Patents

Literature

10882 results about "Diesel fuel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Diesel fuel /ˈdiːzəl/ in general is any liquid fuel used in diesel engines, whose fuel ignition takes place, without any spark, as a result of compression of the inlet air mixture and then injection of fuel. (Glow plugs, grid heaters and block heaters help to achieve high temperatures for combustion during engine startup in cold weather.) Diesel engines have found broad use as a result of higher thermodynamic efficiency and thus fuel efficiency. This is particularly noted where diesel engines are run at part-load; as their air supply is not throttled as in a petrol engine, their efficiency still remains very high.

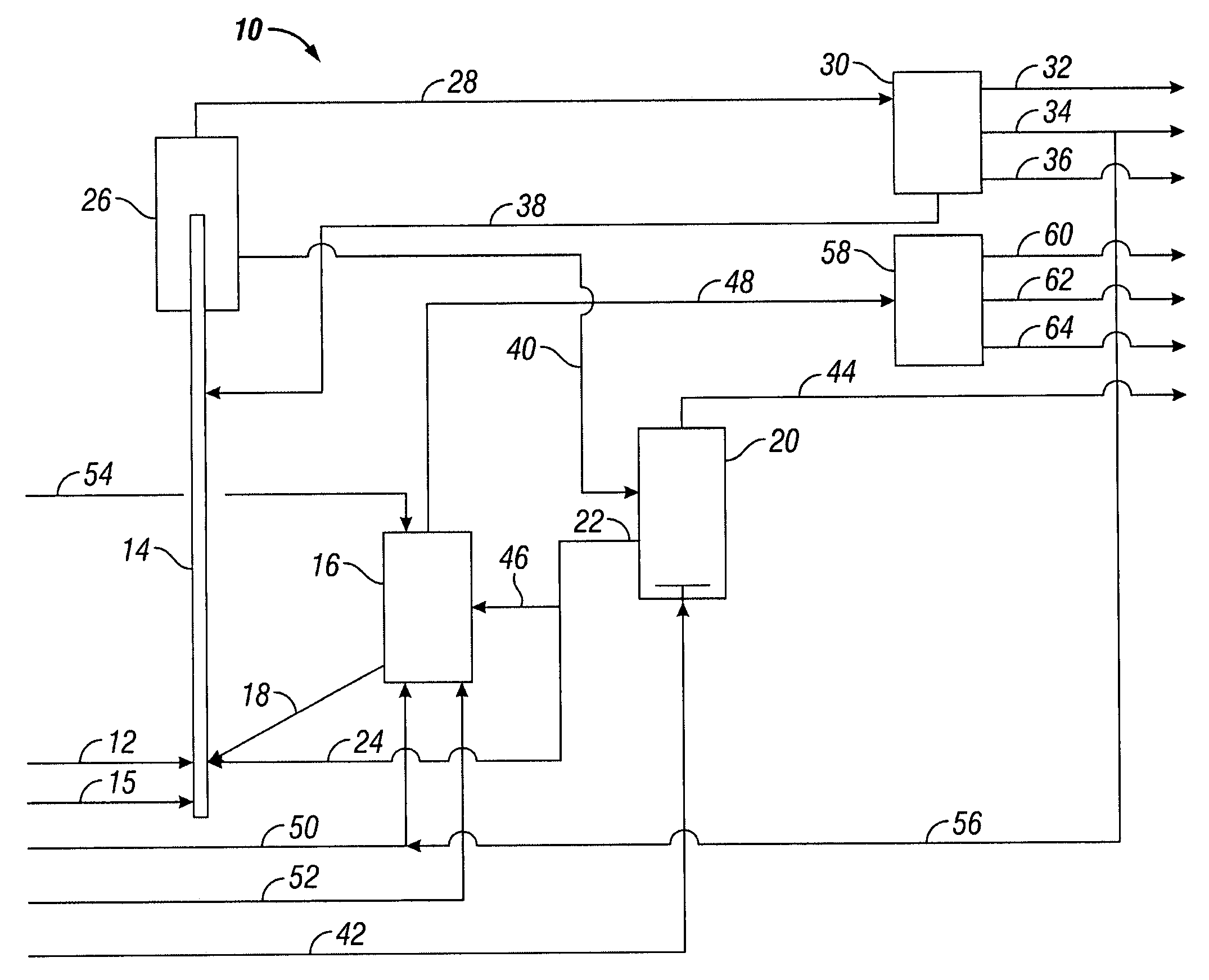

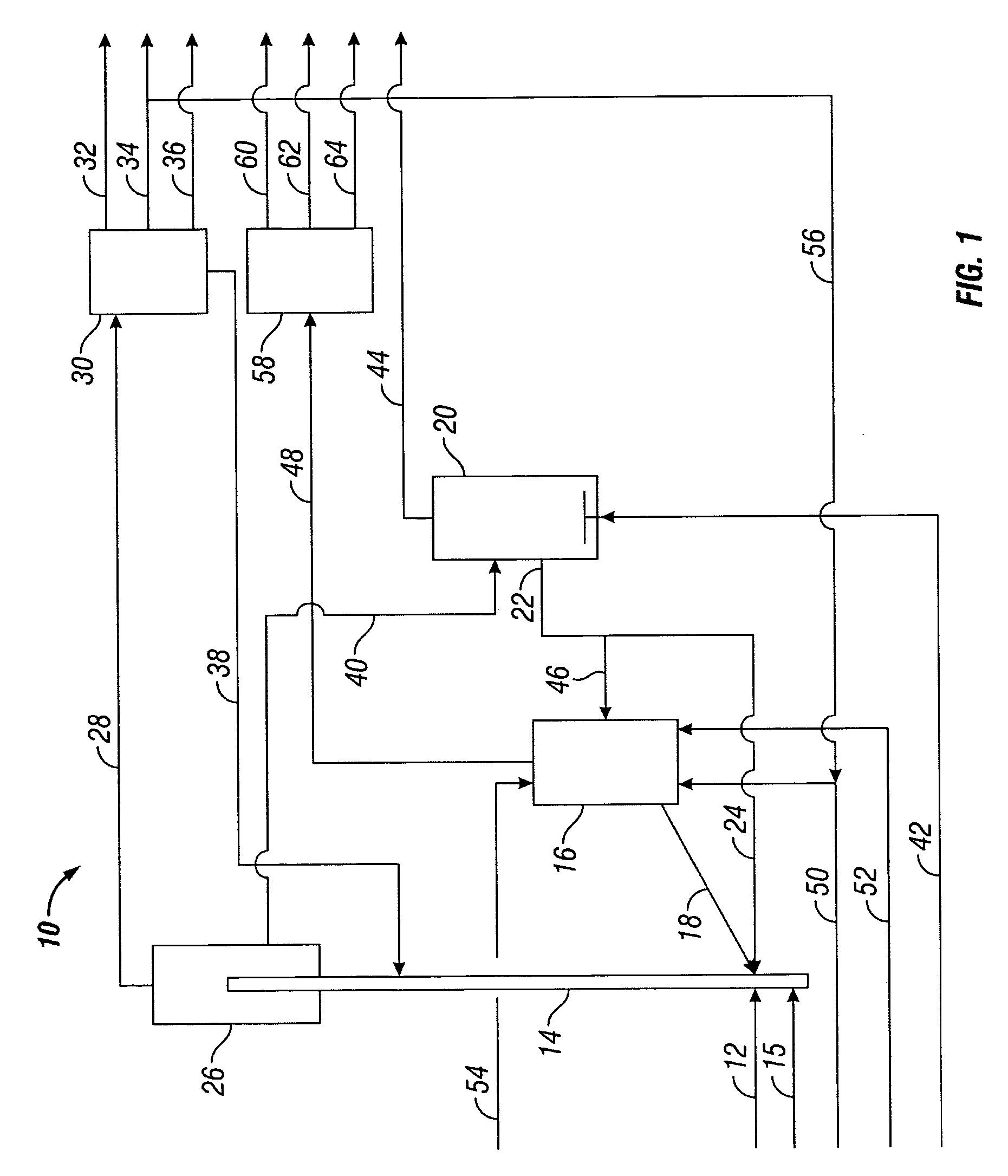

Synthesis of liquid fuels and chemicals from oxygenated hydrocarbons

ActiveUS20080216391A1Organic compound preparationHydrocarbon from oxygen organic compoundsFuranLiquid fuel

