Patents

Literature

2441 results about "Nanofibrous membrane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Biopolymer nano tunica fibrosa material capable of being biological degraded and absorbed, preparing method and uses of the same

InactiveCN101172164AGood biocompatibilityPromote degradationSurgeryFilament/thread formingFiberCellulose

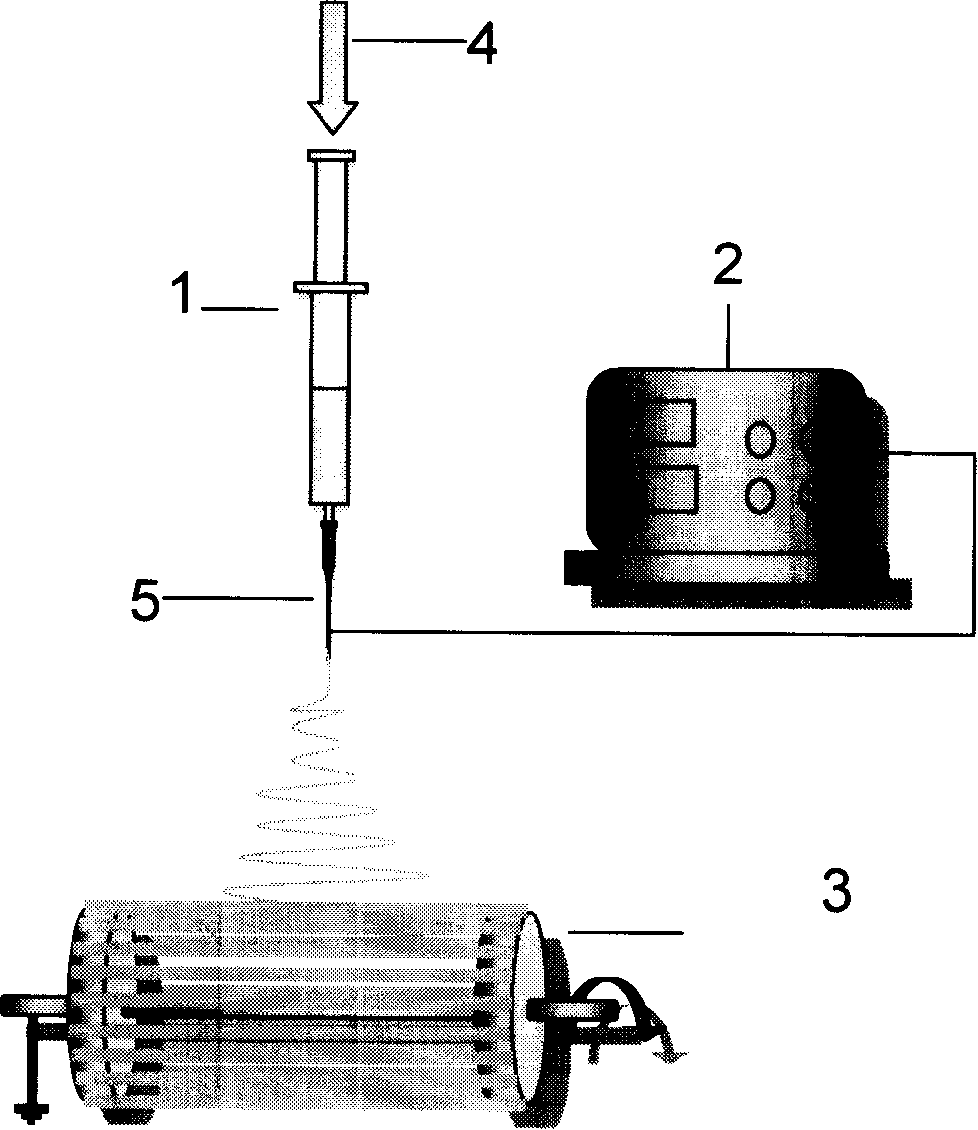

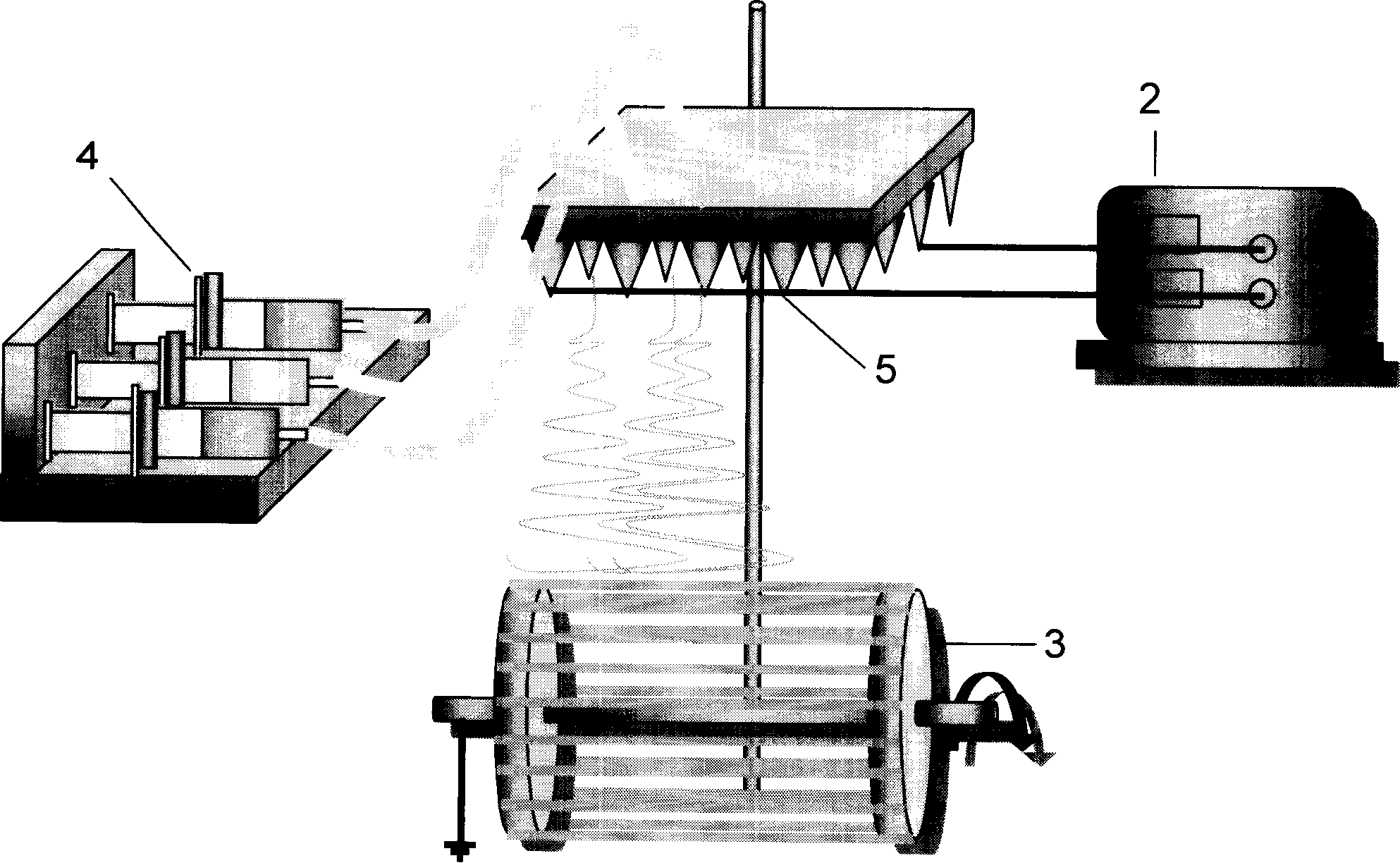

The invention relates to compound millimicron fibrous membrane material of cellulose and cellulose matrix which can perform the biological degradation and the biological absorption and a preparation method thereof and an industry and medical purpose, and belongs to the biological macro-molecule non woven fabric material field which can perform the biological degradation and the biological absorption. Electrostatic spinning equipment is used to obtain the fibrous membrane material which can perform the biological degradation and the biological absorption, the weight of the cellulose is taken as basic reference, the component of the material comprises cellulose more than 0 and less than or equal to 100 weight parts, other biomacromolecule more than and equal to 0 and less than 100 weight parts, 0 to 10 weight parts of curative drug or 0 to 50 weight parts of inorganic catalyzer and / or 0 to 50 weight parts of inorganic strengthening agent. The material of the invention has good biological compatibility, biological degradation property and degradation absorptivity, and can be used for haemostasia material, wound cladding material, organization engineering supporting rack material, the transportation and release of medicine, artificial skin and blood vessel, and postoperation anti blocking material, beauty material and catalyzer carrier, filtering membrane and radiation protection material and so on.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Nano copolymer fibrous membrane material capable of being biodegraded and absorbed and preparation process and use thereof

InactiveCN1961974AOvercome the technical problem of difficult spinningSurgical adhesivesPharmaceutical containersFiberAqueous solution

The invention relates to a gelatin nanometer fiber film which can biologically degrade and absorb, and relative preparation, wherein it via the control on static spin realizes the static spin on gelatin water solution and gelatin / macromolecule mixture water, to obtain the nanometer fiber, which comprises: 0 A61L 27 / 14 A61K 45 / 00 D01D 5 / 00 D01F 1 / 00 A61L 27 / 60 A61L 33 / 06 A61L 24 / 04 A61L 15 / 22 A61F 2 / 02 2 14 3 2005 / 11 / 9 1961974 2007 / 5 / 16 000000000 Institute of Chemistry Chinese Academy of Science Beijing 100080 Han Zhichao He Aihua Li Junxing libai 31002 Shanghai Patent Agency of the Chinese Academy of Sciences No.319 Yueyang Road, Shanghai 200031

Owner:INST OF CHEM CHINESE ACAD OF SCI

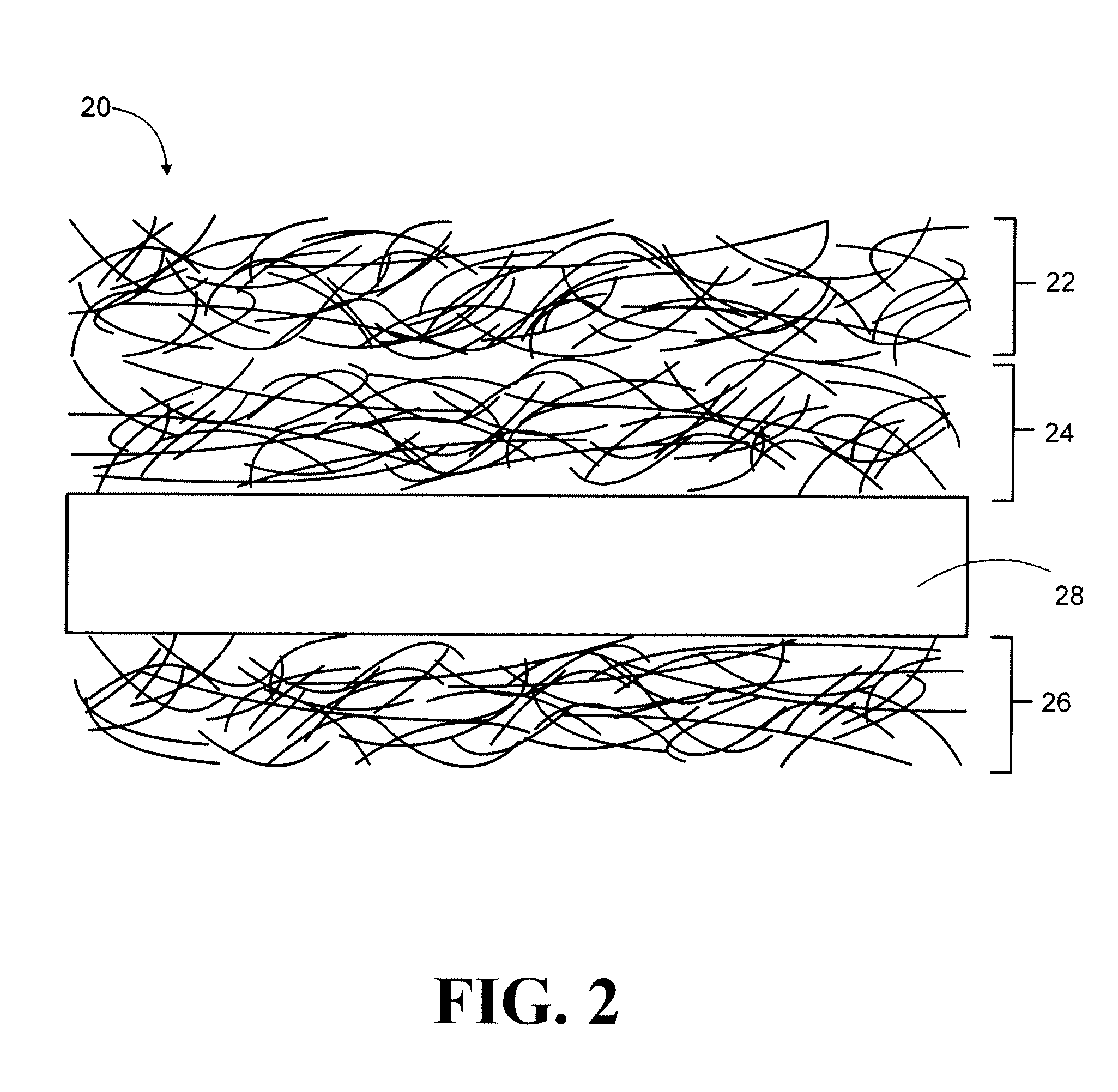

Composite thermal interface material including aligned nanofiber with low melting temperature binder

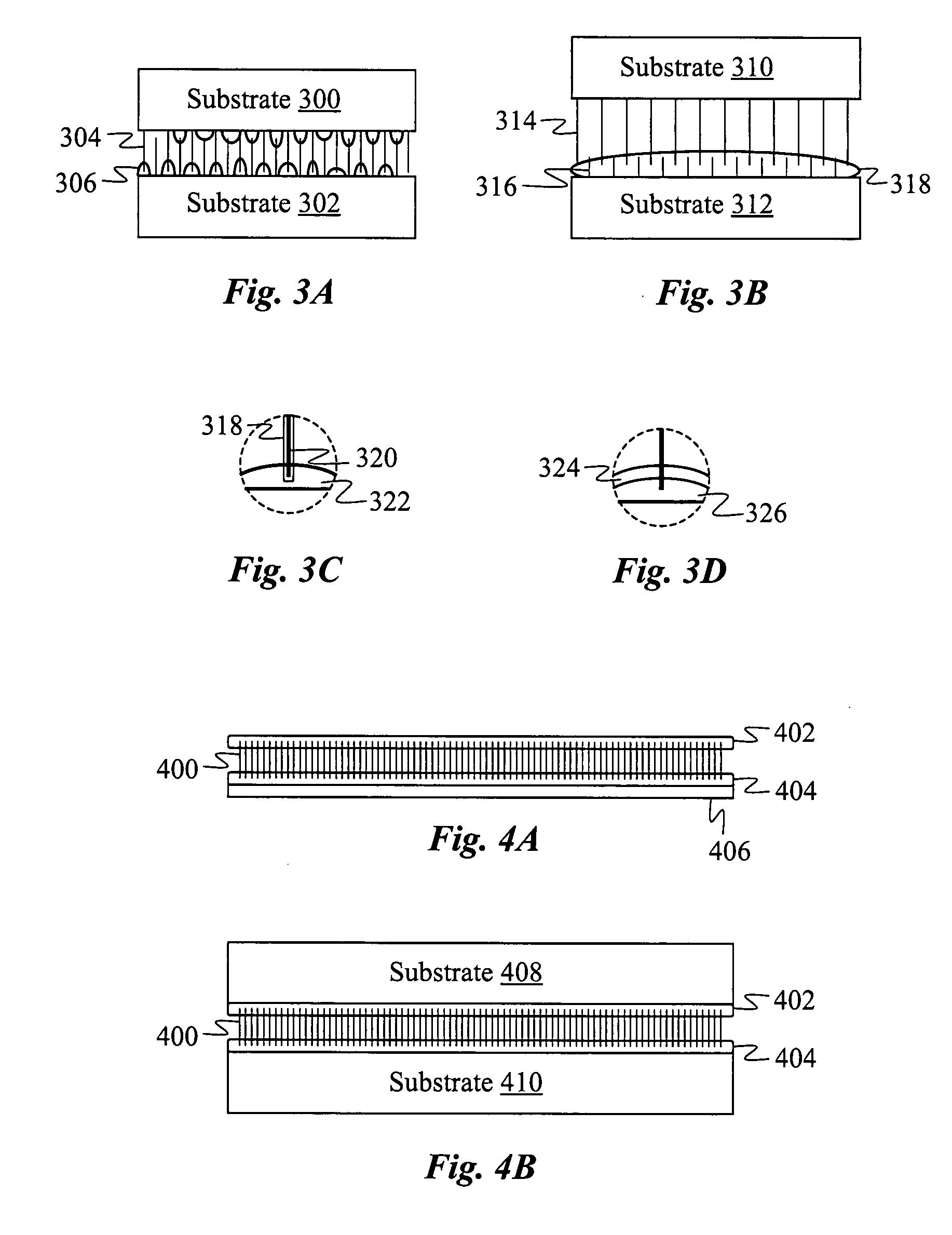

ActiveUS20090068387A1Improve thermal conductivityMaterial nanotechnologyLamination ancillary operationsFiberAdhesion process

A thermal interface material includes a mechanically compliant vertically aligned nanofiber film and a binder material for joining the nanofibers of the film to the surfaces of two substrates. Preferably, the binder material comprises a non-hydrocarbon-based material such as a metallic eutectic with a melting temperature below a nanofiber thermal damage threshold temperature of the film. The film is grown on a substrate which is then bonded to another substrate by the binder material in an adhesion process that may include pressure and heat. Alternatively, the film may be released from the substrate to produce a stand-alone thermal tape which may later be placed between two substrates and bonded.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

