Patents

Literature

352results about "Wood feeding arangements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

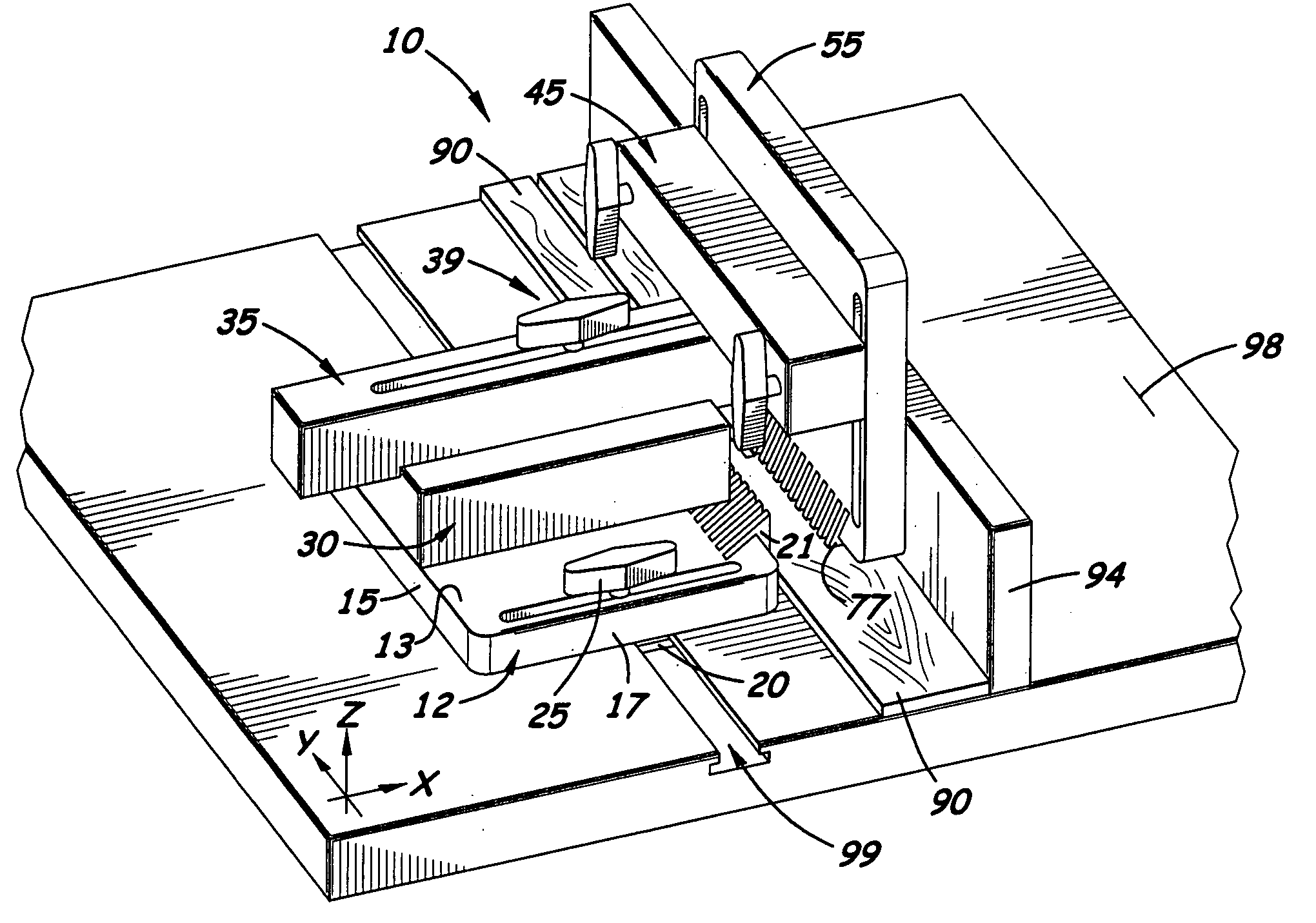

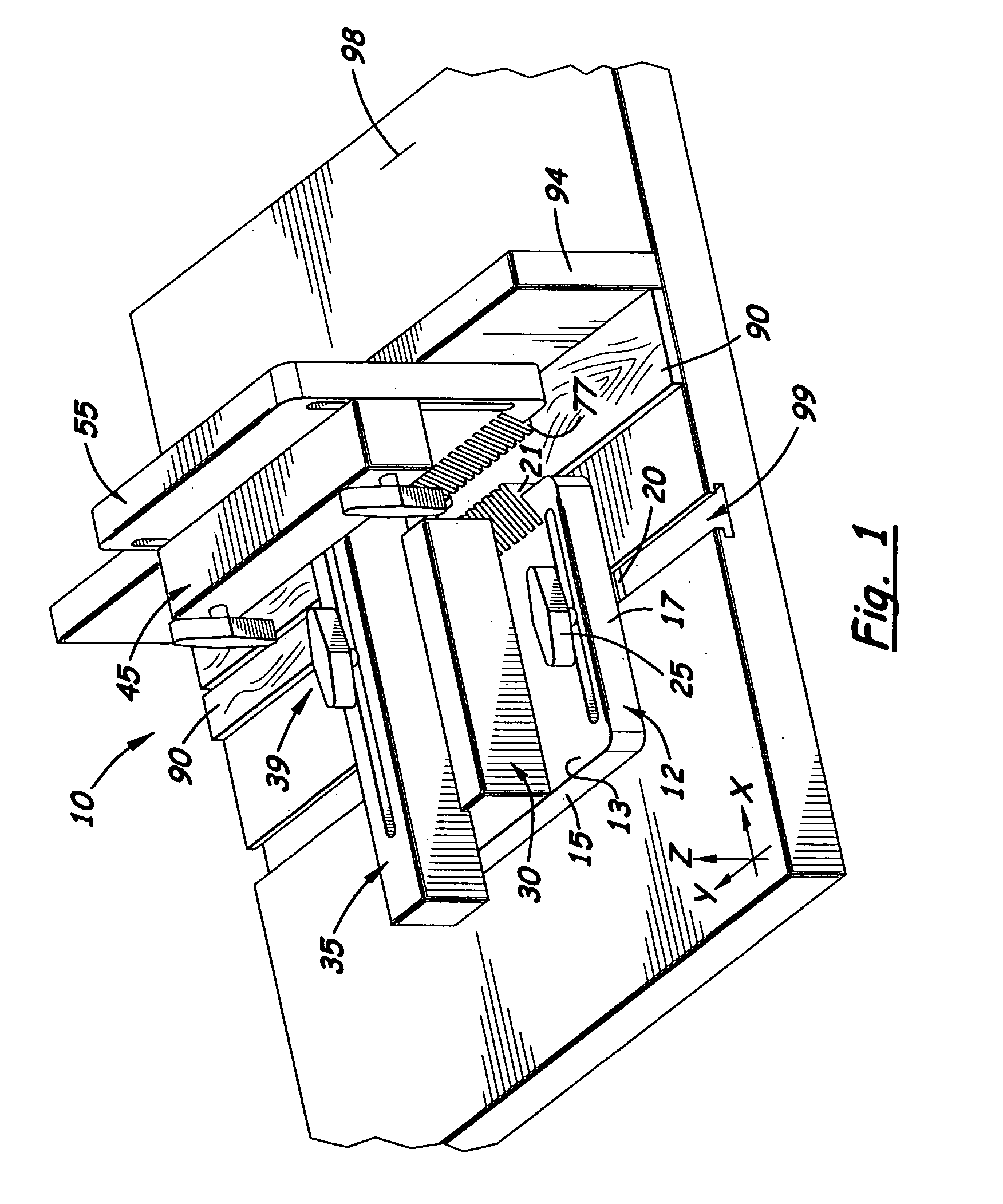

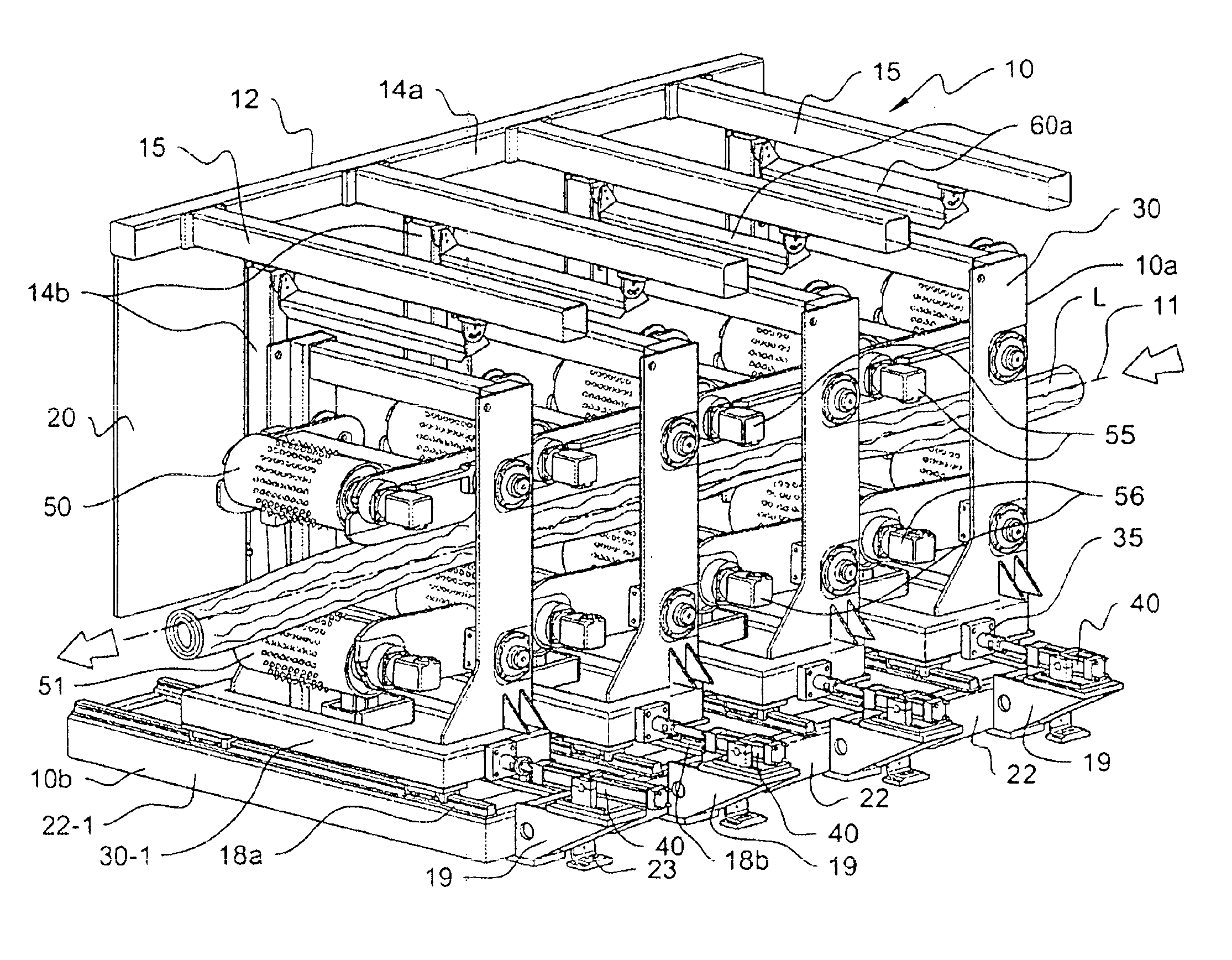

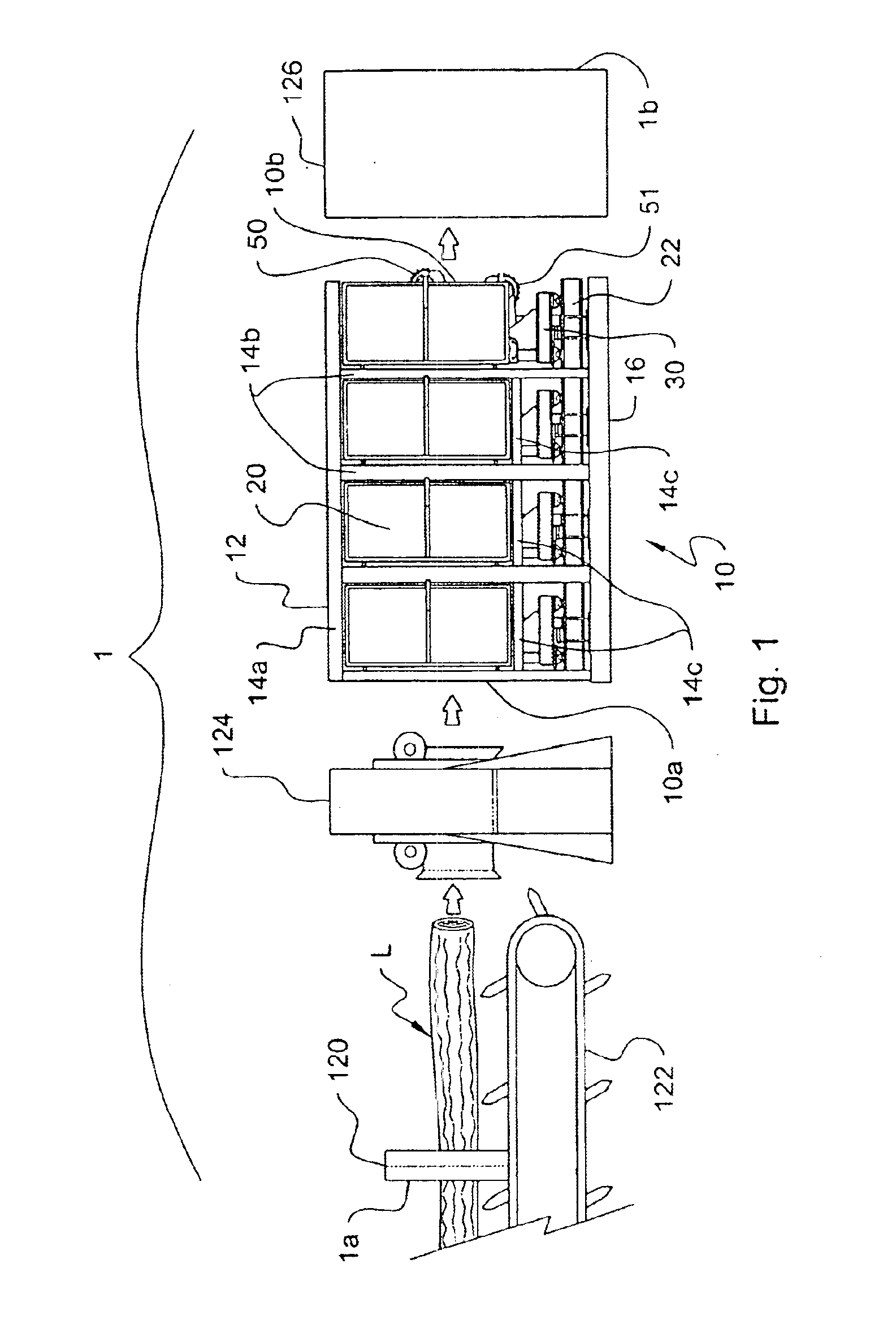

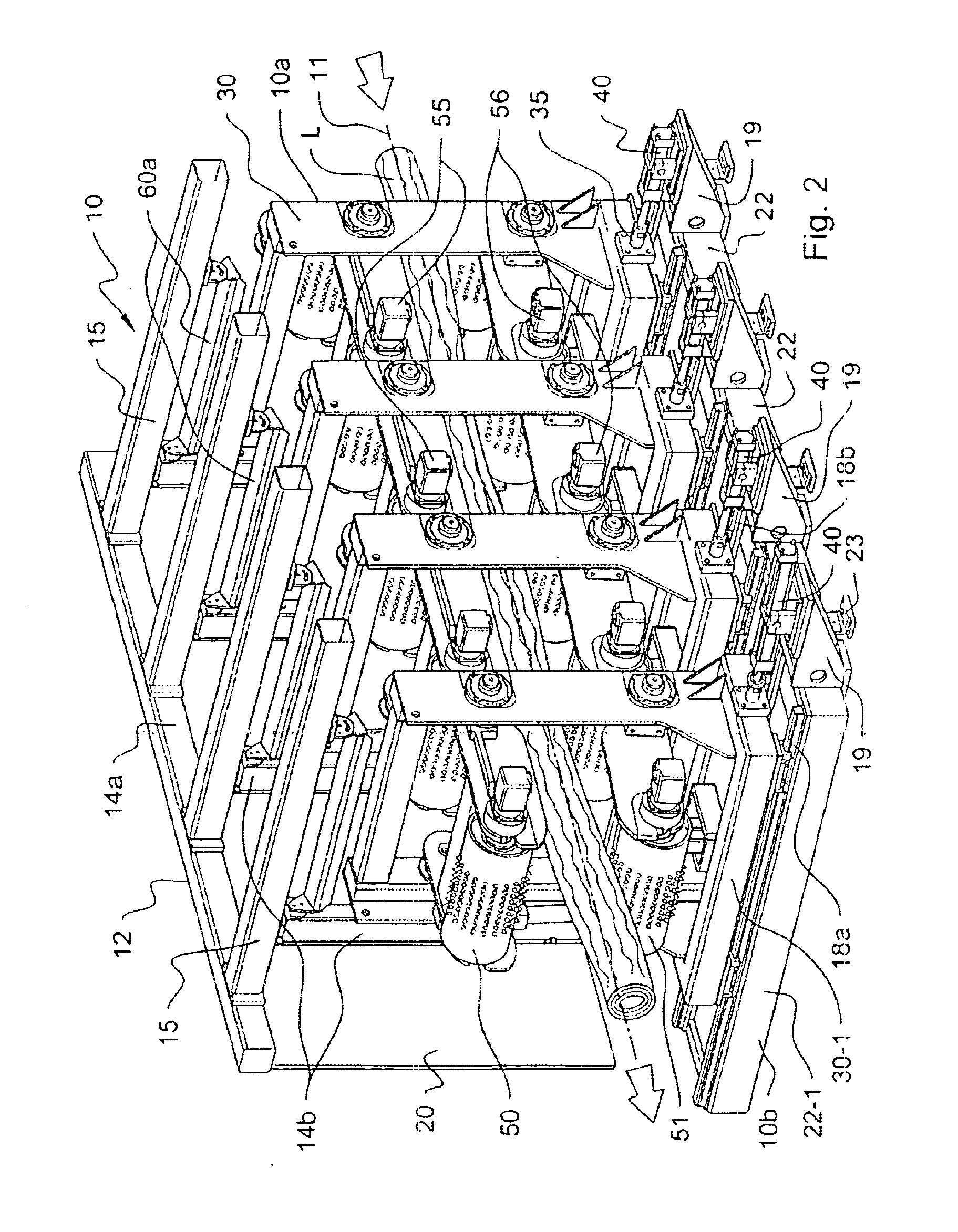

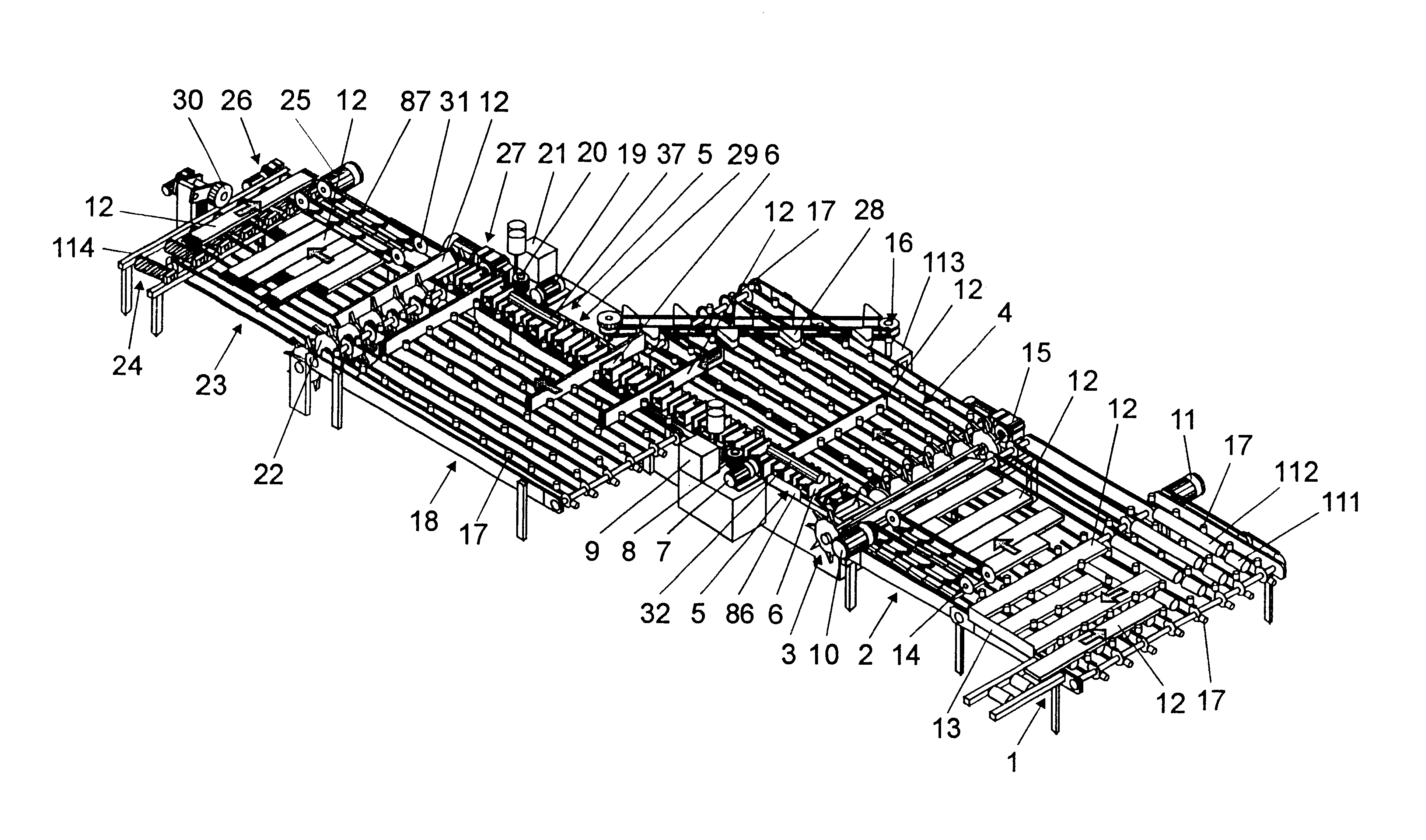

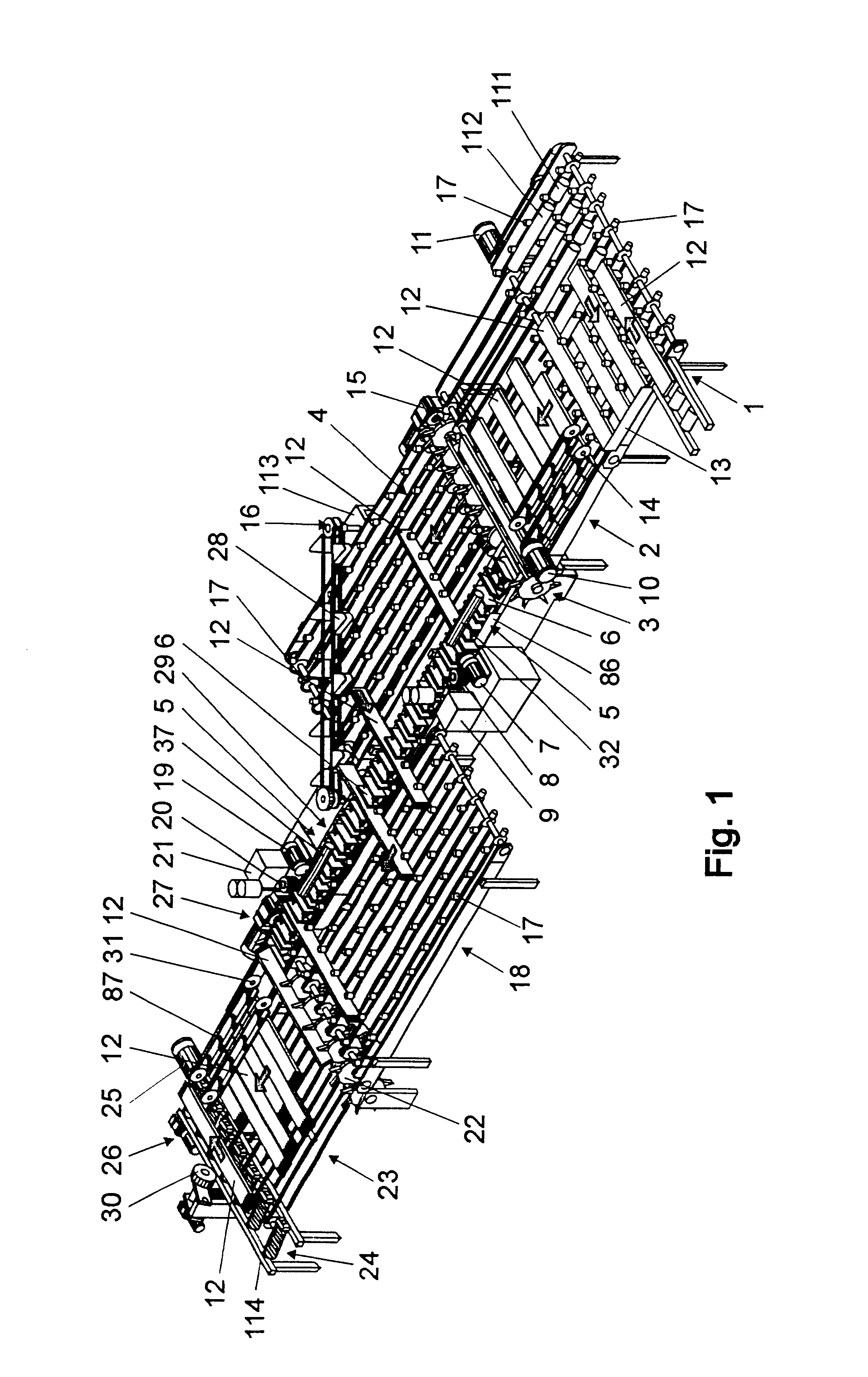

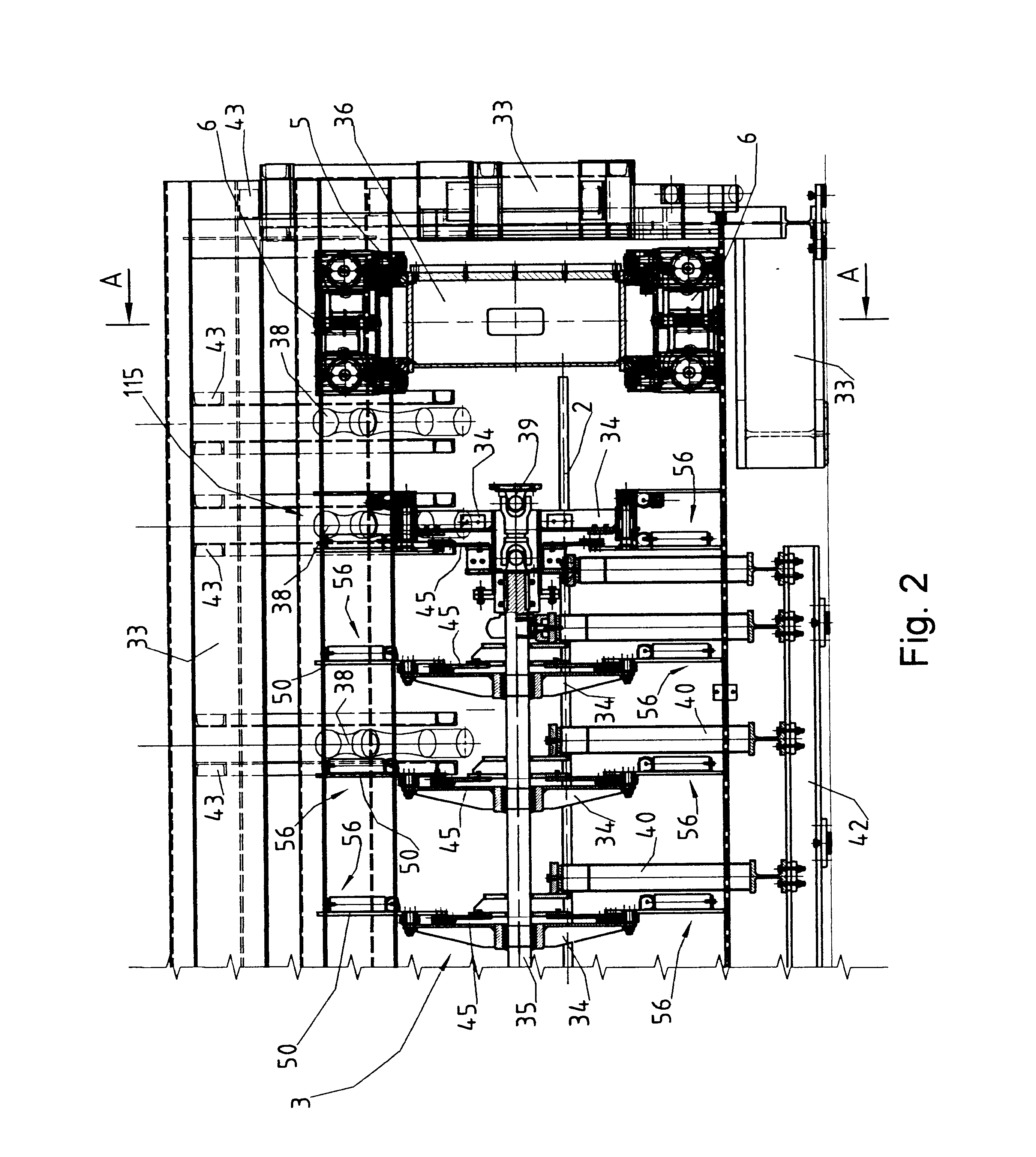

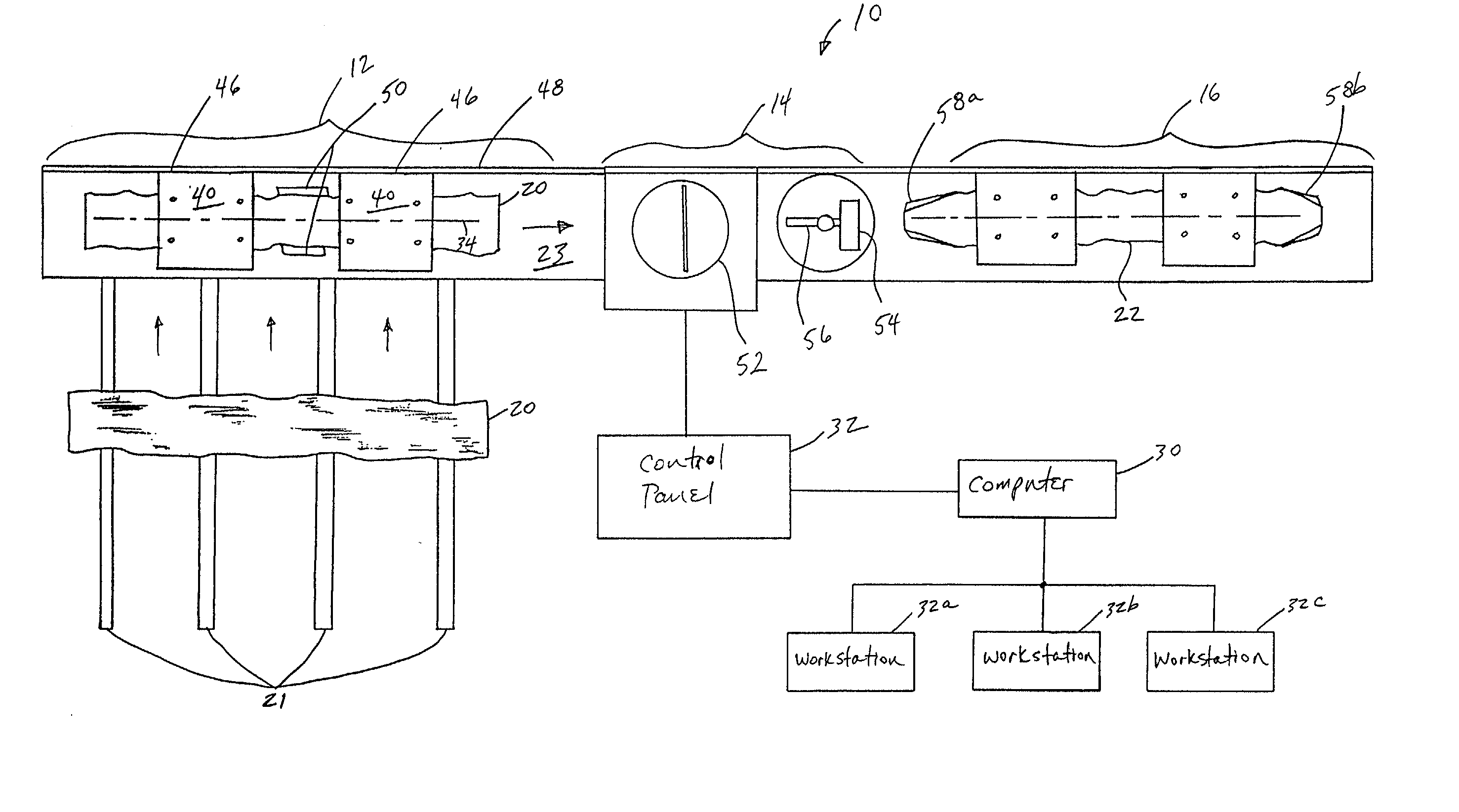

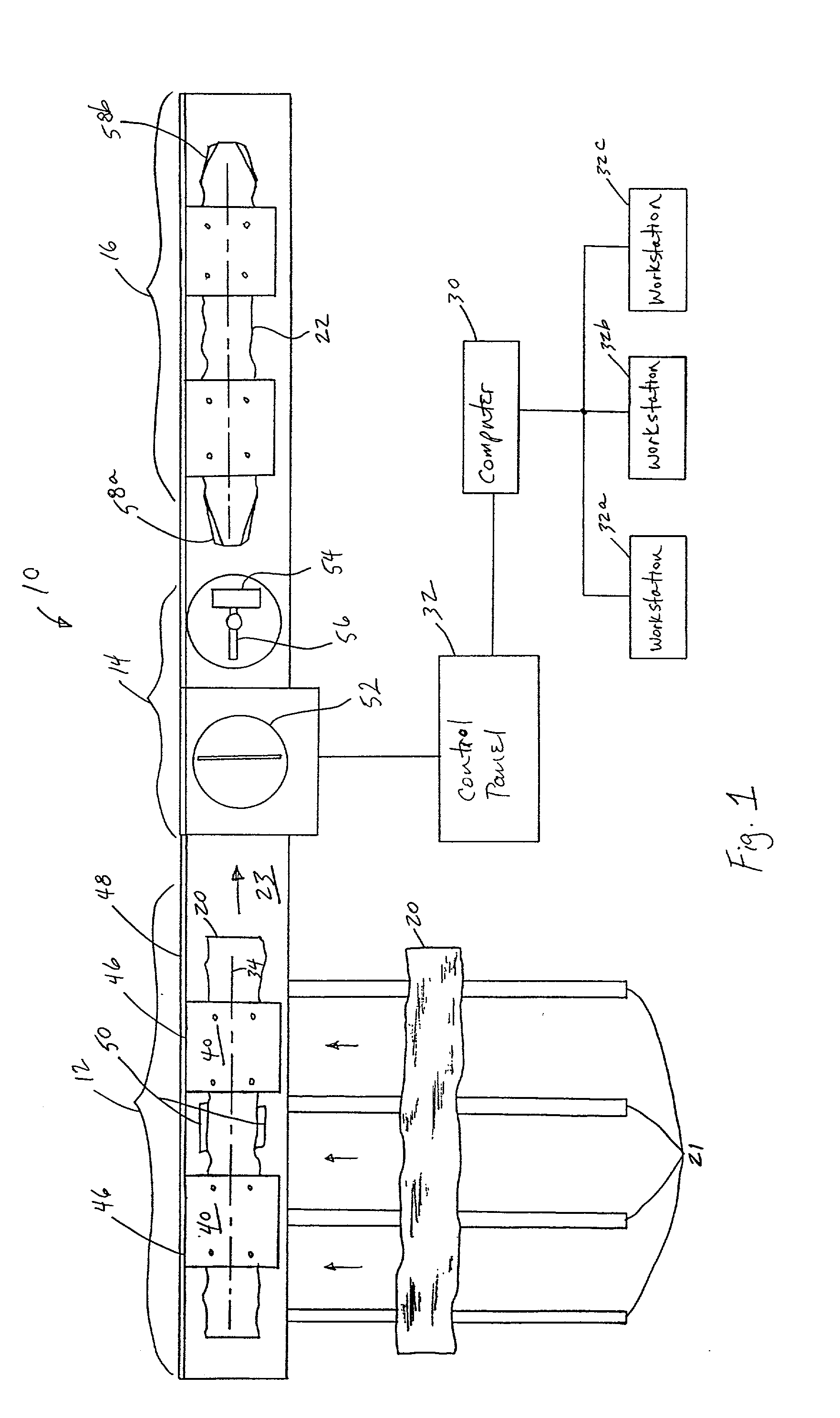

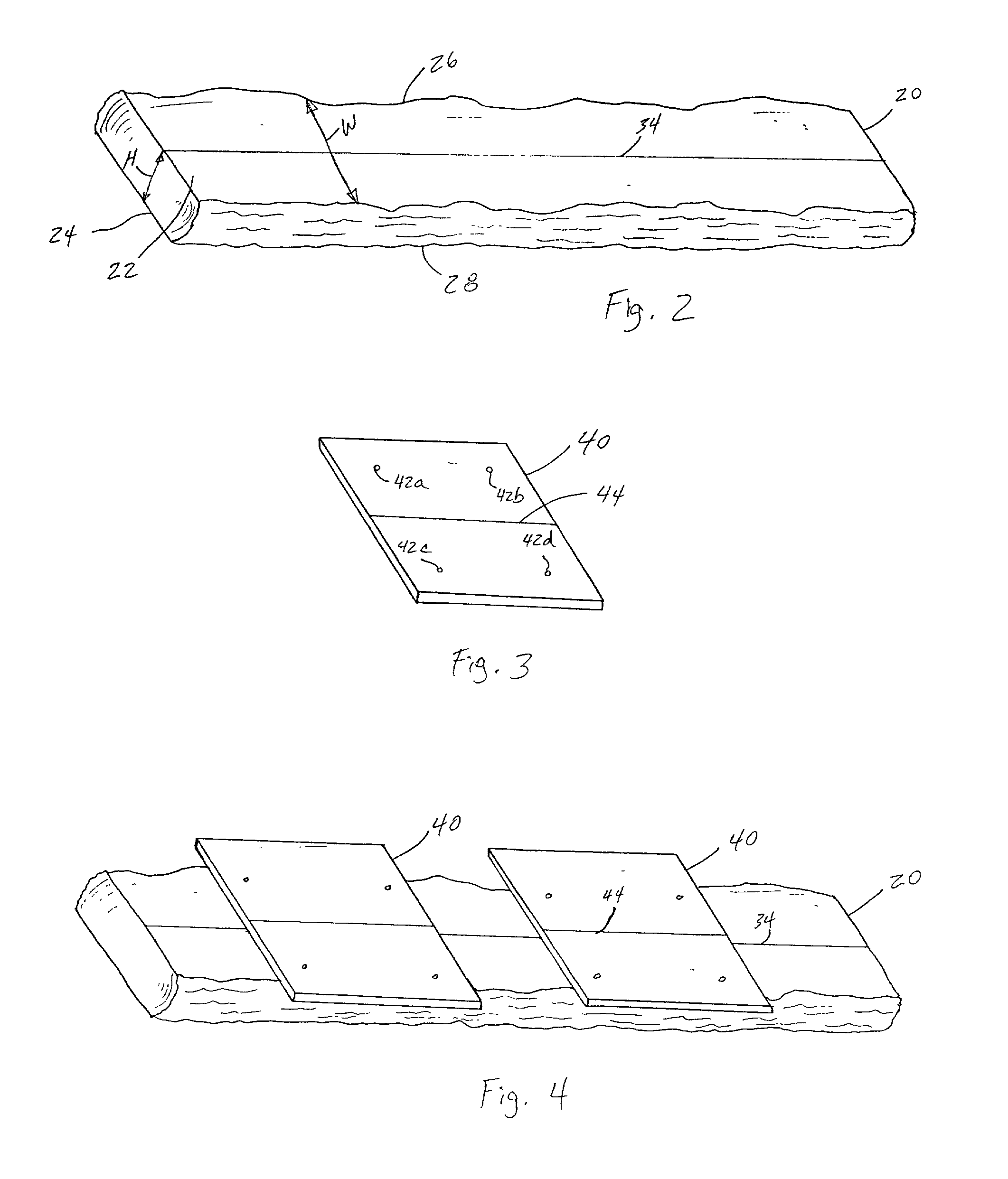

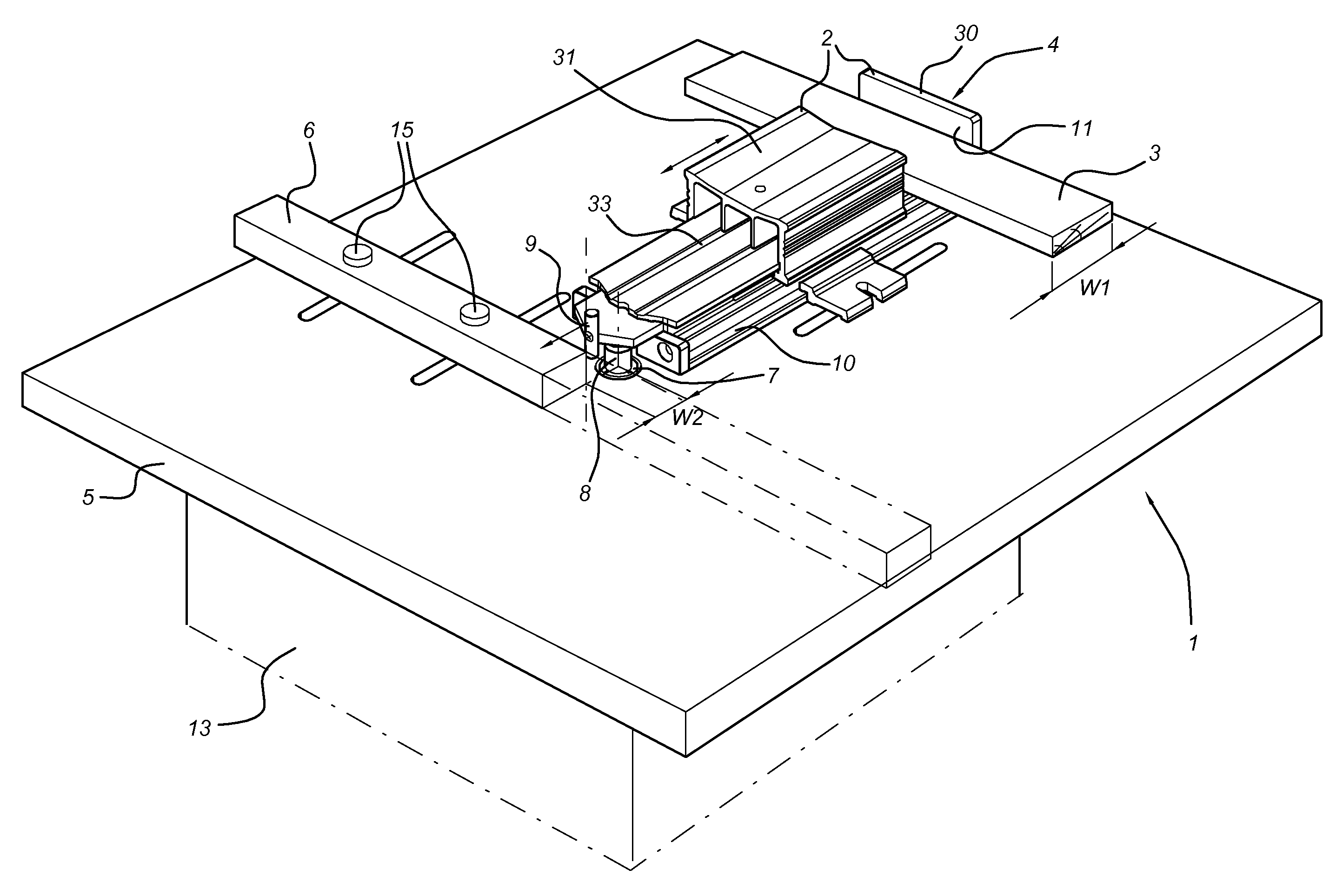

Process and system for sub-dividing a laminated flooring substrate

ActiveUS20070209736A1Good for healthAvoid mistakesMulti-purpose machinesAdjusting equipmentEngineeringControl unit

