Patents

Literature

4602 results about "Atomic layer deposition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Atomic layer deposition (ALD) is a thin-film deposition technique based on the sequential use of a gas phase chemical process; it is a subclass of chemical vapour deposition. The majority of ALD reactions use two chemicals called precursors. These precursors react with the surface of a material one at a time in a sequential, self-limiting, manner. Through the repeated exposure to separate precursors, a thin film is slowly deposited. ALD is a key process in the fabrication of semiconductor devices, and part of the set of tools available for the synthesis of nanomaterials.

Process for atomic layer deposition

ActiveUS20080182358A1Suitable for processingAllowed to operateAdditive manufacturing apparatusSemiconductor/solid-state device manufacturingZincAtomic layer deposition

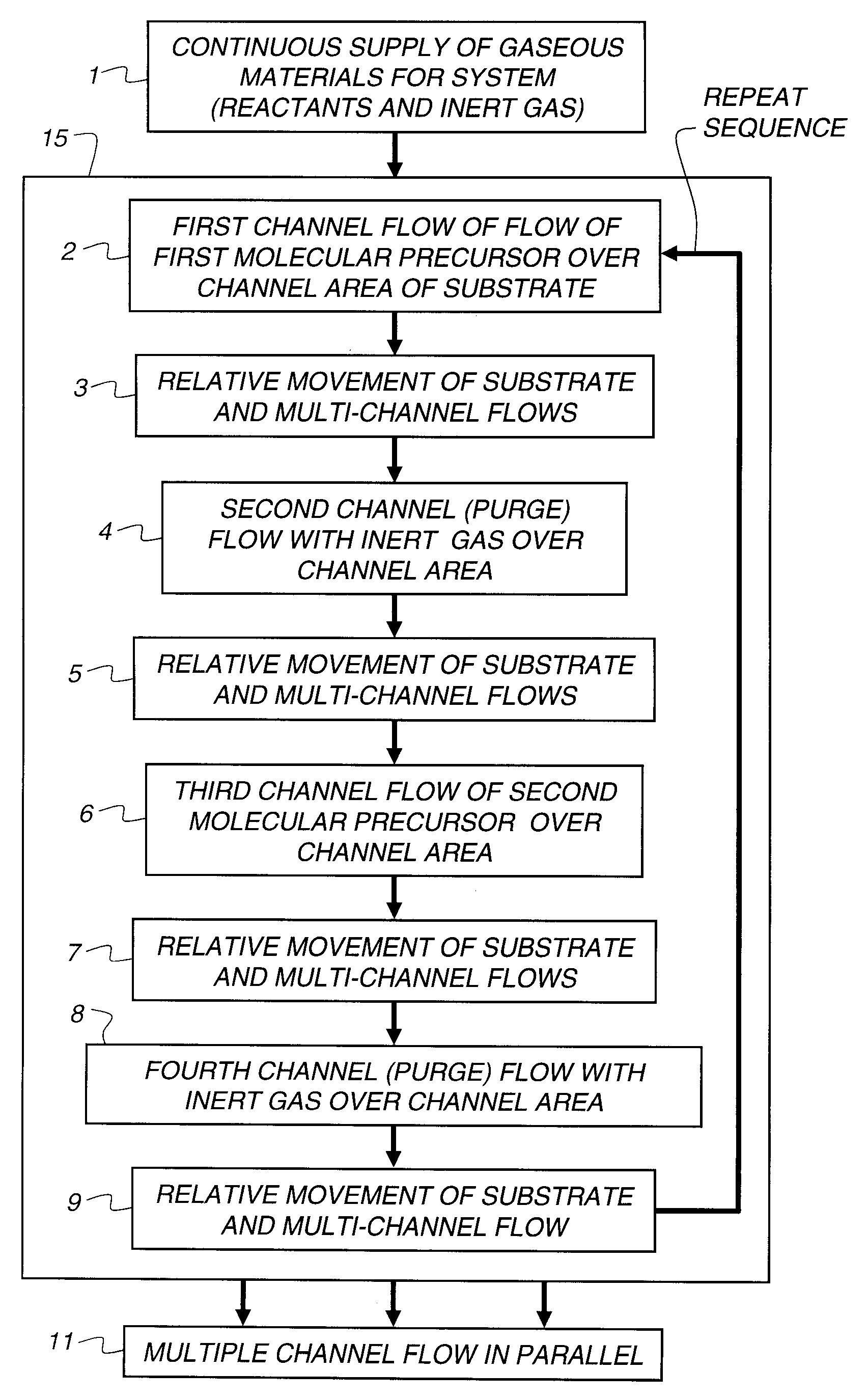

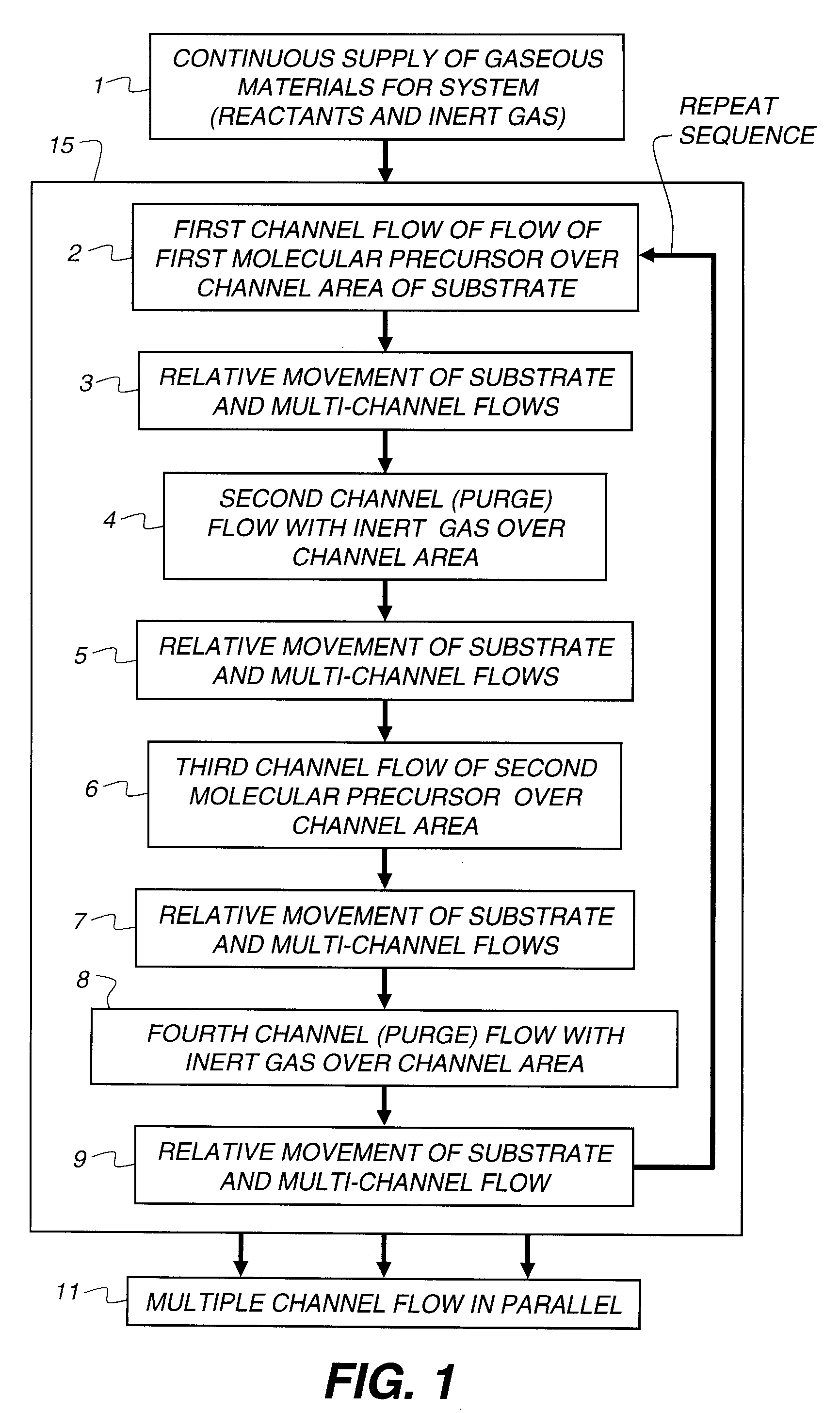

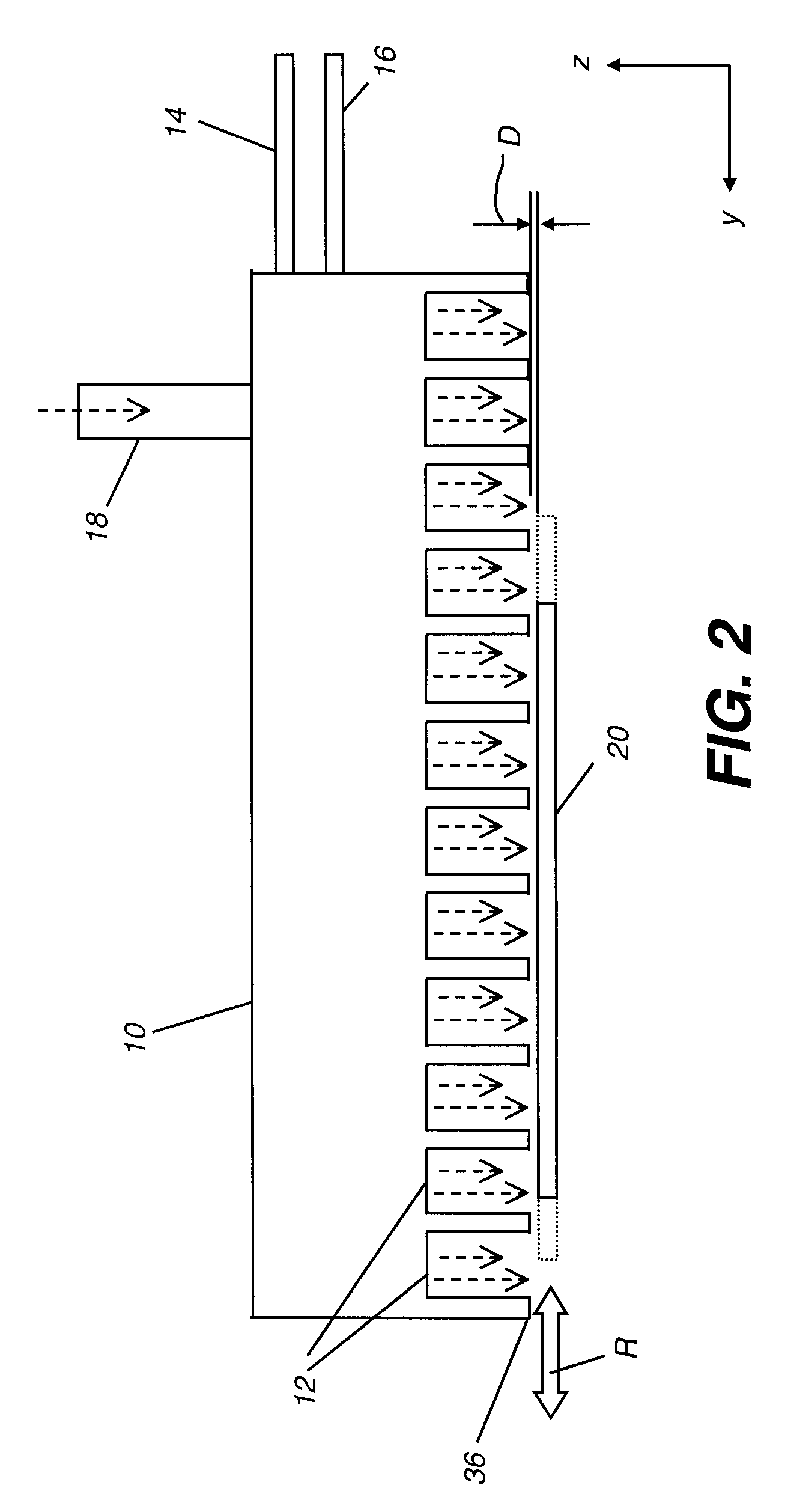

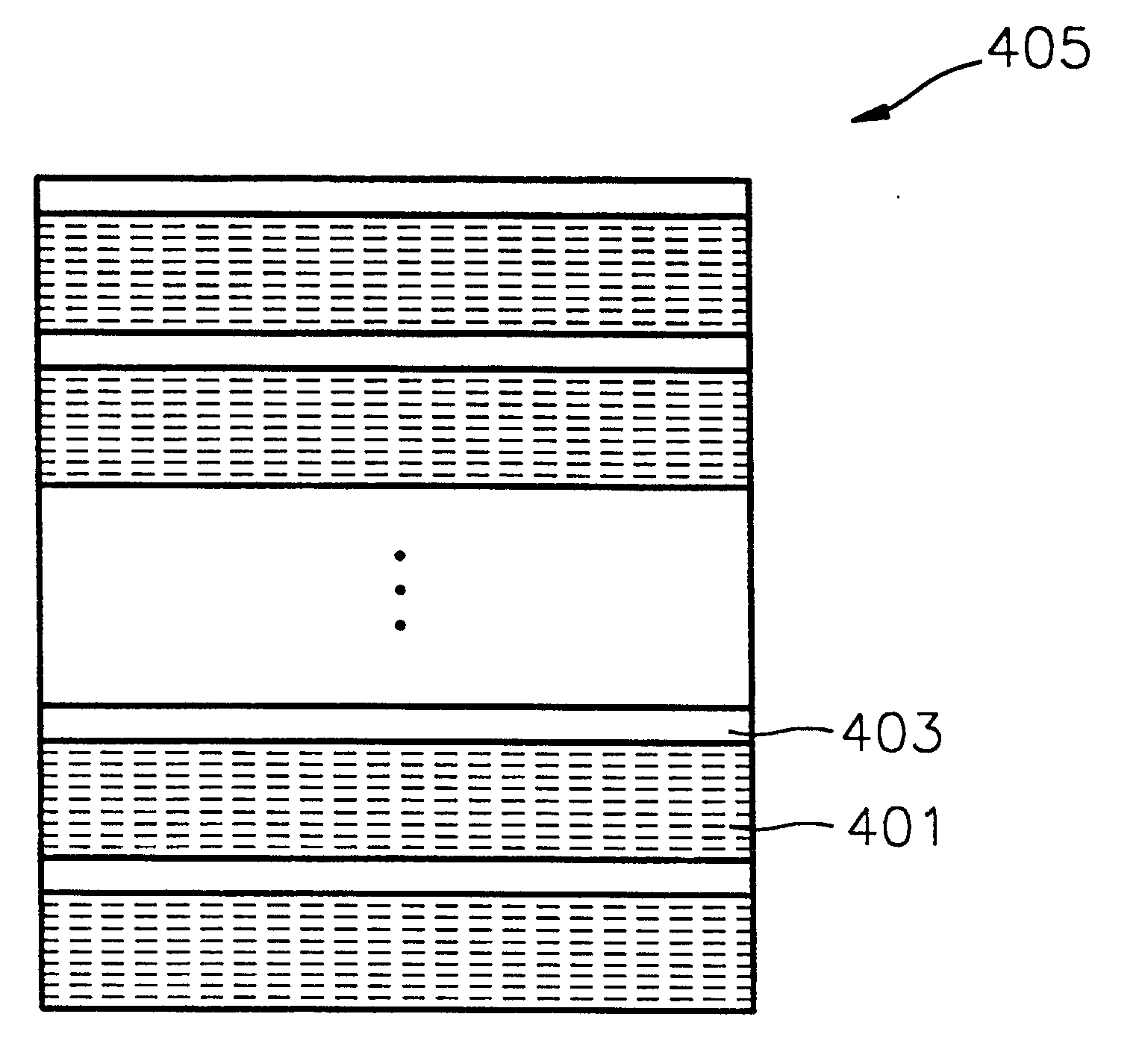

The present invention relates to a process of making a zinc-oxide-based thin film semiconductor, for use in a transistor, comprising thin film deposition onto a substrate comprising providing a plurality of gaseous materials comprising at least first, second, and third gaseous materials, wherein the first gaseous material is a zinc-containing volatile material and the second gaseous material is reactive therewith such that when one of the first or second gaseous materials are on the surface of the substrate the other of the first or second gaseous materials will react to deposit a layer of material on the substrate and wherein the third gaseous material is inert with respect to reacting with the first or second gaseous materials.

Owner:EASTMAN KODAK CO

Method of forming metal layer using atomic layer deposition and semiconductor device having the metal layer as barrier metal layer or upper or lower electrode of capacitor

InactiveUS6287965B1High thermal resistantEasy to adjustSemiconductor/solid-state device manufacturingCapacitorsNiobiumDevice material

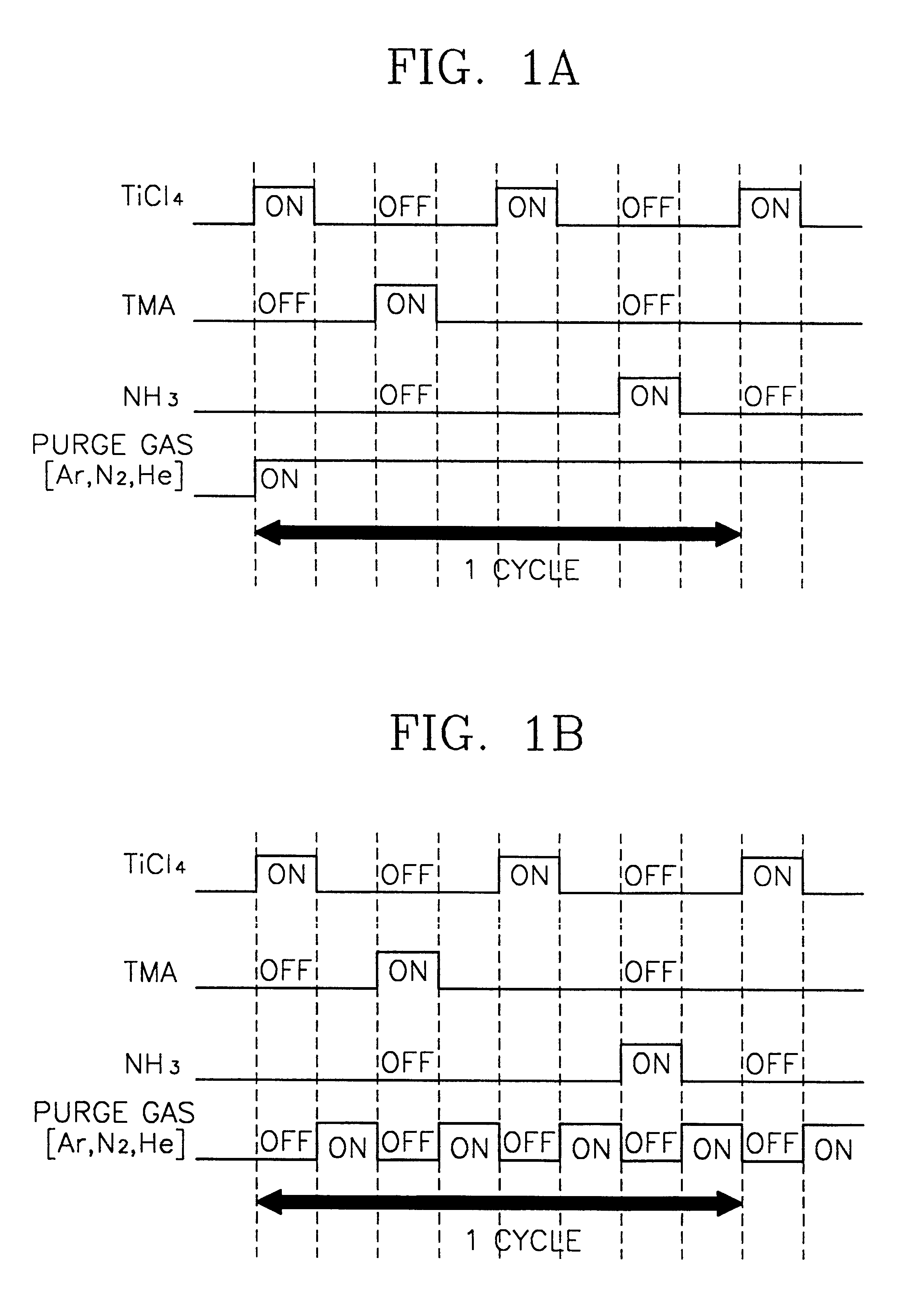

A method of forming a metal layer having excellent thermal and oxidation resistant characteristics using atomic layer deposition is provided. The metal layer includes a reactive metal (A), an element (B) for the amorphous combination between the reactive metal (A) and nitrogen (N), and nitrogen (N). The reactive metal (A) may be titanium (Ti), tantalum (Ta), tungsten (W), zirconium (Zr), hafnium (Hf), molybdenum (Mo) or niobium (Nb). The amorphous combination element (B) may be aluminum (Al), silicon (Si) or boron (B). The metal layer is formed by alternately injecting pulsed source gases for the elements (A, B and N) into a chamber according to atomic layer deposition to thereby alternately stack atomic layers. Accordingly, the composition ratio of a nitrogen compound (A-B-N) of the metal layer can be desirably adjusted just by appropriately determining the number of injection pulses of each source gas. According to the composition ratio, a desirable electrical conductivity and resistance of the metal layer can be accurately obtained. The atomic layers are individually deposited, thereby realizing excellent step coverage even in a complex and compact region. A metal layer formed by atomic layer deposition can be employed as a barrier metal layer, a lower electrode or an upper electrode in a semiconductor device.

Owner:SAMSUNG ELECTRONICS CO LTD

Methods of forming thin films by atomic layer deposition

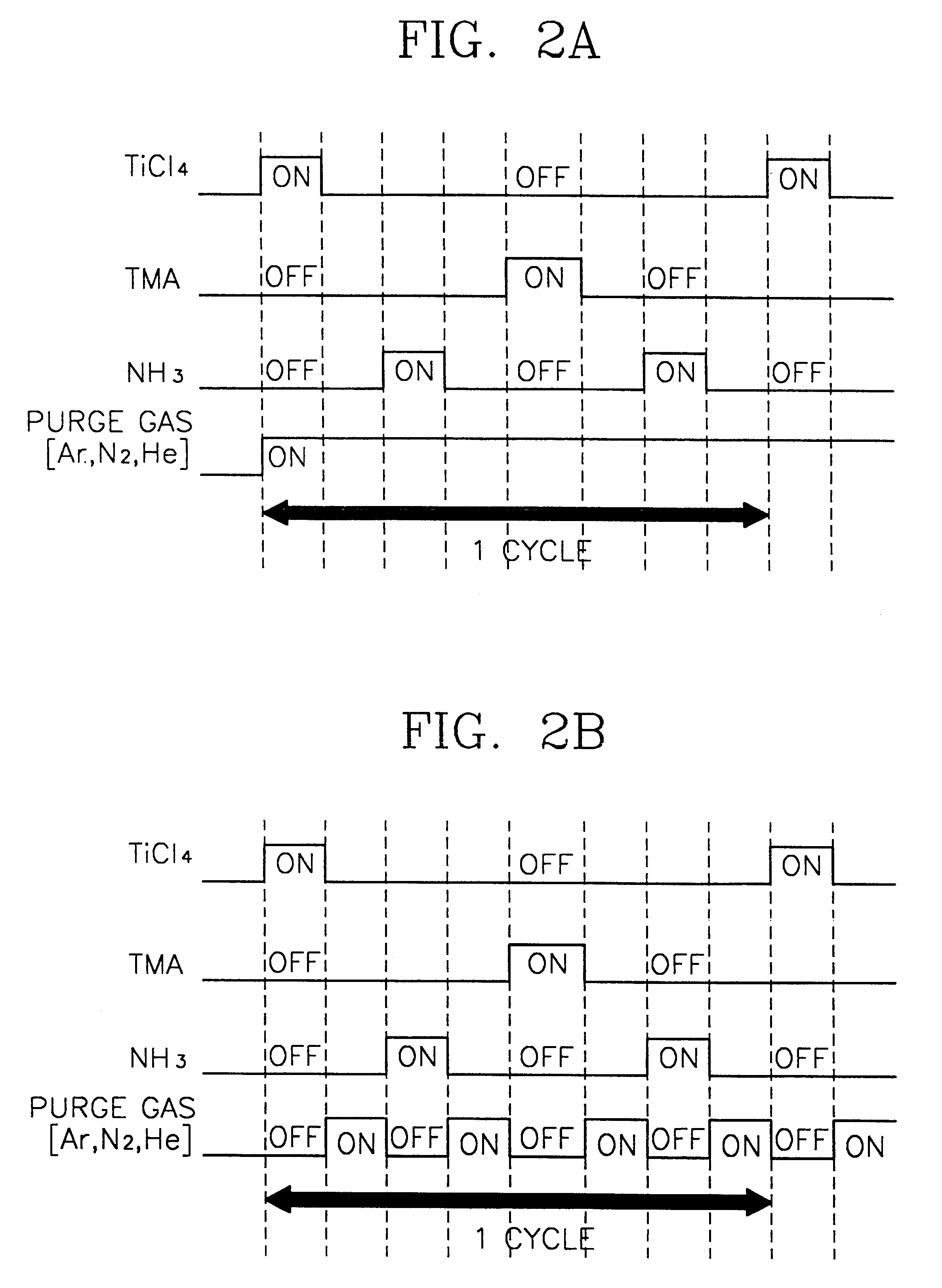

InactiveUS6468924B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingHydrogenProduct gas

Methods of forming thin films include forming a first layer comprising a first element that is chemisorbed to a surface of a substrate, by exposing the surface to a first source gas having molecules therein that comprise the first element and a halogen. A step is then performed to expose the first layer to an activated hydrogen gas so that halogens associated with the first layer become bound to hydrogen provided by the activated hydrogen gas. The first layer may then be converted to a thin film comprising the first element and a second element, by exposing a surface of the first layer to a second source gas having molecules therein that comprise the second element.

Owner:SAMSUNG ELECTRONICS CO LTD

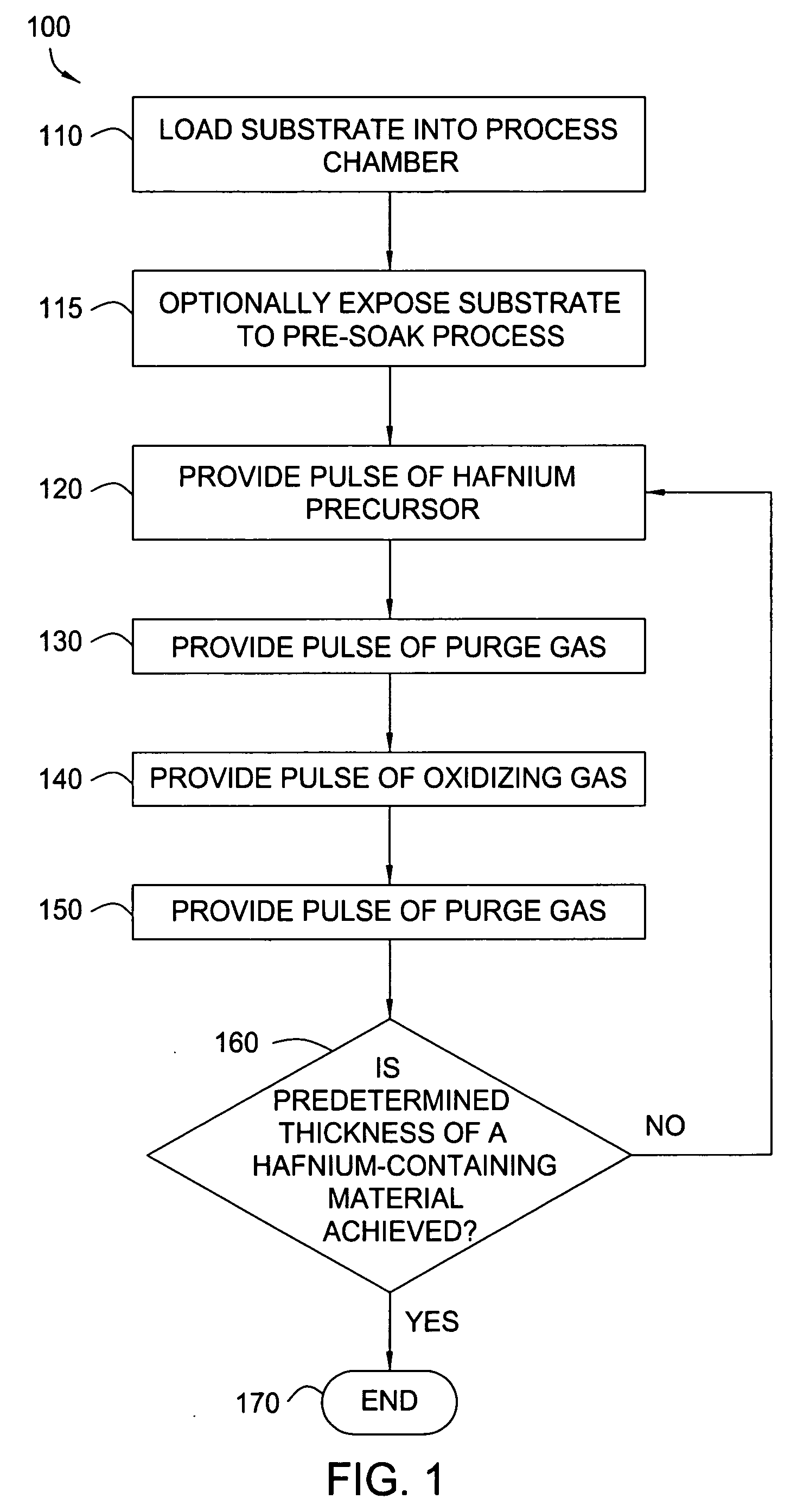

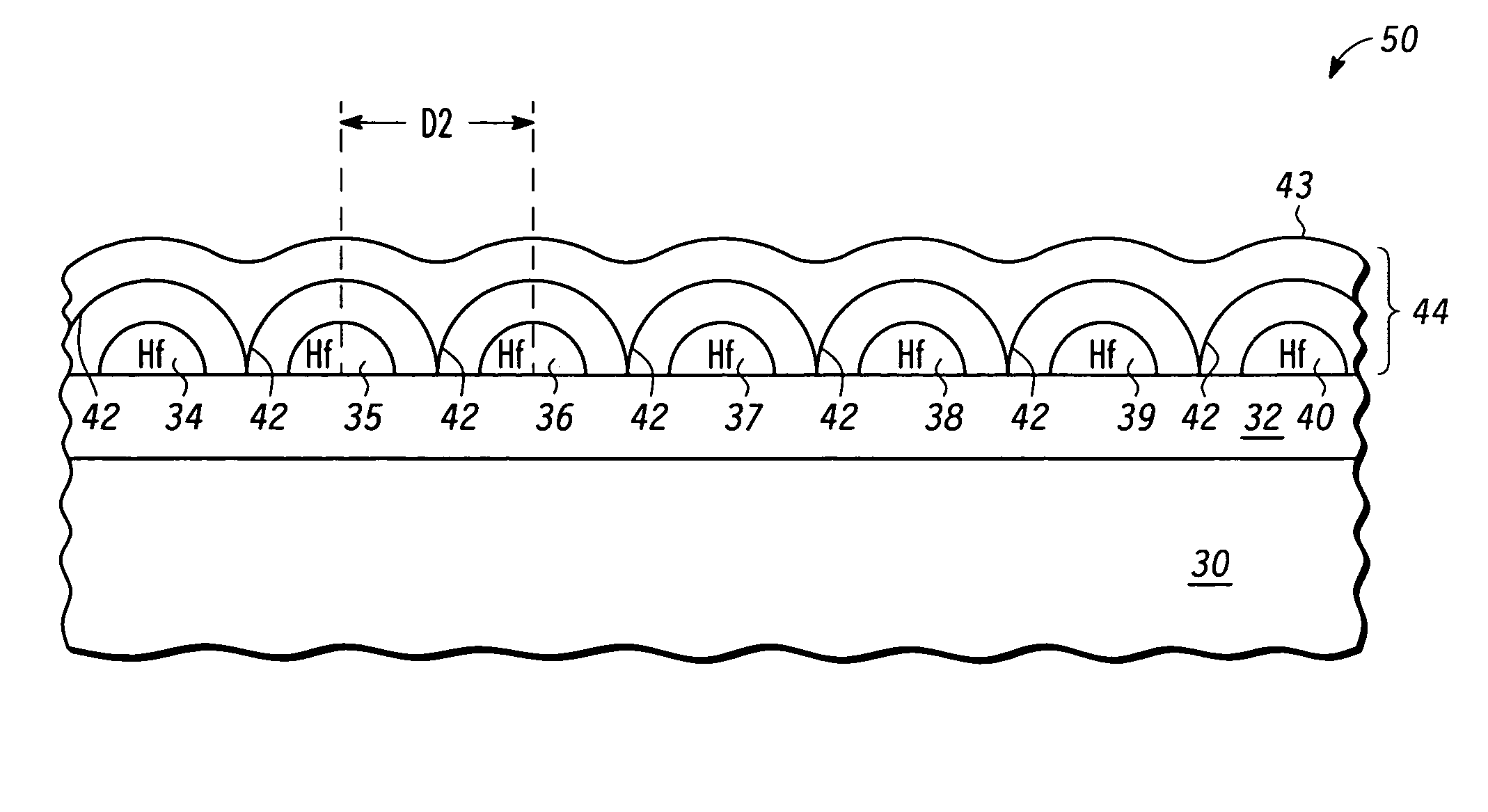

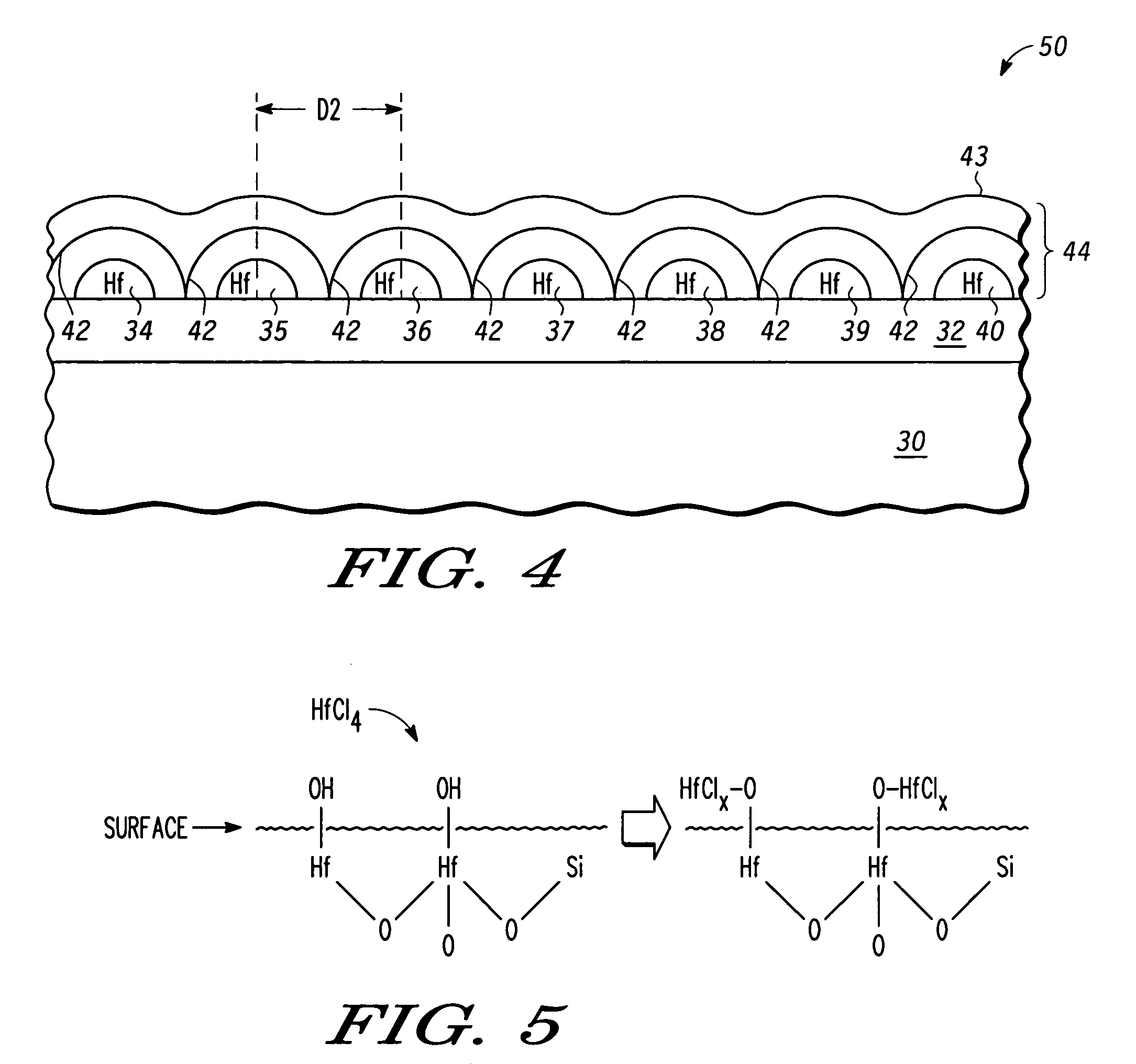

Apparatuses and methods for atomic layer deposition of hafnium-containing high-k dielectric materials