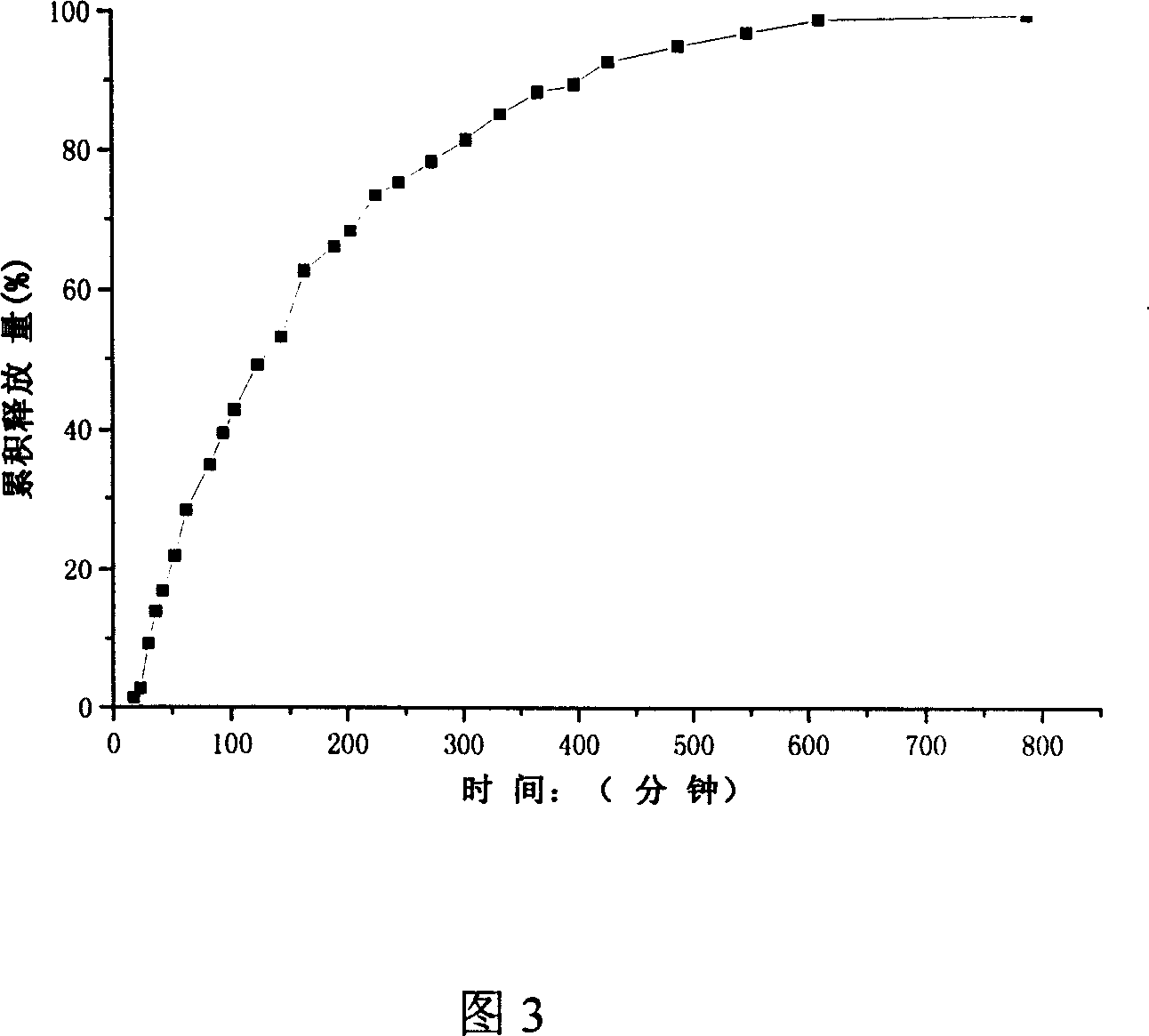

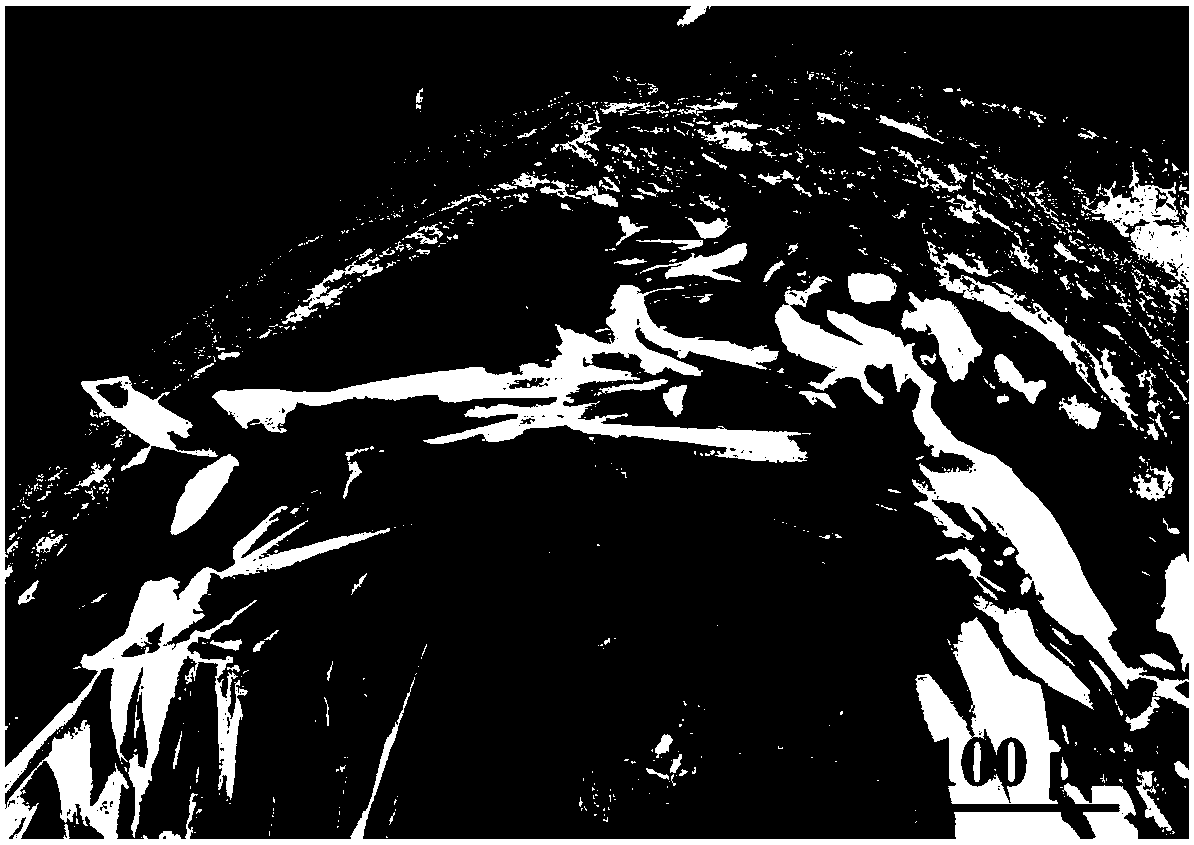

Nanofibrous nonwoven membrane of silk fibroin for guided bone tissue regeneration and manufacturing method thereof

InactiveUS20060095137A1Easy to controlSimple processMaterial nanotechnologyElectric discharge heatingBone tissueBiocompatibility Testing

The present invention relates to a membrane for guided bone tissue regeneration and, more particularly, to a membrane for guided bone tissue regeneration having a structure that silk fibroin nanofibers obtained by removing sericin from silk fibers are formed as a nonwoven, and a manufacturing method thereof. A membrane for guided bone tissue regeneration according to the present invention has a predetermined strength, biocompatibility, and biodegradability, and may maintain a sustained drug release system, when drugs are added in the manufacturing process. Additionally, a membrane for guided bone tissue regeneration according to the present invention may be modified corresponding to the condition of usage, because a thickness of the membrane may be adjusted by controlling fineness of nanofibers, compactness of nanofibers, and pore size of a multiporous structure may be adjusted, in a nonwoven manufacturing process. A nanofibrous membrane for guided bone tissue regeneration according to the present invention is manufactured by freezing rapidly, drying a silk fibroin solution obtained by removing sericin from silk fibers, and by electrospinning after dissolving the dried silk fibroin in an electrospinning solvent. The membrane according to the present invention has excellent adhesion and air permeability, and is thereby effective in regeneration of damaged periodontal tissues.

Owner:SEOUL NAT UNIV R&DB FOUND

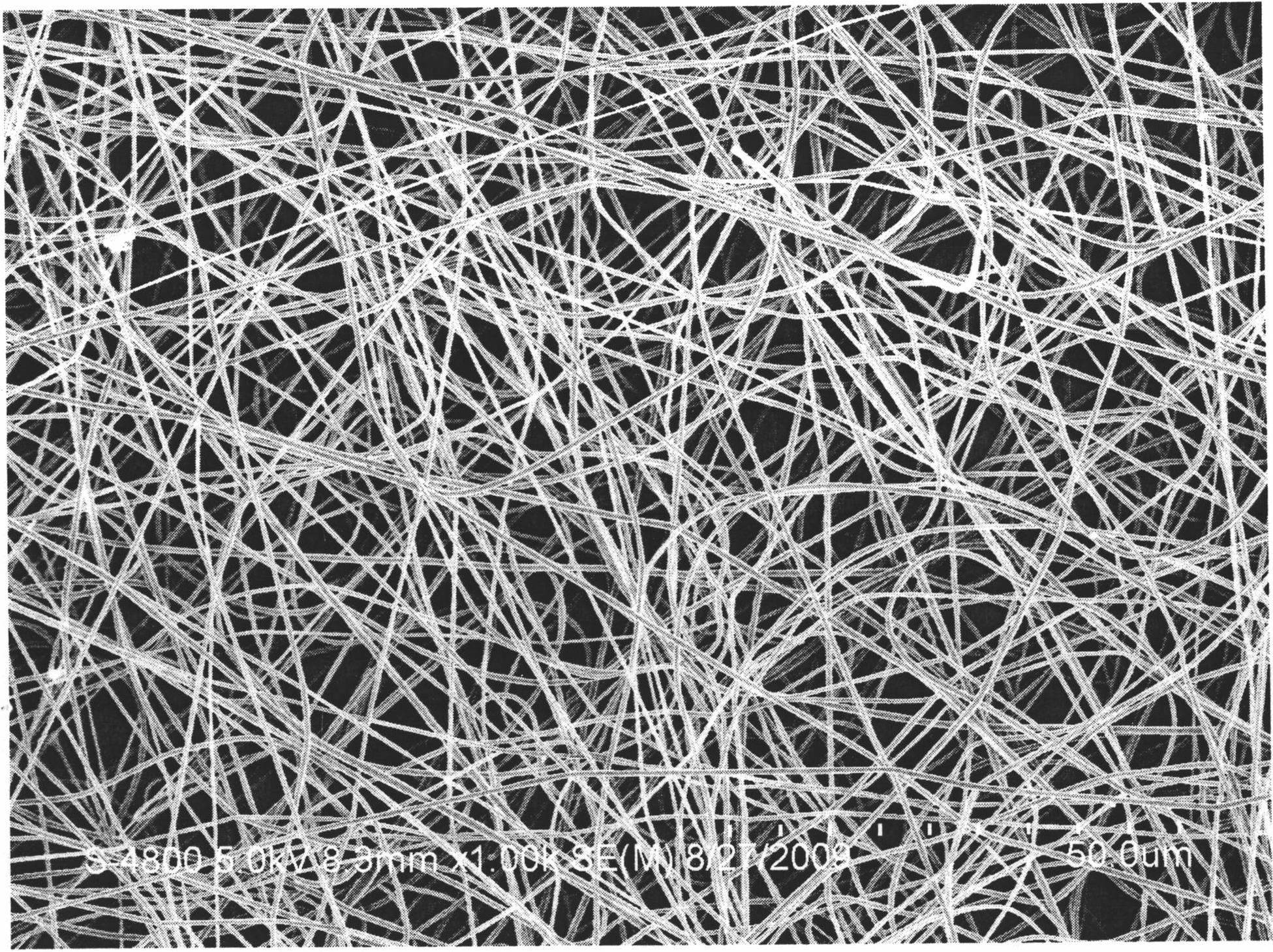

Nano fibre protective filtering material and its preparation method

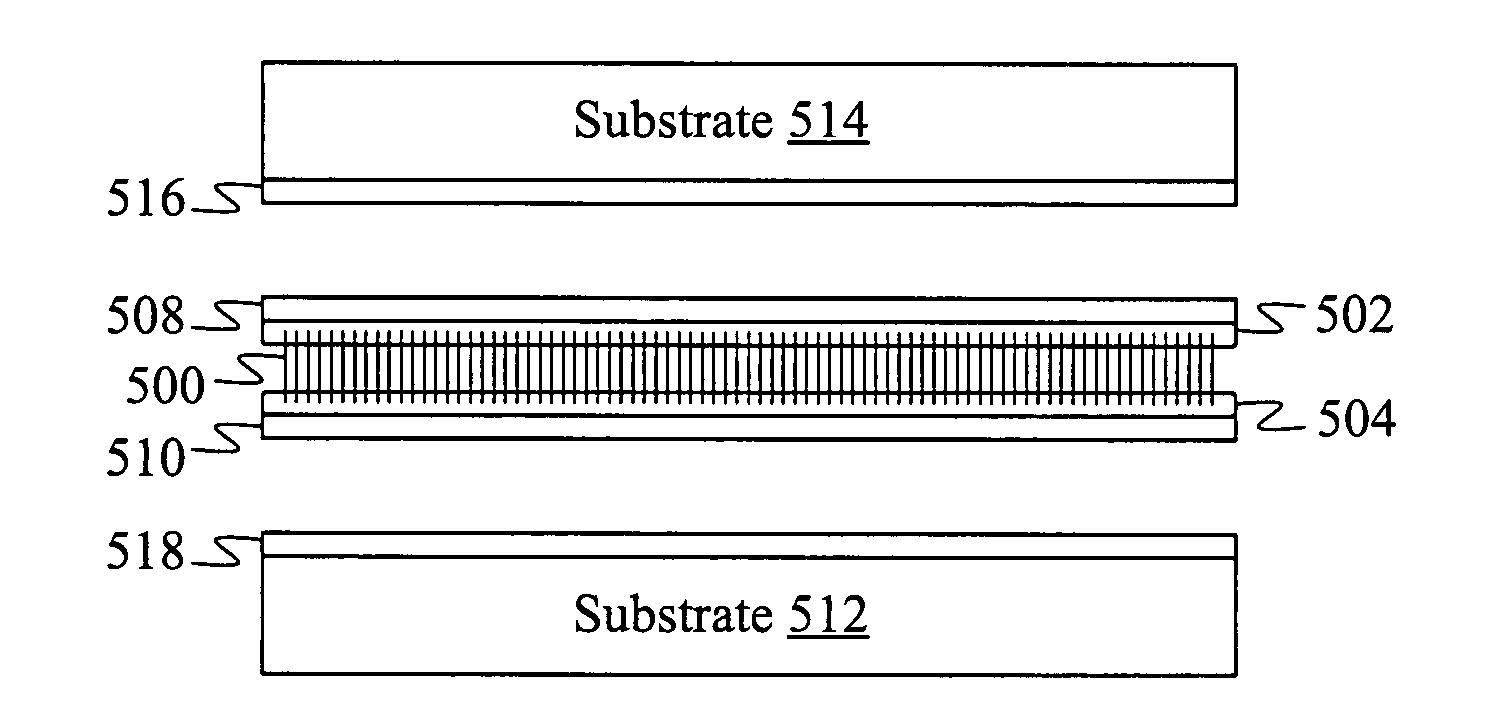

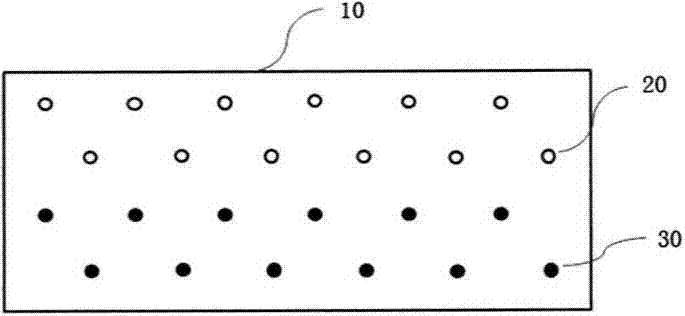

InactiveCN1460534ASimple processing technologyHigh strengthLayered productsFilament/thread formingMicrometerNanofiber

The nano fibre protective material is made into the form of a laminar structure, its middle layer is made of high-molecular nano fibre membrane material, the diameter of the nano fibre is 10 nano-3000 nano, and its external layer is respectively one layer or multilayer natural fibre or synthetic fibre or blended fabric on non-woven fabric, and the diameter of fibre is 1 micrometer-100 micrometers. Its preparation method includes the following steps: dissolving or dispersing one or several kinds of high-molecular materials in solvent to obtain transparent solution or mixture, dispersing additive into the above-mentioned solution or melting one or several kinds of high-molecular materials to obtain electric spinning material, then adding said electric spinning material into one or several storage tanks.

Owner:SOUTHEAST UNIV

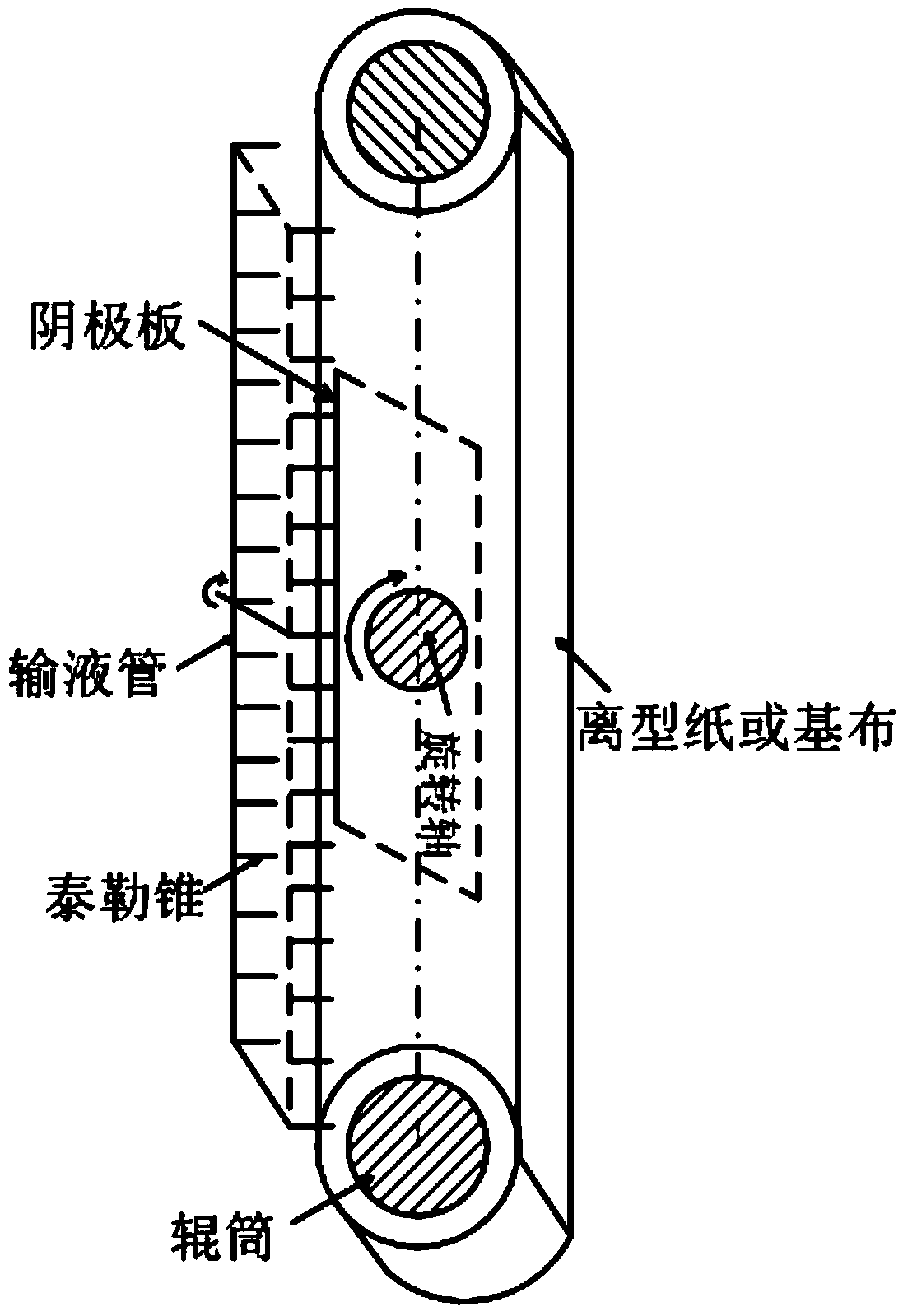

Electrostatic spinning nanofiber membrane as well as preparation method thereof

InactiveCN103437071AIncrease productivityReduce energy consumptionNon-woven fabricsChemical industryFiber

The invention provides an electrostatic spinning nanofiber membrane as well as a preparation method thereof. The electrostatic spinning nanofiber membrane provided by the invention comprises a fiber membrane obtained by electrostatically spinning a high-melting-point polymer and a fiber membrane obtained by electrostatically spinning a low-melting-point polymer, wherein the difference on the melting points of the high-melting-point polymer and the low-melting-point polymer is not less than 10 DEG C. The electrostatic spinning nanofiber membrane provided by the invention is multipurpose and can be applied to the fields such as biomedicines, energy and chemical industry, gas and liquid filtration, waterproofness and windproofness, windproofness and heat insulation, moisture permeability and ventilation, environmental management and semiconductor sensors. According to the electrostatic spinning nanofiber membrane provided by the invention, electrostatic spinning is respectively carried out on the high-melting-point polymer and the low-melting-point polymer, and the high-melting-point polymer fiber membrane and the low-melting-point polymer fiber membrane obtained are composited and hot-pressed to obtain the electrostatic spinning nanofiber membrane. The preparation method provided by the invention is high in production efficiency and low in energy consumption, and is suitable for industrial production.