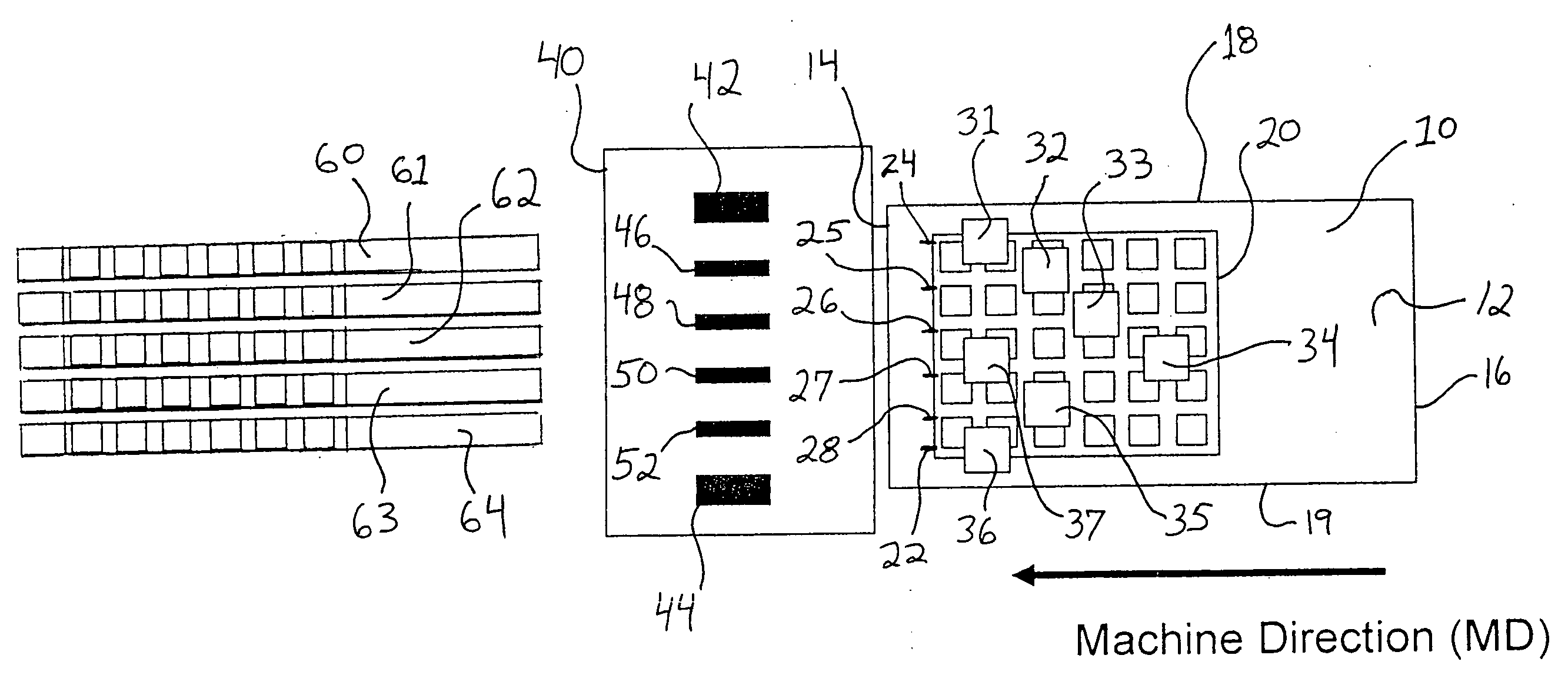

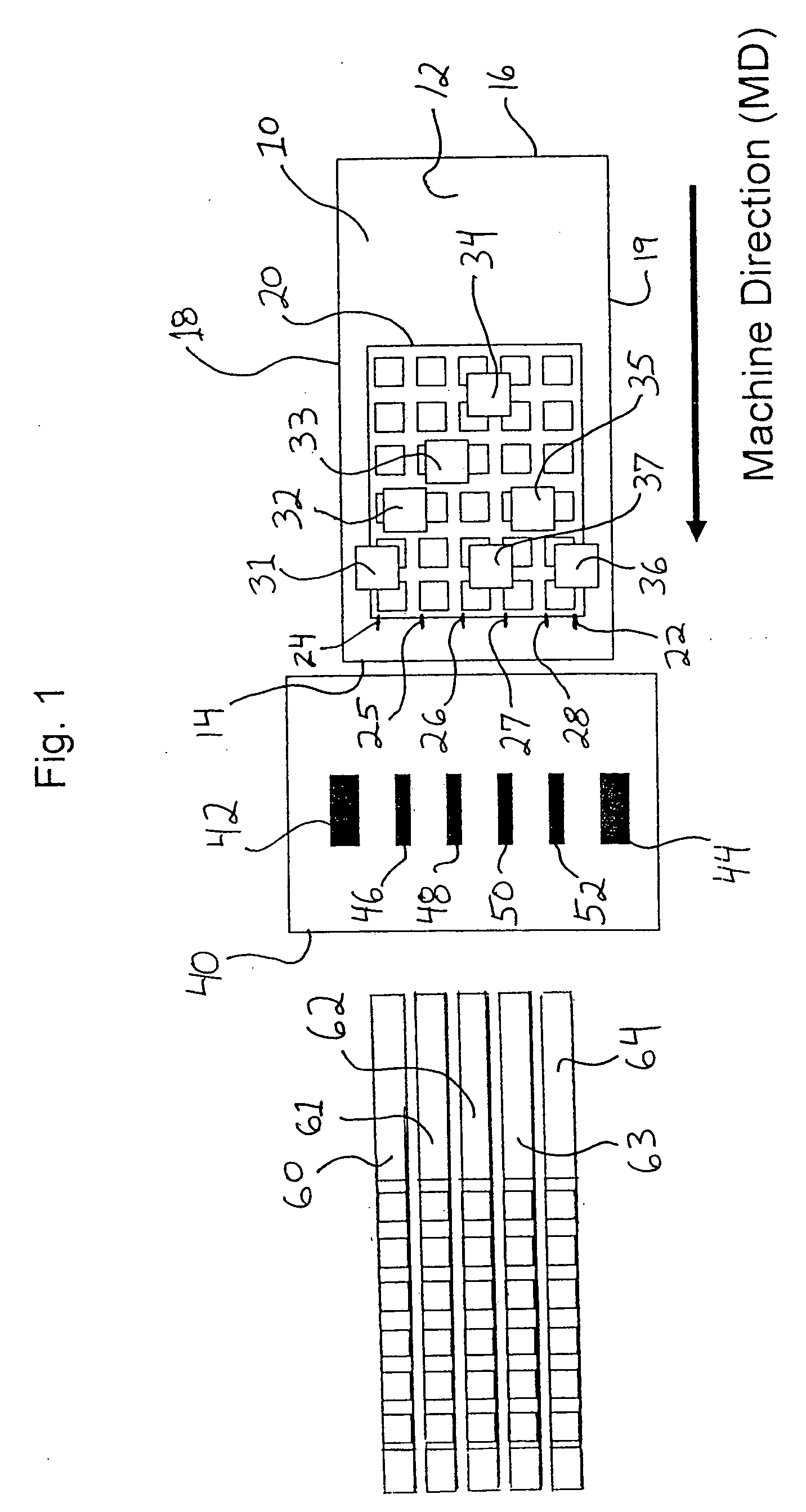

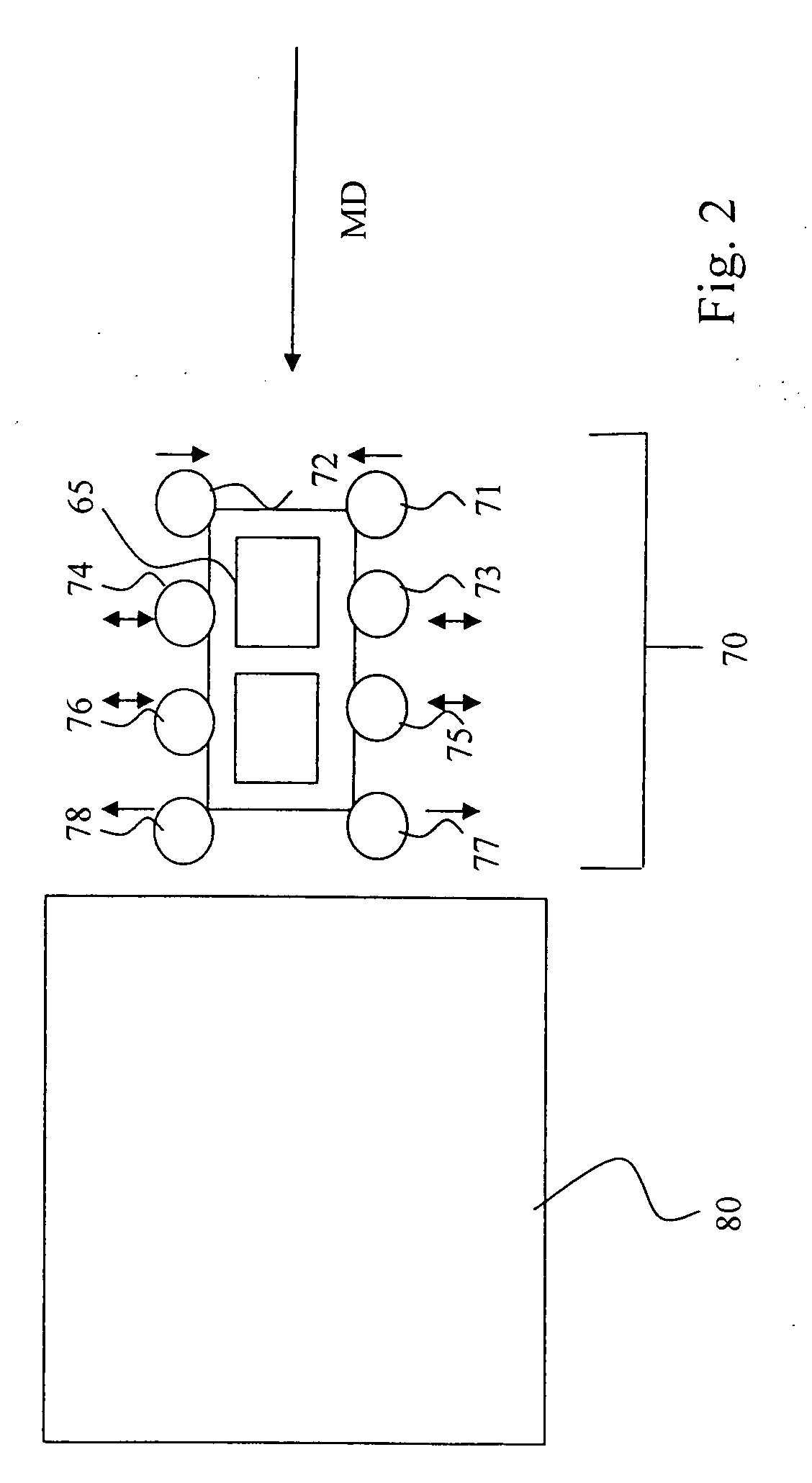

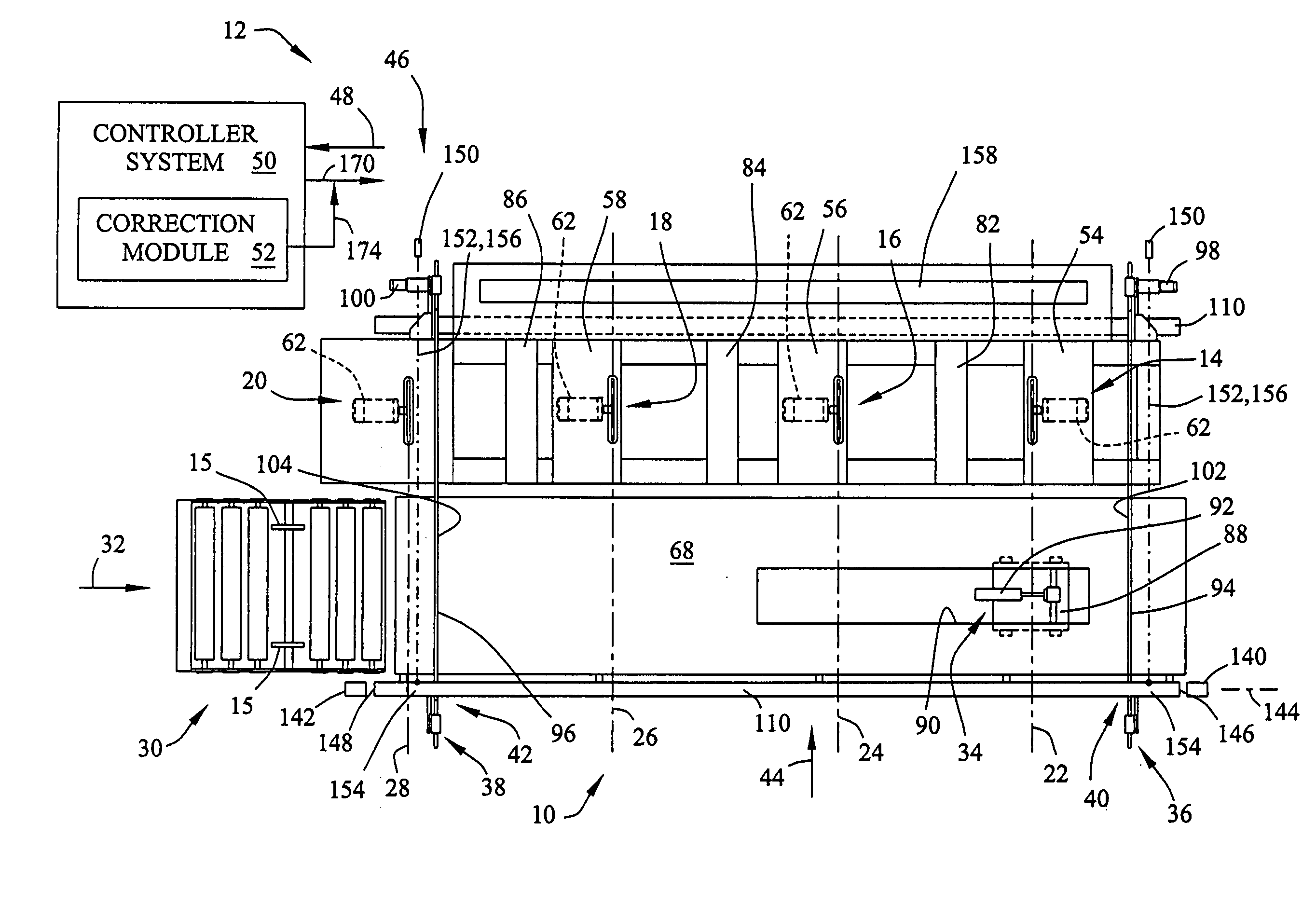

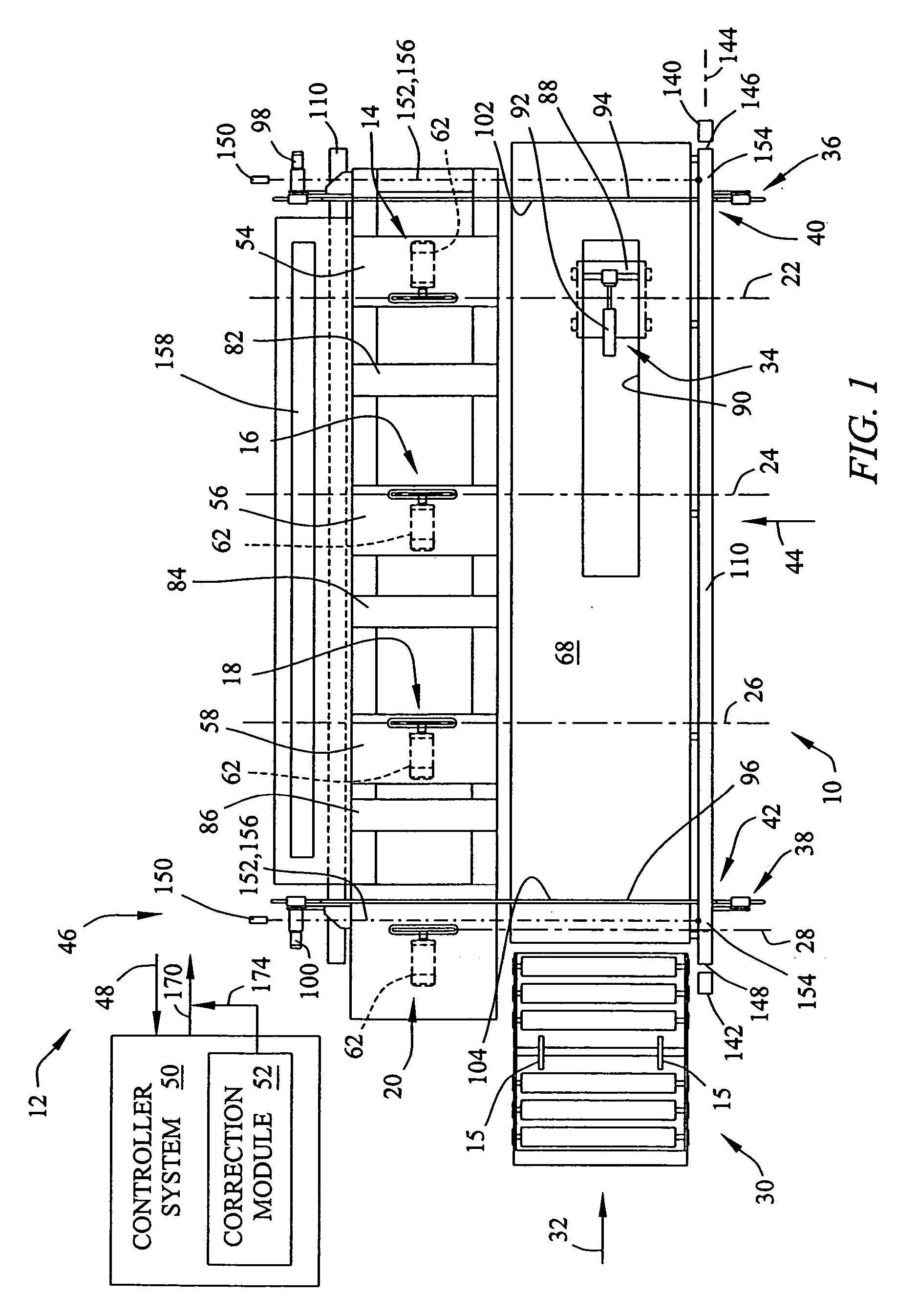

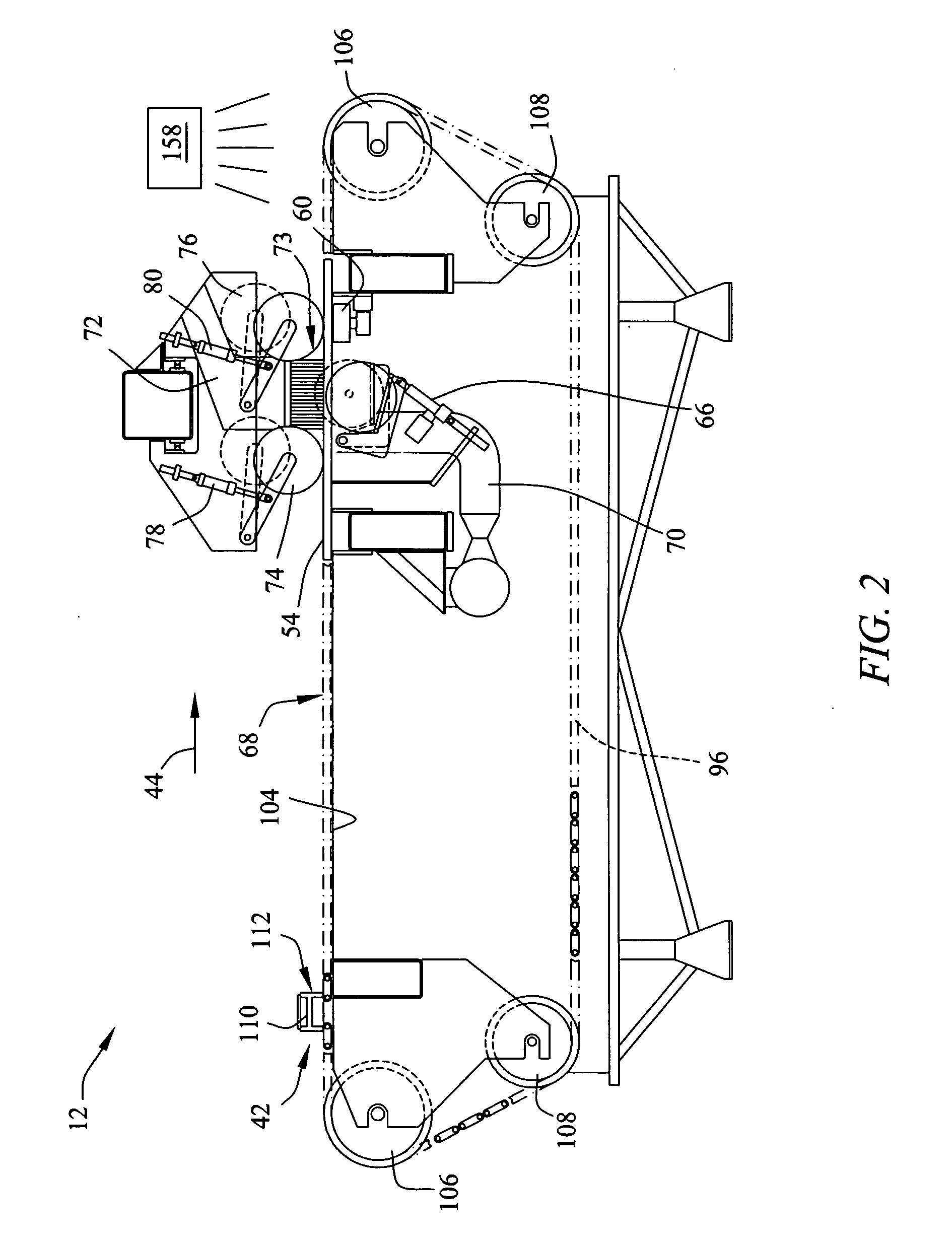

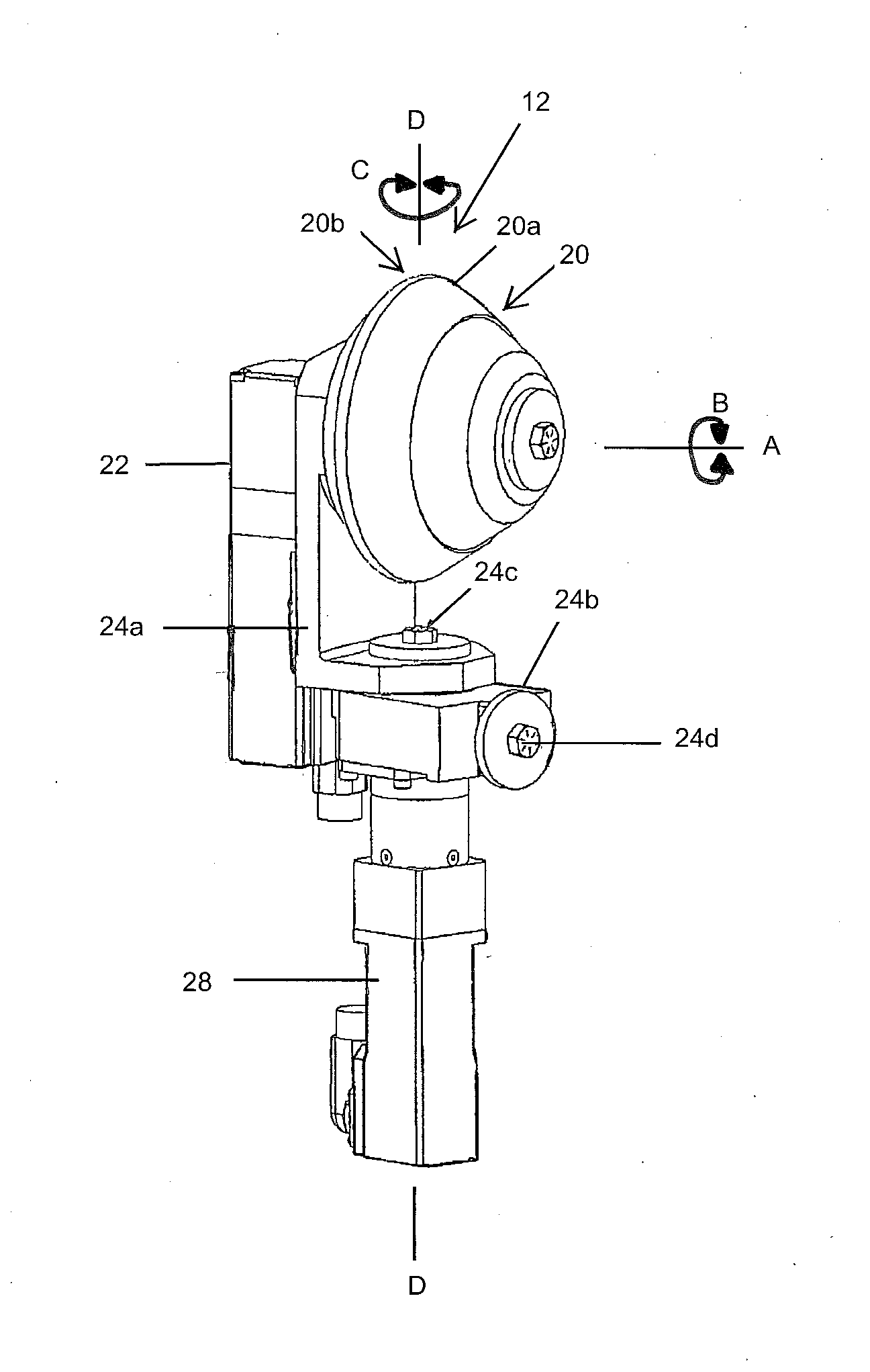

A process for sub-dividing a laminated flooring substrate into a plurality of laminated flooring planks and a system therefore are described. The process can include providing a laminated flooring substrate having a decorative pattern on a core wherein the decorative pattern can include a plurality of indicators, and independently detecting the indicators with a plurality of detecting devices, each assigned a respective indicator. The detecting devices can individually obtain the position of the detected indicators and a control unit can align a separate saw blade per each position detected. The system includes a cutting unit with individually adjustable saws or an alignment device configured to align the laminated flooring substrate with the saws, to cut the laminated flooring substrate along positions relative to the detected indicators, for example, in the center thereof or off-set therefrom.

