Patents

Literature

157results about How to "Improve rubbing fastness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ink composition, ink jet recording apparatus, and recorded article

ActiveUS20140022321A1Avoid cloggingImprove rubbing fastnessMeasurement apparatus componentsInksChemistry

Owner:SEIKO EPSON CORP

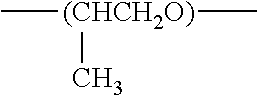

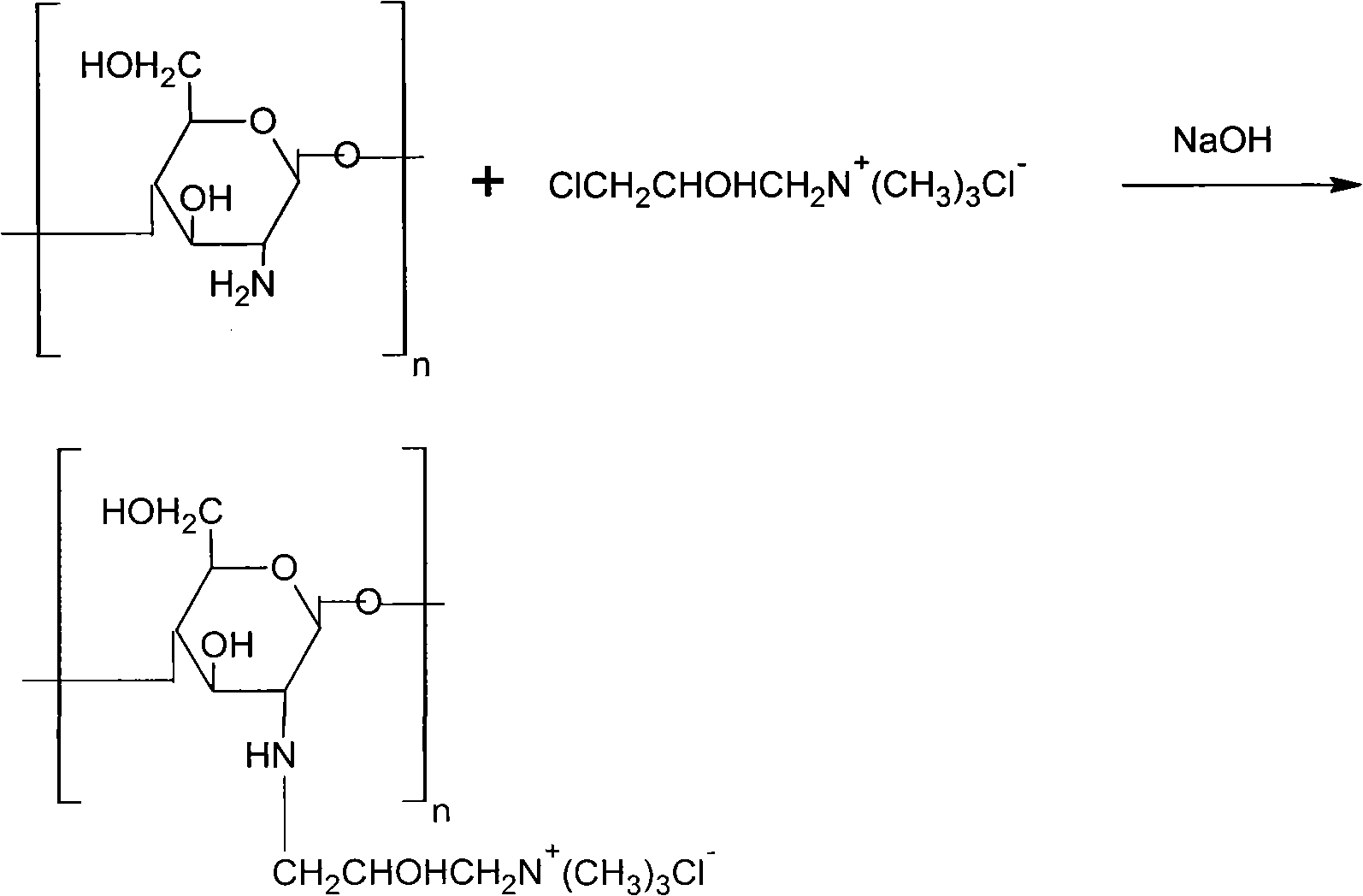

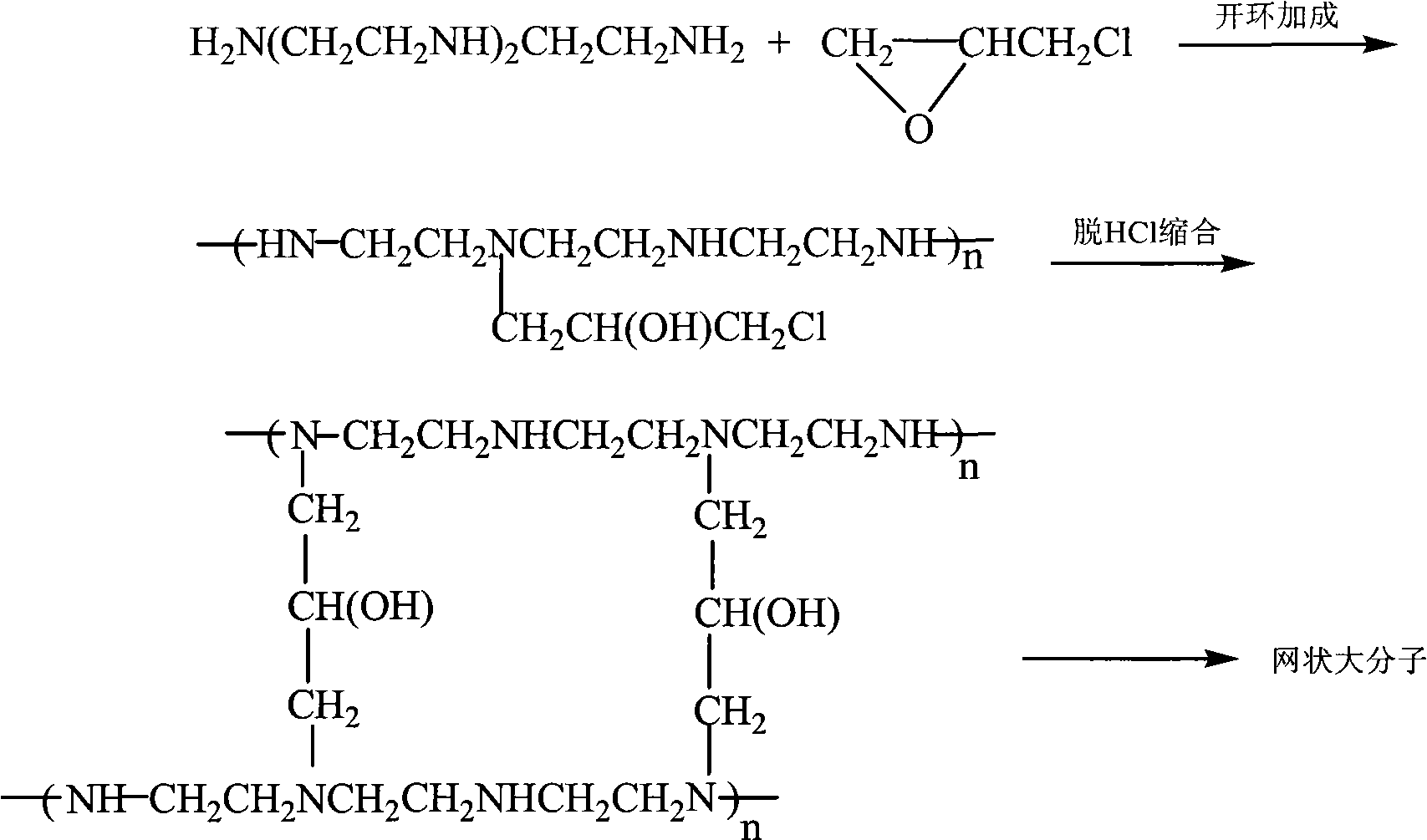

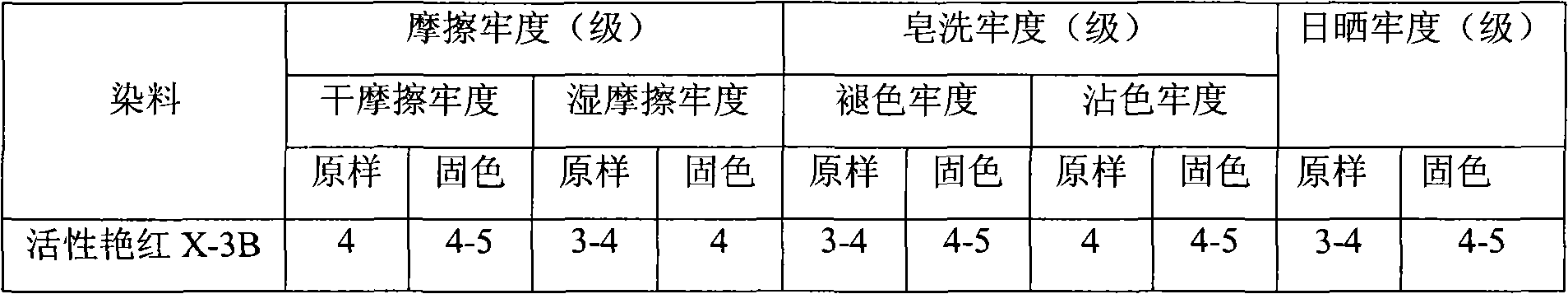

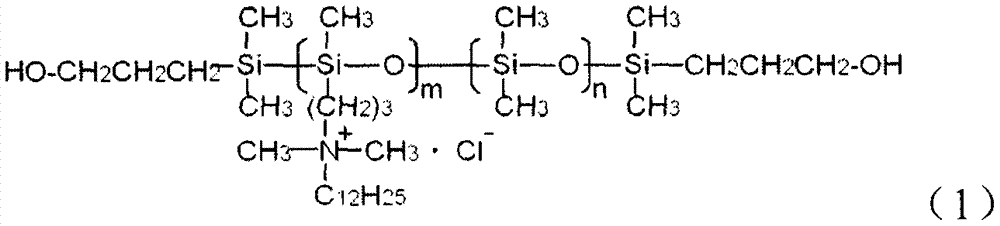

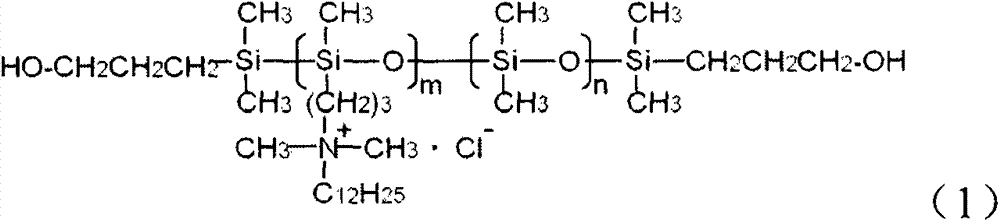

Preparation method of formaldehyde-free active dye fixing agent

InactiveCN101768883AImprove rubbing fastnessImprove washing fastnessDyeing processUltrasound - actionTetramine

The invention relates to a preparation method of a formaldehyde-free active dye fixing agent. The compound prescription of the active dye fixing agent consists of two components, component 1 is chitosan quaternary ammonium salt produced by 3-chlorine-2-hydroxypropyl trimethyl ammonium chloride grafted with chitosan under ultrasonic, and component 2 is reactive fixing agent produced after reaction of one weight part of triethylene tetramine and three weight parts of epoxy chloropropane; the mass ratio of the component 1 and the component 2 is 1:3. The method of the invention can be applied to fixing treatment of cotton fabric dyed by active dye, can improve rubbing fastness, washing fastness and light fastness of the fabric without influence on the chromatic light and the fabric hand feel; the prepared fixing agent which is free from formaldehyde, nontoxic and environment-friendly is a novel printing and dyeing assistant.

