Patents

Literature

58 results about "Direct yellow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ink, ink jet recording method, ink cartridge, and ink jet recording apparatus

InactiveUS7208033B2Excellent developabilityGood weather resistanceMeasurement apparatus componentsDuplicating/marking methodsPhthalocyaninePolymer chemistry

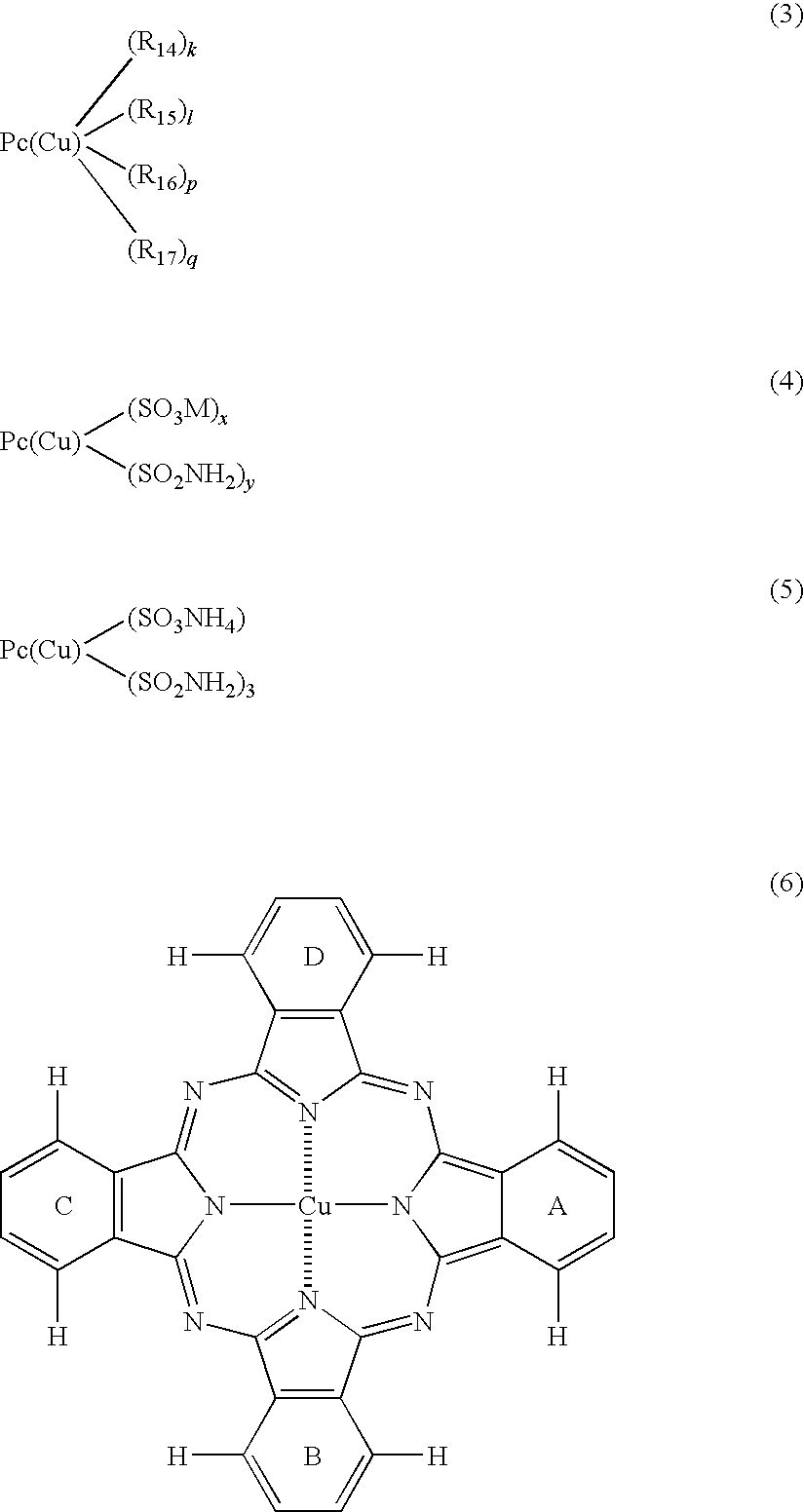

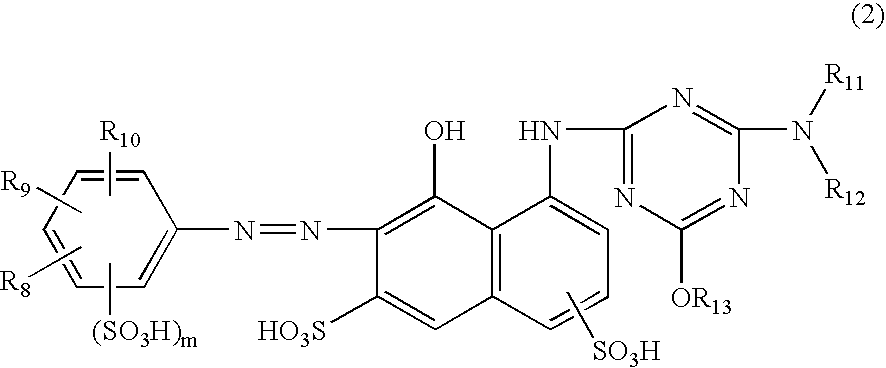

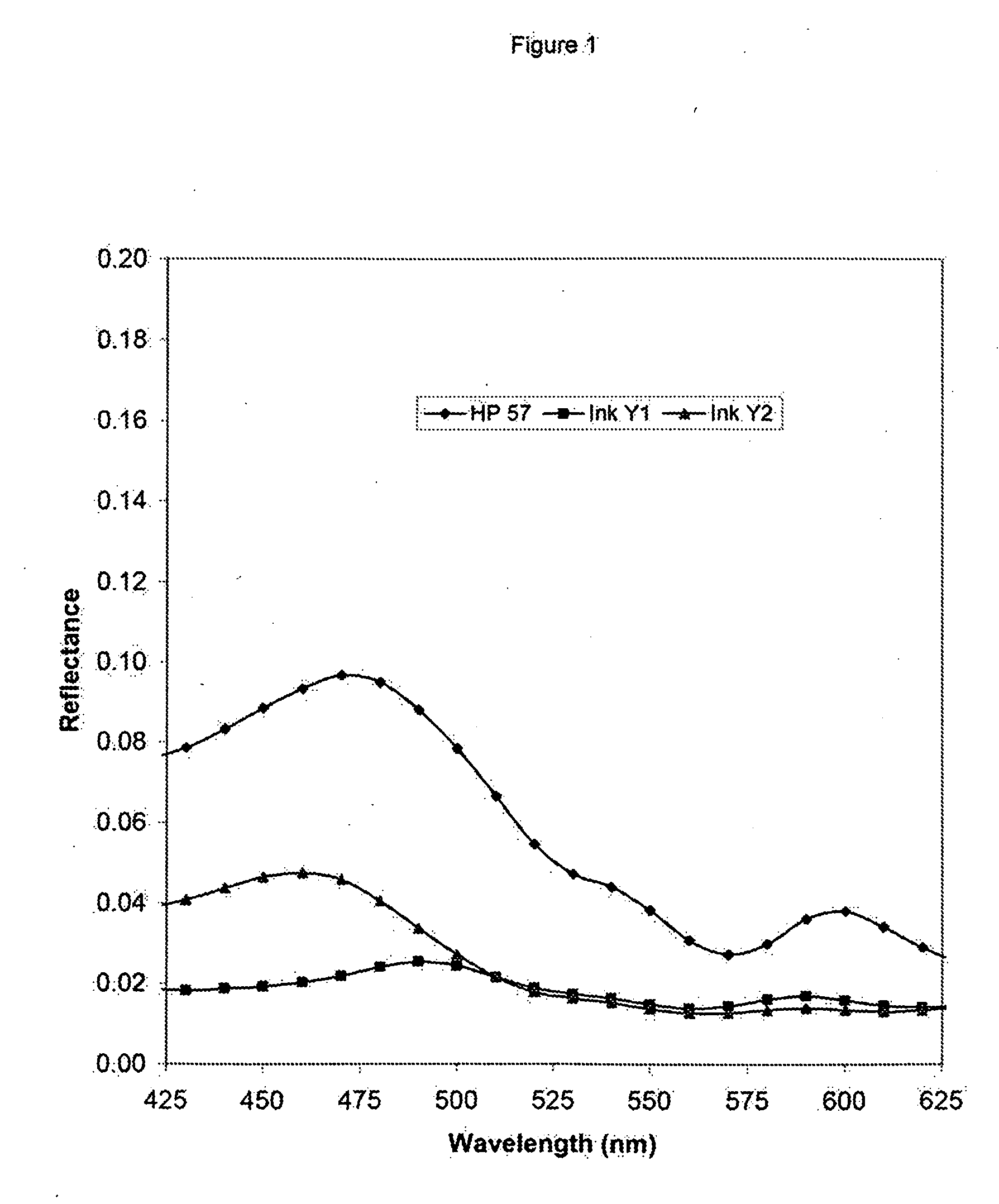

An ink comprising yellow colorants and a colorant having a phthalocyanine skeleton, in which the yellow colorants are at least a colorant represented by the following general formula I and C.I. Direct Yellow 132

Owner:CANON KK

Inkjet ink having yellow dye mixture

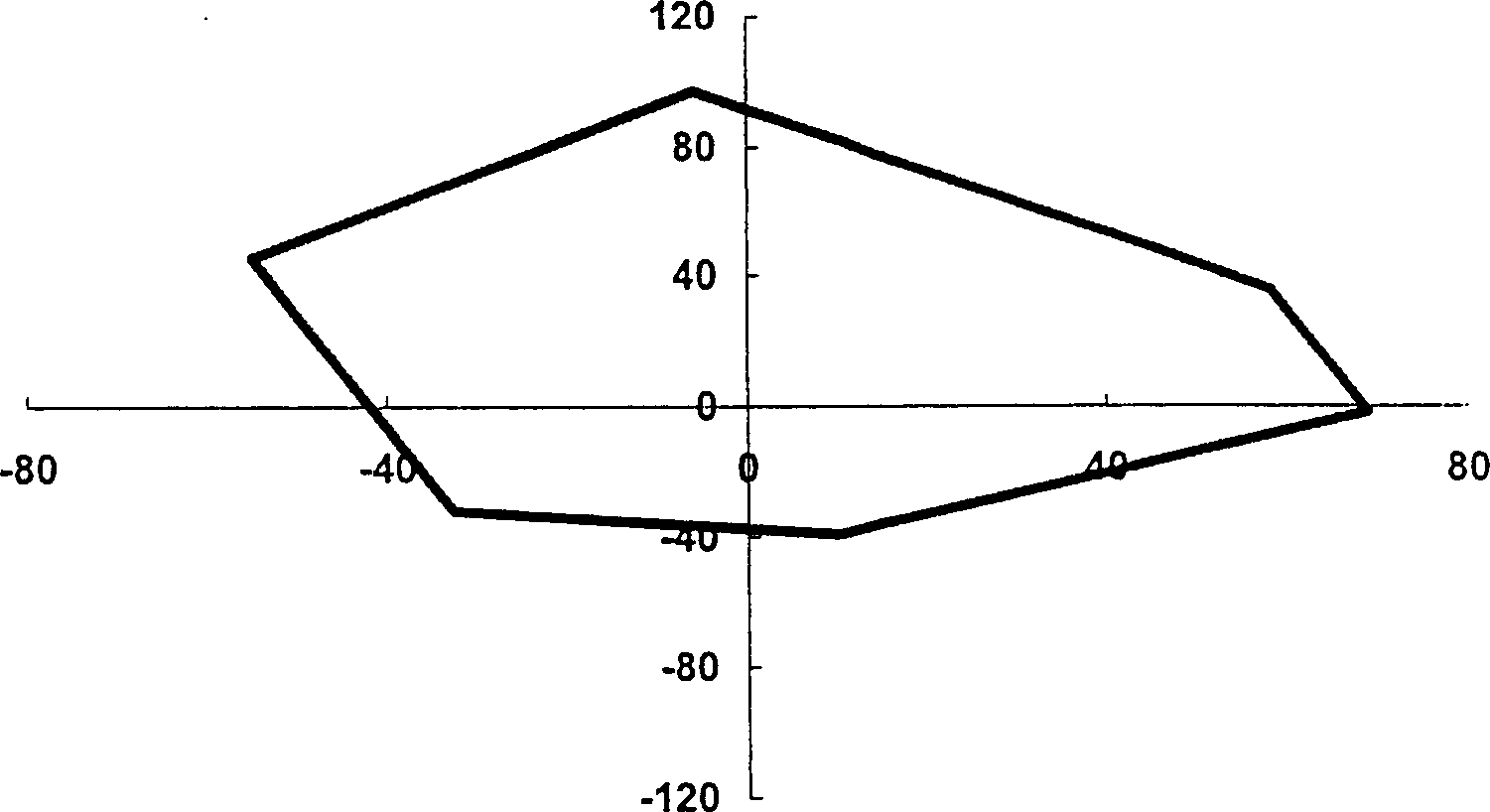

InactiveUS7040746B2Good chromaGood lightfastnessMeasurement apparatus componentsInksYELLOW DYEPhotochemistry

