Patents

Literature

1765 results about "Vertical bar" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The vertical bar ( | ) is a computer character and glyph with various uses in mathematics, computing, and typography. It has many names, often related to particular meanings: Sheffer stroke (in logic), verti-bar, vbar, stick, vertical line, vertical slash, bar, pike, or pipe, and several variants on these names. It is occasionally considered an allograph of broken bar (see below).

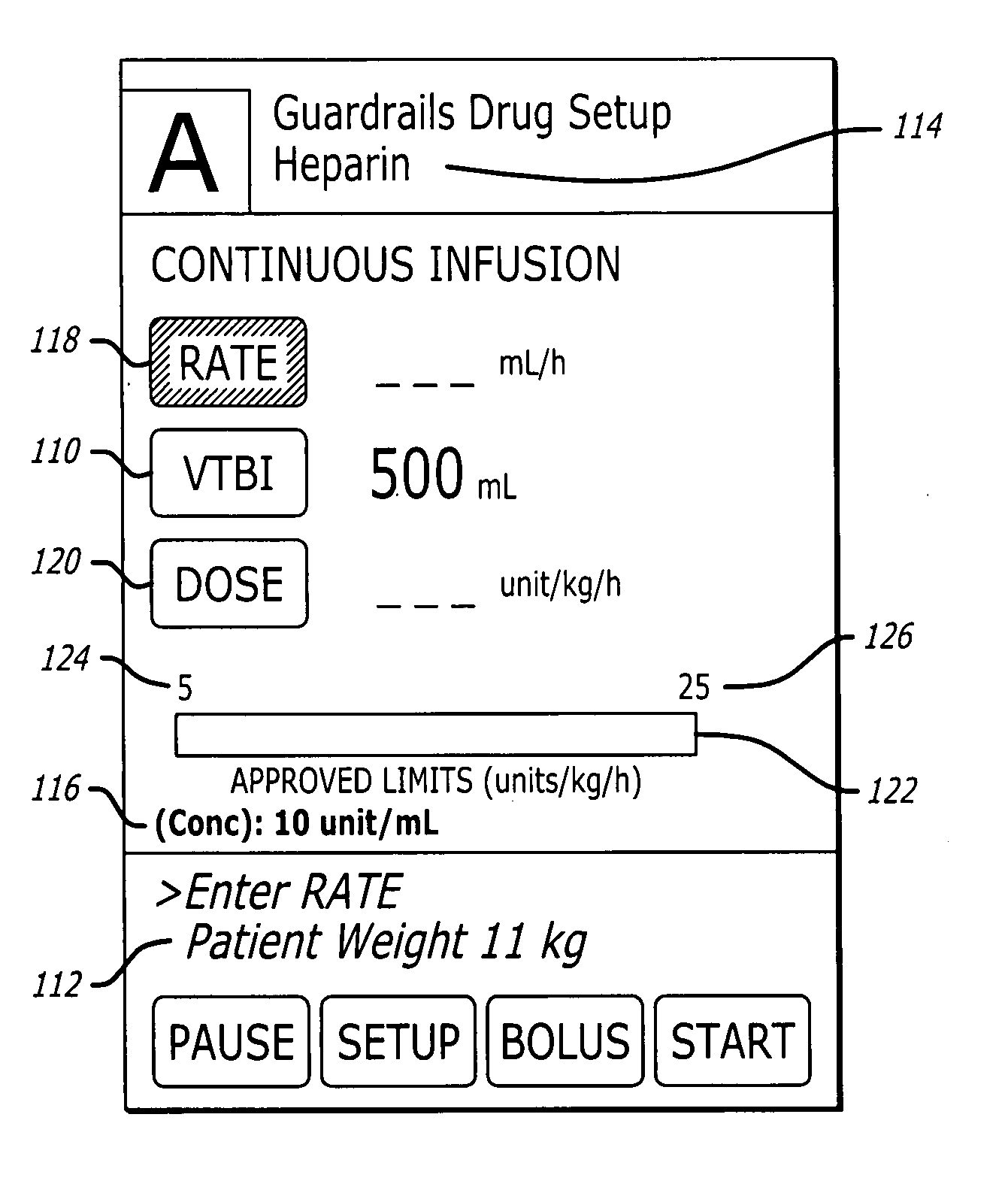

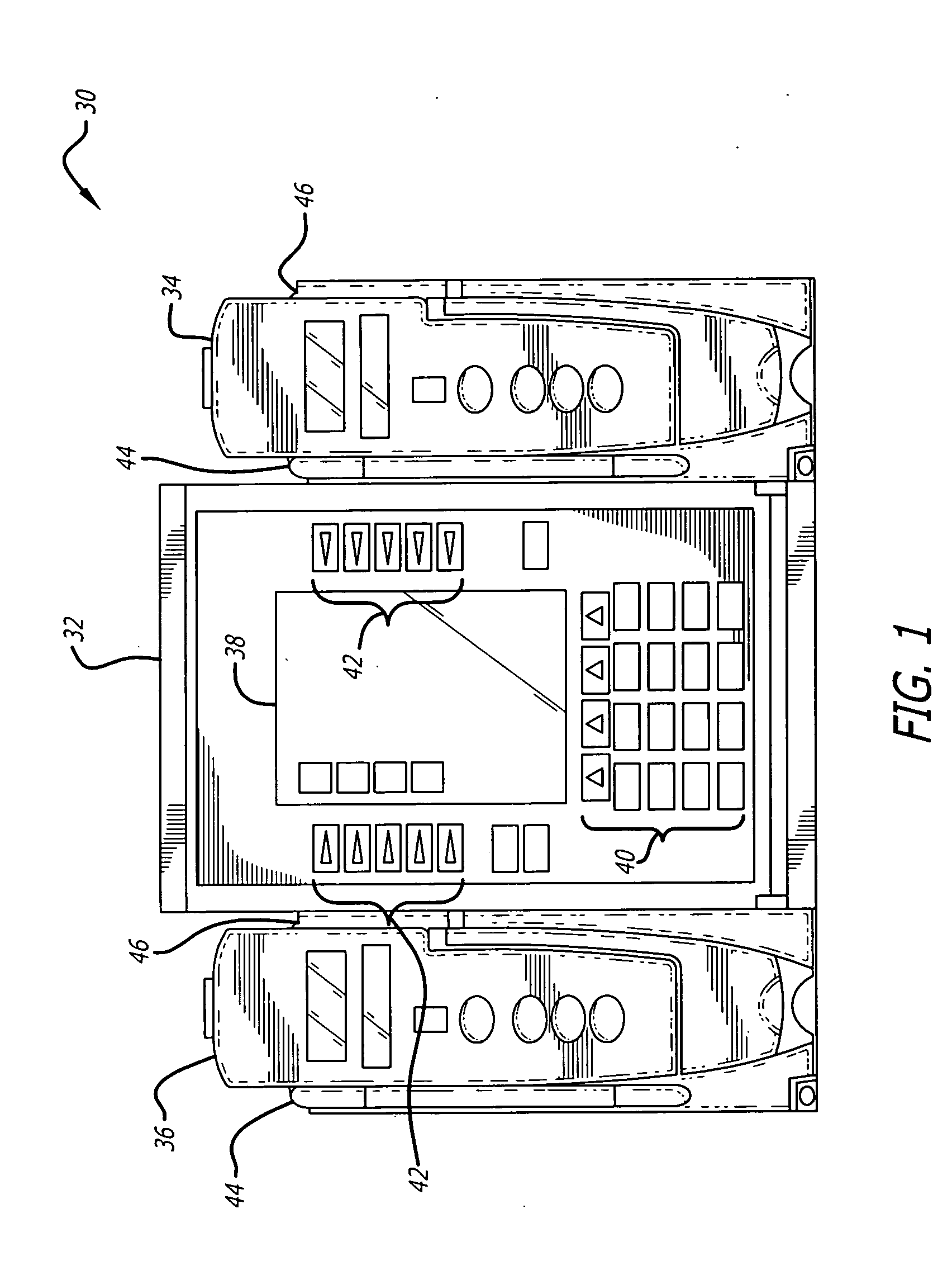

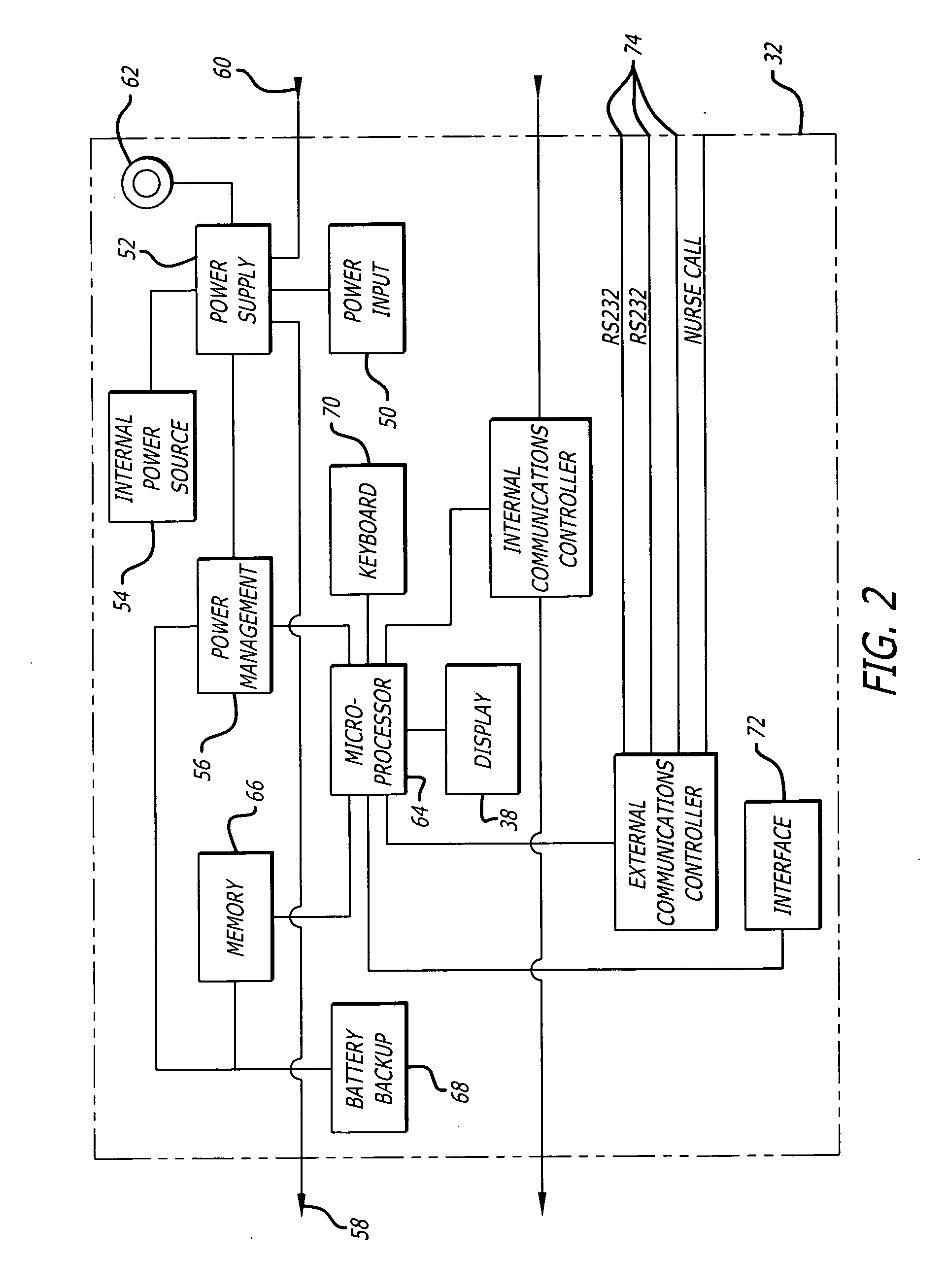

Graphical display of medication limits and delivery program

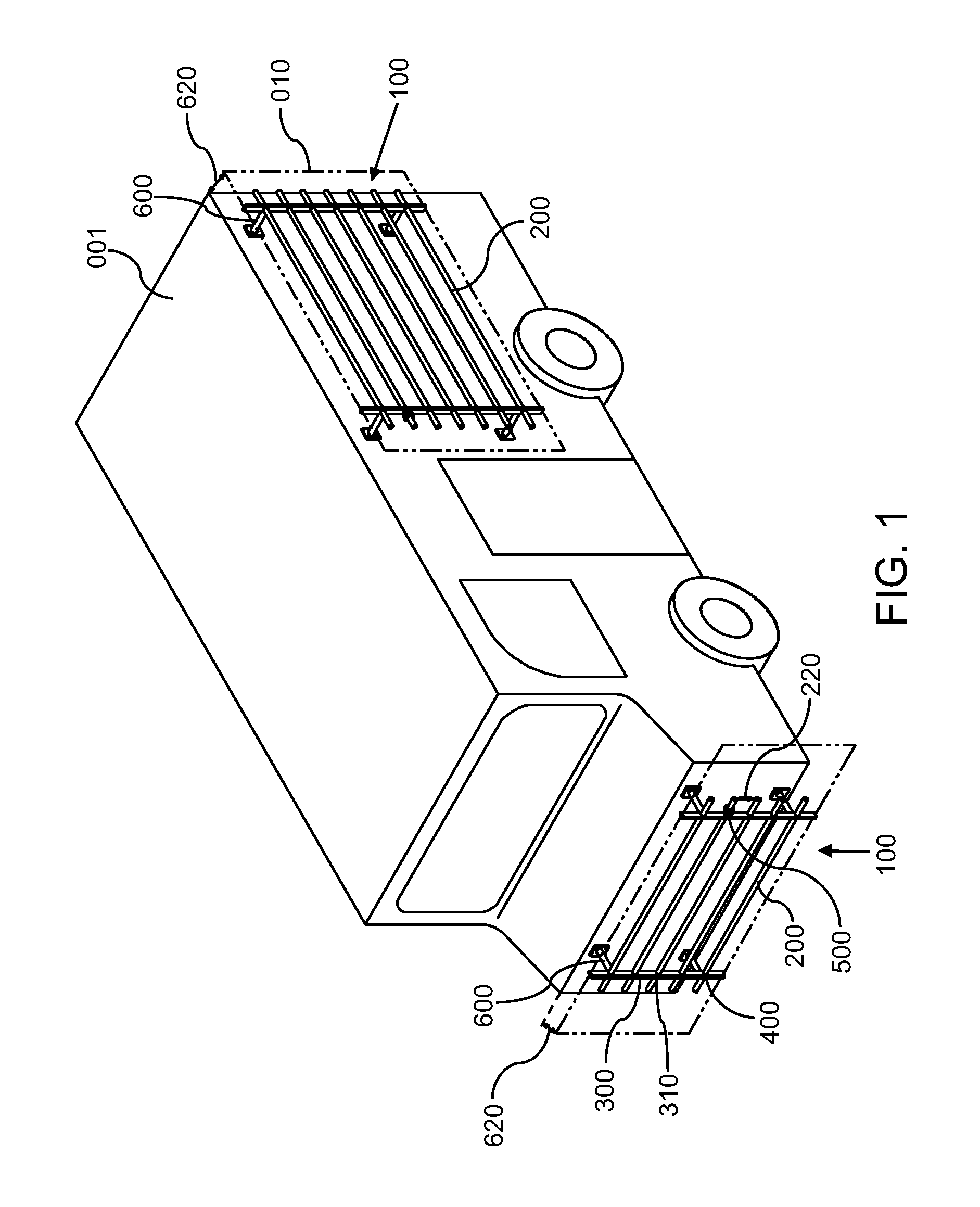

InactiveUS20060258985A1Efficient and effective careQuick selectionDrug and medicationsPharmaceutical delivery mechanismGraphicsVertical bar

This invention describes a medication delivery system and method that displays in graphical form a selected delivery parameter or parameters in association with predetermined acceptable ranges of such values so that the clinician can visualize where in the acceptable range the selected value lies. The graphical form is a vertical bar graph in one embodiment that includes an acceptable area, a caution area, and an unacceptable area within which the selected delivery parameter value may fall. When the selected value falls in the caution or unacceptable areas, a text message is displayed cautioning against over dosage of the particular medical fluid being delivered and in another embodiment, an acceptable value of the delivery parameter is suggested. With such a system, any clinician monitoring the delivery of the medical fluid to the patient can immediately ascertain where in the care facility's acceptable range of delivery values this particular patient's medication is being delivered.

Owner:CAREFUSION 303 INC

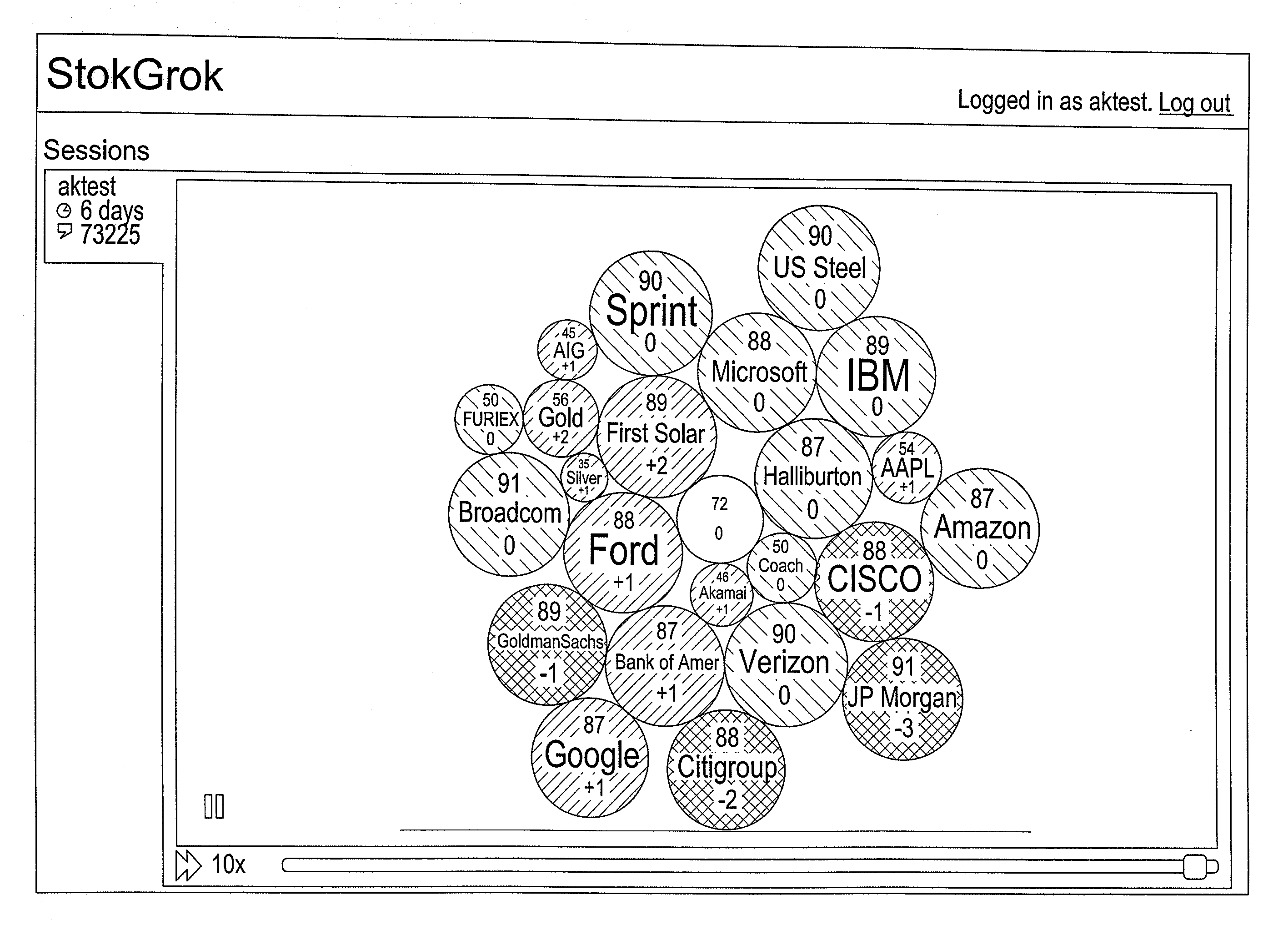

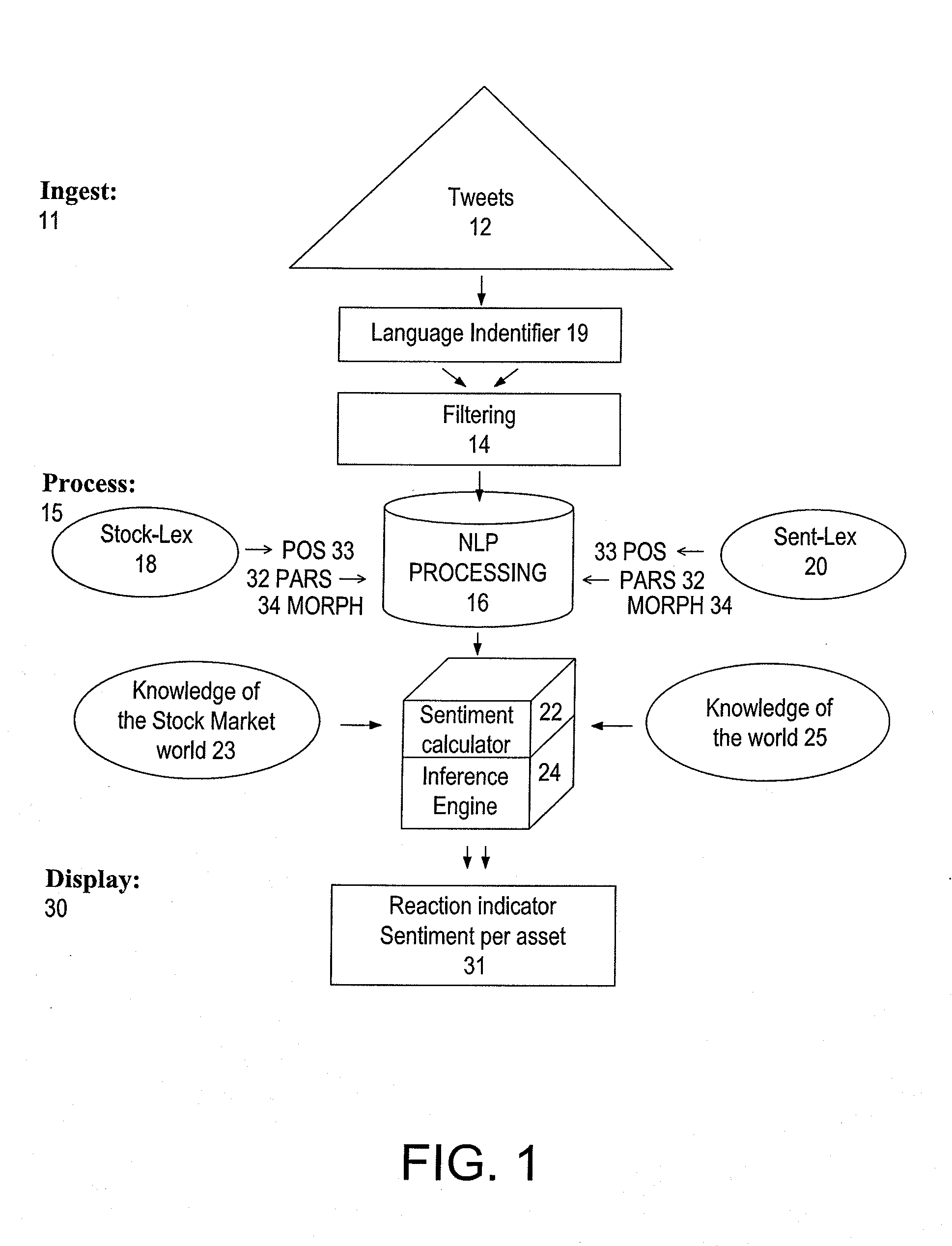

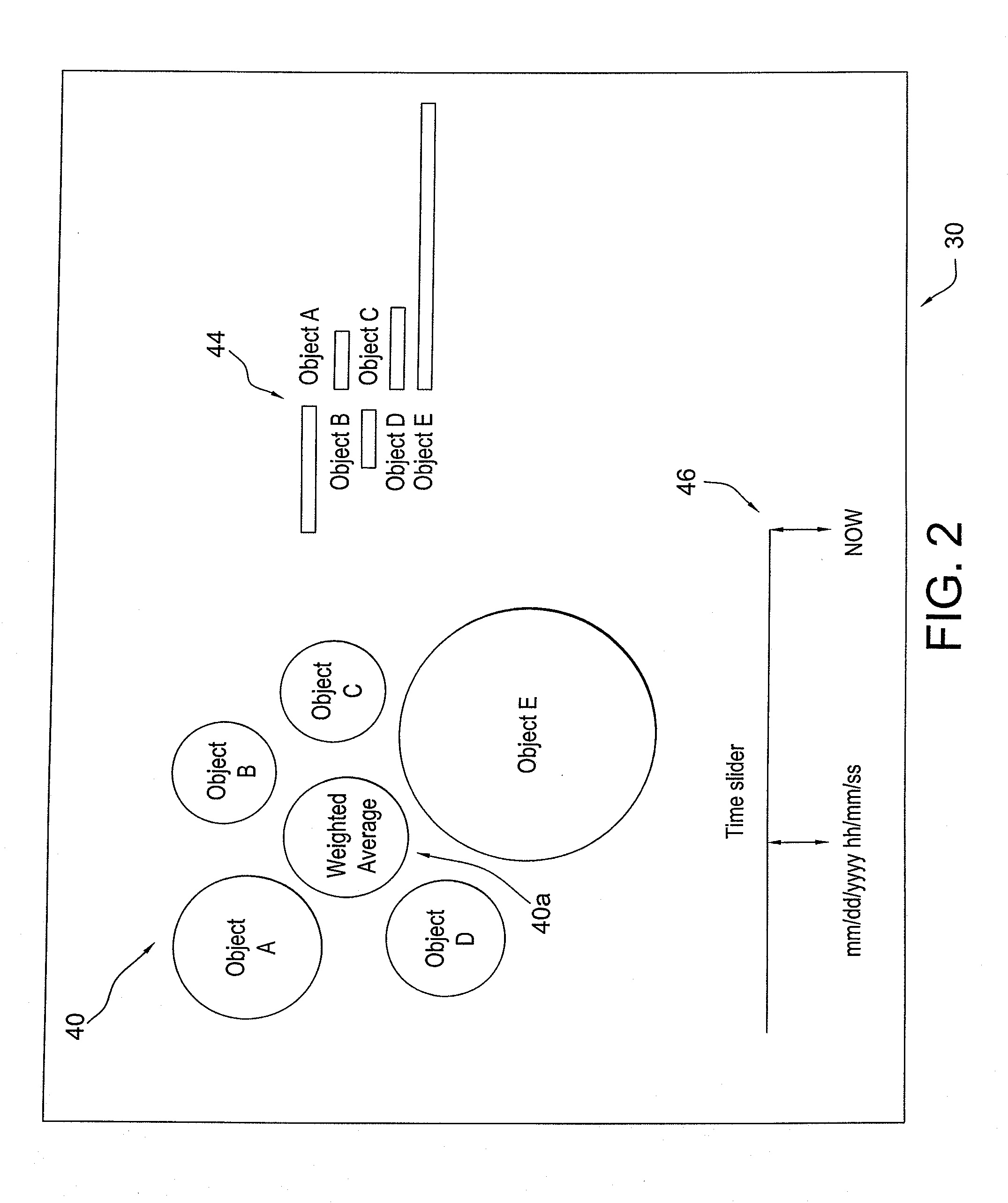

Reaction indicator for sentiment of social media messages

A reaction indicator in the form of a graphical user interface is disclosed. The reaction indicator combines sentiment and intensity data relating to an asset for use in real-time evaluation of publicly traded assets, in particular equities and commodities. The reaction indicator includes graphic objects displayed upon a monitor that depict social media market sentiment, a timeline slider object, and a vertical bar chart object. The sentiment is derived based upon pairs of lexical items in local syntactic context found in a volume of social media messages.

Owner:ISENTIUM

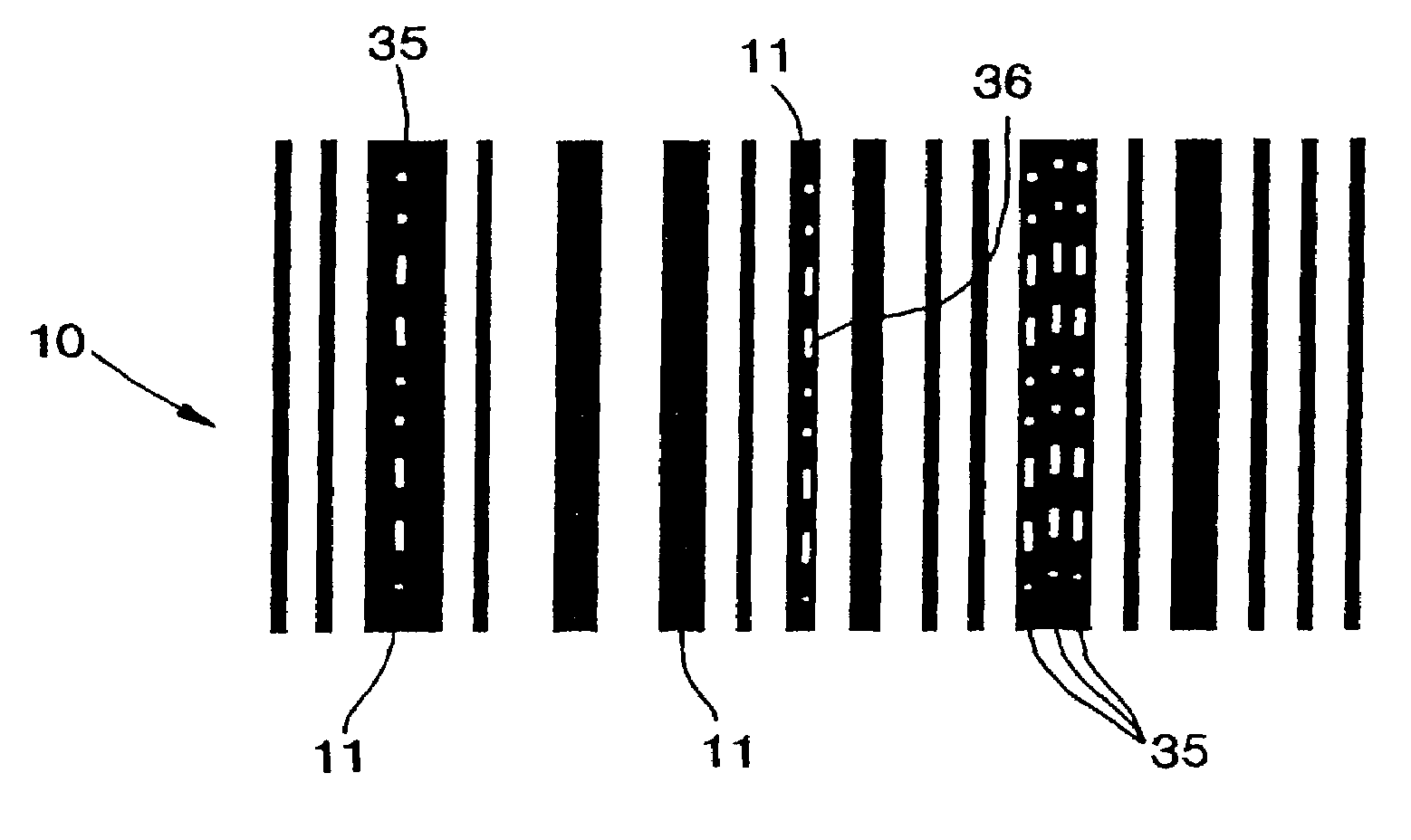

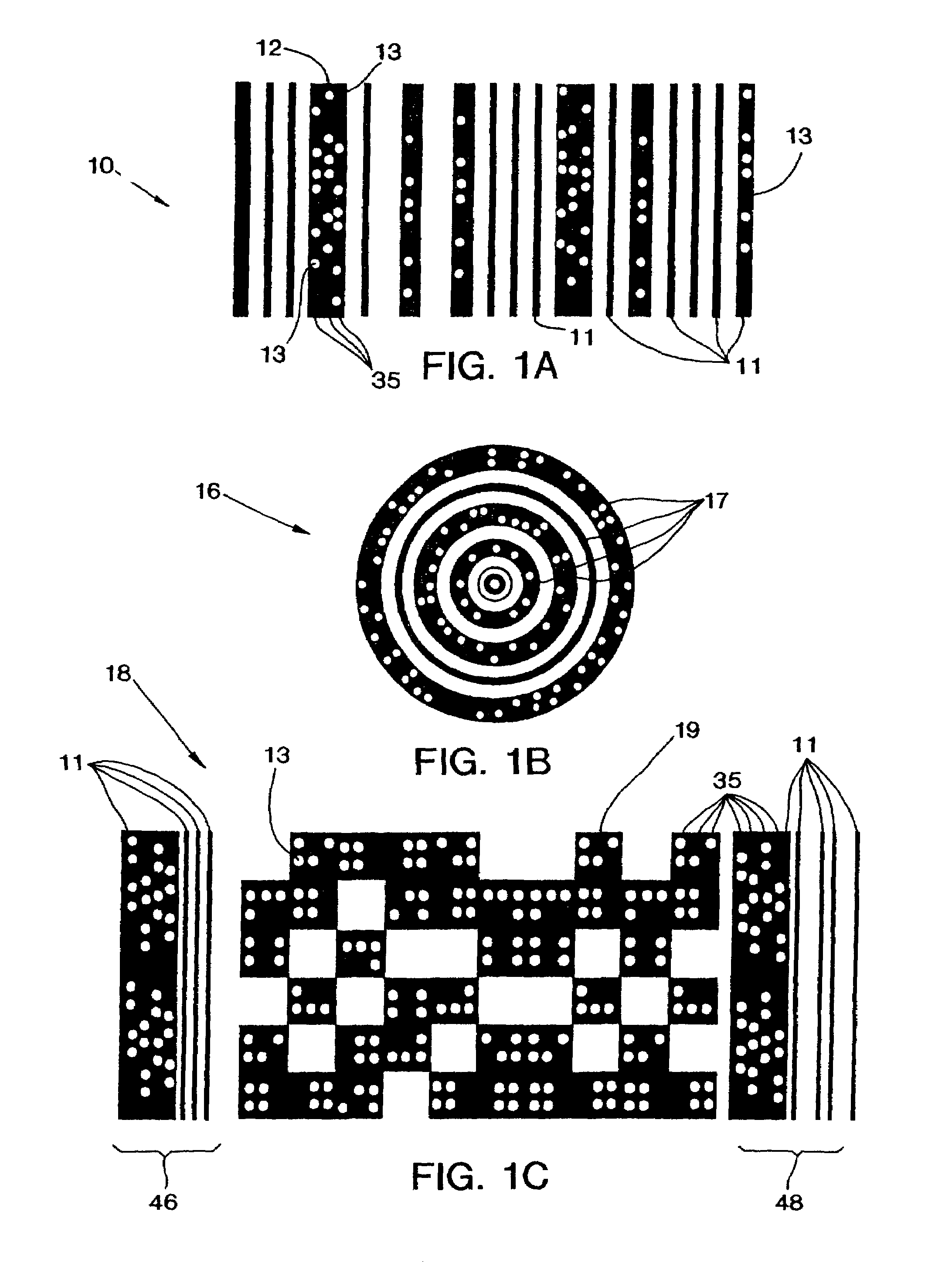

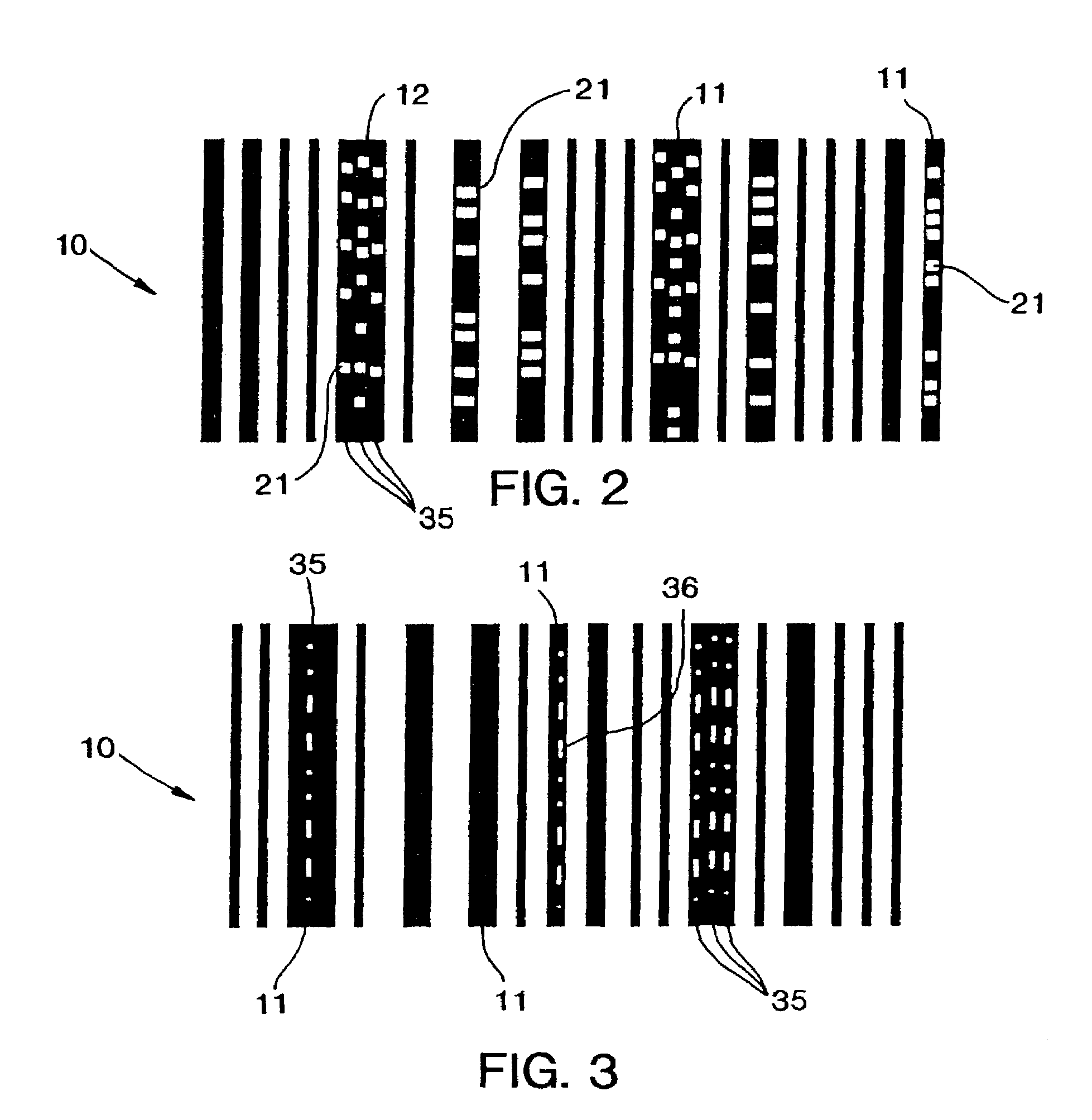

Method and apparatus for encoding and decoding bar codes with primary and secondary information and method of using such bar codes

InactiveUS6991164B2Character and pattern recognitionRecord carriers used with machinesScannerIn plane

A bar code (10) has primary information (46, 48, 50, 51) encoded in one direction (e.g., horizontally) and secondary information (13, 21, 36) encoded in another direction (e.g., vertically) in single (11) or multiple tracks (35) in selected ones of the vertical bars (11) of a bar code (10). Using a non-linear, variable amplitude scanner, all of the bars are scanned in the one direction to obtain all of the primary information and all of those vertical bars having secondary information are scanned in the other direction to obtain all of the secondary information. The one direction which is perpendicular to the vertical bars (11), is determined by first rotating the scan path axis (86, 87) until both start (46) and end (48) code bars are read thereby placing the scan path entirely within the total bar code, and, then, further rotating the scan path (88, 89) to determine the direction of the minimum crossing width (Lsc 80) of the total bar code (10). Secondary information is scanned in planes orthogonal to the one direction after those vertical bars (11) having such information are first identified and selected. In a preferred embodiment, the decoded secondary information may be used to control selected station process operations for selected products in a continuous manufacturing assembly line.