Owner:QINGDAO UNIV

Method for preparing polyacrylate/amino modified oxidized graphene compound leather finishing agent by adopting ultrasonic-assisted method

ActiveCN104212295AImprove rubbing fastnessHigh elongation at breakCoatingsLeather surface finishingEmulsionPolyvinyl alcohol

The invention relates to a method for preparing a polyacrylate / amino modified oxidized graphene compound leather finishing agent by adopting an ultrasonic-assisted method. The method for preparing the polyacrylate / amino modified oxidized graphene compound leather finishing agent by adopting the ultrasonic-assisted method comprises the following steps: carrying out ultrasonic dispersion on oxidized graphene, sulfur dichloride and dimethylformamide; adding dimethylformamide, carrying out spiral evaporating, adding triethylamine and ammonia water, carrying out ice bath reaction and suction filtration, and washing; adding sodium hydroxide and bromine, carrying out ice bath reaction, then adding products obtained through suction filtration, stirring, carrying out suction filtration, and washing to obtain amino modified oxidized graphene; mixing sodium dodecyl sulphate, polyvinyl alcohol 400 and deionized water, dropwise adding part of methyl methacrylate, butyl acrylate, acrylic acid, hydroxyethyl acrylate and an initiating agent, warming, and then dropwise adding the rest part, so that polyacrylate emulsion is obtained; and regulating pH of the polyacrylate emulsion, then adding the amino modified oxidized graphene, and carrying out ultrasonic dispersion, so that the product polyacrylate / amino modified oxidized graphene compound leather finishing agent is obtained. The method for preparing the polyacrylate / amino modified oxidized graphene compound leather finishing agent by adopting the ultrasonic-assisted method has the advantages that defects of polyacrylate are overcome by utilizing physical and mechanical advantages of graphene and application performance of the polyacrylate / amino modified oxidized graphene compound leather finishing agent is effectively enhanced.

Owner:SHAANXI UNIV OF SCI & TECH

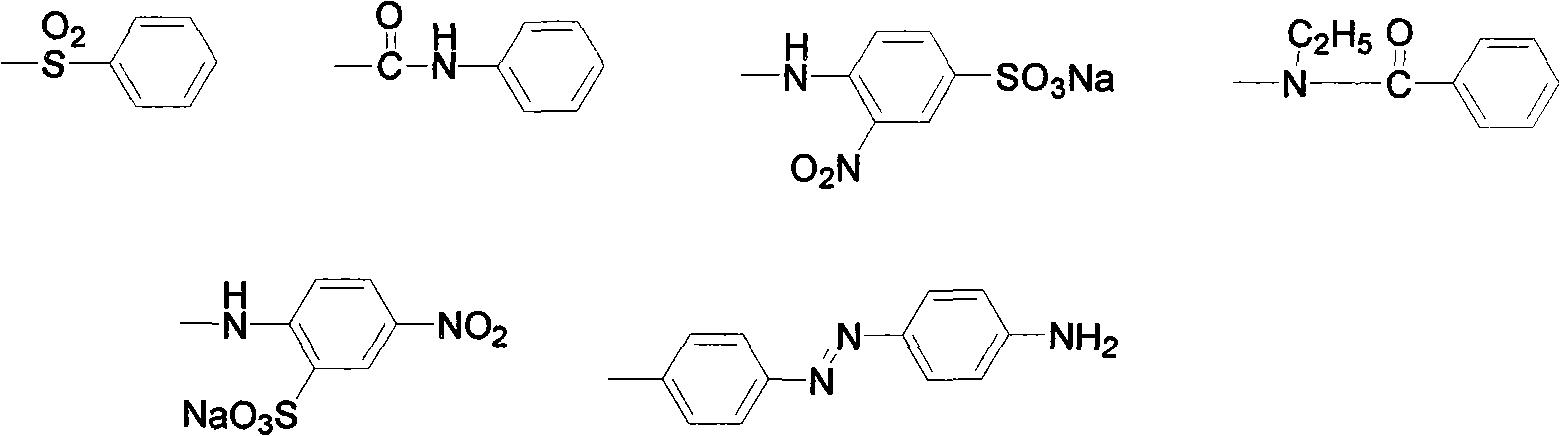

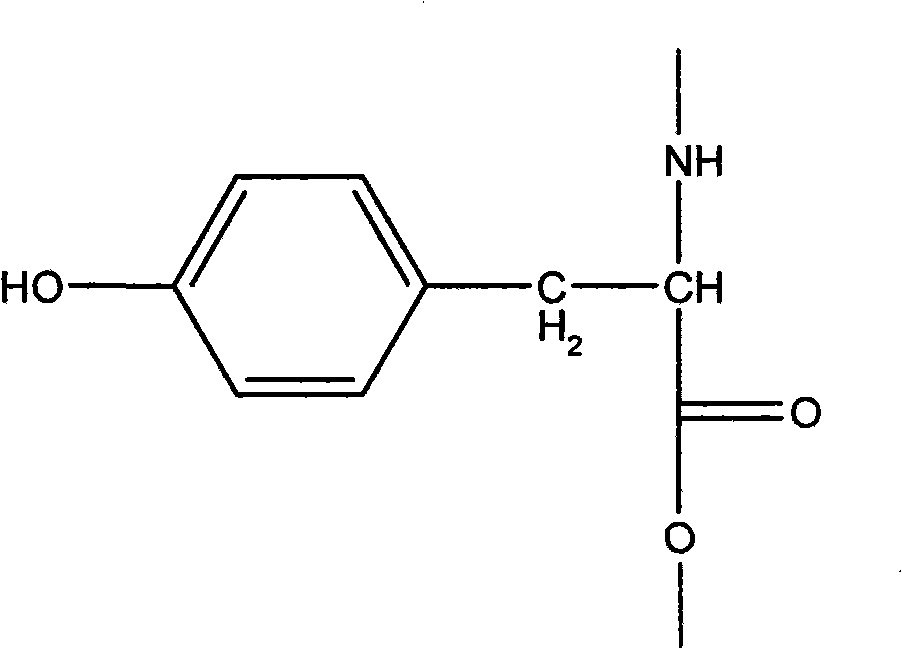

Dyeing method of protein material

The invention discloses a dyeing method of protein material. Arylamine compound is diazotized and then is directly coupled with tyrosine segment in protein molecule, so as to generate coloured substance containing azo bond; dosage of arylamine compound is equivalent to 0.1-5% of weight of protein material, and dyeing bath ratio is 1:20-100. Arylamine compound is taken as colour base and diazotized and then is directly coupled with tyrosine segment in protein molecule, and coloured substance connected with main chain by covalent bond in protein molecule, thus realizing dyeing on protein material and obtaining various colours by selecting arylamine colour bases in different structures. The dyeing method has the advantages of low energy consumption, less pollution and high colour fastness. The protein fiber fabric obtained by the method has higher wet-processing fastness; and the dyed protein powder also has higher fastness. The invention also provides a new dyeing method for protein material.

Owner:ZHEJIANG SCI-TECH UNIV

High-efficiency environment protection acidic color fixing agent and manufacture method thereof

InactiveCN101245563ARaw material environmental protectionWill not affect healthDyeing processMeth-Hazardous substance

The invention relates to an effective environment protective acid fixing agent that is prepared by a polypropylene acid fixing agent, an addition agent and a solvent which are matched. The polypropylene acid fixing agent is prepared by the following steps: mixing isopropanol, methacrylic acid, 2-acrylamido-2-methylpropane sulfoacid, acrylic acid and sodium persulfate in deionized water to be reacted for 1 to 5 hours at 80 to 90 DEG C and acquiring a reaction product, namely, the polypropylene acid fixing agent by post treatment. The preparation method of the effective environment protective acid fixing agent includes: adding proper water, adding all the materials under the condition of stirring at 40 to 50 DEG C in sequence to be mixed for 2 to 3 hours, uniformly dissolving, filtering, discharging and controlling the pH to be 6 to 7. The materials of the invention are environment-protective, can reduce the treatment cost of waste water and can generate remarkable social and economic benefits.

Owner:杭州下沙恒升化工有限公司

Printing and dyeing process

ActiveCN103628336ASimple printing and dyeing processEasy to implementLiquid/gas/vapor removalDyeing processEconomic benefitsChloride sodium

The invention discloses a printing and dyeing process which comprises the following steps: (1) preprocessing; (2) dyeing, namely putting a preprocessed fabric into a dyeing solution, heating the dyeing solution to 45-55 DEG C at speed of 1-2 DEG C / min, and keeping the temperature for 20-40 minutes; adding sodium chloride, heating to 60-70 DEG C at the speed of 1-2 DEG C / min, and keeping the temperature for 20-40 minutes; adding sodium carbonate, heating to 80-90 DEG C at speed of 0.2-1 DEG C / min, and keeping the temperature for 20-40 minutes; finally cooling at the speed of 1-2 DEG C / min to finish the dyeing process; (3) post-processing. According to the printing and dyeing process, the dye-uptake rate and the dye-uptake process are adjusted to be optimal through controlling temperature ranges in the dyeing process, so that a printed and dyed product is good in dyeing uniformity and high in color fastness. The printing and dyeing process is simple, can realize large-scale industrialization production and bring good economic benefits to enterprises, and has a wide prospect.