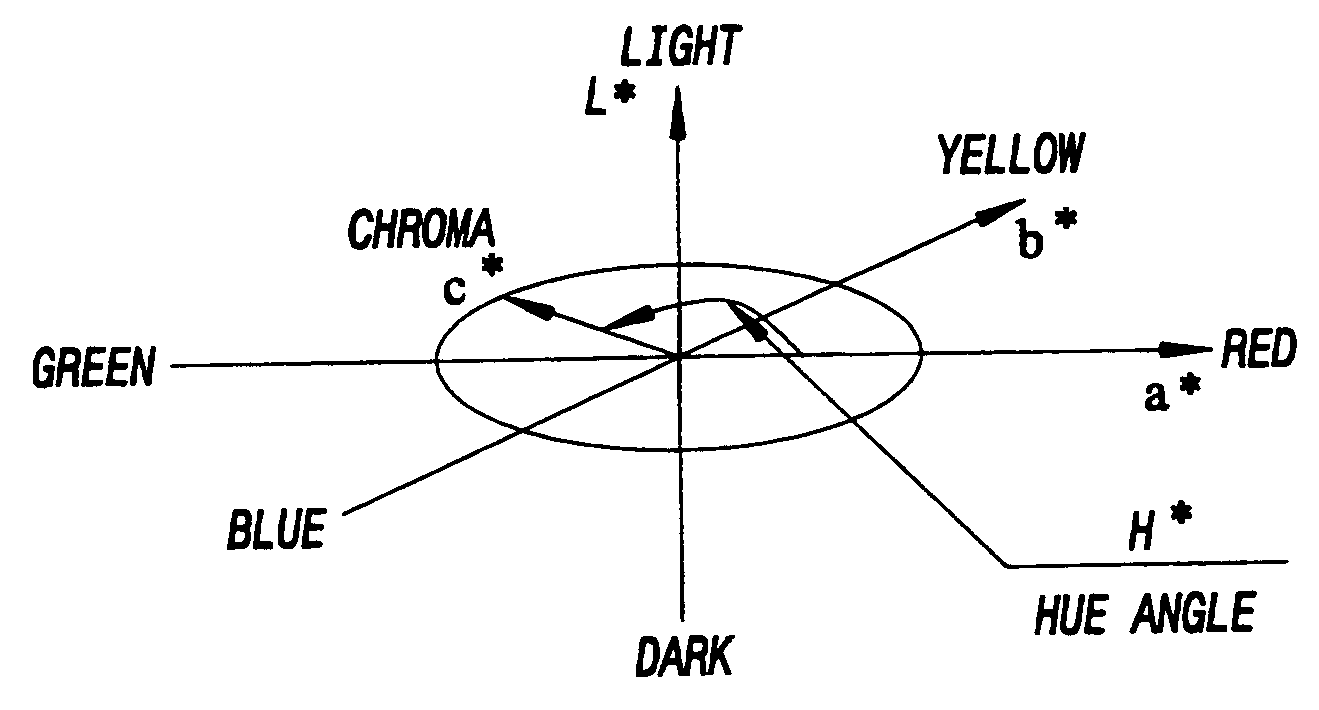

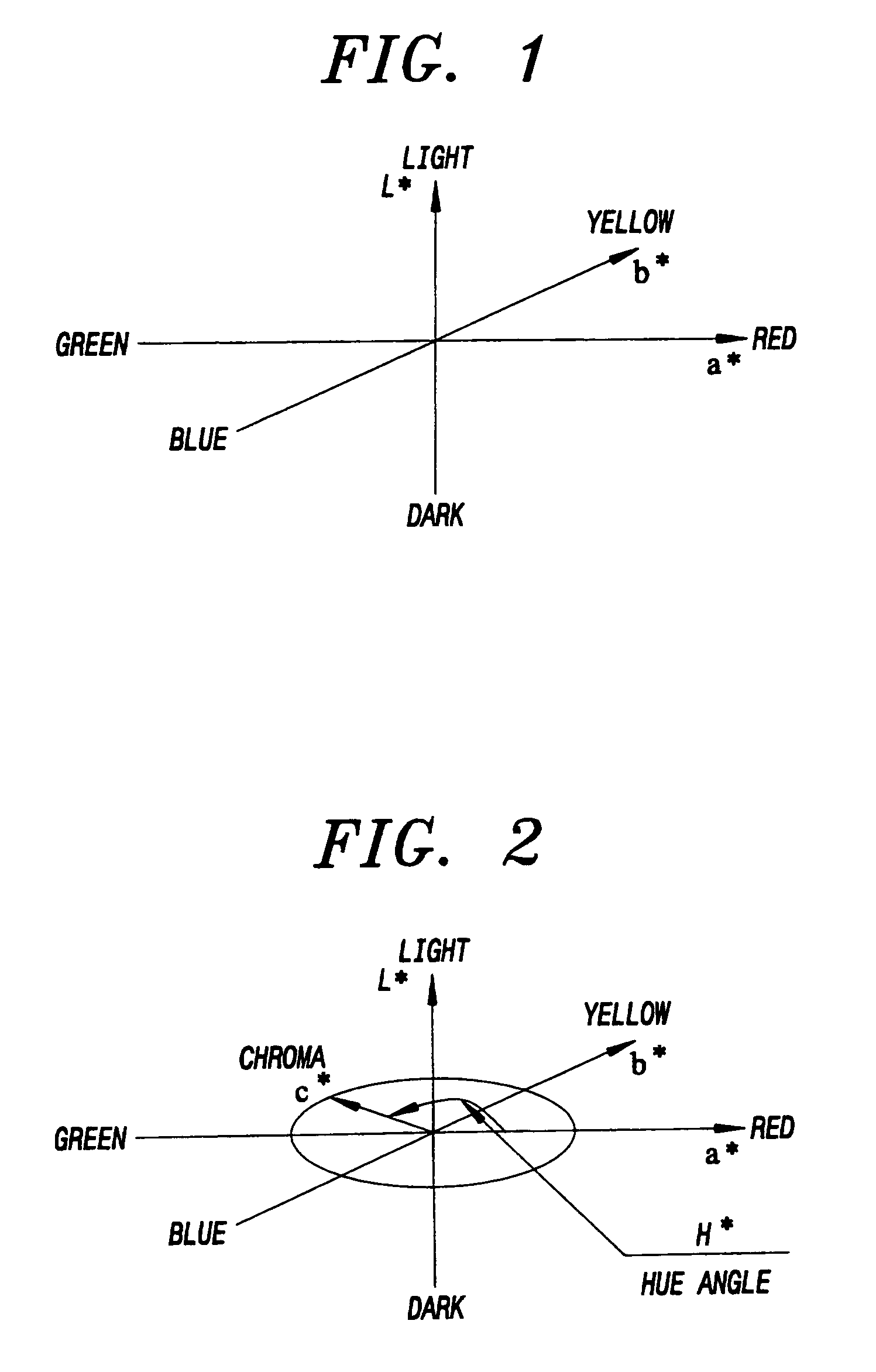

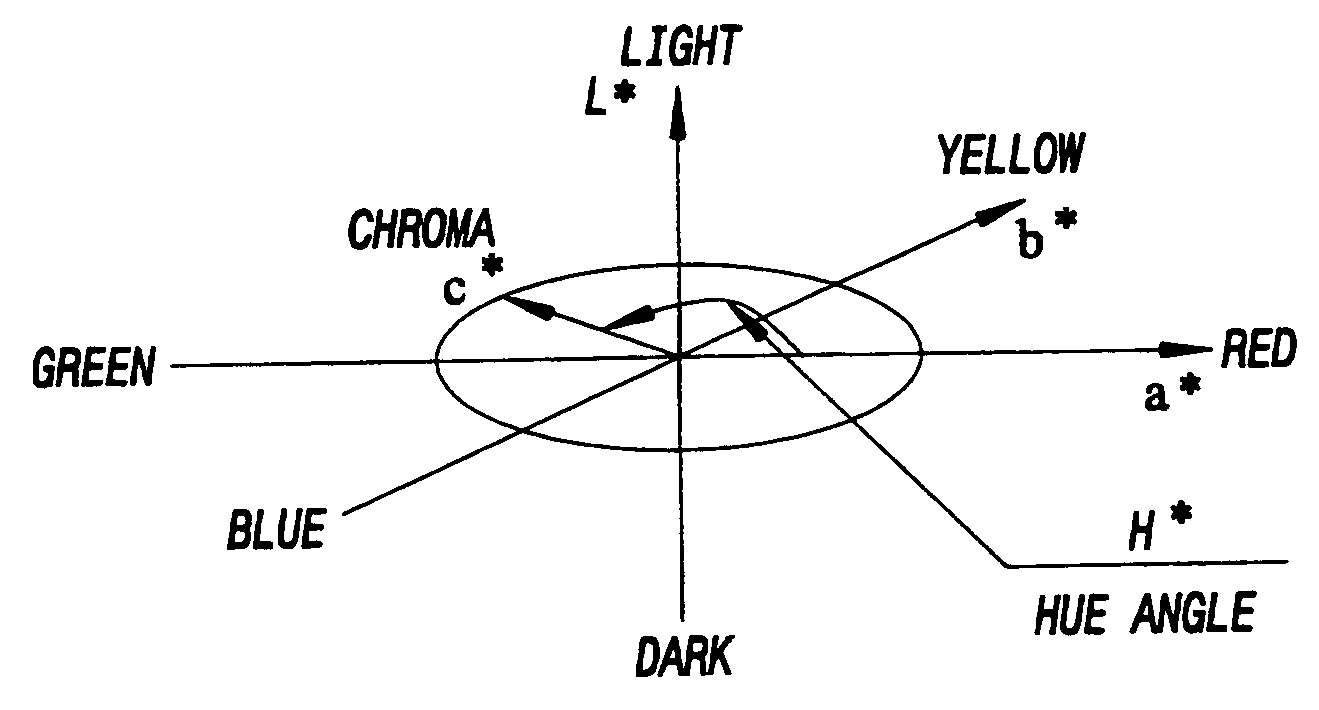

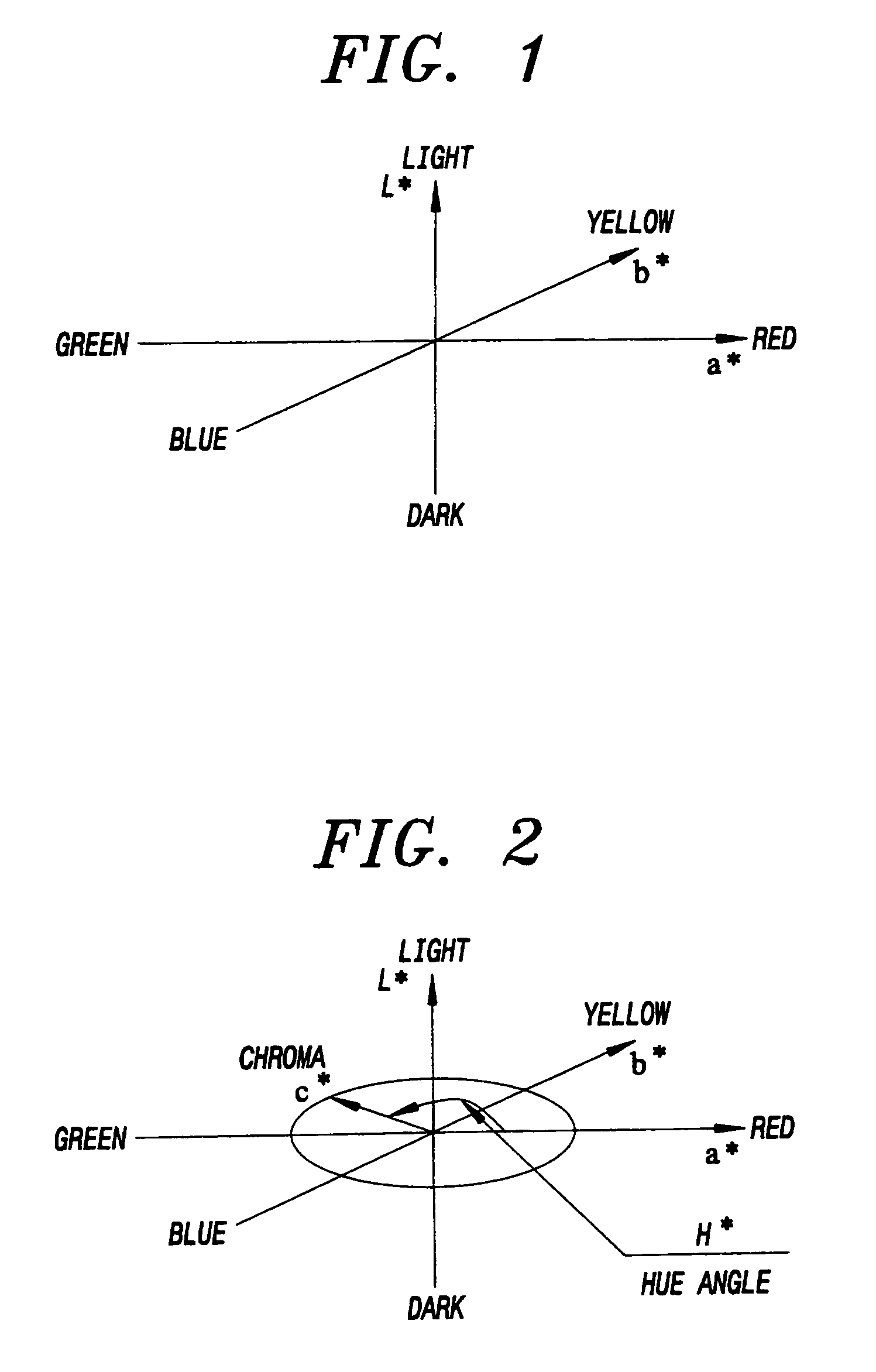

An inkjet ink of exceptional overall color characteristics having about 4% by weight Direct Yellow 132 in acid form, about 1% by weight Acid Yellow 17 in acid form in water, also having a humectant, a penetrant and other generally known additives. The ink having chroma of at least about 108.5.

Owner:BRADY JOHN A +1

Ink jet ink, method for producing ink jet ink, ink jet recording method and ink cartridge

InactiveUS20060139429A1Excellent developabilityIncrease resistanceOrganic chemistryMeasurement apparatus componentsPolymer chemistryDirect yellow

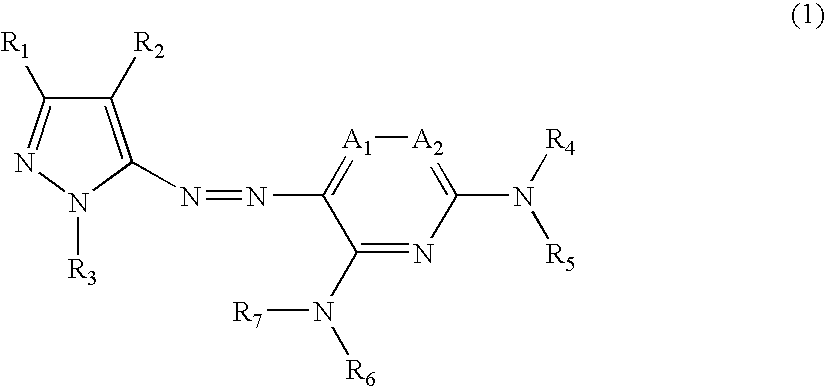

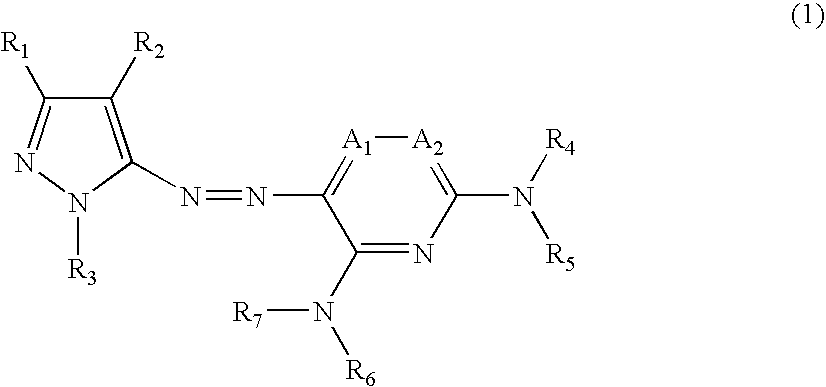

An ink jet ink includes at least a coloring material. The coloring material is composed of at least one selected from the group consisting of C.I. Direct Yellow 86, C.I. Acid Yellow 23, C.I. Direct Yellow 173, C.I. Direct Yellow 132 and C.I. Direct Yellow 59, and a compound represented by the following the general formula (I) or a salt thereof.

Owner:CANON KK

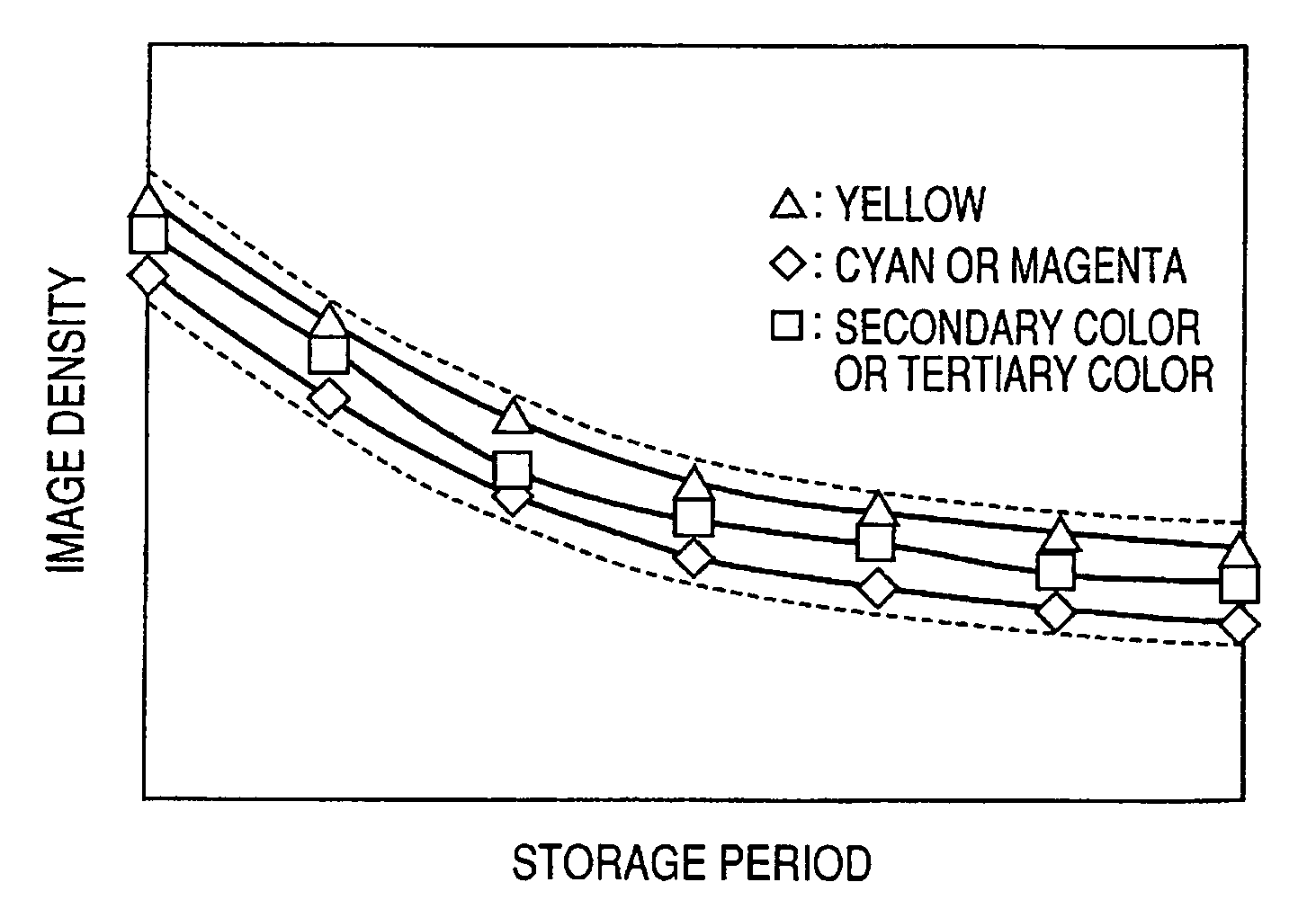

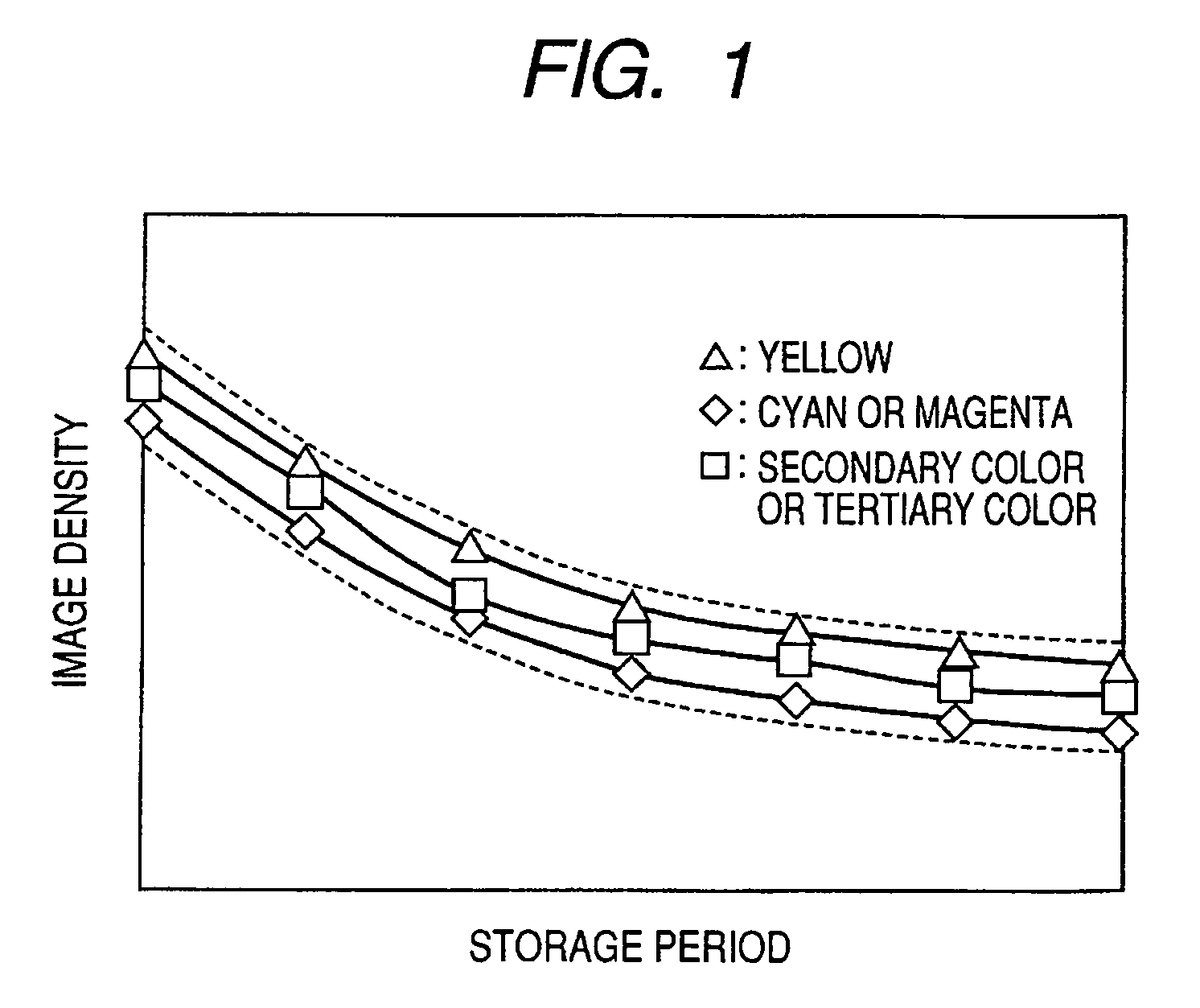

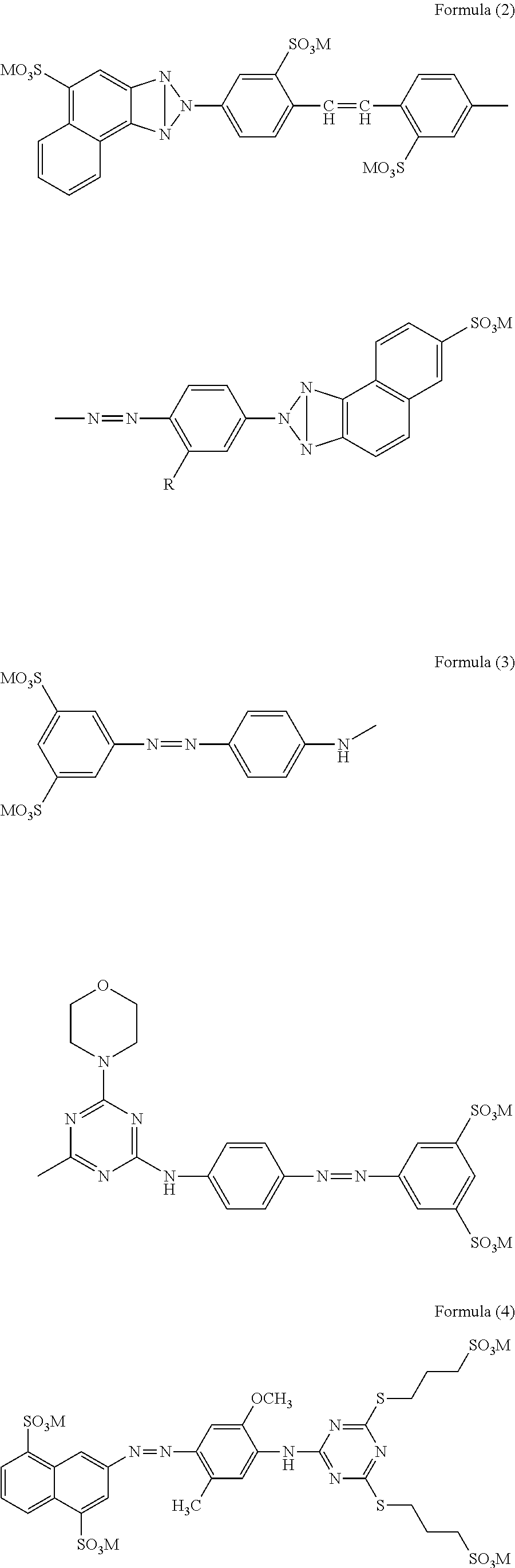

Ink jet yellow ink, ink set, ink jet recording method, ink cartridge, recording unit, and ink jet recording apparatus

InactiveUS7241332B2Good storage stabilityStable storageDuplicating/marking methodsInksLightfastnessDirect yellow