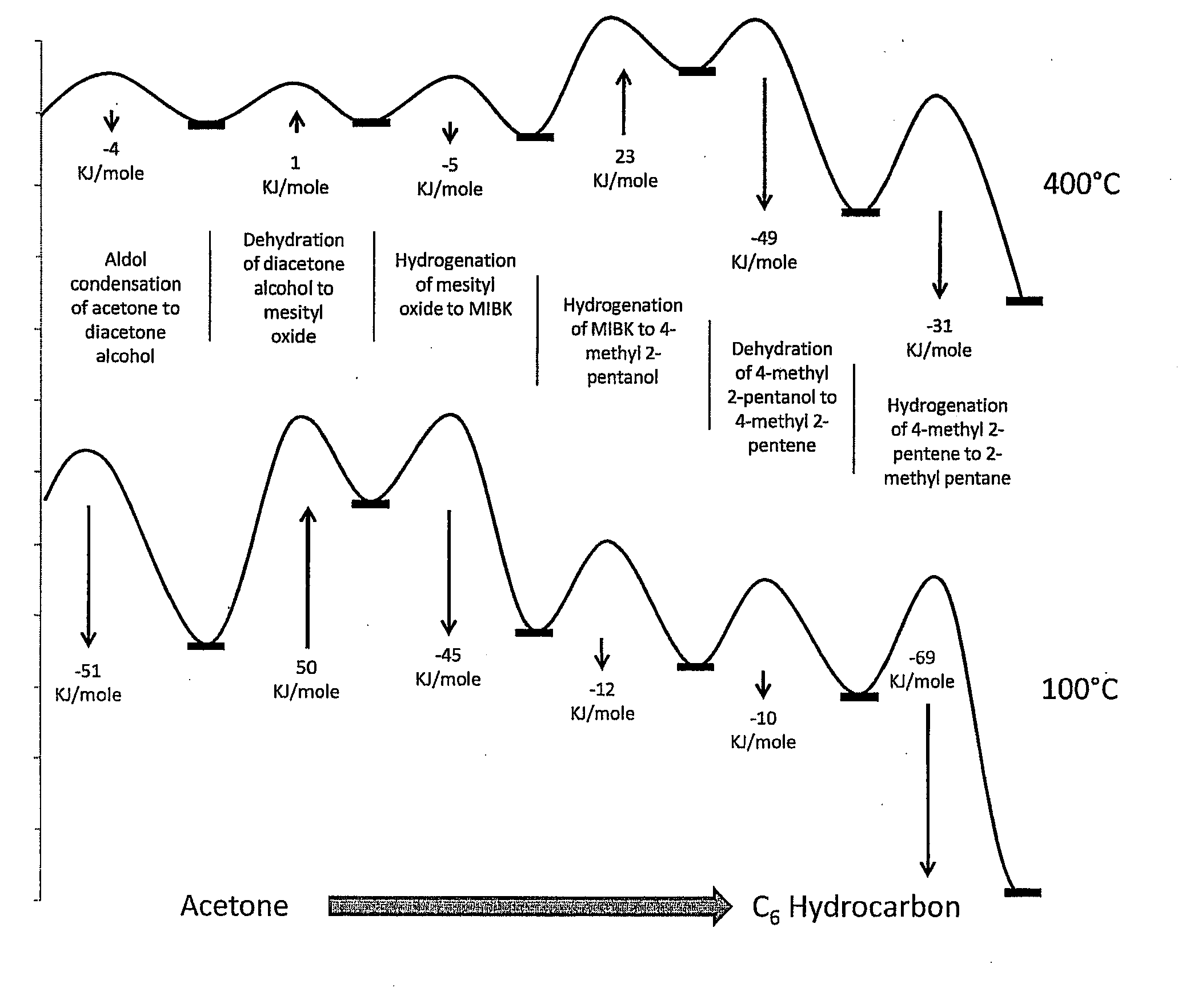

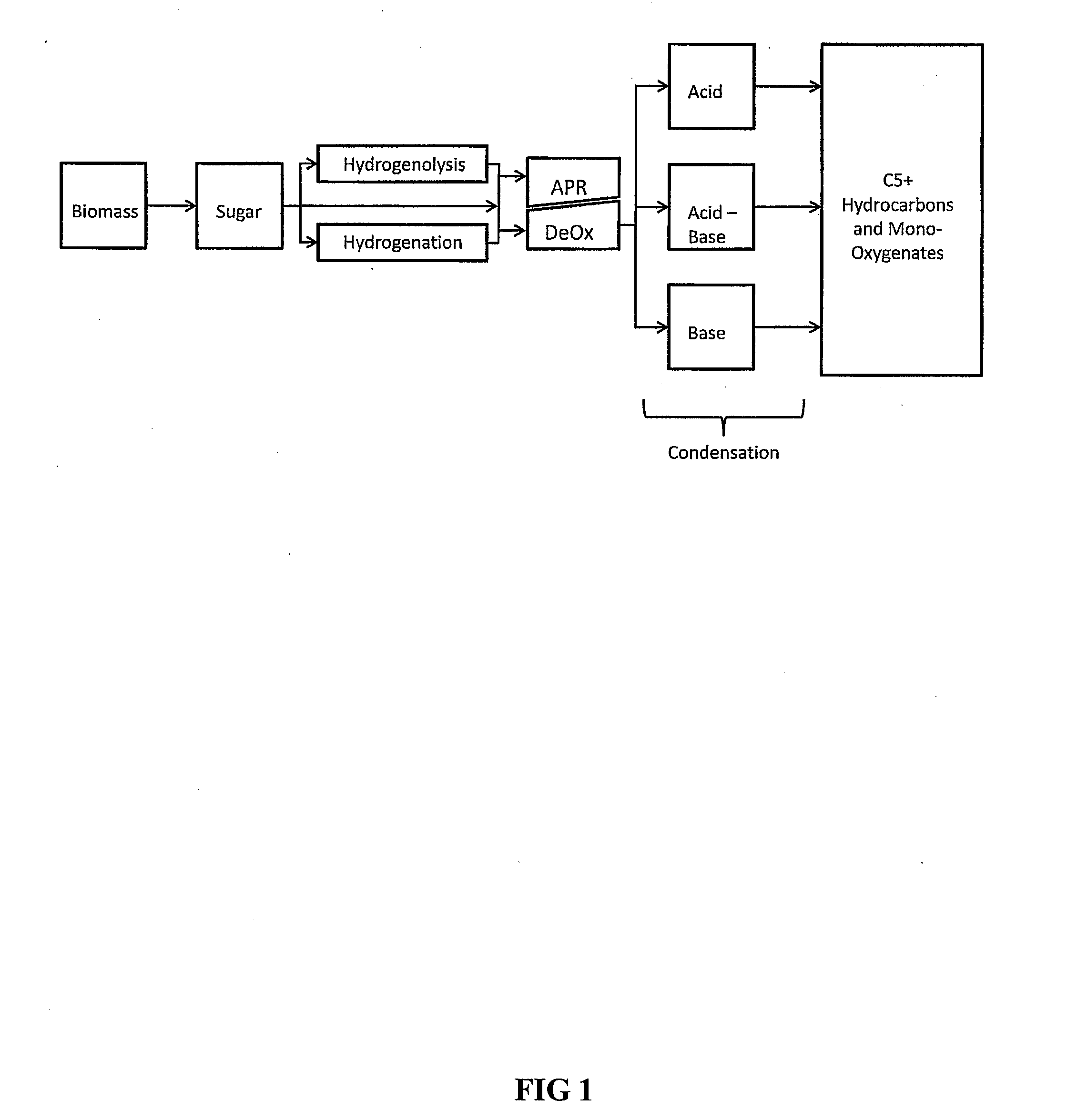

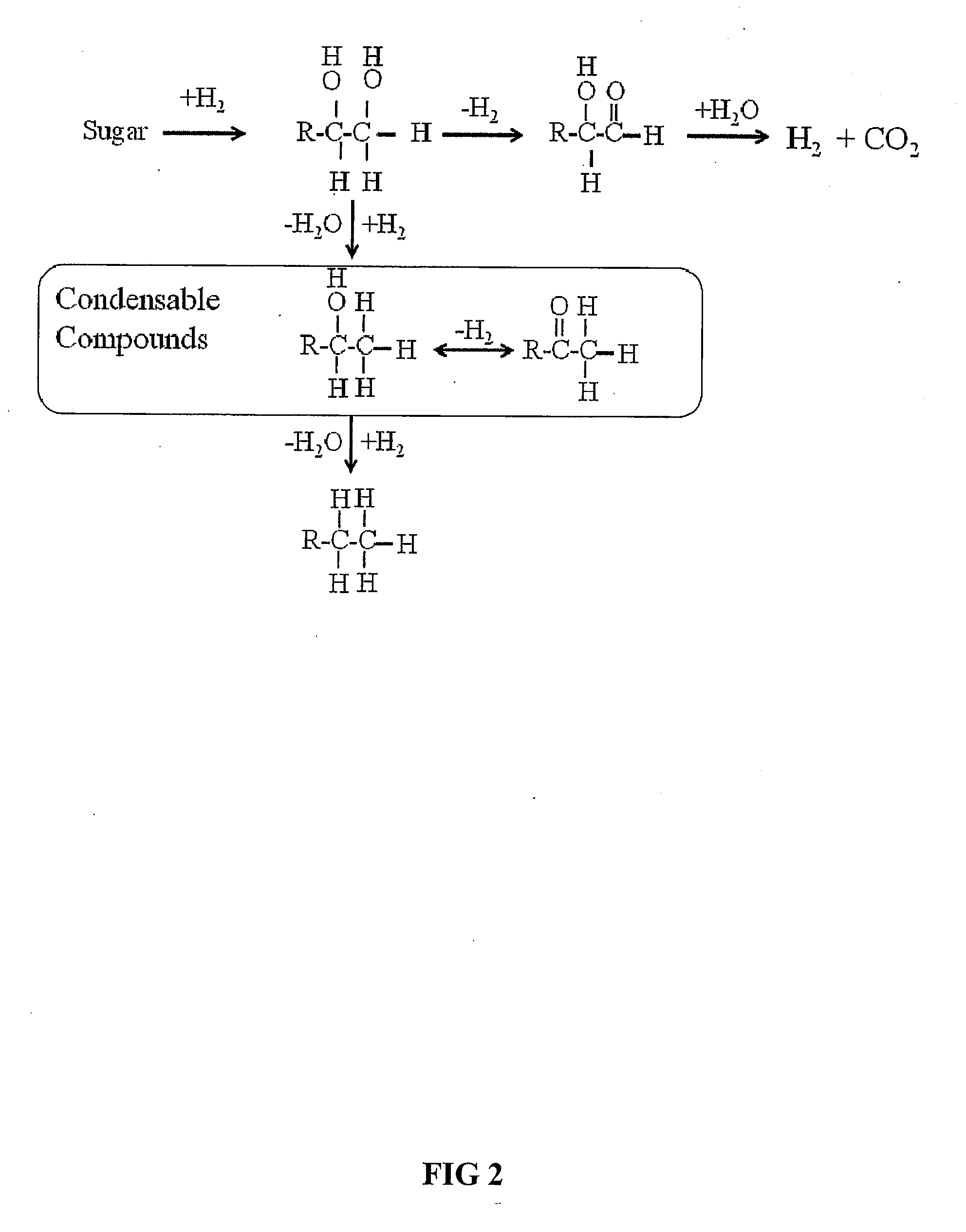

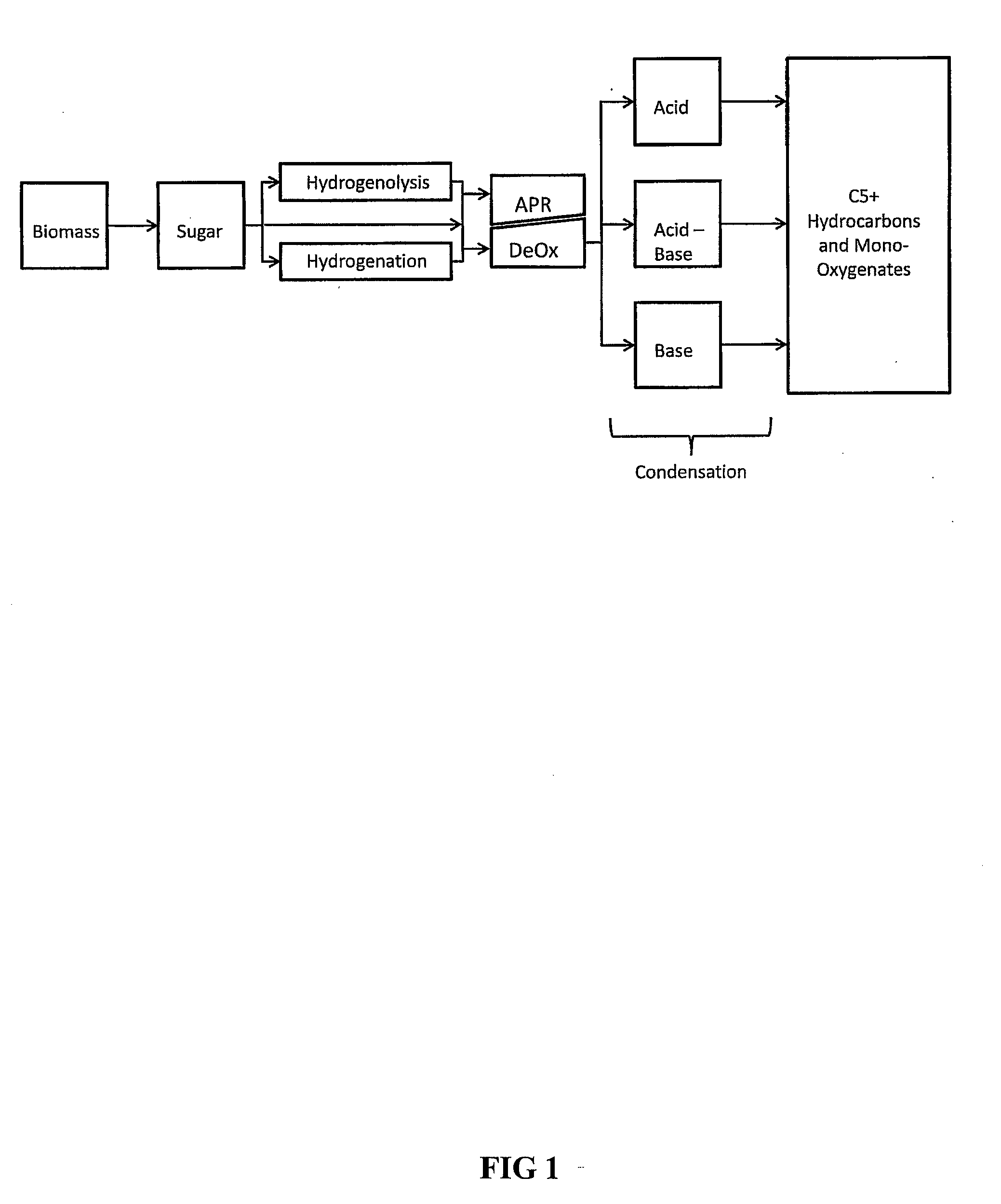

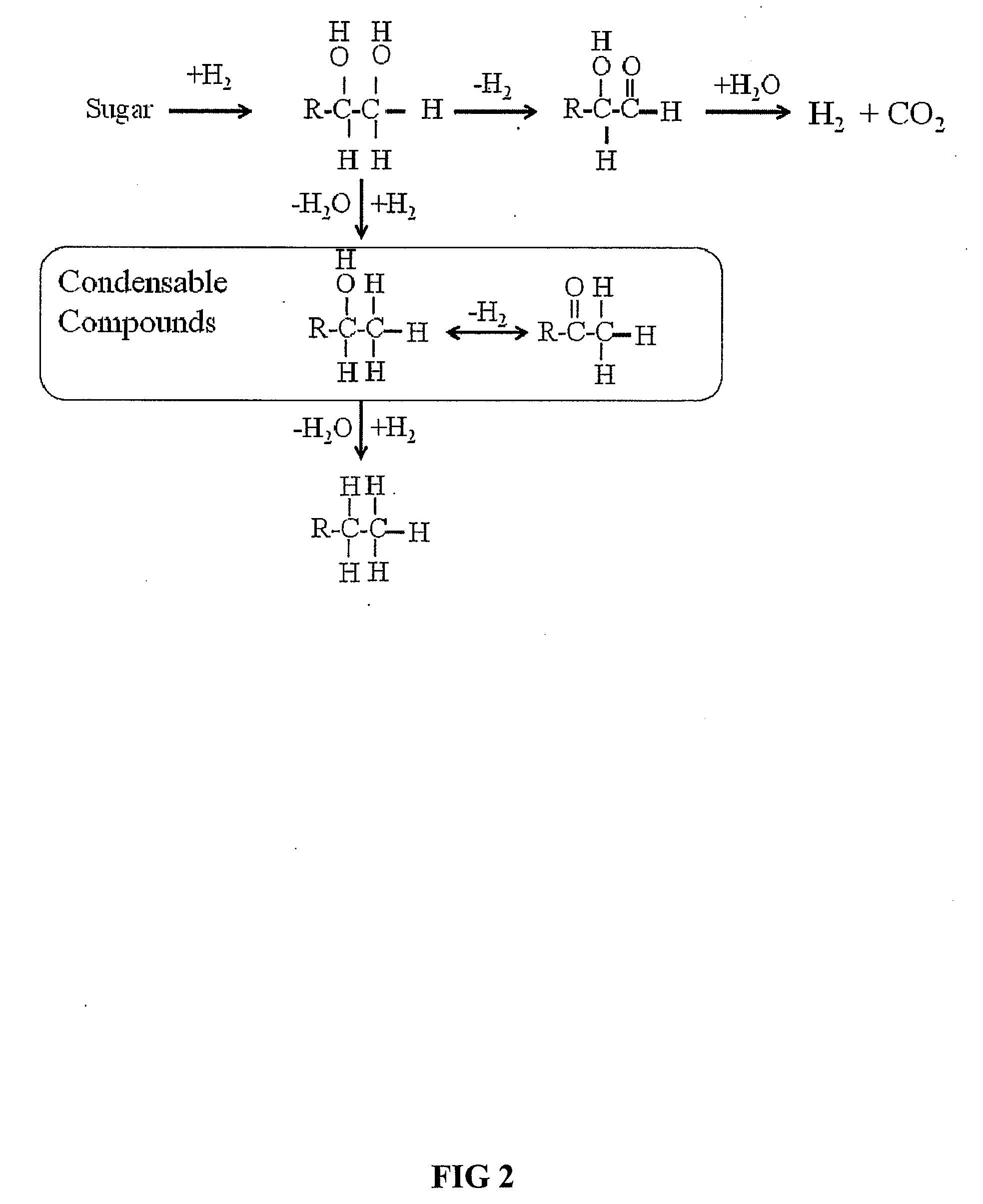

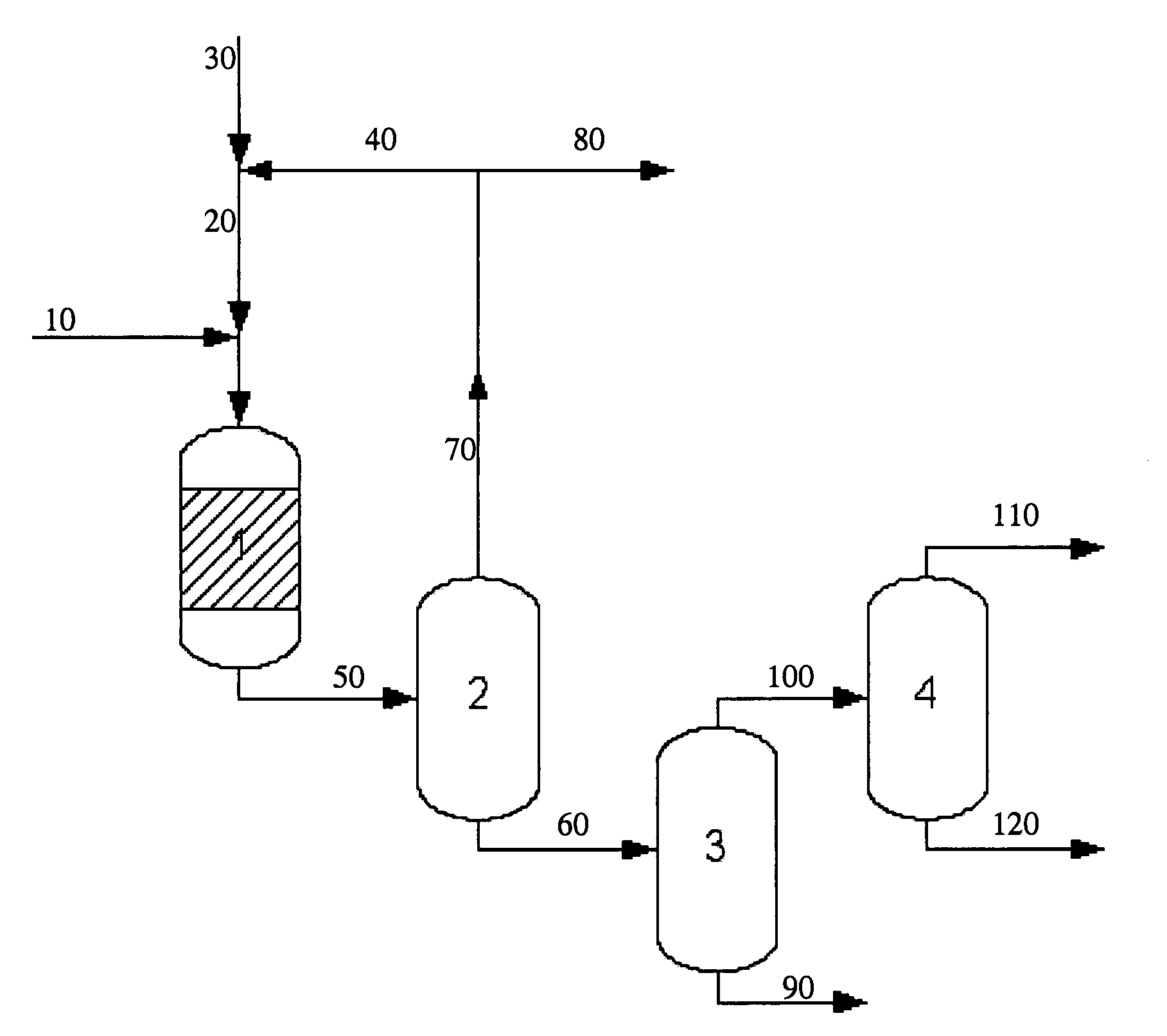

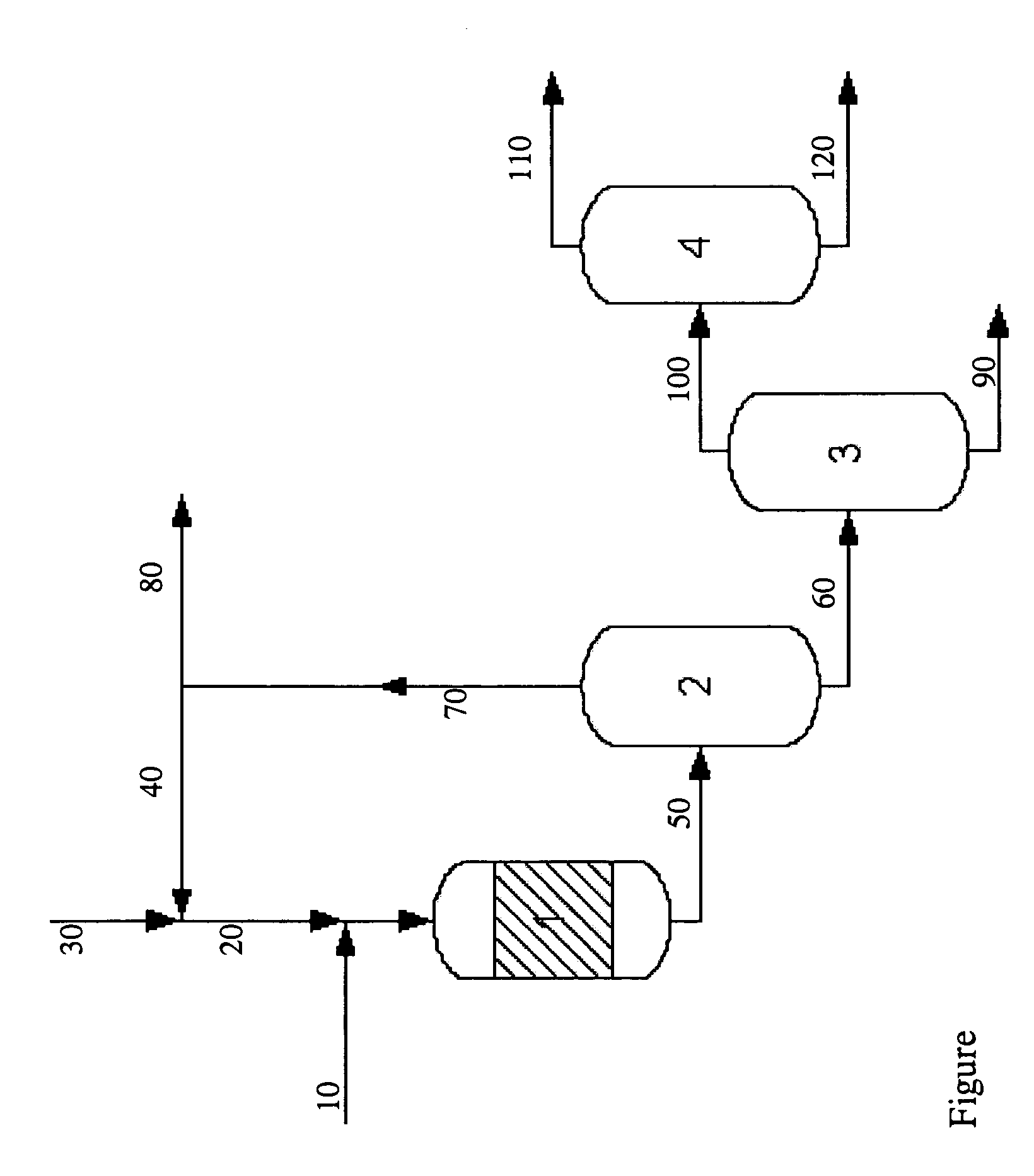

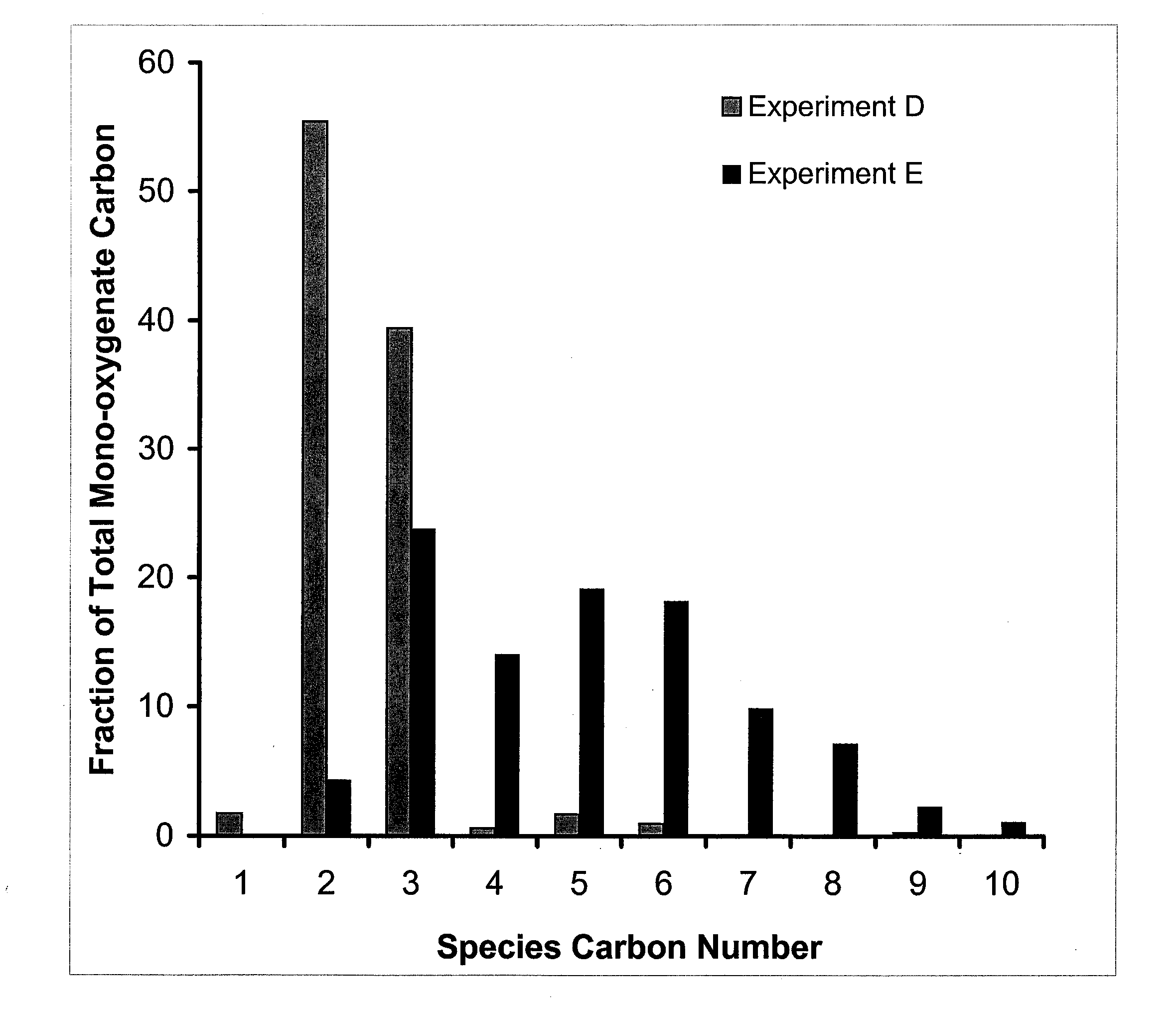

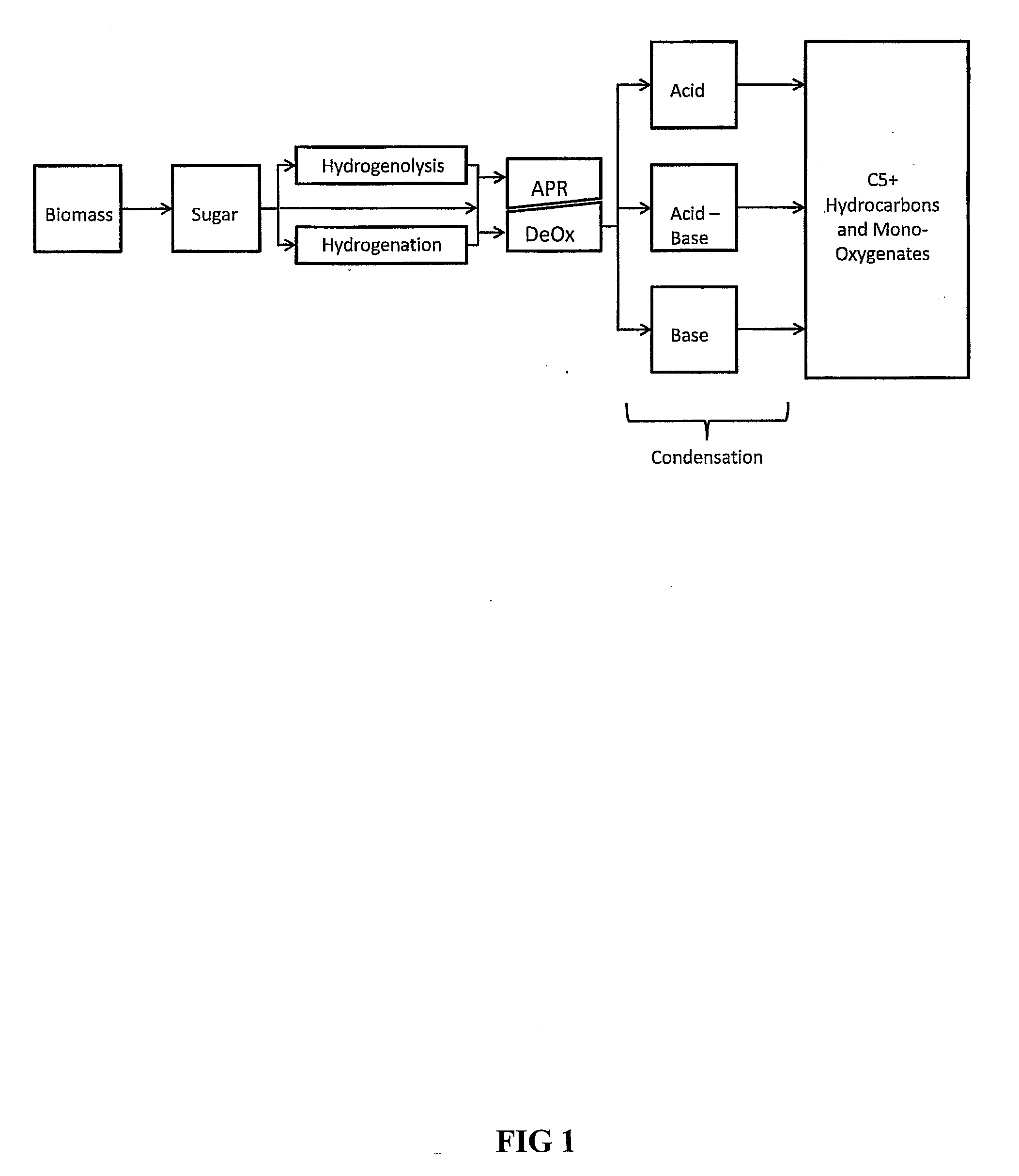

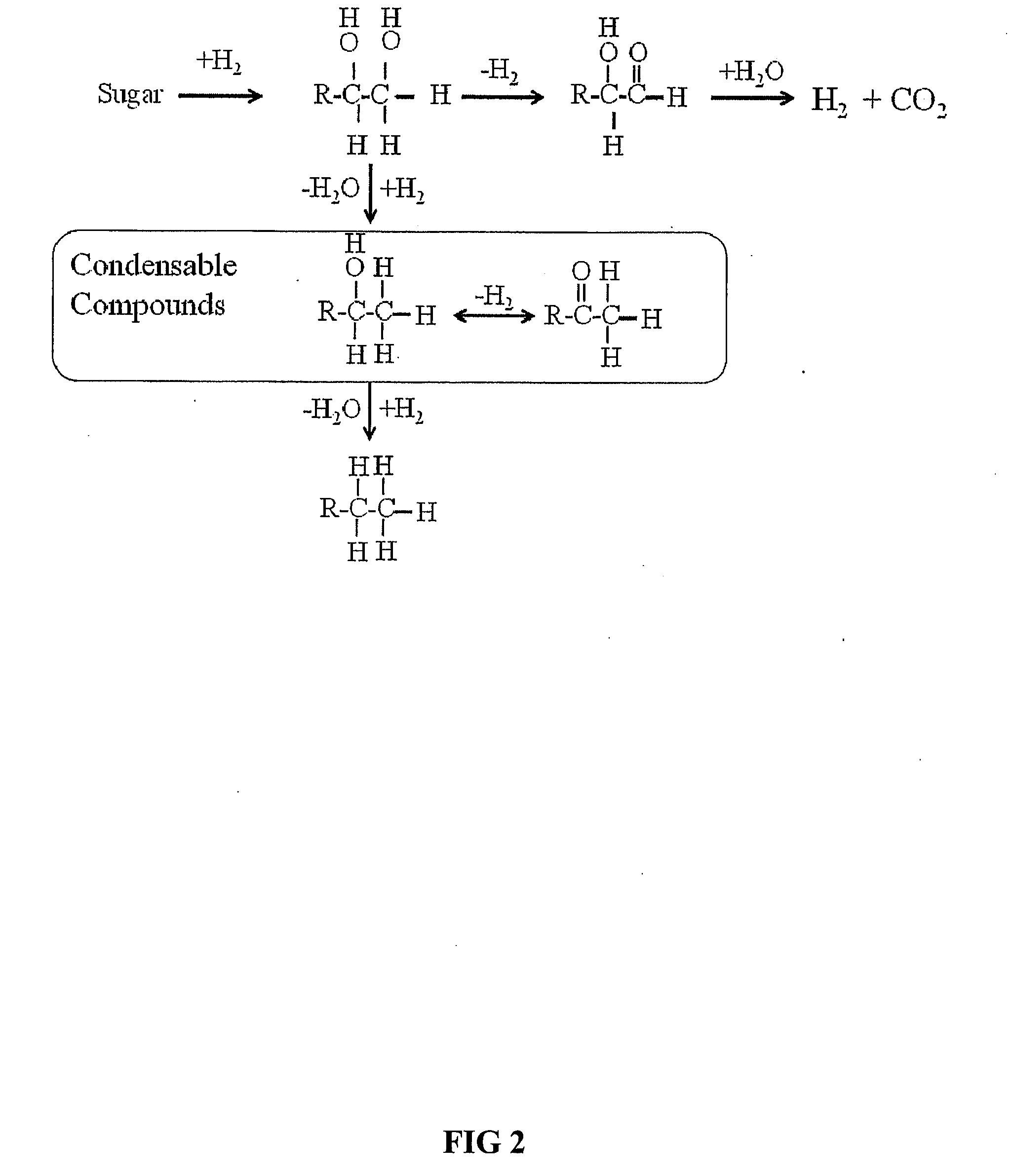

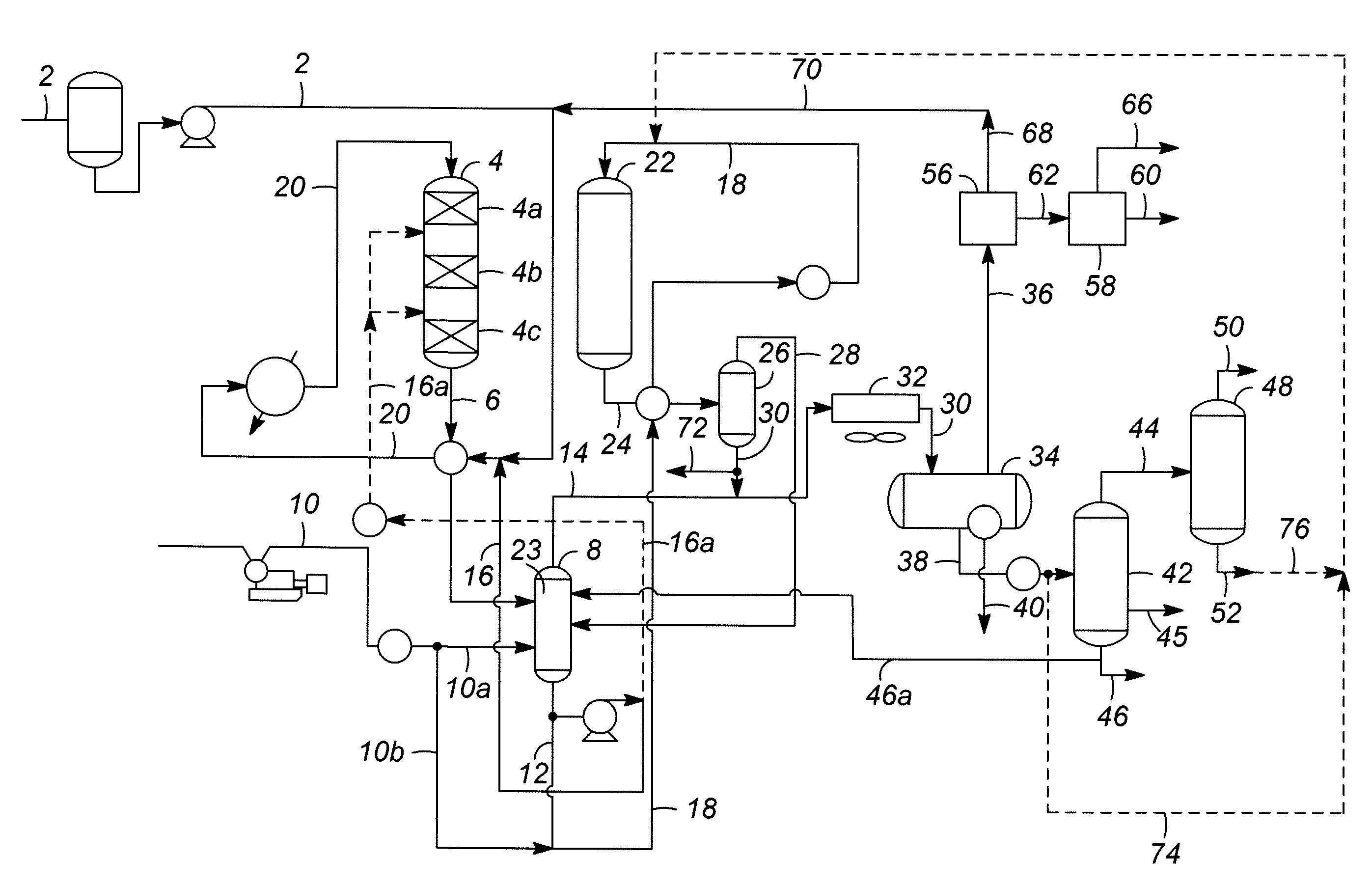

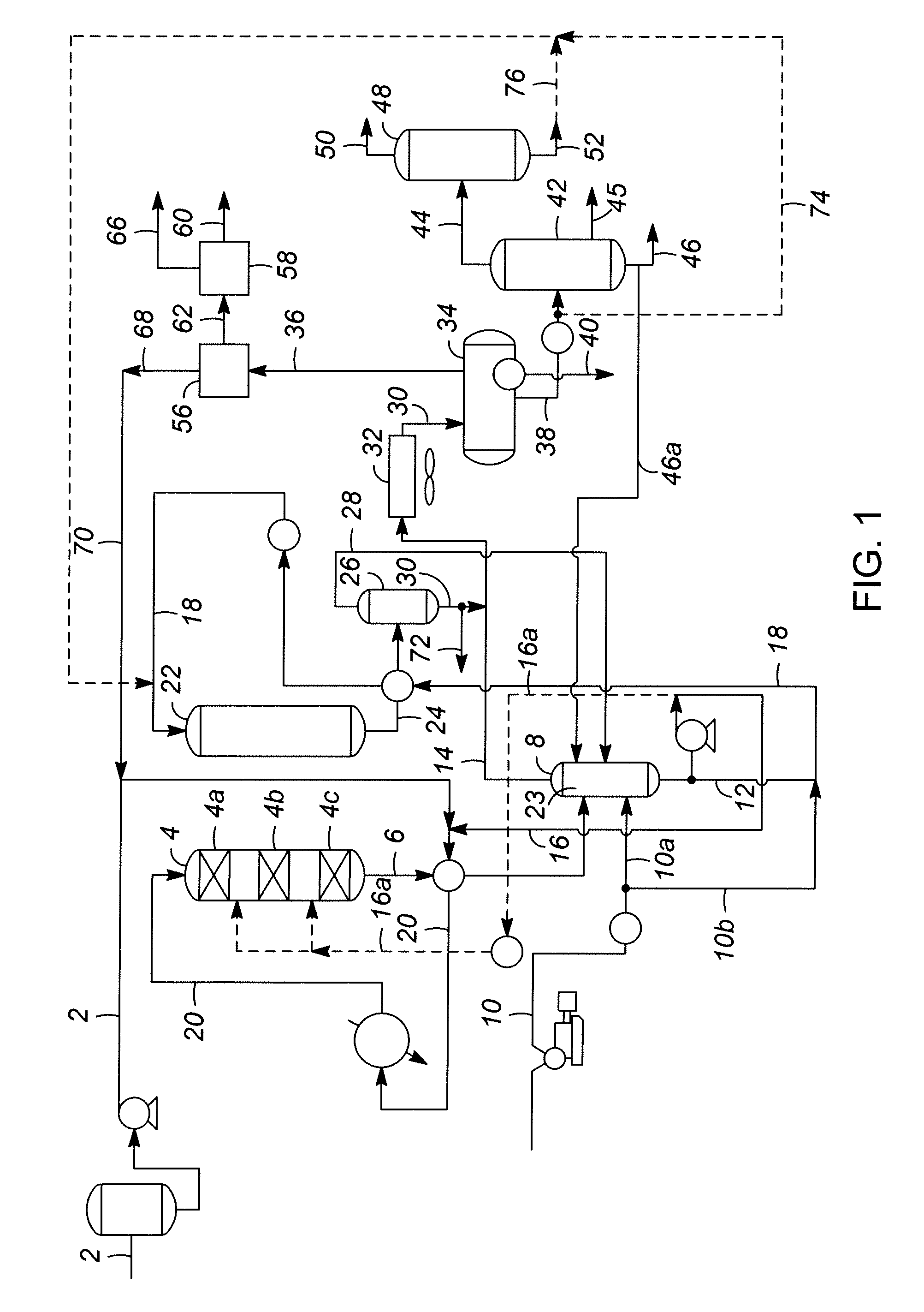

Processes and reactor systems are provided for the conversion of oxygenated hydrocarbons to hydrocarbons, ketones and alcohols useful as liquid fuels, such as gasoline, jet fuel or diesel fuel, and industrial chemicals. The process involves the conversion of mono-oxygenated hydrocarbons, such as alcohols, ketones, aldehydes, furans, carboxylic acids, diols, triols, and / or other polyols, to C4+ hydrocarbons, alcohols and / or ketones, by condensation. The oxygenated hydrocarbons may originate from any source, but are preferably derived from biomass.

