Patents

Literature

372results about How to "Improve light fastness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

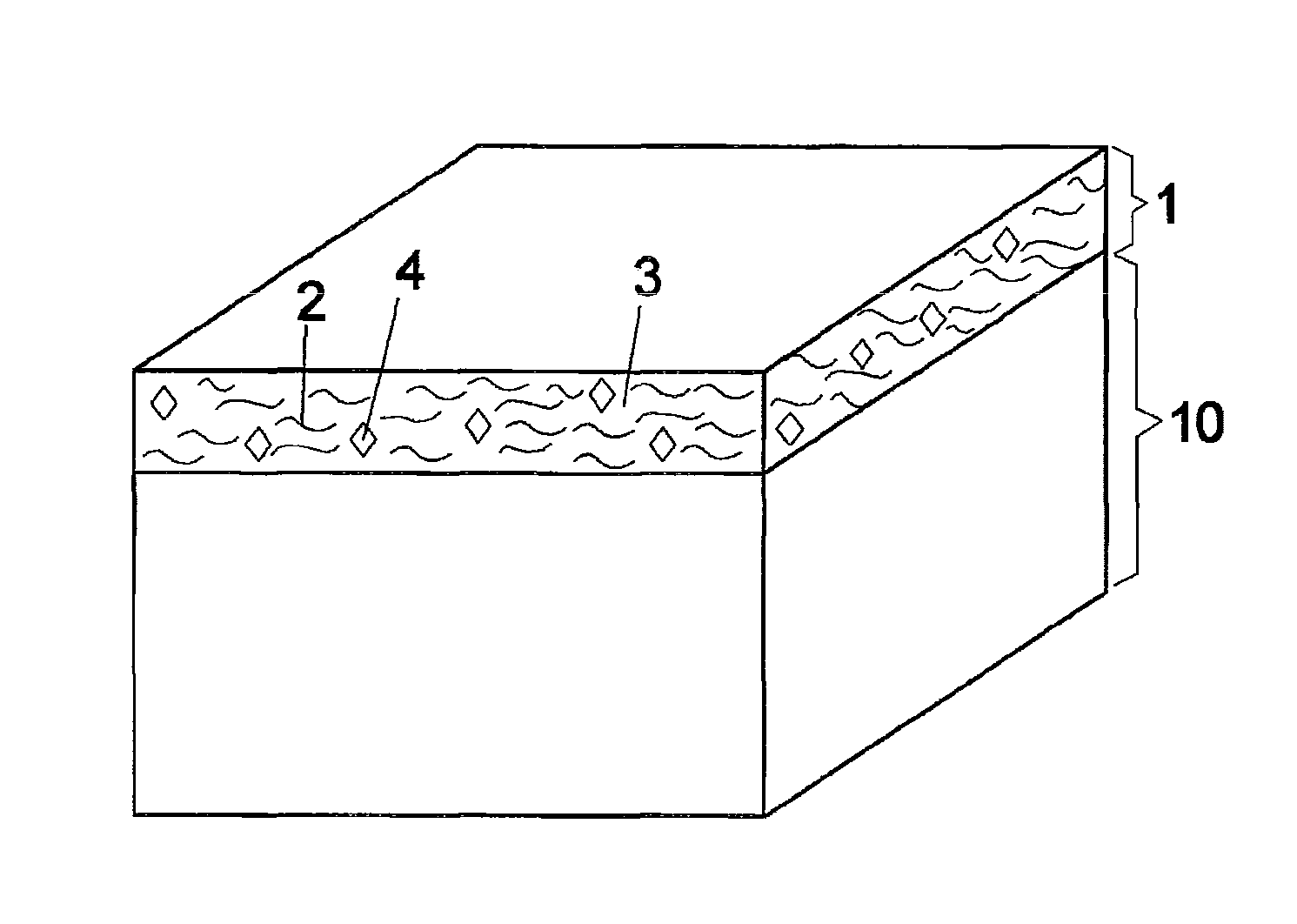

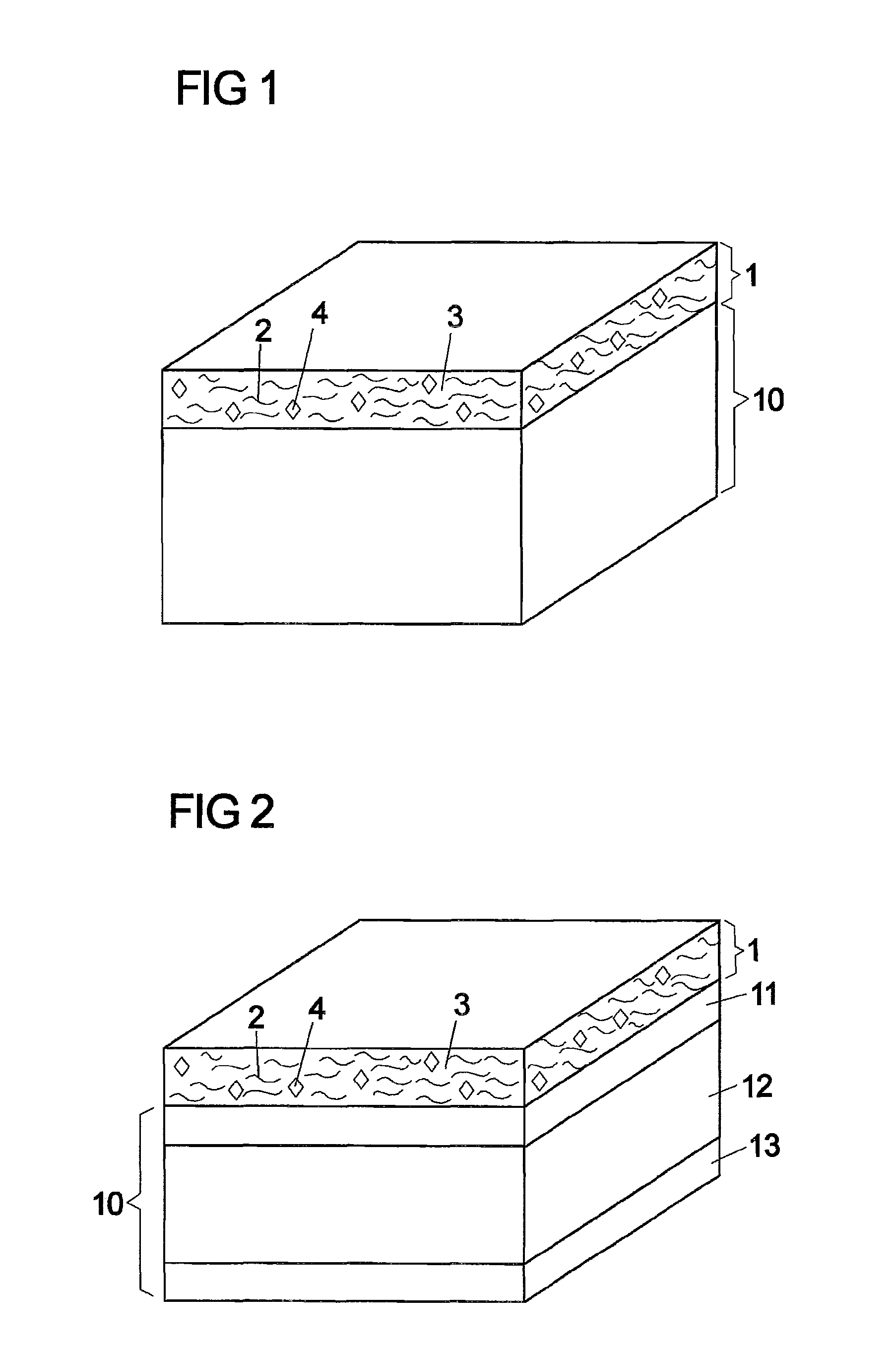

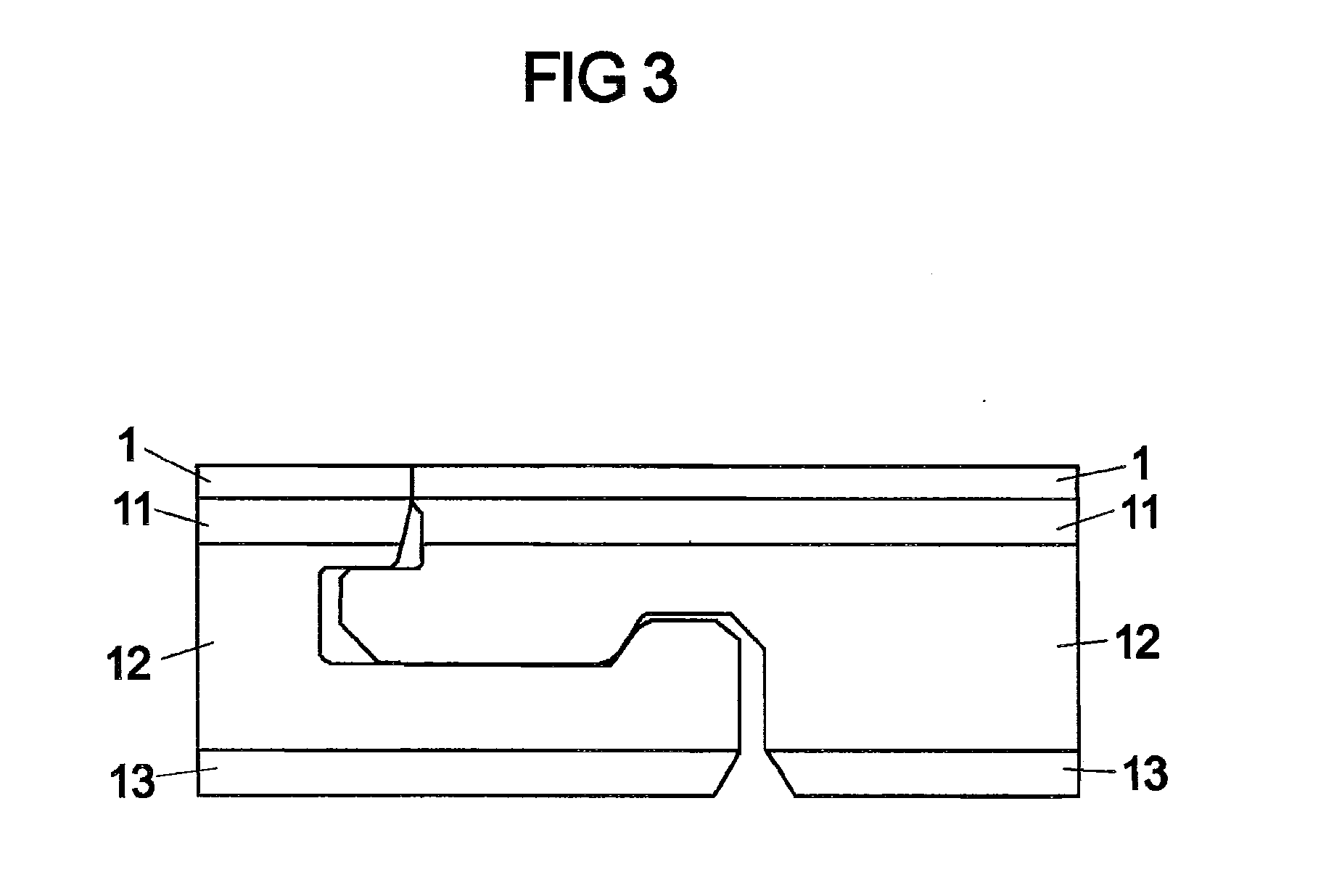

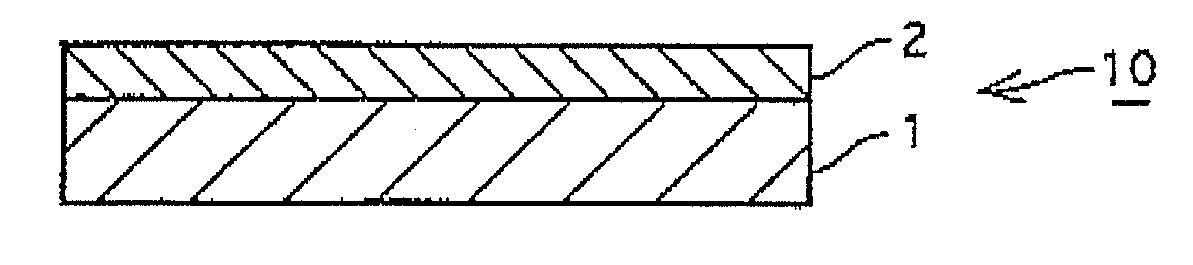

Panel, Use of a Panel, Method for Manufacturing a Panel and a Prepreg

InactiveUS20100323187A1Improve light fastnessSpecial ornamental structuresWood working apparatusSurface layerWear resistant

Described are panels including a surface layer on a substrate. The surface layer includes a) cellulose fibers, b) at least one binder and (c) wear resistant particles. The use of different panels and a method for manufacturing is also described.

