Patents

Literature

317 results about "Atomic oxygen" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Atomic oxygen is an elemental form of oxygen that does not exist in Earth's atmosphere. In space, however, it is common in the area where satellites orbit Earth.

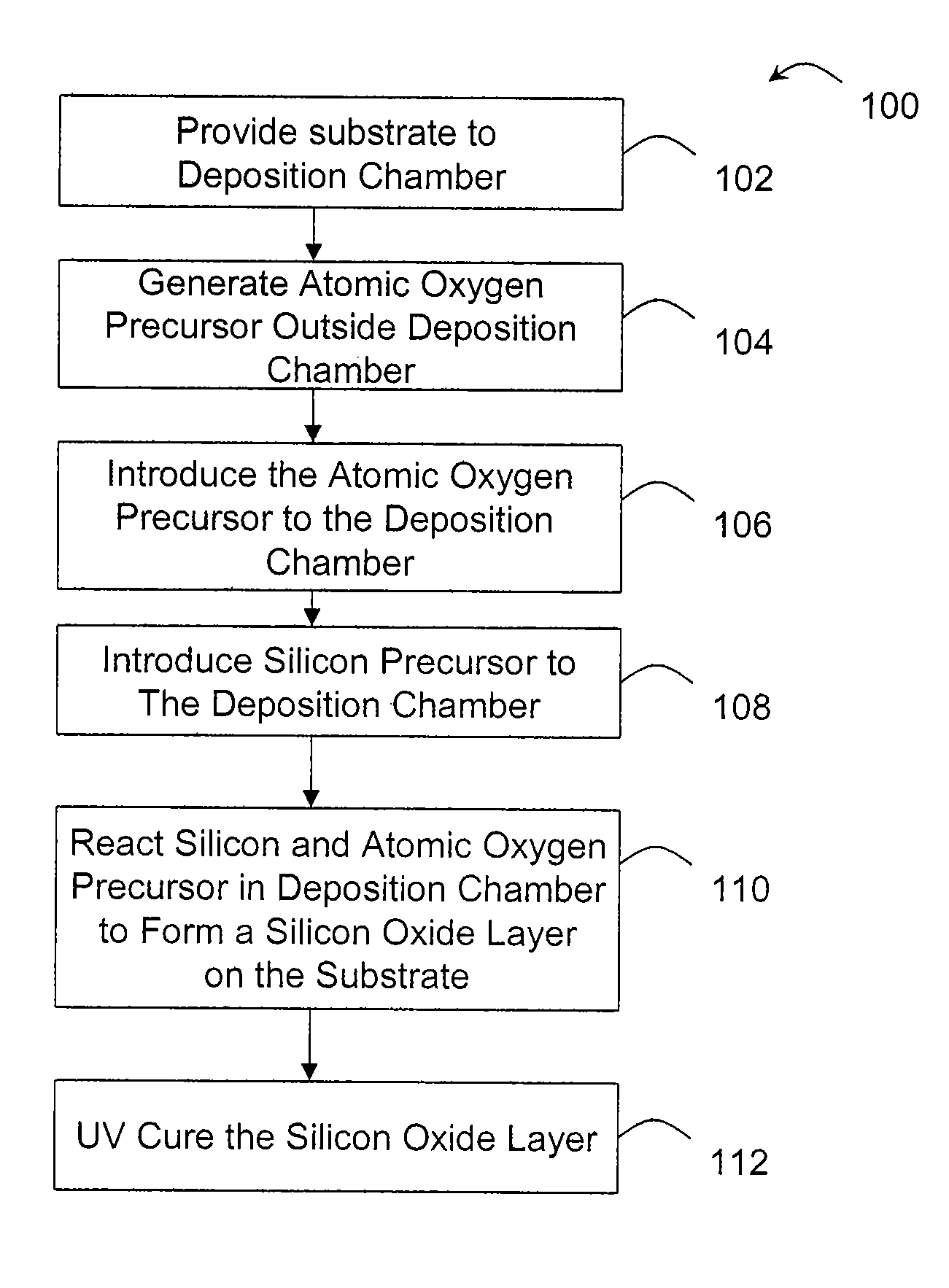

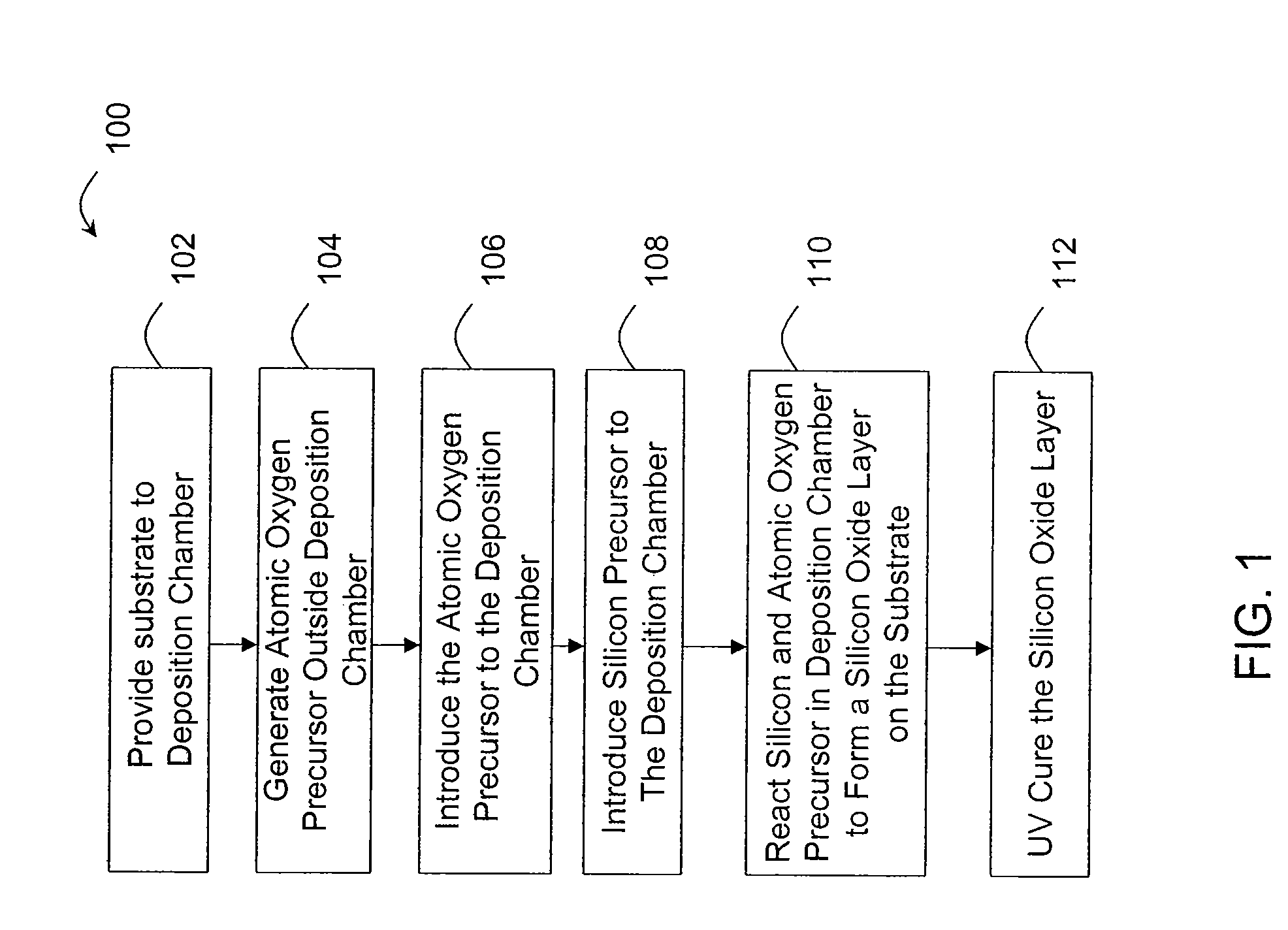

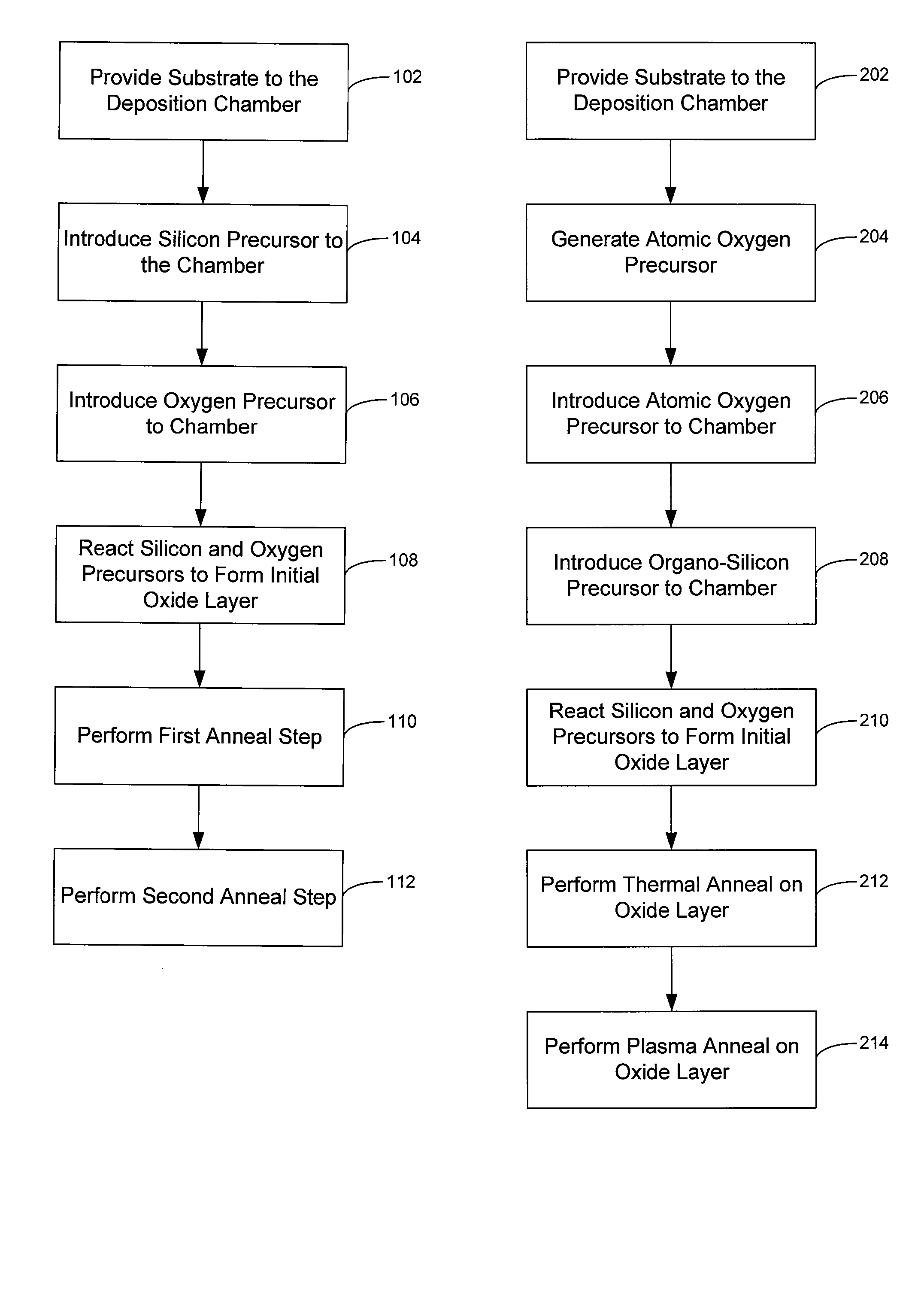

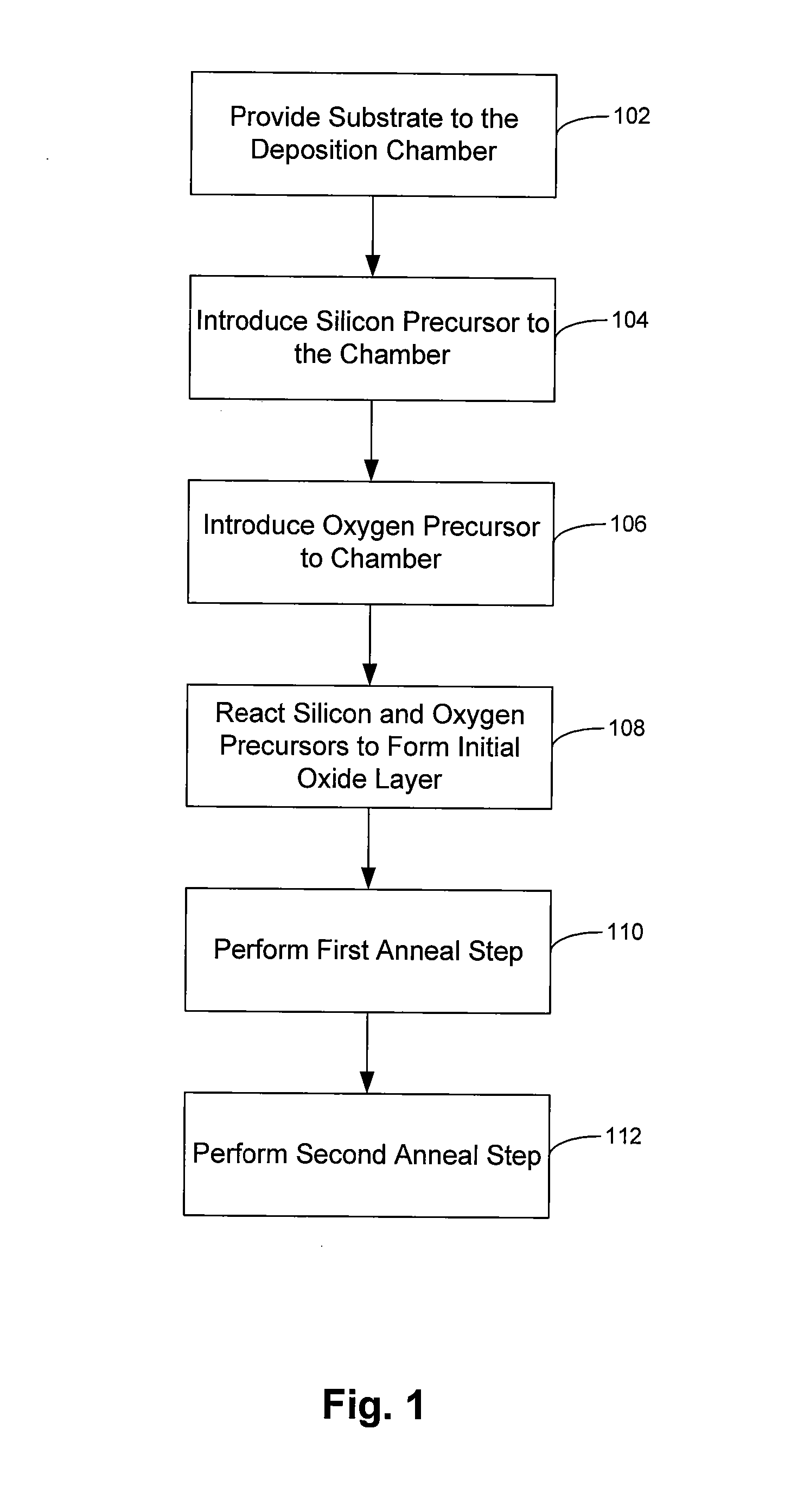

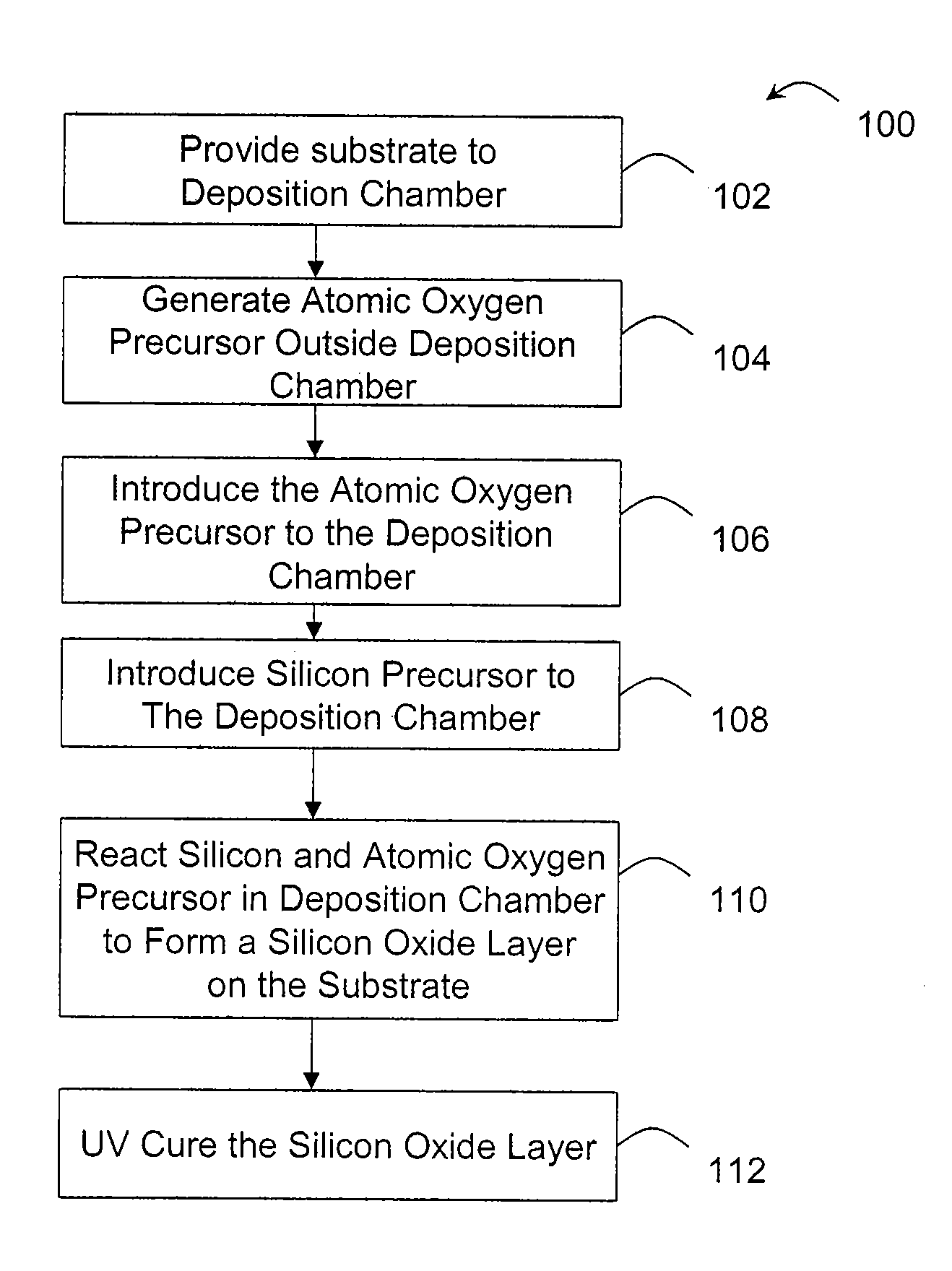

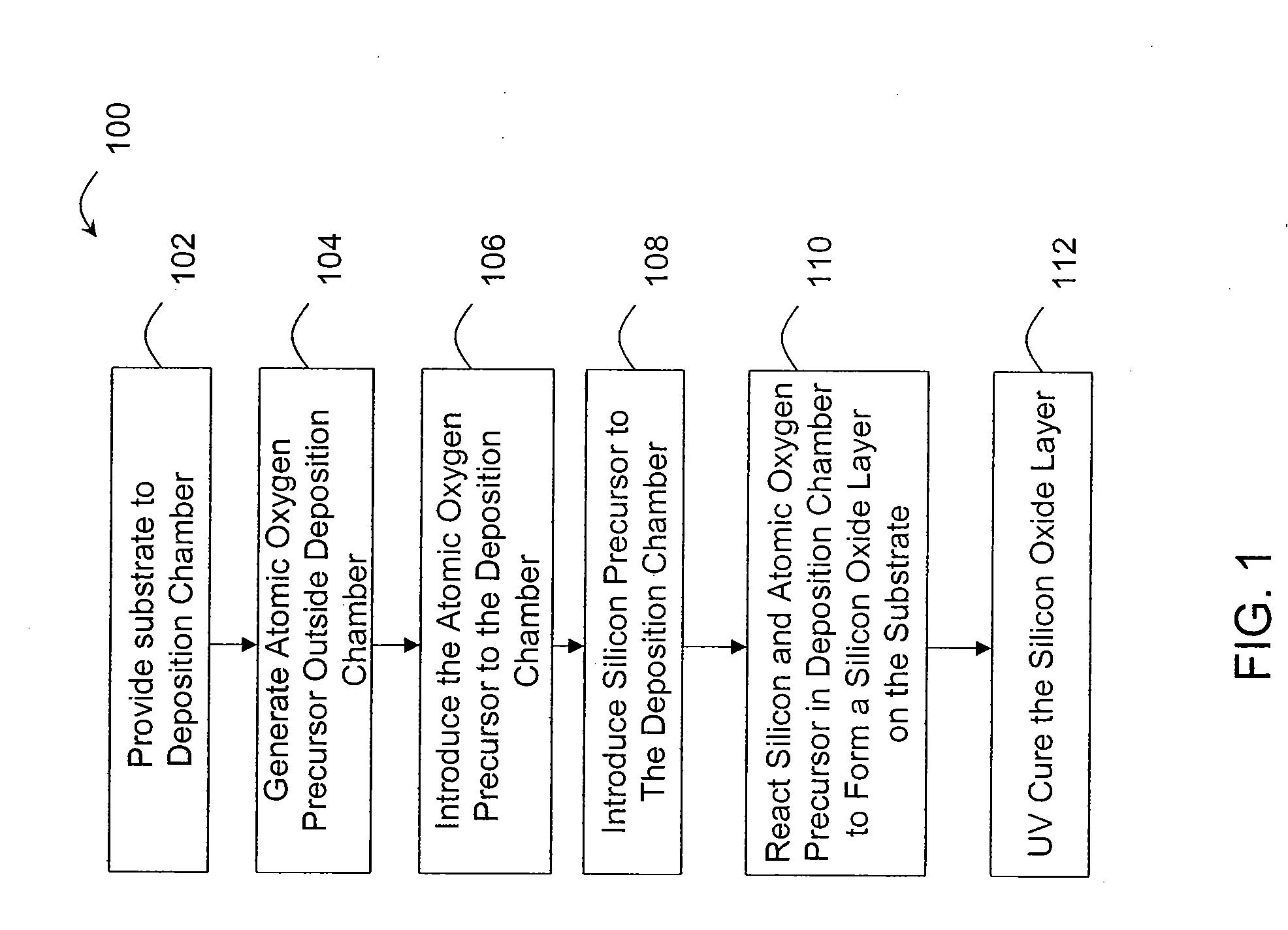

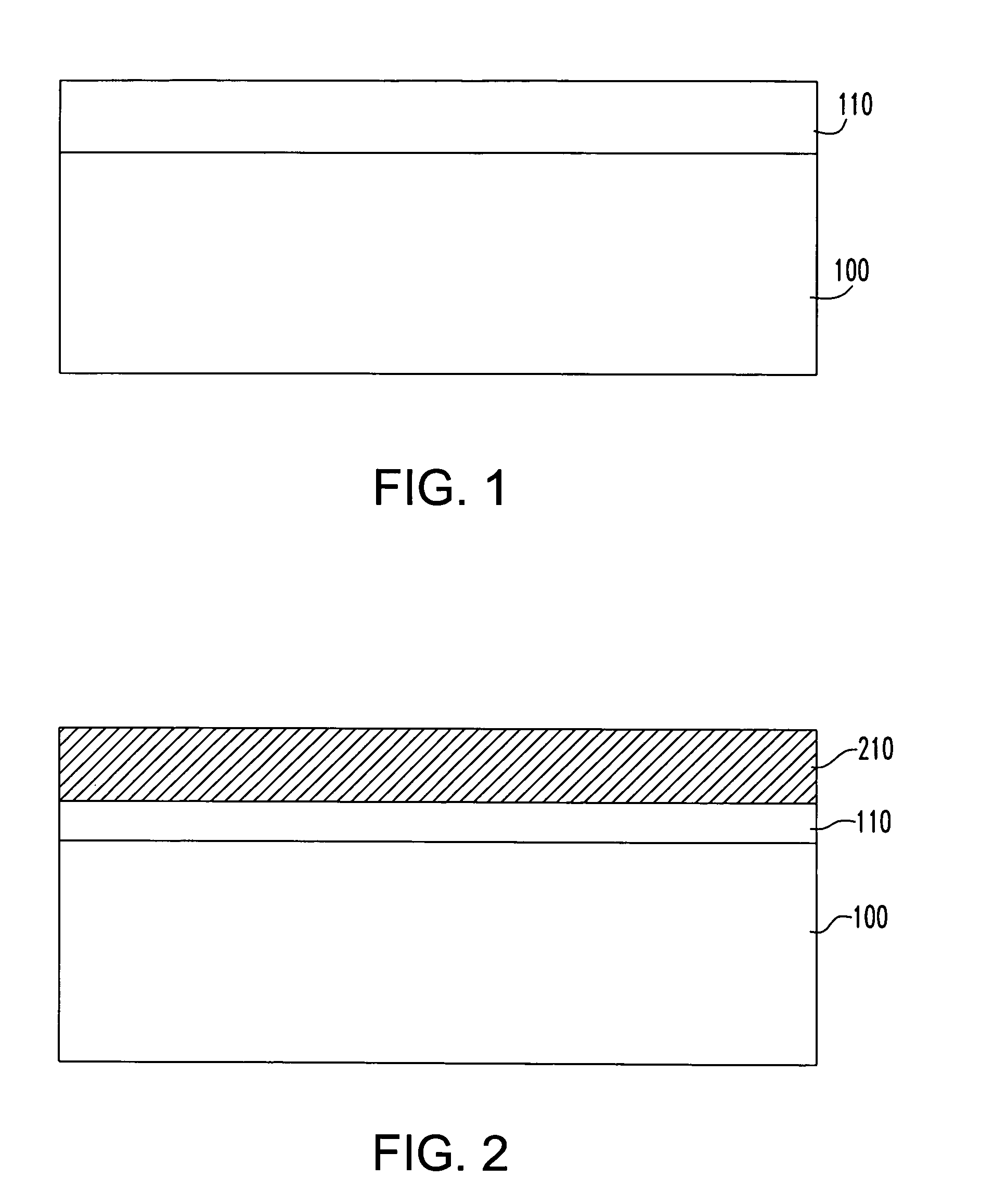

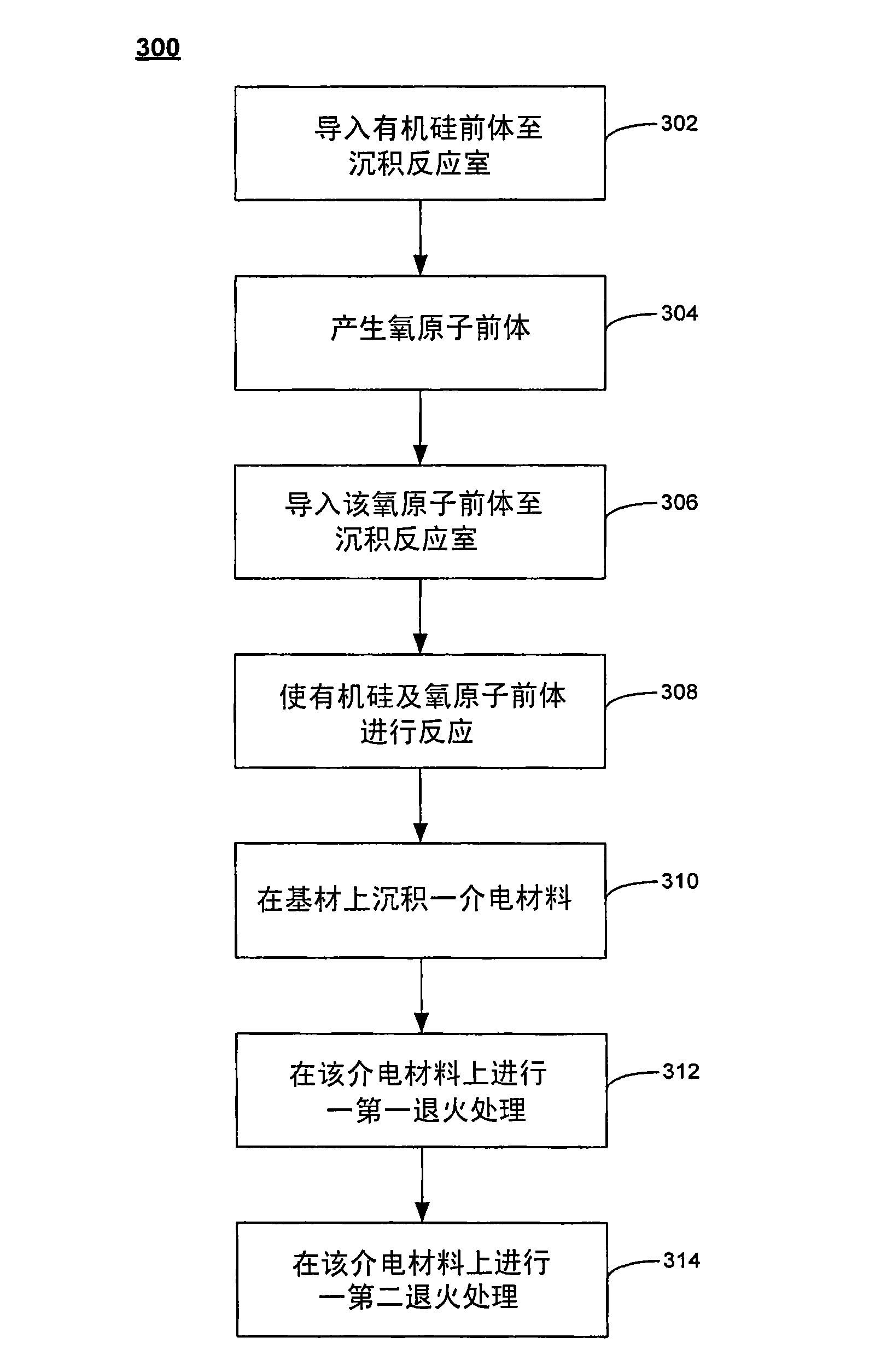

Chemical vapor deposition of high quality flow-like silicon dioxide using a silicon containing precursor and atomic oxygen

ActiveUS20070281496A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingGas phaseSilicon oxide