Owner:ZHEJIANG WEIXING IND DEV

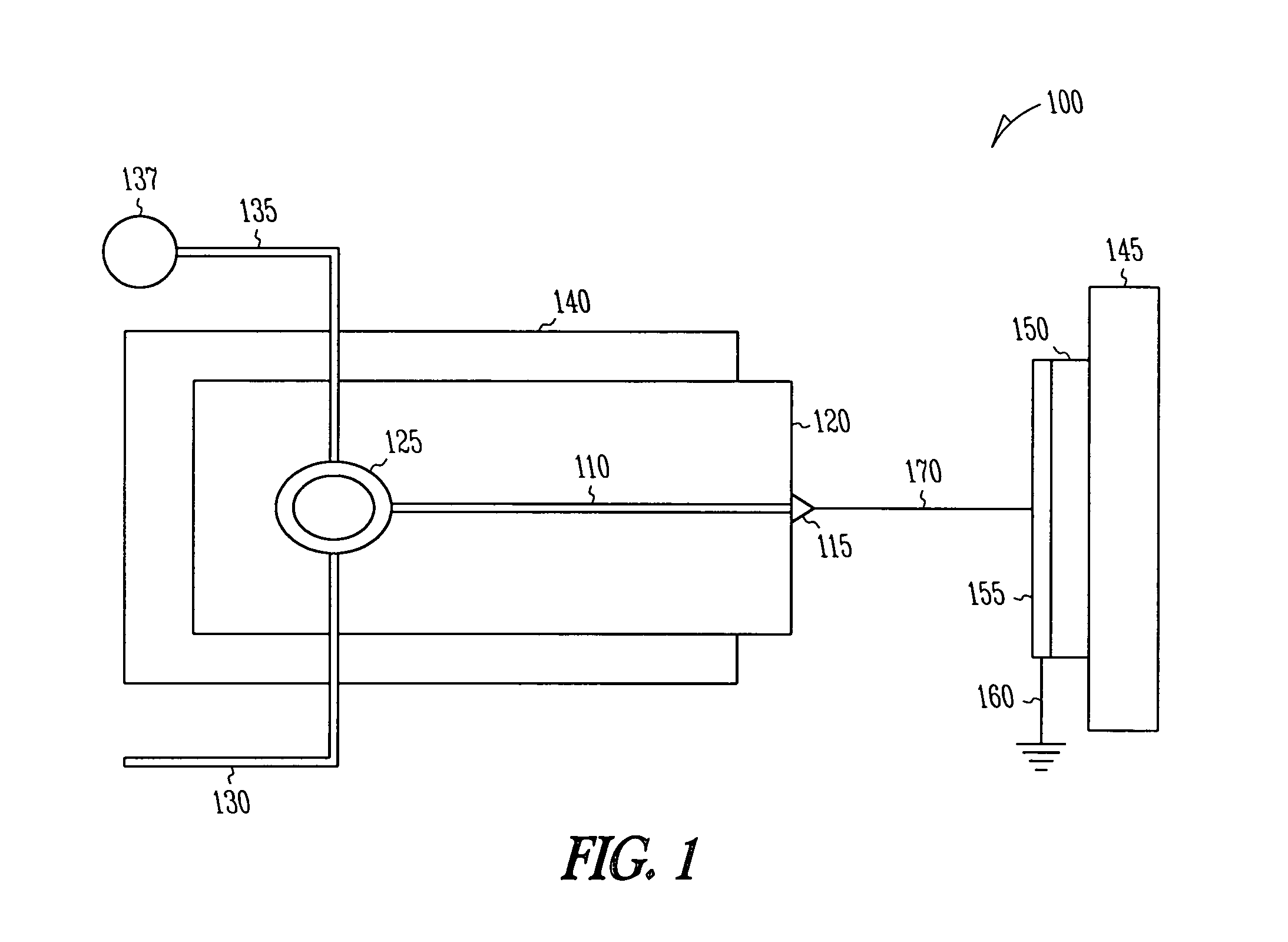

Electromagnetic interference shielding structure including carbon nanotube or nanofiber films and methods

ActiveUS20100188833A1Substantial internal reflectionMaterial nanotechnologyShielding materialsFiberElectromagnetic interference

A composite material for electromagnetic interference shielding is provided. The composite material comprises a stack including at least two electrically conductive nanoscale fiber films, which are spaced apart from one another by at least one insulating gap positioned between the at least two nanoscale fiber films. The stack is effective to provide a substantial multiple internal reflection effect. An electromagnetic interference shielded apparatus and a method for shielding an electrical circuit from electromagnetic interference is provided

Owner:FLORIDA STATE UNIV RES FOUND INC

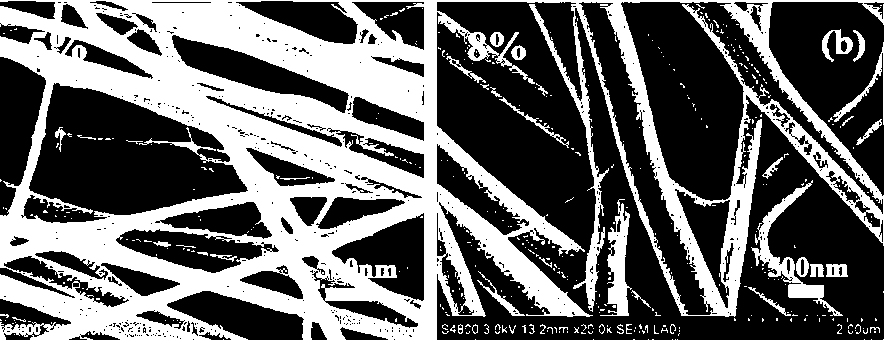

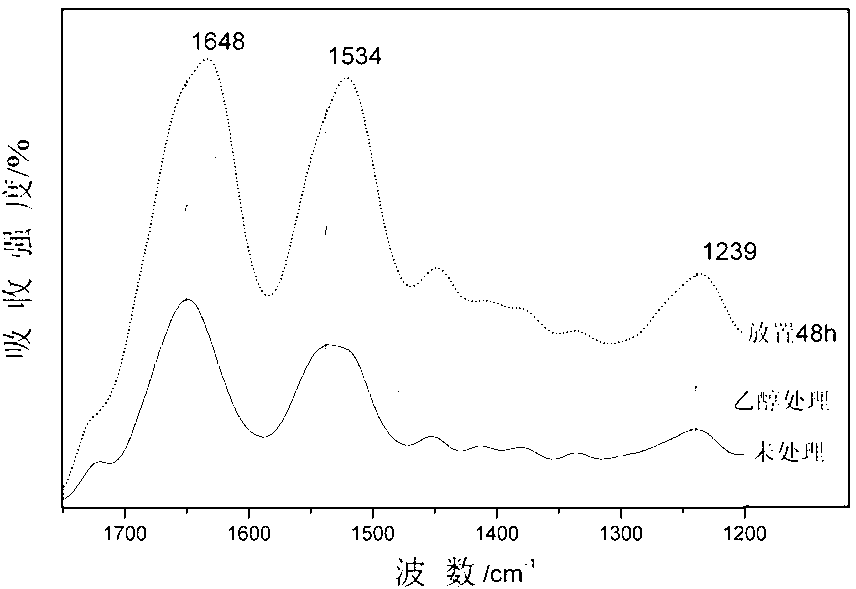

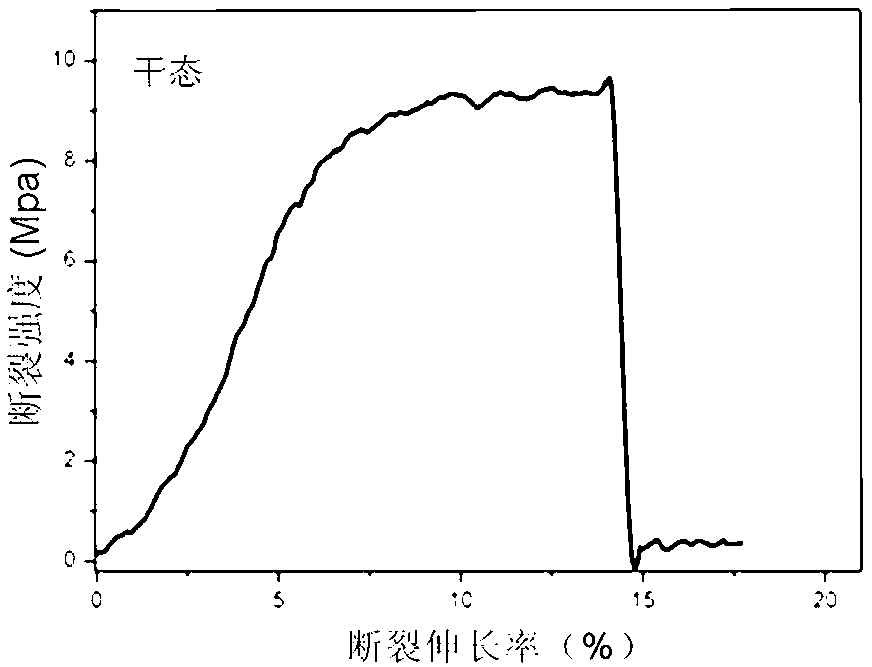

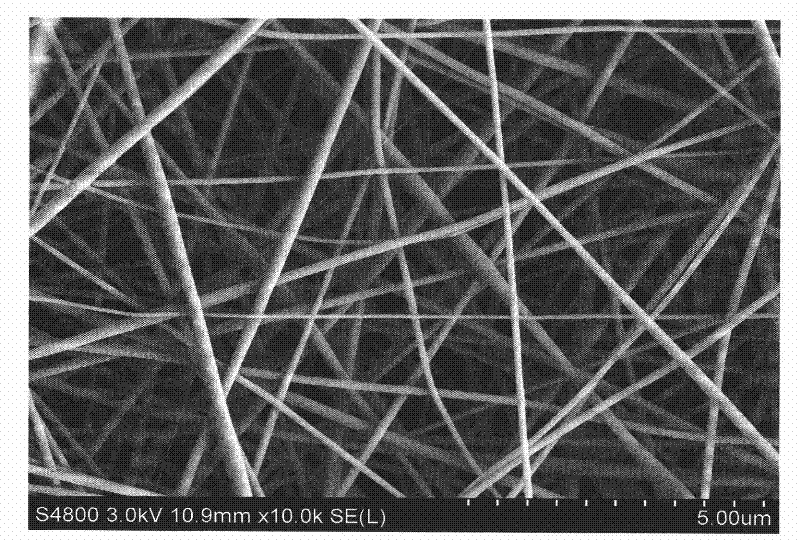

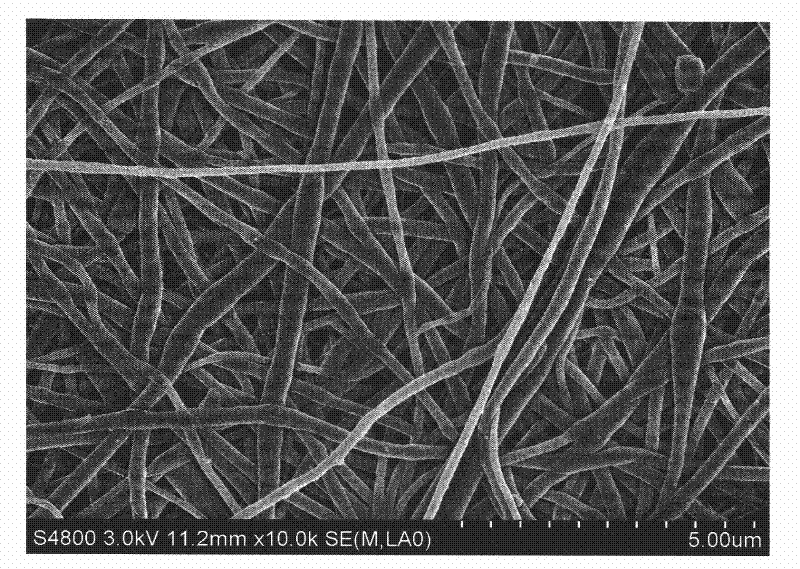

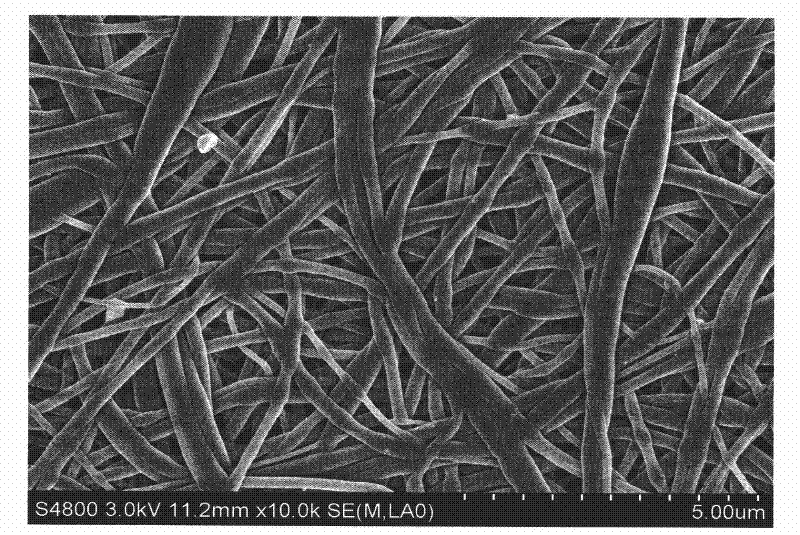

Silk fibroin nanofiber membrane and preparation method thereof

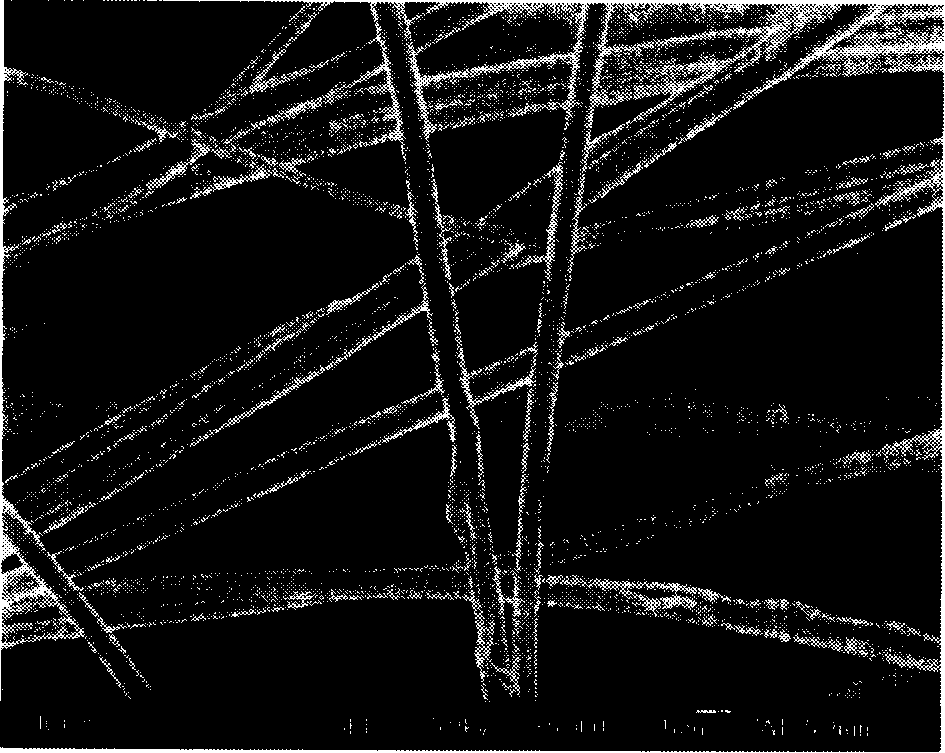

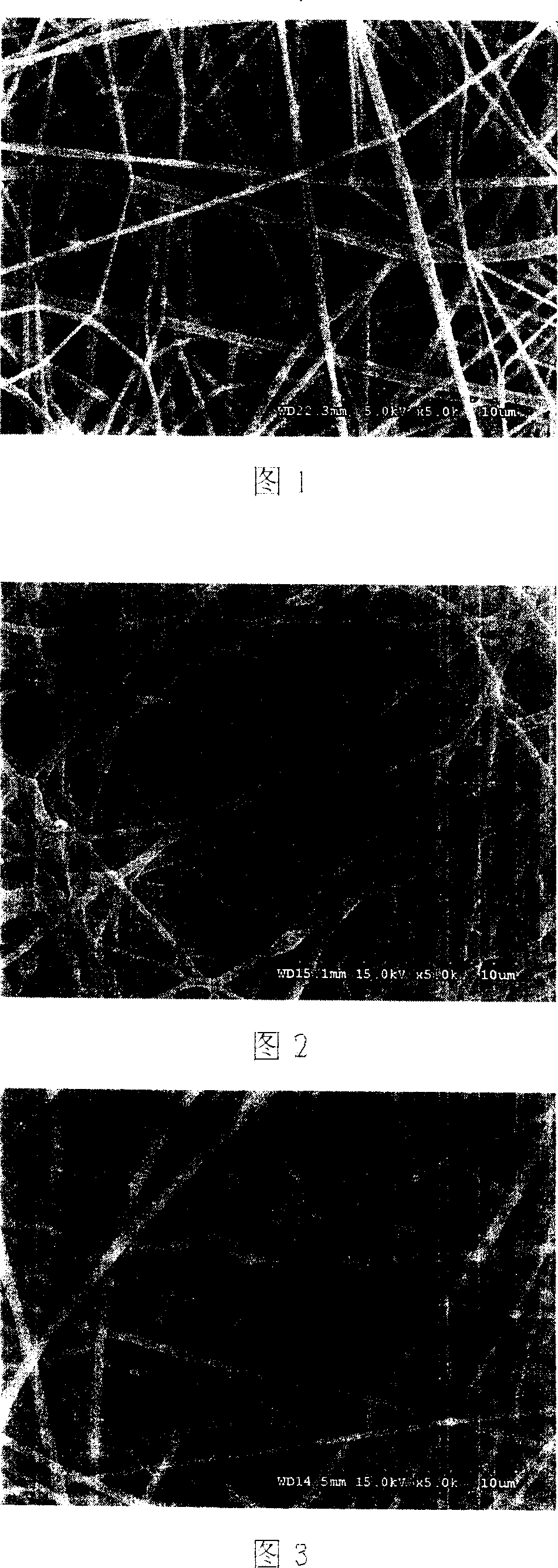

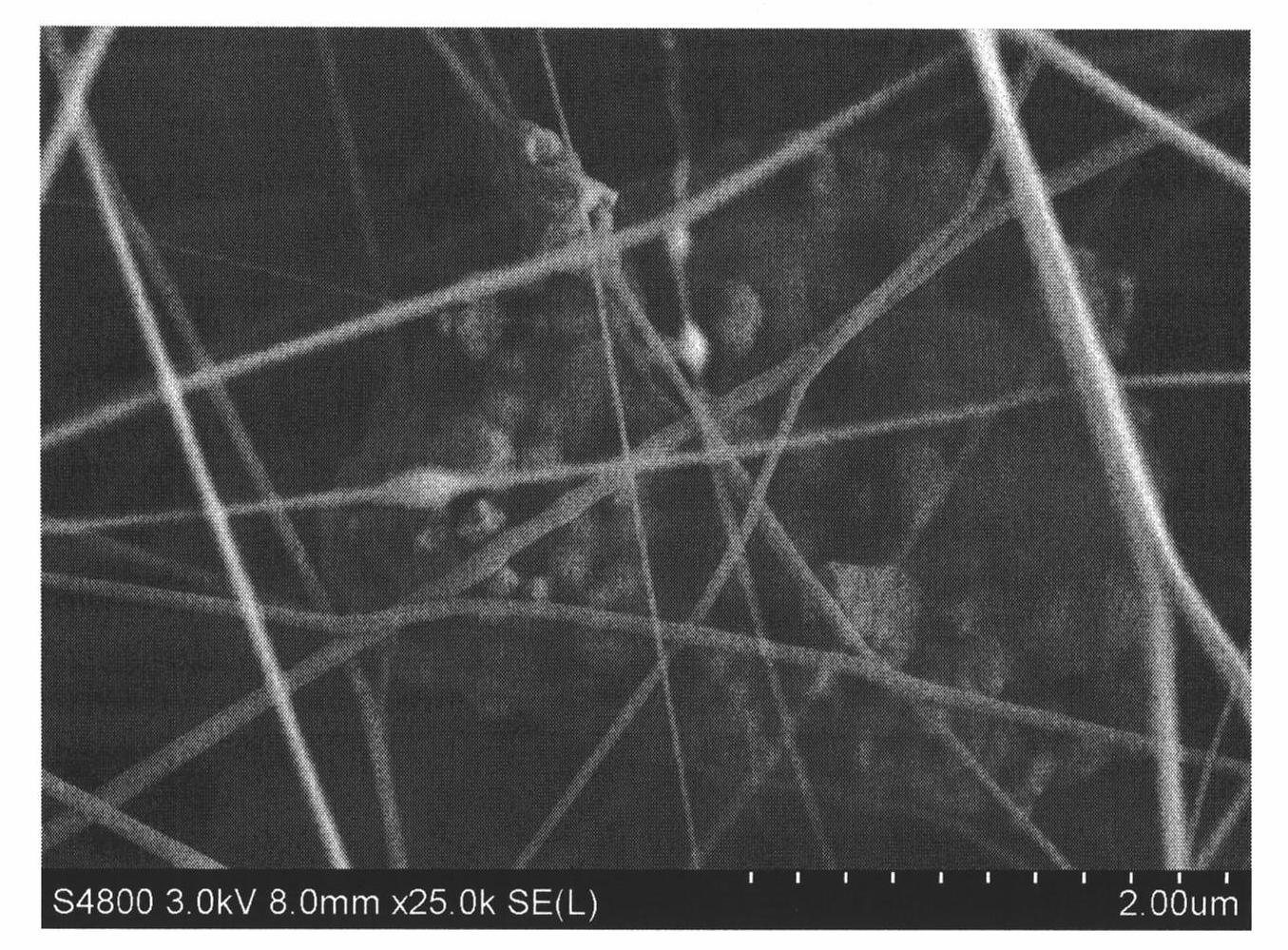

The invention discloses a silk fibroin nanofiber membrane and a preparation method of the silk fibroin nanofiber membrane. The preparation method comprises the following specific steps of: dissolving natural silk taken as a main raw material by an acid salt solution, forming a membrane, desalting the membrane, dissolving the membrane by methanoic acid and hexafluoroisopropanol to prepare a spinning solution, and carrying out electrostatic spinning to prepare the silk fibroin nanofiber membrane. The silk fibroin nanofiber membrane comprises fibers with the diameter of 10nm-10 microns and has the excellent mechanical property, the breaking strength of greater than 8Mpa at dry state, the breaking elongation of greater than 15% at dry state, the breaking strength of greater than 1Mpa at wet state and the breaking elongation of greater than 100% at wet state. In addition, the silk fibroin nanofiber membrane prepared by the method is stable and controllable in structure, has good biocompatibility and can serve as a medicinal biological material. The preparation method disclosed by the invention is simple and short in flow path, has high film formation and spinning efficiency and is suitable for industrialization large-scale production.