Owner:LEMELSON MEDICAL EDUCATION & RES FOUND PARTNERSHIP

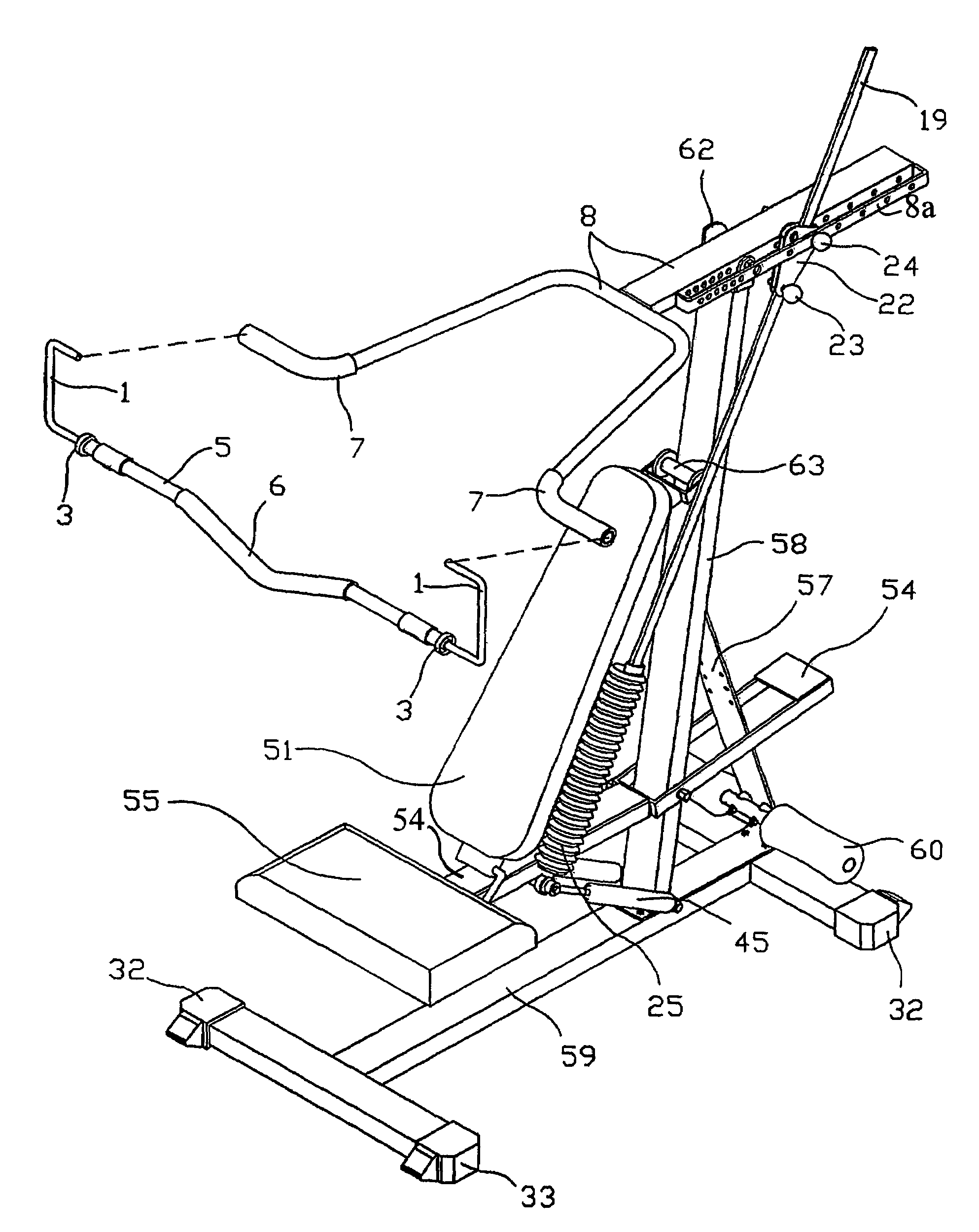

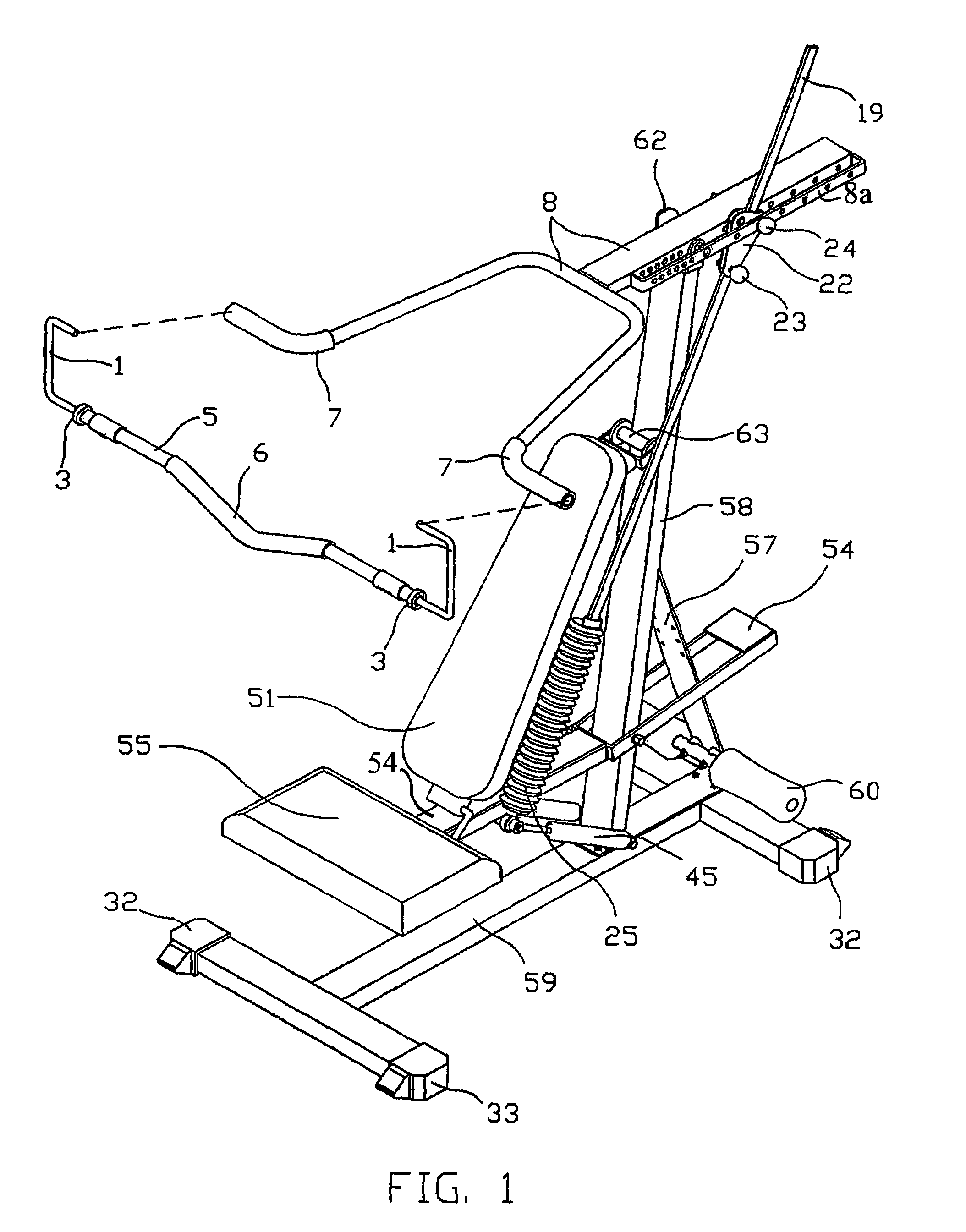

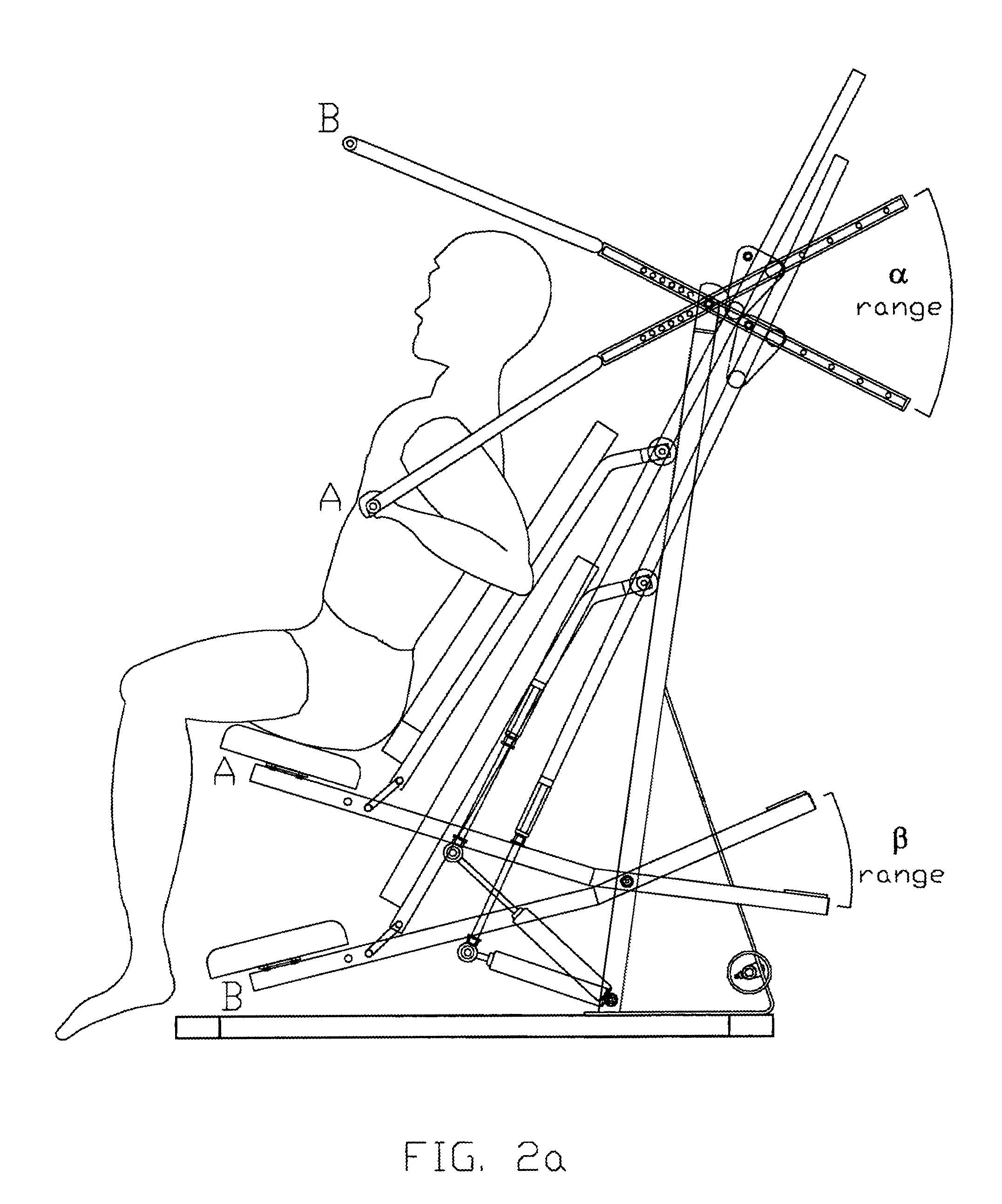

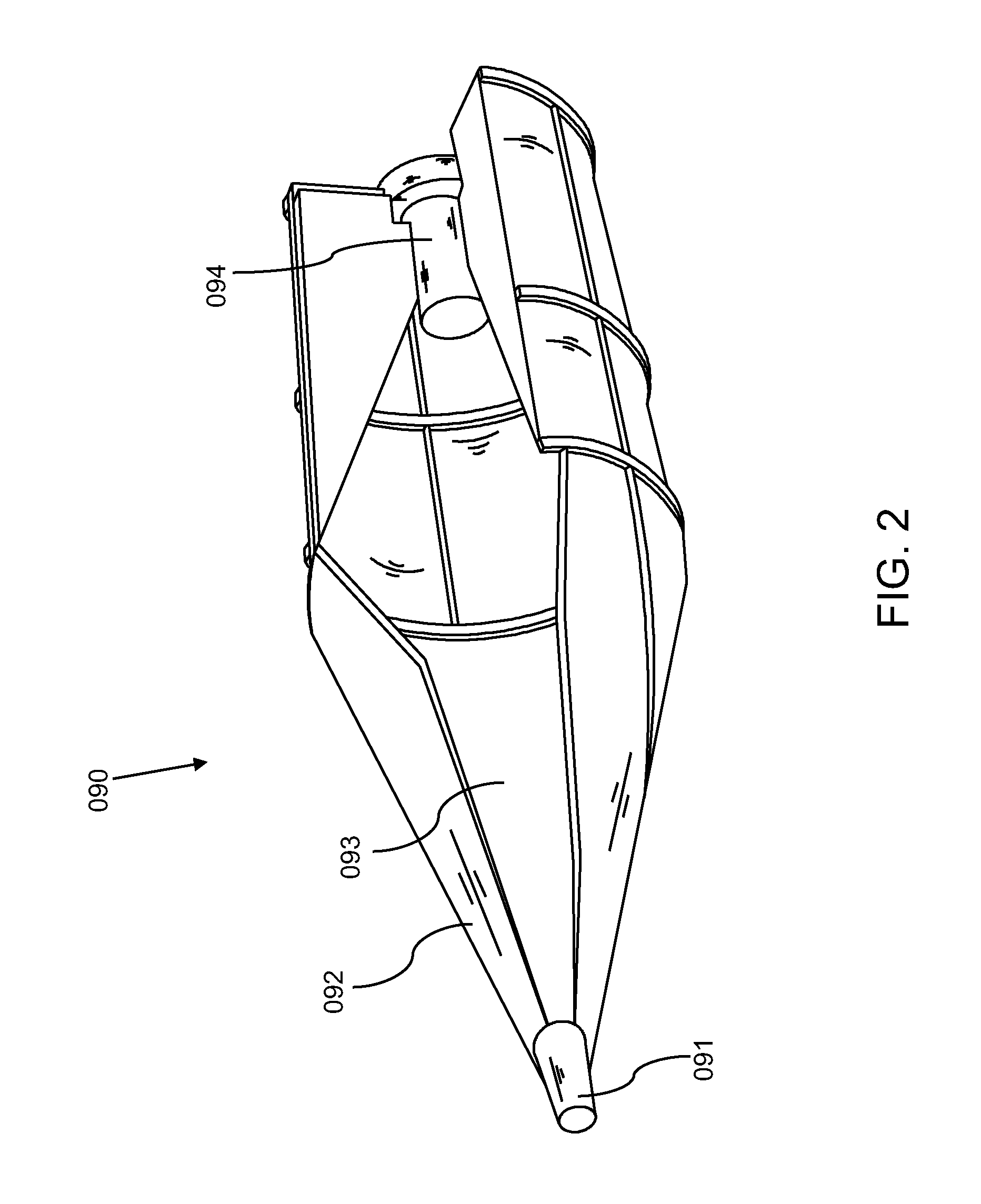

Body weight gravity apparatus

An exercise machine making use of the body weight of an exerciser as a load weight thereof comprises a horizontal base, a vertical bar member, an upper rocking bar member, a lower rocking bar member, a connection bar, a seat pad, a back pad, a handle, a pivoting cross member (V bar) and cushioning members. Unlike a conventional exercise machine, the exercise machine is composed of no weights. The vertical tube bar member is affixed to the base. The position of the upper rocking bar member can be adjusted by adjusting the pivoting position of the connection bar via the shuttle and two key pins. The exerciser can use the machine by sifting, kneeling, or standing on the seat pad of the machine for doing the muscle-building exercise.

Owner:MATTHEWS PRODN

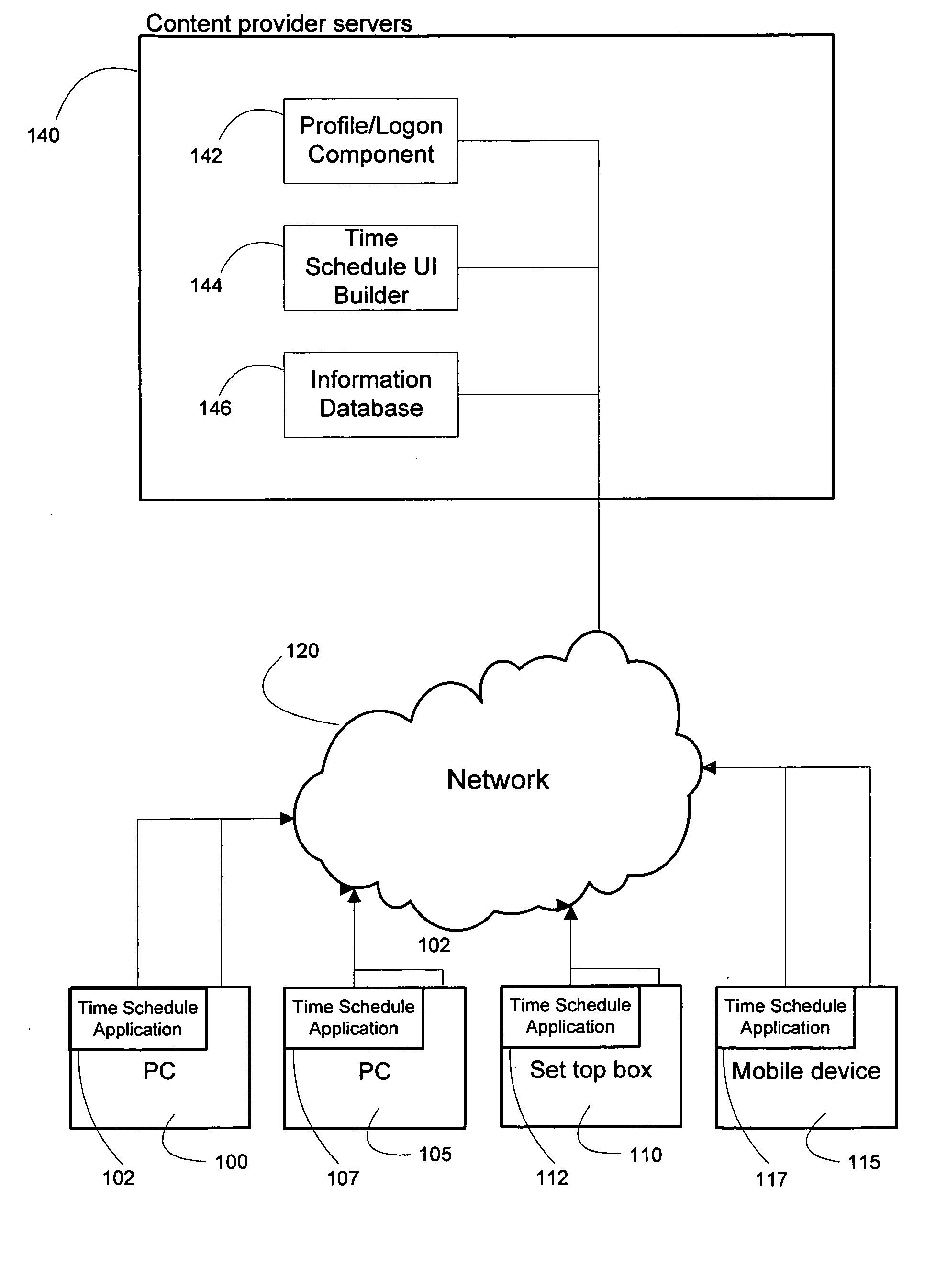

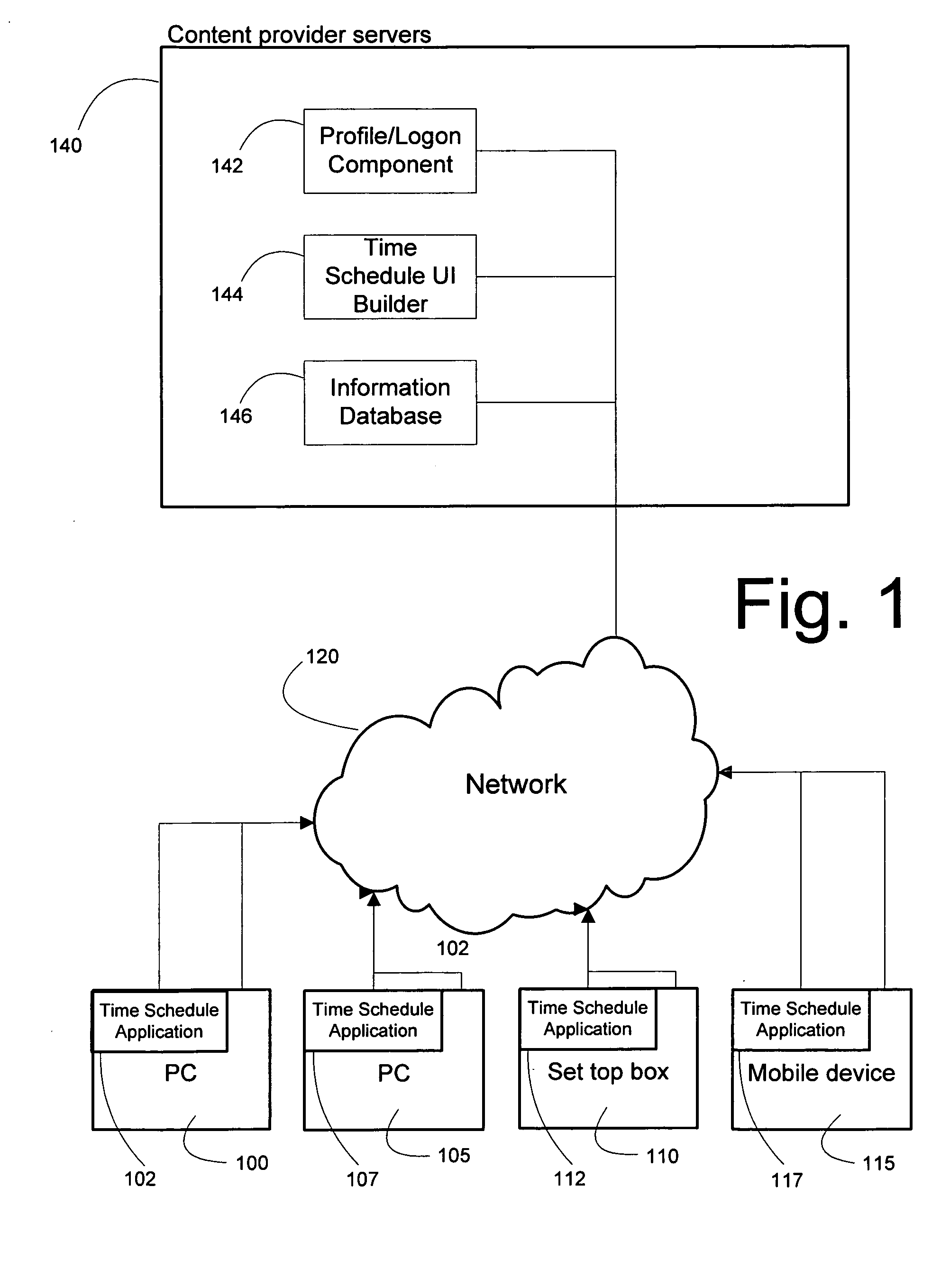

Method and user interface tool for navigation through grid of scheduled items

InactiveUS20080126989A1Easy to watchThe process is convenient and fastTelevision system detailsSelective content distributionTime scheduleVertical bar

Methods and software tools are described for allowing users to navigate through a time schedule quickly and easily. The time schedule interface facilitates a user viewing multiple time periods on an information schedule on a client device quickly without having to completely remake or redraw the entire interface. A user of a computer or similar device is presented with a time schedule interface. This schedule interface may resemble a schedule such as program guide or a train schedule. The schedule typically is composed of a grid or blocks of information defined by two parameters. One parameter is almost always time, while the other parameter depends on the type of schedule. The interface in this invention includes a moveable virtual slider. The slider rests on or is attached to a time scale axis. This time scale axis may be implemented as a horizontal or vertical bar and in addition may contain markings corresponding to time intervals much like a ruler. A user may select and control this slider along the time scale axis. The position of the slider along the time scale axis controls the time periods displayed in the schedule.

Owner:R2 SOLUTIONS

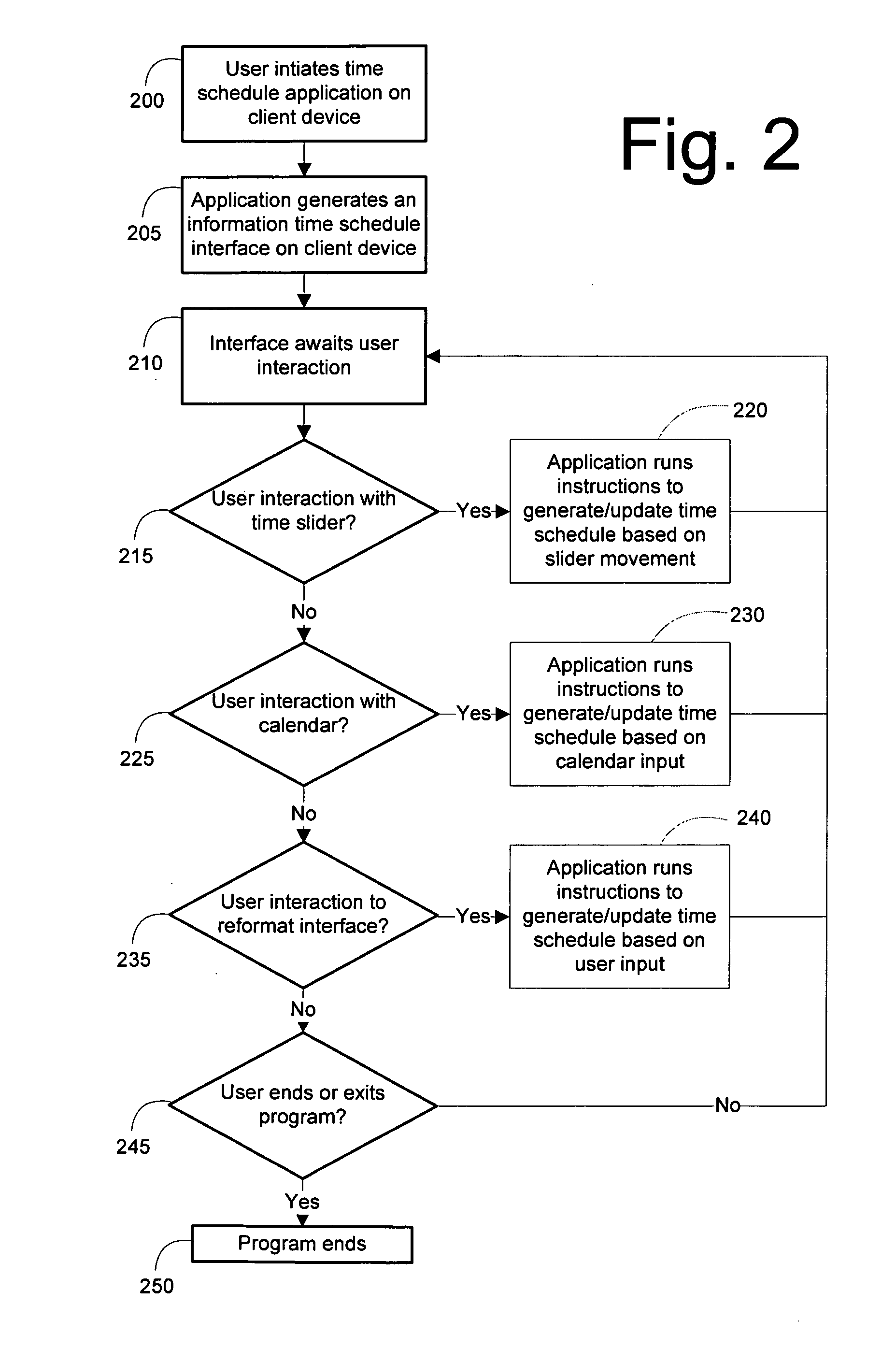

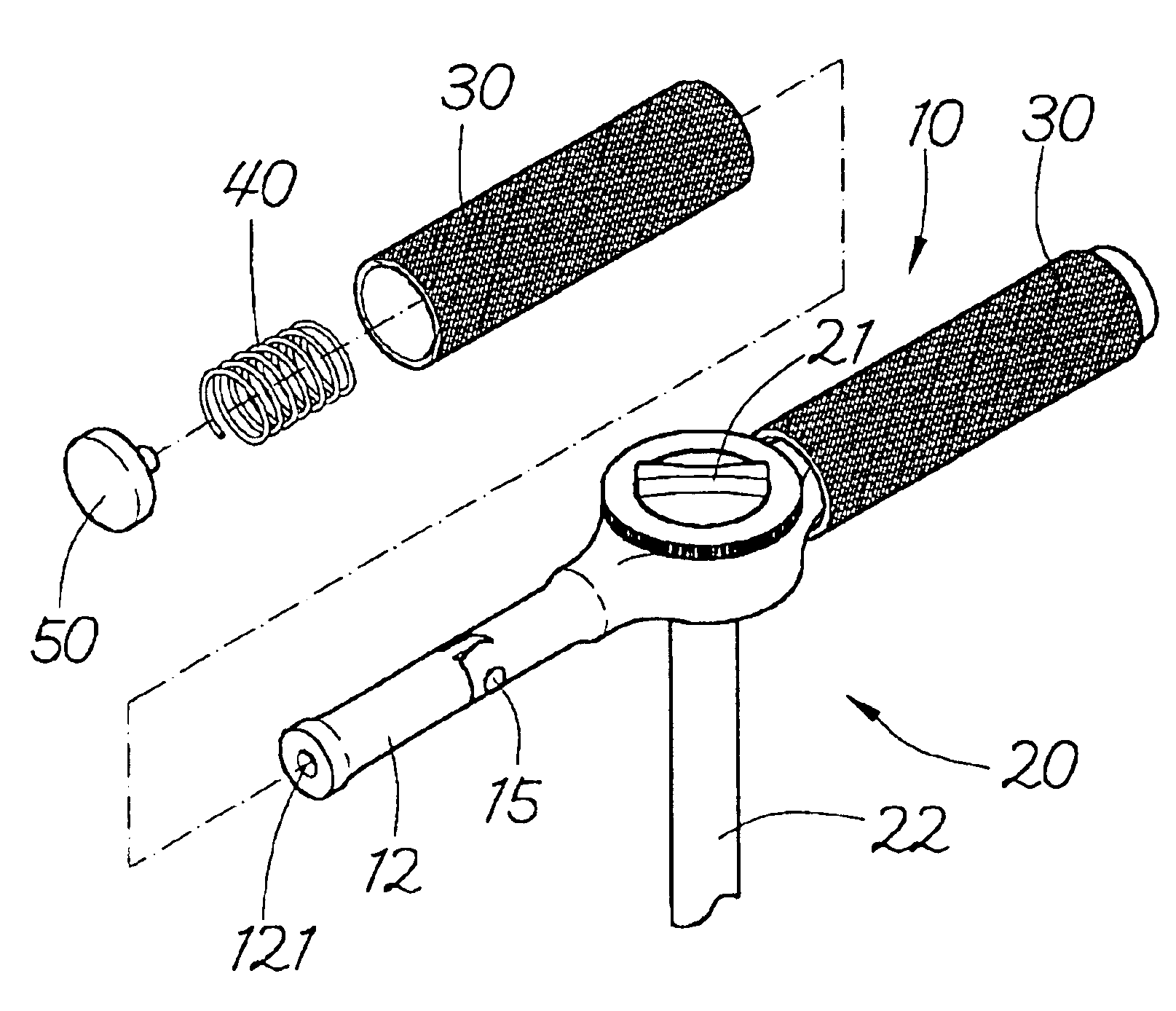

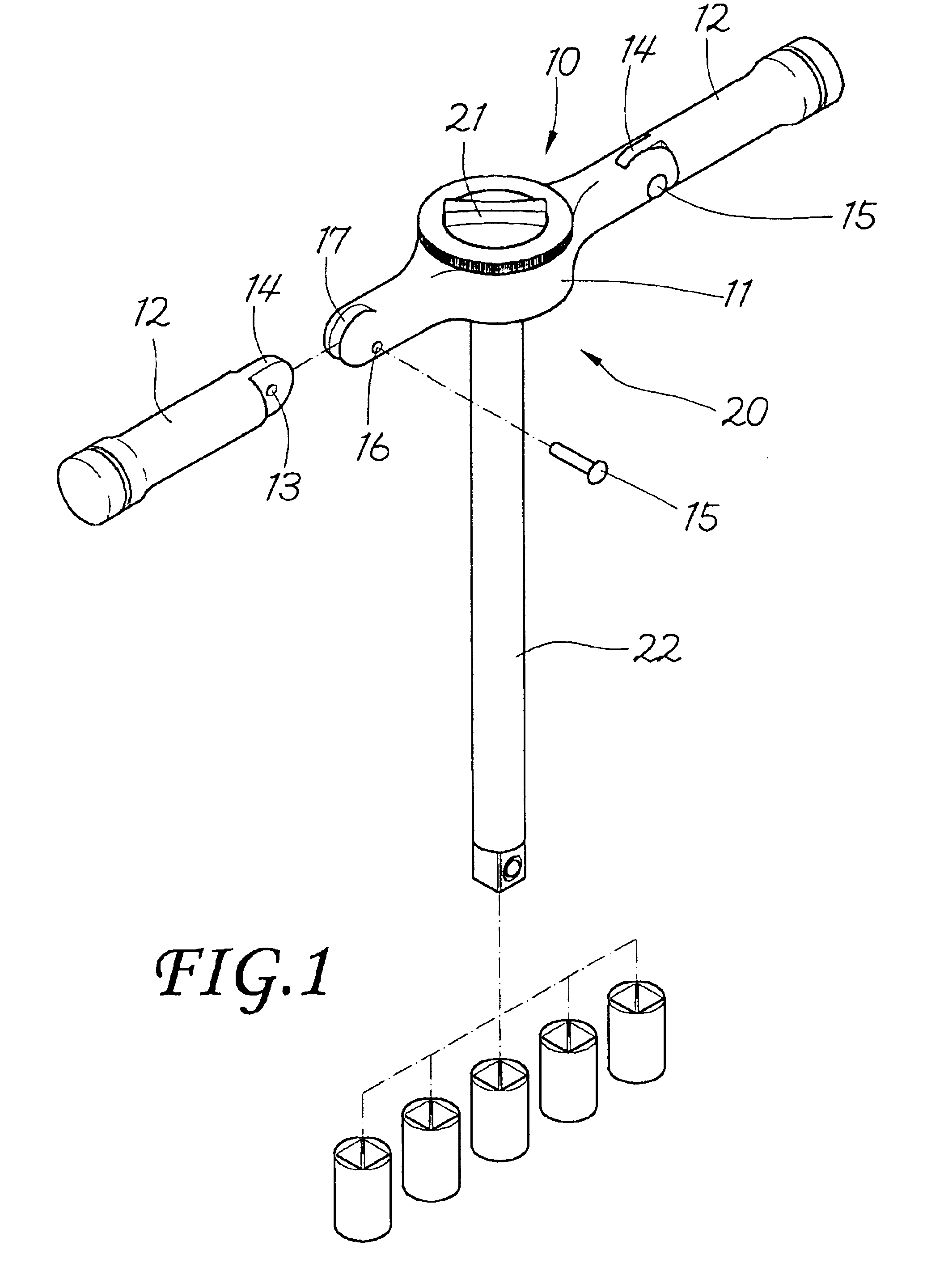

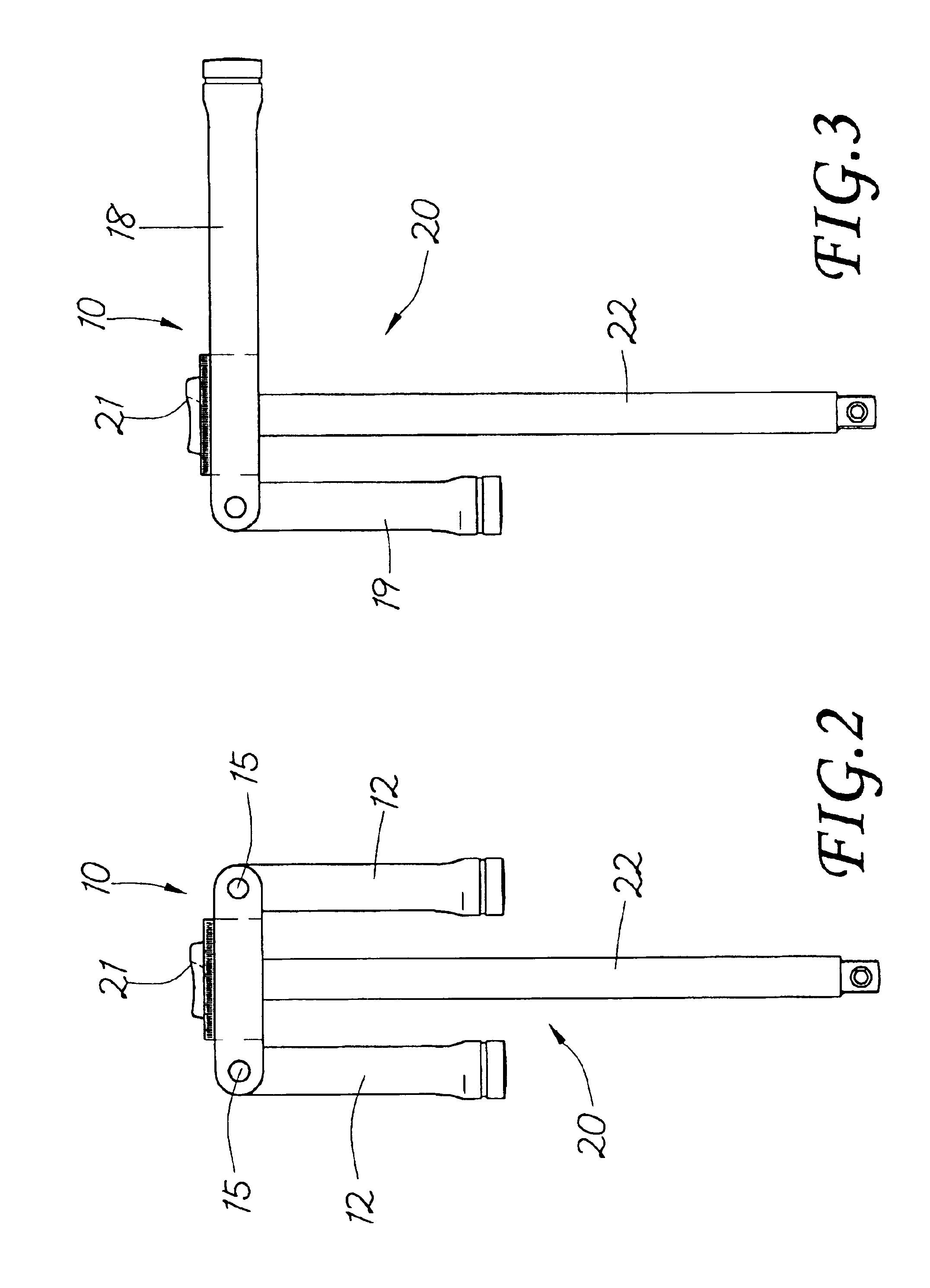

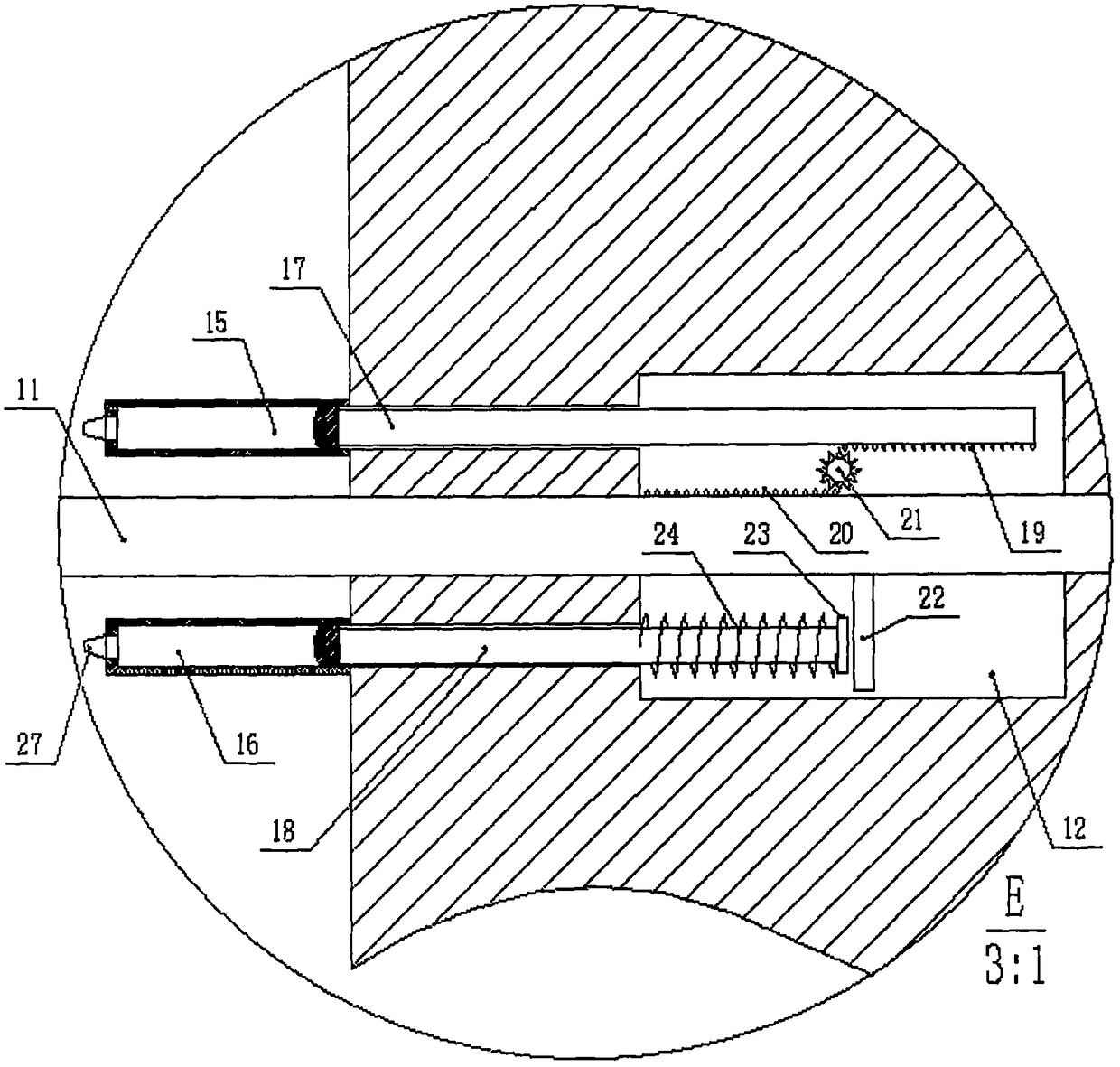

T-handle ratchet wrench

InactiveUS6898998B2Minimize occupied spaceEasily apply his forceSpannersWrenchesVertical barEngineering

