Jet printing type steel guard rail

A technology for guardrails and steel pipes, applied in the directions of roads, road signs, traffic signals, etc., can solve the problems of iron connectors that need to be welded, the edges and corners are easy to scratch the human body, and the processing cycle is long, so as to achieve high safety and avoid scratching the human body. , the effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

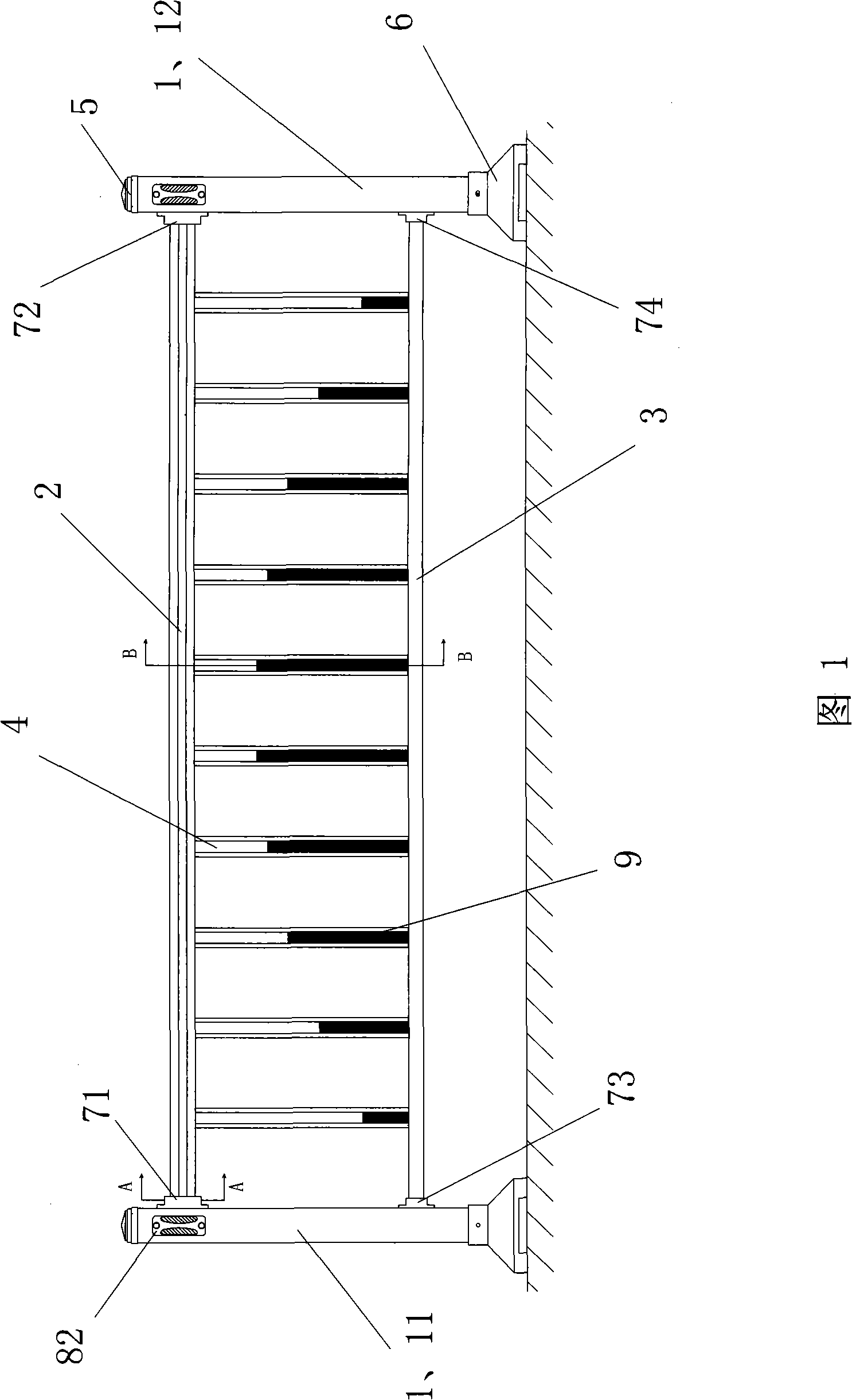

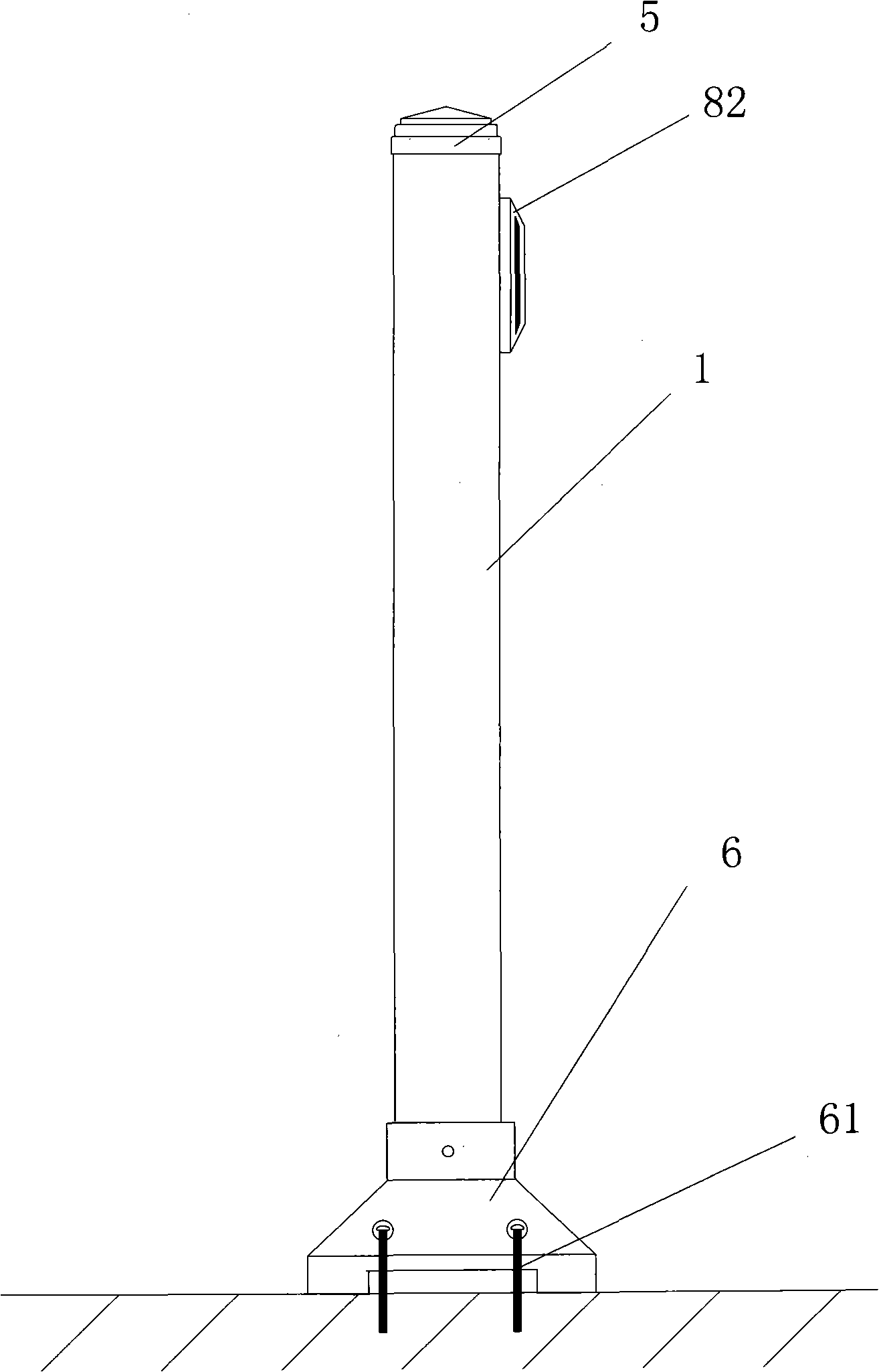

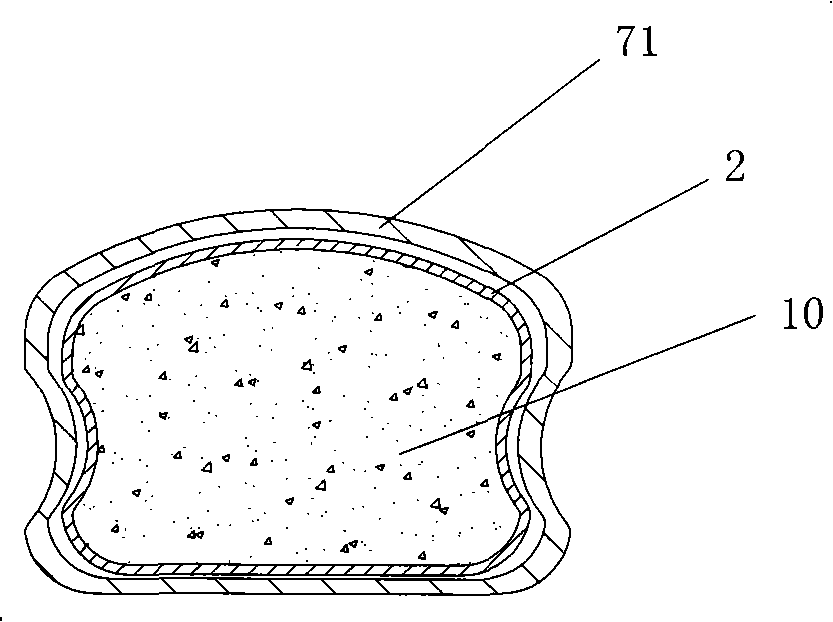

[0032] See Figure 1 to image 3 , The spray-painted steel guardrail of this embodiment includes two uprights 1, an upper cross bar 2, a lower cross bar 3 and ten vertical bars 4, the upright post 1, the upper cross bar 2, the lower cross bar 3 and the vertical bars 4 The main bodies are all integral steel