Owner:VÄLINGE INNOVATION AB

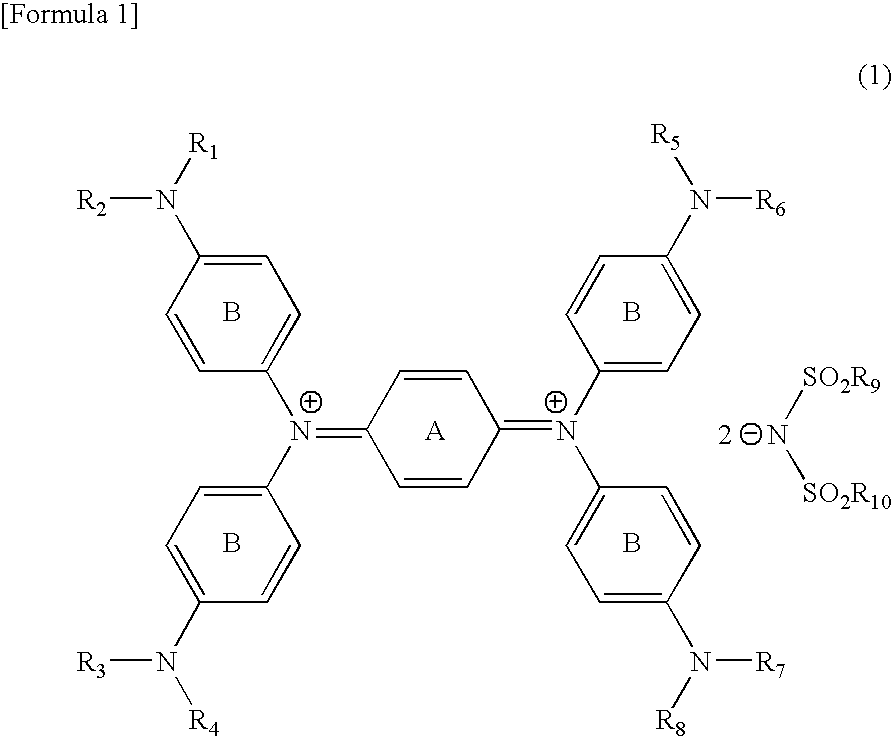

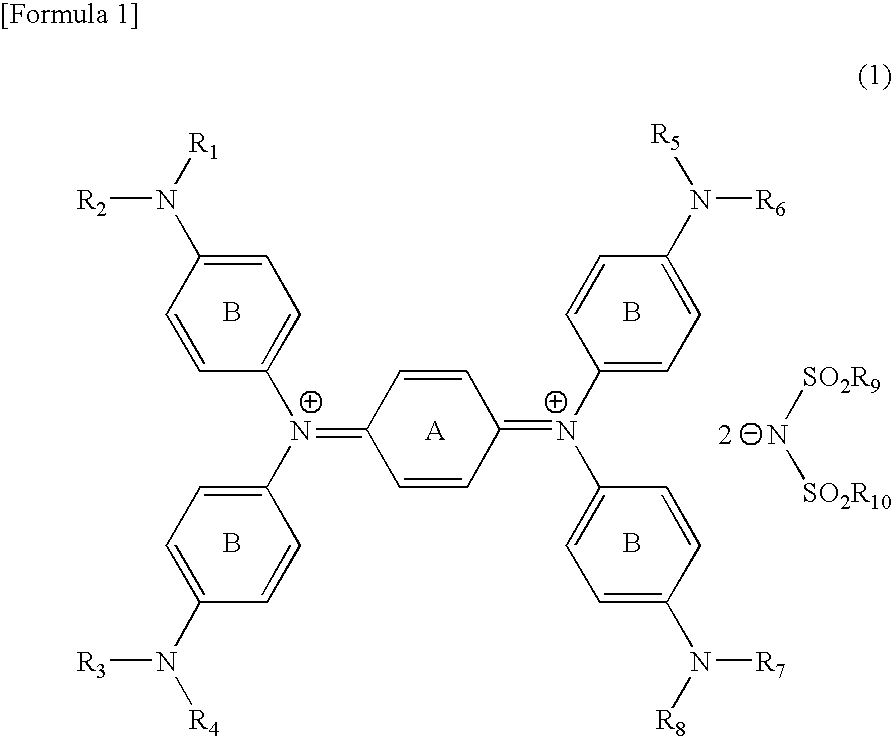

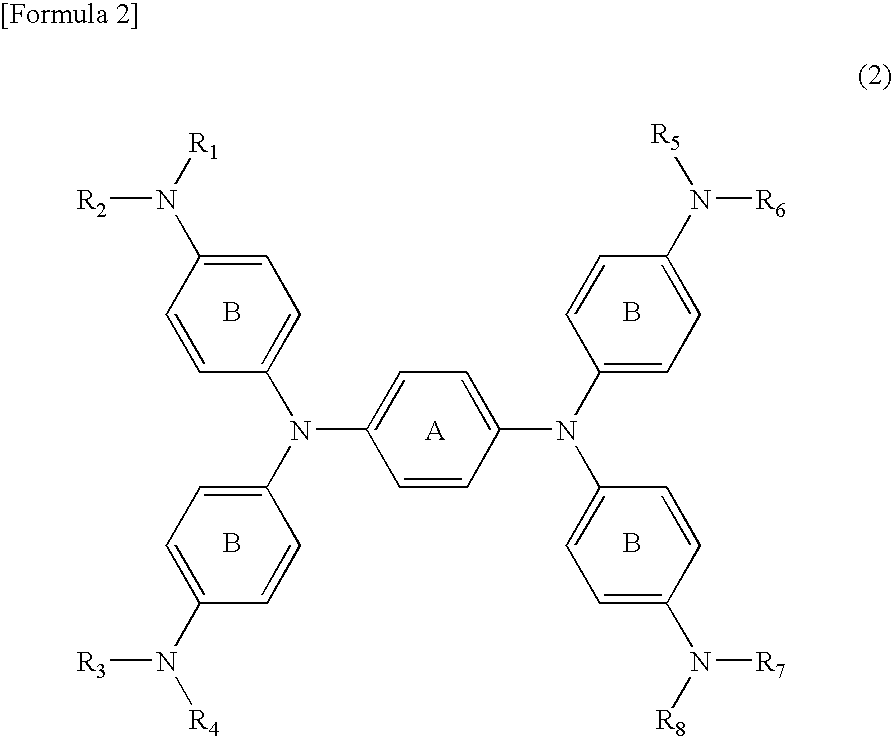

Diimmonium compound and use thereof

InactiveUS20050148786A1High visible light transmittanceHigh light transmittanceOrganic chemistryPhotomechanical apparatusInfraredAmmonium compounds

To provide a near-IR absorption compound free from antimony or arsenic and excellent in stability, especially, in heat resistance, light fastness, and moisture-and-heat resistance and also an IR absorption filter, an optical information recording medium, and a resin composition excellent in durability by using the near-IR absorption compound. The near-IR absorption compound is a diimmonium compound having the following structure and the resin composition contains the diimmonium compound: (wherein R1 to R8 independently denote hydrogen atom or an optionally substituted aliphatic hydrocarbon group; R9 and R10 independently denote an aliphatic hydrocarbon group optionally containing a halogen atom; and rings A and B may further have substituent groups.).

Owner:NIPPON KAYAKU CO LTD

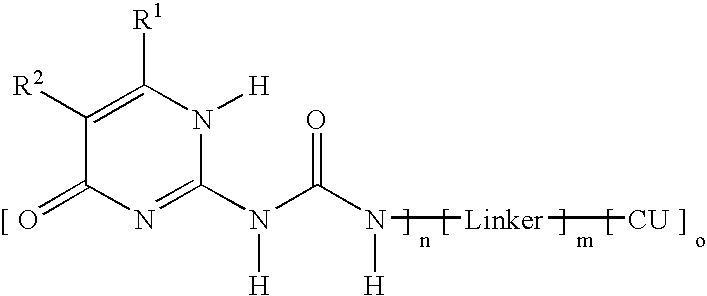

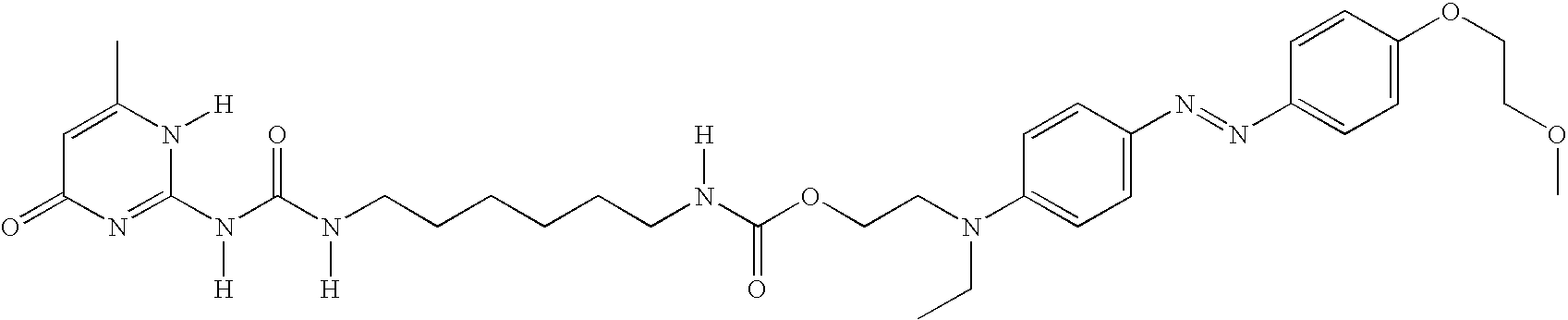

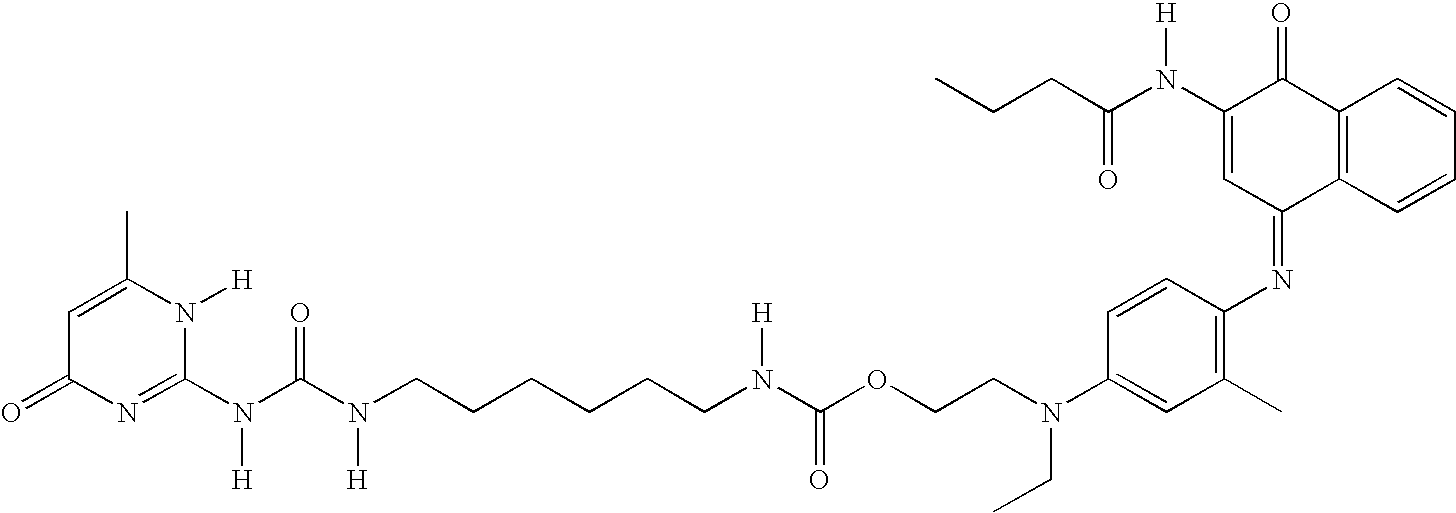

Ink composition containing a particular type of dye, and corresponding ink-jet printing process

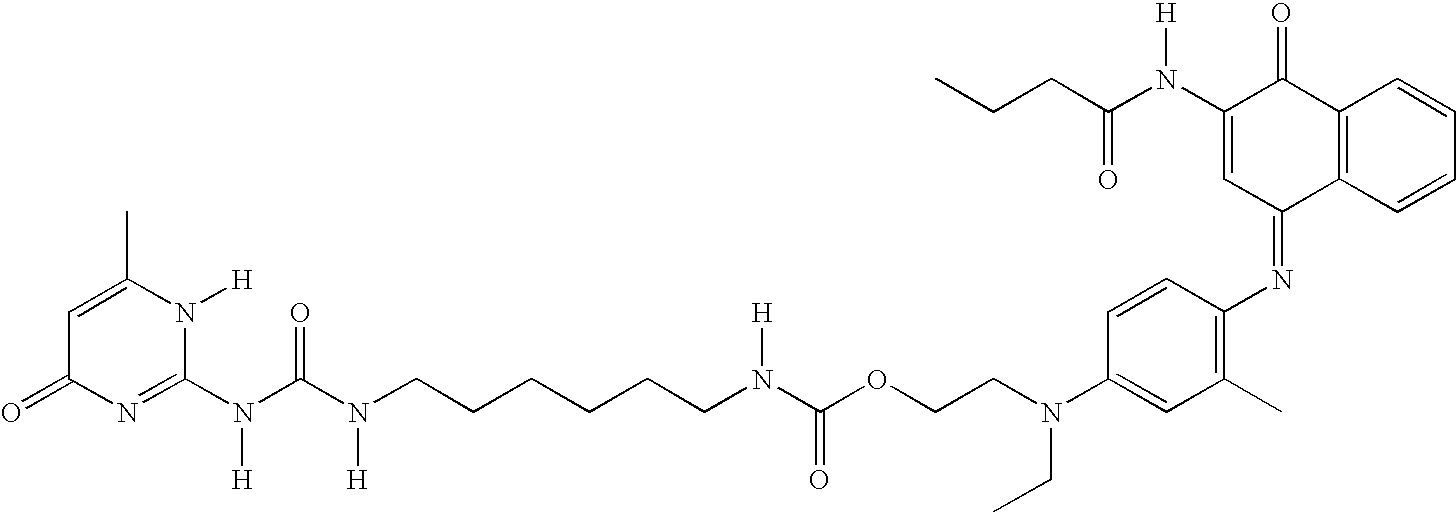

InactiveUS20040206270A1Improve light fastnessImprove stabilityOrganic chemistryMeasurement apparatus componentsCompound (substance)Organic chemistry

An ink composition is disclosed which contains at least one novel dye (CU)n(SAU)m that is capable of self-assembling under appropriate conditions to form supramolecular structures. More than one novel dye (CU)n(SAU)m and / or at least one non-colored self-assembling compound (SAU')p(X)q may be incorporated in these supramolecular structures. Also disclosed is an ink-jet printing process using these novel dyes, and an ink-jet printing apparatus provided with an ink cartridge containing such a dye.

Owner:AGFA NV

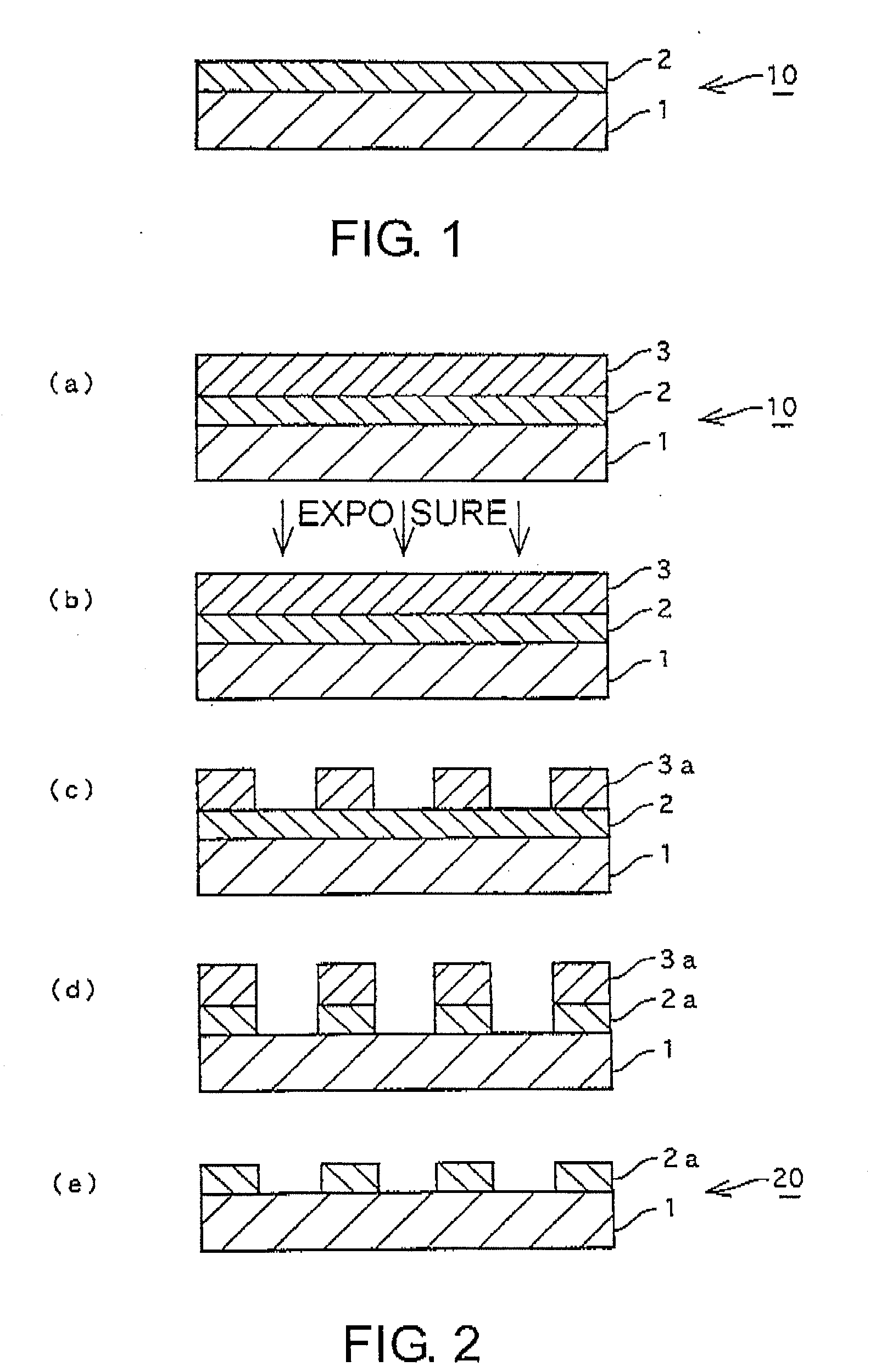

Photomask blank manufacturing method and photomask manufacturing method

ActiveUS20100167185A1Extended service lifeImprove light fastnessSemiconductor/solid-state device manufacturingOriginals for photomechanical treatmentLength waveOxygen

A thin film made of a material containing a metal and silicon is formed on a light-transmissive substrate. Then, a treatment is performed to modify a main surface of the thin film in advance so that when exposure light having a wavelength of 200 nm or less is accumulatively irradiated on a thin film pattern of a photomask to be produced by patterning the thin film, the transfer characteristic of the thin film pattern does not change more than a predetermined degree. This treatment is performed by carrying out, for example, a heat treatment in an atmosphere containing oxygen at 450° C. to 900° C.