The invention relates to a T-handle ratchet wrench including a lateral bar and a ratchet set. The lateral bar has a hollow connection part located in the center of the lateral bar and used for installing the ratchet set. Two flanks of the lateral bar make up a handgrip, respectively. The top of ratchet set is provided with a rotation button while a vertical bar extends downwardly from the rotation button. At least one of the handgrips includes a pivotal ear with a through hole, and the pivotal ear can be fitted into an insertion slot with a through hole at the free end of the lateral bar. A pivotal pin then passes through the through hole in the pivotal ear and the through hole in the insertion slot. This permits a pivotal movement of the handgrip on the pivotal pin. Accordingly, this configuration will considerably minimize the occupied space in packing, transport, storage and carrying. Particularly, the operators can more easily apply his force on the driver under special operation environments.

Owner:SHYU WEN TSAI

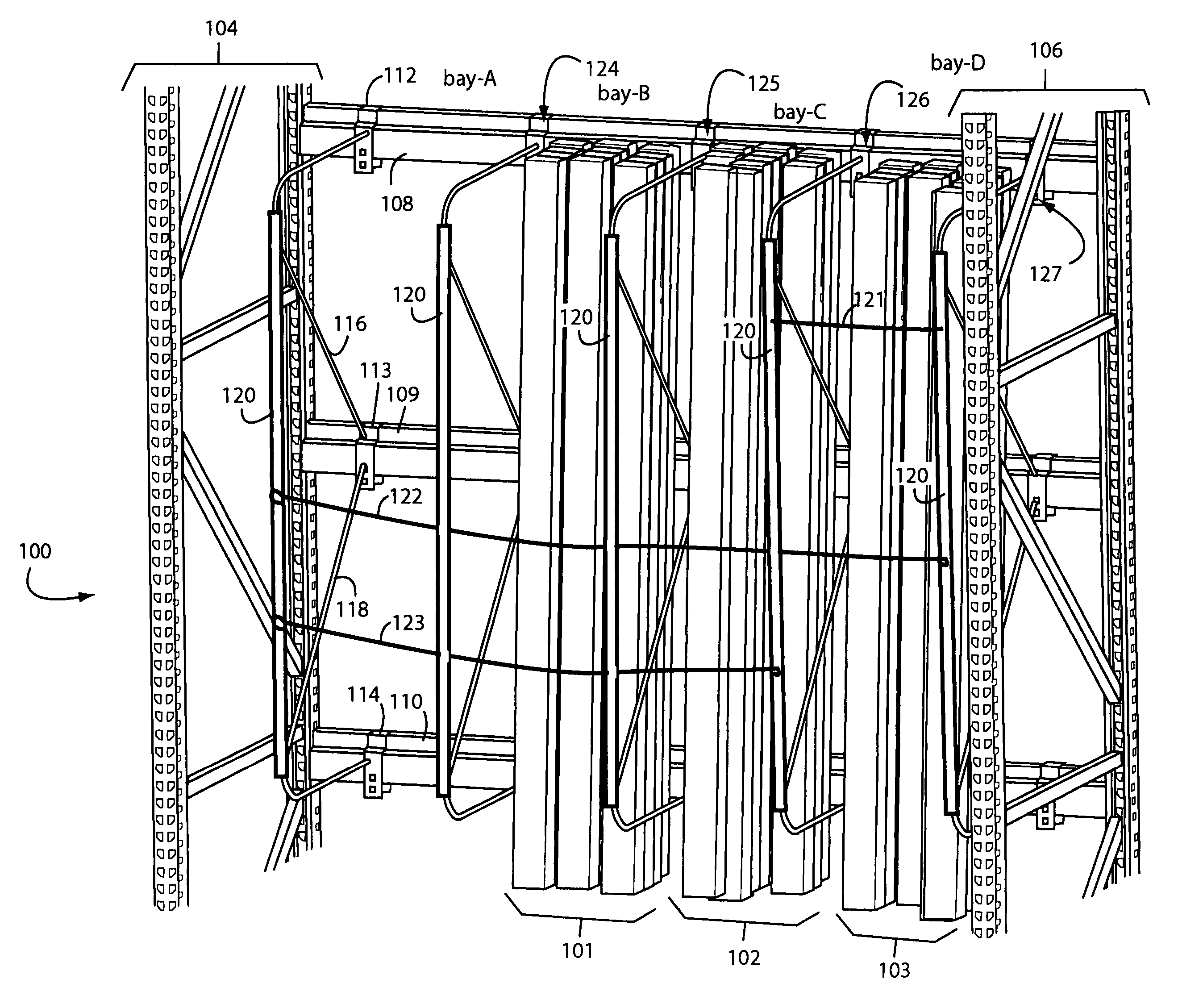

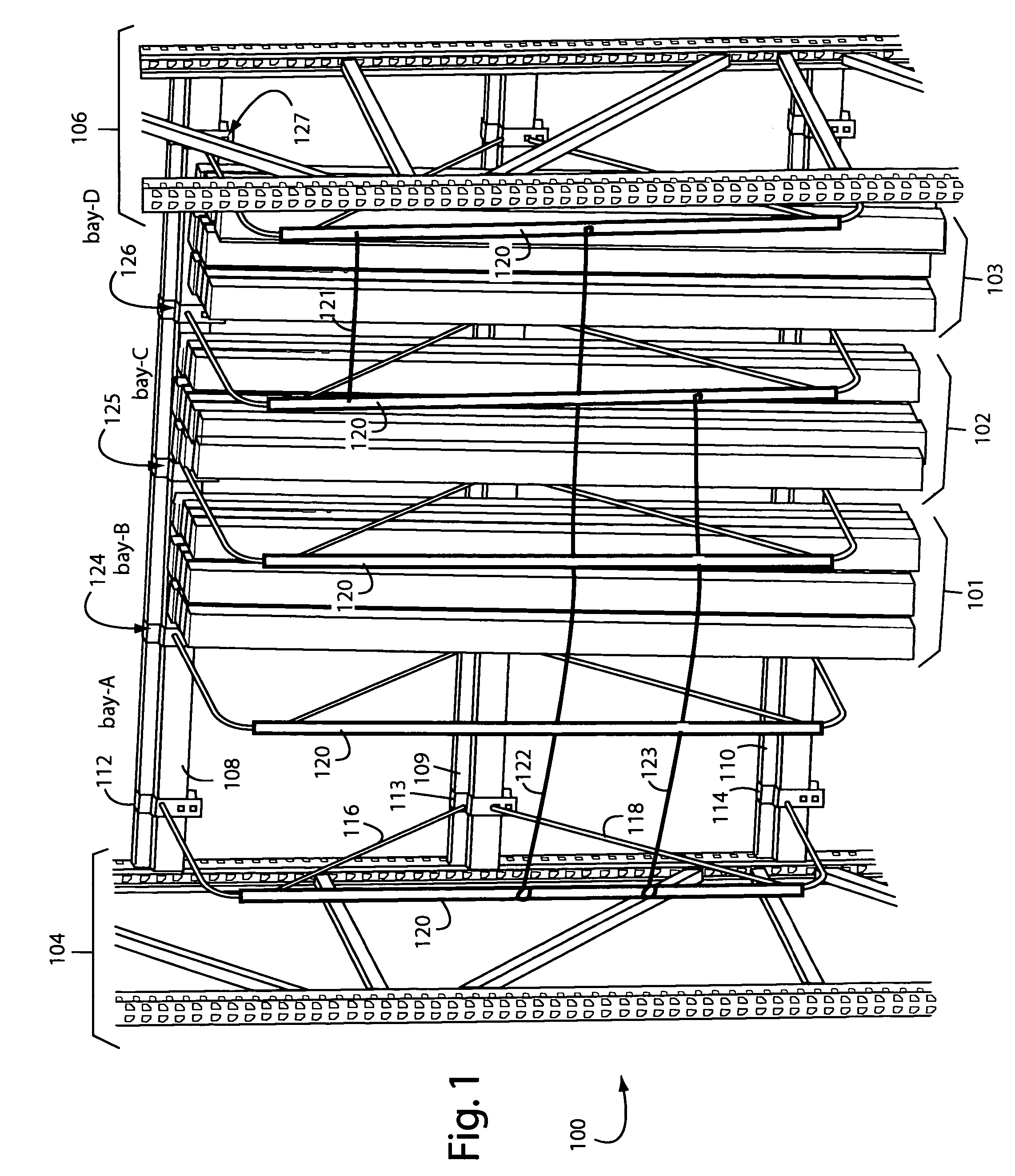

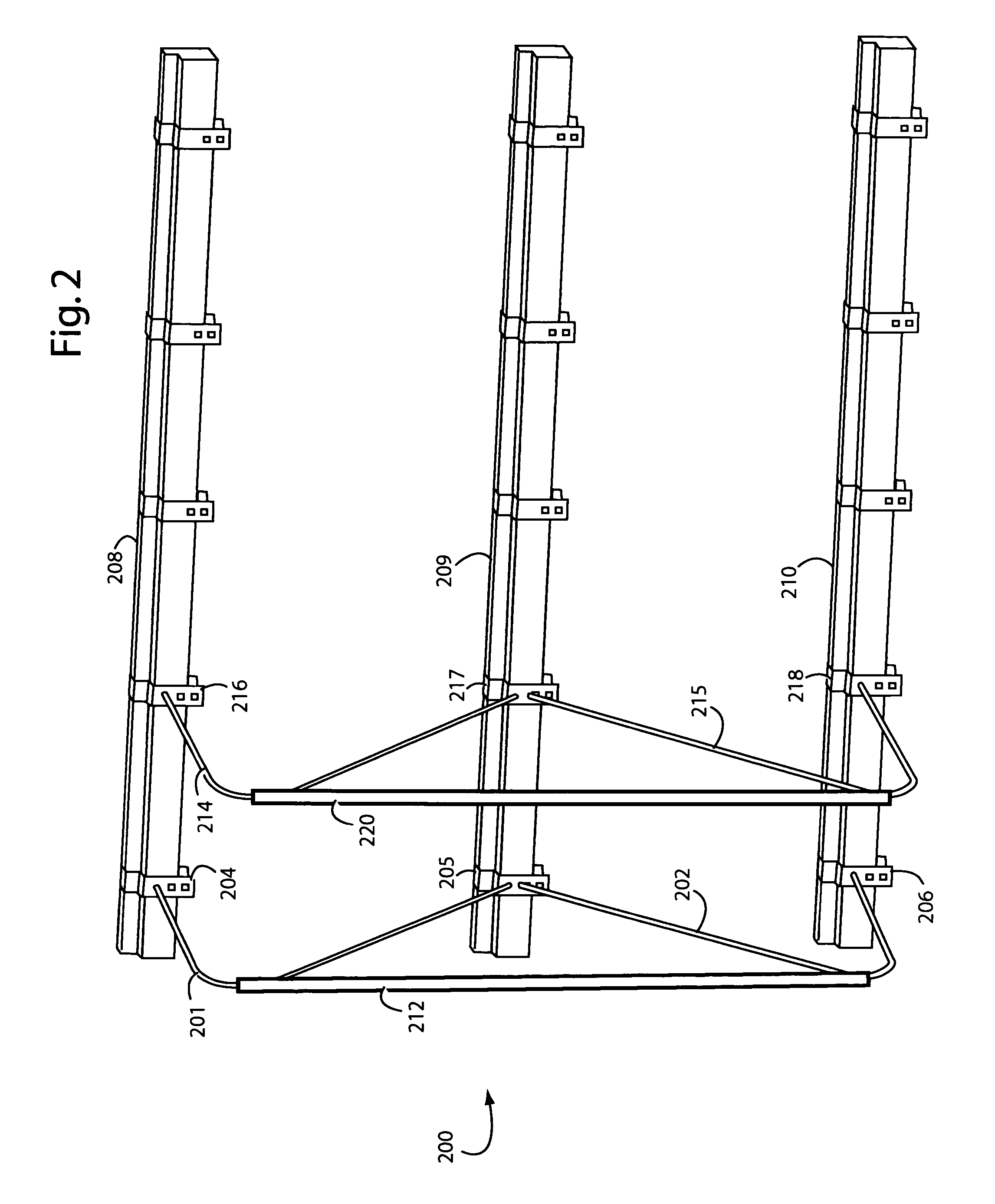

M-divider material-bay restraining cable system

InactiveUS7150361B2Efficient use ofEasy to adjustWindow cleanersFurniture partsVertical barEngineering

A restraining cable and rack system comprises material-bay dividers with cable restraints that can be laced-through, end-attached, and adjusted to a variety of heights on vertical bars. Long sticks or sheets of material are stood on-end inside the bays for retail display. The restraining cables are positioned to prevent the retail material from falling out of the bays.

Owner:CALLEJA MICHAEL J

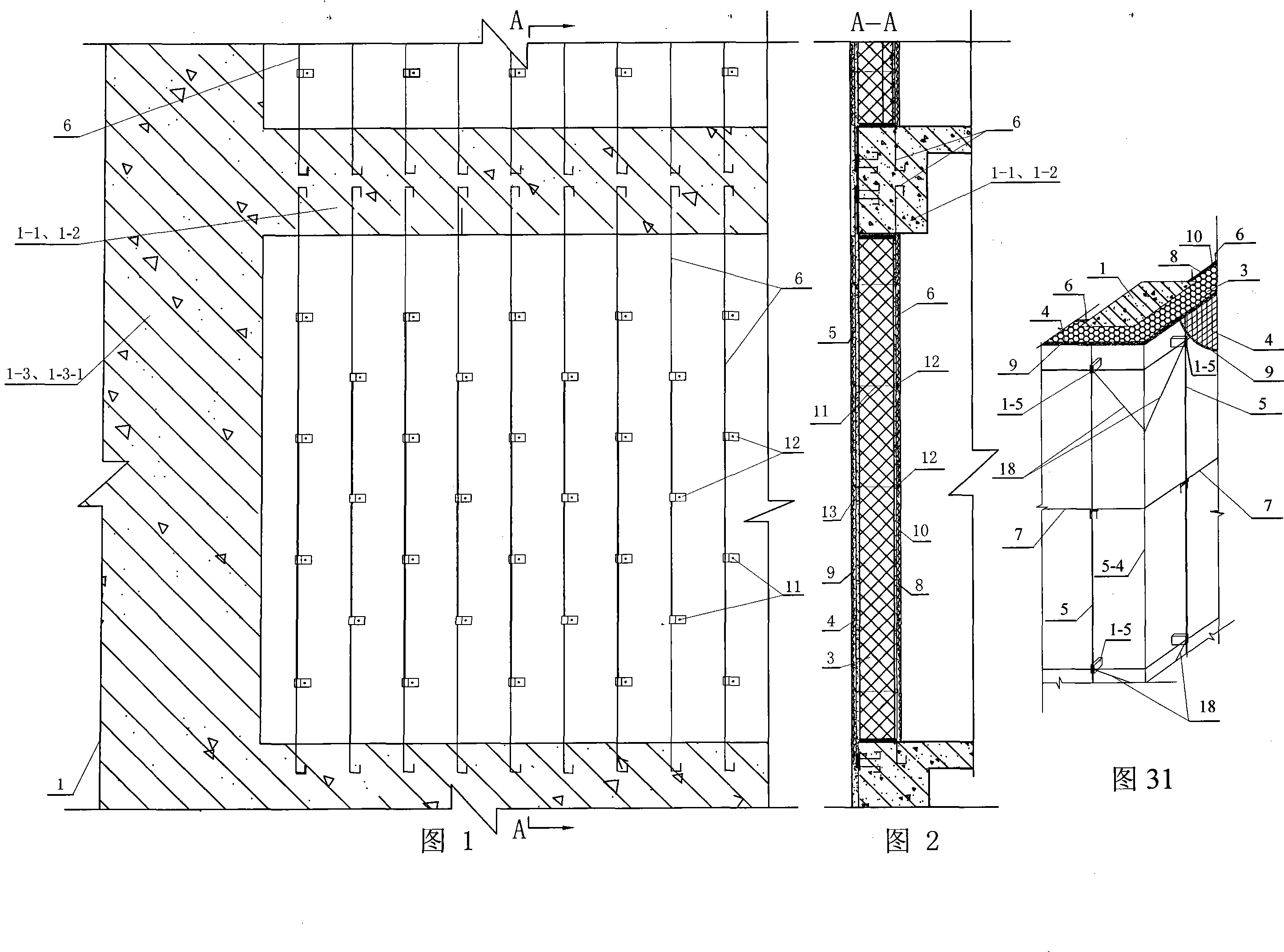

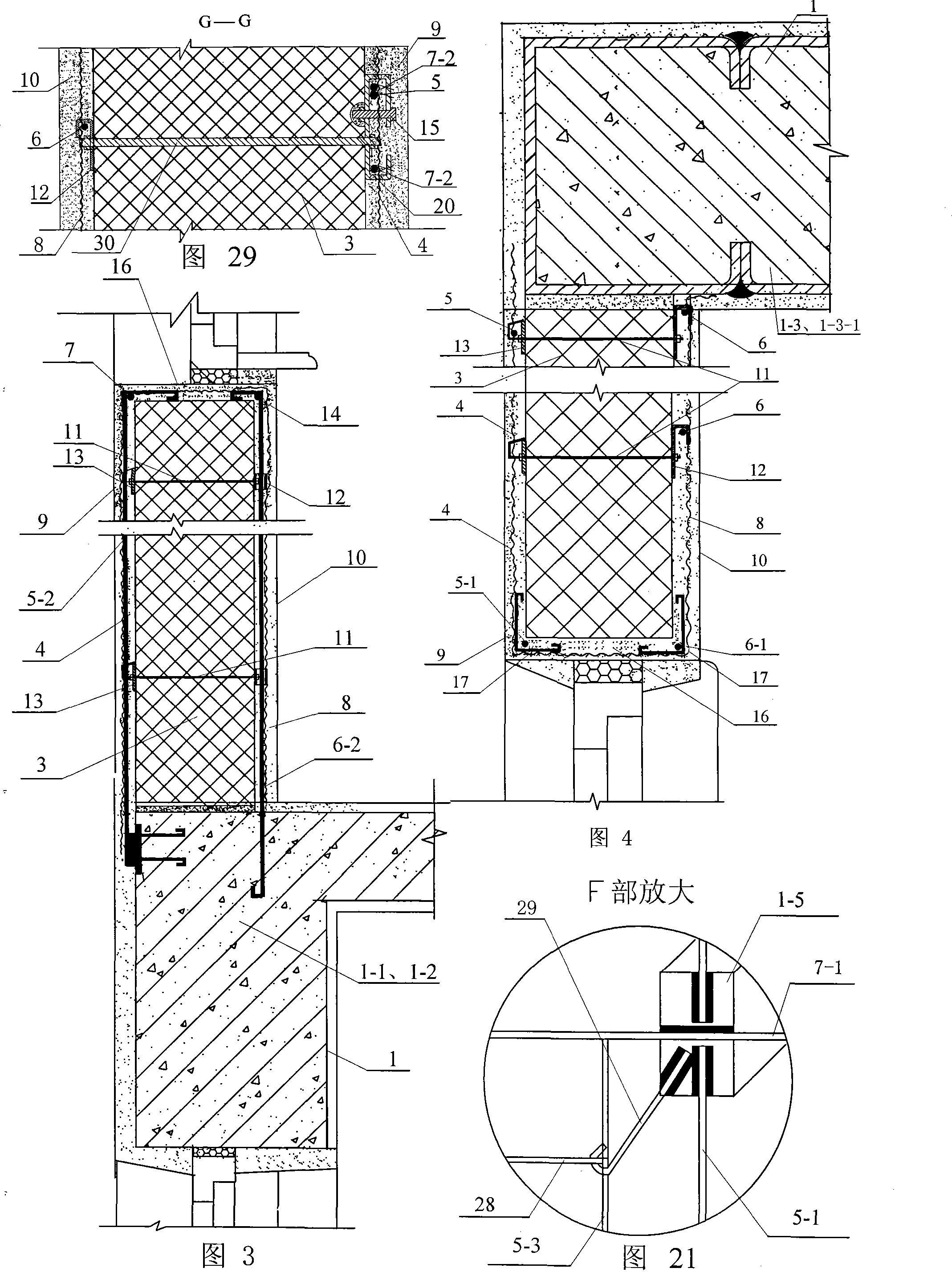

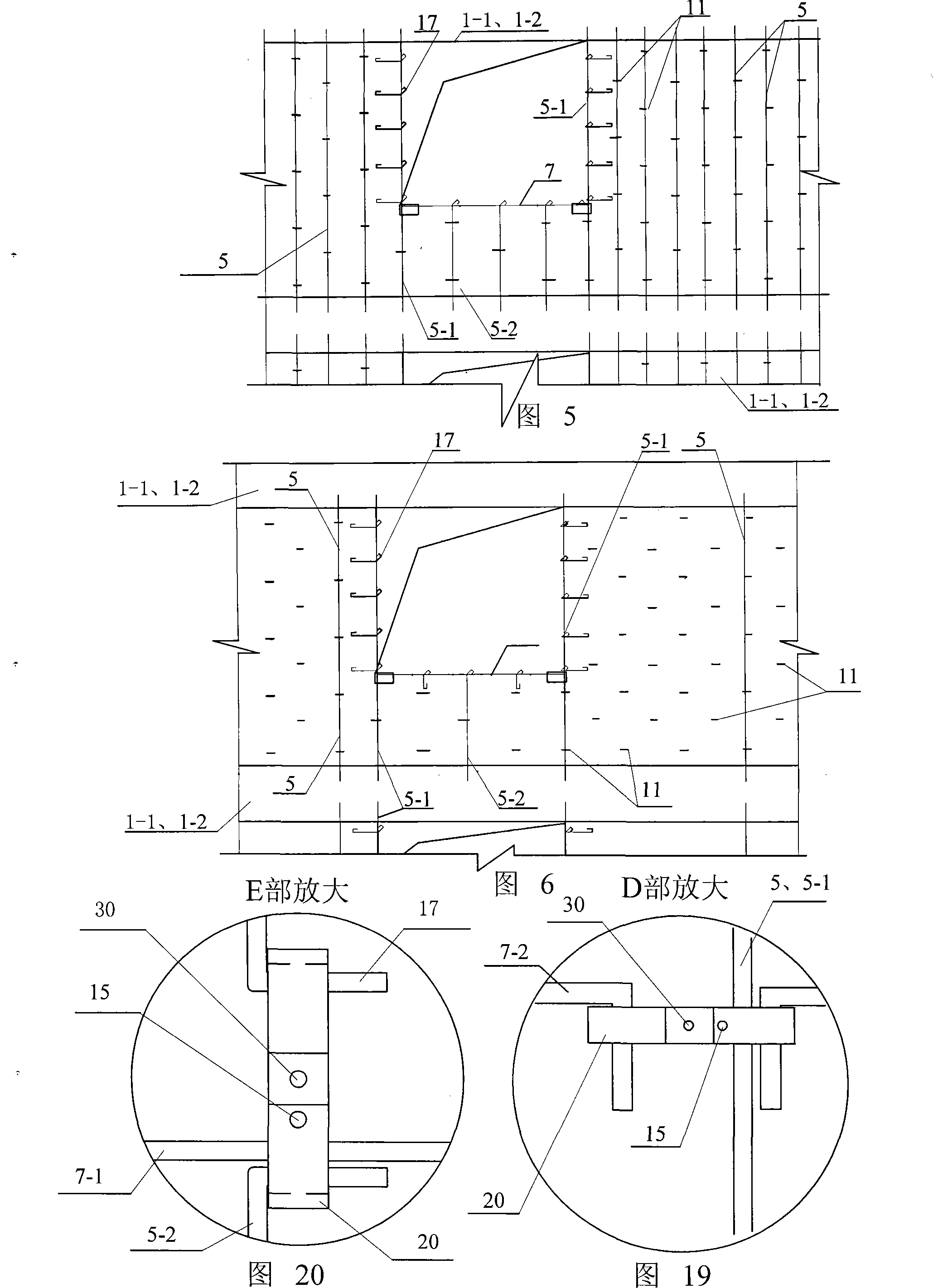

Plastering composite wall with reinforcing steel bar and/or metal net equipped at inter and outer or two-side

InactiveCN101168977AImprove securityImprove mechanical performanceCovering/liningsWallsFloor slabRebar

The utility model relates to a compound wall with reinforcing bars and / or metal mesh plastering on the inside and outside or on both sides, which relates to a building compound wall. Aiming at the incomplete structure of the bundled composite thermal insulation wall with support. Option 1: Outdoor vertical steel bars (5) and indoor vertical steel bars (6) are fixed to the outside and inside of the load-bearing member (1) of the main building structure, and the inner and outer sides of the core layer (3) are provided with inner and outer protection plan 2: the vertical steel bar (5-2) under the outdoor window sill and the vertical steel bar (6-2) under the indoor window sill are fixed to the cantilever plate (1-2); plan 3: indoor The vertical reinforcement (6) is fixed to the indoor floor of the load-bearing member (1) of the main structure of the building; scheme 4: the indoor vertical reinforcement (6) on both sides of the air layer, and the inner and outer sides of the indoor metal mesh are provided with protective layers (10 -1), the air layer (3-1) is located between the protective layers (10-1) on both sides. The invention has the advantages of good earthquake resistance, good wind load resistance, low cost, convenient construction, good safety of the outer decorative surface layer, increased indoor usable area, and meets the requirements of low energy consumption buildings.

Owner:吴淑环

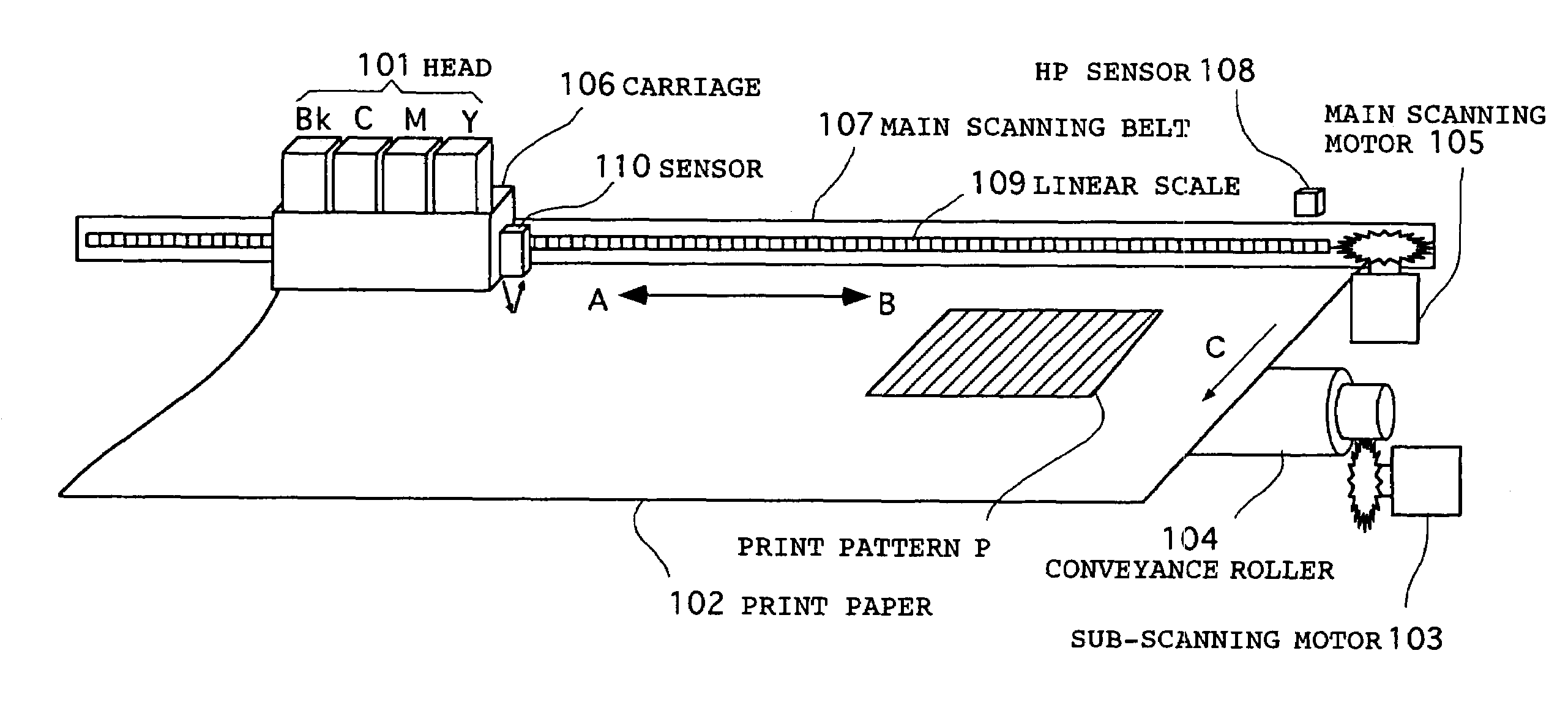

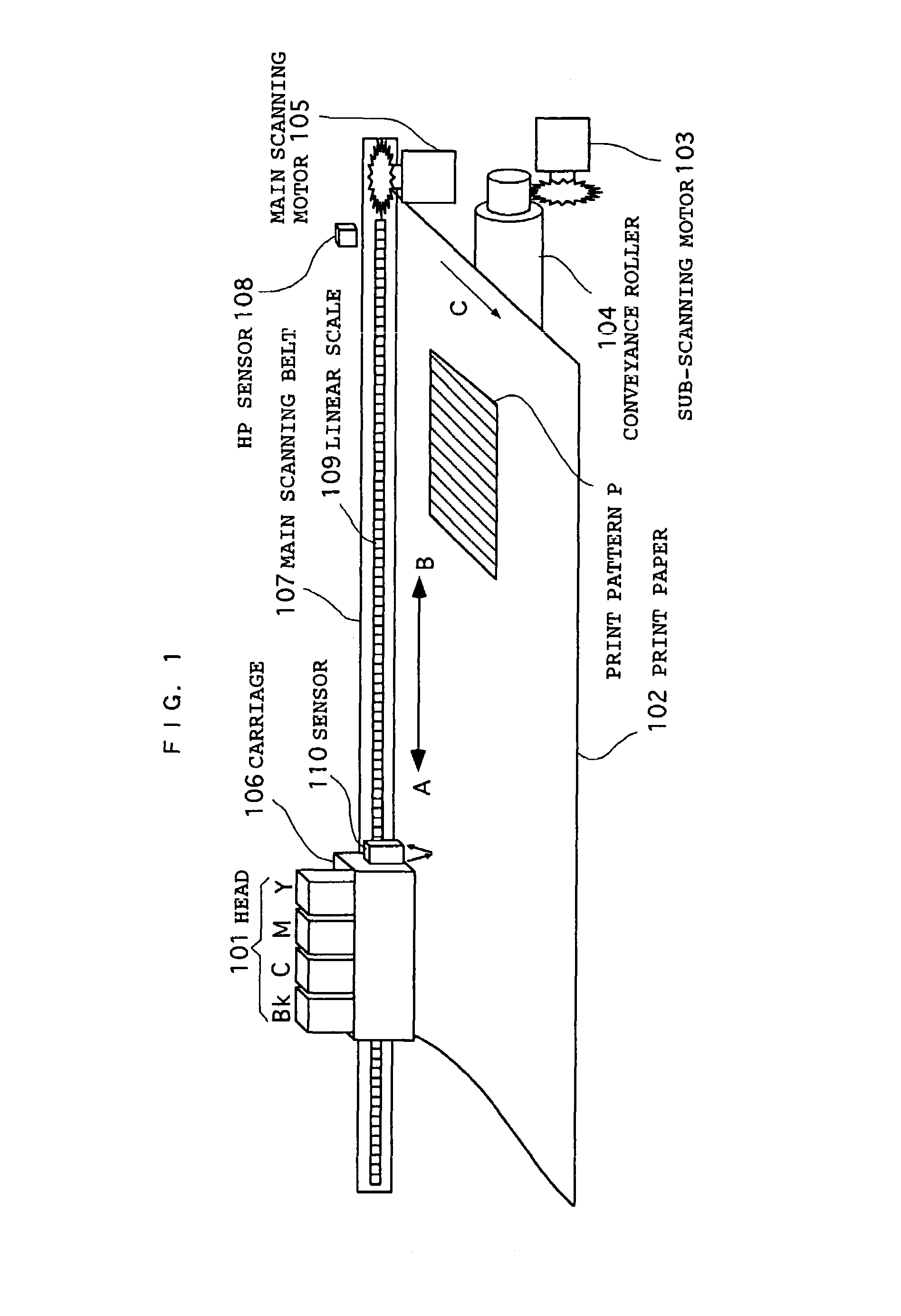

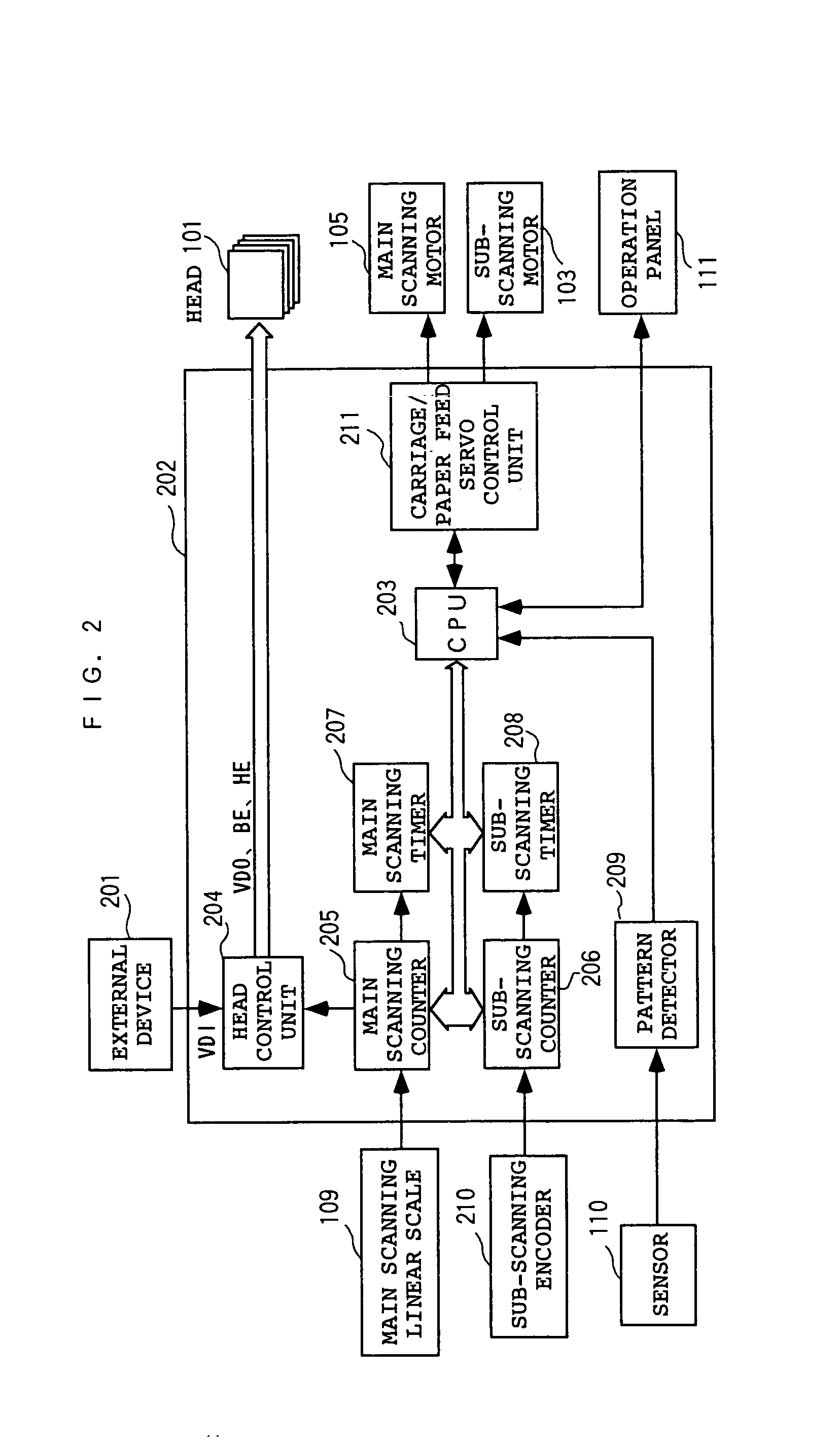

Image forming device

InactiveUS7014289B1Accurate detectionReduce positioningOther printing apparatusVertical barPattern detection

A head (101) prints a predetermined test pattern under the control of a head control unit (204) in order to precisely detect a head deviation when a head has been changed, the printed test pattern is read by a sensor 110 and detected by a pattern detector (209). Every time an interrupt signal corresponding to the edge of a detected pattern element is input to the CPU (203), a value of a main scanning counter (205) / main scanning timer (207) (and / or a sub-scanning counter (206) / sub-scanning timer (208)) is read, the printing position of each pattern element is detected from the value, and the mounting deviation of the head is calculated based on the detection result of the printing position of each pattern element printed by the head. The vertical bar of a test pattern may be printed in multiple passes. A plurality of edges may be detected at different longitudinal positions of the bar and the detected results are averaged to determine an edge position.

