Patents

Literature

1131results about "Abrasion resistant fibres" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing super-hydrophobic textile from thiol-ene click chemistry-modified fiber

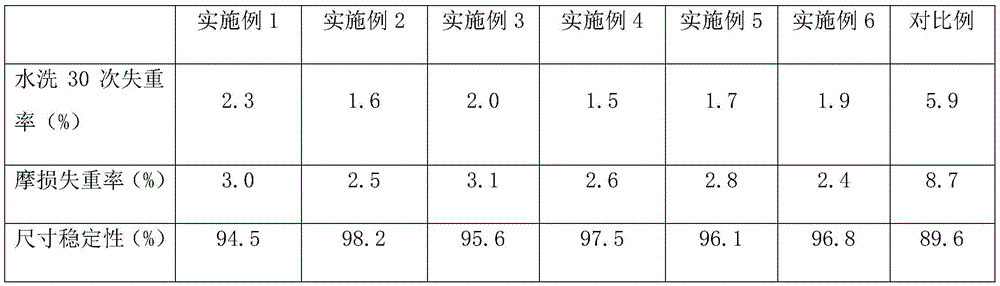

InactiveCN105696306AWashableWear-resistantLiquid repellent fibresAbrasion resistant fibresFiberPolyester

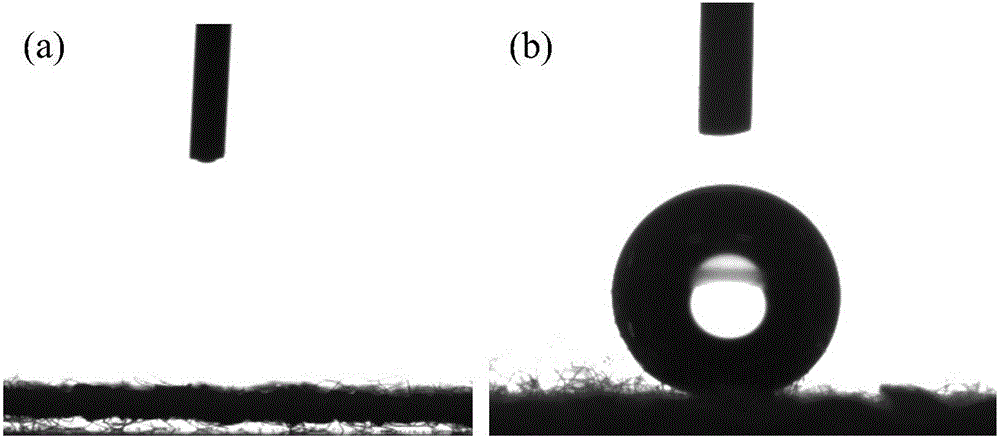

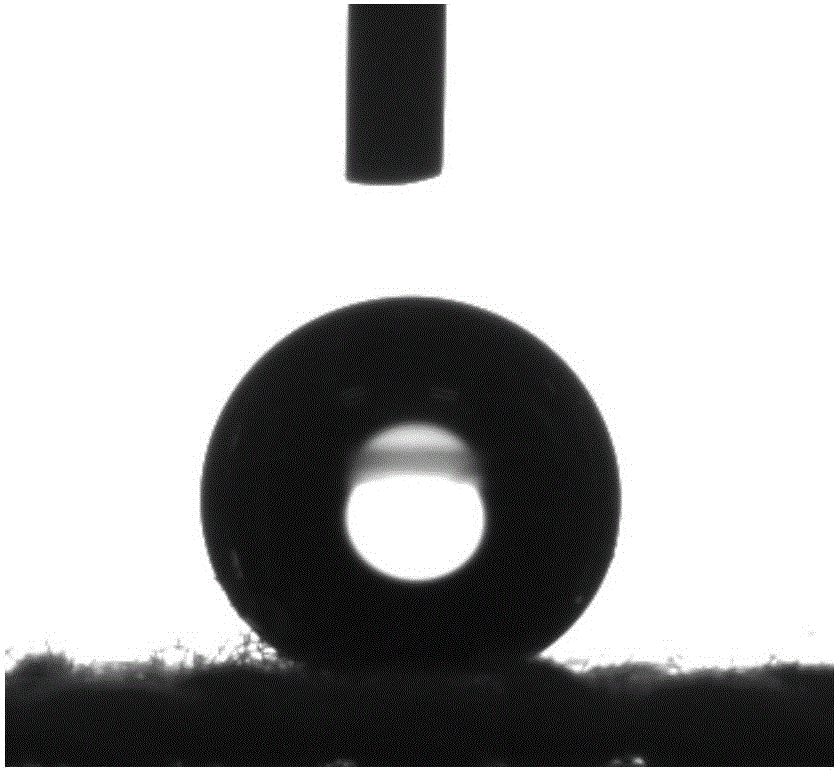

The invention relates to a preparation method of a functional textile, and belongs to the field of textile surface grafting modification. The method for preparing a super-hydrophobic textile from a thiol-ene click chemistry-modified fiber is characterized by comprising the steps that alkali liquor steaming treatment is performed on a polyester fiber, then mercaptosilane is fixed to the surface of the polyester fiber, finally a methacrylate monomer is grafted to the surface of the polyester through a thiol-ene click chemistry reaction to reduce the surface tension of the fiber, and then the super-hydrophobic polyester textile is obtained. The contact angle between the polyester textile prepared through the method and water drops is larger than 150 degrees, and the polyester textile is stable to acid, alkali, salt and solvent and capable of resisting friction and washing and has the very good hydrophobic stability.

Owner:SHAANXI UNIV OF SCI & TECH

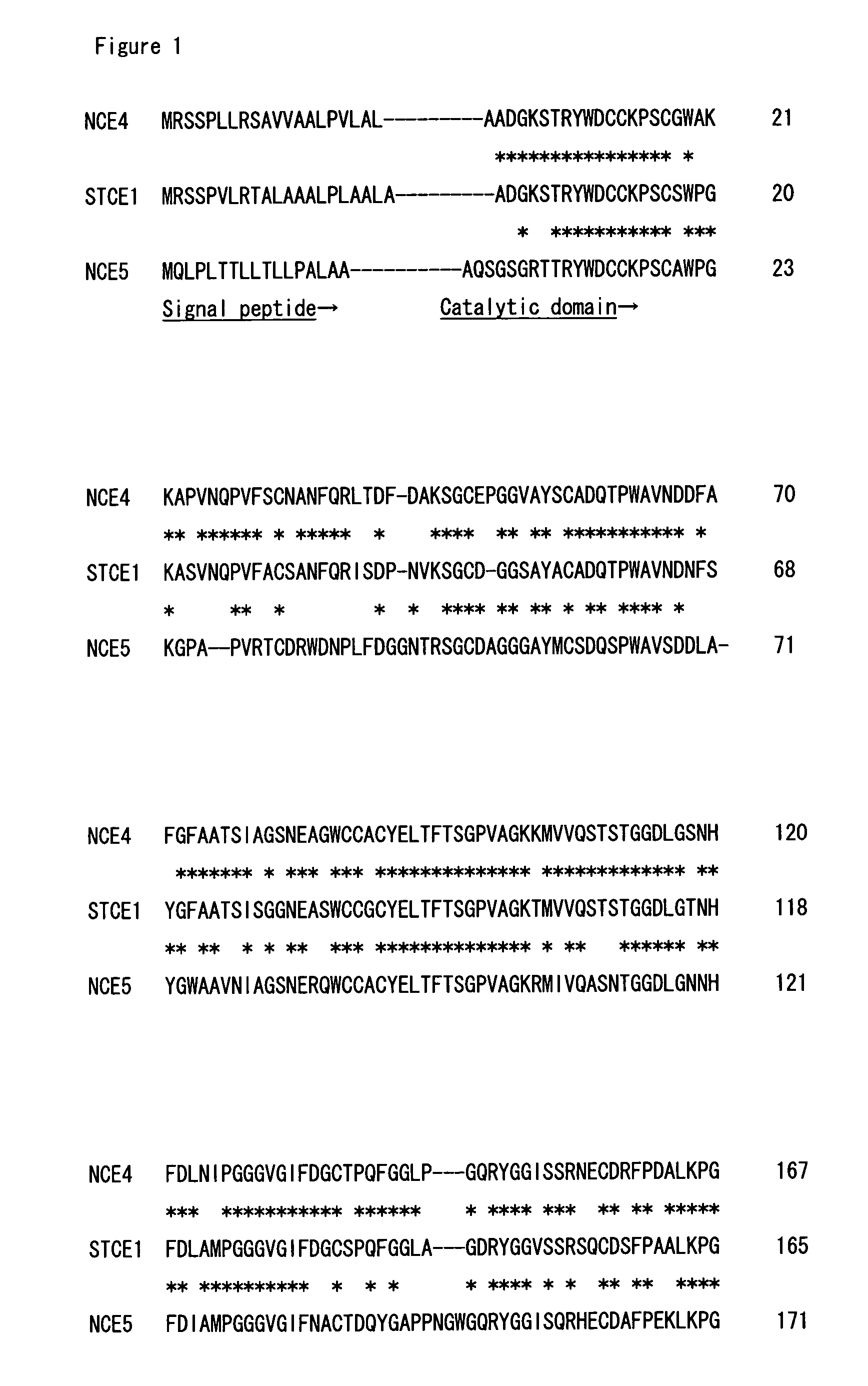

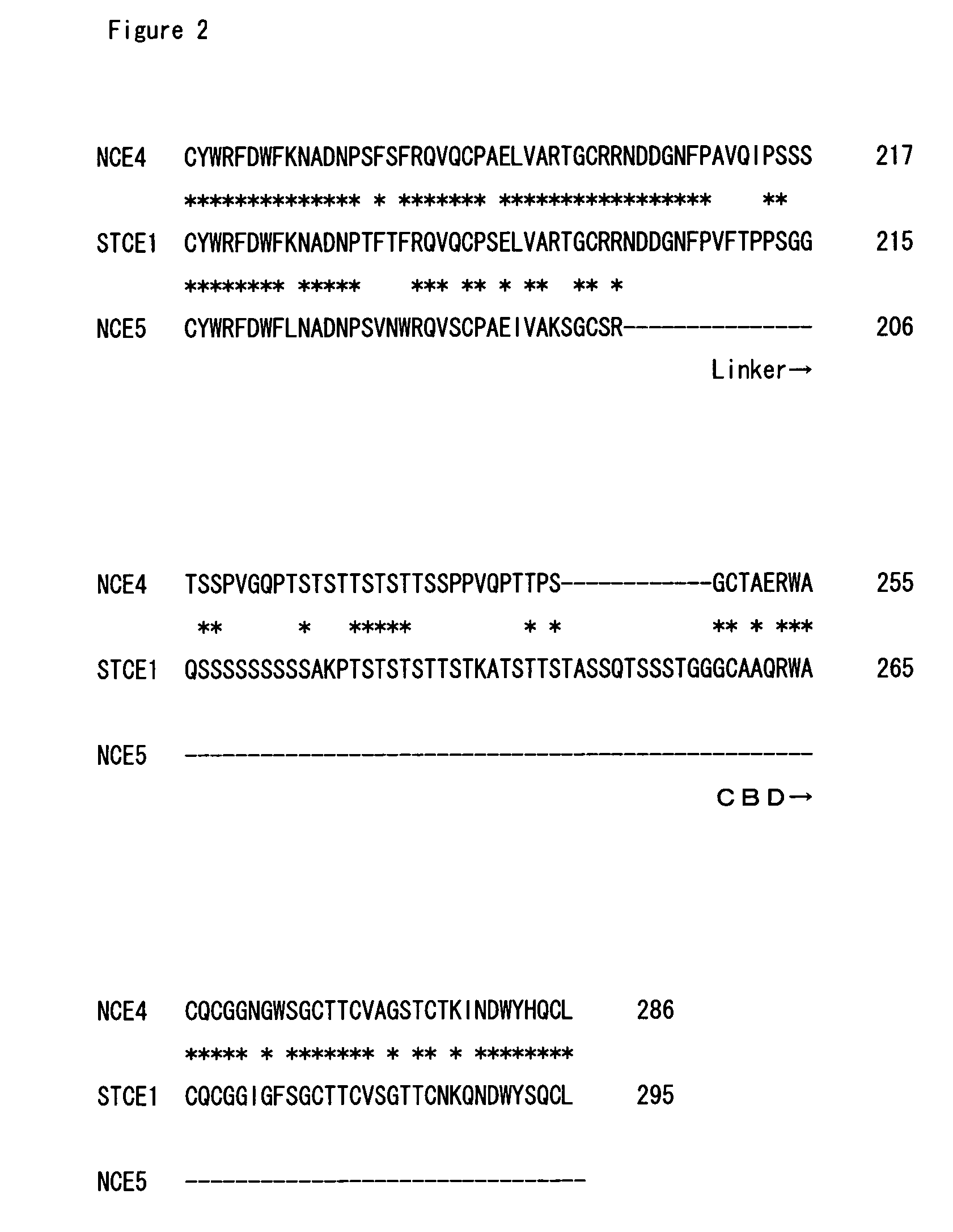

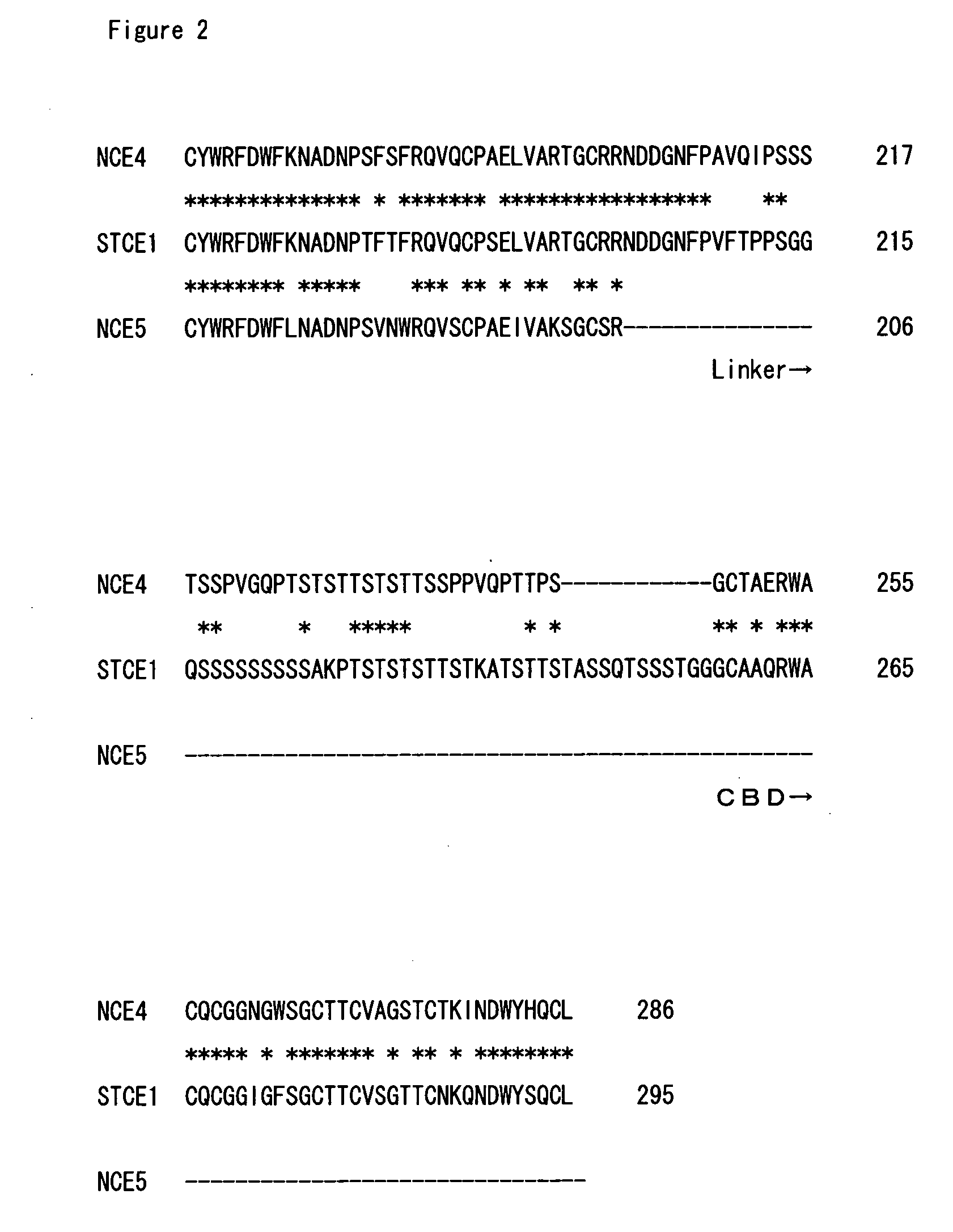

Endoglucanase STCE and cellulase preparation containing the same

ActiveUS7595182B2Improvement of touch feel and appearance of fabricReduction of fuzzFungiBacteriaGlucanaseColor changes

Owner:MEIJI SEIKA KAISHA LTD

Carbon Fiber Bundle, Method for Producing The Same, and Molded Article Made Thereof

ActiveUS20130122262A1Improve adhesionGood compatibilityCarbon fibresSynthetic resin layered productsCarbon fibersFiber bundle

A carbon fiber bundle includes carbon fibers and a copolymerized polyolefin attached to the surface of the carbon fibers. The copolymerized polyolefin contains an aromatic vinyl compound and an acid and / or acid anhydride as copolymerization components. The amount of the copolymerized polyolefin attached is 0.01 to 10 parts by mass per 100 parts by mass of the carbon fiber bundle. The carbon fiber bundle may be used or contained in a random mat, a composite material, and various molded articles.

Owner:TEIJIN LTD

Endoglucanase stce and cellulase preparation containing the same

ActiveUS20070111278A1Improvement of touch feel and appearance of fabricReduction of fuzzFungiBacteriaGlucanaseStaphylococcus aureus

A novel endoglucanase derived from Staphylotrichum coccosporum, a polynucleotide encoding the endoglucanase, and a cellulase preparation containing the endoglucanase are disclosed. The endoglucanase or cellulase preparation is available for a washing use or fabric processing, such as a color clarification of a cellulose-containing fabric, a reduction of fuzz, an improvement of the touch feel and appearance of the fabric, providing a localized color change to the fabric, or a reduction of stiffness.

Owner:MEIJI SEIKA KAISHA LTD

Flame Resistant Fabrics Having Improved Resistance to Surface Abrasion or Pilling and Methods for Making Them

ActiveUS20090178186A1Improve the immunityImprove surface wear resistanceChemical protectionHeat protectionFiberYarn

Flame resistant fabrics and garments that have improved resistance to pilling and / or abrasion are disclosed. The fabrics, the fibers or yarns that make up the fabrics, or garments made from the fabrics are treated with a finish composition that is applied to the fibers, yarns, fabrics, or garments and then cured. The finish composition increases the resistance to pilling and / or abrasion of the fibers, yarns, fabrics, or garments. The finish composition includes a polymeric abrasion resistance aid, an alkylfluoropolymer, a polyethylene, and a wetting agent.

