Patents

Literature

74results about How to "Improve color brightness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Color display devices

ActiveUS8422116B2Improve color brightnessStatic indicating devicesNon-linear opticsDisplay deviceSolvent

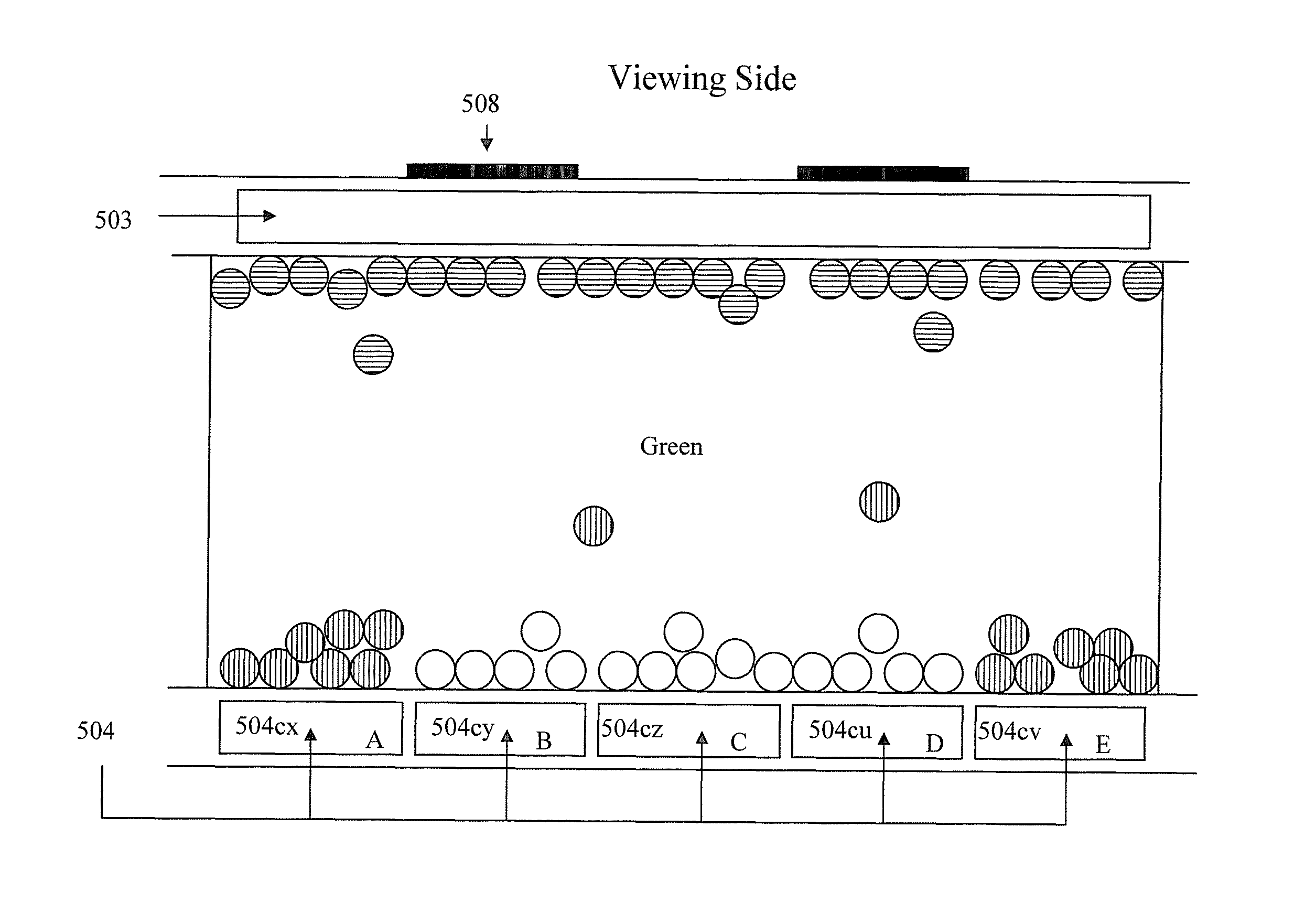

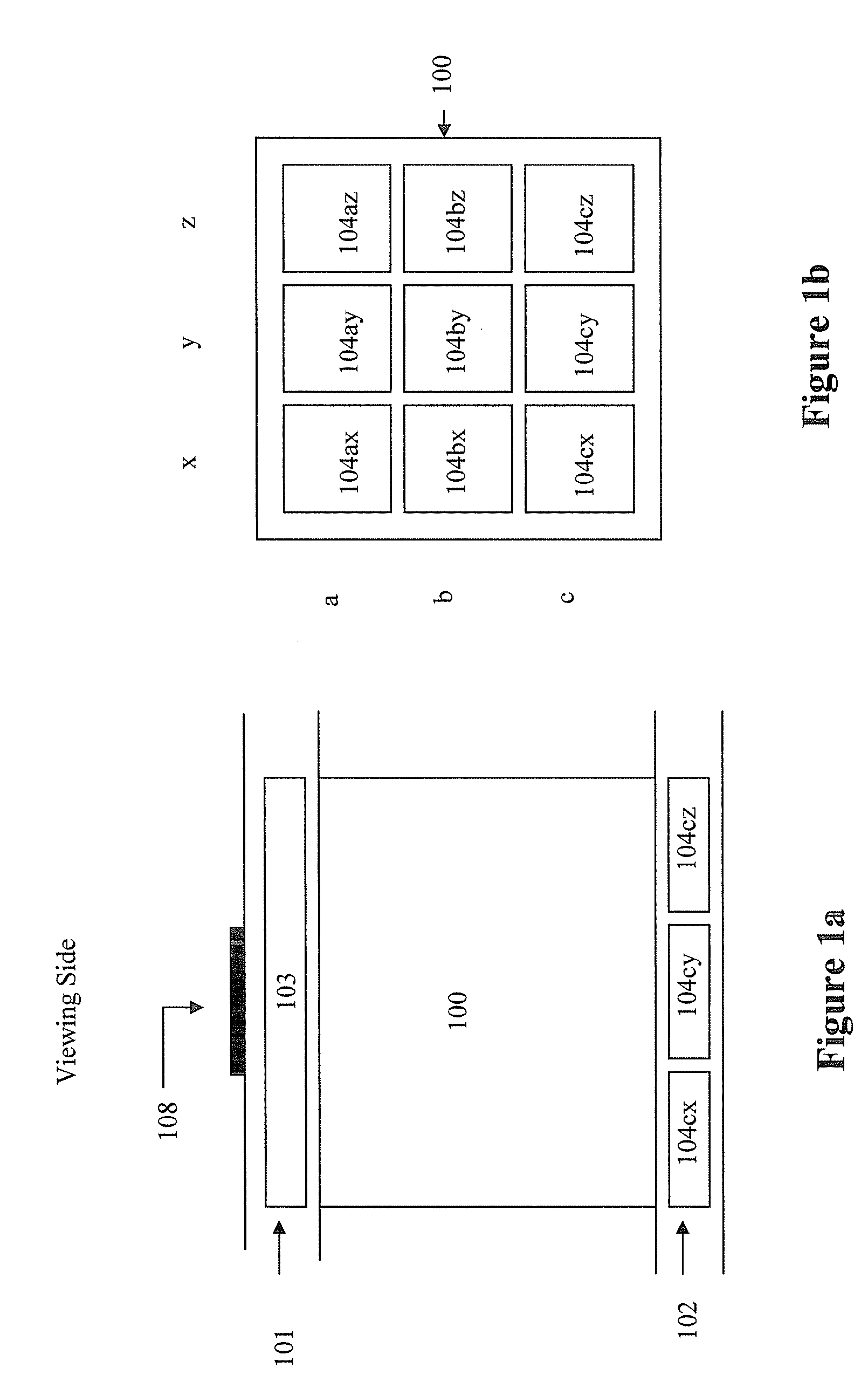

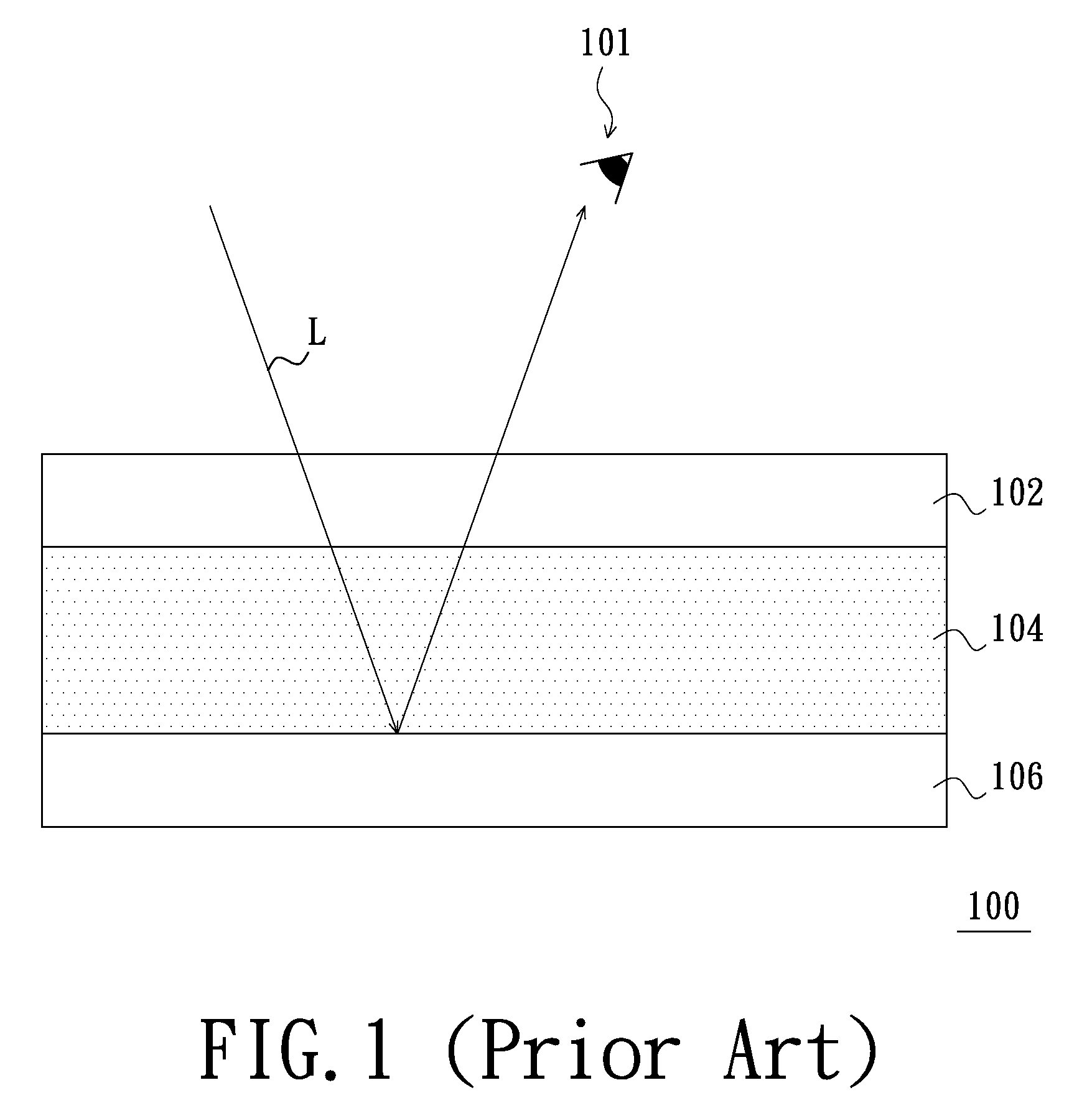

The present invention is directed to color display devices which are capable of displaying multiple color states. The display device comprises a plurality of display cells, wherein each of said display cells is (a) sandwiched between a first layer comprising a common electrode and a second layer comprising a plurality of driving electrodes, wherein at least one of the driving electrodes is a designated electrode, (b) filled with an electrophoretic fluid comprising at least two types of pigment particles dispersed in a solvent or solvent mixture, and (c) capable of displaying at least four color states. The display device may also comprise hiding layers or a brightness enhancement structure on the viewing side.

Owner:E INK CORPORATION

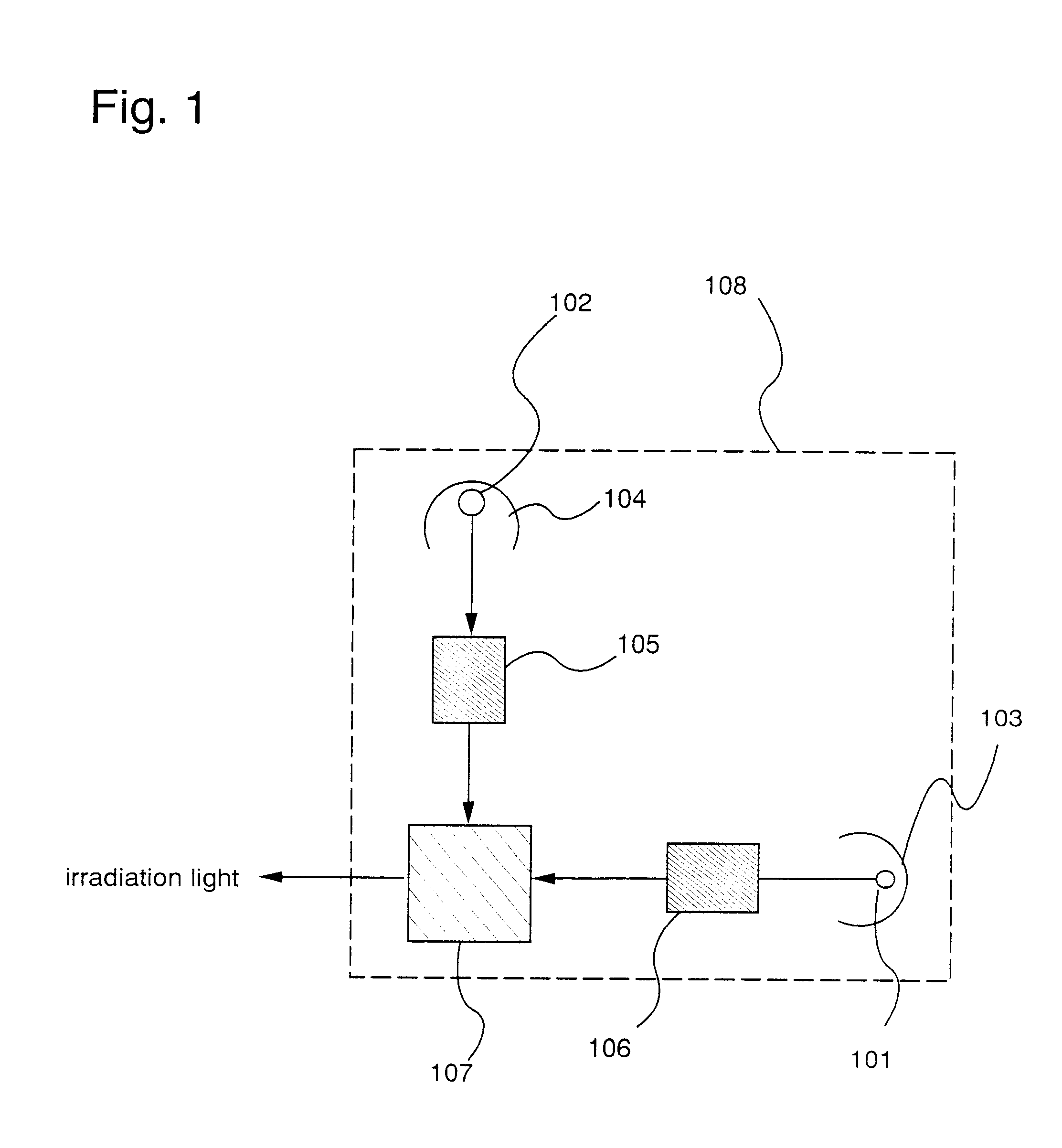

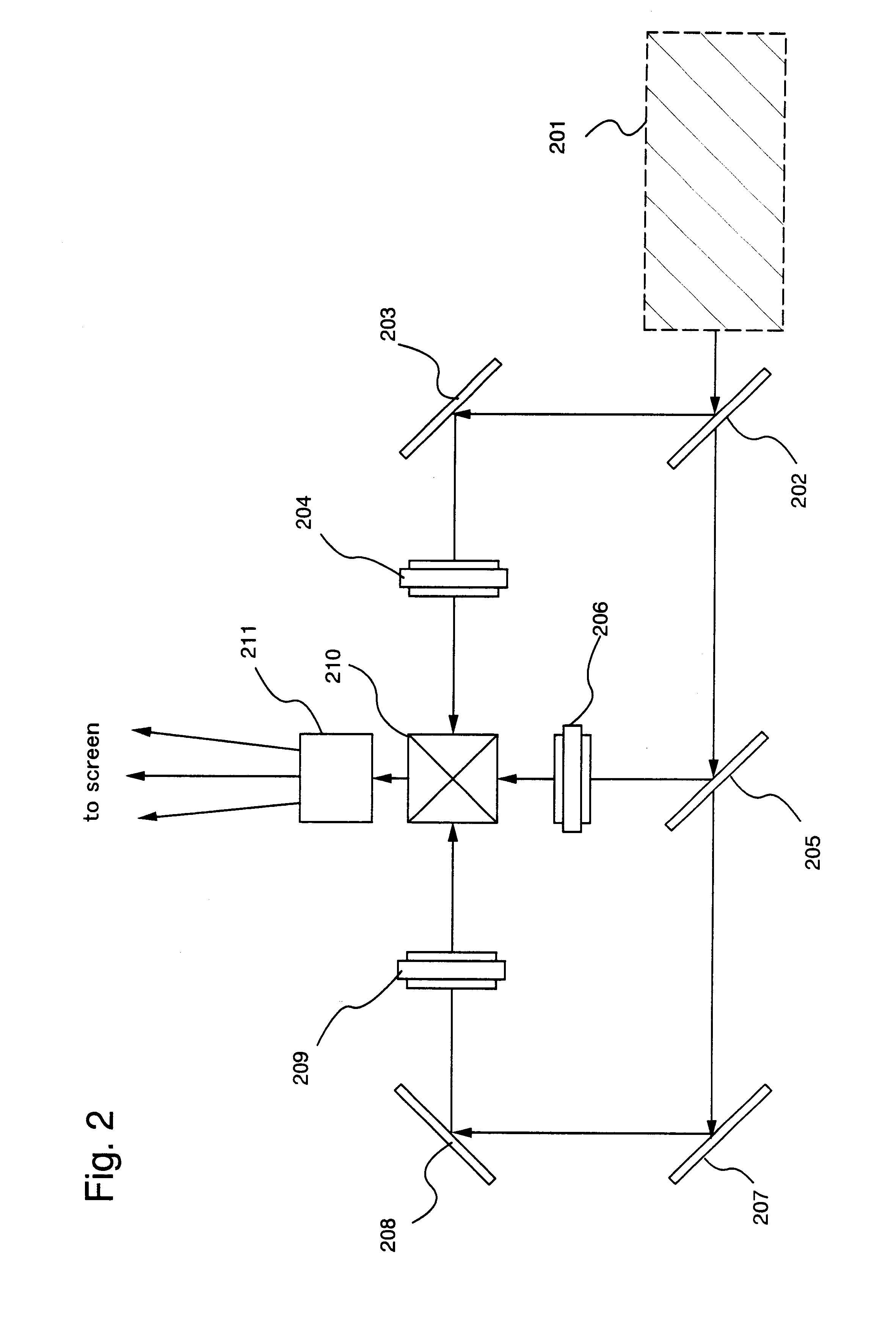

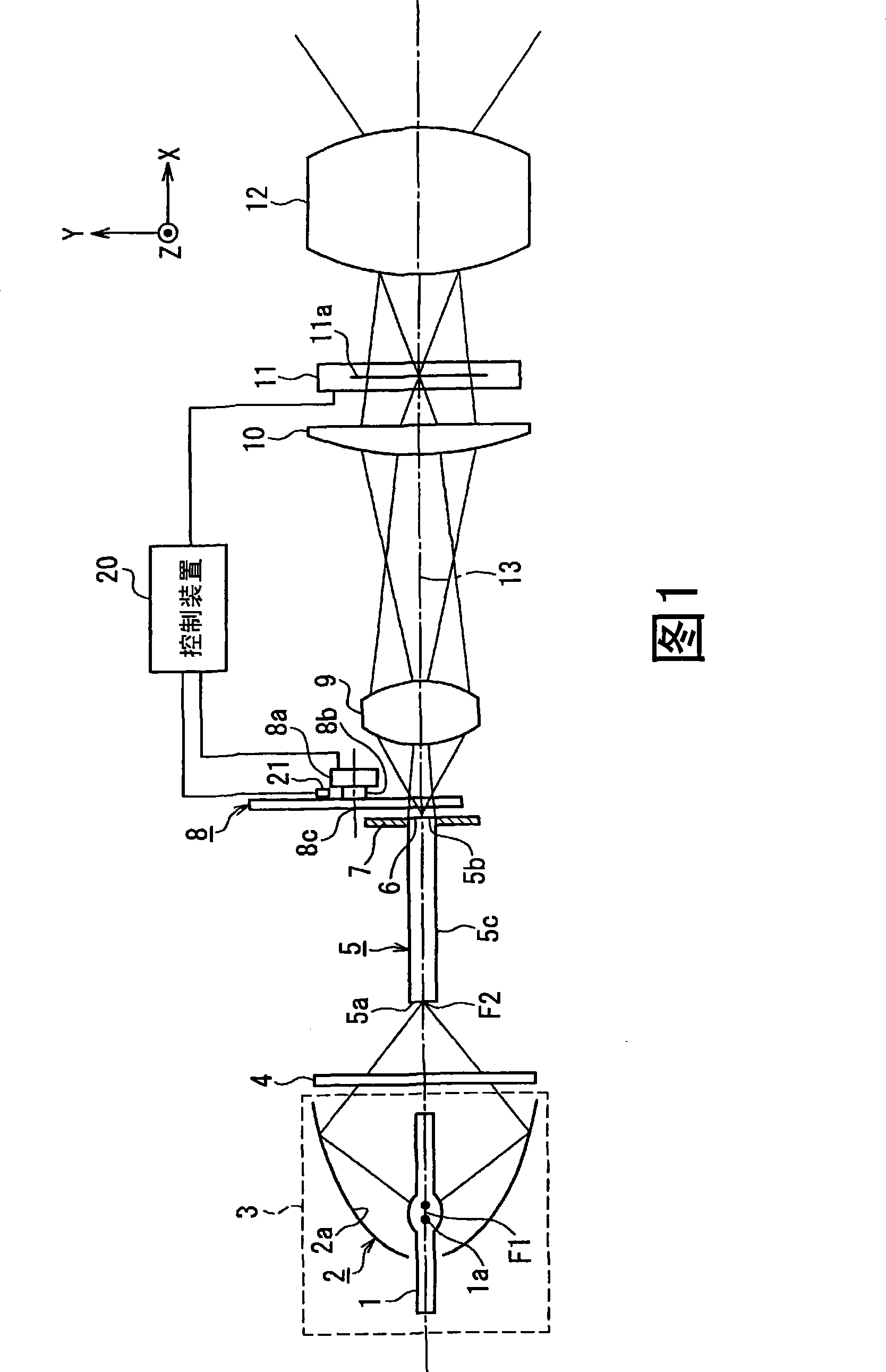

Light source optical system and projector having first and second lamps of different spectral distributions

