Patents

Literature

641results about "Cerium oxides/hydroxides" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flame made metal oxides

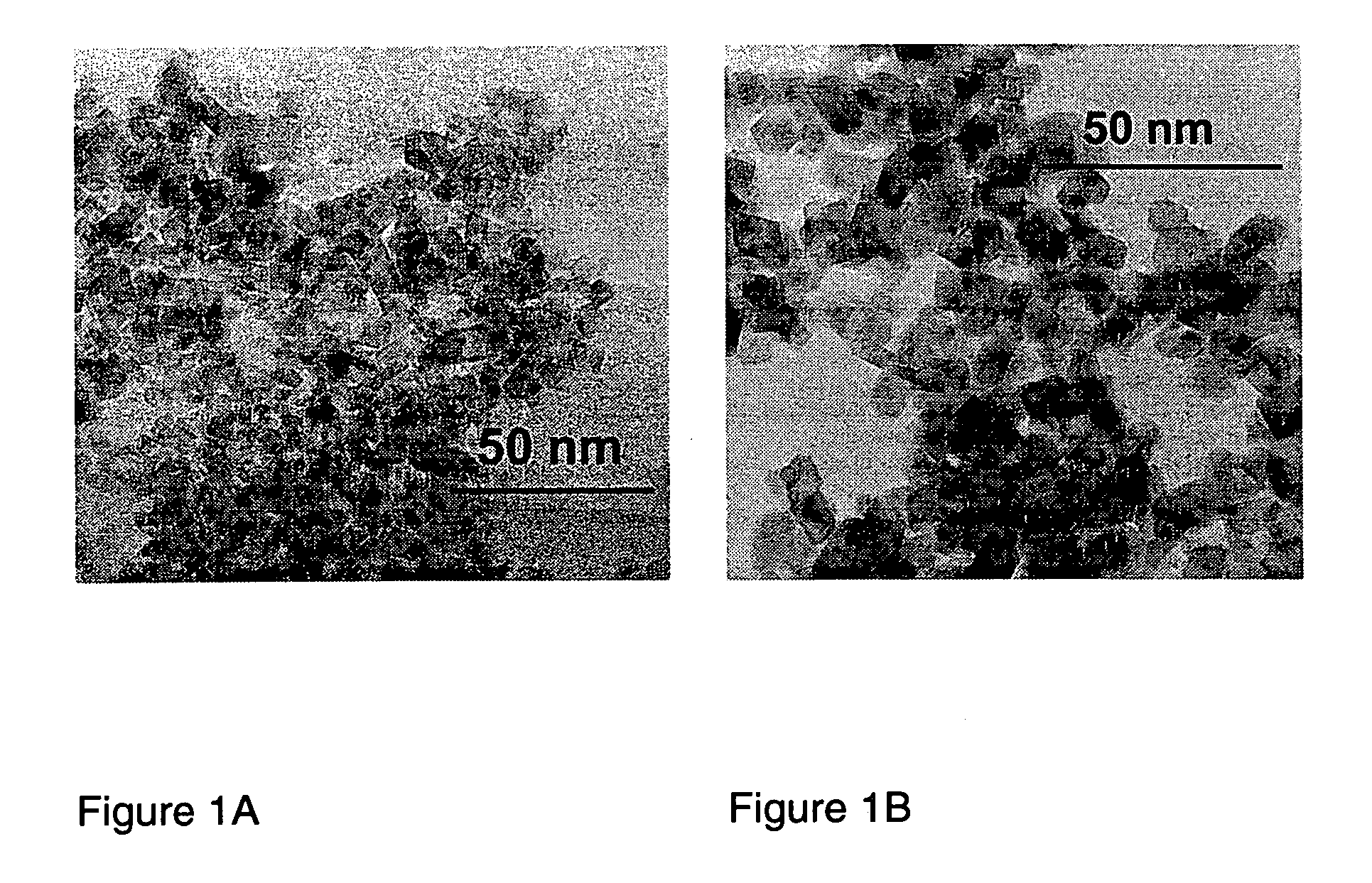

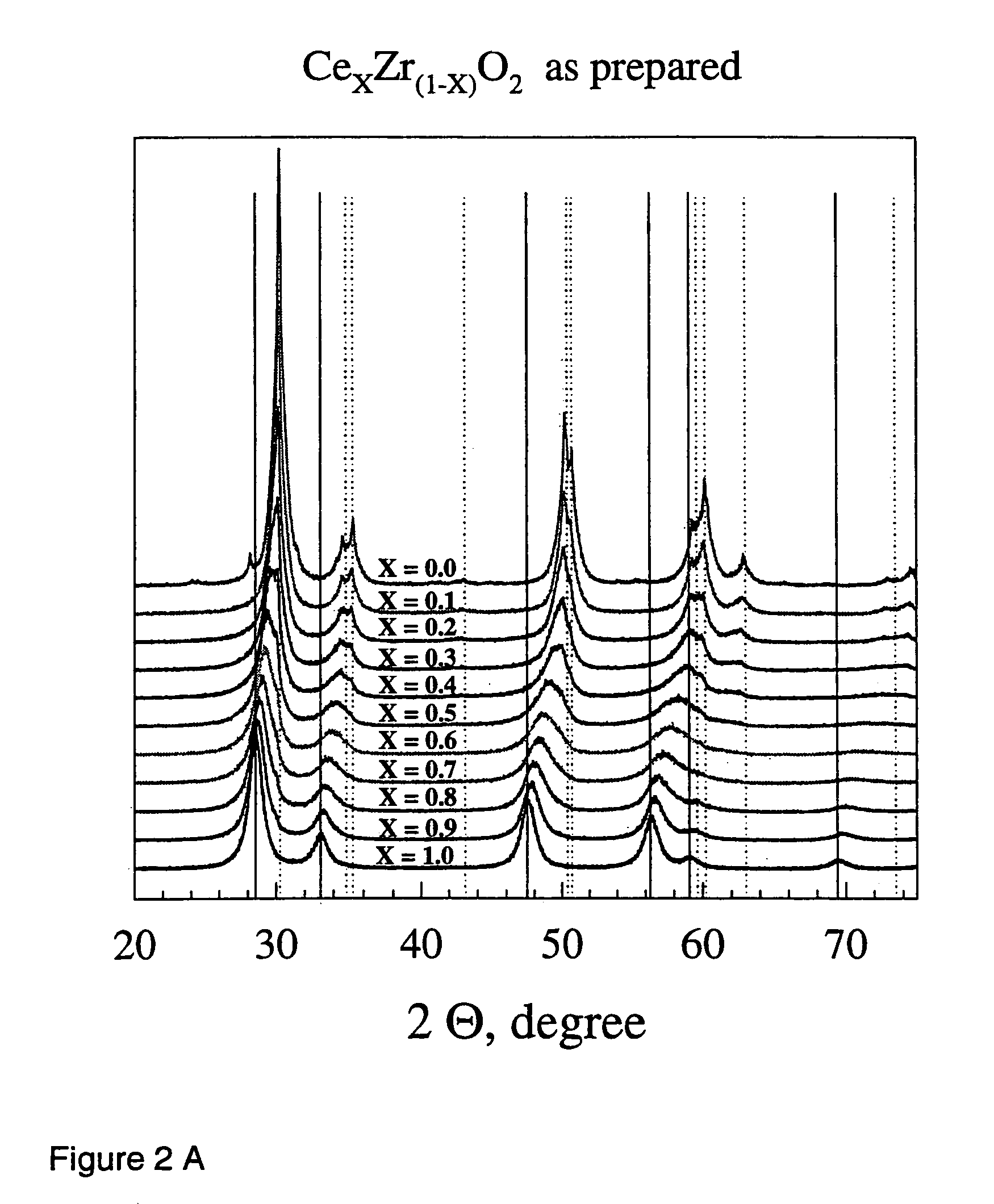

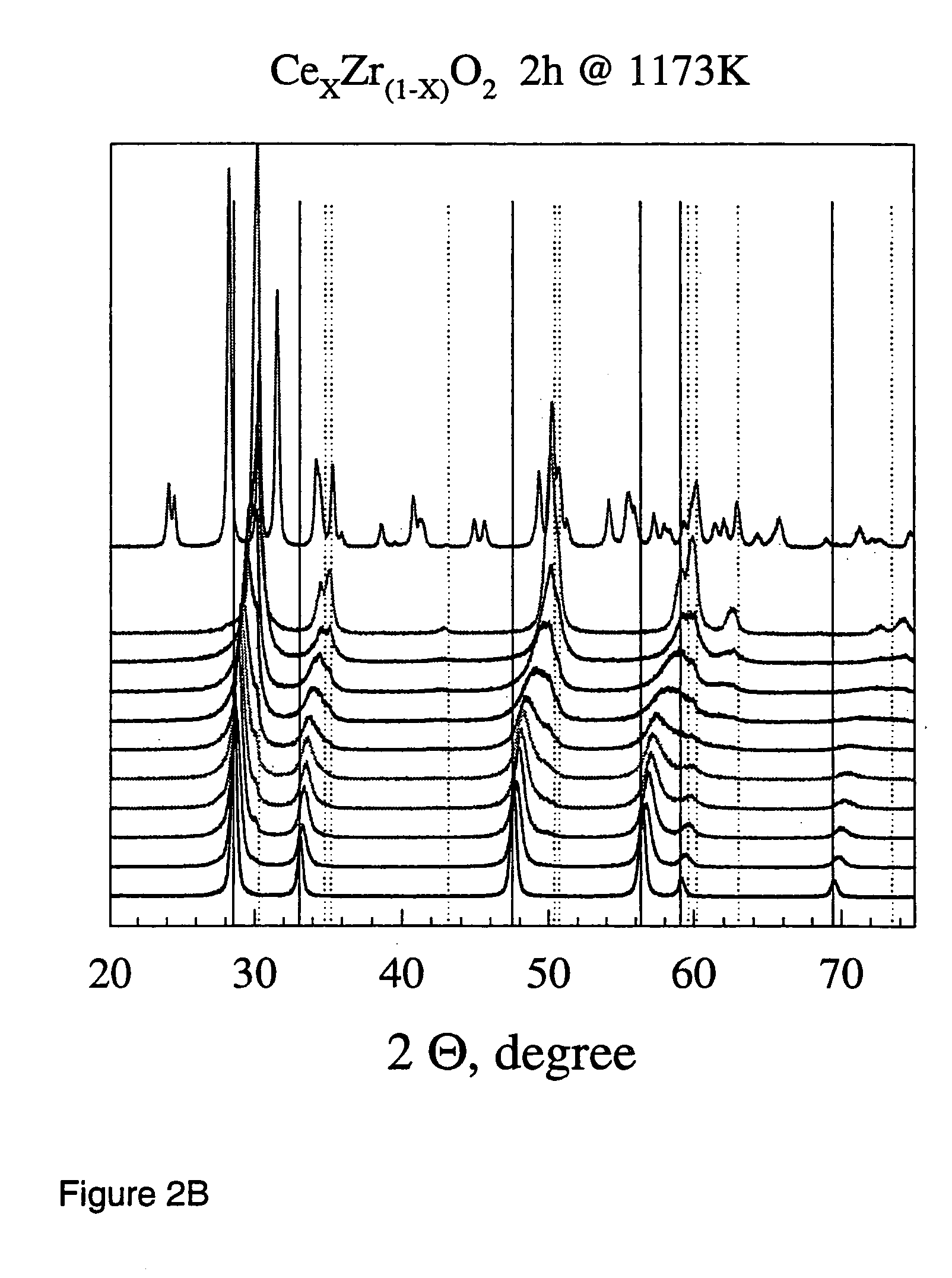

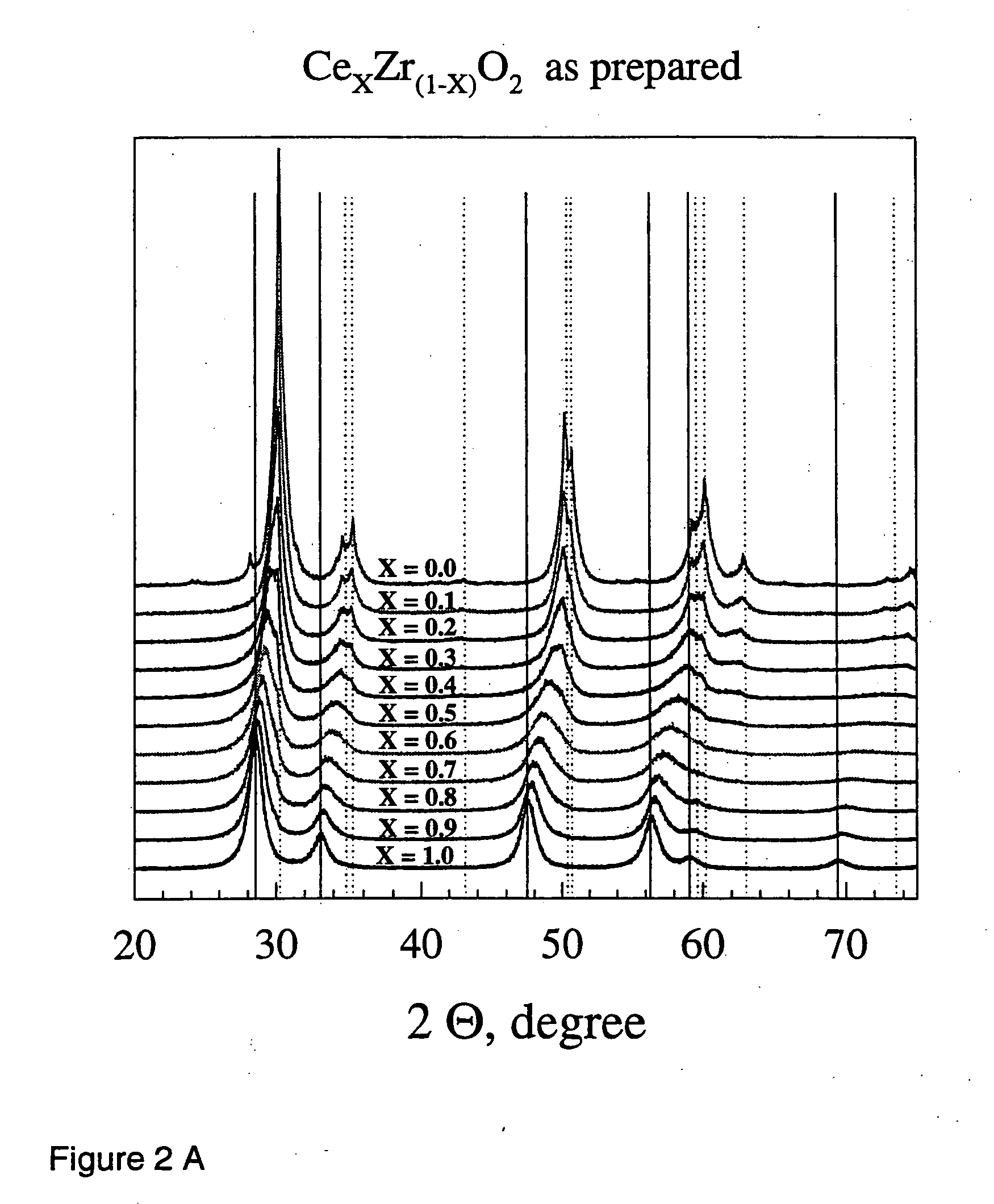

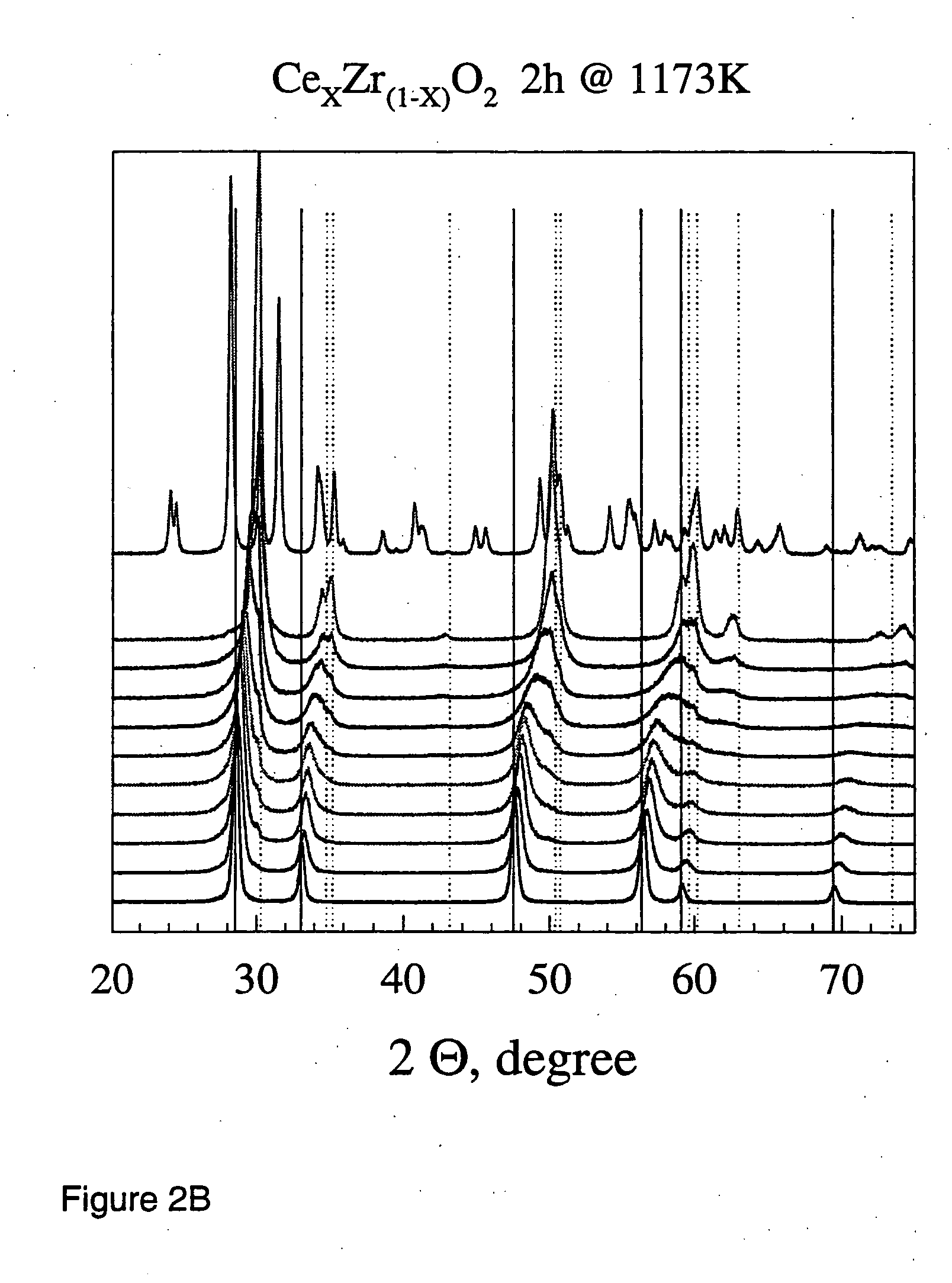

ActiveUS7211236B2Add featureWell mixedMaterial nanotechnologyZirconium oxidesSpray pyrolysisCarboxylic acid

Described is a method for the production of metal oxides by flame spray pyrolysis, in particular mixed metal oxides such as ceria / zirconia, and metal oxides obtainable by said method. Due to high enthalpy solvents with a high carboxylic acid content said metal oxides have improved properties. For example ceria / zirconia has excellent oxygen storage capacity at high zirconium levels up to more than 80% of whole metal content.

Owner:EIDGENOSSISCHE TECHN HOCHSCULE ZURICH

Process for the production of ultrafine powders of metal oxides

InactiveUS6503475B1Low costHigh yield rateAlkaline earth titanatesMaterial nanotechnologyDiluentBiological activation

A process for the production of ultrafine powders that includes subjecting a mixture of precursor metal compound and a non-reactant diluent phase to mechanical milling whereby the process of mechanical activation reduces the microstructure of the mixture to the form of nano-sized grains of the metal compound uniformly dispersed in the diluent phase. The process also includes heat treating the mixture of nano-sized grains of the metal compound uniformly dispersed in the diluent phase to convert the nano-sized grains of the metal compound into a metal oxide phase. The process further includes removing the diluent phase such that the nano-sized grains of the metal oxide phase are left behind in the form of an ultrafine powder.

Owner:SAMSUNG CORNING PRECISION MATERIALS CO LTD +1

Metal oxide particle and its uses

InactiveUS20070154561A1High transparencyPromote absorptionMaterial nanotechnologyBiocideAcyl groupUltraviolet absorption

An object of the present invention is to provide a metal oxide particle which exercises more excellent ultraviolet absorbency as a matter of course and combines therewith merits of, for example, either being shifted in ultraviolet absorption edge toward the longer wavelength side and being excellent also in the absorption efficiency of a long-wavelength range of ultraviolet rays, or having good transparency and, for example, even in cases where added into or coated onto substrates, not damaging the transparency or hue of the substrates. As a means of achieving this object, a metal oxide particle according to the present invention is a metal oxide particle such that a hetero-element is contained in a particle comprising an oxide of a specific metal element (M), wherein the metal oxide particle is: 1) a metal oxide particle in the form of a fine particle wherein the hetero-element is at least one specific metal element (M′); 2) a metal oxide particle wherein the hetero-element includes at least two specific metal elements (M′); 3) a metal oxide particle wherein: the hetero-element is a more specified metal element (M′) and at least a part thereof is 2 in valence; or the metal element (M) is a more specified metal element and the metal oxide particle is in a specific range in crystal grain diameter in the vertical direction to each of the (002) plane and the (100) plane; or 4) a metal oxide particle wherein: the hetero-element is at least one specific nonmetal element and an acyl group is contained in the particle; or the hetero-element includes at least two specific nonmetal elements; or the hetero-element is at least one specific nonmetal element and a component derived from a metal element (M′) other than the metal element (M) is contained in the particle.

Owner:NIPPON SHOKUBAI CO LTD

Nanoparticle additives and lubricant formulations containing the nanoparticle additives

ActiveUS20080161213A1Reduce frictionReduce wearMaterial nanotechnologyCerium oxides/hydroxidesNanoparticleBase oil

A method for reducing a friction coefficient adjacent a lubricated surface, and a lubricant composition for reducing a friction coefficient between lubricated surfaces. The method includes providing an amount of metal-containing dispersed in a fully formulated lubricant composition containing a base oil of lubricating viscosity, wherein the nanoparticles have an average particles size ranging from about 1 to about 10 nanometers. The lubricant composition containing the metal-containing nanoparticles is applied to a surface to be lubricated.