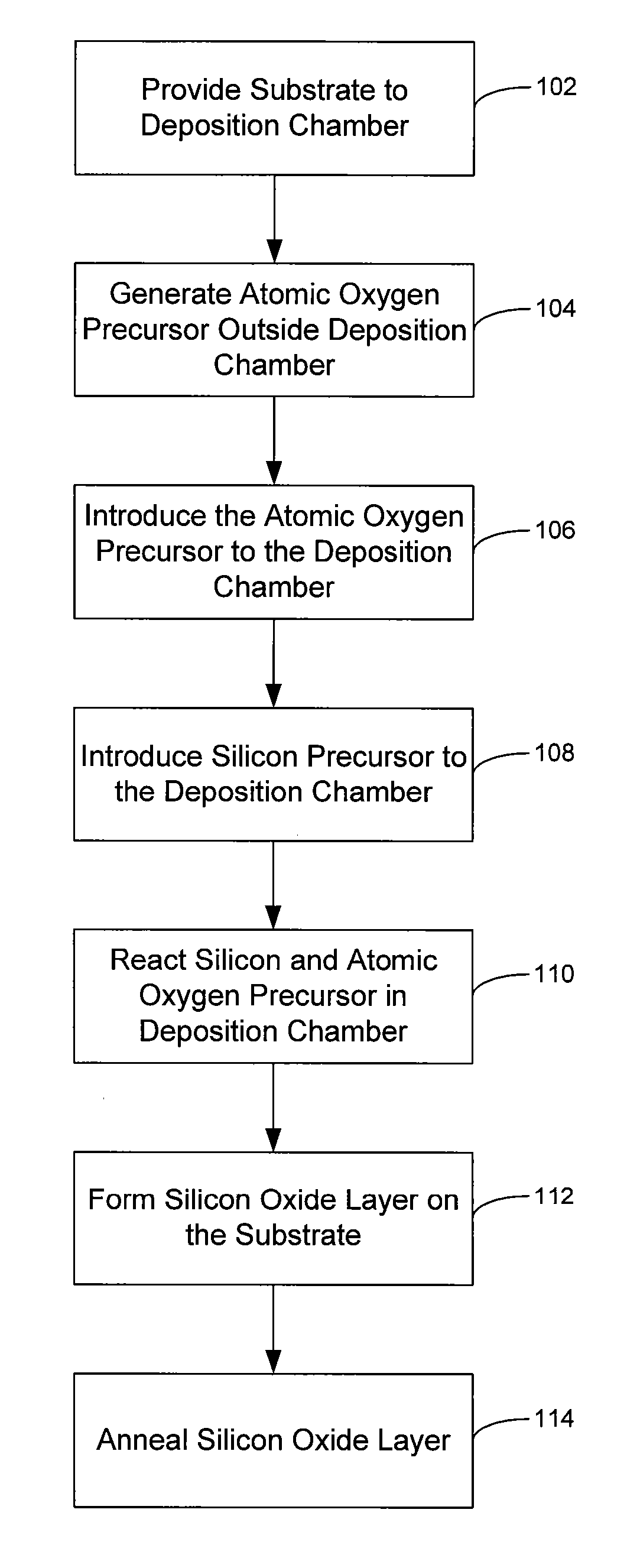

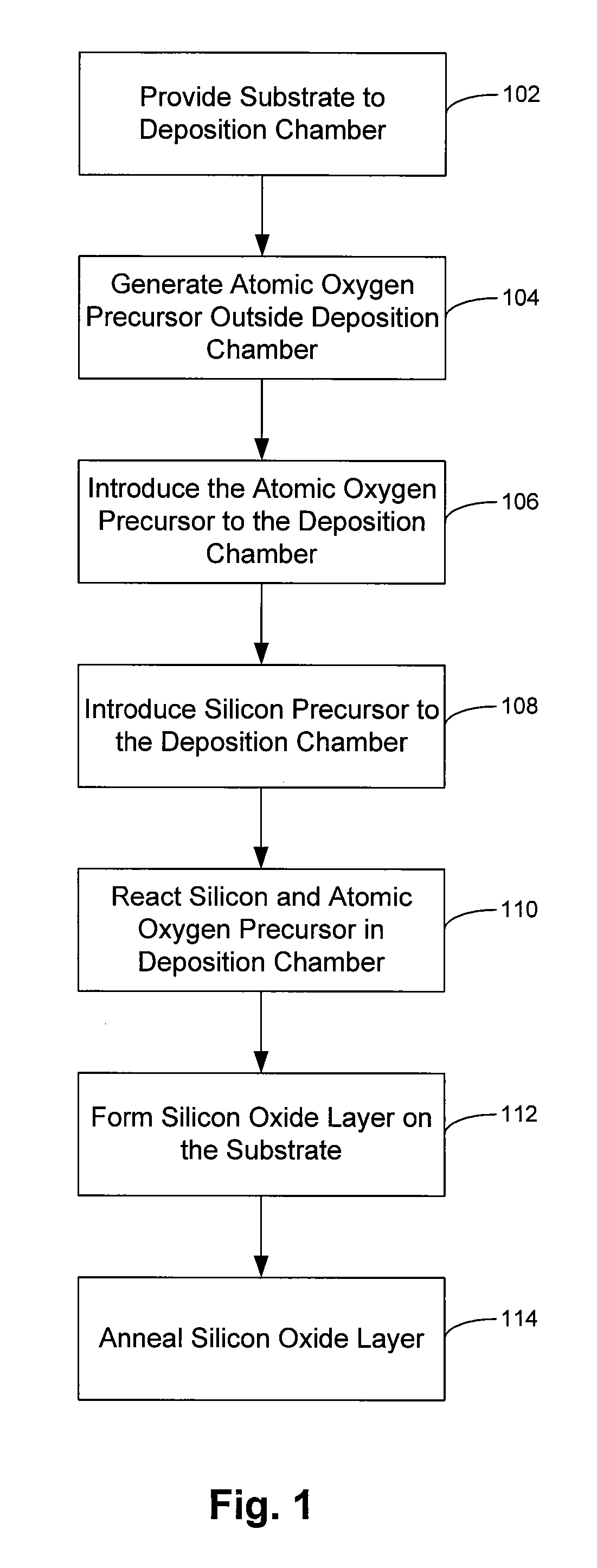

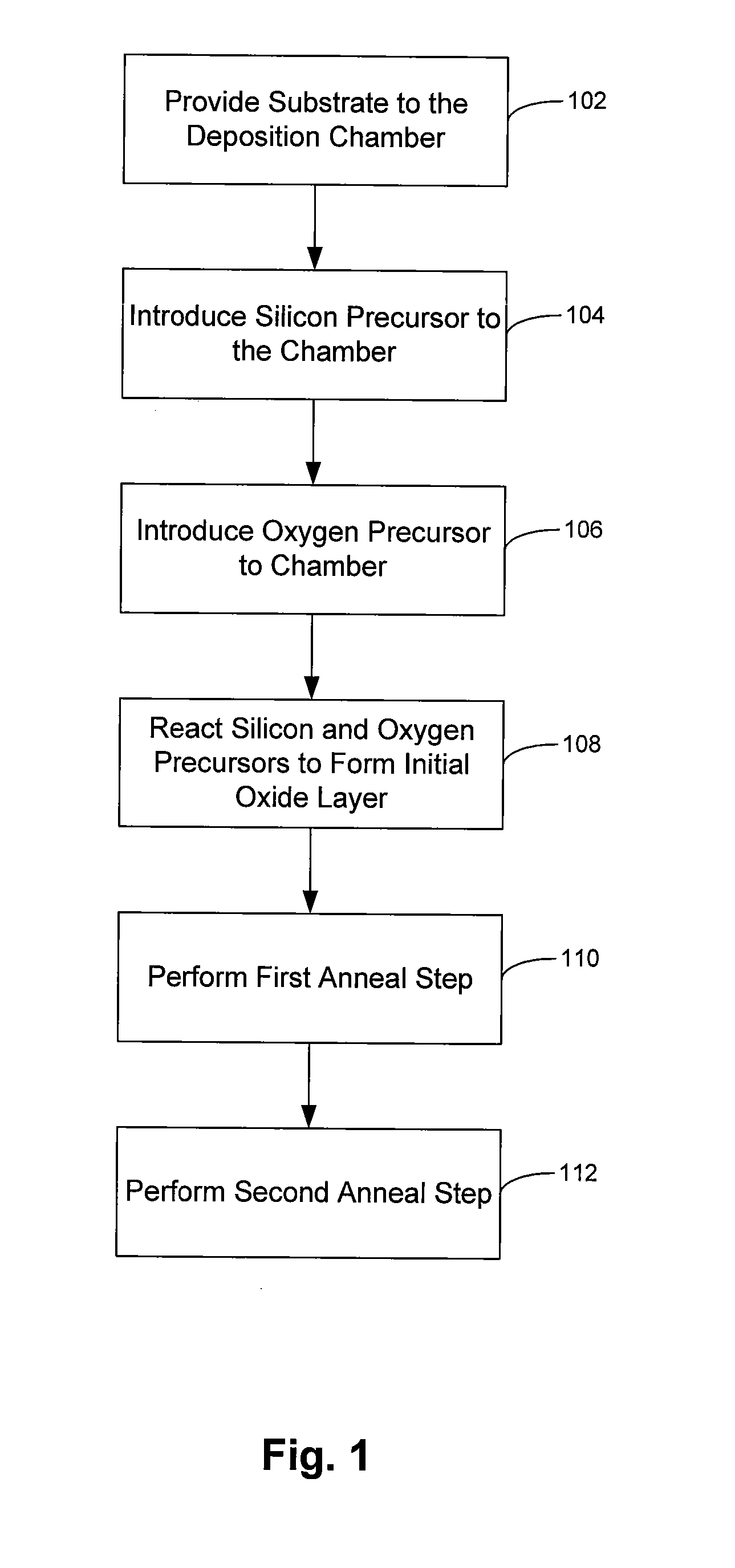

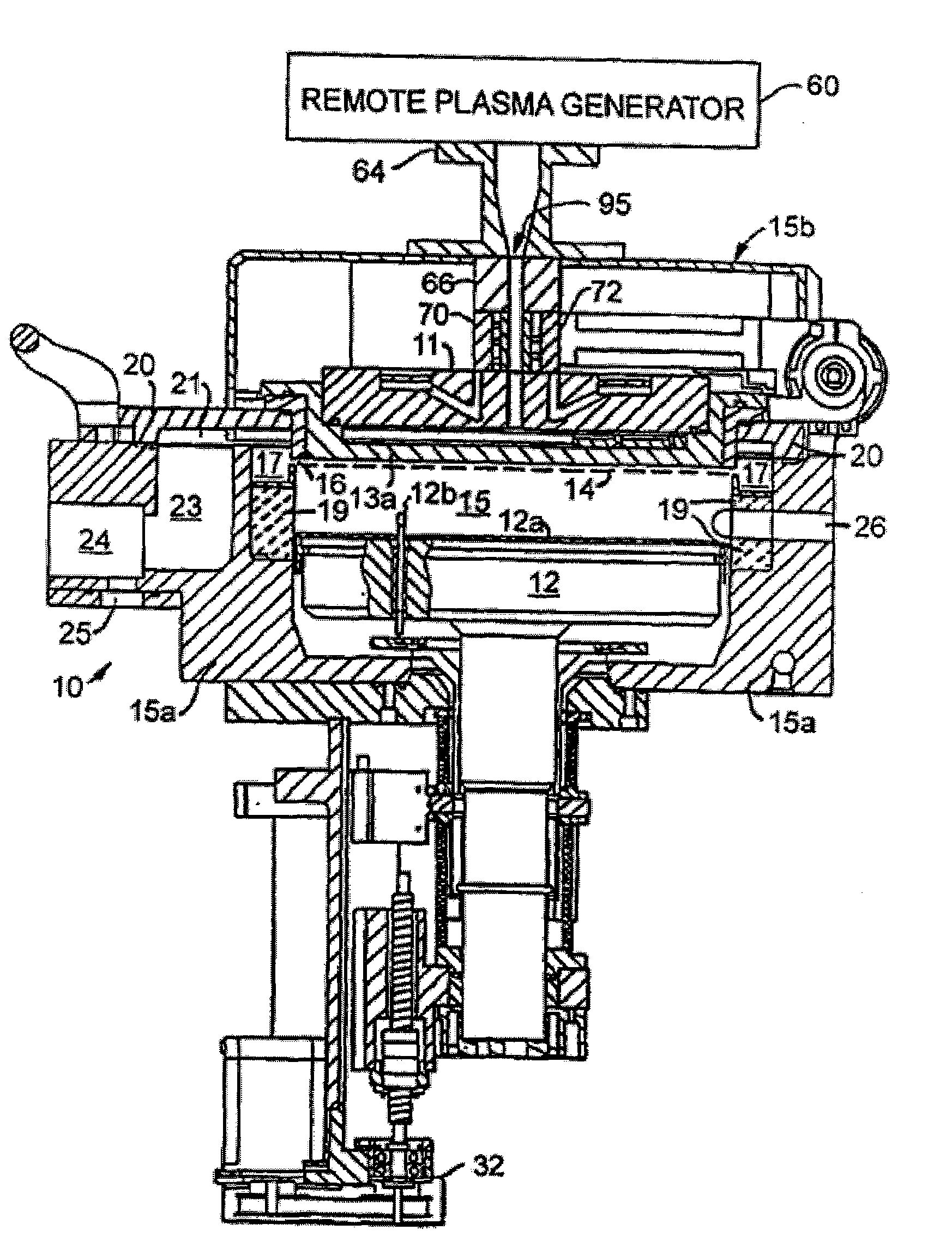

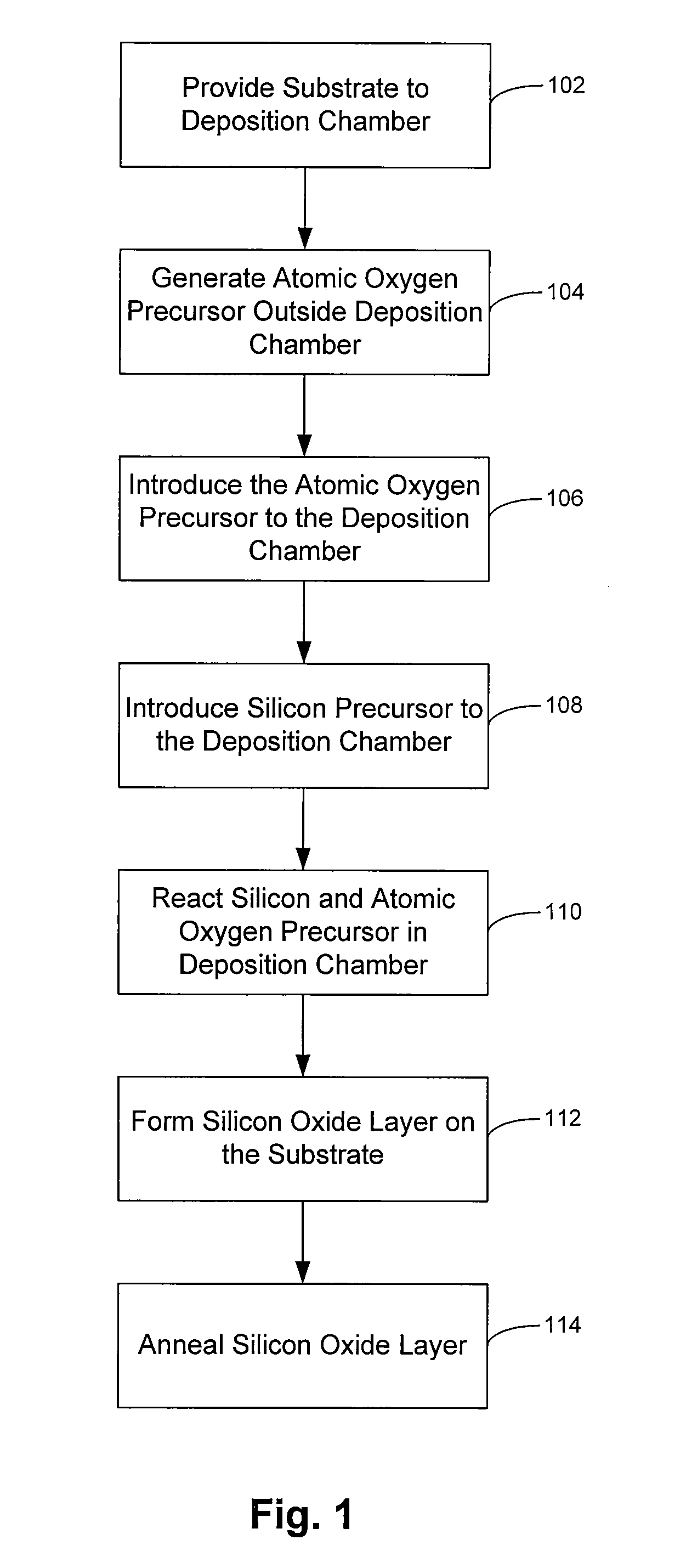

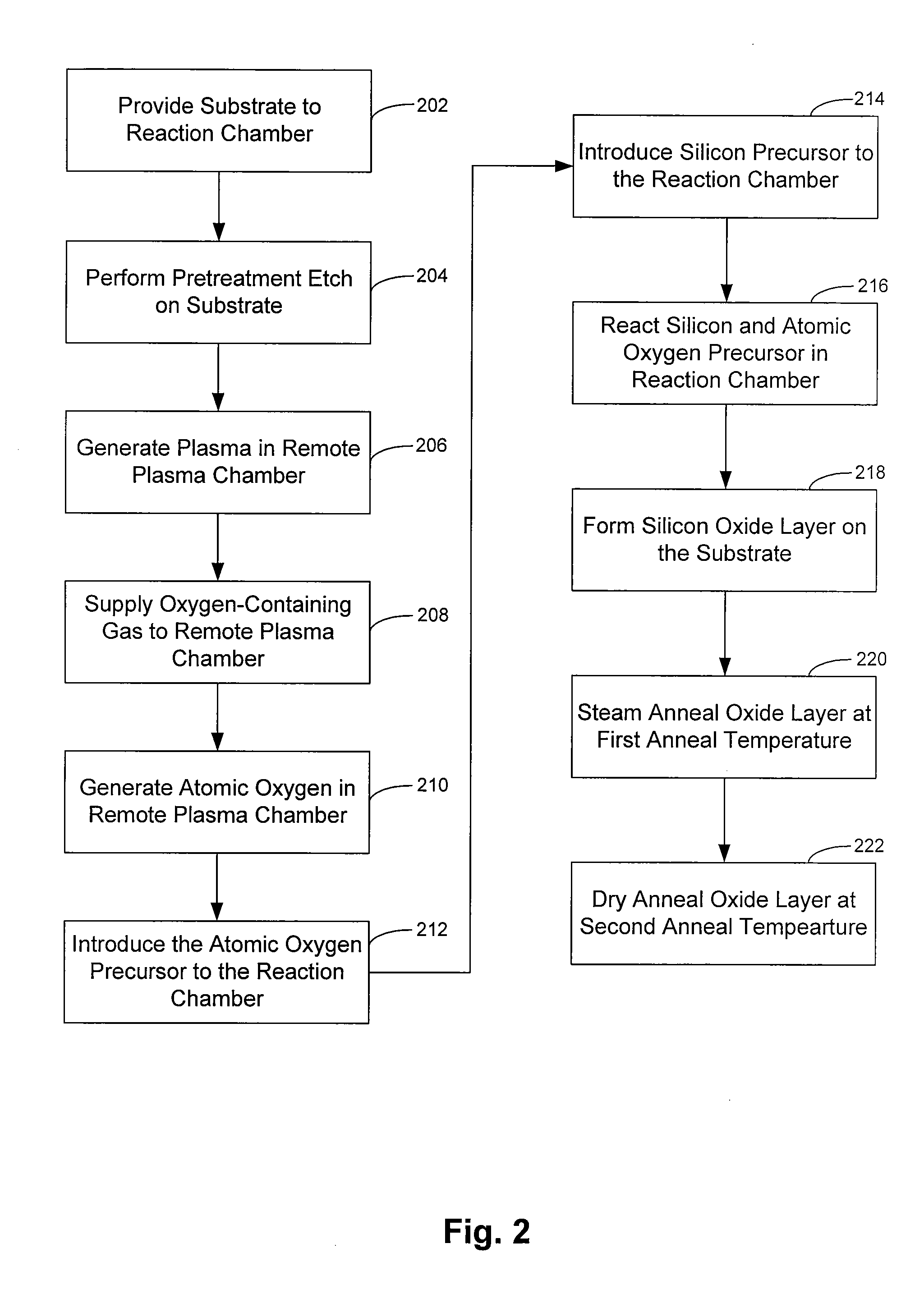

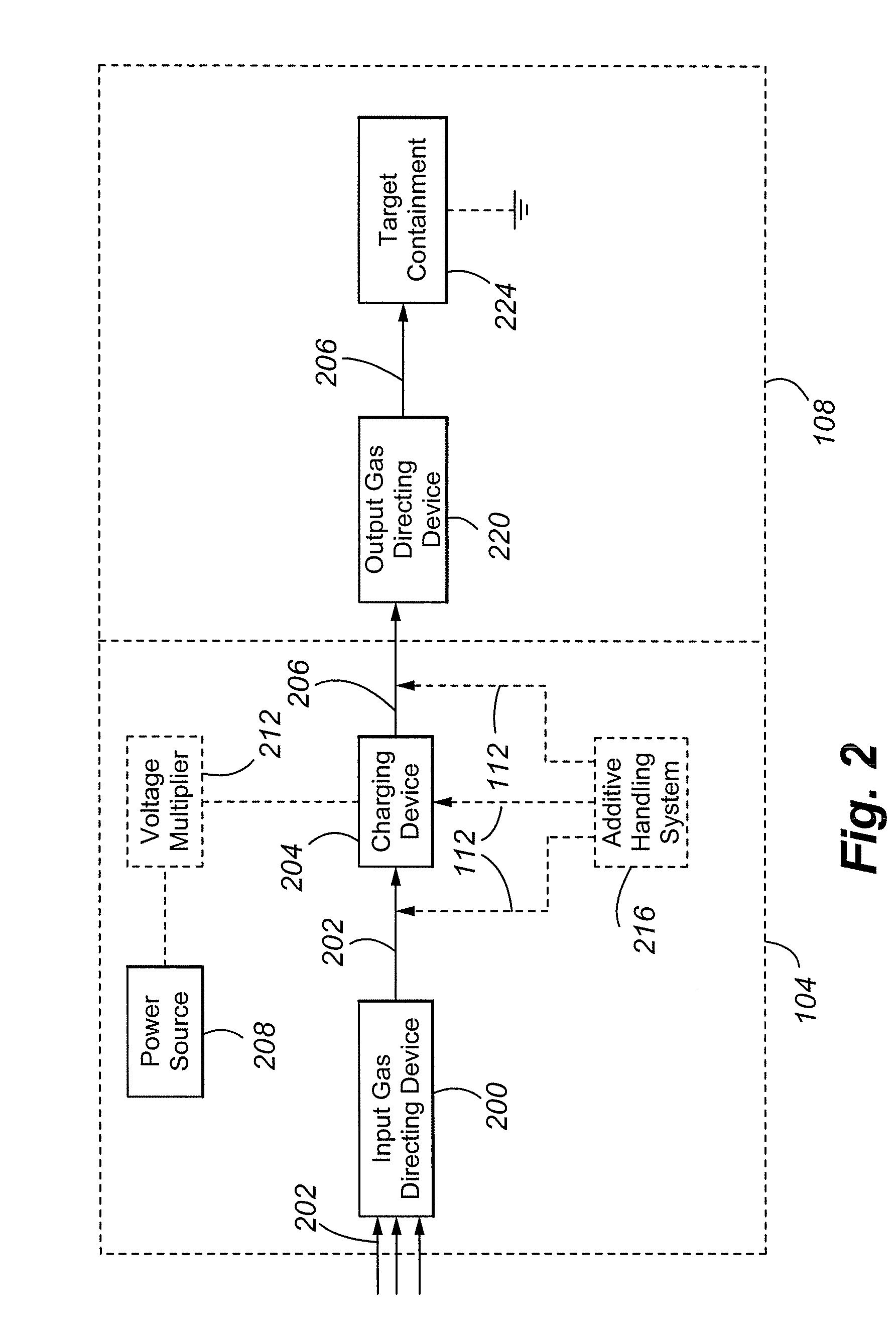

Methods of depositing a silicon oxide layer on a substrate are described. The methods may include the steps of providing a substrate to a deposition chamber, generating an atomic oxygen precursor outside the deposition chamber, and introducing the atomic oxygen precursor into the chamber. The methods may also include introducing a silicon precursor to the deposition chamber, where the silicon precursor and the atomic oxygen precursor are first mixed in the chamber. The silicon precursor and the atomic oxygen precursor react to form the silicon oxide layer on the substrate, and the deposited silicon oxide layer may be annealed. Systems to deposit a silicon oxide layer on a substrate are also described.

Owner:APPLIED MATERIALS INC

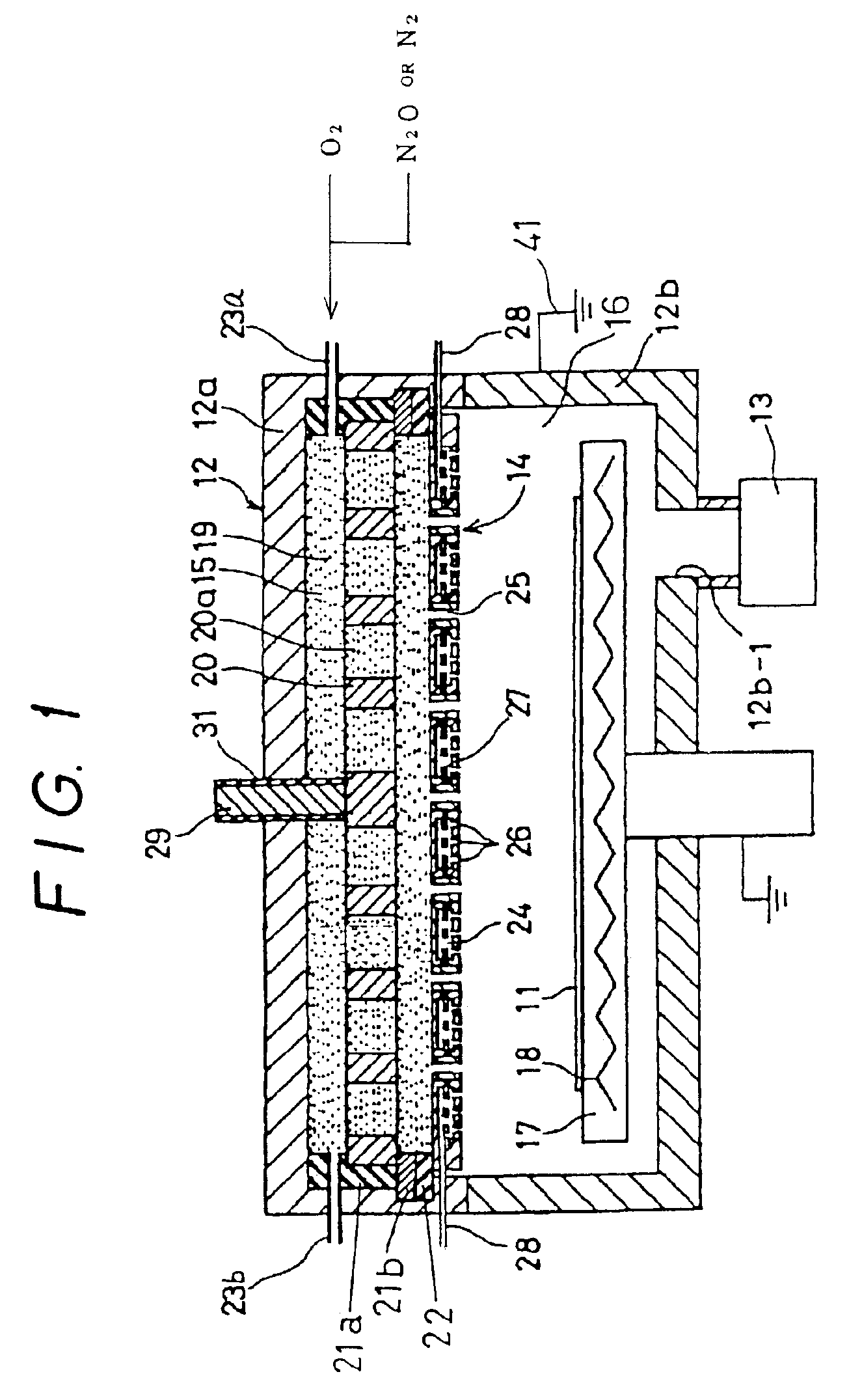

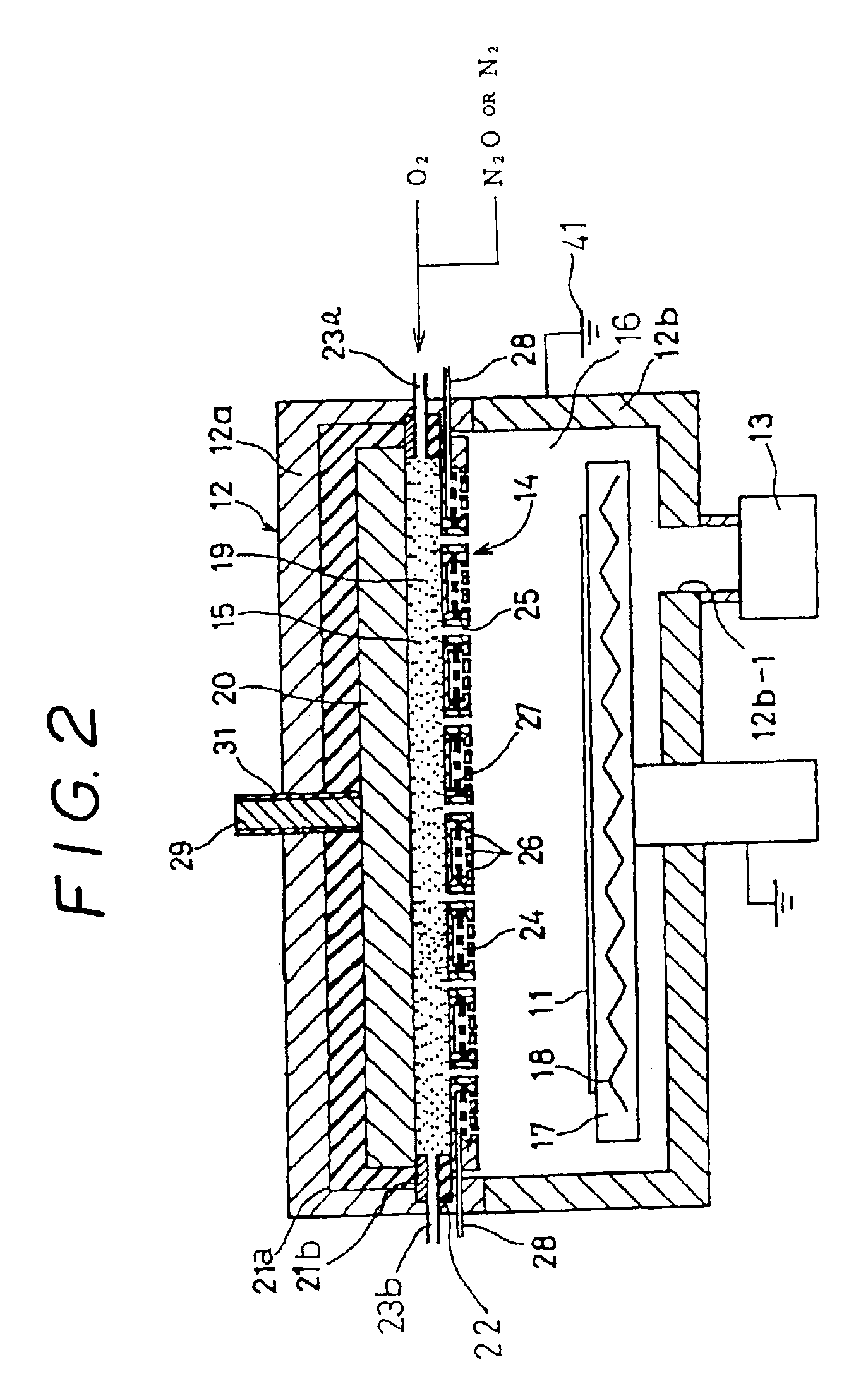

Silicon oxide film formation method

InactiveUS6955836B2Improve efficiencyQuality improvementSemiconductor/solid-state device manufacturingChemical vapor deposition coatingPhysical chemistrySilicon oxide

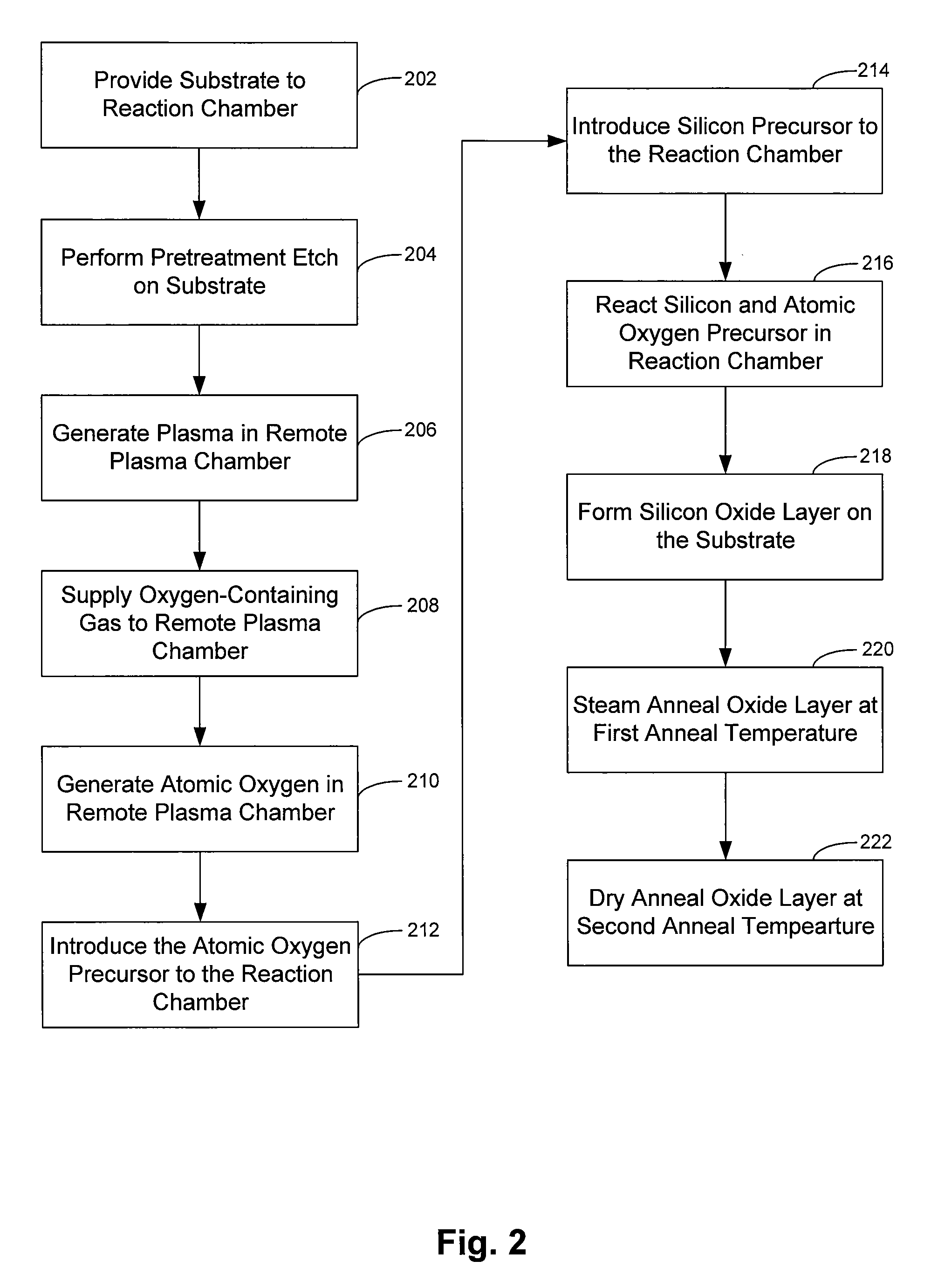

A silicon oxide film formation method enhances the efficiency of generating atomic oxygen and improves film quality of a silicon film (SiO2 film) in forming the silicon oxide film using an RS-CVD system. Nitrogen atom containing gas (N2 gas, NO gas, N2O gas, NO2 gas or the like) is added to oxygen atom containing gas (O2 gas, O3 gas or the like) introduced into a plasma generating space in a vacuum container to produce plasmas with these gases and to thereby increase the quantity of atomic oxygen generated by the plasmas in the plasma generating space.

Owner:ANELVA CORP +1

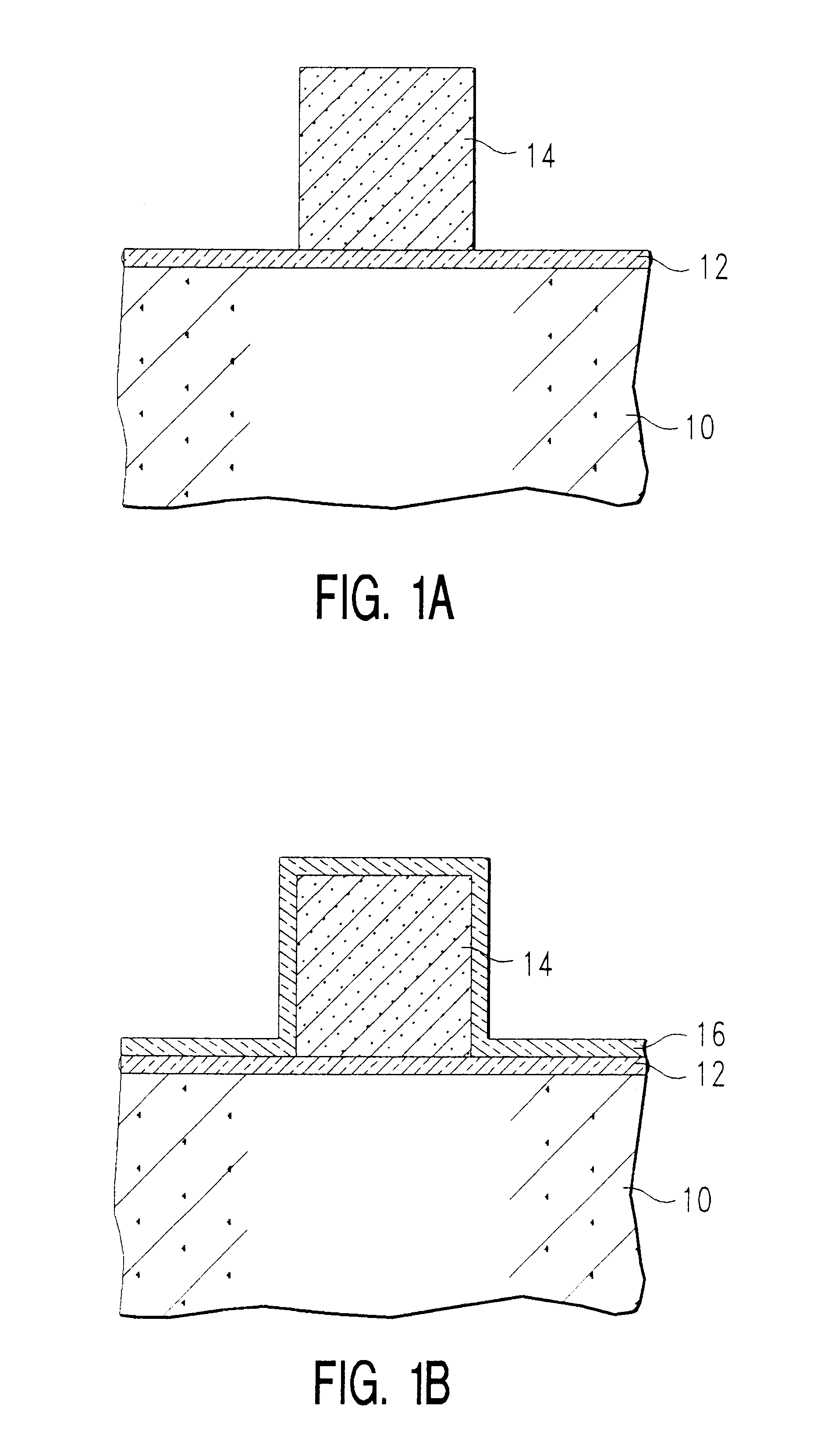

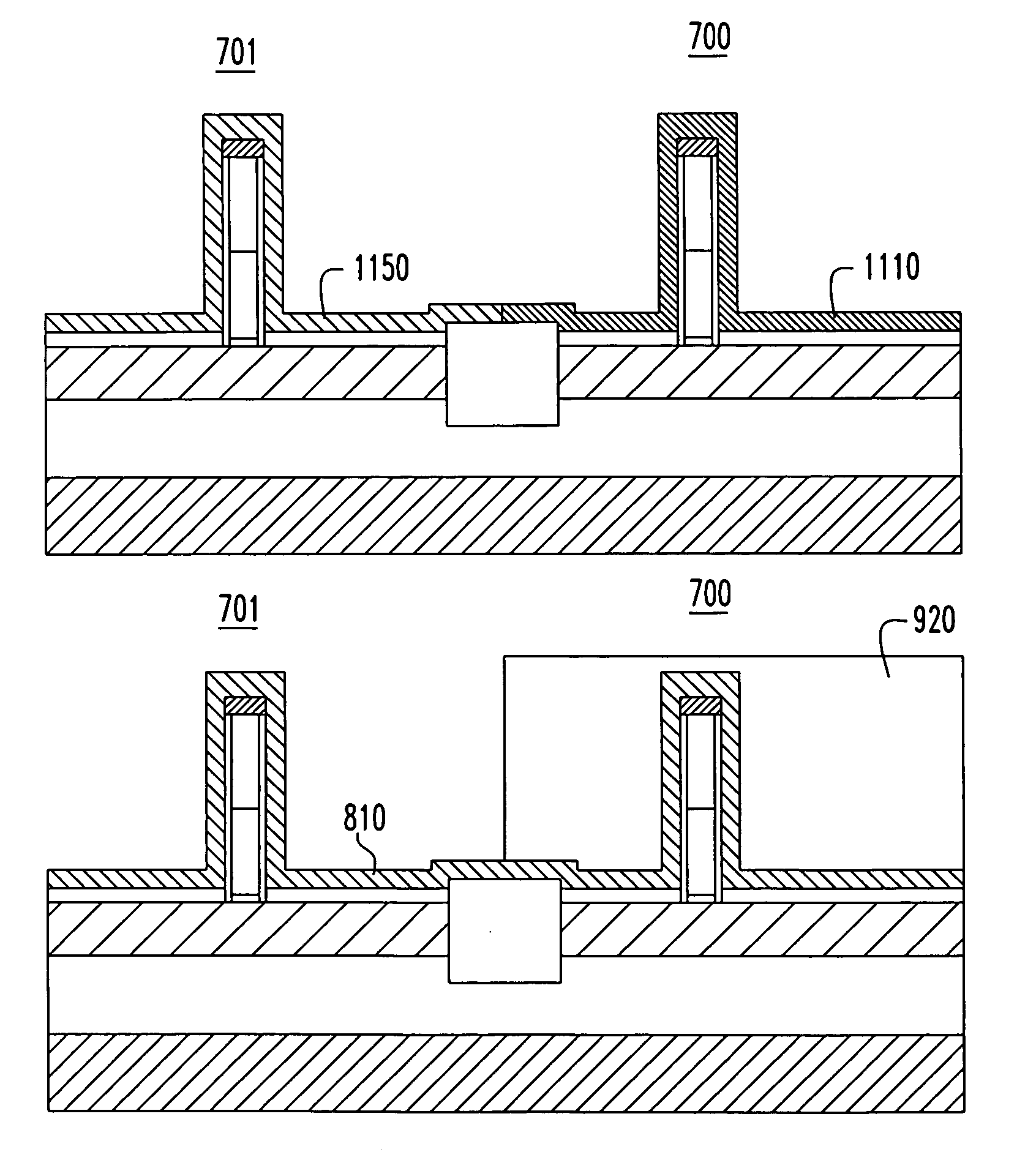

Methods for forming a dielectric layer within trenches

ActiveUS7803722B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingSemiconductor structureUltraviolet

A method for forming a semiconductor structure includes reacting a silicon precursor and an atomic oxygen or nitrogen precursor at a processing temperature of about 150° C. or less to form a silicon oxide or silicon-nitrogen containing layer over a substrate. The silicon oxide or silicon-nitrogen containing layer is ultra-violet (UV) cured within an oxygen-containing environment.

Owner:APPLIED MATERIALS INC

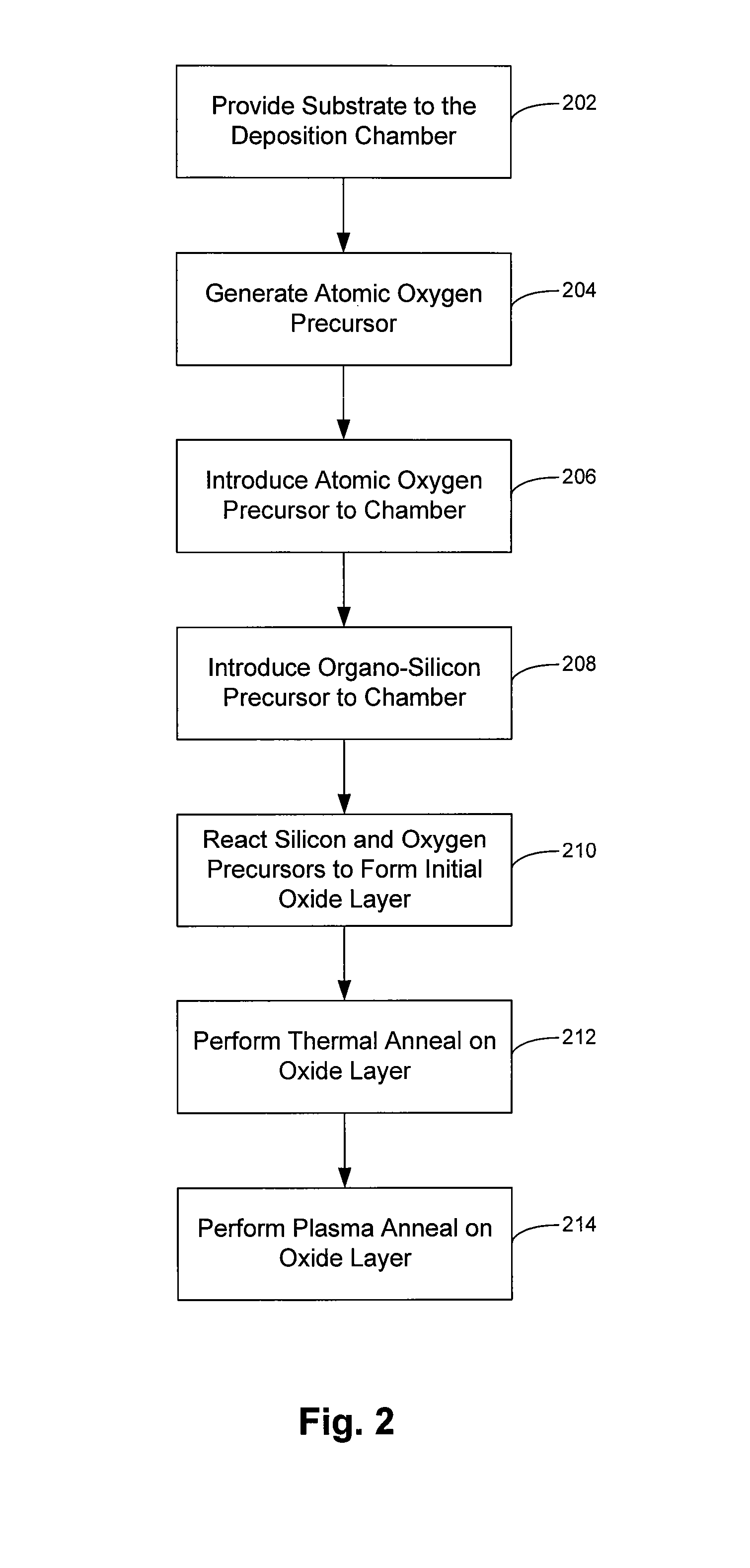

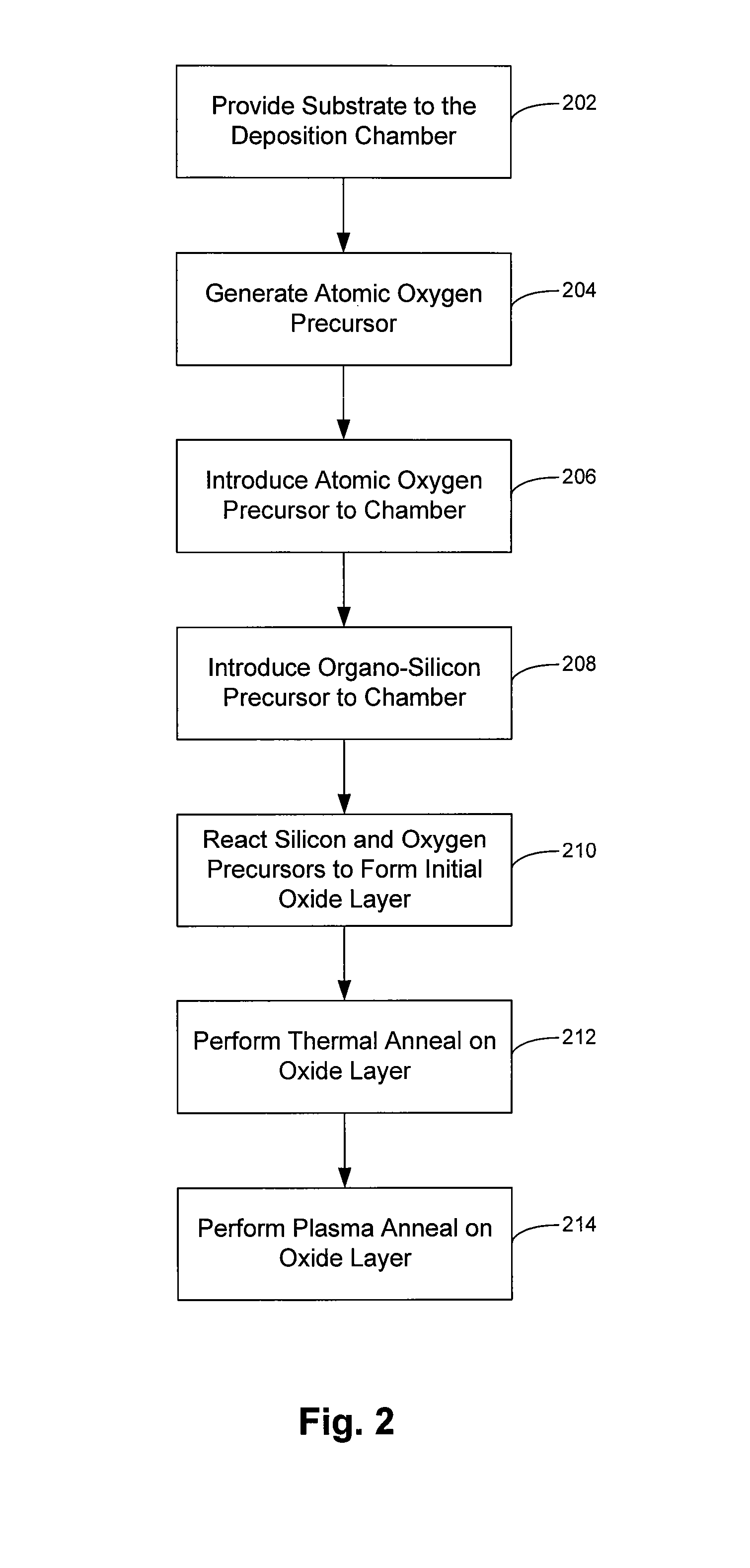

Method for depositing and curing low-k films for gapfill and conformal film applications

ActiveUS20080026597A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingSilicon oxideAtomic oxygen

Methods of making a silicon oxide layer on a substrate are described. The methods may include forming the silicon oxide layer on the substrate in a reaction chamber by reacting an atomic oxygen precursor and a silicon precursor and depositing reaction products on the substrate. The atomic oxygen precursor is generated outside the reaction chamber. The methods also include heating the silicon oxide layer at a temperature of about 600° C. or less, and exposing the silicon oxide layer to an induced coupled plasma. Additional methods are described where the deposited silicon oxide layer is cured by exposing the layer to ultra-violet light, and also exposing the layer to an induced coupled plasma.

