Highly-waterproof highly-breathable nanofiber membrane and preparation method thereof

A nanofiber membrane and nanofiber technology, applied in the direction of fiber type, fiber treatment, wear-resistant fiber, etc., can solve the problems of poor strength of nanofiber membrane, unsatisfactory waterproof and breathable performance, etc., achieve good hydrophobicity and improve application defects , the effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

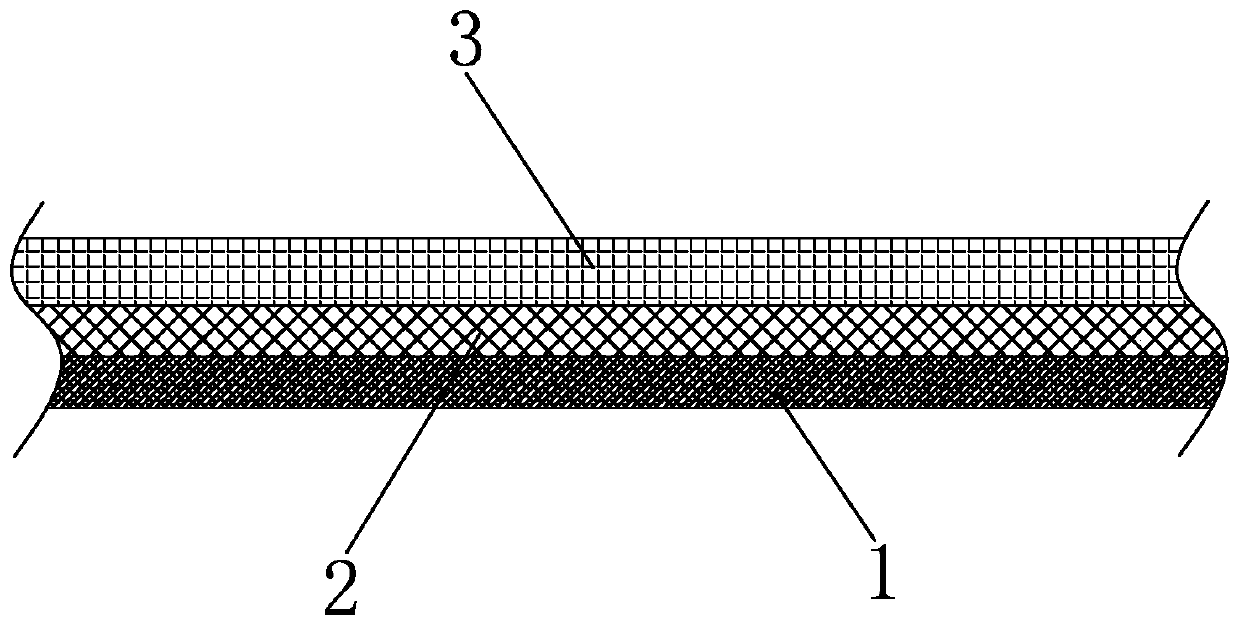

[0023] A highly waterproof and highly breathable nanofiber membrane adopts a three-layer composite sandwich structure, including PVB electrospun membrane 1, PVDF electrospun membrane 2, and FPU electrospun membrane 3, which are laminated sequentially from the inside to the outside. The PVB electrospun membrane 1 is formed by interweaving polyvinyl butyral nanofibers. The PVDF electrospun membrane 2 is formed by interweaving polyvinylidene fluoride nanofibers. The FPU electrospun membrane 3 is interwoven with fluorosilane-modified polyurethane nanofibers.

[0024] The preparation method of this highly waterproof and highly breathable nanofiber membrane comprises the following steps:

[0025] Step 1, prepare PVB electrospun film 1; Weigh a certain quality of PVB powder, add absolute ethanol, and prepare a PVB spinning solution with a mass fraction of 6-8%, and fully stir it with a magnetic stirrer to make the PVB powder fully Dissolve; Then prepare PVB electrospun film 1 by sp...

Embodiment 2

[0031] A highly waterproof and highly breathable nanofiber membrane adopts a three-layer composite sandwich structure, including PVB electrospun membrane 1, PVDF electrospun membrane 2, and FPU electrospun membrane 3, which are laminated sequentially from the inside to the outside. The PVB electrospun membrane 1 is formed by interweaving polyvinyl butyral nanofibers. The PVDF electrospun membrane 2 is formed by interweaving polyvinylidene fluoride nanofibers. The FPU electrospun membrane 3 is interwoven with fluorosilane-modified polyurethane nanofibers.

[0032] The preparation method of this highly waterproof and highly breathable nanofiber membrane comprises the following steps:

[0033] Step 1, prepare PVB electrospun film 1; Weigh a certain quality of PVB powder, add absolute ethanol, and prepare a PVB spinning solution with a mass fraction of 6-8%, and fully stir it with a magnetic stirrer to make the PVB powder fully Dissolve; Then prepare PVB electrospun film 1 by sp...

Embodiment 3

[0039] A highly waterproof and highly breathable nanofiber membrane adopts a three-layer composite sandwich structure, including PVB electrospun membrane 1, PVDF electrospun membrane 2, and FPU electrospun membrane 3, which are laminated sequentially from the inside to the outside. The PVB electrospun membrane 1 is formed by interweaving polyvinyl butyral nanofibers. The PVDF electrospun membrane 2 is formed by interweaving polyvinylidene fluoride nanofibers. The FPU electrospun membrane 3 is interwoven with fluorosilane-modified polyurethane nanofibers. In order to better coordinate the three, the thickness of the PVB electrospun membrane 1 is 0.010-0.025mm. The thickness ratio of PVB electrospun membrane 1 to FPU electrospun membrane 3 is 1:(1.2-1.6). In order to improve the wear resistance of the surface of the FPU electrospun membrane 3 and improve the hydrophobicity of the FPU electrospun membrane 3 , the surface of the FPU electrospun membrane 3 is coated with a silico...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com