Owner:上海丝波敦生物科技有限公司

High flux high efficiency nanofiber membranes and methods of production thereof

A membrane is provided including a coating layer having cellulose nanofibers produced from oxidized cellulose microfibers and an electrospun substrate upon which the coating layer is applied. The nanofibers of the electrospun substrate have a diameter greater than that of the cellulose nanofibers. The membrane also has non-woven support upon which the electrospun substrate is disposed. Microfibers of the non-woven support have a diameter greater than that of the nanofibers of the electrospun substrate. Application of electrospun membrane is in microfiltration area, while the cellulose nanofiber membrane serves in ultra-filtration, nanofiltration, and reverse osmosis after chemical modification.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

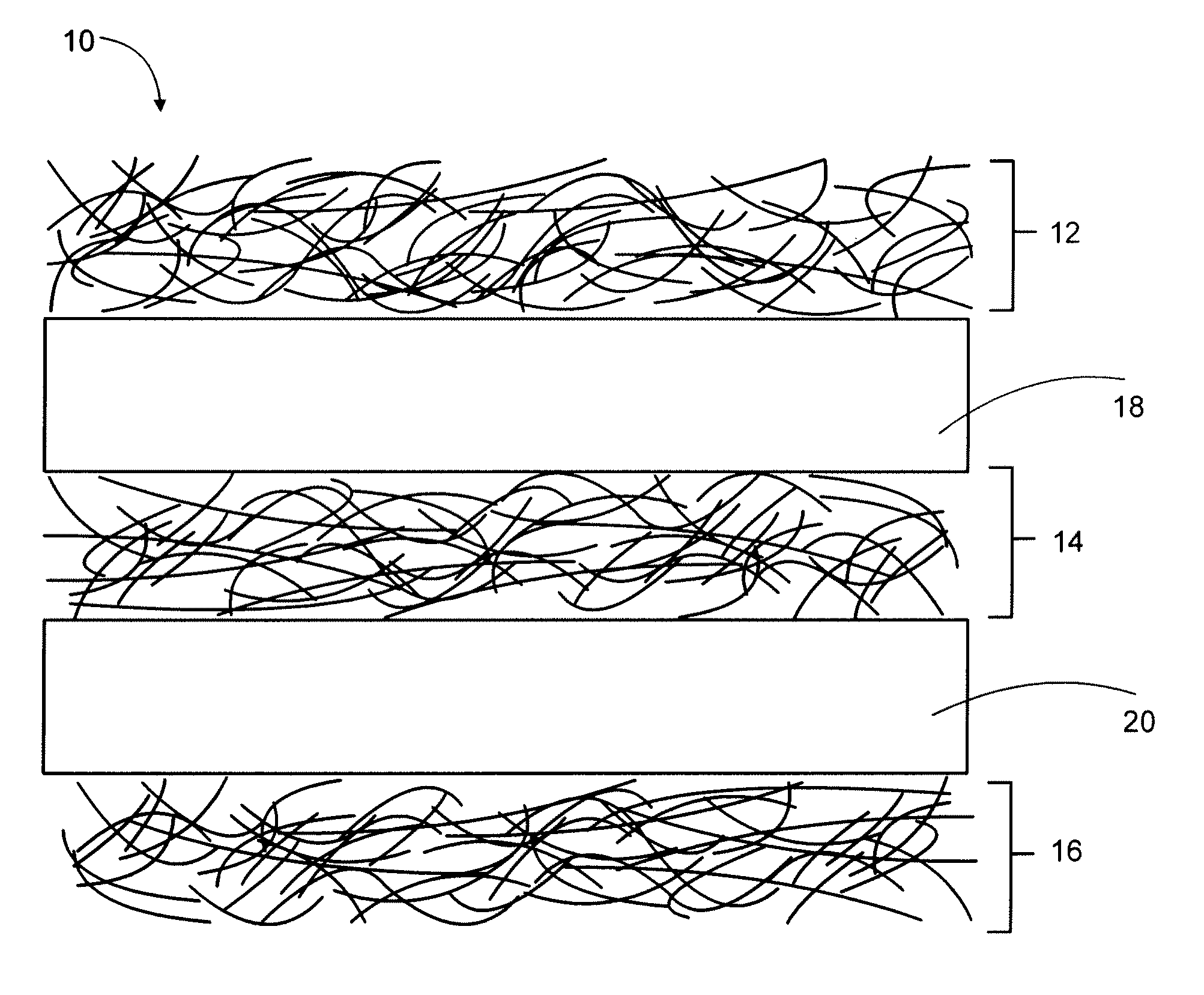

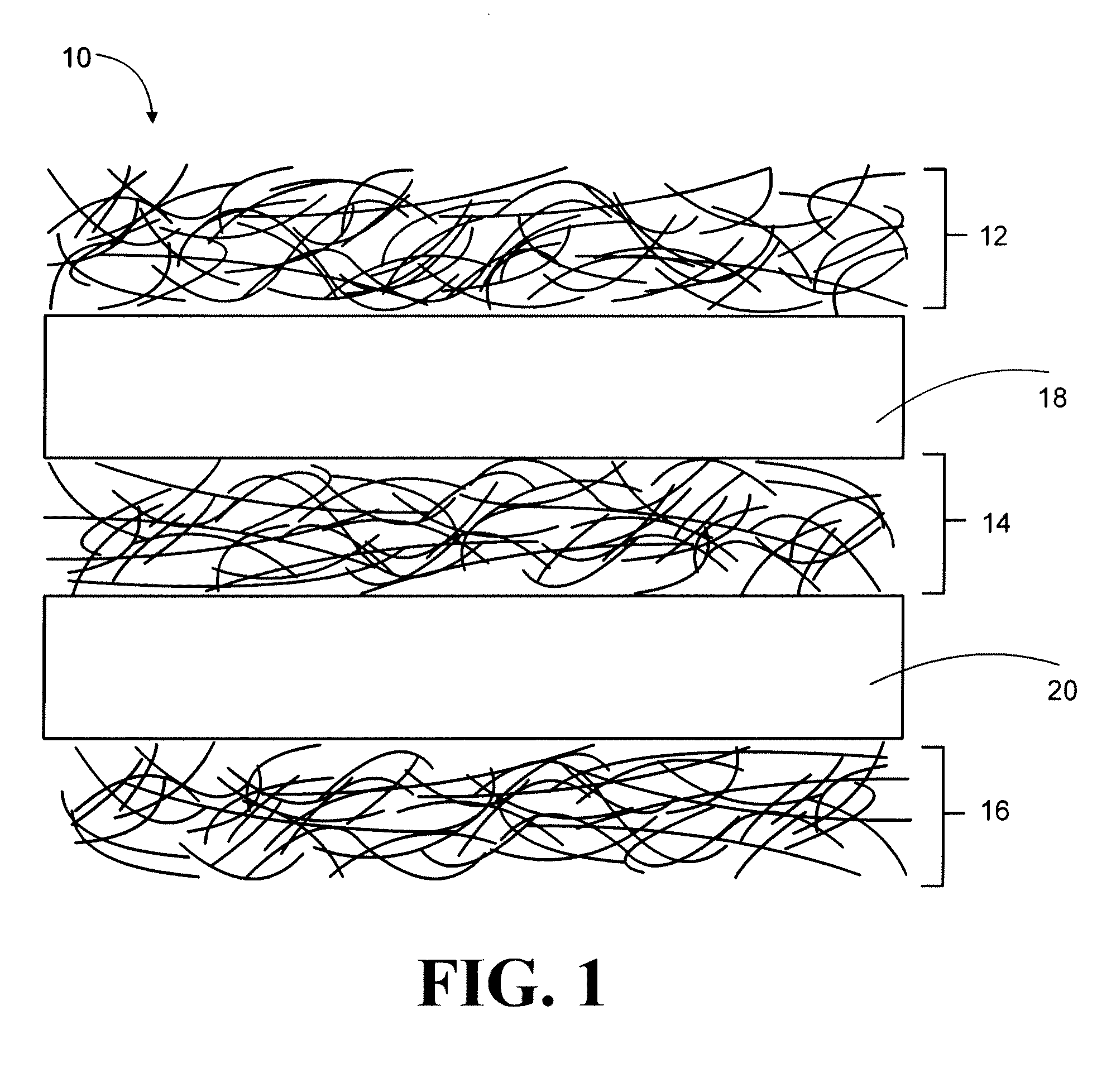

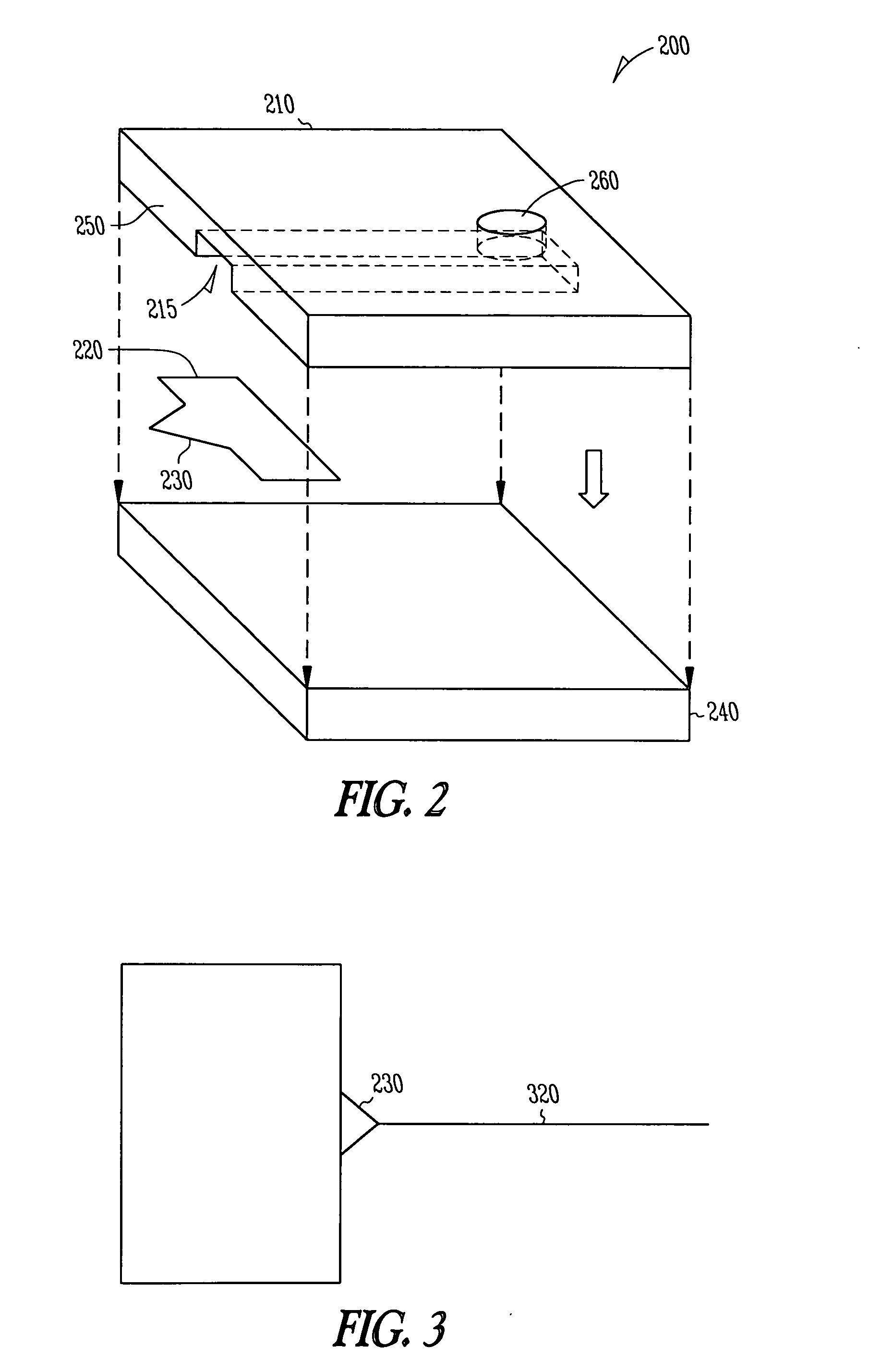

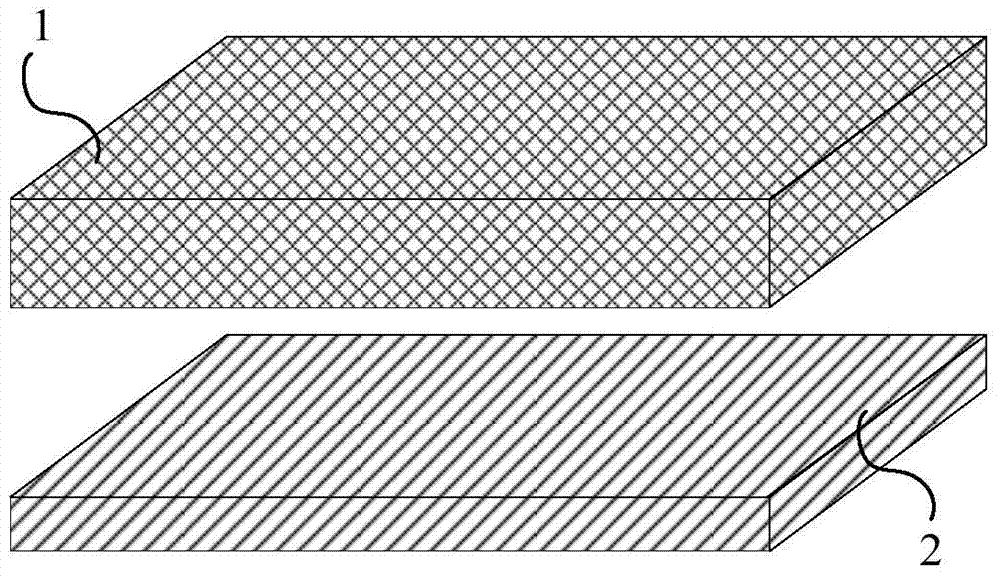

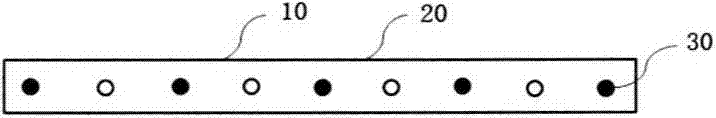

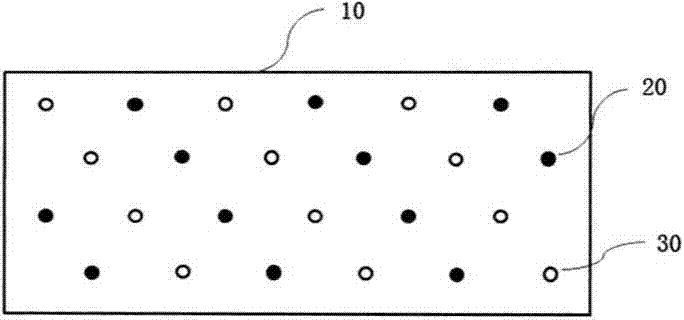

Microfiber supported nanofiber membrane

A nanofiber membrane is formed on a microfiber membrane. The nanofiber membrane may be electro sprayed directly onto the microfiber membrane and becomes integrated with the microfiber membrane to form a filter. The microfiber membrane provides structural integrity to for the nanofiber membrane, and an additional microfiber membrane may be added to sandwich the nanofiber membrane.

Owner:CORNELL RES FOUNDATION INC

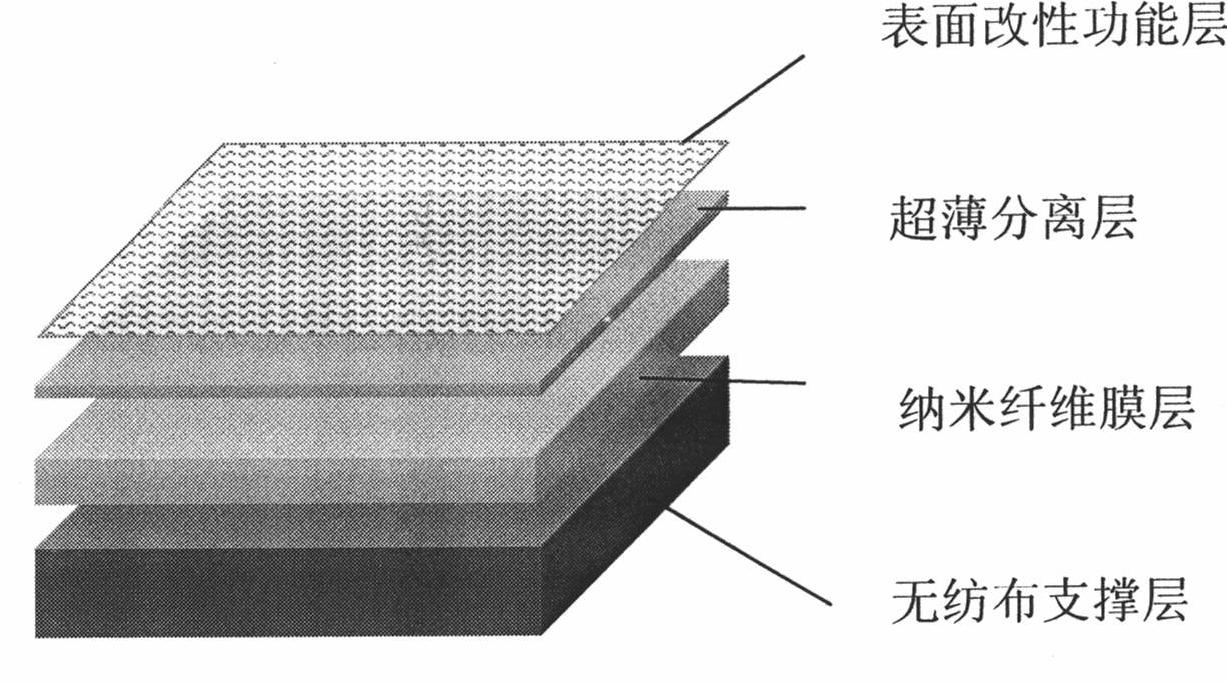

Hyperfiltration membrane or nanofiltration membrane with multi-layered composite structure and preparation method thereof

InactiveCN102139187AIncrease water fluxHigh retention rateSemi-permeable membranesEnvironmental resistanceHydrophilic polymers

The invention relates to a hyperfiltration membrane or nanofiltration membrane with a multi-layered composite structure and a preparation method thereof. The hyperfiltration membrane or nanofiltration membrane is a polymer electrostatic spinning nanofiber membrane layer characterized in strong chemical resistance prepared through an electrostatic spinning method, a hydrophilic polymer ultra-thin separation layer obtained through interfacial polymerization, and a functional group surface modification functional layer formed through the grafting reaction of reactant gases on the surfaces of hydrophilic polymers, or a long-chain polymer surface modification functional layer formed through the grafting reaction of the reaction gases on the surfaces of the hydrophilic polymers, or a functionalgroup-containing long-chain polymer surface modification functional layer through the grafting reaction of the reaction gases with the functional groups on the surfaces of the hydrophilic polymers. The hyperfiltration membrane or nanofiltration membrane with the multi-layered composite structure has the advantages of high water flux, high cutting rate and stable chemical performances. The filtration membrane can be used for the production of domestic water, drinking water or water in special conditions, and is suitable for the medical field, food field, environmental protection field and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