Owner:SOUTHERN MILLS

Durable finishes for textiles

InactiveUS6872424B2Improve stabilityGood water solubilitySynthetic resin layered productsPretreated surfacesTextile fiberAlcohol

The present invention relates to textile treatment compositions for imparting desirable characteristics durably to textile fibers and fabrics, including softness, hydrophobicity, oleophobicity, surface lubricity, abrasion resistance, tear resistance, improved drape, and pilling resistance. More particularly, in one embodiment, the invention is directed to preparations that comprise a carboxylate-functionalized fluorinated polymer and a catalyst that is capable of forming reactive anhydride rings between carboxyl groups on the polymer. In another embodiment, the invention is directed to preparations comprising a polymeric softener having at least one anhydride functional group or at least one reactive group capable of forming an anhydride functional group, together with a catalyst for forming anhydrides from the reactive group or groups. In either embodiment, the resulting reactive anhydride rings bind to substrates, such as textiles and other webs, having free sulfhydryl, alcohol, or amine groups. The invention is further directed to the process for treating textiles and other webs with desirable finishes durable to repeated cleanings. This invention is further directed to the yarns, fibers, fabrics, textiles, finished goods, or nonwovens (encompassed herein under the terms “textiles” and “webs”) treated with the textile-reactive preparations of the invention. Such textiles and webs exhibit a greatly improved, durable characteristics, such as softness and / or hydrophobicity, even after multiple launderings.

Owner:NANO TEX

Fabric post-finishing agent based on modified silk fibroin solution and preparation method of fabric post-finishing agent

ActiveCN105544210ASkin-friendlyHigh affinityBiochemical fibre treatmentGrip property fibresDissolutionSolvent

The invention provides a fabric post-finishing agent based on a modified silk fibroin solution and a preparation method of the fabric post-finishing agent. The preparation method comprises the following specific operational steps: (1) removing impurities from waste silk, putting the impurity-free waste silk in a sodium bicarbonate solution for boiling and degumming, taking out and wringing out the degummed waste silk, washing with clean water till the greasy feel is eliminated, putting the primarily treated waste silk in the sodium bicarbonate solution again for boiling and degumming, taking out and wringing out the degummed waste silk again, washing again with clean water till the greasy feel is eliminated, putting the secondarily treated waste silk in an oven for drying, so as to obtain degummed silk; (2) putting the degummed silk in a lithium bromide solution for standing and dissolution, taking out the treated silk, and performing cooling, dialysis and concentration to obtain a silk fibroin solution; and (3) adding glycerin and gelatin into the silk fibroin solution, uniformly stirring to form a membrane solution, adjusting the pH value of the membrane solution and then adding glutaraldehyde and chitosan, uniformly stirring, and finally mixing the treated membrane solution with a solvent containing additives, so as to obtain the fabric post-finishing agent. The fabric post-finishing agent obtained according to the preparation method covers the fabric surface in the form of a composite membrane; and the preparation method is beneficial to improvements in the membrane forming property, the ductility and the like of a silk fibroin finishing agent.

Owner:SUZHOU INSILK CO LTD

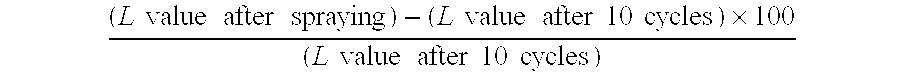

Fabric color restoration composition, article, and method

InactiveUS20090178212A1Good flexibilityReduce and eliminate needGrip property fibresDyeing processStatic friction coefficientMaximum level

The present invention relates to a stable, preferably well dispersed, more preferably translucent, and even more preferably clear, aqueous fabric color-restoring composition, fabric color-restoring methods, and articles of manufacture that use such fabric color-restoring composition. The fabric color-restoring composition comprises an effective amount of a silicone polymer fabric color-restoring agent, typically the minimum levels of fabric color-storing agent included in the composition are at least about 1.75%, preferably at least about 2.0%, more preferably at least about 2.5%, even more preferably at least about 3.0% and typically maximum levels of fabric color-restoring agent are less than about 10.0%, preferably less than about 7.0%, particularly in the range of about 3.0% to about 6.0%; and optionally, but preferably, an effective amount to increase the coefficient of static friction, of a static friction-increasing agent.

Owner:THE PROCTER & GAMBLE COMPANY

High-quality wide bamboo fiber woven fabric and production method thereof

ActiveCN105177819ASimple production processEasy to operateSucessive textile treatmentsLiquid/gas/vapor removalFiberEngineering

The invention discloses high-quality wide bamboo fiber woven fabric and a production method thereof. The production method includes the steps of singeing, preprocessing, dyeing, shrink-resistant finishing, anti-pilling finishing, mechanical pre-shrinking, inspection and package. The dyeing technology is carried out on a large-capacity jig dyeing machine. The production technology is simple, operation is convenient, product performance is excellent, the warp and weft direction washing dimension change of the fabric ranges from -3% to 1.0%, the anti-pilling level is larger than or equal to the third to fourth level, and color fastness is larger than or equal to the fourth level.