Owner:VIRENT

Process for the manufacture of diesel range hydrocarbons

ActiveUS20070010682A1Fatty oils/acids recovery from wasteHydrocarbon by isomerisationIsomerizationReaction temperature

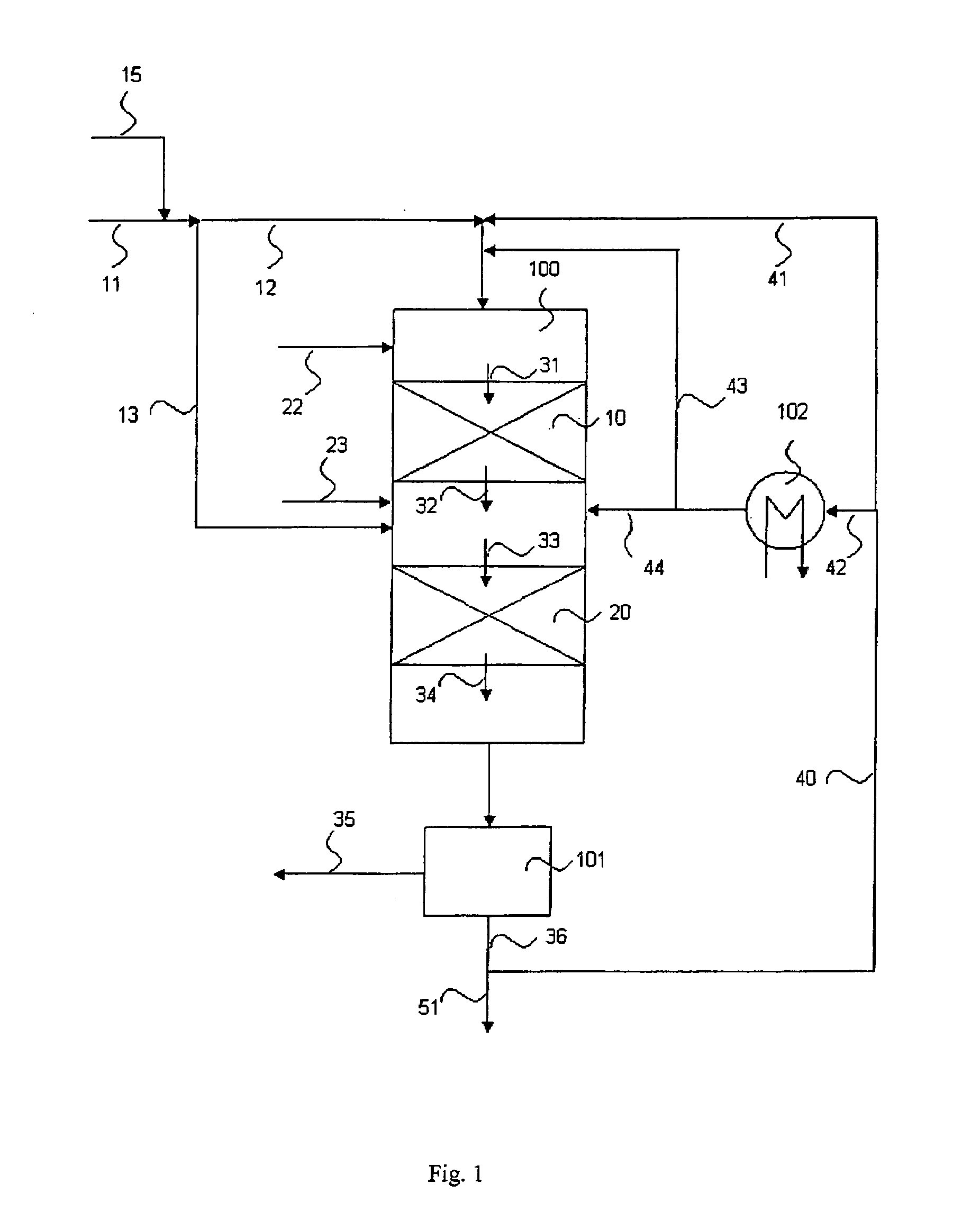

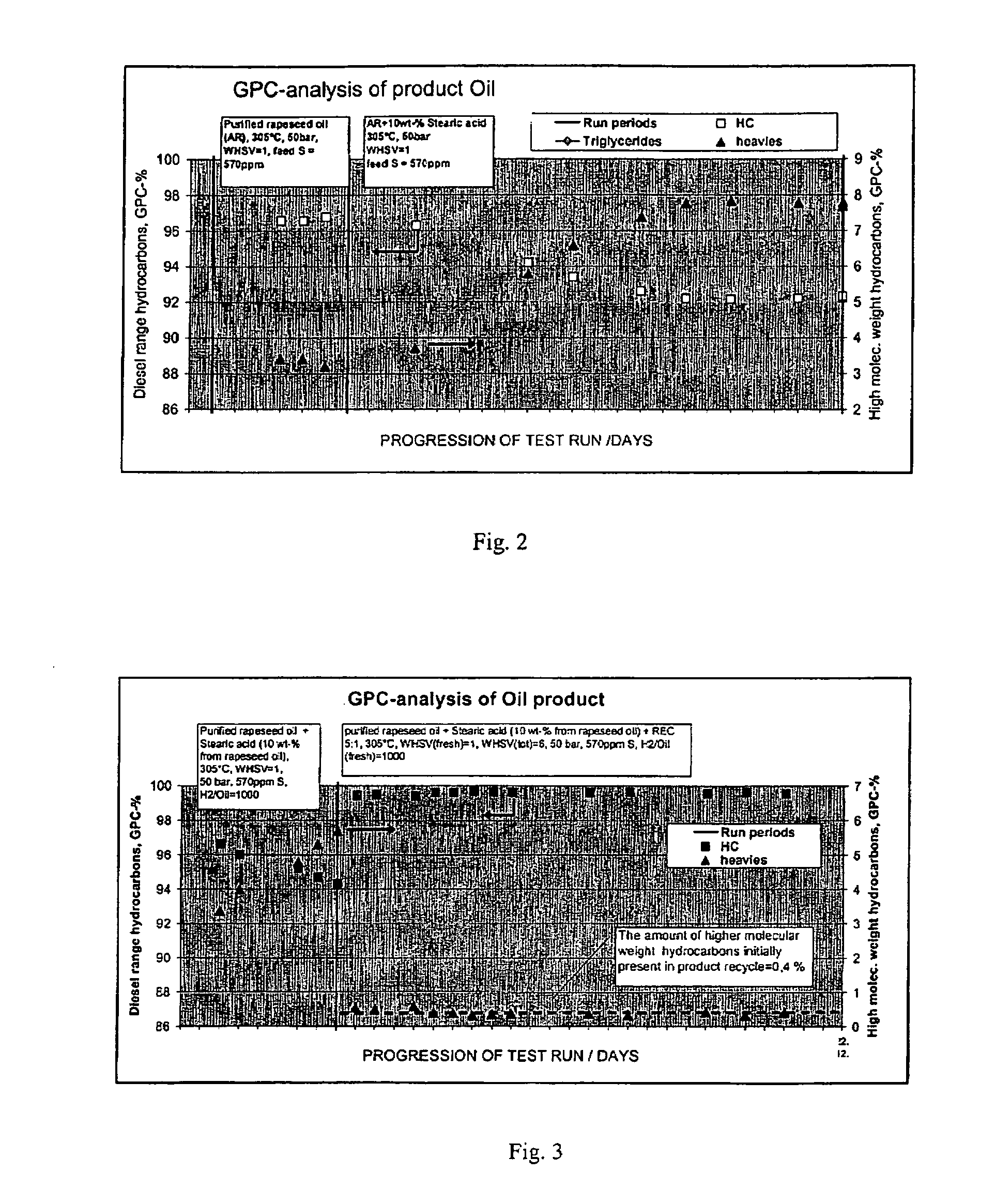

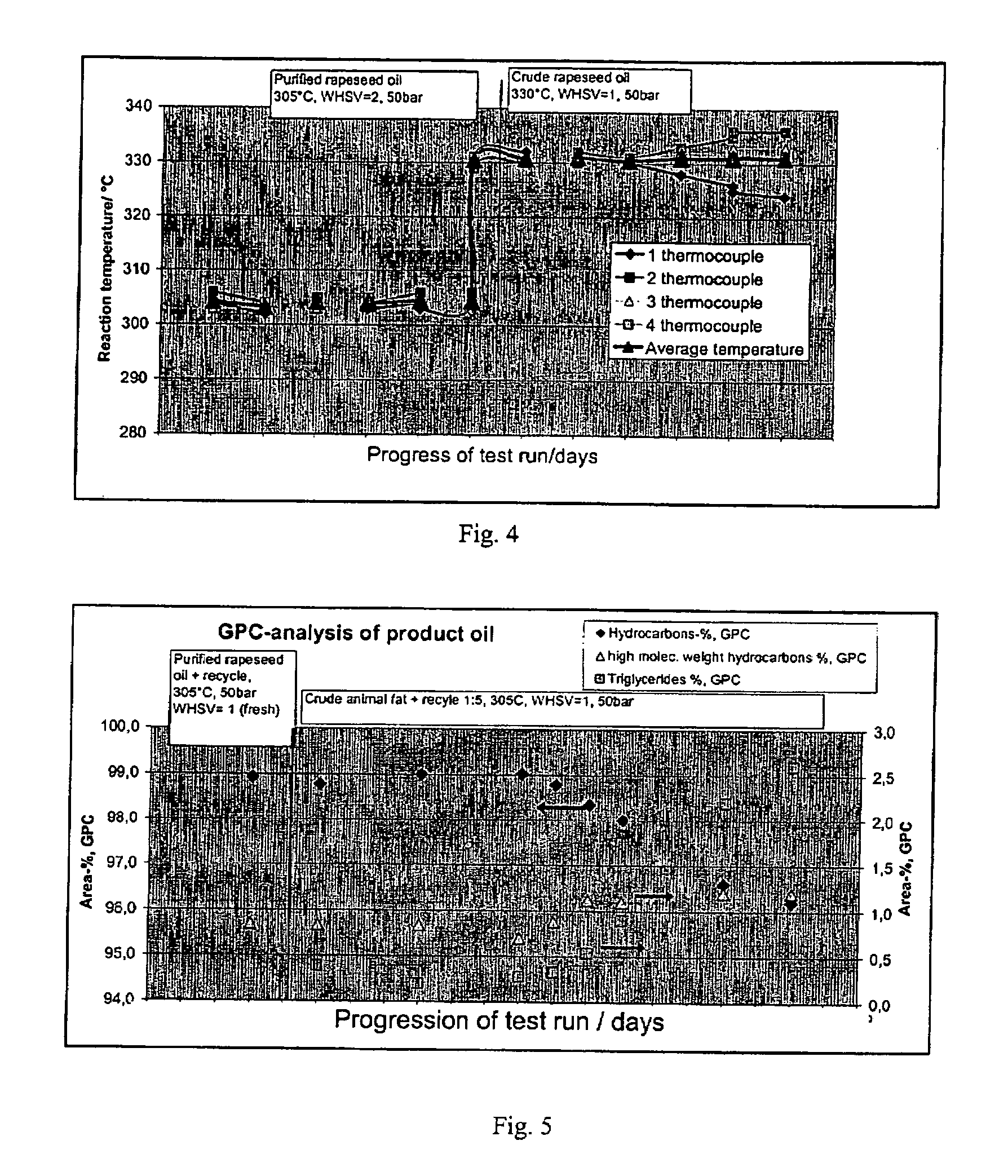

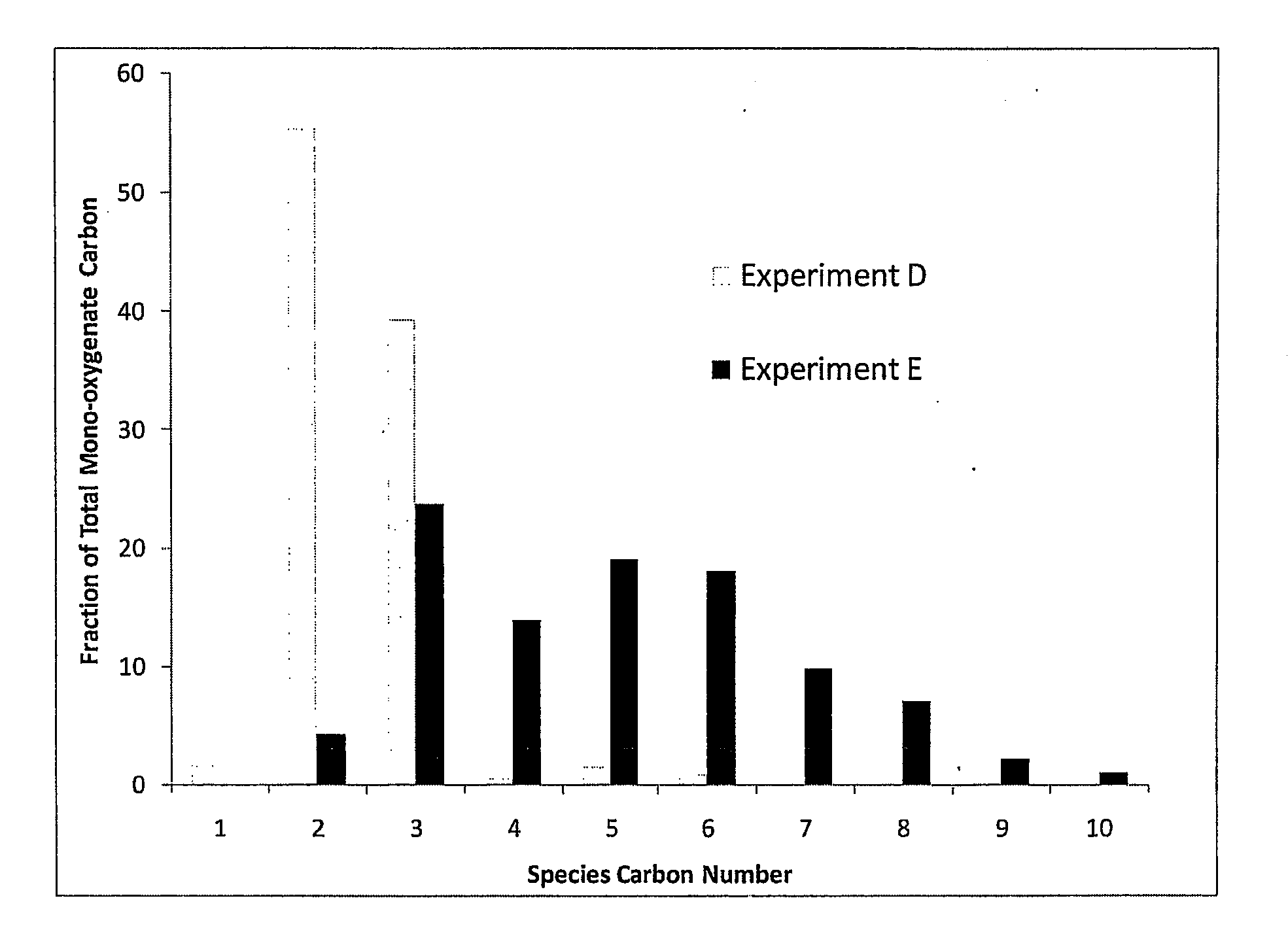

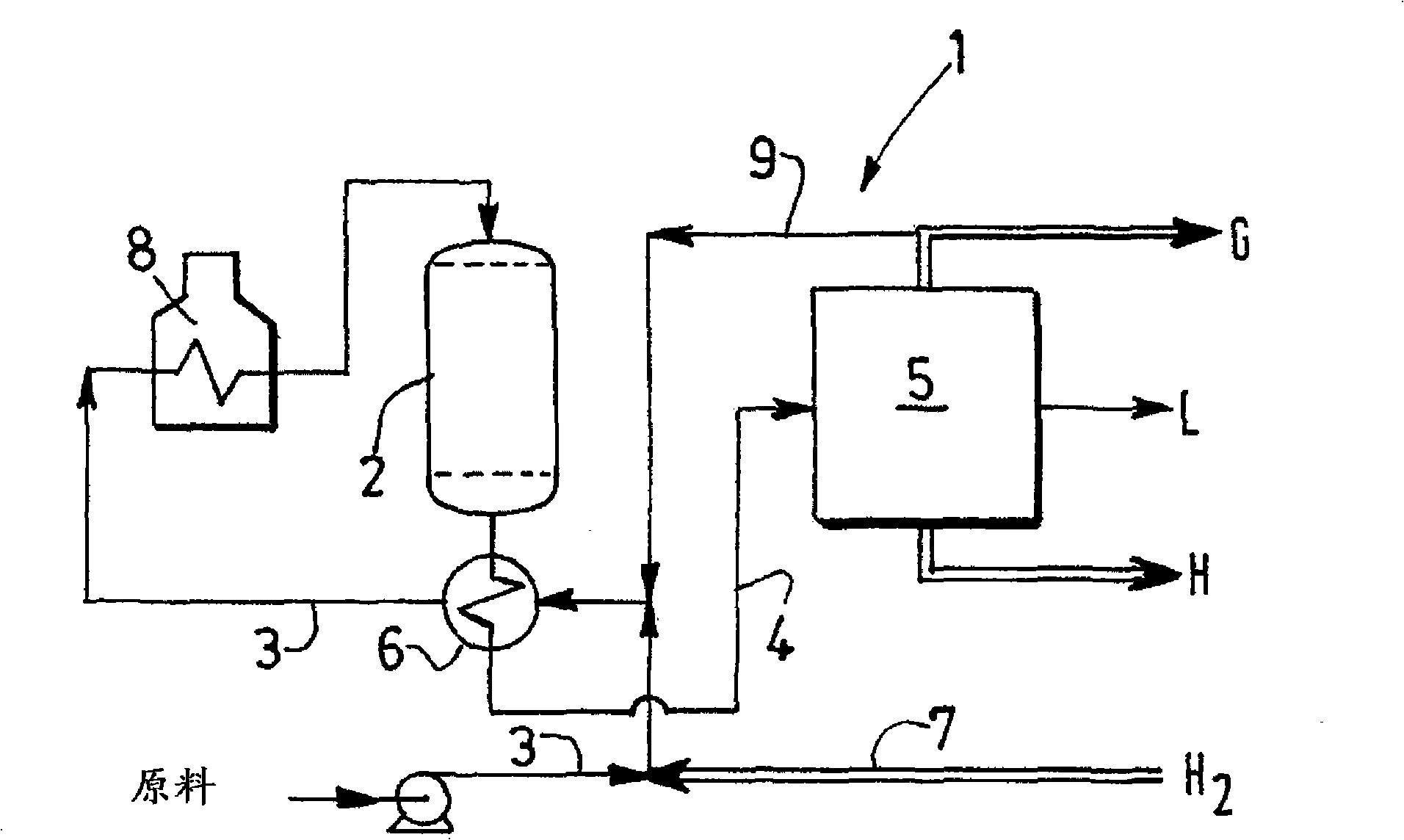

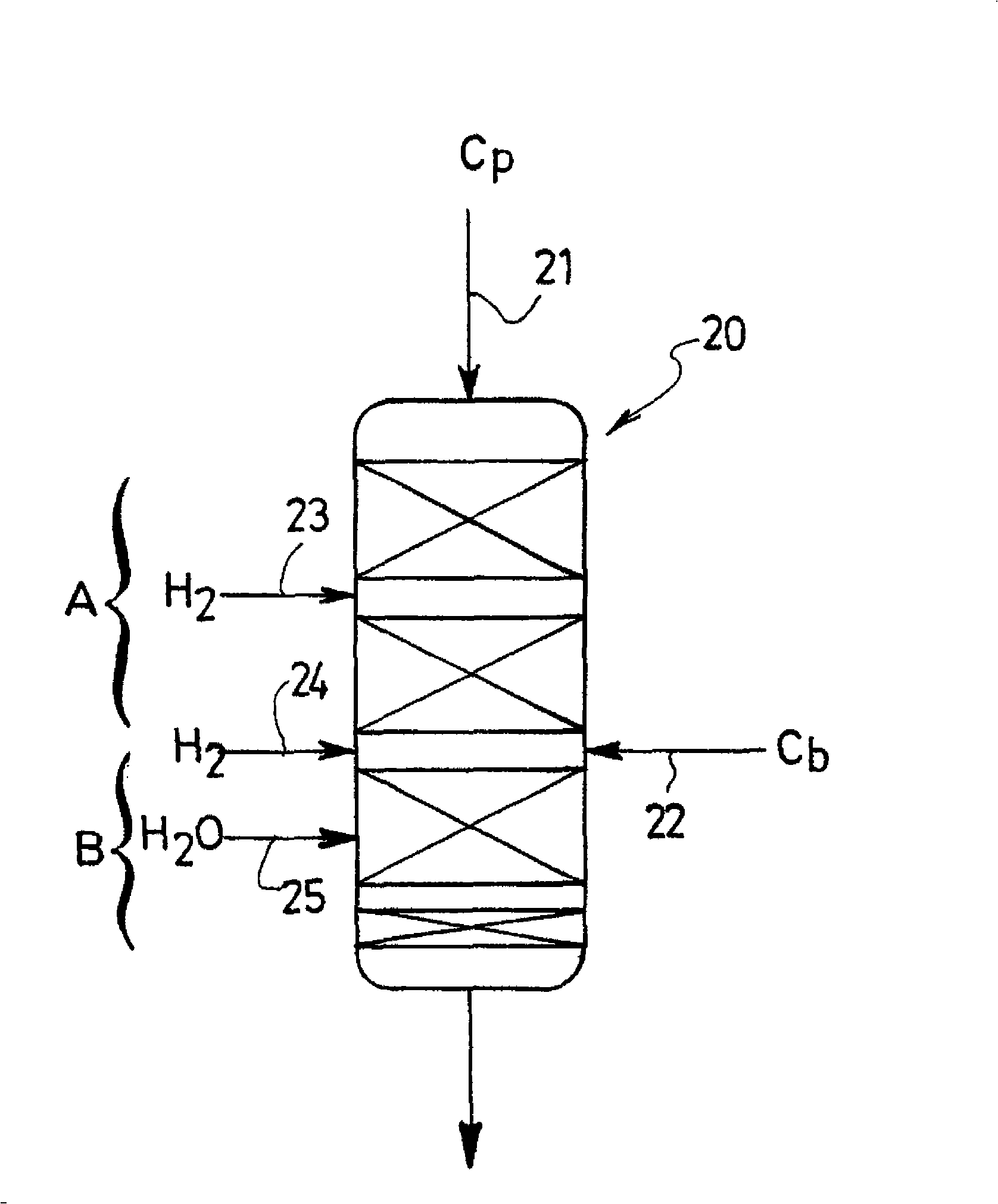

The invention relates to a process for the manufacture of diesel range hydrocarbons wherein a feed is hydrotreated in a hydrotreating step and isomerised in an isomerisation step, and a feed comprising fresh feed containing more than 5 wt % of free fatty acids and at least one diluting agent is hydrotreated at a reaction temperature of 200-400° C., in a hydrotreating reactor in the presence of catalyst, and the ratio of the diluting agent / fresh feed is 5-30:1.

Owner:NESTE OIL OY

Synthesis of liquid fuels and chemicals from oxygenated hydrocarbons

ActiveUS20080300435A1Oxygen-containing compound preparationLiquid hydrocarbon mixture productionFuranLiquid fuel

Processes and reactor systems are provided for the conversion of oxygenated hydrocarbons to hydrocarbons, ketones and alcohols useful as liquid fuels, such as gasoline, jet fuel or diesel fuel, and industrial chemicals. The process involves the conversion of mono-oxygenated hydrocarbons, such as alcohols, ketones, aldehydes, furans, carboxylic acids, diols, triols, and / or other polyols, to C4+ hydrocarbons, alcohols and / or ketones, by condensation. The oxygenated hydrocarbons may originate from any source, but are preferably derived from biomass.

Owner:VIRENT

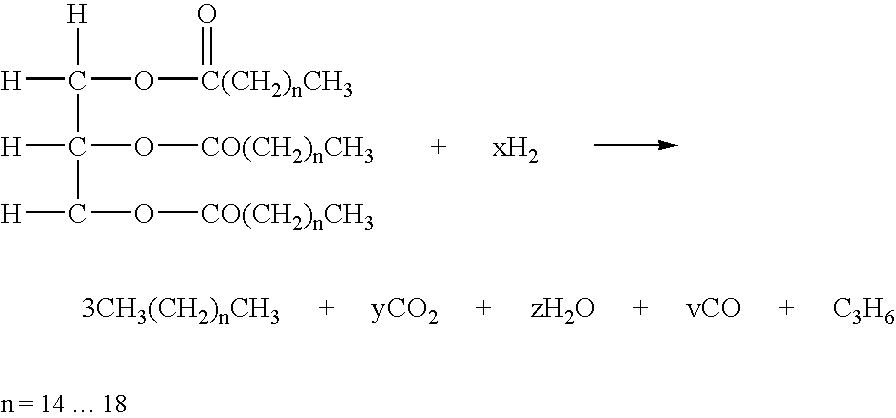

Production of diesel fuel from vegetable and animal oils

A process for producing a fuel composition from vegetable and / or animal oil comprises hydrodeoxygenating and hydroisomerizing the oil in a single step. The fuel composition has acceptable lubricity and comprises a mixture of C14 to C18 paraffins having a ratio of iso to normal paraffins of 2 to 8 and less than 5 ppm sulfur.

Owner:BEN GURION UNIVERSITY OF THE NEGEV

Synthesis of liqiud fuels and chemicals from oxygenated hydrocarbons

ActiveUS20080300434A1Oxygen-containing compound preparationHydrocarbon purification/separationFuranCarboxylic acid

Processes and reactor systems are provided for the conversion of oxygenated hydrocarbons to hydrocarbons, ketones and alcohols useful as liquid fuels, such as gasoline, jet fuel or diesel fuel, and industrial chemicals. The process involves the conversion of mono-oxygenated hydrocarbons, such as alcohols, ketones, aldehydes, furans, carboxylic acids, diols, triols, and / or other polyols, to C4+ hydrocarbons, alcohols and / or ketones, by condensation. The oxygenated hydrocarbons may originate from any source, but are preferably derived from biomass.

Owner:VIRENT

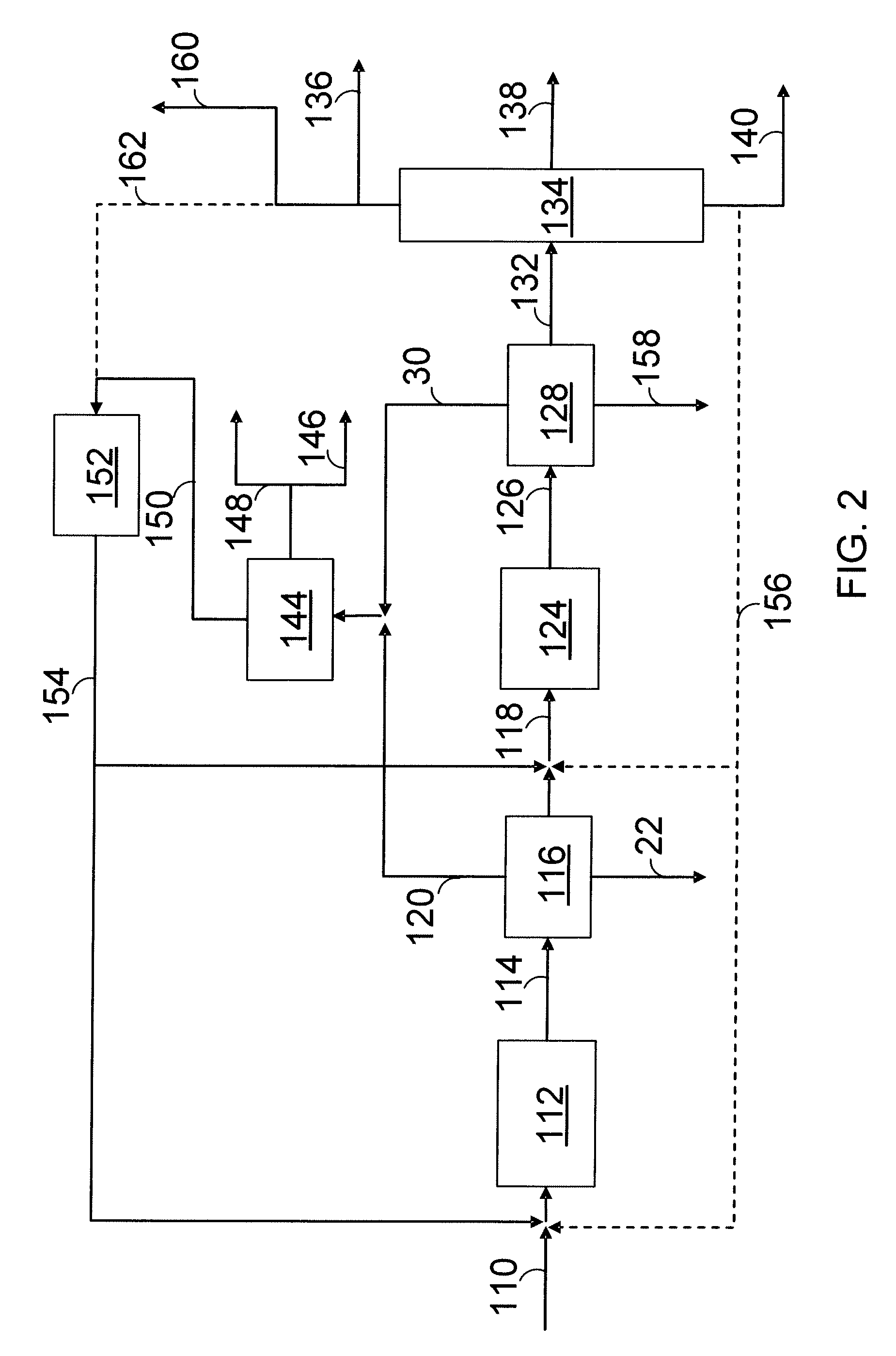

Production of Blended Fuel from Renewable Feedstocks

A process for producing a blended fuel from a paraffin rich component and a cyclic rich component, where each of the components are generated from a renewable feedstock, is presented. The paraffin rich component is generated from a first renewable feedstock comprising at least one component selected from the group consisting of glycerides, free fatty acids, biomass, lignocellulose, free sugars, and combinations thereof. The cyclic rich component is generated from a second renewable feedstock comprising at least one component selected from the group consisting of glycerides, free fatty acids, free fatty alkyl esters, biomass, lignocellulose, free sugars, and combinations thereof. The blended fuel may a gasoline boiling point range blended fuel, a diesel boiling point range blended fuel, an aviation boiling point range blended fuel, any combination thereof, or any mixture thereof.