Owner:HOYA CORP

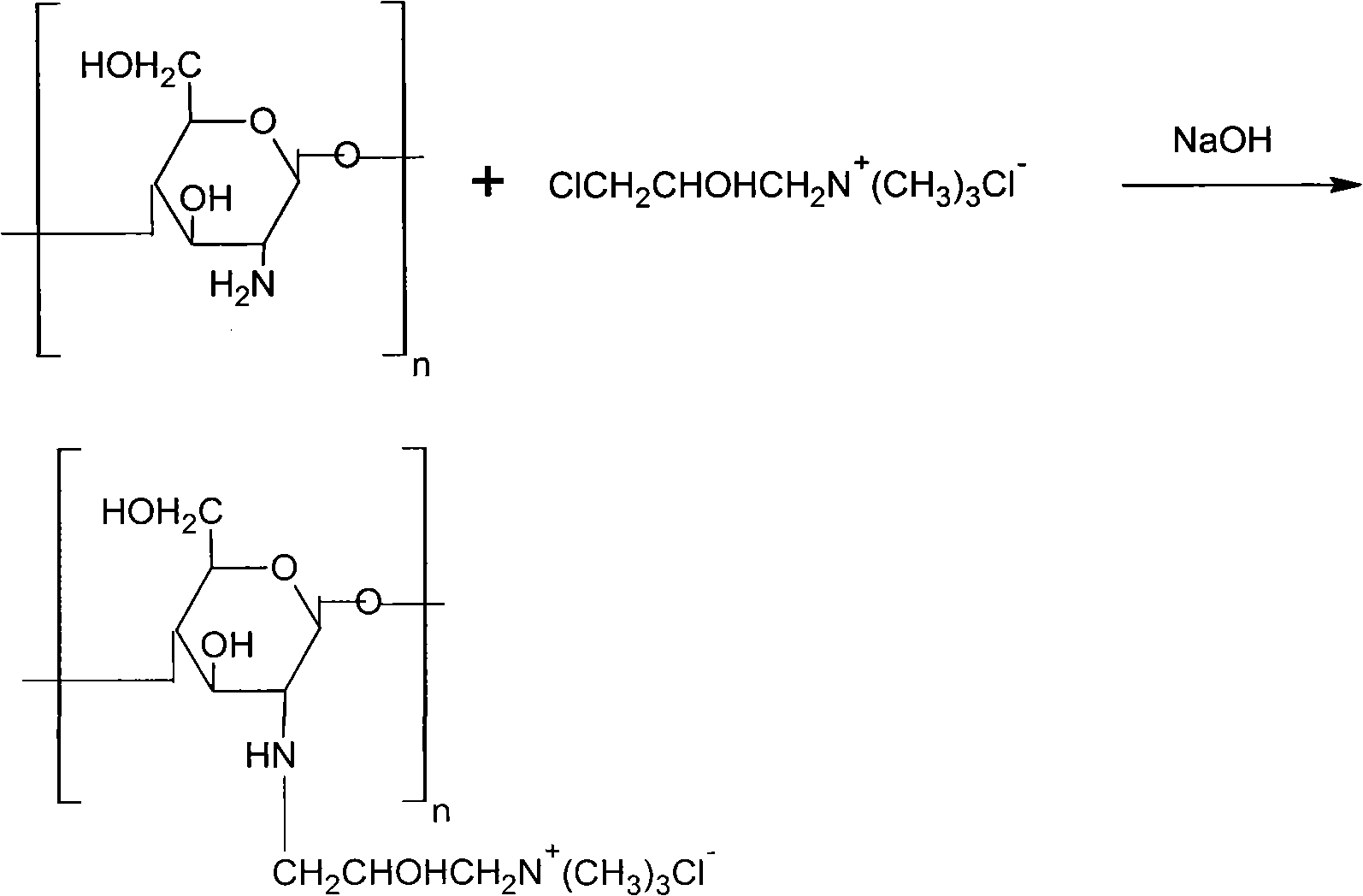

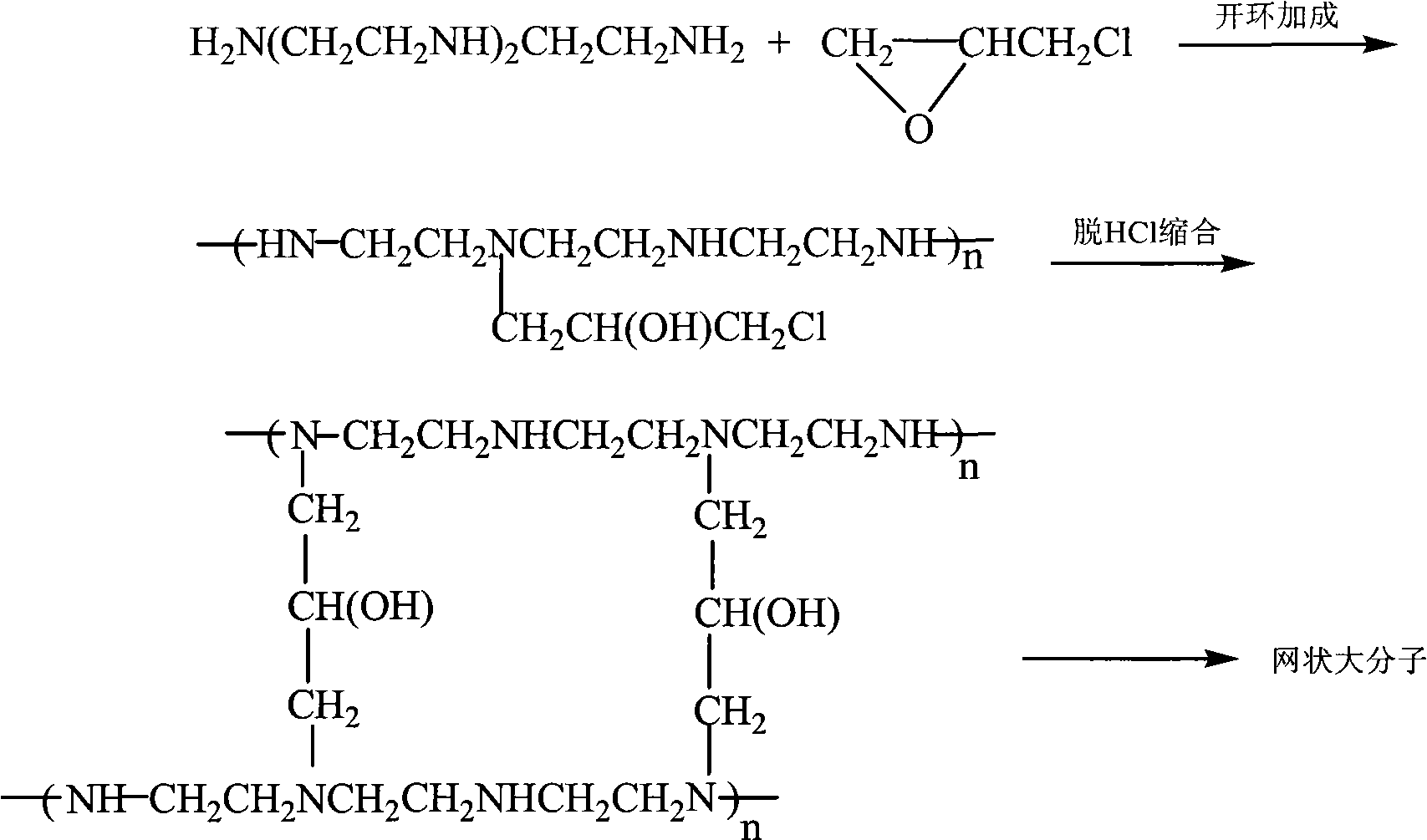

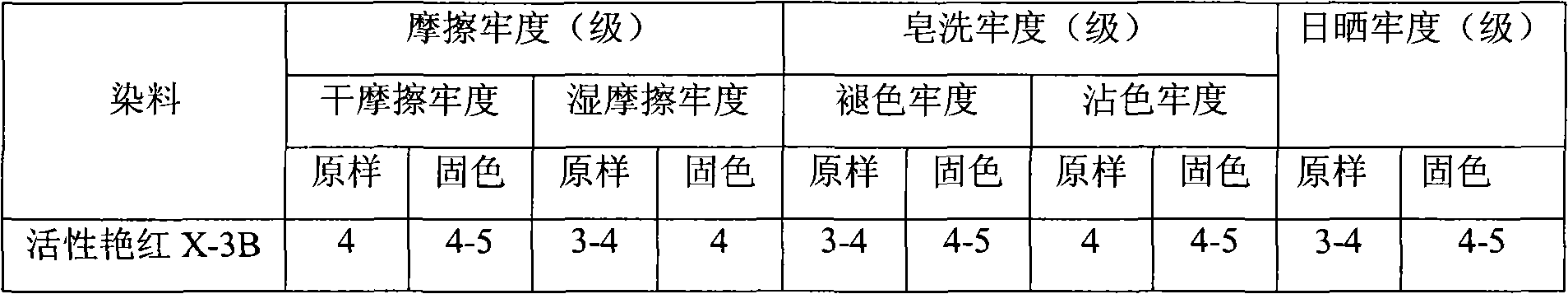

Preparation method of formaldehyde-free active dye fixing agent

InactiveCN101768883AImprove rubbing fastnessImprove washing fastnessDyeing processUltrasound - actionTetramine

The invention relates to a preparation method of a formaldehyde-free active dye fixing agent. The compound prescription of the active dye fixing agent consists of two components, component 1 is chitosan quaternary ammonium salt produced by 3-chlorine-2-hydroxypropyl trimethyl ammonium chloride grafted with chitosan under ultrasonic, and component 2 is reactive fixing agent produced after reaction of one weight part of triethylene tetramine and three weight parts of epoxy chloropropane; the mass ratio of the component 1 and the component 2 is 1:3. The method of the invention can be applied to fixing treatment of cotton fabric dyed by active dye, can improve rubbing fastness, washing fastness and light fastness of the fabric without influence on the chromatic light and the fabric hand feel; the prepared fixing agent which is free from formaldehyde, nontoxic and environment-friendly is a novel printing and dyeing assistant.

Owner:QINGDAO UNIV

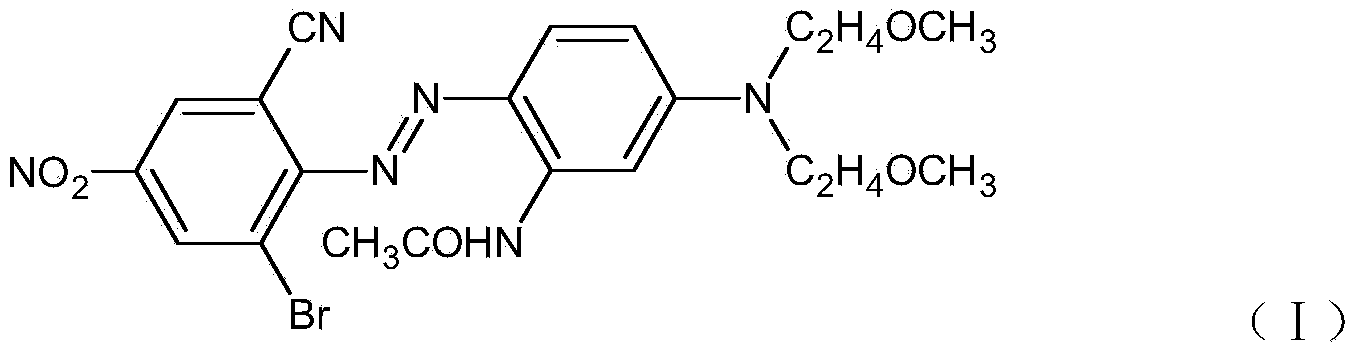

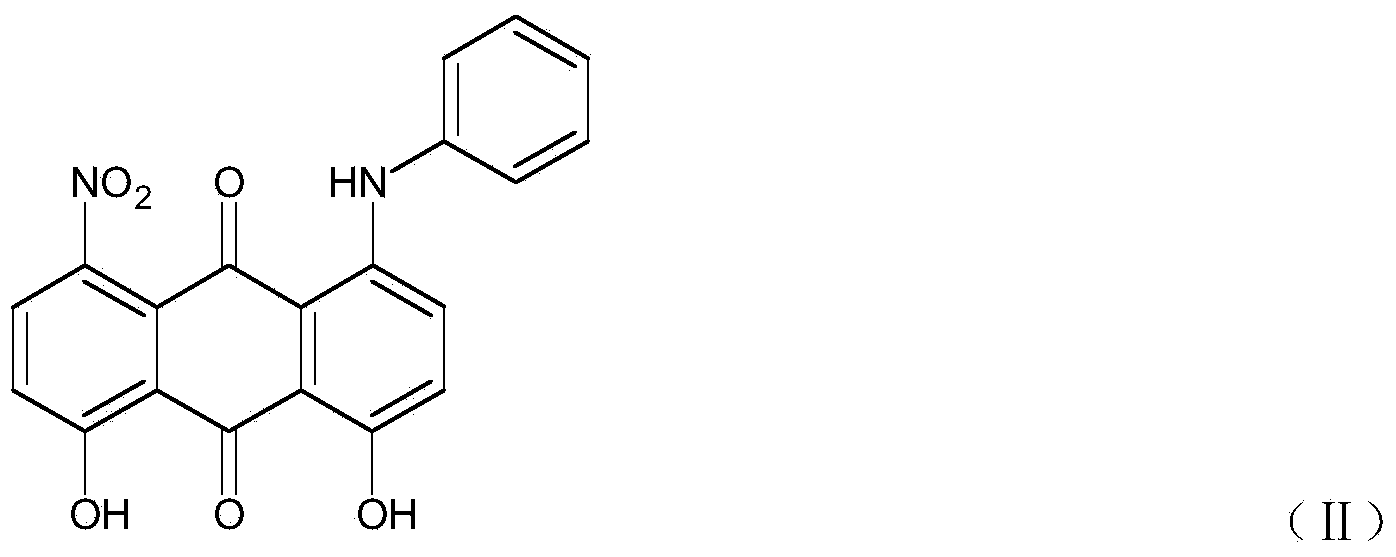

Ink jet ink, ink set, ink jet recording method, ink cartridge, recording unit, and ink jet recording apparatus

ActiveUS7285159B2Improve light resistanceImprove light fastnessMeasurement apparatus componentsDuplicating/marking methodsImaging qualityLightfastness

Provided is an ink jet ink comprising at least a coloring material comprising a compound represented by the general formula (I) or a salt thereof; and a compound represented by the general formula (II). Thereby, there can be provided an ink jet ink that provides image quality comparable to silver halide photograph and provides a recorded article having high light fastness

Owner:CANON KK

Lamp lens or bezel with visual effect

InactiveUS20030189838A1Broad paletteImprove lighting qualityPoint-like light sourceMeasurement apparatus componentsCamera lensVisibility

Lenses and bezels for lamps provide an appealing aesthetic look in the form of a colored glow at the edges of the lens or bezel by incorportation of an photoluminescent material in a molded polycarbonate body. The lenses are particularly suitable for use as an automotive outer lens, and can also improve the quality of the light emitted through this outer lens by interacting with the light bulb. The emitted beam is of a legal color and intensity as defined per the SAE J578 standard. The lighting performance may also be improved in such manner as reducing glare, increasing brightness or producing a beam that enhances road visibility at night to the human eye.

