Patents

Literature

212results about How to "Low deposition temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low Temperature Deposition of Silicon-Containing Films

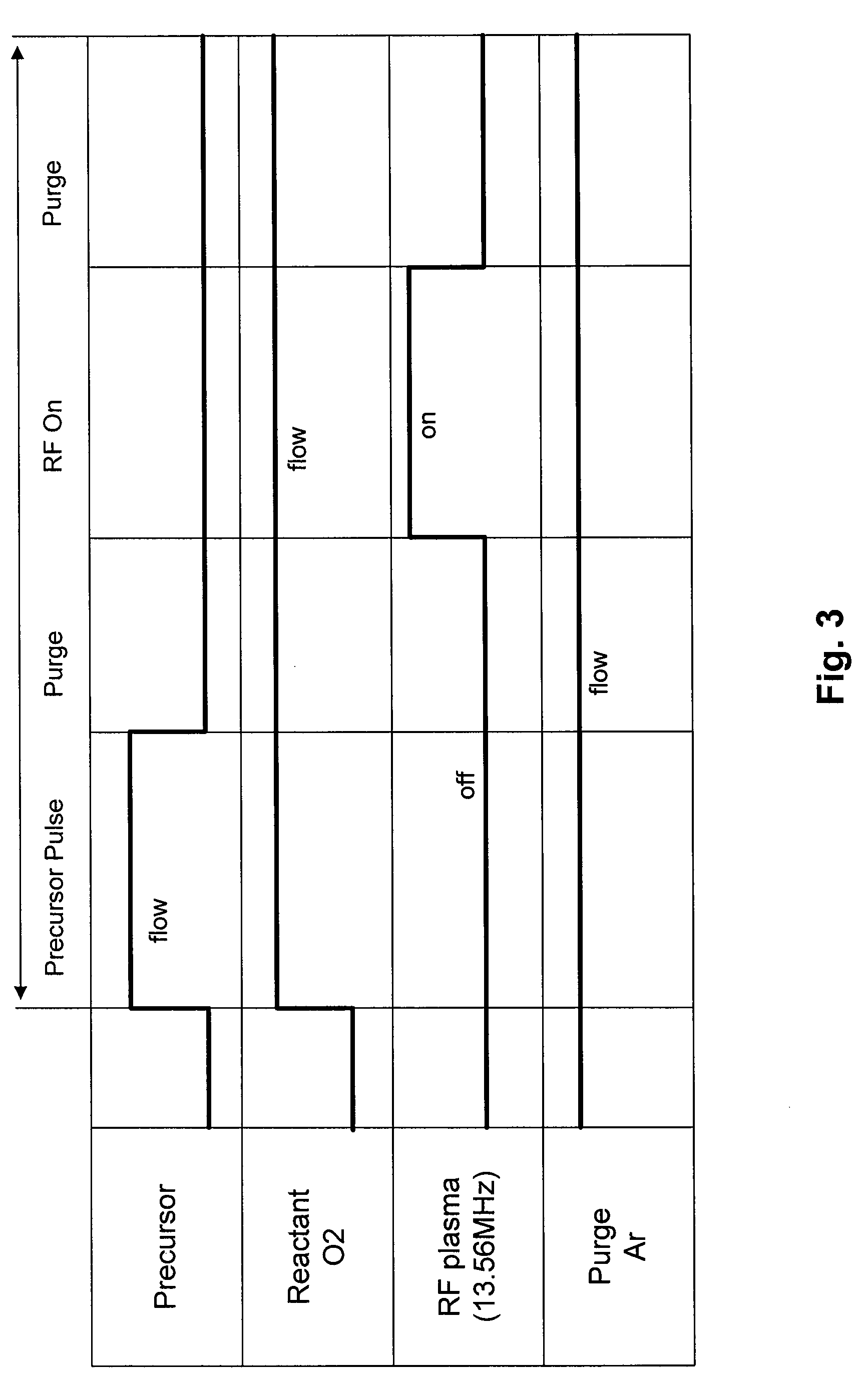

ActiveUS20100304047A1Low deposition temperatureSemiconductor/solid-state device manufacturingSpecial surfacesLow temperature depositionDeposition temperature

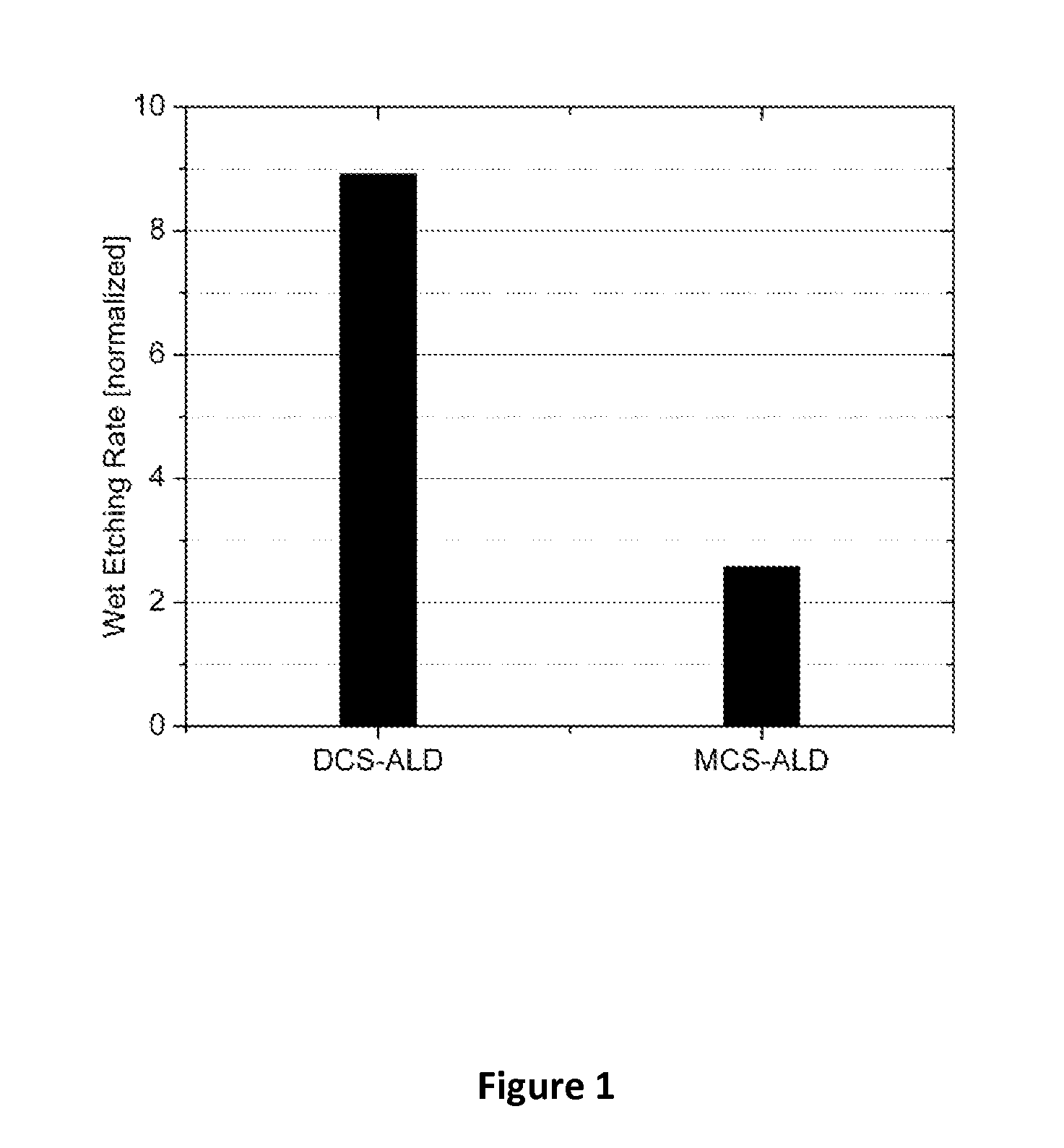

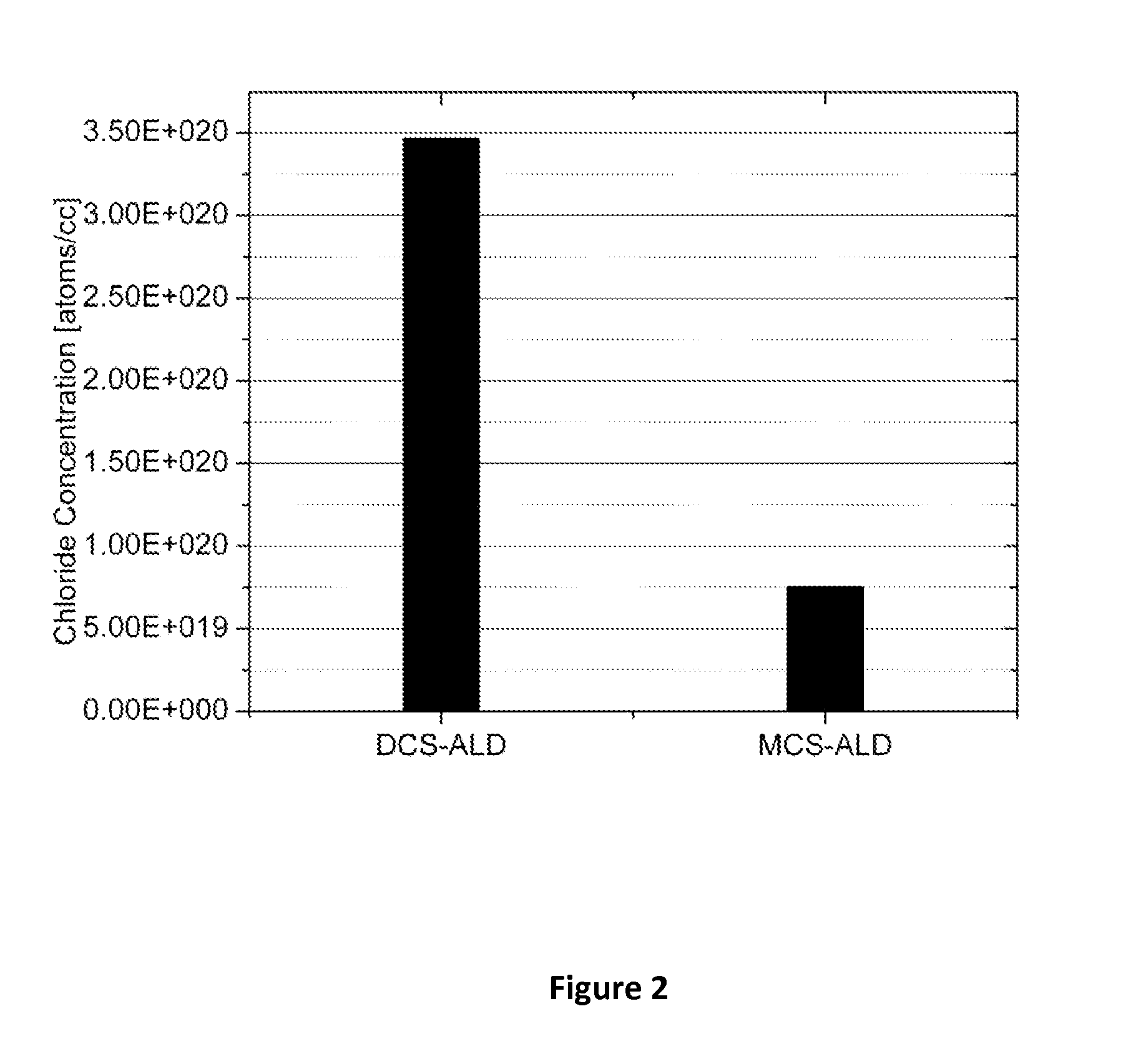

This invention discloses the method of forming silicon nitride, silicon oxynitride, silicon oxide, carbon-doped silicon nitride, carbon-doped silicon oxide and carbon-doped oxynitride films at low deposition temperatures. The silicon containing precursors used for the deposition are monochlorosilane (MCS) and monochloroalkylsilanes. The method is preferably carried out by using plasma enhanced atomic layer deposition, plasma enhanced chemical vapor deposition, and plasma enhanced cyclic chemical vapor deposition.

Owner:TOKYO ELECTRON LTD +1

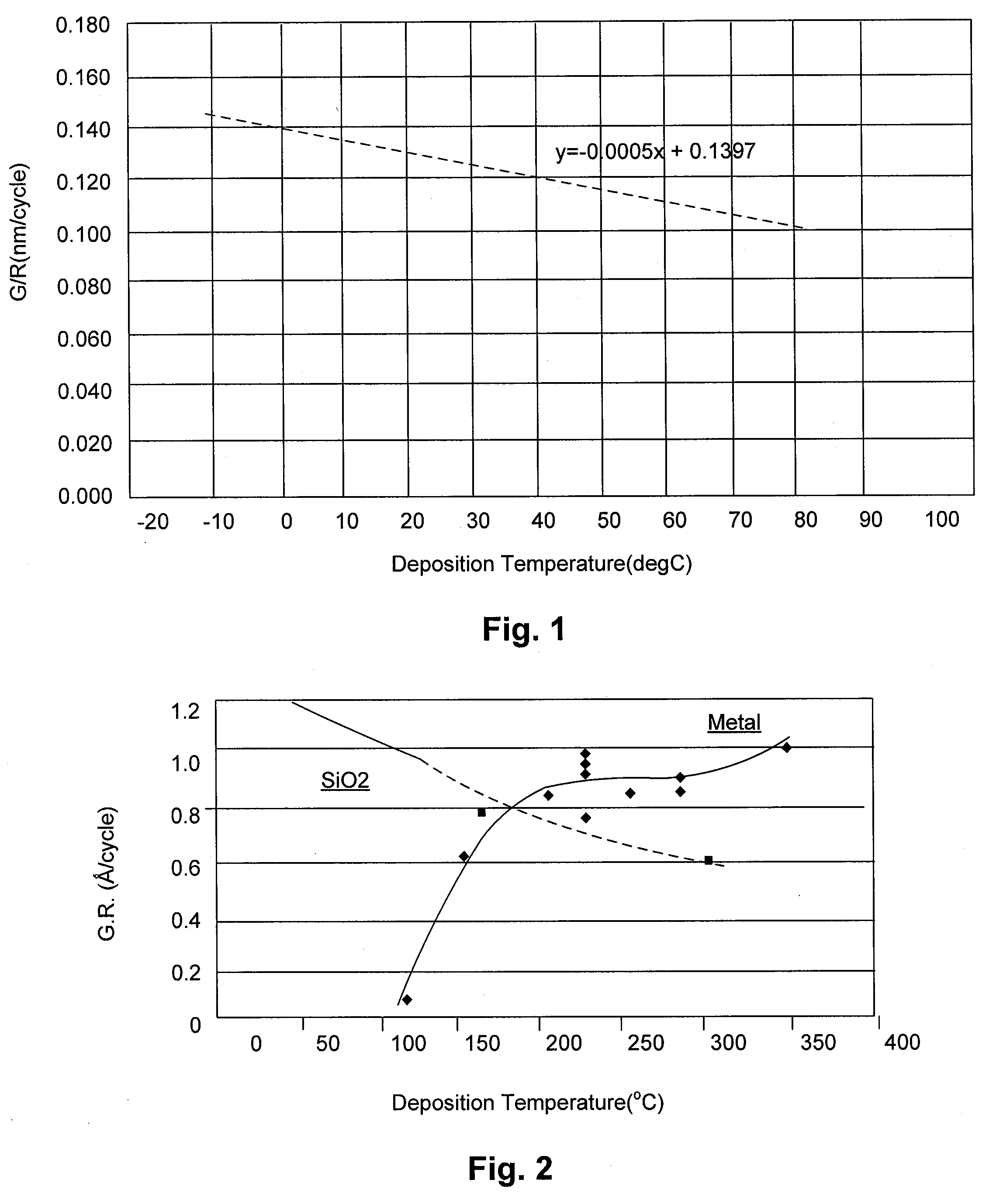

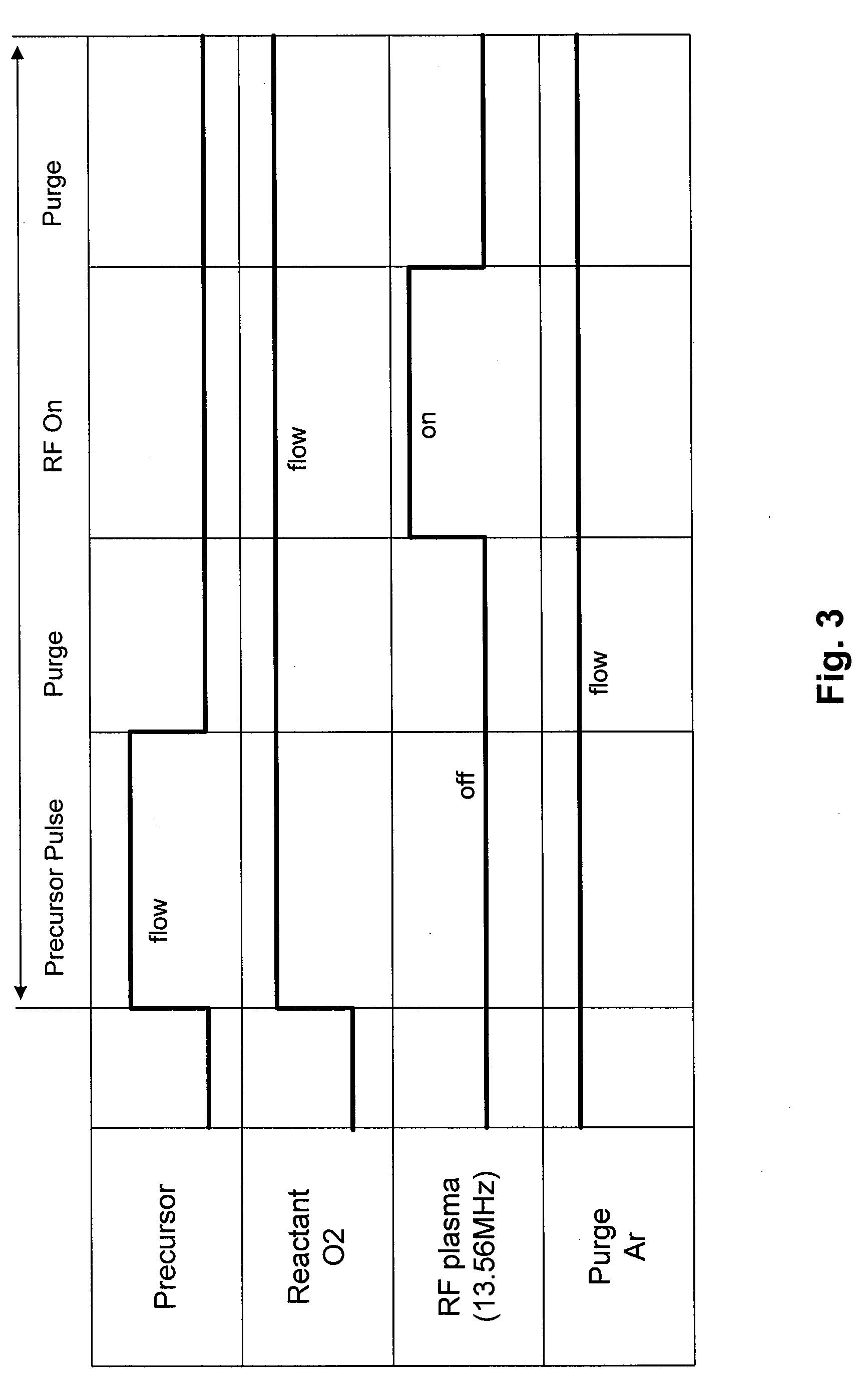

Method of depositing silicon oxide film by plasma enhanced atomic layer deposition at low temperature