Owner:杭州开源风云信息技术有限公司

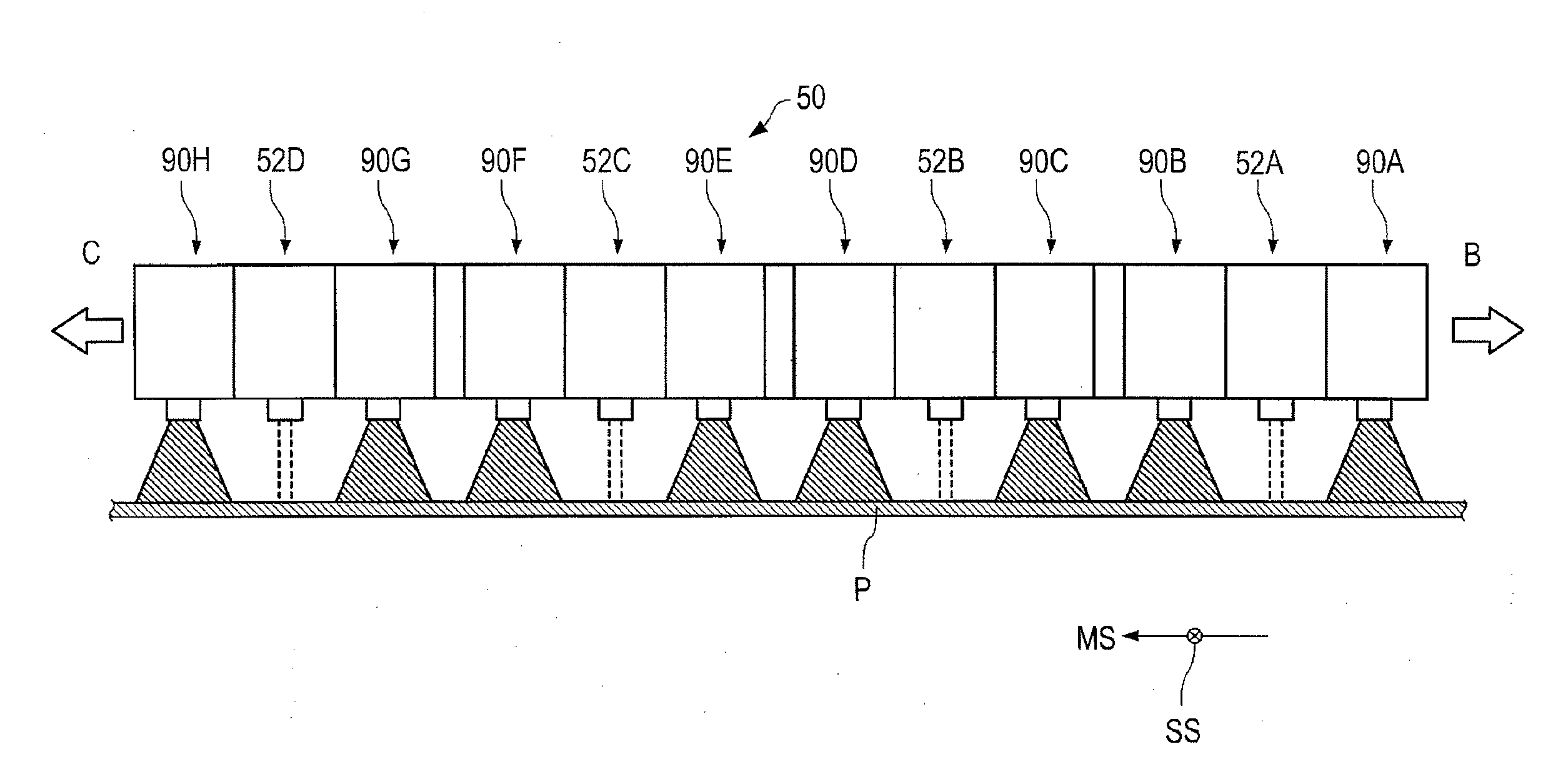

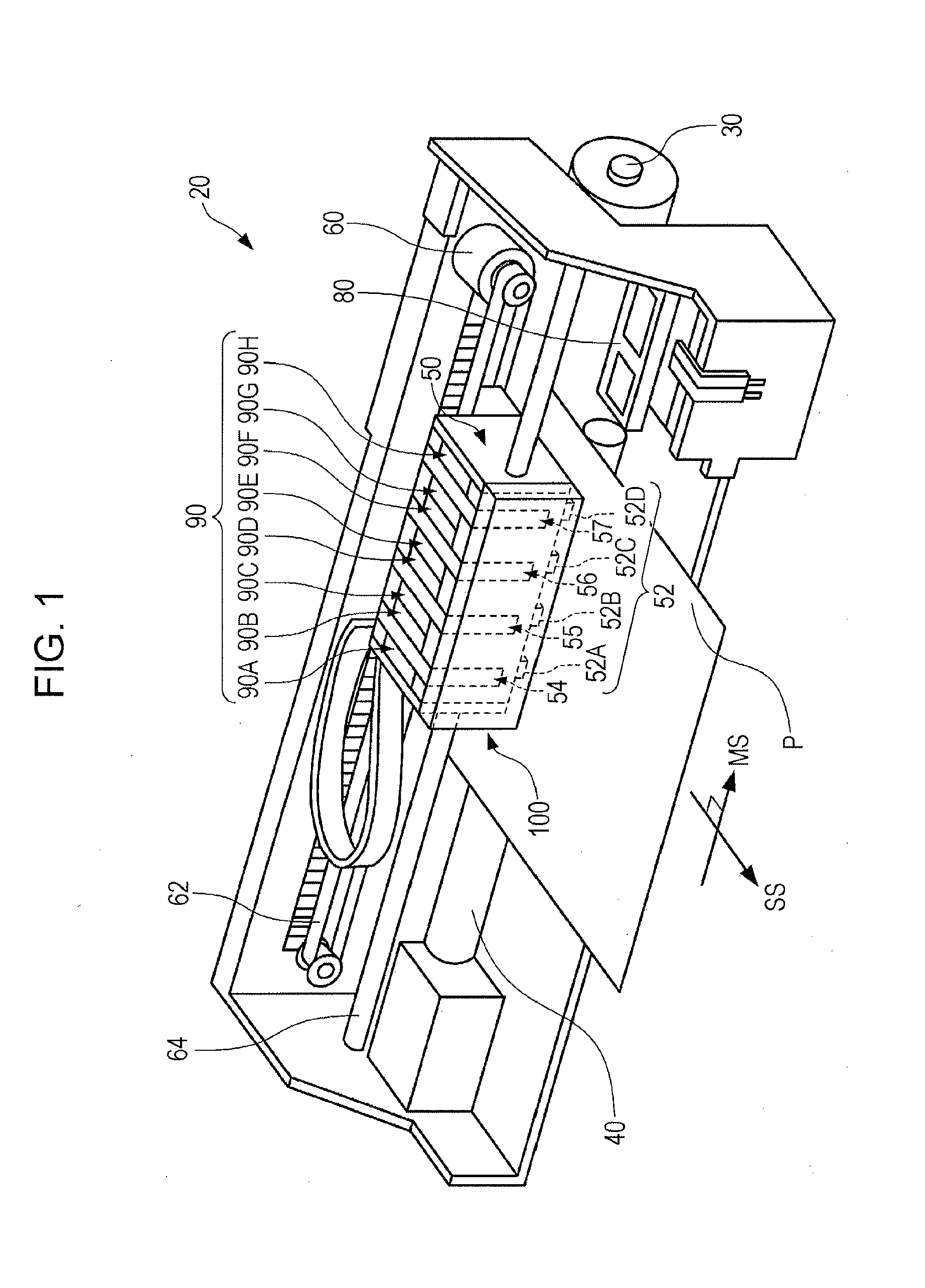

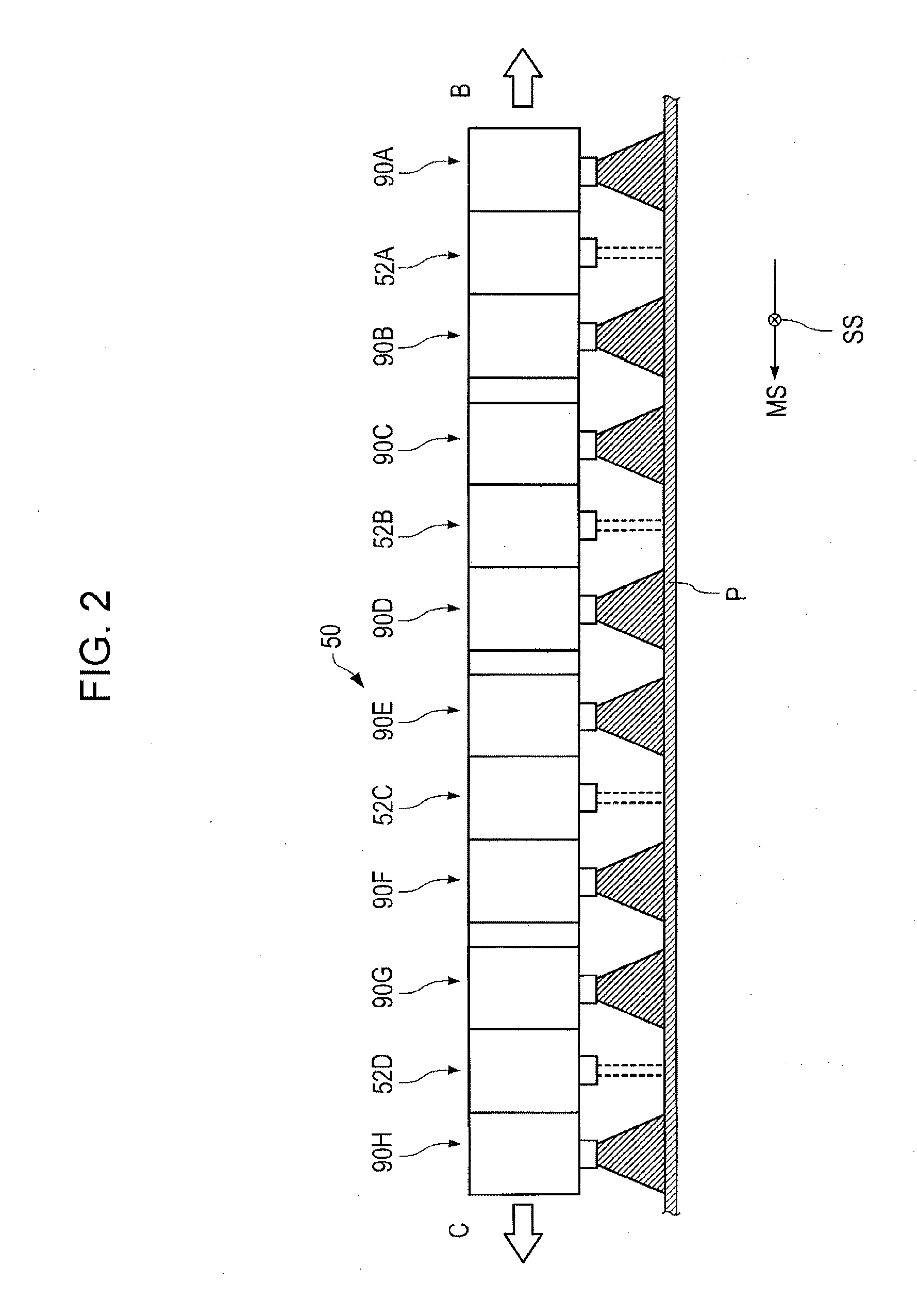

Ink jet recording method and ink jet recording apparatus

ActiveUS20120007912A1Optimal irradiation energyHigh color densityInksOther printing apparatusFluenceEngineering

An ink jet recording method uses an ink jet recording apparatus including a plurality of heads arranged in parallel in a first direction, each of which ejects droplets of a different radiation-curable ink composition onto a recording medium, and first light sources provided for corresponding heads so as to be disposed at a predetermined side of the corresponding heads. The first light sources emit active radiation to irradiate the droplets on the recording medium. The method includes ejecting droplets of the ink compositions from the heads onto the recording medium, and performing a first irradiation by irradiating the droplets of each ink composition with the active radiation from the corresponding first light source at an irradiation energy within 500 ms after the droplets have landed. The irradiation energy is in the range of 5% to 10% of the energy E90 at which the ink composition is 90% cured.

Owner:SEIKO EPSON CORP

White ink composition and recorded material using the same

A white ink composition contains a white pigment and fixing resins. The fixing resins include a vinyl chloride resin or a urethane resin, a fluorene resin, and a polyolefin wax.