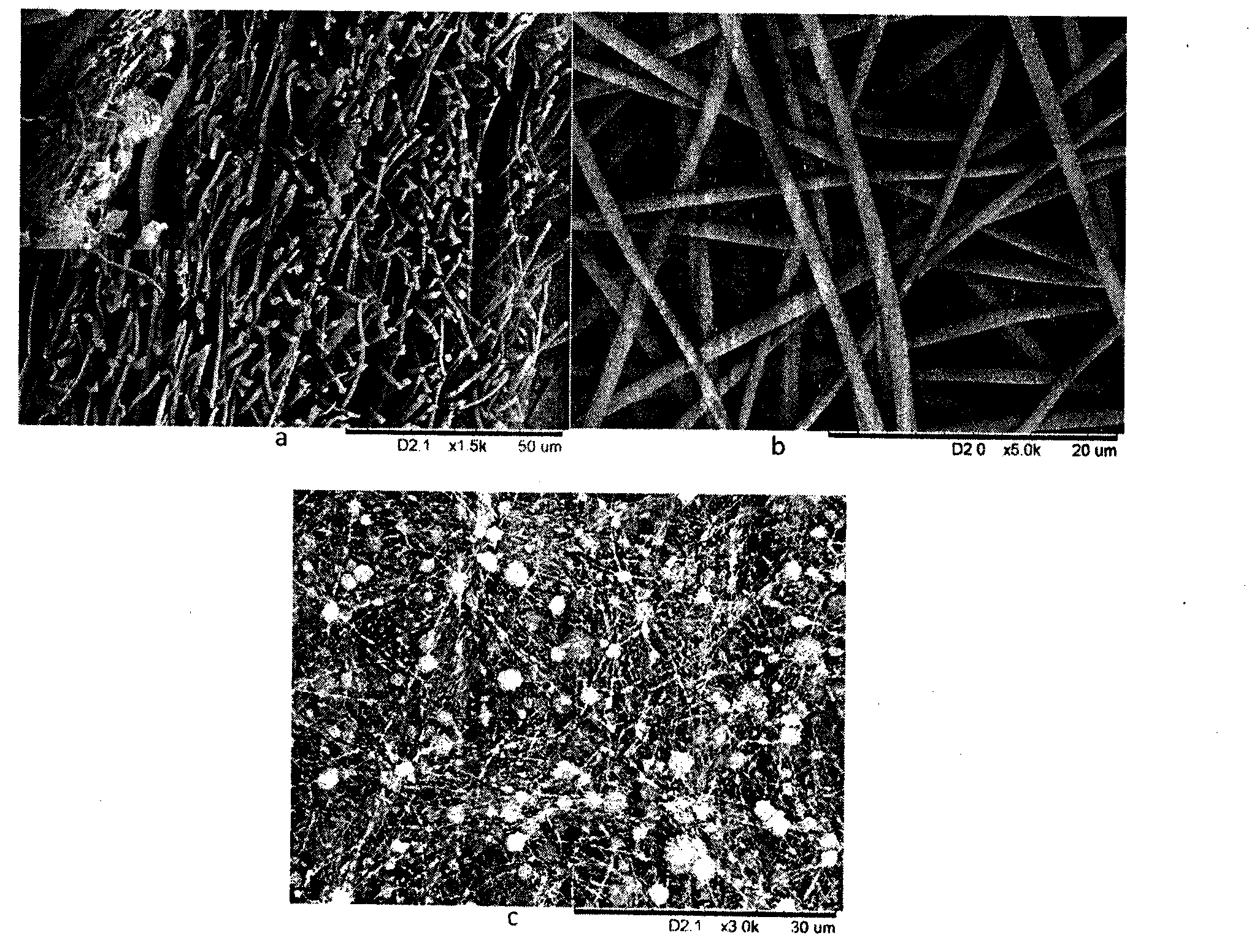

Polymer-ceramic compound nanometer fibrous membrane as well as preparation method and application thereof

ActiveCN102242464AUniform thicknessHigh porositySemi-permeable membranesFixed capacitor dielectricFiberPorosity

The invention relates to a polymer-ceramic compound nanometer fibrous membrane prepared by using an electrostatic spinning method and an application thereof. A polymer material and a ceramic material are compounded, thereby forming the polymer-ceramic compound nanometer fibrous membrane, wherein the weight of the polymer material is 60-90% of the weight of the polymer-ceramic compound nanometer fibrous membrane; the weight of the ceramic material is 10-40% of the weight of the polymer-ceramic compound nanometer fibrous membrane; a porosity factor between polymer-ceramic compound nanometer fibers in the polymer-ceramic compound nanometer fibrous membrane is 40-75%; and an aperture of a hole formed between the polymer-ceramic compound nanometer fibers is 0.2-10 microns. The polymer-ceramic compound nanometer fibrous membrane can be used as a membrane of a lithium ion battery, a supporter of a micro-filtration material, a supporter of a super-filtration material, a supporter of a nano-filtration material, and the like.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

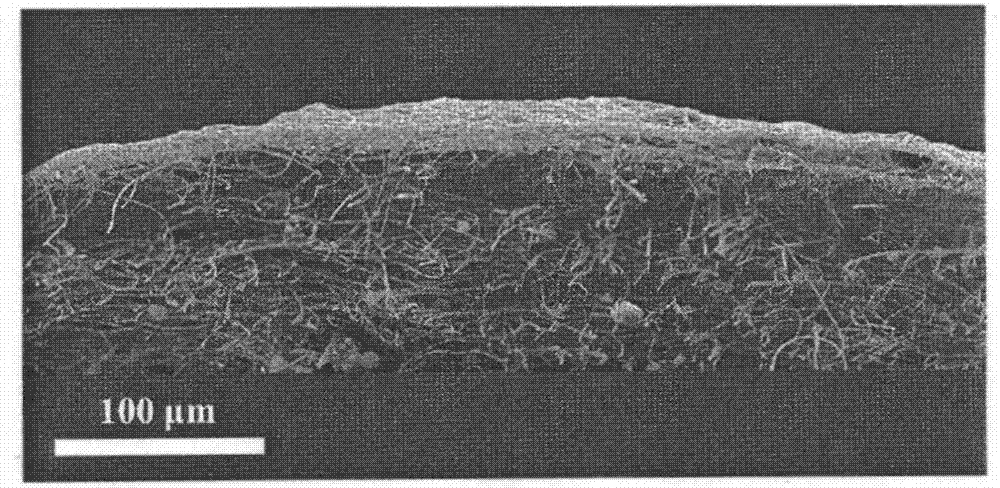

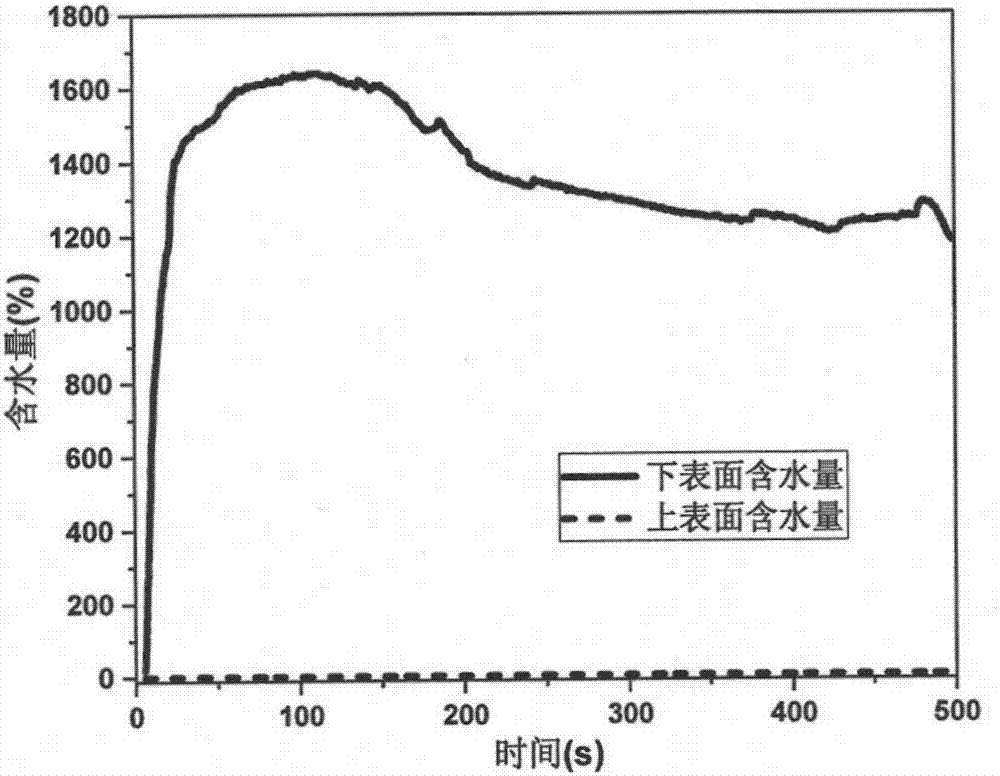

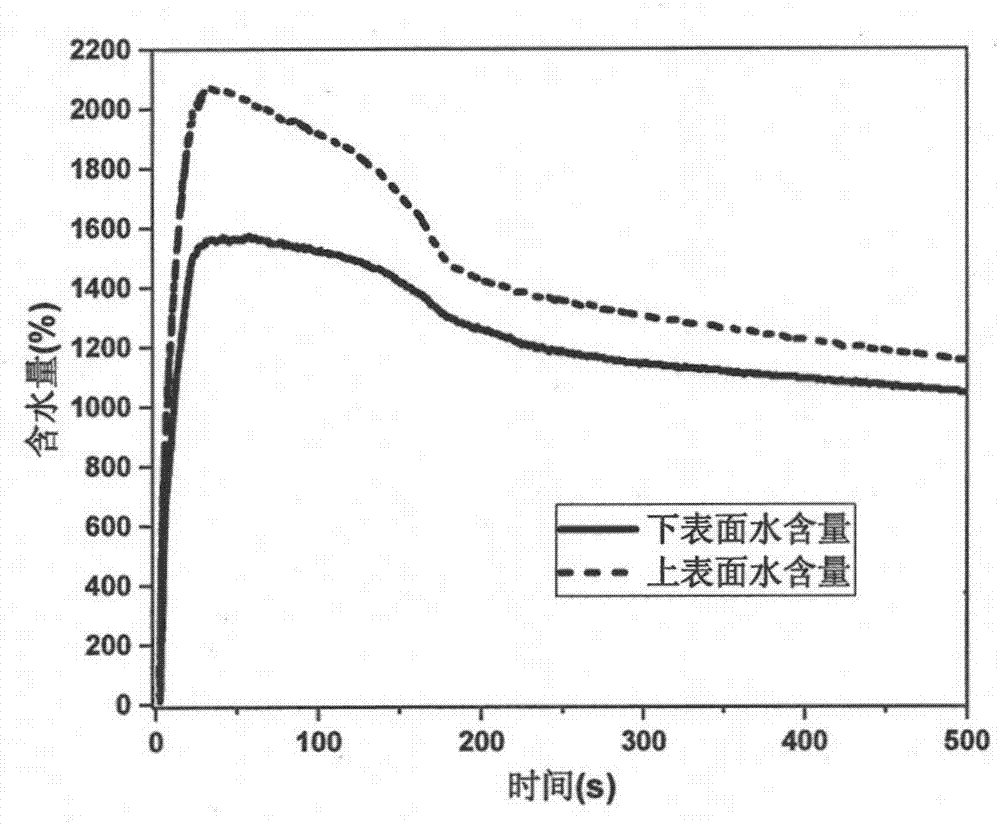

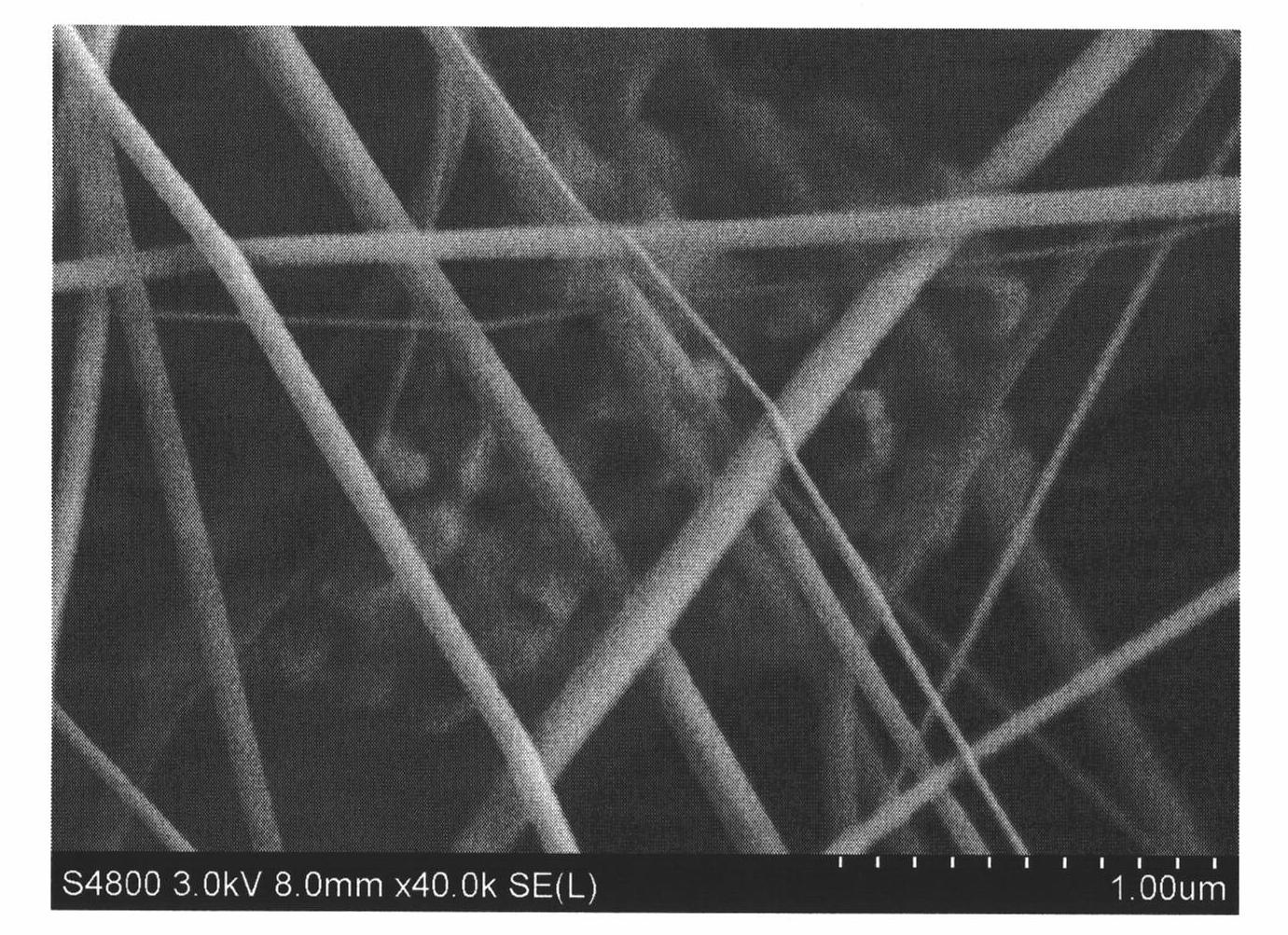

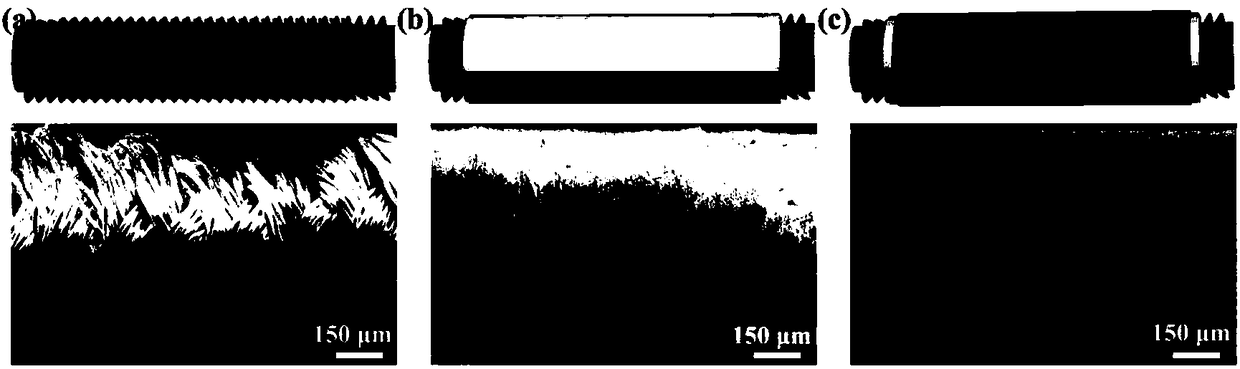

Preparation method of one-way wet conduction nano-fiber multilayer composite membrane with wettability gradient

InactiveCN107059251AExcellent unidirectional moisture transfer performanceWaterproofNon-woven fabricsFiberHydrophobic polymer

The invention discloses a preparation method of a one-way wet conduction nano-fiber multilayer composite membrane with the wettability gradient. The method comprises the following steps that hydrophilic nano materials are dispersed in solvent, the nano materials are dispersed uniformly through ultrasound, a hydrophilic polymer is dissolved in the dispersing agent, a spinning solution A1 is obtained, and a hydrophilic nano-fiber membrane is deposited on a receiving base material through an electrostatic spinning method; hydrophilic nano materials are dispersed in solvent, the nano materials are dispersed uniformly through the ultrasound, a hydrophilic polymer is dissolved in the dispersing agent, and a spinning solution A2 is obtained; a hydrophobic polymer is dissolved in solvent, and a spinning solution B1 is obtained; the two spinning solutions are deposited on the hydrophilic nano-fiber membrane to form at least one diversion layer through the electrostatic spinning method; a hydrophobic polymer is dissolved in solvent, a spinning solution B2 is obtained, a hydrophobic nano-fiber membrane is deposited on the diversion layers through the electrostatic spinning method, and the one-way wet conduction nano-fiber multilayer composite membrane with the wettability gradient is obtained.

Owner:DONGHUA UNIV

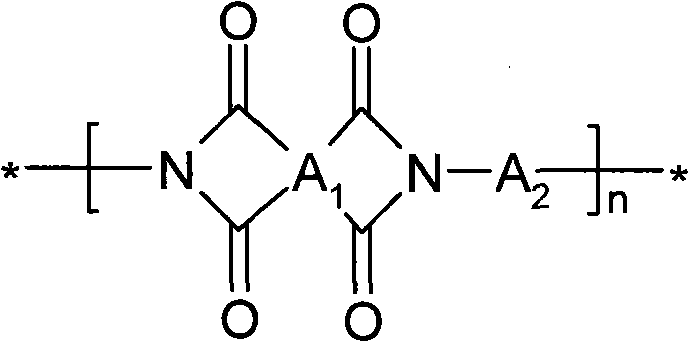

Inorganic/organic composite polyimide-based nanofiber membrane and its preparation method and application

ActiveCN102277648AAperture adjustableHigh tensile strengthFilament/thread formingMonocomponent synthetic polymer artificial filamentFiberPolyamide

The invention relates to an inorganic / organic composite polyimide nanometer fibrous film. The inorganic / organic composite polyimide nanometer fibrous film is formed by an inorganic nanoparticle-doped polyimide nanometer fiber, wherein the mass of the inorganic nanoparticles accounts for 0.1-30% of the mass of polyamide acids; the diameter of the polyimide nanometer fiber is 20-500nm, the thickness of the film is 15-100mum, and the air permeability of the film is 10-500s, apertures on the upper surface; and apertures on the upper surface and the lower surface and in the film symmetrically and uniformly distribute, diameters of the apertures are less than 300nm, and the tensile strength of the film is 100-250MPa. According to the invention, a mixed solution of the inorganic nanoparticles and the polyamide acids is subjected to static spinning, machinery rolling, and high temperature imidization to prepare the film, so a preparation method of the film is suitable for large scale preparation. The inorganic / organic composite polyimide nanometer fibrous film can be applied to high capacity energy storage batteries and high power density power lithium ion batteries.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Preparation method and application of polycaprolactone/natural polymer composite porous scaffold

InactiveCN102277737AImprove hydrophilicityEasy to spreadLayered productsFibre typesFiberPolymer science

Preparation method and application of polycaprolactone / natural polymer composite porous scaffold, method: including preparation of polycaprolactone electrospun nanofiber membrane; (1) placing polycaprolactone electrospun nanofiber membrane in alkaline solution reaction, soaking and rinsing in deionized water; (2) putting the fiber membrane obtained in (1) into DMTMM or natural polymer solution of DTMMM to react, immersing and rinsing in deionized water, and then immersing in natural polymer for room temperature reaction, to remove Ionized water soaking and rinsing; (3) Evenly coating and casting the mixed solution of natural polymer materials on the fiber membrane obtained in (2), freeze-drying, and extracting the solvent; (4) Applying the double-layer scaffold obtained in (3) After soaking in the cross-linking room temperature reaction, soaking in deionized water, rinsing, and freeze-drying. The porous scaffold prepared by the invention is stable, has suitable pore diameter, good biocompatibility and fast degradation rate, and can be used for skin and clinical tissue and organ defect repair, reconstruction or wound dressing.