Owner:MANNINGTON MILLS

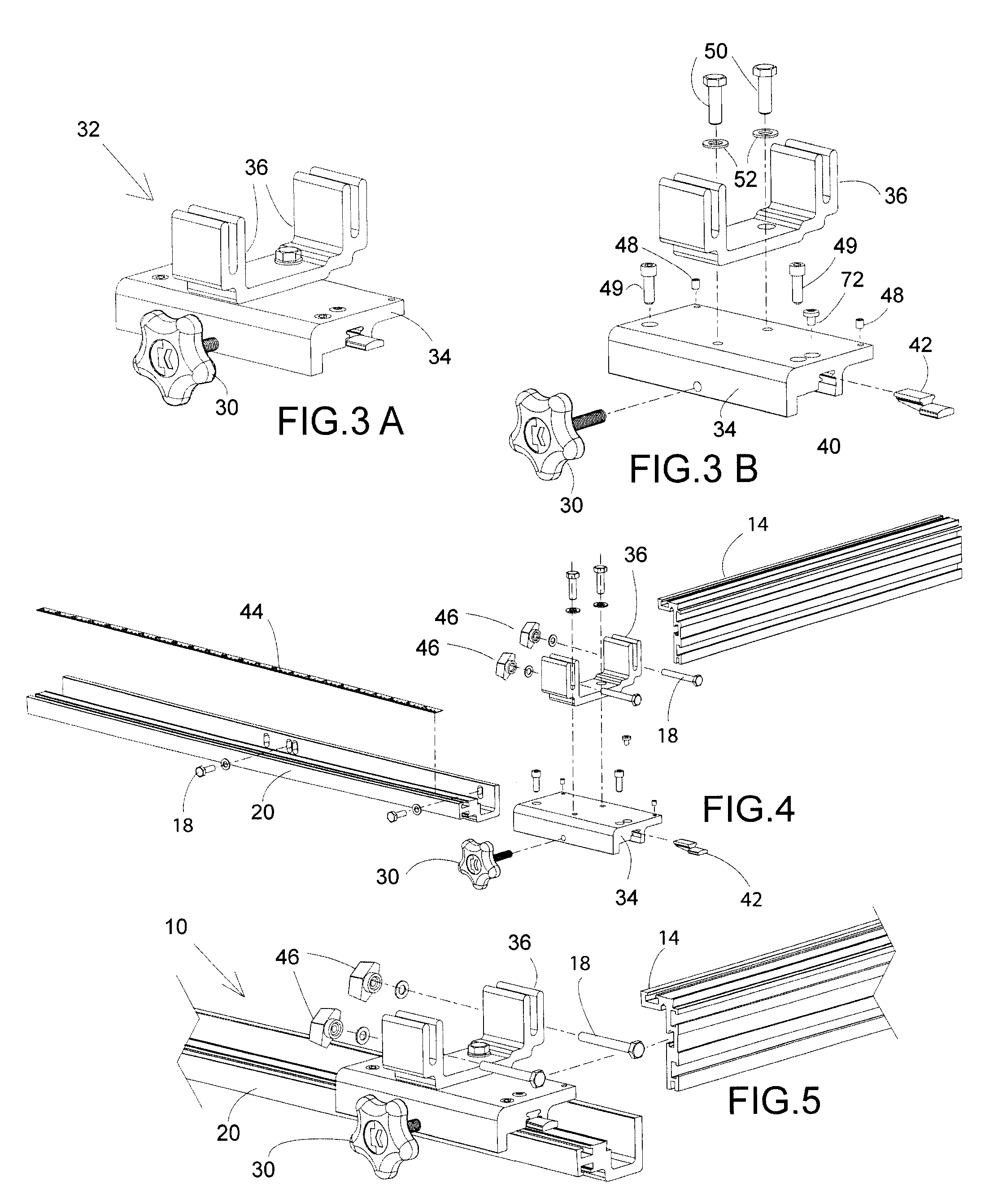

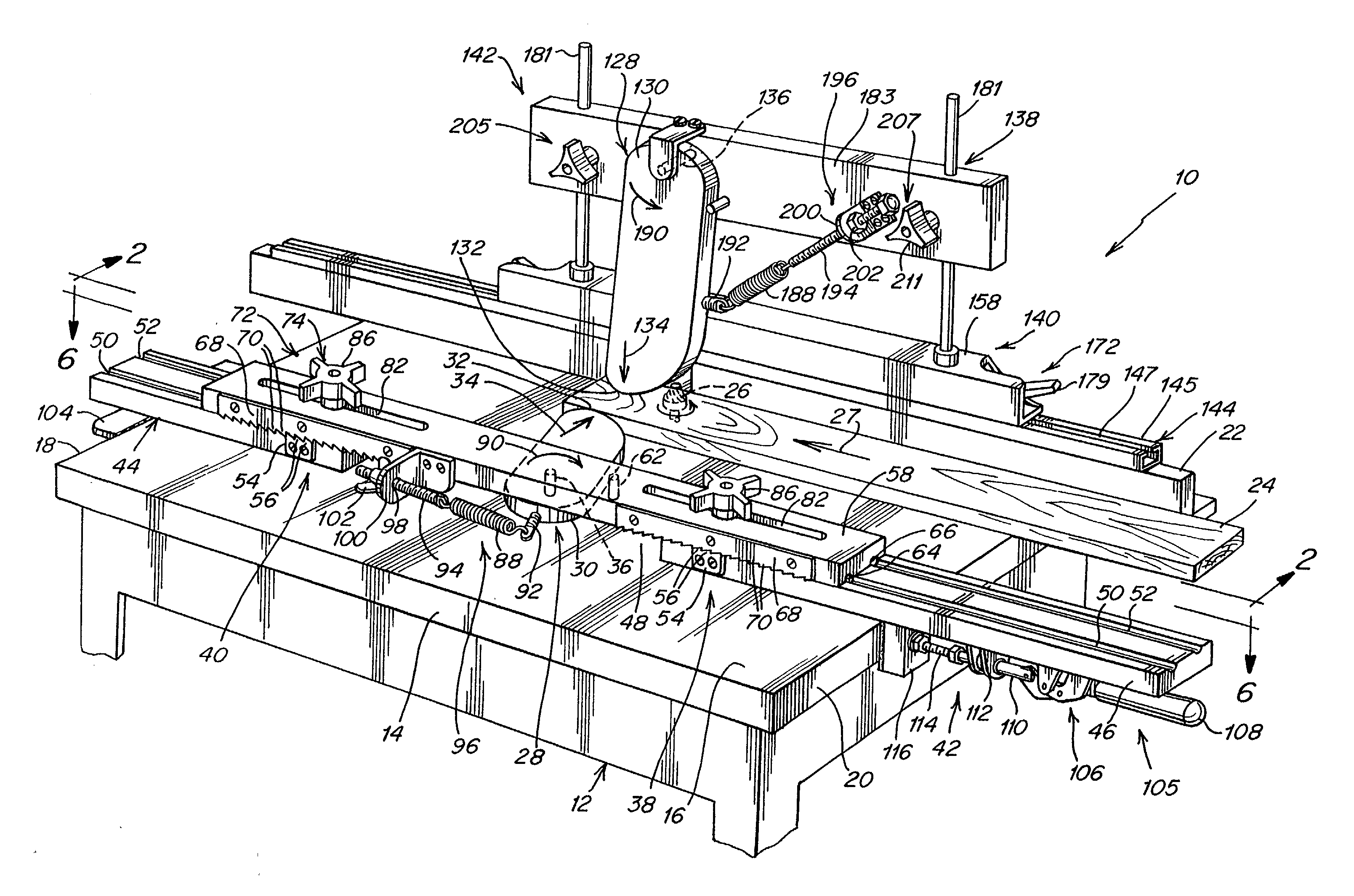

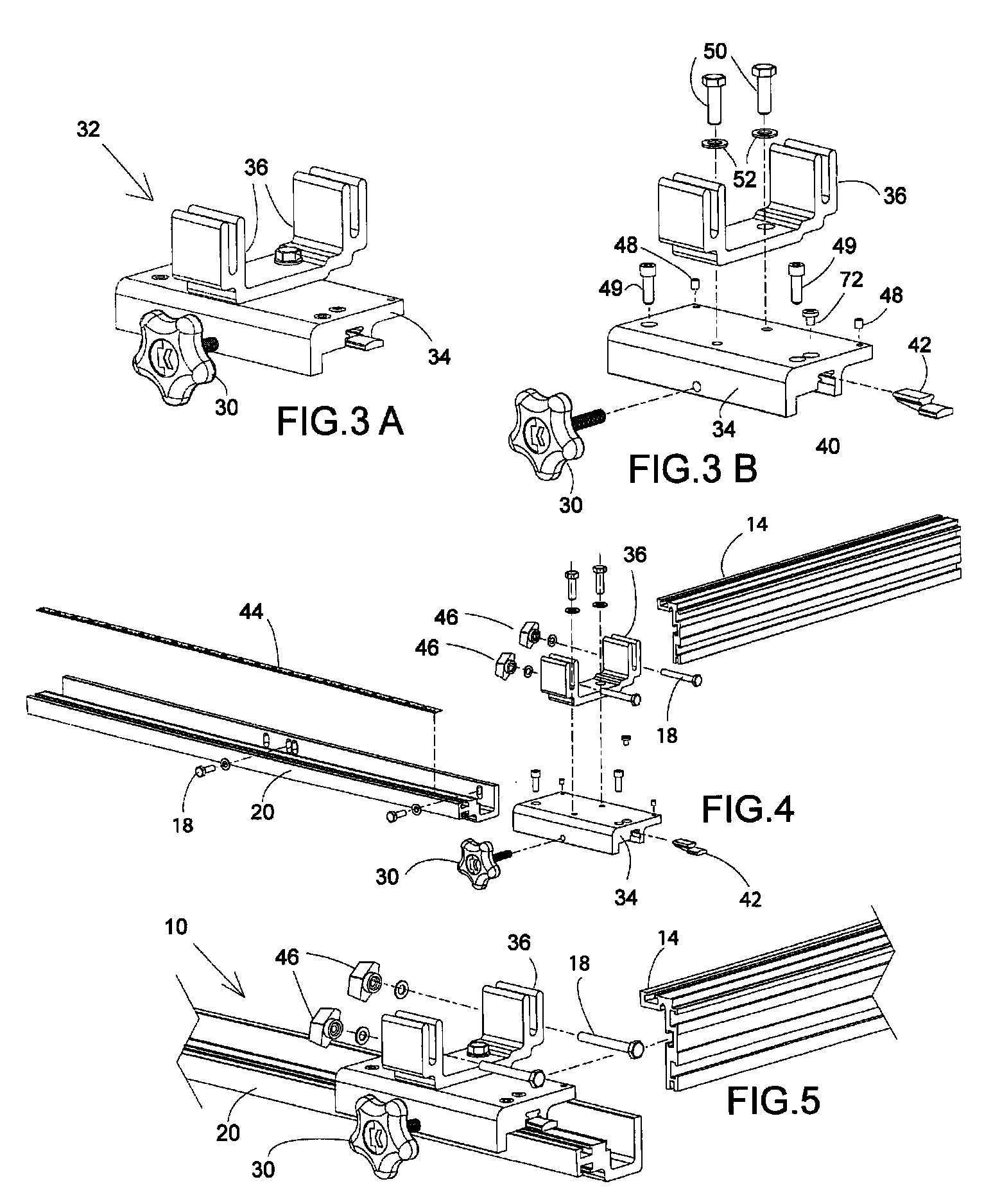

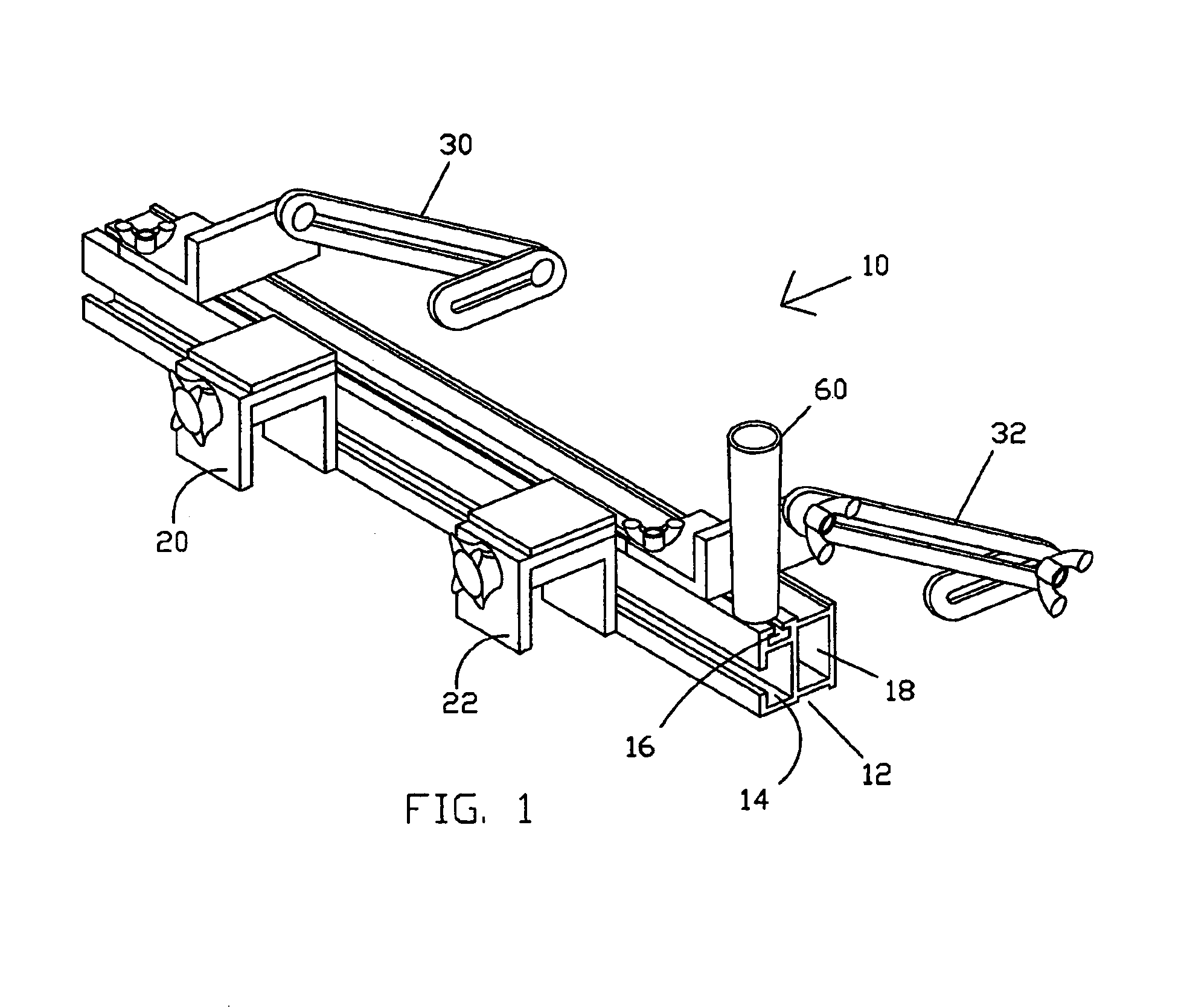

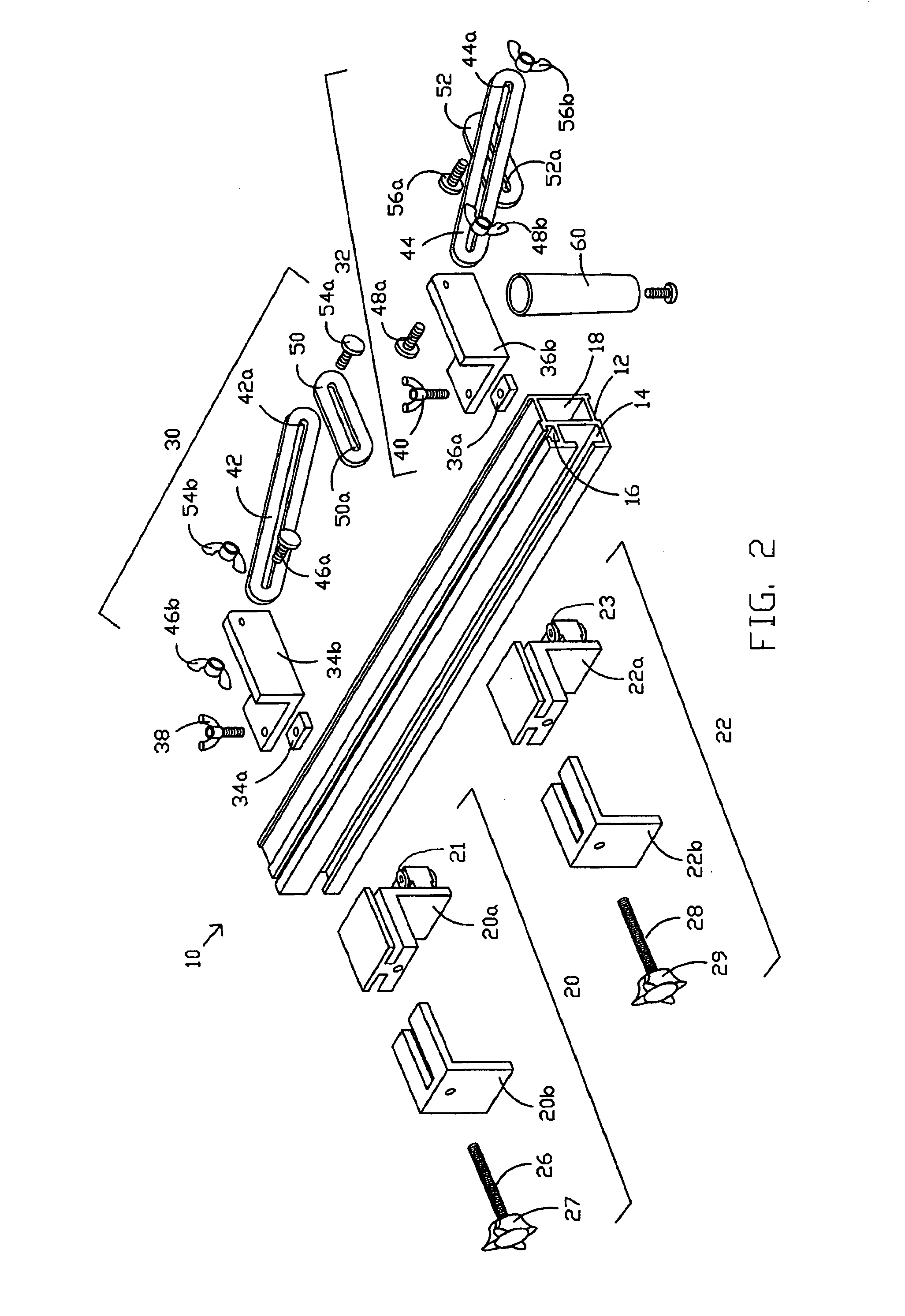

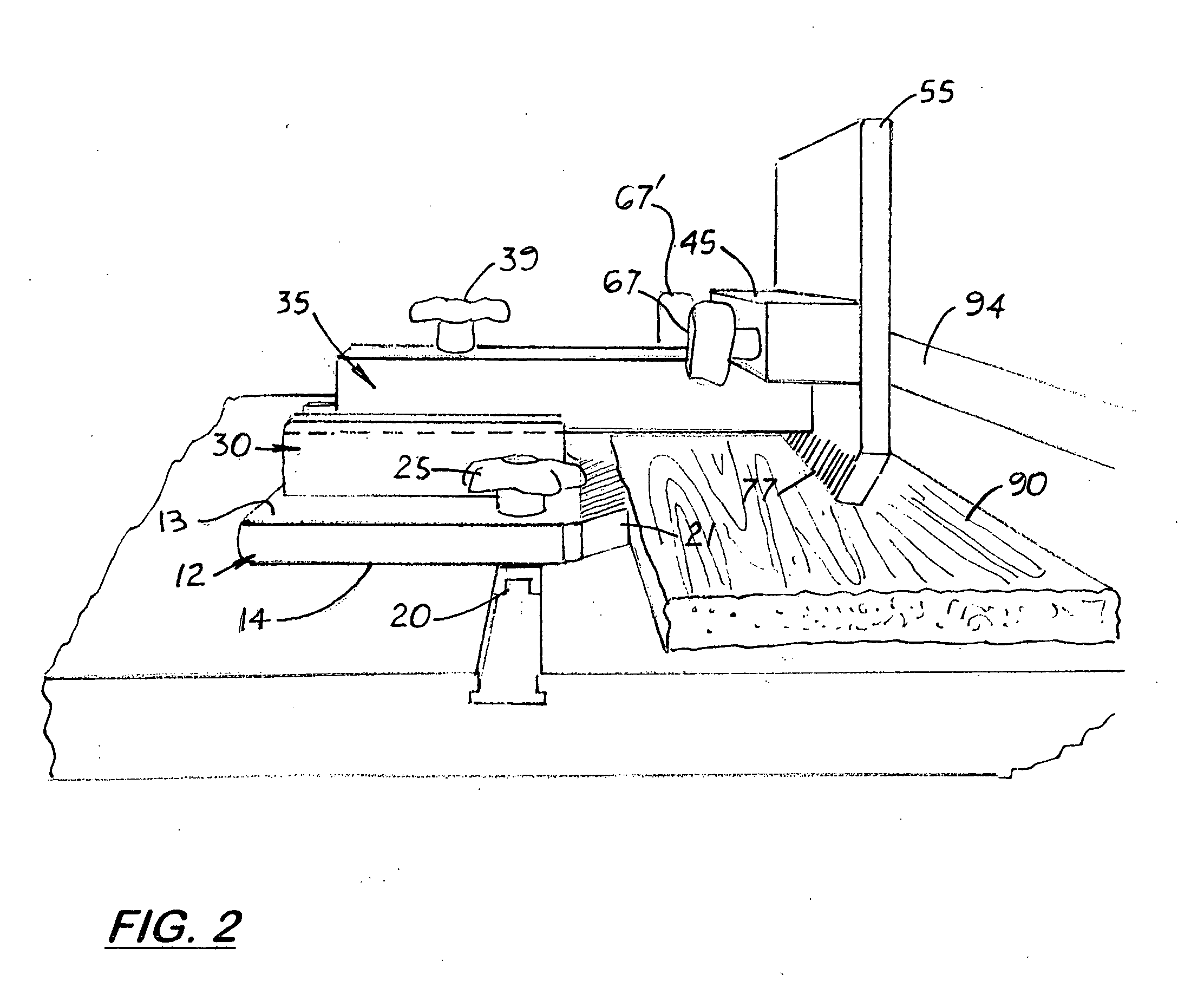

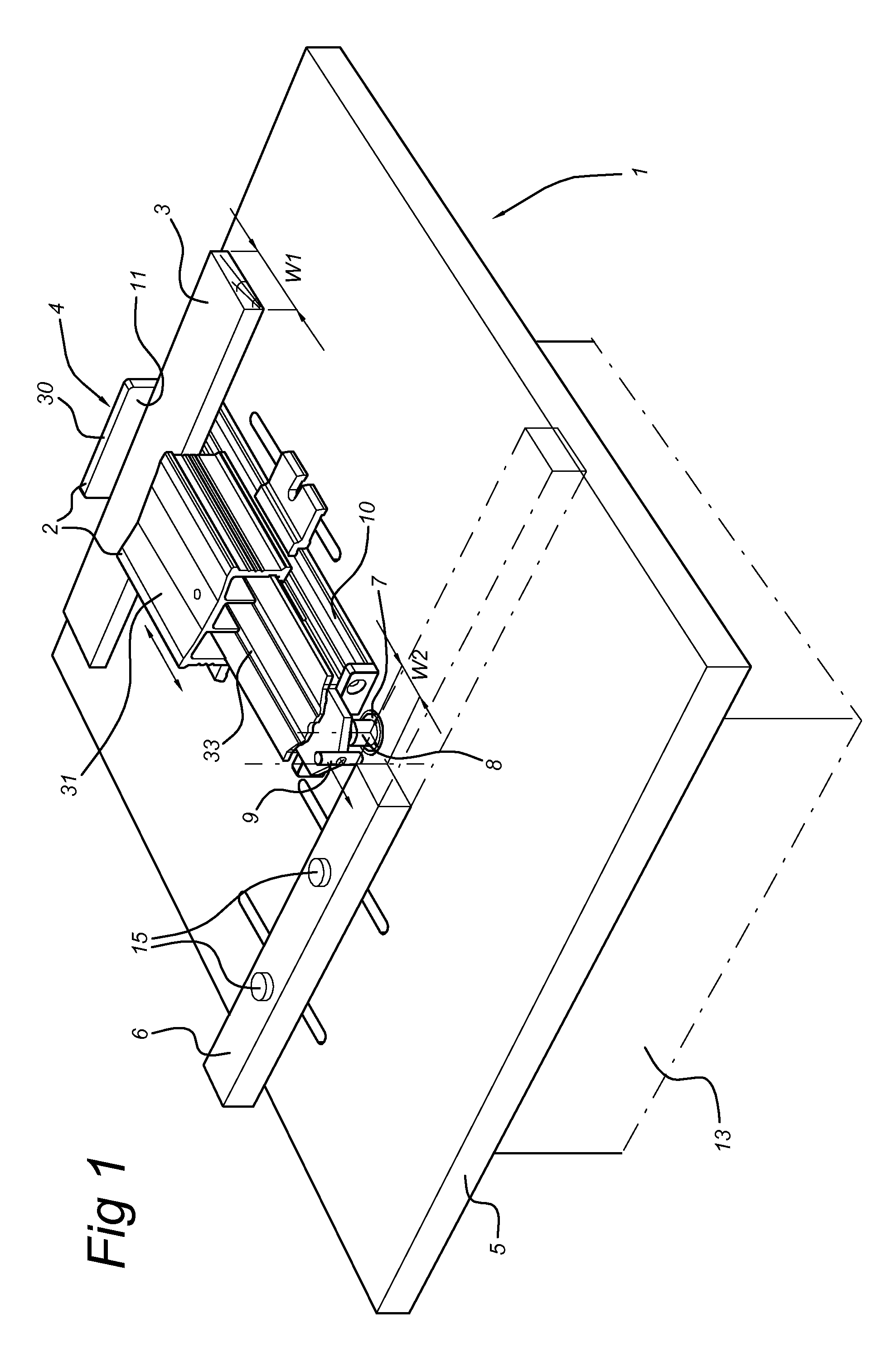

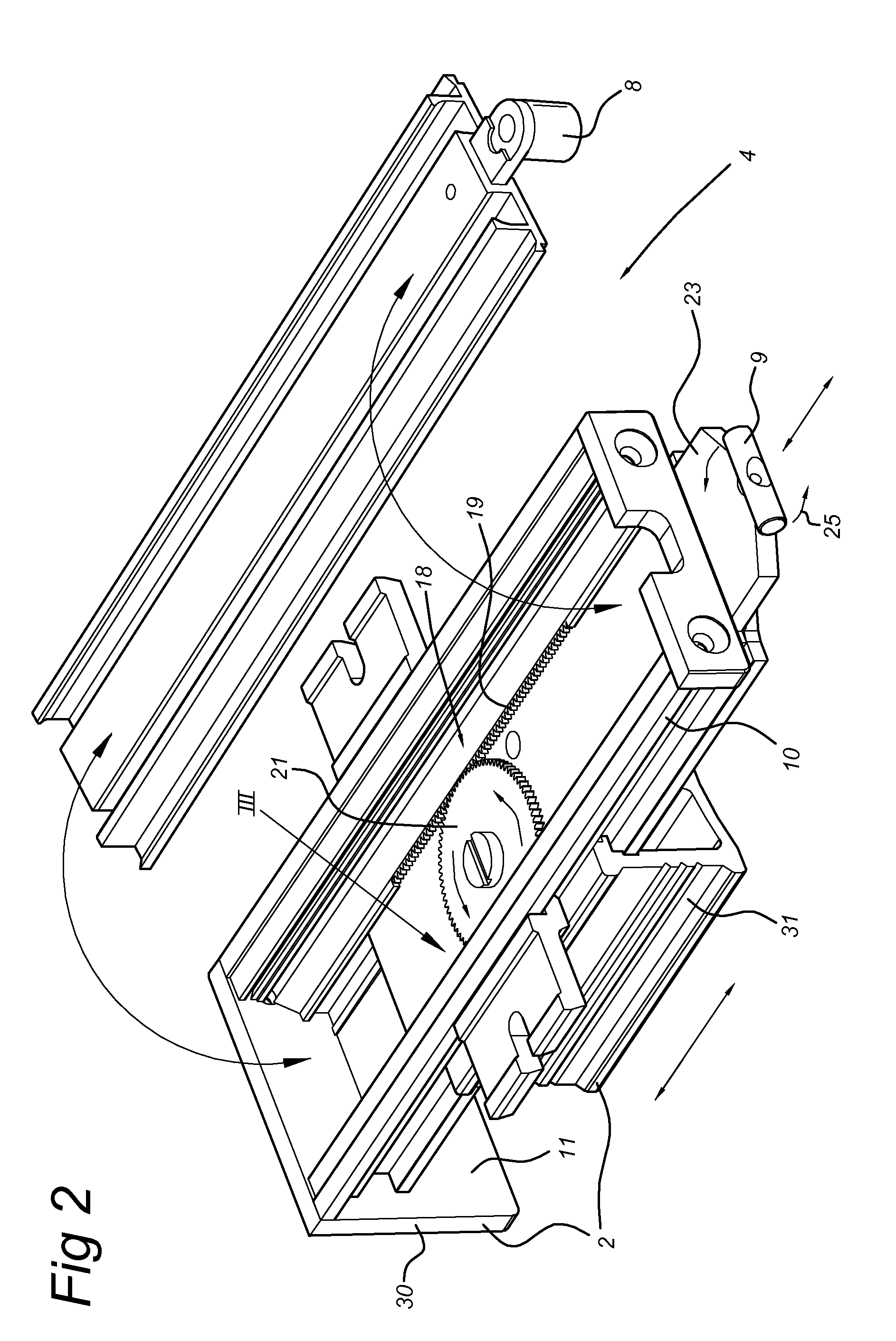

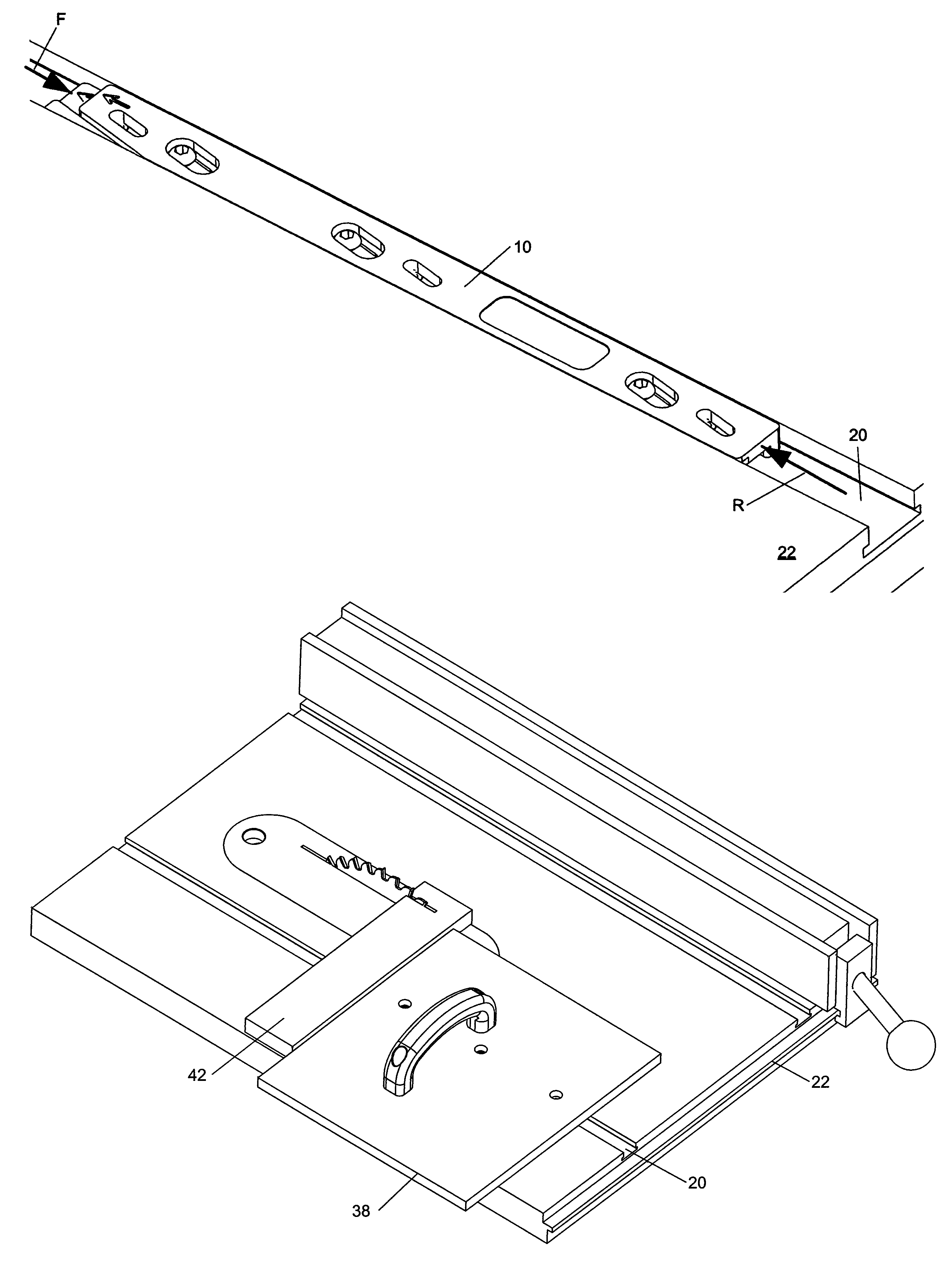

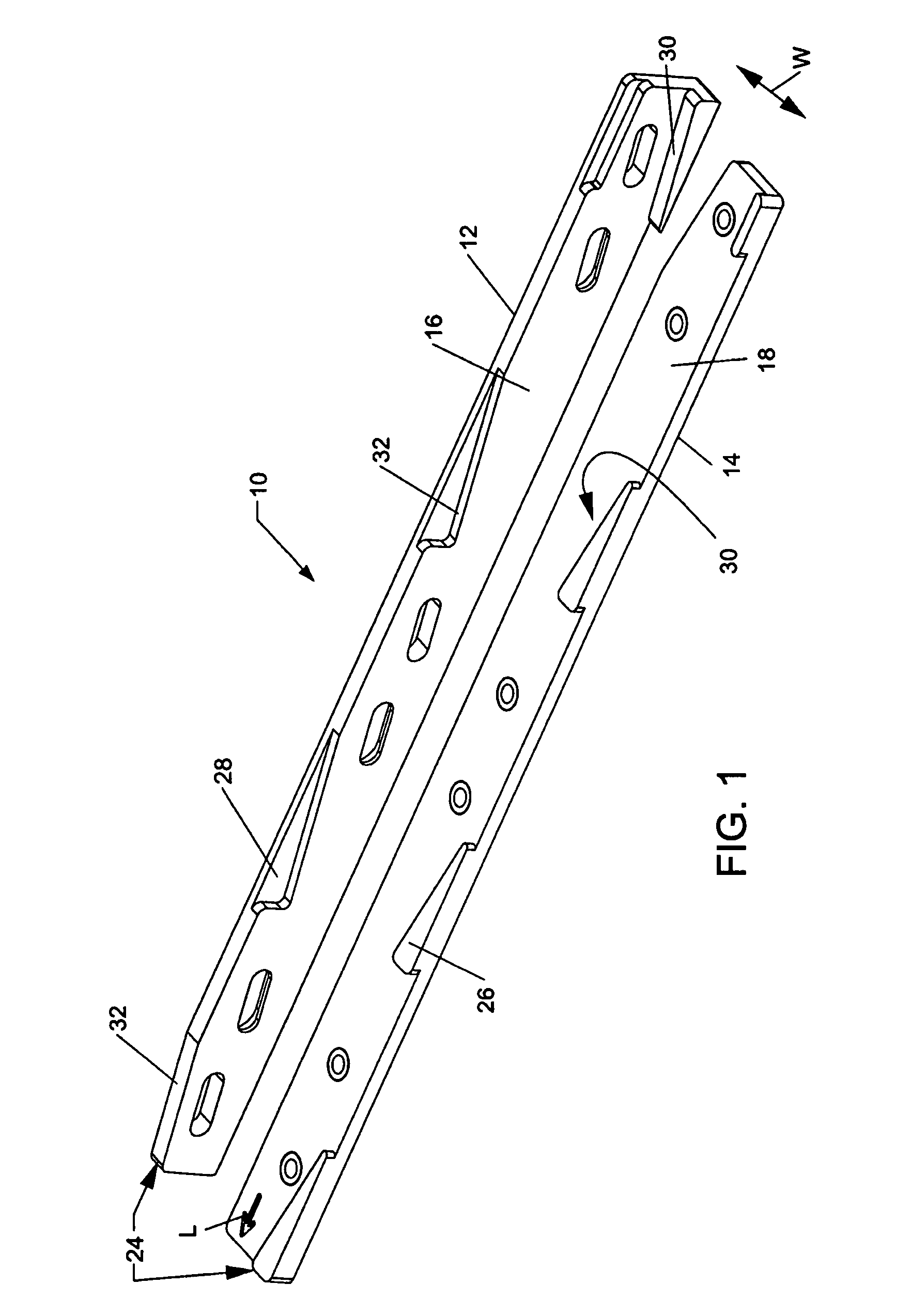

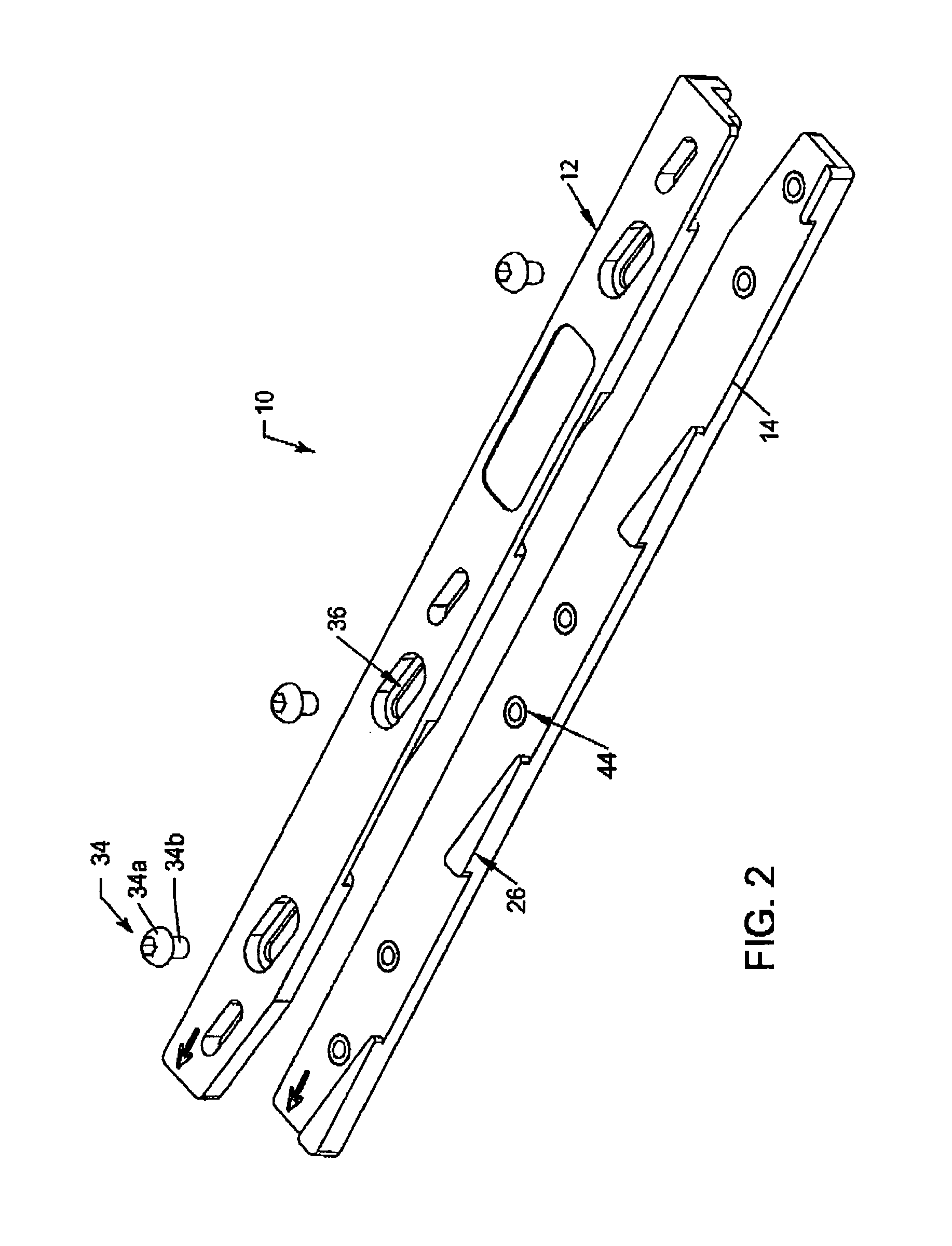

Woodworking machinery jig and fixture system

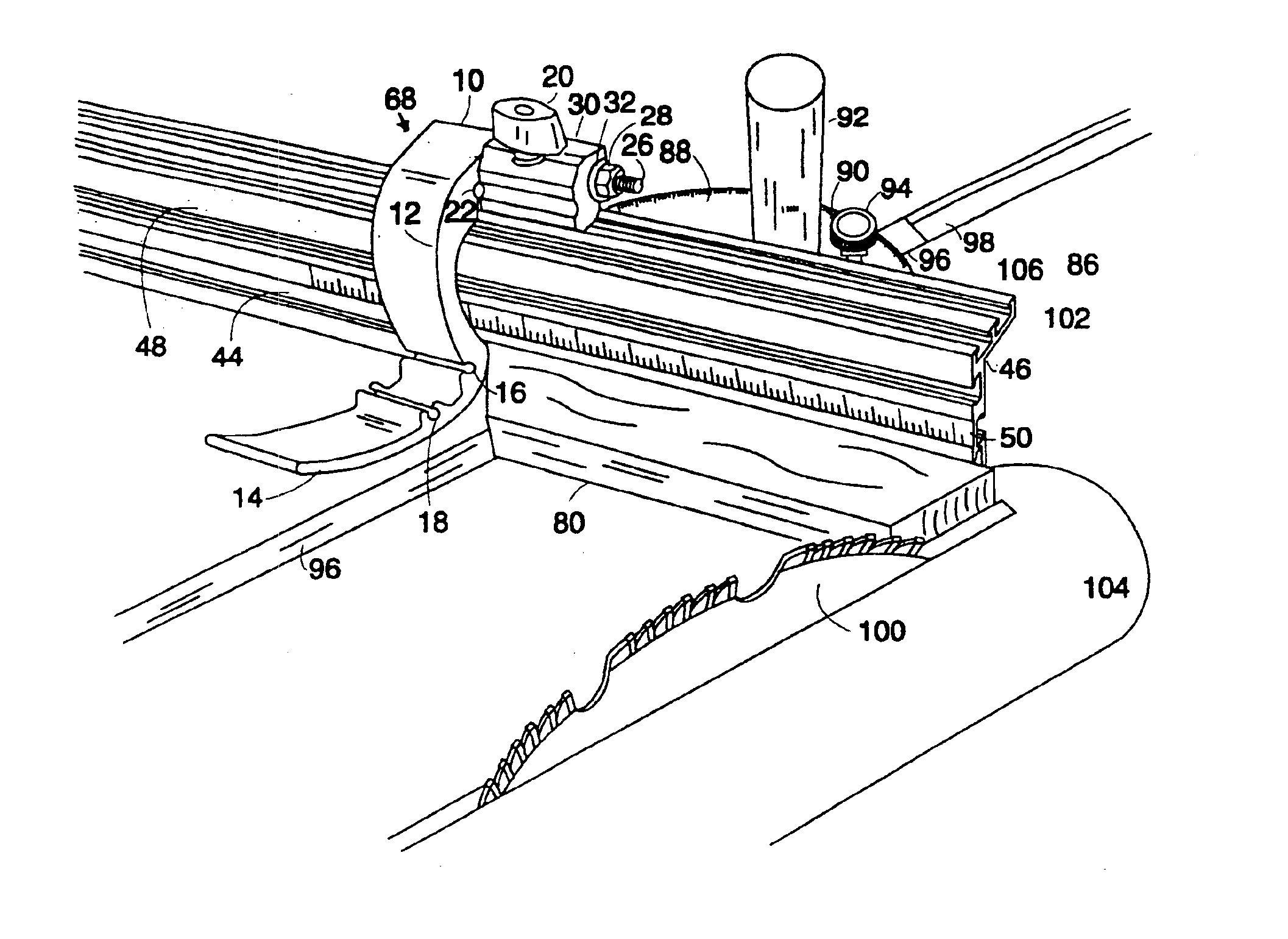

A woodworking machinery jig and fixture system includes a track which is or may be attached to a fence, a convex-concave curved flip stop and a base which mounts the stop to the track. The stop has a projecting portion which penetrates the plane of the fence so the stop isn't lifted by the point of a mitered board. The stop also has a lower convex surface which faces the work support surface and curves up at both ends. The top leg of the stop is concave toward the fence to allow clearance for a zero-clearance board and make the stop adaptable to different track and fence configurations. The base has opposite sides of different widths bordered by steps on one side and a ramp on the other side so the base can be used in a large range of T-track slot widths. The arm mounting hole of the base is offset from the base mounting so as to provide an offset to accommodate a ¾″ zero clearance board by turning the base a half turn relative to the slot. A two slot track is provided in which one of the slots can mount a sliding measurement tape or a base, and the other slot can also mount a base. In another track, a sidewall flange is provided which can be filed to accurately fit into a miter gauge slot of a cutting tool table.

Owner:KREG ENTERPRISES

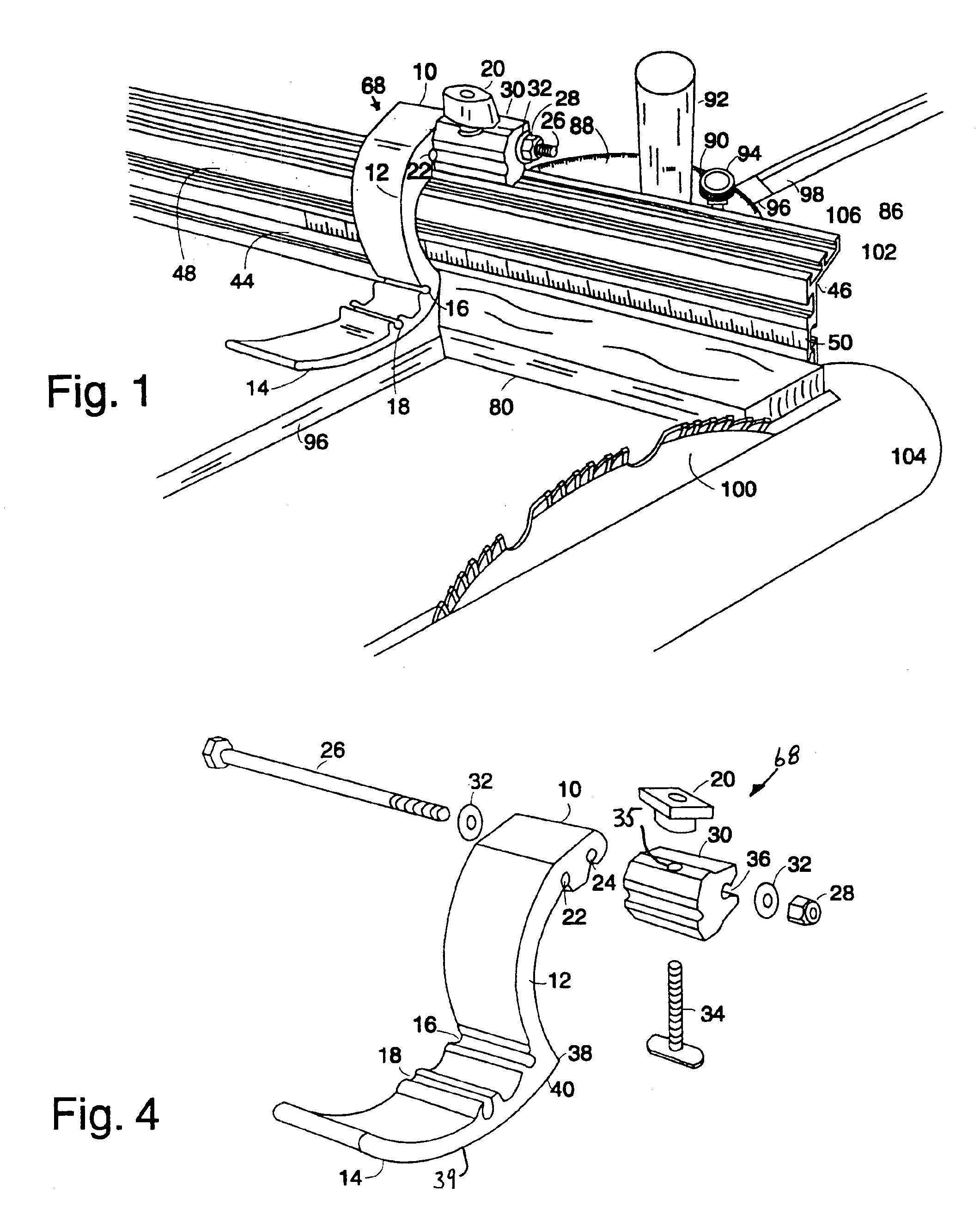

Improved Universal Machinery Fence System

A universal machinery fence system includes an L-shaped fence or a box shaped fence and clamp block which clamps to a rail extrusion with a half dovetail on the front on the edge of a table saw, band saw, shaper, router table, mortiser, or other woodworking or metal working machines. A U-shaped front rail is provided for attaching the fence to the cast iron table of a table saw, shaper, or band saw. The band saw fence U-shaped rail is predrilled to fit the table fence mounting holes of the most popular 14″ band saws. Optional extruded front rails are also provided for attaching the fence to shop made 0.750″ tables such as used on a drill press. Also provided is a fence rail extrusion for mounting the fence on the front and back of the popular 1.125″ size router table. An optional extruded front rail which is adjustable in height is also provided for attaching the fence to shop made tables between 0.750″ and 1.5″ in thickness. A re-saw guide fitted to the fence extrusion has a convex surface for supporting a workpiece on edge allowing the operator to easily adjust for blade drift. An optional micro-adjuster allows the fence to move accurately in small increments. A router table with holes and slots allows the fence to be used to guide the workpiece in the router table mode and then be used to guide the router or a saw on top of the workpiece.

Owner:KREG ENTERPRISES

Woodworking machinery stop and track system

Owner:KREG ENTERPRISES

Horizontal hold down jig

InactiveUS7341081B1Uniform pressureEasy to useWood feeding arangementsFeeding devicesCompressive strengthMechanical engineering

A horizontal rotary hold down jig for use in horizontally guiding a piece of wood to be cut on one of a portable table saw and a portable router table comprising a spring biased rotatable wheel that can be secured to the table. The spring biasing can be adjusted to provide uniform or enhanced pressure through use of a plurality of substitutable compression springs of varying compressive strength characteristics to laterally stabilize a piece of wood of varying consistency, wood grain angle, feed cutting speed, width, and thickness or depth of cut.

Owner:VILLIGER ERIC J

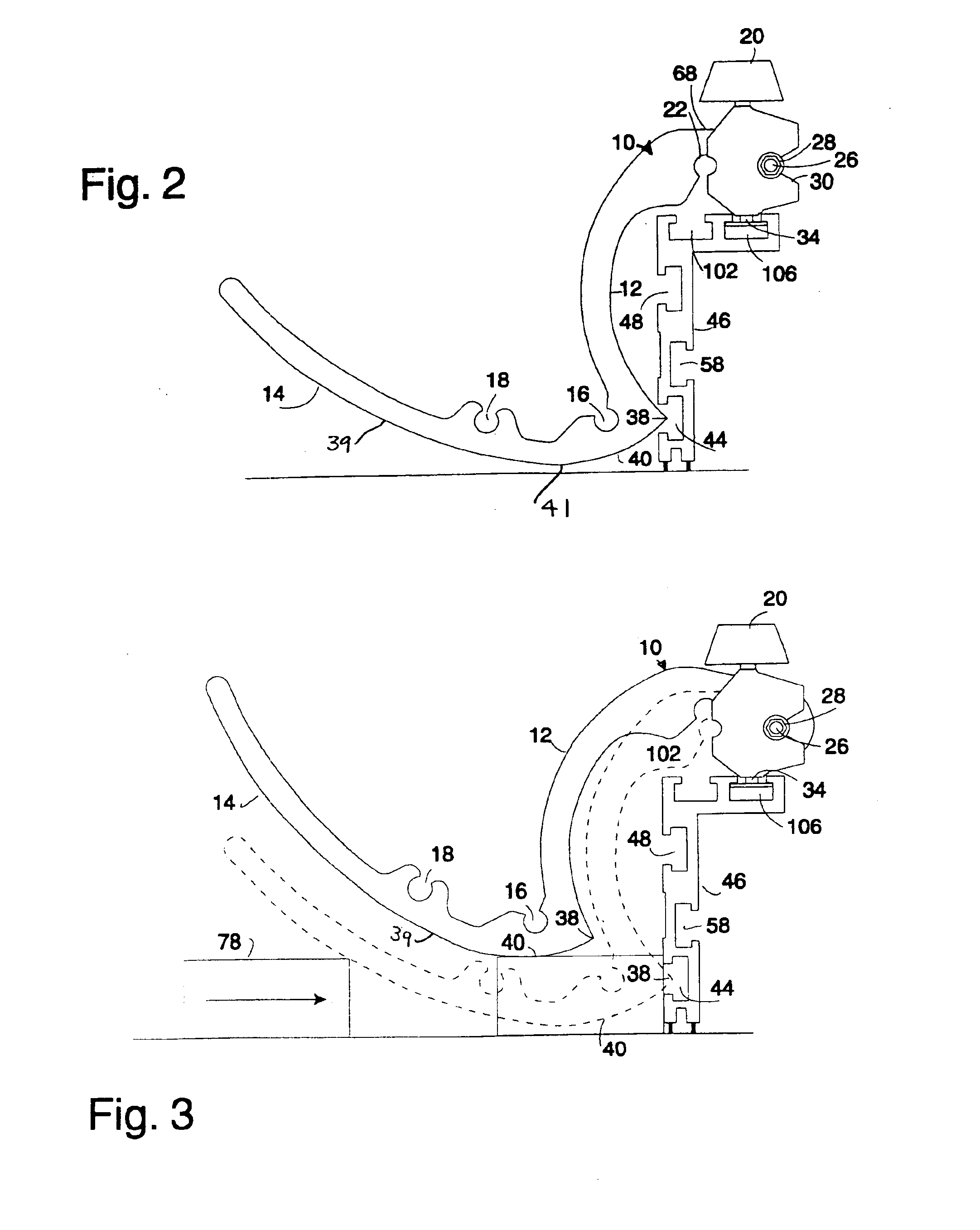

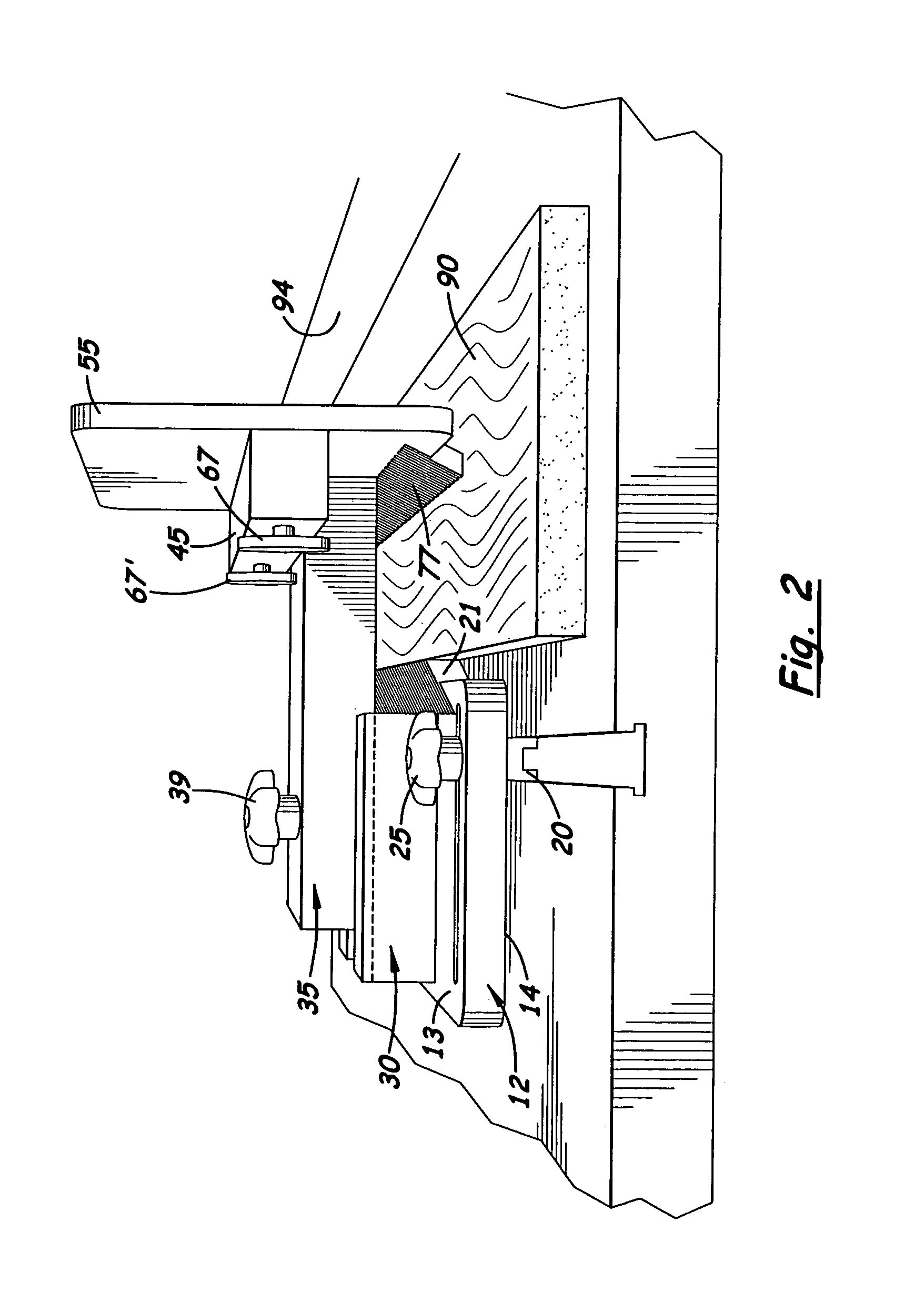

Combination workpiece positioning/hold-down and anti-kickback device for a work table

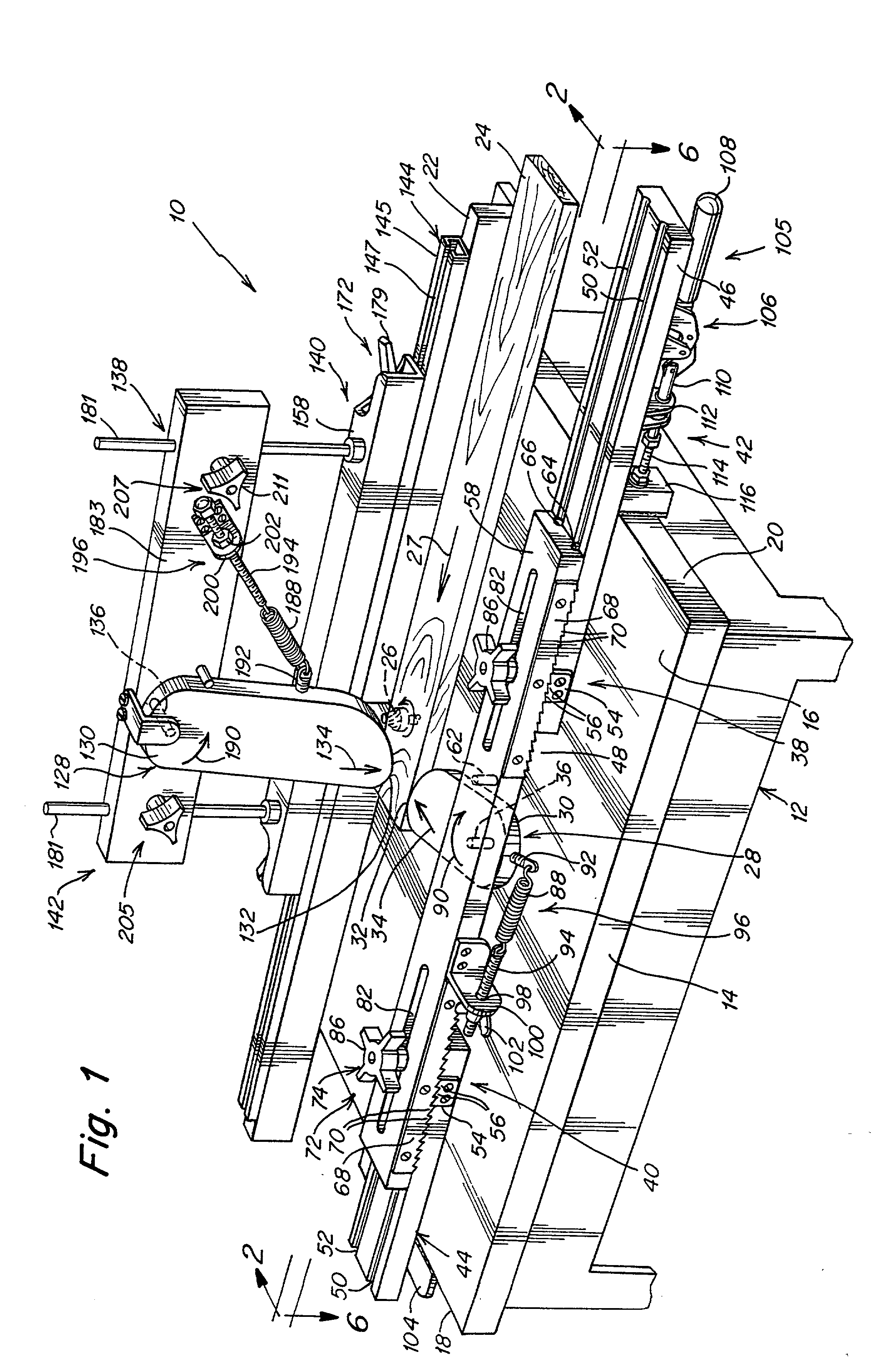

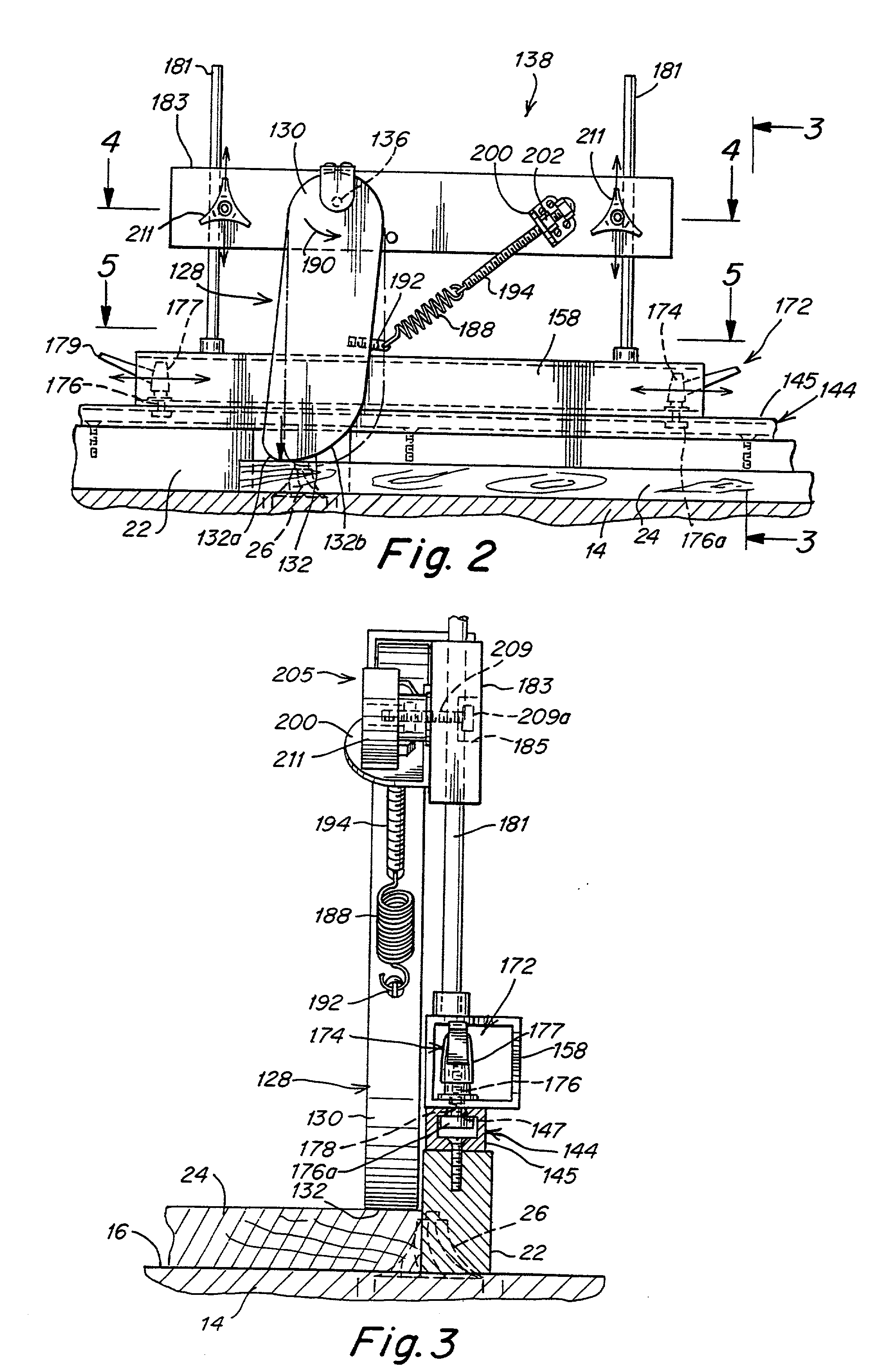

InactiveUS20020029822A1Preventing kick-backInherent disadvantageMetal sawing devicesWood feeding arangementsEngineeringCam

A combination workpiece positioning, hold-down and anti-kickback device for a work table having a fence against which a workpiece is guided, includes a non-rotatable positioning member having an arcuate cam surface at one edge for engaging a side surface of a workpiece on the work table; an adjustment device for moving the positioning member in lengthwise and transverse directions relative to the workpiece and for locking the same thereat; a pivot pivotally mounting the positioning member to the adjustment device; a spring connected between the positioning member and the adjustment device for biasing the positioning member in a pivot direction into engagement with the side surface of the workpiece; a variable tensioning device for variably adjusting the biasing force of the spring; a non-rotatable hold-down member having a second arcuate cam surface at one edge for engaging an upper surface of the workpiece; an adjustment device for moving the hold-down member in lengthwise and vertical directions relative to the workpiece, and for locking the same thereat; a pivot pivotally mounting the hold-down member to the second adjustment device; a second spring connected between the hold-down member and the adjustment device for biasing the hold-down member in a second pivot direction into engagement with the upper surface of the workpiece; and a second variable tensioning device for variably adjusting the biasing force of the second spring.