Owner:COPYER

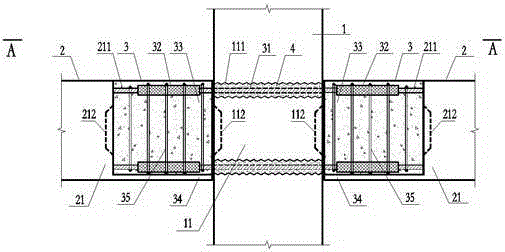

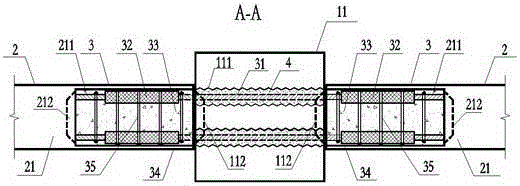

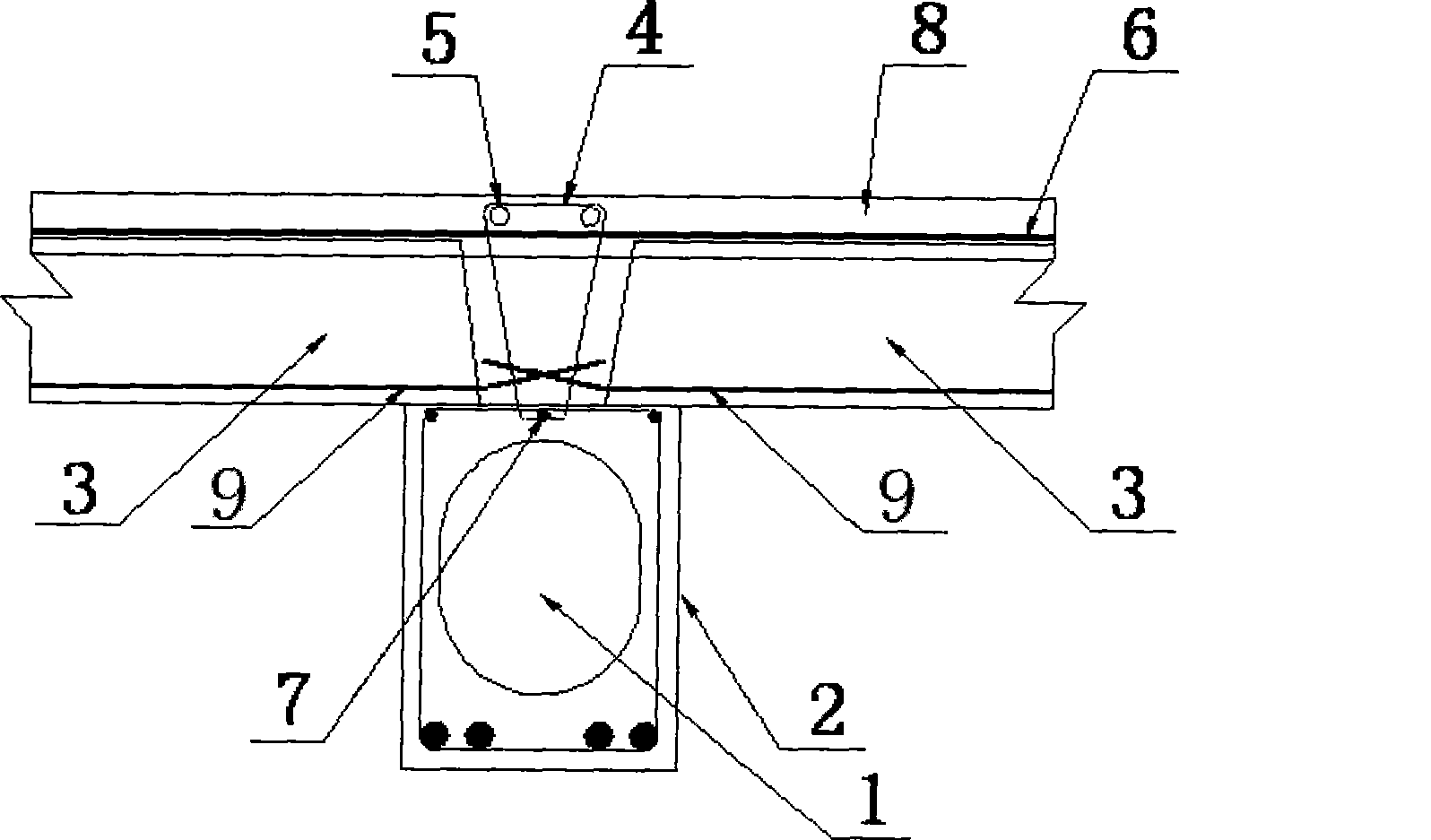

Prefabricated beam-column connection in prefabricated concrete buildings and construction method thereof

InactiveCN105155683ASimple structureImprove integrityBuilding material handlingVertical barAgricultural engineering

Owner:SICHUAN PROVINCIAL ARCHITECTURAL DESIGN & RES INST

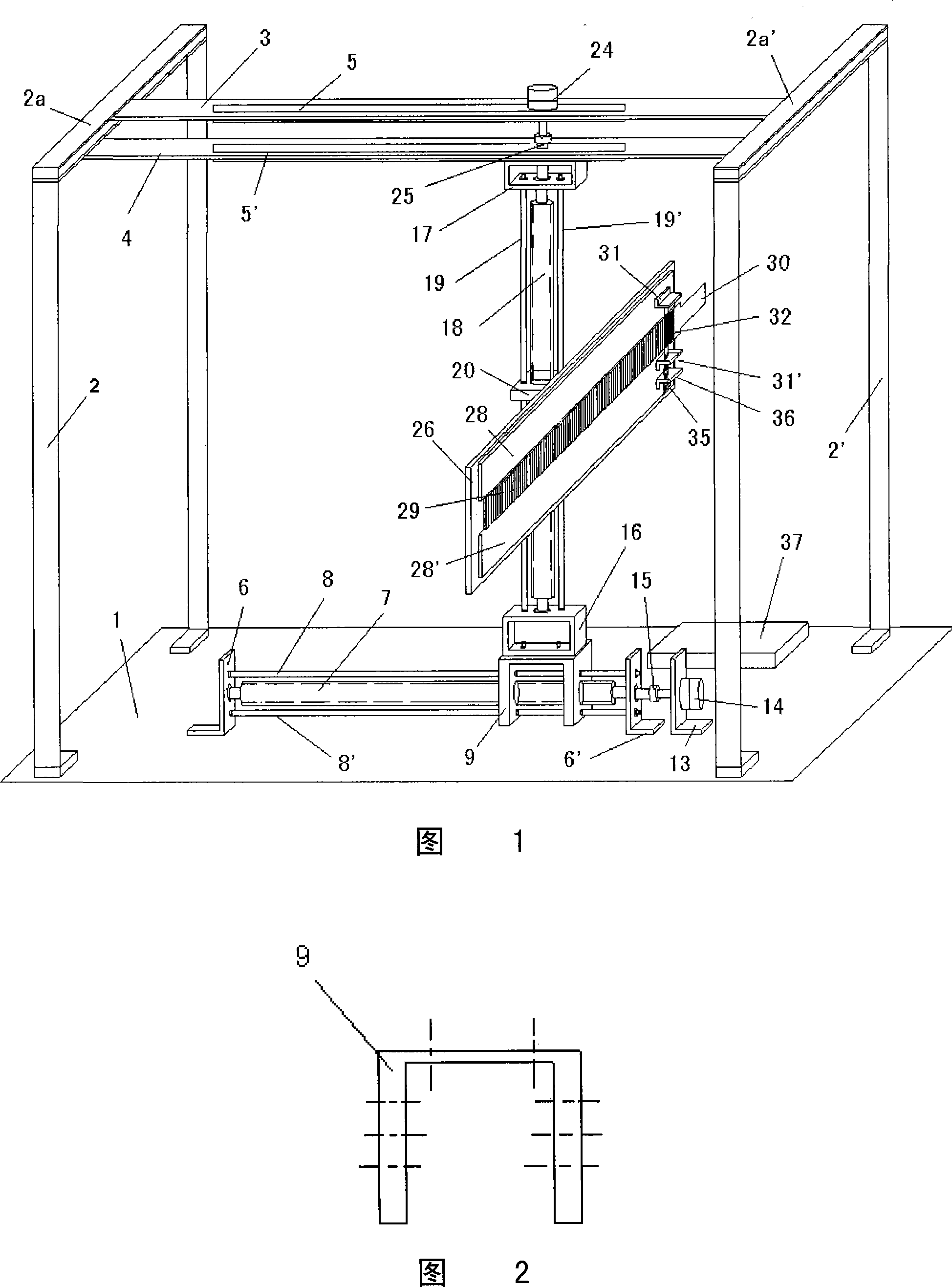

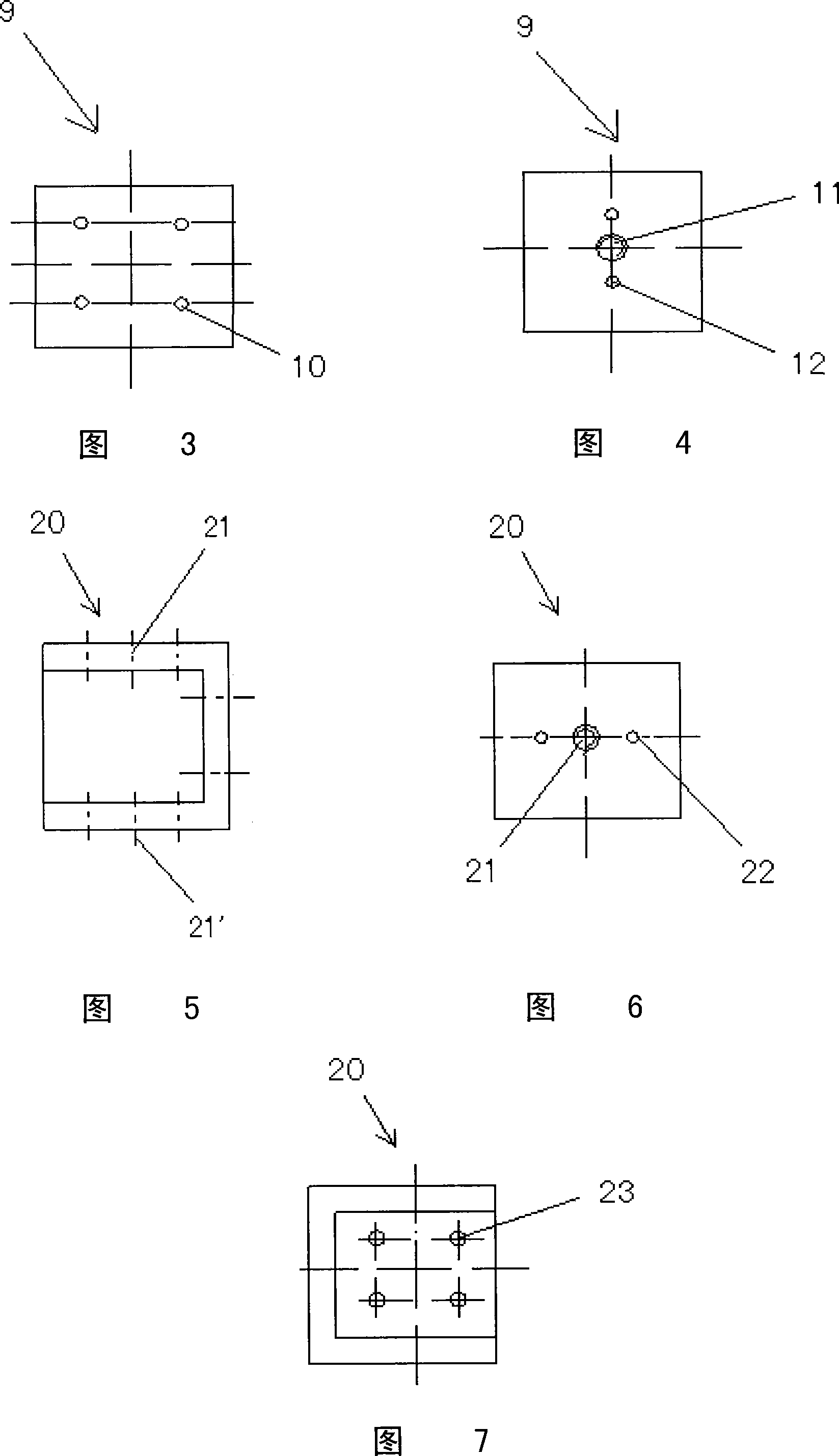

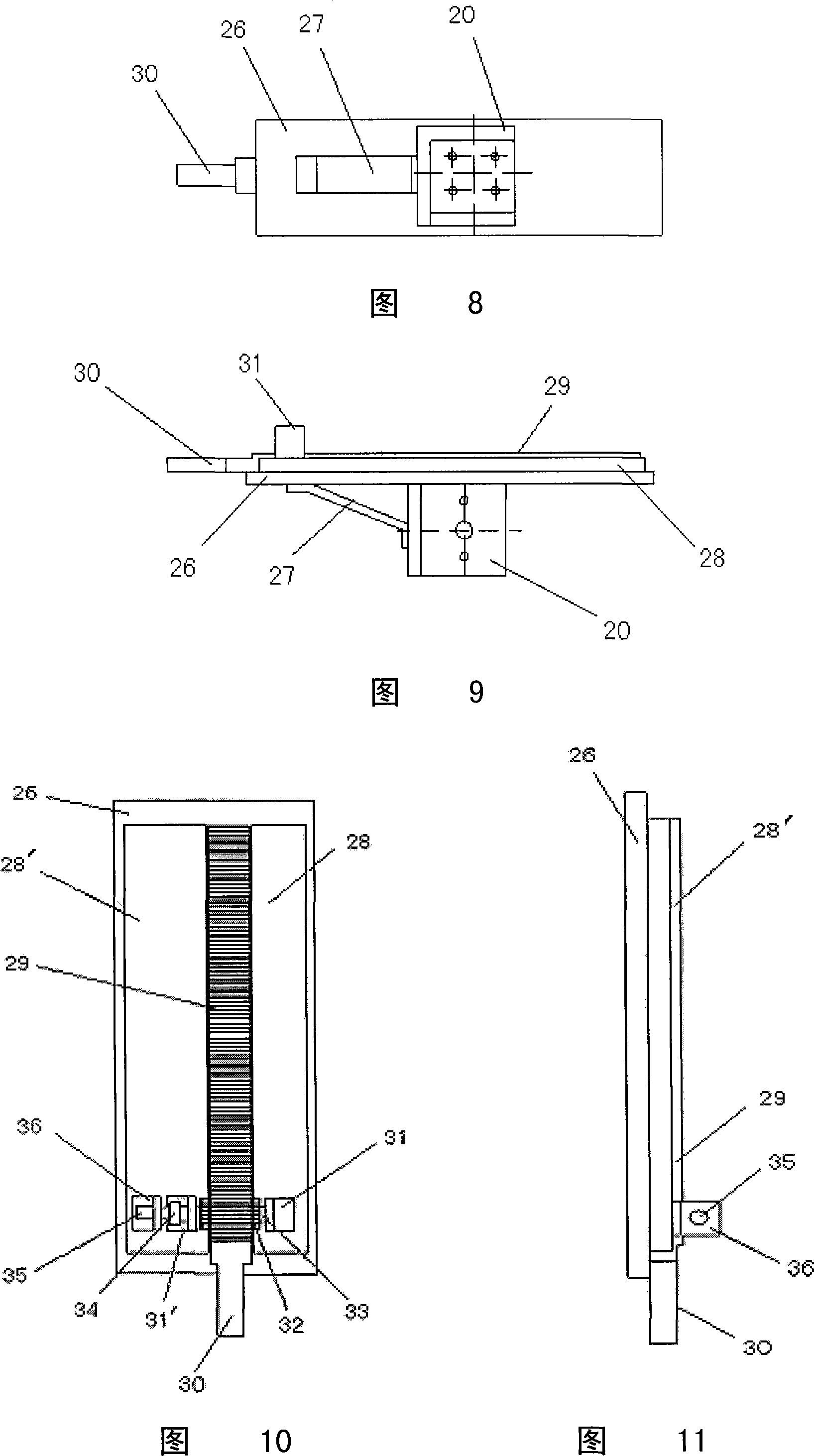

Cartesian coordinate type fruit picking mechanical arm device

InactiveCN101142878AEasy to moveFlexible and accurate operationPicking devicesVertical barMotor drive

The invention relates to a Cartesian coordinate fruit picking manipulator, which includes a working support, a horizontal movement mechanism, a vertical movement mechanism and a depth movement mechanism; the working support includes a flat workbench and an upper support, and a horizontal slideway is arranged on the upper support; The horizontal movement mechanism includes a horizontal lead screw driven by a horizontal motor through a harmonic reducer, a horizontal slider connected to the horizontal lead screw and guided by two horizontal light rods; the vertical movement mechanism includes a vertical motor through a harmonic deceleration The vertical lead screw driven by the device, a vertical slider connected to the vertical lead screw and guided by two vertical light rods, the bottom of the vertical movement mechanism is connected to the top of the horizontal slider, and the top of the vertical movement mechanism is slid on the level of the upper bracket. In the slideway; the depth moving mechanism includes a rack driven by a gear motor through a gear, the rack is set on a rack support plate, and the rack support plate is fixedly connected to one side of the vertical slider; the picking claw is connected to the rack one end. The invention can be widely applied to the automatic picking of vertical hanging fruits.

Owner:CHINA AGRI UNIV

Method for detecting welding seam segmentation and defects of digital X-ray images

InactiveCN102175700AEasy to detectReduce false positive rateImage enhancementMaterial analysis by transmitting radiationVertical barX-ray

The invention relates to a method for detecting the welding seam segmentation and defects of digital X-ray images, belonging to the field of nondestructive testing. In the invention, aiming at the defect detection of a series of vertical bar-shaped X-ray welding seam images with a specific width range, when the welding seam segmentation is carried out, a segmentation method based on the welding seam horizontal width and vertical continuity in the welding images is adopted, and the segmentation method comprises the following steps: filtering, intensifying the images, segmenting a threshold, looking for the welding seam position, extracting the welding seam and carry out other steps. In the extraction of the defects, a method for combining edge detection and a subtraction method are utilized. The method provided by the invention can be used for rapidly and effectively segmenting the welding seam in the images, and the syncretic defect extraction algorithm can be used for better detecting the defects.

Owner:SHANDONG UNIV

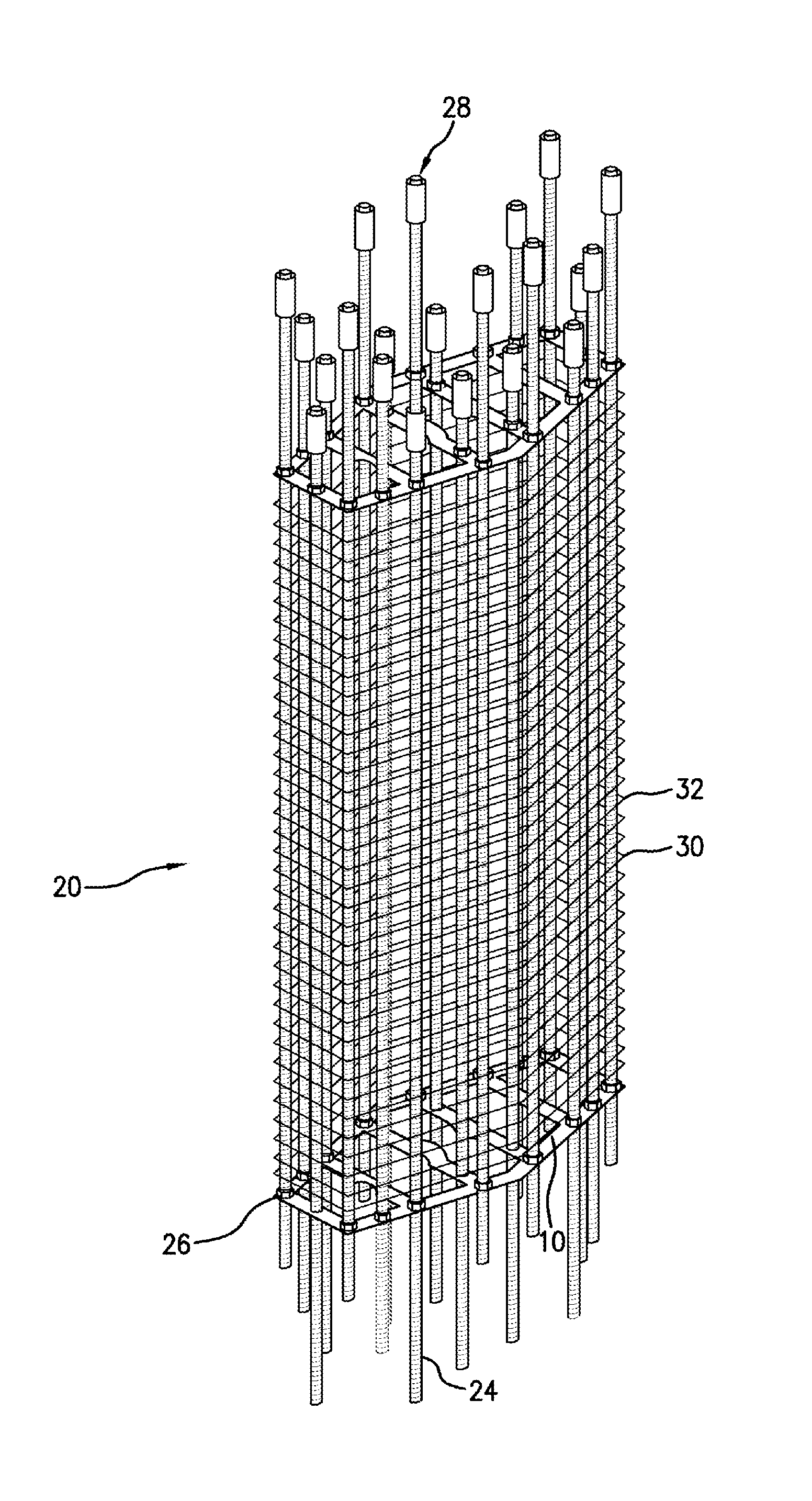

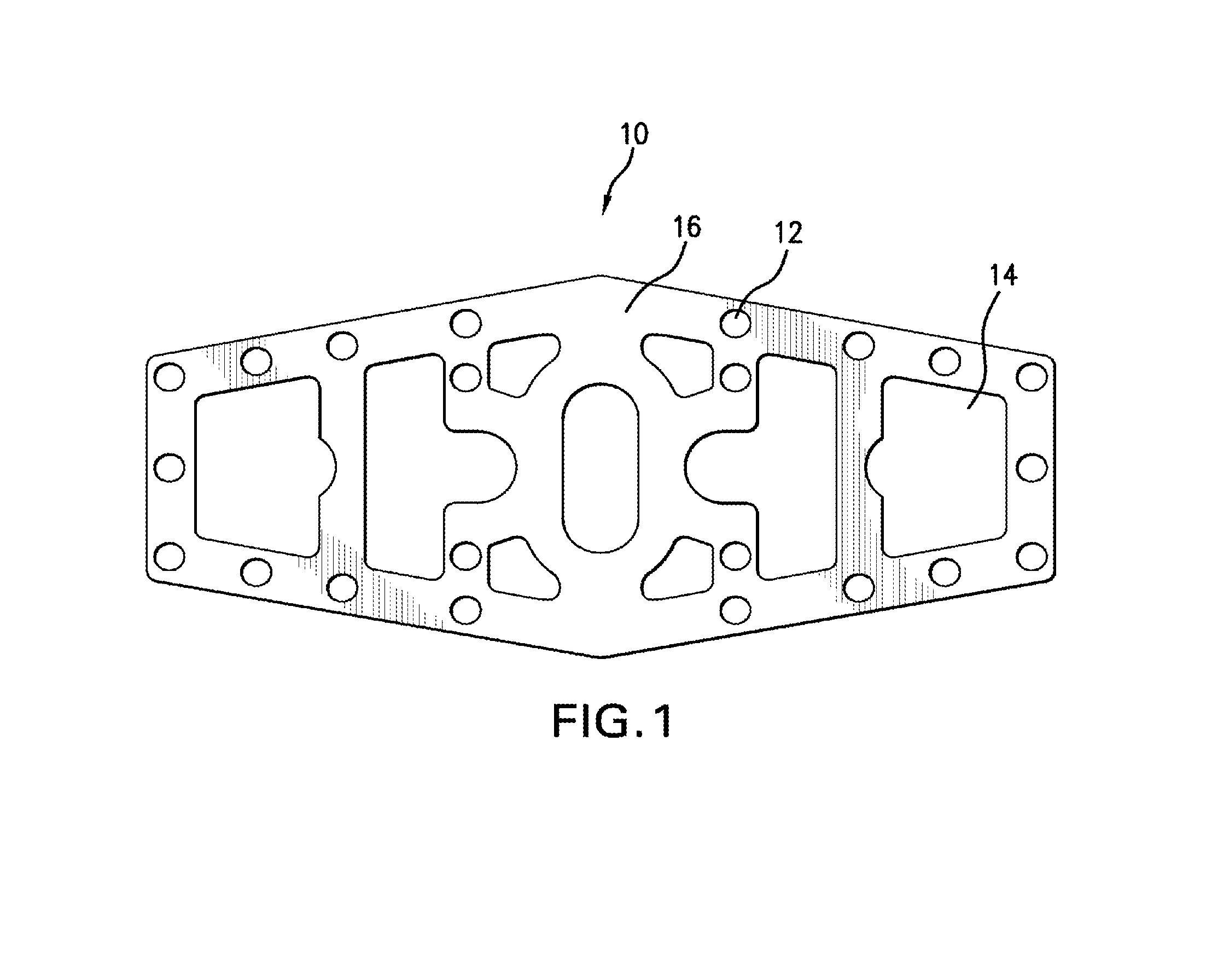

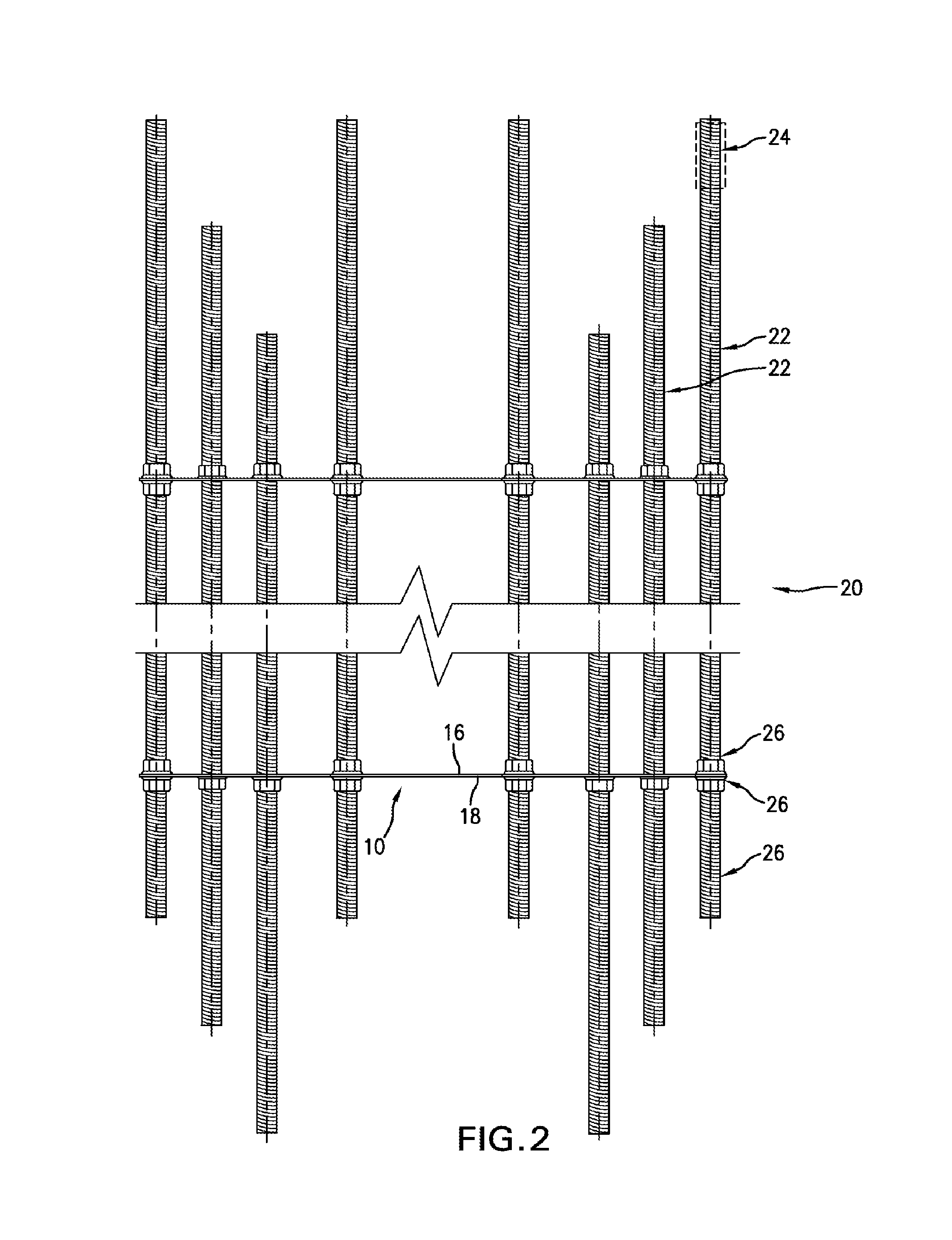

Methods for construction of pre-fabricated modular reinforcement cages for concrete structures

Owner:SAS STRESSTEEL INC +1

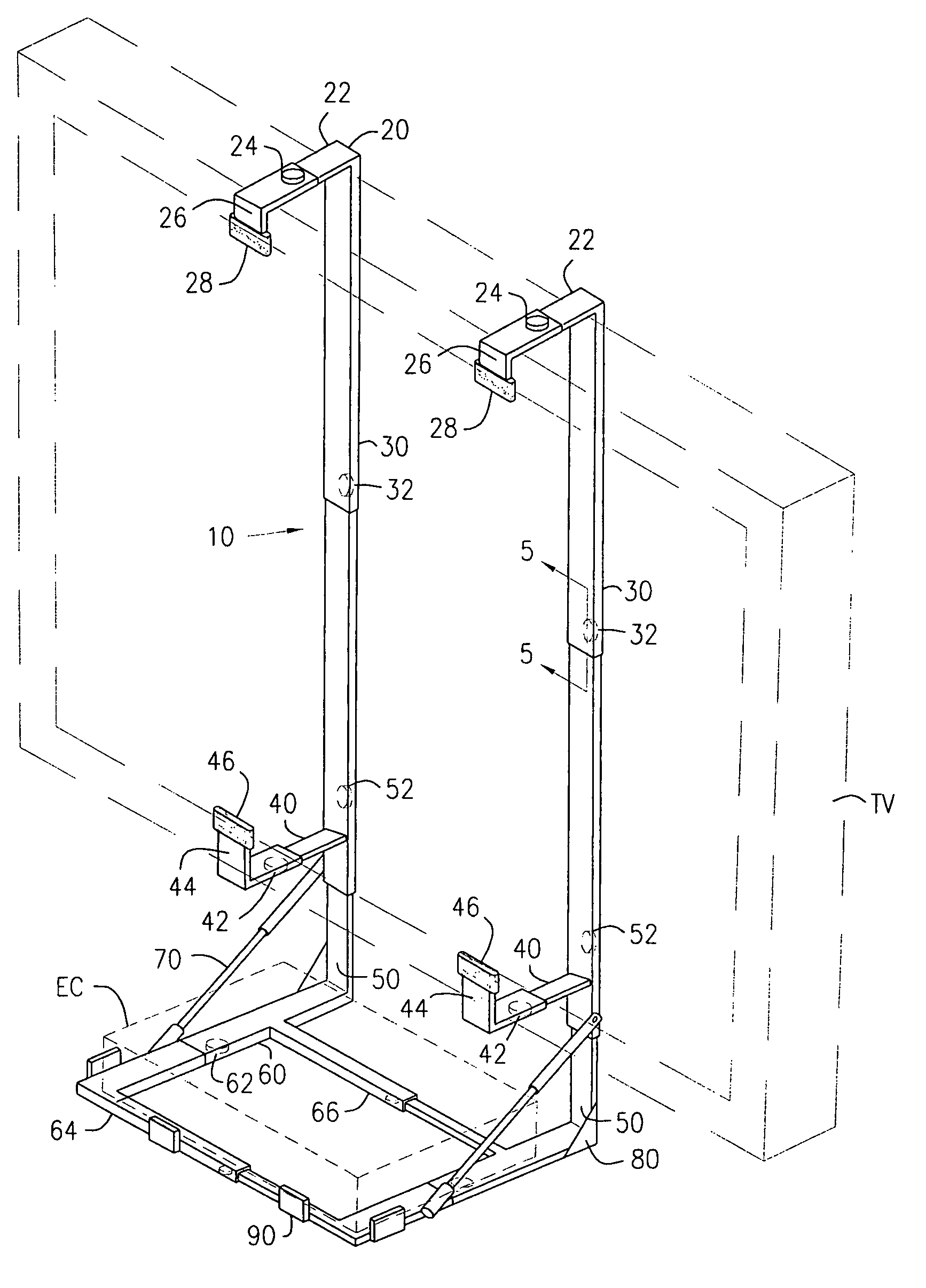

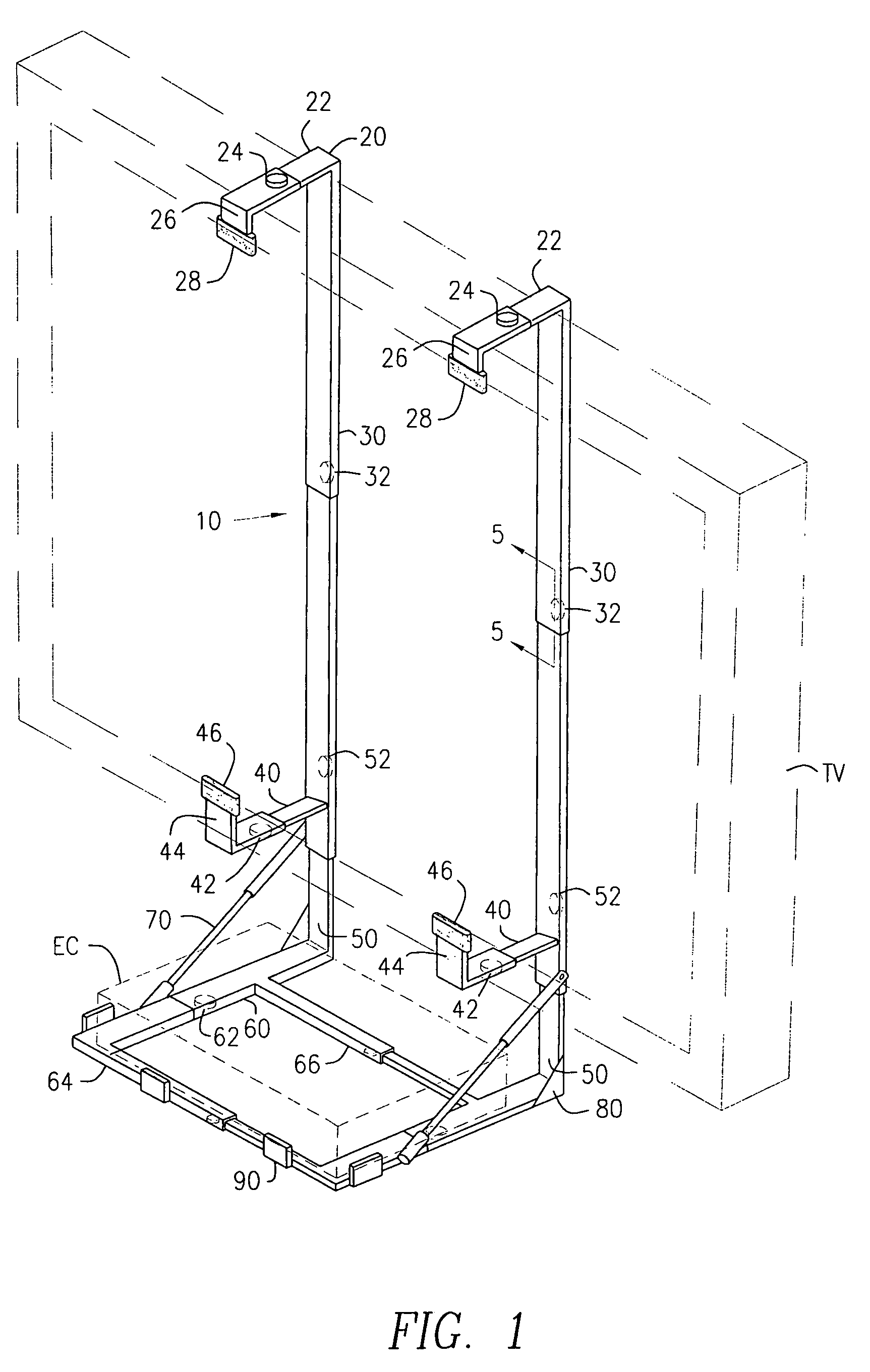

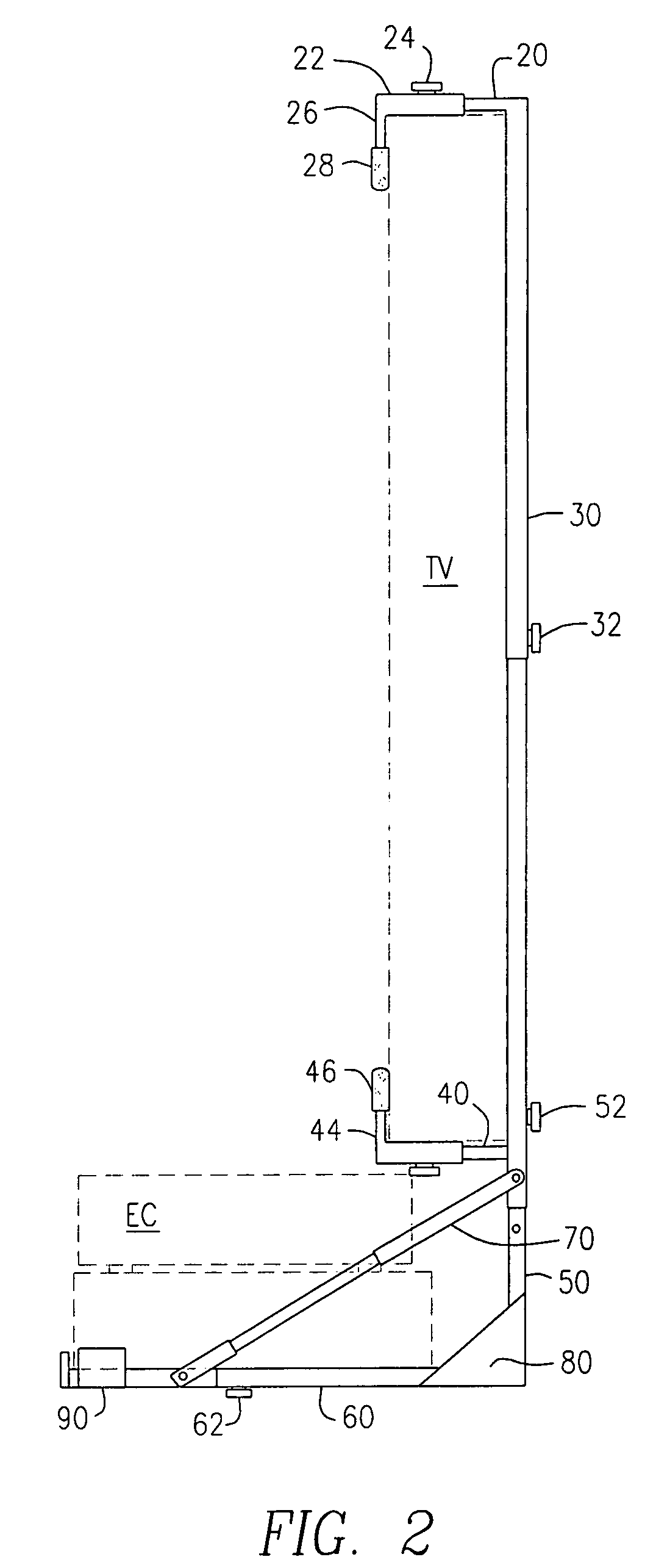

Device for attaching electronic components to flat-screen television

Bracket for attachment to a flat-screen television having a support platform for positioning electronic components below the television. The caddy comprises top support brackets which hook over the top of the television or over the television wall mount bracket and has a horizontal member abutting the top of the television, and front vertical extension member that extends down in front of the television. Extending down from the top support brackets are side vertical bars in back of the television. Attached to the bottom of the side vertical bars are horizontal bottom support brackets upon which the television sits. The electronic component support platform is attached to the bottom of the two vertical bottom side bars which includes lateral and perpendicular support bars which function to support the electronic components. Many of the bars telescope allowing its use with a variety of sized televisions and electronic components of varying sizes.