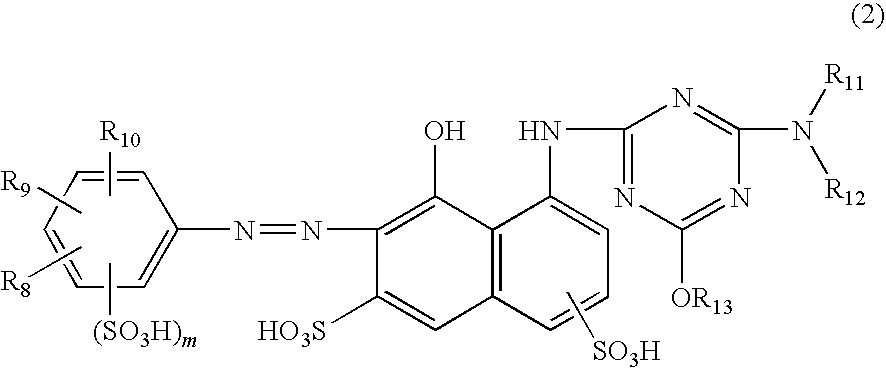

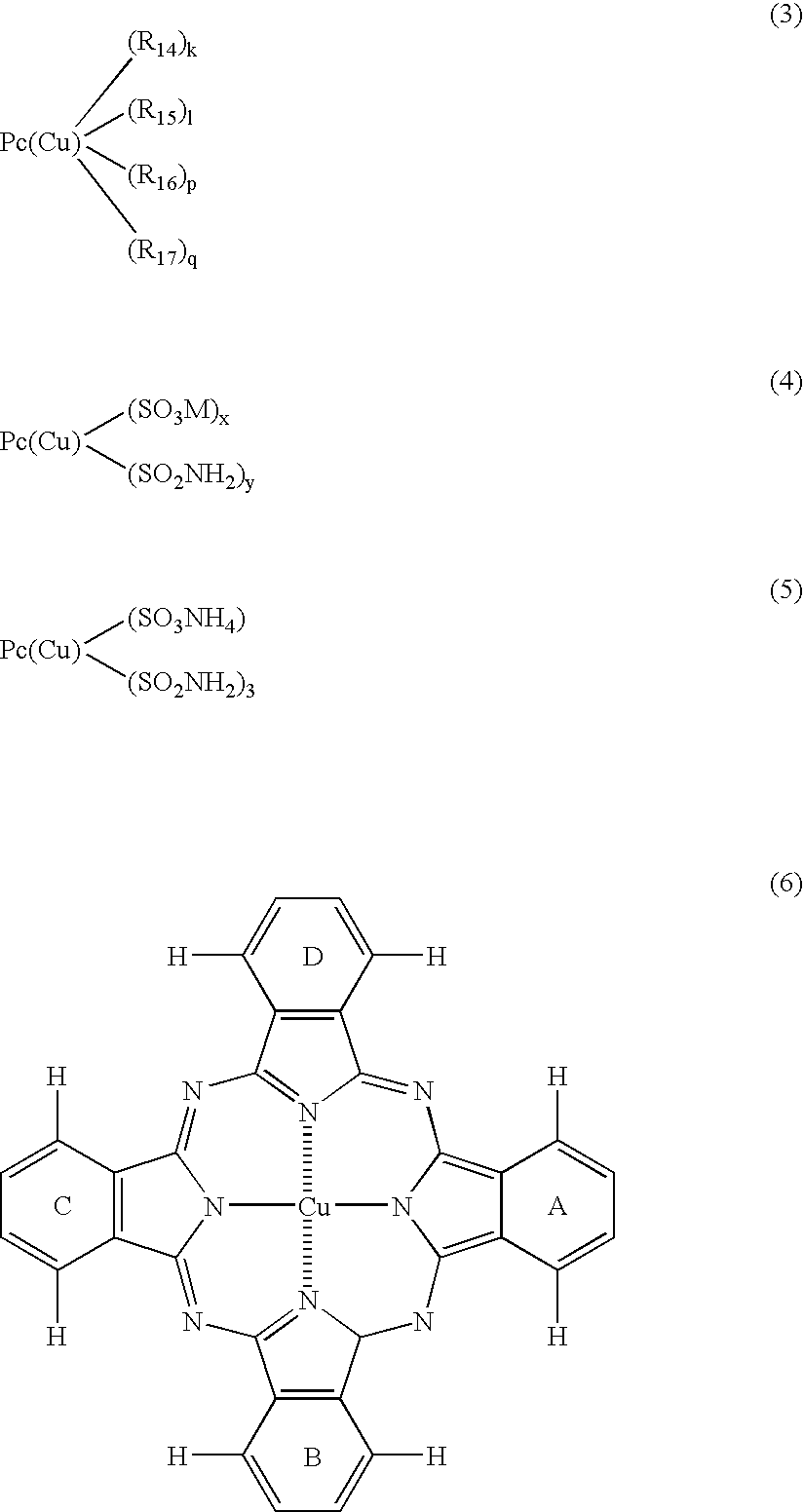

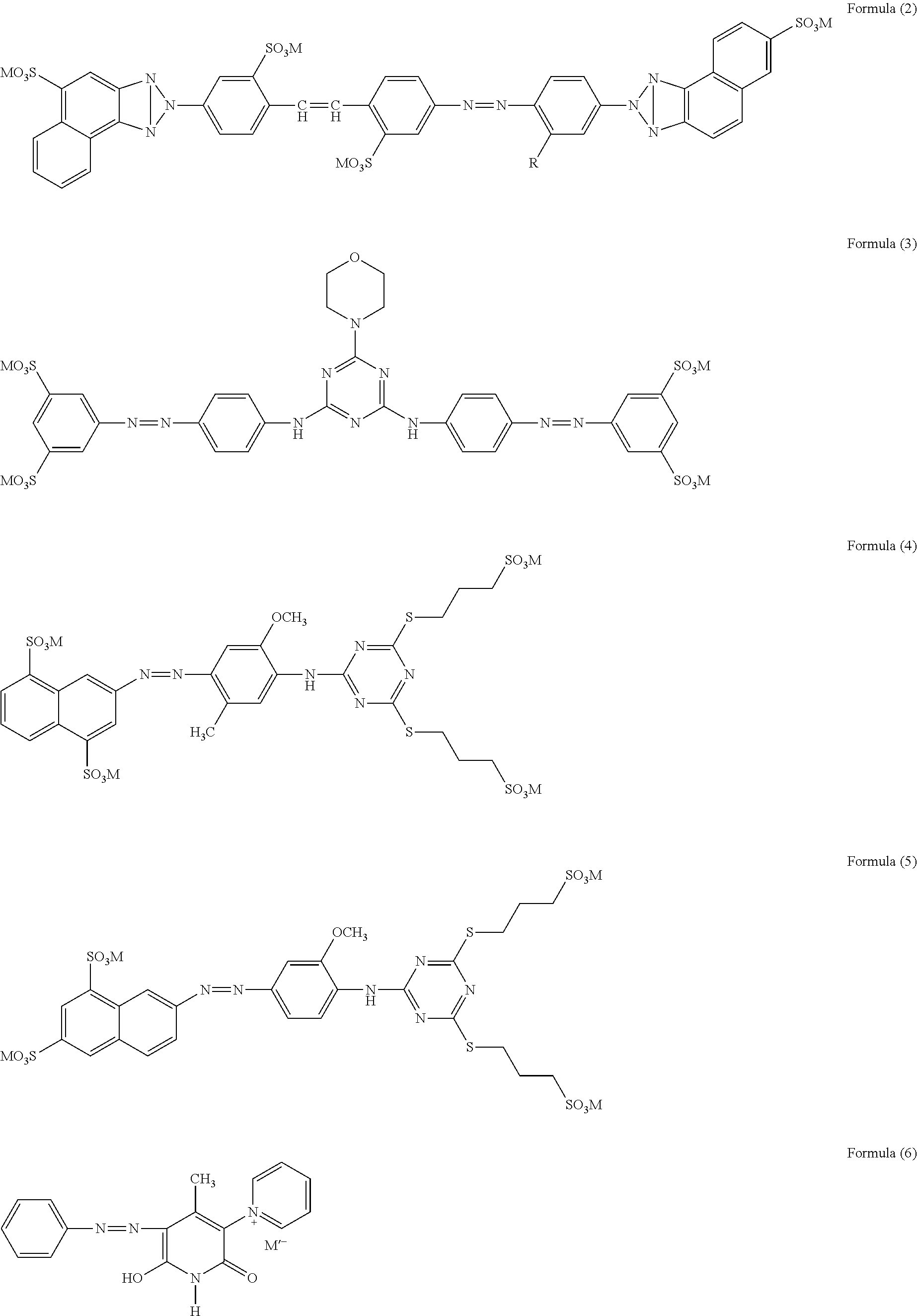

To provide an ink jet yellow ink to be used in combination with ink excellent in light resistance and environmental gas resistance with a color fading balance with respect to light and an environmental gas between the inks uniformized. The ink jet yellow ink is an ink jet yellow ink to be used for forming an image together with a cyan ink comprising a compound represented by a general formula (1) or a compound represented by a general formula (2) as a coloring material, the ink jet yellow ink comprising: at least one kind of coloring material selected from the following A group; and at least one kind of coloring material selected from the following B group.A group: C.I. Direct Yellow 132 and C.I. Direct Yellow 173B group: C.I. Direct Yellow 142, C.I. Direct Yellow 86, and a compound represented by a general formula (3).

Owner:CANON KK

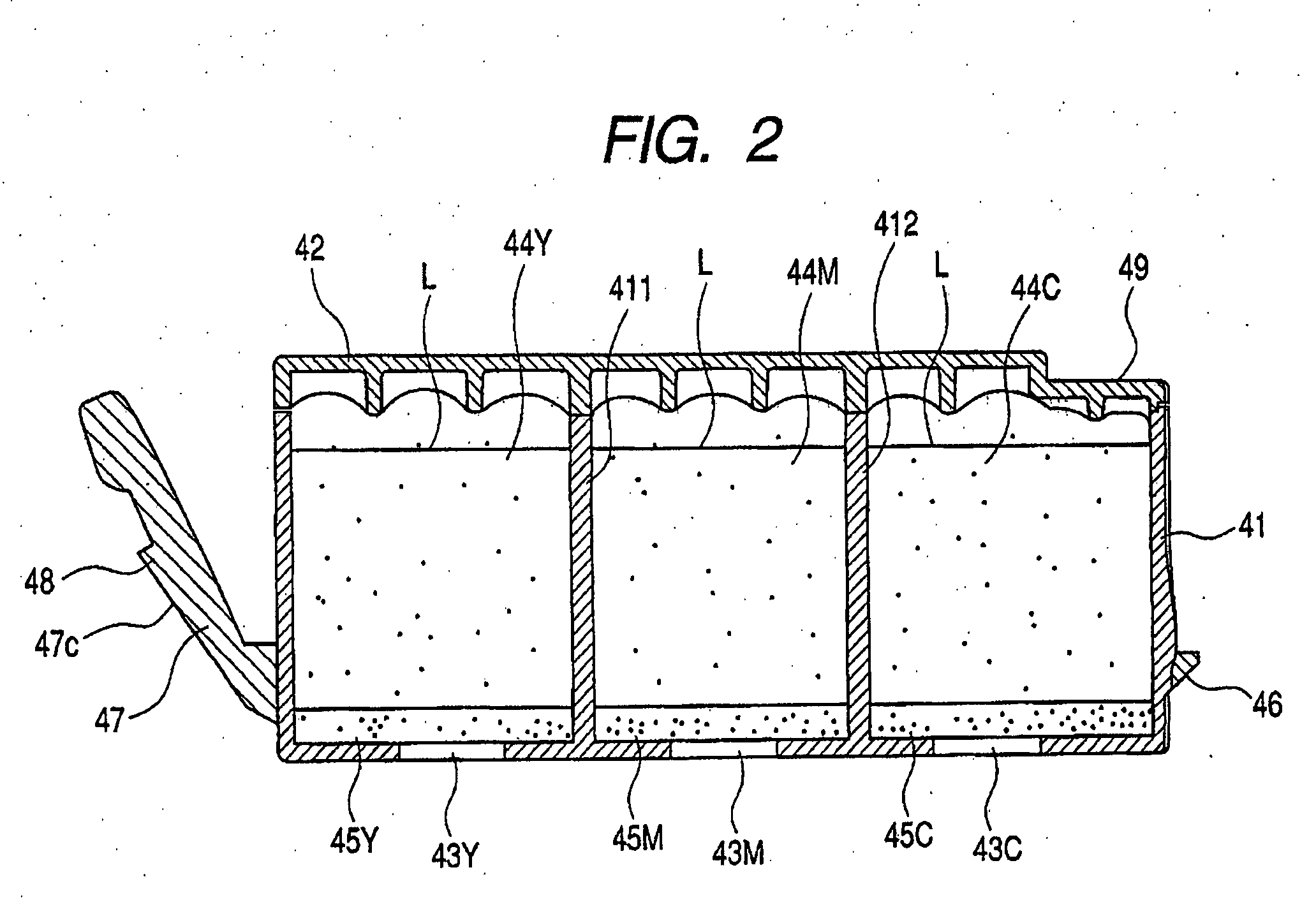

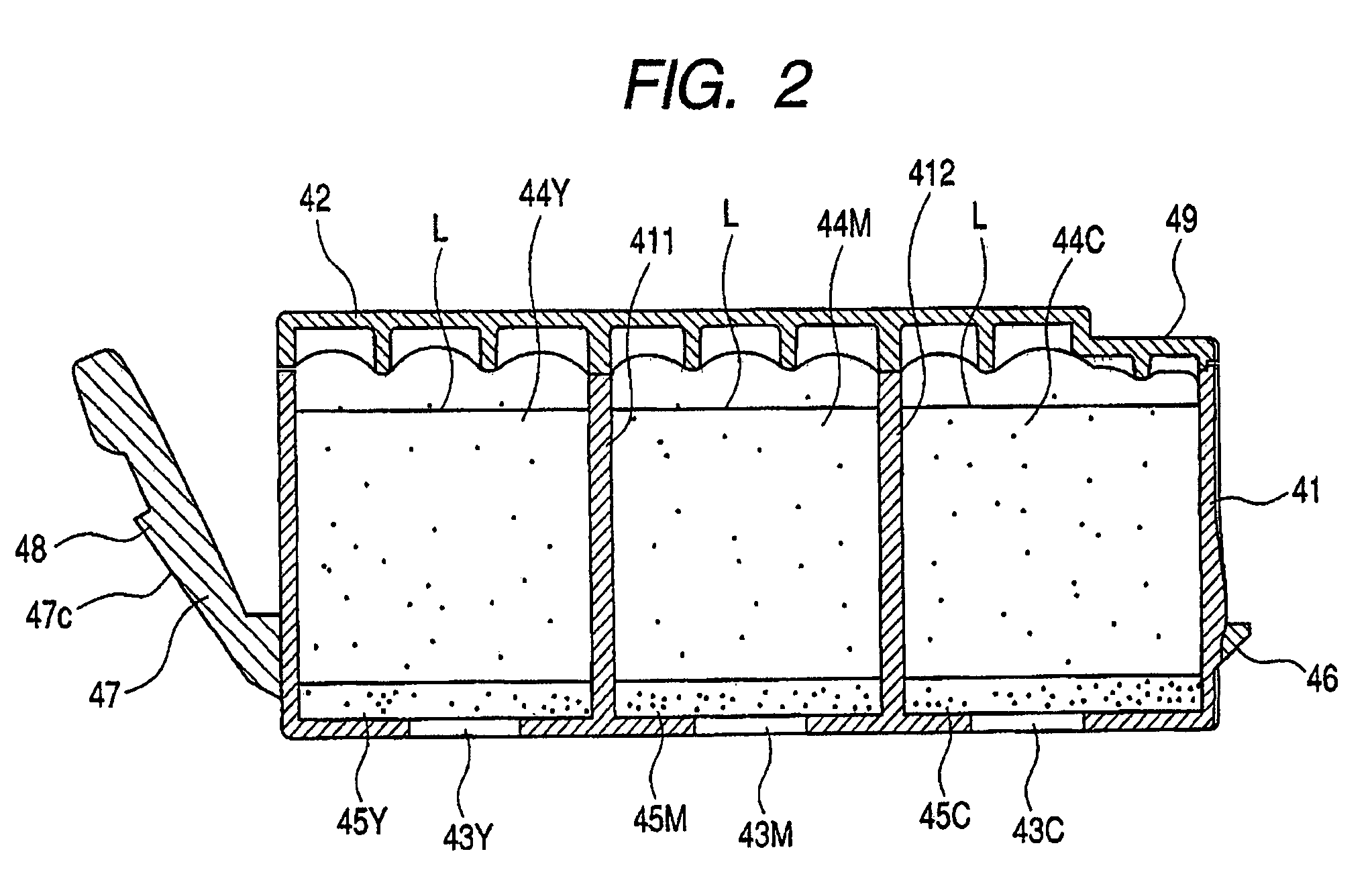

Ink set for ink-jet recording

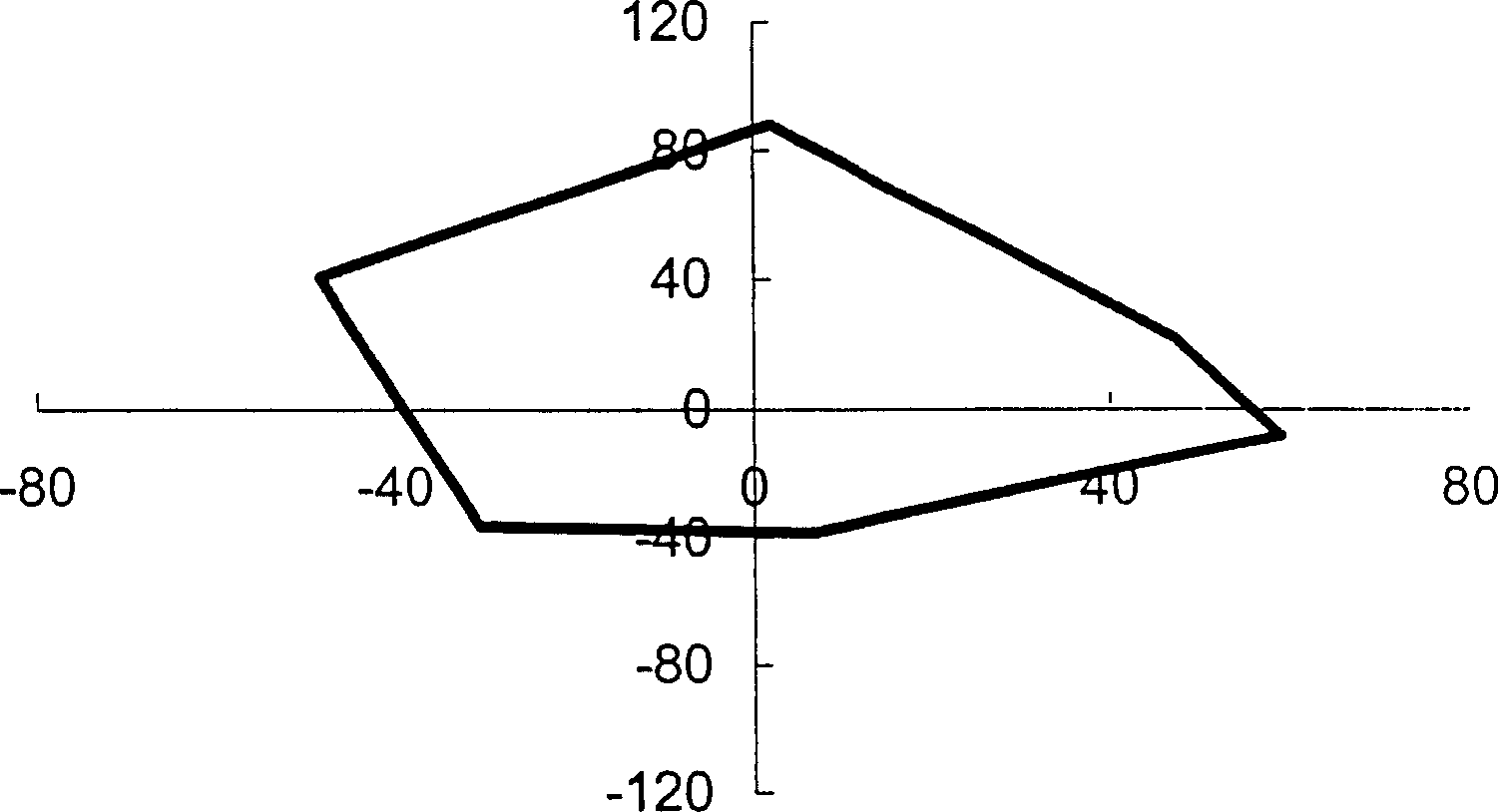

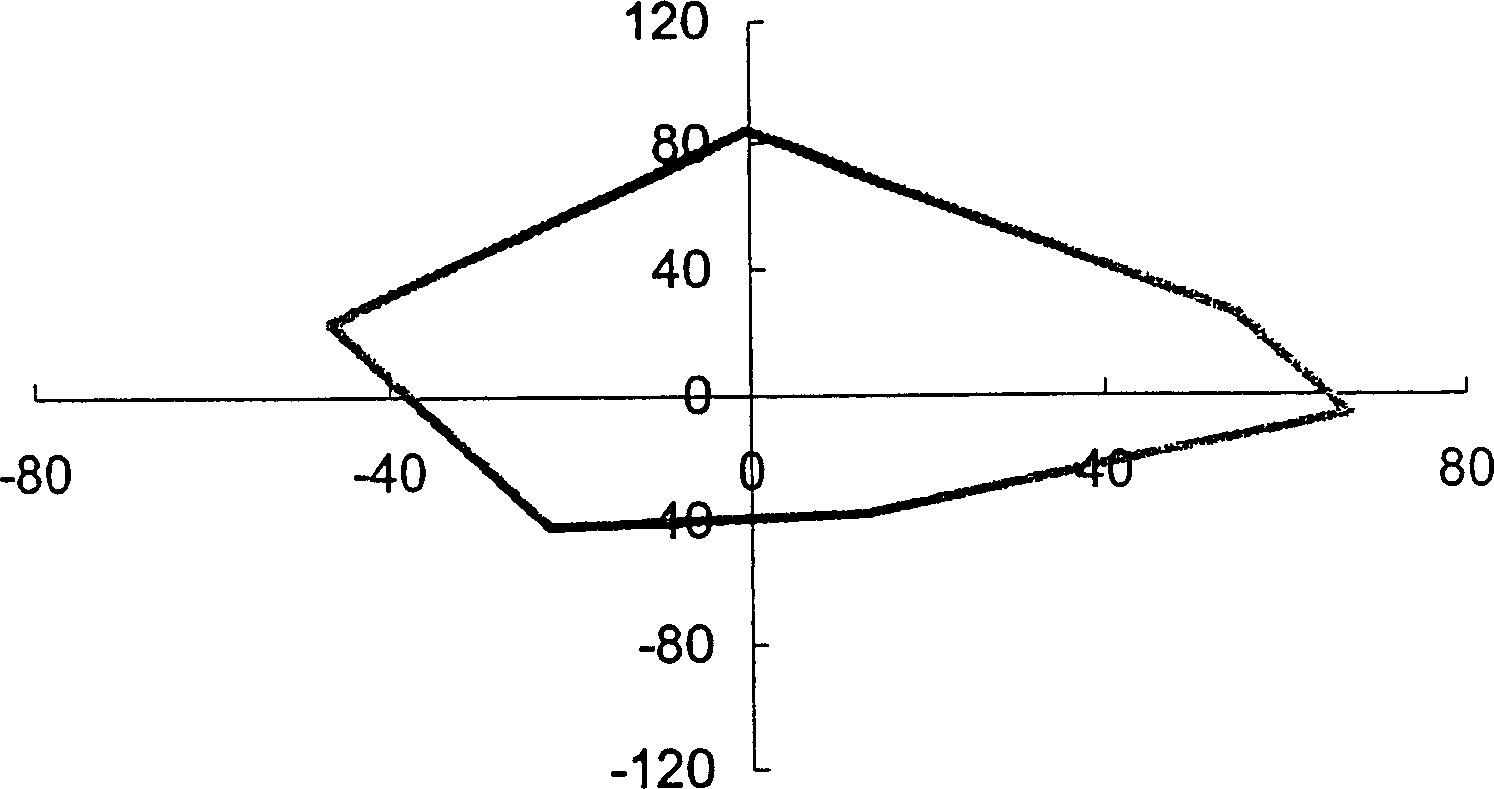

ActiveUS7713343B2Uniform processImprove featuresMonoazo dyesDuplicating/marking methodsMagentaPhotochemistry