InactiveUS6623122B1Good balance in brightnessHigh color purityTelevision system detailsPoint-like light sourceOptoelectronicsOptic system

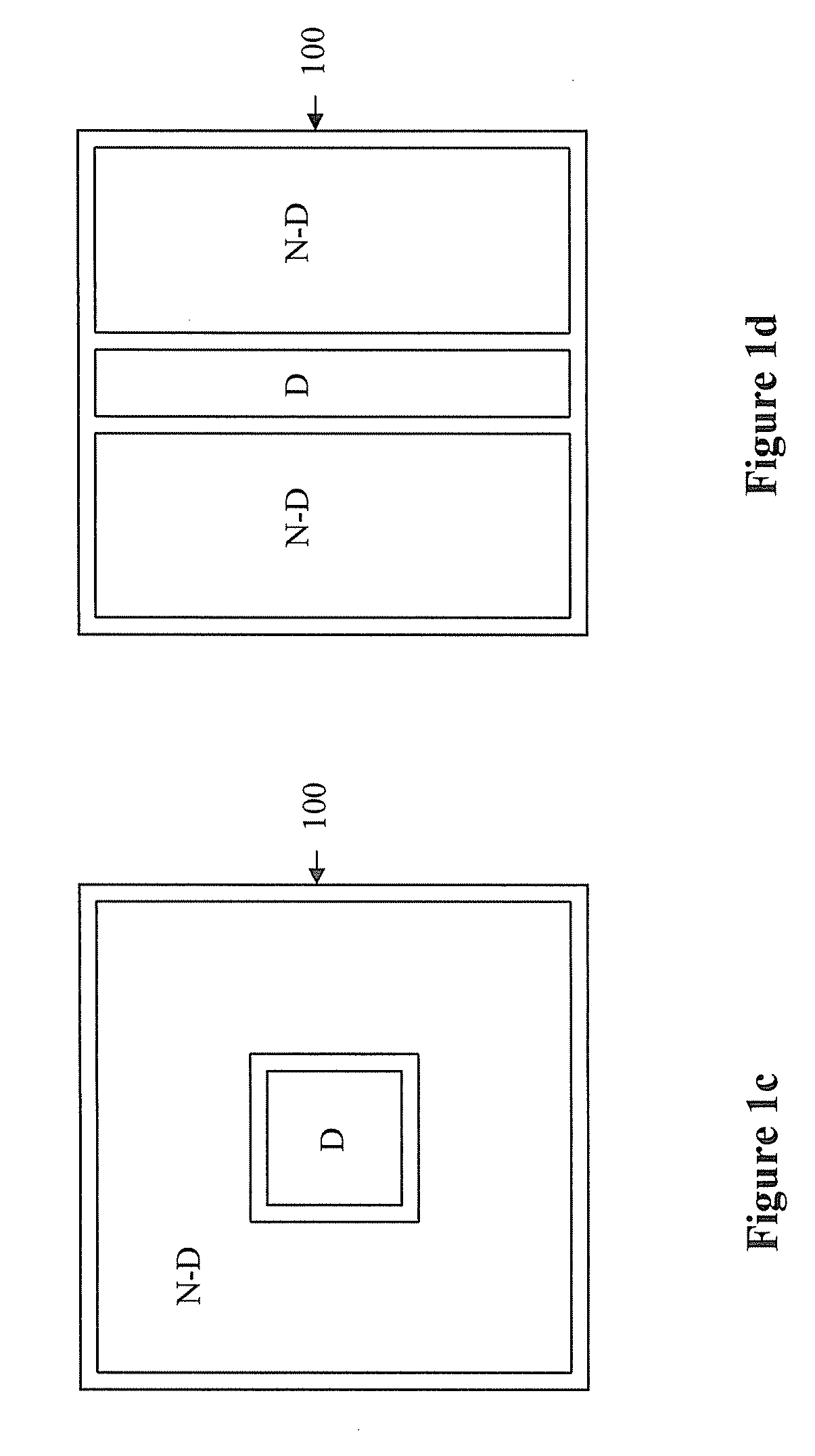

A light source optical system capable of forming an image having good balance in brightness of red, blue, and green color light, having high overall brightness, and having good color reproducibility, on a screen is provided. The light source optical system has a first lamp, a second lamp, and a condensing optical system for synthesizing a first light emitted from the first lamp and a second light emitted from the second lamp to form irradiation light. The light source optical system is characterized in that the first light and the second light have mutually differing spectral distributions.

Owner:SEMICON ENERGY LAB CO LTD

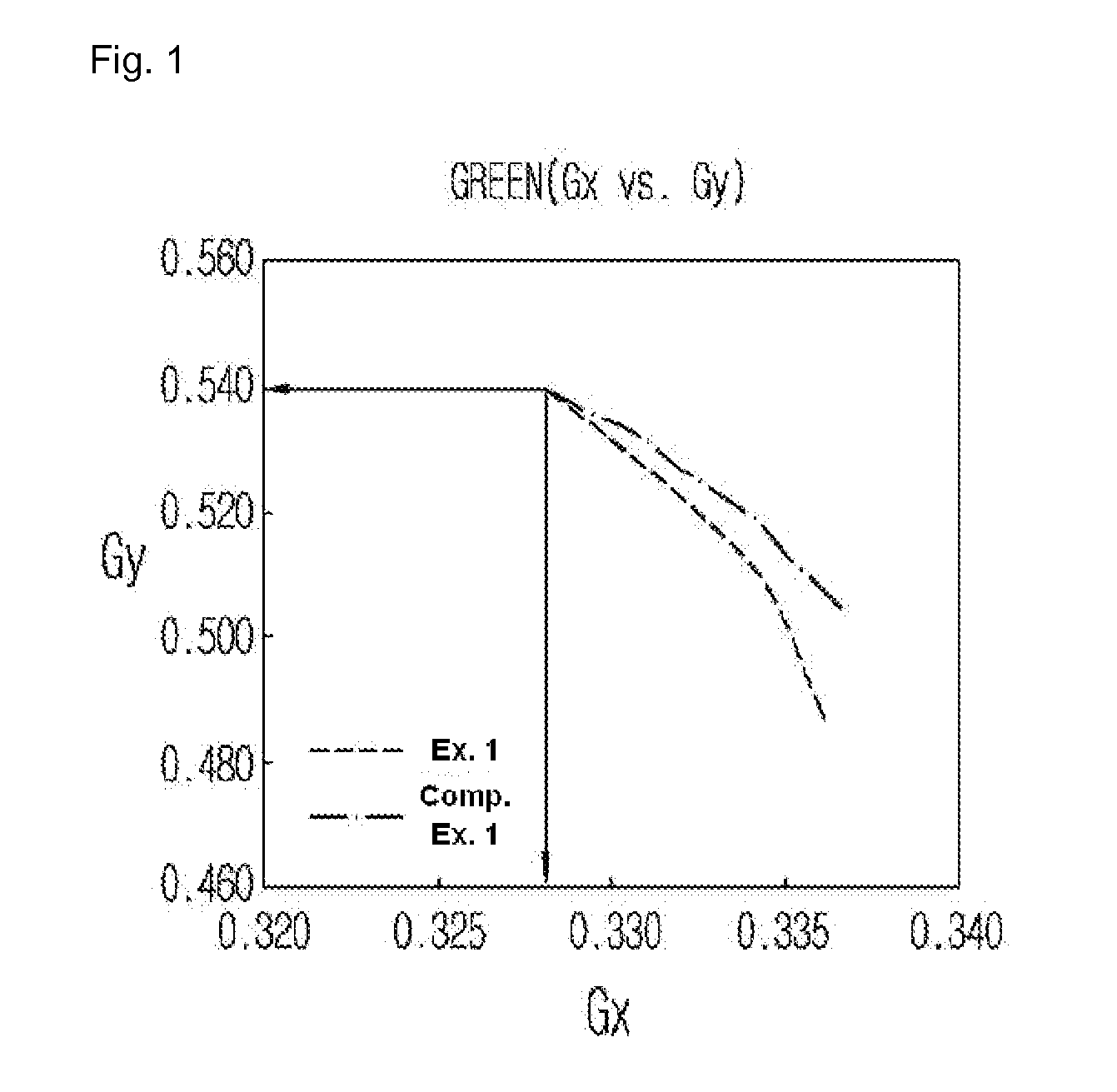

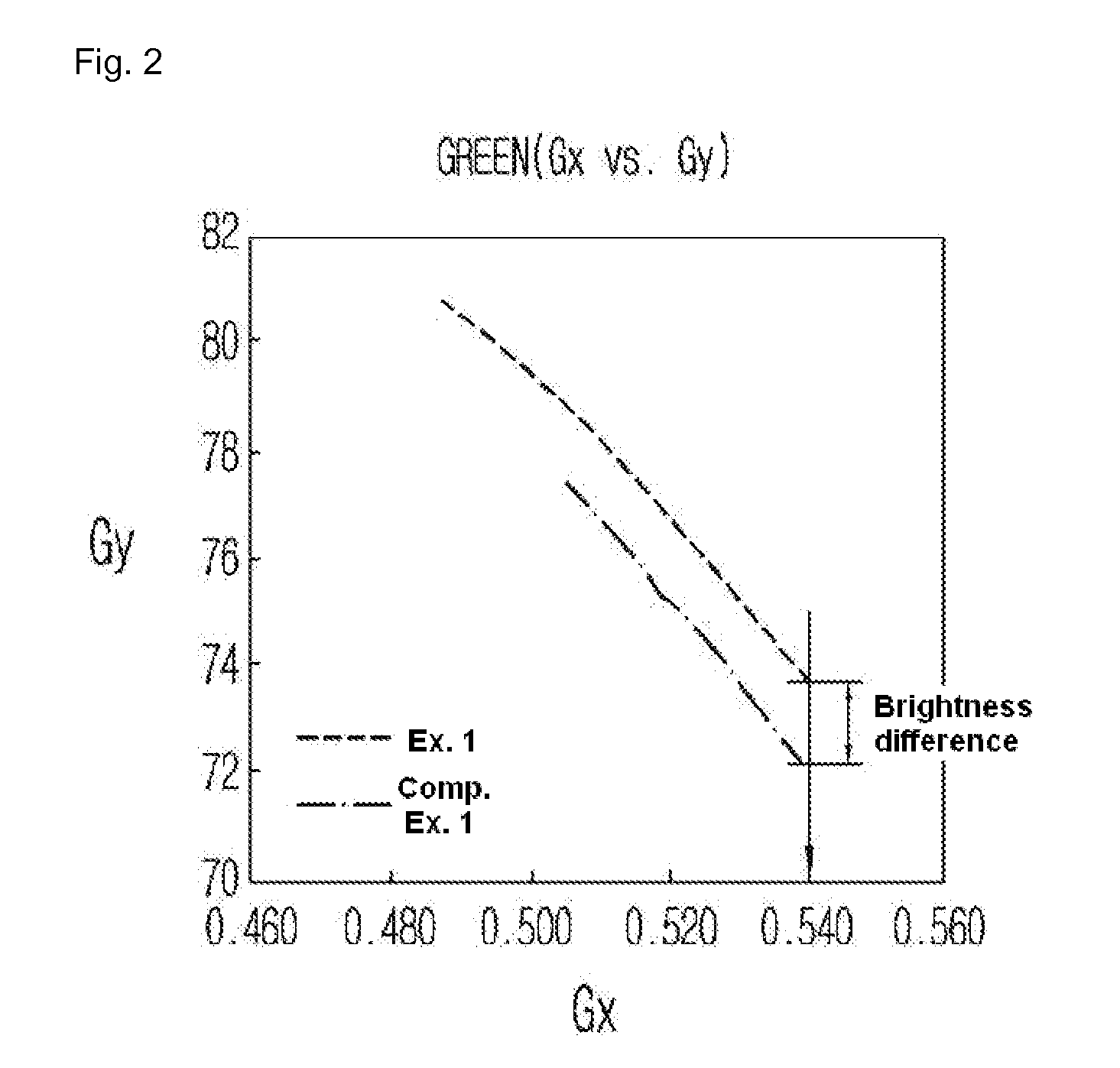

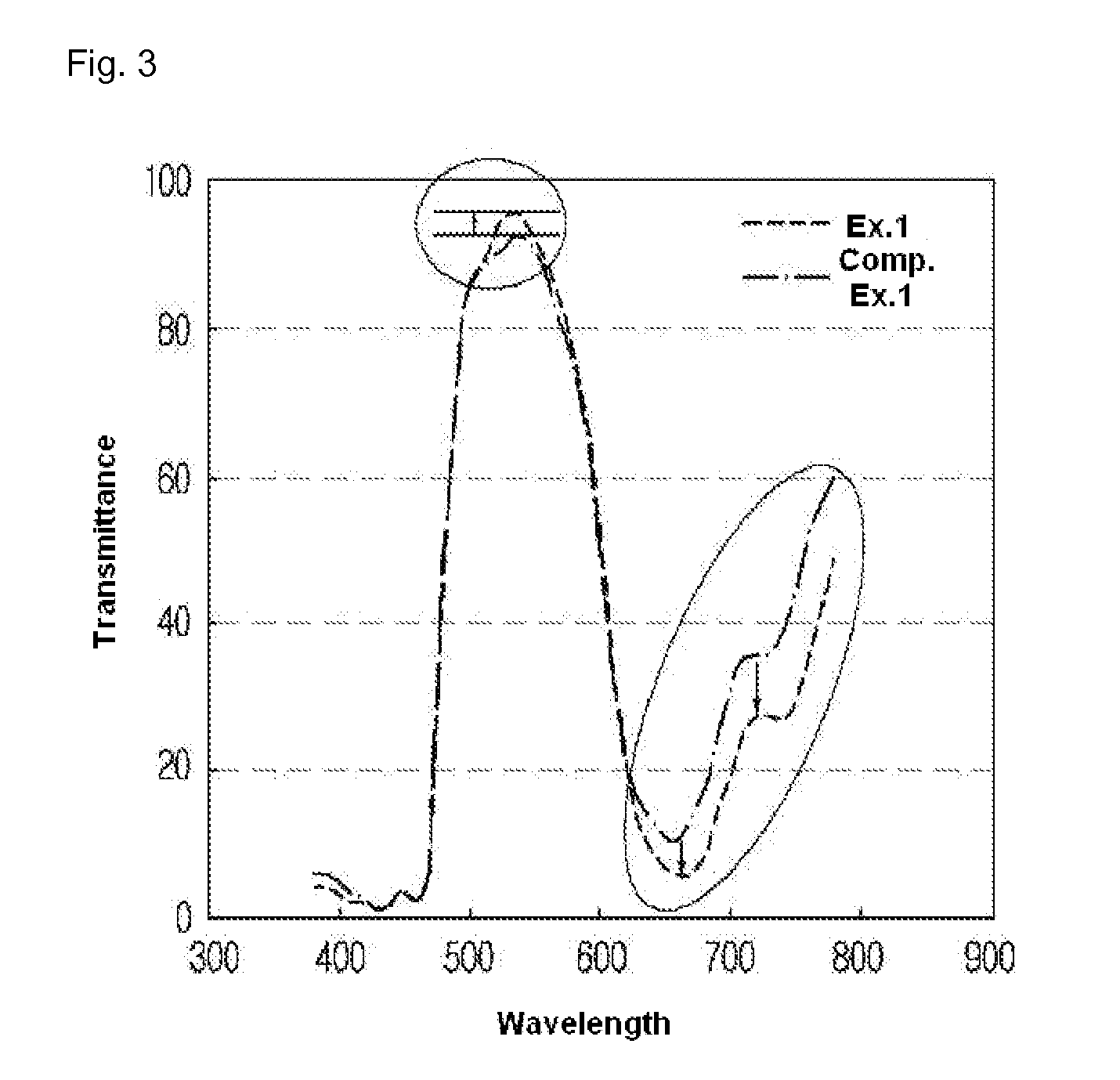

Green Photosensitive Resin Composition and Color Filter Prepared Therefrom

InactiveUS20080160432A1Increase brightnessExcellent developabilityPhotomechanical apparatusDevelopersPhthalocyanineZinc

The present invention relates to a photosensitive resin composition and a color filter prepared therefrom, and more particularly to a photosensitive resin composition comprising a zinc-containing, phthalocyanine-based green pigment with superior brightness improvement effect and a color filter prepared therefrom. The photosensitive resin composition of the present invention provides improved developability and chemical resistance, together with outstanding improved brightness.

