Cation formaldehyde-free dye-fixing agent emulsion

A cationic and color-fixing agent technology, applied in the field of printing and dyeing auxiliaries, can solve the problems of reducing fabric fastness and weakening the same-color effect of color-fixing agents, so as to avoid adverse effects, have a good color-fixing synergistic effect, and enhance fabric rubbing fastness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

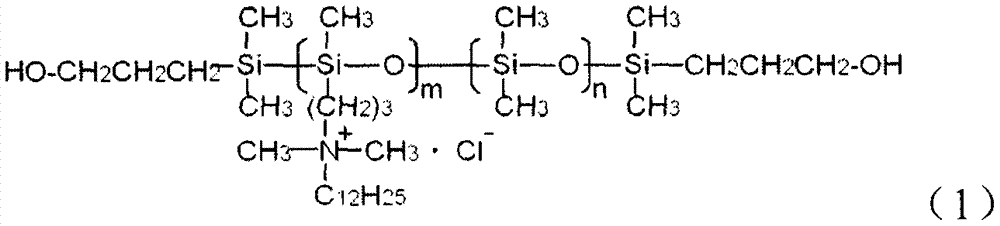

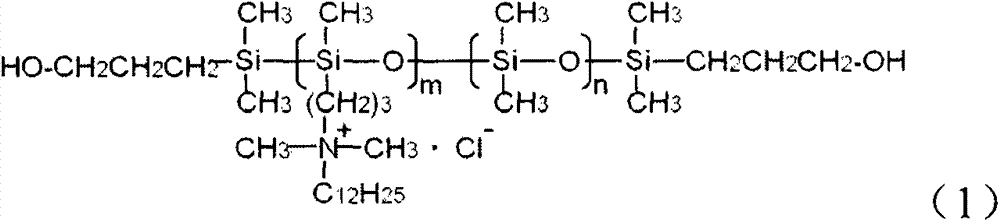

[0021] A cationic formaldehyde-free color-fixing agent emulsion, which is made from a cationic polymerizable emulsifier, a silicon-containing cationic monomer, a silane coupling agent, an initiator, and deionized water through a soap-free emulsion polymerization method, and each raw material component is in parts by mass Calculated as: 32 parts of cationic polymerizable emulsifier, 22 parts of silicon-containing cationic monomer, 20 parts of silane coupling agent vinyltrimethoxysilane, 1 part of initiator sodium persulfate, 600 parts of deionized water; The polymeric emulsifier consists of 10 parts of diethyl maleate bis[(octadecyldimethyl) chloride / ammonium bromide], 13 parts of diethyl maleate bis[(octyl dimethyl) Alkyl dimethyl) chloride / ammonium bromide], 9 parts of diethyl maleate diethylenyl bis (octyl dimethyl ammonium bromide) composite;

[0022] Cationic formaldehyde-free color-fixing agent emulsion polymerization method comprises the steps:

[0023] (1) Add 570 pa...

Embodiment 2

[0026] A cationic formaldehyde-free color-fixing agent emulsion, which is made from a cationic polymerizable emulsifier, a silicon-containing cationic monomer, a silane coupling agent, an initiator, and deionized water through a soap-free emulsion polymerization method, and each raw material component is in parts by mass Calculated as: 37 parts of cationic polymerizable emulsifier, 25 parts of silicon-containing cationic monomer, 23 parts of silane coupling agent vinylmethyldiethoxysilane, 1.5 parts of initiator potassium persulfate, 680 parts of deionized water; , The cationic polymerizable emulsifier consists of 8 parts of diethylmaleic acid diethylenyl bis[(octadecyldimethyl) chloride / ammonium bromide], 16 parts of diethylmaleic acid diethylenyl bis [(octyl dimethyl) chloride / ammonium bromide], 13 parts of diethyl maleate diethylenyl bis (octyl dimethyl ammonium bromide) compounded;

[0027] Cationic formaldehyde-free color-fixing agent emulsion polymerization method comp...

Embodiment 3

[0031] A cationic formaldehyde-free color-fixing agent emulsion, which is made from a cationic polymerizable emulsifier, a silicon-containing cationic monomer, a silane coupling agent, an initiator, and deionized water through a soap-free emulsion polymerization method, and each raw material component is in parts by mass Calculated as: 42 parts of cationic polymerizable emulsifier, 27 parts of silicon-containing cationic monomer, 26 parts of silane coupling agent vinyltriethoxysilane, 2 parts of initiator ammonium persulfate, 770 parts of deionized water; The polymerizable emulsifier consists of 12 parts of diethylmaleic acid diethylenyl bis[(octadecyldimethyl) chloride / ammonium bromide], 19 parts of maleic acid diethylenyl bis[( Octyl dimethyl) chloride / ammonium bromide], 11 parts of maleic acid diethylenyl bis (octyl dimethyl ammonium bromide) composite;

[0032] Cationic formaldehyde-free color-fixing agent emulsion polymerization method comprises the steps:

[0033] (1)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com