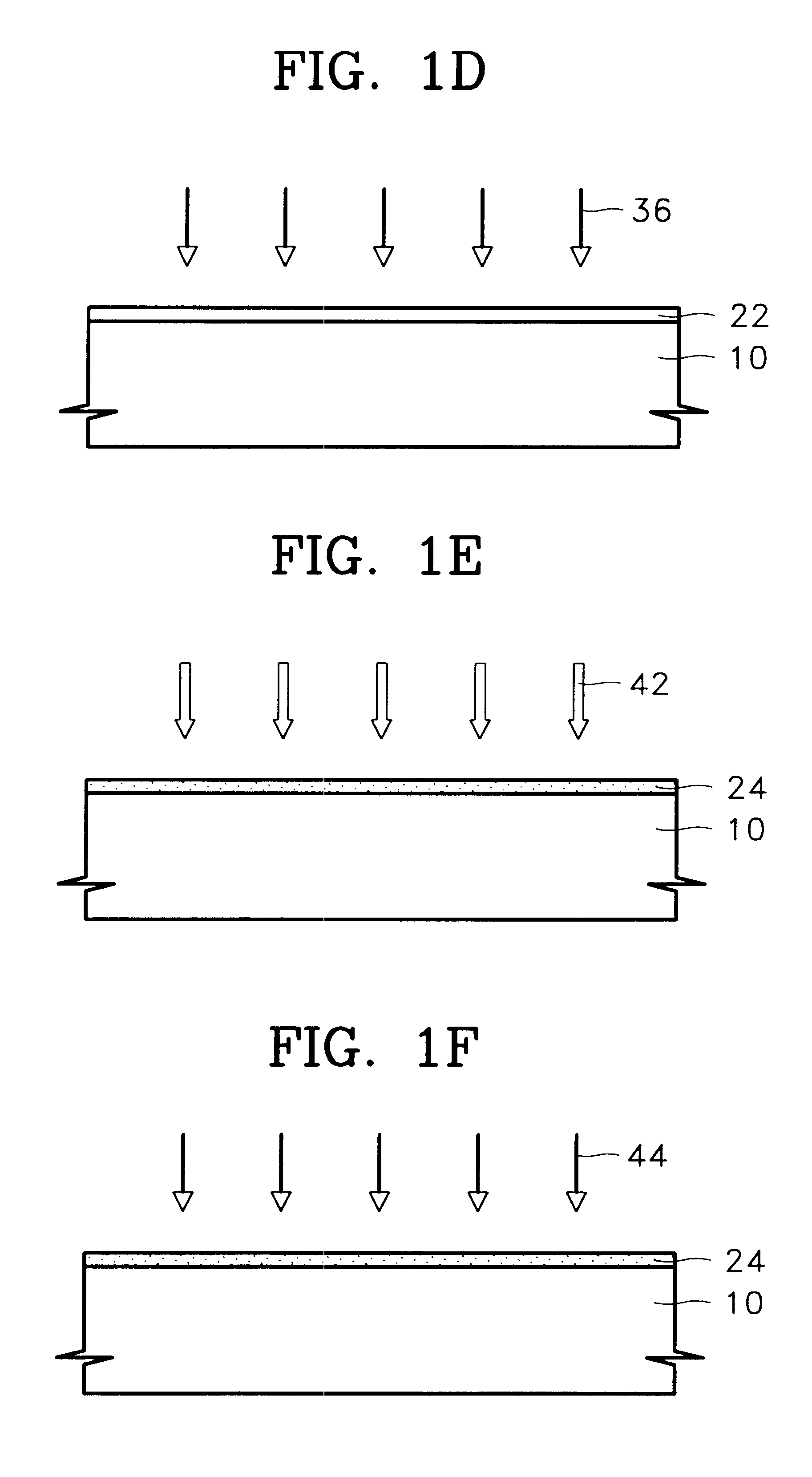

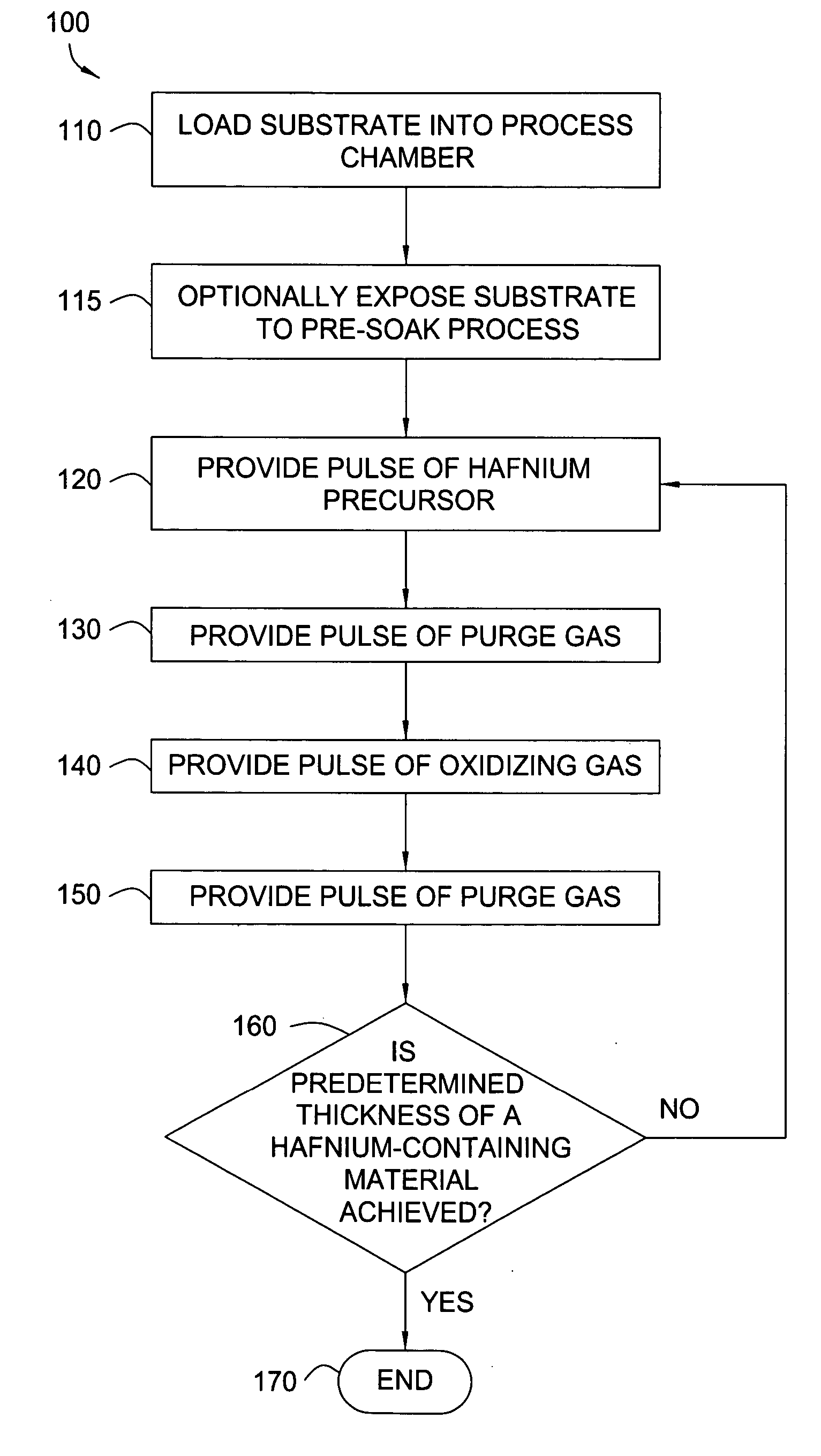

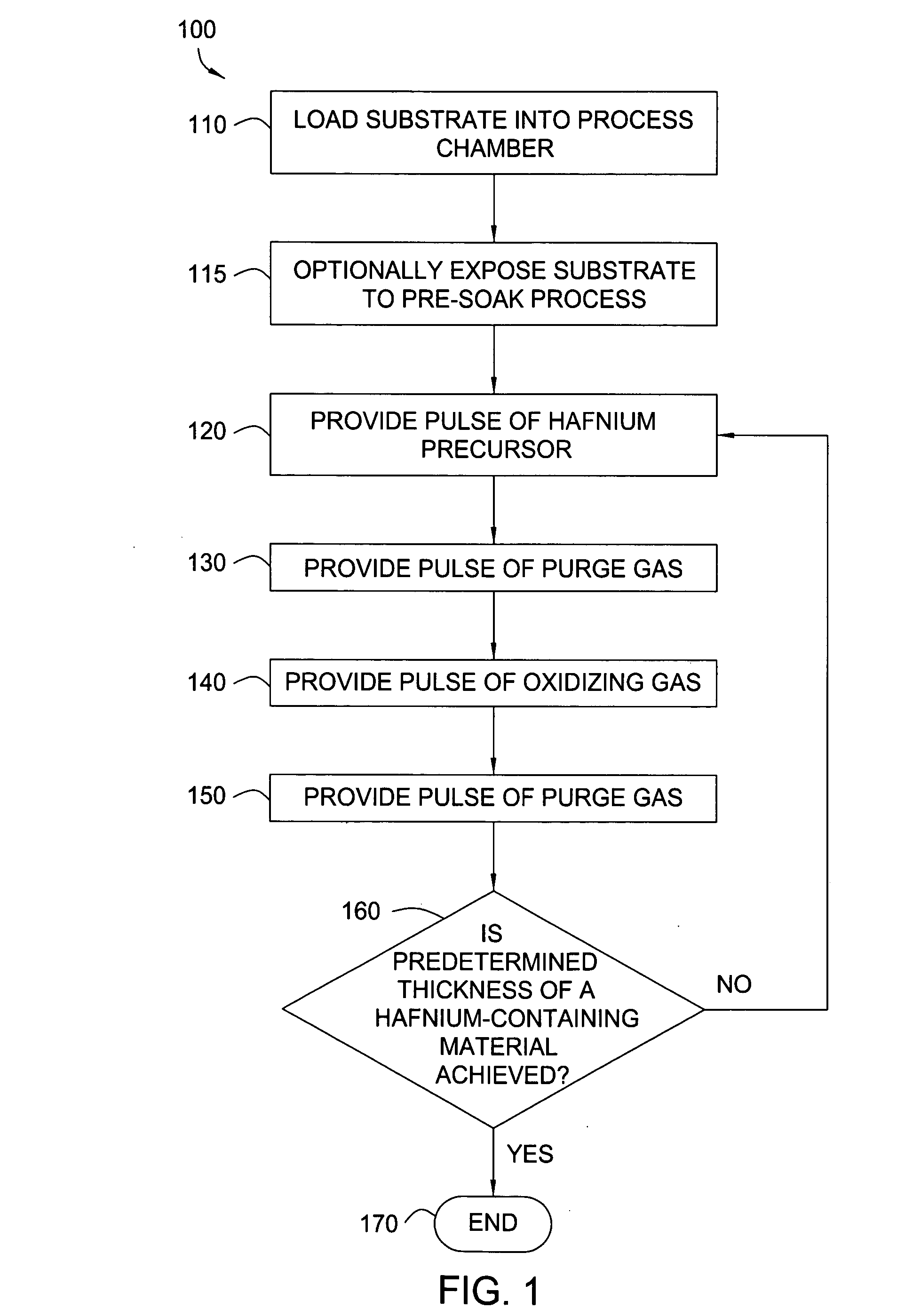

InactiveUS20050271813A1Steam generation heating methodsDecorative surface effectsGas phaseWater vapor

Embodiments of the invention provide methods for depositing dielectric materials on substrates during vapor deposition processes, such as atomic layer deposition (ALD). In one example, a method includes sequentially exposing a substrate to a hafnium precursor and an oxidizing gas to deposit a hafnium oxide material thereon. In another example, a hafnium silicate material is deposited by sequentially exposing a substrate to the oxidizing gas and a process gas containing a hafnium precursor and a silicon precursor. The oxidizing gas usually contains water vapor formed by flowing a hydrogen source gas and an oxygen source gas through a water vapor generator. In another example, a method includes sequentially exposing a substrate to the oxidizing gas and at least one precursor to deposit hafnium oxide, zirconium oxide, lanthanum oxide, tantalum oxide, titanium oxide, aluminum oxide, silicon oxide, aluminates thereof, silicates thereof, derivatives thereof or combinations thereof.

Owner:APPLIED MATERIALS INC

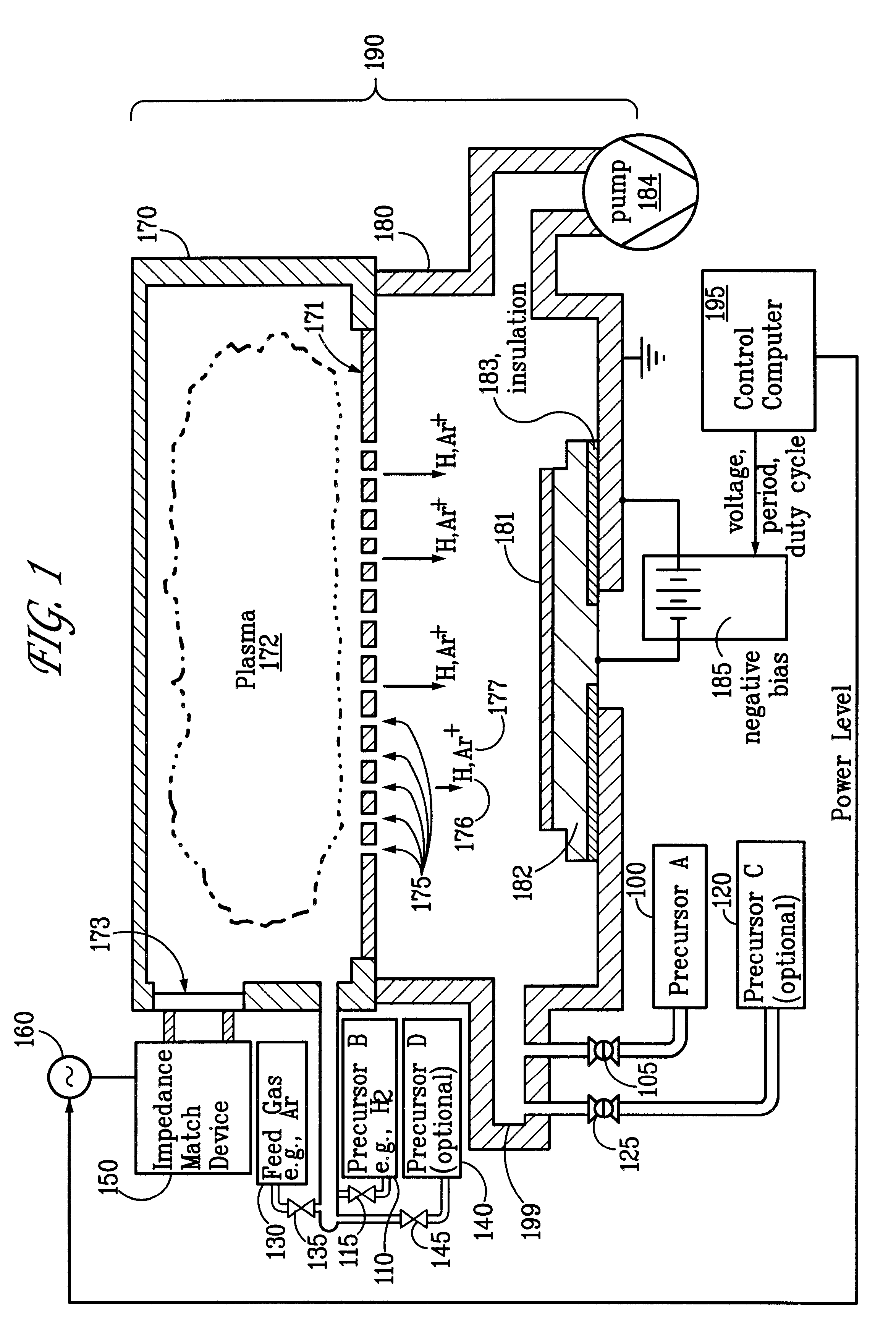

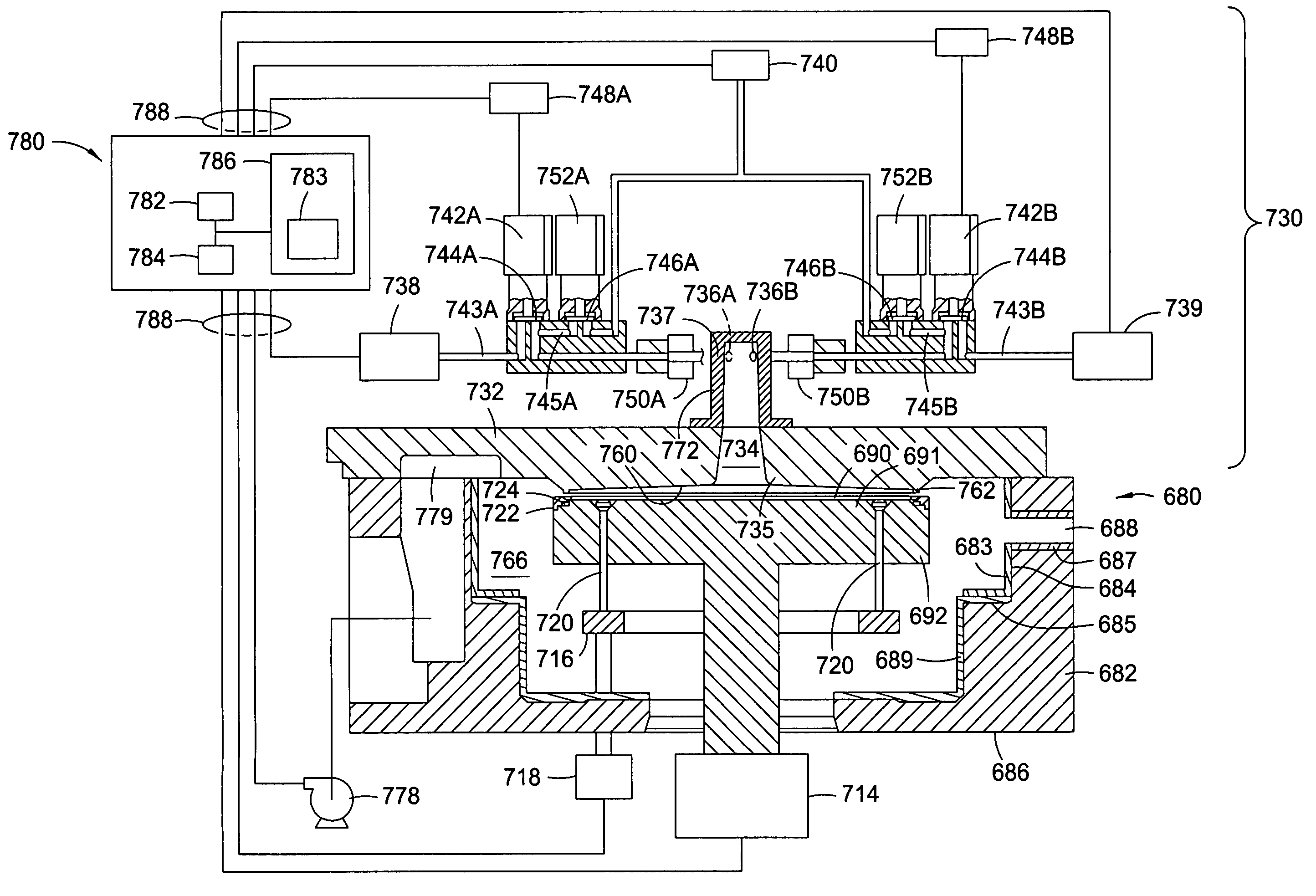

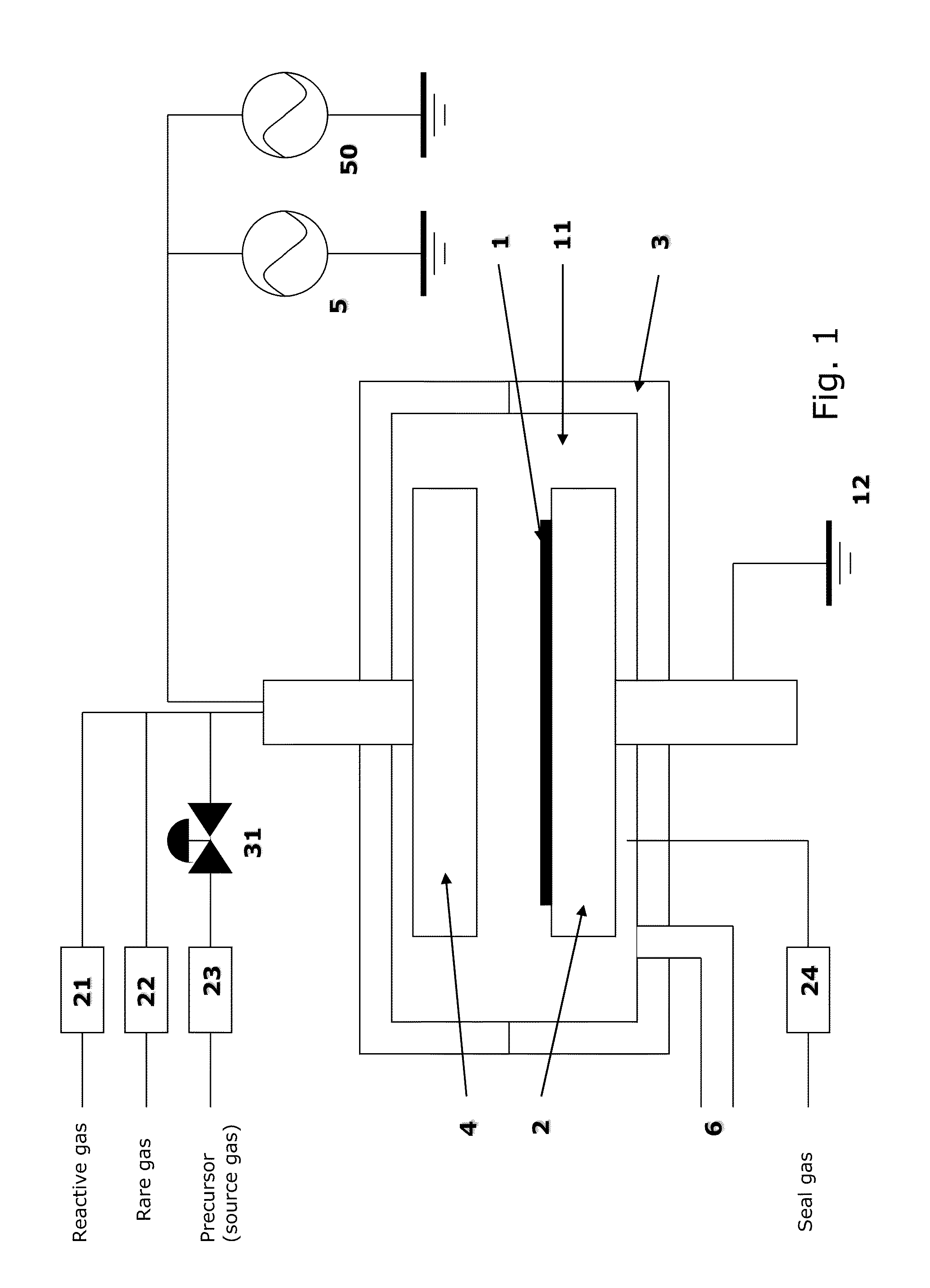

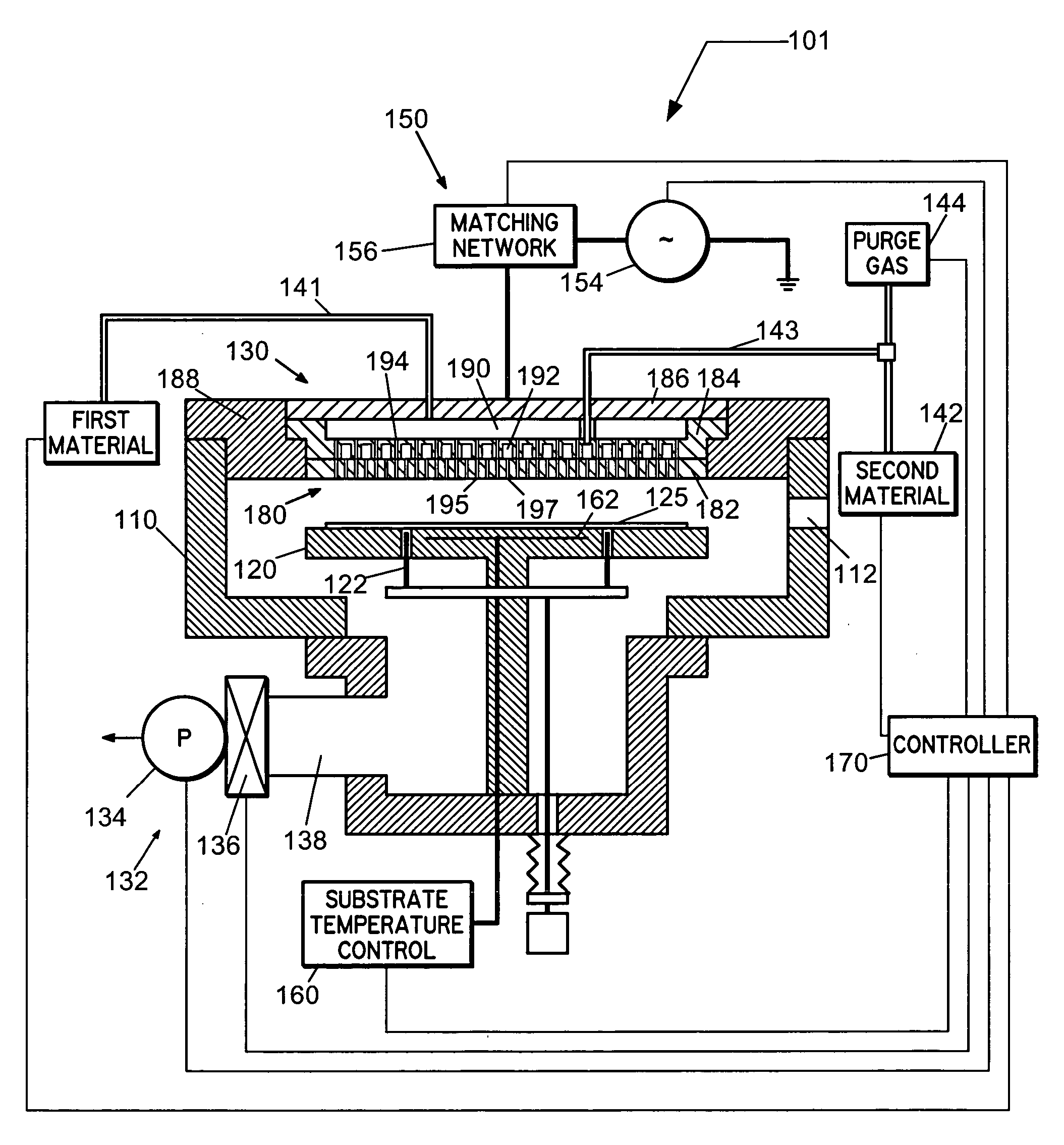

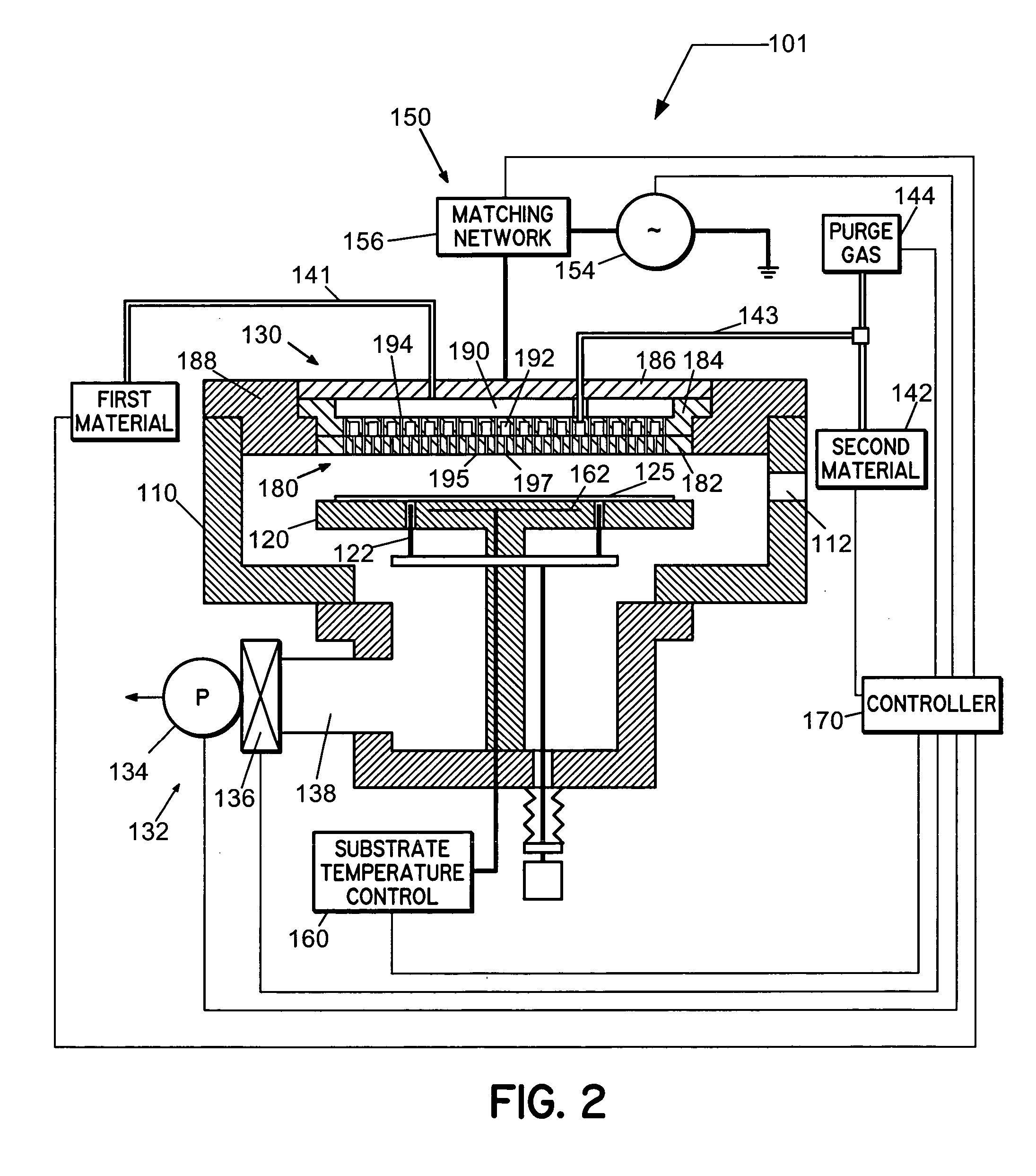

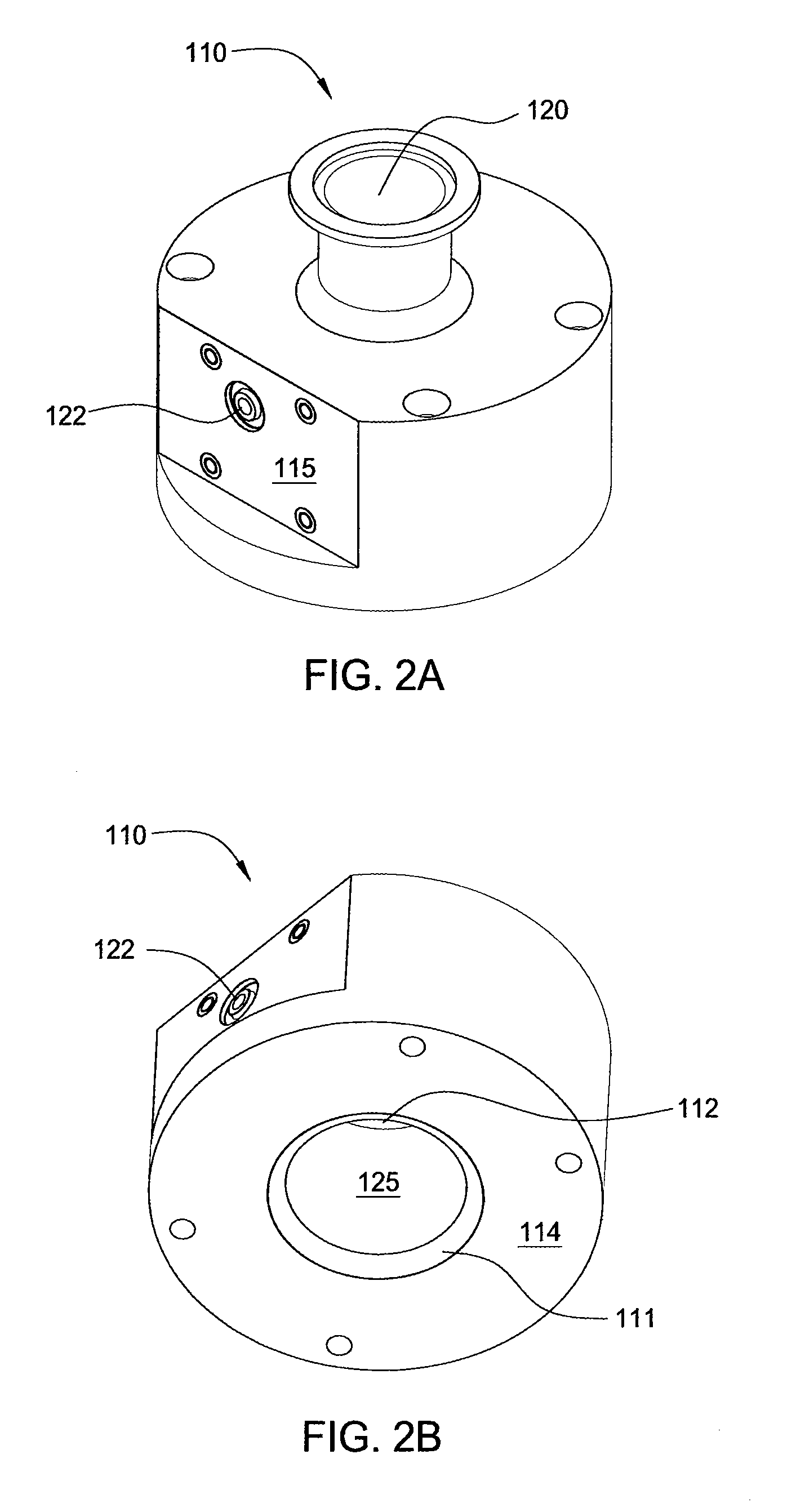

Apparatus and process for plasma-enhanced atomic layer deposition

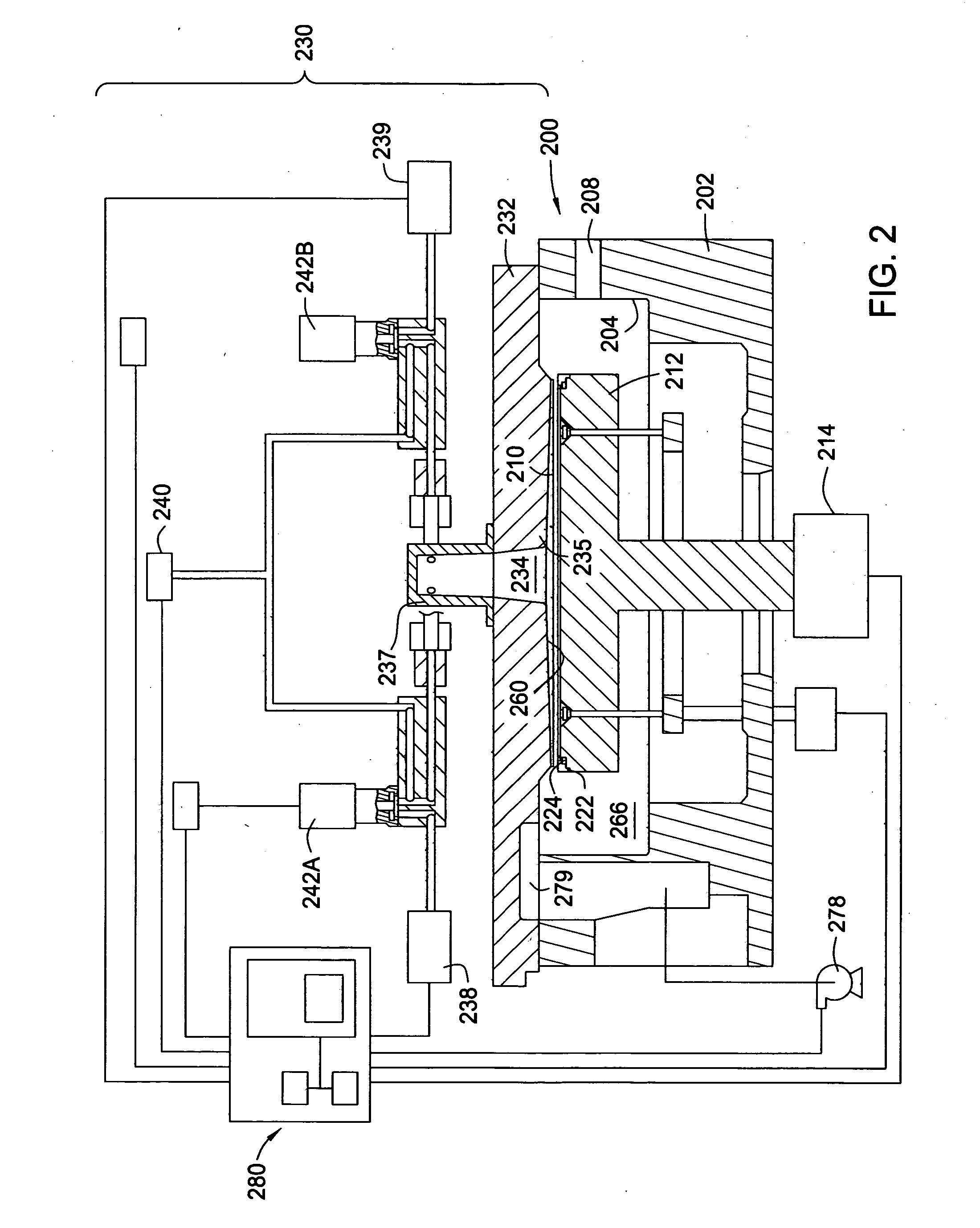

Embodiments of the invention provide an apparatus configured to form a material during an atomic layer deposition (ALD) process, such as a plasma-enhanced ALD (PE-ALD) process. In one embodiment, a process chamber is configured to expose a substrate to a sequence of gases and plasmas during a PE-ALD process. The process chamber comprises components that are capable of being electrically insulated, electrically grounded or RF energized. In one example, a chamber body and a gas manifold assembly are grounded and separated by electrically insulated components, such as an insulation cap, a plasma screen insert and an isolation ring. A showerhead, a plasma baffle and a water box are positioned between the insulated components and become RF hot when activated by a plasma generator. Other embodiments of the invention provide deposition processes to form layers of materials within the process chamber.