Owner:NANCHANG UNIV

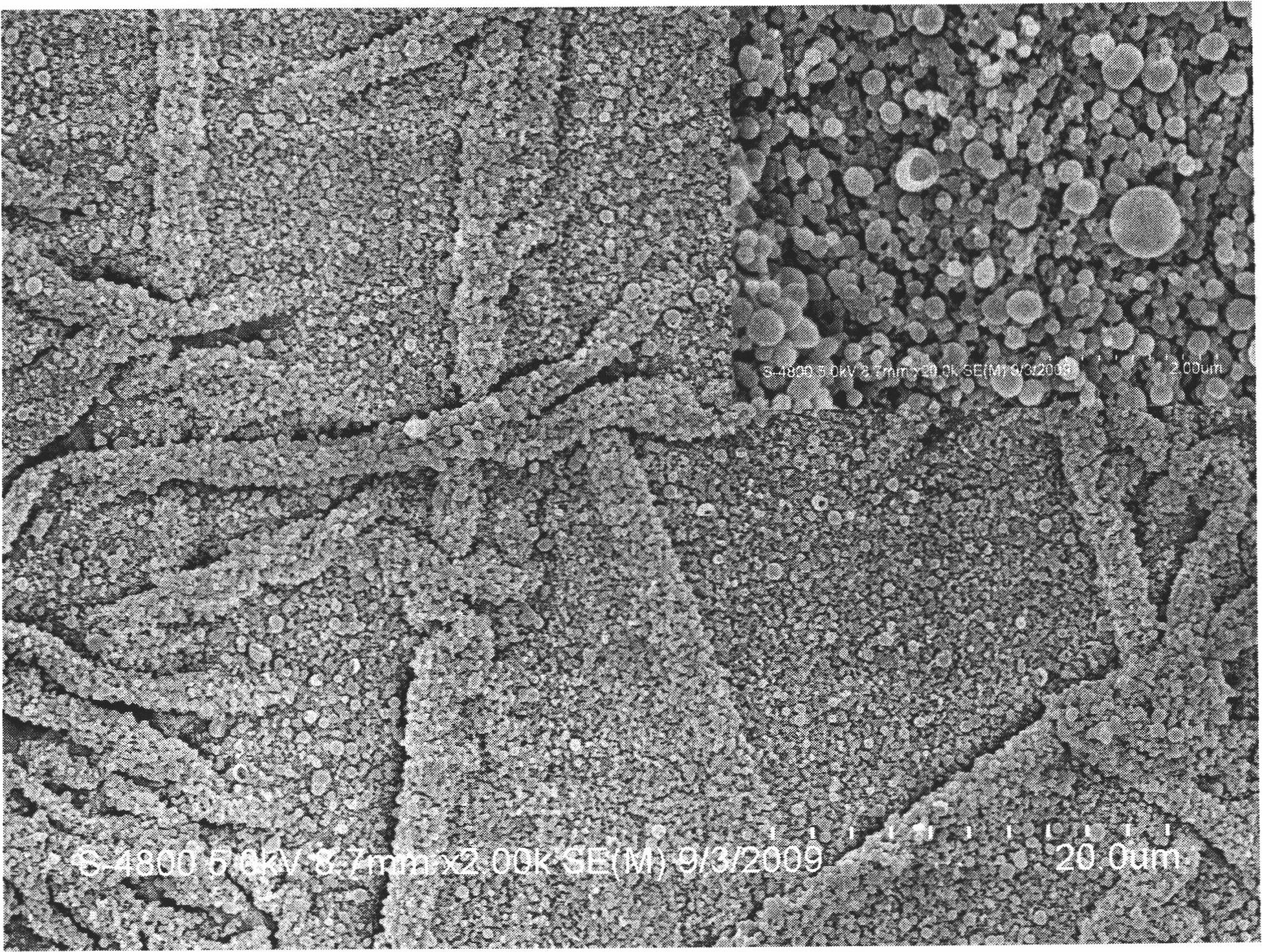

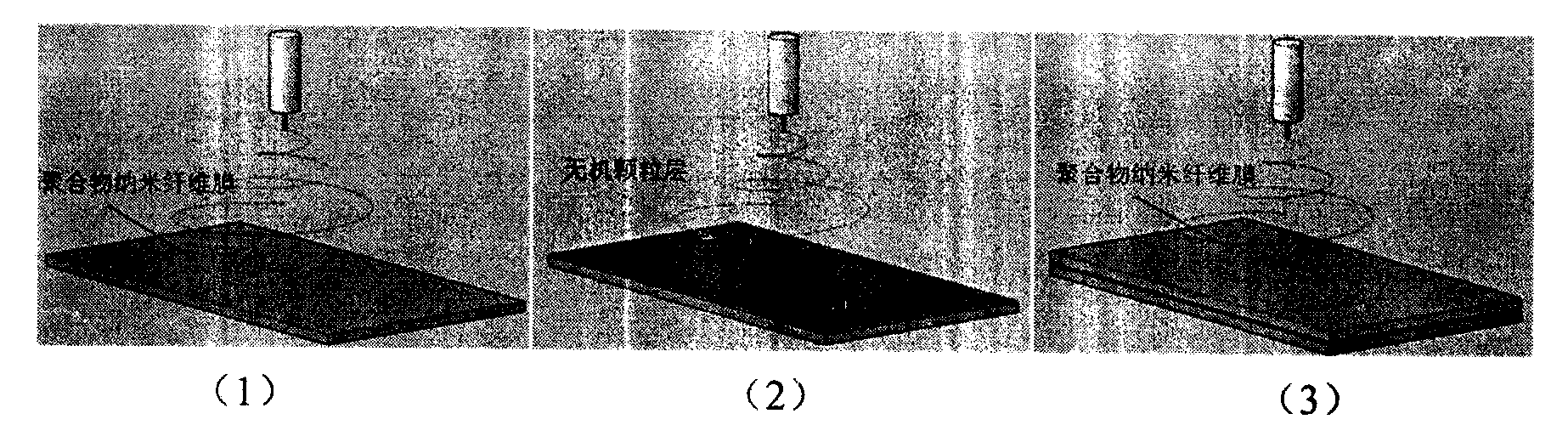

Method for preparing composite lithium-ion battery separator through electrostatic spinning/electrostatic spraying

InactiveCN103474610AExcellent heat shrinkage resistanceIncrease fluid retentionCell component detailsNon-woven fabricsFiberOrganic solvent

The invention relates to the field of lithium-ion batteries, in particular to a method for preparing a composite lithium-ion battery separator through electrostatic spinning / electrostatic spraying. The method specifically includes the steps of firstly, adding high molecular polymer into an organic solvent, dissolving the high molecular polymer through mechanical stirring to form a transparent solution, and obtaining an electrostatic spinning solution; secondly, mixing inorganic nanometer particles with the high molecular polymer and adding the mixture into the organic solvent, and conducting mechanical stirring to obtain inorganic nanometer particle suspension liquid; thirdly, conducting electrostatic spinning on the spinning solution prepared in the first step to prepare a lower layer nanometer fiber film, and enabling the inorganic nanometer particle suspension liquid prepared in the second step to be deposited on the lower layer nanometer fiber film through electrostatic spraying to obtain an interlayer; finally, receiving an electrostatic spun nanometer fiber layer on an inorganic particle layer to obtain the composite lithium-ion battery separator. The composite lithium-ion battery separator has the high imbibing rate and good electrochemical stability under the room temperature and has good heat shrinkage resistance performance at the same time.

Owner:TIANJIN POLYTECHNIC UNIV

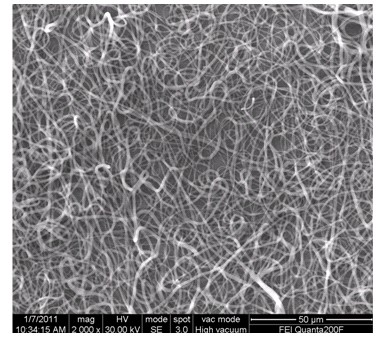

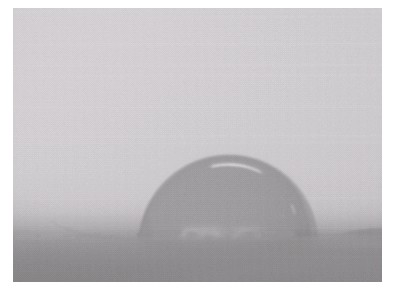

Preparation method of electrostatic spinning hydrophobic nanofiber porous membrane for membrane distillation

The invention relates to a preparation method of an electrostatic spinning hydrophobic nanofiber porous membrane for membrane distillation. The method comprises the following steps of: dissolving a hydrophobic functional polymer material in the solvent to get a 1-35wt% polymer spinning solution, performing electrostatic spinning to get a hydrophobic nanofiber porous membrane, and further performing thermal treatment, thereby obtaining the electrostatic spinning hydrophobic nanofiber porous membrane for membrane distillation. The preparation method provided by the invention is simple and practicable, and can be used for conveniently and accurately controlling the thickness and uniformity of the nanofiber membrane and realizing operations of mass production more easily; the high-hydrophobicity nanofiber porous membrane prepared by the preparation method can be used for signally improving the defects of the conventional membrane for membrane distillation that the water flux is low and the membrane pores get wet easily, so that the membrane distillation technology can compete with a reverse osmosis technology in the seawater desalination field.

Owner:DONGHUA UNIV

Porous complex gel-nanofiber oxygen permeation dressing and preparation method thereof

ActiveCN104491914AHigh oxygen permeabilityImprove antibacterial propertiesAbsorbent padsBandagesWound dressingFreeze-drying

The invention discloses a porous complex gel-nanofiber oxygen permeation dressing and a preparation method thereof. The method comprises the following steps: obtaining a collagen nanofiber membrane by adopting a collagen solution by virtue of an electrostatic spinning method; performing chemical crosslinking on two natural and non-toxic macromolecule polysaccharides such as chitosan and alginic acid, and preparing complex gel; and preparing the porous sponge-nanofiber double-layer composite material in a freeze-drying mode, wherein the upper gel layer of the dressing is in a sponge state during drying and is in a gel state after moisture absorption. The biological wound dressing is prepared under the condition that any toxic chemical crosslinking agent is not added, the process is simple, and the safety is high. The prepared biological wound dressing disclosed by the invention has the characteristics of excellent oxygen permeation performance, water-absorbing quality, water permeability, moisture penetrability and high biocompatibility, a physiological wet environment of the wound surface can be maintained, wound healing and effective haemostasis are promoted, wound infection can be avoided, the recovery is accelerated, the wound surface can be effectively recovered, and the dressing is applied to multiple wound surfaces such as trauma, burns and ulceration.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

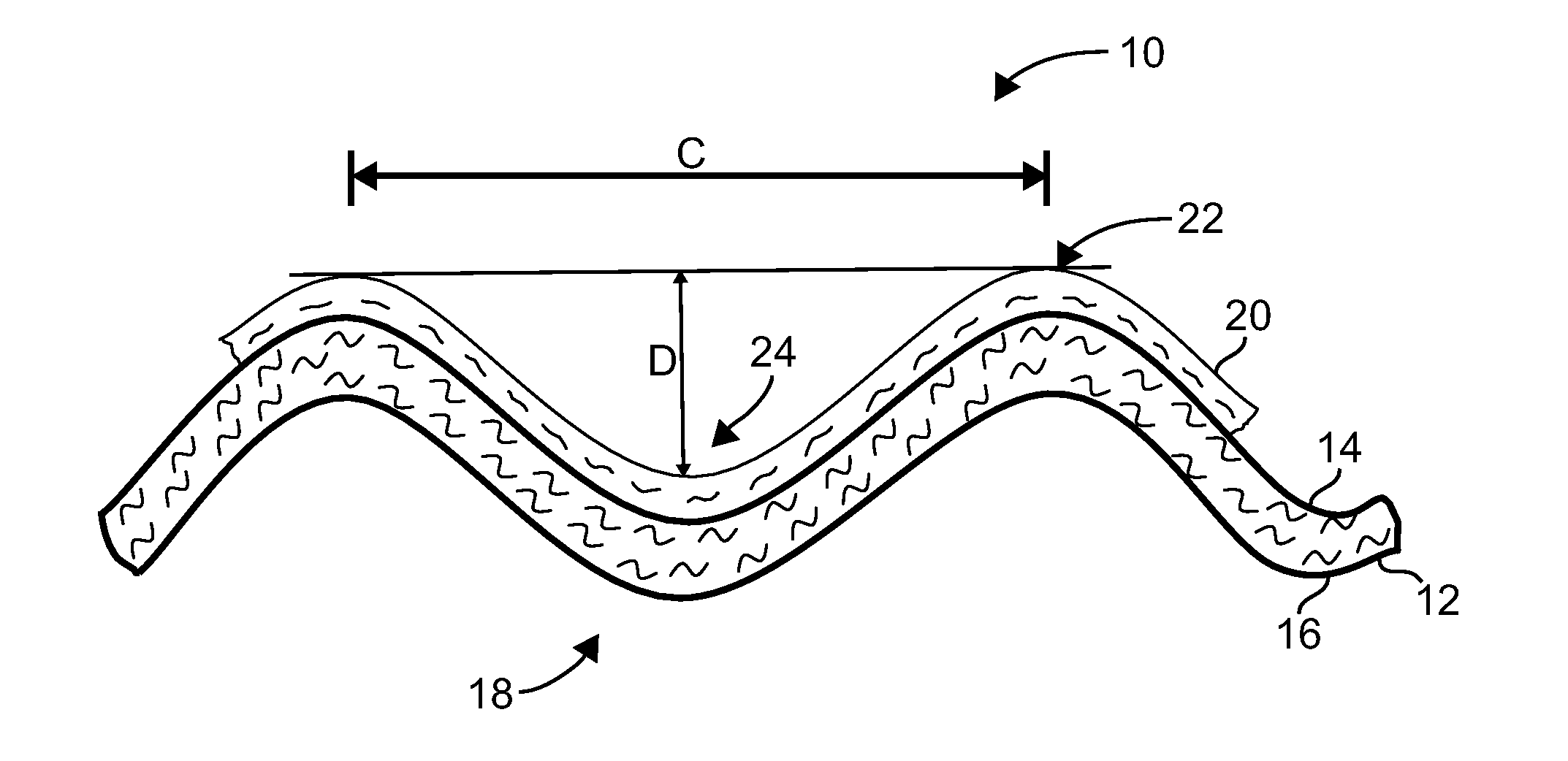

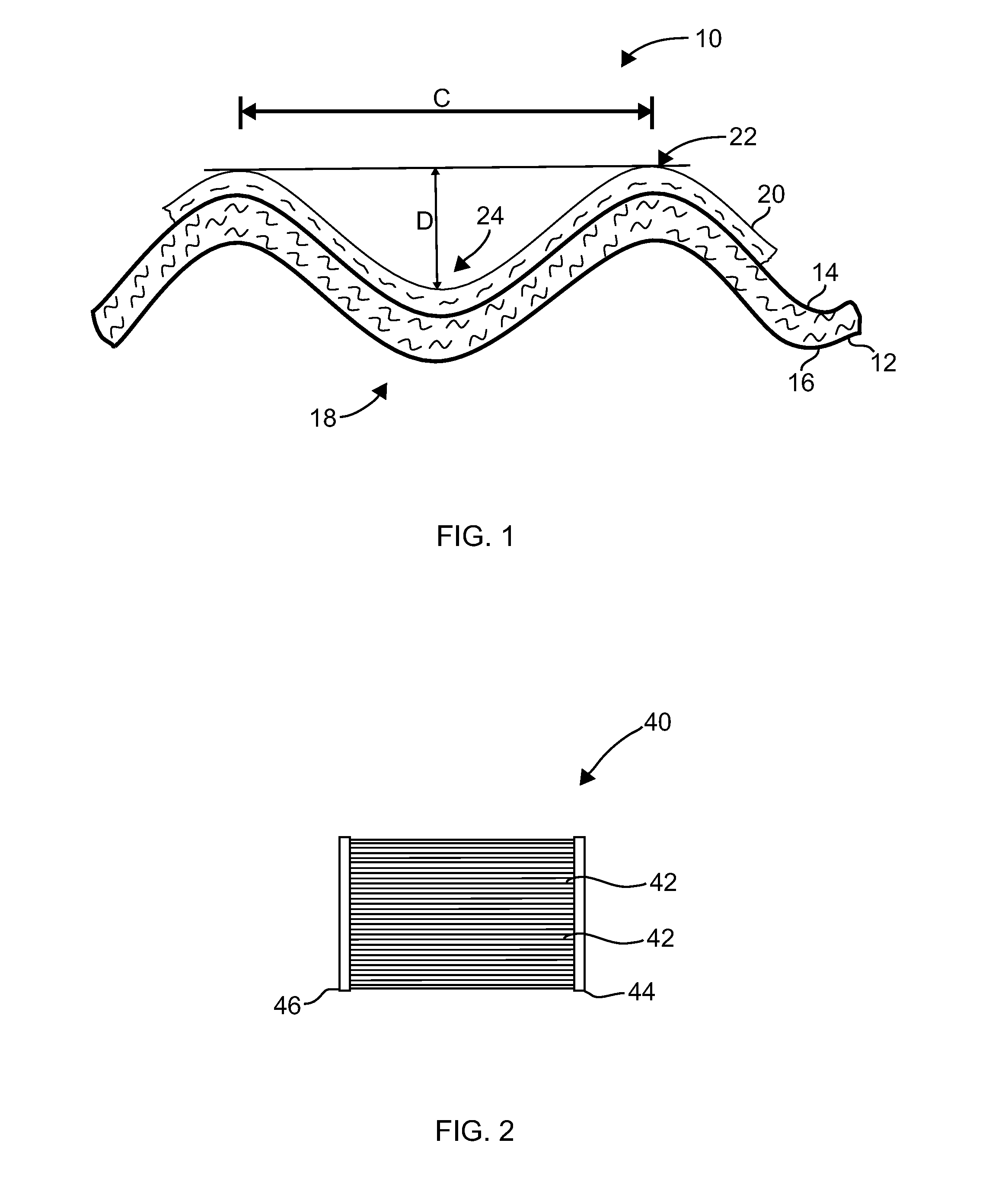

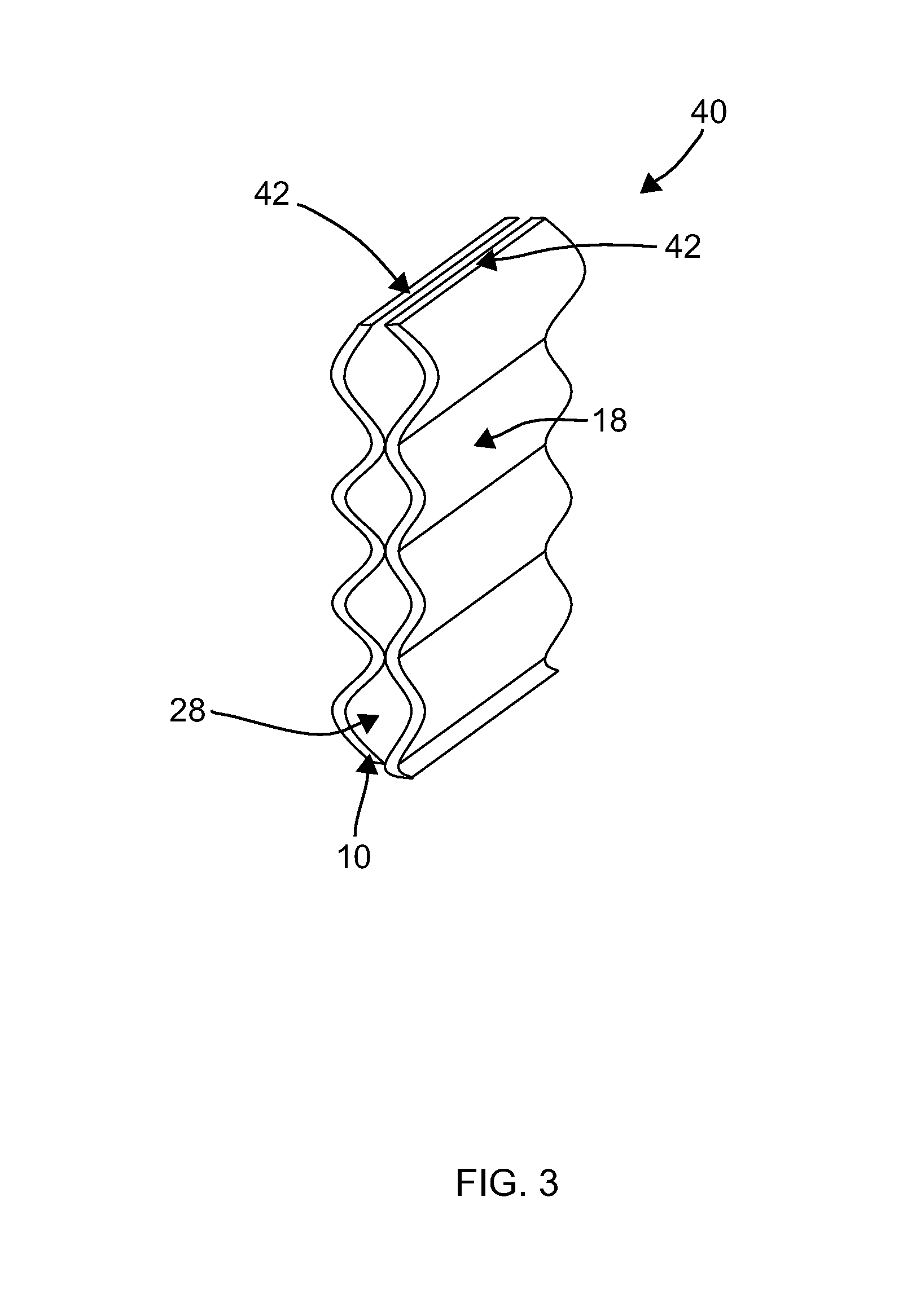

Composite filter media and methods of manufacture

A composite filter media structure is provided. In an exemplary embodiment, the composite filter media structure includes a corrugated base substrate that includes a nonwoven synthetic fabric formed by a dry-laid process that corrugates the base substrate during the forming process. The composite filter media structure also includes a nanofiber membrane deposited on at least one side of the base substrate by an electro-blown spinning process.