Owner:APPLIED MATERIALS INC

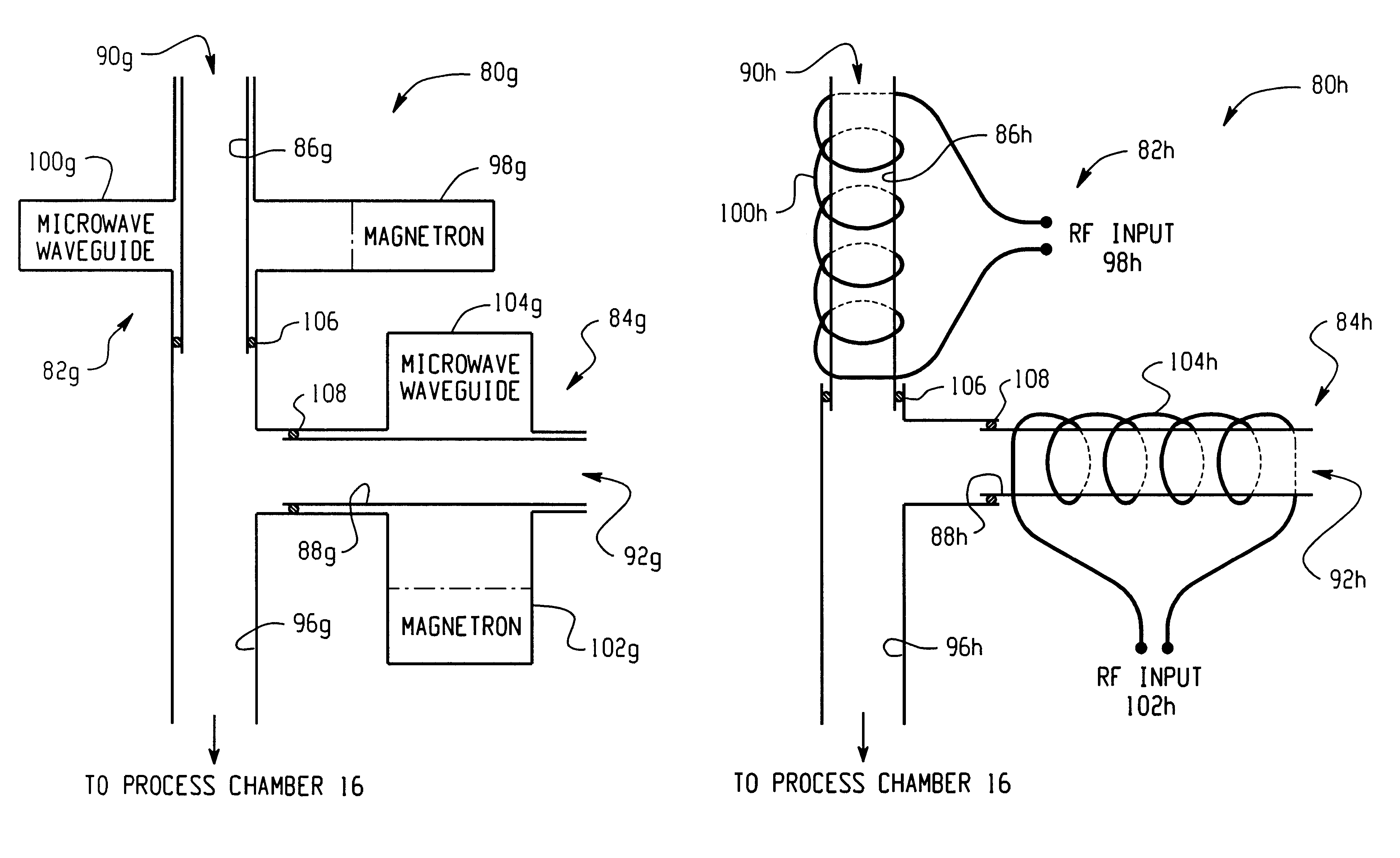

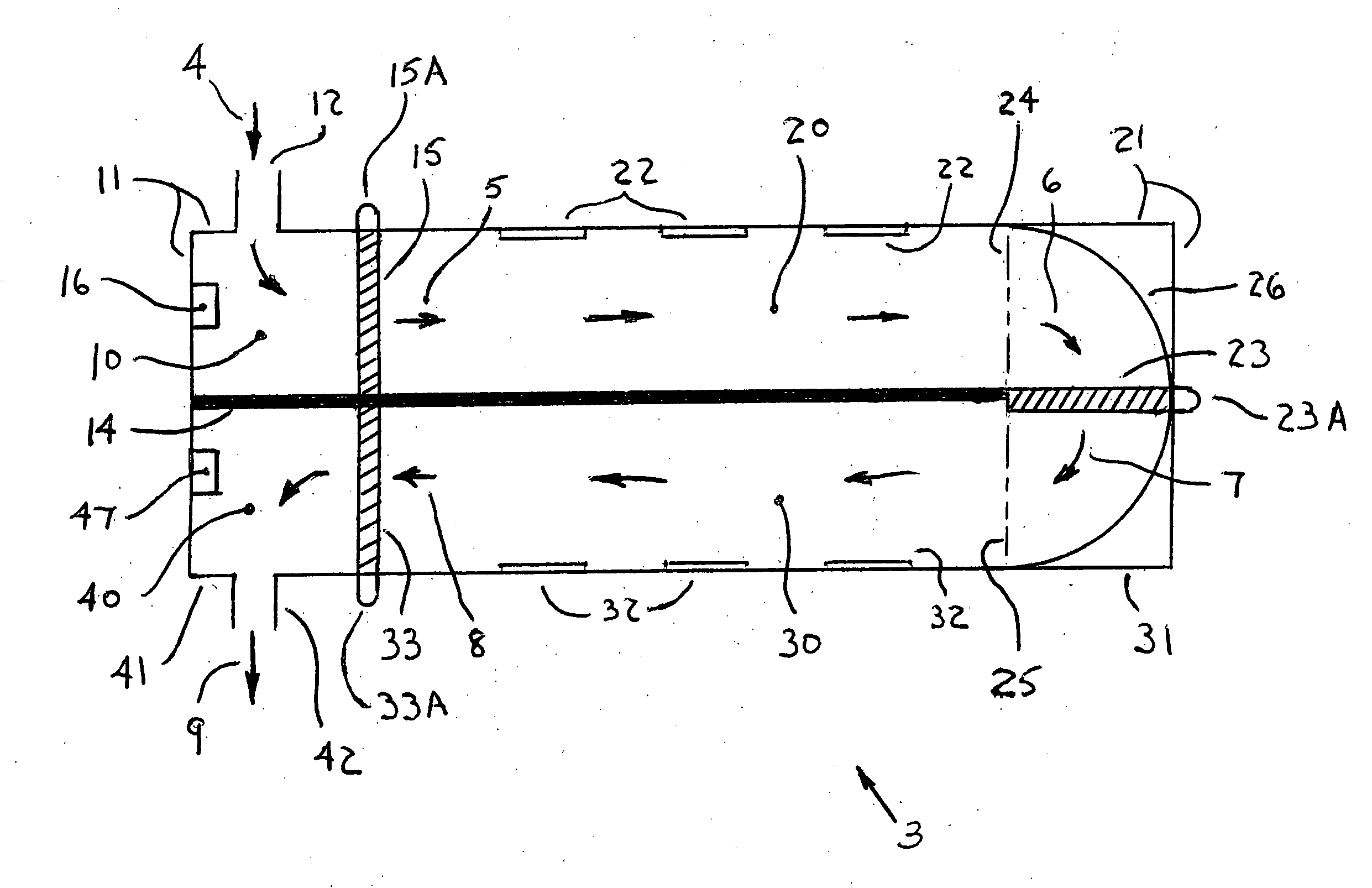

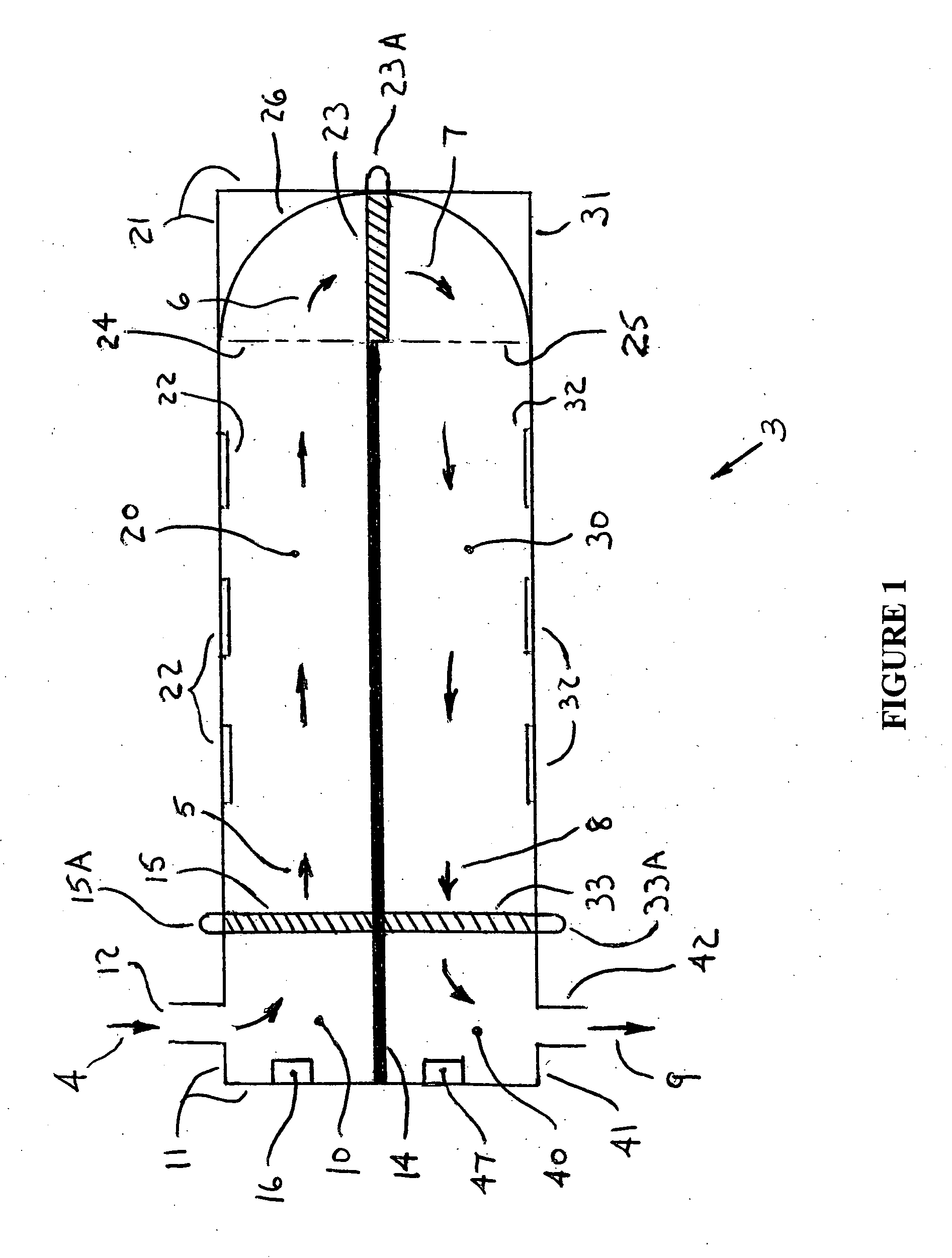

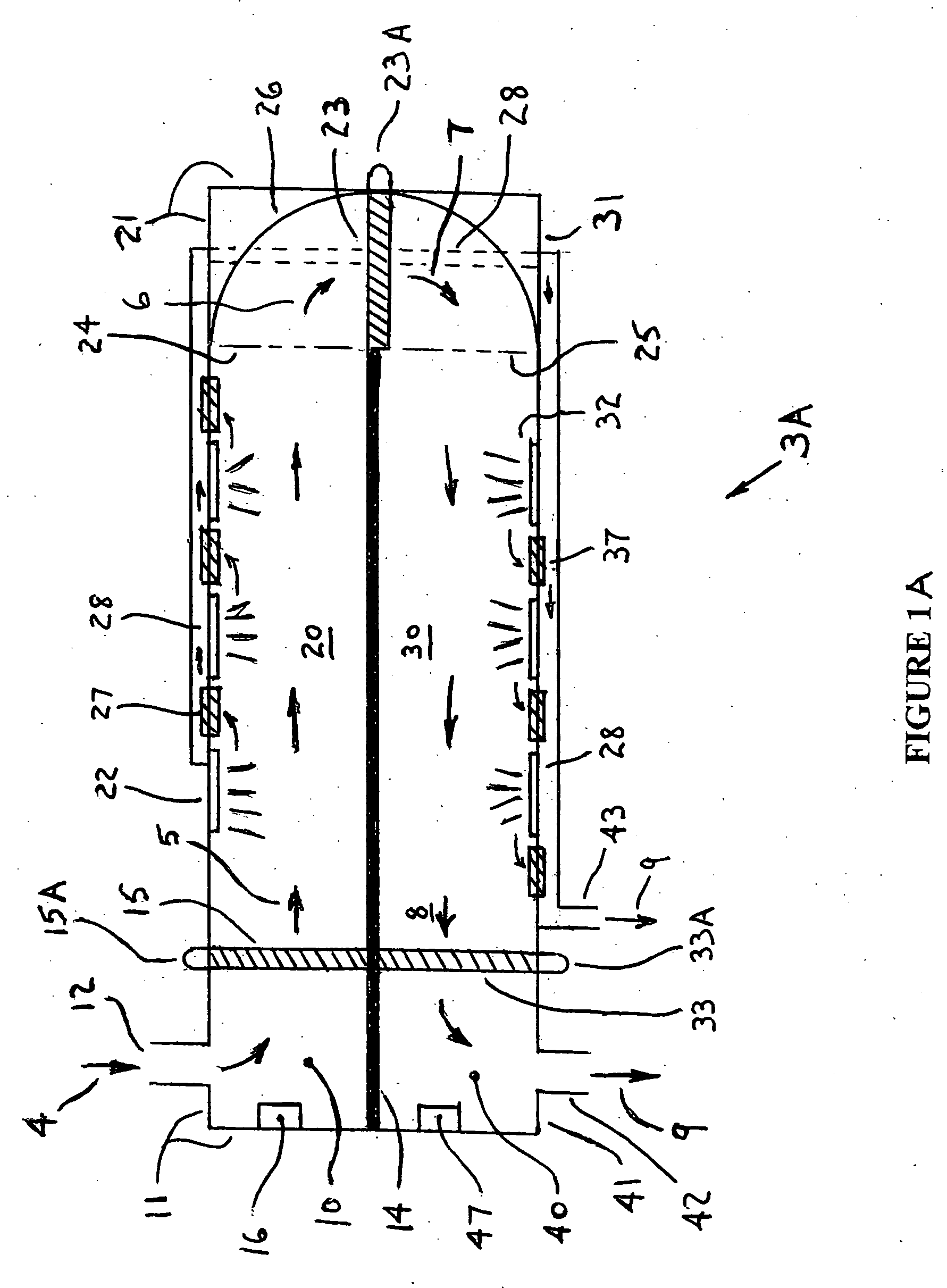

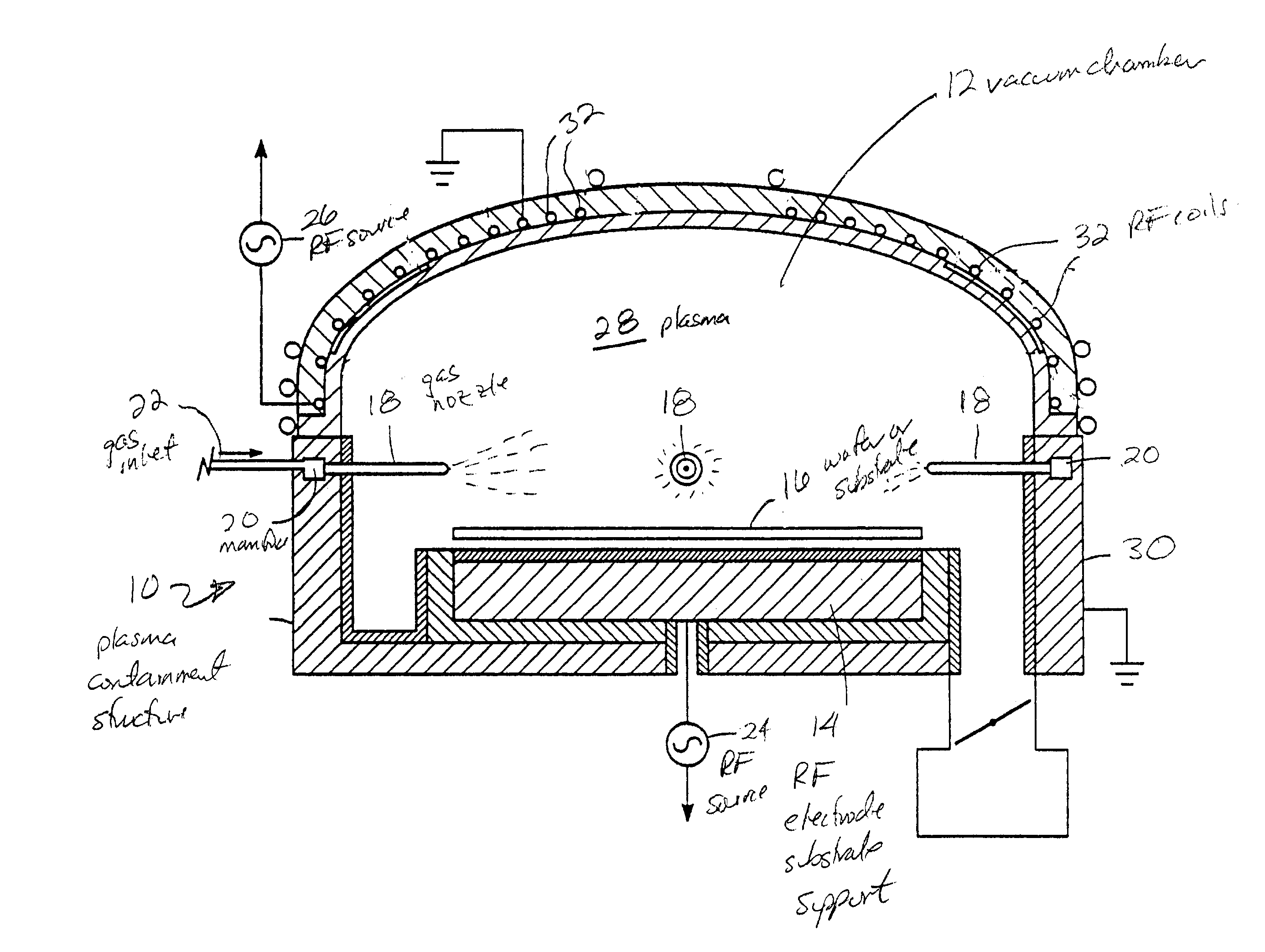

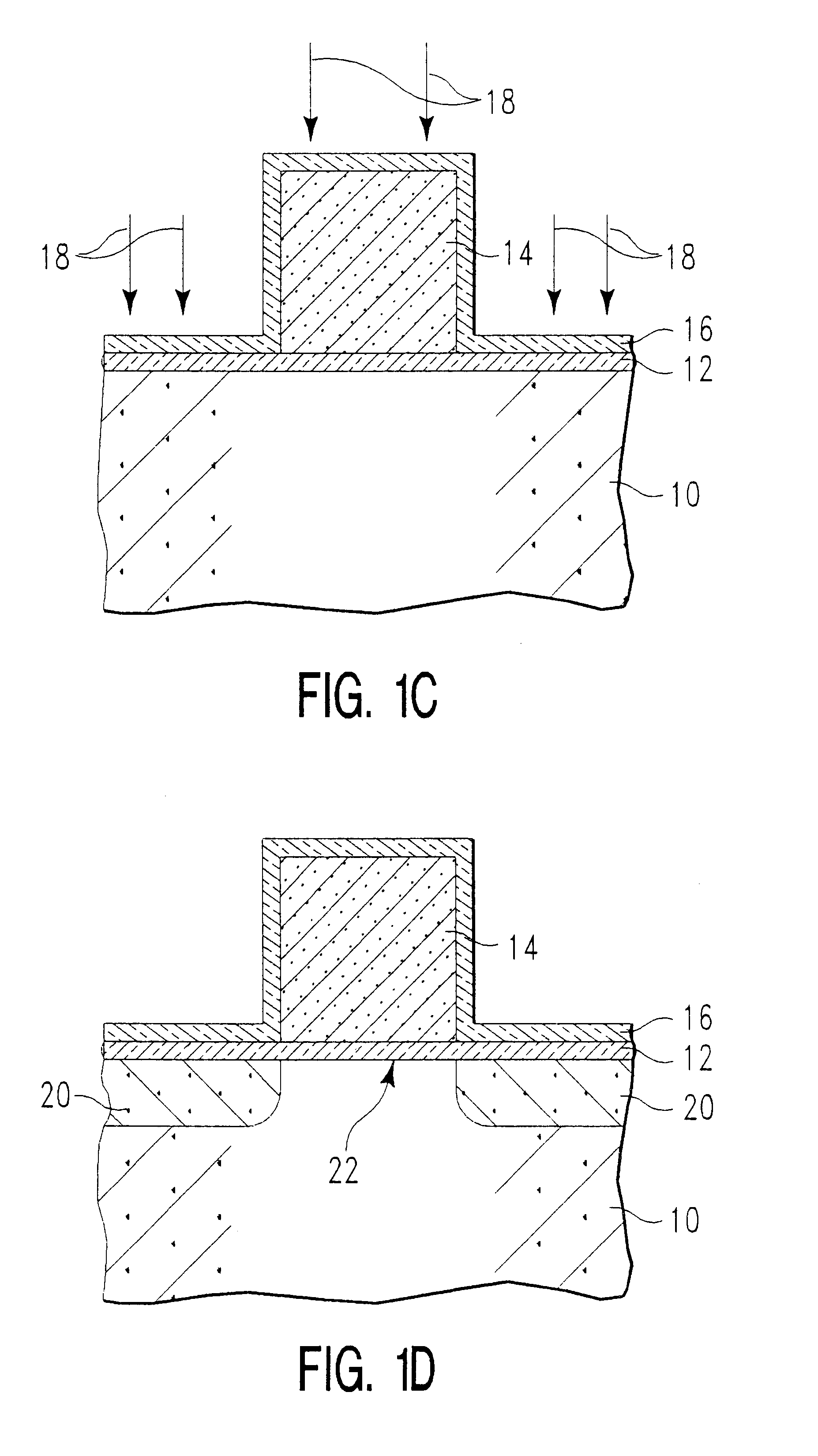

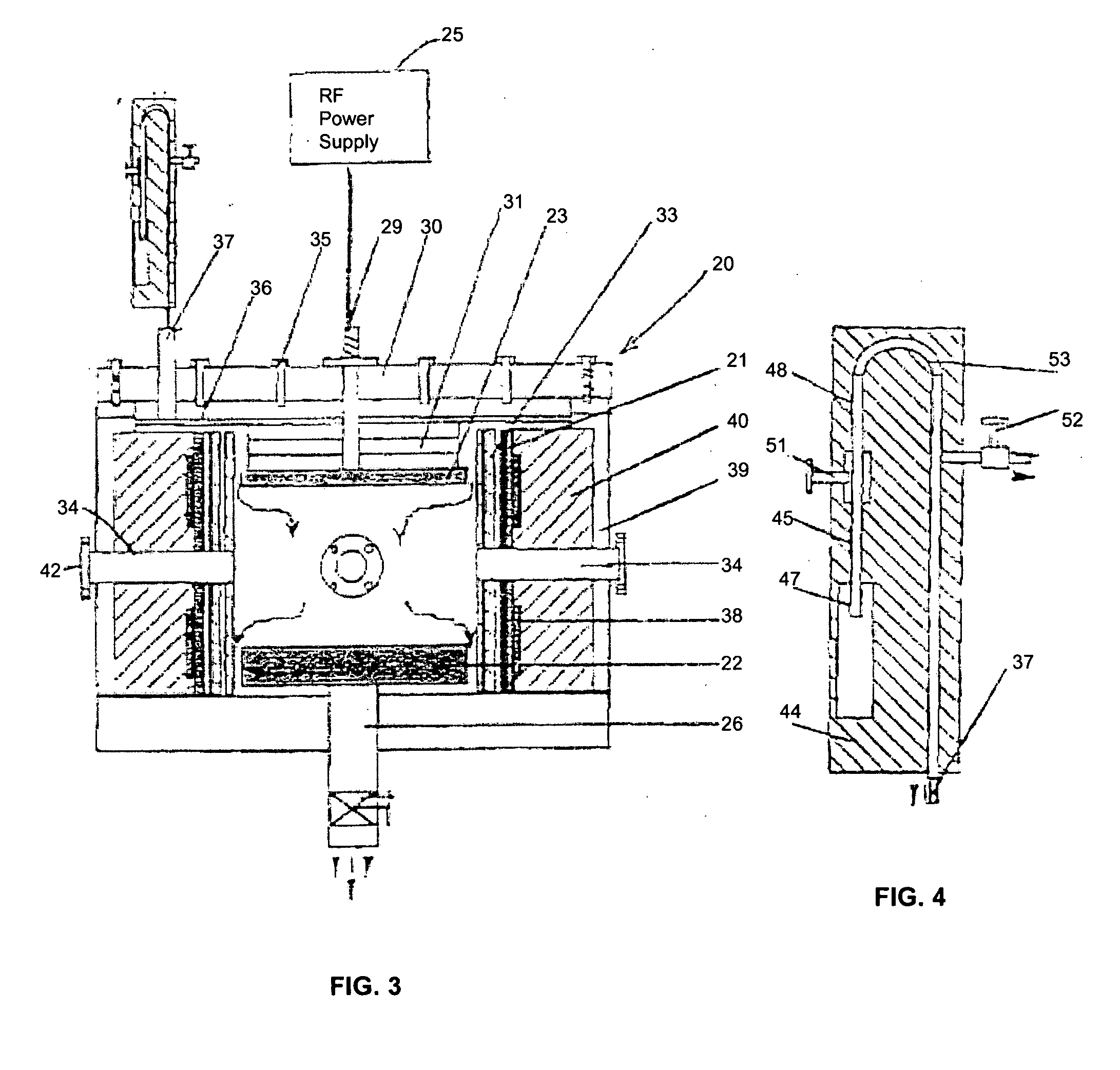

Dual plasma source for plasma process chamber

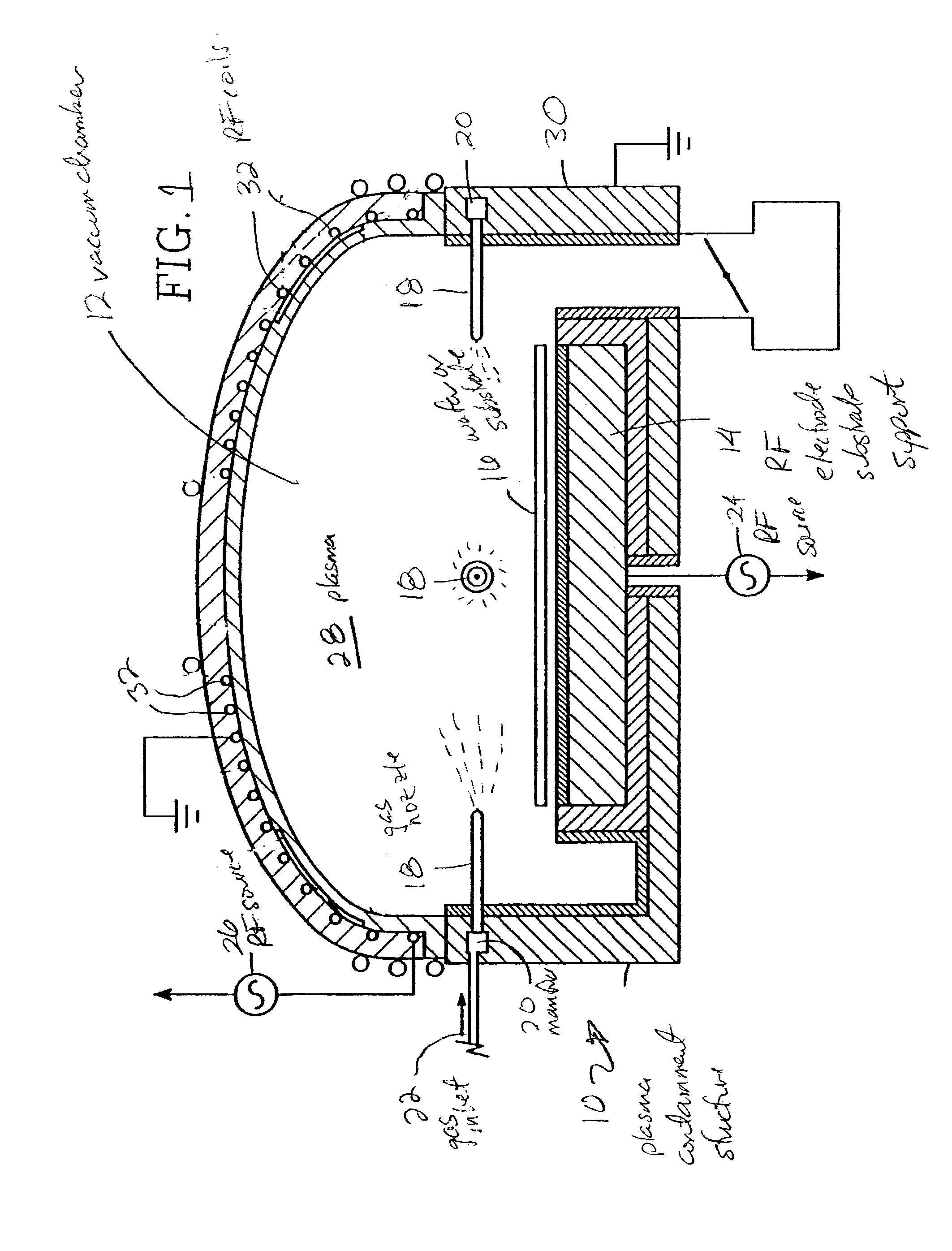

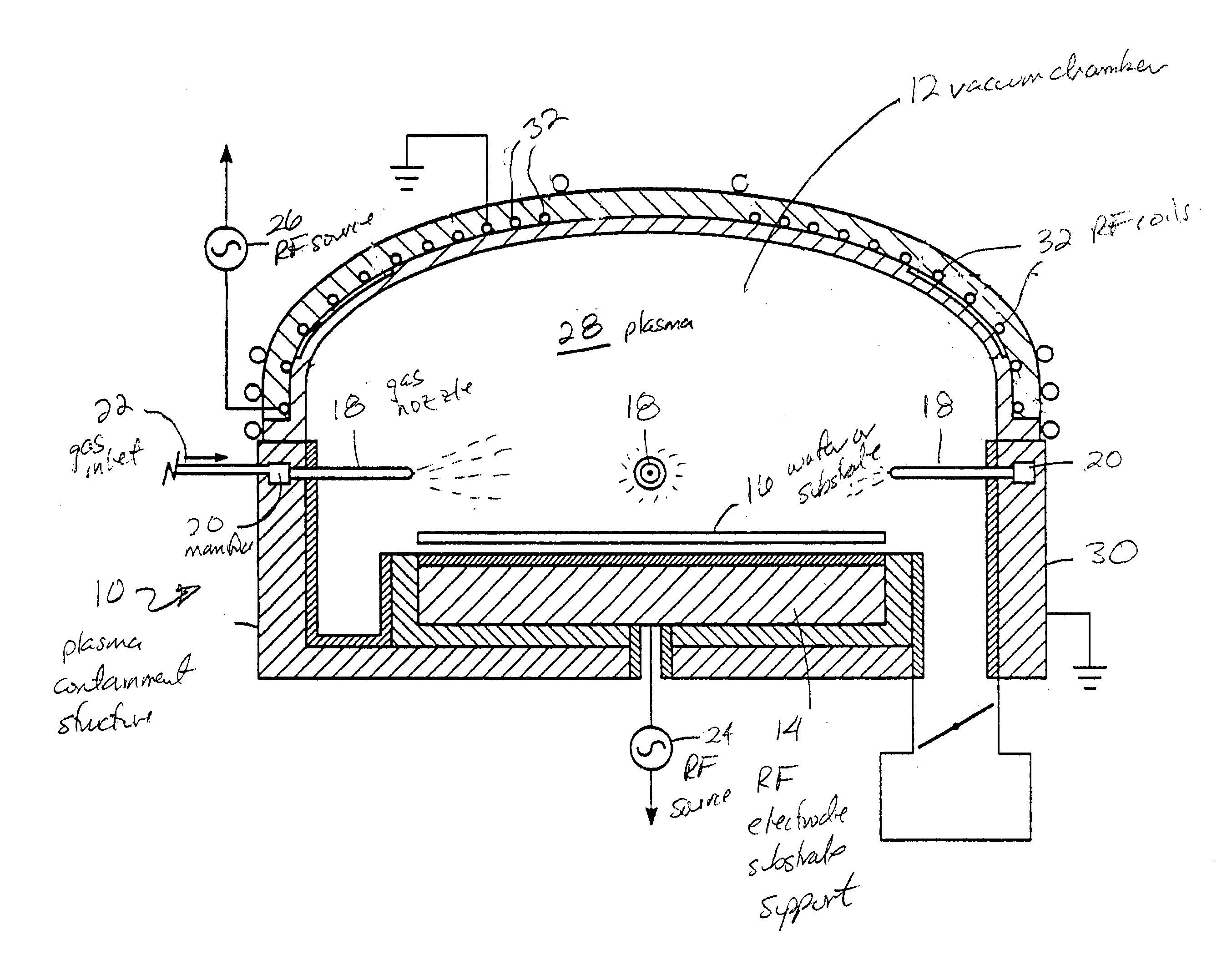

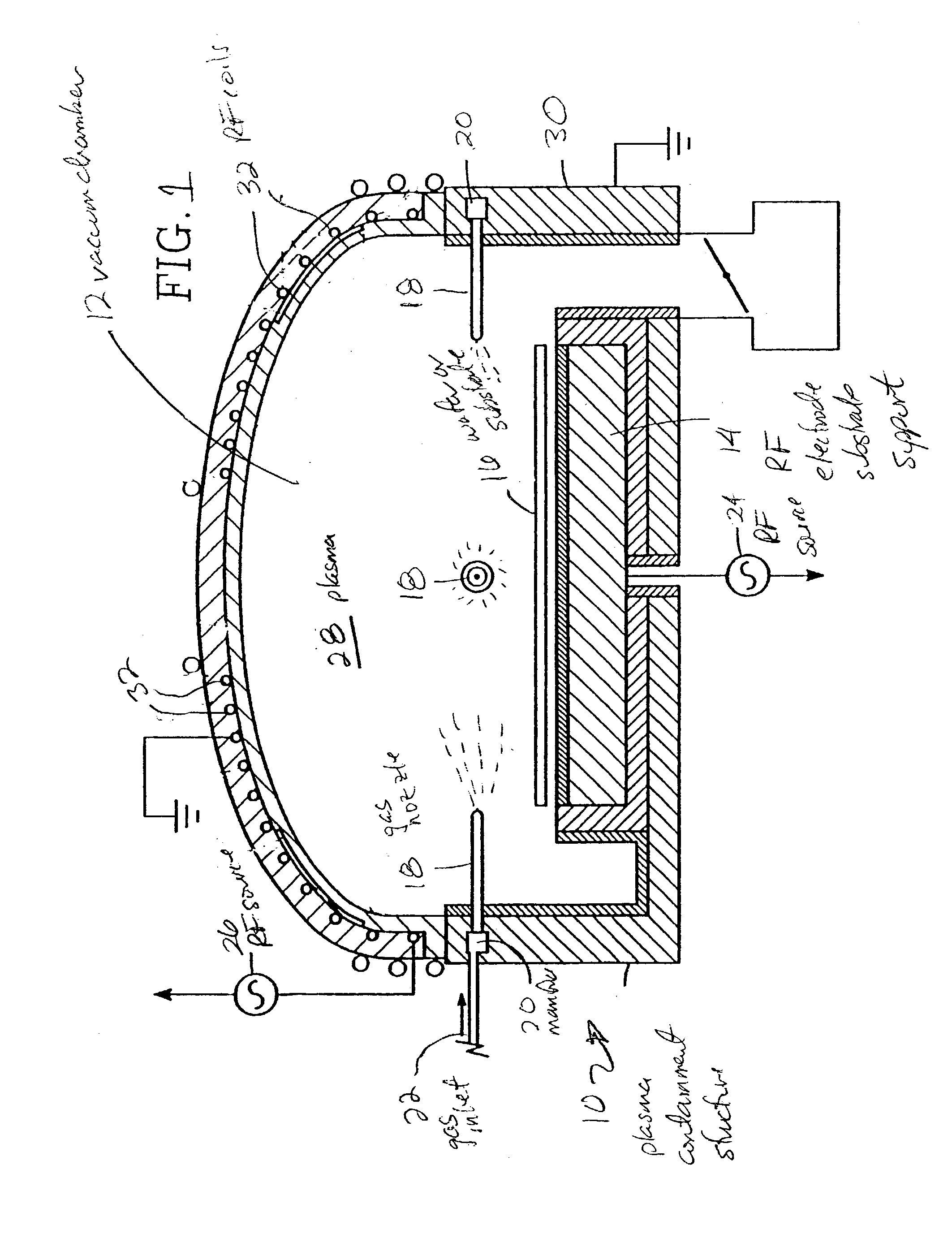

InactiveUS6225745B1Delayed recombinationSemiconductor/solid-state device manufacturingElectric arc lampsSingle crystalSapphire

A dual plasma source (80) is provided for a plasma processing system (10), comprising a first plasma source (82) and a second plasma source (84). The first plasma source (82) has a first plasma passageway (86) for transporting a first plasma therethrough toward a processing chamber (16), the first plasma passageway providing a first inlet (90) for accepting a first gas mixture to be energized by the first plasma source. The second plasma source (84) is connected to the first plasma source (82) and has a second plasma passageway (88) for transporting a second plasma therethrough toward the processing chamber (16), the second plasma passageway providing a second inlet (92) for accepting a second gas mixture to be energized by the second plasma source. The first plasma passageway (86) is constructed from a material that resists atomic oxygen recombination with the first plasma, and the second plasma passageway (88) is constructed from a material that resists etching by the second plasma. In a more limited embodiment, the first plasma passageway (86) is constructed from quartz (SiO.sub.2) and the second plasma passageway is (88) constructed from alumina (Al.sub.2 O.sub.3) or single crystal alumina (sapphire).