Owner:SABIC GLOBAL TECH BV

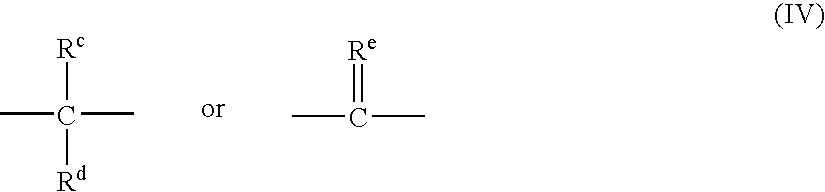

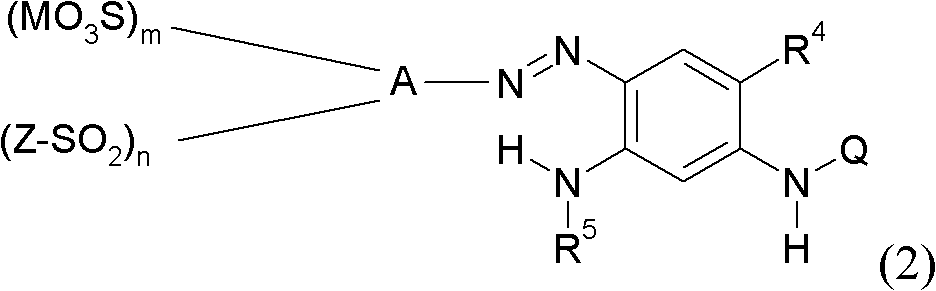

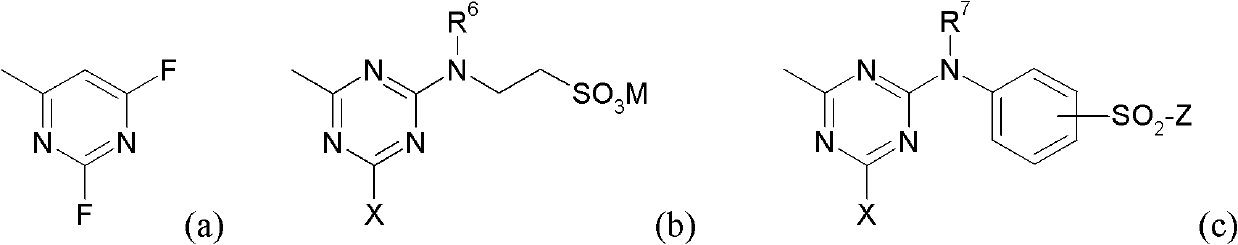

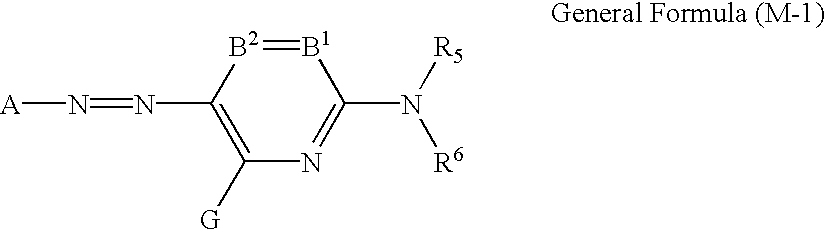

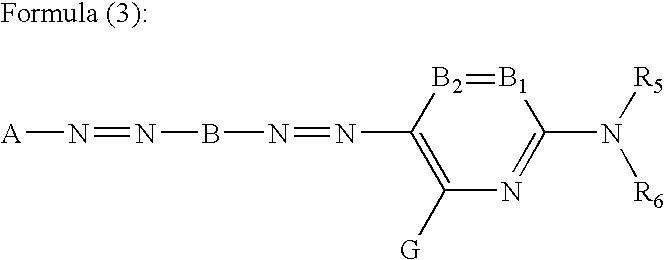

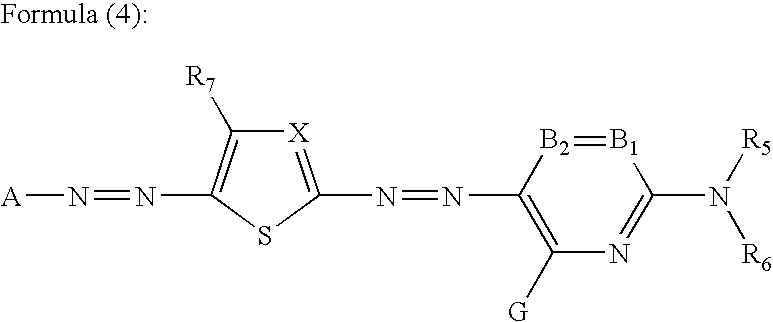

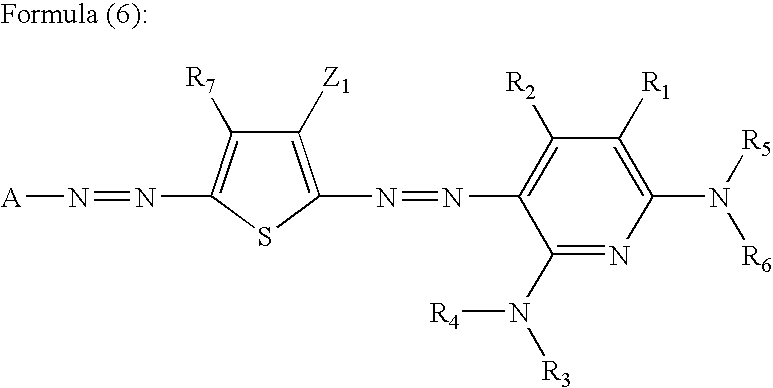

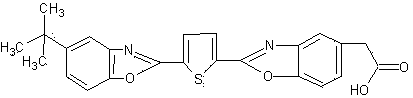

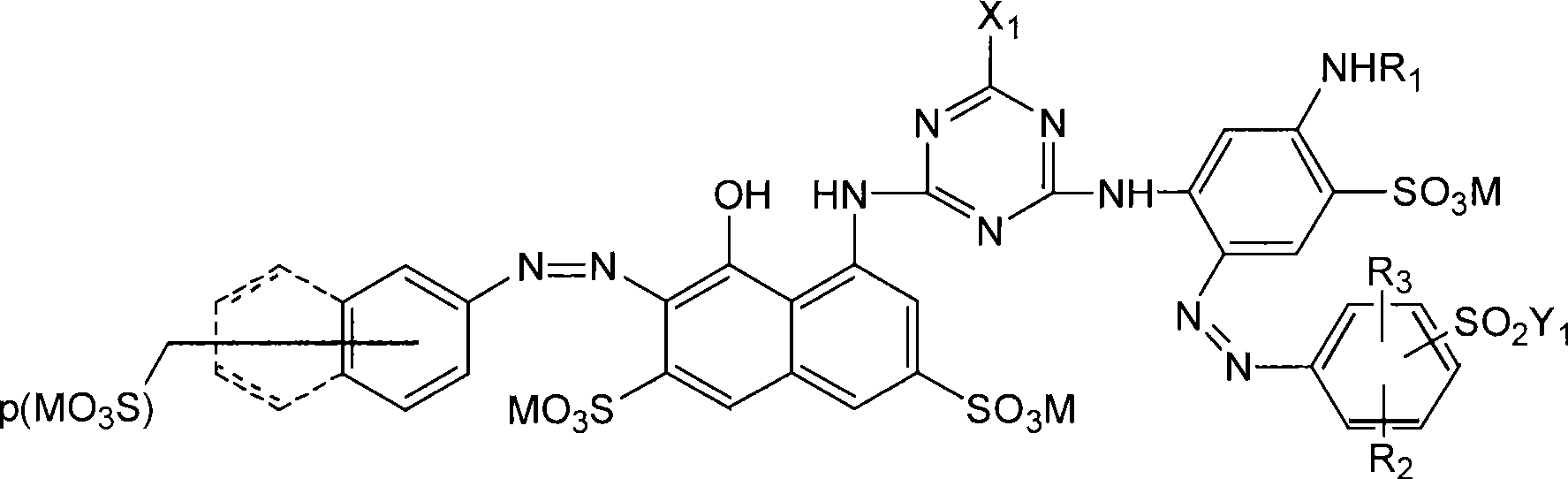

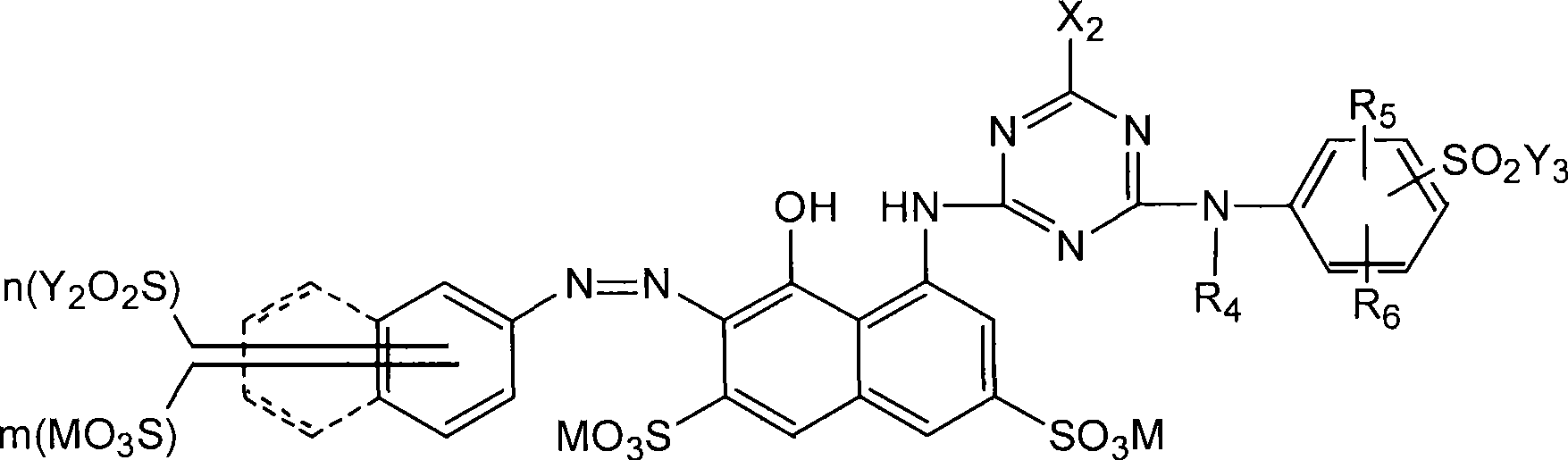

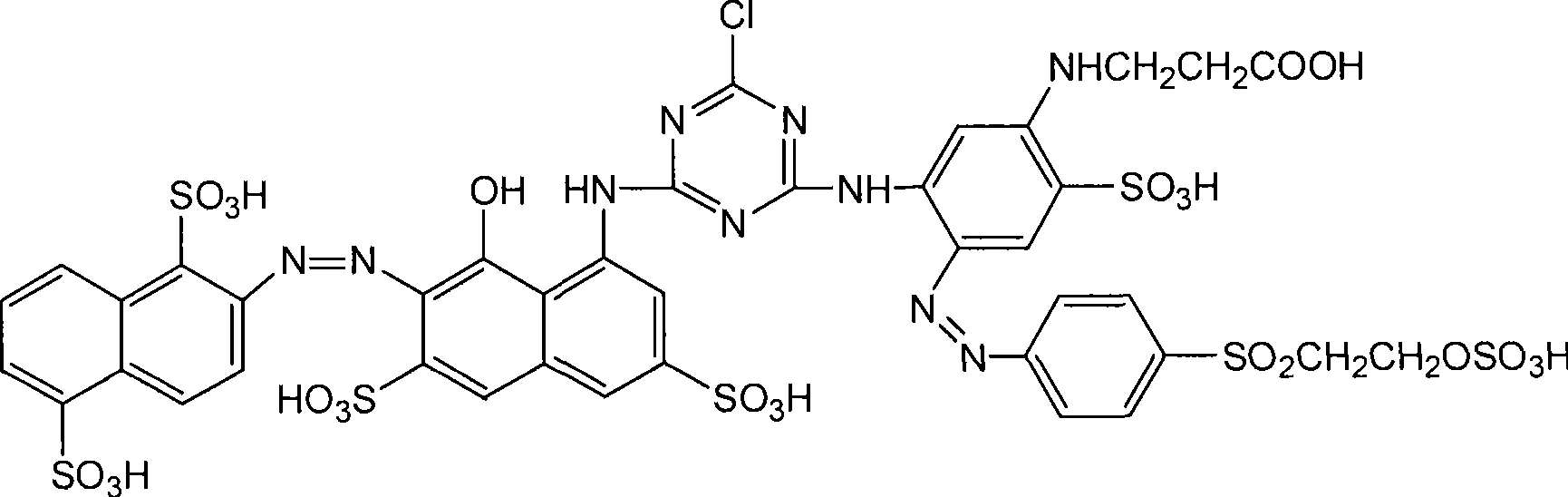

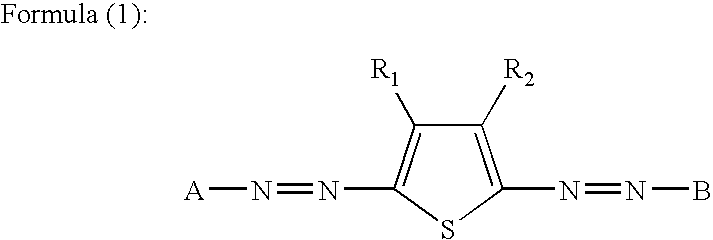

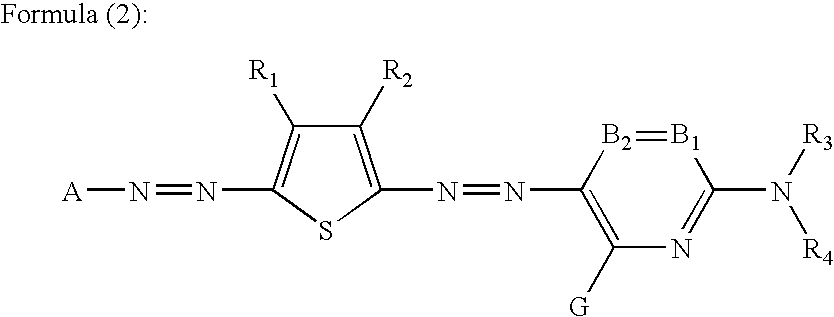

Fiber-reactive azo dyes and dye mixtures, preparation thereof and use thereof

Owner:DYSTAR COLOURS DISTRIBUTION GMBH

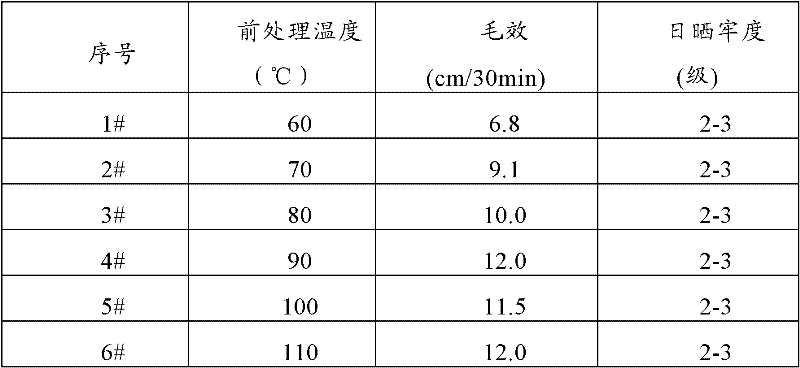

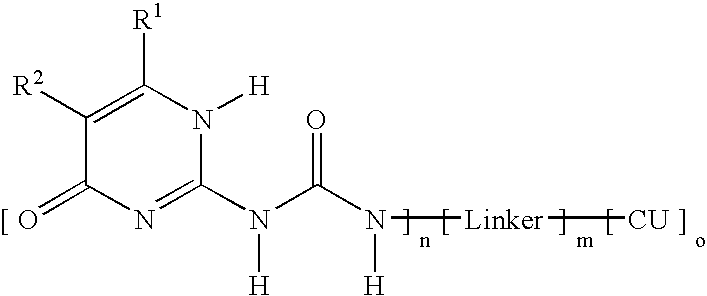

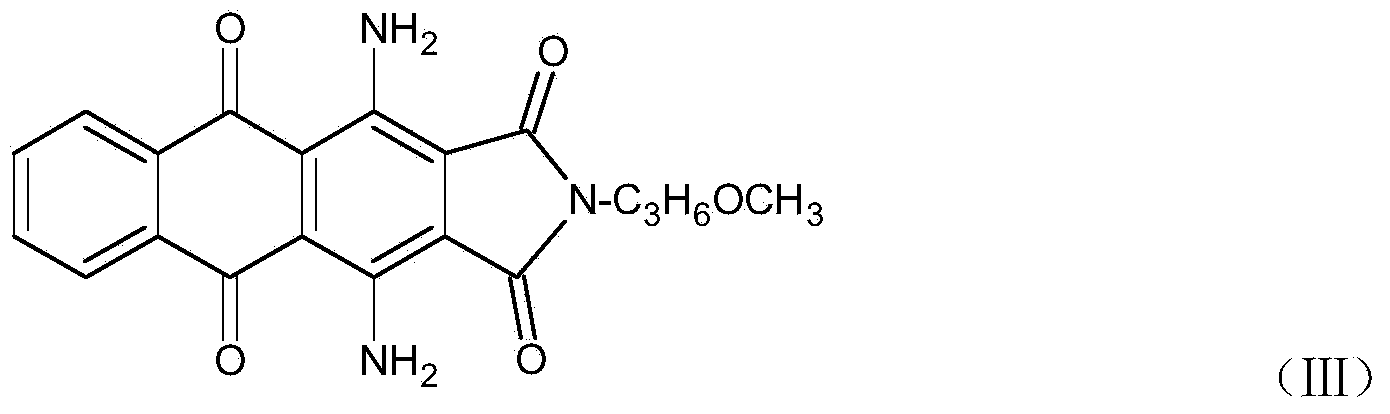

Coloring composition, and cured film, color filter, pattern forming method, method for manufacturing color filter, solid-state imaging device, image display device, and dye multimer, each using the coloring composition

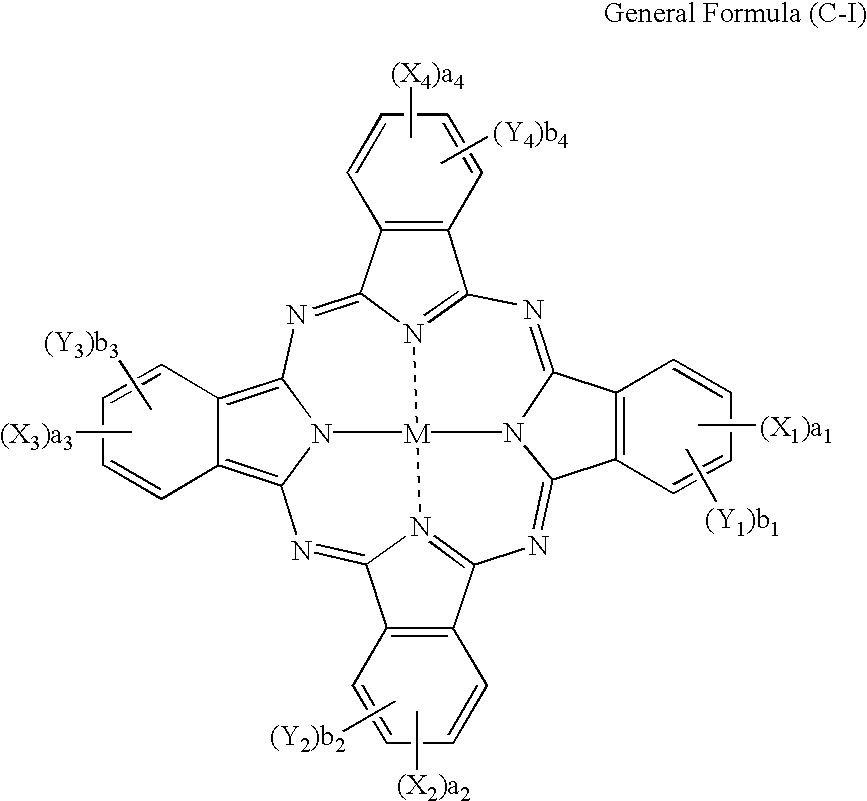

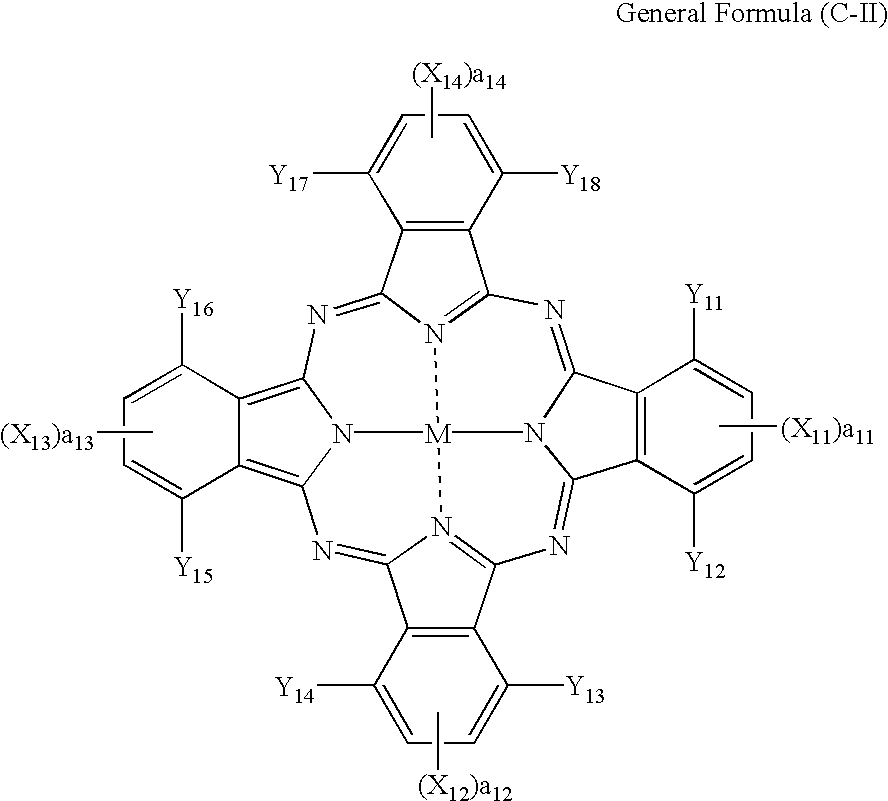

ActiveUS20160327859A1Good exposure sensitivityGood light fastnessOptical filtersOrganic dyesColor gelPhysical chemistry

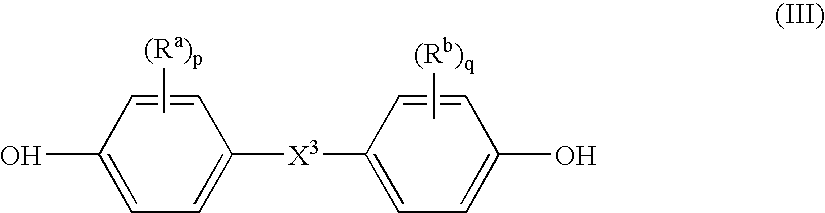

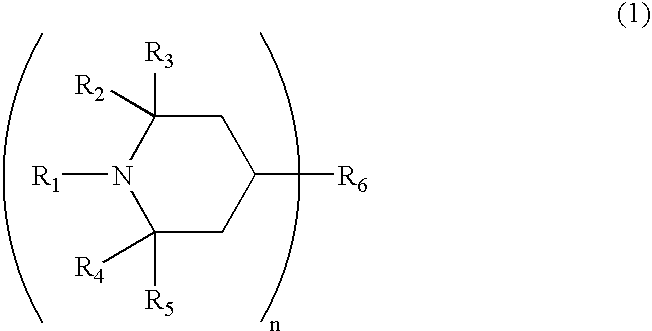

A coloring composition having good light fastness and exposure sensitivity in the case of preparing a cured film; and a cured film, a color filter, a pattern forming method, a method for manufacturing a color filter, a solid-state imaging device, an image display device, and a dye multimer, each using the coloring composition, are provided. The coloring composition contains a dye multimer having a colorant structure and at least one structure selected from structures of Formulas (1) to (5) in the same molecule (Formula (1) is shown below), and a curable compound:

Owner:FUJIFILM CORP

Multifunctional cotton fabric finishing agent and method for making same

The invention relates to a multifunctional cotton fabric finishing agent with anti-ultraviolet rays, improved fabric light fastness, antibacterial and wrinkle resistance and a preparation method thereof. The steps of the preparation method include: preparing a water phase; preparing an oil phase; preparing an emulsion; preparation. The invention solves the compatibility problem between functional components, the finishing agent has good stability, and there is a promotion effect between functional components, polycarboxylic acid, polycarboxylic acid and chitosan play the role of crosslinking agent, Improves the durability of various functions.

Owner:SOUTH CHINA UNIV OF TECH +1

Ink set, container for storing the same, inkjet recording method, and method for preventing discoloration of inkjet-recorded image

InactiveUS6939399B2High fastnessImage can be preventedMeasurement apparatus componentsInksYELLOW DYEMagenta

An ink set having a yellow ink containing at least one yellow dye, a magenta ink containing at least one magenta dye, and a cyan ink containing at least one cyan dye, wherein an oxidation potential of the magenta dye and an oxidation potential of the cyan dye are each higher than 0.8 V (vs SCE), and an inkjet recording method using the ink set.

Owner:FUJIFILM CORP