Owner:AFTON CHEMICAL

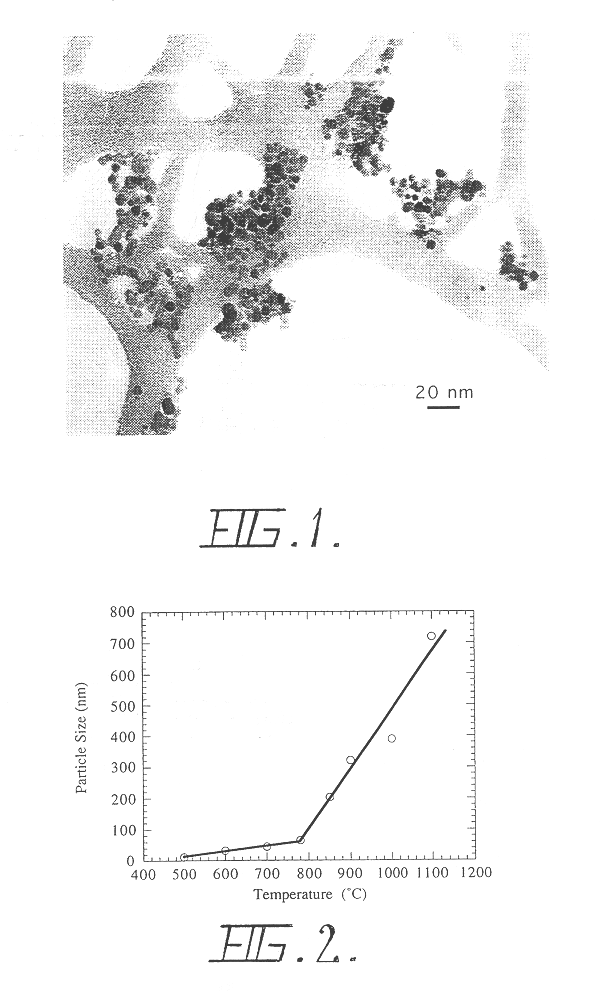

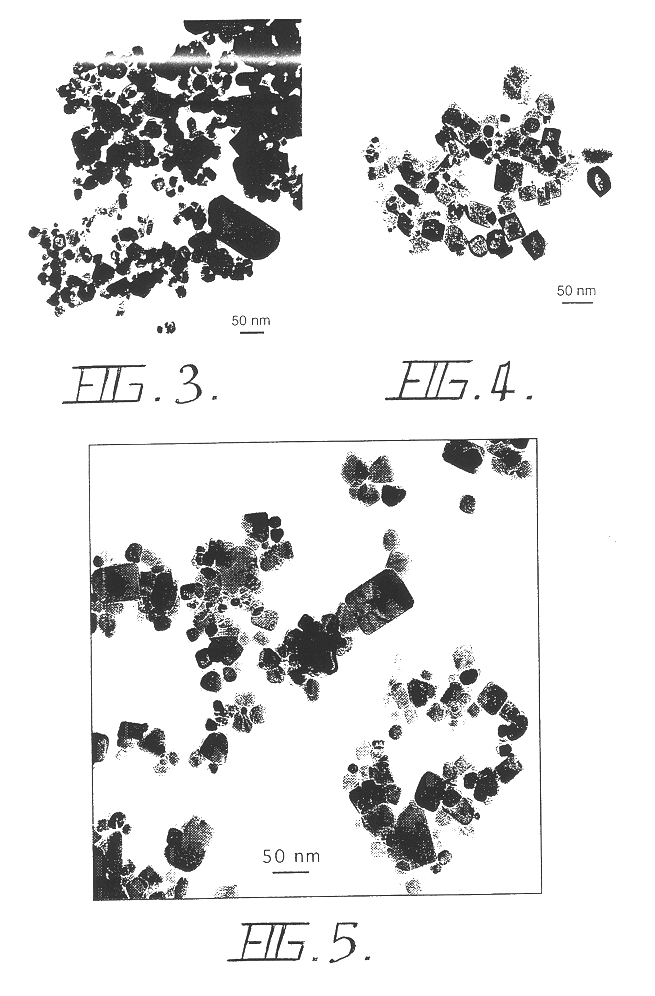

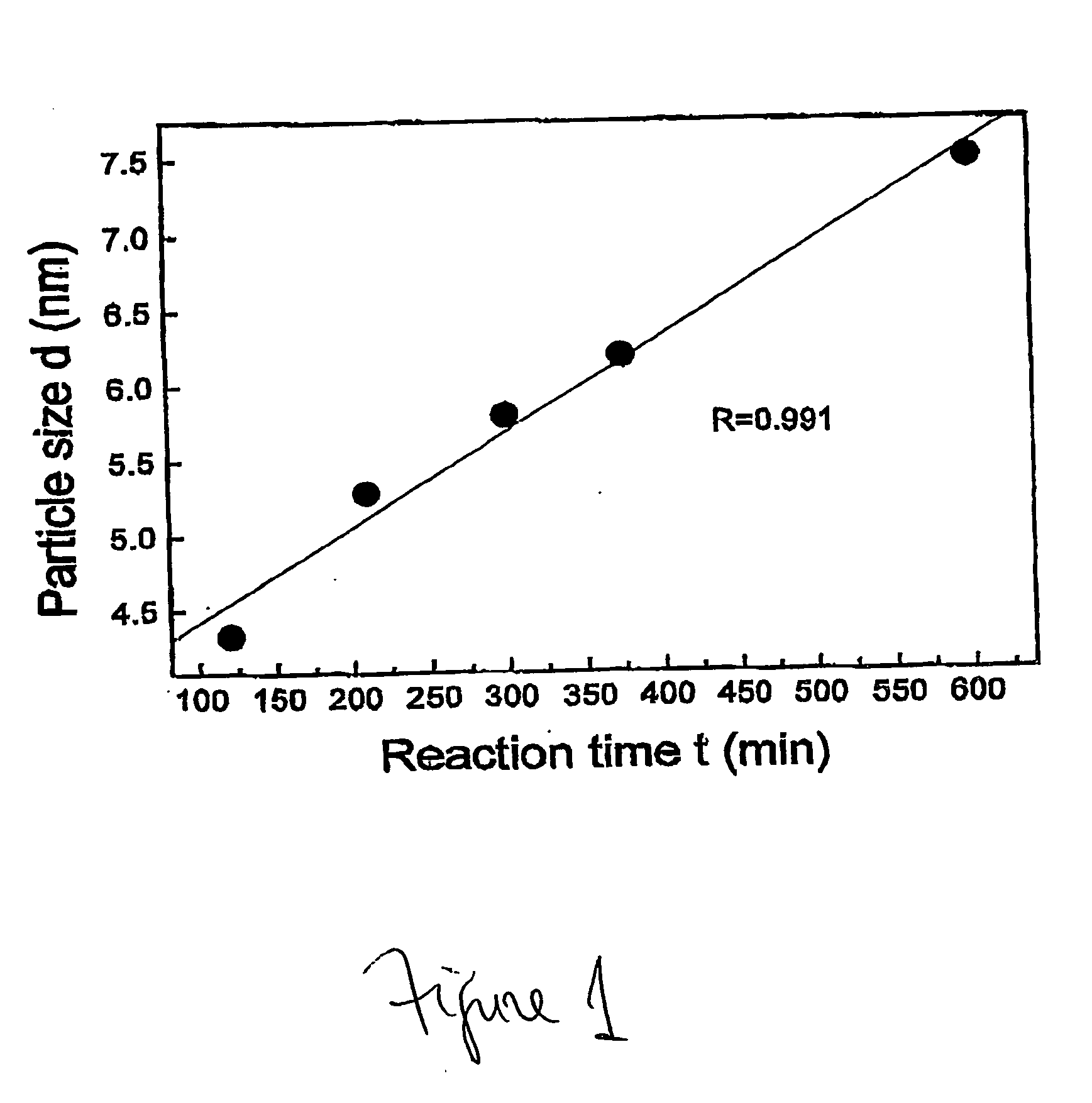

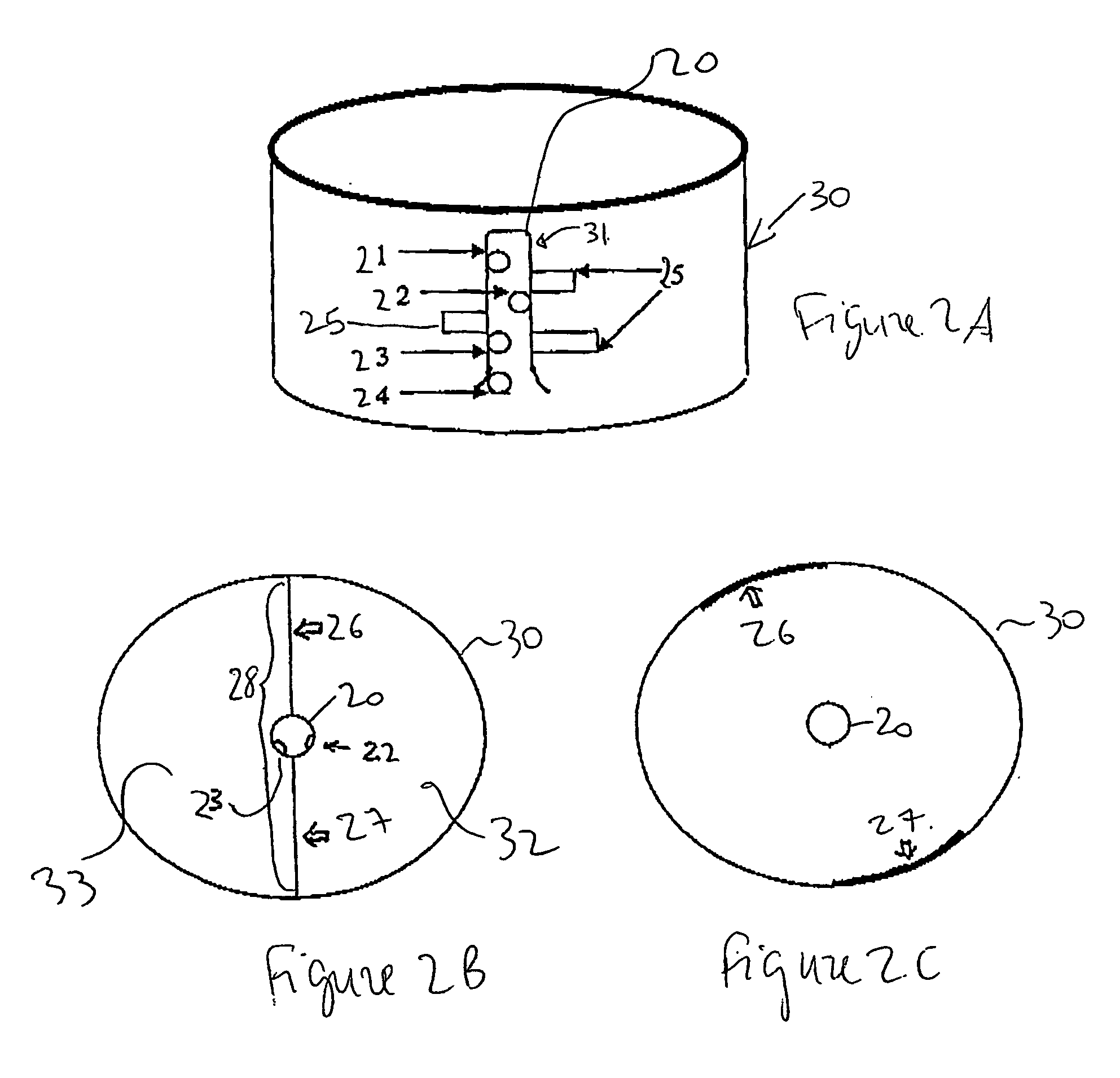

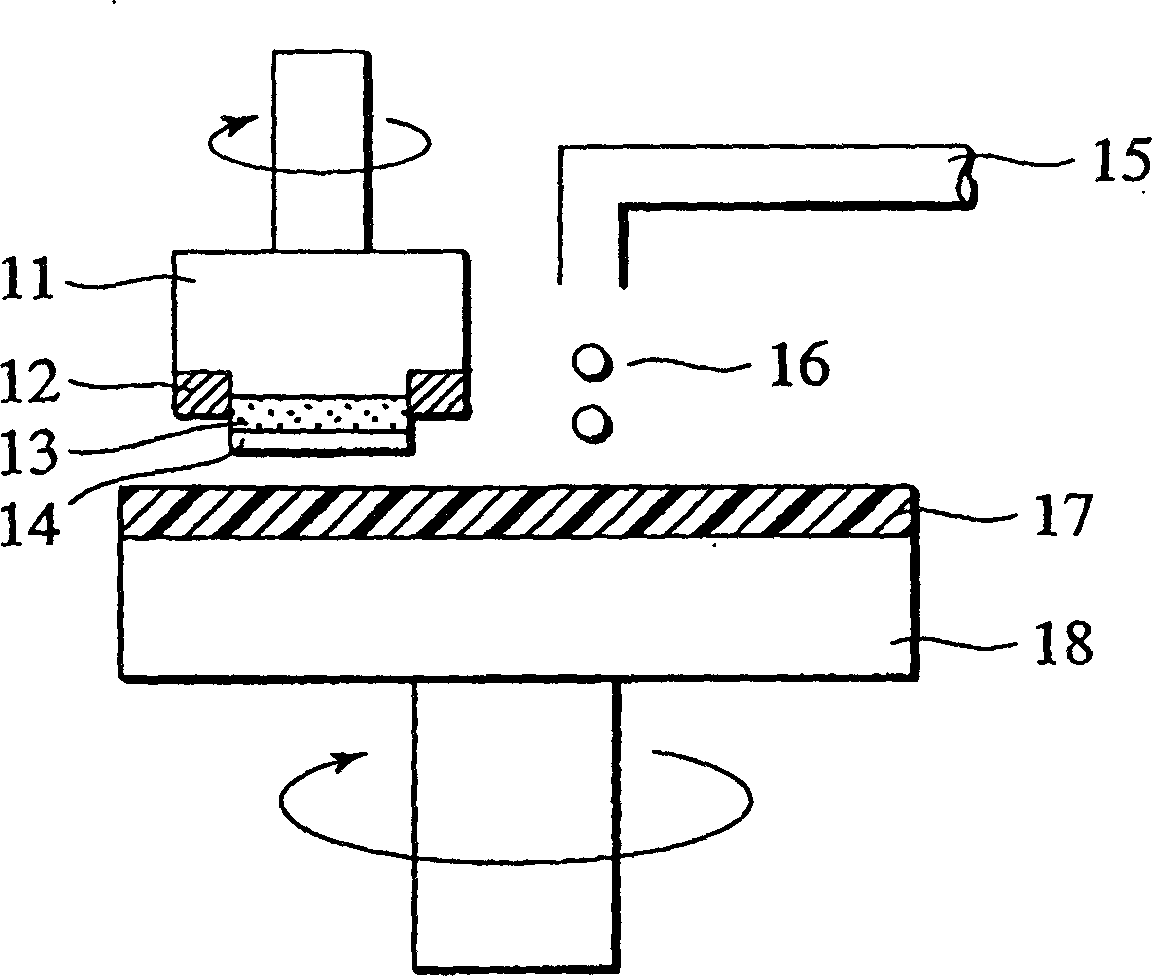

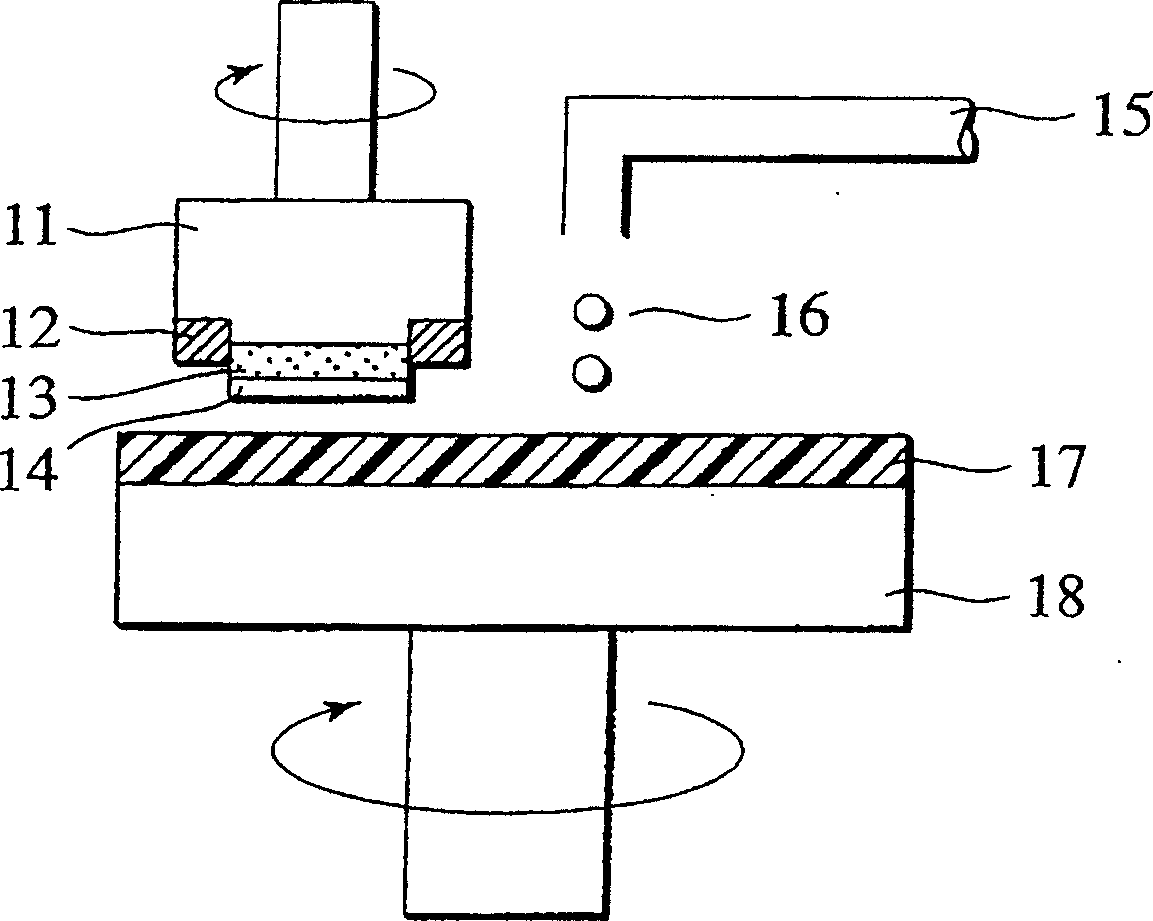

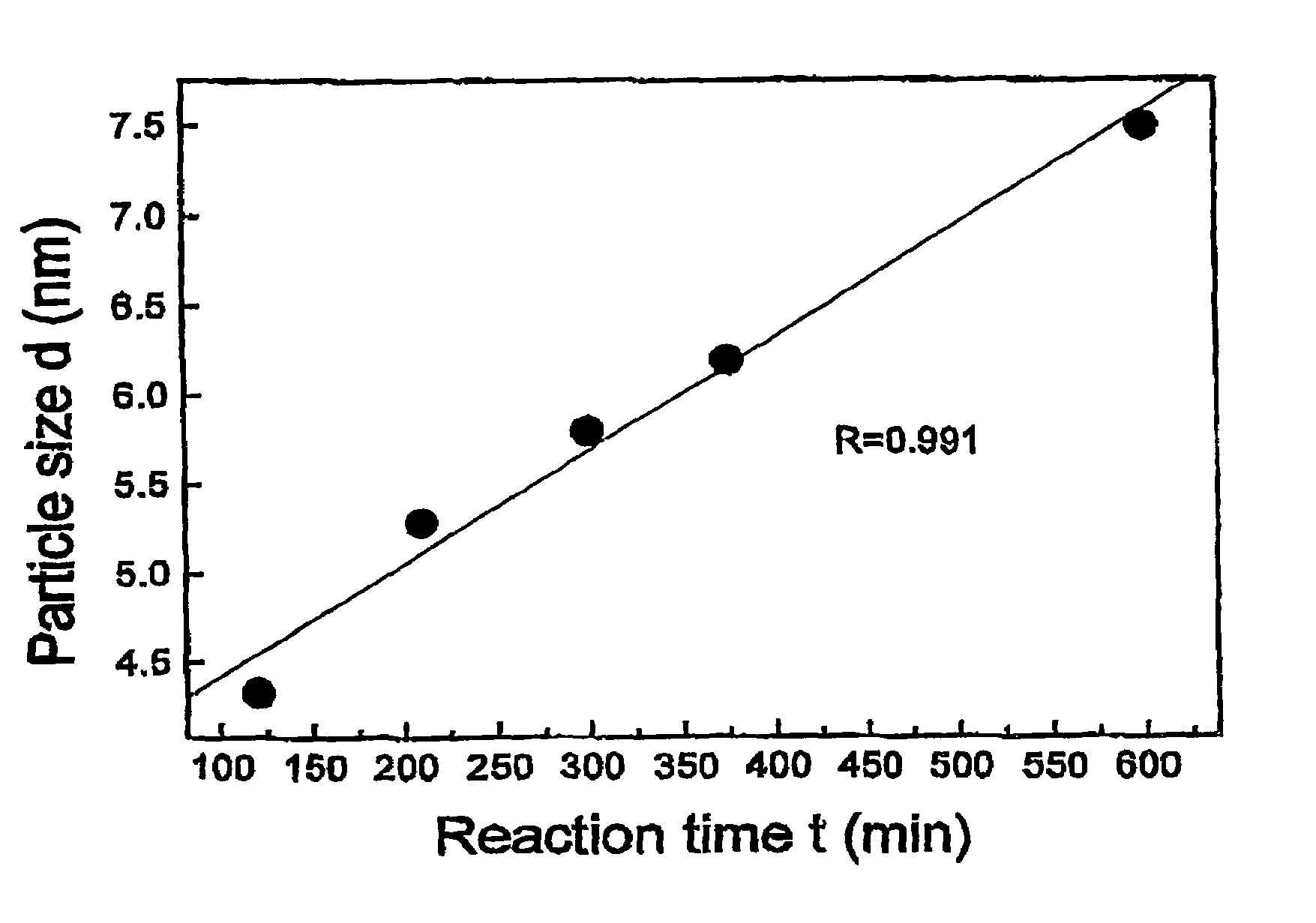

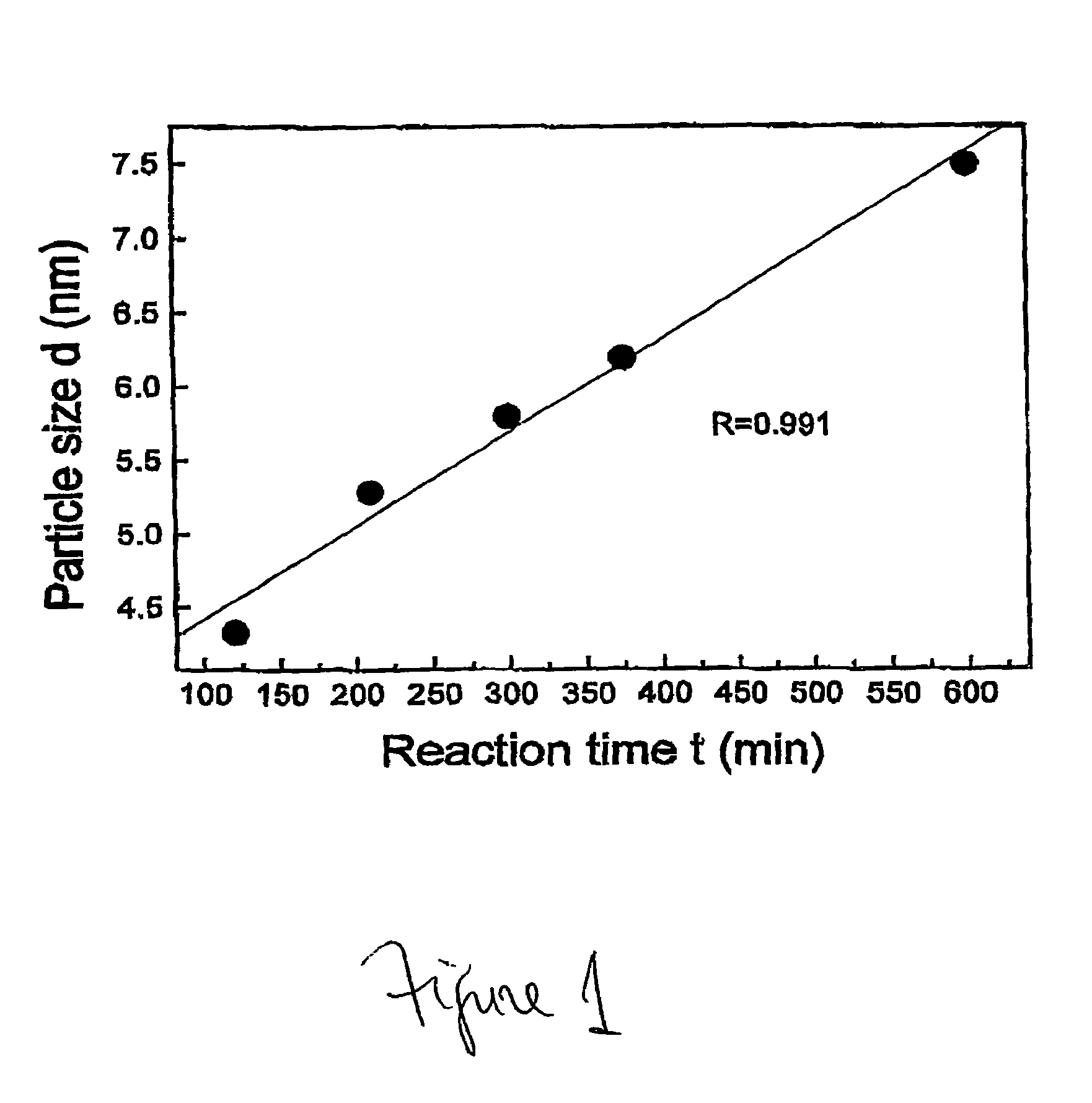

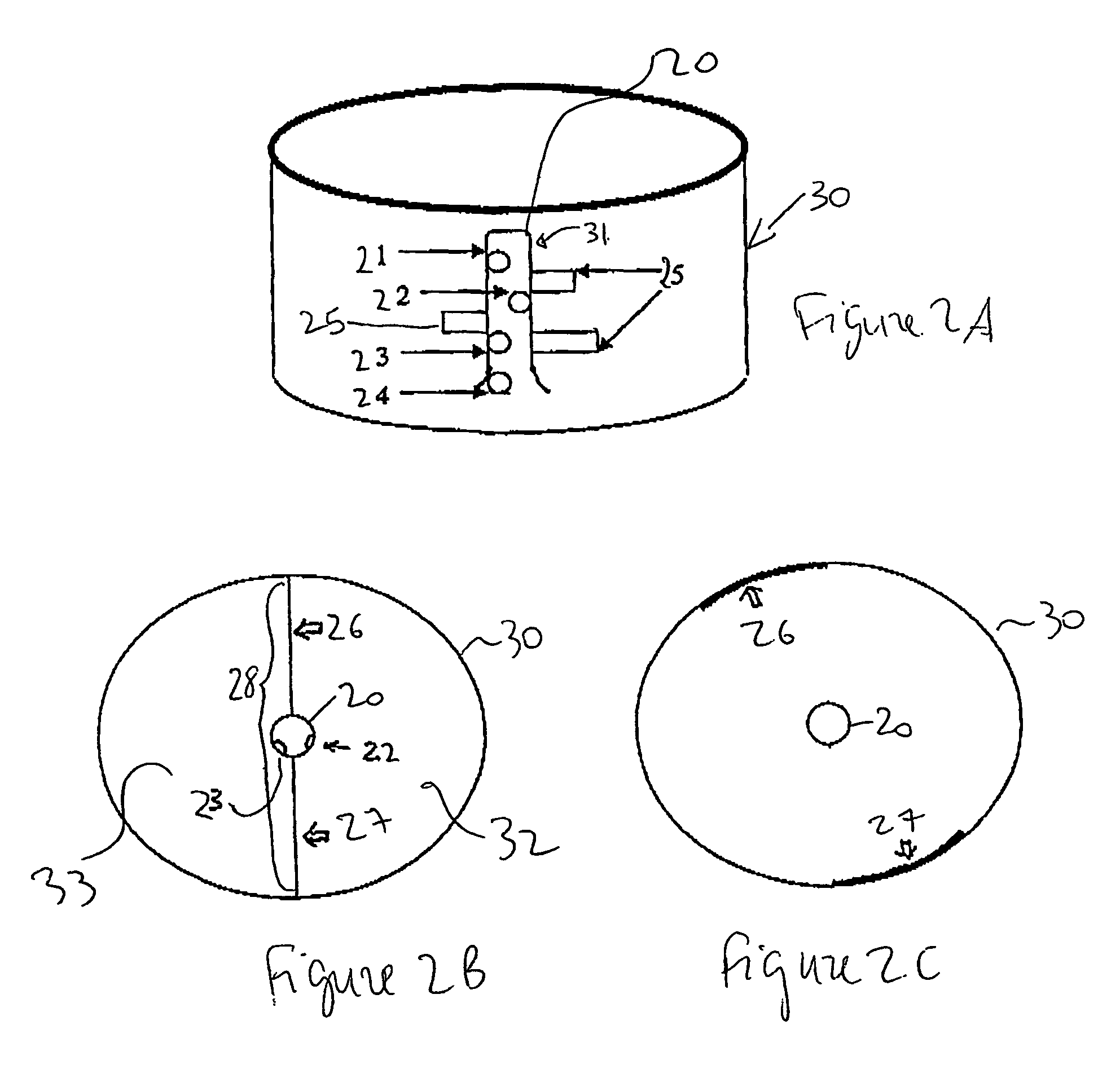

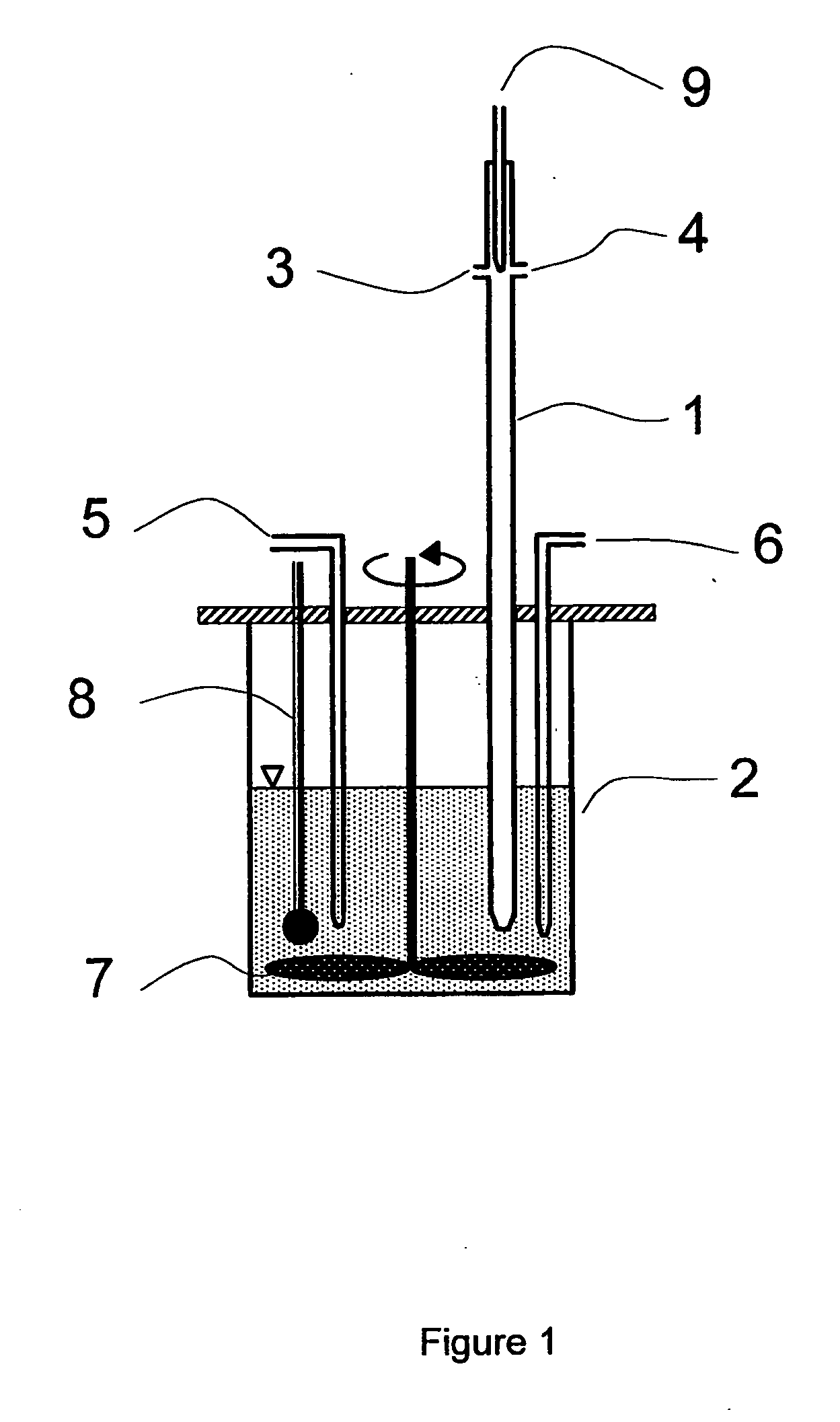

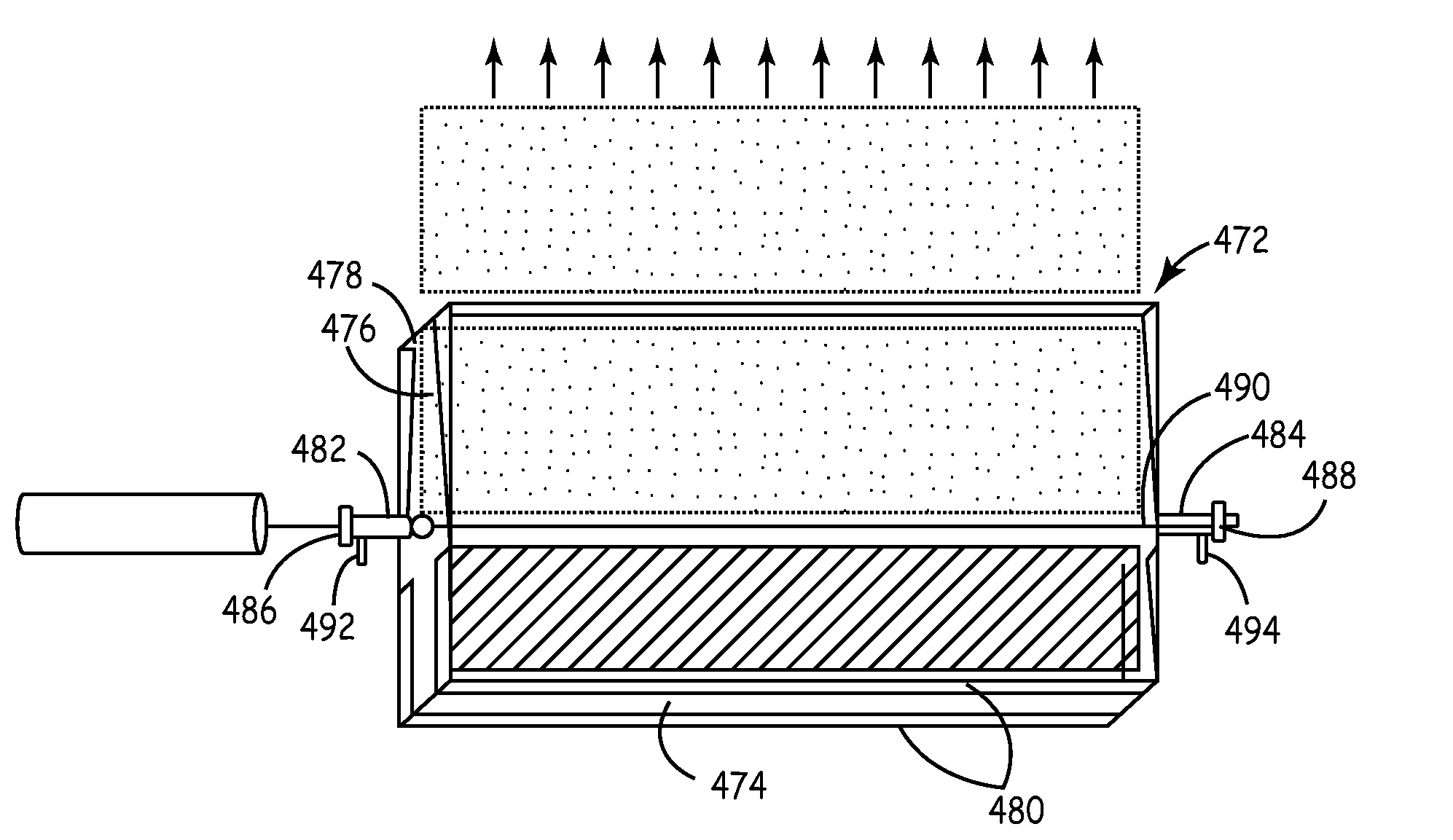

Apparatus and method for preparing cerium oxide nanoparticles

InactiveUS20050031517A1Quick responseReaction time is thus limitedMaterial nanotechnologyMixing methodsCerium nitrateNanoparticle