ActiveUS8197915B2Increase deposition rateInhibition is effectiveSemiconductor/solid-state device manufacturingPhotosensitive material processingResistDeposition temperature

Owner:ASM JAPAN

Method of Depositing Silicon Oxide Film by Plasma Enhanced Atomic Layer Deposition at Low Temperature

ActiveUS20100255218A1Increase deposition rateInhibition is effectiveLiquid surface applicatorsSemiconductor/solid-state device manufacturingResistDeposition temperature

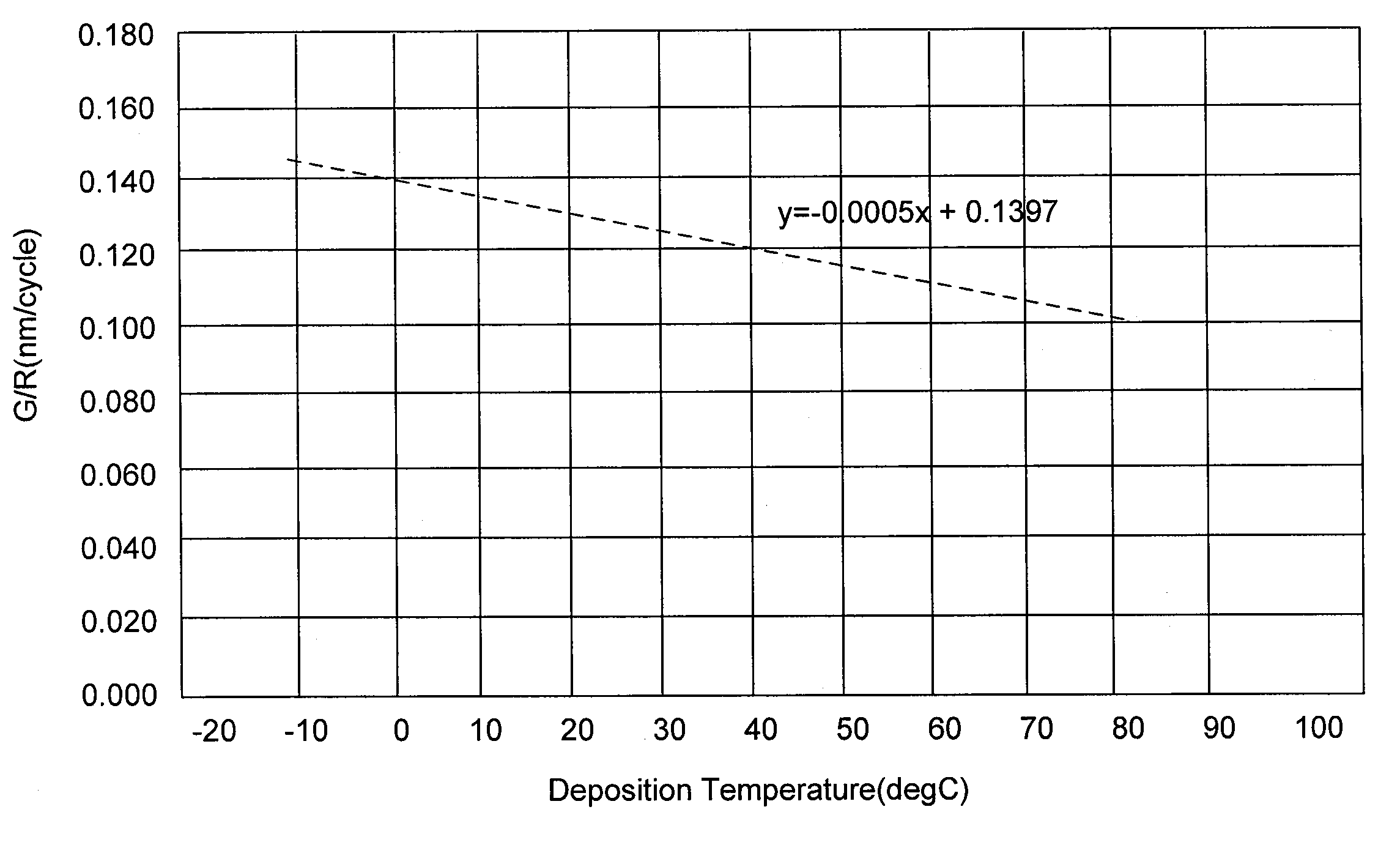

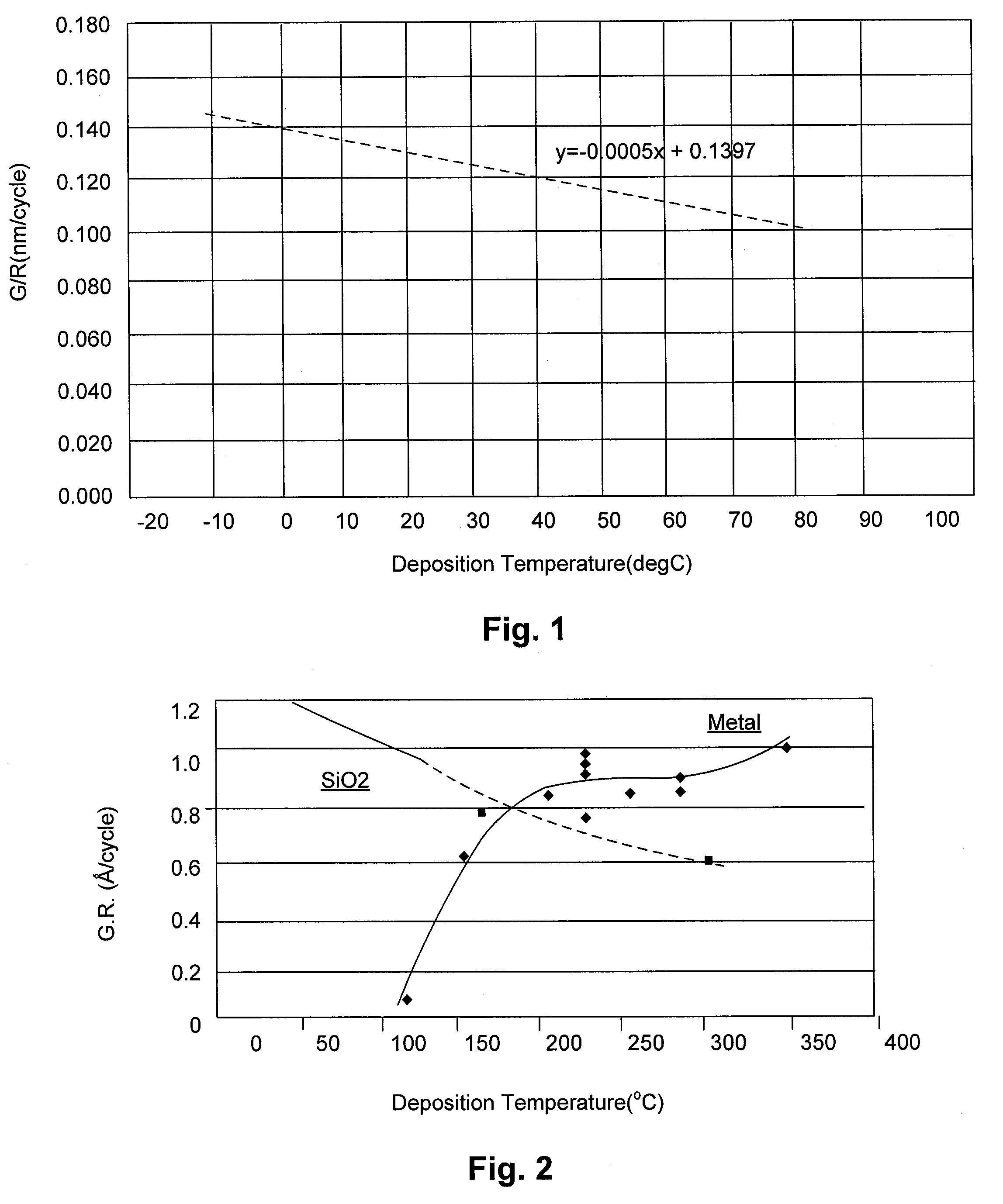

A method of depositing a silicon oxide film on a resist pattern or etched lines formed on a substrate by plasma enhanced atomic layer deposition (PEALD) includes: providing a substrate on which a resist pattern or etched lines are formed in a PEALD reactor; controlling a temperature of a susceptor on which the substrate is placed at less than 50° C. as a deposition temperature; introducing a silicon-containing precursor and an oxygen-supplying reactant to the PEALD reactor and applying RF power therein in a cycle, while the deposition temperature is controlled substantially or nearly at a constant temperature of less than 50° C., thereby depositing a silicon oxide atomic layer on the resist pattern or etched lines; and repeating the cycle multiple times substantially or nearly at the constant temperature to deposit a silicon oxide atomic film on the resist pattern or etched lines.

