Horizontal hot-air-melting waste plastic recycling and granulating machine

A technology of waste plastics and granulator, which is applied in the field of granulator, can solve the problems of low production efficiency, large crushing noise, secondary pollution, etc., and achieve the effects of reducing energy consumption, avoiding noise, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

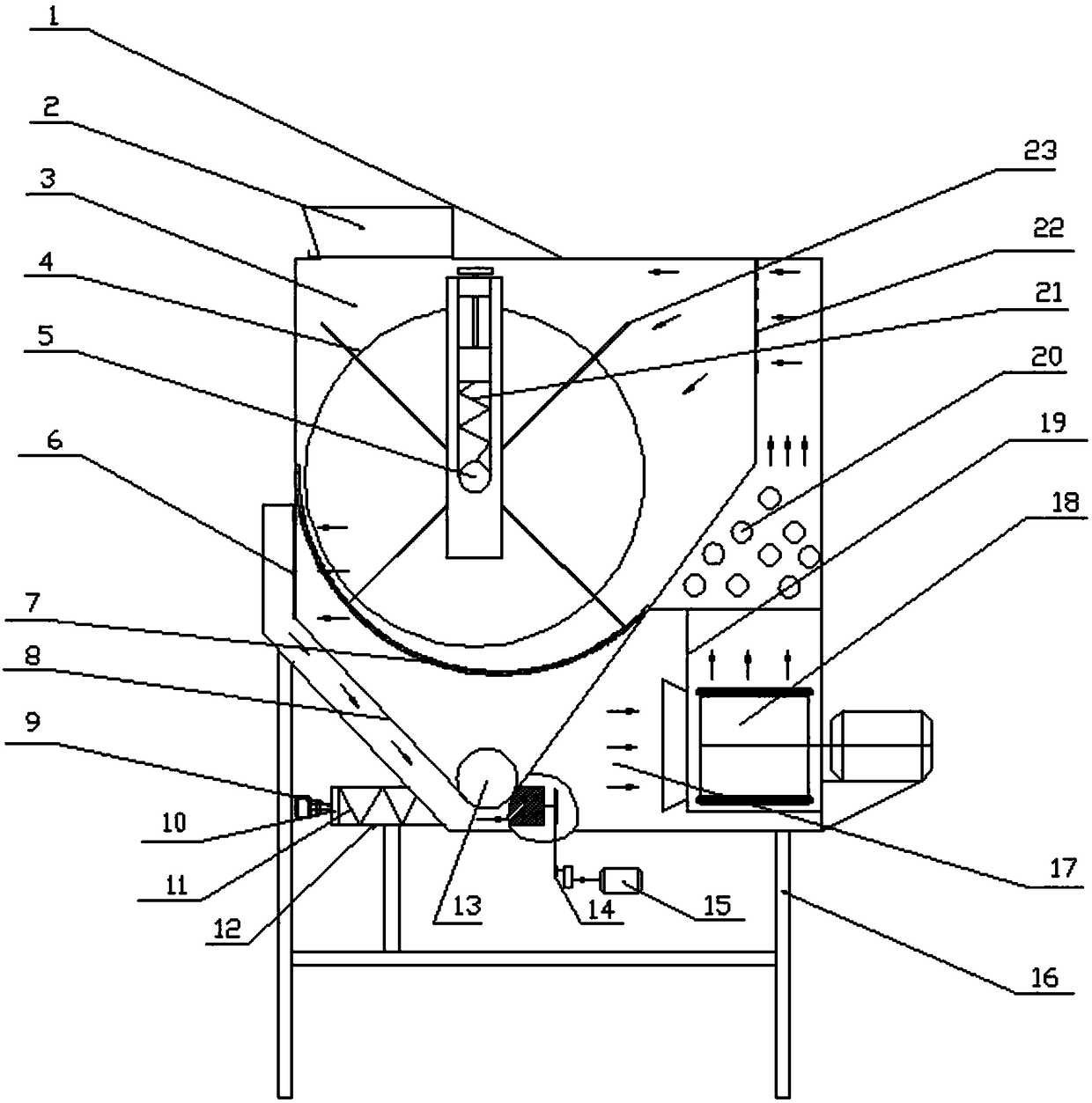

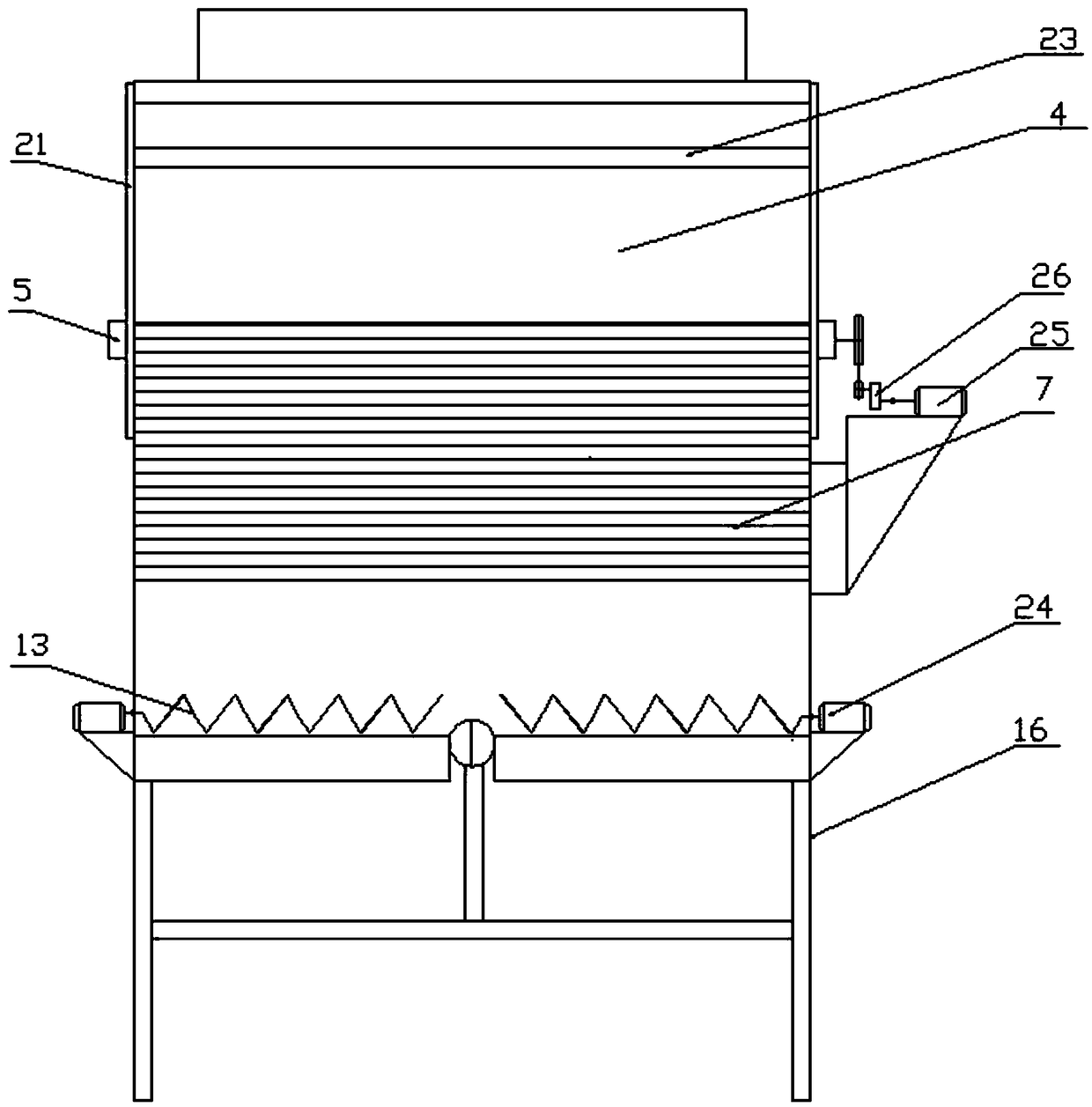

[0016] Embodiment 1, see figure 1 and figure 2 , a horizontal hot air melting waste plastic recycling granulator, including a box cover 1, a hopper 2, a melting chamber 3, a drum 4, a drum shaft 5, an exhaust gas circulation outlet 6, a curved screen 7, a V-shaped hopper 8, Pelletizing mechanism 9, die 10, extruding screw 11, machine barrel 12, conveyor belt 13, screw transmission mechanism 14, screw driving device 15, frame 16, hot air circulation box 17, fan 18, partition 19, Heating pipe 20, spring device 21, hot air circulation inlet 22, stirring blade 23, reduction motor 24, stirring drive device 25 and stirring transmission mechanism 26, wherein: a box cover 1 is provided above the melting chamber 3, and one side of the box cover 1 A hopper 2 is fixedly welded on the top, a V-shaped hopper 8 is fixedly welded on the lower end of the melting chamber 3, and the V-shaped hopper 8 is fixedly installed on the frame 16. Hot air circulation is provided on the outside of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com