Owner:CHEIL IND INC

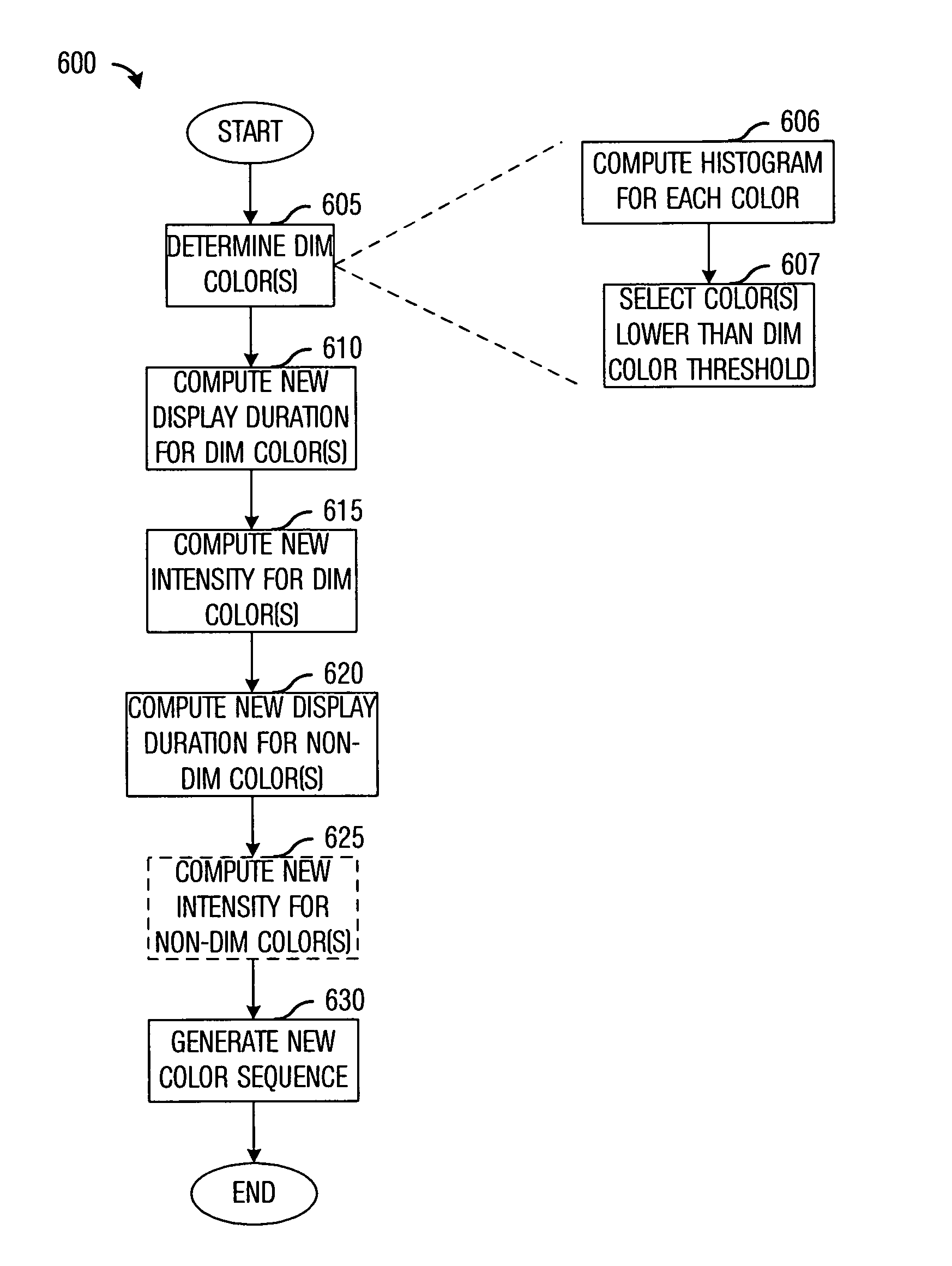

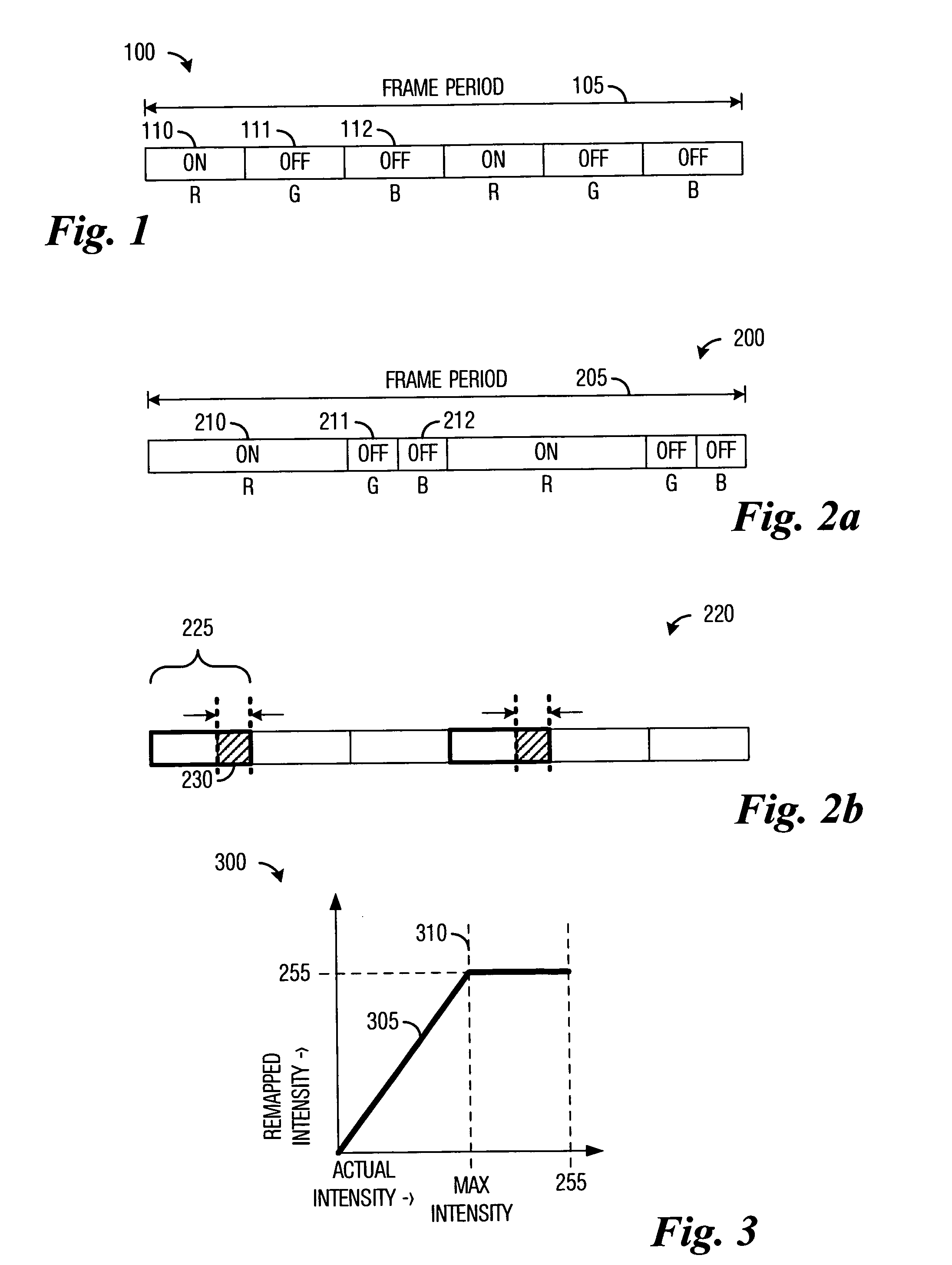

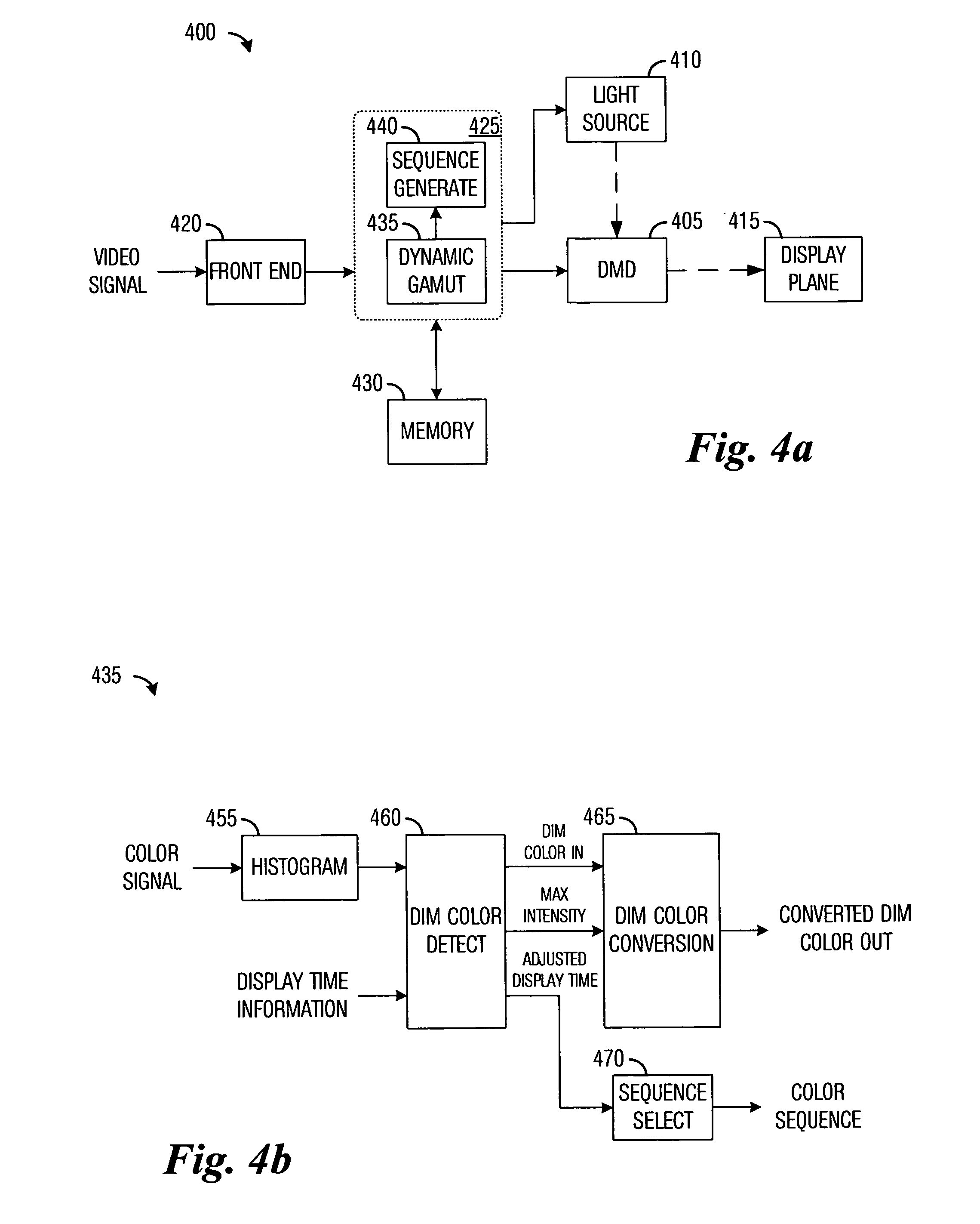

System and method for dynamically altering a color gamut

ActiveUS20080143736A1Increase image brightnessImprove color brightnessCathode-ray tube indicatorsNon-linear opticsGamutComputer graphics (images)

System and method for dynamically altering a color gamut used in projection display systems. An embodiment comprises determining a dim color from colors used in representing an image, adjusting the dim color to increase an available display time for a non-dim color used to represent the image, adjusting the non-dim color using the available display time, and generating a color sequence based on the adjusted dim color and the adjusted non-dim color. The pixel intensities of a dim color are increased, permitting a shortening of the display time of the dim color. The newly freed display time can be reallocated to all colors to increase the amount of light used to display the image, thereby increasing image brightness or altering color point.

Owner:TEXAS INSTR INC

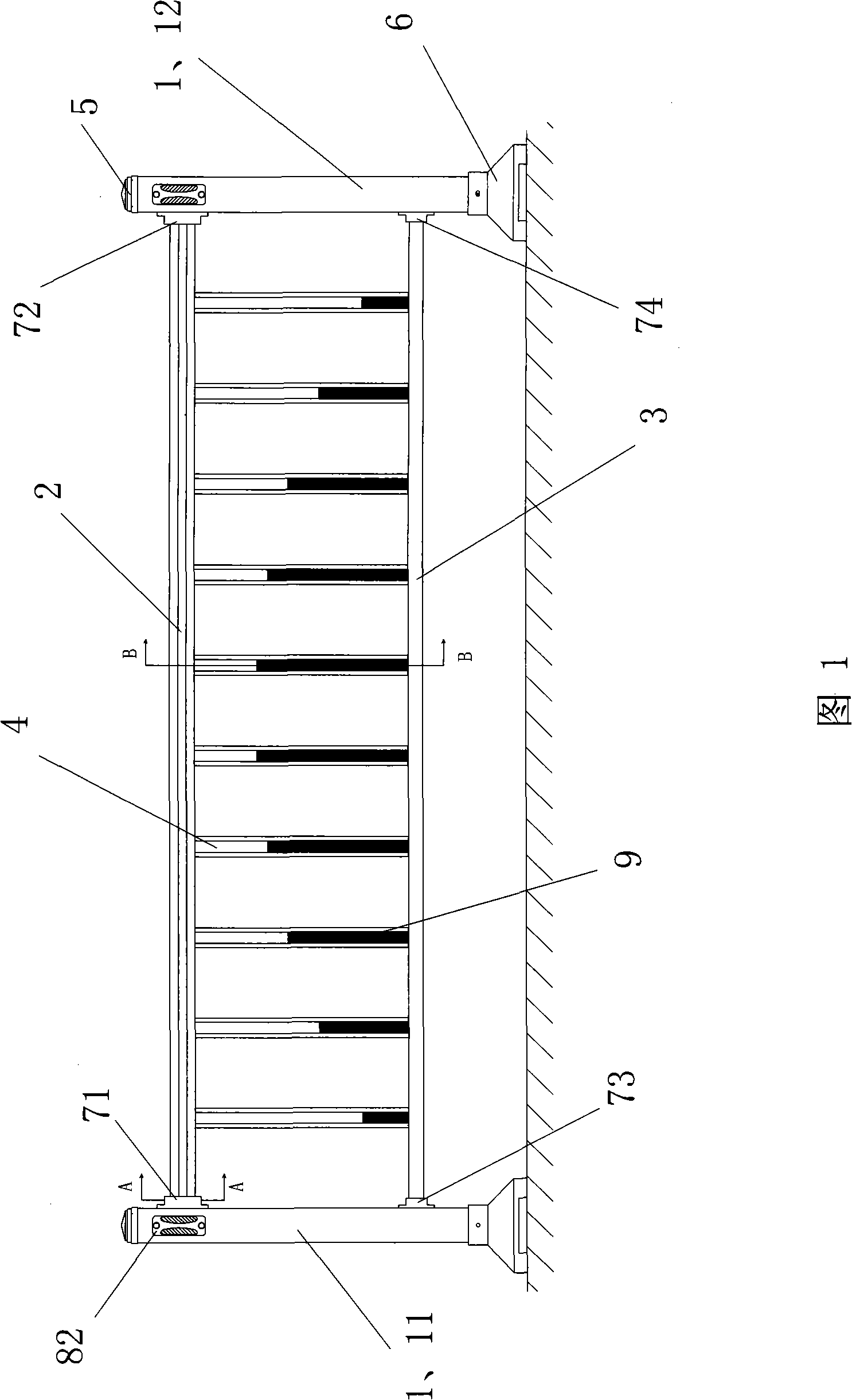

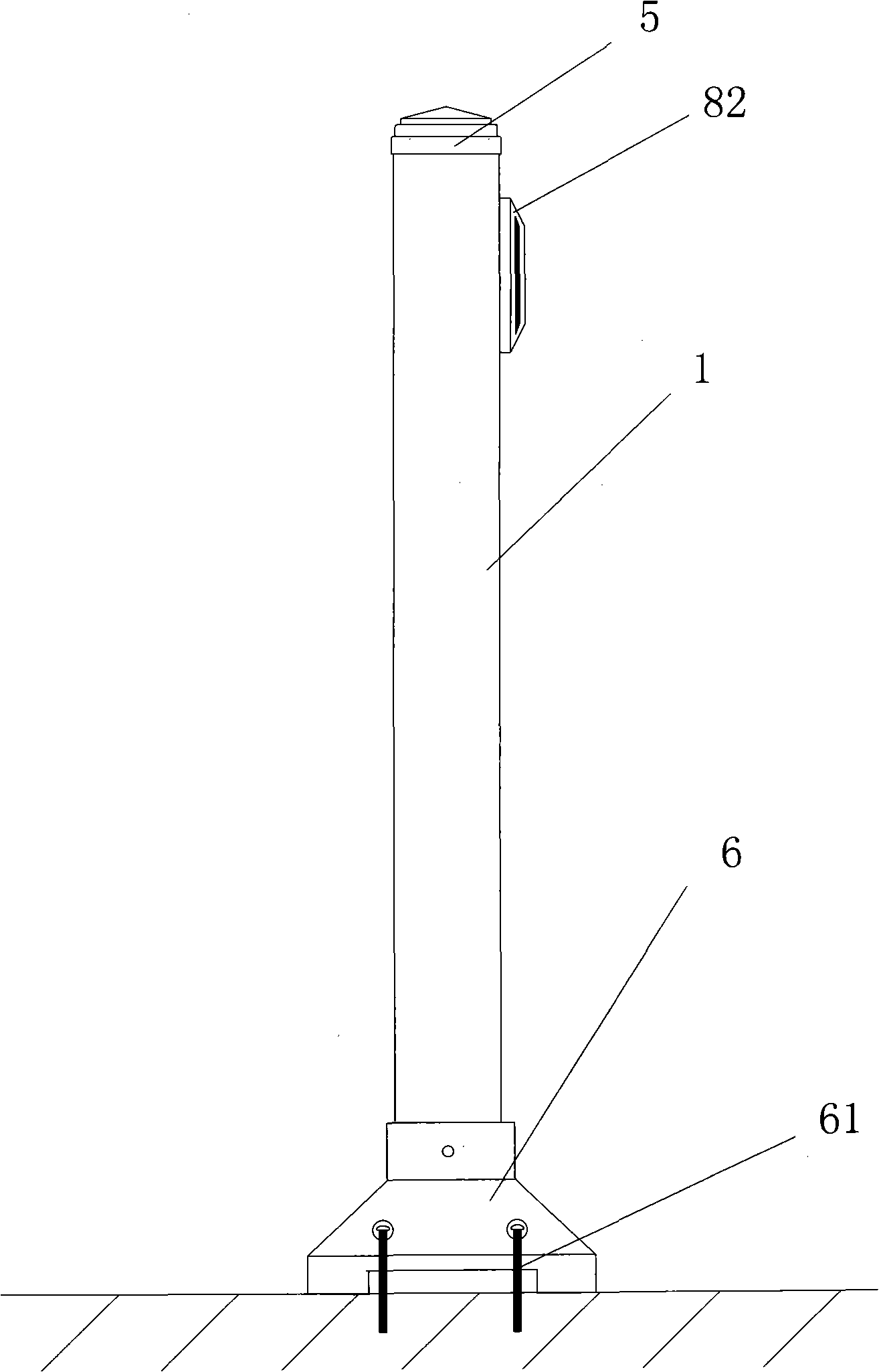

Jet printing type steel guard rail

ActiveCN101265694AImprove structural strengthAvoid deformationTraffic signalsRoad signsVertical barEngineering

The invention discloses a spraying type steel barrier, which comprises columns, upper cross bars, lower cross bars and vertical bars. The main bodies of the columns, the upper cross bars, the lower cross bars and the vertical bars are all integrated style steel works. The columns are made from the galvanized steel strip, made into steel pipe of a certain shape and sprayed with plastic or paint; the upper cross bars, the lower cross bars and the vertical bars are integrated parts which the upper cross bars, the lower cross bars and the vertical bars are respectively made from the galvanized steel strip, steel pipes of a certain shape are made through extrusion forming of the steel pipe stock mould, seam welding of the high frequency induction welder and extrusion forming of the steel pipe shaping mould and the integrated parts are formed by placing the vertical bars between the upper cross bars and the lower cross bars, welding and fixing, and at last spraying plastic or paint on the exterior surface of the integrated parts. The spraying type steel barrier has the advantages of high structural strength, deformation resistance, beautiful and clean barrier surface, rustiness resistance, easy cleaning, greatly reduced maintenance cost, both the beautiful appearance of the PVC plastic steel barrier and the high strength of the assembly type barrier.

Owner:JIANGSU AIKEQING IND

Water-based non-chrome-zinc-aluminum anticorrosive paint and preparation method thereof

ActiveCN107022300AAvoid pollutionThe solution is not easy to storeAnti-corrosive paintsWater basedMaterials science

The invention discloses a water-based non-chrome-zinc-aluminum anticorrosive paint, which is prepared from a component A and a component B with the mass ratio being (1 to 1.3):1. The component A is prepared from the following materials in percentage by weight: 20 to 32 percent of zinc-aluminum powder, 15 to 25 percent of wetting agent, 1 to 5 percent of dispersing agent, and 0.5 to 1.5 percent of nanometer SiO2; the component B is prepared from the following materials in percentage by weight: 15 to 25 percent of organic silicon resin emulsion, 20 to 30 percent of deionized water, 0.5 to 1.0 percent of corrosion inhibitor, 0.05 to 0.5 percent of thickening agent, 1 to 5 percent of adhesion promoter, 0.05 to 0.5 percent of antifoaming agent, and 0.05 to 0.5 percent of coalescing agent, flatting agent and brightener. The paint provided by the invention is low in content of VOCs (Volatile Organic Chemicals), green and environmentally-friendly, high temperature resistant, high in adhesive force and good in corrosion resistance, and the anti-salt spray capability is larger than or equal to 720h.

Owner:INST OF ANALYSIS GUANGDONG ACAD OF SCI (CHINA NAT ANALYTICAL

Fluorescent wool-like elastic gabardine spinning yarns, lining prepared thereby and preparation method thereof

ActiveCN101397704AHigh strengthImprove color brightnessDyeing processWoven fabricsFluorescenceEngineering

The invention relates to a fluorescent wool-like elastic gabardine spinning yarn which is characterized in that the spinning yarn is formed by the steps of adopting 100D cationic polyester low stretch yarns and 32S R / triangular polyester to carry out air cladding to 40D urethane elastic fibers by a networking threading machine; in addition, the R / triangular polyester comprises the following raw materials according to weight ratio: 77 percent to 83 percent of viscose staple fibers and 17 percent to 23 percent of bright triangular polyester. The invention also discloses a fluorescent wool-like elastic gabardine fabric and a preparation method thereof. Compared with the prior art, the invention has the advantages of making full use of the respective features of filament yarns and the staple fibers so as to greatly improve the color light, the strength and the curly and fluffy feeling and the like of the yarn, thereby causing the obtained fabric to have a remarkably full and smooth style; by the coloring difference after post treatment and the dyeing contrast of the white color of bright polyester, the fabric has the light effect of peekaboo fluorescence.

Owner:山东正凯新材料股份有限公司

Bone meal nutritious fresh wet noodle and making method thereof

InactiveCN102028146AIncrease elasticityImprove extensibilityDough treatmentFood preparationChemistryFineness

The invention relates to a bone meal nutritious fresh wet noodle. According to the formula, the noodle comprises the following components in part by weight: 100 parts of flour, 32 to 38 parts of water, 0.8 to 1.5 parts of table salt, 0.15 to 0.3 part of dietary alkali, 1.2 parts of bone meal, 0.5 part of soya bean lecithin and 3 parts of potato starch, wherein the fineness of the bone meal is between 120 and 200 meshes. The bone meal nutritious fresh wet noodle is produced by the following steps of: mixing raw materials and auxiliary materials according to the formula; kneading dough; performing secondary curing and tabletting; and finally shredding. The invention has the characteristics that: the bone meal is added into the flour; and the bone meal nutritious fresh wet noodle which has high tensile property and bright color and can difficultly thicken soup can be produced by optimizing the formula of an additive and improving a making process.