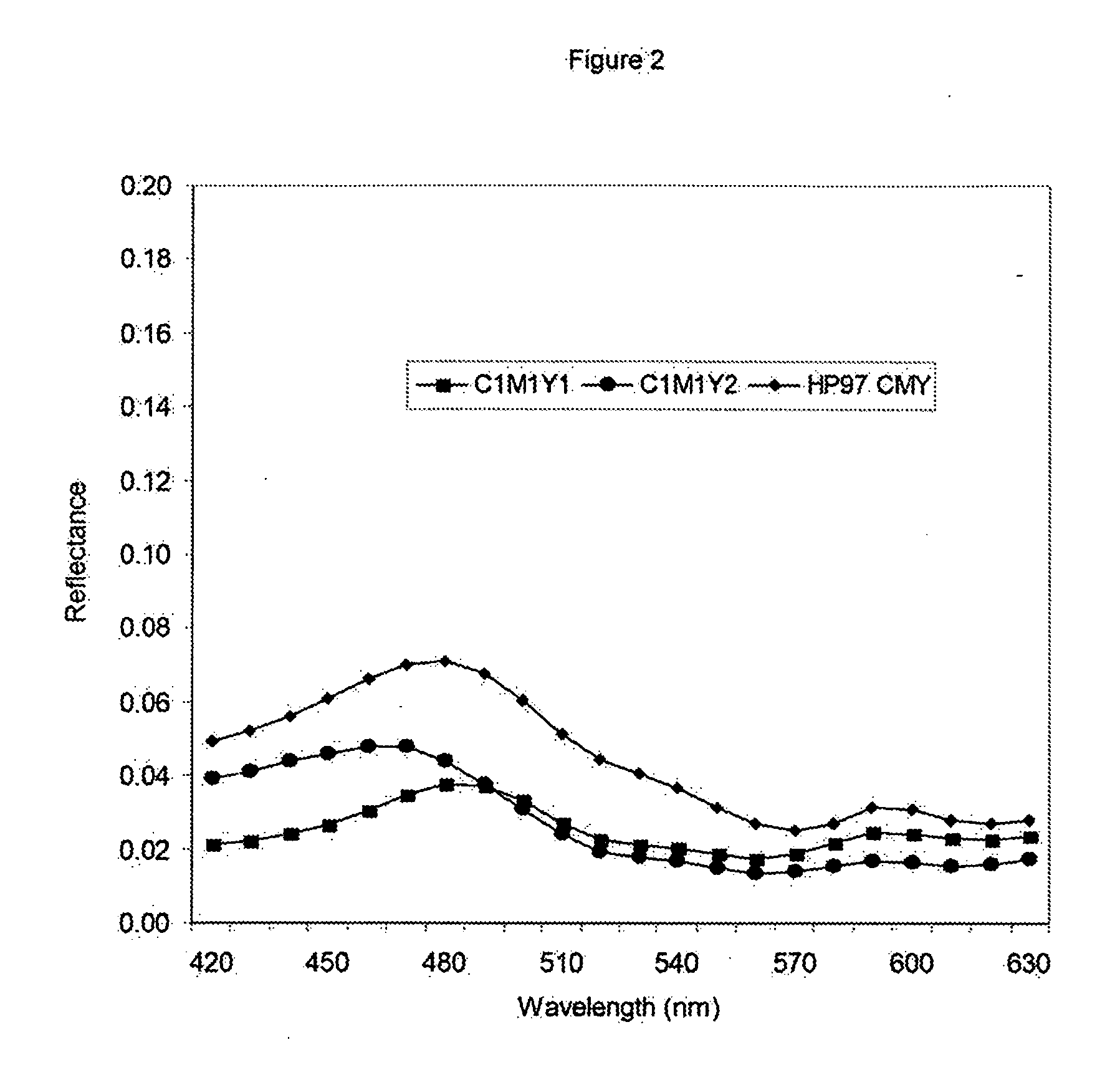

An ink set for ink-jet recording is formed from a yellow ink in which C. I. Direct Yellow 132 and C. I. Direct Yellow 86 are employed, a magenta ink in which a specific pyrazolylazopyridine-based (or pyrazolylazopyrazine-based) dye and another specific dye are employed, and a cyan ink in which two specific types of copper phthalocyanine-based dyes are employed.

Owner:BROTHER KOGYO KK

Ink Set for Ink-Jet Recording

ActiveUS20070186806A1Excellent ejection stabilityGood storage stabilityMonoazo dyesDuplicating/marking methodsMagentaPhotochemistry

An ink set for ink-jet recording is formed from a yellow ink in which C. I. Direct Yellow 132 and C. I. Direct Yellow 86 are employed, a magenta ink in which a specific pyrazolylazopyridine-based (or pyrazolylazopyrazine-based) dye and another specific dye are employed, and a cyan ink in which two specific types of copper phthalocyanine-based dyes are employed.

Owner:BROTHER KOGYO KK

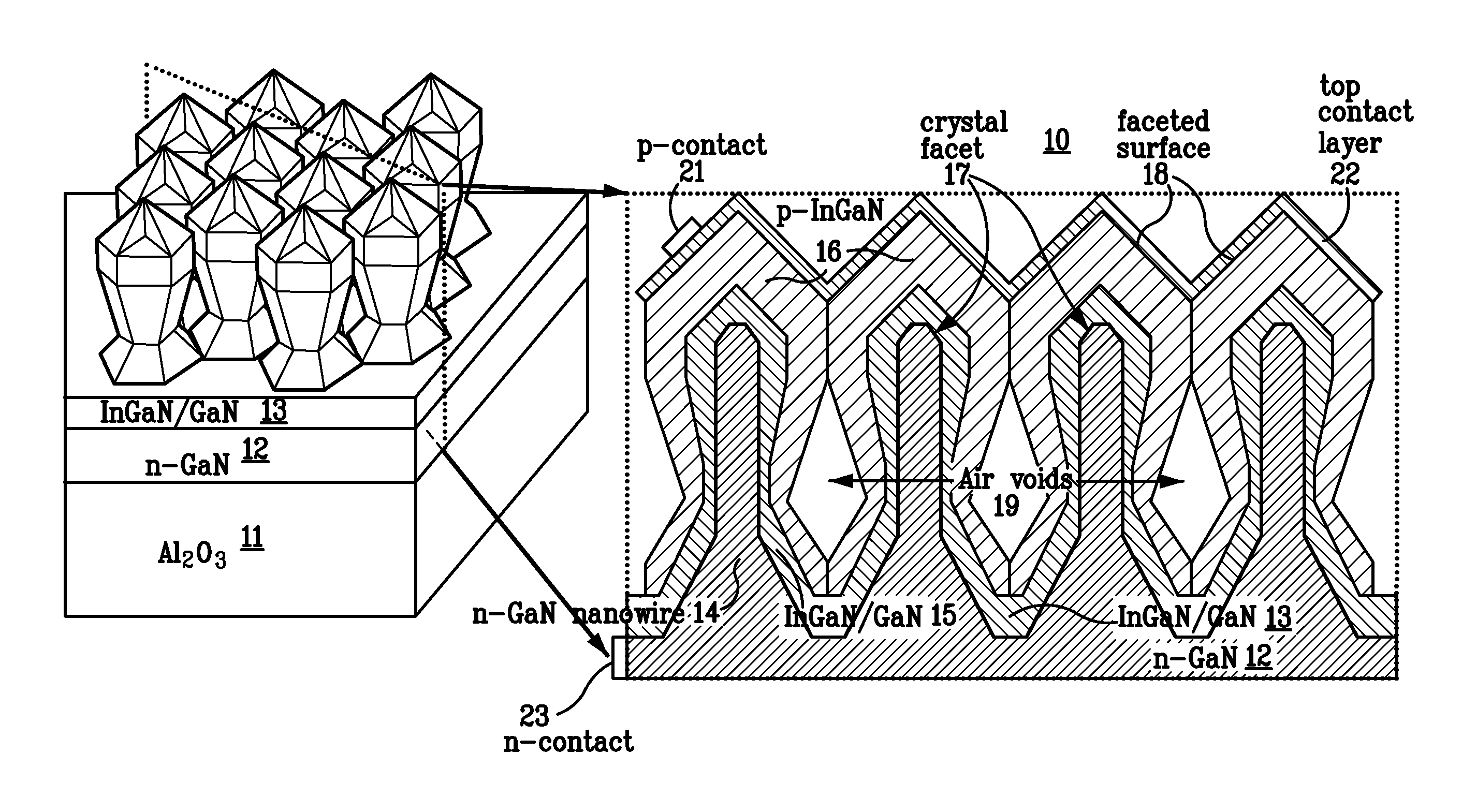

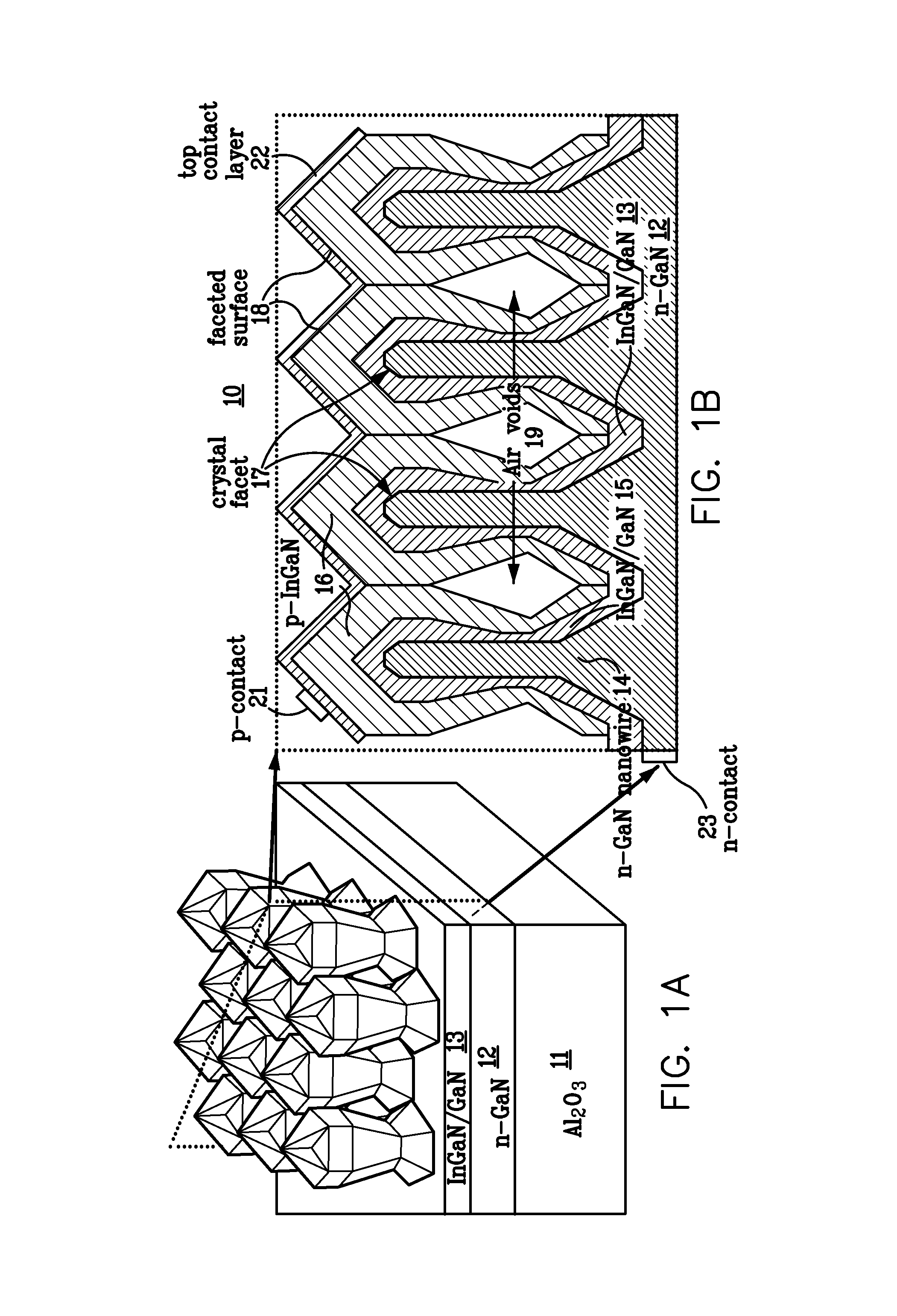

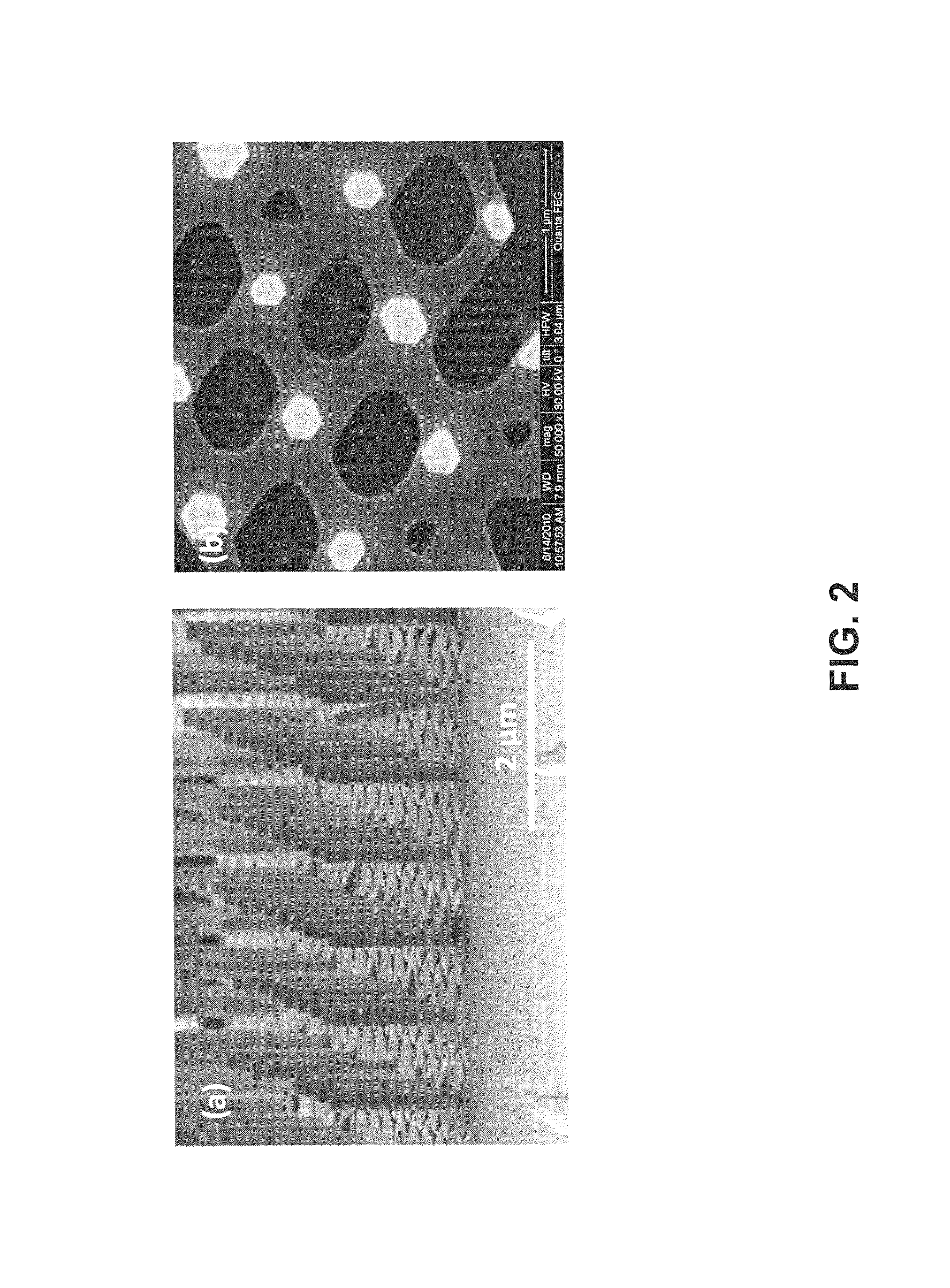

Amber light-emitting diode comprising a group III-nitride nanowire active region

ActiveUS8785905B1Improve material qualityImprove quantum efficiencyMaterial nanotechnologySemiconductor devicesNanowireIndium

A temperature stable (color and efficiency) III-nitride based amber (585 nm) light-emitting diode is based on a novel hybrid nanowire-planar structure. The arrays of GaN nanowires enable radial InGaN / GaN quantum well LED structures with high indium content and high material quality. The high efficiency and temperature stable direct yellow and red phosphor-free emitters enable high efficiency white LEDs based on the RGYB color-mixing approach.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

Light fastness of inkjet images by adding salts into inkjet media

InactiveUS6423375B1Improve light fastnessDuplicating/marking methodsPretreated surfacesSodium thiocyanateSodium iodide

At least one of the following compounds is applied as a re-wet solution to media: potassium iodide, sodium iodide, sodium thiosulfate, potassium thiosulfate, and sodium thiocyanate. The addition of at least one of these compounds to the re-wet solution can improve light fastness on the order of eight to thirteen times or more on porous glossy media. These additives are particularly effective with water-soluble dyes, including dyes such as Reactive Black 31 (Pacified) (RB31), Direct Blue 199 (DB199), Magenta 377 (M377), and Direct Yellow 132 (DY132).

Owner:HEWLETT PACKARD DEV CO LP

Light fastness of inkjet images by adding salts into inkjet inks and print media

InactiveUS6432523B1Improve light fastnessLayered productsDuplicating/marking methodsSodium thiocyanateSodium iodide

At least one of the following compounds is included on a surface layer of a print medium and in an inkjet ink formulation to be printed thereon: potassium iodide, sodium iodide, sodium thiosulfate, potassium thiosulfate, and sodium thiocyanate. The addition of at least one of these compounds to both the print medium and the inkjet ink can improve light fastness on the order of eight to thirteen times or more on porous glossy media. These additives are particularly effective with water-soluble dyes, including such dyes as Reactive Black 31 (Pacified) (RB31), Direct Blue 199 (DB199), Magenta 377 (M377), and Direct Yellow 132 (DY132).

Owner:HEWLETT PACKARD DEV CO LP

Ink, ink jet recording method, ink cartridge, and ink jet recording apparatus

InactiveUS20060065157A1High color developabilityGood weather resistanceMeasurement apparatus componentsDuplicating/marking methodsPhthalocyaninePolymer chemistry

An ink comprising yellow colorants and a colorant having a phthalocyanine skeleton, in which the yellow colorants are at least a colorant represented by the following general formula I and C.I. Direct Yellow 132.

Owner:CANON KK

Ink jet ink, method for producing ink jet ink, ink jet recording method and ink cartridge

InactiveUS7297199B2Excellent developabilityIncrease resistanceOrganic chemistryMeasurement apparatus componentsOrganic chemistryDirect yellow

An ink jet ink includes at least a coloring material. The coloring material is composed of at least one selected from the group consisting of C.I. Direct Yellow 86, C.I. Acid Yellow 23, C.I. Direct Yellow 173, C.I. Direct Yellow 132 and C.I. Direct Yellow 59, and a compound represented by the following the general formula (I) or a salt thereof.