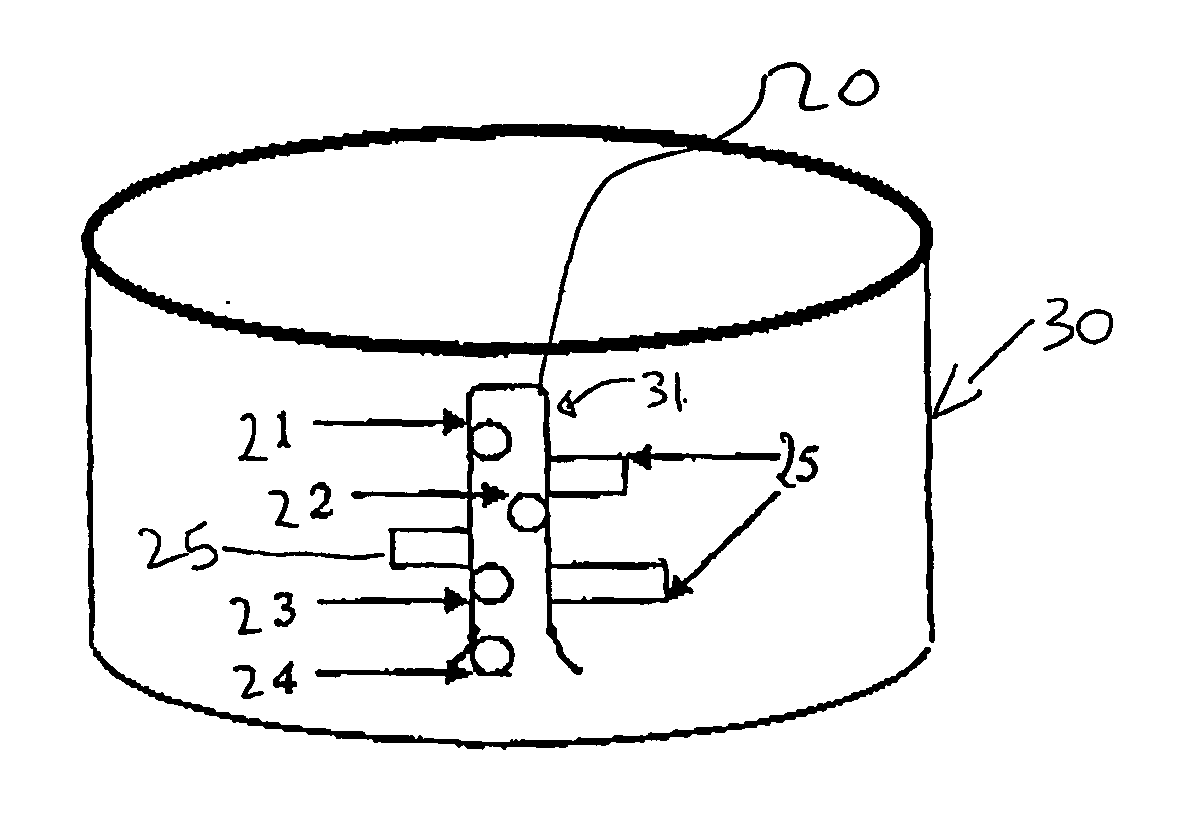

This invention provides a method for preparing cerium oxide nanoparticles with a narrow size distribution. The cerium oxide nanoparticles obtained by the method of the invention are nearly all crystalline. The method comprises providing a first aqueous solution comprising cerium nitrate and providing a second aqueous solution comprising hexamethylenetetramine. The first and second aqueous solutions are mixed to form a mixture, and the mixture is maintained at a temperature no higher than about 320° K to form nanoparticles. The nanoparticles that are formed are then separated from the mixture. A further aspect of the present invention is an apparatus for preparing cerium oxide nanoparticles. The apparatus comprises a mixing vessel having a first compartment for holding a first aqueous solution comprising cerium nitrate and a second compartment for holding a second aqueous solution comprising hexamethylenetetramine. The mixing vessel has a retractable partition separating the first and second compartments. When the retractable partition is retracted, rapid mixing of the first aqueous solution with the second aqueous solution takes place to form a mixture, and the mixture is maintained at a temperature no higher than about 320° K to form nanoparticles therein.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

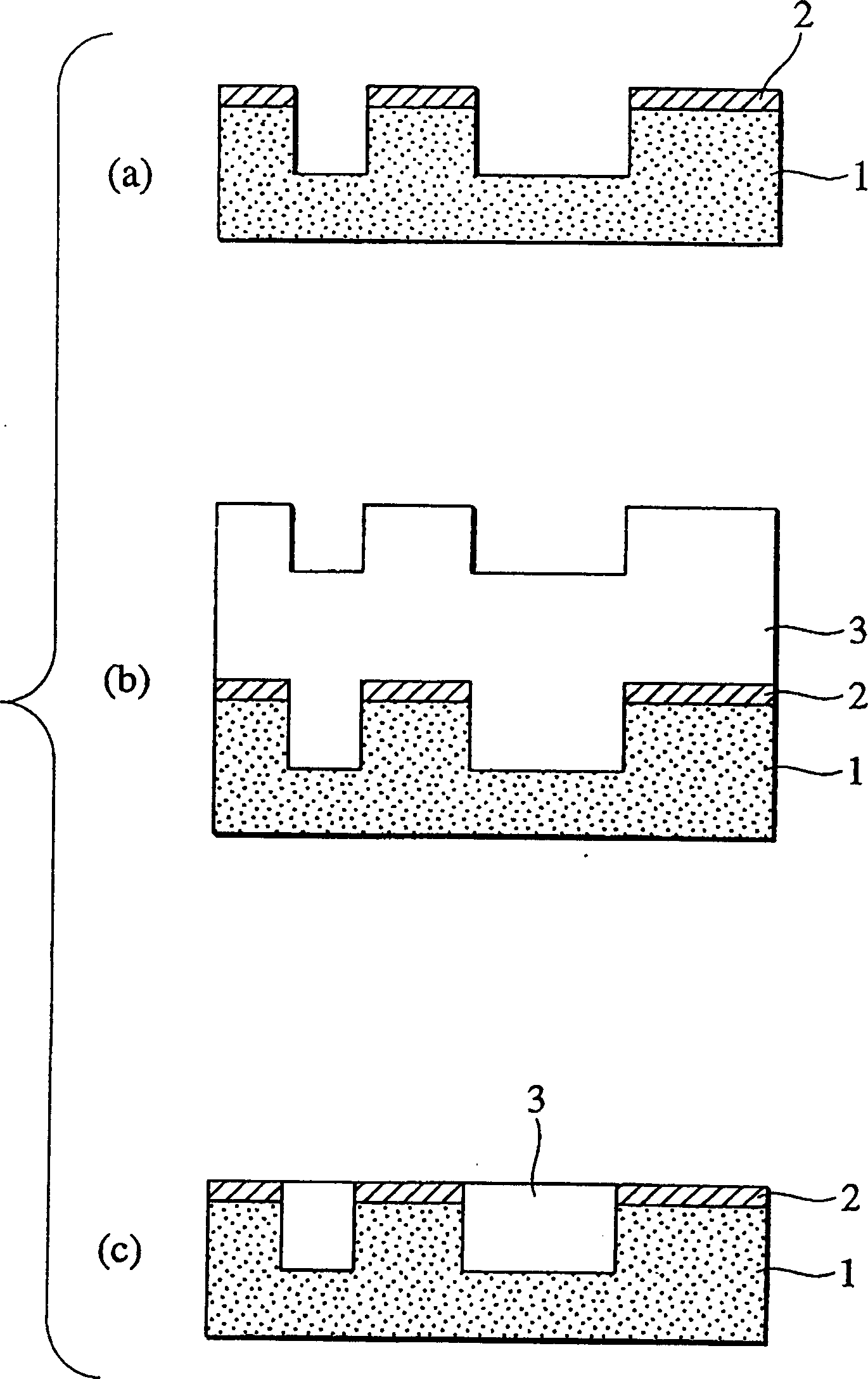

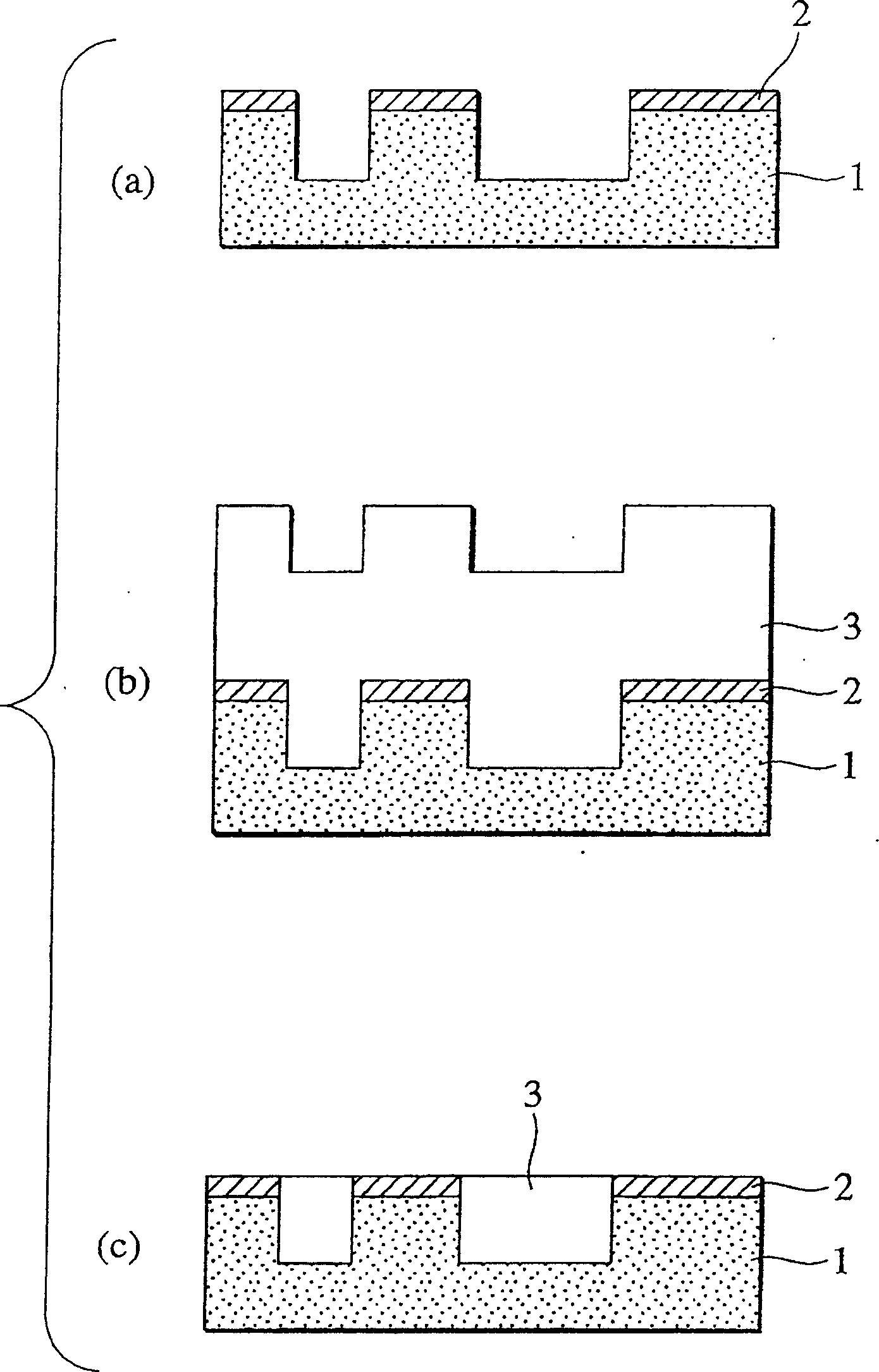

Polishing compound and method for polishing substrate

InactiveCN1457506AGood dispersionEasy to manageOther chemical processesZirconium compoundsCeriumVolumetric Mass Density

A polishing slurry and a polishing method which are suitably used in a CMP technique for flattening a surface of a substrate in a production process of a semiconductor device. The polishing slurry comprises particles and a medium in which at least a part of the particles are dispersed, wherein the particles are made of at least one of (1) a cerium compound selected from cerium oxide, cerium halide and cerium sulfide and having a density of 3 to 6 g / cm<3> and an average particle diameter of secondary particles of 1 to 300 nm and (2) a tetravalent metal hydroxide. A polishing method using the polishing slurry takes advantage of a chemical action of particles in the polishing slurry and minimizes a mechanical action of the particles, thereby achieving a decrease in scratches caused by the particles and an increase in polishing rate at the same time.

Owner:HITACHI CHEM CO LTD

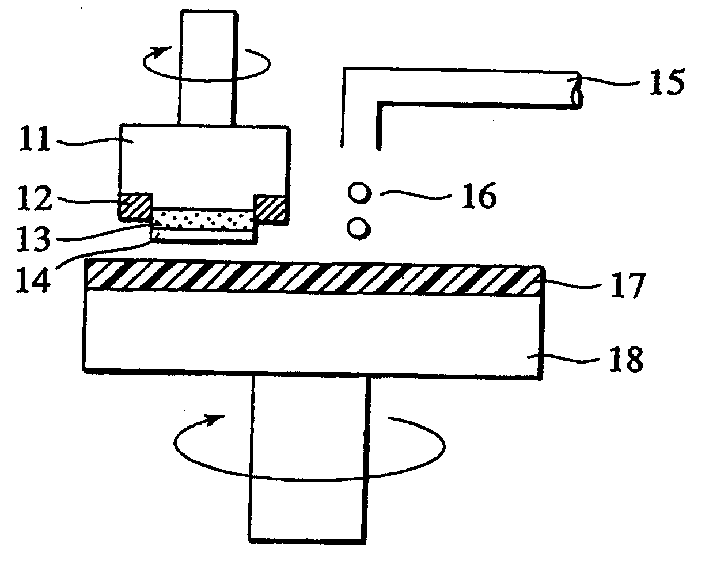

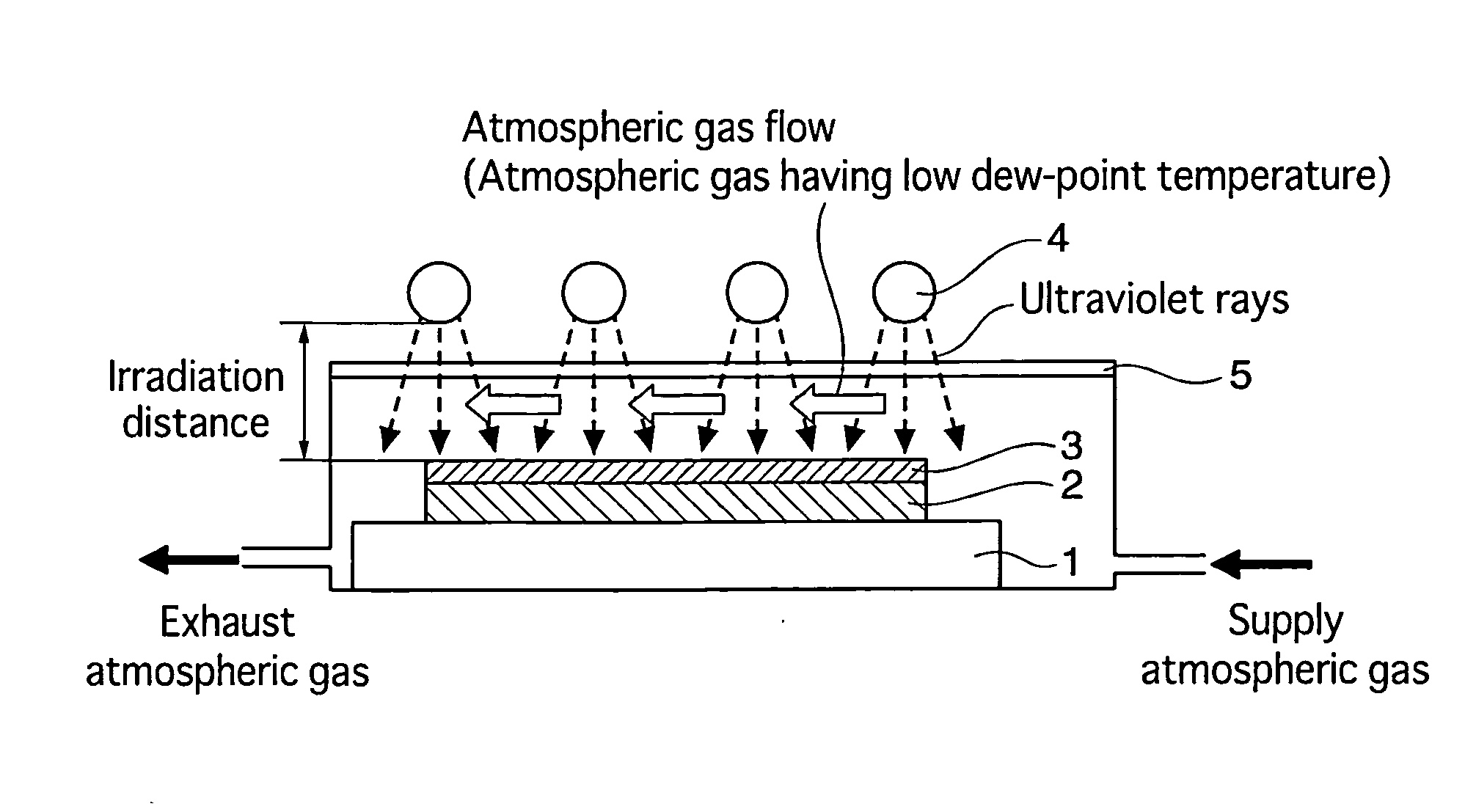

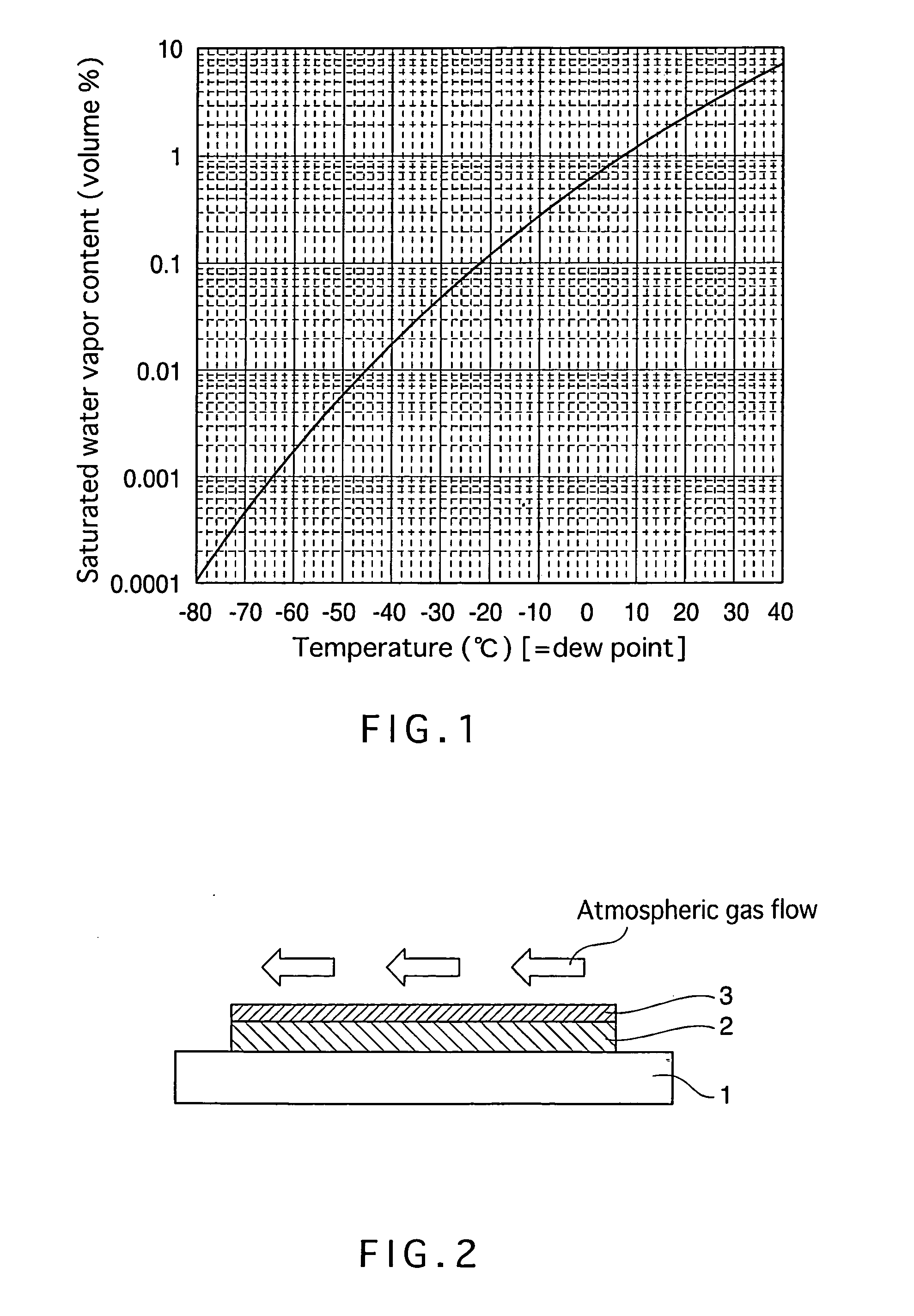

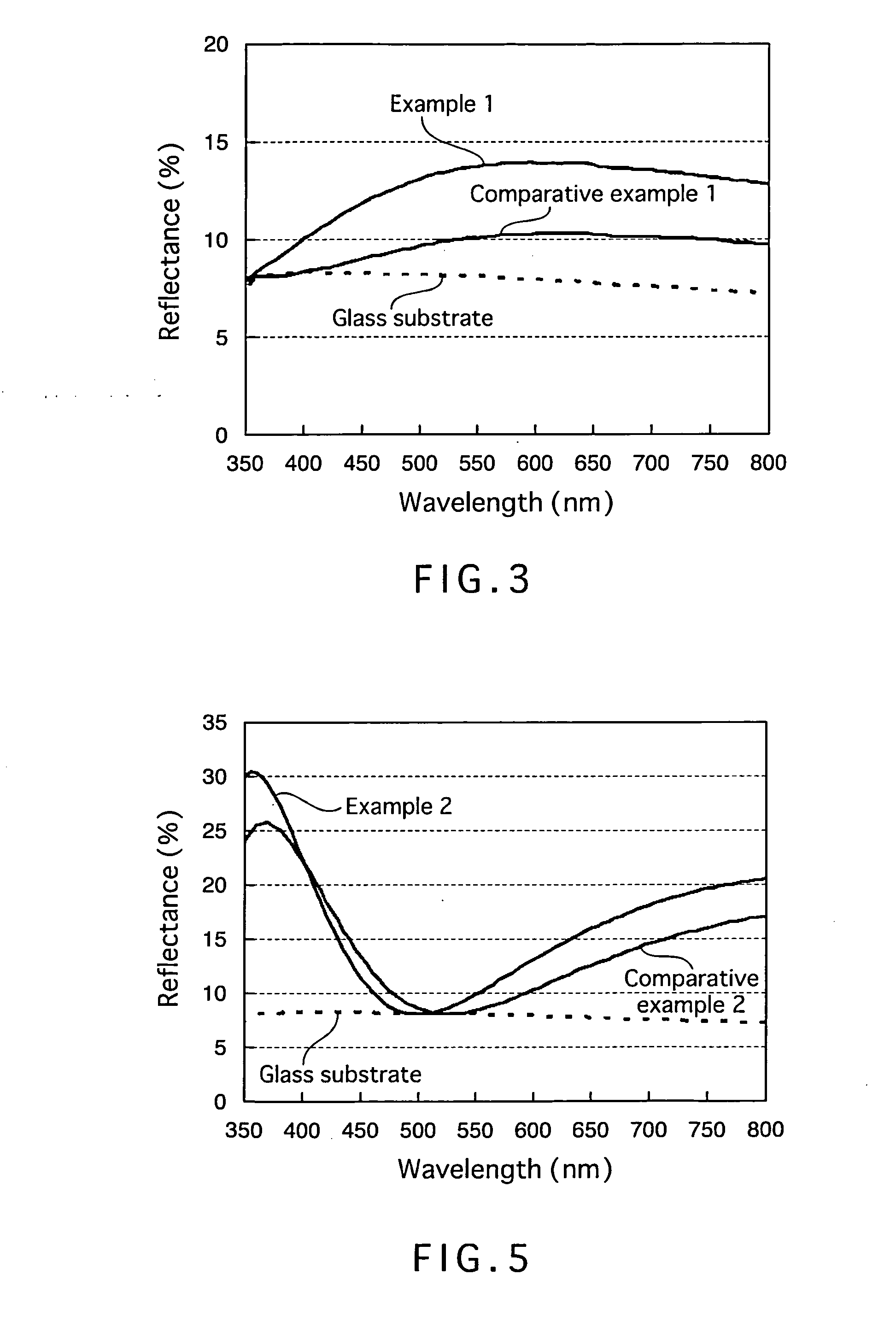

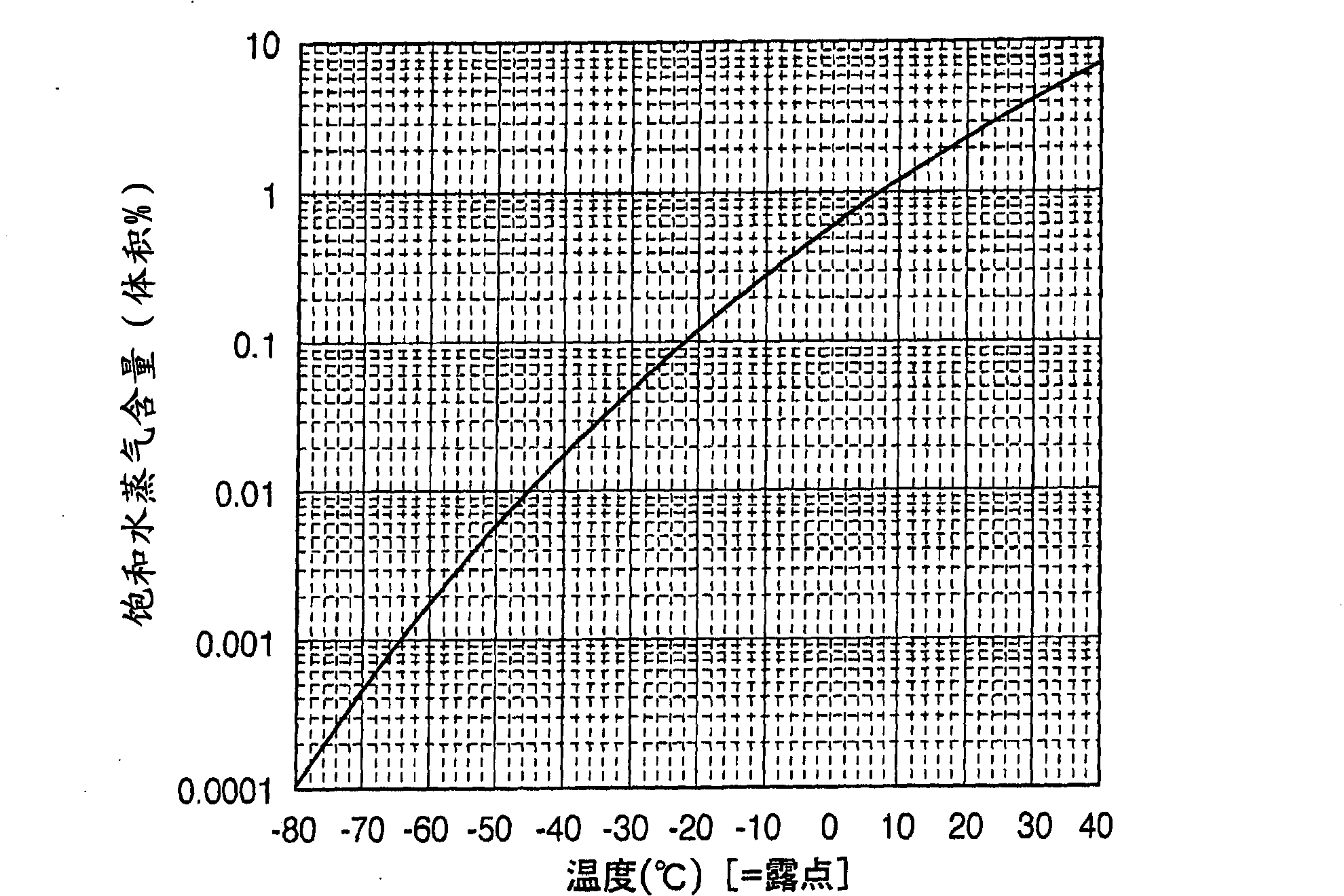

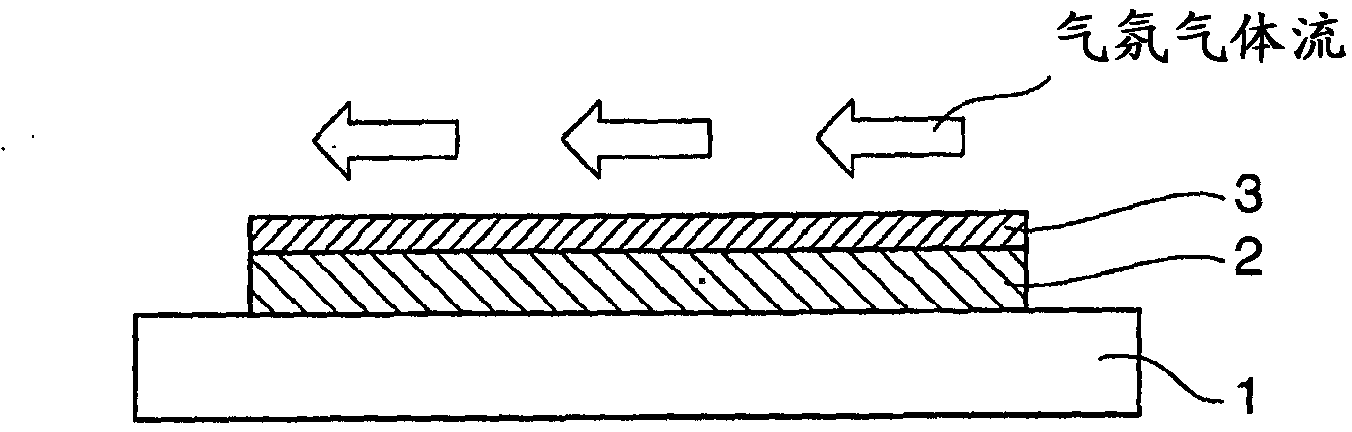

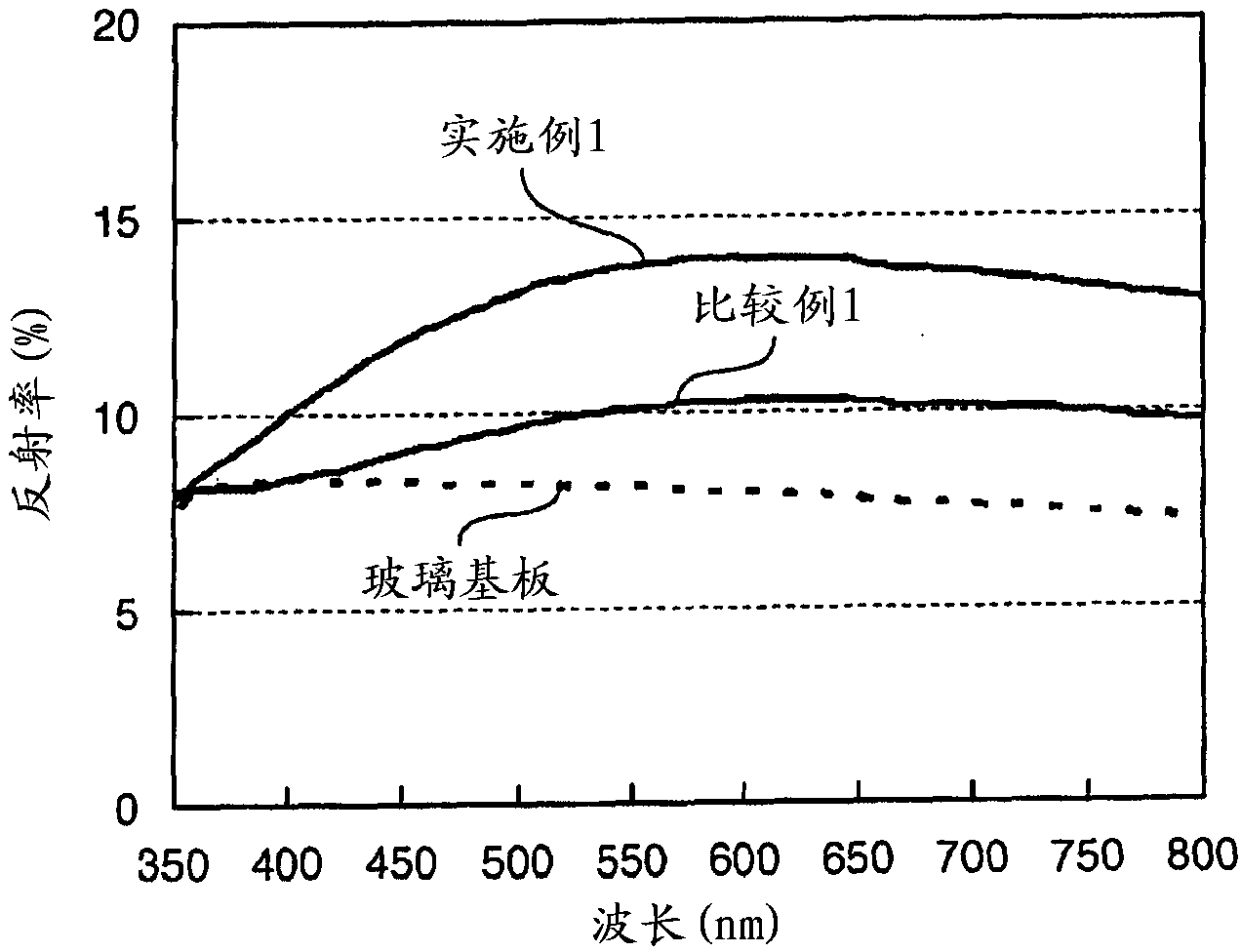

Method of manufacturing metal oxide film, metal oxide film, element using the metal oxide film, substrate with metal oxide film, and device using the substrate with metal oxide film

InactiveUS20130101867A1High densityHigh film strengthTantalum compoundsSemiconductor/solid-state device detailsOxygenMaterials science

Provided is a method of manufacturing a metal oxide film to be formed through the following processes: a coating process of forming a coating film on a substrate by using a coating liquid for forming metal oxide film containing any of various organometallic compounds; a drying process of making the coating film into a dried coating film; and a heating process of forming an inorganic film from the dried coating film under an oxygen-containing atmosphere having a dew-point temperature equal to or lower than −10° C.