Owner:SPINELLI THOMAS

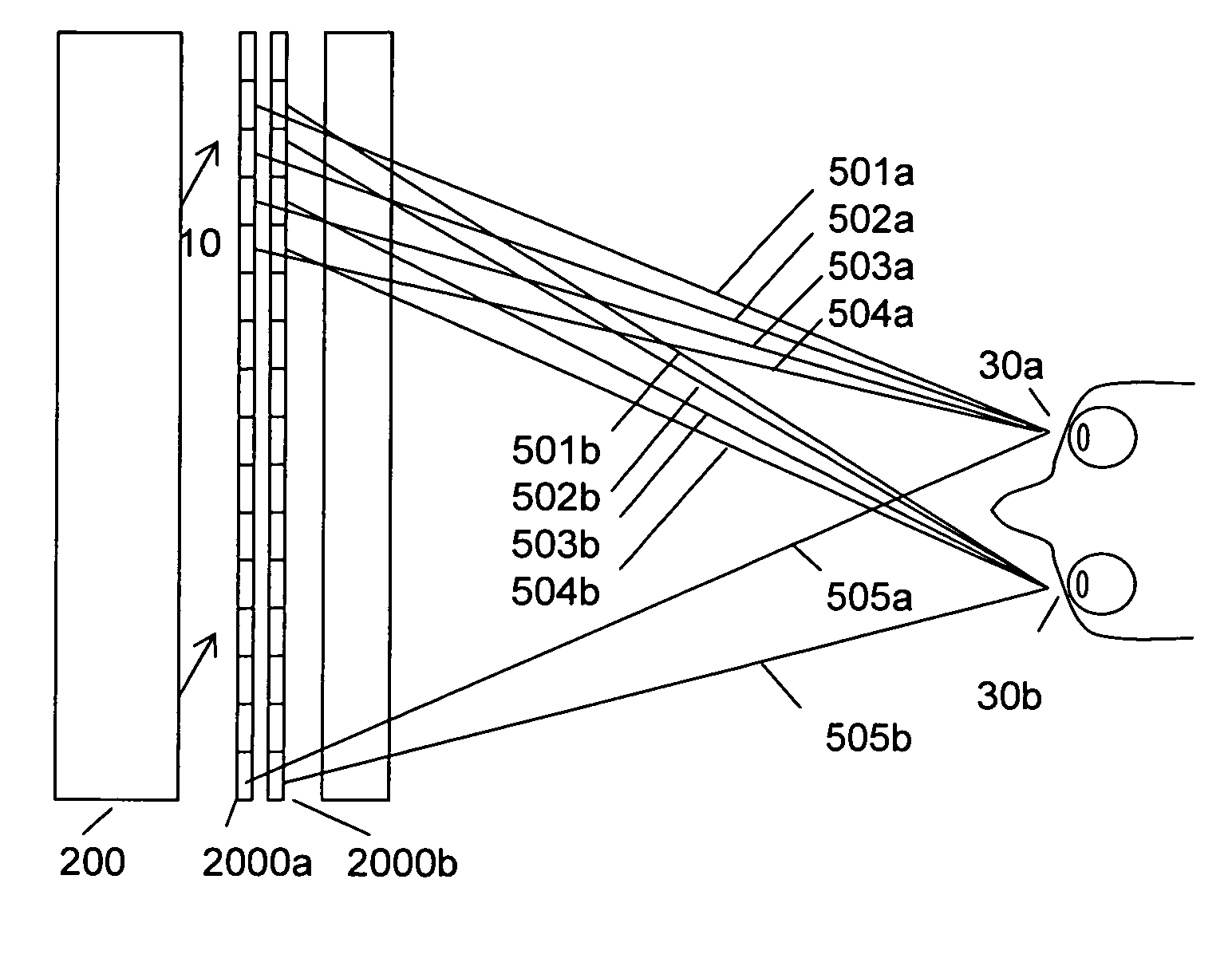

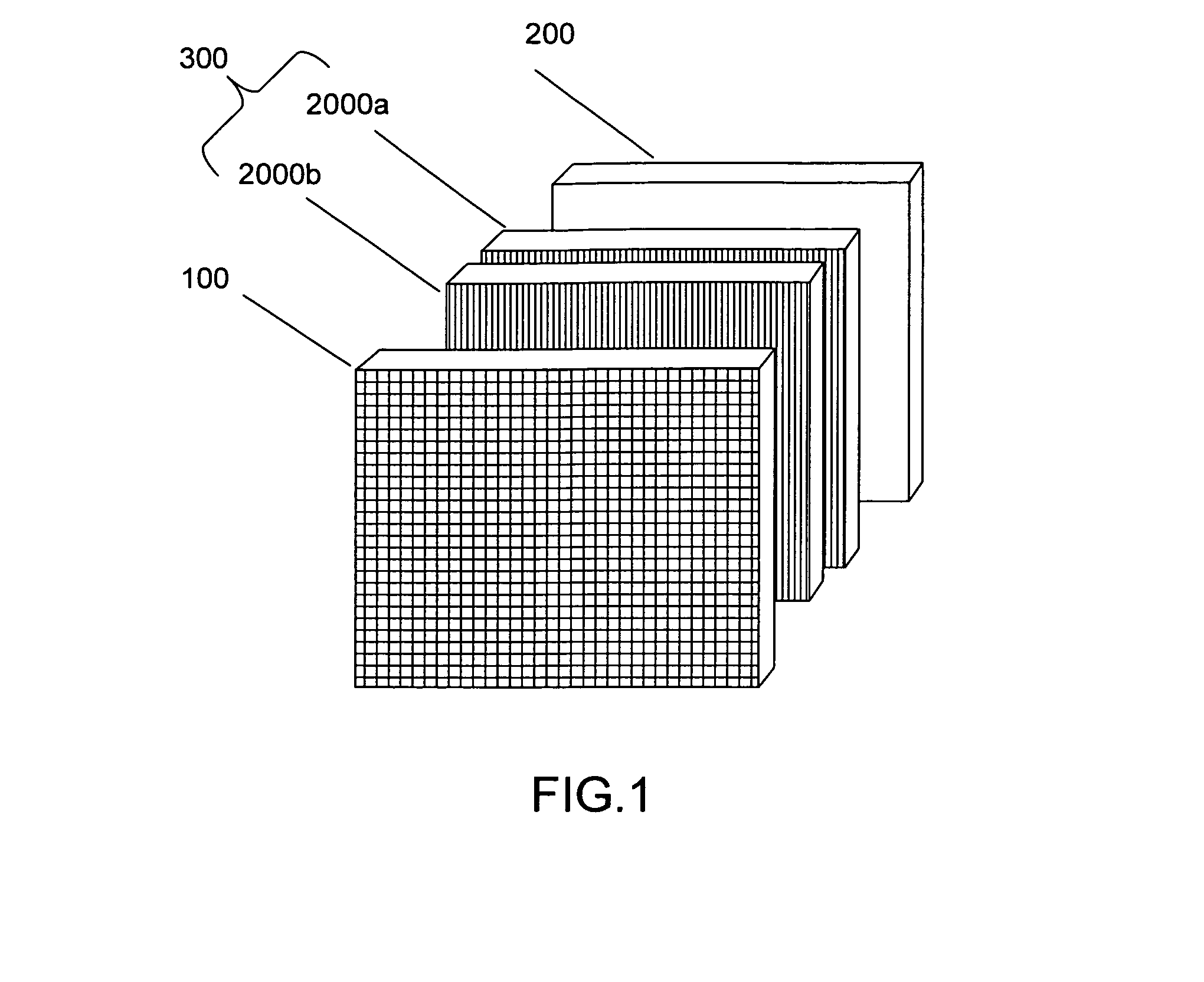

Autostereoscopic display

InactiveUS20130077154A1Quality improvementHigh quality imagingSteroscopic systemsNon-linear opticsVertical barSpatial light modulator

An autostereoscopic display is provided comprising a Spatial Light Modulator (SLM), an illuminator, and first and second light redirecting grids. The light directing grids comprise vertical bar-shaped electrically switchable diffractive elements. The light redirecting grids direct light from the illuminator through the SLM towards left and right eye positions.

Owner:POPOVICH MILAN MOMCILO +1

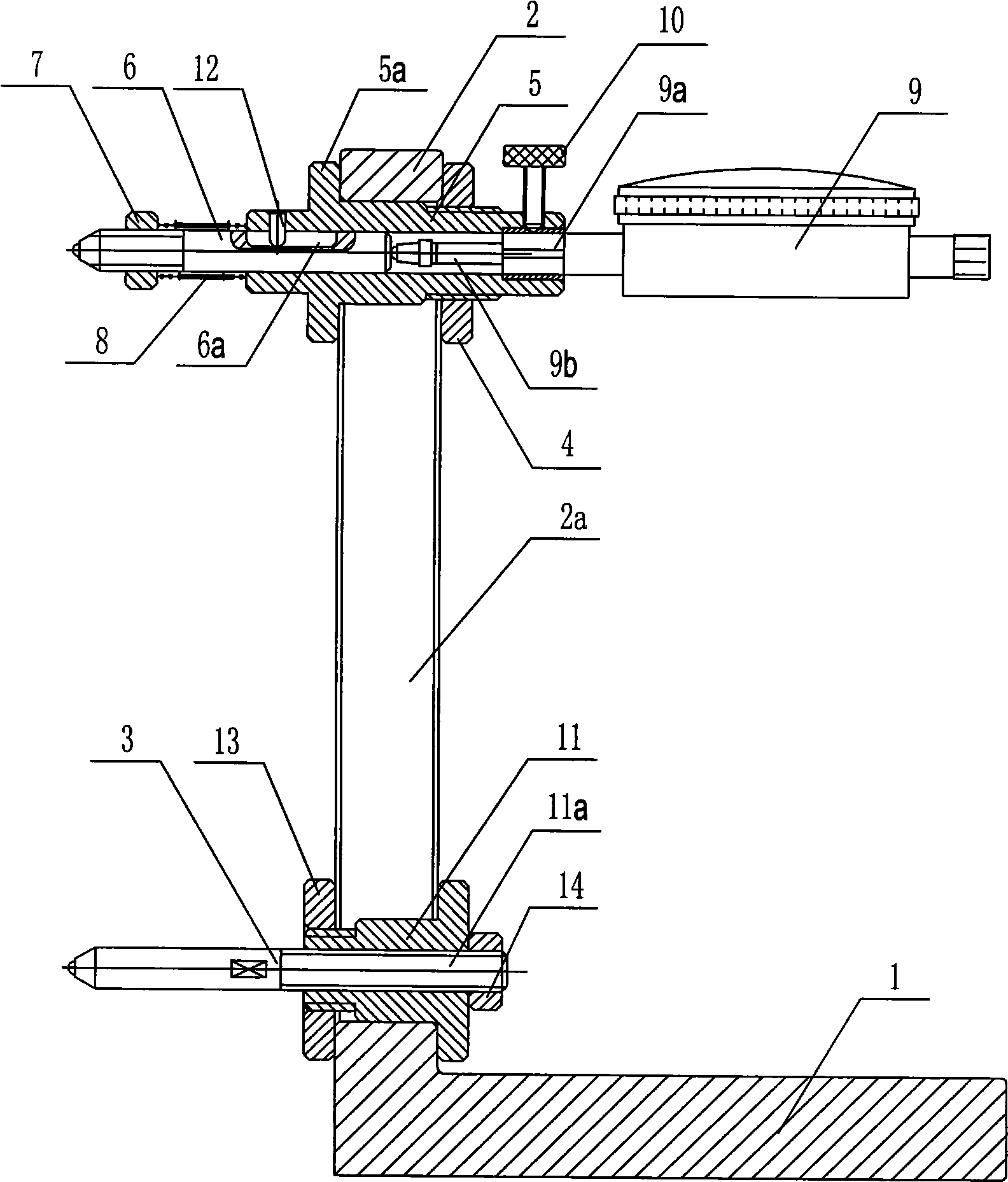

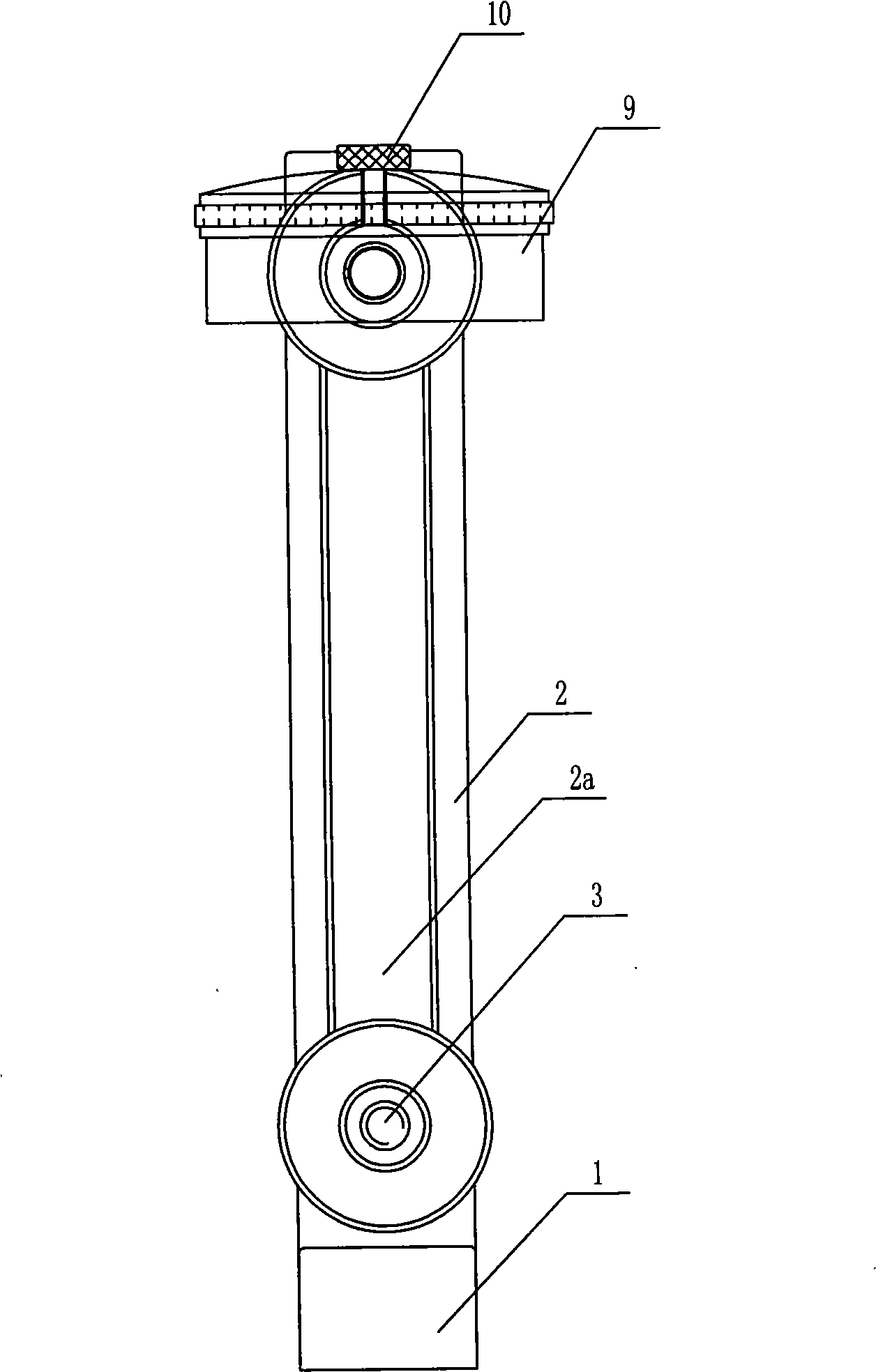

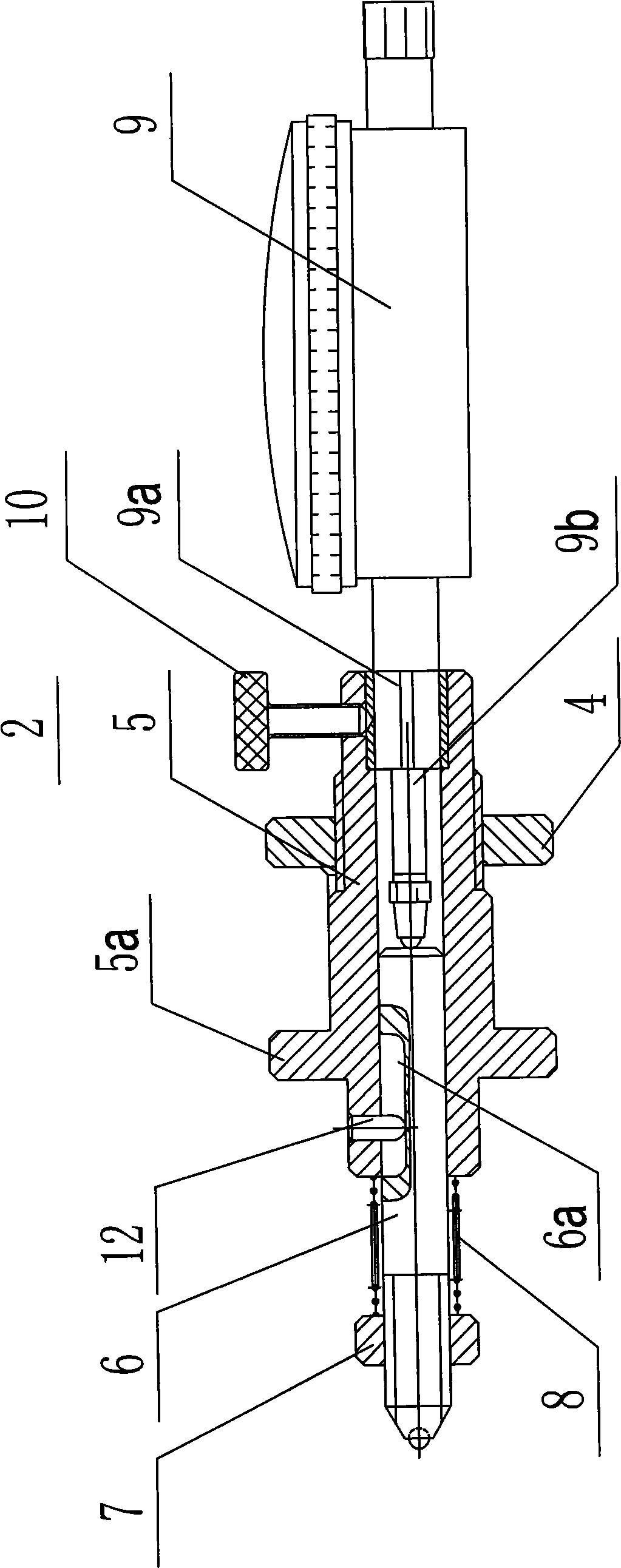

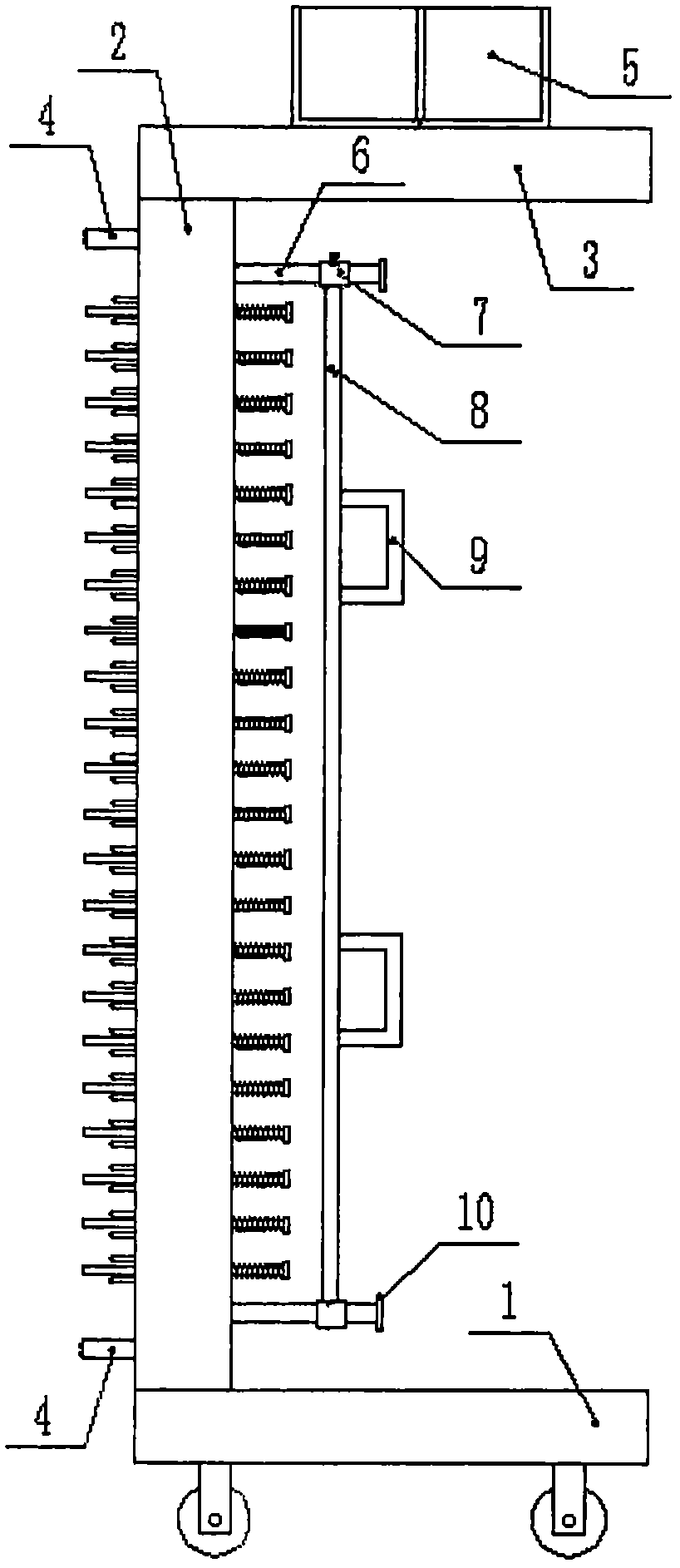

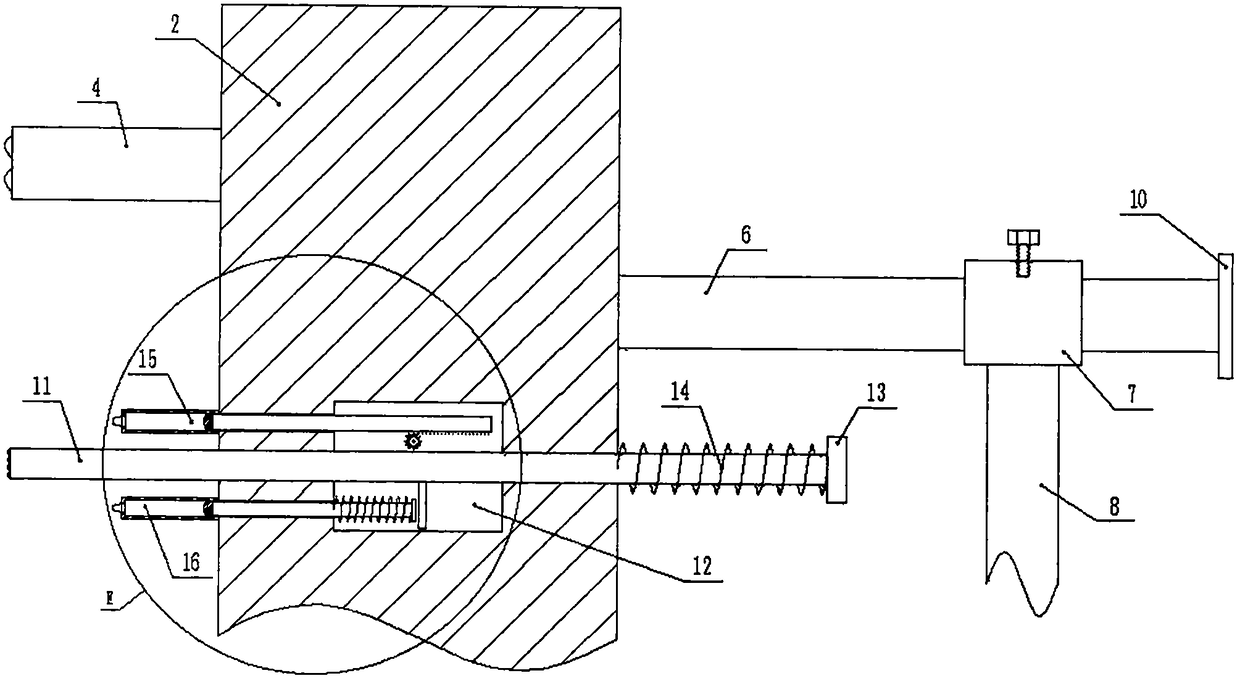

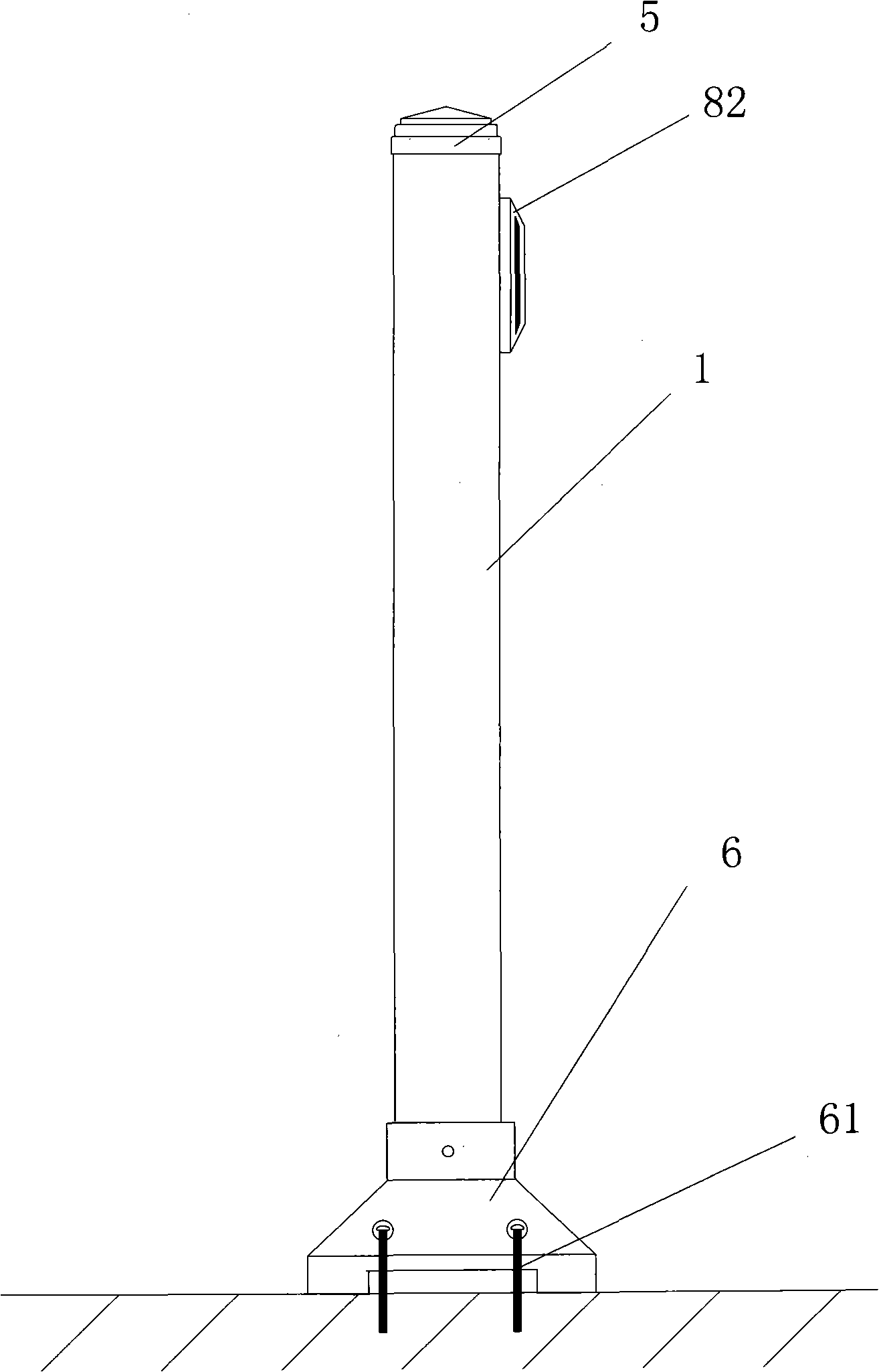

Device and method for measuring verticality

ActiveCN101545751AEasy to detectMeet testing needsMechanical measuring arrangementsVertical barEngineering

The invention discloses a device for measuring the verticality. The device is provided with a horizontal base and a vertical support, wherein the vertical support is provided with a benchmark detection mechanism and a declination detection mechanism. The device is characterized in that the vertical support is provided with a vertical bar-shaped through hole; a horizontal positioning rod in the declination detection mechanism is arranged on the vertical support, and extends out of the vertical bar-shaped through hole; the declination detection mechanism passes through the vertical bar-shaped through hole, and a sliding body of the declination detection mechanism is provided with a horizontal through hole; and a measuring rod is inserted at one end of the horizontal through hole, a dial gauge is inserted at the other end of the horizontal through hole, and a detection head of the dial gauge is contacted with the measuring rod. The measuring method comprises the correction method and the detection method. The device and the method have the advantages of making correction detection more convenient, improving the detection accuracy, easily measuring vertical faces of structures in different shapes, and meeting the detection requirements on various workpieces.

Owner:力帆科技(集团)股份有限公司

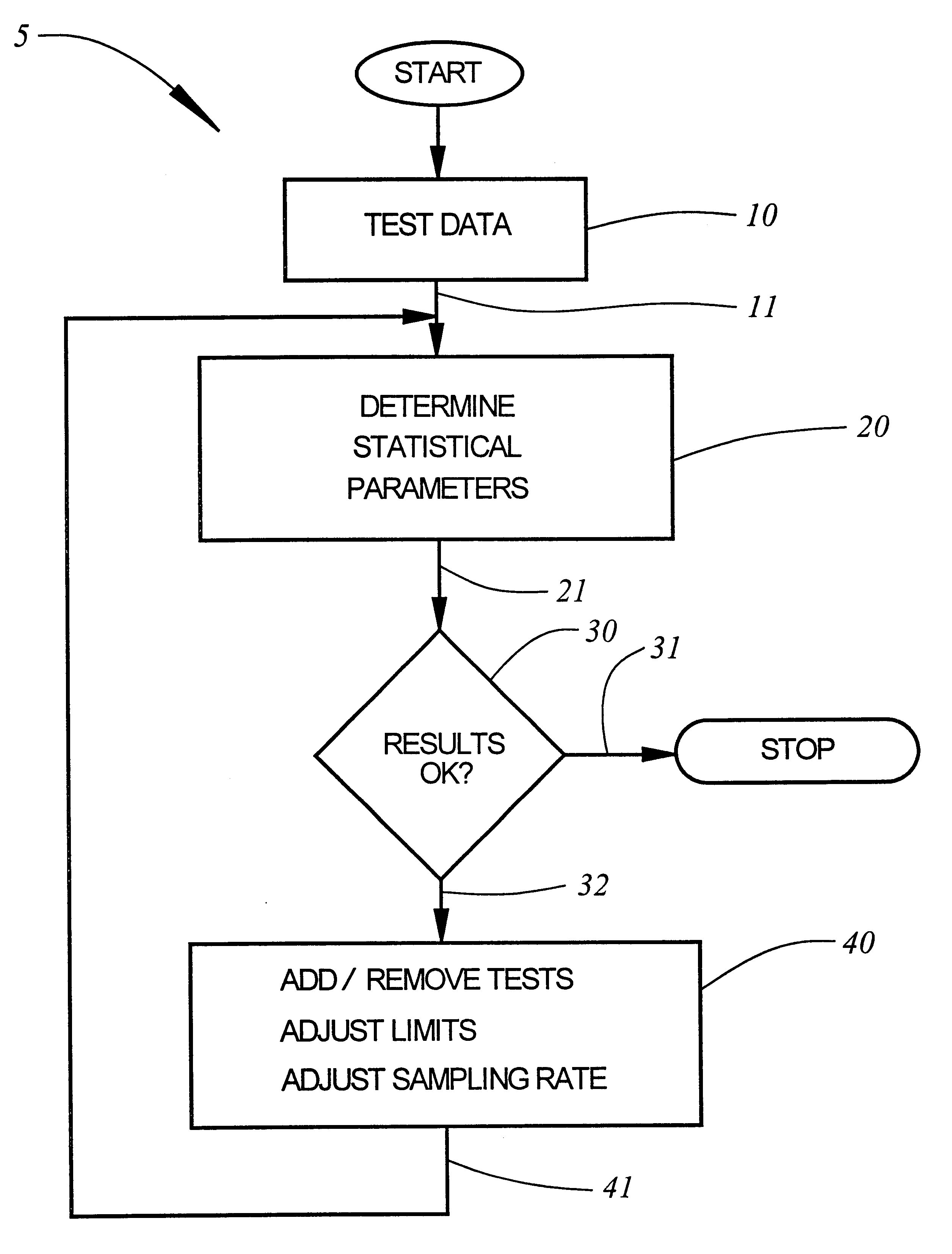

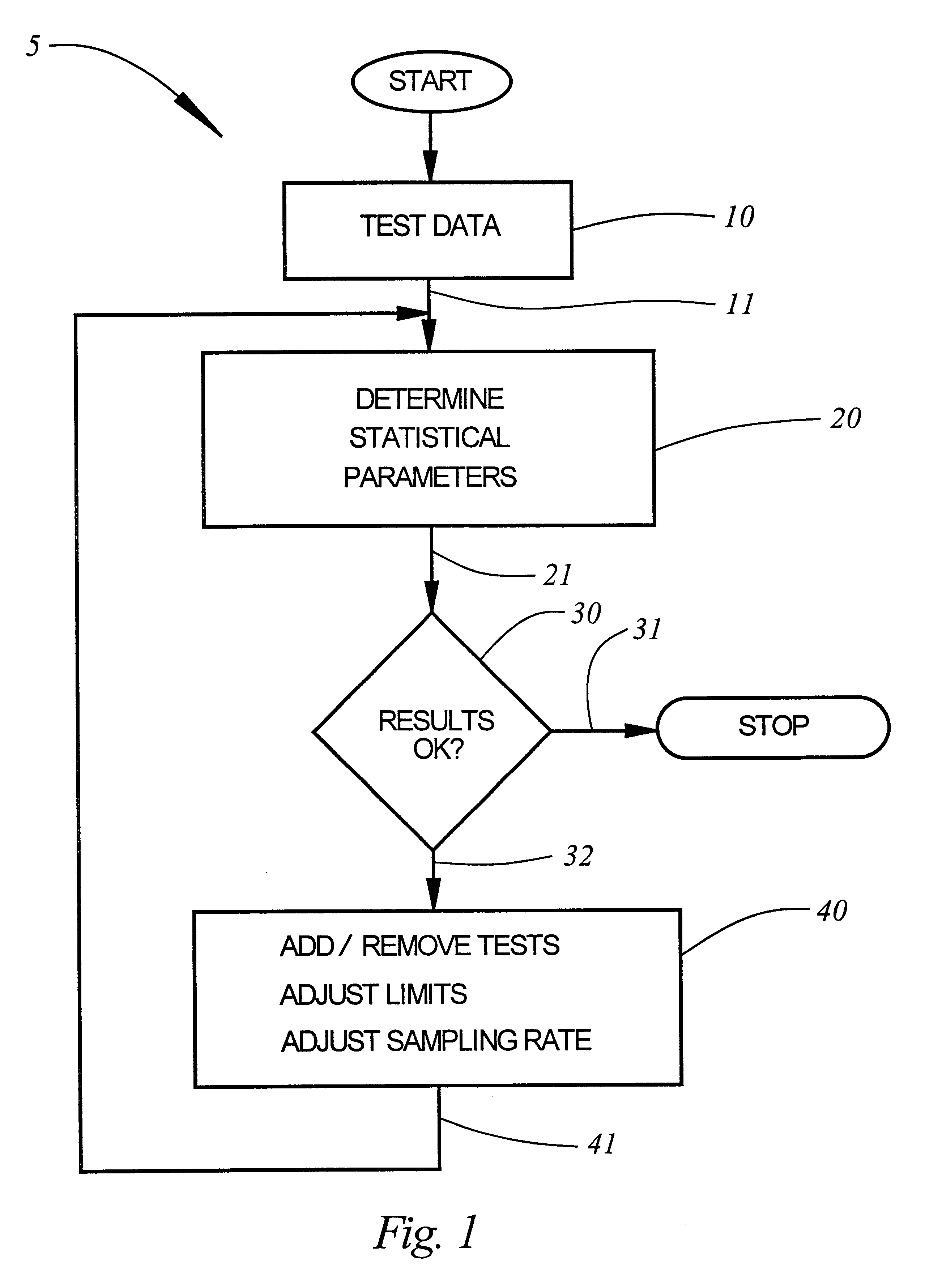

Method, apparatus and product for evaluating test data

Method, apparatus and product for analyzing a quality control regimen comprising one or more quality control tests, to determine if the tests are in statistical control, and therefore could be removed from the regimen or sampled at a different rate. On sample data relating to each of the tests, there is determined Cpi, a measure of the spread of the data, which is simply the ratio of the magnitude of the actual range of the data, to the magnitude of calculated statistical range of the data. There is also determined CPKi, which is a measure of how close the spread of the data is to the upper or lower limit of the data. For convenience, the magnitude of Cpi is represented as a vertical bar graph, with the value of CPKi shown as a position of the bar graph within normalized limits. Using Cpi and CPKi decisions regarding removal of each the test can be made. One or more tests are then selected for removal or to have a different sampling rate, and "What If" scenarios then performed to see how the testing regimen would have performed without the test(s) or at the different sampling rate.