Owner:EI DU PONT DE NEMOURS & CO +1

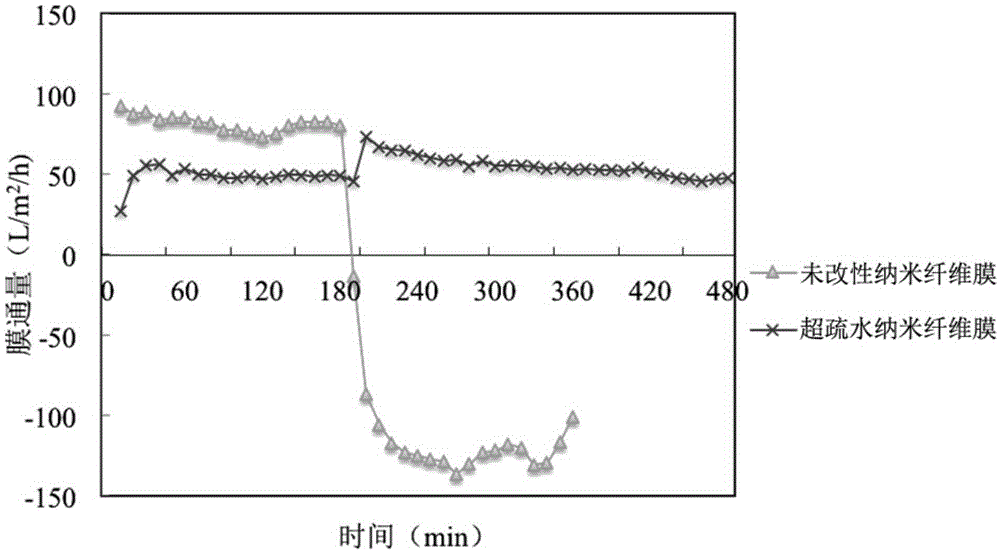

Preparation method and application of super-hydrophobic membrane

The invention provides a preparation method of a super-hydrophobic membrane. The preparation method comprises steps as follows: hydrophobic organic polymer materials and nano granules are dissolved in an organic solvent, the mixture is stirred and left to stand, and an electrostatic spinning solution is prepared; high-pressure electrostatic spinning parameters are set, electrostatic spinning membrane preparation is performed, and a nanofiber membrane is obtained and subjected to thermal treatment; TiO2 is prepared, the surface of the nanofiber membrane is covered with TiO2, and thermal treatment, water-bath heating, washing and ultraviolet radiation treatment are performed; silane solutions are prepared, the nanofiber membrane surface covered with TiO2 is covered with the silane solutions, thermal treatment, washing and airing are performed, and the super-hydrophobic membrane is obtained. The invention further provides an application of the super-hydrophobic membrane in the membrane distillation process. By means of the method, the super-hydrophobic nanofiber membrane is prepared. The membrane simultaneously has super-hydrophobicity and high throughput performance, the wet resistance of the membrane is effectively improved, and the service life of the membrane is prolonged.

Owner:SHANGHAI JIAO TONG UNIV

Antibacterial type blended electro spinning nanometer fiber membrane biological dressing and the preparing method thereof

InactiveCN101062426AIncrease the areaHigh porosityFilament/thread formingAbsorbent padsFiberPolyvinyl alcohol

The invention discloses a blending electric spun nanometer fiber film biological compress and preparing method in medicinal biological compress technical domain, which is characterized by the following: choosing chitose or polyvinyl alcohol or water-soluble antibacterial drugs as main raw material; adopting electrostatic spinning method; producing nanometer fiber film. This product possesses the advantages of higher strength, good air perviousness and good biological compatibility.

Owner:BEIJING UNIV OF CHEM TECH

Preparation method of antibacterial nanofiber membrane

ActiveCN105200663AImprove antibacterial propertiesOvercome mechanical propertiesSolvent-treatmentSucessive textile treatmentsFiberCross-link

The invention provides a preparation method of an antibacterial nanofiber membrane. The method comprises the procedures of preparation of a nanofiber membrane, preparation of germicide solutions and modification of the nanofiber membrane by the germicide solutions. The method is characterized in that the antibacterial nanofiber membrane is prepared by soaking the nanofiber membrane in the germicide solutions of different concentrations; the nanofiber membrane is formed by being subjected to a polymerization reaction in an organic monomer or a solution of the organic monomer and an inorganic germicide, or is formed by being directly soaked in a polymer solution or a germicide solution of a polymer and an inorganic mixed solution. The preparation method comprises the following steps: step (1), preparing the germicide solutions; step (2), preparing a polymer electrostatic spinning solution and preparing the nanofiber membrane; step (3), modifying the nanofiber membrane by the germicide solutions; an obtained hierarchical-pore nanofiber cross-linked-structure thin film of a core-shell structure is an antibacterial nanofiber membrane finished product.

Owner:上海展恒环保科技有限公司

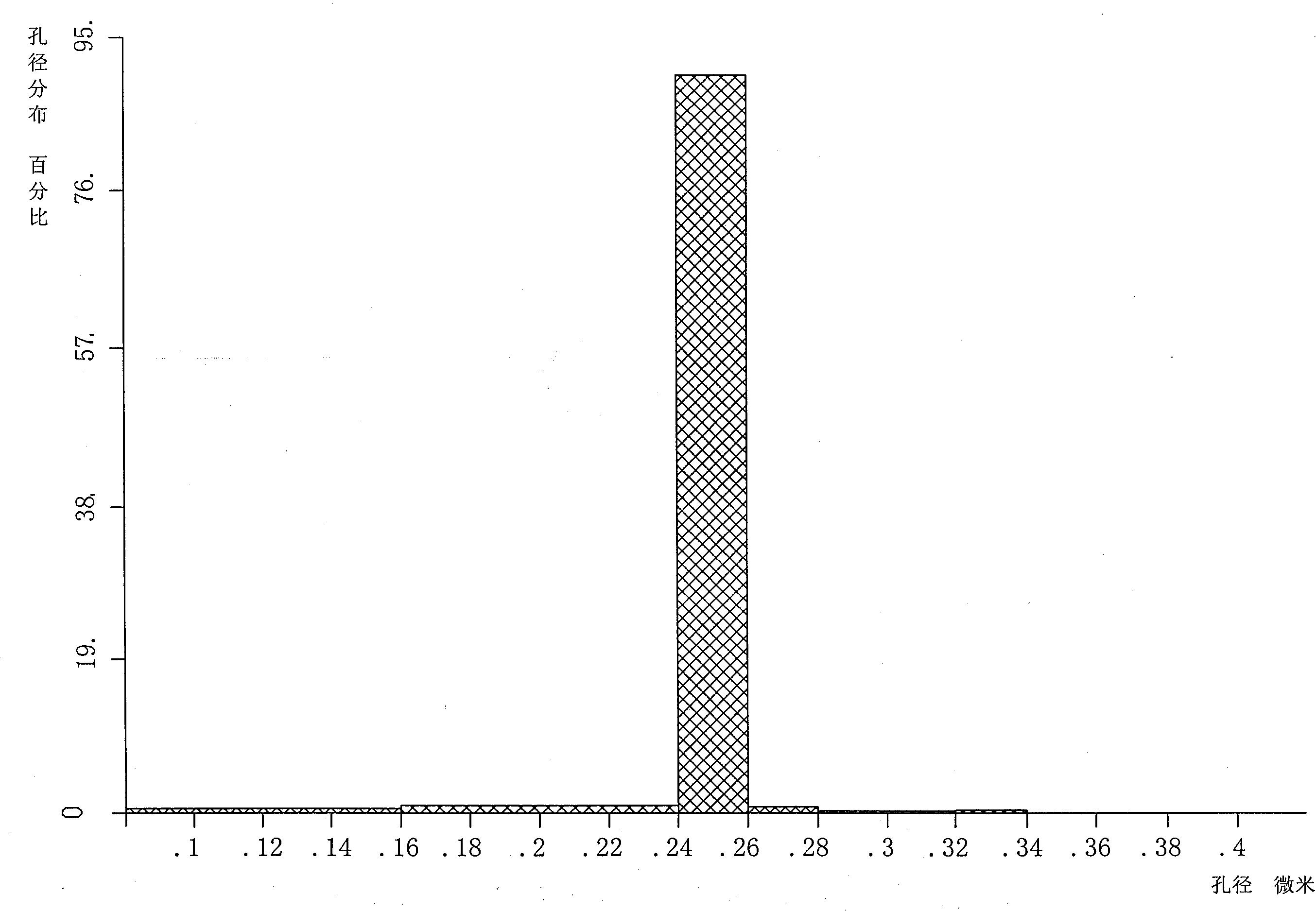

Polyimide-base nano fibrous membrane, and preparation method and application thereof

ActiveCN102251307AEasy to manufactureUniform pore structureFilament/thread formingMonocomponent synthetic polymer artificial filamentFiberPore distribution

The invention discloses a polyimide-base nano fibrous membrane which can be used as a lithium ion secondary battery membrane. The polyimide-base nano fibrous membrane is composed of polyimide nano fibers of which the diameters are 20-500 nanometers, the membrane thickness is 15-100 micrometers, and the air penetrability of the membrane is 10-500 seconds; and the pore distribution of the upper andlower surfaces and the inside is symmetrical and uniform, the average pore size is 100 nanometers, and the tensile strength is 100-250mpa. The invention also discloses a preparation method of the polyimide-base nano fibrous membrane. When being used as the lithium ion battery membrane, the polyimide-base nano fibrous membrane has favorable heat resistance, and can not produce the phenomenon of short circuit even at 150 DEG C; and therefore, the battery membrane disclosed by the invention is especially suitable for high-capacity and high-power lithium ion batteries.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

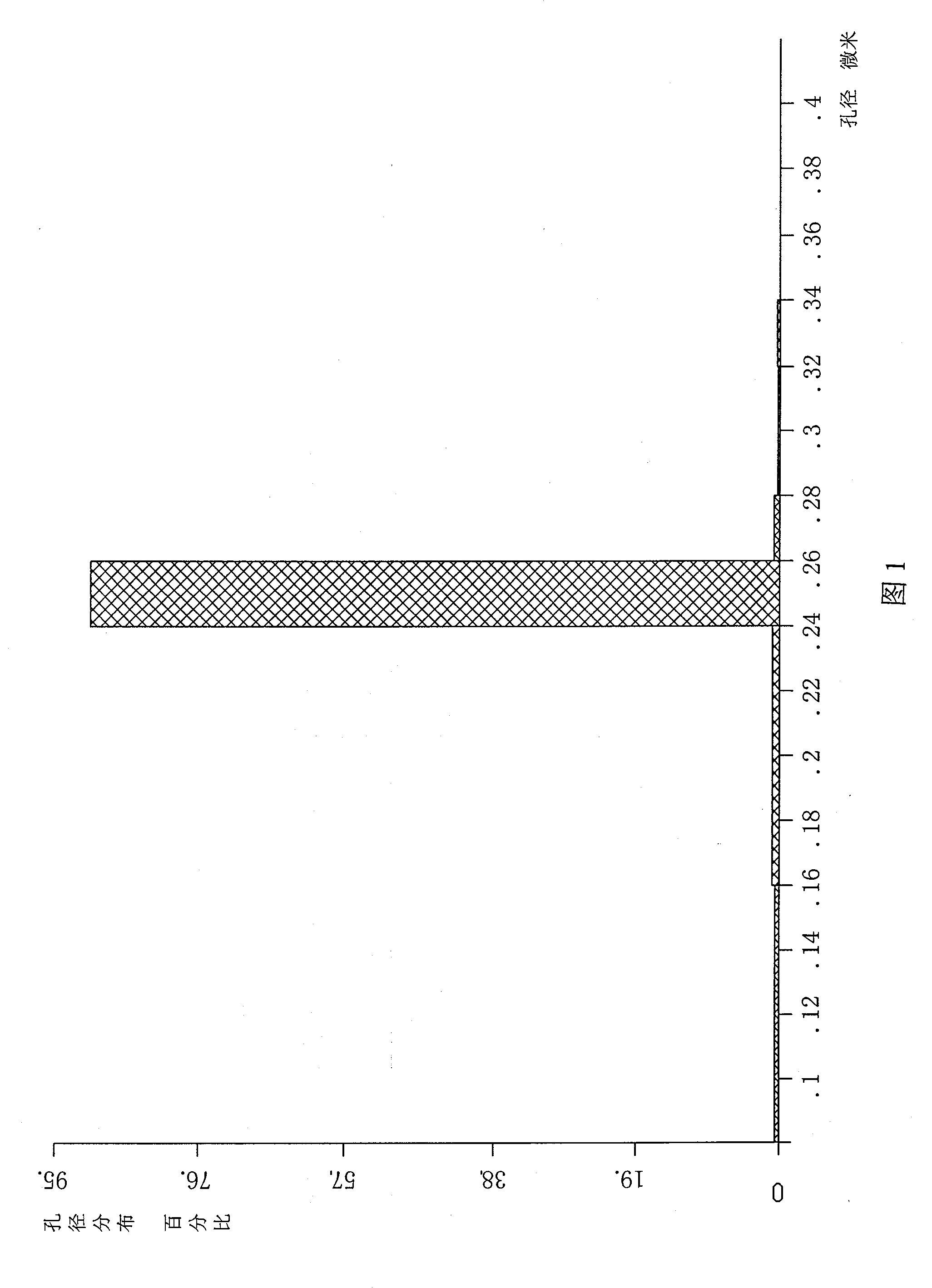

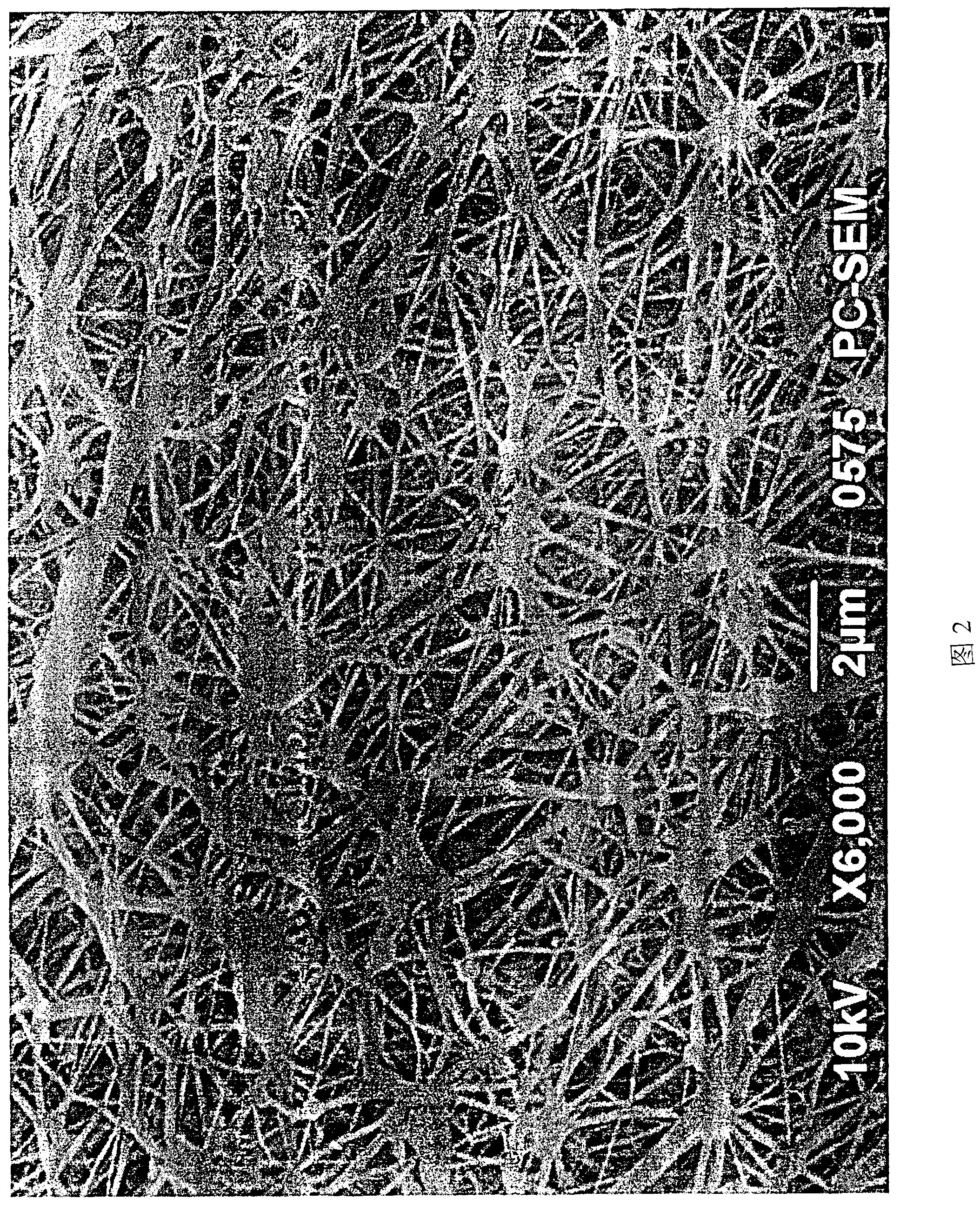

Polyfluortetraethylene nanofibre membrane and preparation method thereof

InactiveCN101543734BAvoid filter efficiencyHigh water pressure resistanceSemi-permeable membranesFlat articlesAir filtrationWater resistant

The invention relates to a polyfluortetraethylene nanofibre membrane and a preparation method thereof. The aperture distribution of the polyfluortetraethylene nanofibre membrane is concentrated within a range of + / -100 nanometers and occupies more than 90 percent of the total volume of each level aperture; the stretching process of the preparation method adopts low-temperature segmenting stretching, thus the stretching temperature is stable, the polyfluortetraethylene nanofibre membrane is uniformly heated, and giant molecule segmers are equally unfolded; the produced polyfluortetraethylene nanofibre membrane has concentrated aperture distribution and high uniformity so as to generate high water pressure resistance, long water resistant time and high membrane fibering degree, and the obstructing efficiency of bacteria reaches more than 99.99 percent, thereby the polyfluortetraethylene nanofibre membrane can meet the requirement of oil-water separation and high-end gas filtration of anoperation isolation mattress with high-pressure steam filtration and high water pressure resistance and can be used in fields of superclean room entering air filtration, and the like, such as medicaltreatment and health protection, health matter cultivation, semiconductor devices, integrated circuit, medicine, and the like.

Owner:北京千叶宝莲科技有限公司

Preparation method of flexible strain sensor based on conductive fiber and application thereof

ActiveCN108560250AHigh ability to adapt to deformationExpand the detection rangeFibre treatmentCatheterYarnFiber

The invention provides a preparation method of a flexible strain sensor based on conductive fiber and application thereof. The conductive fiber comprises a metal nanowire as a conductive layer, an electrospun polymer nanofiber membrane as a protective layer and an elastic yarn as an elastic carrier. In the preparation process, the surface of the elastic yarn is coated with a layer of polymer nanofiber membrane by an electrospinning technology first and then the metal nanowire is deposited on the surface structure thereof through multiple dip coating. The prepared flexible strain sensor based on the conductive fiber has the ability of quickly detecting various deformations such as stretching, bending and twisting, and the sensitivity thereof is still maintained to be 90% or above after thenumber of stretching cycles reaches 10,000; the flexible strain sensor can achieve simultaneous detection of human pulse beat, vocal cord vibration and more complex multiple sites, and has a great application potential in smart wearable devices such as virtual reality, human-machine interfaces and health monitoring.