Owner:LAM RES CORP

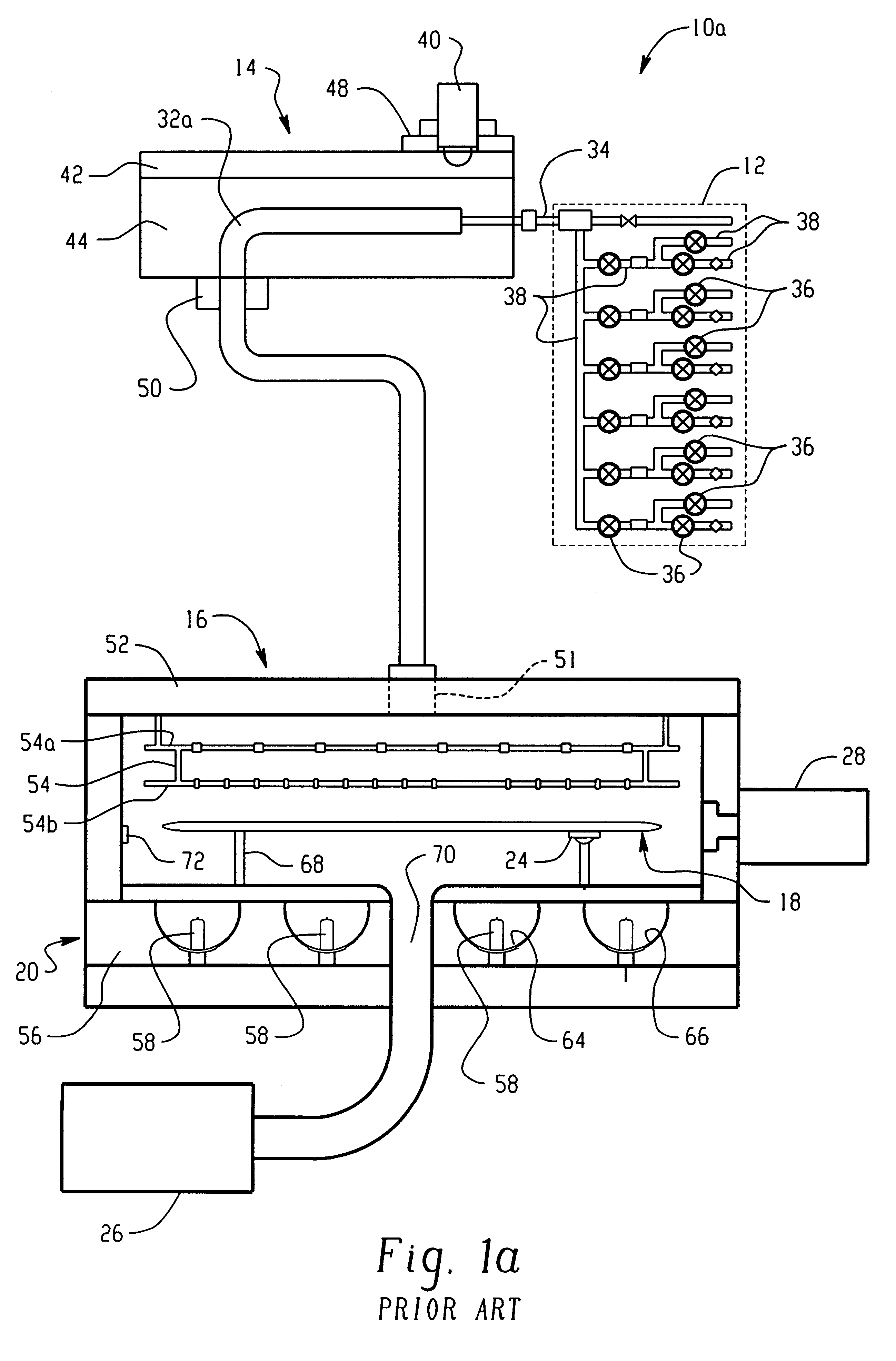

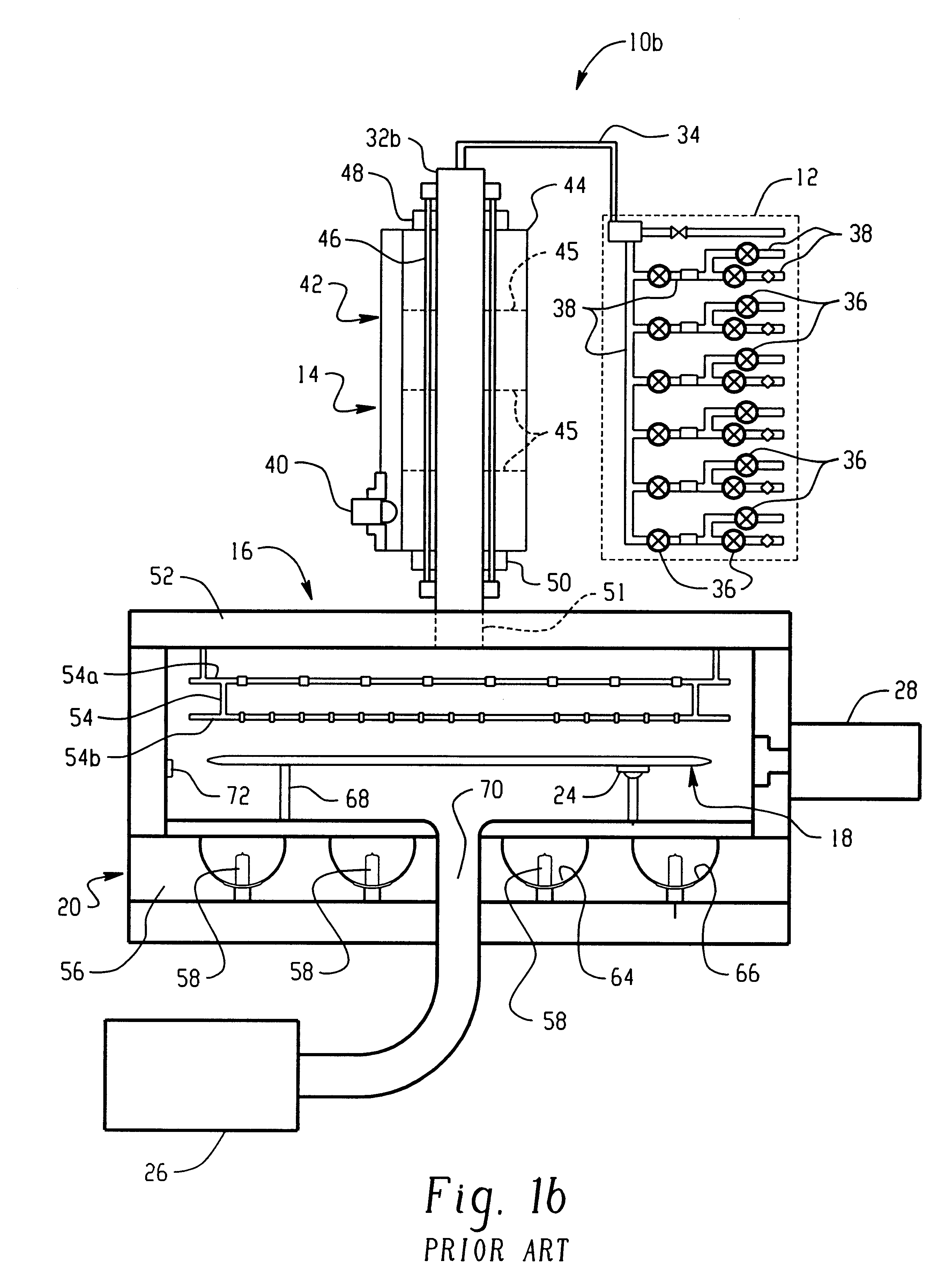

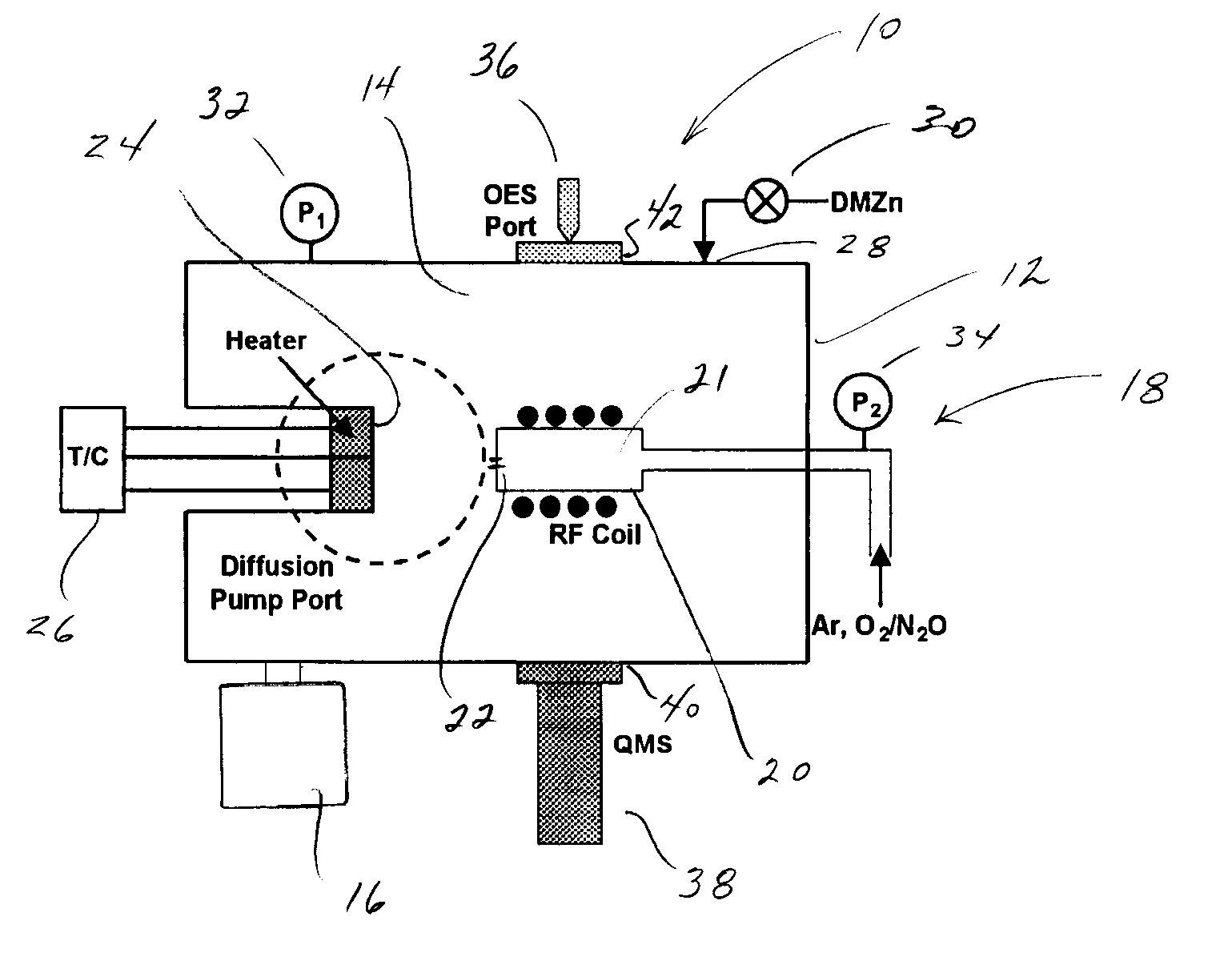

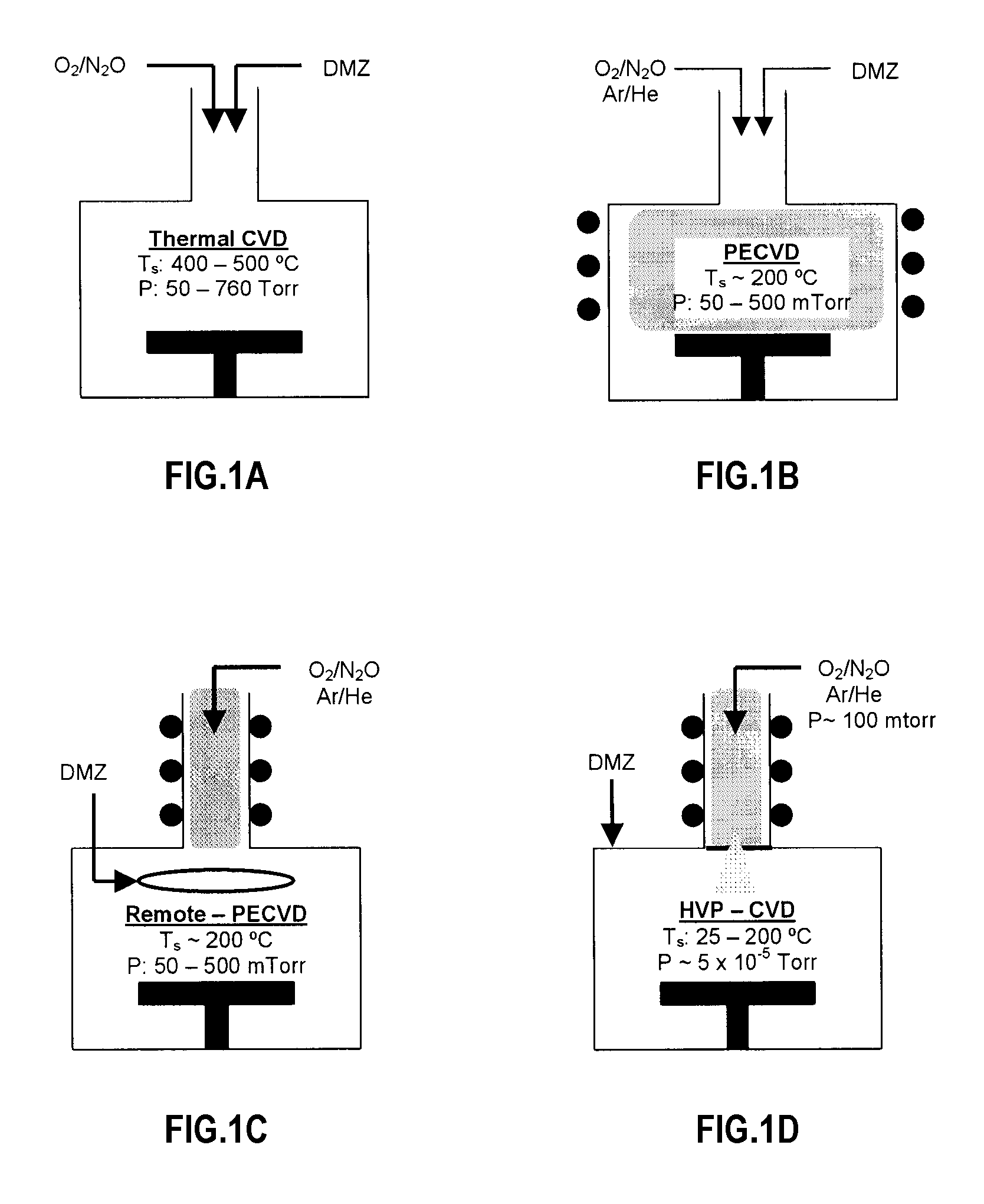

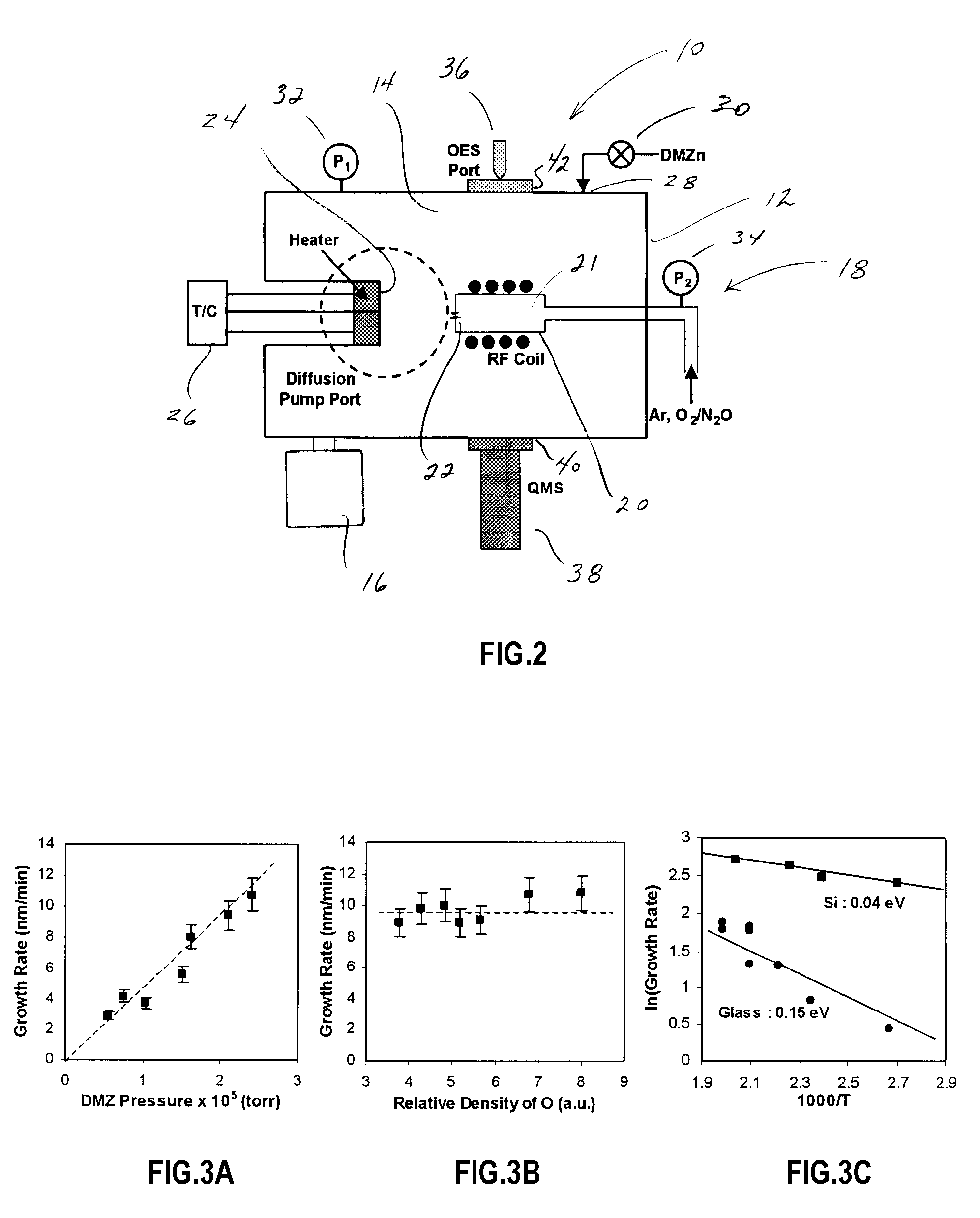

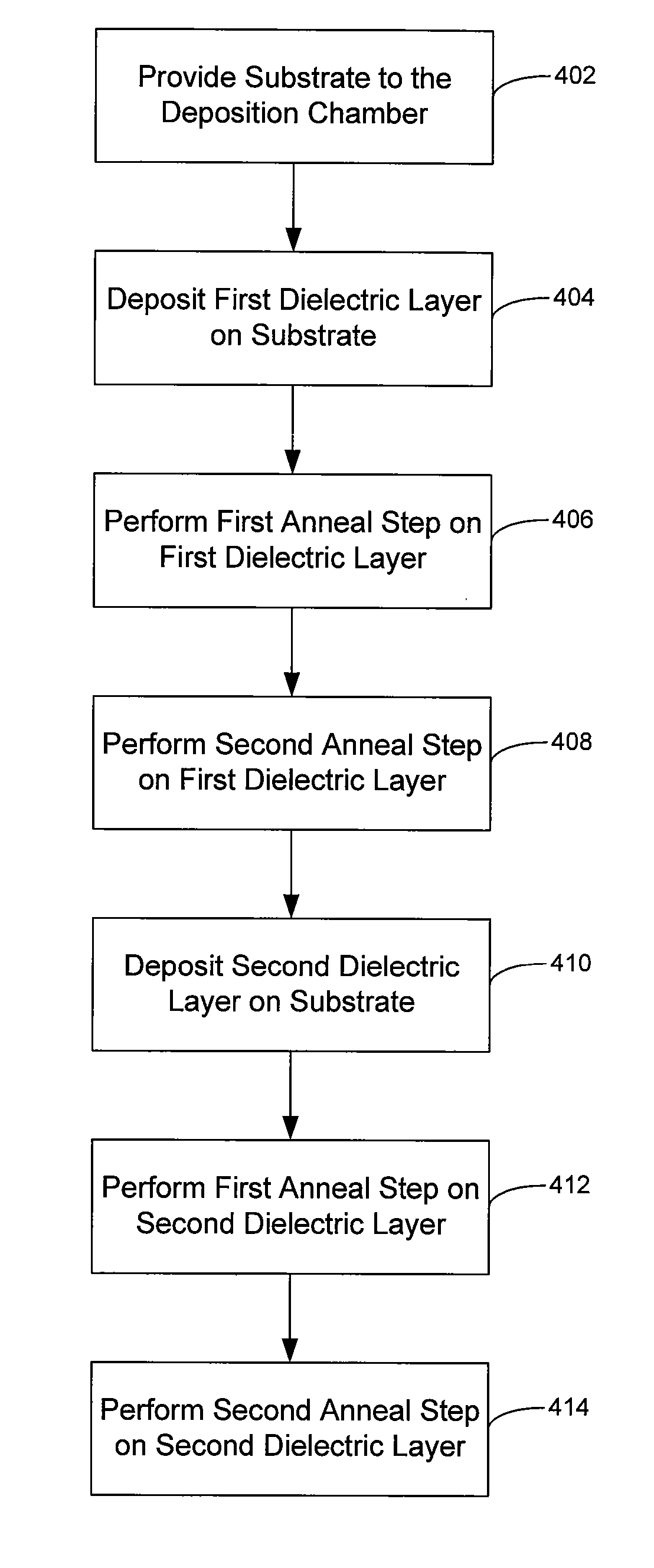

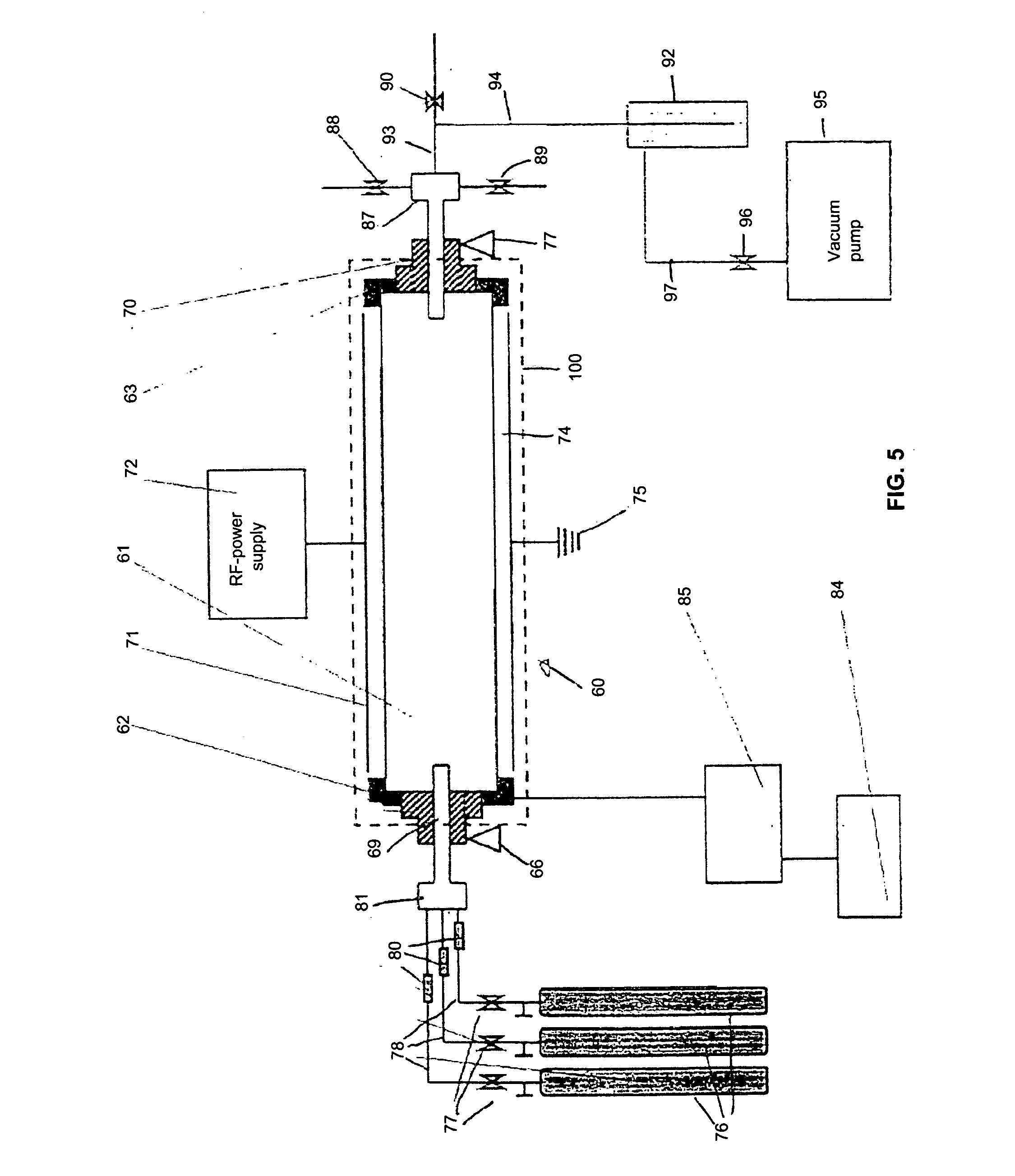

High Vacuum Plasma-Assisted Chemical Vapor Deposition System

The invention is directed to a novel approach to thin film synthesis that is described as high vacuum plasma-assisted chemical vapor deposition (HVP-CVD). In one application of HVP-CVD, atomic oxygen and organometallic precursors are simultaneously introduced into a high vacuum chamber. Gas-phase chemistry is eliminated or substantially eliminated in the collisionless or substantially collisionless environment, allowing the surface chemistry between atomic oxygen and the precursor(s) to be interrogated directly. In preliminary work it has been observed that the presence of atomic oxygen greatly accelerates the desorption of organic ligands, facilitating oxide formation. The prominent advantages of the HVP-CVD include reduced substrate temperature, significant rates, inherent uniformity, facilitated doping, and the ability to directly study these processes in-situ with high vacuum diagnostics that are not compatible with conventional CVD technologies.

Owner:COLORADO SCHOOL OF MINES

Method for depositing and curing low-k films for gapfill and conformal film applications

ActiveUS7790634B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingSilicon oxideAtomic oxygen

Methods of making a silicon oxide layer on a substrate are described. The methods may include forming the silicon oxide layer on the substrate in a reaction chamber by reacting an atomic oxygen precursor and a silicon precursor and depositing reaction products on the substrate. The atomic oxygen precursor is generated outside the reaction chamber. The methods also include heating the silicon oxide layer at a temperature of about 600° C. or less, and exposing the silicon oxide layer to an induced coupled plasma. Additional methods are described where the deposited silicon oxide layer is cured by exposing the layer to ultra-violet light, and also exposing the layer to an induced coupled plasma.

Owner:APPLIED MATERIALS INC

Methods for Forming a Dielectric Layer Within Trenches

ActiveUS20090104790A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingSemiconductor structureUltraviolet

A method for forming a semiconductor structure includes reacting a silicon precursor and an atomic oxygen or nitrogen precursor at a processing temperature of about 150° C. or less to form a silicon oxide or silicon-nitrogen containing layer over a substrate. The silicon oxide or silicon-nitrogen containing layer is ultra-violet (UV) cured within an oxygen-containing environment.

Owner:APPLIED MATERIALS INC

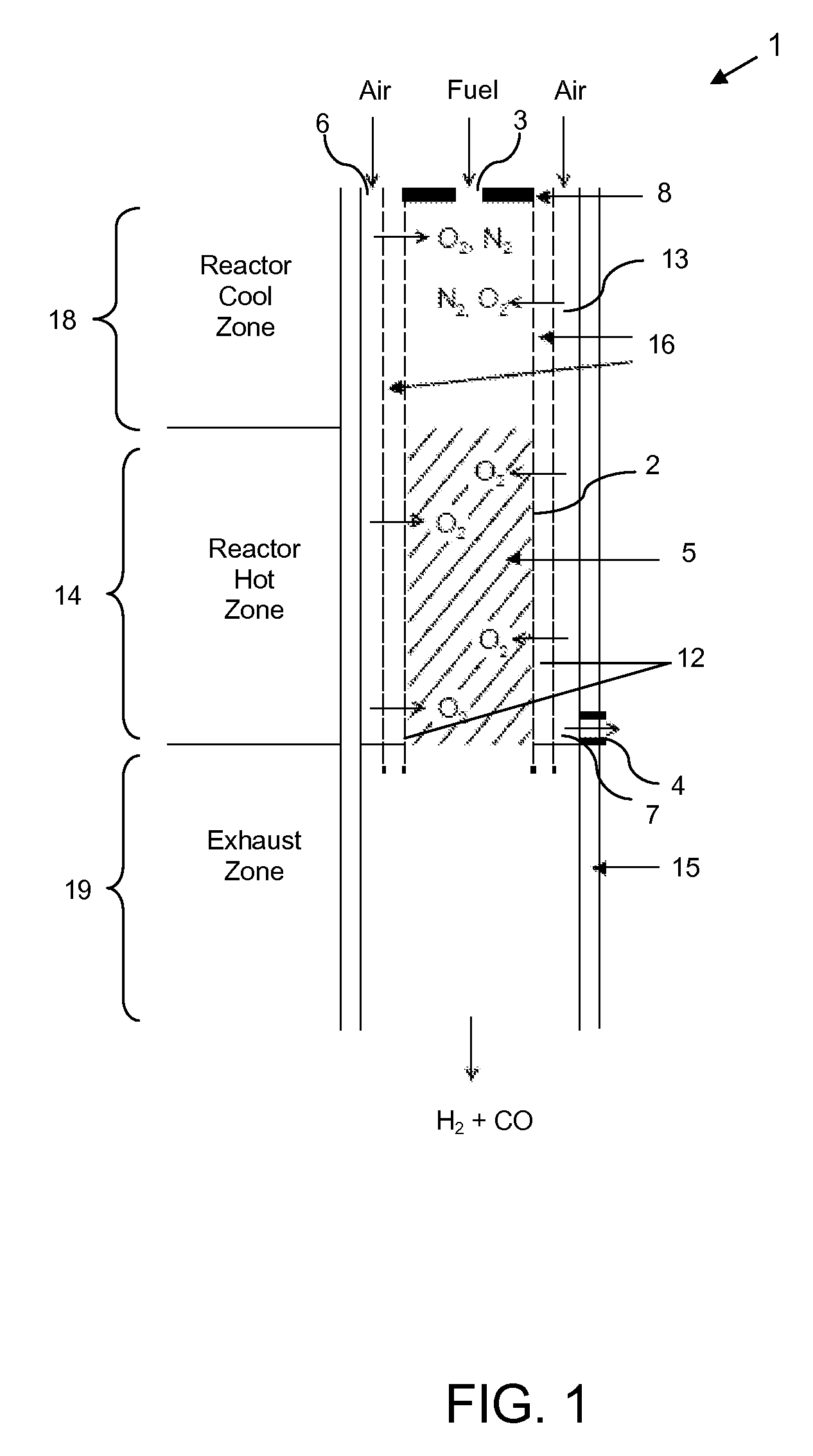

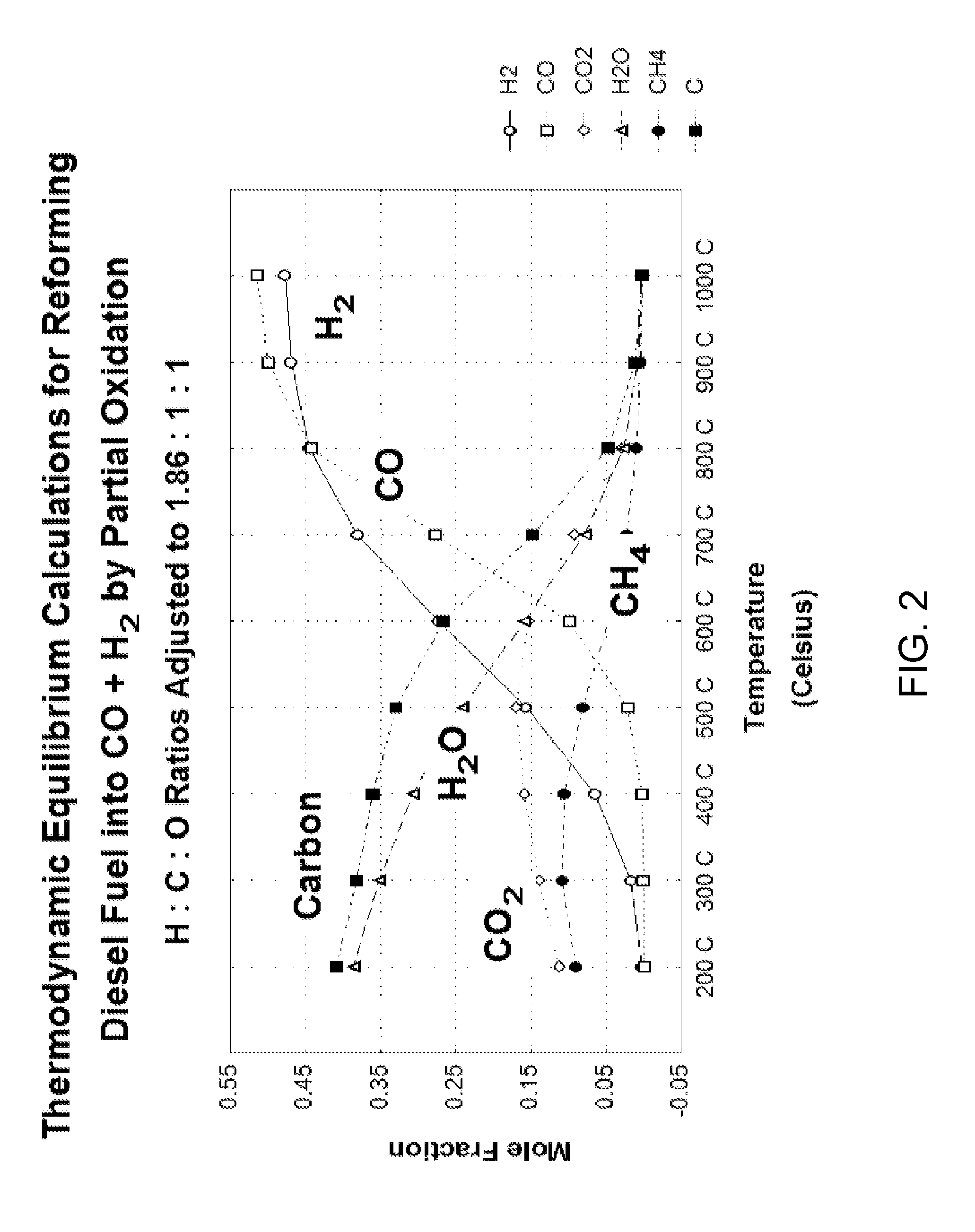

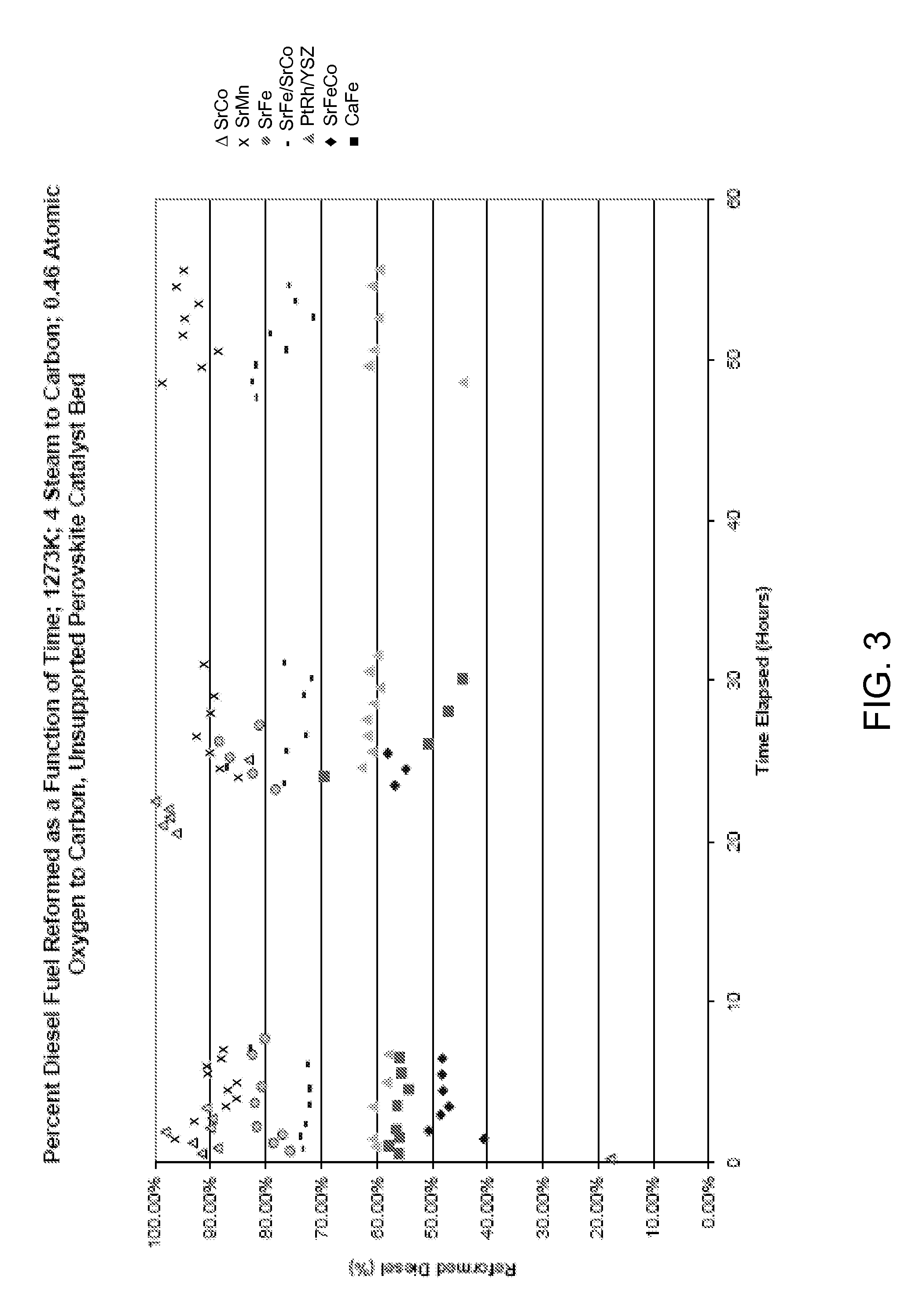

Catalytic membrane reactor and method for production of synthesis gas

InactiveUS20080169449A1High oxygen fluxHydrogenSemi-permeable membranesSulfur containingPhotochemistry

A solid state membrane for a reforming reactor is disclosed which comprises at least one oxygen anion-conducting oxide selected from the group consisting of hexaaluminates, cerates, perovskites, and other mixed metal oxides that are able to adsorb and dissociate molecular oxygen. The membrane adsorbs and dissociates molecular oxygen into highly active atomic oxygen and allows oxygen anions to diffuse through the membrane, to provide high local concentration of oxygen to deter formation and deposition of carbon on reformer walls. Embodiments of the membrane also have catalytic activity for reforming a hydrocarbon fuel to synthesis gas. Also disclosed are a reformer having an inner wall containing the new membrane, and a process of reforming a hydrocarbon feed, such as a high sulfur-containing diesel fuel, to produce synthesis gas, suitable for use in fuel cells.