Owner:CANON KK

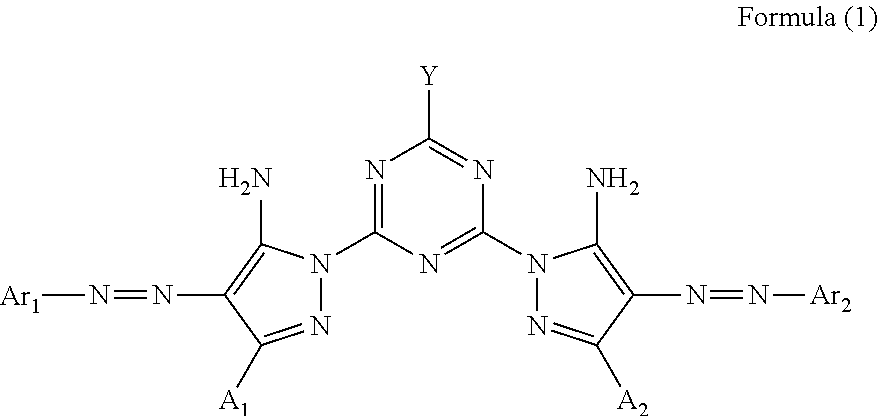

Ink composition, inkjet recording ink composition, ink set, ink cartridge, inkjet recording method and recorded matter

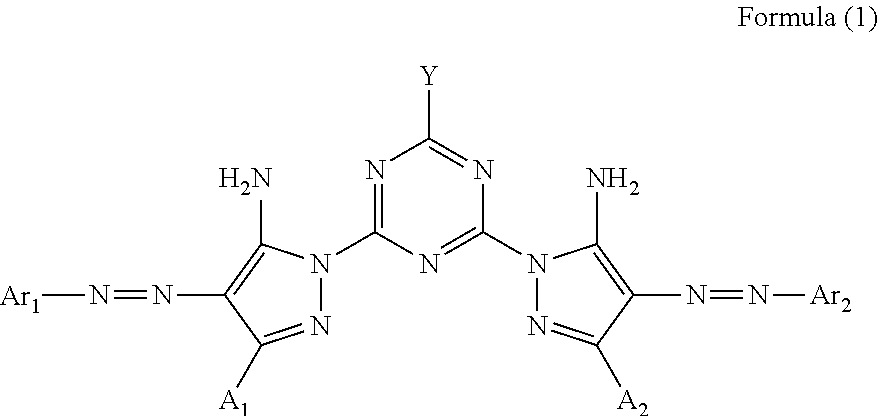

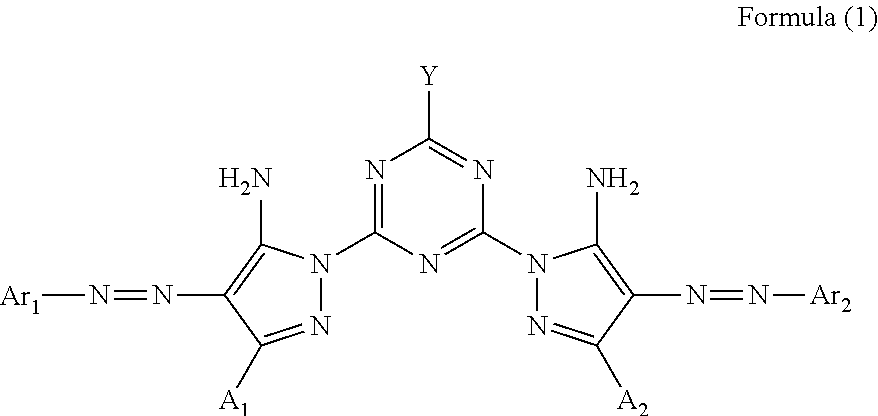

InactiveUS20110104458A1Improve discharge performanceHydrolysis is inducedDisazo dyesDecorative surface effectsArylHydrogen atom

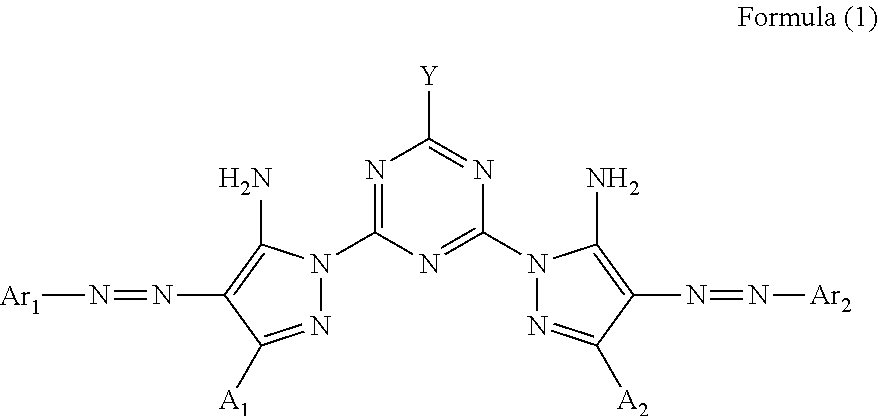

An ink composition having a suitably-adjusted hue and causing no decomposition of dyes during storage is provided. The ink composition contains a compound (a) represented by the following formula (1), an ingredient (c) and moisture-retentive agents, characterized by being from 0.1 mass % to lower than 7.0 mass % in content of the compound represented by the formula (1), 10.0 mass % or lower in content of a moisture-retentive agent having 3 or more hydroxyl groups (b) and lower than 30.0 in molar ratio of the moisture-retentive agent having 3 or more hydroxyl groups to the compound represented by the formula (1):wherein each of Ar1 and Ar2 preferably represents an aromatic heterocyclic group, each of A1 and A2 represents a hydrogen atom or a substituent, Y represents —OM or —NR1R2, M represents a hydrogen atom or a metal ion and each of R1 and R2 represents a hydrogen atom, an alkyl group, an aryl group, a heterocyclic group or the like. The ingredient (c) is at least one compound selected from C.I. Direct Yellow 59, id. 86, id. 132 or the like.

Owner:FUJIFILM CORP

Inkjet ink and ink set

The present invention pertains to a yellow ink for inkjet printing and, in particular, to a yellow ink comprising a combination of specific yellow colorants, namely Acid Yellow 79 and either one or both of Direct Yellow 169 and Acid Orange 33. The present invention further pertains to an ink set comprising this yellow ink. The ink and ink set are particularly advantageous for printing on plain and photo glossy paper.

Owner:EI DU PONT DE NEMOURS & CO

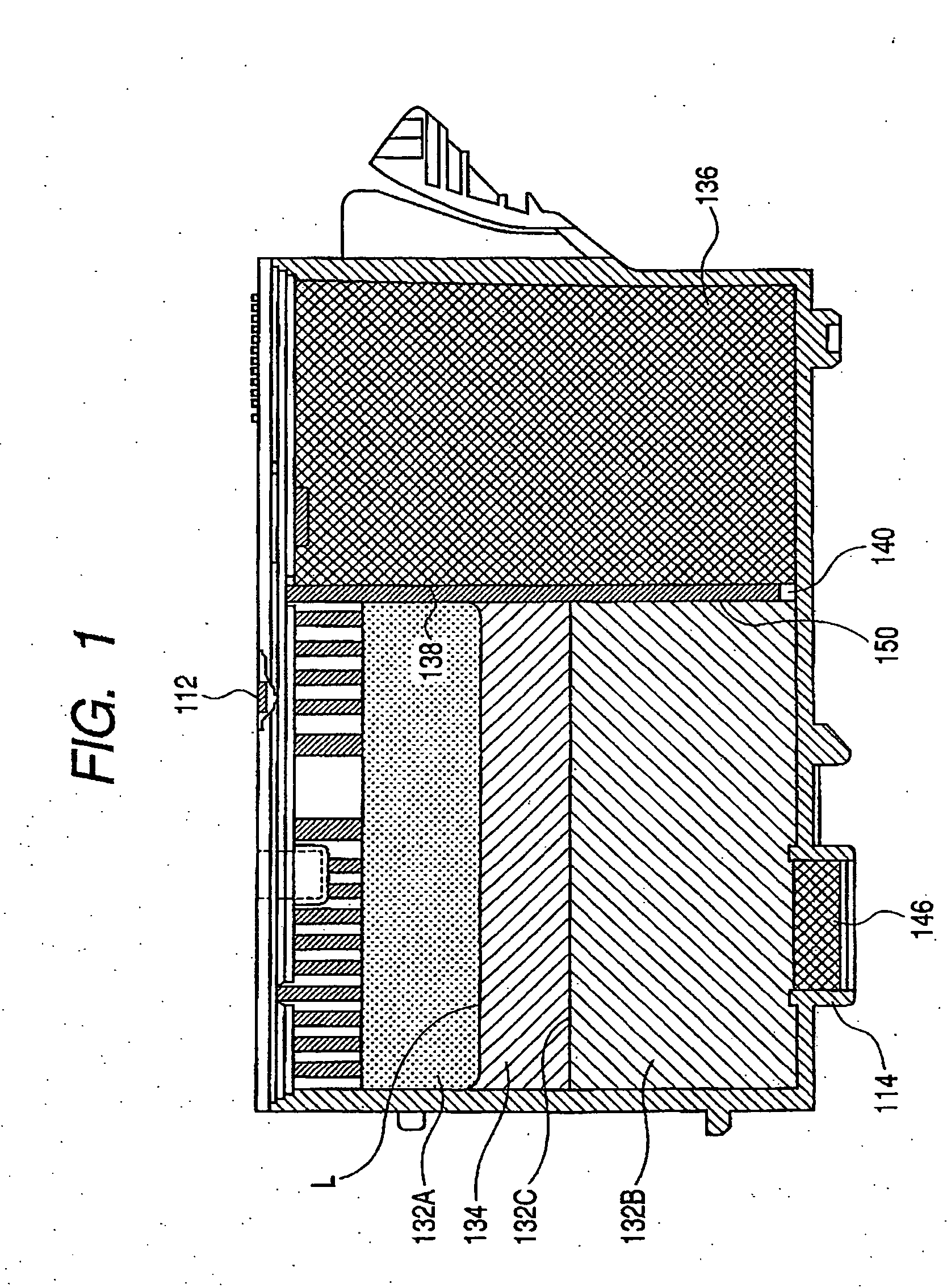

Ink jet ink set and ink jet recording system

ActiveUS20140218451A1Maintain good propertiesImprove stabilityMeasurement apparatus componentsInksDiethylene glycolMagenta

An ink jet ink set, at least has a cyan ink, a magenta ink, and a yellow ink, in which the cyan ink contains at least either one of C.I. Acid Blue 9 or C.I. Direct Blue 199, the magenta ink contains at least either one of C.I. Acid Red 249 or C.I. Reactive Red 141, the yellow ink contains at least either one of C.I. Direct Yellow 86 or C.I. Direct Yellow 132, and the cyan ink, the magenta ink, and the yellow ink all contain an alkylene oxide adduct of acetylene glycol having 12 or more carbon atoms in the main chain, acetylene glycol having 10 or more carbon atoms in the main chain, and polyoxy alkylene alkyl ether.

Owner:SEIKO EPSON CORP

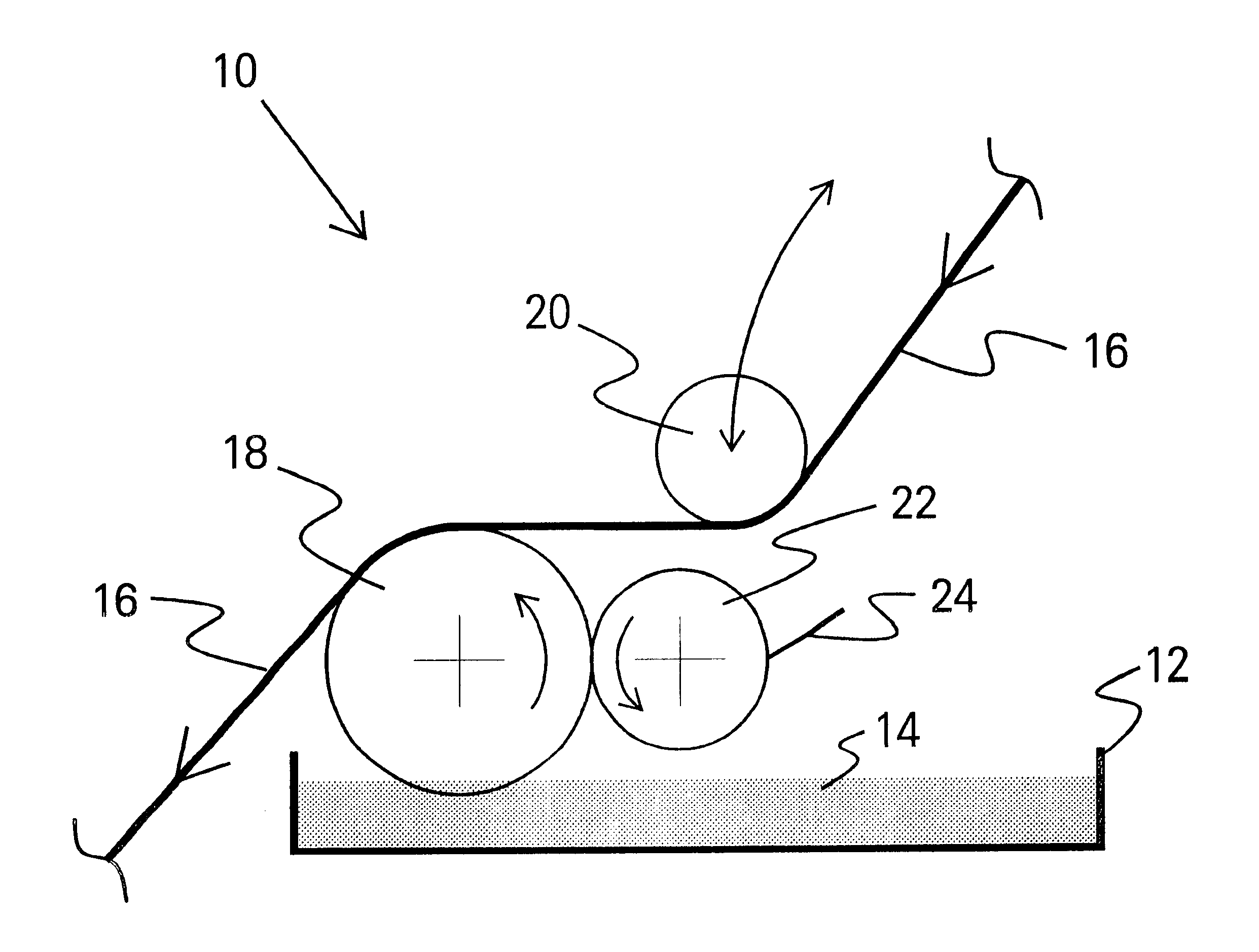

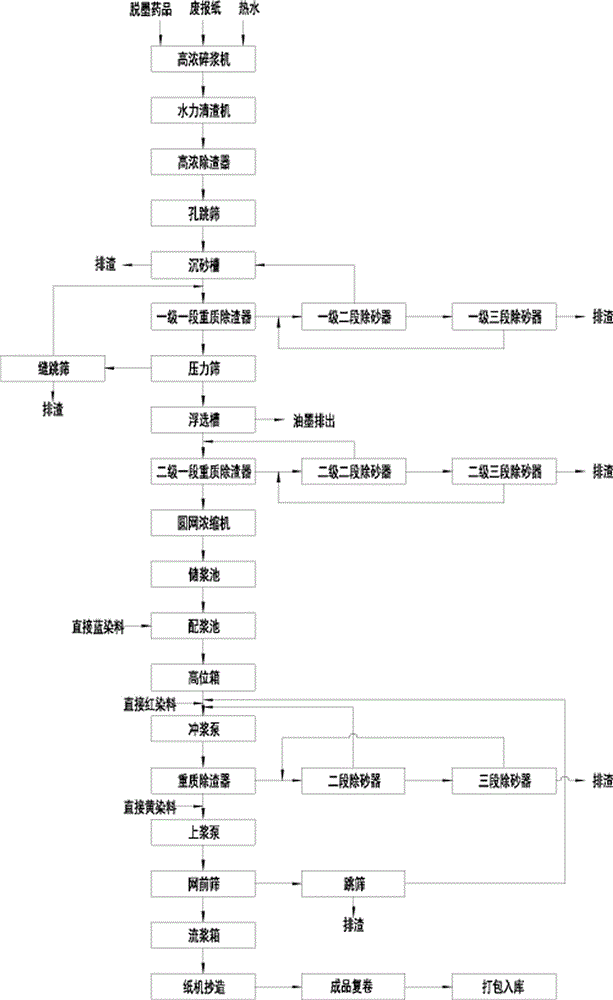

Method for producing kraft paper by waste newspaper

The invention provides a method for producing kraft paper by waste newspaper. The method comprises the following steps: carrying out deinking and pulping on the waste newspaper; storing prepared pulp in a pulp storage pond; after feeding the pulp in the pulp storage pond into a pulp preparing pond, adding direct blue dyestuff in the pulp preparing pond; after discharging the pulp dyed by direct blue from the pulp preparing pond, adding direct red dyestuff before slag is removed; after slag is removed from the pulp dyed by direct red, adding direct yellow dyestuff; and after the pulp dyed by the direct yellow dyestuff is subjected to papermaking through a paper machine, rewinding finished products, and finally packing and warehousing. By the method, the kraft paper with the qualified color standard is produced by the waste newspaper, resources of the waste newspaper are utilized effectively, and costs are reduced.

Owner:HUBEI BAOTA PAPER

Inkjet ink and ink set

InactiveUS20090092755A1Easy to understandMeasurement apparatus componentsInksEngineeringDirect yellow

The present invention pertains to a yellow ink for inkjet printing and, in particular, to a yellow ink comprising a combination of specific yellow colorants, namely Direct Yellow 169 and Acid Yellow 79. The present invention further pertains to an ink set comprising this yellow ink. The ink and ink set are particularly advantageous for printing on plain and photo glossy paper.

Owner:EI DU PONT DE NEMOURS & CO

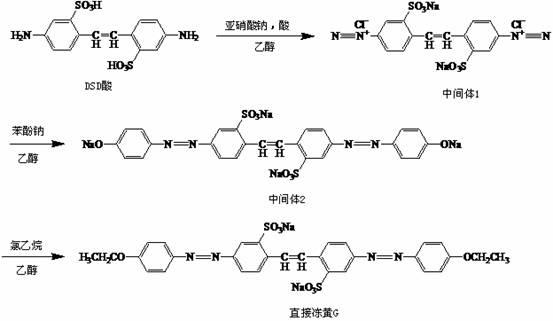

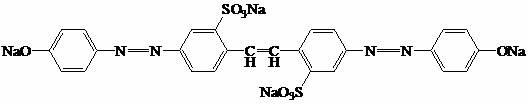

Method for preparing direct yellow G

ActiveCN102040855AReduce manufacturing costHigh color strengthPreparation by etherificationIndustrial waste waterPhenol

The invention discloses a method for preparing direct yellow G. DSD acid is taken as an initial raw material, and the method comprises the following steps of: reacting with sodium nitrite, phenol and chloroethane in turn, and respectively performing diazotization, coupling and chloroethane etherification to obtain the direct yellow G, wherein a solvent in diazotization, coupling and chloroethane etherification is ethanol. The DSD acid is taken as the initial raw material and is subjected to diazotization, coupling and chloroethane etherification respectively to form a dye of the direct yellow G, the ethanol is adopted as a reaction solvent in the diazotization, coupling and chloroethane etherification and can be recycled after reaction, a large amount of water is prevented from serving as the reaction solvent, the problem that a large amount of industrial wastewater is difficult to treat is radically solved and the zero emission of the industrial wastewater is achieved.