Owner:NANTONG JINSHAIDA SPECIAL FAB CO LTD

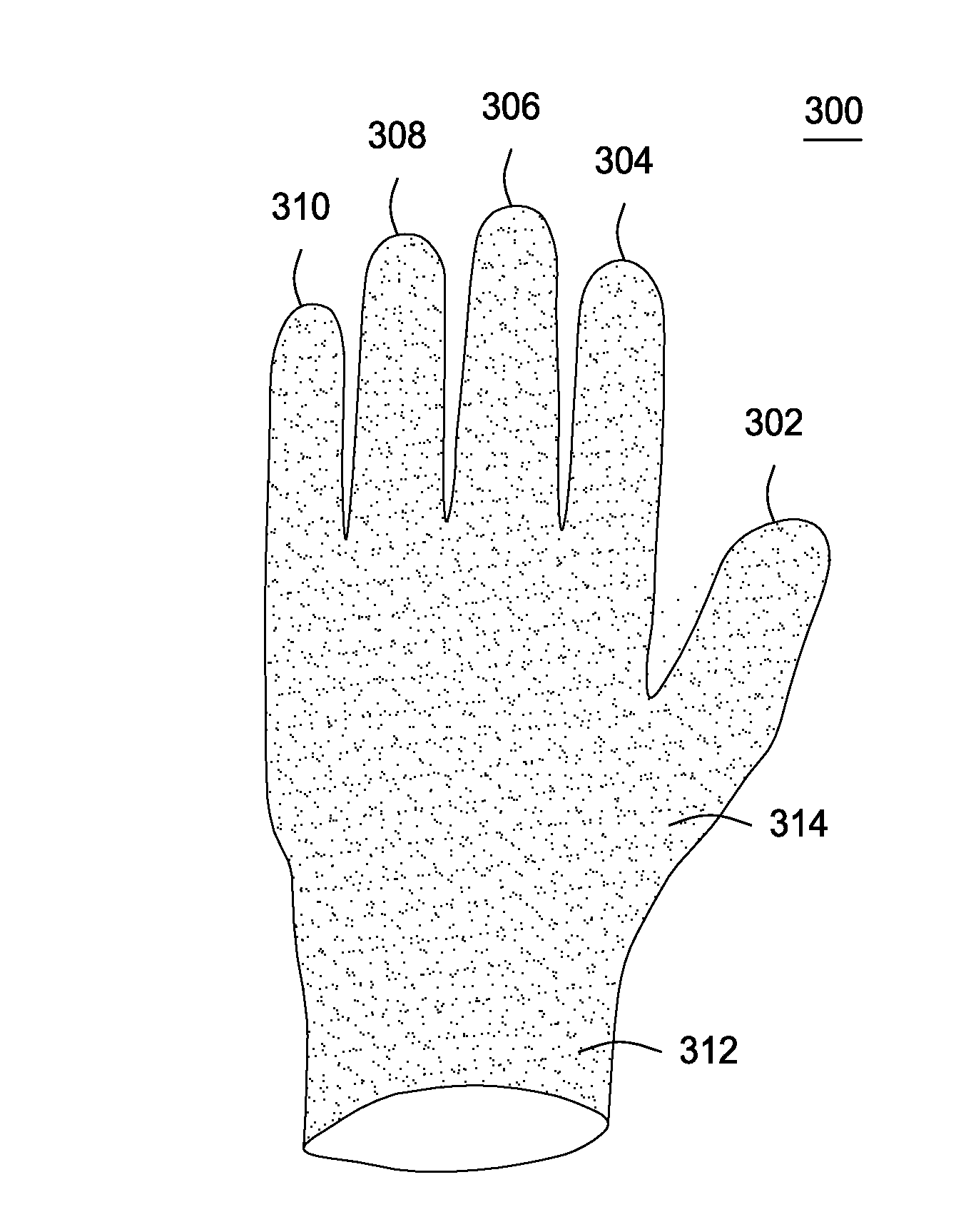

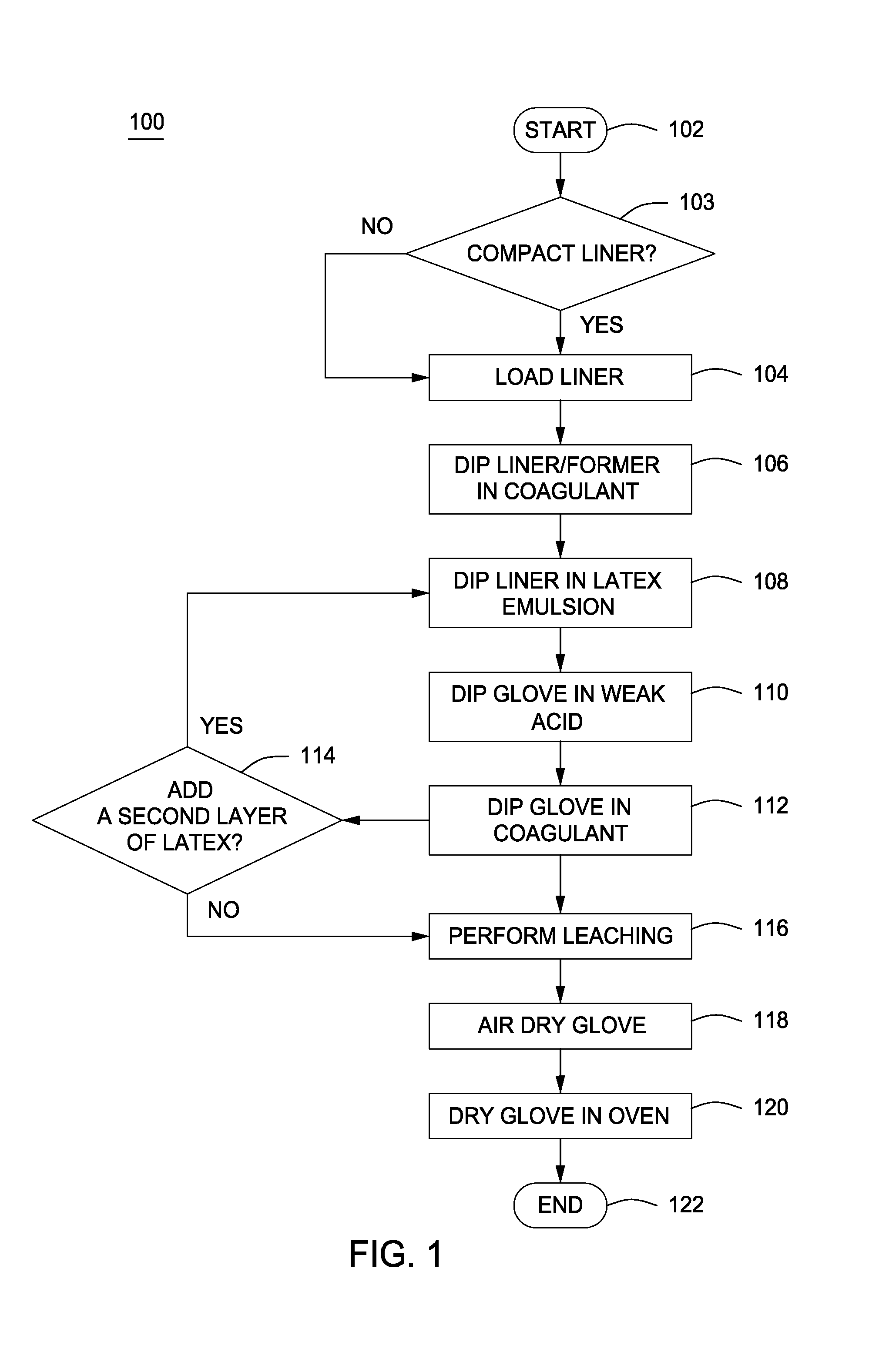

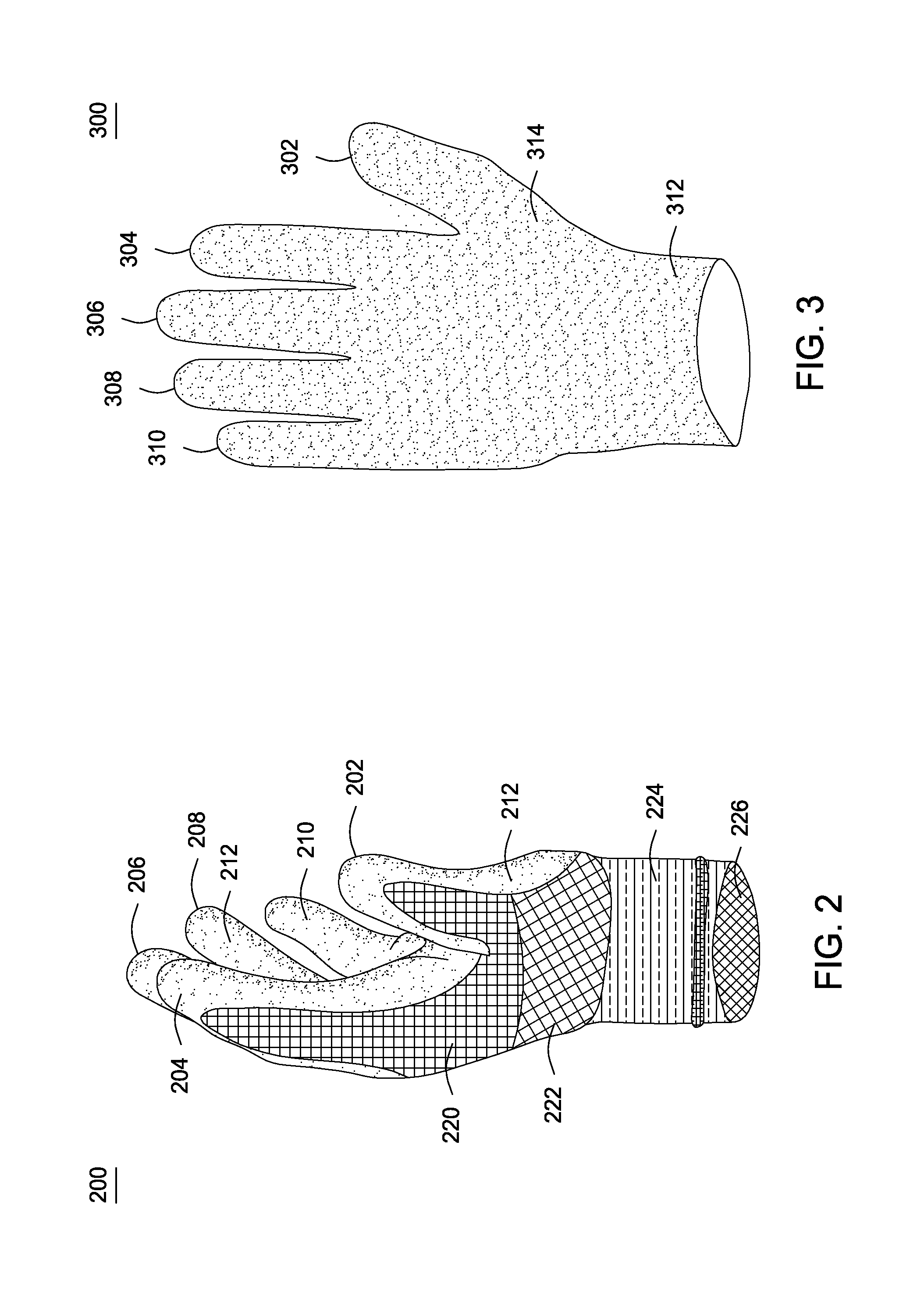

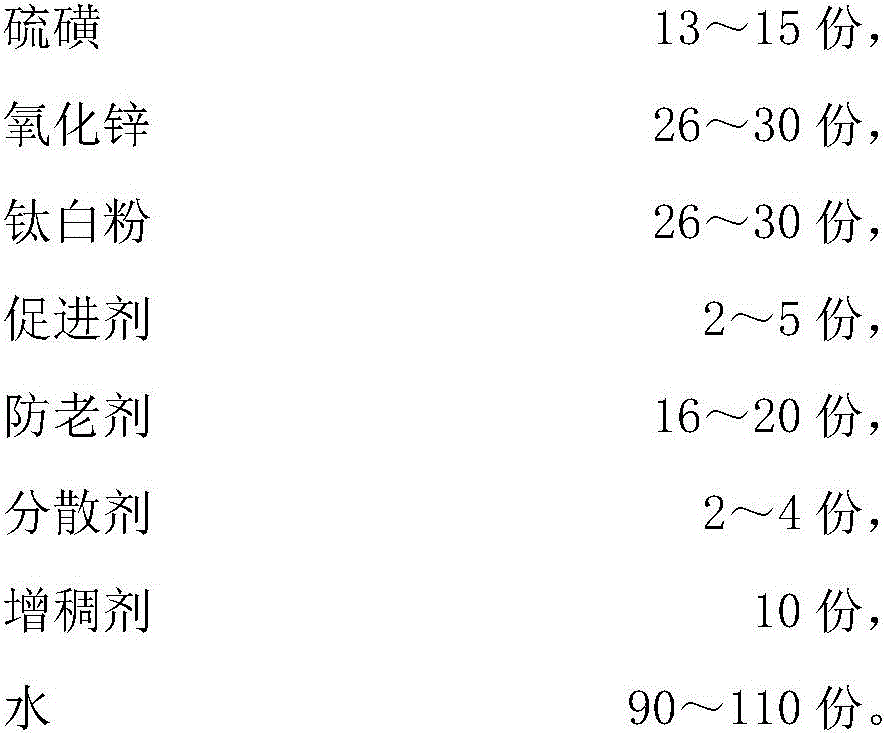

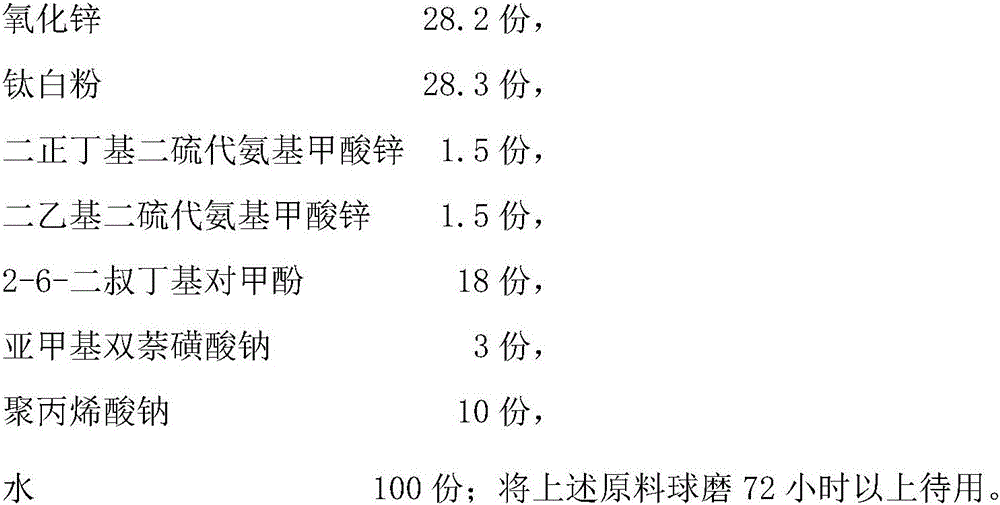

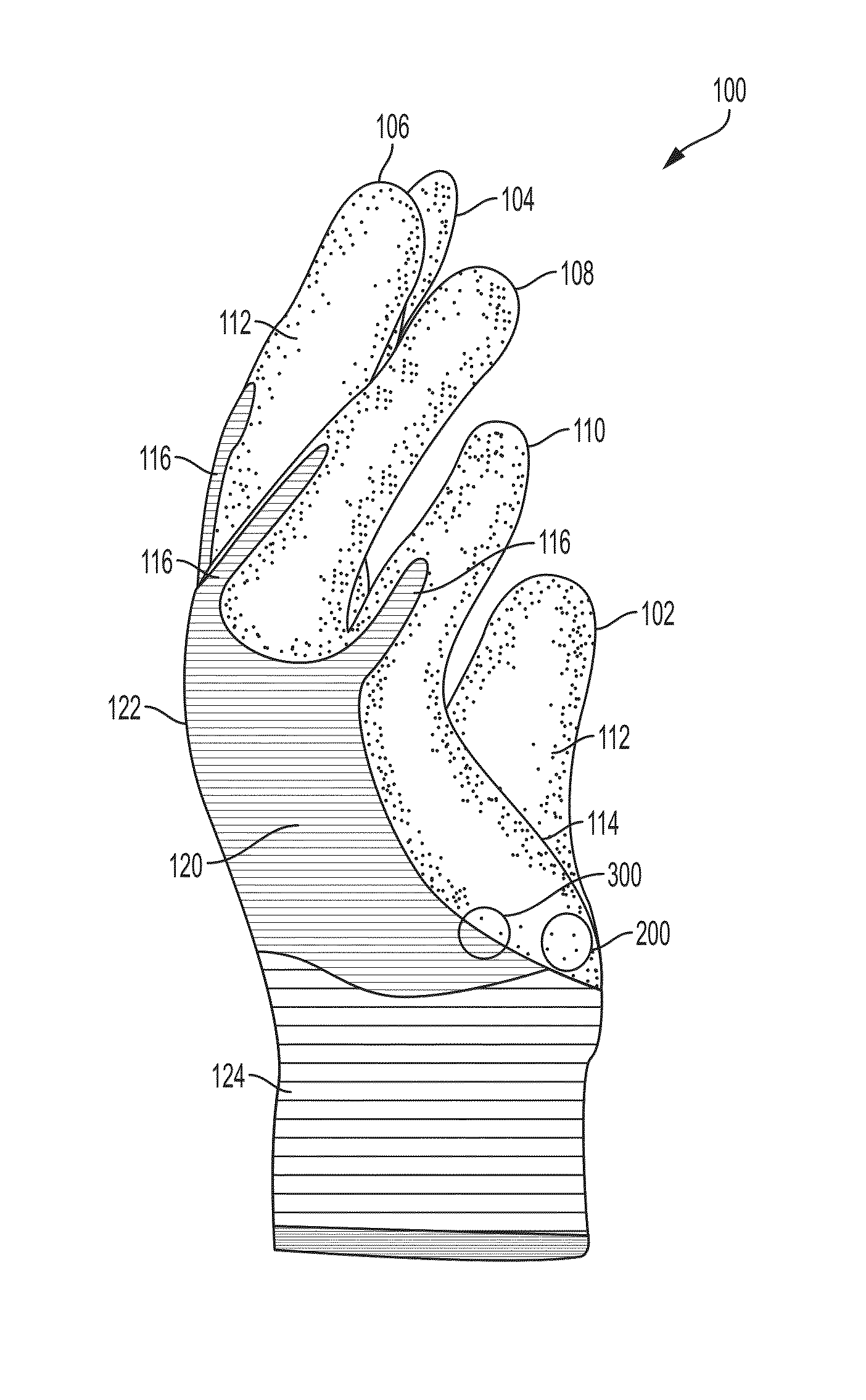

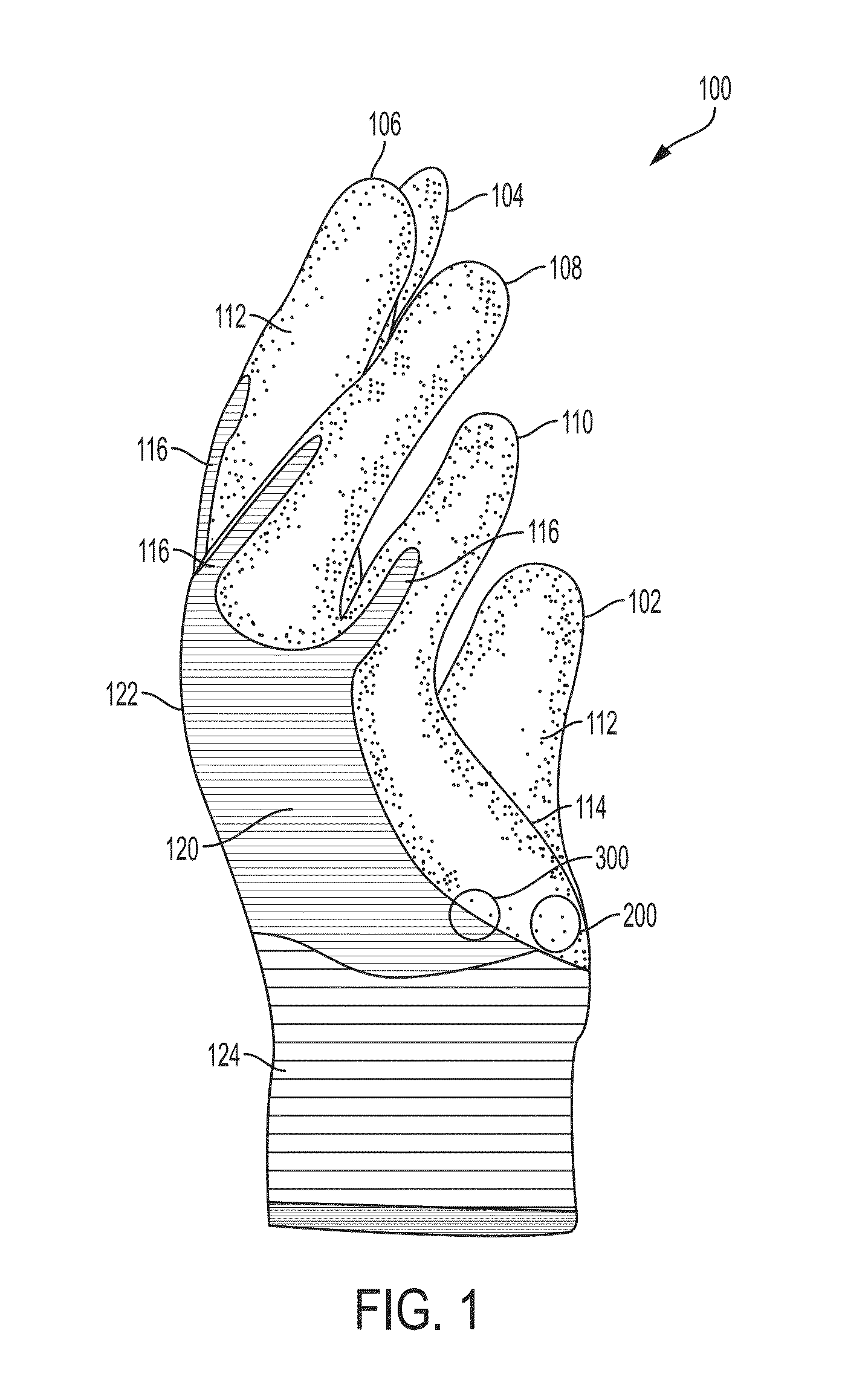

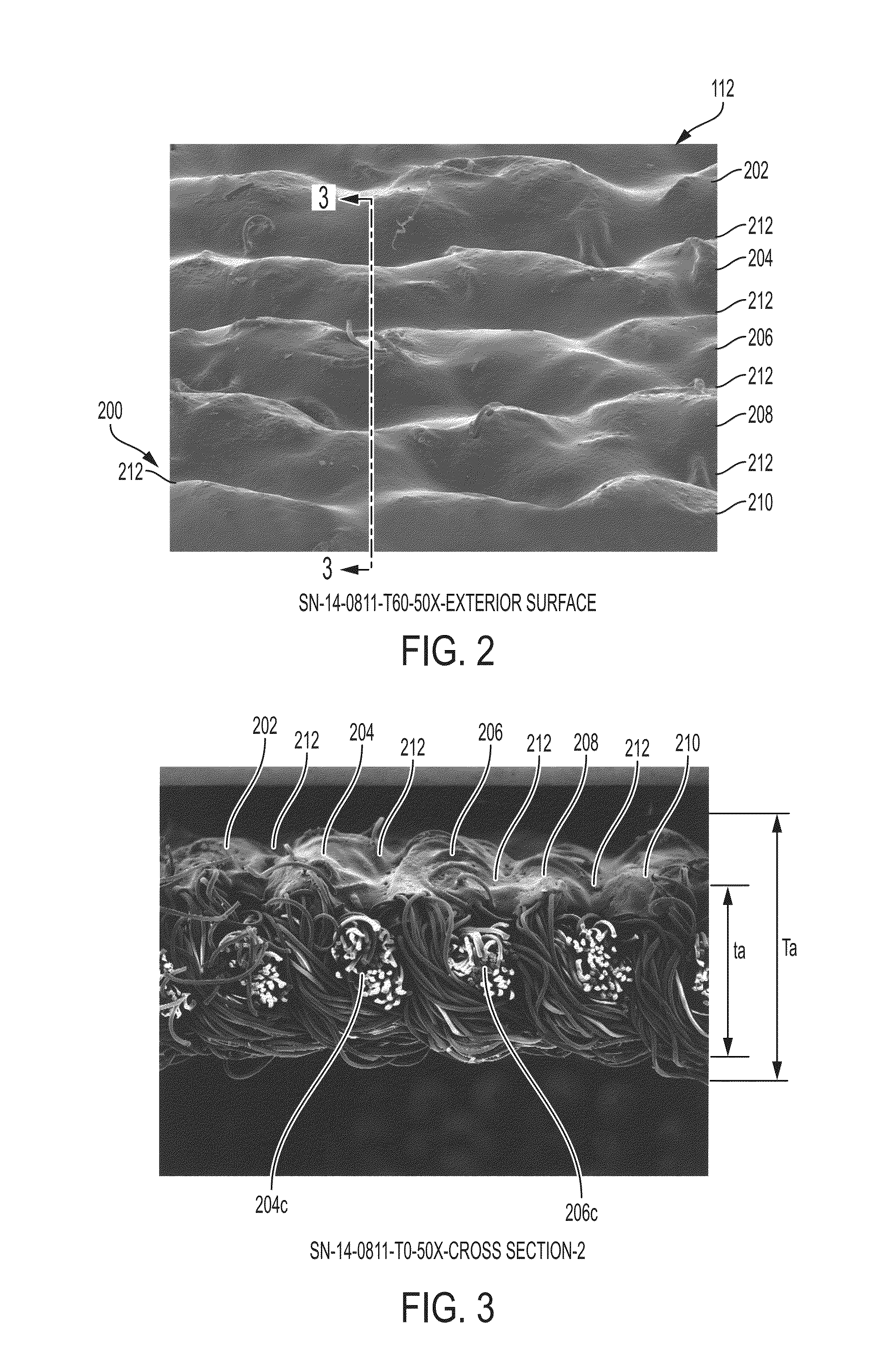

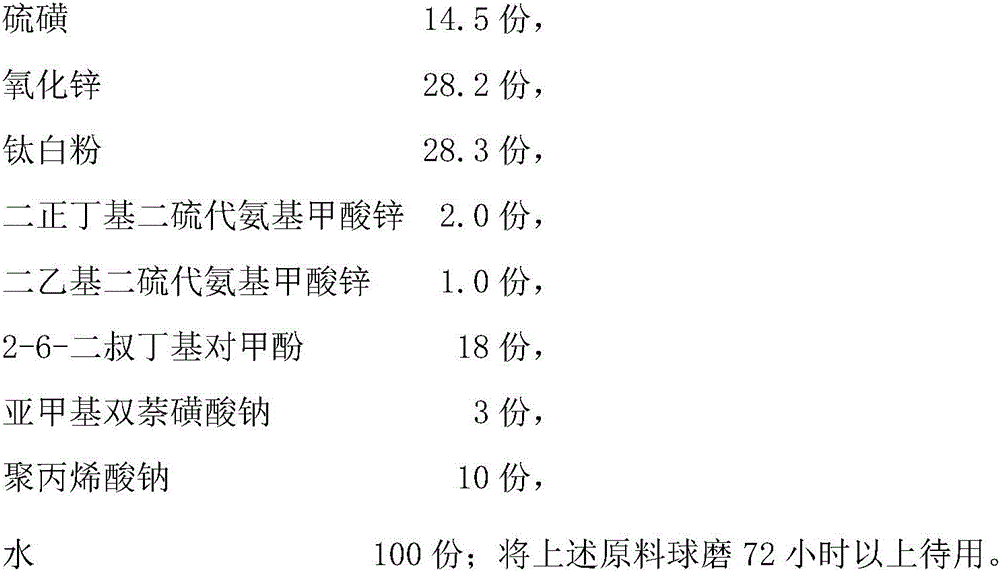

Preparation method of nitrile latex frosted gloves

InactiveCN106835720ASoft touchImprove breathabilityGlovesLiquid repellent fibresWater basedNitrile rubber

The invention discloses a preparation method of nitrile latex frosted gloves. The method comprises the following steps: mixing 1-2 parts by weight of 10 wt% KOH and 7-8 parts by weight of water, and slowly adding the mixture into the 100 parts by weight of nitrile rubber in the stirring state; sequentially adding water-based polyurethane, 4-10 parts by weight of chloroprene rubber or natural latex, 2-3 parts by weight of emulsifier and 6-7 parts by weight of ball milling material in the stirring state; continuing stirring for 1-4 hours, and standing for 10 hours or above to obtain a nitrile frosted slurry; immersing knitted gloves into a solidifying agent, pouring the solidifying agent, immersing into the nitrile frosted slurry, and pouring the slurry to perform homogenizing treatment; spraying a sodium chloride or sodium sulfate layer on the glove surface, and carrying out prevulcanization drying; cleaning the prevulcanized gloves by soaking in water; and carrying out high-temperature drying on the cleaned gloves. The nitrile latex frosted gloves have the advantages of soft feeling, favorable air permeability, favorable elasticity, favorable grabbing power and excellent wear resistance.