Owner:HEFEI UNIV OF TECH

Thin and light elastic women wear fabric and method for preparing fabric

A thin and light elastic women wear fabric is prepared by weaving warp yarn and weft yarn, and is characterized in that the warp yarn is formed by covering 40 D cotton elastic yarn and 20 D network yarn; the cotton elastic yarn is composed of twelve fibers; the weft yarn is four-color woof; the first weft yarn is 150 D black dacron low-elasticity network yarn; the second weft yarn is 150 D cation dacron low-elasticity network yarn; the third weft yarn is 32 British teams of combing pure cotton yarn; and the fourth weft yarn is 80 D silvery bright yarn. The invention further discloses a method for preparing the fabric. Compared with the prior art, the invention has the following advantages: the warp yarn combines the cotton with the polyurethane fiber; the weft yarn uses four raw materials; the fabric is colored and has different raw material properties, and has the advantages of colorful color, smooth handle, good rebound resilience, good color fastness, strong hygroscopicity, good service, and the like.

Owner:正凯纺织有限公司

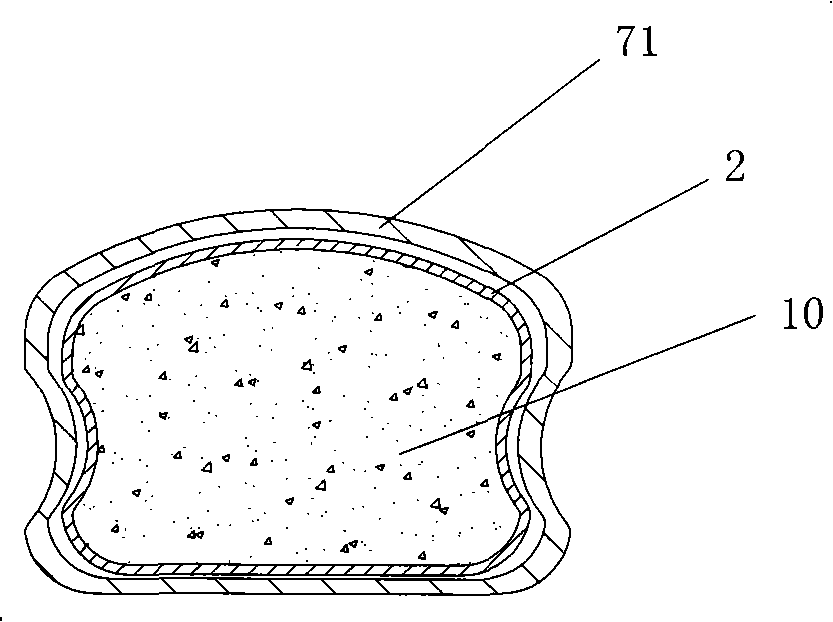

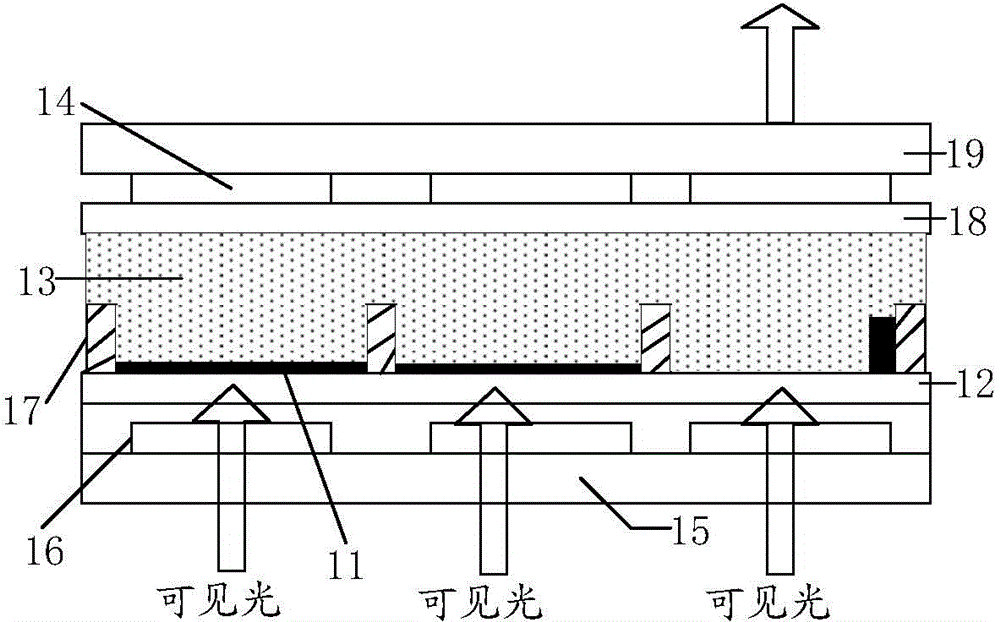

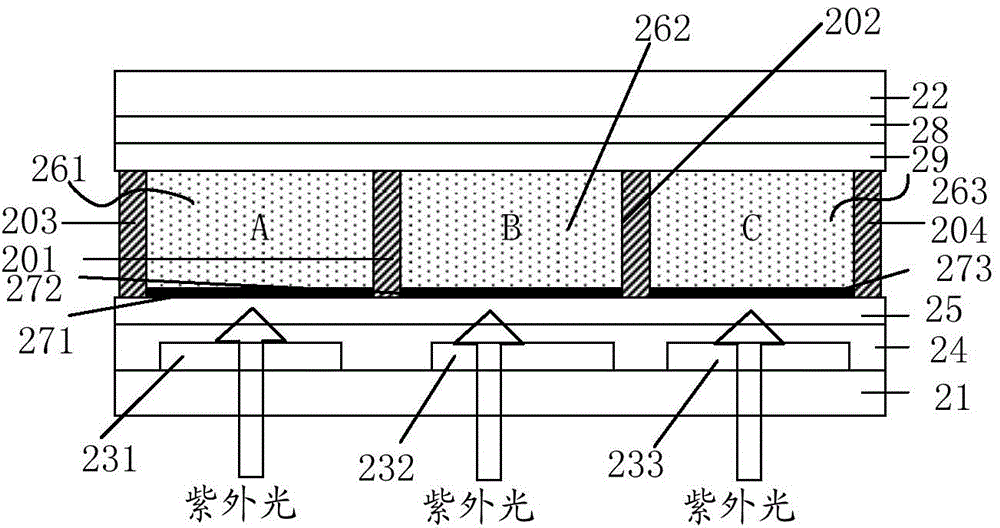

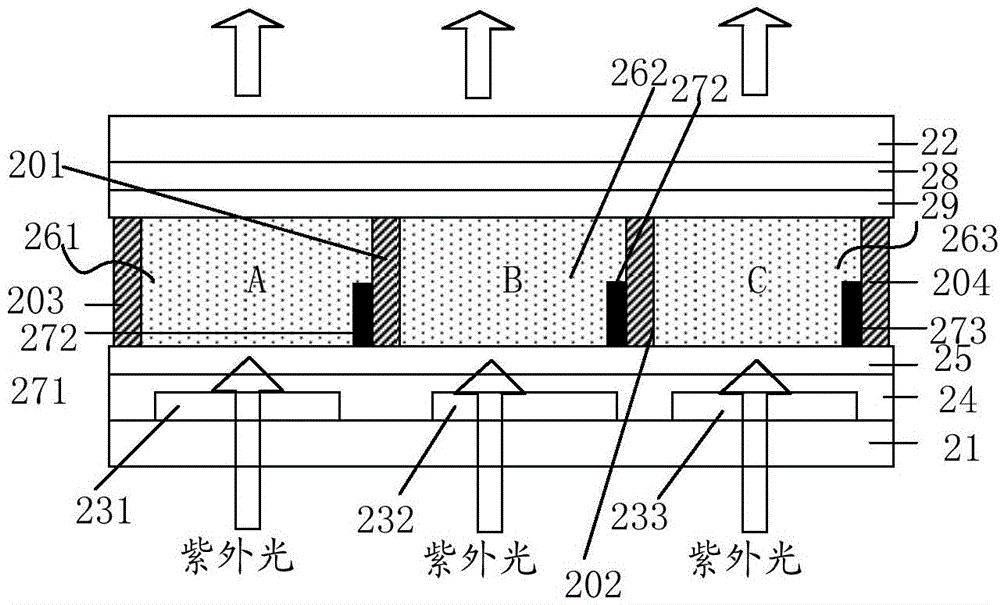

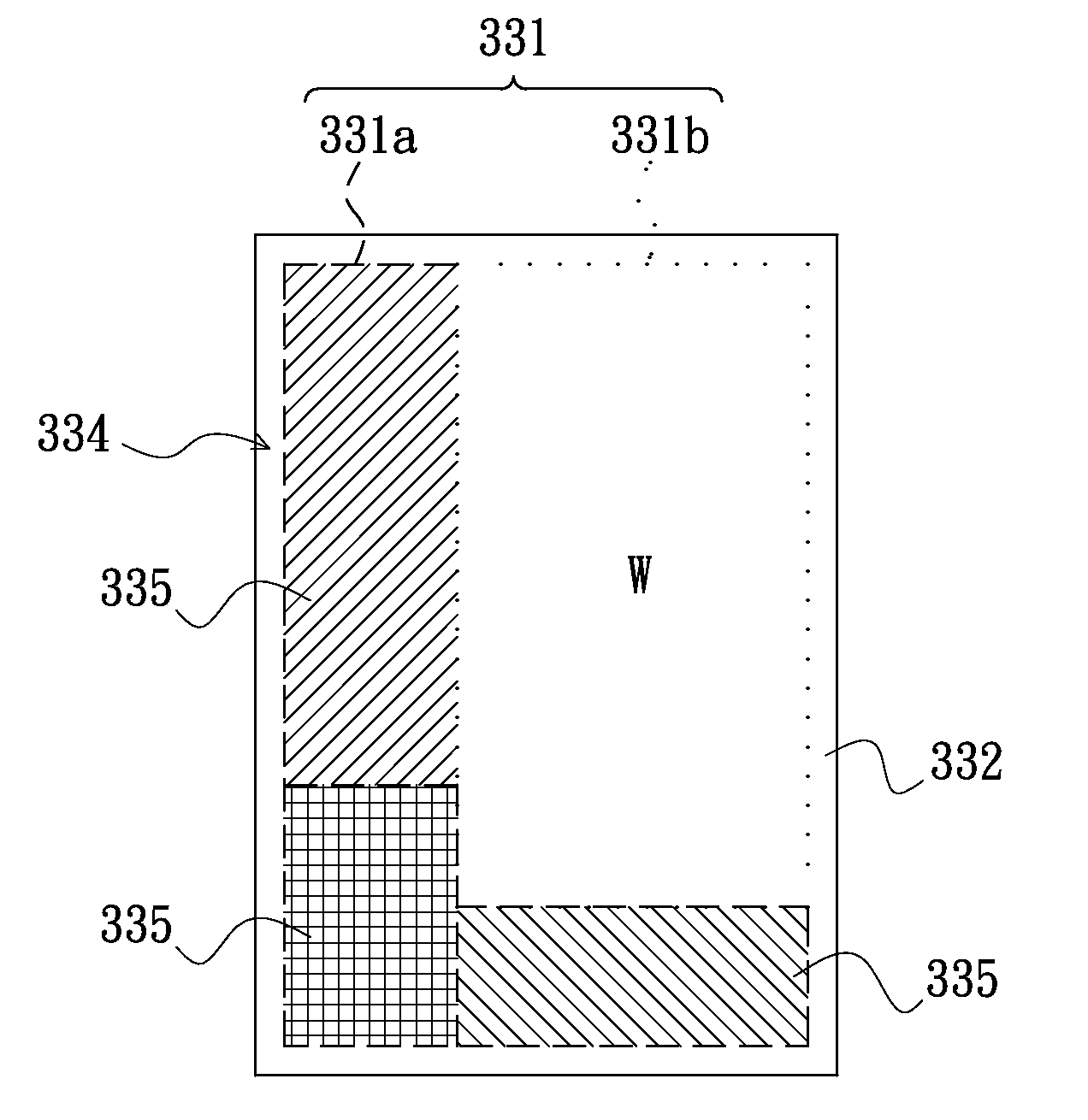

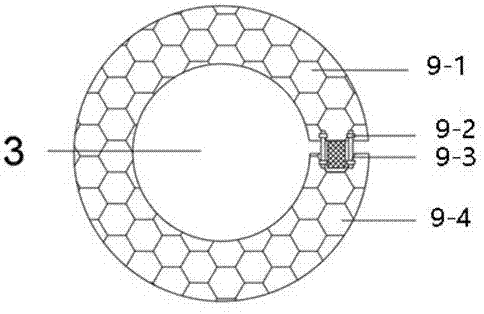

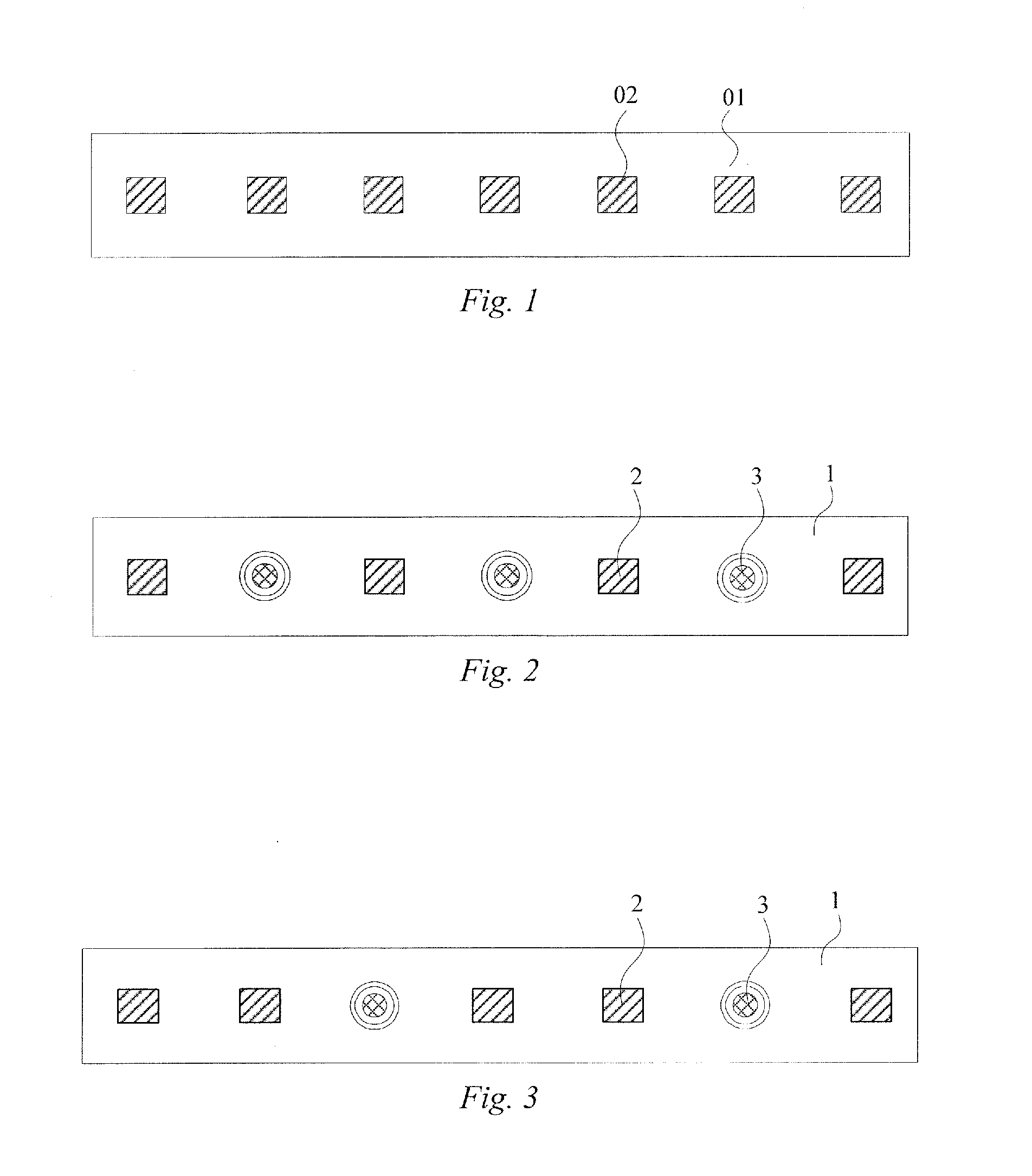

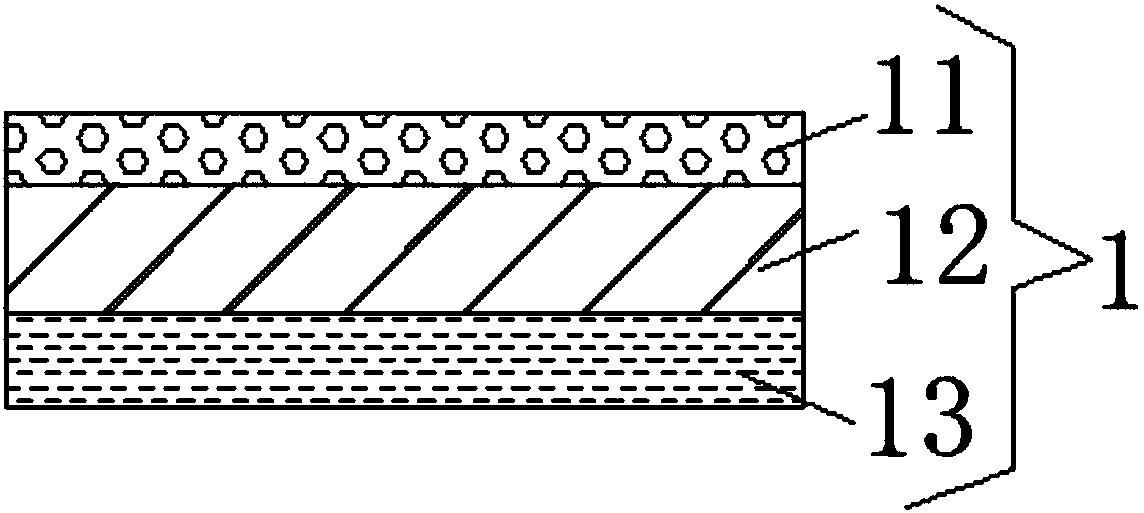

Electro-wetting display panel, manufacturing method of electro-wetting display panel and electro-wetting display device

The invention provides an electro-wetting display panel, a manufacturing method of the electro-wetting display panel and an electro-wetting display device. The electro-wetting display panel comprises a first substrate, a second substrate, a dielectric layer, a plurality of sub pixel unit definition regions, first liquid and second liquid, wherein the first substrate and the second substrate are fastened together; the dielectric layer is arranged on the first substrate; the sub pixel unit definition regions are arranged between the dielectric layer and the second substrate, correspond to sub pixel units and isolated from one another; the first liquid and the second liquid are accommodated in the sub pixel unit definition regions; the first liquid can emit color light under the irradiation of excitation light; the second liquid can absorb the excitation light; when no electric filed is applied, the affinity of the dielectric layer to the second liquid is greater than that of the dielectric layer to the first liquid; and under the action of an electric filed, the affinity of the dielectric layer to the second liquid is less than that of the dielectric layer to the first liquid. The electro-wetting display panel can realize color display under the premise of not adopting a color layer.