Owner:APPLIED MATERIALS INC

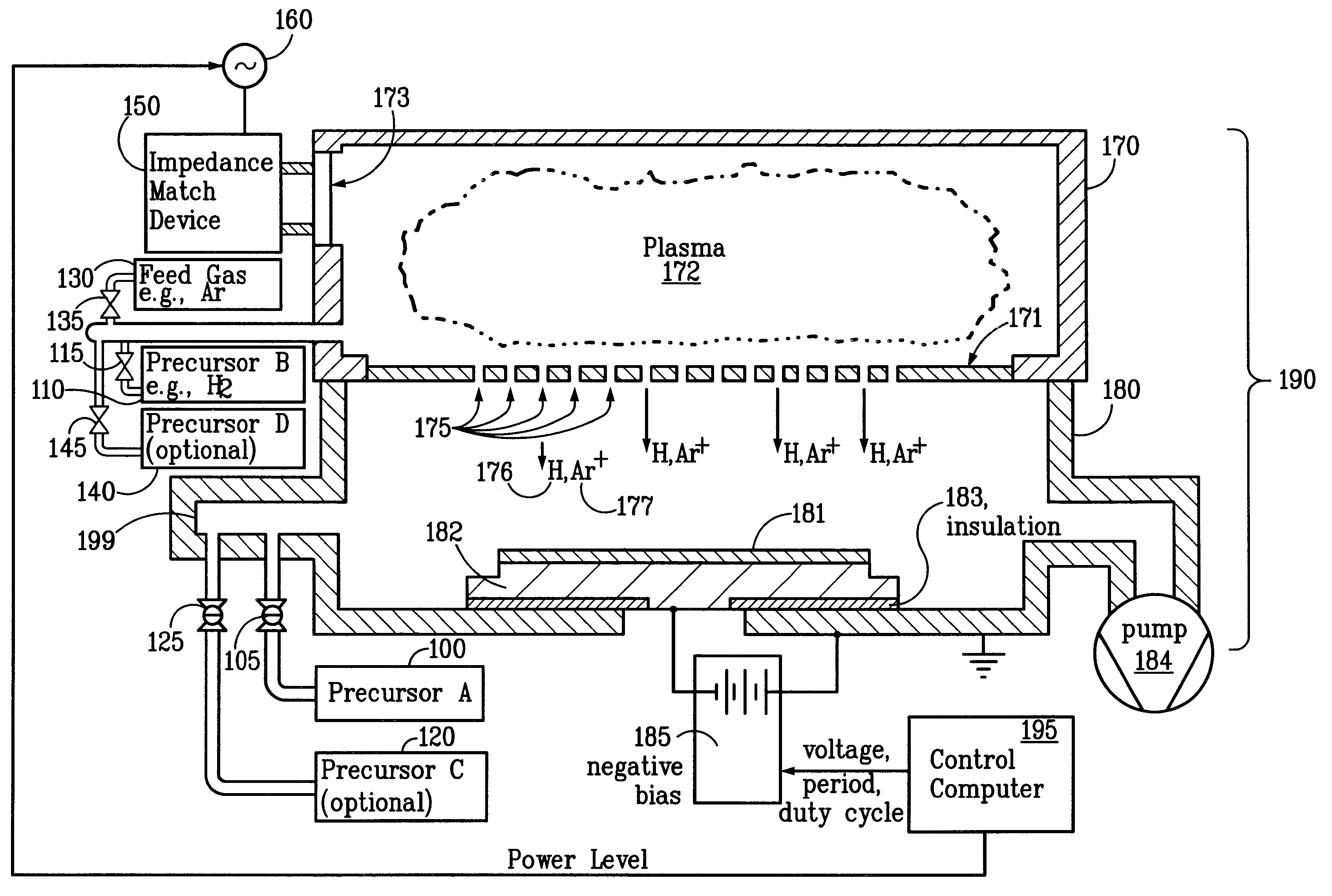

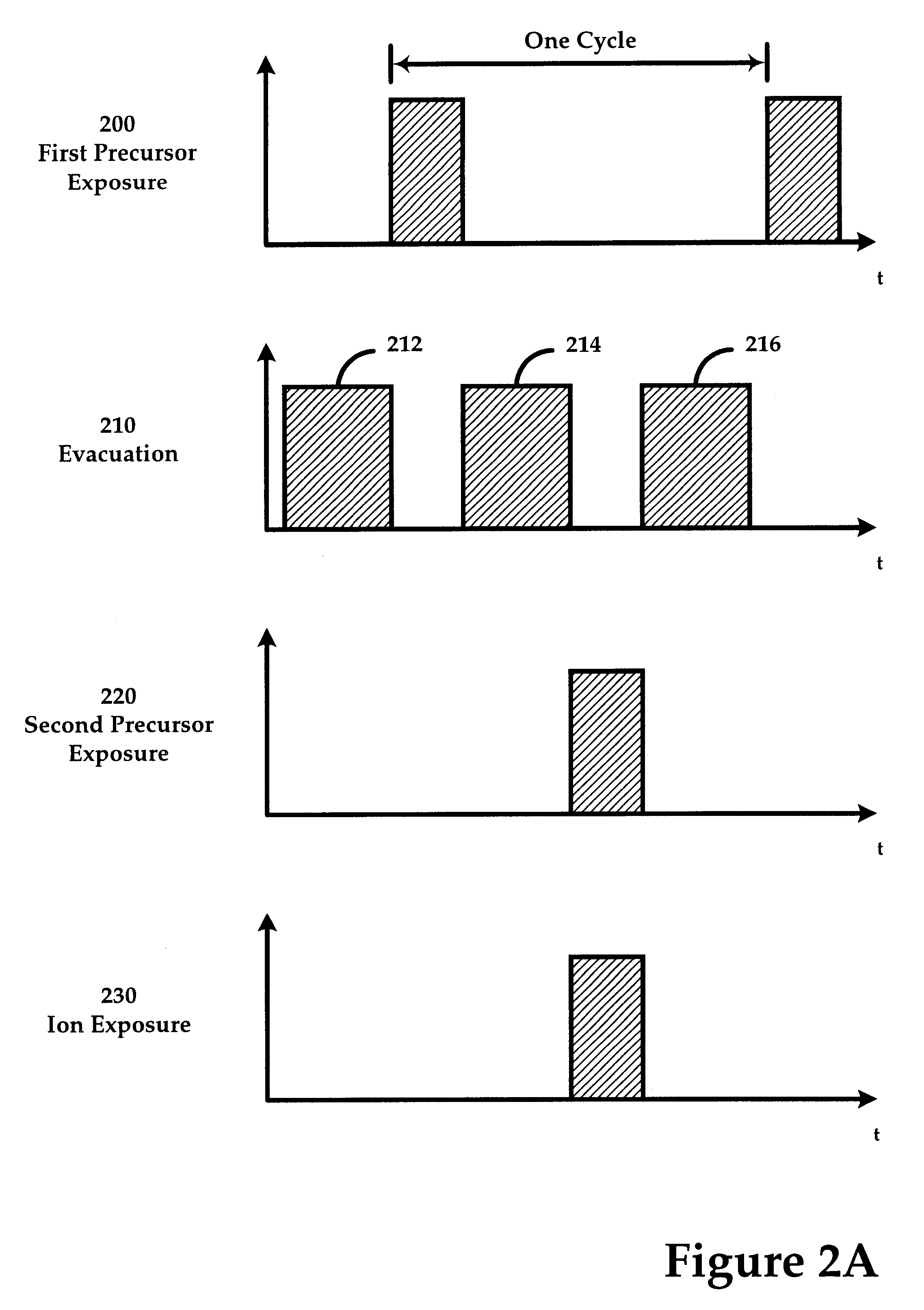

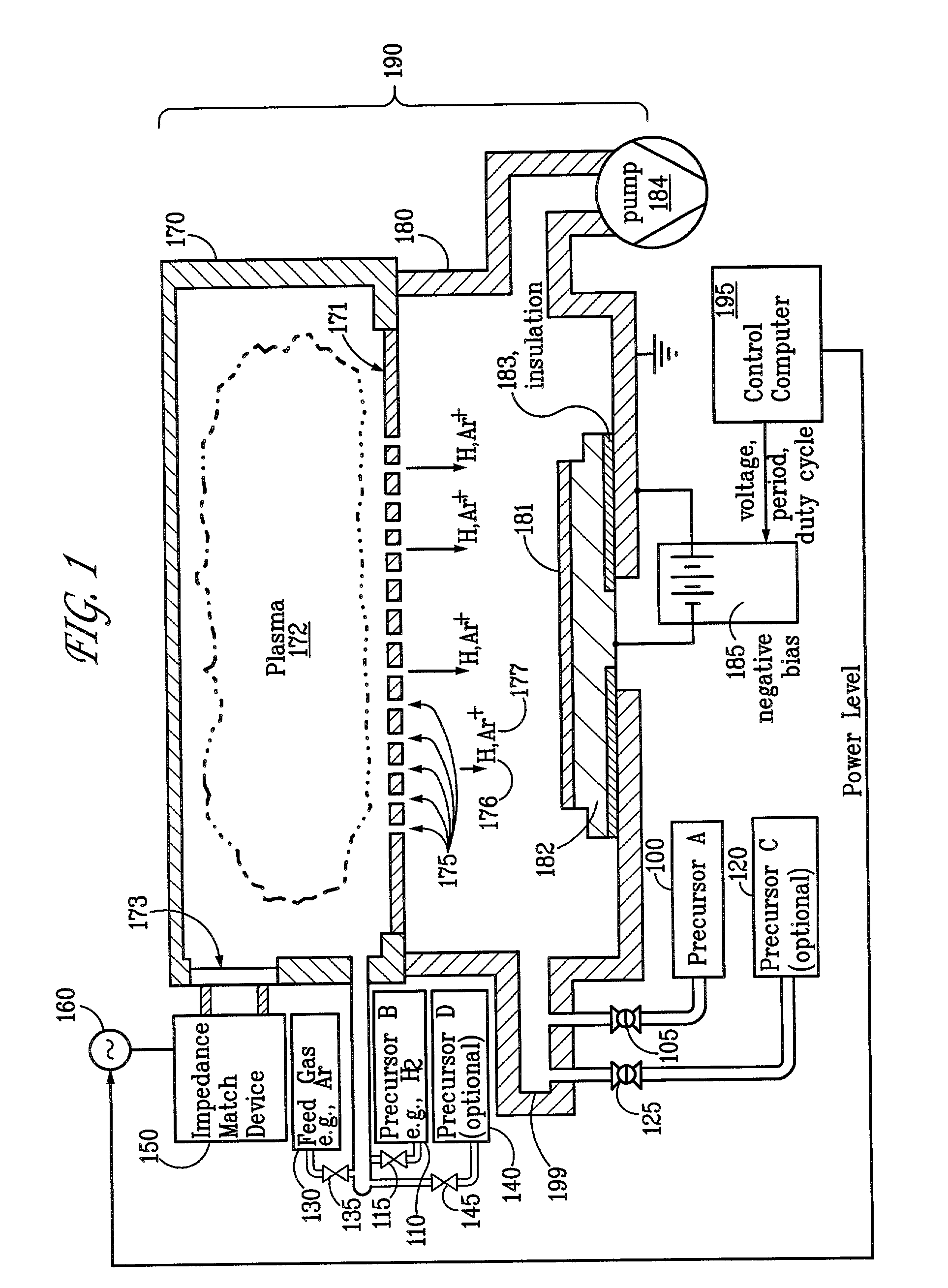

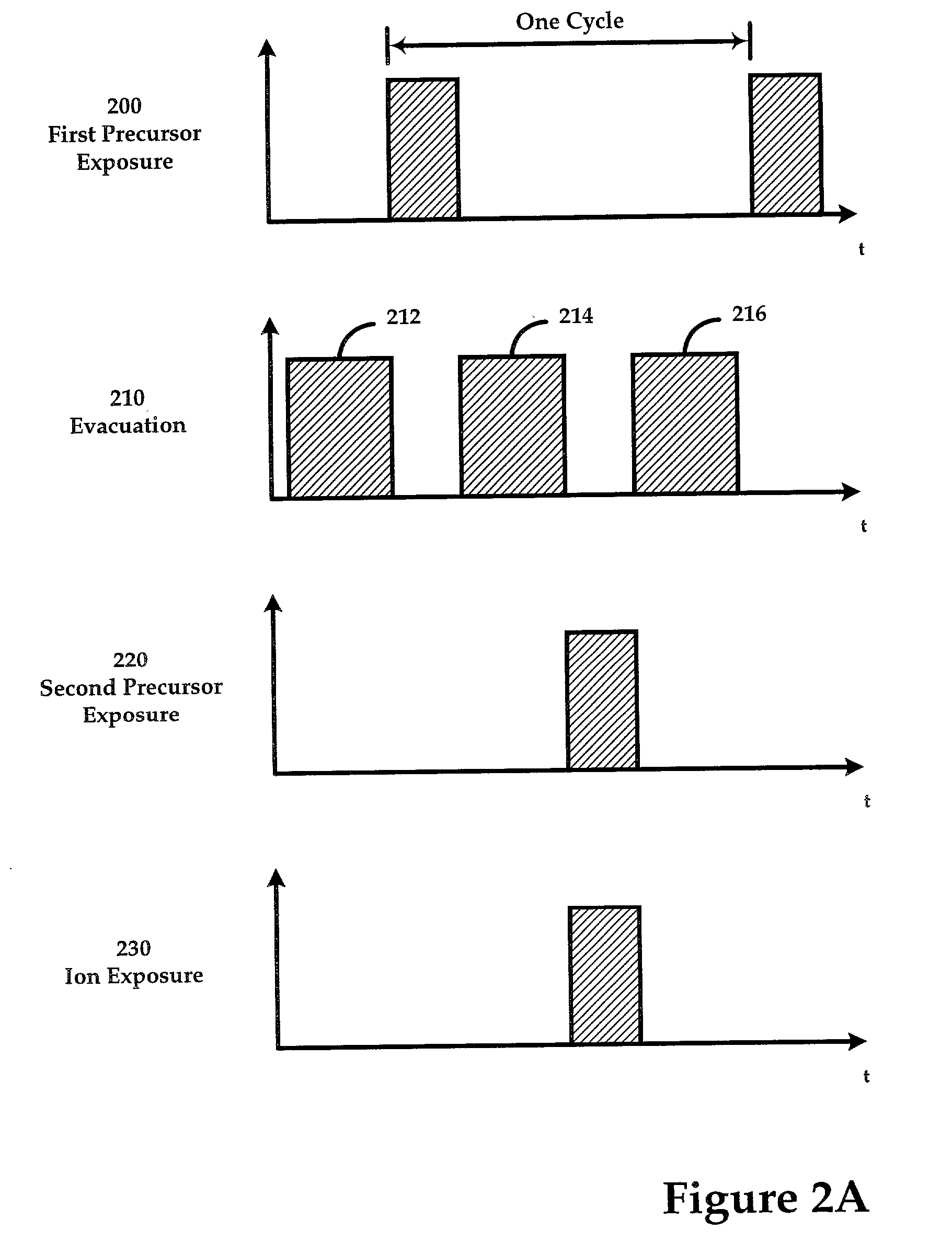

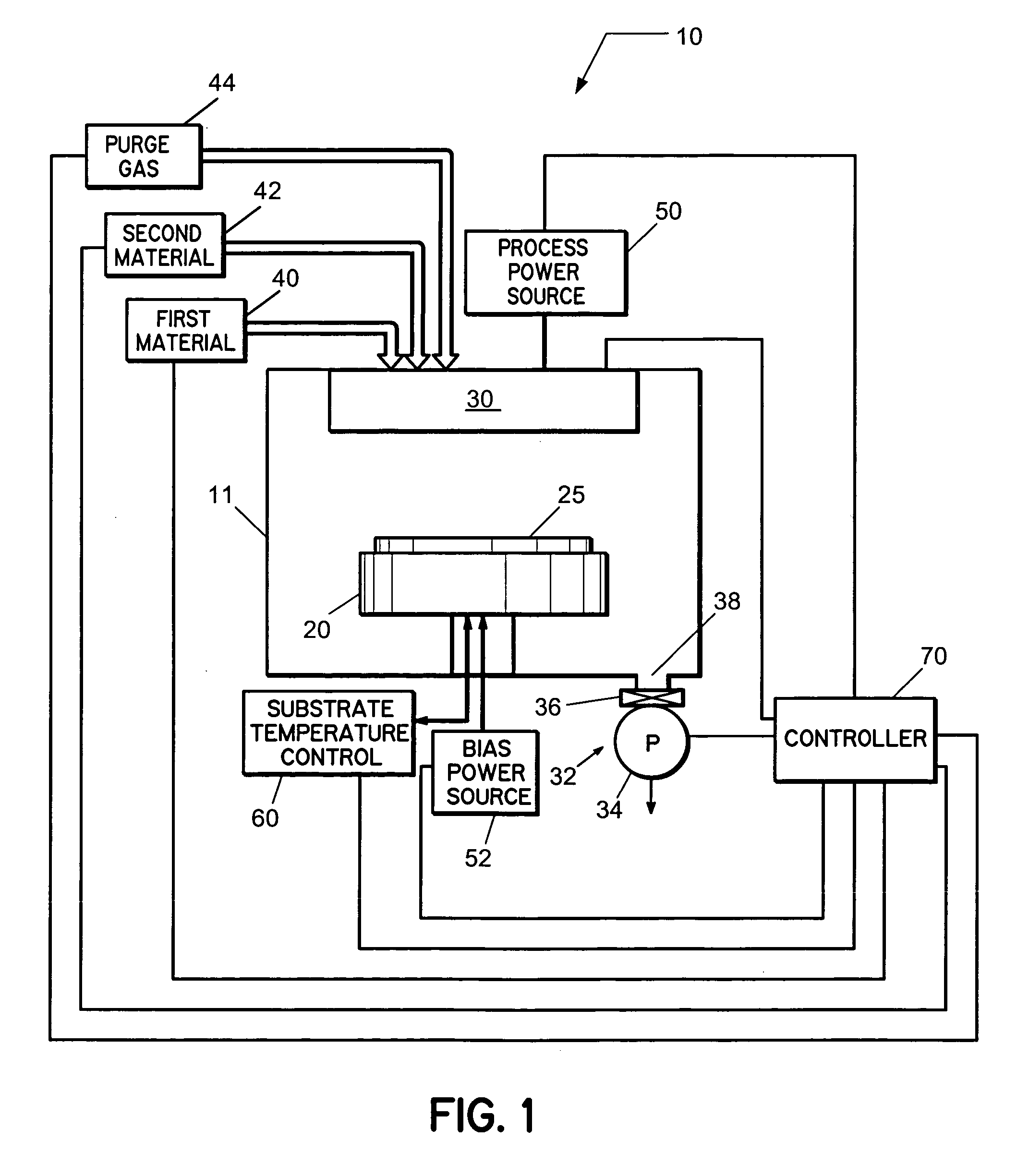

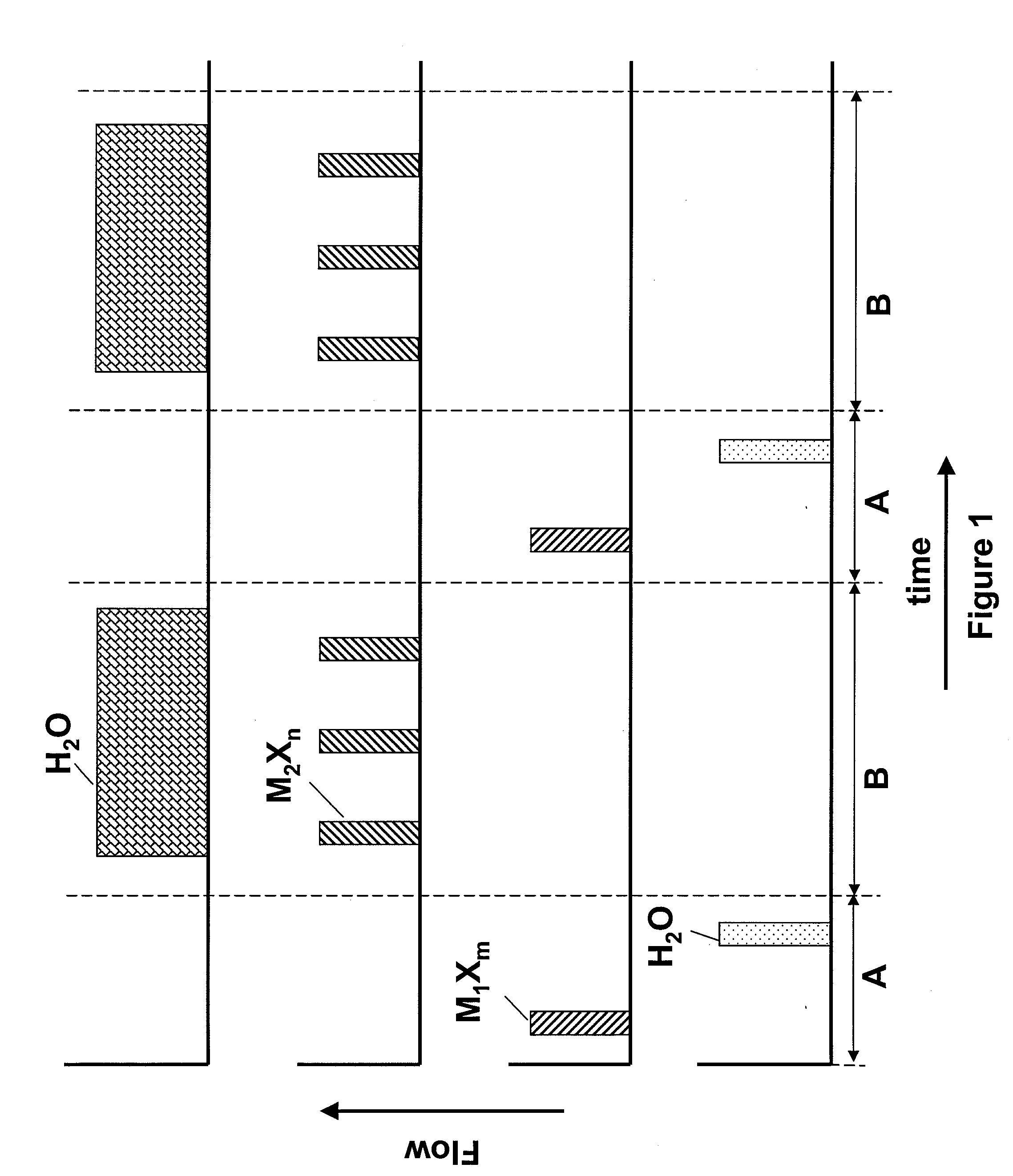

Sequential method for depositing a film by modulated ion-induced atomic layer deposition (MII-ALD)

InactiveUS6428859B1Faster efficient meanSimple methodVacuum evaporation coatingSputtering coatingSequential methodHigh density

The present invention relates to an enhanced sequential atomic layer deposition (ALD) technique suitable for deposition of barrier layers, adhesion layers, seed layers, low dielectric constant (low-k) films, high dielectric constant (high-k) films, and other conductive, semi-conductive, and non-conductive films. This is accomplished by 1) providing a non-thermal or non-pyrolytic means of triggering the deposition reaction; 2) providing a means of depositing a purer film of higher density at lower temperatures; and, 3) providing a faster and more efficient means of modulating the deposition sequence and hence the overall process rate resulting in an improved deposition method. It is emphasized that this abstract is provided to comply with the rules requiring an abstract that will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure. It is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims.

Owner:NOVELLUS SYSTEMS

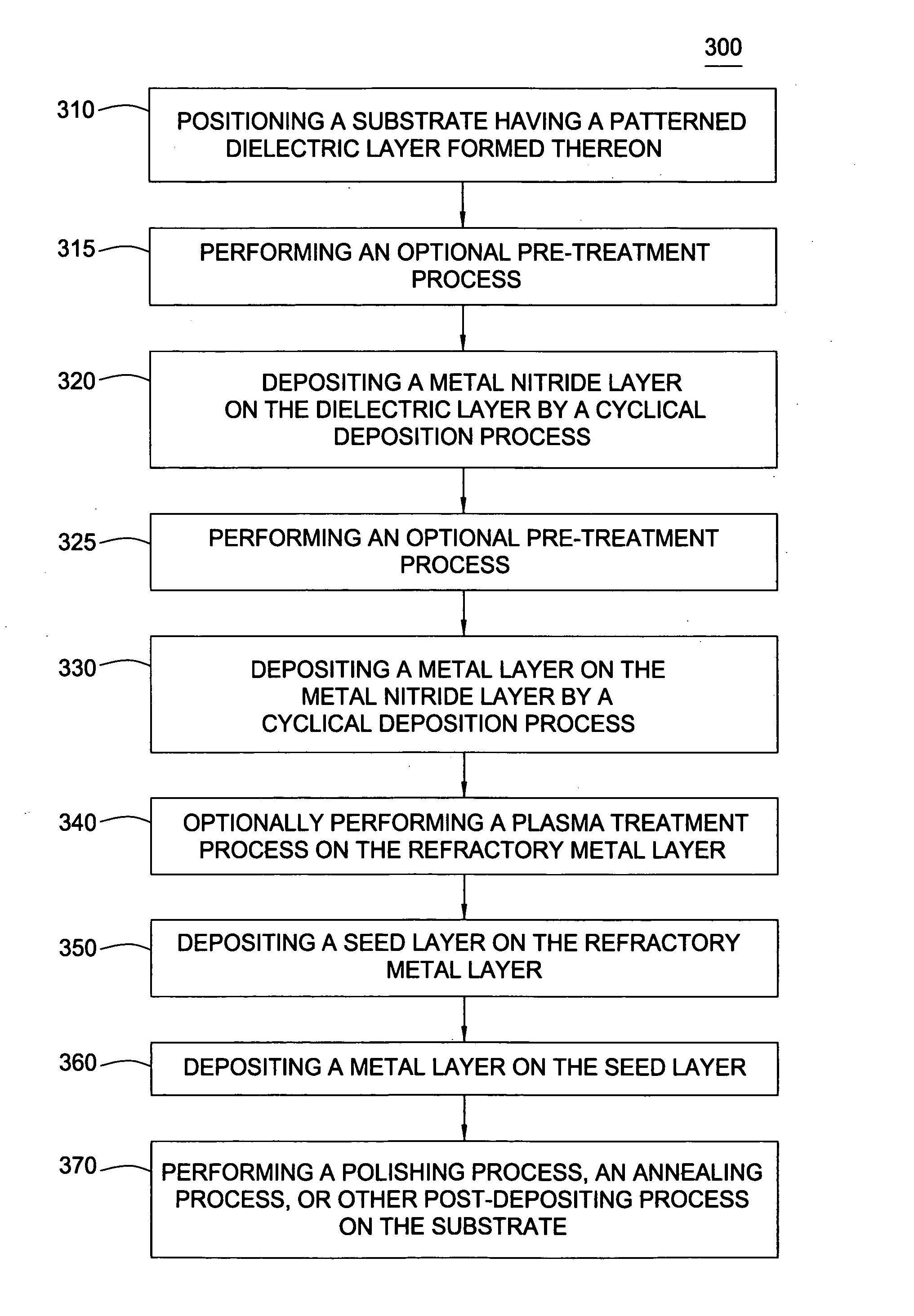

Atomic layer deposition of barrier materials

InactiveUS20050009325A1Material nanotechnologySemiconductor/solid-state device manufacturingNitrogenNitride

Methods for processing substrate to deposit barrier layers of one or more material layers by atomic layer deposition are provided. In one aspect, a method is provided for processing a substrate including depositing a metal nitride barrier layer on at least a portion of a substrate surface by alternately introducing one or more pulses of a metal containing compound and one or more pulses of a nitrogen containing compound and depositing a metal barrier layer on at least a portion of the metal nitride barrier layer by alternately introducing one or more pulses of a metal containing compound and one or more pulses of a reductant. A soak process may be performed on the substrate surface before deposition of the metal nitride barrier layer and / or metal barrier layer.

Owner:APPLIED MATERIALS INC

Vapor deposition method for ternary compounds

InactiveUS20100102417A1High resistivitySolid-state devicesSemiconductor/solid-state device manufacturingNitrogen plasmaGas phase

Embodiments provide a method for depositing or forming titanium aluminum nitride materials during a vapor deposition process, such as atomic layer deposition (ALD) or plasma-enhanced ALD (PE-ALD). In some embodiments, a titanium aluminum nitride material is formed by sequentially exposing a substrate to a titanium precursor and a nitrogen plasma to form a titanium nitride layer, exposing the titanium nitride layer to a plasma treatment process, and exposing the titanium nitride layer to an aluminum precursor while depositing an aluminum layer thereon. The process may be repeated multiple times to deposit a plurality of titanium nitride and aluminum layers. Subsequently, the substrate may be annealed to form the titanium aluminum nitride material from the plurality of layers. In other embodiments, the titanium aluminum nitride material may be formed by sequentially exposing the substrate to the nitrogen plasma and a deposition gas which contains the titanium and aluminum precursors.

Owner:APPLIED MATERIALS INC

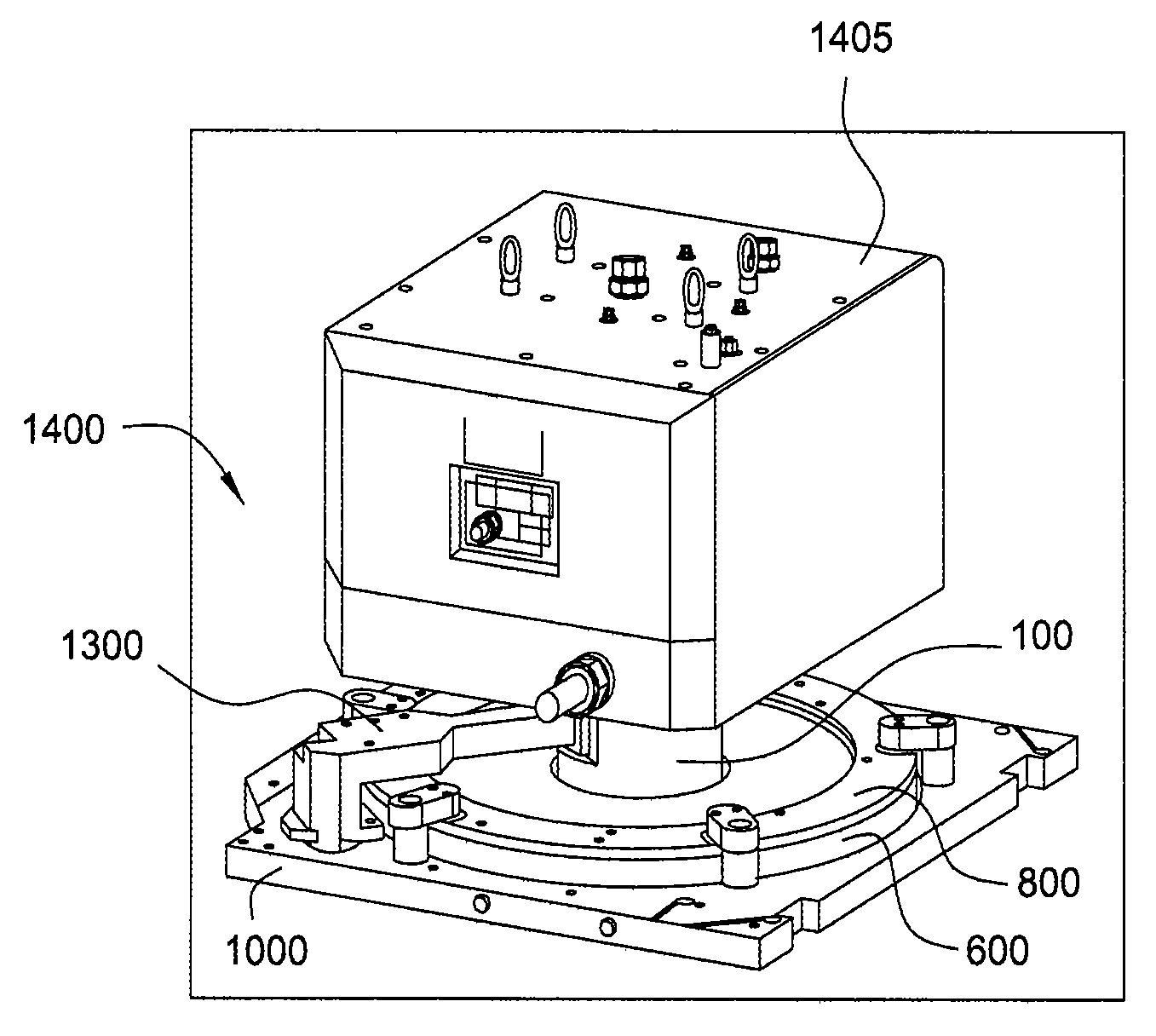

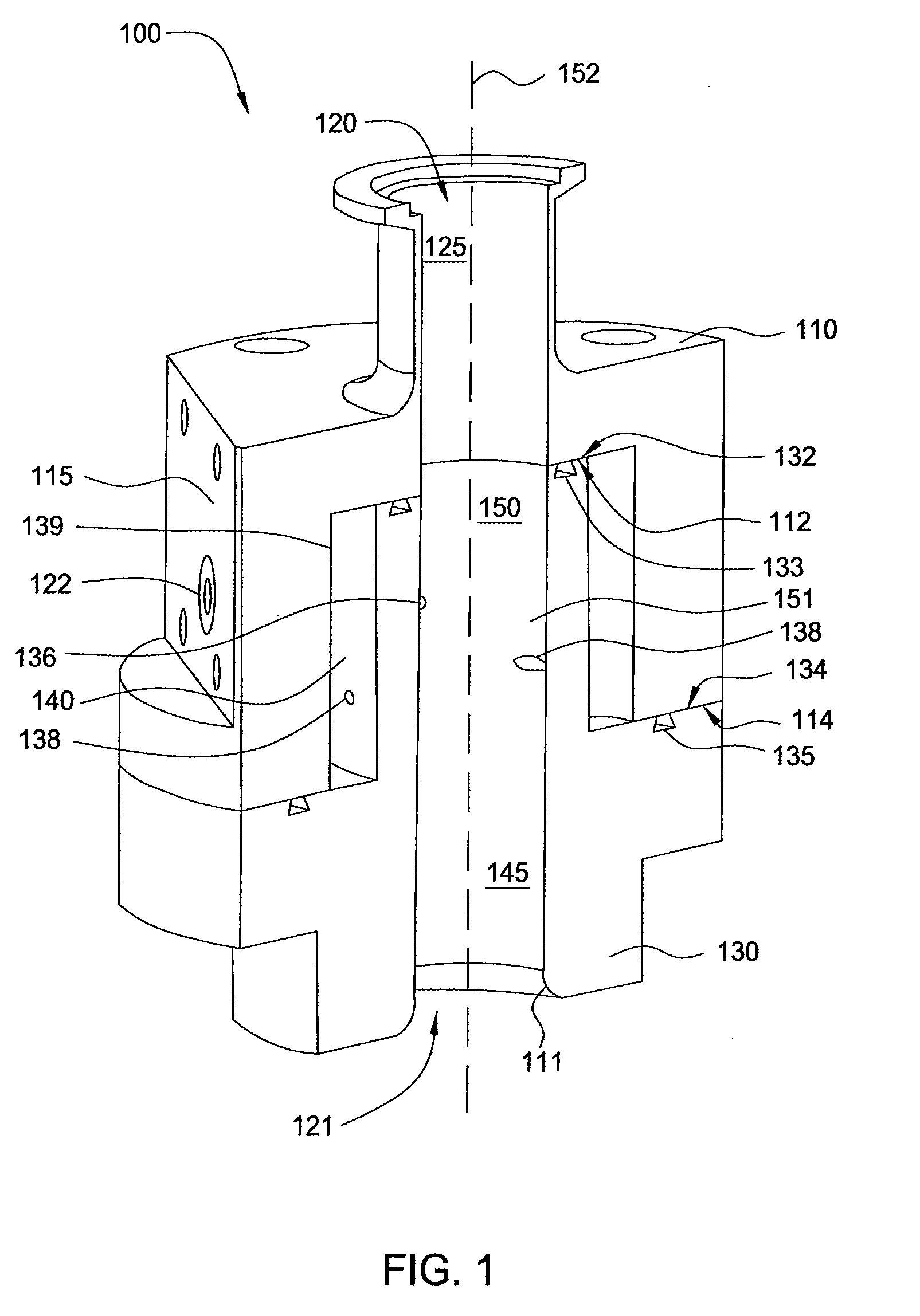

Plasma atomic layer deposition system and method

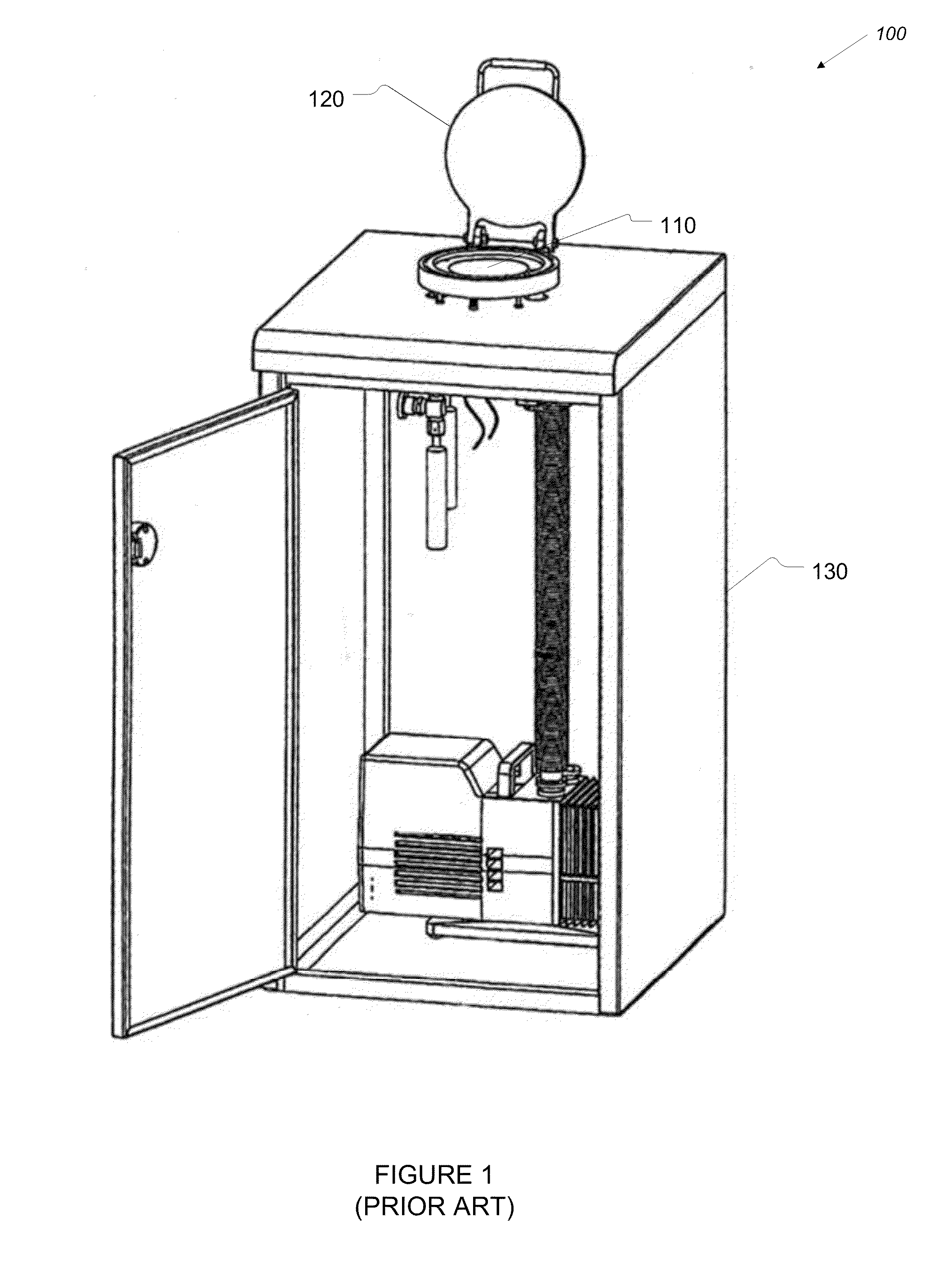

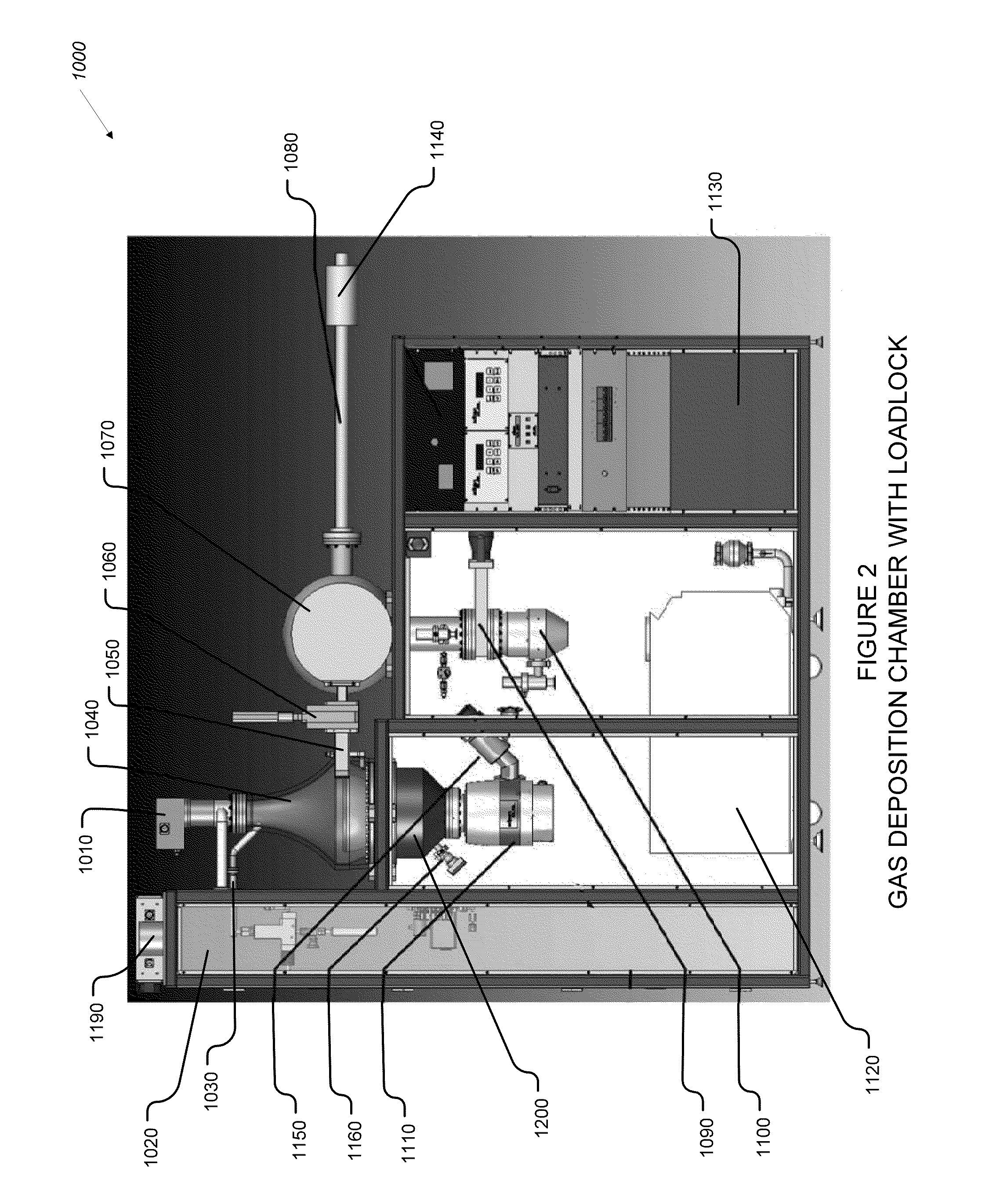

InactiveUS20100183825A1Lower the volumeShorten cycle timeChemical vapor deposition coatingPlasma techniqueEngineeringAtomic layer deposition

An improved gas deposition chamber includes a hollow gas deposition volume formed with a volume expanding top portion and a substantially constant volume cylindrical middle portion. The hollow gas deposition volume may include a volume reducing lower portion. An aerodynamically shaped substrate support chuck is disposed inside gas deposition chamber with a substrate support surface positioned in the constant volume cylindrical middle portion. The volume expanding top portion reduces gas flow velocity between gas input ports and the substrate support surface. The aerodynamic shape of the substrate support chuck reduces drag and helps to promote laminar flow over the substrate support surface. The volume reducing lower portion helps to increase gas flow velocity after the gas has past the substrate support surface. The improved gas deposition chamber is configurable to 200 mm diameter semiconductor wafers using ALD and or PALD coating cycles. An improved coating method includes expanding process gases inside the deposition chamber prior to the process gas reaching surfaces of a substrate being coated. The method further includes compressing the process gases inside the deposition chamber after the process gas has flowed past surfaces of the substrate being coated.