Owner:平顶山市铭源化工有限公司

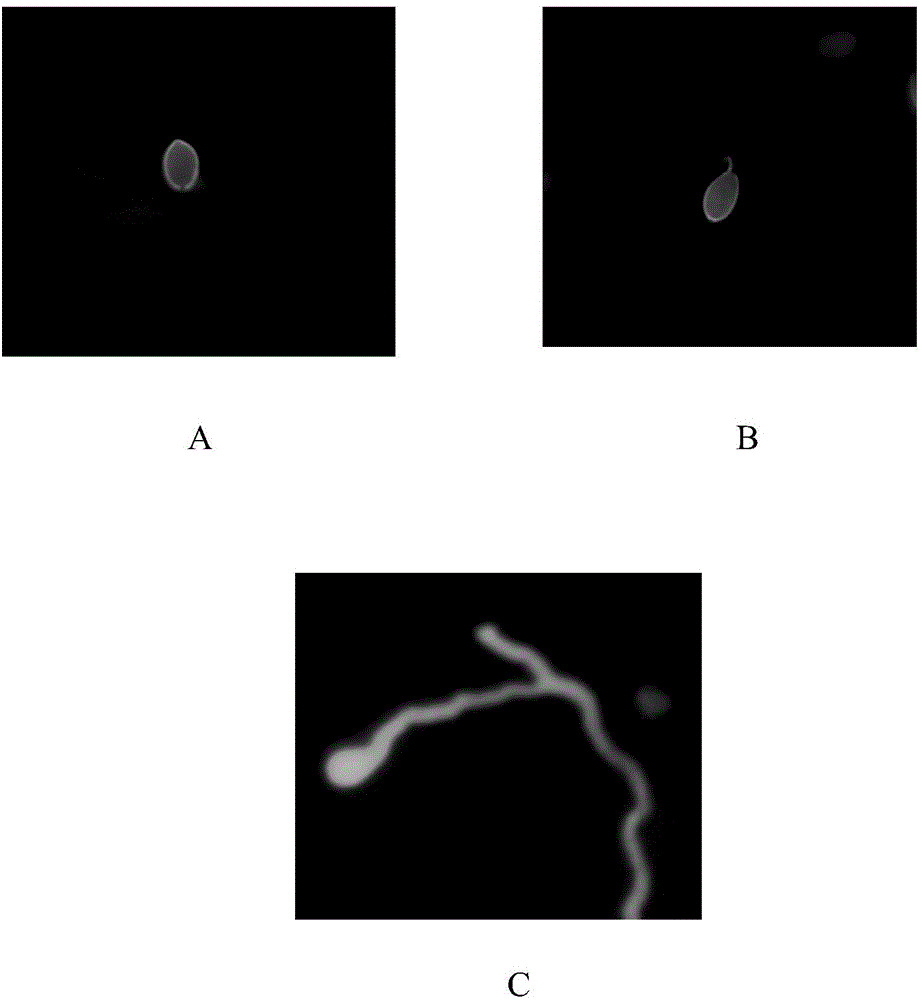

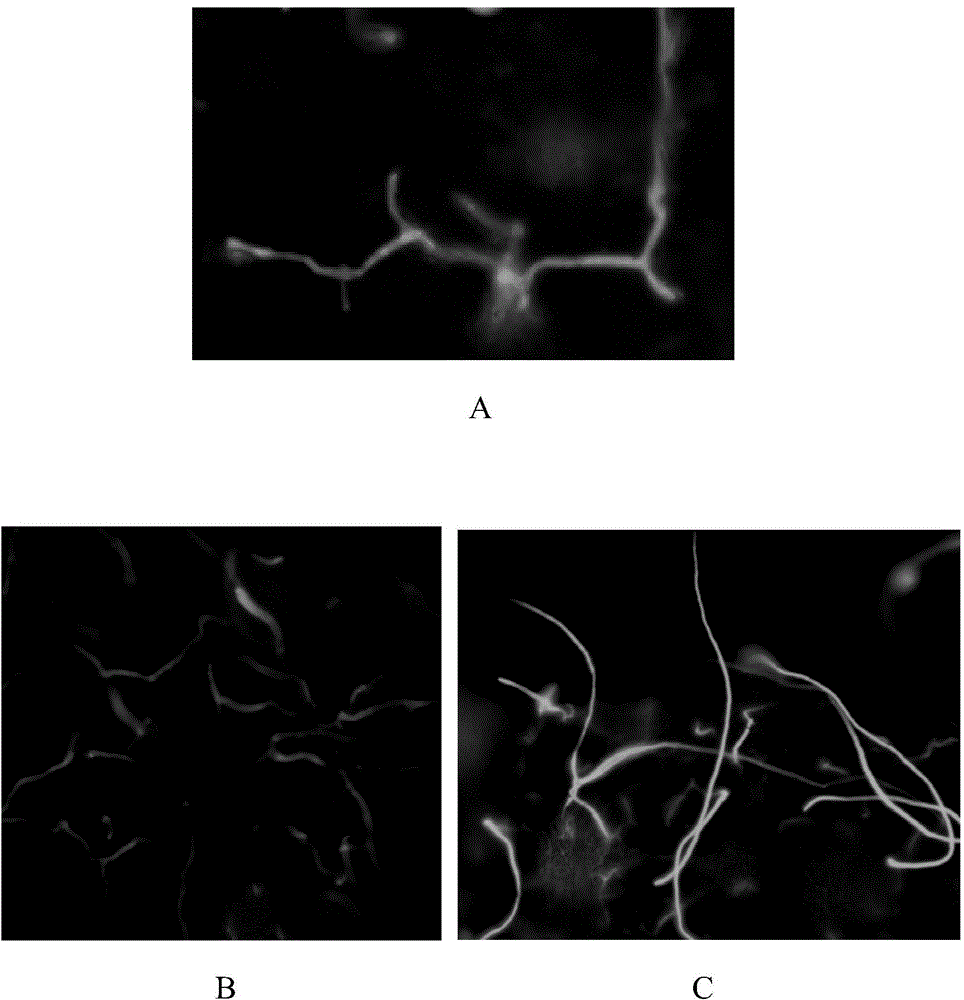

Fungus fluorescence staining method and application thereof

InactiveCN104894211AEasy to operateDoes not affect the dyeing effectMicrobiological testing/measurementPreparing sample for investigationWater bathsStaining

The invention discloses a fungus fluorescence staining method. The method includes firstly, spraying a staining solution [dissolving direct yellow 96 in a 0.1M Tris-Hcl buffer solution with the pH (potential of hydrogen) of 8.5] on the surfaces of host plant leaves uniformly directly to observe conditions of pathogenic fungal spores on the surfaces of the host plant leaves; secondly, soaking leaves decayed by pathogenic fungal hyphae into 95% (v / v) ethyl alcohol in boiling water bath to remove chlorophyll completely; thirdly, taking out the leaves, and cleaning the leaves by 50% (v / v) ethyl alcohol, 50mM sodium hydroxide and pure water sequentially; finally, soaking the leaves into the staining solution to stain so as to observe the conditions after pathogenic fungi invade host leaf tissues. The fungus fluorescence staining method has the advantages that all reagents used in the method are poisonless and harmless and are safer and more environment friendly than reagents such as chloroform, phenol, trichloroacetic acid and pyridine used in conventional decoloration methods; the fungus fluorescence staining method is simple and feasible, and a slicing process is omitted and staining steps are simplified on the premise of not affecting the staining effect.

Owner:HUNAN AGRICULTURAL UNIV

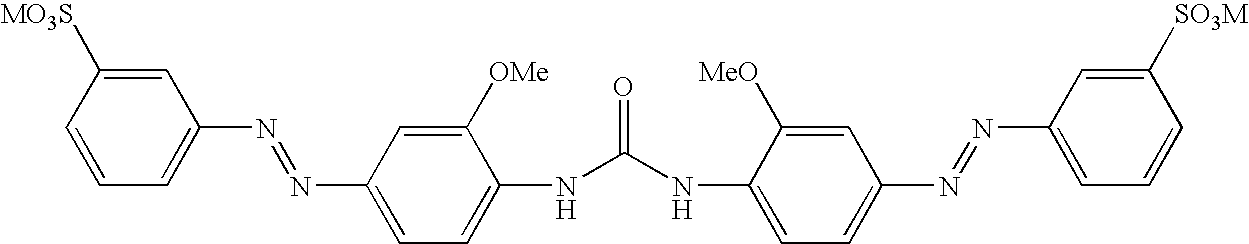

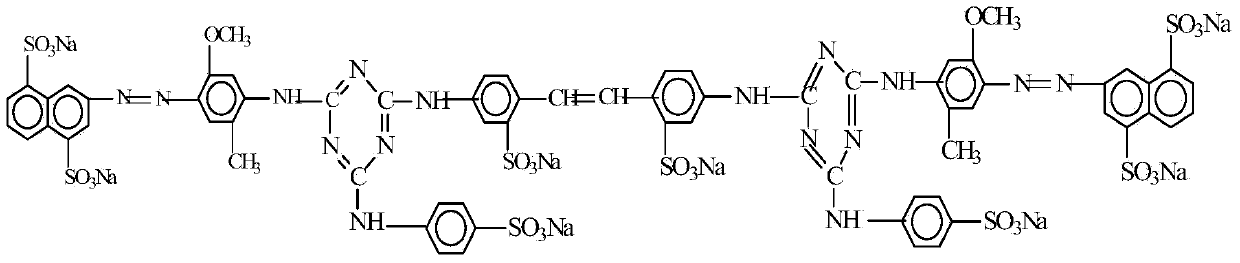

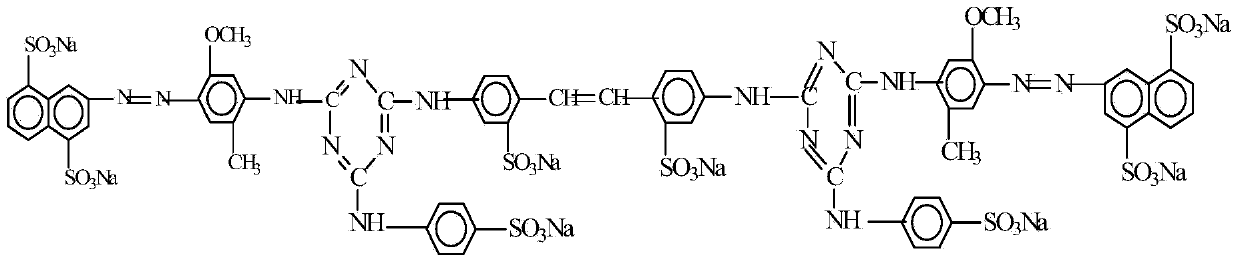

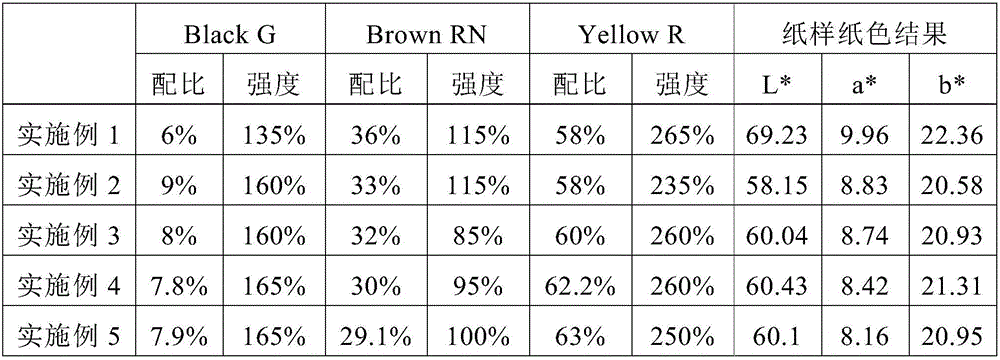

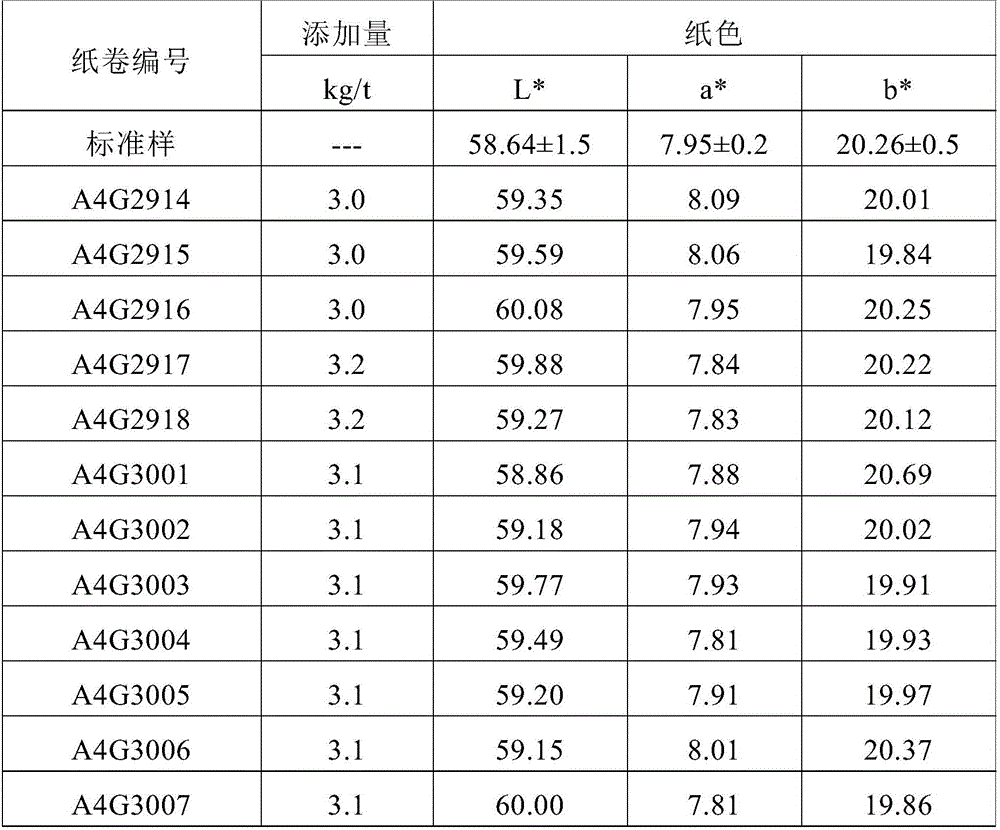

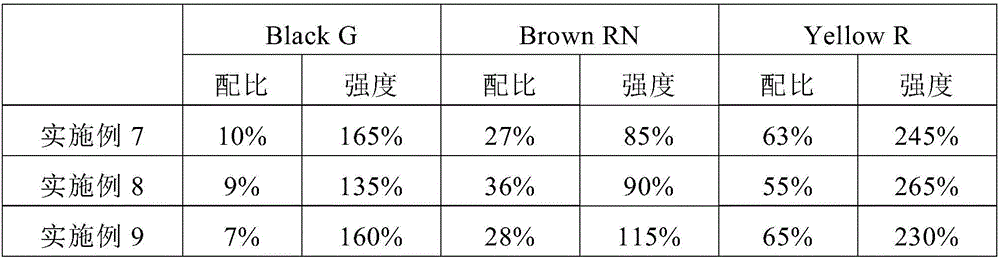

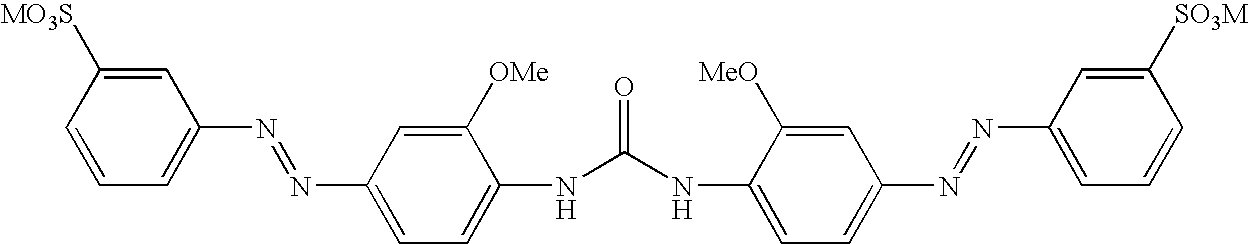

Method for producing direct yellow blend dye

The invention relates to a method for producing a direct yellow blend dye. The method includes the steps of conducting a diazo reaction, conducting a coupled reaction, conducting a first condensation reaction, conducting a second condensation reaction, conducting a third condensation reaction and conducting spray drying on a product to obtain the direct yellow blend dye. According to the method, on the premise of not changing the quality standards of an original product, the spray drying cleaner production mode is adopted, waste residuals and process wastewater are not generated, the technological process is simplified, investment of equipment is reduced, production efficiency is improved by 10 percent, the yield of the products is improved by 3 percent, the production cost is saved by 10 percent, and the method is an environmentally friendly dye production method.