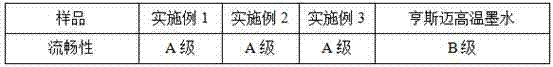

High-temperature direct-injection disperse ink as well as preparation method and application thereof

The invention discloses high-temperature direct-injection disperse ink as well as a preparation method and an application thereof. The ink is prepared from the following raw materials in parts by weight: 15-60 parts of high-temperature disperse dye, 0.3-20 parts of dispersant, 30-60 parts of organic solvent, 10-50 parts of water, 0.5-10 parts of surfactant, 0.05-0.2 part of preservative and 0.05-0.2 part of defoamer. The preparation method comprises the steps of evenly mixing the high-temperature disperse dye, the dispersant, the organic solvent and water together, adding zirconium beads for grinding and dispersing, and then adding the rest organic solvent, water, the surfactant, the preservative and the defoamer to the mixture, mixing evenly, and filtering to obtain the filtrate. The ink is applied to a novel industrial digital textile printing machine and in particular to a textile printing machine with a precision work 508GS nozzle; the ink can be directly injected for printing by using the printing machine, and therefore, the utilization rate of the ink is increased, the cost is reduced and the environmental pollution is reduced; the ink can be dyed quickly at high temperature without transfer printing, and thus has the advantages of short dyeing time, firm dyeing and the like.

Owner:深圳市墨库图文技术有限公司

Ink jet ink, ink set, ink jet recording method, ink cartridge, recording unit, and ink jet recording apparatus

ActiveUS20060103706A1Improve light resistanceImprove light fastnessMeasurement apparatus componentsDuplicating/marking methodsImaging qualityLightfastness

Provided is an ink jet ink comprising at least a coloring material comprising a compound represented by the general formula (I) or a salt thereof; and a compound represented by the general formula (II). Thereby, there can be provided an ink jet ink that provides image quality comparable to silver halide photograph and provides a recorded article having high light fastness.

Owner:CANON KK

Black toner

InactiveUS20070020545A1Improve light fastnessImproved color neutralityDevelopersElectrographic processes using charge patternEngineeringPigment

A black toner particle for use in a printing toner, the particle comprising: a polymer: carbon black; and a plurality of different colored pigments; wherein the carbon black and pigments are dispersed in the polymer.

Owner:HEWLETT PACKARD DEV CO LP

Light fastness of inkjet images by adding salts into inkjet media

InactiveUS6423375B1Improve light fastnessDuplicating/marking methodsPretreated surfacesSodium thiocyanateSodium iodide

At least one of the following compounds is applied as a re-wet solution to media: potassium iodide, sodium iodide, sodium thiosulfate, potassium thiosulfate, and sodium thiocyanate. The addition of at least one of these compounds to the re-wet solution can improve light fastness on the order of eight to thirteen times or more on porous glossy media. These additives are particularly effective with water-soluble dyes, including dyes such as Reactive Black 31 (Pacified) (RB31), Direct Blue 199 (DB199), Magenta 377 (M377), and Direct Yellow 132 (DY132).

