Preparation method of formaldehyde-free active dye fixing agent

A technology of reactive dyes and fixatives, used in dyeing, textiles and papermaking, etc., can solve the problems of discoloration, high dyeing cost, and increased dye consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

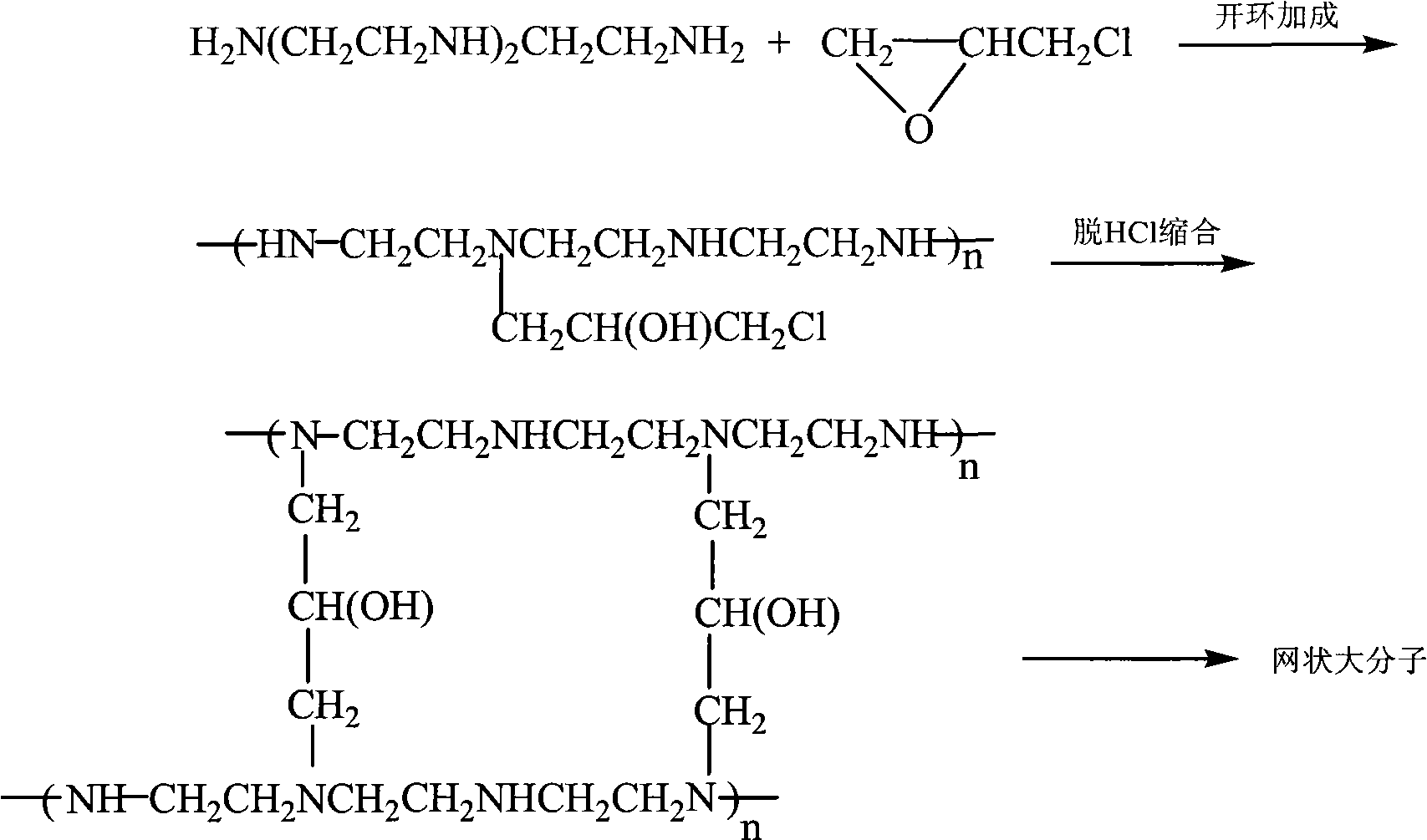

Method used

Image

Examples

Embodiment 1

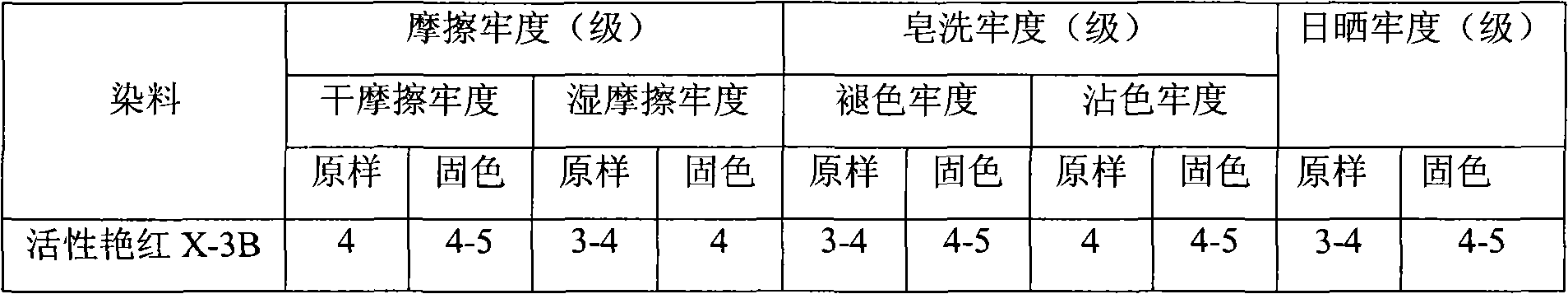

[0016] Embodiment 1: Select the cotton fabric dyed with reactive brilliant red X-3B.