Owner:ASM JAPAN

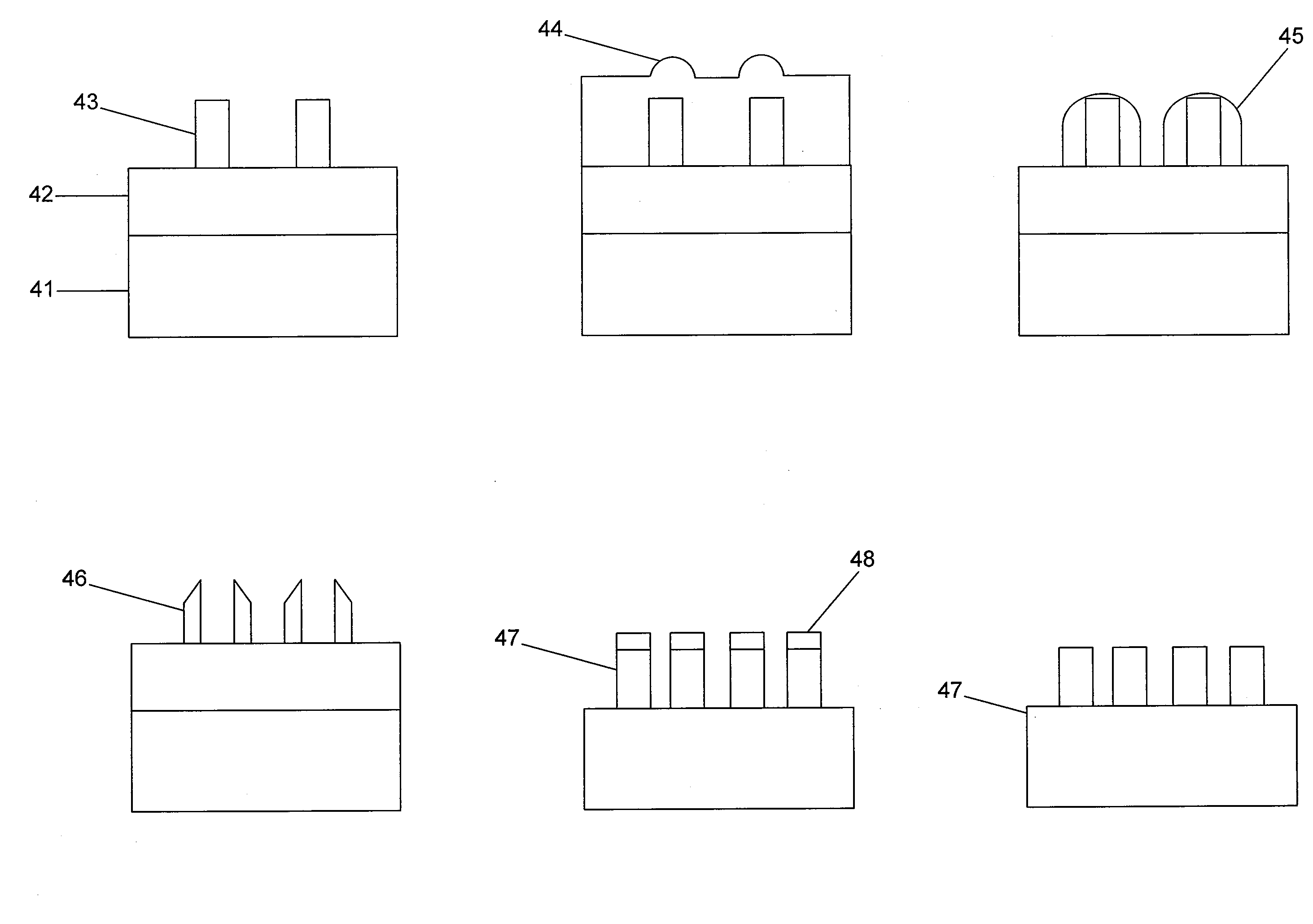

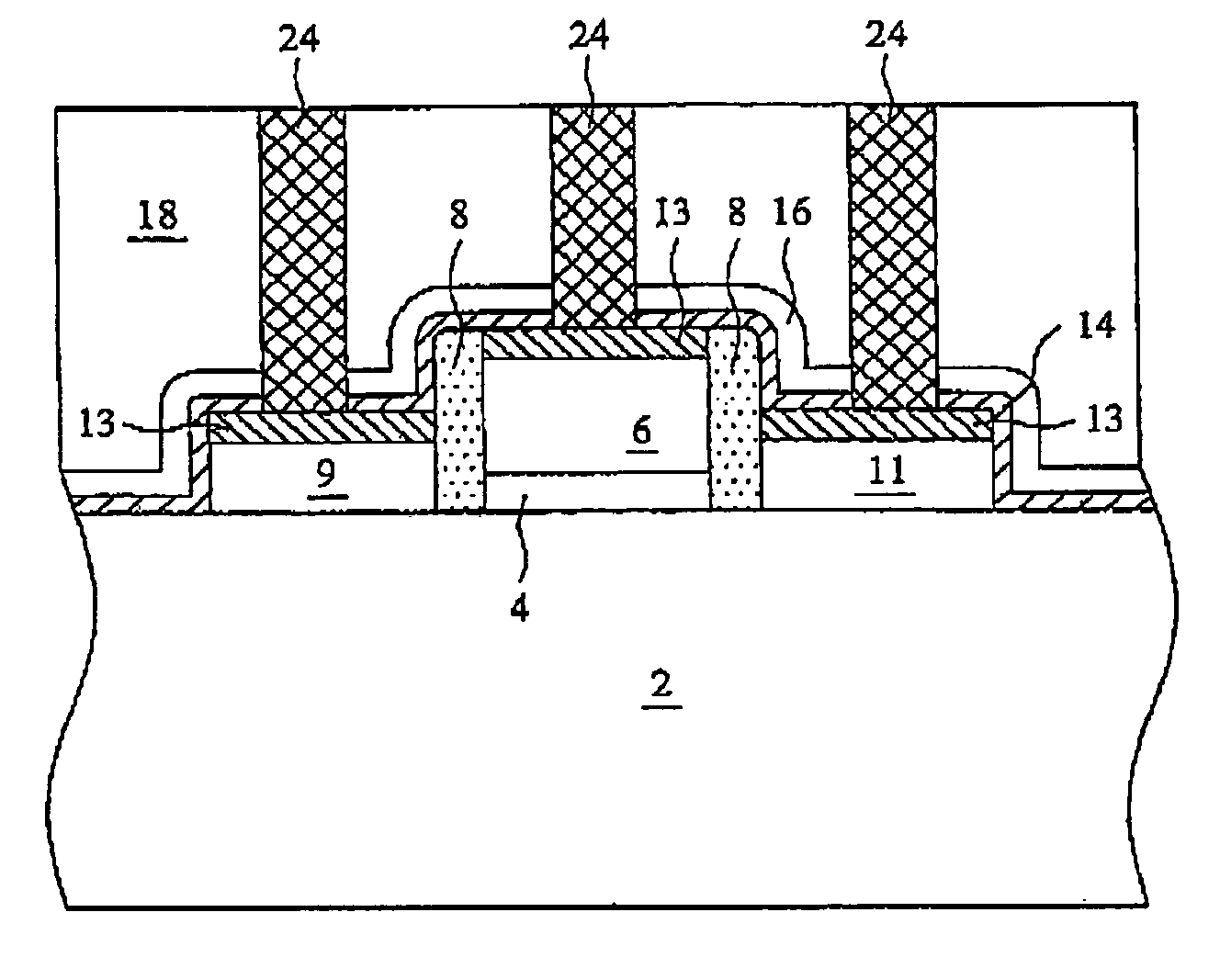

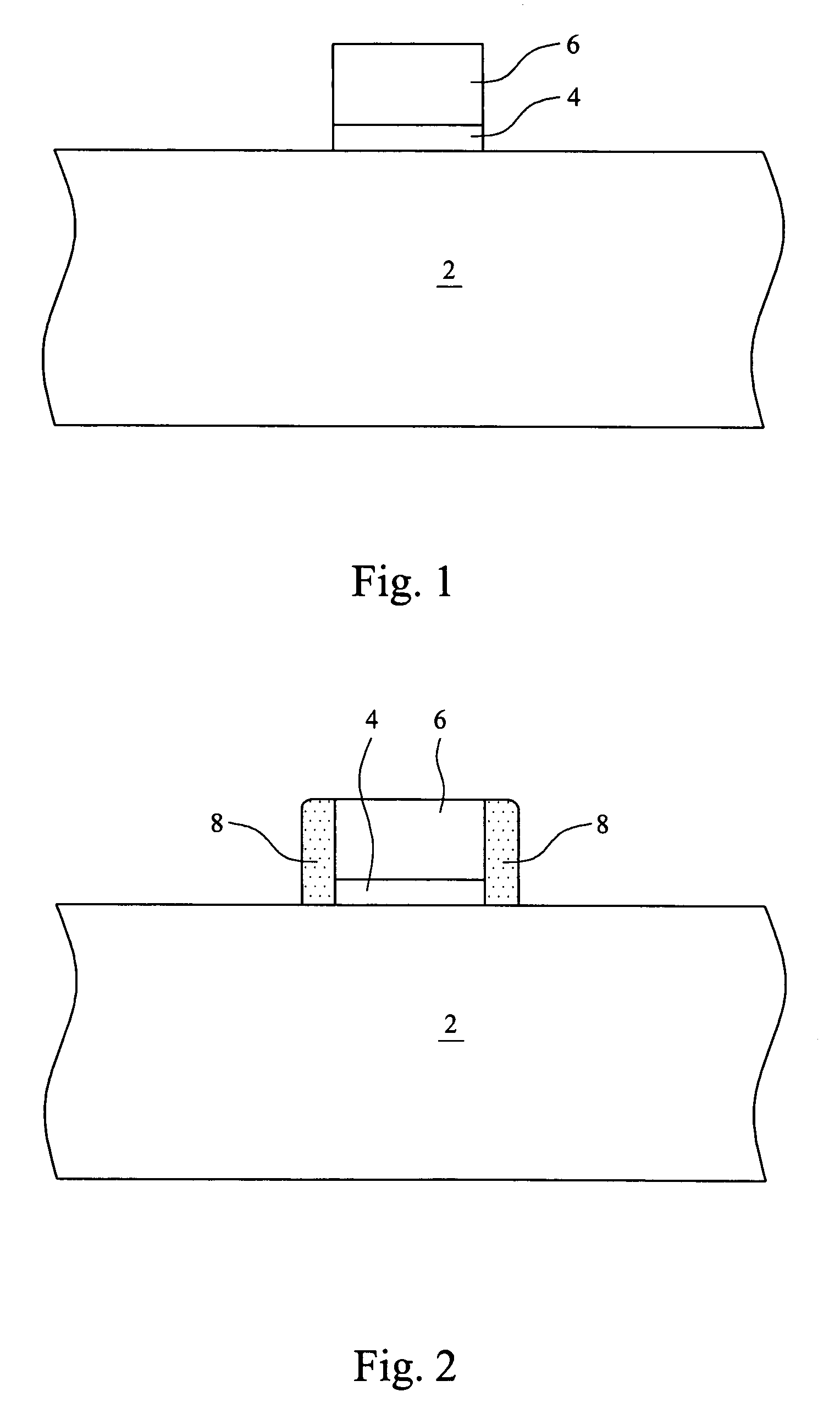

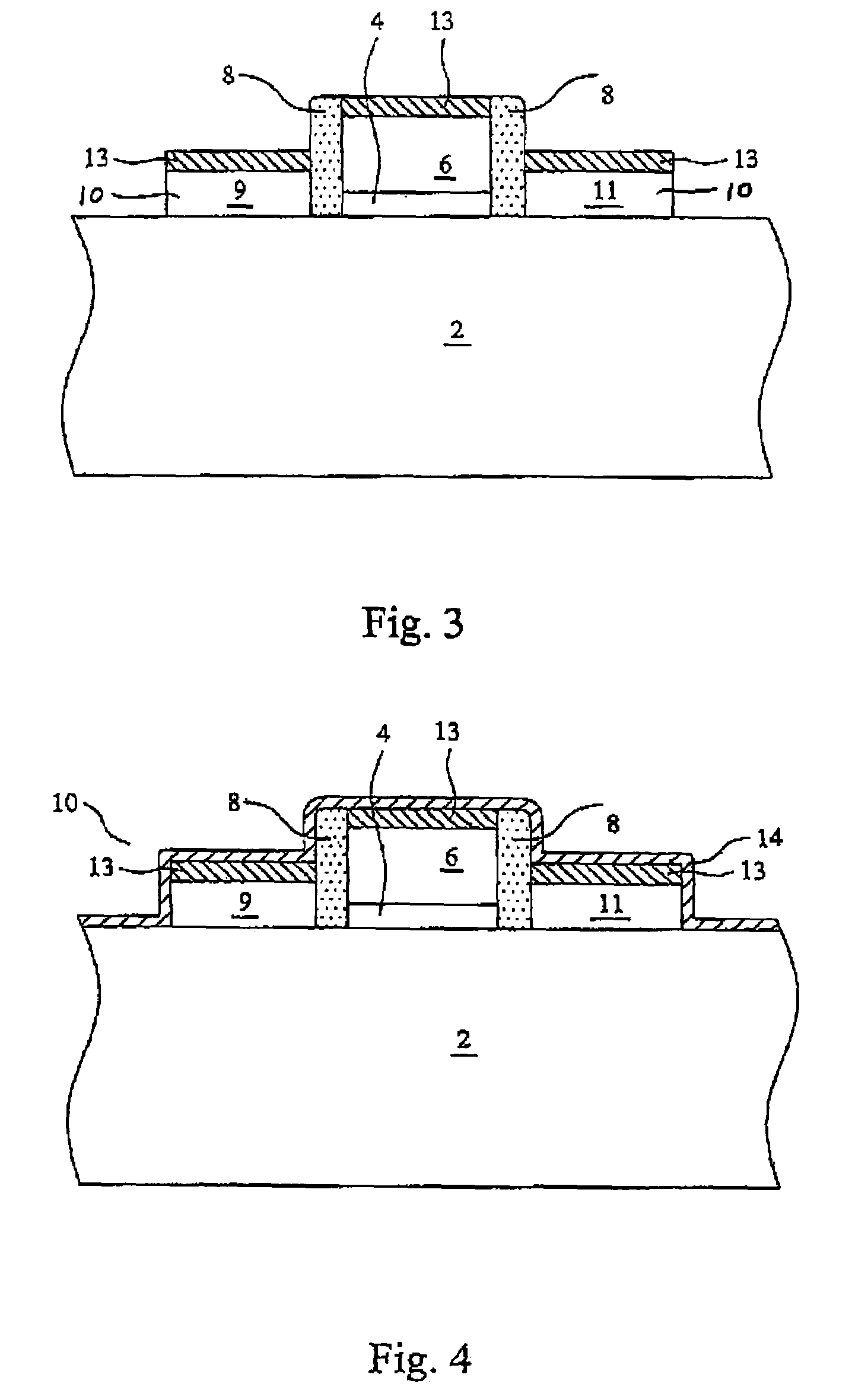

Silicon oxycarbide and silicon carbonitride based materials for MOS devices

ActiveUS7115974B2Increase deposition rateLow deposition temperatureSemiconductor/solid-state device detailsSolid-state devicesGate dielectricMaterials science

In the preferred embodiment, a gate dielectric and an electrode are formed on a substrate. A pair of spacers is formed along opposite sidewalls of the gate electrode and the gate dielectric. Spacers are preferably formed of SiCO based material or SiCN based material. The source and drain are then formed. A contact etch stop (CES) layer is formed on the source / drain regions and the spacers. The CES layer is preferably formed of SiCO based material or SiCN based material. An Inter-Level Dielectric (ILD) is then formed on the CES layer.

Owner:TAIWAN SEMICON MFG CO LTD

Active bio piezoelectric ceramic coating layer and method of preparing said coating layer on titanium base body surface

InactiveCN1785439AReduce bond strengthHigh bonding strengthAnodisationImpression capsPlasma electrolytic oxidationMicro arc oxidation

A coated active biologic piezoelectric layer on Ti substrate is prepared from fluorohydroxy apatite (FHA) and barium titanate (BT) through cleaning the surface of Ti substrate, microarc oxidizing to form a porous oxide film layer, and electrophoretic deposition to form a FHABT layer on the surface of Ti substrate. Its advantages are easy control to content of F, high implantation stability, binding power to interface, biocompatibility and bioactivity, and high effect to promote generation of biologic bone and taking part energy conversion in human body.

Owner:HARBIN ENG UNIV

Method for preparing selective emitter by one-time diffusion

InactiveCN101794845ALow deposition temperatureLow costFinal product manufactureSemiconductor devicesDeposition temperatureMetallic electrode

The invention relates to the technical field of production methods of solar cells, in particular to a method for preparing a selective emitter by one-time diffusion, which sequentially comprises the following process steps: making texture on a silicon wafer, carrying out uniform heavy diffusion, depositing silicon nitride film on the surface of the silicon wafer after diffusing, and printing corrosive slurry in a non-metallic electrode region of the silicon wafer so as to etch the silicon nitride film; and finally, etching the silicon in the non-metallic electrode region with an acid solution or alkali solution to obtain a shallow diffusion region, and the electrode region being a heavy diffusion region. The heavy diffusion process can achieve double-sided gettering, the deposition temperature of the silicon nitride film is low, the whole process is simple and easy to control, the surface is not damaged and has no dead layer, and the cost is low.

Owner:TRINA SOLAR CO LTD

Preparation method of alumina film

InactiveCN102409293AFast preparationAvoid damageVacuum evaporation coatingSputtering coatingSurface engineeringIon bombardment

The invention relates to a preparation method of an alumina film and belongs to the technical field of surface engineering. The method comprises the following steps: putting a flexible polymer film base in a vacuum chamber, and vacuumizing the vacuum chamber till pressure in the vacuum chamber is less than or equal to 2.0*10<-3> Pa; carrying out argon ion bombardment on the base with an ion source, thereby improving the adhesion of a plated film layer, wherein the flow of argon is 15sccm, the discharge voltage of an ion beam is 280V, and the current of the ion beam is 1A; and depositing an alumina film by using an oxygen ion beam aided impulse reaction magnetron sputtering technology, wherein a target source is an aluminum target. In the preparation process, the base is always maintained at room temperature, thus the damage of high temperature to the flexible polymer film base can be avoided; and the rapid deposition of the high-quality alumina film can be realized on the flexible polymer base.

Owner:NO 510 INST THE FIFTH RES INST OFCHINA AEROSPAE SCI & TECH

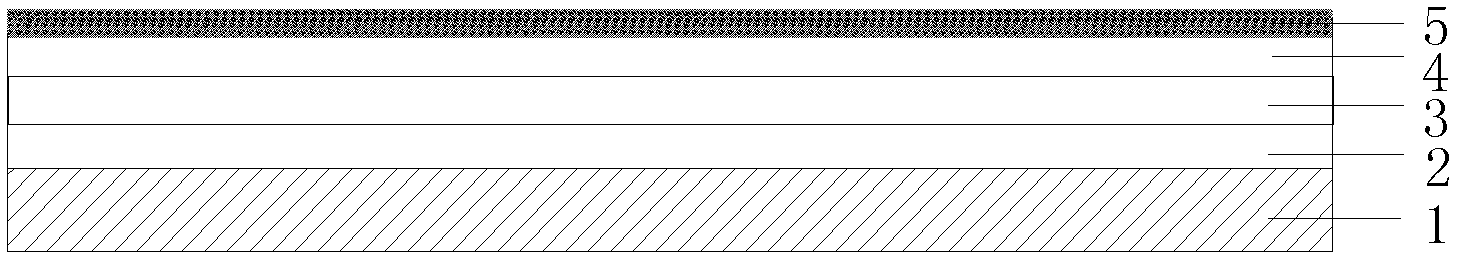

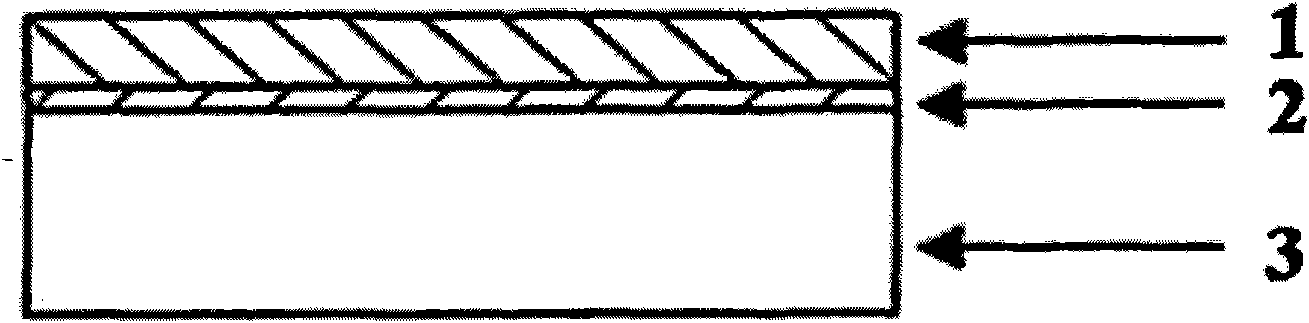

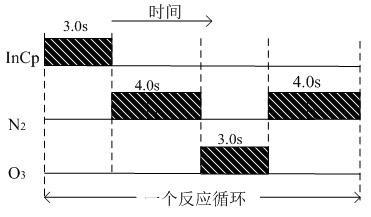

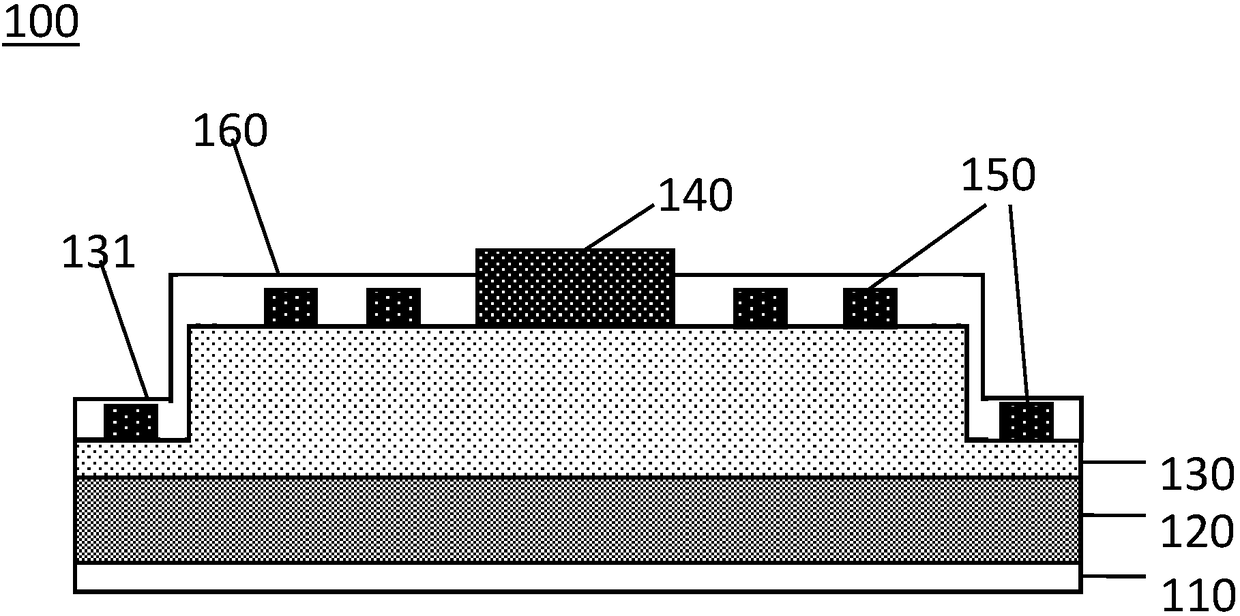

Packaging structure of OLED

InactiveCN102437288ALow deposition temperatureSave floor space and equipment investment costsSolid-state devicesSemiconductor/solid-state device manufacturingOrganic electroluminescenceOrganic film

The invention relates to a packaging structure of an OLED. The structure comprises a substrate of the OLED. One side of the substrate is provided with an anode of the OLED, an organic layer and a cathode. The outboard of the cathode is at least provided with a packaging layer. The packaging layer is a multilayer composite membrane structure which is formed by alternative deposition of two inorganic insulating materials through an atomic layer deposition system. The packaging structure of the OLED in the invention has a low deposition temperature. The organic layer of a luminescent device can not be damaged. Other organic film formation equipment is not needed. Equipment investment costs and land occupation areas can be saved. The inorganic film layer structure alternatively prepared by using an atomic layer deposition method is compact. Pinholes are less. Water and oxygen can be effectively avoided to penetrate into a device. A protection layer is processed on the packaging layer so as to effectively protect the packaging layer and obstruct the water and the oxygen.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

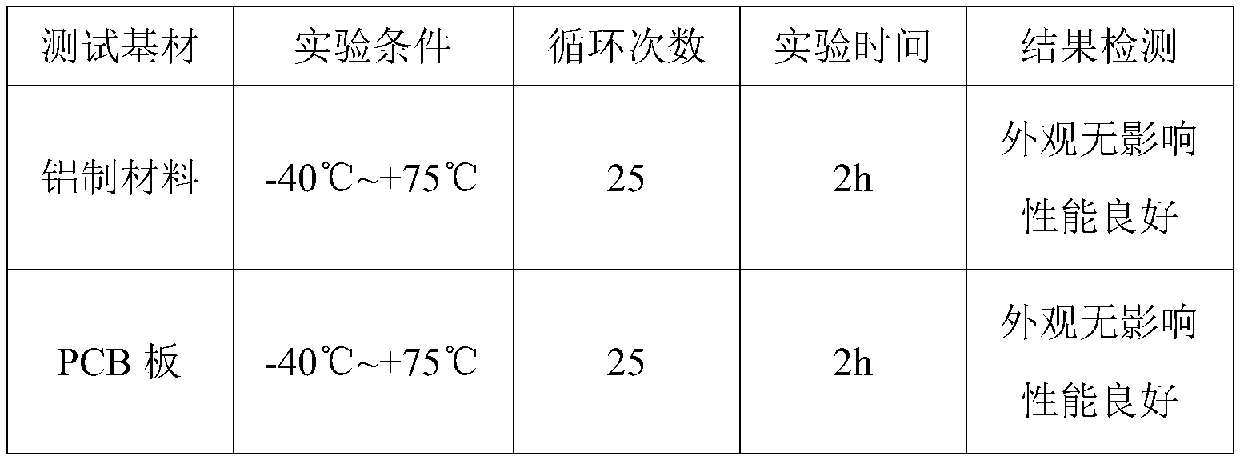

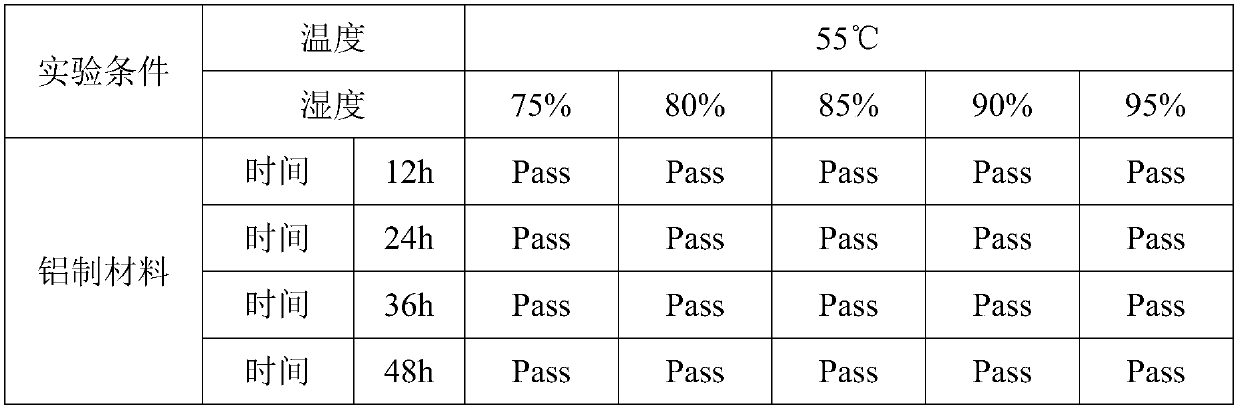

Preparation method of high-insulating nanometer protective coating

InactiveCN107699868AImprove controllabilityOptionalChemical vapor deposition coatingParyleneGas phase

The invention relates to a preparation method of a high-insulating nanometer protective coating, and belongs to the technical field of plasmas. According to the method, a reaction cavity is vacuumized, inert gas is led in to enable a base material to move, monomer steam is led into the reaction cavity, plasma discharging is started, chemical vapor deposition is carried out, and the high-insulatingnanometer protective coating is prepared by conducting chemical vapor deposition on the surface of the base material; the monomer steam is a mixture of at least one kind of low dipole moment organicmatter monomer and at least one kind of polyfunctional unsaturated hydrocarbon and hydrocarbon ramification; and according to the method, the organic matter monomers with the low dipole moment and thehigh chemical inertia are screened out, the free volume and the compactness of the coating are regulated and controlled through the polyfunctional monomer, due to the fact the plasma chemical vapor deposition method can be suitable for many monomers and can be high in controllability on the ingredient and the structure of the formed coating, the deposited coating has the more excellent protectionperformance and insulation performance compared with existing coatings like parylene under the condition that the thickness is the same.