Owner:BOE TECH GRP CO LTD

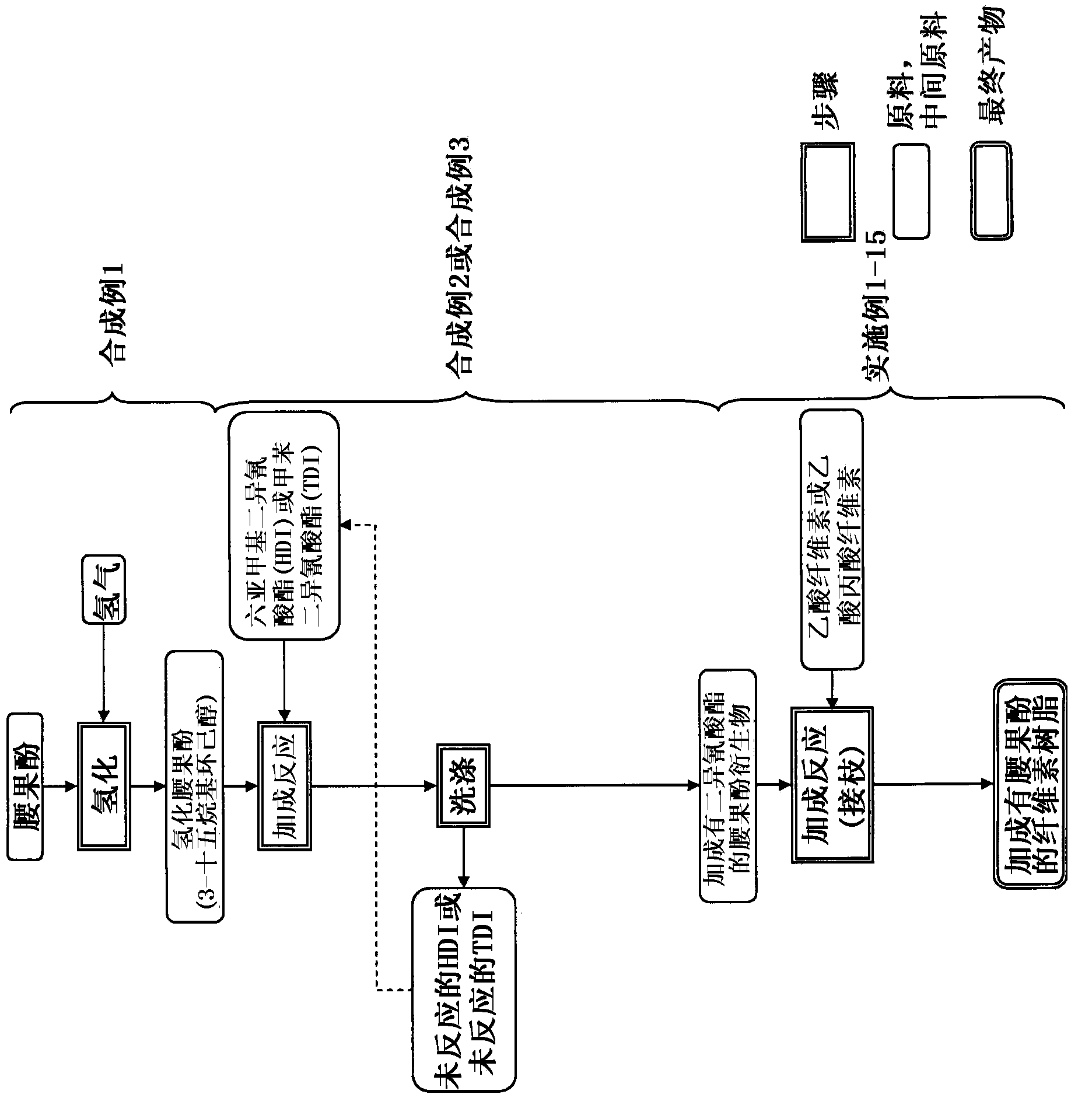

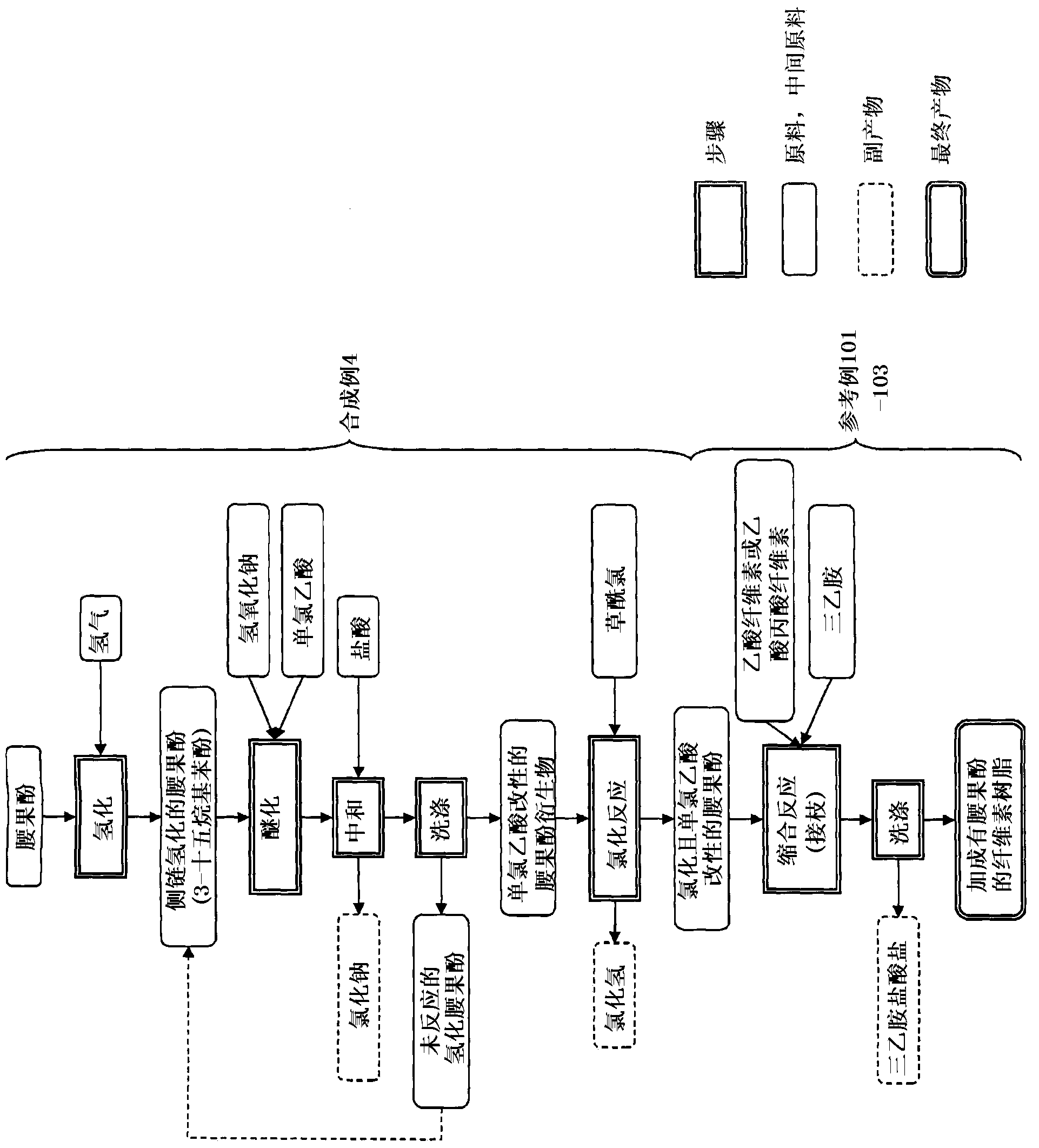

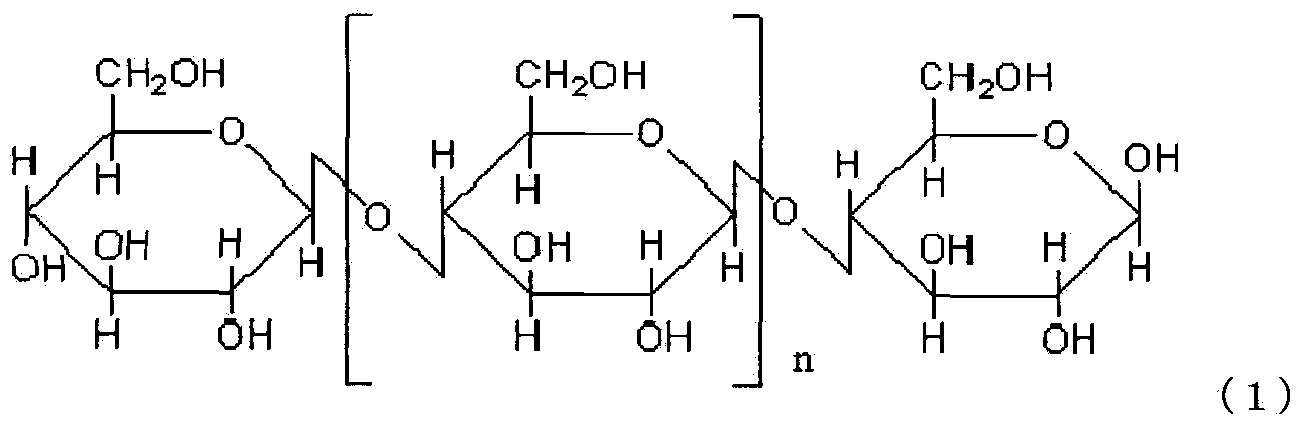

Cellulose resin and method for producing same

Provided is a cellulose resin resulting from bonding a hydrogenated cardanol and cellulose or a derivative thereof by means of the reaction of an isocyanate group of a diisocyanate compound and a hydroxyl group of the cellulose or a derivative thereof and a hydroxyl group of the hydrogenated cardanol, which contains 3-pentadecyl cyclohexanol.

Owner:NEC CORP

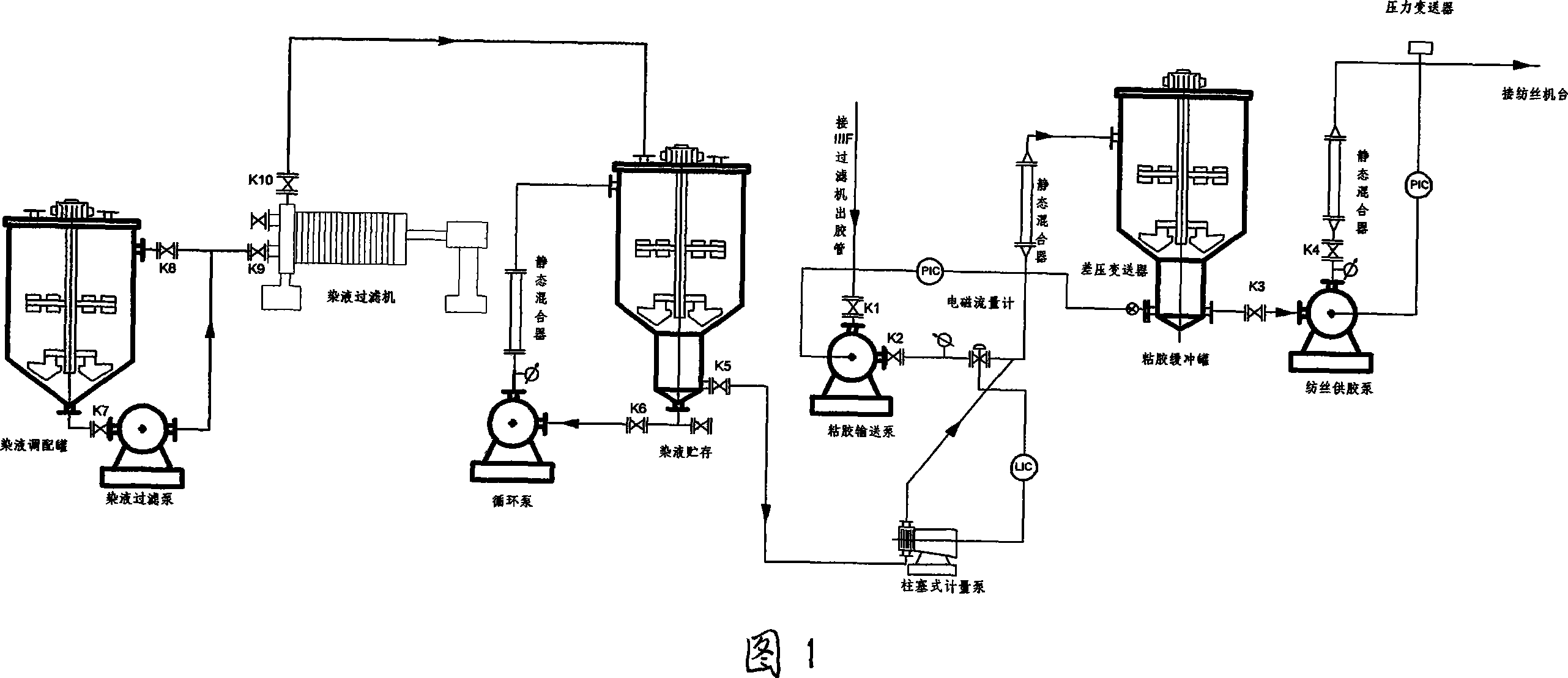

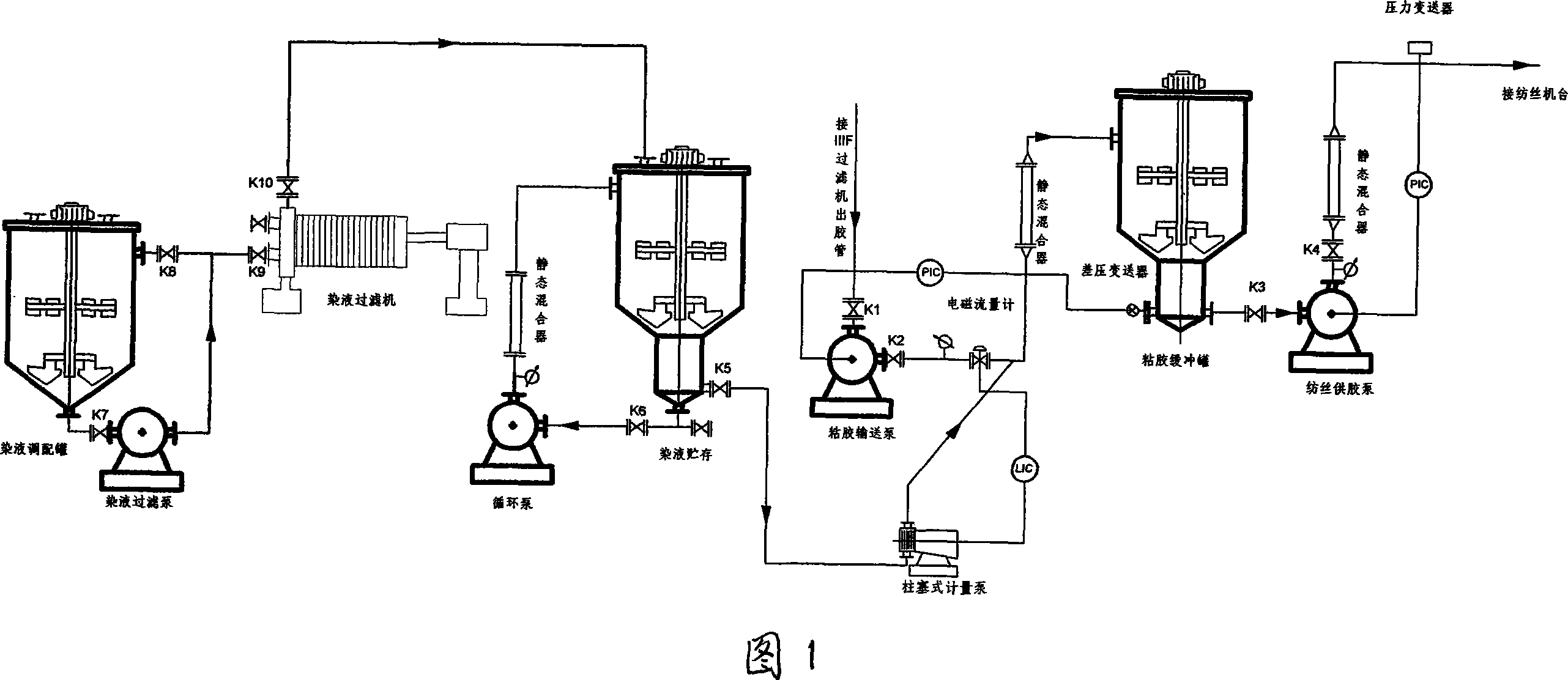

Method for producing spinning dyeing viscose fiber and spinning dyeing viscose fiber thereof

InactiveCN101104961AGuaranteed recovery before spinningGuaranteed spinning oxidation color developmentMonocomponent cellulose artificial filamentYarnYarnOxidizing agent

The invention discloses a method of spinning dyed viscose fibers and dyed viscose fibers produced by the method, and overcomes the problems in the prior art of colored viscose fibers. The method comprises adding a reducer and an oxidizer in the dye, mixing the resulting mixture with a viscose glue to obtain colored viscose glue, and spinning. During the processes from formation to refining of reduced spinning threads or after the spinning process is completely, reduced threads are oxidized and stained under an acidic or alkaline condition to form spinning dyed viscose fibers. Based on the research of dyeing mechanism, the invention breaks through the conventional process of pre-spinning dyeing and late finishing, and directly produces colored viscose fibers. The invention realizes the monofilament dyeing and improves the dyeing uniformity, color fastness and color brightness, enriches the color tone, and meets the standard of stitch yarn. Additionally, the invention can greatly reduce the production cost and avoid the contamination of the subsequent processing. The product has beautiful color, uniform dyeing, comfortable feel and wide application range.

Owner:YIBIN HIEST FIBER

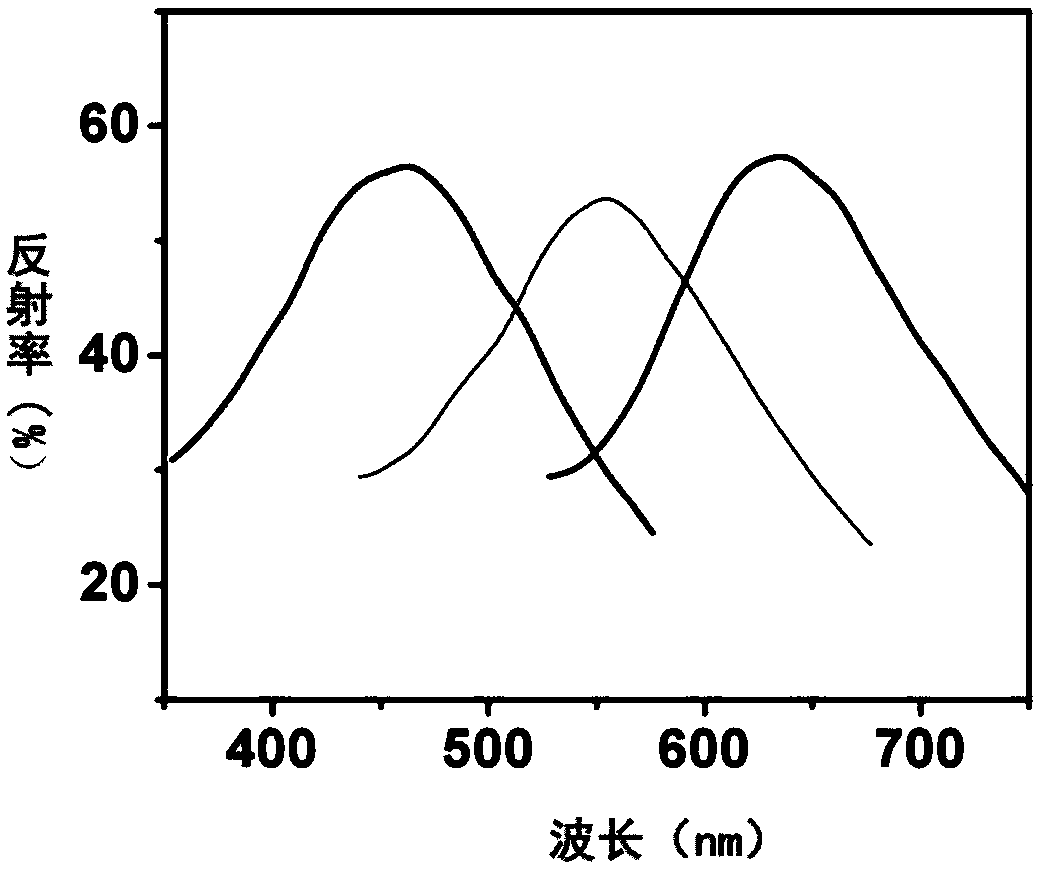

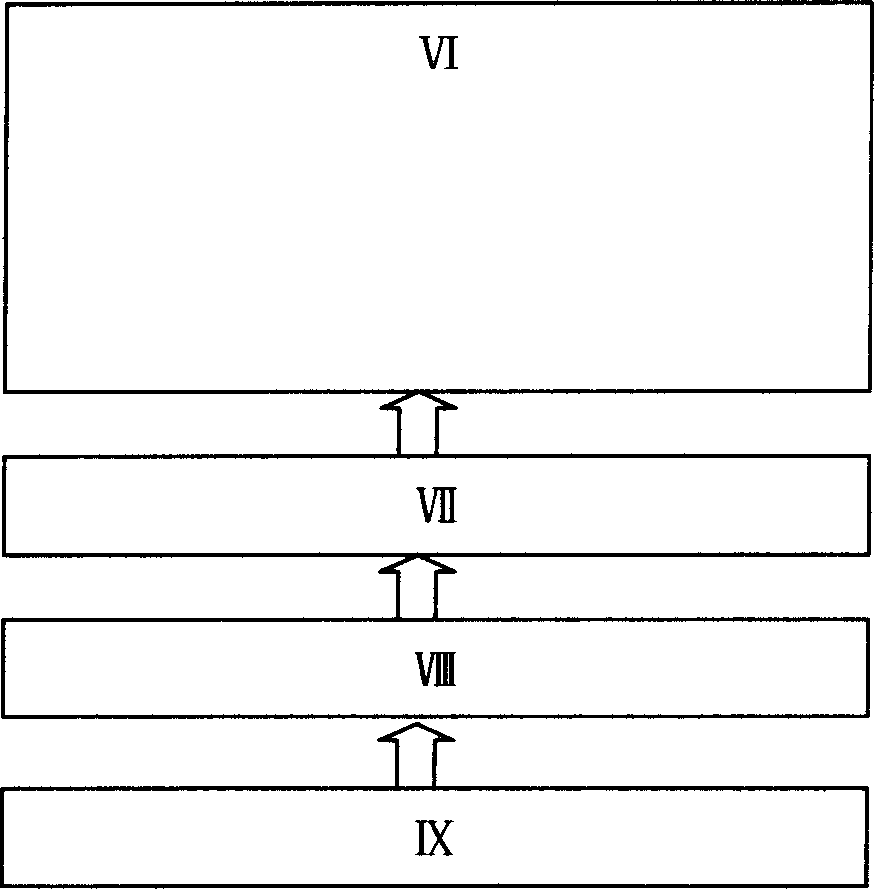

Method for improving color brightness of non-rainbow structural color

ActiveCN108227053AImprove color brightnessMake up for the technical problem of low color brightnessOptical elementsRainbowPhotoluminescence

The invention discloses a method for improving color brightness of non-rainbow structural color by introducing black nanoparticles and graphene quantum dots into a disordered optical structure. The method comprises the following steps of firstly, mixing monodisperse colloidal particles, black nanoparticles and graphene quantum points of different particle sizes according to a certain ratio, and uniformly dispersing into water, so as to form an emulsion; placing the emulsion onto a substrate by drip coating, rotary coating, soaking coating, lifting, spraying, ink jet printing and the like, anddrying, so as to form a non-rainbow structural color material with high structural color brightness. The non-rainbow structural color material with high structural color brightness obtained by the method has important application prospect in the fields of chemical / biological sensors, reflective monitors, pigments, decorative pattern layers and the like. The method has the advantages that the photoluminescence of the graphene quantum dots is effectively regulated, controlled and enhanced; the graphene quantum dots are promoted to be applied to optical devices.

