A kind of high strength and high heat resistance polyimide microporous film and preparation method thereof

A polyimide and microporous film technology, applied in the field of polymer material preparation, can solve problems such as uneven cell structure, poor mechanical properties, and poor high-temperature performance, and achieve enhanced interaction, improved mechanical properties, and heat resistance good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The preparation method of the high-strength and high-heat-resistant polyimide microporous film provided by the present invention comprises the following steps:

[0040](1) Dissolving the aromatic tetra-acid dianhydride in an organic solvent, adding diamine in an equimolar amount to the dianhydride and a certain amount of porogen, stirring and reacting for 6-8 hours, and finally obtaining a homogeneous polyamic acid solution.

[0041] (2) Uniformly coating the obtained polyamic acid resin solution on a glass plate to prepare a resin film with uniform thickness.

[0042] (3) heat-treat the obtained polyamic acid resin film in a nitrogen-filled oven at 80°C for 10 hours, then gradually raise the temperature to 280-300°C and keep it for 3-5 hours for thermal imidization, and finally obtain polyimide micropores film.

[0043] In the present invention, the dianhydride is one of pyromellitic dianhydride, 4,4'-biphenyltetracarboxylic dianhydride, and 3,3',4,4'-benzophenone eth...

Embodiment 1

[0054] At 0°C, add 26.34g of N,N-dimethylacetamide solvent into the three-necked flask, and add 3.22g (0.01mol) of 3,3',4,4'-benzophenone ether tetracarboxylic acid di anhydride and stir to dissolve, after the dissolution is complete, add 1.6g (0.008mol) 4,4'-diaminodiphenyl ether and 0.448g (0.002mol) 2-(4-aminophenyl)-5-aminobenzimidazole, and then Then, 3.512 g of dibutyl phthalate was added and stirred for 6 hours to obtain a homogeneous polyamic acid resin solution. The obtained polyamic acid resin solution was evenly coated on a glass plate to prepare a film with a uniform thickness of 400 μm. The polyamic acid resin film was heat-treated in a nitrogen-filled oven at 80°C for 10 hours, then gradually raised to 300°C and kept for 4 hours for thermal imidization, and finally a polyimide microporous film was obtained.

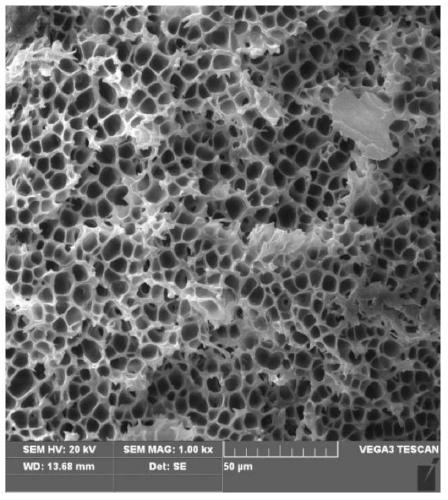

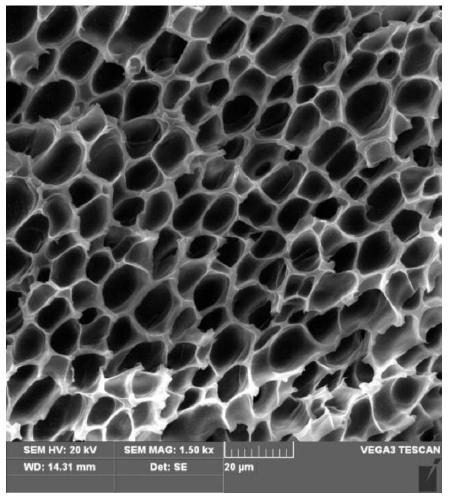

[0055] The performance of the obtained polyimide microporous film is measured, and the microscopic appearance of the obtained microporous film is as follow...

Embodiment 2

[0057] At 0°C, add 32.44g of N,N-dimethylacetamide solvent into the three-necked flask, and add 3.22g (0.01mol) of 3,3',4,4'-benzophenone ether tetracarboxylic acid di anhydride and stir to dissolve, after the dissolution is complete, add 1.608g (0.006mol) 2-trifluoromethyl-4,4'-diaminodiphenyl ether and 0.896g (0.004mol) 2-(4-aminophenyl)-5 -Aminobenzimidazole, then add 9.54g dibutyl phthalate and stir for 6 hours. Finally, a homogeneous polyamic acid resin solution is obtained. The obtained polyamic acid resin solution was evenly coated on a glass plate to prepare a film with a uniform thickness of 200 μm. The polyamic acid resin film was heat-treated in a nitrogen-filled oven at 80°C for 10 hours, then gradually raised to 300°C and kept for 3 hours for thermal imidization, and finally a polyimide microporous film was obtained.

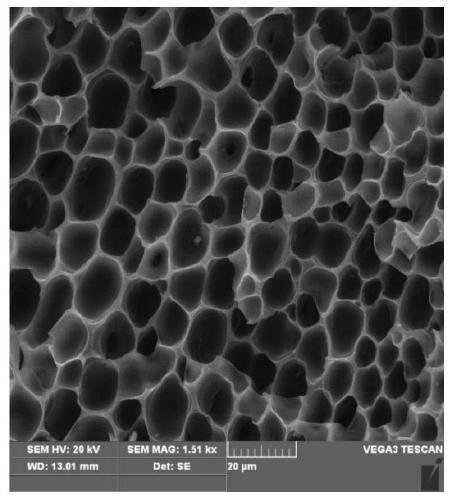

[0058] The obtained polyimide microporous film performance is measured, and the microscopic appearance of the polyimide microporous film obtained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Aperture size | aaaaa | aaaaa |

| Aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com