Owner:JIANGSU FAVORED NANOTECHNOLOGY CO LTD

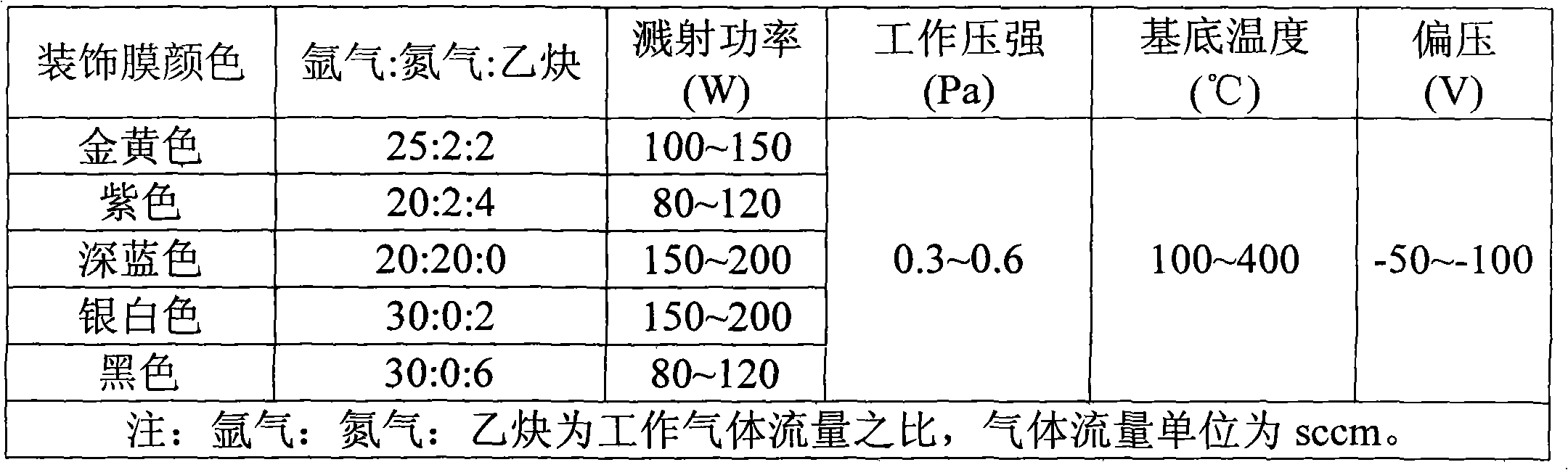

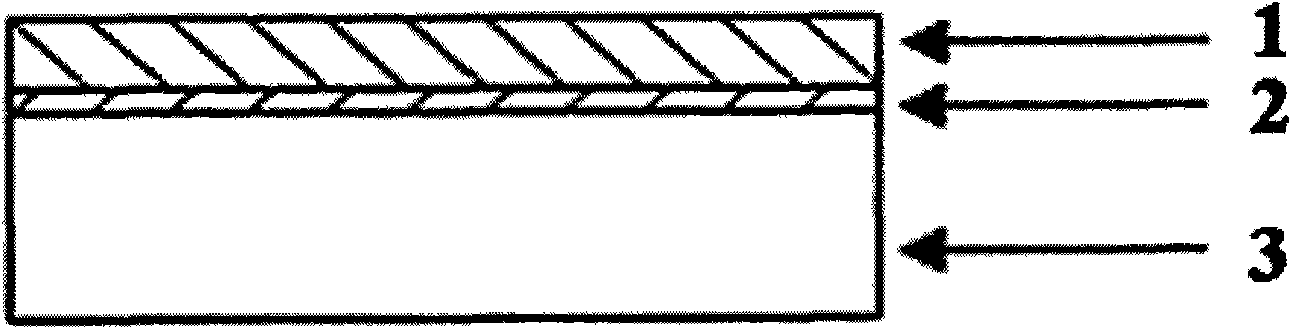

Method for preparing corrosion-resistant colored decorative film

InactiveCN101830092AAccurate film thicknessSimple processVacuum evaporation coatingSpecial ornamental structuresRadio frequency magnetron sputteringAlloy

The invention relates to a corrosion-resistant colored decorative film and a preparation method thereof. The method prepares the corrosion-resistant colored decorative film on the surface of a metal material by adopting radio-frequency magnetron sputtering technology, and the prepared decorative film has good bonding force with a substrate. The metal material is zinc, copper, aluminum or alloy of the metals. The decorative film prepared by the method has a double-layer film structure, wherein the first layer is a titanium film, and the second layer is a (carbonized or azotized) titanium film. The method can prepare the acid, alkali and corrosion resistant decorative film with different colors comprising golden yellow, purple, dark blue, silvery white, black and the like. The method has the advantages of no environmental pollution, simple operation, low cost and capability of large-scale production; the prepared film has high quality; and the method is suitable for preparing the decorative film by using the metal material or the similar metal material as a base material.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Method for depositing vanadium dioxide thin film on glass under low temperature

InactiveCN101265036ALower crystallization temperatureLow deposition temperatureSeed crystalVanadium dioxide

Based on the crystal heteroepitaxial growth principle, the invention provides a low-temperature preparation method of depositing a vanadium dioxide film on a glass substrate without changing the quality (thermochromatism) of the vanadium dioxide film. Using glass as substrate, the method comprises the following steps: 1) cleaning and pre-treating the glass substrate; 2) depositing a vanadium dioxide diffusion barrier layer on the glass substrate; 3) depositing a zinc oxide seed crystal layer on the vanadium dioxide diffusion barrier layer; and 4) depositing a vanadium dioxide thermochromic layer on the zinc oxide seed crystal layer. The vanadium dioxide thermochromic layer has low crystallization temperature and lattice constant matched with vanadium dioxide, and is particularly suitable for the heteroepitaxial growth of the vanadium dioxide film. Therefore, the invention can efficiently reduce the deposition temperature of vanadium dioxide film, simplify the process of producing intelligent vanadium dioxide glass, minimize cost and energy consumption, and greatly reduce the difficulty in industrialization of intelligent vanadium dioxide glass.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Composite processing method for realizing metallization of surfaces of diamonds

InactiveCN103409732AFacilitates the speed of the diffusion reactionPrevent graphitizationLiquid/solution decomposition chemical coatingChemical platingCrucible

The invention discloses a composite processing method for realizing metallization of the surfaces of diamonds. The method comprises the following steps: performing chemical plating processing on diamond particles to enable the surfaces of the diamond particles to be uniformly coated with chemical plating layers; performing metallized processing on the surfaces of the diamond particles, packing a wave-absorbing material and the diamond particles subjected to chemical plating into a ball mill jar for realizing uniform material mixing, filling a corundum crucible with the mixture, sealing the surface of the corundum crucible and placing the corundum crucible in a vacuum micro-wave heating oven, and slowly rotating the oven for heating and insulating, wherein the heating temperature is 750-900 DEG C, the heating and insulating process takes 10-30 minutes, and the vacuity is 1.3*10<-3>Pa; separating the diamond particles from the wave-absorbing material. According to the invention, the chemical plating technology and the vacuum microwave quick heating technology are combined, so that the deposition temperature of the chemical plating becomes low, and obtained plating can be more uniform and compact; heat energy can be more effectively utilized through vacuum micro-wave heating; moreover, metallurgy diffusion reaction rate is promoted, the processing time is shortened, and graphitization of the diamonds can be well prevented in a vacuum processing environment.

Owner:SOUTHWEST PETROLEUM UNIV

Preparation method of coating with thiol compound as transition layer

ActiveCN108425104AImprove controllabilityOptionalChemical vapor deposition coatingEpoxyBound property

The invention discloses a preparation method of a coating with a thiol compound as a transition layer, and belongs to the technical field of plasmas. According to the method, a sulfydryl-containing thin layer is adopted as the transition layer between the coating and a substrate; before the coating is deposited, the thin layer of 1-10 nm is deposited on the surface of the substrate by using a sulfydryl-containing monomer, wherein the sulfydryl at one end of the monomer reacts with the surfaces of copper, gold, nickel, epoxy resin and the like, so that a chemical bond is formed, the excellent binding property is kept, and the other end of the monomer is polymerized, and has the excellent binding property with the coating on the upper layer. According to the method for depositing the transition layer, the binding force of the coating and the substrate is greatly improved; according to the method , the environmental protection property is high, the deposition temperature is low, the speedis higher, and the controllability of the coating structure and the composition is high, and the selectivity of the monomer is high; the deposition efficiency is high, and the compactness of the obtained organic silicon nano-protection coating is remarkably improved; and the binding force obtained by the coating on different substrates can be improved by 30-50%.

Owner:JIANGSU FAVORED NANOTECHNOLOGY CO LTD

Double-layer anti-reflecting film of crystal silicon solar cell and preparation method thereof

InactiveCN101577294ALow costLow deposition temperatureFinal product manufacturePhotovoltaic energy generationSilver pasteSilicon based

The invention discloses a double-layer anti-reflecting film of a crystal silicon solar cell and a preparation method thereof. The double-layer anti-reflecting film is characterized in that the film consists of a loose layer TiO2 film, a compact layer TiO2 film and a SiO2 passivation layer in turn, wherein the SiO2 passivation layer is positioned between the compact layer TiO2 film and a silicon-based substrate. The preparation method comprises the following steps: depositing the compact layer TiO2 film and the loose layer TiO2 film on the right surface of the silicon-based substrate; and after electrode silver paste is printed, through conventional sintering at the temperature between 400 and 900 DEG C, forming the SiO2 passivation layer at an interface of the silicon-based substrate and the compact TiO2. A TiO2 / TiO2, quasi double-layer anti-reflecting film of the invention is finished once by changing the depositing condition, is optimized on the process and equipment, and has better anti-reflecting effect compared with a single-layer anti-reflecting film.