Owner:ELTRON RES

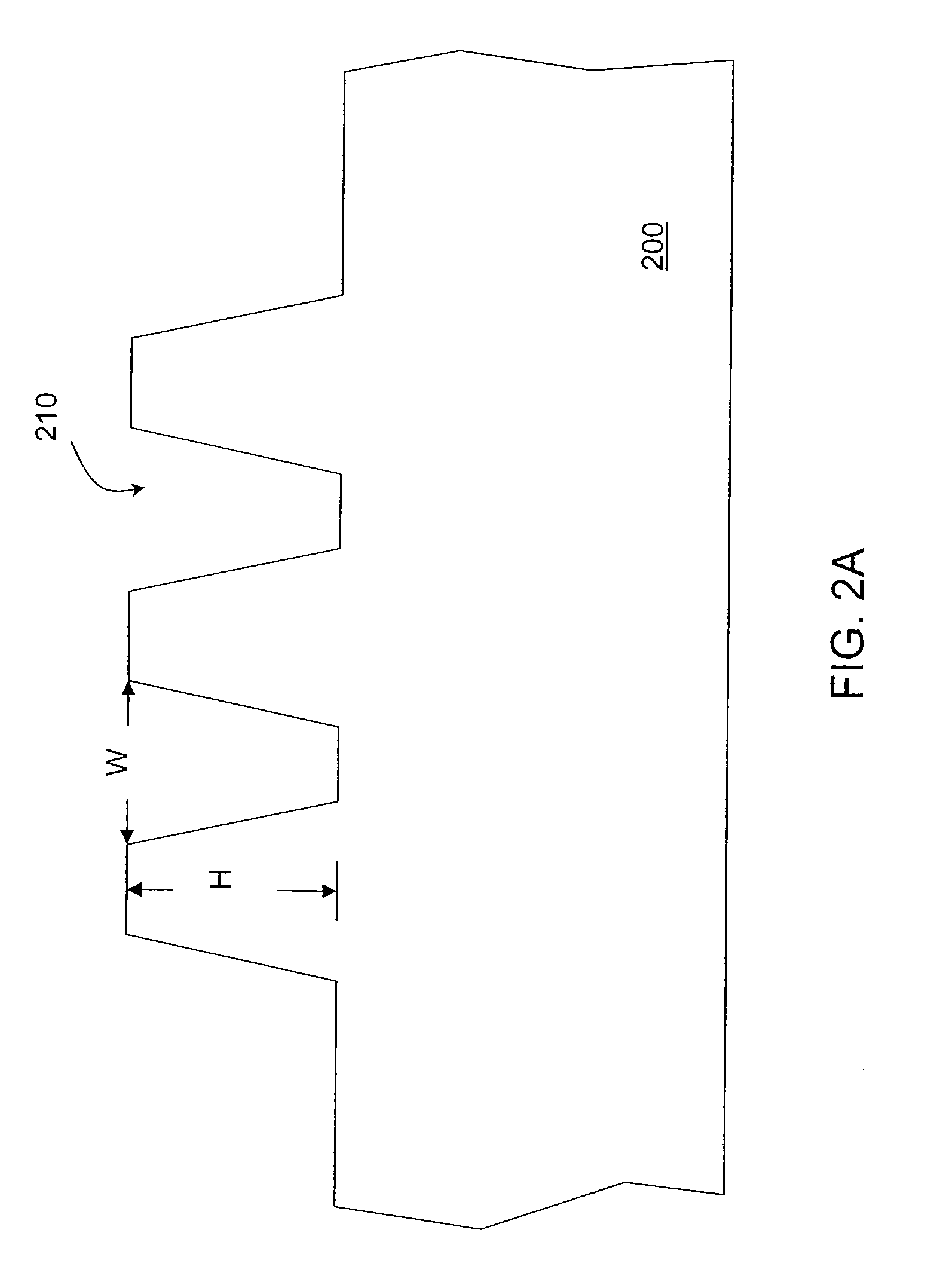

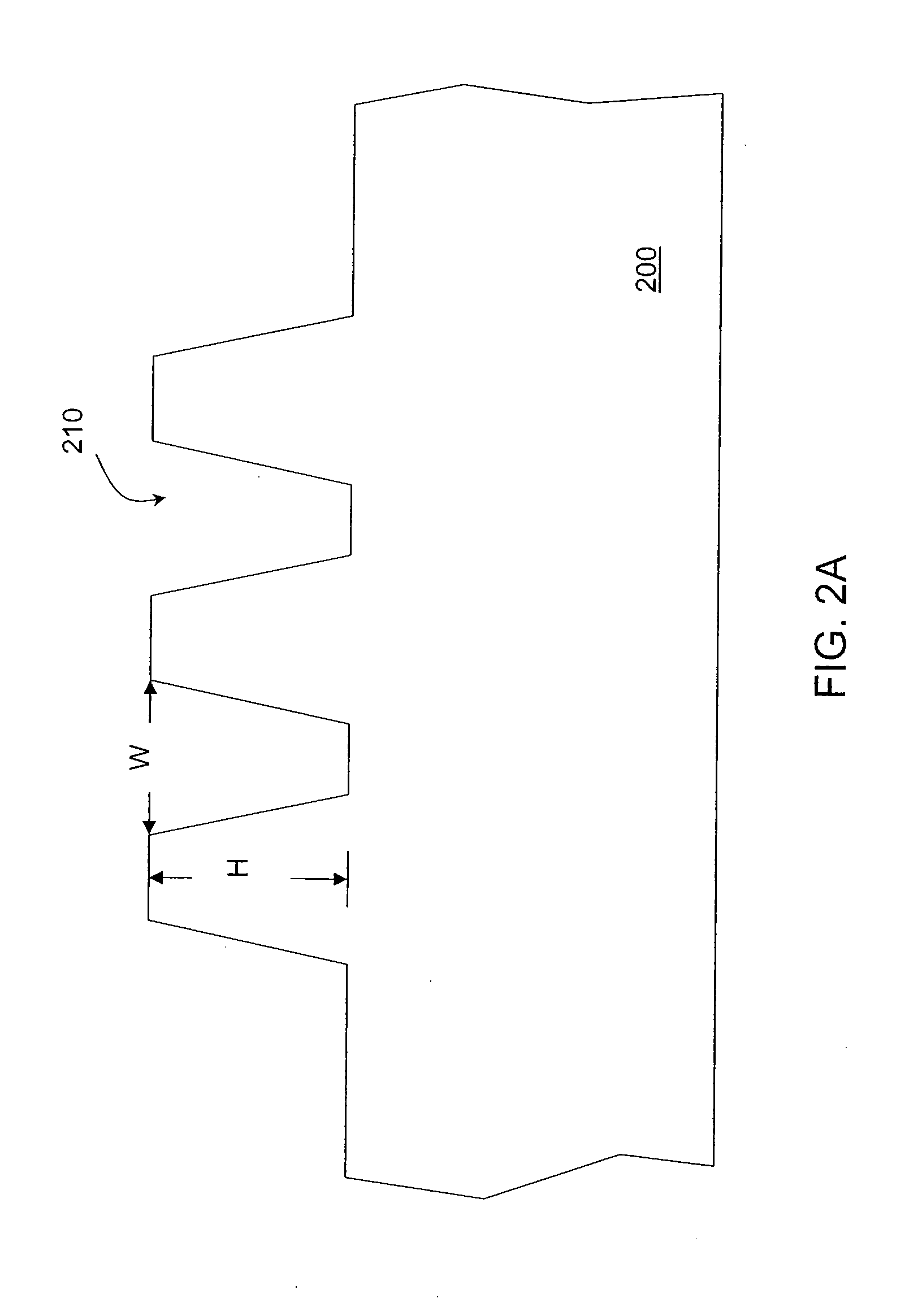

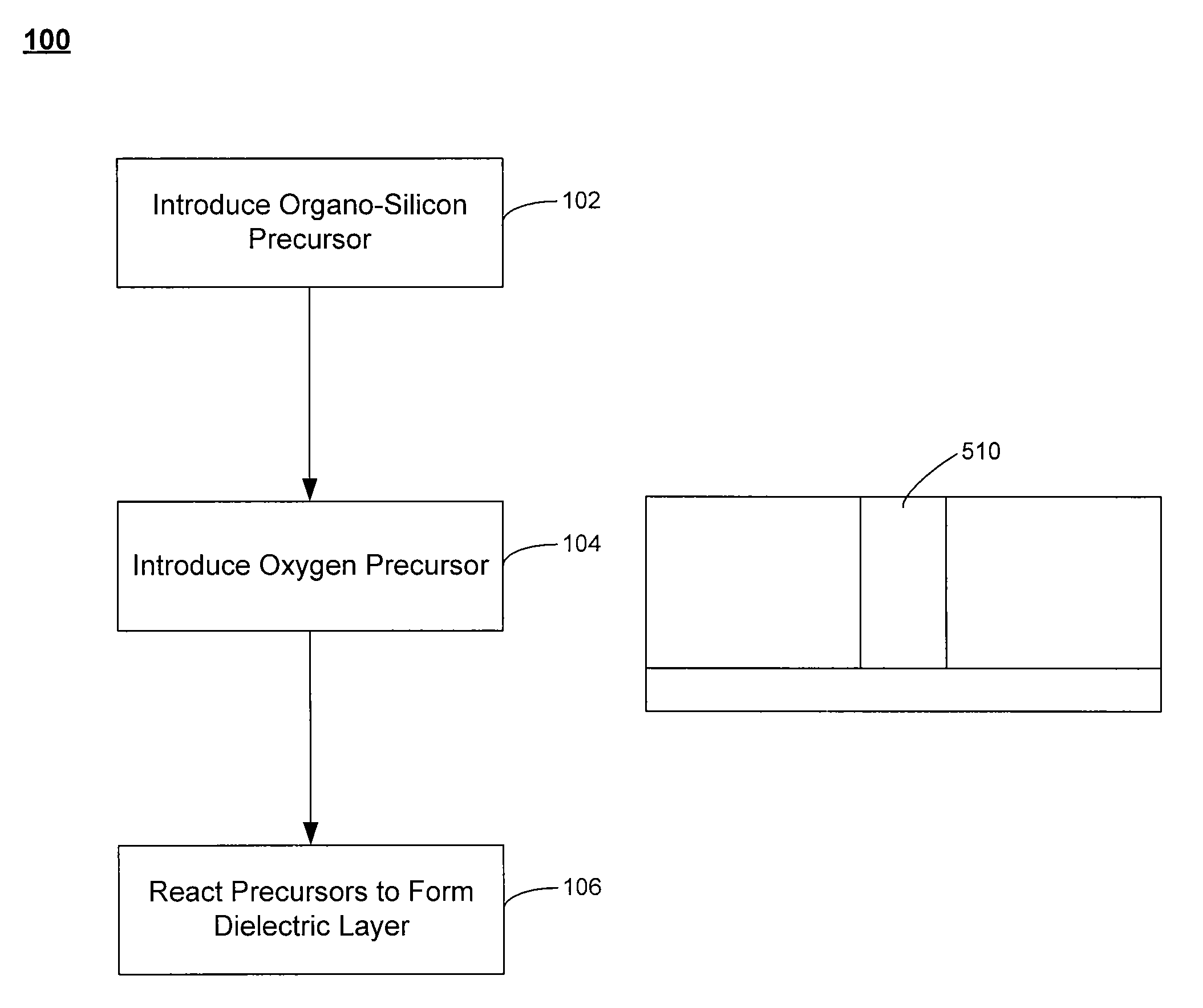

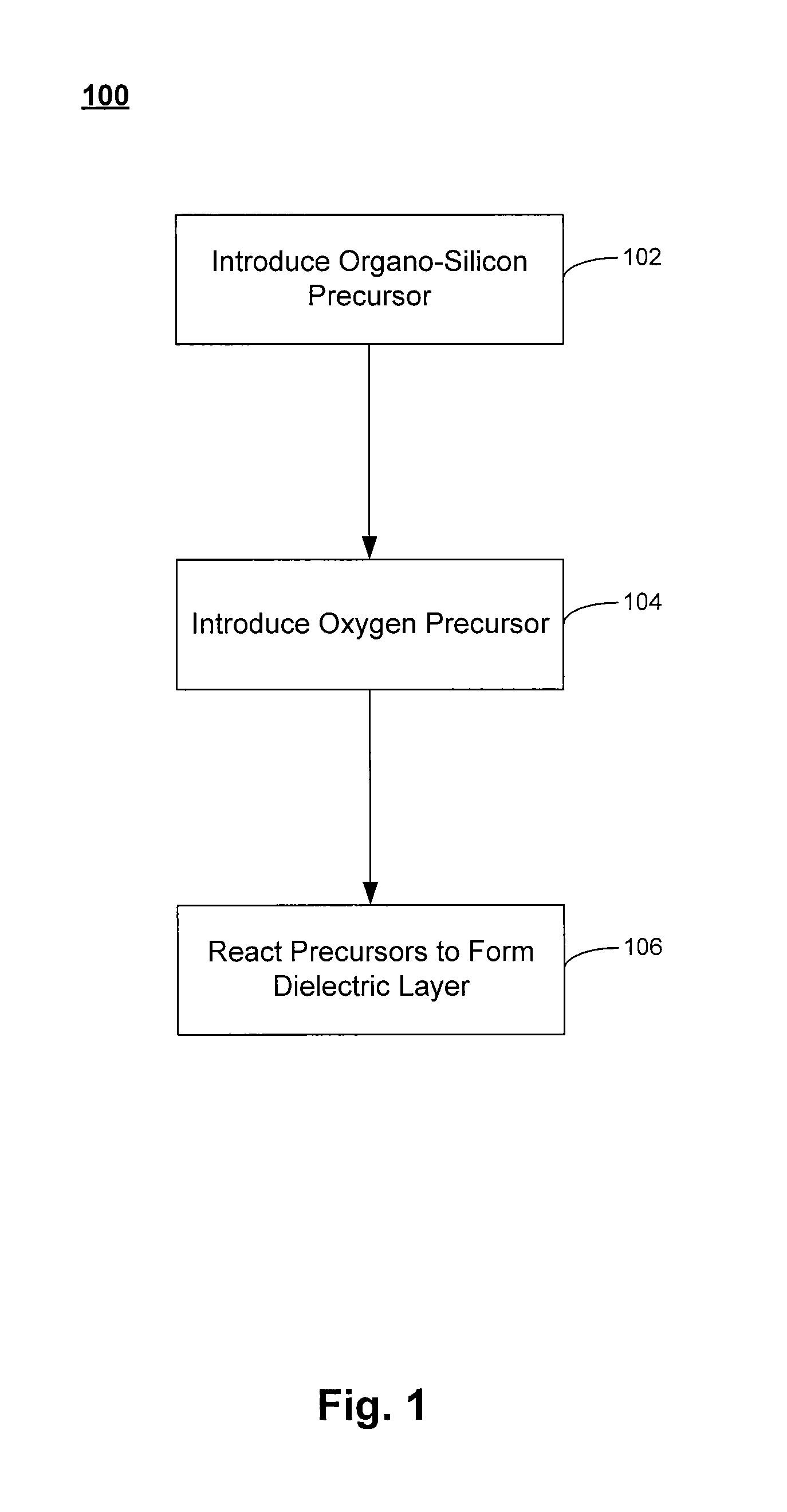

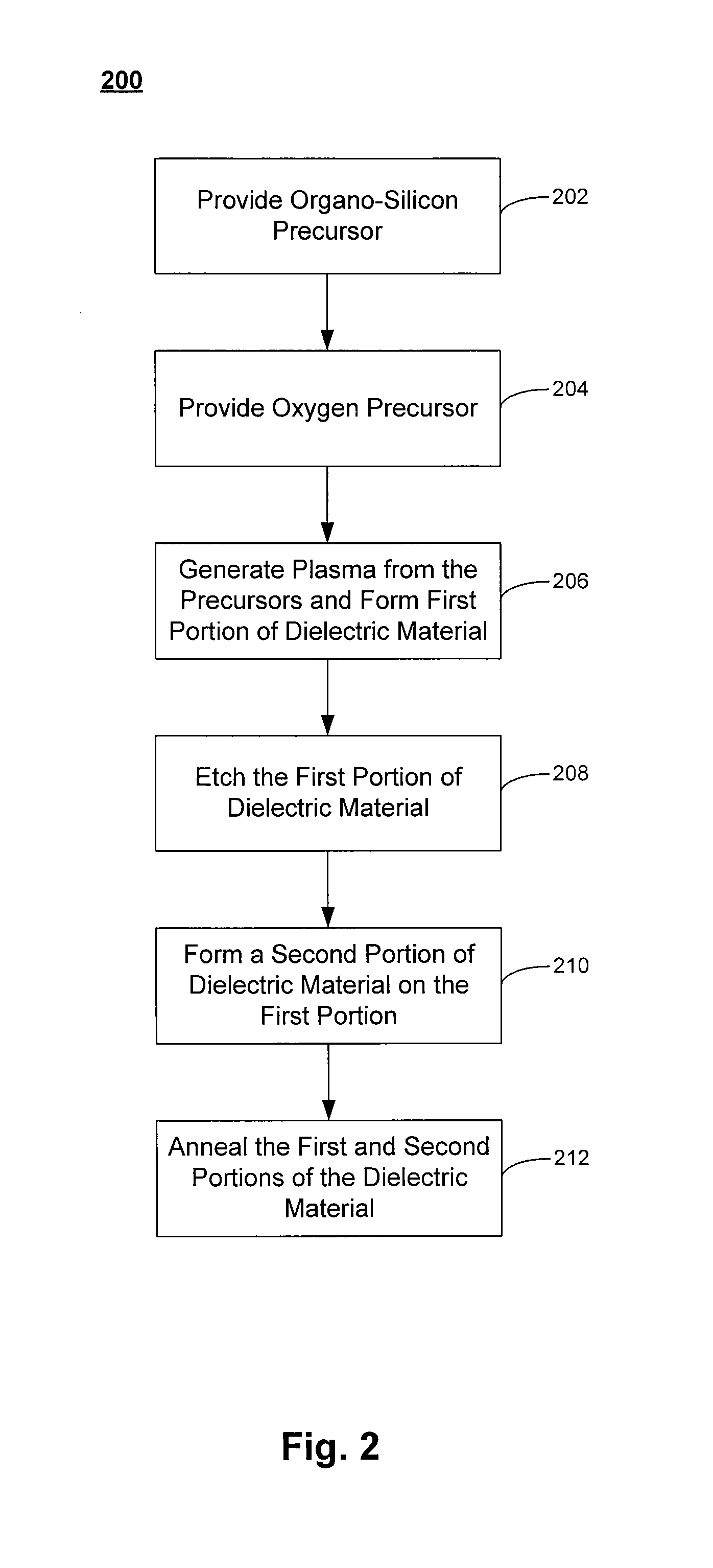

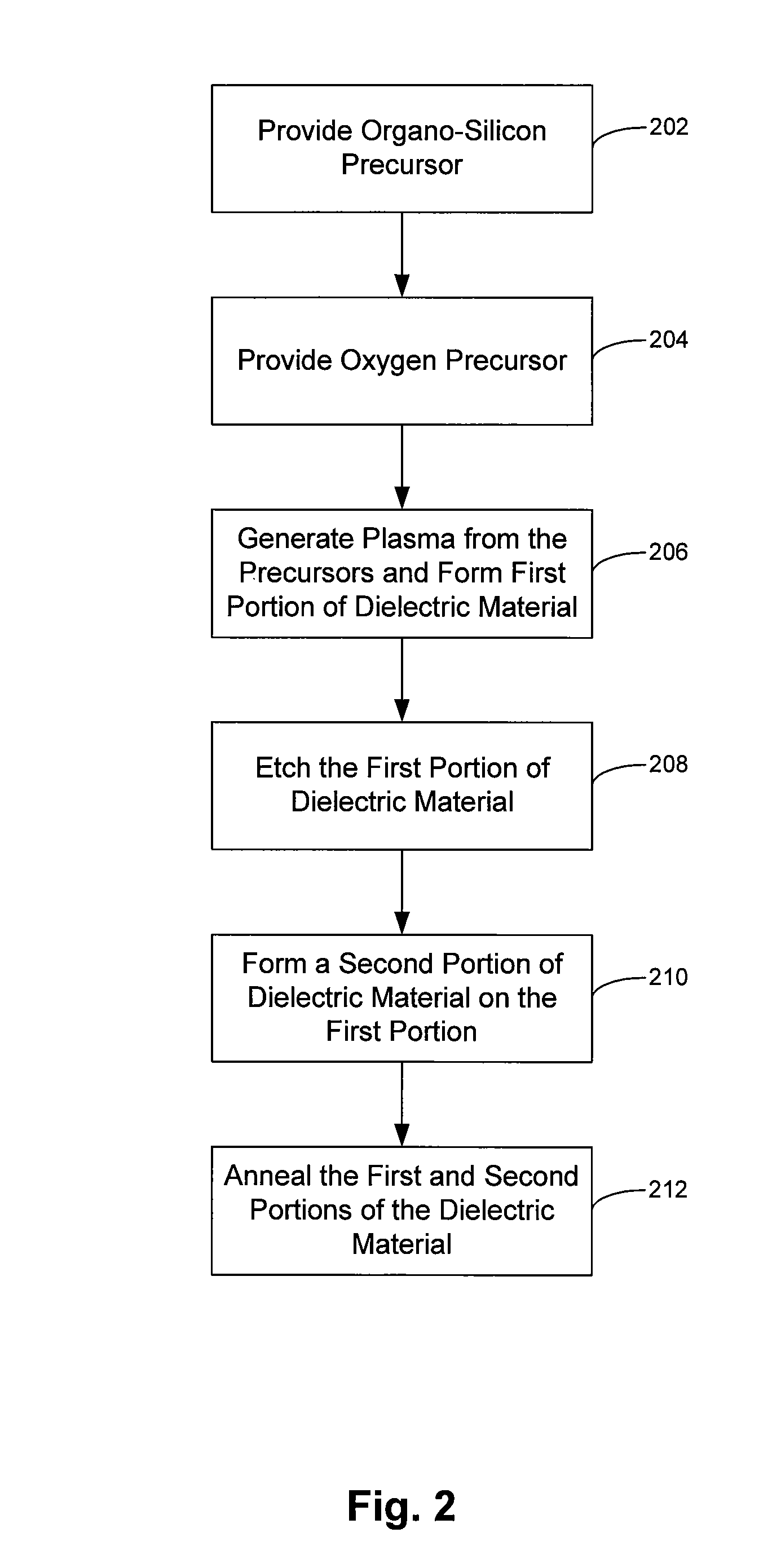

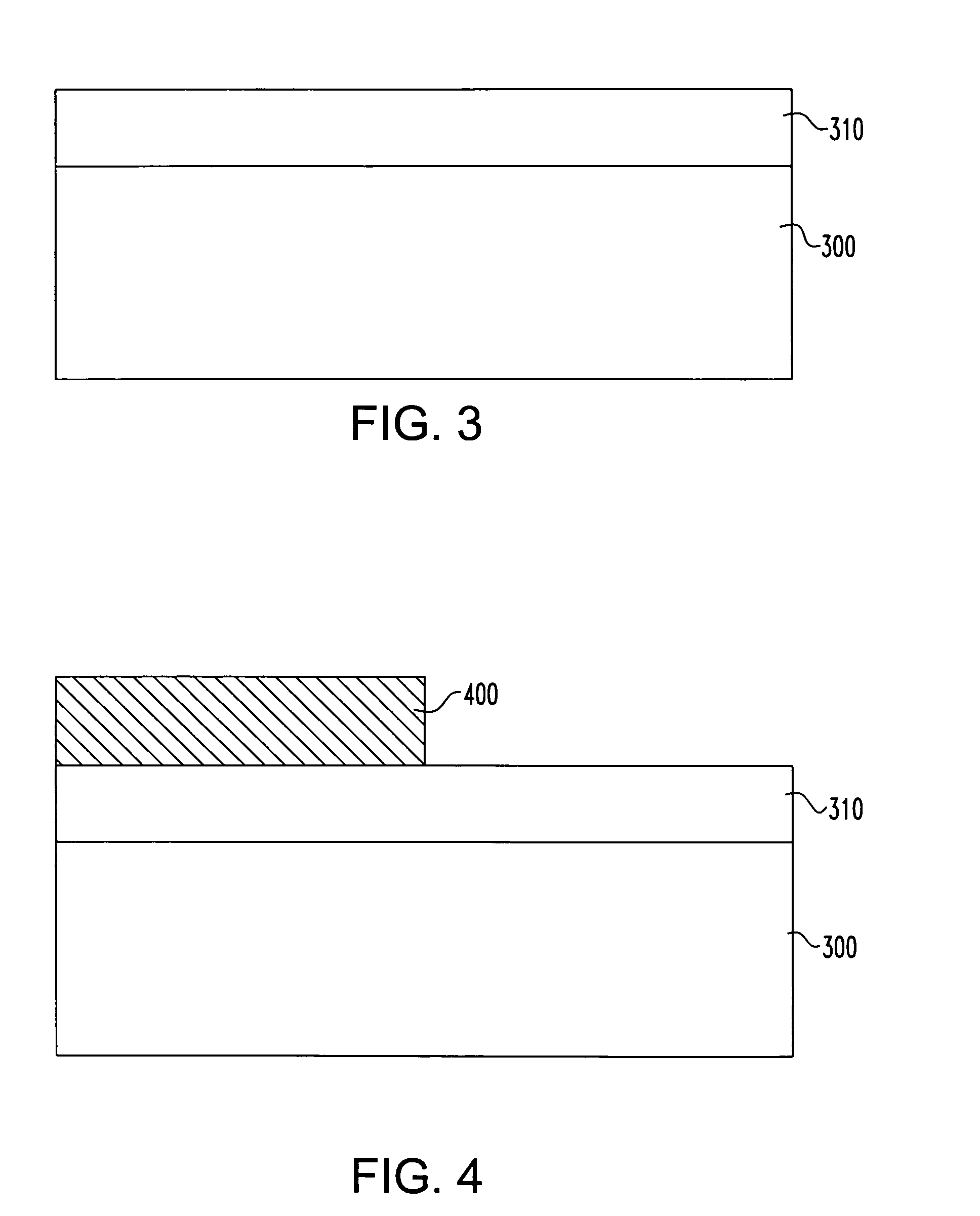

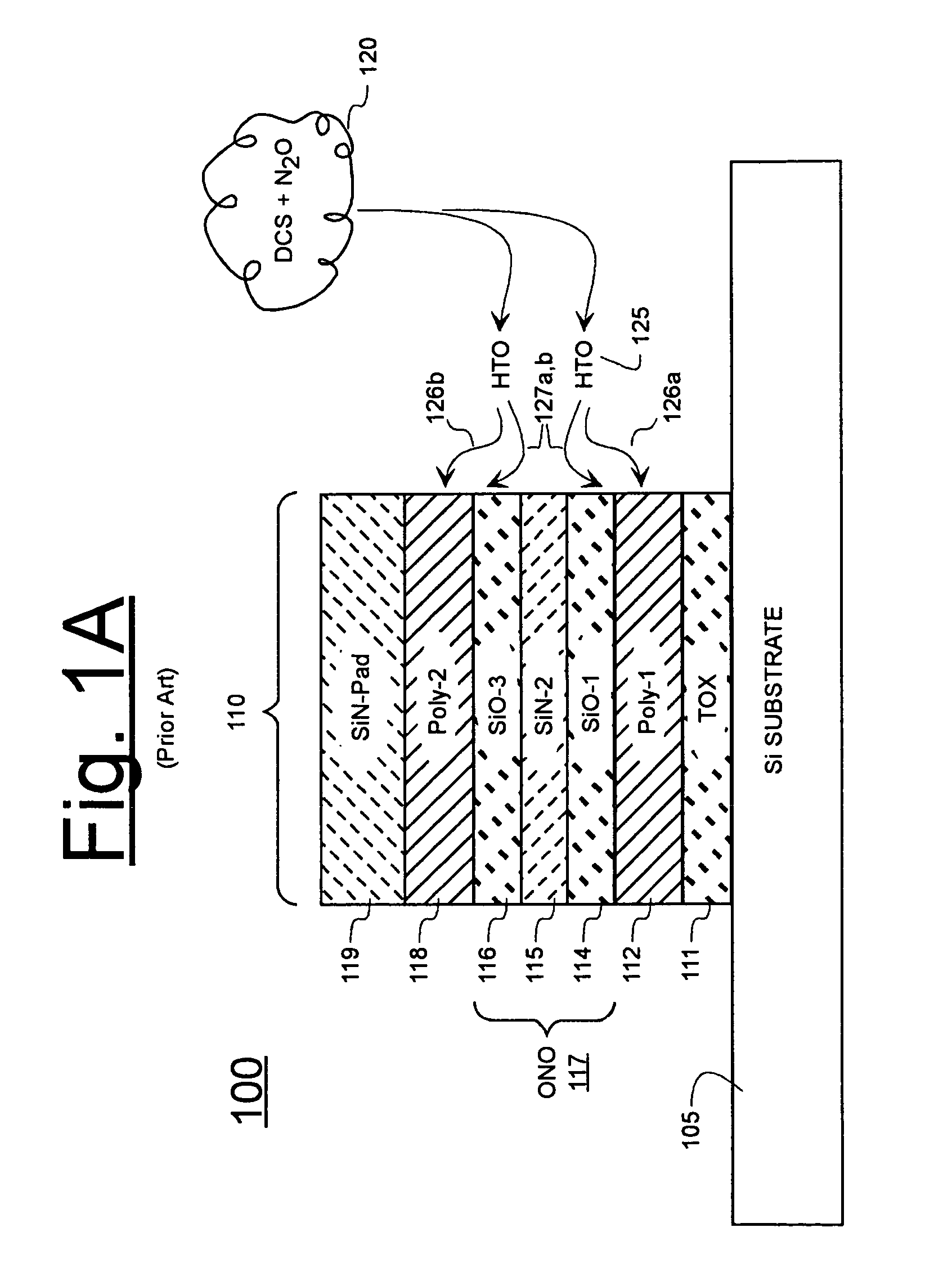

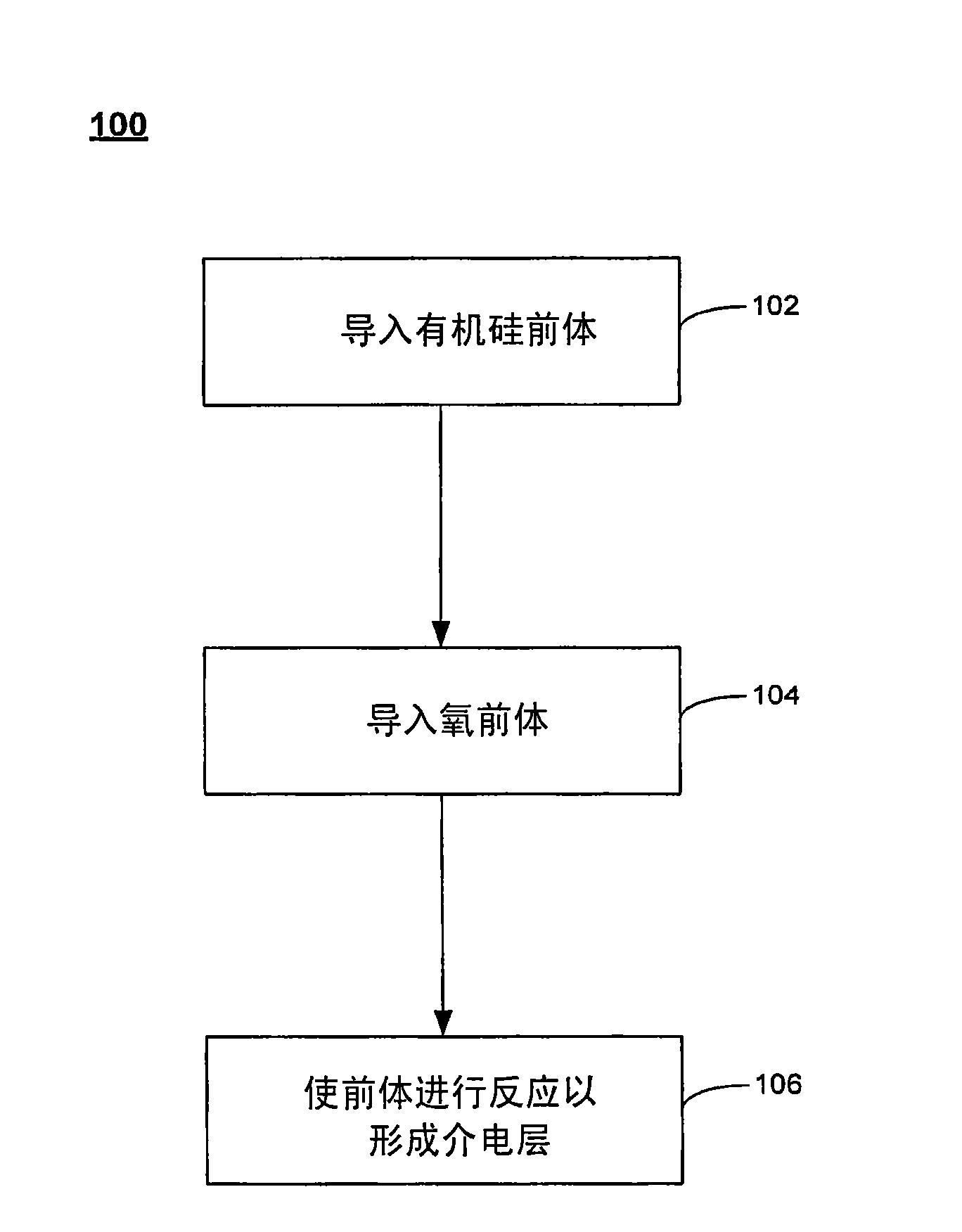

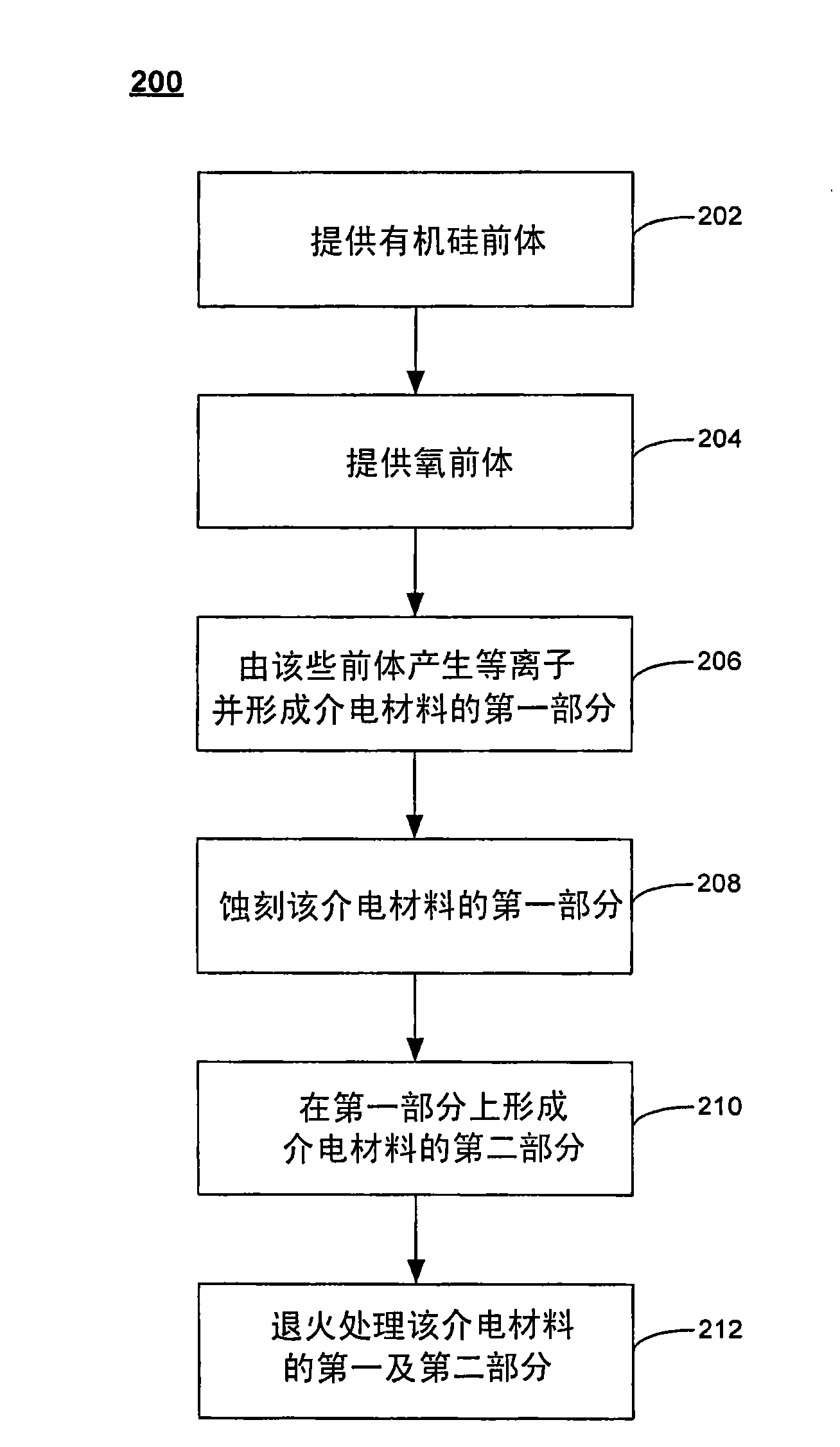

Formation of high quality dielectric films of silicon dioxide for STI: usage of different siloxane-based precursors for harp II-remote plasma enhanced deposition processes

ActiveUS7498273B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingRemote plasmaDeposition process

Methods of depositing a dielectric layer in a gap formed on a substrate are described. The methods include introducing an organo-silicon precursor and an oxygen precursor to a deposition chamber. The organo-silicon precursor has a C:Si atom ratio of less than 8, and the oxygen precursor comprises atomic oxygen that is generated outside the deposition chamber. The precursors are reacted to form the dielectric layer in the gap. Methods of filling gaps with dielectric materials are also described. These methods include providing an organo-silicon precursor having a C:Si atom ratio of less than 8 and an oxygen precursor, and generating a plasma from the precursors to deposit a first portion of the dielectric material in the gap. The dielectric material may be etched, and a second portion of dielectric material may be formed in the gap. The first and second portions of the dielectric material may be annealed.

Owner:APPLIED MATERIALS INC

Formation of high quality dielectric films of silicon dioxide for sti: usage of different siloxane-based precursors for harp ii - remote plasma enhanced deposition processes

ActiveUS20070281495A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingRemote plasmaDeposition process

Methods of depositing a dielectric layer in a gap formed on a substrate are described. The methods include introducing an organo-silicon precursor and an oxygen precursor to a deposition chamber. The organo-silicon precursor has a C:Si atom ratio of less than 8, and the oxygen precursor comprises atomic oxygen that is generated outside the deposition chamber. The precursors are reacted to form the dielectric layer in the gap. Methods of filling gaps with dielectric materials are also described. These methods include providing an organo-silicon precursor having a C:Si atom ratio of less than 8 and an oxygen precursor, and generating a plasma from the precursors to deposit a first portion of the dielectric material in the gap. The dielectric material may be etched, and a second portion of dielectric material may be formed in the gap. The first and second portions of the dielectric material may be annealed.