Owner:SUMITOMO METAL MINING CO LTD

Polishing compound and method for polishing substrate

InactiveCN1746255AGood dispersionEasy to manageOther chemical processesZirconium compoundsCeriumVolumetric Mass Density

A polishing slurry and a polishing method which are suitably used in a CMP technique for flattening a surface of a substrate in a production process of a semiconductor device. The polishing slurry comprises particles and a medium in which at least a part of the particles are dispersed, wherein the particles are made of at least one of (1) a cerium compound selected from cerium oxide, cerium halide and cerium sulfide and having a density of 3 to 6 g / cm<3> and an average particle diameter of secondary particles of 1 to 300 nm and (2) a tetravalent metal hydroxide. A polishing method using the polishing slurry takes advantage of a chemical action of particles in the polishing slurry and minimizes a mechanical action of the particles, thereby achieving a decrease in scratches caused by the particles and an increase in polishing rate at the same time.

Owner:RESONAC CORPORATION

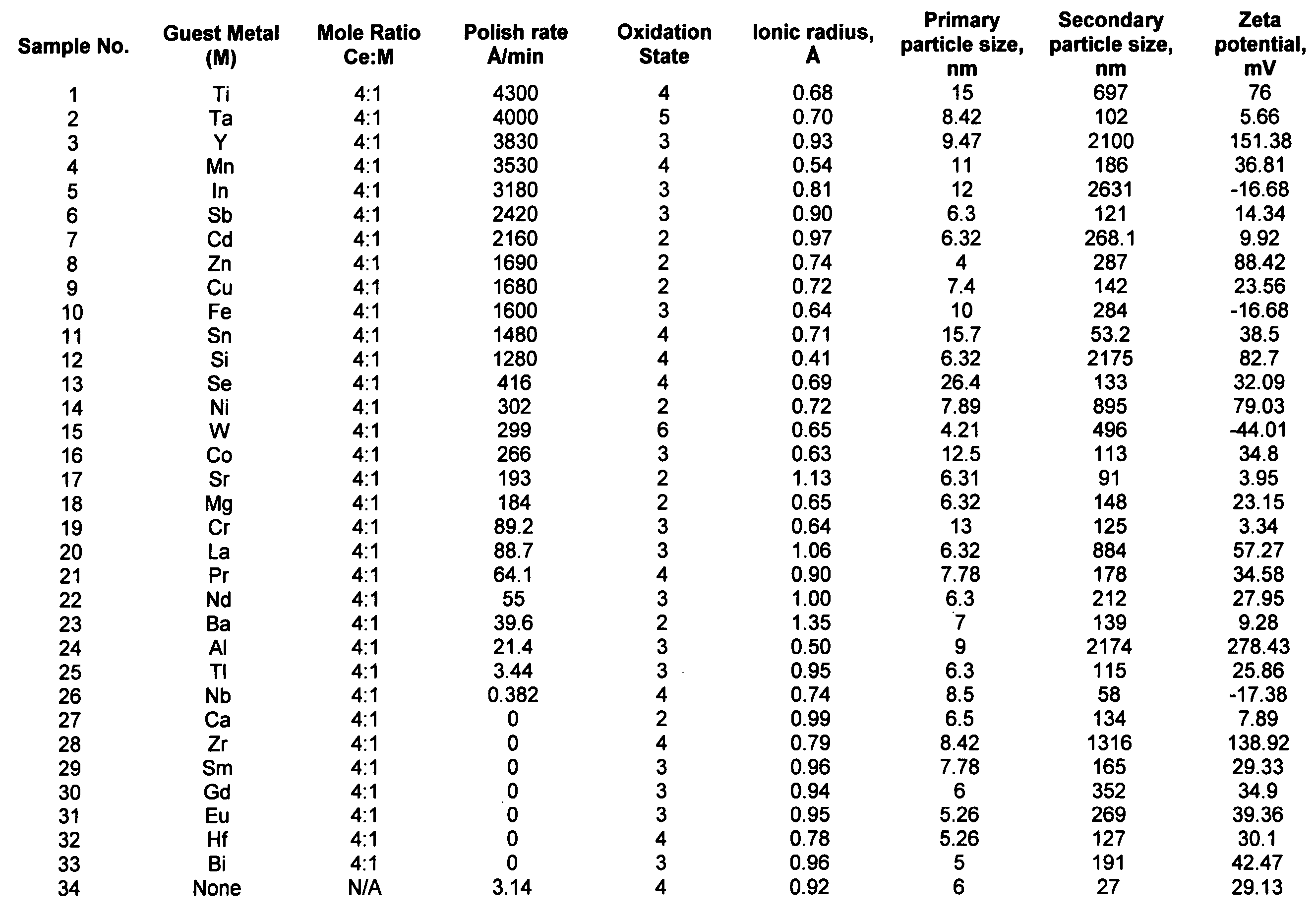

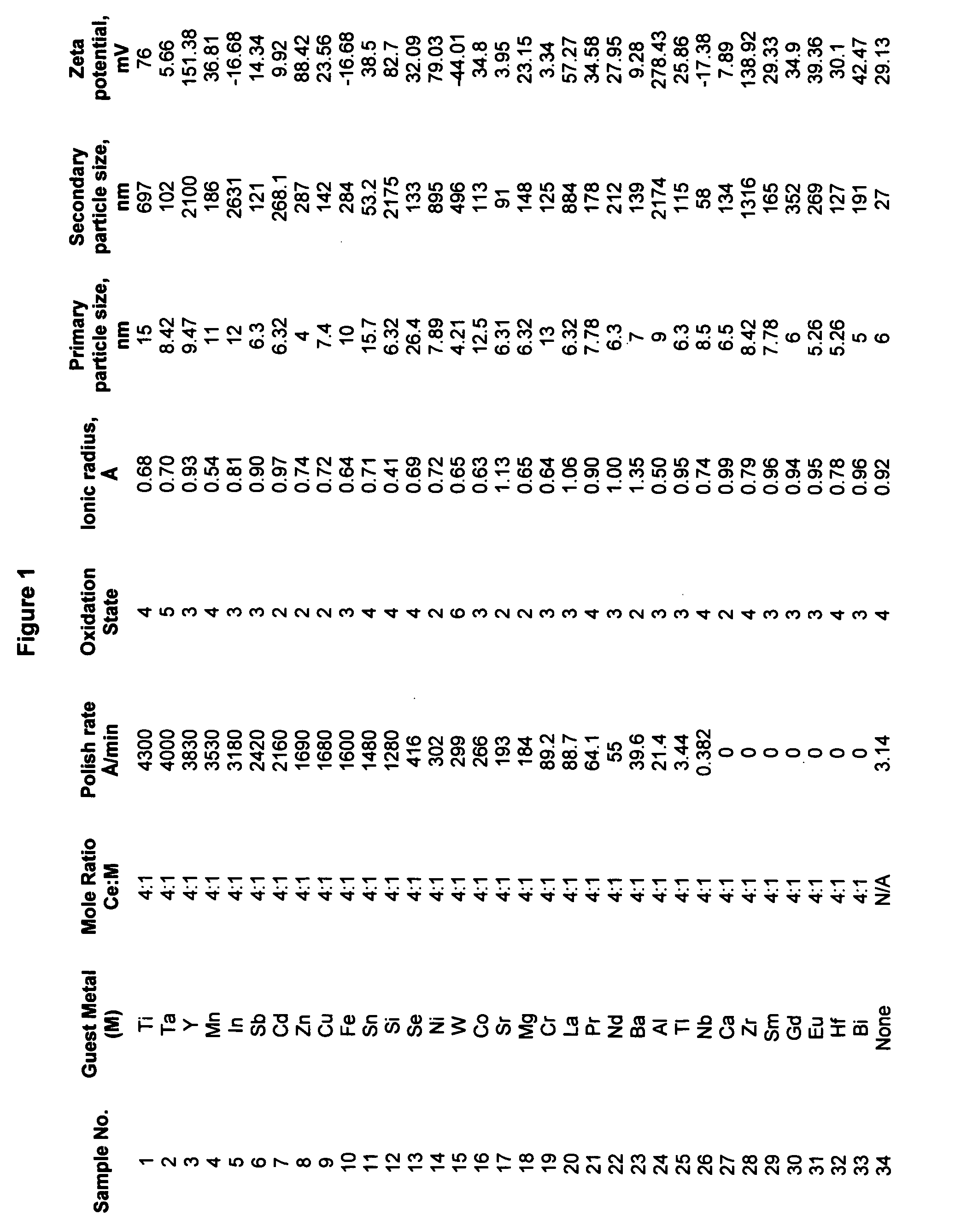

Synthesis of chemically reactive ceria composite nanoparticles and CMP applications thereof

InactiveUS20050003744A1Eliminate concernsReduce environmental impactPigmenting treatmentMaterial nanotechnologyChemical reactionCerium

The present invention provides a method of synthesizing nanosized abrasive particles and methods of using the same in chemical mechanical polishing slurry applications. The nanosized abrasive particles according to the invention are produced by hydrothermal synthesis. The crystallites of the particles include cerium atoms and atoms of metals other than cerium. In a preferred embodiment of the invention, the crystallites exhibit a cubic crystal lattice structure. The differences in electric potential between the cerium atoms and the atoms of metals other than cerium facilitate the polishing of films without the need for chemical oxidizers.

Owner:FERRO CORP

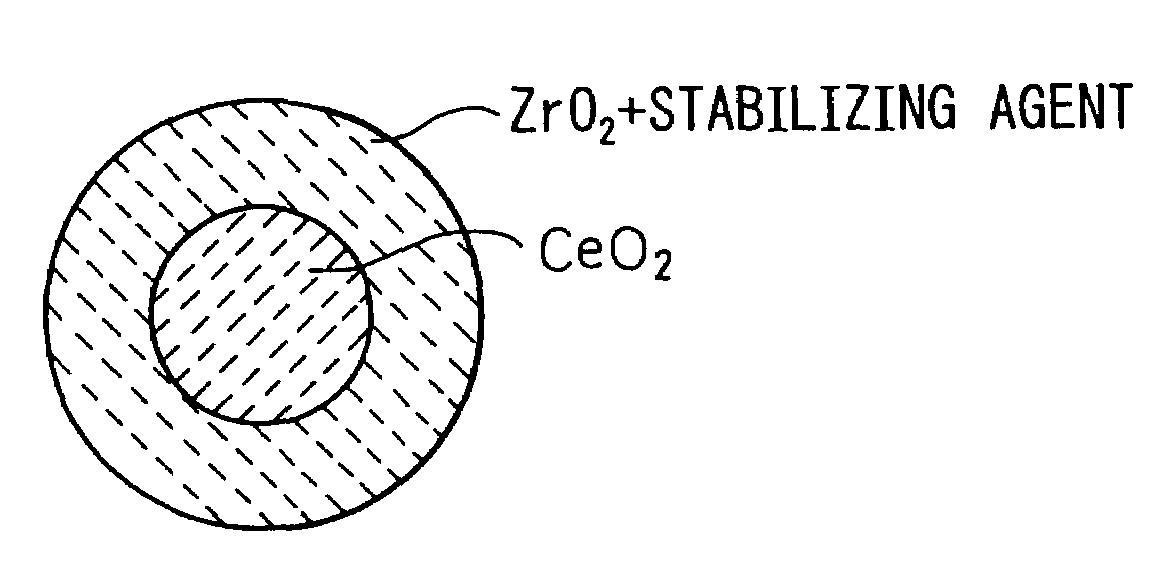

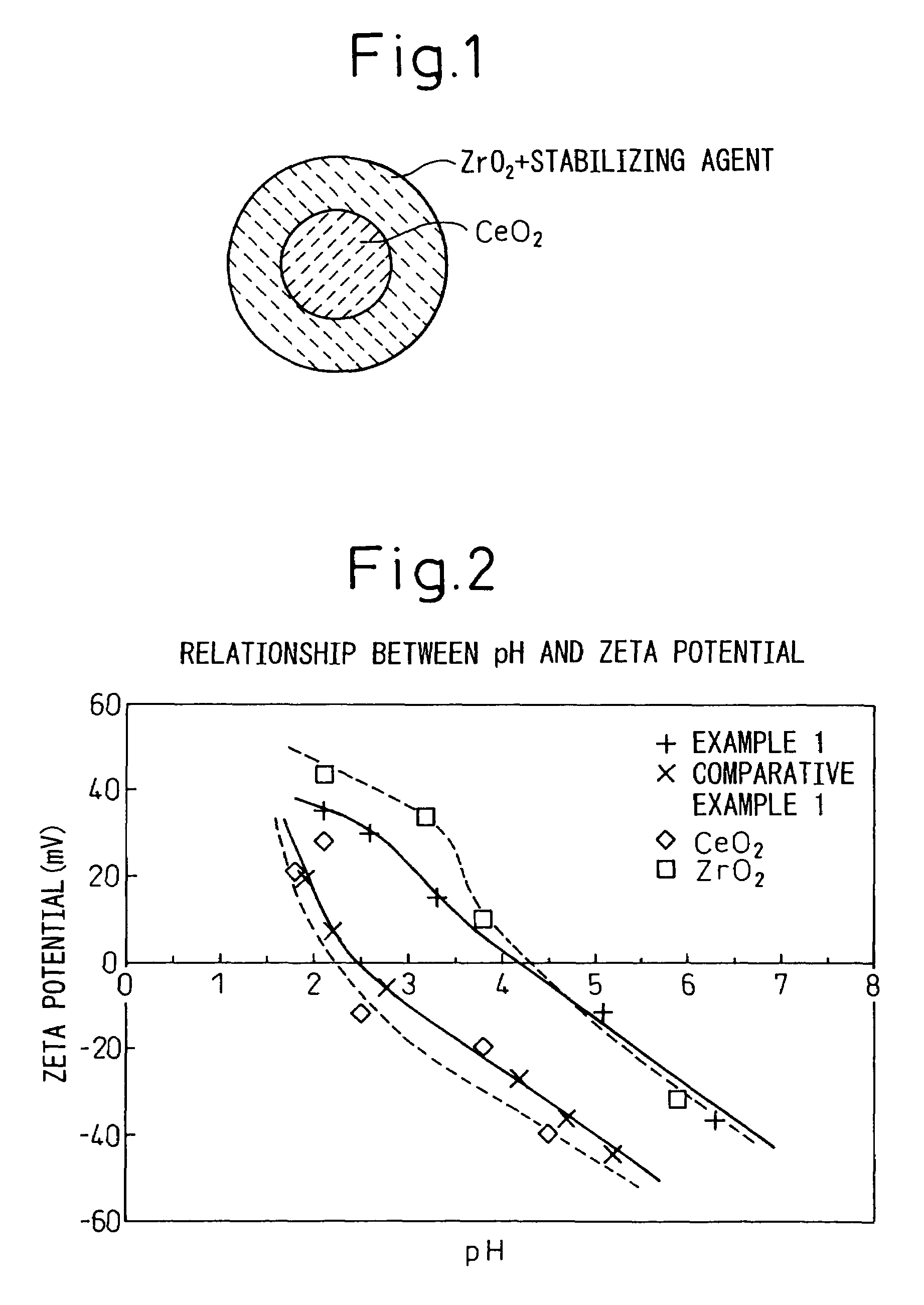

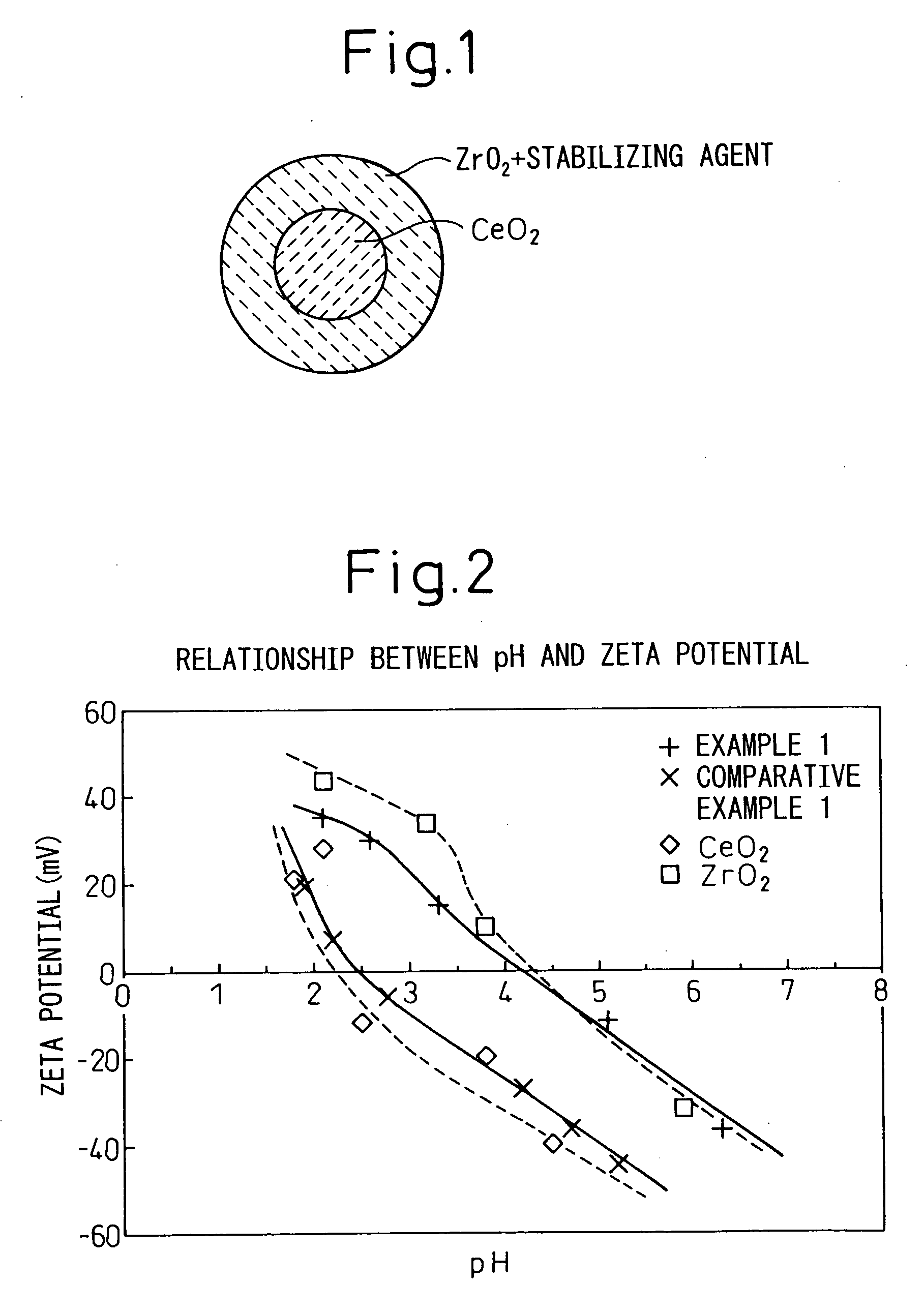

Cerium-zirconium composite metal oxide

ActiveUS7384888B2Increased durabilityIncrease capacityGas treatmentInternal combustion piston enginesMischmetalCerium

A cerium-zirconium composite metal oxide having improved durability at high temperature and a stable oxygen storage capacity is provided. The cerium-zirconium composite metal oxide is characterized in that the total mole number of Ce and Zr is at least 85% based on the total mole number of metal in the composite metal oxide, a molar ratio Ce / Zr is within a range from 1 / 9 to 9 / 1, and an isoelectric point of the composite metal oxide is more than 3.5. Preferably, the molar ratio Ce / Zr is within a range from 3 / 7 to 7 / 3 and the isoelectric point is within a range from 3.8 to 5.0, and the cerium-zirconium composite metal oxide contains a rare earth metal (excluding Ce) in a concentration of less than 15% by mole based on the total mole number of metal in the composite metal oxide. Also the present invention provides a cerium-zirconium composite metal oxide, characterized in that CeO2 forms a core surrounded by ZrO2.

Owner:TOYOTA JIDOSHA KK

Cerium oxide abrasive and method of polishing substrates

InactiveUS6863700B2Increase chanceNot be smoothly removedPigmenting treatmentOther chemical processesMetallurgyX-ray

A cerium oxide abrasive slurry having, dispersed in a medium, cerium oxide particles whose primary particles have a median diameter of from 30 nm to 250 nm, a maximum particle diameter of 600 nm or smaller, and a specific surface area of from 7 to 45 m2 / g, and slurry particles have a median diameter of from 150 nm to 600 nm. The cerium oxide particles have structural parameter Y, representing an isotropic microstrain obtained by an X-ray Rietvelt method (with RIETAN-94), of from 0.01 to 0.70, and structural parameter X, representing a primary particle diameter obtained by an X-ray Rietvelt method (with RIETAN-94), of from 0.08 to 0.3. The cerium oxide abrasive slurry is made by a method of obtaining particles by firing at a temperature of from 600° C. to 900° C. and then pulverizing, then dispersing the resulting cerium oxide particles in a medium.

Owner:HITACHI CHEM CO LTD

Method for producing metal oxide film, metal oxide film, element using the metal oxide film, substrate with metal oxide film, and device using the substrate with metal oxide film

InactiveCN102933496AImprove compactnessHigh strengthConductive layers on insulating-supportsTantalum compoundsPhysical chemistryThermal treatment

Disclosed are: a metal oxide film, which is formed by a coating method that is one of the methods for producing a metal oxide film, and which has a good balance between excellent transparency and high electrical conductivity, while having excellent film strength; and a method for producing the metal oxide film. Specifically disclosed is a method for producing a metal oxide film, which comprises: a coating step wherein a coating film is formed on a substrate using a metal oxide film-forming coating liquid that contains various organic metal compounds; a drying step wherein the coating film is changed into a dry coating film; and a heating step wherein an inorganic film is formed from the dry coating film. The method for producing a metal oxide film is characterized in that in the heating step, the dry coating film, which is mainly composed of the various organic metal compounds, is heated to a temperature at which at least mineralization of organic metal compound components occurs or higher in an oxygen-containing atmosphere at a temperature not higher than the temperature that is lower by 10 DEG C than the dew point, so that the organic components in the dry coating film are removed by thermal decomposition or combustion, or by thermal decomposition and combustion, thereby forming a metal oxide fine particle layer which is densely filled with metal oxide fine particles that are mainly composed of various metal oxides.

Owner:SUMITOMO METAL MINING CO LTD

Apparatus and method for preparing cerium oxide nanoparticles

InactiveUS7141227B2Quick responseMaterial nanotechnologyTransportation and packagingCerium nitrateHexamethylenetetramine

This invention provides a method for preparing cerium oxide nanoparticles with a narrow size distribution. The cerium oxide nanoparticles obtained by the method of the invention are nearly all crystalline. The method comprises providing a first aqueous solution comprising cerium nitrate and providing a second aqueous solution comprising hexamethylenetetramine. The first and second aqueous solutions are mixed to form a mixture, and the mixture is maintained at a temperature no higher than about 320° K to form nanoparticles. The nanoparticles that are formed are then separated from the mixture. A further aspect of the present invention is an apparatus for preparing cerium oxide nanoparticles. The apparatus comprises a mixing vessel having a first compartment for holding a first aqueous solution comprising cerium nitrate and a second compartment for holding a second aqueous solution comprising hexamethylenetetramine. The mixing vessel has a retractable partition separating the first and second compartments.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