Owner:HEWLETT PACKARD DEV CO LP

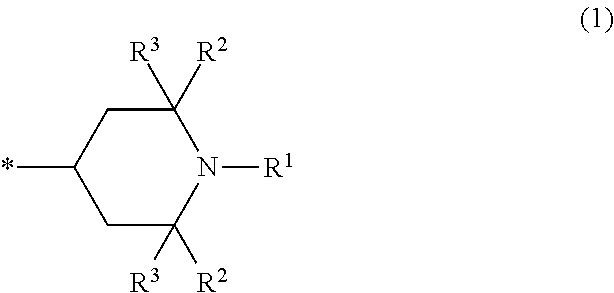

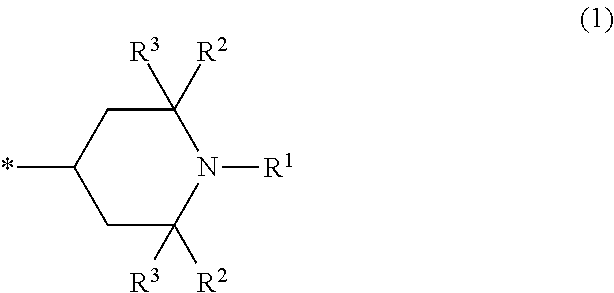

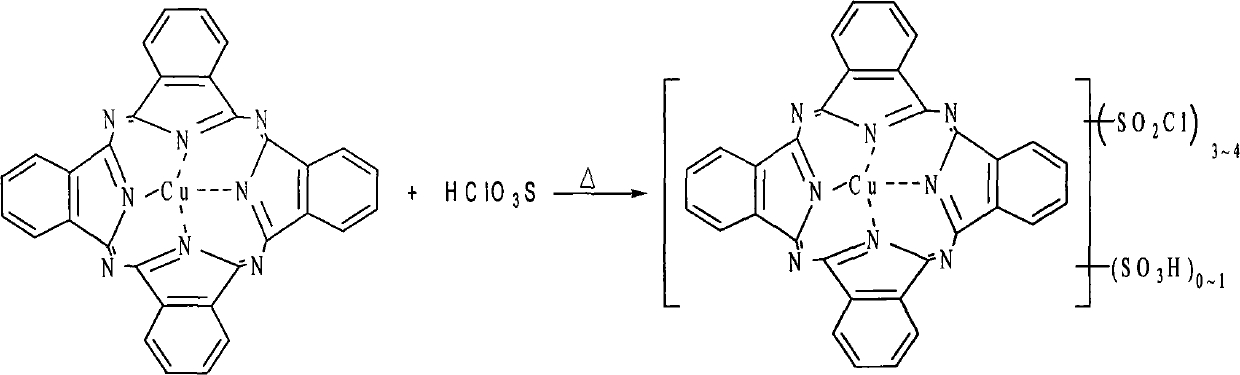

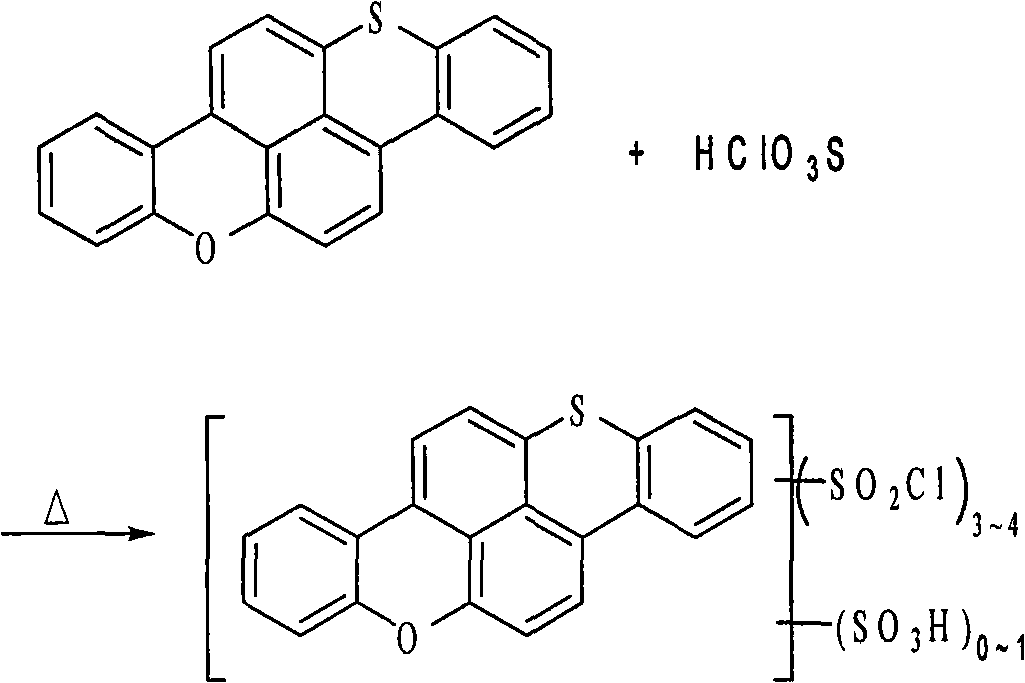

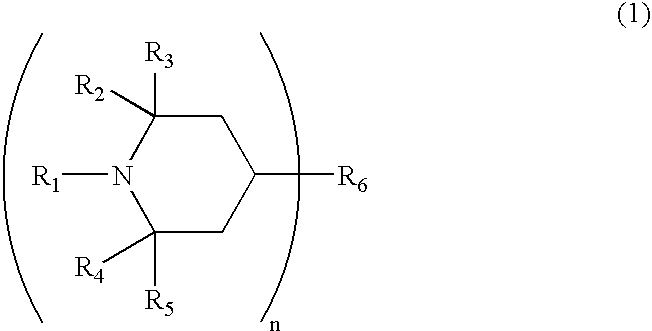

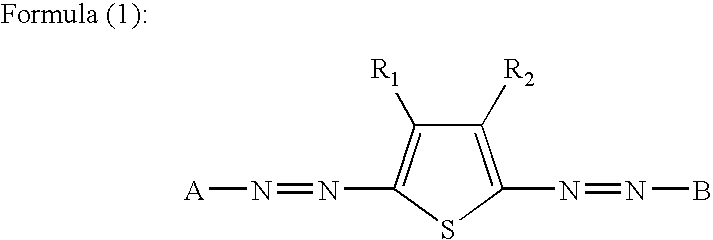

Sunproof water-soluble dye, method for preparing same and application thereof

InactiveCN101864188AImprove light fastnessHigh coloring rateInksPaper/cardboardSolubilityPhthalocyanine dye

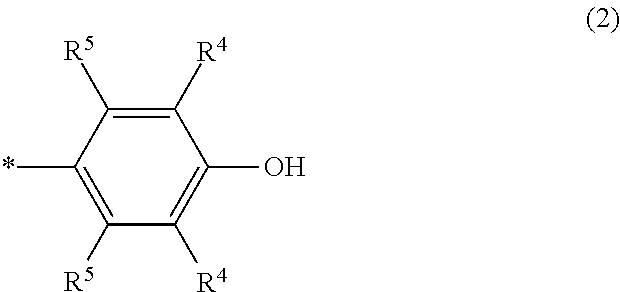

The invention relates to sunproof water-soluble dye having the general formula (1), a method for preparing the same and application thereof. The sunproof water-soluble dye imports the group of hindered amine 4-Z-2,2,6,6-tetramethylpiperidine and the water-soluble group of sulfonic groups based on the common water-insoluble dye, so that under a condition of ensuring good water solubility of the dye, the light stability of the dye is improved, and the sunproof property of the dye is also improved. In a general formula(1), A represents a dye matrix selected from a group formed by dioxazine dye, anthraquinone dye and phthalocyanine dye which are water-insoluble; R1 represents a general formula(2): -(SO2-R)m(2); R2 represents a general formula(3): -(SO3H)n(3); in the general formula(2) and the general formula(3), m and n are both a natural number, preferably m is a natural number between 1 and 16, and n is a natural number between 0 and 2.

Owner:上海汇友精密化学品有限公司

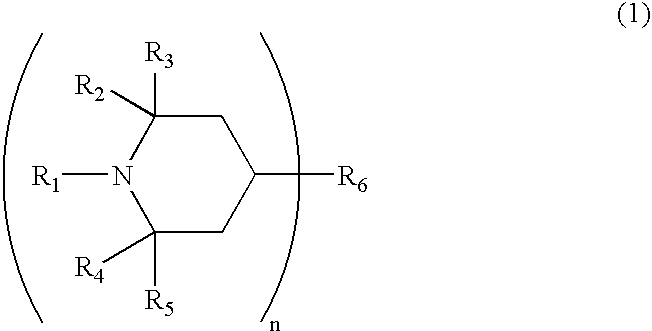

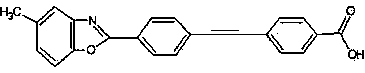

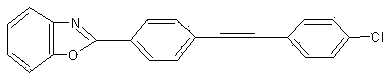

Inkjet ink, inkjet recording method and color toner composition

A coloring composition such as printing ink for inkjet printing or the like or electrophotographic color toner is provided, which can give a colored image or material excellent in the color hue and fastness, and also provide an inkjet recording method capable of forming an image having good color hue and high fastness to light and active gases in the environment, particularly ozone gas, and which is an inkjet ink comprising an azo dye having a specific structure containing an alkyl chain having 4 to more carbon atoms and not containing an ionic hydrophilic group; an inkjet recording method using the ink; and a color toner composition comprising the above-described azo dye.

Owner:FUJIFILM CORP

Photochromic material

ActiveUS20050012081A1High densityImprove fastnessPhotosensitive materialsDiffusing elementsOligomerSpiropyran

A photochromic material comprising a styrene-based oligomer having a weight average molecular weight of from 200 to 6000 and a photochromic compound selected from the group consisting of spirooxazine derivatives and spiropyran derivatives.

Owner:PILOT PEN CO LTD +1

Fluorescent microsphere and preparation method and application thereof

ActiveCN104046350AWith fluorescent whitening effectGood ballMicroballoon preparationLuminescent compositionsColored whiteBright-white

The invention relates to a fluorescent microsphere and its preparation method. Particle size of the fluorescent microsphere is within the range of 0.1-10 micrometer. The fluorescent microsphere has good sphericity and narrow particle size distribution and also has fluorescent brightening groups. The fluorescent brightening groups are uniformly or randomly distributed in a polysiloxane microsphere or on the surface of the polysiloxane microsphere such that the polysiloxane microsphere has a fluorescent brightening effect, has high light fastness, has excellent heat resistance and high chemical stability, can absorb ultraviolet rays to prevent aging of a product, is especially suitable for an originally yellowish product, endows a product with bright white appearance, can make a colored product more dazzlingly beautiful when used in the colored product, and can enhance brightness of a product when used in a black product. The invention, on the other hand, provides a preparation method of the above fluorescent microsphere and a prepared photodiffusion material.

Owner:GUANGZHOU SHINE POLYMER TECH

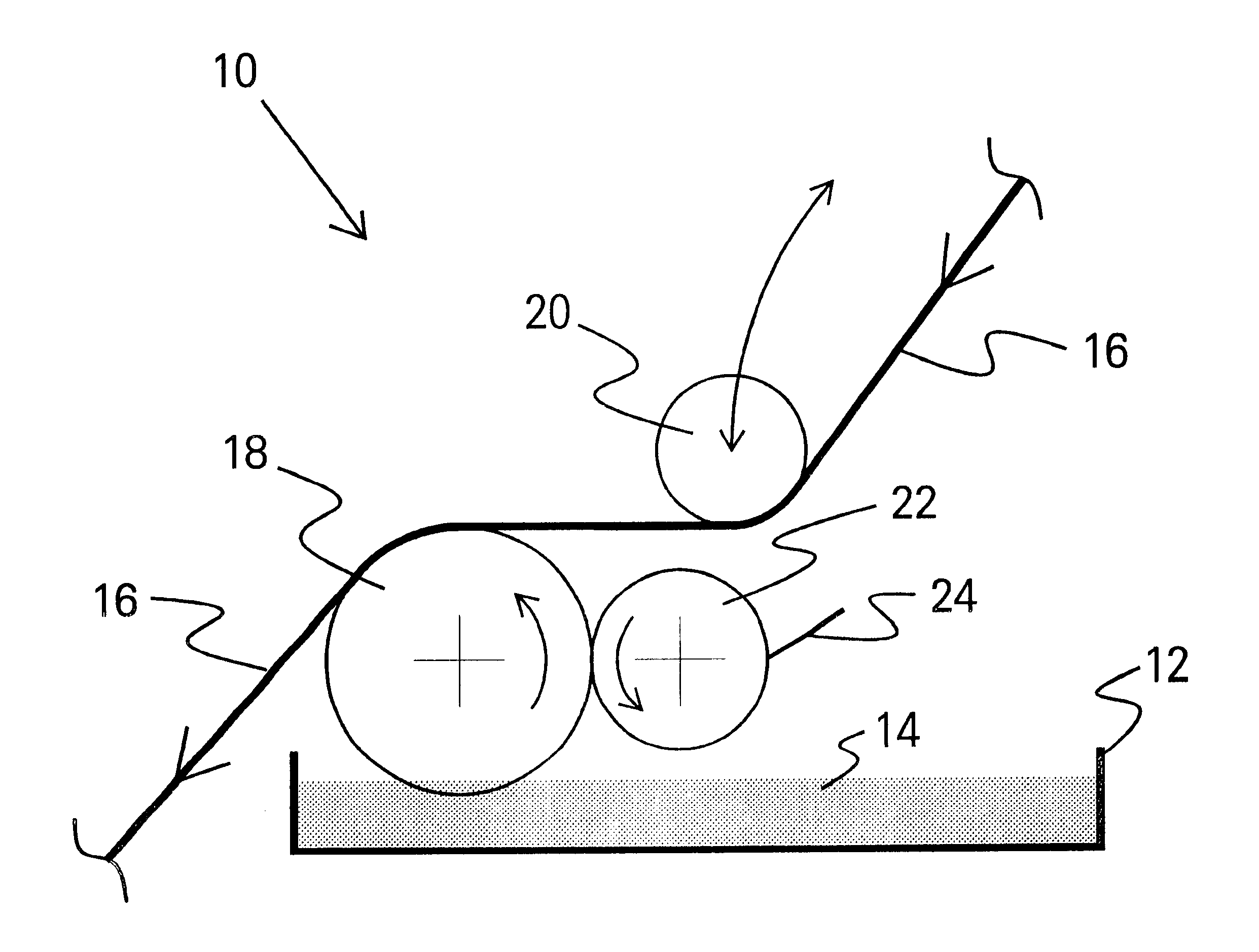

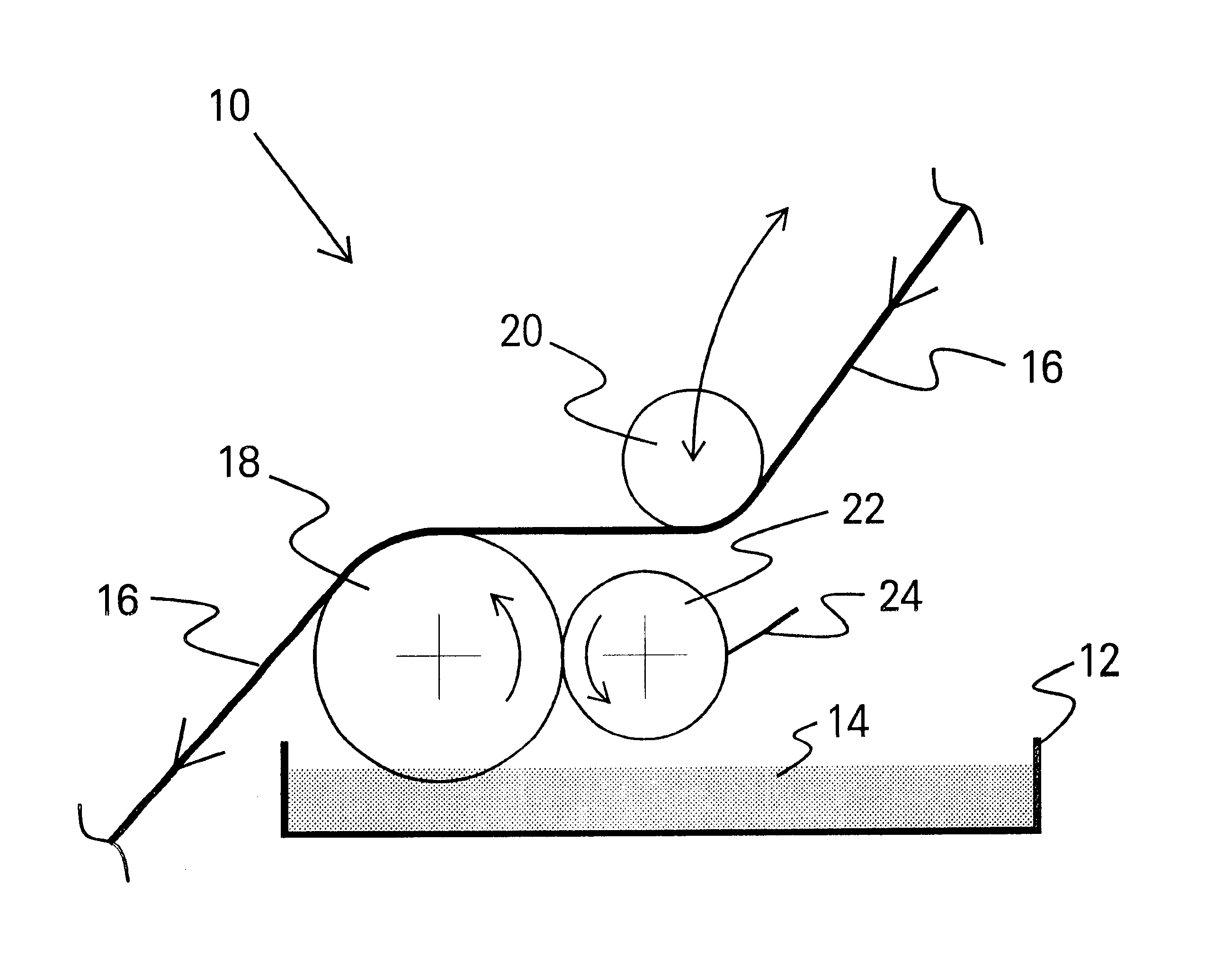

Cold transfer decal process of disperse dyes

ActiveCN102776791AAvoid pollutionHigh activity energyFibre treatmentTransfer printing processDisperse dyeAlcohol

A cold transfer decal process of disperse dyes comprises processes including body paper precoating, dispersing dye based ink printing, pretreatment of fabric, cold transferring paper and fabric driving fit transferring, printed fabric fixation, washing and sizing. The printing ink is composed of macromolecule disperse dyes, thickener, dispersing agent and deionized water. The pretreatment agent is composed of binding agent, slip agent, emulsifying agent, defoaming agent and deionized water. The cold transfer decal process of disperse dyes enables the environment of manufacturing shops to meet environmental protection requirements, and printed fabric end products do not contain residues including methyl alcohol, butyl alcohol and the like.