Owner:UOP LLC

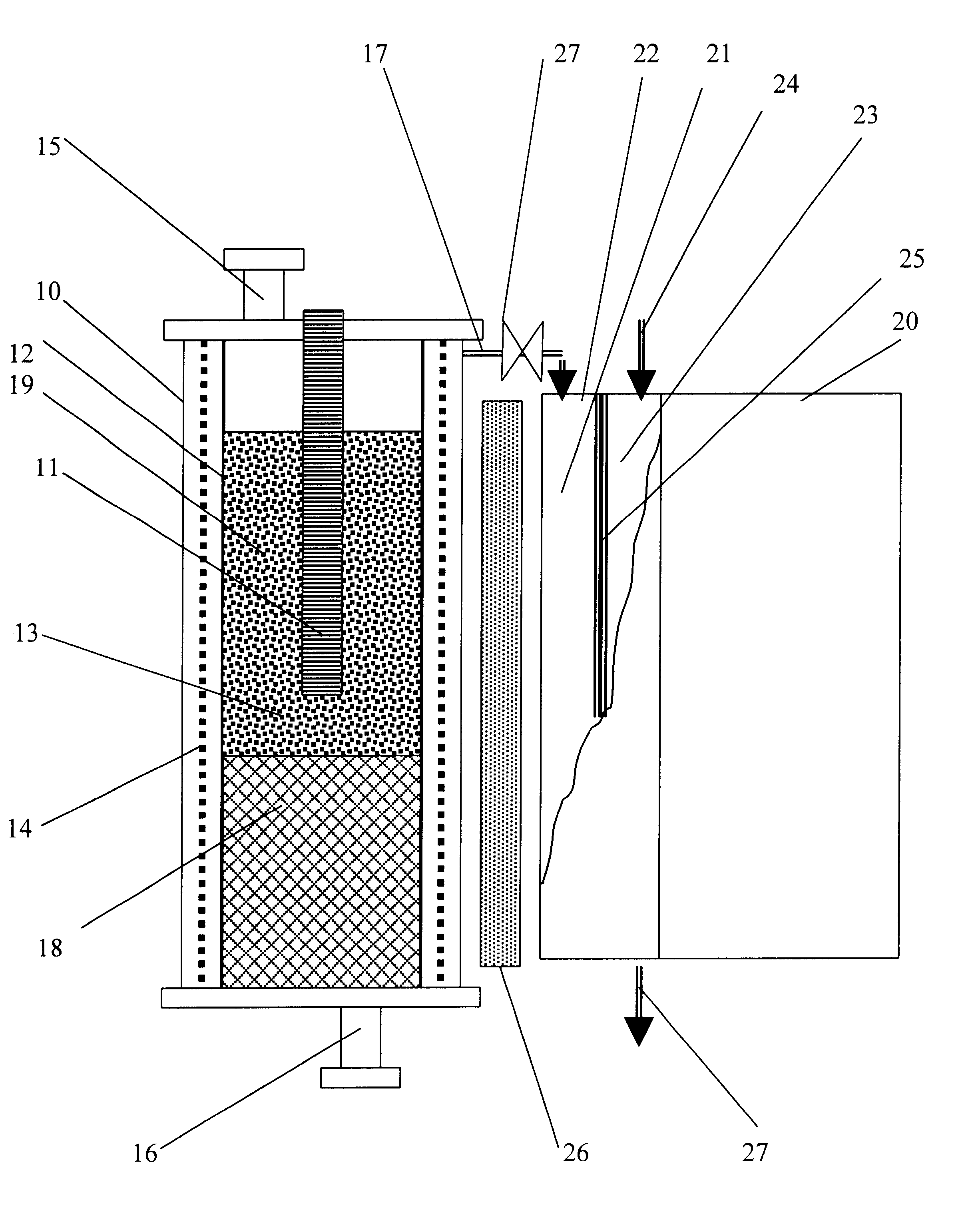

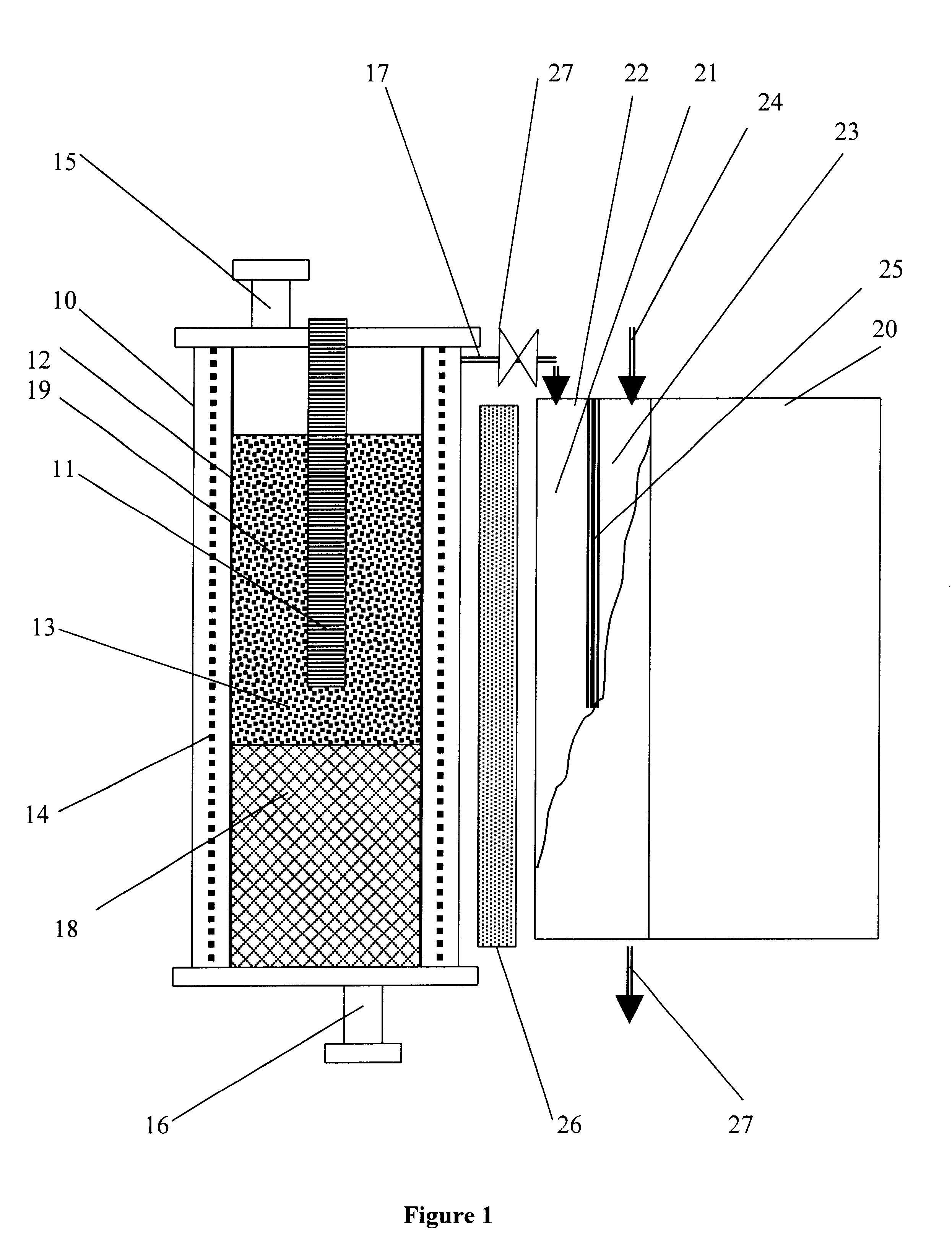

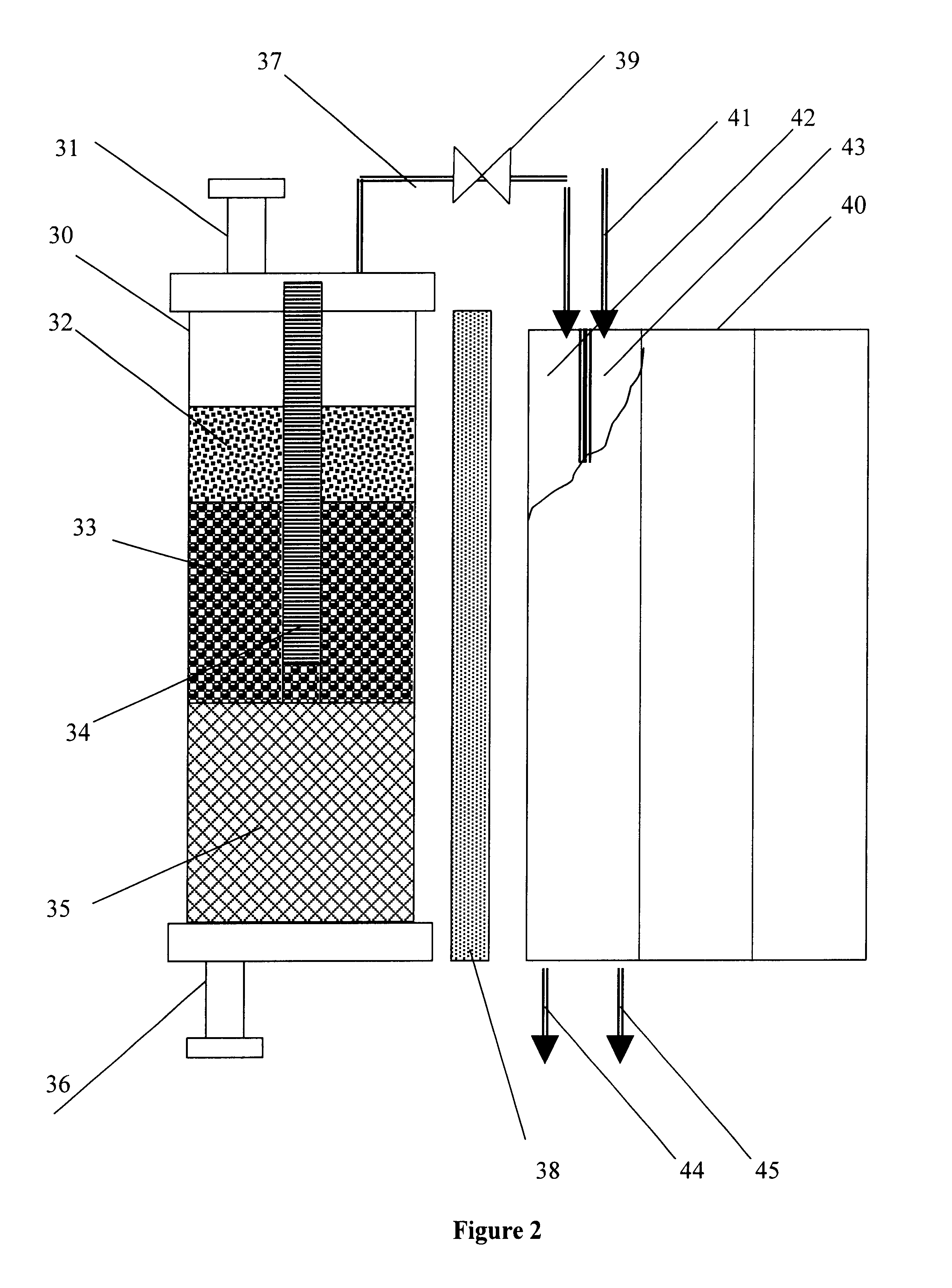

Sorbent composition, process for producing same and use in desulfurization

A particulate adsorbent composition comprising a mixture of zinc oxide, silica, alumina and substantially reduced valence cobalt for use in desulfurizing a cracked gasoline or diesel fuel feed stream in a desulfurization zone by: The desulfurization zone contacts the feed stream, then separates the resulting low sulfur content stream and the sulfurized adsorbent, regenerates and activates the separated adsorbent, and then returns to the desulfurization zone.

Owner:CHINA PETROLEUM & CHEM CORP

Ultrastable Y-type RE molecular sieve active component and its prepn process

InactiveCN1506161AReasonable matching activityIncreased hydrogen transfer activityMolecular sieve catalystsMolecular sieveActive component

The active component of ultrastable Y-type RE molecular sieve is composite modified Y-zeolite containing RE oxide 8-25 wt%, P 0.1-3.0 wt% and sodium oxide 0.3-2.5 wt%, and with degree of crystallization 30-55 % and unit cell parameter 2.455-2.477 nm. It is prepared with Y-zeolite as material and through the steps of exchange with RE and the first roasting to obtain RE-Na Y-zeolite; reaction with RE, reaction with P-containing compound, and the second roasting. The ultrastable Y-type RE molecular sieve is used as the active component of cracking catalyst and has the obvious effect of lowering olefin content in gasoline and the features of resulting in moderate coke yield and high diesel oil yield. The preparation process is simple and high in the utilization of the modifying elements.

Owner:PETROCHINA CO LTD

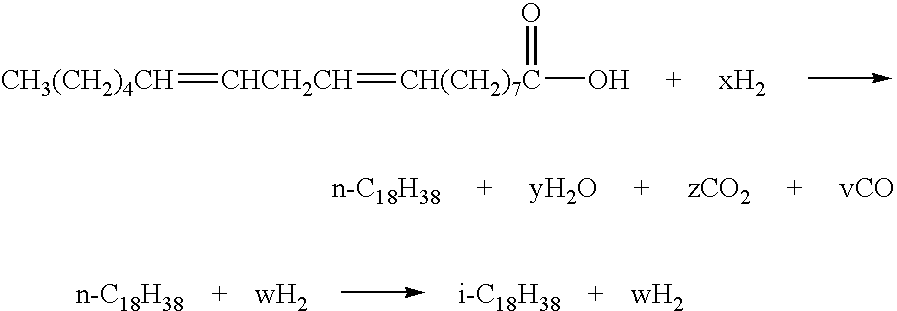

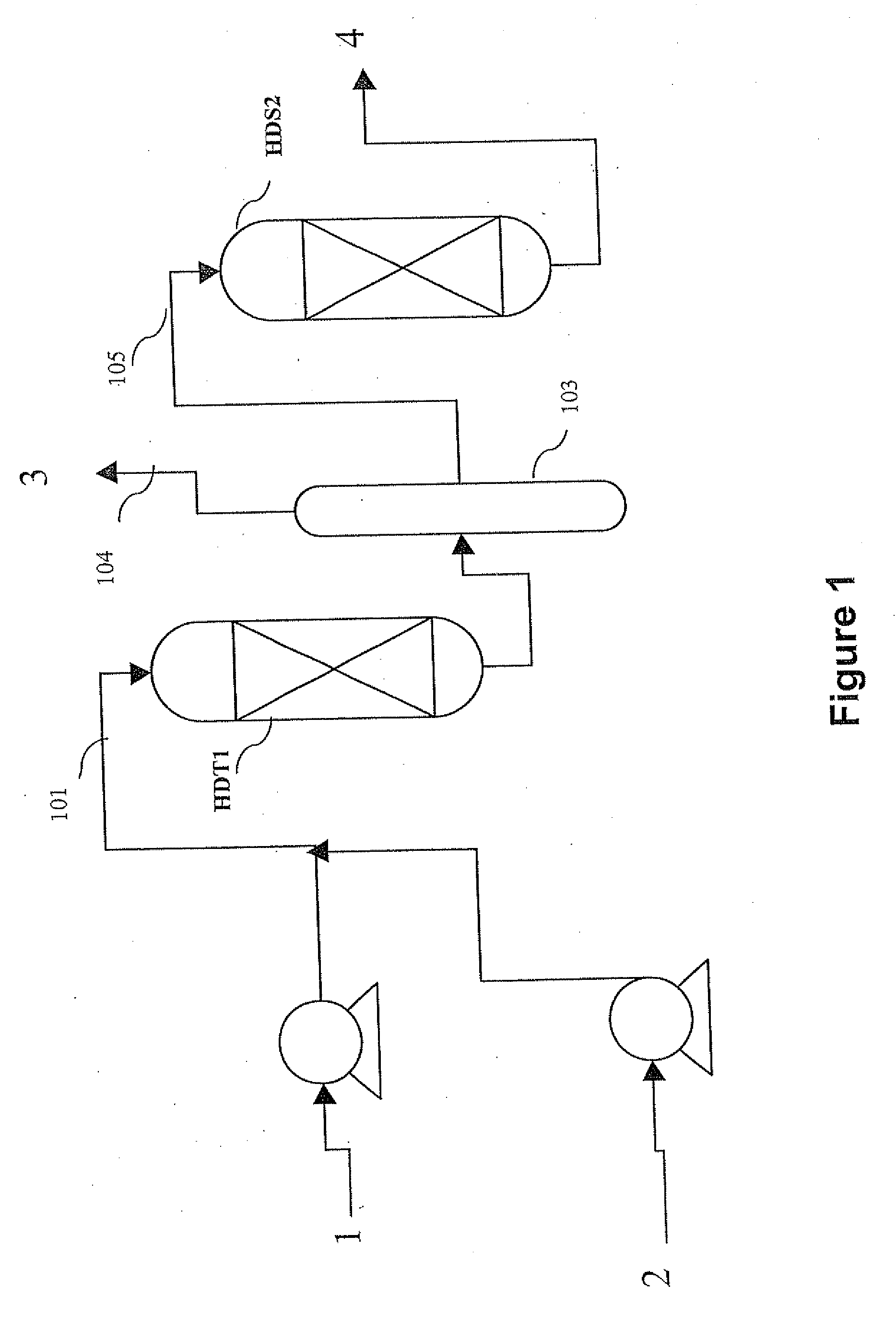

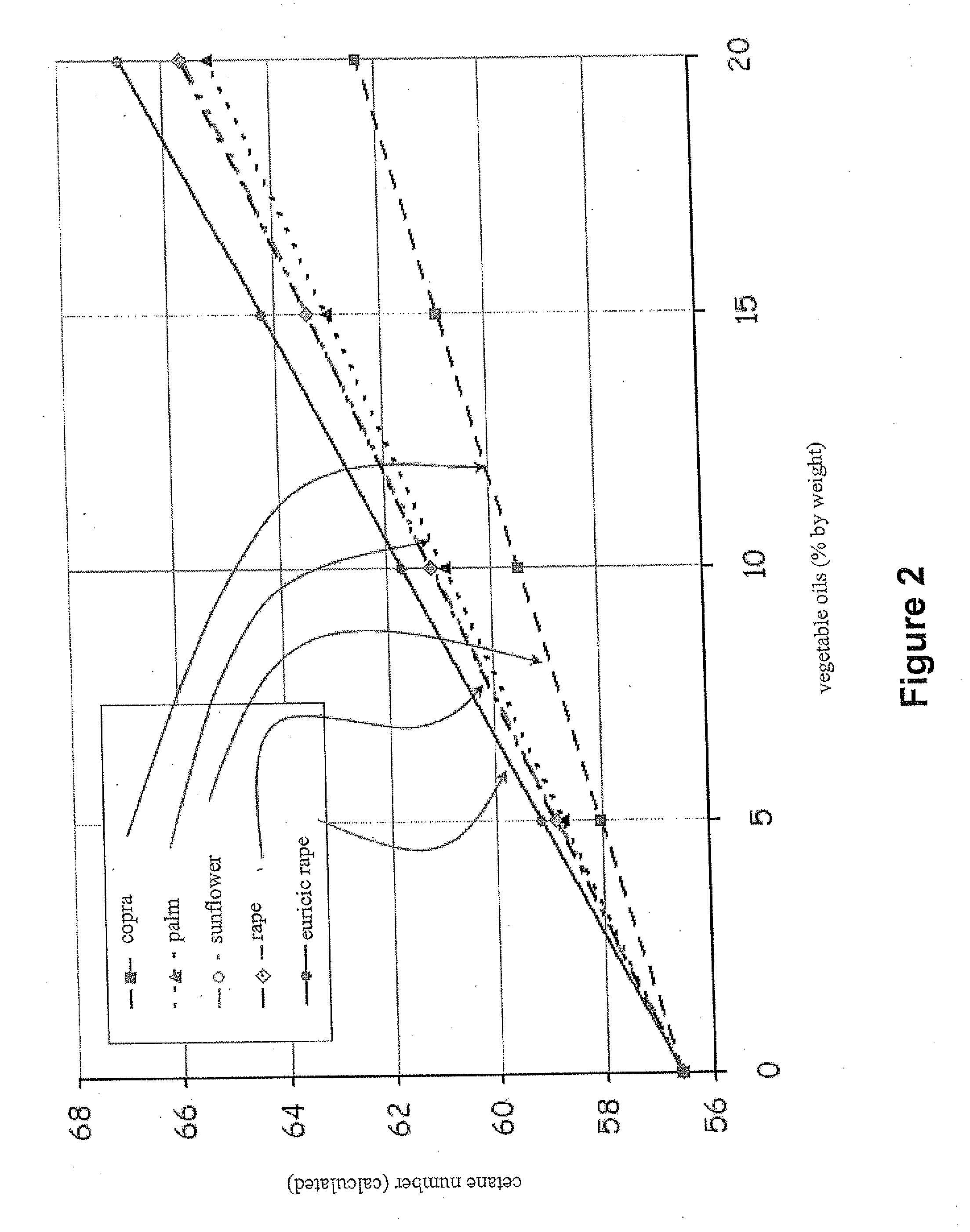

Process for the manufacture of diesel range hydro-carbons

ActiveUS20070006523A1Improve low temperature performanceBig ratioBiofuelsLiquid carbonaceous fuelsChemical industryAlkane

The invention relates to chemical industry and is directed to the production of middle distillate from vegetable oils. In the first step of the production method, the fatty acids or triglycerides of said vegetable oils are hydrogenated to give n-paraffins, and in the second step, the n-paraffins are catalytically converted to paraffins with branched chains. Using this process having two steps, a high-quality middle distillate useful as a component of diesel fuels without any particular specifications may be produced.