Owner:ULTRATECH INT INC

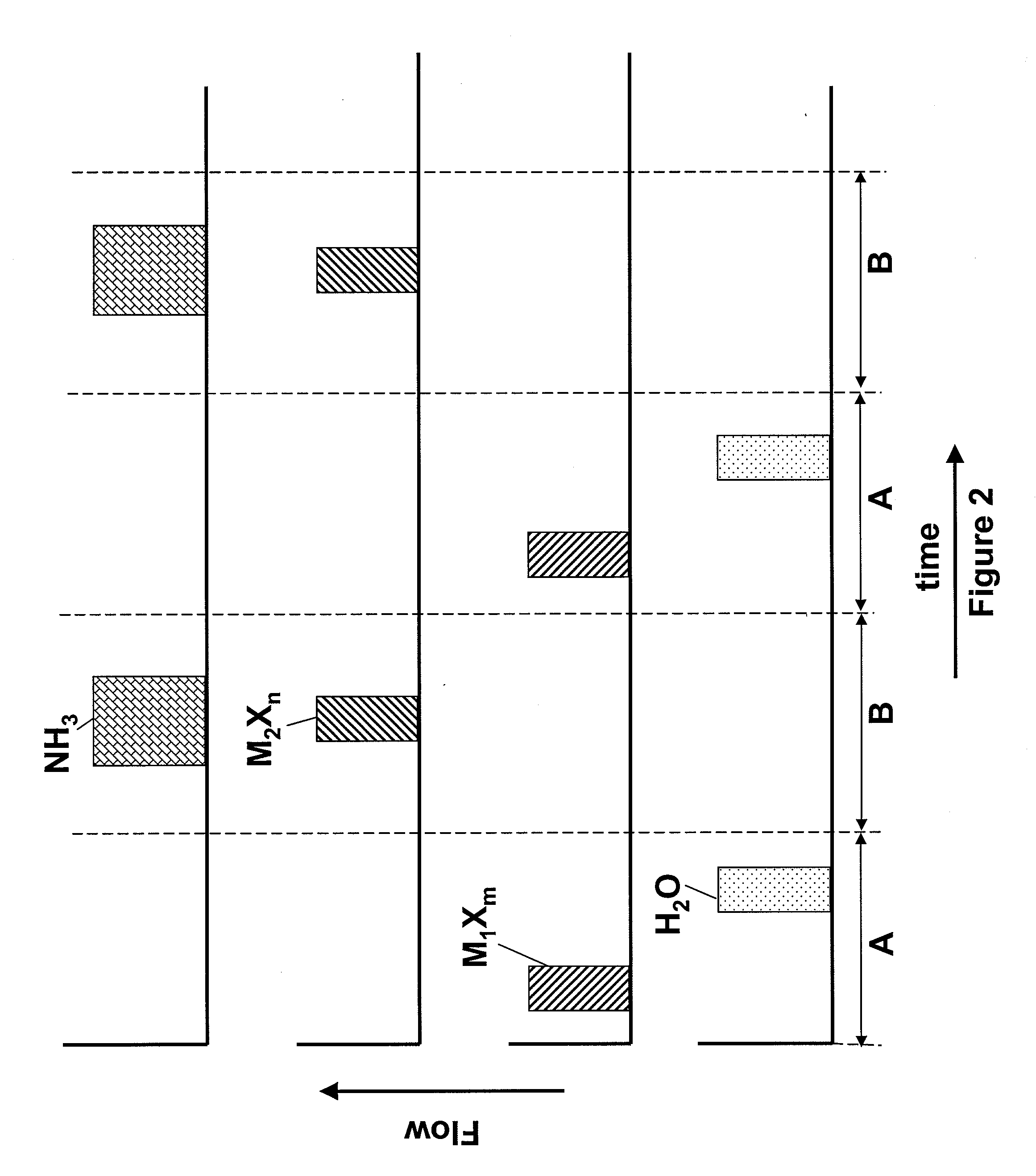

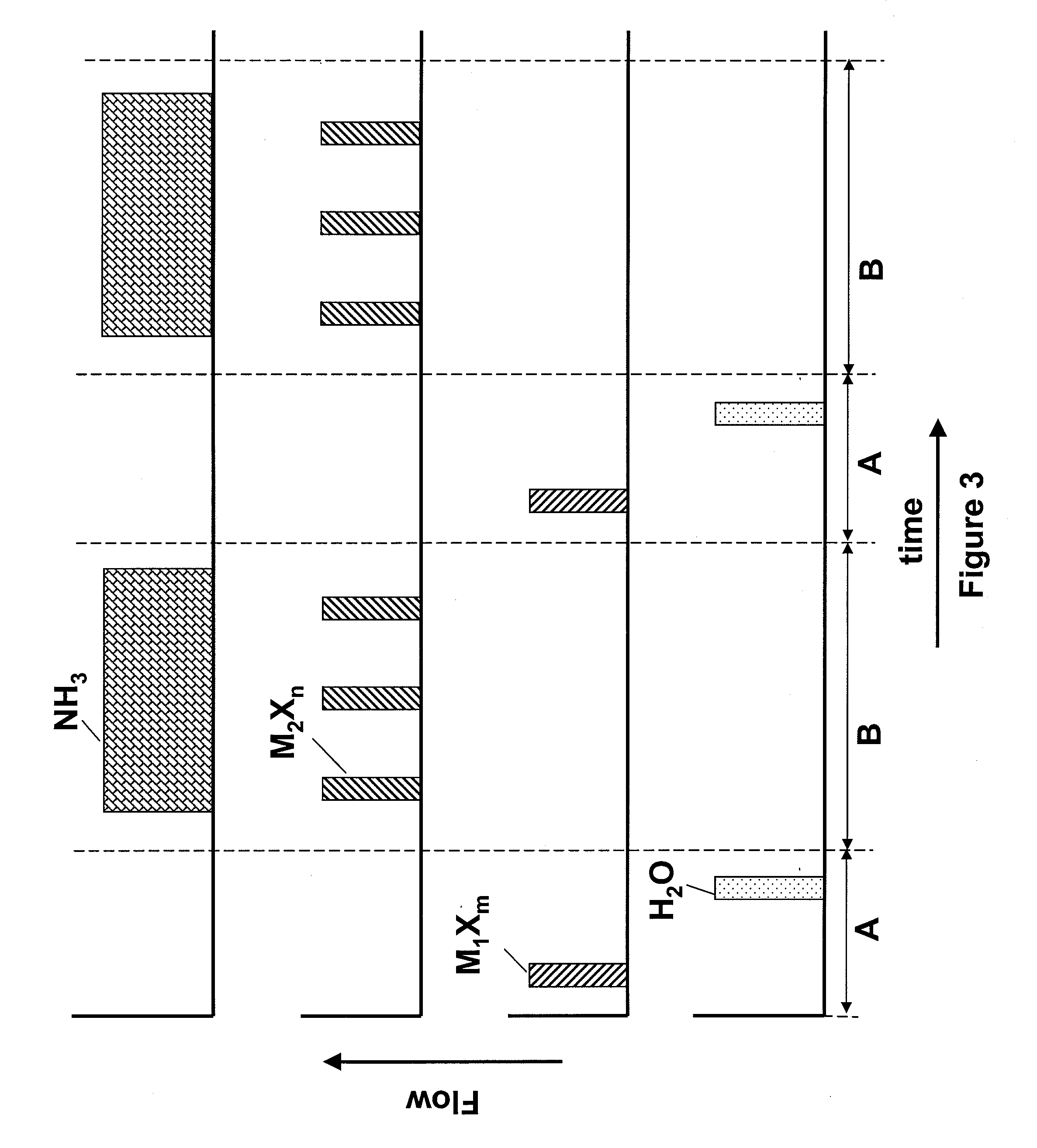

Treatment processes for a batch ALD reactor

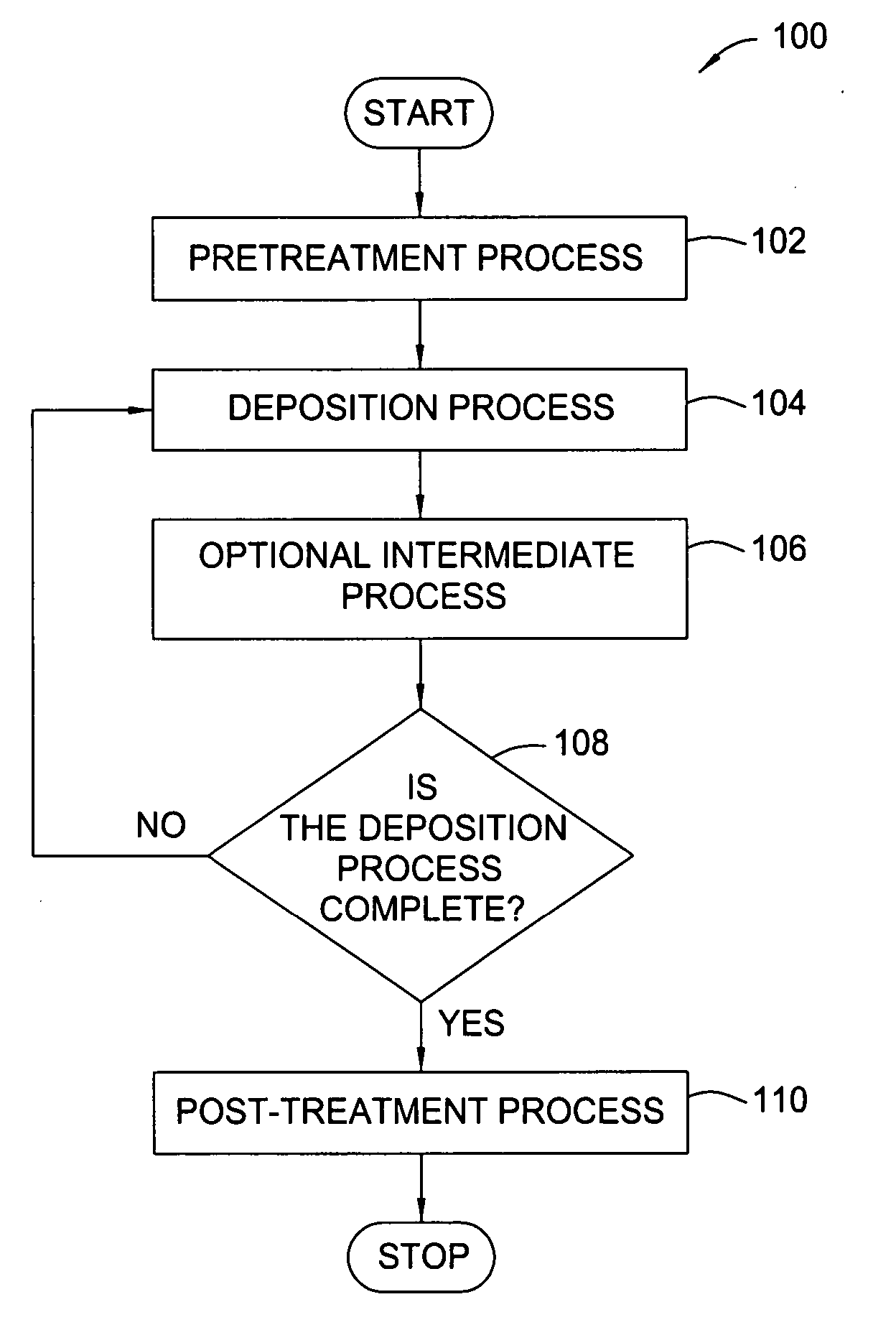

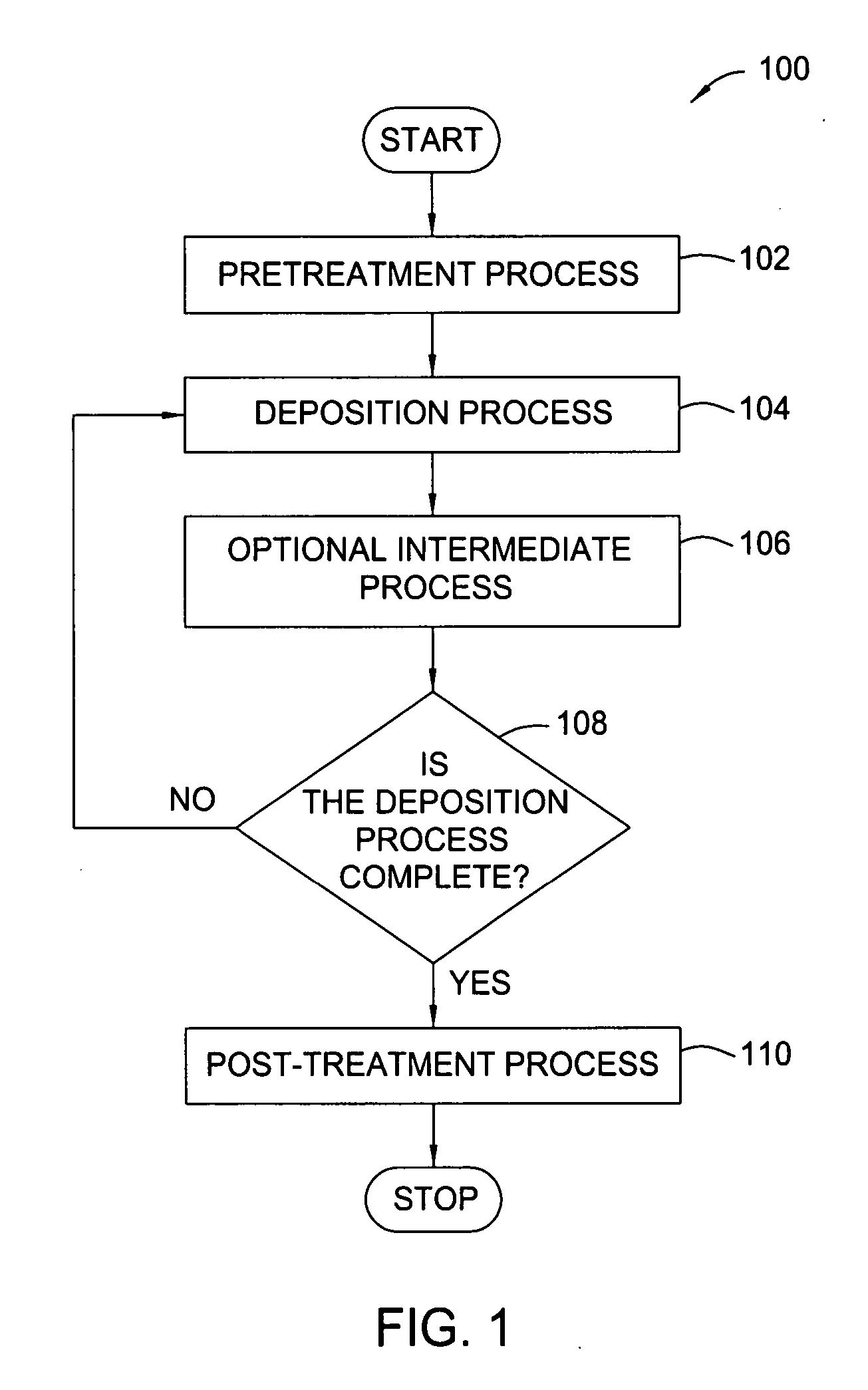

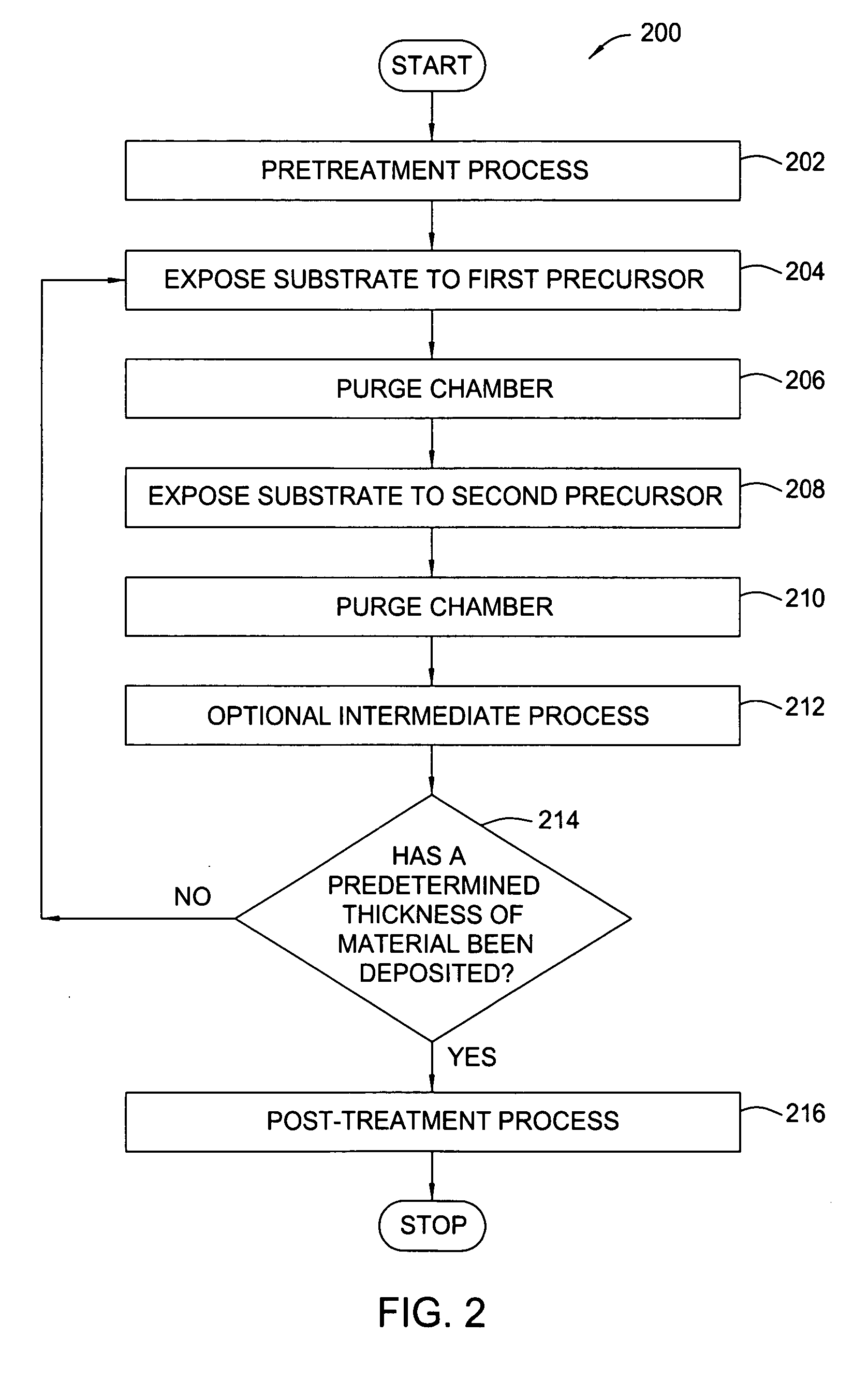

Embodiments of the invention provide treatment processes to reduce substrate contamination during a fabrication process within a vapor deposition chamber. A treatment process may be conducted before, during or after a vapor deposition process, such as an atomic layer deposition (ALD) process. In one example of an ALD process, a process cycle, containing an intermediate treatment step and a predetermined number of ALD cycles, is repeated until the deposited material has a desired thickness. The chamber and substrates may be exposed to an inert gas, an oxidizing gas, a nitriding gas, a reducing gas or plasmas thereof during the treatment processes. In some examples, the treatment gas contains ozone, water, ammonia, nitrogen, argon or hydrogen. In one example, a process for depositing a hafnium oxide material within a batch process chamber includes a pretreatment step, an intermediate step during an ALD process and a post-treatment step.

Owner:APPLIED MATERIALS INC

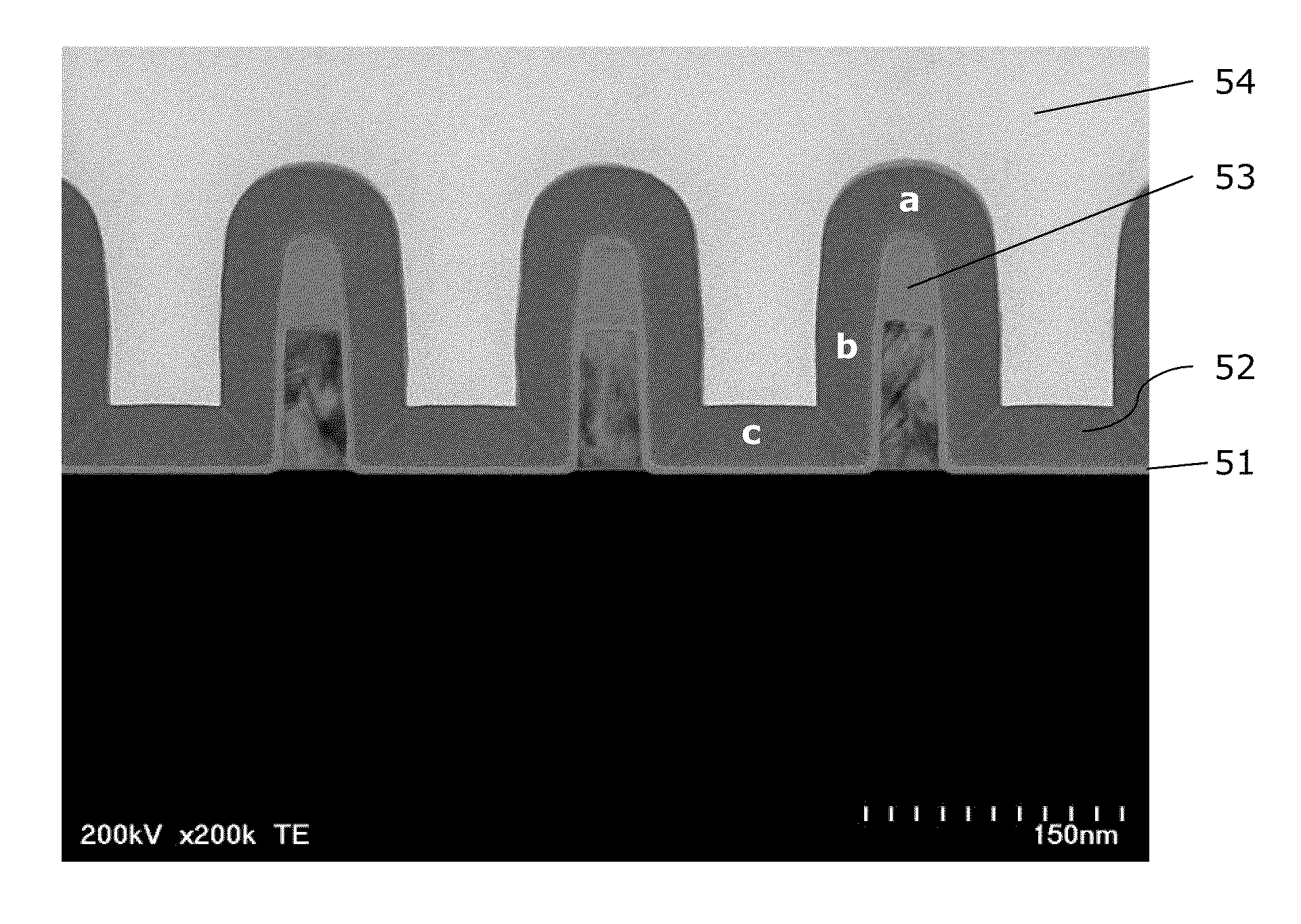

PEALD Deposition of a Silicon-Based Material

InactiveUS20070251444A1Avoiding considerable slow-downInhibition formationPolycrystalline material growthFrom chemically reactive gasesAtomic layer depositionSemiconductor

A process for depositing a silicon-based material on a substrate uses the technology of plasma-enhanced atomic layer deposition. The process is carried out over several cycles, wherein each cycle includes: exposing the substrate to a first precursor, which is an organometallic silicon precursor; and applying a plasma of at least a second precursor, different from the first precursor. Semiconductor products such as 3D capacitors, vertical transistor gate spacers, and conformal transistor stressors are made from the process.

Owner:STMICROELECTRONICS SRL

Systems and methods for thin-film deposition of metal oxides using excited nitrogen-oxygen species

ActiveUS20140346650A1Enhance growth rate and uniformityUniform growthLiquid surface applicatorsSemiconductor/solid-state device detailsNitrogenOptoelectronics

The present invention relates to a process and system for depositing a thin film onto a substrate. One aspect of the invention is depositing a thin film metal oxide layer using atomic layer deposition (ALD).

Owner:ASM IP HLDG BV

Apparatuses and methods for atomic layer deposition of hafnium-containing high-k dielectric materials

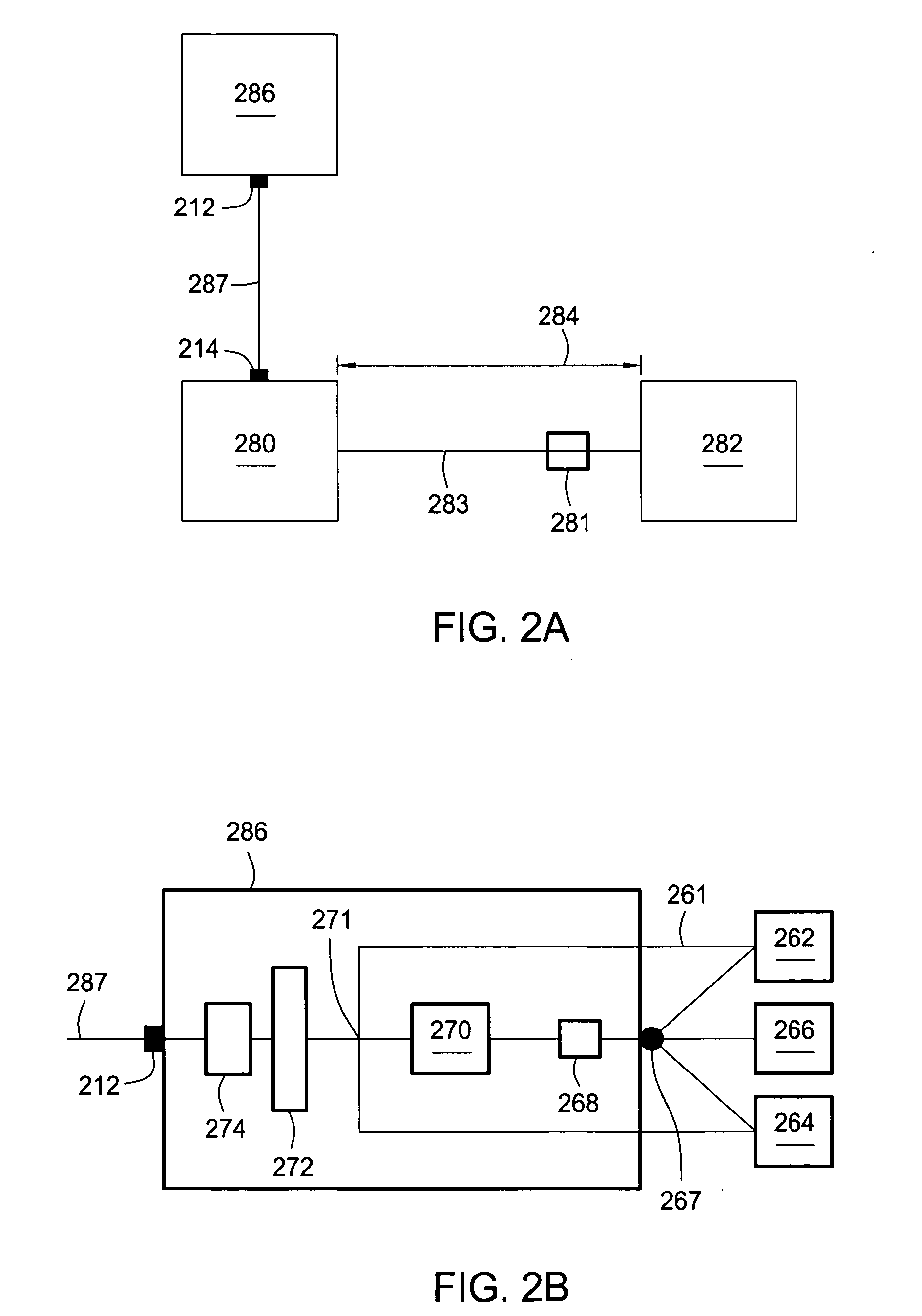

ActiveUS20050271812A1Steam generation heating methodsEfficient propulsion technologiesWater vaporGas phase

Embodiments of the invention provide apparatuses and methods for depositing materials on substrates during vapor deposition processes, such as atomic layer deposition (ALD). In one embodiment, a chamber contains a substrate support with a receiving surface and a chamber lid containing an expanding channel formed within a thermally insulating material. The chamber further includes at least one conduit coupled to a gas inlet within the expanding channel and positioned to provide a gas flow through the expanding channel in a circular direction, such as a vortex, a helix, a spiral or derivatives thereof. The expanding channel may be formed directly within the chamber lid or formed within a funnel liner attached thereon. The chamber may contain a retaining ring, an upper process liner, a lower process liner or a slip valve liner. Liners usually have a polished surface finish and contain a thermally insulating material such as fused quartz or ceramic. In an alternative embodiment, a deposition system contains a catalytic water vapor generator connected to an ALD chamber.

Owner:APPLIED MATERIALS INC

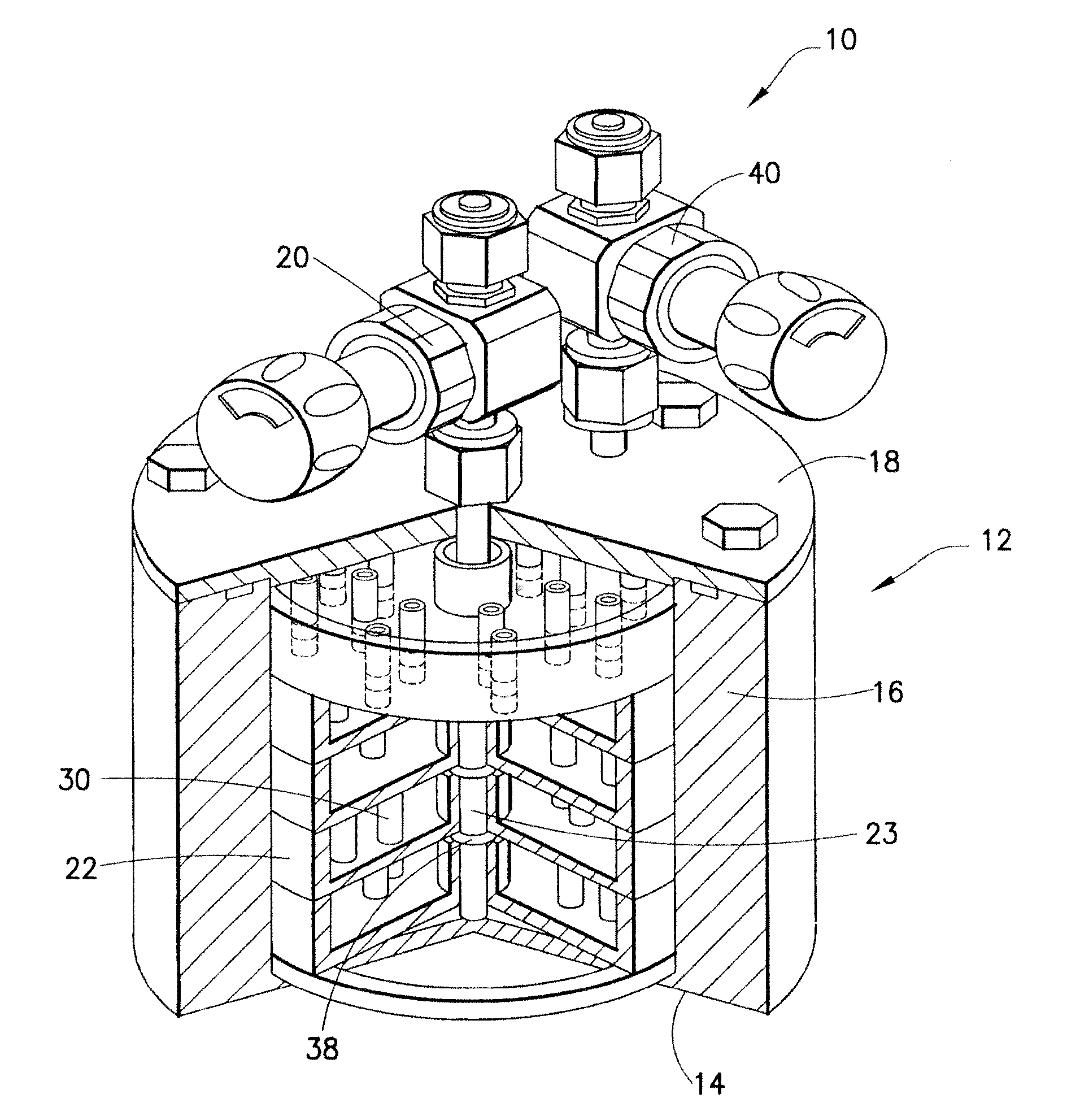

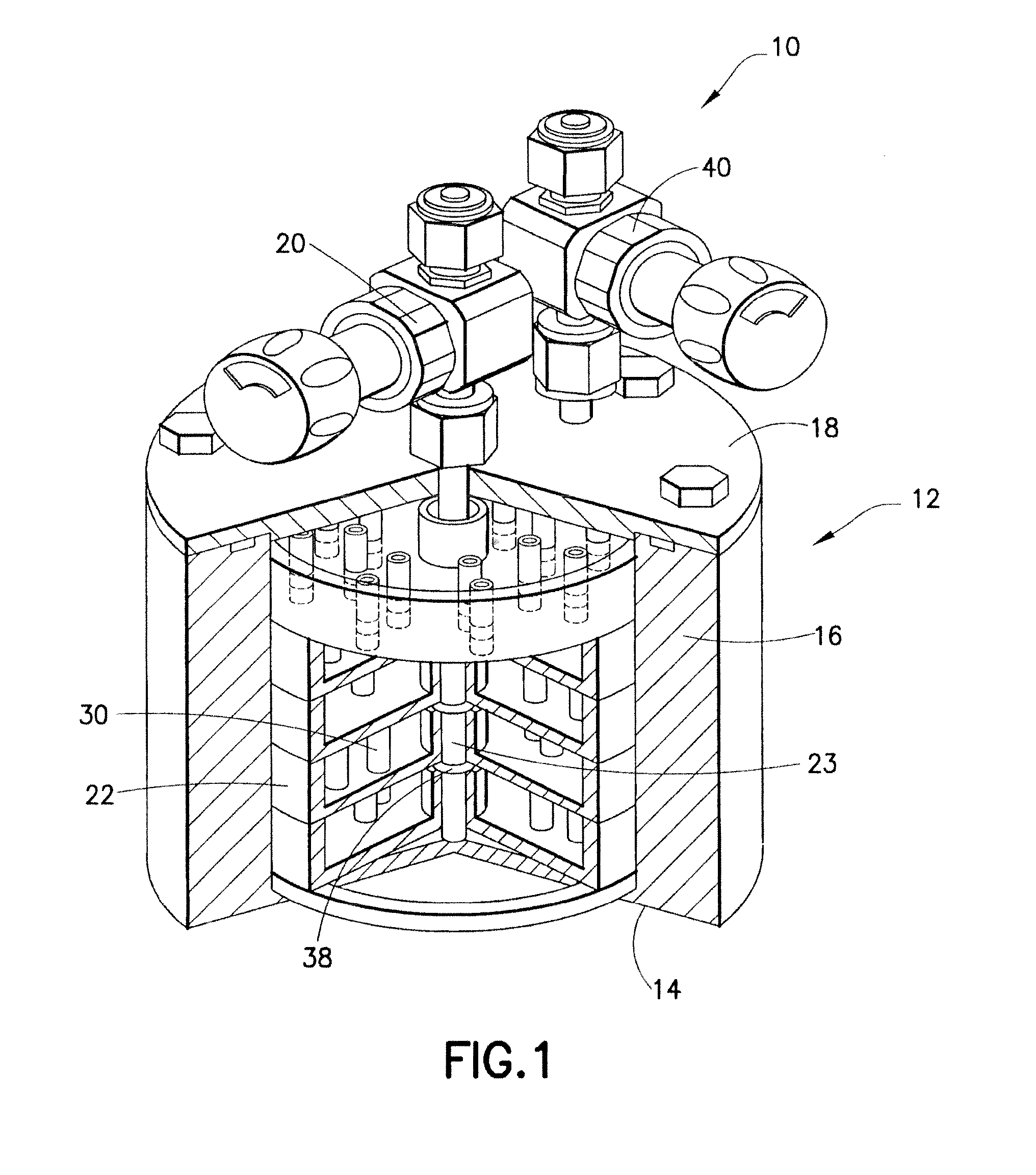

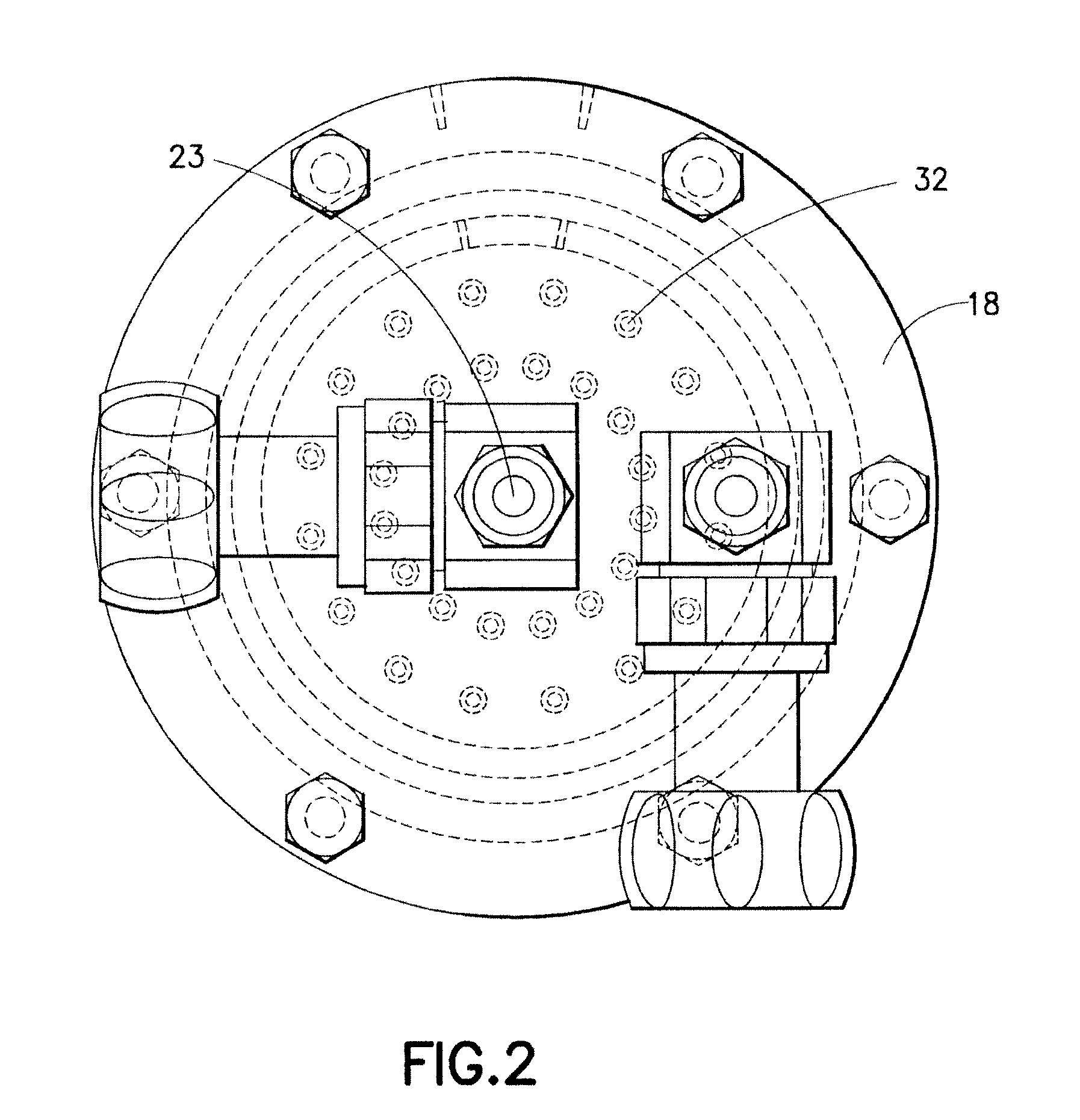

Solid precursor-based delivery of fluid utilizing controlled solids morphology

ActiveUS20100255198A1Vacuum evaporation coatingSputtering coatingMetal halidesAtomic layer deposition

Apparatus and method for volatilizing a source reagent susceptible to particle generation or presence of particles in the corresponding source reagent vapor, in which such particle generation or presence is suppressed by structural or processing features of the vapor generation system. Such apparatus and method are applicable to liquid and solid source reagents, particularly solid source reagents such as metal halides, e.g., hafnium chloride. The source reagent in one specific implementation is constituted by a porous monolithic bulk form of the source reagent material. The apparatus and method of the invention are usefully employed to provide source reagent vapor for applications such as atomic layer deposition (ALD) and ion implantation.