Owner:内蒙古美力坚科技化工有限公司

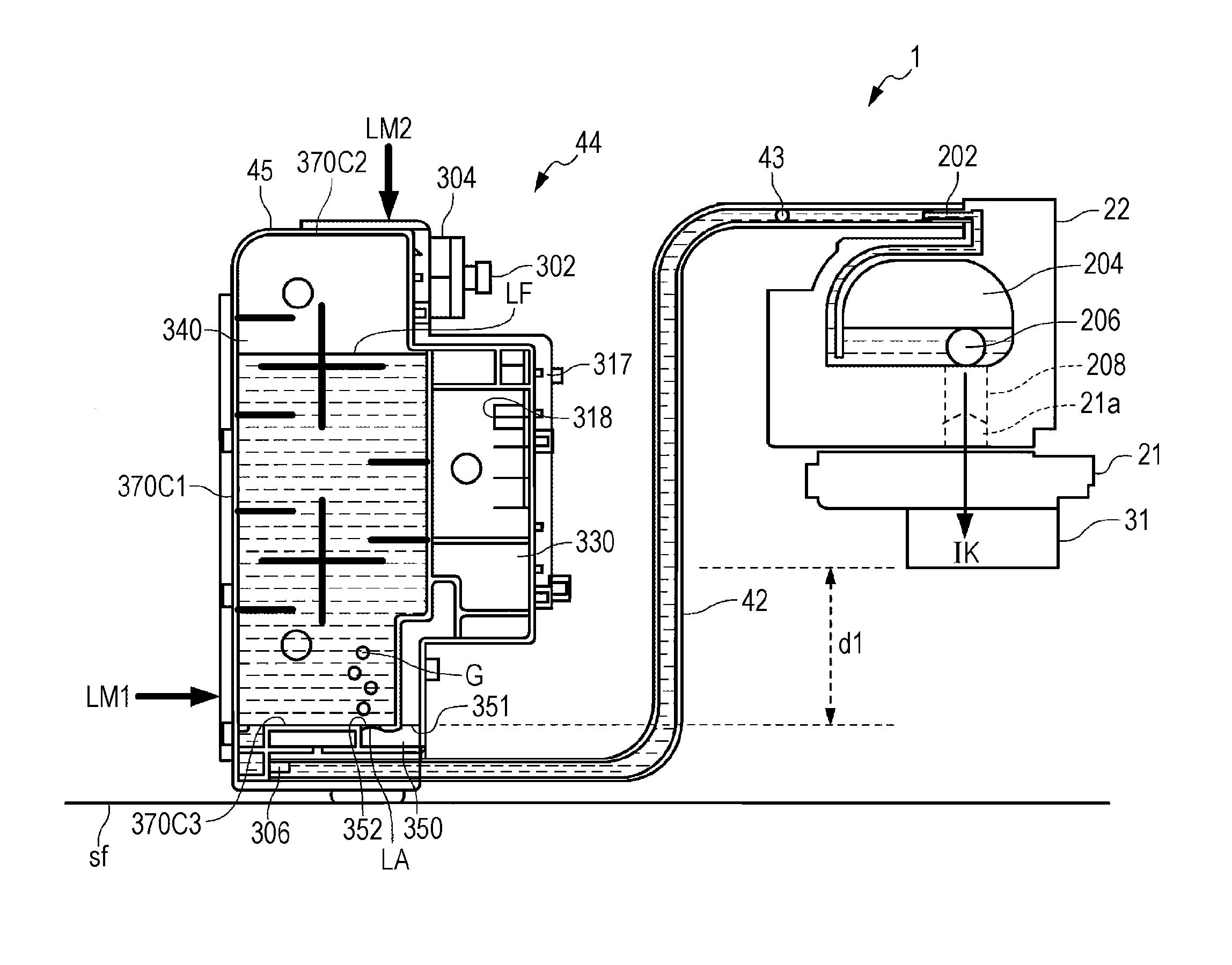

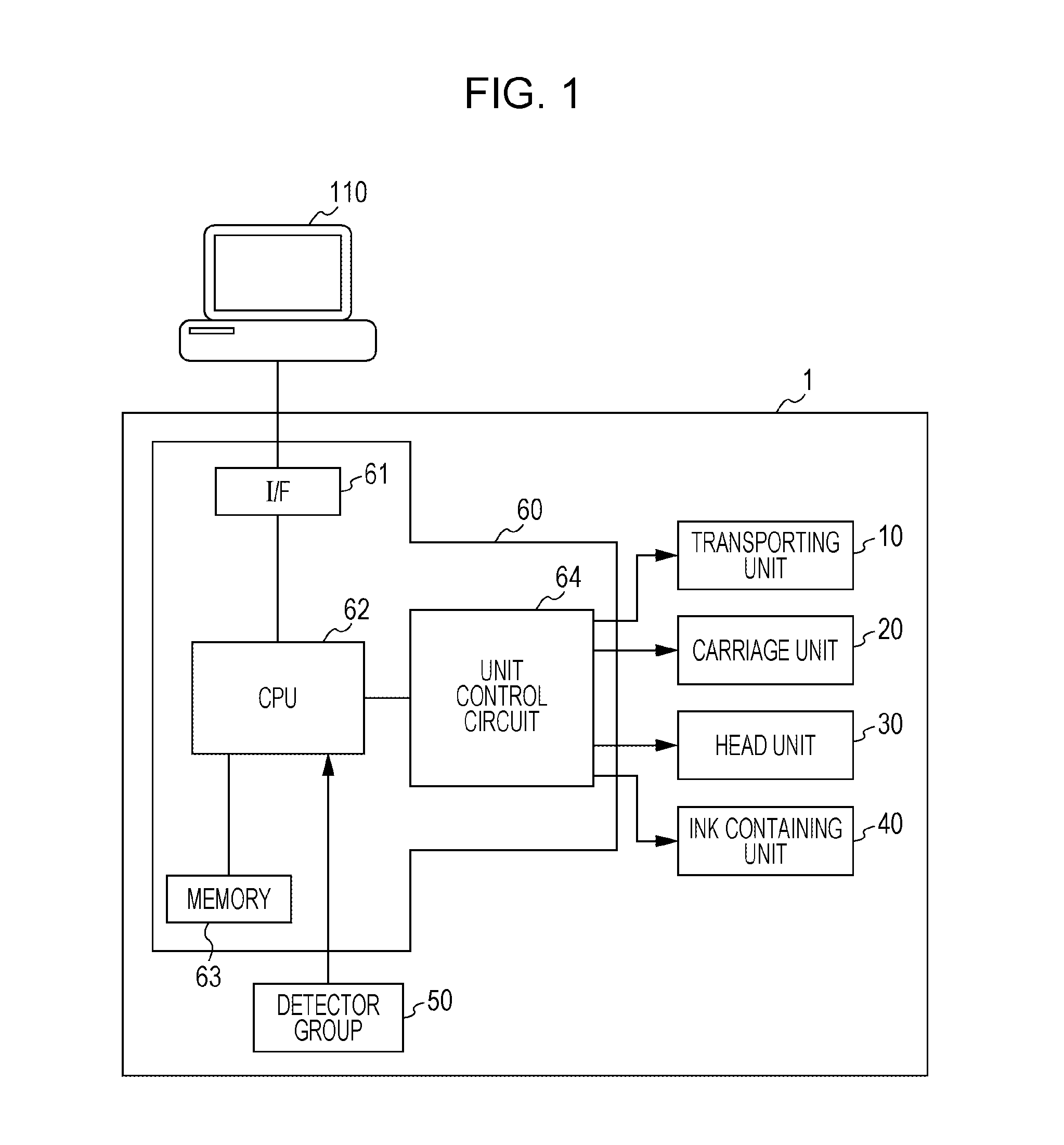

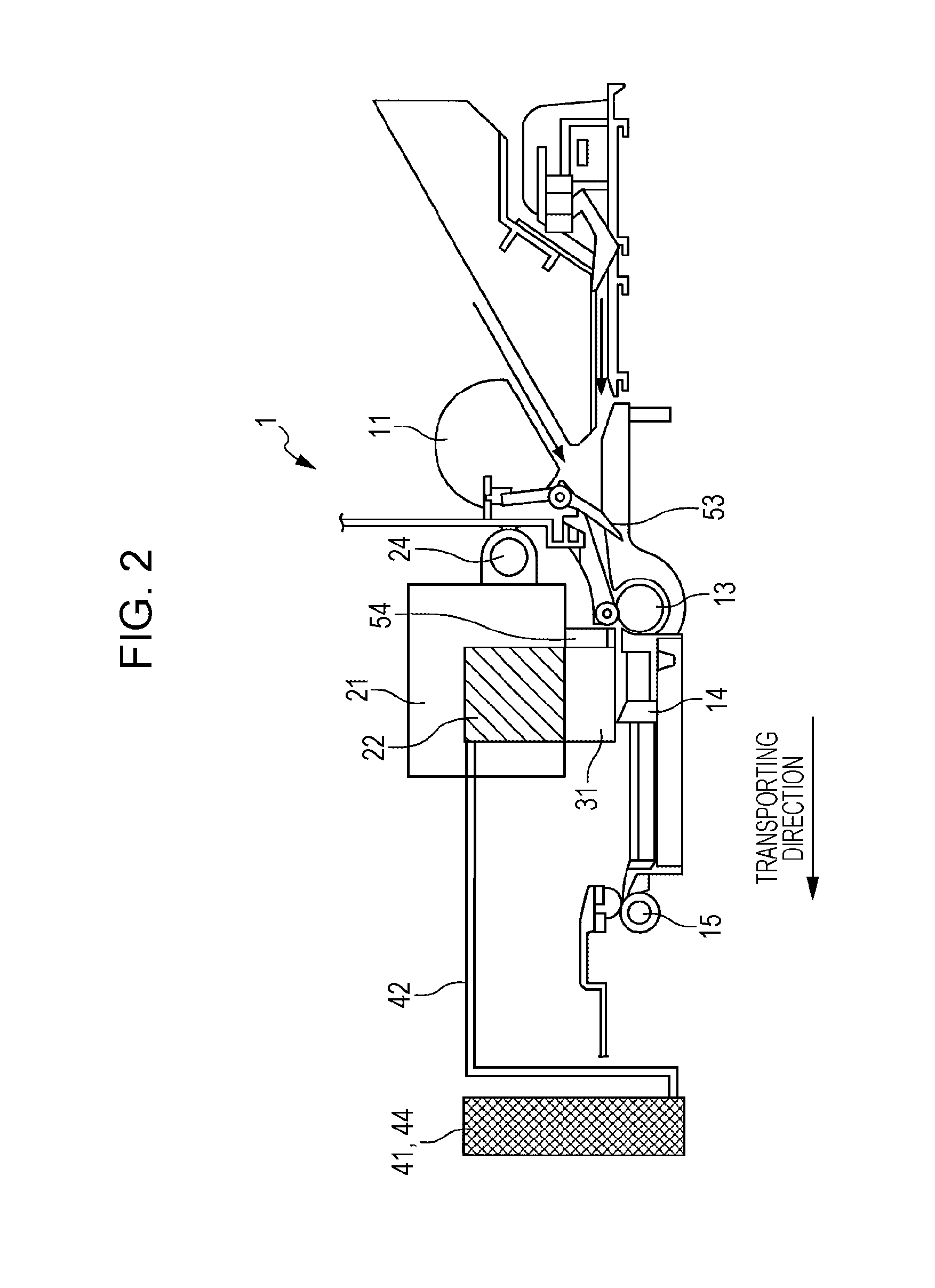

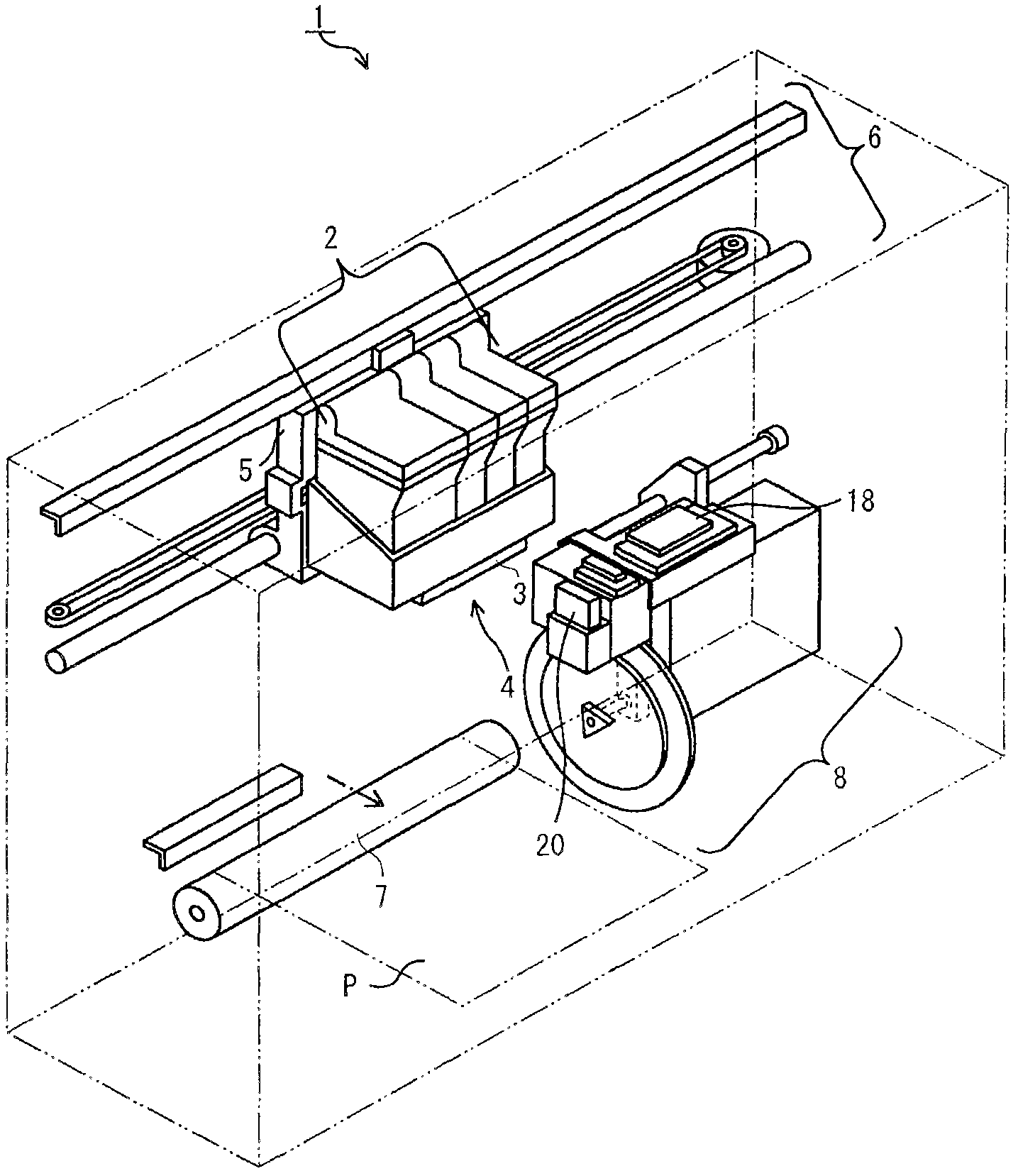

Ink jet ink, method of producing ink jet ink, ink jet recording method, ink cartridge, and yellow ink

InactiveUS20090074967A1Avoid bleedingGood colorMeasurement apparatus componentsInksOrganic solventEngineering

An object of the present invention is to provide an ink jet ink capable of suppressing bleeding and excellent in color developability, a method of producing the ink with an aid of a unit preferable in terms of economy and environmental protection, and an ink jet recording method providing an image which can suppress the occurrence of bleeding and which is excellent in color developability. The ink jet ink comprises water, coloring materials, and a water-soluble organic solvent, in which the coloring materials comprise at least one dye selected from the group consisting of C.I. Direct Yellow 86, C.I. Acid Yellow 23, C.I. Direct Yellow 173, C.I. Direct Yellow 132, and C.I. Direct Yellow 59, and C.I. Pigment Yellow 74; the water-soluble organic solvent comprises a poor medium for C.I. Pigment Yellow 74; and a surface tension of the ink is 34.0 mN / m or more.

Owner:CANON KK

Ink jet ink, method of producing ink jet ink, ink jet recording method, ink cartridge, and yellow ink

InactiveUS7695554B2High levelExcellent developabilityMeasurement apparatus componentsInksOrganic solventEngineering

An object of the present invention is to provide an ink jet ink capable of suppressing bleeding and excellent in color developability, a method of producing the ink with an aid of a unit preferable in terms of economy and environmental protection, and an ink jet recording method providing an image which can suppress the occurrence of bleeding and which is excellent in color developability. The ink jet ink comprises water, coloring materials, and a water-soluble organic solvent, in which the coloring materials comprise at least one dye selected from the group consisting of C.I. Direct Yellow 86, C.I. Acid Yellow 23, C.I. Direct Yellow 173, C.I. Direct Yellow 132, and C.I. Direct Yellow 59, and C.I. Pigment Yellow 74; the water-soluble organic solvent comprises a poor medium for C.I. Pigment Yellow 74; and a surface tension of the ink is 34.0 mN / m or more.

Owner:CANON KK

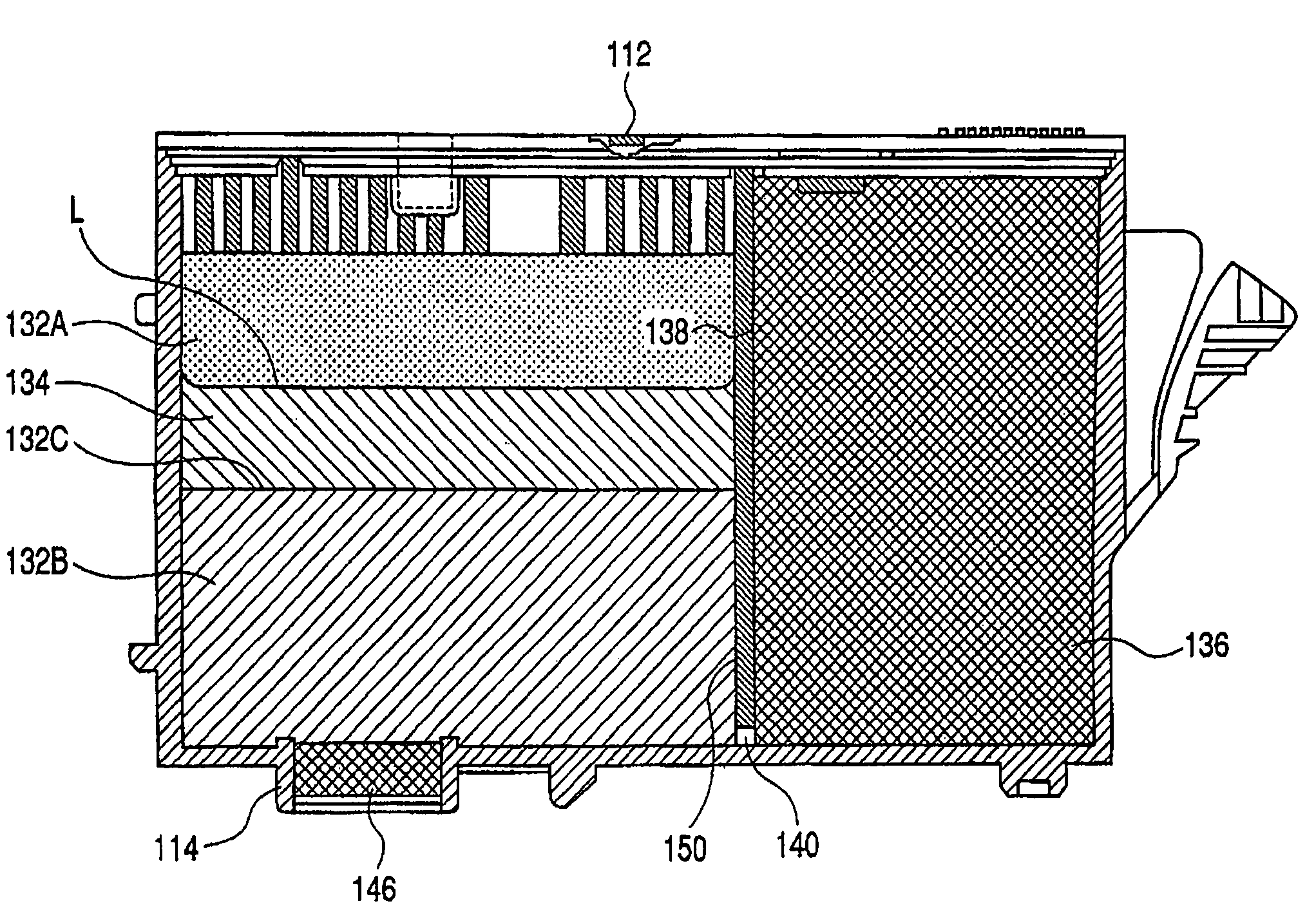

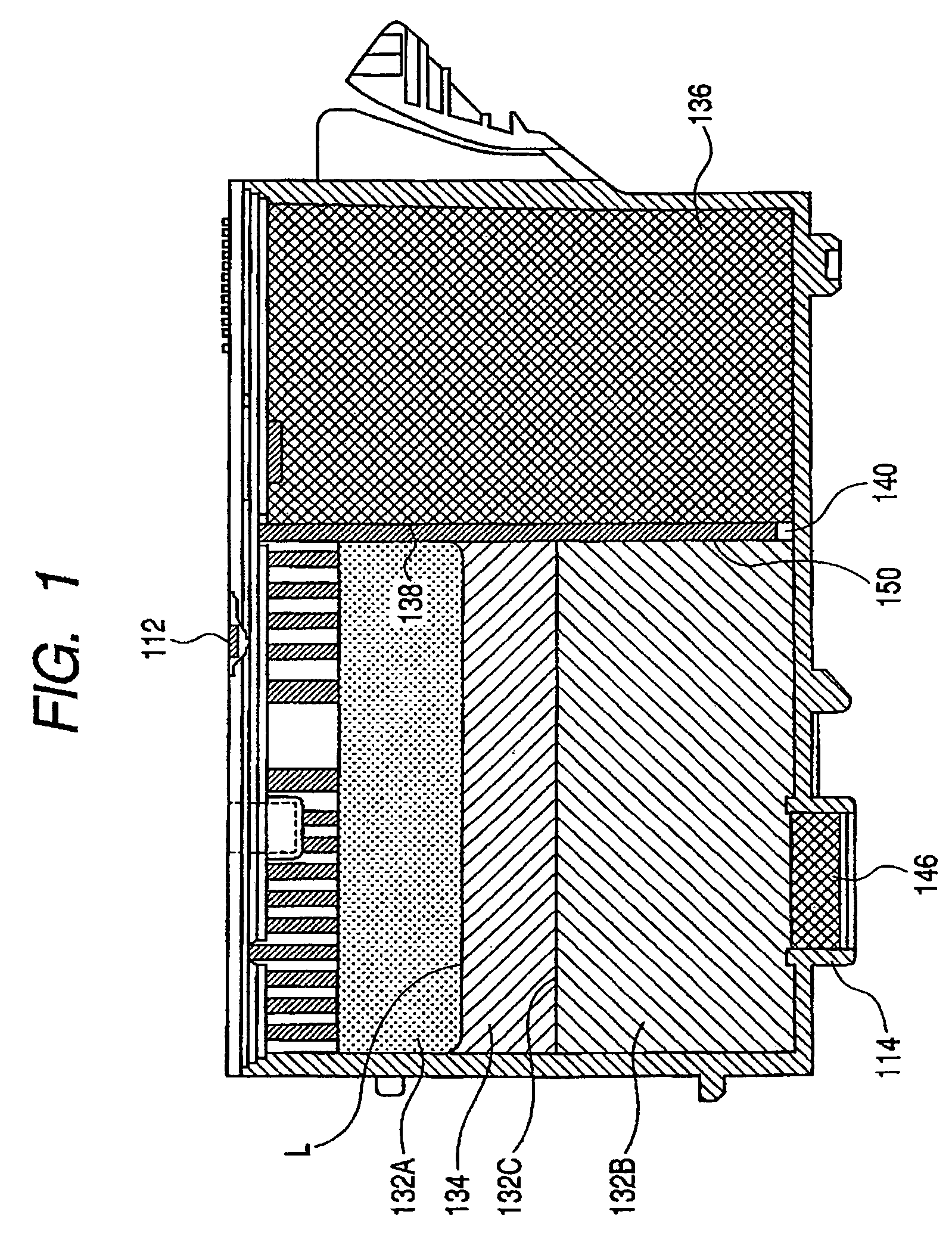

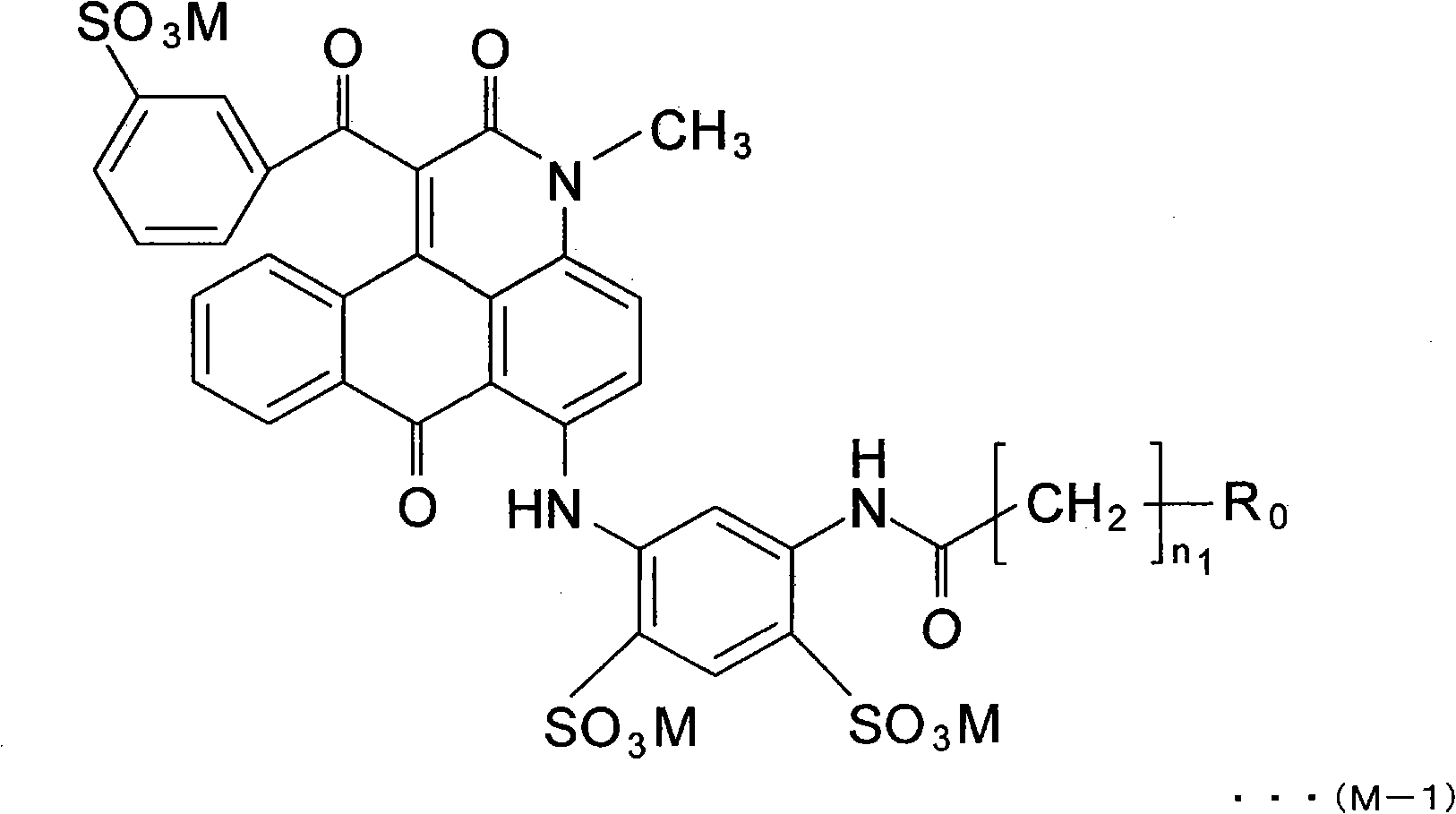

Inkjet ink, method for producing the same, ink cartridge, and inkjet recording method

An inkjet ink contains at least one coloring material selected from the group of C. I. Acid Yellow 23, C. I. Direct Yellow 86, C. I. Direct Yellow 132, and C. I. Direct Yellow 173, and a coloring material including a compound expressed by general formula (I):wherein in the formula (I), each M independently represents hydrogen, an alkali metal, ammonium, or an organic ammonium.

