Dyeing method of water insoluble natural pigment on silk fabric

A water-insoluble, natural pigment technology, applied in the field of textile dyeing and finishing, can solve problems such as inability to dye silk fabrics, and achieve the effect of high fastness and uniform dyeing of fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

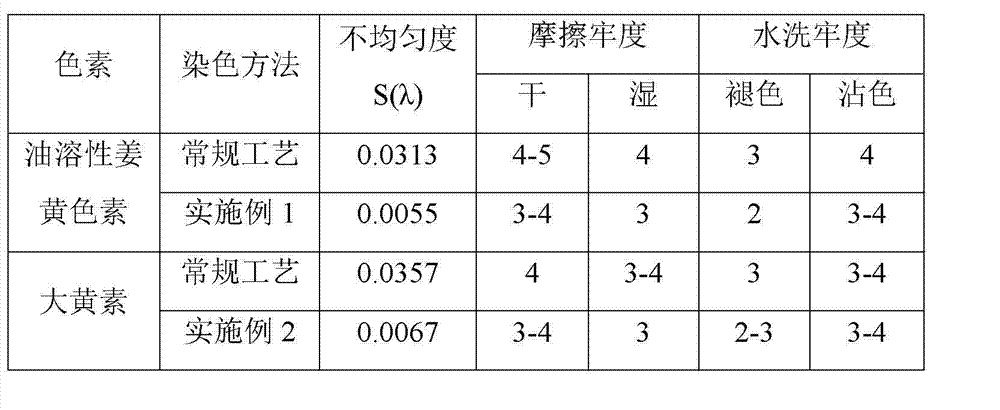

[0012] The method described in this embodiment is suitable for dyeing silk fabrics with oil-soluble curcumin.

[0013] Weigh 0.5g of oil-soluble curcumin and dissolve it in 10ml of benzyl alcohol in a 250ml beaker. After it is completely dissolved, add 10g of fatty alcohol polyoxyethylene ether AEO9 and stir. After stirring evenly, the fixed stirring speed is 3000r / min, gradually add 150mL of deionized water within 30min under stirring conditions, continue to stir and stir for 60min, to obtain a curcumin microemulsion, add deionized water to make the volume up to 200mL.

[0014] The fatty alcohol polyoxyethylene ether used is AEO9, which is an existing conventional industrial product.

Embodiment 2

[0016] The method described in this embodiment is suitable for dyeing silk fabrics with emodin.

[0017] Weigh 0.5g of emodin and dissolve it in 8ml of phenethyl alcohol in a 250ml beaker. After it is completely dissolved, add 5g of fatty alcohol polyoxyethylene ether AEO9 and 5g of AEO7 for stirring. After stirring, the constant stirring speed is 2500r / min, gradually add 150mL of deionized water within 30min under stirring conditions, continue to stir and stir for 70min to obtain a microemulsion of emodin, add deionized water to make the volume to 200mL.

[0018] The fatty alcohol polyoxyethylene ether used adopts AEO9 and AEO7, and both AEO9 and AEO7 are existing conventional industrial products.

[0019] The dyeing method of the pigment microemulsion is to place the water-insoluble pigment microemulsion obtained in the above examples in an oscillating water bath, add 10 g of the silk fabric that has undergone pre-degumming treatment, and perform dyeing at elevated temperature unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com