Owner:APPLIED MATERIALS INC

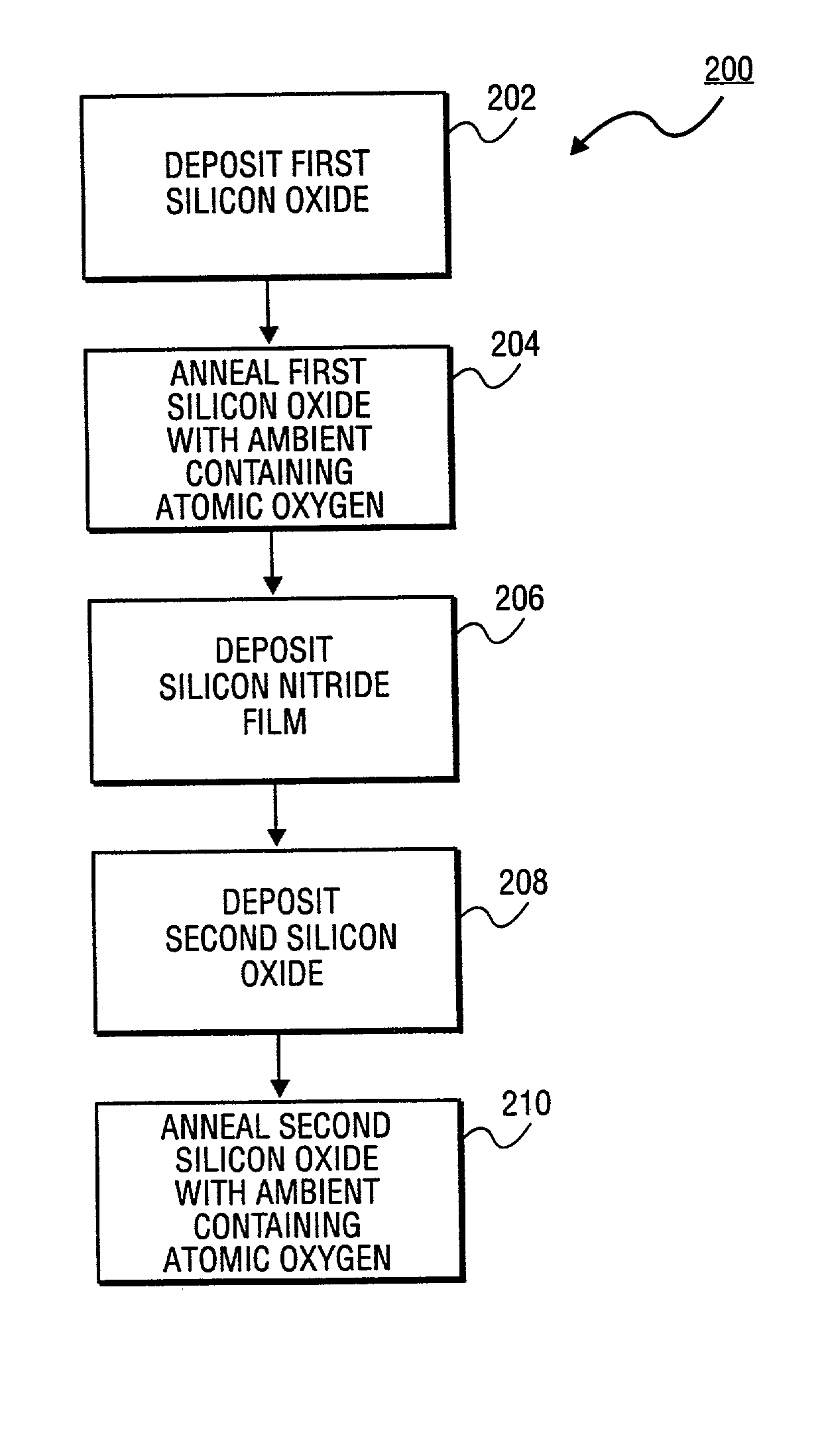

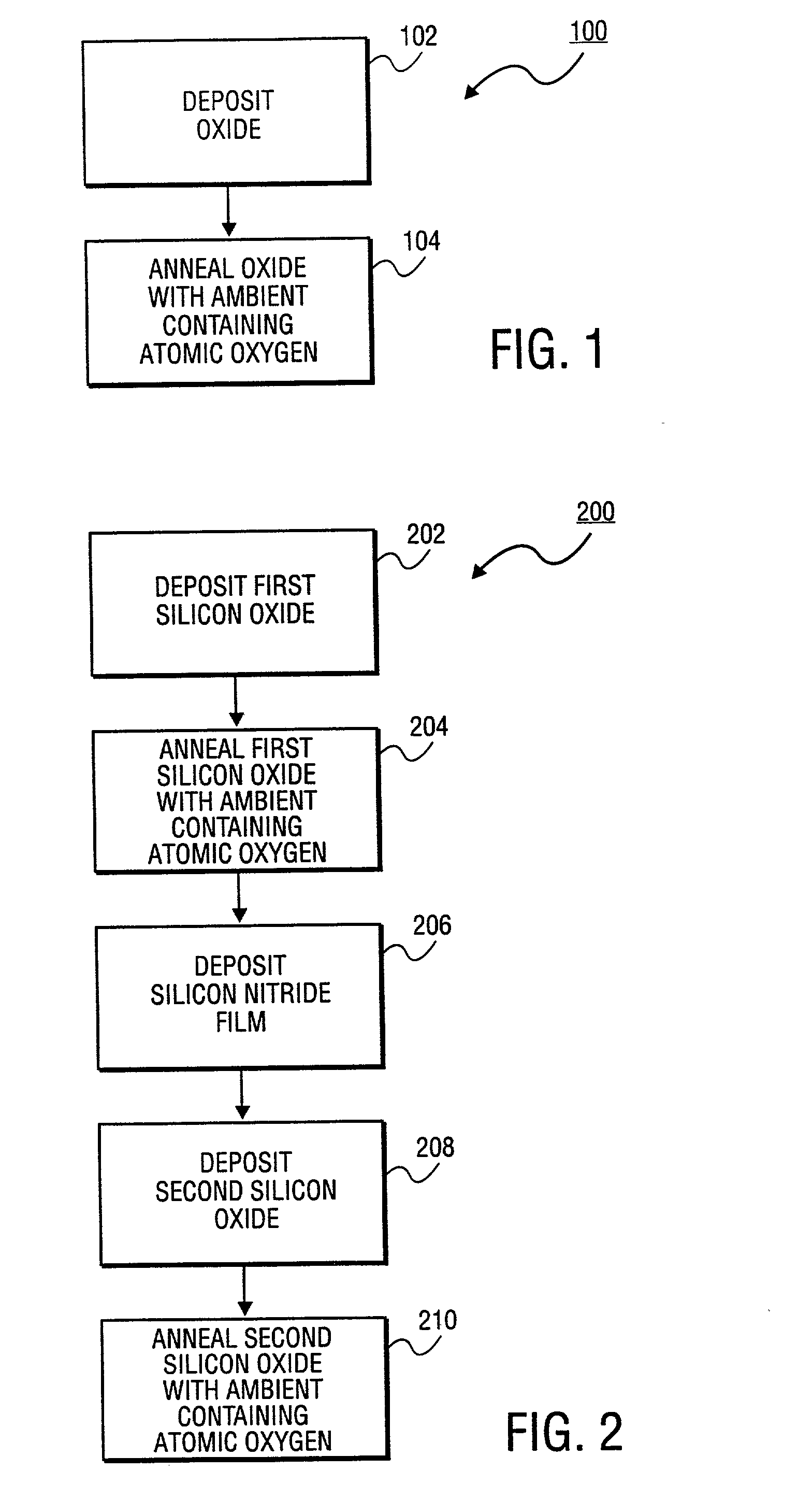

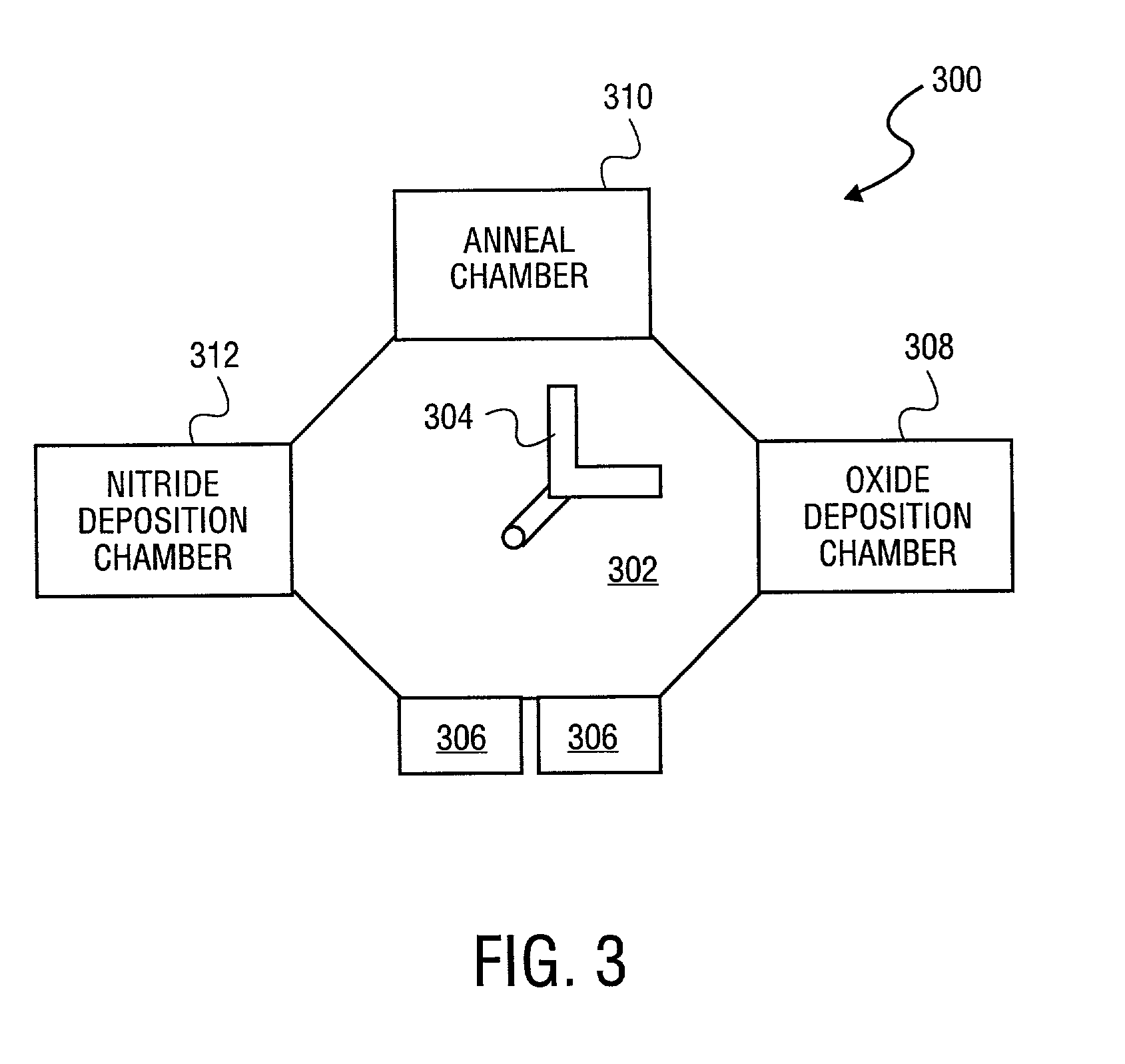

Method of annealing an oxide film

InactiveUS20030124873A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingHydrogenPhysical chemistry

The present invention is a method of annealing an oxide film. According to the present invention, an oxide film is deposited over a substrate. The oxide film is then annealed by exposing the oxide film to an ambient containing atomic oxygen for a predetermined period of time. In an embodiment of the present invention, the ambient containing atomic oxygen (O) is formed in the chamber by reacting a hydrogen containing gas and an oxygen containing gas together. In another embodiment of the present invention, the ambient containing atomic oxygen (O) is formed by decomposing N2O.

Owner:APPLIED MATERIALS INC

Chemical vapor deposition of high quality flow-like silicon dioxide using a silicon containing precursor and atomic oxygen

InactiveUS20090031953A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingGas phaseSilicon oxide

Methods of depositing a silicon oxide layer on a substrate are described. The methods may include the steps of providing a substrate to a deposition chamber, generating an atomic oxygen precursor outside the deposition chamber, and introducing the atomic oxygen precursor into the chamber. The methods may also include introducing a silicon precursor to the deposition chamber, where the silicon precursor and the atomic oxygen precursor are first mixed in the chamber. The silicon precursor and the atomic oxygen precursor react to form the silicon oxide layer on the substrate, and the deposited silicon oxide layer may be annealed. Systems to deposit a silicon oxide layer on a substrate are also described.

Owner:APPLIED MATERIALS INC

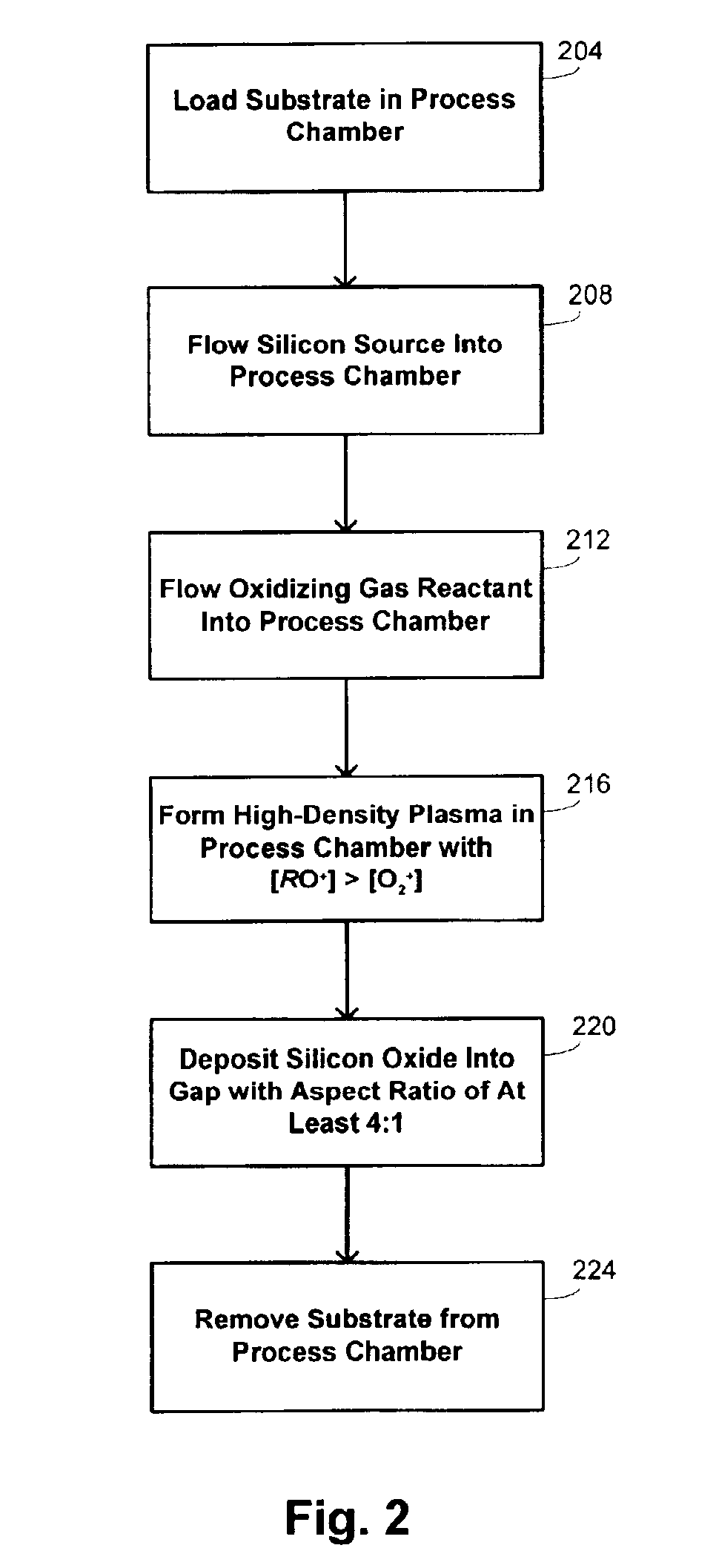

Methods and systems for high-aspect-ratio gapfill using atomic-oxygen generation

InactiveUS6958112B2Improved redeposition characteristicReduce the impactVacuum evaporation coatingSemiconductor/solid-state device manufacturingIon densitySilicon oxide

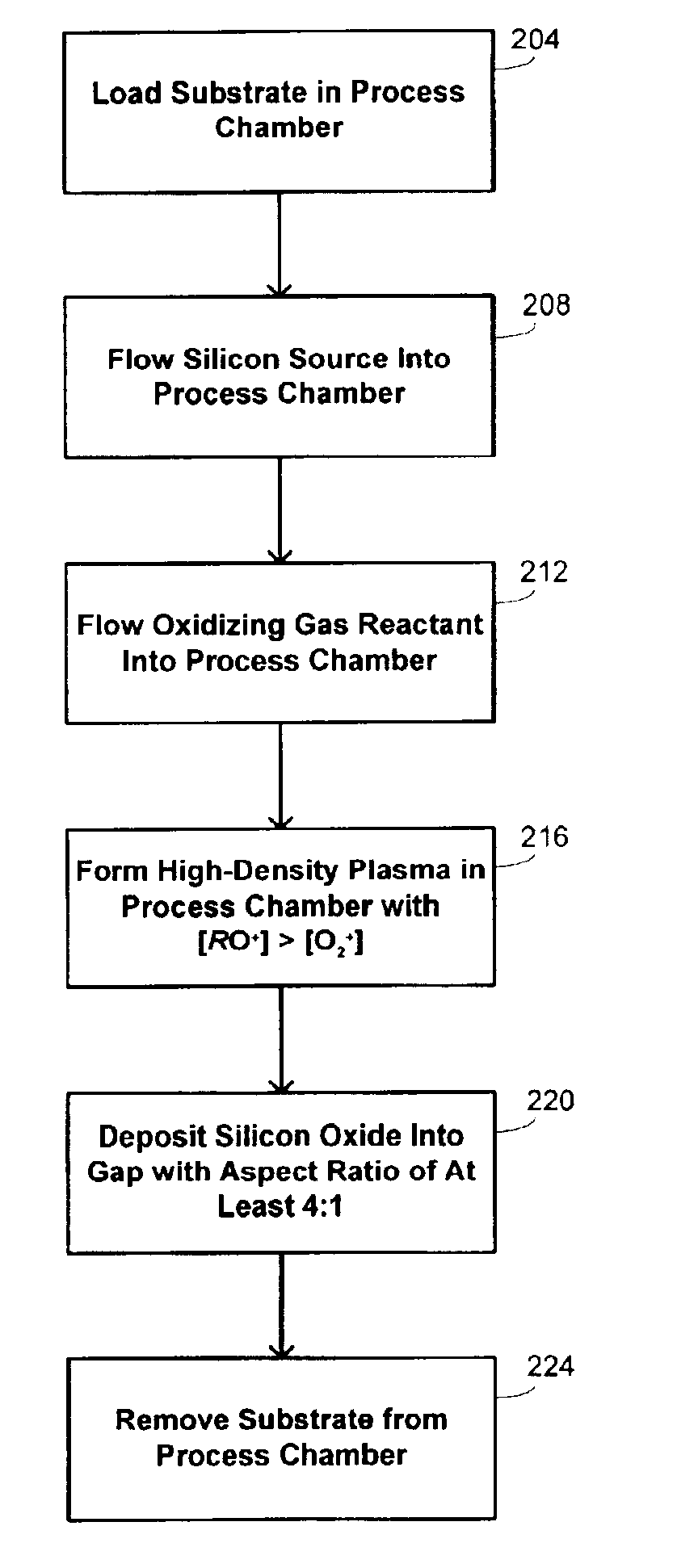

Methods and systems are provided for depositing silicon oxide in a gap on a substrate. The silicon oxide is formed by flowing a process gas into a process chamber and forming a plasma having an overall ion density of at least 1011 ions / cm3. The process gas includes H2, a silicon source, and an oxidizing gas reactant, and deposition into the gap is achieved using a process that has simultaneous deposition and sputtering components. The probability of forming a void is reduced by ensuring that the plasma has a greater density of ions having a single oxygen atom than a density of ions having more than one oxygen atom.