Owner:SEIKO EPSON CORP

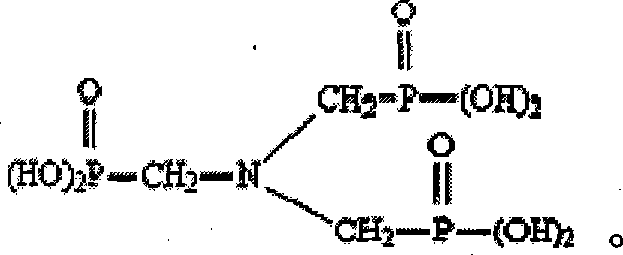

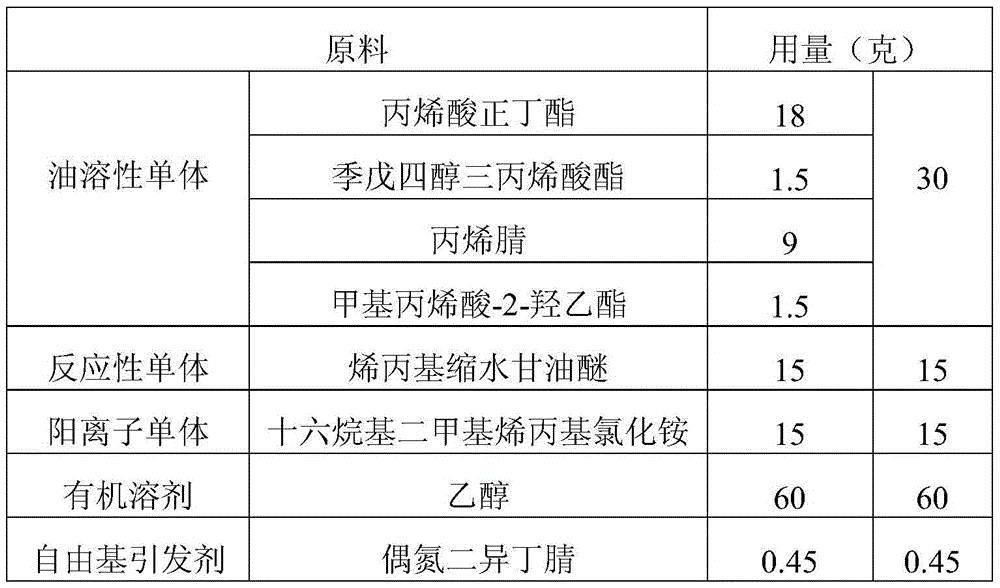

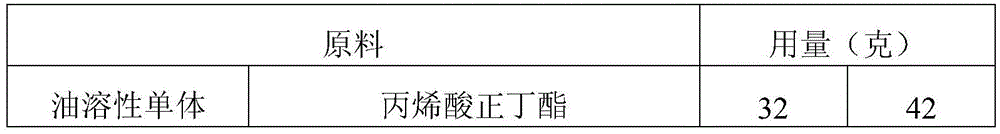

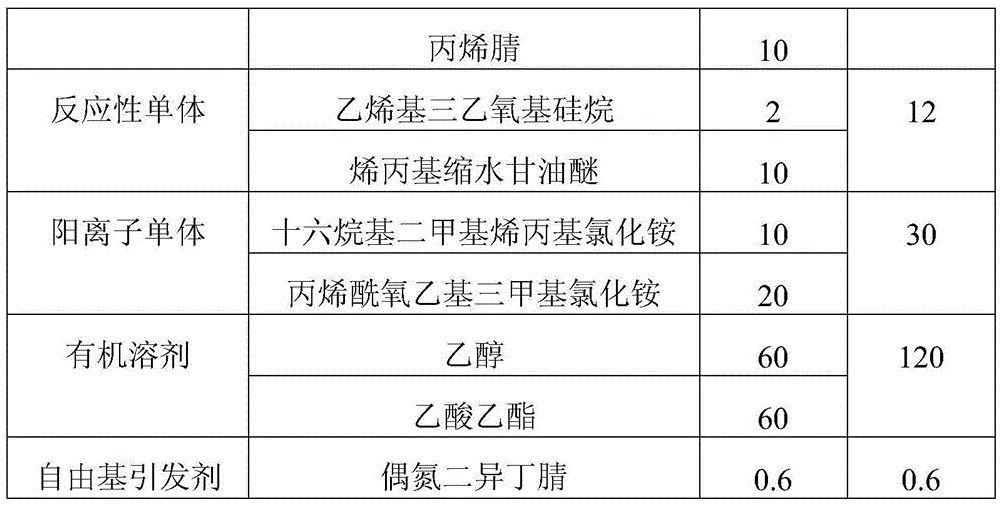

Cationic color fixing agent and preparation method and application thereof

The invention provides a cationic color fixing agent and a preparation method and application thereof. The cationic color fixing agent is obtained by polymerization reaction of an oil-soluble monomer, a cationic monomer and a reactive monomer in a solvent under the action of a radical initiator, wherein the oil-soluble monomer is one or the combination of several of styrene, acrylonitrile and acrylate; the cationic monomer is one or the combination of acryloxyethyl alkyl quaternary ammonium salt and / or allyl alkyl quaternary ammonium salt; the reactive monomer is one or the combination of several of allyl glycidyl ether, hydroxyl-containing acrylics, vinyl trimethoxy silane, vinyl triethoxy silane, acrylamide, crylic acid and methacrylic acid. The cationic color fixing agent is insoluble in water and can be dissolved in a weak polar solvent and / or non-polar solvent; besides, after non-aqueous solvent dyeing of reactive dyes, the cationic color fixing agent can be directly used in the on-going fixing process without washing.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