Owner:HEBEI NORMAL UNIV

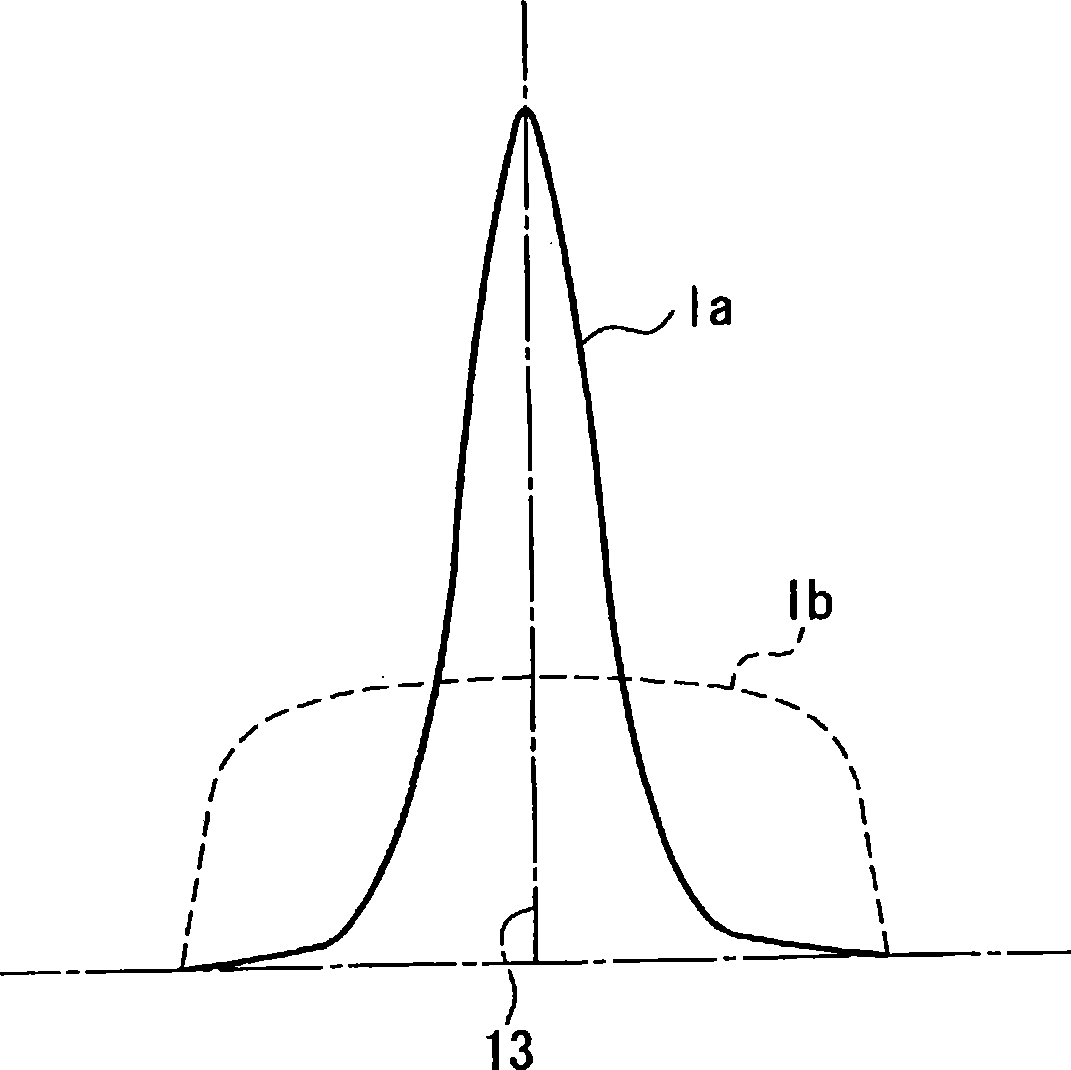

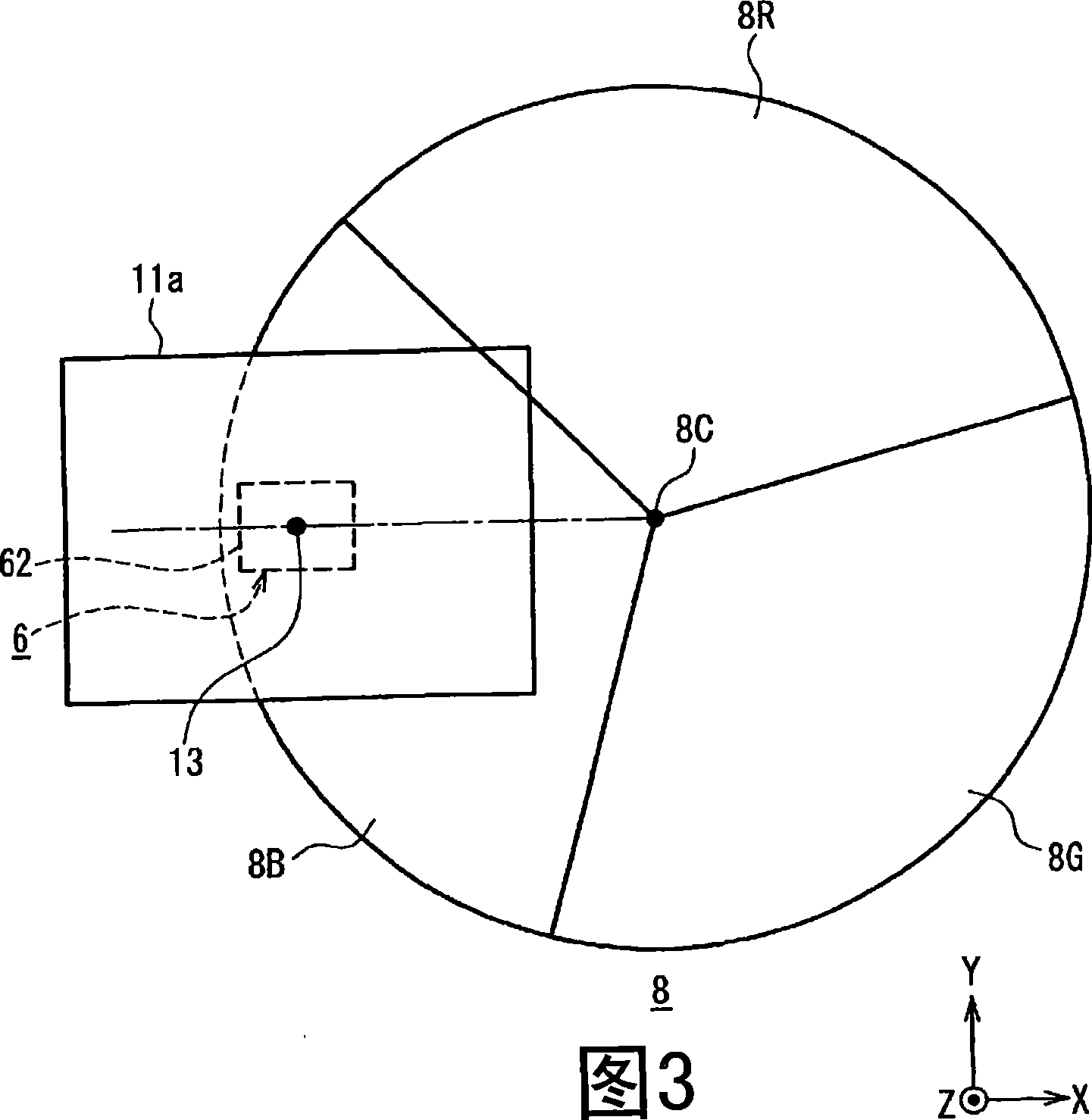

Projection type display apparatus

ActiveCN101454719AImprove utilization efficiencyImprove color brightnessStatic indicating devicesProjectorsColor filter arrayLightness

A projection type display apparatus comprises a rotational color filter (8) having color filters (8R, 8G, 8B) that transmit a white light to a specific color light emitted from a light emitting surface (6), a spatial light modulation element (11) disposed substantially in a conjugate relationship with the light emitting surface and modulating the incident light from the rotational color filter to perform an image display, and a controller (20) performing control so that the rotation of the rotational color filter is synchronized with the image display performed by the spatial light modulation element. In synchronization with passing of the borderlines (51, 52, 53), which are between the filters of each color of the rotational color filter, across each of partial light emitting regions (6a, 6b, 6c, ...) set by dividing the light emitting surface, the controller switches between the normal image display and the OFF-state in which light is blocked, for each of the partial display regions (14, 15, 16, ...) of the spatial light modulation element corresponding to each of the partial light emitting regions. The use efficiency of illumination light by the spatial light modulation element is increased, so that the color brightness of a projected image can be enhanced while sufficiently maintaining the effect of preventing the color mixture caused by adjacent color filters.

Owner:PANASONIC CORP

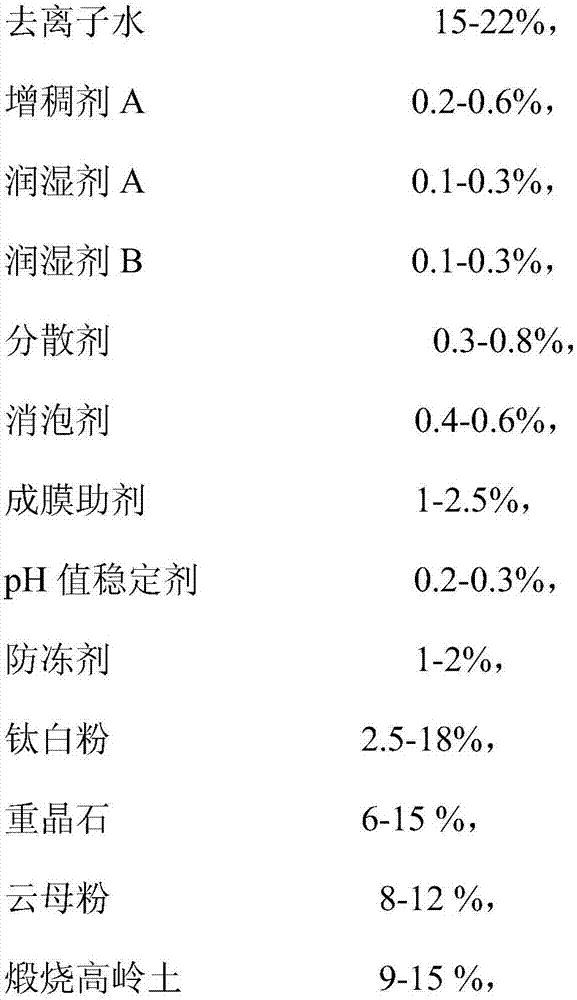

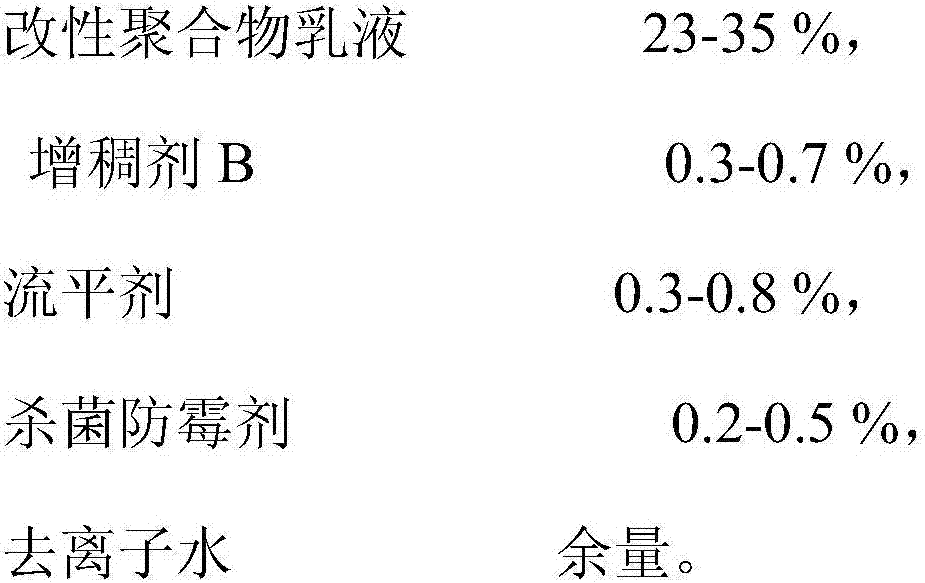

Super-weatherability anti-acid rain raindrop imprint-resistant external wall water paint and preparation method thereof

InactiveCN106978025AStrong dustproof abilityImprove heat resistanceAntifouling/underwater paintsPaints with biocidesMildewPolymer emulsion

The invention discloses super-weatherability anti-acid rain raindrop imprint-resistant external wall water paint and a preparation method thereof. The super-weatherability anti-acid rain raindrop imprint-resistant external wall water paint comprises deionized water, a thickener A, a wetting agent A, a wetting agent B, a dispersant, a defoamer, a film forming aid, a pH stabilizer, an antifreezing agent, titanium dioxide, barite, mica powder, calcined kaolin, a modified polymer emulsion, a thickener B, a leveling agent, a bactericidal mildew preventive and deionized water according to mass percents. The super-weatherability anti-acid rain raindrop imprint-resistant external wall water paint has acid and alkali resistance, weatherability, water resistance, mildew proof effects, raindrop imprint resistance, scrubbing resistance, environmental friendliness and energy saving.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

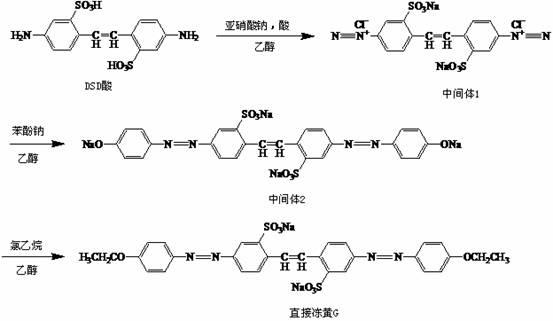

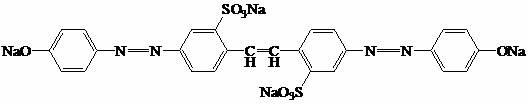

Method for preparing direct yellow G

ActiveCN102040855AReduce manufacturing costHigh color strengthPreparation by etherificationIndustrial waste waterPhenol

The invention discloses a method for preparing direct yellow G. DSD acid is taken as an initial raw material, and the method comprises the following steps of: reacting with sodium nitrite, phenol and chloroethane in turn, and respectively performing diazotization, coupling and chloroethane etherification to obtain the direct yellow G, wherein a solvent in diazotization, coupling and chloroethane etherification is ethanol. The DSD acid is taken as the initial raw material and is subjected to diazotization, coupling and chloroethane etherification respectively to form a dye of the direct yellow G, the ethanol is adopted as a reaction solvent in the diazotization, coupling and chloroethane etherification and can be recycled after reaction, a large amount of water is prevented from serving as the reaction solvent, the problem that a large amount of industrial wastewater is difficult to treat is radically solved and the zero emission of the industrial wastewater is achieved.

Owner:平顶山市铭源化工有限公司

Color filter and color reflective display device with the same

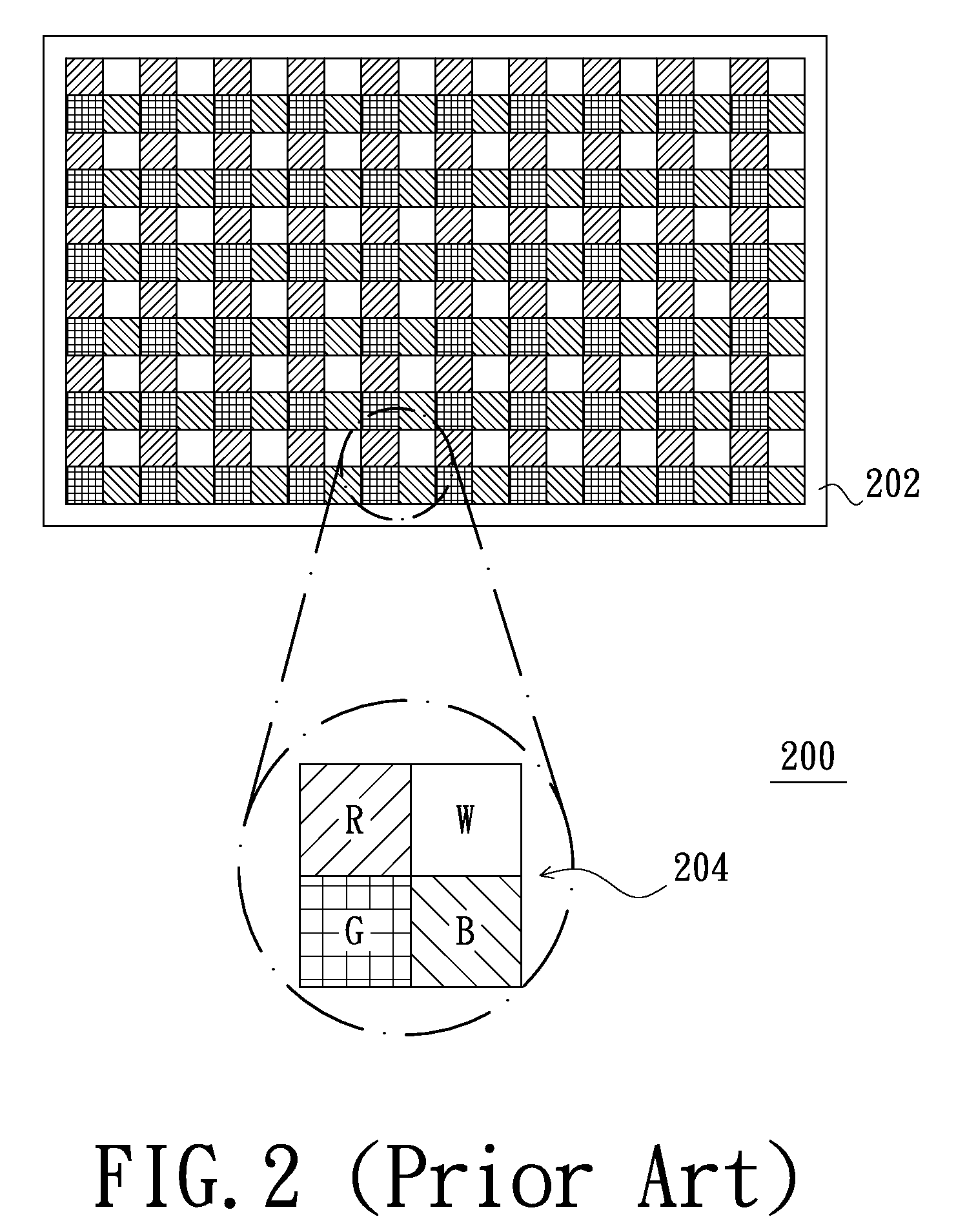

ActiveUS8130437B2Improving chromatic recognizabilityIncrease lighting brightnessNon-linear opticsOptical elementsTransmittanceDisplay device

A color filter including a substrate, a plurality of pixel units and a transparent electrode layer is provided. The substrate has a plurality of pixel regions. Each pixel region has a plurality of first sub-pixel regions and a second sub-pixel region. Each pixel unit is disposed in one of the pixel regions corresponding thereto and includes a plurality of and a white filter film. Each color filter film is disposed in one of the first sub-pixel regions corresponding thereto and the white filter film is disposed in the second sub-pixel region. Since the area of the white filter film is larger than the area of each color filter film, the color filter has high light-transmittance. The transparent electrode layer is disposed on the pixel units. Furthermore, a color reflective display device with the color filter is disclosed.