Owner:NANTONG QIANGSHENG SAFETY PROTECTION TECHNOLOGY CO LTD

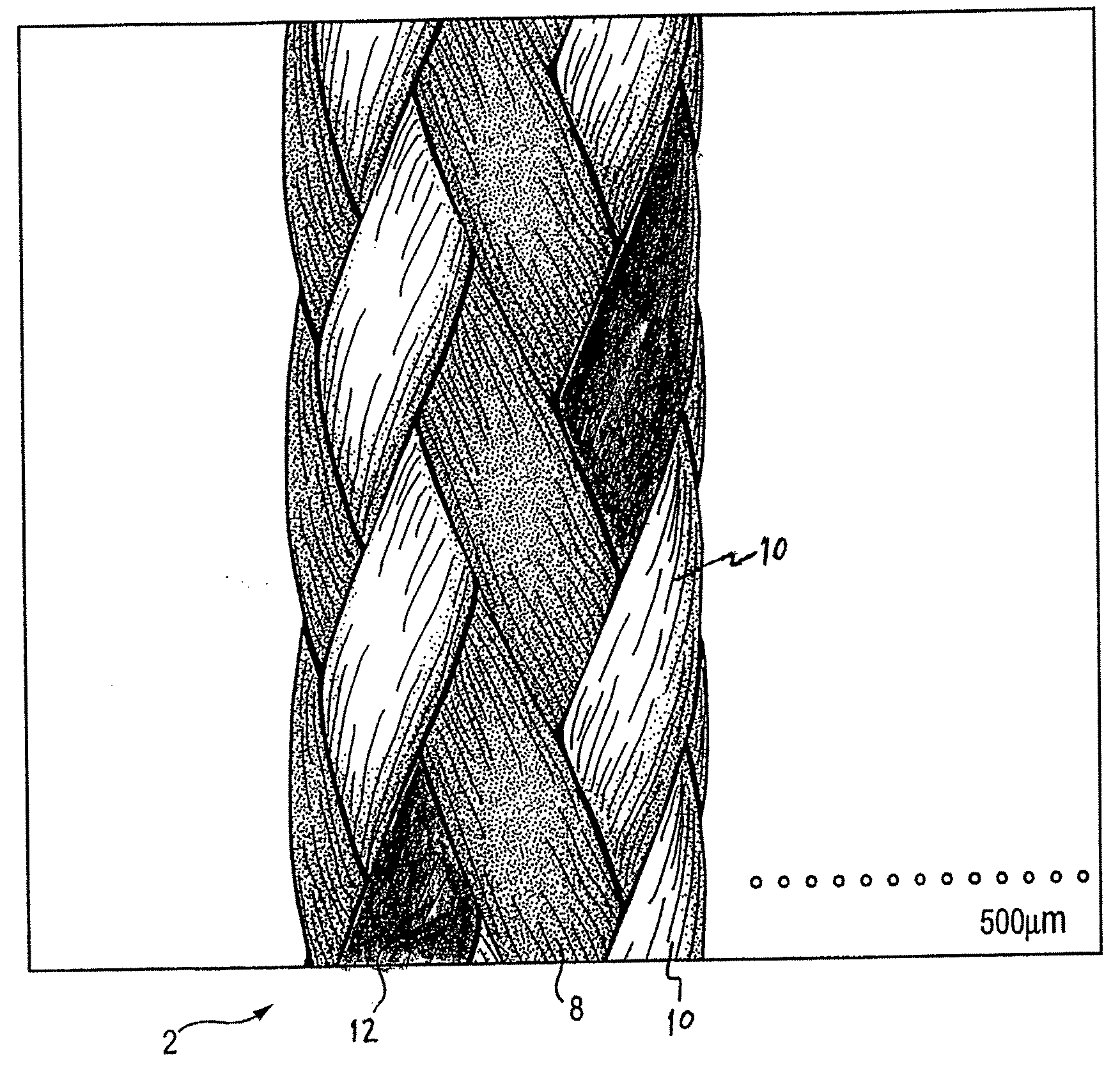

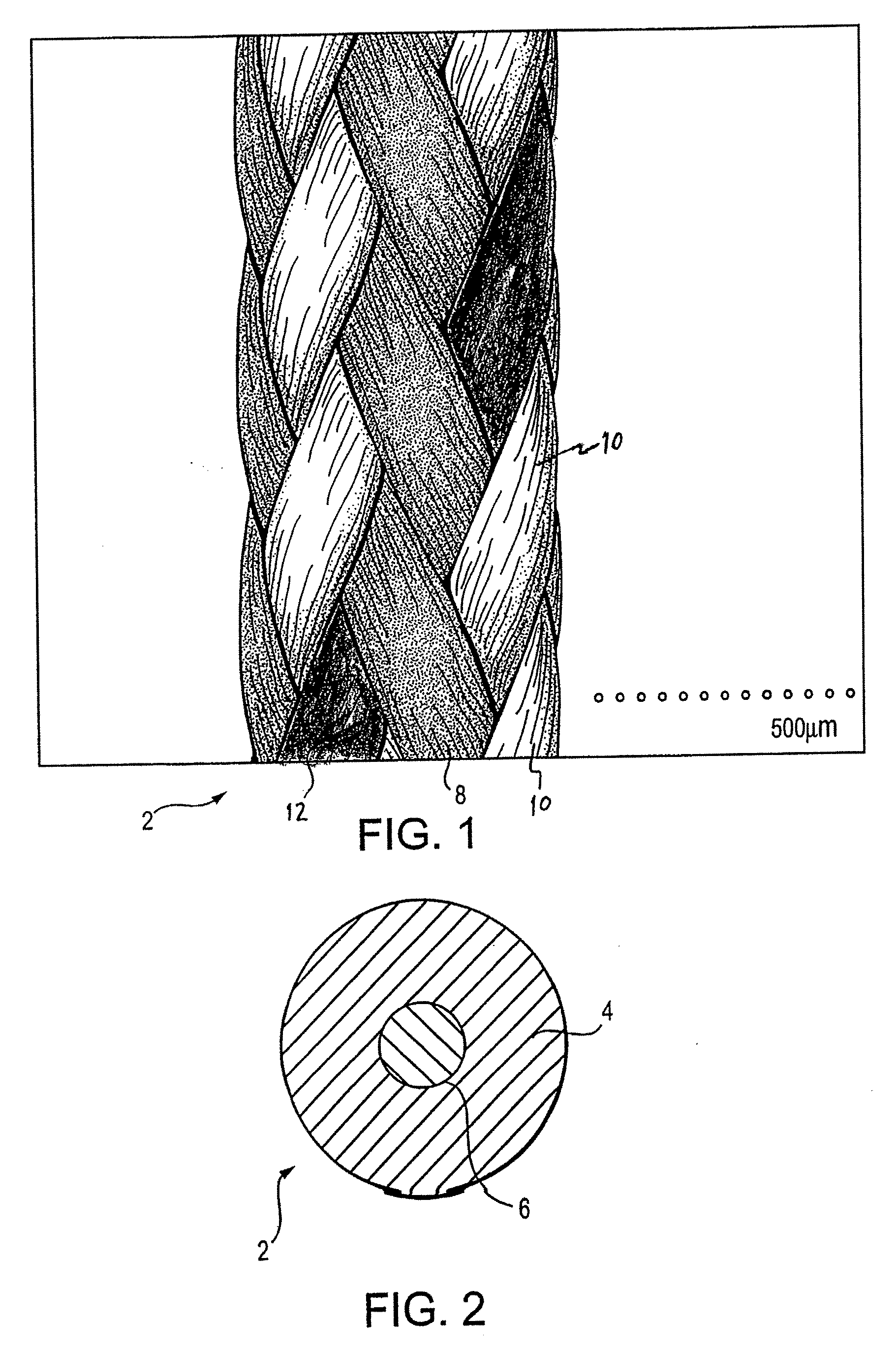

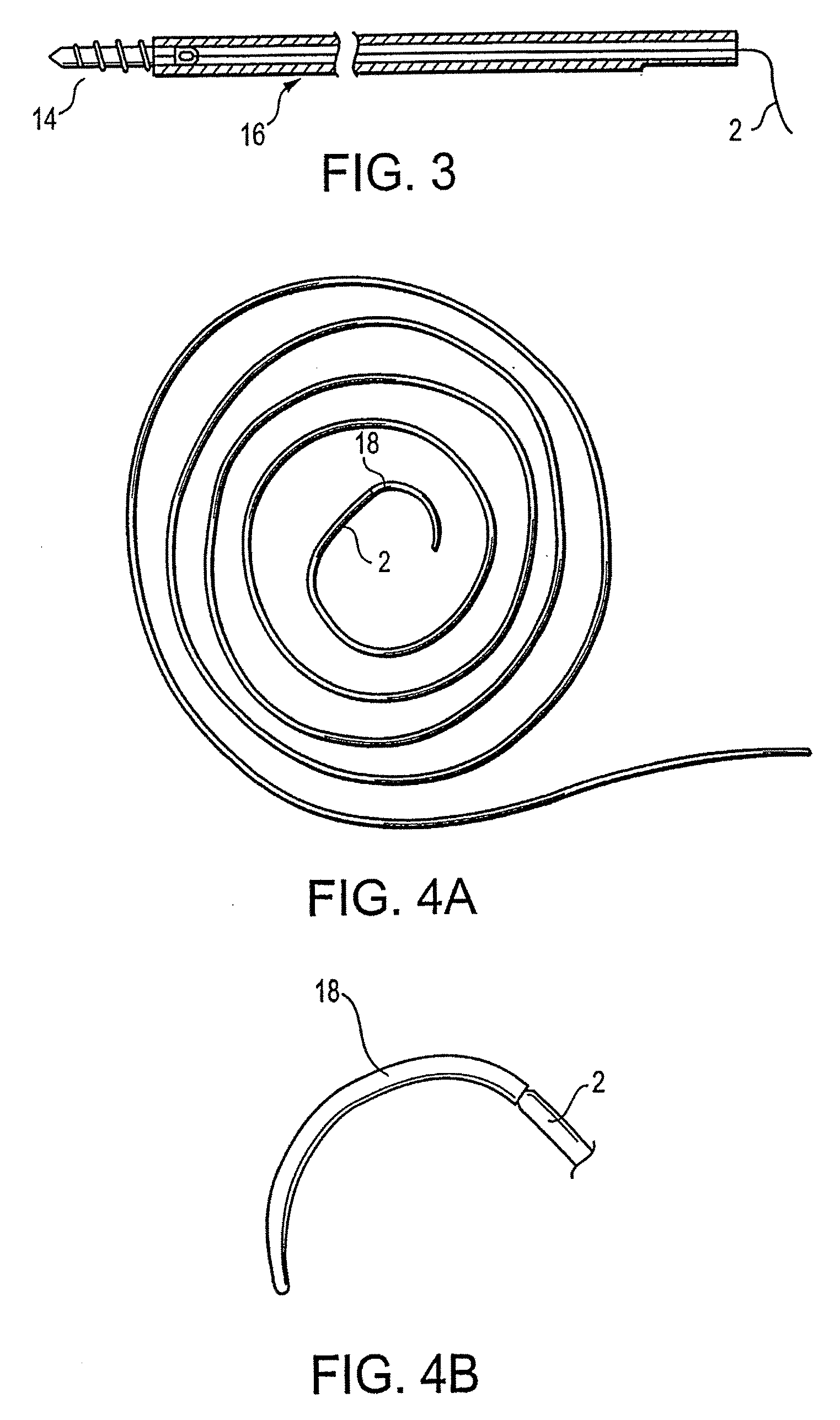

High strength suture coated with rgd peptide

InactiveUS20080051835A1High strengthImproved tie down characteristicSuture equipmentsSurgical needlesSurgical materialYarn

A high strength surgical material with improved tie down characteristics and tissue compliance formed of ultrahigh molecular weight polyethylene (UHMWPE) yarns, the suture being coated with arginine-glycine-aspartate (RGD) peptide. The suture has exceptional strength, is ideally suited for most orthopedic procedures, and can be attached to a suture anchor or a curved needle.

Owner:UNIV OF CONNECTICUT

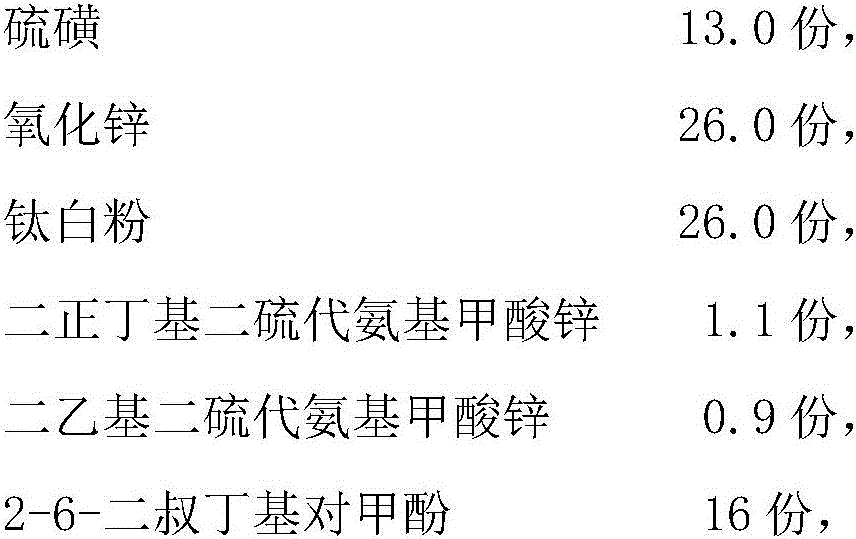

Preparation method of graphene-butadiene-acrylonitrile latex frosted gloves

InactiveCN106835721AStrong high conductivityConductive strongBiochemical fibre treatmentGlovesPolymer scienceAdhesive

The invention discloses a preparation method of a pair of graphene-butadiene-acrylonitrile latex frosted gloves. The preparation method comprises the following steps: preparing graphene-butadiene-acrylonitrile latex frosted composite slurry, wherein the composite slurry comprises 100 parts of butadiene-acrylonitrile rubber, 4-10 parts of waterborne polyurethane, chloroprene rubber adhesive or natural latex, 2-3 parts of an emulsifying agent, 6-7 parts of a ball-milled material, 0.025-5 parts of graphene, 1-2 parts of 10wt% KOH and 7-8 parts of water; the solid content of the butadiene-acrylonitrile rubber is 40-50%, and the solid content of the waterborne polyurethane, chloroprene rubber adhesive or natural latex is 40-60%; after a pair of knitted gloves is immersed with a coagulating agent, immersing the composite slurry, then spraying a sodium chloride or sodium sulfate layer on the surface of the pair of gloves, then carrying out presulfurization, drying, soaking in water, cleaning, and carrying out high temperature drying, so that the pair of graphene-butadiene-acrylonitrile latex frosted gloves is obtained. The pair of graphene-butadiene-acrylonitrile latex frosted gloves prepared by adopting the preparation method disclosed by the invention has good air permeability, good elasticity, excellent grip strength and extremely strong wear resistance and also fully plays the advantages of the graphene such as high conductivity, high strength, strong antibacterial property and far infrared rays.

Owner:NANTONG QIANGSHENG SAFETY PROTECTION TECHNOLOGY CO LTD

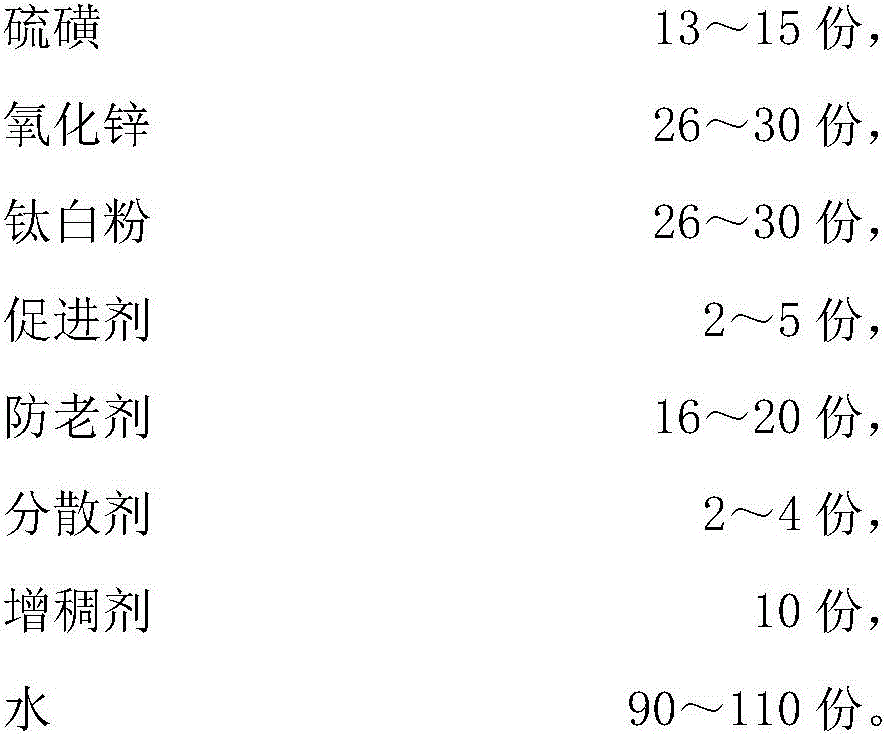

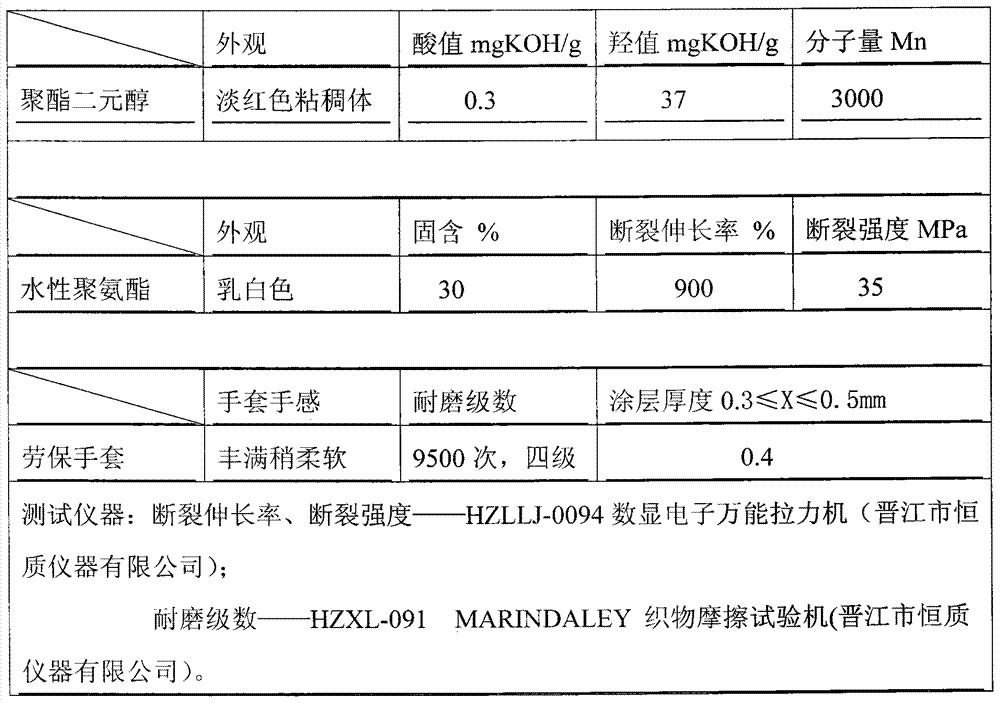

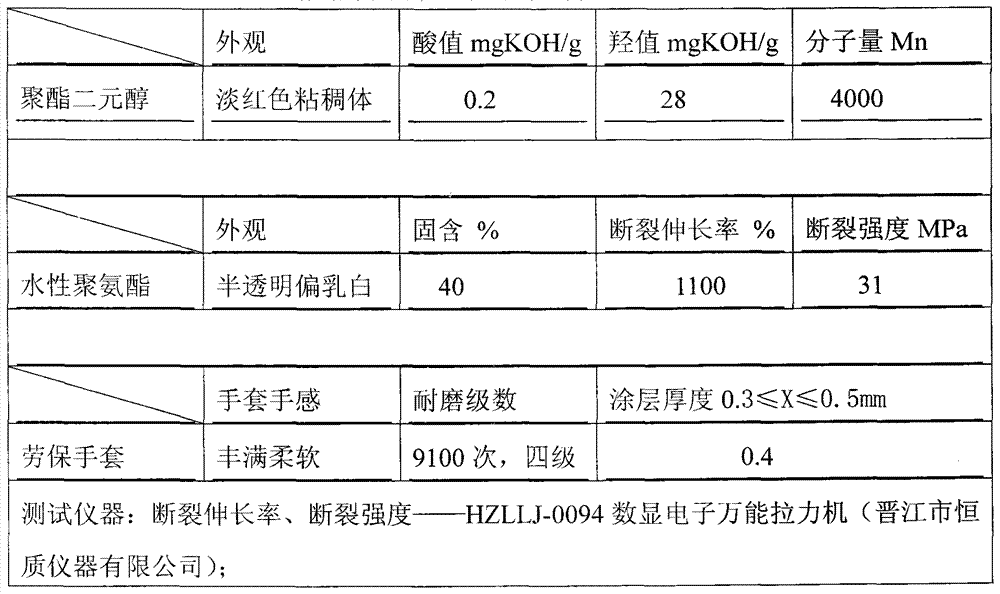

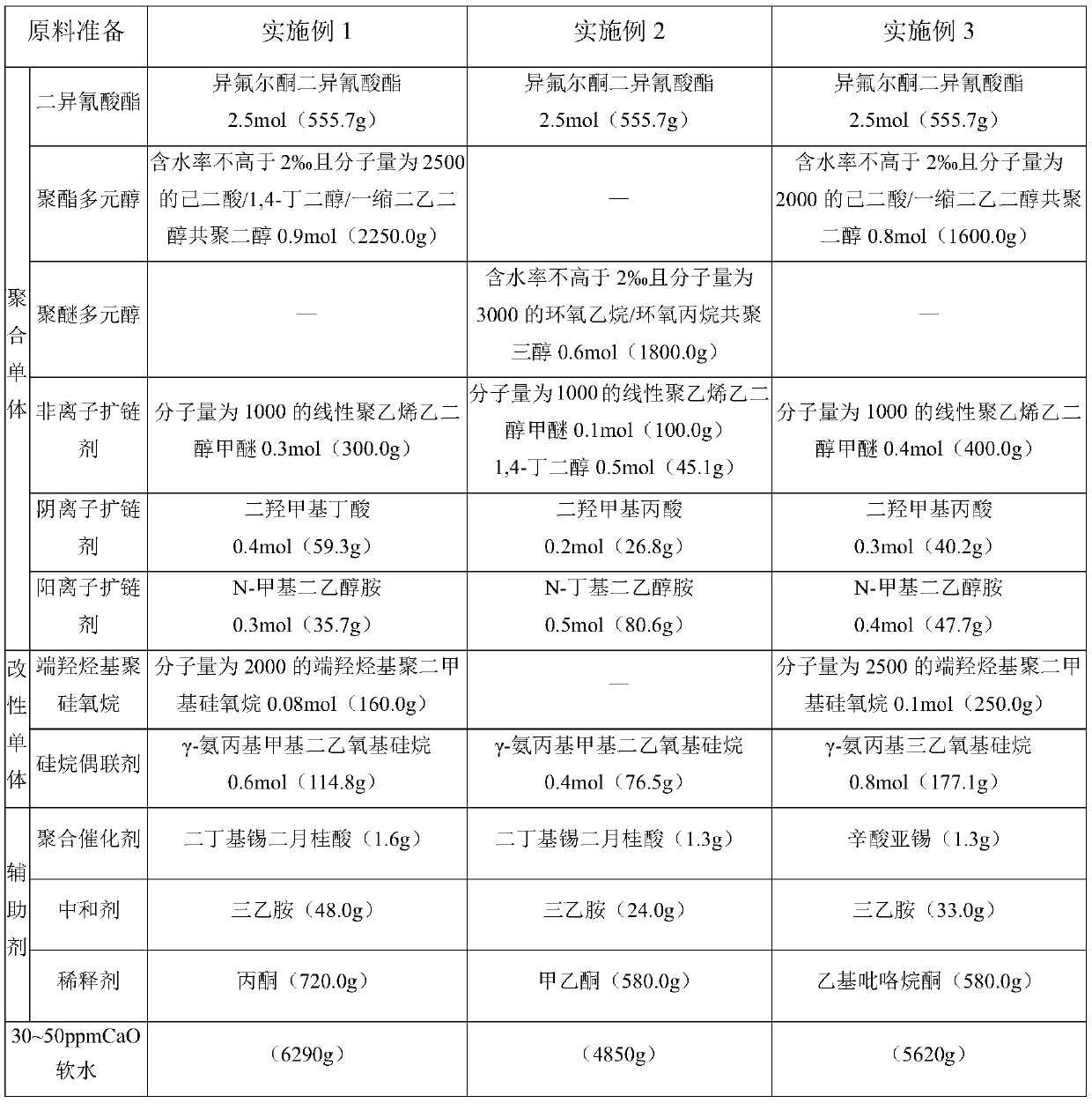

Super-elastic wear-resisting waterborne polyurethane resin and composition and application of super-elastic wear-resisting waterborne polyurethane resin and composition

InactiveCN104497258ASolve the hard feelingSolving Elasticity ProblemsAbrasion resistant fibresPolyesterSlurry

The invention discloses super-elastic wear-resisting waterborne polyurethane resin which is prepared by polymerizing polyester glycol and polyisocyanates. The invention further discloses a preparation method of the resin. By adopting the super-elastic wear-resisting waterborne polyurethane resin disclosed by the invention, slurry can be prepared to coat the surfaces of knitted gloves, so that the problems that in the prior art, knitted gloves made by using a conventional method are hard in hand feeling, poor in resilience, low in wearing resistance, and the like.