Owner:JUKOFF PETER

Adjustable router guide template assembly

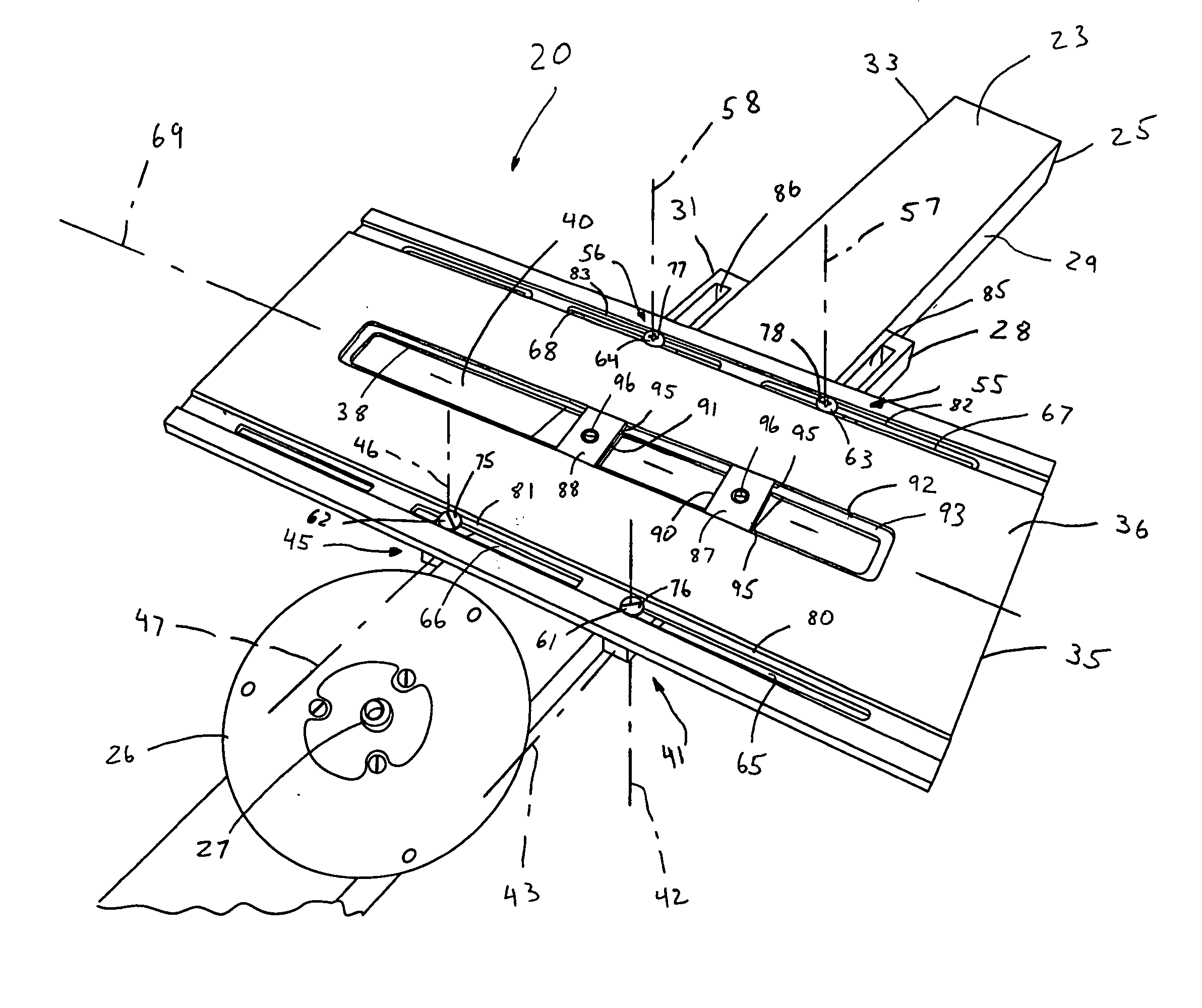

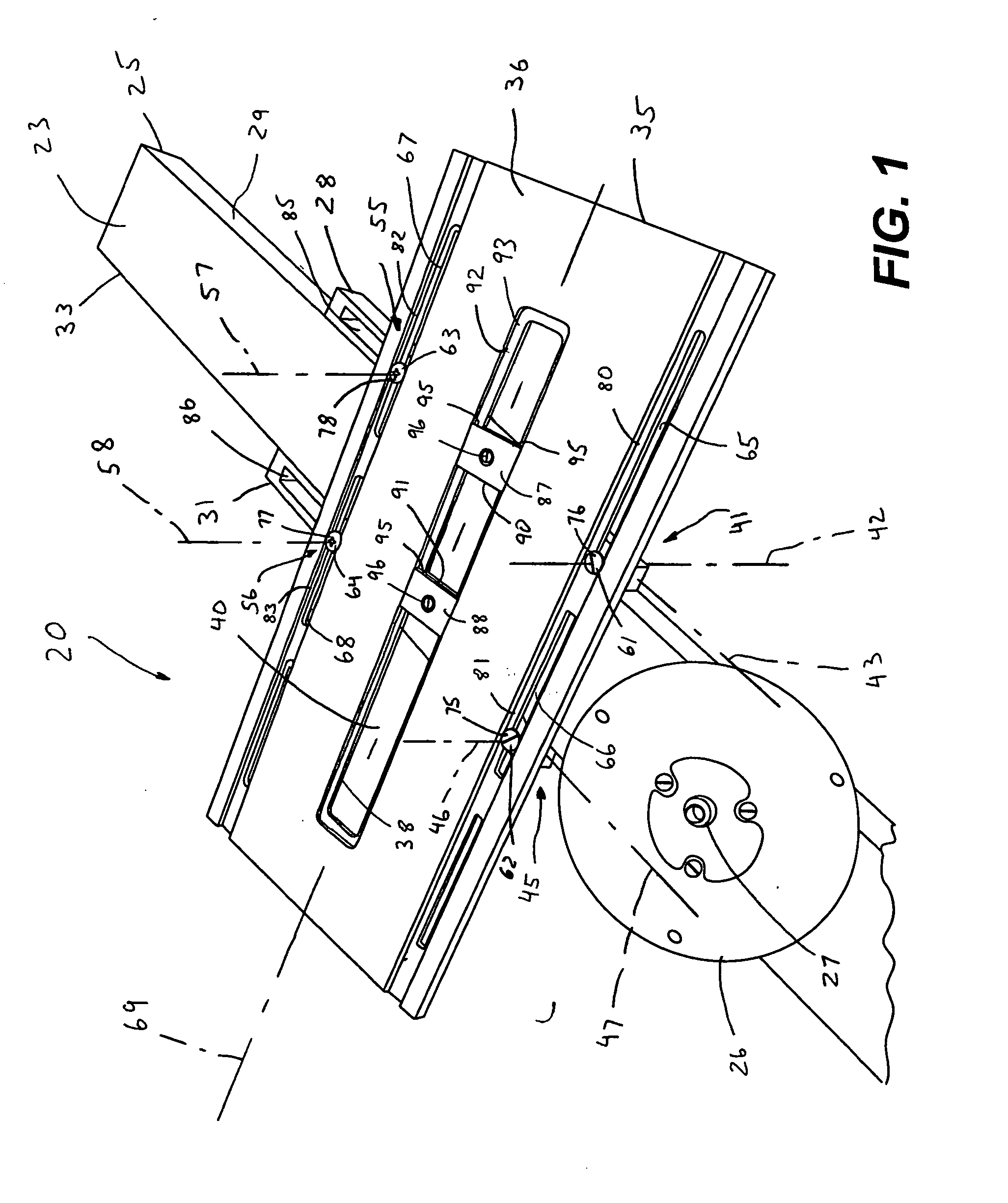

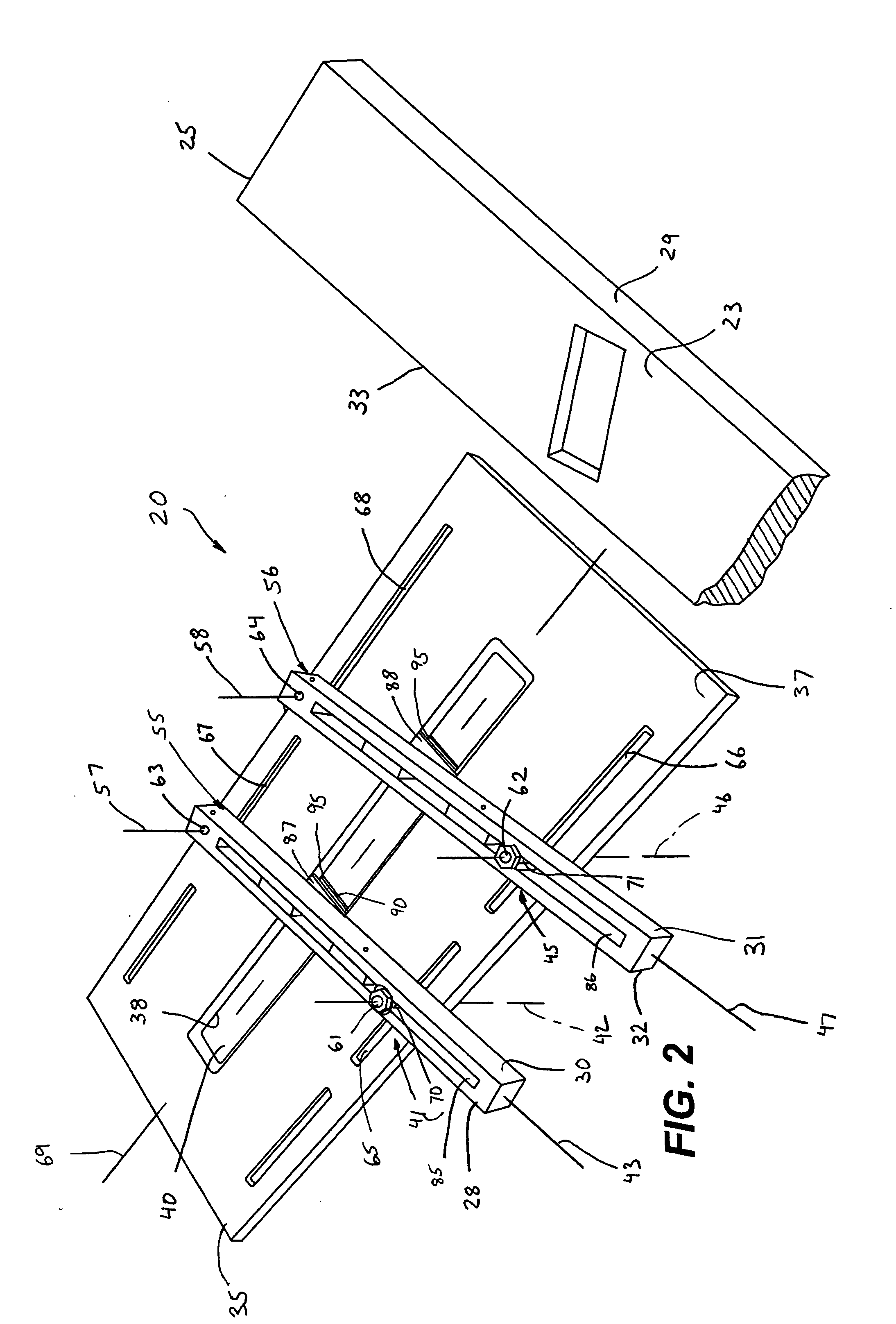

InactiveUS20050236069A1Easy to operateEasily interchangeableWood feeding arangementsFeeding devicesInterconnectionEngineering

An adjustable guide assembly to guide a cutter bit of a tool device about a cutting surface of a workpiece. The guide assembly includes an elongated first guide rail having a first abutting surface adapted to abut a first side wall of the workpiece, and a second guide rail spaced-apart from the first guide rail, and having a second abutting surface adapted to abut a second side wall of the workpiece. A base member is positioned over the first and second guide rails, and includes a tool support surface and an opposed workpiece support surface. The base member includes a contacting wall defining a bit passage therethrough. A first and second interconnection assembly is configured to releasably lock the first and second guide rail, respectively, to the base member in a manner enabling the first guide rail to pivot about a first axis substantially perpendicular to a longitudinal axis of the first guide rail, and the second guide rail to pivot about a second axis substantially perpendicular to a longitudinal axis of the second guide rail, respectively. Further, the first interconnection assembly and the second interconnection assembly enable the first guide rail and the second guide rail to slide along the base member along respective paths adjacent to the bit passage. The first guide rail and the second guide rail are adjusted to abut the workpiece first side wall and the workpiece second side wall in a manner releasably positioning a targeted cutting region of the workpiece cutting surface in the bit passage.

Owner:OBRIEN VINCENT E

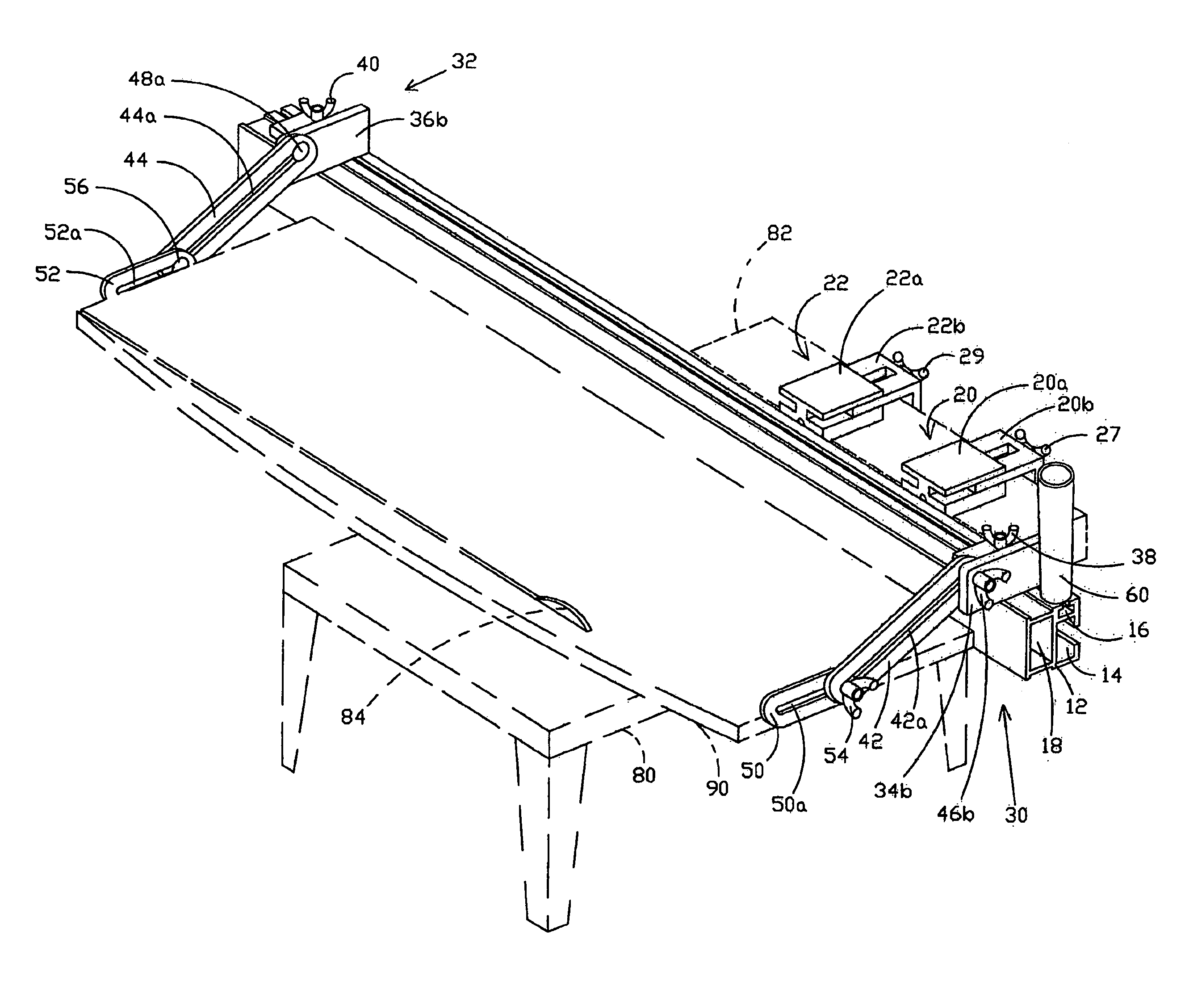

Cutting table fence

A fence is described for attachment to a cutting table or in combination with a cutting table. The fence includes pair of elongated guide rails with brackets configured to be mounted to the cutting table. An endless chain is provided on each guide rail, trained about sprockets rotatably mounted on the guide rail. Each chain includes a working flight that extends along the associated guide rail. Each chain further includes sprocket tooth receiving spaces. A shaft interconnects, one of the sprockets on one guide rail with one of the sprockets on the remaining guide rail such that rotation of the shaft will result in all the sprockets rotating in unison, causing uniform and equal movement of the chain. An elongated cutting guide is provided with aligning lugs that are releasably received within selected tooth receiving spaces of the chains in such a manner that the cutting guide may be selectively engaged with the chains and lifted from the chains. A locking mechanism is configured to secure the cutting guide in a selected position along the working flights of the chains.

Owner:KENNELLY JOHN P

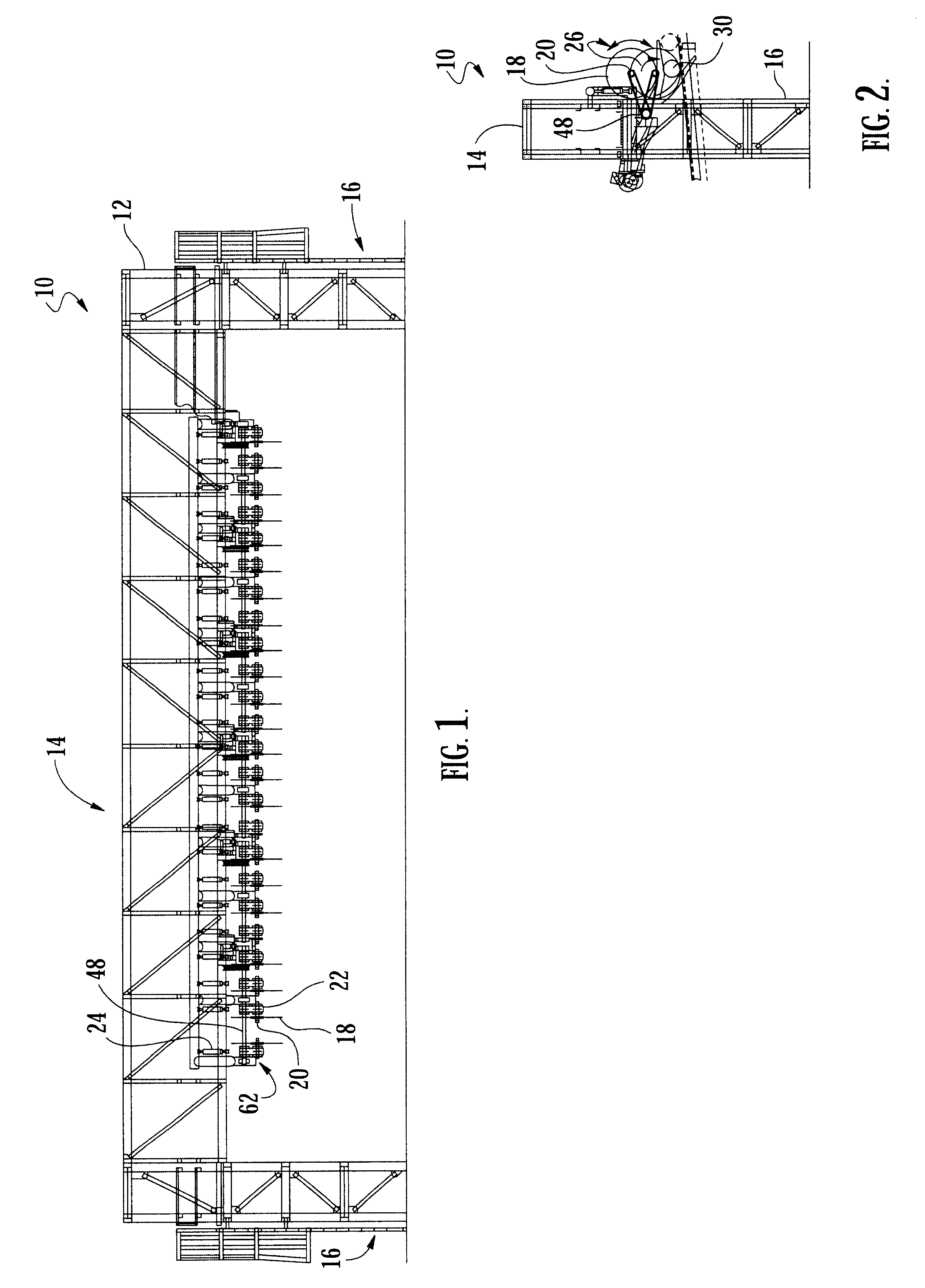

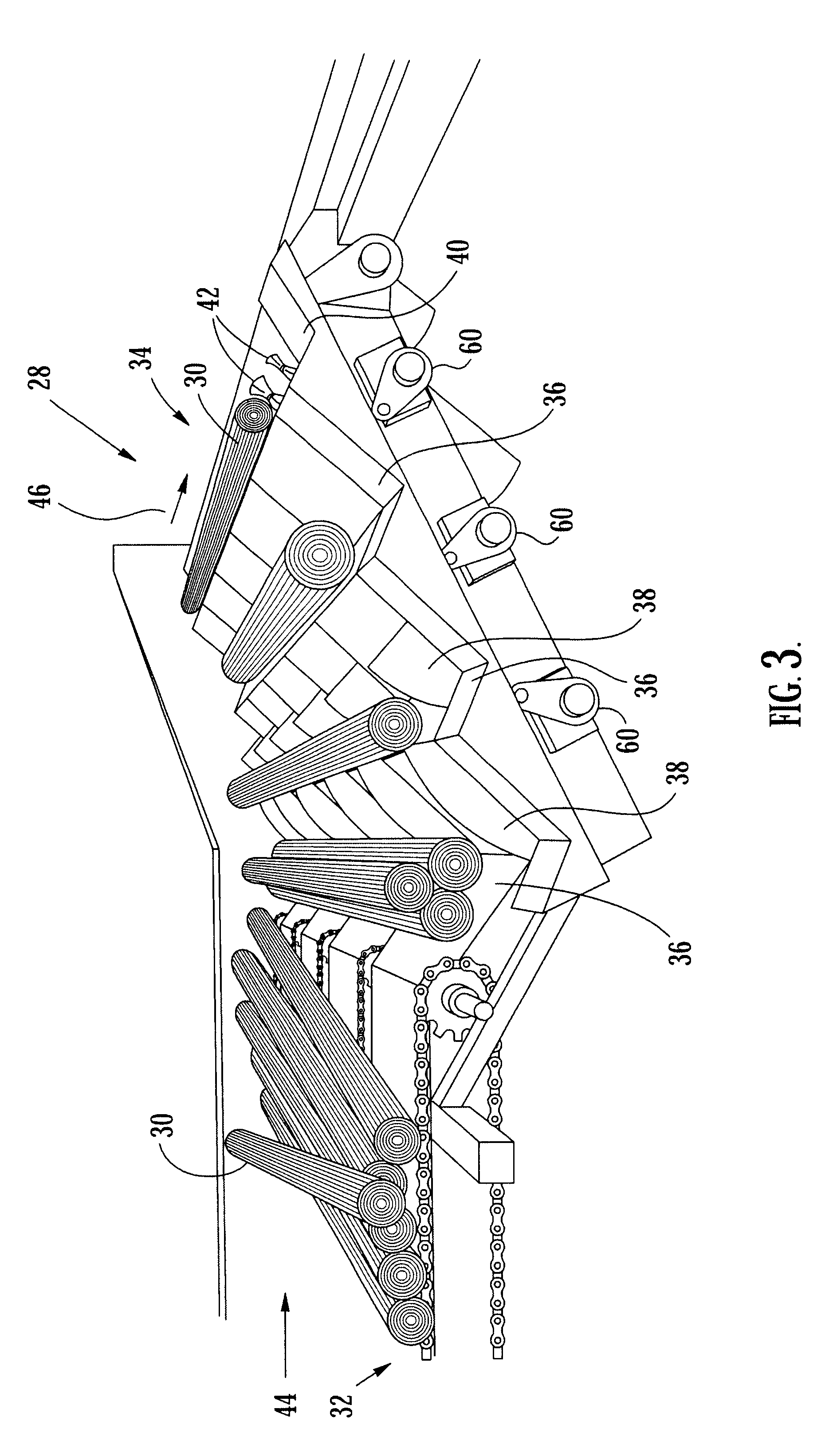

Systems and methods for end squaring and dividing elongated materials

ActiveUS20050189040A1Reduce maintenance costsReducing machine down timeFeeding apparatusCircular sawsEngineering

Owner:GLOBE MACHINE MFG

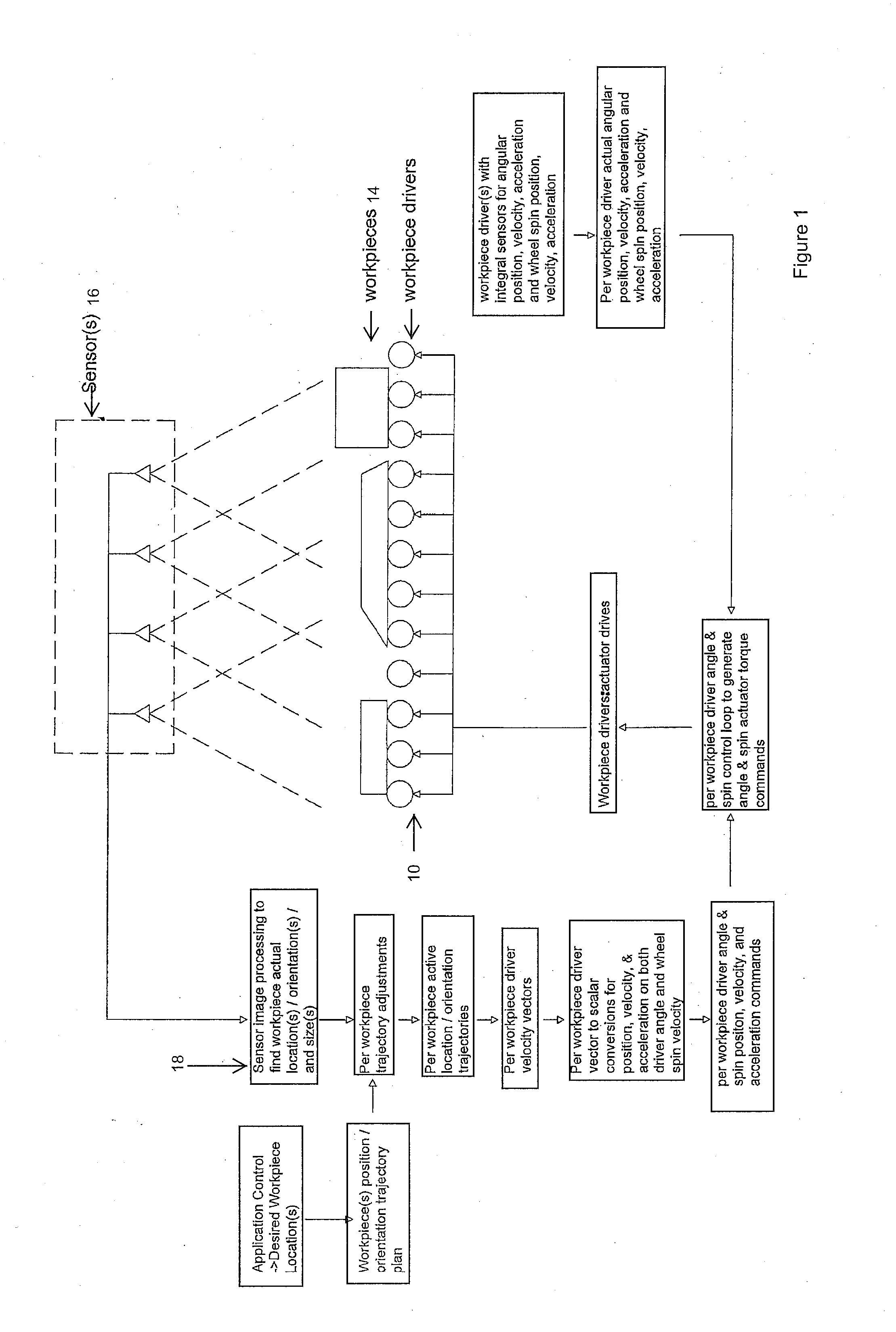

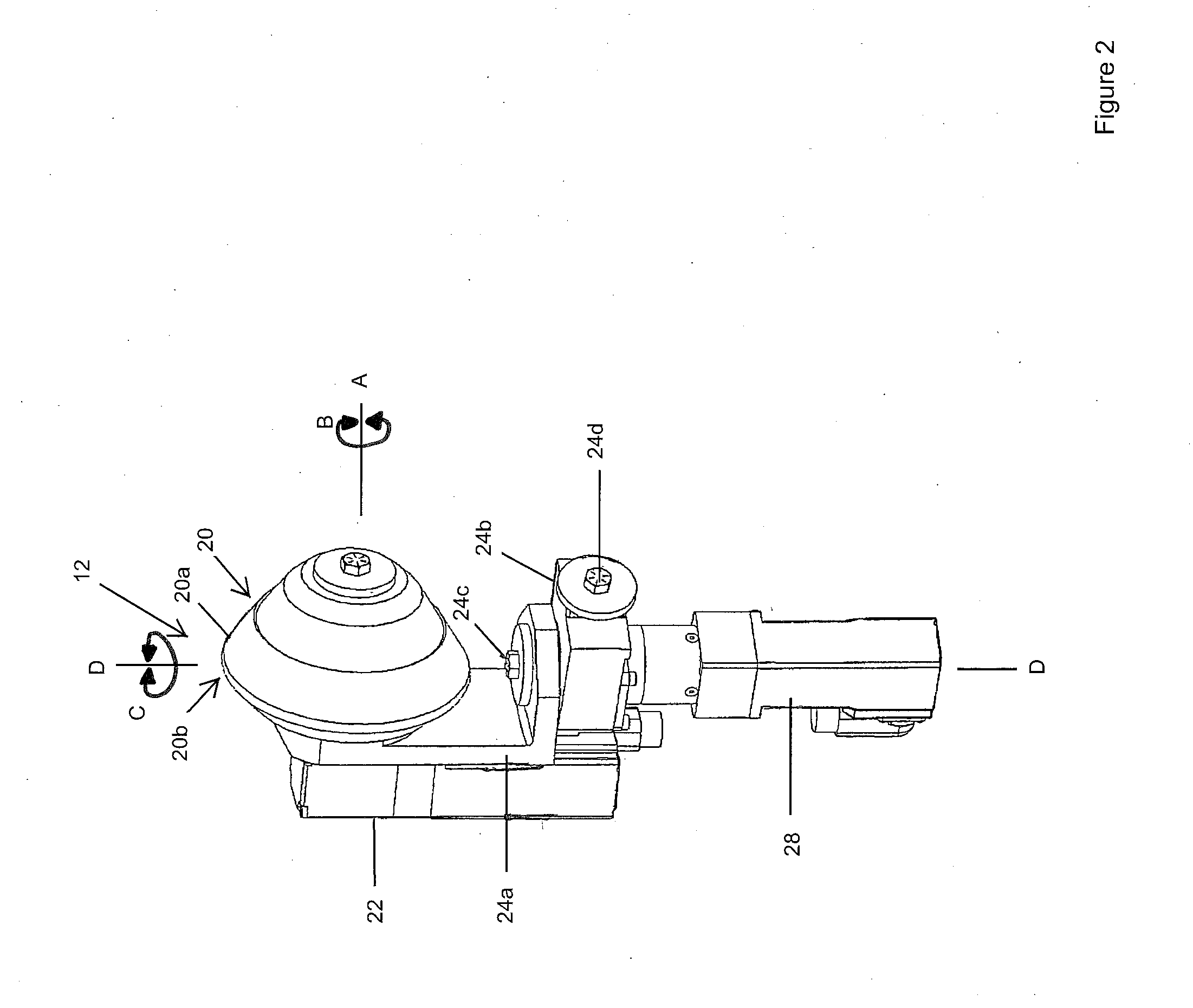

Positioning table

A material handling system includes an array of independently controlled positioning devices, a positioning table which support and manipulate workpiece attributes such as position, orientation, velocity and / or acceleration of workpieces on the table. The positioning devices are arrayed such that no single positioning device supports more than one workpiece at a time, thereby allowing for simultaneous and independent control of each workpiece.