Owner:ENTEGRIS INC

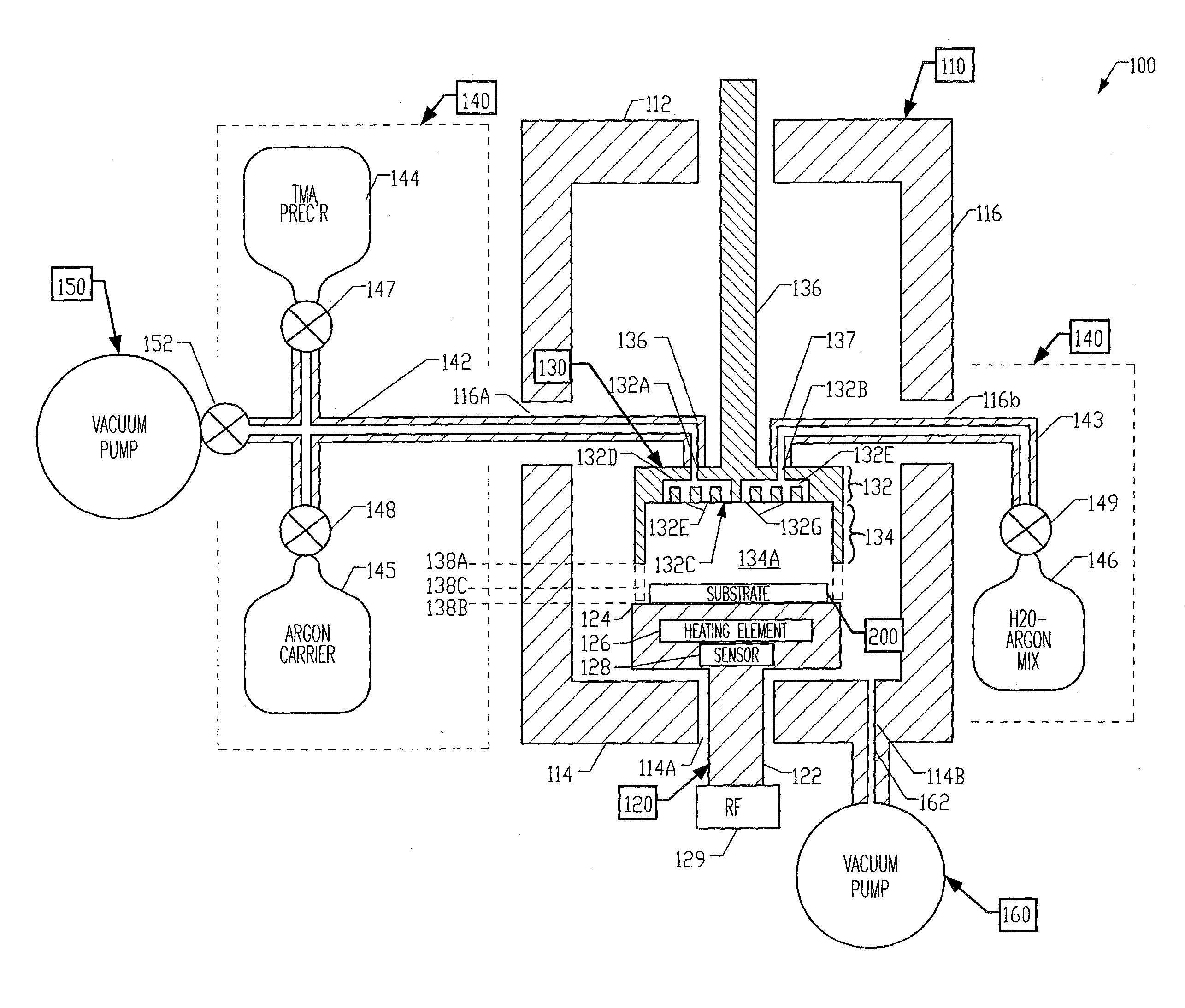

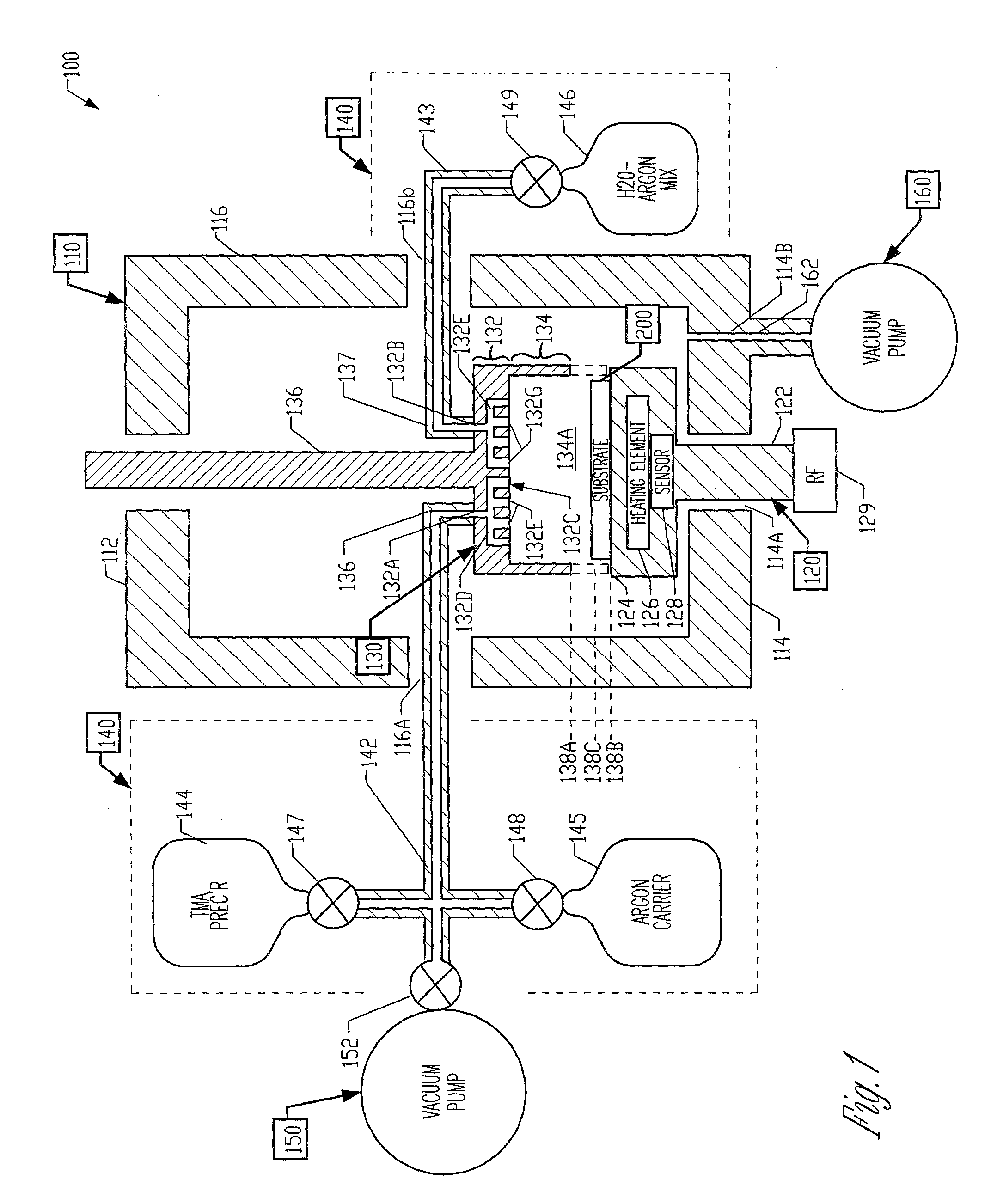

Methods, systems, and apparatus for atomic-layer deposition of aluminum oxides in integrated circuits

InactiveUS20030207032A1Small volumeConsumes less gasPretreated surfacesChemical vapor deposition coatingProduct gasIntegrated circuit layout

Integrated circuits, the key components in thousands of electronic and computer products, are generally built layer by layer on a silicon substrate. One common layer-formation technique, known as chemical-vapor deposition (CVD), produces uneven layers and covers vertical surfaces poorly. An emergent technique, atomic-layer deposition, overcomes these shortcomings, but has others, such as slow deposition rates and longer than desirable cycle times, particularly as applied to deposition of aluminum oxide. Accordingly, the inventors devised unique atomic-layer deposition systems, methods, and apparatus suitable for aluminum-oxide deposition. One exemplary system includes an outer chamber, a substrate holder, and a gas-distribution fixture that engages or cooperates with the substrate holder to form an inner chamber within the outer chamber. The inner chamber has a smaller volume than the outer chamber, which ultimately requires less time to fill and purge and thus promises to reduce cycle times for deposition of materials, such as aluminum oxide.

Owner:MICRON TECH INC

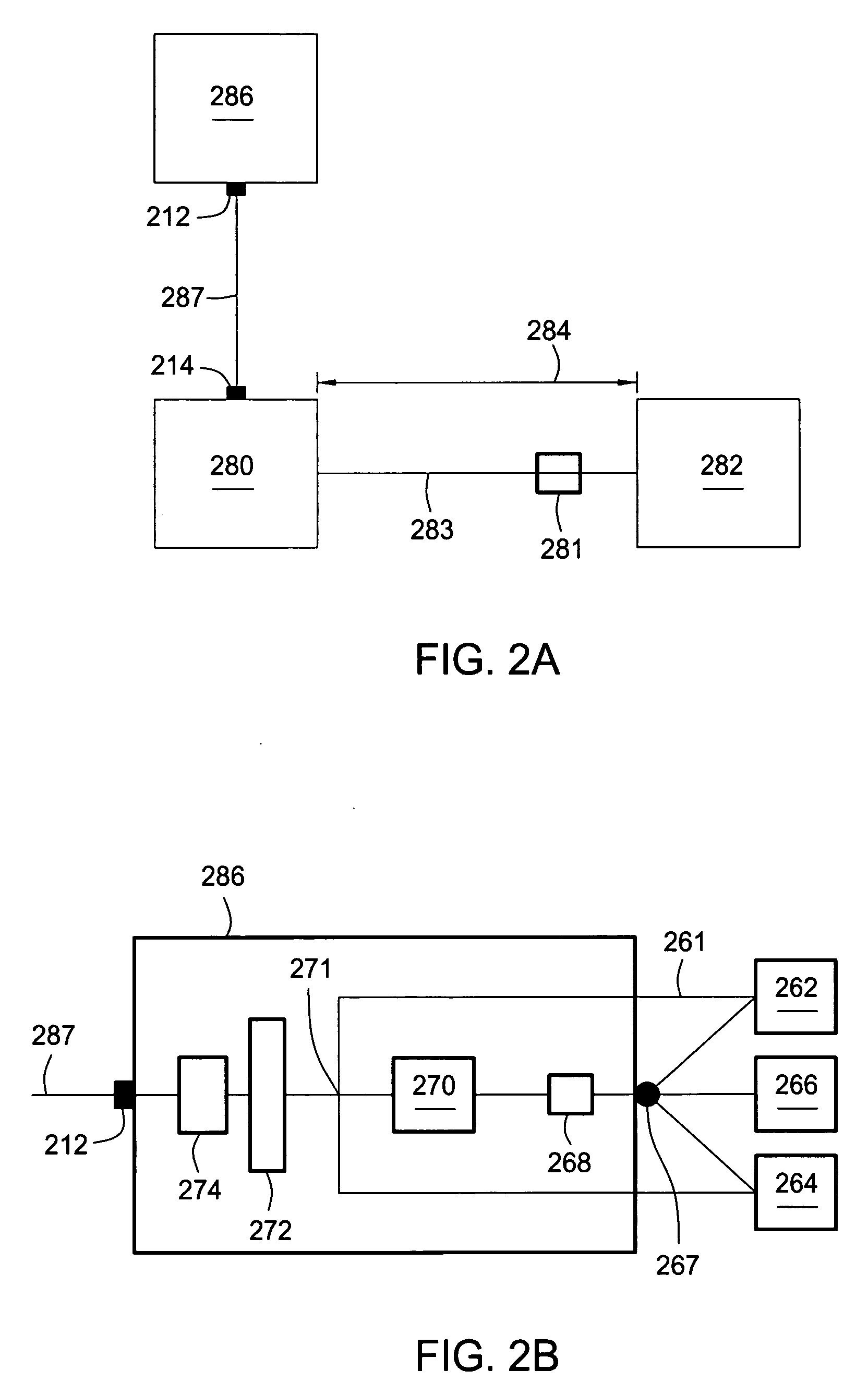

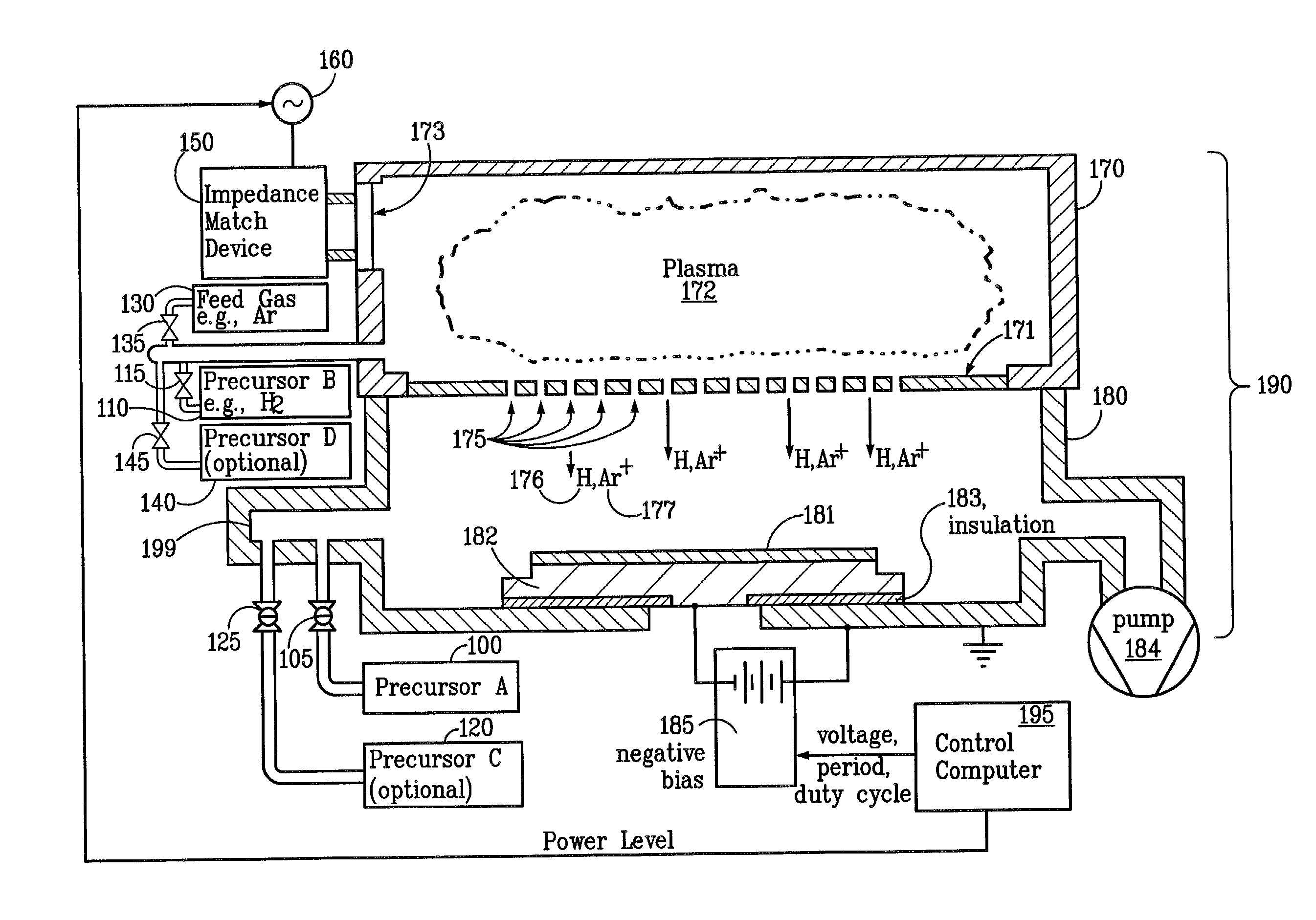

System and method for modulated ion-induced atomic layer deposition (MII-ALD)

InactiveUS20020104481A1Faster efficient meanSimple methodSemiconductor/solid-state device manufacturingChemical vapor deposition coatingHigh densitySubject matter

The present invention relates to an enhanced sequential or non-sequential atomic layer deposition (ALD) apparatus and technique suitable for deposition of barrier layers, adhesion layers, seed layers, low dielectric constant (low-k) films, high dielectric constant (high-k) films, and other conductive, semi-conductive, and non-conductive films. This is accomplished by 1) providing a non-thermal or non-pyrolytic means of triggering the deposition reaction; 2) providing a means of depositing a purer film of higher density at lower temperatures; 3) providing a faster and more efficient means of modulating the deposition sequence and hence the overall process rate resulting in an improved deposition method; and, 4) providing a means of improved radical generation and delivery. It is emphasized that this abstract is provided to comply with the rules requiring an abstract that will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure. It is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims. [37 C.F.R. § 1.72(b)].

Owner:ANGSTRON SYST

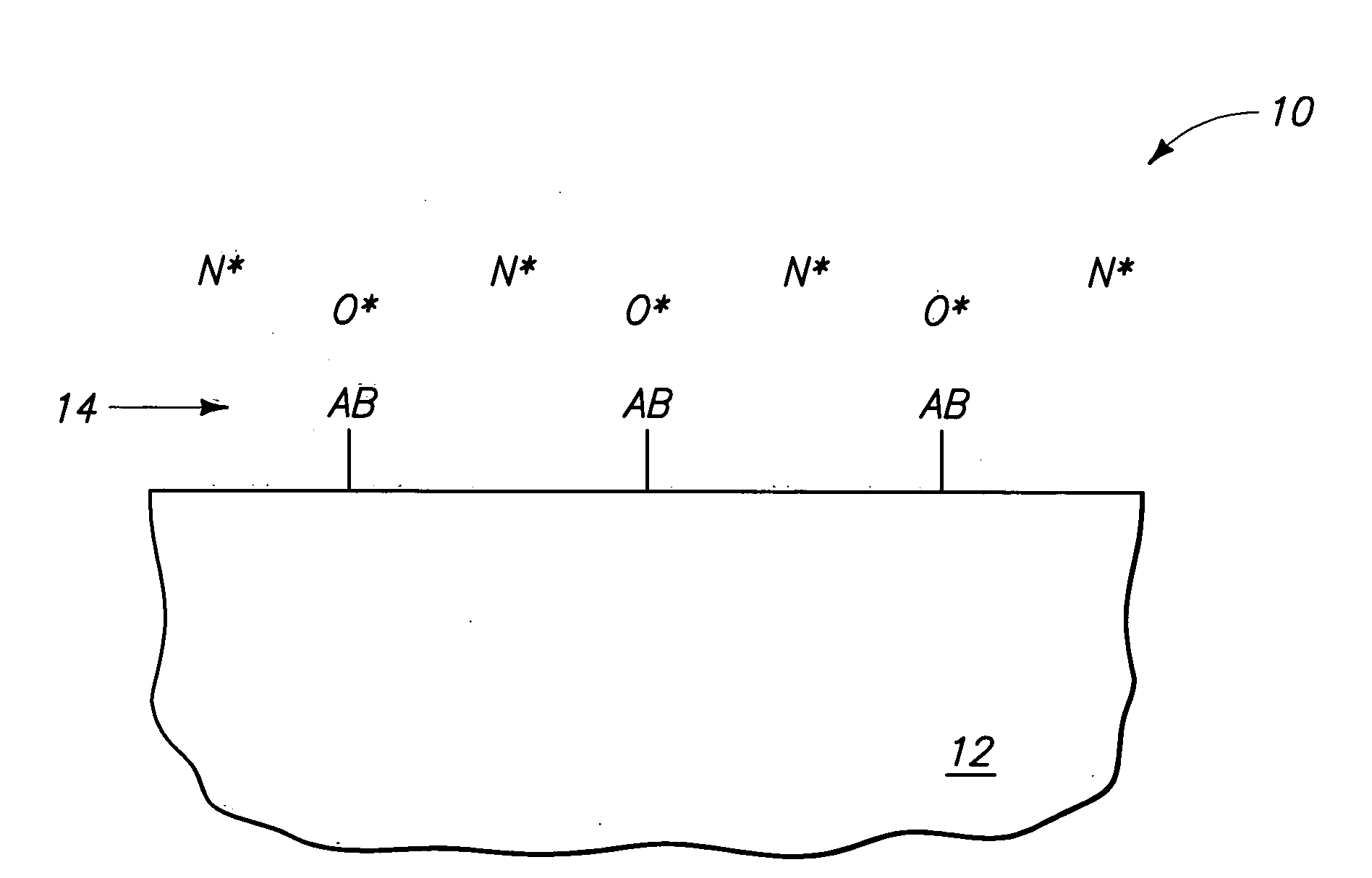

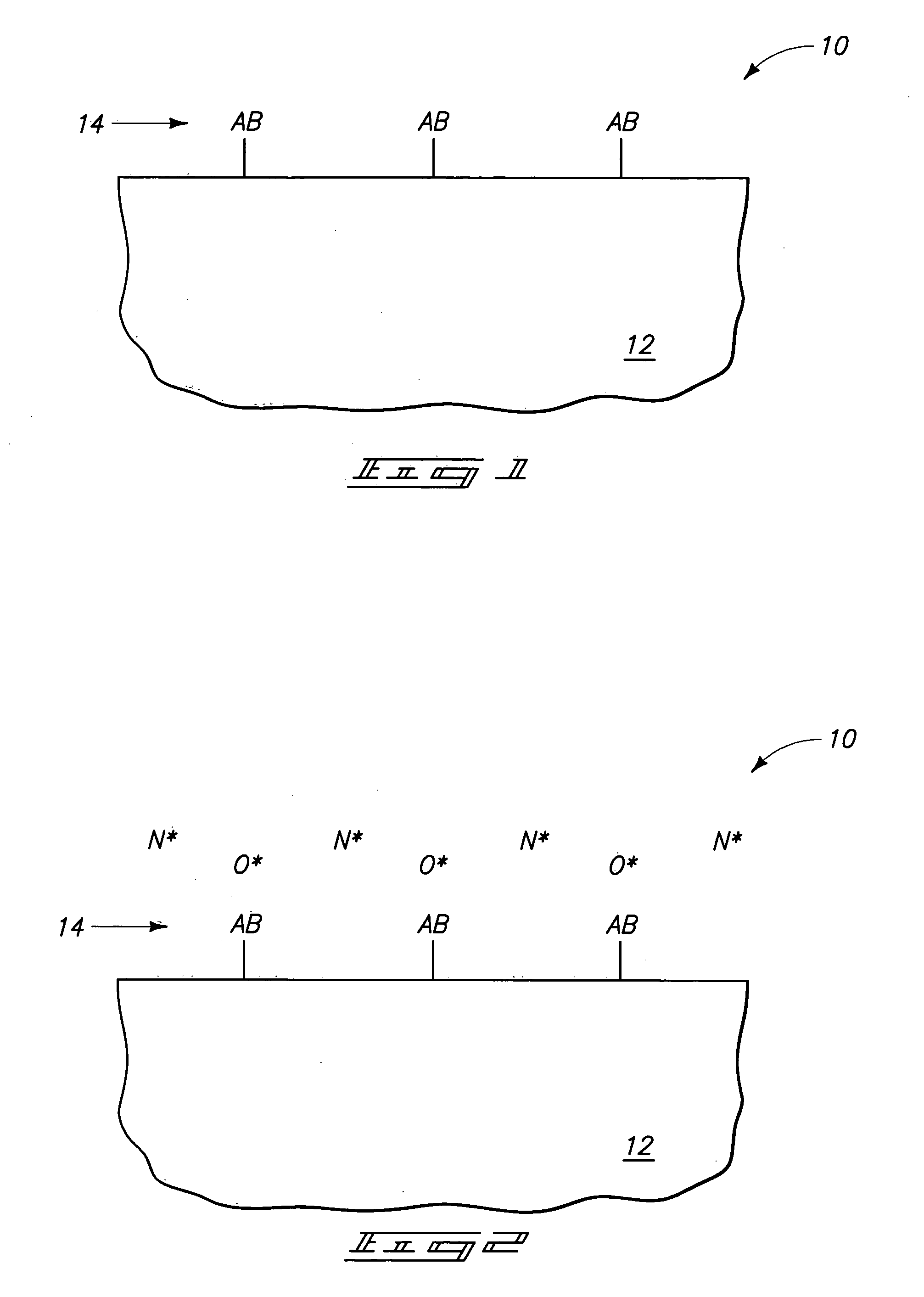

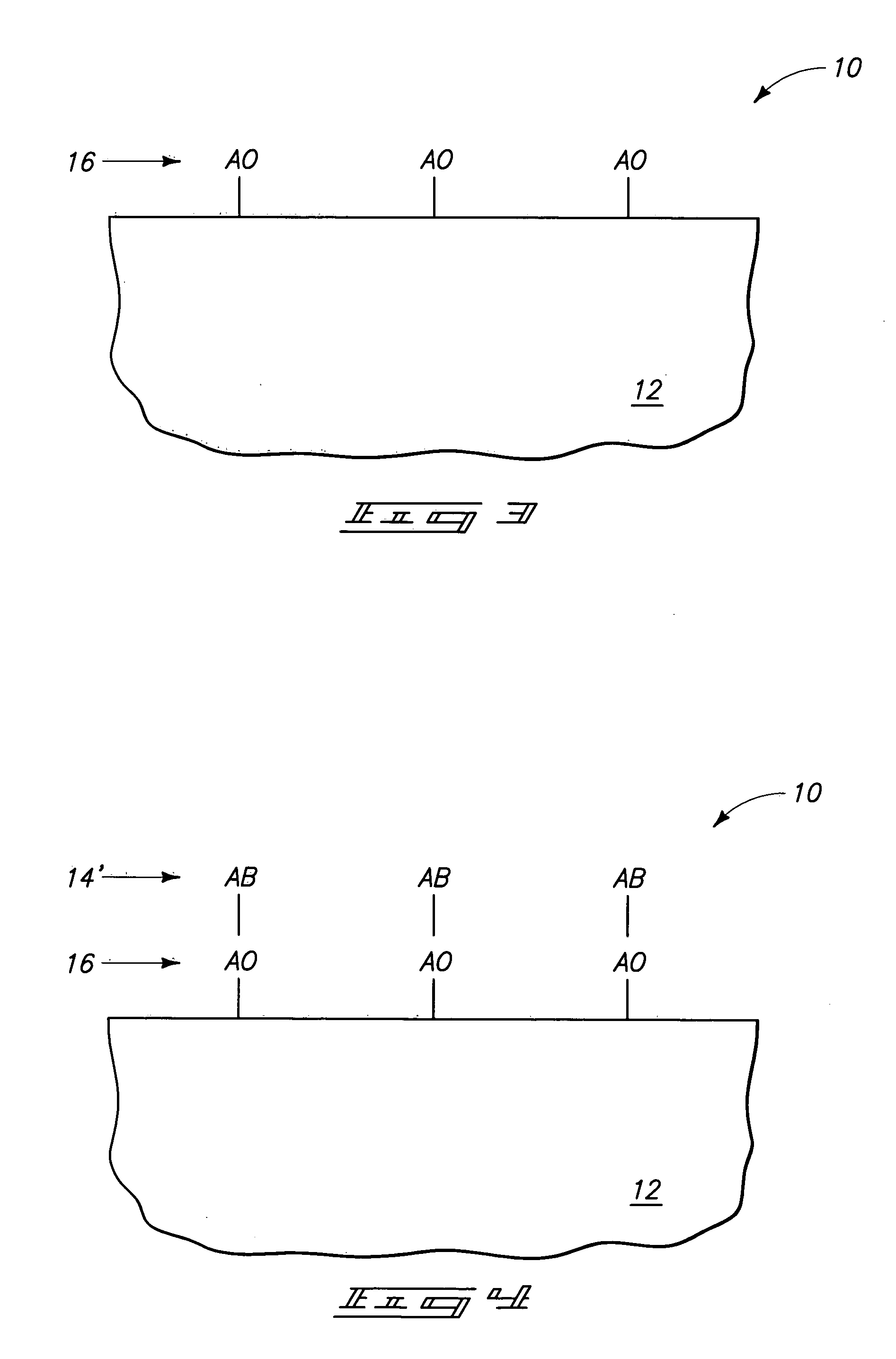

Atomic layer deposition method of depositing an oxide on a substrate

The invention includes atomic layer deposition methods of depositing an oxide on a substrate. In one implementation, a substrate is positioned within a deposition chamber. A first species is chemisorbed onto the substrate to form a first species monolayer within the deposition chamber from a gaseous precursor. The chemisorbed first species is contacted with remote plasma oxygen derived at least in part from at least one of O2 and O3 and with remote plasma nitrogen effective to react with the first species to form a monolayer comprising an oxide of a component of the first species monolayer. The chemisorbing and the contacting with remote plasma oxygen and with remote plasma nitrogen are successively repeated effective to form porous oxide on the substrate. Other aspects and implementations are contemplated.