Owner:ANHUI LINGDA CHEM TECH

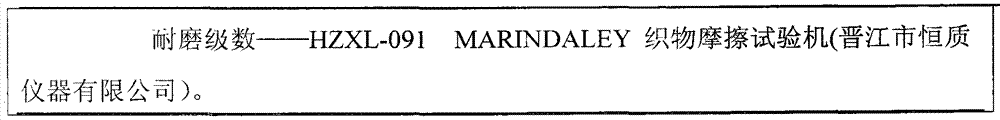

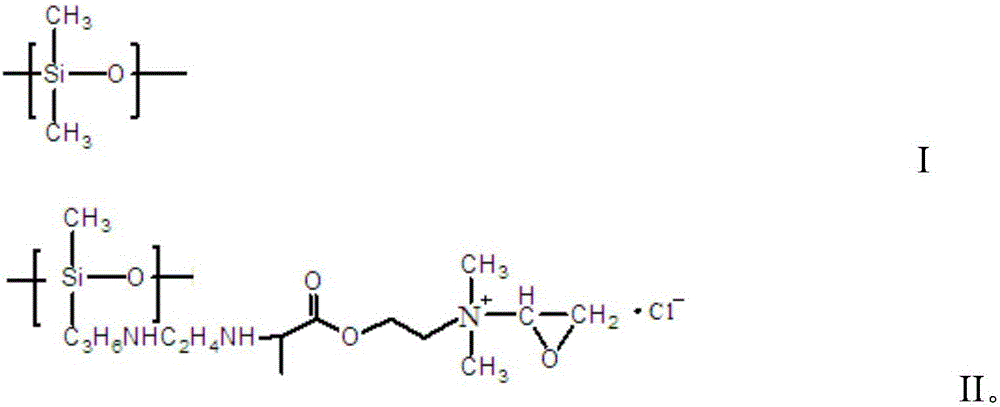

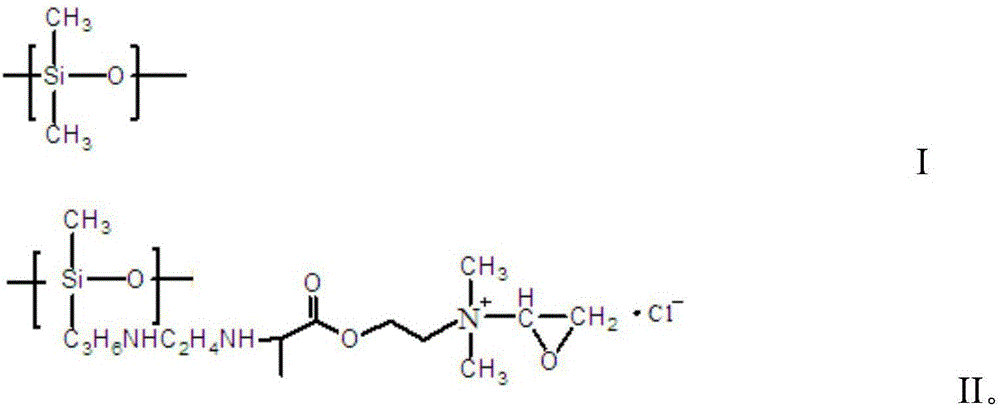

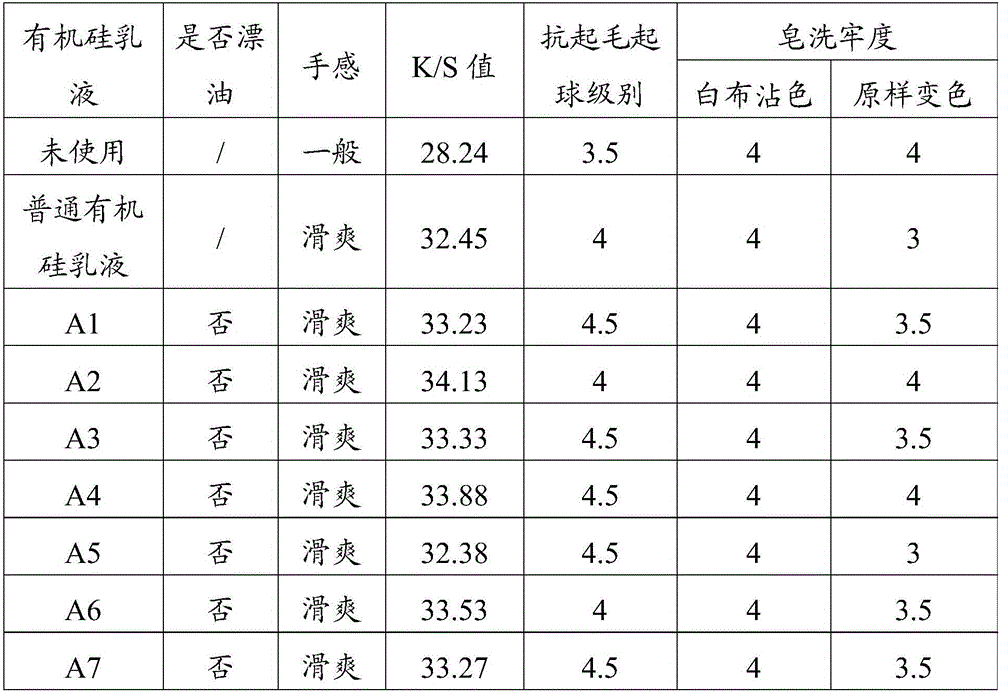

Organosilicon emulsion and preparation method thereof, and fabric finishing agent

ActiveCN105837823AImprove performanceSmall particle sizeGrip property fibresAbrasion resistant fibresSelf emulsifyingAlkaline catalyst

The invention relates to the field of textiles, specifically to a preparation method for an organosilicon emulsion. The preparation method comprises the following steps: subjecting an aqueous solution of a highly basic catalyst, a linear compound of octamethylcyclotetrasiloxane, an ammonia type coupling agent and an end-capping reagent to mixing and reaction so as to obtain amino silicon oil; then reacting the amino silicon oil with dimethylaminoethyl methacrylate so as to obtain modified amino silicon oil; and adding the modified amino silicon oil into chloropropylene oxide and carrying out quaternization. Compared with the prior art, the preparation method for the organosilicon emulsion in the invention has the advantages that Michael addition is employed, and a novel preparation method for the organosilicon emulsion is provided; and the prepared organosilicon emulsion does not need emulsification by an emulsifier and can realize self-emulsifying. The invention also discloses the organosilicon emulsion and a fabric finishing agent.

Owner:科凯精细化工(上海)有限公司

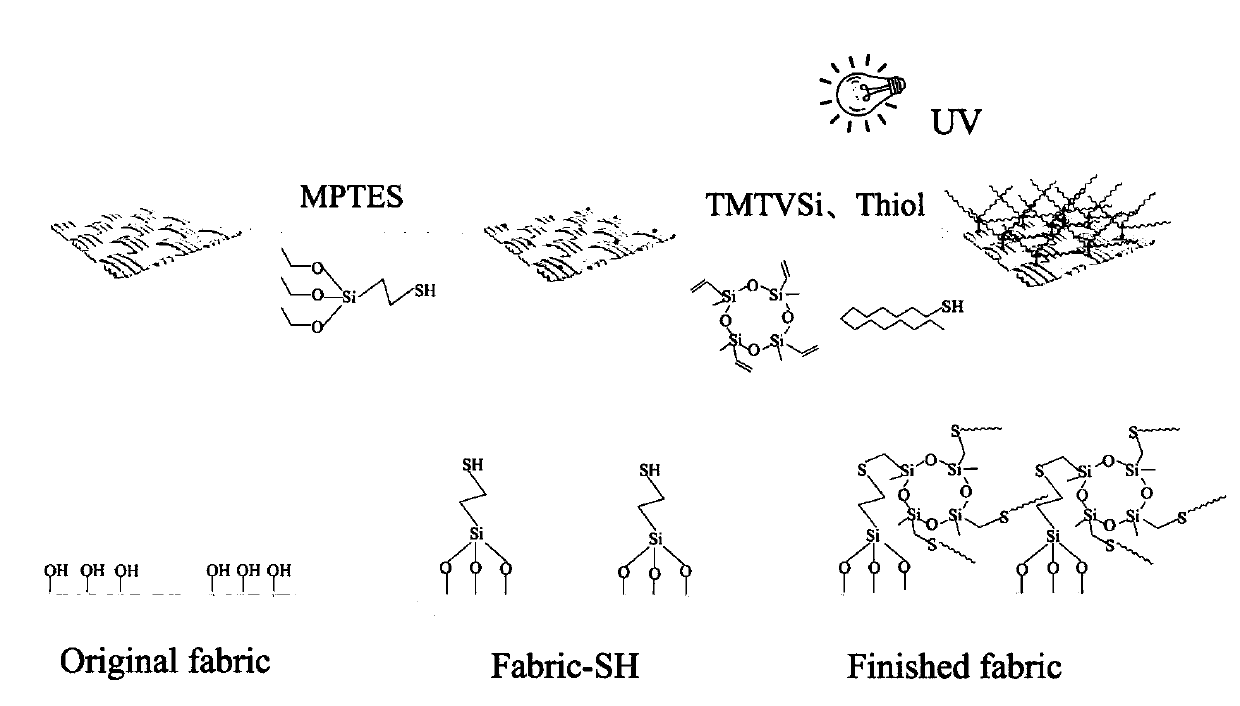

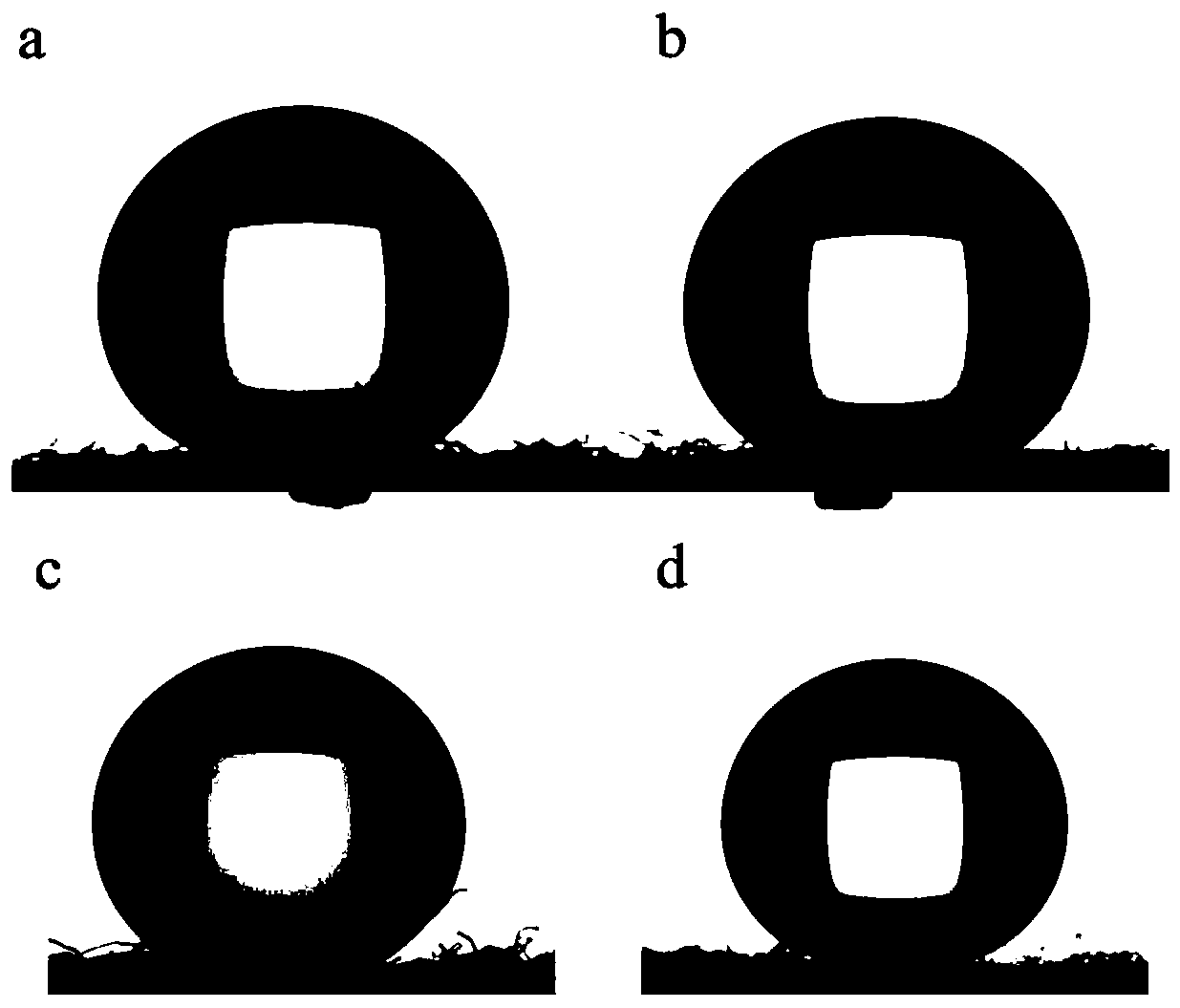

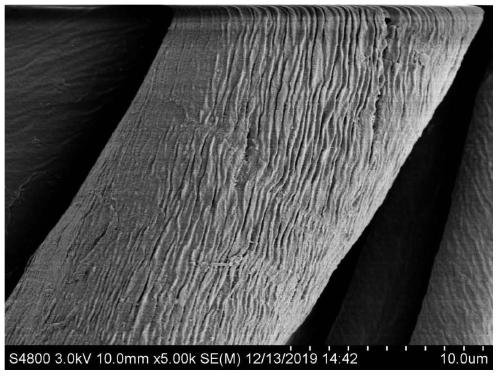

Method for preparing superhydrophobic cotton textile by thiol-ene click chemistry modification

ActiveCN111188183AImprove hydrophobicityLower surface energyPhysical treatmentLight resistant fibresFiberPolymer science

The invention discloses a method for preparing a superhydrophobic cotton textile by thiol-ene click chemistry modification. The method comprises the following steps of Step 1, pretreating cotton fabrics so that thiol groups are introduced to the fiber surfaces; Step 2, grafting thiol silane onto the surfaces of the pretreated cotton fabrics; and Step 3, soaking the cotton fabrics grafted with thethiol silane into a mixed solution prepared from ethyl acetate, 2,4,6,8-Tetravinyl-2,4,6,8-tetramethylcyclotetrasiloxane, octadecanethiol and benzoin dimethyl ether to take a reaction through UV irradiation, and after the reaction is completed, performing cleaning and drying to obtain the superhydrophobic cotton textile. The invention also discloses the superhydrophobic cotton textile prepared bythe method. The superhydrophobic cotton textile prepared by the method provided by the invention has the advantages that hydrophobic substances are grafted onto the surfaces of the fabrics in a chemical bond form; and the performance of resisting acid, alkali, water washing, friction, UV irradiation and the like of the superhydrophobic textiles can be improved.

Owner:NANTONG TEXTILE & SILK IND TECH RES INST +1

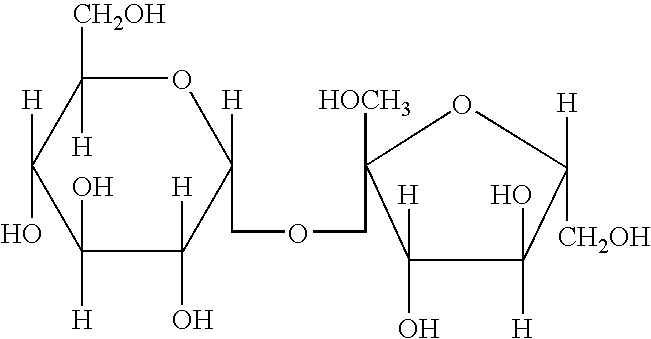

Strength and abrasion resistance of durable press finished cellulosic materials

InactiveUS20060272102A1Improves abrasionImproves strength retentionOrganic dyesWrinkle resistant fibresCross-linkCellulose

The invention relates to a method for improving the abrasion resistance and tensile strength of durable press finished cellulosic materials, such as cotton. According to the method of the present invention the cellulosic material is treated with an enzyme composition capable of removing cross links from the cellulosic material, especially cross links on the material surface.

Owner:NOVOZYMES NORTH AMERICA INC

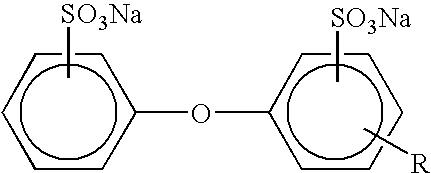

Silicone modified weak zwitterionic polyurethane emulsion and preparation method thereof

ActiveCN109970945AGood compatibilitySimple application processGrip property fibresAbrasion resistant fibresPolymer scienceEmulsion

The invention relates to the field of textiles, and discloses a silicone modified weak zwitterionic polyurethane emulsion and a preparation method thereof. The preparation method comprises the following steps of raw material preparation including a polymerizing monomer, a modifying monomer, an auxiliary agent and water, pre-polymerization, chain extension, end-capping and emulsification to obtainthe siliconemodified weak zwitterionic polyurethane emulsion product. The preparation method has strong controllability and smooth process. The silicone modified weak zwitterionic polyurethane emulsion prepared by the method can be widely used for the function finishing processing of various textile products such as style hand feeling, surface decoration and anti-pilling performance. A polyurethane polymer has an appropriate amount of polyether side chain and a small amount of anionic and cationic groups, has excellent compatibility with various common textile chemicalsand is convenient and safe to use. A polyurethane polymer tail group is also introduced with an appropriate amount of cross-linking type active end capping, rubber film is elastic, a hand feeling is smooth and delicate, andthe silicone modified weak zwitterionic polyurethane emulsionhas a silicone style.