Owner:NEWTECH TEXTILE TECH DEV SHANGHAI

Coloring agent composition for textiles and production method of coloring agent composition

InactiveCN102418287AGood staining with good resultsExcellent fastness performanceDyeing processPolyesterAcid fuchsin

The invention provides a coloring agent composition for textiles and a production method of the coloring agent composition and relates to the technical field of dyeing of the textiles, in particular to the coloring agent composition for the textiles and the production method of the coloring agent composition. The coloring agent composition is prepared by combining various dyeing raw materials, an additive, a levelling agent and a penetrating agent, wherein the dyeing raw materials are formed by blending acid violet, acid leather red and an acid fuchsin according to equal amount; the levelling agent comprises the following components in percentage by weight: 10-15 percent of methylenebis naphthalenesulfonate, 15-20 percent of lignosulfonate, 2-5 percent of carboxymethyl cellulose, 2-5 percent of urea and the balance water. The coloring agent composition and the production method thereof have the advantages of favorable dying effect and firmness for dyeing of purified cotton, blend fabric and polyester-cotton fabric, simple production process, low cost and improved work efficiency.

Owner:DAFENG HAILONG CHEM

Method for dyeing vivid fluorescent green on cotton knitwear

InactiveCN101597867AMeet the requirements of bright colorMeet quality indicatorsDyeing processFluorescenceEmerald

The invention relates to a method for dyeing cotton knitwear, in particular to a method for dyeing fluorescent green on cotton knitwear. The method comprises the following steps: 1) pretreating grey cloth; 2) placing the grey cloth and eightfold weight of water into a dye vat; 3) heating the grey cloth and the water to a temperature of 60 DEG C, adding reactive emerald blue MZ-HGN, 7GFF fluorescent yellow and salt into the dye vat in sequence to reserve the temperature for 30 minutes; 4) continuously heating the mixture to a temperature of 80 DEG C, and gradually adding calcined soda for fixation, and reserving the temperature for 30minutes; 5) continuously heating the mixture to a temperature of 100 DEG C, and reserving the temperature for 15 minutes; 6) comparing the grey cloth with a sample, cooling the grey cloth to a temperature of 70 DEG C, and removing dye liquor; 7) washing the grey cloth with water twice after the steps; 8) washing the water washed grey cloth with soap once at a temperature of 90 DEG C; 9) washing the grey cloth which is washed by the soap for 2 or 3 times with water; 10) carrying out softening treatment on the water washed grey cloth at 40 DEG C, reserving the temperature for 15 minutes and taking the grey cloth out of the dye vat; 11) dehydrating the grey cloth; 12) drying the grey cloth; 13) shaping the grey cloth. The cloth dyed through the method not only can meet the requirement of clients on color brightness, but also achieves the corresponding quality index.

Owner:ZHEJIANG YINHE PRINTING & DYEING

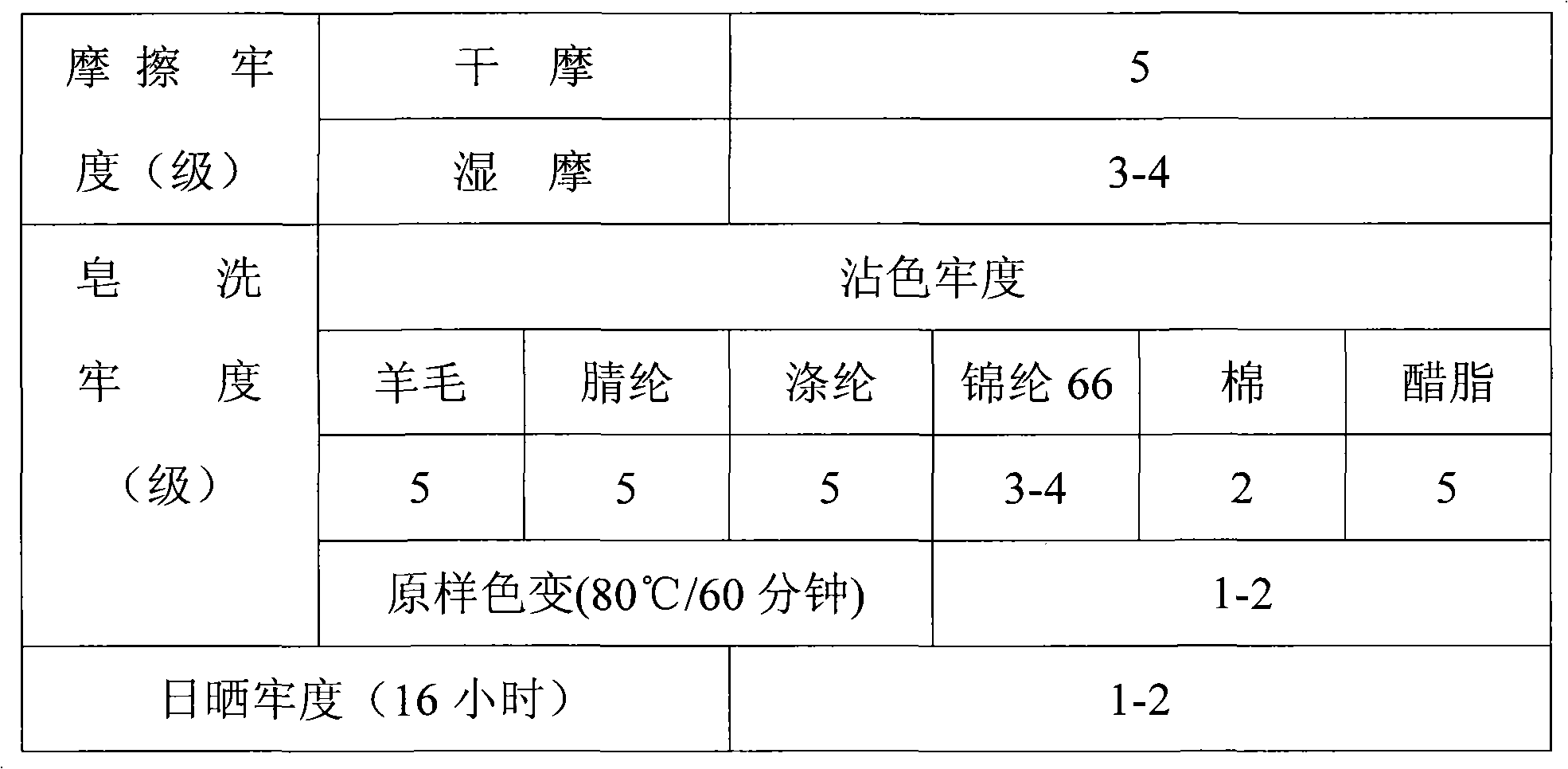

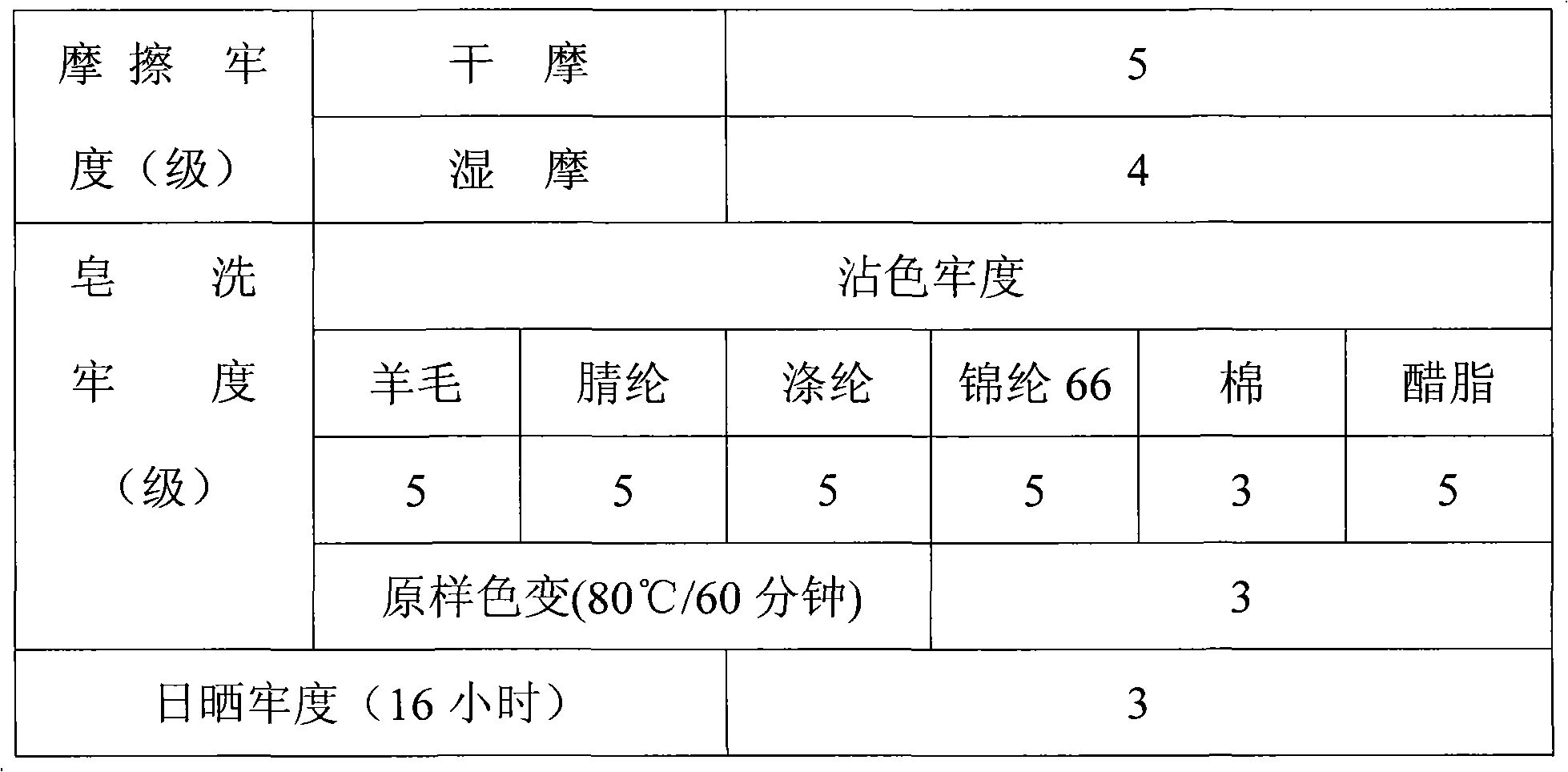

Red reactive dye composition and application thereof

ActiveCN101497747AHigh color fastnessImprove soaping fastnessOrganic dyesDyeing processHuePhotochemistry

The invention provides a red reactive dye compound comprising one or a plurality of known red reactive dye I and red reactive dye II which are mixed together according to a certain proportion. The red reactive dye compound has bright color, wide hue range and excellent various dye fastness. Compared with the red reactive dye I and the red reactive dye II which are the components of the red reactive dye compound, the red reactive dye compound is obviously improved in the color fixation rate, the color promotion rate, the migration property, the different bath ratios during dying and the stability of different electrolyte used. More importantly, compared with the red reactive dye I, the red reactive dye compound is remarkably improved in the light fastness and the fastness to chlorine.