Owner:APPLIED MATERIALS INC

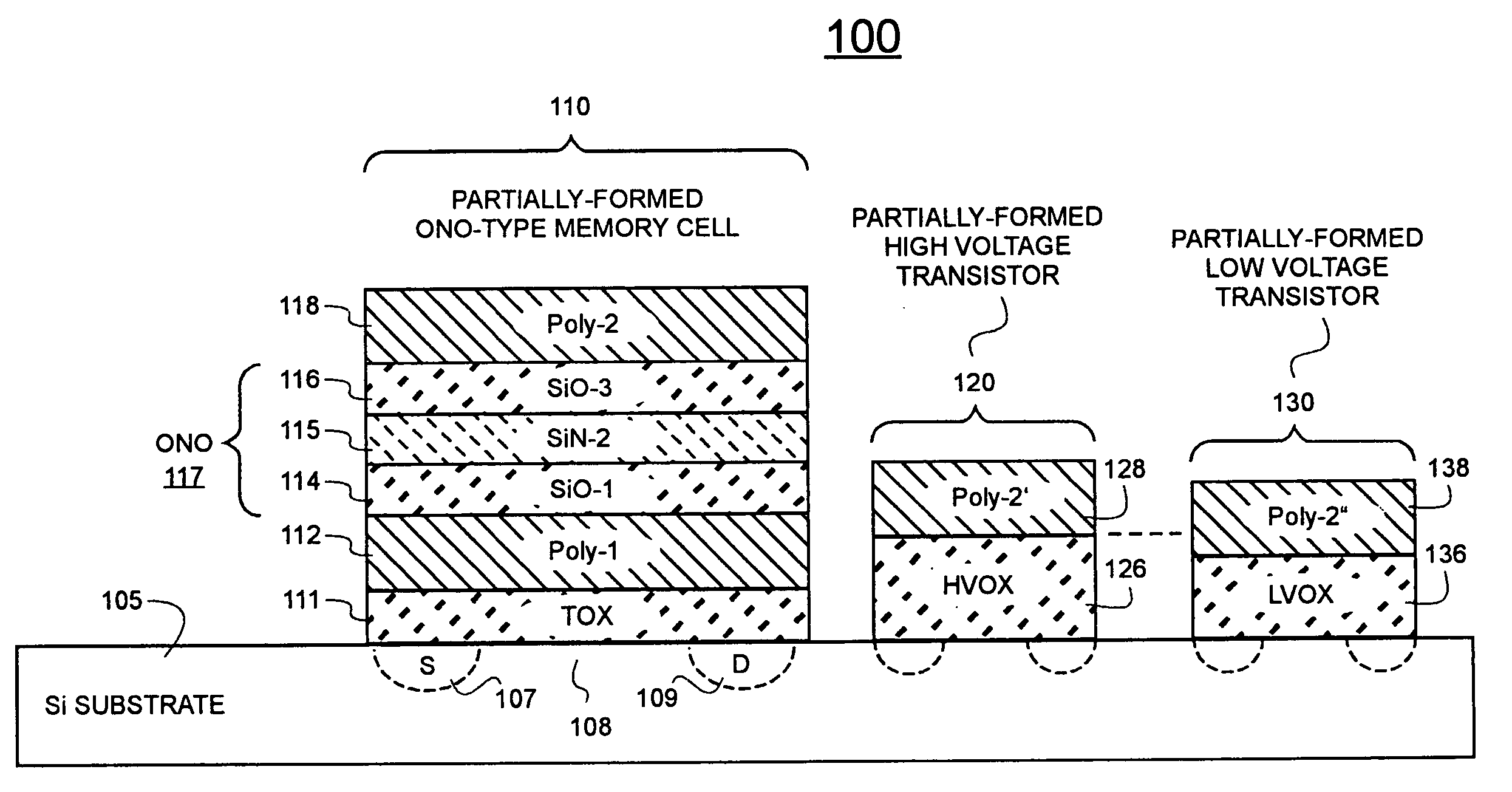

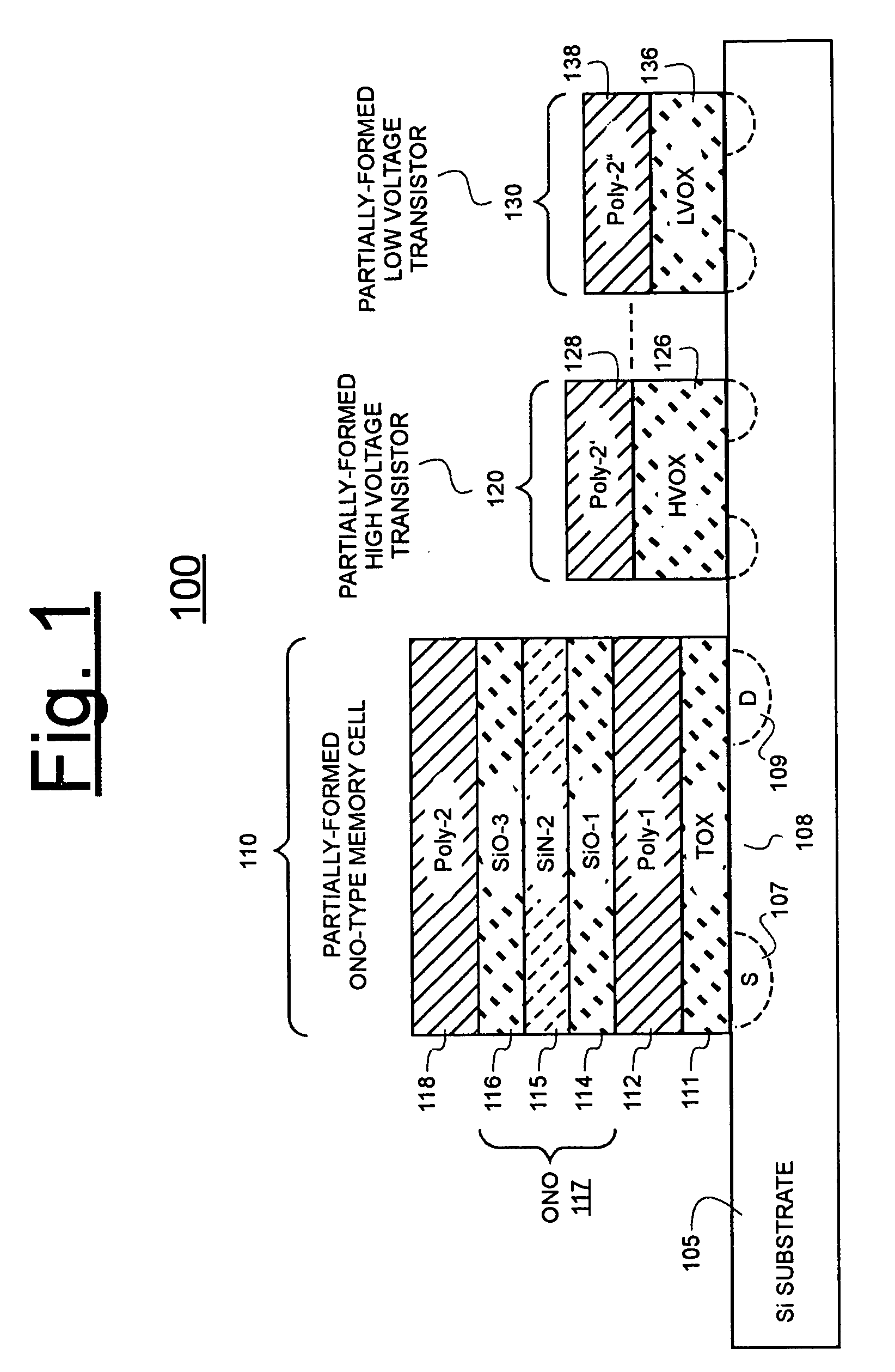

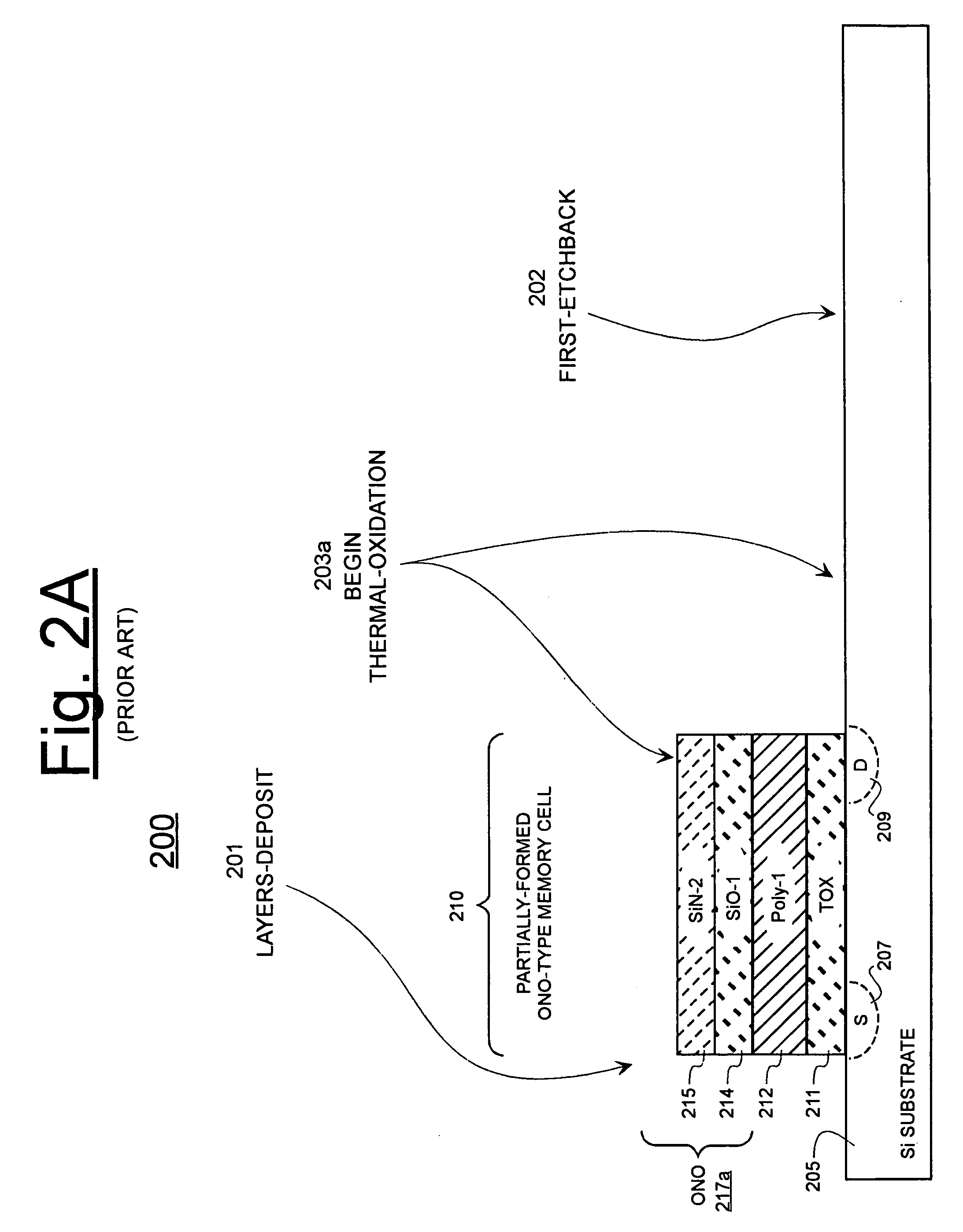

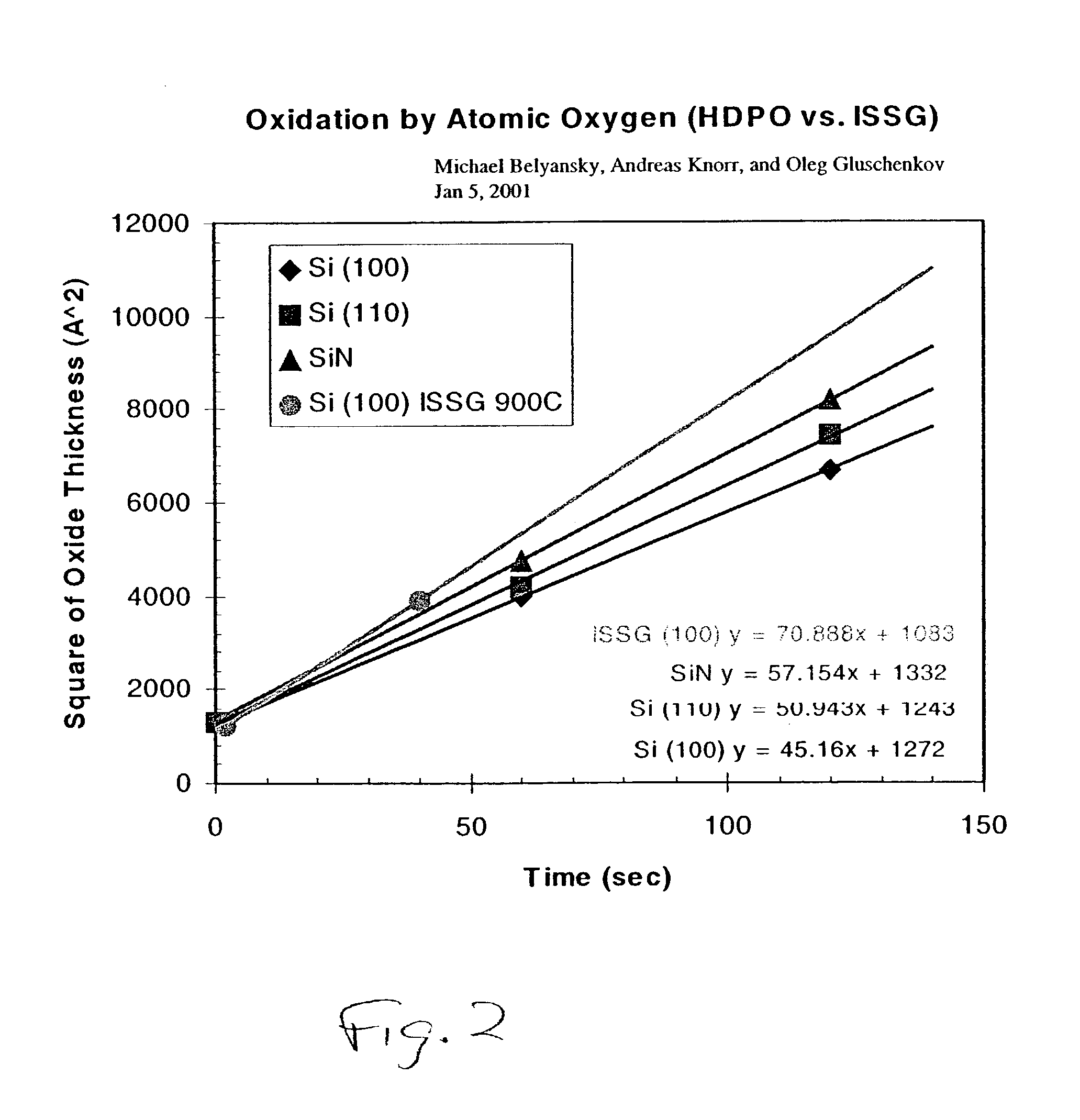

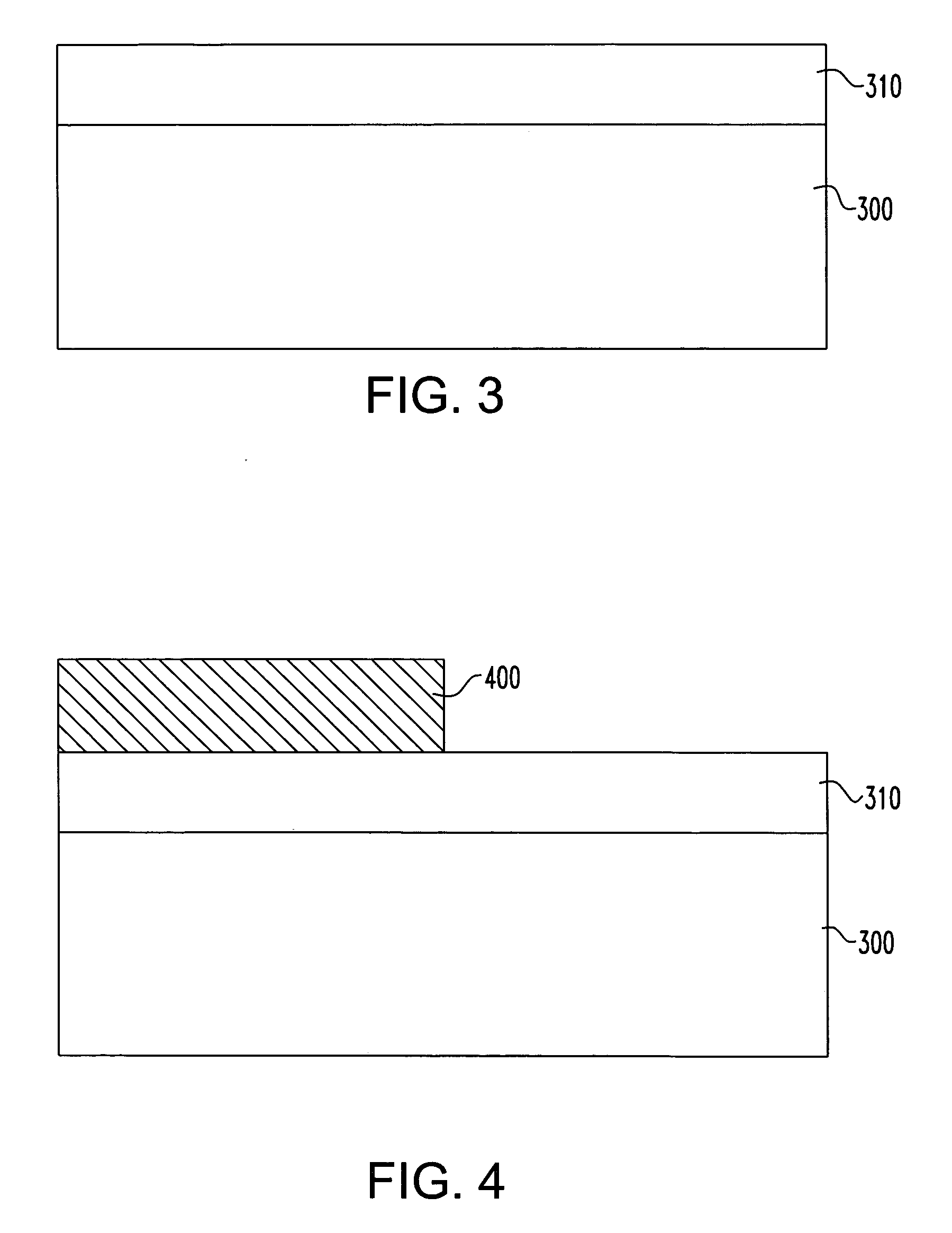

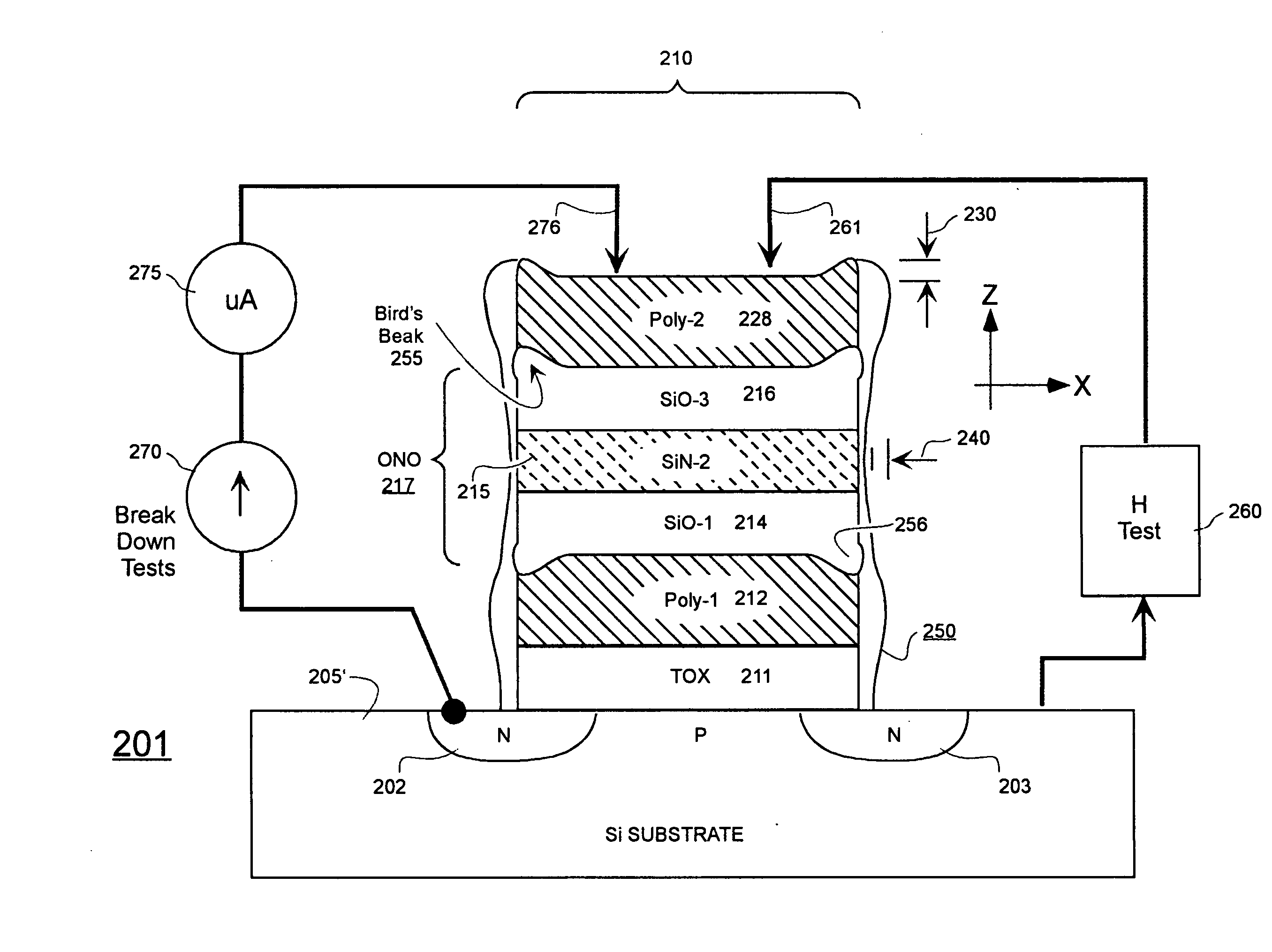

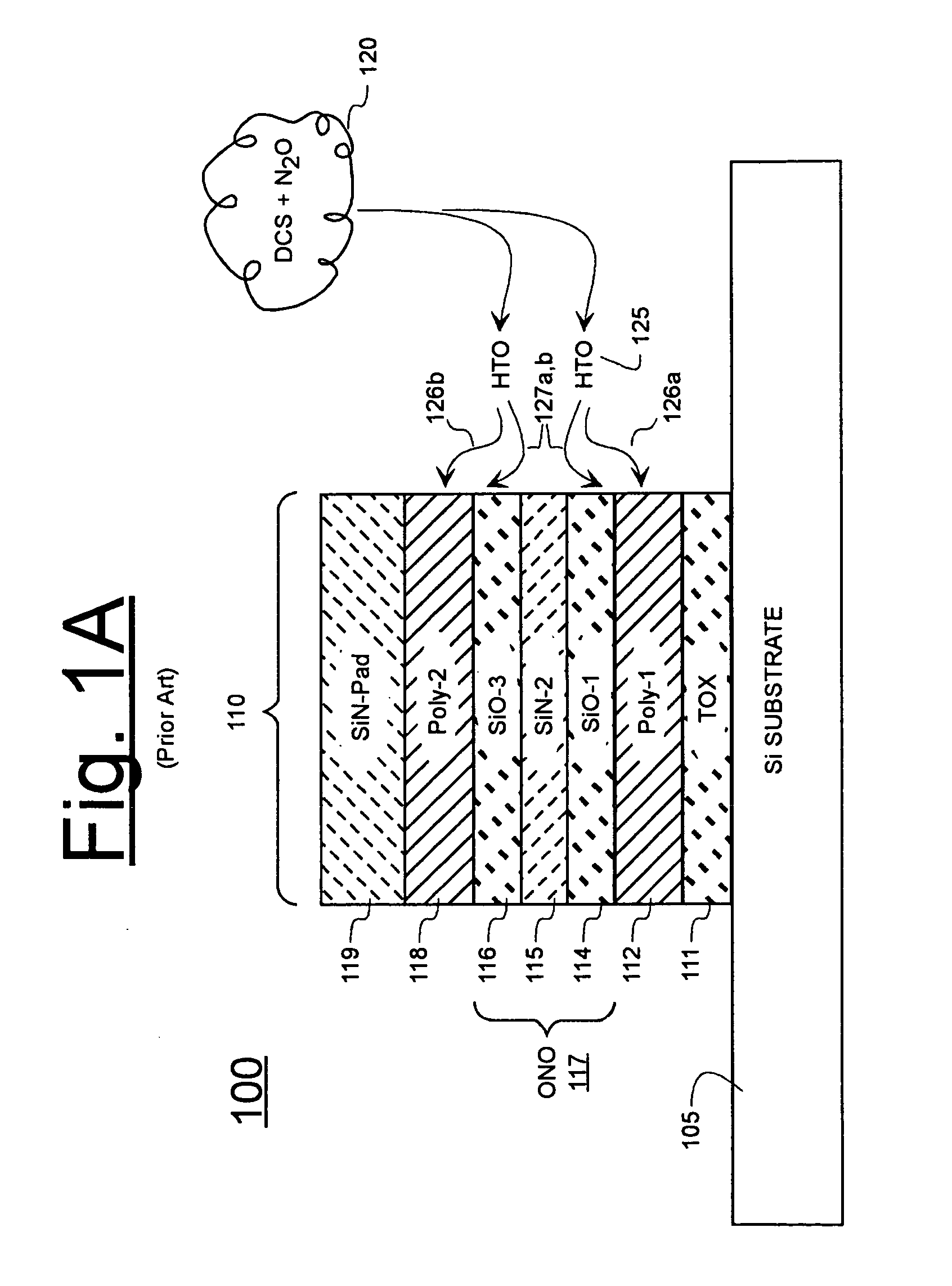

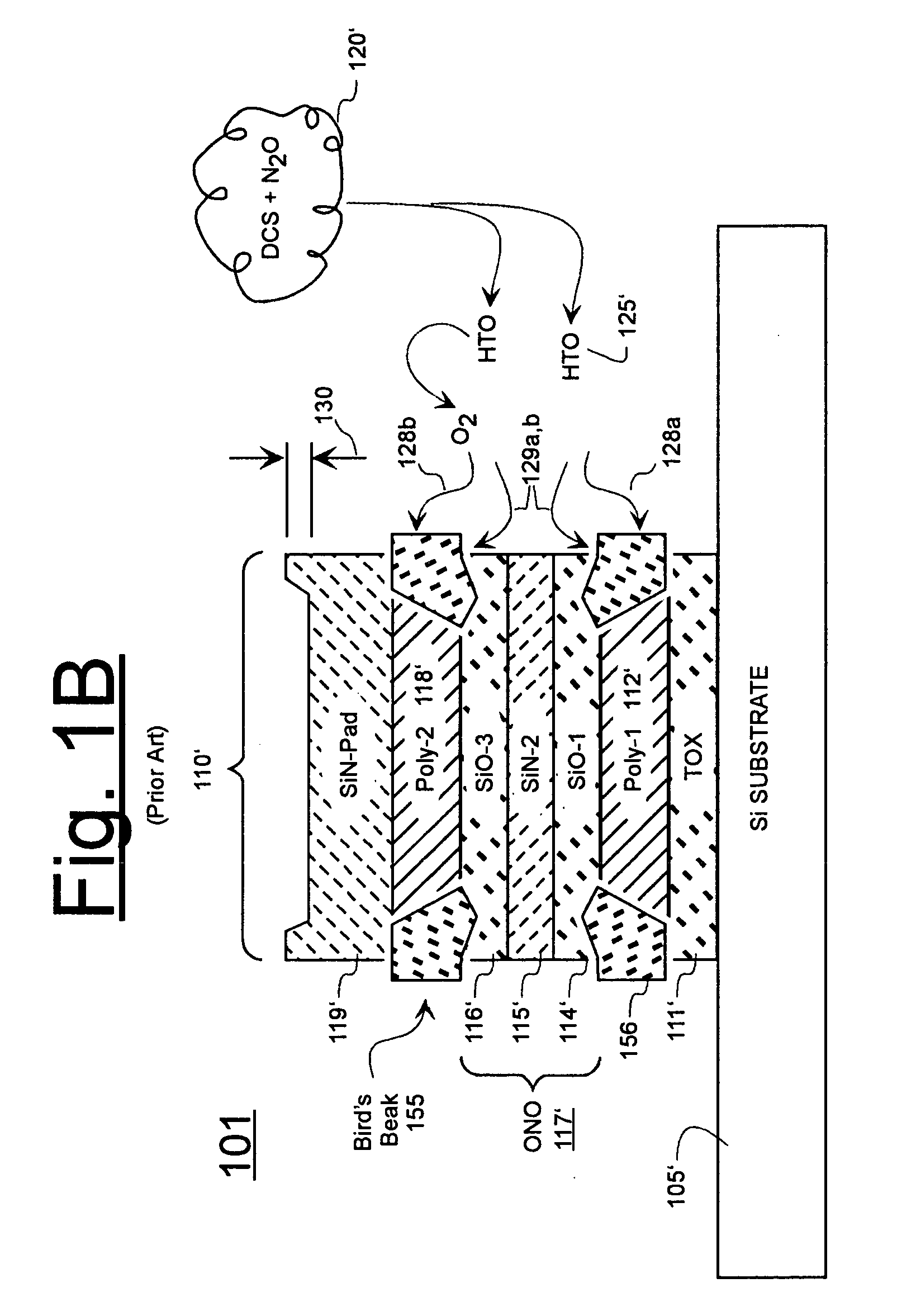

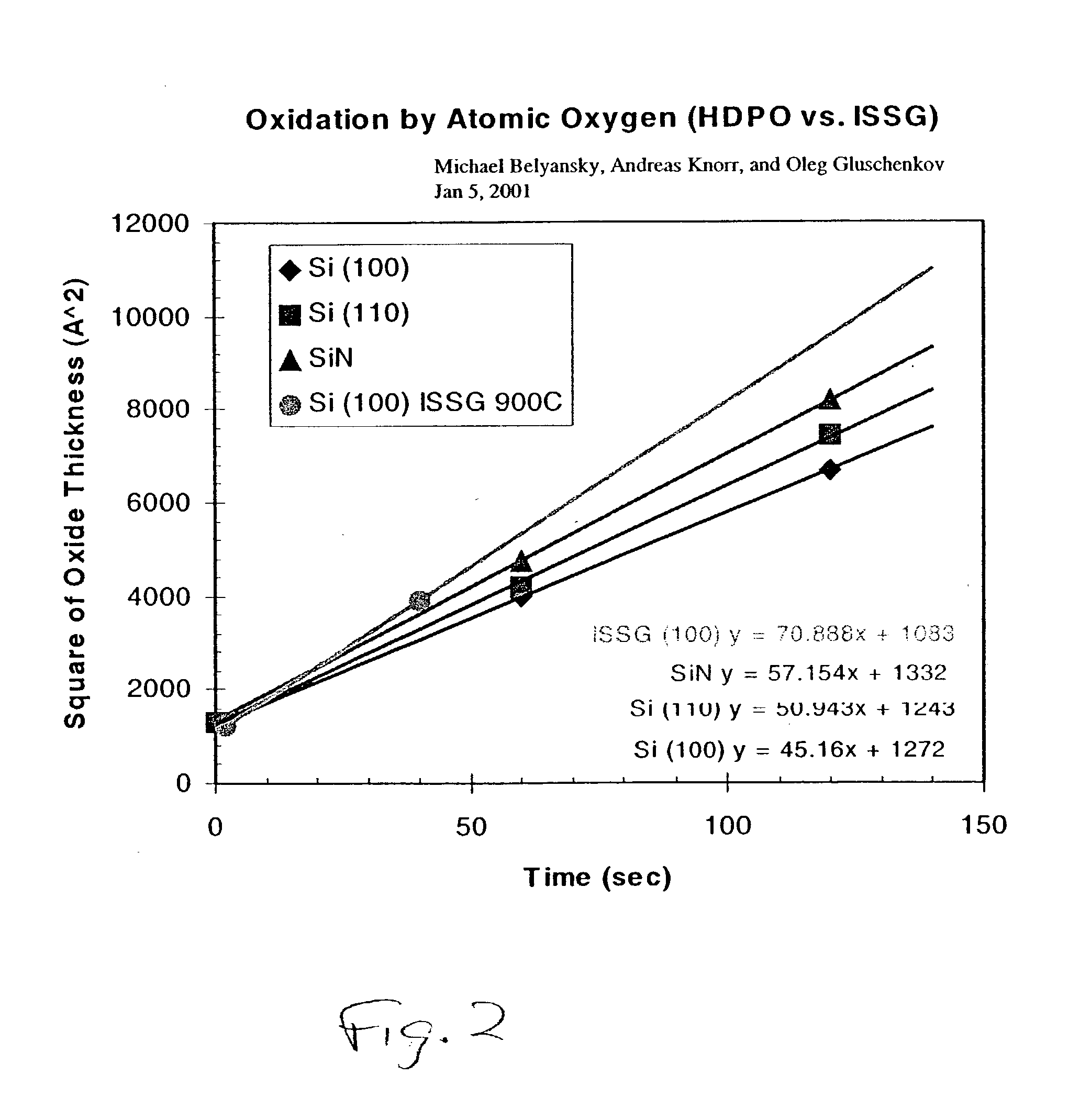

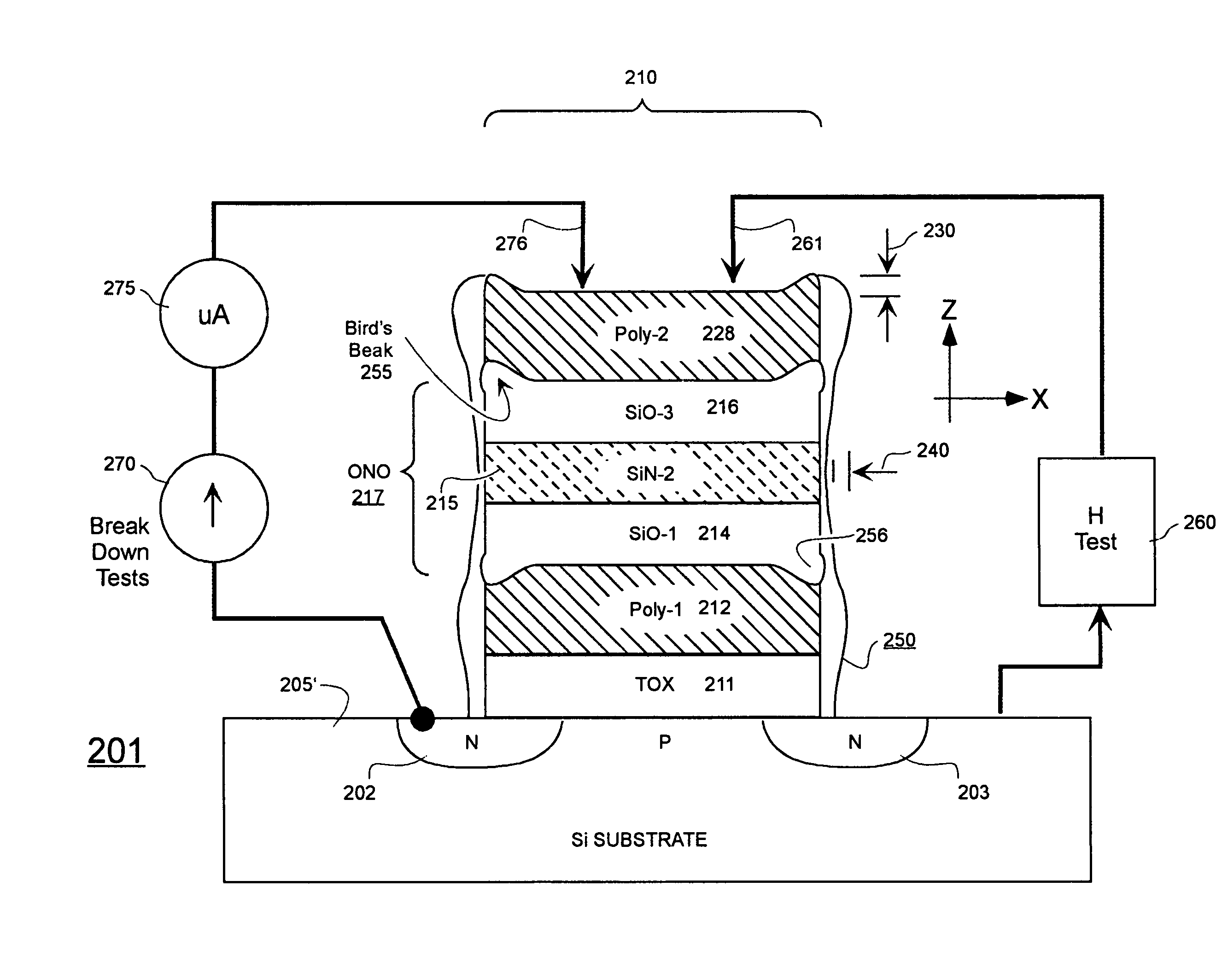

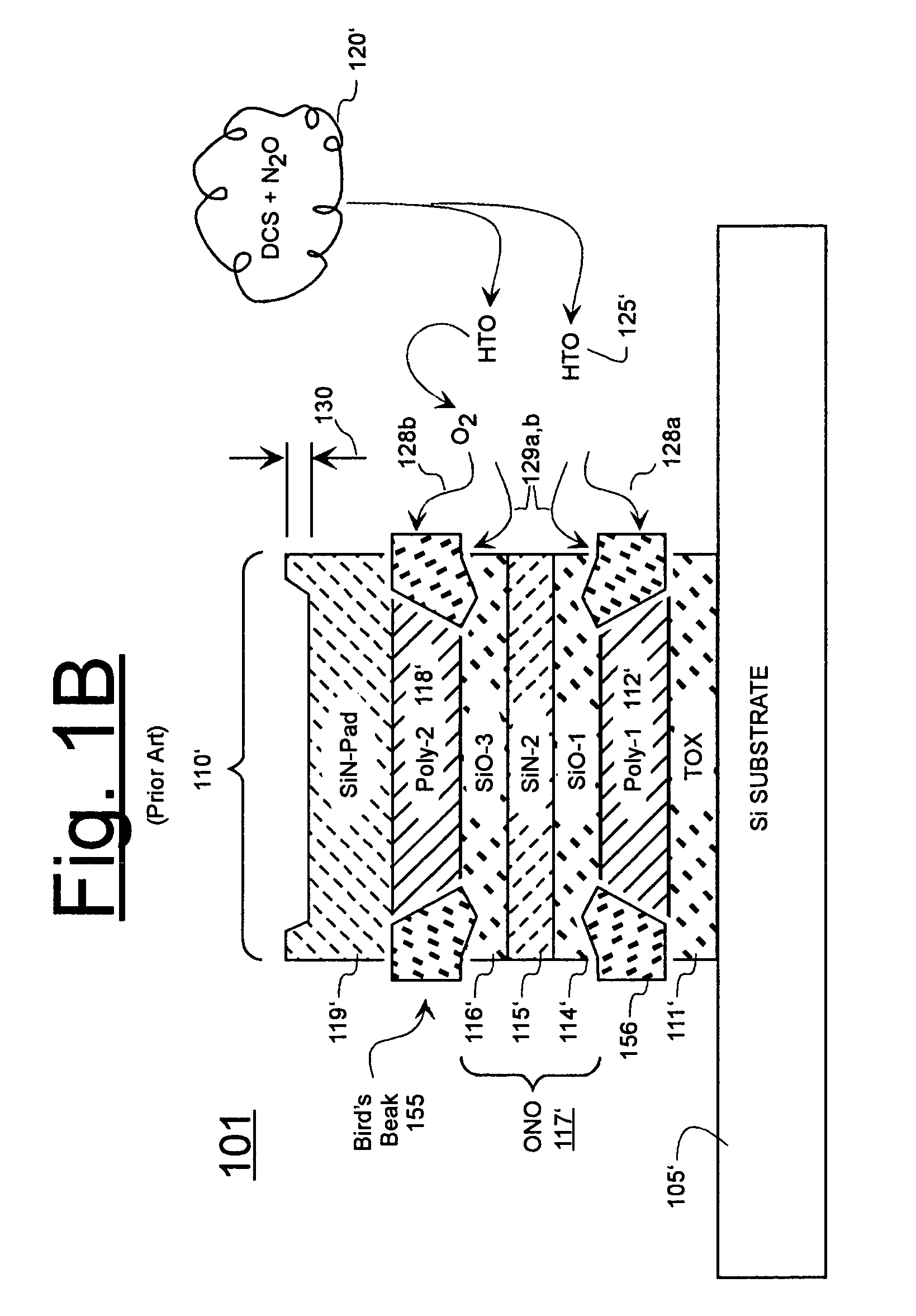

Method for simultaneously fabricating ONO-type memory cell, and gate dielectrics for associated high voltage write transistors and gate dielectrics for low voltage logic transistors by using ISSG

ActiveUS20060017092A1Solid-state devicesSemiconductor/solid-state device manufacturingDielectricGate dielectric

Conventional fabrication of top oxide in an ONO-type memory cell stack usually produces Bird's Beak. Certain materials in the stack such as silicon nitrides are relatively difficult to oxidize. As a result oxidation does not proceed uniformly along the multi-layered height of the ONO-type stack. The present disclosure shows how radical-based fabrication of top-oxide of an ONO stack (i.e. by ISSG method) can help to reduce formation of Bird's Beak. More specifically, it is indicated that short-lived oxidizing agents (e.g., atomic oxygen) are able to better oxidize difficult to oxidize materials such as silicon nitride and the it is indicated that the short-lived oxidizing agents alternatively or additionally do not diffuse deeply through already oxidized layers of the ONO stack such as the lower silicon oxide layer. As a result, a more uniform top oxide dielectric can be fabricated with more uniform breakdown voltages along its height. Additionally, adjacent low and high voltage transistors may benefit from simultaneous formation of their gate dielectrics with use of the radical-based oxidizing method.

Owner:PROMOS TECH INC

Atmospheric molecular respirator

InactiveUS20100111792A1Purifying substantial volumes of room airRobust methodProductsGas treatmentActivated carbon filtrationAtmospherics

An apparatus for removing contaminants from air, including nitrogen oxides, carbon monoxide, carbon dioxide, and sulphur dioxide. In one of the chambers of a multi-chambered enclosure, polluted inlet air is exposed to one or more first light sources emitting light at wavelengths less than or equal to 242.3 nm to cause dissociation of contaminant molecules, creating ozone plus remaining atoms. The remaining atoms are largely filtered by activated charcoal filters having an appropriate thickness which is sized to achieve suitable dwell times, and which also serves as an oxygen rich medium permitting the ozone generated to undergo atomic rearrangement, whereby ozone molecules (O3) and atomic oxygen atoms (O) form oxygen molecules (O2). In another downstream chamber, the air flow is exposed to one or more second light sources emitting light at wavelengths greater than 242.3 nm but less than 280 nm, causing conversion of remaining ozone into oxygen molecules.

Owner:NELSON EDWARD D

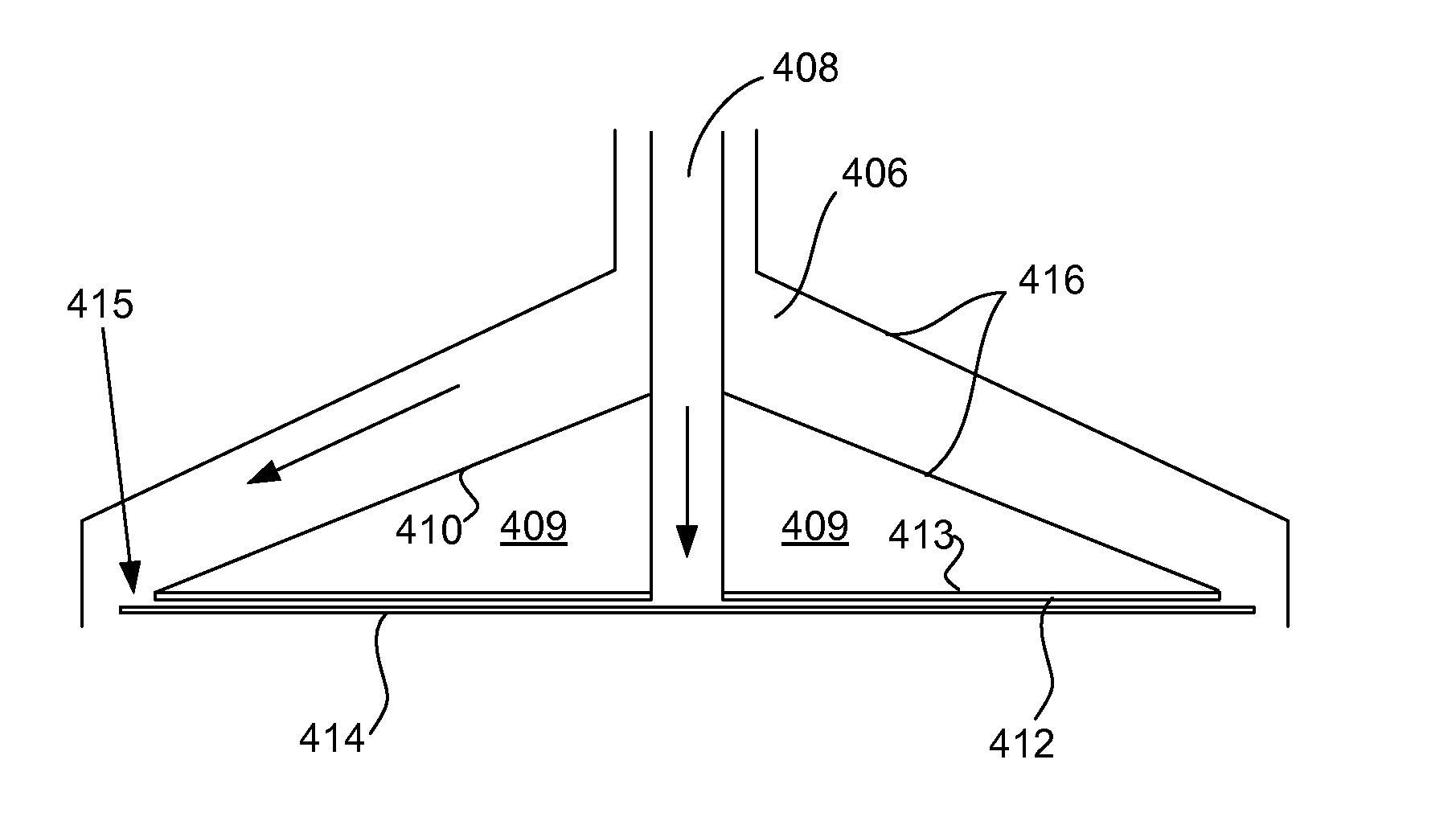

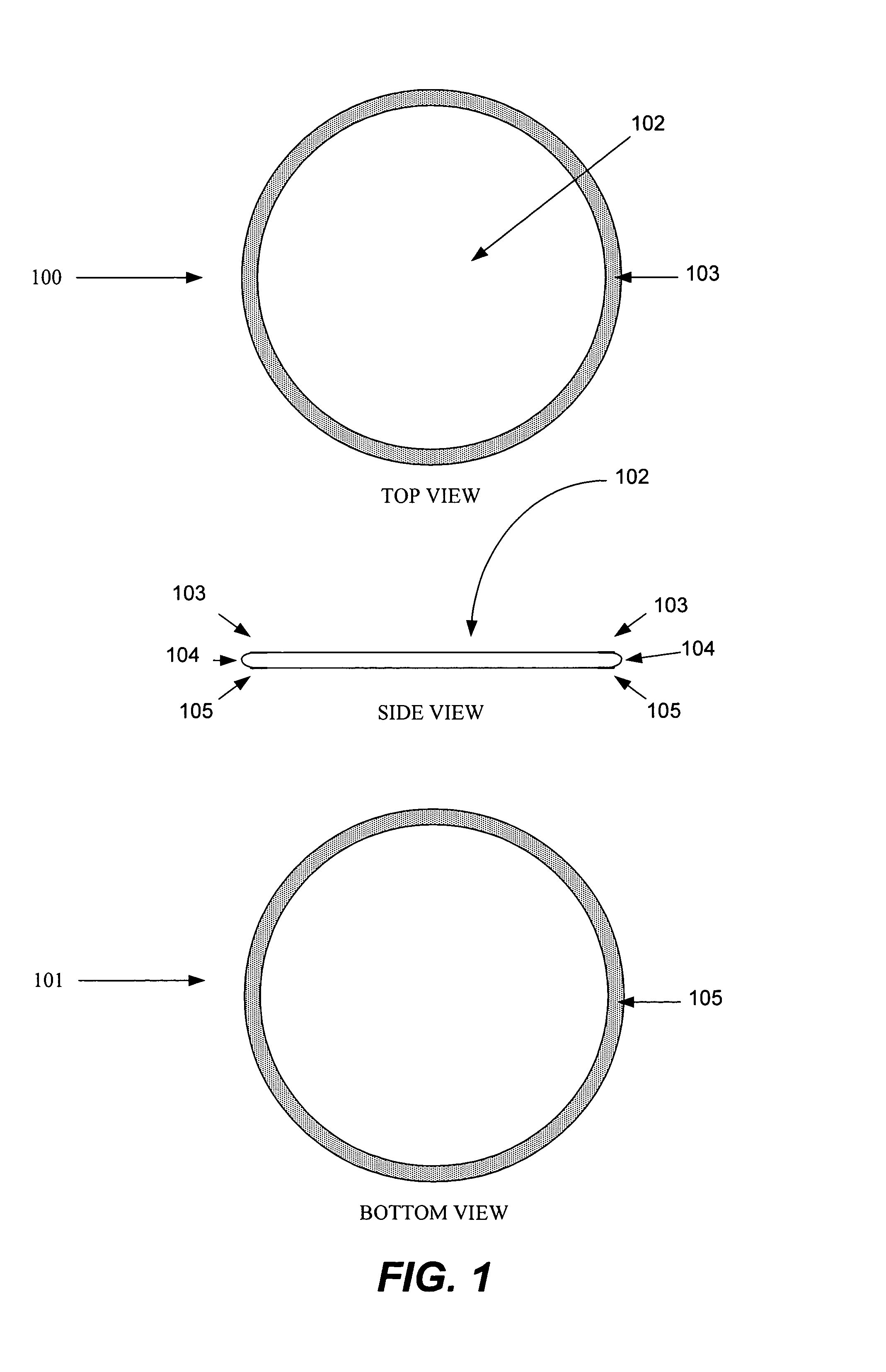

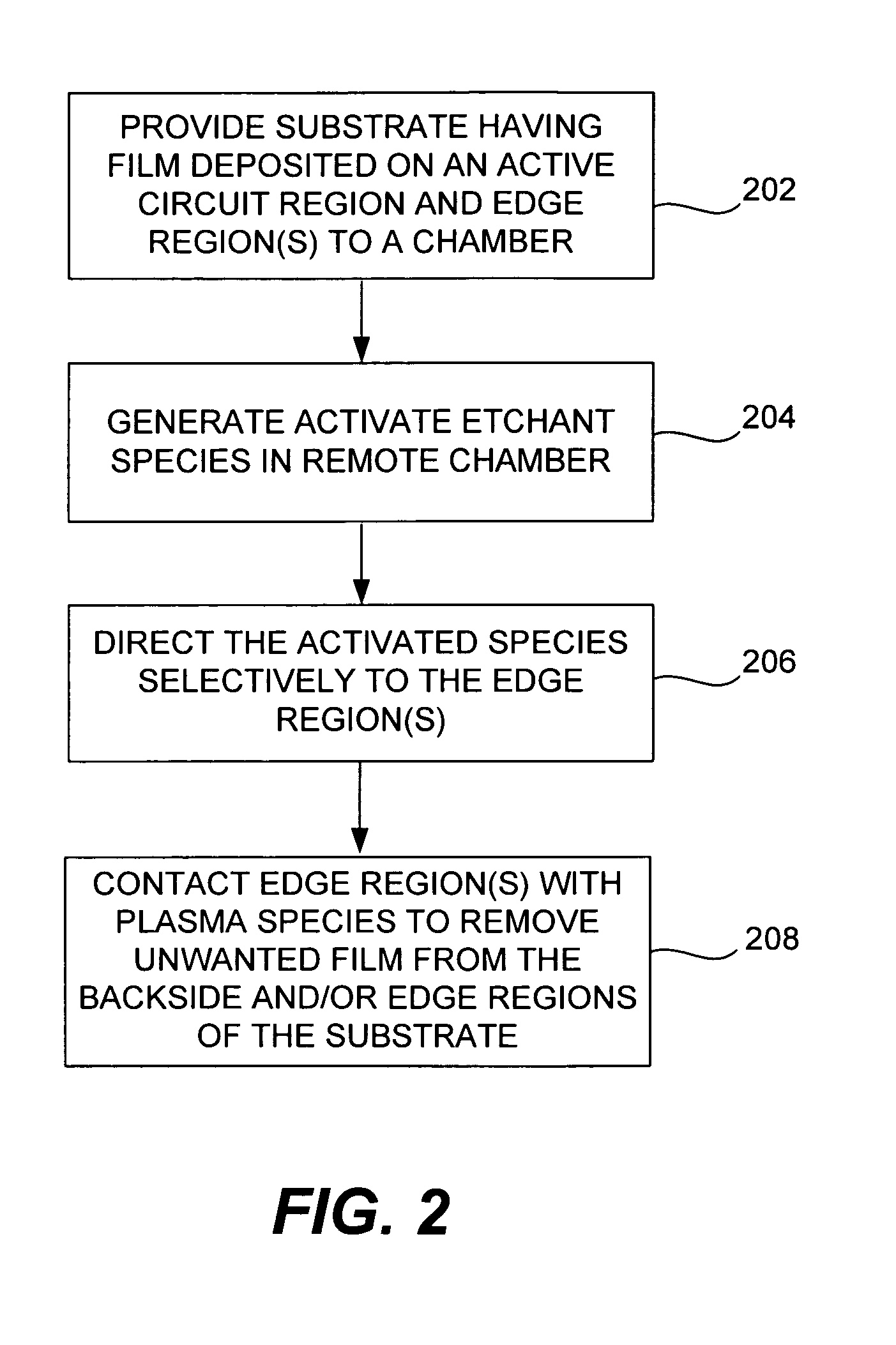

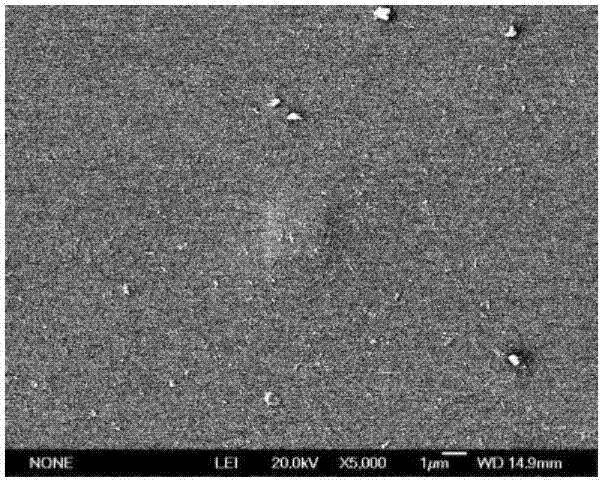

Edge removal of films using externally generated plasma species

ActiveUS8100081B1InhibitionElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringAtomic oxygen

The present invention provides methods and apparatuses for removing unwanted film from the edge area of substrate using remotely-generated plasmas. Activated plasma species are directed to the edge of the substrate to contact and remove the unwanted film, while intrusion of the activated species to areas above the active circuit region (where the film is desired) is suppressed. In certain embodiments, intrusion of the activated species is suppressed by the use of a purge gas and / or the use of materials that promote recombination of plasma species. In particular embodiments, atomic oxygen is used to remove ashable films from the edge of semiconductor wafers.

Owner:NOVELLUS SYSTEMS

High density plasma oxidation

InactiveUS7273638B2High degreeReduce the temperatureElectric discharge tubesDecorative surface effectsHigh densityMetal silicide

A method of oxidizing a substrate having area of about 30,000 mm2 or more. The surface is preferably comprised of silicon-containing materials, such as silicon, silicon germanium, silicon carbide, silicon nitride, and metal suicides. A mixture of oxygen-bearing gas and diluent gas normally non-reactive to oxygen, such as Ne, Ar, Kr, Xe, and / or Rn are ionized to create a plasma having an electron density of at least about 1e12 cm−3 and containing ambient electrons having an average temperature greater than about 1 eV. The substrate surface is oxidized with energetic particles, comprising primarily atomic oxygen, created in the plasma to form an oxide film of substantially uniform thickness. The oxidation of the substrate takes place at a temperature below about 700° C., e.g., between about room temperature, 20° C., and about 500° C.

Owner:INT BUSINESS MASCH CORP +1

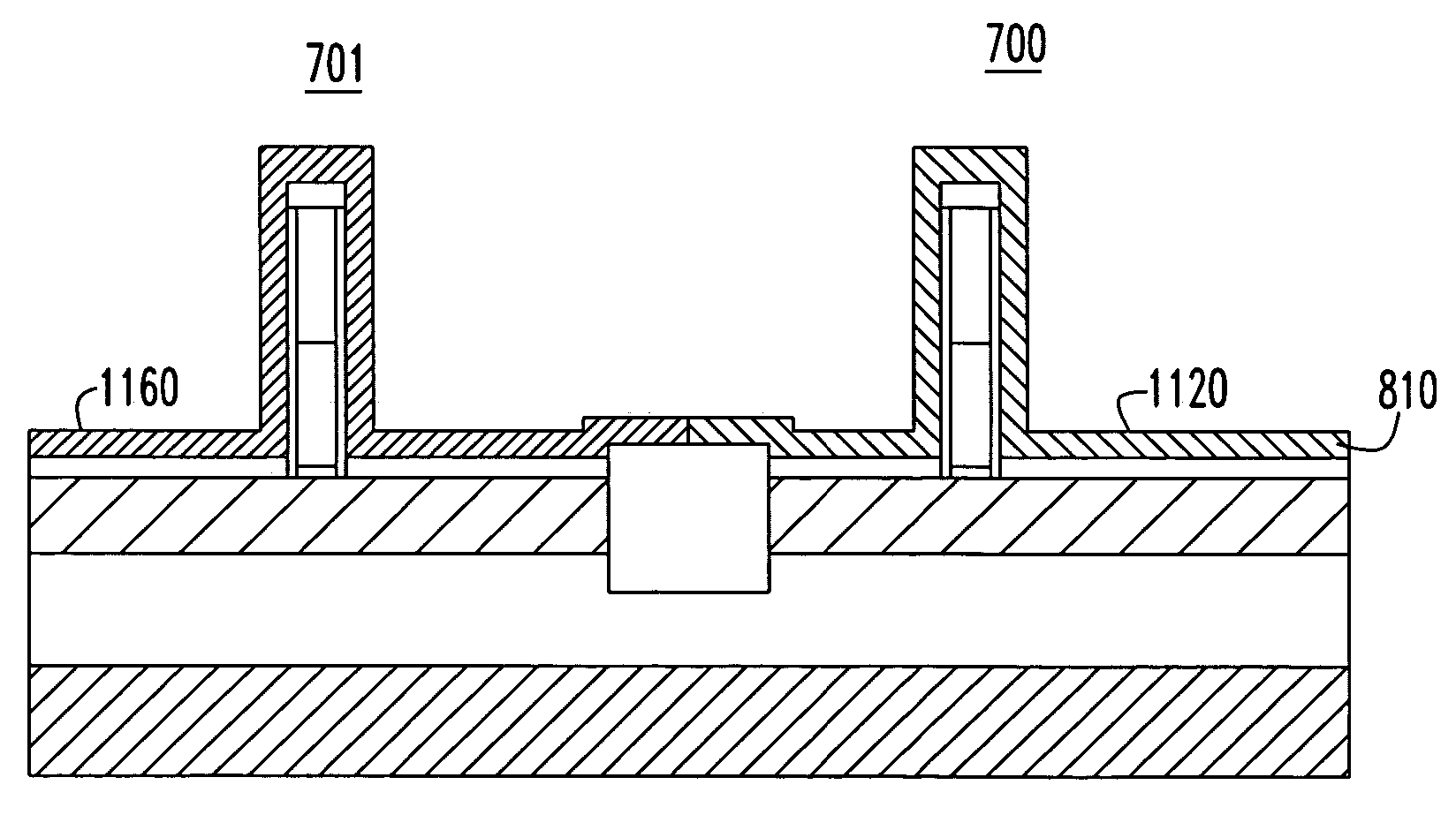

Oxidation method for altering a film structure and CMOS transistor structure formed therewith

A structure and method are provided in which a stress present in a film is reduced in magnitude by oxidizing the film through atomic oxygen supplied to a surface of the film. In an embodiment, a mask is used to selectively block portions of the film so that the stress is relaxed only in areas exposed to the oxidation process. A structure and method are further provided in which a film having a stress is formed over source and drain regions of an NFET and a PFET. The stress present in the film over the source and drain regions of either the NFET or the PFET is then relaxed by oxidizing the film through exposure to atomic oxygen to provide enhanced mobility in at least one of the NFET or the PFET while maintaining desirable mobility in the other of the NFET and PFET.