Owner:NESTE OIL OY

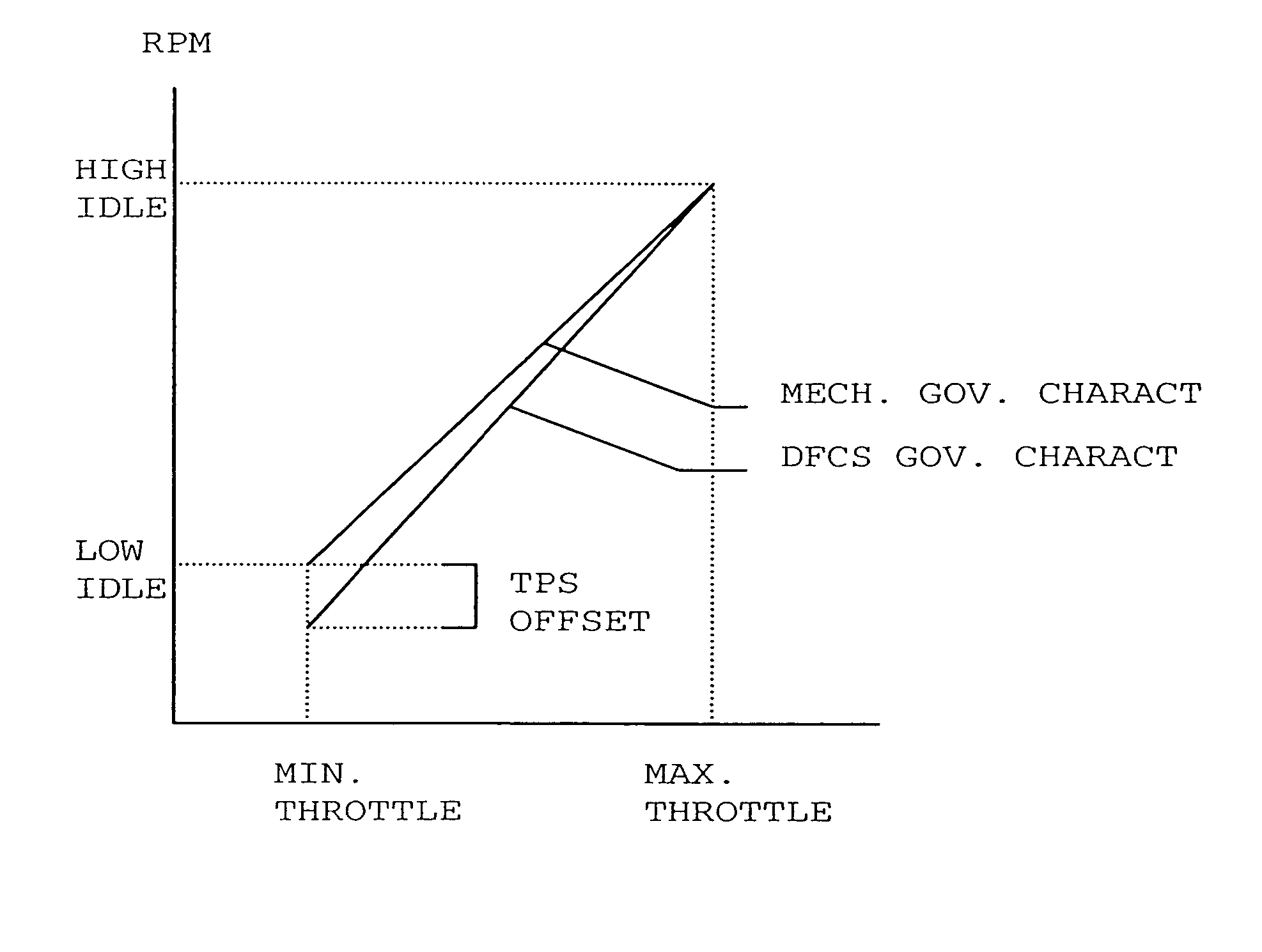

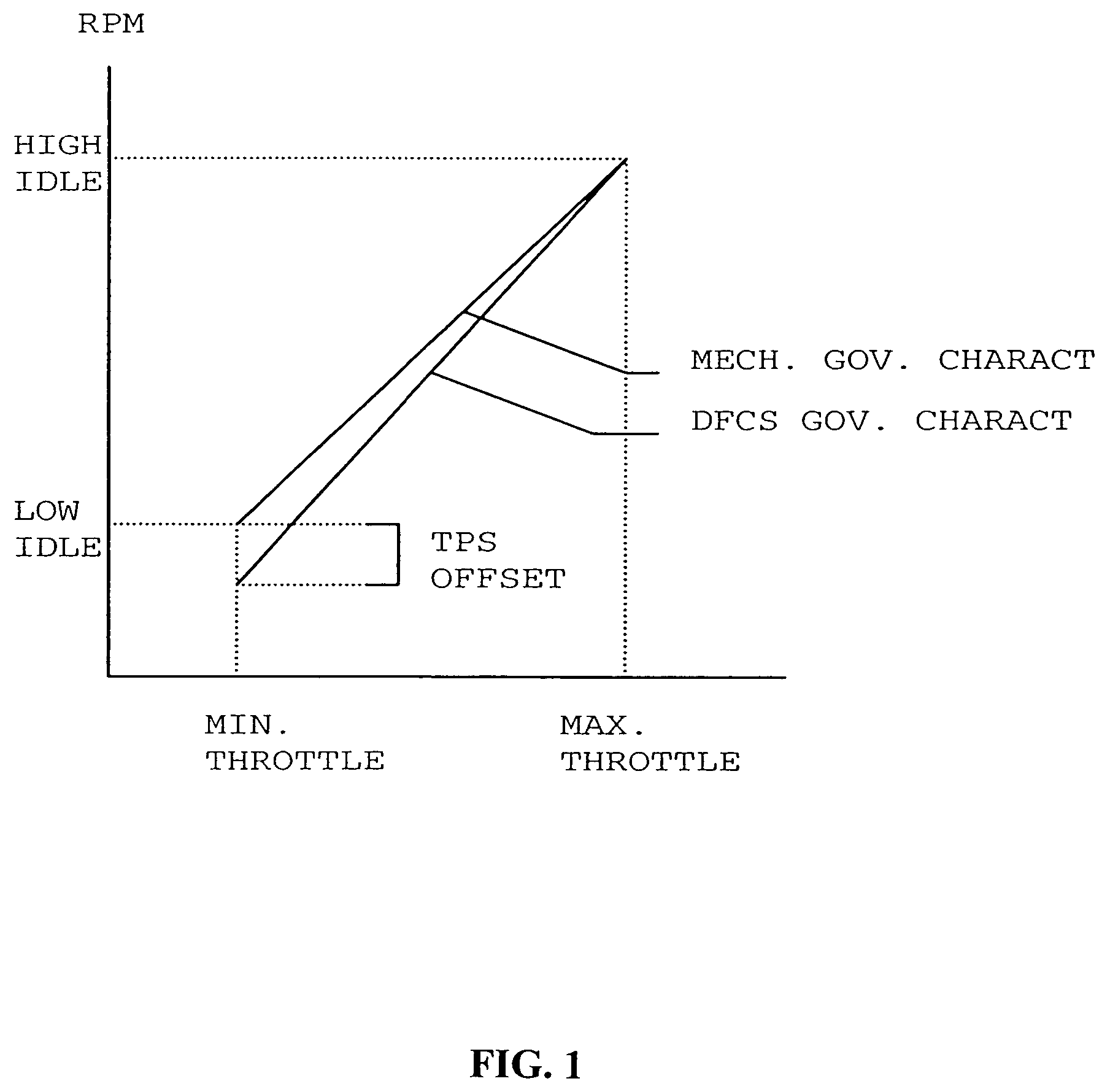

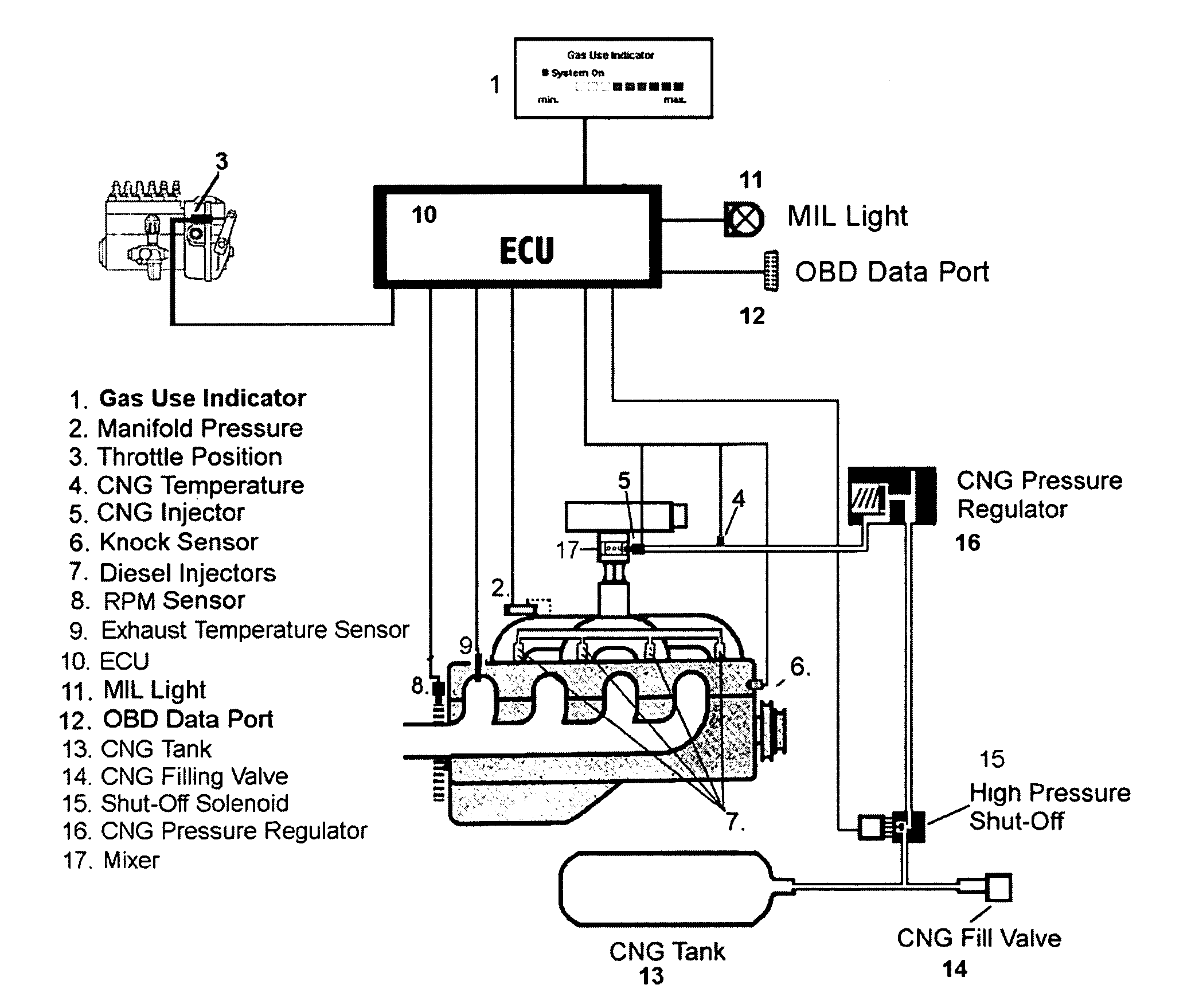

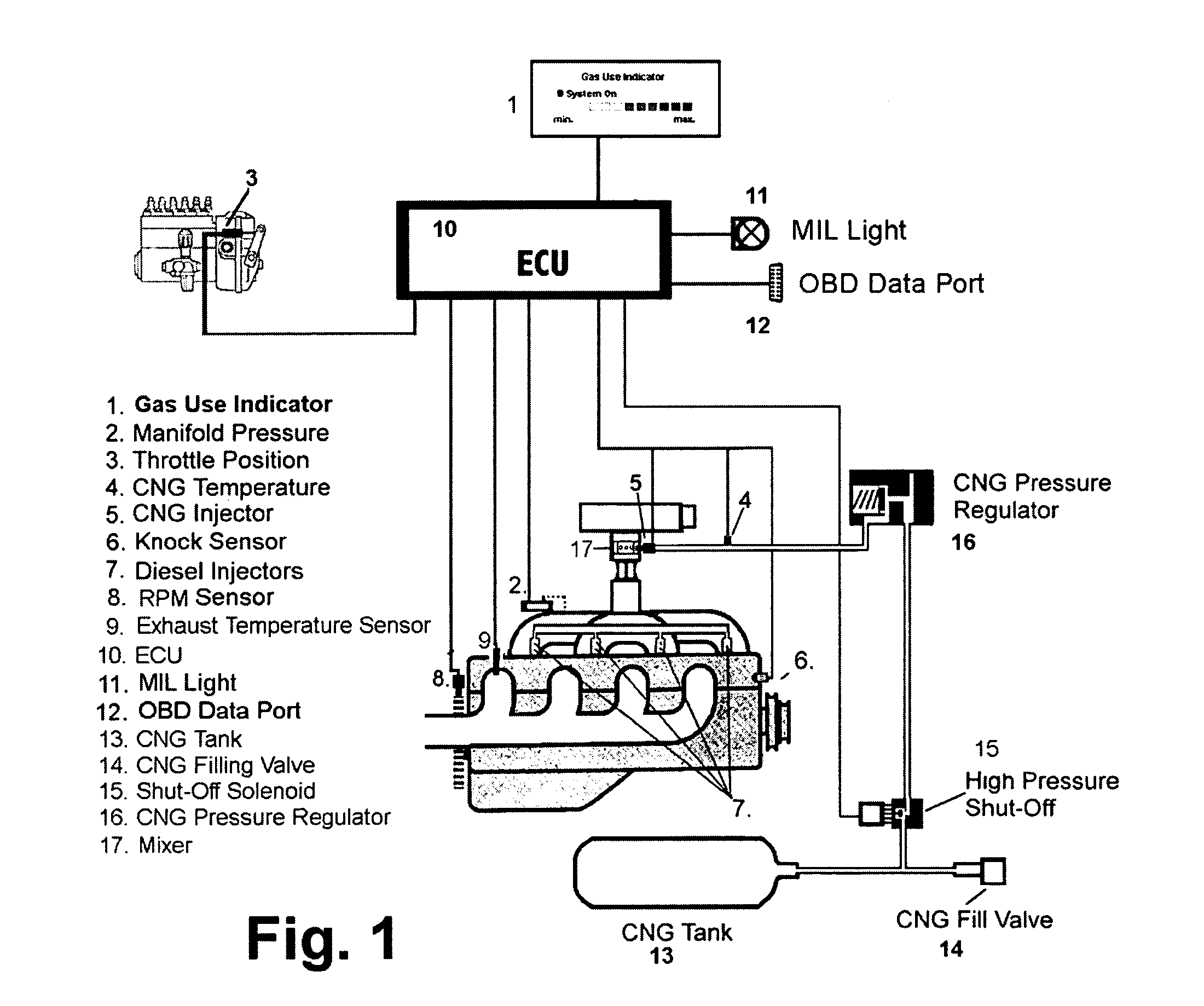

Methods and apparatus for operation of multiple fuel engines

Methods and apparatus are disclosed for operation of a multiple fuel engine, which runs on a combination of two or more fuels. An electronic control unit (ECU) may be connected to the existing components of an engine system in order to control operation of the multiple fuel engine. The engine system may be mechanically governed or electronically controlled. The ECU inputs operating characteristics of the engine system, determines governing characteristics for multiple fuel operation based on the operating characteristics, and controls the amounts of fuel delivered to the engine based on the governing characteristics. In a preferred embodiment, a dual fuel engine operates using diesel as a first fuel and natural gas as a second fuel. The operating characteristics may include engine speed, throttle position, engine exhaust temperature, gas pressure of the second fuel, gas temperature of the second fuel, boost pressure of an intake manifold, or engine coolant temperature.

Owner:2FUEL TECH INC +1

Heavy distillate oil hydrotreating method

ActiveCN101348732AQuality improvementQuality assuranceHydrocarbon oils refiningGasoline stabilisationWaxOil and grease

The invention relates to a method for hydrotreating heavy oil, in particular to the method for hydrotreating heavy oil, which improves the quality of diesel oil. Heavy distillate oil and animal and vegetable oil are used as raw material oil; under the hydrotreatment condition, the raw material oil and hydrogen gas are mixed and pass through a hydrotreatment reaction region; hydrogen-rich gas which is obtained by separating oil generated by hydrotreatment is circulated and utilized; and liquid obtained by separation is distillated to prepare a diesel oil product and hydrogenated wax oil. Compared with the prior art, the method can effectively improve the material source of a wax oil hydrotreatment device, ensure the quality of the hydrogenated wax oil, substantially increase the quality ofthe hydrotreated diesel oil and improve the storage stability of the animal and vegetable oil as fuel oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

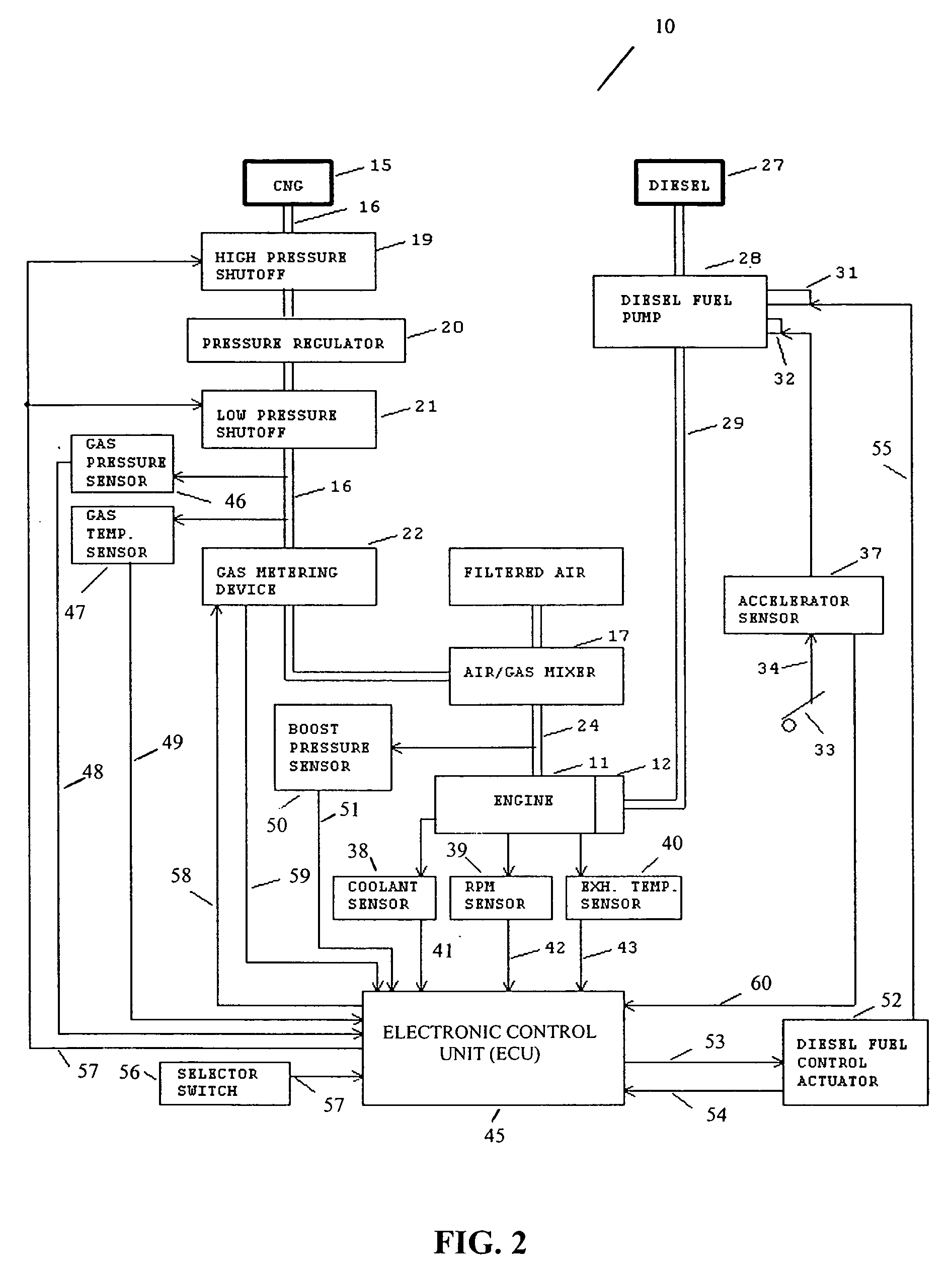

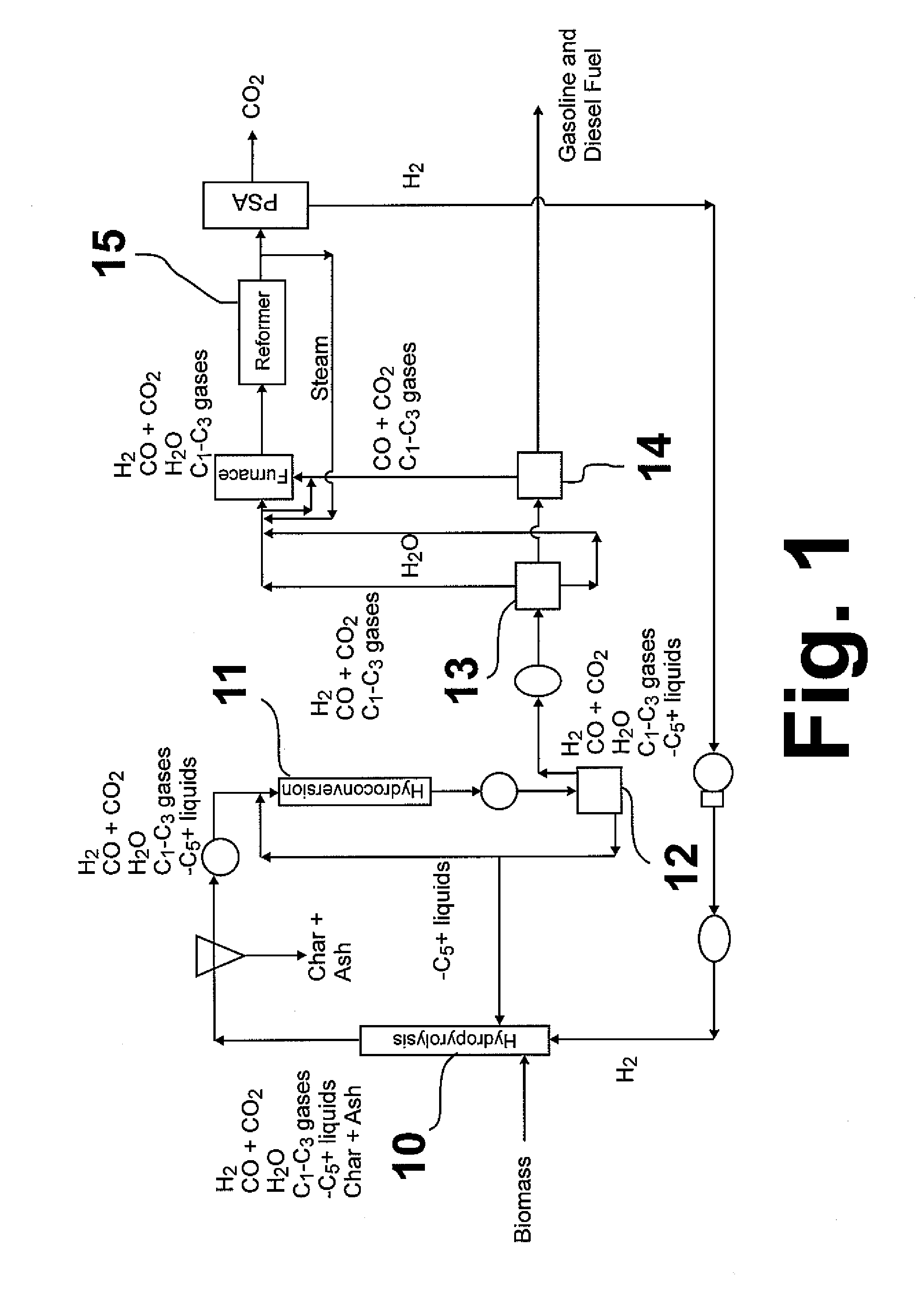

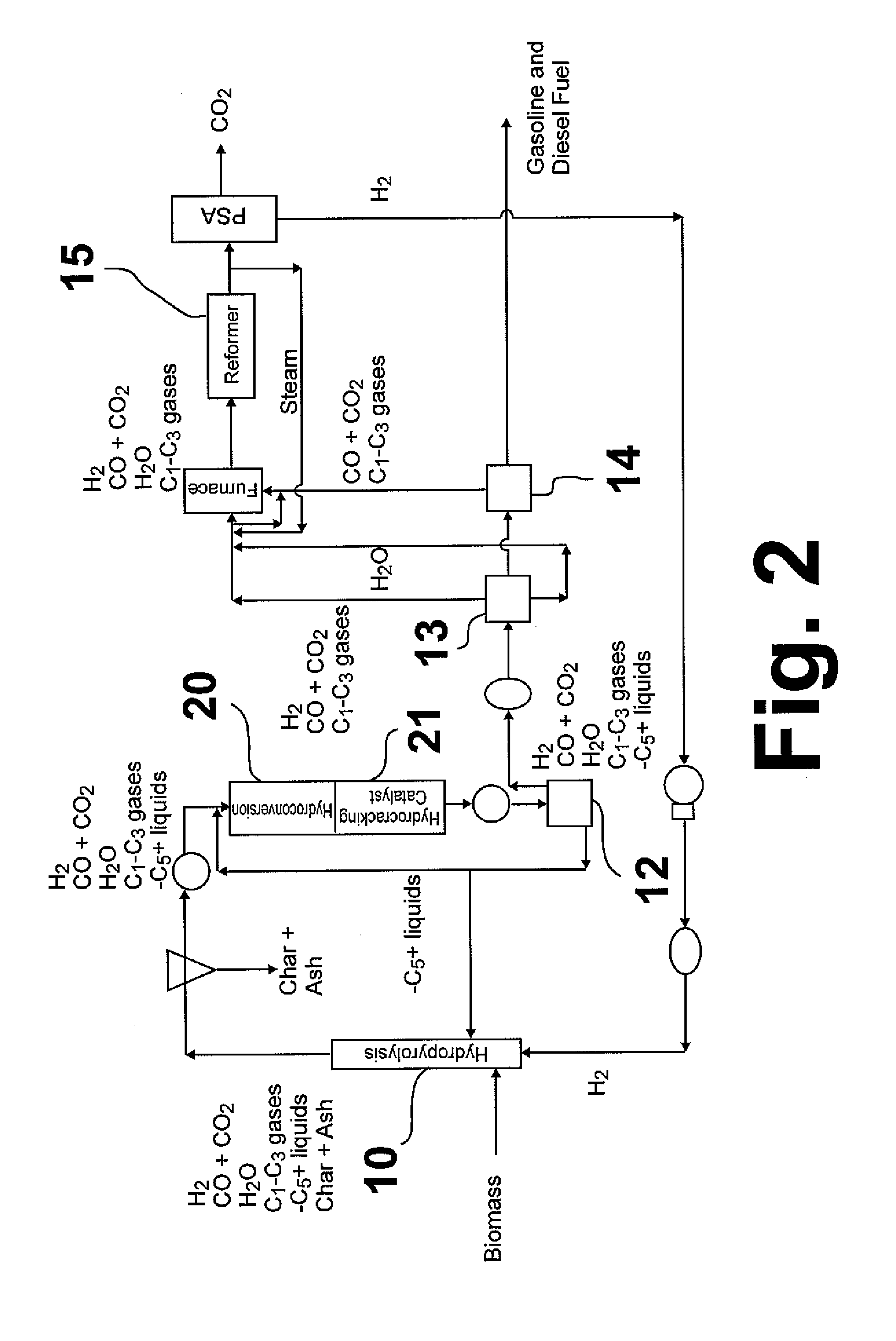

Hydropyrolysis of biomass for producing high quality liquid fuels

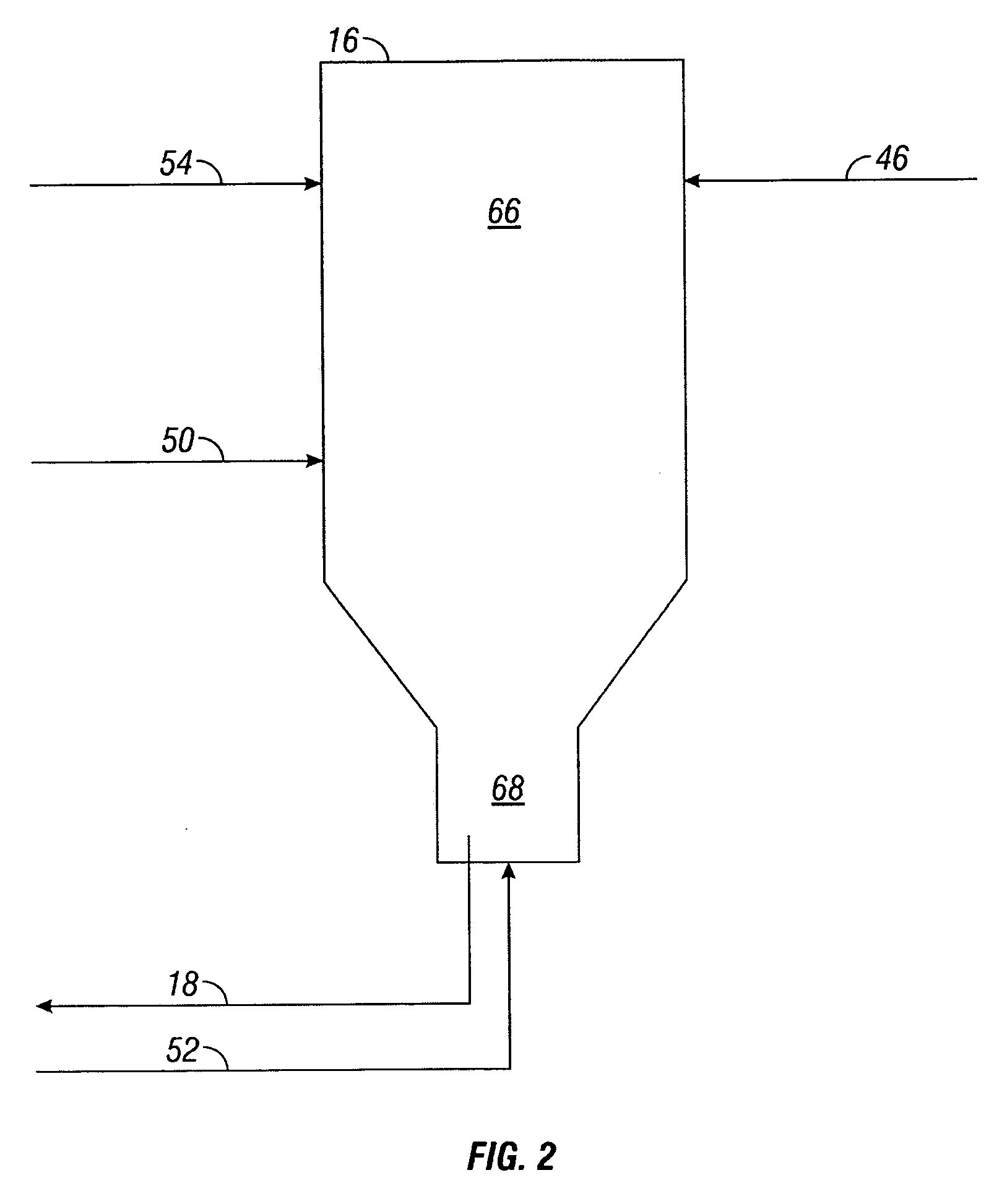

A self-sustaining process for producing high quality liquid fuels from biomass in which the biomass is hydropyrolyzed in a reactor vessel containing molecular hydrogen and a deoxygenating catalyst, producing a partially deoxygenated hydropyrolysis liquid, which is hydrogenated using a hydroconversion catalyst, producing a substantially fully deoxygenated hydrocarbon liquid and a gaseous mixture comprising CO and light hydrocarbon gases (C1-C3). The gaseous mixture is reformed in a steam reformer, producing reformed molecular hydrogen, which is then introduced into the reactor vessel for hydropyrolizing the biomass. The deoxygenated hydrocarbon liquid product is further separated to produce diesel fuel, gasoline, or blending components for gasoline and diesel fuel.

Owner:GAS TECH INST

Cracking catalyst for petroleum hydrocarbon, and preparation method

A cracking catalyst for petroleum hydrocarbon is proportionally prepared from clay, aluminum oxide prepared from alpha-AlO(OH), Y-type molecular sieve containing RE and P and silicon oxide. Its advantages are strong power to convert heavy oil and high output rate of diesel oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for producing bio-derived fuel with alkyl ester and iso-paraffin components

InactiveUS20080163543A1Improve low temperature performanceImprove the lubrication effectBiofuelsLiquid carbonaceous fuelsAlkaneParaffin oils

A process for producing a diesel fuel of biological origin. The process includes a biological component to be trans-esterified into a fatty acid alkyl ester. A fraction of the fatty acid alkyl ester is hydrodeoxygenated and hydroisomerized to produce an iso-paraffinic hydrocarbon. The fatty acid alkyl ester and the iso-paraffin components are combined into a middle distillate product suitable for direct use as diesel or jet fuel.