Owner:AMS SOLUTIONS

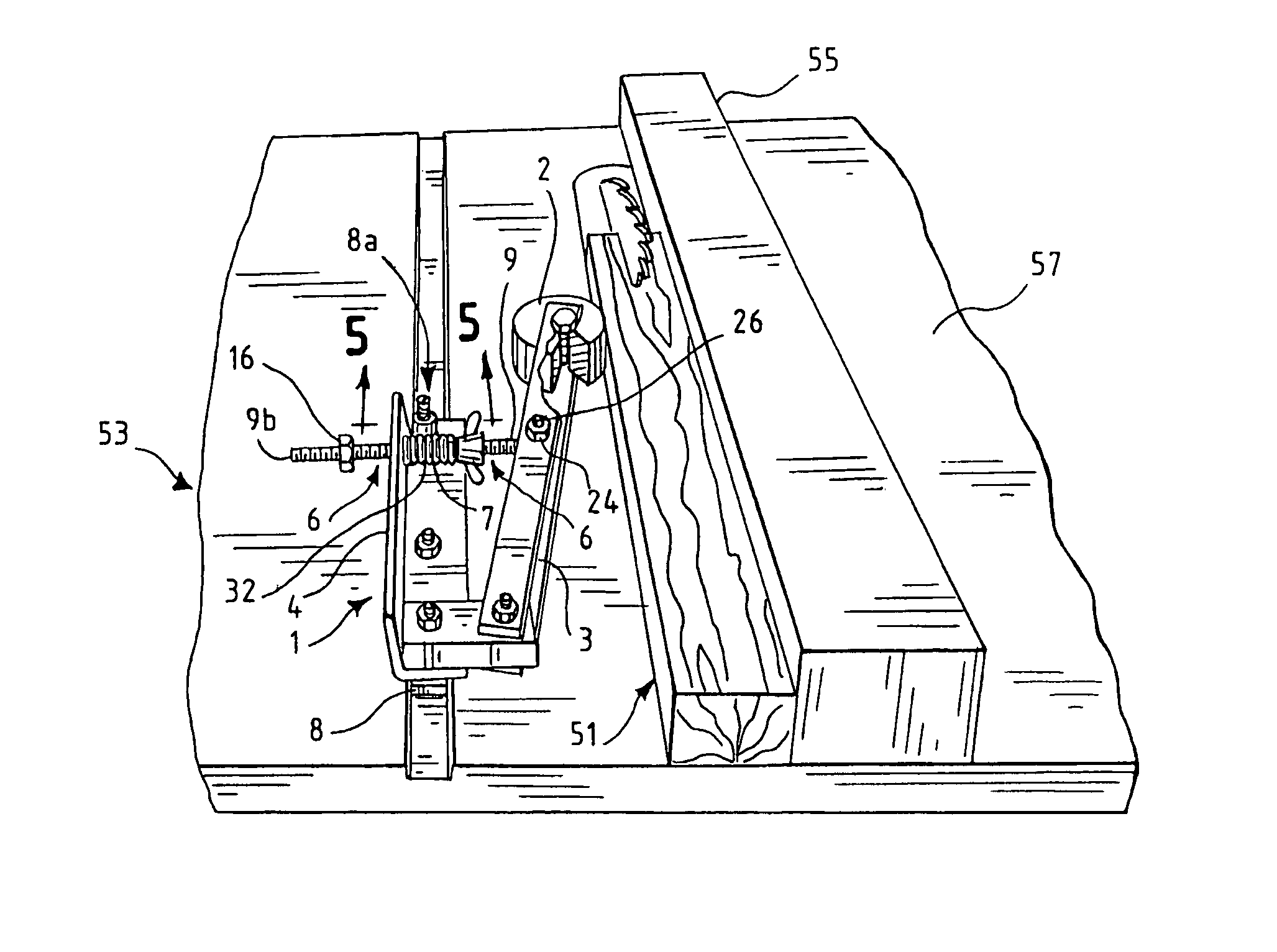

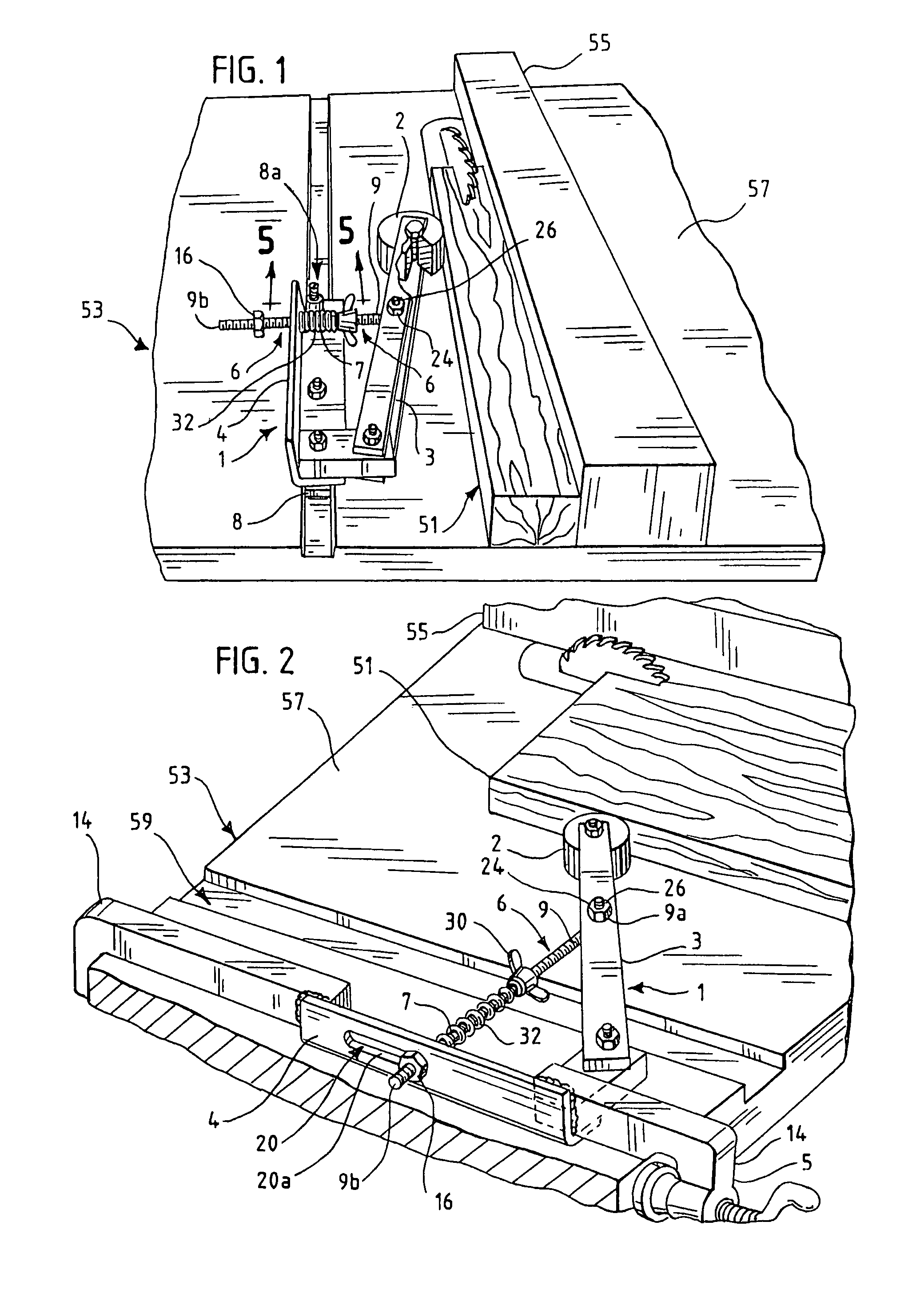

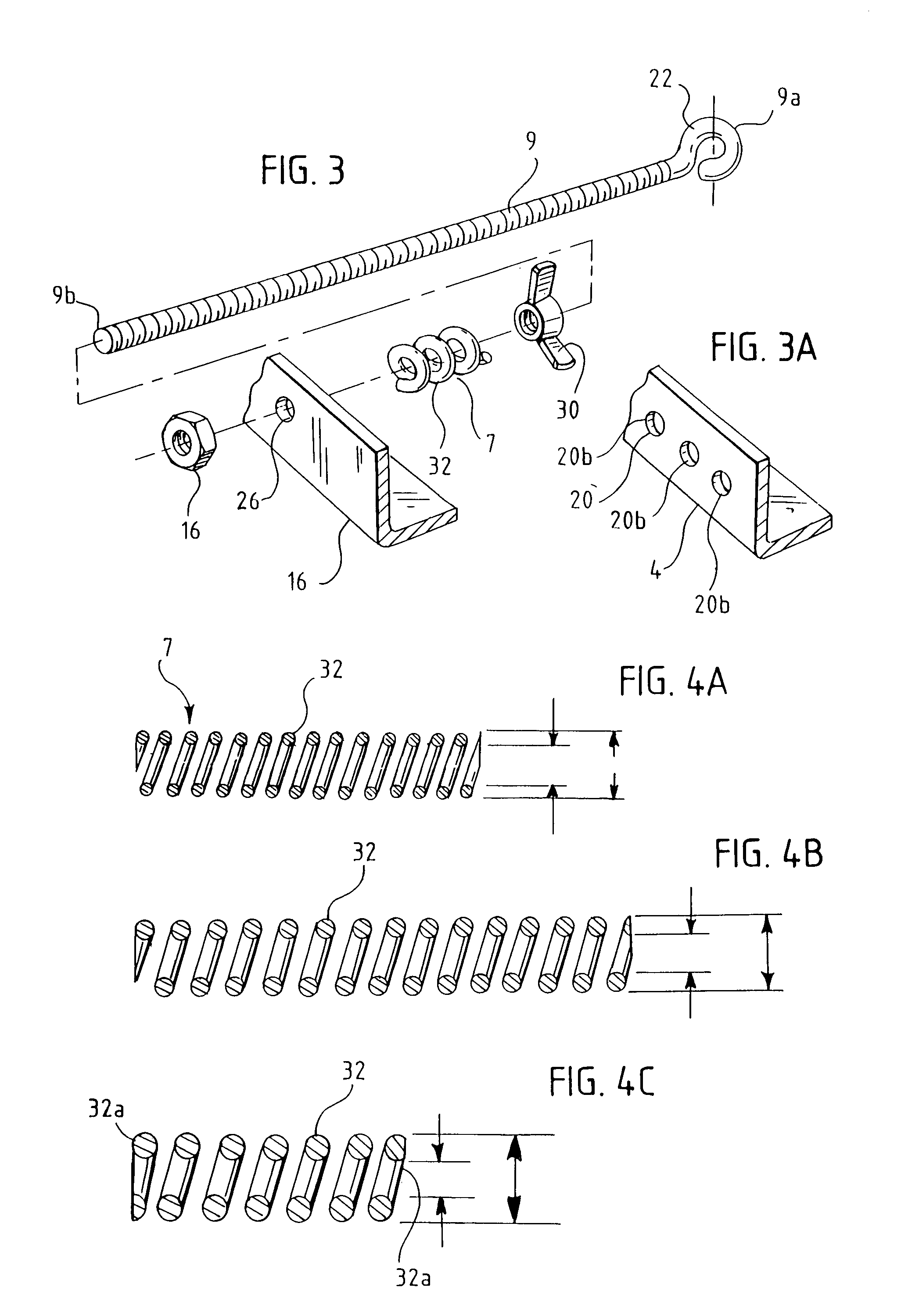

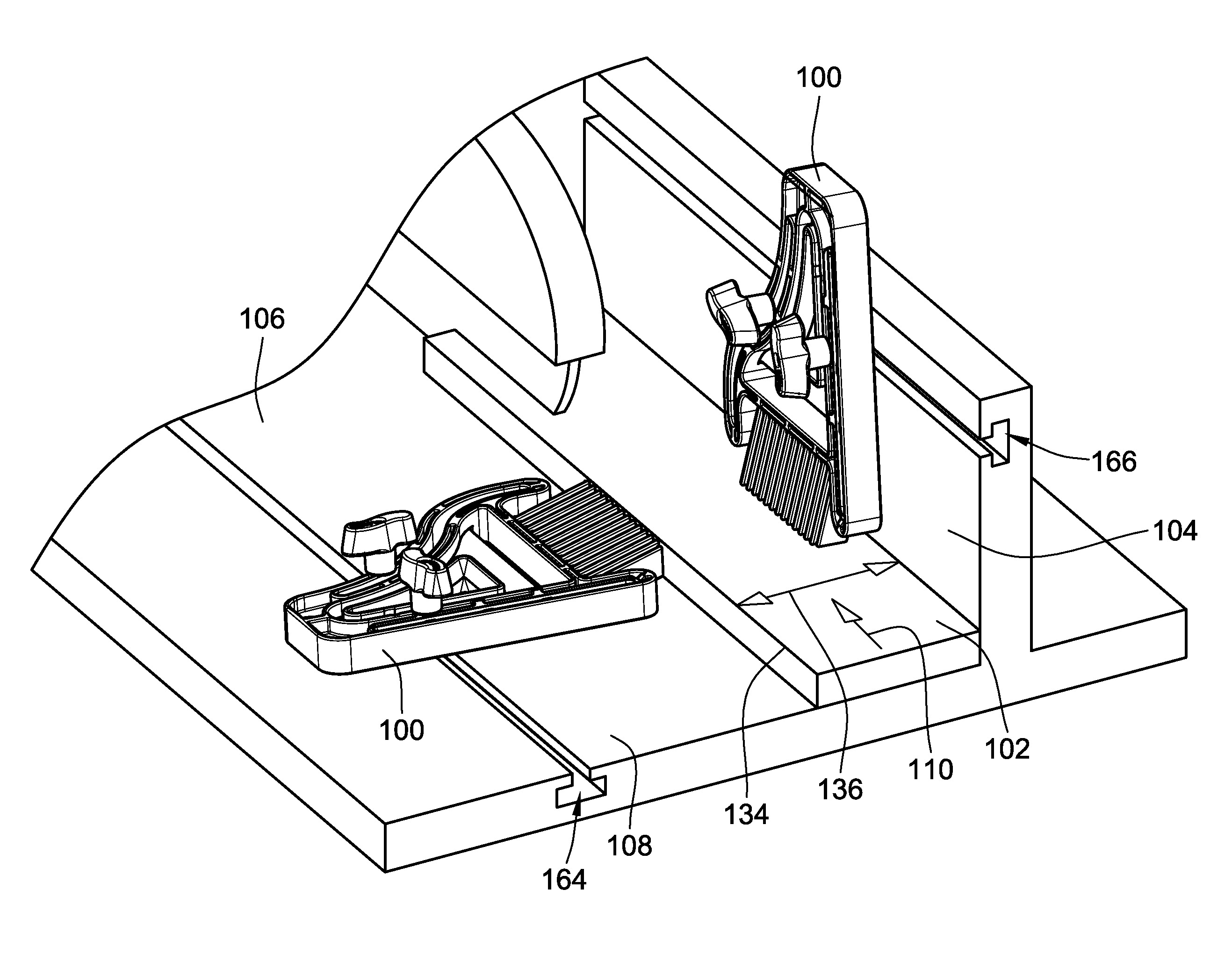

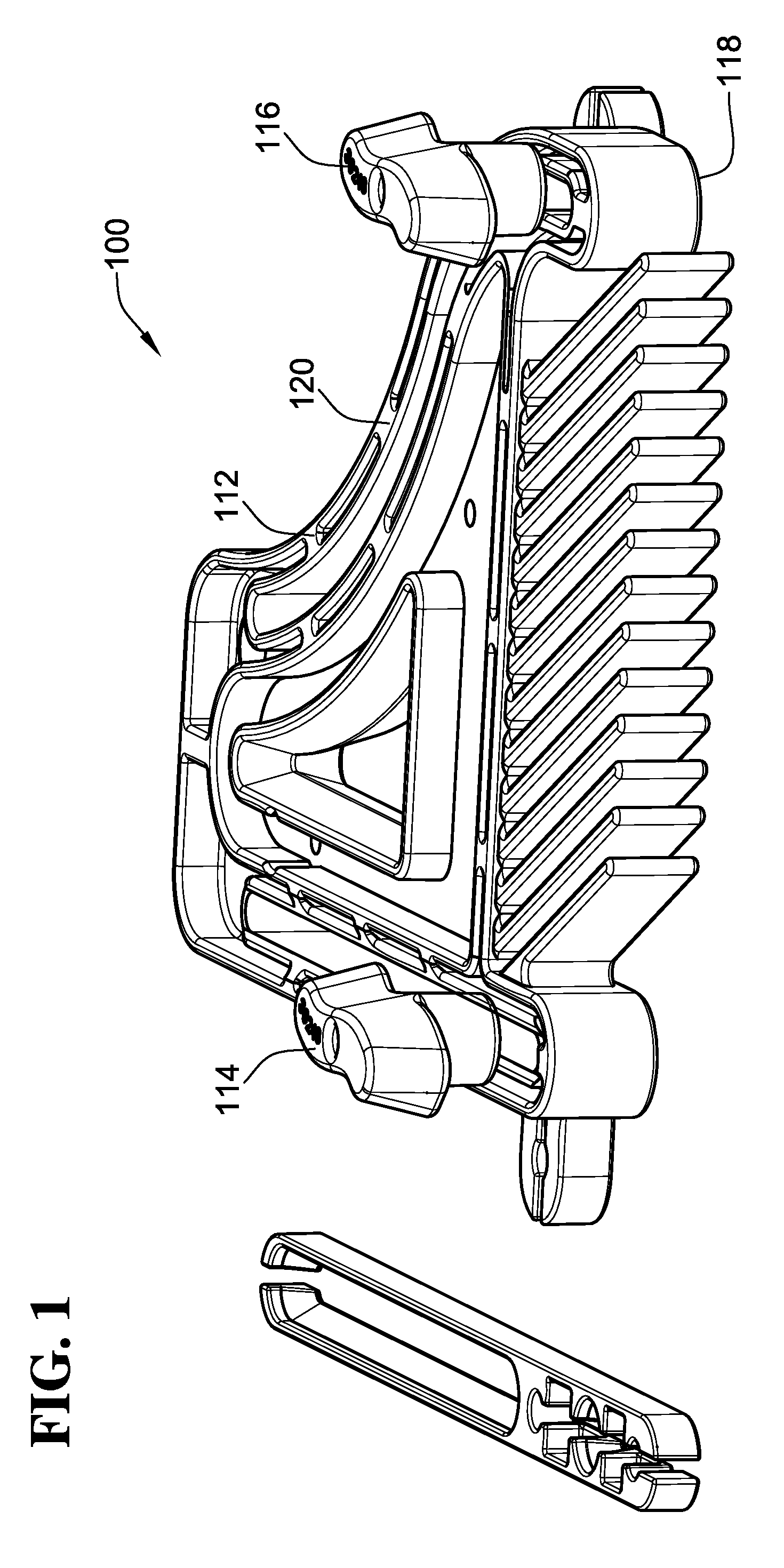

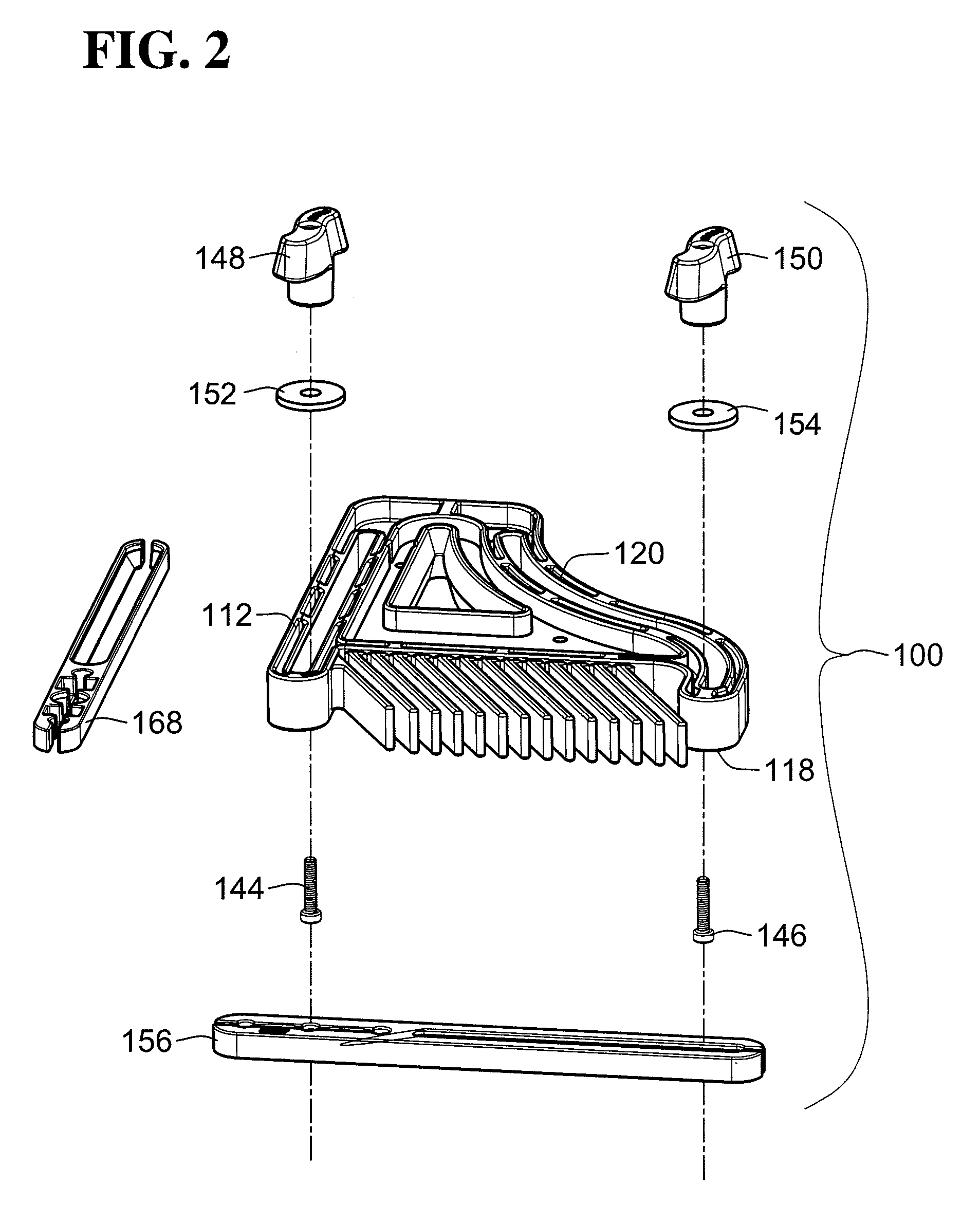

Dual adjustable feather jig

A dual adjustable feather jig for simultaneously holding a piece of wood stock firmly against a stationary rip fence and against the top surface of a worktable. The feather jig includes a lower feather board with a ‘T’ in channel bar adjustably mounted on the bottom surface of the lower feather board to laterally adjust the lower feather board over the worktable. Mounted transversely on the lower feather board is an upper feather board assembly that includes a vertical feather board to hold the wood piece against the worktable. The vertical feather board is connected to a slider arm that slides longitudinally over a riser block securely mounted to the lower feather board. Formed on the lateral and lower edges of the lower and vertical feather boards, respectively, are diagonally aligned fingers that press the wood piece against the rip fence and against the top surface of the worktable.

