A kind of polyimide material and its preparation method and application

A polyimide and polyimide resin technology, applied in the field of functional film materials, can solve the problems of proton oxygen erosion, inability to take into account anti-static discharge, etc. Harmful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] In some embodiments of the present invention, the preparation method of polyimide material specifically includes the following steps:

[0032] (A) uniformly mixing the composite solution containing the silicon-containing antioxidant atom filler and the phosphorus-containing polyimide resin with the dispersion solution containing the conductive filler to obtain a mixed solution;

[0033] (B) The mixed solution is heated and solidified.

[0034] In some embodiments of the present invention, the curing at elevated temperature includes spreading the mixed solution on the surface of the substrate, and after curing at elevated temperature, a polyimide film is obtained.

[0035] In some specific embodiments of the present invention, the organic solution of the phosphorus-containing polyimide resin is uniformly mixed with the organic solution in which the silicon-containing antigenic oxygen filler is dissolved to obtain a composite solution.

[0036] In some specific embodimen...

Embodiment 1

[0056] The polyimide film provided in this embodiment is a polyimide film containing 10 wt % graphene and 18 wt % trisilanol phenyl cage polysilsesquioxane (TSP-POSS).

[0057] The preparation method of the polyimide film provided by this embodiment is:

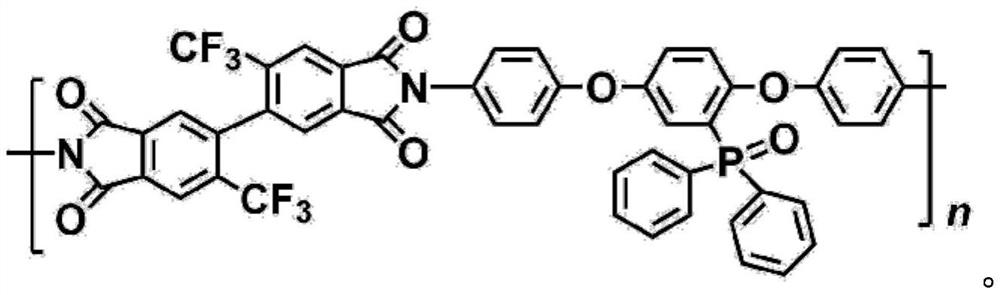

[0058] To a 500 mL volume three-necked flask equipped with a mechanical stirrer, an electric heating bath, a Dean-Stark trap, and a nitrogen inlet and outlet at room temperature, was charged with 2,5-bis[(4-aminophenoxy)benzene base] diphenylphosphine oxide (BADPO, 24.6250g, 50mmol) and N,N-dimethylacetamide (DMAc, 120.0g), under nitrogen protection, stirred to obtain a homogeneous solution, then, 2,2' -Bis(trifluoromethyl)-4,4',5,5'-biphenyltetracarboxylic dianhydride (6FBPDA, 21.5105g, 50mmol) and N,N-dimethylacetamide (DMAc, 64.5g) added to the solution. The solids content of the reaction mixture was controlled to 20 wt%. The reaction was stirred at 25° C. for 20 h to generate a polyamic acid (PAA) reaction solution. T...

Embodiment 2

[0061] The polyimide film provided in this embodiment is a polyimide film containing 10 wt % of carbon nanotubes and 18 wt % of trisilanol phenyl cage polysilsesquioxane (TSP-POSS).

[0062] The preparation method of the polyimide film provided by this embodiment is:

[0063] The preparation method of phosphorus-containing polyimide resin is the same as that in Example 1.

[0064] For the preparation method of the polyimide film, refer to Example 1, except that graphene is replaced with carbon nanotubes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com