Owner:REG SYNTHETIC FUELS LLC

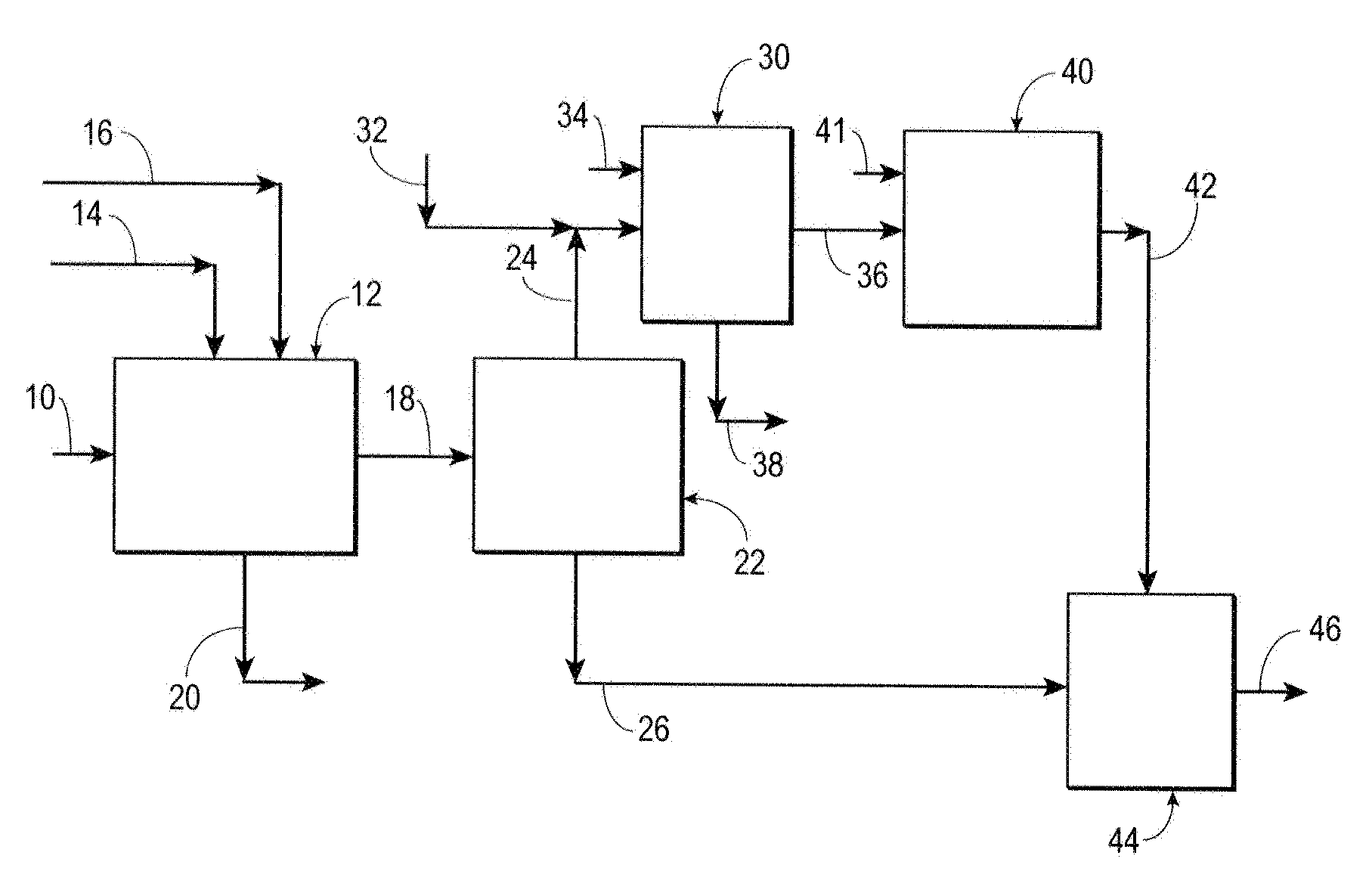

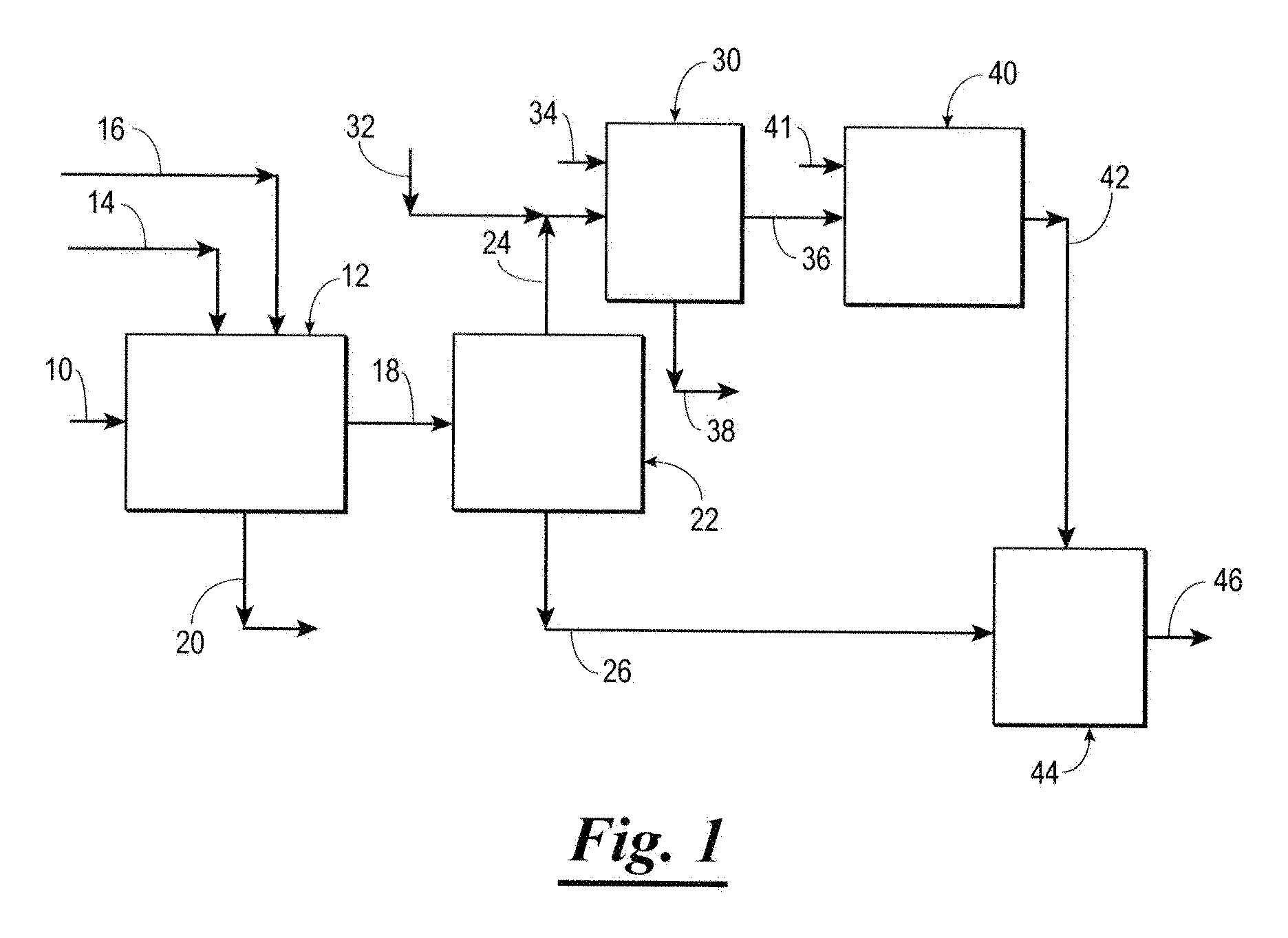

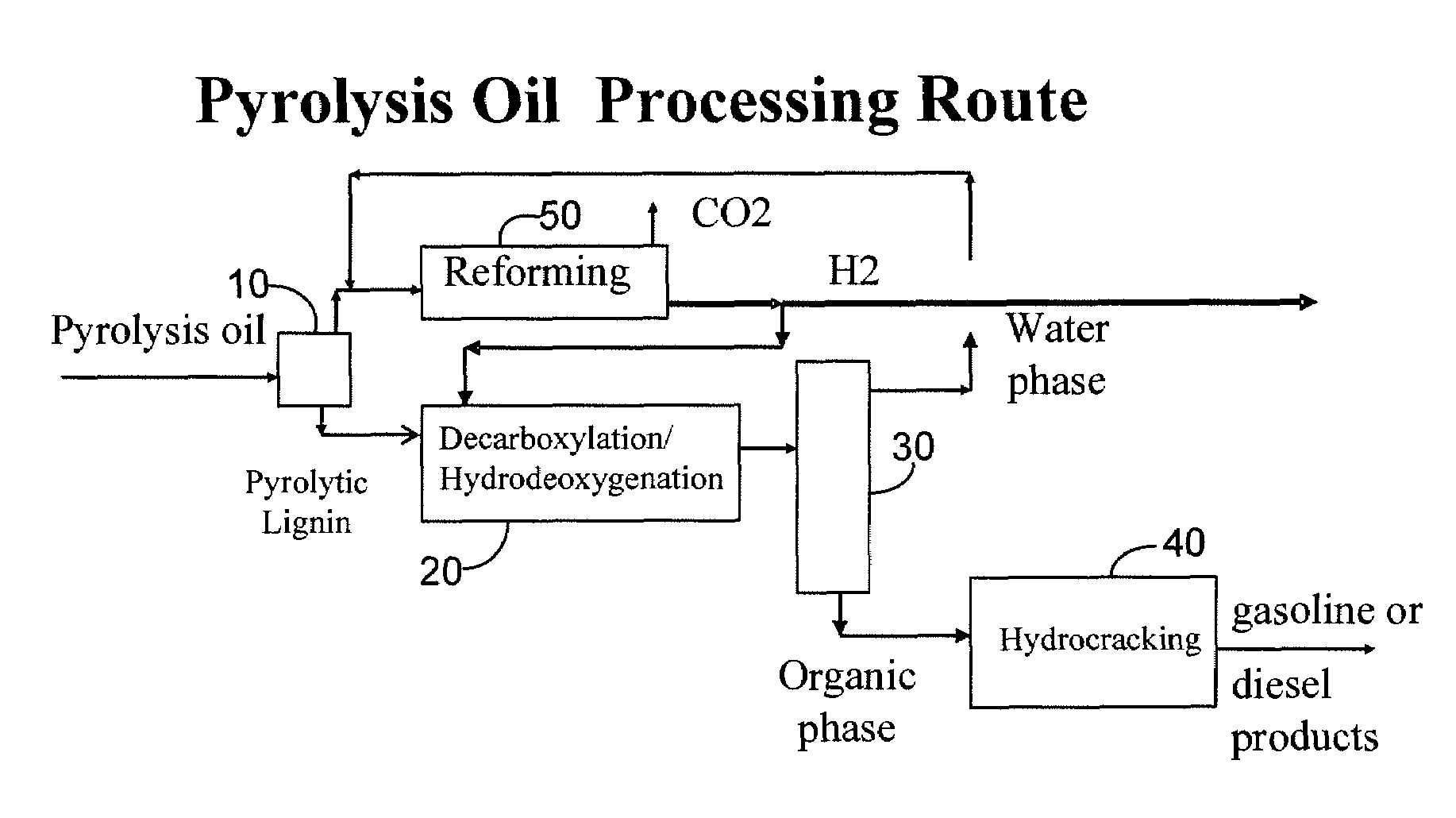

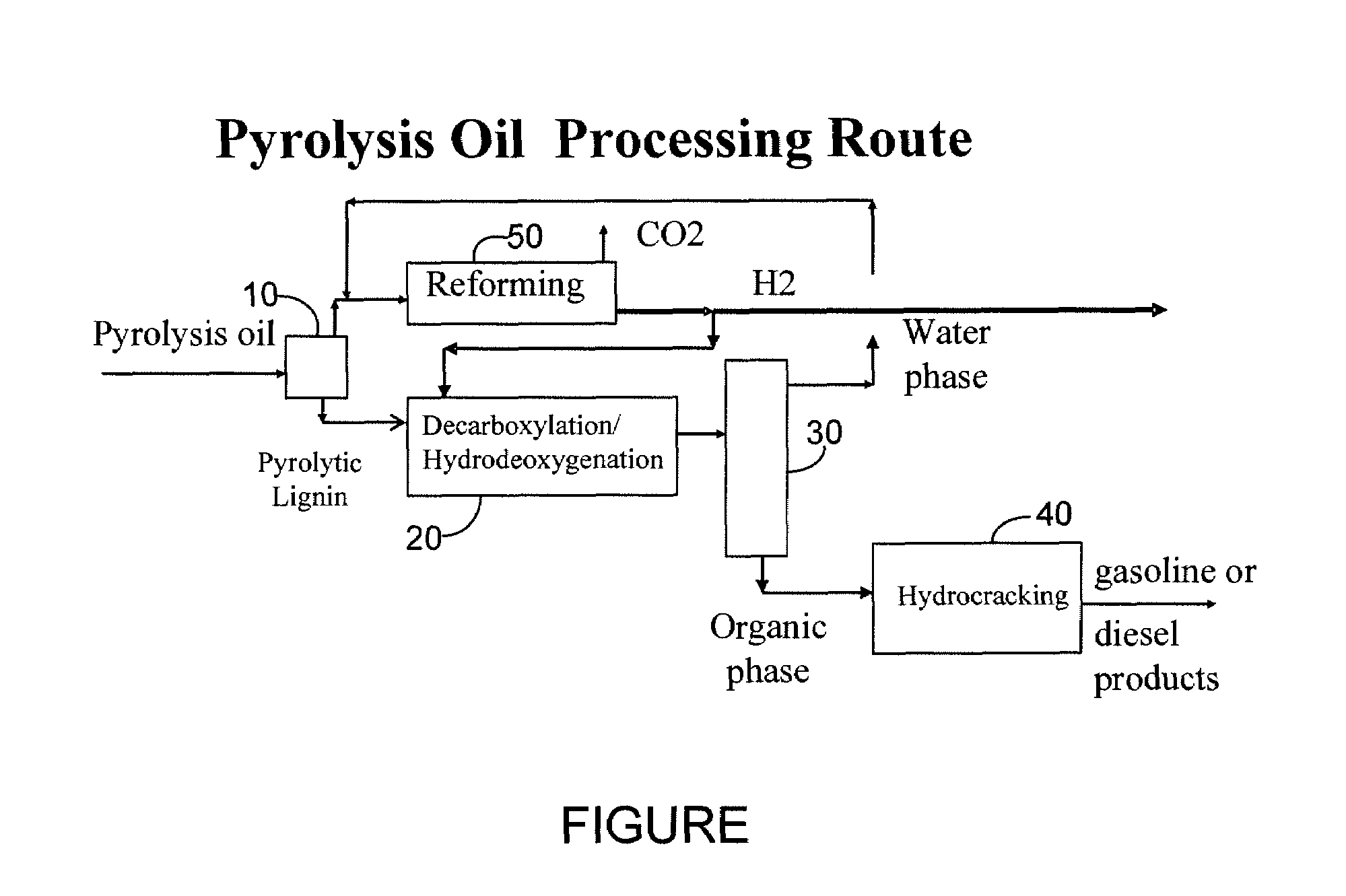

Gasoline and diesel production from pyrolytic lignin produced from pyrolysis of cellulosic waste

InactiveUS7578927B2Treatment with plural serial cracking stages onlyTreatment with plural serial stages onlyCelluloseNaphtha

A process for the conversion of biomass to a liquid fuel is presented. The process includes the production of diesel and naphtha boiling point range fuels by hydrocracking of pyrolysis lignin extracted from biomass.

Owner:UOP LLC

Multi-fuel engine conversion system and method

Systems, methods and apparatus' of converting an engine into a multi-fuel engine are provided. One embodiment reduces particulate emissions and reduces the amount of combusted gasoline or diesel fuel by replacing some of the fuel with a second fuel, such as natural gas, propane, or hydrogen. One feature of the present invention includes a control unit for metering the second fuel. Another feature of the present invention includes an indicator that indicates how much second fuel is being combusted relative to the diesel or gasoline. This Abstract is provided for the sole purpose of complying with the Abstract requirement rules that allow a reader to quickly ascertain the subject matter of the disclosure contained herein. This Abstract is submitted with the explicit understanding that it will not be used to interpret or to limit the scope or the meaning of the claims.

Owner:OMNITEK ENG

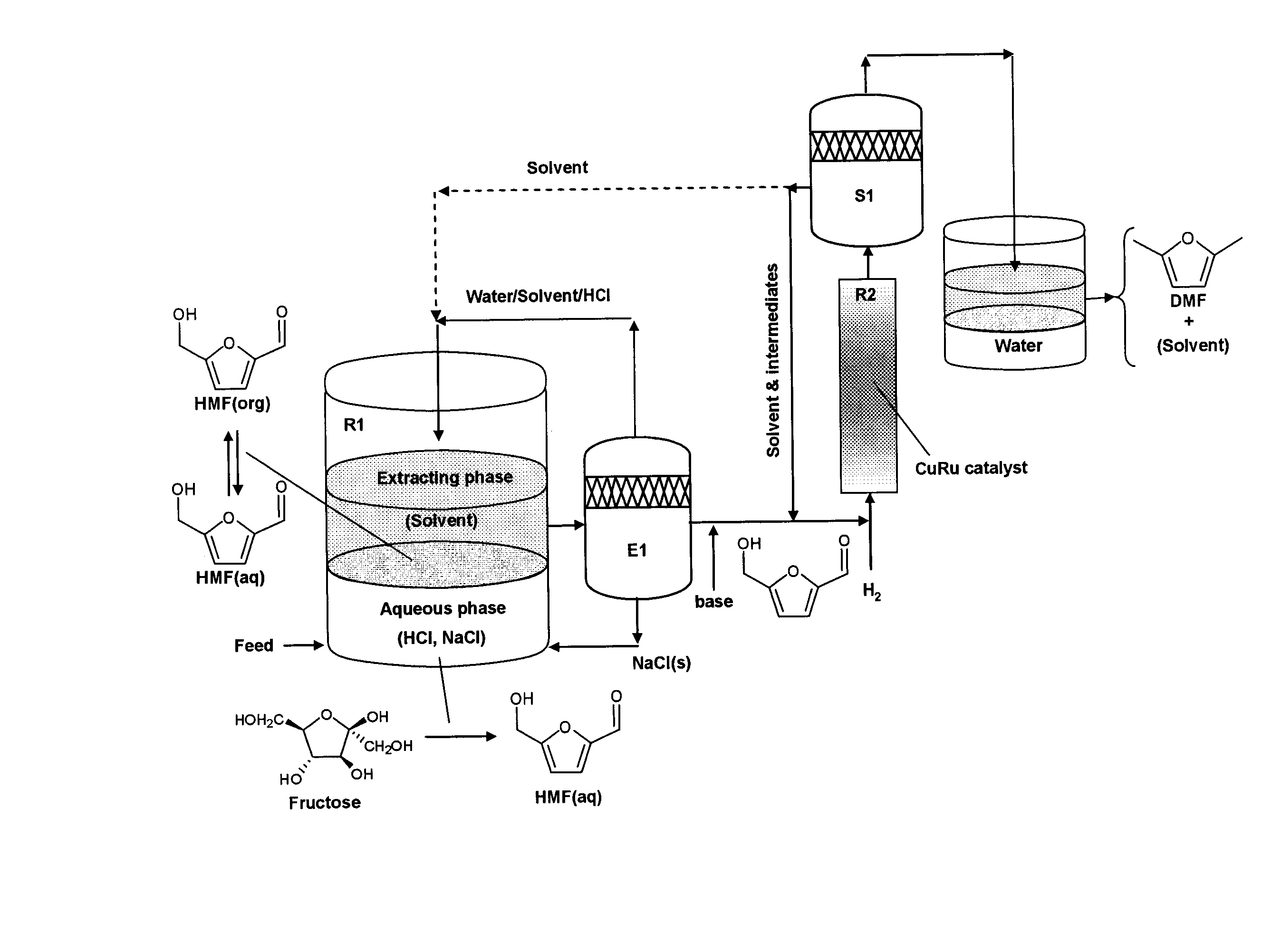

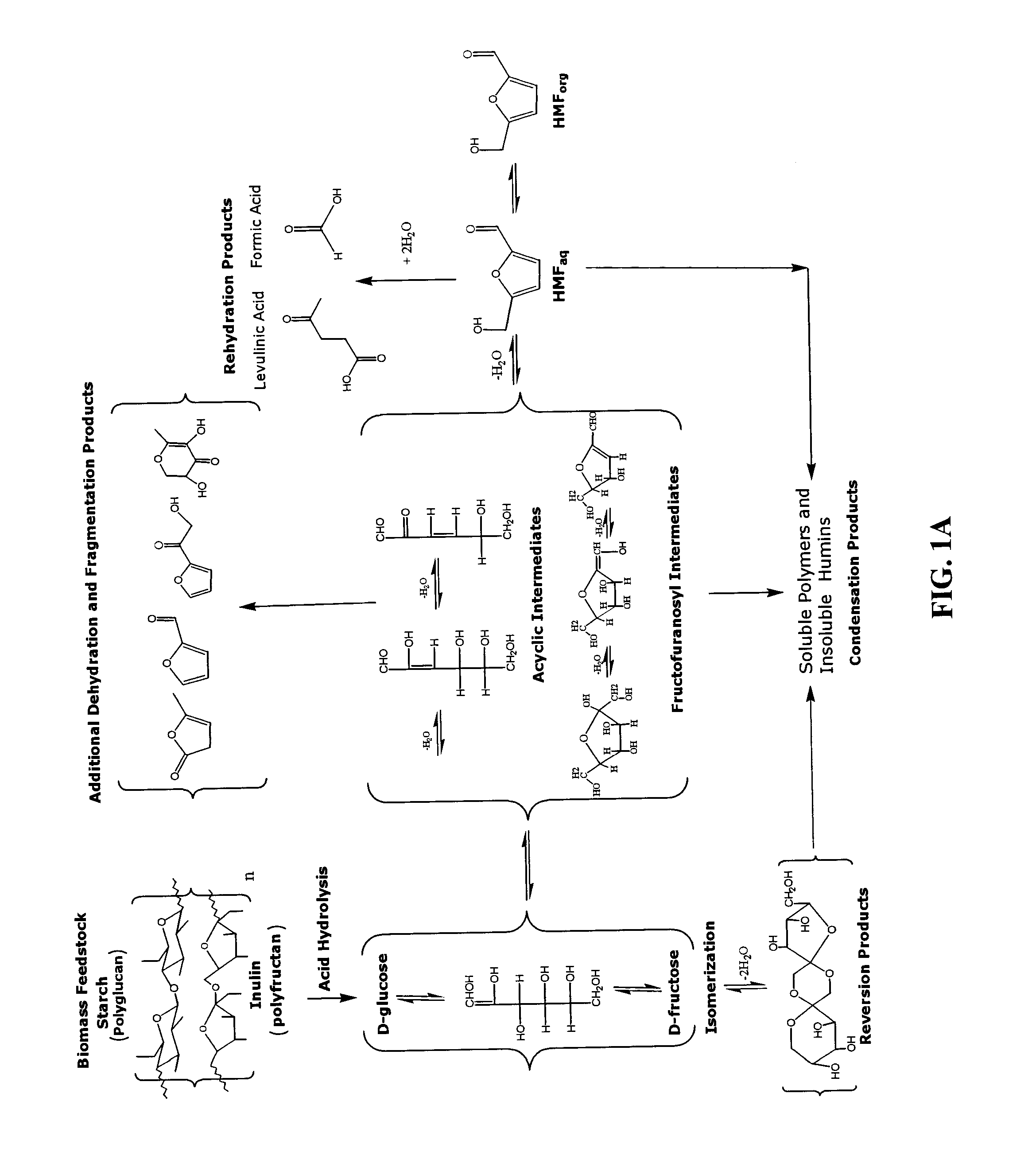

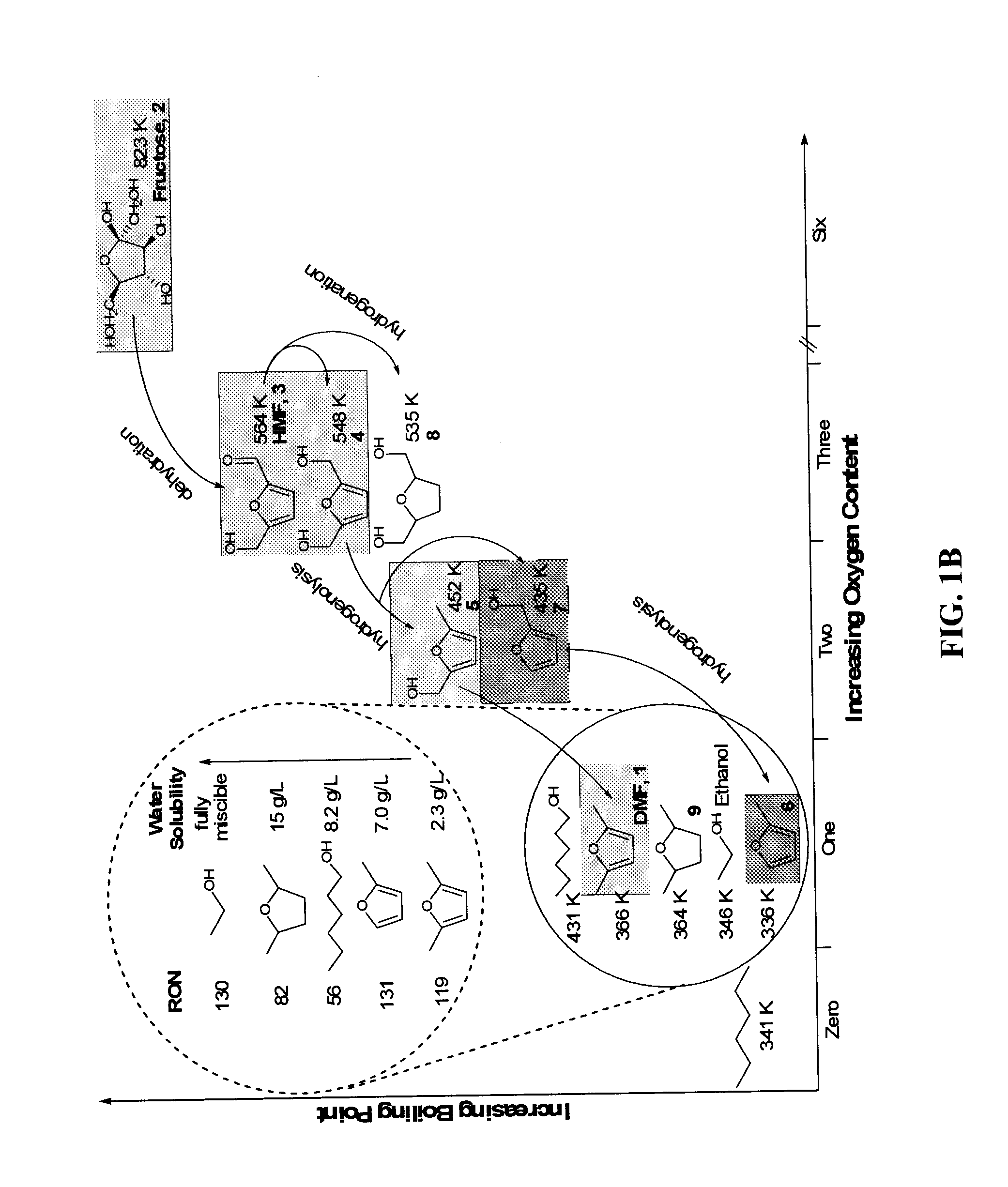

Catalytic process for producing furan derivatives in a biphasic reactor

Described is a catalytic process for converting sugars to furan derivatives (e.g. 5-hydroxymethylfurfural, furfural, dimethylfuran, etc.) using a biphasic reactor containing a reactive aqueous phase and an organic extracting phase. The process provides a cost-effective route for producing di-substituted furan derivatives. The furan derivatives are useful as value-added intermediates to produce polymers, as precursors to diesel fuel, and as fuel additives.

Owner:WISCONSIN ALUMNI RES FOUND

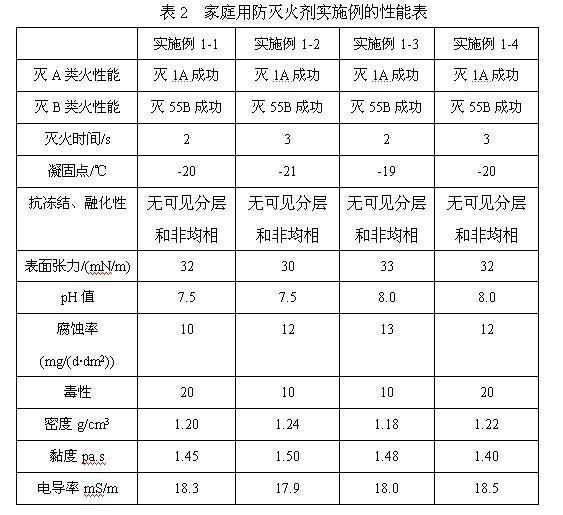

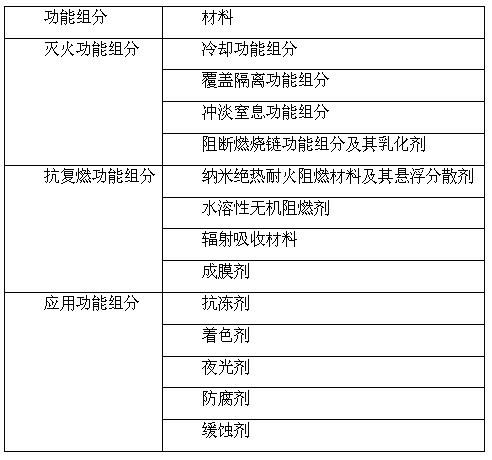

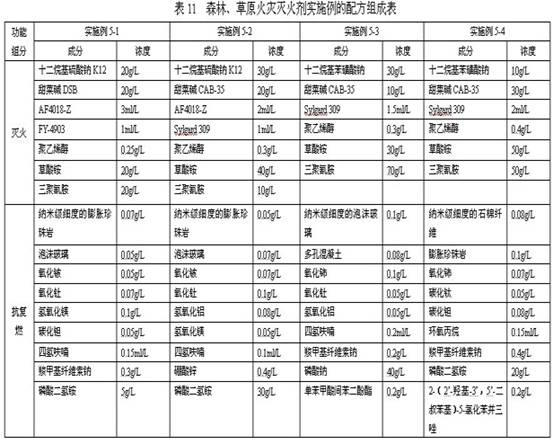

Built-up synergetic class-A/B water extinguishing agent series

The invention discloses a built-up synergetic class-A / B water extinguishing agent series. Class-A fires caused by solid substances (such as woods, cottons, wools, linens, paper) and products thereof and class-B fires caused by liquid or melted solids such as gasoline, kerosene, diesel oil, crude oil, methanol, ethanol, asphalt, paraffin waxes and the like can be put out rapidly through the functions such as heat absorption and cooling, diluting and smothering, insulating and covering, suppressing and blocking combustion chains, and the like which are synergetically performed by various extinguishing functional components, and a high-temperature-resistant thermal-insulation and fire-retarding covering layer is formed on the surface of an inflammable matter by various after-combustion functional components so as to achieve the effect of after-combustion resistance. Because the class A / B fires relate to multiple occasions of daily life and production activities, the extinguishing agent disclosed by the invention can be used in the fields of home fire prevention and extinguishing, urban architecture fire prevention and extinguishing, oil depot and gasoline station fire prevention and extinguishing, vehicle and ship fire prevention and extinguishing, forest and grassland fire prevention and extinguishing, mine fire prevention and extinguishing, confined spaces (such as civil air-defense architectures) fire prevention and extinguishing.