Owner:MICRON TECH INC

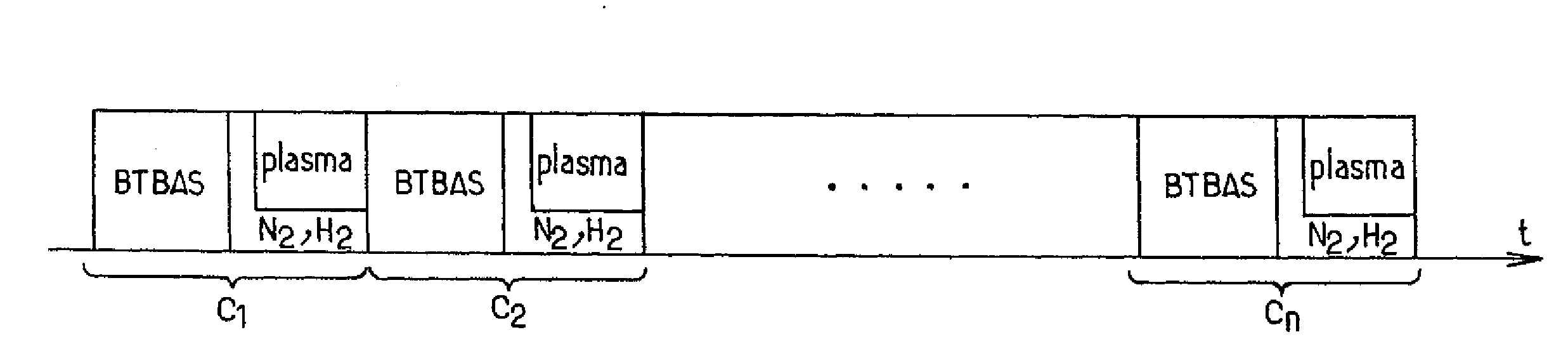

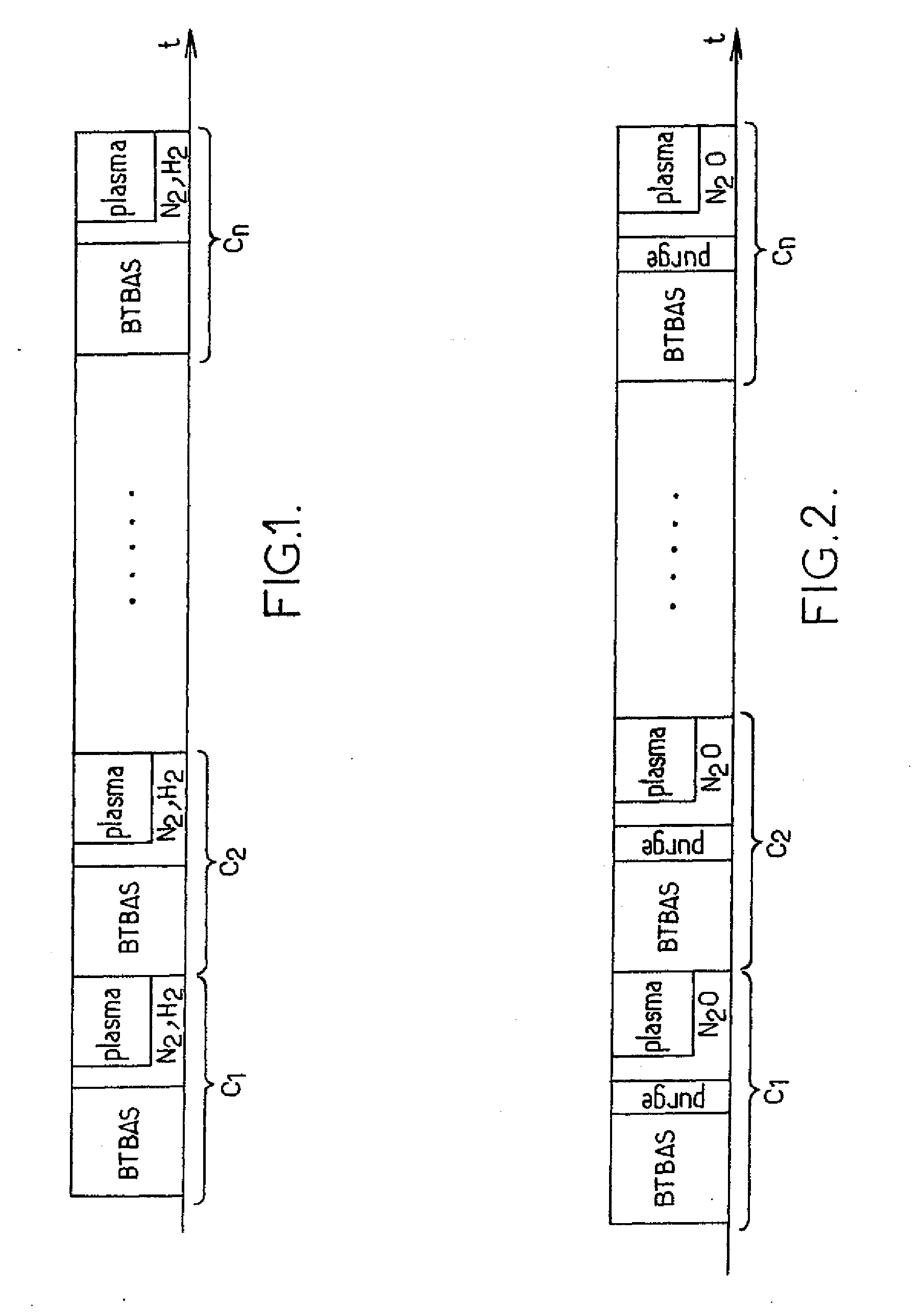

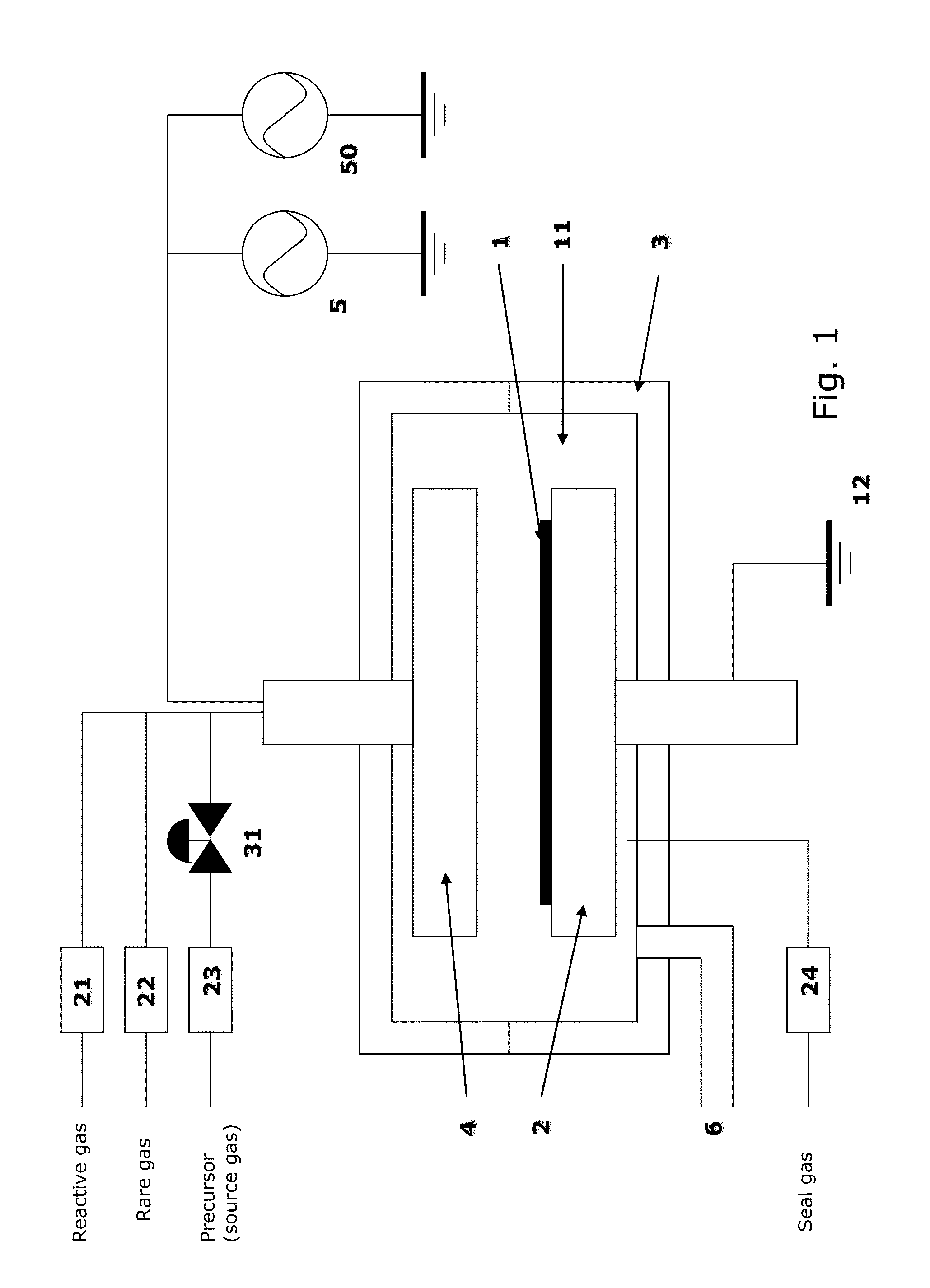

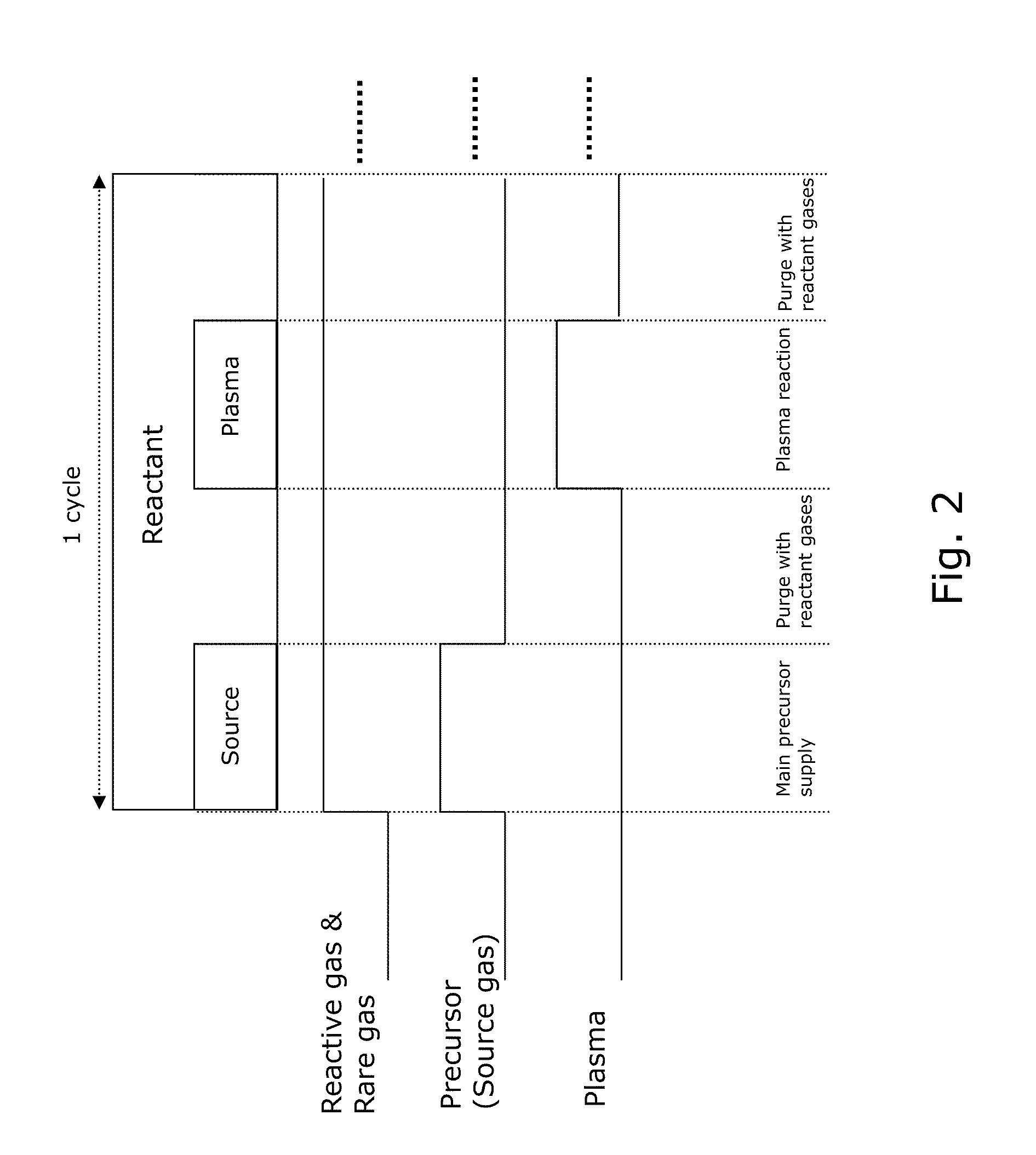

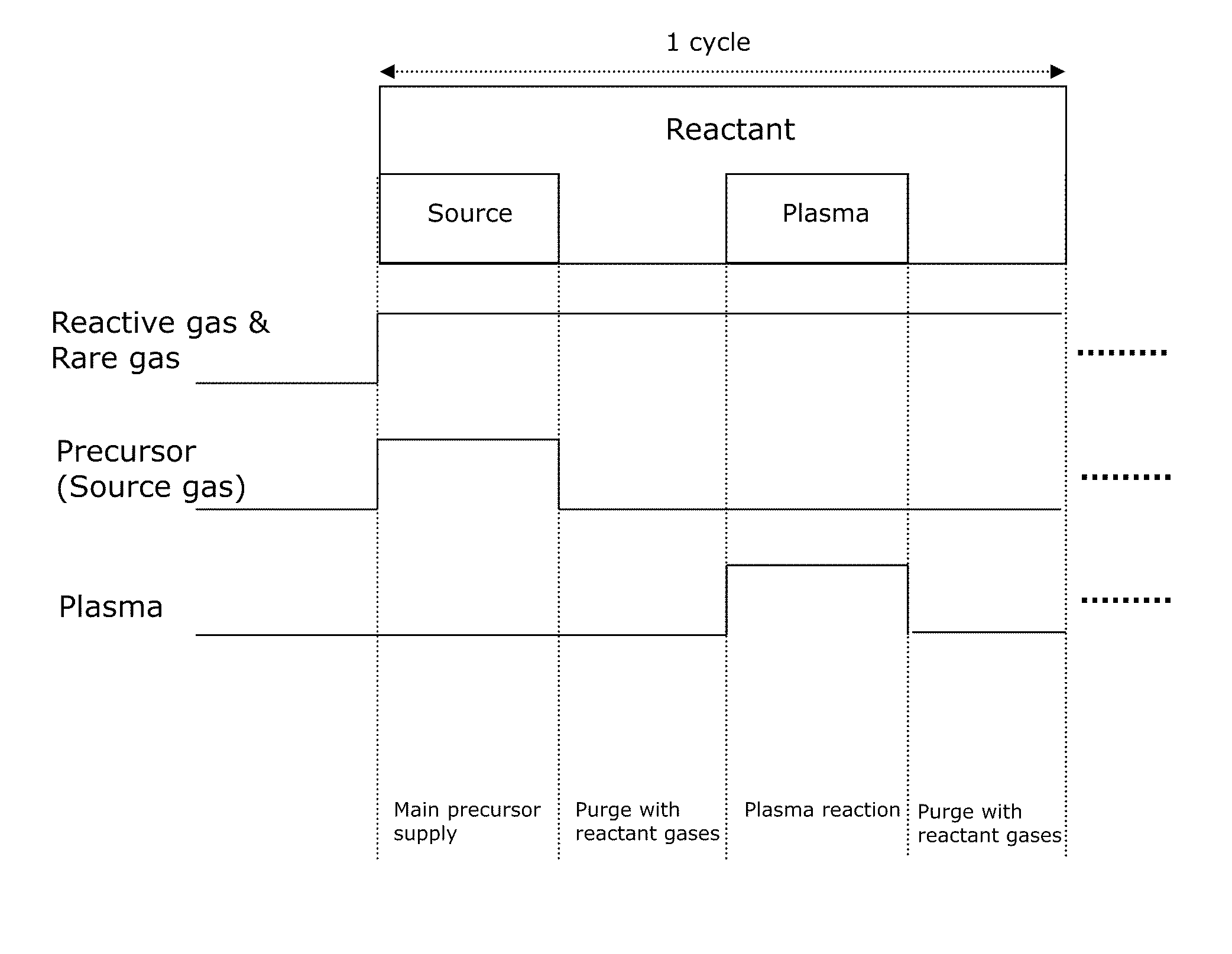

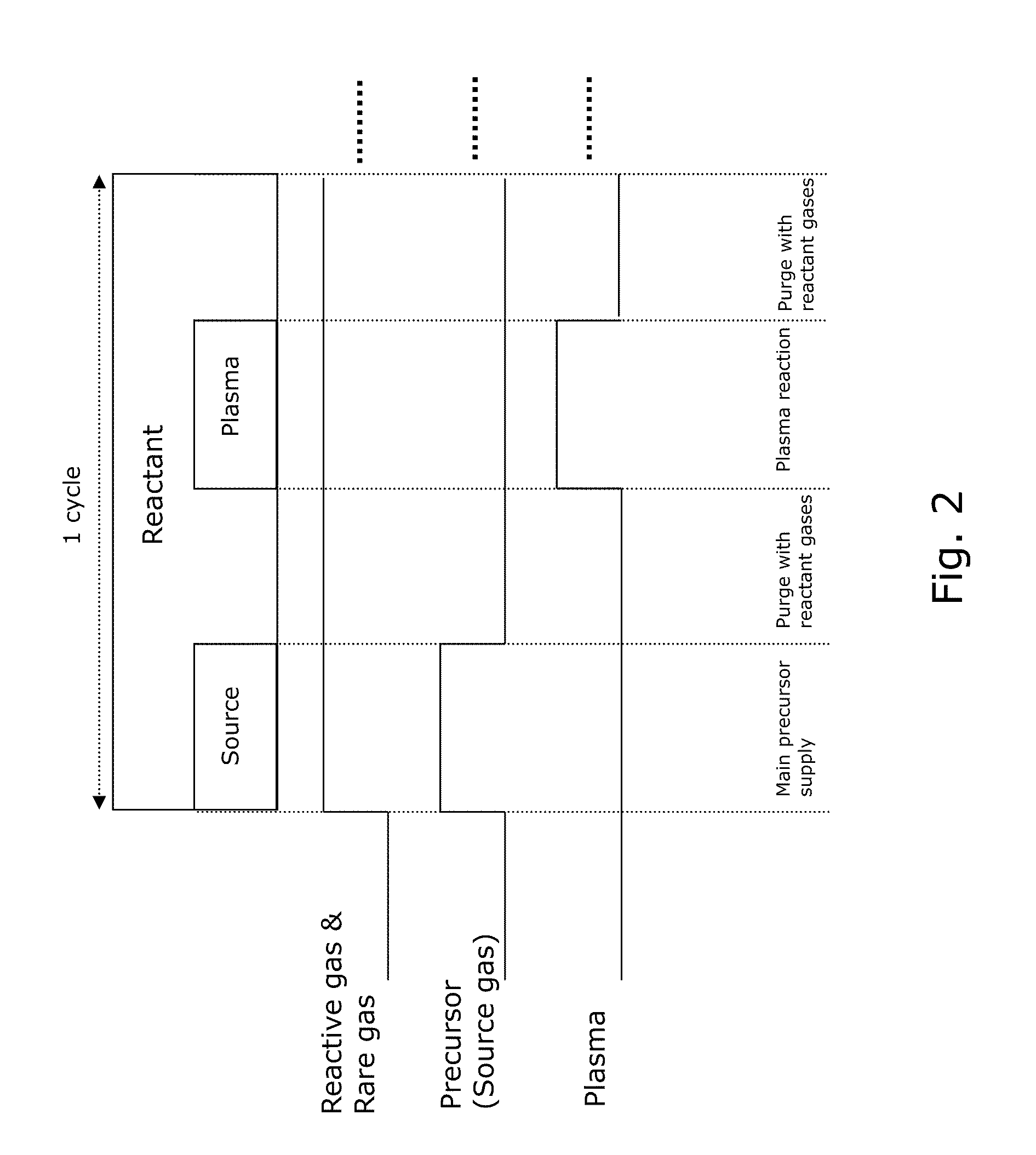

METHOD OF DEPOSITING DIELECTRIC FILM HAVING Si-N BONDS BY MODIFIED PEALD METHOD

ActiveUS20110086516A1High conformalityIncrease deposition rateSemiconductor/solid-state device manufacturingChemical vapor deposition coatingDielectricNoble gas

A method of forming dielectric film having Si—N bonds on a semiconductor substrate by plasma enhanced atomic layer deposition (PEALD), includes: introducing a nitrogen- and hydrogen-containing reactive gas and a rare gas into a reaction space inside which the semiconductor substrate is placed; introducing a hydrogen-containing silicon precursor in pulses of less than 1.0-second duration into the reaction space wherein the reactive gas and the rare gas are introduced; exiting a plasma in pulses of less than 1.0-second duration immediately after the silicon precursor is shut off; and maintaining the reactive gas and the rare gas as a purge of less than 2.0-second duration.

Owner:ASM JAPAN

Method of depositing dielectric film having Si-N bonds by modified peald method

ActiveUS8173554B2Increase deposition rateHigh conformalitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingDielectricHydrogen

A method of forming dielectric film having Si—N bonds on a semiconductor substrate by plasma enhanced atomic layer deposition (PEALD), includes: introducing a nitrogen- and hydrogen-containing reactive gas and a rare gas into a reaction space inside which the semiconductor substrate is placed; introducing a hydrogen-containing silicon precursor in pulses of less than 1.0-second duration into the reaction space wherein the reactive gas and the rare gas are introduced; exiting a plasma in pulses of less than 1.0-second duration immediately after the silicon precursor is shut off; and maintaining the reactive gas and the rare gas as a purge of less than 2.0-second duration.

Owner:ASM JAPAN

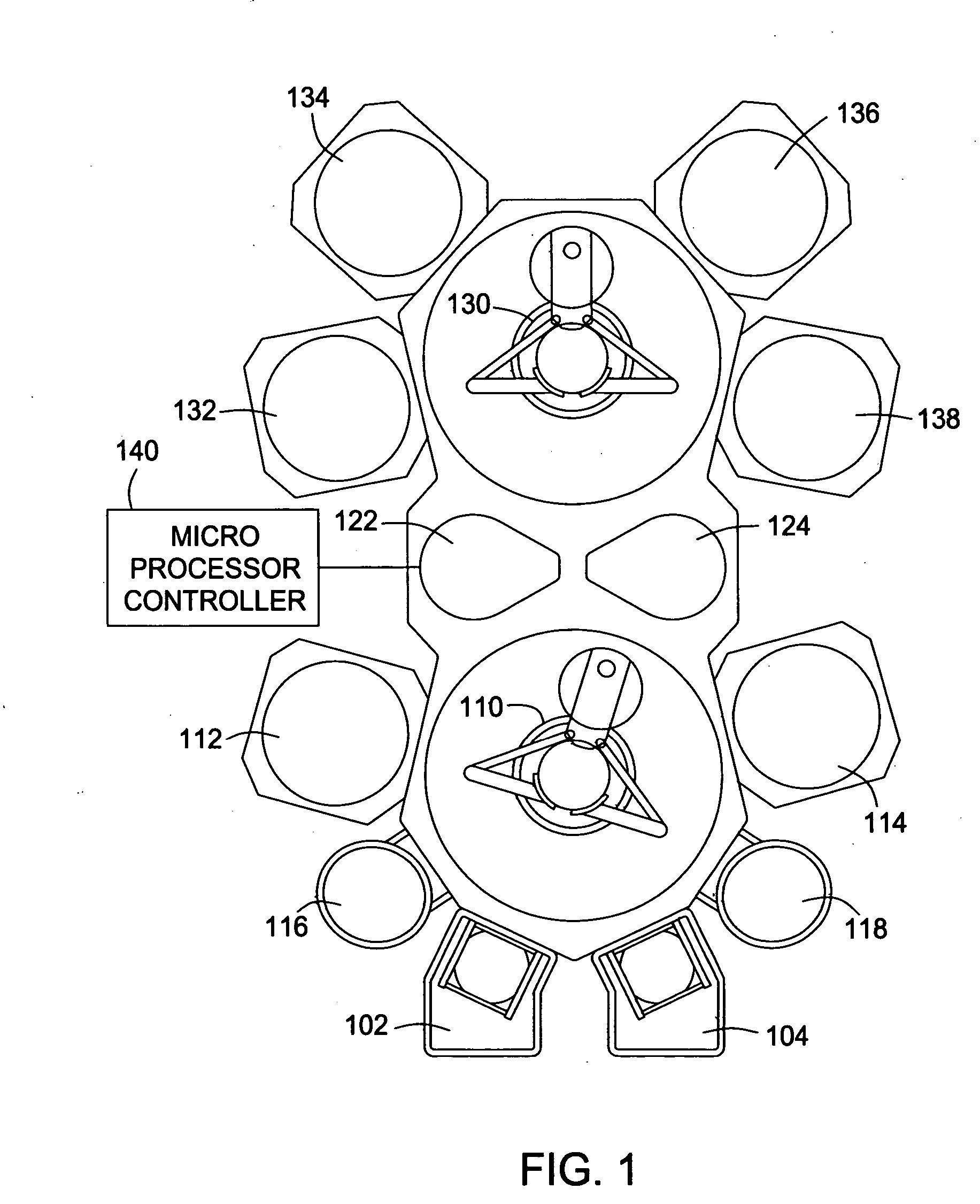

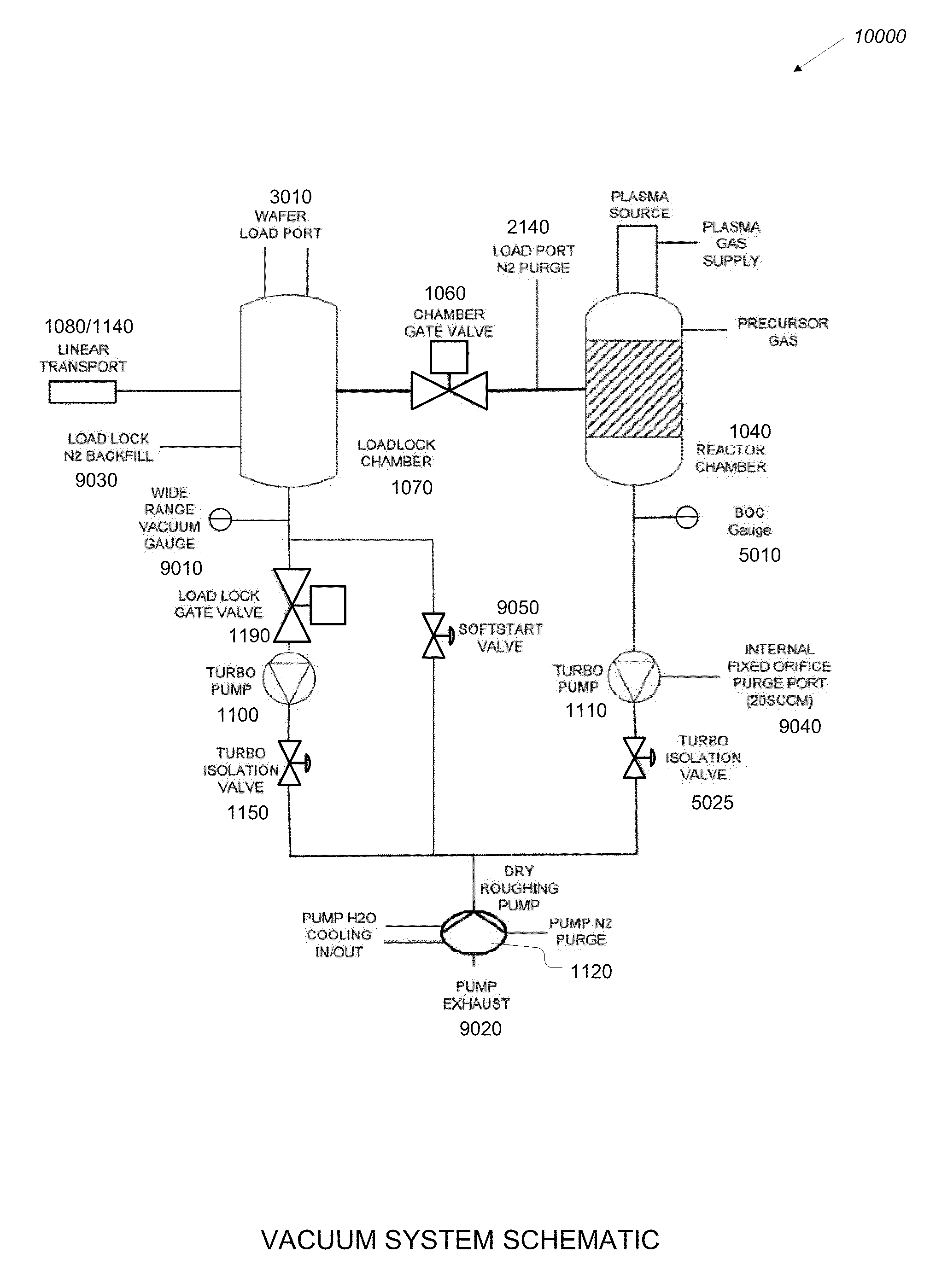

Plasma enhanced atomic layer deposition system having reduced contamination

ActiveUS20060213439A1Trend downThin film depositionLiquid surface applicatorsSemiconductor/solid-state device manufacturingAtomic layer depositionContamination

A plasma enhanced atomic layer deposition (PEALD) system is described, wherein the system comprises a processing space and a high vacuum, ultra-clean transfer space. During processing, the substrate to which the thin conformal film is formed is exposed to the processing space. During substrate transfer, the substrate is exposed to the high vacuum space. Processing gases are introduced sequentially and alternately to the process chamber and the pressures and gas flows within, to and from, and between the process chamber and the high vacuum transfer space are controlled to keep the transfer space ultra-clean.

Owner:TOKYO ELECTRON LTD

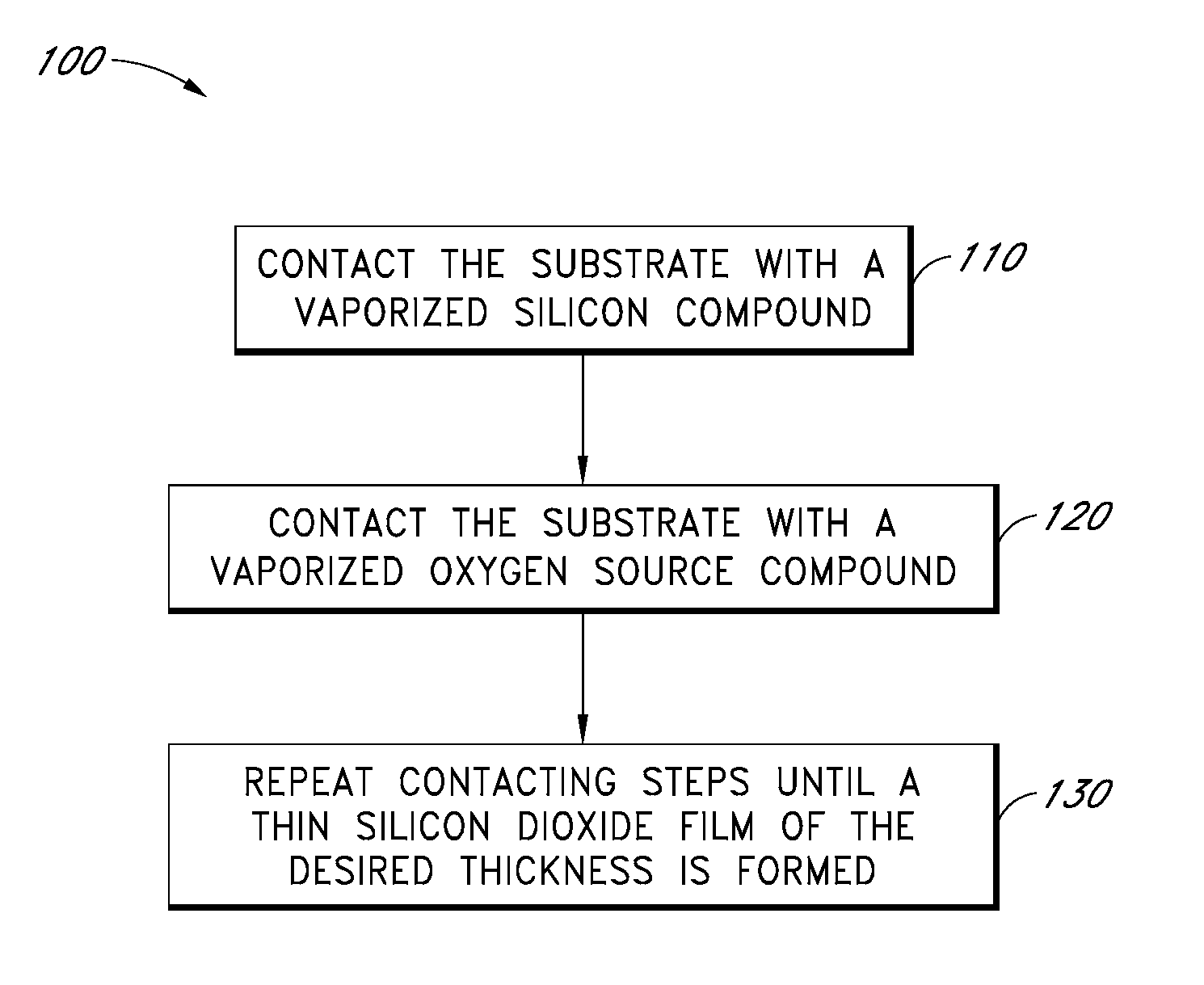

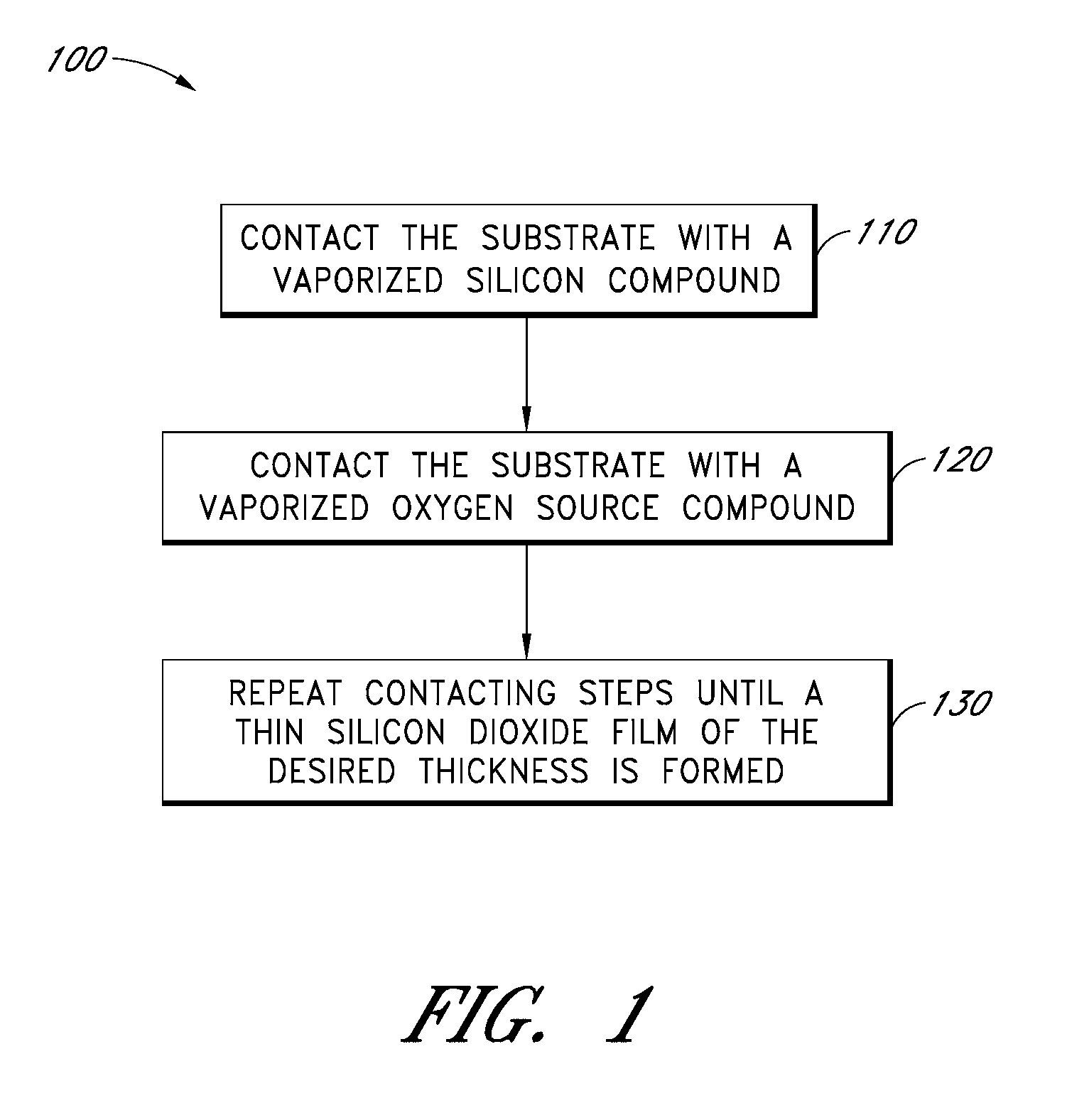

Silicon Dioxide Thin Films by ALD

ActiveUS20090209081A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingSilicon dioxideAtomic layer deposition

Methods are provided for depositing silicon dioxide containing thin films on a substrate by atomic layer deposition ALD. By using disilane compounds as the silicon source, good deposition rates and uniformity are obtained.