Owner:IBM CORP

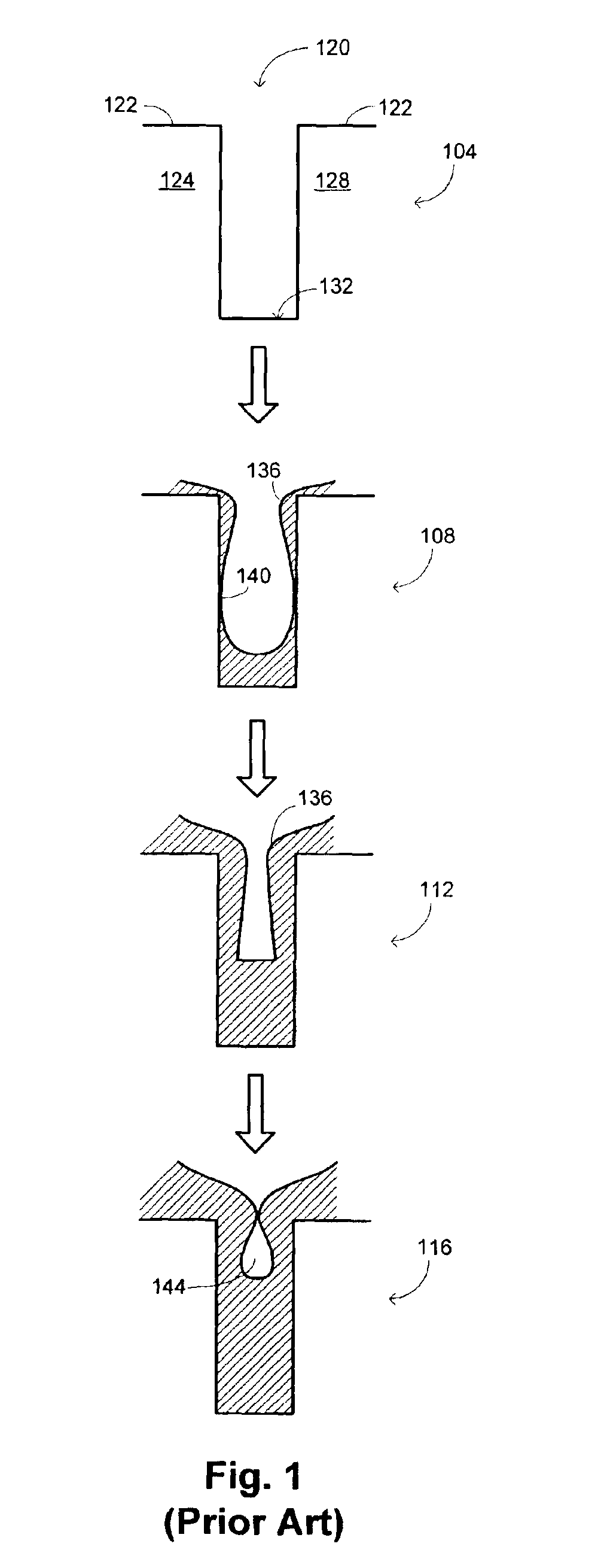

Method of forming ONO-type sidewall with reduced bird's beak

Conventional fabrication of sidewall oxide around an ONO-type memory cell stack usually produces Bird's Beak because prior to the fabrication, there is an exposed sidewall of the ONO-type memory cell stack that exposes side parts of a plurality of material layers respectively composed of different materials. Certain materials in the stack such as silicon nitrides are more difficult to oxidize than other materials in the stack such polysilicon. As a result oxidation does not proceed uniformly along the multi-layered height of the sidewall. The present disclosure shows how radical-based fabrication of sidewall dielectric can help to reduce the Bird's Beak formation. More specifically, it is indicated that short-lived oxidizing agents (e.g., atomic oxygen) are able to better oxidize difficult to oxidize materials such as silicon nitride and the it is indicated that the short-lived oxidizing agents alternatively or additionally do not diffuse as deeply through already oxidized layers of the sidewall such as silicon oxide layers. As a result, a more uniform sidewall dielectric can be fabricated with more uniform breakdown voltages along it height.

Owner:PROMOS TECH INC

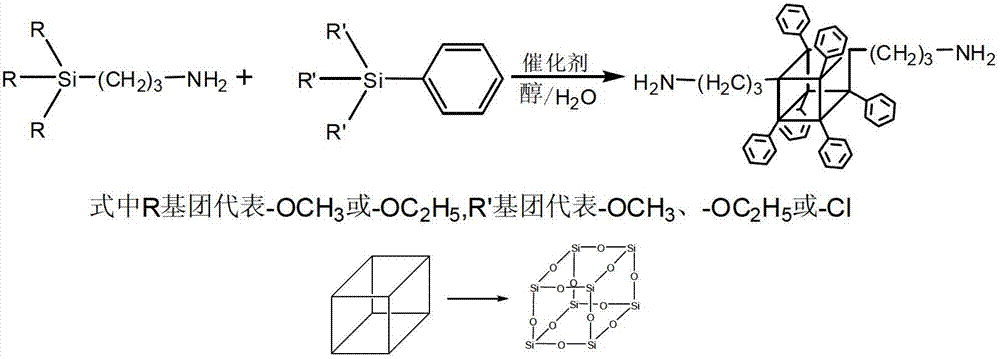

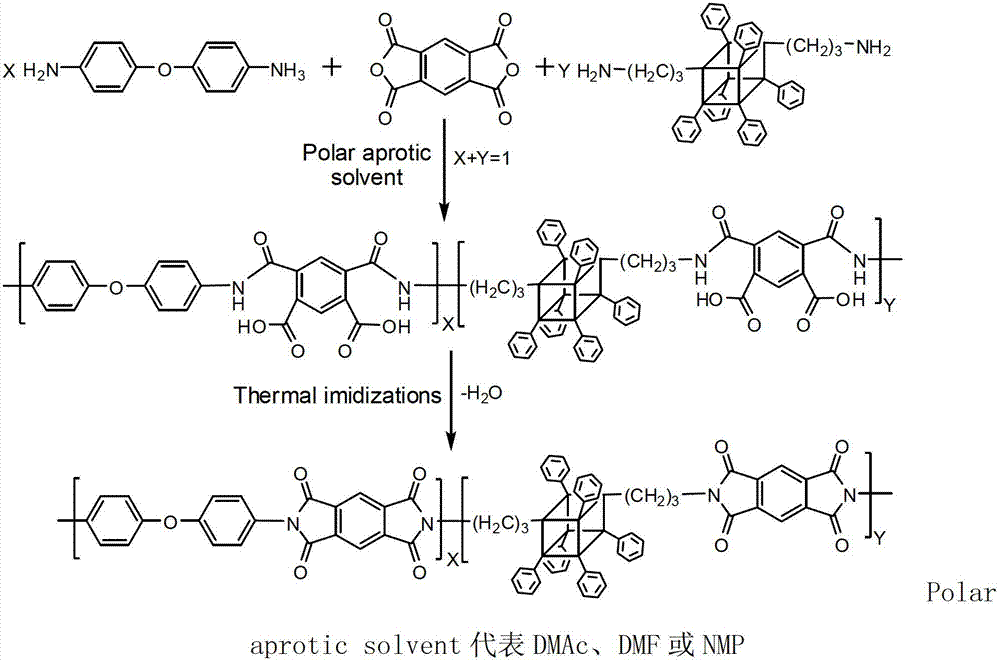

Preparation method of atomic oxygen-resistant polyimide hybrid films containing POSS (polyhedral oligomeric silsesquioxanes) structures

InactiveCN102731809AImprove anti-atomic oxygen performanceMild reaction conditionsSilicon organic compoundsAviationAlcohol

The invention relates to a preparation method of atomic oxygen-resistant polyimide hybrid films containing POSS structures. The preparation method comprises the following steps: reacting phenyl-containing monomers with aminopropyl-containing silane monomers in an alcohol / water cosolvent system under the action of a catalyst, volatilizing the solvent, washing, lyophilizing to obtain diamine POSS, modifying a polyimide material with the diamine POSS to prepare polyamide acid containing the POSS structure, and carrying out thermal imidization to obtain a series of polyimide hybrid films with different contents of the diamine POSS. Reaction conditions for synthesizing the diamine POSS are mild, the cost is low, and the POSS structure is introduced to the main chain of a polyimide molecule in a chemical bond manner, so the polyimide material has an excellent intrinsic atomic oxygen resistance, the hybrid films have excellent comprehensive performances, and the atomic oxygen resistances of the hybrid films are 6 times higher than that of unmodified Kapton polyimide films, thereby the hybrid films of the invention have important meanings to the development of the aviation and space industry.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

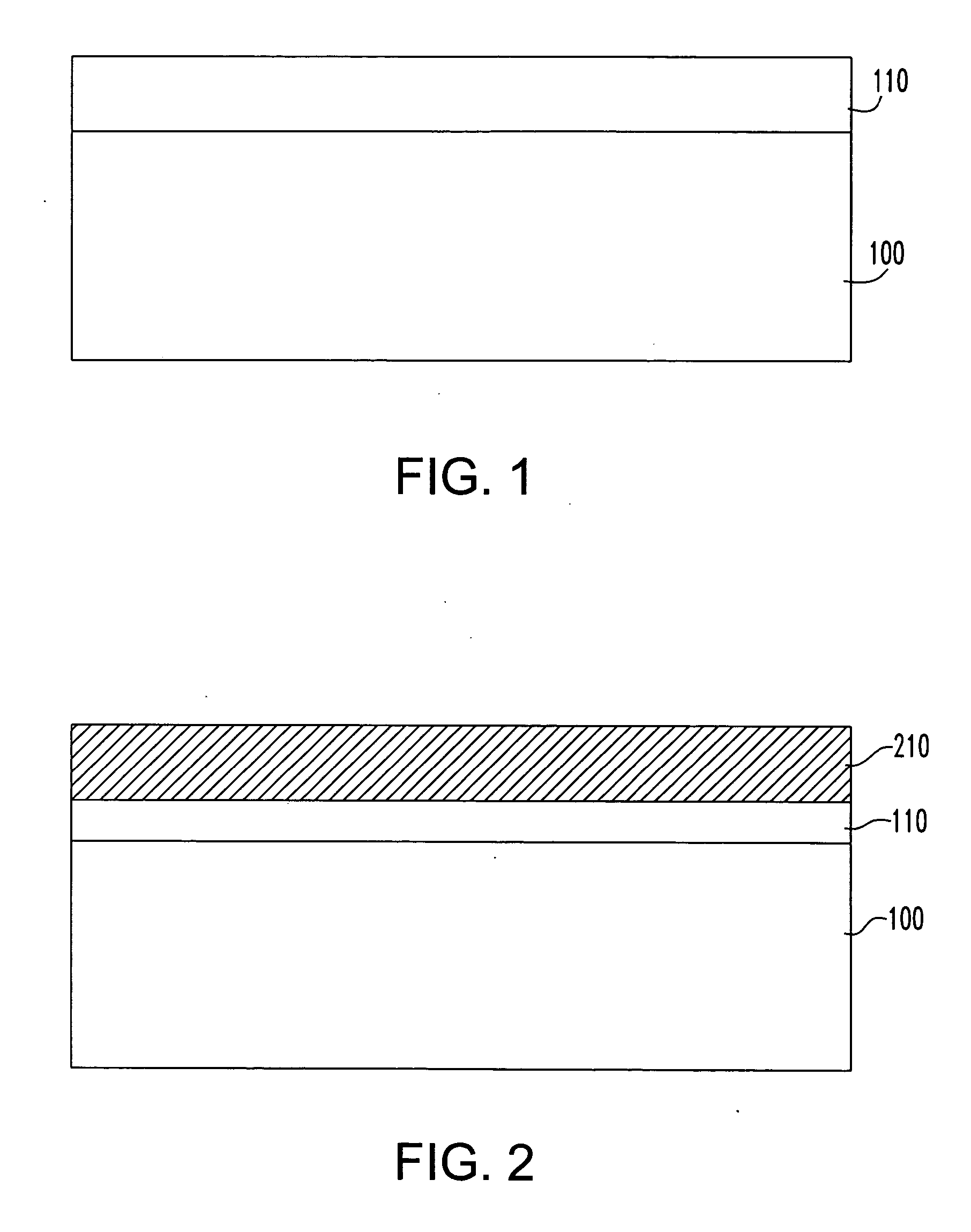

Method of improving gate activation by employing atomic oxygen enhanced oxidation

InactiveUS6566210B2Budget is reducedSmall granularityTransistorSolid-state devicesElectrical conductorSemiconductor

The present invention provides a method of preparing a Si-based metal-insulator-semiconductor (MIS) transistor which prevents the polycrystalline grains of the gate conductor from getting significantly larger by reducing the thermal budget of the sidewall oxidation process. The thermal budget of the inventive sidewall oxidation process is reduced one or two orders of magnitude over conventional prior art sidewall oxidation processes by utilizing atomic oxygen as the oxidizing ambient. The present invention also provides Si-based MIS transistors having a gate conductor having grain sizes of about 0.1, preferably 0.05, .mu.m or less.

Owner:IBM CORP

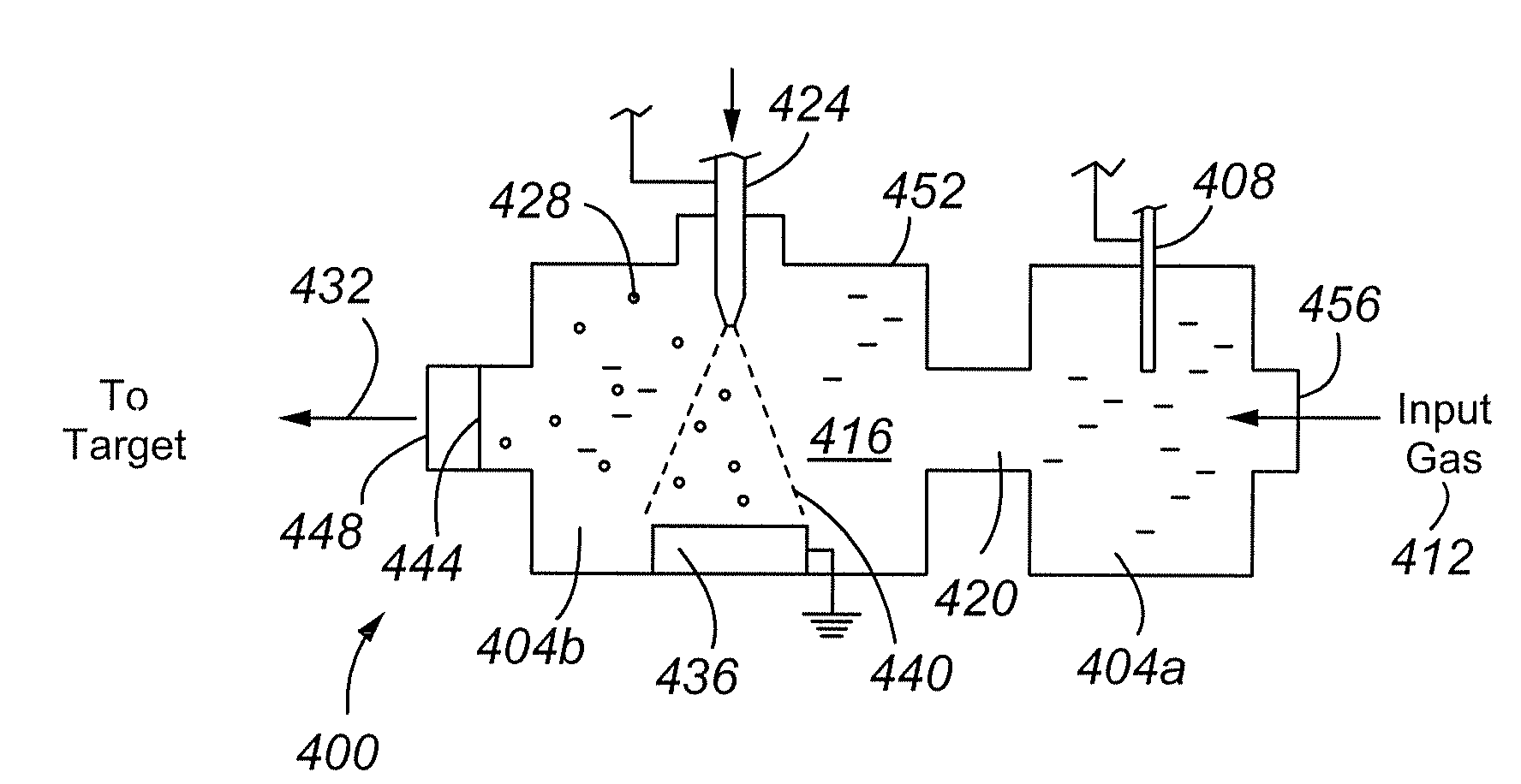

Electrotherapeutic treatment device and method

InactiveUS20090114218A1Improve eliminationGood effectMedical devicesInhalatorsBiological bodyAirflow

The present invention is directed to a treatment method and system that (a) while controlling ozone production, electrically charges a plurality of (i) atomic particles (e.g., diatomic oxygen and water molecules) and / or (ii) electrically charged droplets in an input gas stream to form a charged gas stream and (b) provides the charged gas stream to a living organism to be treated.

Owner:ADA TECH

High density plasma oxidation

InactiveUS20040129673A1High degree of oxide uniformityHigh degreeElectric discharge tubesDecorative surface effectsHigh densityMetal silicide

A method of oxidizing a substrate having area of about 30,000 mm<2 >or more. The surface is preferably comprised of silicon-containing materials, such as silicon, silicon germanium, silicon carbide, silicon nitride, and metal suicides. A mixture of oxygen-bearing gas and diluent gas normally non-reactive to oxygen, such as Ne, Ar, Kr, Xe, and / or Rn are ionized to create a plasma having an electron density of at least about 1e12 cm<-3 >and containing ambient electrons having an average temperature greater than about 1 eV. The substrate surface is oxidized with energetic particles, comprising primarily atomic oxygen, created in the plasma to form an oxide film of substantially uniform thickness. The oxidation of the substrate takes place at a temperature below about 700° C., e.g., between about room temperature, 20° C., and about 500° C.

Owner:IBM CORP +1

Oxidation method for altering a film structure and CMOS transistor structure formed therewith

Owner:IBM CORP

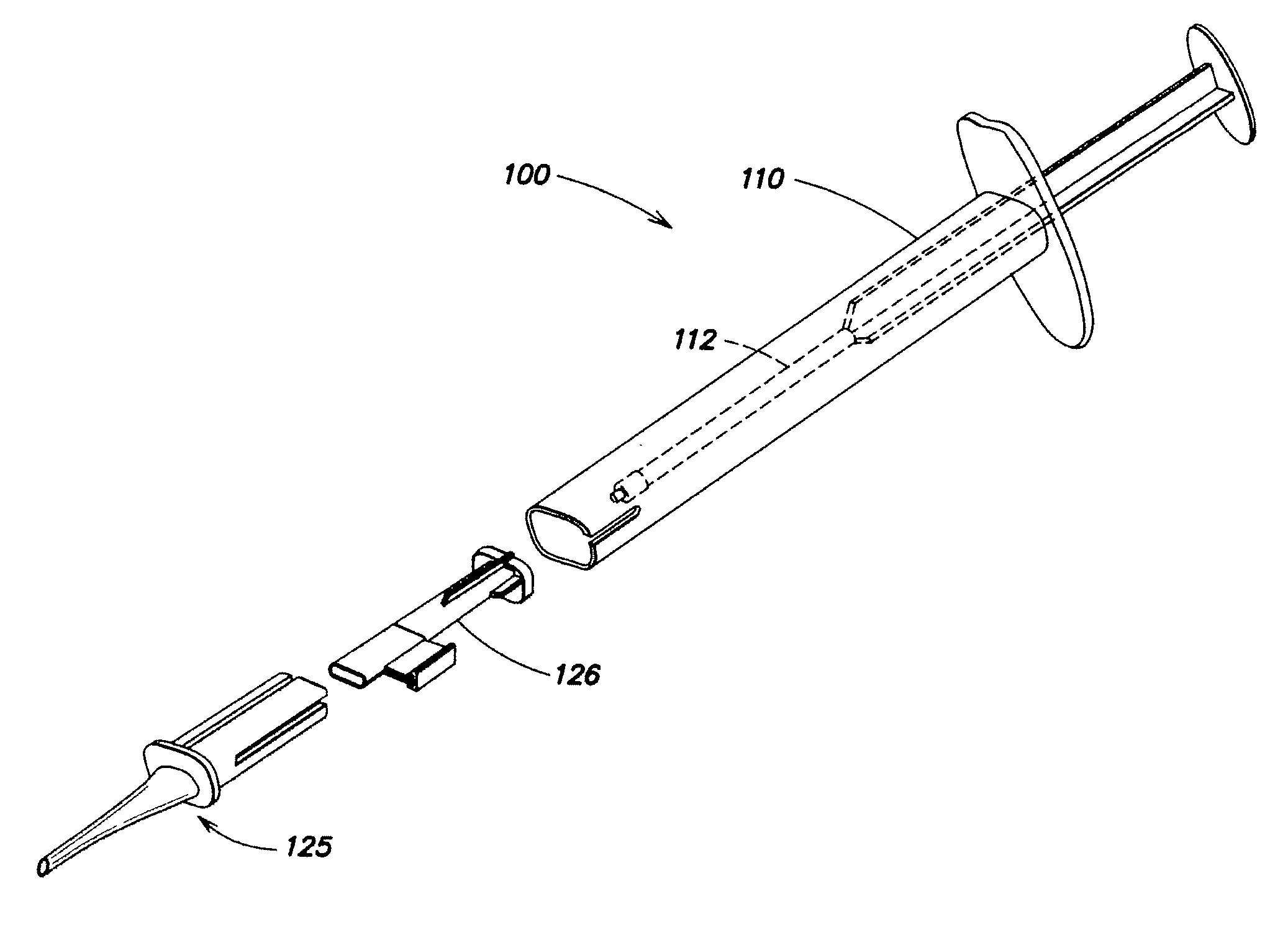

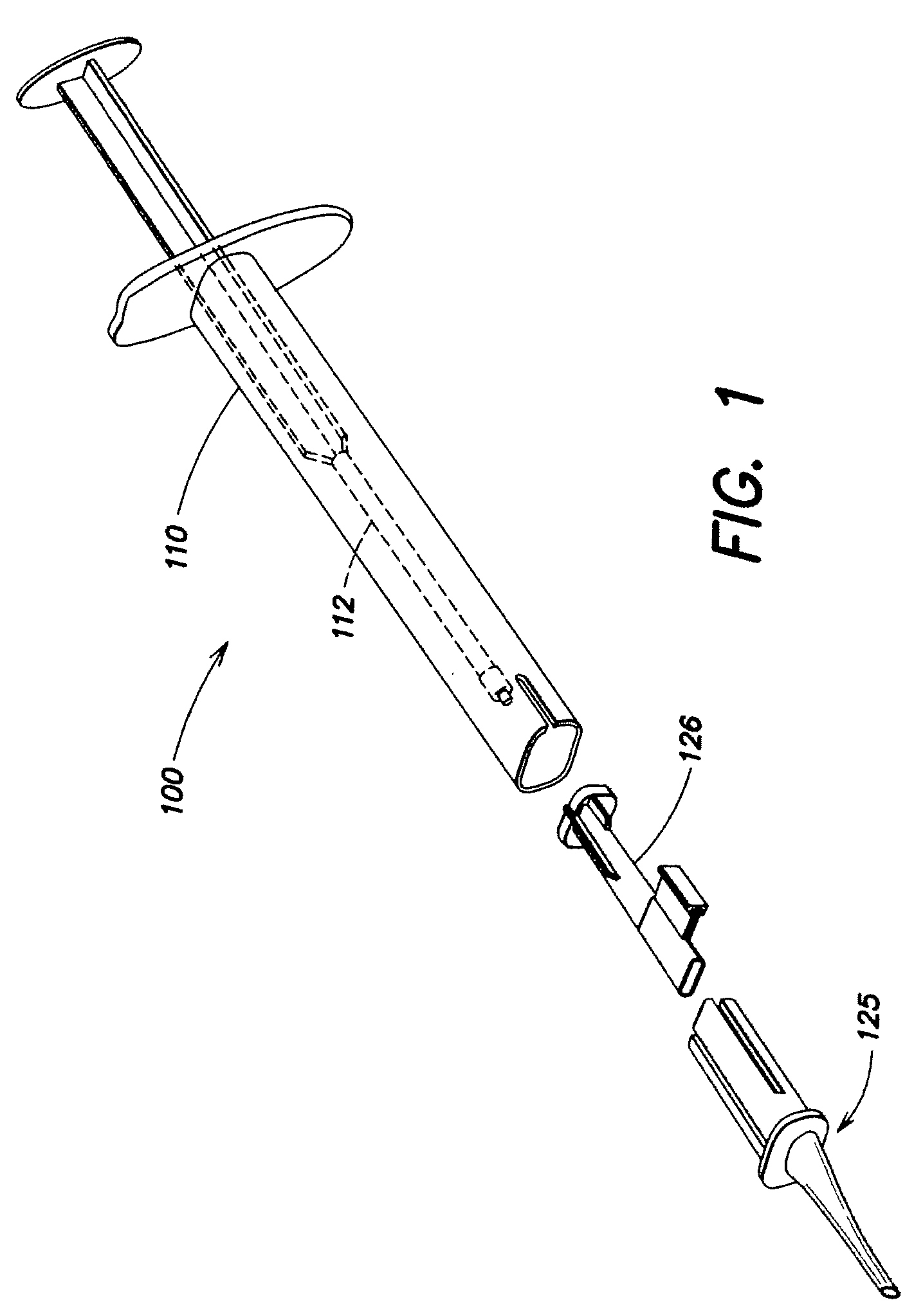

Intraocular Lens Injector with Hydrophilic Coating

InactiveUS20100256651A1Easy accessExtended shelf lifeEye surgeryOptical articlesHydrophilic coatingElectron

An IOL injector that includes one or more polymeric portions that include a hydrophilic coating component that is effective to facilitate the passage of the IOL through the injector, particularly an injector tip. The IOL injector is prepared by a process that includes irradiating at least a portion of a polymeric, IOL injector with UV light in an environment comprising oxygen to provide a positive percent change in the atomic oxygen content of the polymer material at the surface as determined by X-ray Photoelectron Spectroscopy (XPS). A portion or the entire irradiated portion is then contacted with a solution comprising a hydrophilic coating component. The hydrophilic coating component is selected from a hydrophilic polymer, a hydrophilic copolymer or any one mixture thereof to provide a solution coated portion. The solution coated portion is then heated at a temperature to provide portions of the IOL injector with a shelf-stable, lubricious hydrophilic coating to facilitate delivery of an IOL from the injector.

Owner:BAUSCH & LOMB INC

Method of forming ONO-type sidewall with reduced bird's beak

Conventional fabrication of sidewall oxide around an ONO-type memory cell stack usually produces Bird's Beak because prior to the fabrication, there is an exposed sidewall of the ONO-type memory cell stack that exposes side parts of a plurality of material layers respectively composed of different materials. Certain materials in the stack such as silicon nitrides are more difficult to oxidize than other materials in the stack such polysilicon. As a result oxidation does not proceed uniformly along the multi-layered height of the sidewall. The present disclosure shows how radical-based fabrication of sidewall dielectric can help to reduce the Bird's Beak formation. More specifically, it is indicated that short-lived oxidizing agents (e.g., atomic oxygen) are able to better oxidize difficult to oxidize materials such as silicon nitride and the it is indicated that the short-lived oxidizing agents alternatively or additionally do not diffuse as deeply through already oxidized layers of the sidewall such as silicon oxide layers. As a result, a more uniform sidewall dielectric can be fabricated with more uniform breakdown voltages along it height.

Owner:PROMOS TECH INC

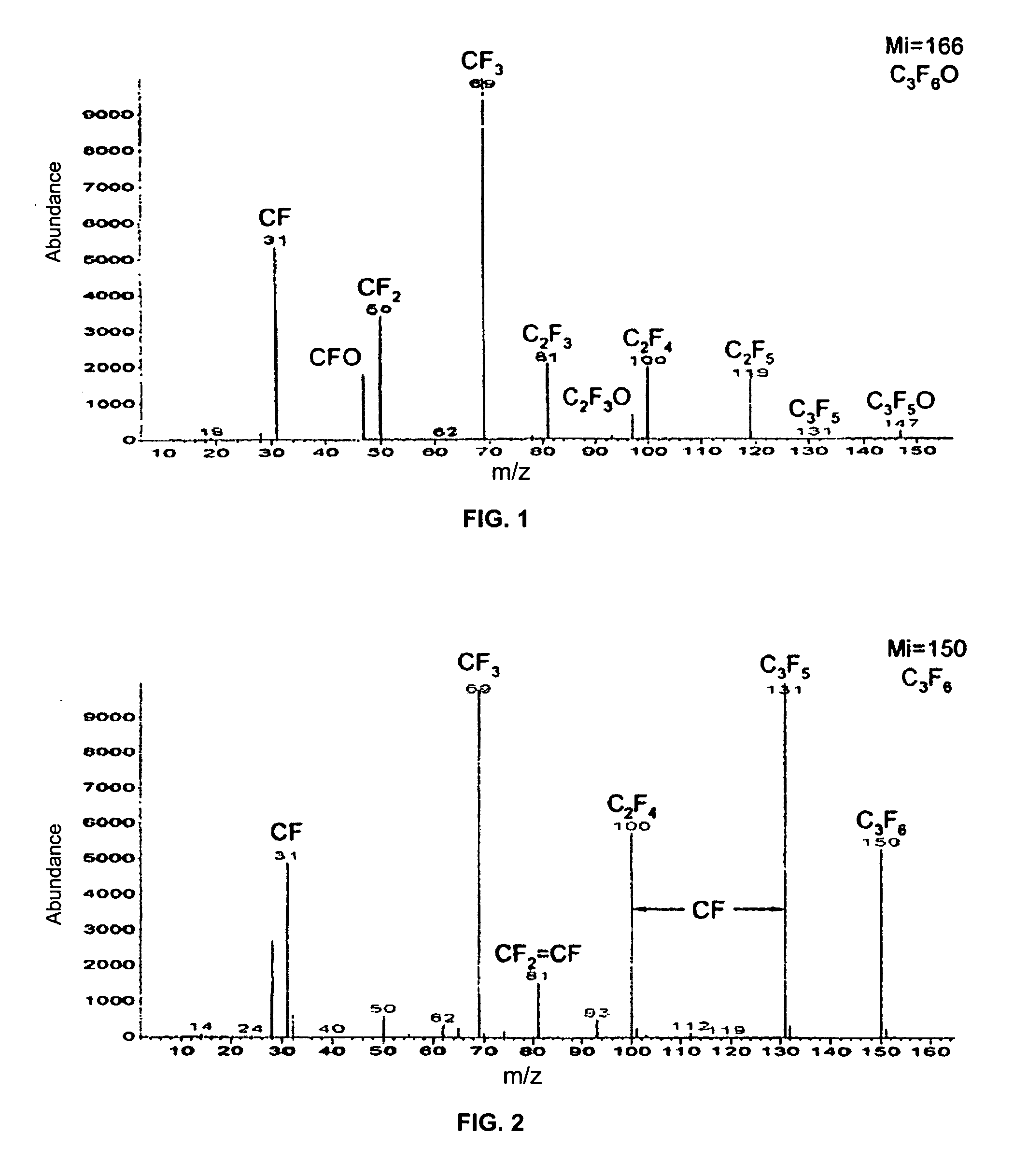

RF plasma-enhanced deposition of fluorinated films

InactiveUS20070172666A1Avoid stickingPrevent and minimize surface oxidationSynthetic resin layered productsPretreated surfacesFluorinated gasesPolymer science

Low- or atmospheric pressure RF plasma-enhanced thin film deposition methods are provided for the deposition of hydrophobic fluorinated thin films onto various substrates. The methods include at least two steps. In the first step, RF plasma-mediated deposition is used to deposit a fluorinated film onto a substrate surface. In a second step, plasma-generated active sites on the fluorinated film are quenched by reacting them with stable fluorinated gas-phase molecules in situ, in the absence of plasma, to provide a hydrophobic fluorinated thin film having a very low oxygen content. In some instances the hydrophobic fluorinated thin films have an atomic oxygen concentration of no more than about 3%.

Owner:WISCONSIN ALUMNI RES FOUND

Formation of high quality dielectric films of silicon dioxide for sti: usage of different siloxane-based precursors for harp II-remote plasma enhanced deposition processes

InactiveCN101528974ASemiconductor/solid-state device manufacturingChemical vapor deposition coatingRemote plasmaDeposition process

Methods of depositing a dielectric layer in a gap formed on a substrate are described. The methods include introducing an organo-silicon precursor and an oxygen precursor to a deposition chamber. The organo-silicon precursor has a C:Si atom ratio of less than 8, and the oxygen precursor comprises atomic oxygen that is generated outside the deposition chamber. The precursors are reacted to form the dielectric layer in the gap. Methods of filling gaps with dielectric materials are also described. These methods include providing an organo-silicon precursor having a C:Si atom ratio of less than 8and an oxygen precursor, and generating a plasma from the precursors to deposit a first portion of the dielectric material in the gap. The dielectric material may be etched, and a second portion of dielectric material may be formed in the gap. The first and second portions of the dielectric material may be annealed.

Owner:APPLIED MATERIALS INC

Low Temperature Polymer Bonding Using UV/Ozone Surface Treatment

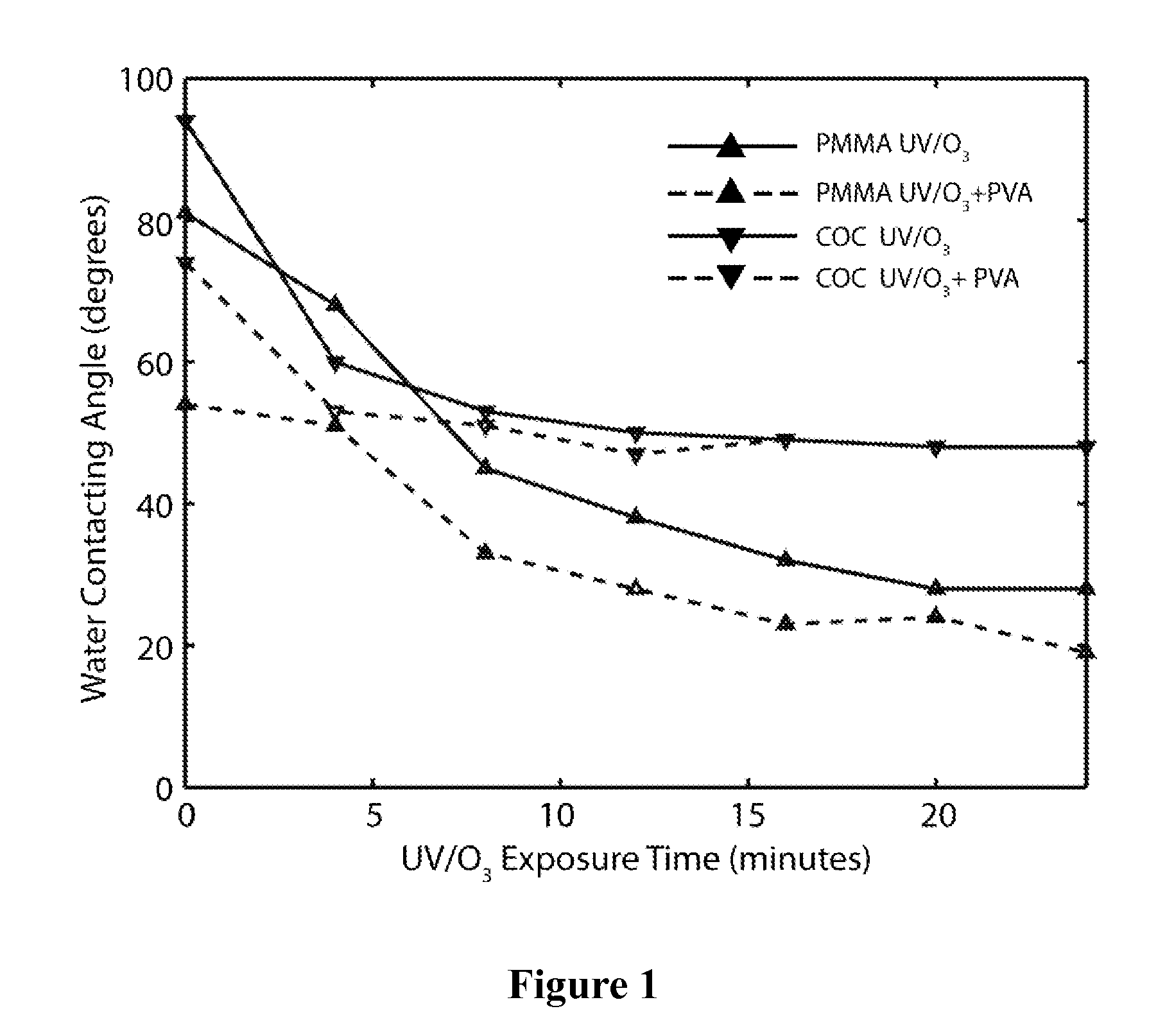

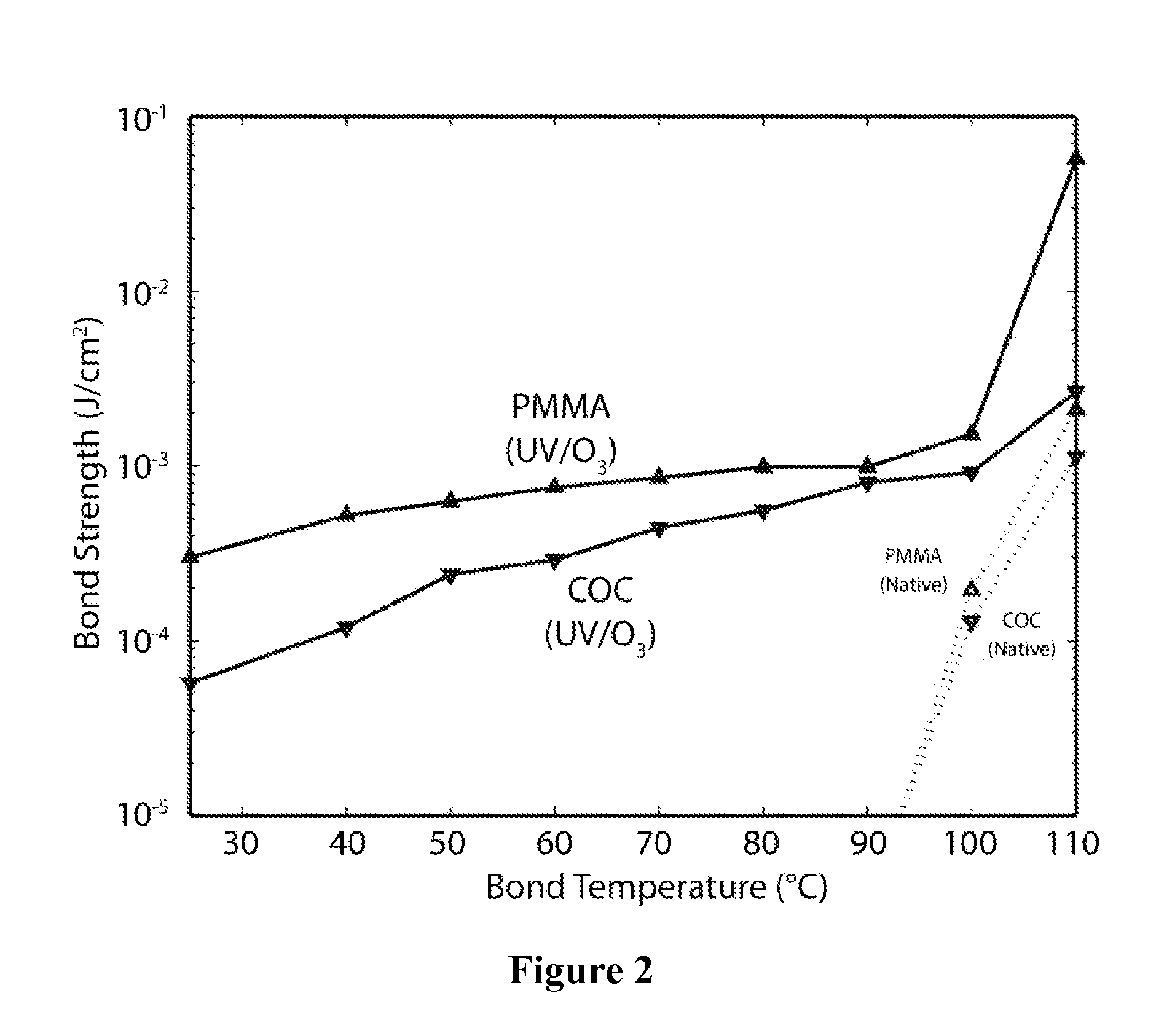

InactiveUS20090227755A1High bonding strengthLow costPretreated surfacesGroup 3/13 element organic compoundsThermoplasticVitrification

The present invention relates to a method for bonding two surfaces to one another. The invention particularly pertains to the use of such method in which one of the surfaces is a polymeric plastic (and more preferably a polymeric thermoplastic (especially poly-(methyl methacrylate) (“PMMA”) or cyclic olefin copolymer (“COC”)). More particularly, the invention relates to treating at least one of the contacting surfaces with UV in the presence of oxygen to thereby generate ozone (O3) and atomic oxygen under conditions of temperature below that of the glass transition temperature of the polymeric plastic. The UV / O3-mediated bonding results in high bond strength and zero-deformation method. This bonding method can be applied to micro / nano-scale polymer devices, and particularly to microfluidic devices, for a low cost, high throughput, high yield advantage.

Owner:UNIV OF MARYLAND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com