Owner:PDF SOLUTIONS INC

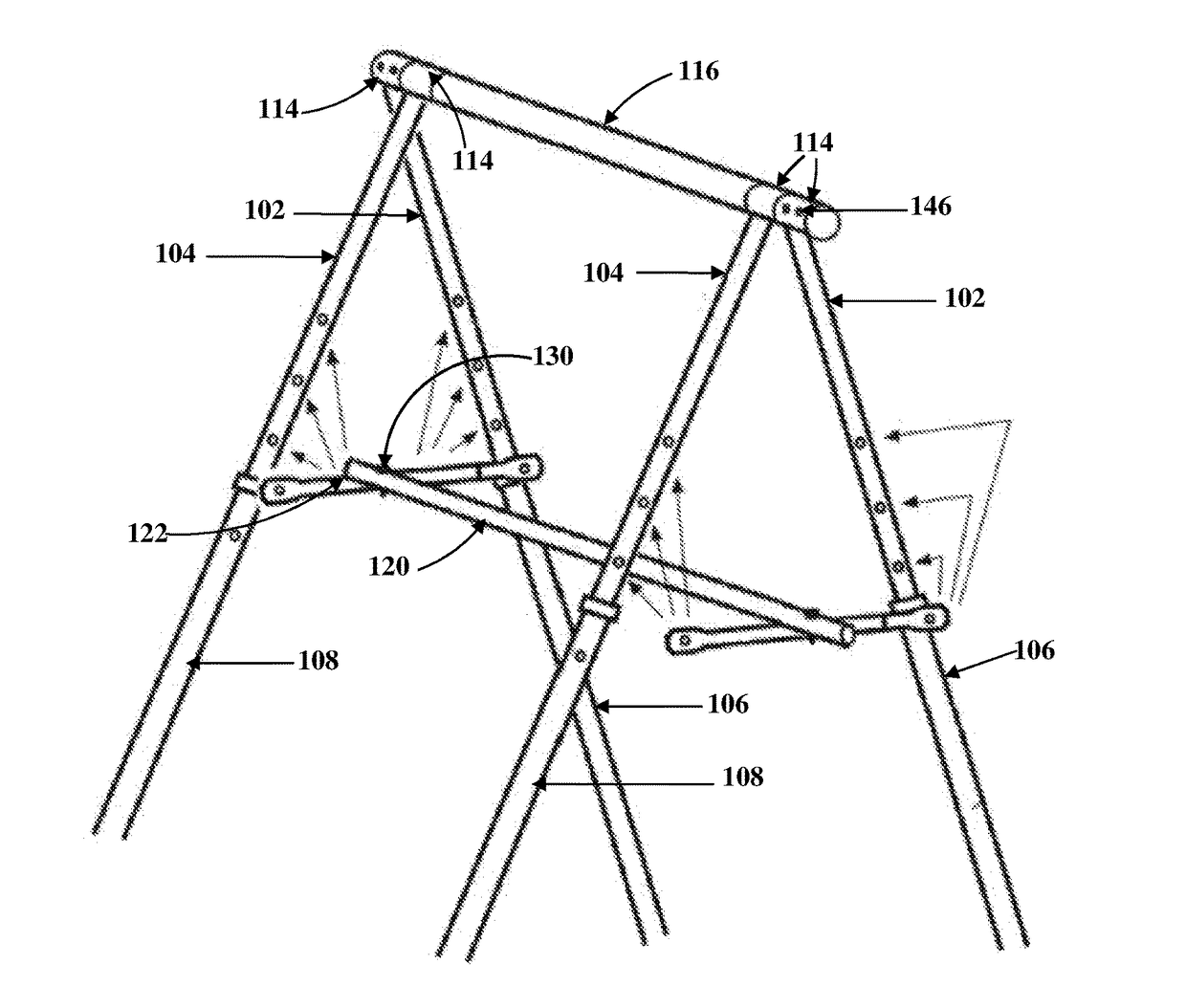

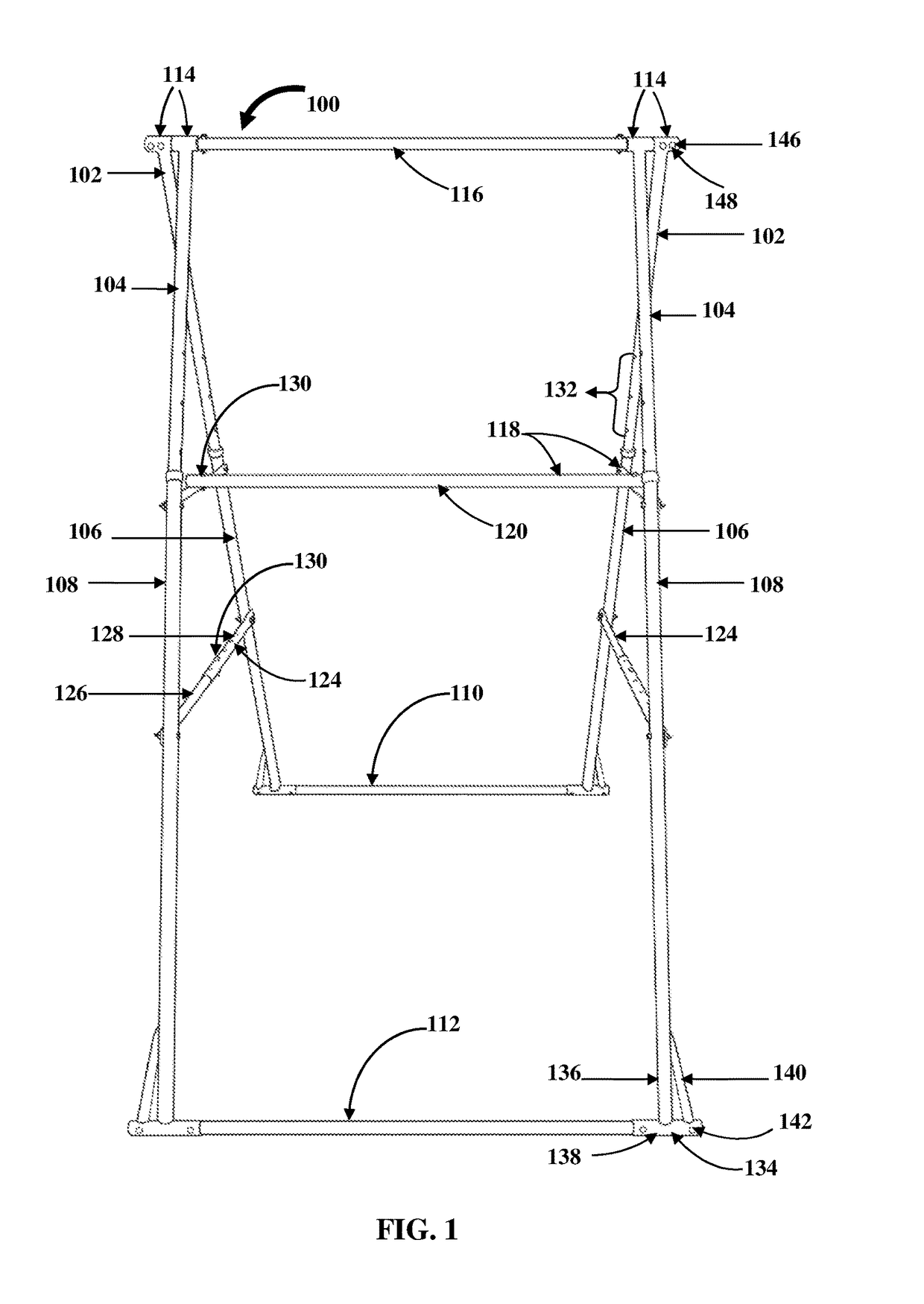

Collapsible free standing exercise apparatus

A collapsible free standing exercise apparatus for performing multiple body weight exercises is disclosed. The collapsible free standing exercise apparatus comprises a pair of hollow vertical bars separated at a predetermined distance via a connector bar assembly removably fastened at a lower portion of each hollow vertical bar. A first handle bar is removably fastened to each vertex joint on each pair of hollow vertical bars and a second handle assembly removably fastened between each pair of hollow vertical bars at a predetermined position via a support section disposed at distal ends of the second handle bar. A method of fixing the collapsible free standing exercise apparatus for use is also disclosed.

Owner:LE NGUYEN KHANH TRINH

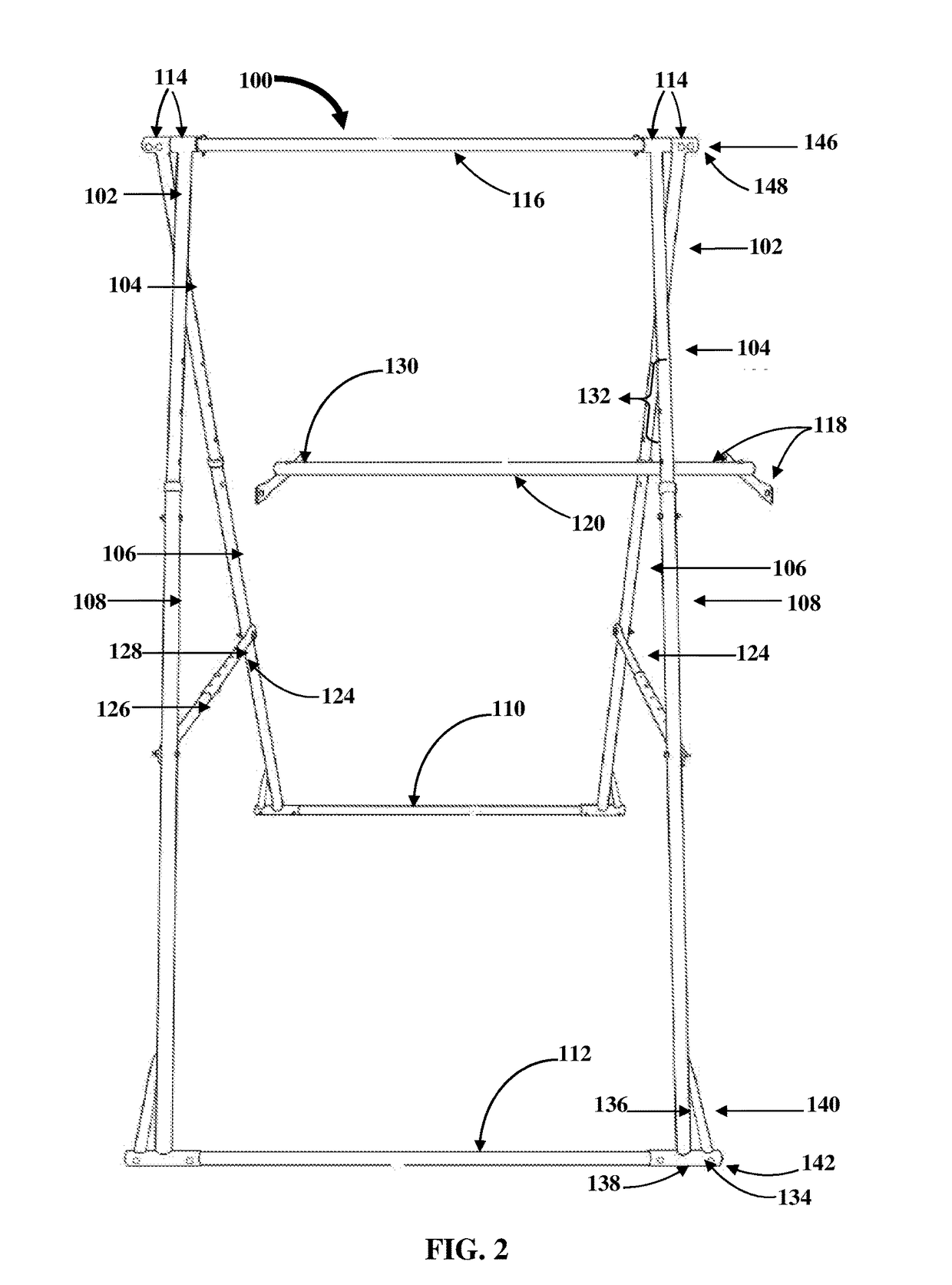

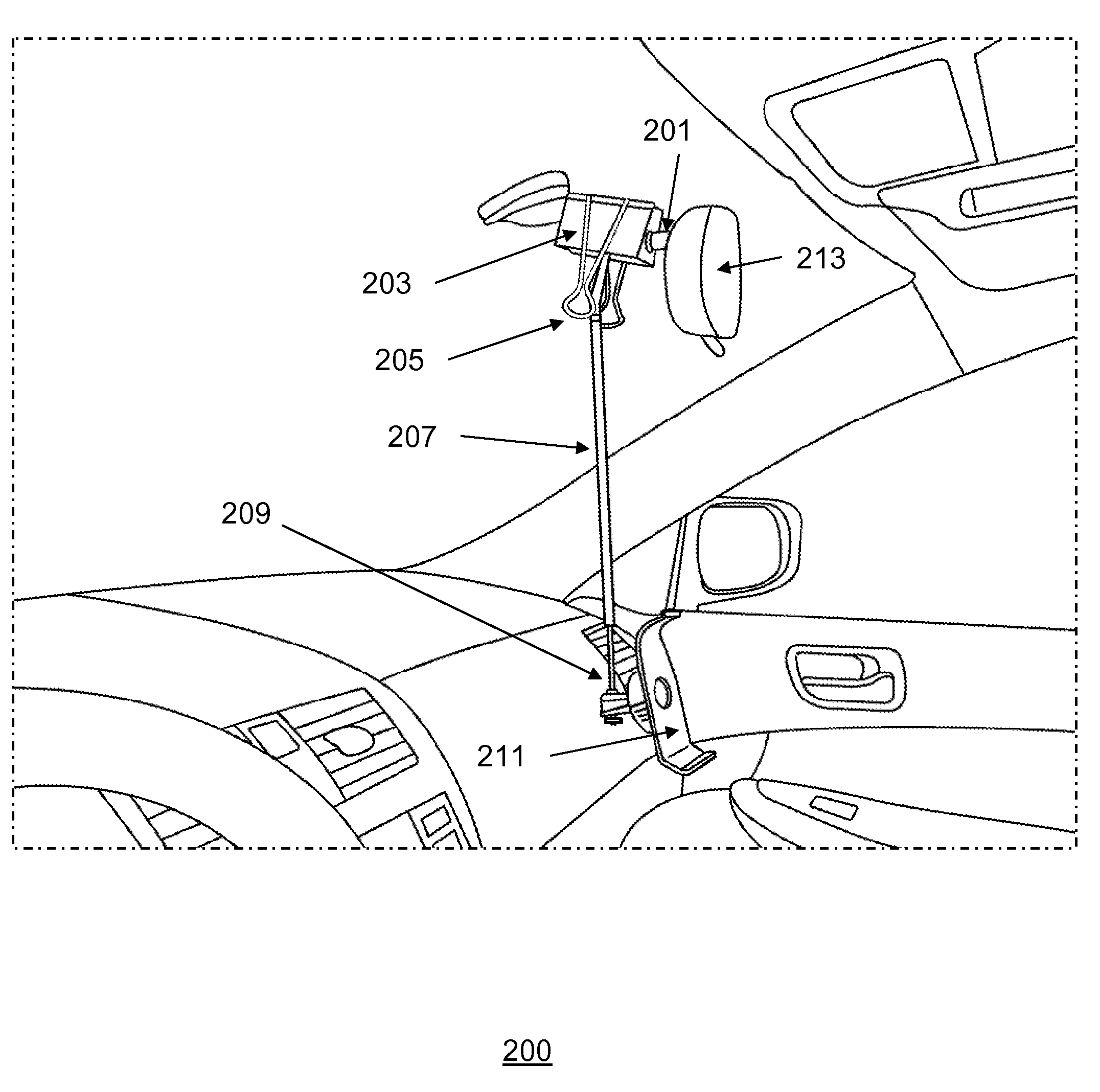

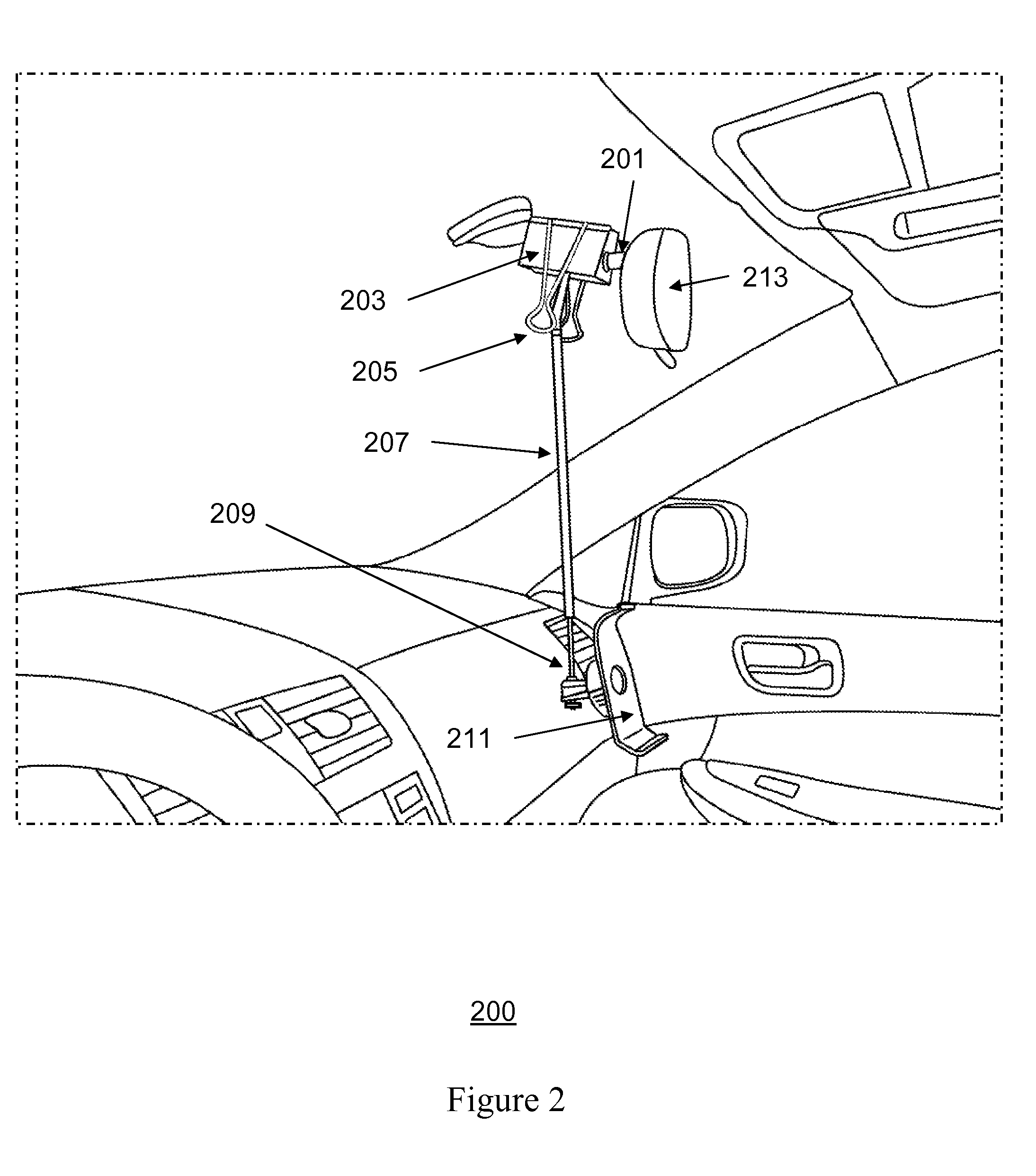

Apparatus and method for holding a portable electronic device

An apparatus and a method are disclosed for holding a portable electronic device such as a navigation system unit, a multimedia / music player, a cellular phone, and a satellite radio. In one embodiment of the invention, a clamp enables a firm and removable attachment of a novel portable electronic device holder to a neck of a center rear view mirror in a vehicle. In an alternate embodiment, a C-clamp with a turning screw is used instead. A vertical bar or a non-straight-line-shaped extension operatively attached to the clamp is typically extendable and retractable to allow a user to adjust the novel portable electronic device holder to a comfortable length. The design of the novel portable electronic device holder does not require a use of an air suction cup or adhesive materials for a base piece attachment to a vehicle's dashboard which provides several advantages over conventional designs.

Owner:PERNIA PATRICK

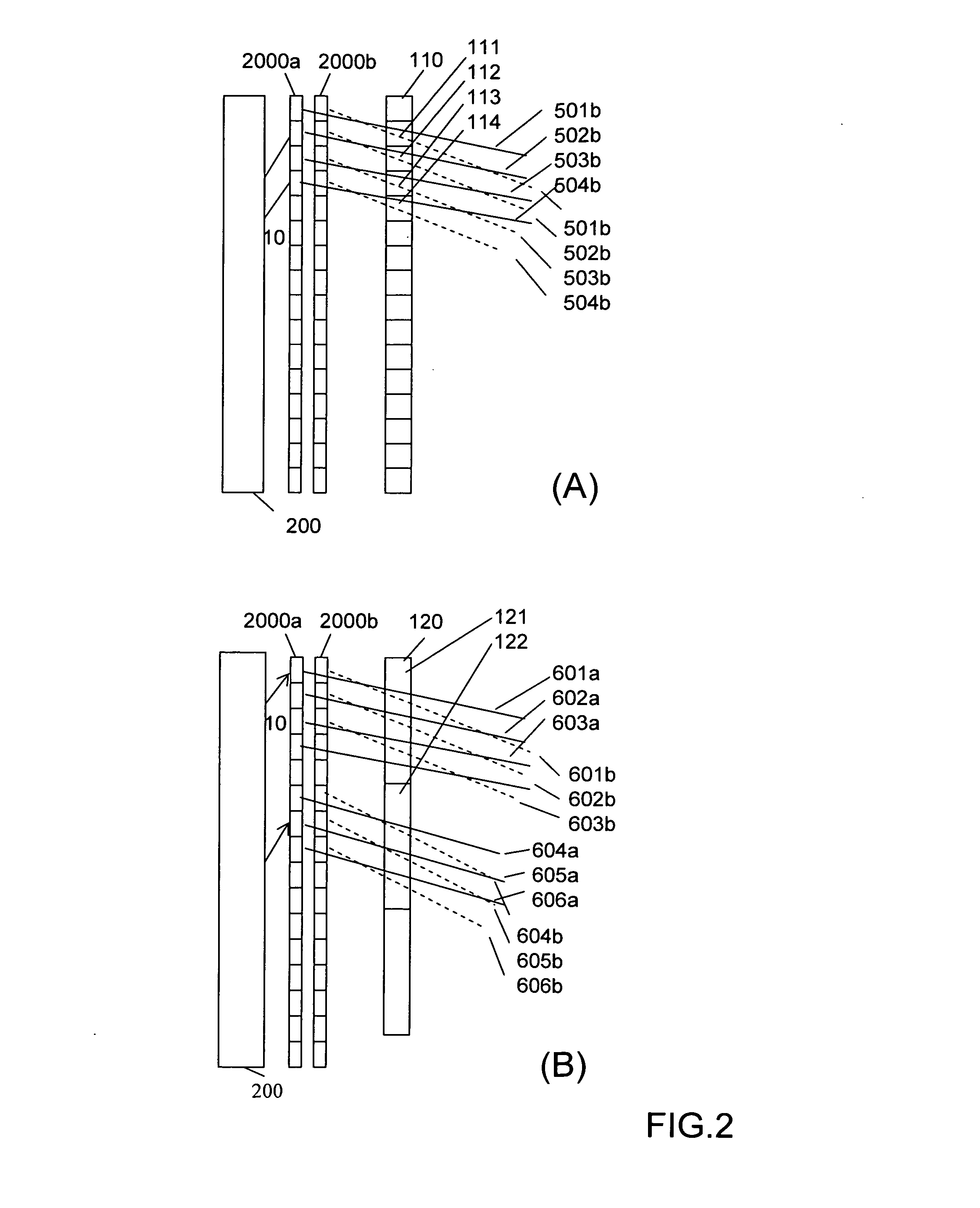

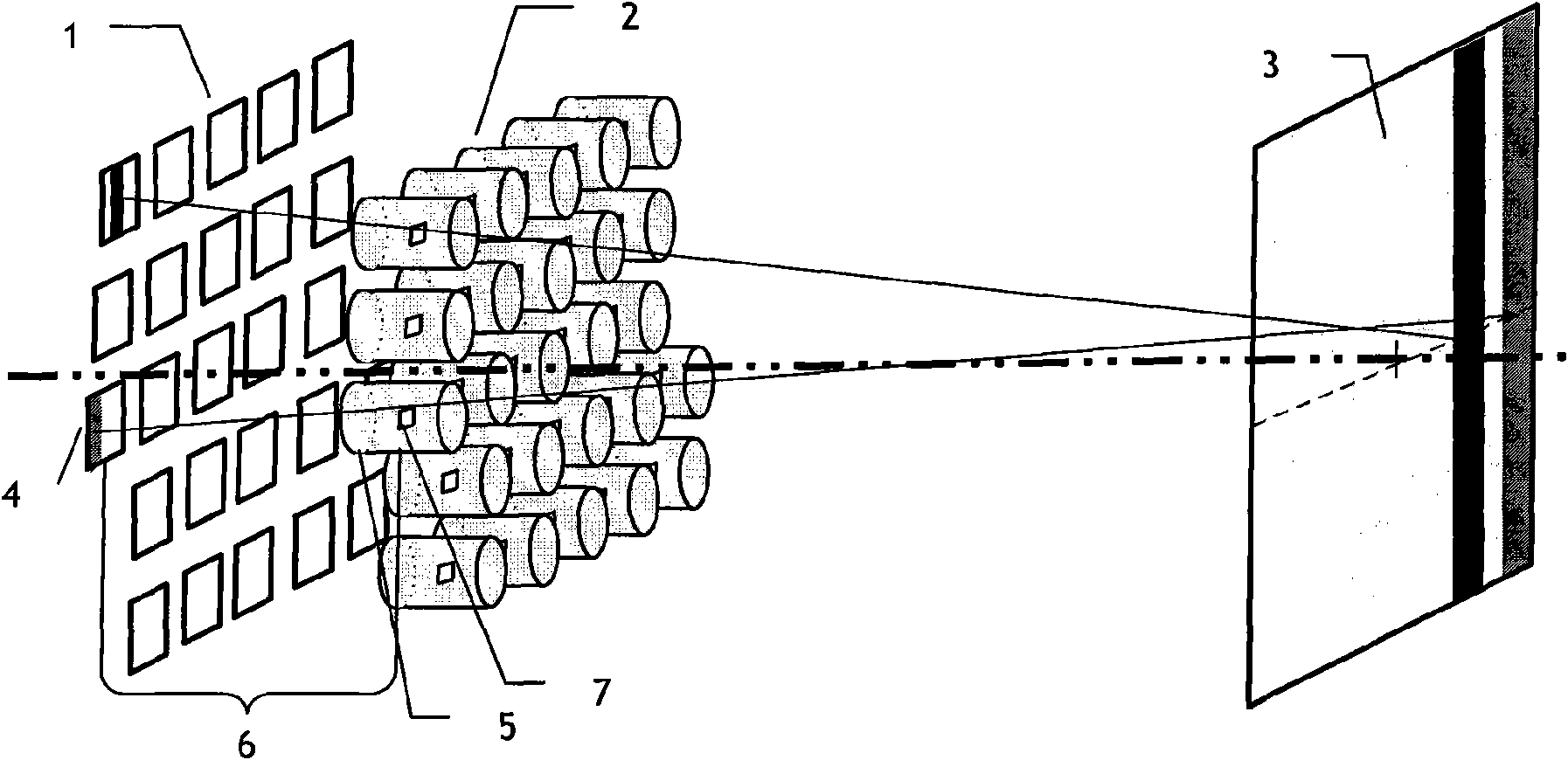

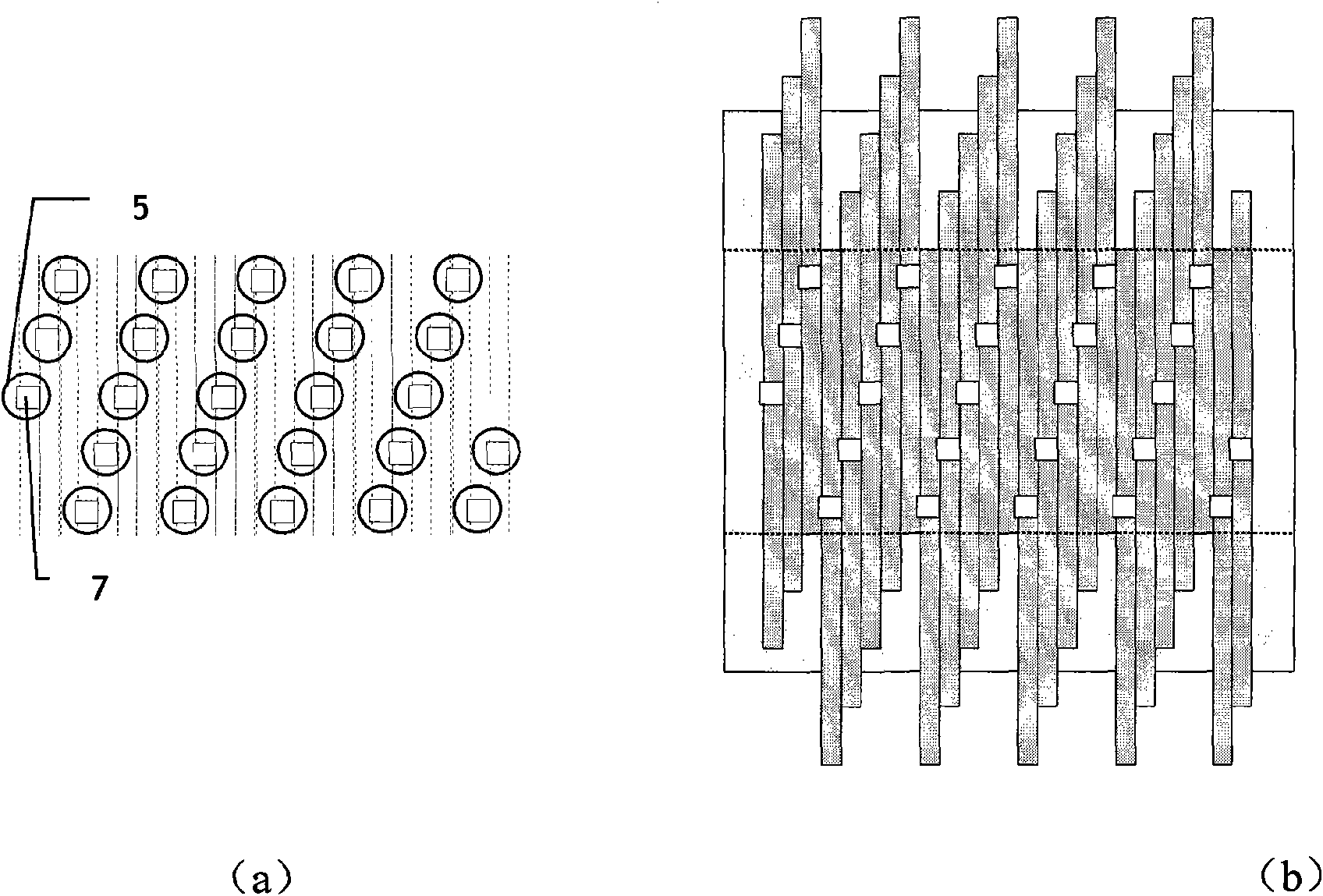

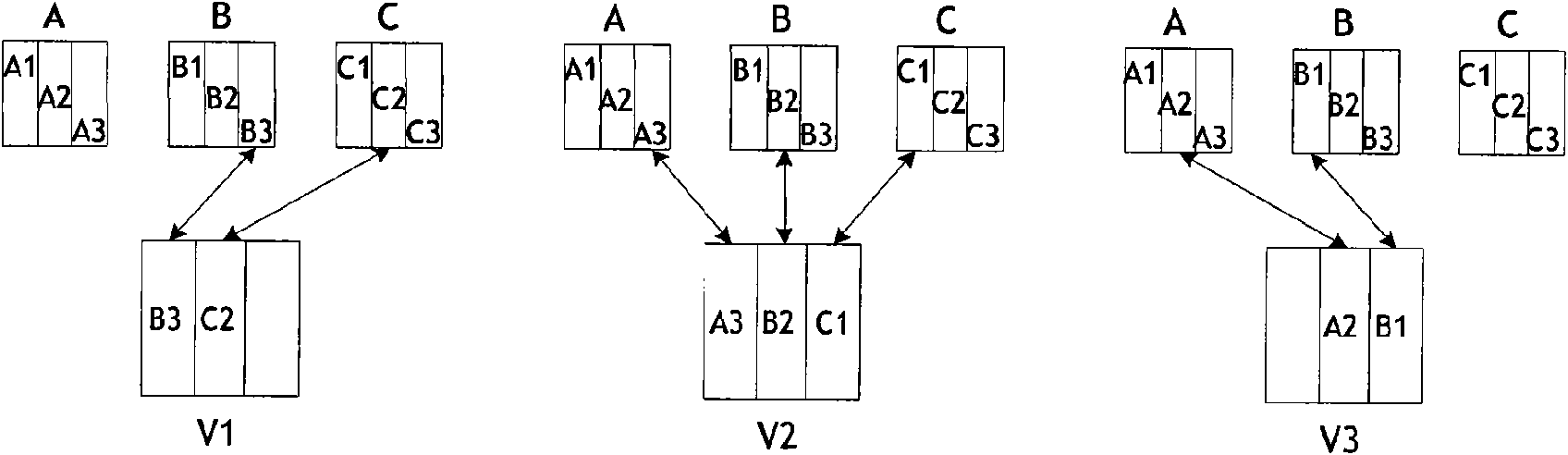

Splicing view field stereoscopic three-dimensional display device and method thereof

InactiveCN101644884AHigh image resolutionHigh viewing angle resolutionStereoscopic photographyVertical barCamera lens

The invention discloses a splicing view field stereoscopic three-dimensional display device and a method thereof. The device sequentially comprises a display screen array, a projection lens array anda directional diffuser screen; wherein each display screen and a projection lens arranged at right front thereof form a projector, and all the projectors are lengthways arranged by means of dislocation position and project images which are displayed corresponding to the display screen on the same position of the directional diffuser screen. The image respectively displayed by the each display screen in the splicing view field stereoscopic three-dimensional display method is spliced by one vertical bar image of the different viewing angles of a three-dimensional object, each vertical bar imageis projected to an original view angle by a developing lens, and the directional diffuser screen displays the images of the three-dimensional object with different view angles at traverse different directions. The invention has the advantage of being capable of generating three-dimensional images with high image distinguish ratio and high view distinguish ratio. Extreme fine view angle isolation can bring complete continues no-hop three-dimensional perception to observers.