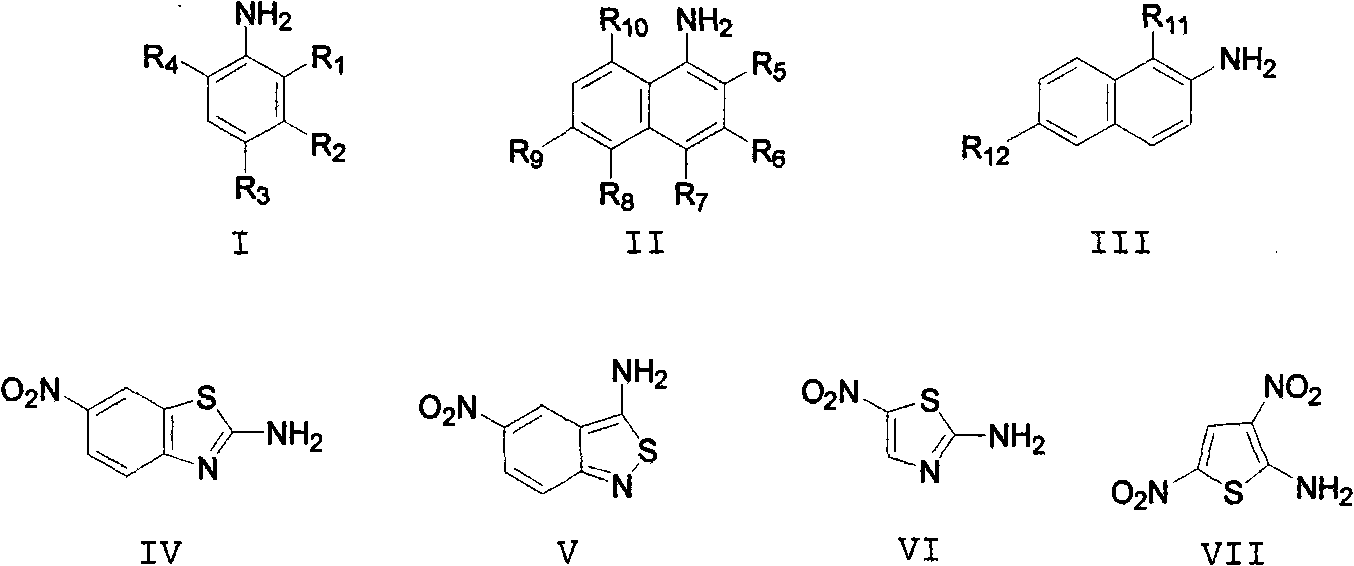

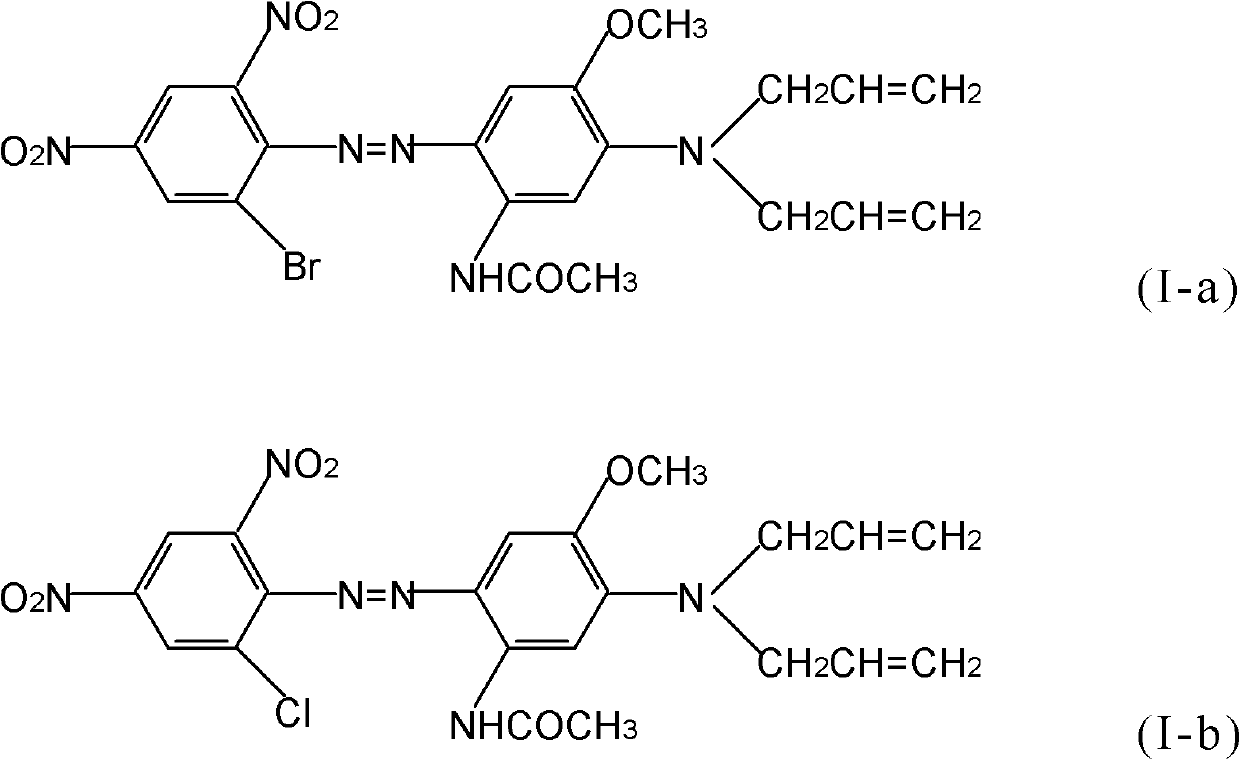

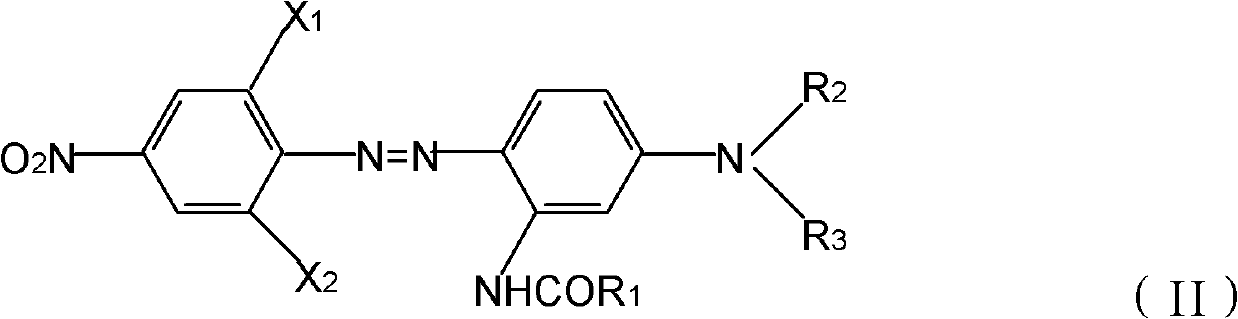

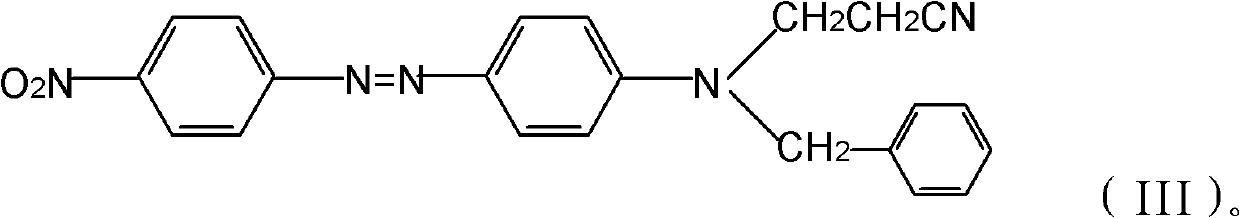

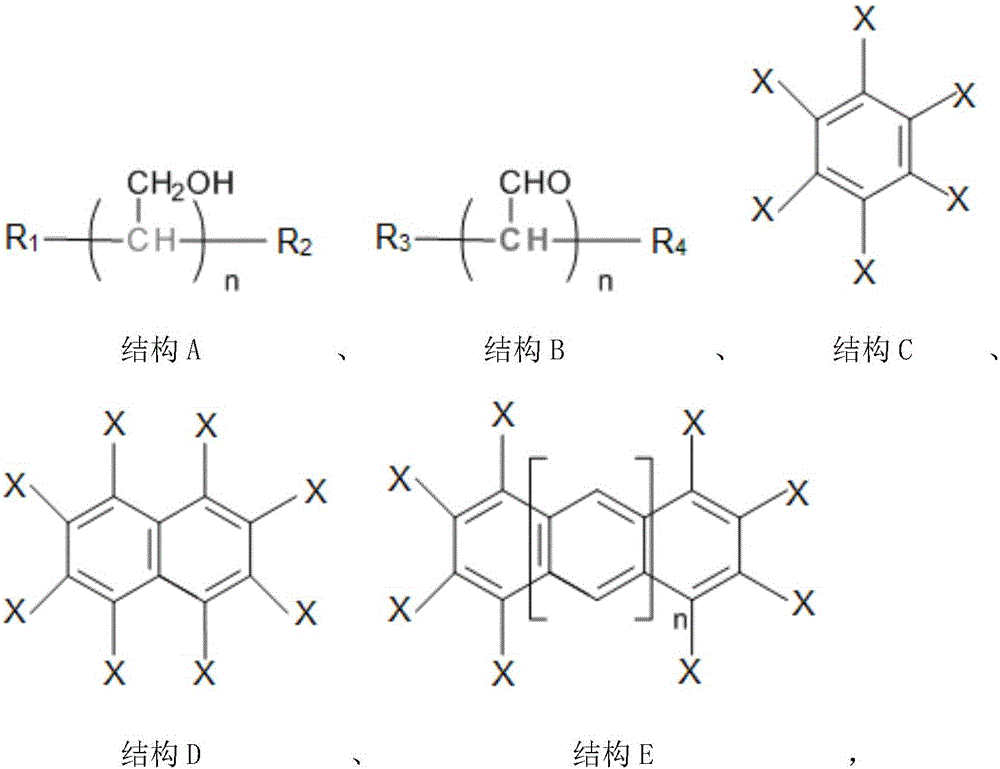

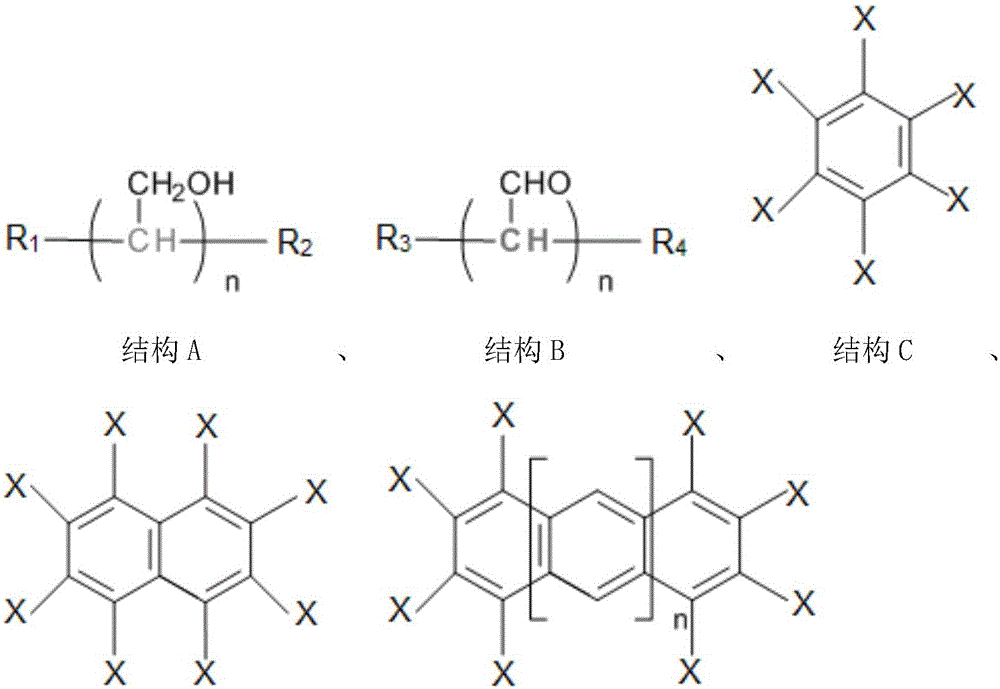

Composite dye composition, composite disperse dye and preparation method thereof

The invention relates to a composite dye composition, composite disperse dye and a preparation method thereof. The composite dye composition is composed of compounds as shown in a formula (I-a), a formula (I-b), a formula (II) and a formula (III). The composite disperse dye prepared from the composite dye composition has good comprehensive fastness property and high lifting force, and is suitable for dyeing and printing terylene and blend fabrics.

Owner:ZHEJIANG RUNTU

Preparation method for blocked waterborne polyurethane and application of blocked waterborne polyurethane to preparation of digital printing waterborne paint ink

ActiveCN106947049AImprove dispersion stabilityGood dispersionDyeing processFiberDispersion stability

The invention discloses a preparation method for blocked waterborne polyurethane. The method is characterized in that polyurethane is modified by synthesizing a partially-esterified styrene-maleic anhydride copolymer carrying hydroxyl, so that a polyurethane chain plays a role in strongly anchoring organic pigment particles, the dispersion stability of the organic pigment particles in waterborne polyurethane emulsion and the adhesion of a pigment by a waterborne polyurethane adhesive during inkjet curing are facilitated, and the friction resistance and washing fastness are improved. Meanwhile, the polyurethane is subjected to active blocking, so that an unblocked NCO group can react with an OH group on fiber during heating curing after digital printing waterborne paint ink prepared by taking the blocked waterborne polyurethane emulsion prepared by the method as an adhesive is directly jetted onto a fiber fabric, thereby remarkably improving the color fixing firmness and friction resistance. A printed pattern is bright in color, and is soft in handfeel.

Owner:SUN YAT SEN UNIV +1

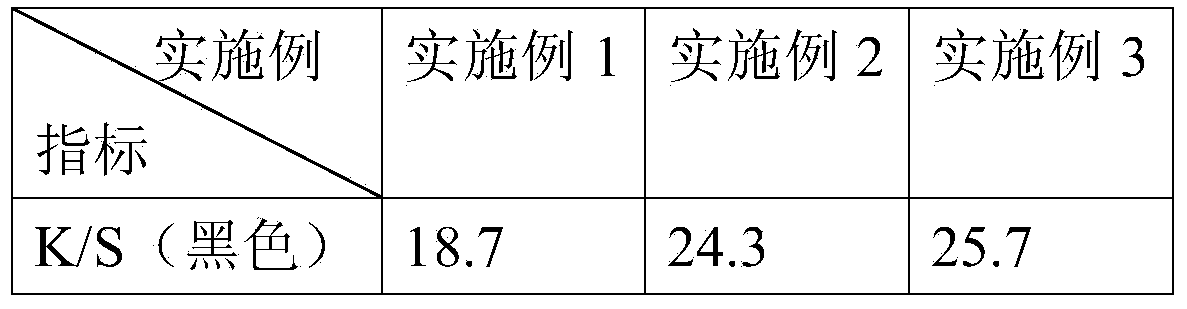

Graphene functional cotton fabric and preparation method thereof

ActiveCN106917304AGood electrical conductivityImprove rubbing fastnessDyeing processTemperature resistanceReactive dye

The invention provides a graphene functional cotton fabric and a preparation method thereof, which belong to the technical fields of intelligent wearing and functional textile. The graphene functional cotton fabric is characterized in that graphene oxide is subjected to amination or sulfhydrylation modification, then is composited with a multi-active reactive dye to obtain a graphene oxide reactive dye, the cotton fabric is subjected to dip dyeing in the graphene oxide reactive dye under ultrasonic condition to obtain the graphene oxide cotton fabric, and the graphene functional cotton fabric is reduced by a reducing agent. The graphene functional cotton fabric integrates dyeing and conductivity functions, endows the common cotton fabric with excellent electricity function of graphene, and stability, high temperature resistance and friction color fastness are obviously increased.

Owner:山东利特纳米技术有限公司

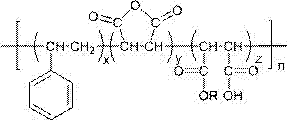

Polymeric decontamination color fixing agent for fabric

InactiveCN102127873AHigh color fastnessImprove rubbing fastnessFibre treatmentDyeing processRubbingPolymer chemistry

The invention relates to a polymeric decontamination color fixing agent for a fabric. The color fixing agent is copolymer formed by initiating 2-acrylamide-2-methylpropanesulfonic acid, acrylamide, dimethyl diallyl ammonium chloride, dimethyl diallylamine, high molecular weight polyvinyl pyrrolidone (PVP) and an emulsifier through an initiator, wherein preferably, the high molecular weight PVP is PVPK90-K95, the emulsifier is an ethylene oxide propylene oxide (EOPO) emulsifier, and the initiator is azobis(isobutylamidine hydrochloride); and preferably, the color fixing agent comprises 1g of 2-acrylamide-2-methylpropanesulfonic acid, 20g of dimethyl diallyl ammonium chloride, 5g of dimethyl diallylamine, 20g of acrylamide, 2g of high molecular weight PVP and 2g of emulsifier. The color fixing agent can enhance the hydrophilic breathability and decontamination capability of the fabric, improve the wet rubbing fastness of the fabric and effectively improve the content of formaldehyde in the fabric, is healthy and environmental-friendly, improves the quality and functions of the fabric, and has a wide market prospect.

Owner:崔伟

Printing method of Shu Velveteen mixed textile fabrics

ActiveCN103726366AImprove printing effectHigh color fastnessBleaching apparatusDyeing processEngineeringDehydration

The invention discloses a printing method of Shu Velveteen mixed textile fabrics. The method adopts the pre-processing technology of soak dehydration after twice washing, a special printing processing technology, self-made improved dyes, and the technology of ageing for color fixing, softening for sizing and shrunk finish to be finished. The method has the advantages that printing effects are good, color fastness is high, rubbing fastness is high, the technologies are simple, the method is simple in industrialized operation, the production efficiency of work is increased, and the product quality is increased.

Owner:苏州市居之禾服饰有限公司

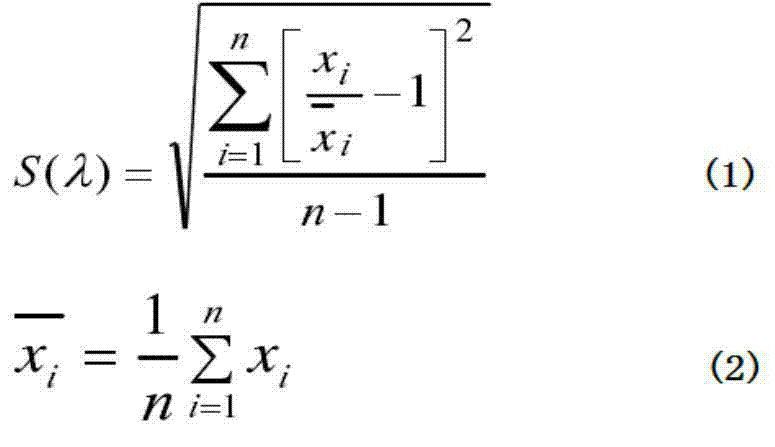

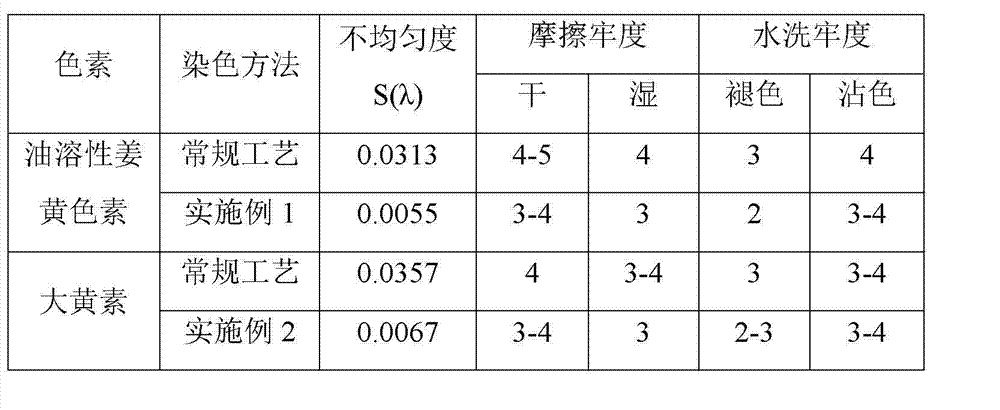

Dyeing method of water insoluble natural pigment on silk fabric

The invention discloses a dyeing method of water insoluble natural pigment on silk fabric. The water insoluble natural pigment is one of oil soluble curcumin, emodin, chrysophanol and oil soluble paprika oleoresin. The method comprises the following steps: step 1: dissolving the water insoluble pigment in an organic solvent to obtain a pigment solution; step 2: adding an emulsifier in the pigment solution to obtain a mixed solution; step 3: stirring the solution while adding deionized water into the mixed solution; after the addition, continuing to stir to obtain an oil-in-water pigment microemulsion liquid; and step 4: dyeing the silk fabric in the pigment microemulsion liquid. The invention overcomes the boundedness that water insoluble natural pigment is unable to dye the silk fabric in water, so as to realize uniform dyed fiber of silk fabric by water insoluble natural pigment, and high fastness.

Owner:XINYUAN COCOON SILK GROUP

Printing method of prolivon blended fabric

ActiveCN103669027AImprove printing effectHigh color fastnessFibre treatmentDyeing processEngineeringRubbing

The invention discloses a printing method of a prolivon blended fabric. A soaking and dehydration pretreatment process after secondary water washing is used, a special printing treatment process is used, self-blended improved dye is adopted, and finally, the prolivon blended fabric is obtained through ageing fixation, softness sizing and shrunk finish processes. The printing method has the advantages that the printing effect is good, the color fastness and the rubbing fastness are high, the processes are simple, the industrial operation is easy, and the operation production efficiency and the product quality are improved.