Owner:CENT SOUTH UNIV

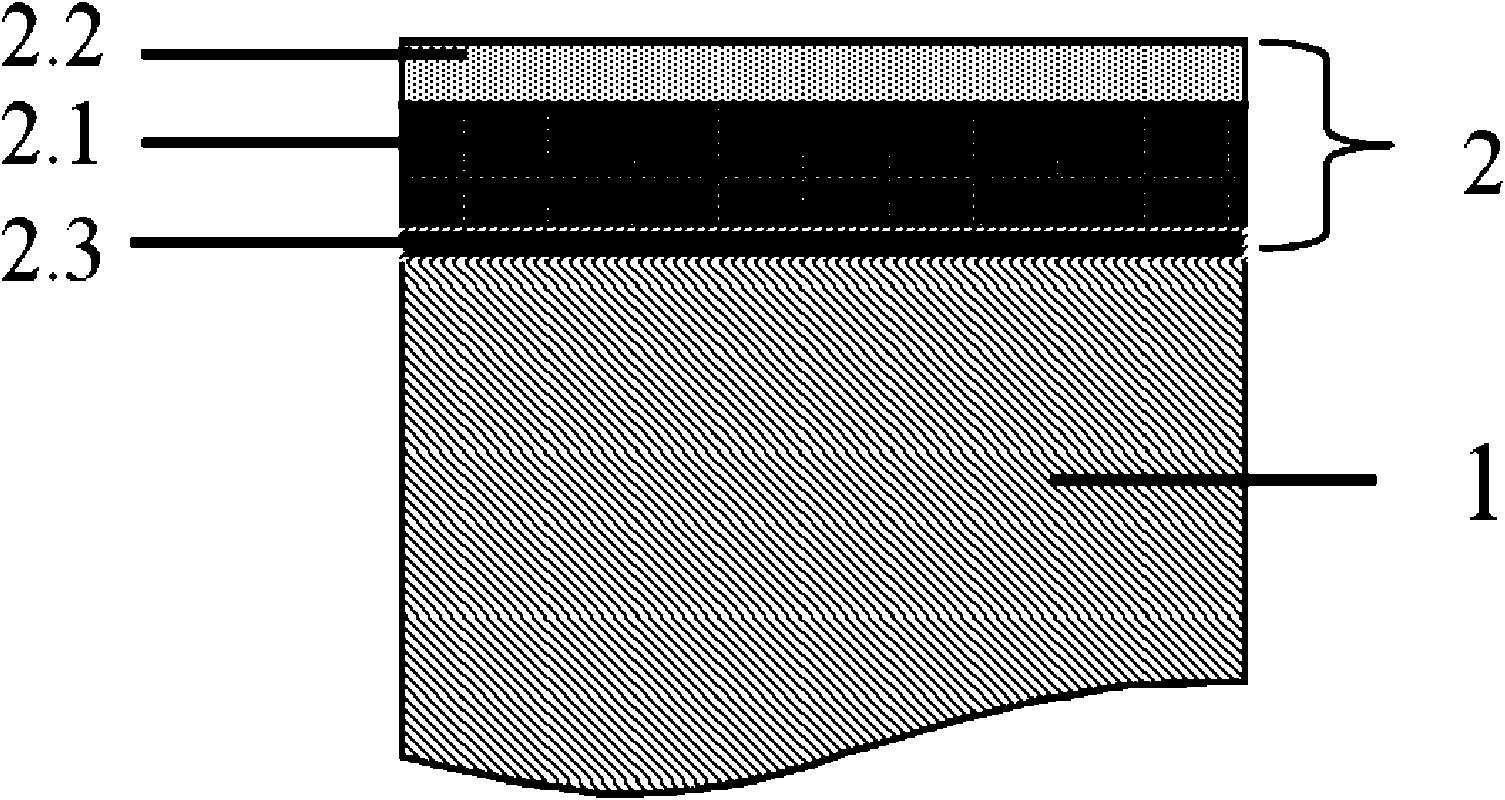

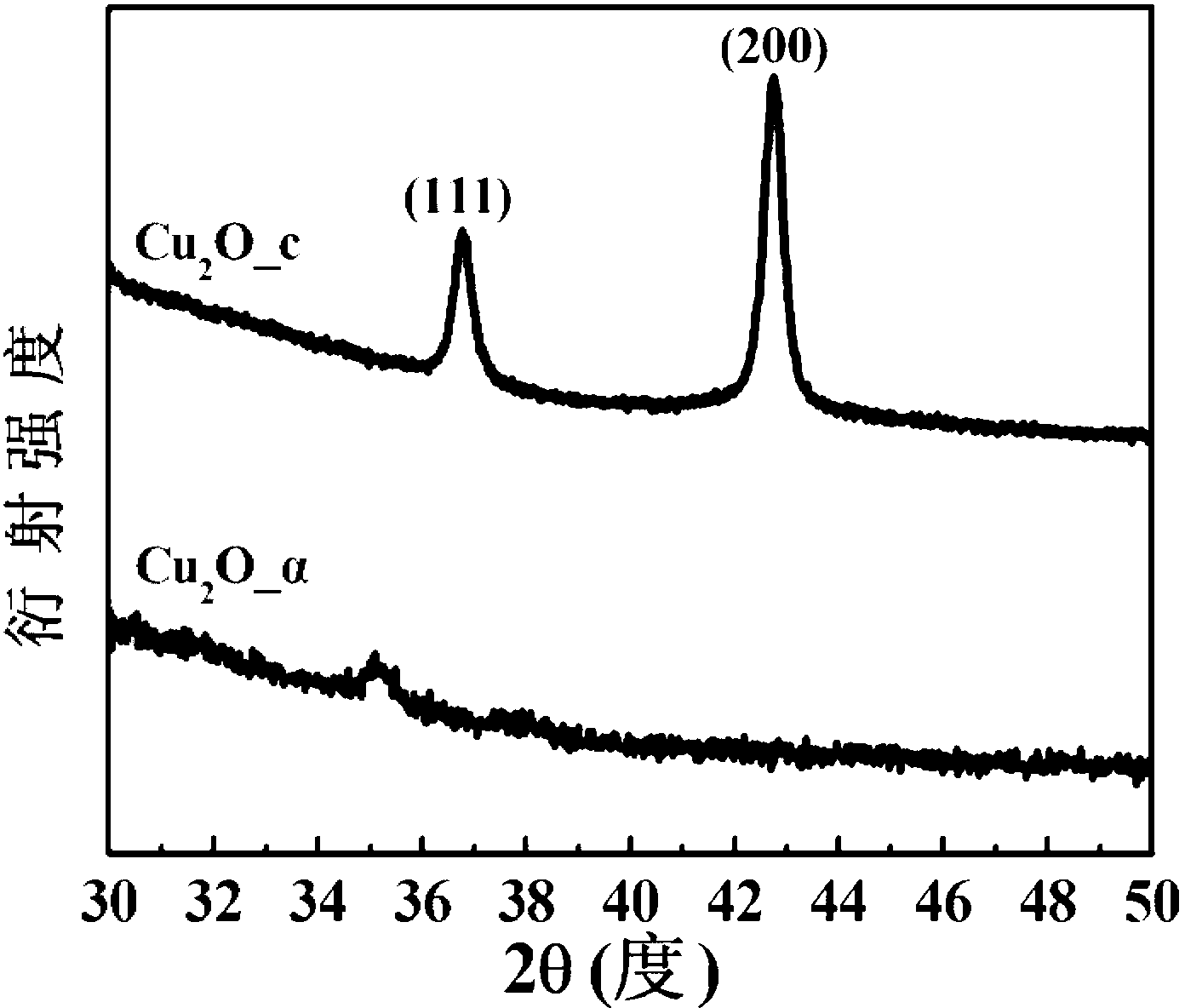

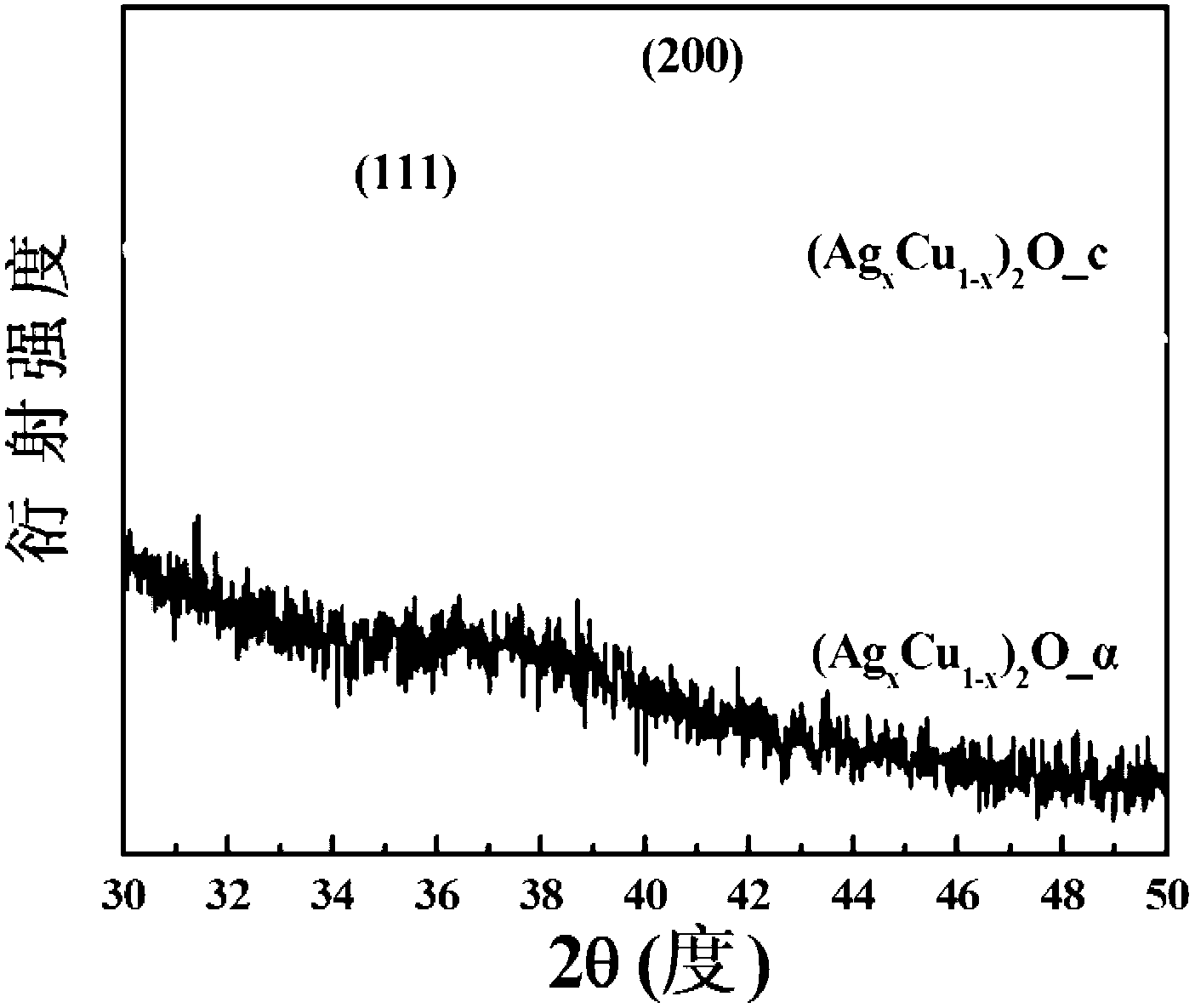

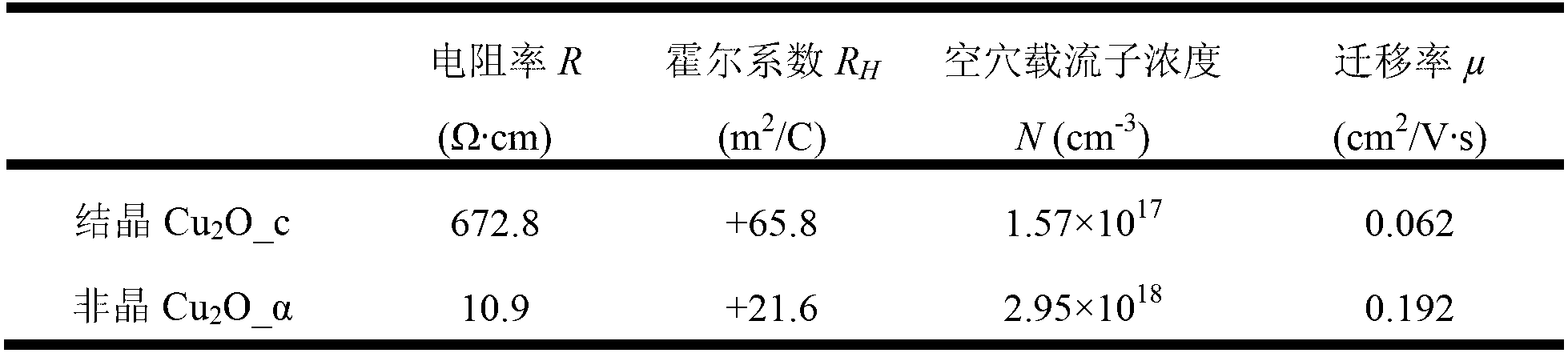

Preparation method of (doped amorphous) p-type transparent conductive oxide films

InactiveCN103173732AThe principle is simpleLow deposition temperatureVacuum evaporation coatingSputtering coatingCrystalline oxideDeposition temperature

The invention discloses a preparation method of films of (doped amorphous) p-type transparent conductive oxide films, and relates to the technical field of semiconductor films. The amorphous films having a higher hole carrier concentration and a higher mobility than crystallized oxide films are prepared through adopting a reaction magnetron sputtering process and controlling technological parameters. The preparation method has the advantages of simple principle, low deposition temperature, strong controllability of the technological parameters, low preparation cost, and huge scale production potential.

Owner:BEIHANG UNIV

Low temperature deposition method of hypovanadic oxide thin film on glass

InactiveCN101280413ALow deposition temperatureReduce difficultyVacuum evaporation coatingSputtering coatingVanadium dioxideLow temperature deposition

The invention provides a low temperature deposition method of vanadium dioxide thin film on a glass substrate by utilizing a principle of template induction function for the crystal growth. Glass is taken as a substrate, and the low temperature deposition method comprises the steps in sequence that firstly, the glass substrate is cleaned and pre-heated; secondly, a silicon dioxide diffusing blocked layer is prepared; thirdly, a metal oxide buffer layer is prepared; fourthly, a vanadium dioxide thermal color layer is prepared. The material of the metal oxide buffer layer adopted by the invention is transparent in the visible light area and has low crystallization temperature, the crystal shape of the material can be well matched with the vanadium dioxide, and the template induction function can be generated during the growing process of the vanadium dioxide thin film, therefore, the deposition temperature of the vanadium dioxide thin film can be greatly reduced. The preparing process of the vanadium dioxide intelligent glass is simplified, the cost is reduced, the energy consumption is saved, and the difficulty of the industrialization process of the vanadium dioxide intelligent glass is greatly reduced.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

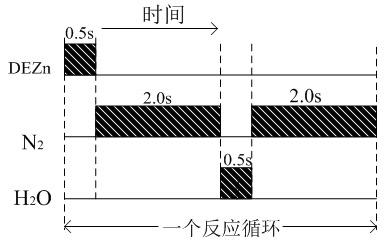

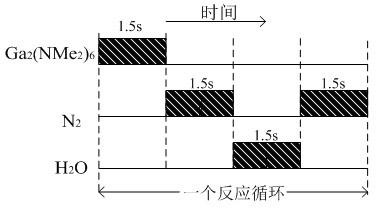

Method for producing amorphous indium gallium zinc oxide thin film by atomic layer deposition

InactiveCN102618843ASimple processLow deposition temperatureSemiconductor/solid-state device manufacturingChemical vapor deposition coatingAtomic layer depositionMaterials science

The invention belongs to the technical field of semiconductor integrated circuits, and particularly discloses a method for growing an amorphous indium gallium zinc oxide thin film by the ALD (atomic layer deposition) technique. The method mainly includes the steps: using diethylzinc as a reaction source for growing ZnO, and using water or hydrogen peroxide as oxidant; using Ga2 (NMe2)6 as a reaction source for growing Ga2O3, and using water as oxidant; growing In2O3 for multiple cycles, using cyclopentadienylindium as a reaction source for growing In2O3, and using mixture of water and oxygen or ozone as oxidant; and repeating the steps for multiple times as required to obtain an IGZO thin film of certain thickness. The temperature of a reaction chamber in growth is controlled within a range of from 100 DEG C to 300 DEG C. In addition, the steps above are free to order and combine. The IGZO thin film grown by the method is high in uniformity, density and shape retention, suitable for large-area disposition, and widely applicable to the fields of thin film transistors, thin film transistor memories and transparent electronic devices.

Owner:FUDAN UNIV

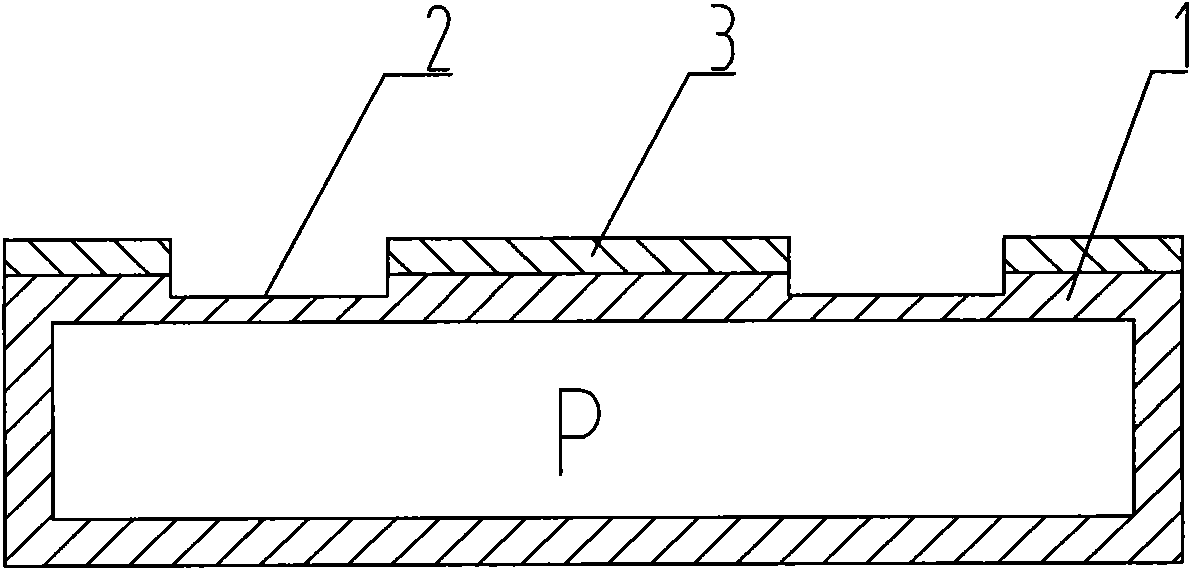

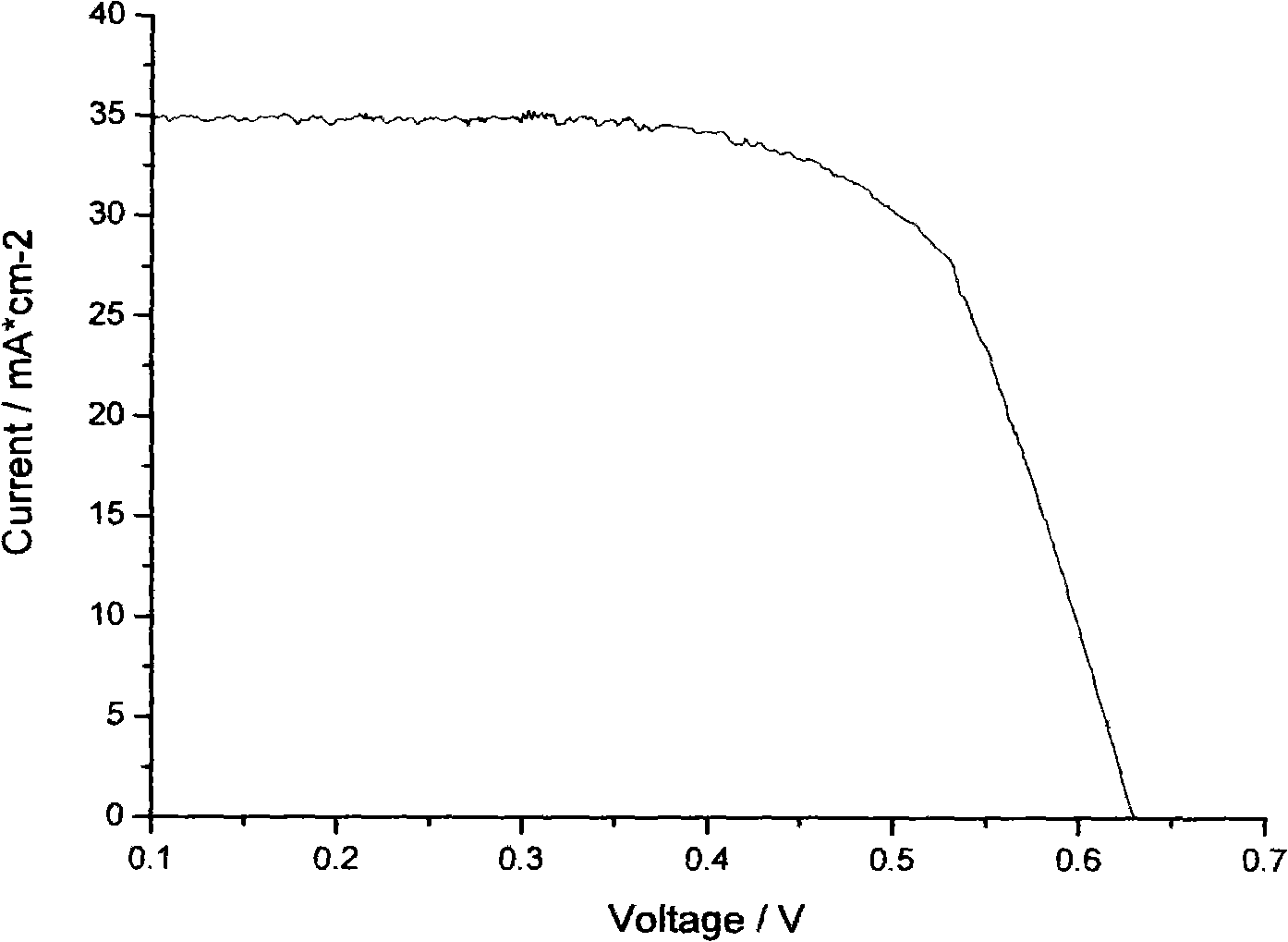

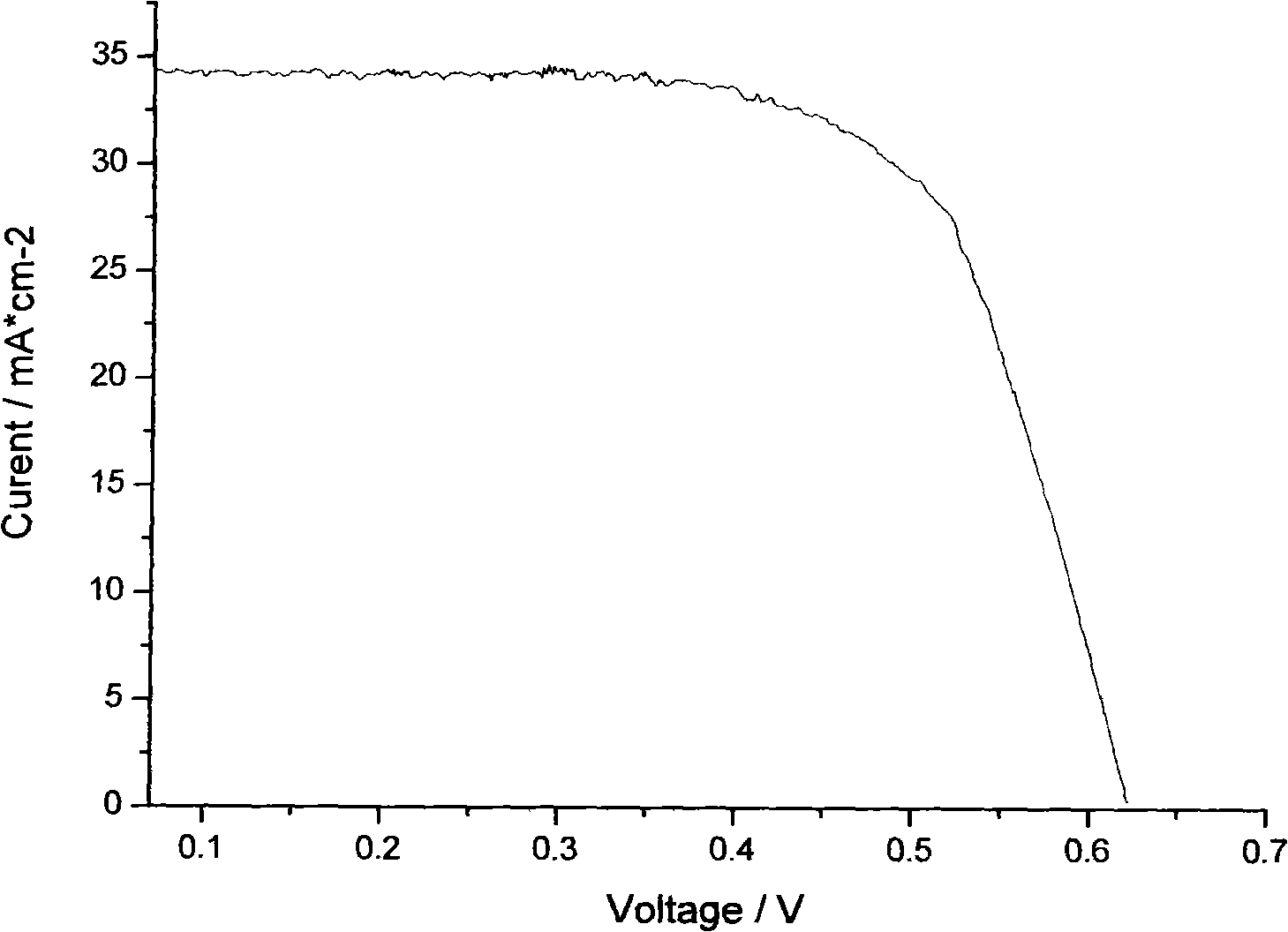

Tube type PERC single-sided solar cell, preparation method thereof and special equipment thereof

ActiveCN107256894AReduce the ratio of scratchesReduce impact forceFinal product manufactureSemiconductor/solid-state device manufacturingScratchingSilica membrane

The invention discloses a tube type PERC single-sided solar cell, which comprises a main silver back gate, an all-aluminum back electric field, a back-side composite film, a P-type silicon, an N-type emitting electrode, a front-side passivation film and a positive silver electrode. The back-side composite film is composed of one or more selected from an aluminum oxide film, a silicon dioxide film, a silicon oxynitride film and a silicon nitride film and is deposited at the back of a silicon chip by adopting tube type PECVD equipment. The tube type PECVD equipment comprises four gas pipelines of silane, ammonia, trimethyl aluminum and laughing gas. The appliance of the tube type PECVD equipment, used for loading and unloading silicon chips, is a graphite boat. The depth of a sticking point groove of the graphite boat is 0. 5-1 mm. The invention also discloses a preparation method and special equipment of the tube type PERC single-sided solar cell. According to the invention, the photoelectric conversion efficiency is high. Meanwhile, the appearance yield and the EL yield are high. The problems of scratching, winding and plating can be solved.

