Dyeing technology for polyester brocade sydney down cotton-imitated fabric

A technology of imitating cotton fabrics and pears, which is applied in the dyeing process of polyester-nylon pear velvet imitation cotton fabrics, can solve the problems of easy falling off of disperse dyes, poor rubbing fastness, poor light fastness, etc., and achieve light and rubbing fastness Improve and solve the effects of poor fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

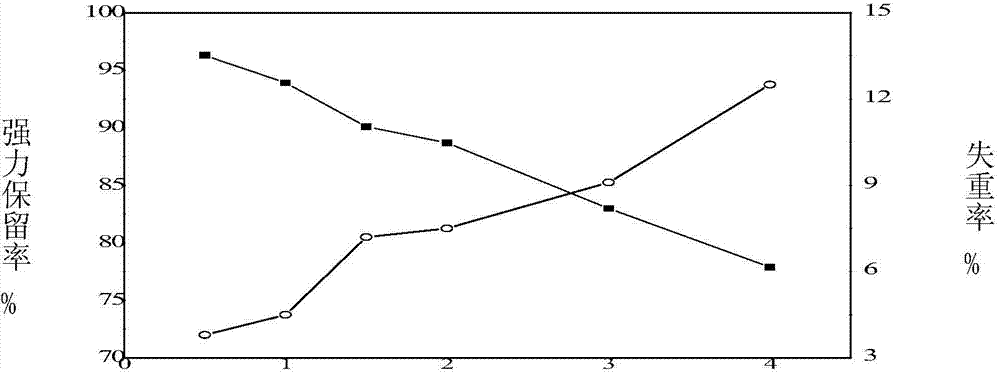

[0041]Embodiment: a kind of dyeing process of cotton-like fabric of polyester velvet and snow pear

[0042] A dyeing process of polyester-nylon Sydney velvet imitation cotton fabric, the pre-treatment of polyester-nylon composite fiber fabric gray cloth includes cold stacking process, open-width process, machine-alkali re-fiber opening process, and the dyed polyester-nylon composite fiber fabric gray cloth is also carried out Styling process.

[0043] The first step: cold stacking process

[0044] Firstly adopt uniform padding machine to carry out padding treatment to polyester nylon composite fiber fabric gray cloth, then cold stack 48 hours under 35-40 ℃ room temperature condition through the polyester nylon composite fiber fabric gray cloth of padding treatment; Described padding treatment uses Every liter of padding treatment liquid contains 100 grams of liquid caustic soda, 2 grams of hydrogen peroxide, 2 grams of oxidation desizing agent TF-127K, and 0.5 gram of high-ef...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com