Owner:GENERAL HOSPITAL OF PLA +1

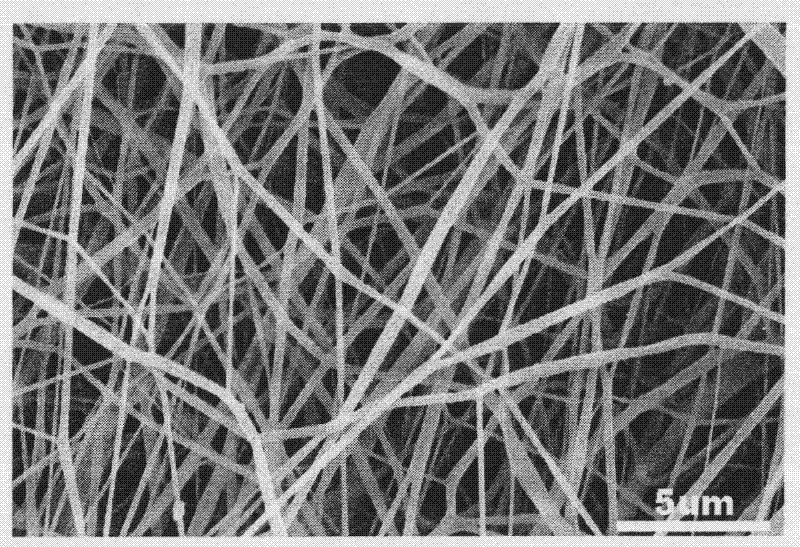

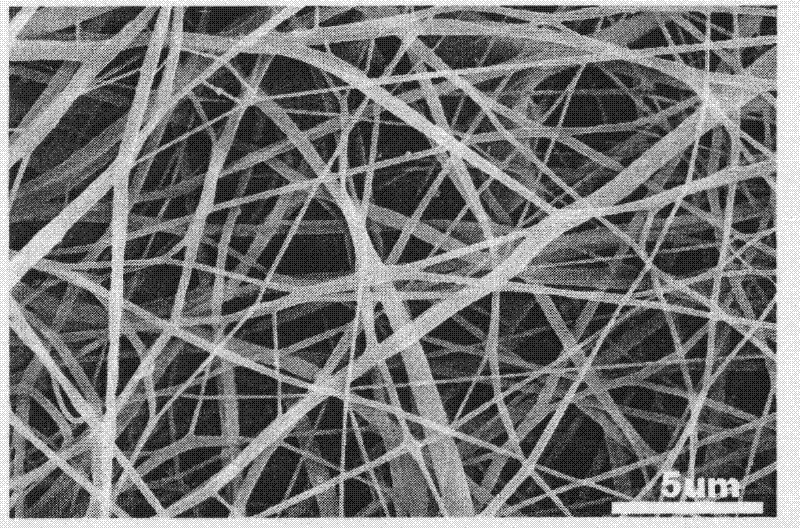

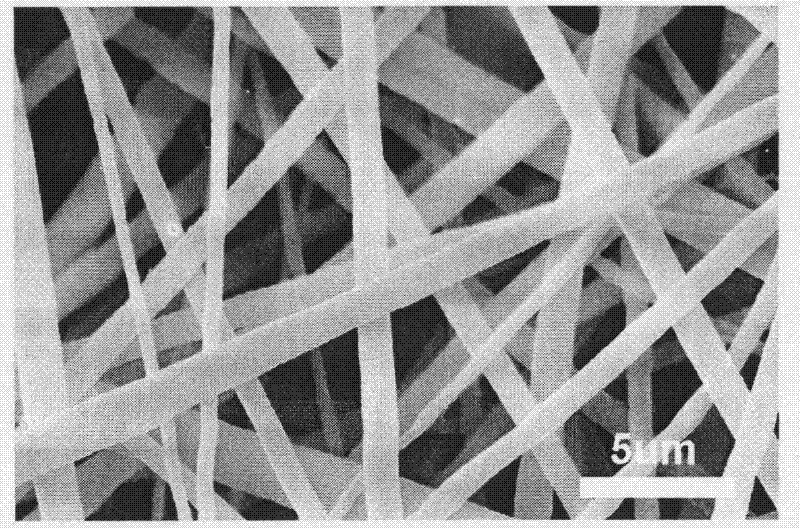

Method for enhancing electrostatic spinning nanofiber membrane

ActiveCN103541149AImprove mechanical propertiesEasy to manufactureElectro-spinningNon-woven fabricsFiberPolymer science

The invention discloses a method for enhancing an electrostatic spinning nanofiber membrane. The blending electrostatic spinning-hot rolling bonding net fixing technology which can effectively improve the strength of the electrostatic spinning nanofiber membrane is provided. The method for enhancing the electrostatic spinning nanofiber membrane is characterized in that interphase blending electrostatic spinning is conducted through multiple types of thermoplastic high polymers with the fusion point at least 20 DEG C lower than that of other components or low-fusion-point thermoplastic high polymers and non-thermoplastic high polymers, electrostatic spinning jet flows of the components are distributed frontwards and backwards in the moving direction of a receiving device, and fibers are distributed randomly in a staggered mode; after hot rolling is conducted on a blending electrostatic spinning fiber membrane, the blending electrostatic spinning fiber membrane is treated, the hot pressing temperature is slightly higher than the fusion starting temperature of the low-fusion-point thermoplastic high polymers, time ranges from 1min to 10min, the pressure ranges from 1MPa to 20MPa, after hot pressing is conducted, part of the low-fusion-point thermoplastic high polymers is fused, point adhesion is generated on the nanofiber intersection portions, and a hole is not blocked. The method for enhancing the electrostatic spinning nanofiber membrane has the advantages that the strength of the prepared enhanced electrostatic spinning nanofiber membrane is far higher than that of a common electrostatic spinning membrane and original good performance of the electrostatic spinning nanofiber membrane can be kept.

Owner:TIANJIN POLYTECHNIC UNIV

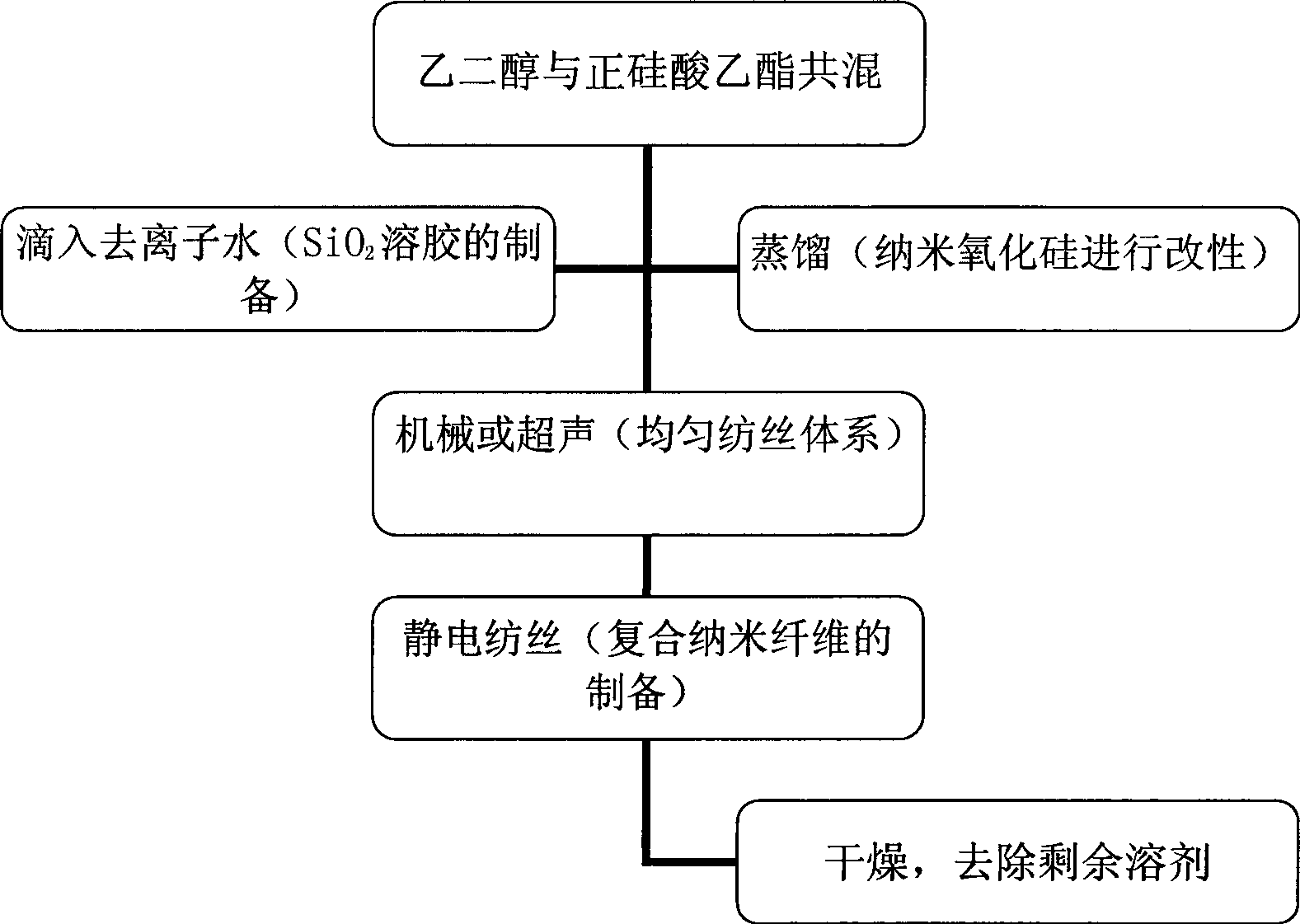

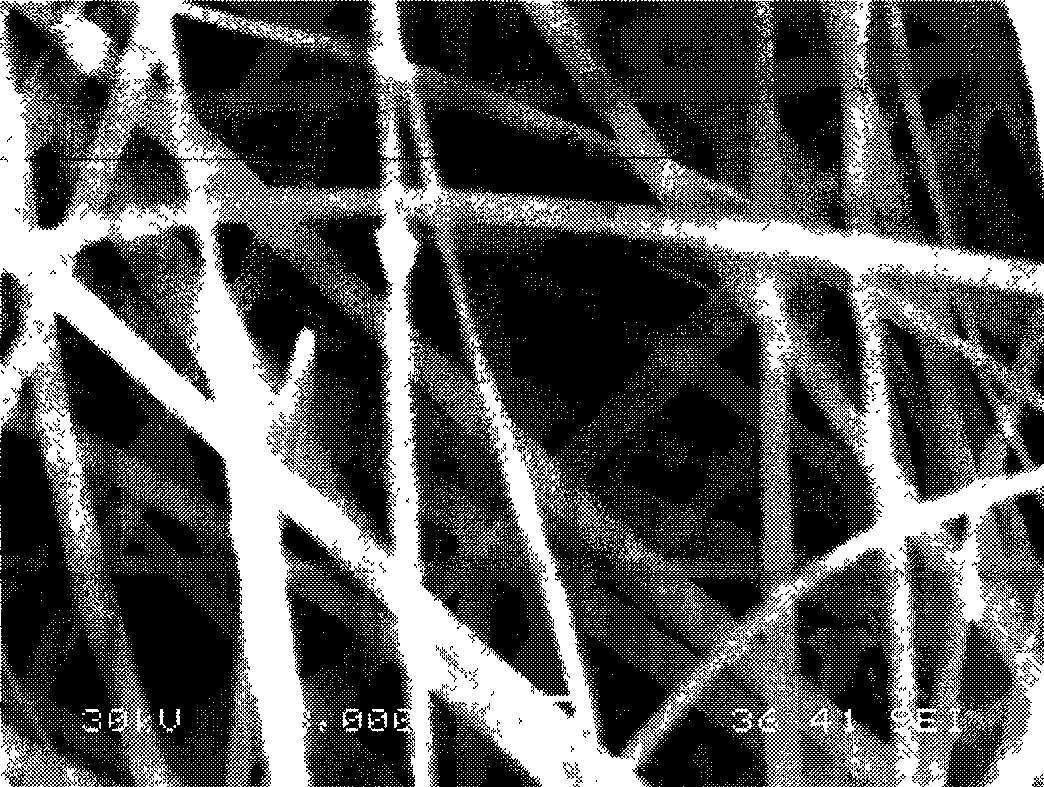

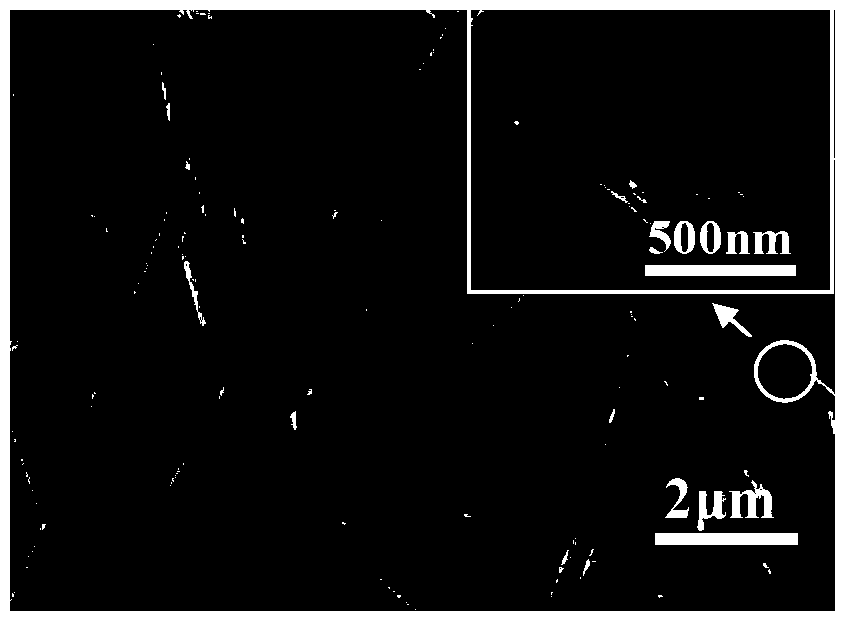

Preparation of silicon dioxide / polyvinylidene fluoride composite nano fiber film

InactiveCN101481855AHigh strengthImprove photoelectric performanceFilament/thread formingNon-woven fabricsLithium-ion batterySilicon dioxide

A preparation method of a silicon dioxide / polyvinylidene fluoride composite nano-fiber membrane relates to the technical fields of preparing modified nano-silicon dioxide by a sol-gel method, preparing a silicon dioxide / polyvinylidene fluoride nano-fiber membrane by an electrostatic spinning device and the like. The preparation method comprises the following steps: preparing the modified nano-silicon dioxide in virtue of a sol-gel principle by a one-step method; mixing the modified nano-silicon dioxide with the polyvinylidene fluoride; and preparing the composite nano-fiber by an electrostatic spinning technology. The preparation method helps relieve the disadvantages of low strength of the nano-fiber, long preparation flow of the modified nano-silicon dioxide, complex process and the like in the electrostatic spinning technology. The nano-fiber prepared by the method has the advantages of high strength, high machinability, short fiber diameter and uniform distribution and can be widely applied to a plurality of fields such as lithium ion battery diaphragm, filtering, biomedical material and the like.

Owner:JIANGNAN UNIV

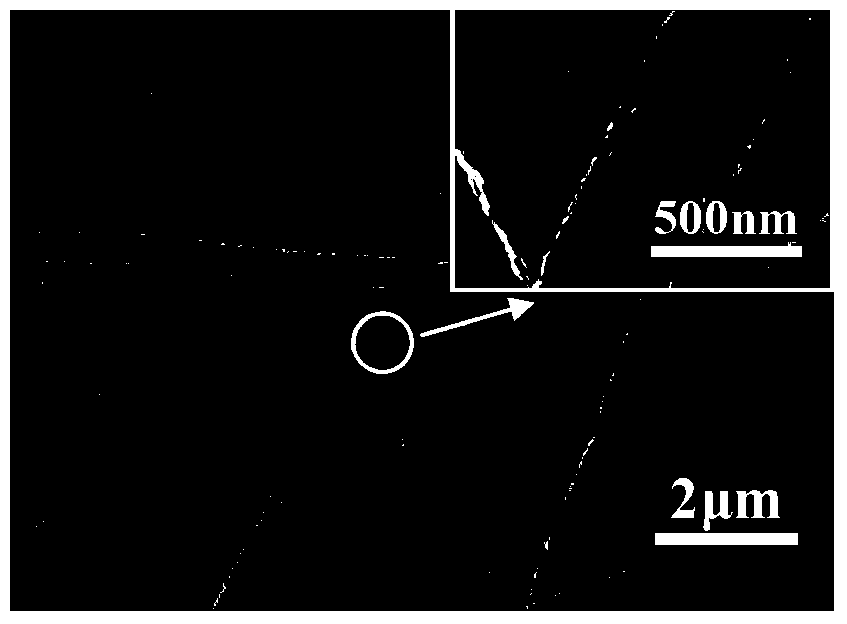

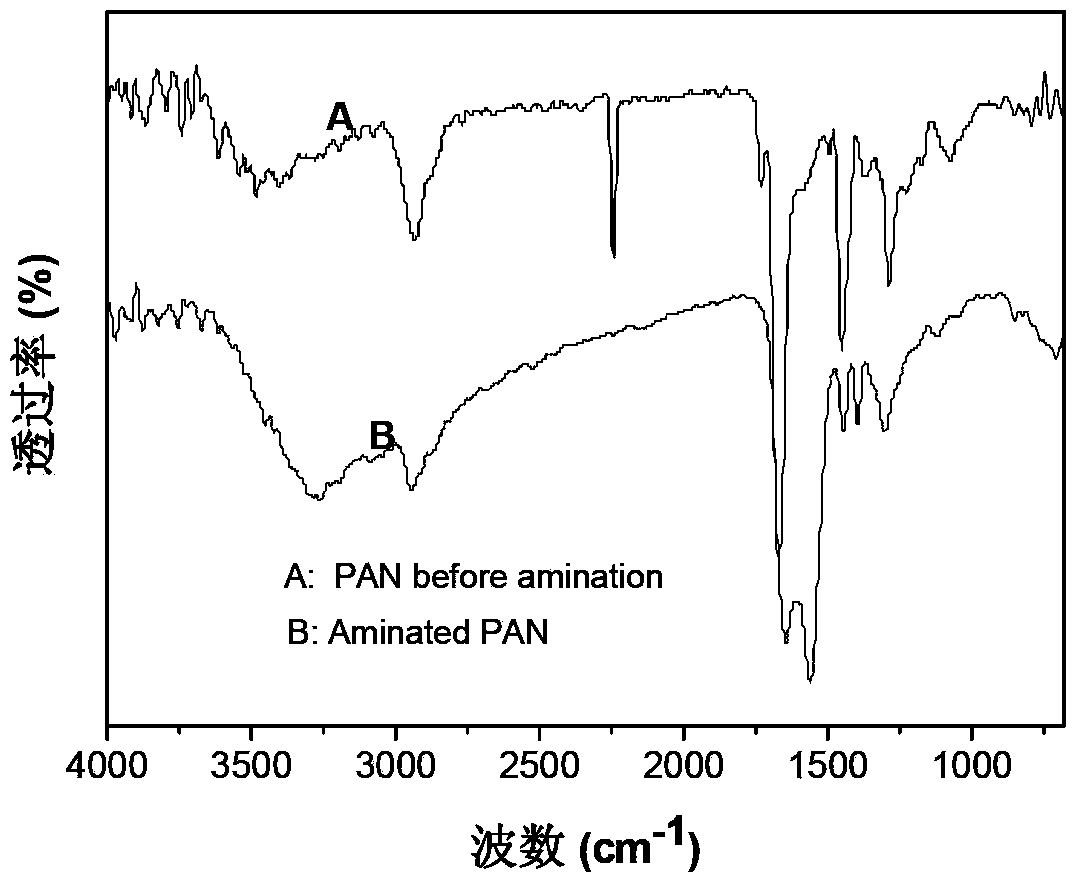

Preparation method of aminated nanofiber membrane with high specific surface area

InactiveCN103394334ALarge specific surface areaIncreased amine contentOther chemical processesFibre treatmentFiberNano structuring

The invention relates to a preparation method of an aminated nanofiber membrane with a high specific surface area. The preparation method comprises the following steps of: dissolving two polymer materials with the weight ratio of 1: (0.1-10) or dissolving a polymer material and an inorganic salt into a solvent, dissolving while stirring at the temperature of 20-80 DEG C for 4-96h, and carrying out electrostatic spinning to obtain a composite nanofiber membrane; soaking the composite nanofiber membrane into water, regulating the pH value, soaking at the temperature of 20-95 DEG C for 2-48h, washing and drying to obtain a nanofiber membrane with a porous micro / nano structure and a high specific surface area; and immersing the nanofiber membrane with a porous micro / nano structure and a high specific surface area into water, adding an amination reaction reagent to carry out amination reaction at the temperature of 50-200 DEG C, then, taking out the fiber membrane, washing the fiber membrane to be neutral, and drying the fiber membrane to obtain the aminated nanofiber membrane with a high specific surface area. The product provided by the invention is applied to fields such as adsorption and separation of precious metal ions, heavy metal ions and transition metal ions, chemical probes, sensors, environment monitoring, catalysts, biological medicines and the like.

Owner:DONGHUA UNIV

Method for preparing chitosan-based silver-loaded composite antimicrobial superfine fiber membrane

InactiveCN103705969ABroad-spectrum antibacterialImprove antibacterial propertiesAbsorbent padsNon-woven fabricsFiberPolyvinyl alcohol

The invention provides a method for preparing a chitosan-based silver-loaded composite antimicrobial superfine fiber membrane. The method is characterized by particularly comprising the following steps: 1, adding silver nitrate powder into an acetic acid aqueous solution with the mass fraction of 50-90%, stirring to dissolve to obtain a solution, weighing and adding chitosan and polyoxyethylene or polyvinyl alcohol powder into the solution, and stirring to obtain a spinning solution; and 2, adding the spinning solution into an electrostatic spinning device, carrying out electrostatic spinning under the conditions that the voltage is 10-20kv, the spinning solution injecting speed is 0.1-1.0mL / h, the receive distance is 8-30cm, the spinning temperature is 20-50 DEG C and the relative humidity is 10-55%, carrying out vacuum drying on the obtained white nanofiber membrane for 12-36 hours, and removing the residual solvent to obtain the chitosan-based silver-loaded composite antimicrobial superfine fiber membrane. The electrospun fiber membrane has the advantages of a certain mechanical property, good antimicrobial property and water absorbing ability and can be used for the fields of wound surface nursing and medical dressings with different anti-infection requirements through designing the compositing ratio of the chitosan and the nanometer silver.

Owner:DONGHUA UNIV

Preparation method of super-hydrophobic or super-hydrophilic nanofiber membrane with antibacterial performance

ActiveCN105568556AThickness is easy to controlImprove selective wettabilityFilament/thread formingNon-woven fabricsFiberNanoparticle

Owner:上海展恒环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com