Owner:苏州市居之禾服饰有限公司

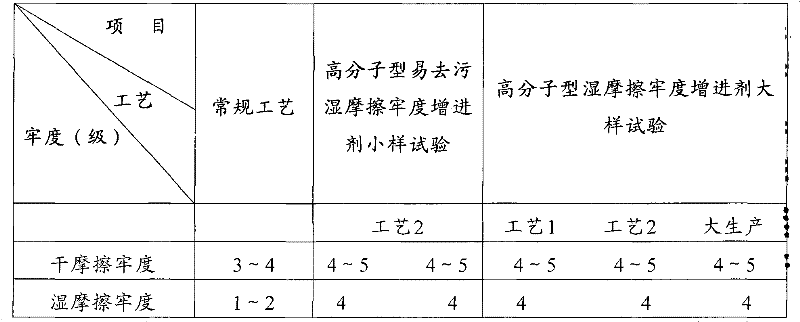

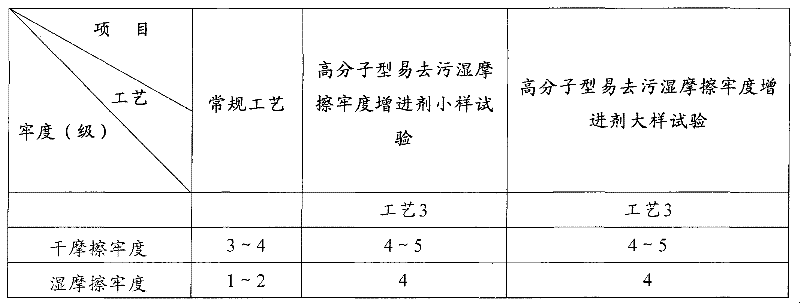

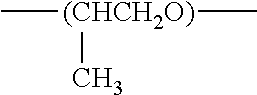

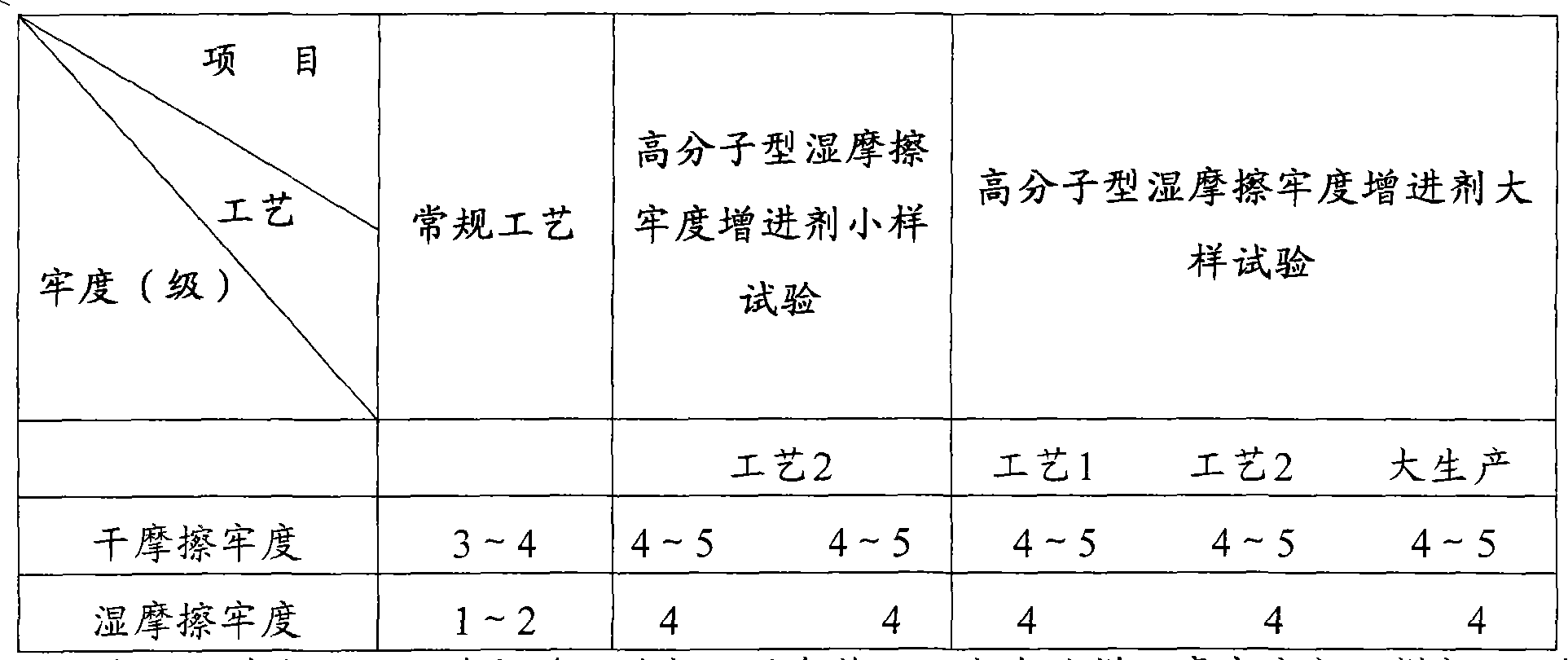

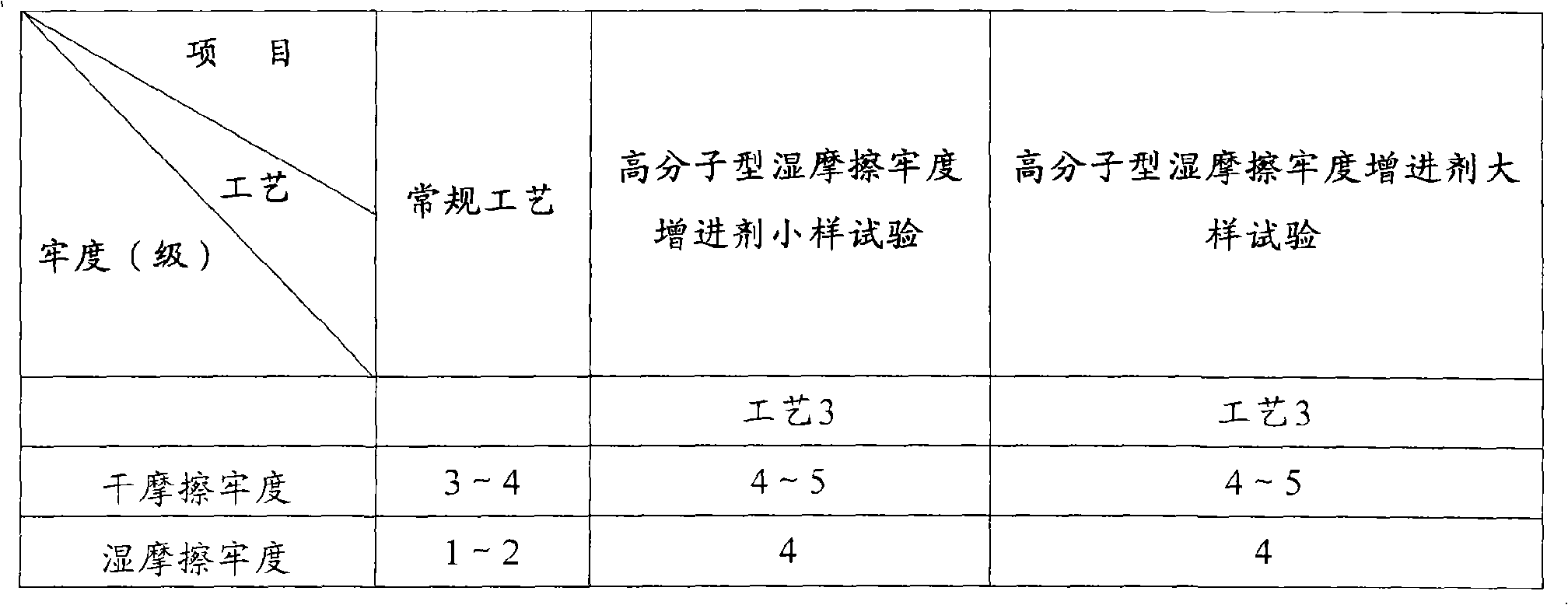

Macromolecule type wet friction fastness improver

InactiveCN101492883AHigh color fastnessImprove rubbing fastnessFibre treatmentDiallyldimethylammonium chlorideHydrochloride

Owner:SHANGHAI YUKING WATER SOLUBLE MATERIAL TECH

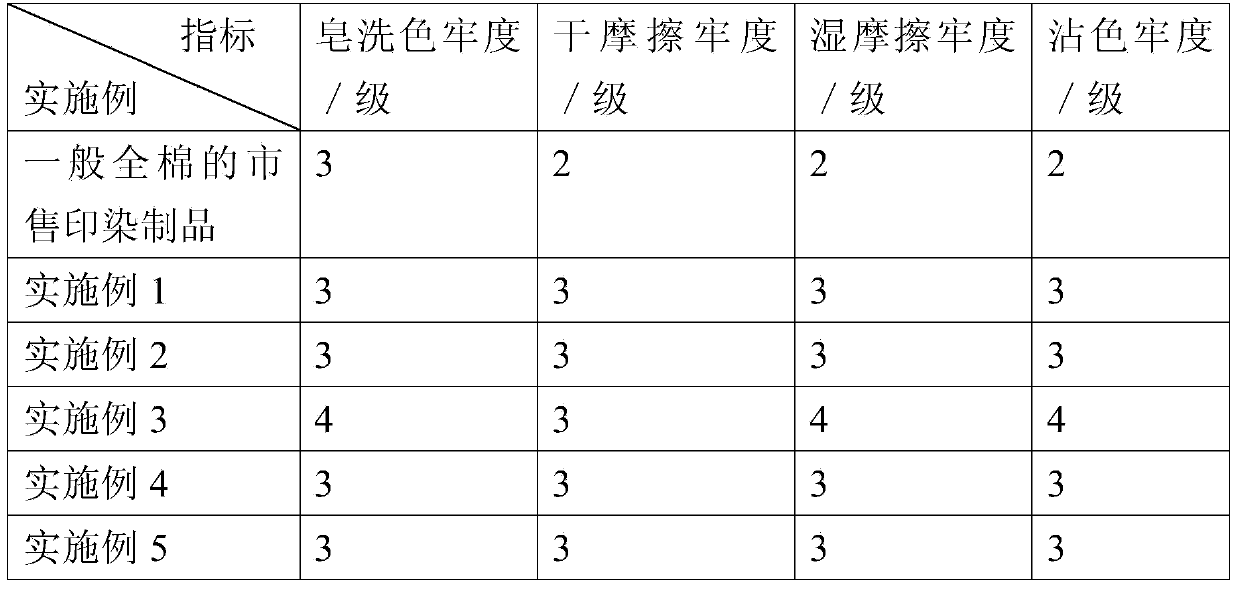

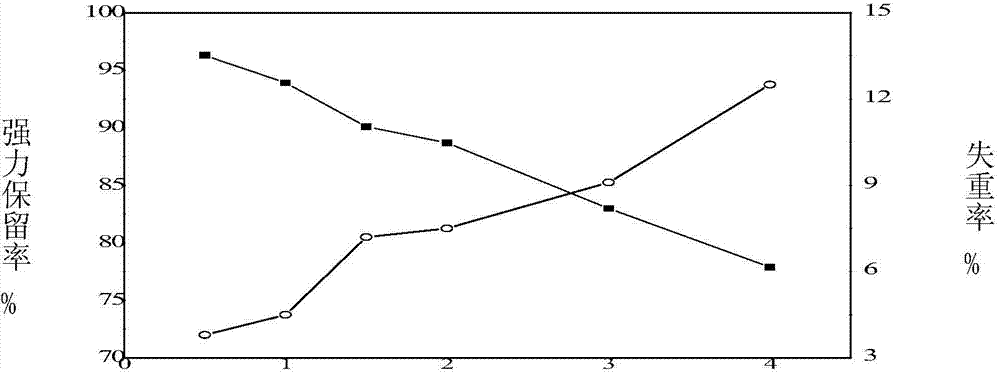

Rubbing fastness improving finishing process of deep color cotton and blended fabric thereof

ActiveCN105625060AReduce swellingReduce the chance of bondingLiquid/gas/vapor removalDyeing processRubbingSulfonic acid ester

The present invention provides a rubbing fastness improving finishing process of a deep color cotton and a blended fabric thereof. According to the present invention, a fabric is subjected to a color fixation treatment with an aromatic sulfonic acid condensate, drying is performed, and finishing is performed with a slightly-turbid-state rubbing fastness improving working liquid containing a cationic aqueous polyurethane compound, such that the dry rubbing fastness and the wet rubbing fastness of the good hydrophilicity deep color cotton and the blended fabric thereof can achieve more than or equal to grade 3, and the difficult problem that the rubbing fastness is difficult improved through the conventional processing process is effectively solved.