Owner:SCHWARTZ NEAL K

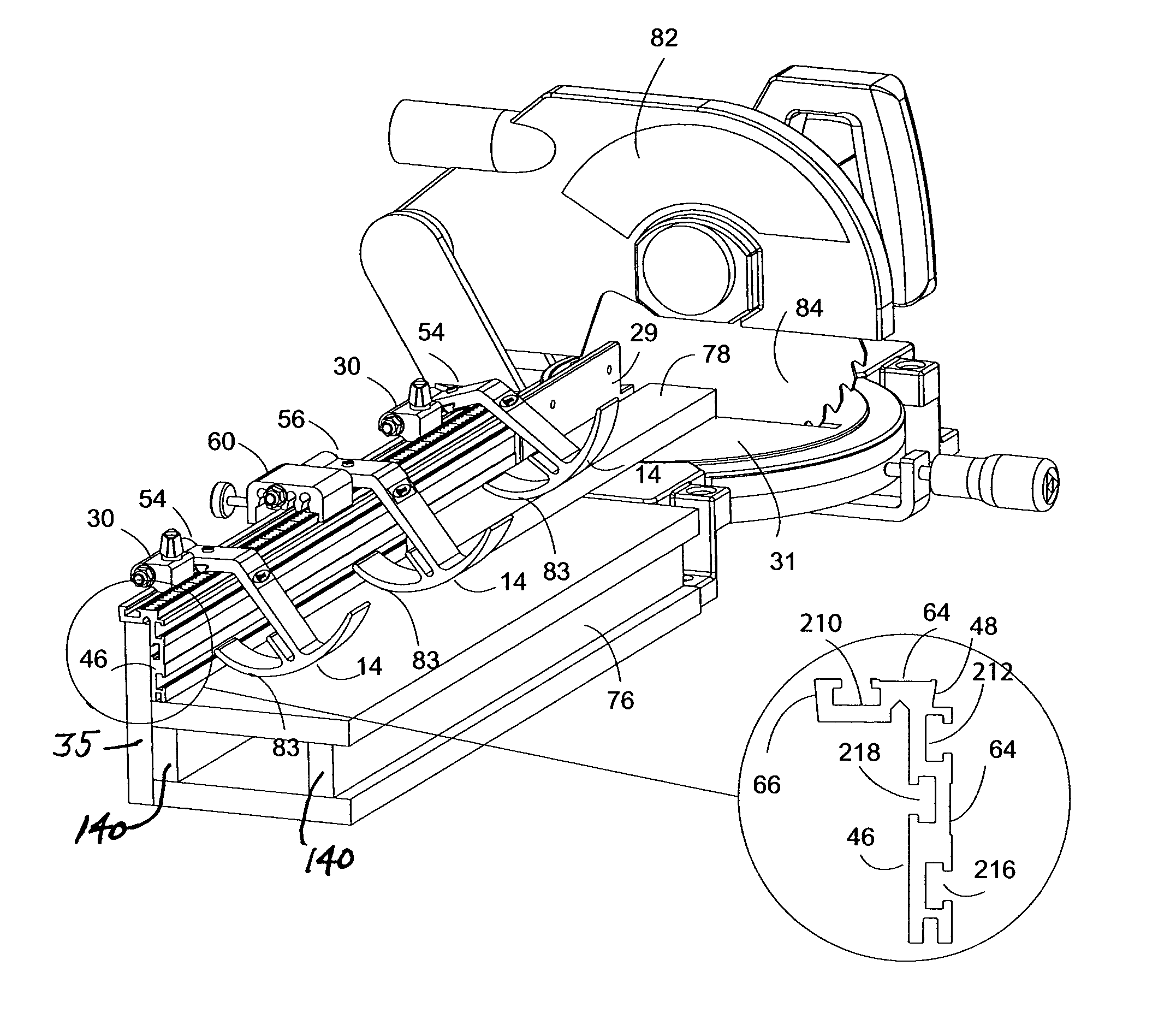

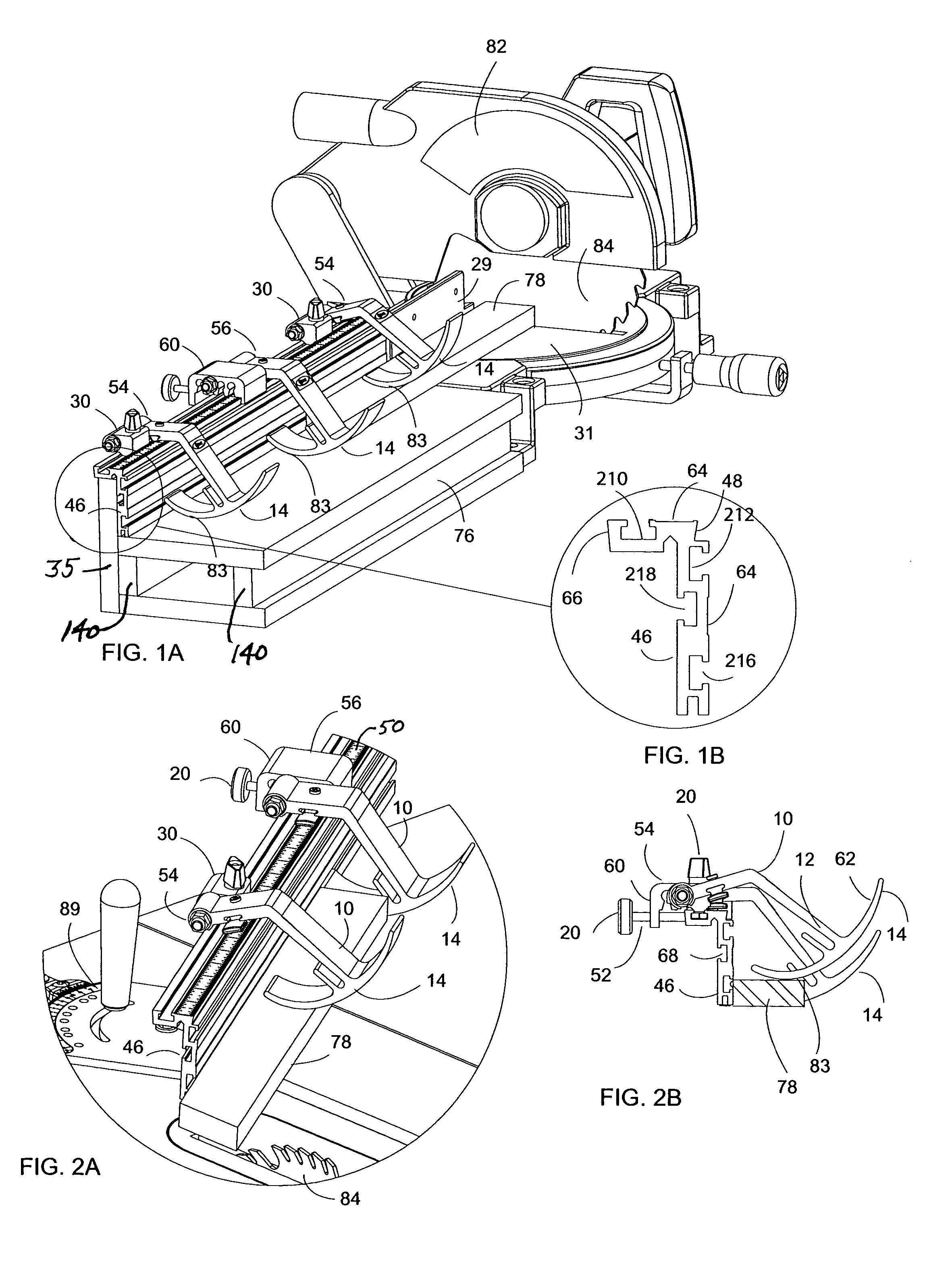

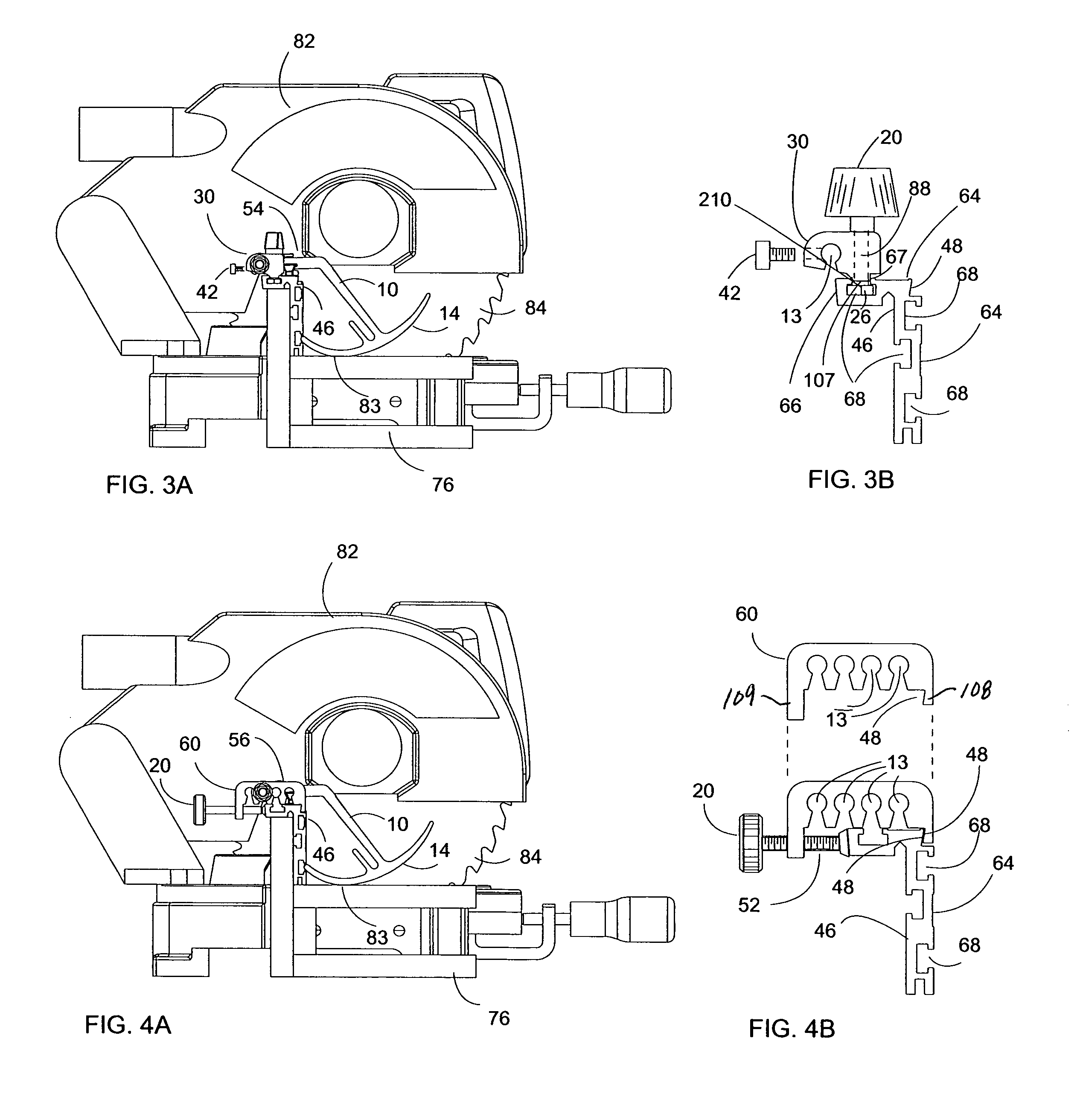

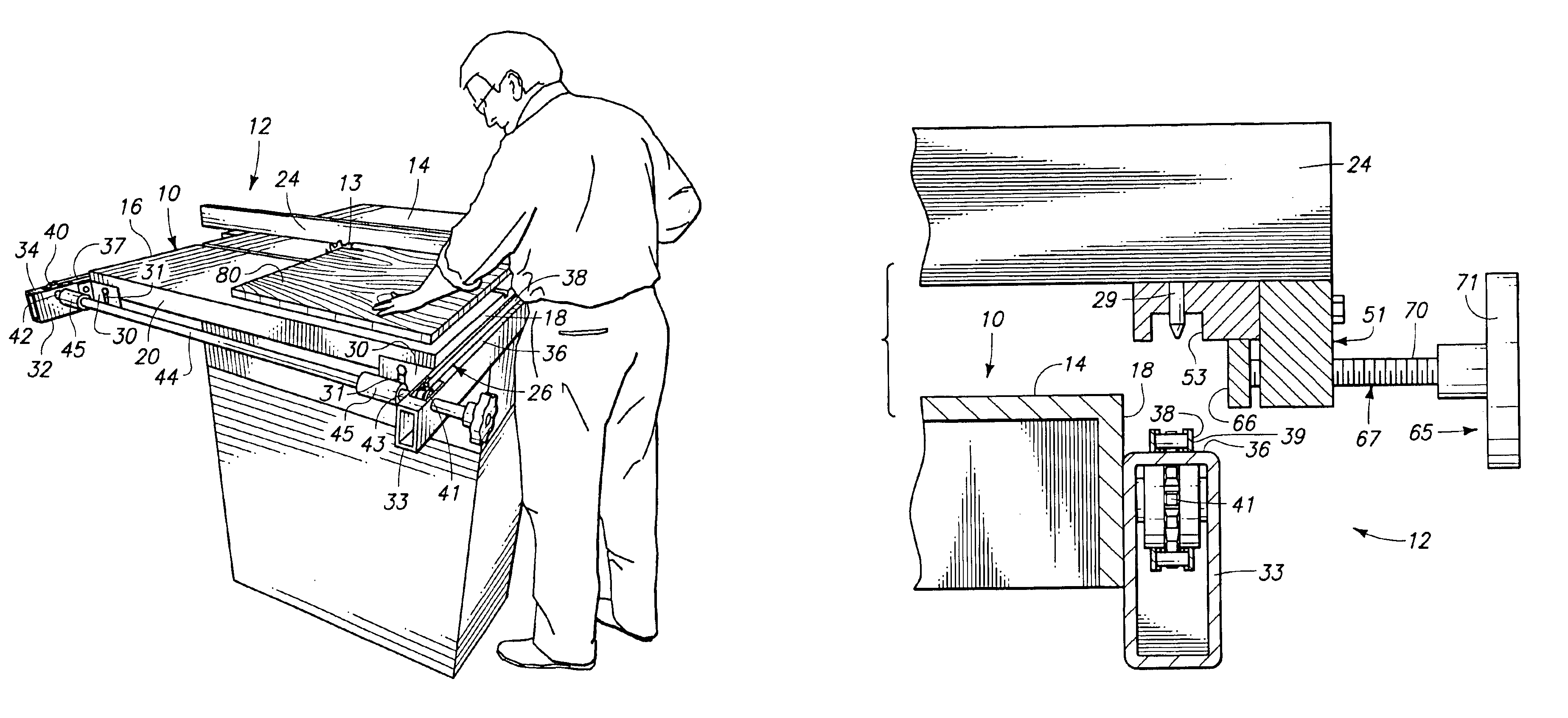

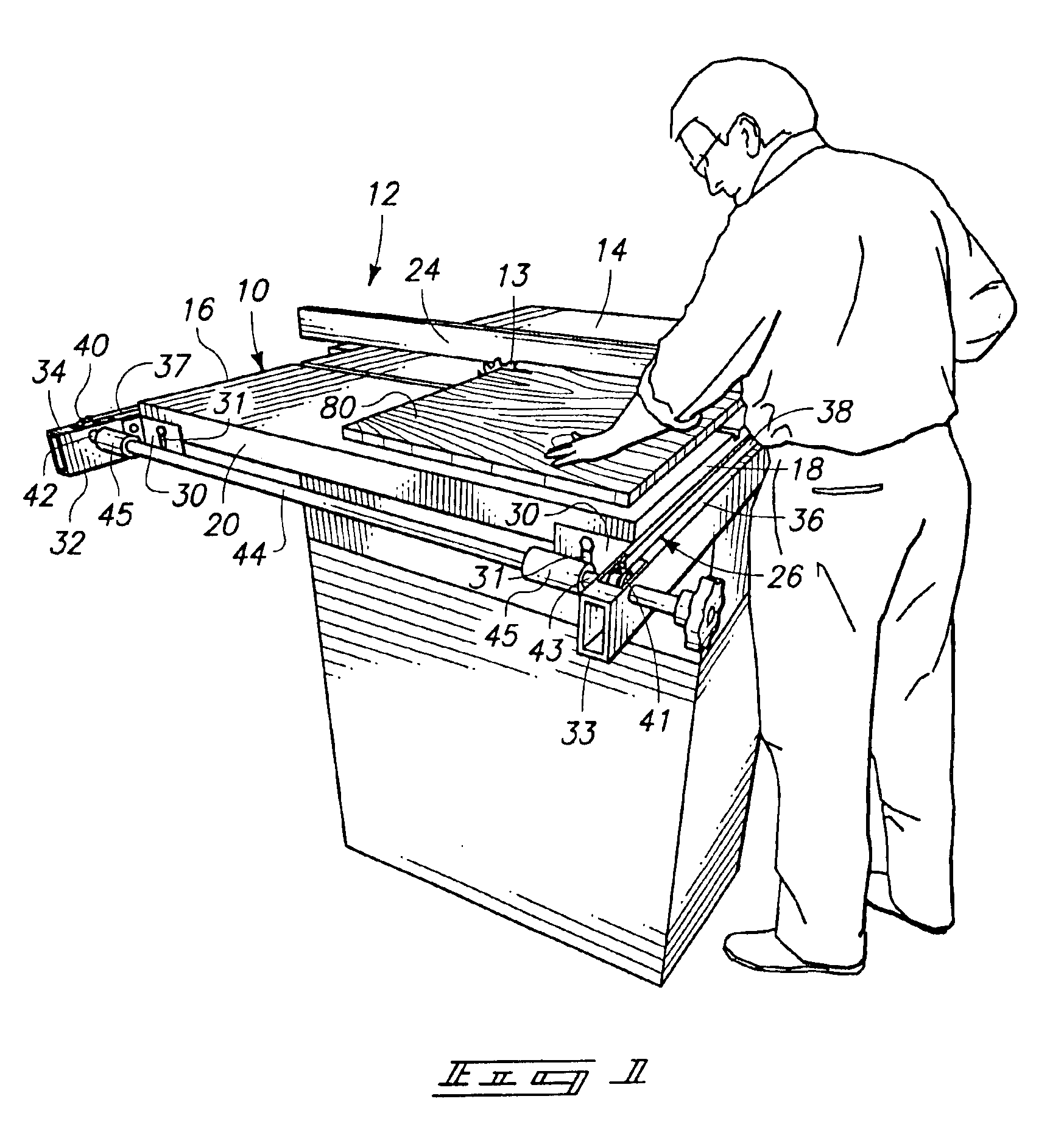

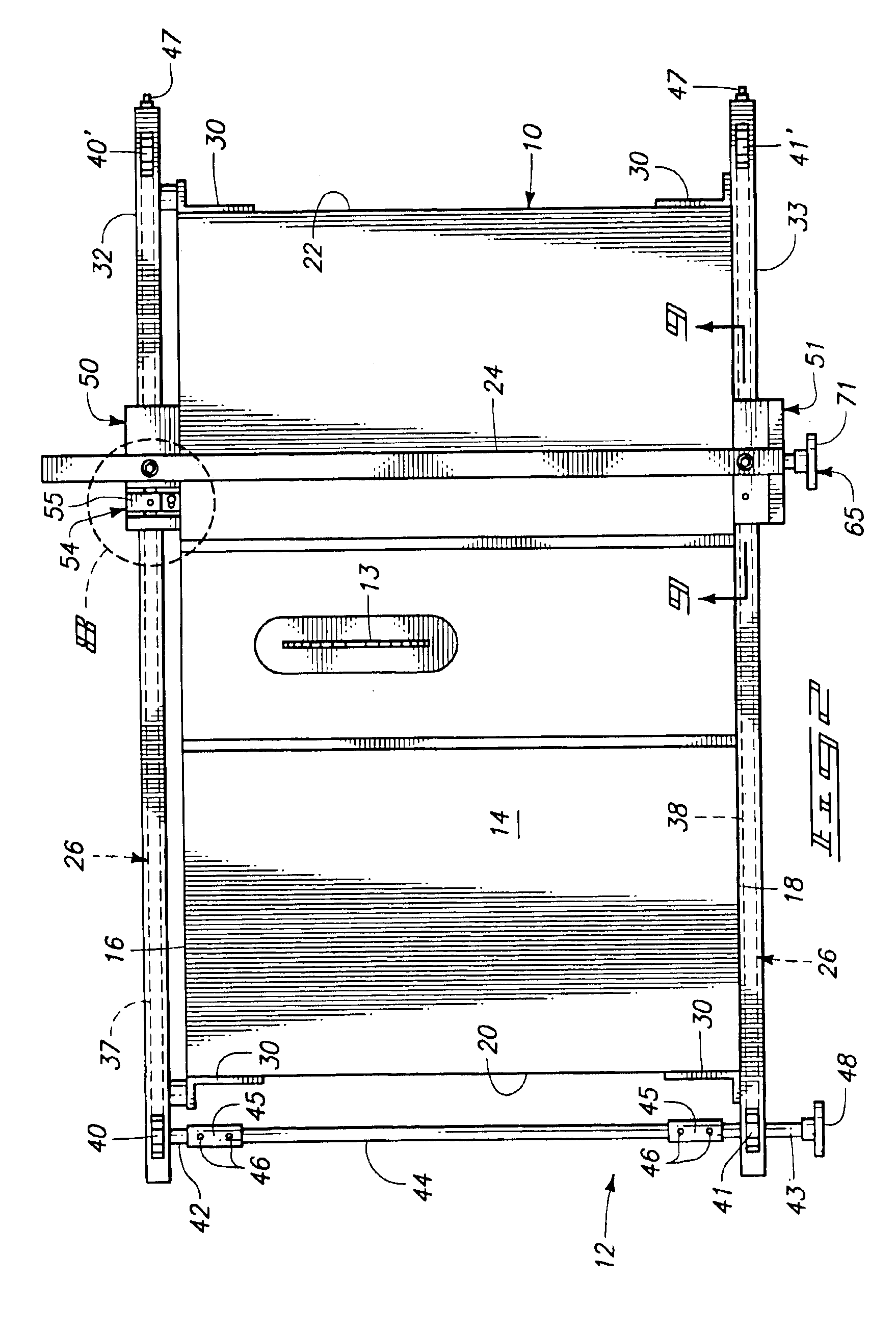

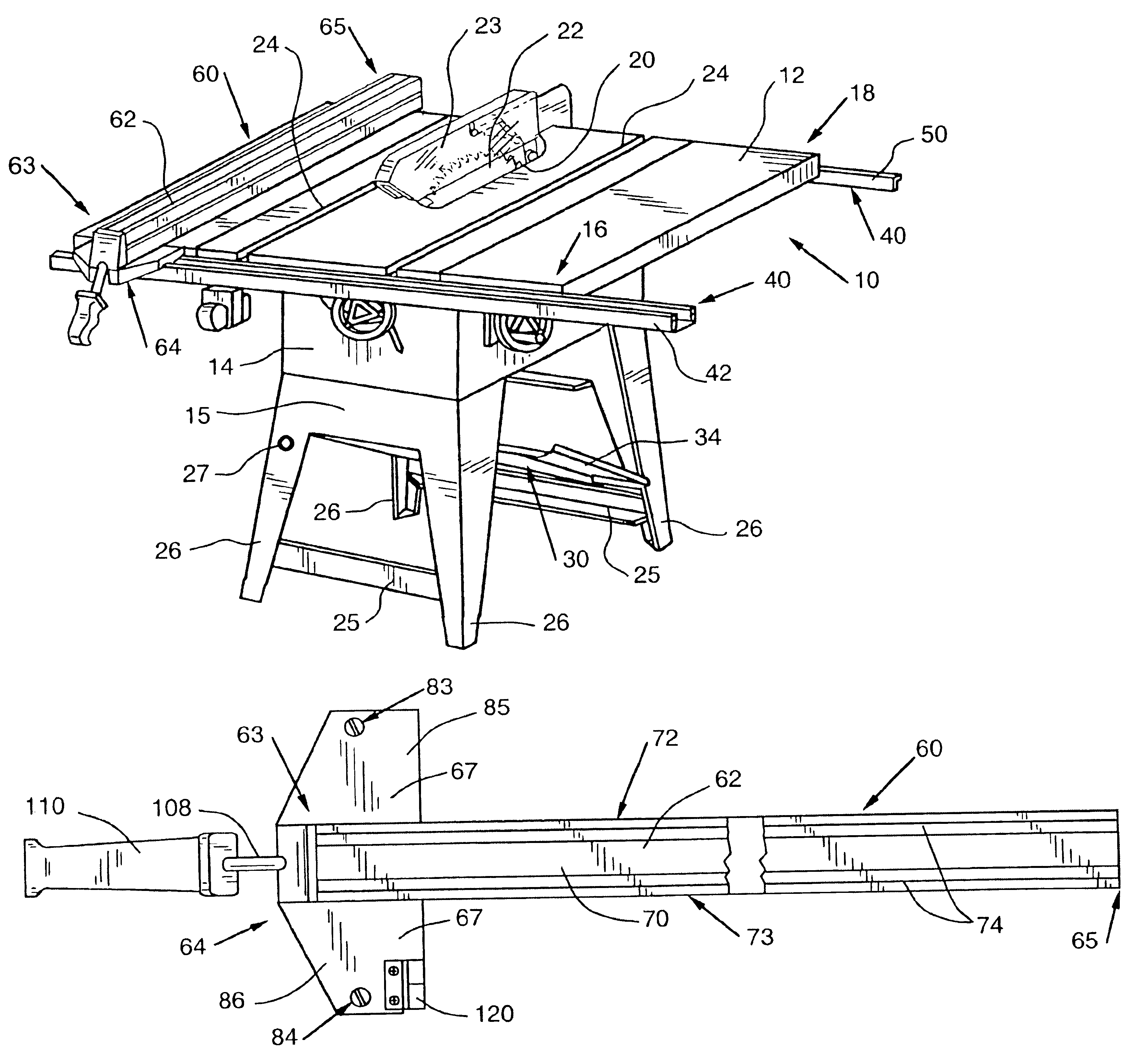

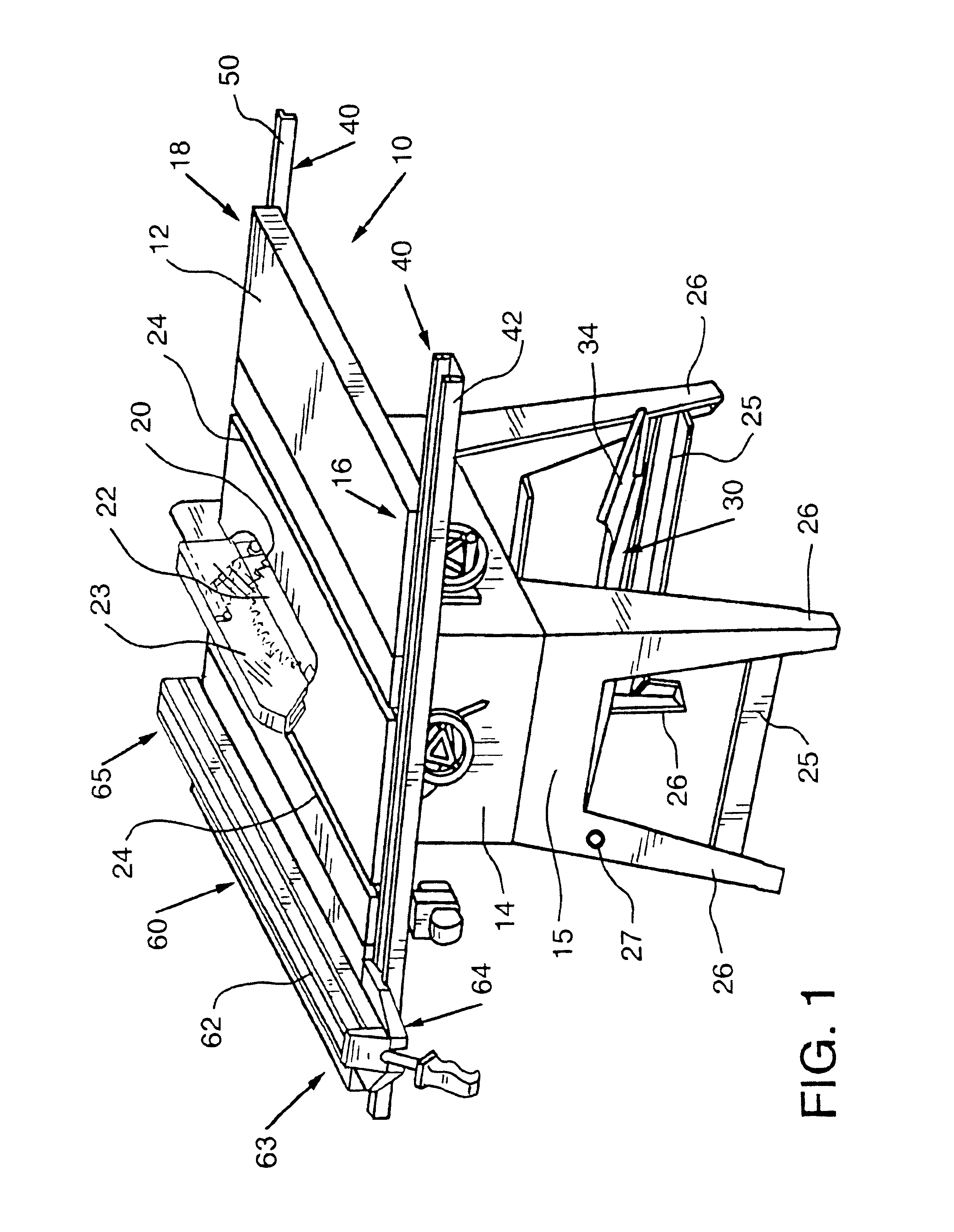

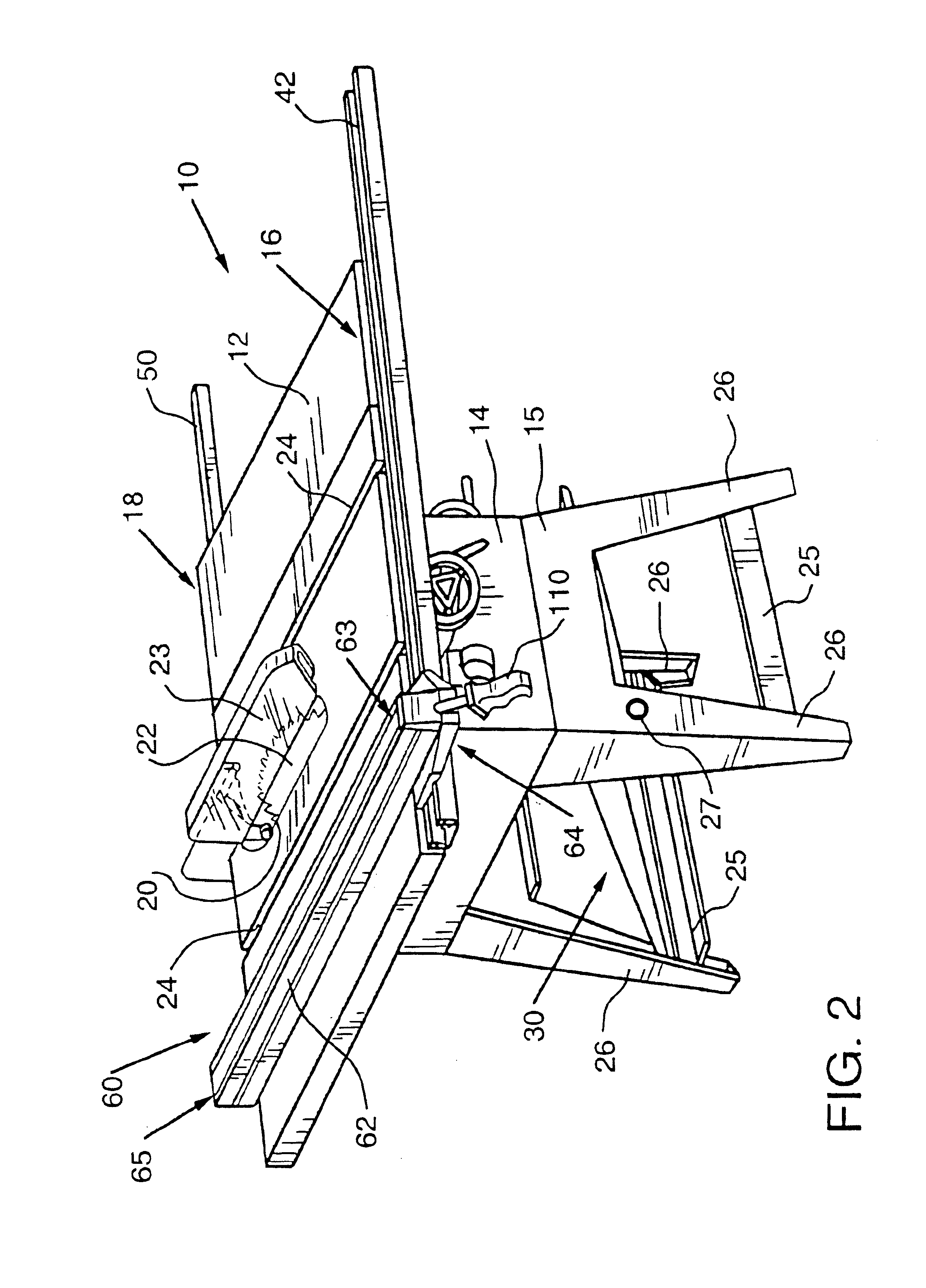

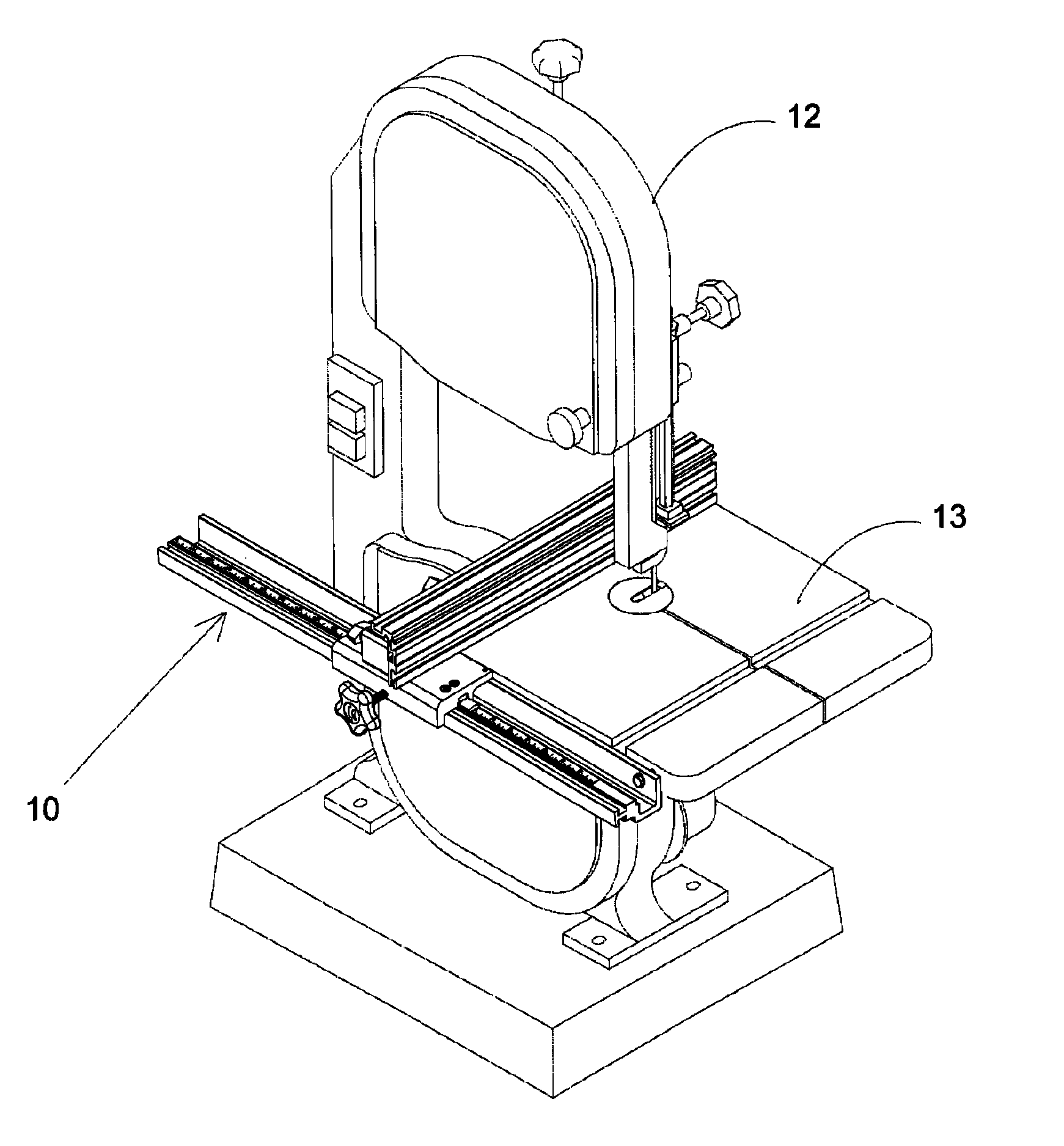

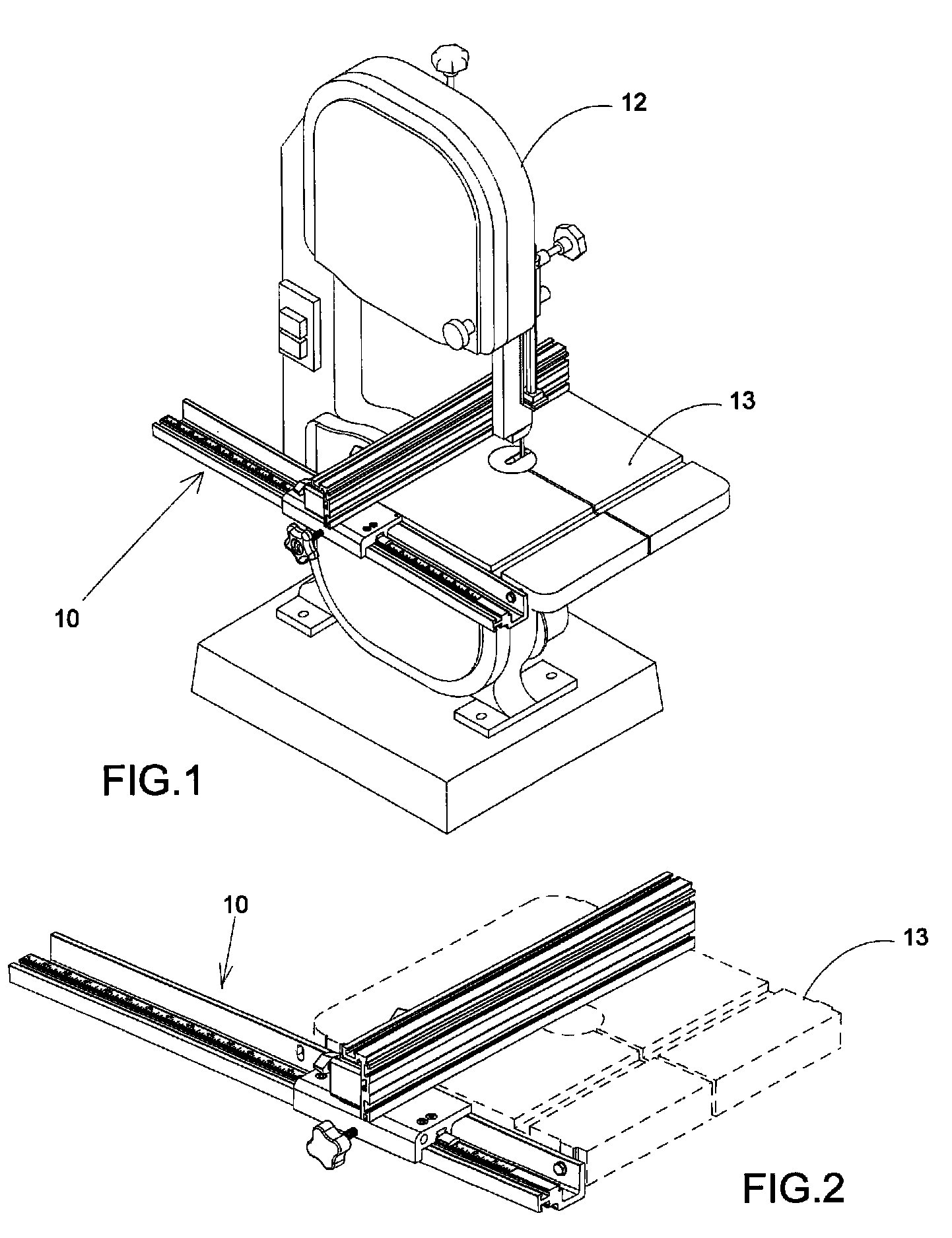

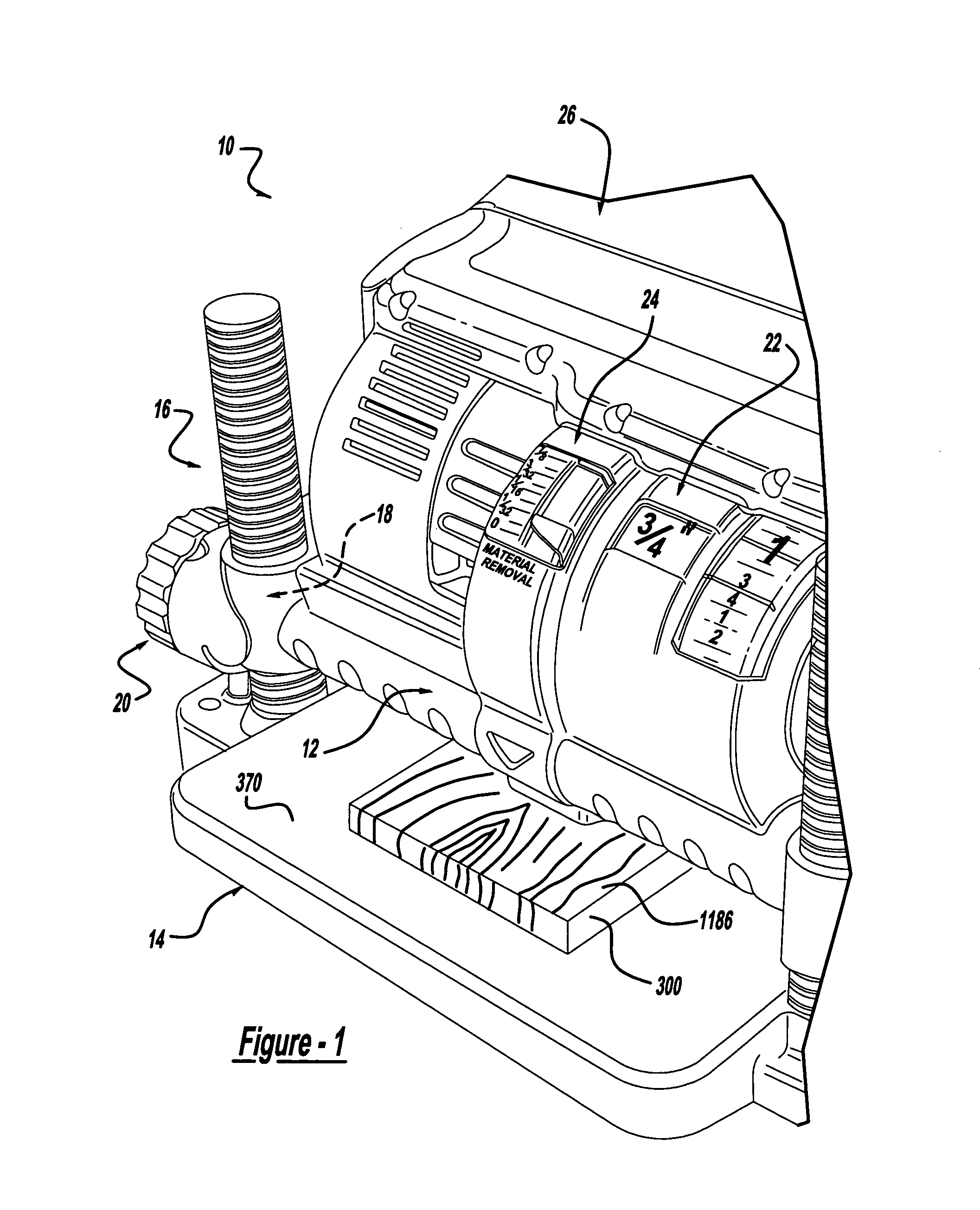

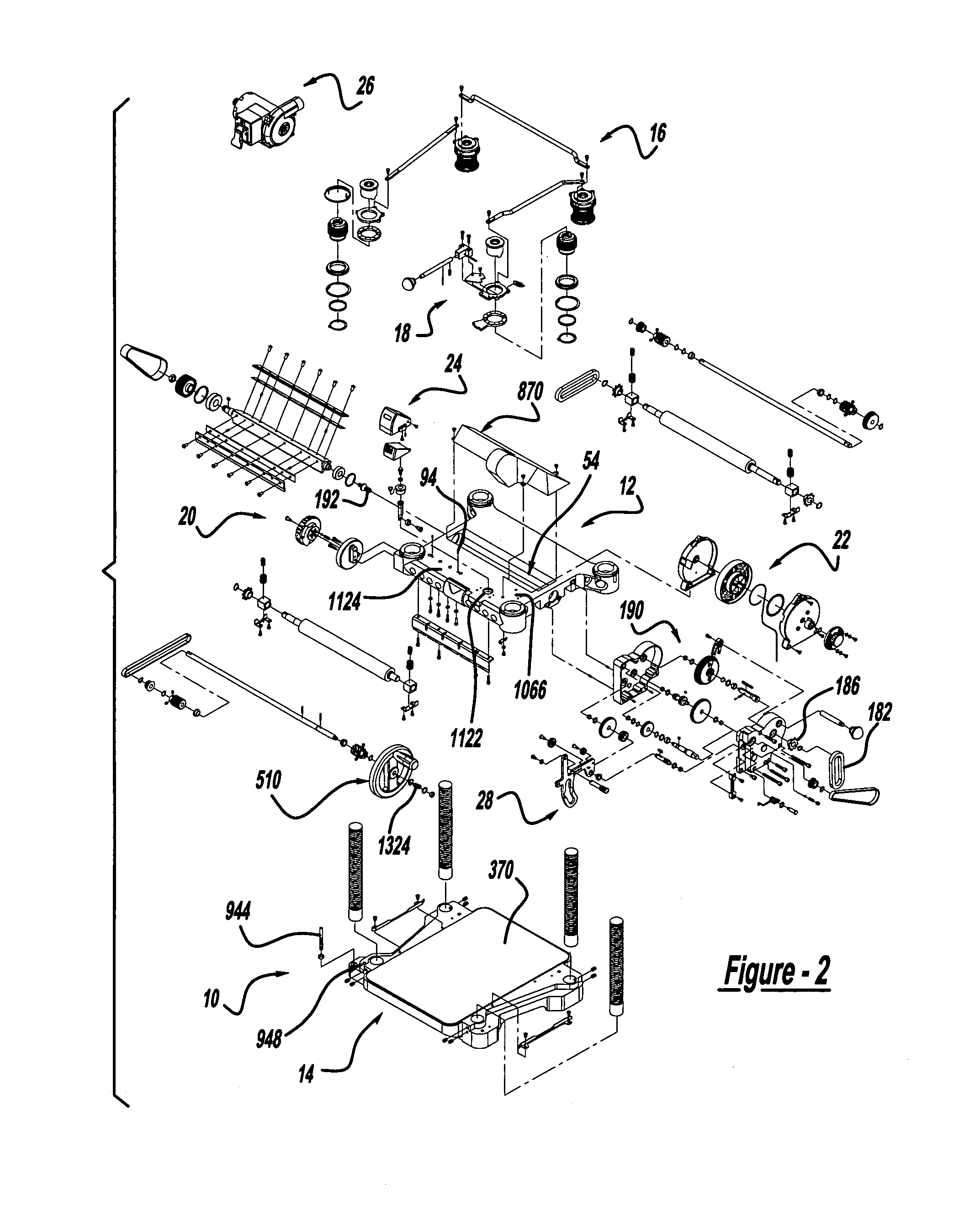

Sawing apparatus and saw fence system

InactiveUS6899004B1Consistent supportEasy to adjustWood feeding arangementsGuide fencesCollection systemMechanical engineering

A sawing apparatus and a saw fence. The saw apparatus may include a work surface. The saw may include a rail system disposed along the edges of the work surface, for the attachment of accessories thereto. The saw may be provided with workpiece guide adapted to be attached to the rail system for guiding workpieces during the operation of the saw. The workpiece guide may also be provided with an infeed extension that rides on the rail system and is capable of supporting workpieces during the operation of the saw. The infeed extension may be adjusted relative to the work surface of the saw. The saw may further be provided with a debris collection system for the collection of debris produced by the cutting operations of the saw.

Owner:BLACK & DECKER INC

Universal machinery fence system

A universal machinery fence system includes an L-shaped fence or a box shaped fence and clamp block which clamps to a rail extrusion with a half dovetail on the front on the edge of a table saw, band saw, shaper, router table, mortiser, or other woodworking or metal working machines. A U-shaped front rail is provided for attaching the fence to the cast iron table of a table saw, shaper, or band saw. The band saw fence U-shaped rail is predrilled to fit the table fence mounting holes of the most popular 14″ band saws. Optional extruded front rails are also provided for attaching the fence to shop made 0.750″ tables such as used on a drill press. Also provided is a fence rail extrusion for mounting the fence on the front and back of the popular 1.125″ size router table. An optional extruded front rail which is adjustable in height is also provided for attaching the fence to shop made tables between 0.750″ and 1.5″ in thickness. A re-saw guide fitted to the fence extrusion has a convex surface for supporting a workpiece on edge allowing the operator to easily adjust for blade drift. An optional micro-adjuster allows the fence to move accurately in small increments. A router table with holes and slots allows the fence to be used to guide the workpiece in the router table mode and then be used to guide the router or a saw on top of the workpiece.

Owner:KREG ENTERPRISES

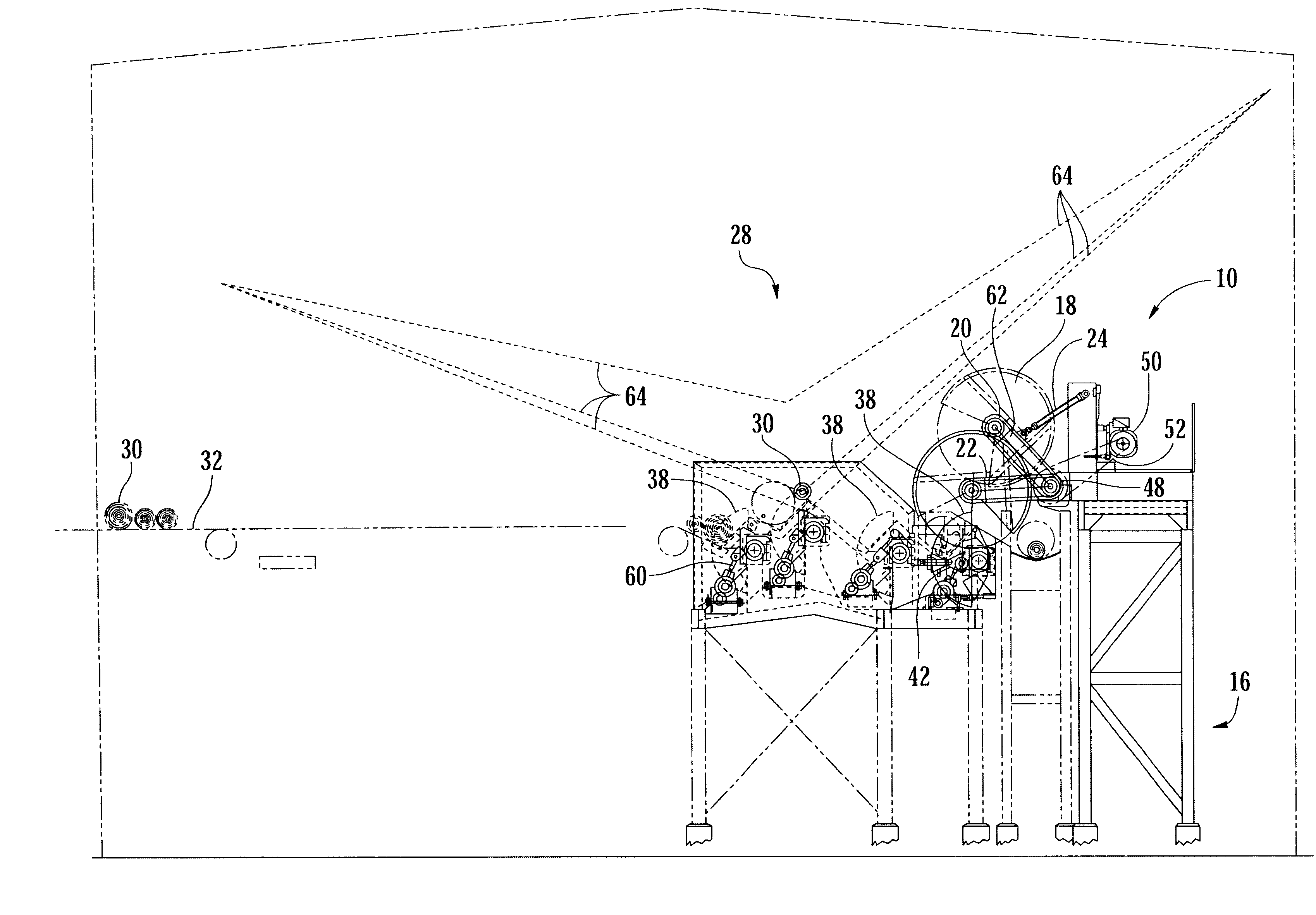

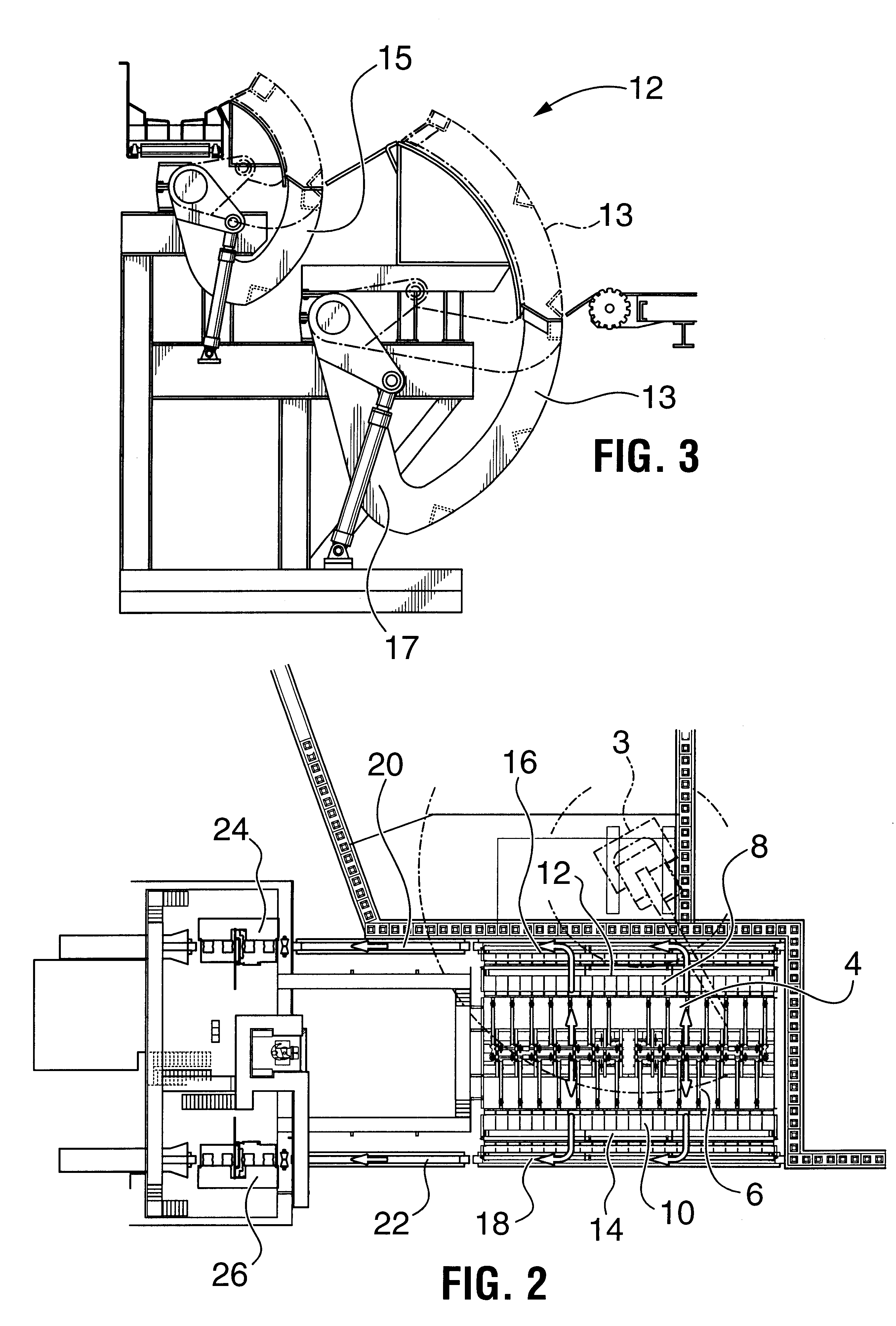

Log cutting system

The present invention discloses a log sawing system comprising multiple cutting blades. The multiple cutting blades are positioned to cut laterally or perpendicular to the centerline of the log which is to be cut. The logs are transported into cutting position using some type of log positioner. The multiple cutting blades are rotatably mounted on an arm which is pivotally mounted on a shaft in groups, being driven by an electrical or like motor, all of which are mounted onto a platform positioned adjacent to the log to be cut. Hydraulic lifters are used to partially rotate the saw blades into the cutting position adjacent the log. Means utilizing a computer and lasers are provided to develop a log cutting solution to best utilize the logs.

Owner:PSI SALES

Method and apparatus for singulating, debarking, scanning and automatically sawing and sorting logs into lengths

InactiveUS6539993B1Reduce stepsMinimize travelMulti-purpose machinesAdjusting equipmentComputer hardwareAlgorithm

Owner:WEYERHAEUSER CO

Log positioning and conveying apparatus

InactiveUS6896019B2Automatic control devicesWood feeding arangementsEngineeringMechanical engineering

Owner:SAVICO LTEE +1

Featherboard assembly

A featherboard assembly for use with a work table. The featherboard assembly includes a featherboard having a body and an axis. The featherboard assembly further includes an adjustment mechanism associated with the featherboard for attaching the featherboard to the work table. The adjustment mechanism permits the featherboard to be adjusted on the table along a first axis and permits the featherboard to be adjusted along a second axis. The adjustment mechanism is capable of locking the featherboard against movement along the second axis while the featherboard is moved along the first axis and locking the featherboard against movement along the first axis while the featherboard is moved along the second axis.

Owner:JESSEM TOOL CORP

Guide for a cutting tool

InactiveUS7127976B1Cutting and similar operationEasy to cutDovetailed workMulti-purpose machinesEngineeringKnife blades

A guide comprises one or more brackets for securing the guide to a cutting tool, a horizontal support member secured to and moveable with respect to the brackets, and one or more arm assemblies secured to the horizontal support member and adapted to secure a working piece relative to the horizontal support member. With the working piece secured to the guide in this manner, the working piece may be readily advanced over a blade of the cutting tool by grasping and moving the horizontal support member relative to the brackets, thus ensuring a precise cutting of the working piece while also allowing a user to keep their hands away from the blade.

Owner:FITZSIMMONS GEORGE

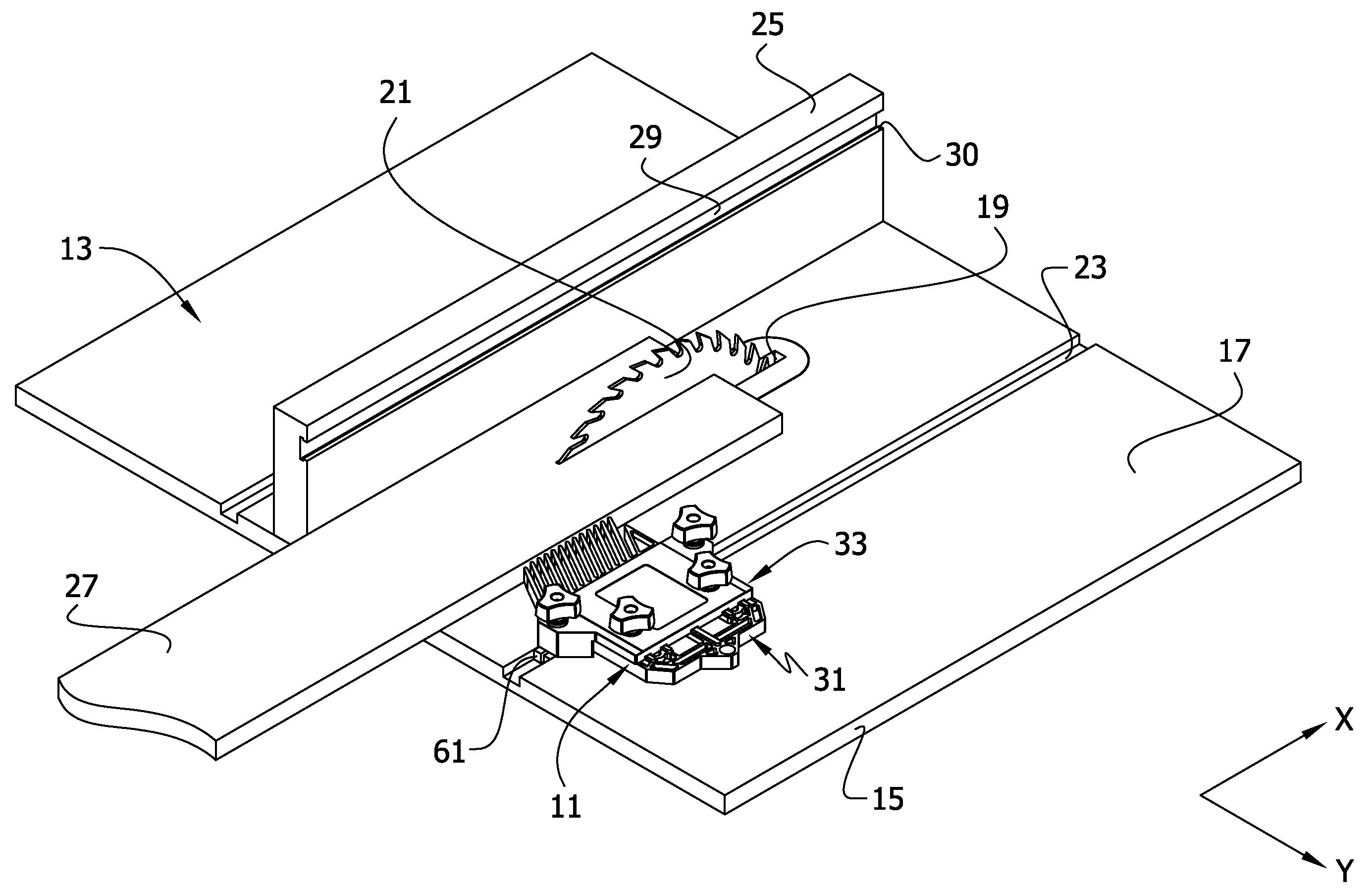

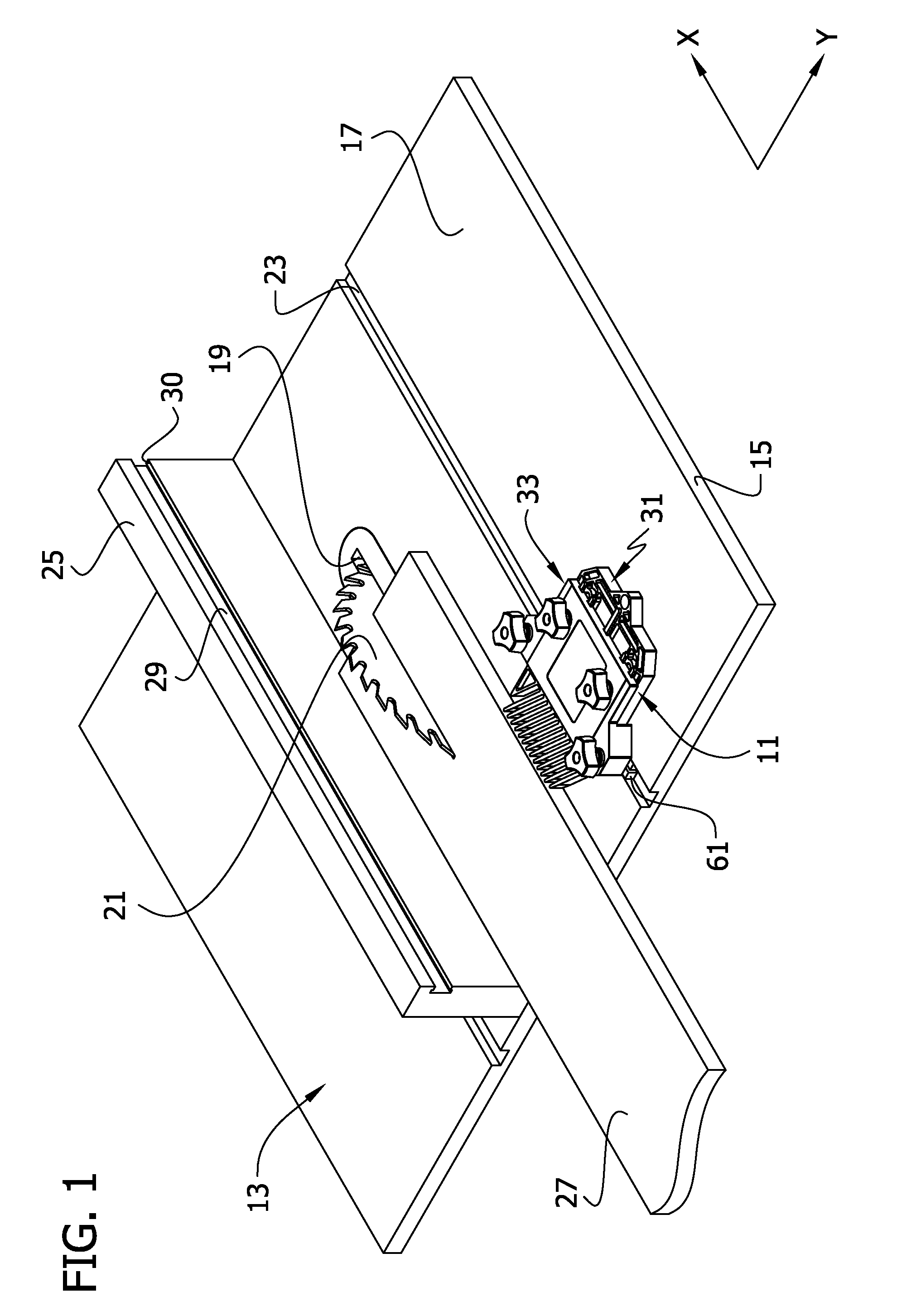

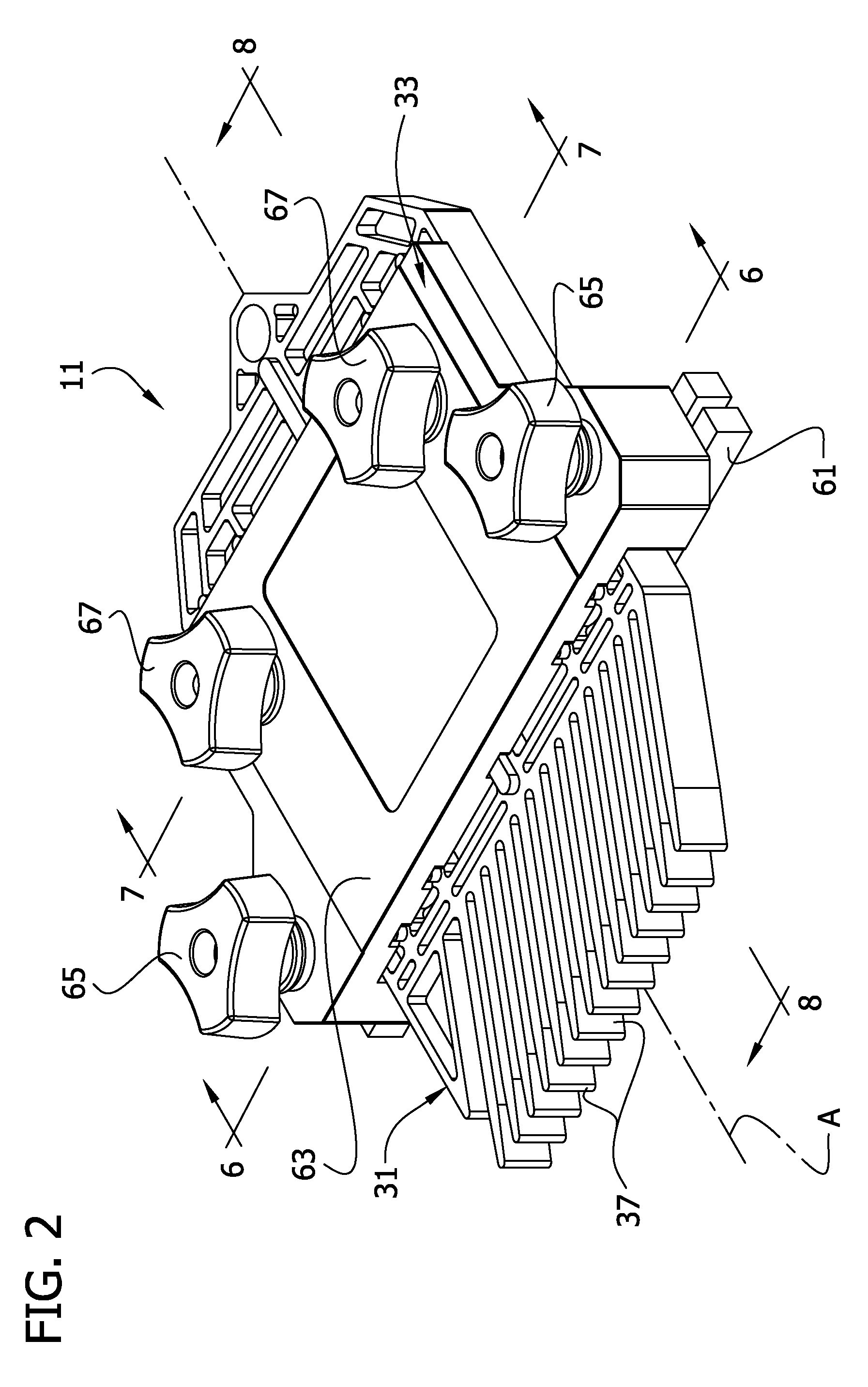

Dual adjustable feather jig

A dual adjustable feather jig for simultaneously holding a wood piece firmly against a stationary rip fence and against the top surface of the worktable. The feather jig includes a lower feather board with a ‘T’ channel bar adjustably mounted on the bottom surface of the lower feather board capable of engaging the ‘T’ slot formed on a standard worktable. The ‘T’ channel is adjustably mounted on the lower feather board to allow the lower feather board to move laterally (X direction) over the worktable when the ‘T’ channel bar is inserted into the ‘T’ slot. Mounted transversely on the lower feather board is an upper feather board assembly that includes a vertical feather board designed to be extended over a piece of wood stock to hold it down against the worktable. The vertical feather board is connected to a slider arm that slides longitudinally over a riser board securely mounted to the top surface of the lower feather board. Formed on a lateral edge and lower edges of the lower and upper feather boards, respectively, are two sets of diagonally aligned fingers that press against a piece of wood stock against a standard rip fence and against the top surface of the worktable.

