Polymer-ceramic compound nanometer fibrous membrane as well as preparation method and application thereof

A ceramic composite material, nanofiber membrane technology, applied in fiber processing, fiber chemical characteristics, chemical instruments and methods, etc., can solve problems such as poor mechanical strength of nanofiber membranes, and achieve high mechanical strength, high porosity, specific surface area. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

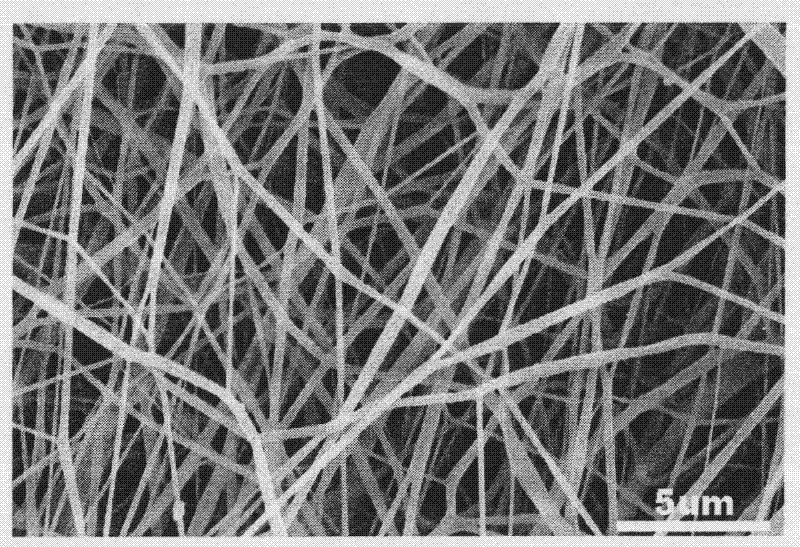

Embodiment 1

[0036] 1) Preparation of composite spinning solution

[0037]Dissolve 8g of polyvinylidene fluoride in 64.4g of N,N-dimethylformamide and 27.6g of acetone, and stir at a temperature of 55°C for 24 hours to obtain a clear and transparent A solution, wherein the polyvinylidene fluoride in A solution The mass concentration of ethylene is 8%; 0.88g fumed silica (diameter is 200nm) nanoparticle joins 10gN, in the N-dimethylformamide, mixes with A solution after ultrasonic dispersion 3 hours, at room temperature with The planetary ball mill grinds for 24 hours to obtain a composite spinning solution; the mass of the ceramic material in the composite spinning solution is 40% of the total mass of the polyvinylidene fluoride and the ceramic material.

[0038] 2) Preparation of polymer-ceramic composite nanofiber membrane by electrospinning

[0039] Place the polyvinylidene fluoride-nanometer silicon dioxide composite spinning solution prepared in step 1) in the liquid injection device...

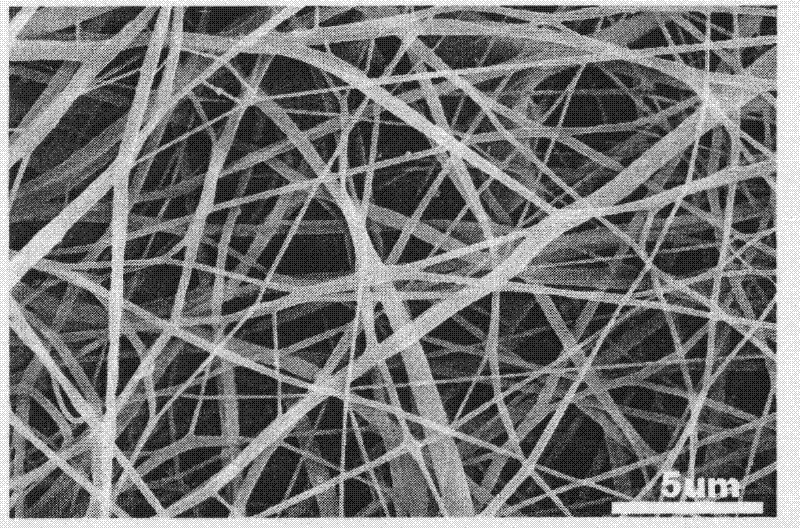

Embodiment 2

[0045] 1) Preparation of composite spinning solution

[0046] Dissolve 8g of vinylidene fluoride-hexafluoropropylene copolymer in 44.4g of N,N-dimethylformamide and 27.6g of acetone, and stir at 55°C for 24 hours to obtain a clear and transparent A solution, wherein, A solution The mass concentration of the vinylidene fluoride-hexafluoropropylene copolymer in the mixture is 10%; 2g fuming titanium dioxide (diameter is 300nm) nanoparticles are added to 20gN, in the N-dimethylformamide, after ultrasonic dispersion 1 hour, mix with A The solutions are mixed and ground at room temperature for 24 hours with a planetary ball mill to obtain a composite spinning solution; the mass of the ceramic material in the composite spinning solution is 20% of the total mass of the vinylidene fluoride-hexafluoropropylene copolymer and the ceramic material.

[0047] 2) Preparation of polymer-ceramic composite nanofiber membrane by electrospinning

[0048] Place the vinylidene fluoride-hexafluorop...

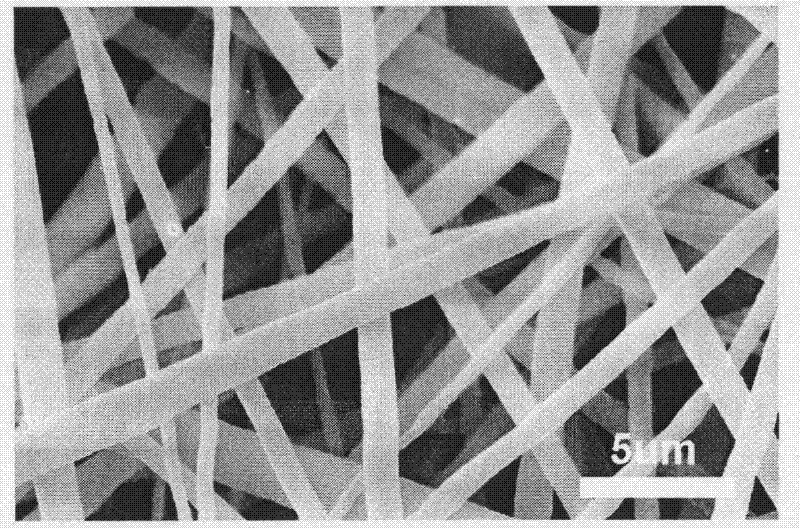

Embodiment 3

[0052] 1) Preparation of composite spinning solution

[0053] Dissolve 8g of vinylidene fluoride-hexafluoropropylene copolymer in 44.4g of N,N-dimethylformamide and 27.6g of acetone, and stir at 55°C for 24 hours to obtain a clear and transparent A solution, wherein, A solution The mass concentration of the vinylidene fluoride-hexafluoropropylene copolymer in the mixture is 10%; 0.89g of aluminum oxide (diameter is 500nm) nanoparticles are added to 10g of N, N-dimethylformamide, after ultrasonic dispersion for 3 hours Mix with solution A, and grind for 24 hours with a planetary ball mill at room temperature to obtain a composite spinning solution; the mass of the ceramic material in the composite spinning solution is 10% of the total mass of the vinylidene fluoride-hexafluoropropylene copolymer and the ceramic material.

[0054] 2) Preparation of polymer-ceramic composite nanofiber membrane by electrospinning

[0055] Place the vinylidene fluoride-hexafluoropropylene copolyme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com