Owner:WUHAN TEXTILE UNIV

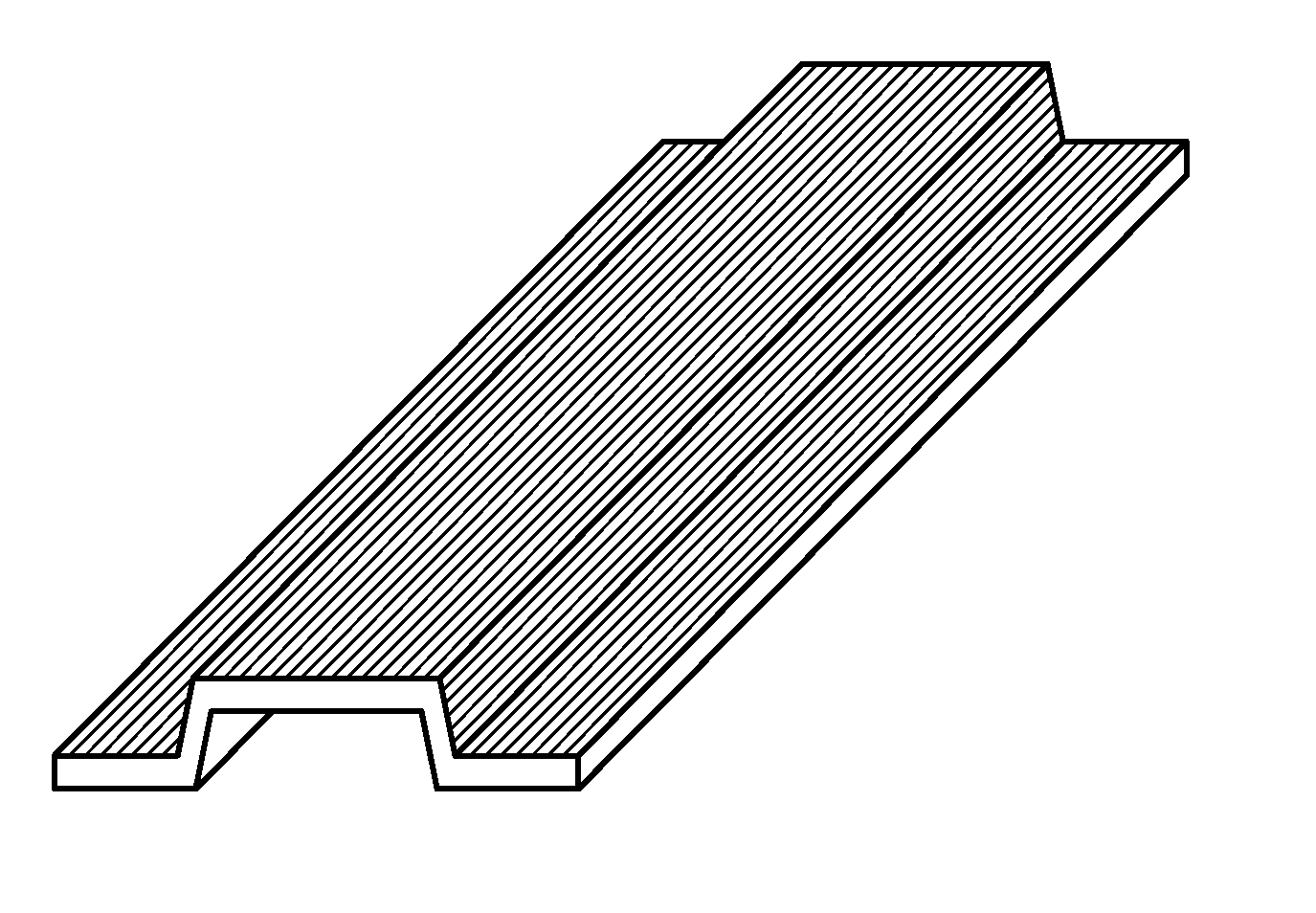

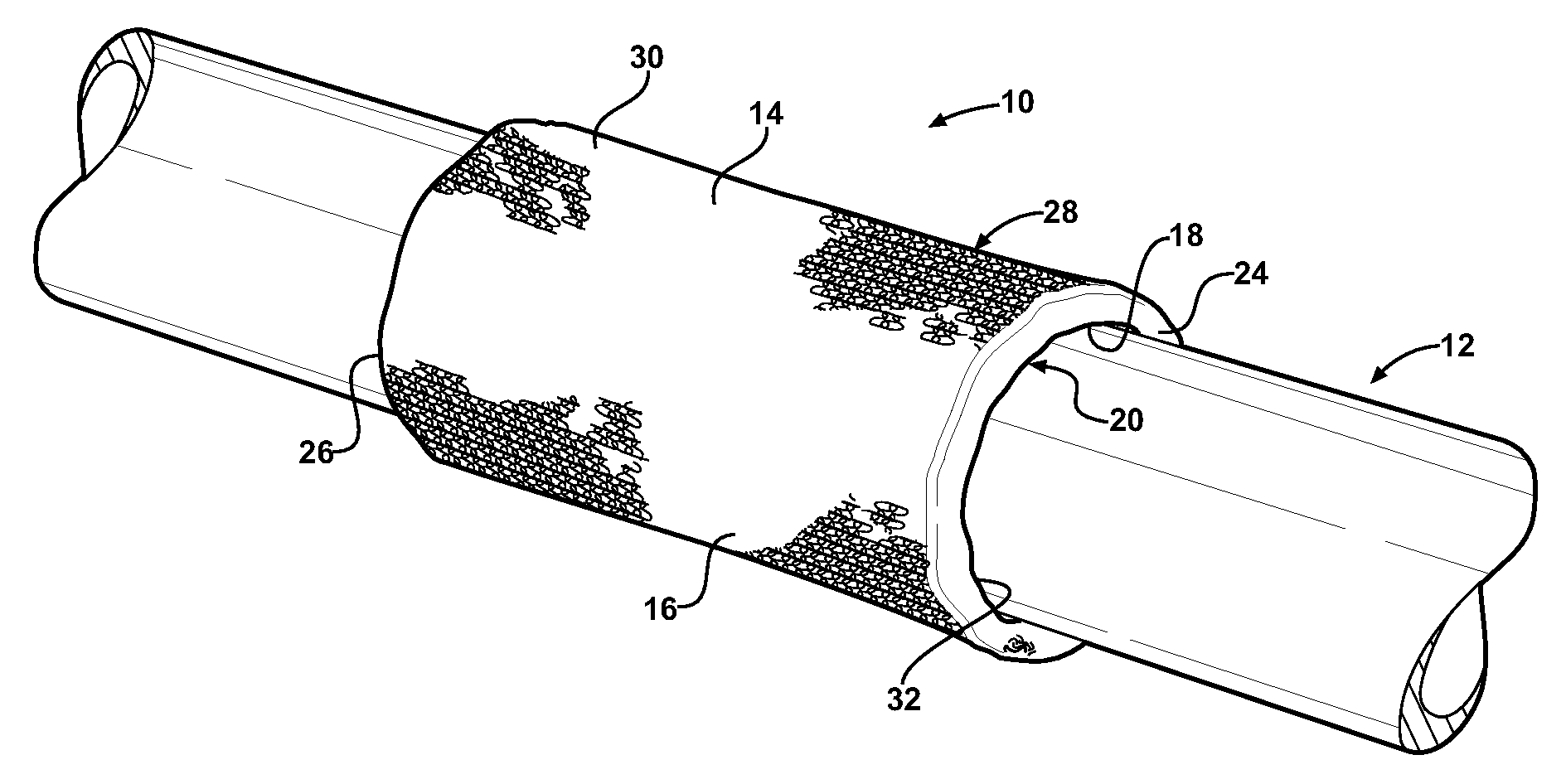

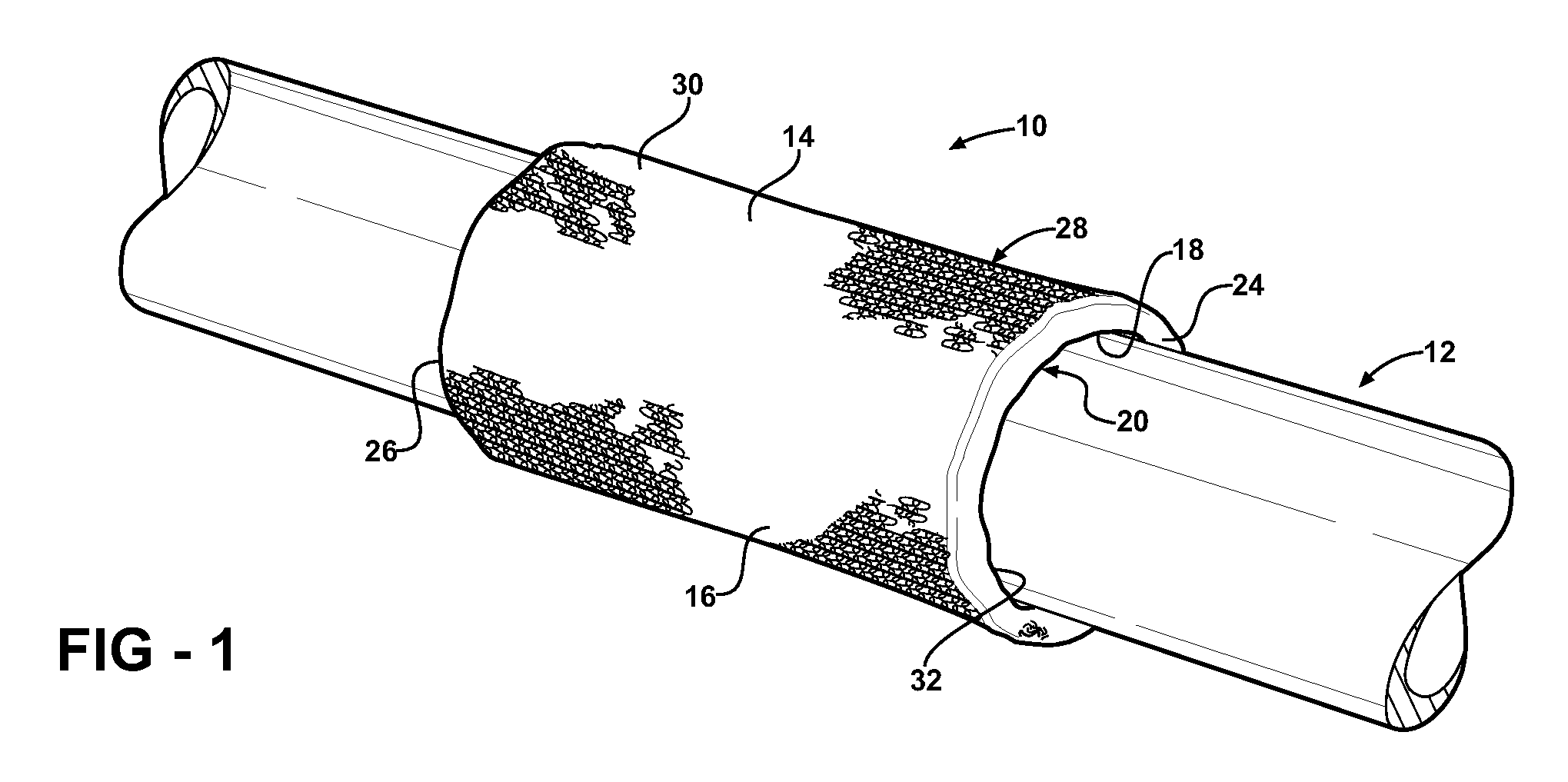

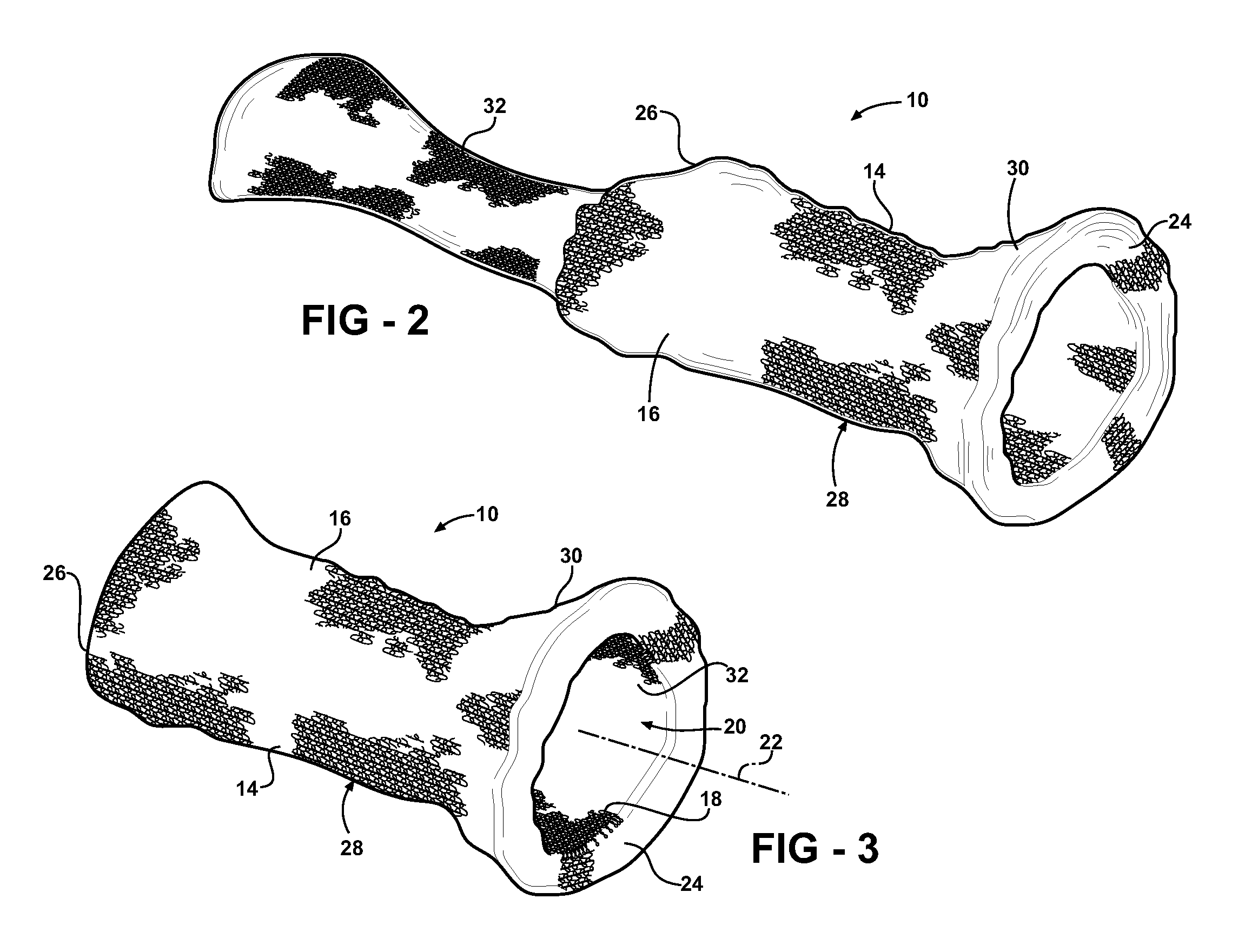

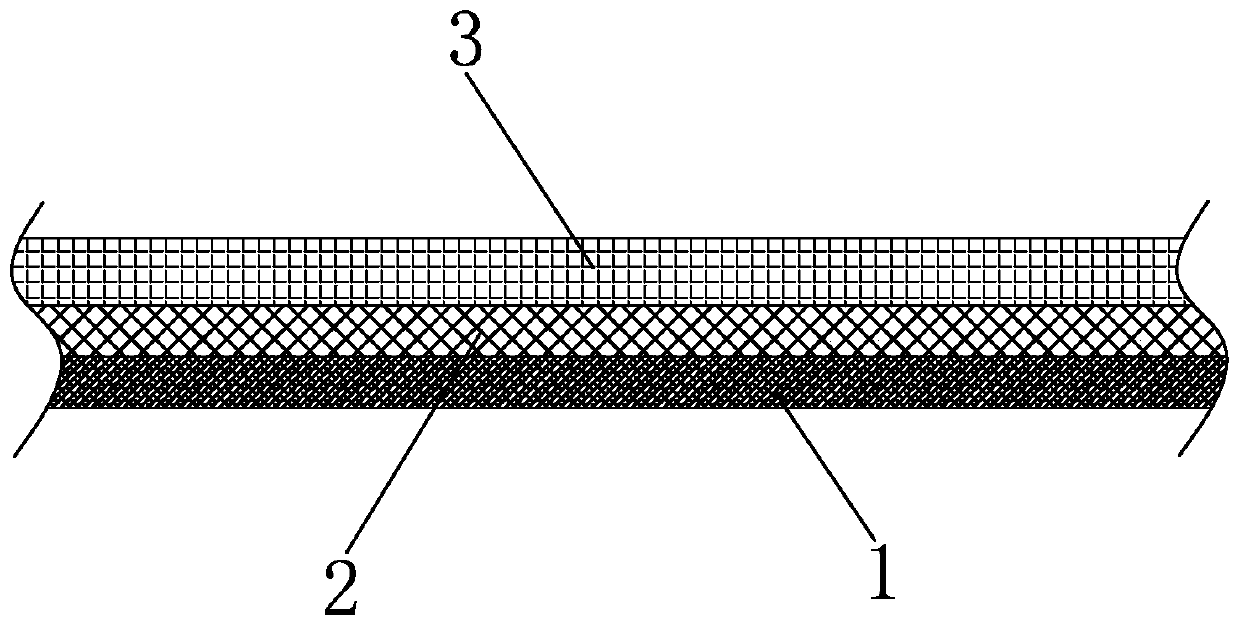

Textile sleeve with high temperature abrasion resistant coating and methods of assembly, construction and curing thereof

InactiveUS20100316822A1Easy to stretchGood for wear protectionCarbon fibresLayered productsCross-linkYarn

A textile sleeve for protecting elongate members with a high temperature abrasion resistant coating and methods of assembly, construction and curing thereof is provided. The textile sleeve includes a tubular textile wall formed of non-heatsettable yarn with interstices formed between adjacent filaments of the yarn. The wall has an outer surface and an inner surface providing an inner cavity for receipt of the elongate members. A fluoropolymer-based coating having about an 80 wt % fluoropolymer content is applied to the wall outer surface. The coating is substantially absorbed within the outer surface with the interstices being preserved. The coating is dried to an uncured state, and then subsequently cured at about 700 degrees Fahrenheit or greater. Upon being exposed and cured at a temperature of about 700 degrees Fahrenheit or more, the fluoropolymer-based coating melts and cross-links, thereby providing enhanced abrasion resistance protection to the wall.

Owner:MALLOY CASSIE M

Highly-waterproof highly-breathable nanofiber membrane and preparation method thereof

PendingCN110258021AImprove yieldGood flexibilityLiquid repellent fibresAbrasion resistant fibresPolyvinyl butyralFiber

The invention discloses a highly-waterproof highly-breathable nanofiber membrane and a preparation method thereof. The highly-waterproof highly-breathable nanofiber membrane comprises a PVB electrospun membrane, a PVDF electrospun membrane and a FPU electrospun membrane which are stacked and composited from inside to outside, the PVB electrospun membrane is formed by interweaving polyvinyl butyral nanofiber of 150-400nm in average diameter, the PVDF electrospun membrane is formed by interweaving polyvinylidene fluoride nanofiber of 400-600nm in average diameter, and the FPU electrospun membrane is formed by interweaving fluorosilane modified polyurethane nanofiber of 200-300nm in diameter. The preparation method is simple and reasonable in process and low in manufacturing cost, and the highly-waterproof highly-breathable nanofiber membrane prepared by the method is high in strength, waterproofness and one-way breathability.

Owner:江苏三丰特种材料科技有限公司

Preparation method of modified polyester fancy style knitted fabric

InactiveCN107354728AAppropriate twistIntense and uniform colorWeft knittingHeating/cooling textile fabricsFiberPolyester

The invention provides a preparation method of a modified polyester fancy style knitted fabric, and relates to a knitted fabric. The method comprises the following steps of step A, selecting modified polyester fiber or modified polyester fiber and Spandex filaments; weaving the materials into fabric blank cloth with undershirt cloth, sanding undershirt cloth, rib fabric, color rib fabric, terry fabric, flannelette or air layers through weaving equipment; step B, performing open-width water washing on the fabric blank cloth; step C, pre-shaping the fabric blank cloth; step D, performing pretreatment on the fabric blank cloth; step E, dyeing the fabric blank cloth through cationic dyeing agents; step F, drying the fabric blank cloth; step G, re-shaping the fabric blank cloth. Compared with the existing product, the modified polyester fabric produced by the method has the advantages that the styles are various; the colors are vivid and rich; the performance achieves long effect and stability; the color fastness is good; the color dyeing is uniform; the functions of moisture absorption and fast drying, fuzzing and pilling resistance, static electricity resistance and the like are also achieved; in the production process, the energy consumption is low; the consumption of auxiliary agents is low; the cost is low; the fabric belongs to an environment-friendly fabric.