Owner:DYMATIC CHEM

Method for continuously dyeing yarns

The invention provides a method for continuously dyeing yarns. The method comprises the following steps: selecting yarns as a dyeing raw material; selecting an azoic coupling component AS-BO as a prime liquid; dissolving the azoic coupling component; exhausting fluid for the yarns; diazotizing colorradical blue BB which is selected as a color developing agent; dissolving color salt; adding a neutralizer and antalkaline; performing a coupled developing process, controlling the concentration, pH value, temperature, time and other parameters during coupling; rinsing and soaping, and rinsing; and dyeing for the second time, calculating the dosage of a bottoming agent in refill and dosage added into caustic soda, and repeating the process of developing, rinsing, soaping and rinsing to complete continuous dyeing for yarns. According to the method, a dyeing method is improved, a repeated durable dyeing process operation is adopted, the stability for material dyeing is reinforced, the coloring effect is uniform, and defects occurring in single printing and dyeing process is avoided by means of repeated printing and dyeing.

Owner:广州弘雅服装科技有限公司

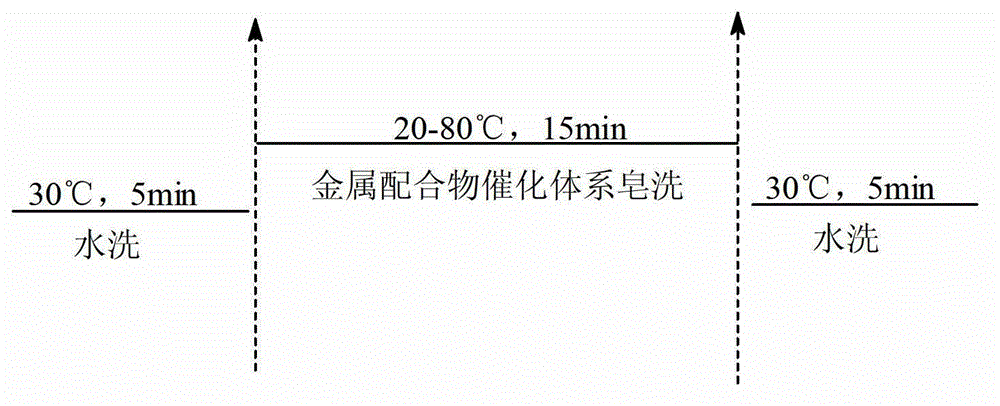

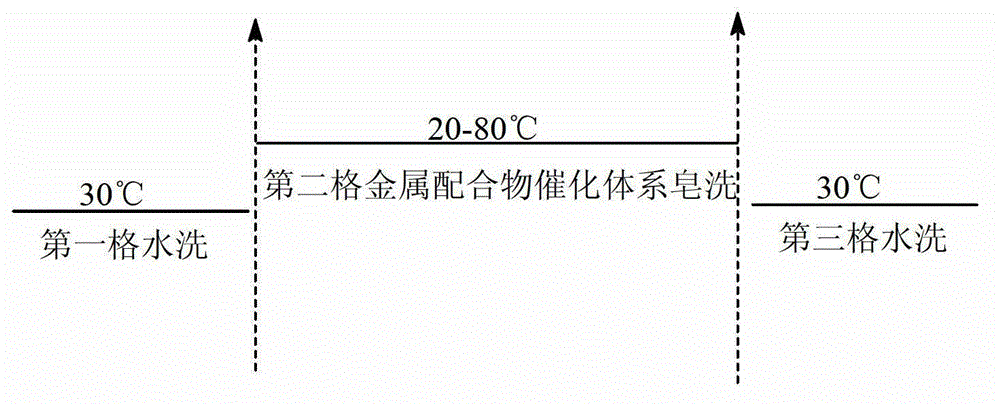

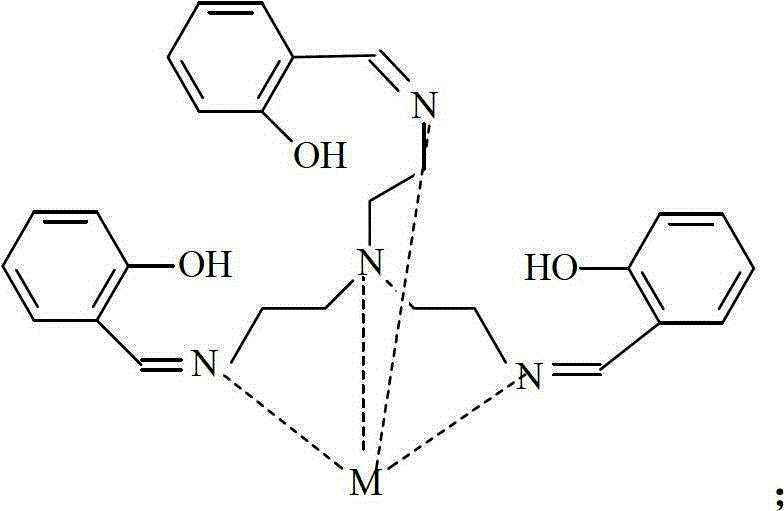

Metal complex oxidation system and application thereof

InactiveCN102943004AReduce chromaReduce CODFibre treatmentBleaching apparatusChemical oxygen demandCoordination complex

The invention relates to a metal complex oxidation system and an application thereof. The metal complex oxidation system comprises metal complex and peroxide. The metal complex oxidation system is used for soaping the dyed textiles, and the soaping temperature is between 20 and 80 DEG C. The metal complex oxidation system is simple in operation of a low-temperature soaping method, is low in production cost, has a good soaping effect and is suitable for various dyes; and the anti-color staining capability is strong, the textile damage is small, energy and water consumption is saved, the decolorization ratio to soaping residual liquid is above 90%, and the chemical oxygen demand (COD) and chromaticity of dyeing soaping wastewater can be greatly reduced.

Owner:DONGHUA UNIV

Dyeing technology for polyester brocade sydney down cotton-imitated fabric

The invention relates to a dyeing technology for polyester brocade sydney down cotton-imitated fabric. The dyeing technology comprises steps of firstly adding a colouring agent and a dyeing auxiliary into the grey cloth of polyester brocade composite fiber fabric, gradually heating up to 123-127 DEG C, keeping warm for 38-42 minutes at 123-127 DEG C, and next fixing color, washing and neutralizing. By screening the dye and controlling the new technology, the fastness of the polyester brocade composite fiber fabric are improved. According to the new dyeing technology, the soaping fastness of the polyester brocade composite fiber is improved by about 1-1.5 grade, the light fastness and crockfastness are improved by about one grade, and the polyester brocade composite fiber has good smooth and soft feel.

Owner:SHENGHONG GRP CO LTD

Terylene reduction cleaning agent and preparation method thereof

ActiveCN106638054AImprove stabilityImprove reliabilityDyeing processSpontaneous combustionCleansing Agents

The invention discloses a reduction cleaning agent for terylene. The reduction cleaning agent for the terylene is characterized by comprising deionized water, an unsaturated reduction system, a surfactant system and a pH value buffering system, in parts by mass: 84 to 35 parts of the deionized water, 10 to 50 parts of the unsaturated reduction system, 5 to 10 parts of the surfactant system and 1 to 5 parts of the pH value buffering system. The reduction cleaning agent for the terylene is stable in state, avoids heating and spontaneous combustion conditions, does not have pungent smell, is convenient to transport and store, and has an excellent cleaning effect.

Owner:GUANGDONG CHUANHUA FULIAN FINE CHEM CO LTD

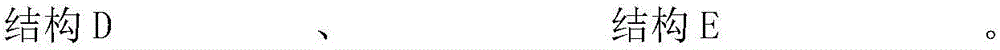

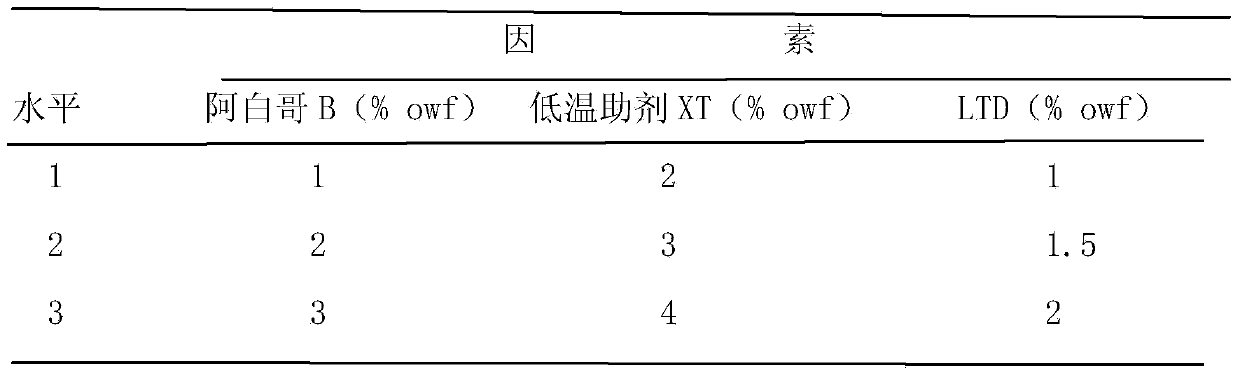

Dyeing formula and technology for enhancing color fastness of dark cashmere product

InactiveCN103952926AImprove surface propertiesReduce internal damageDyeing processFiberColour fastness

The invention provides a dyeing formula for enhancing the color fastness of a dark cashmere product. A dye is prepared from 1owf% of abegnoli B, 2owf% of low-temperature auxiliary XT, 2owf% of low-temperature auxiliary MiralanLTD and 4owf% of dye, and a bath ratio is 1:10. Compared with the prior art, the dyeing formula has the advantages that auxiliary adding and microwave pretreatment are combined, so that the color fastness and the coloring rate of the product are effectively improved; the abegnoli B and the dye are matched to enhance the dissolving property of the dye and the levelling property of cashmere fibers. A chemical method and a physical method are effectively combined, so that the color fastness and the coloring rate of the product are greatly improved; furthermore, by adding of the auxiliaries, the using amount of the dye is reduced, and the whole dyeing process is environmentally friendly.

Owner:浙江丝之美服饰染整有限公司

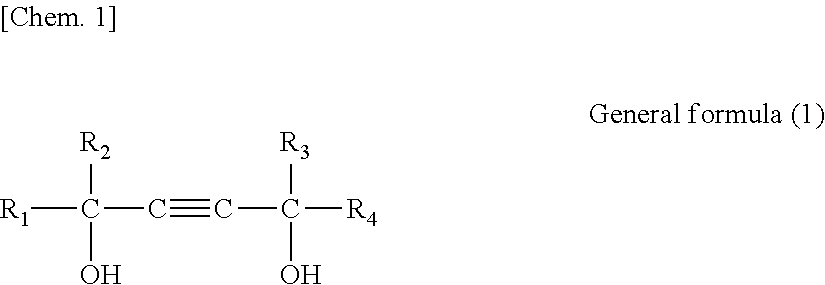

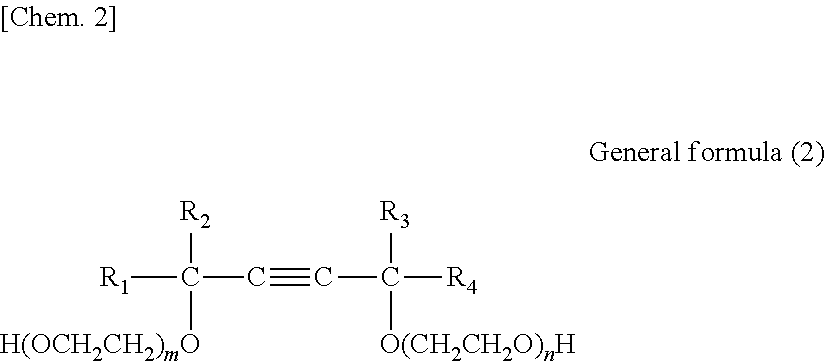

Method for producing binder for inkjet printing ink, inkjet printing ink, and printed material

ActiveUS20120219769A1Good ink dischargeabilityImprove blend stabilityDecorative surface effectsLayered productsOrganic solventPolyol

An object of the present invention is to provide a method for producing a binder for inks and for use in producing an inkjet printing ink that has both good ink dischargeability and blend stability. A method for producing a binder for inkjet printing inks, the binder containing a hydrophilic-group-containing urethane resin (A), an acetylene compound (B), and an aqueous medium (C), includes step (1) of allowing Ga polyol (a1) containing a hydrophilic-group-containing polyol to react with a polyisocyanate (a2) in an organic solvent or in the absence of a solvent and feeding the organic solvent as needed to prepare an organic solvent solution [I], step (2) of mixing the organic solvent solution [I] with the acetylene compound (B) and the aqueous medium (C) to prepare a mixture [II], and step (3) of removing the organic solvent contained in the mixture [II].