Owner:ARGUS SHANGHAI TEXTILE CHEM

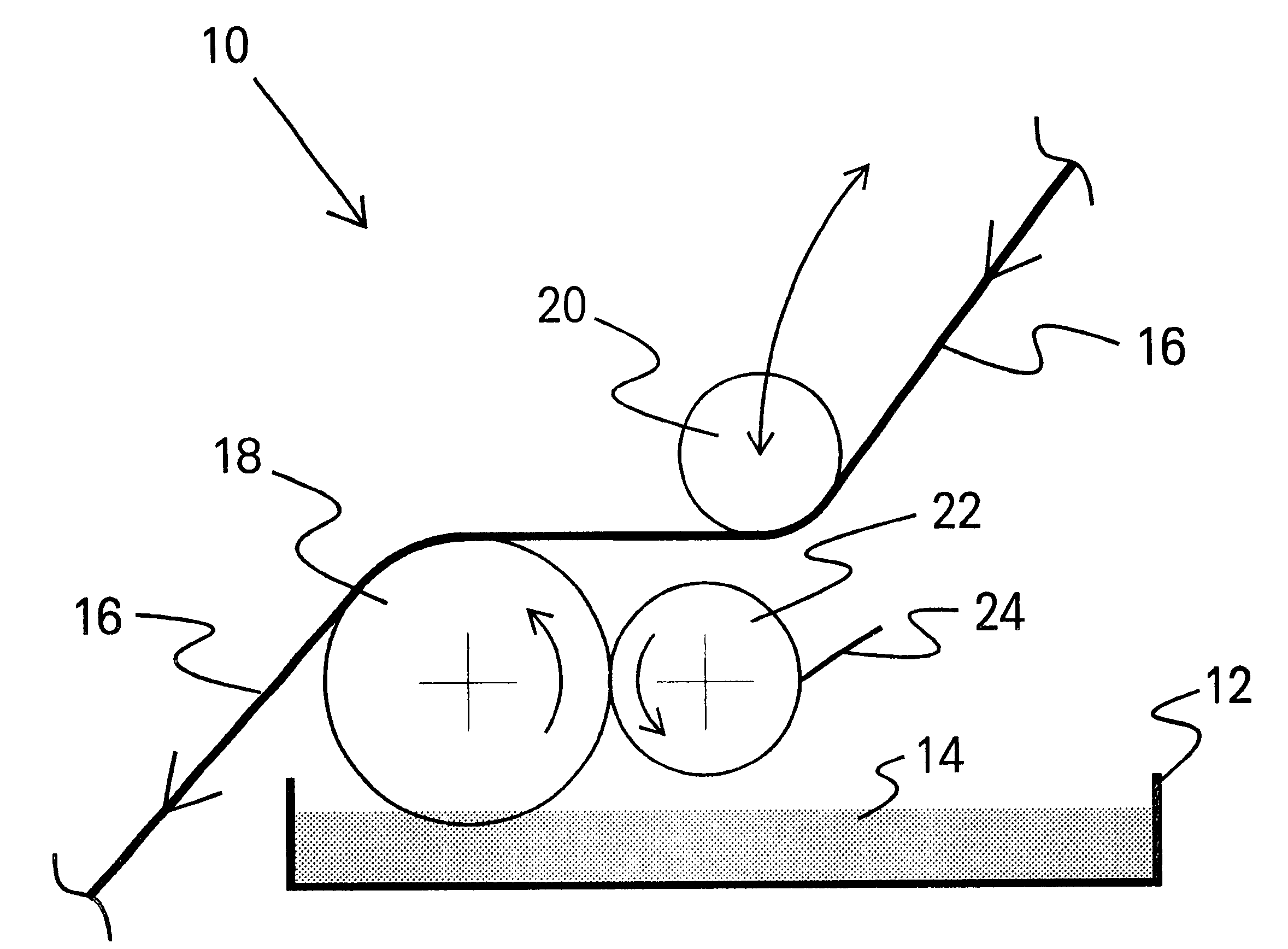

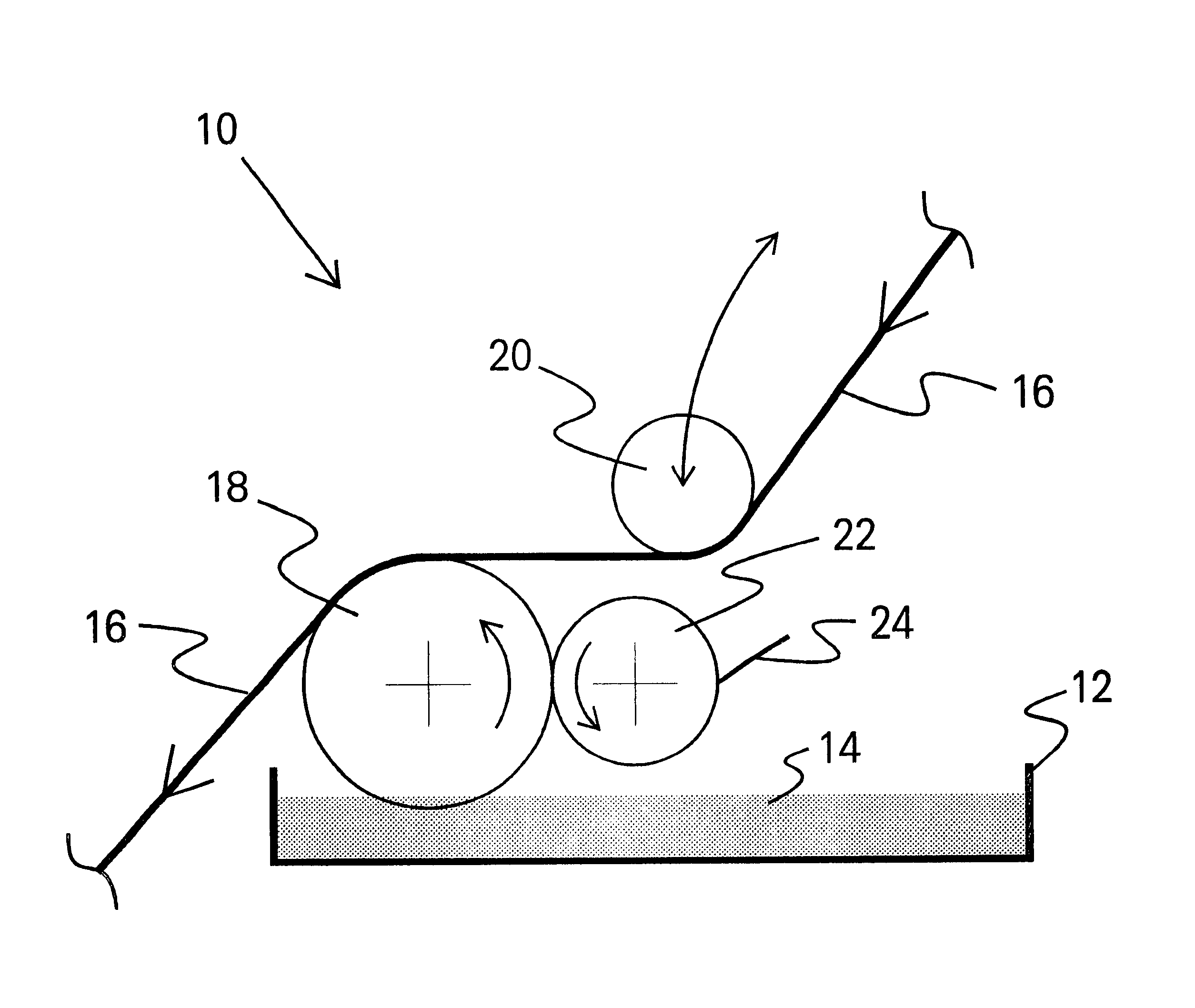

Light fastness of inkjet images by adding salts into inkjet inks and print media

InactiveUS6432523B1Improve light fastnessLayered productsDuplicating/marking methodsSodium thiocyanateSodium iodide

At least one of the following compounds is included on a surface layer of a print medium and in an inkjet ink formulation to be printed thereon: potassium iodide, sodium iodide, sodium thiosulfate, potassium thiosulfate, and sodium thiocyanate. The addition of at least one of these compounds to both the print medium and the inkjet ink can improve light fastness on the order of eight to thirteen times or more on porous glossy media. These additives are particularly effective with water-soluble dyes, including such dyes as Reactive Black 31 (Pacified) (RB31), Direct Blue 199 (DB199), Magenta 377 (M377), and Direct Yellow 132 (DY132).

Owner:HEWLETT PACKARD DEV CO LP

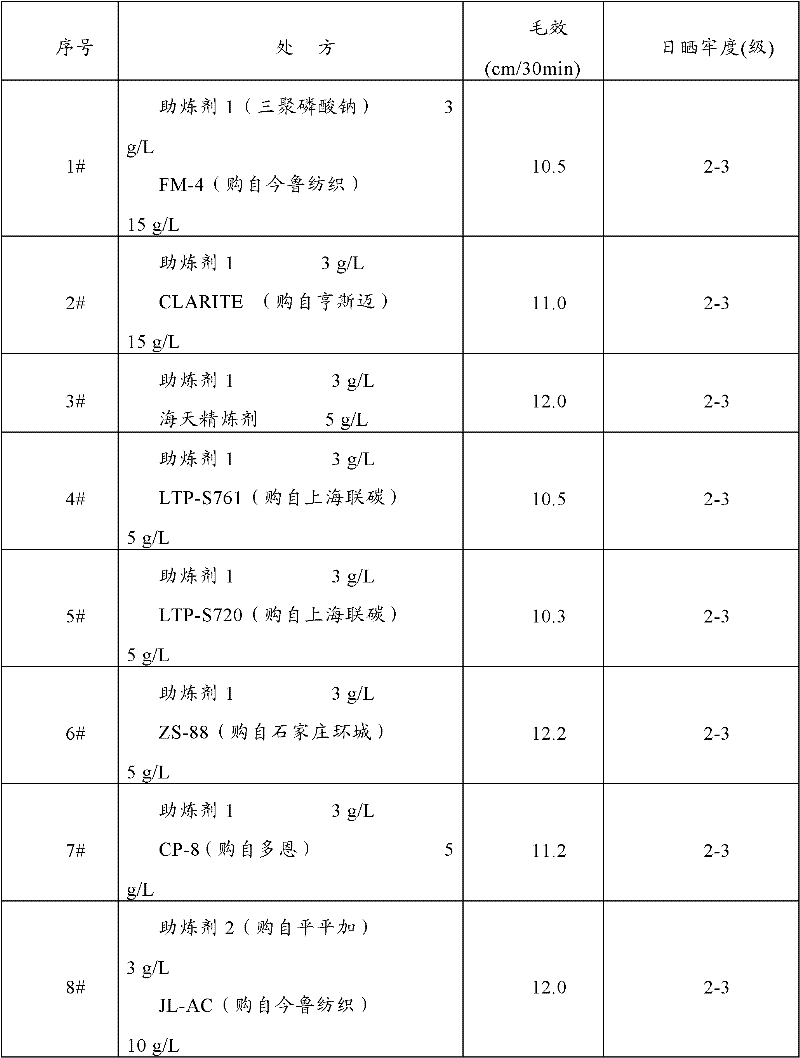

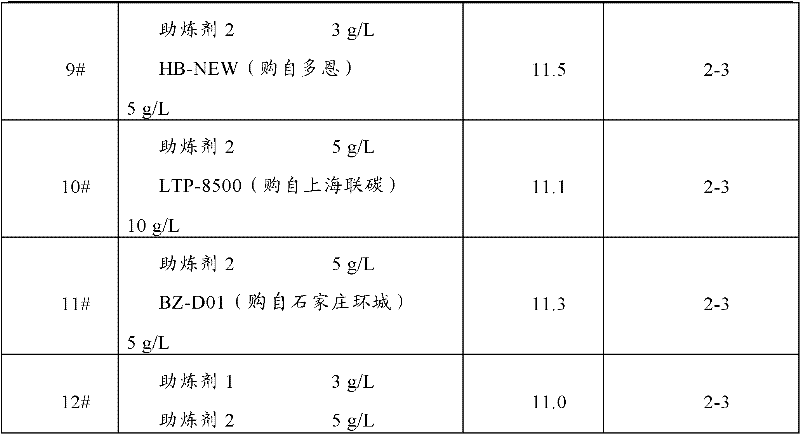

Method for improving light fastness of natural green colored cotton

InactiveCN102561009AImprove antistatic performanceGood moisture permeabilityVegetal fibresNational standardMaterials science

The invention provides a method for improving the light fastness of natural green colored cotton. The method comprises the steps as follows: green colored cotton grey cloth is pre-processed through preprocessing addition agents; metal complexation and softening treatment are carried out after the capillary effect of the grey cloth reaches 10 to 12 cm / 30min; and then the light fastness of the grey cloth is enabled to reach 4 level, so that green colored cotton with beautiful color and stable performance is obtained. The sample production can be carried out by adopting the prescription and the technology of the processing method, so that the technology achieves good reproducibility, the light fastness of natural green colored cotton reaches 4 level, and good capillary effect and hand feeling can be achieved. Fabrics that are obtained by processing 75 percent of green colored cotton by adopting the method achieve beautiful colors and stable performances, and all the indexes of the fabrics can meet the requirements (National Standard 18401).

Owner:BEIJING GUANGHUA TEXTILE GRP

Aqueous ink and inkjet recording ink

ActiveUS7083670B2Good storage stabilityGood colorDuplicating/marking methodsAzo dyesPolymer sciencePhenyl group

Owner:FUJIFILM CORP

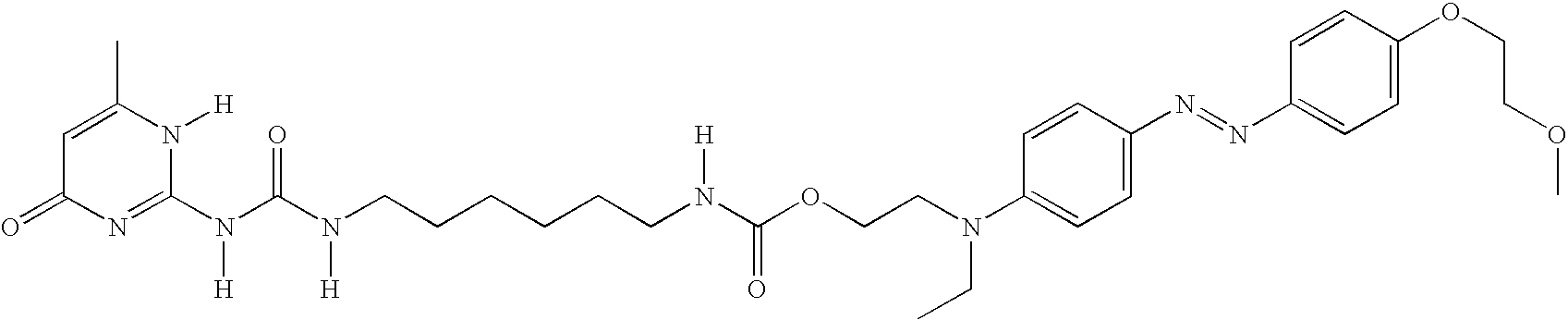

Ink composition containing a particular type of dye, and corresponding ink-jet printing process

InactiveUS7025813B2Improve light fastnessImprove stabilityOrganic chemistryMeasurement apparatus componentsPhotochemistrySelf assembled

An ink composition is disclosed which contains at least one novel dye (CU)n(SAU)m that is capable of self-assembling under appropriate conditions to form supramolecular structures. More than one novel dye (CU)n(SAU)m and / or at least one non-colored self-assembling compound (SAU′)p(X)q may be incorporated in these supramolecular structures. Also disclosed is an ink-jet printing process using these novel dyes, and an ink-jet printing apparatus provided with an ink cartridge containing such a dye.

Owner:AGFA NV

Nano sun-resisting finishing agent and its preparation method and finishing method for textile

InactiveCN1560353AGood sun protectionHas the function of moisture absorption and vapor permeabilityFibre treatmentScreening effectAdhesive

The invention relates to a sun-screening finishing agent and its preparing method as well as a fabric post-finishing method, and the nano sun-screening finishing agent is basically composed of nano titanium dioxide, adhesive, amino-functional silicone, moisture-absorbing and perspiring agent, and water. The preparing method: a. weighing the above matters in specified proportion; b. heating the adhesive, adding the TiO2 in the adhesive, and stirring at high speed; c. keeping temperature at 65 deg.C, and adding in amino-functional silicone, and moisture-absorbing and perspiring agent in turn to stir at high speed; d. keeping 65 deg.C, and adding in water for high-speed stirring. The post-finishing method: a. selecting textile fabrics; b. soaking in dip-rolling liquor; c. drying; d. baking to make the finished product. It has good clothing property and sun-screening effect and largely increase sunlight and dyeing fastness, the product has no toxicity and does not stimulate the skin, the handle is soft, good breathbility, and can used in clothing and sun shields.

Owner:西安华捷科技发展有限责任公司

Dyeing method of cellulosic fiber fabric

InactiveCN105603782AModified Surface PropertiesChange surface propertiesDyeing processInorganic saltsCellulose fiber

The invention discloses a dyeing method of a cellulosic fiber fabric. The dyeing method comprises the following steps: (1) pre-treating; (2) modifying the cellulosic fiber fabric; (3) washing with water; (4) dyeing; (5) softening; and (6) post-treating. With the adoption of the dyeing method, the cellulosic fiber fabric is modified by adopting a cation modifying agent, and the surface performance of the fabric is changed; the dyeing rate and fixation rate of various types of anion dyes are greatly improved; an inorganic salt is not used in a dyeing process and the emission amount of printing and dyeing wastewater is reduced; and a medium-temperature type active dye is used so that the dyeing is uniform and the color fastness is relatively high.

Owner:FOSHAN JUCHENG BIOCHEM TECH RES & DEV CO LTD

Blue disperse dye composition with high washing fastness and high light fastness

The invention relates to a blue disperse dye composition with high washing fastness and high light fastness. The dye is composed of the following components in percentage by weight: 0-70% of dye monomer A, 0-80% of dye monomer B, 0-40% of dye monomer C, 0-10% of dye monomer D, 0-20% of dye monomer E and the balance of assistant. The disperse dye composition has quite high light fastness and washing fastness, the difficulty that the disperse dye can not take into account of the light fastness and the washing fastness is solved, meanwhile, the dye has good uniform dyeing property and excellent other color fastness, so that the blue disperse dye composition is a high-grade dye suitable for automobiles and outdoor sports series.

Owner:JIANGSU YABANG DYE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com