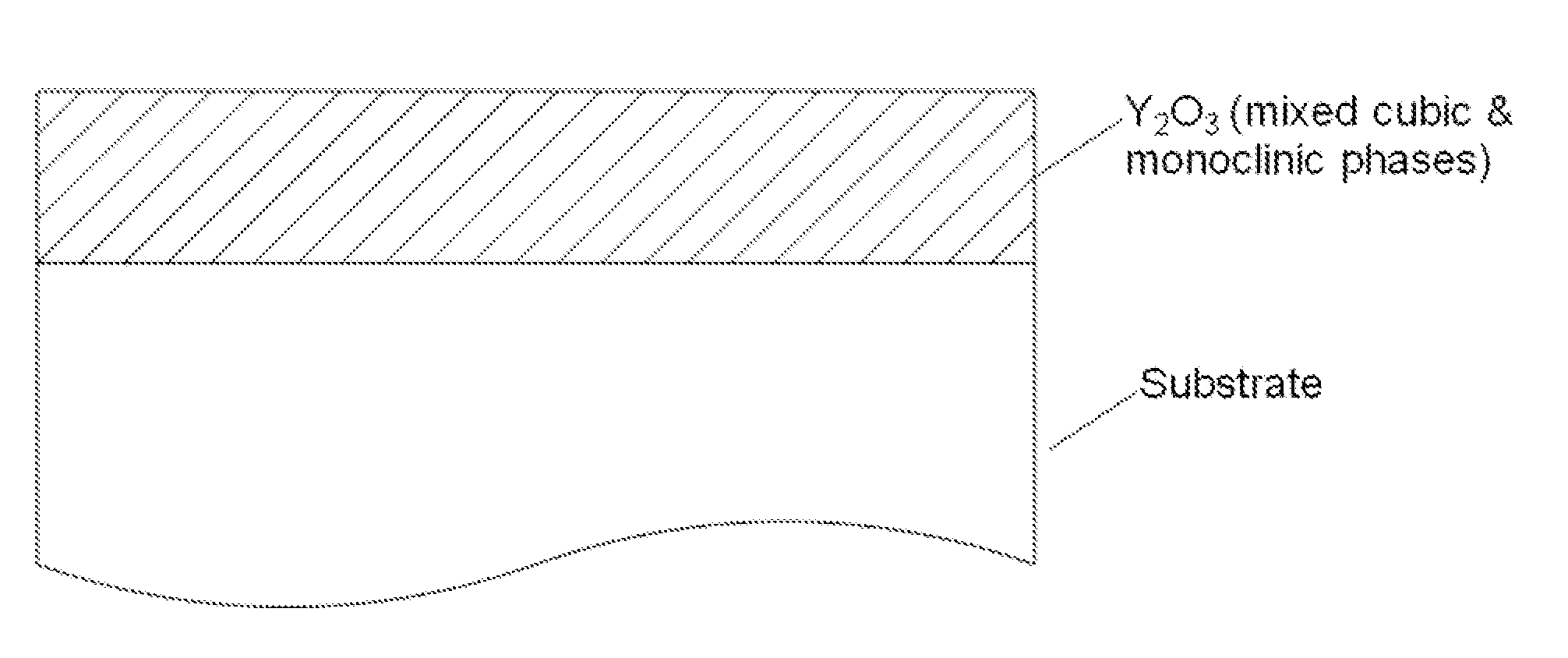

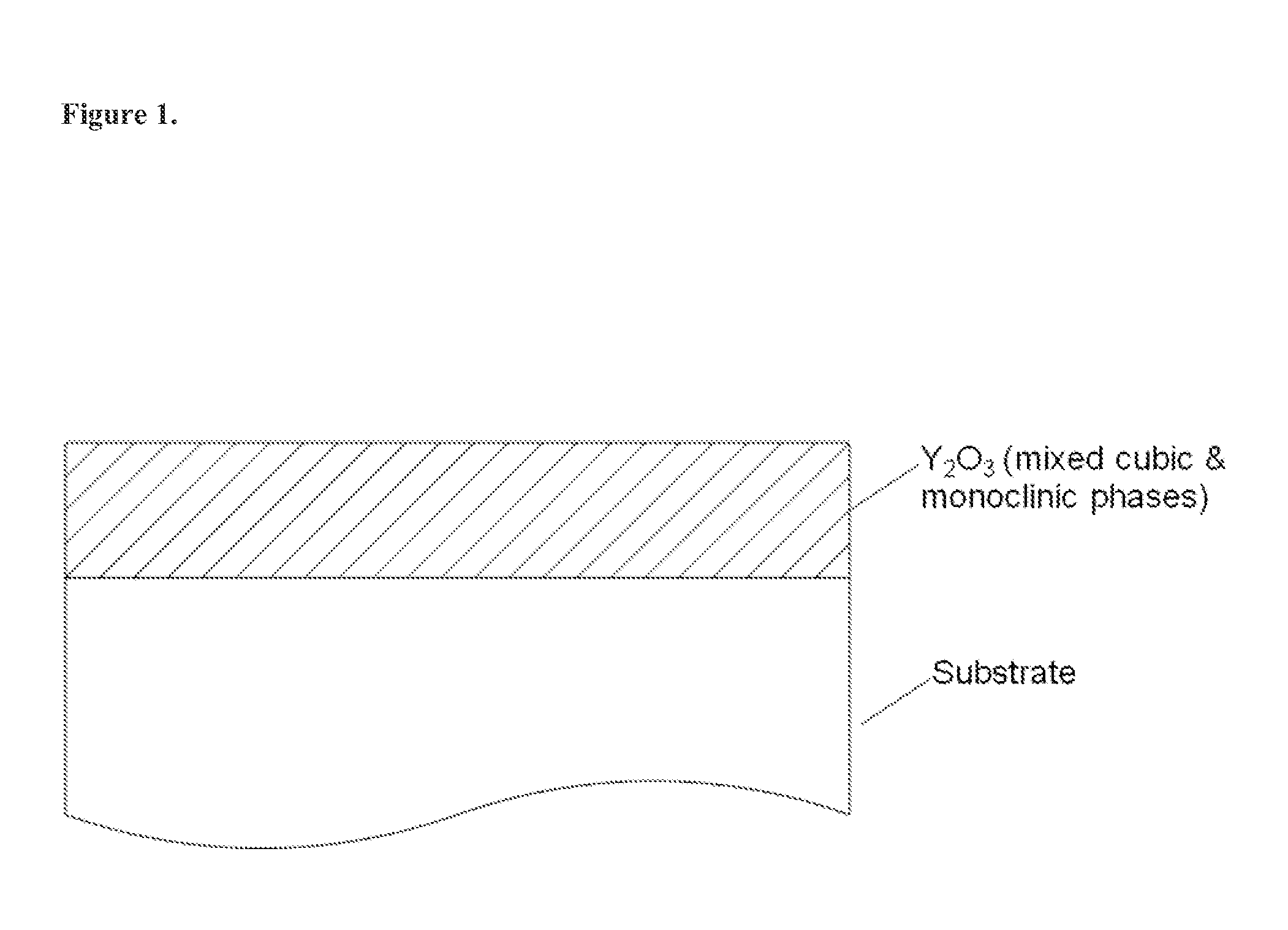

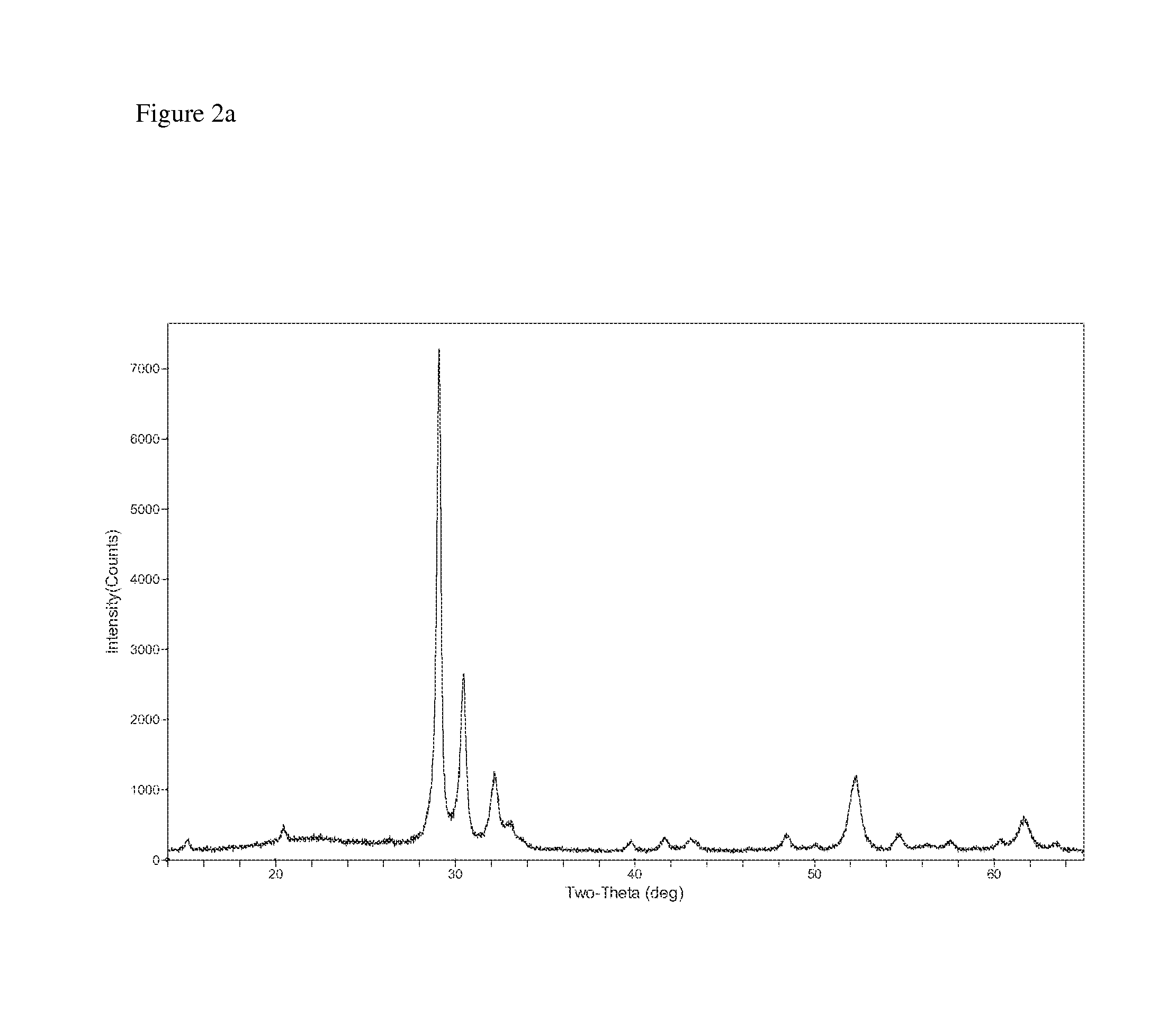

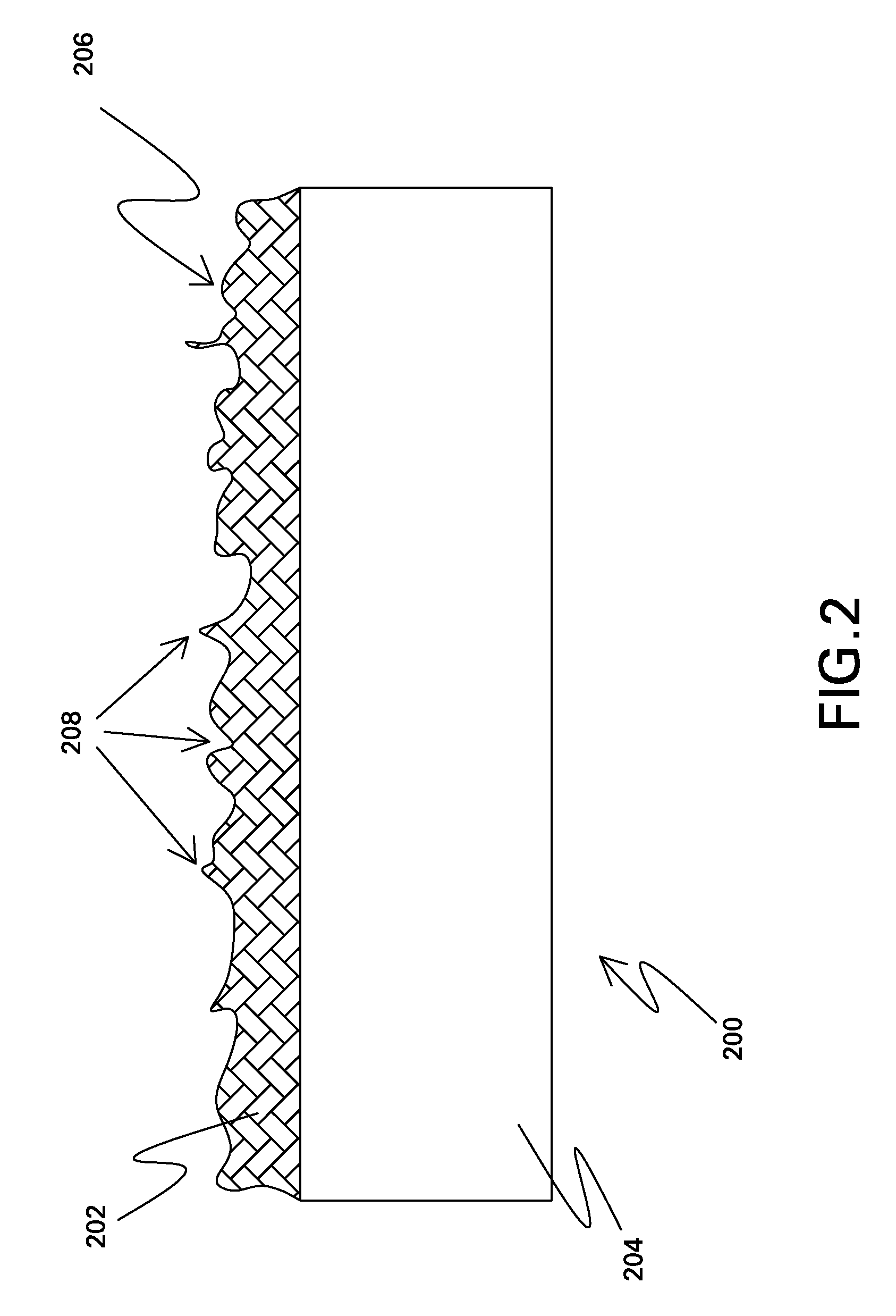

Plasma Etch Resistant Films, Articles Bearing Plasma Etch Resistant Films and Related Methods

InactiveUS20140099491A1Increasing substrate resistanceImprove fracture toughnessDecorative surface effectsSynthetic resin layered productsGas plasmaMaterials science

The invention includes a plasma etch-resistant film for a substrate comprising a yttria material wherein at least a portion of the yttria material is in a crystal phase having a crystal lattice structure, wherein at least 50% of the yttria material is in a form of a monoclinic crystal system. The film may be treated by exposure to a fluorine gas plasma. Also included are plasma etch-resistant articles that include a substrate and a film, wherein the film comprises an yttria material and at least a portion of the yttria material is present in the film in a crystal phase having a crystal lattice structure and at least 50% of the yttria material is in a form of a monoclinic crystal system. Several methods are contemplated within the scope of the invention.

Owner:GREENE TWEED TECH

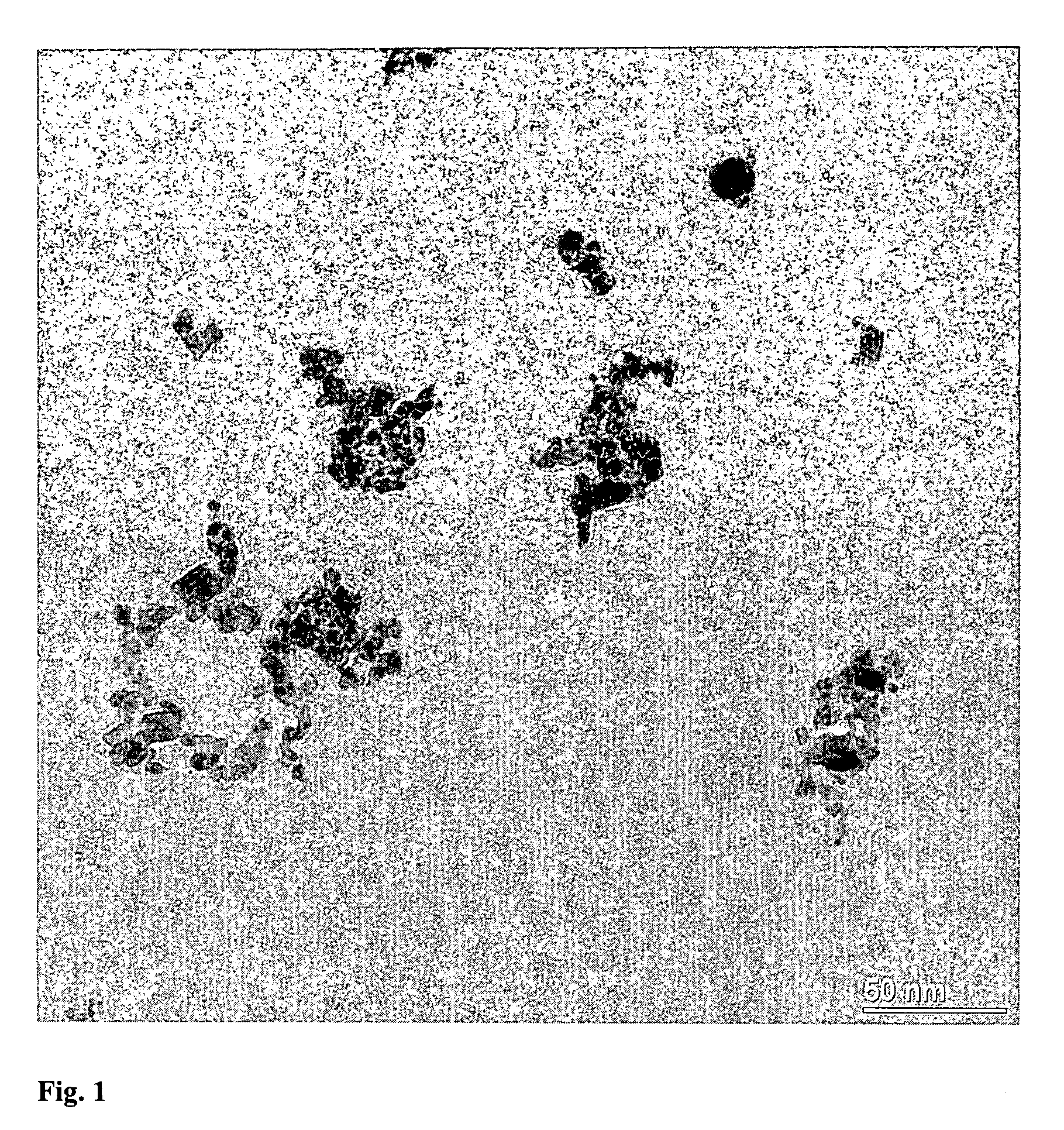

Aggregates of ceric oxide crystallites and reduction of vehicular emissions therewith

InactiveUS6093223ASmall sizeImprove stabilityMaterial nanotechnologyDispersed particle separationDebyeCerium

Vehicular emissions are reduced / purified via combustion of the hydrocarbon fuel therefor, e.g., diesel fuel, in the presence of a cerium compound, preferably a cerium (IV) compound, to produce soots having depressed ignition temperatures that contain effective purifying amounts of aggregates of ceric oxide crystallites, the largest particle size dimension of which ranging from 50 ANGSTROM (5 nanometers) to 10,000 ANGSTROM (1,000 nanometers) and the crystallite sizes of which, measured by Debye-Scherrer technique, ranging from 50 ANGSTROM (5 nanometers) to 250 ANGSTROM (25 nanometers).

Owner:RHONE POULENC CHEM SA

Cerium oxide particles and production method therefor

InactiveUS7431758B2Increase temperatureIncrease productionPigmenting treatmentOther chemical processesProduction rateCerium

The production method for cerium oxide particles of the present invention is a method of producing a cerium oxide particle by heating a cerium compound from a normal temperature to a temperature range of 400° C. to 1200° C., and comprises at least a temperature raising stage of a temperature rise speed of 2° C. / hour to 60° C. / hour, or proceeds via a stage of heating while supplying a humidified gas in a temperature raising process. By the method of the present invention, a cerium oxide powder whose particle diameter distribution of primary particles is narrow can be obtained. An aqueous cerium oxide slurry produced from the powder enables an improvement in the productivity and a reduction in the cost of a polishing step, because if it is used as an abrasive a high-quality polished face is obtained without deteriorating the polishing speed. The aqueous cerium oxide slurry of the present invention is particularly useful as an abrasive for final finish of a substrate whose main component is silica.

Owner:NISSAN CHEM CORP

Metal delivery system for nanoparticle manufacture

ActiveUS20060229197A1Improve productivityWell mixedRare earth metal oxides/hydroxidesMolten spray coating2-Ethylhexanoic acidMetallacarboxylic acid

Described is a method for the production of pure or mixed metal oxides, wherein at least one metal precursor that is a metal carboxylate with a mean carbon value per carboxylate group of at least 3, e.g. the 2-ethyl hexanoic acid salt, is formed into droplets and e.g. flame oxidized. The method is performed at viscosities prior to droplet formation of usually less than 40 mPa s, obtained by heating and / or addition of one or more low viscosity solvents with adequately high enthalpy.

Owner:ETH ZURICH THE SHORT NAME OF EID GENOSSISCHE TECHN HOCHSCHULE ZURICH

Nanoparticles of rare earth oxides

ActiveUS20070104629A1Increase volumeLow cost productionMaterial nanotechnologyLanthanum oxide/hydroxidesCeriumScandium

Rare earth compositions comprising nanoparticles, methods of making nanoparticles, and methods of using nanoparticles are described. The compositions of the nanomaterials discussed may include scandium (Sc), yttrium (Y), lanthanum(La), cerium (Ce), praseodymium (Pr), neodymium (Nd), promethium (Pm), samarium (Sm), europium (Eu), gadolinium(Gd), terbium (Tb), dysprosium (Dy), holmium (Ho), erbium (Er), thulium (Tm), ytterbium (Yb), and lutetium (Lu). The nanoparticles can be used to make organometallics, nitrates, and hydroxides. The nanoparticles can be used in a variety of applications, such as pigments, catalysts, polishing agents, coatings, electroceramics, catalysts, optics, phosphors, and detectors.

Owner:PPG IND OHIO INC

Metal oxide nanoparticles and process for producing the same

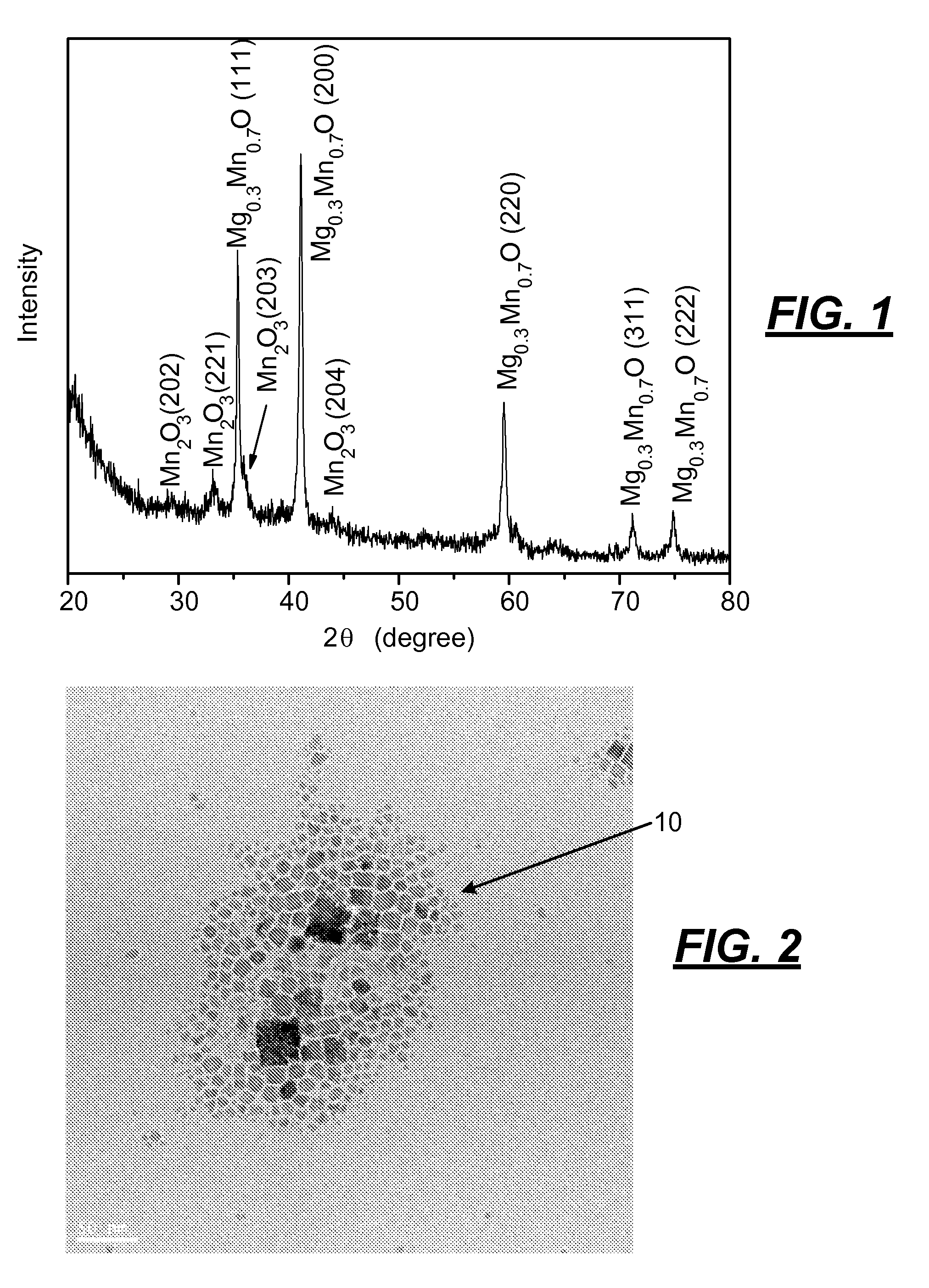

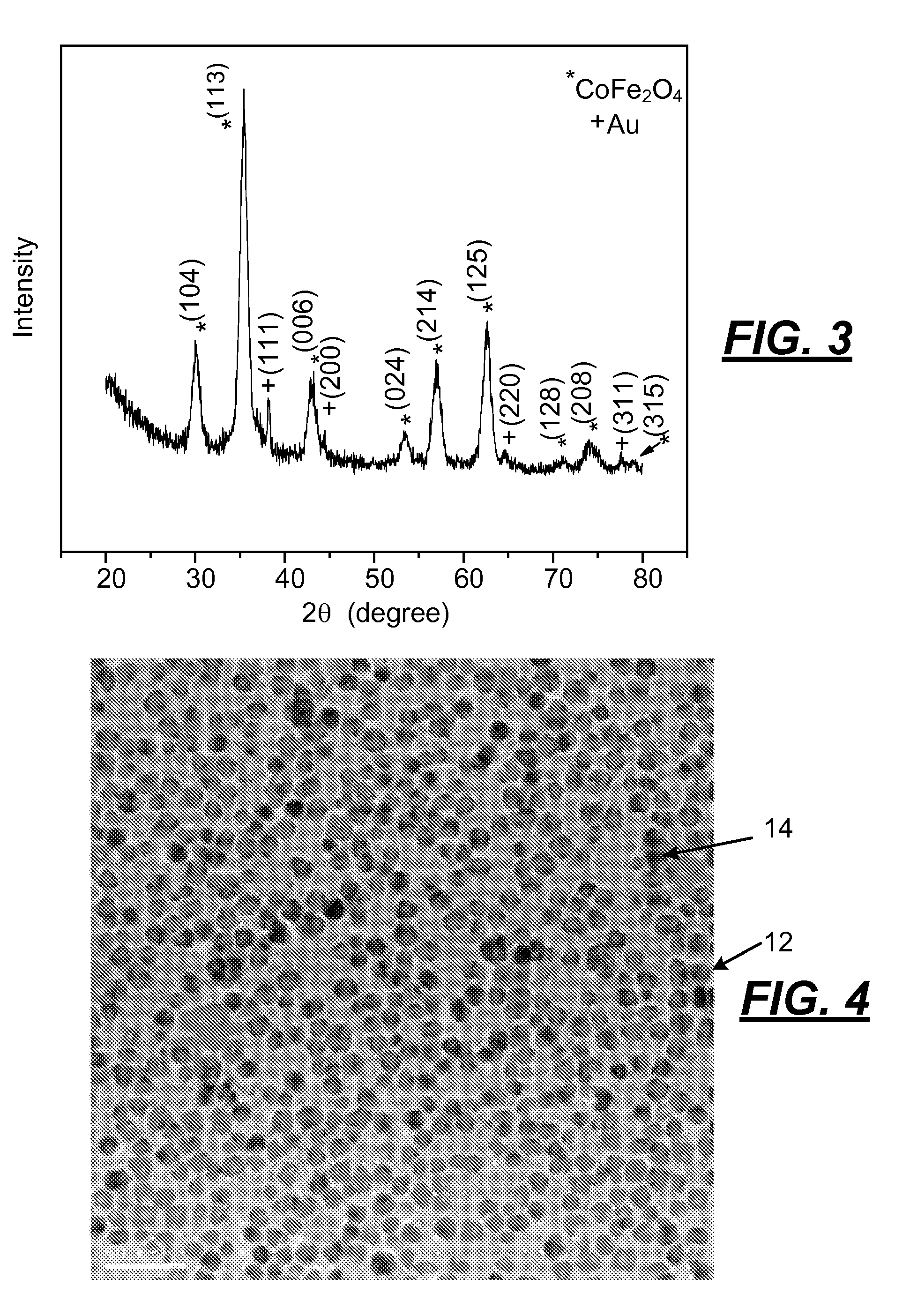

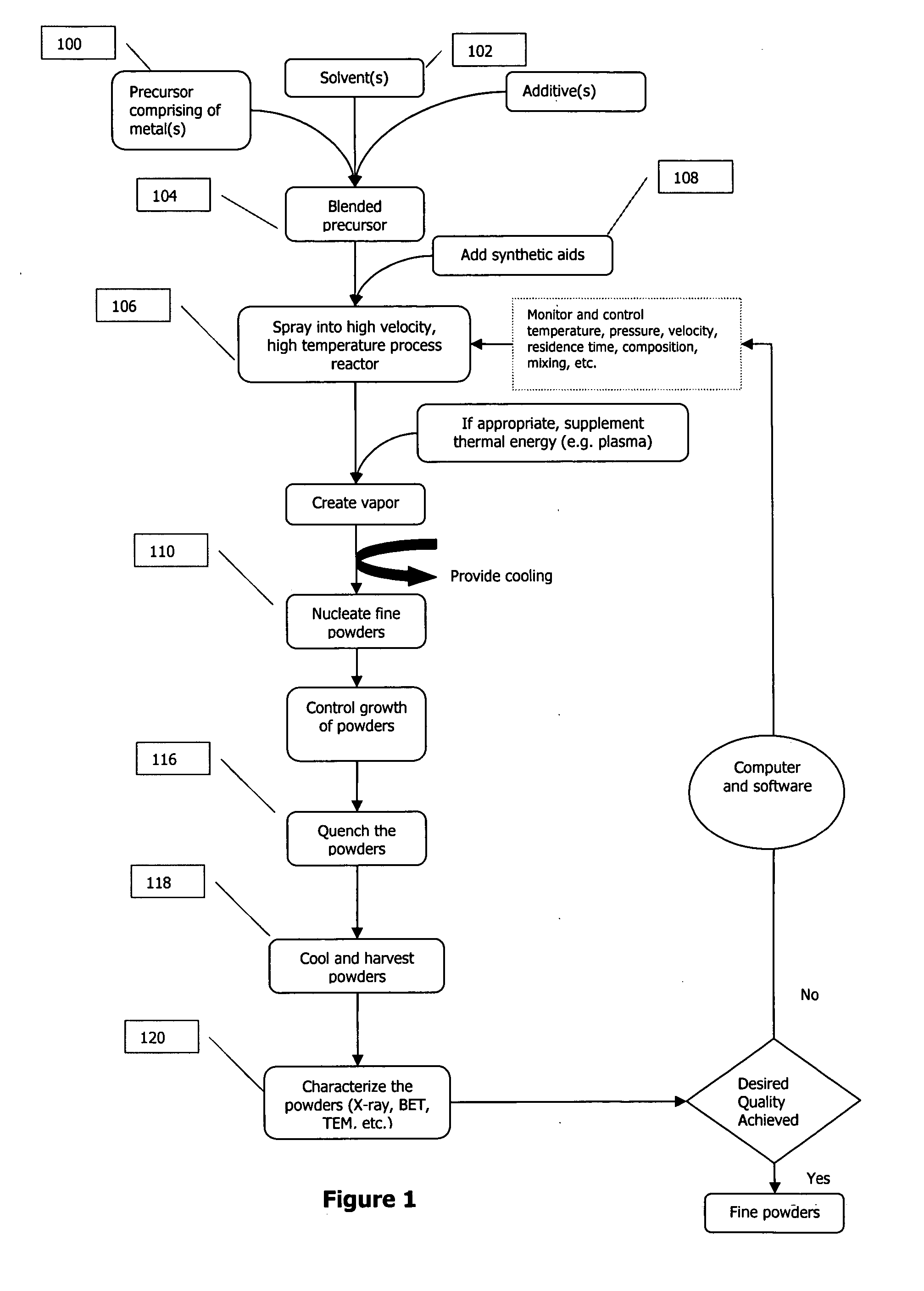

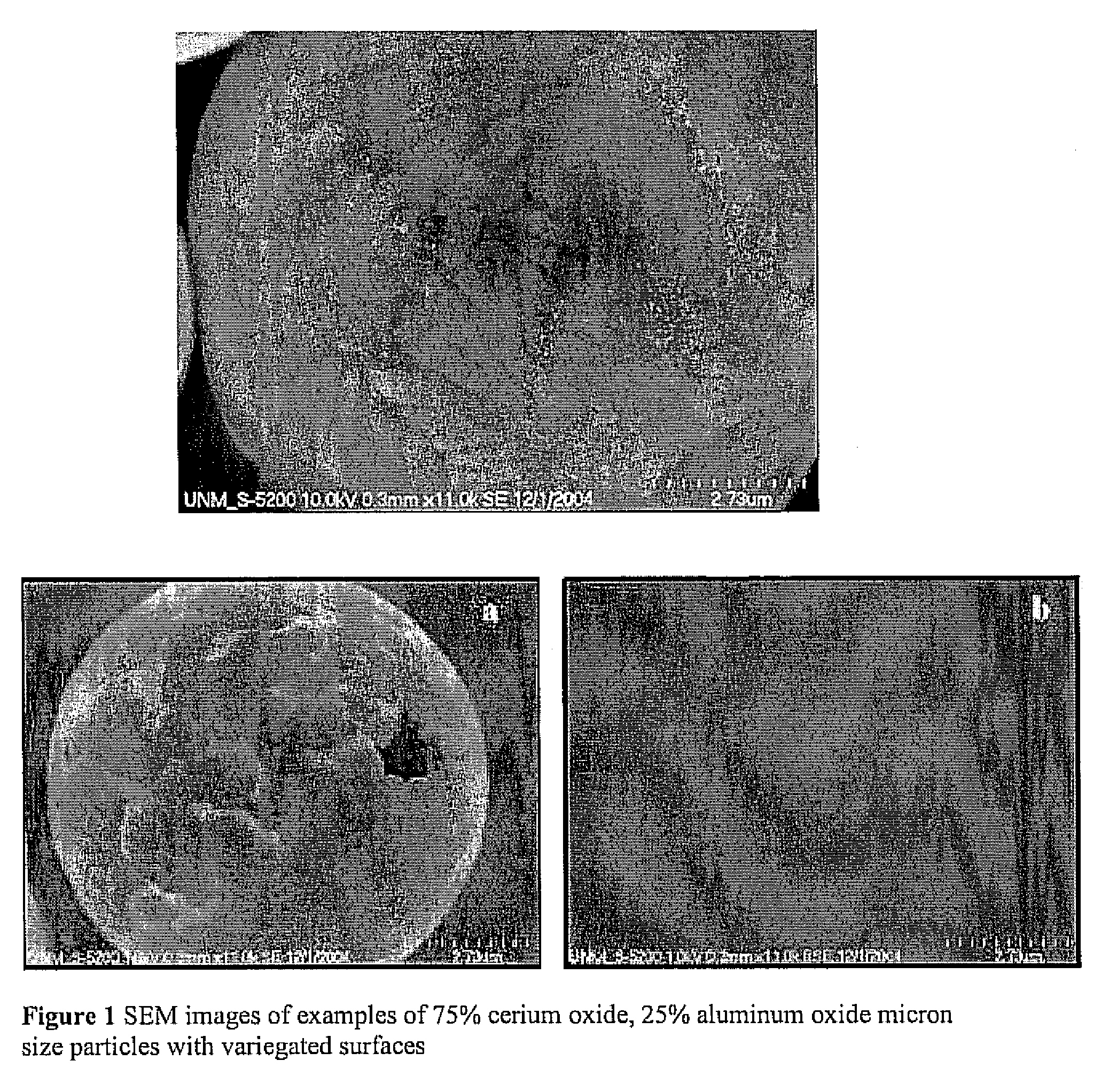

There is disclosed a process for producing metal oxide nanoparticles. The process includes the steps of: a) providing at least two precursor metal salt materials, b) passing the at least two precursor metal salt materials through a plasma torch forming a vaporized material, and then c) condensing the vaporized material forming a metal oxide nanoparticle.