parts, and the corners of the column 1, the upper cross bar 2, the lower cross bar 3 and the vertical bar 4 are arc-shaped corners. Every column 1 upper end is all covered with column cap 5, and column cap adopts iron parts. Be positioned at upper cross bar 2 height places on every column 1 and two-way reflective seat 82 is housed, and two-way reflective seat 82 is a plastic part. The lower end of each column 1 is installed in the base 6, and the base 6 is fixed on the ground by spikes 61. The base 6 of this embodiment is made of resin SMC. A reflective film 9 is attached to each vertical bar 4, and the height of the reflective film 9 gradually increases from both sides to ...

Embodiment 2

[0038] See Figure 6 and Figure 7 , The spray-painted steel guardrail of this embodiment includes two uprights 1, an upper cross bar 2, a lower cross bar 3 and ten vertical bars 4, the upright post 1, the upper cross bar 2, the lower cross bar 3 and the vertical bars 4 The main bodies are all integral steel parts, and the corners of the column 1, the upper cross bar 2, the lower cross bar 3 and the vertical bar 4 are arc-shaped corners. The upper end of each column 1 is covered with a column cap 5, and the column cap is made of aluminum die-casting. One-way reflective seat 81 is equipped with on every column 1 and is positioned at upper cross bar 2 height places, and one-way reflective seat 81 is a plastic part. The lower end of each column 1 is welded and fixed on the base 6 , the base 6 of the present embodiment is an iron plate, and the base 6 is fixed on the ground by spikes 62 . A reflective film 9 is pasted on each vertical bar 4, and the height of the reflective film ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com