Dyeing and finishing process of t/c blended woven tooling fabric with high washability

A processing technology and washing-resistant technology, applied in textiles and papermaking, adding dyes to spinning solution, adding pigments to spinning solution, etc., can solve the problem of anti-wrinkle, anti-pilling, anti-pilling and discoloration, which can not meet customer needs well, etc. problems, to achieve the effect of reducing the use of hydrosulfite and NaOH, reducing the difficulty of the process, and high washability and wearability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] T / C65 / 35 14*14 80*52 2 / 1 150cm yarn card black

[0049] Process flow: pre-treatment - dyeing - finishing - finished product;

[0050] (1) Pre-treatment: gray fabric preparation--singeing (two positive and two negative, speed 110m / min)--deboiling (padding working solution, steaming at 100°C for 50min, speed 70m / min)--bleaching (padding work liquid, steamed at 100°C for 30min, speed 70m / min)-mercerizing (NaOH 220--240g / L, speed 80m / min)-setting (210°C, speed 60m / min);

[0051] The deboiled working solution consists of the following components per liter of working solution:

[0052]

[0053]

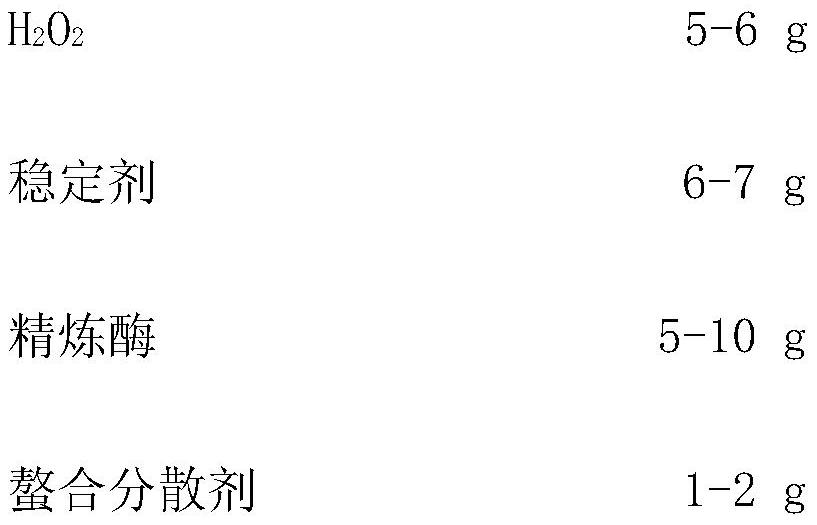

[0054] The composition of the bleaching working solution is that each liter of working solution contains the following components:

[0055]

[0056] Adjust PH=10.5-11;

[0057] (2) Dyeing: pad dyeing solution (passing rate 60--65%, one more padding) - drying - padding fixation solution - steaming (100°C, 60s) - washing, soap wash - dry;

[0058] The composition of the d...

Embodiment 2

[0077] The production variety and quality requirements described in the present embodiment are the same as in Example 1, and the color is brown.

[0078] The processing steps described in this embodiment are all identical with embodiment 1, and difference is:

[0079] The deboiled working solution consists of the following components per liter of working solution:

[0080]

[0081] The composition of the bleaching working solution is that each liter of working solution contains the following components:

[0082]

[0083] The composition of the vat dye solution is that each liter of the solution contains the following components:

[0084]

[0085] The vat dye fixing solution is composed of the following components per liter of fixing solution:

[0086] Sodium Hydrochloride 45g

[0087] NaOH 50g;

[0088] The finishing solution is composed of the following components per liter of finishing solution:

[0089]

Embodiment 3

[0091] The production variety and quality requirements described in the present embodiment are the same as in Example 1, and the color is lavender.

[0092] The processing steps described in this embodiment are all identical with embodiment 1, and difference is:

[0093] The deboiled working solution consists of the following components per liter of working solution:

[0094]

[0095] The composition of the bleaching working solution is that each liter of working solution contains the following components:

[0096]

[0097] The composition of the dye solution is that each liter of the dye solution contains the following components:

[0098]

[0099] The dye fixing solution is composed of the following components per liter of fixing solution:

[0100] NaOH 3g

[0101] Na 2 CO 3 30g

[0102] NaCl 200g;

[0103] The finishing solution is composed of the following components per liter of finishing solution:

[0104]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com