Owner:SCHWARTZ NEAL K

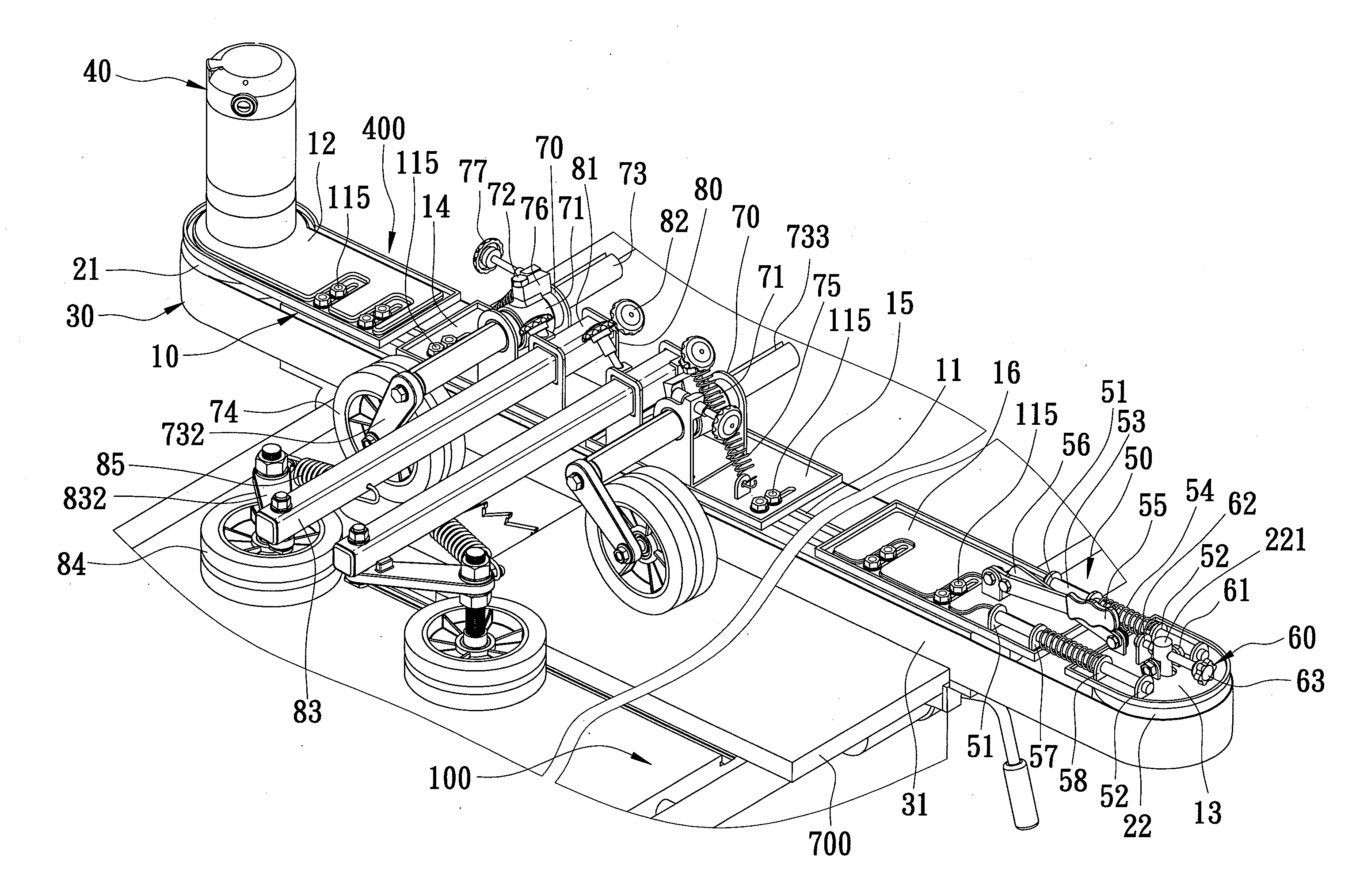

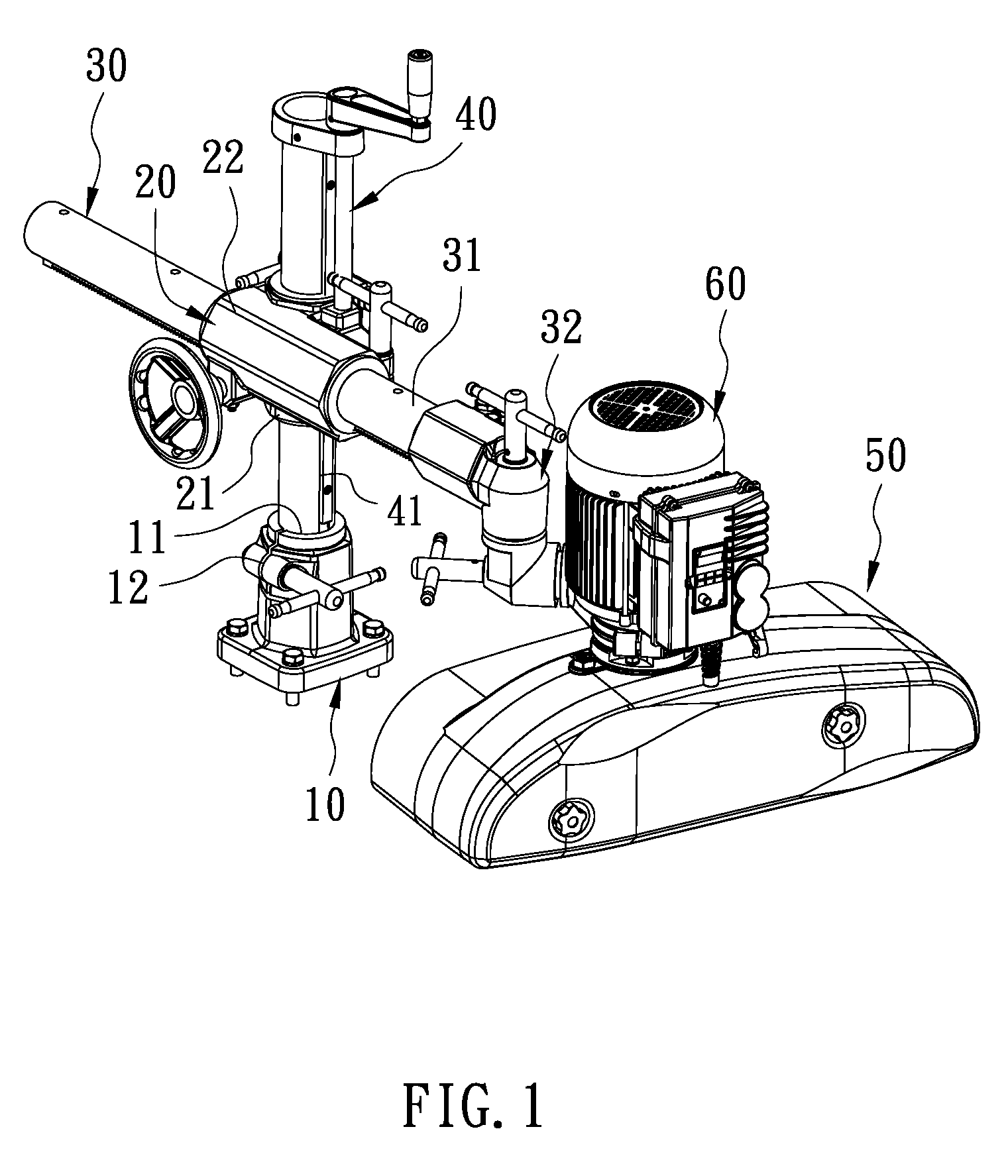

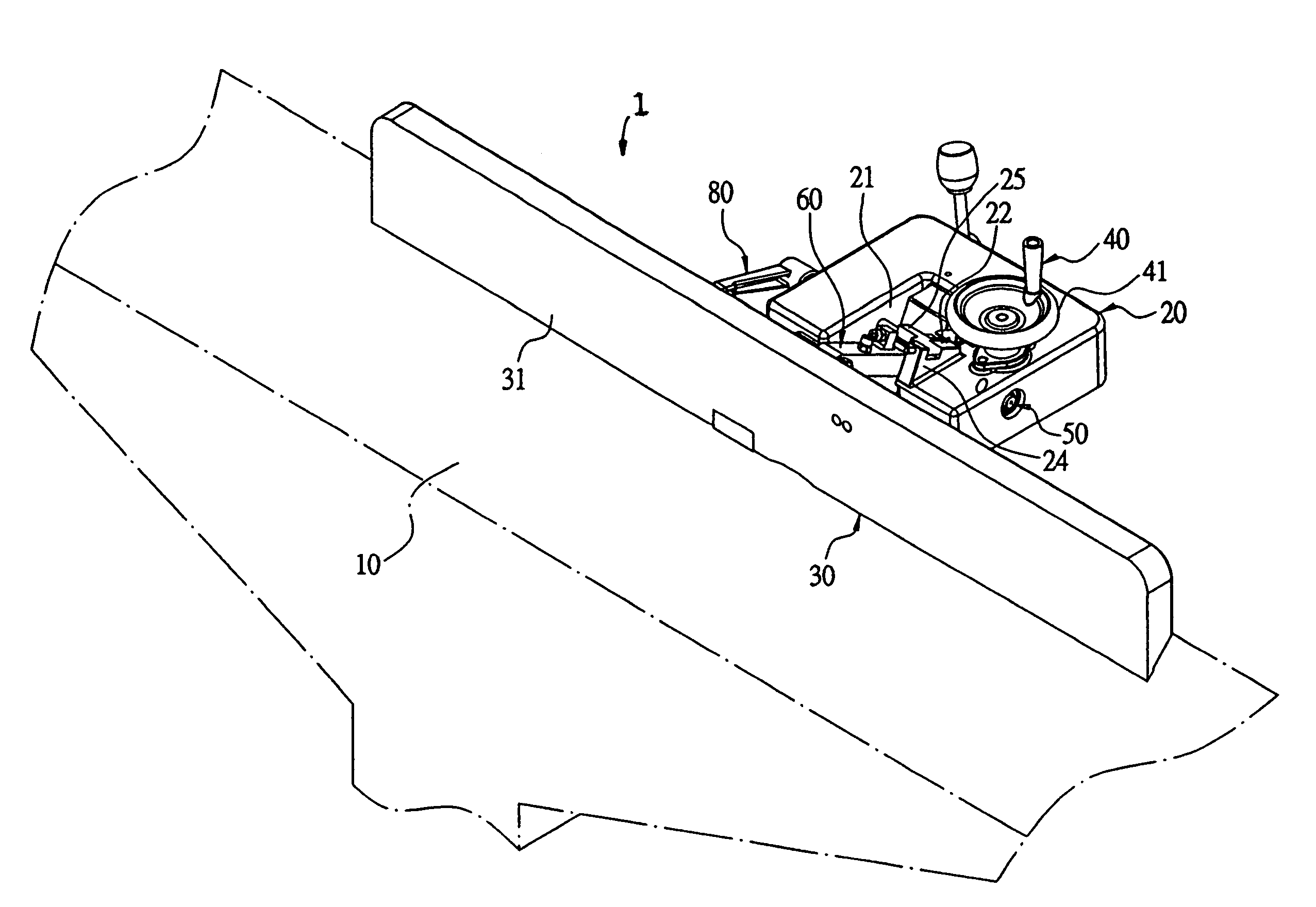

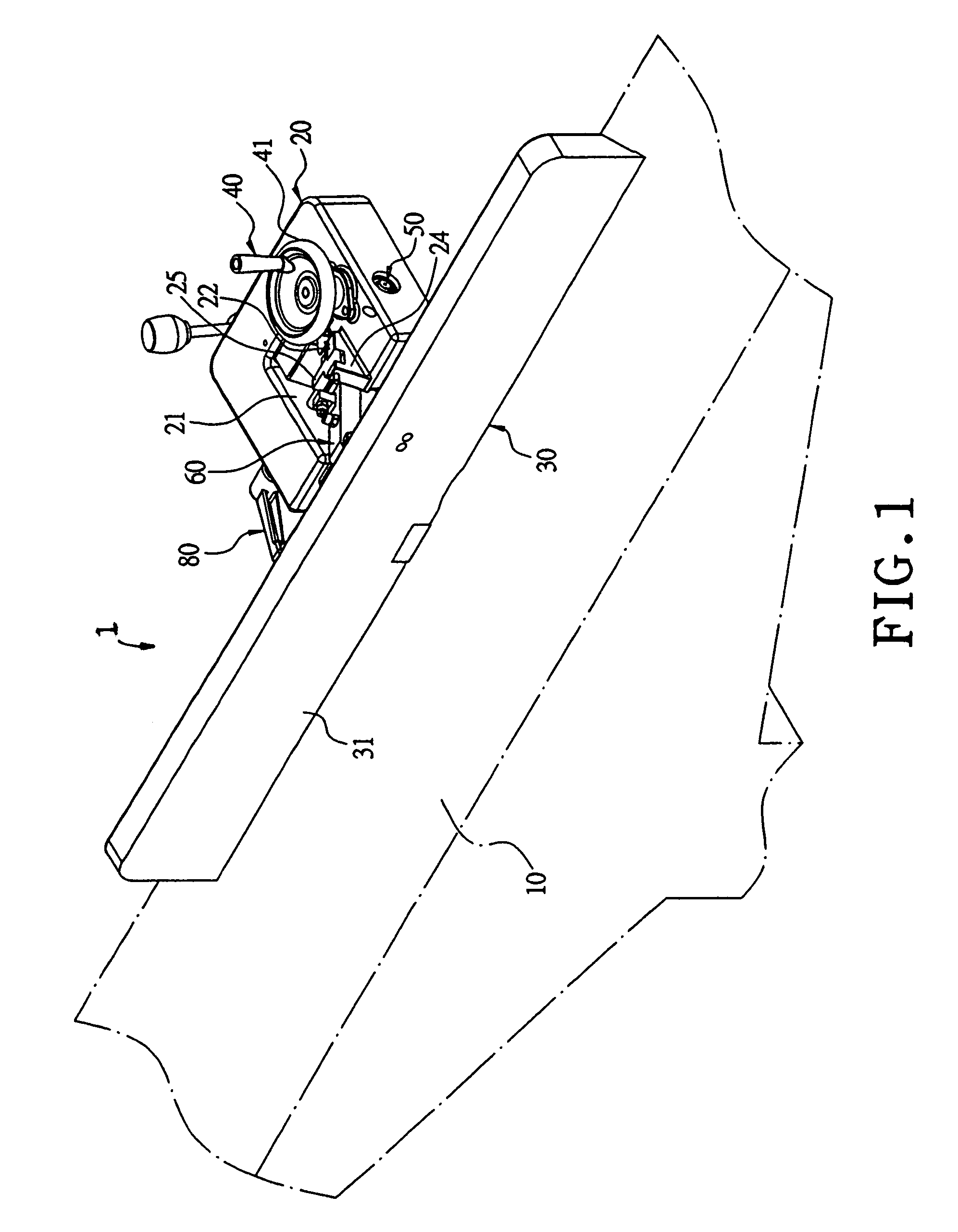

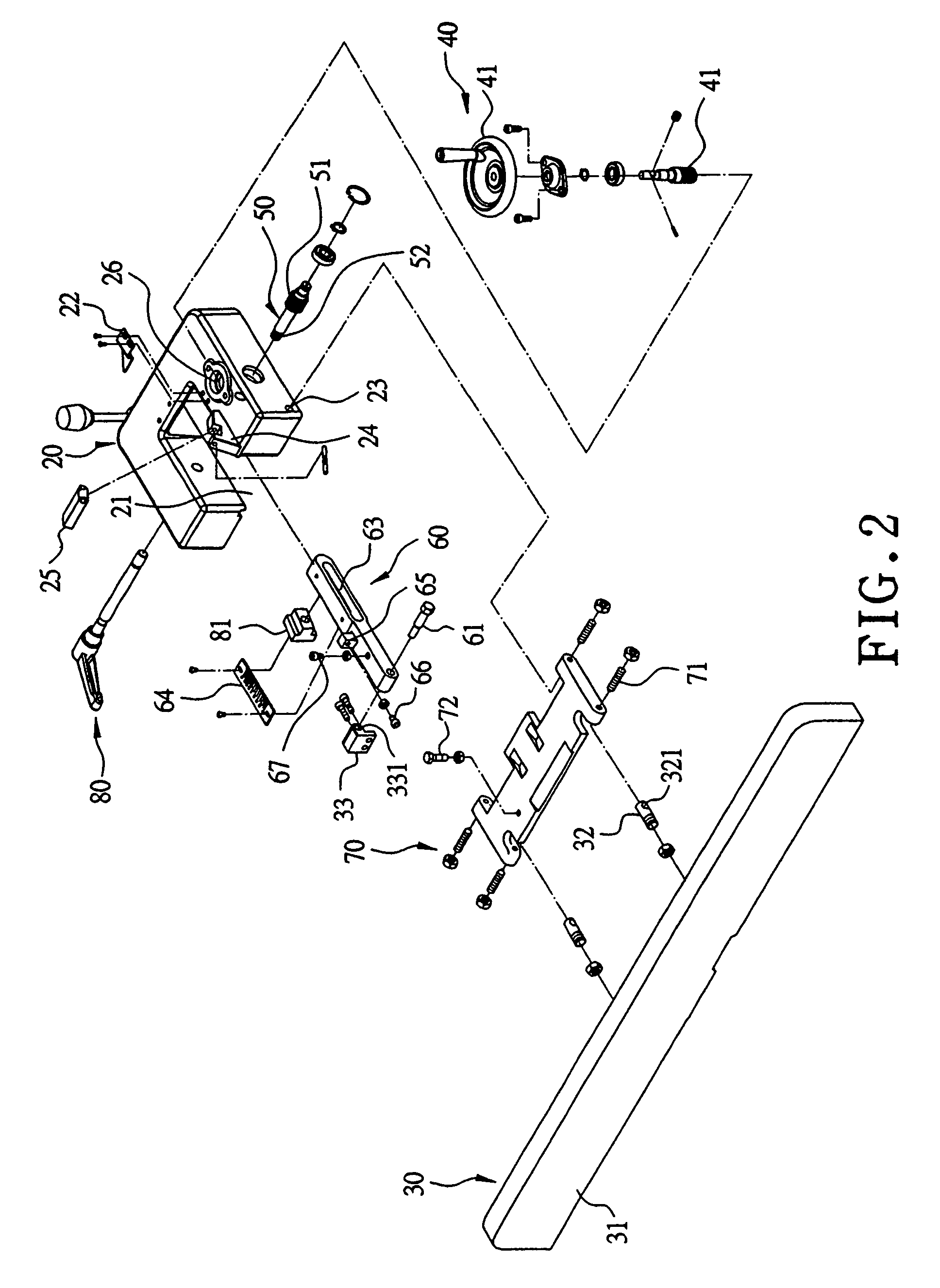

Workpiece-Advancing Device for a Wood Cutting Apparatus

InactiveUS20090049969A1Prevent deviationWood feeding arangementsFeeding devicesEngineeringWood cutting

A workpiece-advancing device includes: a slider mounted on a worktable; a workpiece-driving unit mounted on the slider and including a pair of driving rollers and a belt trained on the driving rollers and having a portion adapted to abut against a workpiece and movable relative to the slider for driving movement of the workpiece on the worktable; and a positioning mechanism including an urging unit, a supporting arm unit mounted on the slider and passing through a lateral side of the slider, and an abutting unit mounted on the supporting arm unit and urged by the urging unit so as to be adapted to abut against the workpiece and so as to prevent the workpiece from deviating from a predetermined cutting path.

Owner:LIN CHING CHI

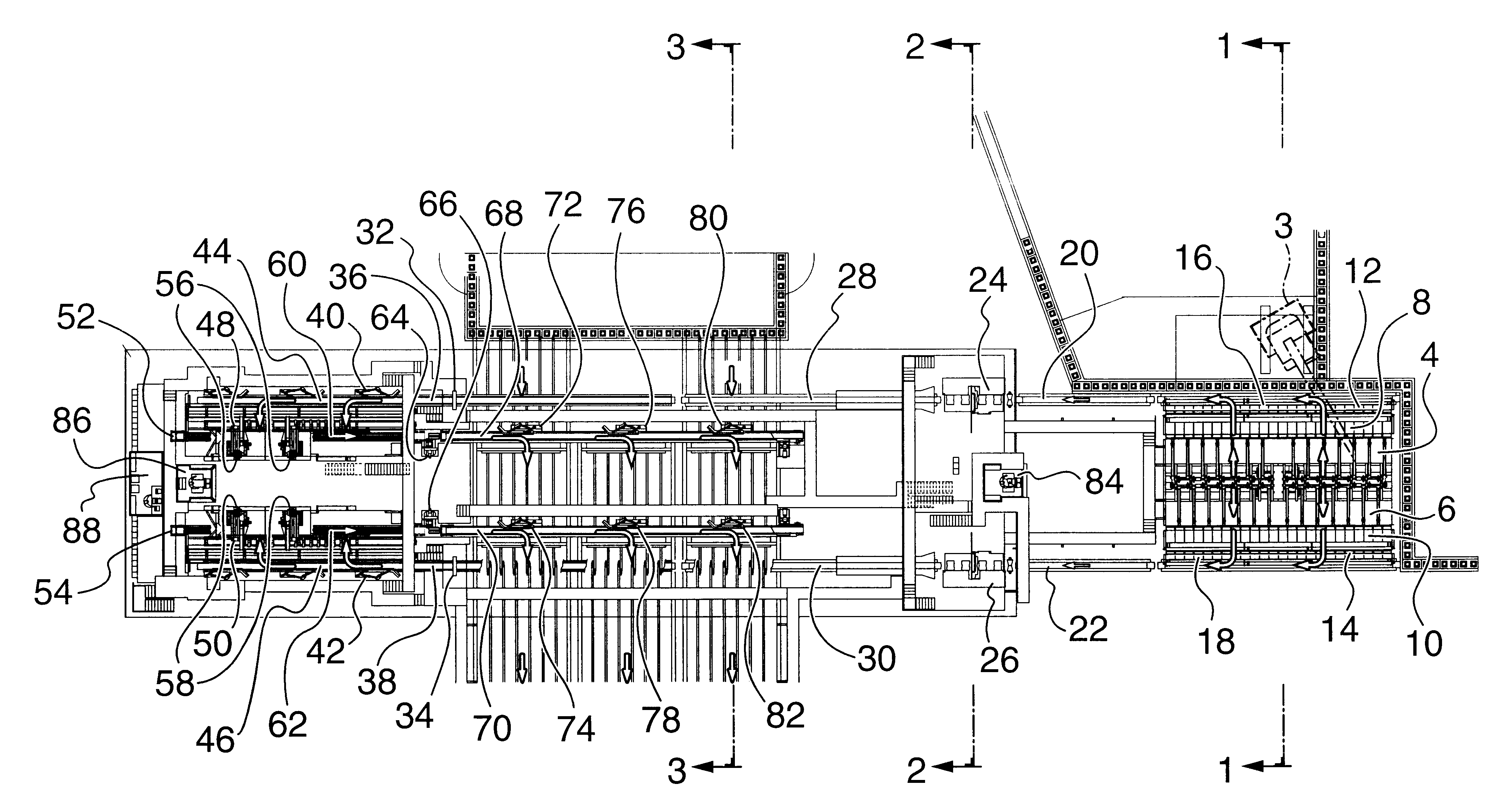

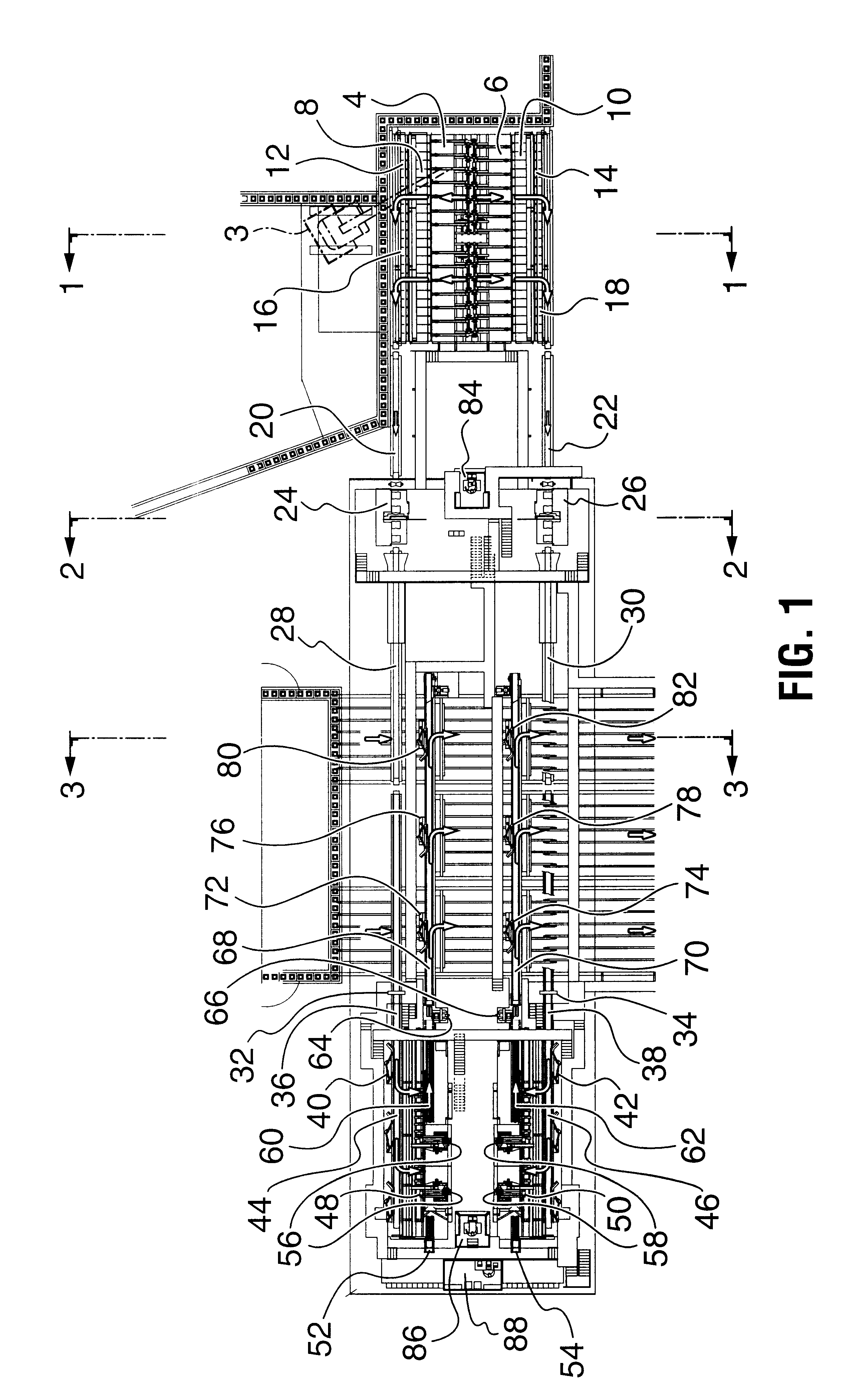

Machine for profile working of front surfaces on oblong wood workpieces

Machine for profile working of front surfaces on oblong wood workpieces resolves the problem of simple, accurate and fluent or continued working of workpieces front surfaces of various lengths and intersections, and the machine is of a compact construction. It is characteristic by the construction of the entrance turnover device transversely placed between longitudinal conveyors with carriers, which has on the periphery of rotating wheels constructed movable bearing couplings, and by them fixed guiding plates with the groove inside which there are movably inserted guided bearings of bearing couplings. In the area of the entrance turnover device there are placed under an optional angle the oblique roller conveyors, inside which there are flexibly and circularly movably inserted rolls. Between the longitudinal conveyors there is placed the endless conveying chain, which has to its entire extent fastened clamping units that have inside the fixed housing inserted the clamping mechanism, the operation of which is regulated by the control field and control indicator. Over the free corner of the longitudinal conveyor there runs the oblique conveyor with carriers tilted to the longitudinal conveyor. Between longitudinal conveyors there is transversely placed the exit turnover device, which has on the periphery of rotating wheels constructed movable bearing cranks, being through the chain connected with the control chain wheel and control panel, the guided bearing of which is movably inserted inside the channel guide fixed on the rotating wheels.

Owner:LEDINEK PAVEL +1

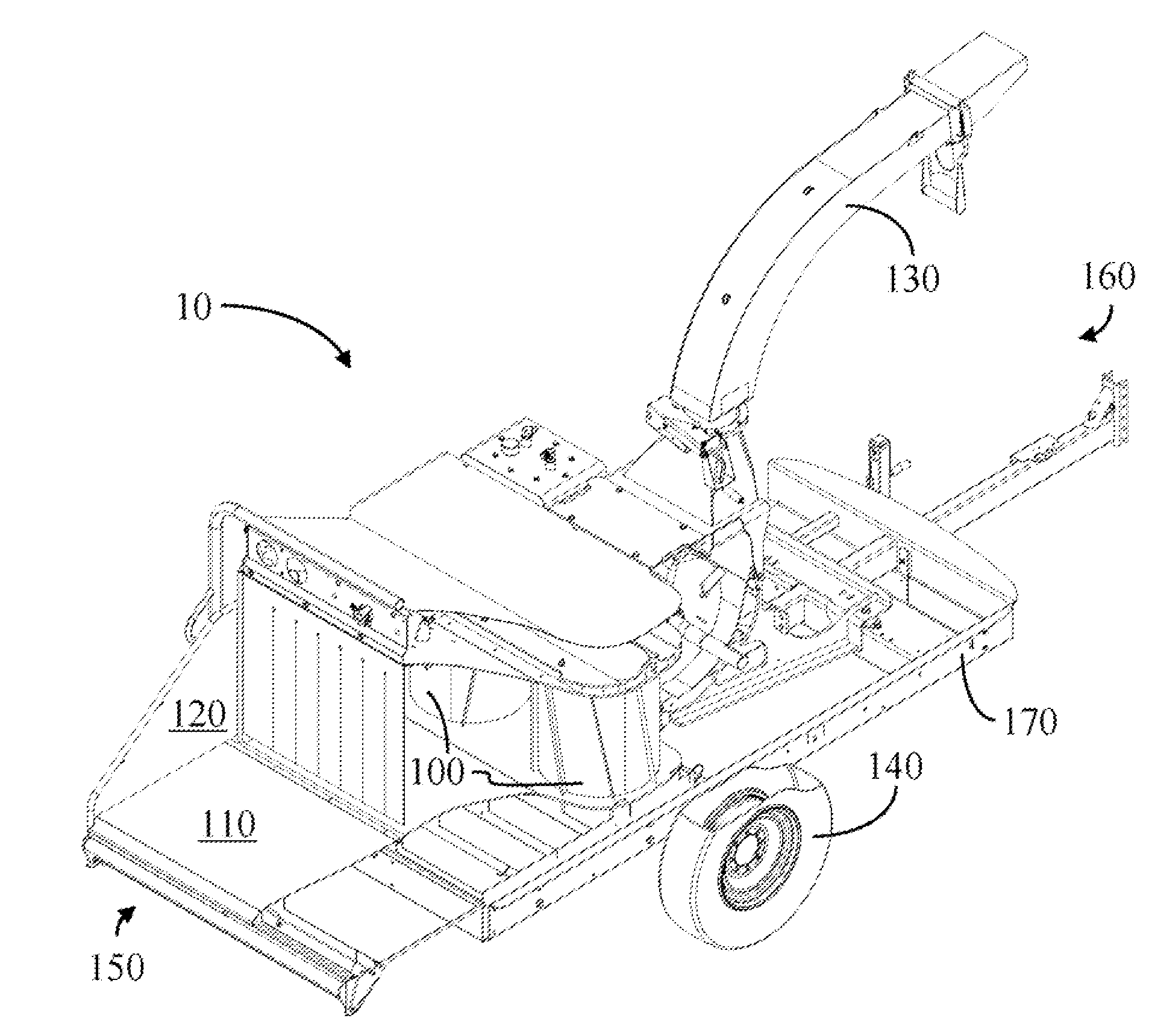

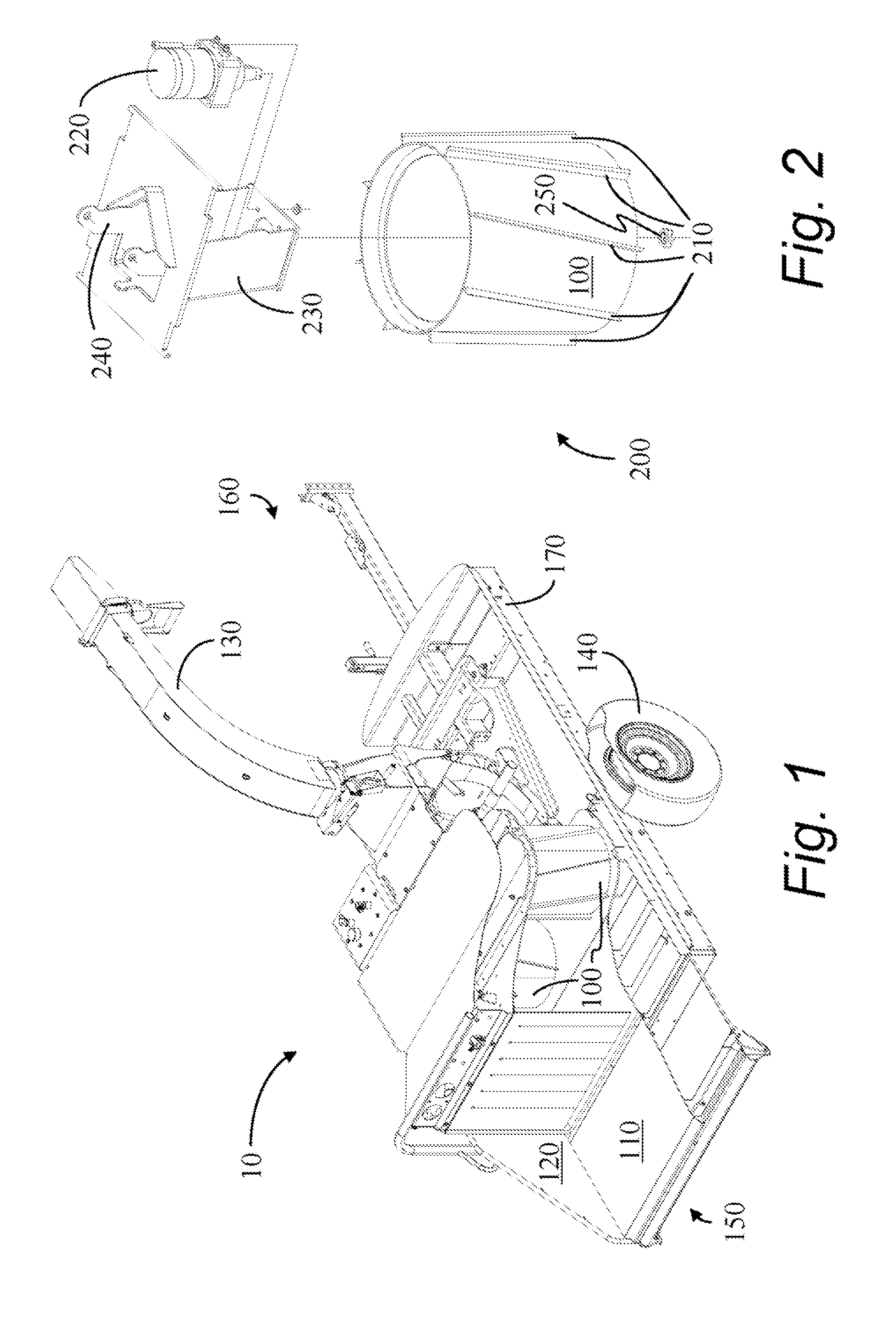

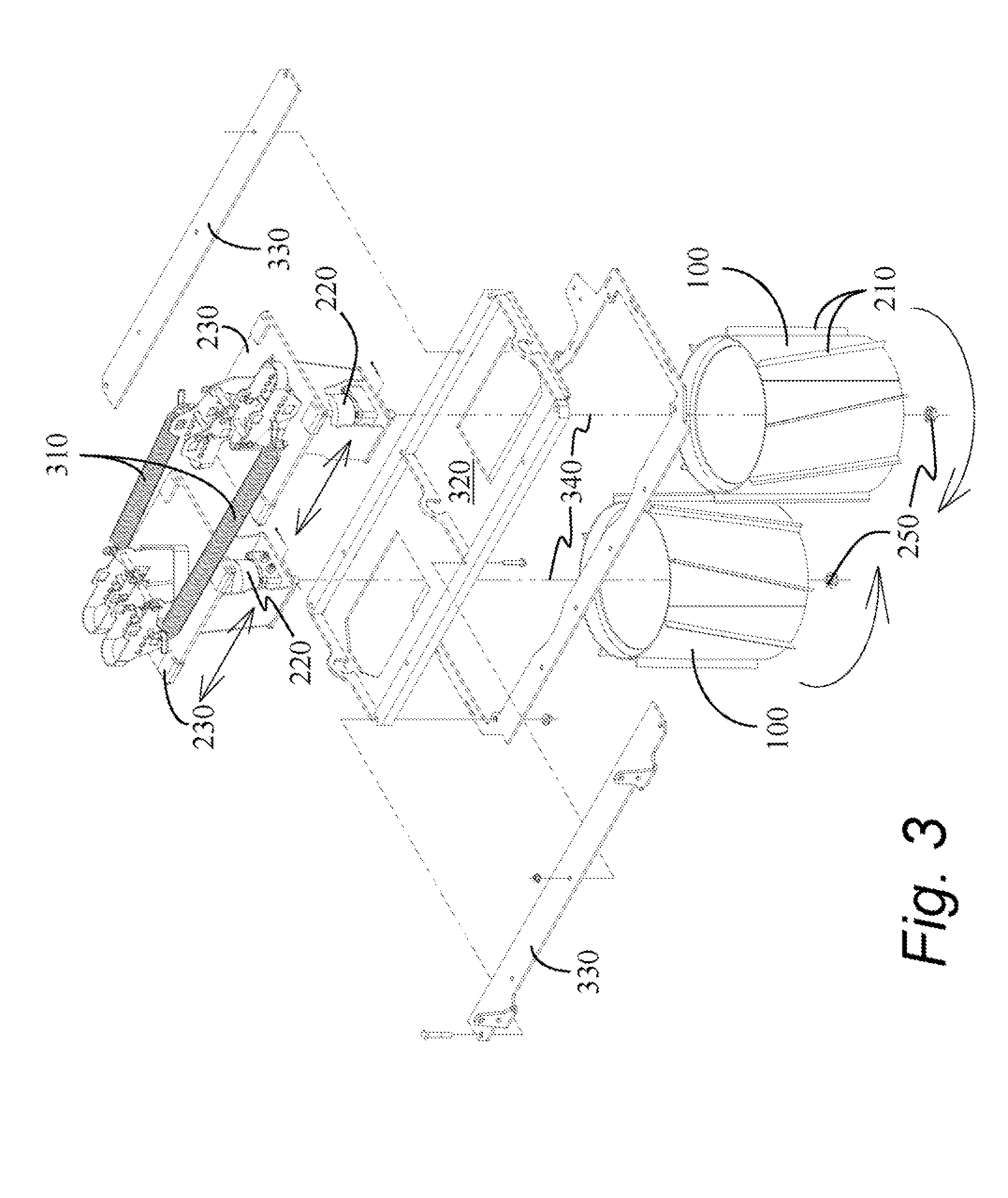

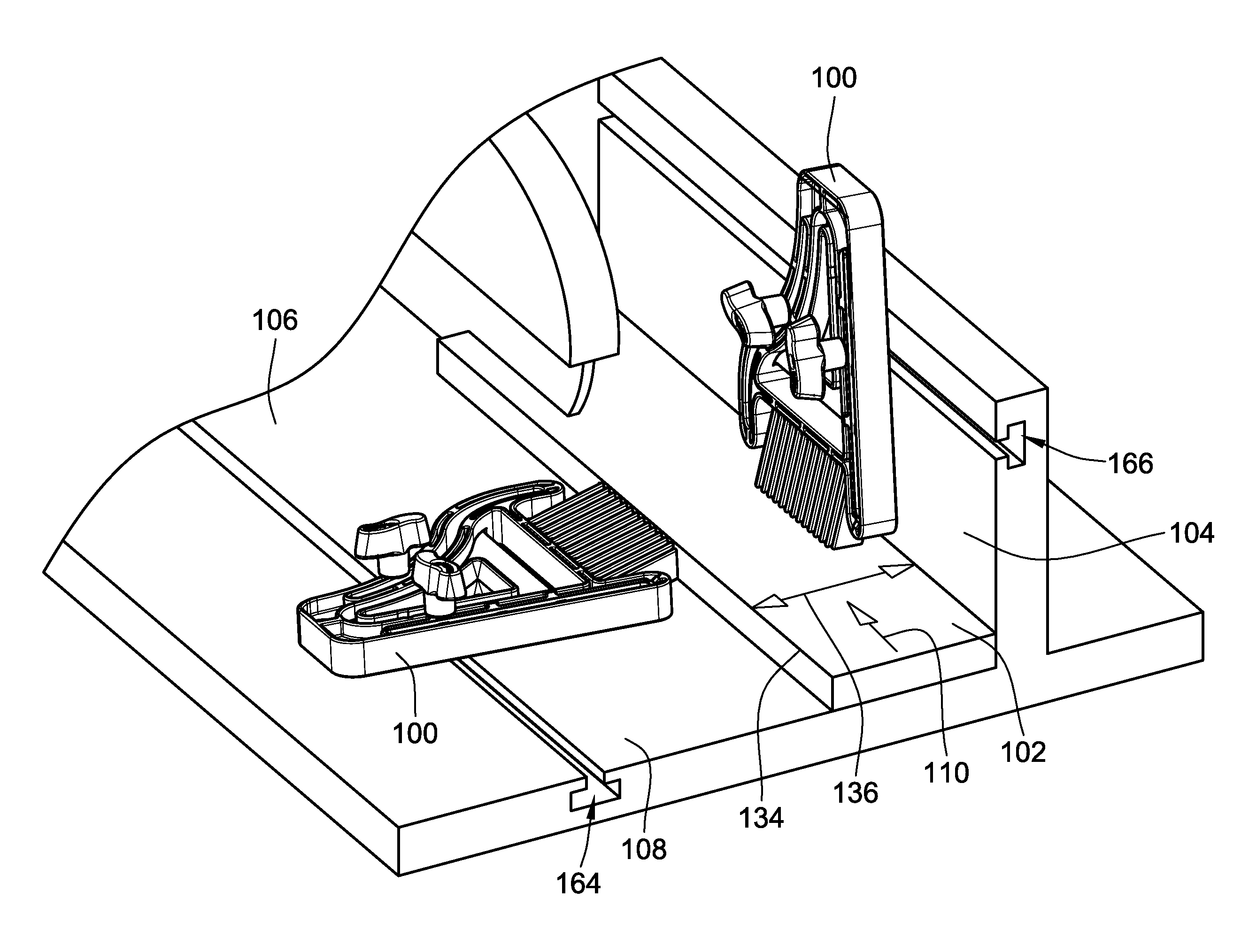

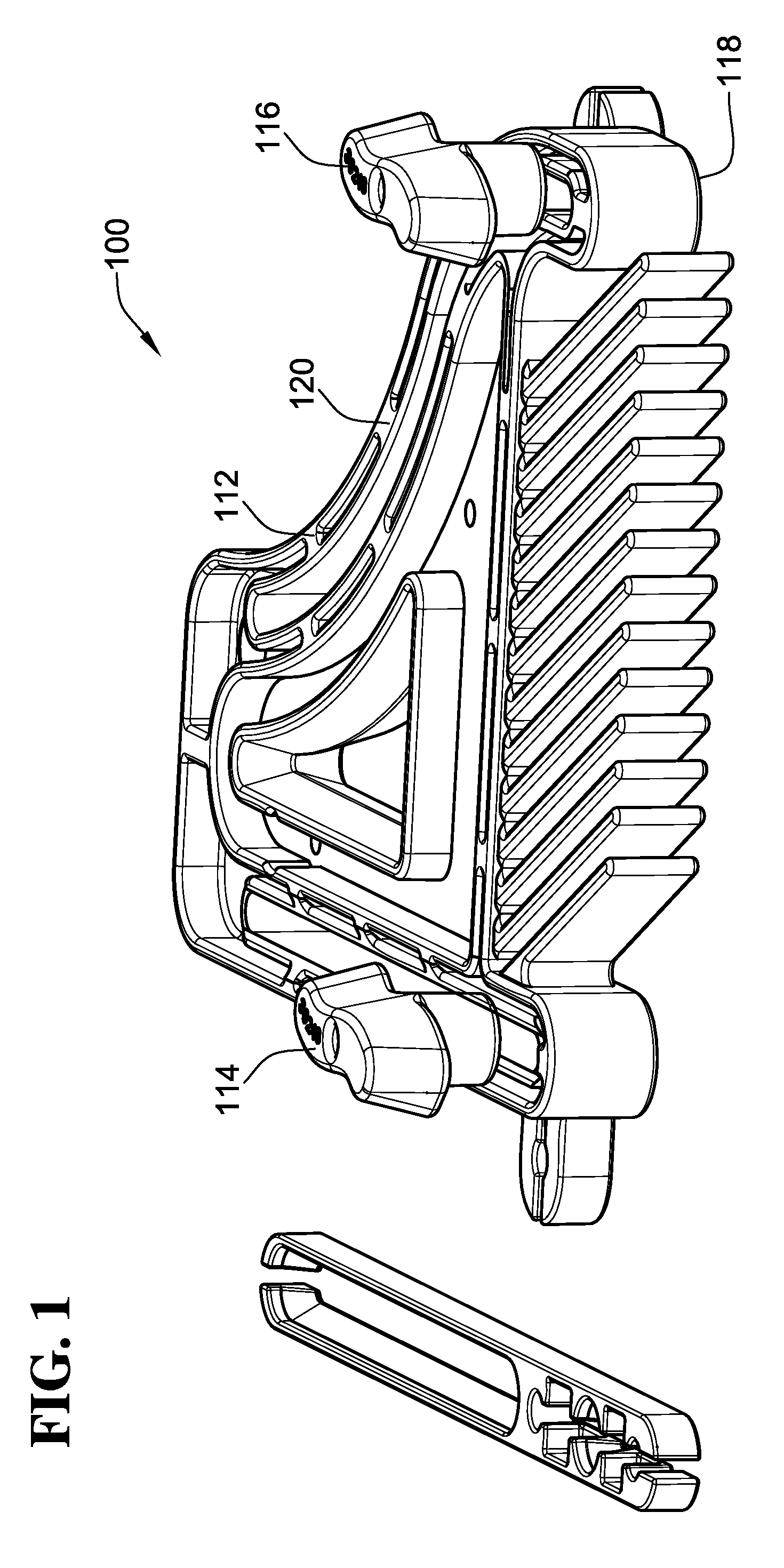

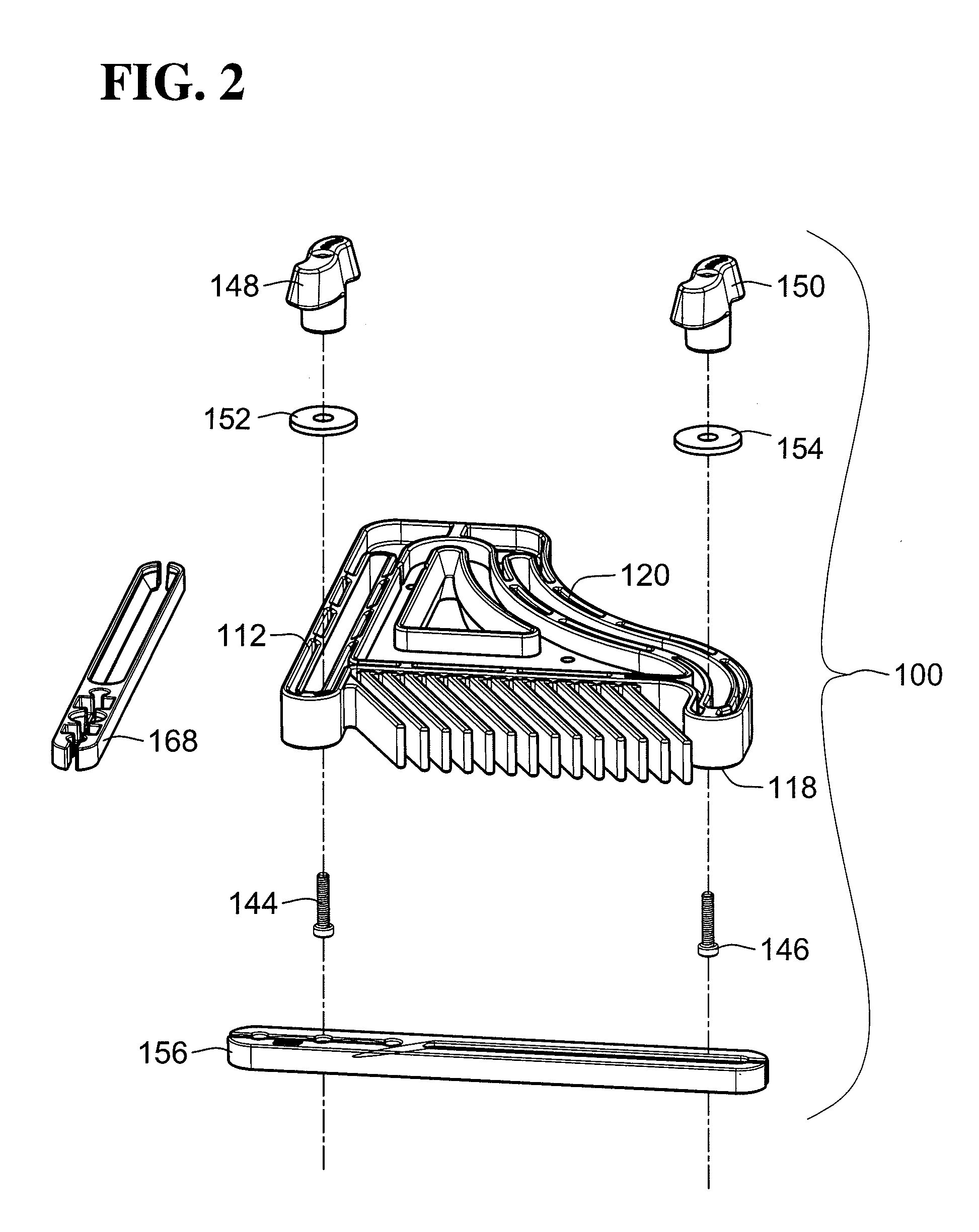

Brush chipper with improved feed rollers

ActiveUS7546964B2Reduce generationReduce chanceWood feeding arangementsFeeding devicesEngineeringMechanical engineering

An improved feed roller assembly wherein the feed roller provides a force perpendicular to the feed direction of the brush material. In a first embodiment, cleats that are not parallel to an axis of rotation of the feed roller are affixed to a periphery of the feed roller. When the feed roller is oriented with its axis of rotation in a substantially vertical position, each cleat is arranged with its upper end ahead of its lower end, in a direction of rotation. This configuration provides a downward force on the logs or brush being fed into the chipper, thereby reducing the occurrence of bucking. In an additional embodiment, the axes of rotation of the feed rollers lean toward the outfeed end of the brush chipper.