Owner:ASM IP HLDG BV

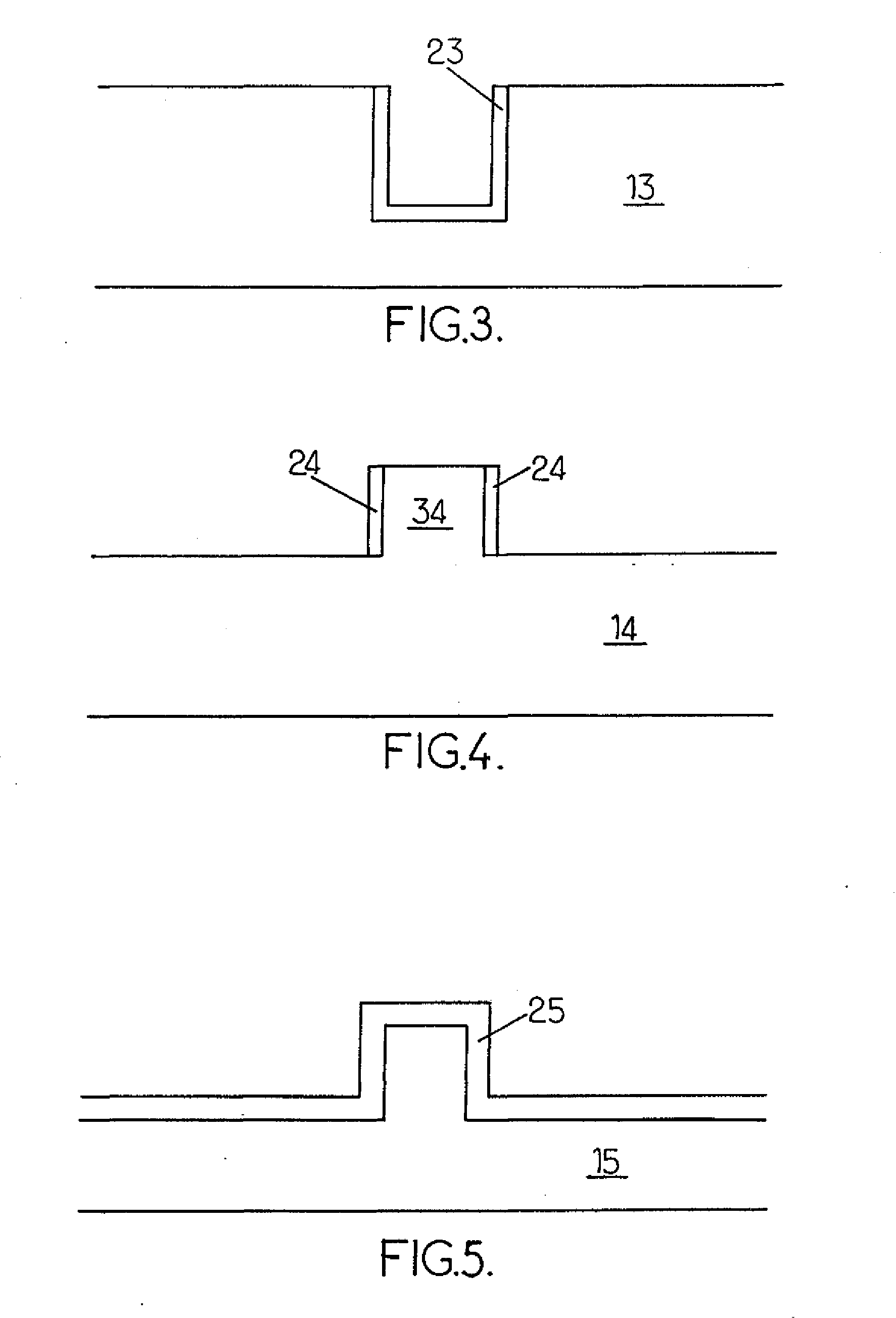

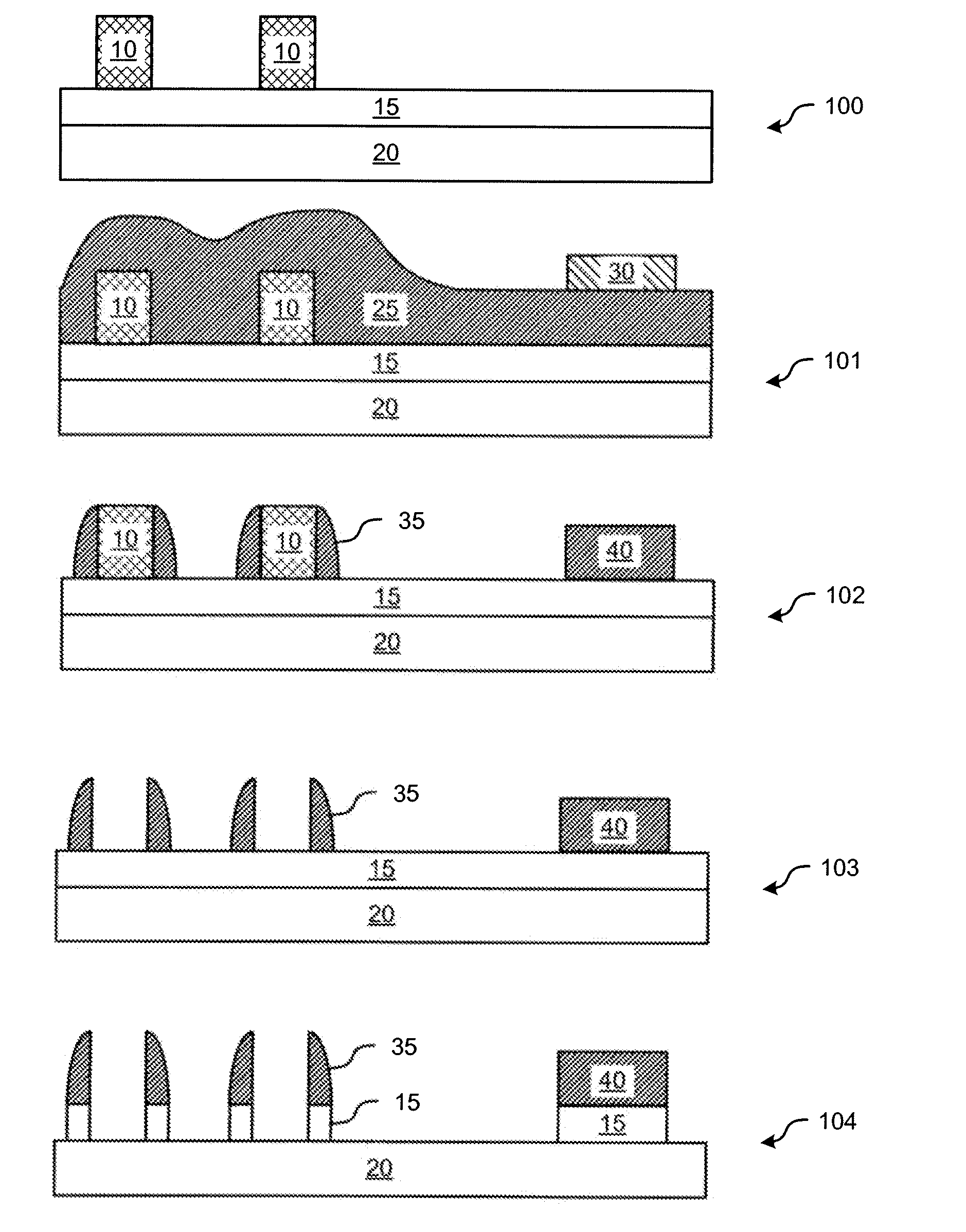

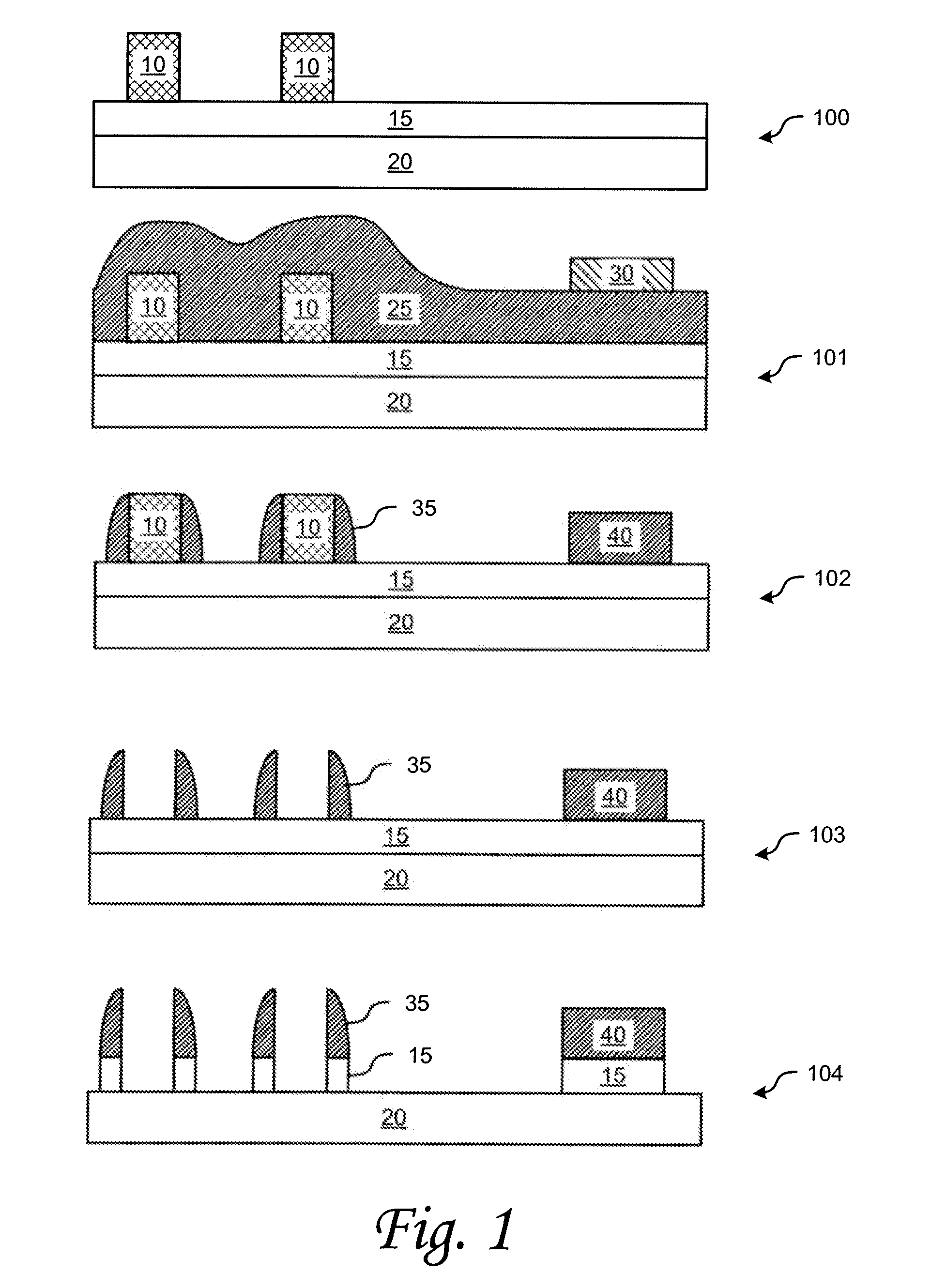

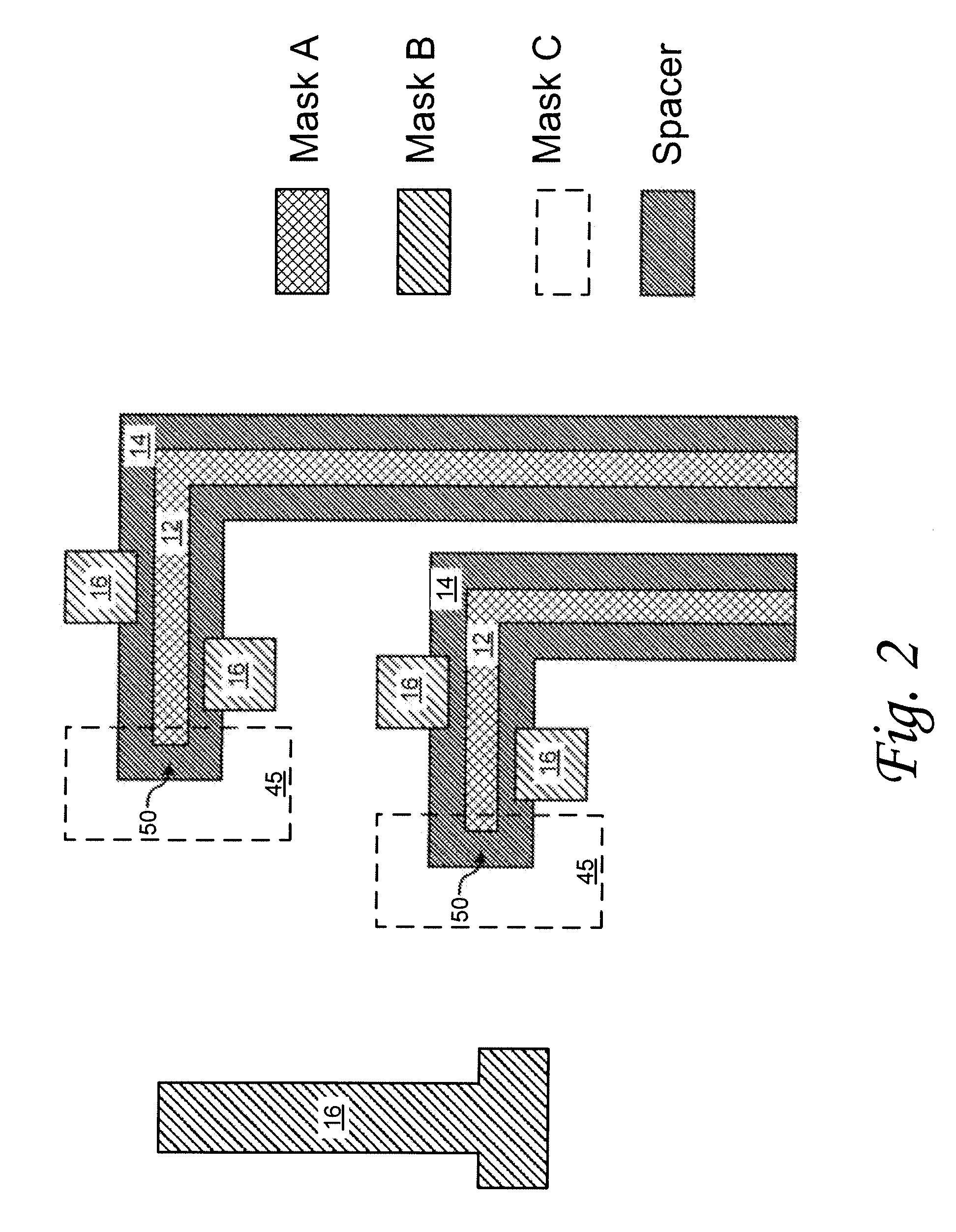

Method of eliminating a lithography operation

ActiveUS20090146322A1Semiconductor/solid-state device detailsSolid-state devicesLithographic artistEngineering

Methods of semiconductor device fabrication are disclosed. An exemplary method includes processes of depositing a first pattern on a semiconductor substrate, wherein the first pattern defines wide and narrow spaces; depositing spacer material over the first pattern on the substrate; etching the spacer material such that the spacer material is removed from horizontal surfaces of the substrate and the first pattern but remains adjacent to vertical surfaces of a wide space defined by the first pattern and remains within narrow a space defined by the first pattern; and removing the first pattern from the substrate. In one embodiment, the first pattern can comprise sacrificial material, which can include, for example, polysilicon material. The deposition can comprise physical vapor deposition, chemical vapor deposition, electrochemical deposition, molecular beam epitaxy, atomic layer deposition or other deposition techniques. According to another embodiment, features for lines and logic device components having a width greater than that of the lines are formed in the spacer material in the same mask layer.

Owner:CADENCE DESIGN SYST INC

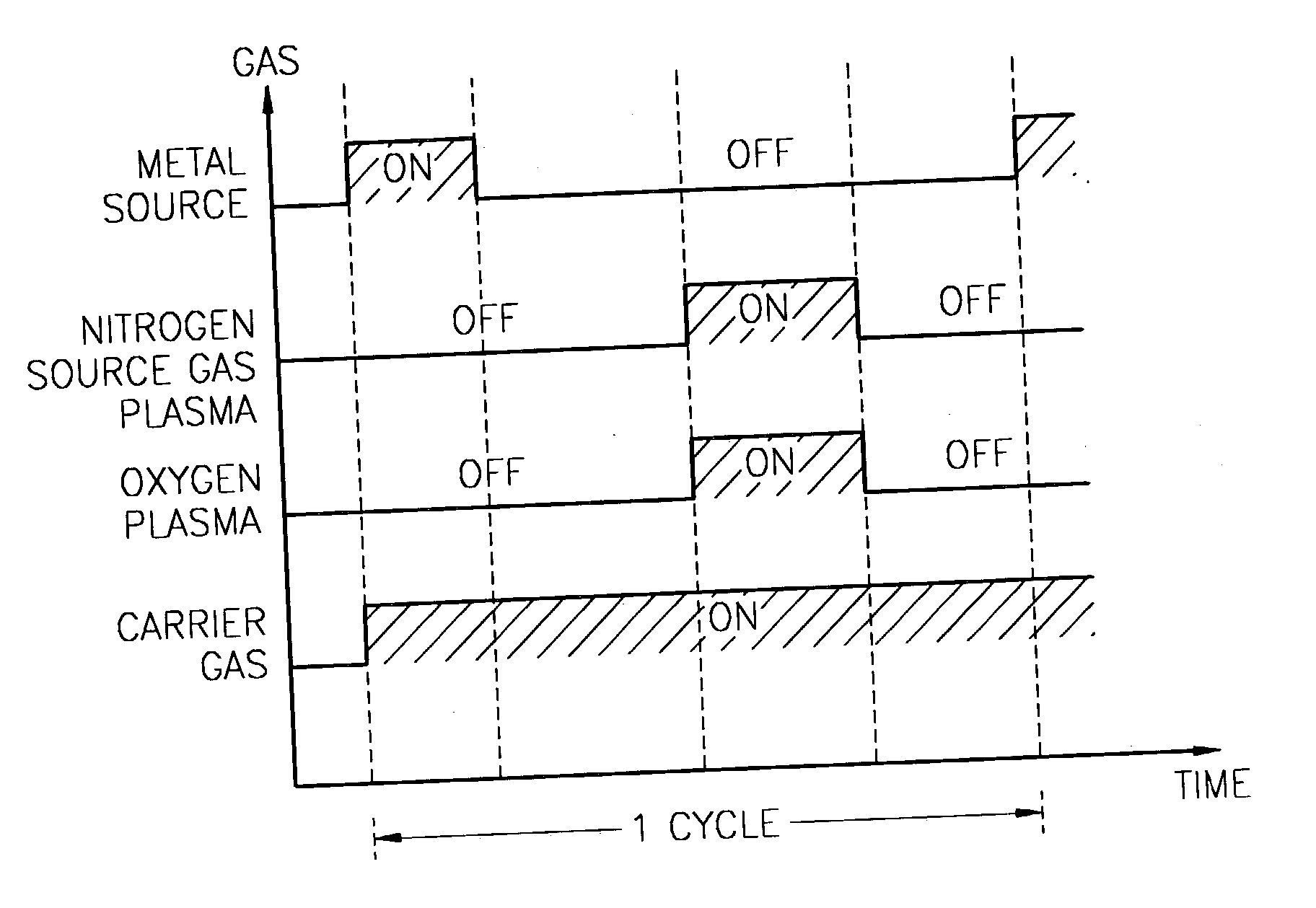

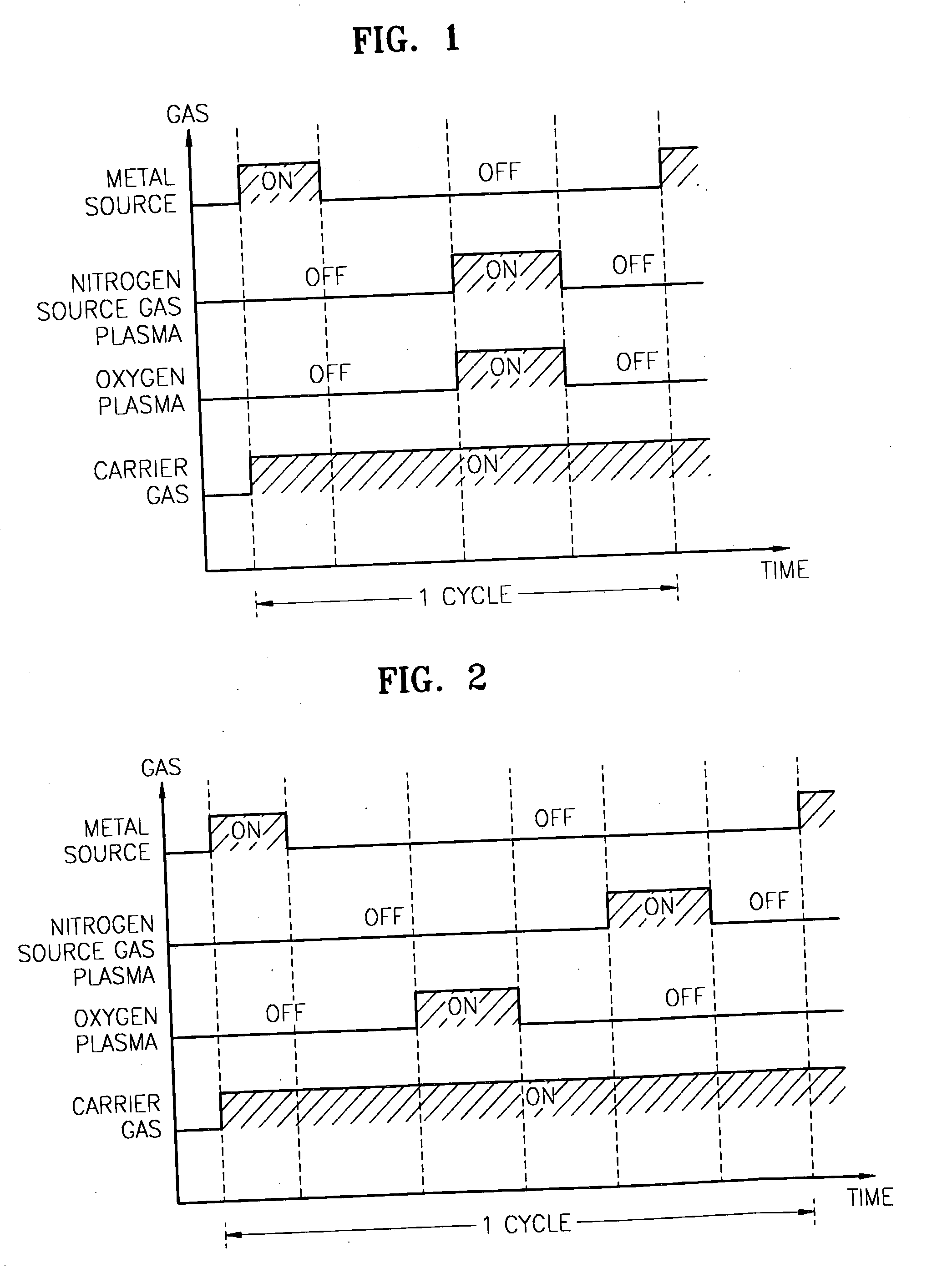

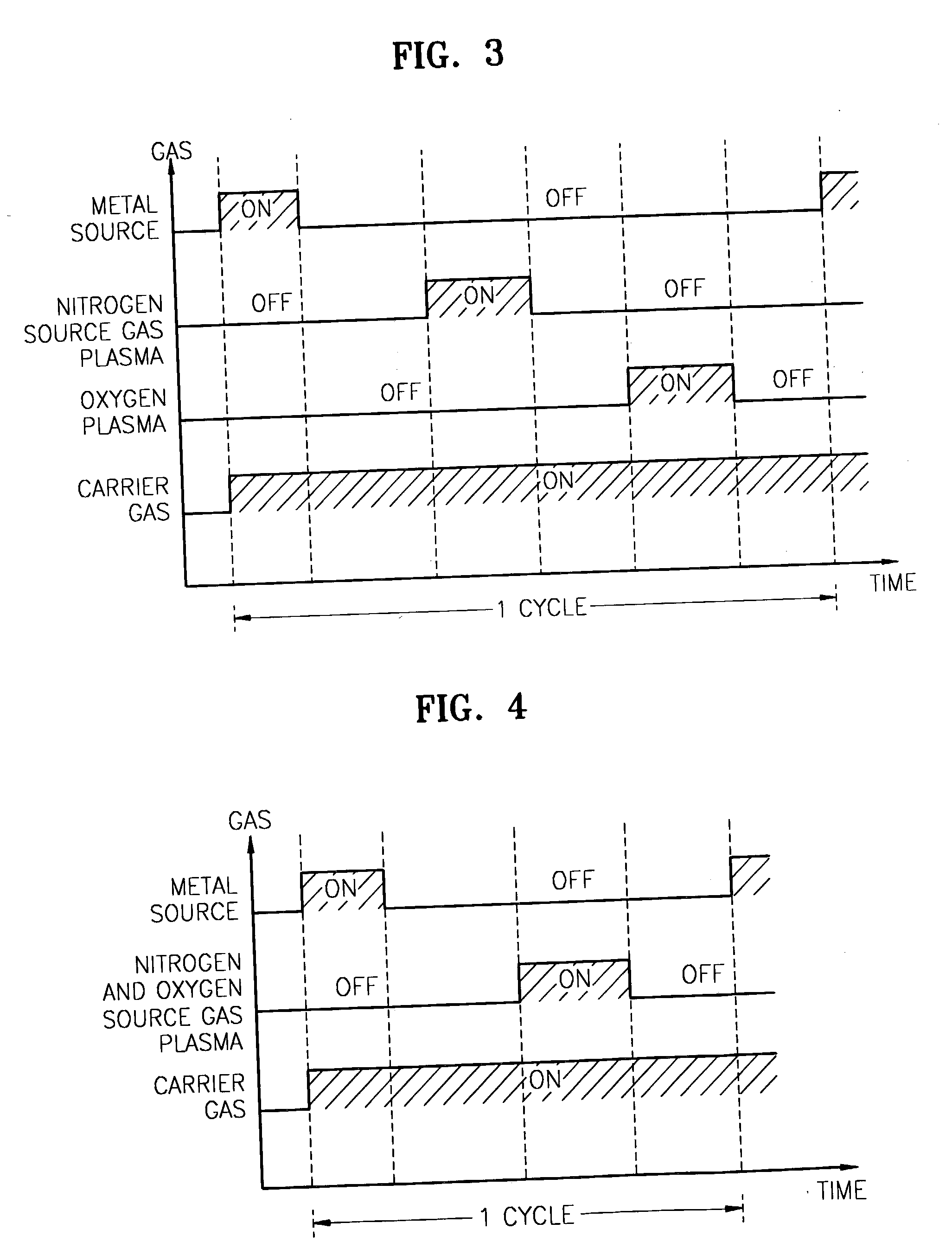

Method for forming introgen-containing oxide thin film using plasma enhanced atomic layer deposition

InactiveUS20040077182A1Density of thinThin rateSemiconductor/solid-state device manufacturingChemical vapor deposition coatingHigh rateNitrogen source

A method for forming a nitrogen-containing oxide thin film by using plasma enhanced atomic layer deposition is provided. In the method, the nitrogen-containing oxide thin film is deposited by supplying a metal source compound and oxygen gas into a reactor in a cyclic fashion with sequential alternating pulses of the metal source compound and the oxygen gas, wherein the oxygen gas is activated into plasma in synchronization of the pulsing thereof, and a nitrogen source gas is further sequentially pulsed into the reactor and activated into plasma over the substrate in synchronization with the pulsing thereof. According to the method, a dense nitrogen-containing oxide thin film can be deposited at a high rate, and a trace of nitrogen atoms can be incorporated in situ into the nitrogen-containing oxide thin film, thereby increasing the breakdown voltage of the film.

Owner:ELECTRONICS & TELECOMM RES INST

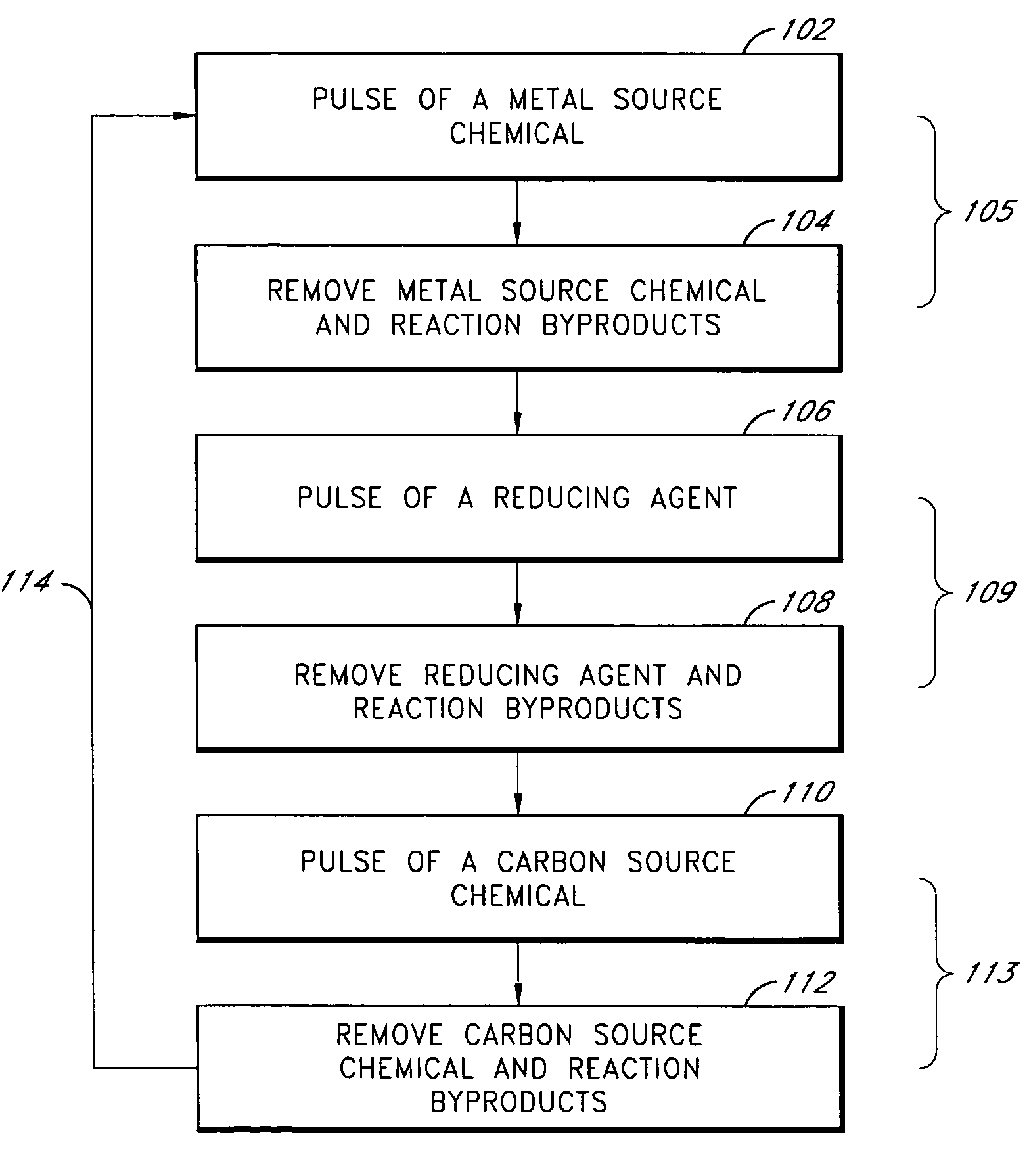

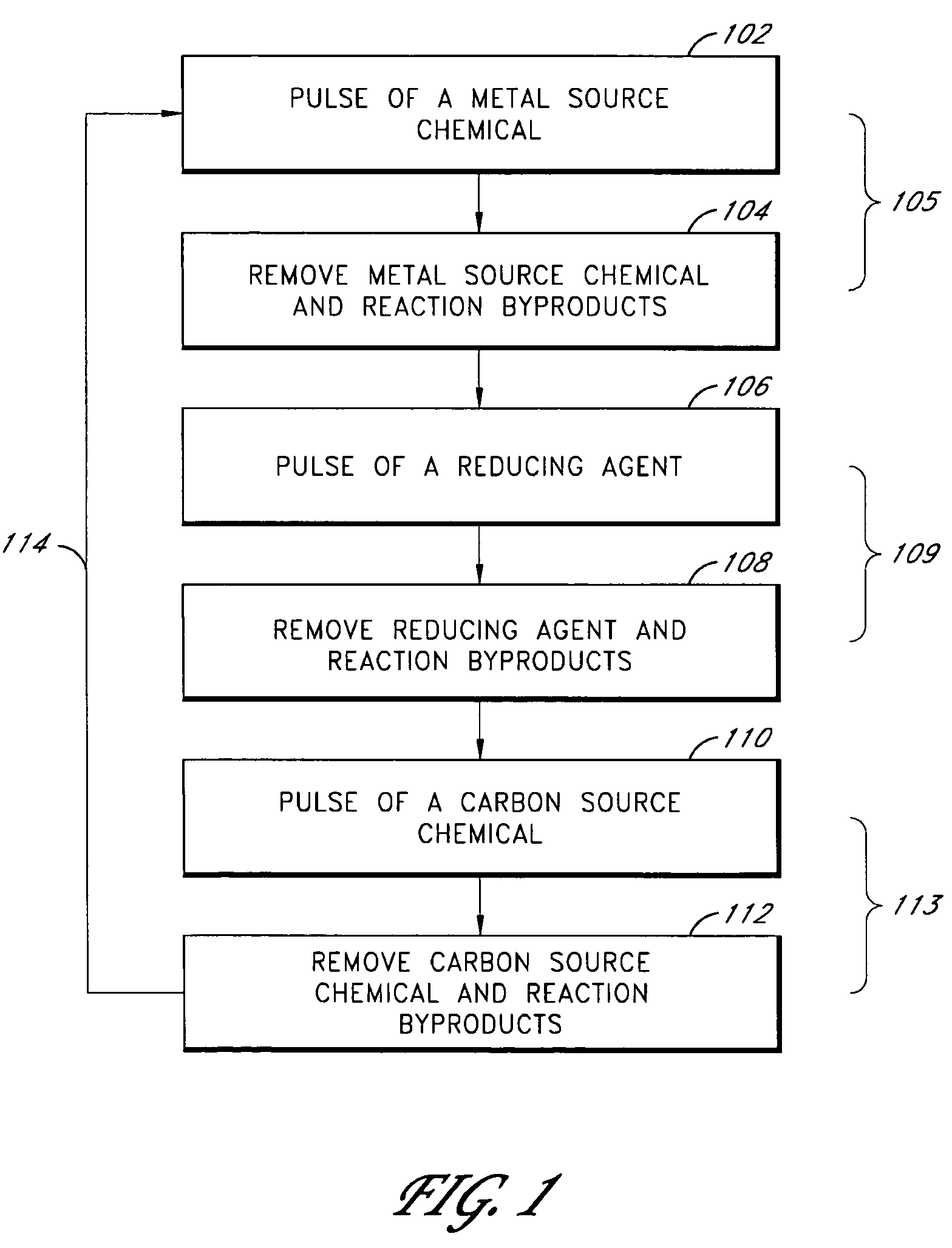

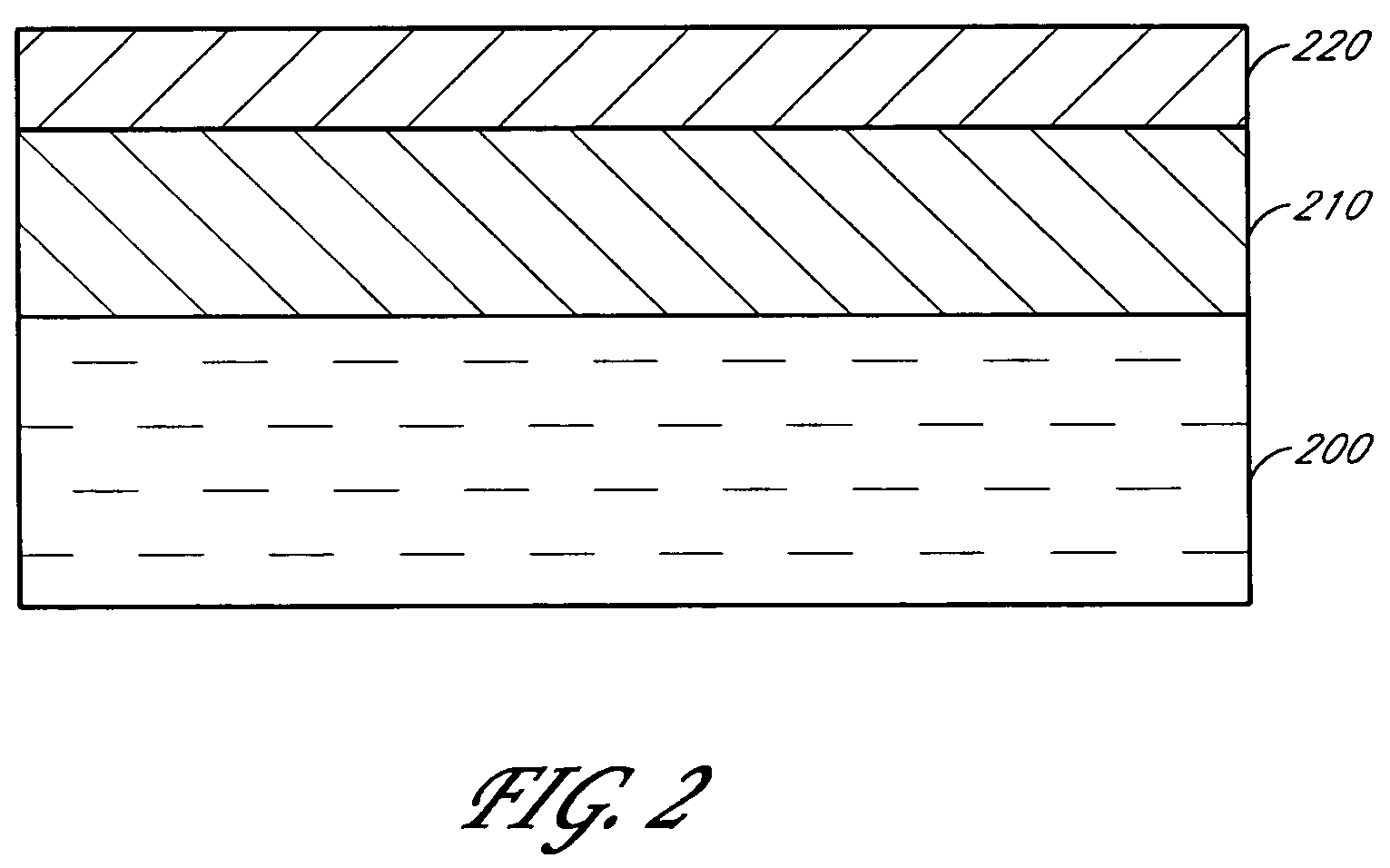

Vapor deposition of metal carbide films

Methods of forming metal carbide thin films are provided. According to preferred embodiments, metal carbide thin films are formed in an atomic layer deposition (ALD) process by alternately and sequentially contacting a substrate in a reaction space with spatially and temporally separated vapor phase pulses of a metal source chemical, a reducing agent and a carbon source chemical. The reducing agent is preferably selected from the group consisting of excited species of hydrogen and silicon-containing compounds.

Owner:ASM IP HLDG BV

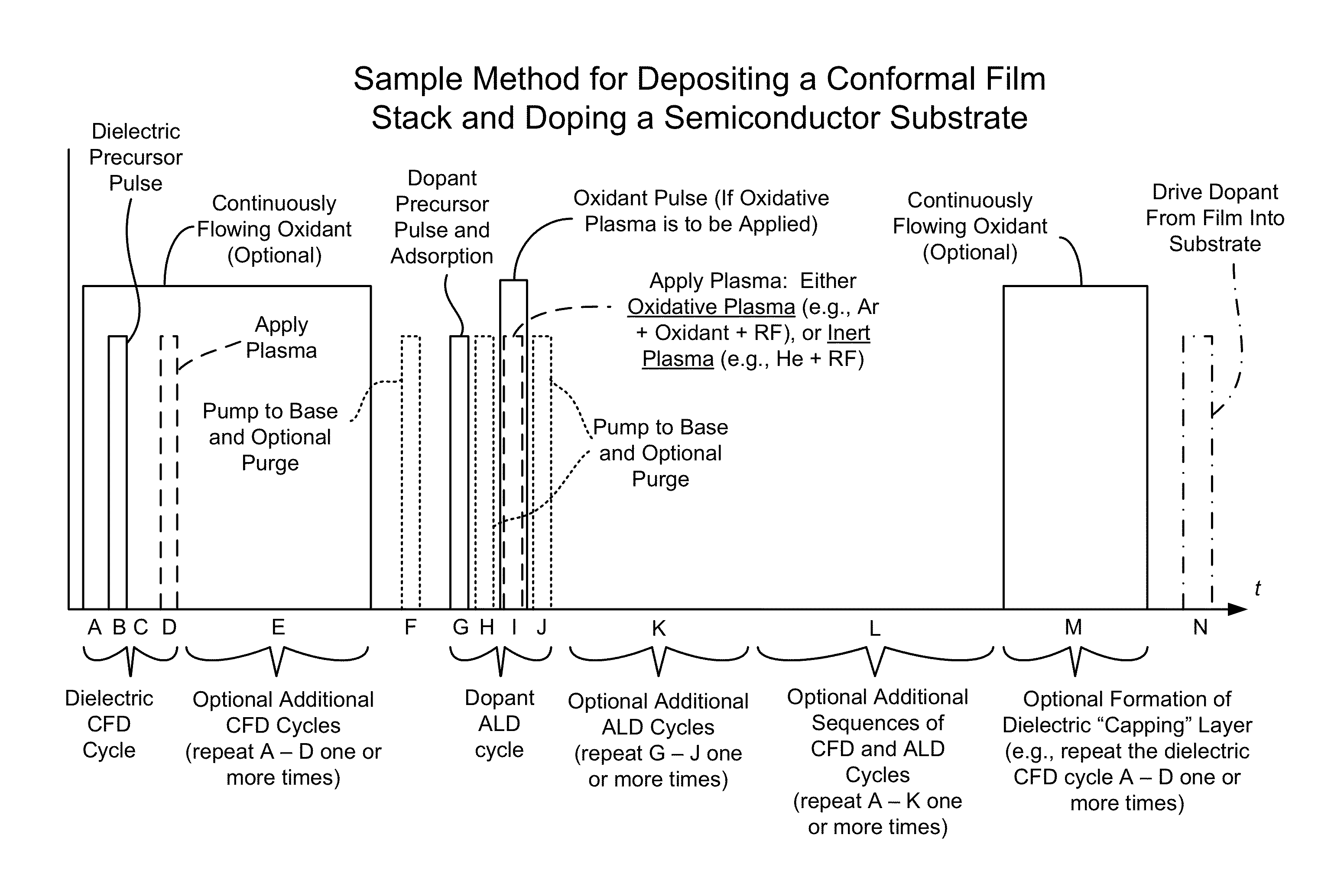

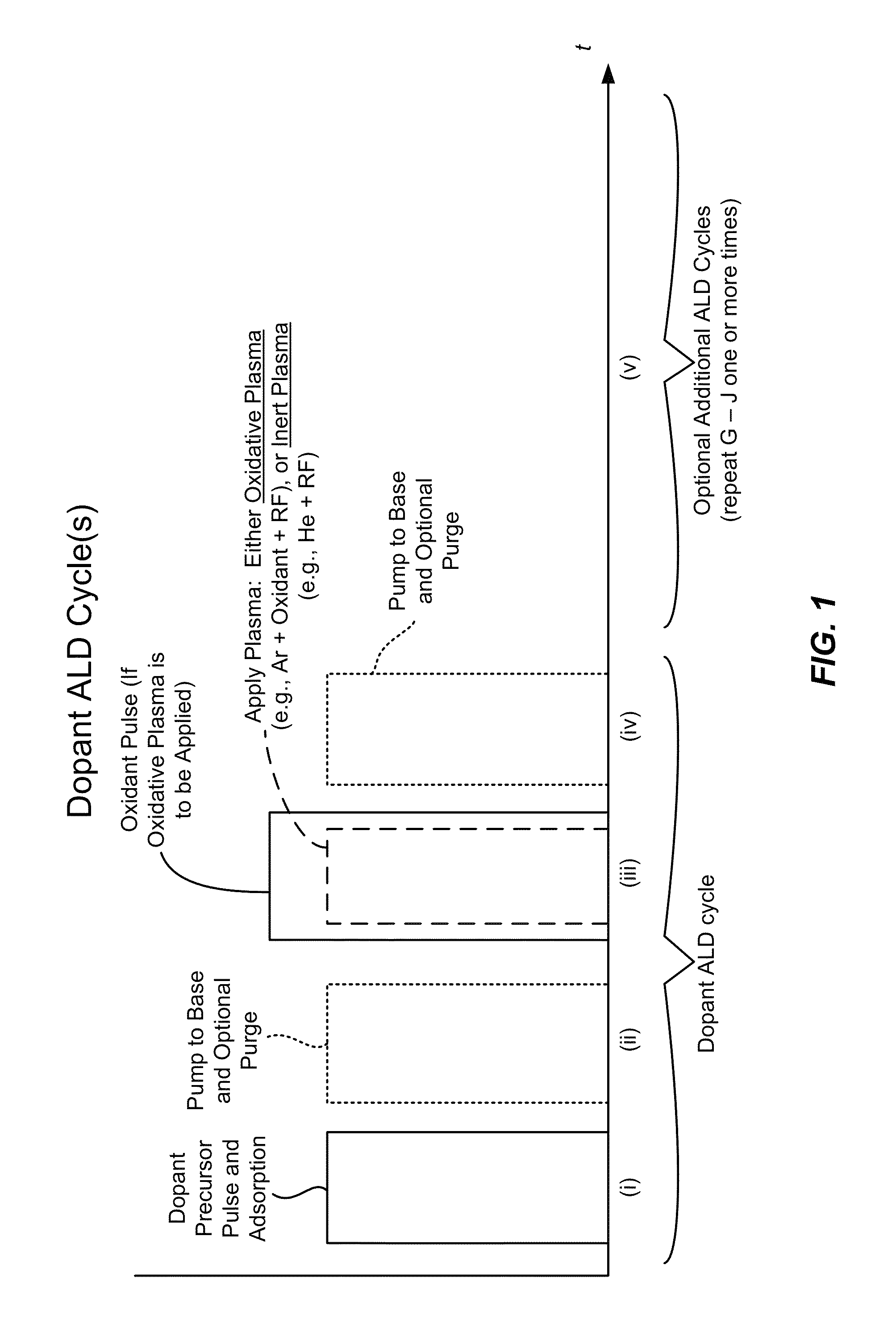

Conformal doping via plasma activated atomic layer deposition and conformal film deposition

ActiveUS8956983B2Liquid surface applicatorsSemiconductor/solid-state device manufacturingDopantPatterned substrate

Disclosed herein are methods of doping a patterned substrate in a reaction chamber. The methods may include forming a first conformal film layer which has a dopant source including a dopant, and driving some of the dopant into the substrate to form a conformal doping profile. In some embodiments, forming the first film layer may include introducing a dopant precursor into the reaction chamber, adsorbing the dopant precursor under conditions whereby it forms an adsorption-limited layer, and reacting the adsorbed dopant precursor to form the dopant source. Also disclosed herein are apparatuses for doping a substrate which may include a reaction chamber, a gas inlet, and a controller having machine readable code including instructions for operating the gas inlet to introduce dopant precursor into the reaction chamber so that it is adsorbed, and instructions for reacting the adsorbed dopant precursor to form a film layer containing a dopant source.