Owner:E INK HLDG INC

Viscose fiber spinning dyeing embroidery thread and producing method thereof

InactiveCN101104971AGuaranteed recovery before spinningGuarantee the production requirements of spinning oxidation color developmentYarnDye addition to spinning solutionYarnEngineering

The invention discloses a viscose fiber spinning dyed stitch yarn and the production process thereof, and overcomes the problems of tinted yarn, such as poor spinning property, high production costs, dull color of product and failure to produce stitch yarns. The raw materials used in the invention comprises a dyeing viscose glue which is a mixture of color paste and viscose glue, a base solution, a reducer and an oxidizer. Reduced threads made from the dyeing viscose glue are directly processed to viscose fiber spinning dyed stitch yarns in the refining procedure, with the action of oxidizer and acid or base. The invention has the advantages of uniform dyeing, high color fastness and color brightness, rich colors, compliance with the standards of stitch yarn, reduced production costs, no contamination of the next processing, comfortable feeling, and wide application range.

Owner:YIBIN HIEST FIBER

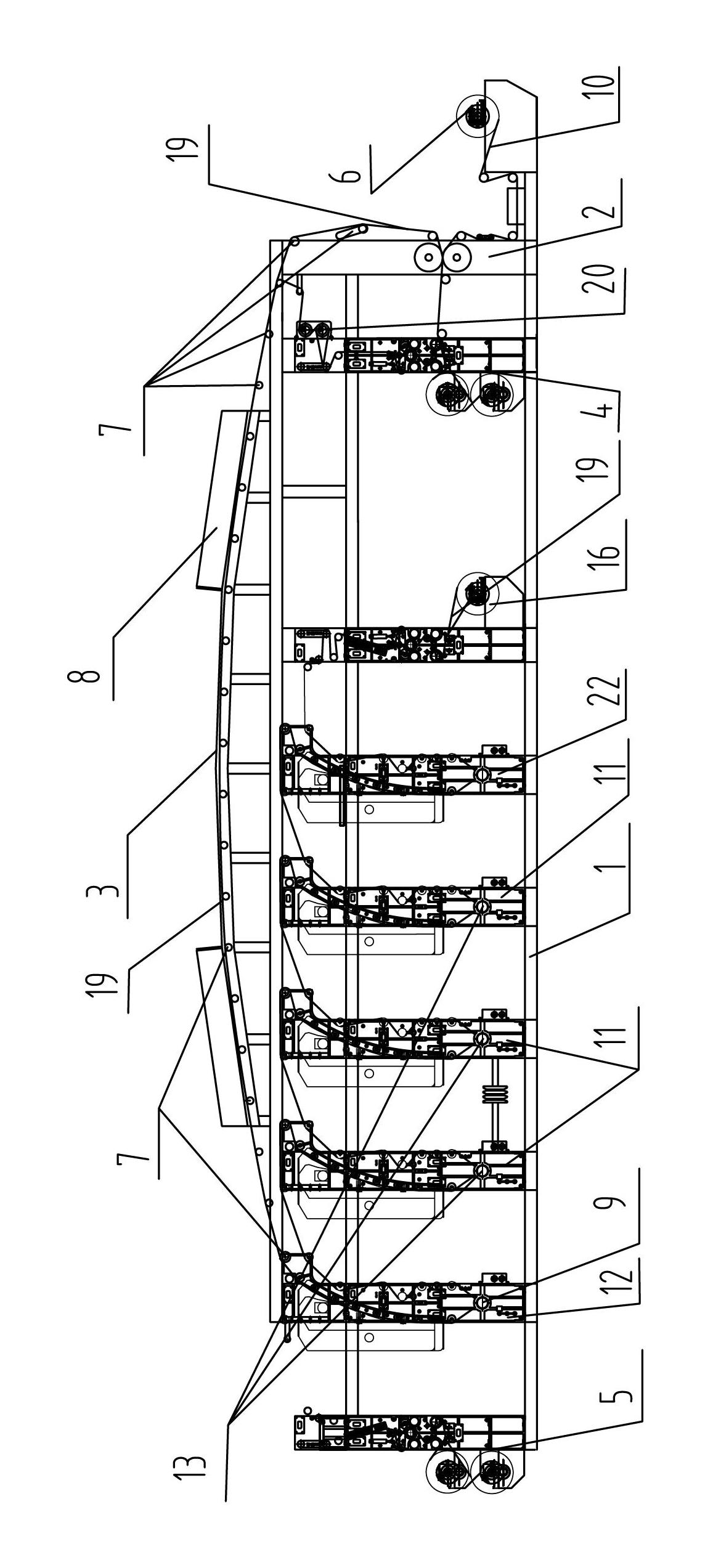

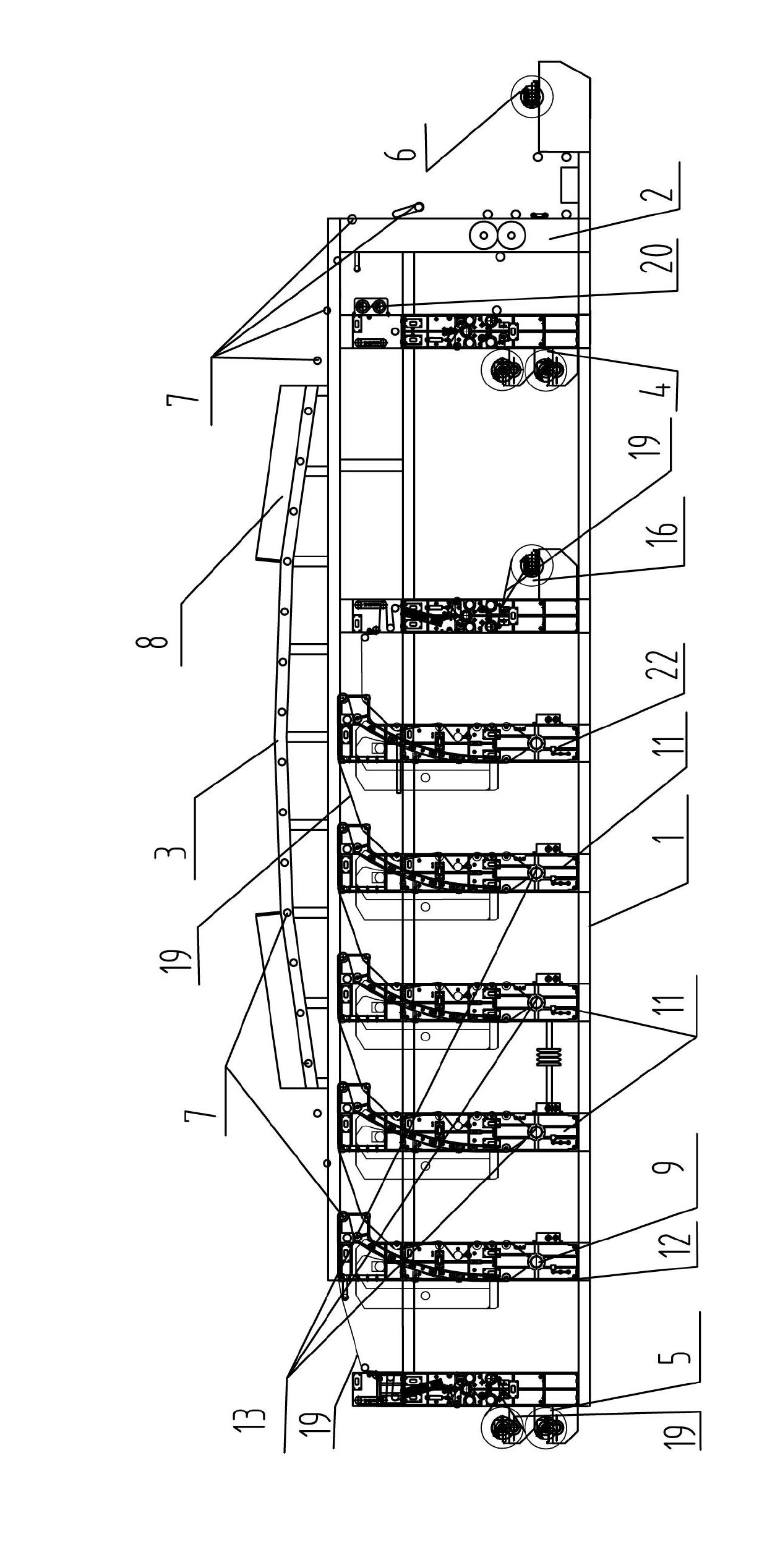

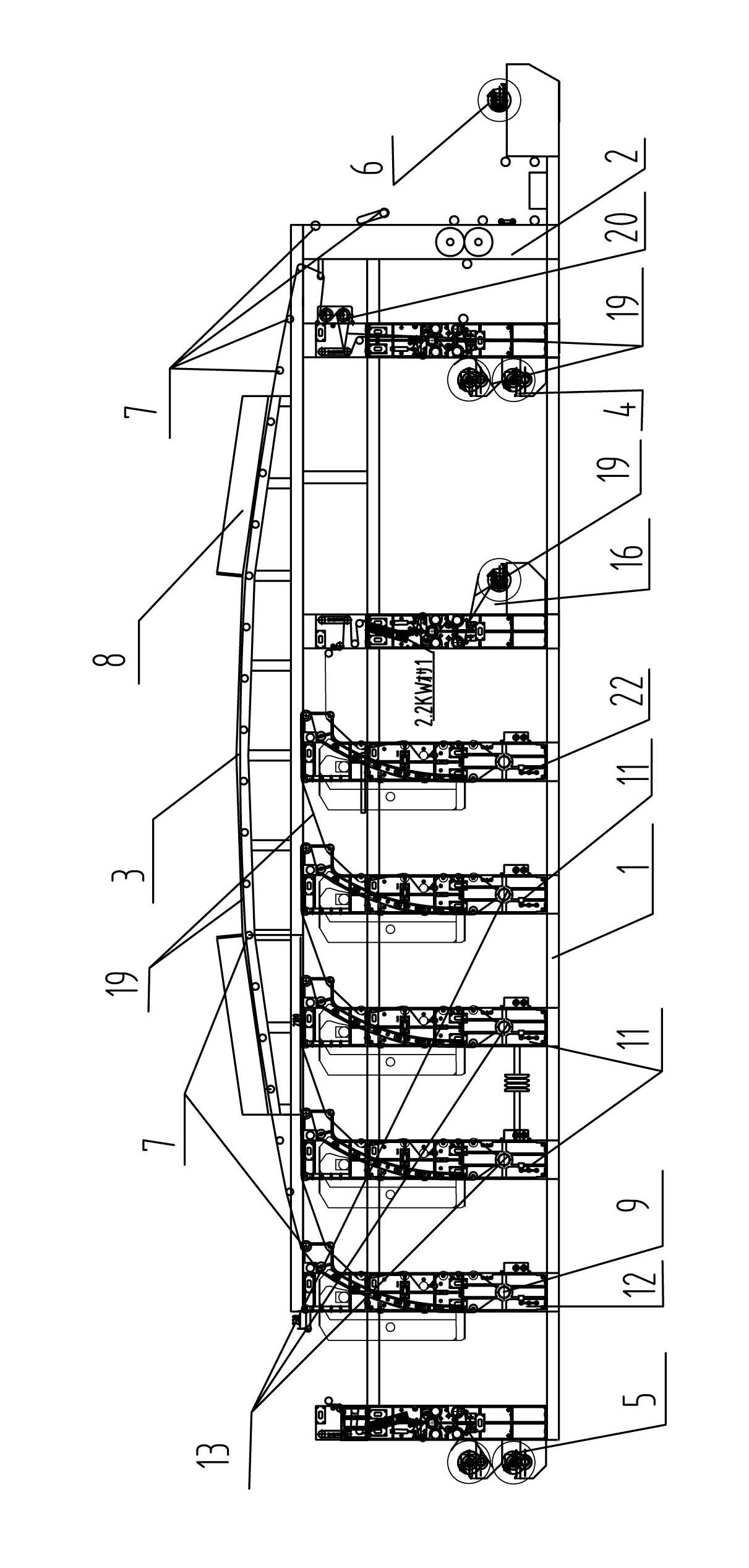

Multifunctional printing positioning machine and production process of multifunctional printing positioning machine

ActiveCN102673110AOvercome the disadvantage of not being able to apply resin synthetic glueReduce usageTransfer printingDuplicating/marking methodsProcess engineeringPrinting press

The invention discloses a multifunctional printing positioning machine and a production process of the multifunctional printing positioning machine. The multifunctional printing positioning machine comprises a printing machine, a material placing device, a composite hot pressing transfer device, a drying system, a cooling device and a coiling device, wherein one side of the printing machine is sequentially provided with the coiling device, the composite hot pressing transfer device and the material placing device, the drying system is erected on the upper top parts of the printing machine, the coiling device and the composite hot pressing transfer device and is respectively and fixedly connected with the printing machine, the coiling device and the composite hot pressing transfer device, and the top of the coiling device is fixedly connected with the cooling device. The multifunctional printing positioning machine and the production process have the characteristics that the assembly is convenient, the cost is low, the manufactured finished products are diversified, in addition, the color fastness is good, the ventilation performance is good, the three-dimensional effect is high, and safety and environment friendliness are realized.

Owner:王天友

Spinning and dyeing method for viscose

InactiveCN101058898AGuaranteed RestoreGuaranteed recovery before spinningMonocomponent cellulose artificial filamentCelluloseTextile dyeing

The present invention discloses a dyeing method of textile dyeing cellulose viscose, in order to overcome the drawbacks of the prior dyeing method can not guarantee the oxidation-reduction process be controlled effectively in colored cellulose viscose production. The method adds reducing agent and oxidizer into color paste, adds the standby color paste into viscose, the dyeing viscose is prepared after mixing fully, then the dyeing viscose forms reduced thread-line after ejected from spinnerette; in the textile process of reduced thread-line from forming to degumming or when the textile process is completed, the thread-line starts color development on the role of oxidant and acids or alkali, the color is fixed into desired color after reaction is completed. The invention breaks the traditional technology of the traditional ordinary cellulose viscose is colored before textile and is dyed and finished in late processes, it can achieve single filament dyeing, improve dyeing uniformity, color stability and color brightness of thread-line, and achieve the use standard of cotton embroidery thread, as well as decrease production costs significantly; the follow-up processing is pollution-free, the color of produces is bright, dyeing is uniform, hand feeling is comfortable and application is wide.

Owner:YIBIN HIEST FIBER

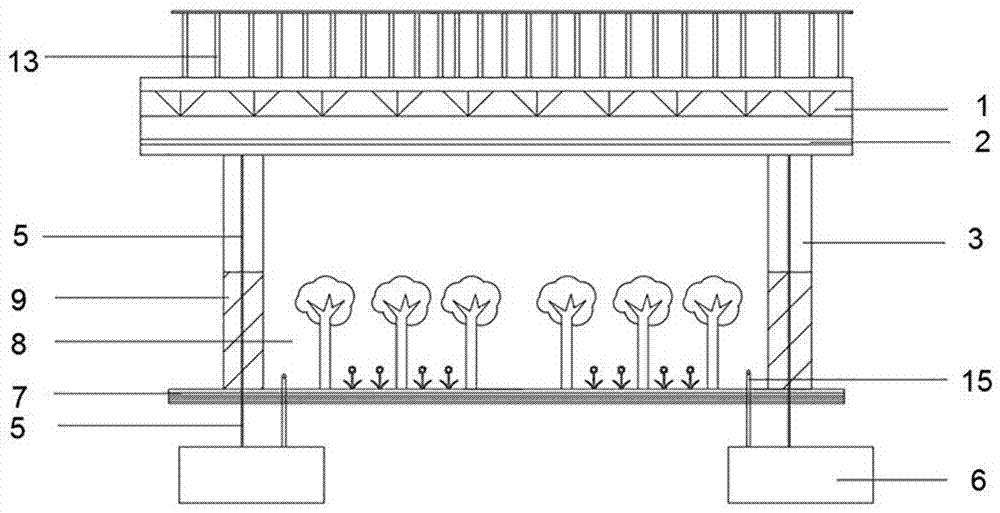

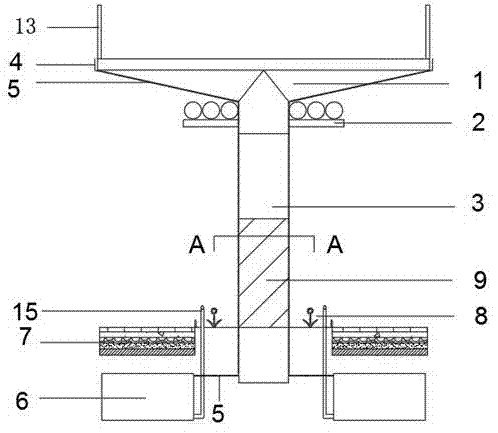

Elevated ecological bicycle path

The invention relates to an elevated ecological bicycle path, and belongs to the field of bridges. The elevated ecological bicycle path comprises an elevated ecological bicycle path, an elevated bicycle path guiderail, and an elevated ecological bicycle path pier. The elevated ecological bicycle path is characterized in that the elevated ecological bicycle path adopts a steel box girder; the steel box girder is prefabricated and assembled; a pipeline platform is arranged at the lower part of the steel box girder of the elevated ecological bicycle path; the elevated ecological bicycle path pier adopts a steel pier; the elevated ecological bicycle path pier is provided with a drainage tank; the drainage tank is communicated with a drainage channel; a downpipe is connected to the lower part of the drainage tank and extends downwards; a reservoir is arranged at the tail end of the downpipe and on the two sides of the steel pier; a sidewalk used for jogging and the like is arranged above the reservoir. The elevated ecological bicycle path provides an elevated exit passageway for bicycles, the traffic accidents are reduced, the traffic pressure is eased, the environmental pollution is alleviated, the rain water is effectively collected, the energy is saved, the prefabrication and assembly process is adopted in the construction, the operations are conducted simultaneously from multiple points, and the construction efficiency is greatly improved.

Owner:SHENYANG JIANZHU UNIVERSITY

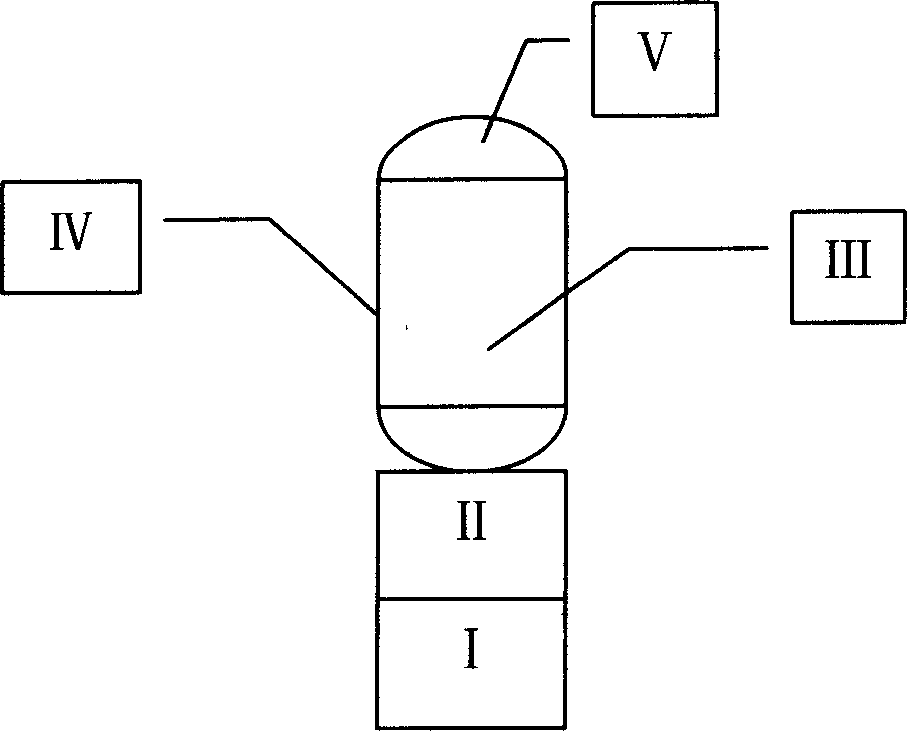

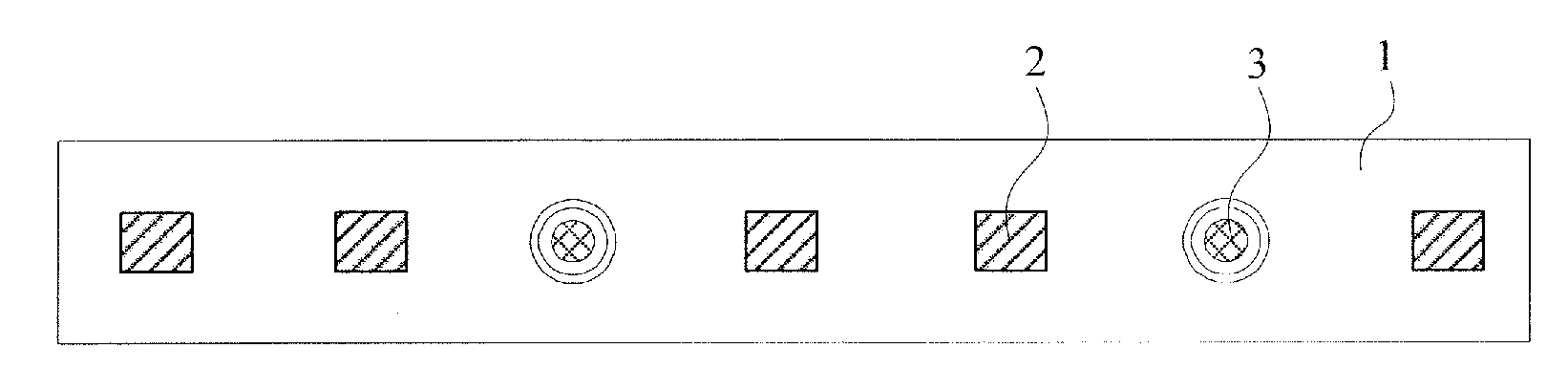

Highly efficient energy-saving information display technique

The invention provides a high-performance and energy-saving information display technique, which is a new information display technique and can effectively blend the electronic display mode and the printing display mode. The information contents can be timely refreshed (the electric power supply or electric battery is needed) as well as the electronic display mode, and the information contents can be maintained for a long time as well as the printing display mode and can,t consume any electric energy when they are not changing. Meanwhile, the reading information is different from the printing display mode in the contents display mode of and displays the contents by reflecting external ambient lights, thus is better in conserving energy and protecting environment. The picture element points of the display information are composed by a micro machinery electronic control cell (for monochrome display) or three micro machinery electronic control cells according to fixed law. A micro machinery electronic control cell consists of rotatable machine part III, multiple-resolution chromatape IV, electric execution unit III and electric control block I.