Owner:STC UNM +2

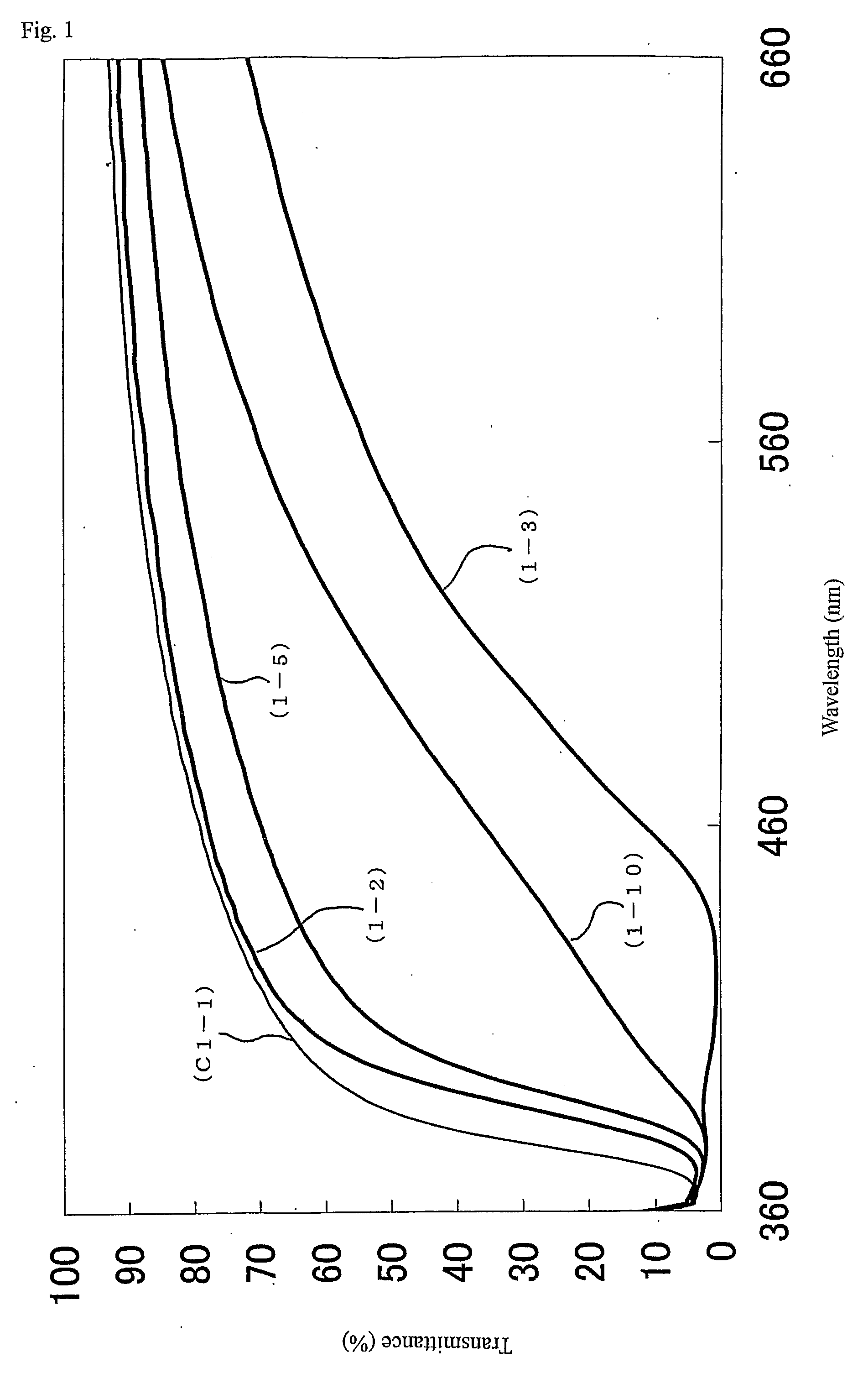

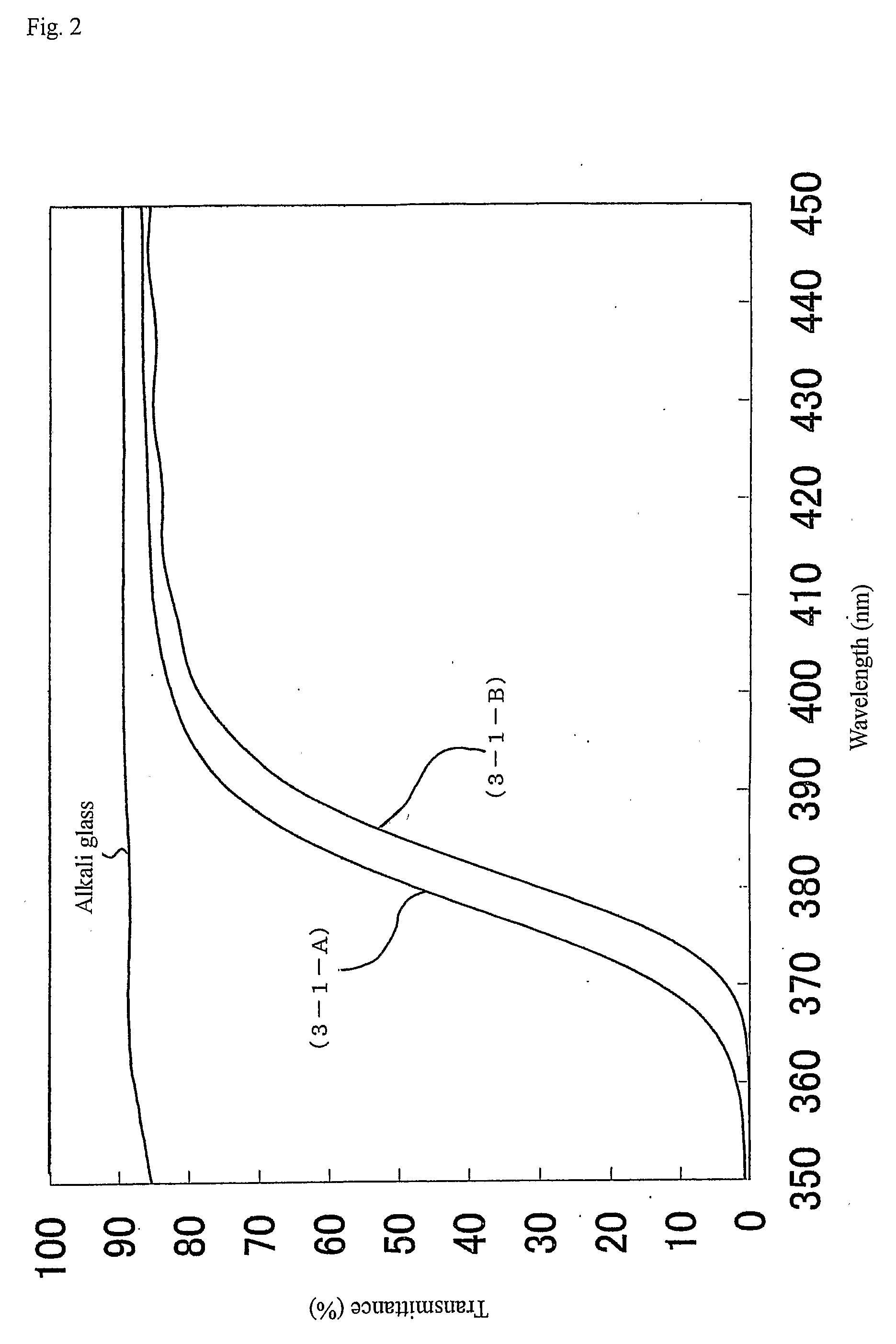

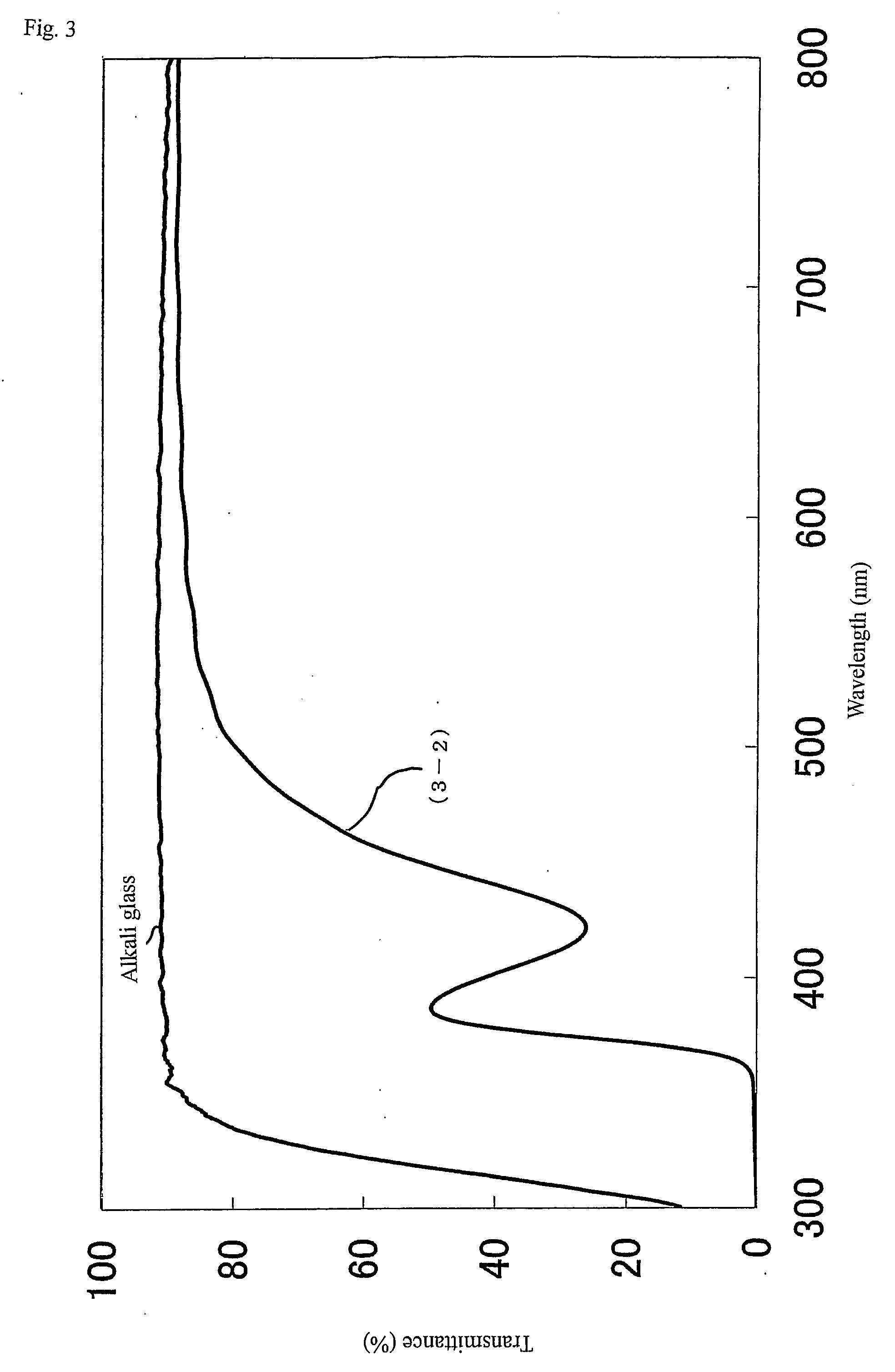

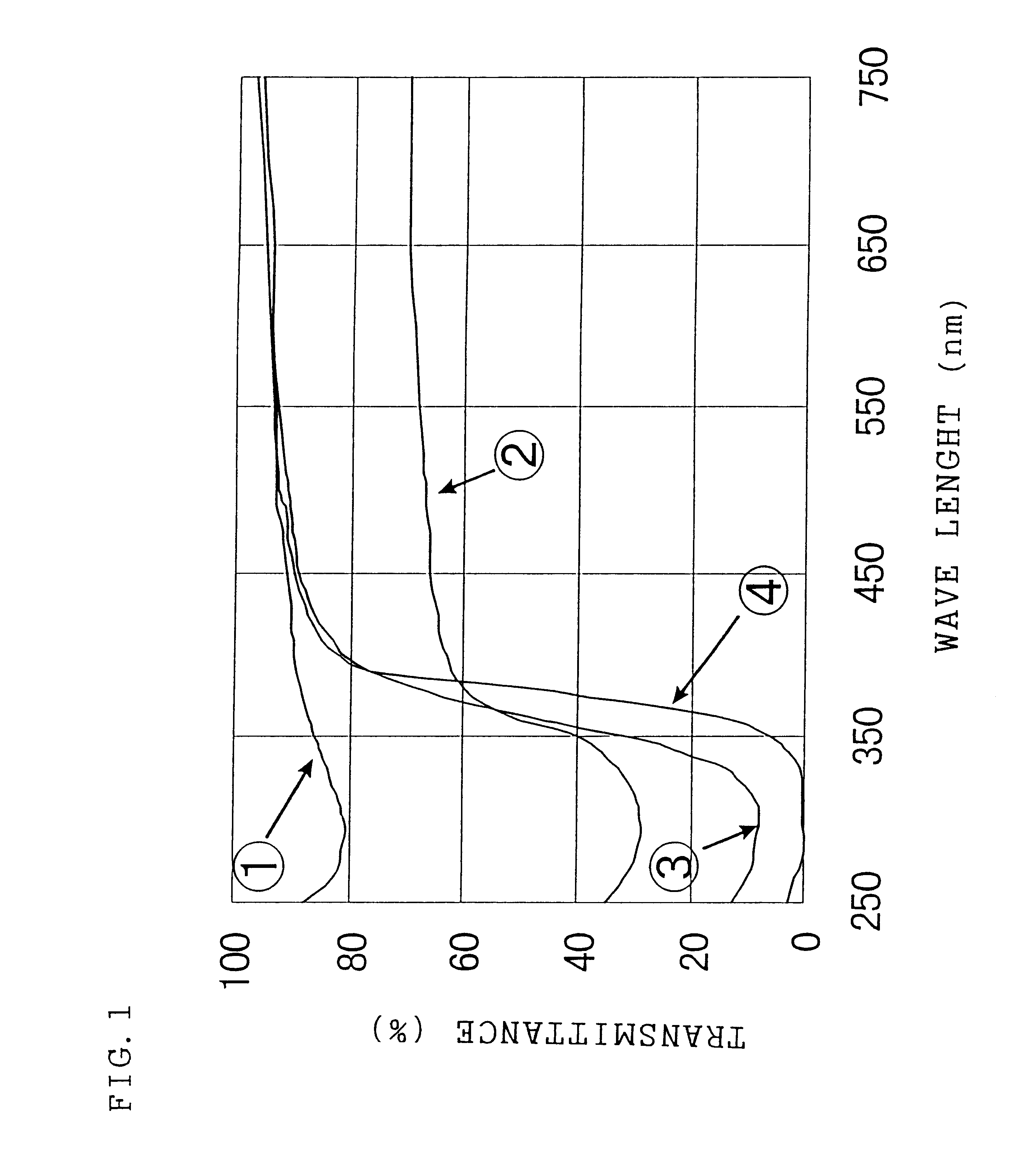

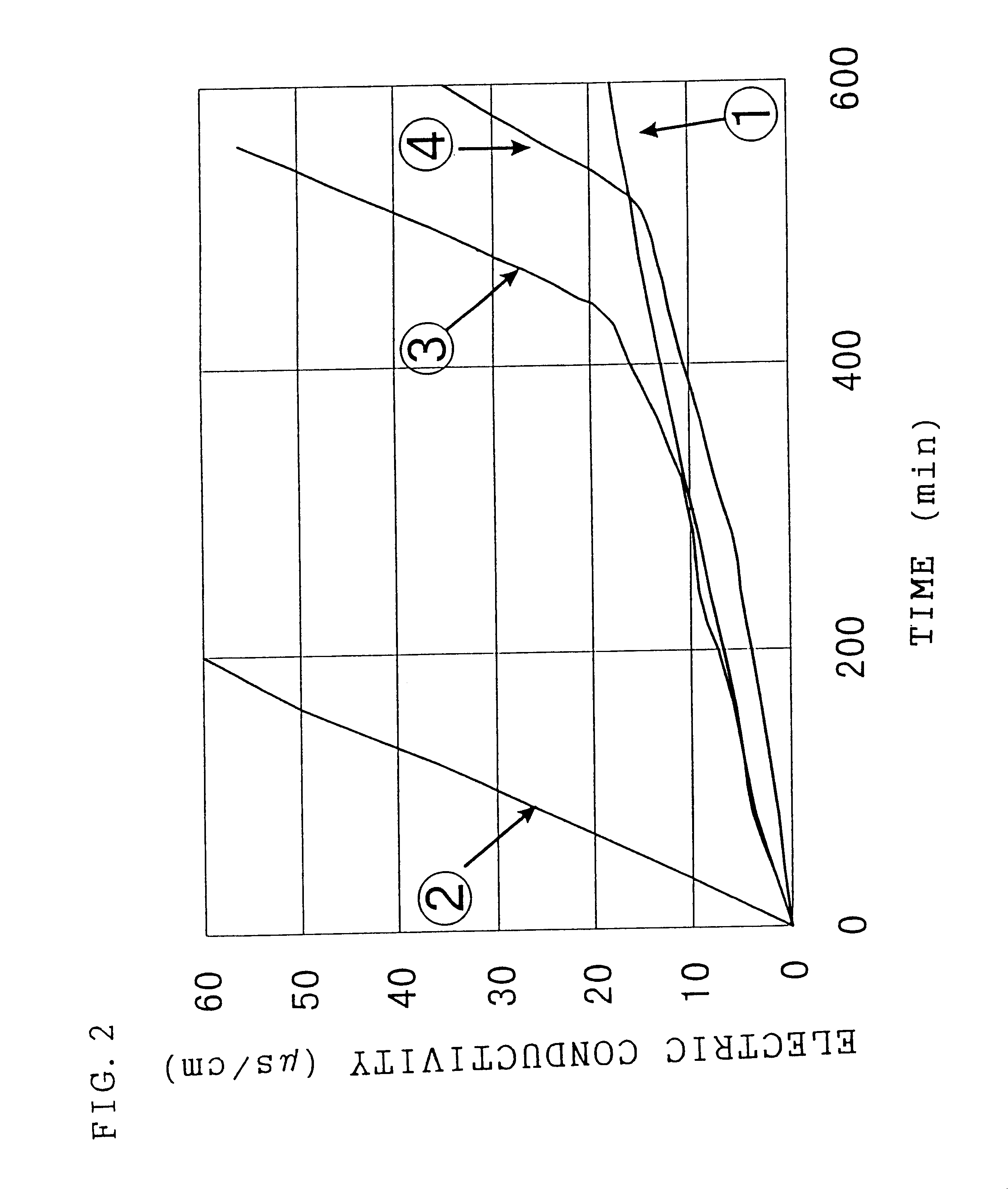

Method for preparation of metal oxide doped cerium oxide

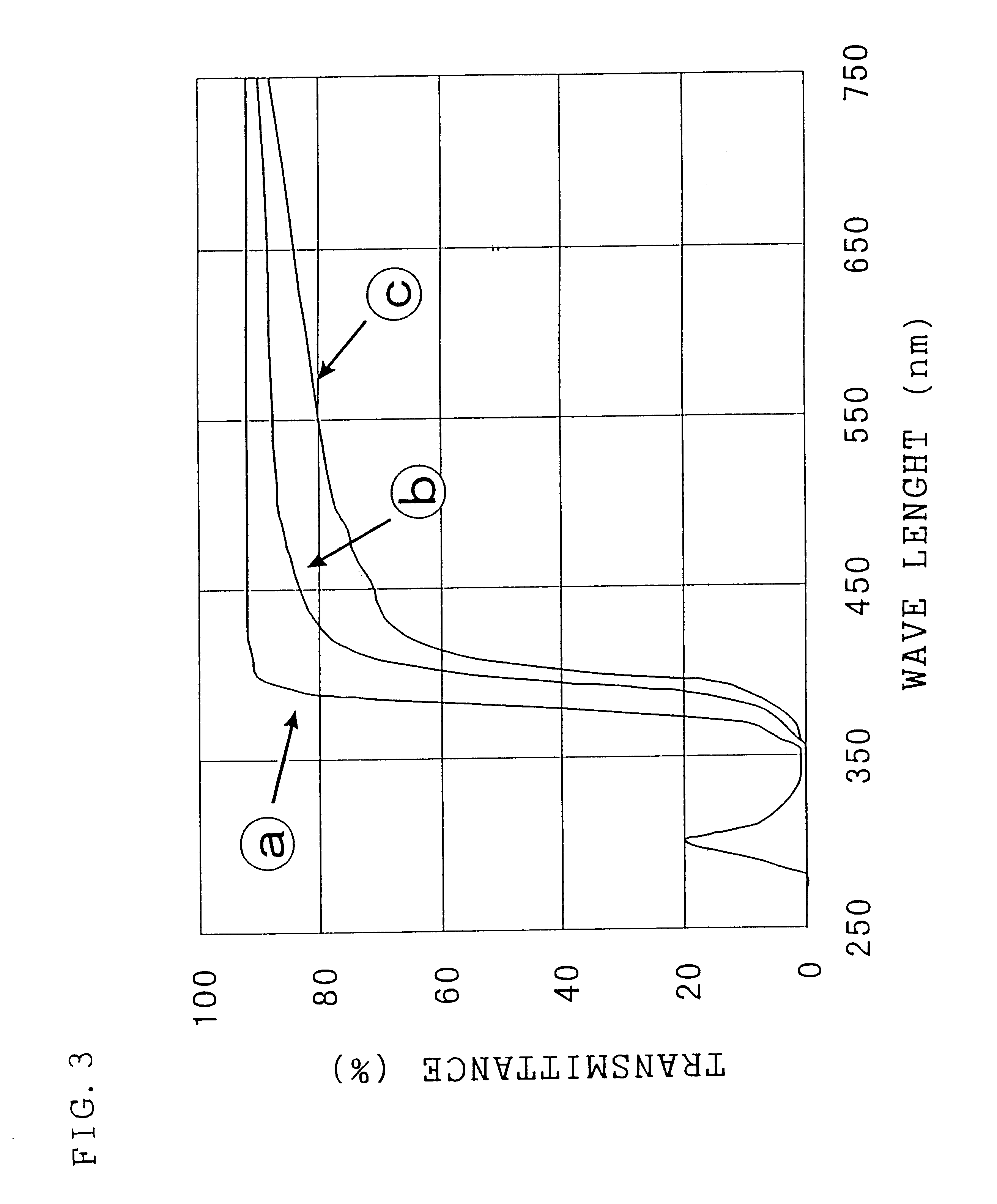

InactiveUS6589496B1Improve shielding effectHigh transparencyCosmetic preparationsMaterial nanotechnologyCeriumUltraviolet

A metal oxide doped cerium oxide has an excellent ultraviolet ray shielding effect and transparency and reduced catalytic activity. The doping mextal oxide is an oxide of a metal ion having larger ion radius than that of Ce4+ and / or lower valence metal ion than Ce4+, such as Ca2+, Y3+, La3+, Nd3+, Eu3+, Tb3+, Sm3+, Mg2+, Sr2+, Ba2+, Ce3+. The metal oxide doped cerium is prepared by reacting aqueous solution of cerium salt, aqueous solution of metal ion having larger ion radius than that of Ce4+ and / or lower valence metal ion than Ce4+ and alkali at a temperature lower than 60° C. and at pH higher than 5. An oxidizing agent may be present together with the alkali or added subsequently. Resin compositions or cosmetic compositions blended with the metal oxide doped cerium oxide have improved ultraviolet shielding effect without spoiling transparency in the visible ray region.

