Preparation method of atomic oxygen-resistant polyimide hybrid films containing POSS (polyhedral oligomeric silsesquioxanes) structures

An anti-atomic oxide polyimide and thin film preparation technology, applied in the direction of silicon organic compounds, can solve the problems of uneven thermal expansion coefficient of coating and film, difficult large-scale production of thin film, and discounted service life of thin film, etc., to achieve effective It is beneficial to large-scale industrial production, improving the anti-atomic oxygen performance, and the effect of improving the anti-atomic oxygen performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

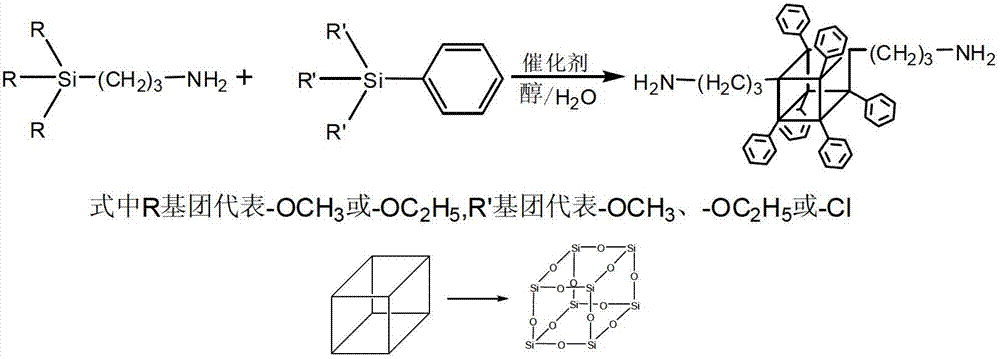

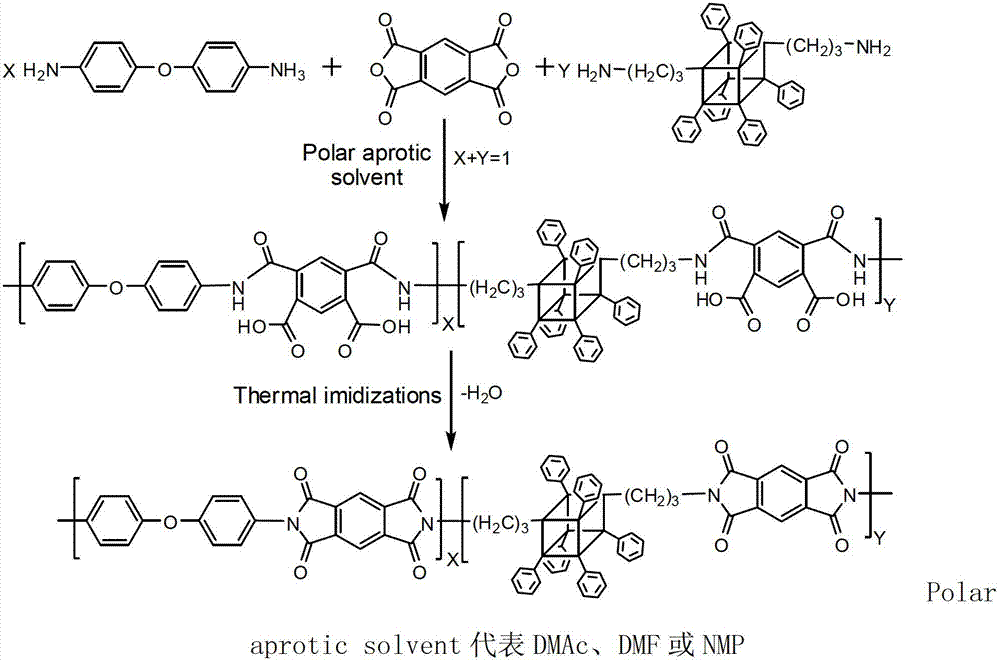

Method used

Image

Examples

Embodiment 1

[0034] Example 1: Add 250mL of ethanol, 12mL of distilled water and 3mL of TEAOH (methanol solution with a mass fraction of 25%) in sequence into a container equipped with an electric stirrer, a condenser and a thermometer, and at the same time start stirring and raise the temperature of the system. When the temperature rose to 50°C, a mixture of 5.50 mL of γ-aminopropyltriethoxysilane and 14.18 mL of phenyltriethoxysilane was added to the system in Step 1 within 2 hours. After the addition, keep the reaction conditions unchanged and continue to stir for 50h. After the reaction, the solvent was evaporated, the product was washed 3 to 5 times with distilled water, centrifuged, and freeze-dried to obtain a white powdery solid, that is, diamine POSS.

Embodiment 2

[0035] Example 2: Add 210mL of methanol, 10mL of distilled water and 2.5mL of TMAOH (methanol solution with a mass fraction of 25%) to a container equipped with an electric stirrer, a condenser tube and a thermometer in sequence, and at the same time start stirring and raise the temperature of the system. When the temperature rose to 40°C, a mixture of 4.06 mL of γ-aminopropyltrimethoxysilane and 10.74 mL of phenyltrimethoxysilane was added to the system in Step 1 within 2 hours. After the addition, keep the reaction conditions unchanged and continue to stir for 40h. After the reaction, the solvent was evaporated, the product was washed 3 to 5 times with distilled water, centrifuged, and freeze-dried to obtain a white powdery solid, that is, diamine POSS.

Embodiment 3

[0036] Example 3: Add 220mL of methanol, 10mL of distilled water and 2.5mL of TEAOH (methanol solution with a mass fraction of 25%) into a container equipped with an electric stirrer, a condenser tube and a thermometer in sequence, start stirring and raise the temperature of the system at the same time. When the temperature rose to 45°C, a mixture of 4.15 mL of γ-aminopropyltrimethoxysilane and 14.18 mL of phenyltriethoxysilane was added to the system in Step 1 within 2 hours. After the addition, keep the reaction conditions unchanged and continue to stir for 45h. After the reaction, the solvent was evaporated, the product was washed 3 to 5 times with distilled water, centrifuged, and freeze-dried to obtain a white powdery solid, that is, diamine POSS.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com