Owner:GUANGDONG AIKO SOLAR ENERGY TECH +1

Preparation method for high-insulation hard nanometer protection coating of composite structure

ActiveCN107587119AHigh hardnessImprove insulation performanceChemical vapor deposition coatingPlasma technologyWear resistant

The invention provides a preparation method for a high-insulation hard nanometer protection coating of a composite structure, belonging to the field of plasma technology. According to the method, a reaction cavity is vacuumized and inert gas is introduced to allow a substrate to move, so organosilicon monomers with low dipole moment and high chemical inertia are screened out; the free volume and compactness of a coating are regulated and controlled through multifunctionality monomers, so the coating is allowed to have insulating properties and excellent protection performance and wear resistance at the same time; and an organosilicon coating is deposited on the coating with high insulating properties, and surface hard treatment is carried out so as to form a hard coating with a compact structure. The high-insulation hard nanometer protection coating provided by the invention has more excellent protection performance, insulating properties and wear resistance compared with conventionalcoatings such as parylene under the condition of same thickness. The preparation method provided by the invention overcomes the problems of poor wear resistance, too great thickness, low production efficiency and the like of conventional parylene coatings; and through hard treatment, a composite wear-resistant silica structure is increased in the coating, and the hardness and wear resistance of the coating are effectively improved.

Owner:JIANGSU FAVORED NANOTECHNOLOGY CO LTD

Three-layer film structure coating layer and fabrication method thereof

ActiveCN109082641AReduce stressPrevents Diffusion Adhesive WearVacuum evaporation coatingSputtering coatingRadio frequency magnetron sputteringSuperalloy

The invention belongs to the technical field of fabrication of a metal coating layer, and discloses a three-layer film structure coating layer and a fabrication method thereof. The three-layer film structure coating layer comprises a dual-phase Cr+Alpha-(Al, Cr)2O3 matrix pasting layer, a single phase Alpha-(Al, Cr)2O3 support layer and a single-phase nanometer Alpha-Al2O3 surface layer. The fabrication method comprises the steps of sequentially depositing the Cr+Alpha-(Al, Cr)2O3 matrix pasting layer and the Alpha-(Al, Cr)2O3 support layer by DC magnetron sputtering and by a CrAl alloy target; and obtaining the single-phase nanometer Alpha-Al2O3 surface layer by radio-frequency magnetron sputtering by an Al+Alpha-Al2O3 compost target. The surface working layer of the obtained coating layer is of a single-phase nanometer Alpha-Al2O3 structure, the coating layer is high in hardness, good in toughness, high in high-temperature thermal stability, low in friction coefficient during friction with a metal matrix and is firmly combined with a matrix such as high-speed steel, a hot work die steel and high-temperature alloy.

Owner:SOUTH CHINA UNIV OF TECH

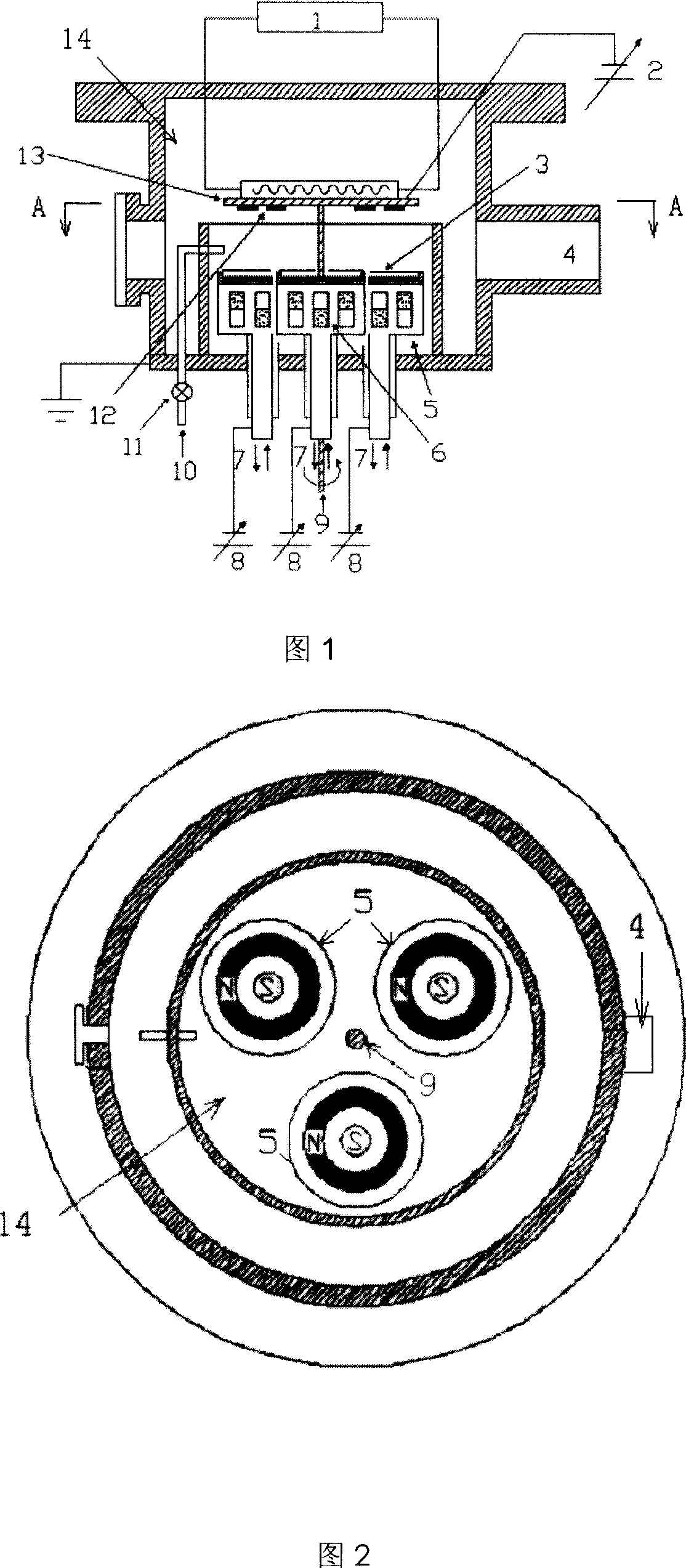

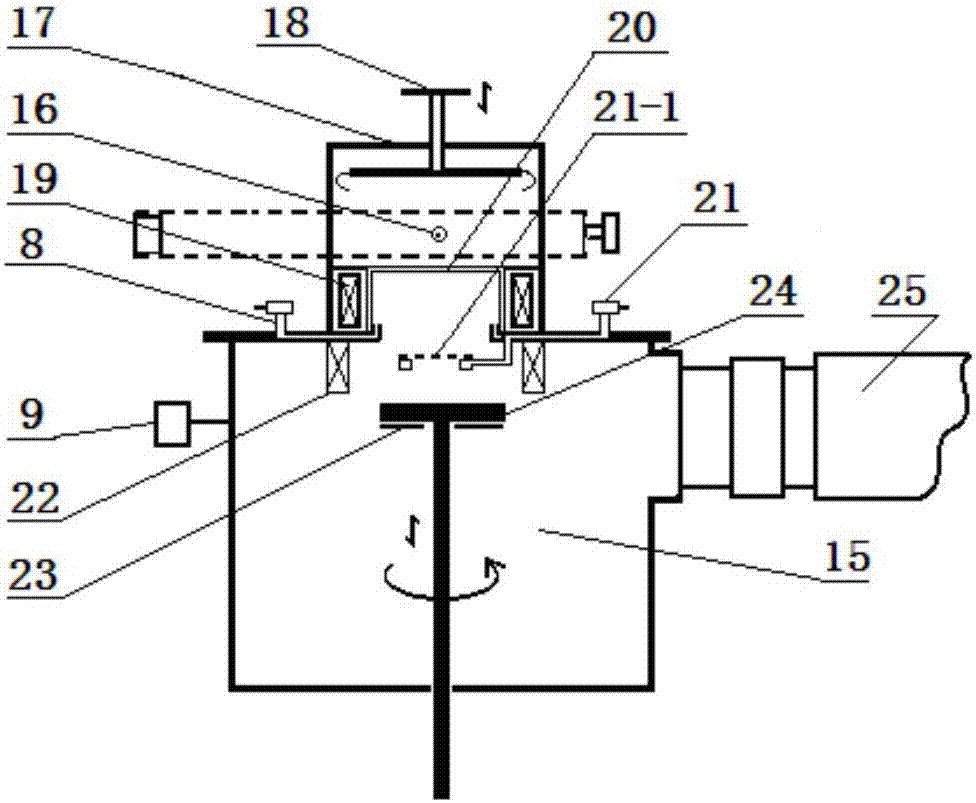

Method and device for preparing rare earth doped gallium nitride light-emitting film

InactiveCN1962932ALow deposition temperatureLarge film forming areaVacuum evaporation coatingSputtering coatingNitrogen gasMetal

The invention discloses a preparing method of gallium nitride luminous film doped by rare earth, which is characterized by the following: controlling the substrate temperature within 0-500 Deg C; adopting nitrogen or composite gas of nitrogen and argon as splashing gas; proceeding magnetic control splashing for metal gallium of doped rare earth powder in the vacuum; sedimenting rare earth doped gallium nitride luminous film on the substrate of target position. The invention also provides magnetic control splashing device to prepare the product, which contains vacuum chamber; the rotary substrate rack with substrate and 3-5 magnetic targets are set in the vacuum chamber; the magnetic control target is set on the substrate, which makes substrate bottom parallel the magnetic control target; each magnetic control target connects DC anode directly; the cooling chamber is set in the magnetic control target, which possesses cooling dielectric inlet an outlet.

Owner:WUHAN UNIV

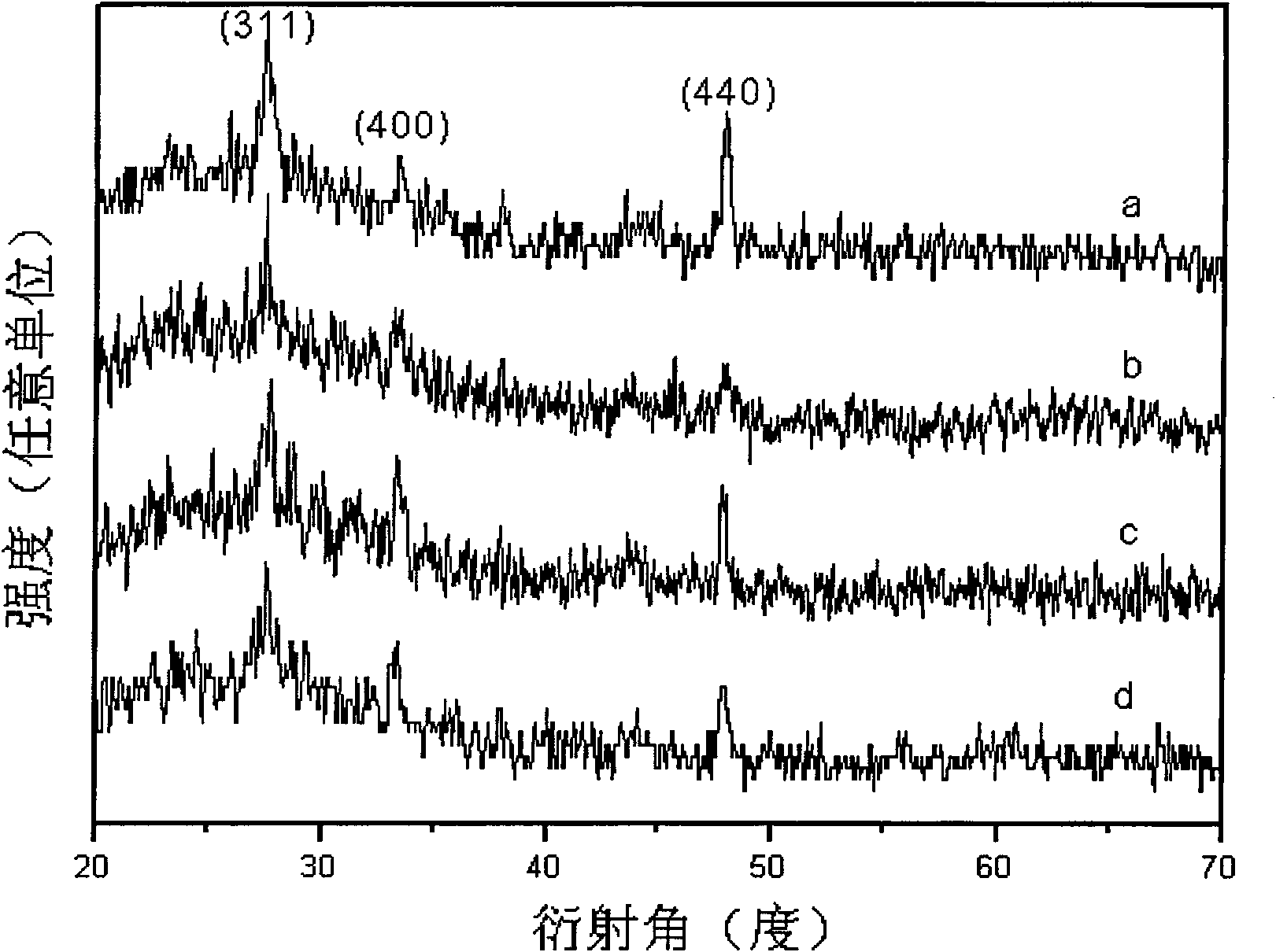

Method for depositing indium sulfide thin film by chemical bath

InactiveCN101608304AHigh crystallinityAvoid adsorptionGallium/indium/thallium compoundsLiquid/solution decomposition chemical coatingWater bathsIndium

The invention relates to a method for depositing an indium sulfide thin film by a chemical bath, which belongs to the technical field of preparation of functional thin film materials. The prior method for preparing indium sulfide has higher requirements on deposition conditions, needs high-temperature heating and has great limitations in substrate deposition. The method for preparing the indium sulfide adopts citric acid or malonic acid as a complexing agent, and the uniform, dense and high crystalline indium sulfide thin film with a cubic structure can be obtained on modified ordinary glass under a water bath environment which is lower than 100 DEG C. The method has no selectivity to a substrate, is synthesized in low temperature solution and has the advantages of good crystallinity, simple process and low cost, thereby being applicable to large-scale production application.