Owner:CANON KK

Mixed solid dye and application thereof

ActiveCN106283883AIncrease profitGood processing effectSpecial paperNon-macromolecular organic additionTreatment effectDark color

The invention relates to a mixed solid dye and application thereof to production of dyed pattern product by utilization of pulping and papermaking waste. The mixed solid dye is mainly formed by mixing Brown RN, Black G and Yellow R, wherein Brown RN is direct red brown RN, and accounts for 27-36 wt%, Black G is direct black 19, and accounts for 6-10 wt%, and Yellow R is direct yellow 11, and accounts for 55-65 wt%. Compared with the prior art, a proper mixed dye is provided for production of a pattern meeting use requirements by utilizing the papermaking waste, the utilization rate of the solid waste by a pulping and papermaking enterprise is improved, three basic dyes of yellow, brown and black are adopted for blending, a proper formula is developed, the treatment effect on the solid dye with darker color is obvious, and through adoption of the mixed dye, the paper color modulation cost is reduced, and the market competitiveness of the paper product is improved.

Owner:SHANGHAI EMPEROR OF CLEANING HI TECH

Inkjet ink having yellow dye mixture

InactiveUS20050093950A1Good chromaGood lightfastnessMeasurement apparatus componentsInksYELLOW DYEPhotochemistry

An inkjet ink of exceptional overall color characteristics having about 4% by weight Direct Yellow 132 in acid form, about 1% by weight Acid Yellow 17 in acid form in water, typically also having a humectant, a penetrant, and other generally known additives.

Owner:BRADY JOHN A +1

Multi-color dye composition with high tone and ink-jetting ink composition

A combination of high chroma multi-colour dyestuff and the ink-jet ink for the chromatic colour ink-jet print is disclosed. The combination of dyestuff include: a. direct blue dyestuff 199,acidic blue dyestuff 9, direct blue dyestuff 87 b. active red dyestuff 158, active red dyestuff 159, acidic red dyestuff 92 c. acidic yellow dyestuff 23, direct yellow dyestuff 86. The combination dyestuff has not only the light and water resistance but also the unique viscosity and interfacial force. It can improve the quality of the print because of the wide colour gamut and high quality colour imagery.

Owner:BENQ CORP

Water base ink for ink-jet recording

Owner:BROTHER KOGYO KK

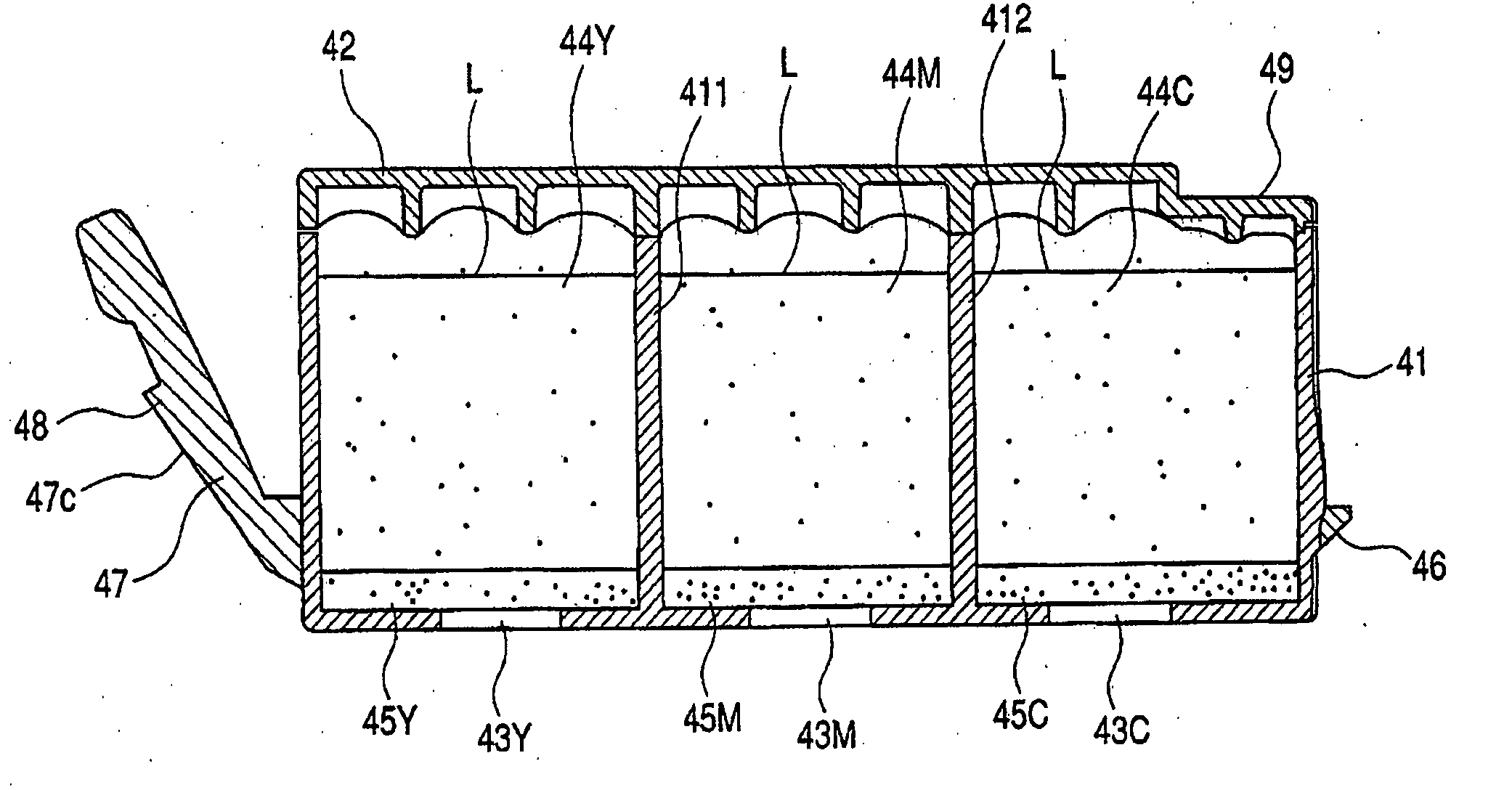

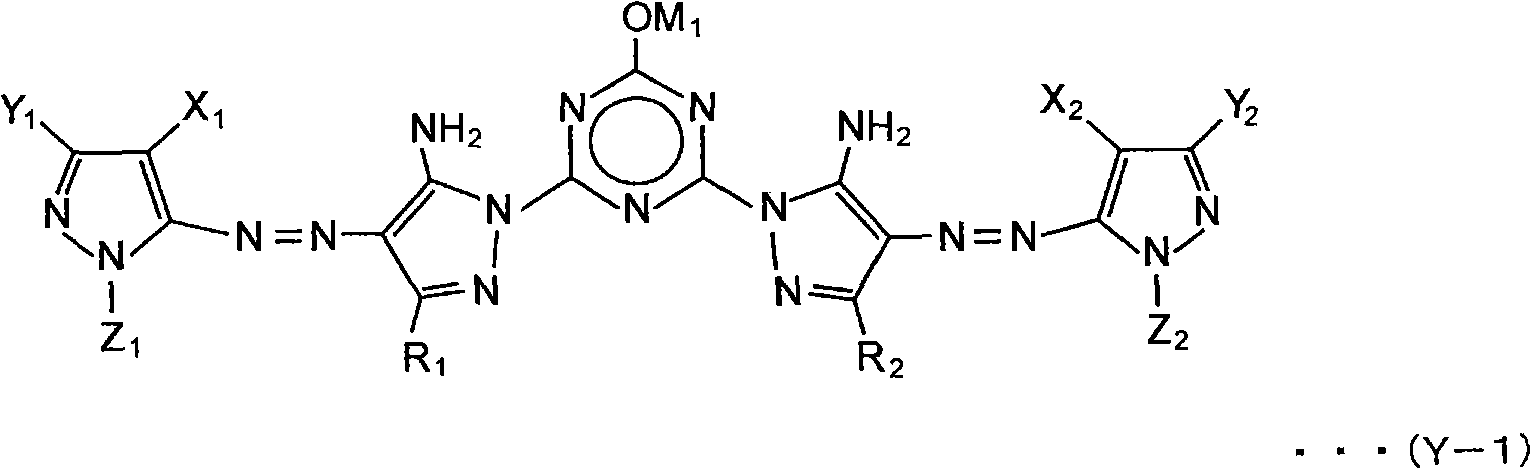

Water-based ink set for ink jet recording, ink cartridge, and ink-jet recording apparatus

A water-based ink set includes a yellow ink, a magenta ink, and a cyan ink, each including a coloring agent, water, and a water-soluble organic solvent. The yellow ink includes dyes (Y-1) and (Y-2), the magenta ink includes dyes (M-1) and (M-2), and the cyan ink includes a dye (C-1). Dye (Y-1): a dye represented by the formula (Y-1) Dye (Y-2): at least one dye selected from the group consisting of C. I. Direct Yellow 86, C. I. Direct Yellow 132, and C. I. Direct Yellow 142 Dye (M-1): a dye represented by the formula (M-1) Dye (M-2): at least one dye selected from the group consisting of dyes represented by a formula (M-2a), dyes represented by the formula (M-2b), C. I. Acid Red 1, and C. I. Acid Red 254 Dye (C-1): a dye represented by the formula (C-1).

Owner:BROTHER KOGYO KK

Ink composition, inkjet recording ink composition, ink set, ink cartridge, inkjet recording method and recorded matter

InactiveUS8523990B2Improve discharge performanceHydrolysis is inducedDisazo dyesDecorative surface effectsArylHydrogen atom

An ink composition having a suitably-adjusted hue and causing no decomposition of dyes during storage is provided. The ink composition contains a compound (a) represented by the following formula (1), an ingredient (c) and moisture-retentive agents, characterized by being from 0.1 mass % to lower than 7.0 mass % in content of the compound represented by the formula (1), 10.0 mass % or lower in content of a moisture-retentive agent having 3 or more hydroxyl groups (b) and lower than 30.0 in molar ratio of the moisture-retentive agent having 3 or more hydroxyl groups to the compound represented by the formula (1):wherein each of Ar1 and Ar2 preferably represents an aromatic heterocyclic group, each of A1 and A2 represents a hydrogen atom or a substituent, Y represents —OM or —NR1R2, M represents a hydrogen atom or a metal ion and each of R1 and R2 represents a hydrogen atom, an alkyl group, an aryl group, a heterocyclic group or the like. The ingredient (c) is at least one compound selected from C.I. Direct Yellow 59, id. 86, id. 132 or the like.

Owner:FUJIFILM CORP

Method for improving direct yellow 11 dye-uptake

The invention discloses a method for improving direct yellow 11 dye-uptake, and relates to a method for improving dye-uptakes. 4-nitrotoluene-2-sulfonic acid as raw material and a NaOH solution undergo a self condensation reaction to produce direct yellow 11. The method comprises the following steps of weighing diethylene glycol monoethyl ether, putting it into a three-necked flask, weighing 4-nitrotoluene-2-sulfonic acid, putting it into the same three-necked flask, carrying out stirring well, weighing alcohol amine, slowly and dropwisely adding the alcohol amine into the mixed solution, stirring the mixed solution until the 4-nitrotoluene-2-sulfonic acid is completely dissolved, heating the mixed solution to a certain temperature, slowly and dropwisely adding a NaOH solution into the reaction solution, carrying out heat preservation for a period of time, adding an ethylene glycol monomethyl ether solution into the mixed solution, carrying out stirring well, then carrying out cooling, regulating the pH value by a H2SO4 solution, carrying out suction filtrating, and carrying out direct drying to obtain the direct yellow 11 solids. The direct yellow 11 prepared by the method has a high dye-uptake and is environmental friendly.

Owner:常州悦朋科技有限公司

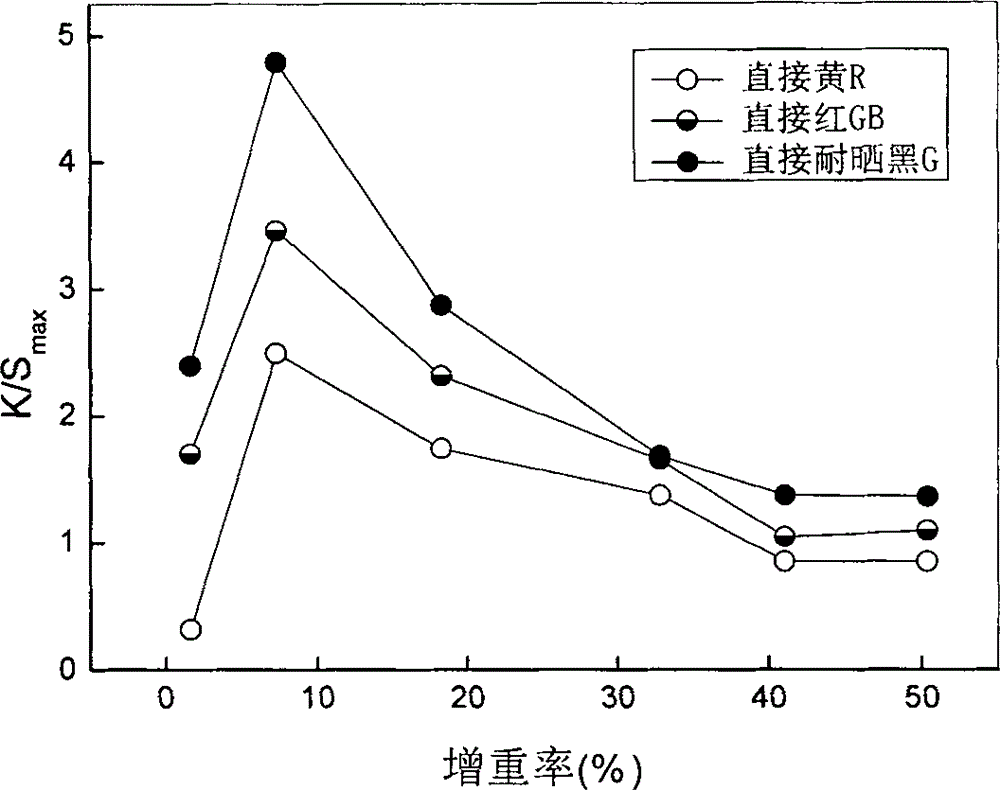

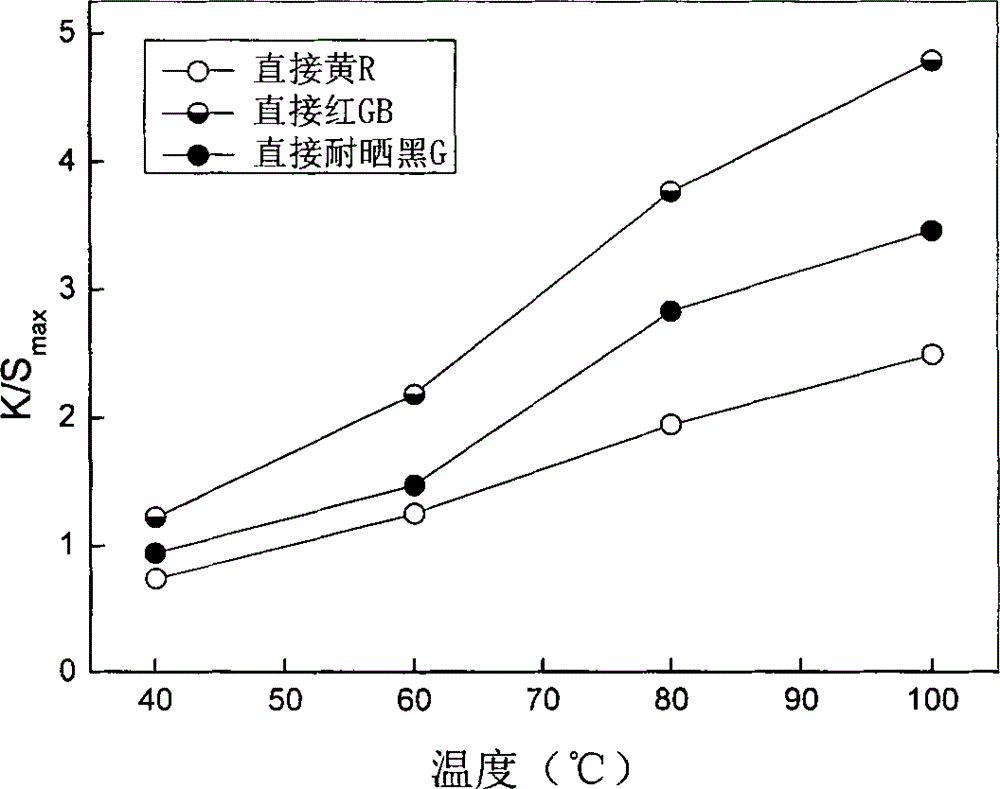

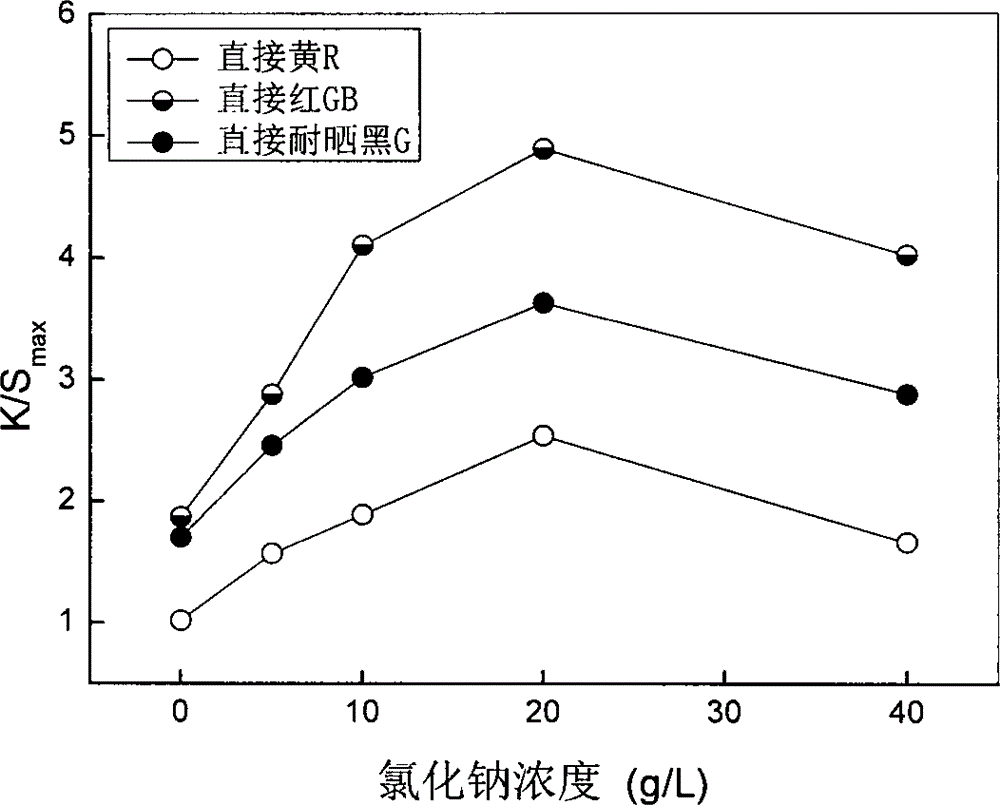

Direct dye dyeing method of polyacrylonitrile fibers

InactiveCN105421116AImprove washing fastnessImprove wet fastnessFibre typesDry-cleaning apparatus for textilesYarnHydroxylamine Hydrochloride

The invention relates to a direct dye dyeing method of polyacrylonitrile fibers. The method is characterized in that the dyeing method is mainly composed of four steps that firstly, the polyacrylonitrile fibers are modified through hydroxylamine hydrochloride, and the modified polyacrylonitrile fibers are dyed though direct dye. A hydroxylamine hydrochloride aqueous solution is 0.10-0.80 mol / L, pH is 5.0-6.0, and the direct dye can be direct yellow R, direct red GB, direct fast black G or other textile dye. The dyeing method is used for dyeing treatment of polyacrylonitrile fibers. The polyacrylonitrile fibers can be bright in color. The dyeing method is used for dyeing of the polyacrylonitrile fibers. The finished products are bright and uniform in color, complete in chromatography, good in firmness degree, simple in technology and favorable for industrial popularization. Meanwhile, the polyacrylonitrile fibers can be yarn, wool, woven fabric, knitted fabric and non-woven fabric.

Owner:TIANJIN POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com