Owner:DAITO KASEI KOGYO CO LTD

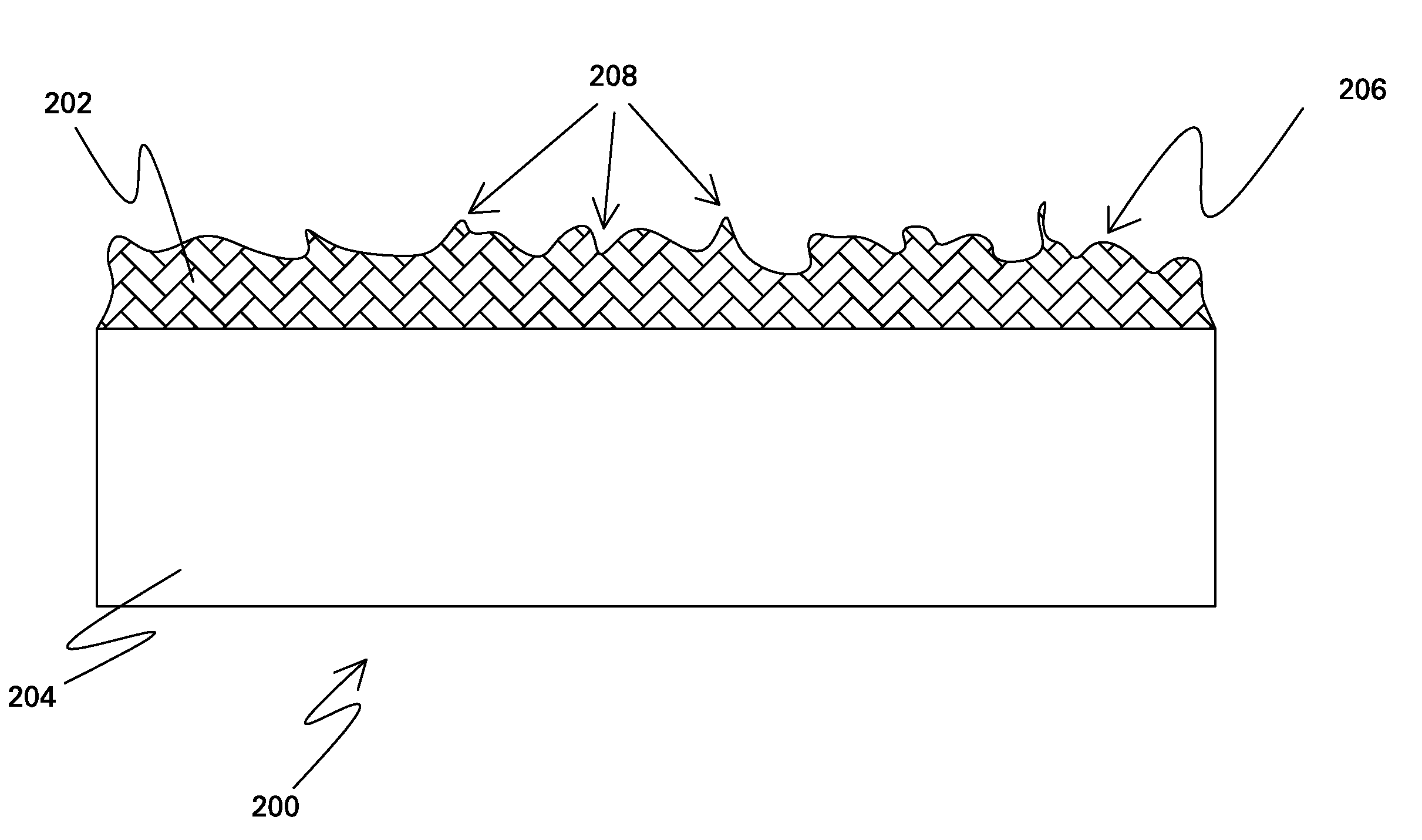

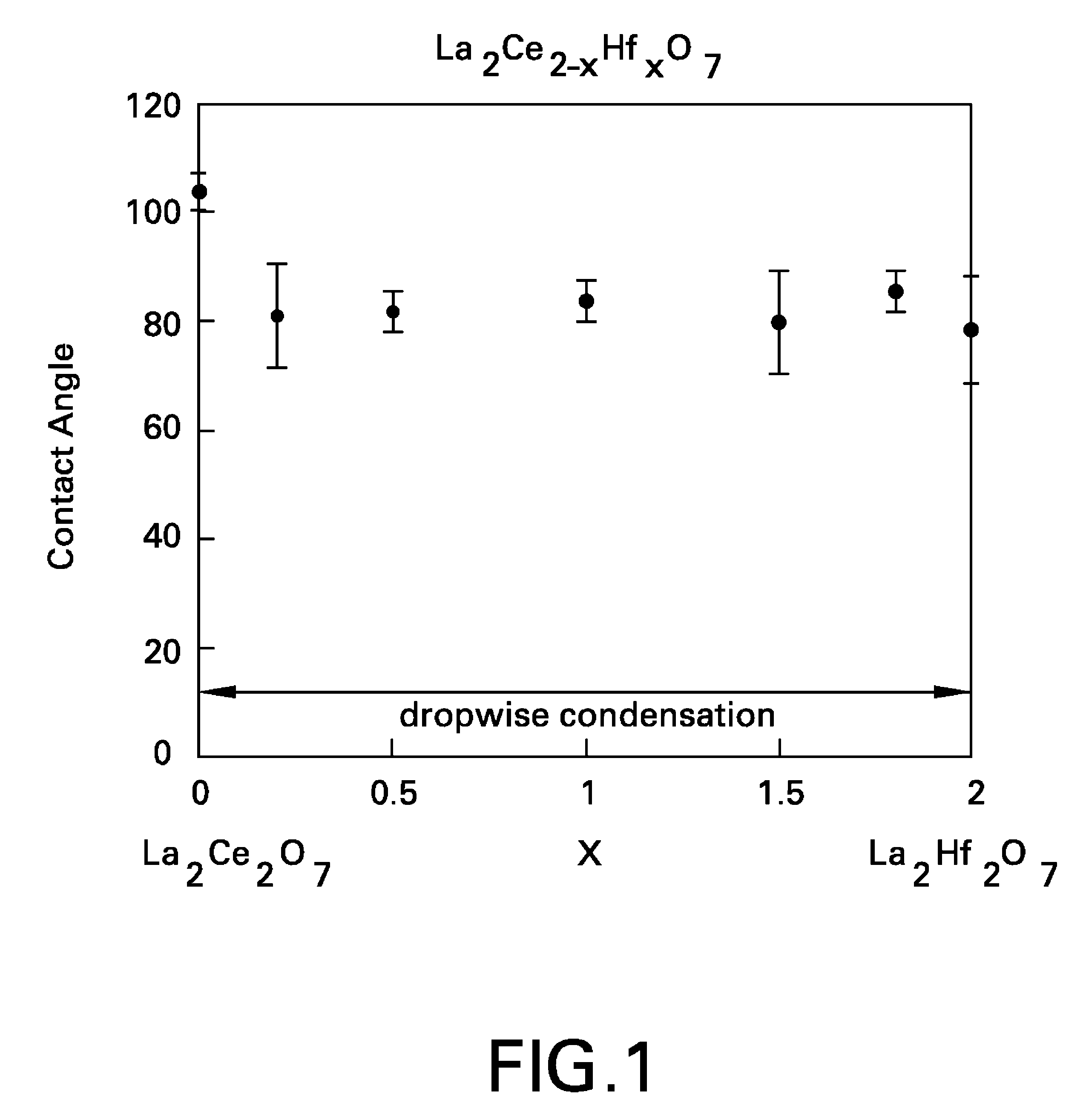

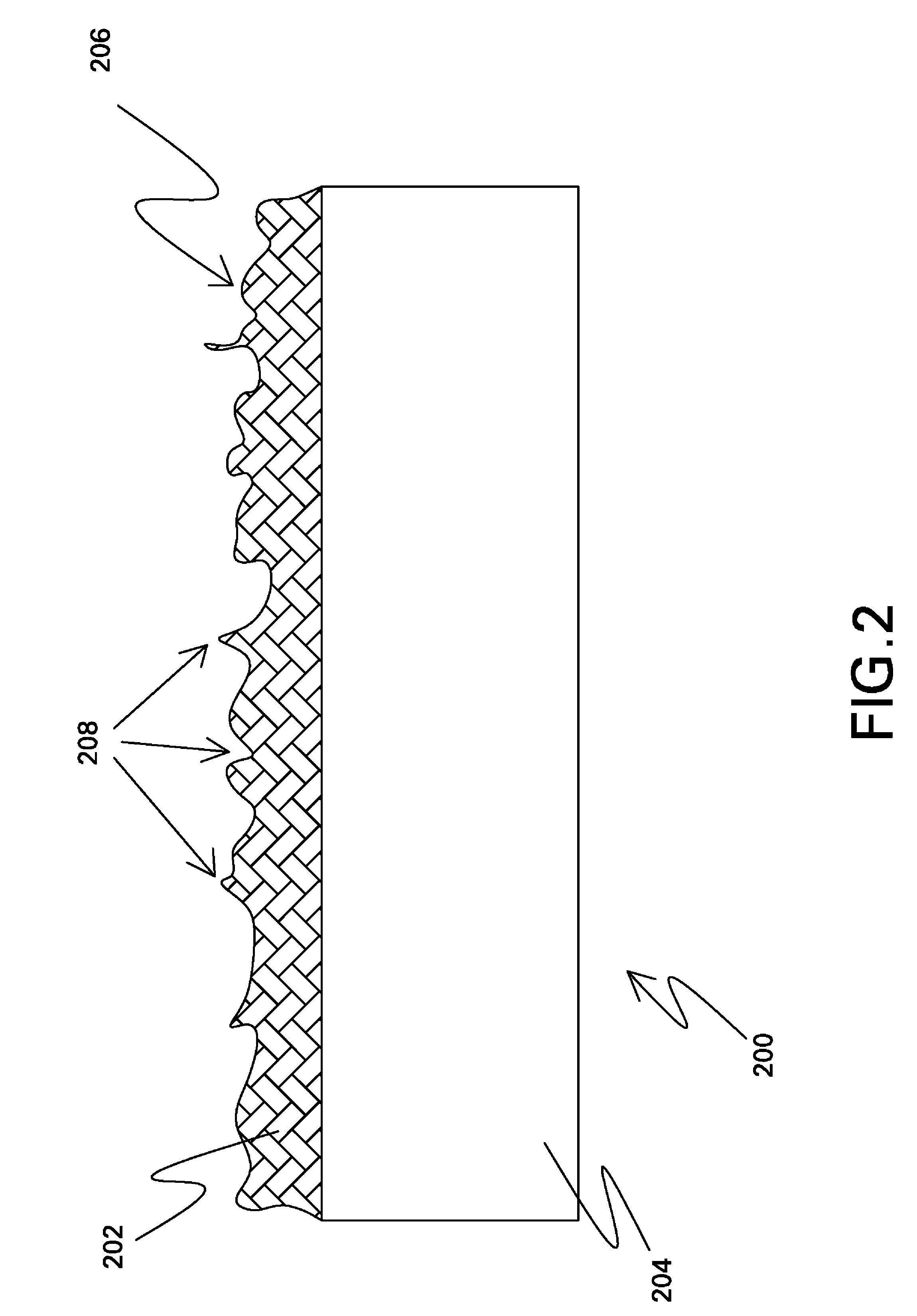

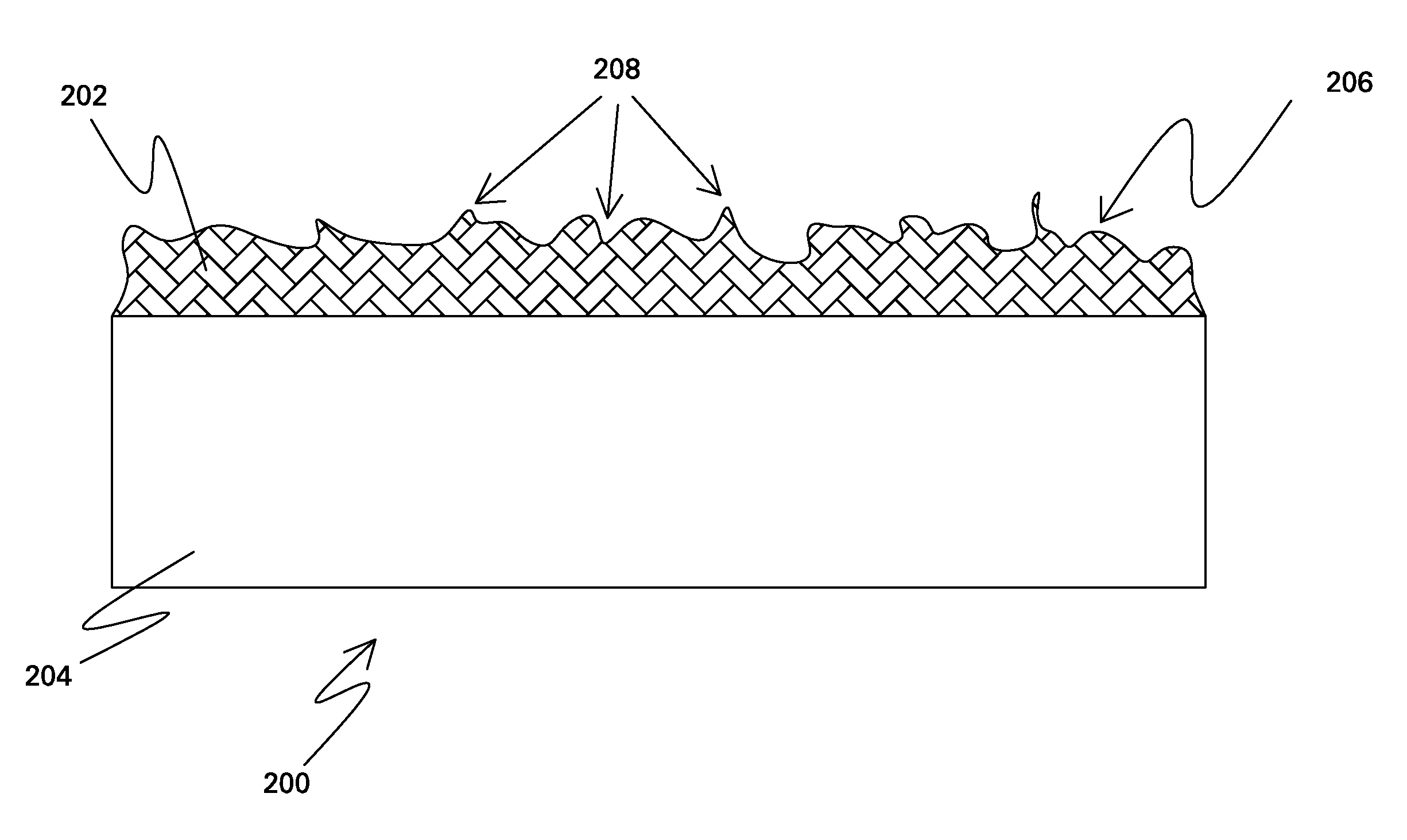

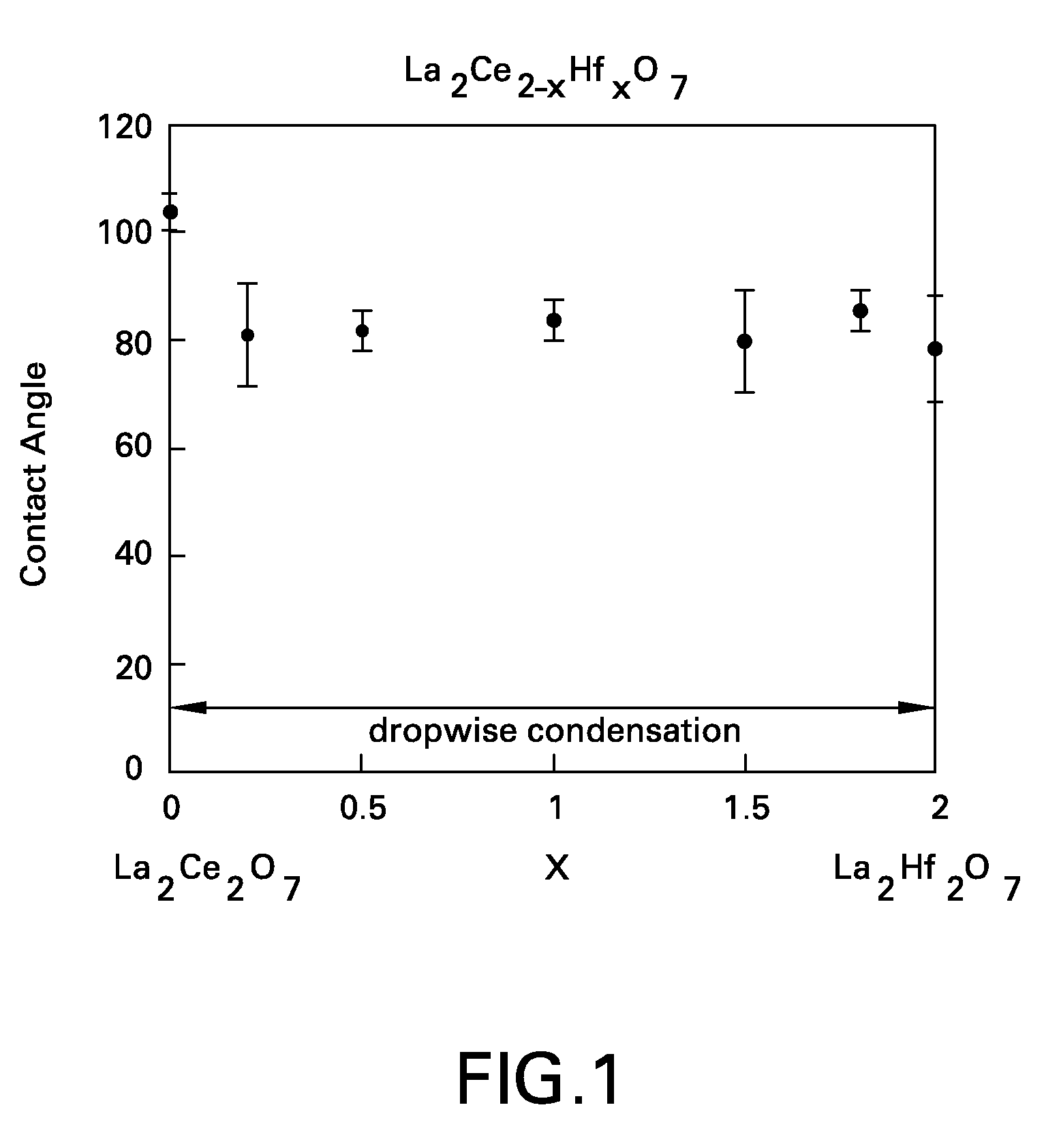

Wetting resistant materials and articles made therewith

Ceramic materials with relatively high resistance to wetting by various liquids, such as water, are presented, along with articles made with these materials, methods for making these articles and materials, and methods for protecting articles using coatings made from these materials. One particular embodiment is an article that comprises a coating having a surface connected porosity content of up to about 5 percent by volume. The coating comprises a material that comprises a primary oxide and a secondary oxide, wherein (i) the primary oxide comprises a cation selected from the group consisting of cerium, praseodymium, terbium, and hafnium, and (ii) the secondary oxide comprises a cation selected from the group consisting of the rare earth elements, yttrium, and scandium. The material is transparent to electromagnetic radiation of at least one type selected from the group consisting of ultraviolet radiation, visible light, and infrared radiation.

Owner:GENERAL ELECTRIC CO

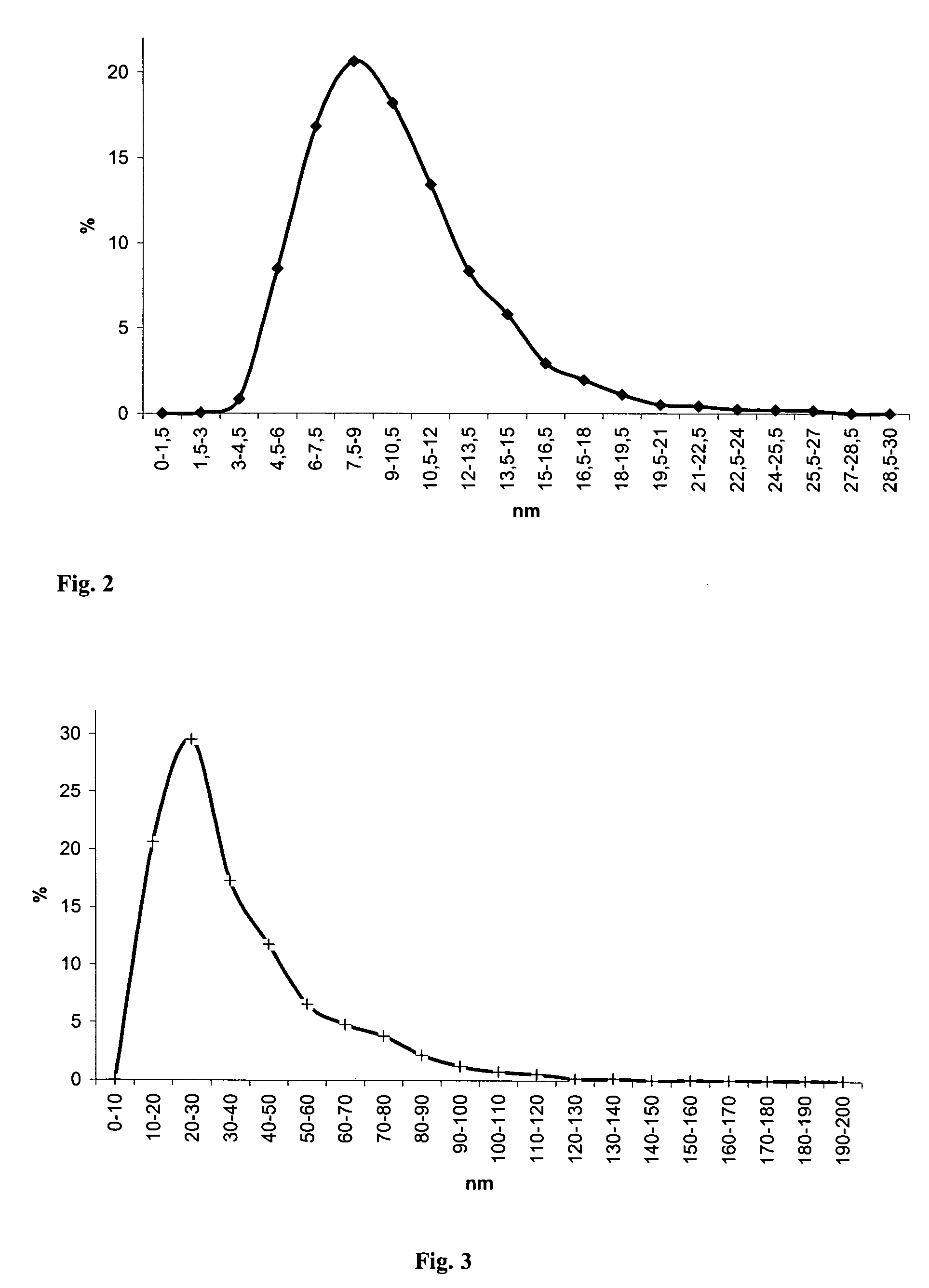

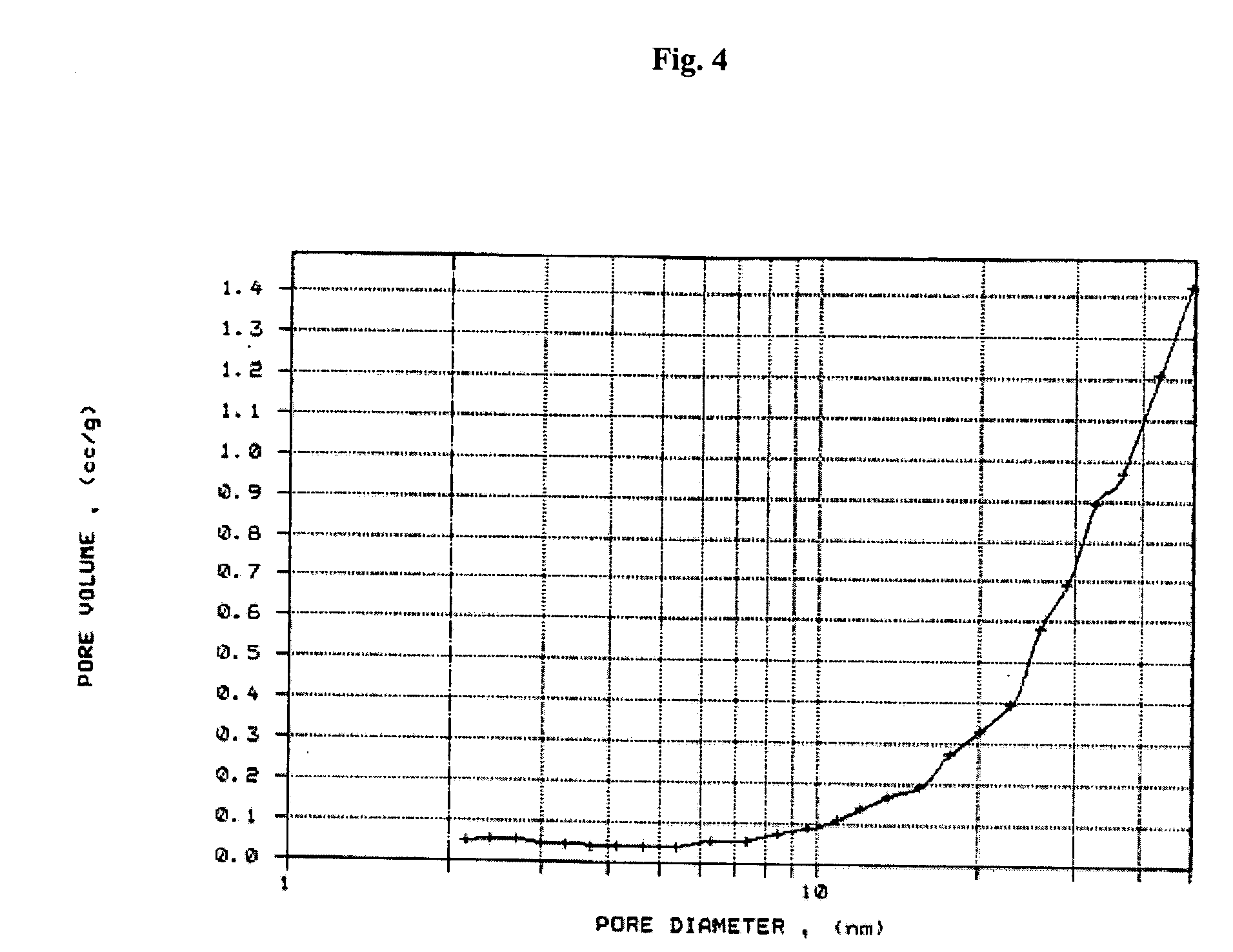

Cerium oxide powder

ActiveUS20050036928A1Improve stabilityEasy to mergePigmenting treatmentMaterial nanotechnologyHydrogenMetallurgy

Polycrystalline cerium oxide powder in the form of aggregates of primary particles with a specific surface of between 70 and 150 m2 / g, an average primary particle diameter of between 5 and 20 nm and an average, projected aggregate diameter of between 20 and 100 nm. It is produced in that an aerosol is reacted in a flame obtained from a hydrogen-containing combustible gas and primary air and the solid obtained is then separated from the gaseous substances.

Owner:EVONIK OPERATIONS GMBH

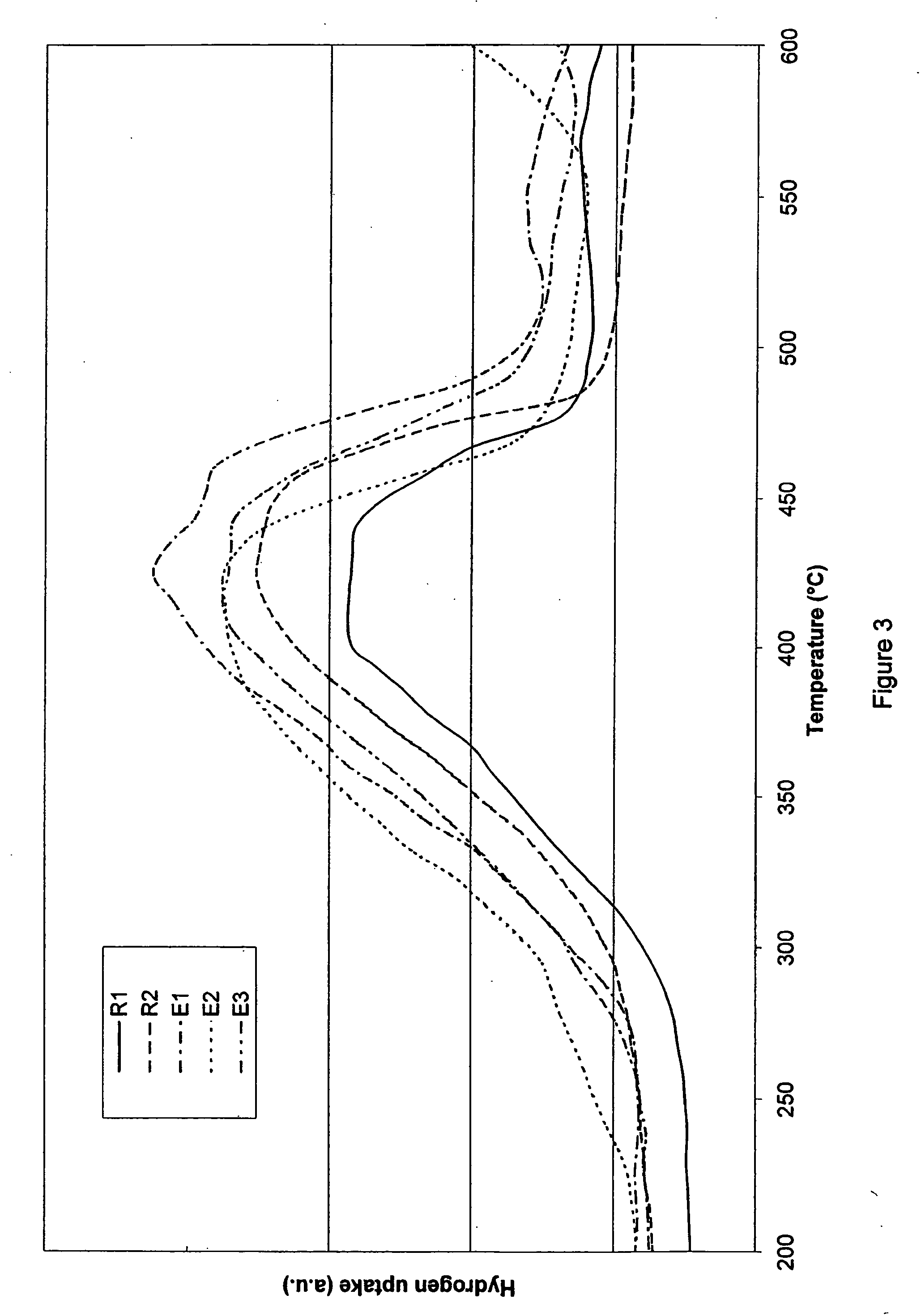

Flame made metal oxides

ActiveUS20040126298A1Improve stabilitySmall crystal sizeMaterial nanotechnologyZirconium oxidesCarboxylic acidSolvent

Described is a method for the production of metal oxides, in particular mixed metal oxides such as ceria / zirconia, and metal oxides obtainable by said method. Due to high enthalpy solvents with a high carboxylic acid content said metal oxides have improved properties. For example ceria / zirconia has excellent oxygen storage capacity at high zirconium levels up to more than 80% of whole metal content.

Owner:EIDGENOSSISCHE TECHN HOCHSCULE ZURICH

Wetting resistant materials and articles made therewith

Ceramic materials with relatively high resistance to wetting by various liquids, such as water, are presented, along with articles made with these materials, methods for making these articles and materials, and methods for protecting articles using coatings made from these materials. One embodiment is an article comprising a material that is transparent to electromagnetic radiation of at least one type selected from the group consisting of ultraviolet radiation, visible light, and infrared radiation. The material comprises a primary oxide and a secondary oxide. The primary oxide comprises cerium and hafnium. The secondary oxide comprises a secondary oxide cation selected from the group consisting of the rare earth elements, yttrium, and scandium. Another embodiment is an article comprising a material that is transparent to electromagnetic radiation of at least one type selected from the group consisting of ultraviolet radiation, visible light, and infrared radiation. The material comprises a primary oxide and a secondary oxide. The primary oxide comprises cerium or hafnium. The secondary oxide comprises (i) praseodymium or ytterbium, and (ii) another cation selected from the group consisting of the rare earth elements, yttrium, and scandium.