Owner:ZHEJIANG UNIV

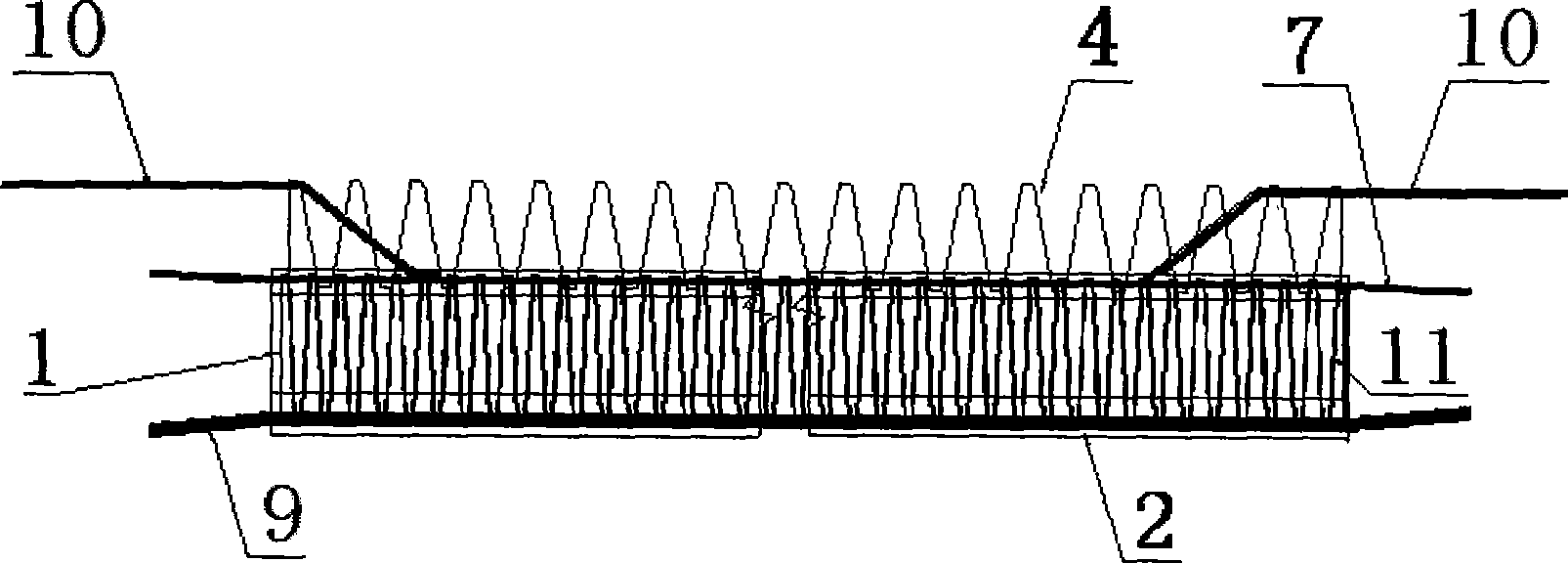

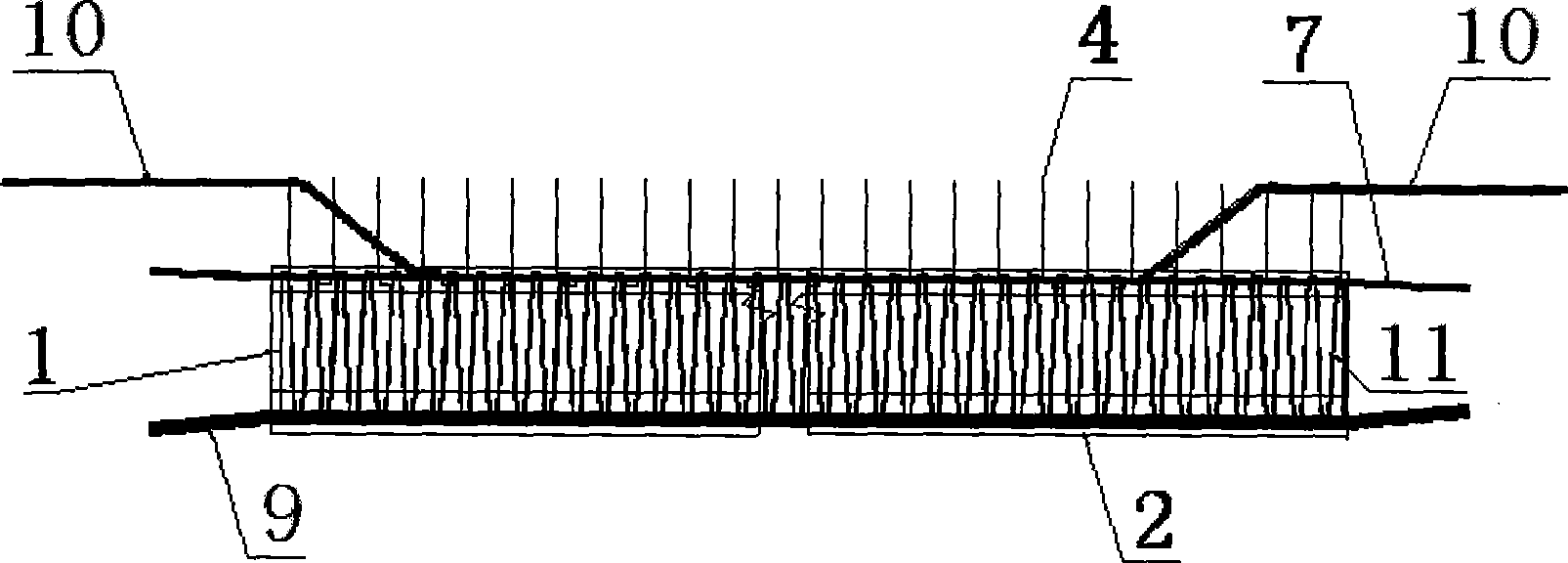

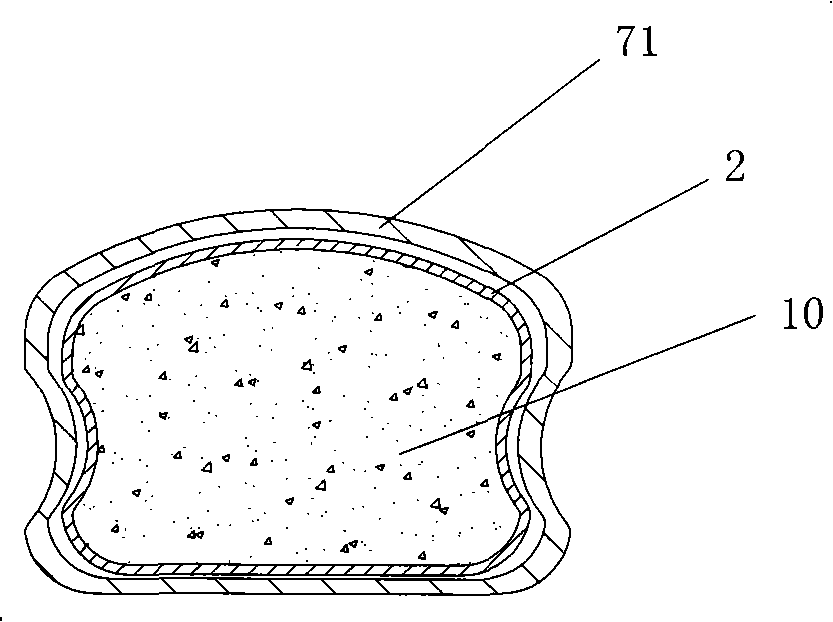

Prefabricated hollow superposed beam, and cast-in-situ construction method for beam and precast slab

A cast-in-place construction method for a prefabricated folded hollow beam and a precast slab belongs to the technical field of building elements. The section center of a beam body (2) is provided with a through hole (1). A vertical fiber (4) which is connected with a vertical bar of an inner frame (7) of the beam body (2) is arranged at the upper part of the beam body (2). The method comprises the following steps: A. the two sides of the upper plane surface of the beam body (2) are relatively provided with precast slabs (3), and a pouring joint is reserved between the precast slabs (3) and the vertical fiber (4); and B. the contact joint of the precast slabs (3) of the beam body (4) is cast with concrete until the vertical fiber (4) is buried by the concrete, or the concrete is cast entirely above the beam body (2) and the precast slabs (3), and then the cast-in-place beam slab can be formed after jolt ramming, trowelling, curing and solidification. The weight of the beam body (2) can be reduced. The additive effect generated by the vertical fiber leads to comparatively large enhancement of the beam height, and no occupation of inner space of the building structure. The cast-in-place beam slab is suitable for the buildings of the frame structure and the high rise buildings.

Owner:刘馨裕

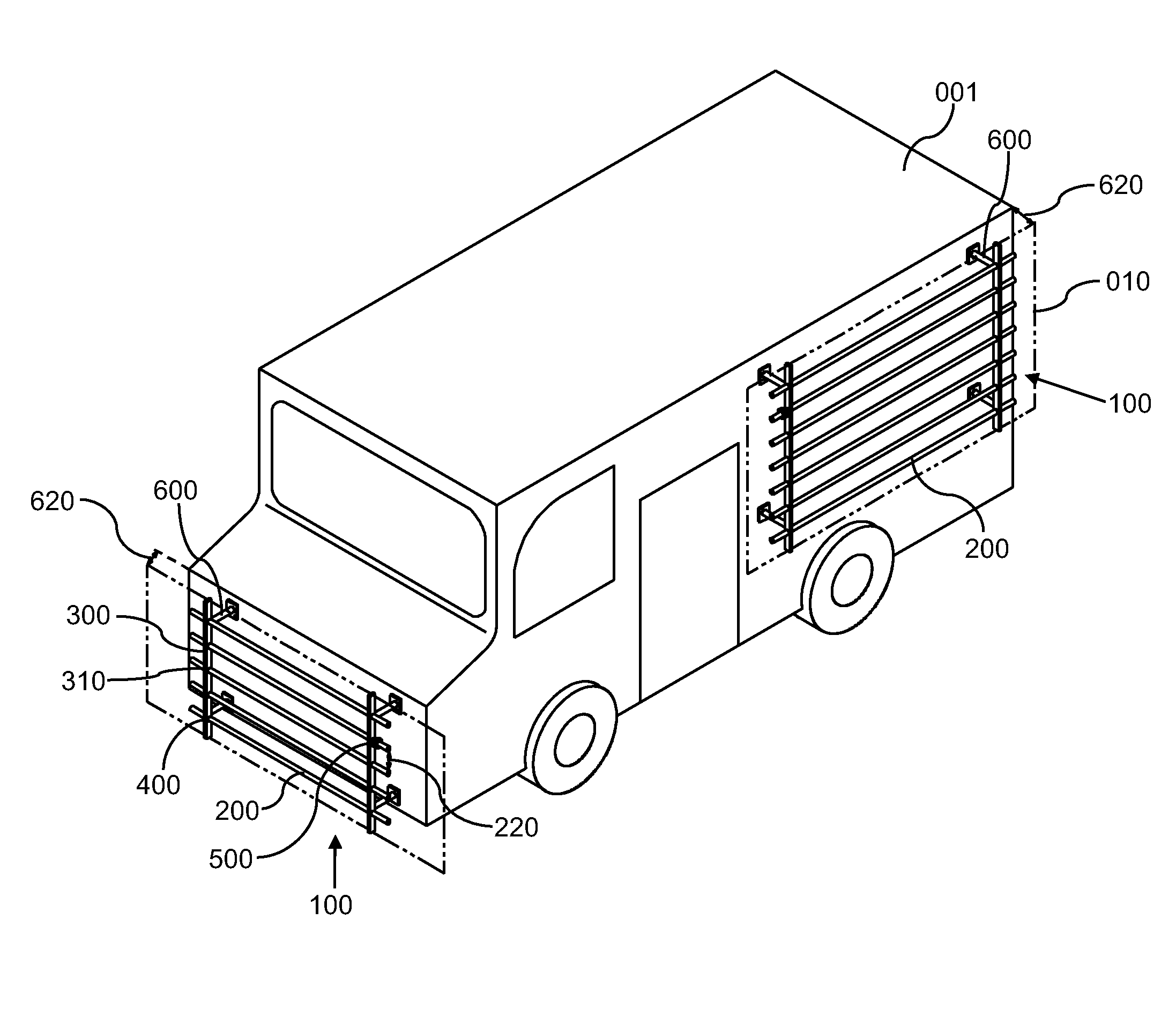

Bar armor system for protecting against rocket-propelled grenades

InactiveUS20110232472A1Optimize geometryInhibition of translationArmourArmoured vehiclesVertical barShaped charge

A bar armor system is provided for reducing damage caused by RPGs launched towards a vehicle. The bar armor system includes at least one bar array, comprised of lateral bars and vertical bars, wherein the lateral bars are set in predetermined positions so as to reduce the possibility of shaped charges being directed towards the target vehicle. Tubular shaft retainers are provided to be positioned in annular openings in the vertical bars. The lateral bars can be of a round or hexagonal cross-section, and when hexagonal lateral bars are employed, the flat surfaces of the cross-section are positioned horizontally by the tubular shaft retainers so as to minimize the area presented to an oncoming RPG, particularly when the RPG strikes at a non-normal incidence. Push washers can be employed at the outside surfaces of the vertical bars so as to hold them in position. A mounting system is provided that is capable of positioning the bar armor system at close distances to the vehicle so that the overall size and weight of the vehicle is not unduly increased by the bar armor system. The mounts can include rotary latches to provide easy installation and removal. The system can also be of an electrically-conductive unified composition so that efficient electrostatic coating techniques can be used to cover the system. The system can also be provided in the form of kits for ready installation and for more economical repair.

Owner:GENERAL ATOMICS

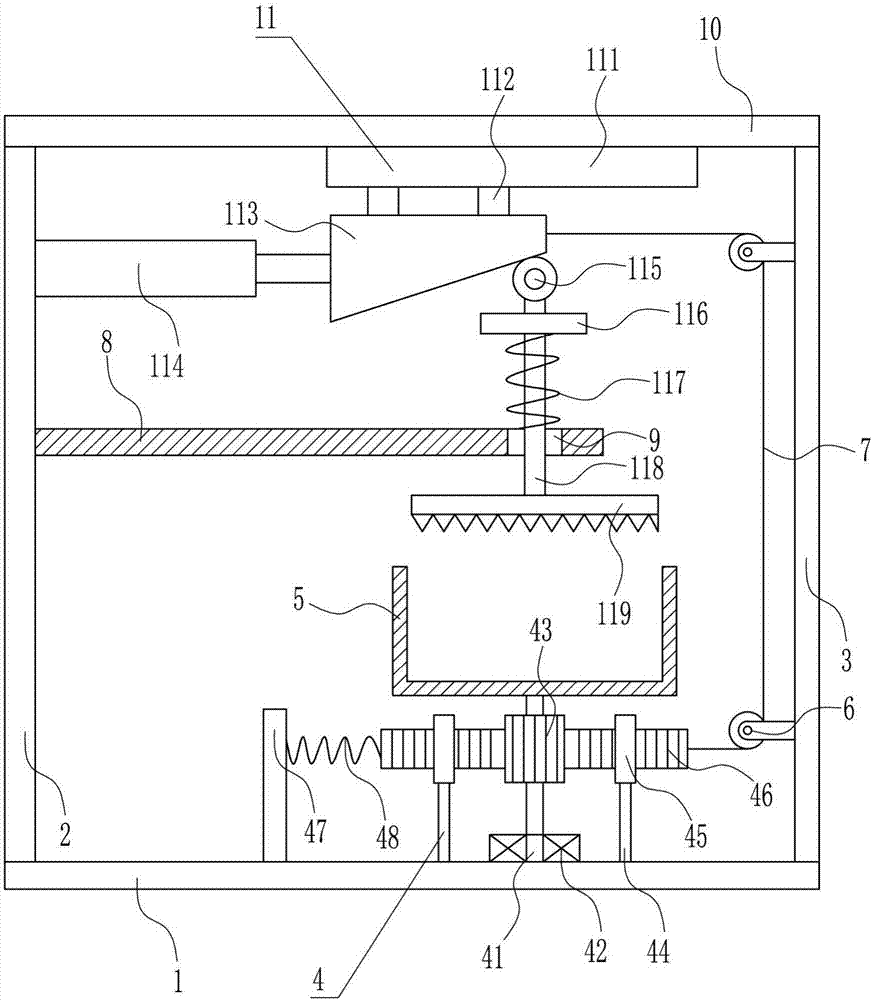

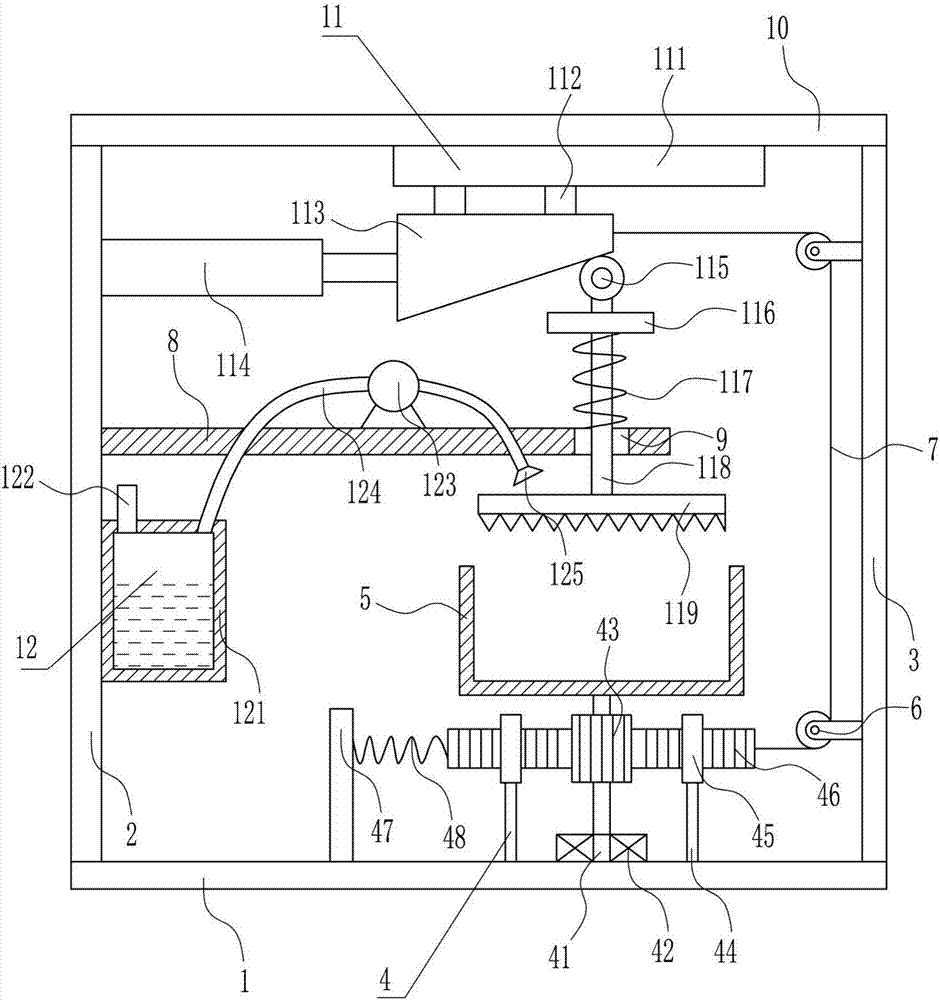

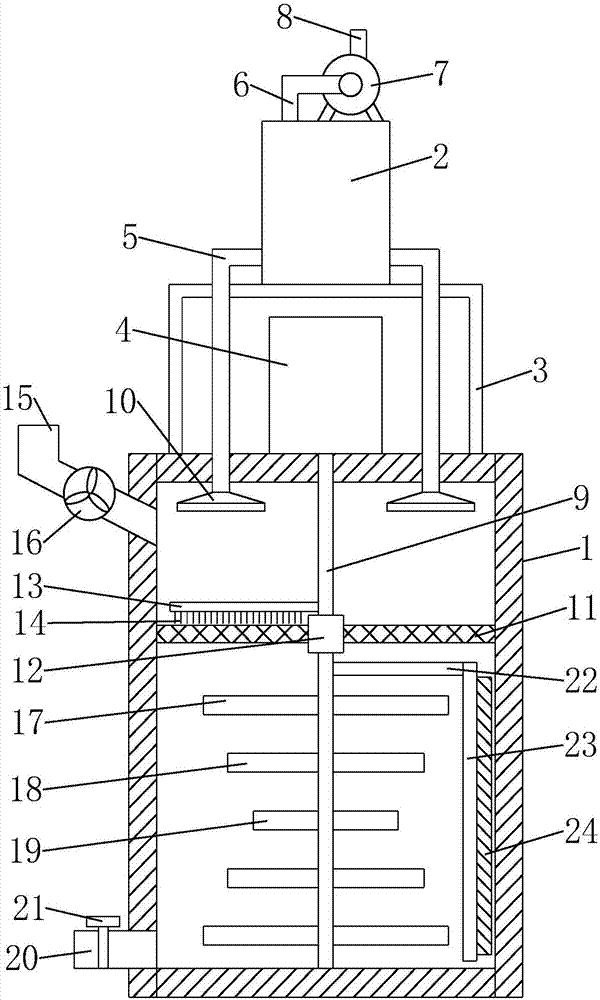

Quick crushing device for building ceramic chips

InactiveCN107029820ANot diffusedImprove crushing efficiencyUsing liquid separation agentGrain treatmentsVertical barMaterials science

The invention relates to a crushing device for building ceramic chips, in particular to a quick breaking device for building ceramic chips. The technical problem to be solved by the present invention is to provide a quick crushing device for building ceramic chips that saves time and labor, has high crushing efficiency, and can absorb dust so as not to affect the surrounding environment. In order to solve the above-mentioned technical problems, the present invention provides such a rapid crushing device for building ceramic chips, which includes a bottom plate, a left side plate, a right side plate, a rotating device, a crushing frame, a pulley, a pull wire, etc.; the top of the bottom plate is provided with a rotating device , the rotating device includes a rotating shaft, a bearing seat, a gear, a vertical rod, a sliding sleeve, a rack, a fixed plate and a first spring, and the right side of the top of the bottom plate is installed with a bearing seat through bolt connection. The invention can suck the dust away when the ceramic sheet is crushed by the dust suction device, can protect the surrounding environment from being diffused by the dust, saves time and labor, has high crushing efficiency, and can suck the dust.

Owner:何伯春

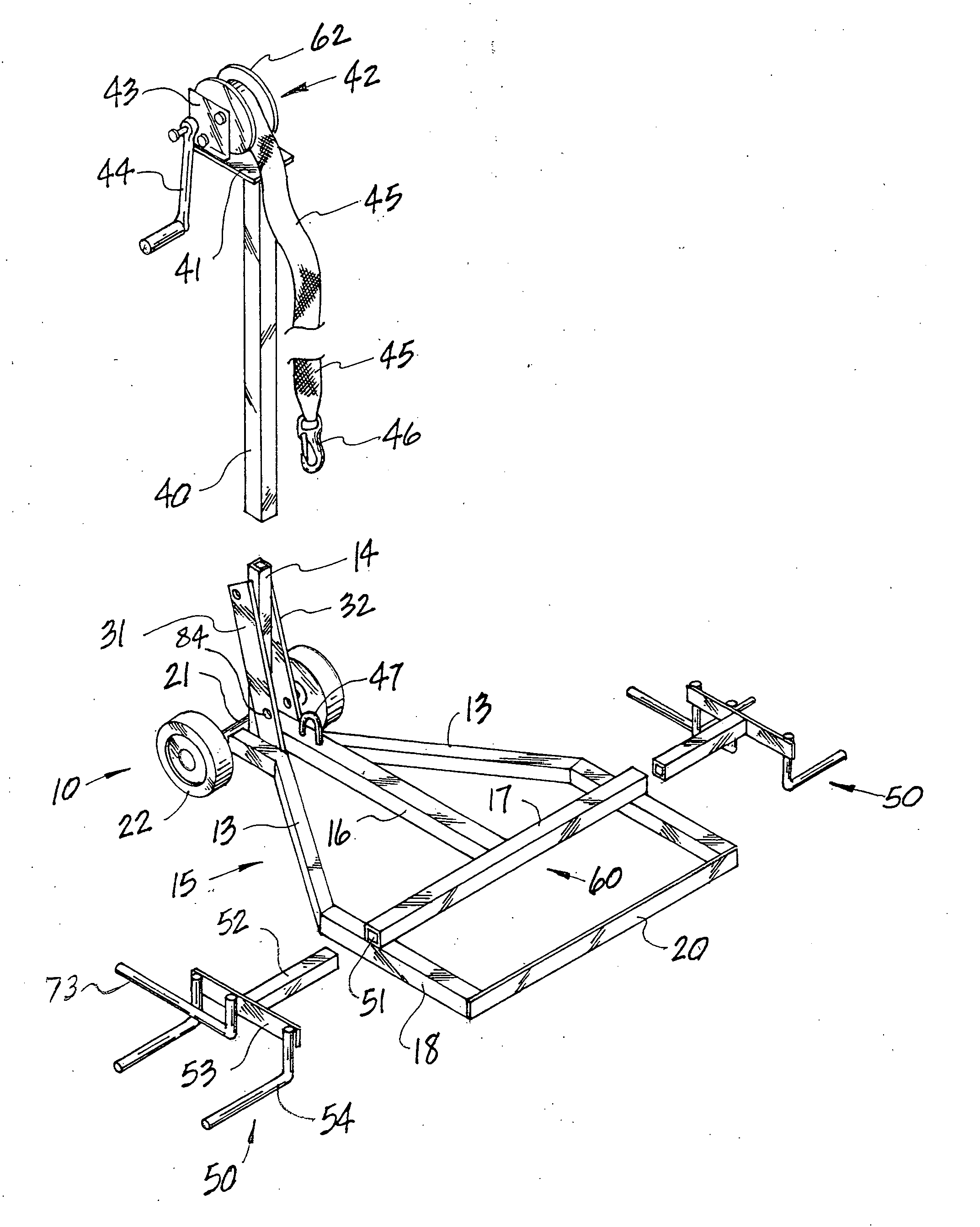

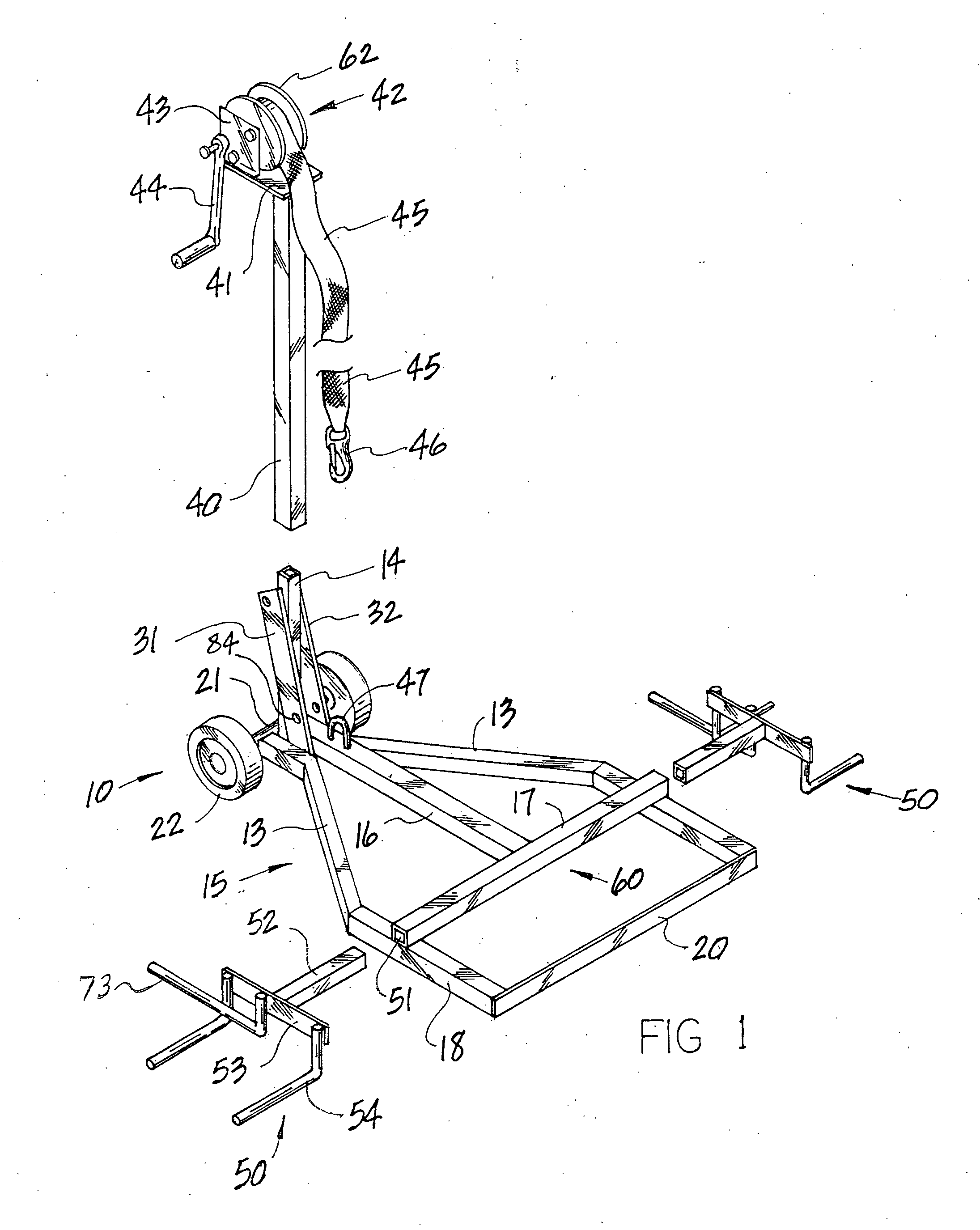

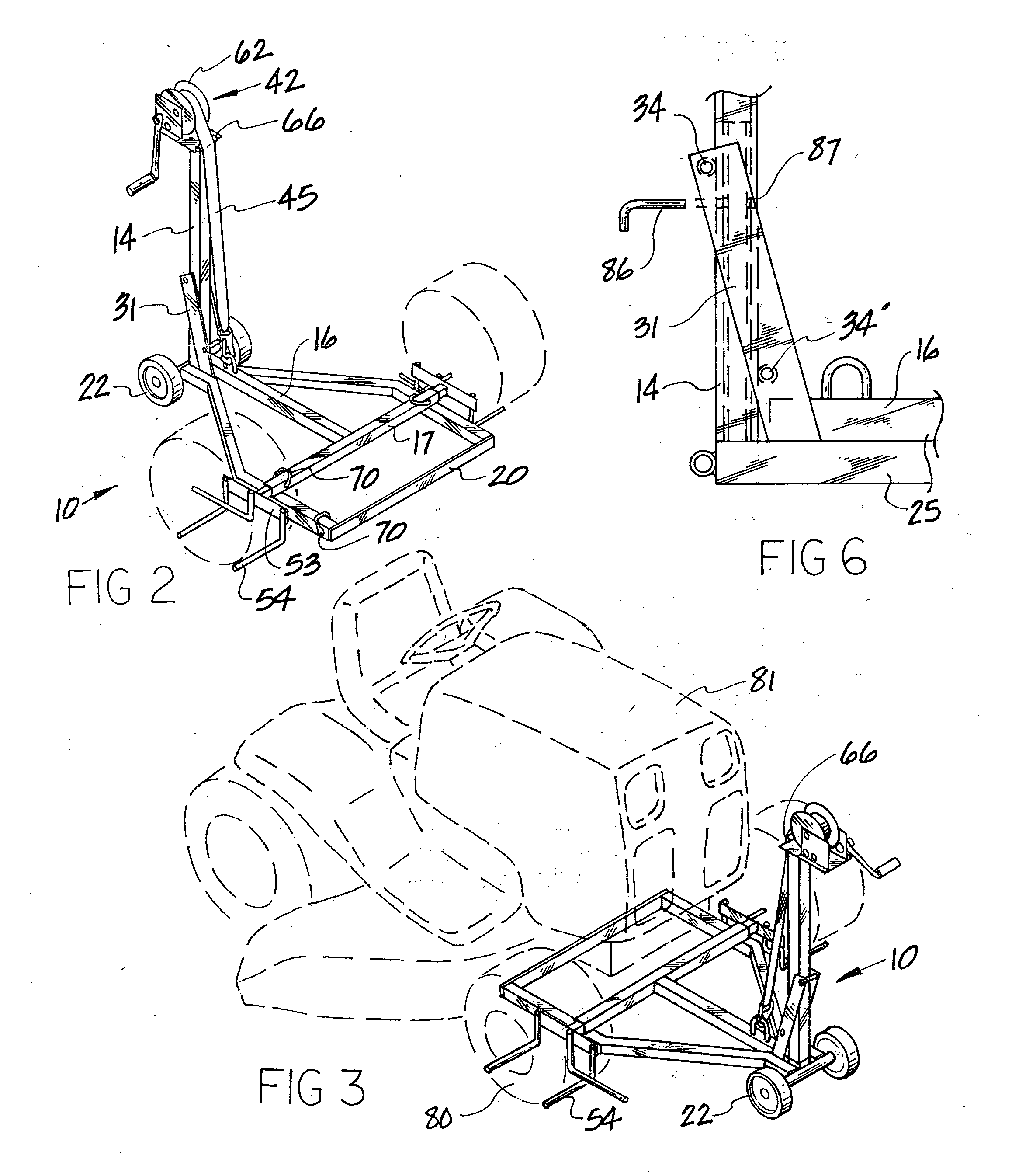

Small vehicle jack apparatus

InactiveUS20060278855A1Convenient heightNeed can be simplifiedWheel mounting apparatusLifting framesScroll wheelVertical bar

A small vehicle jack, having the ability to lift vehicles having a variety of wheel bases, and axle configurations. A support frame provides stability for a vertical bar, which supports a winch means. The winch means raises a lifting frame using a strap means, and the lifting frame which follows the vertical bar using an improved sleeve means, in which rollers are used on either side of the vertical bar. The jack may have adjustable and detachable wheel support means, in which the wheels of the vehicle are used as the contact points to raise the vehicle. The jack may also be used without wheel support means, but instead use hook means to attach to an axle.

Owner:MOJACK DISTRIBUTORS

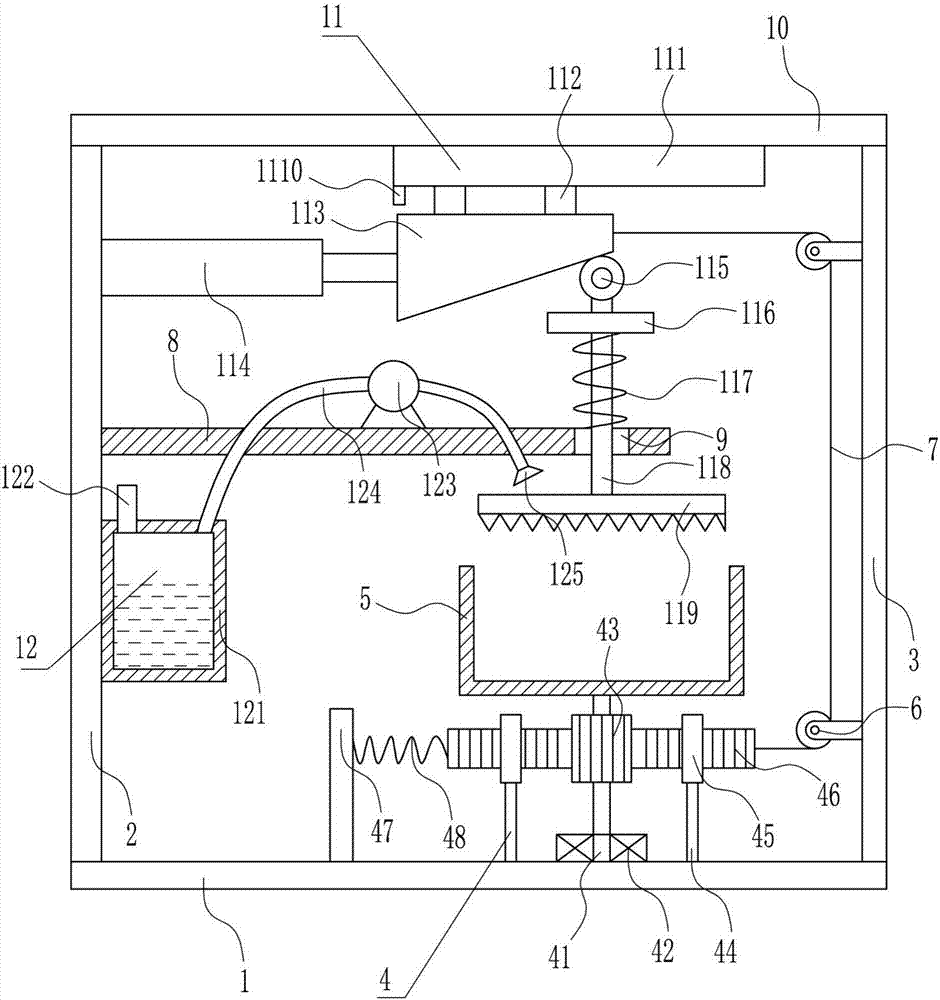

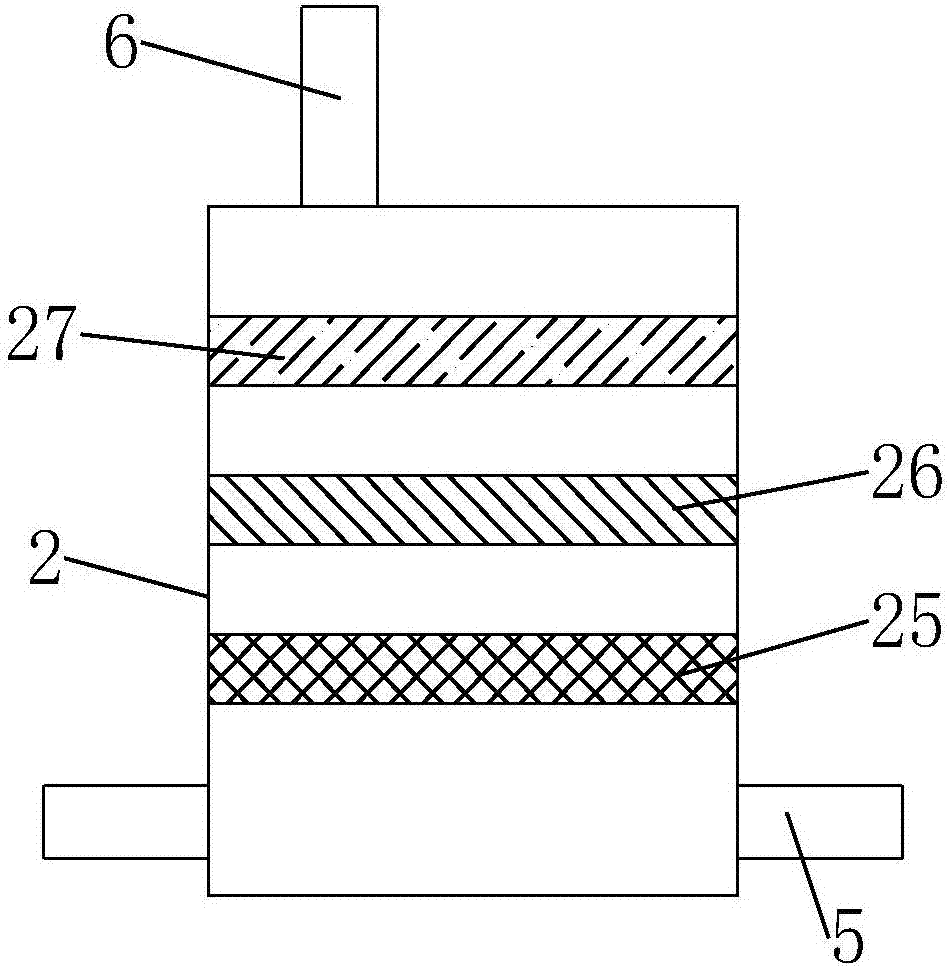

Architectural decorative water-soluble paint mixing device

InactiveCN107344086ADissolve fastImprove dissolution rateGas treatmentTransportation and packagingVertical barWorking environment

The invention discloses an architectural decorative water-soluble paint mixing device which comprises a mixing tank and an air purification tank, wherein a rotating shaft is arranged in the mixing tank; a filter screen is arranged in an inner cavity of the upper part of the mixing tank; three groups of mixing blade assemblies which are oppositely arranged from top to bottom are fixedly arranged on a lower outer ring of the rotating shaft; a first fixed cross bar is fixedly arranged on an upper outer ring of the rotating shaft; a plurality of hairbrushes are uniformly distributed on the lower surface of the first fixed cross bar; a second fixed cross bar is also fixedly arranged on the upper outer ring of the rotating shaft; a fixed vertical bar is fixedly arranged on the lower surface of the end part of the second fixed cross bar; and a scraper blade is fixedly arranged on the outer surface of the fixed vertical bar. The architectural decorative water-soluble paint mixing device is simple in structure and convenient to use, the dissolution of a water-soluble paint can be accelerated and the paint is mixed evenly and is high in quality, meanwhile, the influence of pungent smell generated by the paint on the work environment is effectively relieved and the architectural decorative water-soluble paint mixing device is suitable for popularization and application.