Owner:NANJING UNIV OF SCI & TECH

Fuel compositions comprising farnesane and farnesane derivatives and method of making and using same

A fuel composition comprises farnesane and / or farnesane derivatives and a conventional fuel component selected from diesel fuel, jet fuel, kerosene or gasoline. The farnesane or farnesane derivative can be used as a fuel component or as a fuel additive in the fuel composition. The fuel composition may further comprise a conventional fuel additive. Methods of making and using the fuel composition are also disclosed.

Owner:AMYRIS INC

Method for manufacturing cleaner fuels

InactiveUS6248230B1Long catalyst lifeReduce hydrogen consumptionLiquid hydrocarbon mixture productionTreatment with hydrotreatment processesBoiling pointGasoline

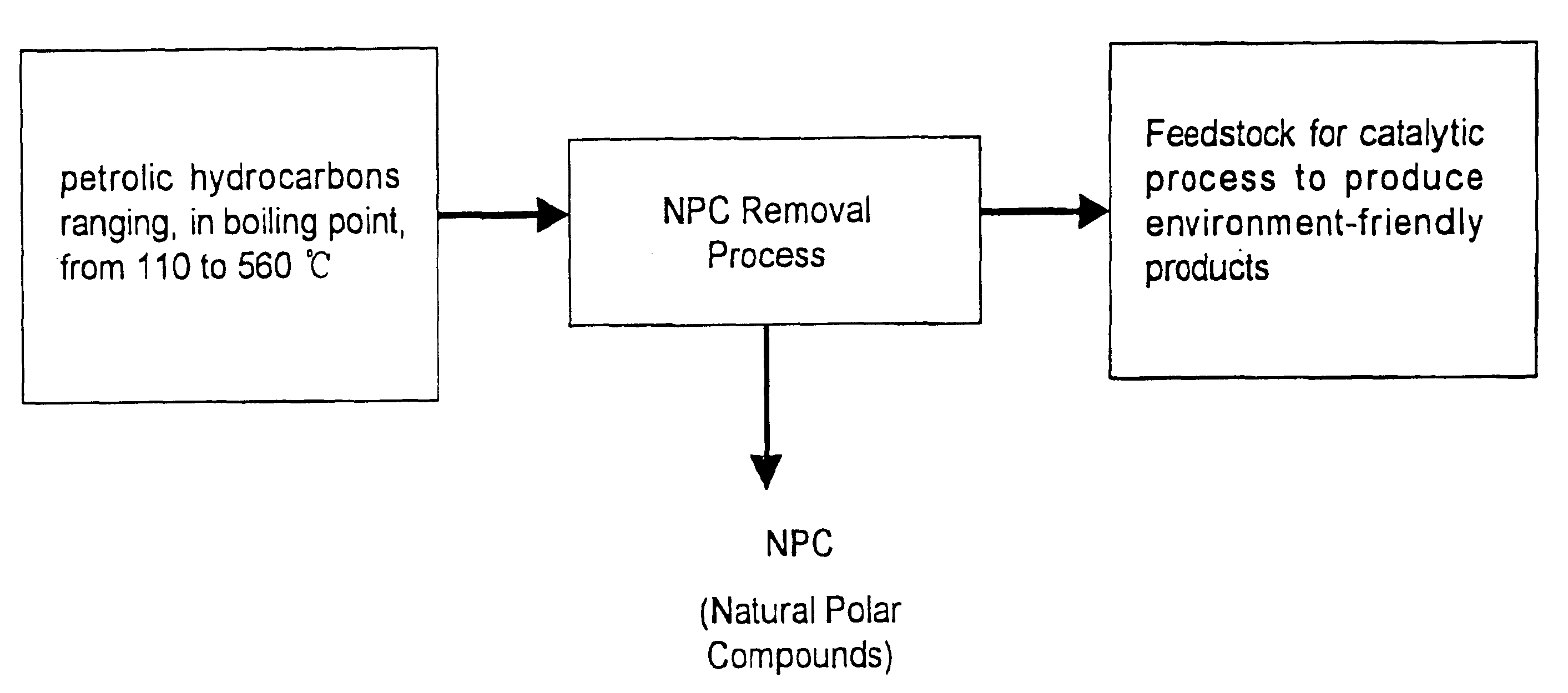

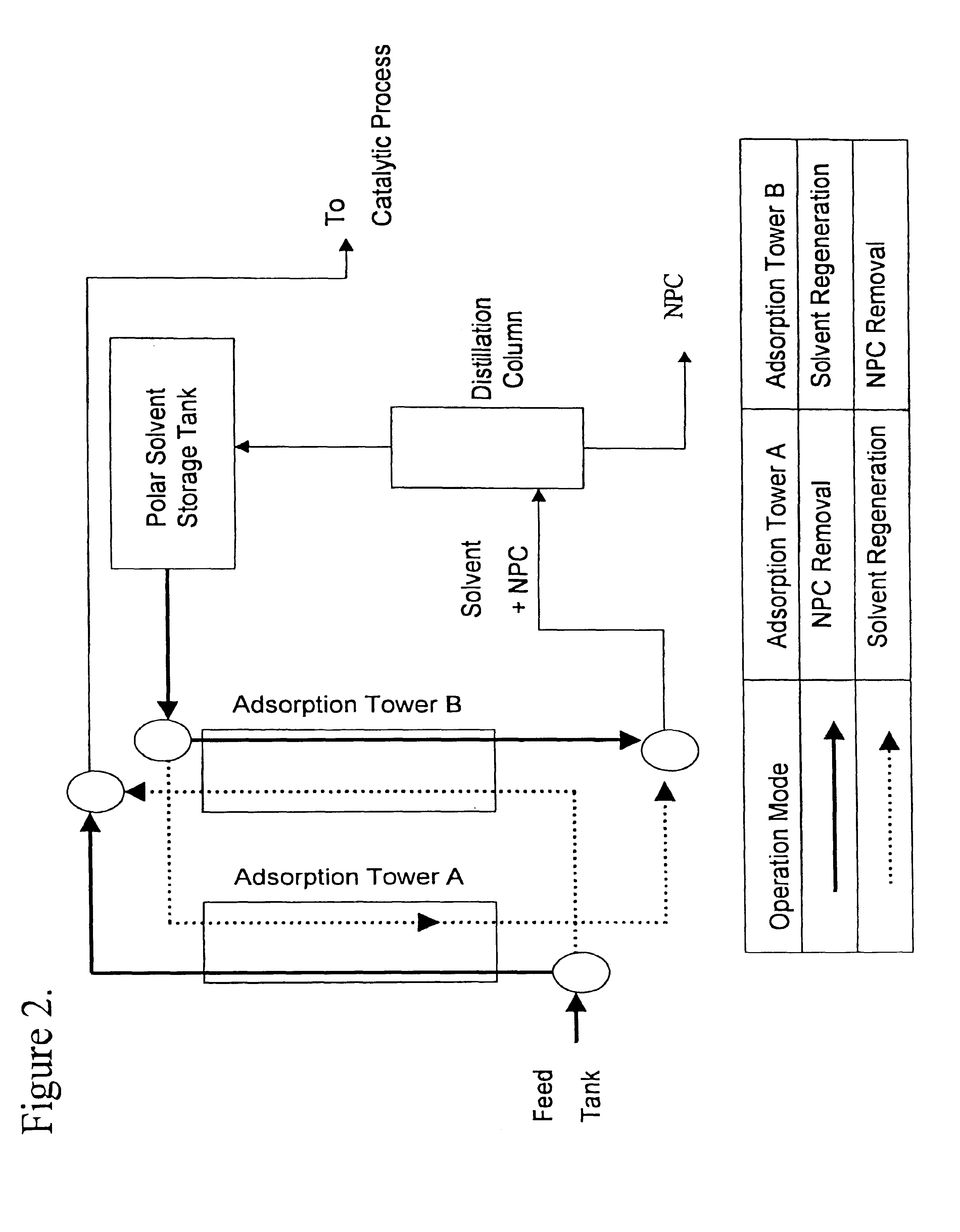

A method is provided for manufacturing cleaner fuels, in which NPC (Natural Polar Compounds), naturally existing in small quantities within various petrolic hydrocarbon fractions, are removed from the petrolic hydrocarbon fractions ranging, in boiling point, from 110 to 560° C. and preferably from 200 to 400° C., in advance of catalytic hydroprocessing. The removal of NPC improves the efficiency of the catalytic process and produces environment-friendly products, such as diesel fuel with a sulfur content of 50 ppm (wt) or lower. Also, the NPC can be used to improve fuel lubricity.

Owner:SK ENERGY CO LTD (KR)

Method for the hydro-processing of a gas oil feedstock, and corresponding hydro-refining unit

InactiveCN101517038AShort stayReduce volumeLiquid hydrocarbon mixture productionEthylene productionFixed bedPetroleum

The invention relates to a method for the catalytic hydro-processing of a petroleum feedstock of the gas oil type and of a biological feedstock containing vegetal oils and / or animal fats, in a catalytic fixed-bed hydro-processing unit, said method being characterised in that the petroleum feedstock is introduced into the reactor upstream from the biological feedstock. The invention also relates to a catalytic hydro-processing unit for implementing said method, and to a corresponding hydro-refining unit.

Owner:TOTAL RAFFINAGE MARKETING

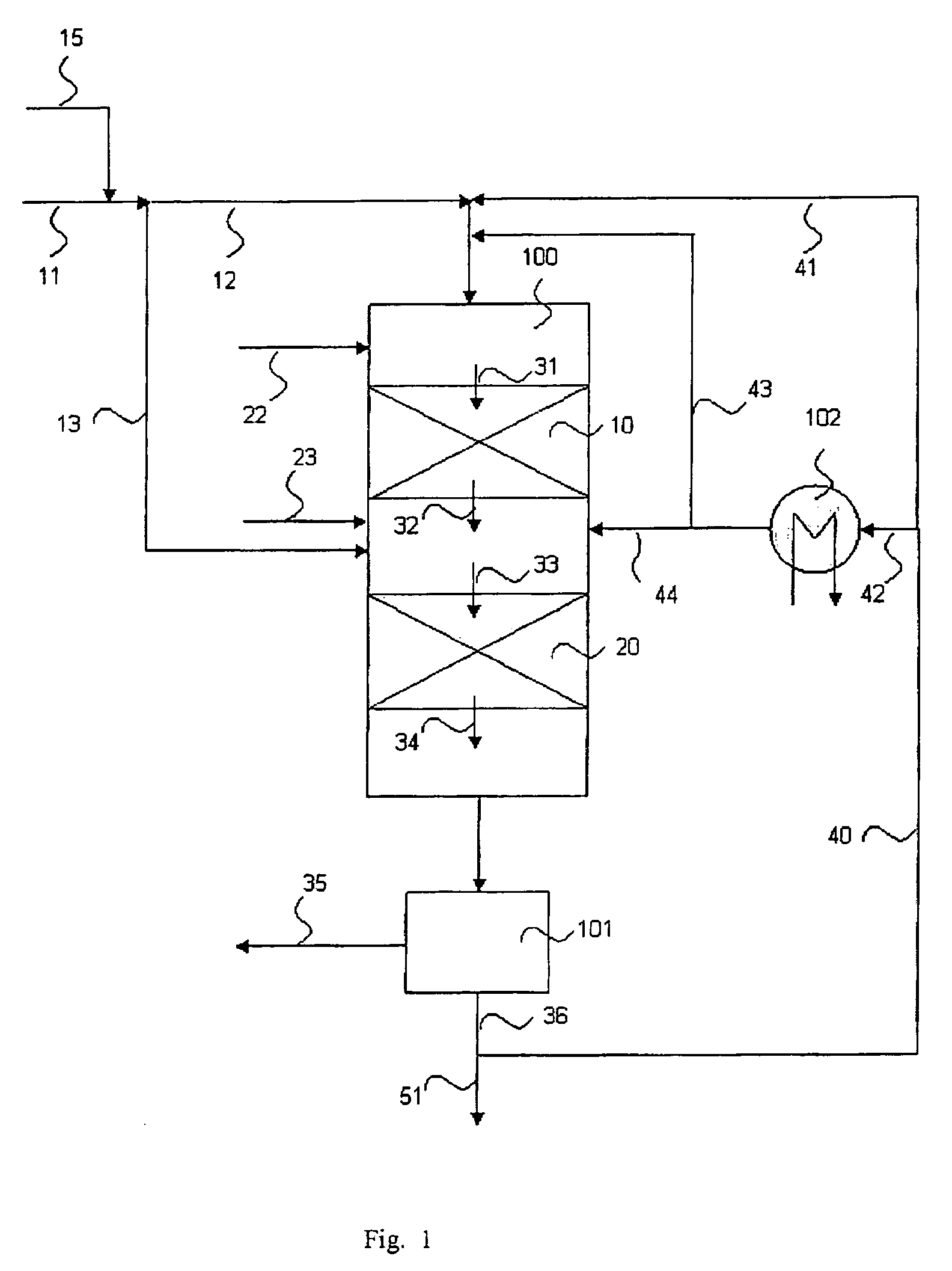

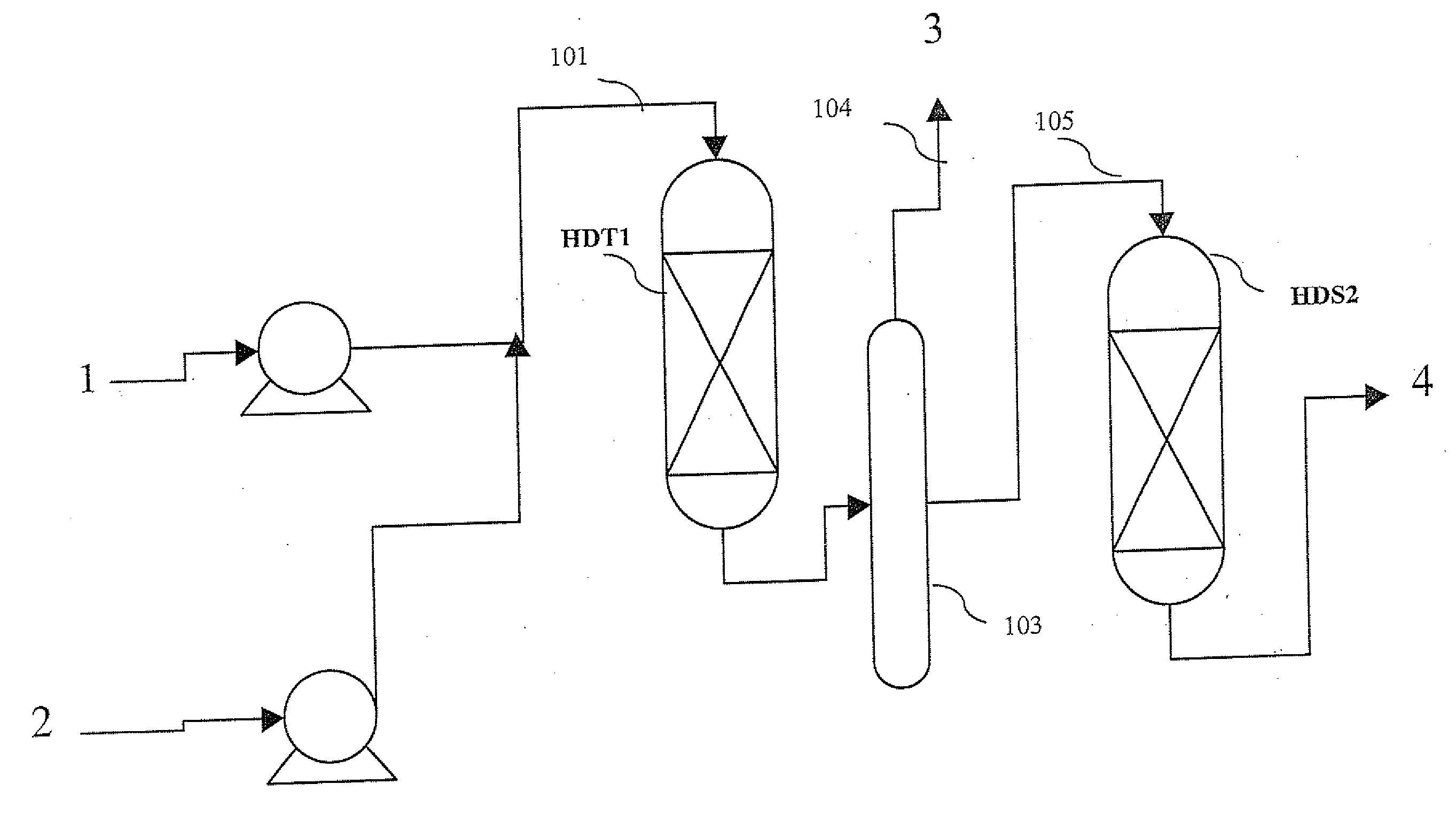

Methods of hydrotreating a mixture made up of oils of animal or vegetable origin and of petroleum cuts with intermediate stripping

ActiveUS20080161614A1Low costLimit consumption of hydrogenThermal non-catalytic crackingCatalytic crackingVegetable oilVolumetric Mass Density

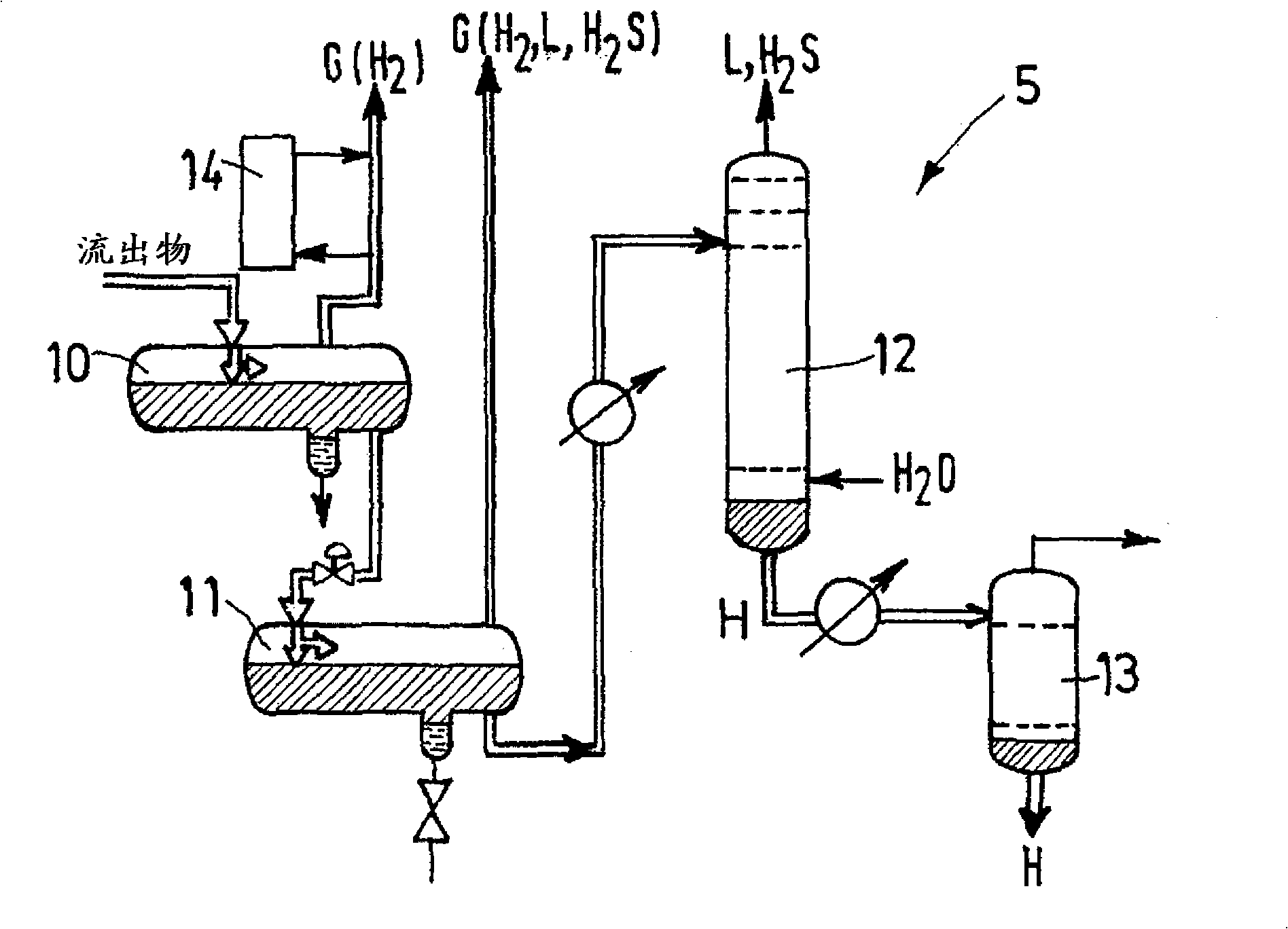

The invention relates to a hydrotreating method (HDT) using two plants working under different operating conditions with an intermediate stripping for co-treating a mixture made up of oils of vegetable or animal origin and petroleum cuts (gas oil cuts (GO) and middle distillates) in order to produce gas oil fuel bases meeting specifications. The first plant (HDT1) is more particularly dedicated to the reactions concerning oils of vegetable or animal origin in comixture while pretreating the hydrocarbon feed, whereas the second plant (HDS2) works under more severe conditions to obtain diesel fuel according to standards, in particular in terms of effluent sulfur content, density and cold properties. The process economy, the activity and the stability of the catalyst of the second plant are greatly improved by the intermediate stripping.