Owner:GENERAL ELECTRIC CO

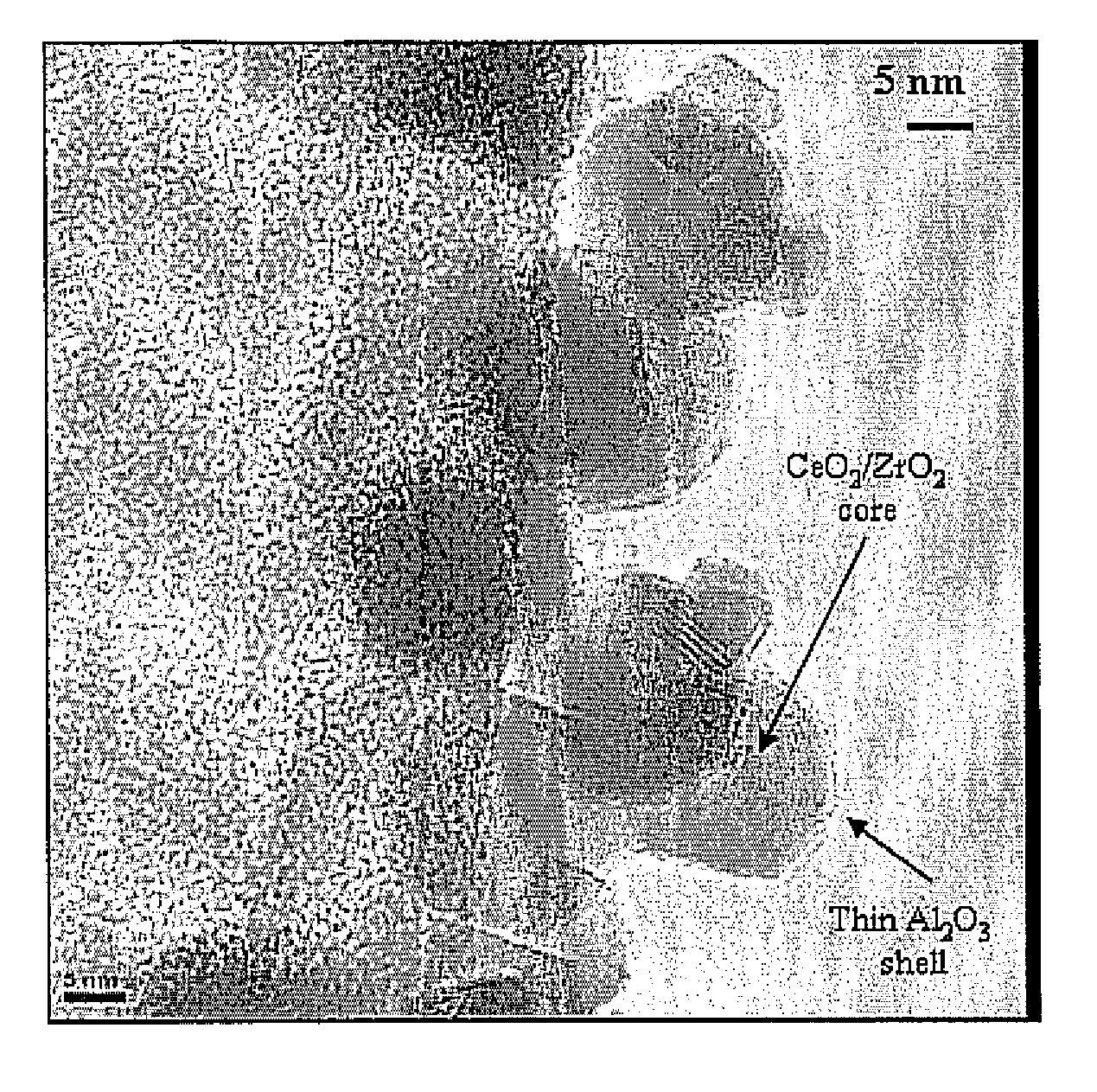

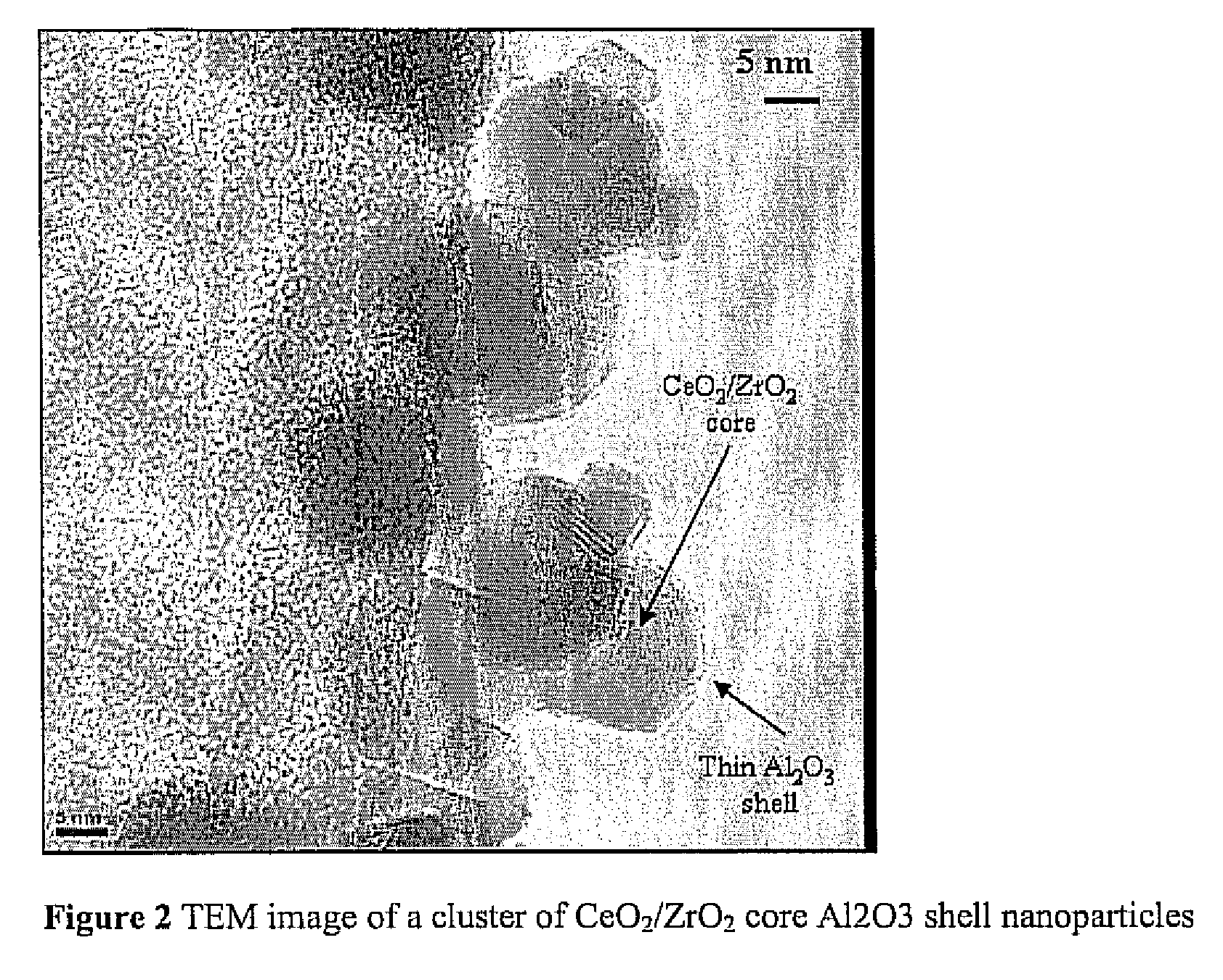

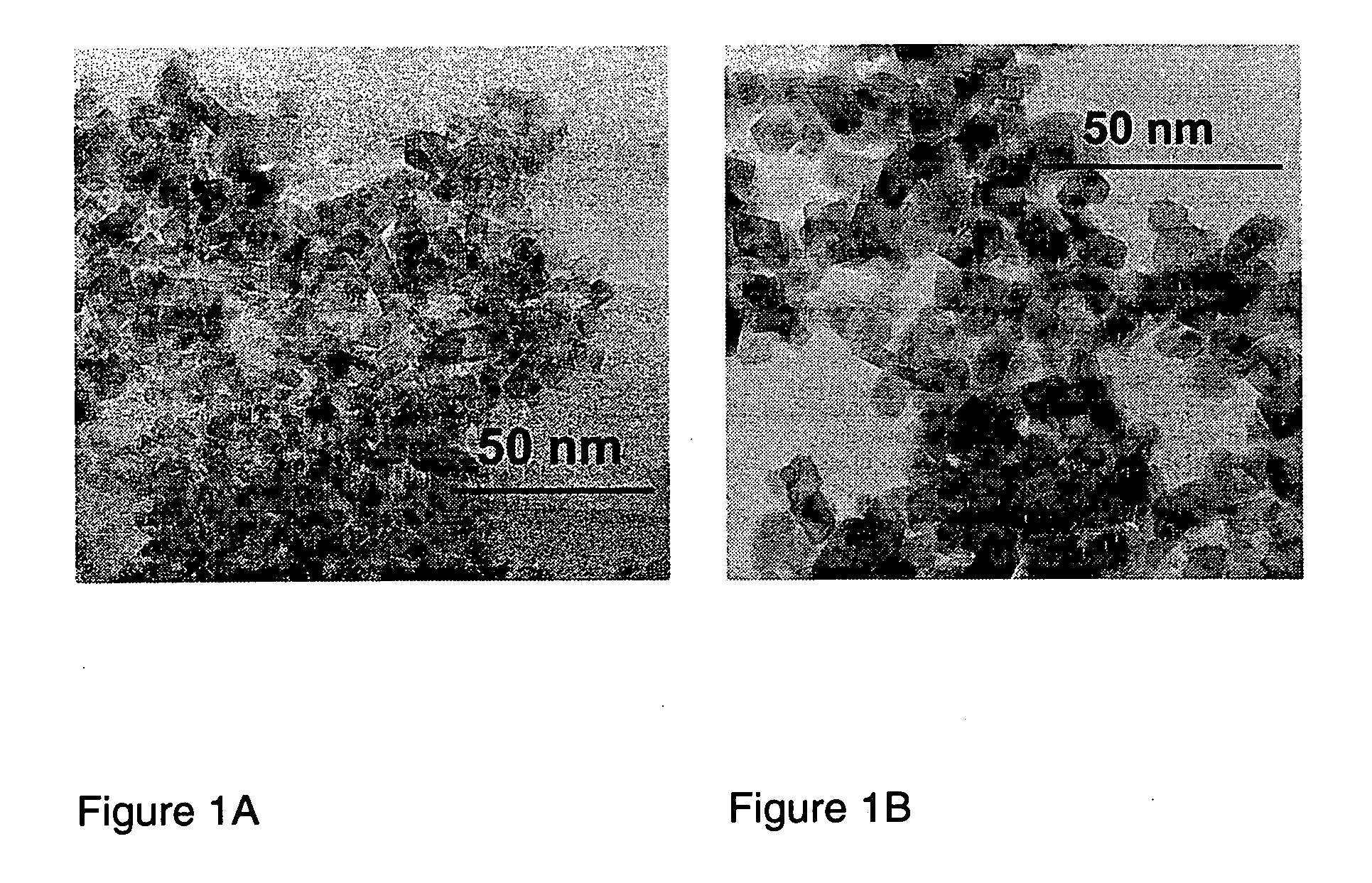

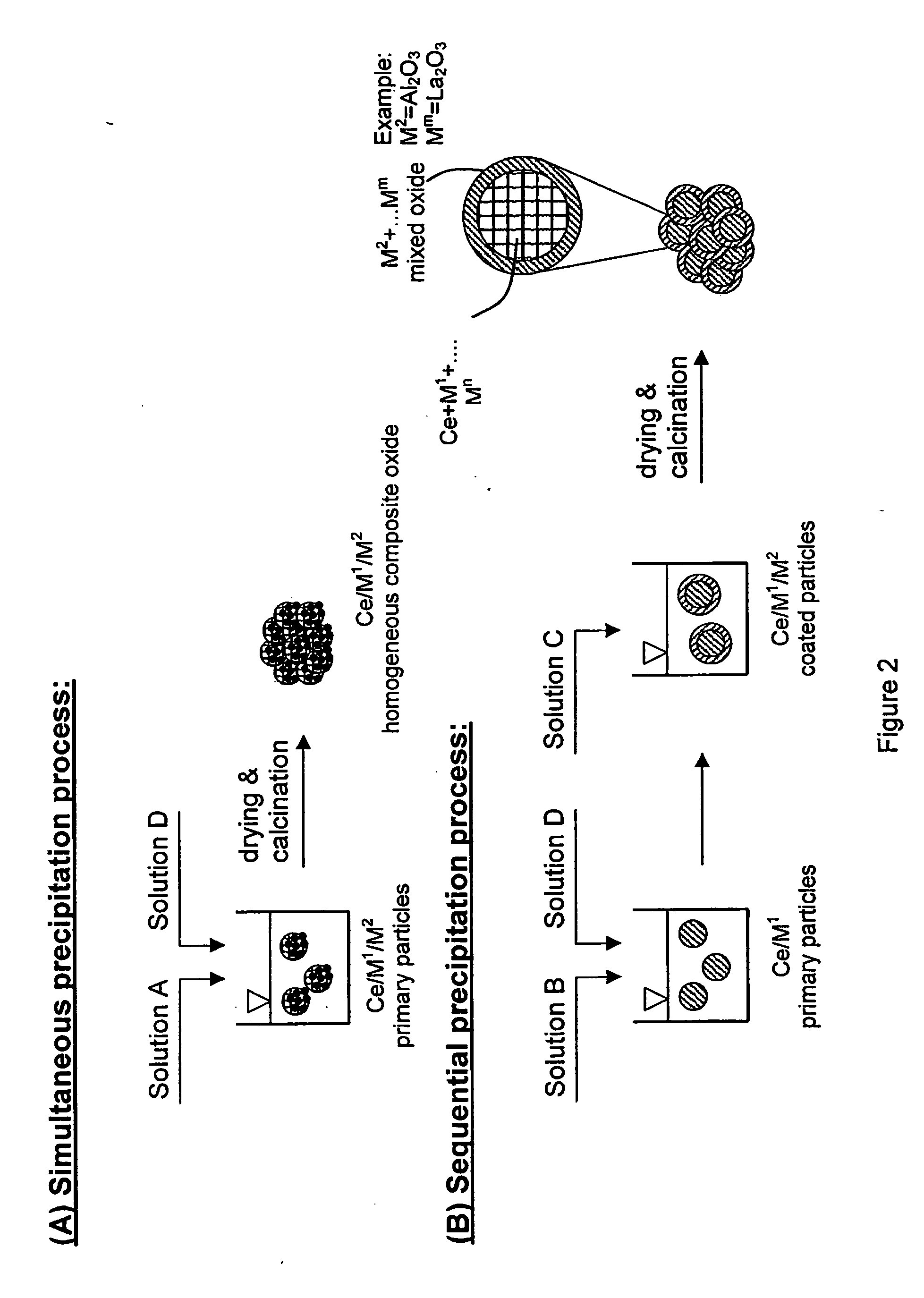

Oxygen storage material, process for its preparation and its application in a catalyst

InactiveUS20060052243A1Improve oxygen storage capacityImprove dynamic performanceMaterial nanotechnologyOxygen/ozone/oxide/hydroxideMixed oxideSolid solution

An oxygen storage material comprising cerium oxide and at least one second oxide of a metal M1 is disclosed as well as a process for manufacturing the material and the use of this material in an exhaust gas cleaning catalyst. In a preferred embodiment the oxygen storage material comprises particles from a Ce / M1 mixed oxide solid solution coated with an oxide of another metal M2. Metal M1 e.g. can be calcium or zirconium while metal M2 most preferably is aluminum.

Owner:UMICORE AG & CO KG

Cerium-zirconium composite metal oxide

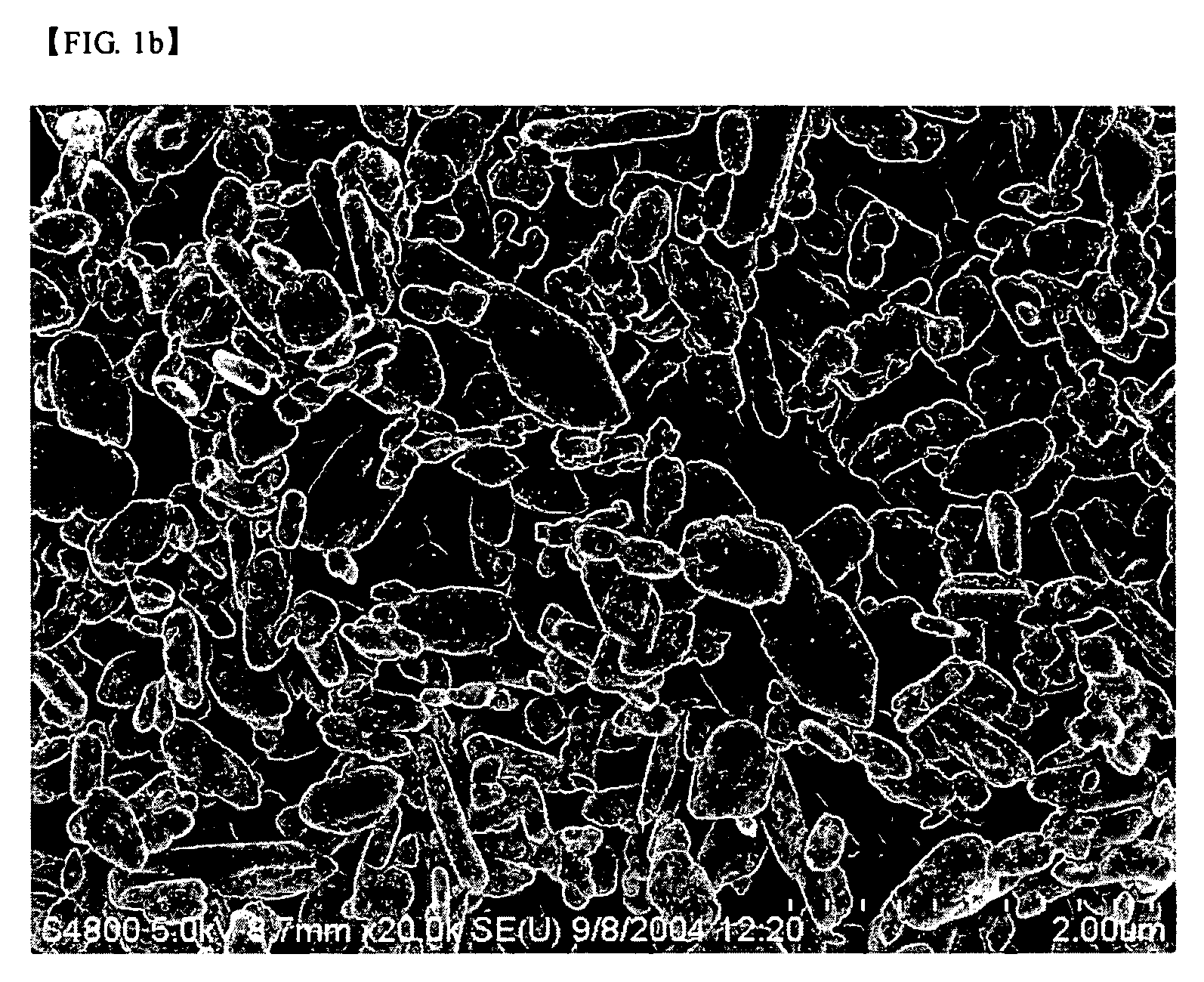

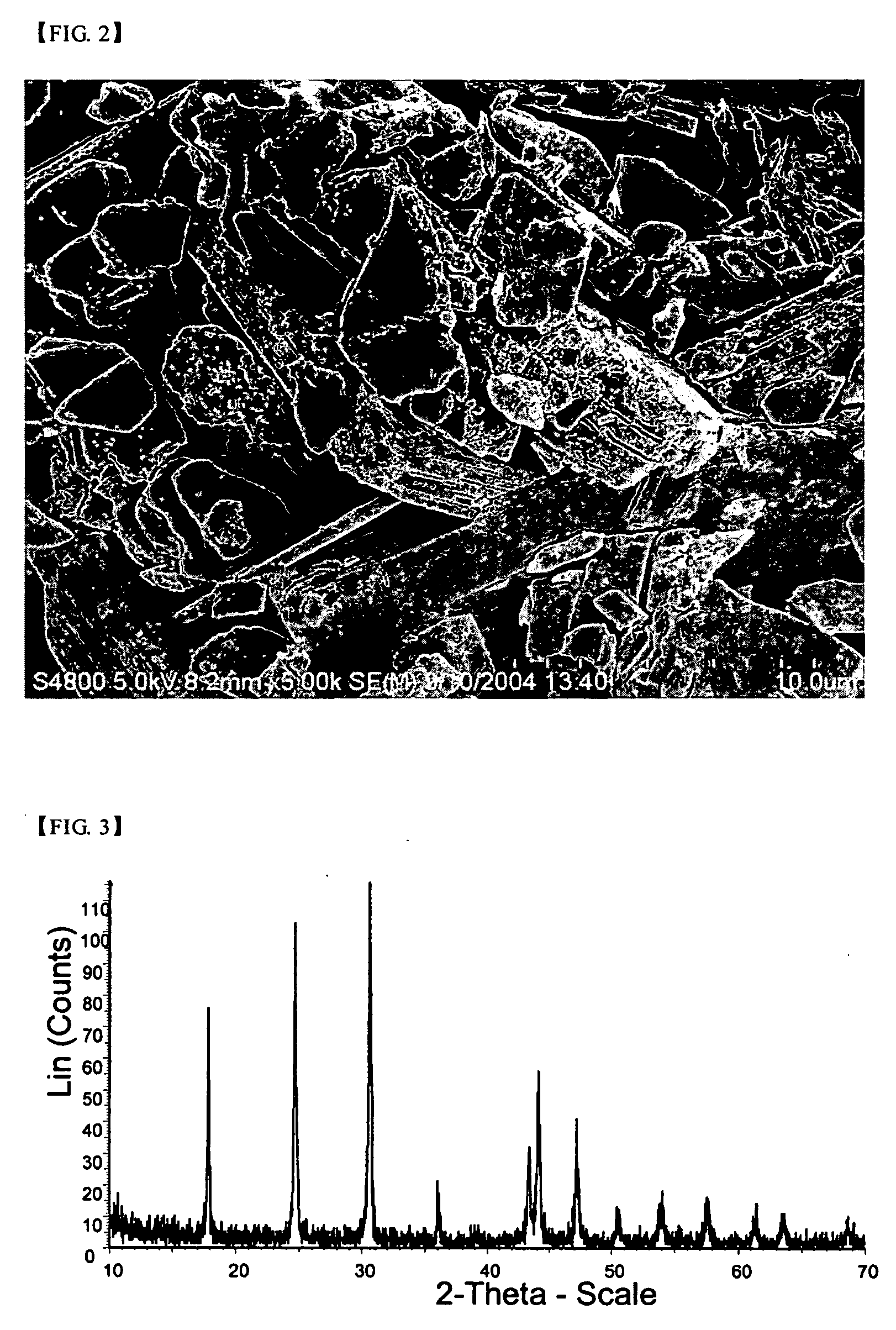

ActiveUS20050059547A1Increased durabilityImprove oxygen storage capacityGas treatmentInternal combustion piston enginesMischmetalCerium

A cerium-zirconium composite metal oxide having improved durability at high temperature and a stable oxygen storage capacity is provided. The cerium-zirconium composite metal oxide is characterized in that the total mole number of Ce and Zr is at least 85% based on the total mole number of metal in the composite metal oxide, a molar ratio Ce / Zr is within a range from 1 / 9 to 9 / 1, and an isoelectric point of the composite metal oxide is more than 3.5. Preferably, the molar ratio Ce / Zr is within a range from 3 / 7 to 7 / 3 and the isoelectric point is within a range from 3.8 to 5.0, and the cerium-zirconium composite metal oxide contains a rare earth metal (excluding Ce) in a concentration of less than 15% by mole based on the total mole number of metal in the composite metal oxide. Also the present invention provides a cerium-zirconium composite metal oxide, characterized in that CeO2 forms a core surrounded by ZrO2.

Owner:TOYOTA JIDOSHA KK

High specific surface area mixed oxide of cerium and of another rare earth, preparation method and use in catalysis

ActiveUS20100329954A1Effective supportReduce the risk of contaminationNitrogen compoundsInternal combustion piston enginesMixed oxideLiquid medium

The mixed oxide of the invention mainly consists of cerium oxide and of at least one oxide of another rare earth. It has a specific surface area of at least 20 m2 / g after calcining at 1000° C. for 5 hours. It is obtained by forming a liquid medium comprising a cerium compound; by heating this medium; by adding to the precipitate obtained a compound of the other rare earth, by heating the medium thus obtained and by bringing its pH to a basic value and by calcining the precipitate. The mixed oxide may be used as a catalyst support.

Owner:ANAN KASEI CO LTD

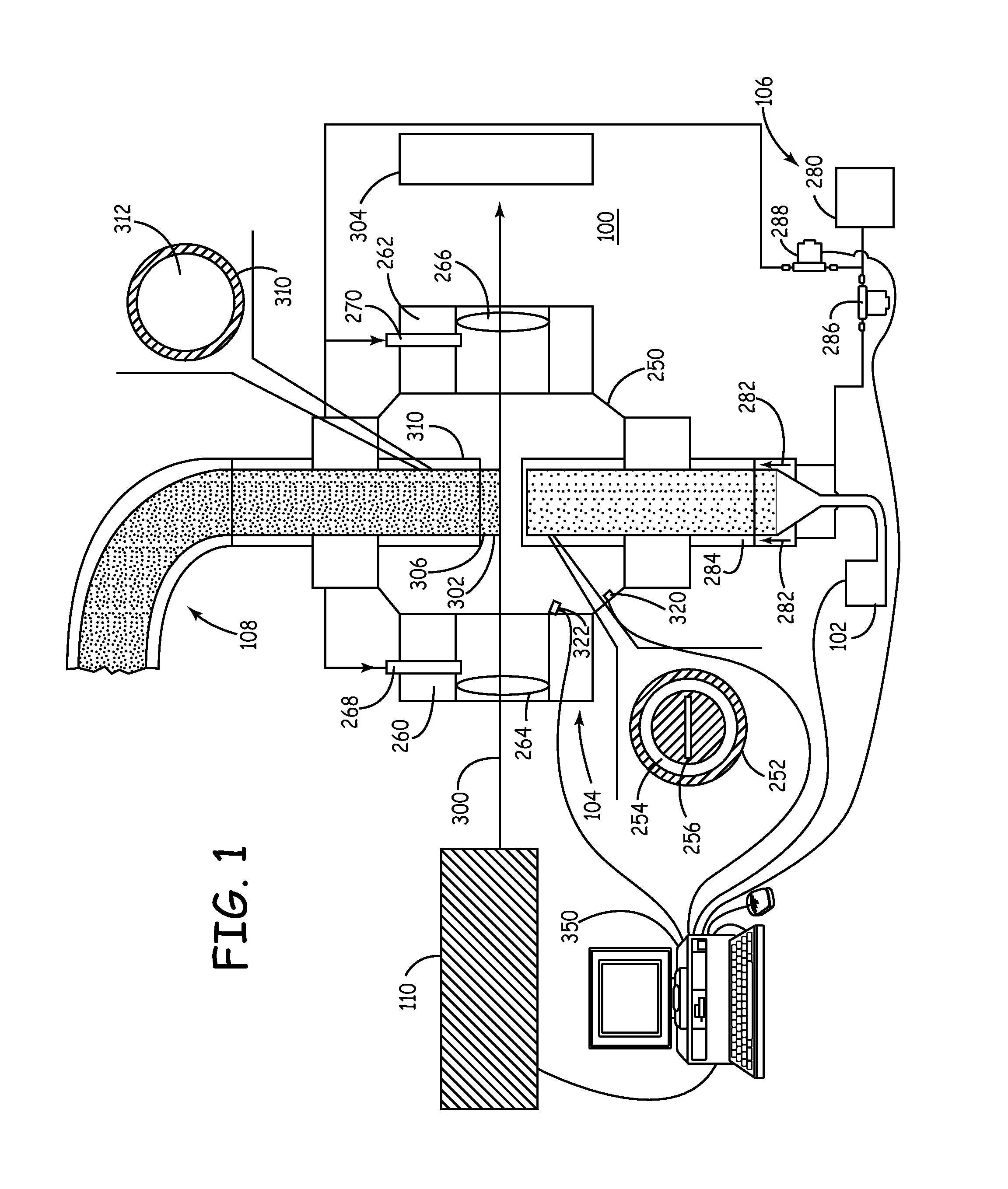

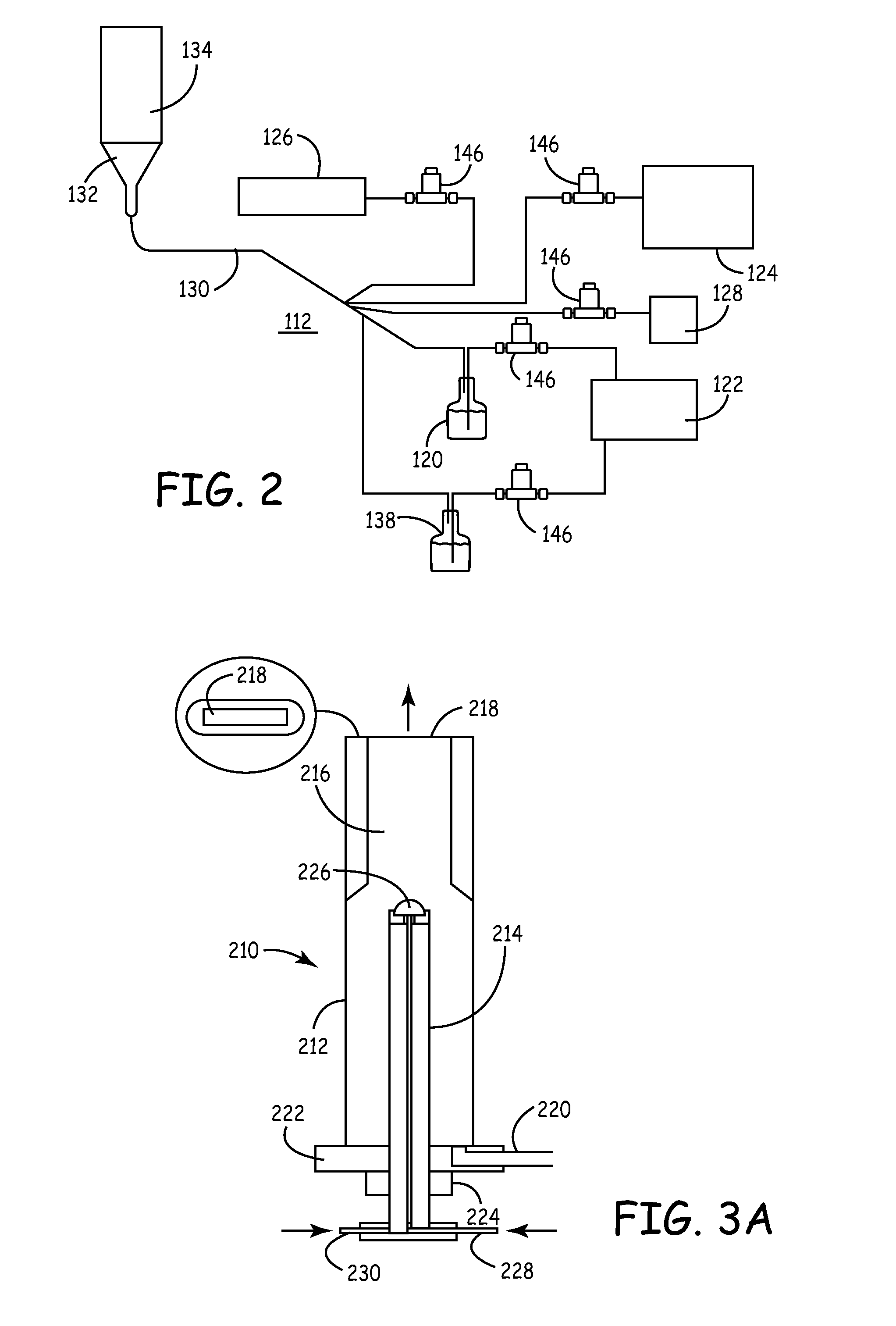

Methods for synthesizing submicron doped silicon particles

Methods are described that have the capability of producing submicron / nanoscale particles, in some embodiments dispersible, at high production rates. In some embodiments, the methods result in the production of particles with an average diameter less than about 75 nanometers that are produced at a rate of at least about 35 grams per hour. In other embodiments, the particles are highly uniform. These methods can be used to form particle collections and / or powder coatings. Powder coatings and corresponding methods are described based on the deposition of highly uniform submicron / nanoscale particles.

Owner:NANOGRAM

Production of fine-grained particles

InactiveUS20050025698A1Heating fastMaterial nanotechnologyNanostructure manufactureMaterials scienceCrystallization

Particles of mixed metal oxide include at least two metal species. The particles have a grain size within the range of 1-100 nm. The particles are substantially crystalline. The particles contain only small or negligible amounts of amorphous material. The at least two metal species are uniformly dispersed in the particles.

Owner:VERY SMALL PARTICLE CO LTD

Cerium oxide abrasive and slurry containing the same

InactiveUS20060162260A1Dispersion force can be reducedSlow polishing rateMaterial nanotechnologyPigmenting treatmentCeriumCrystal structure

Disclosed are a cerium oxide abrasive for selectively polishing various SiO2 films and SiO2—Si3N4 films; and a slurry containing the same. The cerium oxide abrasive and the polishing slurry of the present invention have a high polishing rate and are also free from microscratches in a polished surface upon polishing since polycrystalline cerium oxide having a mean crystalline particle size of 5 nm or less is synthesized by using hexagonal cerium carbonate having a hexagonal crystal structure as a raw material of cerium.

Owner:LG CHEM LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com