Owner:BEIJING UNIV OF TECH

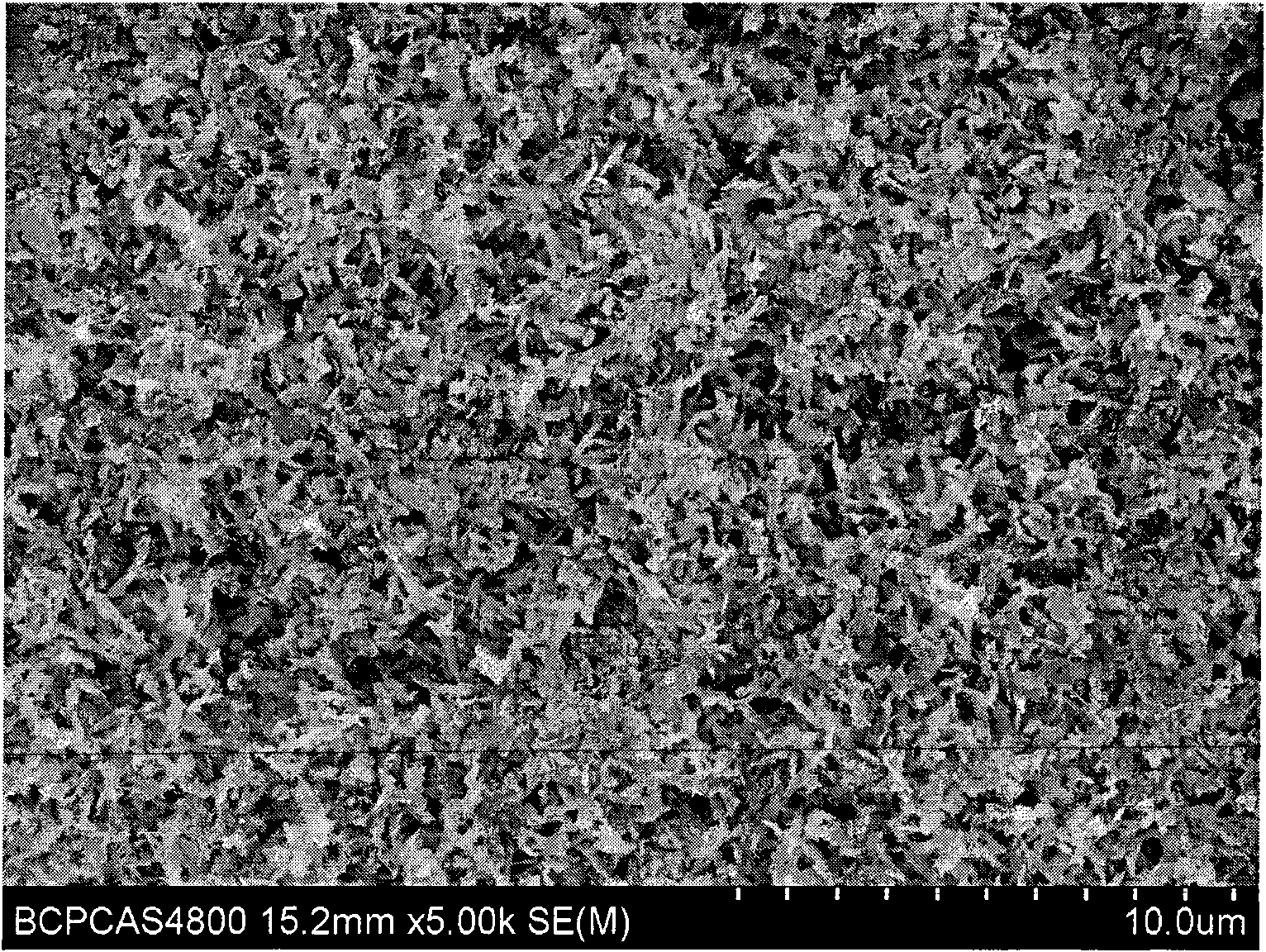

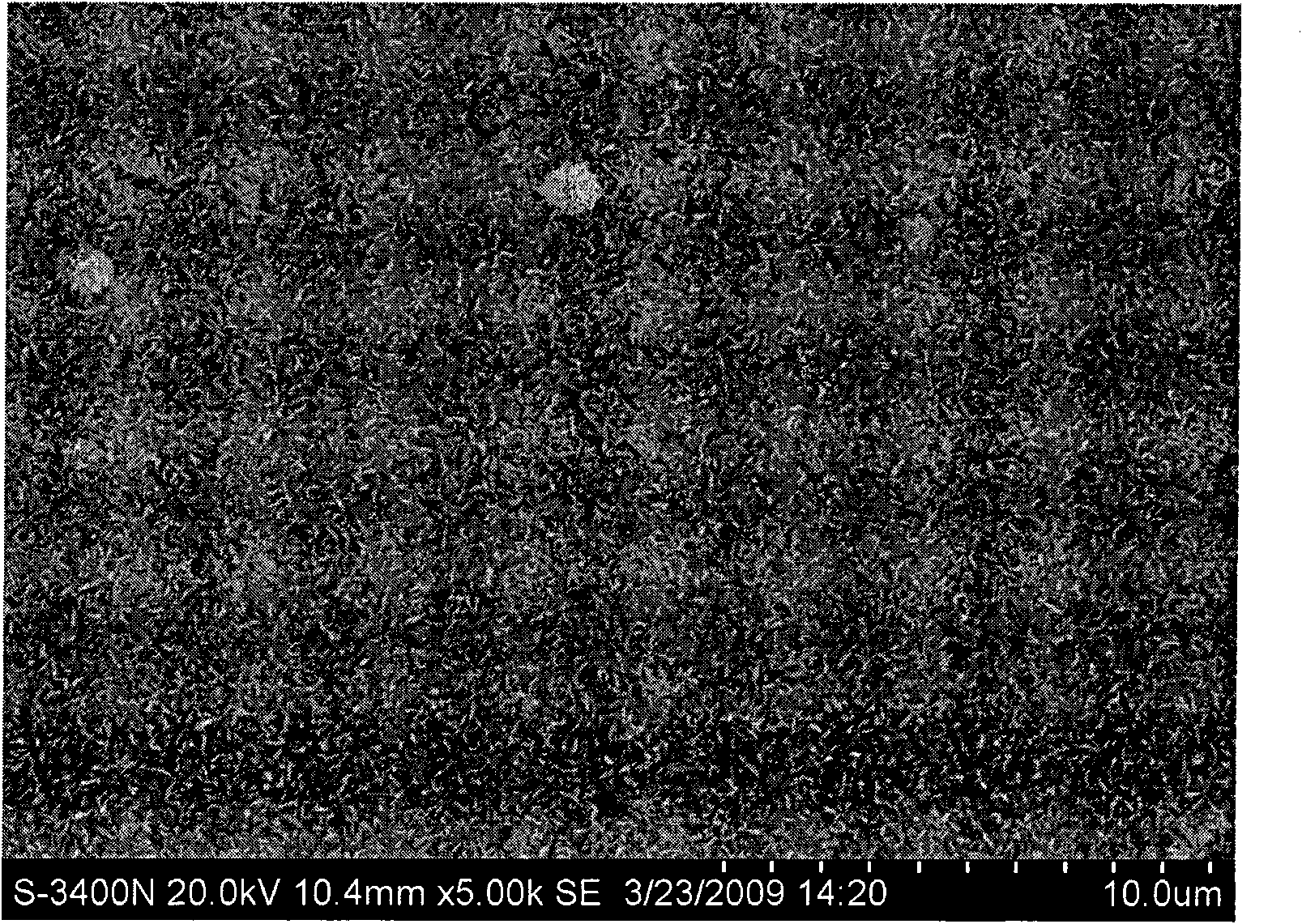

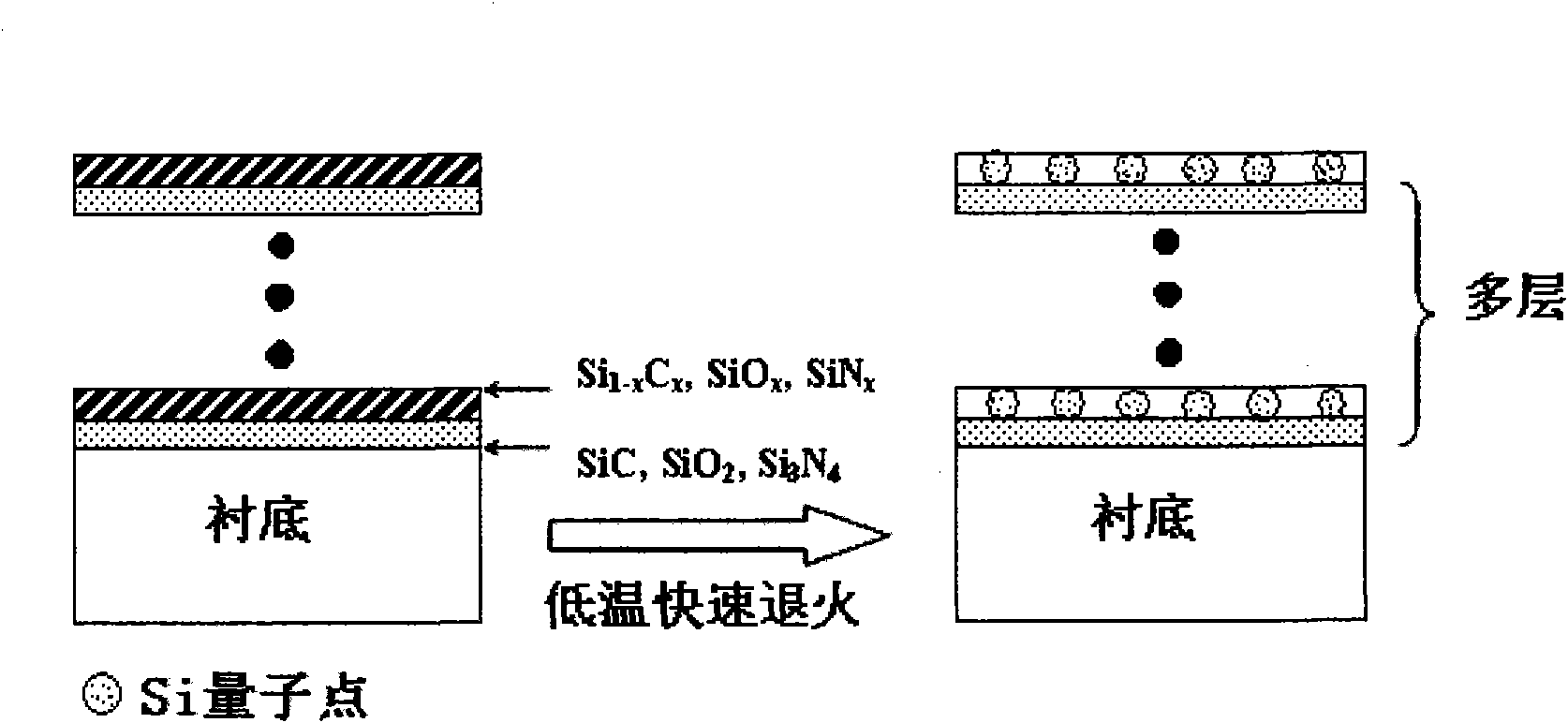

Low-temperature growth method of silicon quantum dots for solar battery

InactiveCN101626048AIncrease flexibilityImprove uniformityFinal product manufactureSemiconductor devicesGas phaseSolar battery

The invention relates to a low-temperature growth method of silicon quantum dots for a solar battery, which belongs to the technical field of silicon quantum dot material. The method comprises the following steps: alternately growing a silicon compound dielectric layer of the stoichiometric proportion and a silicon compound layer containing Si which is several nanometers thick in stoichiometric ratio on a silicon wafer or a quartz sheet or a glass sheet or a stainless steel sheet or high-temperature resistant polymer substrate material at the temperature lower than 450 DEG C by using the plasma chemical vapour deposition (PCVD) technology; carrying out post annealing treatment at the temperature lower than or equal to 550 DEG C by using the rapid photo-thermal annealing technology, so that the residual Si in the silicon compound layer containing Si generates diffusion transfer and solid phase crystallization to form the Si quantum dots, wherein the formed Si quantum dots are arranged in a layered mode, the size of each Si quantum dot is controlled by the thickness of the originally-grown silicon compound layer containing Si, and the density of each Si quantum dot is determined by the content of Si in the original SiN<x> layer containing Si. The invention has the advantages of low depositing temperature, quick speed and good technology controllability and repeatability, thus the uniformity of the grown silicon quantum dot material is good; and the invention is favorable for integrated manufacture and cost reduction of devices.

Owner:YUNNAN NORMAL UNIV

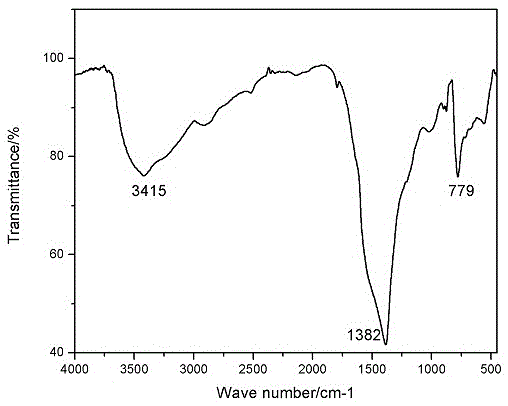

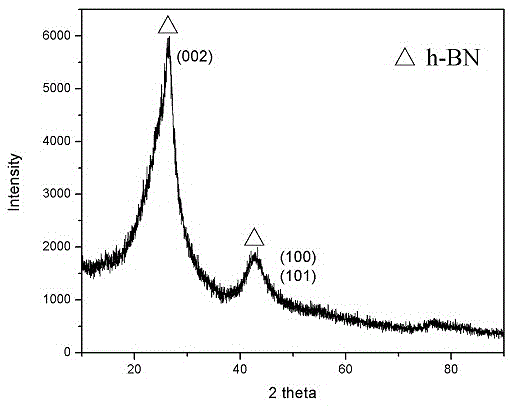

Low-temperature low-pressure preparation method of boron nitride coating

InactiveCN105669253AStrong penetration abilityUniform and controllable thicknessChemical vapor deposition coatingBoron nitrideBoron trichloride

The invention discloses a low-temperature low-pressure preparation method of a boron nitride coating. The method of the invention is used for solving the problem that required preparation temperature is high by a chemical vapor deposition method in the prior art. Boron trichloride (BCl3) and ammonia gas (NH3), which are used as main raw materials, undergo chemical vapor deposition under the condition of low temperature; a sample obtained undergoes high-temperature heat treatment; and through Fourier transformed infrared and X-ray diffraction detection, a boron nitride coating which has stronger infiltration capacity, uniformly and controllable thickness and high degree of crystallization is prepared. The method can be used for preparation of a composite material boron nitride interface and for preparation of a sample surface coating. By the method, deposition temperature of boron nitride chemical vapor deposition is reduced from 1300-1800 DEG C to 300-800 DEG C. The method mainly comprises low-temperature chemical vapor deposition and high-temperature heat treatment.

Owner:SHANGHAI UNIV +1

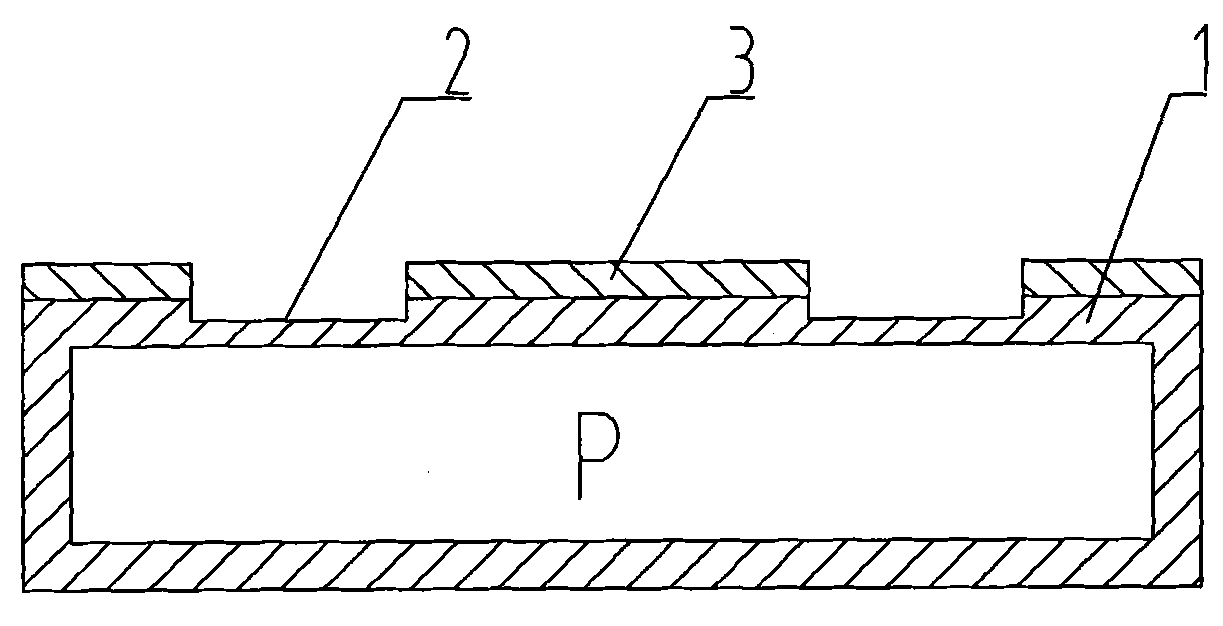

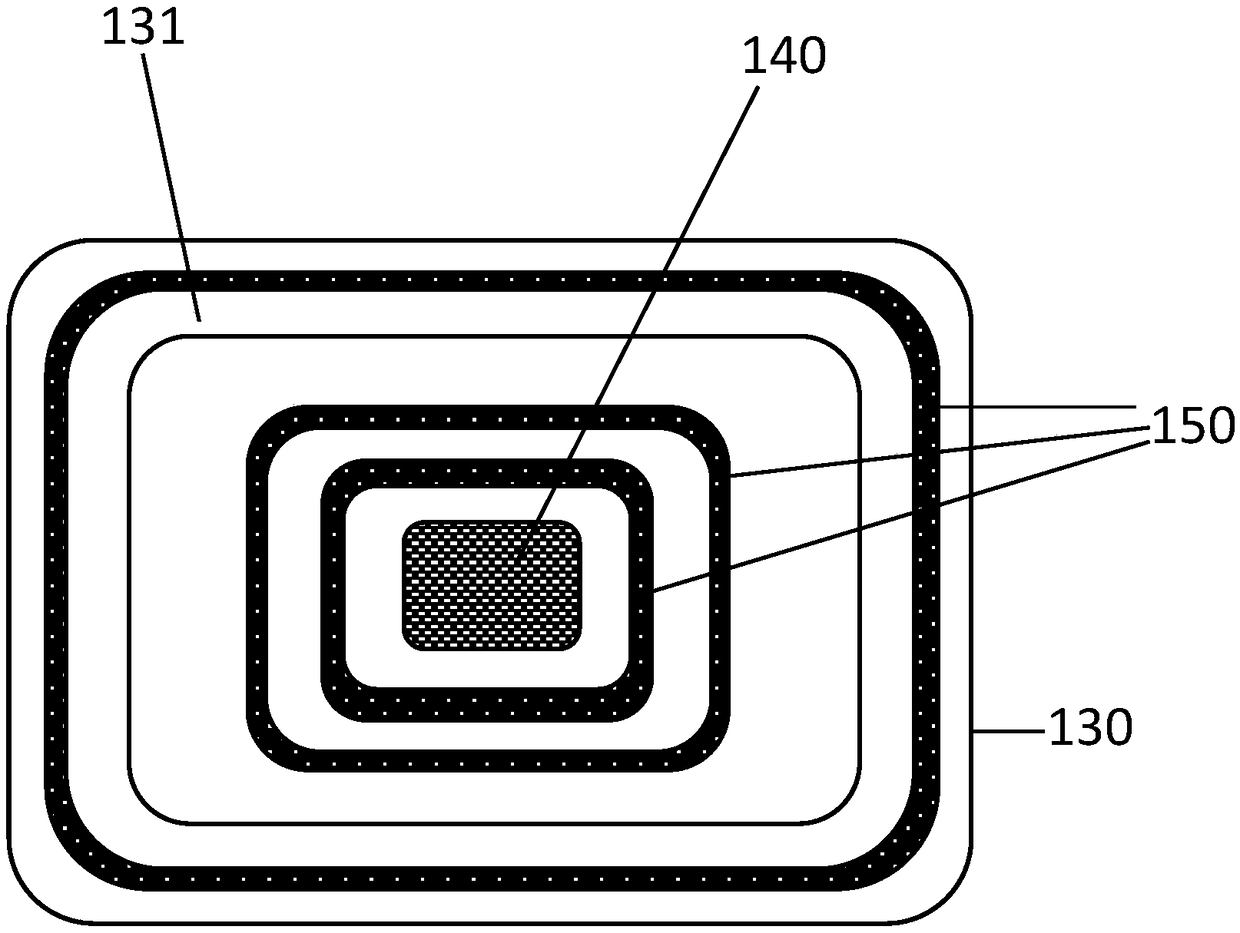

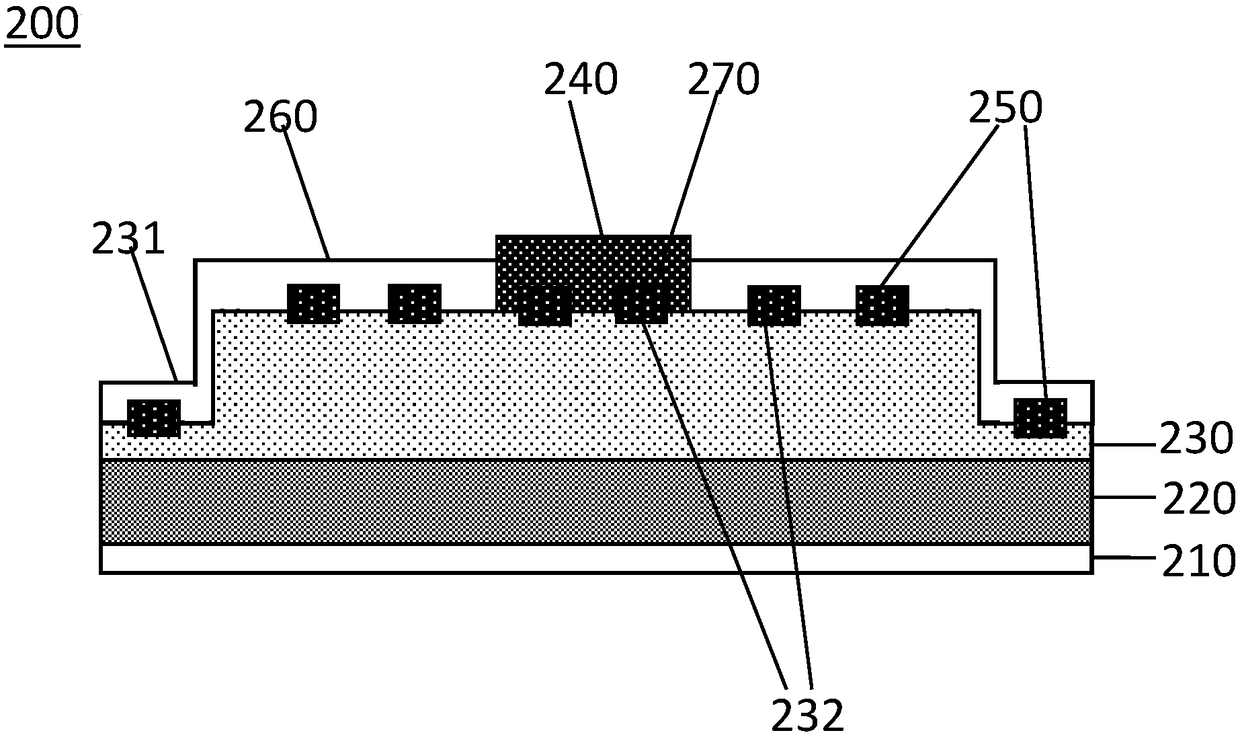

Silicon carbide power device having step structure and fabrication method of silicon carbide power device

