each of a sliding and pivoting movement of the rule member relative to the base member. Linear measuring scale indicia is provided in each of the base and rule members. Angular measuring scale indicia and a squaring groove is also provided within the base member. A spring biased pin is movably mounted within the knob for defining pivot axis and facilitating arc scribing effort.

Owner:FERNANDES PATRICK

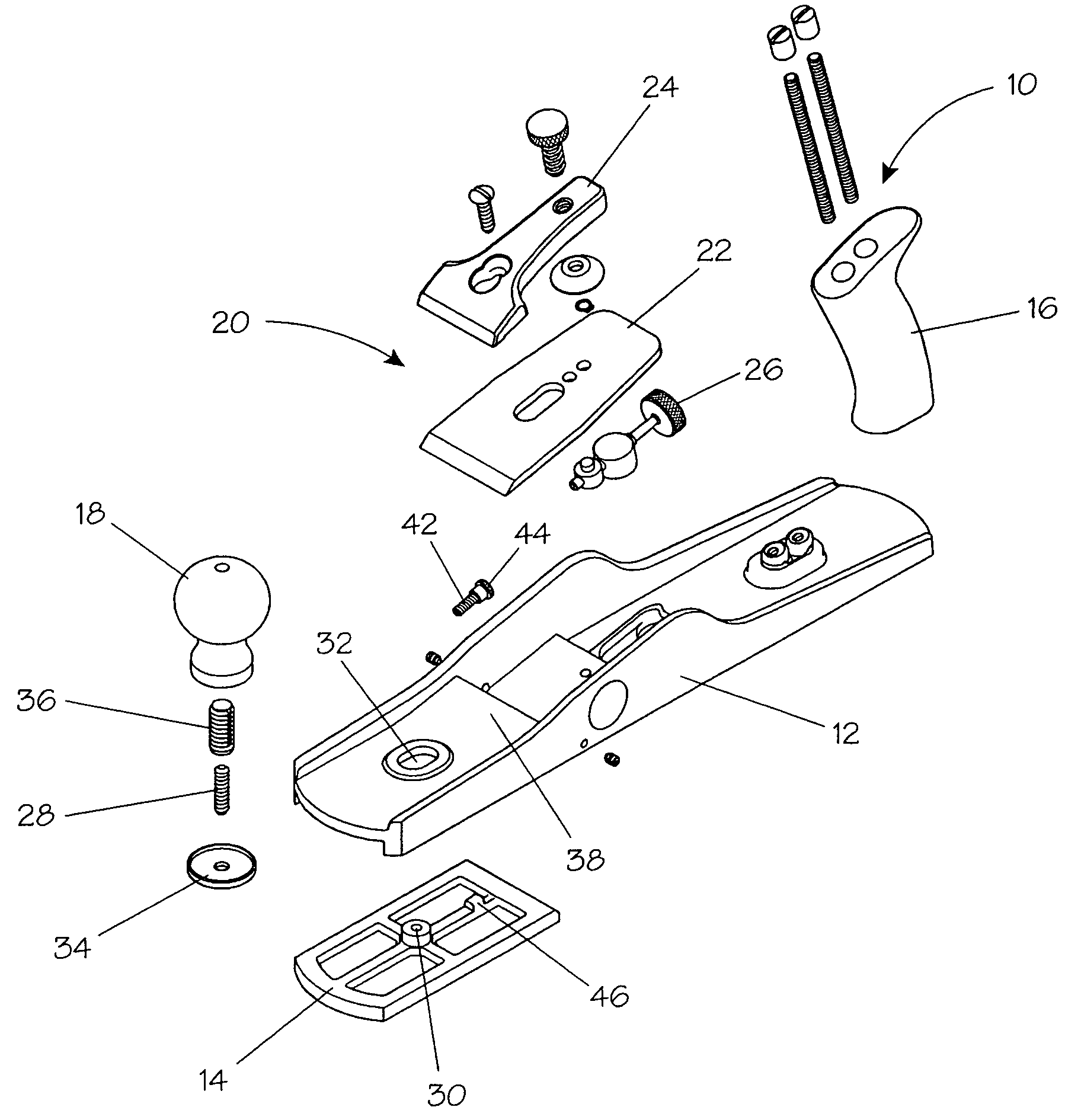

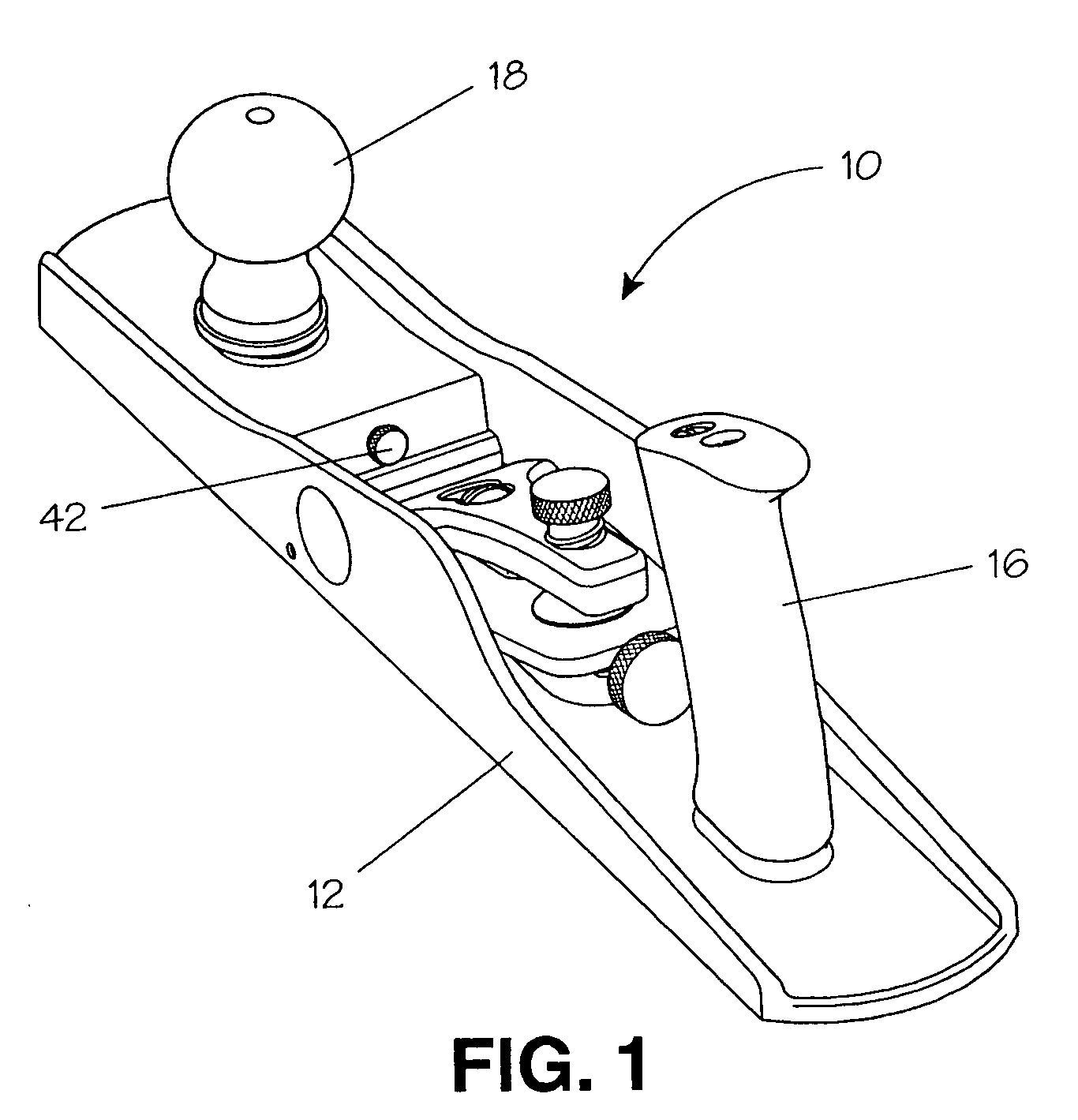

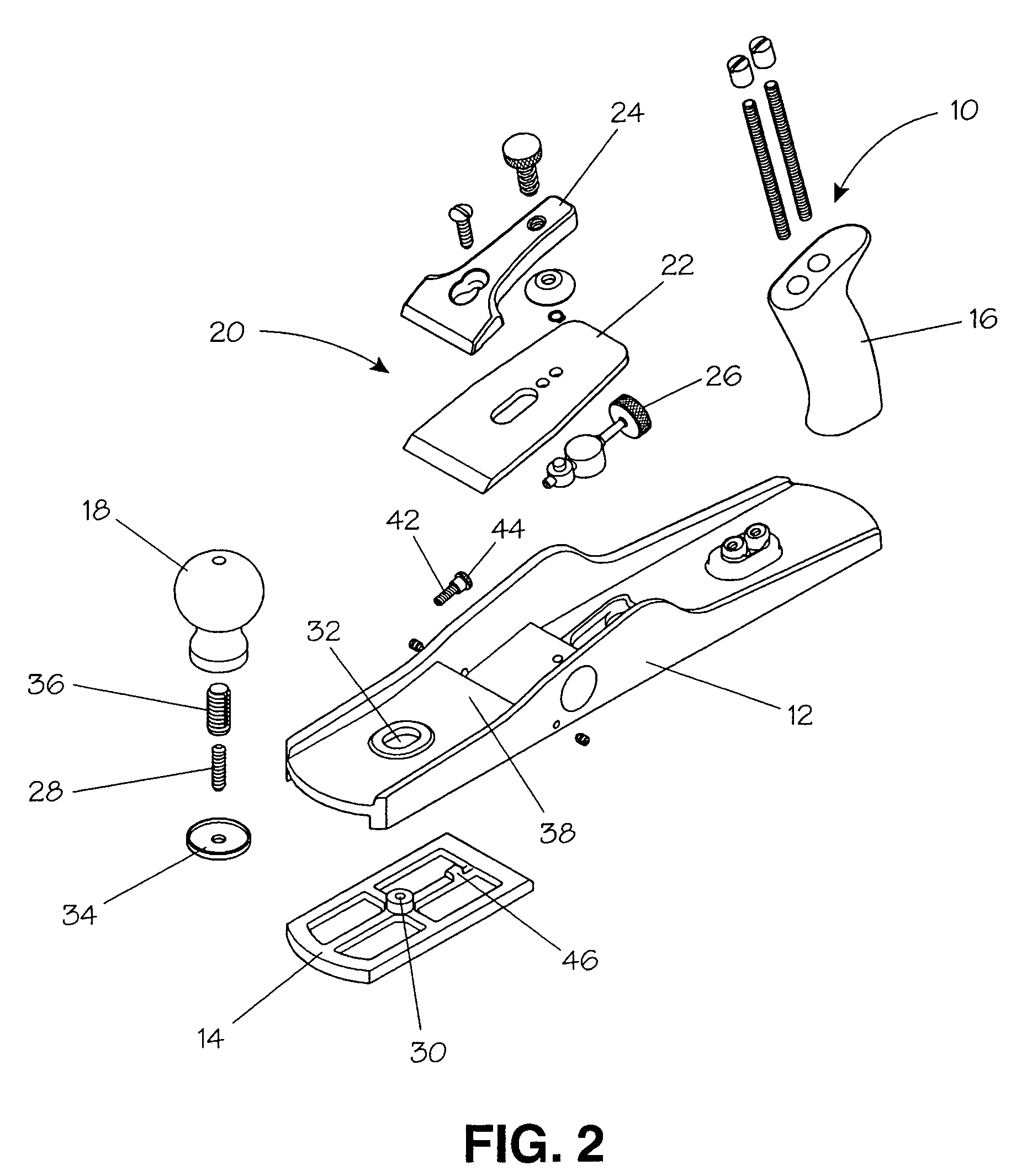

Woodworking plane with adjustable mouth

ActiveUS20050229409A1Easy to openEasy to changeManual wood toolsMetal-working hand toolsJackscrewKnife blades

A plane such as a low angle jack plane having an adjustable toe that cannot inadvertently slide backwards in the plane body so that it contacts and possibly damages the plane blade. A threaded stop mounted in the plane body bears against the toe establishing the point to which the toe can slide back in the plane body. Rotation of the threaded stop moves the end of the stop by small, easily controlled increments, making it easy to change the width of the mouth while preventing contact between the toe and the plane blade.