Owner:DAINIPPON INK & CHEM INC

Printing method of polar fleece bended fabric

InactiveCN103669028AImprove printing effectHigh color fastnessFibre treatmentDyeing processEngineeringRubbing

The invention discloses a printing method of a polar fleece blended fabric. A pretreatment process of soaking and dehydration after secondary washing is adopted, then a special printing treatment process is performed, self-prepared improved dye is adopted, and finally the printing is finished after ageing fixation, soft setting and preshrinking finish processes. The printing method has the advantages of good printing effect, high color fastness, high rubbing fastness, simple process, proneness to industrial operation and improvement on operation production efficiency and product quality.

Owner:JIANGSU BOBOBEAR TEXTILE

Cation formaldehyde-free dye-fixing agent emulsion

ActiveCN104744641AImprove rubbing fastnessGood flexibilityDyeing processEmulsionEmulsion polymerization

The invention relates to a cation formaldehyde-free dye-fixing agent emulsion. The cation formaldehyde-free dye-fixing agent emulsion is prepared by performing soap-free emulsion polymerization on a cation polymerizable emulsifier, a silicon-containing cationic monomer, a silane coupling agent, an initiator and deionized water which are used as raw materials. The cation formaldehyde-free dye-fixing agent emulsion overcomes the problems that after the current cation formaldehyde-free dye-fixing agent polymer forms a film, the hole can be formed because the film can be swelled or the emulsifier can absorb water in the water environment and can be separated out, the fixation effect of the dye-fixing agent can be weakened and the fastness problem of the fabric is reduced. The dye-fixing agent emulsion provided by the invention has good film forming ability and high cationic density, reinforces the fabric crockfastness improving effect, avoids the harmful effect of the emulsifier on the emulsion film and improves the hand feel of the textile.

Owner:ZHEJIANG IND POLYTECHNIC COLLEGE

Printing method for super soft short floss fabric

InactiveCN103757941AFast coloringImprove printing effectDry-cleaning apparatus for textilesDyeing processEngineeringRubbing

The invention discloses a printing method for a super soft short floss fabric. According to the method, a pretreatment process composed of two washing, soaking and dehydration is adopted, then a special printing treatment process using a self-made improved dye is conducted, and finally by means of ageing fixation, softening shaping and pre-shrinking finishing processes, the printing can be completed. The method provided by the invention has the advantages of good printing effect, high color fastness, high rubbing fastness, simple process and easy industrial operation, and can improve production efficiency and product quality.

Owner:JIANGSU BOBOBEAR TEXTILE

Method for improving dyeing property of natural plant dye

InactiveCN110924190ASolve the disadvantages of dyeingImprove dyeing effectDyeing processColour fastnessFiber

The invention relates to the technical field of new material processing, and discloses a method for improving a dyeing property of a natural plant dye. A dyeing auxiliary is added into the natural plant dye, and a physical treatment means is supplemented, so that a mixed dye is obtained through uniformly dispersing so as to be used for dyeing; the prepared auxiliary is beneficial to driving dye molecules to enter a textile material fiber crystalline region, so that penetration dyeing is facilitated, the dyeing rate can be accelerated, a repulsive force between electric charges is reduced, thedye molecules are combined onto a fabric to be dyed through a bonding way, the dyeing degree and various color fastness are improved, and the color fading problem brought by hot and humid conditions,illumination and the like can be solved; and the process can well overcome the defects occurred during existing natural plant dye dyeing, the dyeing strength of the prepared natural plant dye is remarkably improved, and the comprehensive utilization rate of the natural plant dye is improved, so that the cost is saved, and the color degree, the washability and the sunproofness of the natural plantdye are improved.

Owner:安徽融创化工科技股份有限公司

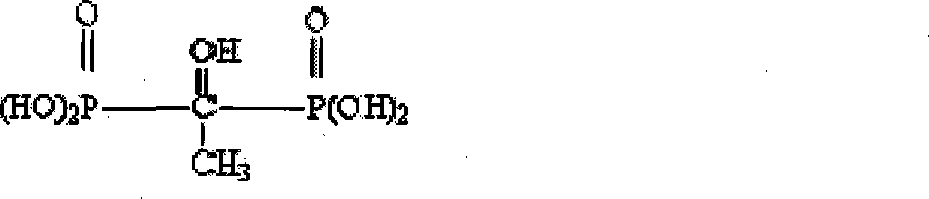

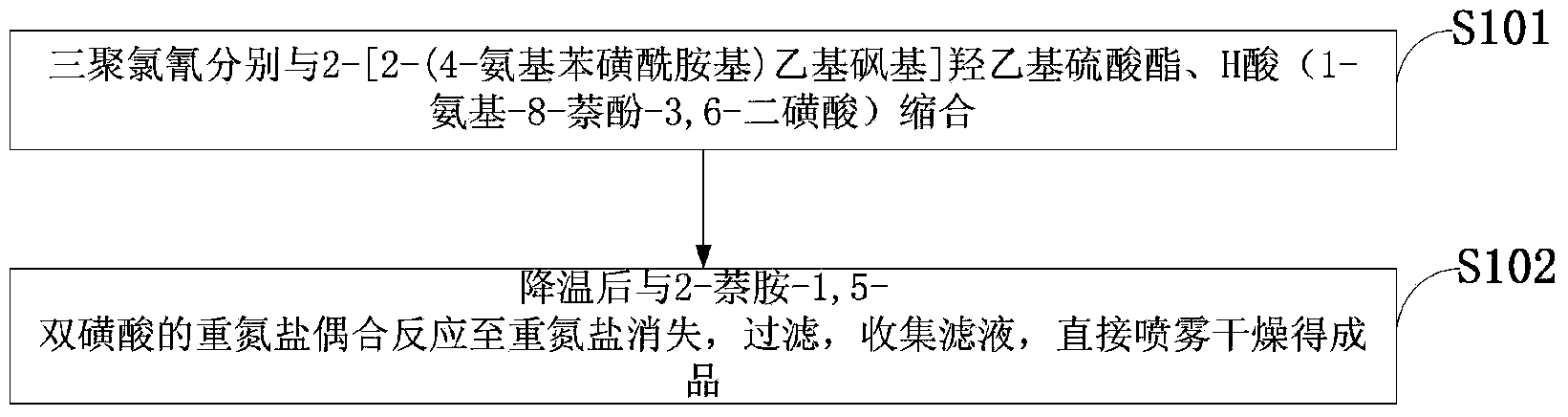

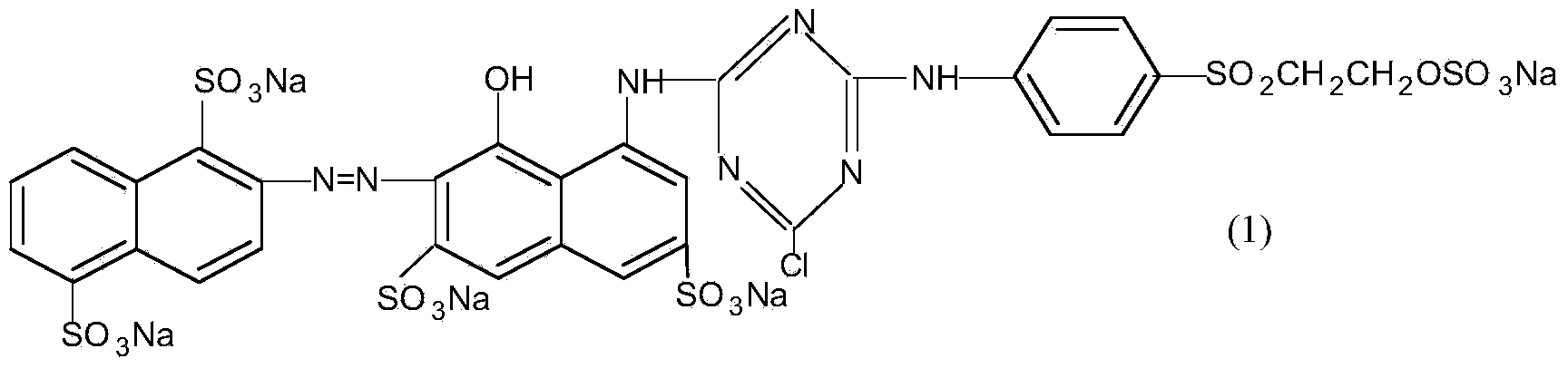

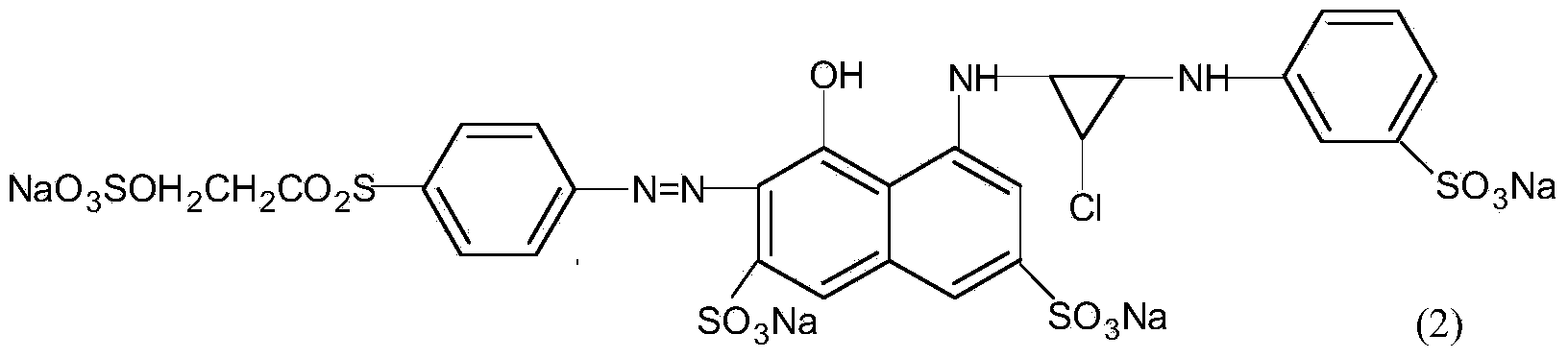

Reactive red dye with high washing fastness and rubbing fastness and preparation method of reactive red dye

ActiveCN104277493ALow amount of isomersReduce dosageReactive dyesDyeing processSolubilityCellulose fiber

The invention discloses a reactive red dye with high washing fastness and rubbing fastness and a preparation method of the reactive red dye. Acetanilide reacts with chlorosulfonic acid and sulfoxide chloride to generate acetylsulfanilyl chloride; acetylsulfanilyl chloride is condensed with a sulfide generate by reacting a 2-chlorethamin hydrochloride with mercaptoethanol to obtain thioether; the thioether is oxidized and esterified to obtain 2-[2-(4-aminobenzenesulfonamido) ethyl sulfuryl] hydroxyethyl sulfate which is primarily condensed with cyanuric chloride and secondarily condensed with H acid to obtain a condensation compound; the condensation compound is cooled and then coupled with the diazonium salt of 1.5 acid under an alkaline condition, and the product is filtered and then the filtrate is collected and is subjected to direct spray drying to obtain a semi-finished product. The reactive red dye has the characteristics of bright color, high solubility high substantivity, high compatibility, high lifting power, high fixation rate, excellent diversified fastness and the like. The reactive red dye is suitable for dyeing, printing and pad dyeing of cellulosic fibers, protein fibers, viscose and polyarmide fibers, and higher than common types in rubbing fastness and washing fastness by 0.5 to 1 level.

Owner:TAIXING JINYUN DYESTUFF

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com