ActiveCN108281491AImprove breakdown voltageImprove edge electric field concentration phenomenonSemiconductor/solid-state device manufacturingSemiconductor devicesHeterojunctionClosed loop

The invention discloses a silicon carbide power device having a step structure and a fabrication method of the silicon carbide power device. The silicon carbide power device comprises an ohmic contactelectrode, an N<+>SiC substrate layer, an N<->SiC epitaxial layer and a Schottky contact electrode from bottom to top and also comprises a plurality of P-type junction terminals, wherein the Schottkycontact electrode is arranged in the center of the N<->SiC epitaxial layer, the P-type junction terminals are of closed-loop structures and are sequentially arranged around the Schottky contact electrode in an encircling way, an edge of an upper surface of the N<->SiC epitaxial layer is lower than an annular step formed in the center, the P-type junction terminals are arranged on a high step surface and a lower step surface of the annular step of the N<->SiC epitaxial layer, and the P-type junction terminals and the N<->SiC epitaxial layer form a PN heterojunction. By the silicon carbide power device, the concentration phenomenon of an edge electric field of a SiC power device junction can be improved, and the SiC power device with a high breakdown voltage is obtained.

Owner:HUNAN SANAN SEMICON CO LTD

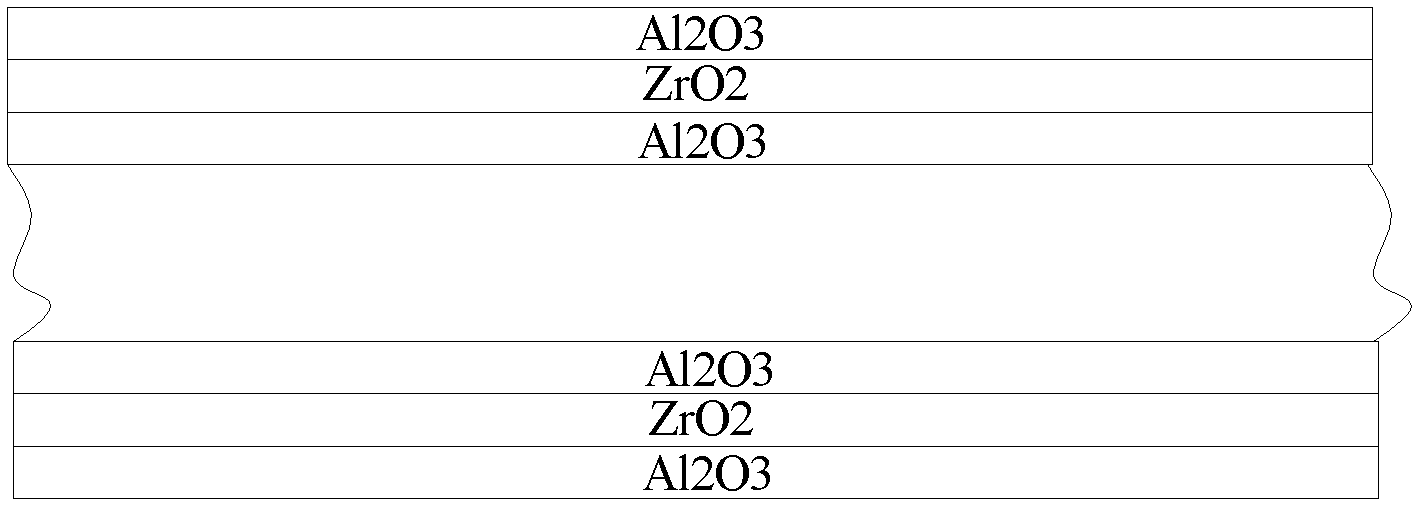

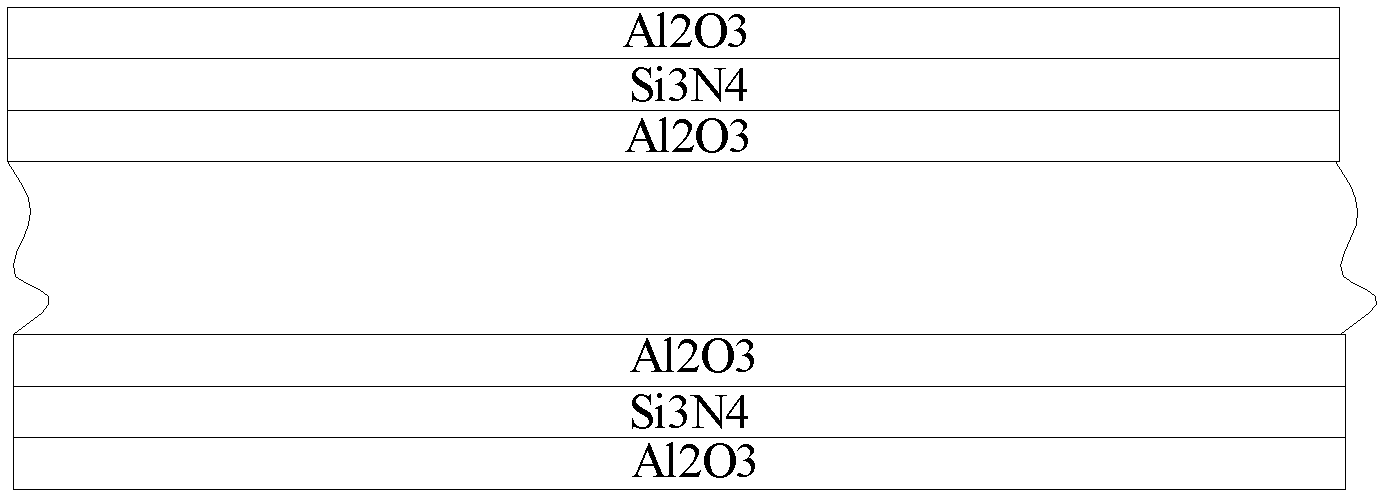

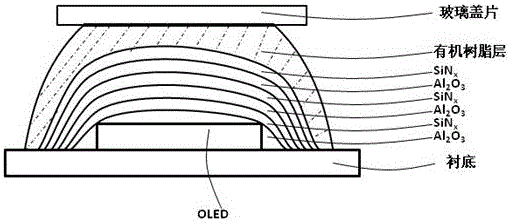

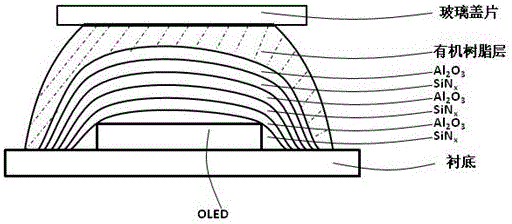

Organic light-emitting device (OLED) packaging structure and method

InactiveCN105679964AImprove compactnessMake up for the shortcomings of not being able to cover dust particles wellSolid-state devicesSemiconductor/solid-state device manufacturingGlass coverThin membrane

The invention discloses an organic light-emitting device (OLED) packaging structure and a method. The packaging structure is characterized by comprising a substrate, the OLED, a thin film packaging layer, an organic resin layer and a glass cover sheet, wherein Al2O3 thin films and SiNx thin films are sequentially overlapped to form the thin film packaging layer. In the packaging method, the Al2O3 thin film is prepared by using an atomic layer deposition technology, the SiNx thin film is prepared by using a plasma chemical vapor deposition or sputtering technology, and thus, the thin film packaging layer has high compactness, water vapor can be prevented from corroding the OLED, and the thin film packaging layer making efficiency is also improved. As the organic resin layer and the glass cover sheet are arranged on the thin film packaging layer, by using the full covering effects of the organic resin layer and the protection effects of the glass cover sheet, the service life of the device is further improved.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

Preparation method for organic silicon nanometer hard protective coating

ActiveCN107523809AAvoid wasting waterAvoid wastingChemical vapor deposition coatingGas phaseWater vapor

The invention discloses a preparation method for an organic silicon nanometer hard protective coating, and belongs to the technical field of plasmas. In the method, a reaction chamber is vacuumized, an inert gas is charged to enable a base material to move, monomer steam is charged, chemical vapor deposition is carried out, and an organic silicon nanometer coating is prepared on the surface of the base material through the chemical vapor deposition; and the component of the monomer steam is the mixture of at least one organic silicon monomer containing double bonds and a Si-Cl structure or a Si-O-C structure or a Si-N-Si structure or a Si-O-Si structure or a cyclic structure, and at least one polyfunctional unsaturated hydrocarbon and hydrocarbon derivative, charging for the monomer steam is stopped, oxygen and / or vapor is charged, and hard treatment is carried out on the surface of the organic silicon nanometer coating. According to the preparation method disclosed by the invention, the traditional organic carbonate hydroxide compound monomer is replaced by the organic silicon monomer, each silicon atom at least provides 1-4 active sites, high activity is achieved, a part of oxygen is introduced into the monomer, organic silicon can be oxidized into nanometer silicon dioxide, and the hardness of the coating can be greatly increased due to a dispersion strengthening effect.

Owner:JIANGSU FAVORED NANOTECHNOLOGY CO LTD

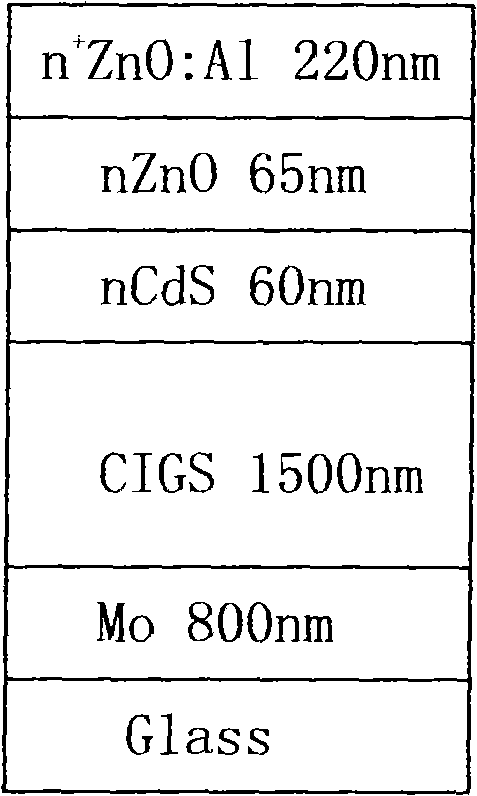

Method for preparing efficient thin-film solar cell light absorption layer

InactiveCN101527332ASimple preparation processImprove efficiencyFinal product manufactureSemiconductor devicesVulcanizationNew energy

The invention relates to the technical field of photovoltaic new energy in semiconductive thin film preparation, in particular to a method for preparing an efficient thin-film solar cell light absorption layer. The method comprises the following steps: Cu2S and S are added to hydrazine solution and evenly mixed to obtain solution A; In2Se3 and Se or In2Se3 and the S are added to the hydrazine solution to obtain solution B; the Se and the S are added to the hydrazine solution to obtain solution C; Ga and the Se or Ga and the S are added to the hydrazine solution to obtain solution D; the prepared solution A, solution B, solution C and solution D or the solution A, the solution B and the solution C are mixed to prepare reactive precursor solution; and then the precursor solution is coated on a conducting substrate by a physical method to prepare a CIGS thin film. Compared with the prior art, the method has simple process; can help accurately adjust and control the proportions of various metal atoms in the absorption layer, ensure 14-18% of higher photoelectric conversion efficiency and avoid selenylation or vulcanization post-processing process.

Owner:上海纳晶科技有限公司

Preparation method of oxide ceramic coating layer on surface of silicon carbide fiber

InactiveCN104213099AGood lookingUniform and dense coatingChemical vapor deposition coatingOxide ceramicCarbide silicon

The invention discloses a preparation method of an oxide ceramic coating layer on a surface of a silicon carbide fiber. The preparation method comprises the following steps: (1) the silicon carbide fiber is removed glue for cleaning; (2) the silicon carbide fiber is put in an ALD reaction chamber to repeatedly vacuumize and replace nitrogen for three times; (3) a reaction precursor is selected according to the type of a deposited oxide coating layer; and the parameters of a deposition process are set; (4) precursor steam is guided in the ALD reaction chamber under the carrying of nitrogen or argon; (5) the reaction chamber is blown by the nitrogen or argon; (6) oxygen source steam is guided in the ALD reaction chamber under the carrying of the nitrogen or argon; (7) the reaction chamber is blown by the nitrogen or argon; (8) the steps (4)-(7) are repeated until the needed thickness of the coating layer is deposited; and (9) the coating layer is put in a high-temperature tube furnace, and is thermally treated under the nitrogen protection. The preparation method can be used for preparing the uniform and compact oxide ceramic coating layer with few impurities and precisely controlled thickness on the surface of the SiC fiber.

Owner:NAT UNIV OF DEFENSE TECH

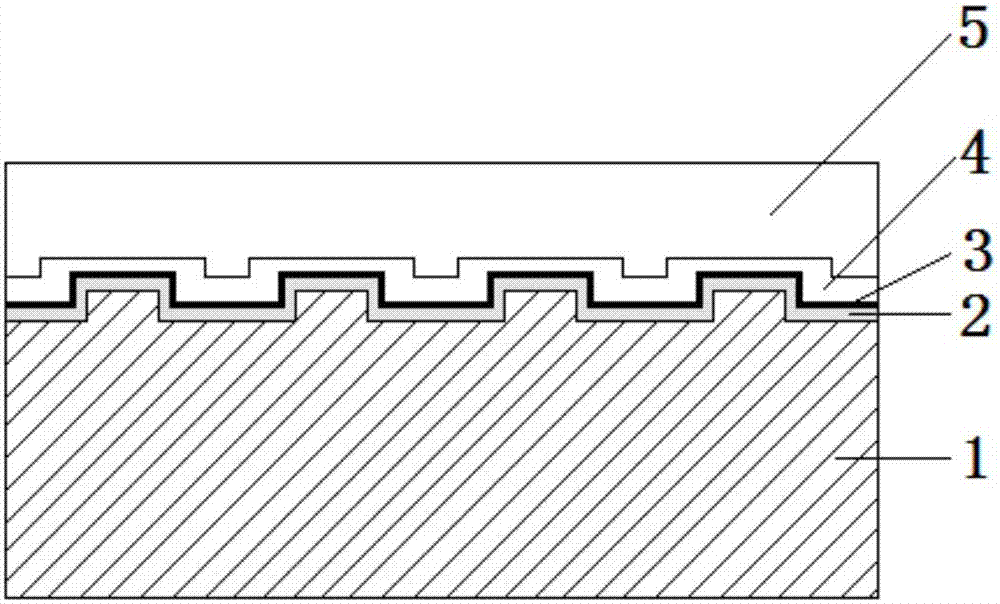

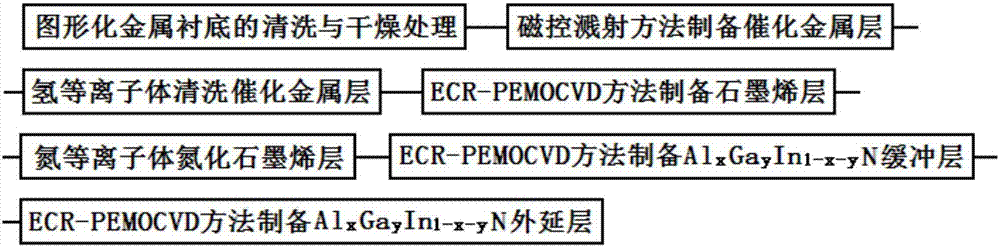

Gallium-nitride-based film on graphene-modified patterned metal substrate and preparation method

InactiveCN107083535AUniform large areaThickness is easy to controlVacuum evaporation coatingSputtering coatingDislocationCvd graphene

The invention belongs to the technical field of manufacturing of gallium-nitride-based films and gallium-nitride-based devices and provides a gallium-nitride-based film on a graphene-modified patterned metal substrate and a preparation method of the gallium-nitride-based film on the graphene-modified patterned metal substrate. Patterned metal is used as the substrate; a catalytic metal layer is prepared on the metal substrate through a magnetron sputtering method firstly; and then, an electron cyclotron resonance-plasma enhanced metal organic chemical vapor deposition method is adopted to sequentially conduct nitrogen plasma cleaning on the catalytic metal layer, prepare a graphene layer, prepare an AlxGayIn1-x-yN buffering layer and prepare AlxGayIn1-x-yN epitaxial layer. The gallium-nitride-based film which is low in dislocation density and high in crystalline quality can be prepared on a low-cost non-monocrystal metal substrate. The prepared gallium-nitride-based film can be directly used as a template substrate and the like of the gallium-nitride-based devices and has a broad application prospect.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com