Owner:LEE VALLEY TOOLS

Woodworking Machine with Sensing Device

Owner:META INT

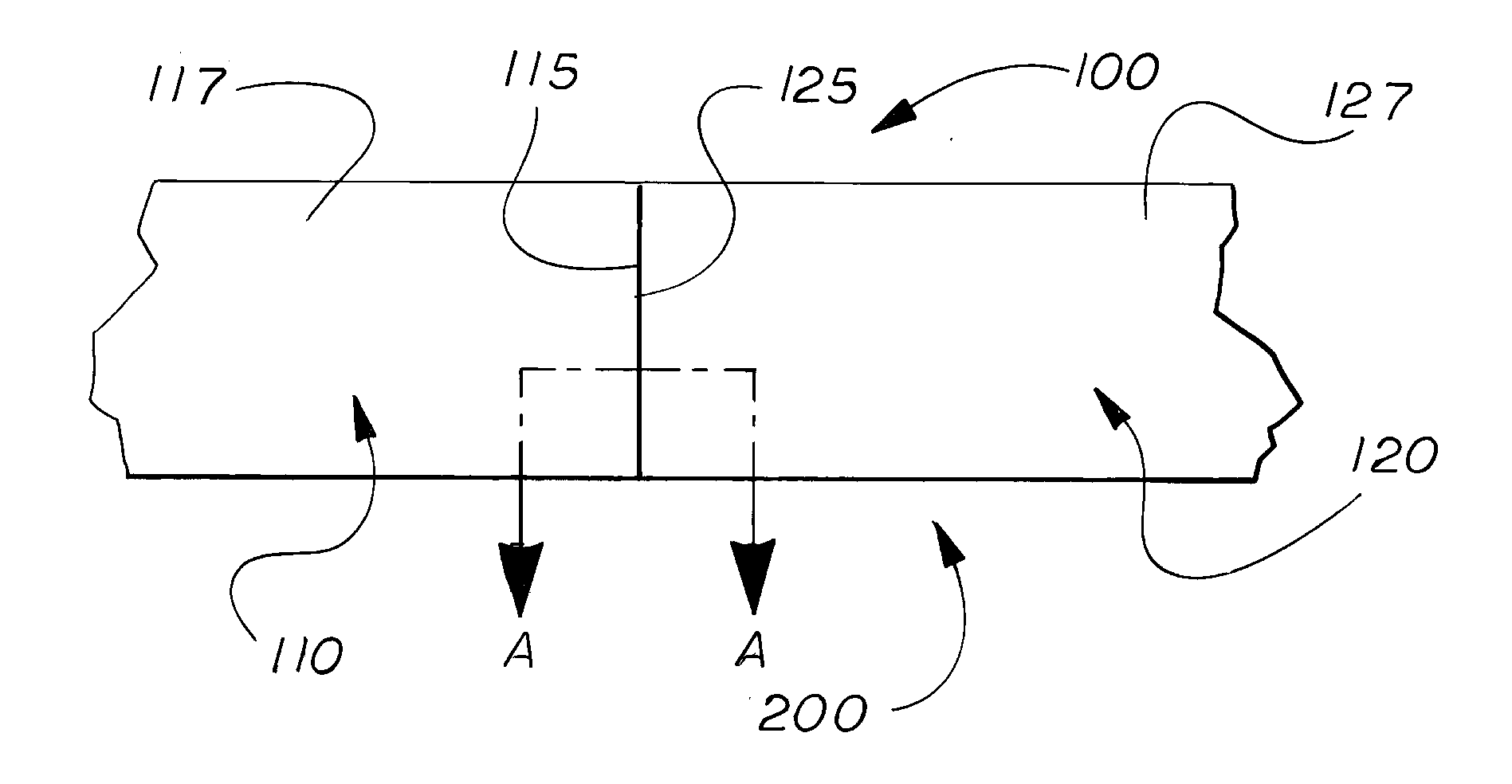

Siding joinery

InactiveUS20130255174A1Seam smoothLess apparentRoof covering using tiles/slatesCovering/liningsWoodworkingEngineering

A panel system includes elongated panels coupled together at a seam portion with respective interlocking portions at corresponding vertical ends to provide a substantially planar surface. In siding panel systems, joined siding panels are provided in vertically arranged rows that further couple together along adjacent horizontal edges of the respective rows of siding panels.

Owner:GENERAL ELECTRIC CO ADMINISTATIVE AGENT AS SUCCESSOR BY MERGER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com