Owner:NINGBO DAQIAN TEXTILE

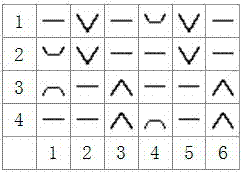

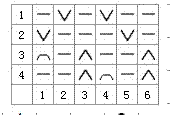

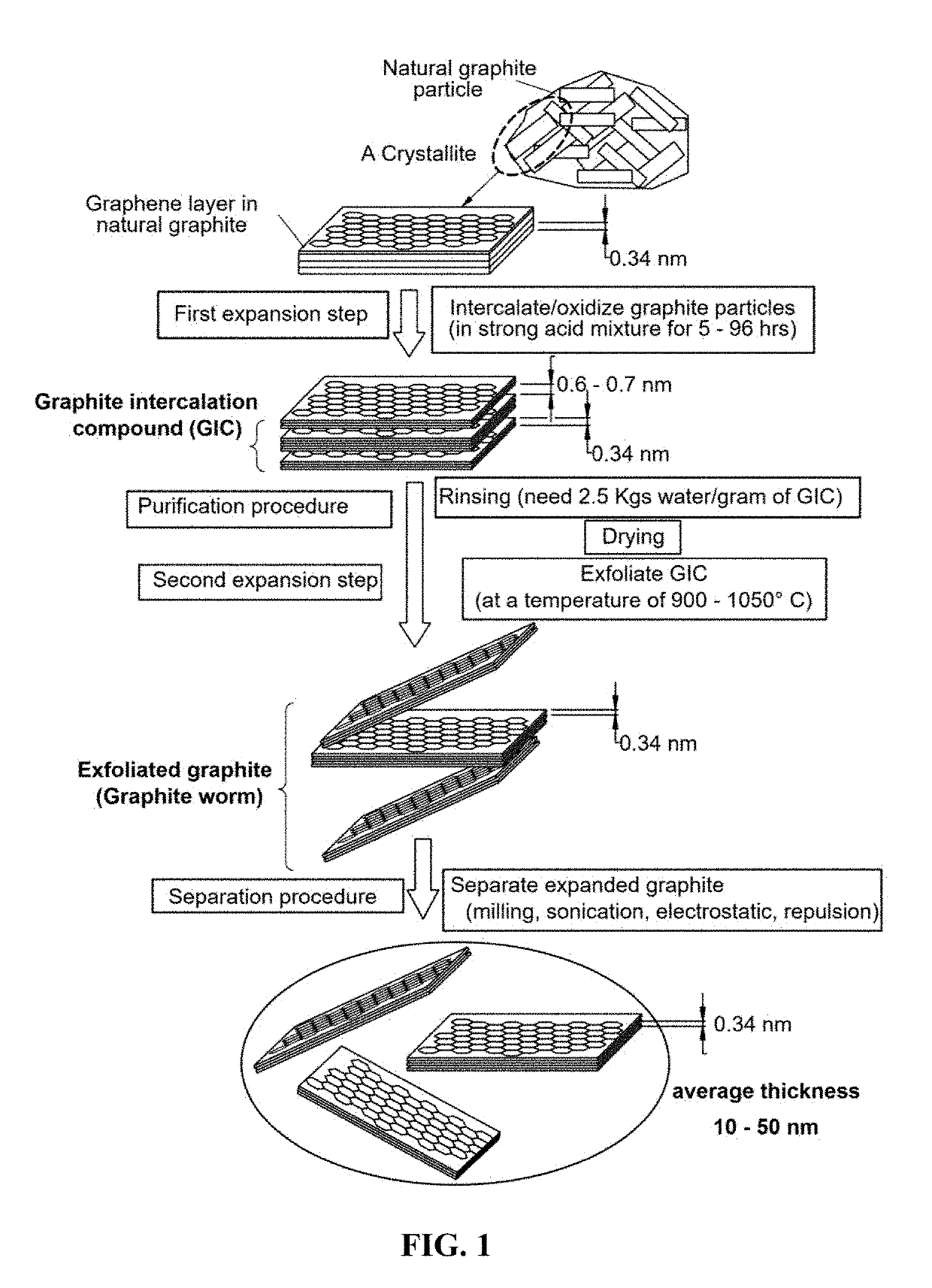

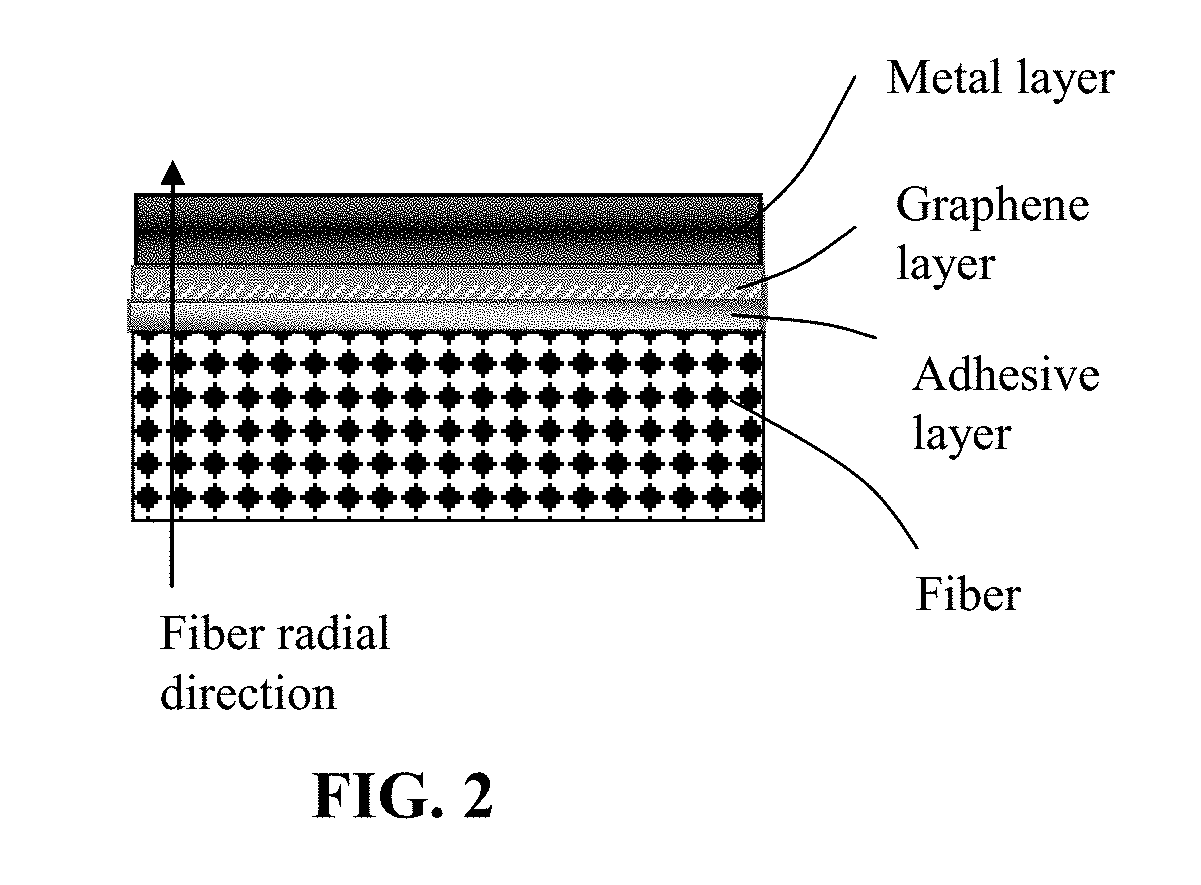

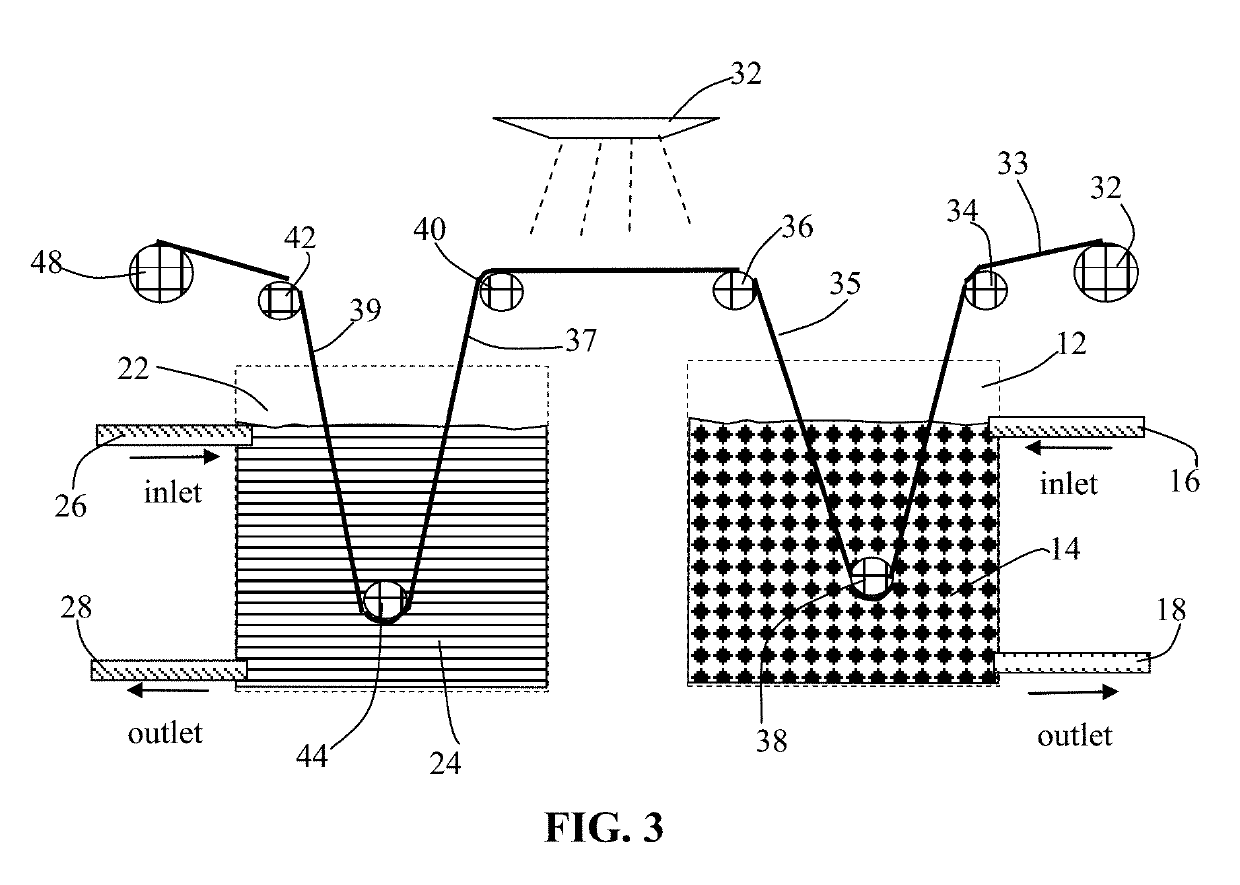

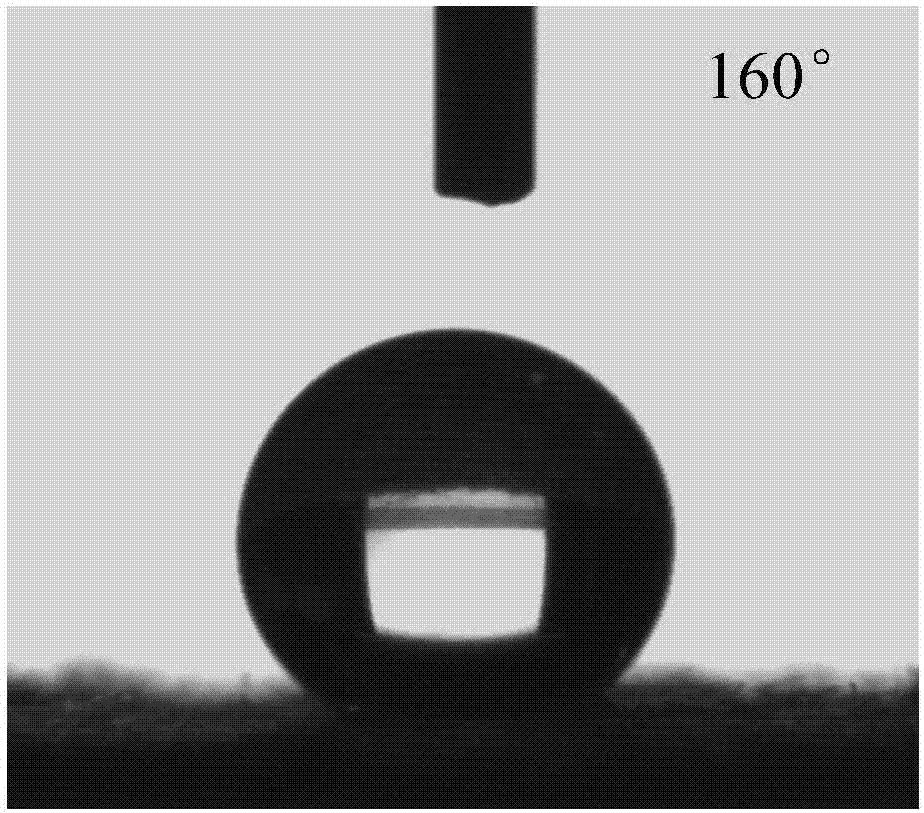

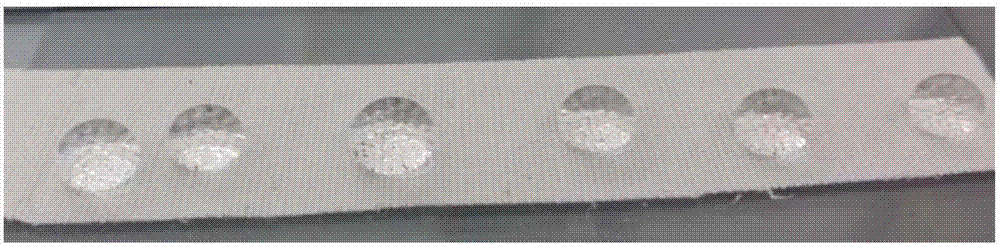

Process for graphene-mediated metallization of fibers, yarns, and fabrics

Provided is process for producing a surface-metalized fiber, yarn, or fabric, the process comprising: (a) Feeding a continuous fiber, yarn, or fabric from a feeder roller into a graphene deposition chamber containing therein a graphene dispersion comprising multiple graphene sheets and an optional conducive filler dispersed in a first liquid medium and an optional adhesive resin dissolved in the first liquid medium; (b) Operating the graphene deposition chamber to deposit the graphene sheets and optional conductive filler to a surface of the fiber, yarn, or fabric for forming a graphene-coated fiber, yarn, or fabric; (c) Moving the graphene-coated fiber, yarn, or fabric into a metallization chamber which accommodates a plating solution therein for plating a layer of a desired metal onto the graphene-coated fiber, yarn, or fabric to obtain a surface-metalized fiber, yarn, or fabric; and (d) Operating a winding roller to collect the surface-metalized fiber, yarn, or fabric.

Owner:GLOBAL GRAPHENE GRP INC

Far infrared heating surface fabric and processing method thereof

The invention relates to a far infrared heating surface fabric and a processing method thereof. The surface fabric is formed by weaving warp yarns and weft yarns, wherein the warp yarns are woven by blending the following raw materials in parts by weight: 40 to 80 parts of far infrared polypropylene fibres, 10 to 30 parts of coffee carbon fibres, 10 to 20 parts of soybean protein fibres, and 5 to 20 parts of spandex; the weft yarns are woven by blending the following raw materials in parts by weight: 40 to 80 parts of bamboo charcoal fibres, 20 to 30 parts of cotton fibres, 10 to 20 parts of polyacrylonitrile fibres, and 5 to 10 parts of the spandex; the surface fabric is treated by an antibacterial finishing liquid after being woven. The surface fabric has an ultra-strong antibacterial property, is cool and anti-pilling, high in air permeability and hygroscopicity, soft in texture and wear-resistant, and is very suitable for the application in the field of underwear, pajamas, evening dresses, shirts and the like.

Owner:杜敏

Multifunctional super-hydrophobic textile finishing agent, and preparation method and applications thereof

ActiveCN107326651AReduce usageSimple manufacturing processStain/soil resistant fibresBiochemical fibre treatmentHydrolysisSkin protection

The invention discloses a multifunctional super-hydrophobic textile finishing agent, and a preparation method and applications thereof. The preparation method comprises following steps: a precursor of an oxide sol and a graphite oxide aqueous dispersion are dispersed in deionized water, an anionic surfactant is added, a catalyst is added for hydrolysis and condensation reaction after uniform dispersion so as to obtain a mixed reaction system, and the mixed reaction system is heated to 30 to 50 DEG C for 3 to 12h of reaction so as to obtain a hydrosol; a functional agent is added into the hydrosol so as to obtain the multifunctional super-hydrophobic textile finishing agent. The multifunctional super-hydrophobic textile finishing agent is safe, is friendly to the environment, is excellent in effect, is used for super hydrophobic and multifunctional finishing of textile, is capable of providing textile with six functions including super-hydrophobic property, flame resistance, antibacterial property, stain resistance, ultraviolet resistance, and skin protection performance, is capable of eliminating adverse effect of the plurality of functions, improving the synergistic effect; the preparation method is simple and convenient, is easy to control, and is suitable for large scale production.

Owner:石狮市杰立纺织科技有限公司

Treatment for rubber-reinforcing fibers, reinforcing fibers, and reinforced rubbers

InactiveUS6262154B1Excellent to flex fatigueImprove heat resistanceSynthetic fibresSpecial tyresThiolPolymer science

A reinforcing fiber for a rubber product that has excellent heat resistance, water resistance and resistance to flex fatigue without undergoing a complicated production process and a treatment agent therefore. This treatment agent comprises a rubber latex, a resorcin-formaldehyde water-soluble condensate and triazine thiol.