Owner:INST FR DU PETROLE

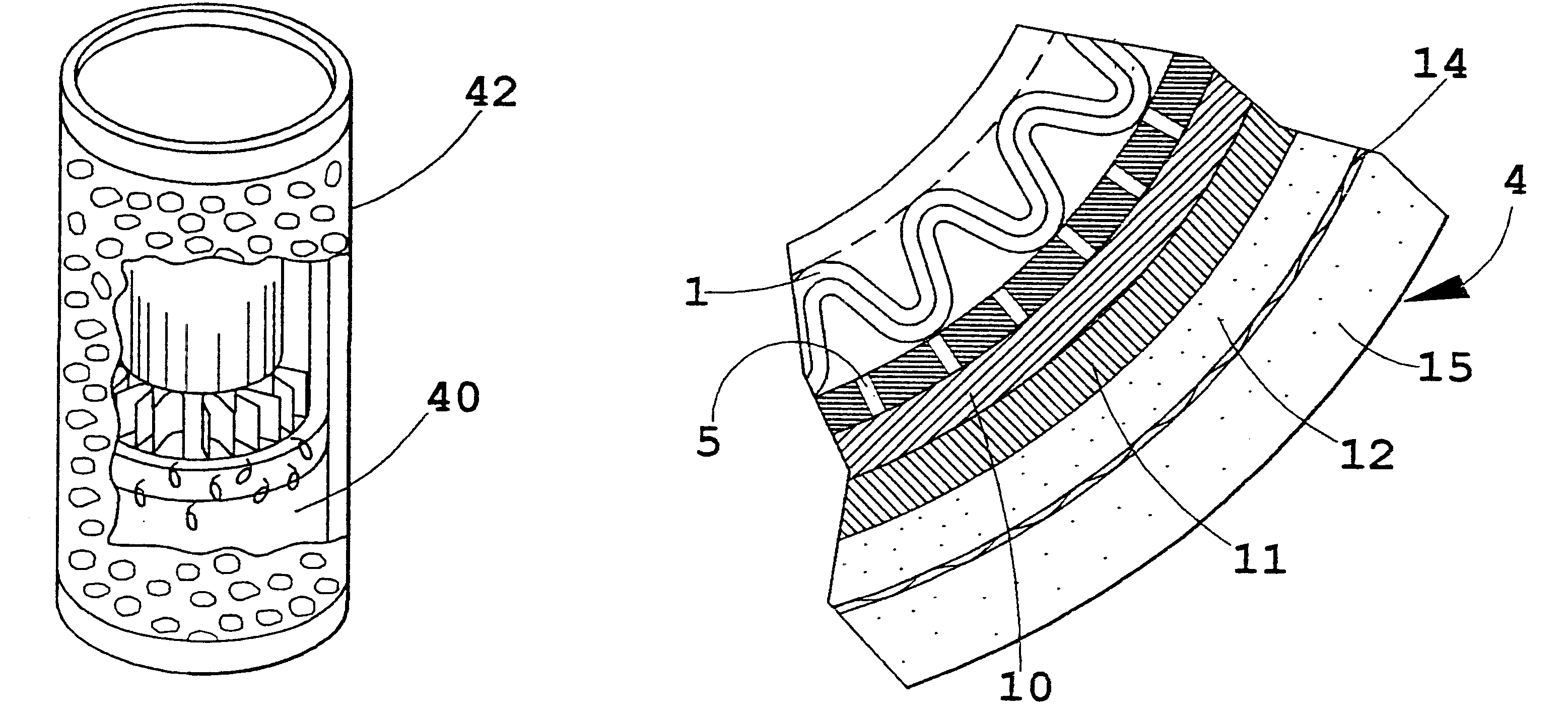

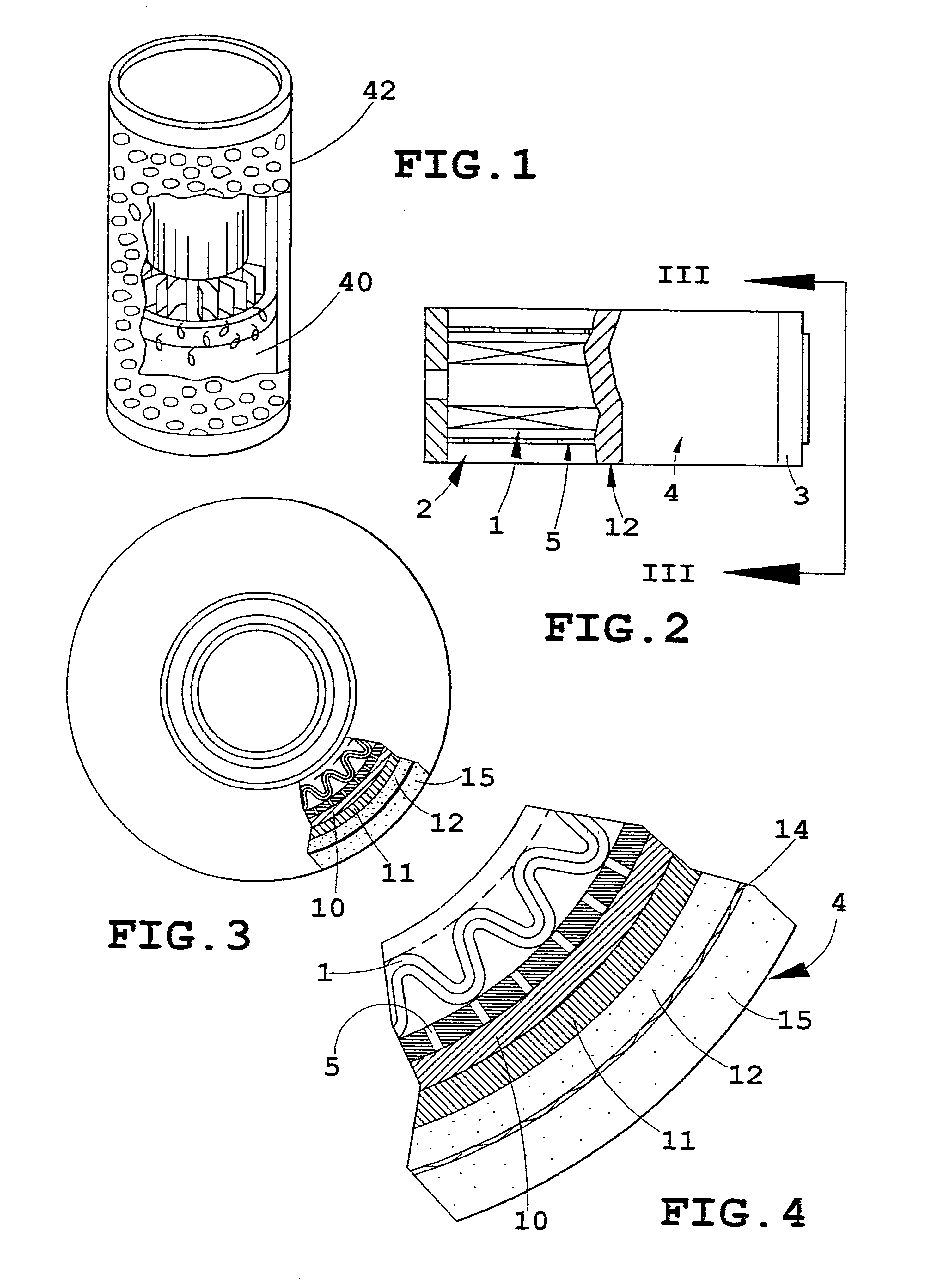

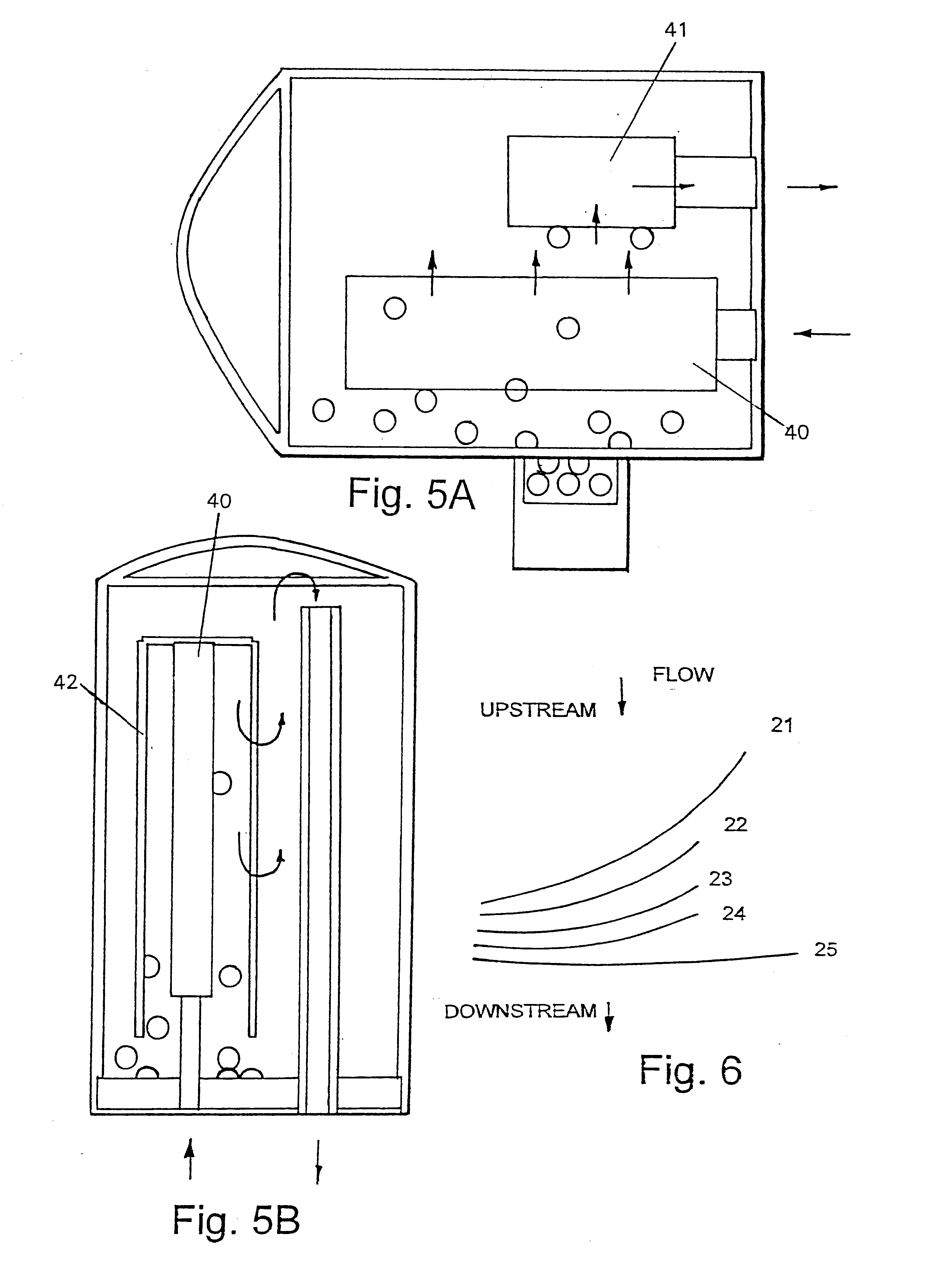

Coalescer for hydrocarbons containing surfactant

A coalescer filter element for the separation of water from hydrocarbon fluids, such as kerosene, jet fuel, diesel fuel, and gasoline under surfactant conditions such as thermal stability additive and dispersant. Coalescer fibrous material has hydrophobic properties which resist surfactant coating of the fibers thereby allowing breakdown of water emulsion in the hydrocarbon fluids. The coalescer has a negative media density gradient in the liquid flow direction.

Owner:KAYDON CUSTOM FILTRATION CORP

Method for the manufacture of hydrocarbons

ActiveUS20060161032A1Reduce hydrogen consumptionMaterial nanotechnologyRefining to change hydrocarbon structural skeletonHydrogenDistillation

Feedstock originating from renewable sources is converted to hydrocarbons in diesel fuel distillation range by contacting with a supported catalyst comprising VIII group metal / metals, whereby the consumption of hydrogen is decreased.

Owner:NESTE OIL OY

Fuel Composition

ActiveUS20080229654A1Maximize product yieldYield maximizationFatty acid isomerisationFatty acid oxidationIsomerizationVegetable oil

Compositions and methods for forming hydrocarbon products from triglycerides are disclosed. In one aspect, the methods involve the thermal decomposition of fatty acids, which can be derived from the hydrolysis of triglycerides. The thermal decomposition products can be combined with low molecular weight olefins, such as Fischer-Tropsch synthesis products, and subjected to molecular averaging reactions. Alternatively, the products can be subjected to hydrocracking reactions, isomerization reactions, and the like. The products can be isolated in the gasoline, jet and / or diesel fuel ranges. Thus, vegetable oils and / or animal fats can be converted using water, catalysts, and heat, into conventional products in the gasoline, jet and / or diesel fuel ranges. These products are virtually indistinguishable from those derived from their petroleum-based analogs, except that they can have virtually no aromatic, sulfur or nitrogen content, they are derived, in whole or in part, from renewable resources, and can also be derived from domestically available coal and / or natural gas.

Owner:BRADIN DAVID

Method and apparatus for making a middle distillate product and lower olefins from a hydrocarbon feedstock

ActiveUS20060178546A1Yield maximizationCatalytic crackingCatalytic naphtha reformingPetroleum productGasoline

Disclosed is a process for making middle distillate and lower olefins. The process includes catalytically cracking a gas oil feedstock within a riser reactor zone by contacting under suitable catalytic cracking conditions within the riser reactor zone the gas oil feedstock with a middle distillate selective cracking catalyst that comprises amorphous silica alumina and a zeolite to yield a cracked gas oil product and a spent cracking catalyst. The spent cracking catalyst is regenerated to yield a regenerated cracking catalyst. Within an intermediate cracking reactor such as a dense bed reactor zone and under suitable high severity cracking conditions a gasoline feedstock is contacted with the regenerated cracking catalyst to yield a cracked gasoline product and a used regenerated cracking catalyst. The used regenerated cracking catalyst is utilized as the middle distillate selective catalyst.

Owner:SHELL USA INC

Portable hydrogen generator-fuel cell apparatus

InactiveUS6653005B1Increase specific energy and overall energy efficiencyHydrogenFuel cell auxillariesKeroseneImpurity

A compact hydrogen generator is coupled to or integrated with a fuel cell for portable power applications. Hydrogen is produced via thermocatalytic decomposition (cracking, pyrolysis) of hydrocarbon fuels in oxidant-free environment. The apparatus can utilize a variety of hydrocarbon fuels, including natural gas, propane, gasoline, kerosene, diesel fuel, crude oil (including sulfurous fuels). The hydrogen-rich gas produced is free of carbon oxides or other reactive impurities, so it could be directly fed to any type of a fuel cell. The catalysts for hydrogen production in the apparatus are carbon-based or metal-based materials and doped, if necessary, with a sulfur-capturing agent. Additionally disclosed are two novel processes for the production of two types of carbon filaments, and a novel filamentous carbon product. The hydrogen generator can be conveniently integrated with high temperature fuel cells to produce an efficient and self-contained source of electrical power.

Owner:UNIV OF CENT FLORIDA RES FOUND INC +1

Fuel composition for a diesel engine

InactiveUS20040055209A1Meet quality requirementsImprove low temperature performanceSolid fuelsLiquid carbonaceous fuelsProcess engineeringDiesel engine

The invention is directed to a fuel composition for diesel engines. The fuel composition comprises 0.1-99% by weight of a component or a mixture of components produced from biological raw material originating from plants and / or animals and / or fish. The fuel composition comprises 0-20% of components containing oxygen. Both components are mixed with diesel components based on crude oil and / or fractions from Fischer-Tropsch process.

Owner:NESTE OIL OY

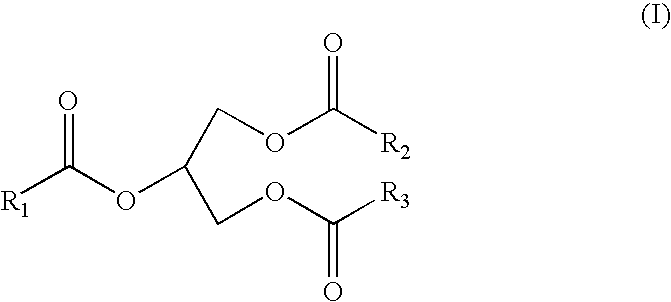

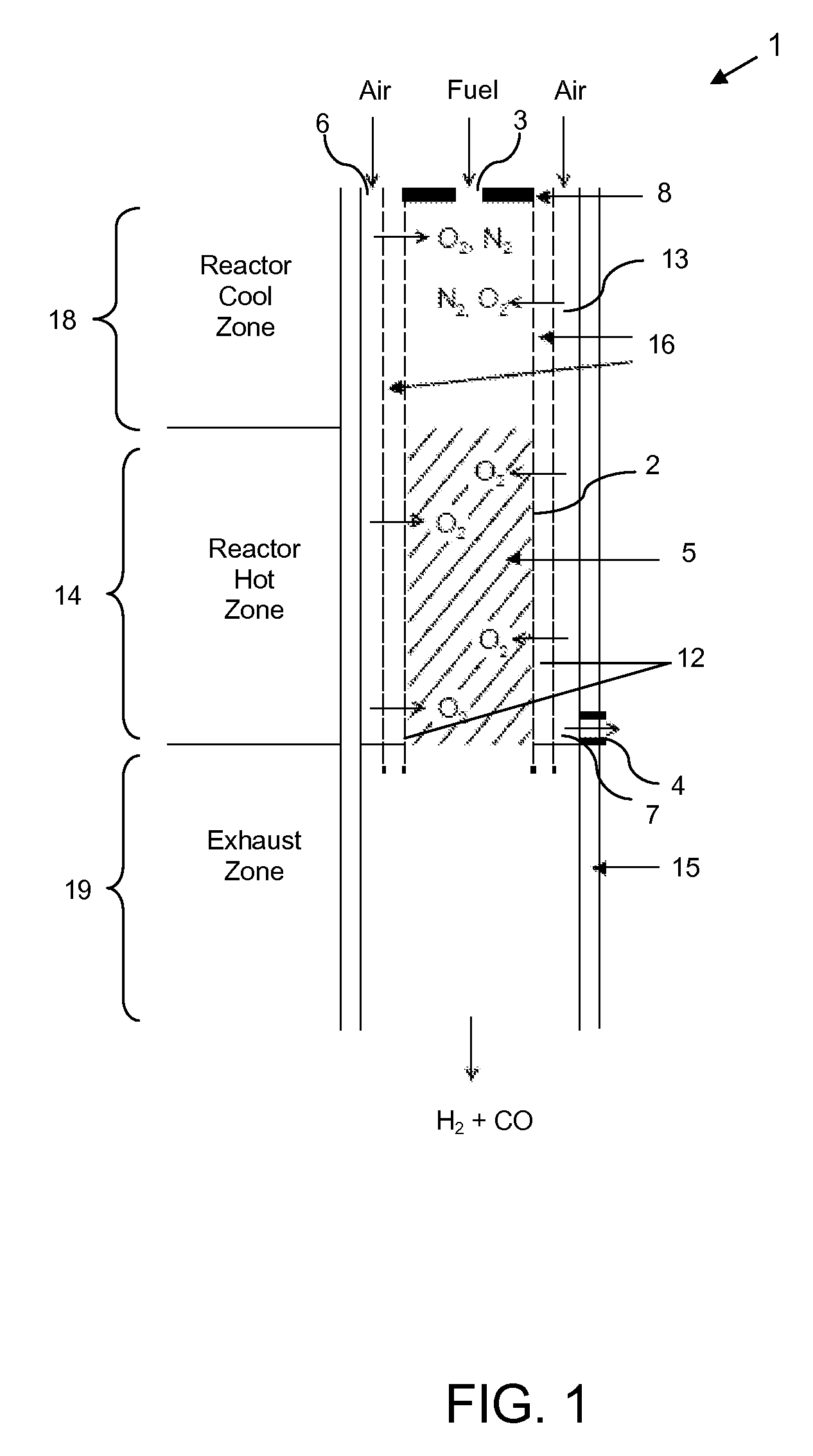

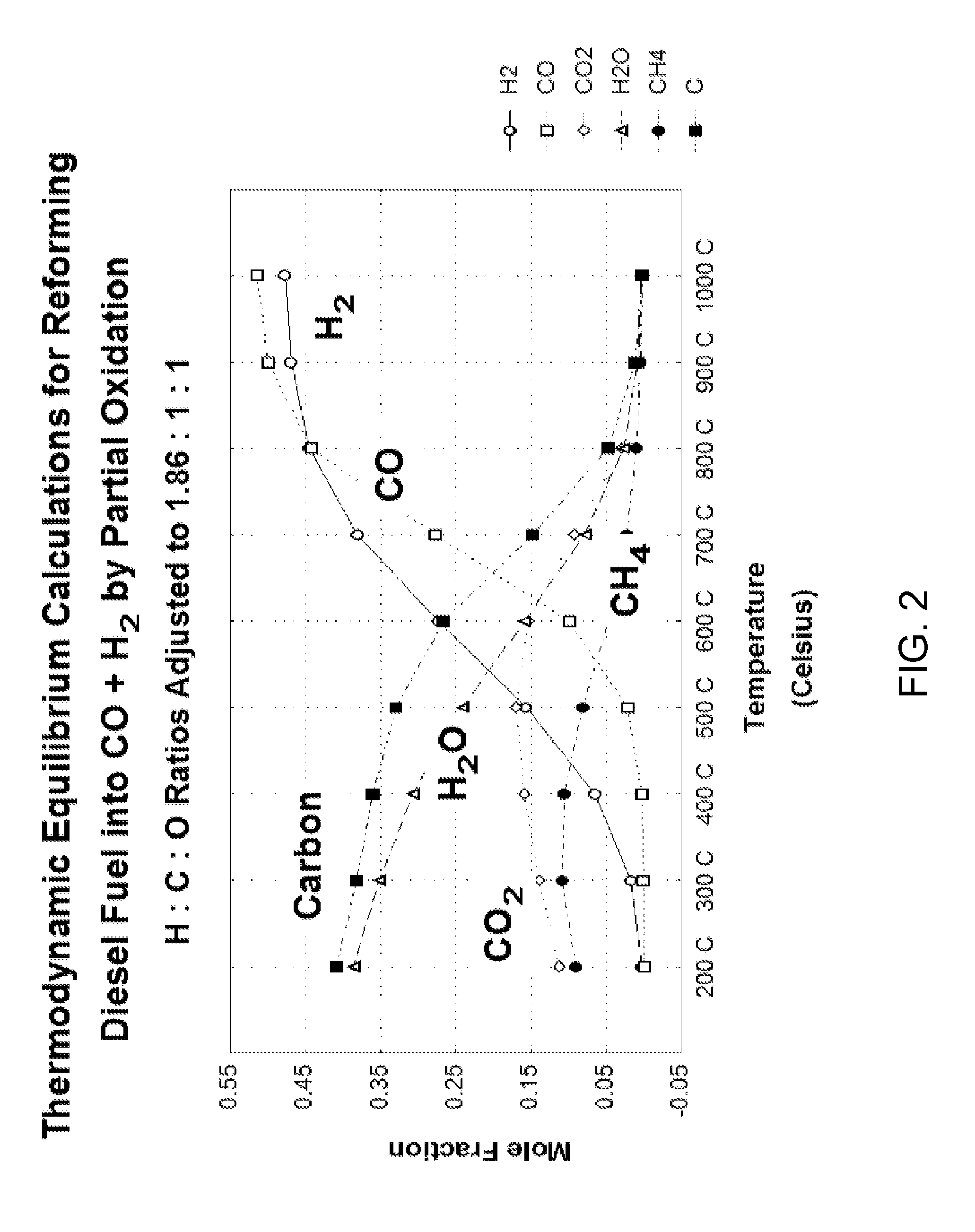

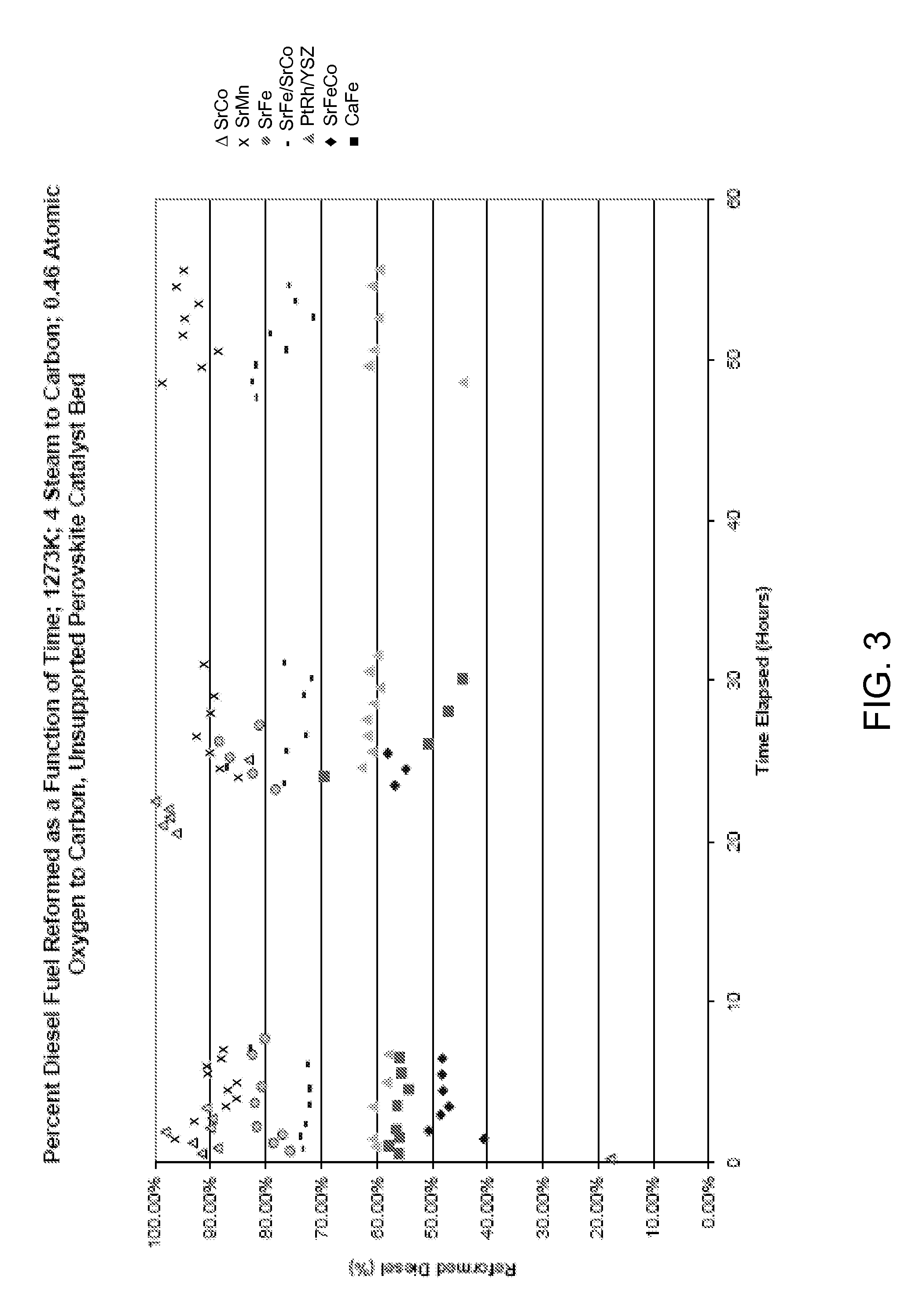

Catalytic membrane reactor and method for production of synthesis gas

InactiveUS20080169449A1High oxygen fluxHydrogenSemi-permeable membranesSulfur containingPhotochemistry

A solid state membrane for a reforming reactor is disclosed which comprises at least one oxygen anion-conducting oxide selected from the group consisting of hexaaluminates, cerates, perovskites, and other mixed metal oxides that are able to adsorb and dissociate molecular oxygen. The membrane adsorbs and dissociates molecular oxygen into highly active atomic oxygen and allows oxygen anions to diffuse through the membrane, to provide high local concentration of oxygen to deter formation and deposition of carbon on reformer walls. Embodiments of the membrane also have catalytic activity for reforming a hydrocarbon fuel to synthesis gas. Also disclosed are a reformer having an inner wall containing the new membrane, and a process of reforming a hydrocarbon feed, such as a high sulfur-containing diesel fuel, to produce synthesis gas, suitable for use in fuel cells.

Owner:ELTRON RES

Hydrocracking catalyst and preparation method thereof

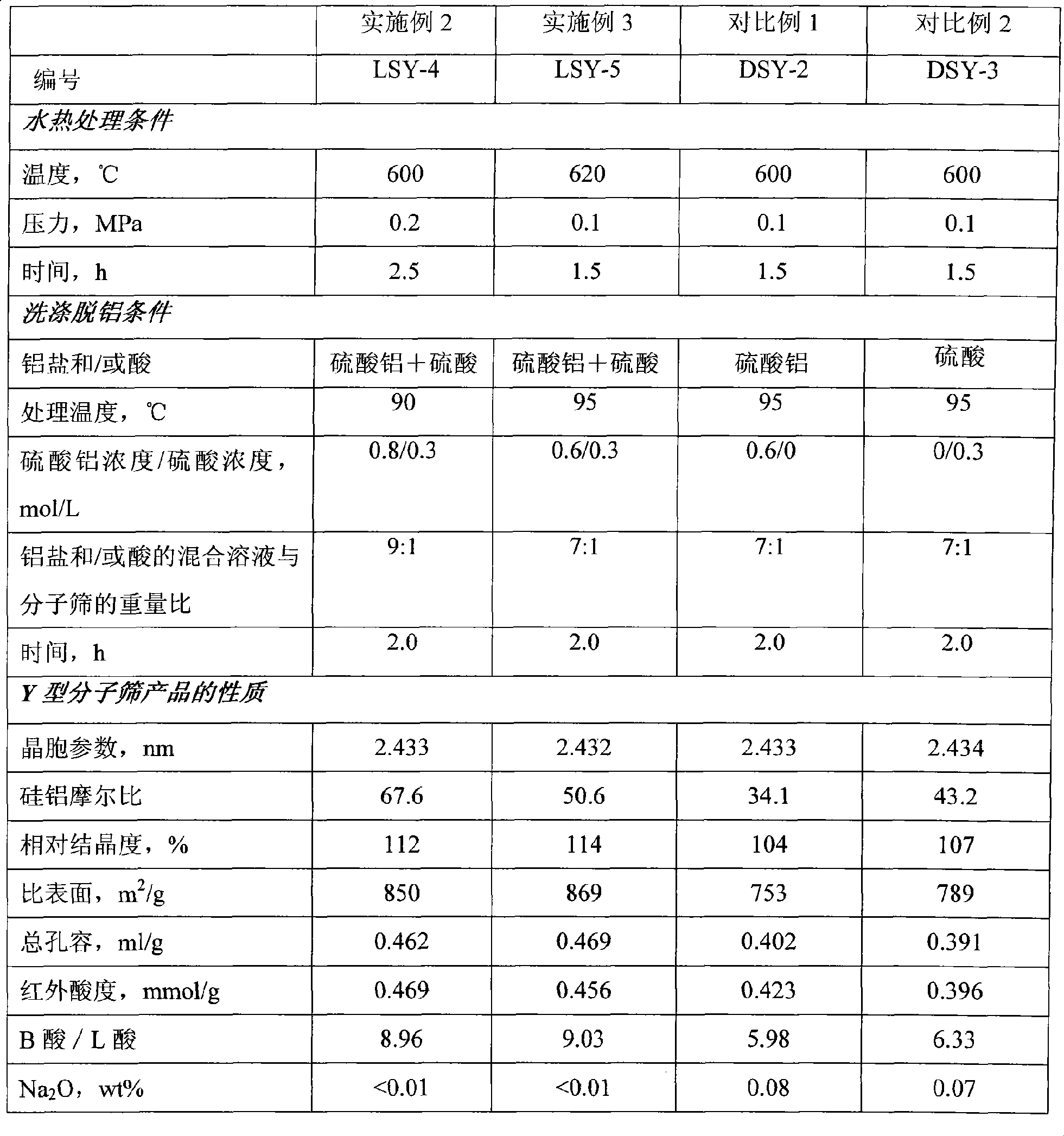

ActiveCN101380589AHigh ratio of silicon to aluminumLarger than surfaceMolecular sieve catalystsHydrocarbon oil crackingCrystallinityCell parameter

The invention discloses a hydrocracking catalyst and a preparation method thereof. The catalyst comprises hydrogenation active metals and a carrier containing modified Y molecular sieve, alumina and amorphous aluminium silicon, wherein, the Y molecular sieve is prepared by the following method: the Y molecular sieve undergone hydro-thermal treatment by mixed water solution of aluminium salt and acid is adopted; the performance of the Y molecular sieve is as follows: specific surface is 800m<2> / g-900m<2> / g, total aperture volume is 0.40ml / g-0.50ml / g, relative crystallinity is 90%-130%, cell parameter is 2.434-2.440nm, aluminium silicon mol ratio is 20-100, infrared acid volume is 0.3-0.8mmol / g, the mol ratio of acid B and acid L is above 7.0, sodium oxide content is less than or equal to 0.05wt%. The catalyst prepared by the invention has the advantages of high catalytic activity, good target product selectivity and can produce heavy naphtha, aviation fuel and diesel fuel, and the like, with high yield and good quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com