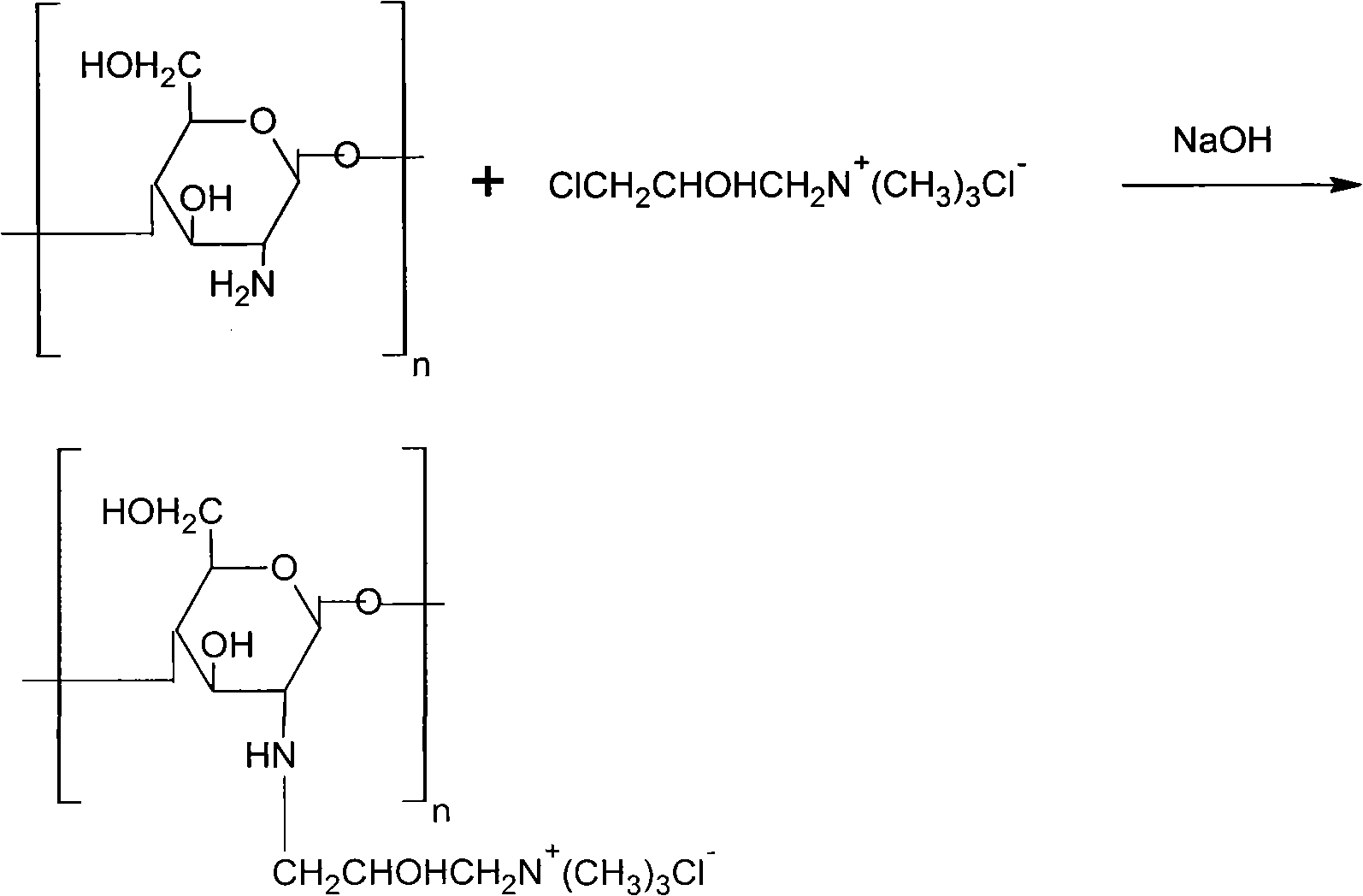

[0017] (1) Add 1 part by weight of chitosan to an aqueous solution containing 1 part by weight of sodium hydroxide, use isopropanol as a solvent, heat to 55°C under stirring, basify at a constant temperature for 4 hours, then heat to 60°C in a water bath, and place the reaction vessel in an ultrasonic On the cleaning instrument, under the power of 100W, add 6 parts by weight of a solution of 3-chloro-2-hydroxypropyltrimethylammonium chloride dropwise, and control the rate of addition. Material; the slurry is adjusted to pH=7.0 with hydrochloric acid of ω=0.1 and suction filtered, and the filter residue is soaked and washed with 60ml ω=0.85 ethanol aqueous solution and suction filtered (repeated three times), and continued to be soaked and washed with dehydrated alcohol and suction filtered (repeated three times) ; Finally, the material is placed in a blast drying oven, and dried to a constan...

Embodiment 2

[0025] Choose Reactive Brilliant Blue X-B R Dyed cotton fabric.

[0026] (1) Add 1 part by weight of chitosan to an aqueous solution containing 1 part by weight of sodium hydroxide, use isopropanol as a solvent, heat to 55°C under stirring, basify at a constant temperature for 4 hours, then heat to 60°C in a water bath, and place the reaction vessel in an ultrasonic On the cleaning instrument, under the power of 100W, add 6 parts by weight of a solution of 3-chloro-2-hydroxypropyltrimethylammonium chloride dropwise, and control the rate of