Owner:王少平

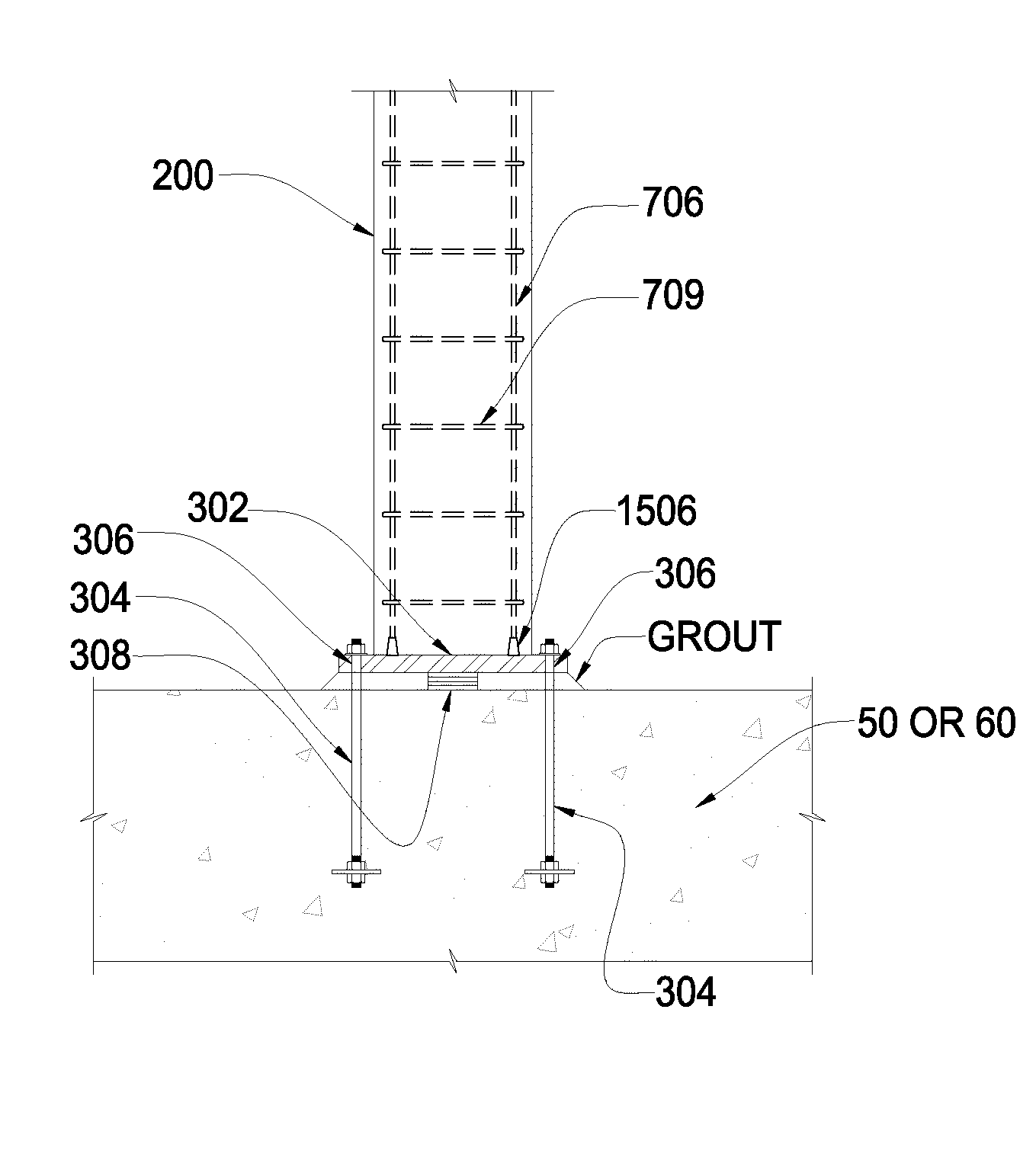

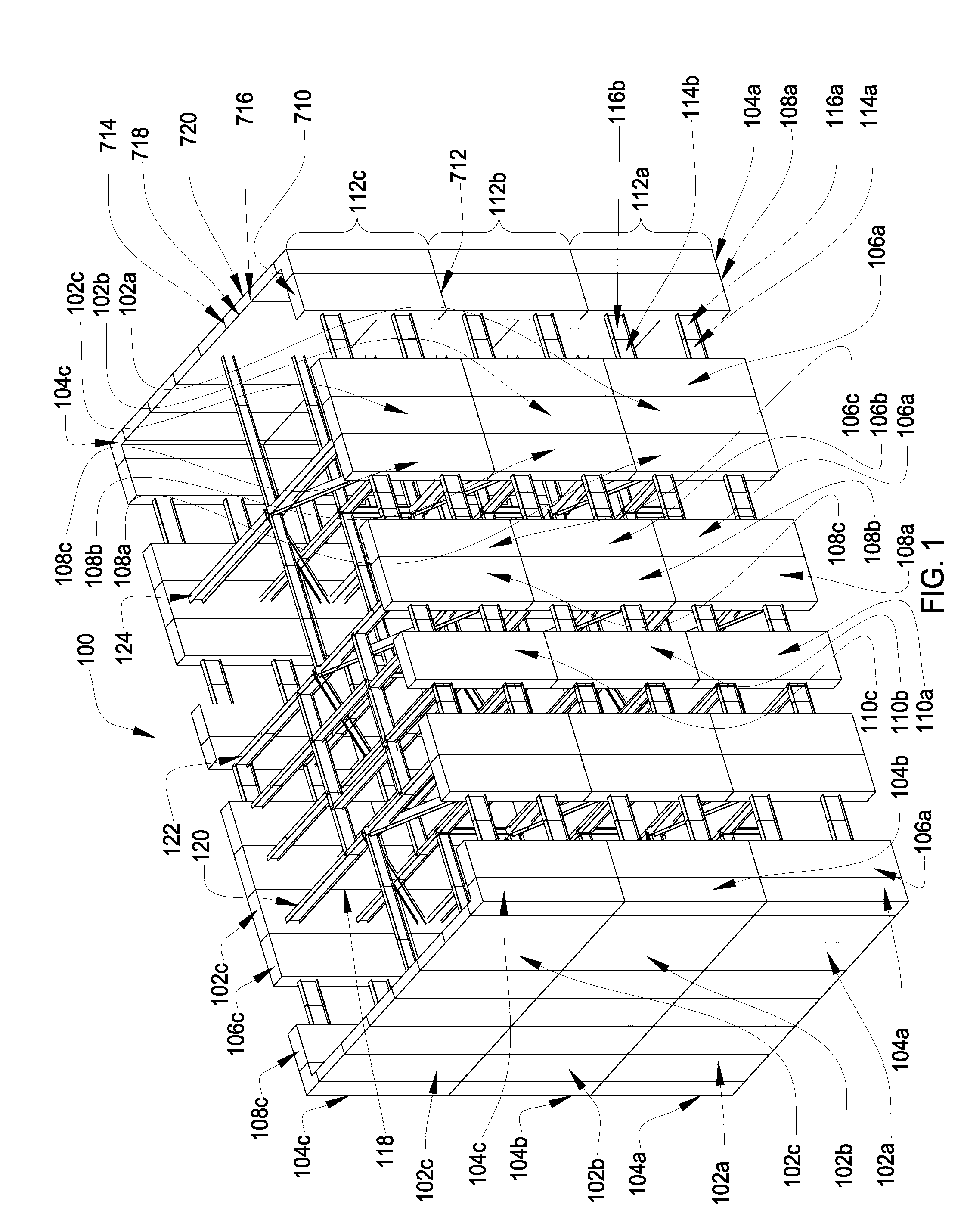

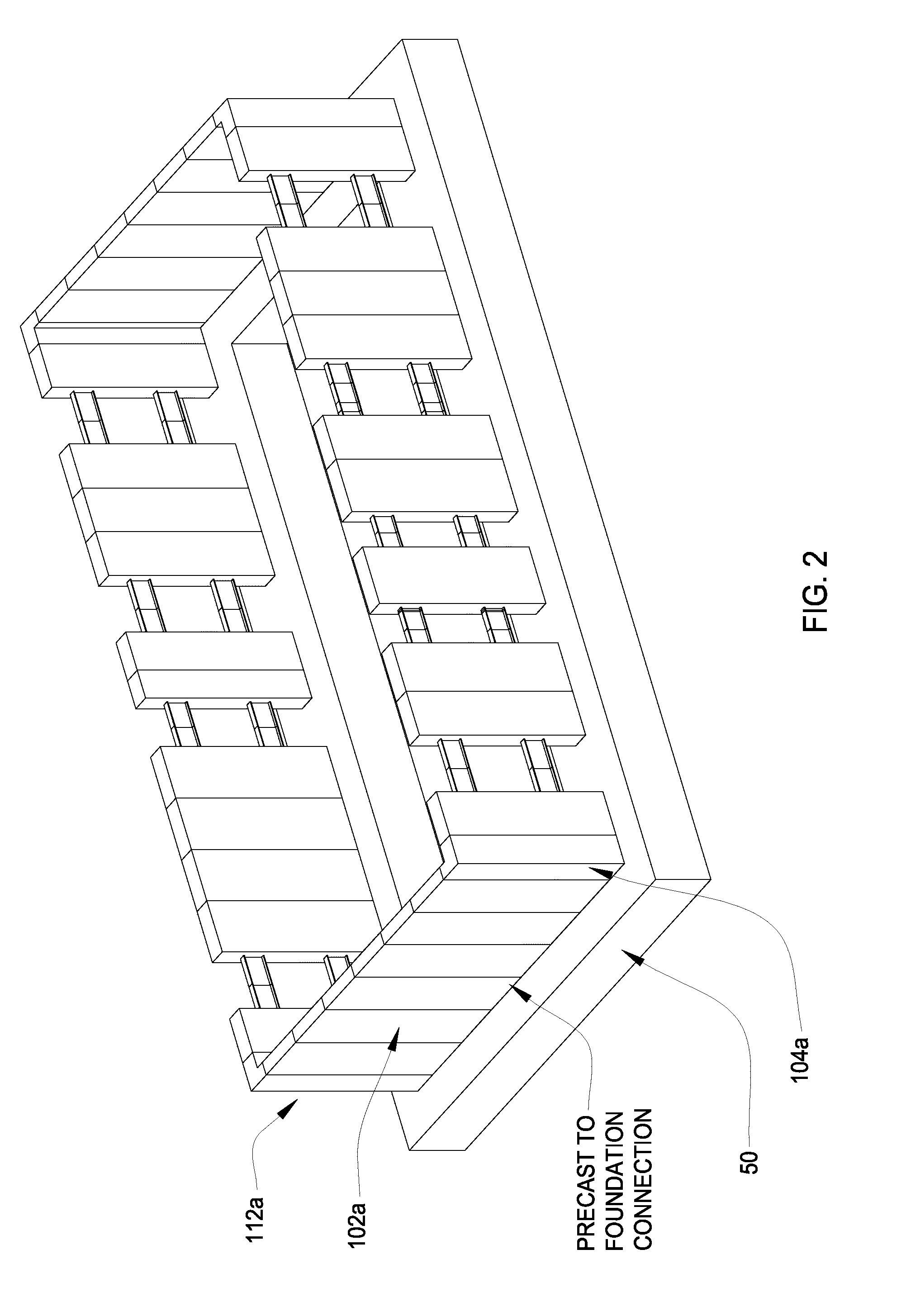

Precast wall panels and method of erecting a high-rise building using the panels

ActiveUS20110126484A1Improve quality controlProduct qualityStrutsConstruction materialVertical barEngineering

Precast wall systems and methods for constructing a high-rise building using the precast wall system is disclosed. In one embodiment, the system includes a plurality of interconnected precast panels, each having a top end plate, a bottom end plate, a plurality of vertical bars disposed between the end plates and a cementitious material encasing the vertical bars and defining a plurality of sides of the respective panel. A first of the precast panels has a first column member half defining a right side of the first panel, a second of the precast panels has a second column member half defining a left side of the second panel such that, when the right side of the first precast panel and the left side of the second precast panel are disposed horizontally adjacent to each other, the first column member half and the second column member half collectively form a column member.

Owner:NEWCO VENTURES +1

Wall surface roughness detection apparatus

InactiveCN108801124AEasy to trimReasonable designMechanical roughness/irregularity measurementsVertical barArchitectural engineering

The invention discloses a wall surface roughness detection apparatus. The wall surface roughness detection apparatus includes a base plate, wherein a vertical plate is vertically fixed at the upper end of the base plate; a top plate is fixed at the upper end of the vertical plate; support rods are horizontally fixed on the upper and lower ends of one side of the vertical plate, and cross bars arehorizontally fixed on the upper and lower ends of the other side of the vertical plate; a hopper is fixed on the upper end of the top plate; two cavities are arranged in the hopper; a sleeve is slidably connected with each cross bar; a vertical bar is fixed between the sleeves; the vertical bar is made of iron material, and a handle is fixed on the vertical bar; the each sleeve is locked through abolt which is in threaded connection with the sleeve; a retaining plate A for preventing the sleeve from falling off is fixed on each cross bar; a plurality of detecting rods are inserted in the vertical plate horizontally; a plurality of cavities corresponding to the detecting rods are arranged in the vertical plate; one end, located on the corresponding support rod, of each detecting rod is connected with a plurality of balls in a rolling manner; and during the movement detection process, the rough locations of the wall can be marked at the same time, and after the detection is completed, the wall mark can be directly observed, so as to obtain the determination result which is clear at a glance, and at the same time, the mark is more conspicuous, thus being convenient to repair the rough parts in the later stage.

Owner:桐乡市龙翔众心纺织有限公司

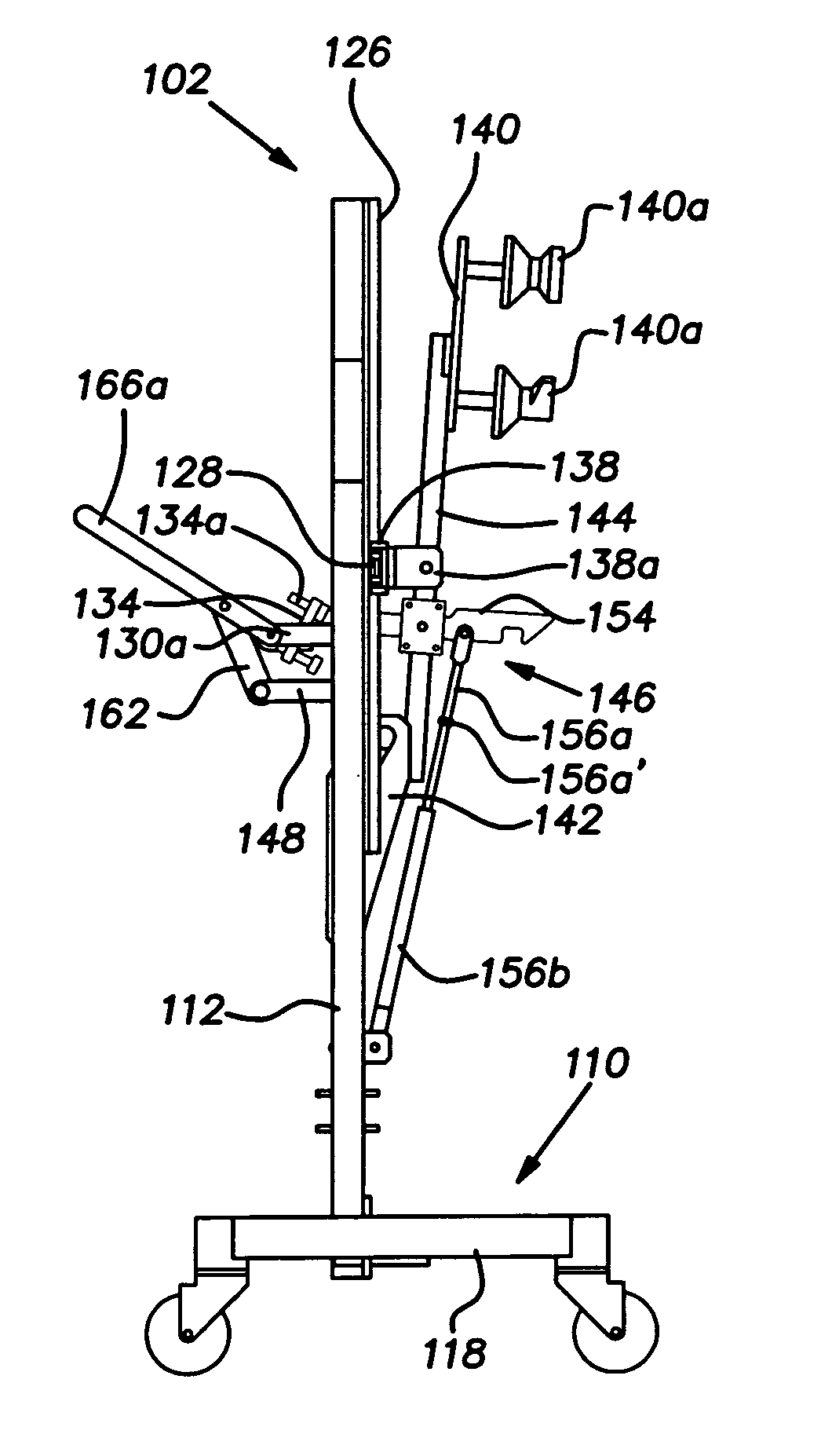

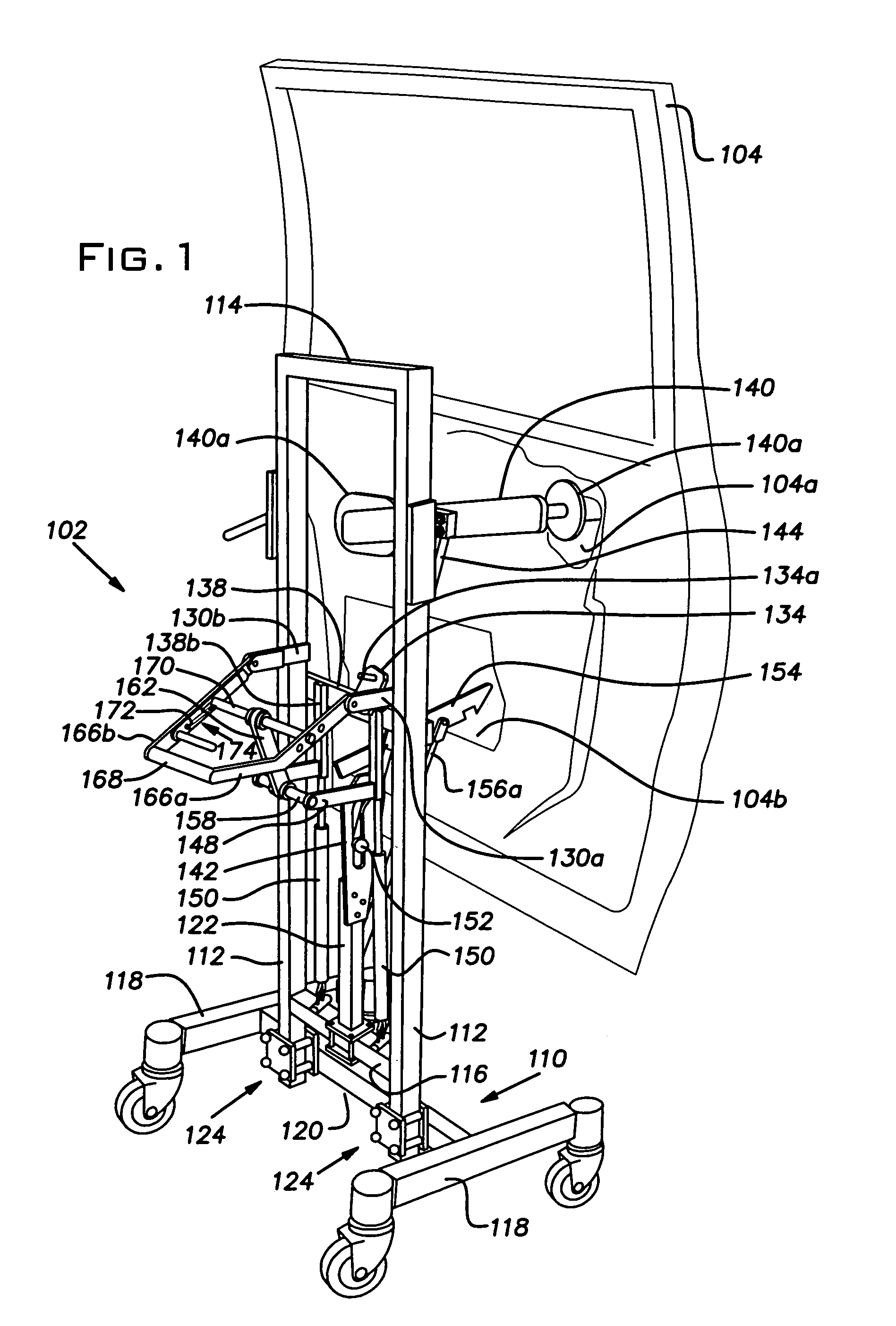

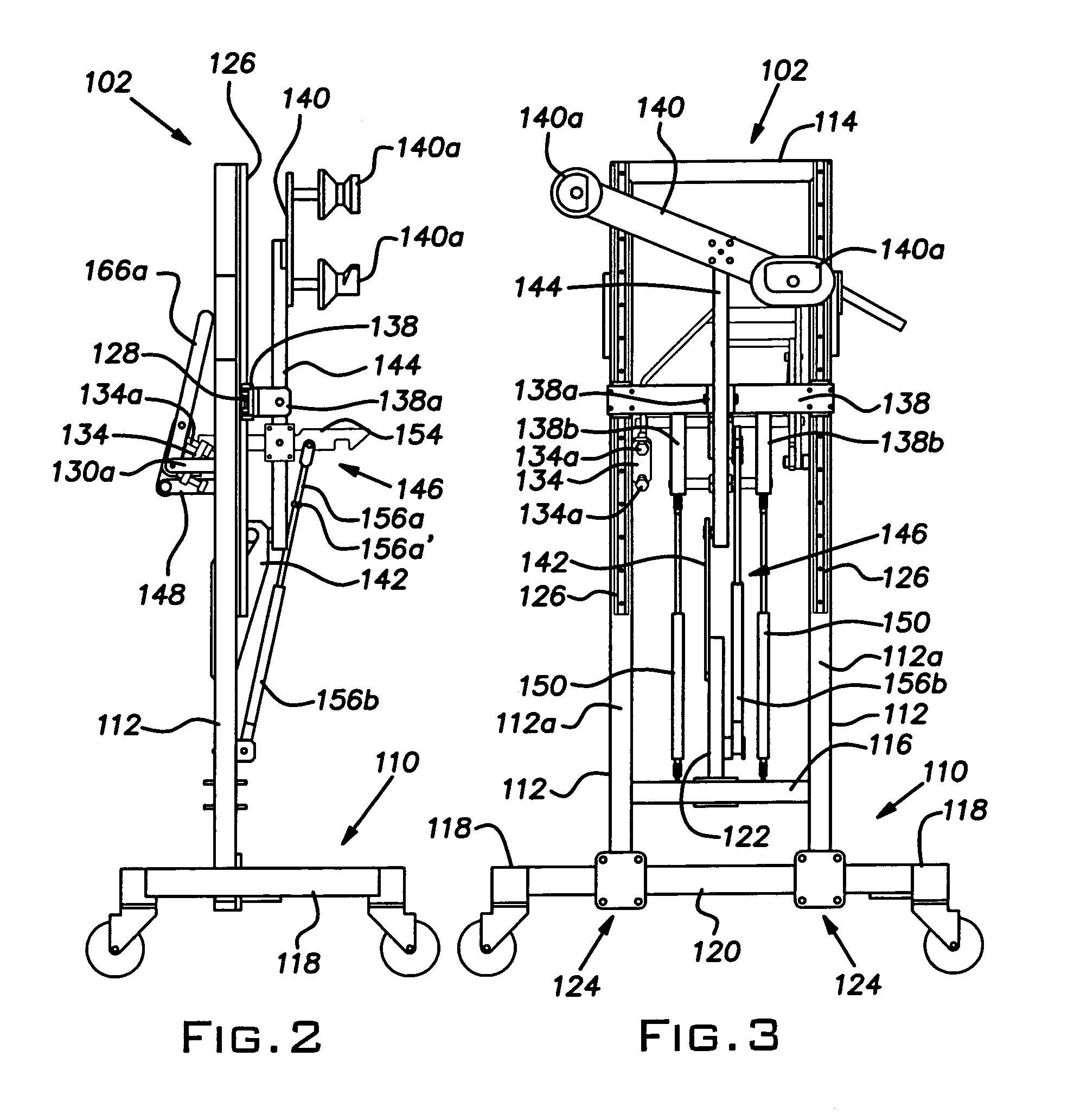

Door lifting apparatus and method

InactiveUS7008165B1Lifting and lowering doorSemiconductor/solid-state device manufacturingSoil-shifting machines/dredgersVertical barCam

A door lifting apparatus includes a frame and a lift mechanism. The lift mechanism includes a slide assembly and a lever assembly. The slide assembly includes a vertical bar, a door support beam supporting a plurality of door holders, and a horizontal bar that are movable together vertically up and down relative to the frame as the lever assembly is moved between a lifted position, an intermediate position, and a lowered position. The vertical bar is associated with a cam plate secured to the frame such that the vertical bar, and the door support beam and door secured thereto, pivots as the lever assembly is moved between the lifted and the lower position.

Owner:HONDA MOTOR CO LTD

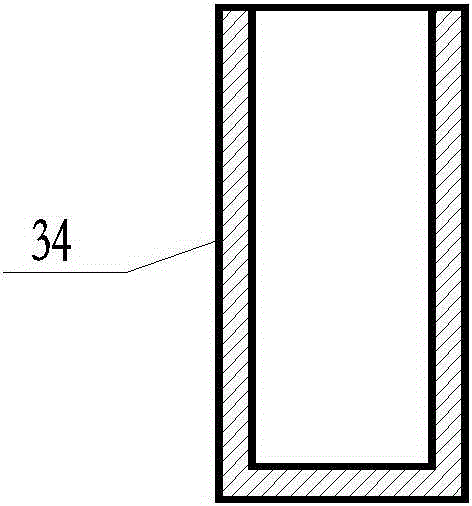

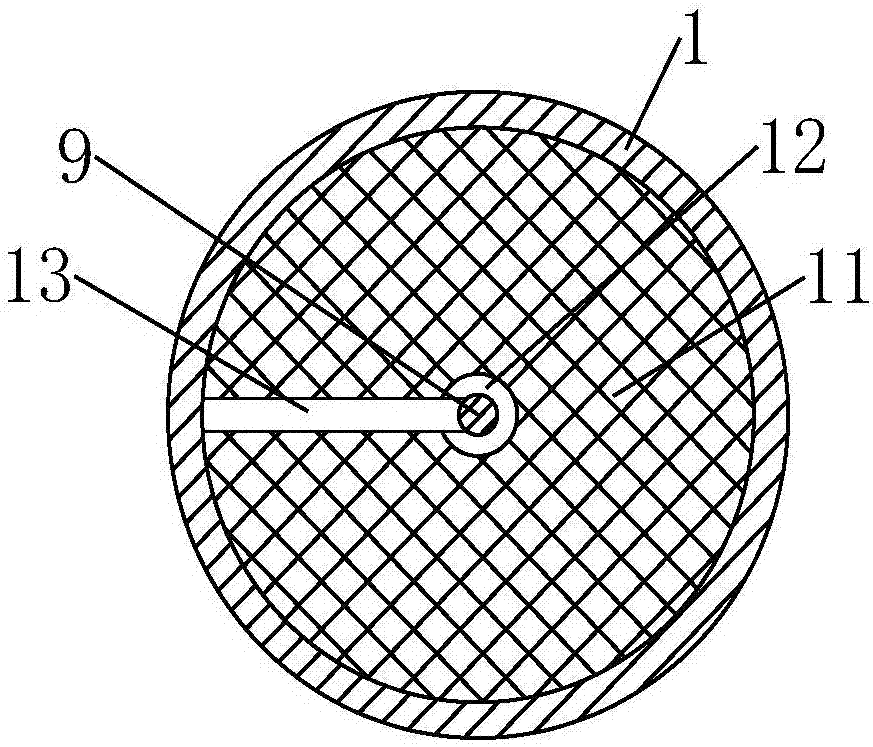

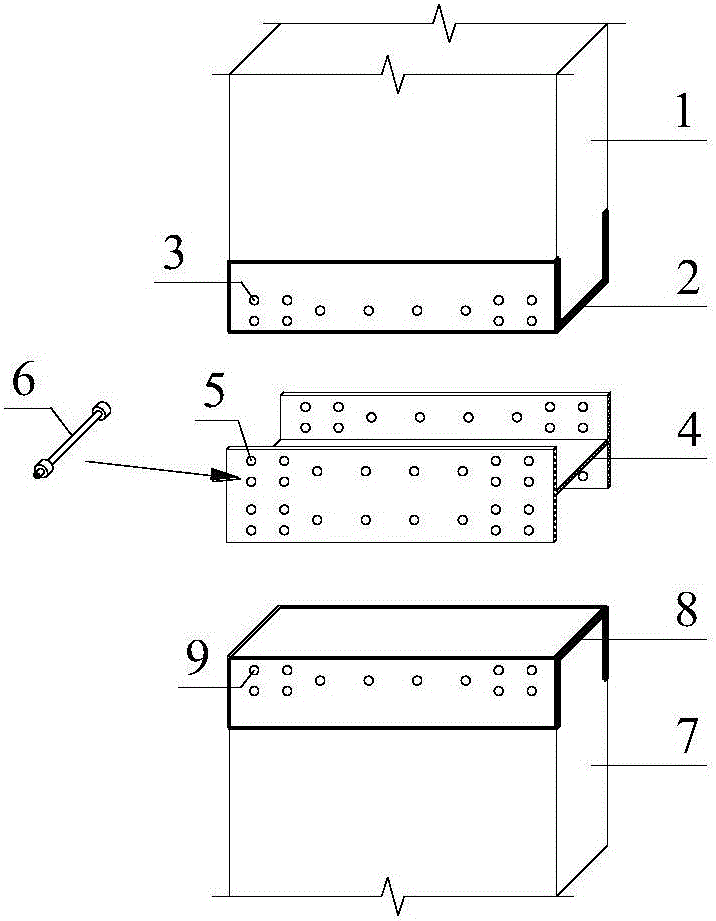

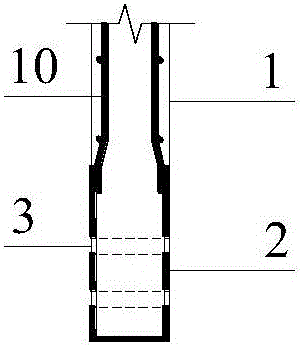

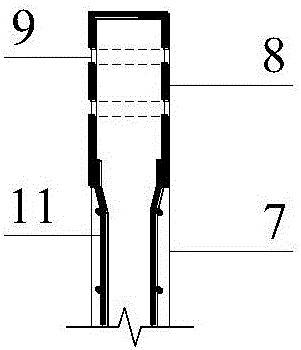

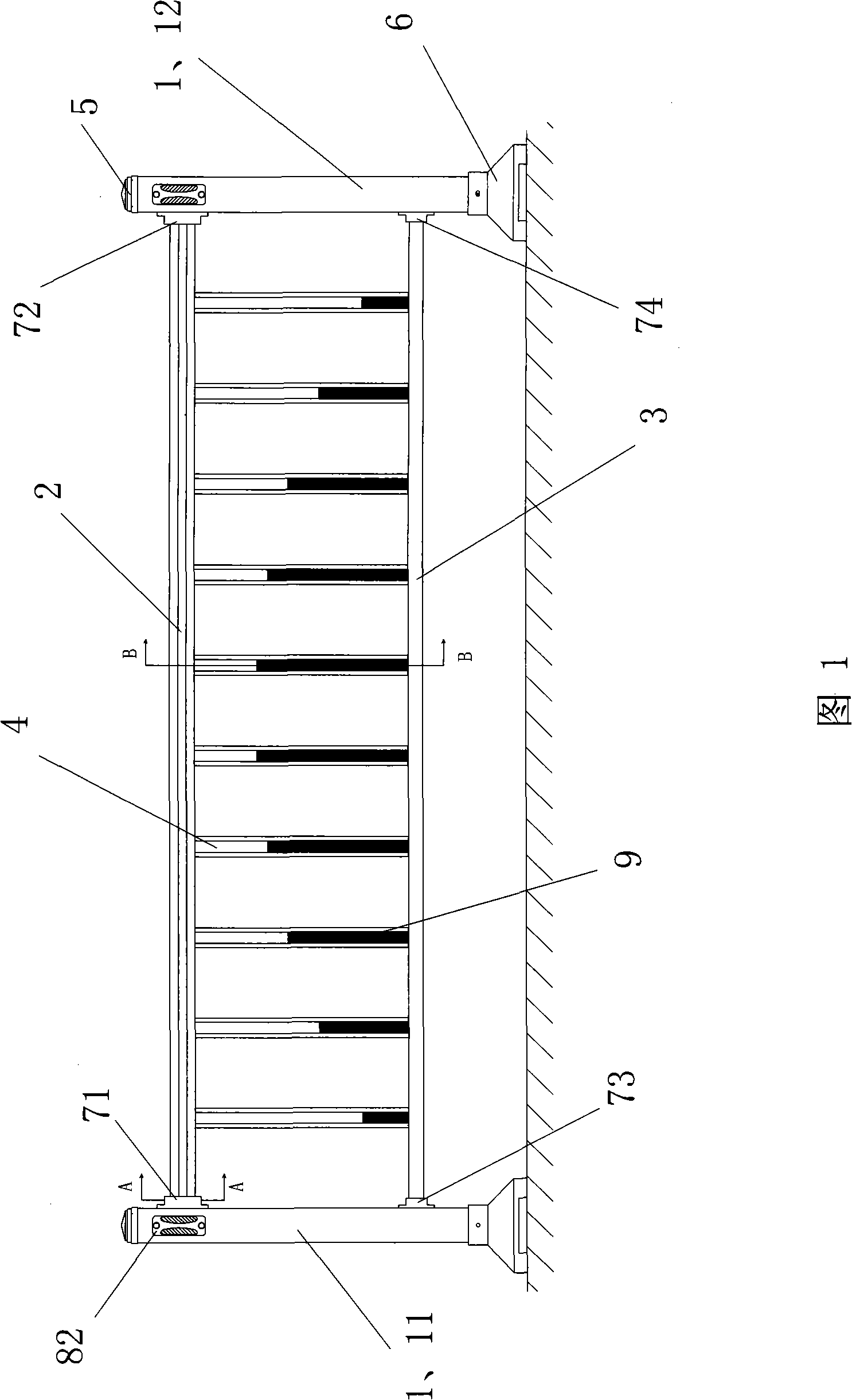

Fabricated reinforced concrete shear wall and manufacturing method thereof

InactiveCN106013517AImprove construction efficiencyPrecise positioningWallsVertical barReinforced concrete

The invention discloses a fabricated reinforced concrete shear wall and a manufacturing method thereof. U-shaped embedded steel parts are arranged on the upper edge and the lower edge of prefabricated shear walls. The ends of vertical bars of the shear walls are welded to the inner sides of the flanges of the U-shaped embedded steel parts. The upper prefabricated shear wall and the lower prefabricated shear wall are inserted into an H-shaped steel connecting part and positioned. Bolts penetrate through reserved bolt holes in the prefabricated shear walls, reserved bolt holes in the U-shaped embedded steel parts and reserved bolt holes in the H-shaped steel connecting part, and finally the bolts are screwed, so that connection of the upper prefabricated shear wall and the lower prefabricated shear wall is completed. Compared with the traditional methods of sleeve connection, indirect splicing of reserved hole grouting and the like, the manufacturing method has the characteristics that the assembly level is high, field installation is easy and fast, green construction is achieved, and pollution is avoided; and full-assembly of the prefabricated shear walls is achieved, and the manufacturing method can be applied to prefabricated concrete shear wall structures of multistoried buildings and high-rise buildings.

Owner:SOUTHEAST UNIV

Jet printing type steel guard rail

ActiveCN101265694AImprove structural strengthAvoid deformationTraffic signalsRoad signsVertical barEngineering

The invention discloses a spraying type steel barrier, which comprises columns, upper cross bars, lower cross bars and vertical bars. The main bodies of the columns, the upper cross bars, the lower cross bars and the vertical bars are all integrated style steel works. The columns are made from the galvanized steel strip, made into steel pipe of a certain shape and sprayed with plastic or paint; the upper cross bars, the lower cross bars and the vertical bars are integrated parts which the upper cross bars, the lower cross bars and the vertical bars are respectively made from the galvanized steel strip, steel pipes of a certain shape are made through extrusion forming of the steel pipe stock mould, seam welding of the high frequency induction welder and extrusion forming of the steel pipe shaping mould and the integrated parts are formed by placing the vertical bars between the upper cross bars and the lower cross bars, welding and fixing, and at last spraying plastic or paint on the exterior surface of the integrated parts. The spraying type steel barrier has the advantages of high structural strength, deformation resistance, beautiful and clean barrier surface, rustiness resistance, easy cleaning, greatly reduced maintenance cost, both the beautiful appearance of the PVC plastic steel barrier and the high strength of the assembly type barrier.

Owner:JIANGSU AIKEQING IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com