Preparation method for organic silicon nanometer hard protective coating

A protective coating and nano-coating technology, which is applied in coatings, metal material coating processes, gaseous chemical plating, etc., can solve problems such as poor controllability of coating thickness, adverse effects of electronic products, and difficulty in controlling nano-levels , to achieve the effect of improving protection performance, improving compactness and speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

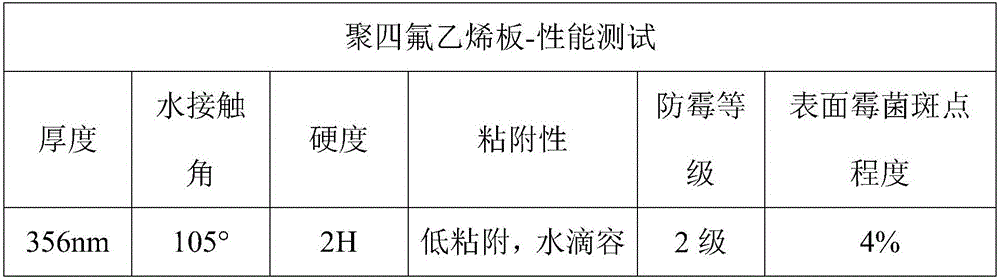

Embodiment 1

[0091] A preparation method of organosilicon hard nano protective coating, comprising the following steps:

[0092] (1) Pre-processing:

[0093] Place the substrate in the reaction chamber of the nano-coating preparation equipment, close the reaction chamber and continuously evacuate the reaction chamber, pump the vacuum in the reaction chamber to 10 mTorr, pass in the inert gas Ar, and open the movement mechanism , causing the substrate to move in the reaction chamber;

[0094] In step (1), the base material is a solid material, and the solid material is a block-shaped polytetrafluoroethylene plate.

[0095] In the step (1), the reaction chamber is a rotating chamber, the volume of the reaction chamber is 50 L, the temperature of the reaction chamber is controlled at 30° C., and the flow rate of the inert gas is 5 sccm.

[0096] In step (1), the substrate moves in the reaction chamber, and the substrate moves in a circular motion relative to the reaction chamber at a speed ...

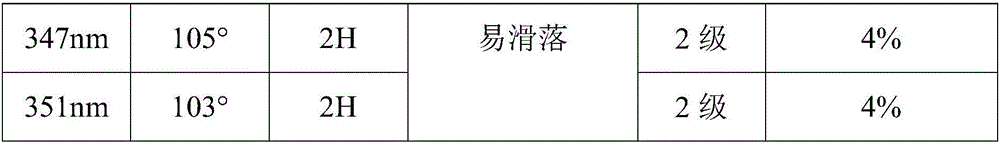

Embodiment 2

[0116] A preparation method of organosilicon hard nano protective coating, comprising the following steps:

[0117] (1) Pre-processing:

[0118] Place the substrate in the reaction chamber of the nano-coating preparation equipment, close the reaction chamber and continuously evacuate the reaction chamber, evacuate the vacuum in the reaction chamber to 60 millitorr, feed inert gas He, start the movement mechanism, move the substrate;

[0119] In step (1), the base material is a solid material, and the solid material is a block aluminum alloy material.

[0120] In step (1), the reaction chamber is a cubic chamber with a volume of 250 L, the temperature of the reaction chamber is controlled at 43° C., and the flow rate of the inert gas is 18 sccm.

[0121] In step (1), the base material performs planetary motion, with a revolution speed of 2 revolutions / min and an autorotation speed of 6 revolutions / min.

[0122] (2) Silicone coating preparation:

[0123] Introduce monomer va...

Embodiment 3

[0141] A preparation method of organosilicon hard nano protective coating, comprising the following steps:

[0142] (1) Pre-processing:

[0143] Place the substrate in the reaction chamber of the nano-coating preparation equipment, close the reaction chamber and continuously evacuate the reaction chamber, pump the vacuum in the reaction chamber to 130 mTorr, and introduce a mixture of inert gases Ar and He The gas activates the movement mechanism to make the substrate move;

[0144] In step (1), the base material is a solid material, and the solid material is a bulk alloy steel plate material.

[0145] In the step (1), the reaction chamber is a rotating chamber, the volume of the reaction chamber is 480L, the temperature of the reaction chamber is controlled at 50° C., and the flow rate of the inert gas is 80 sccm.

[0146] In step (1), the base material performs circular motion at a speed of 8 revolutions / min.

[0147] (2) Silicone coating preparation:

[0148] Introduce ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com