Owner:VERMEER MFG CO

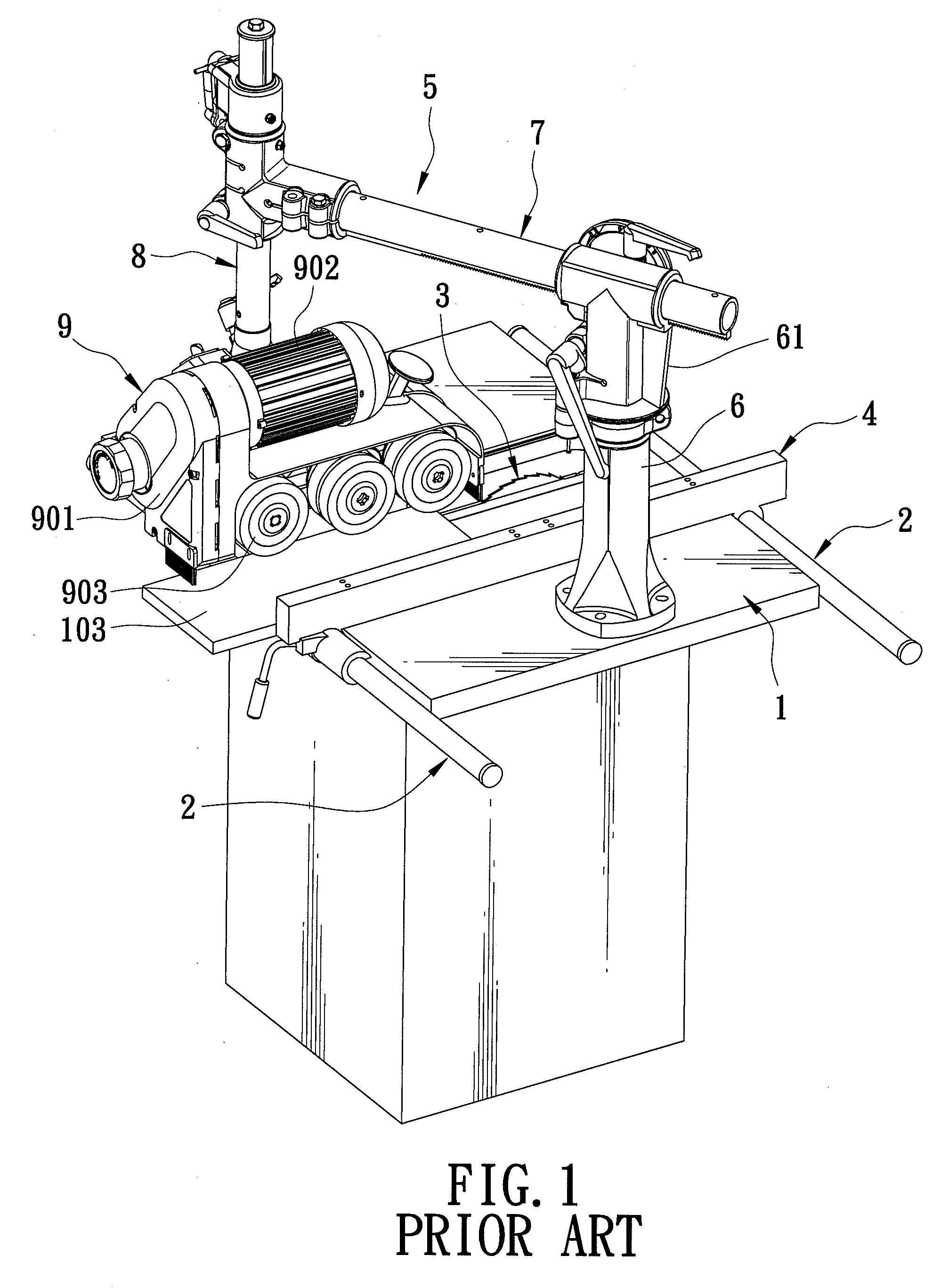

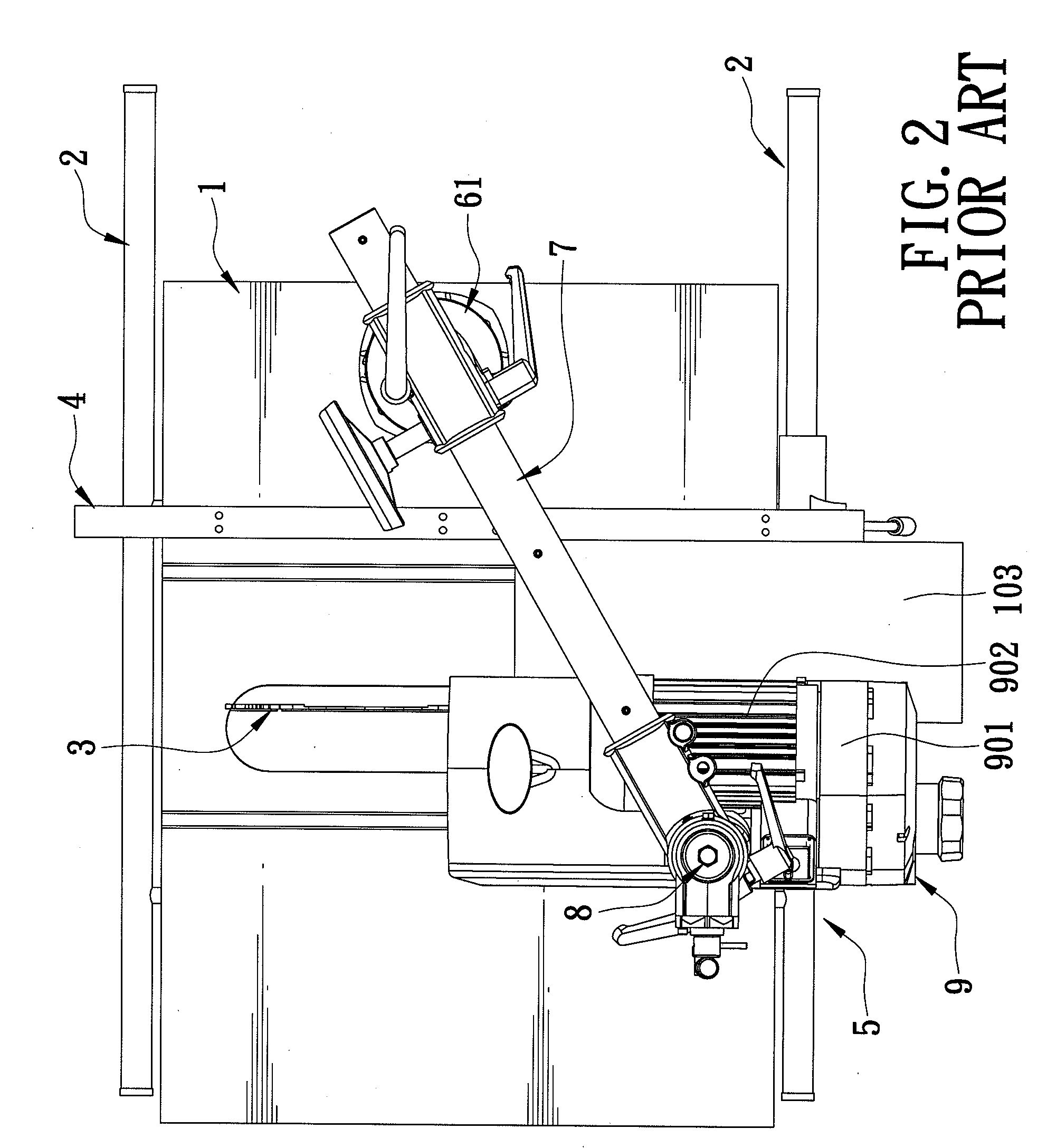

Log home fabrication process and associate log cutting machine

InactiveUS20030041919A1Tongue/grooves making apparatusMulti-purpose machinesComputer scienceComputer control

A log processing machine and associate method employs one or more log guides to make joinery cuts in a processed log which has at opposed edges of the processed log the raw log's natural external contour. In a preferred embodiment of the invention, each log guide includes a straight edge and is attached to the processed log to create an artificial straight edge for guiding the processed log through the joinery machine. Prior to attachment, centerlines are marked on the log guide and the processed log, and the centerlines are aligned when the log guide is attached to the processed log. The processed log, with the log guide attached, is then moved through the machine with the aid of computer control while the straight edge of the log guide follows a fence. In this manner, the position of the processed log and its centerline are always known so that the computer can make the programmed joinery cuts with high precision. An alternate embodiment of the invention employs one or more fence extensions as log guides. The fence extensions are positionable in guide channels formed in the contoured edges of the processed log. A further embodiment of the invention employs an opposed pair of clamping / alignment elements which are controlled by a computer to align and guide the log through the joinery machine.

Owner:HEARTHSTONE

Feather Board Apparatus And Method

ActiveUS20080277024A1Limit pivotingMetal sawing devicesWood feeding arangementsEngineeringMechanical engineering

An improved feather board apparatus and method are provided, for use in holding a work piece against a guide surface as the work piece is guided in a feed direction, and for precluding motion of the work piece in a direction opposite the feed direction, through use of a feather board apparatus, having a feather board clamping arrangement which allows for limited amount of pivoting of the feather board about an in feed side clamping point, as the work piece is fed past the feather board.

Owner:NOMIS

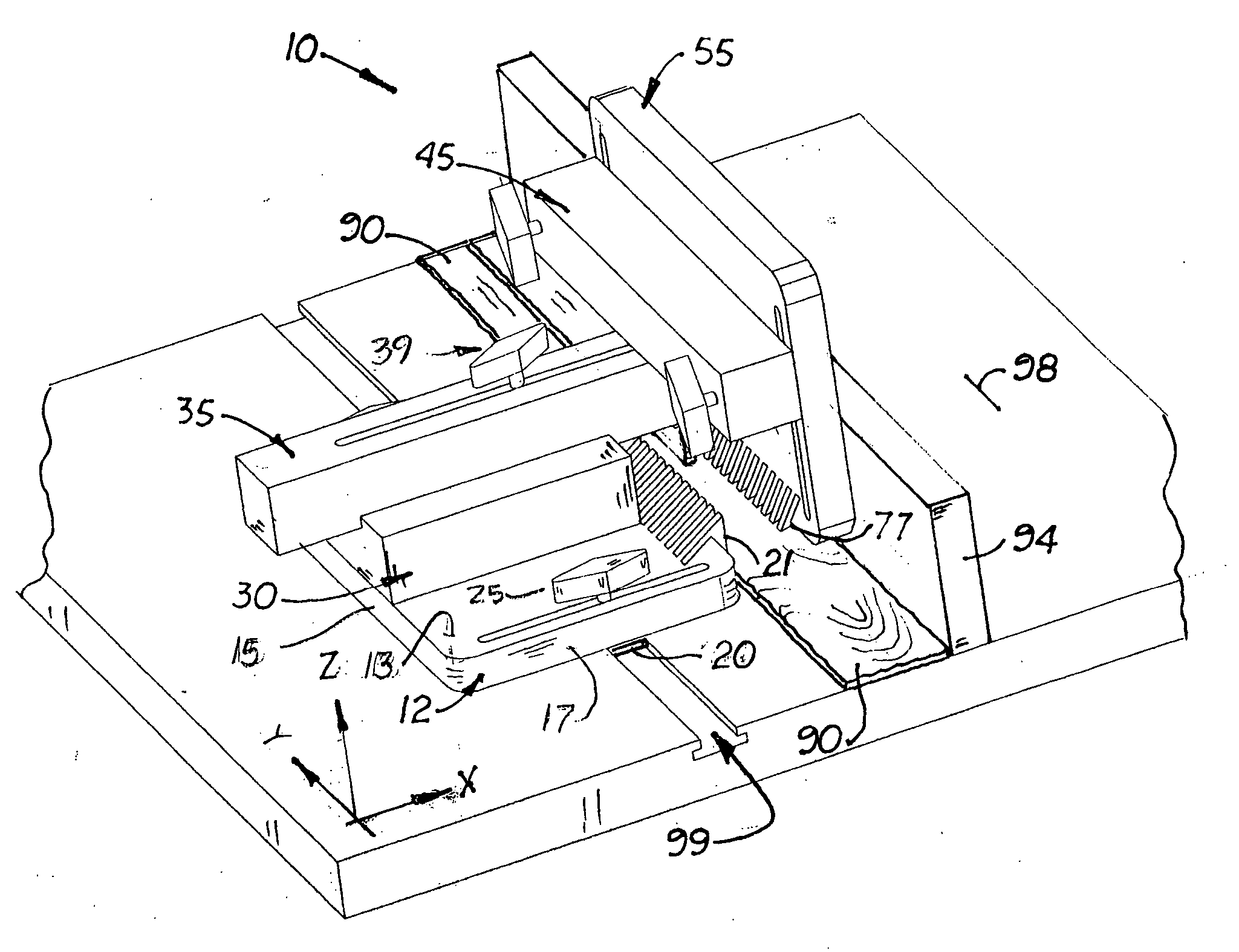

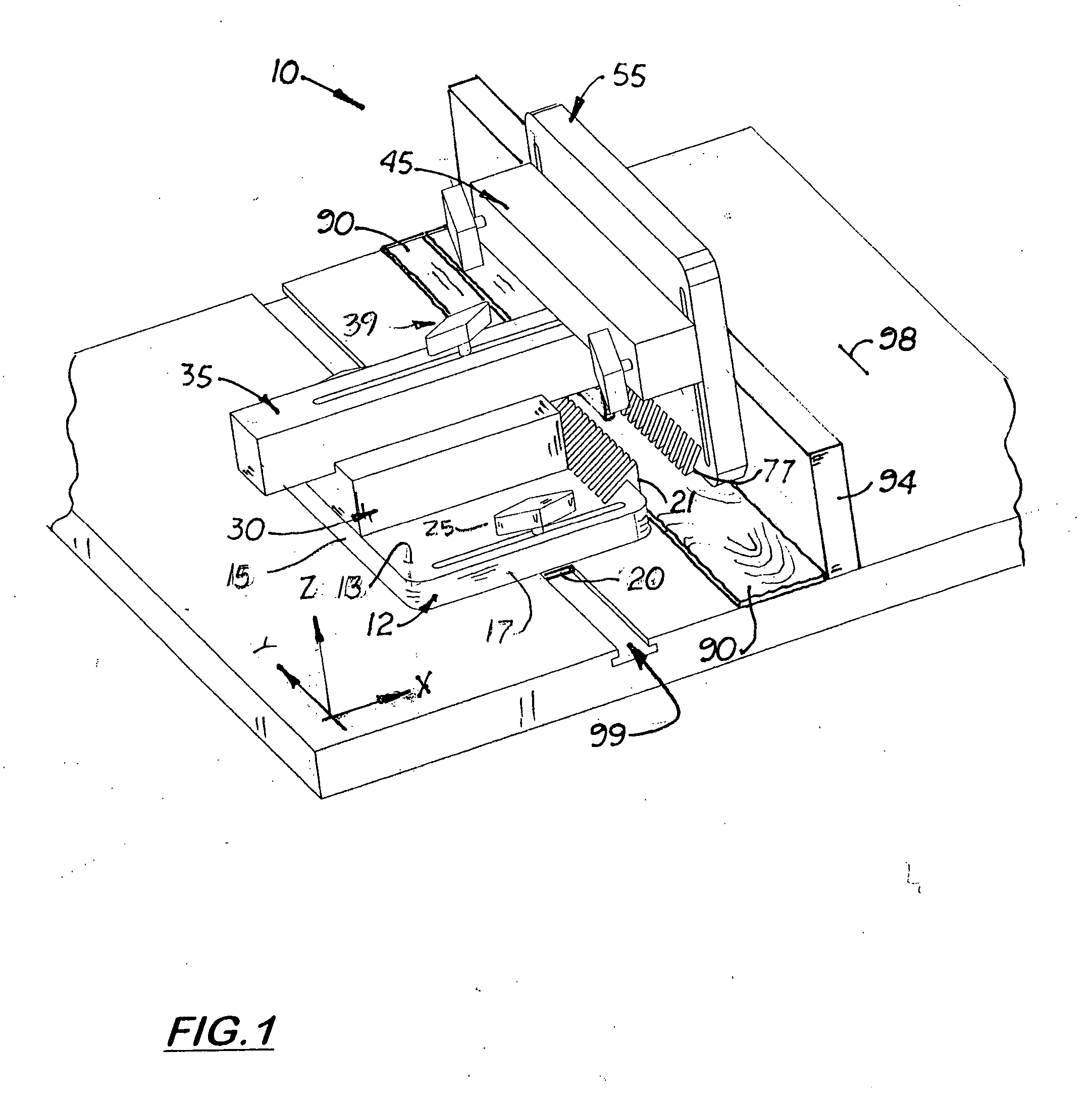

System and device for positioning a workpiece relative to a router and use thereof

InactiveUS7997312B2Accomplished fast, accurately and/or easilySolve the real problemWood feeding arangementsDrilling/boring measurement devicesComputer networkComputer science

A system positions a workpiece with respect to a router bit. The system may include a router for routing out a part of the workpiece, a router table for supporting the workpiece, a router fence arranged and constructed to position the workpiece relative to the router during machining, and a positioning device arranged and constructed to position the router fence relative to the router before machining the workpiece, wherein the router comprises a router collet positioned beneath the router table, the router collet being constructed and arranged to engage a router bit extending through an opening in the router table for machining the piece.

Owner:VAN VALKENBURG SJOERD ANNE

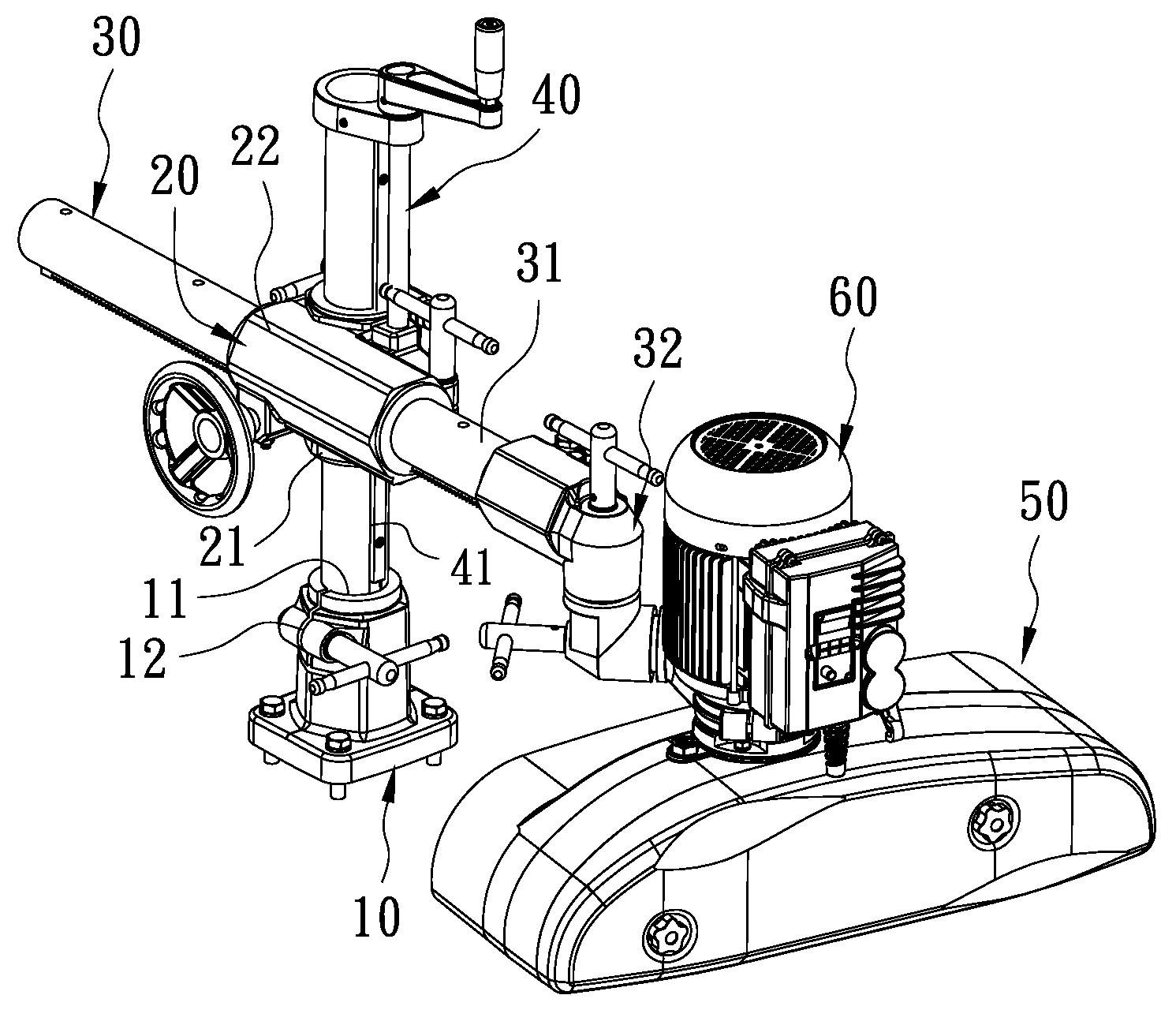

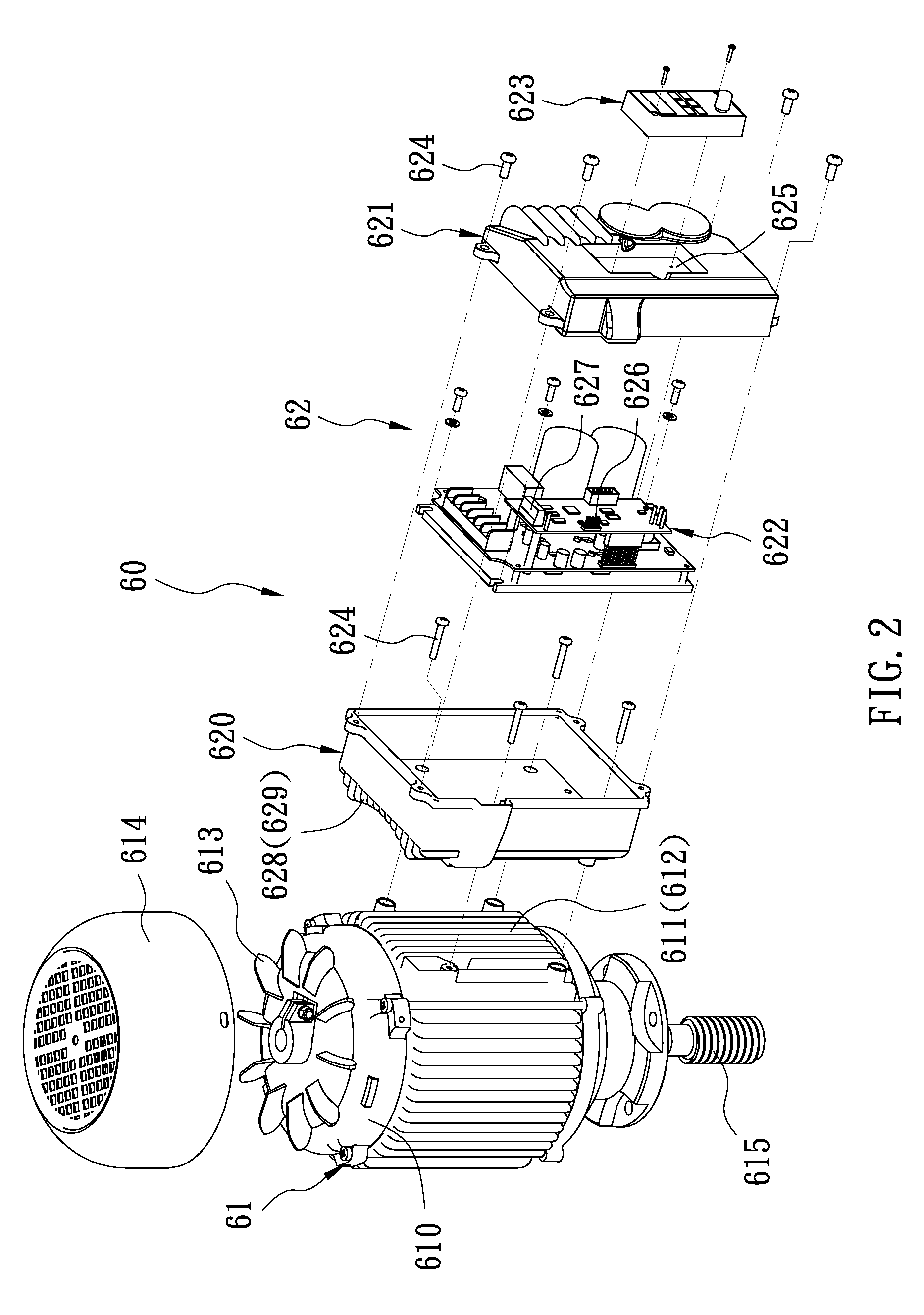

Stock feeder for woodworking equipment

ActiveUS8931528B2Efficient heat dissipationImprove dustproofWood feeding arangementsAssociation with control/drive circuitsVertical barEngineering

A stock feeder for woodworking equipment includes a base, a cross clamp, a horizontal bar unit, a vertical bar unit, a feeding unit, and an electrical unit. The electrical unit has an electrical unit main body and a variable-frequency drive. The electrical unit main body has a first housing, a plurality of heat dissipation grooves provided on the outer periphery of the first housing, and a power fan which is independently mounted on a top portion of the first housing and in communication with the heat dissipation grooves. The variable-frequency drive has a second housing, a variable-frequency circuit sealed in the second housing, and a control panel exposed outside the second housing. The second housing has an outer surface provided with a plurality of heat dissipation slots corresponding in position to and in communication with the heat dissipation grooves of the electrical unit main body.

Owner:HSIUNG TAI YUAN

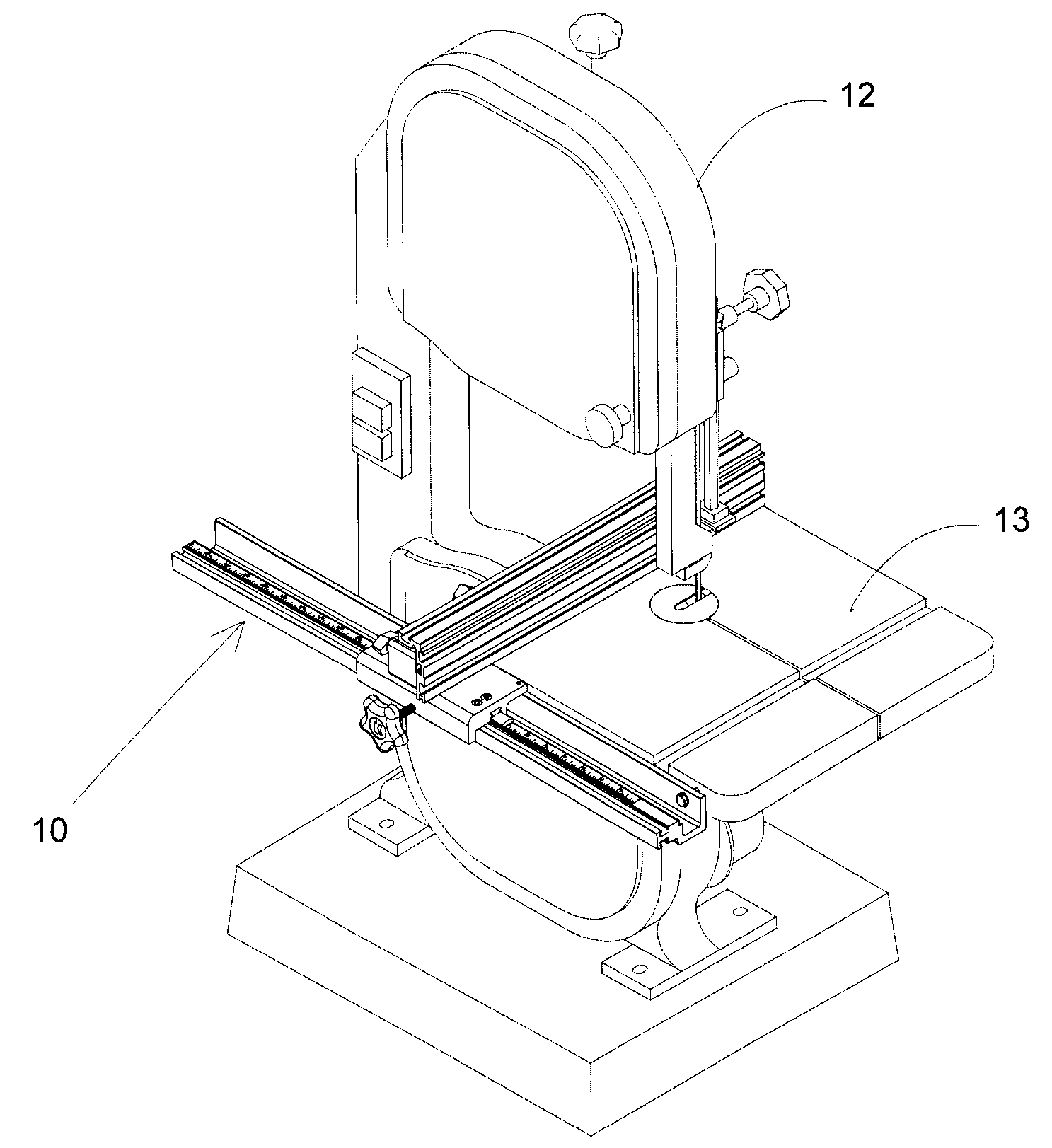

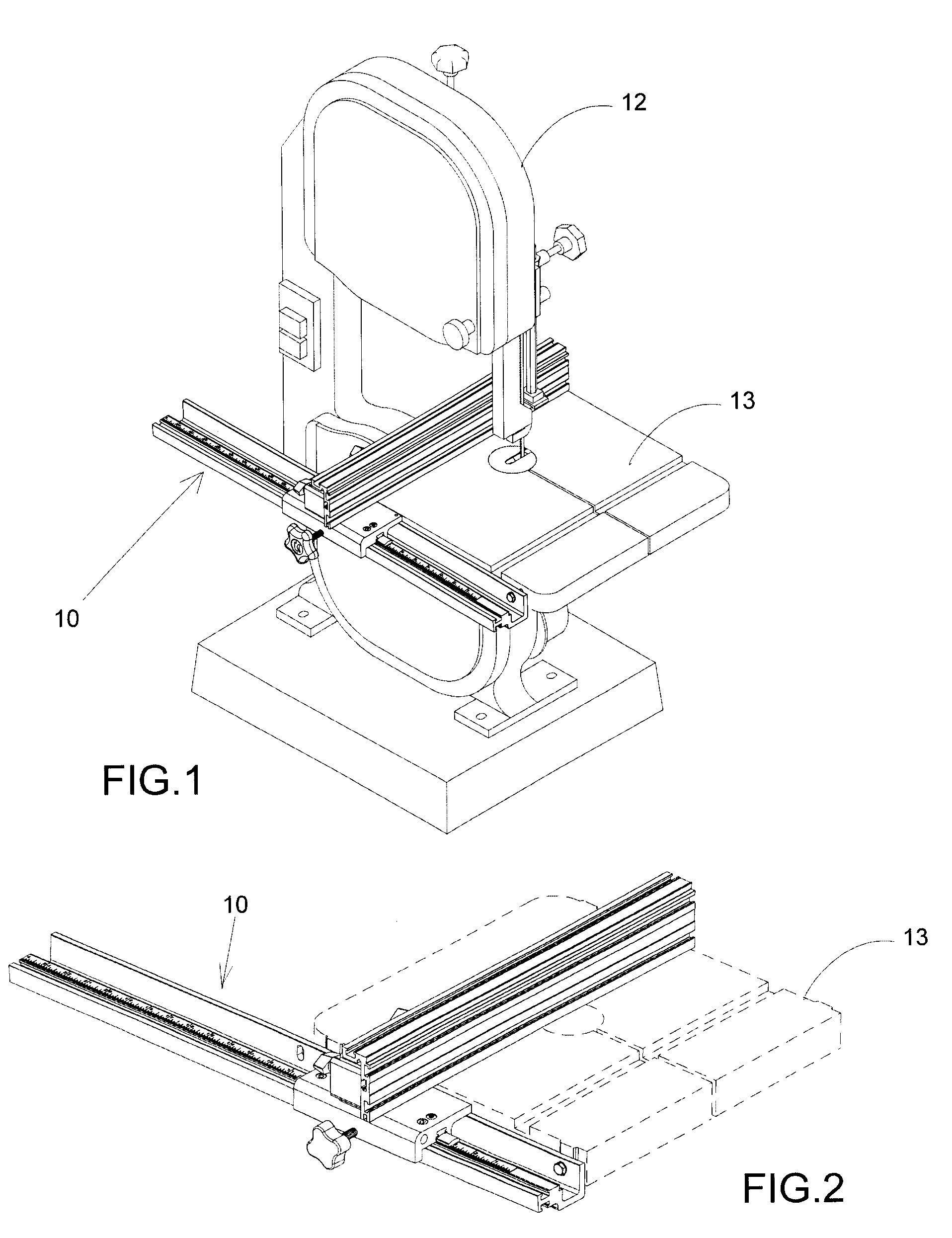

Adjustable guide bar for woodworking table slot

Owner:WANG HENRY

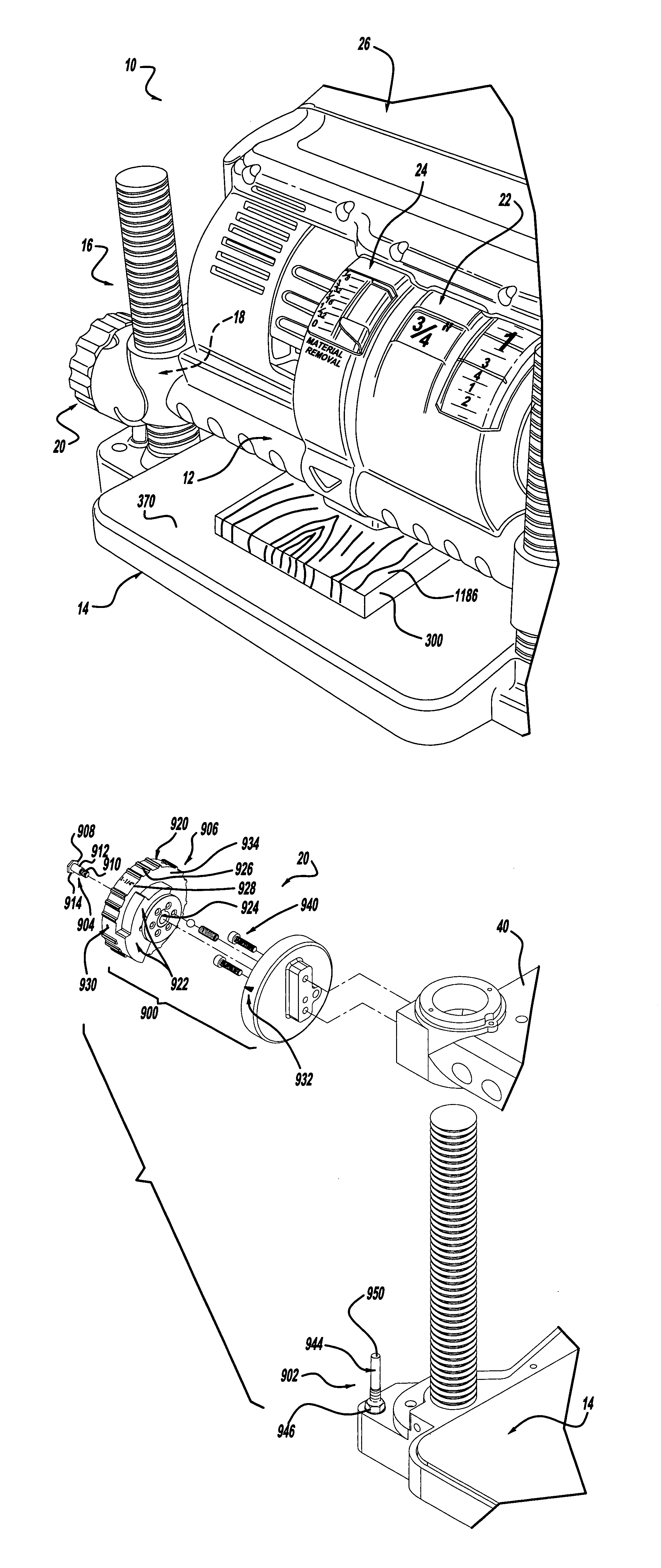

Micro-adjustment device for the angle stop plank of a planer

InactiveUS7392830B2Accurately micro-adjustQuick and accurate adjustmentWood feeding arangementsFeeding devicesDisplay devicePower tool

An adjustable stop plank for a power tool includes a drive mechanism connected to the stop plank for continuous adjustment of the angle of the stop plank with respect to the work surface and has a display for indicating the current angle of the stop plank. In one form, the micro-adjusting device for the stop plank of a power tool includes a hand wheel unit provided on the holding frame operable to continuously adjust the angle of the stop plank. The power tool may include indicia to indicate a plurality of angles for the stop plank and an index for indicating on the indicia the current angle of the stop plank.

Owner:JPW IND

Feather board apparatus and method

ActiveUS7942174B2Limit pivotingMetal sawing devicesWood feeding arangementsEngineeringMechanical engineering

An improved feather board apparatus and method are provided, for use in holding a work piece against a guide surface as the work piece is guided in a feed direction, and for precluding motion of the work piece in a direction opposite the feed direction, through use of a feather board apparatus, having a feather board clamping arrangement which allows for limited amount of pivoting of the feather board about an in feed side clamping point, as the work piece is fed past the feather board.

Owner:NOMIS LLC

Portable power planer

InactiveUS6886615B2Avoid distanceWood feeding arangementsThicknessing machinesPortable powerKnife blades

A portable power planer for planing the top surface of a workpiece. The portable power planer includes a base, which defines a reference surface, a cutting blade, which defines a cutting plane, and a setting mechanism may be employed to prevent a distance between the reference surface and the cutting plane from being adjusted to a dimension that is smaller than a height dimension that is selected from a group of predetermined dimensions. The setting mechanism includes first and second stop members, one being coupled to the base and the other being associated with the cutting blade. One of the stop members includes a plurality of differently dimensioned sectors or contact points that may be selectively positioned inline with the other stop member to inhibit movement of the cutting blade toward the base if the dimension therebetween is equal to a dimension associated with a given one of the contact points.

Owner:BLACK & DECKER INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com