Owner:李博航

Polyester fiber dyeing liquid and dyeing process thereof

PendingCN111058312AImprove dye uptakeIncrease contactHeating/cooling textile fabricsDyeing processPolyesterFiber

The invention relates to a polyester fiber dyeing liquid and a dyeing process thereof. The polyester dyeing liquid comprises a macromolecular film forming agent, a dye and activated water; particles of the polyester dyeing liquid are ultrasonically crushed by using ultrasonic waves, and the high-stability polyester dyeing liquid with the particle size of one micron or less is obtained. Particles of the polyester dyeing liquid are ultrasonically crushed through ultrasonic waves, so that the absorption of the dye on the surface of fibers is accelerated, the dyeing rate of the fibers is improved,the activity of the fiber amorphous region chain segment is increased, and the bonding effect of the dyeing liquid and the fibers is comprehensively improved; the invention also provides the dyeing process of the dye; and the dye dyeing process is good in dyeing effect, low in energy consumption, less in pollution emission, and energy-saving and environment-friendly, and the dyeing quality reaches the national standard.

Owner:苏州爱地利新材料科技有限公司

Luminous fabric pressing panel

InactiveCN101429731AImprove color brightnessStrong Appreciation ValueTextile decorationMetallurgyLight source

The invention provides a luminous textile iron tablet. The surface of the textile iron tablet contains a composition of 10 to 90 percent of luminous powder and 90 to 100 percent of paint in weight proportion, and the textile iron tablet can be added with anti-settling agent according to requirement to make the luminance of the luminous powder even. The product is applied to clothes to absorb and store light in the daytime and naturally light at night in order to make the clothes present colorful and transparent light, so the luminous textile iron tablet is beautiful and novel, and has high appreciation value.

Owner:李商熙 +1

Compound enzyme wool fiber impurity removal agent

InactiveCN107574671APromote sheddingImprove color brightnessBiochemical fibre treatmentAnimal fibresCutinaseProteinase activity

The invention discloses a compound enzyme wool fiber impurity removal agent. The compound enzyme wool fiber impurity removal agent comprises the following components in parts by volume: a component A:100 parts of compound enzyme, 10-15 parts of a stabilizer, 2-7 parts of a penetrant, 5-9 parts of a chelating agent, 20-30 parts of coconut oleoyle monoethanolamine, and 10-18 parts of fatty alcoholsulfate; and a component B: 40-60 parts of aspergillic protease, 30-50 parts of cutinase, 10-17 parts of phytic acid, and 10-15 parts of a stabilizer. The invention further provides a use method of the compound enzyme wool fiber impurity removal agent. The impurity removal agent can effectively remove the wool fat and smoits in the raw wool, the impurity removal efficiency is high, and the effectis good. In addition, the compound enzyme wool fiber impurity removal agent is excellent in stability and has a relatively long service life.

Owner:苏州凯邦生物技术有限公司

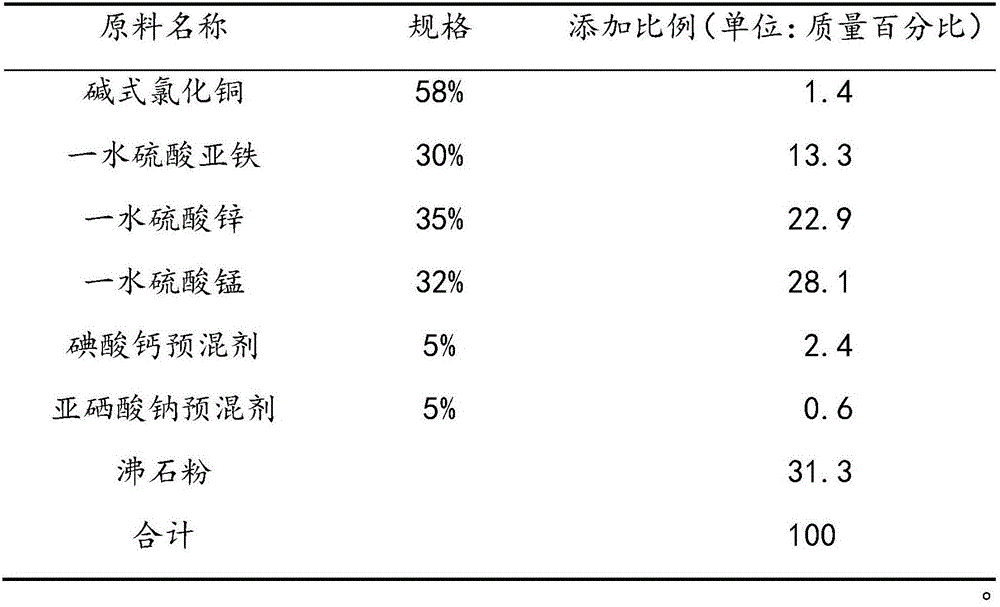

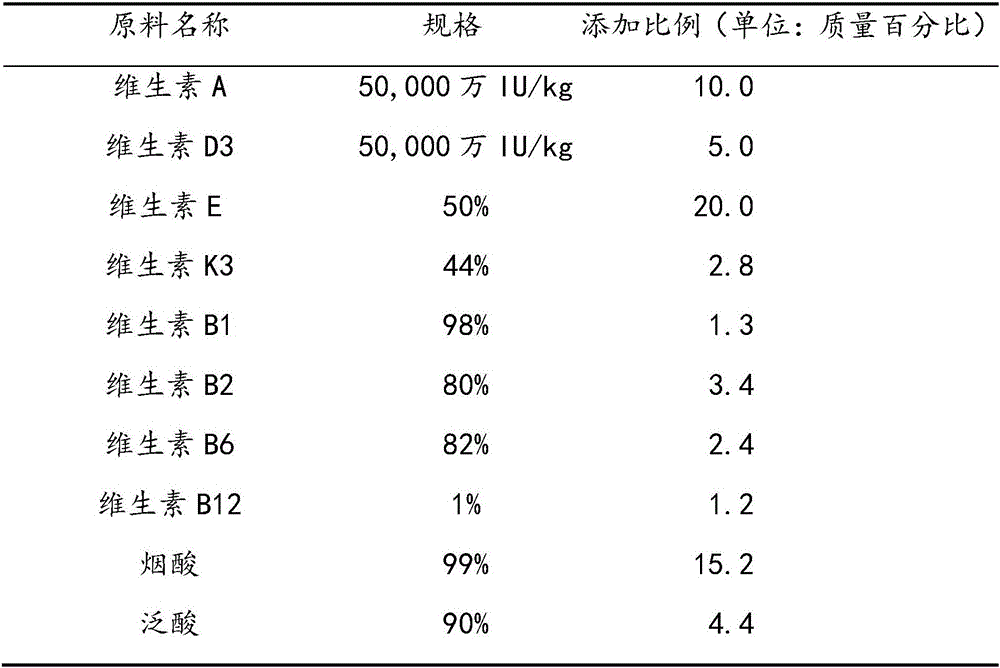

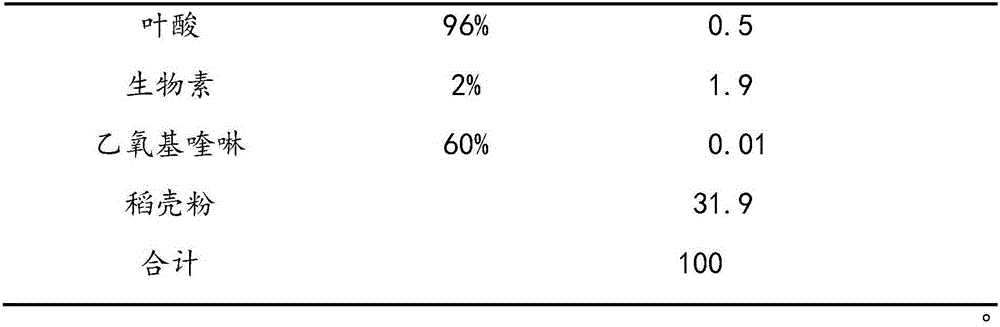

Premix feed for laying hens at egg laying later stage

PendingCN106721426AAvoid quality problemsFunction increaseAccessory food factorsNutrientReproductive organ

The invention is suitable for the technical field of feed preparation, provides a premix feed for laying hens at an egg laying later stage, and aims to solve the problem that in the prior art, the weight of eggs is increased due to the fall of the egg laying rate at the egg laying later stage, so that the reproductive organs of laying hens are damaged. The addition mass ratio of the premix feed in a completed feed is 1-5%, wherein basic ration is 0.5-4.74%, fulvic acid is 0.2-0.4%, vitamin C is 0.02-0.05%, and organic trace element combination is 0.04-0.05%. According to the premix feed for the laying hens at the egg laying later stage disclosed by the invention, the utilization rate of nutrient substances of the feed can be increased, the eggshell quality of eggs produced by the laying hens can be improved, the premix feed has good effects on the laying hens at the egg laying later stage, which are low in egg laying functions, poor in absorption capacity of nutrient substances and poor in eggshell quality, the cost is reduced, and the economic benefits of breeding households are increased.

Owner:沈阳波音饲料有限公司

White LED light source, backlight module and display device

InactiveUS20160011361A1Good colorImprove display qualityMechanical apparatusPlanar/plate-like light guidesGamutLiquid-crystal display

The present disclosure relates to a white LED light source, a backlight module and a liquid crystal display device. The white LED light source comprises a light strip having a plurality of LED units and a plurality of laser units. Each LED unit has a chip emitting lights of a first color light and a fluorescent module induced by the lights of the first color to emit lights of a second color. The plurality of laser units emit lights of a third color so as to form white lights by mixing the lights of the second color emitted by the LED units and the lights of the third color emitted by the laser units. In the white LED light source according to the present disclosure, laser units are used so as to expand the color gamut of the liquid crystal display device.

Owner:BOE TECH GRP CO LTD +1

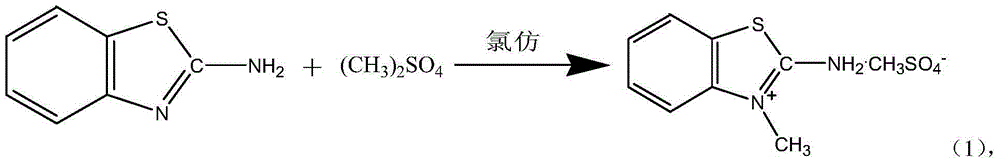

Preparation method of cation bright yellow 7GL

The invention relates to a preparation method of cation bright yellow 7GL. The method comprises the following steps: (1) synthetizing 3-ethyl thiazole truxene hydrazone: A) methylation: taking 2-aminobenzothiazole, dichloroethane and a catalyst I, stirring and mashing the aminobenzothiazole, the dichloroethane and the catalyst I, adding dimethyl sulphate to the mixture at 30-35 DEG C, wherein the total adding time is 60-100 minutes, then, carrying out heating till the temperature is 60-70 DEG C, carrying out reaction for 1-2 hours to the end, adding water, carrying out heating for temperature rise and recovering dichloroethane, recovering to 90 DEG C, finishing the recovery of the dichloroethane so as to obtain a water solution containing an intermediate as shown in the formula 1; B contracting and mixing: in a solution of the intermediate as shown in in the formula 1, firstly adding the catalyst II, regulating the pH to be 2-4, then adding hydrazine hydrate to reach 98-99 DEG C, carrying out reaction for 4-5 hours, after reaction, lowering the temperature, performing filtration so as to obtain the 3-ethyl thiazole truxene hydrazone containing an intermediate as shown in the formula 2; (2) synthetizing 2-chlorine methyl imidazole truxene; (3) synthetizing a dye. The preparation method disclosed by the invention is high in yield, low in expense, environment-friendly and zero in pollution.

Owner:刘晨义

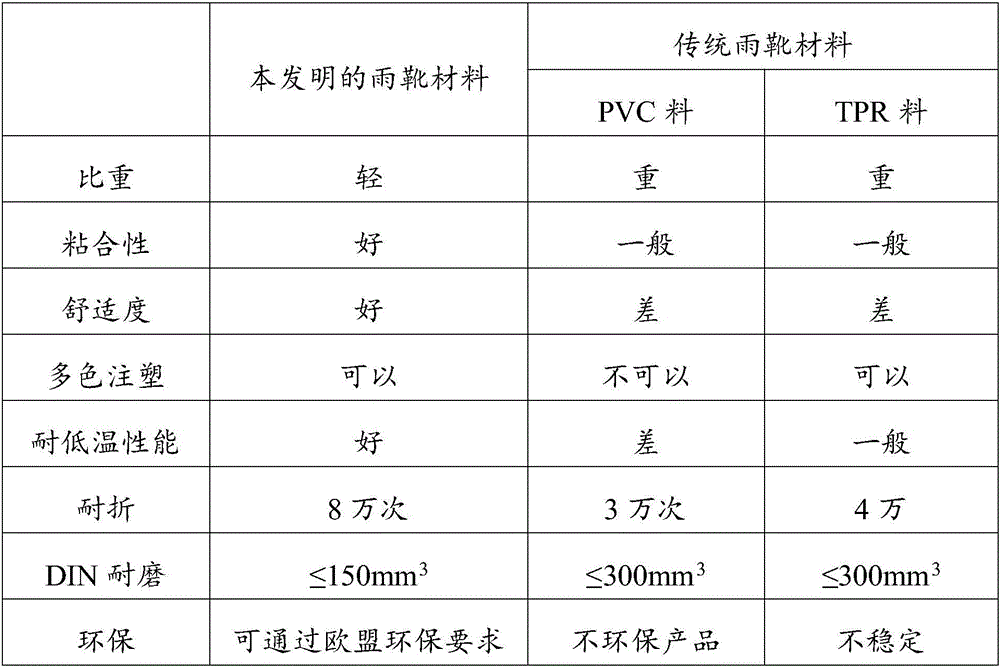

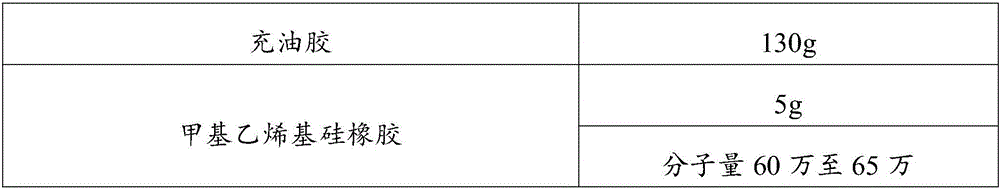

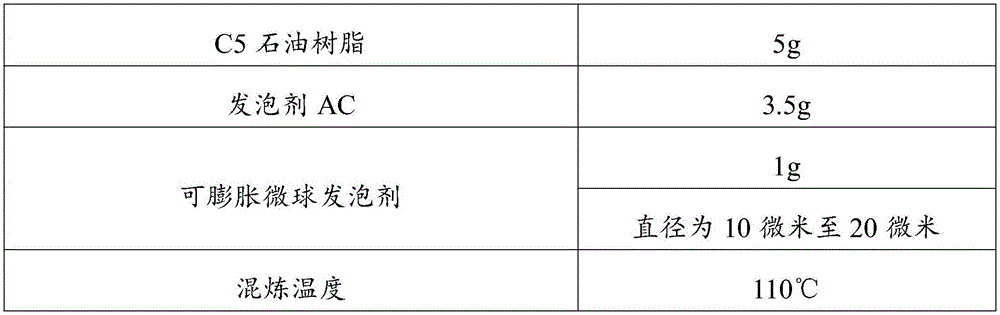

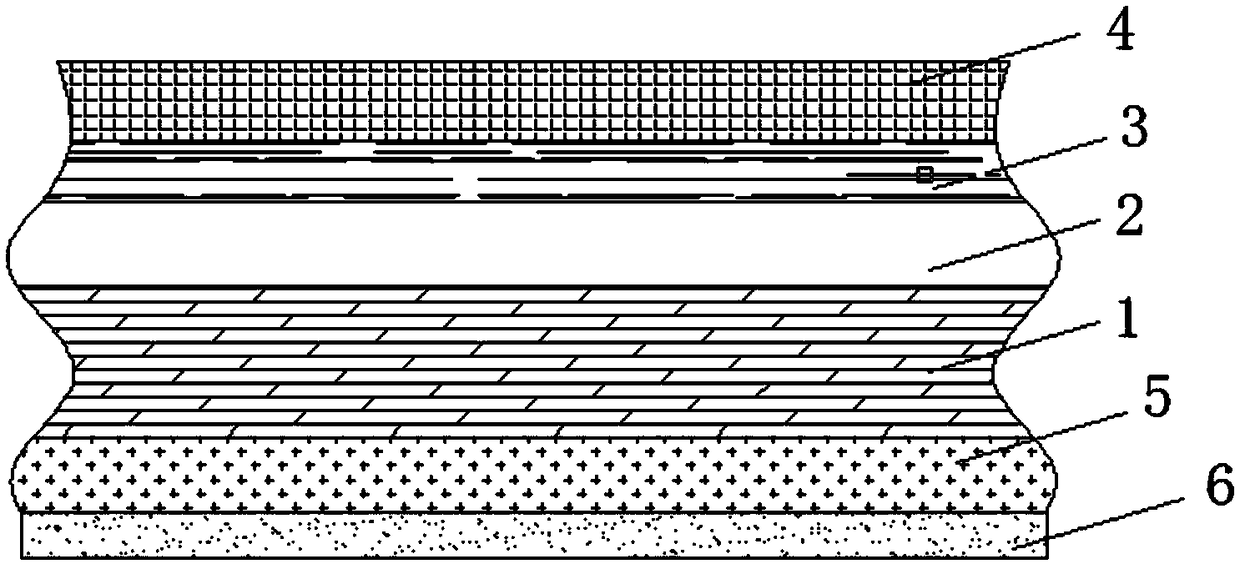

Processing method of rain boot material, rain boot material, rain boot and rain boot processing method

The invention provides a processing method of a rain boot material and a rain boot material prepared through the method. The rain boot material is formed by mechanically mixing a hard material and a soft material. The hard material is formed by melting, extruding and granulating oil-extended rubber, polystyrene, K resin, polyphenyl ether, maleic anhydride modified polyolefin elastomer and / or heavy calcium powder. The soft material is formed by mixing, smelting and granulating oil-extended rubber, methyl vinyl silicone rubber, C5 petroleum resin, foaming agent AC and expandable microsphere foaming agent. The oil-extended rubber is formed by mixing styrene-butadiene-styrene segmented copolymer and softening oil. The invention further provides a rain boot and a rain boot processing method. The prepared rain boot or rain boot material has the advantages of being good in color, luster and brightness, light in weight, resistant to wear and cold, good in processing performance, high in production efficiency, recyclable, environmentally friendly and the like.

Owner:福建斯达新材料科技有限公司

Anti-scraping and anti-wear color coated steel plate

InactiveCN108312664AImprove wear resistanceStrong scratch resistanceSynthetic resin layered productsMetal layered productsChemical reactionAlloy

The invention discloses an anti-scraping and anti-wear color coated steel plate, which comprises a base plate, wherein the base plate comprises a low-carbon steel plate, a hot galvanized layer and analloy anti-wear layer; the alloy anti-wear layer is laminated on the lower surface of the low-carbon steel plate; the hot galvanized layer is laminated on the lower surface of the alloy anti-wear layer; an anti-scraping and anti-wear layer is laminated on the upper surface of the low-carbon steel plate; the top end of the anti-scraping and anti-wear layer is coated with a finishing coat layer; a protective layer is arranged on the outer surface of the finishing coat layer; a chemical reaction layer is arranged on the lower surface of the hot galvanized layer; and the lower end of the chemicalreaction layer is coated with a primer layer. The anti-scraping and anti-wear color coated steel plate is high in wear resistance and high in anti-scraping strength; the anti-scraping and anti-wear layer is made of polyvinylidene fluoride; quartz powder is added and used as a reinforce; and therefore, the wear resistance of the polyvinylidene fluoride is improved, and the strength is enhanced.

Owner:SUZHOU XINGHEYUAN COMPOSITE MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com