Owner:NOVELLUS SYSTEMS

Forming capping layer over metal wire structure using selective atomic layer deposition

InactiveUS7084060B1Material nanotechnologySemiconductor/solid-state device detailsDielectricSemiconductor structure

Methods of forming a capping layer over a metal wire structure of a semiconductor device are disclosed. In one embodiment, the method includes providing a partially fabricated semiconductor device having exposed surfaces of the metal (e.g., copper) wire structure and a dielectric around the metal wire structure. The exposed surface of the metal wire structure is then activated by forming a seed layer thereon. The capping layer is then formed over the exposed surface of the metal wire structure by performing a selective atomic layer deposition (ALD) of a capping layer material onto the metal wire structure. As an alternative, the dielectric may be masked off to further assist the selectivity of the ALD. The invention also includes a semiconductor structure including the metal wire structure having an atomic layer deposition capping layer over an upper surface thereof.

Owner:IBM CORP

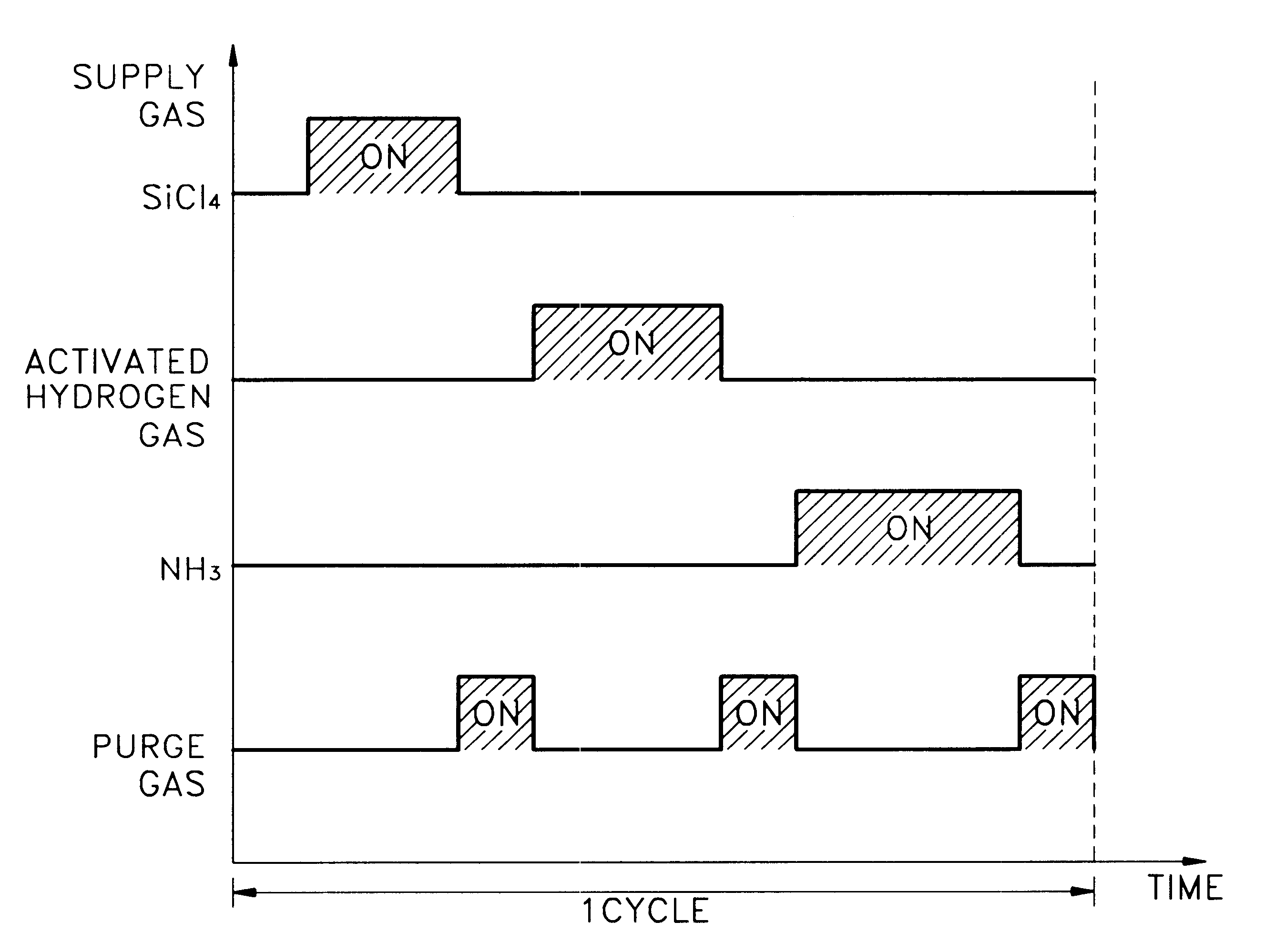

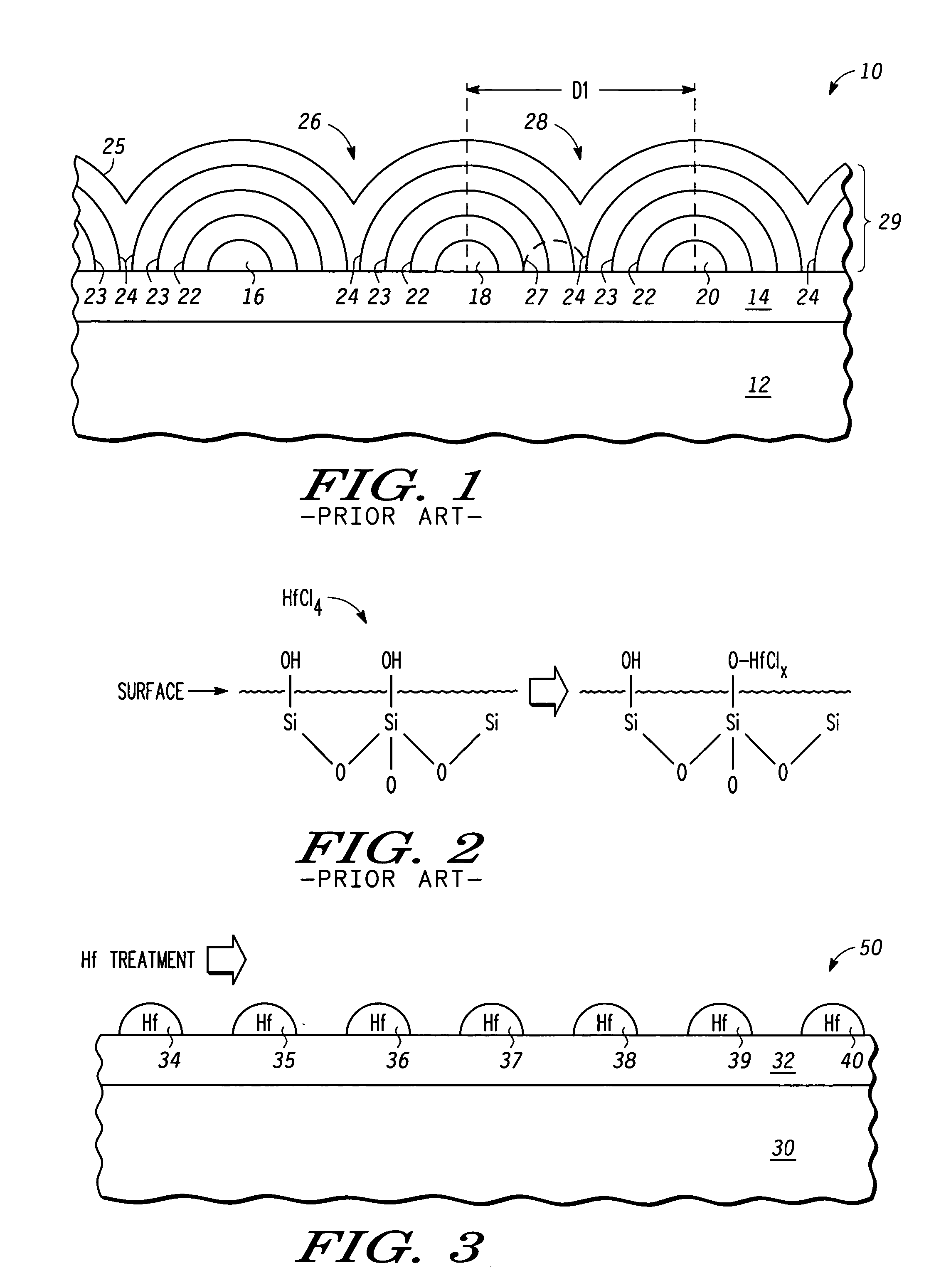

Method for treating a semiconductor surface to form a metal-containing layer

ActiveUS7132360B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingMaterial growthPhysical chemistry

A method for treating a semiconductor surface to form a metal-containing layer includes providing a semiconductor substrate having an exposed surface. The exposed surface of the semiconductor substrate is treated by forming one or more metals overlying the semiconductor substrate but not completely covering the exposed surface of the semiconductor substrate. The one or more metals enhance nucleation for subsequent material growth. A metal-containing layer is formed on the exposed surface of the semiconductor substrate that has been treated. The treatment of the exposed surface of the semiconductor substrate assists the metal-containing layer to coalesce. In one embodiment, treatment of the exposed surface to enhance nucleation may be performed by spin-coating, atomic layer deposition (ALD), physical layer deposition (PVD), electroplating, or electroless plating. The one or more metals used to treat the exposed surface may include any rare earth or transition metal, such as, for example, hafnium, lanthanum, etc.

Owner:NXP USA INC +1

Method for depositing thin films by mixed pulsed CVD and ald

ActiveUS20080317972A1Easy to customizeImprove responseSemiconductor/solid-state device manufacturingChemical vapor deposition coatingChemical vapor depositionAtomic layer deposition

Films are deposited on a substrate by a process in which atomic layer deposition (ALD) is used to deposit one layer of the film and pulsed chemical vapor deposition (CVD) is used to deposit another layer of the film. During the ALD part of the process, a layer is formed by flowing sequential and alternating pulses of mutually reactive reactants that deposit self-limitingly on a substrate. During the pulsed CVD part of the process, another layer is deposited by flowing two CVD reactants into a reaction chamber, with at least a first of the CVD reactants flowed into the reaction chamber in pulses, with those pulses overlapping at least partially with the flow of a second of the CVD reactants. The ALD and CVD parts of the process ca be used to deposit layers with different compositions, thereby forming, e.g., nanolaminate films. Preferably, high quality layers are formed by flowing the second CVD reactant into the reaction chamber for a longer total duration than the first CVD reactant. In some embodiments, the pulses of the third reactant at separated by a duration at least about 1.75 times the length of the pulse. Preferably, less than about 8 monolayers of material are deposited per pulse of the first CVD reactant.

Owner:ASM INTERNATIONAL

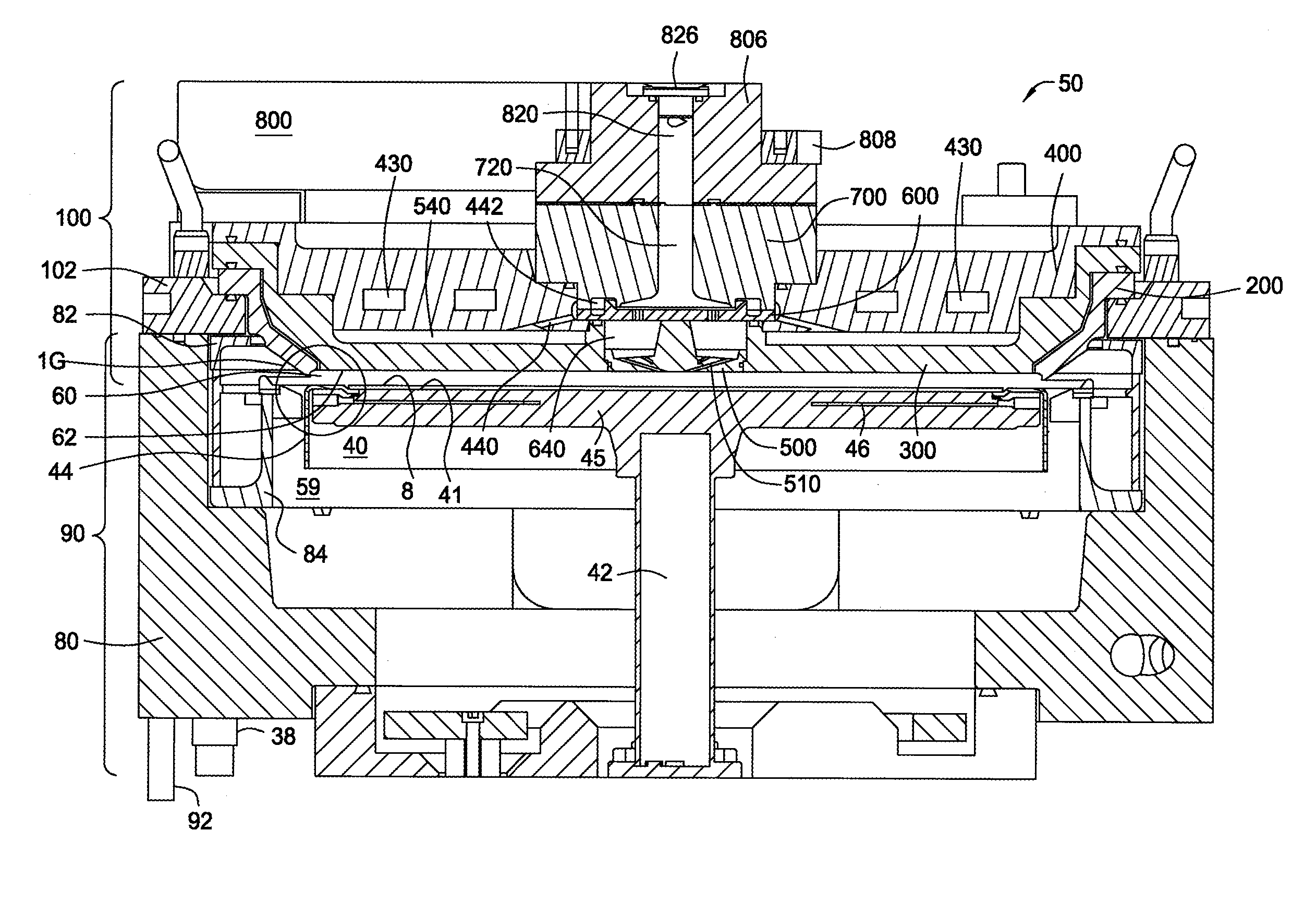

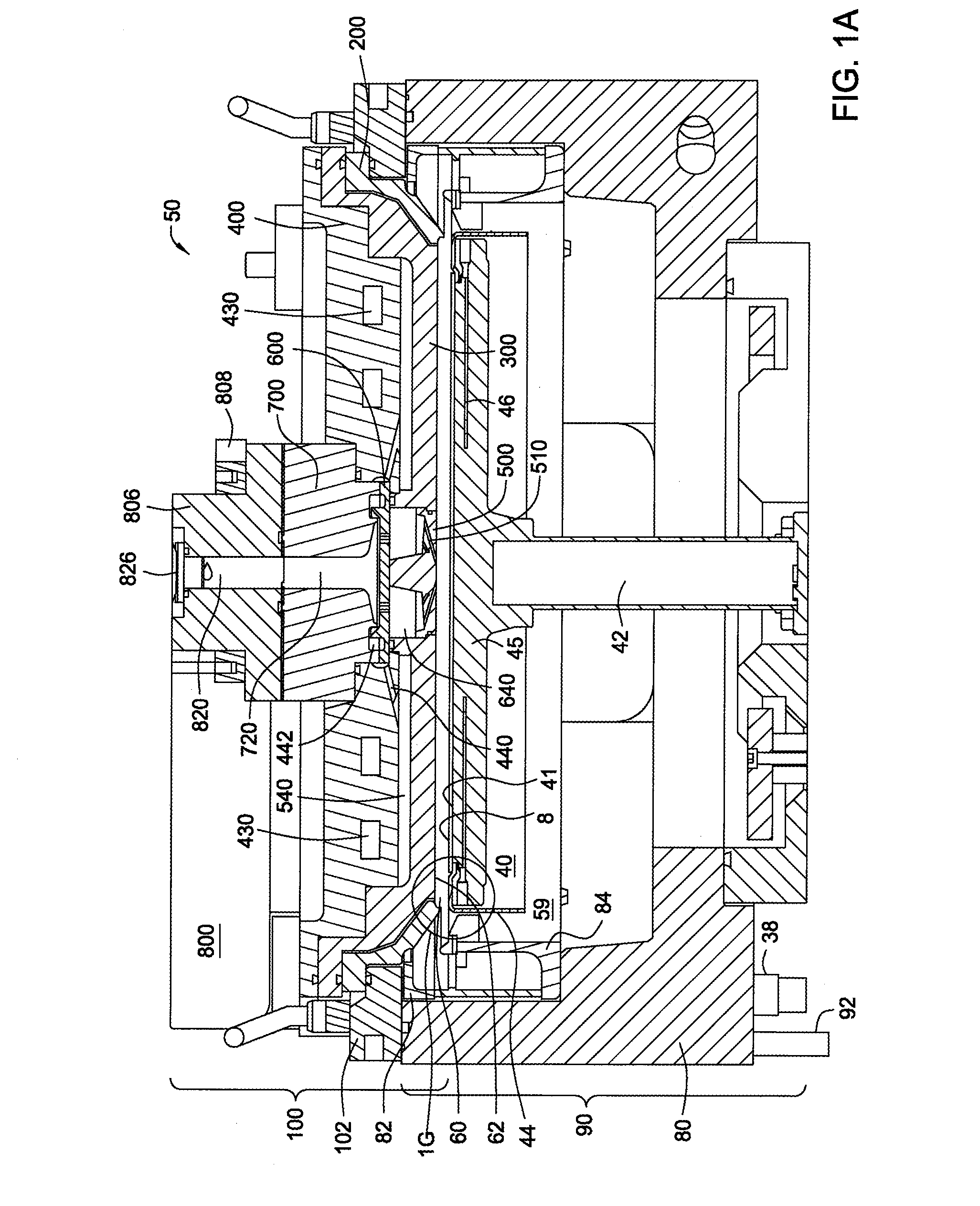

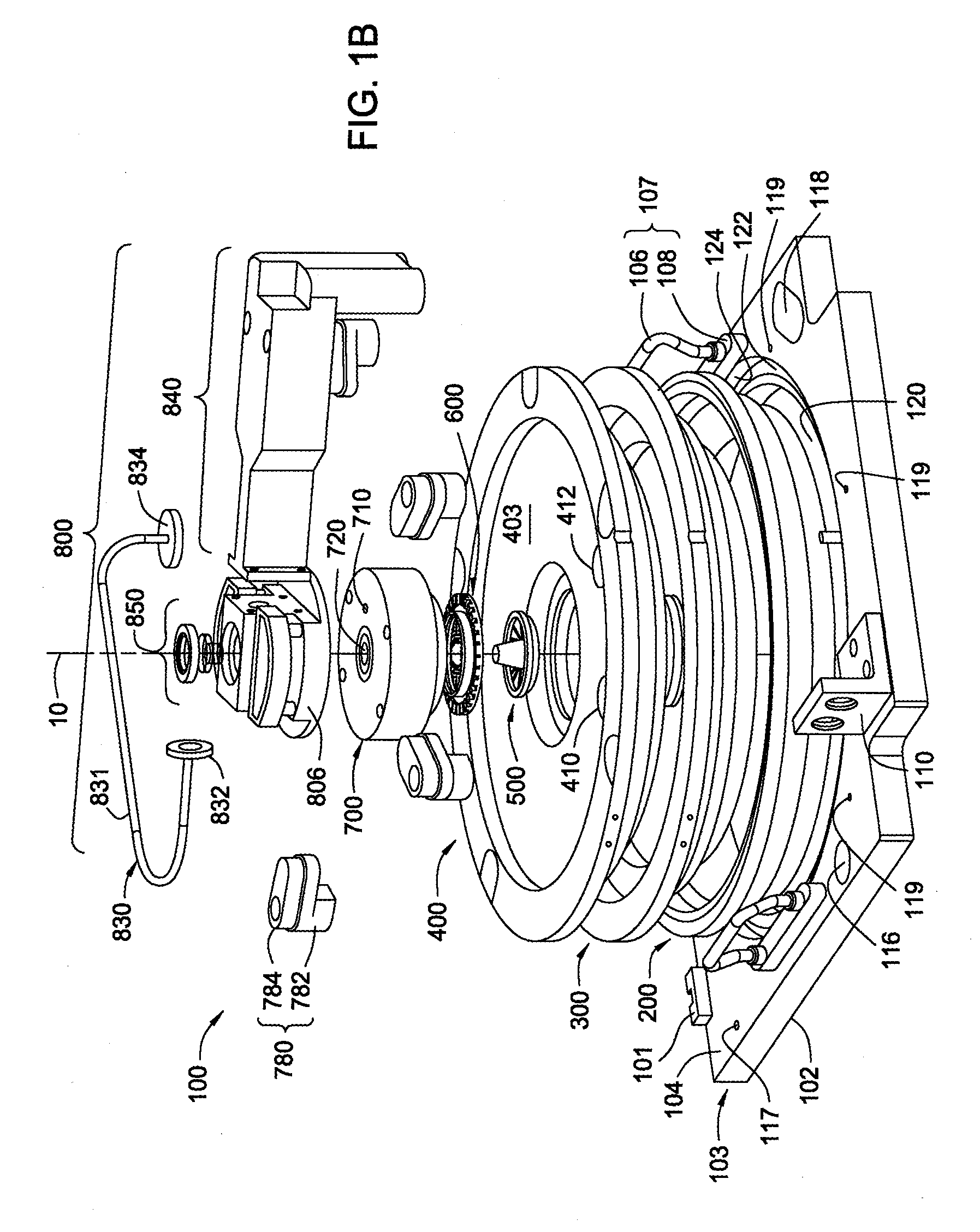

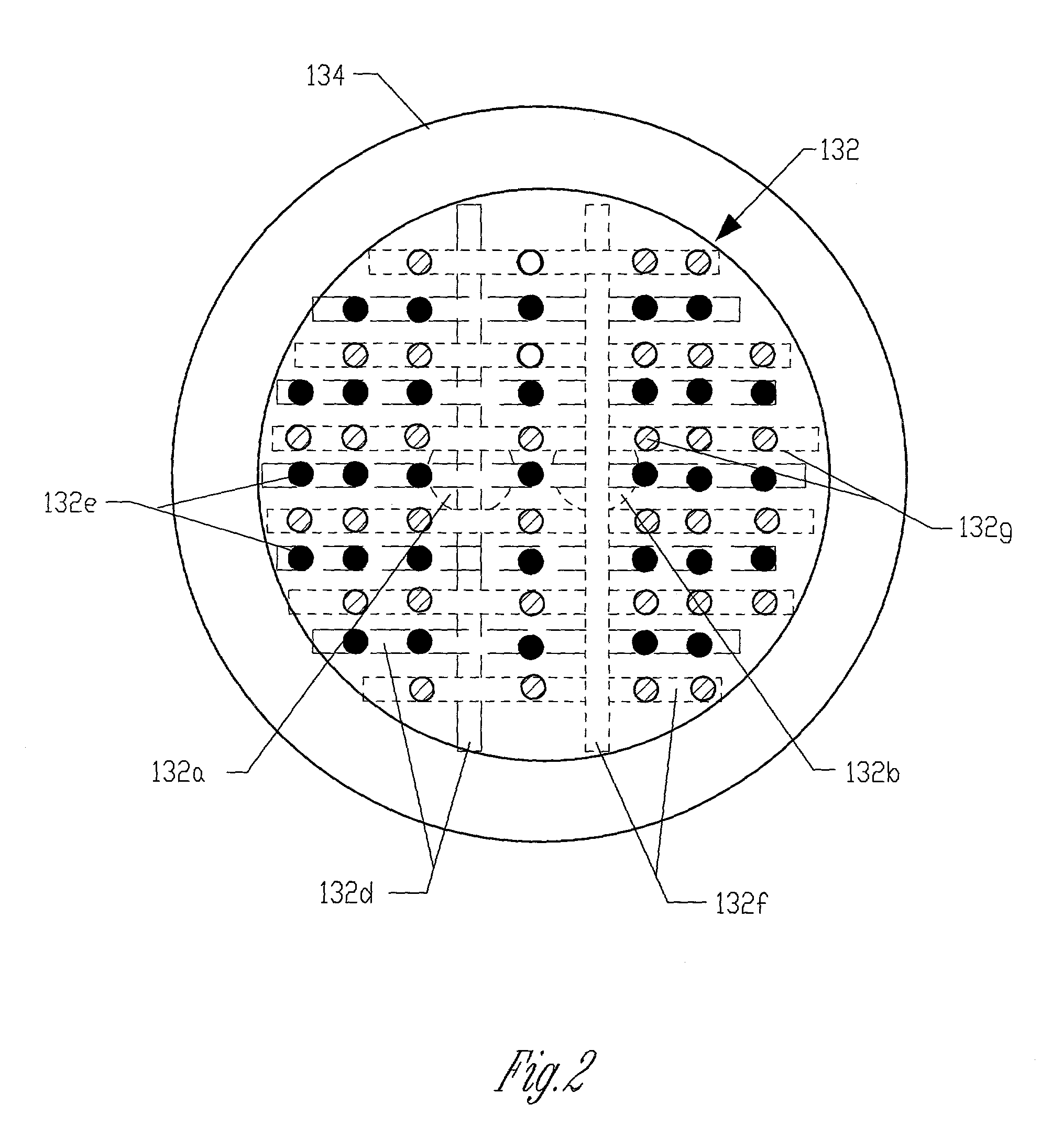

Apparatuses and methods for atomic layer deposition

ActiveUS20100003406A1Hole densityHigh hole densityElectric discharge tubesSemiconductor/solid-state device manufacturingRemote plasmaAtomic layer deposition

Embodiments of the invention provide apparatuses and methods for atomic layer deposition (ALD), such as plasma-enhanced ALD (PE-ALD). In some embodiments, a PE-ALD chamber is provided which includes a chamber lid assembly coupled with a chamber body having a substrate support therein. In one embodiment, the chamber lid assembly has an inlet manifold assembly containing an annular channel encompassing a centralized channel, wherein the centralized channel extends through the inlet manifold assembly, and the inlet manifold assembly further contains injection holes extending from the annular channel, through a sidewall of the centralized channel, and to the centralized channel. The chamber lid assembly further contains a showerhead assembly disposed below the inlet manifold assembly, a water box disposed between the inlet manifold assembly and the showerhead assembly, and a remote plasma system (RPS) disposed above and coupled with the inlet manifold assembly, and in fluid communication with the centralized channel.

Owner:APPLIED MATERIALS INC

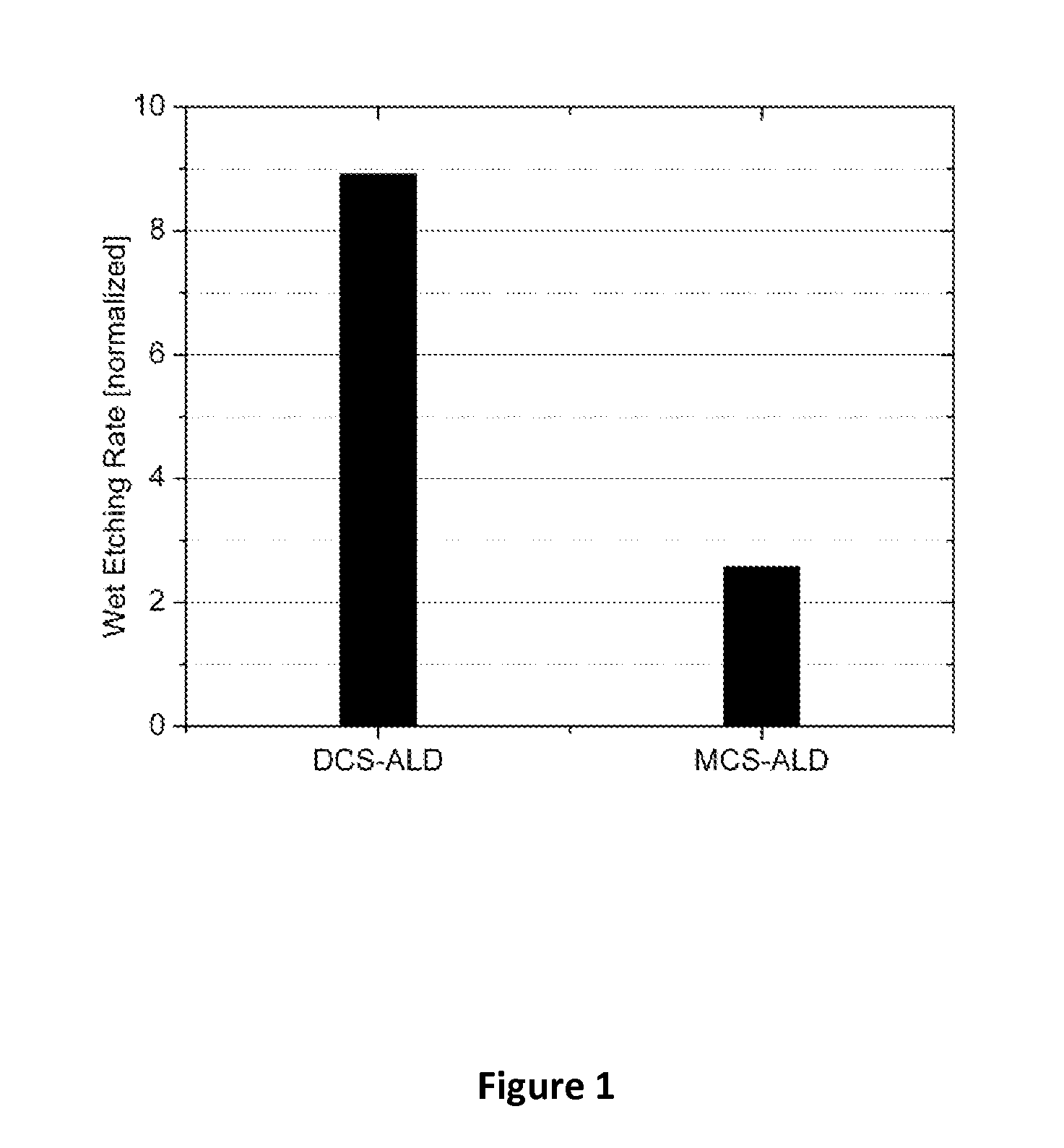

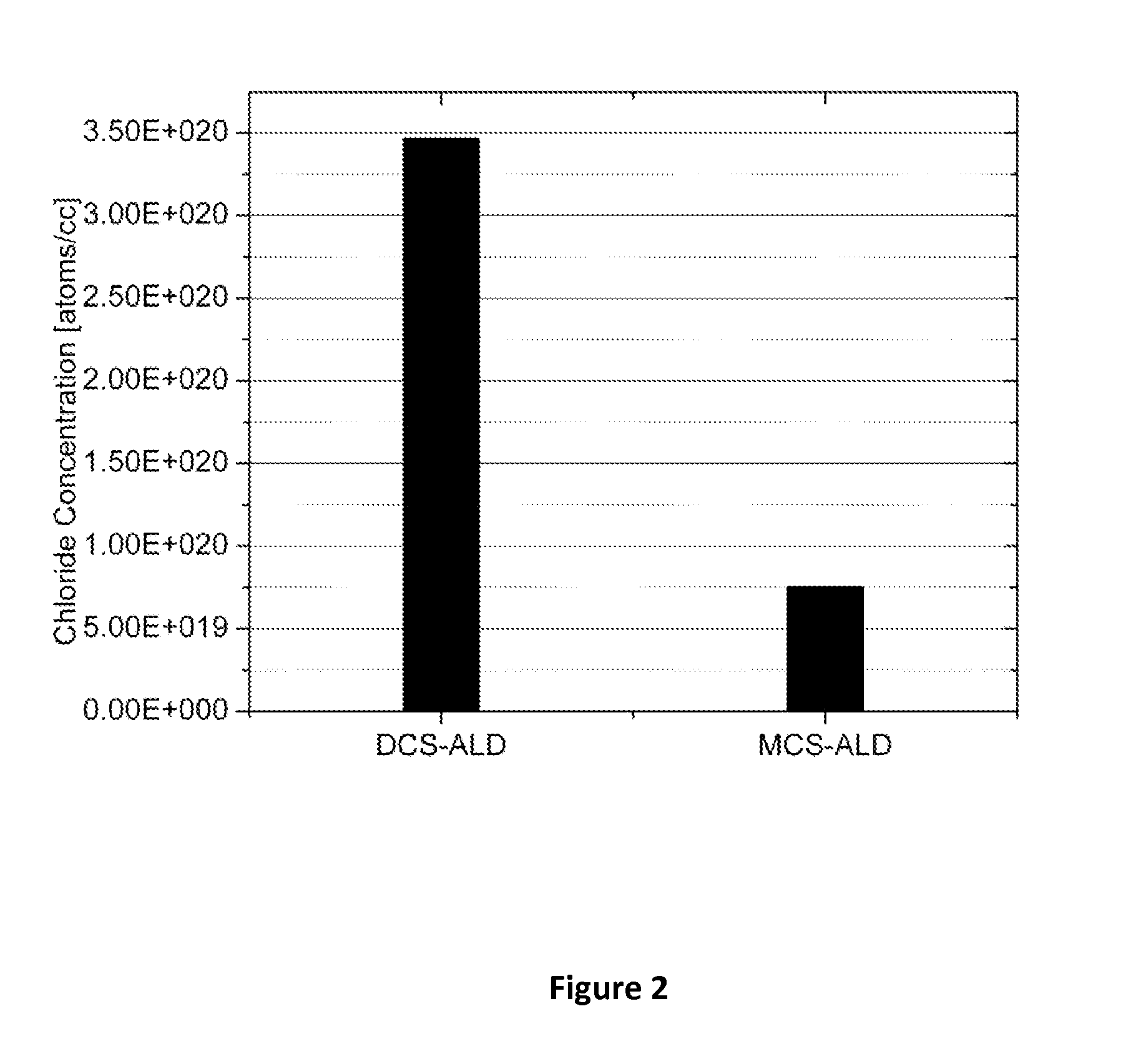

Low Temperature Deposition of Silicon-Containing Films

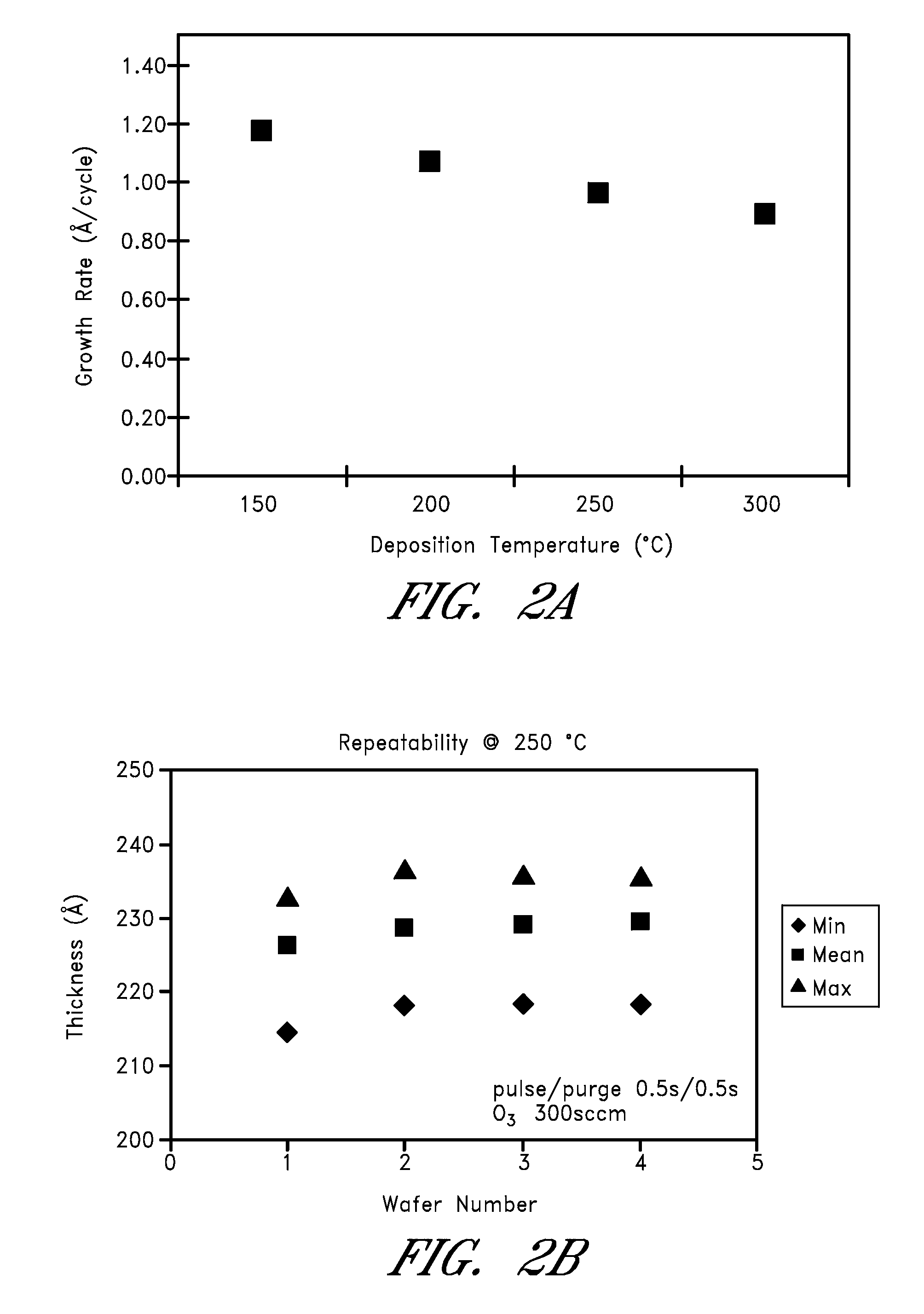

ActiveUS20100304047A1Low deposition temperatureSemiconductor/solid-state device manufacturingSpecial surfacesLow temperature depositionDeposition temperature

This invention discloses the method of forming silicon nitride, silicon oxynitride, silicon oxide, carbon-doped silicon nitride, carbon-doped silicon oxide and carbon-doped oxynitride films at low deposition temperatures. The silicon containing precursors used for the deposition are monochlorosilane (MCS) and monochloroalkylsilanes. The method is preferably carried out by using plasma enhanced atomic layer deposition, plasma enhanced chemical vapor deposition, and plasma enhanced cyclic chemical vapor deposition.

Owner:TOKYO ELECTRON LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com