addition. Material; the slurry is adjusted to pH=7.0 with hydrochloric acid of ω=0.1 and suction filtered, and the filter residue is soaked and washed with 60ml ω=0.85 ethanol aqueous solution and suction filtered (repeated three times), and continued to be soaked and washed with dehydrated alcohol and suction filtered (repeated three times) ; Finally, the material is placed in a blast drying oven, and dried to a constant weight at a temper...

Embodiment 3

[0035] Select the cotton fabric dyed with reactive bright yellow K-6G.

[0036] (1) Add 1 part by weight of chitosan to an aqueous solution containing 1 part by weight of sodium hydroxide, use isopropanol as a solvent, heat to 55°C under stirring, basify at a constant temperature for 4 hours, then heat to 60°C in a water bath, and place the reaction vessel in an ultrasonic On the cleaning instrument, under the power of 100W, add 6 parts by weight of a solution of 3-chloro-2-hydroxypropyltrimethylammonium chloride dropwise, and control the rate of addition. Material; the slurry is adjusted to pH=7.0 with hydrochloric acid of ω=0.1 and suction filtered, and the filter residue is soaked and washed with 60ml ω=0.85 ethanol aqueous solution and suction filtered (repeated three times), and continued to be soaked and washed with dehydrated alcohol and suction filtered (repeated three times) ; Finally, the material is placed in a blast drying oven, and dried to a constant weight at a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com