Owner:ZEON CORP +1

Antibiotic textile and production method thereof

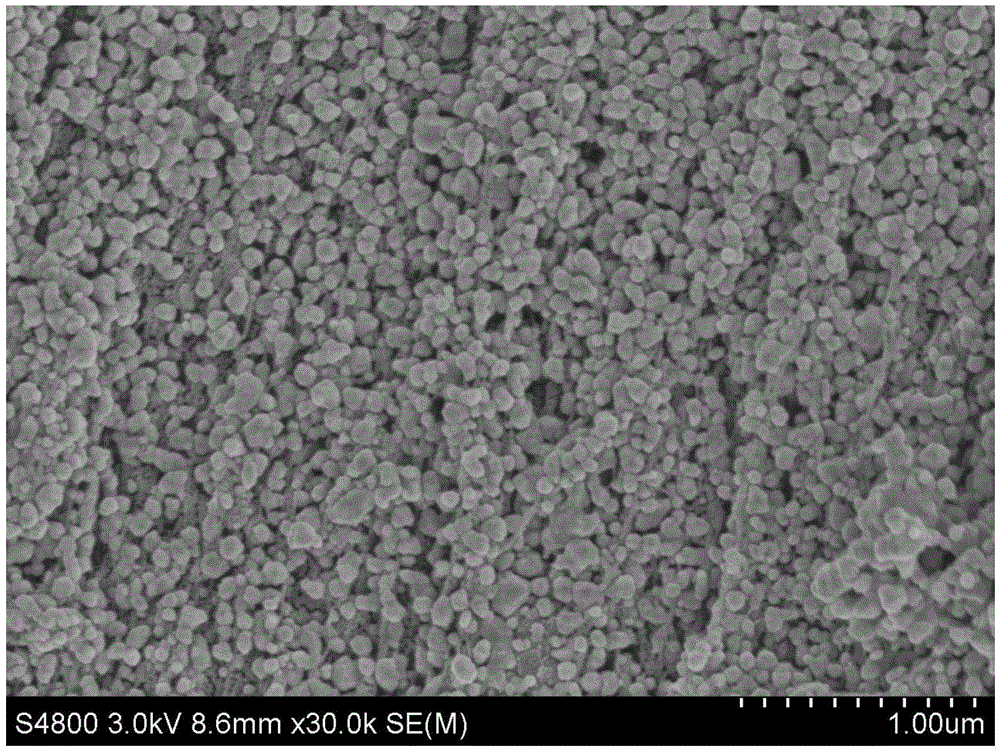

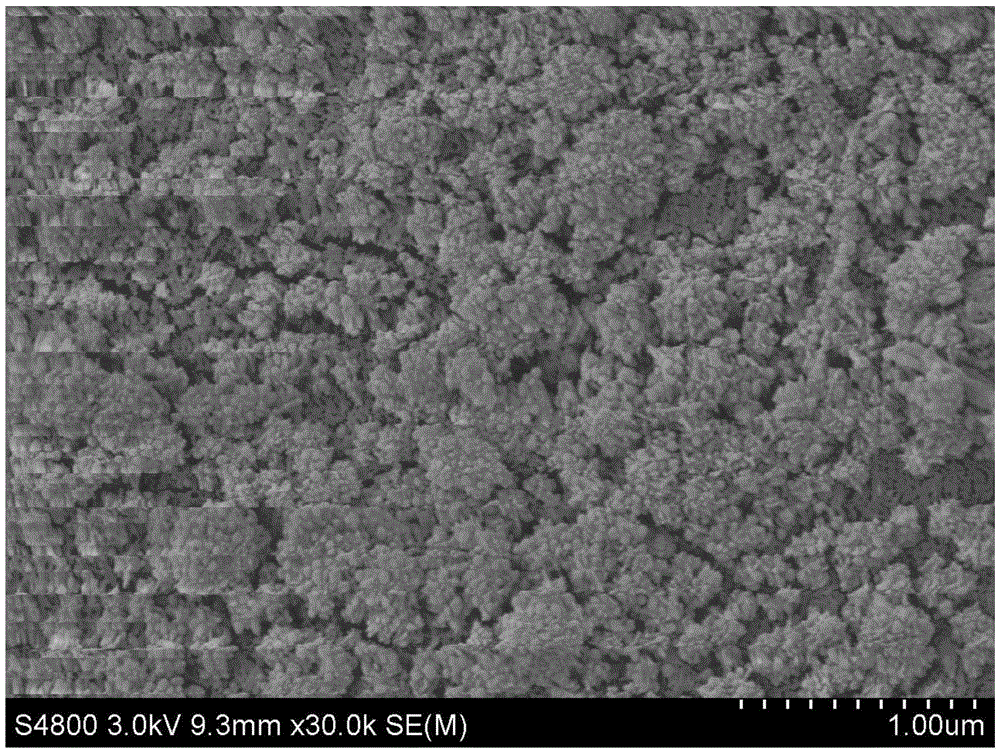

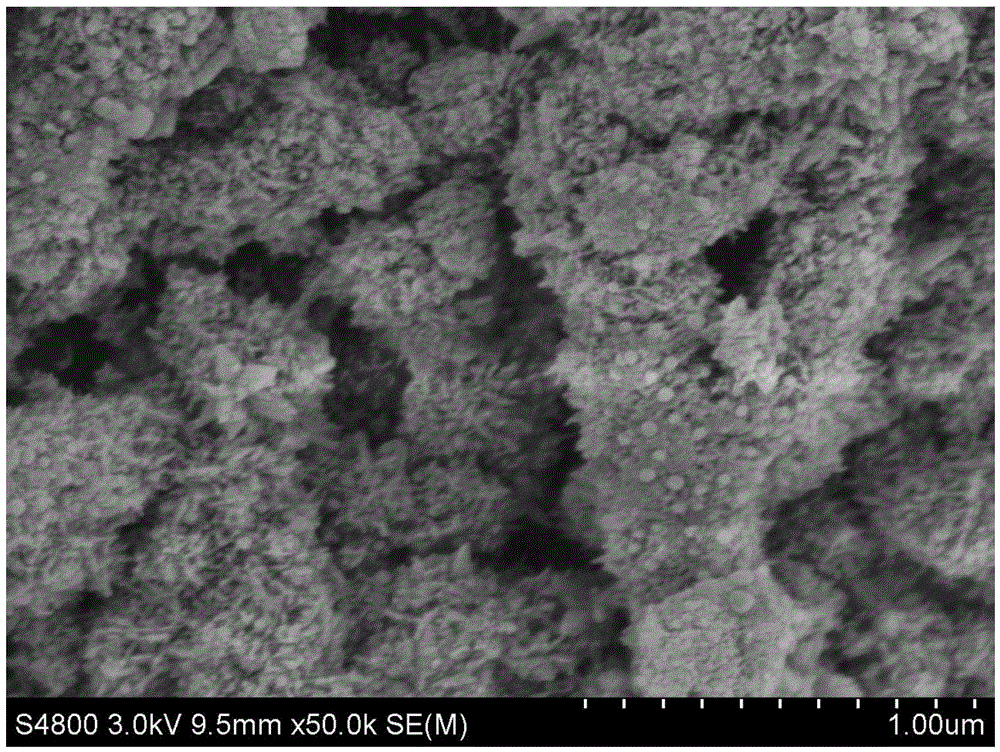

ActiveCN105568669AImprove washabilitySimple methodBiochemical fibre treatmentAbrasion resistant fibresTitanium dioxideSilver nanoparticle

The invention provides an antibiotic textile and a production method thereof. The antibiotic textile is obtained through depositing silver nanoparticles on a titanium dioxide supported textile. Titanium dioxide is deposited on the textile, the morphology of the titanium dioxide has flower type, and the silver nanoparticles are deposited on the titanium dioxide supported textile, so the antibiotic textile obtained in the invention has good washing fastness. The production method of the antibiotic textile has the advantages of simplicity, short production period and few three wastes.

Owner:泉州坤润纳米科技有限公司

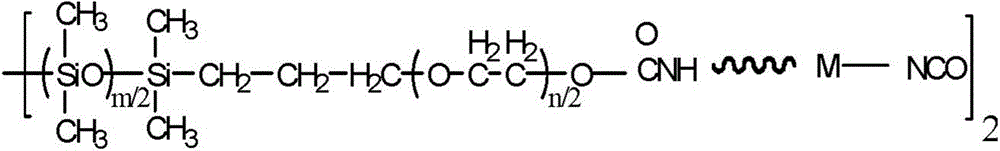

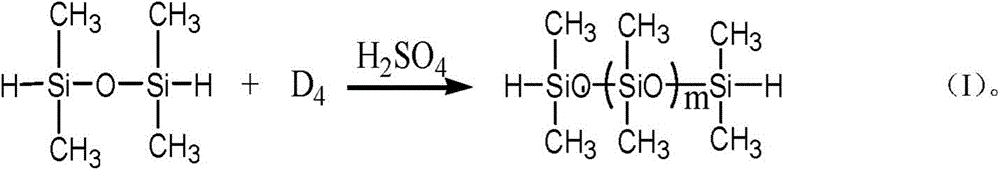

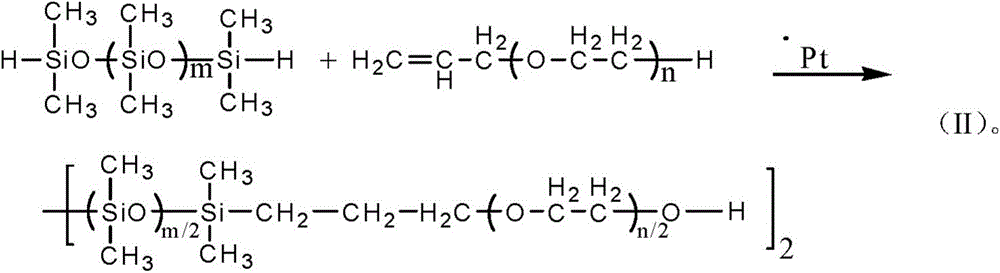

Preparation method of blocked organosilicone waterborne polyurethane anti-fluffing-and-pilling agent

InactiveCN105693989AHigh film strengthImprove compactnessLight resistant fibresGrip property fibresHydrogenPolymer science

The invention discloses a preparation method of a blocked organosilicone waterborne polyurethane anti-fluffing-and-pilling agent. The preparation method includes following steps: preparing terminated hydrogen group modified silicone oil; preparing terminated hydroxyl blocked silicone oil; preparing the blocked organosilicone waterborne polyurethane anti-fluffing-and-pilling agent. The preparation method is simple in process, and the agent prepared by the method is high in film forming strength, compactness and continuity; fabric finished by using the agent is not clammy and free of adhesion with a roller in the process of application, anti-fluffing-and-pilling effect is improved obviously, and the fabric after being finished is good in hand feeling.

Owner:南通曙光染织有限公司

Preparation and application of organic silicon polymer super-hydrophobic textile finishing agent

InactiveCN109518468AEasy to prepareSimple preparation processLiquid repellent fibresGrip property fibresFiberPolymer science

The invention discloses an organic silicon polymer super-hydrophobic textile finishing agent. The organic silicon polymer super-hydrophobic textile finishing agent is prepared by adding organic silicon and organic silane into an alkaline alcohol-water solution and carrying out hydrolytic condensation. The organic silicon polymer super-hydrophobic textile finishing agent contains a hydrophobic group and a coupling group; and in dip-coating and high-temperature curing processes, the coupling group can be chemically bonded with fibers of a textile and the hydrophobic group has a super-hydrophobiceffect. The textile is dipped and coated in an organic silicon textile finishing agent solution which is diluted for 5 to 10 times for 2 to 10min and then is cured at 80 to 180 DEG C for 2 to 10min to obtain the super-hydrophobic textile. The super-hydrophobic textile disclosed by the invention has the advantages of excellent super-hydrophobic performance, washing resistance and the like and canbe used for constructing various super-hydrophobic textiles; and the textile does not need to be pre-treated, so that a preparation technology is extremely simplified, and properties including intrinsic mechanical strength, flexibility, luster, hand feeling and the like are kept.

Owner:山东鑫纳超疏新材料有限公司 +1

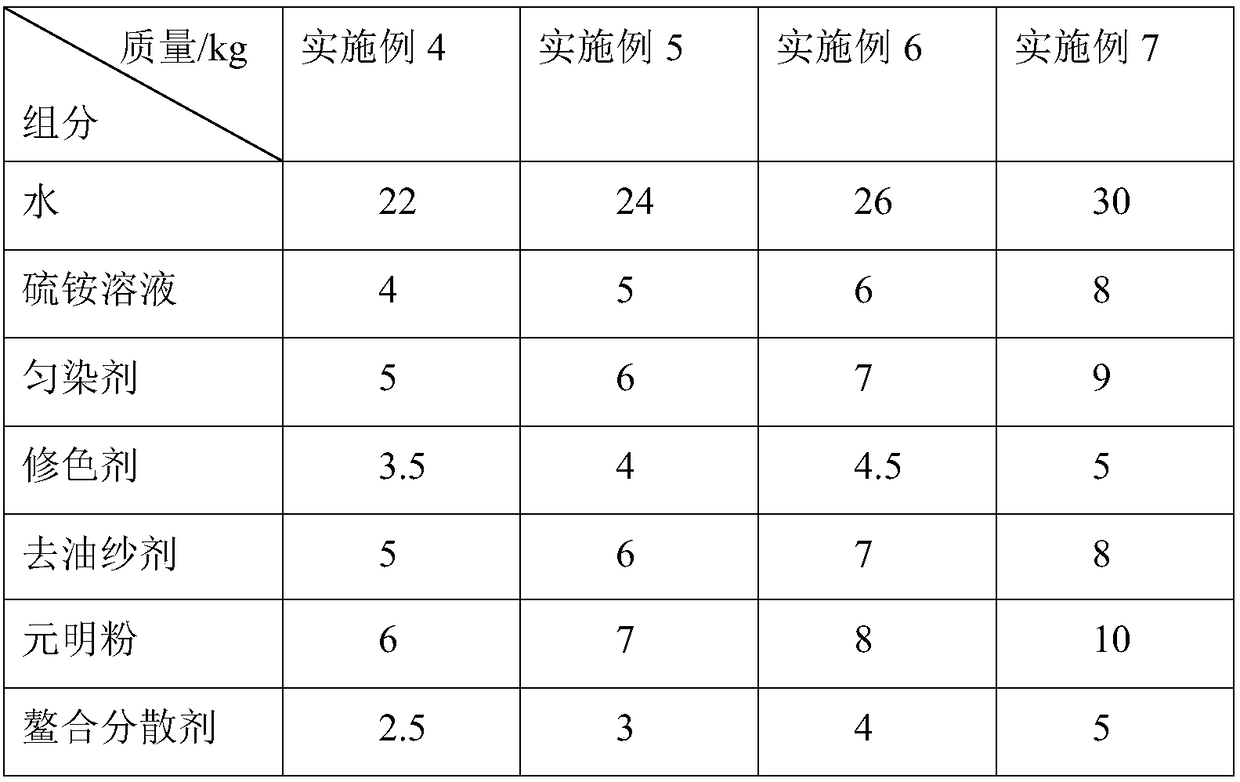

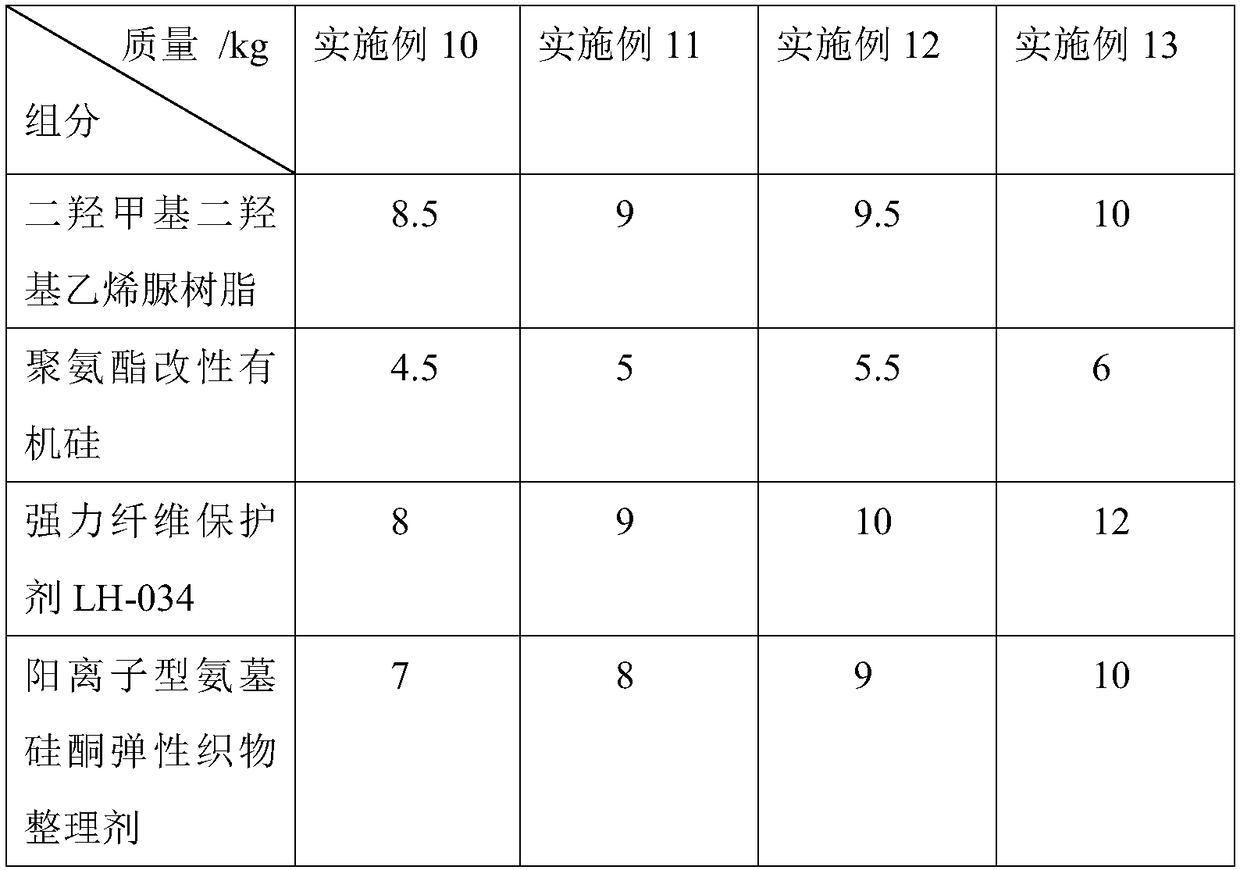

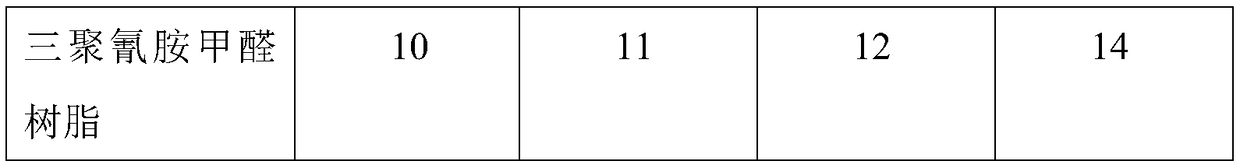

Dyeing production process for full-cotton knitted fabric

InactiveCN109371721AImprove wettability and permeabilityEasy accessWrinkle resistant fibresDyeing processWater bathsEthylenediamine

The invention discloses a dyeing production process for a full-cotton knitted fabric. The dyeing production process comprises the following steps: (1) pretreatment, (2) neutralization, (3) deoxygenization, (4) dyeing, (5) neutralization, (6) soaping, and (7) formation, wherein the step (1) comprises the steps of adding water into a dye vat, heating to 40-50 DEG C, adding pretreatment liquid into the dye vat, uniformly stirring, carrying out temperature-maintenance treatment for 3-5 minutes, adding a gray fabric into the water in a water bath ratio of (1 to 8)-10, heating to 90-100 DEG C, and washing with clean water for 1-2 times; and the pretreatment liquid contains the following substances in parts by weight: 3-5 parts of a penetrating agent, 3-7 parts of hydrogen peroxide, 4-8 parts ofcaustic soda liquid, 4-7 parts of a degreaser, 3-8 parts of a stabilizer, 5-8 parts of tetraacetyl ethylenediamine, 2-8 parts of butyl acetate, 1-3 parts of sodium sulfate, 1-3 parts of 4-(2-nonanoyloxyethoxycarbonyloxy)sodium benzenesulfonate and 1-5 parts of tris(hydroxymethyl)methylglycine. The dyeing production process has the advantages of high dyeing rate and uniformity in dyeing.

Owner:绍兴勇舜印染有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com